Page 1

SIMATIC Industrial PC SIMATIC Panel PC 877

DOCUMENTATION

Operating Instructions Edition 07/2006

Industrial PC

Panel PC 877

simatic

DOCUMENTATION

Page 2

Page 3

SIMATIC

Industrial PC

SIMATIC Panel PC 877

Operating instructions

Foreword

Safety information

Description

Application planning

Installation

Connecting

Integration into an

automation system

Commissioning

1

2

3

4

5

6

7

8

Operation and configuration

Operation

Functions

Maintenance and service

Alarm, error and system

messages

Troubleshooting/FAQs

Technical data

Dimension drawings

9

10

11

12

13

14

15

16

Release 07/2006

A5E00877780-01

Detailed descriptions

Appendix

ESD directives

List of

abbreviations / acronyms

17

A

B

C

Page 4

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended by

Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly

as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: A5E00877780-01

Edition 07/2006

Copyright © Siemens AG 2006.

Technical data subject to change

Page 5

Table of contents

1 Foreword ................................................................................................................................................ 1-1

1.1 Overview .................................................................................................................................... 1-1

2 Safety information................................................................................................................................... 2-3

2.1 Safety information ...................................................................................................................... 2-3

2.2 General information ................................................................................................................... 2-6

3 Description.............................................................................................................................................. 3-1

3.1 Design........................................................................................................................................ 3-1

3.2 Technical features...................................................................................................................... 3-3

3.3 Accessories................................................................................................................................ 3-5

4 Application planning................................................................................................................................ 4-1

4.1 Overview .................................................................................................................................... 4-1

4.2 Unpacking and checking the delivery ........................................................................................4-2

4.3 Device identification data........................................................................................................... 4-3

4.4 Mounting Positions and Fastening............................................................................................. 4-4

4.4.1 Installation guidelines................................................................................................................. 4-4

4.4.2 Permitted mounting positions..................................................................................................... 4-6

4.4.3 Type of fixation........................................................................................................................... 4-7

4.4.4 Protection against dust and water ............................................................................................. 4-8

4.5 Mounting cut-out ........................................................................................................................ 4-9

4.5.1 Preparing the mounting cut-out.................................................................................................. 4-9

4.5.2 Mounting depth of the device................................................................................................... 4-11

4.6 EMC directive........................................................................................................................... 4-12

5 Installation .............................................................................................................................................. 5-1

5.1 Securing the device with clamps................................................................................................ 5-1

5.2 Securing the device with screws................................................................................................ 5-3

6 Connecting ............................................................................................................................................. 6-1

6.1 Connection and operator control components........................................................................... 6-1

6.2 Connecting the 100 V to 240 V AC power supply...................................................................... 6-4

6.3 Connecting the 24 V DC power supply...................................................................................... 6-6

6.4 Connecting the equipotential bonding circuit............................................................................. 6-7

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

iii

Page 6

Table of contents

7 Integration into an automation system .................................................................................................... 7-1

7.1 Overview .................................................................................................................................... 7-1

7.2 Device in a SIMATIC S7 configuration.......................................................................................7-2

7.2.1 MPI/PROFIBUS-DP network...................................................................................................... 7-2

7.2.2 Connecting an S7 automation system .......................................................................................7-3

7.3 Networking via Industrial Ethernet ............................................................................................. 7-4

8 Commissioning ....................................................................................................................................... 8-1

8.1 Overview .................................................................................................................................... 8-1

8.2 Switch on the device .................................................................................................................. 8-2

8.3 Setting up the Microsoft Windows operating system ................................................................. 8-3

8.4 Installing applications and drivers .............................................................................................. 8-4

8.5 BIOS settings ............................................................................................................................. 8-9

8.6 Microsoft Windows operating system ...................................................................................... 8-10

8.6.1 Enables .................................................................................................................................... 8-10

8.6.2 Windows 2000 Professional..................................................................................................... 8-11

8.6.3 Windows XP Professional........................................................................................................ 8-12

8.7 USB.......................................................................................................................................... 8-13

9 Operation and configuration.................................................................................................................... 9-1

9.1 Normal operation........................................................................................................................ 9-1

9.1.1 Switch on the device .................................................................................................................. 9-1

9.1.2 Logging on to the operating system via the onscreen keyboard (OSK) .................................... 9-3

9.1.3 Switching off the device ............................................................................................................. 9-4

9.2 Additional Drivers and Applications ........................................................................................... 9-5

9.2.1 Overview .................................................................................................................................... 9-5

9.2.2 Calibrating the touch screen, UPDD.......................................................................................... 9-6

9.2.3 Enable/disable touch functionality.............................................................................................. 9-8

9.2.4 Windows Security Center (Windows XP Professional only) .................................................... 9-10

9.2.5 KeyTools (for key panel devices only) ...................................................................................

.. 9-12

9.2.6 Screen keyboard (for touch panel device only)........................................................................ 9-13

9.2.7 Setbrightness ........................................................................................................................... 9-14

9.2.8 CheckLanguageID ................................................................................................................... 9-15

9.2.9 Multilingual settings for the operating system.......................................................................... 9-16

9.2.10 DVD ROM/CD RW ................................................................................................................... 9-18

9.2.11 USB keyboard controller .......................................................................................................... 9-19

10 Operation.............................................................................................................................................. 10-1

10.1 Status displays ......................................................................................................................... 10-1

10.2 General control elements ......................................................................................................... 10-2

10.3 Device with key panel .............................................................................................................. 10-3

10.3.1 Using the keyboard .................................................................................................................. 10-4

10.3.2 Using the direct control key module....................................................................................... 10-10

10.3.3 Labelling function keys and softkeys ..................................................................................... 10-14

10.3.4 Using the integrated mouse ................................................................................................... 10-16

10.4 Device with touch screen ....................................................................................................... 10-17

10.4.1 Using the touch screen .......................................................................................................... 10-18

10.5 Disk drive................................................................................................................................ 10-19

10.6 Transferring authorizations .................................................................................................... 10-20

SIMATIC Panel PC 877

iv Operating instructions, Release 07/2006, A5E00877780-01

Page 7

Table of contents

11 Functions.............................................................................................................................................. 11-1

11.1 Overview .................................................................................................................................. 11-1

11.2 Safecard on Motherboard (SOM)............................................................................................. 11-2

11.3 Temperature monitoring........................................................................................................... 11-4

11.4 Watchdog (WD)........................................................................................................................ 11-5

11.5 Fan monitoring ......................................................................................................................... 11-6

12 Maintenance and service...................................................................................................................... 12-1

12.1 Servicing .................................................................................................................................. 12-1

12.2 Replacement parts................................................................................................................... 12-3

12.3 Separating the control unit from the computer unit.................................................................. 12-4

12.4 Installing and removing hardware components ....................................................................... 12-7

12.4.1 Repairs..................................................................................................................................... 12-7

12.4.2 Open the device....................................................................................................................... 12-8

12.4.3 Installing and removing memory modules ............................................................................. 12-10

12.4.4 Installing PCI / AT cards ........................................................................................................ 12-12

12.4.4.1 Notes on the modules ............................................................................................................ 12-12

12.4.4.2 Installing / removing expansion modules............................................................................... 12-13

12.4.4.3 Exchanging the RAID controller PCI card.............................................................................. 12-15

12.4.5 Disk drives.............................................................................................................................. 12-16

12.4.5.1 Options of installing disk drives.............................................................................................. 12-16

12.4.5.2 Installing / removing a drive bay ............................................................................................ 12-18

12.4.5.3 Removing and installing an optical drive ............................................................................... 12-21

12.4.5.4 Removing and installing a 3.5" hard disk............................................................................... 12-24

12.4.6 Replacing the backup battery ................................................................................................ 12-25

12.4.7 Removing/Installing the Power Supply .................................................................................. 12-27

12.5 Installing Software.................................................................................................................. 12-29

12.5.1 General installation procedure............................................................................................... 12-29

12.5.2 Setting up the partitions for Windows operating systems...................................................... 12-30

12.5.3 Compatibility of the Restore DVD .......................................................................................... 12-32

12.5.4 Restoring the factory state of the software using the Restore DVD ...................................... 12-33

12.5.5 Installing Microsoft Windows operating systems ..........

......................................................... 12-35

12.5.5.1 Operating system not installed............................................................................................... 12-35

12.5.5.2 Booting from the Recovery CD .............................................................................................. 12-36

12.5.5.3 Installing the Microsoft Windows operating system (not for RAID)........................................ 12-37

12.5.5.4 Installing the Microsoft Windows operating system (for RAID).............................................. 12-38

12.5.6 Installing individual drivers..................................................................................................... 12-39

12.5.7 Operation of two hard disks ................................................................................................... 12-40

12.5.7.1 2 HDD system........................................................................................................................ 12-40

12.5.7.2 RAID system with Promise Fast Track Controller TX2300.................................................... 12-41

12.5.7.3 Installing the RAID Controller software.................................................................................. 12-44

12.5.8 Installing burner and DVD software ....................................................................................... 12-45

12.5.9 Backing up the hard disk........................................................................................................ 12-46

13 Alarm, error and system messages ...................................................................................................... 13-1

13.1 Boot error messages................................................................................................................ 13-1

13.2 Introduction to the BIOS beep codes....................................................................................... 13-3

13.3 BIOS beep codes..................................................................................................................... 13-5

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

v

Page 8

Table of contents

14 Troubleshooting/FAQs.......................................................................................................................... 14-1

14.1 General problems..................................................................................................................... 14-1

14.2 Problems when Using Modules of Third-party Manufacturers................................................. 14-2

14.3 Temperature limits ................................................................................................................... 14-3

15 Technical data ...................................................................................................................................... 15-1

15.1 General technical data ............................................................................................................. 15-1

15.2 Power requirements of the components .................................................................................. 15-8

15.3 Device with AC voltage supply................................................................................................. 15-9

15.4 Device with DC voltage supply .............................................................................................. 15-10

15.5 Keyboard table ....................................................................................................................... 15-11

16 Dimension drawings ............................................................................................................................. 16-1

16.1 Panel PC 877 dimensional drawing ......................................................................................... 16-1

16.2 Dimensional drawings for the installation of expansion modules ............................................16-3

17 Detailed descriptions ............................................................................................................................ 17-1

17.1 Motherboard............................................................................................................................. 17-1

17.1.1 Structure and functions of the motherboard............................................................................. 17-1

17.1.2 Technical features of the motherboard .................................................................................... 17-2

17.1.3 Position of the ports on the motherboard................................................................................. 17-4

17.1.4 External interfaces ................................................................................................................... 17-5

17.1.5 Front interfaces ...................................................................................................................... 17-13

17.1.6 Internal interfaces................................................................................................................... 17-18

17.2 Bus board ............................................................................................................................... 17-24

17.2.1 Layout and principle of operation........................................................................................... 17-24

17.2.2 Assignment of the PCI IRQ channels to the PCI slots........................................................... 17-25

17.2.3 Exclusive PCI hardware interrupt........................................................................................... 17-26

17.2.4 ISA slot pin assignment.......................................................................................................... 17-27

17.3 Operating system licenses ..................................................................................................... 17-29

17.4 Cables .................................................................................................................................... 17-30

17.5 System resources .................................................................................................................. 17-31

17.5.1 Currently allocated system resources.................................................................................... 17-31

17.5.2 System resources used by the BIOS/DOS ............................................................................ 17-32

17.5.2.1 I/O address allocation ............................................................................................................ 17-32

17.5.2.2 Interrupt Assignments ............................................................................................................ 17-34

17.5.2.3 Memory address assignments ............................................................................................... 17-35

17.6 BIOS setup ............................................................................................................................. 17-36

17.6.1 Overview ................................................................................................................................ 17-36

17.6.2 Starting BIOS Setup............................................................................................................... 17-37

17.6.3 BIOS setup menus ................................................................................................................. 17-38

17.6.4 Main menu.............................................................................................................................. 17-40

17.6.5 Advanced menu ..................................................................................................................... 17-51

17.6.6 Security menu ........................................................................................................................ 17-59

17.6.7 Power menu ........................................................................................................................... 17-61

17.6.8 Boot menu.............................................................................................................................. 17-62

17.6.9 Version menu ......................................................................................................................... 17-64

17.6.10 Exit menu ............................................................................................................................... 17-65

17.6.11 BIOS setup default settings.................................................................................................... 17-66

SIMATIC Panel PC 877

vi Operating instructions, Release 07/2006, A5E00877780-01

Page 9

Table of contents

A Appendix.................................................................................................................................................A-1

A.1 Certificates and guidelines.........................................................................................................A-1

A.1.1 Guidelines and declarations....................................................................................................... A-1

A.1.2 Certificates and approvals ......................................................................................................... A-3

A.1.3 Electrostatic charging of individuals...........................................................................................A-5

A.2 Additional support ...................................................................................................................... A-6

B ESD directives........................................................................................................................................B-1

B.1 ESD guideline ............................................................................................................................ B-1

C List of abbreviations / acronyms .............................................................................................................C-1

C.1 Abbreviations .............................................................................................................................C-1

Glossary ..................................................................................................................................... Glossary-1

Index................................................................................................................................................ Index-1

Tables

Table 4-1 Dimensions for the mounting cut-out in mm ............................................................................ 4-10

Table 10-1 Keyboard codes ..................................................................................................................... 10-11

Table 13-1 Converting the beep codes in a Hex display ........................................................................... 13-3

Table 16-1 Panel PC 877 dimensions in mm............................................................................................. 16-2

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

vii

Page 10

Table of contents

SIMATIC Panel PC 877

viii Operating instructions, Release 07/2006, A5E00877780-01

Page 11

Foreword

1.1 1.1 Overview

Purpose of the manual

These operating instructions contain all the information you need for commissioning and

using the SIMATIC Panel PC 877.

It is intended both for programming and testing personnel who commission the device and

connect it with other units (automation systems, programming devices), as well as for service

and maintenance personnel who install add-ons or carry out fault/error analyses.

Required basic knowledge

A solid background in personal computers and Microsoft operating systems is required to

understand this manual. General knowledge in the field of automation control engineering is

recommended.

Scope of this manual

This manual applies to devices with the order numbers 6AV781.…

1

Approvals

For more information, please refer to the chapter "Certificates and Guidelines" in the

appendix.

CE marking

For more information, please refer to "Directives and Declarations" in the "Certificates and

Guidelines" section of the appendix.

Standards

Please refer to sections "Application planning" and "Technical data".

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

1-1

Page 12

Foreword

1.1 Overview

Position in the information landscape

The documentation for the Panel PC includes the following sections:

• SIMATIC Panel PC 877, Operating Instructions (compact) with the following information:

– Commissioning

– Legal information

• SIMATIC Panel PC 877, Operating Instructions

The documentation is supplied with the Panel PC in electronic form as a PDF file on the

"Documentation and Drivers" CD. The documentation is available in German, English,

French, Italian and Spanish.

Additional information about the Windows operating system is available on the Internet at the

Microsoft homepage at http://www.Microsoft.com.

Conventions

The following text notation will facilitate reading this manual:

Representation Validity

"File"

"File > Edit" Operational sequences, e.g., menu commands/shortcut menu

<F1>, <Shift>+<F1> Keys and key combinations

• Terminology that occurs in the user interface, e.g., dialog

names, tabs, buttons, menu commands

• Required parameters such as limit values, tag values

• Path information

commands.

Trademarks

The term "Panel PC 877", "control unit" and "computer unit" is uniformly referred to as the

"device" in these operating instructions. The full term is only used when a concrete reference

is necessary.

Note

A note is important information about the product, handling the product or a reference to

specific sections of the documentation that require special consideration.

All names labeled with ® symbol are registered trademarks of Siemens AG. Other names

used in this documentation may be trademarks, the use of which by third parties for their

own purposes could violate the rights of the owner.

HMI®

SIMATIC®

SIMATIC HMI®

SIMATIC WinCC®

SIMATIC WinCC flexible®

Panel PC 877®

SIMATIC Panel PC 877

1-2 Operating instructions, Release 07/2006, A5E00877780-01

Page 13

Foreword

2.1 Safety information

Safety information

2.1 2.1 Safety information

Warning

Emergencies

In the event of a device fault, interrupt the power supply immediately. Inform the customer

service personnel responsible. Malfunctions can occur when the operator controls or power

cable are damaged or when liquids or foreign objects penetrate the device.

Warning

Following the results of a risk analysis, additional protection equipment on the machine or

the system is necessary to avoid endangering persons. With this, especially the

programming, configuration and wiring of the inserted I/O modules have to be executed, in

accordance with the necessary risk analysis identified safety performance (SIL, PL or Cat.).

The intended use of the device has to be ensured.

2

The proper use of the device has to be verified with a function test on the system. With this

programming, configuration and wiring errors can be identified. The test results have to be

documented and if necessary inserted into the relevant inputs.

Note

This device corresponds to the regulations of the EU low-voltage directive and the GPSG,

verified by conformity with national and international standards (DIN EN, IEC) by a UL

approval (cULuc). Please comply with all the information in these operating instructions

when assembling the device.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

2-3

Page 14

Foreword

2.1 Safety information

Electrical connection

Warning

Disconnect the device from the mains before every intervention.

Do not touch power lines or data transmission lines during electrical storms and do not

connect any cables.

System expansions

Only install system expansion devices designed for this device. If you install other

expansions, you may damage the system or violate the safety requirements and regulations

for radio frequency interference suppression. Contact your technical support team or where

you purchased your PC to find out which system expansion devices may safely be installed.

Caution

If you install or exchange system expansions and damage your device, the warranty

becomes void.

High frequency radiation

Caution

Unintentional operating situations

High frequency radiation, e.g. from cell phones, can cause unintentional operating situations

under some circumstances. Further information is available in the section "EMC

requirements" of the "Technical data" chapter.

SIMATIC Panel PC 877

2-4 Operating instructions, Release 07/2006, A5E00877780-01

Page 15

Foreword

2.1 Safety information

Handling and disposal of lithium batteries

Warning

Danger of explosion and the release of harmful substances!

Do not throw lithium batteries into fire, do not solder onto the cell body, do not open, do not

short circuit, do not reverse pole, do not heat above 100 °C, dispose of according to

regulations, and protect from direct sunlight, moisture and condensation.

Replace lithium batteries with the same brand or a brand recommended by the

manufacturer.

Dispose of used lithium batteries as hazardous waste, individually, in accordance with the

local regulations.

Repairs

Only authorized personnel are permitted to repair the device.

Warning

Unauthorized opening of and improper repairs to the device may result in substantial

damage to equipment or endanger the user.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

2-5

Page 16

Foreword

2.2 General information

2.2 2.2 General information

Overview

Transport

Caution

The device is approved for operation in closed rooms only. The guarantee is void if this

stipulation is ignored.

Avoid extreme environmental operating conditions. Protect your device against dust,

moisture and heat. For additional information, refer to the Technical data.

Do not place the device in direct sunlight.

Unpack the device at its installation location. Transport the device only in the original

packaging. Do not transport the device when it is mounted.

Notice

Adhere to these stipulations each time the device is transported, otherwise the guarantee is

void.

Caution

Condensation

When transporting the device at low temperatures, ensure that no moisture gets on or into

the device. This also applies if the device is subjected to extreme changes in temperature.

Commissioning

Allow the device to slowly adjust to room temperature before commissioning the device. Do

no place the device near heat radiation. If moisture condensation occurs, wait at least 12

hours before you switch on the device.

Vibration

Optical drives are sensitive to vibration. Inadmissible vibration during operation may result in

loss of data or damage to the drive or data medium.

Before transporting the device, wait at least 20 seconds to allow the drive to stop completely.

SIMATIC Panel PC 877

2-6 Operating instructions, Release 07/2006, A5E00877780-01

Page 17

Foreword

2.2 General information

Tools & downloads

Please check regularly if updates and hotfixes are available for download to your device.

Downloads are available on the Internet at http://www.siemens.com/asis under "Support".

Click on "Software Tools & Downloads" on "Overview Panel PCs" Using the global search

function, you can then also search for any downloads you require.

Processor and optical drive

Notice

An optical drive should only be operated in a mechanically undisturbed environment without

vibrations and shock.

Safety-relevant applications

Warning

Maloperation

Do not perform safety-relevant functions of the user software with the touch screen.

Chemical stability

Caution

Adhere to the information regarding chemical resistance of the panel front. Please go to

http://www.siemens.com/asis under "Tools & Downloads" for more information. Enter the

article ID 16532108 as the search term. The available articles are displayed.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

2-7

Page 18

Foreword

2.2 General information

Sources of light

Notice

Position the screen so that it is not subject to direct sunlight or other strong sources of light.

Defective pixels in the display

At present, the manufacturing process of modern displays does not guarantee that all pixels

of the display will be perfect. A small number of defective pixels in the display is therefore

unavoidable. This does not present a functional problem as long as the defective pixels are

not bunched in one location.

Further information is available in the section "General technical data" of the "Technical

data" chapter.

Burn-in dffect on TFT displays

A permanent picture with bright images can lead to a burn-in effect on the TFT LCD.

If a screen saver is activated, please observe the following:

• The liquid crystals in screen savers which actuate active black when the backlighting is

on, e.g. flying stars "starfield simulation," renew themselves. Pay attention to the length of

time the backlighting is activated

• The following applies to screen savers which turn off the the backlighting: Each time the

backlighting is turned on, its life is reduced by 50 minutes.

Consider the following carefully:

• Screen saver

• Switch off the backlighting regularly

• Permanent display of the customer application

SIMATIC Panel PC 877

2-8 Operating instructions, Release 07/2006, A5E00877780-01

Page 19

Description

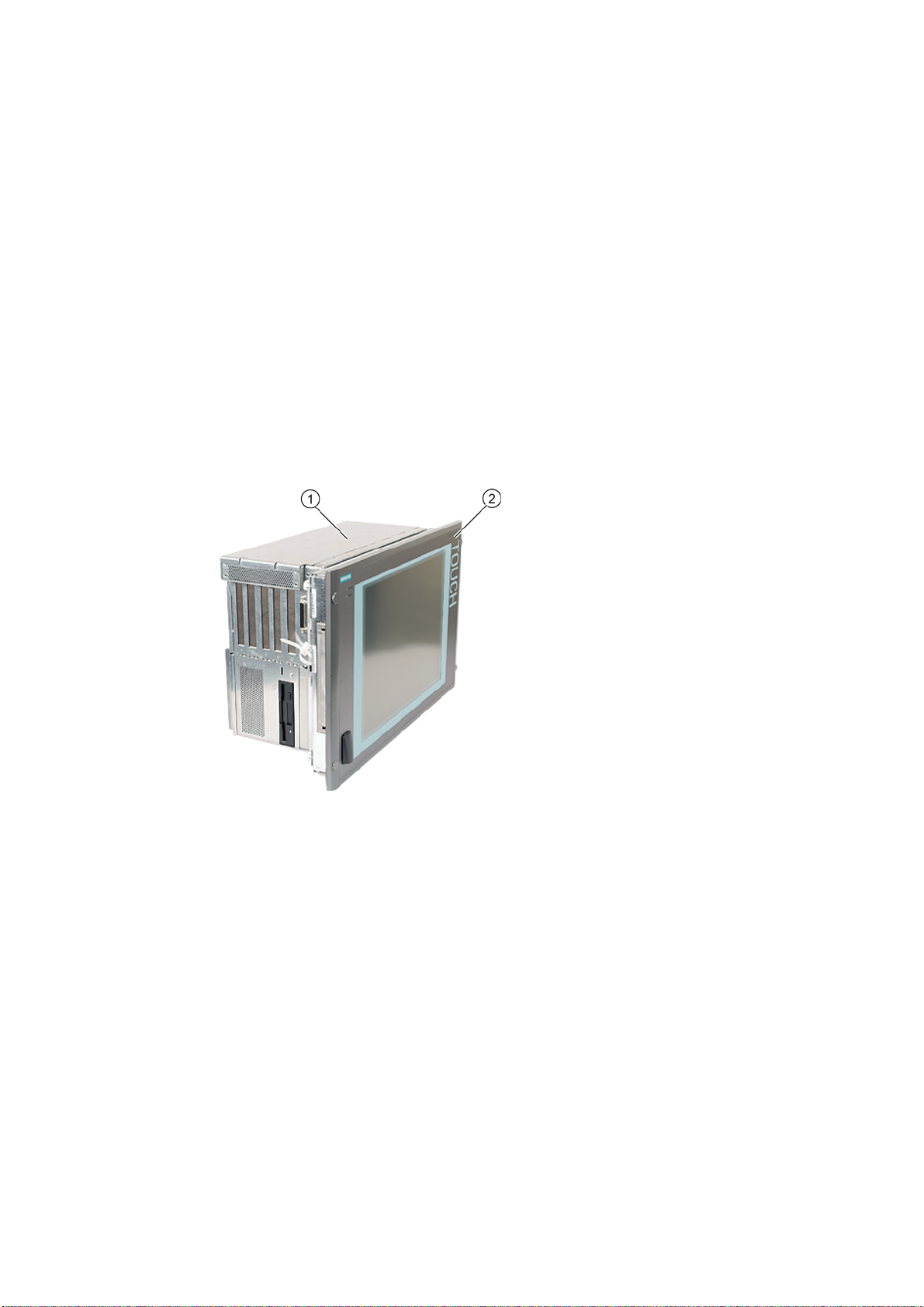

3.1 3.1 Design

Design

3

Figure 3-1 Panel PC 877

1 Computer unit

2 Control unit

Brief description

The device is available with different control units which are distinguished by the size of the

display and by the membrane keyboard or touch screen.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

3-1

Page 20

Description

3.1 Design

Keyboard variants

• Color display with backlighting:

– 12'' TFT technology with 800 x 600 resolution

– 15'' TFT technology with 1024 x 768 resolution

• Membrane keyboard with alphanumeric keys, numeric keys, cursor keys and control keys

• Function keys and softkeys

• Integrated mouse

• LEDs for power supply, temperature, softkeys, <Shift> and <ACK> keys

• Front-mounted USB 2.0 interface for connecting external I/O devices. All fronts are also

available without USB interfaces accessible from the front.

Touch screen variants

• Color display with backlighting

– 15'' TFT technology with 1024 x 768 resolution

– 19'' TFT technology with 1280 x 1024 resolution

• LEDs for power supply and temperature

• Front-mounted USB 2.0 interface for connecting external I/O devices. All fronts are also

available without USB interfaces accessible from the front.

For additional information, refer to the Technical data.

SIMATIC Panel PC 877

3-2 Operating instructions, Release 07/2006, A5E00877780-01

Page 21

Description

3.2 Technical features

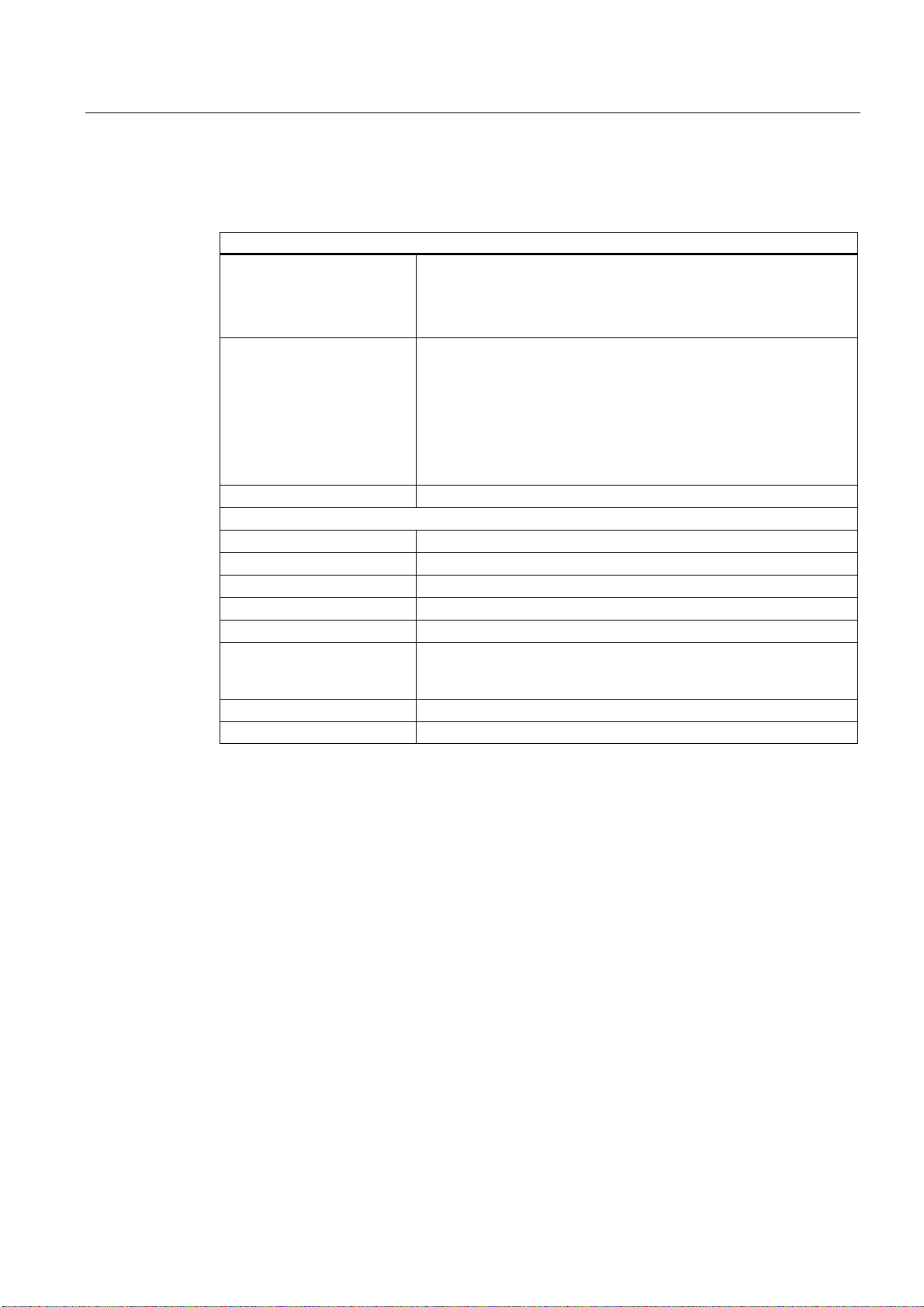

3.2 3.2 Technical features

General features

Slots for add-ons

Graphic VIA ProSavage 8

Disk drive Floppy disk drive

Interfaces

PROFIBUS/MPI 12 Mbps, electrically isolated, compatible to CP 5611

Ethernet 10/100 Mbit/s, RJ45

USB 2x USB 2.0, high current

Serial COM1 V.24, COM2 V.24

Parallel LPT1

Monitor 1 x DVI-I

Keyboard PS/2

Mouse PS/2

• 2x PCI long

• 2x PCI/ISA shared long

• 1x ISA long

• Note: The RAID1 option takes one PCI slot.

Graphics memory 8, 16 or 32 MB taken from main memory

CRT:

• up to 1600 x 1200 pixels, 60 Hz,16-bit color depth

• up to 1280 x 1024 pixels, 100 Hz,32-bit color depth

• LCD:

• LVDS or DVI up to 1280 x 1024 / 18-bit TFT

VGA monitors can be connected with a DVI/VGA adapter, to be

purchased separately.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

3-3

Page 22

Description

3.2 Technical features

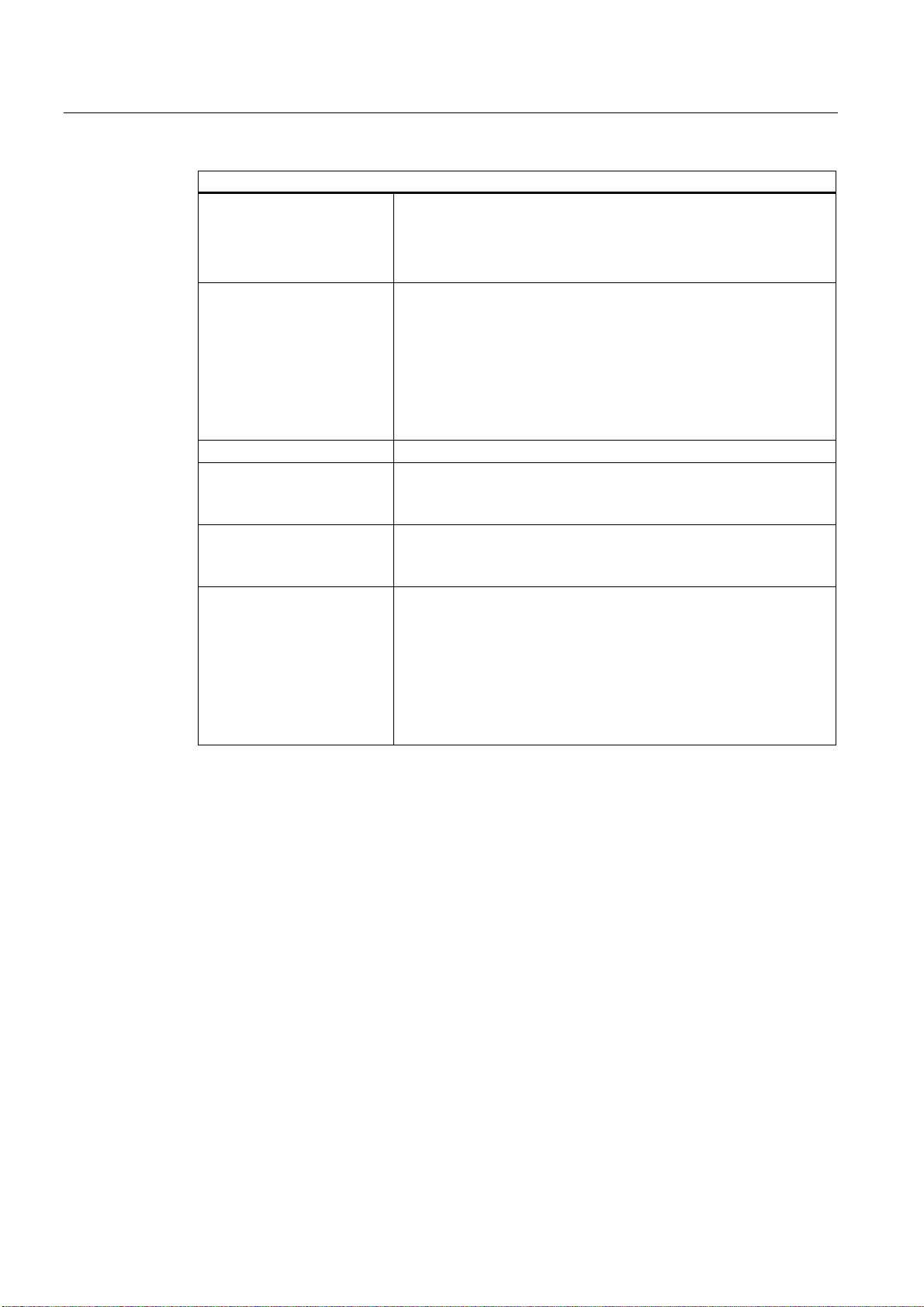

Configuration options

Power supply

Processor

Main memory 2-socket SDRAM DDR266: 256 MB, 512 MB, 1 GB, 2 GB

Hard disks

Disk drive

Operating system Without

• 100V/240V AC, 360 W; wide range; with bridgin

brief power failures in accordance with NAMUR:

maximum 20 ms at 0.85 x U

• 24 V DC, 265 VA, optional, only in connection with

Intel ® Pentium Mobile

• Intel ® Celeron 2 GHz,

400 MHz Front Side Bus FSB,

1024 Kbytes Second Level Cache

• Intel ® Pentium 4 2.8 GHz,

533 MHz Front Side Bus FSB,

512 Kbytes Second Level Cache

• Intel ® Pentium 4 Mobile 2.2 GHz,

400 MHz Front Side Bus FSB,

512 Kbytes Second Level Cache

• 1 x 3.5" hard disk ≥ 40 GB

• 1 x 3.5" hard disk ≥ 80 GB

• 2 x 2.5'' hard disks ≥ 60 GB with RAID 1 system SATA

• Without

• DVD-ROM

• CD-RW/DVD drive

Preinstalled, also provided on the Restore DVD and Microsoft

Recovery CD

• Windows 2000 Professional MUI*

• Windows XP Professional MUI*

*MUI: Multi-lingual user interface; German, English, French, Italian,

Spanish, Japanese, Korean, Chinese simplified and Chinese

traditional

(Un = rated voltage)

n

SIMATIC Panel PC 877

3-4 Operating instructions, Release 07/2006, A5E00877780-01

Page 23

Description

3.3 Accessories

3.3 3.3 Accessories

The accessories comprise the following components:

Accessories Comment Order No.

Direct control key module 6AV7671-7DA00-0AA0

Film for protecting the touch screen panel

against dirt and scratches

for 15" touch screen variant

for 19" touch screen variant

Film for labeling function keys

(slide-in labels)

DVI / VGA adapter A5E00254532

Backing plate for screw fixing of the 19" touch

front

Multi IO module Two parallel and two serial interfaces 6ES7648-2CA00-0AA0

SIMATIC PC DiagMonitor

software V 2.2

SIMATIC PC/PG Image & Partition Creator Software for local data backup 6ES7648-6AA03-0YX0

Module for DDR RAM memory expansion 256 MB

Remote Kit order version

Remote Kit, 24V DC, 5m

Remote Kit, 24V DC, 10m

Remote Kit, 24V DC, 20m

Remote Kit, 24V DC, 30m

Remote Kit, 120/230 V AC, 5m

Remote Kit, 120/230 V AC, 10m

Remote Kit, 120/230 V AC, 20m

Remote Kit, 120/230 V AC, 30m

1)

6AV7671-4BA00-0AA0

6AV7672-1CE00-0AA0

6AV7672-0DA00-0AA0

6AV7672-8KE00-0AA0

Software for monitoring local and remote

SIMATIC PCs:

• Watchdog

• Temperature

• Fan speed

• Hard disk monitoring, SMART

• System monitoring,

Ethernet monitoring: Heartbeat

Communication:

• Ethernet interface, SNMP protocol

• OPC for integrating in SIMATIC software

• Client server architecture

• Layout of log files

512 MB

1 GB

6ES7648-6CA02-2YX0

6ES7648-2AG20-0GA0

6ES7648-2AG30-0GA0

6ES7648-2AG40-0GA0

6AV7671-1EA00-5AA1

6AV7671-1EA01-0AA1

6AV7671-1EA02-0AA1

6AV7671-1EA03-0AA1

6AV7671-1EA10-5AA1

6AV7671-1EA11-0AA1

6AV7671-1EA12-0AA1

6AV7671-1EA13-0AA1

For further accessories, see Catalog or Siemens MALL

1) You can also find the print templates for the slide-in labels on the Internet

at:

http://www.siemens.com/asis

At

Tools & Downloads>Downloads>Produkt Support>Industrie-PC

8782947.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

, enter the entry ID

3-5

Page 24

Description

3.3 Accessories

SIMATIC Panel PC 877

3-6 Operating instructions, Release 07/2006, A5E00877780-01

Page 25

Application planning

4.1 4.1 Overview

Introduction

This section describes the first steps after unpackaging, the permitted mounting positions

and the fixation. This section describes the necessary considerations for EMC.

Field of application

The Panel PC is an industry-standard PC platform for demanding tasks in the field of PCbased automation. The Panel PC is designed for on-site use on the machine, installed for

example in:

• Switchgear cabinet installation

• Swivel arm installation

• Rack installation

4

Note

In the following, the term "switchgear cabinet" also refers to rack, mounting rack,

switchboard, operator panel and console. The term "device" represents the Panel PC and

its variants.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

4-1

Page 26

Application planning

4.2 Unpacking and checking the delivery

4.2 4.2 Unpacking and checking the delivery

Procedure

1. Please check the packaging material for transport damage upon delivery.

2. If any transport damage is present at the time of delivery, lodge a complaint at the

shipping company in charge. Have the shipper confirm the transport damage

immediately.

3. Unpack the device.

Caution

Do not lie the device on its back. This will avoid any damage to an optical drive which

may be present. Lie the front side on a soft surface to avoid damaging the front panel

USB port.

4. Keep the packaging material in case you have to transport the unit again.

Notice

The packaging protects the device during transport and storage. Therefore, never

dispose of the original packaging material!

5. Please keep the enclosed documentation in a safe place. You will need the

documentation when you start up the device for the first time.

6. Check the package contents for completeness and any visible transport damage. Check

for completeness using the enclosed scope of delivery list.

7. Should the contents of the package be incomplete or damaged, please inform the

responsible supply service immediately and fax us the enclosed form "SIMATIC IPC/PG

quality control report".

Warning

Make sure that a damaged device is not installed nor put into operation.

8. Note the identification information as described in the chapter "Identification data of the

device".

SIMATIC Panel PC 877

4-2 Operating instructions, Release 07/2006, A5E00877780-01

Page 27

Application planning

4.3 Device identification data

4.3 4.3 Device identification data

Procedure

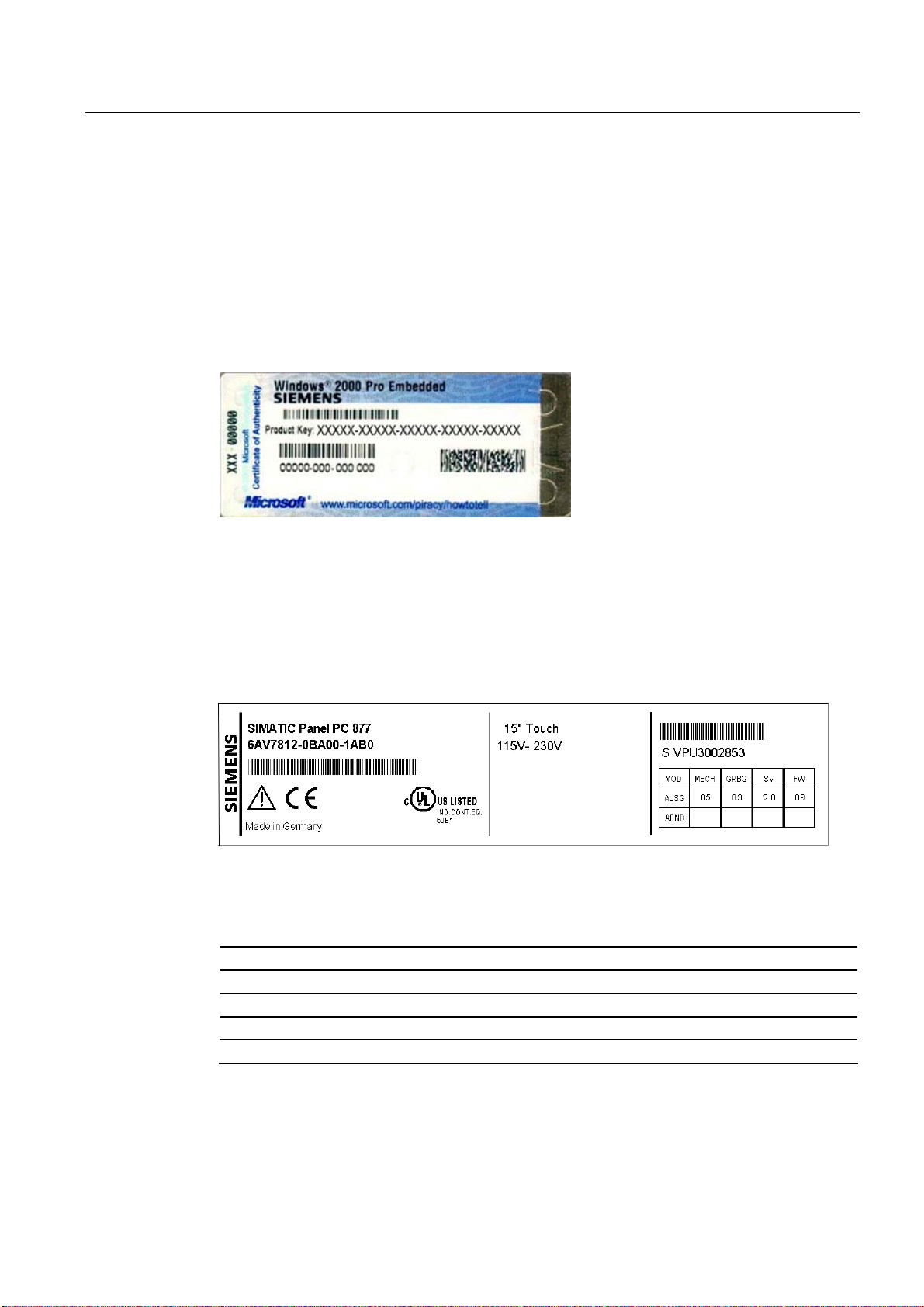

1. Write down the Microsoft Windows Product Key of the Certificate of Authenticity COA in

the table at the end of this section. The COA label is only present in preinstalled Windows

2000 Professional or XP Professional and is affixed to the back of the device. You will

need the product key during the reinstallation of the operating system.

Figure 4-1 COA label, example

2. Write down the manufacturer's number SVP and the order number, for example "6AV...",

and enter it in the table. If repairs are necessary, the device can be identified by the

service center on the basis of the SVP number and order number.

Both numbers are located on the rating label on the computer unit at the top of the fan

side.

Figure 4-2 Panel PC 877 rating plate, example

3. Enter the Ethernet address of the device: The Ethernet address is located in the "Main"

menu of the BIOS setup, "Hardware Options > Ethernet Address."

Identification Number

1 Microsoft Windows Product Key COA

2 SVP number

3 Order number of the device

4 Ethernet address

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

4-3

Page 28

Application planning

4.4 Mounting Positions and Fastening

4.4 4.4 Mounting Positions and Fastening

4.4.1 Installation guidelines

Before installing the device, read the following general notes relating to installation.

Warning

Danger, high voltage

Isolate the power supply to the switchgear cabinet before opening it. Ensure that the power

to the switchgear cabinet cannot be turned on accidentally.

Caution

The device is approved for operation in closed rooms only.

• Ensure that the protective contact socket of the building installation is easily accessible

and that there is a mains disconnect switch in switchgear cabinet installations.

• Position the screen in an ergonomic position favorable to the user. Choose a suitable

installation height.

• Position the screen so that it is not subject to direct sunlight or other strong sources of

light.

• Optical drives are susceptible to shock. Shocks during operation can lead to the loss of

data or damage to the drive or data carrier. Optical drives are not only suitable for

continuous operation.

• Applies to devices which are installed in swivel arm housings: Avoid rapid or jerky

movements of the swivel arm during operation. The ensuing forces could lead to possible

irreversible damage of the hard disk.

The stops of the swivel arm must be damped in order to avoid any mechanical shock

effect to the Panel PC on attachment.

• Applies to devices which are installed in cabinet doors: Prevent the doors being slammed

shut. The ensuing forces could lead to possible irreversible damage of the hard disk.

• The device wtih DC power supply applies in the area of the computer unit and above all

the power supply connection in accordance with the UL approval as "open type" or "open

equipment". For this reason, the device must be installed in a control cabinet or housing

that complies with fire-proofing requirements

SIMATIC Panel PC 877

4-4 Operating instructions, Release 07/2006, A5E00877780-01

Page 29

Application planning

4.4 Mounting Positions and Fastening

Note

The computer unit with AC power supply satisfies fire protection requirements to

EN60950-1. It may therefore be installed without additional fire-proofing measures.

• Provide adequate volume in the switchgear cabinet for air circulation and heat transport.

Keep at least 10 cm distance between the device and switchgear cabinet.

• Ensure that the maximum air intake temperature, measured 10 cm before the air intake

opening on the fan, does not exceed 45°C. The maximum air intake temperature must be

accounted for especially when sizing closed switchgear cabinets.

• The minimum distance between the device and the housing is 10 cm on the air output

side at the fan.

• Position the device in such a way that the air vents of the housing are not covered up

following mounting.

• Ensure there is enough free space in the switchgear cabinet to allow the sheet metal

cover to be removed. You will otherwise have to remove the device from the switchgear

cabinet or swivel arm when replacing memory or the battery.

• Provide enough free space to add on to the device.

• Equip the switchgear cabinet with struts for stabilizing the mounting cut-out. Install struts

where necessary.

• Avoid extreme environmental operating conditions. Protect your device against dust,

moisture and heat.

• Install the device in such a way (see Chapter

danger, e.g. by falling over.

• During assembly, please comply with the approved installation positions.

Technical specifications

) that it poses no

Notice

If you mount the device in an impermissible installation position or you do not observe the

environmental conditions (see Chapter

product safety provided by the UL-approval and compliance with the low-voltage directive

(via EN 60950-1). In additional, the functionality of the device is no longer guaranteed.

Technical specifications

), you endanger the

For additional information, refer to the dimension diagrams in the appendix.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

4-5

Page 30

Application planning

4.4 Mounting Positions and Fastening

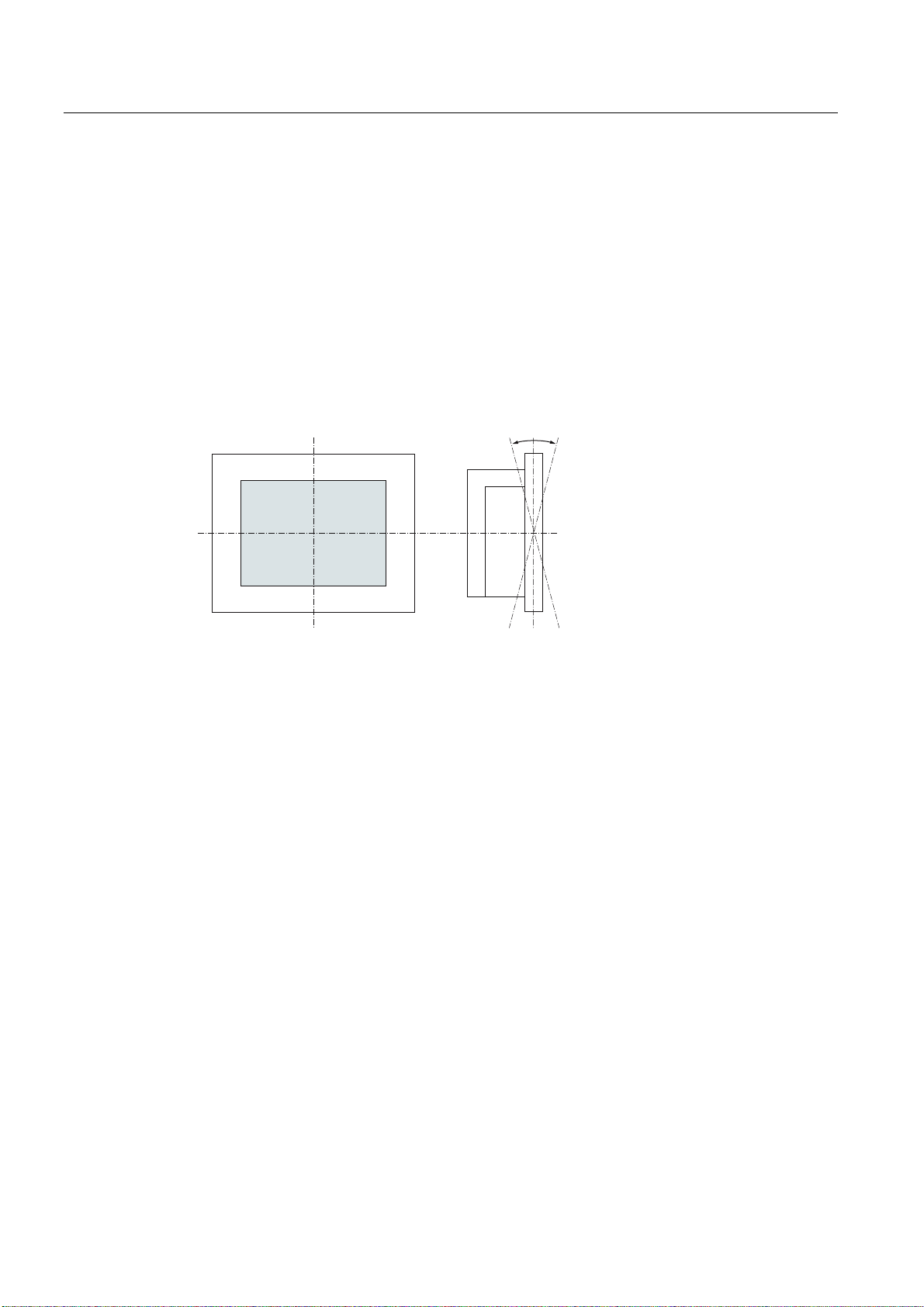

4.4.2 Permitted mounting positions

Approval

Certain mounting positions are approved for the equipment that comprises one control unit

and one computer unit.

Permitted mounting positions

r

r

Vertical installation with deviations between +20° and -20° in the given directions is

permissible.

SIMATIC Panel PC 877

4-6 Operating instructions, Release 07/2006, A5E00877780-01

Page 31

Application planning

4.4 Mounting Positions and Fastening

4.4.3 Type of fixation

The computer unit is secured in the mounting cut-out either with clamps or screws.

Select the type of fixation suitable to your requirements for the degree of protection (see

Section

Protection against dust and water

) .

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

4-7

Page 32

Application planning

4.4 Mounting Positions and Fastening

4.4.4 Protection against dust and water

Principle

The degree of protection provided at the front is assured when the mounting seal lies

completely against the mounting cut-out.

Caution

Please ensure that the material strength at the mounting cut-out is a maximum of 6 mm.

Please follow the specifications for the dimensions in the "Mounting cut-out" section.

The degrees of protection are only guaranteed when the following is observed:

• The material strength at the mounting cut-out is at least 2 mm.

• The surface plane deviation of the mounting cut-out in relation to the external dimensions

of the control unit amounts to ≤ 0.5 mm when the control unit is mounted.

IP65 degree of protection and NEMA4

IP65 degree of protection and compliance with the NEMA4 regulations are only ensured

when clamp mounting together with a ring seal.

IP54 degree of protection

This degree of protection is achieved for screw fixing of all operator control units with a key

front panel and the 15" and 19" operator control units with a touch front panel. This degree of

protection is assured for the 19" operator control unit with a touch front panel when the

mounting components for 19" rack accessories are used.

Note

For screw fixing of the 19" touch panel front, a backing plate is available as an accessory.

For further information, see "http://mall.ad.siemens.com/

".

SIMATIC Panel PC 877

4-8 Operating instructions, Release 07/2006, A5E00877780-01

Page 33

Application planning

4.5 Mounting cut-out

4.5 4.5 Mounting cut-out

4.5.1 Preparing the mounting cut-out

The following illustration show the dimensions for the mounting cut-out.

$

$

6

/

/

/

/ /

/ 6 6 /

66

/ 6 6 /

/

/

/

/

Figure 4-3 Drill holes for the screws and pressure points for the clamp screws

/

PP

(1) Drill hole for screw attachment (4) Clamp

(2) Pressure points for clamp (5) R

(3) Setscrews (6) Seal area

Note

Installed dimensions can be read from the dimension overview or they can be transferred to

the cabinet from the mounting template supplied.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

120 in the seal area

Z

4-9

Page 34

Application planning

4.5 Mounting cut-out

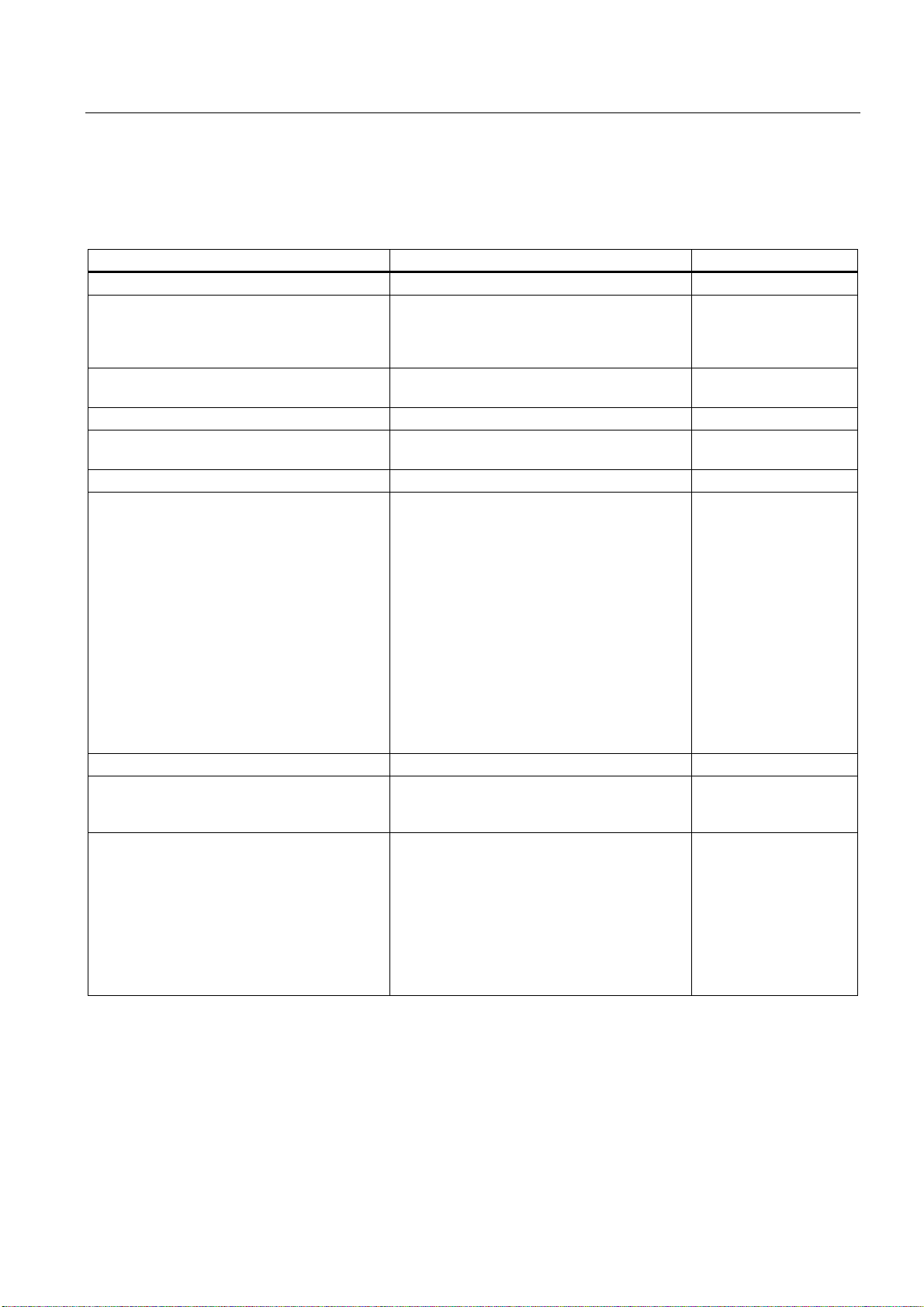

Table 4-1 Dimensions for the mounting cut-out in mm

Control unit L1 L2 L3

1)

L4

L5 L6

2)

L7

2)

L8

2)

L9

2)

A1 A2 S1 S2

S3

S5

3)

S6

S73)

3)

1)

S4

Tolerance +1 +1 ±0.2 ±0.5 ±0.5 ±0.5 ±0.5 +1 ±1 ±1 ±1 ±1 ±1 ±1

Key panel

12" TFT

15" TFT

Touch panel

15" TFT

19" TFT

450

290

465

235

112

450

321

465

279

112

450

290

465

235

112

450

380

465

235

112

1)

M6 thread or drilled holes of 7 mm diameter

2)

Cut-outs for the slots or inserted labels are required for 15'' key panels only

3)

Two clamps are required vertically for clamp mounting for the 19' touch panels only

—

—

—

—

16

10

78

186

135

—

—

—

—

25

165

—

—

—

—

16

17

51

16

10

81

16

10

46

78

51

81

46

56

—

56

—

56

—

—

33

Preparing the mounting cut-out

Steps for preparing the mounting cut-out

1 Select a location suitable for mounting, taking into account the mounting position.

2 On the basis of the dimension diagrams, check whether the required screw and pressure points

on the rear and the seal area are easily accessible after the completion of the mounting cut-out.

Otherwise the mounting cut-out is useless.

3 Complete the mounting cut-out in accordance with the dimensions.

SIMATIC Panel PC 877

4-10 Operating instructions, Release 07/2006, A5E00877780-01

Page 35

Application planning

4.5 Mounting cut-out

4.5.2 Mounting depth of the device

Panel PC with operator

units

Key panel with 12" TFT 192 mm

Key panel with 15" TFT 211 mm

Touch panel with 15"

TFT

Touch panel with 19"

TFT

T

209 mm

217 mm

7

Note

Additional mounting depth with optical drive

The installation depth increases by 21 mm when an optical drive is installed in the device.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

4-11

Page 36

Application planning

4.6 EMC directive

4.6 4.6 EMC directive

Electromagnetic compatibility

The device fulfills the requirements of the EMC law of the Federal Republic of Germany as

well as the EMC directive of the Single European Market.

The device is designed as a built-in device. You ensure compliance with the EN 61000-4-2

(ESD) EMC standard by installing the device in grounded metal cabinets (e.g. 8 MC

cabinets, Siemens catalog NV21).

Note

For additional information about EMC requirements, refer to the Specifications section.

Installing the device according to EMC directive

Basics for interference-free operation:

• Install the controller according to EMC directive

• Use interference immune cable

Note

The instructions "Guidelines for the assembly of interference immune programmable logic

controllers" with the article ID 1064706 and the manual "PROFIBUS networks" with the

article ID 1971286, which also applies to the installation of the device, is located on the

"Documentation and Drivers" CD.

SIMATIC Panel PC 877

4-12 Operating instructions, Release 07/2006, A5E00877780-01

Page 37

Installation

5.1 5.1 Securing the device with clamps

You require 6 clamps in order to mount the device with a 12"/15" display. A device with a 19"

display must be mounted with 8 clamps. The required number of clamps is included in your

Panel PC delivery package.

Required tool for fasting the clamps: 2.5 mm hexagonal spanner

Figure 5-1 Clamp assembly

Rack installation

Steps for fastening the device with clamps

1 Disconnect the device from the power supply.

2 Working from the front, insert the device into the 19" rack.

3 Fasten the control unit in the rack from the rear using the clamps. Tighten the setscrews to a

torque of 0.4-0.5 Nm.

5

Swivel arm installation

Steps for fastening the device with clamps

1 Disconnect the device from the power supply.

2 Working from the front, place the device onto the swivel arm.

3 Fasten the control unit on the swivel arm from the rear using the clamps. Tighten the setscrews

to a torque of 0.4-0.5 Nm.

Switchgear cabinet installation

Steps for fastening the device with clamps

1 Disconnect the device from the power supply.

2 Working from the front, insert the device into the mounting cut-out.

3 Secure the control unit in the mounting cut-out from behind with the clamps, as shown in the

mounting cut-out in the dimensions. Tighten the setscrews to a torque of 0.4-0.5 Nm.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

5-1

Page 38

Installation

5.1 Securing the device with clamps

IP 65 degree of protection

The plant builder is responsible for the correct installation of the device.

The degree of protection IP65 is only guaranteed for the front of the device if the ring seal is

properly applied with the correct size of cutout, the unit has been clamped in place, and the

instructions below are observed.

Notice

Control cabinet installation; Material strength at the mounting cut-out

Please ensure that the material strength at the mounting cut-out is a maximum of 6 mm.

Please follow the specifications for the dimensions in the "Preparing the mounting cut-out"

section.

The degree of protection can only be guaranteed when the following requirements are met:

1. The material strength at the mounting cut-out must be at least 2 mm.

2. The deviation from the plane in relation to the external dimensions for an installed HMI

device is ≤ 0.5 mm

SIMATIC Panel PC 877

5-2 Operating instructions, Release 07/2006, A5E00877780-01

Page 39

Installation

5.2 Securing the device with screws

5.2 5.2 Securing the device with screws

Drilling holes

Note

To secure the 19" front panel with screws, backing plates with Order No. 6AV7672-8KE00-

0AA0 are required on the front.

Steps for drilling holes

1 Drill holes (Ø approx. 2.5 mm) from the rear in the 4 recesses of the control unit.

2 Use a Ø 5.5 mm bit for M5 and a Ø 6.5 mm bit for M6

3 Deburr the holes from the front of the control unit

Notice

Risk of damage

Ensure that no metal cuttings enter the device when the holes are drilled. Cover the device

with film or when drilling, use removal by suction.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

5-3

Page 40

Installation

5.2 Securing the device with screws

Rack installation

Steps for fastening the device with screws

1 Make drill holes at the prepared mounting cut-out in accordance with the specifications for L4

and L5, as shown at the dimensions in the mounting cut-out

2 Working from the front, insert the device into the 19" rack

3 Secure the control unit by inserting suitable screws through the holes and attaching nuts

Swivel arm installation

Steps for fastening the device with screws

1 Make drill holes at the prepared mounting cut-out in accordance with the specifications for L4

and L5, as shown at the dimensions in the mounting cut-out

2 Working from the front, place the device onto the swivel arm

3 Secure the control unit by inserting suitable screws through the holes and attaching nuts

Switchgear cabinet installation

Steps for fastening the device with screws

1 Make drill holes at the prepared mounting cut-out in accordance with the specifications for L4

and L5, as shown at the dimensions in the mounting cut-out

2 Carefully drill the respective holes in the control unit at the designated location from the rear

3 Working from the front, insert the device into the mounting cut-out

4 Secure the control unit by inserting suitable screws through the holes and attaching nuts

SIMATIC Panel PC 877

5-4 Operating instructions, Release 07/2006, A5E00877780-01

Page 41

Installation

5.2 Securing the device with screws

IP 54 degree of protection

The IP54 degree of protection is guaranteed for screw mounting together with the ring seal.

Caution

Observe the panel seal when mounting

Ensure you do not damage the panel seal when mounting the device.

Notice

Control cabinet installation; Material strength at the mounting cut-out

Please ensure that the material strength at the mounting cut-out is a maximum of 6 mm.

Please follow the specifications for the dimensions in the "Preparing the mounting cut-out"

section.

The degree of protection can only be guaranteed when the following requirements are met:

1. The material strength at the mounting cut-out must be at least 2 mm.

2. The deviation from the plane in relation to the external dimensions for an installed HMI

device is ≤ 0.5 mm

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

5-5

Page 42

Installation

5.2 Securing the device with screws

SIMATIC Panel PC 877

5-6 Operating instructions, Release 07/2006, A5E00877780-01

Page 43

Connecting

6.1 6.1 Connection and operator control components

Connection and operator control components of the computer unit

Connection and operator control components of the left-hand side of the device

Item Name Description

(1) PCI / ISA 5 slots for PCI/ISA expansion modules

(2) LPT 1 Parallel interface

(3) DVI/VGA DVI/VGA socket for CRT or LCD

(4) PS/2 Mouse connection

(5) Reset button (6) PS/2 Keyboard connection

(7) COM 2 Serial interface

(8) USB 2 USB 2.0 connections high current

(9) Ethernet RJ45 connection for 10/100 Mbit/s

(10) PROFIBUS/MPI

/DP

(11) COM 1 Serial interface

6

25-pin Sub-D socket

monitor with DVI interface or VGA

monitor via DVI/VGA adapter

9-pin Sub-D connector

(500 mA)

MPI interface (RS485 electrically

isolated)

9-pin Sub-D connector

25-pin Sub-D connector

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

6-1

Page 44

Connecting

6.1 Connection and operator control components

Reset button

The Reset key can trigger the following function during active operation:

Hardware reset: Immediate shutdown of the device without correct shutdown of the

operating system

This function is used to shut down the device when it no longer responds. This triggers a

hardware reset. Press the key briefly with a pointed object. Following a hardware reset, the

device automatically boots up.

Caution

Data loss

A hardware reset can result in a loss of data.

Connection and operator control components of the right-hand side of the device

Item Name Description

(1) 100 / 240 V AC

or 24 V DC

(2) On / Off switch (3) Equipotential

bonding

Connection for AC or DC power

supply (depending on the

product variant, the figure

shows the AC power plug)

The relevant angle is included

with the device for interlocking

the connector.

Connection for low-resistance

grounding connection

Notice

On / Off switch

The On / Off switch does not disconnect the device from mains. When the switch is in 0

position, the device is still connected to the auxiliary voltage.

SIMATIC Panel PC 877

6-2 Operating instructions, Release 07/2006, A5E00877780-01

Page 45

Connecting

6.1 Connection and operator control components

Connection components of the control unit

USB connection control unit

Item Name Description

(1) USB 1 connection USB 2.0 high current (500 mA)

under sealing flap (not available with every

product variant).

Notice

Guarantee for the IP 65 degree of protection

When the sealed cover over the USB interface is removed in order to connect a USB

component, the IP 65 degree of protection for the device is no longer guaranteed.

Note

Use of USB devices

• Wait at least 10 seconds between the unplugging and replugging of USB devices. This

also applies in particular to touch control in control units with touch screen panels.

• When using standard USB peripherals, bear in mind that their EMC immunity level is

frequently designed for office applications only. These devices may be used for

commissioning and servicing. However, only industry-standard devices are allowed for

industrial operation.

• Peripherals are developed and marketed by individual vendors. The respective

manufacturers offer support for the peripherals. Moreover, the terms of liability of the

individual vendors or suppliers apply here.

SIMATIC Panel PC 877

Operating instructions, Release 07/2006, A5E00877780-01

6-3

Page 46

Connecting

6.2 Connecting the 100 V to 240 V AC power supply

6.2 6.2 Connecting the 100 V to 240 V AC power supply

General connection information

Note the following in order to operate the device safely and according to regulation:

Note

Voltage range

The power supply module is designed for operation on 100 to 240 V AC networks. The

device adjusts automatically to the voltage.

Notice

Risk of damage

Do not connect or disconnect power and data cables during thunderstorms.

Notice

Power supply network

The device is designed for operation on grounded power supply networks (TN systems to

VDE 0100, Part 300, or IEC 60364-3).

It is not permissible for operation on ungrounded or impedance-grounded power networks

(IT networks).

Notice

Permitted mains voltage

The local rated voltage must be within the voltage range of the device.

Notice

Power disconnection

The built-in switch does not disconnect the device from mains. The mains connector on the

device must be disconnected to fully isolate the device from mains. The mains connector

must be easily accessible.

If this cannot be guaranteed, in cabinet installation, for example, or the mains connector

clamp is used, an easily accessible power switch must be built into the device.

SIMATIC Panel PC 877

6-4 Operating instructions, Release 07/2006, A5E00877780-01

Page 47

Connecting

6.2 Connecting the 100 V to 240 V AC power supply

Power Factor Correction

The power supply contains an active PFC (Power Factor Correction) circuit to conform to the

EMC guidelines.

Uninterruptible AC power systems (UPS) must supply a sinusoidal output voltage in the

normal and buffered mode when used with SIMATIC PCs with an active PFC.

UPS characteristics are described and classified in the standards EN 50091-3 and IEC

62040-3. Devices with sinusoidal output voltage in the normal and buffered mode are

identified with the classification “VFI-SS-....” or “VI-SS-....”.

Notice

Risk of damage

Operation of the device on a non-sinusoidal mains voltage can cause damage to the power

supply unit.

Country-specific connection information

For the USA and Canada

A UL-listed power supply cable must be used in the United States and Canada.

Power cables are provided as an accessory for the specific country of delivery.

• 120 V supply voltage

Use a flexible power cable with UL approval and the following features: Type SJT with

three leads, min. 18 AWG conductor cross-section, max. 4.5 m long and parallel 15 A

ground contact connector, minimum rating 125 V.

• 230 V supply voltage

Use a flexible power cable with UL approval and the following features: Type SJT with

three leads, min. 18 AWG conductor cross-section, max. 4.5 m long and tandem 15 A

ground contact connector, minimum rating 250 V.

For countries other than the USA and Canada

• Please note local supply voltages

This device is equipped with a safety-tested power cord which may only be connected to

a ground contact power outlet. If you choose not to use this cable, you must use a flexible

cable of the following type: Min 18 AWG conductor cross-section and 15 A / 250 V