Page 1

1

!

2 RS232 PORTS (FOR HMI AND PC)

!

PROVIDES ACCESS TO PROFIBUS NETWORK THRU DB9

CONNECTOR

!

EASILY CONFIGURED USING EDICT97

!

BASE OR DIN RAIL (OPTIONAL) MOUNTING

!

STATUS LEDs

!

FIELDBUS TYPE : PROFIBUS-DP EN 50 170, IMPLEMENTED

USING SIEMENS SPC3 ASIC

!

AUTOMATIC BAUD RATE DETECTION IN THE RANGE

9.6 KBAUD – 12 MBAUD

!

STATION ADDRESS IS SET BY PROFIBUS NETWORK DRIVER

INSTALLED ON HMI PROGRAMMING PORT

!

FREEZE MODE AND SYNCH MODE ARE SUPPORTED

!

CONFIGURATION ALLOWS FOR SINGLE IDENTIFIER AND

SPECIAL IDENTIFIER DATA AREA DESCRIPTIONS, WITHOUT

DATA CONSISTENCY SUPPORT

DESCRIPTION

The PAPBH Paradigm PROFIBUS Host Adapter provides a communication

channel from a PROFIBUS-DP EN50170 Network to a Paradigm Operator

Interface (HMI). The PROFIBUS Network is connected to the PAPBH

(Paradigm PROFIBUS Host Adapter) through a 9-pin sub-miniature D-type

female connector. The PROFIBUS Network is isolated from the control

electronics using high-speed opto-couplers and isolated from the supply with a

DC/DC converter. Three LED’s provide status information.

The PAPBH can be base mounted (using the 4 holes provided in the base

plate) or DIN rail mounted (using the optional DIN rail mounting kit).

In normal operation the P APBH is intended to be connected via it’s HMI port

to the programming port of the HMI. Database download can still be carried out

via a connection from the PC to the PC port of the PAPBH. All connections are

made using standard Red Lion Controls programming cables. Configuration is

by the PROFIBUS Network Driver installed on the HMI programming port.

On power up the PAPBH polls the HMI for its Station Address and

configuration. During start up the PROFIBUS master attempts to parameterize

and configure the PAPBH. Following start up, data is exchanged between the

PAPBH and the HMI.

PNO Conformance and GSD file

The PAPBH has passed the conformance test for PROFIBUS-DP Slave

Devices, Certificate No. Z00584. The PNO Identifier for this PROFIBUS

device is 0x00FC. The characteristics are described in GSD file

PCL00FC.GSD. A disk containing the GSD file and bitmap is included with

each PAPBH.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

ORDERING INFORMATION

SPECIFICATIONS

1. POWER REQUIREMENTS: 11 to 30 VDC @ 3.0 W

Power Up Current: 3 A @ 2 msec

Must use a Class 2 or SELV rated power supply.

2. SERIAL PORTS:

PC Port: RS232 on an RJ-11 jack.

HMI Port: RS232 on an RJ-11 jack.

ProfiBus Port: RS485 on a DB9 connector

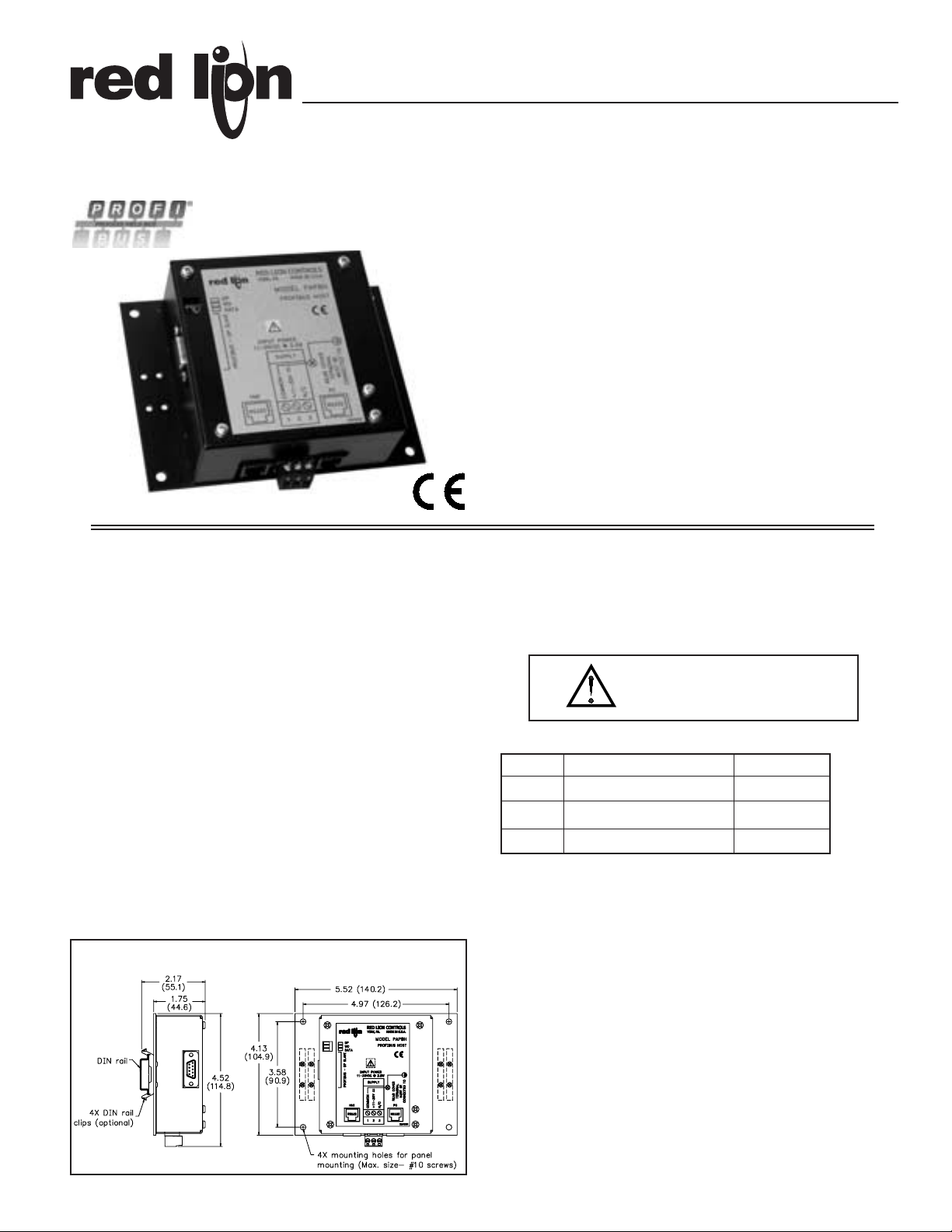

3. PHYSICAL DIMENSIONS: L = 5.52" (140.2 mm), W = 4.52" (114.8 mm),

H = 1.76" (44.7 mm)

4. CONSTRUCTION: Steel base plate and cover. Installation Category I,

Pollution Degree 2

5. ENVIRONMENTAL CONDITIONS:

Operating Temperature: 0 to 40 °C

Storage Temperature: -20 to 80 °C

Operating and Storage Humidity: 80% max. relative humidity (non-

condensing) from 0 °C to 40 °C.

Altitude: Up to 2000 meters

MODEL PAPBH - PARADIGM PROFIBUS HOST ADAPTER

Bulletin No. PAPBH-X

Drawing No. LP0525

Effective 6/01

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion-controls.com

DIMENSIONS In inches (mm)

CAUTION: Read complete instructions prior to

installation and operation of the unit.

MODEL NO. DESCRIPTION PART NUMBER

PAPBH PROFIBUS Host Adapter PAPBH000

—

—

Programming Cable

PAPBH DIN Rail Mounting Kit

(Includes 4 clips and 8 screws)

P890301Z

PAPBHDIN

Page 2

2

6. CERTIFICATIONS AND COMPLIANCES:

SAFETY

IEC 1010-1, EN 61010-1: Safety requirements for electrical equipment for

measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Note:

1. Self-recoverable loss of performance during EMI disturbance at 10 Vrms:

For operation without loss of performance:

Install 1 ferrite core RLC #FCOR0000 or equivalent, to power cable at unit.

I/O cables are routed in metal conduit connected to earth ground.

7. FIELD CONNECTIONS: Removable screw terminal blocks.

8. WEIGHT: 1.25 lb (0.58 kg)

STATUS LED’s

Three LED’s provide status indication and are described in Table 1. The

PROFIBUS–DP state machine is indicated by the data, WD and DP LED’s and

are described in Table 2.

Table 1

Paradigm PROFIBUS Host Adapter Status LED Description

Table 2

Led Indication of Paradigm PROFIBUS Host Adapter State

In PROFIBUS-DP Slave State Machine

WIRING AND CONNECTIONS

POWER SUPPLY REQUIREMENTS

The Operator Interface requires an 11 to 30 VDC power supply rated at

2.25 W unless otherwise stated on the label.

! The terminal may take as little as 100 mA in certain circumstances, so be

sure that the chosen power supply can operate correctly with this load.

Large switch-mode supplies tend to need a certain minimum load before

they will operate correctly.

In any case, it is very important that the power supply is mounted correctly if

the unit is to operate reliably. A very high proportion of reported problems are

caused by incorrect power supply installation, so please take care to observe the

following points...

! The power supply must be mounted close to the unit, with usually not

more than 6 feet of cable between the supply and the PAPBH. Ideally, as

short a length as is possible should be used.

! The wire used to connect the PAPBH’s power supply should be of at least

22 gauge wire. If a longer cable run is used, you should use a heavier

gauge wire. The routing of the cable should be kept away from large

contactors, inverters and other devices which may generate significant

electrical noise.

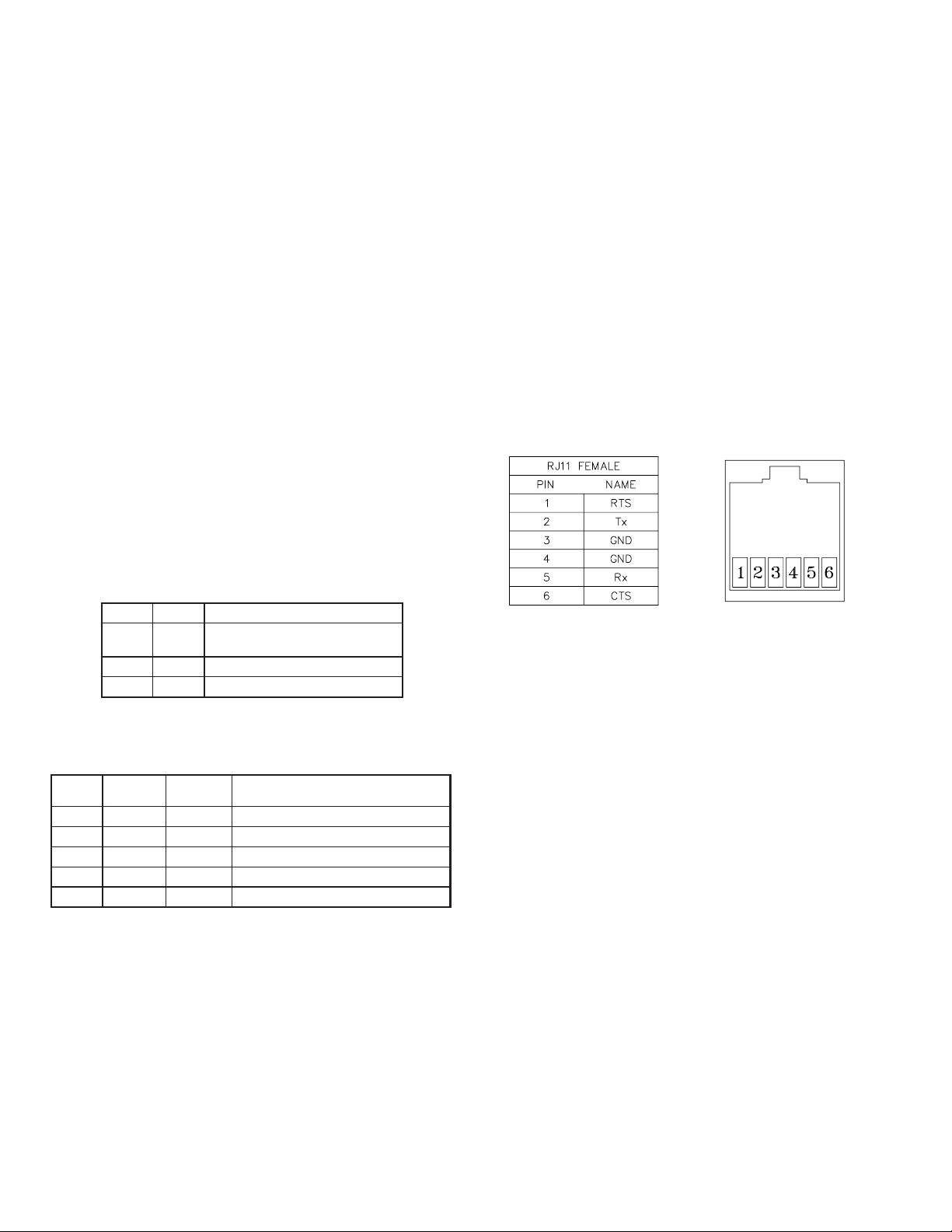

RS232 PORT PIN OUT

Both HMI and PC ports are RS-232 ports and have the same pin-out

described below. The following illustration and table gives the pin-out of these

ports to enable such connections to be made.

The above table denotes the pin names of the RS-232 port. When connecting,

the pin name at the port is connected to the opposite of that pin name at the

destination device.

PROFIBUS CONNECTION

It is recommended that PROFIBUS plug connector such as Siemens part

6ES7 972 – 0BA00 – 0XA0 be used. If the PAPBH is the last unit on the

network, set the terminating resistor switch to the “ON” position.

TROUBLESHOOTING

For further technical assistance, contact technical support at the appropriate

company numbers listed.

Immunity to EN 50082-2

Electrostatic discharge EN 61000-4-2 Level 2; 4 Kv contact

Level 3; 8 Kv air

Electromagnetic RF fields EN 61000-4-3 Level 3; 10 V/m

80 MHz - 1 GHz

Fast transients (burst) EN 61000-4-4 Level 4; 2 Kv I/O

Level 3; 2 Kv power

RF conducted interference EN 61000-4-6

Level 3; 10 V/rms

1

150 KHz - 80 MHz

Emissions to EN 50081-2

RF interference EN 55011 Enclosure class A

Power mains class A

Rear View of Unit

NAME COLOR FUNCTION

DATA Red

WD Green Watchdog State Machine State

DP Red DP Control State Machine State

DATA LED

(Red)

WD LED

(Green)

DP LED

(Red)

PARADIGM PROFIBUS HOST ADAPTER STATE

OFF ON OFF Baud Search state

OFF FLASHING OFF Baud Control State

OFF OFF ON Waiting for Parameterization Telegram

OFF OFF FLASHING Waiting for Configuration Telegram

ON OFF OFF Data Exchange State

PROFIBUS-DP Data Exchange state

(driven by SPC3 DATA_EX pin)

Page 3

3

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

MOUNTING

The PAPBH can be base mounted or installed using the optional DIN rail

mounting kit.

APPLICATION

This drawing shows a typical PROFIBUS Application.

PANEL MOUNTING

DIN RAIL MOUNTING

Page 4

Introduction

The PAPBH is a gateway that allows a Paradigm Operator Interface access to a PROFIBUS-DP Network. The Host Adapter is connected to the Operator Interface

programming port allowing data transfer with Internal Communications Blocks. The PAPBH is auto-configuring for all PROFIBUS properties such as baud rate, but

needs a Station Address configured by the Operator Interface. These are set up using the PROFIBUS Network Driver described here.

Configuration

The Station Address and Input and Output Data Container Blocks are set in the Configuration Edit dialog from the Select Communications Driver dialog.

The Station Address has a default value of 126 and must be in the range 1 to 125 for normal operation.

The Input and Output Data Container Blocks are the data buffers that the PROFIBUS Network writes data to, and reads data from. These correspond to Internal

Communications Blocks and as such these must be set up in the Communications Block Table. A maximum of 116 words may be transferred per block. Data flow is

described with respect to the PROFIBUS Network - thus Input Data is written to the PROFIBUS Network and Output Data is read from the PROFIBUS Network.

Example

This example shows the PROFIBUS Node configured as Station Address 5, Communications Block A as Input Data and Communications Block B as Output Data.

PROFIBUS DP-SLAVE CONFIGURATION

Name Value

Station Address 5

Input Data Container Block A

Output Data Container Block B

COMMUNICATION BLOCKS

DEVICE ADDRESS DATA TYPE SIZE ACCESS UPDATE LINKS ENABLE

A Internal None

16-bit

Signed

10 Read Auto None Default

B Internal None

16-bit

Signed

10 Read Auto None Default

Communication Block Configuration

Driver Configuration

PROFIBUS NETWORK DRIVER APPLICATION NOTE

Red Lion Controls

20 Willow Springs Circle

York PA 17402

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion UK Ltd

Tapton Park

Chesterfield S41 OTZ

Tel +44 (1246) 22 21 22

Fax +44 (1246) 22 12 22

Red Lion Controls France

56 Boulevard du Courcerin, Batiment 21,

ZI Pariest F-77183 Croissy Beaubourg

Tel +33 (64) 80 12 12

Fax +33 (64) 80 12 13

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and workmanship for a period limited to one year from the

date of shipment, provided the products have been stored, handled, installed, and used under proper conditions. The Company’s liability

under this limited warranty shall extend only to the repair or replacement of a defective product, at The Company’s option. The Company

disclaims all liability for any affirmation, promise or representation with respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against damages, claims, and expenses arising

out of subsequent sales of RLC products or products containing components manufactured by RLC and based upon personal injuries, deaths,

property damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be to any extent liable, including

without limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and liability imposed upon any person pursuant to

the Magnuson-Moss Warranty Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those expressly contained herein. The

Customer acknowledges the disclaimers and limitations contained herein and relies on no other warranties or affirmations.

Loading...

Loading...