Page 1

Arnold

Monitor 44cm, 100/120HZ

Maintenance Instructions

Monitor 44cm, 100/120HZ

SP

Monitor 44 cm, 100/120 Hz

The protocol SPR2-230.105.01.02.02 is required for

these instructions

Print No.:

Replaces: SPR2-230.101.01.01.02

SPR2-230.101.01.02.02

01102628

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 08.05

1998

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 2 of 26

Medical Solutions

Page 3

Table of Contents 3

0 Table of Contents

1 _______ General information______________________________________________ 4

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Required documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Required tools, measurement and auxiliary devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Emphasized text. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety information and protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General safety information (in existing documents) . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General electrical safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Radiation safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mechanical safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety information - risk of infection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Information on the protective conductor resistance test . . . . . . . . . . . . . . . . . . . . . . 10

Information on measuring the system leakage current. . . . . . . . . . . . . . . . . . . . . . . 11

Descriptions of abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2 _______ Inspection of exterior and surroundings____________________________ 17

Inspection of exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inspection of surroundings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 _______ Safety inspection _______________________________________________ 19

Mechanical safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 _______ Maintenance, operating value/functional inspection __________________ 23

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 _______ Final result/quality inspection and maintenance _____________________ 24

6 _______ Changes to Previous Version_____________________________________ 25

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 3 of 26

Page 4

4 General information

1-

1 General information

1.1 Requirements

These maintenance instructions apply to the 100/120 Hz standard monitor,

part number 30 64 581 B5310.

The monitor is a component of the system or system configuration. Maintenance for

these systems or system configurations should be performed in accordance with the corresponding maintenance instructions.

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 4 of 26

Medical Solutions

Page 5

General information 5

1.2 Required documents

• Safety information according to ARTD, part 2

• Maintenance protocol SPR2-230.105.01..

• System binder for the system or system configura-

tion

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 5 of 26

Page 6

6 General information

1.3 Required tools, measurement and auxiliary devices

NOTE

Tool For example Material no.:

The indicated articles are listed in the STC (Service Tools Catalog)

unless otherwise stated (the STC is a component of the Spare

Parts Catalog), except for those items identified with "*".

• Standard tool kit*

• Set of Allen keys*

• Protective conductor tester Safety tester UNIMRT 1100 51 38 727

• Luminance meter SPOTMETER for SM fit ACT 77 52 848

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 6 of 26

Medical Solutions

Page 7

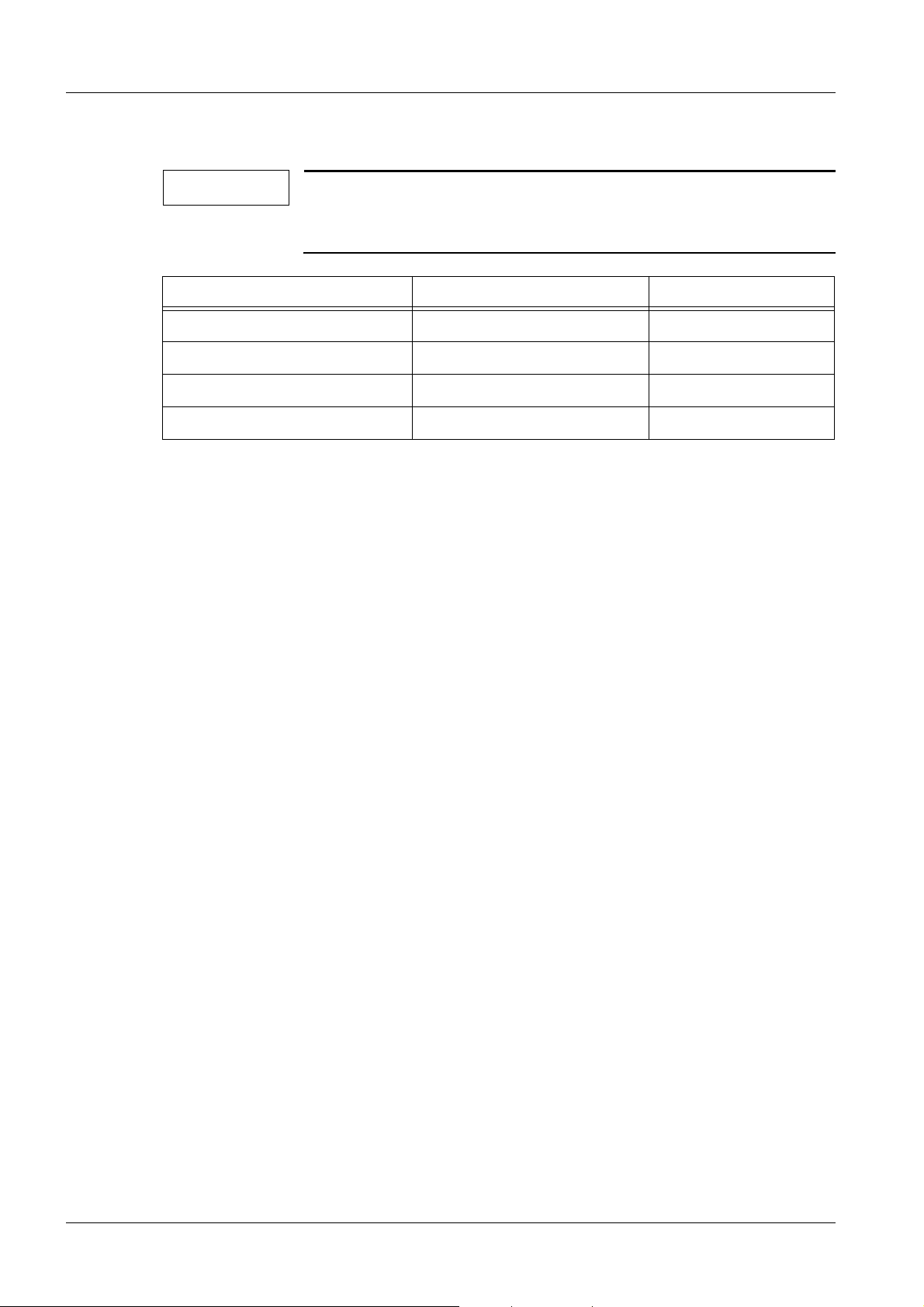

General information 7

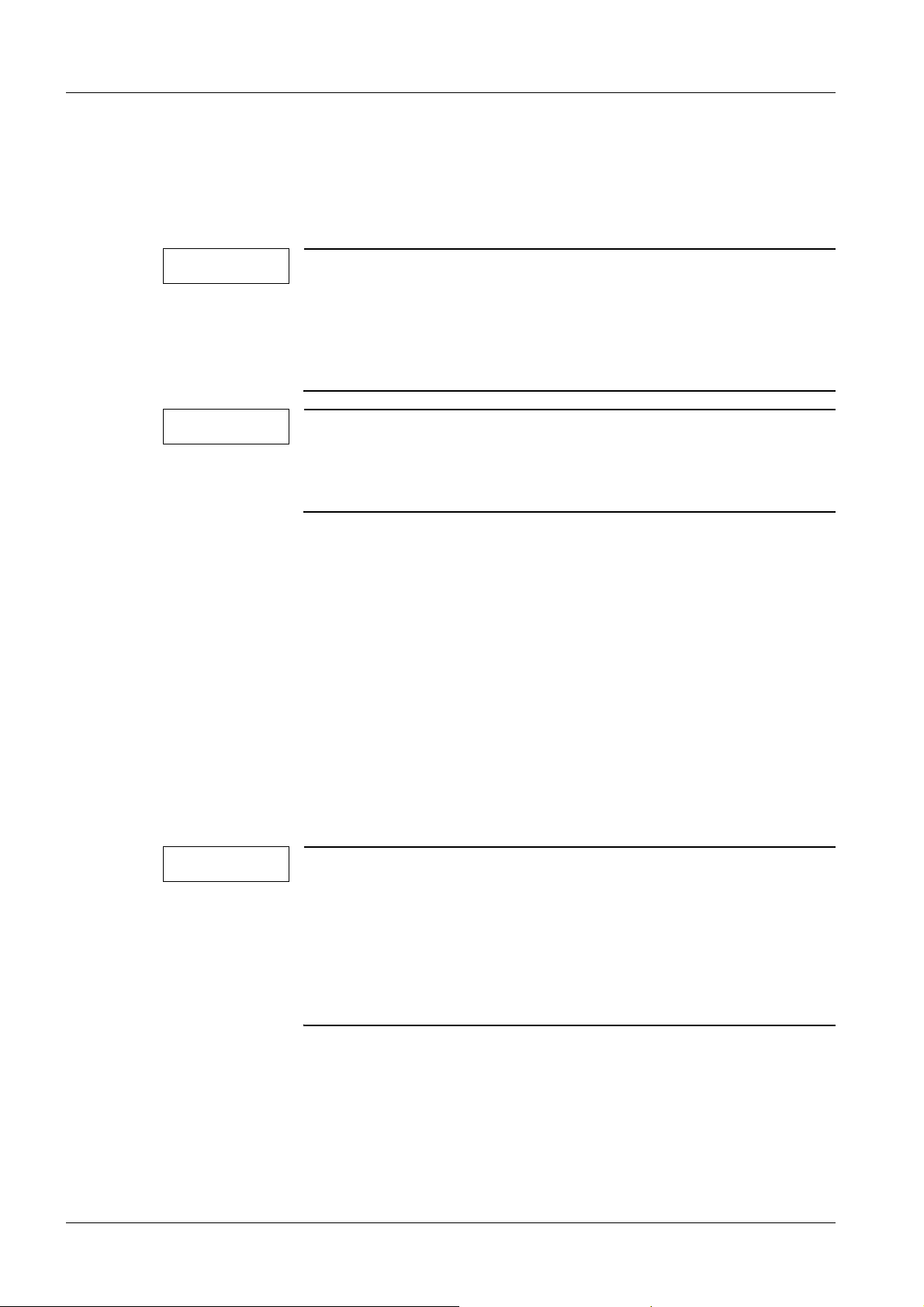

1.4 Emphasized text

!

DANGER

!

WARNING

!

CAUTION

NOTICE

Fig. 1: Safety Notes

DANGER indicates when there is an immediate danger that

l e a d s to death or serious physical injury.

WARNING indicates a risk of danger that m a y l e a d to death

or serious physical injury.

CAUTION used with the safety alert symbol indicates a risk of

danger that leads to slight or moderate physical injury and/ or

damage to property.

NOTICE used without the safety alert symbol indicates a risk of

danger that if disregarded leads or may lead to a potential

situation which may result in an undesirable result or state other

than death, physical injury or property damage.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 7 of 26

Page 8

8 General information

1.5 Safety information and protective measures

1.5.1 General safety information (in existing documents)

WARNING

Risk of injury, death or material damage.

Note

¹ The product-specific safety notes in these instructions,

¹ The general safety information in TD00-000.860.01... and

¹ The safety information in accordance with ARTD Part 2.

¹ Non-compliance can lead to death, injury or material

damage.

1.5.2 General electrical safety information

WARNING

Electrical safety!

Non-compliance can lead to severe injury or even death and mate-

rial damage.

¹ After opening the covers, the parts under voltage are

accessible. To avoid danger, disconnect the system from

the power supply prior to opening the covers. Disconnect the power plug.

CAUTION

¹ If an uninterruptible power supply (UPS) is installed in

the system, the voltage output of the UPS must also be

deenergized or the voltage output plug must be disconnected.

¹ If work has to be performed under electrical voltage, the

general safety information according to

TD00-000.860.01... must be complied with.

Electrical voltage!

Non-compliance can result in material damage.

¹ When working on the system, ESD regulations must be

observed.

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 8 of 26

Medical Solutions

Page 9

General information 9

1.5.3 Radiation safety information

WARNING

X-ray radiation!

Non-compliance can lead to illness, irreversible damage to body

cells and the genotype, severe injury and even death.

When performing work on the system during which radiation must

be released, the radiation protection directives and the rules for radiation protection according to ARTD 02.731.02 must be complied

with.

¹ Please note:

¹ Use available radiation protection devices.

¹ Wear radiation protection clothing (lead apron).

¹ Stay as far away as possible from the radiation source.

¹ Release radiation only if necessary.

¹ Set the radiation activity as low as possible. (low kV and

mA values, short radiation time)

¹ Release radiation for as short a time as possible.

¹ Checks in which radiation must be released are identified

by the radiation warning symbol.

1.5.4 Mechanical safety information

CAUTION

CAUTION

Risk of burns from hot parts or components! Non-compliance can

result in minor to more severe burns, especially on the hands.

Parts and components (e.g., power components, cooling element,

electromagnetic brakes) that can exceed 50 degrees Celsius during operation are accessible after the covers are opened.

¹ To avoid burns, switch the system off prior to touching

parts or components and allow at least 5 minutes of cooling.

Risk of injury from mechanical parts! Non-compliance can result

in minor to more severe injury, especially to the hands.

Parts such as flat plugs, threaded bolts, cut-off cable ties and component edges that, if care is not taken, can cause crushing, abrasion and cuts to the skin, particularly to the hands, can be touched

after the covers are opened.

¹ Perform the required work with special care and atten-

tion to detail.

¹ If needed, wear work gloves.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 9 of 26

Page 10

10 General information

1.5.5 Safety information - risk of infection

WARNING

Risk of infection due to pathogens! Non-compliance can lead to

severe injury and even death.

This product can be contaminated by infected blood or other bodily fluids.

¹ Avoid all contact with blood or other bodily fluids!

¹ Strictly observe the safety information in

ARTD-002.731.37... regarding prevention of infectious

diseases during customer service calls.

1.5.6 Information on the protective conductor resistance test

Observe the instructions in the safety rules for installation and repair (ARTD-002.731.17

...).

The protective conductor resistance is to be measured, documented, and evaluated during maintenance.

NOTE

Evaluate the results by comparing the first measured value to the

corresponding values documented during preceding maintenance

procedures or safety checks.

A sudden or unexpected increase in the measured values may indicate a defect in the protective conductor connections - even if

the limit value of 0.2 ohms is not exceeded.

(Protective conductor or contacts).

The measurement must be performed according to DIN VDE 0751, Part 1 (see ARTD

Part 2). In this case the protective conductor resistance for all touchable conductive parts

must be measured during the normal operating state of the system.

Make sure that control cables or data cables between the components of the system are

not mistaken for a protective conductor connection.

During the measurement, move the power cable and additional connection cables with an

integrated protective conductor section by section to detect cable breaks.

Units with fixed power line connection:

The protective conductor resistance of 0.2 ohms must not be exceeded.

Units with detachable power cable:

The protective conductor resistance of 0.2 ohms for the unit with a power line connection

must not be exceeded.

The protective conductor resistance of 0.1 ohms for the detachable power line connection

must not be exceeded.

The protective conductor resistance of 0.1 ohms between the ground contact of the unit

plug and the touchable conductive unit parts may not be exceeded.

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 10 of 26

Medical Solutions

Page 11

General information 11

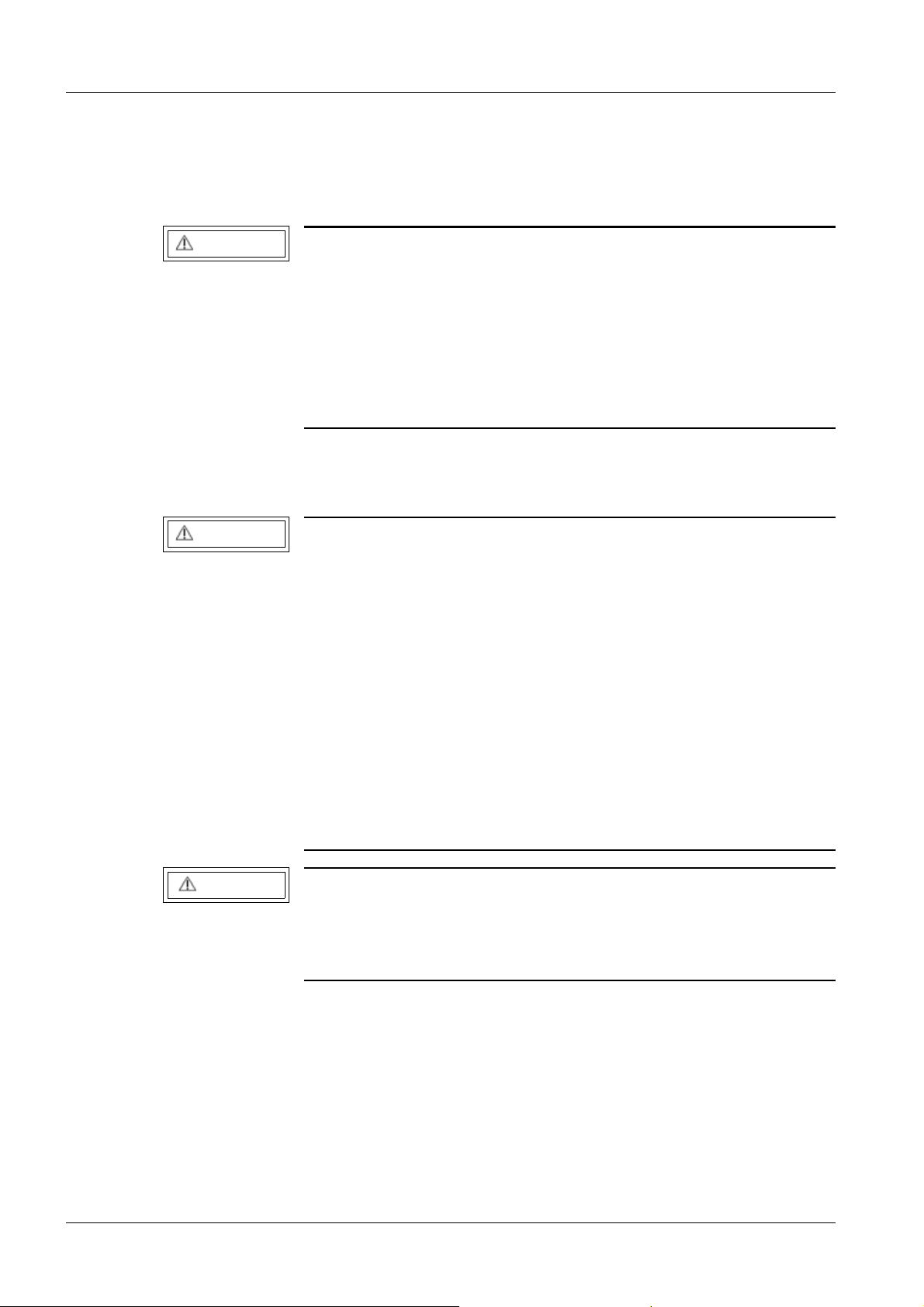

Fig. 2: Measuring circuit for measuring the protective conductor resistance in units/systems that

Pos. 1 System

Pos. 2 Application part (not available)

Pos. 3 Measurement setup (integrated into measuring device)

are permanently connected to the power supply net (according to DIN VDE

0751-1:2001-10, Fig. C3).

The determined values, including the measuring points, must be recorded and assessed

in the protective conductor resistance report.

The measuring procedure and the measuring device used (designation and serial number) are also to be documented.

1.5.7 Information on measuring the system leakage current

NOTE

The system leakage current measurement is to be conducted and

recorded as the repeat measurement during maintenance.

However, the first measured value must be newly determined and

a new report must created under the following conditions:

Lack of system leakage current measurement documentation

Local line voltage or line frequency deviating from the line voltage

and line frequency documented in the report (e.g. in the event of a

site/operator change)

Use of a different procedure for measuring the system leakage current from the one documented in the report.

For the purpose of traceability, reference to the new report is to be

written on the old report. The reason for newly determining the

first measured value is to be documented and confirmed with a

name and signature.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 11 of 26

Page 12

12 General information

Observe the instructions in the safety rules for installation and repair (ARTD-002.731.17

...).

WARNING

Electrical voltage!

Non-compliance can lead to severe injury and even death.

¹ The system leakage current measurement may be per-

formed on systems of protection class I only after the

protective conductor test has been passed.

First measured value

The first measured value was already determined and documented in the system leakage

current report. The measuring procedure was also recorded.

The measurement was performed with the recorded line voltage, line frequency and with

the recorded measuring equipment.

Measurement

Perform the measurement according to DIN VDE 0751, Part 1 (see ARTD-002.731.17....),

and record the determined value.

The measuring procedure indicated in the report must be used.

If the first measured value has to be newly determined (see note), a measuring procedure

can be selected (direct measurement or differential measurement).

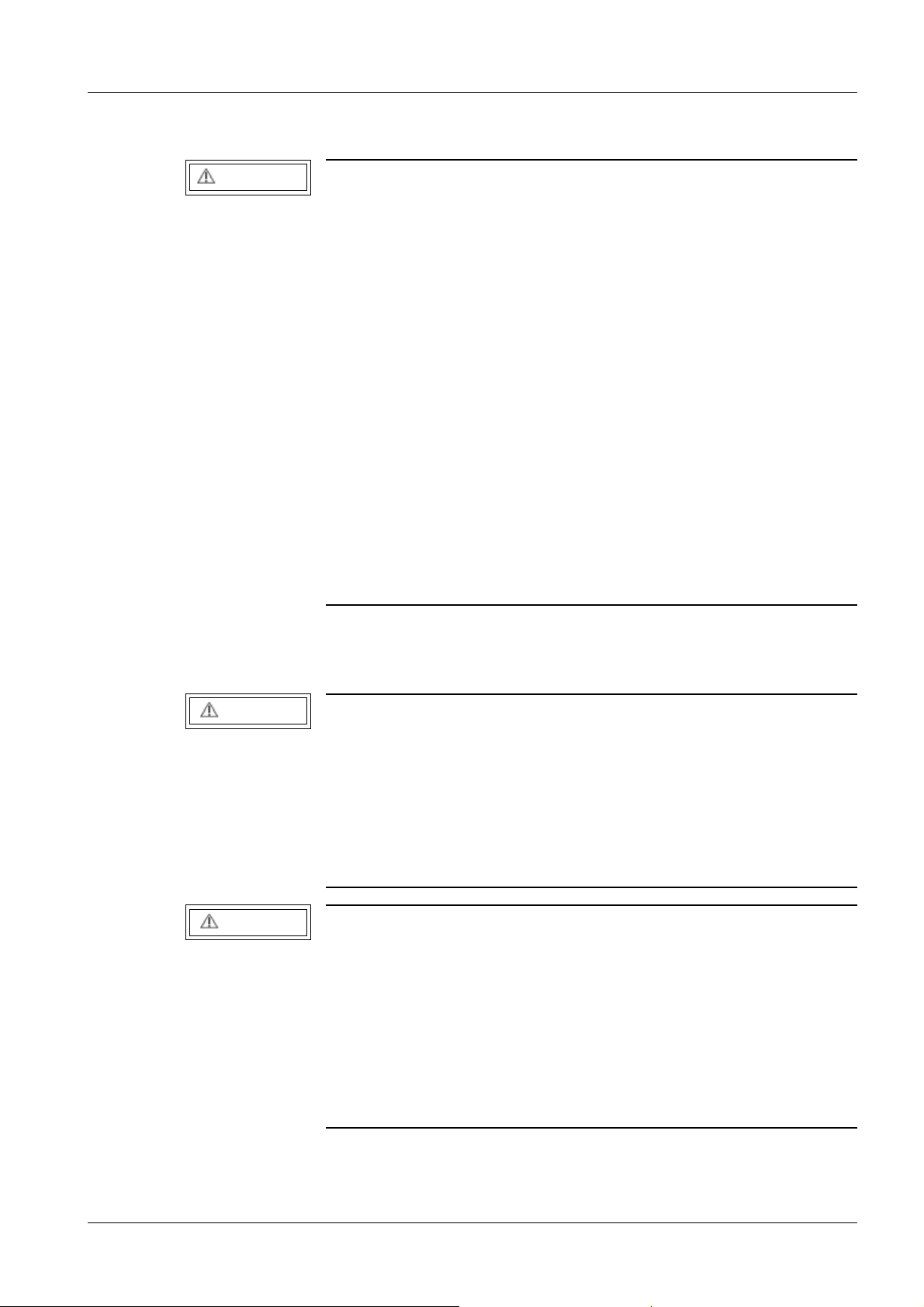

Measurement of the system leakage current according to the differential current method

(Fig.3/p.12) must be given preference, since this method is not dangerous to the per-

son performing the measurement and other persons.

However, please note the minimum resolution of the leakage current measuring instrument and any additional manufacturer's data restricting the use of the measuring device.

Fig. 3: Measuring circuit for measuring the system leakage current according to the differential

current method in compliance with DIN VDE 0751-1:2001-10, Fig. C6 for protection class

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 12 of 26

Medical Solutions

Page 13

General information 13

I.

Pos. 1 System

Pos. 2 Application part (not available)

Pos. 3 Measurement setup (integrated into measuring device)

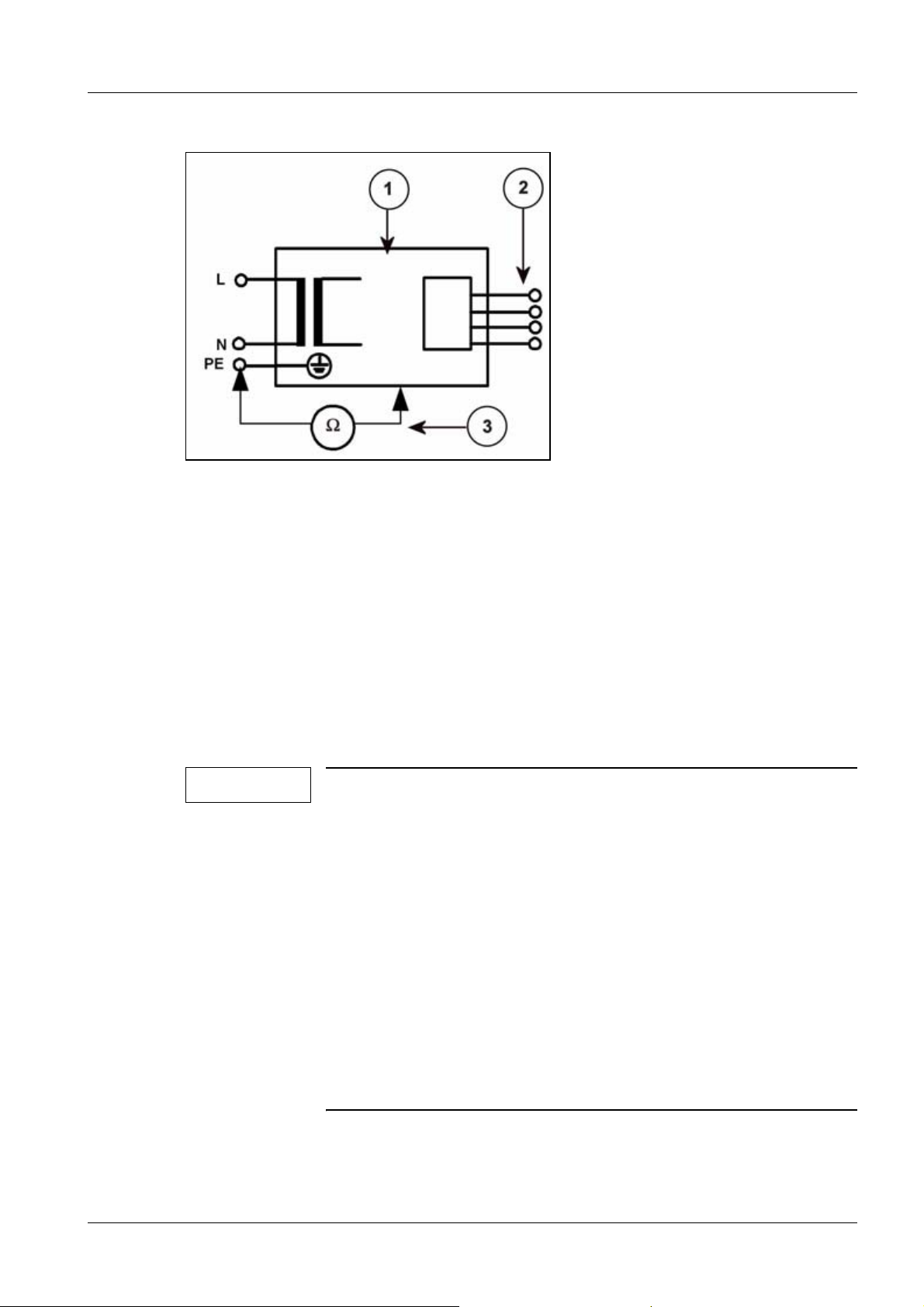

If the direct measurement of the system leakage current is used (Fig.4/p.13), the sys-

tem must be insulated during the measurement and must not be touched.

Fig. 4: Measuring circuit for direct measurement of the system leakage current in compliance

with DIN VDE 0751-1:2001-10, Fig. C5 for protection class I.

Pos. 1 System

Pos. 2 Application part (not available)

Pos. 3 Measurement setup (integrated into measuring device)

WARNING

Electrical voltage!

Non-compliance can lead to severe injury and even death.

No housing parts of the system may be touched during direct mea-

surement of the system leakage current (Fig.4/p.13).

¹ Third-person access to the system must be prevented.

The system must be switched on during measurement. Measuring devices with automated measuring sequences must therefore be set to manual measurement.

The highest value must be entered in the system leakage current report.

This value must not exceed the permissible leakage current values according to DIN VDE

0751-1:2001-10, Table F.1, line "general leakage current information", of 0.5 mA.

Measure and record the current line voltage. If the measured line voltage deviates from

the nominal voltage, correct the measured value to the value corresponding to a measurement at the nominal value of the line voltage. This is also to be documented.

Document the measuring procedure (differential measurement or direct measurement)

and the measuring device used (designation and serial number).

In the case of repeat measurements, the measured value is also to be evaluated.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 13 of 26

Page 14

14 General information

NOTE

Evaluate the results by comparing the first measured value to the

corresponding values documented during preceding maintenance

procedures or safety checks.

A sudden or unexpected increase in the measured values may indicate that a fault has occurred in the primary circuit of the power

supply (damaged insulation, damage caused by water ingress or

humidity, defective interference suppressor, etc.) - even if the limit

value of 2.5 mA is not exceeded.

The evaluation is not necessary in the case of a new determination.

File the report sheet in the system folder or log book.

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 14 of 26

Medical Solutions

Page 15

General information 15

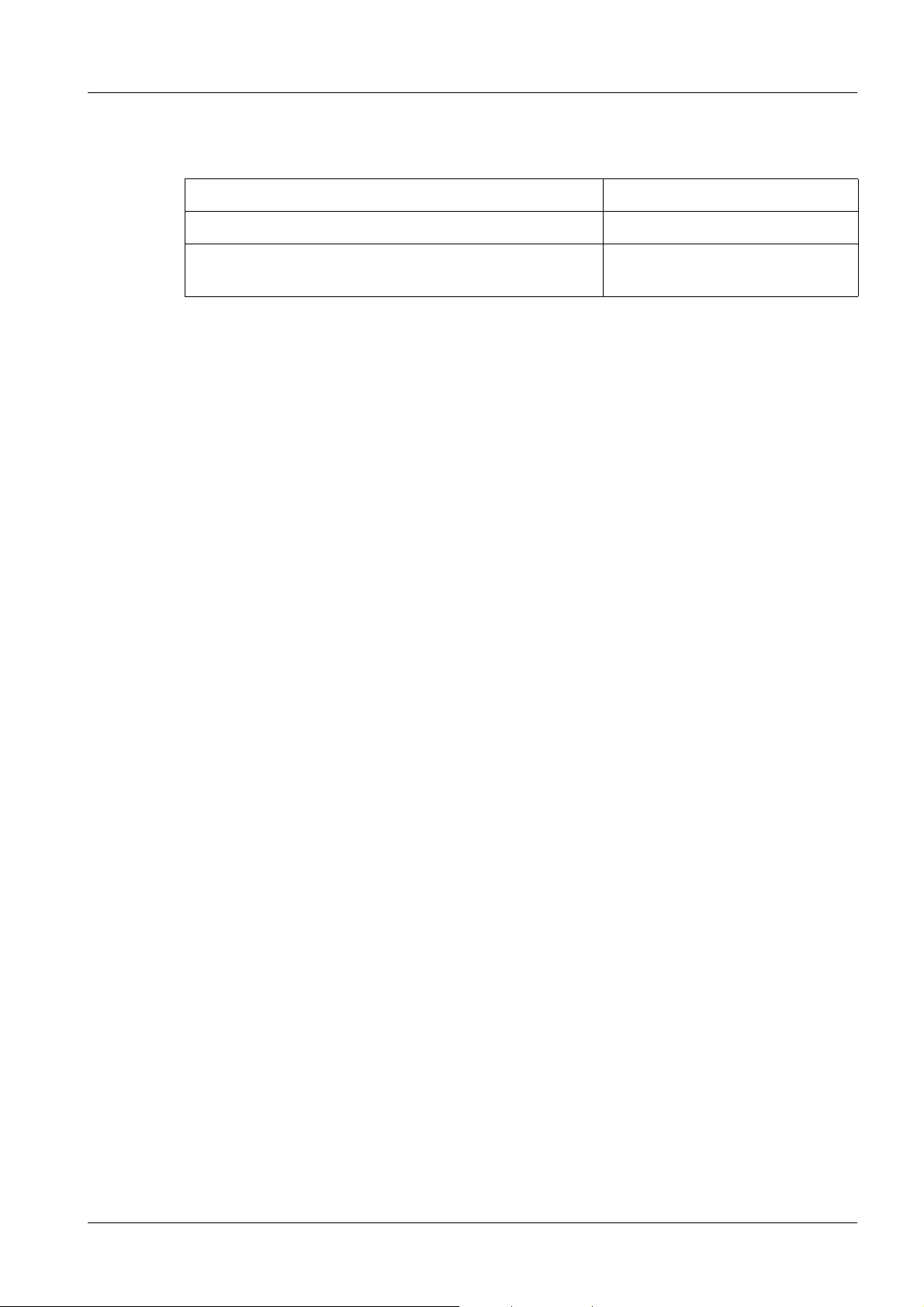

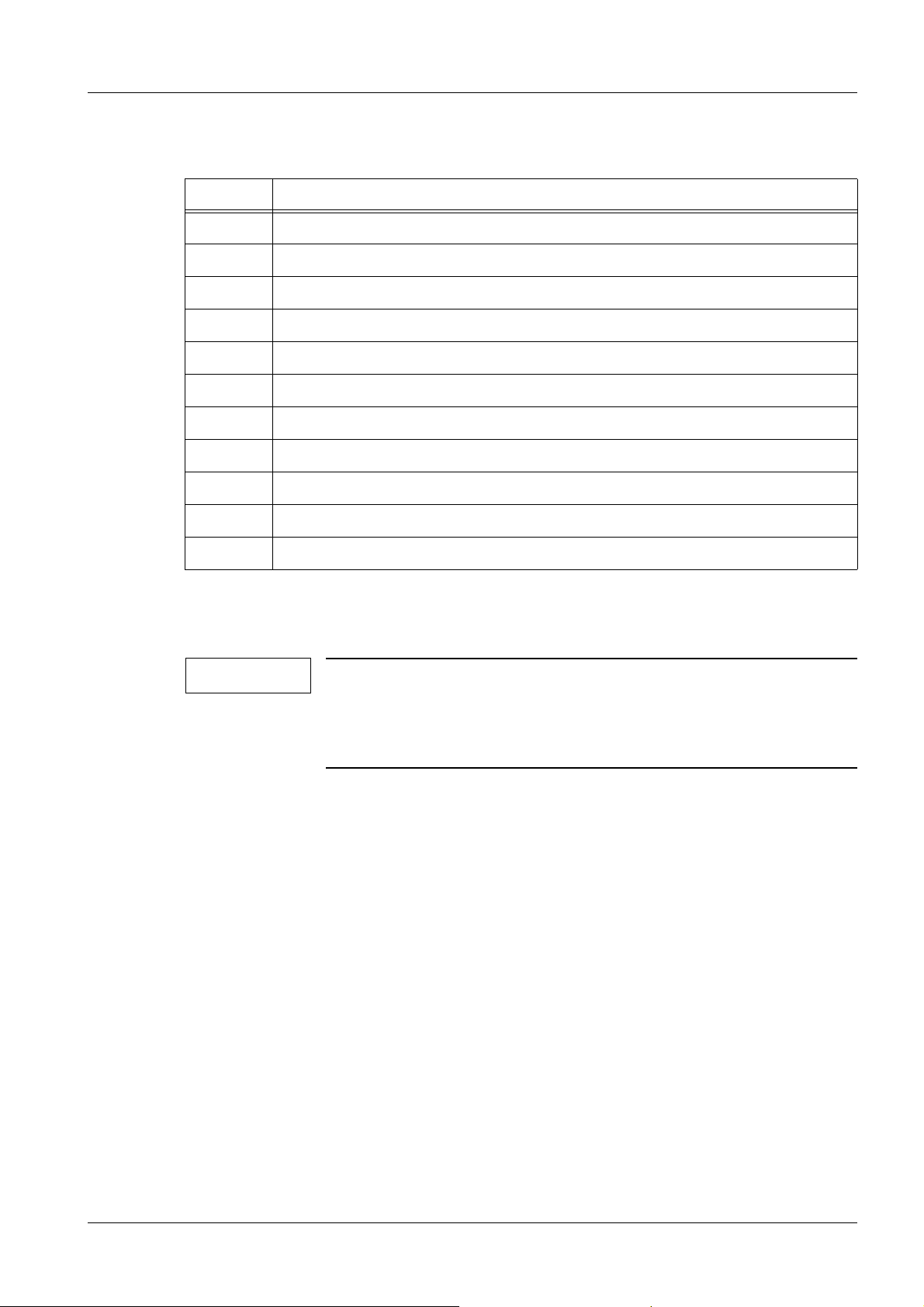

1.6 Descriptions of abbreviations

Abbrev. Description

SI Safety Inspection

SIE Electrical Safety

SIM Mechanical Safety

PM Preventive Maintenance

PMP Periodic Preventive Maintenance

PMA Preventive Maintenance Adjustments

PMF Preventive Maintenance, Operating Value Check, Function Check

Q Quality Check

QIQ Image Quality

QSQ System Quality Check

SW Software Maintenance

The steps identified by these abbreviations are part of the maintenance report and should

be checked off upon completion.

NOTE

The sequence for complete maintenance and inspection is described on the following pages.

Each work step must be performed on an annual basis, if not otherwise specified.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 15 of 26

Page 16

16 General information

1.7 Maintenance interval

12 months

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 16 of 26

Medical Solutions

Page 17

Inspection of exterior and surroundings 17

2-

2 Inspection of exterior and surroundings

2.1 Inspection of exterior

PMP Damage

Inspect the monitor for damage, e.g. to the housing or to the finish.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 17 of 26

Page 18

18 Inspection of exterior and surroundings

2.2 Inspection of surroundings

2.2.1 Power outlets

SIE Damage

For monitors connected directly to the power supply:

• Inspect the power outlet for damage.

SIE Line voltage

• Measure the line voltage and compare this value to the line voltage for the monitor.

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 18 of 26

Medical Solutions

Page 19

Safety inspection 19

3-

3 Safety inspection

3.1 Mechanical safety

SIM Monitor mounting

• Inspect the monitor mounting on the console (rotating/tilting console or monitor holder)

for any mechanic damage.

SIM Console mounting

• Inspect the console (rotating/tilting console or monitor holder) for mechanical damage

and correct mounting.

SIM Warning labels

• Ensure that all required warning labels are attached and in good condition.

¹ Replace any illegible labels.

SIM ID labels

• Ensure that all required ID labels are attached and in good condition.

¹ Replace any illegible labels.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 19 of 26

Page 20

20 Safety inspection

3.2 Electrical safety

SIE Cables and plugs

• Check visible cables and plugs of the monitor for damage

SIE Protective conductor test

NOTE

NOTE

The protective conductor test for the monitors is to be performed

when these are externally mounted (e.g. on a wall console). It is not

necessary to perform the protective conductor test for monitors

mounted on the monitor trolley of the system if they are tested during the protective conductor test of the system (e.g., SIREMOBIL

system).

Observe the notes on the protective conductor test in these instructions. The power cable of the monitor is to be moved section

by section during the protective conductor test to detect cable

breaks.

• If covers were removed, they are to be reattached.

• Perform the protective conductor test according to ARTD-002.731.17... .

• The protective conductor resistance of 0.2 ohms for the unit with a power line connec-

tion must not be exceeded.

The protective conductor resistance of 0.1 ohms for the detachable power cable must

not be exceeded.

The protective conductor resistance of 0.1 ohms between the ground contact of the unit

plug and the touchable conductive unit parts may not be exceeded.

• The determined values, including the measuring points, must be recorded and as-

sessed.

• The measuring procedure and the measuring device used (designation and serial num-

ber) are also to be documented.

NOTE

SIE Leakage current

Evaluate the results by comparing the first measured value to the

corresponding values documented during preceding maintenance

procedures or safety checks.

A sudden or unexpected increase in the measured values may indicate a defect in the protective conductor connection - even if the

limit value of 0.2 ohms is not exceeded.

(Protective conductor or contacts)

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 20 of 26

Medical Solutions

Page 21

Safety inspection 21

NOTE

NOTE

WARNING

WARNING

The leakage current measurement for monitors is to be performed

when these are externally mounted (e.g. on a wall console) and externally connected to a power outlet/power supply.

It is not necessary to perform the leakage current measurement for

monitors mounted on the monitor trolley of the system if they are

part of the secondary circuit of the system power supply (e.g.,

SIREMOBIL Compact/Iso-C/POWERMOBIL/ARCADIS Varic/ARCADIS Orbic).

Observe the leakage current measurement information in these instructions.

Electrical voltage!

Non-compliance can lead to severe injury and even death.

¹ The leakage current measurement may be performed on

systems of protection class I only after the protective

conductor test has been passed.

Electrical voltage!

Non-compliance can lead to severe injury and even death.

¹ No housing parts of the system may be touched during

direct measurement of the leakage current (measurement setup according to Fig. 26). Third-person access to

the system must be prevented.

• If covers were removed, they are to be reattached.

• Perform the leakage current measurement according to ARTD-002.731.17... .

• The highest value must be entered in the leakage current report.

• This value must not exceed the permissible leakage current values according to DIN

VDE 0751-01:2001-10, Table F.1, line "general leakage current information",

• of 0.5 mA.

• Measure and record the current line voltage. If the measured line voltage value devi-

ates from the line voltage, correct the measured value to the value corresponding to a

measurement at the nominal value of the line voltage. This is also to be documented.

• Document the measuring procedure (differential measurement or direct measurement)

and the measuring device used (designation and serial number).

• In the case of repeat measurements, the measured value is also to be evaluated.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 21 of 26

Page 22

22 Safety inspection

NOTE

Evaluate the results by comparing the first measured value and the

values documented during preceding maintenance procedures or

safety checks to the measured value.

A sudden or unexpected increase in the measured values may indicate that an error occurred in the primary circuit of the power

supply (damaged insulation, damage caused by water ingress or

humidity, defective interference suppressor, etc.) - even if the limit

value of 0.5 mA is not exceeded.

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 22 of 26

Medical Solutions

Page 23

Maintenance, operating value/functional inspection 23

4-

4 Maintenance, operating value/functional inspection

4.1 Maintenance

PMP Cleaning the monitor

• Clean the monitor.

- The monitor housing is made of plastic. Do not use any sharp-edged objects or

chemical solvents to remove residues.

- First disconnect the monitor from the power supply and wipe it off with a damp cloth

or cotton swab.

- Use water or a solution of water and a conventional household cleaner to dampen the

cloth.

- Never use cleaners such as acetone, ether, benzine, trichlorohydrocarbons, etc.

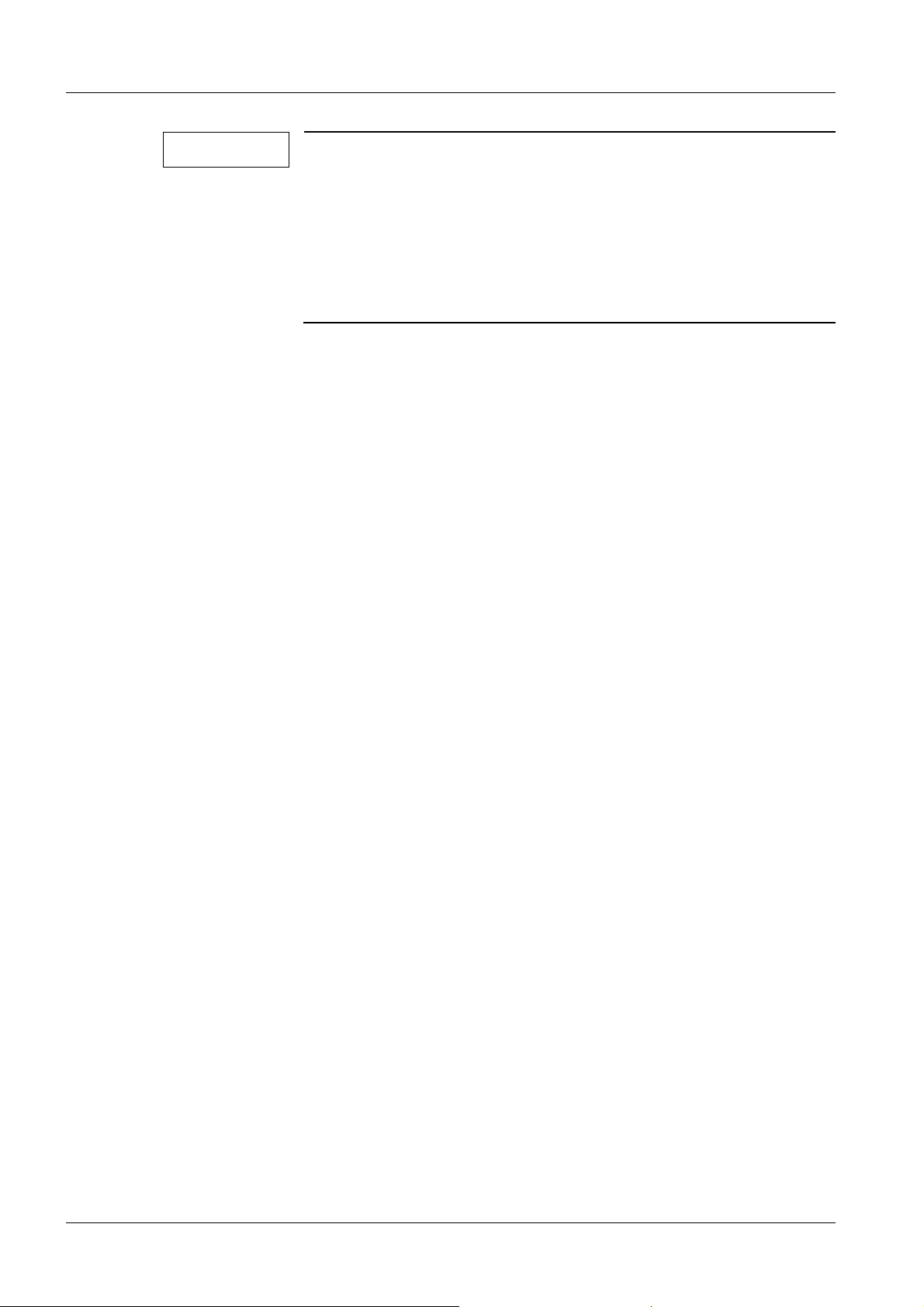

PMP Basic brightness/contrast setting

• Cover the ambient sensor of the monitor in a light-proof manner.

• Call up the "white square" test pattern on the system. The video level at the monitor in-

put must be 1 V

(300 mV Sync, 50 mV blanking signal and 650 mV B-signal).

SS

• Use the luminance meter to adjust the luminance for black and white.

- Black: 0.6 cd/m

- White: 300 cd/m2, +/-20 cd/m

Fig. 1: "White square" test pattern

2

, +/-0.2 cd/m

2

2

• Remove the light-proof cover from the ambient sensor.

• Shine a light on the ambient sensor. The luminance in the white field must reach the val-

2

ue >400 cd/m

.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 23 of 26

Page 24

24 Final result/quality inspection and maintenance

5-

5 Final result/quality inspection and maintenance

SIE IQ test

• Perform the IQ test in accordance with the system or system configuration image quali-

ty test.

• This test is part of system maintenance and should be performed at the end of system

maintenance. The image quality test does not need to be performed twice.

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 24 of 26

Medical Solutions

Page 25

Changes to Previous Version 25

6-

6 Changes to Previous Version

Document was converted to DMS.

Siemens AG SPR2-230.101.01.02.02 Monitor 44cm, 100/120HZ

Medical Solutions

08.05 CS PS 24

Page 25 of 26

Page 26

26 Changes to Previous Version

Monitor 44cm, 100/120HZ SPR2-230.101.01.02.02 Siemens AG

08.05 CS PS 24

Page 26 of 26

Medical Solutions

Loading...

Loading...