Siemens MOBYU-MDSU315, MOBYU-MDSU524, MOBYU-SLGU92-0, MOBYU-MDSU589, MOBYU-MDSU525 User Manual

...Page 1

Table of Contents

MOBYU

Configuration, Installation and

Service

Manual

Preliminary Version

General

Introduction, MOBY U

Configuration and Installation

Guidelines

Mobile Data Memories

Read/Write Devices

Interfaces

Accessories

Documentation

Error Messages

1

2

3

4

5

6

7

A

B

ASCII Table

C

6GT2 597-4BA00-0EA2

Published in December, 2001

Page 2

Notes on safety

This manual contains notes which must be adhered to for your own personal safety and to prevent property

damage. The notes are highlighted with a warning triangle and graduated by amount of danger.

Danger

!

Means that death, severe injury or substantial property damage will occur if these precautions are

not taken.

Warning

!

Means that death, severe injury or substantial property damage may occur if these precautions are

not taken.

Caution

!

Means that injury or property damage may occur if these precautions are not taken.

Note

Is an important piece of information on the product, its handling or a particular part of the

documentation which requires special attention.

Qualified personnel

A device may only be commissioned and operated by qualified personnel. For the purpose of the safety notes in

this manual, qualified personnel are those persons who are authorized to commission, ground and tag devices,

systems and current circuits in accordance with applicable safety standards.

Intended use

Comply with the following.

Warning

!

The product may only be used for the applications described in the catalog and the technical

description and only in connection with Siemens equipment or devices and components of other

manufacturers recommended by Siemens.

Correct and safe operation of the product is based on correct transportation, correct storage, setup

and installation as well as careful operator control and maintenance.

Brand names

SIMATIC and MOBY and SINEC are registered brand names of SIEMENS AG.

The other designations in this publication may be brand names whose use by third parties for their own purposes

may violate the rights of the owner.

Reproduction, utilization and revelation of the contents of this manual is

prohibited unless express permission is obtained. Violations will be

prosecuted. All rights reserved particularly when a patent is granted or a utility

model is registered.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik (A&D)

Geschäftsgebiet Systems Engineering

Postfach 2355, D-90713 Fuerth

Siemens Aktiengesellschaft

Disclaimer of liabilityCopyright Siemens AG 2001 All rights reserved

Although we have checked this publication for agreement with the actual

hardware and software, we cannot fully exclude differences and do not

accept liability for full agreement. The information in this publication is

checked at regular intervals and necessary changes included in the next

release. Your suggestions and ideas are welcome (use the form at the end

of this manual).

Siemens AG 2001

Subject to technical change without prior notice

Order no.

6GT2597-4BA00-0EA2

Page 3

Table of Contents

1 General 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Introduction – MOBY U 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Configuration and Installation Guidelines 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 The Fundamentals 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Transmission Window 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Basic Requirements 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 EMC Guidelines 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Preface 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 General 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Spreading of Interference 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Cabinet Layout 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.5 Avoiding Sources of Interference 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.6 Equipotential Bonding 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.7 Shielding the Cables 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.8 Basic EMC Rules 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 MOBY Shielding Concept 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 SLG Cable between ASM 475 and SLG U92 with RS 422 3–20. . . . . . . . . . . . .

3.5 SLG Cable and Plug Connector Allocations (RS 422) 3–21. . . . . . . . . . . . . . . .

3.5.1 Cable Configuration 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Plug Connector Allocations 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Connection Cables 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 SLG Cable and Plug Allocations (RS 232) 3–26. . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Cable Configuration 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 Connection Cables with Lengths 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Service Cable and Plug Allocations 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.1 Cable Configuration 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.2 Plug Allocations 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.3 Connection Cables with Lengths 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mobile Data Memories 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Introduction 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 MDS U313 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 MDS U524 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 MDS U589 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Read/Write Devices 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 SLG U92 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

i

Page 4

Table of Contents

6 Interfaces 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Introduction 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 ASM 452 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 ASM 473 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 ASM 475 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 MOBY Software 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 MOBY Wide–Range Power Pack 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Documentation A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Error Messages B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 General Errors B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 ASM–Specific Errors B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.1 Error Indicators in FC 45 B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 Filehandler Error Messages for ASM 452/475 B–10. . . . . . . . . . . . . . . . . . . . . . .

C ASCII Table C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 5

Figures

2-1 Overview of the MOBY U components 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Status zones for MDS in transmission field of SLG U92 3–3. . . . . . . . . . . . . . .

3-2 Spreading of interference 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Possible interference coupling 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

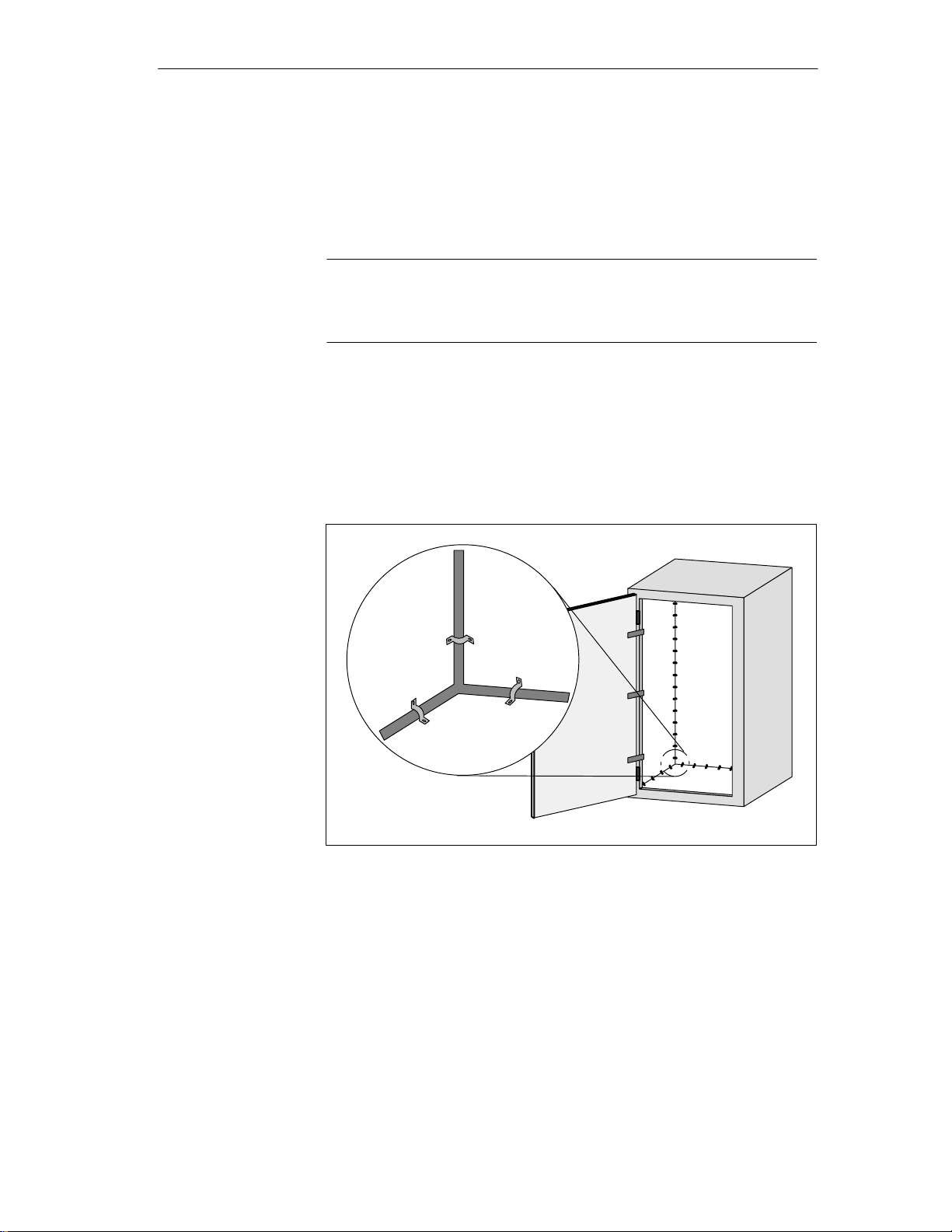

3-4 Shielding by the housing 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

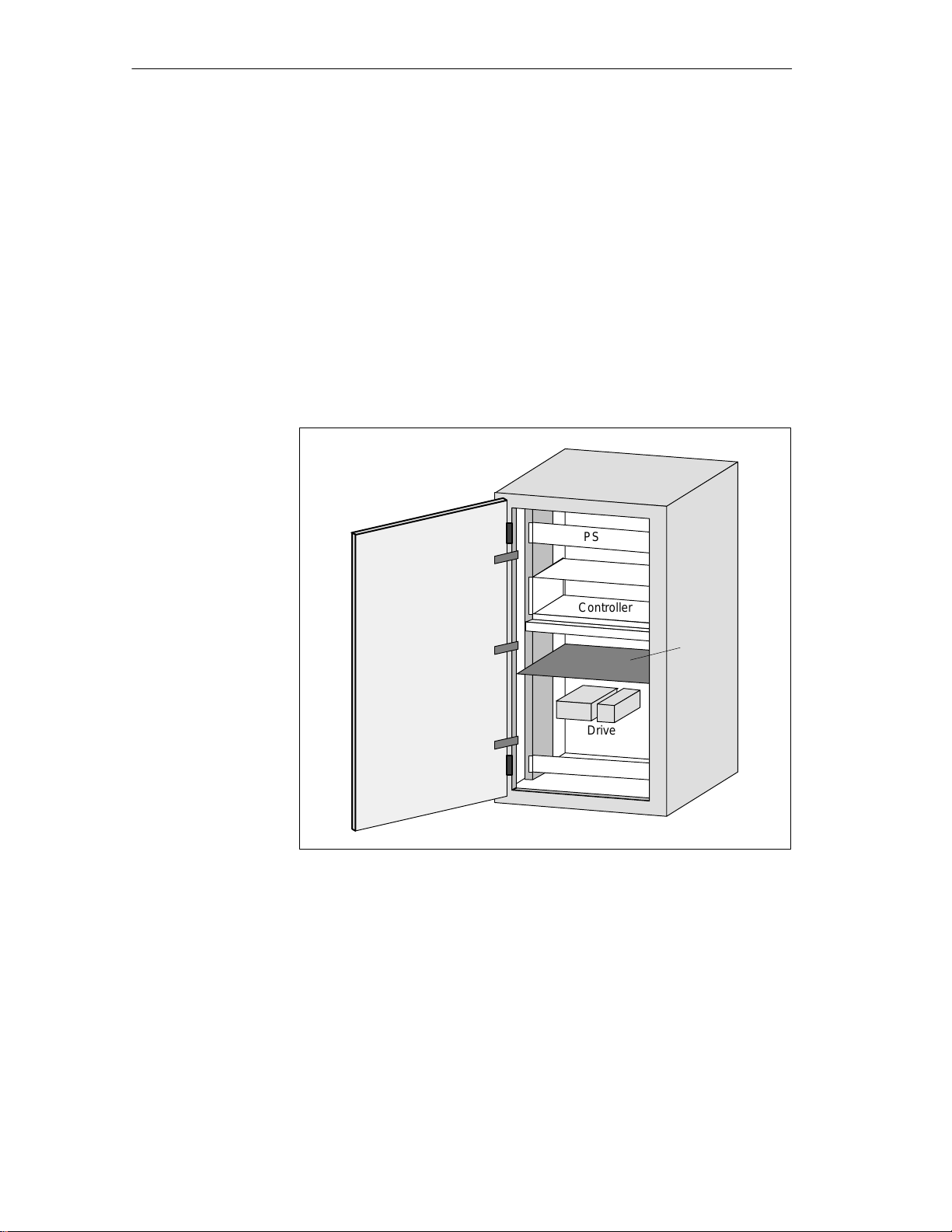

3-5 Avoidance of interference with optimal layout 3–12. . . . . . . . . . . . . . . . . . . . . . . .

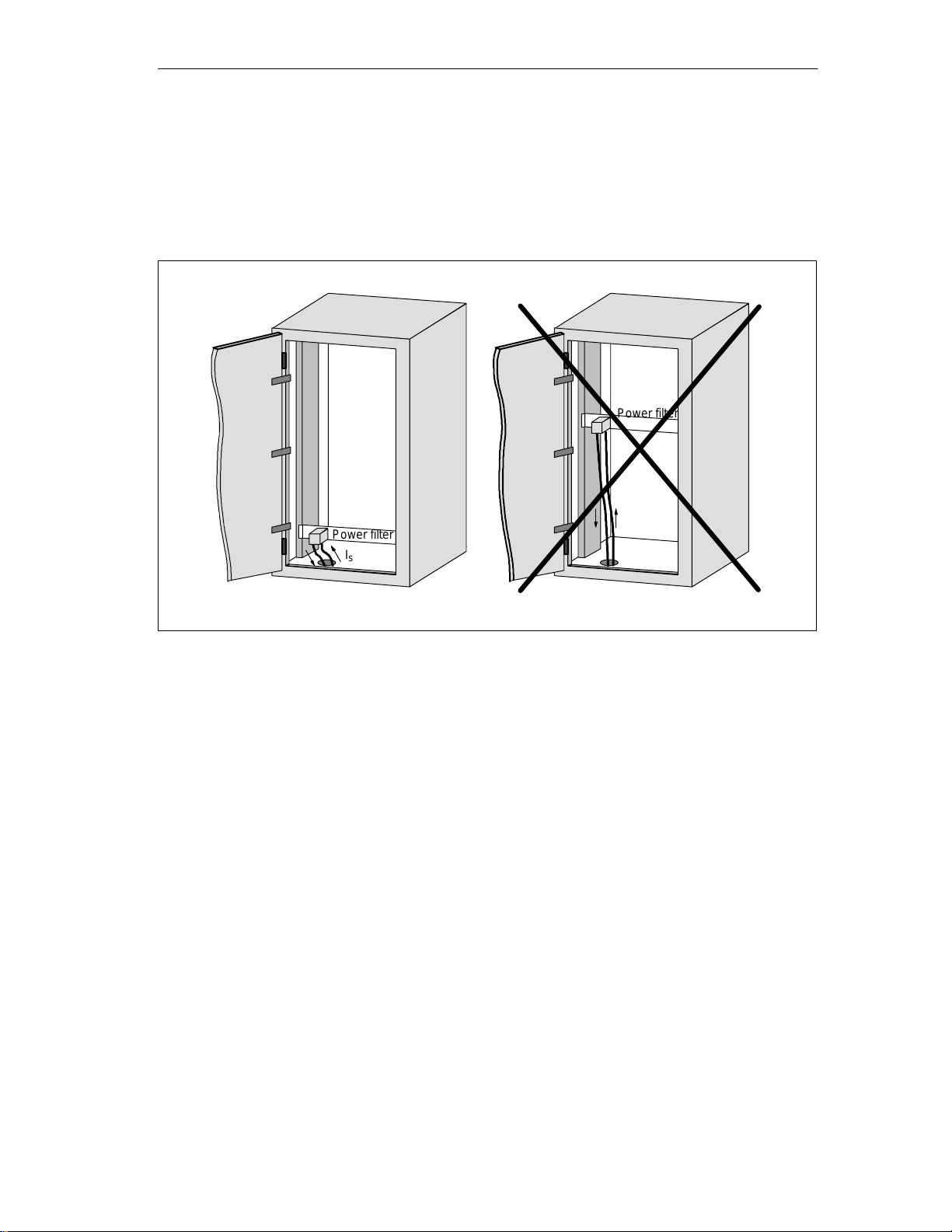

3-6 Filtering the voltage 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

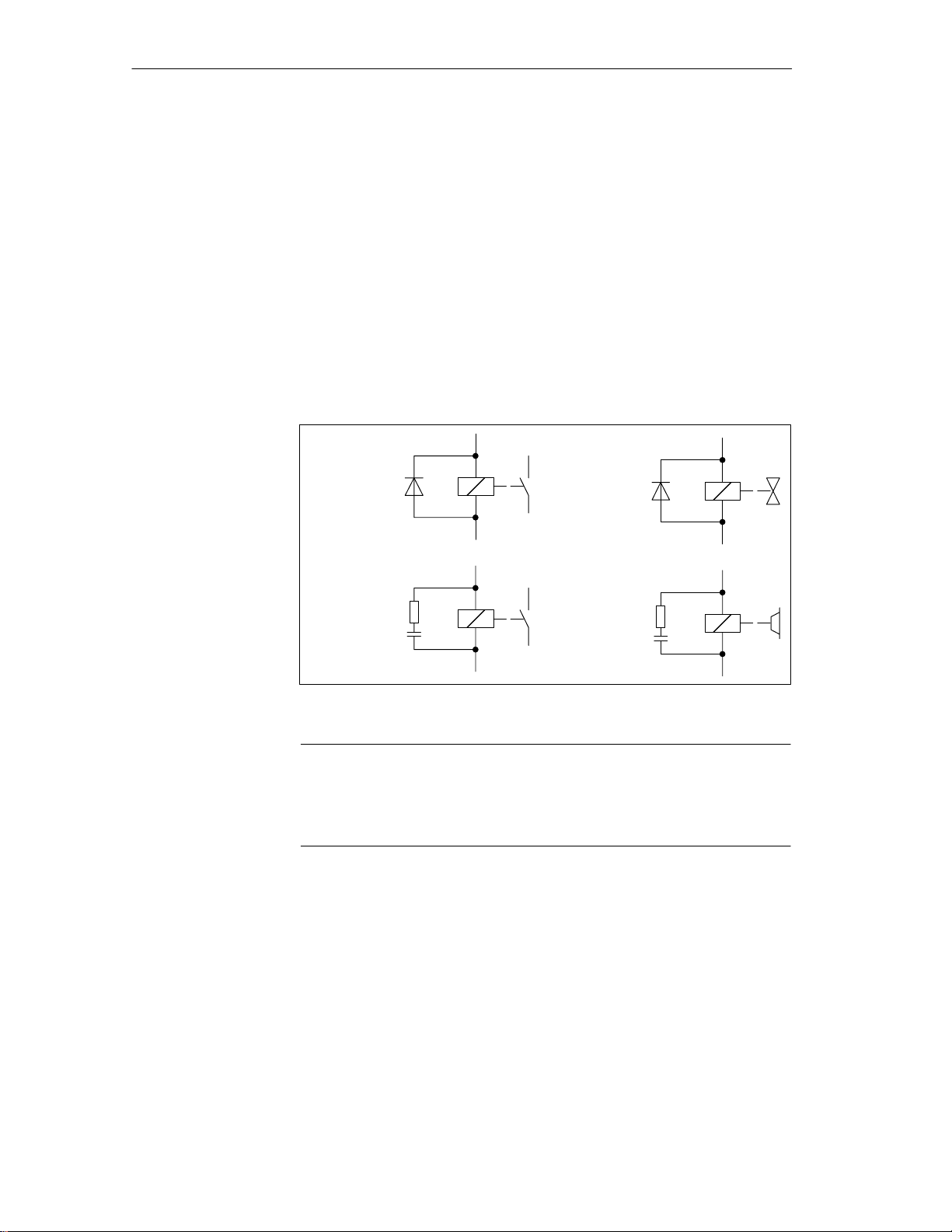

3-7 Suppression of inductivity 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Equipotential bonding 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 Shielding the cables 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 Connecting the shield bar 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11 Interruption of shielded cables 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

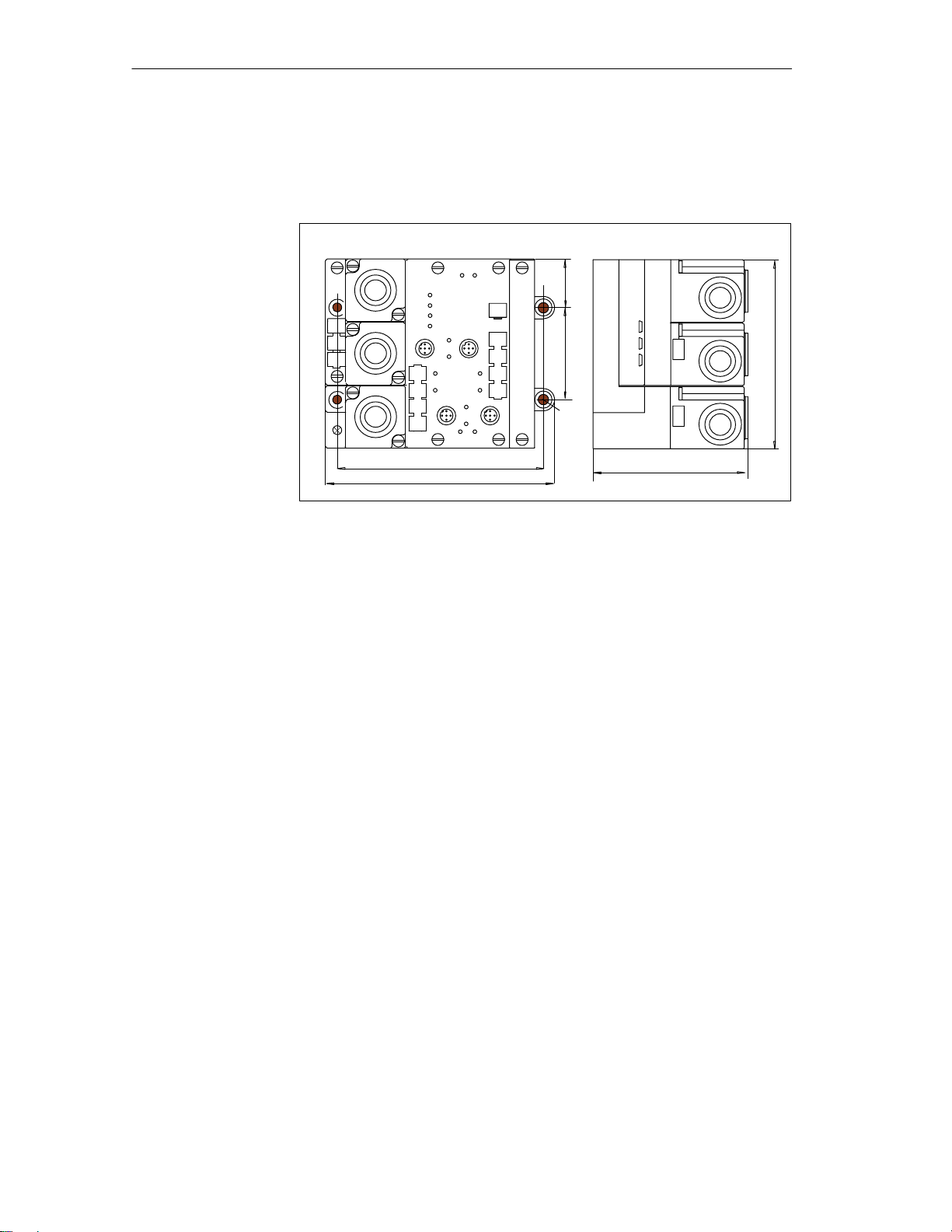

3-12 Layout of the ASM 475 with shield connecting element 3–20. . . . . . . . . . . . . . .

3-13 SLG with extra power pack 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-14 Drawing of how to mount the SLG plug connector 3–23. . . . . . . . . . . . . . . . . . .

3-15 Connection cable ASM 452/473 ↔ SLG U92 with RS 422 3–24. . . . . . . . . . . .

3-16 Connection cable ASM 475 ↔ SLG U92 with RS 422 3–25. . . . . . . . . . . . . . . .

3-17 Wide–range power pack for SLG U92 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-18 Connection cable for PC ↔ SLG U92 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Status zones for MDS in transmission field of SLG U92 4–2. . . . . . . . . . . . . . .

4-2 MDS U313 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Metal–free space, MDS U313 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Dimensions, MDS U313 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 MDS U524 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Metal–free space, MDS U524 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Dimensions of MDS U524 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 MDS U589 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Metal–free space, MDS U589 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Dimensions of the MDS U589 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

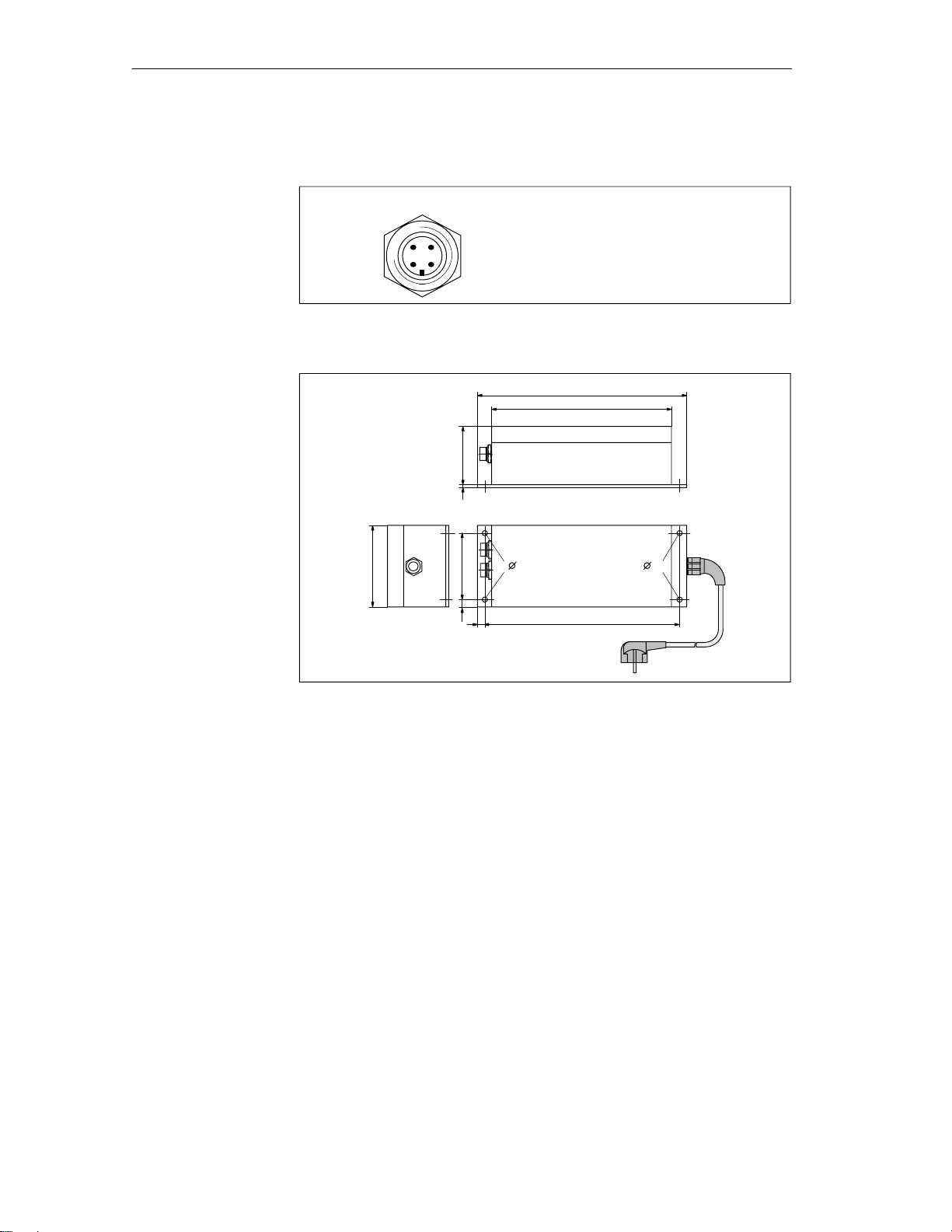

5-1 Read/write device SLG U92 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Transmission window of the SLG U92 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Metal–free space of SLG U92 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Distance D: SLG U92 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Dimensional drawing of the SLG U92 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Interface ASM 452 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Configurator – ASM 452 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Connection plug for ASM 452, 473 ↔ SLG U92 with RS 422

(6GT2 090-0BC00) 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Connection cable for ASM 452, 473 ↔ SLG U92 with RS 422

(6GT2 091-1CH20) 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Dimensional drawing of the ASM 452 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6 Pin allocation and LEDs of the ASM 452 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-7 Length of bared cable for PROFIBUS cable 6–10. . . . . . . . . . . . . . . . . . . . . . . . .

6-8 Setting PROFIBUS address/turning on terminating resistance 6–10. . . . . . . . .

6-9 Interface ASM 473 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10 Configurator for an ASM 473 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-11 Maximum configuration of ASM 473s on one ET 200X 6–15. . . . . . . . . . . . . . .

6-12 Pin allocation and LEDs of the ASM 473 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-13 Dimensions for mounting holes for basic and expansion modules 6–17. . . . . .

6-14 Interface ASM 475 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-15 Configurator for an ASM 475 6–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

iii

Page 6

Table of Contents

6-16 Front plate and inside of the front door of the ASM 475 6–22. . . . . . . . . . . . . . .

6-17 Wiring of the ASM 475 to the SLG U92 with RS 422 (6GT2 091-0E...) 6–24. .

6-18 Baring of the cable shield for customer–fabricated cable 6–24. . . . . . . . . . . . . .

6-19 ASM 475 directory in the hardware catalog 6–25. . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Program directories of ”MOBY Software,” release V 3.0 7–3. . . . . . . . . . . . . .

7-2 MOBY wide–range power pack 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Plug allocation of 24 V output 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 Dimensions of MOBY wide–range power pack 7–6. . . . . . . . . . . . . . . . . . . . . .

iv

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 7

Tables

2-1 Technical data of MOBY U (field components) 2–3. . . . . . . . . . . . . . . . . . . . . . .

3-1 Sources of interference: Origin and effects 3–9. . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Causes of coupling paths 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Cable configuration 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Plug connector allocation of the SLG connector 3–22. . . . . . . . . . . . . . . . . . . . .

3-5 Cable lengths of ASM 475 ↔ SLG U92 with RS 422 3–24. . . . . . . . . . . . . . . . .

3-6 Cable lengths of ASM 475 ↔ SLG U92 with RS 422 3–25. . . . . . . . . . . . . . . . .

3-7 Plug allocation of SLG plug and submin D plug 3–27. . . . . . . . . . . . . . . . . . . . . .

3-8 Cable lengths for PC ↔ SLG U92 with RS 232 3–27. . . . . . . . . . . . . . . . . . . . . .

3-9 Components for individually fabricated cables 3–28. . . . . . . . . . . . . . . . . . . . . . .

4-1 Overview of the MDS 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Operational/ambient conditions of the MDS 4–4. . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Ordering data for the MDS U313 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Technical data of the MDS U313 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Field data of the MDS U313 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Ordering data of the MDS 524 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Technical data of the MDS U524 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Field data of the MDS U524 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Ordering data of the MDS U589 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Technical data of the MDS U589 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11 Field data of the MDS U589 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12 Cycles of the MDS U589at its utmost limits 4–14. . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Ordering data of the SLG U92 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Technical data of the SLG U92 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Technical data of the SLG U92 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Overview of the interfaces 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Ordering data of the ASM 452 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Technical data of ASM 452 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Ordering data of the ASM 473 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Technical data of the ASM 473 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6 Ordering data for ASM 475 6–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-7 Technical data of the ASM 475 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-8 Function of the LEDs on the ASM 475 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-9 Operating states shown by LEDs on the ASM 475 6–23. . . . . . . . . . . . . . . . . . .

7-1 Ordering data for MOBY Software 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Ordering data for MOBY wide–range power pack 7–4. . . . . . . . . . . . . . . . . . . .

7-3 Technical data of the MOBY wide–range power pack 7–5. . . . . . . . . . . . . . . . .

A-1 Ordering data for descriptions A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1 General errors B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-2 error_FCerror variable B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-3 Error variable error_Bus B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

v

Page 8

Table of Contents

vi

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 9

General

1

This manual on configuration, installation and service will help you to plan

and configure your MOBY U system. It contains the configuration and installation guidelines and all technical data on the individual components.

MOBY hotline

Internet

E-mail

We have set up the MOBY hotline so that we can give our MOBY customers

optimum advice and service.

We are available from 8:30 to 11:30 AM and 1:00 to 4:00 PM Mondays

through Fridays under the following telephone number.

++49(0)911/750-2859

++49(0)911/750-2861

On so–called ”bridge” days (i.e., the Friday after or the Monday before a holiday) our hotline is not available.

Of course, you can also fax or e–mail us your questions.

Fax: ++49(0)911/750-2800 or 750-2960

E-mail address: MOBY-HOTLINE@fthw.siemens.de

General news on MOBY U or an overview of our other identification systems

can be found on the Internet under the following address.

http://www.ad.siemens.de/moby

We can also answer special questions on products, give you a list of Siemens

representatives in your area, clarify customer–specific requirements, and so

on under the following e–mail address.

moby@fthw.siemens.de

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

1-1

Page 10

General

1-2

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 11

Introduction – MOBY U

MOBY U is the RF identification system which is especially designed for

long–range applications in industry and logistics. It uses the transmission

frequency in the ISM frequency band of 2.4 GHz in the UHF range (ultra

high frequency). This ISM frequency band is recognized around the world. It

unites the power of innovative HF technologies and, at the same time, ensures continuity at the customer’s by being almost totally compatible with the

proven MOBY I system. Robust housing and power-saving circuiting

technology give you years of maintenance-free operation even under the

most rugged of industrial conditions.

MOBY U covers all transmission ranges up to three meters which means that

it meets the prerequisites for a transparent identification solution in the automotive industry, for instance. It offers the communication distances (much

longer than one meter) required to design optimized working processes and

ensure necessary safety zones during automobile production.

The transmission frequency and the robust modulation not only give you

transmission ranges of several meters but also ensure sufficient distance to

the typical sources of electromagnetic interference in industrial production

plants. With MOBY U, you can forget the old sources of interference such as

welding devices and power switches, pulsed DC drives and switching power

packs and all the time–consuming interference suppression measures which

were needed.

Familiar sources of interference during UHF transmission such as reflection,

interference and over–ranging are handled with appropriate technical measures on the MOBY U. In addition, special coding procedures ensure that

data transmission is correct and data integrity is preserved. Proven methods

and algorithms of mobile radio technology (GSM, UMTS) have been used for

this purpose by the identification system. Specially designed antennas ensure

a homogenous transmission field so that the mobile data memories (MDSs)

are detected reliably even in difficult locations.

2

Conflicts with other users of the 2.4 GHz frequency band are avoided by using very low sending power (less than 50 mV per meter at 3-m intervals) and

automatic selection of free and interference-free frequency channels.

With its 32–Kbyte mobile data memories (MDS U524 and MDS U589 – up

to +220 °C cyclically), MOBY U offers a transparent solution for the automotive industry.

Like the MDSs of MOBY U, UHF transponders with selective read/write

functions always require their own energy (battery) for data communication.

This power–saving circuiting technology guarantees years of maintenance–

free service.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

2-1

Page 12

Introduction – MOBY U

Simple and flexible installation of the read/write devices (SLGs) and the mobile data memories (MDSs) in particular are two common requirements of all

assembly and production lines.

The SLG U92 offers easy system integration via coupling to:

Reliable MOBY interface modules (ASMs) for PROFIBUS-DPV1 and

SIMATIC S7

– ASM 452

– ASM 473

– ASM 475

Directly on a standard PC, SICOMP or PC–PLC

Software tools such as SIMATIC S7 functions (FC) and C library MOBY API

for applications under Windows 98/2000/NT make implementation in specific applications easy.

As with the other MOBY identification systems, the MDSs can be operated

with direct byte addressing or with the filehandler.

The convenient and powerful filehandler of MOBY I with its file addressing

is directly integrated on the SLG U92 with expanded functions. The MOVE

and LOAD commands of the MOBY I filehandler are a thing of the past. The

SLG always fetches the file management information it needs directly from

the MDS.

MOBY U can be used in three different ways.

1. For existing system solutions with MOBY I compatibility (no

bunch/multitag)

– MOBY U with standard settings

– Range of up to 1.5 m (fixed setting)

– Byte addressing via absolute addresses

– Filehandler: With unmodified functions and without MOVE and

LOAD commands

2. For existing system solutions with MOBY I compatibility

plus expansions (no bunch/multitag)

– Just a few expanded commands for changing the standard settings and

requesting diagnostic data

– Range up to 3 m (to be limited in increments)

3. Full use of MOBY U performance (with bunch/multitag)

2-2

– Commands and/or user data with clear allocation due to the MDS

number for bunch/multitag

– Range up to 3 m (to be limited in increments)

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 13

Introduction – MOBY U

With MOBY U, a service and diagnostic interface is installed directly on the

read/write device (SLG) to make commissioning easier. Not only current

transmission parameters can be analysed here but data communication can

also be logged. Additional statistical functions are available for quantitative

and qualitative evaluation of data communication.

Primary

applications

Technical data

MOBY U is primarily used for applications in which objects must be quickly

and reliably identified inductively over long distances (up to three meters)

and the objects are to carry extra production and manufacturing parameters

along with them.

Automobile industry, particularly main assembly lines (raw product

manufacturing, surface treatment and assembly)

Industrial production plants

Container/pallet identification for transportation logistics and distribution

Vehicle identification, vehicle parks, etc.

Traffic control technology

Assembly lines

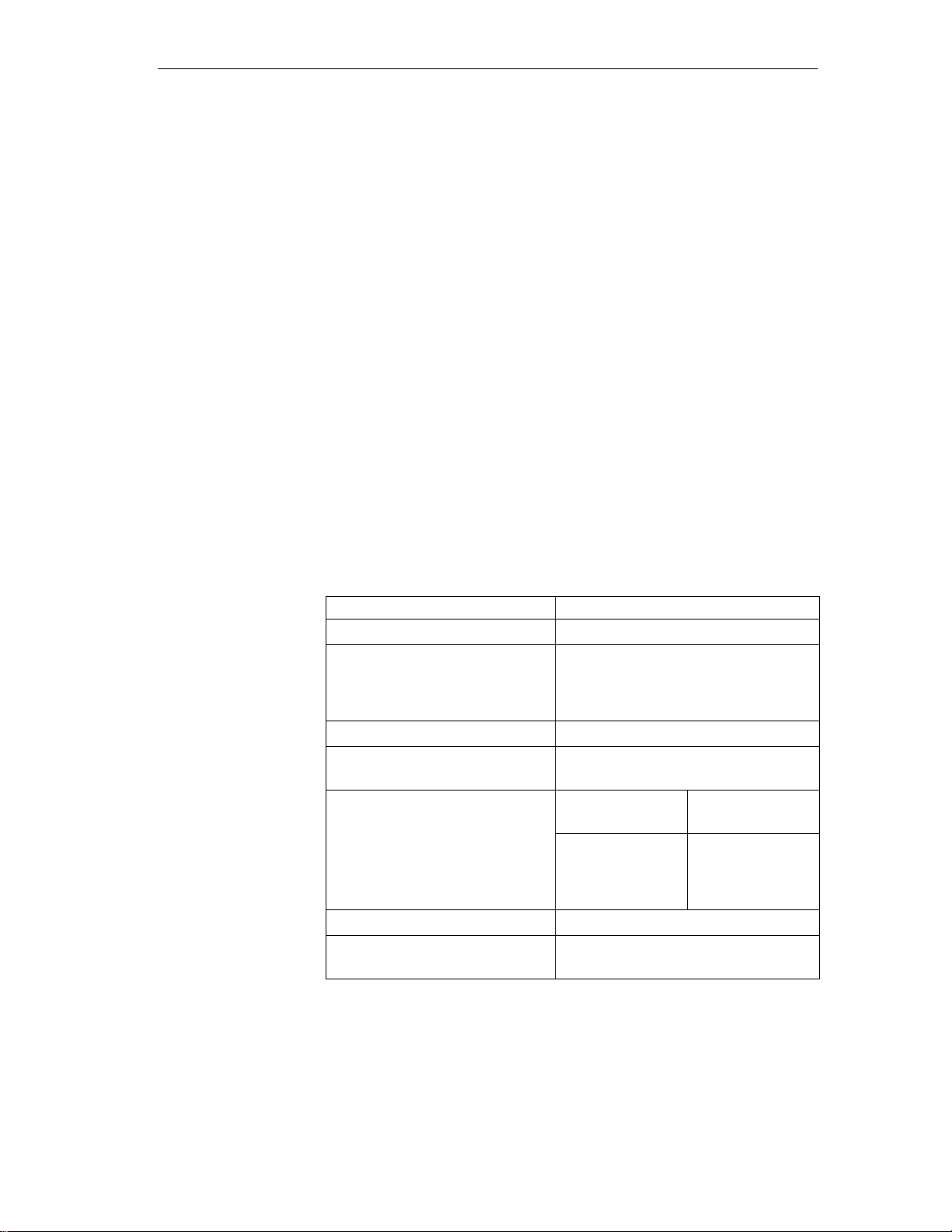

Table 2-1 Technical data of MOBY U (field components)

Fixed code memory MDS ID number (32 bits)

Read–only memory 128 bits, to be written once by the user

Application memory

Memory technology

Memory size

Memory organization

Protection rating IP 67 to IP 68

Operational temperature –25 °C to +70/85 °C, 200 °C (cyclical),

RAM

2 Kbytes or 32 Kbytes

File or address–oriented

220 °C (briefly)

Data transmission speed, SLG-MDS

(net)

Write

Read

Read/write distance 150 mm to 3000 mm

Can be connected to SIMATIC S7, PC, computer, other PLC,

Overview of

the MOBY U

components

MDS: Mobile data memory

SLG: Read and write device

ASM: Interface module

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Without bunch With bunch size = 2

Approx. 16.0 Kbyte/

sec

Approx. 14.4 Kbyte/

sec

PROFIBUS

Approx. 8.0 Kbyte/

sec

Approx. 7.2 Kbyte/

sec

2-3

Page 14

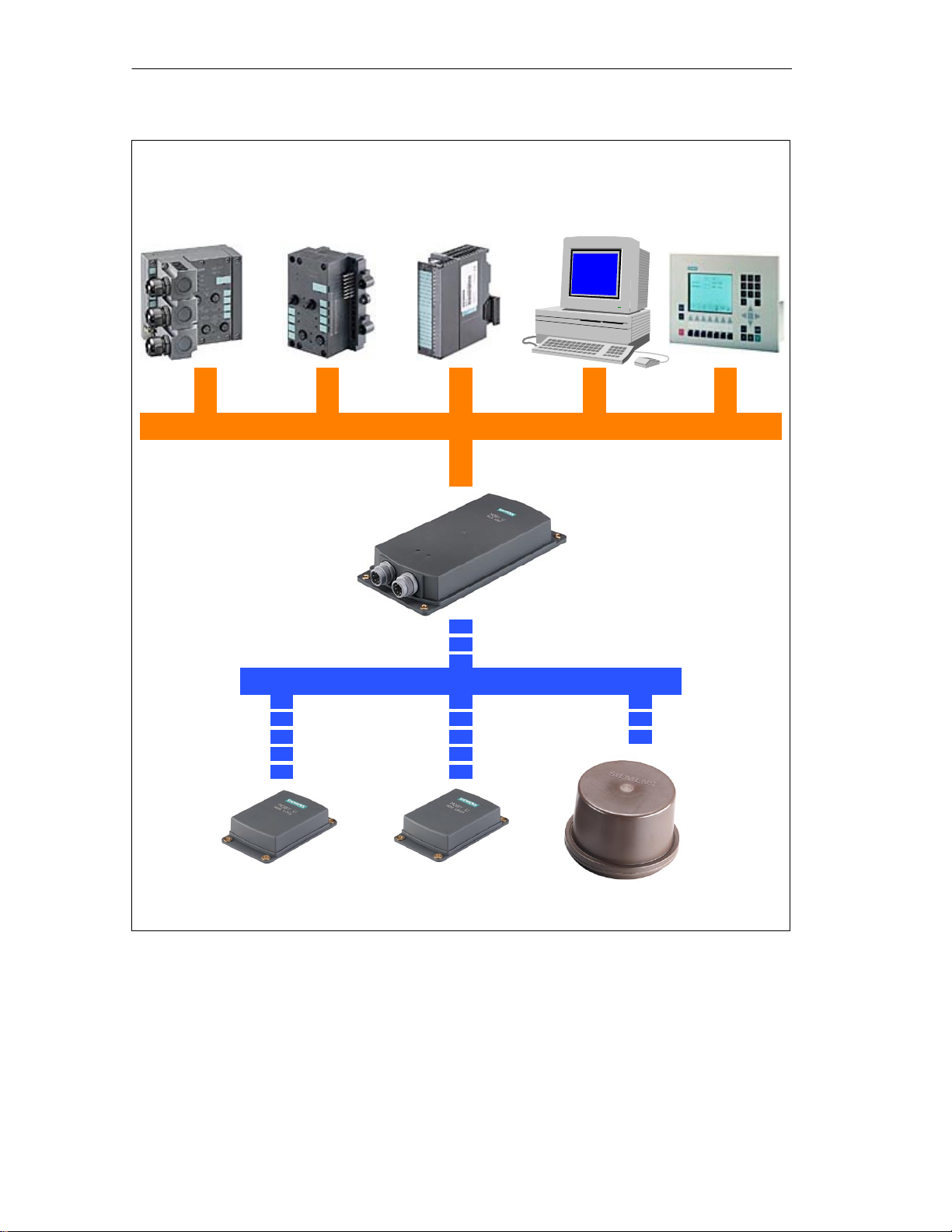

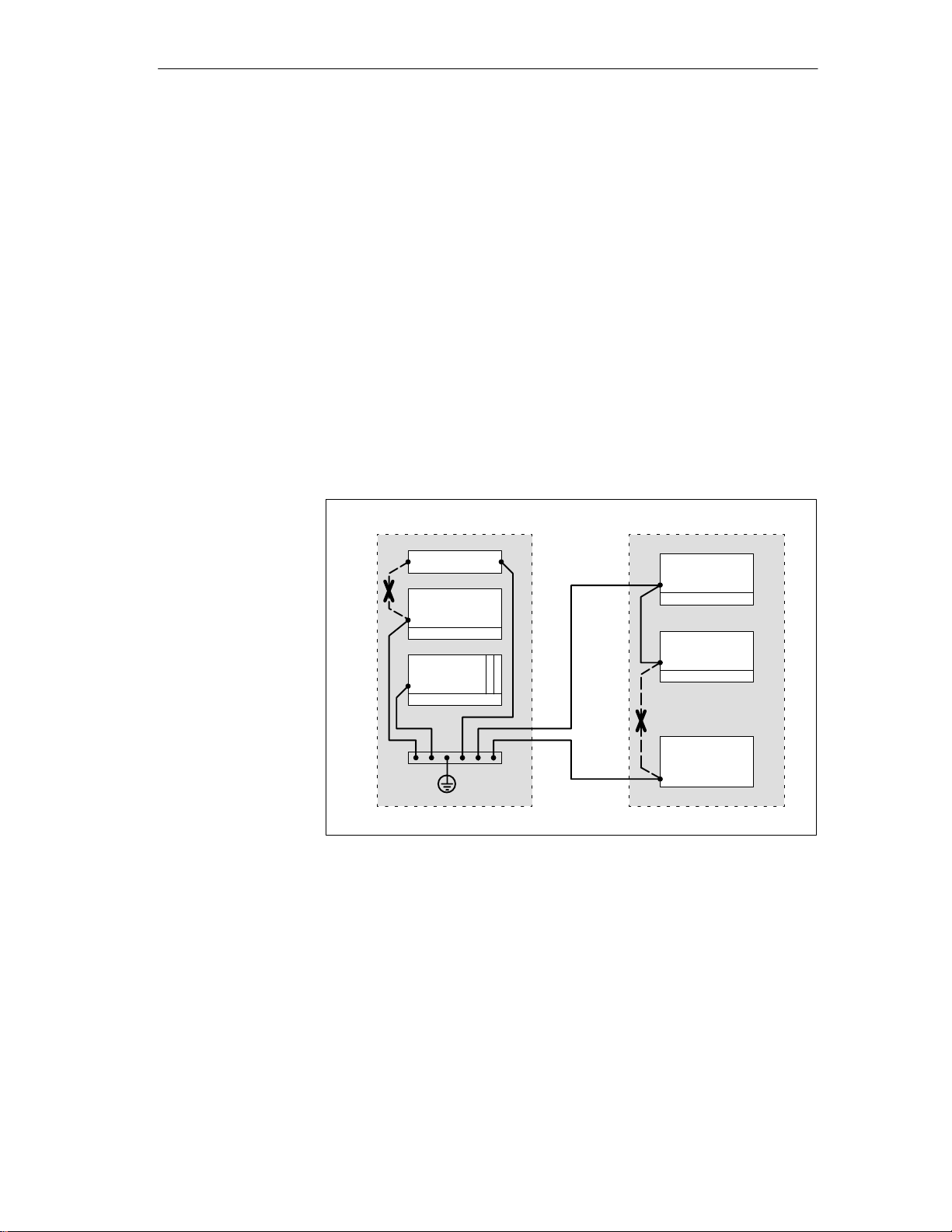

Introduction – MOBY U

ASM 452

for

PROFIBUS-DPV1

FC 45/FC 46

ASM 473

for

ET 200X

FC 45/FC 56

ASM 475

for

SIMATIC S7-300/

ET 200M

PC/computer

V .24/RS 422

MOBY API

FC 45/FC 56

Serial data transmission; max. of 115 kbit/sec

SLG U92

with integrated

antenna

SICOMP/IMC

V .24/RS 422

MOBY API

UHF data transmission, 2.45 GHz

MDS U313

Logistics

Figure 2-1 Overview of the MOBY U components

MDS U524

Production

MDS U589

220 °C (cyclic)

2-4

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 15

Configuration and Installation Guidelines

3

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-1

Page 16

Configuration and Installation Guidelines

3.1 The Fundamentals

MOBY U is a UHF system with powerful features. This makes it much easier

to configure and handle the system.

The range (read/write distance) and communication speed are the same

for all data carriers. However, they do differ in memory size, operational

temperature and lifespan.

Reliable communication due to a homogenous transmission field with

circular polarization in dynamic and static operation. There is no fading

(i.e., temporary ”holes” in the field).

The range (0.15 m to 3 m) permits use throughout production.

The range of the transmission field can be limited (in increments) from

0.5 m to 3 m. This limitation prevents over–ranging and the communication range is clearly specified.

Familiar sources of interference during UHF transmissions such as reflec-

tion and interference have been removed with appropriate technical measures.

Due to the transmission frequency and the robust modulation procedures,

electromagnetic sources of interference can be disregarded.

Simple and flexible installation and customized system integration with

standard hardware and standard function blocks make commissioning fast

and easy.

The robust housing and the power–saving circuiting technology make for

years of maintenance–free operation even under the most rugged of production environments.

Conflicts with other users of the 2.4 GHz frequency band are avoided by

using very low sending power (less than 50 mV per meter at 3-m intervals) and automatic selection of free and interference–free frequency

channels.

Optimum utilization does require adherence to certain criteria.

Transmission window

Time that MDS is in the field (speed and amount of data) during dynamic

transmission

Metal–free space and metallic environment around MDS and SLG

Ambient conditions such as humidity, temperature, chemicals, and so on

Other users of the frequency band at 2.4 GHz

Readiness to communicate: Sleep-time, standby mode, antenna on/off

Bunch size for bunch/multitag

System interface performance

SLG synchronization

Proximity switches

3-2

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 17

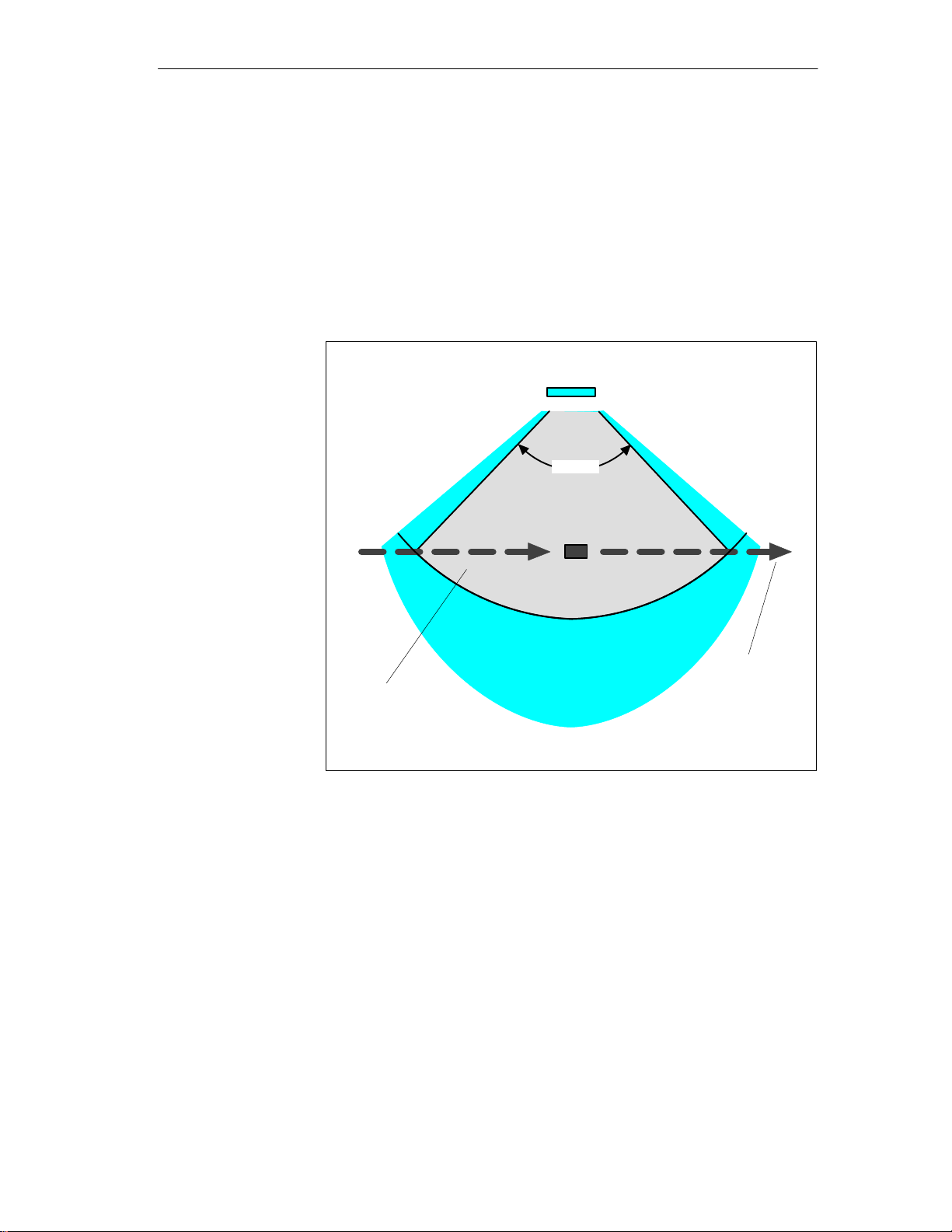

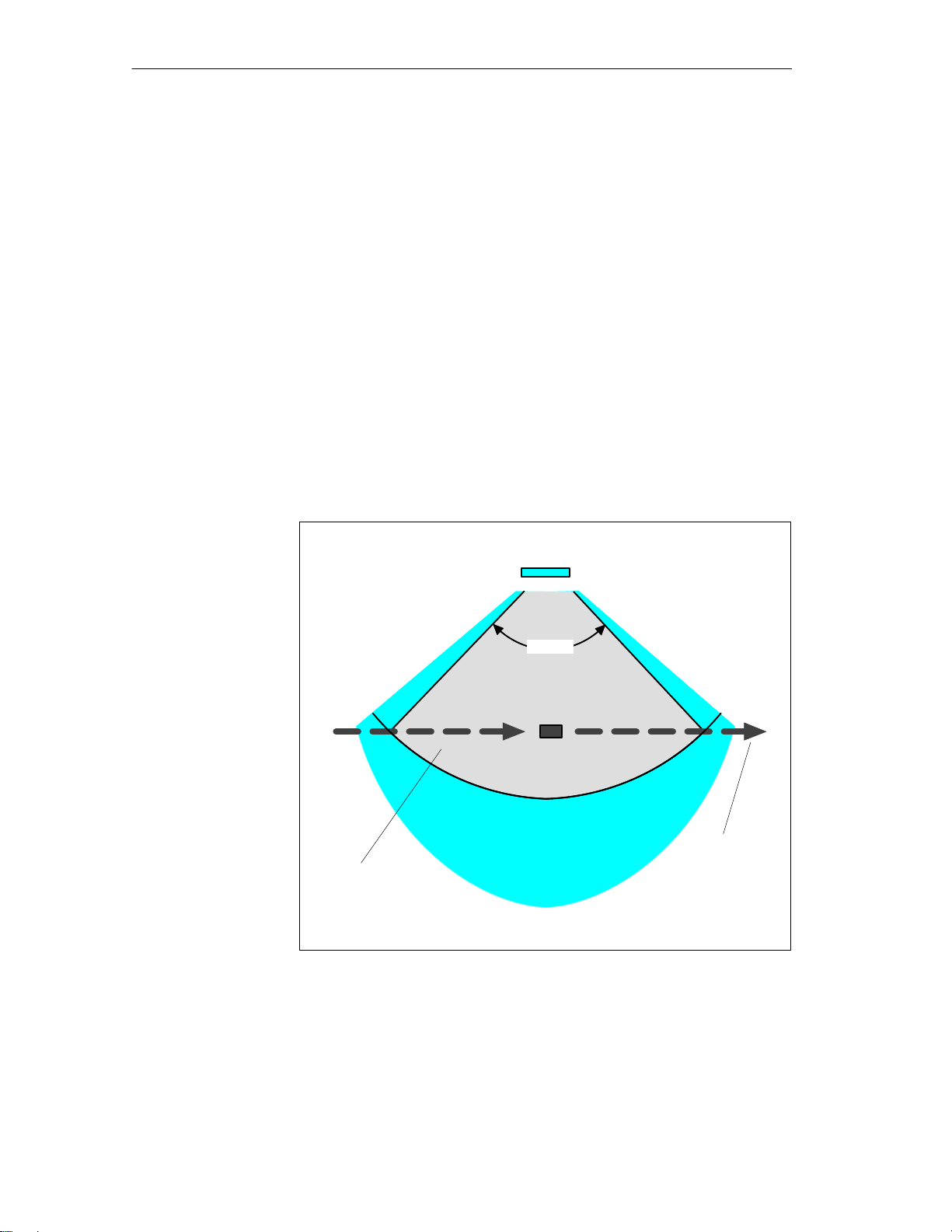

3.1.1 Transmission Window

MOBY U is a UHF system. UHF systems have a relatively wide range despite their low emission power. However, the emission field has a directional

characteristic which depends on the antenna construction. MOBY U has various function zones which depend on direction and distance to keep the

MDS’s power requirements low and to make localization reproducible. The

states and reactions of the affected components vary with the three different

zones of the transmission field (see figure 3-1).

Configuration and Installation Guidelines

SLG U92 with

integrated antenna

> 90°

MDS

Zone 1: r = max. of 3.0 m

Can be adjusted in increments

Zone 2: r = up to approx. 5 m

Transmission

field

Zone 3: r > approx.. 5 m or shielded

Figure 3-1 Status zones for MDS in transmission field of SLG U92

Direction of

MDS’s

movement

Zone 3:

In simplified terms, zone 3 is the UHF–free area. The MDS is asleep and

only wakes up once every < 0.5 sec to listen for an SLG. Power consumption is very low. If other UHF users are in the vicinity and they are using

the same frequency range, this does not shorten the battery life of the

MDS since it does not wake up until it receives a special code.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-3

Page 18

Configuration and Installation Guidelines

Zone 2:

If the MDS receives this special code in the vicinity of an active SLG, it

enters zone 2 (see figure 3-1). Starting immediately it accepts the SLG

and responds briefly with its own ID. However, the SLG ignores all

MDSs which are not in zone 1 (radius can be parameterized on the SLG

in increments). Power consumption in zone 2 is a little higher than in

zone 3.

Zone 1:

When an MDS enters zone 1, it is registered by the SLG and can begin

exchanging data. All read and write functions can now be performed. The

power consumption of the MDS increases briefly during communication.

Since transmission through the air is very fast, total communication time

is very short. The entire 32–Kbyte data memory can be read in less than

four seconds. This means that data communication hardly uses the battery.

As long as the MDS is located in zone 1, it is ready to exchange data

when requested by the SLG. When no command for the MDS is queued,

it still reports at regular parameterizable intervals with its ID when requested by the SLG. Its behavior corresponds to that of zone 2. Current

consumption drops again accordingly.

General

configuration rules

With MOBY U as a UHF system, the following physical characteristics

must be considered when you configure the system.

The waves in the UHF range spread out in straight lines.

The transmission field (zones 1 and 2) is shaped like an ellipse.

The range of the transmission ellipse up to 3 m can be adjusted in incre-

ments for better identification of the MDS.

In simplified terms, the transmission field can be thought of as a cone and

the midpoint of the antenna is located at the peak of this cone. The angle

of opening is approx. 90°. A primarily homogenous field is then assumed

within this parameterized area. Fading (temporary ”holes” in the field) in

this area is offset by technical measures.

Ideally the MDS should penetrate the transmission cone of its basic sur-

face and exit through the surface area so that the MDS remains as long as

possible in the defined recording field.

Since metallic surfaces reflect the waves, they can also be used for shield-

ing or even deflection. Particularly in typical production environments,

the wealth of metallic objects ensures a relatively uniform dispersion of

the transmission waves.

For optimum data communication, metal should be avoided at least in the

vicinity of the vertical waves.

3-4

Both the MDS and the SLG can be mounted directly on metal.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 19

3.2 Basic Requirements

Configuration and Installation Guidelines

FCC Compliance

Statement

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

Note

Changes or modifications of this unit may void the user’s authority to operate the equipment.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-5

Page 20

Configuration and Installation Guidelines

3.3 EMC Guidelines

3.3.1 Preface

These EMC guidelines give you information on the following topics.

Why are EMC guidelines necessary?

What outside interference affects the controller?

How can this interference be prevented?

How can this interference be corrected?

Which standards apply to EMC?

Examples of interference–immune plant setup

This description is only meant for ”qualified personnel.”

Project engineers and planners who are responsible for the plant configu-

ration with the MOBY modules and have to adhere to the applicable

guidelines

Technicians and service engineers who have to install the connection

cables based on this description or correct malfunctions covered by these

guidelines

Warning

!

Non–adherence to the highlighted information may cause hazardous states in

the plant. Individual components or the entire plant may be destroyed as a

result.

3-6

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 21

3.3.2 General

Configuration and Installation Guidelines

Increasing use of electrical and electronic devices creates the following situation.

Increasing density of the components

Increasing power electronics

Increasing switching speeds

Lower power consumption of the components

The more automation, the greater the danger of the devices interfering with

each other.

Electromagnetic compatibility (EMC) means the ability of an electrical or

electronic device to function correctly in an electromagnetic environment

without bothering its surroundings up to a certain degree.

EMC can be divided into three areas.

Own interference immunity

Immunity against internal (i.e., own) electrical interference

Free interference immunity

Immunity against outside electromagnetic interference

Degree of interference emission

Interference emission and influence of the electrical environment

All three areas must be considered when checking an electrical device.

The MOBY modules are checked for adherence to certain limit values. Since

the MOBY modules are only part of a total system and sources of interference can be created just by combining different components, the setup of a

plant must adhere to certain guidelines.

EMC measures usually comprise a whole package of measures which must

all be taken to obtain an interference–immune plant.

Note

The constructor of the plant is responsible for adherence to the EMC

guidelines whereas the operator of the plant is responsible for radio interference suppression for the entire system.

All measures taken while the plant is being set up prevent expensive

modifications and removal of interference later on.

Naturally, the country–specific rules and regulations must be adhered to.

They are not part of this documentation.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-7

Page 22

Configuration and Installation Guidelines

3.3.3 Spreading of Interference

The following three components must be present before interference can occur in a plant.

Source of interference

Coupling path

Potentially susceptible equipment

Source of interference

(instigator)

Example: Drive

Figure 3-2 Spreading of interference

Coupling path

Example: MOBY cable

Potential susceptible

equipment

(malfunctioning device)

Example: ASM 452

If one of these components is missing (e.g., the coupling path between interference source and potentially susceptible equipment), the susceptible device

is not affected even when the source is emitting strong interference.

EMC measures affect all three components to prevent malfunctions caused

by interference. When setting up a plant, the constructor must take all possible precautions to prevent the creation of interference.

Only devices which meet limit value class A of VDE 0871 may be used

in a plant.

All interference–producing devices must be corrected. This includes all

coils and windings.

The cabinet must be designed to prevent mutual interference of the indi-

vidual components or keep this as low as possible.

Precautions must be taken to eliminate external interference.

The next few sections give you tips and hints on good plant setup.

3-8

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 23

Configuration and Installation Guidelines

Sources of

interference

To obtain a high degree of electromagnetic compatibility and thus a plant

with low interference, you must know the most frequent sources of

interference. These sources of interference must then be removed.

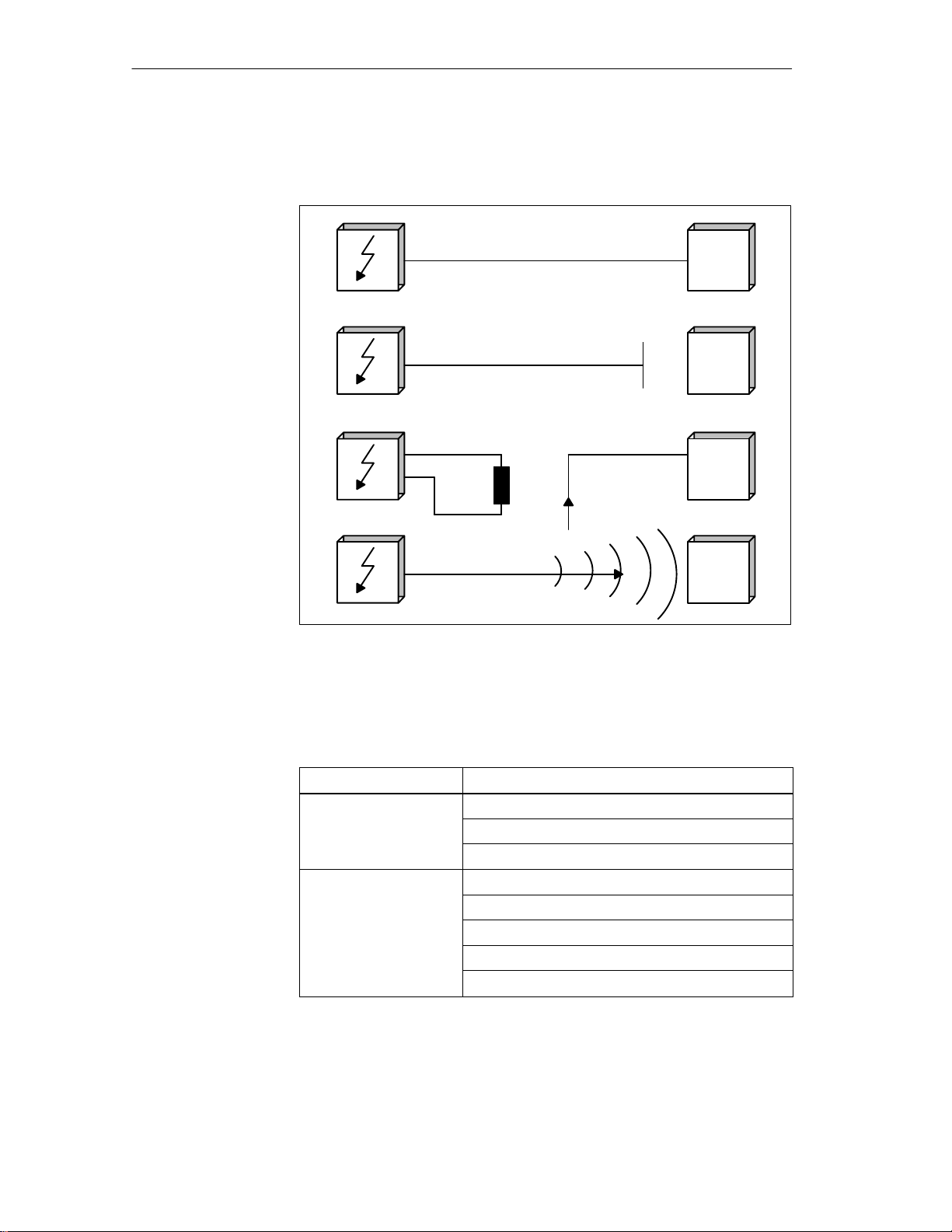

Table 3-1 Sources of interference: Origin and effects

Interference Source

Contactor, electronic

valves

Electric motor Collector Electrical field

Electric welding device Contacts Electrical field

Power pack, pulsed Circuit Electrical and magnetic field,

High–frequency devices Circuit Electromagnetic field

Transmitter

(e.g., plant radio)

Grounding or reference

potential difference

Operator Static charging Electrical discharge current,

High–voltage cable Current flow Electrical and magnetic field,

High–voltage cable Voltage difference Electrical field

Interference Generator Effect on Susceptible

Equipment

Contacts Network interference

Coils Magnetic field

Winding Magnetic field

Transformer Magnetic field, network interfe-

rence, equalizing current

network interference

Antenna Electromagnetic field

Voltage difference Equalizing current

electrical field

network interference

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-9

Page 24

Configuration and Installation Guidelines

Coupling paths

Before a source of interference can create actual interference, a coupling path

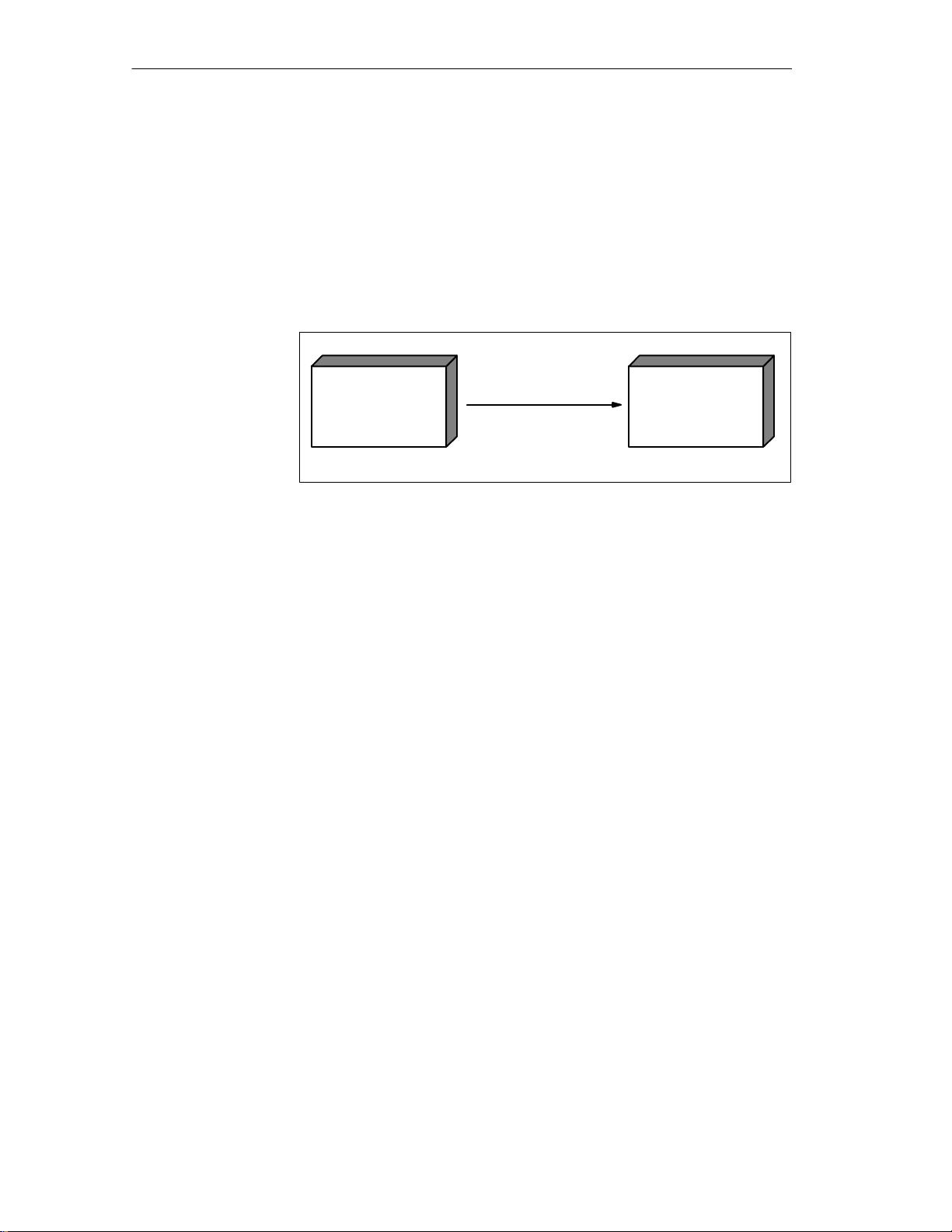

is needed. There are four types of interference coupling.

Galvanic coupling path

I

N

T

E

R

F

E

N

C

E

S

O

U

R

C

E

Capacitive coupling path

Inductive coupling path

Emission coupling

MOBY

ASM or

SLG

MOBY

ASM or

SLG

MOBY

ASM or

SLG

MOBY

ASM or

SLG

S

U

S

C

E

P

T

I

B

L

E

E

Q

U

I

P

M

E

N

T

Figure 3-3 Possible interference coupling

When MOBY modules are used, various components of the total system can

act as coupling paths.

Table 3-2 Causes of coupling paths

Coupling Path

Cables and lines Wrong or poor installation

Shield missing or connected incorrectly

Poor location of the cables

Switching cabinet or SIMATIC housing

Equalizing line missing or incorrectly wired

Grounding missing or faulty

Unsuitable location

Mounted modules not secure

Poor cabinet layout

Caused by

3-10

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 25

3.3.4 Cabinet Layout

User responsibility for the configuration of an interference–immune plant

covers cabinet layout, cable installation, grounding connections and correct

shielding of the cables.

Note

Information on EMC–proof cabinet layout can be taken from the setup

guidelines of the SIMATIC controller.

Configuration and Installation Guidelines

Shielding by

housing

Magnetic and electrical fields as well as electromagnetic waves can be kept

away from susceptible equipment by providing a metallic housing. The better

induced interference current is able to flow, the weaker the interference field

becomes. For this reason all housing plates or plates in the cabinet must be

connected with each other and good conductivity ensured.

Figure 3-4 Shielding by the housing

When the plates of the switching cabinet are insulated against each other, this

may create a high–frequency–conducting connection with ribbon cables and

high–frequency terminals or HF conductive paste. The larger the connection

surface, the better the high–frequency conductivity. Connection of simple

wires cannot handle this task.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-11

Page 26

Configuration and Installation Guidelines

Avoidance of

interference with

optimized layout

Installation of SIMATIC controllers on conductive mounting plates (not

painted) is a good way to get rid of interference. Adhering to the guidelines

when laying out the switching cabinet is a simple way to avoid interference.

Power components (transformers, drives, load power packs) should not be

located in the same room with controller components (relay control parts,

SIMATIC S5).

The following principles apply.

1. The effects of interference decrease the greater the distance between

source of interference and susceptible equipment.

2. Interference can be decreased even more by installing shielding plates.

3. Power lines and high–voltage cables must be installed separately at least

10 cm away from signal lines.

PS

Controller

Drive

Figure 3-5 Avoidance of interference with optimal layout

Shield

plate

3-12

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 27

Configuration and Installation Guidelines

Filtering the

voltage

Power filters can be used to combat external interference over the power

network. In addition to correct dimensioning, proper installation is very

important. It is essential that the power filter be mounted directly on the

cabinet leadin. This keeps interference current from entering the cabinet by

filtering it out from the beginning.

Right

Power filter

I

s

Wrong

Power filter

I

s

Figure 3-6 Filtering the voltage

I

= Interference

s

current

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-13

Page 28

Configuration and Installation Guidelines

3.3.5 Avoiding Sources of Interference

Inclusion of interference sources in a plant must be avoided to achieve a

higher degree of interference immunity. All switched inductivity is frequently a source of interference in plants.

Suppression of

inductivity

Relays, contactors, etc. generate interference voltages which must be

suppressed with one of the following circuits.

24 V coils create up to 800 V even with small relays and 220 V coils generate interference voltages of several kV when the coil is switched. Free wheeling diodes or RC circuits can be used to prevent interference voltage and thus

also inductivity in lines which must be installed parallel to the coil line.

Relay coils

Contactors

Figure 3-7 Suppression of inductivity

Valves

Brakes

3-14

Note

All coils in the cabinet must be interference–suppressed. Don’t forget the

valves and motor brakes. A special check must be made for neon lamps in

the switching cabinet.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 29

3.3.6 Equipotential Bonding

Differences in potential may be created between the parts of the plant by differing layout of plant parts and differing voltage levels. When the parts of the

plant are connected with signal lines, equalizing currents flow over the signal

lines. These equalizing currents may distort the signals.

This makes it very important to provide correct equipotential bonding.

The cross section of the equipotential bonding line must be large enough

(at least 10 mm2).

The distance between signal cable and equipotential bonding line must be

as short as possible (effects of antenna).

A fine–wire line must be used (better high–frequency conductivity).

When the equipotential bonding lines are connected to the central equipo-

tential bonding rail, power components and non–power components must

be combined.

Configuration and Installation Guidelines

Cabinet 1 Cabinet 2

Power pack

EU

Wrong

EU

EU

PLC

Wrong

Drive

Figure 3-8 Equipotential bonding

The better the equipotential bonding in a plant, the less interference is

created by potential fluctuations.

Don’t confuse equipotential bonding with the protective ground of a plant.

Protective ground prevents the creation of high touch voltages on defective

devices.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-15

Page 30

Configuration and Installation Guidelines

3.3.7 Shielding the Cables

To suppress interference coupling in the signal cables, these cables must be

shielded.

The best shielding is achieved by installation in steel tubing. However, this is

only required when the signal line has to be led through high interference.

Use of cables with braided shields is usually sufficient. In both cases, correct

connection is decisive for shielding.

Note

A shield which is not connected or is not connected correctly is not a shield.

The following principles apply.

With analog signals, the shield is connected on one side to the receiver

side.

With digital signals, the shield is applied on both sides to the housing.

Since interference signals are frequently in the HF range (> 10 kHz), a

large–surface shield which meets HF requirements is needed.

Figure 3-9 Shielding the cables

The shield bar must be connected (over a large surface for good conductivity)

to the switching cabinet housing. It must be located as close as possible to the

cable leadin. The cables are bared and then clamped to the shield bar (high–

frequency clamps) or bound with cable binders. Make sure that the connection is very conductive.

3-16

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 31

Configuration and Installation Guidelines

Cable binder

Figure 3-10 Connecting the shield bar

The shield bar must be connected with the PE bar.

Remove

paint

If shielded cables have to be interrupted, the shield must be continued on the

plug case. Only suitable plug connectors may be used.

Fold back shield by 180° and

then connect with plug case.

Rubber sleeve

Figure 3-11 Interruption of shielded cables

If intermediate plug connectors which have no shield connection are used,

the shield must be continued with cable clamps at the point of interruption.

This gives you a large–surface, HF conductive connection.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-17

Page 32

Configuration and Installation Guidelines

3.3.8 Basic EMC Rules

Often the adherence to a few elementary rules is sufficient to ensure electromagnetic compatibility (EMC). The following rules should be observed when

setting up the switching cabinet.

Shielding by the

housing

Surface–shaped

grounding

connection

Protect the programmable controller from external interference by instal-

ling it in a cabinet or housing. The cabinet or housing must be included in

the grounding concept.

Shield the programmable controller from electromagnetic fields of induc-

tivity by using divider plates.

Use metallic plug connector cases for shielded data transmission lines.

Connect all inactive metallic parts over a large surface with low ohmic

HF.

Planning the cable

installation

Make a large–surface connection between the inactive metallic parts and

the central grounding point.

Don’t forget to include the shield bar in the grounding concept. This

means that the shield bar itself must be connected over a large surface

with ground.

Do not use aluminum parts for grounding connections.

Divide the cables into groups and install the groups separately.

Always install high–voltage cables and signal lines in separate ducts or

bundles.

Always have the entire cabling enter the cabinet on only one side and at

only one level.

Install the signal lines as close as possible to grounding surfaces.

Twist the ”to” and ”from” conductors of individual cables in pairs.

3-18

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 33

Shielding the

cables

Power and signal

filters

Configuration and Installation Guidelines

Shield the data transmission cables and apply the shield on both sides.

Shield the analog cables and apply the shield on one side (e.g., on the

drive).

Always apply the cable shields over a large surface on the cabinet leadin

on the shield bar and affix these with clamps.

Continue the applied shield without interruption up to the module.

Use braided shields and not foil shields.

Use only power filters with metal housing.

Connect the filter housing (over a large surface and with low ohmic HF)

to cabinet ground.

Never secure the filter housing on painted surfaces.

Secure the filter on the cabinet’s entry point or in the direction of the

source of interference.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-19

Page 34

Configuration and Installation Guidelines

3.4 MOBY Shielding Concept

With MOBY U, the data are transferred between ASM and SLG at a speed of

19200, 38400, 57600 or 115200 Baud over an RS 422 interface. The distance

between ASM and SLG can be up to 1000 m. With respect to cabling,

MOBY should be handled like a data processing system. Special attention

should be paid to shield installation for all data cables. The following figures

shows the primary factors needed for a reliable setup.

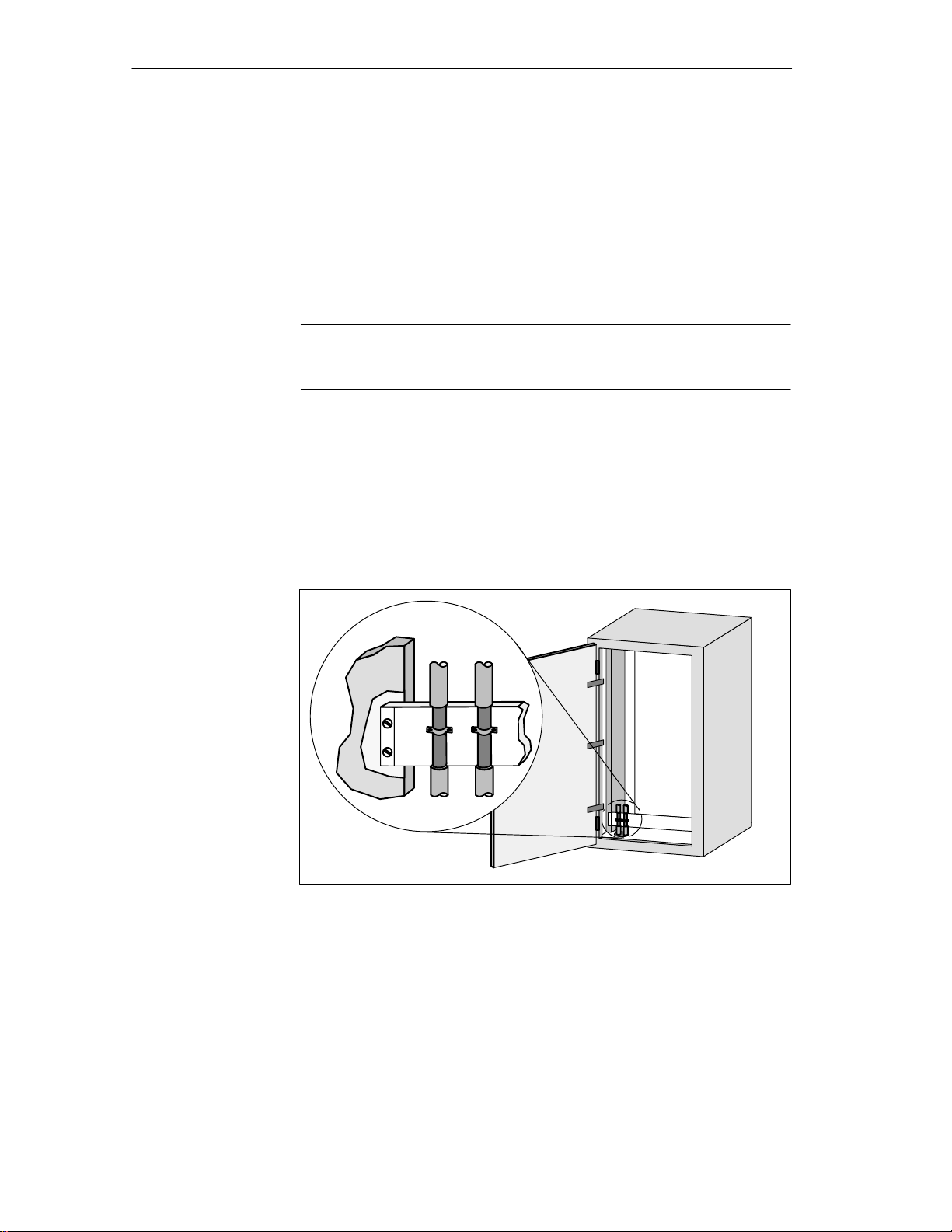

3.4.1 SLG Cable between ASM 475 and SLG U92 with RS 422

Layout of an

S7–300 with MOBY

When the SLG U92 is connected to the ASM 475, it is essential to use a

shield connection terminal for the cable shield. Shield connection terminals

and holder brackets are standard components of the S7–300 product family.

Shield connection terminal

Cable to SLG1

Figure 3-12 Layout of the ASM 475 with shield connecting element

Cable to SLG2

Holding

bracket

3-20

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 35

Configuration and Installation Guidelines

3.5 SLG Cable and Plug Connector Allocations (RS 422)

The jacket used for MOBY SLG connection cables is made of polyurethane

(PUR in acc. w. VDE 0250). This gives the cables very good resistance to oil,

acid, lye and hydraulic fluid.

3.5.1 Cable Configuration

The cable between ASM and SLG has six cores plus shield. Four of these

cores are allocated to the serial data interface. The power supply of the SLG

requires two cores. Regardless of the wire diameter, data can usually be

transmitted up to a distance of 1000 m.

The voltage on the connection cable drops due to the power consumption of

the SLG. For this reason, the permitted cable length is usually shorter than

1000 m. It depends on the current consumption of the SLG and the ohmic

resistance of the connection cable. The following table gives you an overview of the permitted cable lengths.

Grounding of the

SLG cable

Table 3-3 Cable configuration

Conductor

Cross Section in

1 The resistance values are average values. They refer to the ”to” and ”from” conductors.

2 When these conductor cross sections are used, crimp contacts must be used in the SLG

Field highlighted in gray:

2

mm

2

0.07

0.2 0.5 185 85 210

0.5 0.8 70 230 570

2

0.8

2

1.5

A single wire has half the specified resistance.

connection plug. These crimp contacts are not included with the connection plugs.

Standard cable recommended by Siemens (LiYC11Y, 6 x 0.25, shielded). The cable is

available from SIEMENS under the order number ”6GT2 090-0A...”.

Conductor

Cross Section in

mm

2

0.3

2

1.0

2

1.4

Resistance

1

/km

550 30 70

50 320 800

24 660 1000

SLG U92 with RS 422

(I = 300 mA) Max. Cable

Length in m for

UV = 24 V UV = 30 V

We recommend always grounding the shield of the SLG cable over a large

surface to the grounding rail.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-21

Page 36

Configuration and Installation Guidelines

Extra power pack

for SLG

When an extra power pack is installed in the vicinity of the SLG, you can

always use the maximum cable length of 1000 m between ASM and SLG.

Note

The 24 V power supply (pin 2 on the SLG connector)

may not be connected to the ASM.

6–core (with 24 V connection)

24 V =

90 –

230 V

Max. of 1000 m

Figure 3-13 SLG with extra power pack

SLG

The power pack in our drawing can be obtained from Siemens under the

number 6GT2 494-0AA00 (see chapter 7.2).

The cable from the extra power pack to the SLG must be provided by the

customer.

3.5.2 Plug Connector Allocations

Table 3-4 Plug connector allocation of the SLG connector

Plug on SLG

2

3

1

6

4

5

Caution

!

When the extra power pack is used in the vicinity of the SLG, do not wire

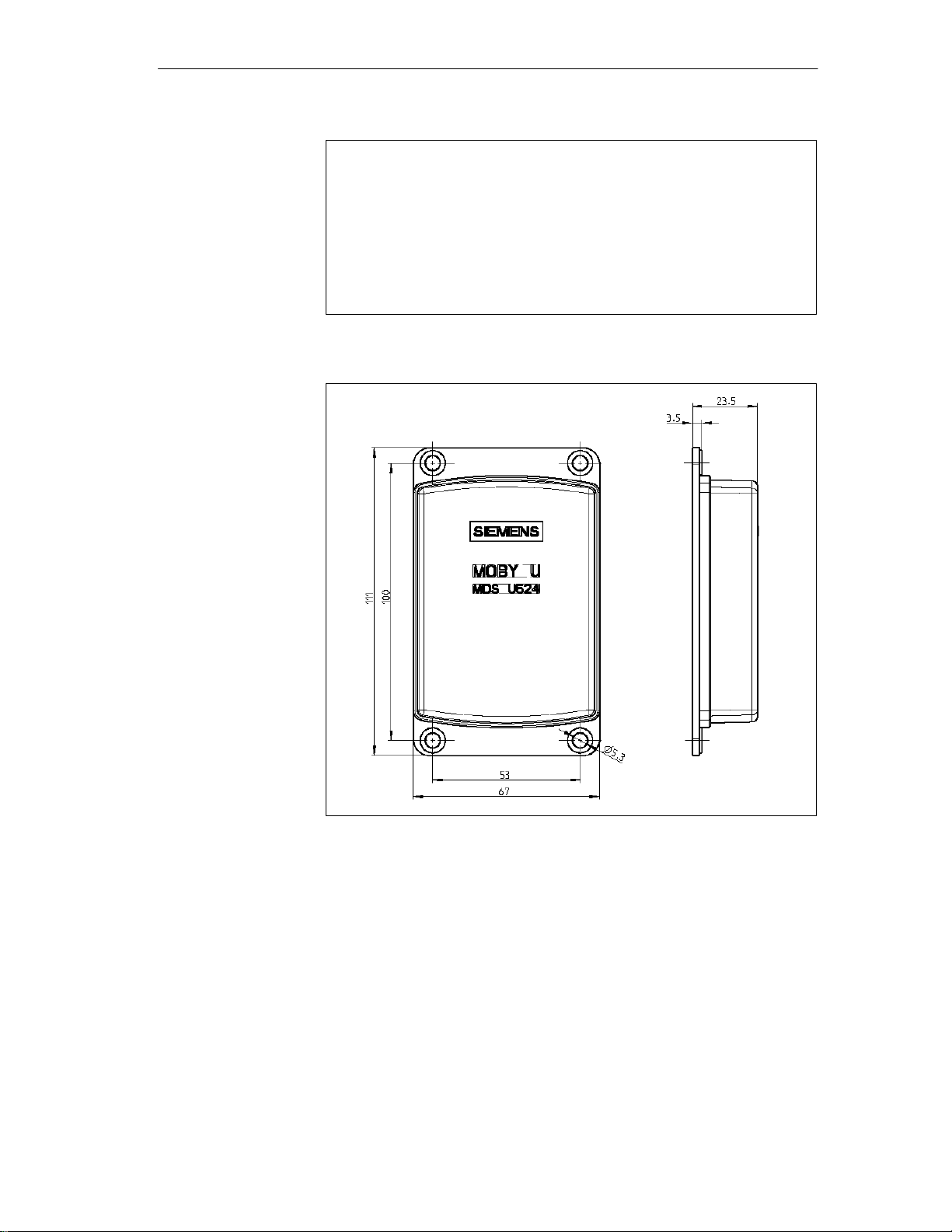

the +24 V pin to the ASM. (Cf. table 3-4.)

Pin

1 - Receive

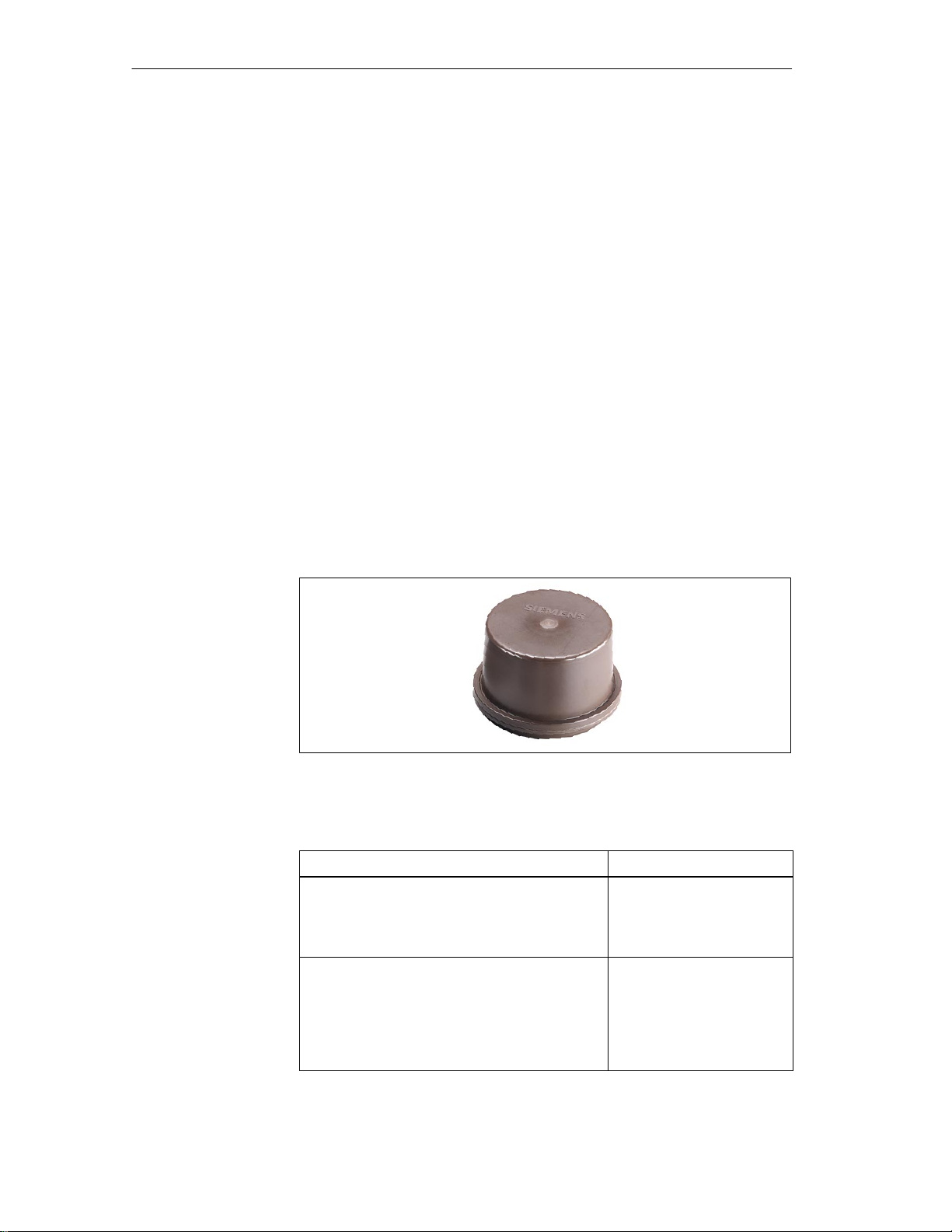

2 +24 Volt

3 Ground (0 V)

4 + Send

5 - Send

6 + Receive

Cable shield

Name

3-22

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 37

Configuration and Installation Guidelines

Installing the SLG

plug connector

If the user has to turn the SLG plug of a prefabricated cable in a different

direction, follow the diagram below and position the contact carrier

differently. The plug connector on the SLG cannot be turned.

Knurled screw for

vibration–proof connections

(no tools required)

Removable housing cover

for easy mounting

Cable holder with cage claw

Crimp contacts

for use with

strong vibration*

Contact carrier must be

affixed at 7 positions.

* Manual crimp pliers: order from:

Hirschmann,

72606 Nürtingen

Tel. 07127/14-1479;

Type XZC0700,

Order no.: 932 507-001

Figure 3-14 Drawing of how to mount the SLG plug connector

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-23

Page 38

Configuration and Installation Guidelines

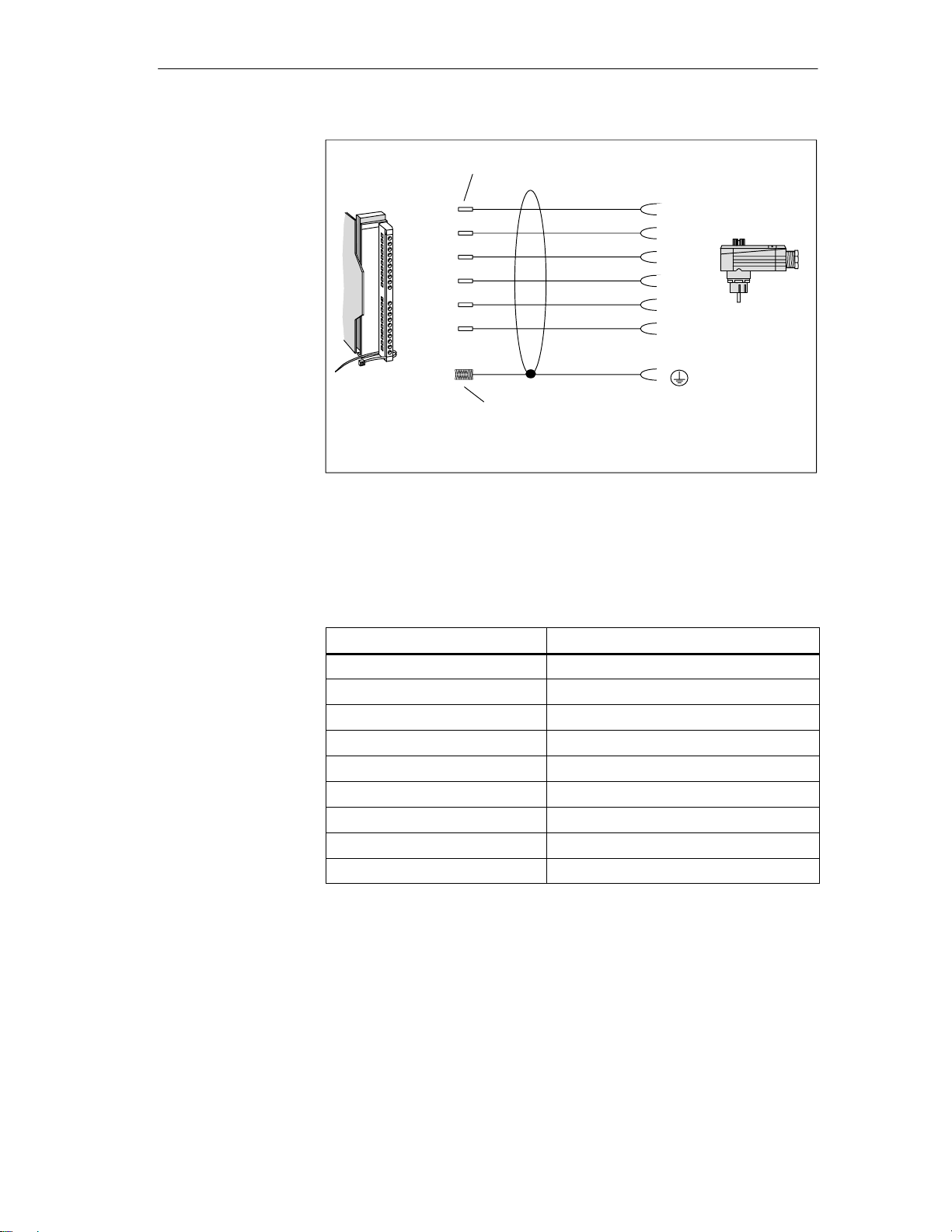

3.5.3 Connection Cables

Connection cable

ASM 452/473 ↔

SLG U92 with

RS 422

6GT2 091-1C...

22.5

18.5

Two 5–pin, round M12 plug

connectors

X1/2

X1/3

x1

X2

X1/1

X1/4

X2/3

X2/1

X1/5

X2/5

SLG plug (socket)

2m

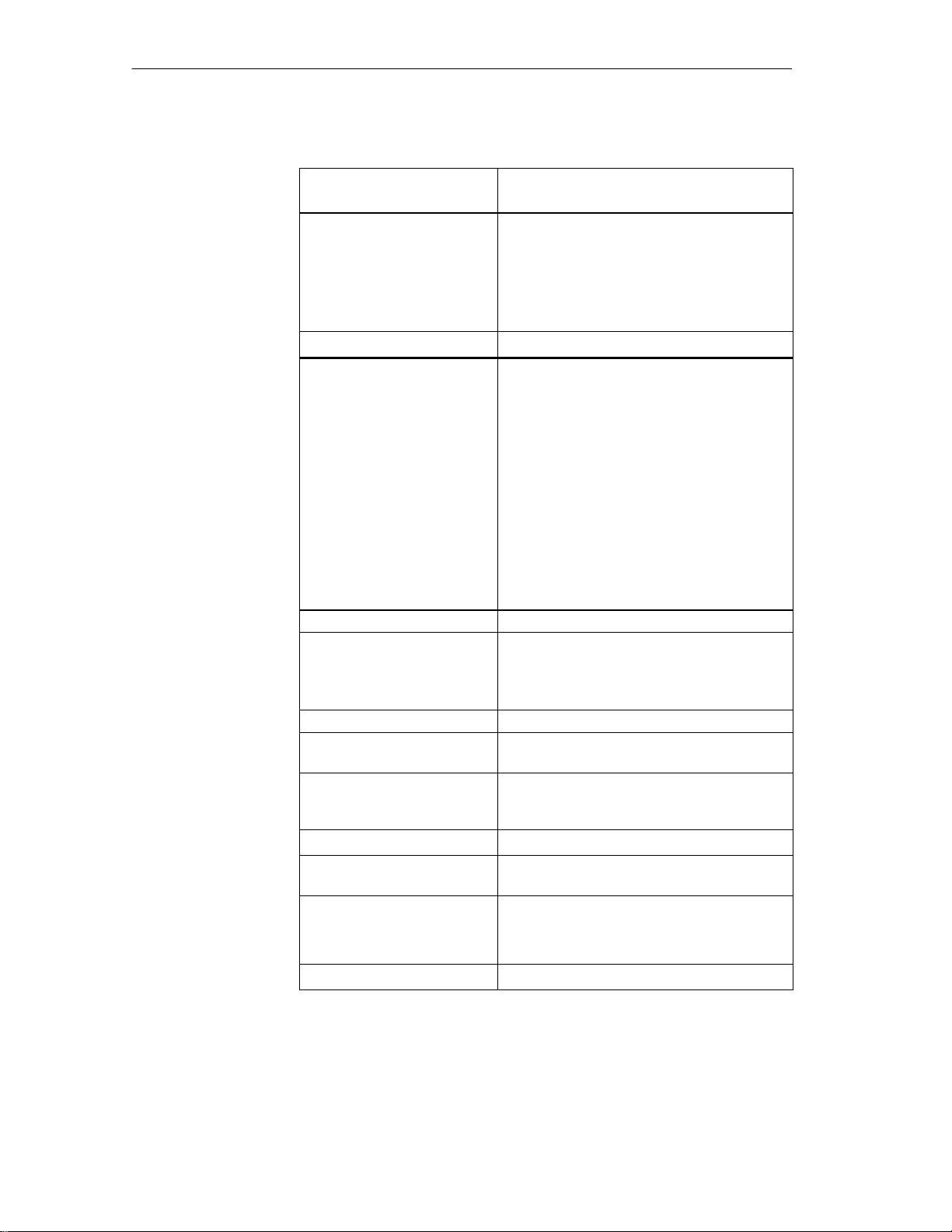

White

Brown

Green

Yellow

Gray

Pink

Figure 3-15 Connection cable ASM 452/473 ↔ SLG U92 with RS 422

The connection cable can be ordered in the following lengths.

Table 3-5 Cable lengths of ASM 475 ↔ SLG U92 with RS 422

Length of Stub Line in m Order Number

1

2

5 6GT2 091-1CH50

10 6GT2 091-1CN10

20 6GT2 091-1CN20

50 6GT2 091-1CN50

2

2

6GT2 091-1CH20

6GT2 091-2CH20

6

1

4

5

3

2

3-24

1 Inexpensive standard length

2 Connection cable with straight SLG plug

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 39

Connection cable

ASM 475 ↔

SLG U92 with

RS 422

6GT2 091-0E...

Configuration and Installation Guidelines

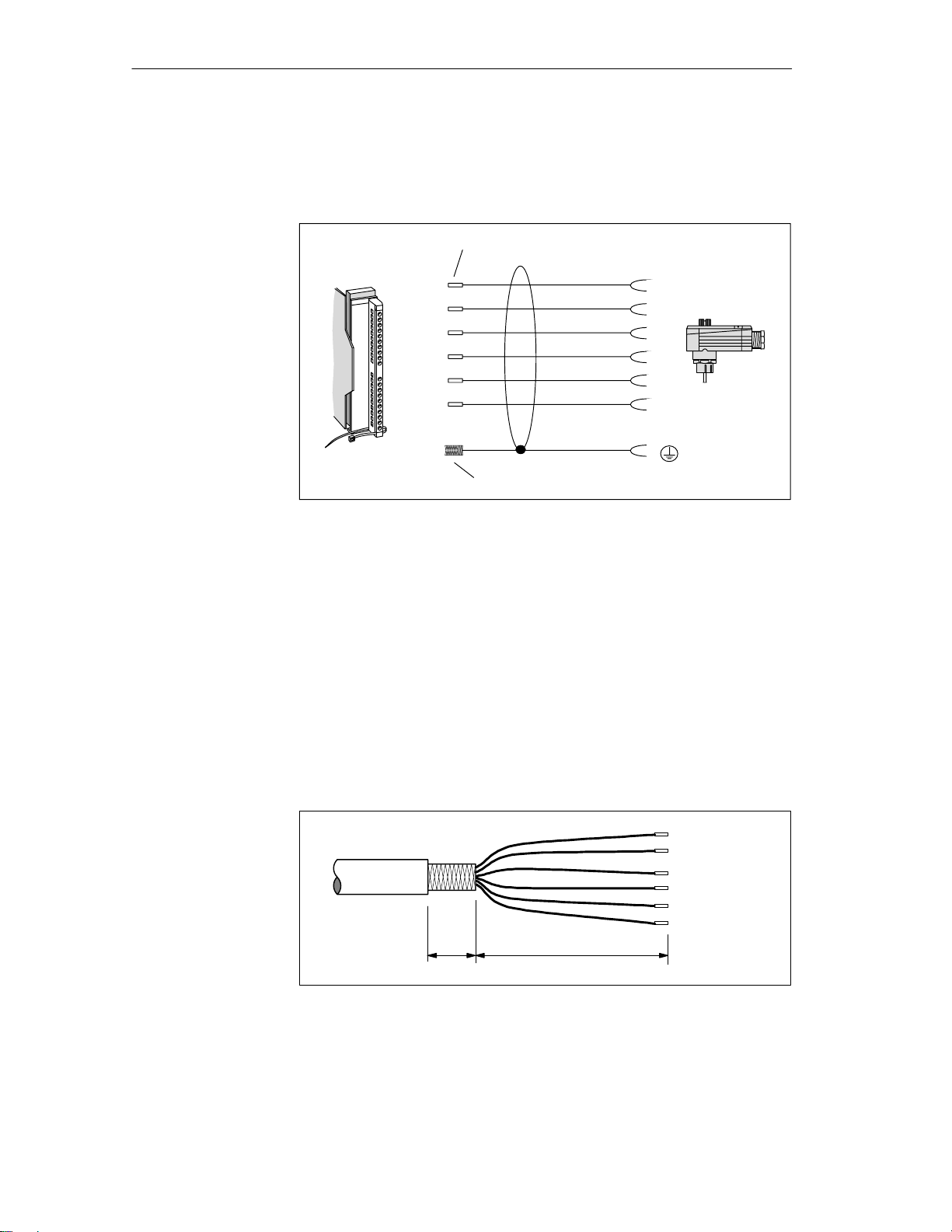

Cable with core sleeves

4 (12)

5 (13)

6 (14)

7 (15)

8 (16)

9 (17)

Cable shield open

16GT2 091-0E... with angled SLG plug (standard)

6GT2 091-2E... with straight SLG plug (not shown)

White

Brown

Green

Yellow

Pink

Gray

(Shield)

Figure 3-16 Connection cable ASM 475 ↔ SLG U92 with RS 422

6

1

4

5

2

3

SLG plug

(socket)

1

The connection cable can be ordered in the following lengths.

Table 3-6 Cable lengths of ASM 475 ↔ SLG U92 with RS 422

Length of Stub Line in m Order Number

2 6GT2 091-0EH20

5 6GT2 091-0EH50

10 6GT2 091-0EN10

20 6GT2 091-0EN20

50 6GT2 091-0EN50

1

2

1

5

1

10

1

50

1 With straight SLG plug

6GT2 091-2EH20

6GT2 091-2EH50

6GT2 091-2EN10

6GT2 091-2EN50

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-25

Page 40

Configuration and Installation Guidelines

3.6 SLG Cable and Plug Allocations (RS 232)

With MOBY U, the data are transferred between PC and SLG at a speed of

19200, 38400, 57600 or 115200 Baud over an RS 232 interface. The distance

between PC and SLG can be up to 32 m.

The SLG cable is comprised of a stub line between PC and SLG and a connection line for the 24 V power supply of the SLG from a standard power

pack (see chapter. 7.2).

The connection line for the power supply has a fixed length of 5 m.

The stub line between PC and SLG is available in two lengths (5 m and

20 m).

The connection cable for the power supply can be extended with a stub line

(order number 6GT2494-0AA0).

The jacket used for MOBY SLG connection cables is made of polyurethane

(PUR in acc. w. VDE 0250). This gives the cables very good resistance to oil,

acid, lye and hydraulic fluid.

3.6.1 Cable Configuration

The RS 232 cable between PC and SLG has three cores plus shield. The

cable for the power supply of the SLG requires two cores.

Grounding of the

SLG cable

Power pack for

SLG U92

We recommend always grounding the shield of the SLG cable over a large

surface to the grounding rail.

6GT2 494-0AA00

6GT2 591-1C...

24 V =

90 –

230 V

Max. of 32 m (with RS 232)

SLG

3-26

Figure 3-17 Wide–range power pack for SLG U92

The power pack in our drawing can be obtained from Siemens under the

number 6GT2 494-0AA00 (see chapter 7.2).

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 41

3.6.2 Connection Cables with Lengths

Connection cable

for PC SLG U92

with RS 232

6GT2 591-1C...

Configuration and Installation Guidelines

N6RFFR

5x RBC162/1AG

1x RBC162AG

KVPG11

5 m

Figure 3-18 Connection cable for PC ↔ SLG U92

Table 3-7

Plug allocation of SLG plug and submin D plug

SLG (RS 232) N6RFFR Sensor 763 (Pin) LIYC11Y Sub D 9B

GND 1 Green 5 (GND)

Vdc+ (power +) 2 2 (24 V DC)

Vdc– (power –) 3 1 (GND) brown

TxD (send data) 4 White 2 (RxD)

n.c. 5

RxD (receive data) 6 Brown 3 (TxD)

Shield GND Shield Housing

LIY11Y-6x0,25

5/20 m

Sensor 763

Nameplate

Sub D 9B

FPGHR

white

The connection cable can be ordered in the following lengths.

Table 3-8 Cable lengths for PC ↔ SLG U92 with RS 232

Length of Stub Line in m

5 6GT2 591-1CH50

20 6GT2 591-1CN20

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Order Number

3-27

Page 42

Configuration and Installation Guidelines

Non prefabricated

cables

Users who want to make their own cables can order the following

components from the MOBY catalog.

Table 3-9 Components for individually fabricated cables

Component

SLG connection plug with screw terminals with angled output

SLG stub line;

T ype: 6 x 0.25 mm

M12 socket

for extension of the 24 V cable

2

6GT2 090-0BA00

6GT2 090-0AN50 (50 m)

6GT2 090-0AT12 (120 m)

6GT2 090-0AT80 (800 m)

6GT2 390-1AB00

Order Number

3-28

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 43

Configuration and Installation Guidelines

3.7 Service Cable and Plug Allocations

3.7.1 Cable Configuration

3.7.2 Plug Allocations

3.7.3 Connection Cables with Lengths

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

3-29

Page 44

Configuration and Installation Guidelines

3-30

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 45

Mobile Data Memories

4

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

4-1

Page 46

Mobile Data Memorie

s

4.1 Introduction

Application area

Construction and

functions

MOBY identifica tion system s ensure that a product is ac com panie d by

meaningful da ta from the be ginning to the end.

First, mobile data memories are affixed to the product or its carrier or its

packaging, then conductively written, changed and read. All information on

production and material flow control is located right on the product. Its

robust construction permits use in rugged environments and makes the MDS

insensitive to many chemical substances.

The primary com ponents of mobil e da ta mem ories (MDSs) are logic, an

antenna, a data memory and a battery.

To keep the MDS’s power consumption low and make localization

reproducible, MOBY U has different function zones based on direction and

distance. The three different zones of the transmission field (see figure 4-1)

represent different states and reactions of the affected components.

SLG U92 with

integrated antenna

> 90°

4-2

MDS

Zone 1: r = max. of 3.0 m

Can be adjusted in increments

Zone 2: r = up to approx. 5 m

Transmission

field

Zone 3: r > approx. 5 m or shielded

Figure 4-1 Status zones for MDS in transmission field of SLG U92

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Direction of

MDS’s

movement

Page 47

Mobile Data Memorie

s

Zone 3:

In simplified terms, zone 3 is the UHF–free area. The MDS is asleep and

only wakes up to listen for an SLG once every < 0.5 sec. Power consumption is very low. If other UHF users are in the vicinity and they are using

the same frequency range, this does not shorten the battery life of the

MDS since it does not wake up until it receives a special code.

Zone 2:

If the MDS receives this special code in the vicinity of an active SLG, it

enters zone 2 (see figure 4-1). Starting immediately it accepts the SLG

and responds briefly with its own ID. However, the SLG ignores all

MDSs which are not in zone 1 (radius can be parameterized on the SLG

in increments). Power consumption in zone 2 is a little higher than in

zone 3.

Zone 1:

When an MDS enters zone 1, it is registered by the SLG and can begin

exchanging data. All read and write functions can now be performed. The

power consumption of the MDS increases briefly during communication.

Since transmission through the air is very fast, total communication time

is very short. The entire 32–Kbyte data memory can be read in less than

four seconds. This means that data communication hardly uses the battery.

As long as the MDS is located in zone 1, it is ready to exchange data

when requested by the SLG. When no command for the MDS is queued,

it still reports at regular parameterizable intervals with its ID (sleep–time,

similar to t–ABTAST with MOBY I) when requested by the SLG. Its

behavior corresponds to that of zone 2. Current consumption drops again

accordingly.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

4-3

Page 48

Mobile Data Memorie

s

Overview

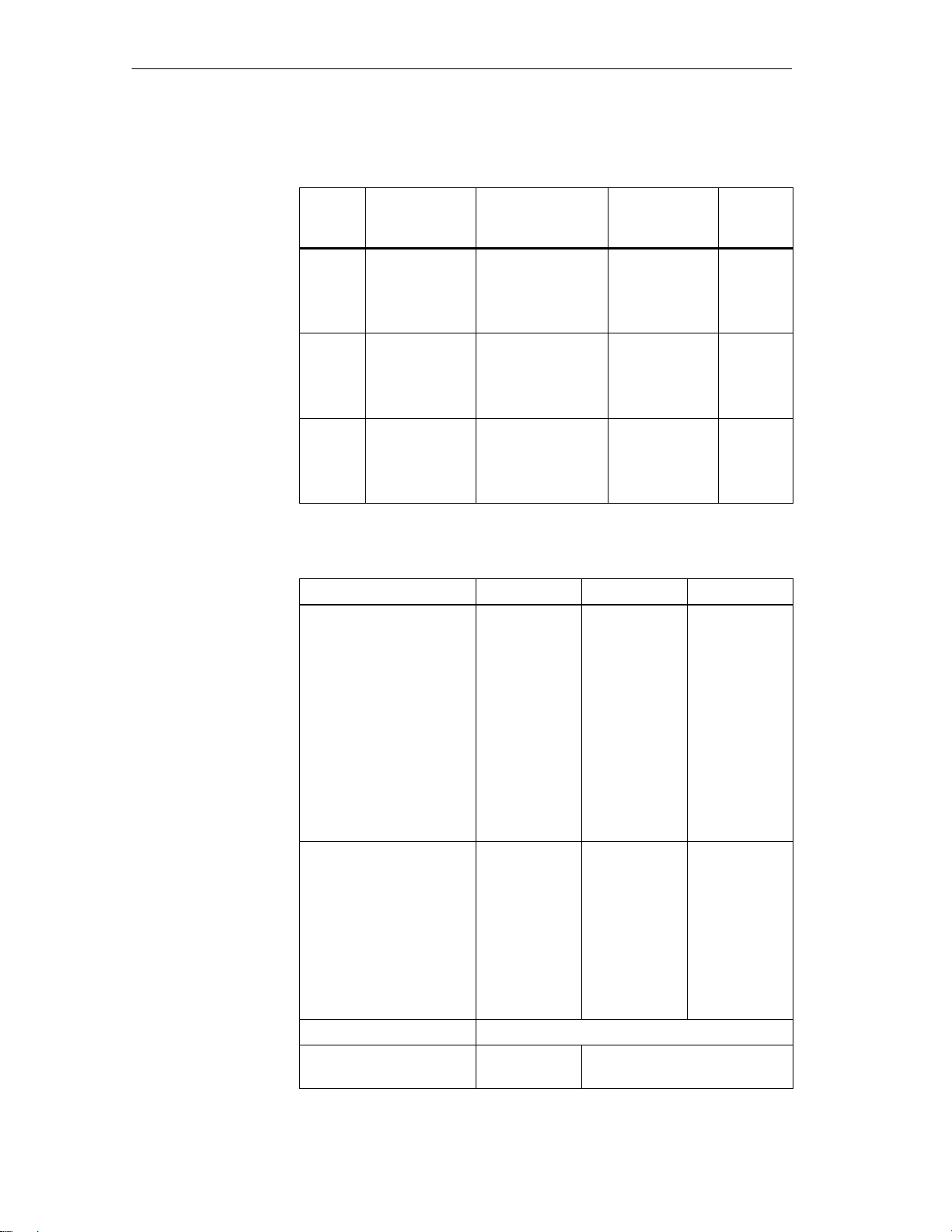

Table 4-1 Overview of the MDS

Operational/ambie

nt conditions

MDS

Type

MDS

U313

MDS

U524

MDS

U589

Table 4-2 Operational/ambient conditions of the MDS

Proof of the physical strength

is provided by the vibration

test in acc. w. DIN EN

721-3-7, class 7 M3

Memory Size T emperature Range

(during Operation)

2–Kbyte RAM

32–bit fixed code

128–bit read–

only memory

32–Kbyte RAM

32–bit fixed code

128–bit read–

only memory

32–Kbyte RAM

32–bit fixed code

128–bit read–

only memory

–25 to +70 °C 111 x 67 x 23.5 IP 67

–25 to +85 °C 111 x 67 x 23.5 IP 68

–25 to +220 °C

(cyclic)

MDS U313 MDS U524 MDS U589

Ø 30 x 10 IP 68

Dimensions

L x W x H

(in mm)

Protection

Rating

Test conditions

Frequency range

Amplitude of the dis-

placement

Acceleration

Test duration per axis

Speed of passage

Proof of the physical strength

is provided by the continuous

shock test in acc. w. DIN EN

721-3-7, class 7 M3

Test conditions

Acceleration

Duration

Test duration per axis

Torsion and bending stress Not permitted

Protection rating in acc. w.

EN 60529

IP 67 IP 68

4-4

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 49

Mobile Data Memorie

s

Table 4-2 Operational/ambient conditions of the MDS

MDS U589MDS U524MDS U313

Ambient temperature

During operation in acc.

w.

EN 60 721-3-7,

class 7 K4

During transportation

and storage in acc. w.

EN 60 721-3-7,

class 7 K3

Temperature gradient over

storage temperature range, in

acc. w. DIN IEC 68, part

2-14

Temperature gradient with

fast temperature change in

acc. w.

DIN IEC 68, part 2-14

Cleaning with water jet – Max. of 5 min at

–25 to +70 °C –25 to +85 °C –25 to +220 °C

(cyclic)

–40 to +85 °C –40 to +85 °C –40 to +85 °C

3 °C/min

Change from 0 °C to 70 °C (85 °C) in 10 sec;

Duration: 30 min;

Change from 70 °C (85 °C) to 0 °C in 15 sec;

100 cycles

max. of 2 bar

Chemical resistance

Definition of IP 67

– Protection against penetration of dust (dustproof)

– Total protection against accidental touch

– Protection against stream of water

Definition of IP 68:

– Protection against penetration of dust (dustproof)

– Total protection against accidental touch

– The MDS can be continuously submerged in water. Ask manufacturer for condi-

tions.

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

4-5

Page 50

Mobile Data Memorie

s

4.2 MDS U313

The MDS U313 is a mobile data memory (MDS) with a storage capacity of 2

Kbytes for use in transportation and logistics. The particularly low current

consumption guarantees a long life of 5 years. The interference–immune and

robust MDS can be read and written at a maximum distance of 3 m. The

MDS U313 is addressed directly with byte memory accesses. The transmission frequency in the ISM frequency band at 2.4 GHz makes the MDS’s net

data transmission speed very fast (up to 16 Kbyte/sec without multitaging

and up to 8 Kbyte/sec with multitaging of two MDSs).

Ordering data

Technical data

Figure 4-2 MDS U313

Table 4-3 Ordering data for the MDS U313

Order No.

MDS U313 mobile data memory with 2–Kbyte

RAM, MDS ID number (32 bits), read–only memory (128 bits)

Table 4-4 Technical data of the MDS U313

Fixed code memory

Read–only memory 128 bits, to be written once by user

Application memory

Memory technology

Memory size

Memory organization

Data retention time 10 years

MTBF (at +40°C) 2.5 x 106 hours (without conside-

Read/write distance 0.15 m up to 3 m

Depends on direction No

Multitaging capability Yes

Power supply Battery

6GT2500-3BD10

MDS ID number (32 bits)

RAM

2 Kbytes

Byte access

ring battery)

4-6

MOBY U – Manual for Configuration, Installation and Service

(4) J31069-D0139-U001-A2-7618

Page 51

Mobile Data Memorie

s

Table 4-4 Technical data of the MDS U313

Battery lifespan > 5 years at 25°C1); no replace-

ment

Shock, vibration in acc. w. DIN EN 721-3-7,

class 7 M3

Free fall 1 m

Mounting 4 M4screws

Tightening moment (at room temperature) 0.8 Nm

Recommended distance from metal Can be mounted directly on metal

Protection rating in acc. w. EN 60529 IP 67

Chemical resistance See table 4-2.

Housing

Dimensions (L x W x H) in mm

Color/material

Ambient temperature

Operation

Transportation and storage

Weight, approx. 100 g

1)

Lifespan depends on temperature, time MDS is in the SLG’s antenna field (zones 1 and

2) and the amount of read/written data (see chapter LEERER MERKER).

50 g/10 g

111 x 67 x 23.5

Anthracite/plastic, PA 12 GF 25

–25 to +70 °C

–40 to +85 °C

Field data (in mm)

Table 4-5 Field data of the MDS U313

Standard Minimal Maximal

Working distance (Sa) 1400 350

Limit distance (Sg) 2000 500

Transmission window (L) 2800 700

Transmission window (W) 2800 700

Minimum distance of MDS to MDS

with