Page 1

Siemens Gas Range

with threeD Surround

Convection

®

Installation Instructions

Models: HG2425UC, HG2528UC

Please read instructions before using.

Important: Save these instructions.

Cuisinières à gaz Siemens

Instructions dinstallation

Modèle: HG2425UC, HG2528UC

Merci de lire les instructions avant d'utiliser.

Important : Conserver ces instructions.

Estufas de gas de Siemens

Instrucciones de instalacin

Modelo: HG2425UC, HG2528UC

Favor de leer las instrucciones antes de usar.

Importante: Guarde estas instrucciones.

Page 2

Page 3

Important Safety Instructions

Safety Instructions

Important Safety Instructions ...................................................................................................... 1

Preparation ............................................................................................................................... 4

Installation ............................................................................................................................... 5

Final Steps ............................................................................................................................... 6

Service ..................................................................................................................................... 8

PLEASE READ AND SAVE ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE.

PARTS PROVIDED:

Table of Contents

Anti-Tip Bracket

TOOLS AND PARTS NEEDED:

• Standard Measuring Tape

• Phillips Head Screwdriver

• 1-1/4” Wrench

• Pencil

• T-20 Torx Screwdriver

• 3/8” Nut Driver

• Screws (2) and Anchors (2) for Anti-tip Bracket

(Style will vary depending on mounting surface)

• Pipe Wrench (2)

• Teflon® Tape* or Pipe Joint Compound

(Appropriate for use with LP gas and Natural gas)

• Channel Lock Pliers

• Gas Leak Test Solution

• Level

• Drill and Drill Bit

• Gas Supply Line (Flexible Metal Appliance

Connector or Rigid Pipe)

• Gas Shut Off Valve (If not already present)

• Gloves and Safety Goggles

* Teflon is a registered trademark of DuPont

WARNING: If the information in this manual

is not followed exactly, a fire or explosion

may result causing property damage,

personal injury or death.

− Do not store or use combustible materials,

gasoline or other flammable vapors and

liquids in the vicinity of this or any other

appliance.

−−

− WHAT TO DO IF YOU SMELL GAS:

−−

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

WARNING

Do not repair or replace any part of the appliance

unless specifically recommended in the manuals.

Improper installation, service or maintenance can

cause injury or property damage. Refer to this manual

for guidance. All other servicing should be done by a

qualified technician.

For Massachusetts Installations:

1. Installation must be performed by a qualified

or licensed contractor, plumber or gas fitter

qualified or licensed by the state, province or

region where this appliance is being installed.

2. Shut-off valve must be a “T” handle gas cock.

3. Flexible gas connector must not be longer

than 36 inches.

WARNING

RANGE TIPPING HAZARD

• All ranges can tip and injury could result. To

prevent accidental tipping of the range,

attach it to the wall, floor or cabinet by

installing the Anti-Tip Device supplied.

• A risk of tip-over may exist if the appliance is

not installed in accordance with these

instructions.

• If the range is pulled away from the wall for

cleaning, service, or any other reason, ensure

that the Anti-Tip Device is properly

reengaged when the range is pushed back

against the wall. In the event of abnormal

usage (such as a person standing, sitting, or

leaning on an open door), failure to take this

precaution could result in tipping of the

range. Personal injury might result from

spilled hot liquids or from the range itself.

Safety Instructions

Preparation

Preparation

Installation

Installation

Final Steps

Final Steps

Service

−−

− Installation and service must be performed

−−

by a qualified installer, authorized service

agency or the gas supplier.

English • 1

Page 4

Important Safety Instructions

WARNING

Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

CAUTION

Unit is heavy and requires at least two persons or

proper equipment to move.

Safety Instructions

Hidden surfaces may have sharp edges. Use caution

Safety Instructions

when reaching behind or under appliance.

Stepping, leaning or sitting on the doors or drawers of

this range can result in serious injuries and also cause

damage to the range. Do not allow children to climb or

play around the range. The weight of a child on an open

Preparation Installation

door may cause the range to tip, resulting in serious

burns or other injury.

Preparation

Do not use the oven or warming drawer (if equipped) for

storage.

Do not store items of interest to children in the cabinets

above the range or on the backguard of a range.

Children climbing on the range to reach items could be

seriously injured.

CAUTION

WARNING

CAUTION

WARNING

• Installation must conform with local codes or, in

the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1.

• The appliance must be electrically grounded in

accordance with local codes or, in the absence of

local codes, with the National Electrical Code

ANSI/ NFPA 70, latest edition. (In Canada,

installation must be in accordance with the CAN 1B149.1 and .2 Installation Codes for Gas Burning

Appliances and/ or local codes).

• Remove all tape and packaging before using the

range. Destroy the carton and plastic bags after

unpacking the range. Never allow children to play with

packaging material.

• Be sure your appliance is properly installed and

grounded by a qualified technician. Installation,

electrical connections and grounding must comply

with all applicable codes.

• Install only per installation instructions

included in the literature package for this range.

• Ask your dealer to recommend a qualified

technician and an authorized repair service.

• Know how to disconnect the power to the range at

the circuit breaker or fuse box and the gas supply at

the shutoff in case of an emergency.

• Do not repair or replace any part of the

appliance unless specifically recommended

in the manuals. All other servicing should be done

by a qualified technician. This may reduce the risk of

personal injury and damage to the range.

• When testing the supply piping system at test

pressures in excess of 1/2 psig (3.5 kPa), the

appliance and its indiviual shut-off valve must

be disconnected from the gas piping system.

This appliance complies with one or more of the following

Installation

Standards:

• UL 858, The Standard for the Safety of Household

Electric Ranges

Final Steps Service

• UL 923, The Standard for the Safety of Microwave

Cooking Appliances

• UL 507, The Standard for the Safety of Electric Fans

• ANSI Z21.1-2000, The American National Standard

for Household Cooking Gas Appliances

• C AN/CSA-C22.2 No. 113-M1984 Fans and Ventilators

• CAN/CSA-C22.2 No. 61-M89 Household Cooking

Ranges

Final Steps

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

• When testing the supply piping system at test

pressures equal to or less than 1/2 psig

(3.5 kPa), the appliance must be isolated from

the gas supply piping system by closing its

individual manual shut-off valve.

• Never modify or alter the construction of a

range by removing leveling legs, panels, wire covers,

anti-tip brackets/screws, or any other part of the

product.

• Do not lift door by door handle. Remove the door

for easier handling and installation. See Section

“Removing Oven Door” in Use and Care manual.

High Altitude Installation Note:

This range is CSA certified for safe operation up to an

altitude of 10,000 ft. without any modifications.

Exception: for use with LP, the range must first be

converted using the LP conversion instructions included in

this literature package.

Page 5

Important Safety Instructions

Safety Instructions

Electrical Safety:

If required by the National Electrical Code (or Canadian

Electrical Code), this appliance must be installed on a

separate branch circuit.

For appliances equipped with a cord and plug, do not cut or

remove the ground prong. It must be plugged into a

matching grounding type receptacle to avoid electrical

shock. If there is any doubt as to whether the wall

receptacle is properly grounded, the customer should have

it checked by a qualified electrician.

Installer - show the owner the location of the circuit breaker

or fuse. Mark it for easy reference.

Important - Save these instructions for the local electrical

inspector's use.

Refer to data plate for more information. See "Product Data

Plate" under "Service" for data plate location.

WARNING

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage is

to be provided, the risk can be reduced by installing a hood

that projects horizontally a minimum of 5 inches beyond

the bottom of the cabinet.

Gas Safety

Install a gas shutoff valve near the appliance. It must be

easily accessible in an emergency.

Leak testing must be conducted by the installer according

to the instructions in this manual.

Installer - show the owner where the gas shut-off valve is

located.

The minimum supply pressure must be 1" water column

above the manifold pressure printed on the data plate:

The maximum supply pressure must not exceed 14.0

inches water column (34.9Millibars).

Propane Safety

Important note for LP users: The appliance is

shipped from the factory for use with natural gas. It

must be converted for use with propane. A qualified

technician or installer must do the conversion.

The propane gas tank must be equipped with its own high

pressure regulator. In addition, the regulator supplied with

this unit must also be used.

Safety Instructions

Preparation

Preparation

Installation

Verify that cabinets above the cooktop are a maximum of

13" (330 mm) deep.

Installation

Final Steps

Final Steps

Service

English • 3

Page 6

Steps 1 through 4: Preparation

1. Install Ventilation

Siemens strongly recommends the installation of a

ventilation hood above this range. For most kitchens a

certified hood rating of not less than 300 CFM is

recommended. The range hood must be installed

according to instructions furnished with the hood.

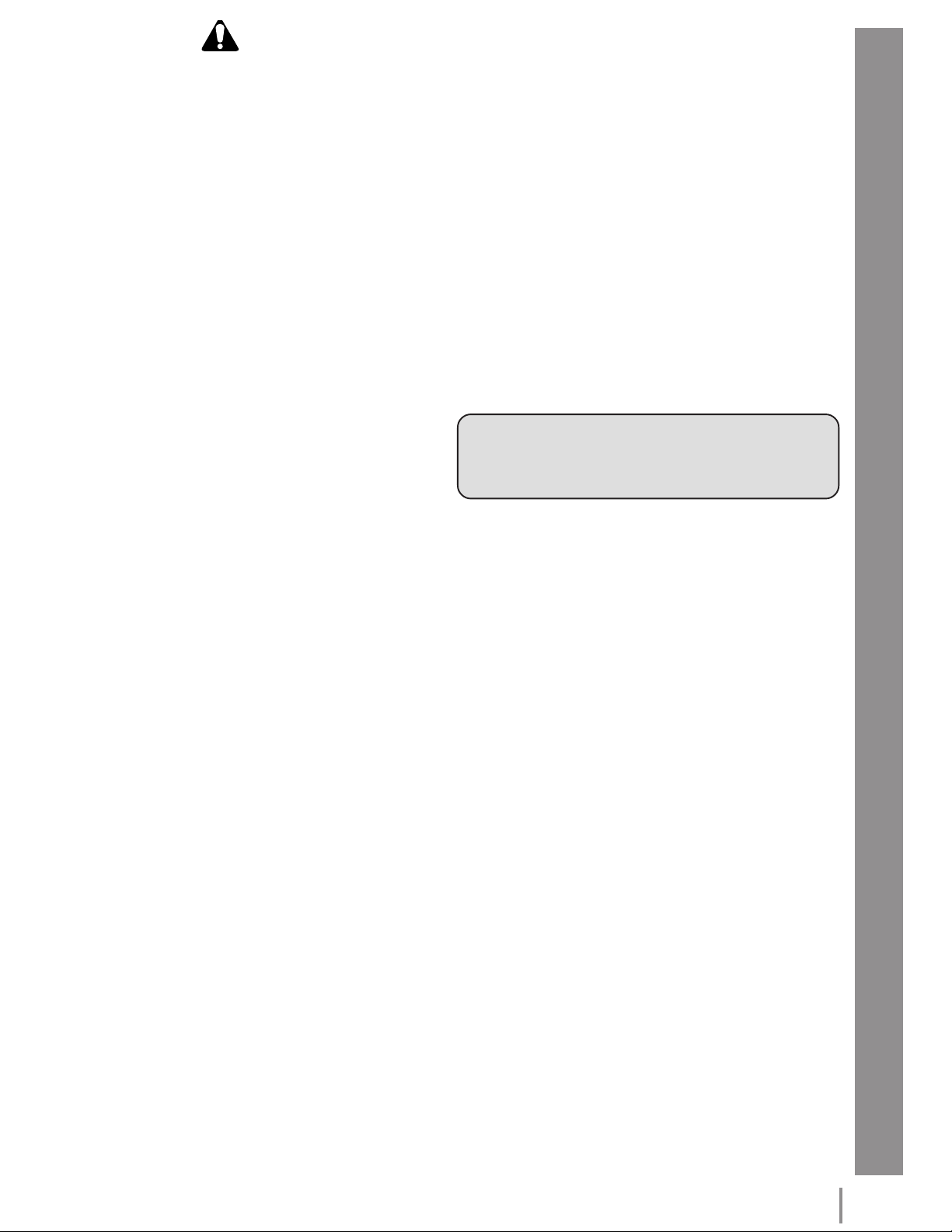

2. Prepare Cabinets

This unit is designed for installation near adjacent

walls and projecting surfaces constructed of

combustible materials.

Allow a minimum of 30 inches between overhead

cabinets where range is to be installed (See Figure 1).

Safety Instructions

Required Clearances*

From cooktop to materials above (See Figure 1)

Safety Instructions

There must be a minimum clearance of 30 inches

between the top of the cooking surface and the

bottom of an unprotected wood or metal cabinet.

24 inches is acceptable when the bottom of the wood

or metal cabinet is protected by (a) not less than1/4"

of flame retardant material which must be covered

with (b) not less than No. 28 MSG sheet metal, 0.015

inch stainless steel’ or 0.024 inch aluminum or copper.

From range walls to adjacent materials (See Fig.1)

Preparation Installation

No clearance is required from unit walls to adjacent

vertical combustible walls on rear, right or left.

Clearance from range top to adjacent vertical walls

must be at least 4”.

NOTE: Some cabinet finishes cannot survive the

Preparation

temperatures allowed by U.L., particularly selfcleaning ovens; the cabinets may discolor or stain.

This is most noticeable with laminated cabinets.

3. Prepare Gas Supply Line and

Electrical Outlet

The gas supply line and electrical outlet must be

located in the shaded space in Figure 2.

4. Prepare Walls and Floor and

Install Anti-Tip Bracket

1. Seal any holes in the walls or floor.

2. Adjust height of range and level by rotating the

Installation

Final Steps Service

adjustable leg supports on the bottom of the

range, using 1-1/4" wrench.

3. Measure to locate bracket position as shown in

Figure 3.

4. Secure bracket with 2 screws adequate for

mounting surface, not included. (i.e.; for wood

floor use wood screws for concrete floor use

concrete anchors and screws).

30” Minimum

Centered

4” Min.

No Clearance to

Cabinet Wall

Figure 1: Cabinet Preparation

Place Gas

Supply Line

and Electrical

Outlet Here

7 1/2"

7 1/2”

4 1/2"

4 1/2”

13 1/8”

Figure 2: Gas Supply Line and Electrical Outlet Placement

Cabinet Sidewall

Figure 3

30”

Min.

Required

13 1/8 "

4” 3 7/8”

30"

30”

Flush

4"

4 1/2”

3 7/8"

Anti-Tip Device

18”

Min.

4” Min.

3 1/2”

3 1/2"

4 1/2"

Backwall

1 9/16”

Gas Connection

Final Steps

Figure 4

*Instructions were determined using Standard American cabinets. Standard base cabinets measure 36" high x 24" deep . Cabinets

over the cooking surface and cabinets adjacent to those over the cooking surface measure 13 inches deep from backwall. If

nonstandard cabinets are used, care should be taken to alter dimensions accordingly.

Page 7

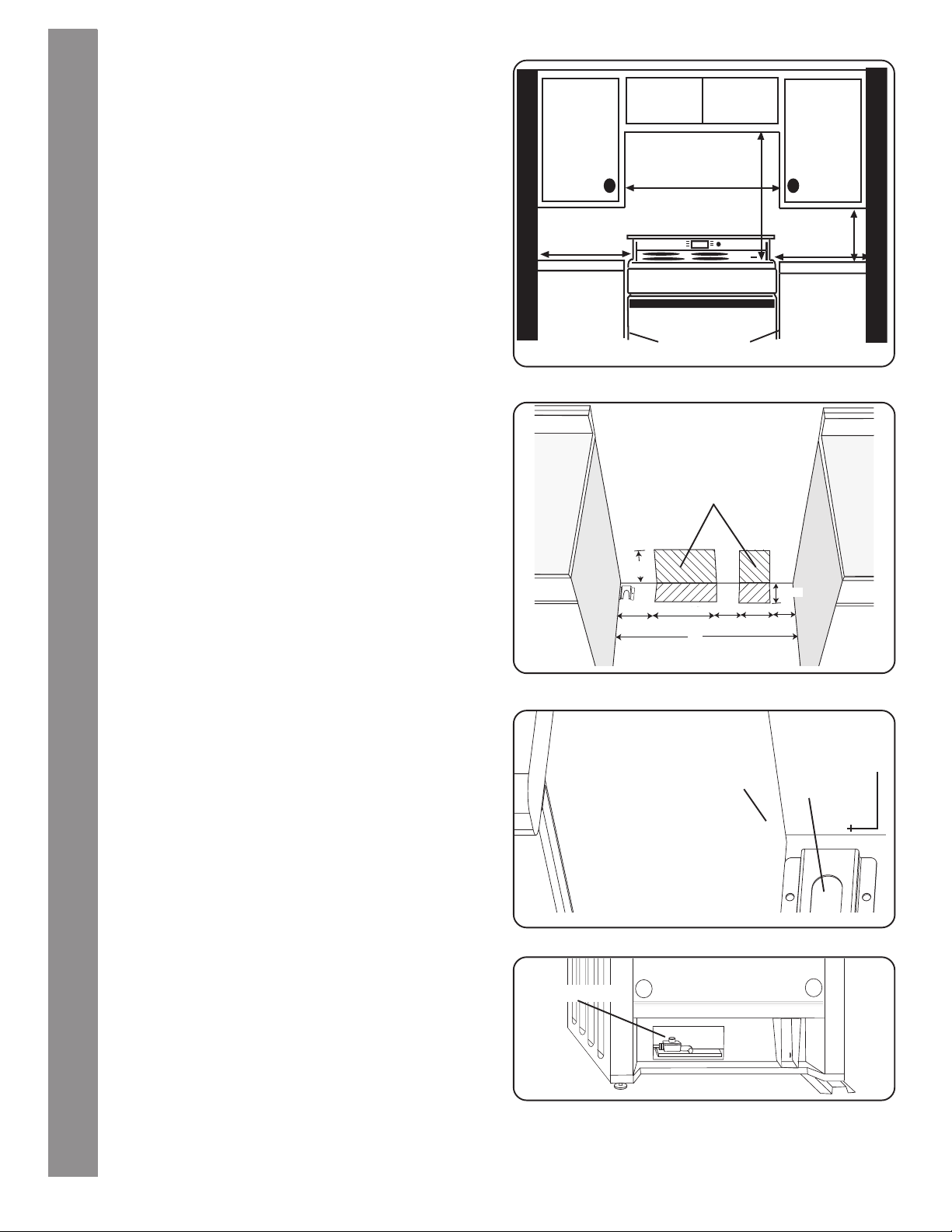

Step 5: Installation - Connect Gas Supply

Important note for LP users: The range is shipped

from the factory for use with natural gas. For use

with propane (LP) gas, your range must first be

converted using the LP conversion kit.

The gas connection is located below the back panel of

the range (See Figure 4, Page 3). It is accessible

through the warming drawer access panel or from the

back of the range. To reach access panel, remove

warming drawer.

Shut off main gas supply valve before disconnecting

the old range and leave it off until the new hook-up

has been completed. Don’t forget to relight the

pilot on other gas appliances when you turn the

gas back on.

The range can be installed using rigid pipe or a CSA

International-certified flexible metal appliance

connector. If using a flexible connector, always use a

new connector.

Apply pipe joint compound or Teflon* tape appropriate for

use with LP gas and Natural gas around all male pipe

threads to prevent leaks.

If not already present, install gas shut off valve in an

easily accessible location. Make sure all users know

where and how to shut off the gas supply to the

range.

Note: The installer should inform the consumer of

the location of the gas shut-off valve.

Flexible Connector Method (see Figure 5)

1. Install male 1/2” flare adaptor at the 1/2” NPT

internal thread of the range inlet. Use a backup

wrench on the elbow fitting to avoid damage.

2. Install male 1/2” or 3/4” flare union adapter on the

NPT internal thread of the manual shut-off valve.

3. Connect flexible metal appliance connector.

4. Make sure circuit breaker is off and then plug

range cord in to electrical outlet.

5. Push range back into position insuring that range

leg slides under the anti-tip bracket. The range will

sit 3/4” away from the wall when properly

installed.

Note: Be careful not to crimp flexible connector!

6. Carefully tip range forward to insure that anti-tip

bracket engages and prevents tip-over.

Rigid Pipe Method (see Figure 6)

The configuration of the rigid pipe connection will

vary depending on the location of the gas pipe stub.

Refer to Figure 6 for details.

1. Make sure circuit breaker is off and then plug

range cord in to electrical outlet.

2. Push range back into position insuring that range

leg slides under the anti-tip bracket. The range will

sit 3/4” away from the wall when properly

installed.

3. Carefully tip range forward to insure that anti-tip

bracket engages and prevents tip-over.

4. Connect pipe to range at union. Access the

connection through the access panel behind the

warming drawer.

Note: Be careful not to apply pressure to warming

drawer element during rigid pipe installation.

Test for Gas Leaks

Leak testing is to be conducted by the installer

according to the instructions given in this section.

Turn on Gas. Apply a non-corrosive leak detection

fluid to all joints and fittings in the gas connection

between the shut-off valve and the range. Include gas

fittings and joints in the range if connections may

have been disturbed during installation. Bubbles

appearing around fittings and connections indicate

a leak.

If a leak appears, turn off supply line gas shut-off

valve and tighten connections. Retest for leaks by

turning on the supply line gas shut-off valve. When

leak check is complete (no bubbles appear), test is

complete. Wipe off all detection fluid residue. Proceed

to Step 6: Final Steps.

CAUTION

NEVER CHECK FOR LEAKS WITH A FLAME.

DO NOT CONTINUE TO THE NEXT STEP UNTIL ALL

LEAKS ARE ELIMINATED.

CAUTION

Before you plug in an electrical cord, be sure all

controls are in the OFF position.

Gas ShutOff Valve

Regulator

Figure 5: Flexible Connector Method

elbow

nipple

union

nipple

elbow:

connect to

regulator

here

gas shut

off valve

1/2” to 3/4”

gas pipe

Flexible

Connector

elbow

nipple

Gas Flow to Range

Figure 6: Rigid Pipe Method

English • 5

Safety Instructions

Safety Instructions

Preparation

Preparation

Installation

Installation

Final Steps

Final Steps

Service

Page 8

Step 6: Final Steps - Test Burner Function

1. Turn on Power at Breaker

If LCD screen flashes and beeps continuously, the wiring is

incorrectly installed. Verify that wiring in house is correctly

installed. If house wiring is correct so, call Siemens

Service.

2. Test Rangetop Burners

Test Burner Ignition. Select a rangetop burner knob.

Push down and turn to the flame symbol. The ignitor/spark

module will produce a clicking sound. Once the air has

been purged from the supply lines, the burner should light

within four (4) seconds.

Test Flame: High Setting. Turn burner on to HI. See

Safety Instructions

Figure 7 for appropriate flame characteristics.

If any of the burners continue to burn mostly or completely

Safety Instructions

yellow, call Siemens Service.

Test Flame: Low Setting. Turn burner on to LO. Verify

that the flame completely surrounds the burner. There

should be a flame at each burner port and there should be

no air gap between the flame and the burner. If any of the

burners do not carry over, call Siemens Service.

Test the ignition and flame of each rangetop burner as

Preparation Installation

described above.

Flame Characteristics

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or mostly yellow, verify that the

regulator is set for the correct fuel. After adjustment, retest.

Some yellow streaking is normal during the initial start-up.

Allow unit to operate 4-5 minutes and re-evaluate before

making adjustments.

Figure 7

Call Siemens Service 866-447-4363 if:

1. Any of the burners do not light.

2. The broil burner or bake burner flame goes

out before either reaches temperature.

3. Any of the burners continue to burn yellow.

WHEN FLAME IS PROPERLY ADJUSTED:

Preparation

There should be a flame at each rangetop

burner port.

There should be no air gap between the

flame and the burner port.

3. Test Oven Burners

Remove the oven bottom cover. Remove the two

rear thumb screws, slide cover forward and out.

Test Bake Burner Ignition. Set the oven to bake at

350° F. After 30-75 seconds, the burner will ignite.

The burner will stay lit until the 350° F is reached and

then shut off. From this point forward, the burner will

cycle on and off to maintain the temperature.

Installation

Test Bake Burner Flame. While the burner is lit,

inspect the flame. See Figure 7 for proper flame

characteristics. If the flame burns completely or

mostly yellow, adjust the bake burner air shutter. See

Final Steps Service

Figure 8 (next page) for details.

Test Broil Burner Ignition. Set cooking mode to Hi

Broil. The burner will ignite after 30-75 seconds.

Test Broil Burner Flame. While the burner is lit,

inspect the flame. See Figure 6 for proper flame

characteristics. If the flame burns completely or

mostly yellow, adjust the broil burner air shutter. See

Figure 8 (next page) for details.

Replace oven bottom cover. Slide cover into place

Final Steps

and replace two rear thumb screws.

If flame adjustment is necessary, continue to next

page. Otherwise, installation is complete at this point.

Page 9

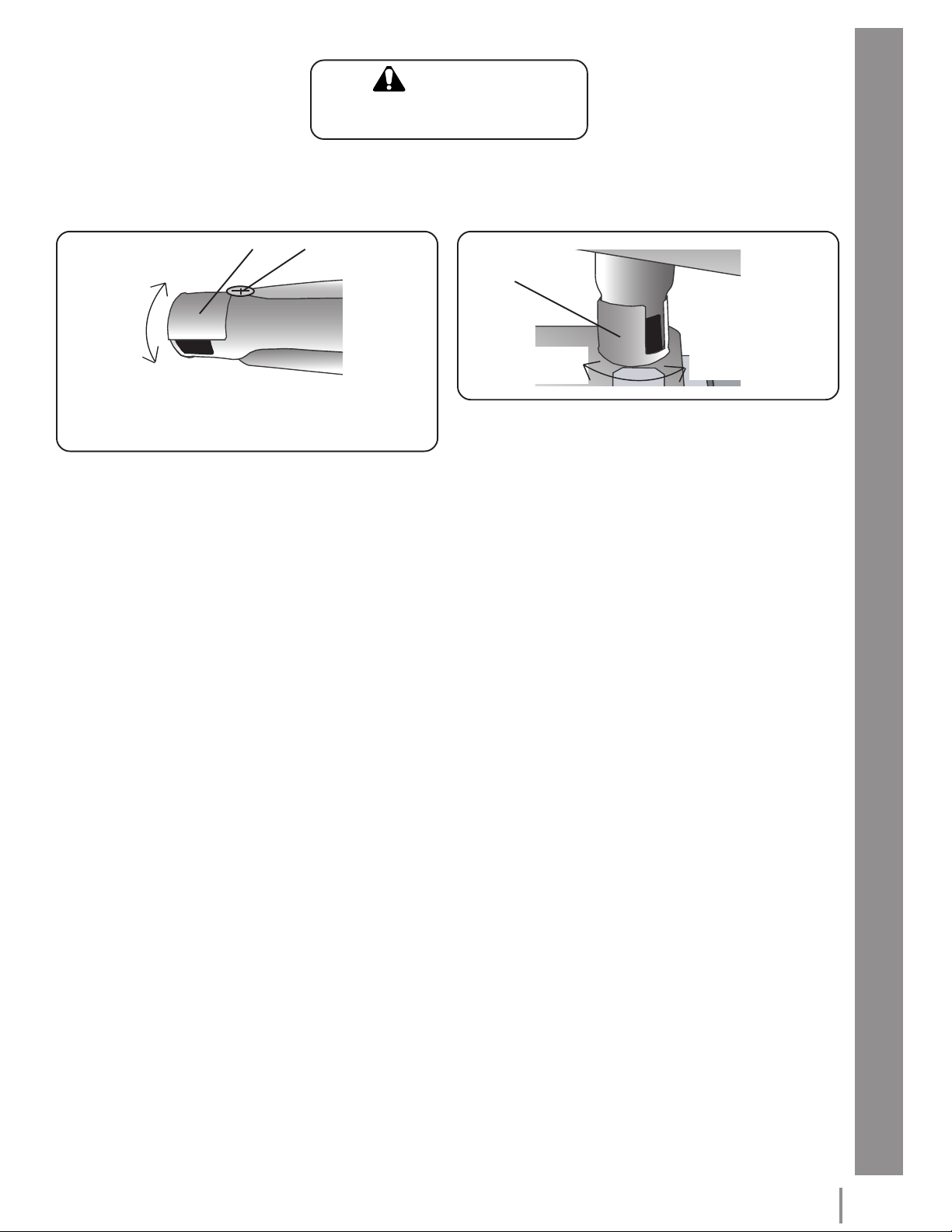

Step 6: Final Steps - Adjust the Flame (if necessary)

Safety Instructions

WARNING:

Allow Burner(s) to cool before

attempting to remove them!

Adjust Broil Burner Air Shutter

(if necessary)

More Open:

•Less Yellow Flame

More Closed:

•Less Blue Flame

•More Carryover

•Less lifting or

blowing

Figure 8

The air shutter is located on the back end of the broil

burner. It is attached to the top of the oven cavity with 7

screws. Remove screws and gently pull broil burner

assembly straight out being careful not to detach electrical

wires. Place broil burner against back wall of oven cavity.

Loosen screw and turn shutter. Close the shutter if the

flame is lifting or blowing or not carrying over. Open the

shutter if it is too yellow (see Figure 8). Tighten screw.

Replace broil assembly being careful to feed all wires

through the back of the oven. Reinsert all 7 screws.

Note: The air shutter on the broil burner fits over the

orifice when installed correctly.

Shutter

Screw

Adjust Bake Burner Air Shutter

(if necessary)

Shutter

More Closed:

•Less Blue Flame

More Open:

•Less Yellow

Flame

Figure 9

The oven burner air shutter is located near the oven

regulator. Reach it through the access hole in the

interior back panel of the warming drawer (loosen

screws and remove access panel). Loosen screw on

shutter. Close the shutter if the flame is lifting or

blowing or not carrying over; Open the shutter if it is

too yellow. Tighten screw. Reattach cover plate and

replace warming drawer (see Figure 9).

•More Carryover

•Less lifting or

blowing

Safety Instructions

Preparation

Preparation

Installation

Installation

Replacement Parts: Visit your Siemens dealer for replacement parts. For a dealer near you contact Siemens Service

866-44SIEMENS (447-4363).

English • 7

Final Steps

Final Steps

Service

Page 10

Before Calling Service

See Use and Care Manual for troubleshooting information.

Refer to the Warranty in the Use and Care Manual.

To reach a service representative, see the contact

information at the front of the manual. Please be prepared

with the information printed on your product data plate

when calling.

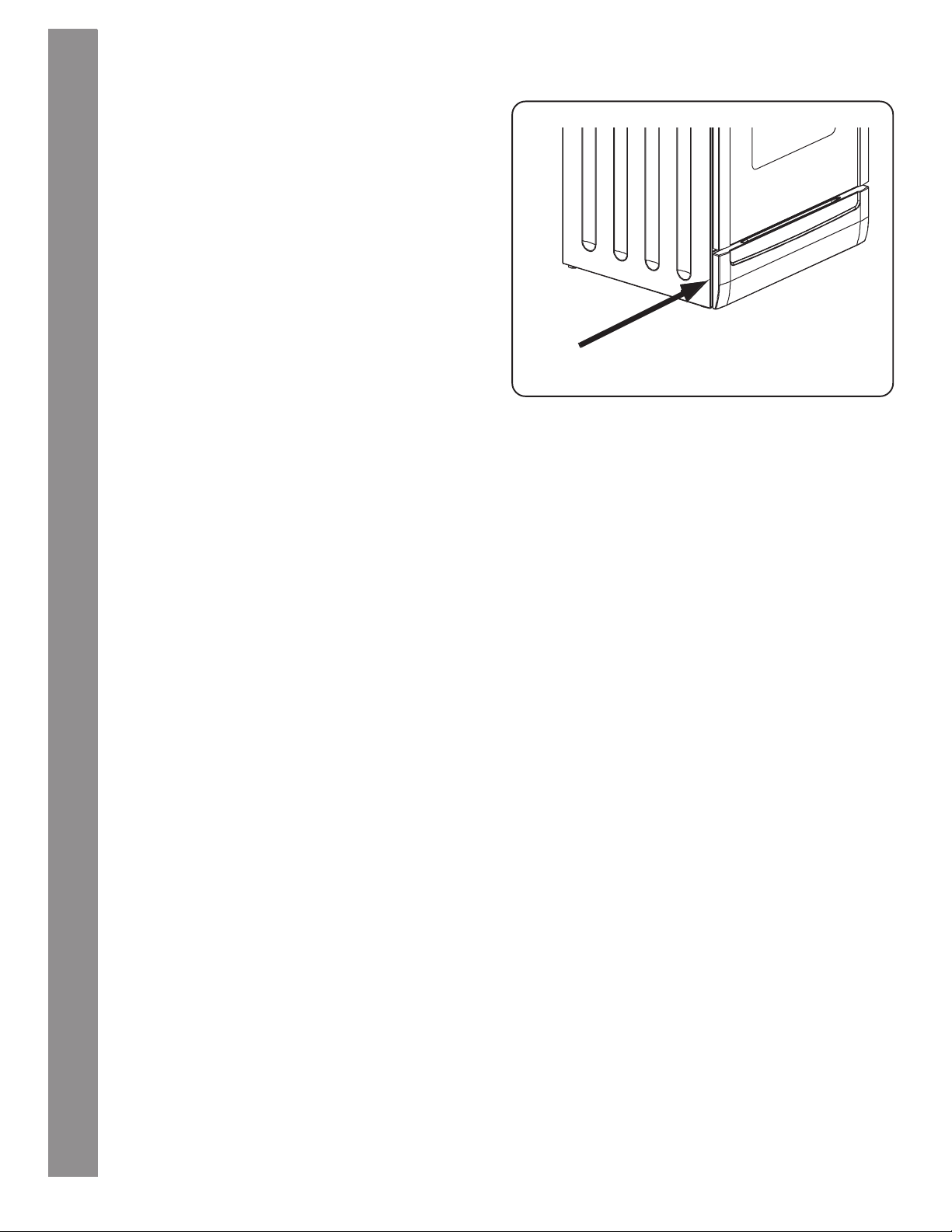

Product Data Plate

The data plate shows the model and serial number. Refer

to the data plate on the appliance when requesting

Safety Instructions

service. It is located on the frame near the drawer.

Safety Instructions

Open the drawer to view it

Data Plate

Preparation Installation

Preparation

Installation

Final Steps Service

Final Steps

Page 11

Page 12

Page 13

Instructions de sécurité importantes

Instructions de sécurité

Instructions de sécurité importantes ............................................................................................. 1

Table des matières

Préparation ................................................................................................................................. 4

Installation ................................................................................................................................. 5

Étapes finales ............................................................................................................................. 6

Service....................................................................................................................................... 8

Lire toutes les instructions avant d’utiliser cet appareil

PIÈCES FOURNIES :

• Fixation antibascule

PIÈCES NÉCESSAIRES :

• Ruban à mesurer standard

• Tournevis à tête Phillips

• Clé 1 1/4 po

•Crayon

• Tournevis T-20 Torx

• Tourne-écrou 3/8 po

• Vis (2) et ancrages (2) pour fixation antibascule

(style variant selon la surface de fixation)

• Clés à tuyau (2)

• Ruban* Teflon® ou pâte isolante à joint

(appropriéepour utilisation avec gaz LP et naturel)

• Pince de verrouillage

• Solution pour tester les fuites de gaz

• Niveau

• Perceuse et mèche

• Canalisation d’alimentation en gaz (connecteur

d’appareil en métal flexible ou tuyau rigide)

• Soupape d’arrêt de gaz (si non déjà présente)

• Lunettes et gants de sécurité

* Teflon est une marque de commerce de DuPont

AVERTISSEMENT

RISQUE DE BASCULE

• Toutes les cuisinières peuvent basculer et il peut en

résulter des blessures. Pour éviter tout accident, fixer

au mur, au plancher ou à l’armoire en installation la

fixation antibascule.

• Un risque debascule peut exister si l’appareil n’est pas

installé conformément aux instructions.

• Si la cuisinière est tirée du mur pour le nettoyage, le

service ou autre raison, s’assurer que la fixation

antibascule est réenclenchée lorsque l’appareil est

remis en place contre le mur. Dans le cas d’une

mauvaise utilisation comme une personne se tenant

debout, s’assoyant ou s’appuyant sur la porte ouverte,

si cette précaution n’est pas prise, l’appareil peut

basculer et causer des blessures par des liquides

chauds ou la cuisinière elle-même.

AVERTISSEMENT

Ne pas réparer ni remplacer toute pièce de l’appareil à

moins que cela ne soit spécifiquement indiqué dans

les guides. Un service, installation ou entretien

inadéquat peut causer des dommages à la propriété

ou des blessures. Consulter ce guide. Tout autre

service doit être effectué par un technicien qualifié.

Pour installations au Massachusetts :

1. L’installation doit être effectuée par un entrepreneur qualifié ou avec licence, un plombier, un ajusteur

de gaz qualifié ou avec licence de l’État, province ou

région où l’appareil est installé.

2. La soupape d’arrêt doit être dotée d’un robinet à

gaz en «T».

3. Un connecteur à gaz flexible ne doit pas être plus

long que 36 po.

AVERTISSEMENT : Si l’information contenue

dans ce guide n’est pas observée, il peut en

résulter un incendie ou une explosion

causant des dommages à la propriété ou des

blessures ou la mort. .

−−

− • Ne pas ranger ni utiliser de matériaux

−−

combustibles, essence ou autres liquides

ou vapeurs inflammables à proximité de

cet appareil ou de tout autre appareil.

−−

− S’IL Y A UNE ODEUR DE GAZ :

−−

• Ne pas allumer cet appareil.

• Ne pas toucher aux interrupteurs

Electriques.

• Ne pas utiliser le téléphone de

l’édifice.

• Téléphoner immédiatement au

fournisseur de gaz chez un voisin.

Suivre les instructions du fournisseur

de gaz.

• Si l’on ne peut rejoindre le fournisseur

de gaz, téléphoner au service des

incendies.

−−

− L’installation et le service doivent être

−−

effectués par un installateur qualifié, une

agence de service autorisée ou le

fournisseur en gaz.

Préparation

Installation

Étapes finales

Service

Français• 1

Page 14

Instructions de sécurité importantes

AVERTISSEMENT

Avant d’installer, mettre l’alimentation hors circuit au

panneau de service. Le verrouiller pour empêcher la

mise en circuit accidentelle.

ATTENTION

L’appareil est lourd et requiert au moins deux

personnes ou un équipement approprié pour le

déplacer.

ATTENTION

Les surfaces dissimulées peuvent avoir des bords

tranchants. Faire attention en allant derrière ou

sous l’appareil.

Instructions de sécuritéPréparation Installation

Monter, s’appuyer ou s’asseoir sur les portes ou les

tiroirs de cette cuisinière peut causer des dommages à

l’appareil ou des blessures. Ne pas laisser les enfants

grimper ni jouer autour de l’appareil. Le poids d’un

enfant sur une porte ouverte peut faire basculer

l’appareil, causant ainsi des blessures ou des brûlures

sérieuses.

AVERTISSEMENT

• L’installation doit être conforme aux codes

locaux ou en l’absence des codes, avec le code

national pour combustibles, ANSI Z223.1.

• Cet appareil doit être mis à la terre

conformément aux codes locaux ou en l’absence

des codes, avec le Code national d’électricité

ANSI/ NFPA 70 dernière édition (au Canada,

l’installation doit être conforme aux codes CAN 1B149.1 et .2 d’installation pour les appareils à gaz et/

ou les codes locaux.

• Retirer tout ruban et emballage avant d’utiliser.

Détruire l’emballage par la suite. Ne jamais laisser

les enfants jouer avec le matériel d’emballage.

• S’assurer que l’appareil est installé et mis à la

terre adéquatement par un technicien qualifié.

L’installation, les connexions électriques et la mise à la

terre doivent être conformes à tous les codes

applicables.

• Installer selon les instructions d’installation

fournies avec la cuisinière.

• Demander au marchand de recommander un

technicien qualifié et un centre de service autorisé.

ATTENTION

Ne pas utiliser le four ou le tiroir réchaud (si équipé) à

des fins de rangement.

AVERTISSEMENT

Ne pas ranger des articles intéressants pour les

enfants dans les armoires au-dessus de la cuisinière

ou sur le dosseret. Les enfants peuvent grimper sur la

cuisinière pour atteindre ces articles et se blesser.

Cet appareil est conforme à une ou plusieurs des normes

ci-dessous :

• UL 858, norme de sécurité pour cuisinières

électriques domestiques

• UL 923, norme de sécurité pour appareil de cuisson à

micro-ondes

• UL 507, norme de sécurité pour ventilateur électrique

• ANSI Z21.1-2000, norme nationale américaine pour

appareils de cuisson à gaz domestiques

Étapes finales

• CAN/CSA-C22.2 n° 113-M1984 ventilateurs

• CAN/CSA-C22.2 n° 61-M89 cuisinières domestiques

Il est de la responsabilité du propriétaire et de

l’installateur de déterminer si des exigences et/ou des

normes additionnelles s’appliquent à une installation

Service

spécifique.

• Il faut savoir comment débrancher l’alimentation

à la cuisinière au coupe-circuit ou au fusible en cas

d’urgence

• Ne pas réparer ni remplacer toute pièces de

l’appareil à moins de recommandations

spécifiques dans les guides. Tout autre service

doit être effectué par un technicien qualifié. Ceci peut

réduire le risque de dommages à la propriété et de

blessures.

• Au moment de tester un système de analisation

à un test de pression excédant 1/2 lb/po

(3,5 kPa), l’appareil et sa soupape d’arrêt

individuelle doivent être débranchés du

système de canalisation de gaz.

2

• Au moment de tester un système de analisation

à un test de pression égal ou inférieur à 1/2 lb/

po2 (3,5 kPa), l’appareil doit être isolé du

système de canalisation de gaz en fermant sa

soupape d’arrêt manuelle individuelle.

• Ne jamais modifier la fabrication de l’appareil

en enlevant les pieds niveleurs, panneaux, couvercles

de fils, vis/fiation antibascule ou toute autre pièce.

Remarque pour installation à haute altitude :

Cette cuisinière est approuvée CSA pour un fonctionnement sûr jusqu’à une altitude de 10 000 pi sans

modification.

Exception : pour utilisation avec gaz LP, la cuisinière doit

d’abord être convertie à l’aide du nécessaire de

conversion LP compris avec la documentation.

Page 15

Instructions de sécurité importantes

Sécurité électrique:

Si requis par le Code national d’électricité (ou Code

d’électricité canadien), cet appareil doit être installé sur

un circuit séparé.

Pour les appareils dotés d’un cordon d’alimentation, ne

pas couper ni enlever la broche de mise à la terre. La fiche

doit être branchée sur une prise mise à la terre

correspondante pour éviter tout choc électrique. En cas de

doute quant à la mise à la terre de la prise, le propriétaire

doit la faire vérifier par un électricien qualifé.

Installateur – indiquer au propriétaire l’emplacement du

coupe-circuit ou du fusible. Le noter à des fins de

références.

Important – conserver ces instructions pour utilisation par

l’inspecteur en électricité local.

Consulter la plaque signalétique pour plus de détails. Voir

« Plaque signalétique » à la rubrique Service pour son

emplacement.

AVERTISSEMENT

Pour éviter les risques de brûlures ou d’incendie en

passant au-dessus des surfaces chaudes, l’espace de

rangement dans les armoires au-dessus de l’appareil doit

être évité. Si une armoire de rangement est en place, le

risque peut être réduit en installant une hotte ayant une

projection horizontale de 5 po du bas des armoires.

Sécurité relative aux équipements à gaz:

Installer une soupape d’arrêt de gaz à proximité de

l’appareil ; elle doit être facilement accessible en cas

d’urgence.

Le test de fuite doit être fait par l’installateur conformément aux instructions données dans cette section.

Installateur – indiquer au propriétaire l’emplacement de la

soupape d’arrêt de gaz.

La pression d’alimentation minimale doit être 1 po,

colonne d’eau, au-dessus de la pression du collecteur,

imprimée sur la plaque signalétique.

La pression d’alimentation maximale ne doit pas excéder

14,0 po, colonne d’eau (34,9 millibarres).

Sécurité gaz propane:

Remarque importante pour gaz LP : La cuisinière est

expédiée de l’usine pour une utilisation avec le gaz

naturel. Pour le gaz propane (LP), il faut la convertir à

l’aide du nécessaire de conversion pour gaz LP.

Le réservoir de gaz propane doit être doté de son propre

régulateur de pression. De plus, le régulateur fourni avec

cet appareil doit être

Instructions de sécurité

Préparation

Installation

S’assurer que les armoires au-dessus de la surface de

cuisson ont un maximum de 13 po (330 mm) de

profondeur.

Étapes finales

Service

Français• 3

Page 16

Étapes 1 à 4 : préparation

1. Installation de la ventilation

Siemens recommande fortement l’installation d’une hotte

au-dessus de la cuisinière. Pour la plupart des cuisines,

une cote de hotte certifiée de pas moins de 300 CFM est

recommandée. La hotte doit être installée selon les

instructions fournies avec la hotte.

2. Préparation des armoires

Cet appareil est conçu pour une installation près de

murs adjacents et surfaces de projection fabriqués de

matériaux combustibles.

Allouer un minimum de 30 po entre les armoires où la

cuisinière est installée (voir figure 1).

Dégagements requis*

De la surface de cuisson jusqu’aux matériaux audessus (figure 1)

Il doit y avoir un dégagement de 30 po entre le haut

de la surface de cuisson et le bas d’une armoire en

métal ou en bois non protégé.

Instructions de sécuritéPréparation Installation

24 po sont acceptables lorsque le bas de l’armoire en

métal ou en bois est protégée par (a) un matériaux

ignifuge de pas moins de 1/4 po qui doit être couvert

par (b) une feuille de métal de pas moins de n° 28

MSGacier inoxydable 0,015 po ou aluminium ou

cuivre 0,024 po.

Depuis les parois de la cuisinière aux matériaux

ajdacents (figure 1)

Aucun dégagement n’est nécessaire depuis les parois

de l’appareil aux murs combustibles verticaux arrière,

droit, gauche.

Le dégagement depuis le haut de la cuisinière aux

murs verticaux adjacents doit être d’au moins 4 po.

REMARQUE : certains finis d’armoire ne peuvent

tolérer les températures permises par U.L.,

particulièrement des fours autonettoyants. Les

armoires peuvent se décolorer ou tacher. Ceci est

remarquable avec des armoires laminées.

3. Préparation de la sortie électrique

La sortie électrique doit être située dans l’espace

ombré à la figure 2.

4. Préparer murs et plancher et

installer la fixation anti bascule

1. Sceller les trous dans les murs et plancher.

2. Régler la hauteur de la cuisinière et mettre de

niveau en tournant les pieds niveleurs au bas de

l’appareil, à l’aide d’une clé 1 1/4 po.

3. Mesurer pour repérer l’emplacement de la fixation

comme à la figure 3.

4. Maintenir la fixation avec 2 vis appropriées pour la

surface de fixation (non comprise) (ex. : pour un

Étapes finales

plancher en bois, utiliser des vis à bois, pour un

plancher en béton, utiliser des vis appropriées).

30 po minimum

centré

30 po

Min.m

4 po min.

Aucun dégagement

requis aux parois

d’armoire

Figure 1: Préparation d’armoire

Placer la

sortie de

canalisation

d’alimentation

en gaz et

électrique ici

7 1/2"

7 1/2”

30”

30"

4"

4” 3 7/8”

Égalité

13 1/8 "

13 1/8”

4 1/2"

4 1/2”

Figure 2: Emplacement de sortie électrique et canalisation en gaz

Paroi latérale de

l’armoire

Figure 3

18 po min.

4 po min.

3 1/2”

3 1/2"

4 1/2"

4 1/2”

3 7/8"

Mur arrière

Fixation anti bascule

1 9/16”

Figure 4

*Les instructions sont déterminées en utilisant des armoires américaines standard. Les armoires de base standard mesurent 36 po de

haut x 24 po de profondeur. Les armoires au-dessus de la surface de cuisson et celles adjacentes à celles au-dessus de la surface de

Service

cuisson mesurent 13 po de profondeur depuis le mur arrière. Si des armoires non standard sont utilisées, il faut prendre soin de

modifier les dimensions de façon appropriée.

Page 17

Étape 5 : installation - connexion de l’alimentation en gaz

Remarque importante pour gaz LP : La cuisinière

est expédiée de l’usine pour une utilisation avec le

gaz naturel. Pour le gaz propane (LP), il faut la

convertir à l’aide du nécessaire de conversion pour

gaz LP.

La connexion de gaz est située en dessous du panneau

arrière de l’appareil. (Voir figure 4, page 3). Ce dernier

est accessible par le panneau du tiroir réchaud ou de

l’arrière de la cuisinière. Pour accéder au panneau,

enlever le tiroir réchaud. Fermer la soupape

d’alimentation en gaz principale avant de débrancher une

ancienne cuisinière et laisser fermer jusqu’à ce que le

nouveau raccordement soit effectué. Ne pas oublier de

rallumer la veilleuse sur les autres appareils à gaz

lorsque l’on remet le gaz en circuit.

L’appareil peut ête installée avec un tuyau rigide ou un

connecteur d’appareil en métal flexible certifié CSA

International. Si l’on utilise un connecteur flexible,

toujours en utiliser un nouveau. Appliquer un produit sur

les joints de tuyau ou du ruban Teflon* approprié pour

l’utilisation avec du gaz LP et le gaz naturel tout autour

des filets de tuyau mâle pour empêcher les fuites.

Si non déjà en place, installer une soupape d’arrêt de gaz

dans un endroit facile d’accès. S’assurer que tous les

utilisateurs savent où est la soupape d’arrêt de gaz de la

cuisinière et comment la fermer.

Remarque : L’installateur doit aviser le consommateur

de l’endroit où se situe la soupape d’arrêt de gaz.

Méthode connecteur flexible (voir figure 5)

1. Installer un adaptateur évasé mâle 1/2 po au filet

interne 1/2 po NPT de l’entrée de la cuisinière.

Utiliser une clé sur le raccord coude pour éviter

les dommages.

2. Installer un adaptateur de lien évasé mâle 1/2 ou

3/4 po sur le filet interne NPT de la soupape

d’arrêt manuelle.

3. Brancher le connecteur d’appareil en métal flexible.

4. S’assurer que le coupe-circuit est hors circuit, puis

brancher le cordon de la cuisinière sur la prise

électrique.

5. Remettre la cuisinière en position en s’assurant

que le pieds glisse sous la fixation anti bascule. La

cuisinière sera à 3/4 po du mur lorsque

adéquatement installée. Remarque : ne pas coincer

le connecteur flexible !

6. Incliner délicatement la cuisinière vers l’avant pour

s’assurer que la fixation anti bascule s’enclenche et

empêche de basculer.

Méthode tuyau rigide (voir figure 6)

La configuration de la connextion avec tuyau rigide varie

selon l’emplacement du bout du tuyau rigide de gaz.

Consulter la figure 6 pour plus de détails.

1. S’assurer que le coupe-circuit est hors circuit, puis

brancher le cordon de la cuisinière sur la prise

électrique.

2. Remettre la cuisinière en position en s’assurant

que le pieds glisse sous la fixation anti bascule. La

cuisinière sera à 3/4 po du mur lorsque

adéquatement installée.

3. Incliner délicatement la cuisinière vers l’avant pour

s’assurer que la fixation anti bascule s’enclenche et

empêche de basculer.

4. Brancher le tuyay à la cuisinière au joint. Accéder à

la connexion par le panneau d’accès derrière le

tiroir réchaud. Remarque : Attention à ne pas

appliquer de pression sur le tiroir réchaud pendant

l’installation du tuyau.

Passer à «Test de fuite de gaz», colonne suivante.

Test pour fuites de gaz

Le test de fuite doit être fait par l’installateur

conformément aux instructions données dans cette

section.

Ouvrir le gaz. Appliquer un liquide de détection non

corrosif pour fuites sur tous les joints et racords de

connexion de gaz entre la soupape d’arrêt et la cuisinière.

Inclure les raccords de gaz et les joints dans la cuisinière si

les connexions doivent être dérangées pendant

l’installation. Des bulles autour des raccords et

connexions indiquent qu’il y a une fuite.

S’il y a une fuite, fermer la soupape d’arrêt de gaz de la

canalisation d’alimentation et serrer les connexions.

Refaire un test de fuite en ouvant la soupape d’arrêt de

gaz de la canalisation. La vérification est complétée

lorsqu’il n’y a pas de bulles. Essuyer le résidu de liquide.

Passer à l’étape 6 : étapes finales.

ATTENTION

NE JAMAIS VÉRIFIER LES FUITES AVEC UNE FLAMME.

NE PAS PASSER À L’ÉTAPE SUIVANTE TANT QUE LES

FUITES NE SONT PAS ÉLIMINÉES.

ATTENTION

Avant de brancher le cordon électrique, s’assurer que

tous les contrôles sont en position OFF.

Soupape

d’arrêt de

gaz

Régulateur

Figure 5: Méthode de connecteur flexible

Coude

nipple

joint

mamelon

coude :

brancher sur

régulateur

ici

Soupape

d’arrêt de gaz

Tuyay de gaz

1/2 à 3/4 po

Connecteur

flexible

Coude

mamelon

Débit de gaz à l’appareil

Figure 6: Méthode de tuyau rigide

Français• 5

Instructions de sécurité

Préparation

Installation

Étapes finales

Service

Page 18

Étape 6: étapes finales - test du fonctionnement du brûleur

1. Mettre en circuit au disjoncteur

Si l’affichage CL clignote et fait un bip continuel, le

câblage est incorrect. Vérifier si le câblage de la maison

est correct. Sinon, téléphoner au service Siemens.

2. Test des brûleurs de la cuisinière

Test allumage des brûleurs. Choisir un bouton de

brûleur sur la cuisinière. Pousser et tourner au

symbole de la flamme. Si le module allumeurétincelle fonctionne adéquatement, il produit un clic.

Une fois l’air purgé des canalisations d’alimentation,

le brûleur devrait s’allumer dans un délai de quatre

(4) secondes.

Test flamme: réglage élevé. Régler le brûleur à HI.

Voir la figure 7 pour les caractéristiques de la

flamme.

Si la flamme est complètement ou presque jaune,

téléphoner le service Siemens.

Test flamme: réglage bas. Régler le brûleur à LO.

Instructions de sécuritéPréparation Installation

Vérifier si la flamme enveloppe complètement le

brûleur. Il devrait y avoir une flamme à chaque port

de brûleur et il ne devrait pas y avoir d’espace entre

la flamme et le brûleur. Si un des brûleurs n’enveloppe

pas, appeler le service Siemens.

Vérifier l’allumage et la flamme sur tous les brûleurs

de la cuisinière comme il est décrit ci-dessus.

Caractéristiques de flamme

Flamme jaune:

Réglage nécessaire.

Pointe jaune sur cône extérieur:

Normal pour gaz LP.

Flamme bleue doux:

Normal pour gaz naturel.

Si la flamme est complètement ou presque jaune, vérifier si le

régulateur est réglé pour le combustible approprié. Après le

réglage, vérifier de nouveau.

Une rainure jaune est normale pendant la mise en marche

initiale.

Laisser l’appareil fonctionner de 4 à 5 minutes et réévaluer avant

d’effectuer d’autres réglages.

Figure 7

Appeler le service Siemens 866-447-4363 si:

1. Si un des brûleurs ne s’allume pas.

2. La flamme de brûleur du grille ou la flamme de

brûleur de cuisson sort avant l’une ou l’autre

température de portée.

3. Si un des brûleurs continue de brûler jaune.

LORSQUE LA FL AMME EST BIEN RÉGLÉE:

Il devrait y avoir une flamme sur chaque port

de brûleur.

Il ne devrait pas y avoir d’espace d’air entre la

flamme et le port de brûleur.

3. Test brûleurs du four

Retirer le couvercle inférieur du four. Retirer les

deux fermetures à vis arrière, glisser le couvercle et le

retirer.

Test allumage du brûleur de four. Régler le four à

350 °F. Après 30 à 75 secondes le brûleur s’allumera.

Le brûleur restera ainsi jusqu’il atteigne le 350 °F et il

se fermera. À partir de ce point, le brûleur alternera

d’allumer à fermer pour maintenir la température.

Test flamme du brûleur de four. À cette étape

vérifier la flamme. Voir figure 7 pour les caractéristiques

appropriées de la flamme. Si la flamme brûle

complètement ou est le plus souvent jaune, régler le volet

d’air du brûleur de four. Voir figure 8 (page suivante) pour

plus de détails.

Test allumage du brûleur de grill. Régler le mode de

cuisson grill à élevé. Le brûleur s’allumera après 30 à

75 secondes.

Étapes finales

Test flamme du brûleur de grill. À cette étape

vérifier la flamme. Voir figure 6 pour les

caractéristiques appropriées de la flamme. Si la

flamme brûle complètement ou est le plus souvent

jaune, régler le volet d’air du brûleur de grill. Voir

figure 8 (page suivante) pour plus de détails.

Replacer le couvercle inférieur du four. Glisser le

Service

couvercle en place et remettre les fermetures à vis

arrières.

Si un ajustement du brûleur/flamme est nécessaire,

aller à l’étape 6 : « ajustement de la flamme » (si

nécessaire), à la page suivante. Autrement, à ce point,

l’installation est terminée.

Page 19

Étape 6: étapes finales - réglage de la flamme (si nécessaire)

AVERTISSEMENT:

Laisser le (les) brûleur(s) se refroidir

avant de tenter de le (les) retirer !

Instructions de sécurité

Réglage du volet d’air

de brûleur de grill (si nécessaire)

Plus ouvert:

•Moins de

flamme jaune

Plus fermé:

•Moins de flamme bleue

•Plus d’entraînement

•Moins de poussée ou de

soufflage

Figure 8

Le volet d’air est situé à l’arrière du brûleur de grill. Il

est attaché avec 7 vis à la cavité du four. Retirer les vis

et tirer doucement l’assemblage du brûleur de grill en

faisant attention pour ne pas détacher les fils

électriques. Placer le brûleur contre l’arrière du mur de

la cavité du four. Desserrer la vis et tourner le volet.

Fermer le volet si la flamme s’élève ou souffle ou

n’entraîne pas ; ouvrir le volet si la flamme est trop

jaune. (Voir figure 8.) Serrer la vis. Replacer

l’assemblage du grill en faisant attention de passer

tous les fils à travers l’arrière du four. Réinsérer les 8

vis.

Remarque : le volet du brûleur de grill se place sur

l’orifice lorsqu’installé correctement.

Volet

Vis

Réglage du volet d’air

de brûleur de four (si nécessaire)

Volet

Plus fermé:

•Moins de flamme

bleue

Plus ouvert:

•Moins de

flamme jaune

Figure 9

Le volet d’air de brûleur du four est situé proche du

régulateur de four. L’atteindre par le trou d’accès à

l’intérieur du panneau arrière du tiroir réchaud.

(Desserrer les vis et enlever le panneau d’accès).

Desserrer les vis sur le volet. Fermer le volet si la

flamme s’élève ou souffle ou n’entraîne pas; ouvrir le

volet si la flamme est trop jaune. Serrer la vis.

Rattacher la plaque du couvercle et replacer le tiroir

réchaud. (Voir figure 9).

•Plus d’entraînement

•Moins de poussée

ou de soufflage

Préparation

Installation

Pièces de rechange : visitez le marchand Siemens pour les pièces de rechange. Pour un marchand dans la région,

communiquer avec le service Siemens 866-447-4363.

Français• 7

Étapes finales

Service

Page 20

Avant d’effectuer un appel de service

Voir le guide de dépannage du guide d’utilisation et

d’entretien. Consulter la garantie.

Pour communiquer avec un représentant de service, voir

l’information au début du guide. Avoir l’information

imprimée sur la plaque signalétique sous la main avant de

téléphoner.

Plaque signalétique

La plaque signalétique donne les numéros de modèle et

de série. La consulter au moment de faire un appel de

service. Elle est située sur le care près du tiroir.

Ouvrir le tiroir pour la voir.

Instructions de sécuritéPréparation Installation

Plaque signalétique

Étapes finales

Service

Page 21

Page 22

Page 23

Por favor lea todas las instrucciones antes de usar este aparato.

Contenido

Instrucciones Importantes de Seguridad .................................................................................... 1

Preparación ................................................................................................................................4

Instalación ................................................................................................................................. 5

Pasos Finales ............................................................................................................................. 6

Servicio ...................................................................................................................................... 8

PARTES INCLUIDAS

Soporte Antivolcadura

HERRAMIENTAS Y PARTES QUE SE

NECESITAN:

• Cinta de Medir Estándar

• Desarmador de Cabeza Phillips (de Cruz)

• Llave de 1-1/4”

• Lápiz

• Desarmador con Cabeza Torx T-20

• Llave para Tuercas de 3/8”

• Tornillos (2) y Anclas (2) para el Soporte

Antivolcadura (El estilo varía dependiendo de la

superficie de montaje)

• Llave para Tubos (2)

• Cinta de Teflón®* o Compuesto para Unir Tubos

(Se puede usar con gas LP y gas Natural)

• Pinzas

• Solución para Probar si hay Fuga de Gas

• Niveleta

• Taladro y Broca

• Línea de Suministro de Gas (Conector Metálico

Flexible o Tubo Rígido)

• Válvula de Cierre de Gas (si no hay)

• Guantes y Lentes de Seguridad

* Teflon es una marca registrada de DuPont

ADVERTENCIA

RIESGO DE VOLCADURA DE LA ESTUFA

• Todas las estufas pueden volcarse y producir lesiones.

Para prevenir la volcadura accidental de la estufa,

fíjela a la pared, al piso o al gabinete con el

Dispositivo Antivolcadura que se incluye.

• Cuando no se instala el aparato de acuerdo con estas

instrucciones, existe el riesgo de una volcadura.

• Cuando se jala la estufa de la pared por motivos de

limpieza, servicio u otra razón, asegúrese de

volver a embonar correctamente el Dispositivo

Antivolcadura al volver a empujar la estufa contra la

pared. En el caso de un uso poco normal (como

alguien sentado, parado o recostado sobre una puerta

abierta), el hecho de ignorar esta precaución puede

causar la volcadura de la estufa y como consecuencia

lesiones debido a líquidos calientes derramados o por

la misma estufa.

Seguridad

ADVERTENCIA

No trate de reparar o reemplazar ninguna parte del

aparato a menos que los manuales lo recomienden

específicamente. La instalación, servicio o

mantenimiento incorrecto puede causar lesiones o

dañar la propiedad. Todo servicio adicional debe ser

realizado por un técnico calificado.

Para Instalaciones en Massachusetts:

1. La instalación debe ser realizada por un contratista,

plomero o técnico de gas calificado o autorizado, quien

está calificado o autorizado por el estado, la provincia

o región donde se está instalando este aparato.

2. La válvula de cierre debe ser un grifo de gas en T.

3. El conector flexible de gas no debe medir más de

36 pulgadas.

ADVERTENCIA: El no observar la información

en este manual puede causar un fuego o

una explosión, y como resultado daños a la

propiedad, lesiones o la muerte.

−−

− No guarde o use materiales combustibles,

−−

gasolina u otros vapores y líquidos

Inflamables cerca de este o cualquier otro

aparato.

−−

− QUÉ HACER CUANDO HUELE A GAS:

−−

• No trate de encender ningún aparato.

• No toque ningún interruptor eléctrico.

• No use ningún teléfono en su edificio.

• Llame de inmediato a su proveedor de

gas desde el teléfono de algún vecino.

Siga las instrucciones de su proveedor de

gas.

• Cuando no pueda localizar a su proveedor

de gas, llame a los bomberos.

−−

− Un instalador calificado, una agencia de

−−

servicio autorizada o el proveedor de gas debe

realizar la instalación y el servicio.

Instrucciones de Seguridad

Preparación

Instalación

Pasos FInales

Servicio

Español • 1

Page 24

Instrucciones Importantes de Seguridad

ADVERTENCIA

Antes de instalar, APAGUE la corriente en el panel de

servicio. Bloquee el panel para evitar que se PRENDA

la corriente accidentalmente.

CUIDADO

La unidad está pesada y debe ser movida por al menos

dos personas o con el equipo apropiado.

CUIDADO

Puede haber superficies ocultas con bordes filosos.

Tenga cuidado cuando meta la mano detrás o

debajo del aparato.

Instrucciones de Seguridad

Pisar, recostarse o sentarse sobre las puertas o los

cajones de esta estufa puede causar lesiones serias y

también dañar la estufa. No permita que los niños se

suban o que jueguen cerca de la estufa. El peso de un

niño sobre una puerta abierta puede causar la

volcadura de la estufa, causando quemaduras serias u

otras lesiones.

ADVERTENCIA

• La instalación debe cumplir con los códigos

locales o, a falta de códigos locales, con el

Código Nacional de Gas Combustible, ANSI

Z223.1.

• Se debe conectar el aparato a tierra conforme a

los códigos locales o, a falta de códigos locales,

conforme al Código Eléctrico Nacional ANSI/NFPA

70, última edición. (En Canadá, la instalación debe

estar conforme a los códigos de instalación para

aparatos que usan gas CAN 1.B149.1 y .2 y/o

conforme a los códigos locales)

• Quite las cintas adhesivas y materiales de

empaque antes de usar la estufa. Destruya el

cartón y las bolsas de plástico después de

desempacar la estufa. Nunca permita que los niños

jueguen con el material de empaque.

• Asegúrese de que su aparato esté instalado y

aterrizado correctamente por un técnico

calificado. La instalación, las conexiones

eléctricas y la puesta a tierra deben cumplir con

todos los códigos aplicables.

• Instale sólo de acuerdo a las instrucciones de

instalación que se incluyen con esta estufa.

• Solicite que su distribuidor recomiende un

técnico calificado y un centro de servicio autorizado.

Preparación Instalación

CUIDADO

No utilice el horno o el cajón calentador (si viene

incluido) para almacenar cosas.

ADVERTENCIA

No almacene cosas de interés para los niños en los

gabinetes arriba de la estufa o la parte trasera de ésta.

Cuando los niños se suben a la estufa para alcanzar

estas cosas, pueden sufrir heridas serias.

Este aparato cumple con una o más de las siguientes

normas:

• UL 858, Norma de seguridad para estufas

electrodomésticas

• UL 923, Norma de seguridad para hornos de

microondas

• UL 507, Norma de seguridad para ventiladores

eléctricos

Pasos Finales

• ANSI Z21.1-2000, Norma americana nacional

para aparatos domésticos de gas

• CAN/CSA-C22.2 No. 113-M1984 Ventiladores

• CAN/CSA-C22.2 No. 61-M89 Estufas domésticas

Es la responsabilidad del propietario y del instalador

determinar si aplican requerimientos y/o normas

Servicio

adicionales en instalaciones específicas.

• Aprenda a desconectar la corriente en el

cortacircuitos o la caja de fusibles y el suministro de

gas en caso de una emergencia.

• No trate de reparar o reemplazar alguna parte

del aparato a menos que los manuales lo

recomienden específicamente. Todo servicio

adicional debe ser realizado por un técnico calificado.

Esto puede reducir el riesgo de heridas personales o

daños a la estufa.

• Cuando ponga a prueba el sistema de la tubería de

suministro a presiones de prueba arriba de 1/2 psig

(3.5 kPa), se deben desconectar el aparato y su

válvula individual de cierre de gas del sistema de la

tubería del gas.

• Cuando ponga a prueba el sistema de la tubería

de suministro a presiones de prueba iguales o

menores de 1/2 psig (3.5 kPa), se debe aislar el

aparato del sistema de la tubería de suministro

de gas cerrando su válvula manual de cierre de

gas.

• Nunca modifique o altere la construcción de una

estufa quitando las patas de nivelación, paneles,

protecciones de cables, soporte antivolcadura/

tornillos o cualquier otra parte del producto.

• No levante la puerta por la agarradera. Quite la

puerta para facilitar el manejo y la instalación. Vea la

Sección ‘Quitar la Puerta del Horno’ en la sección de

Mantenimiento del manual de Uso y Cuidado.

Page 25

Instrucciones Importantes de Seguridad

Nota para instalaciones en gran altitud:

Esta estufa está certificada por CSA para una operación

segura hasta una altitud de 10,000 pies (3,000 m) sin

ninguna modificación.

Excepción: para el uso con gas LP, se debe convertir la

estufa primero usando las instrucciones de instalación LP

que se incluyen en este juego de literatura.

Seguridad

Seguridad con el gas:

Instale una válvula de cierre de gas cerca del aparato.

Debe tener fácil acceso en caso de una emergencia.

El instalador debe revisar si hay fugas de gas de acuerdo

a las instrucciones indicadas en esta sección.

Instrucciones de Seguridad

Seguridad eléctrica:

Si el Código Eléctrico Nacional (o el Código Eléctrico

Canadiense) lo requiere, se debe instalar este aparato en

un circuito de derivación separado.

En los aparatos que incluyen un cable con enchufe, no se

debe cortar o quitar la clavija de tierra. El enchufe debe

ser insertado en una tomacorriente correspondiente para

evitar una descarga eléctrica. En caso que existan dudas

si la tomacorriente está puesta a tierra correctamente, el

cliente debe contratar a un eléctrico calificado para que la

revise.

Instalador – muéstrele al propietario el lugar donde se

encuentra el cortacircuitos o el fusible. Marque este lugar

para futuras referencias.

Importante – Guarde estas instrucciones para el uso del

inspector eléctrico local.

Consulte la placa de datos para más información. Vea

“Placa con información del producto” bajo “Servicio” para

encontrar la placa.

ADVERTENCIA

Para eliminar el riesgo de quemaduras o fuego al

inclinarse encima de superficies calientes, se deben evitar

espacios de almacenamiento en los gabinetes arriba de

las unidades superficiales. En caso de proporcionar

espacio de almacenamiento, se puede reducir el riesgo al

instalar una campana que salga horizontalmente como

mínimo 5 pulgadas (127 mm) debajo del fondo del

gabinete.

Verifique que los gabinetes arriba de la parrilla tengan una

profundidad máxima de 13" (330 mm).

Instalador – muéstrele al propietario donde se encuentra

la válvula de cierre de gas.

La mínima presión de suministro de gas debe ser 1"”

columna de agua arriba de la presión en el manifold

impresa en la placa de información.

La máxima presión de suministro no debe exceder 14.0

pulgadas de columna de agua (34.9 mb).”

Seguridad gas propano:

Aviso importante para usuarios de gas LP: La estufa

viene de fábrica para el uso con gas natural. Para usar gas

propano (LP), ud. debe convertir primero su estufa usando

el kit de conversión a gas LP.

El tanque de gas propano debe tener su propio regulador

de alta presión. Además, se debe usar también el

regulador que viene incluido con este parato.

Preparación

Instalación

Pasos FInales

Español • 3

Servicio

Page 26

Pasos 1 hasta 4: Preparación

1. Instalar la Ventilación

Siemens recomienda fuertemente instalar una campana de

ventilación arriba de esta estufa. Para la mayoría de

cocinas se recomienda una campana con un régimen

eléctrico nominal no menor de 300 CFM. La campana debe

ser instalada de acuerdo a las instrucciones incluidas con

ésta.

2. Preparar los Gabinetes

Se puede instalar esta unidad cerca de paredes

adyacentes y superficies salientes construidas de

materiales combustibles.

Debe haber un mínimo espacio libre de 30 pulgadas

(76 cm) entre los gabinetes donde se va a instalar la

estufa (Vea la Figura 1).

Espacios Libres que se Requieren*

Desde la estufa a los materiales de arriba (vea Fig.1)

Debe haber un espacio libre mínimo de 30 pulgadas

(76 cm) entre la parte superior de la superficie de

cocinar y el fondo de un gabinete de madera o metal

no protegido.

Instrucciones de Seguridad

24 pulgadas (61 cm) son aceptables cuando el fondo

del gabinete de metal o madera está protegido por (a)

no menos de 1/4” de material pirorretardante que debe

estar cubierto con (b) no menos de chapa No. 28 MSG,

0.015 pulgadas (4 mm) de acero inoxidable o 0.024

pulgadas (6 mm) de aluminio o cobre.

Desde las paredes de la estufa a los materiales

adyacentes (Vea Figura 1)

No se requiere ningún espacio libre desde las paredes

de la unidad a las paredes verticales adyacentes

Preparación Instalación

combustibles en la parte trasera, izquierda y derecha.

El espacio libre desde la parte superior de la estufa a

las paredes verticales adyacentes debe ser al menos

4”.

NOTA: El acabado de algunos gabinetes no puede

resistir las temperaturas permitidas por U.L., sobre

todo los hornos de autolimpieza; es posible que los

gabinetes pierdan el color o que se manchen. Esto se

nota aún más con gabinetes laminados.

3. Preparar la Línea de Suministro de

Gas y la Tomacorriente

Se debe ubicar la línea de suministro de gas y la

tomacorriente en el espacio sombreado en la Fig 2.

4. Preparar las paredes y el piso e

instalar el soporte antivolcadura

1. Selle todos los hoyos en las paredes o el piso.

2. Ajuste la altura de la estufa y nivélela girando las

patas ajustables en la parte inferior de la estufa,

utilizando una llave de 1-1/4".

3. Tome medidas para localizar la posición del

Pasos Finales

soporte como se indica en la Figura 3.

4. Fije el soporte con 2 tornillos adecuados para la

superficie de montaje (no se incluyen). (p.ej.,

para pisos de madera utilice tornillos para madera,

para pisos de concreto utilice tornillos o anclajes

para concreto).

30” Mínimo

Centrado

4” Min.

No se requiere

ningún espacio

libre a la

pared del gabinete

Figura 1: Preparación de Gabinetes

Coloque la

Línea de

Suministro de

Tomacorriente

7 1/2"

7 1/2”

13 1/8 "

13 1/8”

4 1/2"

4 1/2”

Figura 2: Colocación de la Línea de Suministro de Gas y de la

Tomacorriente

Pared lateral del

gabinete

Figura 3

Figura 4

30”

Min.

4” Min.

Gas y la

Aquí

3 1/2”

3 1/2"

4 1/2"

3 7/8"

4 1/2”

4"

4” 3 7/8”

30"

30”

Al ras

Dispositivo Antivolcadura

18”

Min.

1 9/16”

*Se determinaron las instrucciones en base a gabinetes americanos estándar. Los gabinetes estándar de piso miden 36” (91 cm) de

Servicio

altura x 24” (61 cm) de profundo. Los gabinetes arriba de la superficie de cocinar y los gabinetes junto a los que están arriba de la

superficie de cocinar miden 13” (33 cm) de profundo de la pared trasera. Cuando se usan gabinetes no estándar, tenga cuidado de

modificar las dimensiones correctamente.

Page 27

Paso 5: Instalación - Conectar el Suministro de Gas

Aviso importante para usuarios de gas LP: La estufa

viene de fábrica para el uso con gas natural. Para usar

gas propano (LP), ud. debe convertir primero su estufa

usando el kit de conversión a gas LP.

La conexión del gas se encuentra abajo del panel trasero

de la estufa (Vea Figura 4, Página 3). Se tiene acceso a

través del panel de acceso del cajón calentador o desde

la parte trasera de la estufa. Para alcanzar el panel de

acceso, quite el cajón calentador.

Cierre la válvula principal del suministro de gas antes de

desconectar la estufa vieja y déjela cerrada hasta

terminar la conexión nueva. No olvide volver a

encender el piloto en otros aparatos de gas cuando

vuelva a prender el gas.

Se puede instalar la estufa usando un tubo rígido o una

manguera metálica flexible certificada por CSA

International. Cuando usa una manguera flexible,

siempre use un conector nuevo.

Aplique un compuesto de unión para tubos o cinta de

Teflón* apropiada para el uso con gas natural y gas LP

alrededor de las roscas macho del tubo para prevenir

fugas.

Si aún no la tiene, instale una válvula de cierre de gas en

un lugar con acceso fácil. Asegúrese que todos los

usuarios sepan dónde y cómo cerrar el suministro de gas

a la estufa.

Nota: El instalador debe informar al consumidor del

lugar de la válvula de cierre del gas.

Método con Manguera Flexible (vea Figura 5)

1. Instale el adaptador macho de 1/2” en la rosca

interna 1/2” NPT de la entrada de la estufa. Use una

llave de reserva sobre la conexión del codo para evitar

daños.

2. Instale el adaptador macho de unión de 1/2” o 3/4”

en la rosca interna NPT de la válvula manual de cierre.

3. Conecte la manguera metálica flexible.

4. Asegúrese que el cortacircuitos esté apagado y

luego enchufe el cable de la estufa en la

tomacorriente.

5. Empuje la estufa de vuelta a su posición,

asegurándose que las patas vuelvan a quedar abajo

del soporte antivolcadura. La estufa descansará a 3/4”

de la pared si queda instalada correctamente.

Nota: Tenga cuidado de no enrollar la manguera flexible!

6. Incline la estufa cuidadosamente hacia ud. para

asegurar que el soporte antivolcadura esté

enganchado para evitar la volcadura.

Método con Tubo Rígido (vea Figura 6)

La configuración de la conexión con tubo rígido varía

dependiendo del lugar del extremo del tubo de gas.

Consulte la Figura 6 para detalles.

1. Asegúrese que el cortacircuitos esté apagado y

luego enchufe el cable de la estufa en la

tomacorriente.

2. Empuje la estufa de vuelta a su posición,

asegurándose que las patas vuelvan a quedar

abajo del soporte antivolcadura. La estufa

descansará a 3/ 4” de la pared si queda instalada

correctamente.

3. Incline la estufa cuidadosamente hacia ud. para

asegurar que el soporte antivolcadura esté

enganchado para evitar la volcadura.

4. Conecte el tubo a la estufa en la unión. Tiene acceso

a la conexión a través del panel de acceso detrás del

cajón calentador.

Nota: Tenga cuidado de no aplicar presión al elemento

del cajón calentador durante la instalación con tubo

rígido.

Siga con “Verificar Fugas de Gas”, siguiente columna.

Seguridad

Verificar Fugas de Gas

El instalador debe revisar si hay fugas de gas de acuerdo

a las instrucciones indicadas en esta sección.

Prenda el Gas. Aplique un líquido no corrosivo para

detectar fugas a todas las uniones y conexiones en la

conexión de gas entre la válvula de cierre y la estufa.

Incluya los accesorios y las uniones de gas en la estufa, si

las conexiones pudieron haber sido perturbadas durante

la instalación. Burbujas que aparecen alrededor de las

conexiones y uniones indican una fuga.

Cuando se presenta una fuga, apague la válvula de cierre

de la línea de suministro de gas y apriete las conexiones.

Vuelva a probar si hay fugas abriendo la válvula del gas.

Al terminar el chequeo de fugas (ya no aparecen

burbujas), la prueba ha terminado. Limpie los residuos

del líquido de detección. Siga con el Paso 6: Pasos

Finales.

CUIDADO

NUNCA REVISE SI HAY FUGAS CON UNA LLAMA.

NO SIGA CON EL SIGUIENTE PASO HASTA HABER

ELIMINADO TODAS LAS FUGAS.

CUIDADO

Antes de enchufar un cable eléctrico, asegúrese que

todos los controles están APAGADOS.

Válvula

de cierre

del gas

Regulador

Figura 5: Método con Manguera Flexible

codo

niple

unión

niple

codo:

conectar al

regulador

aquí

válvula de cierre

del gas

tubo de gas

1/2” a 3/4”

Flujo de Gas a la Estufa

Figura 6: Método con Tubo Rígido

Manguera

Flexible

codo

niple

Español • 5

Instrucciones de Seguridad

Preparación

Instalación

Pasos FInales

Servicio

Page 28

Paso 6: Pasos Finales - Probar el Funcionamiento de los Quemadores

1. Prender el interruptor de corriente

Si parpadea la pantalla LCD y si emite pitidos

continuamente, se conectaron mal los cables. Verifique el

cableado fue instalado correctamente. En caso que sí,

llame al Servicio de Siemens.

2. Probar los quemadores de la estufa

Probar la ignición de quemadores. Seleccione una

perilla de un quemador de la estufa. Presiónela y

gírela al símbolo de la llama. El ignitor módulo de

chispas producirá un sonido de un clic (chasquido).

Una vez que se haya purgado el aire de las líneas de

suministro, el quemador debe encenderse dentro de

cuatro (4) segundos.

Probar la llama: Calor alto. Cambie el quemador a HI

(Alto). Vea la Figura 7 para las características

apropiadas de las llamas.

Si alguno de los quemadores de la estufa sigue

quemándose con un color amarillo, llame al Servicio de

Siemens.

Probar la llama: Calor bajo. Cambie el quemador a LO

(Bajo). Verifique que la llama envuelva completamente el

Instrucciones de Seguridad

quemador. Debe haber una llama en el puerto de cada

quemador y no debe haber un espacio de aire entre la

llama y el quemador. Si alguno de los quemadores no

queda completamente envuelto, llame al Servicio de

Siemens.

Verifique la ignición y la llama de cada quemador de

la estufa del modo mencionado arriba.

Características de la Llama

Llama Amarilla:

Se requiere más ajuste.

Puntas Amarillas sobre Conos:

Normal para Gas LP.

Llama Azul Suave:

Normal para Gas Natural.

Si la llama está casi completamente amarilla, verifique que

el regulador esté ajustado para el gas correcto. Después de

ajustarlo, vuelva a probar.

Ver algunas llamas amarillas al arranque inicial es cosa

normal.

Permita que la unidad opere 4-5 minutos y reevalúe antes de

hacer otros ajustes.

Figura 7

Llame al Servicio de Siemens 866-447-4363 si:

1.Algún quemador no se enciende.

2. La llama del quemador de asar o del quemador de

hornear apagará antes de la temperature alcance.