Page 1

MICROMASTER

Operating Instructions

© Siemens plc 1997

Contents

Safety Instructions..............................................................2

1. OVERVIEW ......................................................................3

2. INSTALLATION ...............................................................4

3. FRONT PANEL CONTROLS & BASIC OPERATION ...14

4. OPERATING MODES....................................................17

5. SYSTEM PARAMETERS...............................................20

6. FAULT CODES..............................................................34

7. SPECIFICATIONS..........................................................35

8. SUPPLEMENTARY INFORMATION .............................37

G85139-H1750-U049-B

26/09/97

Page 2

©

7

Safety Instructions

n

Before installing and putting this equipment into operation, please read these safety instructions and

warnings carefully and all the warning labels attached to the equipment. Make sure that the warning

labels are kept in a legible condition and replace missing or damaged labels.

WARNING

This equipment contains dangerous voltages and

controls dangerous rotating mechanical parts.

Loss of life, severe personal injury or property

damage can result if the instructions contained in

this manual are not followed.

Only suitable qualified personnel should work on

this equipment, and only after becoming familiar

with all safety notices, installation, operation and

maintenance procedures contained in this manual.

The successful and safe operation of this

equipment is dependent upon its proper handling,

installation, operation and maintenance.

•

MICROMASTERS operate at high voltages.

•

Only permanently-wired input power

connections are allowed. This equipment must

be grounded (IEC 536 Class 1, NEC and other

applicable standards).

•

If a Residual Current-operated protective

Device (RCD) is to be used, it must be an

RCD type B.

•

Machines with a three phase power supply,

fitted with EMC filters, must not be connected

to a supply via an ELCB (Earth Leakage

Circuit-Breaker - see DIN VDE 0160, section

6.5).

•

The following terminals can carry dangerous

voltages even if the inverter is inoperative:

- the power supply terminals L/L1, N/L2, L3.

- the motor terminals U, V, W.

•

Only qualified personnel may connect, start

the system up and repair faults. These

personnel must be thoroughly acquainted with

all the warnings and operating procedures

contained in this manual.

•

Certain parameter settings may cause the

inverter to restart automatically after an input

power failure.

•

This equipment must not be used as an

‘emergency stop’ mechanism

9.2.5.4)

• If motor thermal protection is required, then an

external PTC must be used. (

2.3.5.)

• Lowering the fan tray on Frame Size C

MICROMASTER exposes rotating parts

Power must be isolated prior to this operation.

(see EN 60204,

Refer to Sectio

CAUTION

• Children and the general public must be

prevented from accessing or approaching the

equipment!

•

This equipment may only be used for the

purpose specified by the manufacturer.

Unauthorised modifications and the use of

spare parts and accessories that are not sold

or recommended by the manufacturer of the

equipment can cause fires, electric shocks and

injuries.

•

Keep these operating instructions within easy

reach and give them to all users!

European Low Voltage Directive

The MICROMASTER product range complies with the requirements of

the Low Voltage Directive 73/23/EEC as amended by Directive

98/68/EEC. The units are certified for compliance with the following

standards:

EN 60146-1-1 Semiconductor converters - General requirements

EN 60204-1 Safety of machinery - Electrical equipment of

European Machinery Directive

The MICROMASTER inverter series does not fall under the scope of

the Machinery Directive. However, the products have been fully

evaluated for compliance with the essential Health & Safety

requirements of the directive when used in a typical machine

application. A Declaration of Incorporation is available on request.

European EMC Directive

When installed according to the recommendations described in this

manual, the MICROMASTER fulfills all requirements of the EMC

Directive as defined by the EMC Product Standard for Power Drive

Systems EN61800-3.

.

and line commutated converters

machines

UL and CUL listed.

ISO 9001

Siemens plc operates a quality management system which complies

with the requirements of ISO 9001.

G85139-H1750-U049-B

26/09/97

Siemens plc 199

Page 3

1. OVERVIEW English

2

7

1. OVERVIEW

The MICROMASTERS are a range of frequency inverters for controlling the speed of three phase AC motors.

Various models are available, ranging from the compact 120 W single phase input MICROMASTER up to the 7.5

kW three phase input MICROMASTER.

The inverters are microprocessor-controlled and use state of the art IGBT technology for reliability and

flexibility. A special pulse-width modulation method with selectable ultrasonic pulse frequency permits

extremely quiet motor operation. Inverter and motor protection is provided by comprehensive protective

functions.

Features:

• Easy to install, program and commission.

• Closed loop control using a Proportional, Integral (PI) control loop function.

• High starting torque with automatic starting boost.

• Remote control capability via RS485 serial link using the USS protocol with the ability to control up to 31

inverters.

• A comprehensive range of parameters is provided to enable the inverters to be configured for use in

almost any application.

• Membrane-type front panel controls for simple operation.

• Built-in non-volatile memory for storing parameter settings.

• Factory default parameter settings pre-programmed for European and North American requirements.

• Output frequency (and hence motor speed) can be controlled by one of five methods:

(1) Frequency setpoint using the keypad.

(2) High resolution analogue setpoint (voltage input).

(3) External potentiometer to control motor speed.

(4) Fixed frequencies via binary inputs.

(5) Serial interface.

• Built-in DC injection brake with special COMPOUND BRAKING.

• Integral RFI filter on single phase input inverters (MM12 - MM300).

• Acceleration/deceleration times with programmable smoothing.

• Fully programmable single relay output incorporated.

• External Options connector for optional multi-language Clear Text Display (OPM2) or optional PROFIBUS

module.

• Automatic recognition of 2, 4, 6 or 8-pole motors by software.

• Integral software-controlled cooling fan.

• Fast Current Limit (FCL) for reliable trip-free operation.

• Compact design and the ability to mount inverters side by side provides greater space saving.

© Siemens plc 1997 G85139-H1750-U049-B

3

6/09/9

Page 4

English 2. INSTALLATION

©

7

2. INSTALLATION

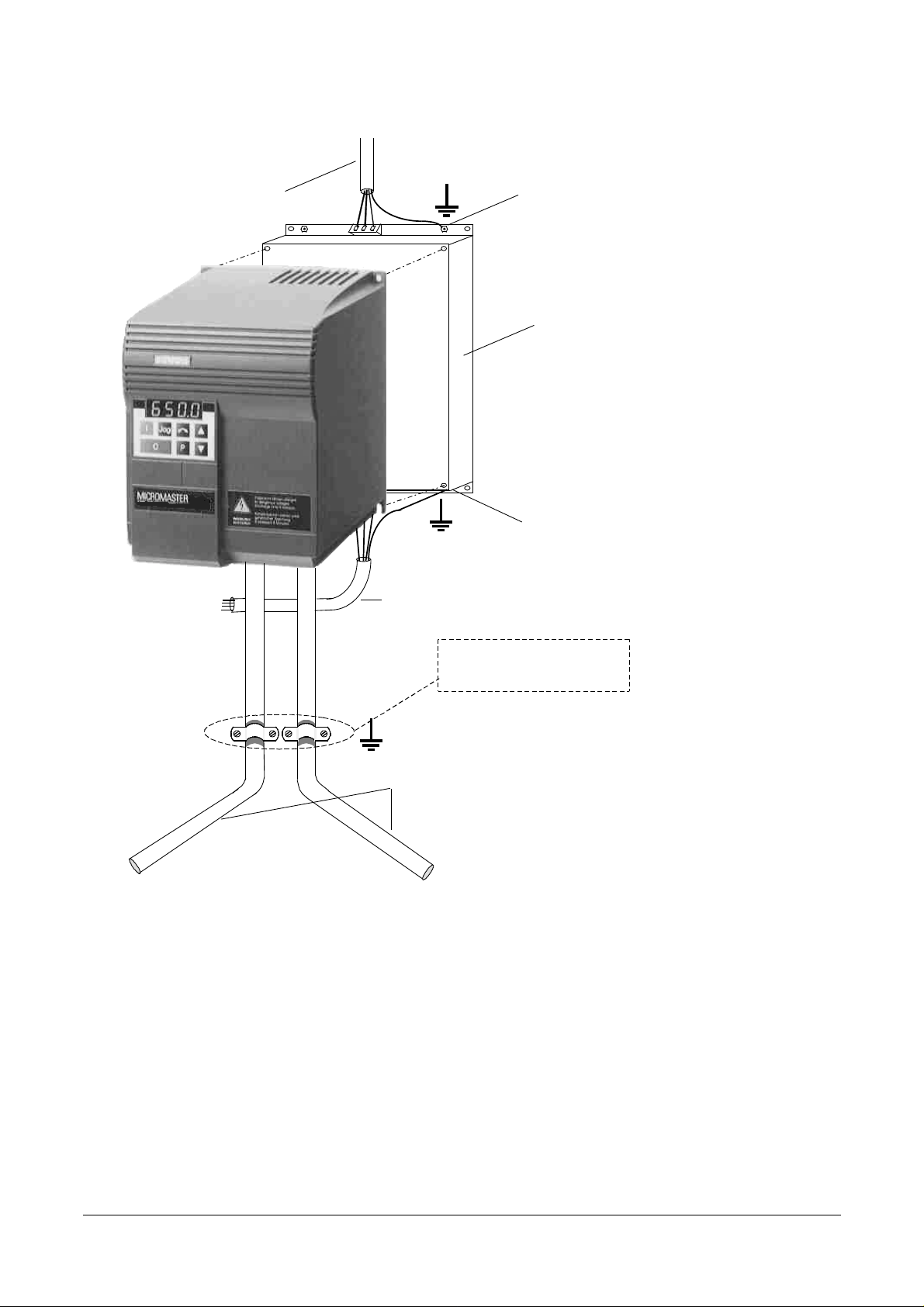

2.1 Wiring Guidelines to Minimi se the Effects of EMI

The inverters are designed to operate in an industrial environment where a high level of Electro-Magnetic

Interference (EMI) can be expected. Usually, good installation practices will ensure safe and trouble-free

operation. However, if problems are encountered, the following guidelines may prove useful. In particular,

grounding of the system 0V at the inverter, as described below, may prove effective. Figure 1 illustr ates how

an RFI suppression filter should be installed.

(1) Ensure that all equipment in the cubicle is well earthed using short, thick earthing cable connected to

a common star point or busbar. It is particularly important that any control equipment that is

connected to the inverter (such as a PLC) is connected to the same earth or star point as the inverter

via a short, thick link. Flat conductors (e.g. braids or metal brackets) are preferred as they have lower

impedance at high frequencies.

The return earth from motors controlled by the inverters should be connected directly to the earth

connection (PE) on the associated inverter.

(2) Wherever possible, use screened leads for connections to the control circuitry. Terminate the ends of

the cable neatly, ensuring that unscreened wires are as short as possible. Use cable glands

whenever possible.

(3) Separate the control cables from the power connections as much as possible, using separate

trunking, etc. If control and power cables cross, arrange the cables so that they cross at 90° if

possible.

(4) Ensure that contactors in the cubicle are suppressed, either with R-C suppressors for AC contactors

or ‘flywheel’ diodes for DC contactors, fitted to the coils. Varistor suppressors are also effective.

This is particularly important if the contactors are controlled from the relay on the inverter.

(5) Use screened or armoured cables for the motor connections and ground the screen at both ends via

the cable glands.

(6) If the drive is to be operated in an Electro-magnetic noise-sensitive environment, the RFI footprint

filter kit should be used to reduce the conducted and radiated interference from the inverter. For

optimum performance, there should be a good conductive bond between filter and metal mounting

plate.

On no account must safety r egulations be compromised when installing inverters!

G85139-H1750-U049-B

26/09/97

4

Siemens plc 199

Page 5

2. INSTALLATION English

2

7

MAINS POWER

Connect to Mains and

PE terminals on Inverter

CABLE

EARTH STUD

FILTER UNIT

Note: There must be a good

conductive bond between filter and

metal panel.

EARTH STUD

(under)

SCREENED

CABLE

When cable glands cannot be

used, terminate screen to metal

panel by removing cable sheath.

SCREENED

CABLE

CONTROL

CABLE

MOTOR

CABLE *

Figure 1: Example of an RFI Suppression Filter Installation

When attempting to meet specific EMC limits by using a filter,

the following points must be observed:

(1) All cables to and from the inverter (including control

cables) must be screened using suitable glands.

(2) The control cable must be kept separate from the motor

and mains cables.

* Note: Screen must be terminated

at the motor.

© Siemens plc 1997 G85139-H1750-U049-B

5

6/09/9

Page 6

English 2. INSTALLATION

©

7

k

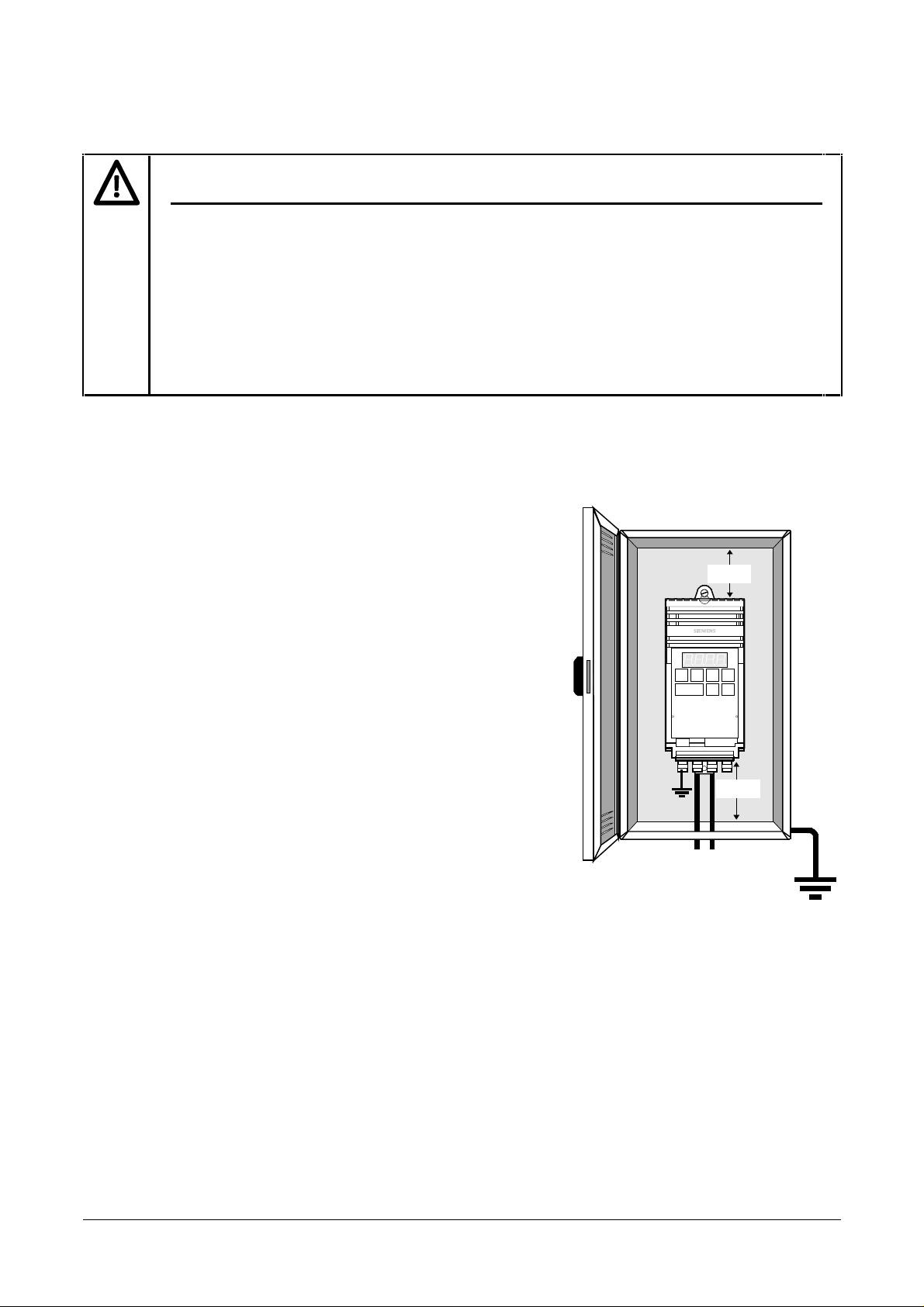

2.2 Mechanical Installation

WARNING

THIS EQUIPMENT MUST BE EARTHED.

To guarantee the safe operation of the equipment it must be installed and commissioned properly

by qualified personnel in compliance with the warni ngs laid dow n in these operati ng instructions.

Take particular note of the general and regional installation and safety regulations regarding wor

on dangerous voltage installations (e.g. VDE), as well as the relevant regulations regarding the

correct use of tools and personal protective gear.

The mains input and motor terminals can carry dangerous voltages even if the inverter is

inoperative. Use insulated screwdrivers only on these terminal blocks.

Environmental Requirements

Hazard Notes Ideal Installation

Temperature

Altitude

Shock

Vibration

Electro-Magnetic

Radiation

Atmospheric

Pollution

Water

Overheating

Min. = 0°C

Max. = 50°C

If the Inverter is to be installed at an altitude >

1000 m, derating will be required.(Refer to DA 64

Catalogue).

Do not drop the inverter or expose to sudden

shock.

Do not install the inverter in an area where it is

likely to be exposed to constant vibration.

Do not install the inverter near sources of

electro-magnetic radiation.

Do not install the inverter in an environment

which contains atmospheric pollutants such as

dust, corrosive gases, etc.

Take care to site the inverter away from potential

water hazards. e.g. Do not install the inverter

beneath pipes that are subject to condensation.

Ensure that the inverter’s air vents are not

obstructed.

Make sure that there is an adequate air-flow

through the cabinet, as follows:

1. Using the formula below, calculate the airflow

required.

Air-flow (m3 / hr) = (Dissipated Watts / ∆T) x 3.1

2. Install cabinet cooling fan(s) if necessary,

Note:

Typical dissipation (Watts) = 3% of inverter

rating.

∆T = Allowable temperature rise within cabinet

in °C.

3.1 = Specific heat of air at sea level.

100 mm

160 mm

G85139-H1750-U049-B

26/09/97

6

Siemens plc 199

Page 7

2. INSTALLATION English

2

7

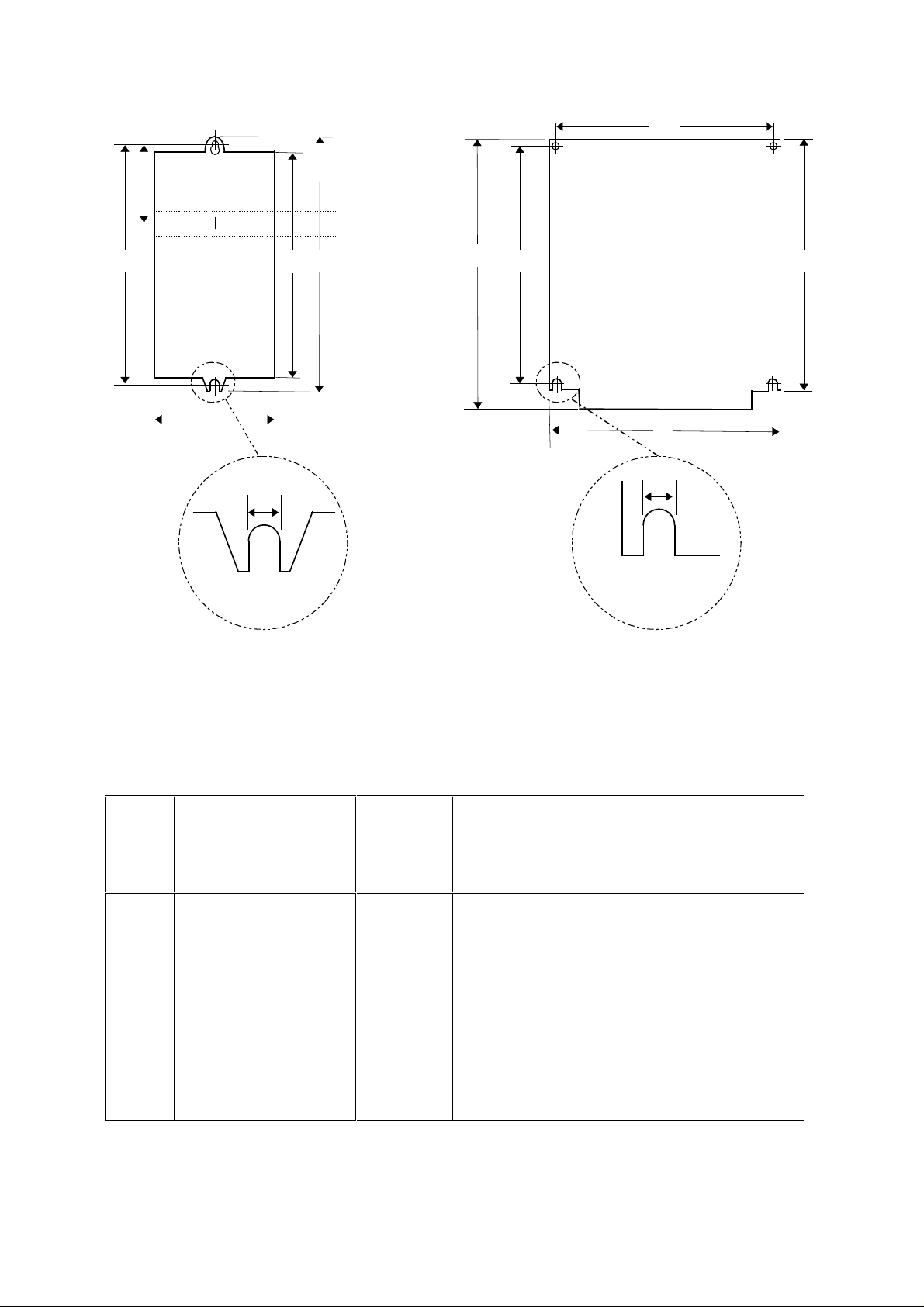

4 washers M4

4 washers M5

W1

F

DIN Rail

Depth D

W

∅ = 4.5 mm

2 bolts M4

2 washers M4

∅

2 nuts M4

H

H2H1

H2

Depth D

HH1

W

∅

Tightening Torque

(with washers fi tted)

2.5 Nm Frame size A and B

3.0 Nm Frame size C

∅ = 4.8 mm (B)

∅ = 5.6 mm (C)

Frame size B:

4 bolts M4

4 nuts M4

Frame size C:

4 bolts M5

4 nuts M5

Frame Size A Frame Sizes B and C

MMxxx

Model

1 AC 230 V

Class A

Filter

MM12

MM25

MM37

MM55

MM75

MM110

MM150

MM220

MM300

MM400

MM550

MM750

A

A

A

A

A

B

B

C

C

-

-

-

Figure 2: Mechanical Installation Diagram

MMxxx/2

1/3 AC 230 V

Without

Filter

A

A

A

A

A

B

B

C

C

C

-

-

MMxxx/3

3 AC 380 -

500 V

Without

Filter

-

A

A

A

A

A

B

B

C

C

C

Frame Sizes

(all measurements in mm)

H W D H1 H2 W1 F

A = 147 x 73 x 141 160 175 - 55

B = 184 x 149 x 172 174 184 138 -

C = 215 x 185 x 195 204 232 174 -

© Siemens plc 1997 G85139-H1750-U049-B

7

6/09/9

Page 8

English 2. INSTALLATION

©

7

Single/three phase 230 V

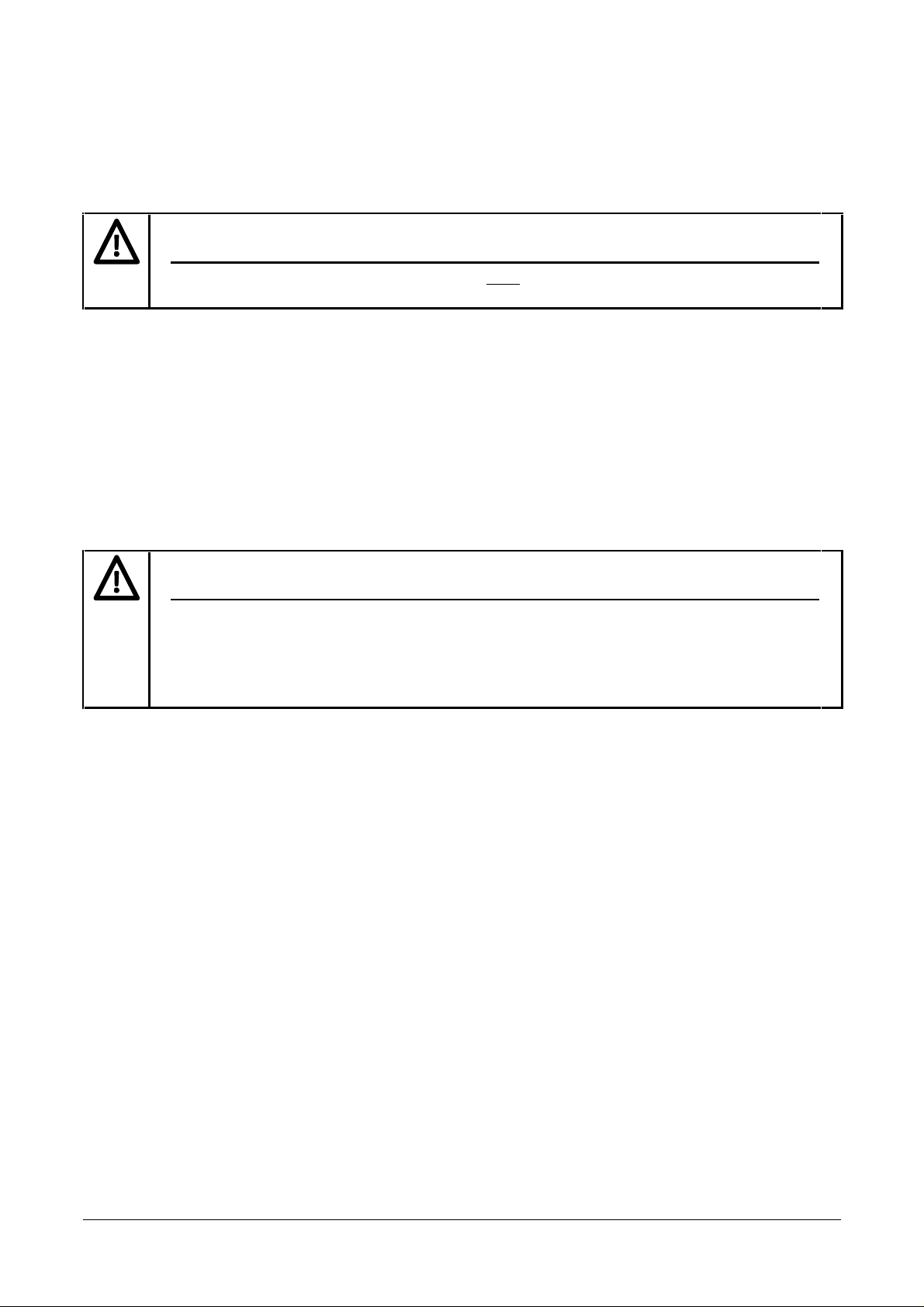

2.3 Electrical Installation

The electrical connectors on the MICROMASTER are shown in Figure 3. Connect the cables to the power

and control terminal blocks in accordance with the information supplied in sections 2.3.1 - 2.3.4. Ensure that

the leads are connected correctly and the equipment is properly earthed as shown in Figure 3.

CAUTION

The control, power supply and motor leads must be laid separately. They must not be fed

through the same cable conduit/trunking.

Use screened cable for the control lead. Use Class 1 60/75oC copper wire only (for UL compliance).

Tightening torque for the power (mains input and motor) terminals is 1.1 Nm.

To tighten up the power/motor terminal screws use a 4 - 5 mm cross-tip screwdriver.

2.3.1 Power and Motor Connections - Frame Size A

Ensure that the power source supplies the correct voltage and is designed for the necessary current

section 7)

between the power supply and inverter

Connect the power and motor connections as shown in Figure 3.

. Ensure that the appropriate circuit-breakers/fuses with the specified current rating are connected

(see section 7)

.

(see

WARNING

Isolate the supply before making or changing connections.

Ensure that the motor is configured for the correct supply voltage.

MICROMASTER S m ust not be connected to a 400 V thr ee phase supply.

When synchronous machines are connected or when coupling several motors in parallel, the

inverter must be operated with voltage/frequency control characteristic (P 077= 0 or 2).

G85139-H1750-U049-B

26/09/97

Siemens plc 199

8

Page 9

2. INSTALLATION English

2

7

FUSES

CONTACTOR

N

L

NL3L2

L1PEPEPEWWV

V

UUFUSES

TYPICAL INSTALLATION

CONTACTOR

FILTER

L3

L1

L2

L3

L2

L1PEPEPEWWVVU

U

Control

Terminals

PE

L/L1

N/L2

L3

Mains Input

Terminals

PE

U

V

W

Motor Term i nals

SINGLE PHASE

FILTER

(Class B only)

MICROMASTER

MICROMASTER

MOTOR

MOTOR

THREE PHASE

Figure 3: Power Connections

© Siemens plc 1997 G85139-H1750-U049-B

9

6/09/9

Page 10

English 2. INSTALLATION

©

7

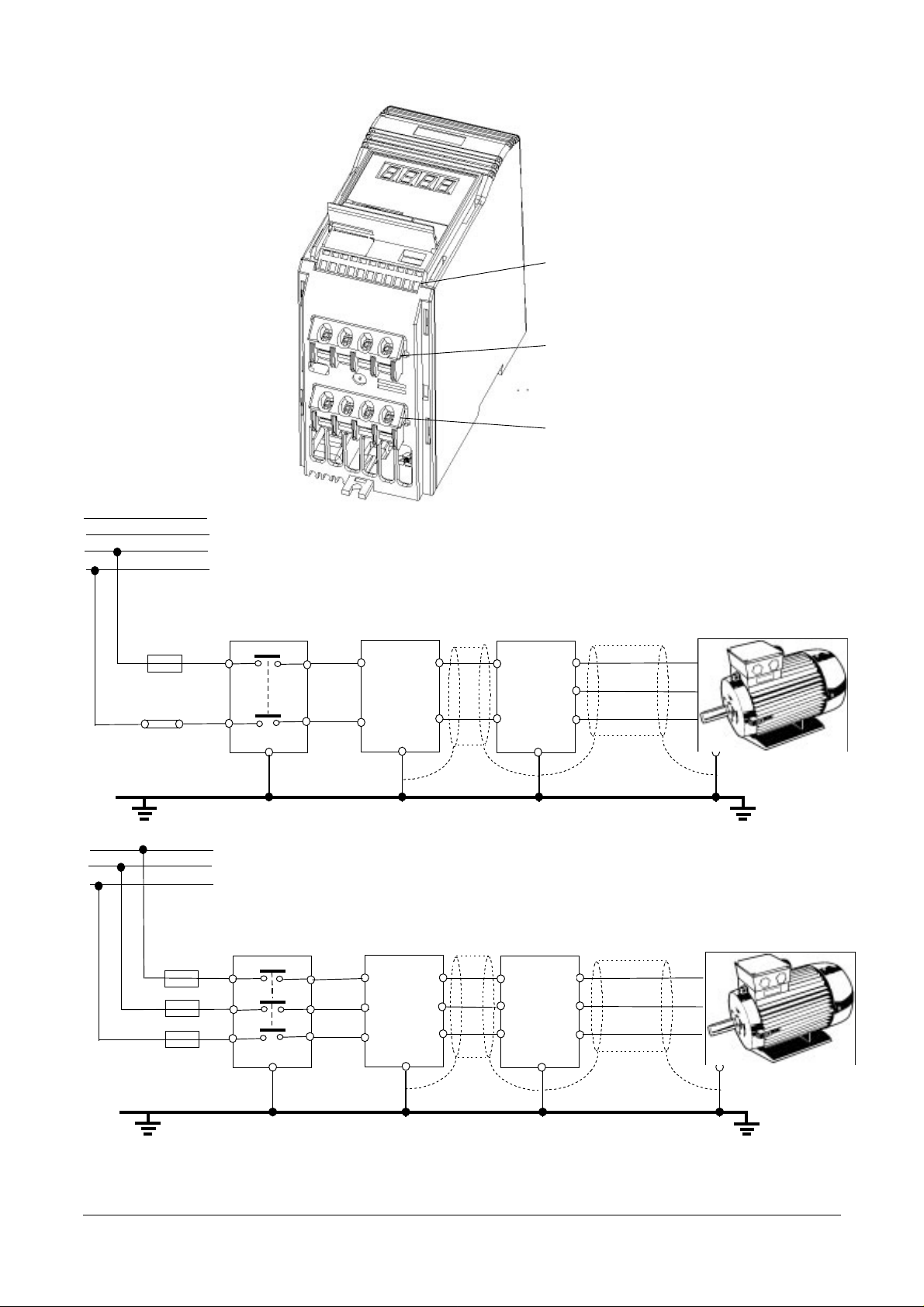

2.3.2 Power and Motor Connections - Frame Size B

The terminal arrangement for frame size B is identical to frame size A

wires can be connected to the terminal blocks, you must lower the terminal access panel and secure the

cables to the gland plate.

Refer to Figures 3 and 4. Proceed as follows:

1. Insert the blade of a small screwdriver into slot A on the side of the inverter and press in the direction of

the arrow. At the same time, apply finger pressure to clip B on the other side of the access panel and

press in the direction of the arrow.

This will release the access panel, which will then swing down on its rear-mounted hinges.

2. Remove the gland plate by applying pressure to release clips C and D in the direction of the arrows.

3. Secure each cable to the correct hole in the gland plate, ensuring that the exposed wires are long enough

to reach the terminal blocks.

4. Before refitting the gland plate, feed the control wires (if used) through hole 1 and the mains input and

motor wires through hole 2. IT IS MOST IMPORTANT THAT THE MOTOR AND CONTROL WIRES ARE

KEPT APART.

5. Refit the gland plate. Ensure that the release clips snap into position.

6. Connect the wires to the terminal blocks as shown in Figure 3. (See section 2.3.4 for information about

connecting the control wires.)

7. Close the terminal access panel.

(see Figure 3)

. However, before the

A

B

E

C

D

F

G

A & B: Terminal cover release tabs

C & D: Gl an d plate release tabs

E: Control cable inpu t (16. 2 mm d ia meter; accepts cables up to 10 mm diameter)

F: Mains cable input (22.8 mm diameter; accepts cables up to 14.5 mm diameter)

G: Motor cable input (22.8 mm diameter; accepts cables up to 14 .5 mm diameter)

Figure 4: Power Connections Access Diagram - Frame Size B

G85139-H1750-U049-B

26/09/97

10

Siemens plc 199

Page 11

2. INSTALLATION English

2

7

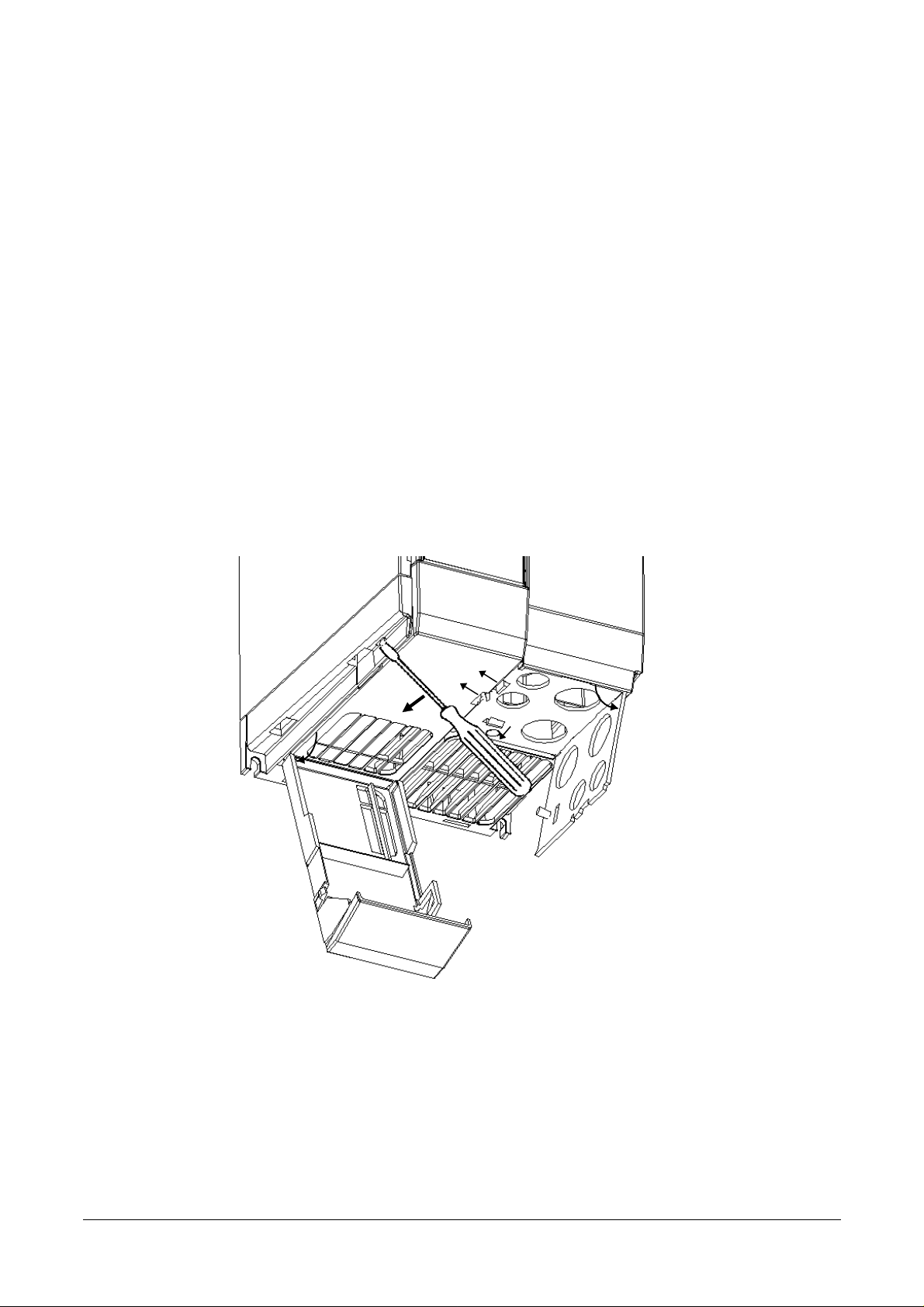

2.3.3 Power and Motor Connections - Frame Size C

The terminal arrangement for frame size C is identical to frame size A

wires can be connected to the terminal blocks, you must lower the fan housing and secure the cables to the

gland plate.

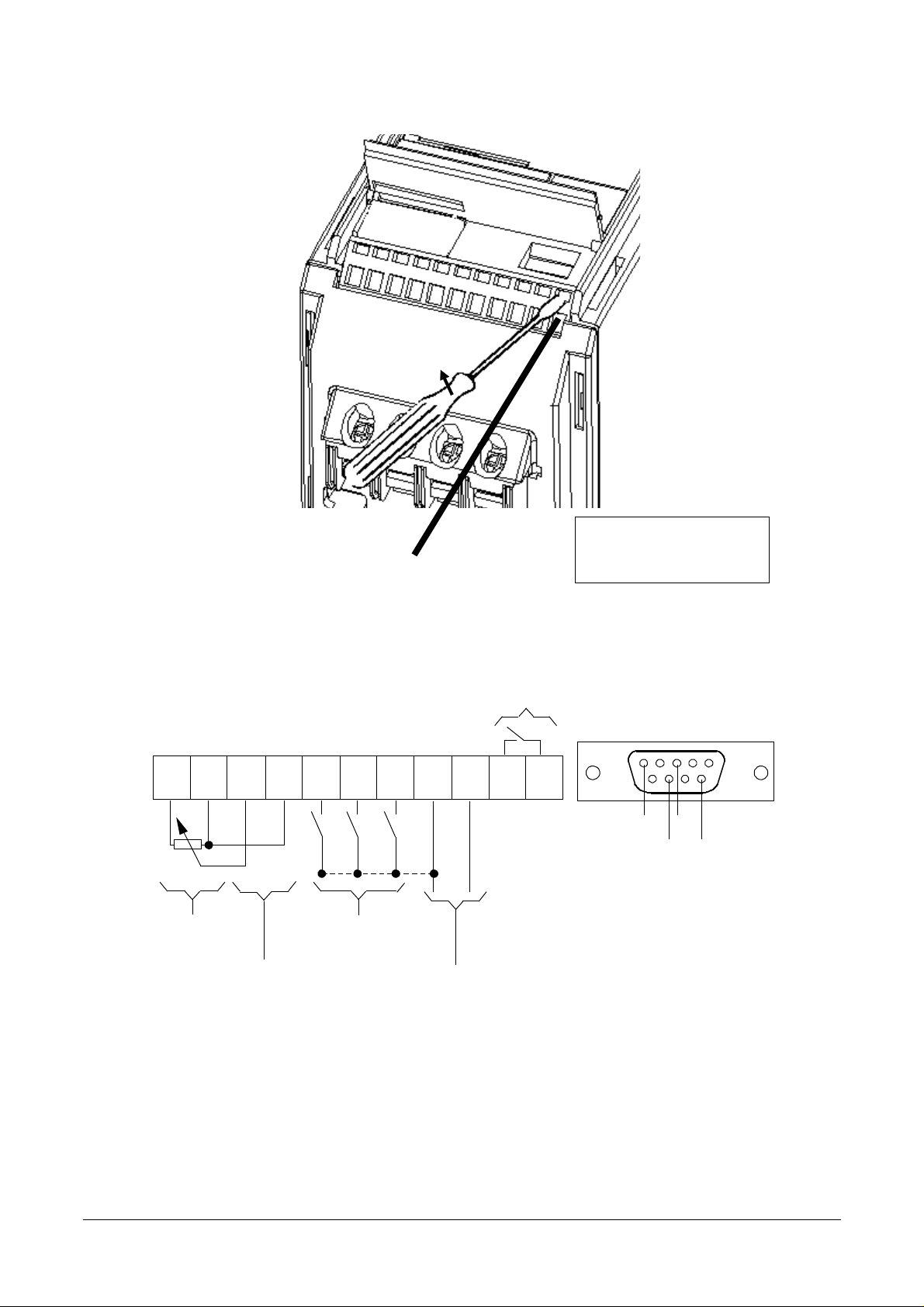

Refer to Figure 5 and proceed as follows:

1. While supporting the fan housing with one hand, insert the blade of a screwdriver into slot A on the

underside of the inverter and press upwards to release the securing tab. Lower the fan housing, allowing

it to swing out to the right on its side-mounted hinges.

2. Applying pressure to the gland plate release clips B and C in the direction of the arrows. Swing the plate

out to the left on its side-mounted hinges,

3. Secure each cable to the correct hole in the gland plate, ensuring that the exposed wires are long enough

to reach the terminal blocks.

4. Connect the wires to the terminal blocks as shown in Figure 3. (See section 2.3.4 for information about

connecting the control wires.) IT IS MOST IMPORTANT THAT THE MOTOR AND CONTROL WIRES

ARE KEPT APART.

5. Swing the gland plate back into the base of the inverter. Ensure that the release clips snap into position.

6. Swing the fan housing back into the base of the inverter.

(see Figure 3)

. However, before the

D

E

F

B

A

C

A: Fan housing release tab

B & C: Gland plate release tabs

D: Control cable input (16.2 mm diameter; accepts cables up to 10 mm diameter)

E: Mains cab le input (22.8 mm diameter; accepts cables up to 14.5 mm diameter)

F: Motor cable input (22.8 mm diameter; accepts cables up to 14.5 mm diameter)

Figure 5: Power Connections Access Diagram - Frame Size C

© Siemens plc 1997 G85139-H1750-U049-B

11

6/09/9

Page 12

English 2. INSTALLATION

©

7

1234856791011

P10+0VAIN+

AIN-

P15+

DIN1

DIN2

DIN3

0V

Insert small blade screwdriver

(max. 3.5 mm) as shown while

N-

0V

P+

615

9

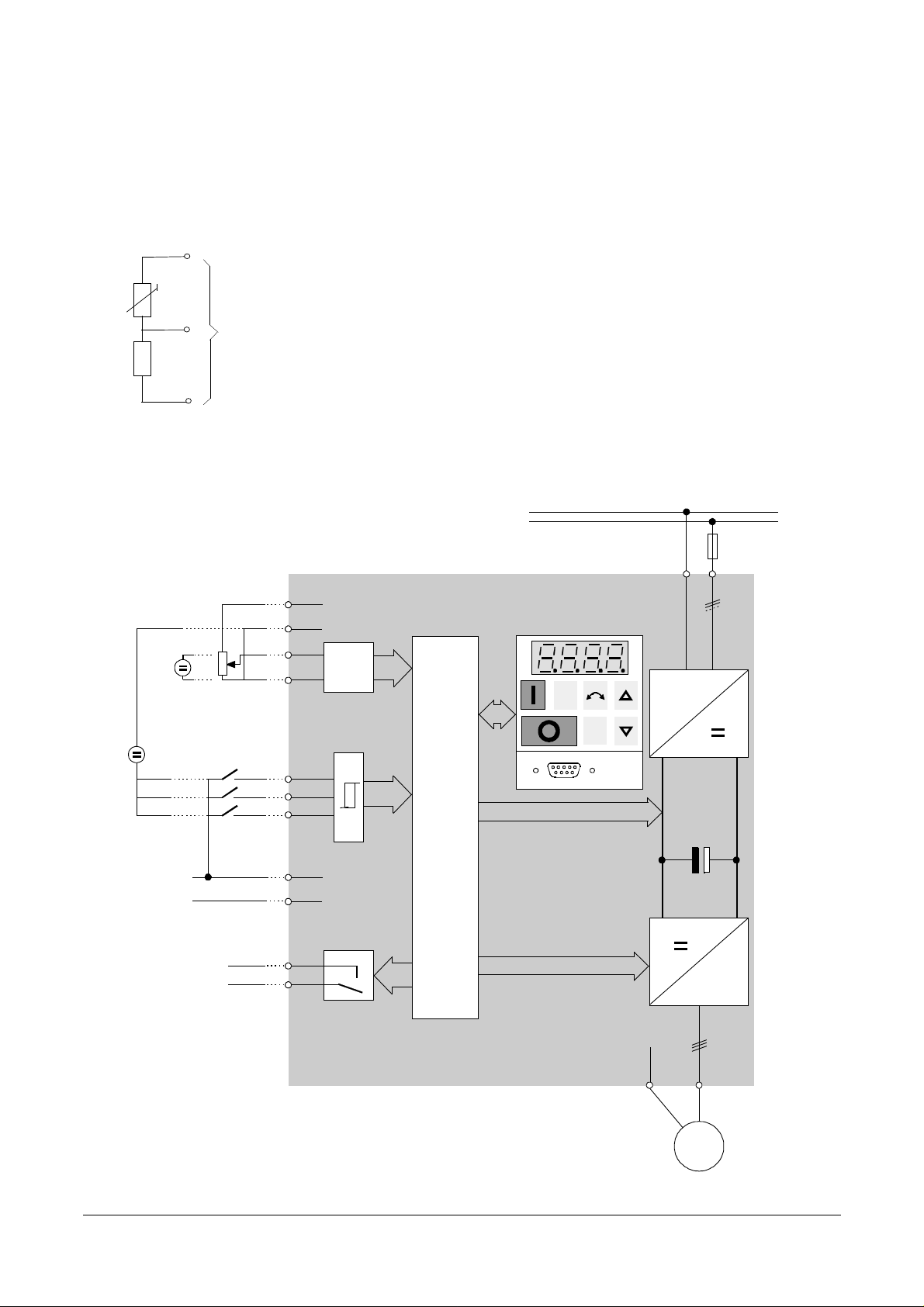

2.3.4 Control Connections

Power Supply

(+10 V, max. 10 mA)

Analogue Input

(input impedance = 70 kΩ)

(0/2 - 10 V)

Digital Inputs

(7.5 - 33 V, max. 5 mA)

max. 0. 4 A / 110 V AC

(resistive rating)

Power Supply

for

PI Feedback

Transducer or other

load

(+15 V, max. 50 mA)

Output Relay

(norm ally open)

1 A / 30 V DC

RL1B

RL1C

(NO)

(COM)

inserting cont rol wire from below.

5V

(max.250 mA)

Front Panel

RS485 D-type

Figure 6: Control Connections

G85139-H1750-U049-B

26/09/97

Control Terminal Block

Siemens plc 199

12

Page 13

2. INSTALLATION English

2

7

PTC

897

CPUADSI

+10V0V–+24 VORORV:0 - 10 V

AIN+

AIN-

DIN1

DIN2

DIN3PERL1

≥ 4.7 k

RL1B

RL1C8+15V

0V9Power Supply for

RS485

2.3.5 Motor Over load Protection

When operated below rated speed, the cooling effect of fans fitted to the motor shaft is reduced.

Consequentially, most motors require de-rating for continuous operation at low frequencies. To ensure that

motors are protected against overheating under these conditions, a PTC temperature sensor must be fitted to

the motor and connected to the inverter control terminals as shown in Figure 7.

Note: To enable the trip function, set parameter P051, P052 or P053 =19.

MOTOR

Inverter Contro l

Terminals

1kΩ

Figure 7: Motor Overload PTC Connection

2.3.6 Block Diagram

PE

2 - 10 V

PI Feedback

Transducer

or othe r load.

1/3 AC 230 V

3 AC 380 - 500 V

Ω

1

2

3

4

Jog

~

L/L1, N/L2

or

L/L1, N/L2, L3

P

5

6

7

10

11

3 ~

PE U, V, W

M

Figure 8: Block Diagram

© Siemens plc 1997 G85139-H1750-U049-B

13

6/09/9

Page 14

English 3. FRONT PANEL CONTROLS & BASIC OPERATION

©

7

Button

Button

Frequency

P

3. FRONT PANEL CONTROLS & BASIC OPERATION

3.1 Front Panel Controls

CAUTION

The digital frequency setpoint has been set at 5.00 Hz in the factory. This means that, it is not

necessary to enter a frequency setpoint via the ∆ button or parameter P005 in order to test

that the motor turns following a RUN command.

All settings must only be entered by qualified personnel, paying particular attention to the

safety precautions and warnings.

The parameter settings required can be entered using the three parameterisation buttons (P, ∆ and ∇) on the

front panel of the inverter. The parameter numbers and values are indicated on the four digit LED display.

LED Display

JOG

RUN

Button

STOP

RS485

Interface

Removable

Cover Strip

Jog

P

FORWARD / REVERSE

Button

UP / INCREASE

DOWN / DECREASE

Frequency

Parameterisation

Button

Pressing this button while the inverter is stopped causes it to start and run at the preset jog frequency. The

Jog

inverter stops as soon as the button is released. Pressing this button while the inverter is running has no

effect. Disabled if P123 = 0.

Press to start the inverter. Disabled if P121 = 0.

Press to stop the inverter.

LED Display

Displays frequency (default), parameter numbers or parameter values (when P is pressed) or fault codes.

Press to change the direction of rotation of the motor. REVERSE is indicated by a minus sign (values < 100)

or a flashing decimal point (values > 100). Disabled if P122 = 0

Press to INCREASE frequency. Used to change parameter numbers or values to higher settings during the

parameterisation procedure. Disabled if P124 = 0.

Press to DECREASE frequency. Used to change parameter numbers or values to lower settings during the

parameterisation procedure. Disabled if P124 = 0.

Press to access parameters. Disabled if P051 - P053 = 14 when using digital inputs.

Figure 9: Front Panel

G85139-H1750-U049-B

26/09/97

Siemens plc 199

14

Page 15

3. FRONT PANEL CONTROLS & BASIC OPERATION English

2

7

3 Mot

/380 V

3.2 Basic Operation

Refer to section 5 for a full description of each parameter.

3.2.1 General

(1) The inverter does not have a main power switch and is live when the mains supply is connected. It waits,

with the output disabled, until the RUN button is pressed or for the presence of a digital ON signal at

terminal 5 (rotate right) or terminal 6 (rotate left) -

(2) If output frequency is selected to be displayed (P001 = 0), the corresponding setpoint is displayed

approximately every 1.5 seconds while the inverter is stopped.

(3) The inverter is programmed at the factory for standard applications on Siemens four-pole standard

motors. When using other motors it is necessary to enter the specifications from the motor’s rating plate

into parameters P081 to P085

(see Figure 10)

unless P009 has been set to 002 or 003.

see parameters P051 - P053

.

. Note: Access to these parameters is not possible

P084

220

P081

cosϕ 0,81 cosϕ 0,81

VDE 0530 S.F. - 1,15

50 Hz

0,61/0,35 A

2745

P083 P082 P085

Figure 10: Typical Motor Rating Plate Example

Note: Ensure that the inverter is configured correctly to the motor, i.e. in the above example delta

terminal connection is for 220 V.

3.2.2 Initial Testing

(1) Check that all cables have been connected correctly

plant/location safety precautions have been complied with.

(2) Apply mains power to the inverter.

IEC 56

IM B3

/Y

∆

0,12

kW

/min

(section 2)

1LA5053-2AA20

Nr. E D510 3053

IP54 Rot. KL 16 I.Cl.F

60 Hz 440 V Y

0,34 A

0,14 kW

3310 /min

12 022

and that all relevant product and

(3) Ensure that it is safe to start the motor. Press the RUN button on the inverter. The display will change to 5.0

and the motor shaft will begin to turn. It will take one second for the inverter to ramp up to 5 Hz.

(4) Press the STOP button. The display will change to 0.0 and the motor slow to a complete stop within one

second.

© Siemens plc 1997 G85139-H1750-U049-B

15

6/09/9

Page 16

English 3. FRONT PANEL CONTROLS & BASIC OPERATION

©

7

3.2.3 Basic Operation - 10 Step Guide

The basic method of setting up the inverter for use is described below. This method uses a digital frequency

setpoint and requires only the minimum number of parameters to be changed from their default settings. It

assumes that a standard Siemens four-pole motor is connected to the inverter

motor type is being used)

Step /Action Button Display

1. Apply mains power to the inverter.

The display will alternate between the actual frequency (0.0 Hz) and the

requested frequency setpoint (5.0 Hz default).

2. Press the parameterisation button.

.

(see section 3.2.1 if a different

P

3. Press the ∆ button until parameter P005 is displayed.

4. Press P to display the current frequency setpoint (5 Hz is the factory

default setting).

P

5. Press the ∆ button to set the desired frequency setpoint

(e.g. 35 Hz).

6. Press P to lock the setting into memory.

7, Press the ∇ button to return to P000.

8. Press P to exit the parameterisation procedure.

The display will alternate between the current frequency and the requested

frequency setpoint.

9. Start the inverter by pressing the RUN button.

The motor shaft will start to turn and the display will show that the inverter

is ramping up to the setpoint of 35 Hz.

Note

The setpoint will be achieved after 7 seconds (35 Hz/50 Hz x 10 s *).

If required, the motor’s speed (i.e. frequency) can be varied directly by

using the ∆ ∇ buttons. (Set P011 to 001 to enable the new frequency

setting to be retained in memory during periods when the inverter is not

running.)

10. Switch the inverter off by pressing the STOP button.

The motor will slow down and come to a controlled stop (takes 7 s **).

P

P

* Default ramp-up time is 10 s to reach 50 Hz (defined by P002 and P013).

** Default ramp-down time is 10 s from 50 Hz (defined by P003 and P013).

G85139-H1750-U049-B

26/09/97

16

Siemens plc 199

Page 17

4. OPERATING MODES English

2

7

4. OPERATING MODES

4.1 Digital Cont rol

For a basic startup configuration using digital control, proceed as follows:

(1) Connect control terminal 5 to terminal 8 via a simple on/off switch. This sets up the motor for clockwise

rotation (default).

(2) Apply mains power to the inverter. Set parameter P009 to 002 or 003 to enable all parameters to be

adjusted.

(3) Check that parameter P006 is set to 000 to specify digital setpoint.

(4) Set parameter P007 to 000 to specify digital input (i.e. DIN1 (terminal 5) in this case) and disable the front

panel controls.

(5) Set parameter P005 to the desired frequency setpoint.

(6) Set parameters P081 to P085 in accordance with the rating plate on the motor

Note: In many cases, when default factory parameters are used, the default stator resistance set in

P089 will generally suit the default power rating set in P085. Should the inverter and motor

ratings differ greatly, it is recommended that the stator resistance of the motor is measured and

entered manually into P089. Continuous Boost (P078) and Starting Boost (P079) are dependent

on the value of Stator Resistance - too high a value may cause overcurrent trips

(7) Set the external on/off switch to ON. The inverter will now drive the motor at the frequency set by P005.

(see Figure 10)

.

4.2 Analogue Control

For a basic startup configuration using analogue voltage control, proceed as follows:

(1) Connect control terminal 5 to terminal 8 via a simple on/off switch. This sets up the motor for clockwise

rotation (default).

(2) Connect a 4.7 kΩ potentiometer to the control terminals as shown in Figure 6 or connect pin 2 (0V) to pin

4 and a 0 - 10 V signal between pin 2 (0V) and pin 3 (AIN+).

(3) Apply mains power to the inverter. Set parameter P009 to 002 or 003 to enable all parameters to be

adjusted.

(4) Set parameter P006 to 001 to specify analogue setpoint.

(5) Set parameter P007 to 000 to specify digital input (i.e. DIN1 (terminal 5) in this case) and disable the front

panel controls.

(6) Set parameters P021 and P022 to specify the minimum and maximum output frequency settings.

(7) Set parameters P081 to P085 in accordance with the rating plate on the motor

Note: In many cases, when default factory parameters are used, the default stator resistance set in

P089 will generally suit the default power rating set in P085. Should the inverter and motor

ratings differ greatly, it is recommended that the stator resistance of the motor is measured and

entered manually into P089. Continuous Boost (P078) and Starting Boost (P079) are dependent

on the value of Stator Resistance - too high a value may cause overcurrent trips

(8) Set the external on/off switch to ON. Turn the potentiometer (or adjust the analogue control voltage) until

the desired frequency is displayed on the inverter.

© Siemens plc 1997 G85139-H1750-U049-B

17

(see Figure 10).

6/09/9

Page 18

English 4. OPERATING MODES

©

7

4.3 Stopping the Motor

Stopping can be achieved in several ways:

• Cancelling the ON command or pressing the OFF button (O) on the front panel causes the inverter to

ramp down at the selected ramp down rate

• OFF2 - operation causes the motor to coast to a standstill

• OFF3 - operation causes rapid braking

• DC injection braking up to 250% causes a rapid stop

(see P003)

.

(see parameters P051 to P053)

(see parameters P051 to P053)

(see P073)

.

.

.

4.4 If the Motor Does Not Start Up

If the display shows a fault code, refer to Section 6.

If the motor does not start up when the ON command has been given, check that the ON command is valid,

check if a frequency setpoint has been entered in P005 and check that the motor specifications have been

entered correctly under parameters P081 to P085.

If the inverter is configured for operation via the front panel (P007 = 001) and the motor does not start when

the RUN button is pressed, check that P121 = 001 (RUN button enabled).

If the motor does not run after parameters have been changed accidentally, reset the inverter to the factory

default parameter values by setting parameter P944 to 001 and then pressing P.

4.5 Local and Remote Control

The inverter can be controlled either locally (default), or remotely via a USS data line connected to the RS485

D-type connector on the front panel. (Refer to parameter P910 in section 5 for the available remote control

options.)

When local control is used, the inverter can only be controlled via the front panel or the control terminals.

Control commands, setpoints or parameter changes received via the RS485 interface have no effect.

When operating via remote control the inverter will not accept control commands from the terminals.

Exception: OFF2 or OFF3 can be activated via parameters P051 to P053 (refer to parameters P051 to P053

in section 5).

Several inverters can be connected to an external control unit at the same time. The inverters can be

addressed individually.

For further information, refer to the following documents

E20125-B0001-S302-A1 Application of the USS Protocol in SIMOVERT Units 6SE21 and

MICROMASTER (German)

E20125-B0001-S302-A1-7600 Application of the USS Protocol in SIMOVERT Units 6SE21 and

MICROMASTER (English)

(available from your local Siemens office)

:

G85139-H1750-U049-B

26/09/97

18

Siemens plc 199

Page 19

4. OPERATING MODES English

2

7

P

4.6 Closed Loop Control

4.6.1 General Description

The MICROMASTER provides a PI control function for closed loop control

for temperature or pressure control, or other applications where the controlled variable changes slowly or

where transient errors are not critical. This control loop is not suitable for use in systems where fast response

times are required.

Note: The closed loop function is not designed for speed control, but can be used for this provided that fast

response times are not required.

When closed loop PI control is enabled (P201 = 002), all setpoints are calibrated between zero and 100%, i.e.

a setpoint of 50.0 = 50%. This allows general purpose control of any process variable that is actuated by

motor speed and for which a suitable transducer is available.

Setpoint

Low Pass

Filter

Scaling

+

P202

–

P206

P211, P212

(see Figure 11)

Acceleration/

Deceleration

Ramp

P002, P003

. PI control is ideal

Motor

M

Feedback

(e.g. duct pressure)

Process

e.g. fan

Feedback

Sample

Rate

I

P203, P207

Transducer

P208

P205

Closed Loop Mode Disabled

P201 = 000

Closed Loop Mode Enabl ed

P201 = 002

P210

Feedback

Monitor

Figure 11: Closed Loop Control

4.6.2 Hardware Setup

Connect the outputs from the external feedback transducer to control terminals 3 and 4. This analogue input

accepts a 0/2 - 10 V signal, has 10-bit resolution and permits a differential (floating) voltage. Ensure that the

values of parameters P023 and P024 are set to 000 and that P006 is set to 000 or 002.

15 V dc power for the feedback transducer can be supplied from terminals 8 and 9 on the control block.

4.6.3 Parameter Settings

Closed loop control cannot be used unless P201 is first set to 002. Most of the parameters associated with

closed loop control are shown in Figure 11. Other parameters which are also associated with closed loop

control are as follows:

P001 (value = 007)

P061 (value = 012 or 013)

P210

P220

Descriptions of all closed loop control parameters are provided in section 5. For further detailed information

about PI operation refer to the Siemens DA 64 Catalogue.

© Siemens plc 1997 G85139-H1750-U049-B

19

6/09/9

Page 20

English 5. SYSTEM PARAMETERS

©

7

5. SYSTEM PARAMETERS

Parameters can be changed and set using the membrane-type buttons to adjust the desired properties of the

inverter, such as ramp times, minimum and maximum frequencies etc. The parameter numbers selected and

the setting of the parameter values are indicated in the four digit LED display.

Note: If you press the ∆ or ∇ button momentarily, the values change step by step. If you keep the buttons

pressed for a longer time, the values scroll through rapidly.

Access to parameters is determined by the value set in P009. Check that the key parameters necessary for

your application have been programmed.

Note: In the following parameter table:

‘•’ Indicates parameters that can be changed during operation.

‘

’ Indicates that the value of this factory setting depends on the rating of the inverter.

To increase the resolution to 0.01 when changing frequency parameters, instead of pressing P momentarily

to return to the parameter display, keep the button pressed until the display changes to ‘- -.n0’ (n = the

current tenths value, e.g. if the parameter value = ‘055.8’ then n = 8). Press ∆ or ∇ to change the value (all

values between .00 and .99 are valid) and then press P twice to return to the parameter display.

If parameters are changed accidentally, all parameters can be reset to their default values by setting

parameter P944 to 1 and then pressing P.

G85139-H1750-U049-B

26/09/97

20

Siemens plc 199

Page 21

5. SYSTEM PARAMETERS English

2

7

Ramp up

Ramp down

Parameter Function Range

[Default]

P000

P001 •

Operating display - This displays the output selected in P001.

Display mode 0 - 8

[0]

P002 •

Ramp up time (seconds) 0 - 650.00

[10.00]

Description / Notes

In the event of a faul t, the relevant fault code (Fxxx) is displayed (see

section 6). In the event of a warning the display flashes. I f output

frequency has been selected (P001 = 0) and the inverter is OFF, the

display alternates between the selected frequency and the actual

frequency.

Display selection:

0 = Output frequency (Hz)

1 = Frequency setpoint (i.e. speed at whi ch inverter i s set t o run)

(Hz)

2 = Motor current (A)

3 = DC-link voltage (V)

4 = Not used

5 = Motor RPM

6 = USS status (see section 8.2)

7 = Closed loop control setpoint (% of full scale)

8 = Output voltage

This is the time taken for the motor to accelerate from standstill to the

maximum frequency as set in P013.

Setting the ram p up ti me t oo short can cause the in verter t o trip (f ault code

F002 - overcurrent).

Frequency

f

max

P003 •

Ramp down time (seconds) 0 - 650.00

[10.00]

0 Hz

time

(0 - 650 s)

Time

This is the time taken f or the mot or to decelerate f rom maxim um frequency

(P013) to standstill.

Setting the ram p down ti me t oo short can cause the in verter t o trip (f ault

code F001 - overvoltage).

This is also the period for which DC inj ecti on braking is applied (see P073)

Frequency

f

max

0 Hz

time

(0 - 650 s)

Time

© Siemens plc 1997 G85139-H1750-U049-B

21

6/09/9

Page 22

English 5. SYSTEM PARAMETERS

©

7

P004

= 5 s

P004

= 5 s

Parameter Function Range

[Default]

P004 •

Smoothing (seconds) 0 - 40.0

[0.0]

P005 •

Digital frequency setpoint (Hz) 0 - 400.00

[5.00]

Description / Notes

Used to smooth the acceleration/deceleration of t he m otor (useful in

applications where it is important to avoid ‘jerking’, e.g. conveyor

systems, t e xtiles, etc.).

Smoothing is only effective if the ramp up/down t i me exceeds 0.3 s.

Frequency

f

max

(P013)

0 Hz

P002 = 10 s

Time

Total acceleration time

= 15 s

Note: The smoot hing curve for decelerat ion is based on the ram p

up gradient (P002) and is added to the ramp down time set

by P003. Therefore, the ramp down ti m e is af fected by

changes to P002.

Sets the frequency that the inverter will run at when operated in digital

mode. Only effective if P006 set to ‘0’.

P006

P007

P009 •

Frequency setpoint source

selection

0 - 2

[0]

Keypad control 0 - 1

[1]

Parameter protection setting 0 - 3

[0]

Sets the control mode of the inverter.

0 = Digital. The inverter runs at t he frequency set in P005.

Alternatively, i f P007 is set t o zero, the frequency may be

controlled by setting any two of bi nary inputs P051 - P053 t o

values of 11 and 12.

1 = Analogue. Control via analogue input signal.

2 = Fixed frequency or motor potentiometer. Fixed frequency is

only selected if the value of at least one binary input (P051 P053) = 6, 17 or 18.

Notes: (1) If P006 = 1 and t he inverter is set up fo r remote

control operation, the anal ogue inputs remain active.

(2) Mot or potentiometer setpoints via digital inputs

are stored when P011 = 1.

0 = Front panel buttons disabled (except STOP, ∆ and ∇). Control is

via digital inputs (see parameters P051 - P053). ∆ and ∇ may still

be used to control frequency provided that P124 = 1 and a digital

input has not been selected to perform this functi on.

1 = Front panel buttons enabled (can be individually disabled

depending on the setting of parameters P121 - P124).

Note: The digital inputs for RUN, REVERSE, JOG and increase/

decrease frequency are disabled.

Determines which parameters can be adjusted:

0 = Only parameters from P001 to P009 can be read/set.

1 = Parameters from P001 to P009 can be set and all other

parameters can only be read.

2 = All parameters can be read/set but P009 automatically resets to 0

when power is removed.

3 = All parameters can be read/set.

G85139-H1750-U049-B

26/09/97

Siemens plc 199

22

Page 23

5. SYSTEM PARAMETERS English

2

7

Parameter Function Range

[Default]

P011

P012 •

P013 •

P014 •

P015 •

P016 •

Frequency setpoint memory 0 - 1

[0]

Minimum motor frequency (Hz) 0 - 400.00

[0.00]

Maximum motor frequency (Hz) 0 - 400.00

[50.00]

Skip frequency 1 (Hz) 0 - 400.00

[0.00]

Automatic restart after mains

failure.

Start on the fly 0 - 2

0 - 1

[0]

[0]

Description / Notes

0 = Disabled

1 = Enabled after switch-off. i.e. The setpoint alterations made with

the ∆ / ∇ buttons or digital inputs are stored even when power

has been removed from the inverter.

Sets the minimum motor frequency (must be less than the value of

P013).

Sets the maximum motor frequency.

A skip frequency can be set with this parameter to avoid the eff ect s of

mechanical resonance. Frequencies within +/-(value of P019) of this

setting are suppressed. Stationary operation is not possible within t he

suppressed frequency range - the range is just passed through.

Setting this parameter to ‘1’ enables the inverter to restart automatically

after a mains break or ‘brownout’, provided the run/stop switch is still

closed, P007 = 0 and P910 = 0, 2 or 4.

0 = Disabled

1 = Automatic restart

Allows the inverter to start onto a spinning mot or.

Under normal circumstances the inverter runs t he mot or up from 0 Hz.

However, if the motor is still spinning or is being driven by the load, it will

undergo braking before running back up to the setpoint - this can cause an

overcurrent trip. By using a f lying rest art, the in verter ‘hom es in’ on t he

motor's speed and runs it up from that speed to t he setpoint . Note: If the

motor has stopped or is rotat ing slowly, some ‘rocking’ may occur as the

inverter senses the direction of rot at ion prior t o restart ing. (See also P020)

0 = Normal restart

1 = Flying restart after power up, fault or OFF2 ( if P018 = 1).

2 = Flying restart every time (useful in circumstances where the

motor can be driven by the load).

P017 •

P018 •

P019 •

P020

P021 •

Smoothing type 1 - 2

[1]

Automatic restart after fault 0 - 1

[0]

Skip frequency bandwidth (Hz) 0 - 10.00

[2.00]

Flying start ramp time (seconds) 0.50 - 25.0

[5.0]

Minimum analogue frequency (Hz) 0 - 400.00

[0.00]

1 = Continuous smoothing (as defined by P004).

2 = Discontinuous smoothing. This provides a fast unsmoothed

response to STOP commands and requests to reduce frequency.

Note: P 004 m ust be set to a value > 0.0 for this parameter to have

any effect.

Automatic restart after fault:

0 = Disabled

1 = The inverter will attempt to restart up to 5 times after a fault. If

the fault is not cleared after t he 5th attempt, the invert er will

remain in the fault state until reset.

WARNING: While waiting to re-start, the display will flash. This

means that a start is pending and may happen at

any time. Fault codes can be observed in P930.

Frequencies set by P014, P027, P028 or P029 that are within +/- the

value of P019 are suppressed.

Used in conjunction with P016 (set longer times if persistent F002 trips

occur).

Frequency corresponding to the lowest analogue input value, i.e.

0 V or 2 V. This can be set to a higher value than P022 to give an

inverse relationship between analogue input and frequency output (see

diagram in P022).

© Siemens plc 1997 G85139-H1750-U049-B

23

6/09/9

Page 24

English 5. SYSTEM PARAMETERS

©

7

Parameter Function Range

[Default]

P022 •

P023 •

P024 •

Maximum analogue frequency

(Hz)

Analogue input function 0 - 2

Analogue setpoint addition 0 - 2

0 - 400.00

[50.00]

[0]

[0]

Description / Notes

Frequency corresponding to the highest analogue input value, i.e.

10 V, determined by P023. This can be set to a lower value t han P 021

to give an inverse relationship between analogue input and frequency

output.

i.e.

Note: The output frequency is limited by values entered for

0 = 0 V to 10 V

1 = 2 V to 10 V

2 = 2 V* to 10 V

If the inverter is not in analogue mode (P006 = 0 or 2), set ting this

parameter to ‘1’ causes the analogue input value to be added.

Note: By selecting a combination of reversed negative fixed

f

P021

P021

P012/P013.

* The inverter will come to a controlled stop if V < 1 V.

WARNING: The motor can automatically run without a

potentiometer or voltage source connected between

pins 3 and 4.

WARNING: With P023=2, the inverter will automatically start

when V goes above 1 V. This equally appl i es to

analogue and digital control (i.e. P 006 = 0 or 1).

0 = No addition.

1 = Addition of the analogue setpoint (defined by P023) t o the

fixed frequency or the motor potentiometer frequency.

2 = Scaling of digital/fixed setpoint by analogue input (P023) in

the range 0 - 100%.

frequency settings and analogue setpoint addition, it is

possible to configure the inverter for ‘centre zero’ operation

with a +/-5 V supply or a 0 - 10 V potentiomet er so t hat the

output frequency can be 0 Hz at any position, including the

centre position.

P022

P022

V

P027 •

P028 •

P029 •

P031 •

P032 •

G85139-H1750-U049-B

26/09/97

Skip frequency 2 (Hz) 0 - 400.00

[0.00]

Skip frequency 3 (Hz) 0 - 400.00

[0.00]

Skip frequency 4 (Hz) 0 - 400.00

[0.00]

Jog frequency right (Hz) 0 - 400.00

[5.00]

Jog frequency left (Hz) 0 - 400.00

[5.00]

See P014.

See P014.

See P014.

Jogging is used to advance the motor by small amounts. It is controlled

via the JOG button or with a non-latching switch on one of the digital

inputs (P051 to P053).

If jog right is enabled (DINn = 7), this parameter controls the f requency

at which the inverter will run when the switch is closed. Unlike other

setpoints, it can be set lower than the minim um frequency.

If jog left is enabled (DINn = 8), this parameter cont rols the frequency

at which the inverter will run when the switch is closed. Unlike other

setpoints, it can be set lower than the minim um frequency.

Siemens plc 199

24

Page 25

5. SYSTEM PARAMETERS English

2

7

Parameter Function Range

[Default]

P041 •

P042 •

P043 •

P044 •

P045

Fixed frequency 1 (Hz) 0 - 400.00

[5.00]

Fixed frequency 2 (Hz) 0 - 400.00

[10.00]

Fixed frequency 3 (Hz) 0 - 400.00

[15.00]

Fixed frequency 4 (Hz) 0 - 400.00

[20.00]

Inversion fixed setpoints for

fixed frequencies 1 - 4

0 - 7

[0]

Description / Notes

Valid if P006 = 2 and P053 = 6 or 18.

Valid if P006 = 2 and P052 = 6 or 18.

Valid if P006 = 2 and P051 = 6 or 18.

Valid if P006 = 2 and P051 = P052 = P053 = 17 .

Sets the direction of rotati on for the fixed frequency:

FF 1 FF 2 FF 3 FF4

P045 = 0 ⇒⇒⇒⇒

P045 = 1 ⇐⇒⇒⇒

P045 = 2 ⇒⇐⇒⇒

P045 = 3 ⇒⇒⇐⇒

P045 = 4 ⇒⇒⇒⇐

P045 = 5 ⇐⇐⇒⇒

P045 = 6 ⇐⇐⇐⇒

P045 = 7 ⇐⇐⇐⇐

⇒ Fixed setpoints not inverted.

⇐ Fixed setpoints inverted.

P046 •

P047 •

P048 •

P050

Fixed frequency 5 (Hz) 0 - 400.00

[25.00]

Fixed frequency 6 (Hz) 0 - 400.00

[30.00]

Fixed frequency 7(Hz) 0 - 400.00

[35.00]

Inversion fixed setpoints for

fixed frequencies 5 - 7

0 - 7

[0]

Valid if P006 = 2 and P051 = P052 = P053 = 17.

Valid if P006 = 2 and P051 = P052 = P053 = 17.

Valid if P006 = 2 and P051 = P052 = P053 = 17.

Sets the direction of rotati on for the fixed frequency:

FF 5 FF 6 FF 7

P050 = 0 ⇒⇒⇒

P050 = 1 ⇐⇒⇒

P050 = 2 ⇒⇐⇒

P050 = 3 ⇒⇒⇐

P050 = 4 ⇒⇒⇒

P050 = 5 ⇐⇐⇒

P050 = 6 or 7 ⇐⇐⇐

⇒ Fixed setpoints not inverted.

⇐ Fixed setpoints inverted.

© Siemens plc 1997 G85139-H1750-U049-B

25

6/09/9

Page 26

English 5. SYSTEM PARAMETERS

©

7

Parameter Function Range

[Default]

P051 Selection control function, DI N1 0 - 19

(terminal 5), fixed frequency 3 [1]

or binary fixed frequency bit 0.

P052 Selection control function, DI N2 0 - 19

(terminal 6), fixed frequency 2. [2]

or binary fixed frequency bit 1.

P053 Selection control function, DI N3 0 - 19

(terminal 7), fixed frequency 1

or binary fixed frequency bit 2. [6]

Description / Notes

Value

Function of P051 to P053

0

Input disabled

1

ON right

2

ON left

3

Reverse

4

OFF2 **

5

OFF3 **

6

Fixed frequencies 1 - 3

7

Jog right

8

Jog left

9

Remote operation

10

Fault code reset

11

Increase frequency *

12

Decrease frequency *

13

Disable analogue input

(setpoint is 0.0 Hz)

14

Disable the ability to change

parameters

15

Enable dc brake

16

Do not use

17

Binary fixed frequency control

(fixed frequencies 1 - 7)

18

As 6, but input high will also

request RUN *

19

External trip/PTC

Function,

low state

Off

Off

Normal

OFF2

OFF3

Off

Off

Off

Local

Off

Off

Off

Analogue on

enabled

Off

Off

Off

Yes (F012)

Function,

high state

On right

On left

Reverse

On

On

On

Jog right

Jog left

Remote

Reset on

rising edge

Increase

Decrease

Analogue

disabled

disabled

Brake on

On

On

No

P056

Digital input debounce time 0 - 2

[0]

* Only effective when P007 = 0.

** See section 4.3.

Binary Coded Fixed Frequency Mapping

(P051, P052, P053 = 17)

DIN3

(P053)

STOP 0 0 0

RUN to FF1 (P041) 0 0 1

RUN to FF2 (P042) 0 1 0

RUN to FF3 (P043) 0 1 1

RUN to FF4 (P044) 1 0 0

RUN to FF5 (P046) 1 0 1

RUN to FF6 (P047) 1 1 0

RUN to FF7 (P048) 1 1 1

0 = 12.5 ms

1 = 7.5 ms

2 = 2.5 ms

DIN2

(P052)

DIN1

(P051)

G85139-H1750-U049-B

26/09/97

26

Siemens plc 199

Page 27

5. SYSTEM PARAMETERS English

2

7

t

A

t

A

f

B

t

B = Brake removed

Parameter Function Range

[Default]

P061

P062

P063

P064

Selection relay output RL1 0 - 13

[6]

Electro-mechanical brake option

control

External brake release delay

(seconds)

External brake stopping time

(seconds)

0 - 4

[0]

0 - 20.0

[1.0]

0 - 20.0

[1.0]

Description / Notes

Value Relay function Active

0 No function assigned (relay not active) Low

1 Inverter is running High

2 Inverter frequency 0.0 Hz Low

3 Motor run right has been selected High

4 External brake on (see parameters P063/P 064) Low

5 Inverter frequency less than or equal to minimum

frequency

6 Fault indication

7 Inverter frequency greater than or equal t o set point High

8 Warning active

9 Output current greater t han or equal to P065 High

10 Motor current limit (warning)

11 Motor over temperature (warning)

1

2

2

2

Low

Low

Low

Low

Low

12 Closed loop motor LOW speed limit High

13 Closed loop motor HIGH speed limit High

1

Inverter switches off (see parameter P930 and section 6).

2

Inverter does not switch off (see paramet er P931).

3

‘Active low’ = relay OPEN. ‘Active high’ = relay CLOSED.

This operates in the same manner as the external brake control

(described in P063/P064), except that the relay is not acti vat ed.

0 = Normal stop mode

1 - 3 = Do not use

4 = Combination stop mode

Only effective if t he relay output is set t o control an ext ernal brake (P061 =

4). In this case when the inverter is switched on, it will run at the minimum

frequency for the time set by t his paramet er before releasi ng the brake

control relay and ramping up (see illustrat ion in P064).

As P063, only effective if the relay output is set t o control an external

brake. This defines the period for which the inverter continues to run at

the minimum frequency after ramping down and while t he ext ernal

brake is applied.

3

ON OFF

f

P063

A = Brake applied

P064

Notes: (1) Settings for P063 and P064 should be slightly longer

than the actual time taken for the external brake to

apply and release respectively.

(2) Setting P063 or P064 to t oo high a value, especially

with P012 set to a high value, can cause an

overcurrent warning or trip as the inverter attempts to

move a locked motor shaft.

P065

Current threshold for relay (A ) 0 - 99.9

[1.0]

This parameter is used when P061 = 9. The relay switches on when

the motor current is greater than the value of P065 and switches off

when the current falls to 90% of the value of P065 (hysteresis).

© Siemens plc 1997 G85139-H1750-U049-B

27

6/09/9

Page 28

English 5. SYSTEM PARAMETERS

©

7

Parameter Function Range

[Default]

P066

P073 •

P074 •

P076 •

Compound braking 0 - 1

[1]

DC injection braking (%) 0 - 250

[0]

I2t motor derating 0 - 1

[1]

Pulse frequency 0 - 7

[0 or 4]

Description / Notes

0 = Off

1 = On. Permits faster ramp-down times and enhances stopping

capability.

This stops the motor by applying a DC current. This causes heat to be

generated in the motor rather than t he invert er and holds t he shaf t

stationary until the end of the braking period. Braking is effective for the

period of time set by P003.

The DC brake can be activated using DIN1 - DIN3 (braking is active for

as long as the DIN is high - see P051 - P053).

WARNING: Frequent use of long periods of dc inj ection braking

can cause the motor to overheat.

If DC injection braking is enabled via a digital i nput

then DC current is applied for as long as the digital

input is high. This causes heat in the motor.

0 = Disabled

1 = Enabled. Causes an F074 trip if the motor exceeds the I2t calculation.

The time taken to tri p is dependent on t he dif ference between t he

overload current and the nominal mot or current rating st ored in P 083 typically a 150% overload will result in a switch-off in 1 - 2 minutes.

WARNING: Where motor thermal pro tectio n is requ ired , an external

PTC must be used.

Sets the pulse frequency (from 2 to 16 kHz) and the PWM mode. I f

silent operation is not absolutely necessary, the losses in the inverter

as well as the RFI emissions can be reduced by selecting lower pulse

frequencies.

0/1 = 16 kHz (230 V default)

2/3 =8 kHz

4/5 = 4 kHz (400 V default)

6/7 =2 kHz

Note: When P 076 = 0/1, the display of the current at frequencies

below 10 Hz is less accurate.

400V inverters require the continuous current rating reduced for

operation below 5Hz, when operating at switching frequencies greater

than 4kHz and with boost values greater than 100% (P078 + P079).

These are typically as follows:

Model P076 =

0 or 12 or 3

MM37/3- MM750/3 50%xP083 80%xP083

G85139-H1750-U049-B

26/09/97

28

Siemens plc 199

Page 29

5. SYSTEM PARAMETERS English

2

7

0 - 400.00

0 - 9999

0.1 - 99.9

0 - 100.0

max

Parameter Function Range

[Default]

P077

P078 •

P079 •

P081

P082

P083

P084

P085

P089 •

Control mode 0 - 2

[1]

Continuous boost (%) 0 - 250

[100]

Starting boost (%) 0 - 250

[0]

Nominal frequency for motor (Hz)

Nominal speed for motor (RPM)

Nominal current for motor (A)

Nominal voltage for motor (V)

Nominal power for motor (kW/hp)

Stator resistance (Ω)

[50.00]

[

[

0 - 1000

[

[

0.01-100.00

[

Description / Notes

Controls the relationship between the speed of the m otor and the

voltage supplied by the inverter. One of two modes can be selected:

0/1 = Linear voltage/frequency

Use this curve for synchronous motors or motors

connected in parallel.

2 = Quadratic voltage/frequency relationship

This is suitable for centrifugal pumps and fans.

V

N

V

VN (P084)

0/1

2

f

(P081)

N

Operates continuously over the whole frequency range.

For many applications it is necessary to increase low frequency torque.

This parameter sets the start-up voltage at 0 Hz to adjust the available

torque for low frequency operation. 100% setting will produce rated

motor current at low frequencies.

WARNING: If P078 is set too high, o verh eating of the motor

and/or an overcurrent trip (F002) can occur.

For drives which require a high initial starting torque, it is possible to

set an additional current (added to the setti ng in P078) during ramping.

This is only effective during initial start up and until the frequency

setpoint is reached.

Note: This increase is in addition to P078.

]

These parameters must be set for the motor used.

Read the specifications on the motor’s rating plate (see Figure 10 in

]

section 3.2.1).

Note: The inverter’s default setting vary according to the power rating.

]

]

The stator resistance of the motor should be entered in t his parameter.

]

The value entered should be the resistance between any two phases

with the motor connected. The m easurement should be made at the

inverter output terminals with power off.

Note: I f the value of P089 is too high then an overcurrent trip

(F002) may occur.

f

P091 •

© Siemens plc 1997 G85139-H1750-U049-B

Serial link slave address 0 - 30

[0]

Up to 31 inverters can be connected via the serial link and controlled

by a computer or PLC using the USS protocol. This paramet er sets a

unique address for the inverter.

29

6/09/9

Page 30

English 5. SYSTEM PARAMETERS

©

7

Parameter Function Range

[Default]

P092 •

P093 •

P094 •

P095 •

P099 •

P101 •

P111

P112

P113

Serial link baud rate 3 - 7

[6]

Serial link timeout (seconds) 0 - 240

[0]

Serial lin k n o minal system se tpoint

(Hz)

USS compatibility 0 - 2

Option module type 0 - 1

Operation for Europe or USA 0 - 1

Inverter power rating (kW/hp) 0.0 - 50.00

Inverter type (model) 1 - 7

Inverter type (power rating) 0 - 29

0 - 400.00

[50.00]

[0]

[0]

[0]

[

[

[

Description / Notes

Sets the baud rate of the RS 485 serial int erface (USS protocol):

3 = 1200 baud

4 = 2400 baud

5 = 4800 baud

6 = 9600 baud

7 = 19200 baud

Note: S o m e RS232 to RS485 converters are not capable of

baud rates higher than 4800.

This is the maximum permissible period between two incoming data

telegrams. This feature is used to turn off the inverter in the event of a

communications failure.

Timing starts after a valid data telegram has been received and if a

further data telegram is not received within the specified time period,

the inverter will trip and display fault code F008.

Setting the value to zero switches off the control.

Setpoints are transmitted t o the inverter via the serial link as

percentages. The value entered in this parameter represents 100%

(HSW = 4000H).

0 = Compatible with 0.1 Hz resolution

1 = Enable 0.01 Hz resolution

2 = HSW is not scaled but represents the actual frequency value to

a resolution of 0.01 Hz (e.g. 5000 = 50 Hz).

0 = Option module not present

1 = PROFIBUS module (enables parameters relating to P ROFI BUS)

This sets the inverter for European or USA supply and motor

frequency:

0 = Europe (50 Hz)

1 = USA (60 Hz)

Note: A fter setting P101 = 1 the inverter m ust be re-set to factory

defaults. i.e. P944 = 1 to aut om atically set P013 = 60 Hz,

P081 = 60 Hz, P082 = 1680 rpm and P085 will be displayed

in hp.

Read-only parameter that indicates the power rating of the inverter in

]

kW. e.g. 0.55 = 550 W

Note: I f P101 = 1 then the rating is displayed in hp.

Read-only parameter.

]

1 = MICROMASTER series 2 (MM2)

2 = COMBIMASTER

3 = MIDIMASTER

4 = MICROMASTER Junior (MMJ)

5 = MICROMASTER series 3 (MM3)

6 = MICROMASTER Vector (MMV)

7 = MIDIMASTER Vector (MDV)

Read-only parameter.

0 = MM12

]

1 = MM25

2 = MM37

3 = MM55

4 = MM75

5 = MM110

6 = MM150

7 = MM220

8 = MM300

10 =MM12/2

11 =MM25/2

12 =MM37/2

13 =MM55/2

14 =MM75/2

15 =MM110/2

16 =MM150/2

17 =MM220/2

18 =MM300/2

19 =MM400/2

20 =MM37/3

21 =MM55/3

22 =MM75/3

23 =MM110/3

24 =MM150/3

25 =MM220/3

26 =MM300/3

27 =MM400/3

28 =MM550/3

29 =MM750/3

G85139-H1750-U049-B

26/09/97

30

Siemens plc 199

Page 31

5. SYSTEM PARAMETERS English

2

7

Parameter Function Range

[Default]

P121

P122

P123

P124

P125

P131

P132

P134

P135

P137

P140

P141

P142

P143

P201

P202 •

P203 •

P205 •

P206 •

P207 •

P208

Enable/disable RUN button 0 - 1

[1]

Enable/disable

FORWARD/REVERSE button

Enable/disable JOG button 0 - 1

Enable/disable ∆ and ∇ buttons

Reverse direction inhibit 0 - 1

Frequency setpoint (Hz) 0.00-400.00

Motor current (A) 0.0 - 99.9

DC link voltage (V) 0 - 1000

Motor RPM 0 - 9999

Output voltage (V) 0 - 1000

Most recent fault code 0 - 9999

Most recent fault code -1 0 - 9999

Most recent fault code -2 0 - 9999

Most recent fault code -3 0 - 9999

Closed loop mode 0 - 2

P gain (%) 0.0 - 999.9

I gain (%) 0.00 - 99.99

Sample interval (x 25 ms) 1 - 2400

Transducer filtering 0 - 255

Integral capture range (%) 0 - 100

Transducer type 0 - 1

0 - 1

[1]

[1]

0 - 1

[1]

[1]

[-]

[-]

[-]

[-]

[-]

[-]

[-]

[-]

[-]

[0]

[1.0]

[0.00]

[1]

[0]

[100]

[0]

Description / Notes

0 = RUN button disabled.

1 = RUN button enabled (only possible if P007 = 1).

0 = FORWARD/REVERSE button disabled.

1 = FORWARD/REVERSE button enabled (onl y possible if P 007 = 1).

0 = JOG button disabled.

1 = JOG button enabled (only possible if P007 = 1).

0 = ∆ and ∇ buttons disabled.

1 = ∆ and ∇ buttons enabled (only possible if P007 = 1).

Note: This applies for frequency adjustment only. The buttons can

still be used to change parameter values.

0 = Reverse direction disabled. Inhibits reverse commands from ALL

sources (reverse RUN commands result in forward rotation)

1 = Normal operation (FORWARD/REVERSE operation allowed)

Read-only parameters. These are copies of the values stored in

P001 but can be accessed directly via the serial link.

The last recorded fault code (see section 6) is stored in this parameter.

This is a copy of the code stored in P930.

This parameter stores the last recorded fault code prior to that st ored

in P140/P930.

This parameter stores the last recorded fault code prior to that st ored

in P141.

This parameter stores the last recorded fault code prior to that st ored

in P142.

0 = Normal operation (closed loop control disabled).

1 = Not used.

2 = Closed loop control using analogue input for transducer feedback

input.

Proportional gain.

Integral gain.

0.01% corresponds to the longest integral action ti m e.

Sampling interval of feedback sensor.

0 = Filter off.

1 - 255 = Low pass filtering applied to sensor.

Percentage error above which integral term is reset to zero.

0 = An increase in motor speed causes an increase in sensor

voltage/current output.

1 = An increase in motor speed causes a decrease in sensor

voltage/current output.

© Siemens plc 1997 G85139-H1750-U049-B

31

6/09/9

Page 32

English 5. SYSTEM PARAMETERS

©

7

Parameter Function Range

[Default]

P210

P211 •

P212 •

P220

Transducer reading (%) 0.0 - 100.0

[-]

0% setpoint 0.00-100.00

[0.00]

100% setpoint 0.00-100.00

[100.00]

PI frequency cut-off

0 - 1

[0]

P700

P701 •

P702

P880

P910 •

Local/Remote mode 0 - 4

[0]

P918 •

P922

P923 •

Software version 0.00 - 99.99

[-]

Equipment system numbe r 0 - 255

[0]

P927 •

P928 •

P930

Most recent fault code 0 - 9999

[-]

Description / Notes

Read only. Value is a percentage of full scale of the selected input.

Value of P210 to be maintained f or 0% setpoint.

Value of P210 to be maintained f or 100% setpoint.

0 = Normal operation

1 = Switch off inverter output at or below minimum frequency.

Specific to PROFIBUS-DP . See PROFIBUS Handbook for furt her

details.

Access only possible with P099 = 1

Sets the inverter for local control or remote control over the serial link:

0 = Local control

1 = Remote control (and setting of parameter values)

2 = Local control (but remote control of frequency)

3 = Remote control (but local control of frequency)

4 = Local control (but remote read and write access to

parameters and facility to reset trips)

Note: When operat ing the inverter via remote control (P910 = 1

or 3), the analogue input remains active when P006 = 1

and is added to the setpoint.

Specific to PROFIBUS-DP . See PROFIBUS Handbook for furt her

details. Access only possible with P099 = 1

Contains the software version number and cannot be changed.

You can use this parameter to allocate a unique reference number to

the inverter. It has no operational effect.

Specific to PROFIBUS-DP . See PROFIBUS Handbook for furt her

details

.

Access only possible with P099 = 1

The last recorded fault code (see section 6) is stored in this parameter.

This parameter can be cleared using the ∆ and ∇ buttons.

P931

P944

G85139-H1750-U049-B

26/09/97

Most recent warning type 0 - 9999

[-]

Reset to factory default setti ngs 0 - 1

[0]

The last recorded warning is stored in this parameter until power is

removed from the inverter:

002 = Current limit active

003 = Voltage limit active

005 = Inverter over-temperature (Internal PTC)

Set to ‘1’ and then press P to reset all param eters except P101 to the

factory default settings.

Siemens plc 199

32

Page 33

5. SYSTEM PARAMETERS English

2

7

Parameter Function Range

[Default]

P947

P958

P963

P967

P968

P970

P971 •

EEPROM storage control 0 - 1

[1]

Description / Notes

Specific to PROFIBUS-DP . See PROFIBUS Handbook for furt her

details.

Access only possible with P099 = 1

0 = Changes to parameter settings (including P971) are lost when

power is removed.

1 = Changes to parameter settings are retained during periods

when power is removed.

WARNING: When using the serial link to update the parameter

set held in EEPROM, care must be taken not to

exceed the maximum number of wri te cycl es to thi s

EEPROM - this is approximately 50,000 write cycles.

Exceeding this number of write cycles would result

in corruption of the stored data and subsequent

data loss. The number of read cycles are unlimited.

© Siemens plc 1997 G85139-H1750-U049-B

33

6/09/9

Page 34

English 6. FAULT CODES

©

7

6. FAULT CODES

In the event of a failure, the inverter switches off and a fault code appears on the display. The last fault that

occurred is stored in parameter P930. e.g. ‘0003’ indicates that the last error was F003.

Fault Code Cause Corrective Action

F001

F002

F003

F005

F008

F010

F011

F012

F013

F018

F030

F031

F033

F036

F074

F106

F112

F151 - F153

F188

F201

F212

Overvoltage Check whether supply voltage is within the limits indicated on the rating plate.

Increase the ramp down time (P003).

Check whether the required braking power is within the specified limits.

Overcurrent Check whether the motor power corresponds to the inverter power.

Check that the cable length limits have not been exceeded.

Check motor lead and motor for short-circuits and earth faults.

Check whether the motor parameters (P081 - P 086) correspond wit h the

motor being used.

Check the stator resistance (P089).

Increase the ramp-up time (P002).

Reduce the boost set in P078 and P079.

Check whether the motor is obstructed or overloaded.

Overload Check whether the motor is overloaded.

Increase the maximum motor frequency if a motor with high slip is used.

Inverter overtemperature

(internal PTC)

USS protocol timeout Check the serial interface.

Initialisation fault / P aram eter loss * Check the entire parameter set. Set P009 to ‘0000’ before power down.

Internal interface fault * Switch off power and switch on again.

External trip (PTC) Check if motor is overloaded.

Programme fault * Switch off power and switch on again.

Auto-restart aft er fault. Automatic re-start af ter fault (P018) is pending.

PROFIBUS link failure Check the integrity of the link.

Option module to link failure Check the integrity of t he link.

PROFIBUS configuration error Check the PROFIBUS configurat ion.

PROFIBUS module watchdog trip Replace PROFIBUS module

Motor overtemperature by I2t

calculation

Parameter fault P006 Parameterise fixed frequency(ies) and/or motor potentiom eter on the digital

Parameter fault P012/ P013 Set param eter P012 < P013.

Digital input parameter fault Check the settings of digital inputs P051 to P 053.

Automatic calibration failure Motor not connected to inverter - connect motor.

P006 = 1 while P201 = 2 Change paramet er P006 and/or P201.

Parameter fault P211/ P212 Set param eter P211 < P212.

Check that the ambient temperature is not too high.