Page 1

SINAMICS GXE

Configured enclosed drive for industry

Technical documentation /

Overview of SINAMICS G120XE

The SINAMICS G120XE is an enclosed drive designed specifically for pumps, fans

and compressors. This rugged drive is based upon the SINAMICS G120X to best

meet the demands of pump, fan and compressor applications, the environment

and the power supply system.

A comprehensive range of pre-designed standard options completes the package.

Additionally, please consult the factory for any custom options that may be needed.

SINAMICS G120XE drives are UL listed to UL508A

usa.siemens.com/sinamics-gxe

Page 2

Depending upon power ratings, the drive enclosure is either a wall-mounted box or a freestanding enclosure. The most common standard options can be accommodated in the base

enclosure. A few options including output filters and reduced voltage soft start (RVSS) bypass

require an add-on or separate options enclosure.

Attention to detail is evident in the design of the drive. For example, the enclosure ventilation

fans are controlled via a relay to run only when needed, i.e. when the drive is running. Not

only does this save energy costs, but it also reduces noise levels in the electrical room.

UL listing

SINAMICS G120XE is an enclosed drive listed to UL508A.

Operator interface

The door-mounted Intelligent Operator Panel IOP-2 is a high resolution color keypad that is

user-friendly and a powerful operator panel. The IOP-2 allow fast local setup, fault diagnostics

and intuitive operation of the G120X and simplifies the adjustment of settings during operation.

It features an intuitive central multi-functional sensor control wheel.

For pump, fan and compressor applications, the IOP-2 application wizards interactively guide

you without the need to know parameter numbers.

Auto / manual control is done using the membrane keyboard and the central sensor control

field and there is a dedicated local / remote button.

SINAMICS IOP-2

14 interface languages available

Process values can be displayed numerically in technological units. Up to two process values

can be displayed graphically as bar graphs. The IOP-2 also allows graphical trending of values.

Motor and drive sizing

The Service Factor must be considered for motors operating at Service Factors beyond 1.0.

Please consult factory for assistance in sizing the drive.

For motors with ratings larger than the drive, please consult the factory as nuisance tripping

may occur if the drive is not properly sized. In sensorless vector control, the rated motor

current (FLA) must be at least 1⁄4 of the rated drive output current. With lower motor currents,

operation is possible in Volts / Hz control mode only.

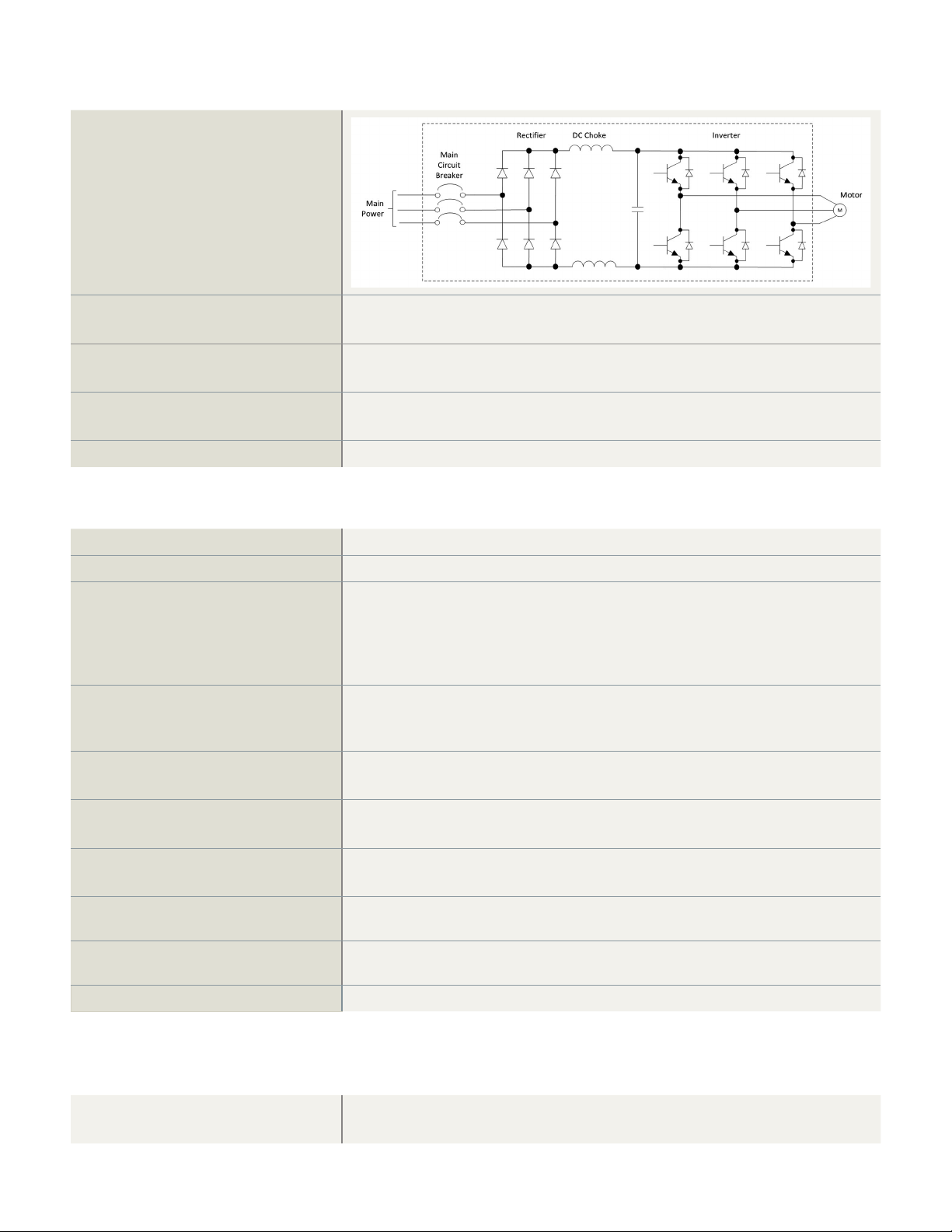

Overload ratings

The SINAMICS G120XE may be operated with either light or high overload duties. The criterion

for overload is that the drive is operated with its base load current before and after the overload

occurs. Light overload duty is based upon 110% base load current for 60 sec. within a cycle

time of 300 sec. or 150% for 60 sec. within a cycle time of 600 sec.

Current

1.1 x

rated

L

L

60 s

Short-time current

Rated current (permanent)

Base load current

for low overload

300 s

L

t

2

Page 3

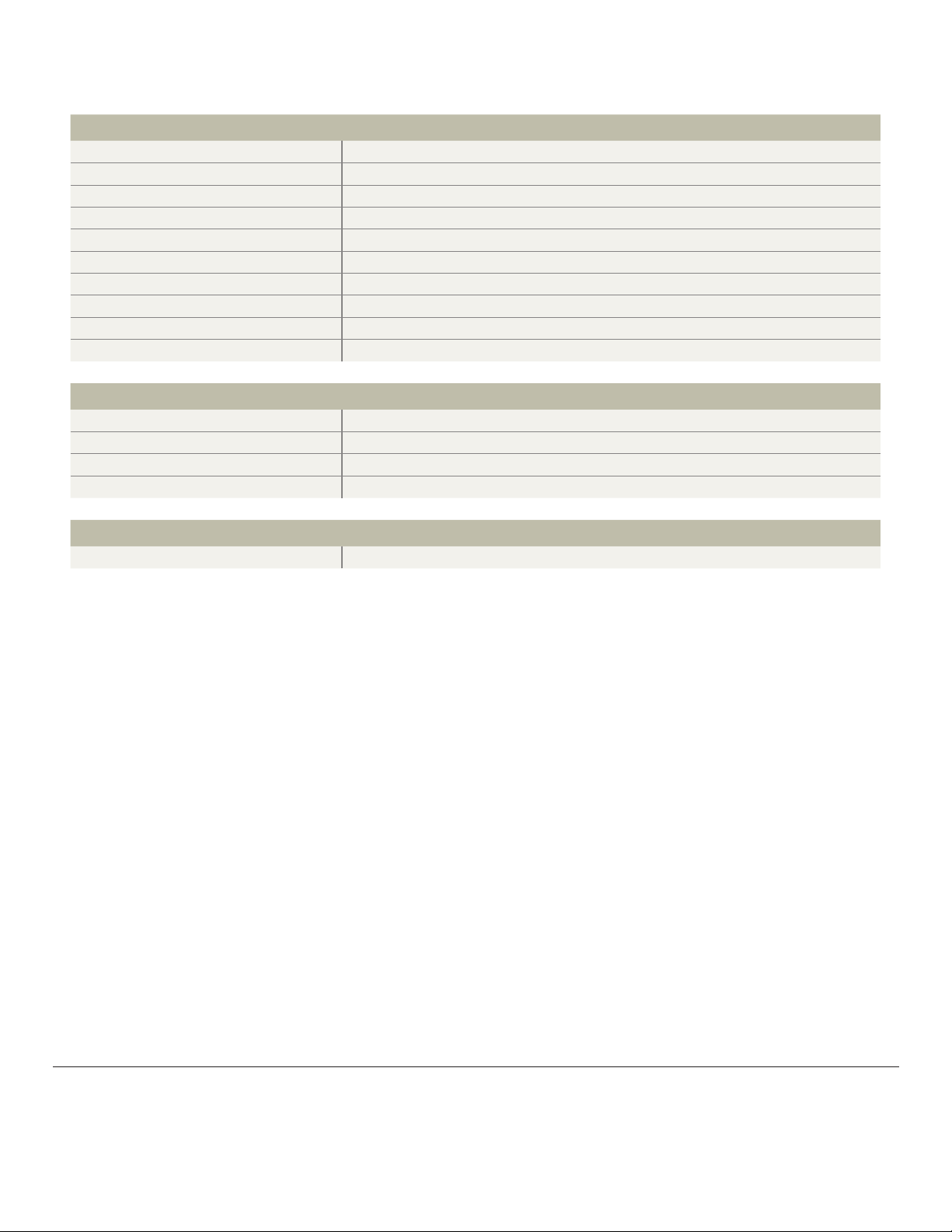

Power circuit configuration

Standard 6-pulse

Application

Pumps, fans and compressors using the G120X (standard), other industrial

applications can be achieved by substituting the PM240-2 for the G120X

Harmonic performance

(depending upon supply impedance)

Power supply system /

emergency power

Summary

THID approx. 25–50%

(with 3% line reactor option THID approx. 20–30%)

Strong and weak supply systems, emergency power generators may require

oversizing due to harmonics

Basic, compact and low-cost configuration

Control unit — SINAMICS G120X PN / EIP (Standard)

Application

Control mode

Pump, fan and compressor drives

V/F (Linear, square law, FCC, ECO), sensorless vector control (SLVC)

Functionality

Pump-specific Deragging protection, blockage, leakage and dry-running protection,

pipe filling mode, cavitation protection, condensation protection,

frost protection, multi-pump operation (pump switchover, stop mode,

service mode, cascade control mode)

Fan-specific Flying restart, automatic restart, fire mode or essential service mode

(emergency systems), no load, torque and rotation (belt) monitoring

with sensor, skip frequency bands, elapsed time

Energy efficiency and

performance-specific

Optimize operation and

Eco mode, bypass mode, hibernation or sleep mode, energy / flow calculator,

real-time clock and programmable timer

Keep running mode, PID controller, dual ramp, multi-speed setpoints

increase system availability

Compatible motor types Asynchronous (induction) motors, permanent magnet synchronous motors,

synchronous reluctance motors

Inputs

Outputs

Integrated Safety (encoderless)

NOTE: Some of the control unit inputs and outputs may be use for options

6 digital (30V)

2 analog (-10–10V, 0/4–20mA)

2 digital (Relay, 2A, 30V DC / 2A, 250V AC)

1 analog

Hardware-based SIL3 Safe Torque Off (STO) function with on / off switch

Commuication bus interface

Industrial Ethernet

PROFINET, EtherNet / IP, Profibus, Modbus RTU/USS, BACnet MS/TP, WiFi

via Smart Access Module (SAM)

3

Page 4

Product specifications

Standard 6-pulse

Light overload High overload

Output

(at 460V,

60 Hz)

HP A HP A A A Model No.

1 2.1 1 1.6 2.1 4.0 FSA Wall 6SL3710-1BJ12-2AU1

1.5 3.0 1.5 2.1 3.0 4.7 FSA Wall 6SL3710-1BJ13-1AU1

2 3.4 2 3.0 3.4 5.0 FSA Wall 6SL3710-1BJ14-1AU1

3 4.8 3 3.4 4.8 6.6 FSA Wall 6SL3710-1BJ16-0AU1

4 6.2 4 4.8 6.2 7.8 FSA Wall 6SL3710-1BJ17-7AU1

5 7.6 5 6.2 7.6 11.8 FSB Wall 6SL3710-1BJ21-0AU1

10 14 7.5 7.6 14 19.0 FSB Wall 6SL3710-1BJ21-8AU1

15 21 10 14 21 26.5 FSC Wall 6SL3710-1BJ22-5AU1

20 27 15 21 27 31.5 FSC Wall 6SL3710-1BJ23-2AU1

25 34 20 27 34 36.5 FSD Wall 6SL3710-1BJ23-8AU1

30 40 25 34 40 41.5 FSD Wall 6SL3710-1BJ24-5AU1

Baseload

current

for 110%

overload

Output

(at 460V,

60 Hz)

Baseload

current

for 150%

overload

Related

output

current

Approx.

max. input

1)

current

Power

module

frame size

Enclosure

mount

type

SINAMICS G120XE

enclosed drive

40 52 30 40 52 53.3 FSD Wall 6SL3710-1BJ26-0AU1

50 65 40 52 65 65.5 FSD Wall 6SL3710-1BJ27-5AU1

60 77 50 65 77 78.5 FSE Wall 6SL3710-1BJ28-9AU1

75 96 60 77 96 95.5 FSE Wall 6SL3710-1BJ31-1AU1

100 124 75 96 124 127 FSF Floor 6SL3710-1BJ31-5AU1

125 156 100 124 156 158 FSF Floor 6SL3710-1BJ31-8AU1

150 180 125 156 180 181 FSF Floor 6SL3710-1BJ32-0AU1

200 240 150 180 240 239 FSF Floor 6SL3710-1BJ32-5AU1

1)

For Standard 6-pulse drives, an allowance of 2.0A (≤20 hp), 4.5A (≤75 hp) or 6.5A (≤200 hp) for auxiliary circuits

The SINAMICS G120XE enclosed drive includes as standard:

n

NEMA 1 enclosure

n

UL 508A listed

n

SCCR (short circuit current rating) 65 kA

n

Circuit breaker disconnect with flange mount operator handle, and mechanical door interlock

n

Intelligent operator panel (IOP-2), door-mounted and wired

n

Enclosure fans with associated control

n

Control power transformer for internal control power

n

Cable entry top or bottom, line and motor side

n

Power module SINAMICS G120X with PWM IGBT inverter

4

Page 5

Standard options

Pre-designed standard options are available to tailor the SINAMICS G120 XE enclosed drive to

customer specifications, maintaining short delivery times from the factory.

Standard 6-pulse

Code Enclosure options

M12

L50

L55

L56

Y09

NEMA12 filters

Cabinet light and outlet

Cabinet space heaters (120VAC)

Motor space heater supply

Special enclosure paint color [specify color]

1)

Code Power circuit and protection options

L08

L10

L13

L15

L24

L27

L28

L29*

L32

L96

L98

L99*

P10

Output reactor

Output dV / dt filter

Input isolation contactor — coil wired to terminals

Output sinusoidal filter

3% Input reactor

2)

Input fuses

2 contactor bypass (output / bypass contactors with overload relay)

RVSS manual bypass (includes RVSS input and output contactor) In additional options enclosure

Output isolation contactor — coil wired to terminals

Input surge protective device

Motor thermal overload relay (already included in option L28)

Motor protection relay (Multilin)

Input voltage monitor (Siemens type 3UG4)

Code Control options

E86

E87

K20

K21

K22

L87*

L97

N55

G60

G81

G83

Isolation amplifier for one analog input

Isolation amplifier for one analog output

Pilot lights (qty. 3), door mounted — ready, run, fault

Additional local controls (L-R and H-O-A switches, speed potentiometer, Start / Stop pushbuttons)

Elapsed time (hour) meter, door-mounted, non-resettable

Ground fault monitor for ungrounded supplies

RTD monitor for 8x Pt100 temperature sensors

ALL STOP mushroom pushbutton, latching, coast to stop

I/O expansion (additional 2 DI, 4 DO, 1AI and 2AO)

Profibus communications (Profinet standard)

USS, Modbus RTU, BacNet MS/TP communication

Code Special options

N75

U91

H21

Please consult the factory for additional custom options

* = only for 100–200 hp (floor-standing enclosure)

1)

For wall-mounted drives, the enclosure options listed above are available only for the VFD enclosure itself, not for the separate options enclosures.

2)

This option needs to be selected when a 5% impedance is needed. The G120X modules are equipped with a DC Choke equivalent to z = 2%.

Expanded voltage range (380–480V supply system)

cUL listing for Canada

3C3 environmental protection (3C2 standard)

5

Page 6

SINAMICS G120XE design data

Wall-mounted drive enclosure

AIR OUT

HN

AIR IN

Side view

Spacing to adjacent units or wall

6” (1–20 hp) or 12” (25–60 hp)

WNDN

Front view

Separate options enclosure

(floor-standing)

HO

Side view

WODO

Front view

Wall-mounted drive enclosure

Output

Model No.

(Light Overload)

at 460V, 60 Hz

hp dB (A) cfm kW lb. kg inch mm

6SL3710-1BJ12-2AU1

1 65 77 0.068 230 104 16 x 13 x 43 406 x 330 x 1092

6SL3710-1BJ13-1AU1 1.5 65 77 0.08 230 104 16 x 13 x 43 406 x 330 x 1092

6SL3710-1BJ14-1AU1 2 65 77 0.096 230 104 16 x 13 x 43 406 x 330 x 1092

6SL3710-1BJ16-0AU1 3 65 115 0.115 230 104 16 x 13 x 43 406 x 330 x 1092

6SL3710-1BJ17-7AU1 4 65 115 0.148 230 104 16 x 13 x 43 406 x 330 x 1092

6SL3710-1BJ21-0AU1 5 65 115 0.161 230 104 16 x 13 x 43 406 x 330 x 1092

6SL3710-1BJ21-8AU1 10 65 182 0.27 230 104 16 x 13 x 43 406 x 330 x 1092

6SL3710-1BJ22-5AU1 15 65 182 0.341 230 104 18 x 13 x 43 457 x 330 x 1092

6SL3710-1BJ23-2AU1 20 65 182 0.421 230 104 18 x 13 x 43 457 x 330 x 1092

6SL3710-1BJ23-8AU1 25 67 318 0.615 330 150 26 x 16 x 46 660 x 406 x 1168

6SL3710-1BJ24-5AU1 30 67 318 0.745 330 150 26 x 16 x 46 660 x 406 x 1168

6SL3710-1BJ26-0AU1 40 67 318 0.855 330 150 26 x 16 x 46 660 x 406 x 1168

6SL3710-1BJ27-5AU1 50 67 360 1.125 330 150 26 x 16 x 46 660 x 406 x 1168

6SL3710-1BJ28-9AU1 60 67 360 1.355 330 150 26 x 16 x 46 660 x 406 x 1168

6SL3710-1BJ31-1AU1 75 67 360 1.755 330 150 26 x 16 x 46 660 x 406 x 1168

Noise level L

(1m) at 60 Hz

Cooling air flow

PA

demand

Heat loss Weight approx.

Drive enclosure Nominal size

WN x DN x H

N

Floor-standing enclosure

Model No.

Output

(Light Overload)

at 460V, 60 Hz

Noise level L

(1m) at 60 Hz

PA

Cooling

air flow demand

Heat loss Weight approx.

Drive enclosure Nominal size

WN x DN x H

N

hp dB (A) cfm kW lb. kg inch mm

6SL3710-1BJ31-5AU1

100 69 504 1.99 720 327 30 x 24 x 94 762 x 610 x 2377

6SL3710-1BJ31-8AU1 125 69 504 2.60 720 327 30 x 24 x 94 762 x 610 x 2377

6SL3710-1BJ32-0AU1 150 69 504 2.40 720 345 30 x 24 x 94 762 x 610 x 2377

6SL3710-1BJ32-5AU1 200 69 504 3.12 720 345 30 x 24 x 94 762 x 610 x 2377

Page 7

Floor-mounted enclosure

AIR OUT

Add-on

options

enclosure

94”

(2377 mm)

AIR IN

AIR IN

(610 mm)

Side view

WO WN24”

Front view

Wall-mounted drive add-on options enclosure

Output

(Light Overload)

Model No.

6SL3710-1BJ12-2AU1

6SL3710-1BJ13-1AU1 1.5 13 x 13 x 13 / 330 x 330 x 330 18 / 8 13 x 13 x 14 / 330 x 330 x 356 21 / 10

6SL3710-1BJ14-1AU1 2 13 x 13 x 13 / 330 x 330 x 330 18 / 8 13 x 13 x 14 / 330 x 330 x 356 25 / 11

6SL3710-1BJ16-0AU1 3 13 x 13 x 13 / 330 x 330 x 330 18 / 8 13 x 13 x 14 / 330 x 330 x 356 25 / 11

6SL3710-1BJ17-7AU1 4 13 x 13 x 13 / 330 x 330 x 330 18 / 8 13 x 13 x 14 / 330 x 330 x 356 27 / 12

6SL3710-1BJ21-0AU1 5 13 x 13 x 13 / 330 x 330 x 330 18 / 8 13 x 13 x 14 / 330 x 330 x 356 27 / 12

6SL3710-1BJ21-8AU1 10 13 x 13 x 13 / 330 x 330 x 330 19 / 9 13 x 13 x 14 / 330 x 330 x 356 34 / 15

6SL3710-1BJ22-5AU1 15 13 x 13 x 13 / 330 x 330 x 330 22 / 10 17 x 17 x 24 / 432 x 432 x 610 79 / 36

6SL3710-1BJ23-2AU1 20 13 x 13 x 13 / 330 x 330 x 330 22 / 10 17 x 17 x 24 / 432 x 432 x 610 82 / 37

6SL3710-1BJ23-8AU1 25 13 x 13 x 13 / 330 x 330 x 330 24 / 11 17 x 17 x 24 / 432 x 432 x 610 86 / 39

6SL3710-1BJ24-5AU1 30 13 x 13 x 13 / 330 x 330 x 330 24 / 11 17 x 17 x 24 / 432 x 432 x 610 95 / 43

6SL3710-1BJ26-0AU1 40 13 x 13 x 13 / 330 x 330 x 330 32 / 15 17 x 17 x 24 / 432 x 432 x 610 101 / 46

6SL3710-1BJ27-5AU1 50 13 x 13 x 13 / 330 x 330 x 330 40 / 18 18 x 21 x 34 / 457 x 533 x 864 136 / 62

6SL3710-1BJ28-9AU1 60 13 x 13 x 13 / 330 x 330 x 330 40 / 18 18 x 21 x 34 / 457 x 533 x 864 147 / 67

6SL3710-1BJ31-1AU1 75 13 x 13 x 13 / 330 x 330 x 330 40 / 18 18 x 21 x 34 / 457 x 533 x 864 147 / 67

at 460V, 60 Hz

hp

1 13 x 13 x 13 / 330 x 330 x 330 18 / 8 13 x 13 x 14 / 330 x 330 x 356 20 / 9

Option enclosure

L10 output dV / dt filter

Wo x Do x H

inch / mm

o

Weight

inch / kg

Option enclosure

L15 output with sinusoidal filter

Wo x Do x H

inch / mm

o

Weight

inch / kg

Floor-standing add-on options enclosure

Output

(Light Overload)

Model No.

6SL3710-1BJ31-5AU1

6SL3710-1BJ31-8AU1 125 20 / 508 452 / 205 20 / 508 540 / 245 20 / 508 463 / 210

6SL3710-1BJ32-0AU1 150 20 / 508 452 / 205 24 / 610 660 / 300 20 / 508 463 / 210

6SL3710-1BJ32-5AU1 200 20 / 508 452 / 205 24 / 610 660 / 300 20 / 508 463 / 210

at 460V, 60 Hz

hp

100 20 / 508 452 / 205 20 / 508 540 / 245 20 / 508 463 / 210

Option enclosure

L10 output dV / dt filter

W

o

inch / mm

Weight

inch / kg

Option enclosure

L15 output with sinusoidal filter

W

o

inch / mm

Weight

inch / kg

Option enclosure

L29 softstart bypass

W

o

inch / mm

Weight

inch / kg

Page 8

Technical information

Electrical

Supply voltages and output ranges

460–480V (optionally 380–480V) 3-phase AC, ±10%, 1–200 hp

Supply systems Grounded or ungrounded supplies

Line frequency 47–63Hz

Output frequency Control mode V/F: 0–550Hz, Control mode Vector: 0–240Hz

Power factor fundamental approx. 0.93

Drive efficiency 6 pulse: 94–98%

Short circuit current rating SCCR 65kA

Control method V/F (Linear, square low, FCC, ECO), sensorless vector control (SLVC)

Fixed speeds 16 fixed frequencies

Skipped frequency ranges 4, programmable

Mechanical

Type of enclosure and color

NEMA 1, optionally NEMA12 (ventilated), ANSI 61 gray

Type of cooling Forced air ventilation

Noise level LpA (1 m) 65–71dB (A) at 60Hz line frequency

Environmental protection 3C2 environmental rating is standard with 3C3 available as an option

Compliance with standards and certifications

UL listing

Listed to UL 508A

Published by

Siemens Industry, Inc.

5300 Triangle Parkway

Norcross, GA 30092

(770) 871-3800

usa.siemens.com/motioncontrol

Order No. DRTD-G120XE-1220

Printed in USA

© 2020 Siemens Industry, Inc.

This document contains only general descriptions or performance features, which do not always apply in

the manner described in concrete application situations or may change as the products undergo further

development. Performance features are valid only if they are formally agreed upon when the contract is closed.

Siemens is a registered trademark of Siemens AG. Product names mentioned may be trademarks or registered

trademarks of their respective companies. Specifications are subject to change without notice.

Loading...

Loading...