Page 1

Date: 2019-12-11 DF MC SNC CSA TCC

- 1 -

Instructions for G120XA FSH-J X9 terminal

How to use the X9 connector which only use in G120XA FSH-J

Tang Huang

Siemens Numerical Control (Nanjing) Co., Ltd., Nanjing

Abstract: When many customers use G120XA FSH-J power section products for

the first time, F7862 alarm will appear after power on operation. Preliminary

inspection shows that there is no obvious abnormality in wiring, and it is impossible

to locate the cause of the problem when they are not familiar with the product.

Keywords:X9,F7862,external fault

1、Fault analysis

Page 2

Date: 2019-12-11 DF MC SNC CSA TCC

- 2 -

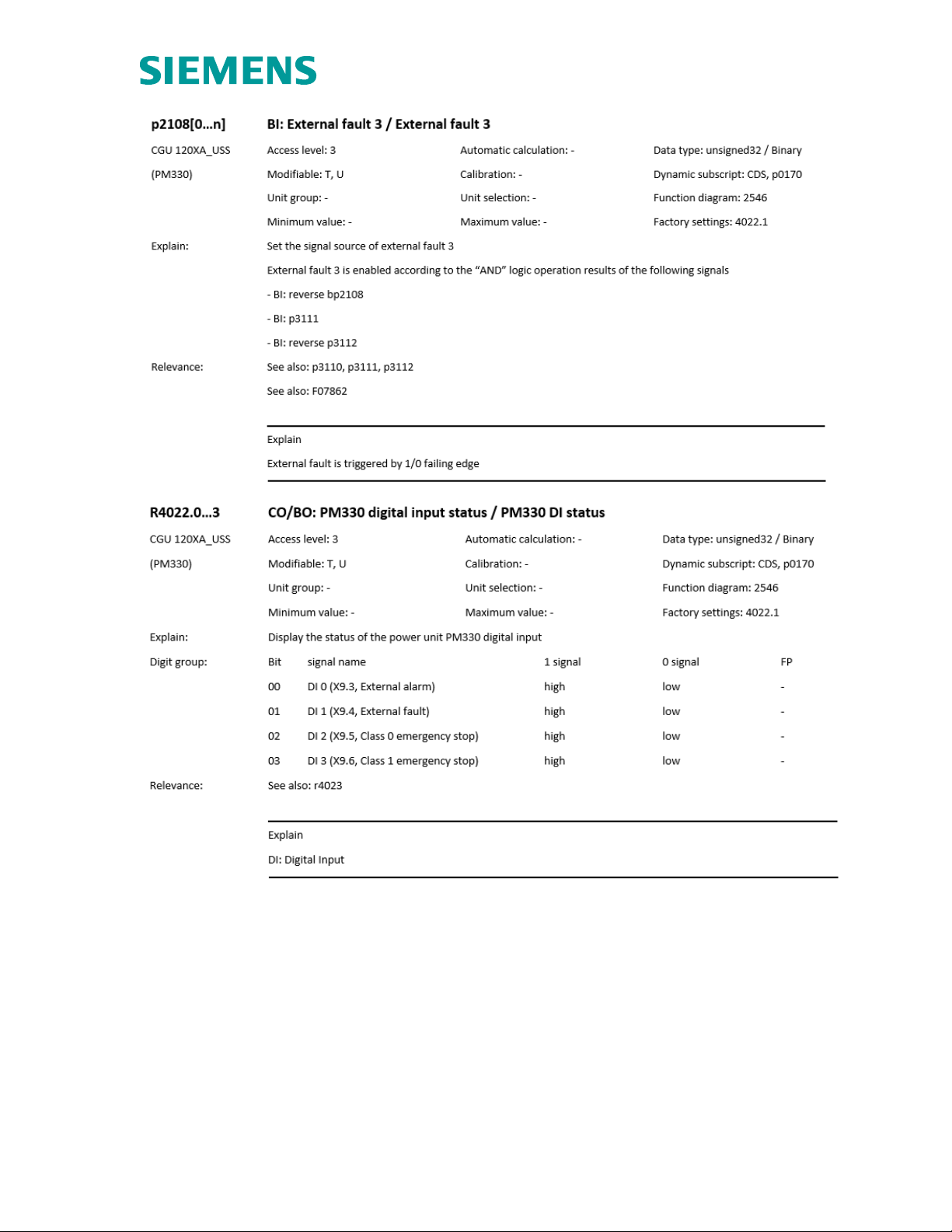

As shown in the figures above, the reason of the appearance of F7862,

according to the user manual of G120XA, is that the input signal of the

signal source r402.1 of external fault 3 is low, and the state of r4022.0~3 is

controlled by X9 terminal. Therefore, when F7862 fault occurs, it is

necessary to confirm whether X9 terminal has been correctly connected!

2、X9 terminal

1. Mechanical installation of G120XA FAH-J X9 terminal

Page 3

Date: 2019-12-11 DF MC SNC CSA TCC

- 3 -

2. G120XA FAH-J X9 terminal function

Terminal strip X9 is used to connect external 24V DC power supply and

main contactor or bypass contactor.

To connect the terminal strip X9, remove the front cover of the converter. Its

DIs can be connected with fault signal and alarm signal.

When the converter is connected to the power supply through the main

contactor, it is necessary to connect the external 24V DC power supply.

The power supply must be near the converter (such as in the same control

cabinet), and the cable length to terminal block X9 shall not exceed 5

meters.

Terminal

Name

meaning

Input/output

Technical data

1

P24

External

power

supply

Input

Voltage:24V DC(20.1V

~28.8V)

Current consumption: 2A

maximum

2 M Electronic

grounding

Reference

3

External

External

Input

Voltage: -3V ...+30V

Page 4

Date: 2019-12-11 DF MC SNC CSA TCC

- 4 -

alert

alarm

Current consumption:

✓ 6.4 mA at 24V DC

✓ 1.3 mA when < 5V

✓ 4 mA when > 15V

✓ 8 mA at 30V

Level (including waviness):

✓ High level:15V ...30V

✓ Low level:-3V ...+5V

4

External

fault

External

fault

Input

5

Stop 0

Emergency

OFF,

category 0

Input

6

Stop 1

Emergency

stop

category 1

Input

7 M

Reference

8

DC link

charged

Enable

signal, “U”

DC link

charged

Output

Voltage:24V DC

Maximum load current: 500mA

Continuous short circuit

protection

The output current is taken from

the power supply via X9

terminal

9

NC

Not

connected

10

NC

Not

connected

11

Activation

line

contactor

Line

contactor

control

Output

Contact type: NO contact

Maximum load current: 4A,

230V AC,cosφ = 0.6ind

Floating potential

For feeders with contactless

outputs (e.g.4A/250V fuses), a

protection device is required to

prevent overload and short

circuit.

The overvoltage limiter must be

connected to the excitation coil

of the main contactor (e.g. RC

circuit).

The following relay contact

characteristic values are

applicable to the control of the

main contactor:

✓ 250V AC,10A(NC and

NO)currency, 85℃

✓ 24V DC, 10A(NC and

NO), currency, 85℃

✓ 30V DC,8A(NO)、6A

(NC), currency, 85℃

✓ B300(NC and NO),

general purpose,85℃

✓ R300(NC and NO),

general purpose, 85℃

✓ 24V AC, 2.0A(NC and

NO), general purpose,

12

Activation

Line

contactor

Line

contactor

control

Output

Page 5

Date: 2019-12-11 DF MC SNC CSA TCC

- 5 -

85℃

Note:

1)The input is low level active

All signal inputs are low level active (anti break).

2)Terminal 3~6 not used

When terminal 3~6 is not in use, DC 24V must be applied. To do this, use an external

power supply or terminal 9 on the control unit. Terminal 2 and 7 with reference potential

X9 and terminal 28 on the control unit. Refer to terminals 2 and 7 with potential X9 and

terminal 28 on the control unit.

3)Main contactor control

When power is supplied to the main contactor via terminals 11 and 12, it is not necessary

to disconnect from the power supply system via the control transformer. 250V/8A fuse

must be used as protection measure.

4)Strain relief

The cables for the control unit and terminal X9 must be fixed to the terminal block in the

cable channel under terminal X9 for strain relief. If the cable is introduced into the cable

channel from the side (at the height of terminal X9), the strain relief must be performed

outside the power module.

5)Wiring standard

Maximum connection cross section: 2.5 mm²(14AWG)

Minimum connection cross section: 0.2 mm²(25AWG)

Maximum tightening torque: 0.5 Nm (4.4 lbf.in)

3、Troubleshooting

1. According to the actual use requirements, the wiring should be correct to

ensure that r4022.03 input is high when there is no abnormal external

alarm/alarm and emergency stop signal.

2. If the current hardware wiring cannot be completed, the alarm can be

shielded by setting parameters. Since pins 3 to 6 on X9 terminal correspond

to external alarm 3, external fault 3, emergency stop category 1 and

emergency stop category 2 respectively, all the 4 corresponding bic0

parameters need to be set high. The specific settings are as follow:

parameter

meaning

Default

value

Setting

value

P2117.0

BI: set the signal source of external alarm 3.

r4022.0

1

P2108.0

BI: set the signal source of external fault 3.

r4022.1

1

P849.0

BI: no fast stop/ fast stop (OFF3) signal source 2/

r4022.2

1

Page 6

Date: 2019-12-11 DF MC SNC CSA TCC

- 6 -

OFF3 signal source 2

P845.0

BI: without slow stop/ slow stall (OFF2) signal

source 2

r4022.3

1

Loading...

Loading...