Page 1

___________________

___________________

___________________

___________________

___________________

SINAMICS

SINAMICS G120P

CU230P-2 Control Units

Compact Operating Instructions

Edition 01/2017

01/2017

A5E38815802B AA

Fundamental safety

instructions

1

Scope of delivery

2

Installing

3

Commissioning

4

More information

5

Page 2

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E38815802B AA

Ⓟ

Copyright © Siemens AG 2015 - 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

01/2017 Subject to change

Page 3

Table of contents

1 Fundamental safety instructions .............................................................................................................. 4

2 Scope of delivery .................................................................................................................................... 6

3 Installing ................................................................................................................................................. 7

4 Commissioning ..................................................................................................................................... 33

5 More information ................................................................................................................................... 49

What is the meaning of the symbols in the manual?

1.1 General safety instructions ....................................................................................................... 4

1.2 Industrial security ...................................................................................................................... 5

3.1 Plugging the Control Unit onto the Power Module .................................................................... 7

3.2 Overview of the interfaces ...................................................................................................... 10

3.3 Terminal strips ........................................................................................................................ 12

3.4 Factory interface settings ........................................................................................................ 14

3.5 Default setting of the interfaces .............................................................................................. 16

4.1 Tools to commission the converter ......................................................................................... 33

4.2 Commissioning with BOP-2 operator panel ............................................................................ 34

4.2.1 Start quick commissioning and select the application class ................................................... 34

4.2.2 Identifying the motor data and optimizing the closed-loop control ......................................... 38

4.3 Connecting the inverter to the fieldbus ................................................................................... 40

4.3.1 PROFINET and PROFIBUS ................................................................................................... 40

4.3.2 Modbus RTU ........................................................................................................................... 43

4.3.3 BACnet MS/TP ........................................................................................................................ 44

4.4 Frequently required parameters ............................................................................................. 46

5.1 Overview of the manuals ........................................................................................................ 49

5.2 Technical support .................................................................................................................... 50

This manual describes how you install the CU230P-2 Control Unit of the SINAMICS G120P

inverter and commission it.

Reference to further information in the manual

An operating instruction starts here.

This concludes the operating instruction.

Download from the Internet

DVD that can be ordered

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

3

Page 4

1

1.1

General safety instructions

WARNING

Danger to life if the safety instructions and residual risks are not observed

WARNING

Danger to life or malfunctions of the machine as a result of incorrect or changed

parameterization

If the safety instructions and residual risks in the associated hardware documentation are

not observed, accidents involving severe injuries or death can occur.

• Observe the safety instructions given in the hardware documentation.

• Consider the residual risks for the risk evaluation.

As a result of incorrect or changed parameterization, machines can malfunction, which in

turn can lead to injuries or death.

• Protect the parameterization (parameter assignments) against unauthorized access.

• Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY

STOP or EMERGENCY OFF).

CU230P-2 Control Units

4 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 5

Fundamental safety instructions

1.2

Industrial security

Note

Industrial security

Siemens provides products and solutions wit

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement

security concept. Siemens products and solutions only represent one component of such a

concept.

The customer is responsible for preventing unauthorized access to its plants, systems,

machines and networks. Systems, machin

the enterprise network or the internet if and to the extent necessary and with appropriate

security measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on approp

account. For more information about industrial security, please visit:

Industrial security (

Siemens’ produ

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and fa

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (

WARNING

Danger to life as a result of unsafe operating states resulting from software manipulation

1.2 Industrial security

h industrial security functions that support the

– and continuously maintain – a holistic, state-of-the-art industrial

es and components should only be connected to

riate security measures should be taken into

http://www.siemens.com/industrialsecurity).

cts and solutions undergo continuous development to make them more

ilure to apply latest updates may increase customer’s exposure to cyber threats.

http://www.siemens.com/industrialsecurity).

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe

operating states in your system that may lead to death, serious injury, and property

damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security

concept.

• Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

5

Page 6

2

Designation

Article number

Fieldbus

P1

CU230P-2 DP

6SL3243-0BB30-1PA3

PROFIBUS DP

Transferring OSS license terms to a PC

Procedure

The delivery comprises at least the following components:

● A CU230P-2 Control Unit ready for operation with installed firmware. Options for

upgrading and downgrading the firmware can be found on the Internet:

Firmware (http://support.automation.siemens.com/WW/news/en/67364620).

The fieldbus interface of the Control Unit depends on the Article No. You can find the

designation, the article number, the hardware version (e.g. 02) and the firmware version

(e.g. 4.6) on the Control Unit rating plate

CU230P-2 HVAC 6SL3243-0BB30-1HA3 USS, Modbus RTU, BACnet MS/TP,

①.

CU230P-2 PN 6SL3243-0BB30-1FA0 PROFINET IO, EtherNet/IP

● Compact Operating Instructions in German and English

● The inverter contains open-source software (OSS). OSS comprises open source text and

satisfies special license terms.

The OSS license terms are saved in the inverter. You can transfer the OSS license terms

to a PC using a memory card where you can read them.

To transfer OSS license terms to a PC, proceed as follows:

1. Switch off the inverter power supply.

2. Insert an empty memory card into the card slot of the inverter.

Overview of the interfaces (Page 10)

3. Switch on the inverter power supply.

4. The inverter writes file "Read_OSS.ZIP" to the memory card within approximately

30 seconds.

CU230P-2 Control Units

6 Compact Operating Instructions, 01/2017, A5E38815802B AA

5. Switch off the inverter power supply.

6. Withdraw the memory card from the inverter.

7. Insert the memory card into the card reader of a PC.

8. Please read the license terms.

You have transferred the OSS license terms to a PC.

Page 7

3

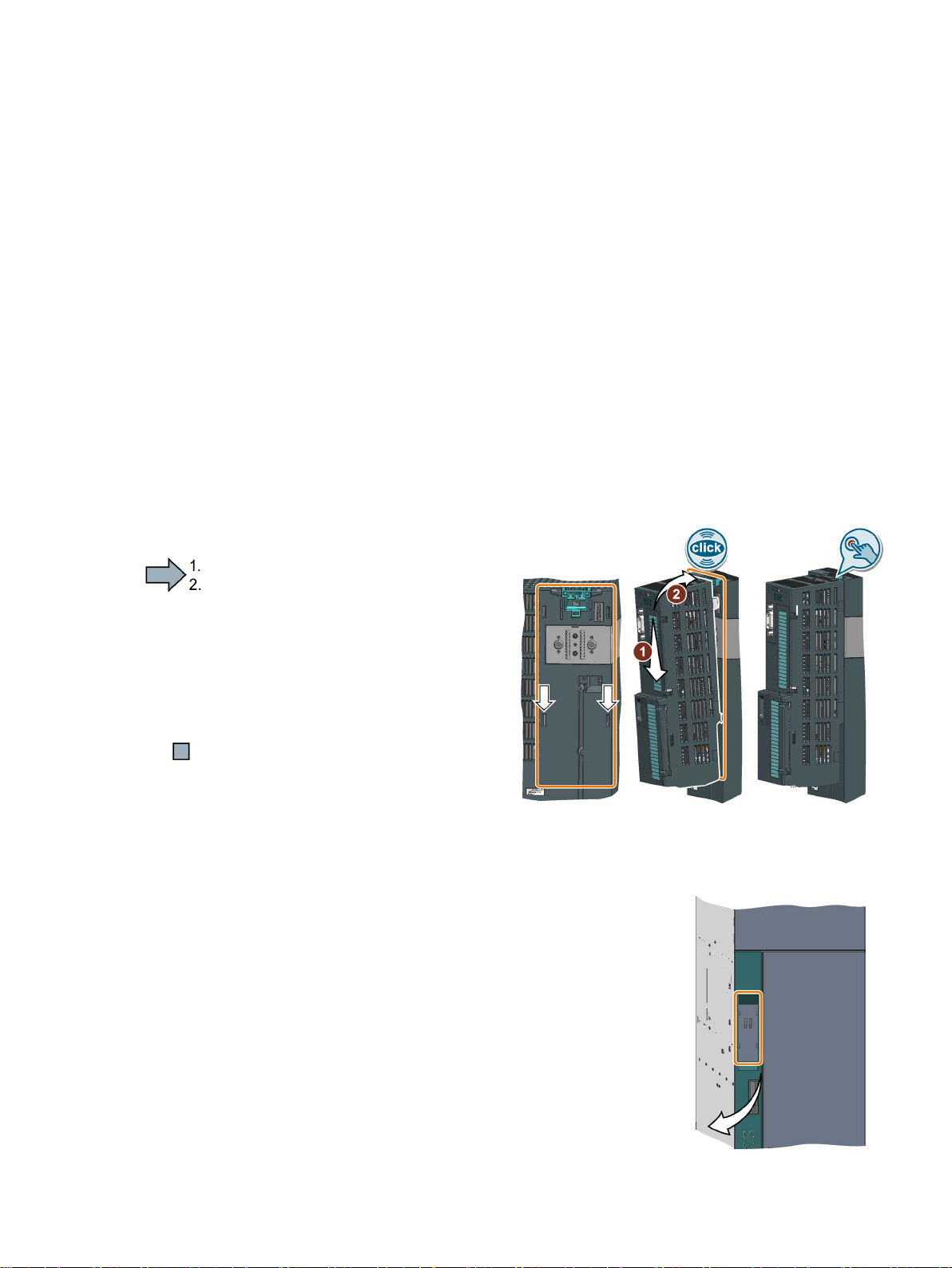

3.1

Plugging the Control Unit onto the Power Module

Permissible Power Modules

You may operate the Control Unit with the following Power Modules:

•

•

•

•

•

Installing the Control Unit - General

Inserting the Control Unit

1.

2.

Power Module until you hear that it

Removing the Control Unit

Special features for the PM330 Power Module

To insert or detach the Control Unit, you must open the left

hand cov

Close the cover before you commission the inverter.

PM230

Each Power Module has an appropriate holder for the Control Unit and a release

mechanism.

Proceed as follows to plug the Control

Unit onto a Power Module:

Place the two catches of the

Control Unit in the matching

grooves of the Power Module.

Press the Control Unit onto the

latches.

You have now plugged the Control

Unit onto the Power Module.

PM240P-2

PM240-2

PM250

PM330

Remove the Control Unit from the Power Module by pressing the release mechanism.

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

er of the Power Module.

-

7

Page 8

Installing

Special features for the PM230 Power Module IP55, FSA … FSC

To insert or detach the

release eight or ten fixing screws of the cover

and then remove the cover.

The Power Module release mechanism is

shown in the diagram.

Attach the cover again before you commission

the inverter. Do not damage the seal of the

cover when attaching it.

Installing the Control Unit, PM230 IP55 - FSD … FSF

To insert or detach the Control Unit, you must

open the front door of the Power Module.

Clos

verter. Check to ensure that the seals are not

damaged.

Plugging on an operator panel

Procedure

1.

2.

3.1 Plugging the Control Unit onto the Power Module

Control Unit, you must

e the door before you commission the in-

To plug an Operator Panel on the Control Unit, proceed as follows:

Locate the lower edge of the Operator Panel into the matching recess

of the Control Unit.

Plug the Operator Panel onto the inverter until the latch audibly

engages.

You have plugged an operator panel onto the Control Unit.

The operator panel is ready for operation when you connect the inverter to the power supply.

CU230P-2 Control Units

8 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 9

Installing

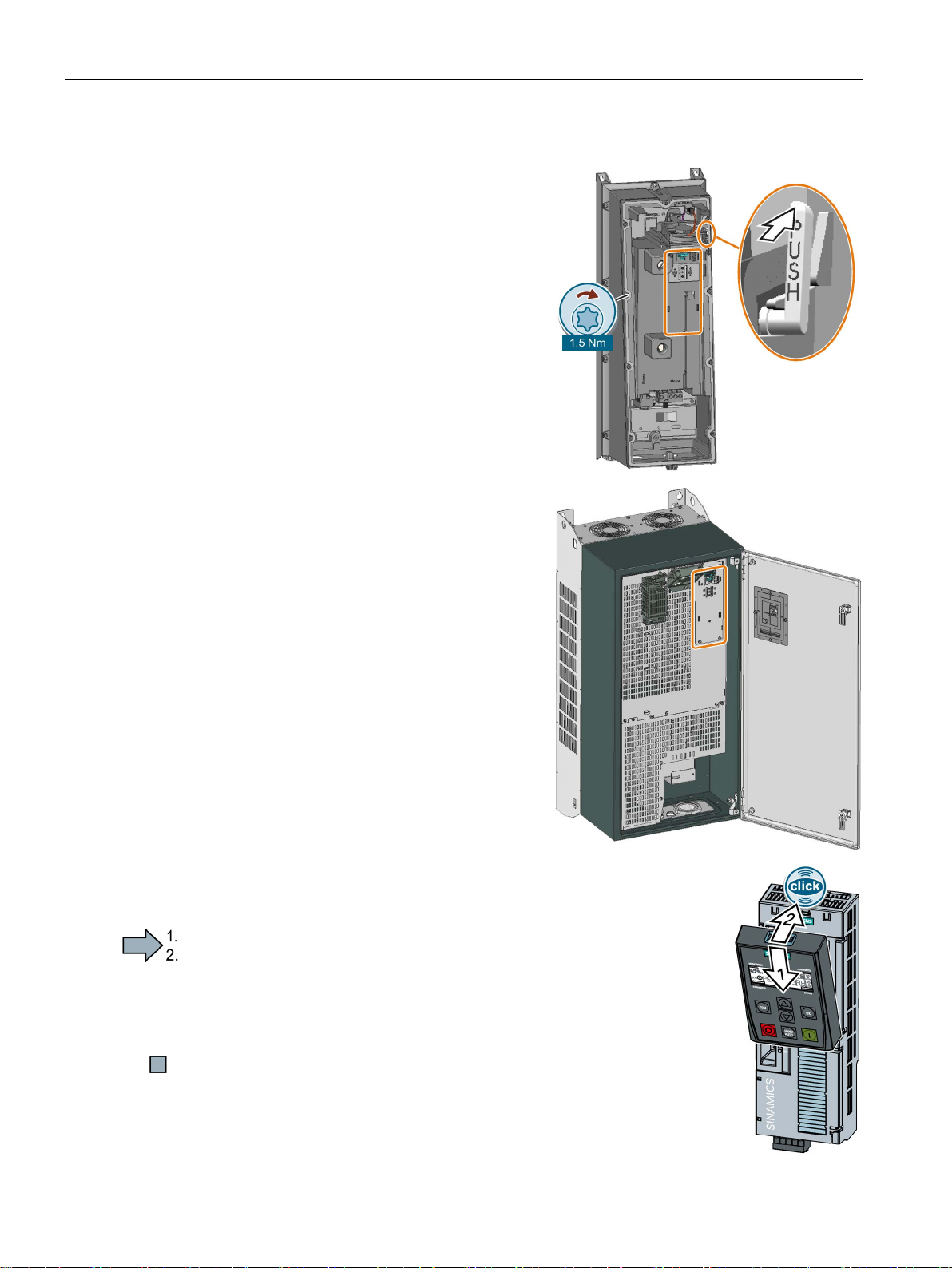

Mounting the operator panel or dummy cover on the IP55 Power Module

①

Attaching the operator panel or dummy cover:

Press the operator panel or dummy cover onto the

inverter as shown until you hear it click into place.

②

Removing the operator panel or dummy cover:

Use a suitable screwdriver to pres

downwards.

Connecting cable

3.1 Plugging the Control Unit onto the Power Module

Either an operator panel or the dummy cover must be plugged on for the inverter to achieve

degree of protection IP55.

s the interlock

Tools to commission the converter (Page 33)

The following accessory is included in the Power Module scope of supply to connect the

Control Unit with the operator panel:

● An adapter, required for PM230 IP55 Power Modules, FSA … FSC

● A connecting cable and a bar to fix the connector, required for PM230 IP55 Power

Modules, FSD … FSF

Adapter

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

9

Page 10

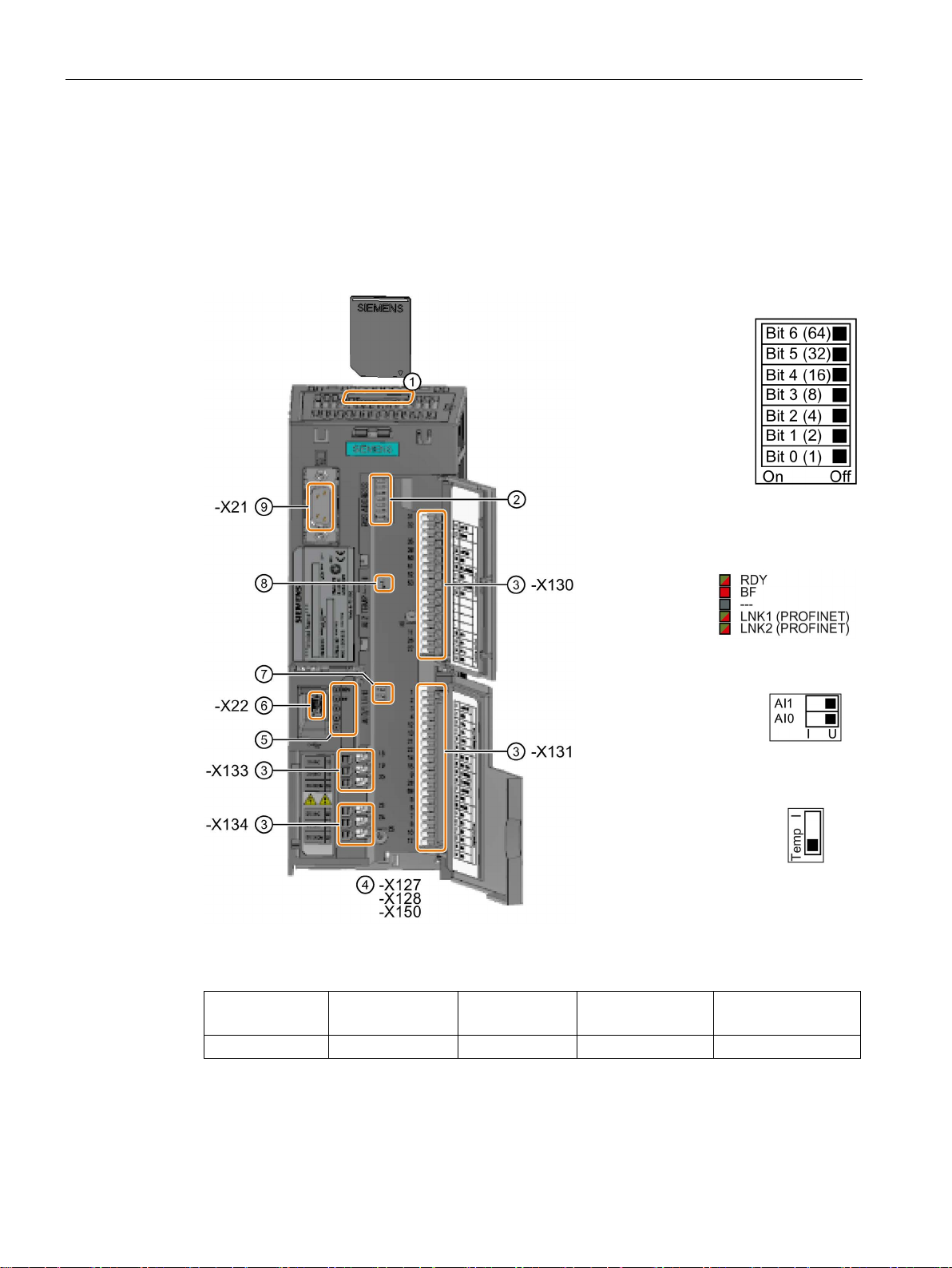

Installing

3.2

Overview of the interfaces

Interfaces at the front of the Control Unit

①

Memory card slot

②

Selecting the

fieldbus address:

•

•

•

③

Terminal strips

④

Fieldbus interfaces at the lower

side

⑤

Status LED

⑥

USB interface for connection to a

PC

⑦

Switch for AI

AI

•

•

⑧

Switch for AI

Current or te

per

⑨

Connection to the operator panel

Digital inputs DI

Digital outputs DO

Analog inputs AI

Analog outputs AO

Input for motor tem-

perature sensor

6 3 4 2 1

3.2 Overview of the interfaces

To access the interfaces at the front of the Control Unit, you must lift the Operator Panel (if

one is being used) and open the front doors.

CU230P-2 DP

CU230P-2

HVAC

CU230P-2 BT

Table 3- 1 Number of inputs and outputs

1 (U/I)

I 0/4 mA … 20 mA

U -10/0 V … 10 V

ature input

0 and

2

m-

CU230P-2 Control Units

10 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 11

Installing

Cables with twin end sleeves are not permissible.

EMC-compliant wiring

Shield connection kit

Article number

interfaces except for PROFINET.

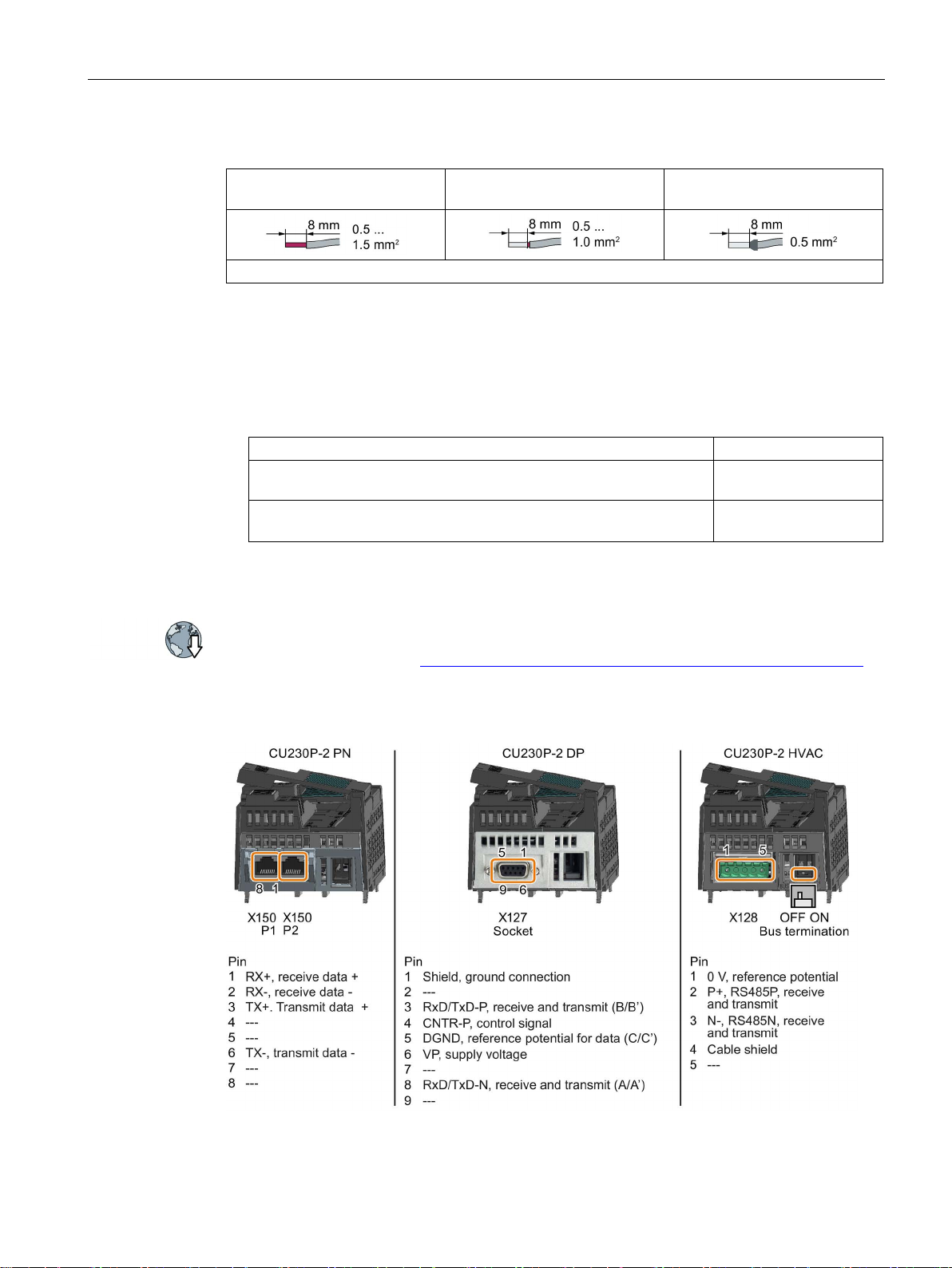

Interfaces at the lower side of the CU230P-2 Control Unit

3.2 Overview of the interfaces

Table 3- 2 Permissible cables and wiring options

Solid or flexible conductors Finely stranded conductor with

Measures to ensure EMC-compliant wiring of the Control Unit:

● Use the shield connection kit of the Control Unit to connect the shield and provide strain

relief for cables/conductors.

● If you use shielded cables, then you must connect the shield to the mounting plate of the

control cabinet or with the shield support of the inverter through a good electrical

connection and a large surface area.

Additional information about EMC-compliant wiring is available on the Internet:

Finely stranded conductor with

non-insulated end sleeve

Shield connection kit 1 for the CU230P-2 Control Units with all fieldbus

Shield connection kit 3 for the CU230P-2 and CU240E-2 Control Units

with PROFINET interface.

partially insulated end sleeve

6SL3264-1EA00-0FA0

6SL3264-1EA00-0HB0

EMC installation guideline (http://support.automation.siemens.com/WW/view/en/60612658)

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

11

Page 12

Installing

3.3

Terminal strips

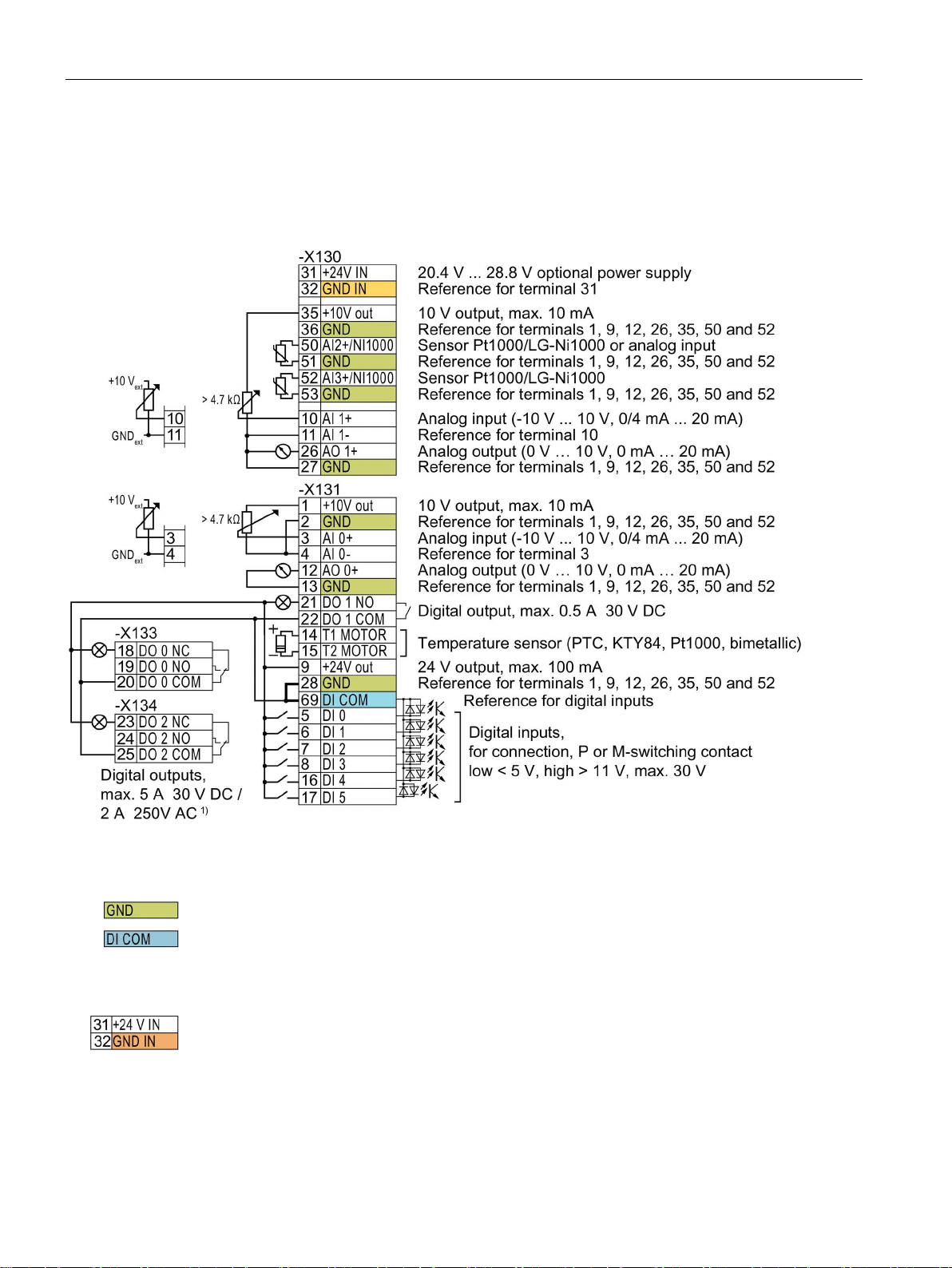

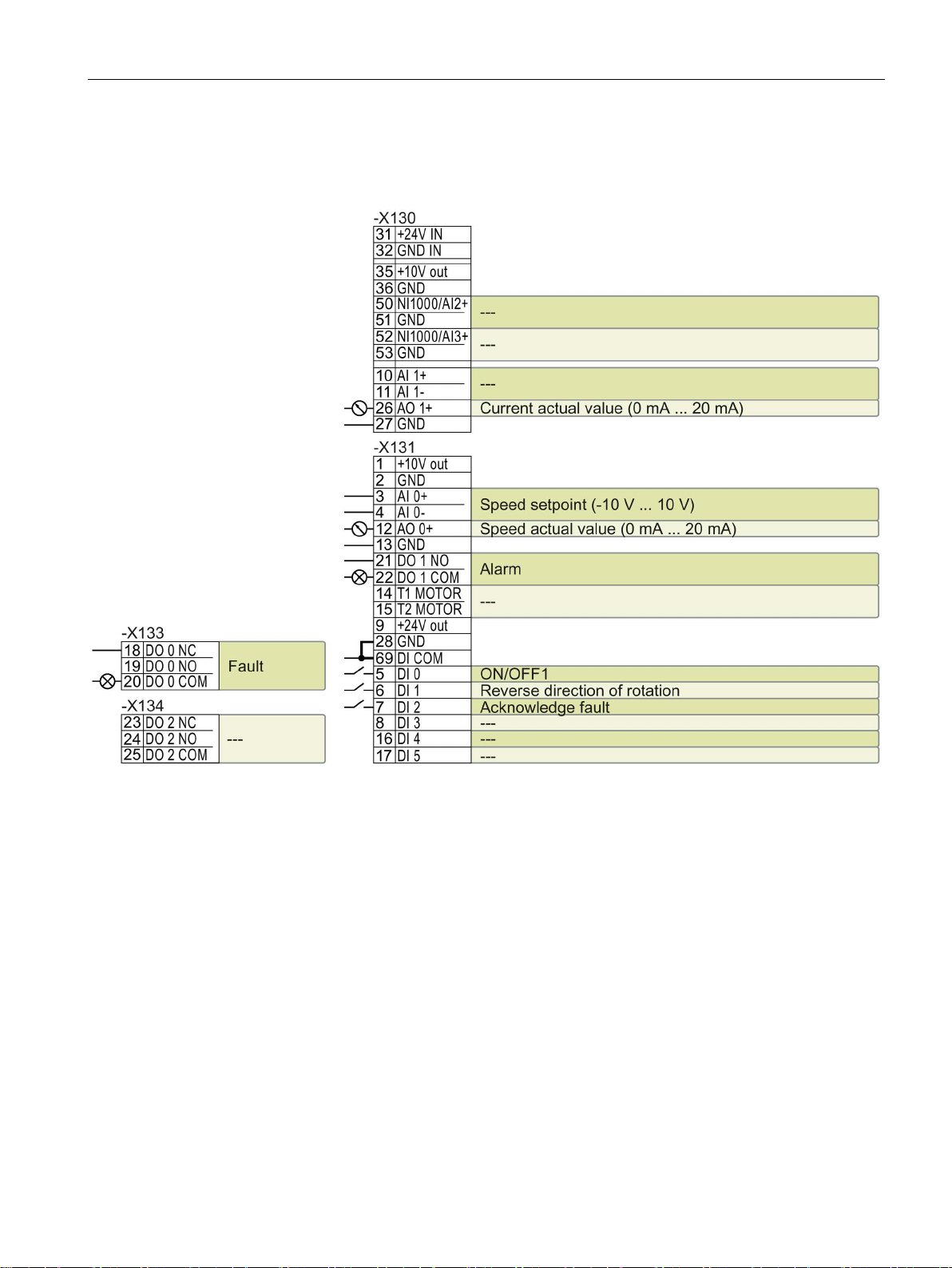

Terminal strips with wiring example

The following applies to systems compliant with UL: Maximum current, 3 A 30 VDC or 2 A 250 VAC

3.3 Terminal strips

1)

Figure 3-1 Wiring the digital inputs with p-switching contacts and an internal 24 V power supply (terminal 9)

All terminals labelled with reference potential "GND" are connected internally in the inverter.

Reference potential "DI COM" is electrically isolated from "GND". The Control Unit is

delivered with a jumper between terminals 28 and 69.

→ If, as shown above, you wish to use the 24-V supply from terminal 9 as supply for the

digital inputs, then it is mandatory that this jumper is used.

When an optional 24 V power supply is connected at terminals 31, 32, even when the Power

Module is disconnected from the line supply, the Control Unit remains in operation. The

Control Unit thus maintains fieldbus communication, for example.

→ At terminals 31, 32, only connect a power supply that is in accordance with SELV (Safety

Extra Low Voltage) or PELV (Protective Extra Low Voltage).

CU230P-2 Control Units

12 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 13

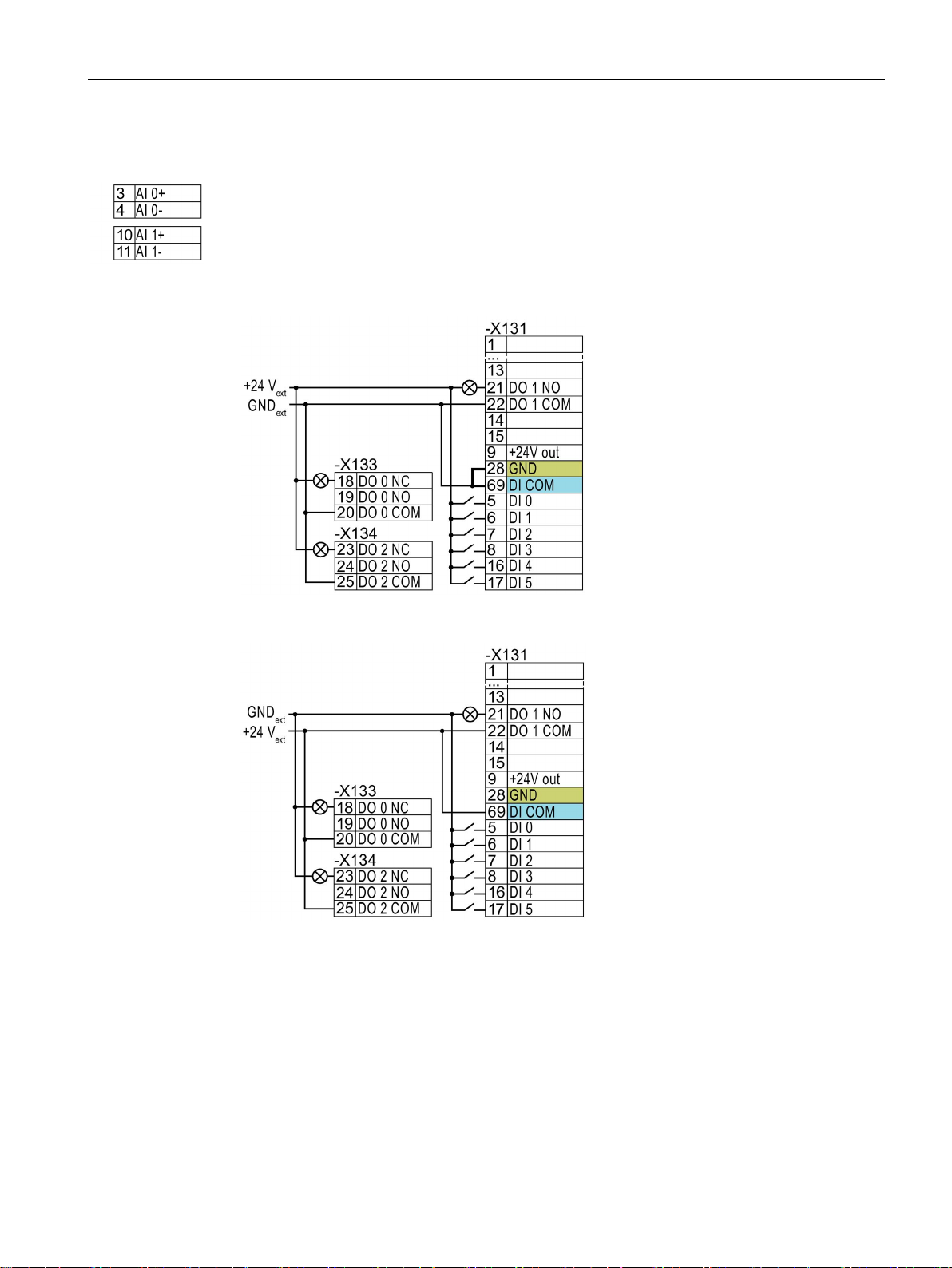

→ if you also wish to use the power supply at terminals 31, 32 for the digital inputs, then you

Additional options for wiring the digital inputs

power supply

You must remove the jumper between

terminals 28 and 69 if it is necessary to

have electrical isolation between the

external power supply and the internal

inverter power supply.

power supply

Remove the jumper between terminals

28 and 69.

must connect "DI COM" and "GND IN" with one another at the terminals.

You may use the internal 10 V power supply or an external power supply for the analog

inputs.

→ When you use the internal 10 V power supply, you must connect AI 0 or AI 1 with "GND".

Installing

3.3 Terminal strips

Connecting P-switching contacts with an external

Connecting M-switching contacts with an external

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

13

Page 14

Installing

3.4

Factory interface settings

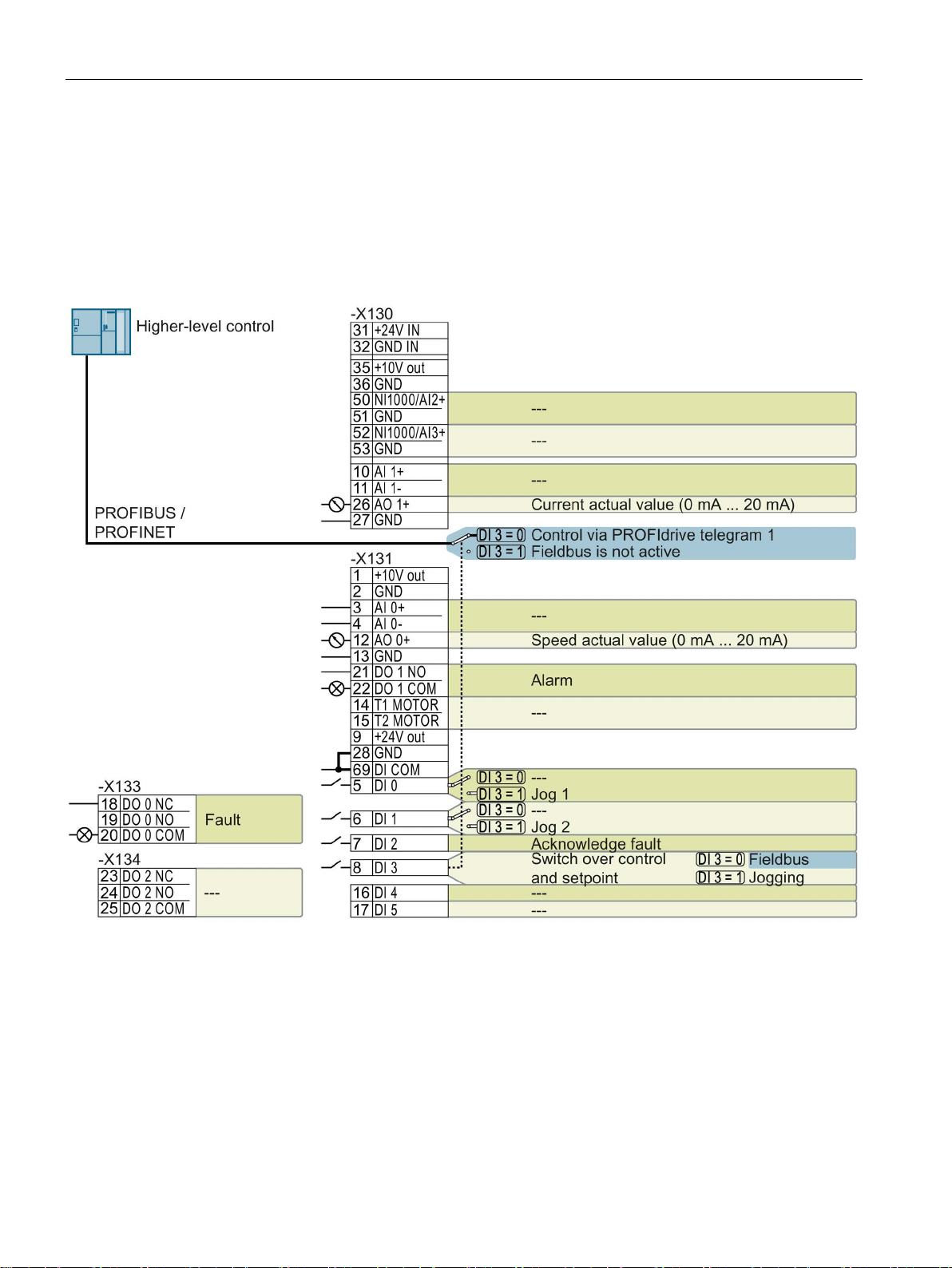

Control Units with PROFIBUS or PROFINET interface

--- No function.

DO x: p073x

AO 0: p0771[0]

DI x: r0722.x

Speed setpoint (main setpoint): p1070[0] = 2050[1]

3.4 Factory interface settings

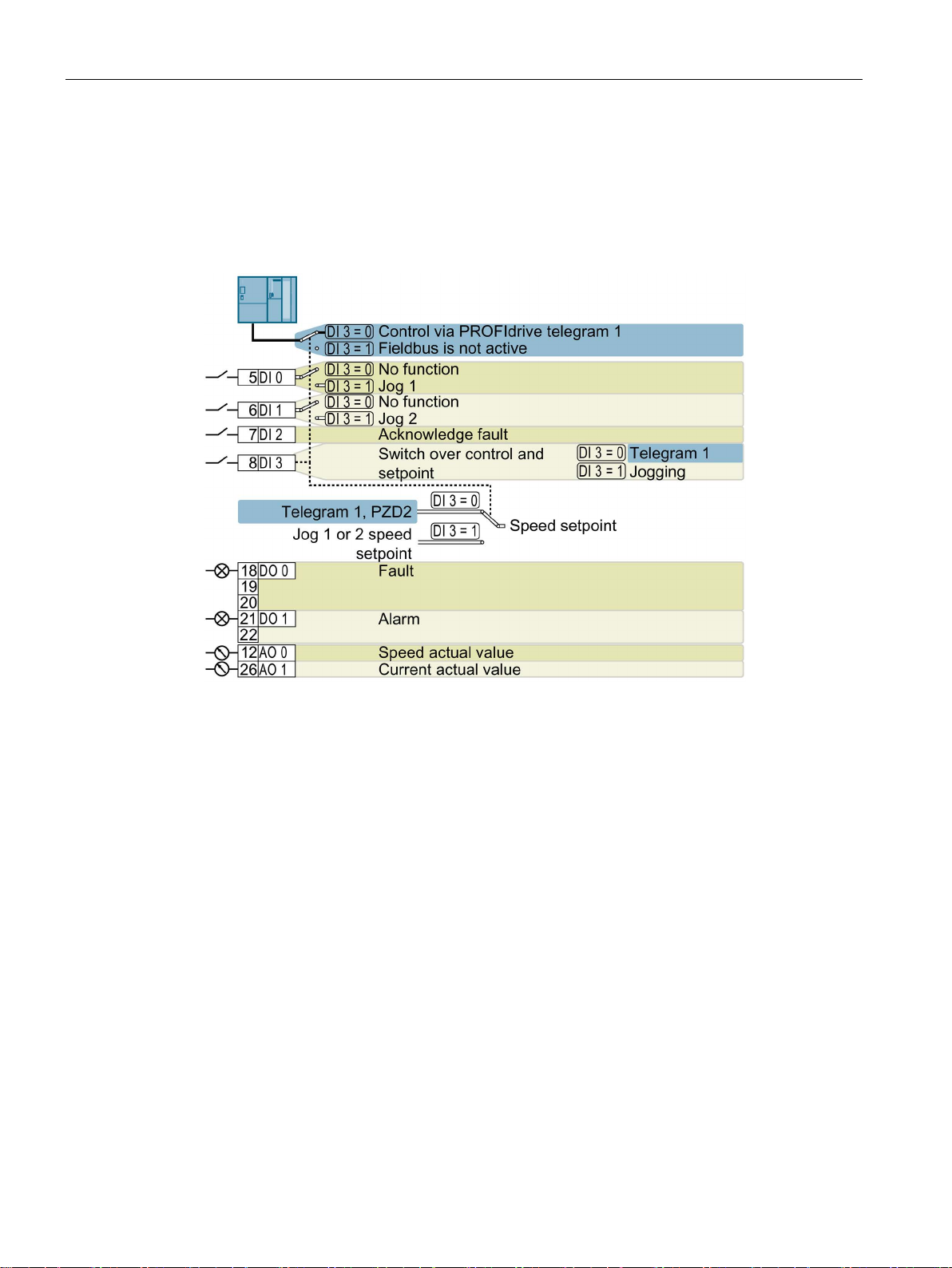

The factory setting of the interfaces depends on the Control Unit.

The function of the fieldbus interface and digital inputs DI 0, DI 1 depends on DI 3.

Figure 3-2 Factory setting of the CU230P-2 DP and CU230P-2 PN Control Units

CU230P-2 Control Units

14 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 15

Installing

Control Units with USS interface

--- No function.

DO x: p073x

AO 0: p0771[0]

DI x: r0722.x

AI 0: r0755[0]

Speed setpoint (main setpoint): p1070[0] = 755[0]

Changing the function of the terminals

3.4 Factory interface settings

The fieldbus interface is not active.

Figure 3-3 Factory setting of CU230P-2 HVAC Control Units

The function of the terminals and fieldbus interface can be adjusted.

In order that you do not have to successively change terminal for terminal, several terminals

can be jointly set using default settings ("p0015 Macro drive unit").

The terminal settings made in the factory described above correspond to the following

default settings:

● Default setting 12 (p0015 = 12): "Standard I/O with analog setpoint"

● Default setting 7 (p0015 = 7): "Fieldbus with data set switchover"

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

15

Page 16

Installing

3.5

Default setting of the interfaces

Default setting 7: "Fieldbus with data set switchover"

DO 0: p0730, DO 1: p0731

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0, …, DI 3: r0722.3

Jog 2 speed setpoint: p1059, factory setting: -150 rpm

Designation in the BOP-2: FB cdS

3.5 Default setting of the interfaces

Factory setting for inverters with PROFIBUS or PROFINET interface

Speed setpoint (main setpoint): p1070[0] = 2050[1]

Jog 1 speed setpoint: p1058, factory setting: 150 rpm

CU230P-2 Control Units

16 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 17

Installing

Default setting 9: "Standard I/O with MOP"

DO 0: p0730, DO 1: p0731

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0, …, DI 3: r0722.3

Speed setpoint (main setpoint): p1070[0] = 1050

Designation in the BOP-2: Std MoP

Default setting 12: "Standard I/O with analog setpoint"

DO 1: p0731

AO 1: p0771[1]

Speed setpoint (main setpoint): p1070[0] = 755[0]

Designation in the BOP-2: Std ASP

3.5 Default setting of the interfaces

Motorized potentiometer, setpoint after the ramp-function generator: r1050

Factory setting for inverters with USS, Modbus, BACnet, MS/TP or P1 interface

DO 0: p0730,

AO 0: p0771[0],

DI 0: r0722.0, …, DI 2: r0722.2 AI 0: r0755[0]

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

17

Page 18

Installing

Default setting 14: "Process industry with fieldbus"

DO 0: p0730, DO 1: p0731

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0, …, DI 5: r0722.5

Speed setpoint (main setpoint): p1070[0] = 2050[1], p1070[1] = 1050

Designation in the BOP-2: Proc Fb

3.5 Default setting of the interfaces

Motorized potentiometer, setpoint after the ramp-function generator: r1050

CU230P-2 Control Units

18 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 19

Installing

Default setting 15: "Process industry"

DO 1: p0731

AO 1: p0771[1]

Speed setpoint (main setpoint): p1070[0] = 755[0], p1070[1] = 1050

Designation in the BOP-2: Proc

Default setting 17: "2-wire (forward/backward 1)"

DO 1: p0731

AO 1: p0771[1]

Speed setpoint (main setpoint): p1070[0] = 755[0]

Designation in the BOP-2: 2-wIrE 1

3.5 Default setting of the interfaces

DO 0: p0730,

Motorized potentiometer, setpoint after the ramp-function generator: r1050

AO 0: p0771[0],

DO 0: p0730,

AO 0: p0771[0],

DI 0: r0722.0, …, DI 5: r0722.5 AI 0: r0755[0]

DI 0: r0722.0, …, DI 2: r0722.2 AI 0: r0755[0]

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

19

Page 20

Installing

Default setting 18: "2-wire (forward/backward 2)"

DO 1: p0731

AO 1: p0771[1]

Speed setpoint (main setpoint): p1070[0] = 755[0]

Designation in the BOP-2: 2-wIrE 2

Default setting 19: "3-wire (enable/forward/backward)"

DO 1: p0731

AO 1: p0771[1]

Speed setpoint (main setpoint): p1070[0] = 755[0]

Designation in the BOP-2: 3-wIrE 1

3.5 Default setting of the interfaces

DO 0: p0730,

AO 0: p0771[0],

DI 0: r0722.0, …, DI 2: r0722.2 AI 0: r0755[0]

DO 0: p0730,

CU230P-2 Control Units

AO 0: p0771[0],

DI 0: r0722.0, …, DI 4: r0722.4 AI 0: r0755[0]

20 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 21

Installing

Default setting 20: "3-wire (enable/on/reverse)"

DO 1: p0731

AO 1: p0771[1]

Speed setpoint (main setpoint): p1070[0] = 755[0]

Designation in the BOP-2: 3-wIrE 2

Default setting 21: "USS fieldbus"

DO 0: p0730, DO 1: p0731

AO 0: p0771[0], AO 1: p0771[1]

DI 2: r0722.2

Speed setpoint (main setpoint): p1070[0] = 2050[1]

Designation in the BOP-2: FB USS

3.5 Default setting of the interfaces

DO 0: p0730,

AO 0: p0771[0],

DI 0: r0722.0, …, DI 4: r0722.4 AI 0: r0755[0]

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

21

Page 22

Installing

Default setting 101: "Universal application"

DO 2: p0732

Designation in the BOP-2: P_F 6PA

3.5 Default setting of the interfaces

DO 0: p0730, …,

Additional settings:

• Fixed speed setpoint 1: p1001 = 800 rpm

• Fixed speed setpoint 2: p1002 = 1000 rpm

• Fixed speed setpoint 3: p1003 = 1200 rpm

• If several of the DI 3 ... DI 5 = high, the inverter adds the corresponding fixed speeds.

• Fixed speed setpoint 15 for essential service mode (ESM): p1015 = 1500 rpm

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

faults and switches on the motor: p1210 = 26

AO 0: p0771[0], AO 1: p0771[1] DI 0: r0722.0, …, DI 5: r0722.5 AI 0: r0755[0]

CU230P-2 Control Units

22 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 23

Installing

Default setting 103: "Pump pressure control"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0

AI 0: r0755[0]

Designation in the BOP-2: P_F dPc

3.5 Default setting of the interfaces

Additional settings:

• Differential pressure control using the technology controller

• Technological unit: p0595 = 1 (%), reference variable: p0596 = 1

• Default setting of the technology controller:

– Enable: p2200 = 1

– Fixed value 1: p2201 = 50 %

– Ramp-up/down time for setpoint: p2257 = p2258 = 30 s

– Ramp-up/down time for controller output: p2293 = 30 s

– Upper and lower limits, actual value: p2267 = 120 %, p2268 = -10 %

– Actual value filter time constant: p2265 = 10 s

– Proportional gain K

p2285 (T

) = 30 s, p2274 (TD) = 0 s

I

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

faults and switches on the motor: p1210 = 26

, integral time TI, differentiation time constant TD: p2280 (KP) = 1,

P

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

23

Page 24

Installing

Default setting 104: "ESM stairwell pressure control"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0

AI 0: r0755[0]

Designation in the BOP-2: P_F Stw

3.5 Default setting of the interfaces

Additional settings:

• Pressure control using the technology controller

• Analog inputs smoothing time constant: p0753 = 500 ms

• Technological unit: p0595 = 1 (%), reference variable: p0596 = 1

• Default setting of the technology controller:

– Enable: p2200 = 1

– Fixed value 1: p2201 = 40 %

– Ramp-up/down time for setpoint: p2257 = p2258 = 30 s

– Ramp-up/down time for controller output: p2293 = 30 s

– Upper and lower limits, actual value: p2267 = 120 %, p2268 = -10 %

– Actual value filter time constant: p2265 = 10 s

– Proportional gain K

p2285 (T

) = 25 s, p2274 (TD) = 0 s

I

– Technology controller minimum limiting p2292 = 30 %

– Technology controller output signal start value p2302 = 35 %

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

faults and switches on the motor: p1210 = 26

, integral time TI, differentiation time constant TD: p2280 (KP) = 1.2,

P

CU230P-2 Control Units

24 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 25

Installing

Default setting 105: "Fan pressure control + ESM with fixed setpoint"

DO 2: p0732

Designation in the BOP-2: P_F Pc5

3.5 Default setting of the interfaces

DO 0: p0730, …,

AO 0: p0771[0], AO 1: p0771[1] DI 0: r0722.0, DI 1: r0722.1 AI 0: r0755[0]

Additional settings:

• Pressure control using the technology controller

• Analog inputs smoothing time constant: p0753 = 500 ms

• Technological unit: p0595 = 1 (%), reference variable: p0596 = 1

• Fixed speed setpoint 15 for essential service mode (ESM): p1015 = 1350 rpm

• Default setting of the technology controller:

– Enable: p2200 = 1

– Fixed value 1: p2201 = 40 %

– Ramp-up/down time for setpoint: p2257 = p2258 = 30 s

– Ramp-up/down time for controller output: p2293 = 30 s

– Upper and lower limits, actual value: p2267 = 120 %, p2268 = -10 %

– Actual value filter time constant: p2265 = 10 s

– Proportional gain K

p2285 (T

) = 35 s, p2274 (TD) = 0 s

I

, integral time TI, differentiation time constant TD: p2280 (KP) = 1.1,

P

– Technology controller minimum limiting p2292 = 20 %

– Technology controller output signal start value p2302 = 50 %

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

faults and switches on the motor: p1210 = 26

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

25

Page 26

Installing

Default setting 106: "Cooling tower with active sensor + hibernation"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0

AI 0: r0755[0]

Designation in the BOP-2: P_F ctF1

3.5 Default setting of the interfaces

Additional settings:

• Temperature control using the technology controller

• Analog inputs smoothing time constant: p0753 = 100 ms

• Technological unit: p0595 = 1 (%), reference variable: p0596 = 1

• Default setting of the technology controller:

– Enable: p2200 = 1

– Fixed value 1: p2201 = 26 %

– Ramp-up/down time for setpoint: p2257 = p2258 = 30 s

– Ramp-up/down time for controller output: p2293 = 30 s

– Upper and lower limits, actual value: p2267 = 120 %, p2268 = -10 %

– Actual value filter time constant: p2265 = 10 s

– Proportional gain K

p2285 (T

) = 25 s, p2274 (TD) = 0 s

I

– Technology controller system deviation inversion: p2306 = 1

• Default setting hibernation mode:

– Activated: p2398 = 1

– Start speed: p2390 = 50 rpm

– Delay time: p2391 = 60 s

– Restart value with technology controller: p2392 = 1 %

– Restart speed relative w/o technology controller: p2393 = 100 rpm

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

faults and switches on the motor: p1210 = 26

, integral time TI, differentiation time constant TD: p2280 (KP) = 1.2,

P

CU230P-2 Control Units

26 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 27

Installing

Default setting 107: "Cooling tower with LG-Ni1000 sensor + hibernation"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0

AI 3: r0755[3]

Designation in the BOP-2: P_F ctF2

3.5 Default setting of the interfaces

Additional settings:

• Temperature control using the technology controller

• Analog inputs smoothing time constant: p0753 = 100 ms

• Technological unit: p0595 = 1 (%), reference variable: p0596 = 1

• Default setting of the technology controller:

– Enable: p2200 = 1

– Fixed value 1: p2201 = 26 %

– Ramp-up/down time for setpoint: p2257 = p2258 = 30 s

– Ramp-up/down time for controller output: p2293 = 30 s

– Upper and lower limits, actual value: p2267 = 120 %, p2268 = -100 %

– Actual value filter time constant: p2265 = 10 s

– Proportional gain K

p2285 (T

) = 25 s, p2274 (TD) = 0 s

I

– Technology controller minimum limiting p2292 = 20 %

– Technology controller system deviation inversion: p2306 = 1

• Default setting hibernation mode:

– Activated: p2398 = 1

– Start speed: p2390 = 50 rpm

– Delay time: p2391 = 60 s

– Restart value with technology controller: p2392 = 1 %

– Restart speed relative w/o technology controller: p2393 = 100 rpm

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

faults and switches on the motor: p1210 = 26

, integral time TI, differentiation time constant TD: p2280 (KP) = 1.2,

P

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

27

Page 28

Installing

Default setting 108: "USS fieldbus"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 2: r0722.2

Designation in the BOP-2: P_F USS

Default setting 109: "Modbus RTU field"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 2: r0722.2

Designation in the BOP-2: P_F Mod

3.5 Default setting of the interfaces

CU230P-2 Control Units

28 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 29

Installing

Default setting 110: "BACnet MS/TP fieldbus"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 2: r0722.2

Designation in the BOP-2: P_F bAc

Default setting 111: "Fixed setpoints"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0, …, DI 3: r0722.3

Designation in the BOP-2: P_F _F55

3.5 Default setting of the interfaces

Additional settings:

• Fixed speed setpoint 1: p1001 = 300 rpm

• Fixed speed setpoint 2: p1002 = 600 rpm

• Fixed speed setpoint 3: p1003 = 900 rpm

• Fixed speed setpoint 4: p1004 = 1200 rpm

• If several of the DI 0 ... DI 3 = high, the inverter adds the corresponding fixed speeds.

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

faults and switches on the motor: p1210 = 26

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

29

Page 30

Installing

Default setting 112: "CO2 sensor, 2 PID setpoints"

DO 2: p0732

Designation in the BOP-2: P_F_CO2

3.5 Default setting of the interfaces

DO 0: p0730, …,

AO 0: p0771[0], AO 1: p0771[1] DI 0: r0722.0, DI 2: r0722.2 AI 0: r0755[0]

Additional settings:

• CO

• Analog inputs smoothing time constant: p0753 = 500 ms

• Technological unit: p0595 = 1 (%), reference variable: p0596 = 1

• Default setting of the technology controller:

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

control using the technology controller

2

– Enable: p2200 = 1

– Fixed value 1: p2201 = 50 %

– Fixed value 3: p2203 = 10 %

– Technology controller setpoint 1: p2253 = r2224 (active fixed value)

– Ramp-up/down time for setpoint: p2257 = p2258 = 30 s

– Upper and lower limits, actual value: p2267 = 120 %, p2268 = -10 %

– Actual value filter time constant: p2265 = 10 s

– Technology controller system deviation inversion: p2306 = 1

faults and switches on the motor: p1210 = 26

CU230P-2 Control Units

30 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 31

Installing

Default setting 113: "Temperature-dependent pressure setpoint"

DO 2: p0732

Designation in the BOP-2: P_F_tP5

3.5 Default setting of the interfaces

DO 0: p0730, …,

AO 0: p0771[0], AO 1: p0771[1] DI 0: r0722.0 AI 0: r0755[0], AI 2: r0755[2]

Additional settings:

• Temperature control using the technology controller

• Technological unit: p0595 = 1 (%), reference variable: p0596 = 1

• Default setting of the technology controller:

– Enable: p2200 = 1

– Upper and lower limits, setpoint: p20229 = 0.5 , p20230 = 0.2

– Ramp-up/down time for setpoint: p2257 = p2258 = 30 s

– Ramp-up/down time for controller output: p2293 = 30 s

– Upper and lower limits, actual value: p2267 = 120 %, p2268 = -10 %

– Actual value filter time constant: p2265 = 10 s

– Technology controller minimum limiting p2292 = 20 %

• "Flying restart" is enabled: p1200 = 1

• Automatic restart is active. After a power failure, the inverter automatically acknowledges possible

faults and switches on the motor: p1210 = 26

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

31

Page 32

Installing

Default setting 114: "P1 fieldbus"

DO 0: p0730, …, DO 2: p0732

AO 0: p0771[0], AO 1: p0771[1]

DI 2: r0722.2

Designation in the BOP-2: p_f_P1

Default setting 120: "PID settings for pumps and fans"

3.5 Default setting of the interfaces

The default setting restores the function of the terminal strip to the factory setting.

Technology controller setting:

● Ramp-up/down time for setpoint: p2257 = p2258 = 30 s

● Ramp-up/down time for controller output: p2293 = 30 s

● Actual value upper limit: p2267 = 120%

● Actual value filter time constant: p2265 = 10 s

Designation in the BOP-2: P_F_PID

CU230P-2 Control Units

32 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 33

4

4.1

Tools to commission the converter

Operator panel

Intelligent Operator Panel (IOP)

Operator Panel BOP-2

PC tools

STARTER

Startdrive

An operator panel is used to commission, troubleshoot and control the inverter, as well as to

back up and transfer the inverter settings.

The

handheld with a connecting cable to the inverter. The graphics-capable plain text display of

the IOP enables intuitive operation and diagnostics of the inverter.

The IOP is available in two versions:

● With European languages

● With Chinese, English and German

is available for snapping onto the inverter, or as

Additional information about the compatibility of the IOP and inverters is available in the

Internet:

Compatibility of the IOP and Control Units

(http://support.automation.siemens.com/WW/view/en/67273266)

The

diagnostics and operating the inverter.

Operating Instructions of the BOP-2 and IOP operator panels:

Overview of the manuals (Page 49)

the inverter, as well as to back up and transfer the inverter settings. You can connect the PC

with the inverter via USB or via the PROFIBUS / PROFINET fieldbus.

Connecting cable (3 m) between PC and inverter: Article number 6SL3255-0AA00-2CA0

STARTER DVD: Article number 6SL3072-0AA00-0AG0

Startdrive DVD: Article number 6SL3072-4CA02-1XG0

STARTER (http://support.automation.siemens.com/WW/view/en/26233208)

and

for snapping onto the inverter has a two-line display for

are PC tools that are used to commission, troubleshoot and control

Startdrive (http://support.automation.siemens.com/WW/view/en/68034568)

STARTER videos (http://www.automation.siemens.com/mcms/mc-drives/en/low-voltage-

inverter/sinamics-g120/videos/Pages/videos.aspx)

Startdrive tutorial (http://support.automation.siemens.com/WW/view/en/73598459)

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

33

Page 34

Commissioning

4.2

Commissioning with BOP-2 operator panel

4.2.1

Start quick commissioning and select the application class

Starting quick commissioning

Preconditions

Procedure

4.2 Commissioning with BOP-2 operator panel

● The power supply is switched on.

● The operator panel displays setpoints and actual values.

Proceed as follows to carry out quick commissioning:

Press the ESC key.

Press one of the arrow keys until the BOP-2 displays the "SETUP" menu.

To start quick commissioning, in the "SETUP" menu, press the OK key.

If you wish to restore all of the parameters to the factory setting before the quick

commissioning, proceed as follows:

1. Press the OK key.

2. Switchover the display using an arrow key: nO → YES

3. Press the OK key.

You must select the application class if you are not using a PM230, but instead, a PM240-2,

PM240P-2 or PM330 Power Module. The next steps after having selected an application

class are described in the operating instructions.

Overview of the manuals (Page 49)

Select the motor standard.

● KW 50HZ: IEC

● HP 60HZ: NEMA

● KW 60HZ: IEC 60 Hz

Set the inverter supply voltage.

Select the motor type. If a 5-digit motor code is stamped on the motor rating plate, select the

corresponding motor type with motor code.

Motors without motor code stamped on the rating plate:

● INDUCT: Third-party induction motor

● 1L… IND: 1LE1, 1LG6, 1LA7, 1LA9 induction motors

CU230P-2 Control Units

34 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 35

Commissioning

4.2 Commissioning with BOP-2 operator panel

Motors with motor code stamped on the rating plate:

● 1LE1 IND 100: 1LE1 . 9

● 1PC1 IND: 1PC1

● 1PH8 IND: Induction motor

● 1FP1: Reluctance motor

Depending on the inverter, the motor list in BOP-2 can deviate from the list shown above.

If you have selected a motor type with motor code, you must now enter the motor code. The

inverter assigns the following motor data corresponding to the motor code.

If you do not know the motor code, then you must set the motor code = 0, and enter motor

data from p0304 and higher from the rating plate.

87 Hz motor operation The BOP-2 only indicates this step if you selected IEC as the motor

standard (EUR/USA, P100 = KW 50HZ).

Rated motor voltage

Rated motor current

Rated motor power

Rated motor frequency

Rated motor speed

Motor cooling:

● SELF: Natural cooling

● FORCED: Forced-air cooling

● LIQUID: Liquid cooling

● NO FAN: Without fan

Select the appropriate application:

● VEC STD: In all applications, which do not fit the other setting options.

● PUMP FAN: Applications involving pumps and fans

● SLVC 0HZ: Applications with short ramp-up and ramp-down times. However, this setting

is not suitable for hoisting gear and cranes/lifting gear.

● PUMP 0HZ: Setting only for steady-state operation with slow speed changes. We

recommend setting VEC STD if load surges in operation cannot be ruled out.

The selection option depends on the Power Module being used. There is no selection option

for PM230 Power Modules.

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

35

Page 36

Commissioning

Select a suitable control mode

Control mode

U/f control with linear or square-law characteris-

tic

Flux current control (FCC)

Vector control without encoder

Closed-loop control characteristics

Typical correction time after a speed change:

Application examples

Motors that can be

operated

Power Modules

that can be operated

Max. output frequency

150 Hz with PM330 Power Module

Commissioning

4.2 Commissioning with BOP-2 operator panel

Select the control mode:

● VF LIN: U/f control with linear characteristic

● VF LIN F: Flux current control (FCC)

● VF QUAD: U/f control with square-law characteristic

● SPD N EN: Sensorless vector control

•

100 ms … 200 ms

• Typical correc-

tion time after a

load surge:

500 ms

• The control

mode is suitable

to address the

following requirements:

– Motor power

ratings < 45 kW

– Ramp-up time 0 → Rated speed (de-

pendent on the rated motor power):

1 s (0.1 kW) … 10 s (45 kW)

– Applications with increasing load torque

without load surges

• The control mode is insensitive with respect

to inaccurate motor data settings

• Typical correction time after a speed change:

< 100 ms

• Typical correction

time after a load

surge: 200 ms

• The vector control

controls and limits

the motor torque

• Torque accuracy

that can be

achieved: ± 5 % for

15 % … 100 % of

the rated speed

• We recommend vector control for the following

applications:

– Motor power ratings > 11 kW

– For load surges 10 % … >100 % of the rat-

ed motor torque

• The vector control is necessary for a ramp-up

time 0 → Rated speed (dependent on the rated

motor power):

< 1 s (0.1 kW) … < 10 s (250 kW).

CU230P-2 Control Units

36 Compact Operating Instructions, 01/2017, A5E38815802B AA

• Pumps, fans, and compressors with flow

characteristic

• Contrary to vector control, no speed control-

ler has to be set

• Pumps and compressors with displacement

machines

Induction motors Induction, synchronous and reluctance motors

No restrictions

550 Hz 240 Hz

Page 37

Commissioning

CAUTION

Material damage caused by the motor unexpectedly accelerating

4.2 Commissioning with BOP-2 operator panel

Select the default setting for the interfaces of the inverter that is suitable for your application.

Default setting of the interfaces (Page 16)

Figure 4-1 Minimum and maximum motor frequency

Depending on the particular Power Module, the inverter sets the minimum frequency p1080

to 20% of the maximum frequency. Also for a setpoint = 0, for p1080 > 0, after the motor is

switched on it accelerates to the minimum frequency. Material damage can occur if the

motor unexpectedly accelerates.

• If the application requires a minimum frequency = 0, then set p1080 = 0.

Scaling of analog input 0

Figure 4-2 Ramp-up and ramp-down time of the motor

Ramp-down time for the OFF3 command

Motor data identification: Select the method which the inverter uses to measure the data of

the connected motor:

● OFF: Motor data is not measured.

● STIL ROT: Recommended setting: Measure the motor data at standstill and with the

motor rotating. The inverter switches off the motor after the motor data identification has

been completed.

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

37

Page 38

Commissioning

4.2.2

Identifying the motor data and optimizing the closed-loop control

WARNING

Risk of death due to machine motion while motor data identification is active

Preconditions

4.2 Commissioning with BOP-2 operator panel

● STILL: Measure the motor data at standstill. The inverter switches off the motor after the

motor data identification has been completed.

Select this setting if one of the following cases is applicable:

– You have selected the control mode "SPD N EN". However, the motor cannot rotate

freely – for example, if the traversing range is mechanically limited.

– You have selected U/f control as control mode, e.g. "VF LIN" or "VF QUAD".

● ROT: Measure the motor data with the motor rotating. The inverter switches off the motor

after the motor data identification has been completed.

Complete quick commissioning:

Switchover the display using an arrow key: nO → YES

Press the OK key.

You have completed quick commissioning.

The inverter has several techniques to automatically identify the motor data and optimize the

speed control.

To start the motor data identification routine, you must switch-on the motor via the terminal

strip, fieldbus or from the operator panel.

For the stationary measurement, the motor can make several rotations. The rotating

measurement accelerates the motor up to its rated speed. Secure dangerous machine

parts before starting motor data identification:

• Before switching on, ensure that nobody is working on the machine or located within its

working area.

• Secure the machine's work area against unintended access.

• Lower hanging/suspended loads to the floor.

● You selected a method of motor data identification during quick commissioning, e.g.

measuring motor data while the motor is stationary.

When quick commissioning is complete, the inverter issues alarm A07991.

● The motor has cooled down to the ambient temperature.

An excessively high motor temperature falsifies the motor data identification results.

CU230P-2 Control Units

38 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 39

Commissioning

Procedure when using the BOP-2 operator panel

4.2 Commissioning with BOP-2 operator panel

To start the motor data identification, proceed as follows:

Press the HAND/AUTO key.

The BOP-2 displays the symbol indicating manual operation.

Switch on the motor.

During motor data identification, "MOT-ID" flashes on the BOP-2.

If the inverter again outputs alarm A07991, then it waits for a new ON command to start the

rotating measurement.

If the inverter does not output alarm A07991, switch off the motor as described below, and

switch over the inverter control from HAND to AUTO.

Switch on the motor to start the rotating measurement.

During motor data identification, "MOT-ID" flashes on the BOP-2.

The motor data identification can take up to 2 minutes depending on the rated motor power.

Depending on the setting, after motor data identification has been completed, the inverter

switches off the motor - or it accelerates it to the setpoint.

If required, switch off the motor.

Switch the inverter control from HAND to AUTO.

You have completed the motor data identification.

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

39

Page 40

Commissioning

4.3

Connecting the inverter to the fieldbus

Where can I find instructions for the fieldbus connection of the inverter?

Description files for fieldbuses

Alternative for the download for GSD and GSDML

4.3.1

PROFINET and PROFIBUS

Examples for telegrams via PROFIBUS and PROFINET

Telegram 1:

STW1

Control word 1

ZSW1

Status word 1

PZD01/02

Process data 16-bit

NSOLL_A

Speed setpoint

NIST_A

Speed actual value

4.3 Connecting the inverter to the fieldbus

Instructions for connecting to a fieldbus can be downloaded from the Internet:

● Application examples (http://support.automation.siemens.com/WW/view/en/60733299)

● Operating Instructions: CU230P-2 operating instructions

(https://support.industry.siemens.com/cs/ww/en/view/109478827)

● "Fieldbuses" function manual: Manuals for the Control Unit

(http://support.automation.siemens.com/WW/view/en/30563628/133300)

The description files are electronic device data sheets which contain all the required

information of a higher-level controller. You can configure and operate the inverter on a

fieldbus with the appropriate description file.

Generic Station Description for PROFIBUS: GSD

(http://support.automation.siemens.com/WW/view/en/23450835)

GSD Markup Language for PROFINET: GSDML

(http://support.automation.siemens.com/WW/view/en/26641490)

Ethernet/IP: EDS (http://support.automation.siemens.com/WW/view/en/78026217)

BACnet MS/TP: PICS (http://www.big-

eu.org/uploads/tx_teproddb/catalog_pdf/PICS_CU230P-2_HVAC_v46_HF.docx)

GSD and GSDML are saved in the inverter. If you insert a memory card in the inverter and

set p0804 = 12, then the inverter writes the GSD or the GSDML to the memory card. You

can then transfer the file to your programming device or PC using the memory card.

CU230P-2 Control Units

40 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 41

Commissioning

Te

STW1

Control word 1

IAIST_GLATT

Smoothed current actual

value

ZSW1

Status word 1

MIST_GLATT

Smoothed torque

PZD01/02

Process data 16-bit

PIST_GLATT

Smoothed active power

NSOLL_A

Speed setpoint

MELD_NAMUR

Control word according to

the VIK

NIST_A_GLATT

Smoothed actual speed value

Control word 1 (STW1), PZD receive word 1 (word: r2050[0], bits: r2090.00 … r2090.15)

Bit

Meaning

Explanation

inverter switches off the motor at standstill.

0 = OFF2

Switch off the motor immediately, the motor then coasts down to a standstill.

1 = No OFF2

Precondition in order to be able to switch on the motor using bit 0 (ON command).

0 = Quick stop (OFF3)

The motor brakes with the OFF3 ramp-down time p1135 down to standstill.

1 = No quick stop (OFF3)

Precondition in order to be able to switch on the motor using bit 0 (ON command).

0 = Inhibit operation

Switch off the motor immediately → motor coasts down to a standstill.

1 = Enable operation

Precondition in order to be able to switch on the motor using bit 0 (ON command).

0 = Disable RFG

The inverter immediately sets its ramp-function generator output to 0.

1 = Do not disable RFG

The ramp-function generator can be enabled.

0 = Stop RFG

The output of the ramp-function generator stops at the actual value.

1 = Enable RFG

The output of the ramp-function generator follows the setpoint.

generator.

1 = Enable setpoint

Motor accelerates with the ramp-up time p1120 to the setpoint.

"closing lockout" state.

8, 9

Reserved

0 = No control via PLC

The inverter ignores the process data from the fieldbus.

1 = Control via PLC

Control via fieldbus, the inverter accepts the process data from the fieldbus.

12

Not used

14

1 = MOP down

Reduce the setpoint saved in the motorized potentiometer.

15

Reserved

Changes over between settings for different operation interfaces (command data sets).

4.3 Connecting the inverter to the fieldbus

legram 20:

-NAMUR definition

0 0 = OFF1 The motor brakes with the ramp-down time p1121 of the ramp-function generator. The

0 → 1 = ON The inverter goes into the "ready" state. If, in addition bit 3 = 1, then the inverter

1

2

3

4

switches on the motor.

5

6 0 = Inhibit setpoint The inverter brakes the motor with the ramp-down time p1121 of the ramp-function

7 0 → 1 = Acknowledge faults Acknowledge fault. If the ON command is still active (bit 0 = 1), the inverter switches to

10

11 1 = Direction reversal Invert setpoint in the inverter.

13 1 = MOP up Increase the setpoint saved in the motorized potentiometer.

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

41

Page 42

Commissioning

Status word 1 (ZSW1), PZD send word 1 (word: p2051[0], bits: p2080[0] … p2080[15])

Bit

Meaning

Comments

0

1 = Ready to start

Power supply switched on; electronics initialized; pulses locked.

2

1 = Operation enabled

Motor follows setpoint. See control word 1, bit 3.

4

1 = OFF2 inactive

Coast down to standstill is not active.

5

1 = OFF3 inactive

Quick stop is not active.

6

1 = Closing lockout active

It is only possible to switch on the motor after an OFF1 followed by ON.

7

1 = Alarm active

Motor remains switched on; no acknowledgement is necessary.

tolerance range

9

1 = Master control requested

The automation system is requested to accept the inverter control.

or exceeded

11

1 = torque limit reached

Comparison value for current or torque has been reached or exceeded.

12

1 = Holding brake open

Signal to open and close a motor holding brake.

ture

1 = Motor rotates clockwise

Internal inverter actual value > 0

clockwise

overload

Fault word according to the VIK-NAMUR definition (MELD_NAMUR), PZD send word 16 (word:

p2051[5], bits: r3113.00 … r3113.15)

Bit

Meaning

0 = Control Unit has a no fault

1

1 = line fault: Phase failure or inadmissible voltage

2

1 = DC link overvoltage

3

1 = Power Module fault, e.g. overcurrent or overtemperature

4

1 = inverter overtemperature

5

1 = ground fault/phase fault in the motor cable or in the motor

6

1 = motor overload

7

1 = communication error to the higher-level control

8

1 = error in a safe monitoring channel

10

1 = internal communication error in the inverter

11

1 = line fault

15

1 = other fault

4.3 Connecting the inverter to the fieldbus

1 1 = Ready Motor is switched on (ON/OFF1 = 1), no fault is active. With the command "Enable

3 1 = Fault active The inverter has a fault. Acknowledge fault using STW1.7.

8 1 = Speed deviation within the

10 1 = Comparison speed reached

13 0 = Alarm, motor overtempera-

14

0 = Motor rotates counter-

operation" (STW1.3), the inverter switches on the motor.

Setpoint / actual value deviation within the tolerance range.

Speed is greater than or equal to the corresponding maximum speed.

--

Internal inverter actual value < 0

15 0 = Alarm, inverter thermal

0

1 = Control Unit fault

CU230P-2 Control Units

42 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 43

Commissioning

4.3.2

Modbus RTU

Settings for Modbus RTU

Parameter

Explanation

Macro drive unit

Fieldbus interface baud rate

8: 38400 baud

13: 187500 baud

Fieldbus interface address

switched on again.

Fieldbus

interface

times

[2] dead time between two telegrams

Fieldbus

interface

error statistics

[7] number of length errors

Fieldbus interface protocol selection

p0015 = 109 sets p2013 = 2 → Modbus RTU

Fieldbus interface Modbus

parity

2: Even parity

4.3 Connecting the inverter to the fieldbus

p0015 = 109

p2020

p2021

p2024

r2029

Set communication via Modbus RTU

Default setting of the interfaces (Page 16)

4: 2400 baud

p0015 = 109 sets p2020 = 6

Valid USS addresses: 1 … 247.

The parameter is only active if address 0 is set at the Control Unit address switch.

A change only becomes active after the inverter power supply is switched off and

[0] Maximum permissible telegram processing time of the Modbus

slave

[0] number of error-free telegrams

[1] number of rejected telegrams

[2] number of framing errors

[3] number of overrun errors

5: 4800 baud

6: 9600 baud

7: 19200 baud

9: 57600 baud

10: 76800 baud

11: 93750 baud

12: 115200 baud

[4] number of parity errors

[5] number of starting character

errors

[6] number of checksum errors

p2030 = 2

p2031

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

0: No parity

1: Odd parity

43

Page 44

Commissioning

4.3.3

BACnet MS/TP

Settings for BACnet MS/TP

Parameter

Explanation

Macro drive unit

Fieldbus interface baud rate

8: 38400 baud

13: 187500 baud

Fieldbus interface address

switched on again.

Fieldbus interface times

timeout)

Fieldbus SS BACnet settings

[3] = maximum master address

Fieldbus interface BACnet COV increment

or and ConfirmedCOVNotification.

Fieldbus

interface

error statistics

[7] number of length errors

Fieldbus interface protocol selection

p0015 = 110 sets p2013 = 5 → BACnet MS/TP

4.3 Connecting the inverter to the fieldbus

p0015 = 110

p2020

p2021

p2024

p2025

p2026

Set communication via BACnet MS/TP

Default setting of the interfaces (Page 16)

4: 2400 baud

p0015 = 110 sets p2020 = 6

Valid USS addresses: 1 … 127.

The parameter is only active if address 0 is set at the Control Unit address switch.

A change only becomes active after the inverter power supply is switched off and

Change in value at which point the inverter sends and UnConfirmedCOVNotification

5: 4800 baud

6: 9600 baud

7: 19200 baud

[0] maximum permissible processing time (APDU

[0] = device object instance number

[1] = info maximum number frames

[2] = APDU number of retries

9: 57600 baud

10: 76800 baud

11: 93750 baud

12: 115200 baud

r2029

p2030 = 5

CU230P-2 Control Units

44 Compact Operating Instructions, 01/2017, A5E38815802B AA

[0] number of error-free telegrams

[1] number of rejected telegrams

[2] number of framing errors

[3] number of overrun errors

[4] number of parity errors

[5] number of starting character

errors

[6] number of checksum errors

Page 45

Commissioning

Control word

Parameter

BACNet

Meaning

r2090

.00

p0840

BV20

ON/OFF1

Switch on motor

(OFF3)

RFG

follows the setpoint

to the setpoint

faults

.09

PLC

process data from the fieldbus

.11

p1113

BV21

Direction reversal

Invert setpoint in the inverter

.12

---

N/A

Reserved

potentiometer

potentiometer

.15

---

N/A

Reserved

4.3 Connecting the inverter to the fieldbus

.01 p0844 BV27 No OFF2 Precondition in order to be able to switch on

.02 p0848 BV28 No quick stop

.03 p0852 BV26 Enable operation

.04 p1140 BV26 Do not disable

.05 p1141 BV26 Enable RFG The output of the ramp-function generator

.06 p1142 BV26 Enable setpoint Motor accelerates with the ramp-up time p1120

.07 p2103 BV22 Acknowledge

.08,

--- N/A Reserved

.10 p0854 BV93 Master control by

.13 p1035 N/A MOP raise Increase the setpoint saved in the motorized

the motor (ON command).

The ramp-function generator can be enabled

Control via fieldbus, the inverter accepts the

.14 p1036 N/A MOP lower Reduce the setpoint saved in the motorized

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

45

Page 46

Commissioning

4.4

Frequently required parameters

Parameter

Explanation

Macro drive unit

r0018

Control Unit firmware version

Application class

2: Dynamic Drive Control

IEC/NEMA mot stds

2: NEMA motor (60 Hz, SI units)

p0304

Rated motor voltage [V]

p0305

Rated motor current [A]

p0307

Rated motor power [kW] or [hp]

p0310

Rated motor frequency [Hz]

p0311

Rated motor speed [rpm]

Motor temperature sensor type

Terminal 14

T1 motor (+)

Terminal 15

T2 motor (-)

p0625

Motor ambient temperature during commissioning [° C]

p0640

Current limit [A]

r0722

Digital inputs status

.1

Terminal 6

DI 1

p2200 technology controller enable

.2

Terminal 7

DI 2

.3

Terminal 8

DI 3

.4

Terminal 16

DI 4

.5

Terminal 17

DI 5

.11

Terminal 3, 4

AI 0

Signal source for terminal DO 0

Selection of the possible settings:

Terminals 18, 20 (NC contact)

upper limit

Signal source for terminal DO 1

Terminals 21, 22 (NO contact)

Signal source for terminal DO 2

4.4 Frequently required parameters

p0015

Set defaults for inputs and outputs via a macro.

p0096

p0100

p0601

.0 Terminal 5 DI 0 Selection of the possible settings:

.12 Terminal 10, 11 AI 1

0: Expert

1: Standard Drive Control

0: Europe 50 [Hz]

1: NEMA motor (60 Hz, US units)

0: No sensor (factory setting)

1: PTC (→ P0604)

p0840 ON/OFF (OFF1)

p0844 no coast down (OFF2)

p0848 no quick stop (OFF3)

p0855 unconditionally release holding brake

p1020 fixed speed setpoint selection bit 0

p1021 fixed speed setpoint selection bit 1

p1022 fixed speed setpoint selection bit 2

p1023 fixed speed setpoint selection bit 3

p1035 motorized potentiometer raise setpoint

p1036 motorized potentiometer lower setpoint

p2103 acknowledge faults

p1055 jog bit 0

p1056 jog bit 1

2: KTY84 (→ P0604)

4: Bimetal

p1110 inhibit negative direction

p1111 inhibit positive direction

p1113 setpoint inversion

p1122 bypass ramp-function generator

p1140 enable/inhibit ramp-function

generator

p1141 continue/freeze rampfunction generator

p1142 enable/inhibit setpoint

p1230 DC braking activation

p2103 acknowledge faults

p2106 external fault 1

p2112 external alarm 1

p0730

Terminals 19, 20 (NO contact)

p0731

p0732

Terminals 24, 25 (NO contact)

Terminals 23, 25 (NC contact)

CU230P-2 Control Units

46 Compact Operating Instructions, 01/2017, A5E38815802B AA

52.0 ready for switching on

52.1 ready for operation

52.2 operation enabled

52.3 fault present

52.4 coast down active (OFF2)

52.5 quick stop active (OFF3)

52.7 alarm present

52.14 motor rotates forwards

53.0 DC braking active

53.1 n_act > p2167 (n_off)

53.2 n_act ≤ p1080 (n_min)

53.3 I_act > p2170

53.4 n_act > p2155

53.5 n_act ≤ p2155

53.6 n_act ≥ n_set

53.10 technology controller output at

lower limit

53.11 technology controller output at

Page 47

Commissioning

Parameter

Explanation

r0755

Analog inputs actual value [%]

[0]

Terminals 3, 4

AI 0

[1]

Terminals 10, 11

AI 1

[3]

Terminals 52, 53

AI 3

Analog input type

10: Temperature sensor DIN Ni 1k (6180 ppm / K)

[0]

AI 0

[1]

AI 1

[2]

AI 2

p0771

Analog outputs signal source

Selection of the possible settings:

[0]

Terminals 12, 13

AO 0

absolute value)

p0776

Analog outputs, type

[0]

AO 0

[1]

AO 1

p0922

PROFIdrive telegram selection

p1001

Fixed speed setpoint 1

p1002

Fixed speed setpoint 2

Fixed speed setpoint 3

p1004

Fixed speed setpoint 4

p1058

Jog 1 speed setpoint

p1059

Jog 2 speed setpoint

Main setpoint

Selection of the possible settings:

1024: Fixed setpoint

p1080

Minimum speed [rpm]

p1082

Maximum speed [rpm]

p1120

Ramp-function generator ramp-up time [s]

p1121

Ramp-function generator ramp-down time [s]

Open-loop/closedloop control operating mode

Selection of the possible settings:

20: Speed control (without encoder)

p1310

Starting (voltage boost) permanent

Pulse frequency setpoint

4.4 Frequently required parameters

[2] Terminals 50, 51 AI 2

p0756

[3] AI 3

[1] Terminals 26, 27 AO 1

0: Unipolar voltage input (0 V …+10 V)

1: Unipolar voltage input monitored (+2 V... +10 V)

2: Unipolar current input (0 mA …+20 mA)

3: Unipolar current input monitored (+4 mA …+20 mA)

4: Bipolar voltage input (-10 V …+10 V)

6: LG-Ni1000 temperature sensor

7: PT1000 temperature sensor

8: No sensor connected

0: Analog output locked

21: Speed actual value

24: Output frequency, smoothed

0: Current output (0 mA … +20 mA)

1: Voltage output (0 V … +10 V)

2: Current output (+4 mA ... +20 mA)

25: Output voltage, smoothed

26: DC-link voltage smoothed

27: Actual current value (smoothed

p1003

p1070

p1300

p1800

0: Main setpoint = 0

755[0]: Analog input 0

0: U/f control with linear characteristic

1: U/f control with linear characteristic and FCC

1050: Motorized potentiometer

2050[1]: PZD 2 from the fieldbus

2: U/f control with parabolic characteristic

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

47

Page 48

Commissioning

Parameter

Explanation

Motor data identification and rotating measurement

ule)

Fieldbus interface protocol

selection

The possible settings depend on the Control Unit:

3: PROFIBUS

10: EtherNet/IP

Words received via fieldbus (16 bit)

r2050[0]: PZD01 … r2050[11]: PZD12

Words sent via fieldbus (16 bit)

p2051[0]: PZD01 … p2051[16]: PZD17

Binector-connector converter, status word 1

p2080[0]: Bit 0 … p2080[15]: Bit 15

PROFIdrive PZD1 receive bit-by-bit (control word 1)

r2090.00: Bit 0 … r2090.15: Bit 15

p2200

Technology controller enable

1: Technology controller is enabled

p2215

Technology controller fixed value 1 ... 15

p2223

Technology controller fixed value selection bit 0 ... 3

r2224

Technology controller fixed value active

p2253

Technology controller setpoint 1

p2254

Technology controller setpoint 2

p2257

Technology controller ramp-up time

p2258

Technology controller ramp-down time

p2264

Technology controller actual value

p2265

Technology controller actual value filter time constant

p2267

Technology controller upper limit actual value

p2268

Technology controller lower limit actual value

Technology controller actual

value inversion (sensor type)

es with increasing motor speed)

p2274

Technology controller differentiation time constant

p2280

Technology controller proportional gain

p2285

Technology controller integral time

p2293

Technology controller ramp-up/ramp-down time

4.4 Frequently required parameters

p1900

0: Locked

1: Identify motor data and optimize the speed controller

2: Identify motor data (at standstill)

3: Optimize the speed controller (rotating in operation)

11: Ident. motor data and opt. speed controller, change to operation (not available with PM230 or PM250

Power Module)

12: Identify motor data (at standstill), change to operation (not available with PM230 or PM250 Power Mod-

p2030

0: No protocol

1: USS

2: Modbus RTU

5: BacNet

7: PROFINET

8: P1

r2050

p2051

p2080

r2090

p2201 …

p2220 …

p2271

CU230P-2 Control Units

48 Compact Operating Instructions, 01/2017, A5E38815802B AA

0: No inversion

1: invert actual value signal (this should be set if the actual value decreas-

Page 49

5

5.1

Overview of the manuals

Manuals with additional information that can be downloaded:

● CU230P-2 Compact Operating Instructions

(https://support.industry.siemens.com/cs/ww/en/view/109482992)

Commissioning the inverter (this manual)

● CU230P-2 operating instructions

(https://support.industry.siemens.com/cs/ww/en/view/109482995)

Installing, commissioning and maintaining the inverter. Advanced commissioning

● EMC installation guideline

(http://support.automation.siemens.com/WW/view/en/60612658)

EMC-compliant control cabinet design, potential equalization and cable routing

● CU230P-2 List Manual (https://support.industry.siemens.com/cs/ww/en/view/109482956)

Parameter lists, alarms and faults. Graphic function diagrams

● "Fieldbus" function manual

(https://support.industry.siemens.com/cs/ww/en/view/109483004)

Configuring fieldbuses.

● BOP-2 operating instructions

(https://support.industry.siemens.com/cs/ww/en/view/109483379)

Using the operator panel.

● IOP operating instructions

(https://support.industry.siemens.com/cs/ww/en/view/109478559)

Using the operator panel, installing the door mounting kit for IOP

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

49

Page 50

More information

5.2

Technical support

5.2 Technical support

● Application manual IOP (https://support.industry.siemens.com/cs/ww/en/view/109483443)

The commissioning wizards in the IOP

● Power Module Installation Manual

(https://support.industry.siemens.com/cs/ww/en/ps/13224/man)

Installing Power Modules, reactors and filters. Technical specifications, maintenance

● Accessories manual (https://support.industry.siemens.com/cs/ww/en/ps/13225/man)

Installation descriptions for inverter components, e.g. line reactors or line filters. The

printed installation descriptions are supplied together with the components.

+49 (0)911 895 7222

+44 161 446 5545

+39 (02) 24362000

+34 902 237 238

+33 (0) 821 801 122

You can find additional telephone numbers for Technical Support in the Internet:

Product support (http://www.siemens.com/automation/service&support)

CU230P-2 Control Units

50 Compact Operating Instructions, 01/2017, A5E38815802B AA

Page 51

Page 52

Loading...

Loading...