Page 1

© Siemens AG 2016

Fuse Systems

SENTRON

Configuration

Manual

Edition

10/2015

siemens.com/lowvoltage

Page 2

© Siemens AG 2016

Page 3

Fuse Systems

© Siemens AG 2016

2 Introduction

NEOZED fuse systems

8 NEOZED fuse links

15 DIAZED fuse systems

Cylindrical fuse systems

24 Cylindrical fuse links and cylindrical

fuse holders

32 Fuse holders in size

10 x 38 mm and Class CC

36 Class CC fuse systems

40 Busbar systems

3NA, 3ND LV HRC fuse systems

45 LV HRC fuse links

68 LV HRC signal detectors

69 LV HRC fuse bases and accessories

SITOR seimconductor fuses

78 LV HRC design

147 Cylindrical fuse design

168 NEOZED and DIAZED design

172 Configuration

Photovoltaic fuses

186 Introduction

186 PV cylindrical fuses

191 PV cumulative fuses

For further technical

product information:

Siemens Industry Online Support:

www.siemens.com/lowvoltage/productsupport

Entry type:

Application example

Certificate

Characteristic

Download

FAQ

Manual

Product note

Software archive

Technical data

Siemens · 10/2015

Page 4

© Siemens AG 2016

Fuse Systems

Introduction

■

Overview

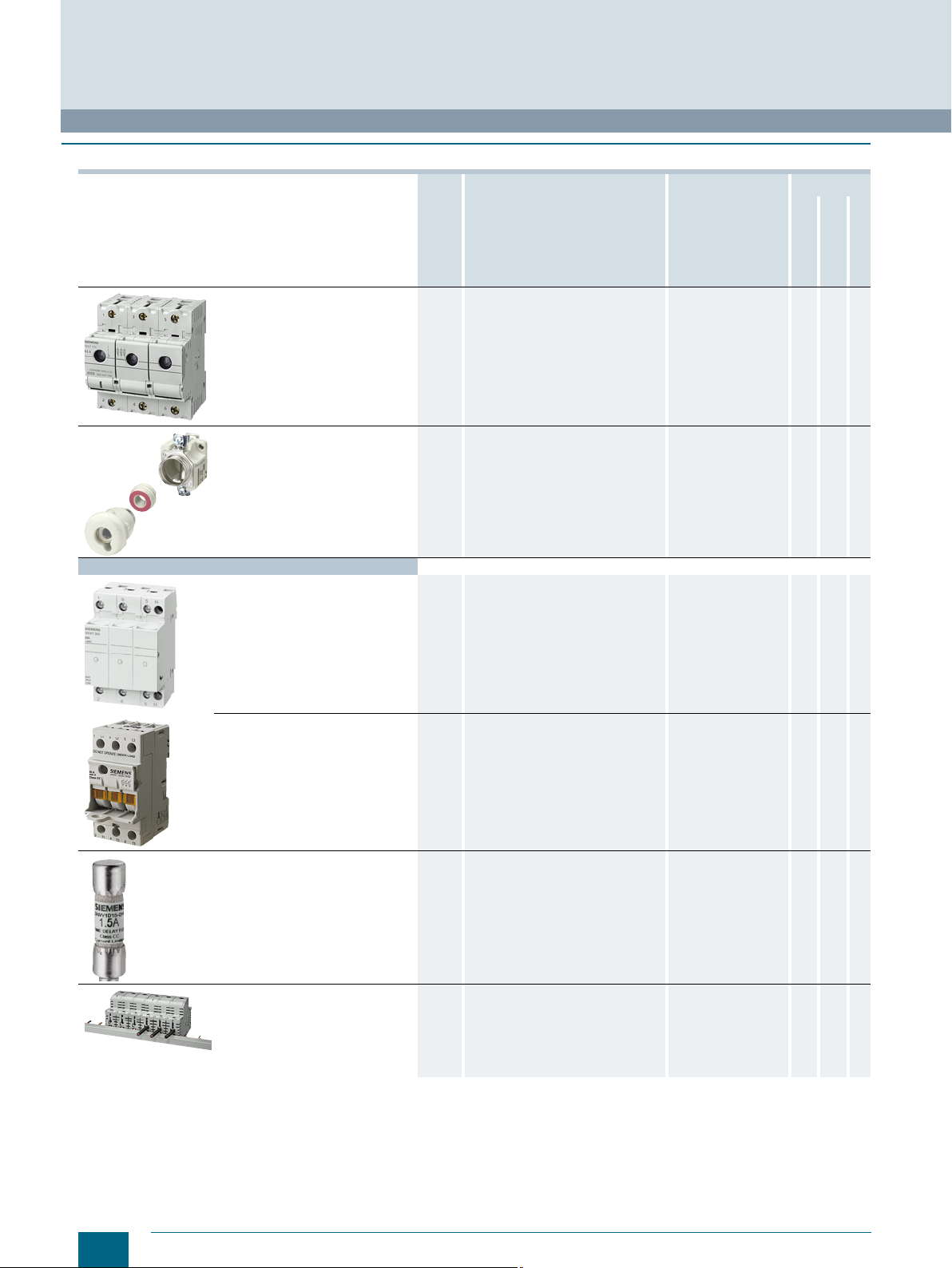

Devices Page Application Standards Used in

NEOZED fuse systems 8 MINIZED switch disconnectors, bases,

DIAZED fuse systems

fuse links from 2 A to 63 A of operational class gG and accessories.

Everything you need for a complete

system.

15 Fuse links from 2 A to 100 A in various

operational classes, base versions with

classic screw base connections.

A widely used fuse system.

Fuse system:

IEC 60269-3;

DIN VDE 0636-3

Safety switching

devices

IEC/EN 60947-3

DIN VDE 0638;

DIN EN 60947-3

(VDE 0660-107)

IEC 60269-3;

DIN VDE 0635;

DIN VDE 0636-3;

CEE 16

Non-residential

buildings

Residential

buildings

✓ ✓ ✓

✓ ✓ ✓

Industry

Cylindrical fuse systems

Cylindrical fuse links and cylindrical

fuse holders

Fuse holders in size 10 x 38 mm and

Class CC

Class CC fuse systems

Busbar systems

24 Line protection or protection of

switching devices.

The fuse holders with touch protection

ensure the safe "no-voltage"

replacement of fuse links.

Auxiliary switches can be retrofitted.

32 For installing fused loaded motor starter

combinations.

36 These comply with American standard

and have UL and CSA approval, for

customers exporting OEM products

and mechanical engineers.

Modern design with touch protection

according to BGV A3 for use in "branch

circuit protection".

40 Busbars for NEOZED fuse bases,

NEOZED fuse disconnectors, MINIZED

switch disconnectors, DIAZED fuse

systems and for the cylindrical fuse

systems.

Compact cylindrical fuse holders for

busbars.

IEC 60269-1, -2, -3;

NF C 60-200;

NF C 63-210, -211;

NBN C 63269-2,

CEI 32-4, -12

Fuse holders:

File No. E171267

IEC 60269-1, -2;

IEC 60947-4;

UL 4248-1,

File No. E171267

CSA 250269, 6225-01

Auxiliary switches:

UL 508,

File No. E334003

Fuse holders:

UL 4248-1, E171267

CSA 22.2

Fuse links:

UL 248-4,

File No. E258218,

CSA 231237, 1422-02

and 1422-82

DIN EN 60439-1

(VDE 0660-500)

UL 4248-1, E337131

✓ ✓ ✓

✓ -- ✓

✓ ✓ ✓

✓ ✓ ✓

2

Siemens · 10/2015

Page 5

© Siemens AG 2016

Fuse Systems

Introduction

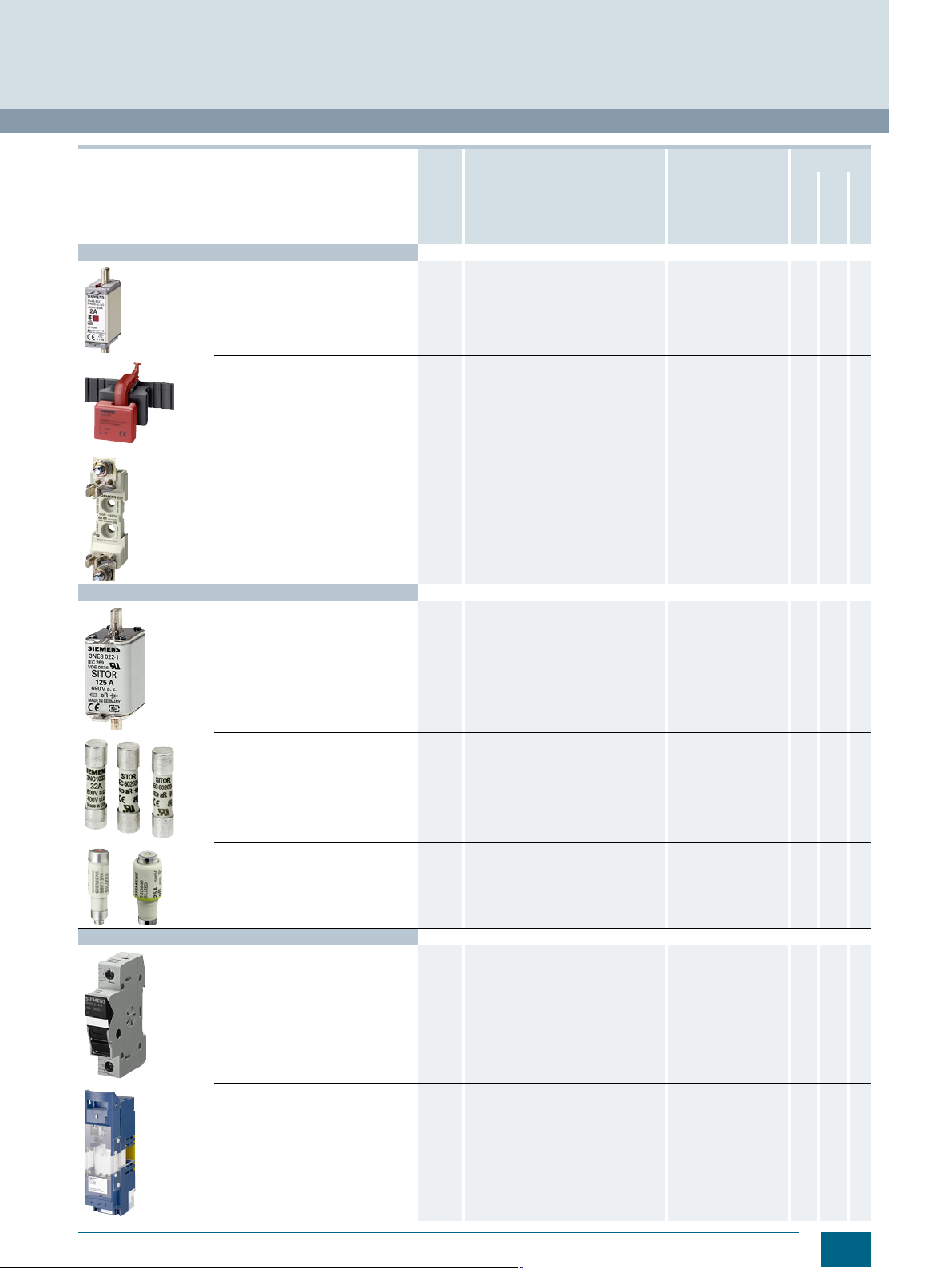

Devices Page Application Standards Used in

Non-residen-

tial buildings

3NA, 3ND LV HRC fuse systems

LV HRC fuse links 45 Fuse links from 2 A to 1250 A for

selective line protection and system

protection in non-residential buildings,

industry and power utilities.

IEC 60269-1, -2;

EN 60269-1;

DIN VDE 0636-2;

CSA 16325 - 1422-02

✓ ✓ ✓

Residential

buildings

Industry

LV HRC signal detectors 68 Signal detectors for when a fuse is

LV HRC fuse bases and

accessories

SITOR semiconductor fuses

LV HRC design 78 Fuse links in LV HRC design and a

Cylindrical fuse design

NEOZED and DIAZED design

tripped on all LV HRC fuse links with

combination or front indicators with

non-insulated grip lugs.

Plus the comprehensive accessory

range required for LV HRC fuse

systems.

69 Fuse bases for screw or snap-on

mounting onto standard mounting rails,

available as 1-pole or 3-pole version.

huge variety of models support a wide

range of applications from 500 V to

1500 V and 150 A to 1600 A.

Fuses with slotted blade contacts,

bolt-on links or female thread, and

special designs.

147 Fuse links, fuse holders – usable as

fuse switch disconnectors and fuse

bases up to 600/690 V AC and

400/700 V DC from 1 A to 100 A

in the sizes 10 × 38 mm, 14 × 51 mm

and 22 × 58 mm.

168 NEOZED fuse links for 400 V AC and

250 V DC and DIAZED for 500 V AC

and 500 V DC.

-- ✓ ✓ ✓

IEC 60269-1, -2;

EN 60269-1;

DIN VDE 0636-2

UL 4248-1,

File No. E171267-IZLT2

(only downstream from

branch circuit protection)

CSA C22.2

No. 4248.1-07

UL 4248-13, File No.

E167357-JFHR2

Fuse links:

UL 4248-13, File No.

E167357-JFHR2

CSA 248170, 1422-30

Fuse holders:

UL 4248-1, File No.

E171267- IZLT

CSA 248170, 6225-01

-- -- -- ✓

✓ ✓ ✓

-- -- ✓

-- -- ✓

Photovoltaic fuses

PV cylindrical fuses 186 Fuses with a rated voltage of

PV cumulative fuses

1000 V DC and operational class gPV

for the protection of photovoltaic

modules, their connecting cables

and other components.

191 Fuses with a rated voltage of 1000 V

and 1500 V DC, a rated current of 63 A

to 630 A and operational class gPV for

the protection of connecting cables and

other components.

IEC 60269-6 ✓ ✓ ✓

IEC60269-6 ✓ ✓ ✓

Siemens · 10/2015

3

Page 6

Fuse Systems

Introduction

■

Overview

Rated voltage U

The rated voltage is the designated voltage of the fuse and is

used to determine its test conditions and operational voltage

limits.

For LV HRC and SITOR fuse links, the rated voltage is always the

rms value of an AC voltage.

For wind power plants and some industrial applications, a higher

voltage tolerance is demanded of the LV HRC and SITOR fuses

than the tolerance of +5 % defined in the standard. On request,

you can obtain a manufacturer's declaration for the rated voltage

of 690 V +10 %.

In the case of NEOZED and DIAZED fuse links, a distinction is

made between AC and DC voltage values.

Rated current I

The rated current of a fuse link is the designated current of the

fuse link and is the current up to which it can be continuously

loaded under prescribed conditions without adverse affects.

Rated frequency

The rated frequency is the frequency for which the fuse link

is rated with regard to power dissipation, current, voltage,

characteristic curve and breaking capacity.

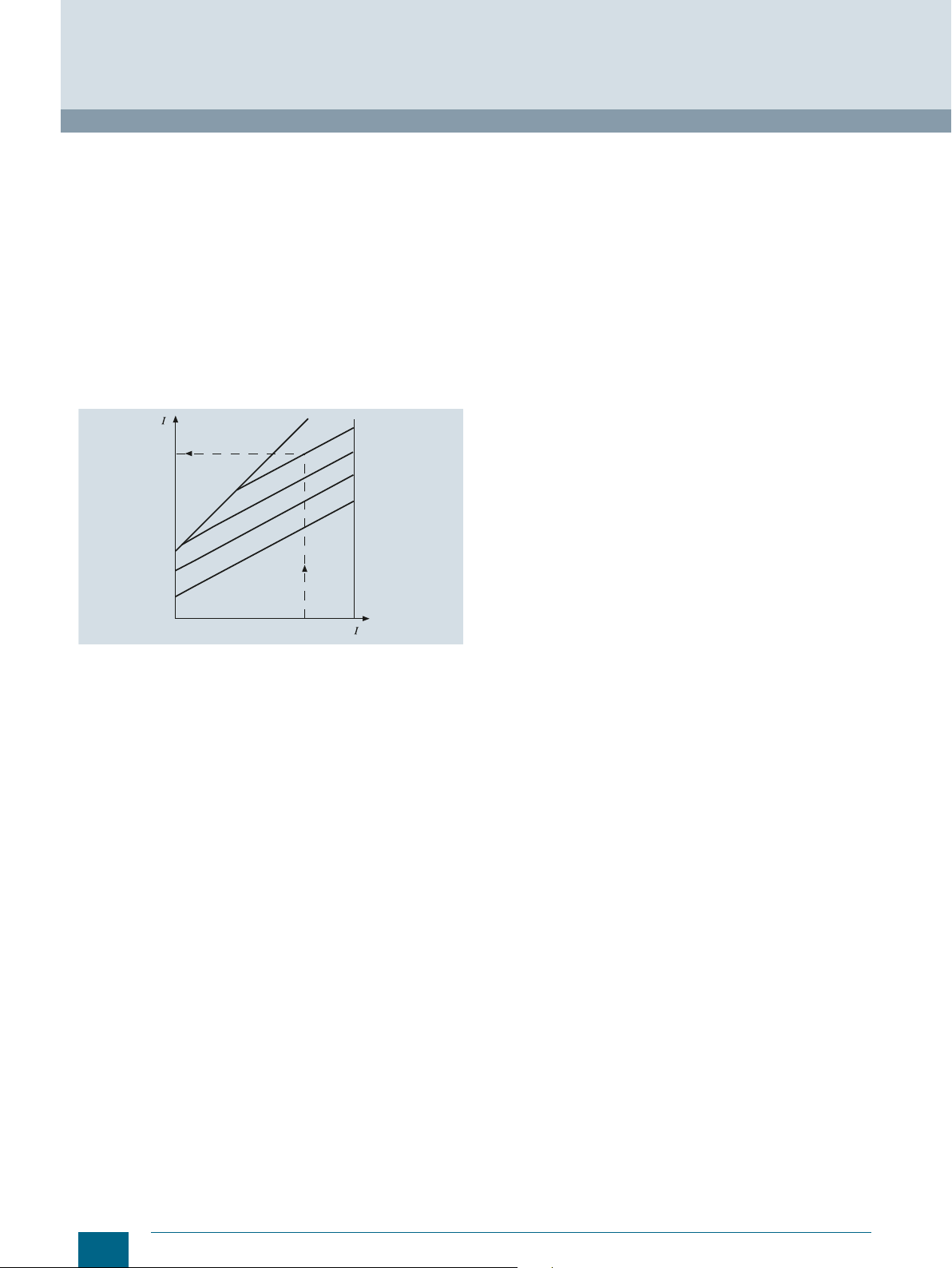

Selectivity

Several fuses are usually connected in series in a system. Selectivity ensures that only the faulty electric circuit and not all operating processes are interrupted in a system in serious cases.

Siemens fuses of operational class gG, at an operational voltage

of up to 400 V AC and a ratio of 1:1.25, are interselective, i.e.

from rated current level to rated current level. This is achieved by

means of the considerably smaller band of scatter of ± 5 % of

the time/current characteristics, which far exceeds the demand

for a ratio of 1:1.6 specified in the standard.

It is therefore possible to use smaller conductor cross-sections

due to the lower rated currents.

Breaking capacity

The rated breaking capacity is the highest prospective shortcircuit current I

conditions.

A key feature of these fuses is their high rated breaking capacity

with the smallest footprint. The basic demands and circuit data

for tests – voltage, power factor, actuating angle, etc. – are

specified in both national (DIN VDE 0636) and international

(IEC 60269) regulations.

However, for a constant fail-safe breaking capacity, from the

smallest non-permissible overload current through to the highest

short-circuit current, a number of quality characteristics need to

be taken into account when designing and manufacturing fuse

links. These include the design of the fuse element with regard

to dimensions and punch dimension and its position in the

fuse body, as well as its compressive strength and the thermal

resistance of the body. The chemical purity, particle size and

the density of the quartz sand also play a key role.

The rated breaking capacity for AC voltage for NEOZED fuses –

and the majority of DIAZED fuses – is 50 kA, and in the case of

our LV HRC fuses (NH type), it is even 120 kA. The various type

ranges of SITOR semiconductor fuses have different switching

capacities ranging from 50 to 100 kA.

.

n

n

that the fuse link can blow under prescribed

p

© Siemens AG 2016

Faster arcing and precise arc quenching are the requirements for a

reliable breaking capacity.

Operational classes

Fuses are categorized according to function and operational

classes. The first letter defines the function class and the second

the object to be protected:

1st letter

a = Partial range protection

Fuse links that carry currents at least up to their specified rated

current and can switch currents above a specific multiple of their

rated current up to their rated breaking current.

g = Full range protection

Fuse links that can continuously carry currents up to at least their

specified rated current and can switch currents from the smallest melting current through to the breaking current. Overload

and short-circuit protection.

2nd letter

G = Cable and line protection

M = Switching device protection in motor circuits

R, S = Semiconductor protection/thyristor protection

L = Cable and line protection

B = Mine equipment protection

Tr = Transformer protection

The designations "slow" and "quick" still apply to DIAZED fuses.

These are defined in IEC/CEE/DIN VDE.

In the case of "quick" characteristics, the fuse blows in the breaking range faster than those of operational class gG.

In the case of DIAZED fuse links for DC railway network protection, the "slow" characteristic is particularly suitable for switching

off direct currents with greater inductance. Both characteristics

are also suitable for the protection of cables and lines.

Full range fuses (gG, gR, quick, slow) reliably break the

current in the event of non-permissible overload and shortcircuit currents.

Partial range fuses (aM, aR) exclusively serve short-circuit

protection.

(

accompanied fuses):

(

general purpose fuses):

(general applications)

(for protection of motor circuits)

(for protection of rectifiers)

(in acc. with the old, no longer valid DIN VDE)

4

Siemens · 10/2015

Page 7

t

v

i

2

dt

I

p

2

------------=

I201_06997b

P

c

sL

U

t

tt

t

c

:

Maximum let-through current

t

s

:

Pre-arcing time

t

L

:

Arcing time

P

:

Peak short-circuit current

Us: Arc voltage

© Siemens AG 2016

The following operational classes are included in the product

range:

gG (DIN VDE/IEC) = Full-range cable and line protection

aM (DIN VDE/IEC) = Partial-range switching device

protection

aR (DIN VDE/IEC) = Partial-range semiconductor protection

gR (DIN VDE/IEC) = Full-range semiconductor protection

gS (DIN VDE/IEC) = Full-range semiconductor protection

and cable and line protection

quick (DIN VDE/IEC/CEE) = Full-range cable and

line protection

slow (DIN VDE) = Full range cable and line protection

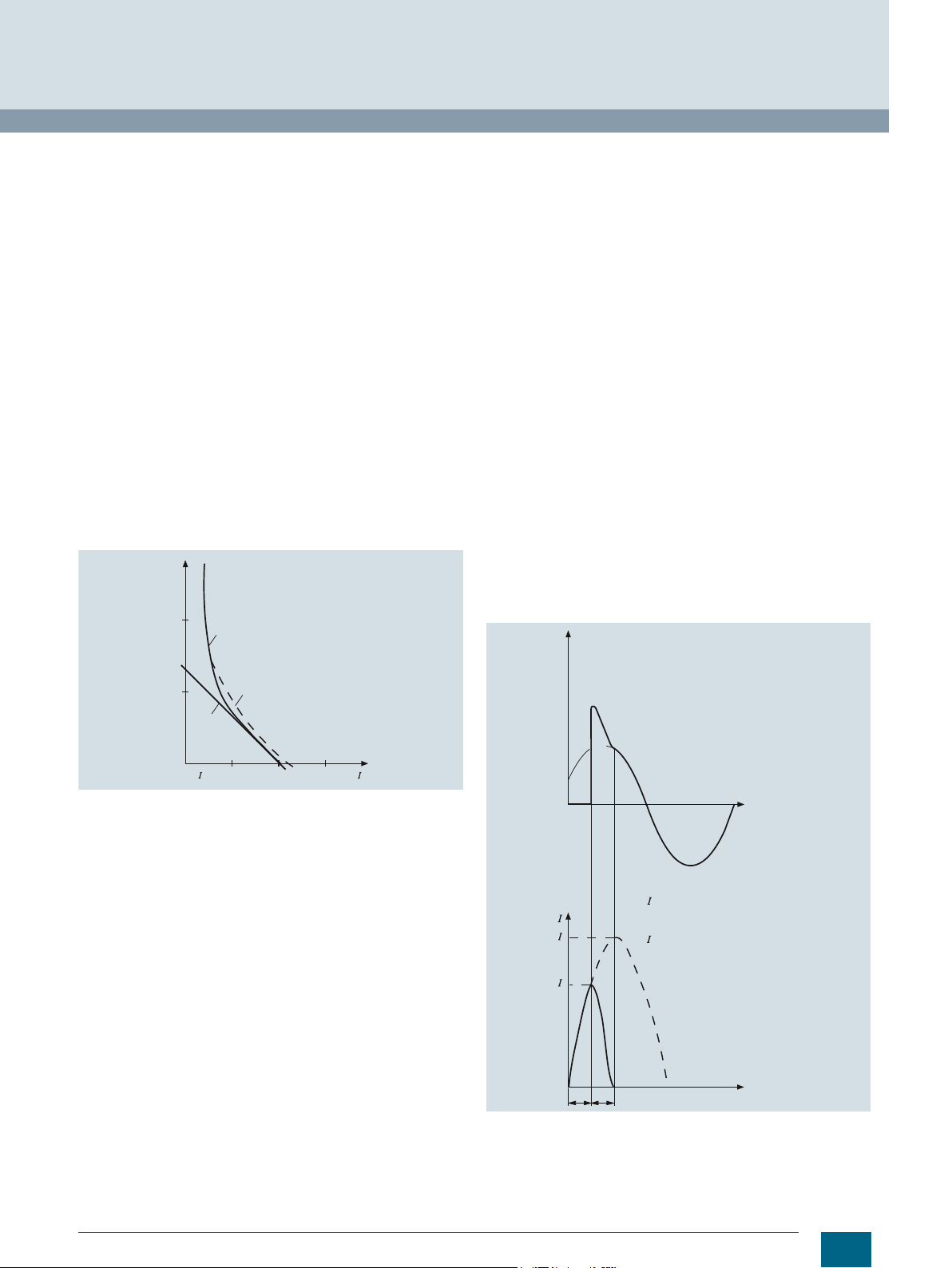

Characteristic curves (time/current characteristic curves)

The time/current characteristic curve specifies the virtual time

(e.g. the melting time) as a function of the prospective current

under specific operating conditions.

Melting times of fuse links are presented in the time/current

diagrams with logarithmic subdivision as a function of their currents. The melting time characteristic curve extends from the

lowest melting current, which still just causes the melting conductor to melt asymptotically to the I

values in the range of higher short-circuit currents, which specifies the constant melting heat value I

the time/current characteristics diagrams omit the I

9

10

[s]

t

5

10

a

2

t line of equal Joulean heat

2

t. For the sake of simplicity,

2

t lines (c).

Fuse Systems

Introduction

Virtual time t

The virtual time is the time span calculated when an I2t value is

divided by the square of the prospective current:

The time/current characteristic curve specifies the prospective

current I

Prospective short-circuit current I

The prospective short-circuit current is the rms value of the

line-frequency AC component, or the value of direct current to

be expected in the event of a short-circuit occurring downstream

of the fuse, were the fuse to be replaced by a component of

negligible impedance.

Let-through current characteristic curves

The let-through current characteristic curve specifies the value

of the let-through current at 50 Hz as a function of the prospective current.

The let-through current I

of the current reached during a switching operation of a fuse.

The fuse element of the fuse links melts so quickly at very high

currents that the surge short-circuit current I

occurring. The highest instantaneous value of the current

reached during the breaking cycle is called the let-through

current I

diagrams, otherwise known as let-through current diagrams.

v

and the virtual melting time tvs.

p

p

is the maximum instantaneous value

c

is prevented from

p

. The current limits are specified in the current limiting

c

1

10

1234

10 10 10 10

General representation of the time/current characteristic curve of a fuse

link of operational class gL/gG

I

: Smallest melting current

min

a: Melting time/current characteristic

b: Breaking time characteristic curve

2

c: I

t line

min

b

c

I201_06996a

[A]

The curve of the characteristic depends on the outward heat

transfer from the fuse element. DIN VDE 0636 specifies tolerance-dependent time/current ranges within which the characteristic curves of the fuse must lie. Deviations of ± 10 % are permissible in the direction of the current axis. With Siemens LV HRC

fuse links of operational class gG, the deviations work out at

less than ± 5 %, a mark of our outstanding production accuracy.

For currents up to approx. 20 I

teristic curves are the same as the breaking time characteristic

curves. In the case of higher short-circuit currents, the two

characteristic curves move apart, influenced by the respective

arc quenching time.

The difference between both lines (= arc quenching time) also

, the melting time/current charac-

n

depends on the power factor, the operational voltage and the

breaking current.

The Siemens characteristic curves show the mean virtual melting time characteristic curves recorded at an ambient temperature of (20 ± 5) °C. They do not apply to preloaded fuse links.

Oscillograph of a short-circuit current breaking operation through

a fuse link

Siemens · 10/2015

5

Page 8

I2ti2td

t

0

t

1

=

© Siemens AG 2016

Fuse Systems

Introduction

Current limiting

As well as a fail-safe rated breaking capacity, the current-limiting

effect of a fuse link is of key importance for the cost effectiveness

of a system. In the event of short-circuit breaking by a fuse, the

short-circuit current continues to flow through the network until

the fuse link is switched off. However, the short-circuit current

is only limited by the system impedance.

The simultaneous melting of all the bottlenecks of a fuse element

produce a sequence of tiny partial arcs that ensure a fast breaking operation with strong current limiting. The current limitation is

also strongly influenced by the production quality of the fuse –

which in the case of Siemens fuses is extremely high. For example, an LV HRC fuse link, size 2 (224 A) limits a short-circuit current with a possible rms value of approximately 50 kA to a letthrough current with a peak value of approx. 18 kA. This strong

current limitation provides constant protection for the system

against excessive loads.

c

100 A

50 A

10 A

6 A

Rated power dissipation

Rated power dissipation is the power loss during the load of

a fuse link with its rated current under prescribed conditions.

The cost effectiveness of a fuse depends largely on the rated

power dissipation (power loss). This should be as low as possible and have low self-heating. However, when assessing the

power loss of a fuse, it must also be taken into account that there

is a physical dependence between the rated breaking capacity

and the rated power dissipation. On the one hand, fuse elements

need to be very thick in order to achieve the lowest possible

resistance value, on the other, a high rated breaking capacity

requires the thinnest possible fuse elements in order to achieve

reliable arc quenching.

Siemens fuses have the lowest possible rated power dissipation while also providing the highest possible load breaking

reliability.

These values lie far below the limit values specified in the r

egulations. This means a low temperature rise, reliable breaking

capacity and high cost effectiveness.

2

I

t value

2

t value (joule integral) is the integral of the current squared

The I

over a specific time interval:

I201_06998a

eff

Current limiting diagram

Let-through current diagram of LV HRC fuse links, size 00

Operational class gL/gG

Rated currents 6 A, 10 A, 50 A, 100 A

Legend

= Virtual melting time

t

vs

I

= Max. let-through current

c

=rms value of the prospective short-circuit current

I

rms

2

I

ts= Melting I2t value

2

I

ta=Breaking I2t value

= Rated current

I

n

P

= Rated power dissipation

v

= Temperature rise

k

= Correction factor for I2t value

A

= Recovery voltage

U

w

Û

= Peak arc voltage

s

I

= Peak short-circuit current

p

$ = Peak short-circuit current with largest DC component

% = Peak short-circuit current without DC component

U =Voltage

i =Current

t

= Melting time

s

= Arc quenching time

t

L

Specifies the I

the breaking cycle ((I

2

I

t value). The melting I2t value, also known as the total I2t value

or breaking I

2

t values for the melting process (I2ts) and for

2

tA, , – sum of melting and quenching

2

t value, is particularly important when dimension-

ing SITOR semiconductor fuses. This value depends on the

voltage and is specified with the rated voltage.

Peak arc voltage Û

s

The peak arc voltage is the maximum value of the voltage

that occurs at the connections of the fuse link during the arc

quenching time.

Residual value factor RV

The residual value factor is a reduction factor for determining the

permissible load period of the fuse link with currents that exceed

the permissible load current I

is applied when dimensioning SITOR semiconductor fuses.

’ (see rated current In). This factor

n

Varying load factor VL

The varying load factor is a reduction factor for the rated current

with varying load states. This factor is applied when dimensioning SITOR semiconductor fuses.

Recovery voltage U

w

The recovery voltage (rms value) is the voltage that occurs at the

connections of a fuse link after the power is cut off.

6

Siemens · 10/2015

Page 9

■

More information

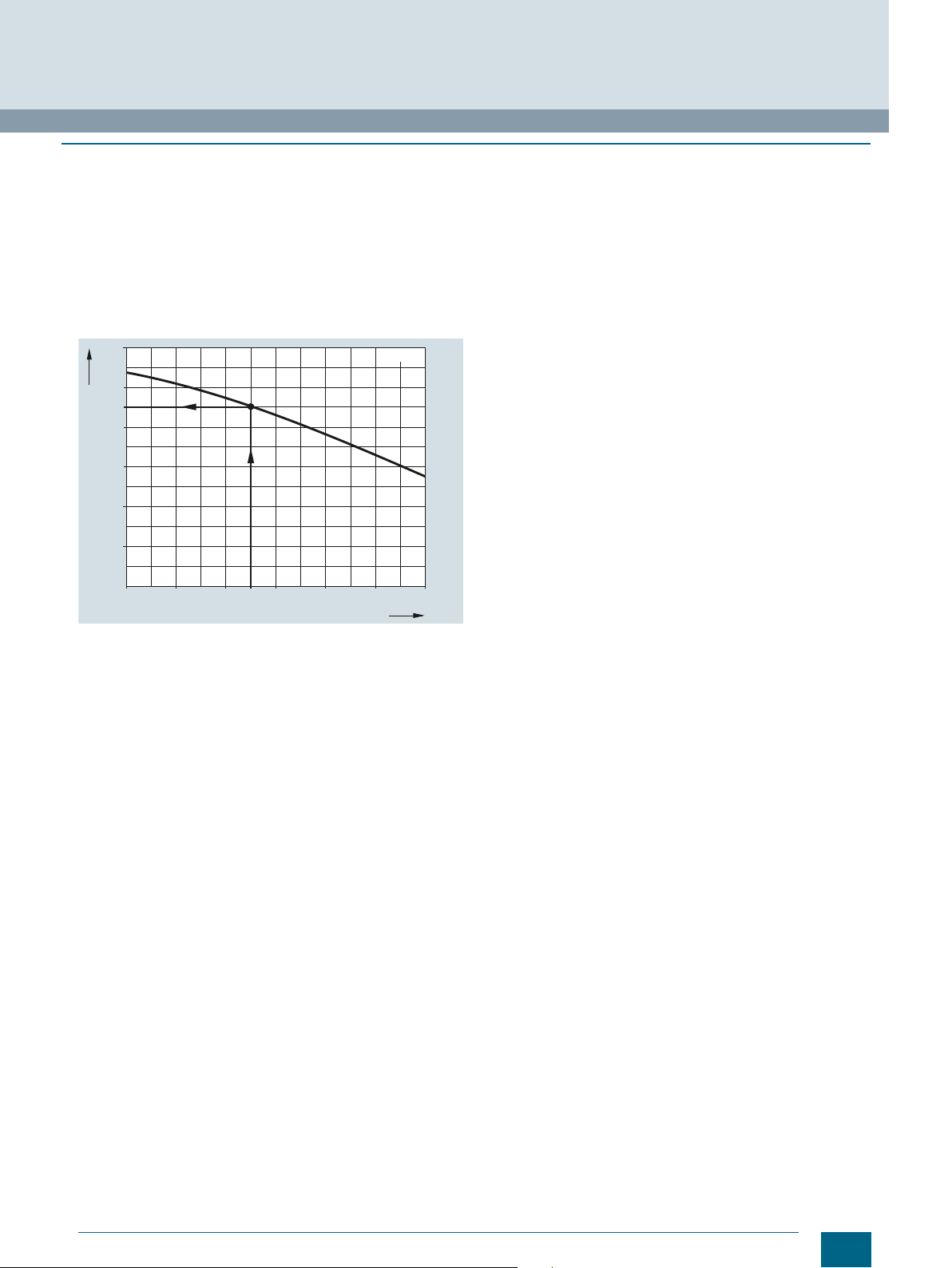

Load capability with increased ambient temperature

The time/current characteristic curve of the NEOZED/DIAZED

and LV HRC fuse links is based on an ambient temperature of

20 °C ± 5 °C in accordance with DIN VDE 0636. When used in

higher ambient temperatures (see diagram) a reduced load-car-

rying capacity must be planned for. At an ambient temperature

of 50 °C, for example, an LV HRC fuse link should be dimensioned for only 90 % of the rated current. While the short-circuit

behavior is not influenced by an increased ambient temperature,

it is influenced by overload and operation at rated value.

120

100

90

80

60

40

Current carrying capacity [%]

20

0

Influence of the ambient temperature on the load capability of

NEOZED/DIAZED and LV HRC fuses of operational class gG with

natural convection in the distribution board.

5020 40 60 80 100 1200

Ambient temperature [°C]

I201_06648c

© Siemens AG 2016

Assignment of cable and line protection

When gG fuses are assigned for cable and line protection

against overloading, the following conditions must be met in

order to comply with DIN VDE 0100 Part 430:

(1) I

= In = Iz (rated current rule)

B

= 1.45 × Iz (tripping rule)

(2) I

2

: Operational current of electrical circuit

I

B

: Rated current of selected protective device

I

n

: Permissible current carrying capacity of the cable or line

I

z

under specified operating conditions

I

: Tripping current of the protective device under specified

2

operating conditions ("high test current").

These days, the factor 1.45 has become an internationally

accepted compromise of the protection and utilization ratio of a

line, taking into account the breaking response of the protective

device (e.g. fuse).

In compliance with the supplementary requirements for

DIN VDE 0636, Siemens fuse links of operational class gG

comply with the following condition:

"Load breaking switching with I

test duration under special test conditions in accordance with

the aforementioned supplementary requirements of

DIN VDE 0636".

This therefore permits direct assignment.

Fuse Systems

Introduction

=1.45 × In during conventional

2

Siemens · 10/2015

7

Page 10

Fuse Systems

NEOZED Fuse Systems

NEOZED fuse links

■

Overview

The NEOZED fuse system is primarily used in distribution technology and industrial switchgear assemblies. The system is easy

to use and is also approved for domestic installation.

The MINIZED switch disconnectors are primarily used in switchgear assemblies and control engineering. They are approved for

switching loads as well as for safe switching in the event of short

circuits. The MINIZED D02 is also suitable for use upstream of

the meter in household applications in compliance with the

recommendations of VDEW according to TAB 2007.

© Siemens AG 2016

Due to its compact design, the MINIZED D01 fuse switch

disconnector is primarily used in control engineering.

The NEOZED fuse bases are the most cost-effective solution for

using NEOZED fuses. All NEOZED bases must be fed from the

bottom to ensure that the threaded ring is insulated during removal of the fuse link. The terminals of the NEOZED bases are

available in different versions and designs to support the various

installation methods.

Fuse bases D01 with terminal version BB

• Incoming feeders, clamp-type terminal B

• Outgoing feeders, clamp-type terminal B

Fuse bases D02, with terminal version SS

• Incoming feeders, saddle terminal S

• Outgoing feeders, saddle terminal S

Fuse bases D02, with terminal version KS

• Incoming feeders, screw head contact K

• Outgoing feeders, saddle terminal S

8

Siemens · 10/2015

Page 11

■

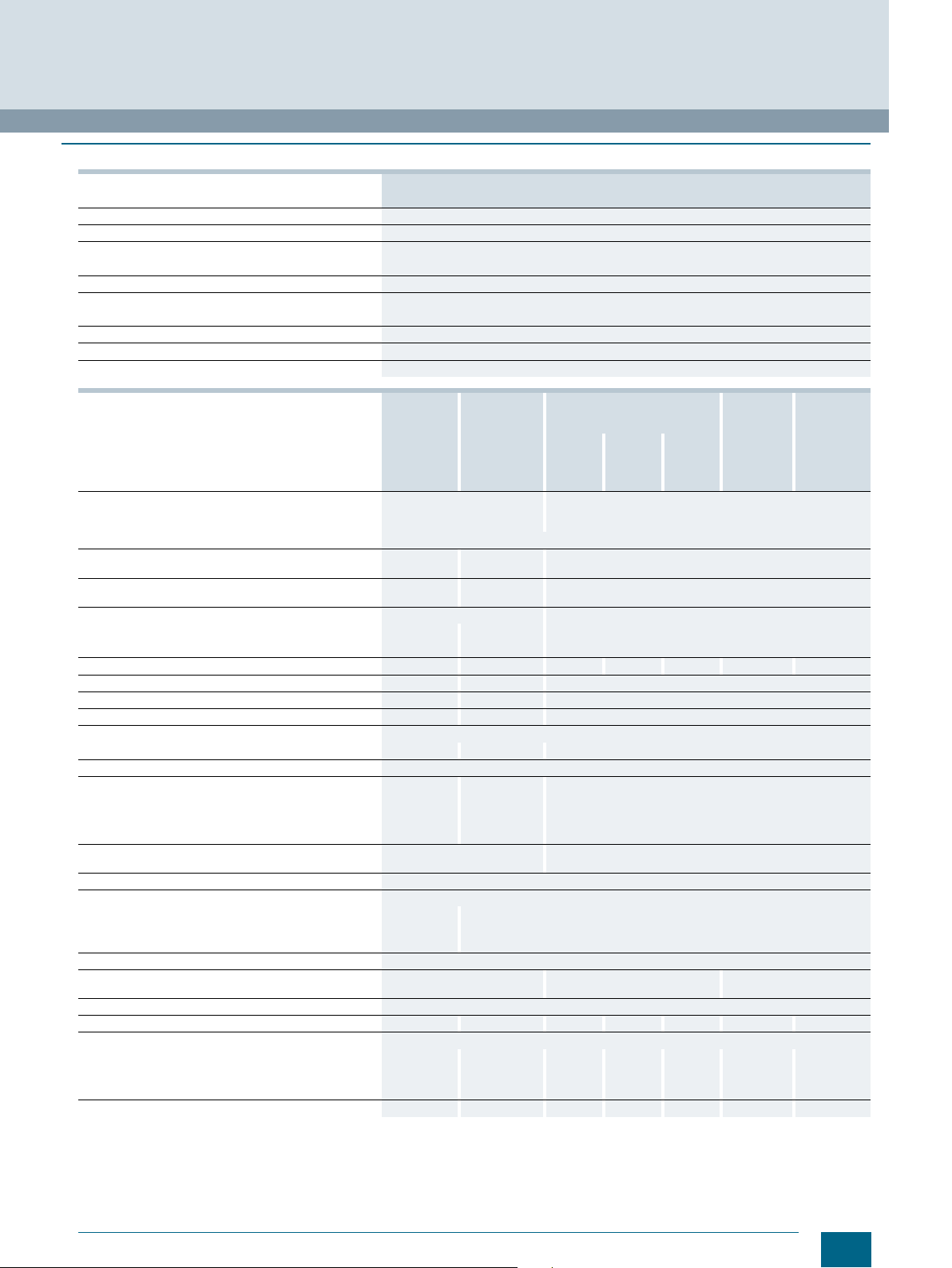

Technical specifications

Standards

Operational class

Rated voltage U

Rated current I

Rated breaking capacity kA AC

Non-interchangeability

Resistance to climate °C

Ambient temperature °C

n

n

NEOZED fuse links

5SE2

IEC 60269-3; DIN VDE 0636-3

gG

VAC 400

VDC

A 2...100

kA DC

250

50

8

Using adapter sleeves

Up to 45 at 95 % rel. humidity

-5 to +40, humidity 90 % at 20

© Siemens AG 2016

Fuse Systems

NEOZED Fuse Systems

NEOZED fuse links

MINIZED

switch disconnectors

D02

5SG71

Standards

Main switch characteristic,

EN 60204-1

Insulation characteristic

EN 60664-1

Rated voltage U

•1P VDC

• 2P in series V DC

Rated current I

Rated insulation voltage VAC

Rated impulse withstand voltage KV AC

Overvoltage category

Utilization category acc. to VDE 0638

•AC-22 A 63 16 --

Utilization category acc. to EN 60947-3

•AC-22A A -- 16 --

•AC-22B A

•AC-23B A

• DC-22 B A

Sealable

When switched on

Mounting position

Reduction factor of I

• Side-by-side mounting 0.9 --

• On top of one another, with vertical standard

mounting rail

Degree of protection acc. to IEC 60529

Terminals

With touch protection acc. to BGV A3

Ambient temperature °C

Terminal versions

Conductor cross-sections

• Solid and stranded mm

• Flexible, with end sleeve mm

• Finely stranded, with end sleeve mm

Tightening torque Nm

1)

Degree of protection IP20 is tested according to regulations using a

straight test finger (from the front), with the device mounted and equipped

with a cover, housing or some other enclosure.

n

n

with 18 pole

n

VAC 230/400, 240/415 400

A 63 16 16 63 100 16/63 16/63

DIN VDE 0638;

EN 60947-3

(VDE 0660-107)

IEC/EN 60947-3

Yes -- --

Yes -- --

65 48 250

130 110 250

500 400 --

6 2.5 --

IV IV --

63 -- --

35 -- --

63 -- --

Yes Yes, with sealable screw caps

Any, preferably vertical

0.87 --

IP20, with connected conductors

Yes No Ye s

-5 to +40, humidity 90 % at 20

-- -- B K, S K/S -- --

2

1.5 ... 35 1.5 ... 16 1.5 ... 4 1.5 ... 25 10 ... 50 0.75 ... 35 1.5 ... 35

2

1.5 ... 35 1.5 1.5 1.5 10 -- --

2

-- -- 0.75 ... 25 -- -- -- --

2.5 ... 3 2.5 1.2 2 3.5/2.5 3.5 3

MINIZED fuse

switch disconnectors

D01

5SG76

Fuse bases,

made of ceramic

D01

5SG15

5SG55

IEC 60269-3; DIN VDE 0636-3

1)

D02

5SG16

5SG56

D03

5SG18

Comfort

bases

D01/02

5SG1. 01

5SG5.01

Fuse bases

5SG1. 30

5SG1. 31

5SG5.30

Siemens · 10/2015

9

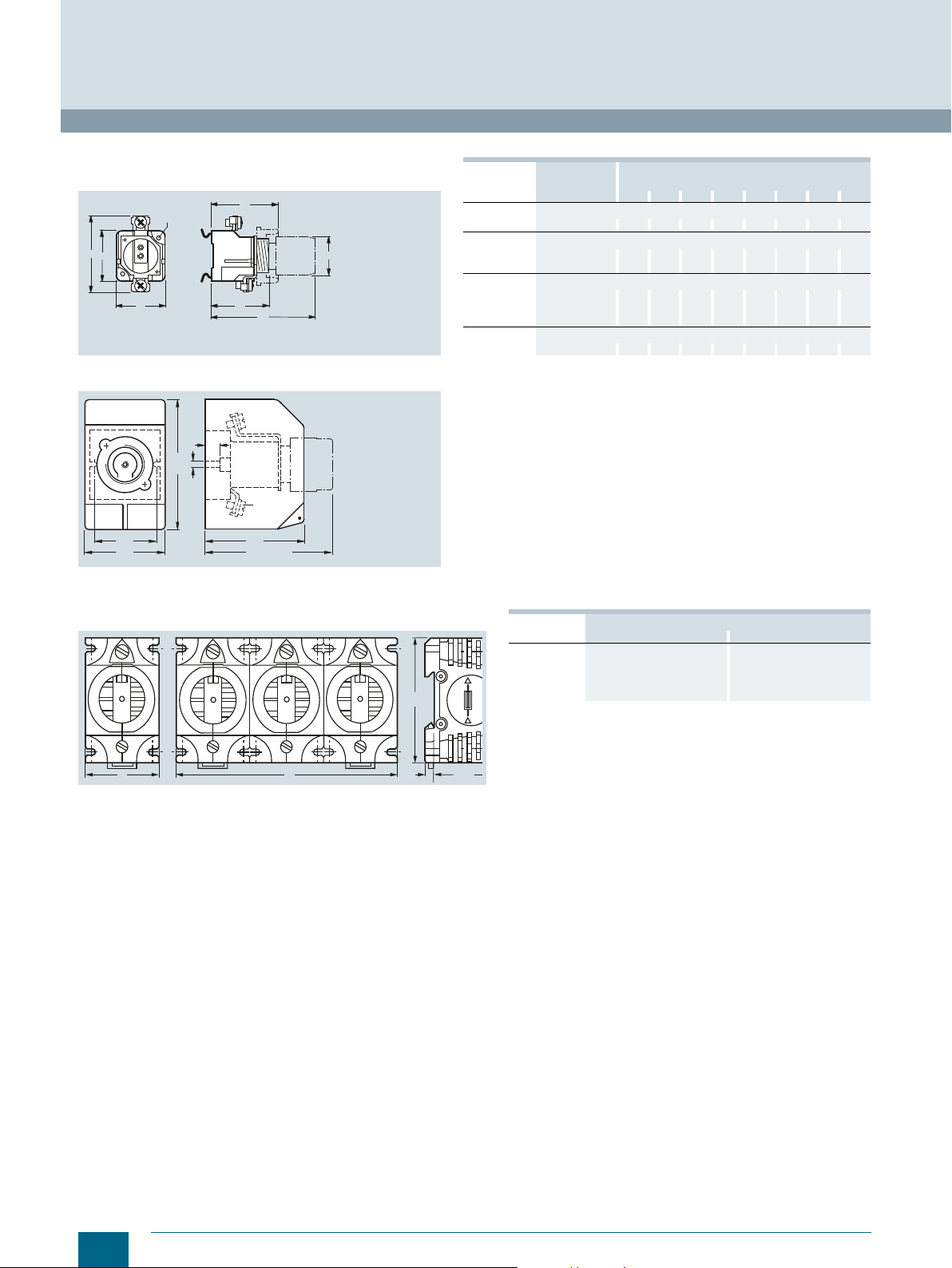

Page 12

214

3

54

214

3

81

6

5

214

3

108

65N

N

70

44

45

5

90

I2_12122

81

27

79

70

44

55

5

90

45

I201_17072

246

135

I201_07988a

18 36 54 72

644

64

107

45

88

70

83

45

64

446,2

I2_12123

I201_07536b

71,5

58,7

45

26,6 79,8

4

44

47,2

59,2

Protective

caps

© Siemens AG 2016

Fuse Systems

NEOZED Fuse Systems

NEOZED fuse links

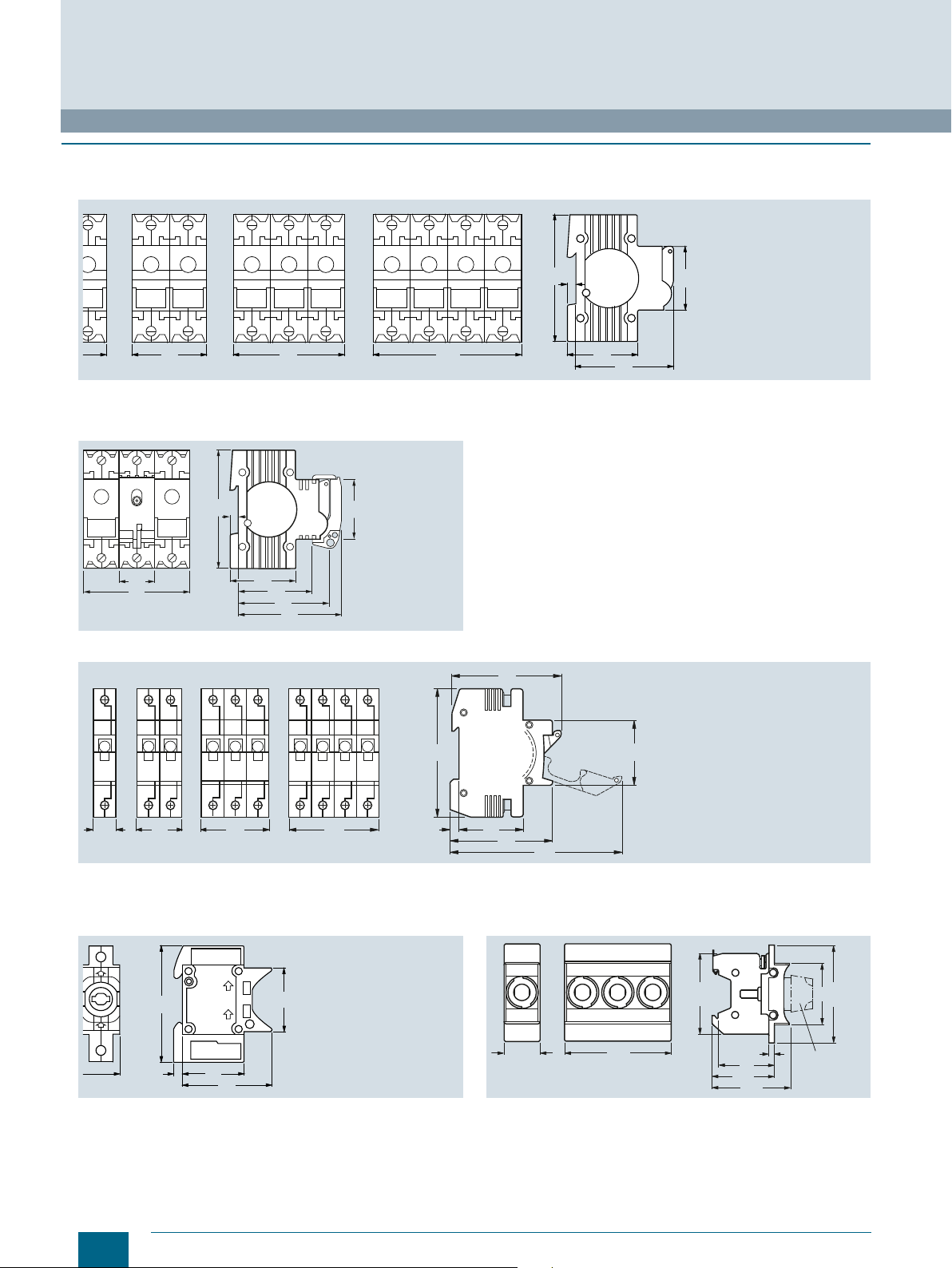

■

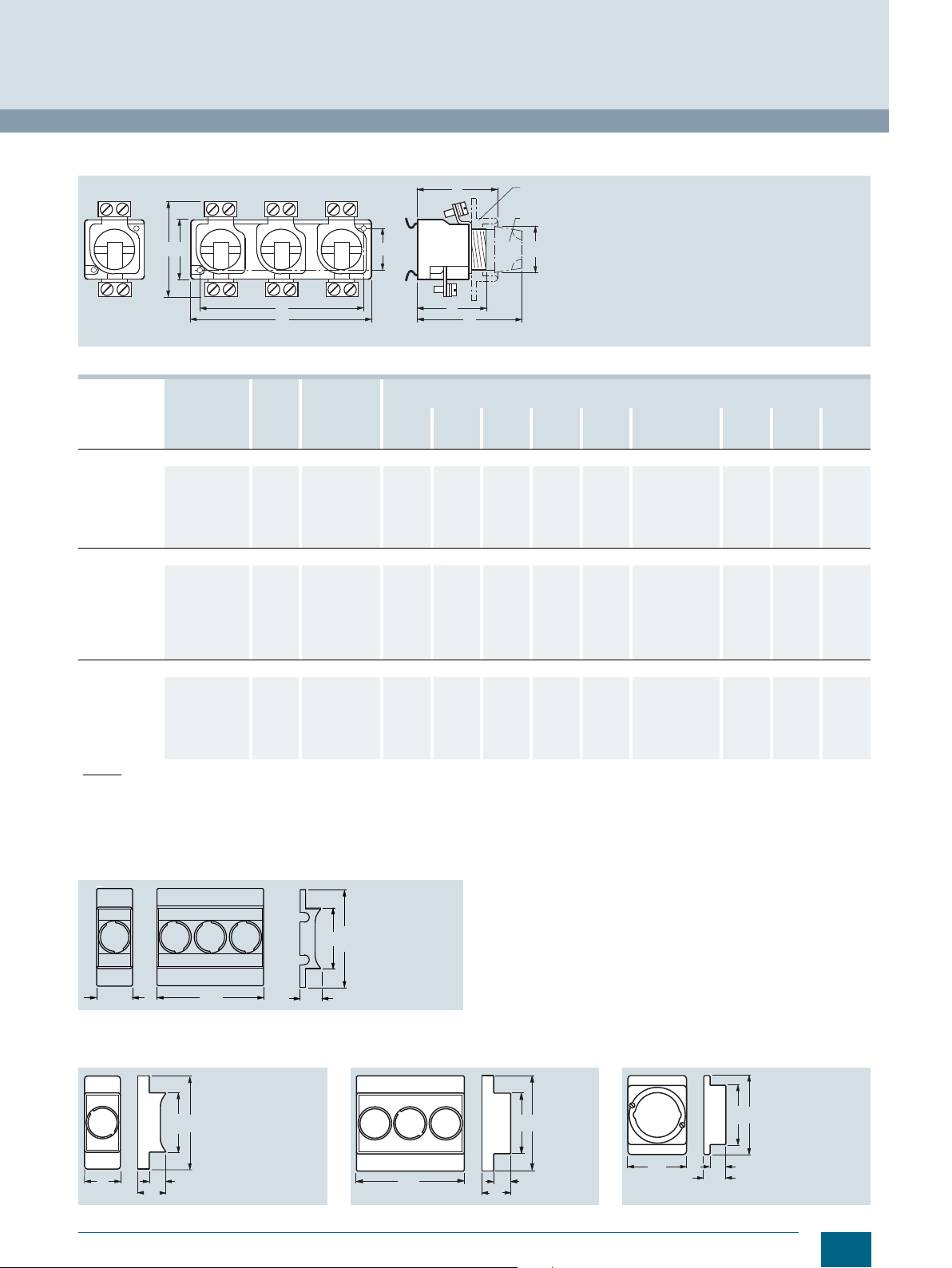

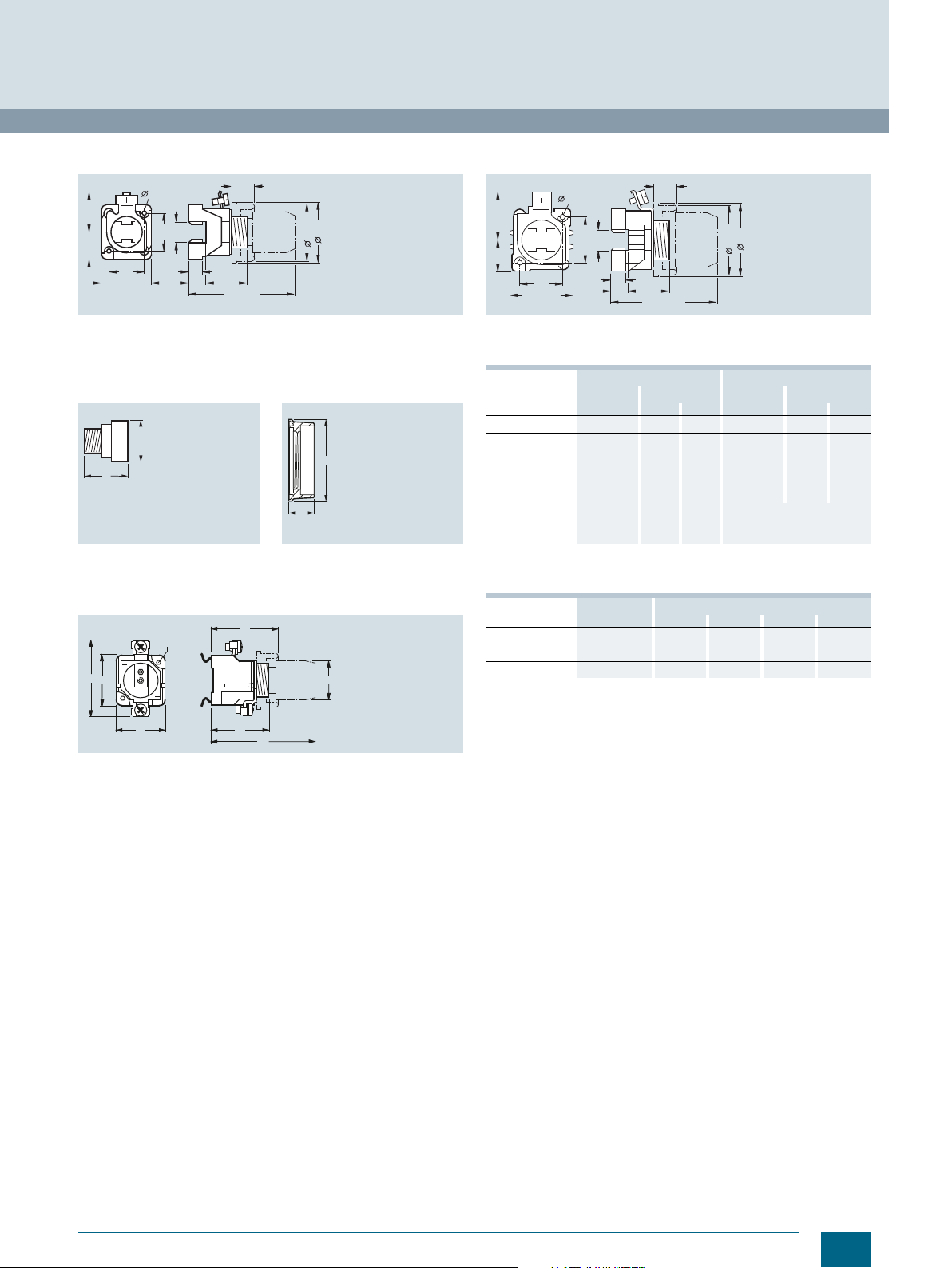

Dimensional drawings

5SG71.3 MINIZED D02 switch disconnectors, with draw-out technology

1P 1P+N 2P 3P 3P+N

Locking cap for MINIZED D02 switch disconnectors

5SG76 MINIZED D01 fuse switch disconnectors, with draw-out technology

1P 1P+N, 2P 3P 3P+N

Fuse bases with touch protection BGVA3 (VBG4), molded plastic

Sizes D01/D02, with combined terminal, can be busbar mounted With cover

5SG1301,

5SG1701

10

5SG5301,

5SG5701

Siemens · 10/2015

5SG1330,

5SG1331,

5SG1730,

5SG1731

5SG5330,

5SG5730

Page 13

NEOZED fuse bases made of ceramic

a

i

e

c

d

b

h

g

k

I201_06258b

screw cap

touch

protection

cover

I2_07537

71,5

45

26,6

79,8

16

I201_06206

45

21

1227

70

18

I201_06207

60

45

45

13

Sizes D01/D02/D03

5SG15 5SG55

© Siemens AG 2016

Fuse Systems

NEOZED Fuse Systems

NEOZED fuse links

Typ e Versio n Size Connection

Snap-on with cover

5SG1553

5SG1653

5SG1693

5SG5553

5SG5653

5SG5693

Snap-on without cover

5SG1595

5SG1655

5SG1695

5SG1812

5SG5555

5SG5655

5SG5695

Screw-on without cover

5SG1590

5SG1650

5SG1810

5SG5550

5SG5650

5SG5690

Legend

Connection type:

K = Screw head contact

B = Clamp-type terminal

S = Saddle terminal

1-pole D01 BB 26.8 36 40 56 70 23/26.5 54 -- --

3-pole D01 BB 80.8 36 40 56 70 23/26.5 54 -- --

1-pole D01 BB 26.8 36 40 56 70 23/26.5 54 -- --

3-pole D01 BB 80.8 36 40 56 70 23/26.5 54 -- --

1-pole D01 BB 26.8 36 40 56 70 23/26.5 54 20 22

3-pole D01 BB 80.8 36 40 56 70 23/26.5 54 74 22

D02 SS 26.8 36 41 56 70 23/26.5 59 -- -D02 KS 26.8 36 41 56 70 23/26.5 60 -- --

D02 SS 80.8 36 41 56 70 23/26.5 59 -- -D02 KS 80.8 36 41 56 70 23/26.5 60 -- --

D02 SS 26.8 36 41 56 70 23/26.5 59 -- -D02 KS 26.8 36 41 56 70 23/26.5 60 -- -D03 KS 44.9 50 44 54.5 76 44 86 -- --

D02 SS 80.8 36 41 56 70 23/26.5 59 -- -D02 KS 80.8 36 41 56 70 23/26.5 60 -- --

D02 SS 26.8 36 41 56 70 23/26.5 59 20 22

D03 KS 44.9 50 46 54.5 76 44 86 32 32

D02 SS 80.8 36 41 56 70 23/26.5 59 74 22

D02 KS 80.8 36 41 56 70 23/26.5 60 74 22

type

Dimensions

a b c d e g

BB = Clamp-type terminal at incoming feeder

SS = Saddle terminal at incoming feeder

KS = Screw head contact at incoming feeder

NEOZED covers made of molded plastic

NEOZED covers for NEOZED fuse bases, made of molded plastic

Clamp-type terminal at outgoing feeder

Saddle terminal at outgoing feeder

Saddle terminal at outgoing feeder

Not sealed/

sealed

h i k

5SH5244 (A1) 5SH5245 (A2)

NEOZED covers for NEOZED fuse bases, made of ceramic

I201_06209

81

5SH5251 (A4) and 5SH5253 (A10) 5SH5252 (A5) and 5SH5254 (A11) 5SH5233 (A6)

45

70

12

21

Siemens · 10/2015

11

Page 14

a

b

Size

n

A

D01/E14 2 ... 16

D02/E18 20 ... 63

D03/M30 80 ... 100

2

1

214

3

1212N

N

123456N

N

© Siemens AG 2016

Fuse Systems

NEOZED Fuse Systems

NEOZED fuse links

NEOZED screw caps

5SH4 Typ e Size Sealable For mounting

5SH4116 D01 -- 70 27.5 24

5SH4163

5SH4316

5SH4363

5SH4100

5SH4317

5SH4362

D02 -- 70 27.5 24

D01 ✔ 70 33 26.5

D02 ✔ 76 33 26.5

D03 -- 70 37 44

D01 -- 70 29.5 25

D02 -- 70 30.5 25

NEOZED fuse links

Size/thread Rated current in A Dimension

D01/E14 2...16 9.8 11 6 36

D02/E18

D03/M30

20 ... 63 13.8 15.3 10 36

80 ... 100 20.8 22.5 36 43

d

2min

depth

Dimension

d

3

Dimensions

a b

Dimension

d

4max

Dimension

h

■

Circuit diagrams

Graphical symbols

5SG71.3 MINIZED D02 switch disconnectors, with draw-out technology

N

1

1

2

2

N

5SG7113 5SG7153 5SG7123 5SG7133

1P 1P+N 2P 3P 3P+N

5

21436

5SG7133-8BA25

5SG7133-8BA35

5SG7133-8BA50

5SG76 MINIZED D01 fuse switch disconnectors, with draw-out technology

123

4

5SG7610 5SG7650 5SG7620 5SG7630 5SG7660

1P 1P+N 2P 3P 3P+N

12345

6

NEOZED fuse bases/fuses in general

5SG1 5SG5

1P 3P

21436

5SG7163

5

N

N

12

Siemens · 10/2015

Page 15

■

p

[A]

[s]

I201_10887

46810

1

24

6810

2

24681032

4

6

10

-2

2

4

6

2

4

6

10

0

2

4

6

10

1

10

-1

2

4

6

2

4

6

10

3

2

4

6

10

4

10

2

2

4

2 A

4 A

6 A

10 A

13 A

16 A

20 A

25 A

32 A

35 A

50 A

40 A

63 A

80 A

100 A

vs

1 0

1

2

64 1 0

2

8

2

64 8 2 64

4

6

1 0

2

4

6

1 0

c

e f f

[ A ]

[ A ]

I 2 _ 1 0 8 8 8

2

4

6

1 0

2

2 4

2

3

4

1 0

3

8

1 0

4

6 8

1 0

5

2 4

1

2

4 A

2 A

1 0 0 A

8 0 A

6 3 A

5 0 A

4 0 A

3 5 A

3 2 A

2 5 A

2 0 A

1 6 A

1 3 A

1 0 A

6 A

2 6 1 01 0 4

0

2

64 1 0

1

8 2 64 1 028

3

8 2 6 1 0448

1 0

2

4

6

1 0

2

4

6

1 0

2

4

6

1 0

2

4

6

1 0

2

4

6

1 0

2

4

6

1 0

I 2 _ 1 0 8 8 9

0

1

2

3

4

5

6

e f f

[ A ]

2

s

[ A s ]

2

6

4

1 00s

1 0

- 1

s 1 0

- 2

s

1 0

- 3

s

1 0

- 4

s

8 0 A

6 3 A

5 0 A

4 0 A

3 5 A

2 5 A

2 0 A

1 6 A

1 3 A

1 0 A

6 A

4 A

2 A

3 2 A

1 0 0 A

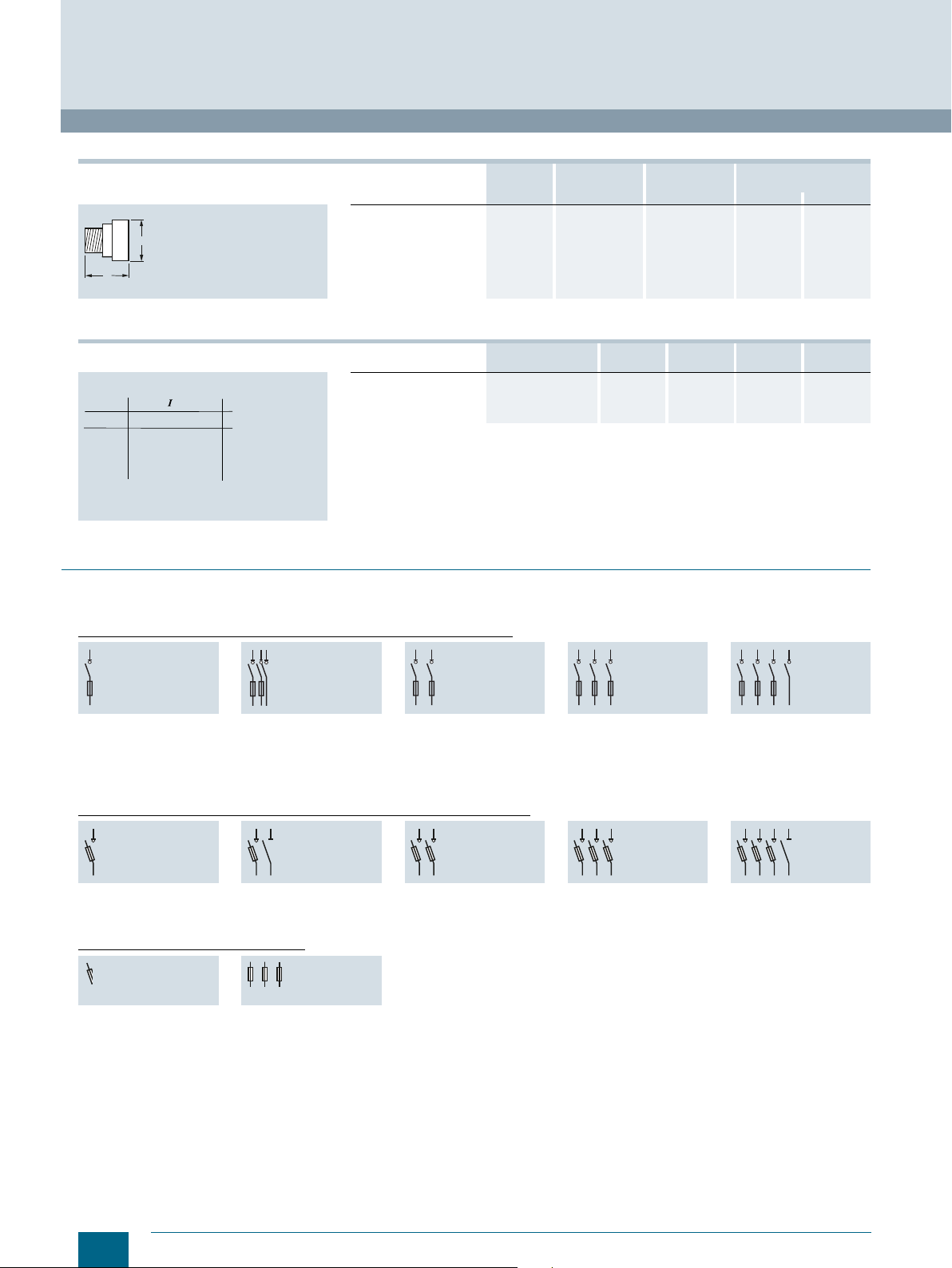

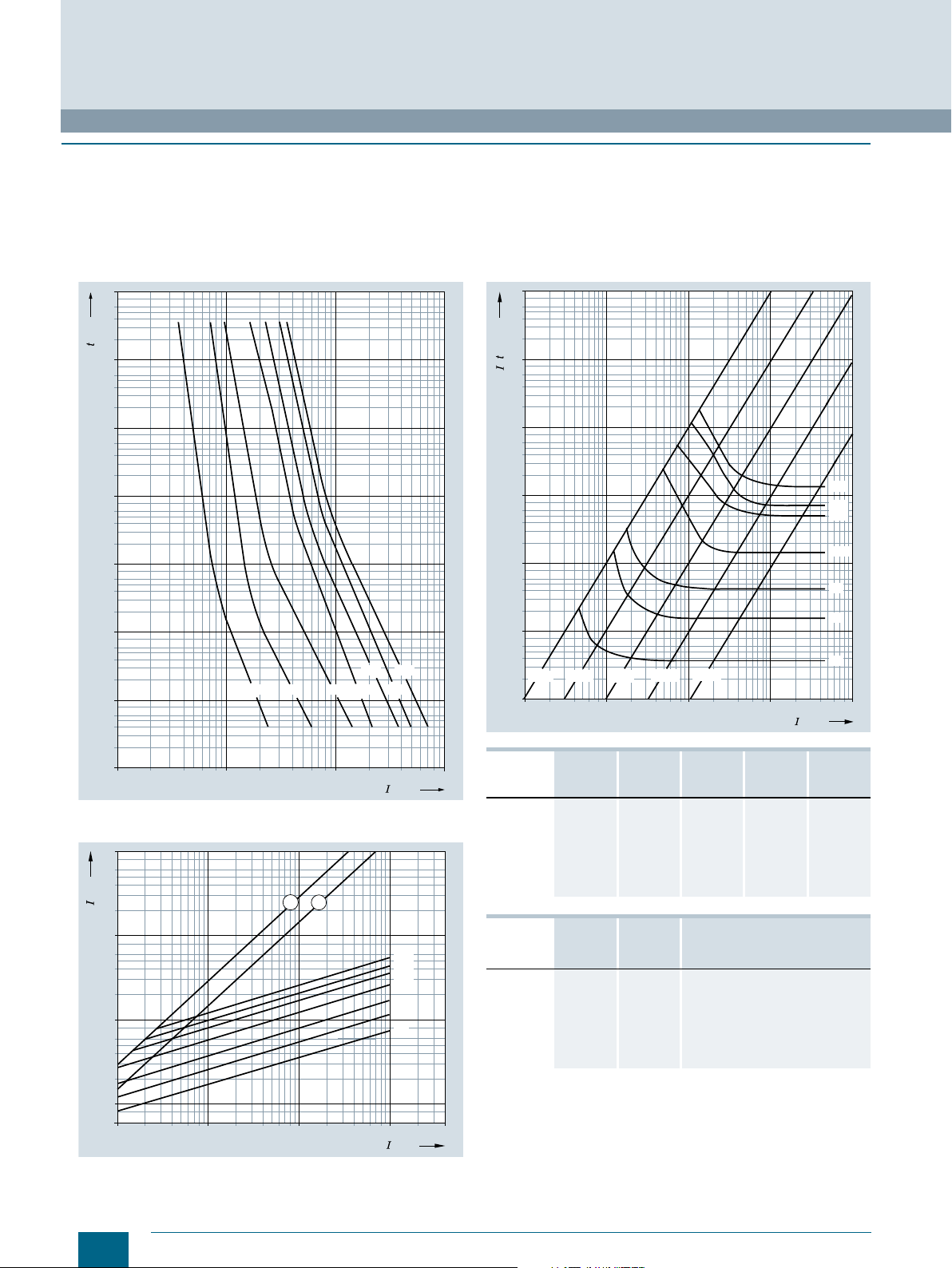

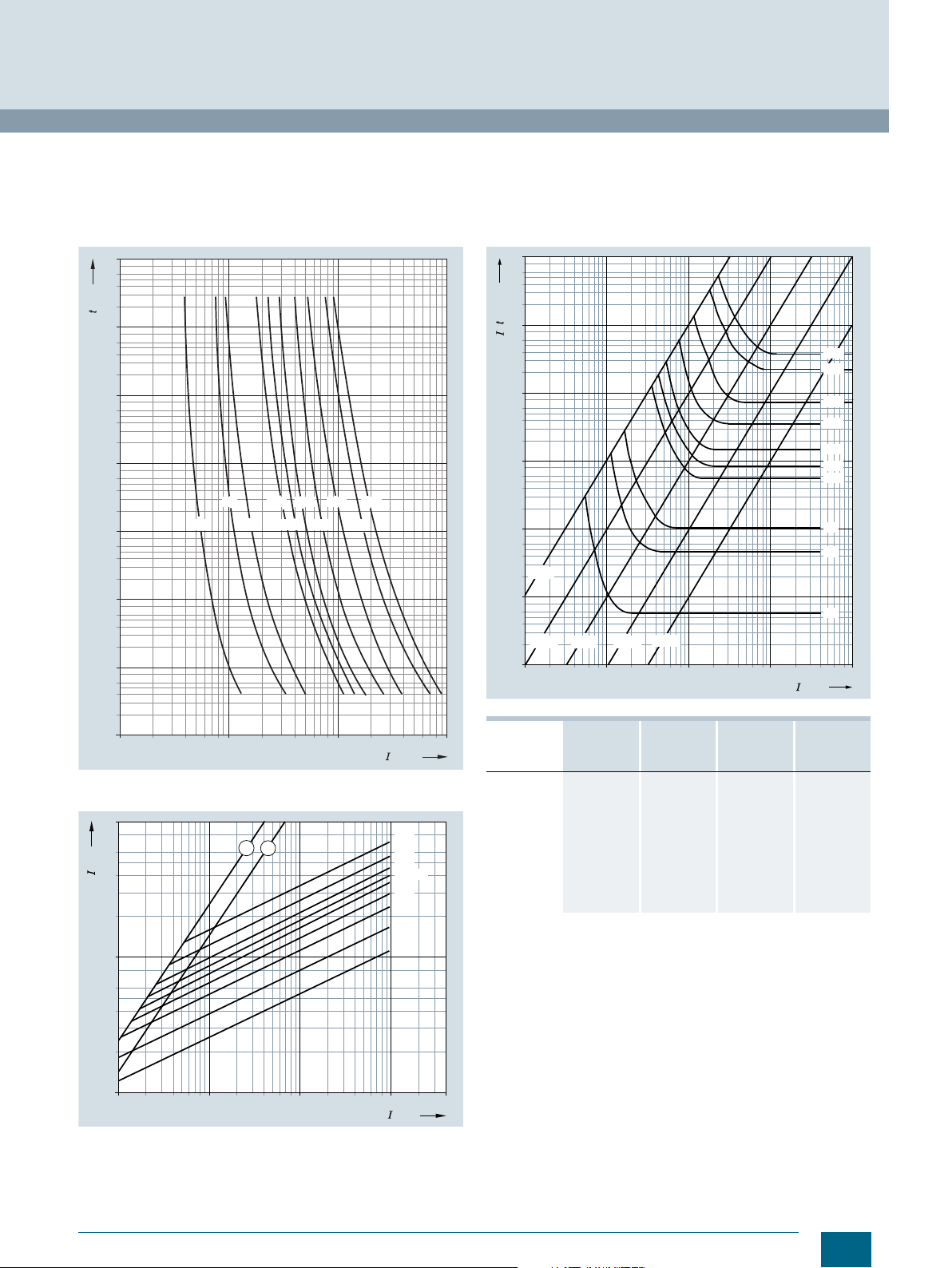

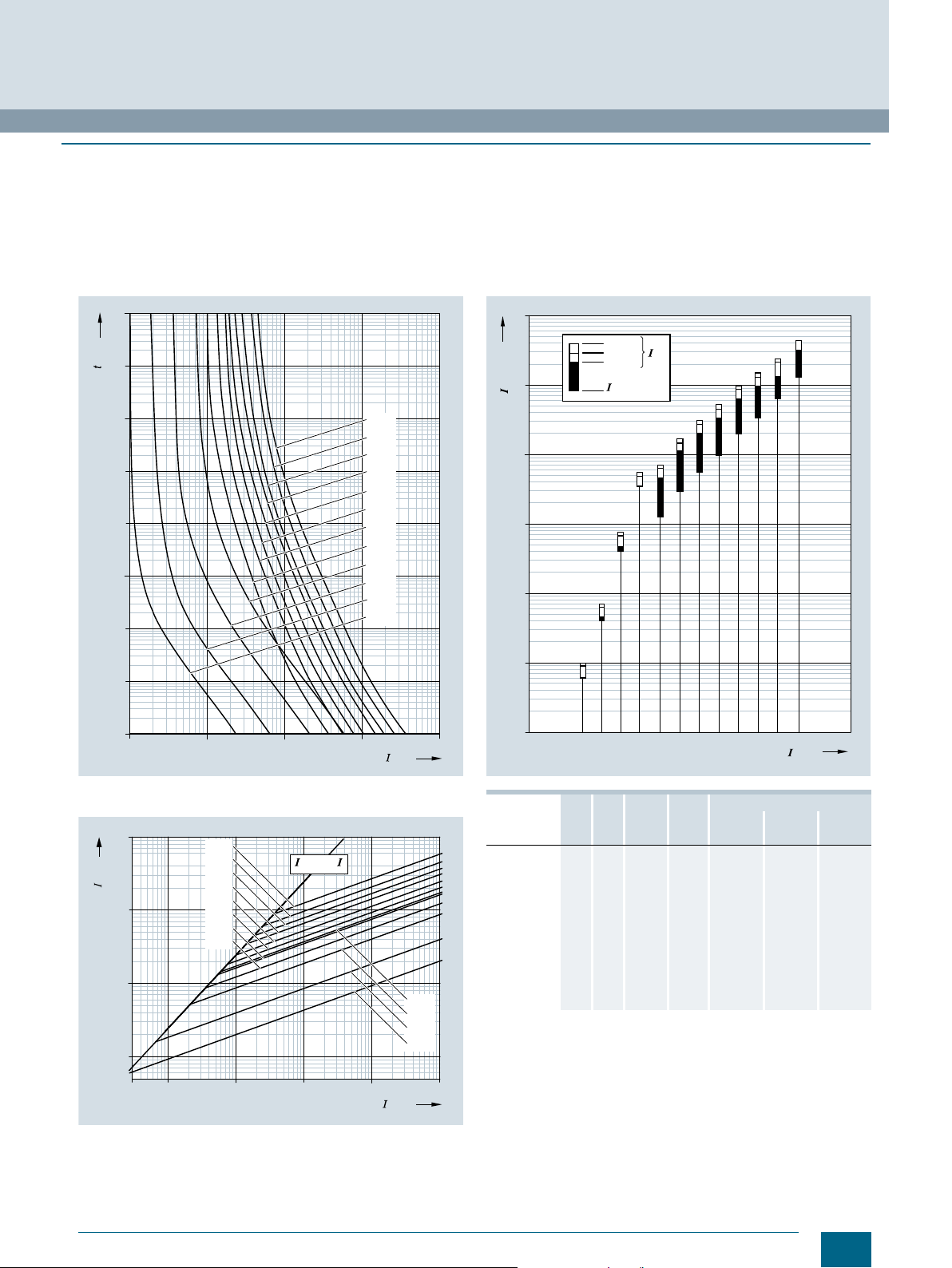

Characteristic curves

Series 5SE2

Sizes: D01, D02, D03

Operational class: gG

Rated voltage: 400 V AC/250 V DC

Rated current: 2 ... 100 A

Time/current characteristics diagram

© Siemens AG 2016

Fuse Systems

NEOZED Fuse Systems

NEOZED fuse links

Melting I2t values diagram

Current limiting diagram

Peak short-circuit current with largest DC component

$

% Peak short-circuit current without DC component

Ta bl e see page 14.

Siemens · 10/2015

13

Page 16

Fuse Systems

NEOZED Fuse Systems

NEOZED fuse links

Series 5SE2

Sizes: D01, D02, D03

Operational class: gG

Rated voltage: 400 V AC/250 V DC

Rated current: 2 ... 100 A

Typ e I

5SE2302

5SE2304

5SE2306

5SE2310

5SE2013-2A

5SE2316

5SE2320

5SE2325

5SE2332

5SE2335

5SE2340

5SE2350

5SE2363

5SE2280

5SE2300

n

A W K A2s A2s A2s A2s

2 1.6 19 1.2 1.4 2.9 3.9

4 1.3 14 12.5 13.6 22 30

6 1.7 19 46.7 48 58 75

10 1.3 16 120 136 220 280

13 2.0 23 220 244 290 370

16 2.1 24 375 410 675 890

20 2.4 26 740 810 1250 1650

25 3.2 33 1210 1300 1900 2600

32 3.6 34 2560 2800 4300 5500

35 3.8 36 3060 3500 5100 6500

40 4.0 37 4320 4800 7900 9500

50 4.2 38 6750 7400 10500 13000

63 5.3 45 10000 10900 16000 20500

80 5.3 43 13000 15400 25000 34500

100 6.4 47 22100 30000 46000 60000

P

v

© Siemens AG 2016

I2t

1ms 4ms 230 V AC 400 V AC

s

I2t

a

(t < 4ms)

14

Siemens · 10/2015

Page 17

■

Overview

The DIAZED fuse system is one of the oldest fuse systems in

the world. It was developed by Siemens as far back as 1906.

It is still the standard fuse system in many countries to this day.

It is particularly widely used in the harsh environments of industrial applications.

The series is available with rated voltages from 500 V to 750 V.

All DIAZED bases must be fed from the bottom to ensure an

insulated threaded ring when the fuse link is being removed.

Reliable contact of the fuse links is only ensured when used

together with DIAZED screw adapters.

The terminals of the DIAZED bases are available in different versions and designs to support the various installation methods.

The high-performing EZR bus-mounting system for screw fixing

is an outstanding feature. The busbars, which are particularly

suited for bus-mounting bases, have a load capacity of up to

150 A with lateral infeed.

DIAZED stands for Dia

system mit Ed

isongewinde (diametral two-step fuse system with

metral gestuftes zweiteiliges Sicherungs-

Edison screw).

© Siemens AG 2016

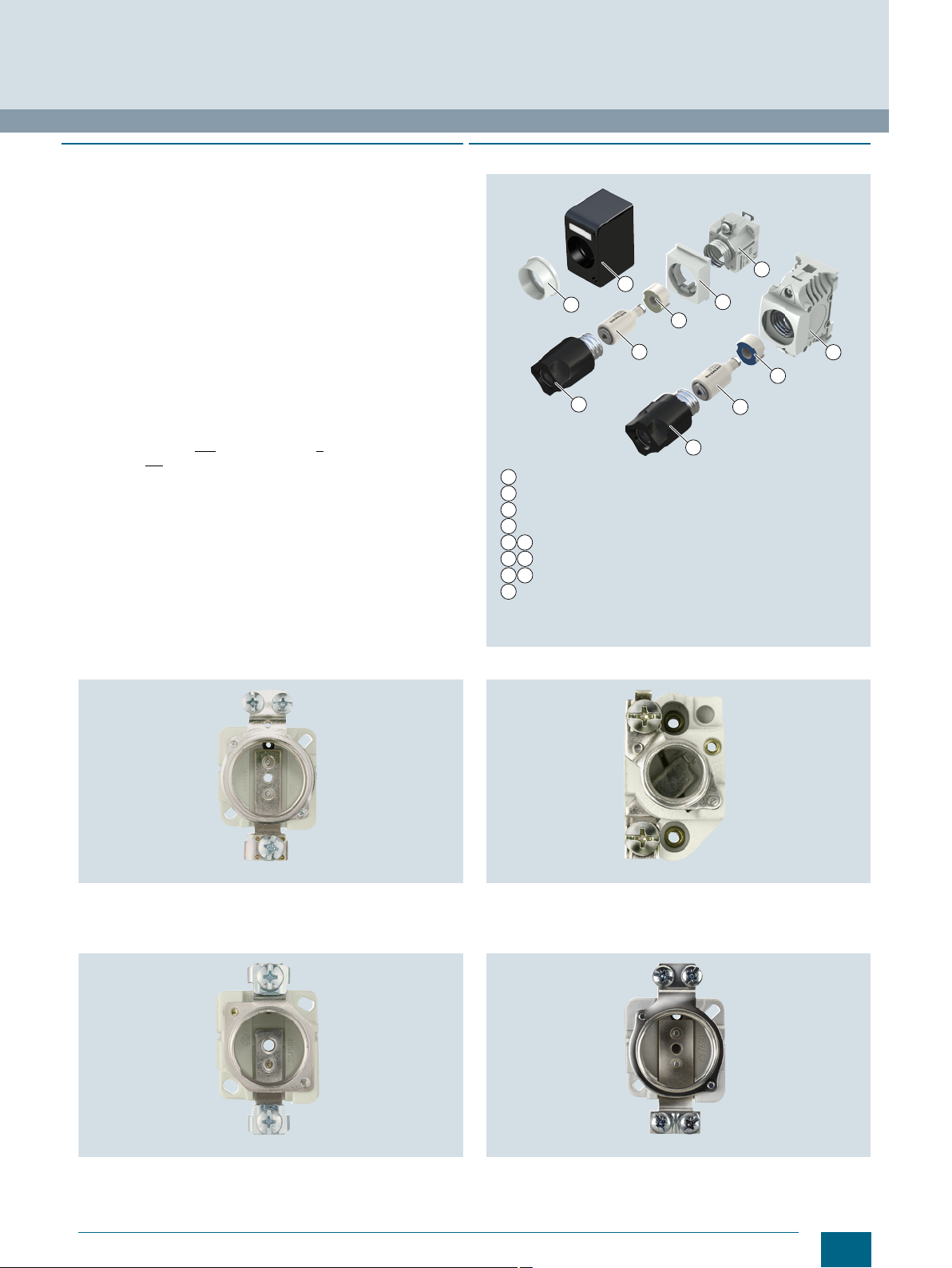

■

Benefits

1

2

3

4

5 9

6 10

7 11

8

Fuse Systems

DIAZED fuse systems

1

2

5

6

7

11

DIAZED cap for fuse bases

DIAZED collar for fuse bases

DIAZED fuse bases

DIAZED cover for fuse bases

DIAZED screw adapter

DIAZED fuse link

DIAZED screw cap

DIAZED fuse base (with touch protection BGV A3)

3

4

9

10

i201_18300

8

DIII fuse bases with terminal version BS

• Outgoing feeders (top), saddle terminal S

• Incoming feeders (bottom), clamp-type terminal B

DIII fuse bases with terminal version BB

• Outgoing feeders (top), clamp-type terminal B

• Incoming feeders (bottom), clamp-type terminal B

NDZ fuse bases with terminal version KK

• Outgoing feeders (top), screw head contact K

• Incoming feeders (bottom), screw head contact K

DIII fuse bases with terminal version SS

• Outgoing feeders (top), saddle terminal S

• Incoming feeders (bottom), saddle terminal S

Siemens · 10/2015

15

Page 18

© Siemens AG 2016

Fuse Systems

DIAZED fuse systems

■

Technical specifications

5SA, 5SB, 5SC, 5SD

Standards

Operational class Acc. to IEC 60269;

Characteristic Acc. to DIN VDE 0635

Rated voltage U

Rated current I

Rated breaking capacity kA AC

Overvoltage category

Mounting position

Non-interchangeability

Degree of protection Acc. to IEC 60529

Resistance to climate °C Up to 45, at 95 % rel. humidity

Ambient temperature °C

1)

Degree of protection IP20 is tested according to regulations using a

straight test finger (from the front), with the device mounted and equipped

with a cover, housing or some other enclosure.

n

n

DIN VDE 0636

V AC 500, 690, 750

V DC

A 2...100

kA DC

IEC 60269-3; DIN VDE 0635; DIN VDE 0636-3; CEE 16

gG

Slow and quick

500, 600, 750

50, 40 at E16

8, 1.6 at E16

III

II (DIAZED fuse bases made of molded plastic for use at 690 V AC / 600 V DC)

Any, preferably vertical

Using screw adapter or adapter sleeves

IP20, with connected conductors

-5 to +40, humidity 90 % at 20

1)

Terminal version

B K S R

Size

Conductor cross-sections

• Rigid, min. mm

• Rigid, max. mm

• Flexible, with end sleeve mm

Tightening torque

• Screw M4 Nm 1.2 --

• Screw M5 Nm

• Screw M6 Nm

• Screw M8 Nm

DII DIII NDz DII DIII DIII DIV DII DIII

2

1.5 2.5 1.0 1.5 2.5 2.5 10 1.5 1.5

2

10 25 6 10 25 25 50 35 35

2

10 25 6 10 25 25 50 35 35

2.0 --

2.5 3.0

3.5 --

16

Siemens · 10/2015

Page 19

49

I201_06251a

13,2

d

I201_06247

d

49

22,5

49

I201_06248

d

28

34,5

57

d

I201_06682

70

I201_06329a

ød

ø28

© Siemens AG 2016

■

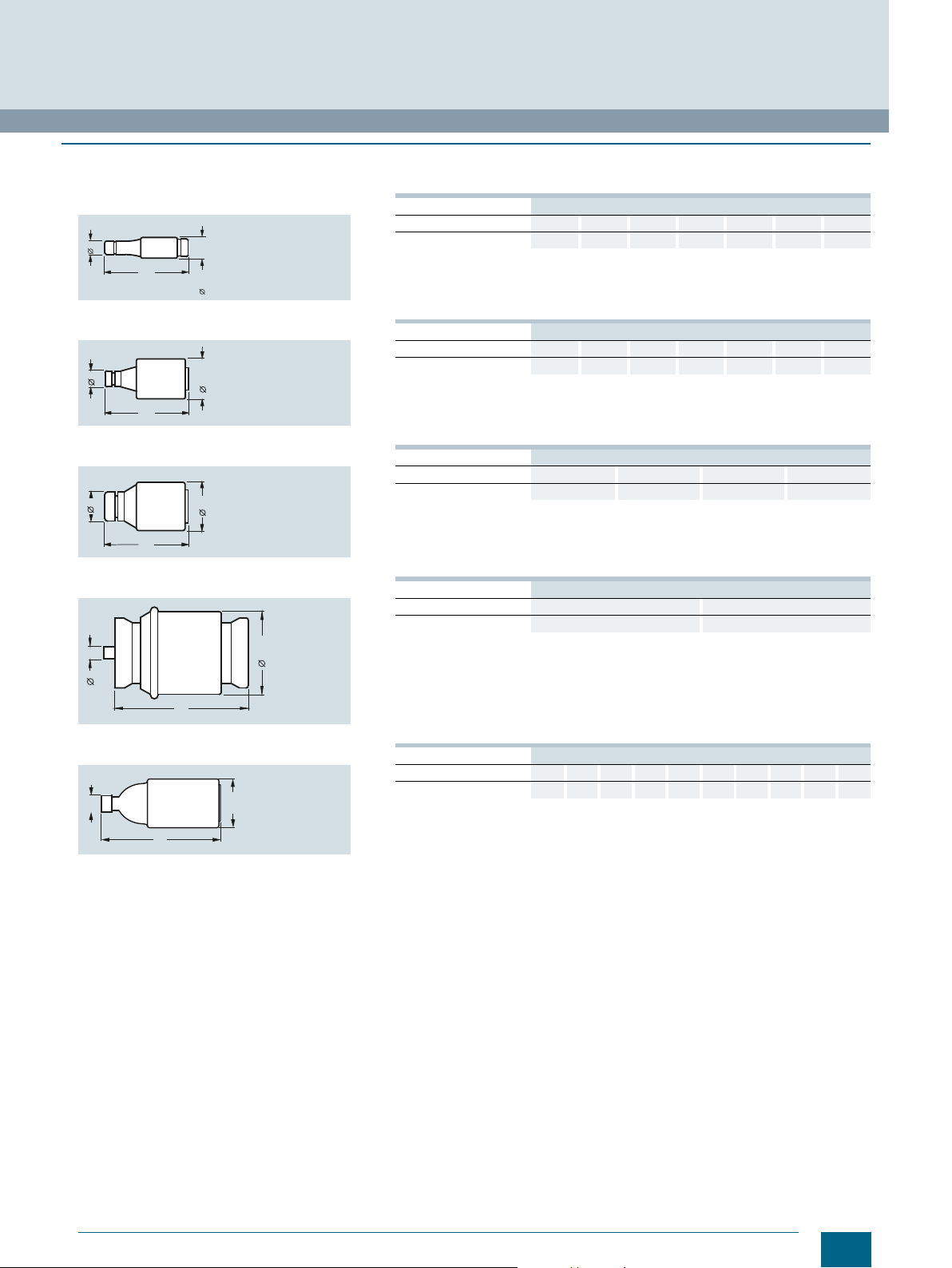

Dimensional drawings

DIAZED fuse links

5SA1, 5SA2 Size/thread TNDz/E16, NDz/E16

Rated current in A 2 4 6 10 16 20 25

Dimension d

5SB1, 5SB2 Size/thread DII/E27

Rated current in A 2 4 6 10 16 20 25

Dimension d

5SB3, 5SB4 Size/thread DIII/E33

Rated current in A 32 35 50 63

Dimension d

6 6 6 8 10 12 14

6 6 6 8 10 12 14

16 16 18 20

Fuse Systems

DIAZED fuse systems

5SC1, 5SC2 Size/thread DIV/R1¼"

Rated current in A 80 100

Dimension d

5SD6, 5SD8 Size/thread DIII/E33

Rated current in A 2 4 6 10 16 20 25 35 50 63

Dimension d

5 7

6 6 6 8 10 12 14 16 18 20

Siemens · 10/2015

17

Page 20

Fuse Systems

I201_06242

a

b

h

Øi

c

g

d

e

80

max.113

12

5

105

50

65

M6

I2_06443a

I201_11344

a

b

43,6

6

80

DIAZED fuse systems

DIAZED fuse bases made of ceramic

5SF1

5SF4230

© Siemens AG 2016

Version

Typ e a b c d e g h i

NDz/25 A

5SF1012 KK 29 49 44.6 55 75 32 49 --

DII/25 A

5SF1005 BB 38.4 41 46.6 53 83 34 63 --

5SF1024

DIII/63 A

5SF1205 BS 45.5 46 47 54 83 43 78 --

5SF1215

5SF1224

DIV/100 A

5SF1401 Flat terminal 68 68 -- 79 110 65 116 6.5

Connection

type

Dimensions

BB 38.4 41 46.6 53 83 34 63 4.3

SS 45.5 46 47 54 83 43 78 -BS 45.5 46 47 54 83 43 78 4.3

DIAZED fuse bases made of molded plastic

5SF1, 5SF5 Typ e Dimensions

5SF1060

5SF1260

5SF5068

5SF5268

a b

40 -50 --

-- 120

-- 150

18

Siemens · 10/2015

Page 21

41,5

45

18

11

14

max.83

31

16

27

max.38,5

30

20,5

31

5

I2_06444a

34

max.49

3722

5,3

34

51,5

55

18

11

14

max.83

31

I2_06445a

16

a

I201_06257

b

I201_13741a

b

a

I201_06242

a

b

h

Øi

c

g

d

e

© Siemens AG 2016

Fuse Systems

DIAZED fuse systems

DIAZED EZR bus-mounting bases

5SF6005 5SF6205

DIAZED screw caps/cover rings made of molded plastic/ceramic

Screw caps Cover rings Screw caps Cover rings

5SH1 5SH3 Size/thread

NDz/E16

DII/E27 5SH1221 42 33 5SH3401 17.5 39.5

DIII/E33 5SH1231 42 40 5SH3411 17.5 49.5

Typ e Dimensions Typ e Dimensions

a b a b

5SH1112 36 24

5SH112 45.5 34 5SH332 17.5 41.5

5SH122 43 39

5SH113 45.5 43 5SH334 19 51.5

5SH123 47 45

5SH1161 48 48

5SH1170 68 43

DIAZED caps made of molded plastic

5SH2 Size/thread Ty pe Dimensions

NDz/E16 5SH201 33 68 51.7 75

DII/E27

DIII/E33

5SH202 43 74.7 53.6 83

5SH222 51 90.5 53.6 83

a

max

b

max

c

max

d

max

Siemens · 10/2015

19

Page 22

Fuse Systems

210

0

10

-3

2

4

6

10

-2

6410

1

82 64

10

2

824

2

4

6

10

-1

2

4

6

10

0

2

4

6

10

1

2

4

6

10

2

2

4

6

10

3

2

4

6

10

4

I2_06069c

6

10

3

8

2 A

vs

[A]

[s]

4 A 6 A 10 A 20 A

16 A 25 A

ef

ef

10

2

2

6410

3

8

2

4

6

2

4

6

10

I2_07032b

5

2 A

c

[A]

[A]

10

2

6

10

3

2

4

6

10

4

2

6410

4

8

2

6410

5

8

2

4

4 A

6 A

10 A

16 A

20 A

25 A

1

2

261010 4

0

2

6410

1

82 6410

2

8

3

82 610448

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

I2_07545c

0

1

2

3

4

5

6

25 A

20 A

16 A

2 A

[A]

2

s

[A s]

2

100s

10-1s

10-2s

10-3s

10-4s

4 A

6 A

10 A

ef

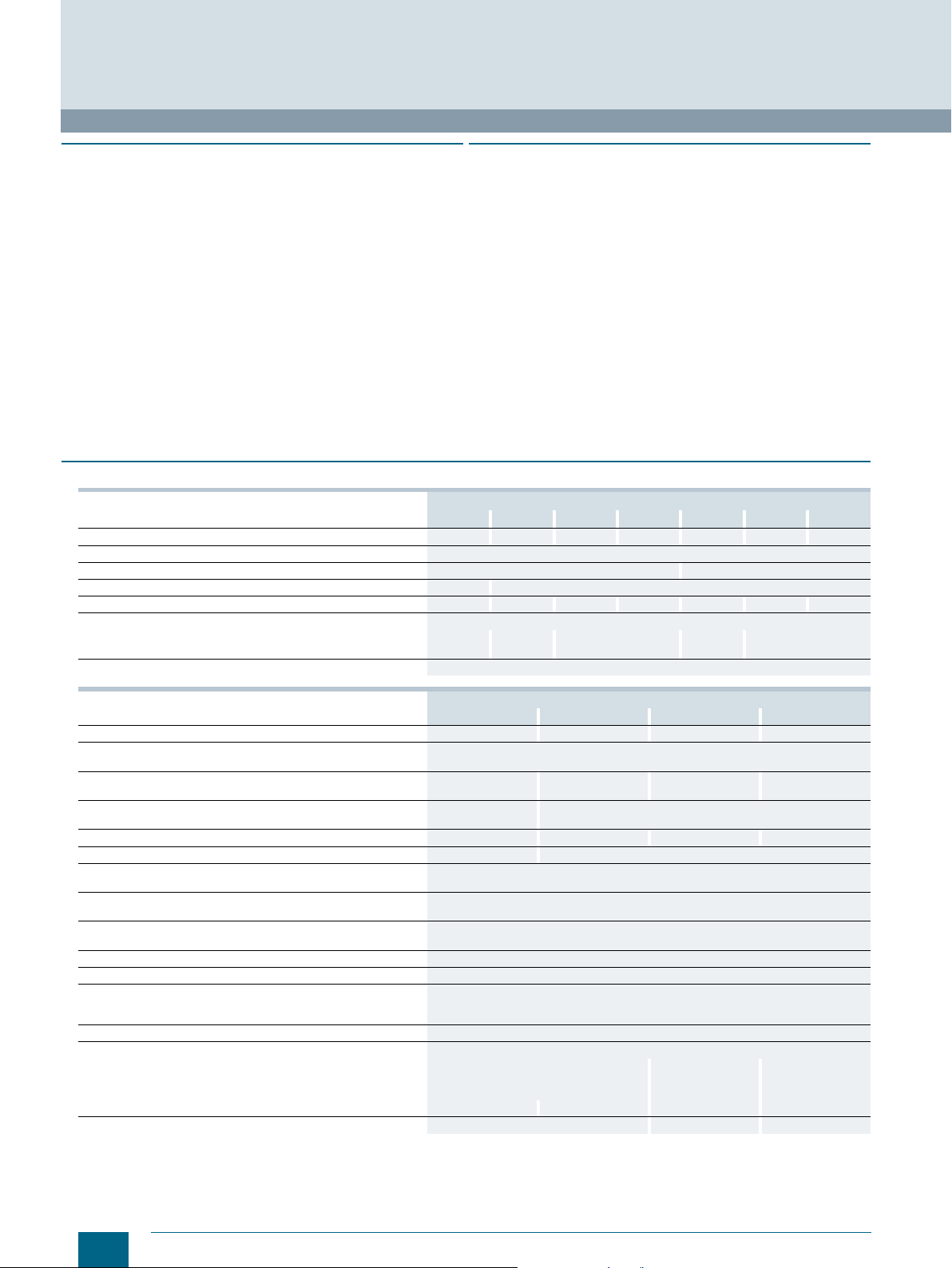

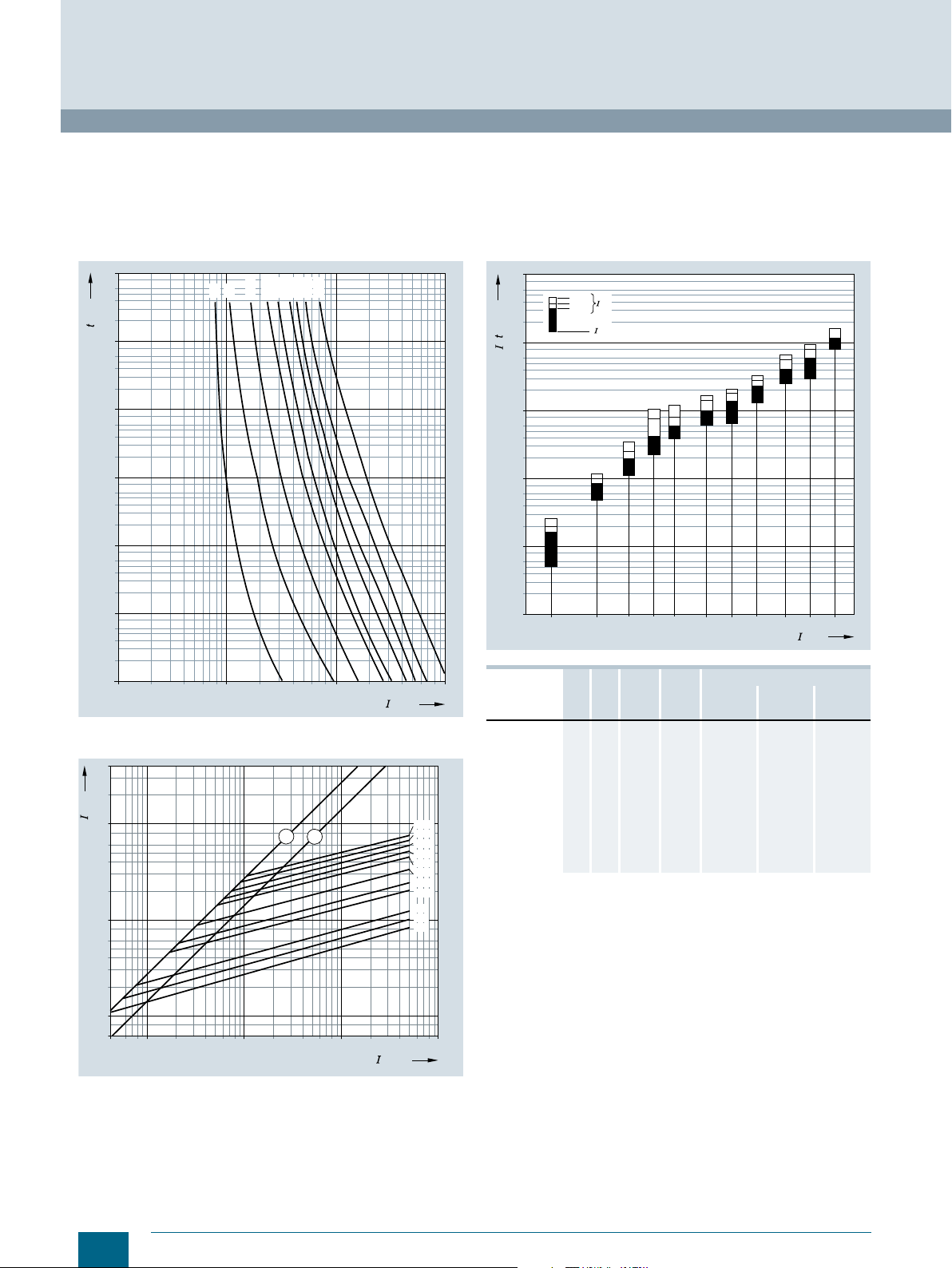

DIAZED fuse systems

■

Characteristic curves

Series 5SA2

Size: E16

Characteristics: Slow

Rated voltage: 500 V AC/500 V DC

Rated current: 2 ... 25 A

Time/current characteristics diagram

© Siemens AG 2016

Melting I2t values diagram

Current limiting diagram

$

Peak short-circuit current with largest DC component

% Peak short-circuit current without DC component

20

Siemens · 10/2015

Typ e I

A W K A2s A2s

5SA211

5SA221

5SA231

5SA251

5SA261

5SA271

5SA281

10 1.4 17 200 190

16 2.4 30 290 550

20 2.6 36 470 1990

25 3.4 34 1 000 2090

Typ e I2t

230 V AC 320 V AC 500 V AC

A2s A2s A2s

5SA211

5SA221

5SA231

5SA251

5SA261

5SA271

5SA281

1200 1350 1620

2400 2600 3450

n

2 0.85 15 1.2 2.3

4 1.3 17 8.5 13

6 1.9 14 40 80

a

22 26 34

66 76 100

240 270 340

890 950 1 090

P

v

6.6 7.8 0.7

I2t

1ms 4ms

s

Page 23

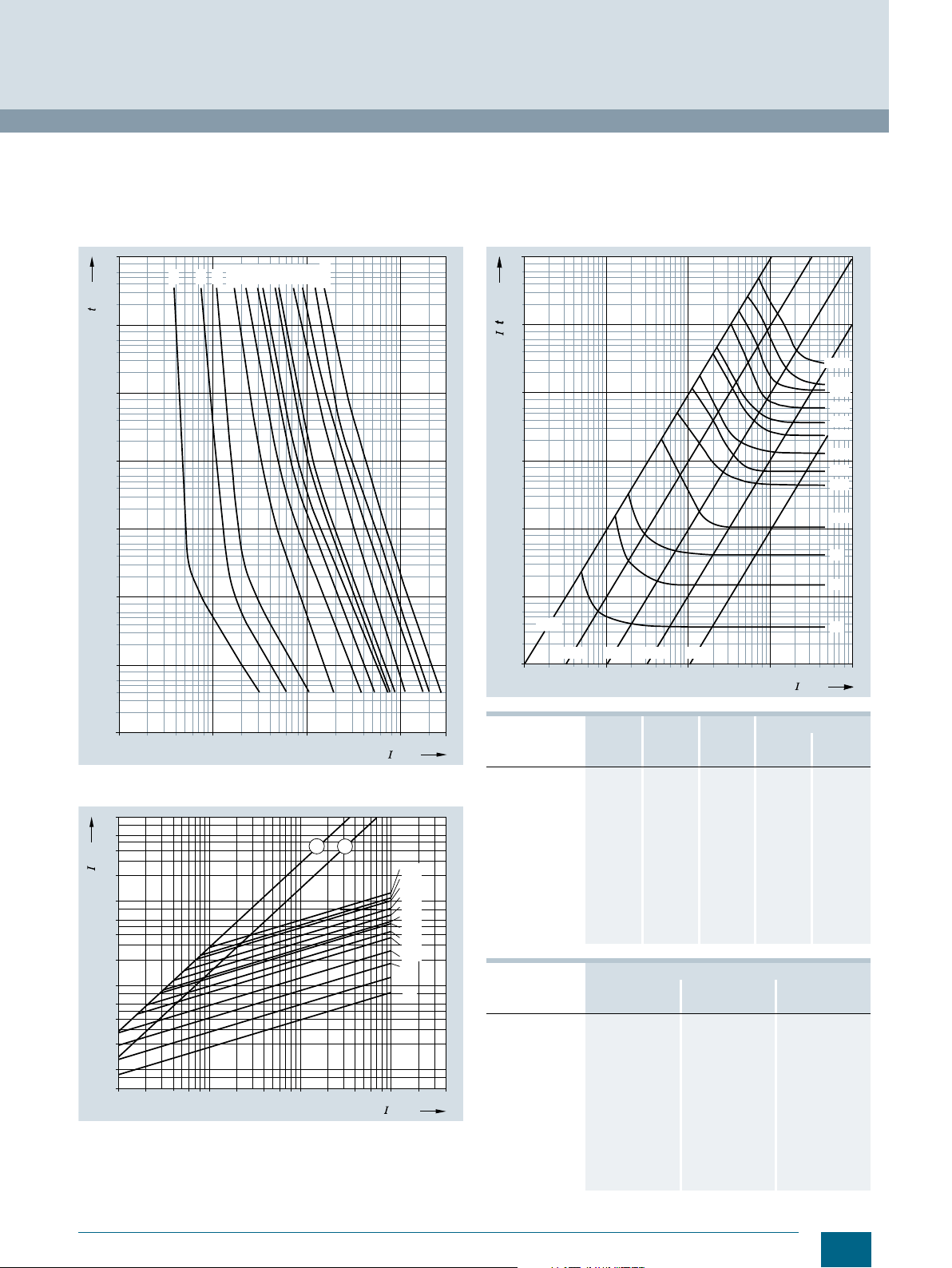

Series 5SB2, 5SB4, 5SC2

210

0

10

-3

2

4

6

10

-2

6410

1

82 64

10

2

824

2

4

6

10

-1

2

4

6

10

0

2

4

6

10

1

2

4

6

10

2

2

4

6

10

3

2

4

6

10

4

6

10

3

8

vs

[A]

[s]

2

I2_07551a

2 A

4 A

6 A

10 A

16 A

20 A

25 A

32 A

35 A

50 A

63 A

80 A

100 A

ef

10

2

2

6410

3

8

2

4

6

2

4

6

10

I2_06055b

5

2 A

c

[A]

[A]

10

2

6

10

3

2

4

6

10

4

2

6410

4

8

2

6410

5

8

2

4

4 A

6 A

10 A

16 A

20 A

25 A

32 A

50 A

63 A

80 A

100 A

1

2

35 A

ef

Size: DII, DIII, DIV

Operational class: gG

Rated voltage: 500 V AC/500 V DC

Rated current: 2 ... 100 A

Time/current characteristics diagram

© Siemens AG 2016

Melting I2t values diagram

6

10

6

4

2

2

[A s]

s

5

10

2

6

4

2

4

10

6

4

2

3

10

6

4

2

2

10

6

4

2

1

10

6

4

2

0

10

0

100s

2

10-1s

10-2s

1

6410

82 6410

10-3s

Fuse Systems

DIAZED fuse systems

10-4s

2

261010 4

8

82 610448

I2_07552a

100 A

80 A

63 A

50 A

35 A

32 A

25 A

20 A

16 A

10 A

6 A

4 A

2 A

3

[A]

ef

Typ e I

Current limiting diagram

$ Peak short-circuit current with largest DC component

% Peak short-circuit current without DC component

5SB211

5SB221

5SB231

5SB251

5SB261

5SB271

5SB281

5SB4010

5SB411

5SB421

5SB431

5SC211

5SC221

Typ e I2t

5SB211

5SB221

5SB231

5SB251

5SB261

5SB271

5SB281

5SB4010

5SB411

5SB421

5SB431

5SC211

5SC221

n

A W K A2s A2s

10 1.6 20 120 140

16 2.4 23 500 580

20 2.6 26 750 1100

25 3.4 38 1600 2000

32 3.6 23 2300 2500

35 3.7 25 3450 3000

50 5.7 41 6500 5200

63 6.9 48 11000 12 000

80 7.5 33 14600 16 400

100 8.8 46 28600 30 000

230 V AC 320 V AC 500 V AC

A2s A2s A2s

1200 1450 1 620

2400 3150 3 450

3450 4150 4 850

5200 6200 7 200

9750 12350 14500

16500 22200 26500

23000 28500 32500

44000 56000 65000

P

v

2 2.6 15 3.7 3.9

4 2.0 13 15 16

6 2.2 14 42 45

a

6.6 8.8 10.7

22 28 34

66 85 100

240 300 340

890 1 060 1090

I2t

s

1ms 4ms

Siemens · 10/2015

21

Page 24

ef

10

2

2

6410

3

8

2

4

6

I2_07101a

2 A

c

[A]

[A]

10

2

6410

4

8

2

6410

5

8

2

4

4 A

6 A

10 A

16 A

20 A

25 A

2

10

3

6

2

4

10

4

6

2

63 A

50 A

35 A

1

2

261010 4

0

2

6410

1

82 6410

2

8

3

82 610448

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

I2_06425b

0

1

2

3

4

5

6

2 A

[A]

2

s

[A s]

2

100s

10-1s

10-2s

10-3s

10-4s

25 A

20 A

16 A

4 A

6 A

10 A

35 A

50 A

63 A

ef

© Siemens AG 2016

Fuse Systems

DIAZED fuse systems

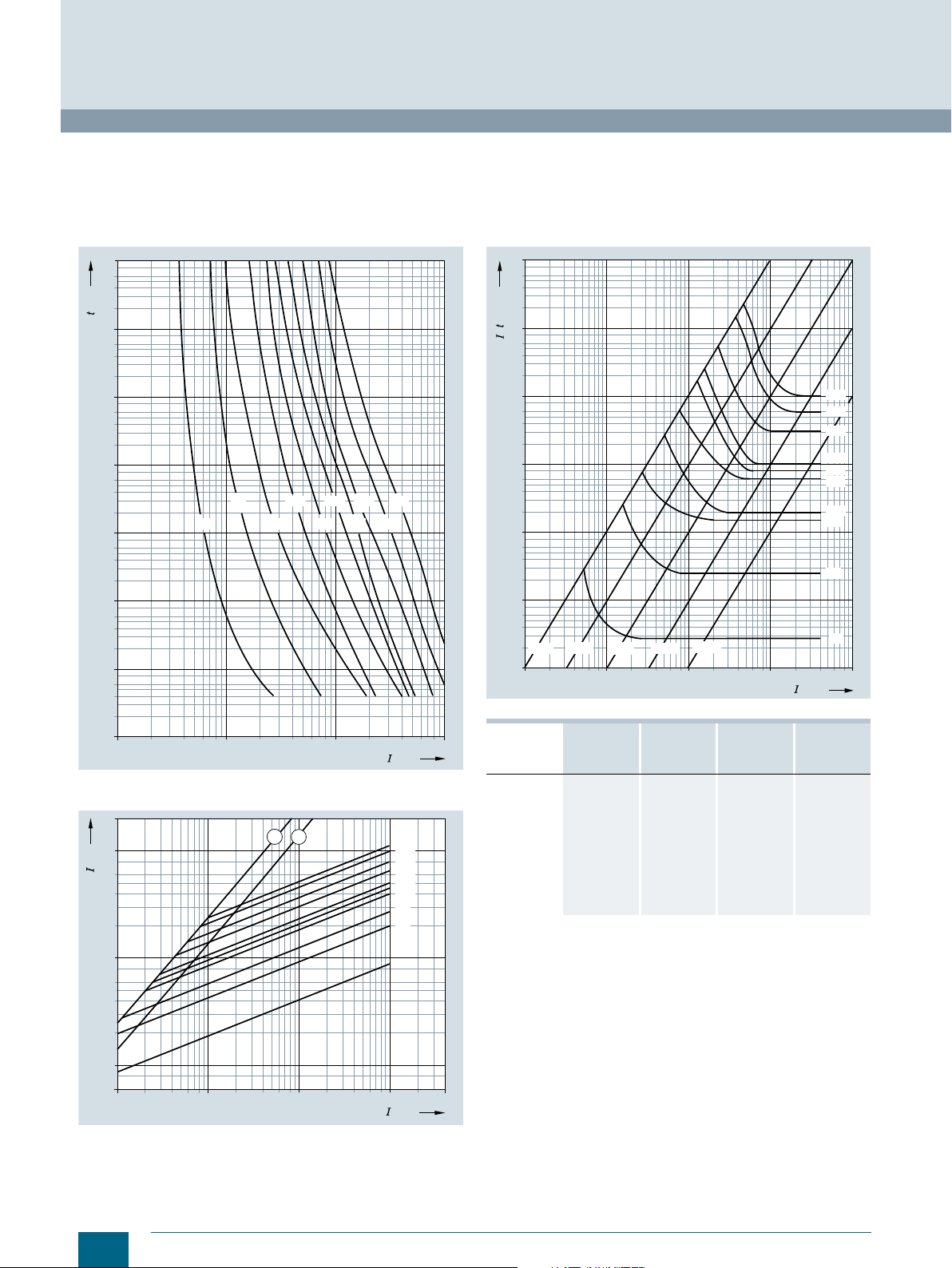

Series 5SD8

Size: DIII

Operational class: gG

Rated voltage: 690 V AC/600 V DC

Rated current: 2 ... 63 A

Time/current characteristics diagram

4

10

6

4

[s]

vs

2

3

10

6

4

2

2

10

6

4

2

1

10

6

4

2

0

10

6

4

2

-1

10

6

4

2

-2

10

6

4

2

-3

10

0

210

4 A 10 A 20 A 30 A 63 A

2 A 6 A 16 A 25 A 50 A

1

6410

82 64

2

10

824

6

8

[A]

ef

Current limiting diagram

$

Peak short-circuit current with largest DC component

% Peak short-circuit current without DC component

22

Siemens · 10/2015

Melting I2t values diagram

I2_06412c

Typ e I

3

10

5SD8002

5SD8004

5SD8006

5SD8010

5SD8016

5SD8020

5SD8025

5SD8035

5SD8050

5SD8063

n

P

v

I2t

s

I2t

a

4ms 242 V AC

A W A2s A2s

2 1 4.4 7

4 1.2 40 62

6 1.6 88 140

10 1.4 240 380

16 1.8 380 600

20 2 750 1 200

25 2.3 2000 3 200

35 3.1 3300 5 100

50 4.6 7000 11 000

63 5.5 9500 15 000

Page 25

21 0

0

1 0

- 3

2

4

6

1 0

- 2

64 1 018 2 64

1 0

2

8 2 4

2

4

6

1 0

- 1

2

4

6

1 0

0

2

4

6

1 0

1

2

4

6

1 0

2

2

4

6

1 0

3

2

4

6

1 0

4

I 2 _ 0 6 0 4 8 a

6

1 0

3

8

v s

e f f

[ A ]

[ s ]

2 A 6 A 5 0 A2 5 A1 6 A

4 A 1 0 A 2 0 A 3 0 A 6 3 A

10

2

2

6410

3

8

2

4

I2_06411a

2 A

c

[A]

[A]

10

2

6410

4

8

2

6410

5

8

2

4

4 A

6 A

10 A

16 A

20/25 A

2

10

3

6

2

4

10

4

6

63 A

50 A

35 A

1

2

ef

261010 4

0

2

6410

1

82 6410

2

8

3

82 610448

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

I2_06077b

-1

0

1

2

3

4

5

[A]

2

s

[A s]

2

6 A

2 A

4 A

10 A

16 A

20 A

25 A

35 A

50 A

63 A

10-1s

10-2s

10-3s

10-4s

100s

ef

© Siemens AG 2016

Series 5SD6

Size: DIII

Operational class: Quick (railway network protection)

Rated voltage: 750 V AC/750 V DC

Rated current: 2 ... 63 A

Time/current characteristics diagram

Fuse Systems

DIAZED fuse systems

Melting I2t values diagram

Typ e I

Current limiting diagram

Peak short-circuit current with largest DC component

$

% Peak short-circuit current without DC component

5SD601

5SD602

5SD603

5SD604

5SD605

5SD606

5SD607

5SD608

5SD610

5SD611

n

A W A2s A2s

2 2.8 0.7 2

4 4 4.5 13

6 4.8 10 29

10 4.8 50 135

16 5.9 78 220

20 6.3 125 380

25 8.3 265 800

35 13 550 1600

50 16.5 1800 5 500

63 18 3100 9 600

P

v

I2t

s

I2t

a

4ms 500 V AC

Siemens · 10/2015

23

Page 26

Fuse Systems

Cylindrical Fuse Systems

Cylindrical fuse links and cylindrical fuse holders

■

Overview

Cylindrical fuses are standard in Europe. There are a range of

different cylindrical fuse links and holders that comply with the

standards IEC 60269-1, -2 and -3, and which are suitable for use

in industrial applications. In South West Europe they are also

approved for use in residential buildings.

The cylindrical fuse holders are also approved according to

UL 512. The cylindrical fuse holders are tested and approved as

fuse disconnectors according to the switching device standard

IEC 60947-3. They are not suitable for switching loads.

Cylindrical fuse holders can be supplied with or without signal

detectors. In the case of devices with signal detector, a small

electronic device with LED is located behind an inspection

window in the plug-in module. If the inserted fuse link is tripped,

this is indicated by the LED flashing.

The switching state of the fuse holder can be signaled over a

laterally retrofitted auxiliary switch, which enables the integration

of the fuses in the automation process.

■

Technical specifications

Size mm × mm

Standards

Operational class

Rated voltages U

Rated current I

Rated breaking capacity

• 500 V versions kA AC

• 400 V versions kA AC

Mounting position

n

n

VAC 400 400 or 500

A 2...20 0.5 ... 32 4...50 8...100 0.5 ... 32 2...50 10 ... 100

© Siemens AG 2016

■

Benefits

• Devices with pole number 1P+N are available in a single

modular width. This reduces the footprint by 50 %

• The sliding catch for type ranges 8 x 32 mm and 10 x 38 mm

enables the removal of individual devices from the assembly

• Space for a spare fuse in the plug-in module enables the

fast replacement of fuses. This saves time and money and

increases system availability

• A flashing LED signals that a fuse link has been tripped.

This enables fast detection during runtime

Cylindrical fuse links

3NW63.. 3NW60.. 3NW61.. 3NW62.. 3NW80.. 3NW81.. 3NW82..

8×32 10 × 38 14 × 51 22 × 58 10 × 38 14 × 51 22 × 58

IEC 60269-1, -2, -3; NF C 60-200; NF C 63-210, -211; NBN C 63269-2, CEI 32-4, -12

gG aM

-- 120 100

20 120 120

Any, preferably vertical

20

120 100

20

Cylindrical fuse holders

3NW73.. 3NW70.. 3NW71.. 3NW72..

Size mm × mm

Standards

Approvals Acc. to UL

Rated voltage U

Rated current I

Rated breaking capacity kA

Breaking capacity

• Utilization category AC-20B (switching without load), DC-20B

No-voltage changing

of fuse links

Sealable

when installed

Mounting position

Degree of protection Acc. to IEC 60529

Terminals with touch protection

according to BGV A3 at incoming

and outgoing feeder

Ambient temperature °C -5 to +40, humidity 90 % at +20

Conductor cross-sections

• Rigid mm

•Stranded mm

• Finely stranded, with end sleeve mm

• AWG (American Wire Gauge) AWG

Tightening torque Nm

1)

Degree of protection IP20 is tested according to regulations using a

straight test finger (from the front), with the device mounted and equipped

with a cover, housing or some other enclosure.

2)

Max. cross-section 10 mm2 with K28 crimper from Klauke.

n

n

Acc. to CSA

Acc. to UL/CSA V AC

VAC 400 690

AAC 20 32 50 100

2

2

2

8×32 10 × 38 14 × 51 22 × 58

IEC 60269-1, -2, -3; NF C 60-200, NF C 63-210, -211; NBN C 63269-2-1; CEI 32-4, -12;

UL 4248-1

-- U U --

-- s s --

400 600

20 100

Ye s

Ye s

Any, preferably vertical

IP20, with connected conductors

Ye s

0.5 ... 10 2.5 ... 10 4...10

0.5 ... 10 2.5 ... 25 4...50

2)

0.5 ... 10

-- 10 ... 20 6...10 --

1.2 2.0 2.5

1)

2.5 ... 16 4...35

24

Siemens · 10/2015

Page 27

31,5

8,5

I2_06702c

58

22,2

I2_06704c

I201_12124

18 18 36 54 54 44

64

45

81

7

2

55

43

90

45

27

54

81 108

I201_07853b

7

70

70

43

45

7

117

I201_07869c

144

108

72

36

48,5

5

45

90

9

I201_10891

49,8

© Siemens AG 2016

Cylindrical Fuse Systems

Cylindrical fuse links and cylindrical fuse holders

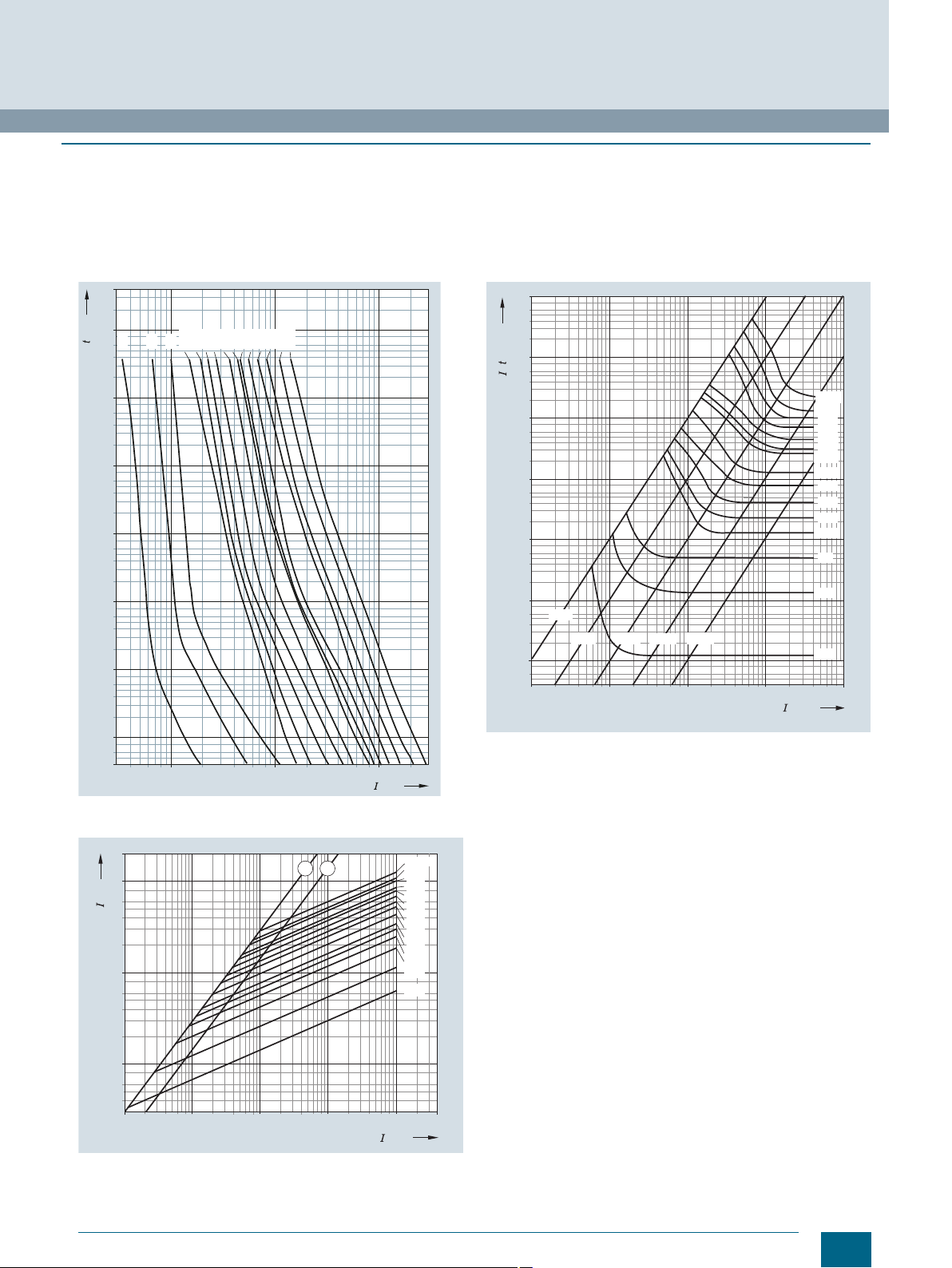

■

Dimensional drawings

I2_06703c

38

Size

8 × 32 mm 10 × 38 mm 14 × 51 mm 22 × 58 mm

3NW70, 3NW73

1P 1P + N 2P 3P 3P+N

10,3

I2_06701c

14,3

51

Fuse Systems

3NW71

1P 1P+N/2P 3P 3P+N

3NW72

1P 1P+N/2P 3P 3P+N

Auxiliary switches

3NW7901

3NW7902

I201_15459

45

83

4469

64

3NW7903

Siemens · 10/2015

25

Page 28

Fuse Systems

2

1

22 14

13/21

22

12

21

11

Cylindrical Fuse Systems

Cylindrical fuse links and cylindrical fuse holders

■

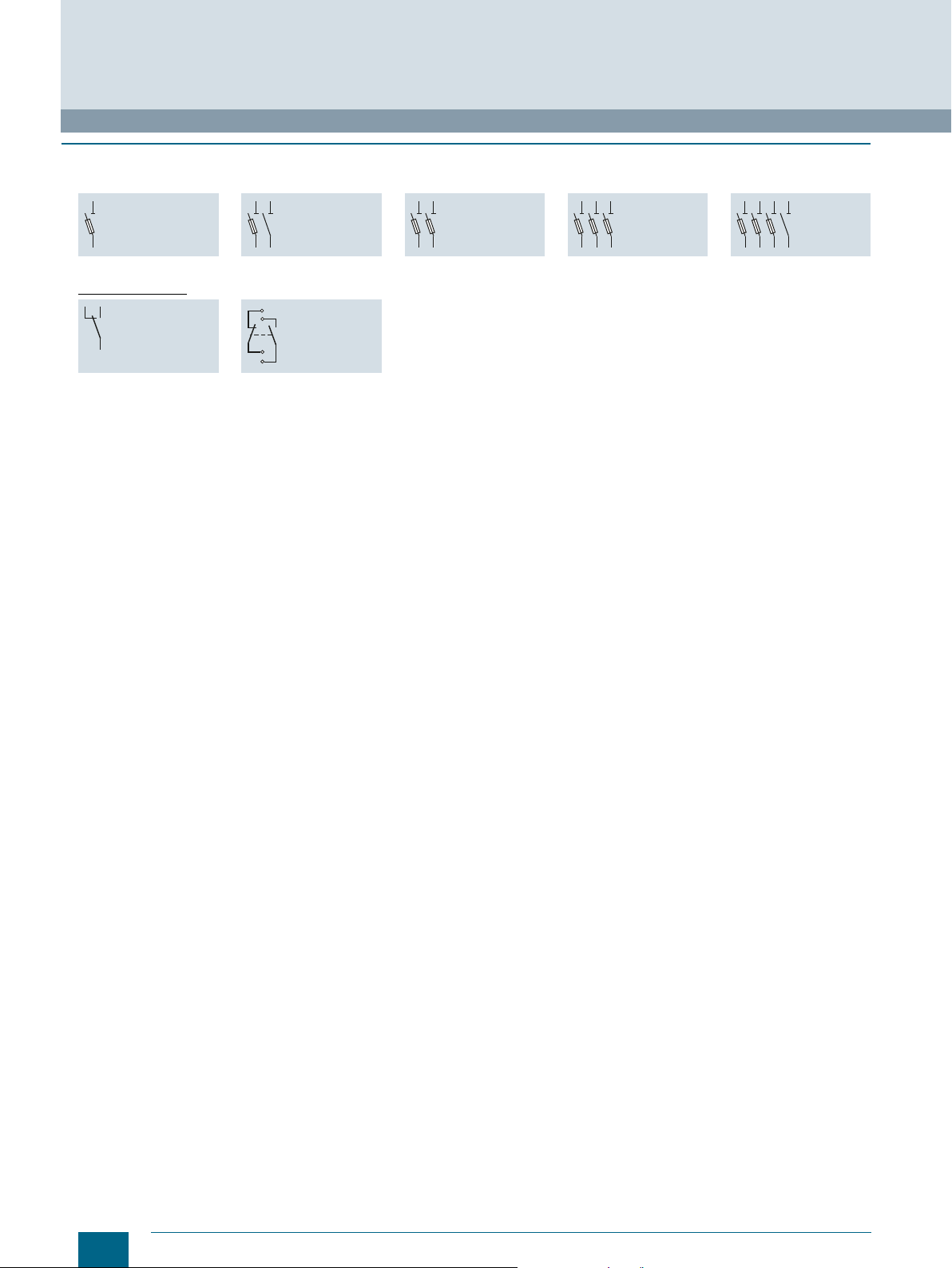

Circuit diagrams

Graphical symbols

21N

© Siemens AG 2016

214

21436

2

N

1P 1P+N 2P 3P 3P+N

3

5

Auxiliary switches

3NW7901

3NW7902

3NW7903

NN56341

26

Siemens · 10/2015

Page 29

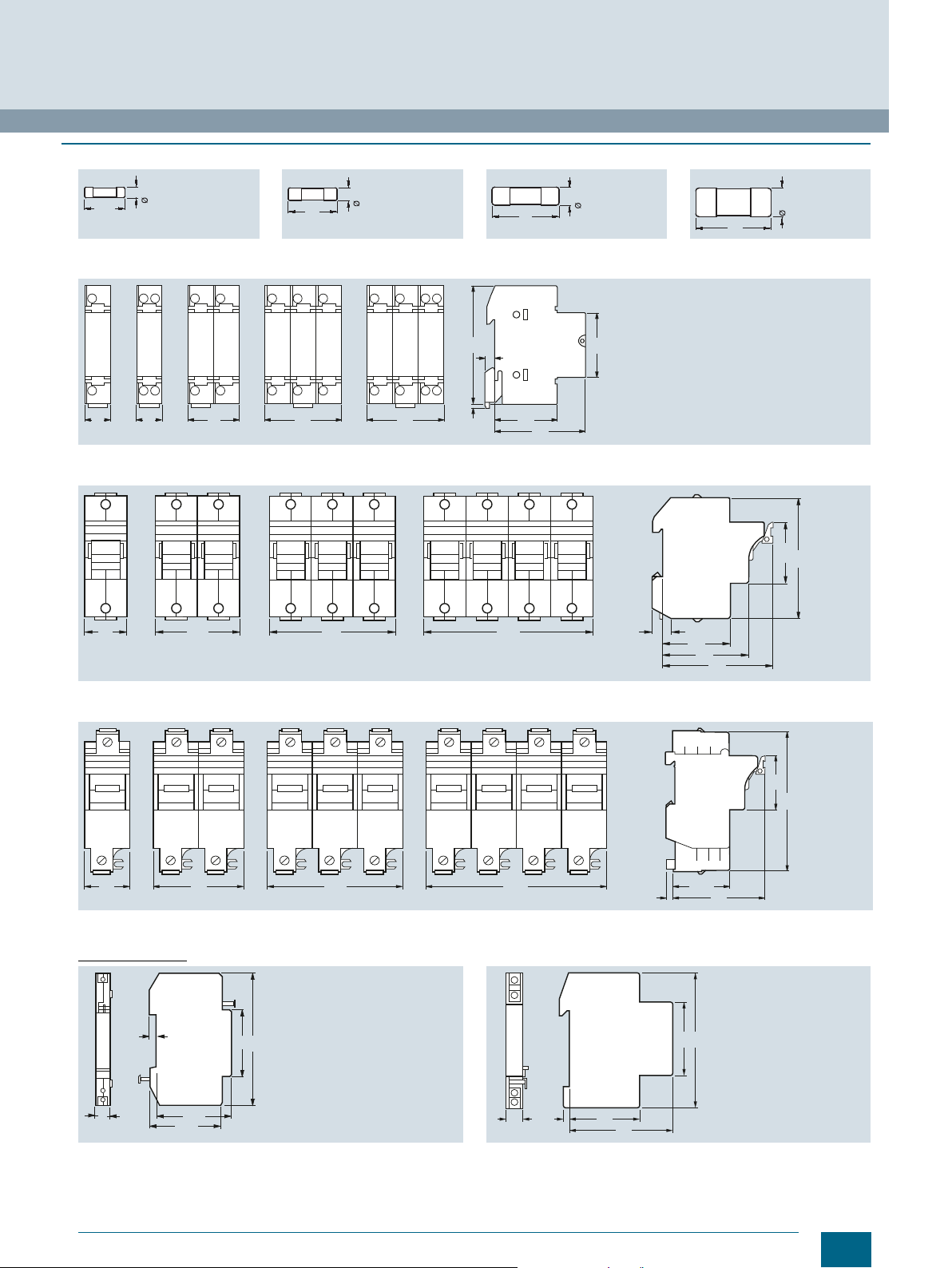

■

2

4

6

2

4

6

2

4

6

2

4

6

2

4

6

2

4

6

2

4

6

2

4

6

2 4 6 8 2 4 6 8 2 4 6 8 2 4 6 8 10

1

10

2

10

3

10

-4

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

10

4

10

4

32 A

25 A

20 A

16 A

12 A

10 A

8 A

6 A

4 A

2 A

1 A

0,5 A

[A]

p

[s]

vs

Prospective short-circuit current

Virtual pre-arcing time

I201_19158

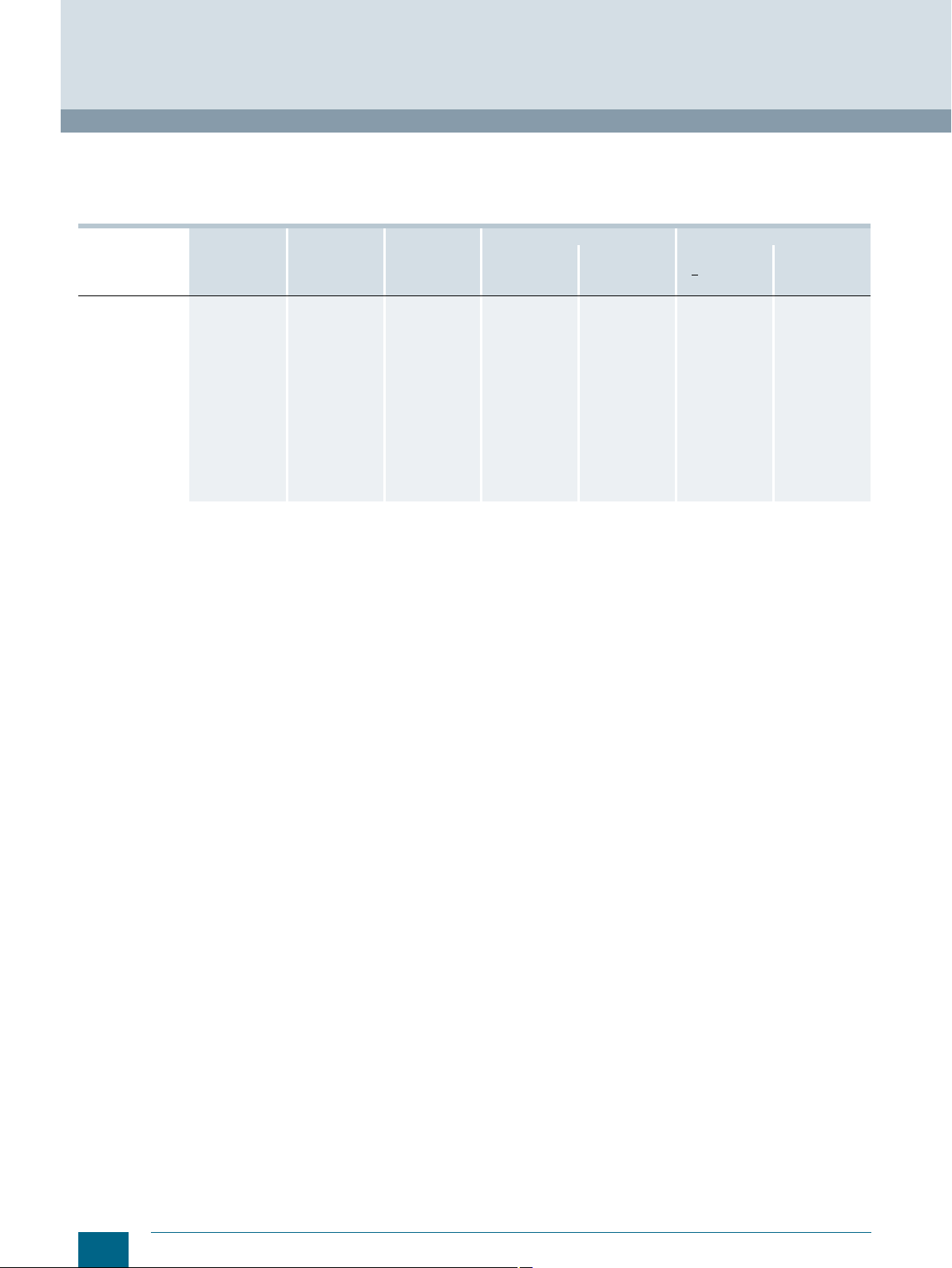

Characteristic curves

3NW60 series

Size: 10 × 38 mm

Operational class: gG

Rated voltage: 500 V AC (0.5 ... 25 A),

400 V AC (32 A)

Rated current: 2 ... 32 A

Time/current characteristics diagram

© Siemens AG 2016

Melting I2t values diagram

10

s]

2

t [A

2

10

10

10

10

10

10

Fuse Systems

Cylindrical Fuse Systems

Cylindrical fuse links and cylindrical fuse holders

4

6

4

2

3

6

4

2

2

6

4

2

1

6

4

2

0

6

4

2

-1

6

4

2

-2

500 V

400 V

230 V

0,512

²t

s

²t

a

681012

4

162025 32

n

[A]

I201_19160a

Current limiting diagram

$

% Peak short-circuit current without DC component

4

10

6

4

[A]

c

2

3

10

6

4

2

Peak current

2

10

6

4

2

1

10

5

36 246 246 246 246

32 A

25 A

20 A

= 2,3

m

p

16 A

12 A

10 A

8 A

6 A

1

10

2

10

Prospective short-circuit current

3

10

10

Peak short-circuit current with largest DC component

Typ e InPv I2tsI2t

a

1ms 230 V AC 400 V AC 500 V AC

A W K A2s A2s A2s A2s

0.5 0.07 On req. 0.06 0.06 0.09 0.10

1 0.45 On req. 0.50 0.45 0.63 0.7

2 0.50 On req. 4 4.80 6.80 7.50

4 0.85 On req. 34 35.70 49.50 55

6 0.95 On req. 12.5 45.50 63 70

8 1.15 On req. 29 10 153 170

10 1.30 On req. 56 201 279 310

12 1.40 On req. 99 344 477 530

16 1.90 On req. 199 630 873 970

20 2.40 On req. 333 975 1350 1500

25 2.70 On req. 619 1560 2160 2400

32 2.80 On req. 1331 3250 4500 --

4 A

I201_19159

3NW6000-1

3NW6011-1

3NW6002-1

3NW6004-1

3NW6001-1

3NW6008-1

3NW6003-1

3NW6006-1

3NW6005-1

3NW6007-1

3NW6010-1

3NW6012-1

2 A

1 A

0,5 A

4

p

5

10

[A]

Siemens · 10/2015

27

Page 30

Fuse Systems

210

0

10

-2

2

4

6

10

-1

6410

1

82 64

10

2

824

2

4

6

10

0

2

4

6

10

1

2

4

6

10

2

2

4

6

10

3

2

4

6

10

4

I2_06603b

6

10

3

8

vs

[A]

[s]

4 A

6 A

10 A

16 A

20 A

25 A

32 A

40 A

50 A

ef

10

2

c

[A]

[A]

10

I201_06560c

2

468 2 10

3

4

6

8

2

10

4

468

210

5

46

8

2

4

6

6

10

3

2

4

2

4

6

10

4

1

2

4 A

6 A

8 A

10 A

12 A

16 A

20 A

25 A

32 A

40 A

50 A

rms

Cylindrical Fuse Systems

Cylindrical fuse links and cylindrical fuse holders

3NW61series

Size: 14 × 51 mm

Operational class: gG

Rated voltage: 500 V AC (4 ... 40 A),

400 V AC (50 A)

Rated current: 4 ... 50 A

Time/current characteristics diagram

© Siemens AG 2016

Melting I2t values diagram

10

6

4

2

2

[A s]

2

10

6

4

2

10

6

4

2

10

6

4

2

10

6

4

2

10

5

500 A

2

400 A

t

a

230 A

2

t

4

3

2

1

0

4

s

6

10 401650

8 12

20 25 32

[A]

n

I2_06599c

Current limiting diagram

Peak short-circuit current with largest DC component

$

% Peak short-circuit current without DC component

28

Siemens · 10/2015

Typ e InPv I2tsI2t

1ms 230 V AC 400 V AC 500 V AC

A W K A2s A2s A2s A2s

3NW6104-1

3NW6101-1

3NW6108-1

3NW6103-1

3NW6106-1

3NW6105-1

3NW6107-1

3NW6110-1

3NW6112-1

3NW6117-1

3NW6120-1

4 1.9 19 5 16 20 26

6 2.5 25 48 85 100 120

8 2.4 18 110 200 250 350

10 0.8 12 230 420 750 1050

12 1.0 16 390 600 800 1200

16 1.6 27 600 1000 1 400 1700

20 2.3 32.5 670 1400 1800 2100

25 2.2 31.5 1300 2300 2800 3200

32 3.2 39.5 2500 4100 5500 6500

40 4.5 48 3600 6100 8 000 9200

50 4.8 55 8000 12 200 16000 --

a

Page 31

3NW62 series

210

1

10

-2

2

4

6

10

-1

6410

2

82 64

10

3

824

2

4

6

10

0

2

4

6

10

1

2

4

6

10

2

2

4

6

10

3

2

4

6

10

4

I2_06604b

6

10

4

8

vs

[A]

[s]

16 A

20 A

25 A

32 A

40 A

50 A

63 A

80 A

100 A

12 A

10 A

8 A

ef

1 0

2

2

64 1 08

1 0

2

4

6

c

e f f

[ A ]

[ A ]

1 0

2

3

2

64 1 08

4

2

64 1 08

5

2

4

I 2 _ 0 6 5 5 8 b

4

1 0

6

2 0 A

1 6 A

2 5 A

3 2 A

2

4

2

3

4

4 0 A

5 0 A

6 3 A

8 0 A

1 0 0 A

1

2

1 2 A

1 0 A

8 A

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

I2_06600c

0

1

2

3

4

n

[A]

2

[A s]

2

t

500 A

400 A

230 A

2

a

t

2

s

2

4

6

10

5

16

8032100

40 50 63

20 25

12108

Size: 22 × 58 mm

Operational class: gG

Rated voltage: 500 V AC (8 ... 80 A),

400 V AC (100 A)

Rated current: 8 ... 100 A

Time/current characteristics diagram

© Siemens AG 2016

Fuse Systems

Cylindrical Fuse Systems

Cylindrical fuse links and cylindrical fuse holders

Melting I2t values diagram

Typ e InPv I2tsI2t

a

1ms 230 V AC 400 V AC 500 V AC

A W K A2s A2s A2s A2s

3NW6208-1

Current limiting diagram

Peak short-circuit current with largest DC component

$

% Peak short-circuit current without DC component

3NW6203-1

3NW6206-1

3NW6205-1

3NW6207-1

3NW6210-1

3NW6212-1

3NW6217-1

3NW6220-1

3NW6222-1

3NW6224-1

3NW6230-1

8 2.5 15 110 200 170 350

10 0.9 10.5 230 420 760 1050

12 1.1 12 390 600 800 1200

16 1.6 14.5 600 1000 1400 1700

20 2.4 22.5 670 1200 1800 2200

25 2.7 24 1300 2100 2 800 3300

32 3.2 28 2450 4400 6 100 7200

40 4.9 35 3600 6200 8 000 10 000

50 5.9 46 6800 11400 16 200 20600

63 6.8 48 12 500 18800 24 000 30 000

80 7.5 48 24 700 30500 43 000 52 500

100 8.4 55 46000 64700 80 000 --

Siemens · 10/2015

29

Page 32

Fuse Systems

210

0

10

-2

2

4

6

10

-1

6410

1

82 64

10

2

824

2

4

6

10

0

2

4

6

10

1

2

4

6

10

2

2

4

6

10

3

2

4

6

10

4

I2_06605b

6

10

3

8

vs

[A]

[s]

4 A 10 A 20 A

2 A 6 A 16 A

ef

10

2

2

64108

10

4

6

2

4

6

2

c

[A]

[A]

10

3

2

3

2

64108

4

2

64108

5

2

4

I2_06559b

4

10

4

6

1

2

2 A

4 A

10 A

16 A

20 A

6 A

ef

2

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

I2_06601c

0

1

2

3

4

n

[A]

2

[A s]

2

4 6 10 16 20

t

400 A

230 A

2

a

t

2

s

Cylindrical Fuse Systems

Cylindrical fuse links and cylindrical fuse holders

3NW630.-1 series

Size: 8 × 32 mm

Operational class: gG

Rated voltage: 400 V AC

Rated current: 2 ... 20 A

Time/current characteristics diagram

© Siemens AG 2016

Melting I2t values diagram

Typ e I

n

P

v

I2t

I2t

s

a

1ms 400 V AC

A W K A2s A2s

3NW6302-1

3NW6304-1

3NW6301-1

3NW6303-1

3NW6305-1

Current limiting diagram

Peak short-circuit current with largest DC component

$

% Peak short-circuit current without DC component

30

Siemens · 10/2015

3NW6307-1

2 2 27 1.6 6

4 1.5 19 5 21

6 1.5 20.5 48 85

10 0.7 15 230 530

16 1.1 29 600 1 400

20 1.7 34.5 790 1 800

Page 33

2

10

-3

2

4

6

10

-2

6410

1

864

10

2

824

2

4

6

10

-1

2

4

6

10

0

2

4

6

10

1

2

4

6

10

2

2

4

6

10

3

I2_06567b

6

10

3

8

vs

[A]

[s]

16 A

20 A

25 A

32 A

40 A

50 A

63 A

80 A

100 A

224

0,5 A

1 A

2 A

4 A

12 A

10 A

8 A

6 A

ef

ef

10

2

6

c

[A]

[A]

10

I2_06566b

2

468 2 10

3

46

8

2

10

4

4682 10

5

468 2

2

4

6

10

3

2

4

6

10

4

2

1

2

0,5 A

100 A

80 A

63 A

50 A

40 A

32 A

25 A

20 A

16 A

12 A

10 A

8 A

6 A

4 A

2 A

1 A

10

2

4

6

10

2

4

6

10

2

4

6

10

2

4

6

10

0

1

2

3

4

n

[A]

2

[A s]

2

1 100

2

4

6

10

5

2

I2_06995b

2

500 A

400 A

t

2

s

468101216

20 25 32 40 50 63 80

© Siemens AG 2016

3NW8 series

Size: 10 × 38 mm, 14 × 51 mm, 22 × 58 mm

Operational class: aM

Rated voltage: 500 V AC,

400 V AC (3NW8120-1, 3NW8230-1)

Rated current: 0.5 ... 100 A

Time/current characteristics diagram

Fuse Systems

Cylindrical Fuse Systems

Cylindrical fuse links and cylindrical fuse holders

Melting I2t values diagram

Current limiting diagram

$ Peak short-circuit current with largest DC component

% Peak short-circuit current without DC component

Typ e Size BK I

3NW8000-1

3NW8011-1

3NW8002-1

3NW8004-1

3NW8001-1

3NW8008-1

3NW8003-1

3NW8006-1

3NW8005-1

3NW8007-1

3NW8010-1

3NW8012-1

3NW8102-1

3NW8104-1

3NW8101-1

3NW8108-1

3NW8103-1

3NW8106-1

3NW8105-1

3NW8107-1

3NW8110-1

3NW8112-1

3NW8117-1

3NW8120-1

3NW8208-1

3NW8203-1

3NW8206-1

3NW8205-1

3NW8207-1

3NW8210-1

3NW8212-1

3NW8217-1

3NW8220-1

3NW8222-1

3NW8224-1

3NW8230-1

mm A V W

10 x 38 aM 0.5 500 0.1

14 x 51 2 690 1

22 x 58 8 690 No info.

n

1 0.1

2 0.1

4 0.3

6 0.4

8 0.6

10 0.6

12 0.8

165 0.9

20 1.1

25 400 1.2

32 1.8

4 0.3

6 0.3

8 0.5

10 0.6

12 0.6

16 1

20 1

25 1.3

32 1.9

40 2

50 500 3.7

10 No info.

12 No info.

16 0.9

20 1.1

25 1.4

32 2

40 2.5

50 2.6

63 4.1

80 4.9

100 500 5.6

U

n

Siemens · 10/2015

P

v

31

Page 34

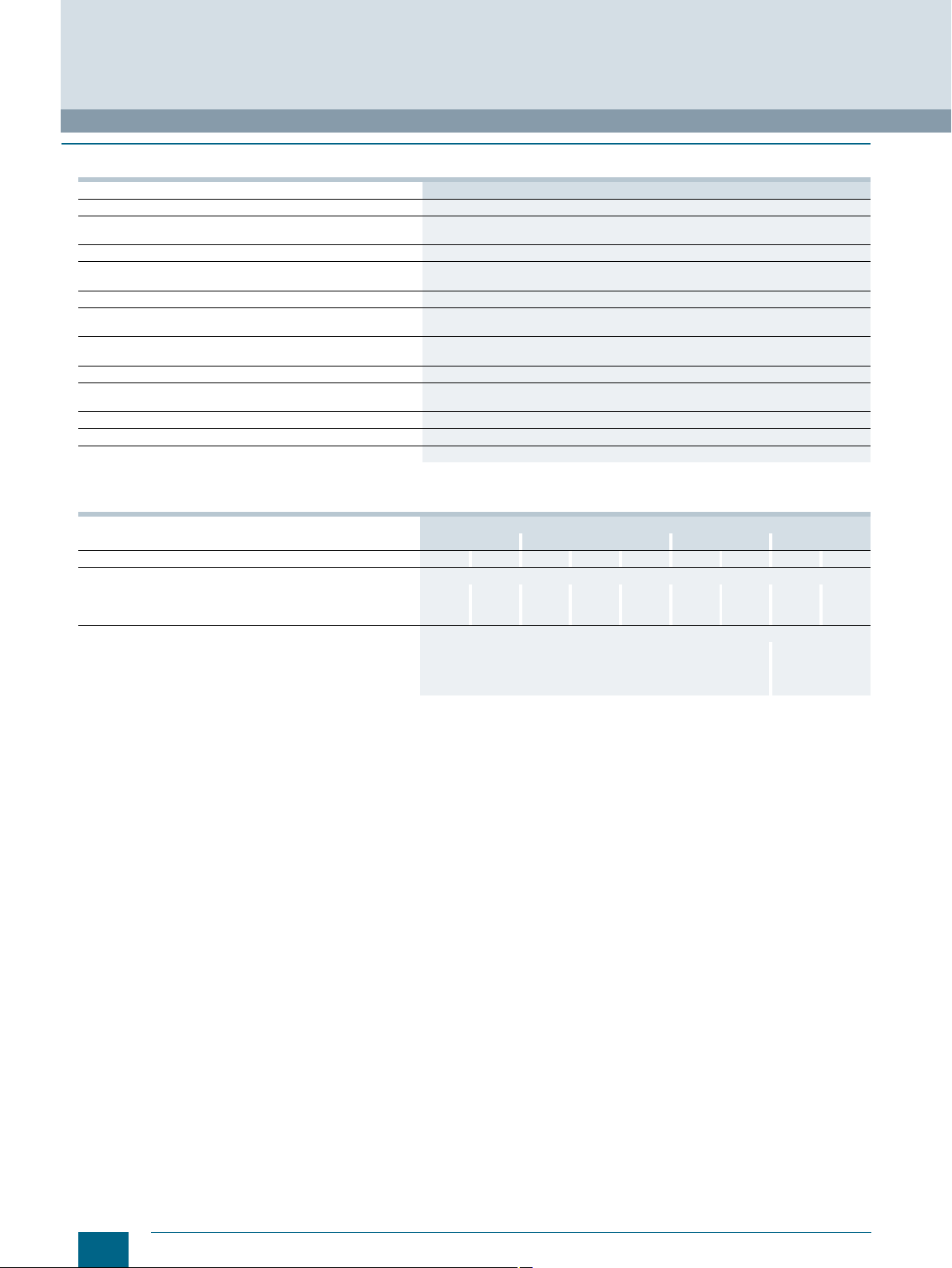

Fuse Systems

Cylindrical Fuse Systems

Fuse holders in size 10 x 38 mm and Class CC

■

Overview

A key feature of our three-pole fuse holders is their ultra compact

design. With a width of only 45 mm, they are ideal for use with