Page 1

sitrans

Field Manual SITRANS FUS1010 NEMA-4X/ IP 65 Clamp-On Multi-Function Flowmeter

SITRANS FUS

8

7

4

3

0

9

6

5

2

1

.

=

MENU

/

*

_

+

HELP

+

/

F1

-

CLR

CTRL

F2 F3

ALT

ENTER

DATA

LOG

F3

1010NFM-3J

Page 2

Siemens Energy & Automation’ s S t andard W arranty

This warranty applies to flow metering and leak detection systems.

SIEMENS ENERGY & AUTOMATION CORPORATION (the Company) warrants to the original

purchaser of this equipment as presented in Section 1 of Siemens Energy & Automation, Inc.

Standard Terms and Conditions of Sale (10/1/2004).

T o obtain repair or replacement within the terms of this Warranty, a Return Merchandise Authorization

number (RMA) must be obtained from Technical Service by calling (631) 231-3600 prior to shipment.

This RMA number must appear prominently on the outside of all returned packages. Returned

merchandise must include packing slip with specification of defect(s) and be shipped freight prepaid,

directly to Siemens Energy & Automation Corporation, 155 Plant Avenue, Hauppauge, NY 11788.

Equipment or material returned for Certification, V alidation, Repair, or Replacement may result in the

loss of memorized pipe site date in equipment computer memory . Siemens Energy & Automation can

save and then restore this data for some NEMA type systems and all Portable systems, if requested at

the time of equipment return. A fee may be imposed for this service.

This Warranty does not extend to costs incurred for removal or reinstallation of the equipment, or to

damage to equipment, accessories or components caused by such removal or reinstallation.

This Warranty does not apply to any equipment or part thereof, which in the opinion of the Company

has been damaged through alteration, improper installation, mishandling, misuse, neglect, lightning

strike, or other accidents. THE EXTENT OF THE COMP ANY’S LIABILITY UNDER THIS W ARRANTY

IS LIMITED TO THE REPAIR OR REPLACEMENT PROVIDED ABOVE AND, IN NO EVENT, SHALL

THE COMPANY’S LIABILITY EXCEED THE PURCHASE PRICE PAID BY PURCHASER FOR THE

PRODUCT.

This Warranty is in lieu of all other express warranties or liabilities. ANY IMPLIED WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR USE ARE

HEREBY EXCLUDED. IN NO CASE SHALL THE COMP ANY BE LIABLE FOR ANY CONSEQUENTIAL

OR INCIDENT AL DAMAGES FOR BREACH OF THIS OR ANY OTHER W ARRANTY, EXPRESS OR

IMPLIED, WHATSOEVER. No person or representative is authorized to assume for the Company

any liability other than expressed herein in connection with the sale of this equipment

.

Page 3

FIELD MANUAL

IMPORTANT NOTICE

Controlotron is now part of:

Siemens Energy & Automation, Inc.

Process Instrumentation Business Unit (PI BU)

CoC Ultrasonic Flow

SITRANS FUS 1010N

NEMA-4X CLAMP-ON

MUL TI-FUNCTION FLOWMETER

This equipment contains components that are

susceptible to electrostatic discharge (ESD).

Please observe ESD control measures during

the handling and connection process.

Field Manual 1010NFM-3J

August 2006

For use with Operating System

Software Version 3.01.05B or later

Prepared By Date

Engineering Date

FOR TECHNICAL ASSISTANCE: FOR GENERAL INFORMATION:

Call: (800) 275-8480 Website: www.controlotron.com

(631) 231-3600 E-mail: info.ultrasonicflow@siemens.com

Fax: (631) 231-3334 Or: sales.ultrasonicflow@siemens.com

E-mail: TSG .ultrasonicflow@siemens.com

Copyright©2006 Siemens Energy & Automation, Inc. All Rights Reserved Made in the USA

Printed August 2006

Page 4

Manual Changes

NOTE: For the latest updates and revisions to this field manual go to

www.controlotron.com/downloads.htm and check the Product Manual listing.

Page 5

MANUAL

ADDENDUM

SETUP PROCEDURE FOR

WET-FLOW CALIBRATED

1010FMA-4

1010 SYSTEMS

System 1010 Uniflow

Portable & NEMA

Flowmeter Systems

Manual Addendum

July 2002

FOR TECHNICAL ASSISTANCE: FOR GENERAL INFORMATION:

Call: (800) 275-8480 Website: www.controlotron.com

(631) 231-3600 E-mail: info.ultrasonicflow@siemens.com

Fax: (631) 231-3334 Or: sales.ultrasonicflow@siemens.com

E-mail: TSG.ultrasonicflow@siemens.com

Copyright©2006 Siemens Energy & Automation, Inc. All Rights Reserved Made in the USA

Page 6

Manual Addendum

SETUP PROCEDURE FOR “WET-FLOW CALIBRATED” 1010 SYSTEM

Caution: DO NOT use the field manual installation procedure to startup a wet-flow

calibrated system. Doing so could void the calibration by corrupting essential data. This addendum contains the only authorized instructions to

be used when commissioning a wet-flow calibrated 1010 system.

1. INTRODUCTION

When the system 1010 is wet-flow calibrated, the flow computer stores the installation parameters in its storage memory. Each flow calibration is assigned a unique site name. Usually , the

site name corresponds to the pipe size. For example, a 3-inch carbon steel, schedule 40 pipe

would be given the name “3CS40.”

The flow calibration report issued with each wet-flow calibration, includes a flow calibration

“Diagnostic Data Sheet.” This data sheet lists the site name and other necessary information

(such as transducer serial number and spacing information), for setting-up the flowmeter. A

wet-flow calibration applies to a specific flowmeter and set of transducers; identified by serial

numbers on the diagnostic data sheet.

1010FMA-4

NOTE: In order for the flow calibration to be valid, the flow computer and transducers

being used must have the same serial numbers as those listed for the site on

the Calibration Diagnostic Data Sheet.

2. SETUP PROCEDURE

2.1 Transducer Installation

2.1.1 Refer to the diagnostic data sheet to find the mounting mode (Direct or Reflect) used

during the wet-flow calibration. Review the transducer installation guidelines in your 1010

field manual.

2.1.2 Refer to the diagnostic data sheet for the transducer spacing index utilized during the

flow calibration. Using the mounting configuration employed during the flow calibration,

install the transducers on the pipe at the above noted spacing positions in accordance

with the instructions provided on the transducer installation drawings.

2.1.3 Attach the transducer cables noting that the cable marked “UP” attaches to the transducer closest to the source of flow.

NOTE: Before proceeding further, ensure that the pipe is full of liquid. It is not impor-

tant at this point that it be flowing.

1

July 2002

Page 7

Manual Addendum

2.2 Flowmeter Setup

NOTE: The following instructions require the use of the keypad and the menu. The

installer should become familiar with their use before proceeding further.

2.2.1 Switch the flowmeter on. Press the <MENU> key .

2.2.2 On multi-channel flowmeters, use the arrow keys to select [Dual Channel Flow] or

[Dual Beam Flow] depending on the mode utilized for the wet-flow calibration.

2.2.3 Use the arrow keys to select either [Clamp-on], [Flow Tube] or [Clamp-on Spool].

2.2.4 Select [Full Site Setup] and use the <Right Arrow> to select [Channel Setup]; then

select [Recall Site Setup].

2.2.5 Use the <Down Arrow> to scroll to the site name indicated on the Calibration Diagnostic Data Sheet. Then press <ENT>.

2.2.6 The meter will perform a momentary “Makeup” routine that will take a few seconds and

then begin operation.

1010FMA-4

2.2.7 Refer to your 1010 field manual for instructions on setting zero flow.

NOTE: Setting zero flow must be performed each time the transducers are installed.

The zero adjustment has no effect on the wet-flow calibration data or the calibration (Kc) factor.

2.2.8 Using the arrow keys, scroll to the Data Sp an/Set/Cal menu location. Verify that the [Kc]

(calibration) factor matches the value indicated on the diagnostic data sheet.

2.2.9 If you are measuring a liquid other than ambient water, select the [Liquid Class] menu

cell and <Down Arrow> from there to [Viscosity]. Enter the correct viscosity for the

liquid you will be monitoring.

2.2.10 Setup is now complete. Press the <MENU> key twice to view the flow rate display . DO

NOT utilize the [Save Site] command when it appears.

2.2.1 1 When measurements are completed, simply turn off the meter . DO NOT save the site.

This might contaminate the wet-flow calibration data already stored.

NOTE: Contact Siemens’ Technical Services Department if any flow calibration data is

accidentally removed or overwritten.

2

July 2002

Page 8

Manual Addendum

3. TRANSFER INSTALL FUNCTION

All 1010 flowmeter operating systems (version 3.00.20 and greater) include the installation facility called “Transfer Install.” This function permits the transducers to be repositioned while maintaining all calibration parameters and operation established during the water calibration. The

Transfer Install function allows the transducers to be optimally positioned for a different fluid,

without the need for a new Initial Makeup procedure.

NOTE: Prior to performing Transfer Install make sure that the water calibration proce-

dure was performed and a saved active site exists.

3.1 Transfer Install Procedure

To initiate the T ransfer Inst all function, proceed as follows:

3.1.1 In the Application Menu press the <Right Arrow> to select the [Liquid Class] menu cell.

Scroll and highlight [Estimated Vs m/s] from the option list.

3.1.2 Use the numeric keys to change the Estimated Vs to the Estimated Vs value of the

customer selected liquid.

3.1.3 To enter new Estimated Vs value press <ENT>.

1010FMA-4

3.1.4 Proceed to the Pick/Install Xdcr menu and select the same transducer , mounting mode

and spacing offset that was selected for the water calibration.

3.1.5 Re-space the transducers to the index position indicated by the flowmeter .

3.1.6 Scroll to the [Install Completed?] menu cell and select [Transfer Install] from the option

list.

NOTE: If [Transfer Install] does not appear in the option list then either the Estimated

Vs or the transducer size was improperly entered. In this case, recall the water

calibration site and start the procedure again at Step 3.1.1 above.

3.1.7 For MultiPath systems repeat Step 3.1.6 above for the remaining p aths.

3.1.8 The flowmeter should now be operational at the new spacing location.

NOTE: Depending on the size of the pipeline, the change in the estimated sonic veloc-

ity (Vs) and the repositioning of transducers, the flowmeter may not operate out

of Fault even if the spool or pipe is filled with liquid. This can be expected when

performing a Transfer Inst all for liquified gases or for clamp-on natural gas flowmeters.

3.2 Saving New Transfer Install Site

3.2.1 To save the Transfer Installed site, scroll to the Channel Setup menu and press the

<Right Arrow>. Press the <Right Arrow> again to select the [Save/Rename] menu cell.

3.2.2 Use the numeric keys to rename the Transfer Installed site with the same site name

used in Step 3.1.2 above, but with a “T” appended to the end of the site name (e.g.,

3CS40T).

3.2.3 Press <ENT> to store data.

3

July 2002

Page 9

MANUAL

ADDENDUM

SYSTEM 1010

1010FMA-14

EXPANDED I/O OPTION

(For Systems Equipped With 1010N-7 Modules)

Manual Addendum

May 2002

FOR TECHNICAL ASSISTANCE: FOR GENERAL INFORMATION:

Call: (800) 275-8480 Website: www.controlotron.com

(631) 231-3600 E-mail:info.ultrasonicflow@siemens.com

Fax: (631) 231-3334 Or: sales.ultrasonicflow@siemens.com

E-mail: TSG .ultrasonicflow@siemens.com

Copyright©2006 Siemens Energy & Automation, Inc. All Rights Reserved Made in the USA

Page 10

Manual Addendum

1010FMA-14

EXPANDED I/O OPTION

(For Systems Equipped With 1010N-7 Modules)

INTRODUCTION

The 1010N-2 I/O Module and 1010N-7 Expanded I/O Module both provide current (Io1, Io2), voltage

(V01 and Vo2) and pulse rate (Pgen 1 and Pgen 2) analog output s. The Expanded I/O Module Option

allows users to drive as many as four additional 4-20 mA loop-powered instrumentation outputs. The

following information is intended to be used with the I/O Data Control and Span Data sections and

Analog Output Trim Menu in the field manual.

The System 1010 flowmeter provides an Analog Output Setup menu (see below) that allows the user

to assign data functions for these output signals (refer to Analog Output Setup in the appropriate 1010

field manual). In addition, refer to Installation Drawings 1010N-2-7 and 1010N-7-7 in the field manual

appendices for additional connection information and terminal block numerical designators.

NOTE: All meters in the System 1010N and DN product family can accept the Expanded I/O

Module Option except 4-Channel meters.

Use this menu to

assign data functions

to analog ou tp uts .

Siemens Dual Path SITE1

Assign Data to Analog Outputs

Analog Out Setup

Relay Setup

Analog Input Setup

I/O Data Control

EXPANDED I/O MODULE OPTION

The Expanded I/O Module Option provides expanded Io analog outputs. It is implemented through the

use of a 1010N-7 Expanded I/O Module occupying the same position as the 1010N-2 I/O Module. This

option allows users to drive up to four additional 4-20mA loop-powered instrumentation outputs. Note

that the meter menu does not indicate that these supplementary outputs are present and available.

The outputs, in addition to being loop-powered, are isolated from one another as well as the meter .

Expanded I/O Module Option Identification

To verify that your meter has the Expanded I/O Module Option installed check the following:

The designation A1 should be part of the flowmeter part number .

For example: 1010ENRE-T1A1KGS

1

May 2002

Page 11

Manual Addendum 1010FMA-14

1010N-2 I/O Module

The conventional 1010N-2 I/O module provides the following:

z T wo self-powered, isolated 4-20 mA current loop s (signals Io1 and Io2) that are assignable and

spannable by the user to many flowmeter variables such as flow , sonic velocity , signal strength,

etc. These self-powered outputs also provide an industry-standard fault indication by dropping

to 2 mA if assigned to flow rate and under fault conditions. Note that these outputs, though

isolated from the system, are NOT isolated from each other.

z Two 0-10 Vdc outputs (signals Vo1 and Vo2) that are also assignable and spannable by the

user as above. These are also self-powered, but are not isolated from the system.

z T wo 0-5000 Hz Pgen signals (Pgen1 and Pgen2) also assignable and spannable by the user.

These are TTL level pulses.

The 1010N/DN class of meters has a total of six analog outputs as indicated above. In addition (refer to

Installation Drawings 1010N-2-7 and 1010N-7-7):

z Alarms/Status/Totalizer pulses are generally presented as relay closures as either Mercury

Wetted Form 1A or Dry Reed Form C relays.

z Analog inputs, when provided, are in the form of 4-20 mA non-isolated inputs.

z The meter also has four non-isolated totalizer command lines providing Totalizer Clear and

T otalizer Hold (NoTot) functionality.

1010N-7 Expanded I/O Module Option

The Expanded I/O Module Option provides all of the above plus the following outputs:

z The four signals that drive the pulse generator outputs (Pgen 1 and Pgen2) and voltage outputs

(Vo1 and Vo2) of the meter create four current outputs: Aux Io1, Aux Io2, Aux Io3 and Aux Io4

(see diagram on next page).

z By spanning and assigning a system variable to 0-10 volt (Vo1 and Vo2) or 0-5000 Hz pulse

output (Pgen1 and Pgen2) the module simultaneously outputs these signals to the Expanded

I/O Module Option Aux outputs. For a 2-Channel meter the programming assignments are as

follows:

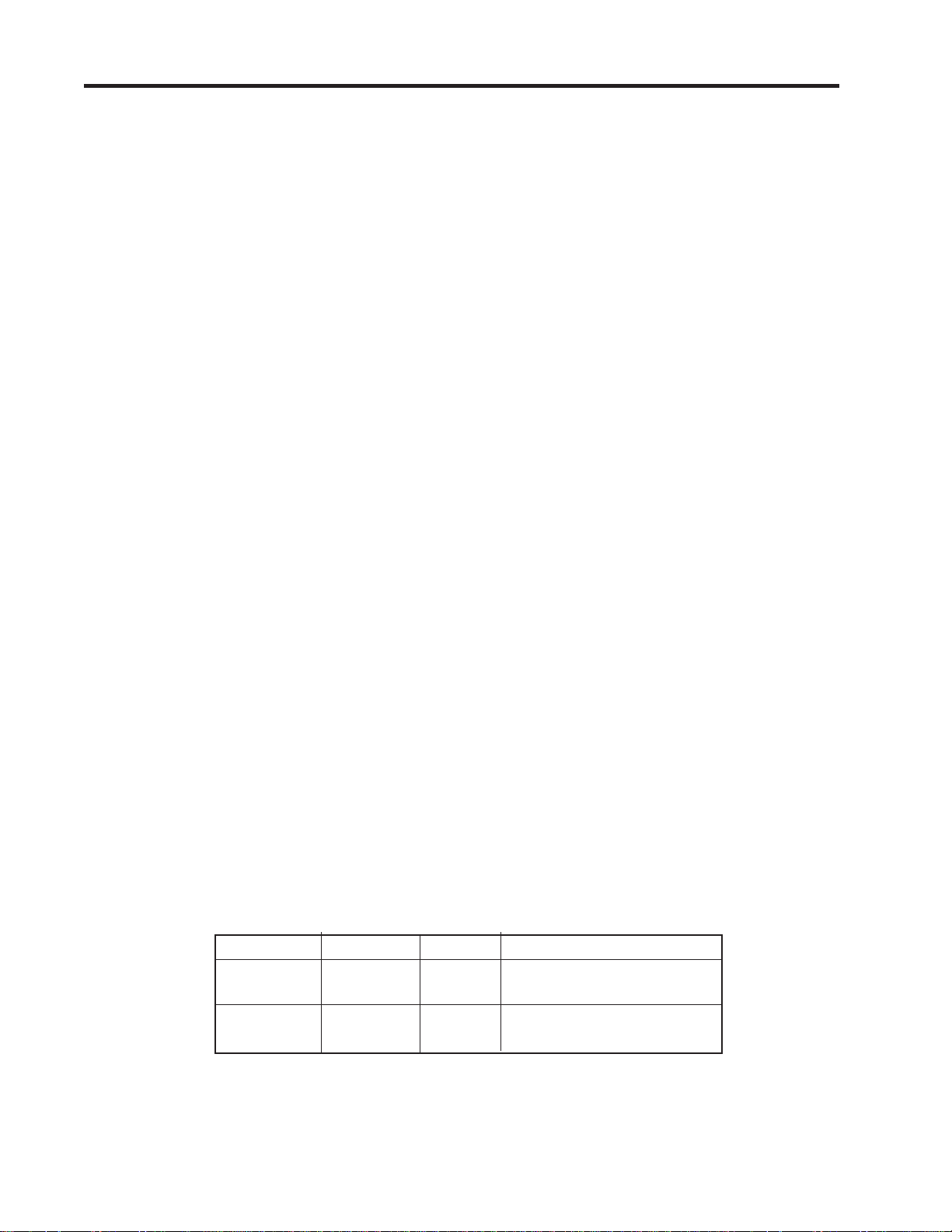

TYPICAL 2-CHANNEL METER EXPANDED I/O OPTION CONNECTIONS

CHANNEL SIGNAL AUX Io METER MENU DISPLAY

CH1 Pgen1 Io1 V o1

Vo1 Io3 Pgen1

CH2 Pgen2 Io2 V o1

Vo2 Io4 Pgen1

z Note that the four Aux Io outputs are externally powered.

2

May 2002

Page 12

Manual Addendum

EXP ANDED I/O MODULE OPTION PROGRAMMING

The diagram below illustrates the Expanded I/O Module Option programming for a Single Channel

meter with a 1010N-7 Expanded I/O Module.

FLOW COMPUTER

INTERNAL

CONNECTIONS

OUTPUT

TERMINAL STRIP

1010FMA-14

Io1

``

Io1

Pgen1

z

Aux Io1

```

Pgen2

Vo1

z

z

Aux Io2

Aux Io3

`

Vo2

NOTE: The 1010N-7 Expanded I/O Module auxiliary output signals (Aux Io1 - Aux Io4) geneated

from Pgen1, Pgen2, Vo1 and Vo2 are “mirrored” output currents. For example, if Vo1

is a 5 Vdc signal then Aux Io3 will be 12 mA.

NOTE: The method used to create auxiliary current loops makes it impractical to generate the

2 mA fault current produced by the primary 4-20 mA output s of the meter.

z

Aux Io4

3

May 2002

Page 13

1010NFM-3J Table Of Contents

TABLE OF CONTENTS

Section 1

1. Getting Started ................................................................................................ 1-1

1.1 Introduction ..................................................................................................... 1-1

1.2 Important Safety Considerations................................................................... 1-1

1.3 Flowmeter Installation Steps ......................................................................... 1-1

1.4 The Keypad Enable Switch ............................................................................ 1-2

Typical System Layout............................................................................. 1-2

1.5 The 1010N Keypad .......................................................................................... 1-3

Keypad Function Chart ............................................................................ 1-3

1.6 Introduction To The 1010N Menu Screens .................................................. 1-3

Typical Inst allation Menu Screen .............................................................. 1-3

Explanation of the Callouts....................................................................... 1-4

1.7 How To Use The Installation Menu ............................................................... 1-4

1.7.1 Accessing And Leaving The Menu................................................................ 1-5

1.7.2 How To Enter Data .......................................................................................... 1-5

Selecting Items from an Option List......................................................... 1-6

Multiple Select Option Lists...................................................................... 1-7

Entering Numeric Data............................................................................. 1-7

Entering Alphanumeric Data .................................................................... 1-8

1.7.3 The Meter Type Menu .................................................................................... 1-8

Dual Channel ........................................................................................... 1-9

Dual Path ................................................................................................. 1-9

Channel 1+2 and Channel 1-2 ................................................................. 1-9

1.7.4 Essential Information For Users of Multi-Channel 1010’s ........................ 1-10

Multi-Channel Meter Setup ..................................................................... 1-10

Arithmetic Operation .............................................................................. 1-10

Multi-Path Operation............................................................................... 1-10

Selecting a Meter T ype............................................................................1-1 1

Creating a New Site Setup..................................................................... 1-12

Flowmeter Installation Flowchart............................................................ 1-14

1.8 Using FASTSTART Setup ............................................................................. 1-15

1.8.1 Choosing The Pipe Class/Size.................................................................... 1-15

1.8.2 Picking And Installing The Transducers ..................................................... 1-16

1.9 1010WX Clamp-On Liquid Flowmeters........................................................ 1-19

Sect./Page

Section 2

2. The 1010N Installation Menu ......................................................................... 2-1

2.1 The Channel Setup Menu .............................................................................. 2-2

Channel Setup Menu Structure ................................................................ 2-2

2.1.1 How To Recall A Site Setup............................................................................ 2-2

2.1.2 How To Enable And Disable A Measurement Channel ................................ 2-3

2.1.3 How To Create/Name A Site Setup ................................................................ 2-4

2.1.4 How To Enable/Disable Site Security ........................................................... 2-4

2.1.5 How To Delete A Site Setup ........................................................................... 2-5

2.1.6

2.2 The Pipe Data Menu ....................................................................................... 2-6

2.2.1 How To Select A Pipe Class ........................................................................... 2-8

How To Save/Rename A Site Setup............................................................... 2-5

The Pipe Data Menu S tructure................................................................. 2-7

i

Page 14

1010NFM-3J Table Of Contents

2.2.2 How To Select A Pipe Size ............................................................................. 2-8

2.2.3 How To Enter The Pipe OD (in. or mm) ........................................................ 2-9

2.2.4 How To Select A Pipe Material ....................................................................... 2-9

2.2.5 How To Enter The Wall Thickness ................................................................ 2-9

2.2.6 Liner Material ................................................................................................ 2-10

2.2.7 Liner Thickness ............................................................................................. 2-10

2.3 The Application Data Menu .......................................................................... 2-10

Application Data Menu S tructure .............................................................2-1 1

2.3.1 How To Select A Liquid Class ...................................................................... 2-13

How to Edit the Estimated Vs (liquid sonic velocity)............................... 2-13

How to Edit the Viscosity (cS) Setting.................................................... 2-14

How to Edit the Density (SG) Setting ..................................................... 2-14

2.3.2 UniMass Table ............................................................................................... 2-14

Application Data Menu Explanations for UniMass T able......................... 2-15

2.3.3 How To Select A Pipe Temperature Range ................................................ 2-18

2.3.4 Pipe Configuration ........................................................................................ 2-19

Pipe Configuration Menu Structure......................................................... 2-19

Additional Compensation Tables ............................................................ 2-20

2.4 The Pick/Install XDCR Menu ........................................................................ 2-20

Pick/Install Xdcr Menu Structure............................................................. 2-22

2.4.1 How To Select A Transducer Model ............................................................ 2-22

2.4.2 How To Select A Transducer Size ............................................................... 2-23

2.4.3 How To Select A Transducer Mount Mode................................................. 2-23

2.4.4 Reviewing The Spacing Method ................................................................. 2-24

2.4.5 How To Use The Spacing Offset ................................................................. 2-24

2.4.6 The Number Index Menu Cell ...................................................................... 2-25

2.4.7 The Ltn Menu Cell ........................................................................................ 2-25

2.4.8 How To Use [Install Completed?]................................................................ 2-25

Force Transmit Procedure..................................................................... 2-27

2.4.9 The Empty Pipe Set Menu ............................................................................ 2-29

How to Use the Actual MTY Command.................................................. 2-29

How to Use the MTYmatic Command.................................................... 2-30

How to Use the Set Empty Command ................................................... 2-30

2.4.10 The Zero Flow Adjust Menu ......................................................................... 2-30

AutoZero................................................................................................. 2-30

Actual Zero ............................................................................................. 2-31

ReversaMatic ......................................................................................... 2-31

ZeroMatic (definition) .............................................................................. 2-31

Using Actual Zero ................................................................................... 2-31

Using ReversaMatic ............................................................................... 2-32

ZeroMatic (optional function) .................................................................. 2-33

2.5 The Operation Adjust Menu......................................................................... 2-34

Operation Adjust Menu S tructure............................................................ 2-35

2.5.1 Damping Control ........................................................................................... 2-35

2.5.2 Deadband Control ......................................................................................... 2-35

2.5.3 Memory/Fault Set .......................................................................................... 2-36

Memory Delay (sec)............................................................................... 2-36

2.5.4 Reflexor Zero/Fault Set Option (Reflexor Mode only) .............................. 2-36

2.6 The Flow/Total Units Menu .......................................................................... 2-37

POSFLOW ............................................................................................ 2-37

NEGFLOW............................................................................................. 2-37

ii

Page 15

1010NFM-3J Table Of Contents

NETFLOW ............................................................................................. 2-37

Totalizer Controls ................................................................................... 2-37

The Flow/T ot al Units Menu S tructure...................................................... 2-38

2.6.1 Flow Volume Units......................................................................................... 2-38

2.6.2 Flow Time Units............................................................................................. 2-39

2.6.3 Flow Display Range....................................................................................... 2-40

2.6.4 Flow Display Scale ........................................................................................ 2-40

2.6.5 Total Volume Units ........................................................................................ 2-40

2.6.6 Totalizer Scale............................................................................................... 2-41

2.6.7 Total Resolution ............................................................................................ 2-41

2.6.8 Totalizer Mode .............................................................................................. 2-42

2.6.9 Batch/Sample Total ....................................................................................... 2-42

2.7 The Data Span/Set/Cal Menu ....................................................................... 2-42

The Data Sp an/Set/Cal Menu S tructure ................................................. 2-43

2.7.1 Span Data....................................................................................................... 2-43

Max Flow ................................................................................................ 2-44

Min Flow ................................................................................................. 2-44

Max Vs m/s ............................................................................................ 2-45

Min Vs m/s ............................................................................................. 2-45

Max Vs m/s ............................................................................................ 2-45

Min Vs m/s ............................................................................................. 2-45

Max S.G .................................................................................................. 2-45

Min S.G ................................................................................................... 2-45

Max Viscosity cS.................................................................................... 2-45

Min Viscosity cS..................................................................................... 2-45

Max T emperature ................................................................................... 2-45

Min T emperature .................................................................................... 2-45

2.7.2 Set Alarm Levels............................................................................................ 2-45

High Flow ............................................................................................... 2-46

Low Flow................................................................................................ 2-46

High S.G . ................................................................................................ 2-46

Low S.G.................................................................................................. 2-46

High Viscosity cS ................................................................................... 2-46

Low Viscosity cS.................................................................................... 2-46

High T emperature................................................................................... 2-46

Low Temperature ................................................................................... 2-46

Interface Vs (m/s) meters-per-second................................................... 2-47

Aeration %.............................................................................................. 2-47

Makeup Latch......................................................................................... 2-47

2.7.3 Calibrate Flow Rate ....................................................................................... 2-48

Kc Calibration......................................................................................... 2-48

MultiPoint Calibration.............................................................................. 2-48

2.8 The StripChart Setup Menu ......................................................................... 2-50

The StripChart Setup Menu Structure .................................................... 2-50

2.8.1 Select Data ..................................................................................................... 2-50

2.8.2 Data Display ................................................................................................... 2-51

2.8.3 Time Base ...................................................................................................... 2-51

2.8.4 StripChart Clear ............................................................................................ 2-52

2.9 The Datalogger Setup Menu ....................................................................... 2-52

The Datalogger Setup Menu Structure ................................................... 2-53

iii

Page 16

1010NFM-3J Table Of Contents

2.9.1 Datalogger Mode ........................................................................................... 2-54

2.9.2 Datalogger Data ............................................................................................. 2-54

Alarm Letter Codes and Descriptions .................................................... 2-55

2.9.3 Log Time Interval .......................................................................................... 2-55

2.9.4 Datalogger Events ........................................................................................ 2-55

2.9.5 Display Datalogger........................................................................................ 2-56

2.10 The I/O Data Control Menu .......................................................................... 2-57

The I/O Data Control Menu S tructure..................................................... 2-58

2.10.1 Analog Out Setup .......................................................................................... 2-58

System 1010 Analog Output s ................................................................ 2-59

Analog Output Data Categories ............................................................. 2-59

Table to Determine Proper I/O installation Drawings.............................. 2-59

Assigning Io Output Functions ............................................................... 2-59

Assigning Vo Output Functions.............................................................. 2-60

Assigning Pgen Output Functions.......................................................... 2-60

Pulse Output Table (Pgen Wiring).......................................................... 2-60

2.10.2 Relay Setup .................................................................................................... 2-60

Assigning Relay 1 and 2 Functions........................................................ 2-61

Relay Option List.................................................................................... 2-61

2.10.3 Analog Input Setup (optional function)....................................................... 2-61

Setting Up the Analog Current Input ....................................................... 2-62

2.1 1 The Diagnostics Data Menu ......................................................................... 2-62

Diagnostic Data Menu Structure ............................................................ 2-63

2.11.1 Main Diagnostics Screen ............................................................................. 2-64

Main Diagnostic Menu Description......................................................... 2-64

2.11.2 Flow Data Menu............................................................................................. 2-64

Flow Data Menu Items ........................................................................... 2-65

Vs m/s.................................................................................................... 2-65

HiFlow and LoFlow................................................................................. 2-66

AnCal ..................................................................................................... 2-66

2.11.3 The Application Info Menu .......................................................................... 2-67

Application Info Menu Items.................................................................... 2-67

2.11.4 The Liquid Data Menu .................................................................................. 2-67

Liquid Data Menu Items.......................................................................... 2-67

2.11.5 The Site Setup Data Menu........................................................................... 2-68

Site Setup Menu Items ........................................................................... 2-68

Introduction to [HF] Menu Item................................................................ 2-69

Using the [HF] Menu Item....................................................................... 2-69

“Manual” Adjustment Procedure ............................................................. 2-70

“Automatic” Adjustment Procedure ........................................................ 2-71

2.11.6 The Test Facilities Menu .............................................................................. 2-72

Test Facilities Commands ..................................................................... 2-72

Makeup................................................................................................... 2-72

Detection Mode ...................................................................................... 2-73

The Test Facilities Graph Screen........................................................... 2-73

Entering The Diagnostic Graph Screen ................................................. 2-74

Diagnostic Text Display.......................................................................... 2-74

Time Base Control ................................................................................. 2-74

Correlated Plot ....................................................................................... 2-74

Command Modes .................................................................................. 2-75

Digital Damping Control: (Hot Key 1 and 2) ................................... 2-75

iv

Page 17

1010NFM-3J Table Of Contents

Transit T ime Adjustment: (Hot Key 3)............................................. 2-75

Zero Crossover Adjustment: (Hot Key 4) ....................................... 2-76

Envelope Threshold Adjustment: (Hot Key 5 & 6) .......................... 2-76

Signal Masking Function: (Hot Key 7) ............................................ 2-77

Description Of Graph Screen Text Display Parameters ........................ 2-77

Hot Key Summary.................................................................................. 2-77

2.1 1.7 Troubleshooting Tips ................................................................................... 2-78

Flow Computer Messages..................................................................... 2-78

Using the “F4” Reset Sequence............................................................. 2-79

2.1 1.8 Troubleshooting With Transducer Test Blocks ......................................... 2-81

2.1 1.9 Using The 1012TB-1 And -2 Test Blocks .................................................... 2-81

2.1 1.10 Using The 996PSP Pipe Simulator .............................................................. 2-83

If a Pipe Simulator/Test-Block Test Fails ................................................ 2-84

2.12 Guide To A Smooth Installation.................................................................... 2-85

2.12.1 Checklist for 1010 Startup & Performance................................................. 2-85

Programming ......................................................................................... 2-85

Installation/Transducer Mount Guidelines............................................... 2-85

St artup.................................................................................................... 2-86

Diagnostic/Performance Verification...................................................... 2-86

2.12.2 Optimization/Correction of Problems ......................................................... 2-86

Incorrect “Measured Vs”......................................................................... 2-86

Low V alc................................................................................................. 2-87

Detection Fault/Low Signal .................................................................... 2-87

High V aer................................................................................................ 2-87

Poor Signal............................................................................................. 2-88

“Official” Coupling Compound................................................................ 2-88

“Alternative” Coupling Compound .......................................................... 2-88

Ideal Vsig Display ................................................................................... 2-89

Section 3

3. Hardware Installation Guide .......................................................................... 3-1

3.1 Preparing To Mount The Transducers ......................................................... 3-1

3.1.1

How To Identify 1011 Transducers and Mounting Hardware...................... 3-1

3.1.2 Selecting A Location For Clamp-On Transducers ....................................... 3-1

3.1.3 Clamp-On Transducer Mounting Modes ..................................................... 3-2

3.1.4 Preparing The Pipe ......................................................................................... 3-3

3.1.5 Reflect Mode - Mounting Frames And Spacer Bar ...................................... 3-4

3.1.6 Reflect Mode With Spacer Bar Only ............................................................. 3-5

3.1.7 Direct Mode-Mounting Frames, Spacer Bar & Spacing Guides ................ 3-7

3.1.8 Using 1012T Mounting Tracks ......................................................................3-11

Installing a 1012T Mounting T rack in Reflect Mode..................................3-11

Installing a 1012T Mounting T rack in Direct Mode .................................. 3-13

3.2 Mounting Temperature Sensors ................................................................. 3-15

3.2.1 Wiring Temperature Sensor To The Analog Input Module....................... 3-16

3.2.2 1010N Supply And Return Connections...................................................... 3-17

3.2.3 Notes On 1010 Analog Input Modules ......................................................... 3-18

Single Channel Model............................................................................. 2-18

Dual Channel Model ............................................................................... 2-18

3.2.4 Clamp-On RTD Installation Notes ............................................................... 3-19

3.2.5 Paralleling RTD Inputs For Dual-Channel Energy Measurement. ............. 3-19

v

Page 18

1010NFM-3J Table Of Contents

Section 4

4. The Meter Facilities Menu And Graphic Display Screens.......................... 4-1

4.1 Preferred Units ................................................................................................ 4-1

4.2 The Table Setups Menu ................................................................................. 4-2

4.2.1 Pipe Table ........................................................................................................ 4-2

Pipe Table Menu Structure ....................................................................... 4-2

4.2.2 Create/Edit Pipe .............................................................................................. 4-3

4.2.3 Delete Pipe ...................................................................................................... 4-4

4.3 Transducer Type Menu .................................................................................. 4-4

Transducer Type Menu S tructure ............................................................. 4-5

4.4 The Datalogger Control Menu ....................................................................... 4-6

4.4.1 Display Datalogger.......................................................................................... 4-6

4.4.2 Output Datalogger .......................................................................................... 4-7

4.4.3 Circular Memory .............................................................................................. 4-7

4.4.4 Est Log Time Left............................................................................................ 4-8

4.4.5 Clear Datalogger ............................................................................................. 4-8

4.5 The Memory Control Menu ............................................................................ 4-8

Data Memory Left..................................................................................... 4-8

Memory Map............................................................................................. 4-8

Defragment .............................................................................................. 4-8

4.5.1 The Analog Output Trim Menu....................................................................... 4-9

4.5.2 Current Output Trim (Io1 & Io2) ..................................................................... 4-9

4.5.3 Voltage Output Trim (Vo1 & Vo2).................................................................... 4-9

4.5.4 Pgen Output Trim (Pgen 1 & Pgen 2).......................................................... 4-10

4.6 The RTD Calibrate Menu (optional) ............................................................ 4-10

RTD Calibrate Menu S tructure................................................................4-11

4.6.1 The RTD Calibrate by Data Entry .................................................................4-11

4.6.2 Ice Bath RTD Calibration ...............................................................................4-11

4.7 The Clock Set Menu ..................................................................................... 4-12

4.7.1 Date ................................................................................................................ 4-12

4.7.2 Time................................................................................................................ 4-12

4.8 RS-232 Setup ................................................................................................. 4-13

RS-232 Menu Structure.......................................................................... 4-13

4.8.1 Baud Rate ...................................................................................................... 4-13

4.8.2 Parity............................................................................................................... 4-14

4.8.3 Data Bits......................................................................................................... 4-14

4.8.4 Line Feed ....................................................................................................... 4-14

4.8.5 Network ID ..................................................................................................... 4-15

4.8.6 RTS Key Time ................................................................................................ 4-15

4.9 Backlight ........................................................................................................ 4-16

4.10 System Info .................................................................................................... 4-16

4.1 1 The 1010 Graphic Display Screens ............................................................. 4-16

Section 5

5. System 1010 Application Notes...................................................................... 5-1

5.1 To Obtain Technical Assistance .................................................................... 5-1

5.2 Considerations For Critical Applications...................................................... 5-1

5.3 Pipe Considerations For Clamp-On Transducers ....................................... 5-2

5.3.1 Pipe Dimensions ............................................................................................. 5-2

5.3.2 Picking The Appropriate Transducer............................................................ 5-2

5.3.3 Flow V elocity Range........................................................................................ 5-2

vi

Page 19

1010NFM-3J Table Of Contents

5.3.4 Overview Of System Performance ................................................................ 5-3

5.3.5 Accuracy ........................................................................................................... 5-3

5.3.6 Repeatability.................................................................................................... 5-3

5.3.7 Data Stability.................................................................................................... 5-3

Data Scatter............................................................................................. 5-3

Data Drift.................................................................................................. 5-4

5.4 Flow Conditions............................................................................................... 5-4

5.4.1 Low Flow Rates ............................................................................................... 5-4

5.4.2 Flow Data Scatter and Damping .................................................................... 5-4

System 1010 Damping and Slewing Controls ......................................... 5-4

Time Average ........................................................................................... 5-4

SmartSlew ............................................................................................... 5-5

5.4.3 Notes On Liquid Conditions .......................................................................... 5-5

5.4.4 Erroneous Liquid Parameter Specification .................................................. 5-5

5.4.5 Liquid Compatibility ........................................................................................ 5-5

5.4.6 Aeration ............................................................................................................ 5-5

5.4.7 Slurries............................................................................................................. 5-6

5.4.8 Two-Phase Liquids .......................................................................................... 5-6

5.4.9 Viscous Liquids ............................................................................................... 5-6

5.4.10 Temperature and Pressure Ratings .............................................................. 5-6

5.5 Overview Of System 1010N Memory Resources......................................... 5-6

5.6 Reference Tables ............................................................................................ 5-7

Sonic Velocity (m/s) For Common Liquids @ 68ºF.................................. 5-7

Sonic Velocity For Pure Water @ Various Temp. (m/s) ........................... 5-8

Vps Values (in/sec) For some Common Metals ...................................... 5-8

Recommended Sonic Coupling Compounds .......................................... 5-9

System 1010 Reynolds Compensation Factor ...................................... 5-10

T erminology Chart...................................................................................5-11

5.7 The Nema Dual-Channel Menu Chart......................................................... 5-13

The Meter T ype Menu............................................................................. 5-13

The Meter Facilities Menu ...................................................................... 5-13

The Clamp-On Meter Menu.................................................................... 5-14

Section 6

6. Operating System 1010N With Flow Tubes................................................... 6-1

6.1 General Installation Guidelines ..................................................................... 6-1

6.1.1 Liquid Applicability And Compatibility............................................................ 6-1

6.1.2 Selecting The Right Flow Tube ..................................................................... 6-2

Flow Tube Pressure And Temperature Ratings ....................................... 6-2

Flow T ube Material, Size & Flow Range Ratings ..................................... 6-2

6.1.3 Flow Tube Mounting Location ....................................................................... 6-2

6.1.4 Flow Data Scatter And Damping .................................................................... 6-3

6.2

Considerations For Critical Applications...................................................... 6-3

To Obtain Technical Information ............................................................... 6-3

6.3 How To Set Up System 1010N For Flow Tube Operation ........................... 6-4

6.3.1 Overview.......................................................................................................... 6-4

6.3.2 Setup Procedure ............................................................................................. 6-4

6.4 Specifications - CPVC Flow Tube.................................................................. 6-9

6.5 Specifications - KYNAR PVDF Flow Tube .................................................... 6-9

6.6 Specifications - TEFLON PFA Flow Tube ................................................... 6-10

6.7 Specifications - 316 Stainless Steel Flow Tube ......................................... 6-10

vii

Page 20

1010NFM-3J Table Of Contents

Additional Installation Notes.....................................................................6-11

101 1FT Series 316 Stainless S teel Flow Tube........................................6-1 1

992DFT Series CPVC or Kynar PDFA Flow Tube.................................. 6-12

992 Series Teflon PFA Flow T ube........................................................... 6-12

Section 7

7. The System 1010N Reflexor Flowmeter ....................................................... 7-1

7.1 Reflexor Installation Steps ............................................................................. 7-1

7.2 Select A Transducer Set For Use By Reflexor............................................. 7-1

7.3 Select The Transducer Mounting Location ................................................. 7-2

7.4 Mounting The Transducers ........................................................................... 7-3

Reflexor Mode - Adjacent Transducer Mounting....................................... 7-3

Reflexor Mode - In-line Transducer Mounting........................................... 7-3

7.5 Connection Of Transducer Cables ............................................................... 7-4

7.6 Select Reflexor Operating Mode .................................................................. 7-4

7.7 Installing Reflexor Operating Mode .............................................................. 7-4

7.8 Access The Install Xdcr (Transducer) Menu................................................ 7-4

7.9 The Spectra Display Screen .......................................................................... 7-5

Example of a Spectra Display Screen ..................................................... 7-5

7.10 Cursor Use On The Spectra Graph .............................................................. 7-6

7.1 1 How To Use Spectra Graph Data and Controls ........................................... 7-6

7.12 Available Adjustments To Spectra Graph ..................................................... 7-7

7.13 Reflexor Diagnostic Data ............................................................................... 7-8

Diagnostic Data ....................................................................................... 7-8

7.14 Display of “F” At No Flow Conditions ........................................................... 7-9

7.15 Selection Of Liquid Composition .................................................................. 7-9

7.16 Other Menu Entries ........................................................................................ 7-9

APPENDICES

Appendix A - Couplant Inst allation Instructions (if applicable)

Appendix B - Site Setup Considerations for 1010N Blind Systems

Appendix C - Engineering Drawings

INDEX

Pipe Table

viii

Page 21

1010NFM-3JSection 1

1. GETTING STARTED

1.1 INTRODUCTION

Congratulations on your purchase of the Siemens SITRANS FUS1010 NEMA Permanent Flowmeter.

Intended for dedicated applications, this versatile transit-time flowmeter is easy to set up and operate.

The Model FUS1010 flowmeter represents the state-of-the-art in computerized instrumentation. We

are confident that in a very short time, you will appreciate its unrivaled performance and features;

especially Siemens’s ground breaking enhanced transit-time Digitally Coded MultiPuls technology and

the on-line automatic and interactive site setup facility . This manual covers FUS1010 Single Channel,

Dual Channel/Dual Path and 4-Channel/4-Path flowmeter types in NEMA-4 or NEMA-7 enclosures.

Only the Model 1010FTN and 1010AN flowmeters are equipped to utilize the flow tubes shown in

Section 6.

This section shows how to install the System FUS1010 flowmeter with a minimal amount of effort. It

will show how to use the Installation Menu to set up the system for transit-time, Reflexor and Flow T ube

Clamp-on operation. It also shows the basic connections to and from the flowmeter. For additional

information on connections, see the drawings at the end of manual.

1.2 IMPORTANT SAFETY CONSIDERATIONS

The FUS1010 NEMA Permanent meter operates from either an external AC or DC power source.

Please observe all the electrical safety codes, etc., that apply to your application. We recommend that

only experienced personnel with knowledge of local electrical codes and safety operating procedures

perform the installation and wiring. It is solely the user’s responsibility to operate this equipment safely.

Siemens cannot accept responsibility for any damage that may occur due to failure to observe any

local safety rules.

If this equipment is used for a hazardous application (high line pressure, hostile liquid characteristics,

perilous atmosphere, etc.), the end-user must ensure that only properly trained personnel are involved

in its installation and operation.

Please do not let the size of the Installation Menu intimidate you. Almost all menu cells already contain

default parameters. To begin operation, you only need to access the menu cells that control a required

parameter , such as the pipe outer diameter. You will see that by accepting most defaults, you can set

up the meter in about five minutes.

1.3 FLOWMETER INSTALLATION STEPS

Typical steps to complete the installation procedure.

z Collect the site data (pipe and liquid data, part numbers, etc.)

z Choose a mounting location for the flow computer and transducers.

z Mount the flow computer at the selected location.

z Prepare pipe for transducer mounting.

z Access the Installation Menu and create a site (see paragraph 1.7.3).

z Enter pipe parameters (see paragraph 2.2).

z Invoke transducer install procedure (see paragraph 2.4).

z Mount transducers on pipe and connect to flow computer (see Section 3).

z Complete transducer install menu operation (see paragraph 2.4).

1-1

Page 22

1010NFM-3JSection 1

1.4 THE KEYPAD ENABLE SWITCH

All System 1010N models provide a keypad enable/disable switch to prevent unauthorized access to

the Installation Menu. In addition, a password entry option is available (see Channel Setup). The keypad

enable/disable switch is located inside the lockable enclosure just above the I/O wiring terminal. Please

switch to the enable position before proceeding further. If necessary, see Drawings 1010N-7, 1010DN7 or 1010MN-7 for location details.

1-2

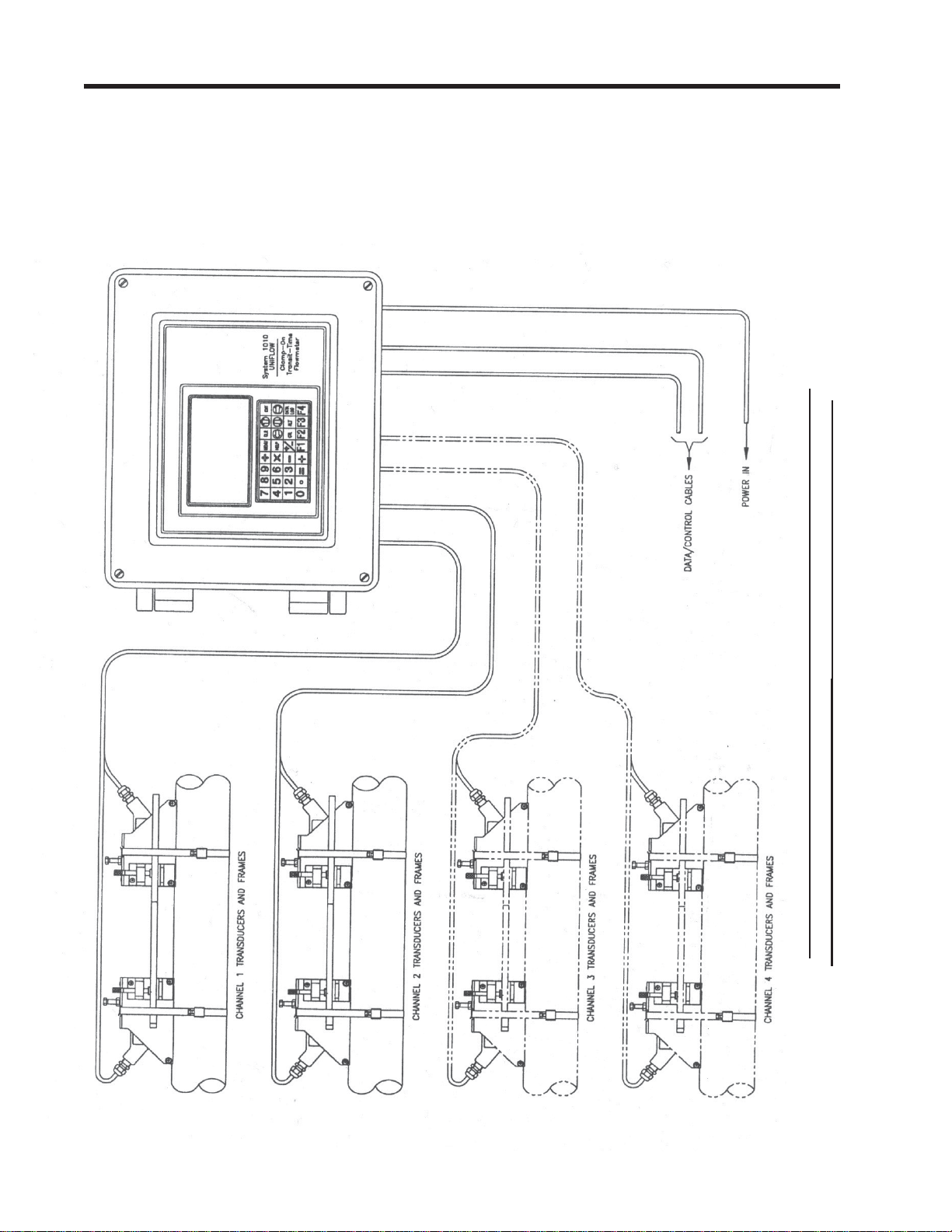

Flow Measurement Sub- system ( 4 channel system depicted here)

TYPICAL SYSTEM - 1010N PERMANENT CLAMP-ON SYSTEM

Page 23

1010NFM-3JSection 1

1.5 THE 1010N KEYPAD

The 1010N integral keypad provides 32 numeric and function keys (see table below). Use these keys to

enter, review or edit the site data. Certain keys control the graphics display, Datalogger and Totalizer.

“Blind Models,” having no keypad or display, must be setup by using their serial dat a port (see Appendix B).

KEYPAD FUNCTION CHART

KEY USAGE

MENU Press to activate the Installation Menu.

ENT Press <ENT> to store numeric data, select from option lists, etc.

LEFT, RIGHT ARROWS Menu navigation keys move cursor in respective directions.

UP, DOWN ARROWS Same as <Left> and <Right>. Also scrolls option list and graphic

display screen.

CLR Clear Key for erasing data, or selecting list options.

NUMBERS 0-9 Use to type numeric data.

DECIMAL POINT Use for decimal points in numeric data.

MATH OPERATORS Allows 4-function math operations in numeric entry cells.

“F” KEYS 1-3 Totalizer control and special function keys.

“F4” KEY CAUTION: SYSTEM RESET KEY (during power up)

CTL & ALT Used as shift keys for alternate key functions.

DATALOG Triggers immediate Datalogger report.

PLUS/MINUS [+/-] Changes the sign of numeric data.

NOTE: The keypad does not have alphabetic keys. Scrolling lists provide alphanumeric char-

acters as needed.

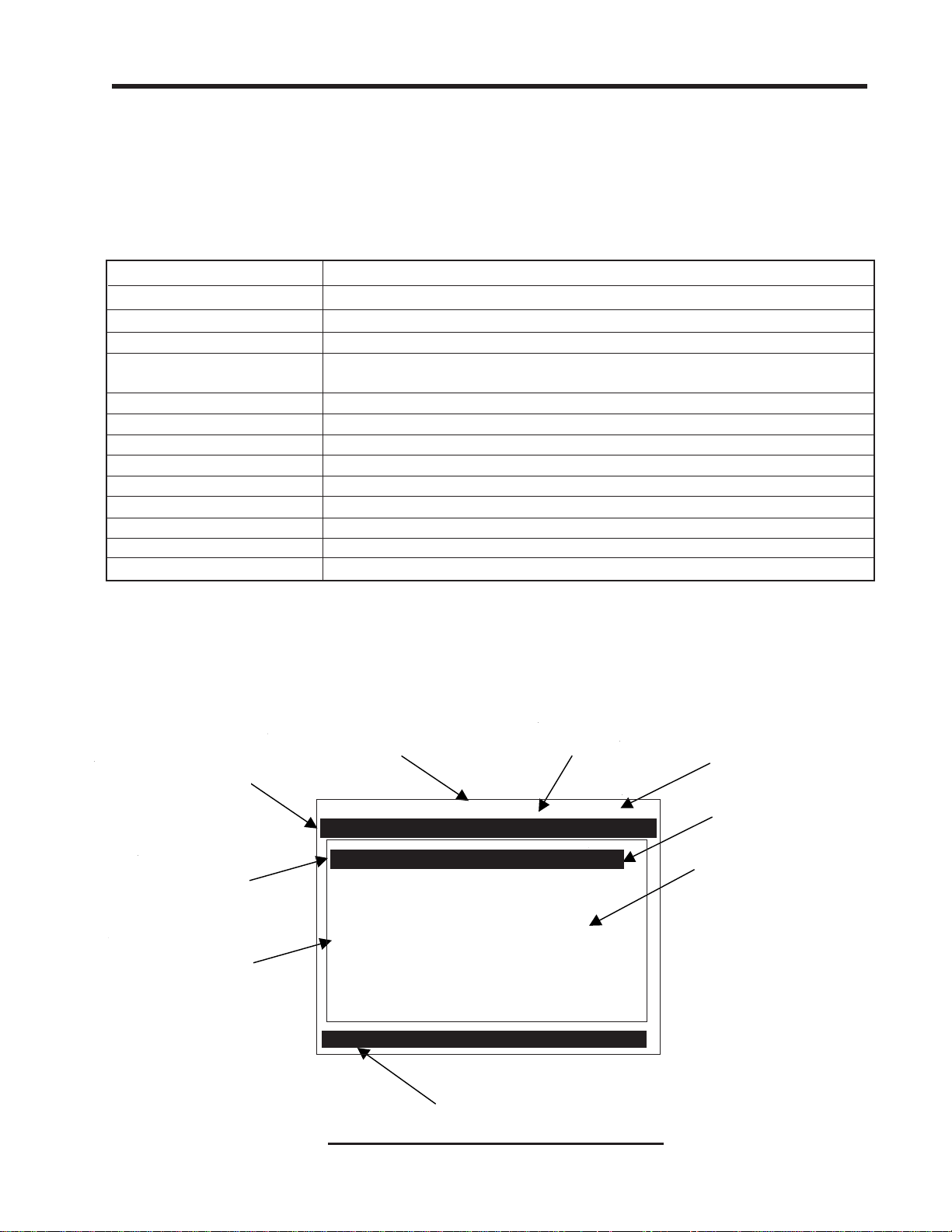

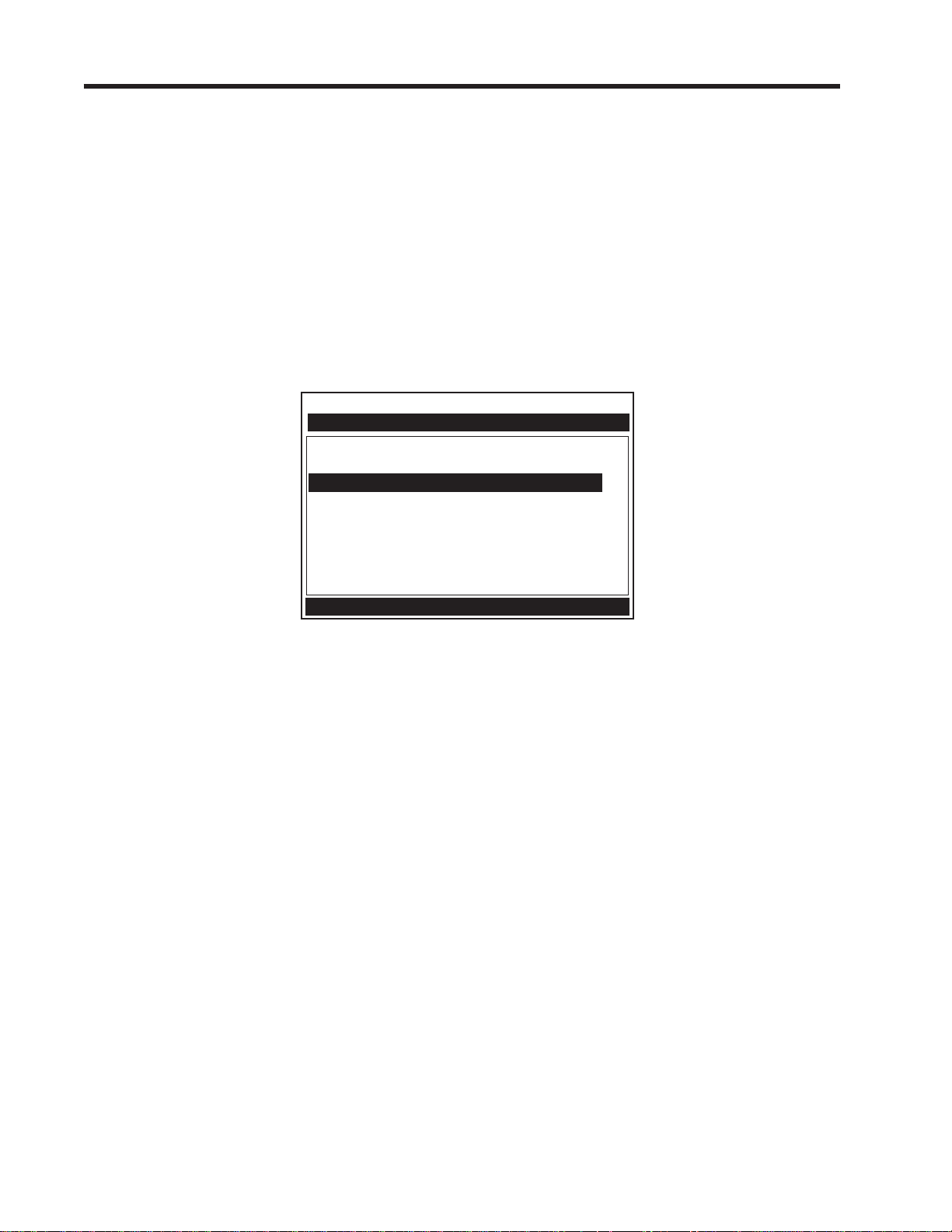

1.6 INTRODUCTION TO THE 1010N MENU SCREENS

The figure below shows a typical 1010N menu screen (in this case, the Pipe Data Menu).

Current Selected

Measurement

Channel

Site Name Identified

Highlighted Data

Menu Cell Data

(right-h and colu mn)

Menu Prompt Line

(Revers e V ideo )

Highlighted

Menu Cell

Menu Cell Data

(left-hand column)

Current Selected

Meter Type

Siemens 2 Channel [1] SITE 1

Select Pipe Class from Pipe T able

Select Pipe Class Manual Entry

Select Pipe Size No Pipes

Pipe OD <in> 0.500

Pipe Material Steel

Wall Thickness 0.100

Liner Material None

Liner Thickness 0.000

Pipe Dataiquid Class

Current Selected Menu

TYPICAL INSTALLATION MENU SCREEN

1-3

Page 24

1010NFM-3JSection 1

EXPLANATION OF THE CALL-OUTS

Menu Prompt Line When you select a menu cell, a highlighted text prompt appears on the top of

the screen to explain the function of the cell.

Current Selected [2 Channel] indicates Dual Channel meter operating mode selected.

Meter Type

Selected Channel The [1] indicates that measurement Channel 1 is currently selected.

Highlighted Menu The menu cursor (highlight bar) shows where you are currently working by

Cell reversing the display colors for that cell (white type on black).

Highlighted Data The right-hand column shows the current value highlighted. Pressing the

<Right Arrow> provides access to an option list or numeric field where you

can change the current value as required.

Menu Cell A menu cell is an individual location within a menu (in this case Pipe Data)

that stores a parameter (either a numeric entry or an option list selection.

Menu Cell Data The right-hand column shows the current value stored by left-hand column

menu cell. The Pipe Data Menu includes option list items and numeric entries.

Current Selected The highlighted bar at the bottom of the screen shows the name of the menu

Menu that you are accessing (e.g., Pipe Data).

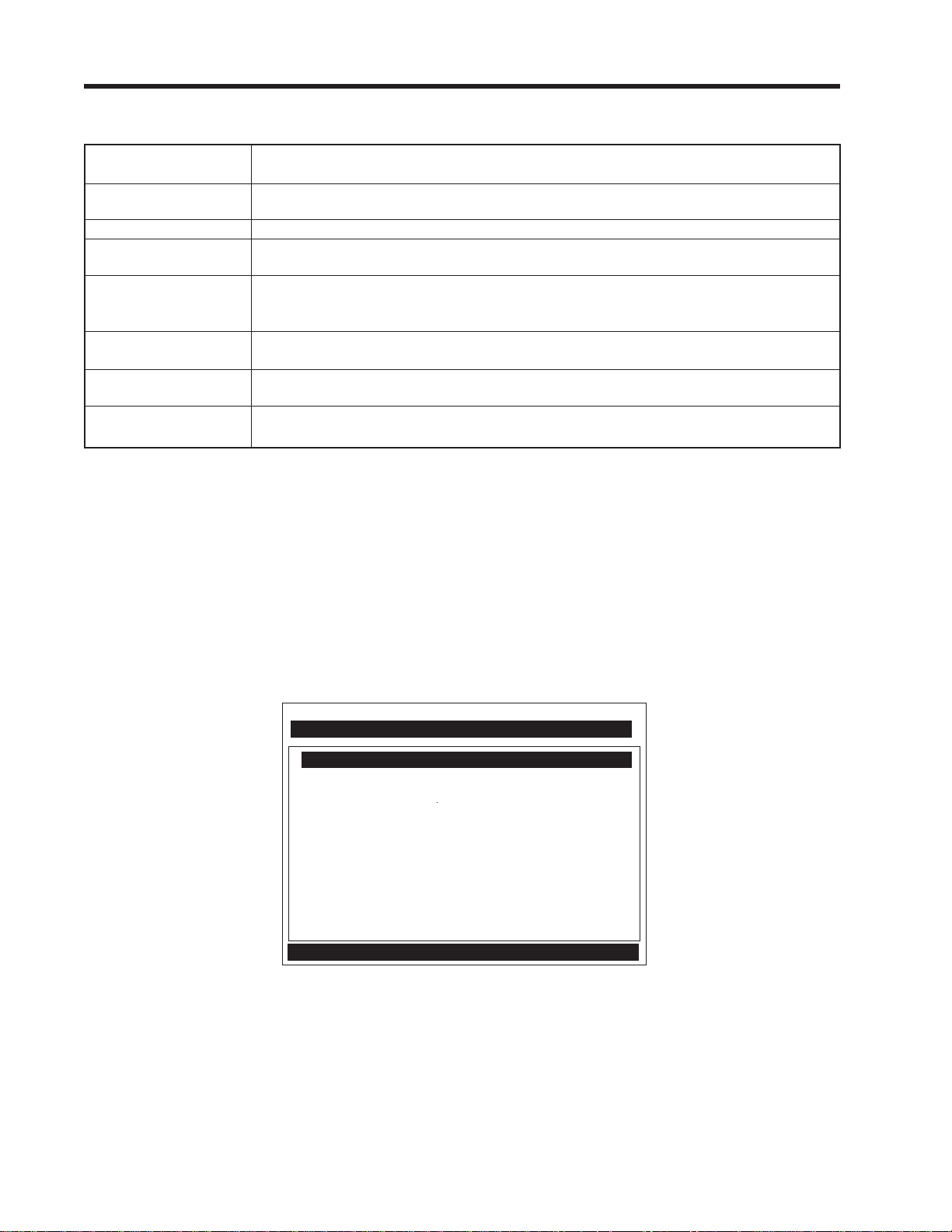

1.7 HOW TO USE THE INSTALLATION MENU

This section introduces the System 1010 Installation Menu. It explains how to access and leave the

Installation Menu and how to enter site data. The Installation Menu consists of sub-menus, each providing individual menu locations (menu cells) that store site data. For convenience, this manual refers

to sub-menus simply as menus (e.g., the Pipe Data Menu). Shown below is the Clamp-on, Full Site

Setup screen for Channel 1 of a dual-channel meter. Single and four channel systems are identical.

Siemens 2 Channel [1]

Create-Name-Recall-Enable & Delete Site

Channel Setup

Pipe Data

Application Data

Pick/Install Xdcr

Operation Adjust

Flow/Tot al Units

Data Span/Set/Cal

Stripchart Setup

Datalogger Setup

I/O Data Control

Diagnostic Data

Clamp-on

1-4

Page 25

1010NFM-3JSection 1

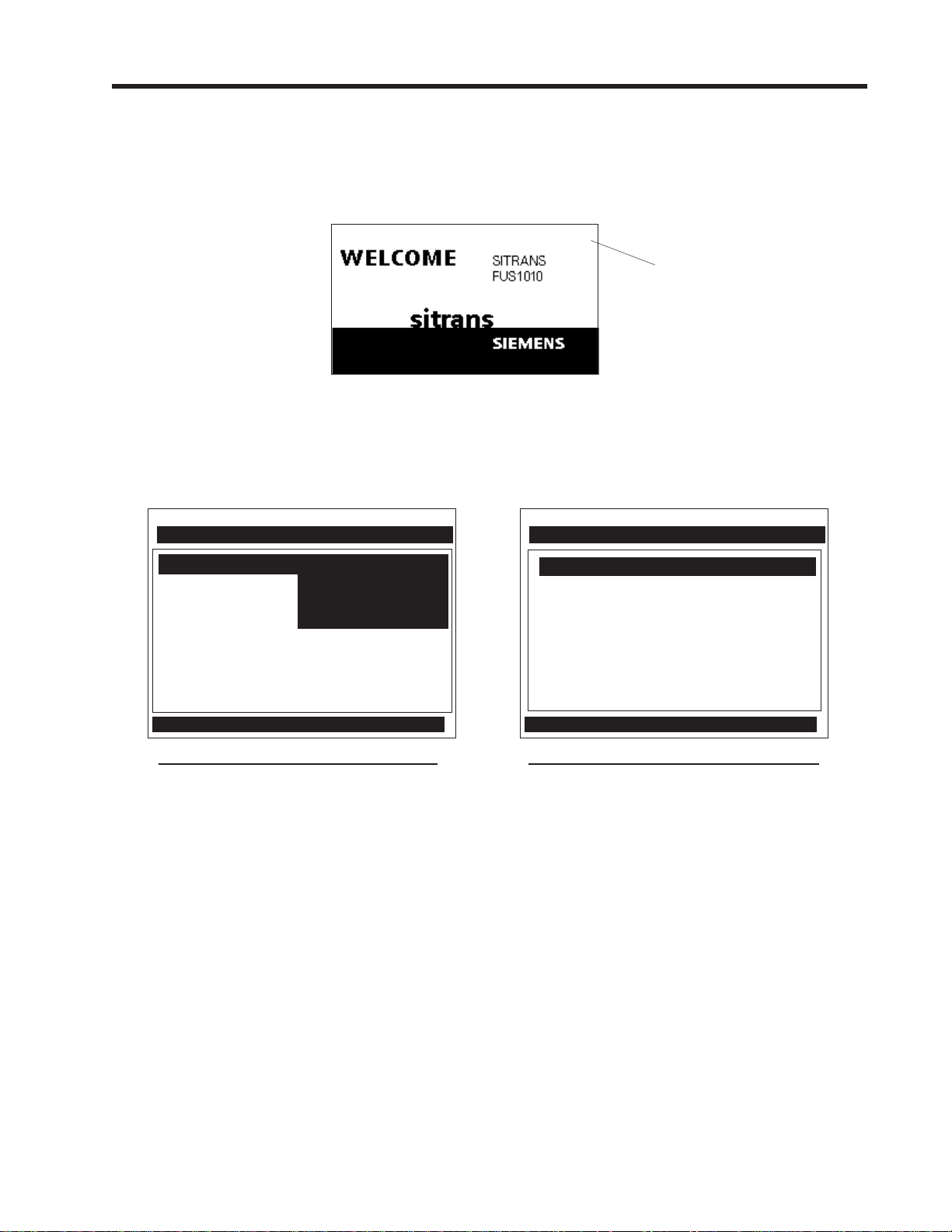

1.7.1 ACCESSING AND LEAVING THE MENU

Upon first turning the meter on you see a Siemens graphic. This means that there is no active site

setup currently stored in memory . Note that this screen identifies the software version of the meter on

the upper right-hand corner of the display .

ver. 3.01.00

Software

Version

(x.xx.xx)

Make sure the keypad enable switch is in the correct position then press the <MENU> key to select the

menu. The first time you access the Installation Menu, you can leave it only by saving a site or by

turning the meter off. After installing and activating a site, use the <MENU> key to toggle between a

graphic display screen and the last accessed menu location.

Siemens 2 Channel [1] Channel 1

Select Meter Type

Meter Type >Dual Channel Flow

Meter Facilities Dual Beam Flow

Using the Menu Ch 1 + 2 Flow

Ch 1 - 2 Flow

Liquid Class

Top menu screen for dual-channel system Top menu screen for single-channel system

Siemens Site [1]

Select Meter Type

Meter Type Single Channel

Meter Facilities

When you press the <MENU> key , the cursor arrives at the first level of the installation menu. Refer to

the sample screens above. The left screen is from a dual-channel model. The right screen is from a

single channel model. Note that two columns, one on the left-hand side and the other on right-hand

side, divide the screen. The first left-hand item, [Meter T ype], is highlighted (white type on black). [Meter

Type] allows you to choose a meter configuration from the highlighted right-hand column list. With

single channel models, the only option is [Single Channel]. The next left-hand selection is [Meter Facilities]. Use the [Meter Facilities] menu to set global meter options and controls.

1.7.2 HOW TO ENTER DATA

The left-hand column shows the menu cells (described previously). Another way to think about lefthand column items is to consider them menu questions. Then you can see that the right-hand column

answers these questions. Right-hand column answers can be:

z Another series of menu cells (may become left column items when selected).

z An item from a scrollable option list (e.g., a class of liquids).

z A numeric entry (e.g., a pipe outer diameter).

z An alphanumeric string (e.g., a site name).

1-5

Page 26

1010NFM-3JSection 1

Selecting Items from an Option List

Examine the screen below. It shows how to use an option list to select a liquid for your application. How

to access this menu will be explained later. Note that the menu name [Application Data] appears

highlighted on lower left of the screen. Note also that the menu cell [Liquid Class] is highlighted - the

right-hand column shows the answer [Water 20C/68F].

Siemens 2 Channel [1] Channel 1

Select Liquid Class from Liquid T able

Liquid Class Water 20C/68F

T emperature Range -40F to 250F

Pipe Configuration Fully Developed

Anomaly Diams 10

Application Data

Pressing the <Right Arrow> changes the left-hand column to [Select Liquid]. Pressing the <Right Arrow> again accesses the option list. This expands the highlighted area to show the list contents. Note

that a cursor (arrow) points to the top item on the list.

Siemens 2 Channel [1] Channel 1

Access Liquid Option List

Select Liquid >Water 20C/68F

Estimated Vs m/s Water 50C/122F

Viscosity cS Water 75C/167F

Density SG ens Water 100C/212F

Water 125C/257F

Water 150C/302F

Water 175C/347F

Water 200C/392F

Water 225C/437F

Water 250C/482F

Acetic Acid

Liquid Class

The <Up and Down Arrows> scroll the option lists. Every press moves the cursor to the next item in

sequence. Due to the size of display screen, some option lists include more items than the display can

show. For example, on the screen above the last option shown is [Acetic Acid]. However , this option list

has more listings. Continue to press the <Down Arrow> to see more liquid selections. When you arrive

at the last item on a list, the next <Down Arrow> press brings you back to the top of the list; because

the option lists are of the “wrap-around” type.

To select an option list item, move the cursor to the item and then press the <ENT> key.This places

your selection at the top of the list and moves you out of the option list to the next menu cell. Examine

screen on next page. The option list item: [Diesel Fuel] has been selected. Note that this appears on

the right-hand column and that the highlighted area moves to the next menu cell in sequence: [Estimated Vs m/s].

1-6

Page 27

1010NFM-3JSection 1

Siemens 2 Channel [1] Channel 1

Access Liquid Option List

Select Liquid Diesel

Estimated Vs m/s 1600

Viscosity cS 2.00

Density SG 1.030

Liquid Class

Multiple Select Option Lists

Certain option lists allow you to make more than one selection. For instance, the Datalogger Data

option list allows you to select any or all of the available data items for your reports. You can use the

<Up and Down Arrows> to move the cursor through the list. If you press <ENT> to select an item, a

plus sign (+) appears next to that item. The cursor remains so that you can make other selections. To

deselect a previously selected item, move cursor next to that item and press <CLR>. Use <Left Arrow> to leave a multiple select option list.

Siemens 2 Channel [1] 1

Select Datalogger Data

Datalogger Mode +Site Id

Datalogger Data +Date

Log Time Interval +Time

Datalogger Events Flow

Display Datalogger +Average Flow

Raw Flow

Total

Liquid Class

Entering Numeric Data

When a menu cell requires a numeric answer, press the <Right Arrow> to access a number entry

field; an equal sign (=) appears before current entry . You can now use the number keys and the decimal point key to type a new value. If applicable, you can use <+/-> keys to change the mathematical

sign of the number. Press <ENT> to store the numeric data.

NOTE: All Numeric Data cells provide a four-function calculator via the keypad’s arithmetic

function keys.

Siemens 2 Channel [1] Channel 1

Enter pipe Outer Diameter manually

Select Pipe Class Manual Entry

Select Pipe Size N/A

Pipe OD (in) = 0.500

Pipe Material Steel Flow

Wall Thickness 0.100

Liner Material None

Liner Thickness 0.000

Pipe Data

1-7

Page 28

1010NFM-3JSection 1

Entering Alphanumeric Strings

An alphanumeric string is a series of numbers and letters; and also the Quotation Mark and the Pound

Sign symbol. You can also use a space. The meter uses these to identify a specific site setup or usermodified table. The 1010N keypad does not provide letter keys. However, when you access a menu

cell that requires an alphanumeric string answer, the menu cell right-hand column provides an eightcharacter entry field. Press the <Right Arrow> to access the field. This selects the first character

position. Note that the prompt changes to a question mark (?). With the cursor at the first character

position, use the <Up> or <Down Arrows> to scroll through a single-character list. For example, as

shown below, an <Up Arrow> at the first character position produces the letter: uppercase [A]. Pressing the <Right Arrow> moves the cursor to the second position.

Controlotron Dual Path Channel 1

Right Arrow & Enter Creates a new Site

Recall Site Setup

Channel Enable No

Create/Name Site ?A

Site Security Off

Delete Site Setup No Sites

Save/Rename Site

Channel/Path Setup

Use the <Right and Left Arrows> to move through the character positions. If you wish touse numbers

in your string, you can type them directly from the keypad. After you finish selecting your string, press

<ENT> to register it.

1.7.3 THE METER TYPE MENU

This is the first list presented upon entering the Installation Menu. Select the type of meter required for

your application. The meter automatically conditions Installation Menu choices to suit the selected

meter type. The following paragraphs introduce the available meter types for dual channel systems.

NOTE: On Single Channel systems, you do not get a choice of meter types, sincethis requires

two independent measurement channels. However, you can operate the single channel with any optionally supplied measurement technology. Some four channel models

provide four-path and channel summing operation.

1-8

Page 29

1010NFM-3JSection 1

Dual Channel

Dual Channel provides two independent measurement channels that operate simultaneously. Depending on the specific model, Dual Channel supports: Clamp-on Transit-time, In-line Transit-time,

Reflexor.

Channel 1

Flow

PIPE `A'

PIPE `B'

Channel 2

Flow

Pipe 'A' Flow Rate

Pipe 'B' Flow Rate

Dual Path

Dual Path uses two measurement channels to achieve a single output via a “virtual” third channel. The

resultant data is the average of the two channels. Only clamp-on or in-line transit-time operation allowed. Benefits include highest available precision and enhanced immunity to distorted flow profile

conditions.

Channel 1

Flow

Pipe

Ch1 + Ch2

2

Output

(average of

Ch 1 & Ch 2)

Channel 2

Flow

Channel 1+2 and Channel 1-2

Arithmetic operation produces data output via a virtual Channel 3, proportional to sum or difference of

the liquid and energy flow of two independent pipes. This requires setting the two channels to operate

independently . Only clamp-on or in-line transit-time operation is supported.

P

Channel 1

PIPE `A'

PIPE `B'

Channel 2

I

P

E

`

A

'

F

L

O

W

R

A

T

E

Ch1 [+/-] Ch2

E

T

A

R

W

O

L

F

'

B

`

E

P

I

P

Output

sum or difference

of Ch1 & Ch2

Channel 1-2 produces a data output via a virtual Channel 3, proportional to the difference of the liquid

and energy flow of two independent pipes. You have to set-up the two channels independently. Only

clamp-on or in-line transit-time operation is supported.

1-9

Page 30

1010NFM-3JSection 1

1.7.4 ESSENTIAL INFORMATION FOR USERS OF MULTI-CHANNEL 1010’s

Multi-Channel Meter Type