Page 1

SITRANS F

Ultrasonic Flowmeters

FST020 IP65 NEMA 4X

Introduction

1

Operating Instructions

Safety notes

Description

Installing/mounting

Connecting

Commissioning

Operating

Service and maintenance

Diagnosing and

troubleshooting

2

3

4

5

6

7

8

9

Technical data

Dimension drawings

Replacement parts

Modbus communication

Certificates and support

SIMATIC PDM

10

11

12

A

B

C

09/2017

A5E41425845-AB

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E41425845

Ⓟ 10/2017 Subject to change

Copyright © Siemens AG 2017.

All rights reserved

Page 3

Table of contents

1 Introduction...................................................................................................................................................9

1.1 Purpose of this documentation.................................................................................................9

1.2 Product compatibility................................................................................................................9

1.3 Document history.....................................................................................................................9

1.4 Device documentation package.............................................................................................10

1.5 Items supplied........................................................................................................................10

1.6 Checking the consignment.....................................................................................................11

1.7 Further Information.................................................................................................................11

1.8 Notes on warranty..................................................................................................................12

2 Safety notes................................................................................................................................................13

2.1 Precondition for use...............................................................................................................13

2.2 Warning symbols on the device.............................................................................................13

2.3 Laws and directives................................................................................................................13

2.4 Conformity with European directives......................................................................................14

2.5 Lithium batteries.....................................................................................................................14

3 Description..................................................................................................................................................15

3.1 Overview................................................................................................................................15

3.2 Design....................................................................................................................................15

3.3 Features.................................................................................................................................16

4 Installing/mounting......................................................................................................................................19

4.1 Chapter overview (transmitter)...............................................................................................19

4.2 Installation location requirements...........................................................................................19

4.2.1 Environment...........................................................................................................................19

4.2.2 Normal environmental conditions...........................................................................................20

4.3 Installation instructions...........................................................................................................20

4.3.1 Wall mount transmitter...........................................................................................................20

5 Connecting.................................................................................................................................................25

5.1 Basic safety notes..................................................................................................................25

5.1.1 Missing PE/ground connection...............................................................................................25

5.1.2 Energized devices..................................................................................................................25

5.2 Disconnecting device.............................................................................................................26

5.3 Device nameplates.................................................................................................................26

5.3.1 Device nameplate..................................................................................................................27

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 3

Page 4

Table of contents

5.4 Transmitter power supply, communications and I/O connections..........................................28

5.4.1 Sensor connections................................................................................................................28

5.4.2 Connecting the power supply.................................................................................................28

5.4.3 Connecting Inputs/Outputs.....................................................................................................30

5.4.4 Connection Wiring..................................................................................................................31

5.4.5 Finishing the transmitter connection (wall mount housing)....................................................33

6 Commissioning...........................................................................................................................................35

6.1 Basic Safety notes.................................................................................................................35

6.1.1 Hazardous contact voltage.....................................................................................................35

6.2 General requirements............................................................................................................36

6.3 Power-up................................................................................................................................36

6.4 Local display..........................................................................................................................36

6.5 Initial startup...........................................................................................................................36

6.6 Commissioning via local display............................................................................................37

6.6.1 Chapter overview...................................................................................................................37

6.6.2 Wizards..................................................................................................................................38

6.6.2.1 Quick Commissioning wizard (menu item 1.1).......................................................................38

6.6.2.2 Quick Commissioning wizard (wizard)...................................................................................38

6.6.2.3 Sensor settings wizard (menu item 1.2).................................................................................38

6.6.2.4 Sensor settings wizard (wizard).............................................................................................39

6.6.2.5 Process Values wizard (menu item 1.3).................................................................................43

6.6.2.6 Process values wizard (wizard)..............................................................................................44

6.6.2.7 Inputs/Outputs wizard............................................................................................................45

6.6.3 Navigating the menu structure...............................................................................................45

6.6.3.1 Chapter overview...................................................................................................................45

6.6.3.2 Navigation view......................................................................................................................45

6.6.3.3 Navigating the menu structure...............................................................................................46

7 Operating....................................................................................................................................................47

7.1 Display views.........................................................................................................................47

7.2 Access control........................................................................................................................47

7.3 Operating the FST020............................................................................................................48

7.3.1 Fixed display texts..................................................................................................................48

7.3.2 Reading the process values...................................................................................................49

7.3.3 Operating the totalizer............................................................................................................51

7.3.4 Handling alarms.....................................................................................................................52

7.3.5 Reading the diagnostic values...............................................................................................53

7.3.6 Reading / changing parameters.............................................................................................53

7.3.6.1 Parameter view introduction...................................................................................................53

7.3.7 Alphanumeric parameters......................................................................................................53

7.3.7.1 Changing the resolution.........................................................................................................55

8 Service and maintenance...........................................................................................................................57

8.1 Basic safety notes..................................................................................................................57

8.1.1 Impermissible repair of the device.........................................................................................57

8.2 Recalibration..........................................................................................................................57

FST020 IP65 NEMA 4X

4 Operating Instructions, 09/2017, A5E41425845-AB

Page 5

Table of contents

8.3 Maintenance and repair work.................................................................................................57

8.3.1 Maintenance...........................................................................................................................57

8.3.2 Service and maintenance information....................................................................................58

8.4 Return procedure...................................................................................................................59

8.5 Disposal.................................................................................................................................59

9 Diagnosing and troubleshooting.................................................................................................................61

9.1 Introduction............................................................................................................................61

9.2 Device status icons................................................................................................................61

9.3 Fault codes and corrective actions.........................................................................................62

9.3.1 Alarm messages....................................................................................................................62

10 Technical data............................................................................................................................................65

10.1 Power.....................................................................................................................................65

10.2 Inputs.....................................................................................................................................65

10.3 Outputs...................................................................................................................................66

10.4 Construction...........................................................................................................................66

10.5 Operating conditions..............................................................................................................67

10.6 Approvals...............................................................................................................................68

10.7 SensorFlash...........................................................................................................................68

11 Dimension drawings...................................................................................................................................69

11.1 Dimension drawing.................................................................................................................69

12 Replacement parts.....................................................................................................................................71

12.1 AC Transmitter exploded view...............................................................................................71

A Modbus communication..............................................................................................................................73

A.1 Modbus addressing model.....................................................................................................73

A.2 Modbus communication.........................................................................................................73

A.3 Coil configuration...................................................................................................................75

A.4 Modbus register mapping.......................................................................................................76

A.5 Integer byte order...................................................................................................................78

A.6 Float byte order......................................................................................................................78

A.7 Modbus function codes..........................................................................................................78

A.8 Access control........................................................................................................................80

A.9 Modbus holding register tables..............................................................................................80

A.9.1 Modbus holding registers tables............................................................................................80

A.9.2 Process values.......................................................................................................................81

A.9.3 Totalizers................................................................................................................................82

A.9.4 Units.......................................................................................................................................84

A.9.5 Device reset...........................................................................................................................89

A.9.6 Setup......................................................................................................................................90

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 5

Page 6

Table of contents

A.9.6.1 Sensor....................................................................................................................................90

A.9.6.2 Process values.....................................................................................................................108

A.9.6.3 Totalizers..............................................................................................................................112

A.9.6.4 Inputs and outputs................................................................................................................113

A.9.6.5 Date and time.......................................................................................................................126

A.9.6.6 Local display........................................................................................................................127

A.9.6.7 Selectable values dependent on the view type....................................................................137

A.9.6.8 Process value filter masks...................................................................................................138

A.9.7 Maintenance and diagnostics...............................................................................................139

A.9.7.1 Identification.........................................................................................................................139

A.9.8 Diagnostic events.................................................................................................................141

A.9.8.1 Active events........................................................................................................................141

A.9.8.2 Diagnostic log.......................................................................................................................145

A.9.8.3 Alarm items..........................................................................................................................146

A.9.9 Diagnostics...........................................................................................................................150

A.9.9.1 Sensor..................................................................................................................................150

A.9.9.2 DSL......................................................................................................................................151

A.9.9.3 Temperature monitoring.......................................................................................................152

A.9.9.4 Inputs and outputs................................................................................................................153

A.9.9.5 Peak values..........................................................................................................................155

A.9.10 Characteristics.....................................................................................................................159

A.9.10.1 Transmitter...........................................................................................................................159

A.9.10.2 Sensor frontend....................................................................................................................159

A.9.11 SensorFlash.........................................................................................................................160

A.9.11.1 SensorFlash.........................................................................................................................160

A.9.11.2 Data logging.........................................................................................................................161

A.9.12 Simulation............................................................................................................................162

A.9.12.1 Inputs and outputs................................................................................................................162

A.9.12.2 Process values.....................................................................................................................164

A.9.12.3 Alarms..................................................................................................................................165

A.9.13 Audit trail..............................................................................................................................167

A.9.13.1 Operating time......................................................................................................................167

A.9.13.2 Parameter change log..........................................................................................................167

A.9.13.3 FW update change log.........................................................................................................169

A.9.14 Communication....................................................................................................................170

A.9.14.1 Service channel....................................................................................................................170

A.9.15 Security................................................................................................................................170

A.9.15.1 Access management............................................................................................................170

B Certificates and support............................................................................................................................173

B.1 Certificates...........................................................................................................................173

B.2 Technical support.................................................................................................................173

B.3 QR code label......................................................................................................................174

C SIMATIC PDM..........................................................................................................................................175

C.1 Commissioning with PDM....................................................................................................175

C.1.1 Introduction..........................................................................................................................175

C.1.2 Functions in SIMATIC PDM.................................................................................................175

C.1.3 Supported SIMATIC PDM versions......................................................................................175

C.1.4 Initial setup...........................................................................................................................176

C.1.5 Integrating the EDD..............................................................................................................176

FST020 IP65 NEMA 4X

6 Operating Instructions, 09/2017, A5E41425845-AB

Page 7

Table of contents

C.1.6 Adding device to communication network............................................................................178

C.1.7 Configuring a new device.....................................................................................................179

C.1.8 Wizard - Quick Start via PDM..............................................................................................180

C.1.9 Wizard - Clamp-On Configuration........................................................................................181

C.1.10 Wizard - Zero point adjustment............................................................................................181

C.1.11 Changing parameter settings using SIMATIC PDM.............................................................182

C.1.12 Parameters accessed via drop-down menus.......................................................................183

C.1.13 Process variables.................................................................................................................184

Index.........................................................................................................................................................187

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 7

Page 8

Table of contents

FST020 IP65 NEMA 4X

8 Operating Instructions, 09/2017, A5E41425845-AB

Page 9

Introduction

1.1 Purpose of this documentation

These instructions contain all information required to commission and use the device. Read

the instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

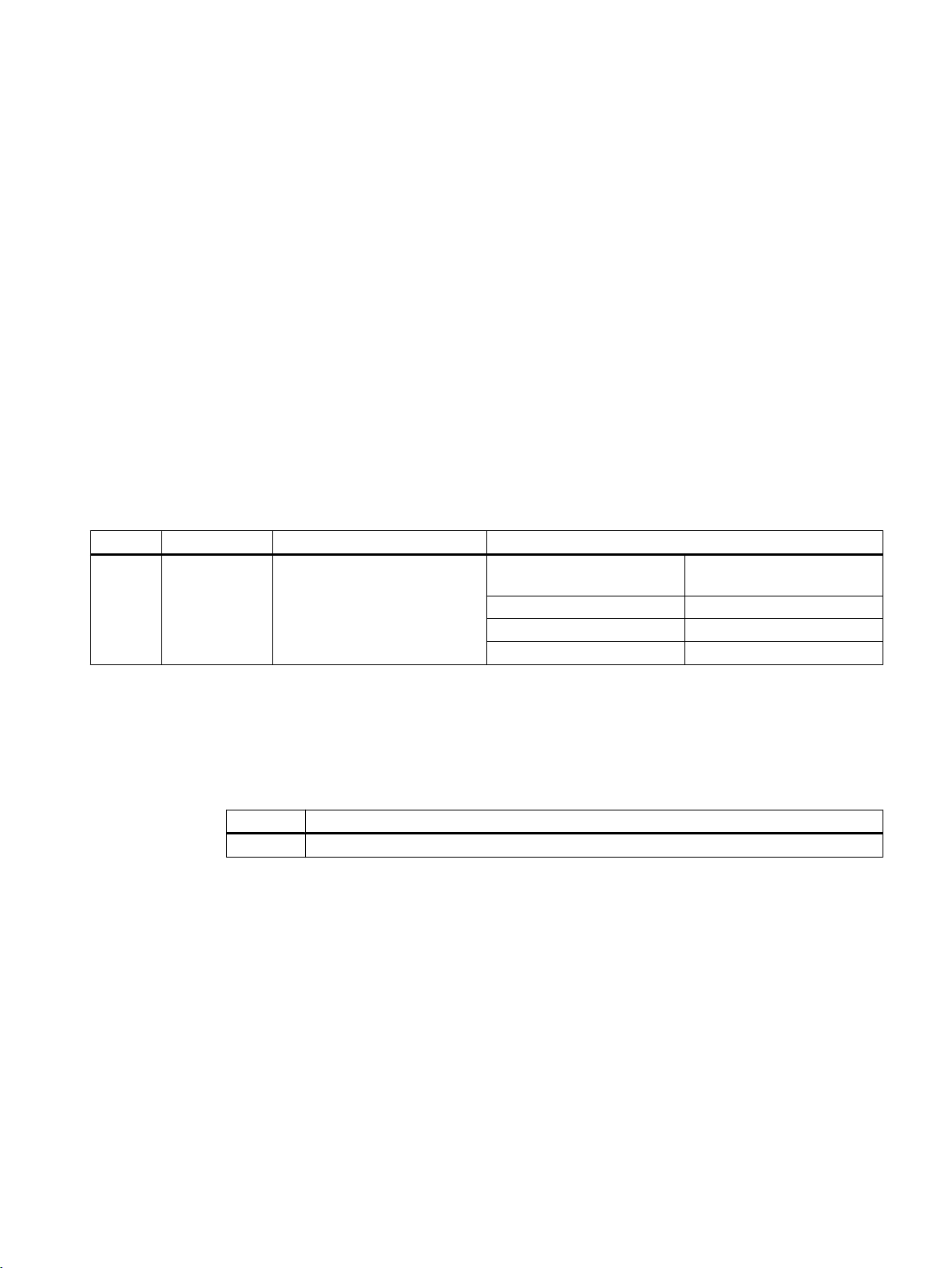

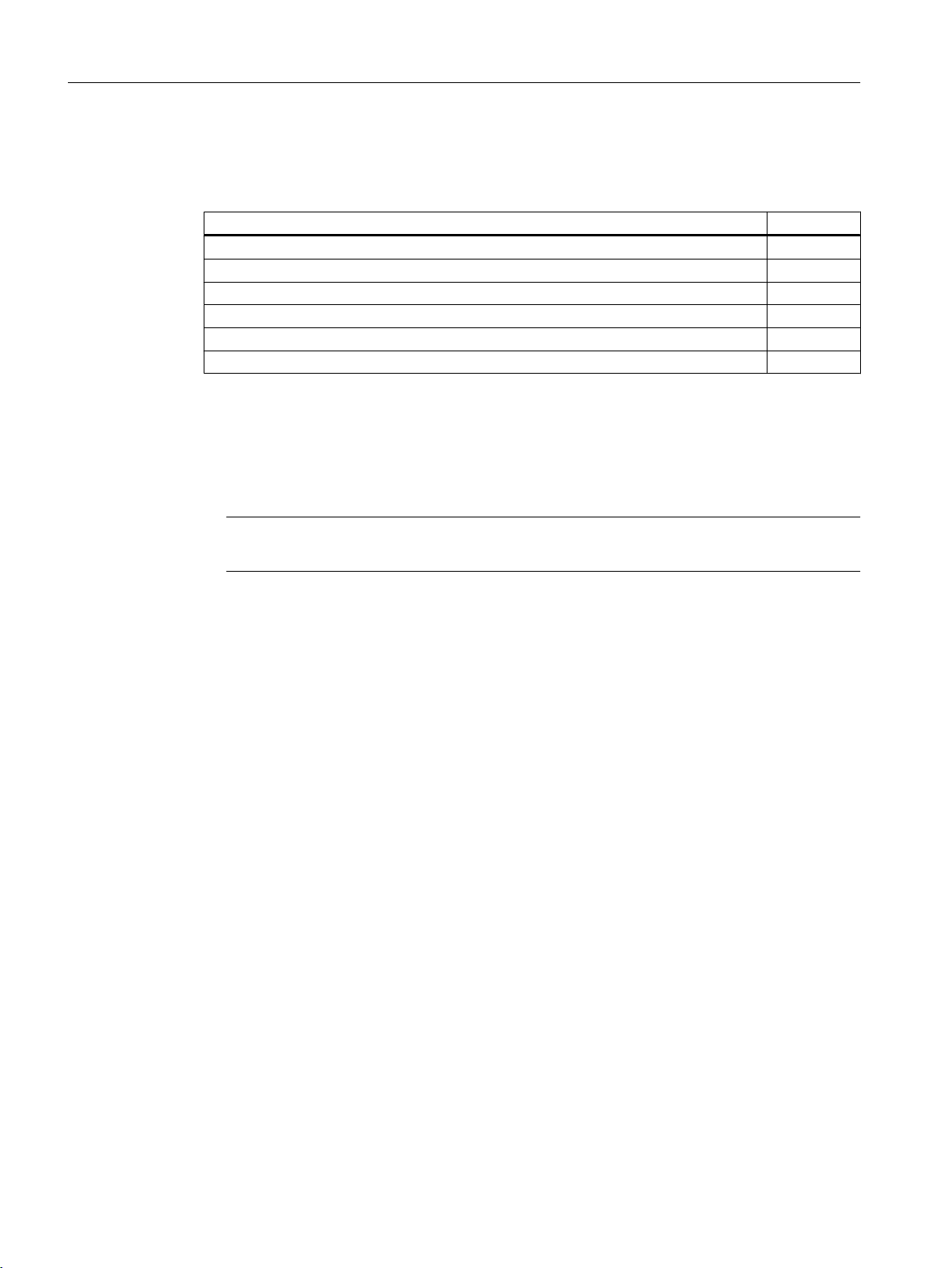

1.2 Product compatibility

Edition Remarks Device revision Compatible device revision integration package

09/2017 First edition Modbus

FW: 2.01.00-04

HW: 002 or later

SIMATIC PDM V8.2 SP1 or

later

AMS Device Manager 12.0 EDD: 1.00.00 or later

SITRANS DTM V4.1 EDD: 1.00.00 or later

Field communicator V3.8 EDD: 1.00.00 or later

EDD: 1.00.00 or later

1

1.3 Document history

The following table shows the most important changes in the documentation compared to each

previous edition.

Edition Note

09/2017 First edition

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 9

Page 10

Introduction

1.5 Items supplied

1.4 Device documentation package

The user documentation package for this product includes the following documents:

Document Purpose Intended users Availability

Operating Instruc‐

tions

Contains all information needed to

● check and identify the delivered

package

● install and electrically connect the

product

● commission the product, (setting

parameters via HMI menu)

● operate and maintain the device on a

daily basis

● troubleshoot and remedy minor

operation interruptions

Instrument techni‐

cians, plant opera‐

tors

● Available for download from

homepage

● Hardcopy can be purchased

via PIA Life Cycle Portal

(only English and German

versions)

1.5 Items supplied

The device is delivered as:

Wall mount enclosure

● FST020 transmitter wall mount enclosure

● Siemens Process Instrumentation disk

containing certificates and manuals.

Note

Supplementary information

Supplementary product and production specific certificates are included on the SensorFlash®

SD card in the transmitter socket.

Note

Scope of delivery may vary, depending on version and add-ons. Make sure the scope of

delivery and the information on the nameplate correspond to your order and the delivery note.

FST020 IP65 NEMA 4X

10 Operating Instructions, 09/2017, A5E41425845-AB

Page 11

1.6 Checking the consignment

Check the device packaging for damage. Inform your supplier of any damage. Retain the

damaged parts for clarification.

Check the scope of delivery by comparing the shipping documents with your order for

correctness and completeness.

Do not take damaged or incomplete devices into operation under any circumstances.

Special conditions for storage and transportation of device listed in Section "Service and

maintenance (Page 57)".

Identification

Note

IMPORTANT

This device is NOT to be used in hazardous areas.

CE declaration is delivered with the device.

Introduction

1.7 Further Information

Transmitter model number is: FST020

The system ordering code represents the transmitter including accessories.

AC System ordering code: 7ME3570-1JA4XXXXXX

DC System ordering code: 7ME3570-1JB4XXXXXX

AC - Transmitter ordering code: 7ME3570 - 1JA40-0AA1

DC - Transmitter ordering code: 7ME3570 - 1JB40-0AA1

1.7 Further Information

Product information on the Internet

The Operating Instructions are available on the documentation disk shipped with the device,

and on the Internet on the Siemens homepage, where further information on the range of

SITRANS F flowmeters may also be found:

Product information on the internet (

Worldwide contact person

http://www.siemens.com/flow)

If you need more information or have particular problems not covered sufficiently by these

Operating Instructions, get in touch with your contact person. You can find contact information

for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner)

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 11

Page 12

Introduction

1.8 Notes on warranty

See also

Technical support (Page 173)

1.8 Notes on warranty

The contents of this manual shall not become part of or modify any prior or existing agreement,

commitment or legal relationship. The sales contract contains all obligations on the part of

Siemens as well as the complete and solely applicable warranty conditions. Any statements

regarding device versions described in the manual do not create new warranties or modify the

existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

FST020 IP65 NEMA 4X

12 Operating Instructions, 09/2017, A5E41425845-AB

Page 13

Safety notes

2.1 Precondition for use

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or symbols

from the device. Always keep the information and symbols in a completely legible state.

2.2 Warning symbols on the device

Symbol Explanation

Caution. The Caution symbol is used throughout the operating instructions.

2

2.3 Laws and directives

Observe the safety rules, provisions and laws applicable in your country during connection,

assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

For CE marked equipment the device complies with the following directives:

● Low voltage directive LVD 2014/35/EU

● EMC directive 2014/35/EU

● Restriction of hazardous substances directive 2011/65/EC and 2015/863/EU

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 13

Page 14

Safety notes

2.5 Lithium batteries

2.4 Conformity with European directives

The CE marking on the device symbolizes the conformity with the following European

directives:

Electromagnetic compatibili‐

ty EMC

2014/30/EU

Low voltage directive LVD

2014/35/EU

Restrictions on Hazardous

Substances

RoHS 2011/65/EC and

2015/863/EU

The applicable directives can be found in the EU declaration of conformity of the specific device.

2.5 Lithium batteries

Lithium batteries are primary power sources with high energy content designed to represent

the highest possible degree of safety.

WARNING

Lithium batteries

Explosion Hazard - Can cause death or serious injury.

Directive of the European Parliament and of the Council on the

harmonisation of the laws of the Member States relating to elec‐

tromagnetic compatibility

Directive of the European Parliament and of the Council on the

harmonisation of the laws of the Member States relating to the

making available on the market of electrical equipment designed

for use within certain voltage limits

EU Directive: Restriction of Hazardous Substances in Electrical

and Electronic Equipment Directive and Annex II Commission

Delegated Directive

Lithium batteries may present an Explosion Hazard if they are abused electrically or

mechanically. This is in most circumstances associated with the generation of excessive heat

where internal pressure may cause the cell to rupture.

Thus the following basic precautions should be observed when handling and using lithium

batteries:

● Do not short-circuit, recharge or connect with false polarity.

● Do not expose to temperature beyond the specified temperature range or incinerate the

battery.

● Do not crush, puncture or open cells or disassemble battery packs.

● Do not weld or solder to the battery’s body.

● Do not expose contents to water.

FST020 IP65 NEMA 4X

14 Operating Instructions, 09/2017, A5E41425845-AB

Page 15

Description

'&32:(5

3.1 Overview

SITRANS FST020 ultrasonic flow meter systems consist of a transmitter and a sensor. The

following table lists the available combinations of transmitters and sensors.

Transmitter Sensor type

FST020 FSS200 family

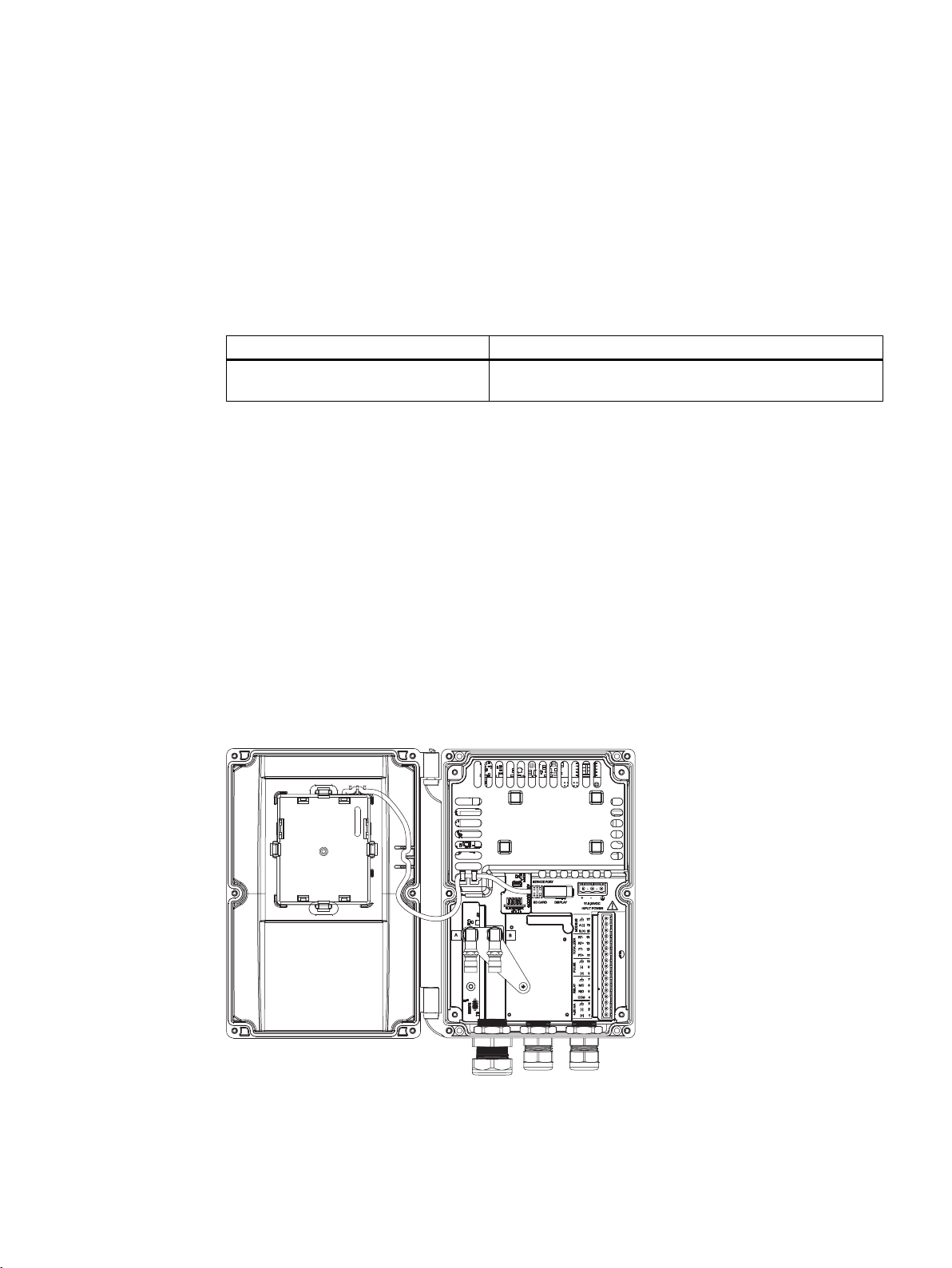

3.2 Design

The transmitter reads the measured process values from the sensor and calculates derived

values. It provides Modbus communications, 1x 4-20ma, 1x relay, and 1x Pulse/Frequency,

USB service port, and a local display. It also adds functionalities such as totalizers, access

control, diagnostics, and configuration. The local user interface consists of a display and four

buttons for user interaction.

The transmitter has a modular design with discrete, replaceable electronic modules and

connection boards to maintain separation between functions and facilitate field service. All

modules are fully traceable and their provenance is included in the transmitter setup.

3

DN 15 to DN 10m (0.5" to 360")

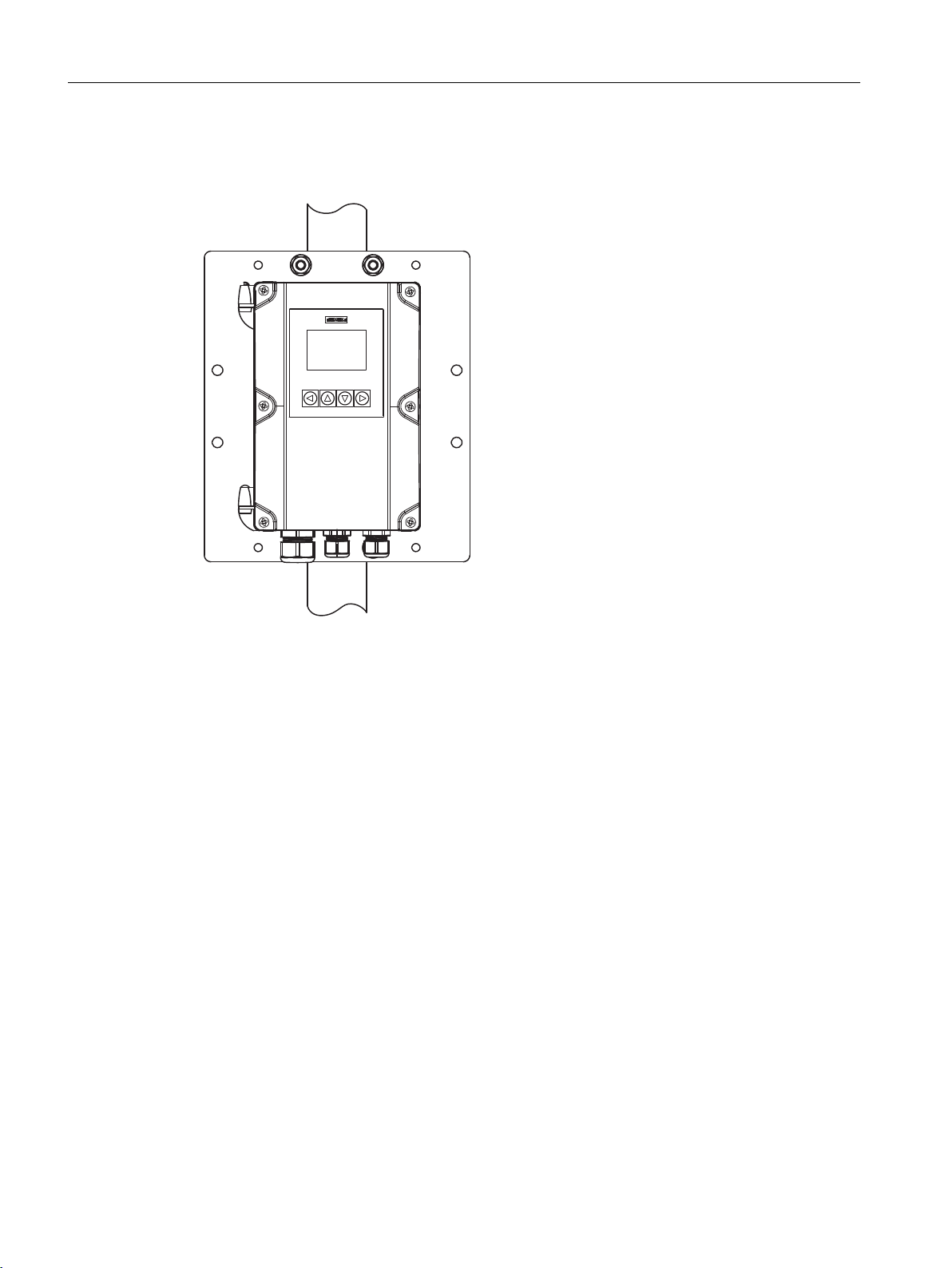

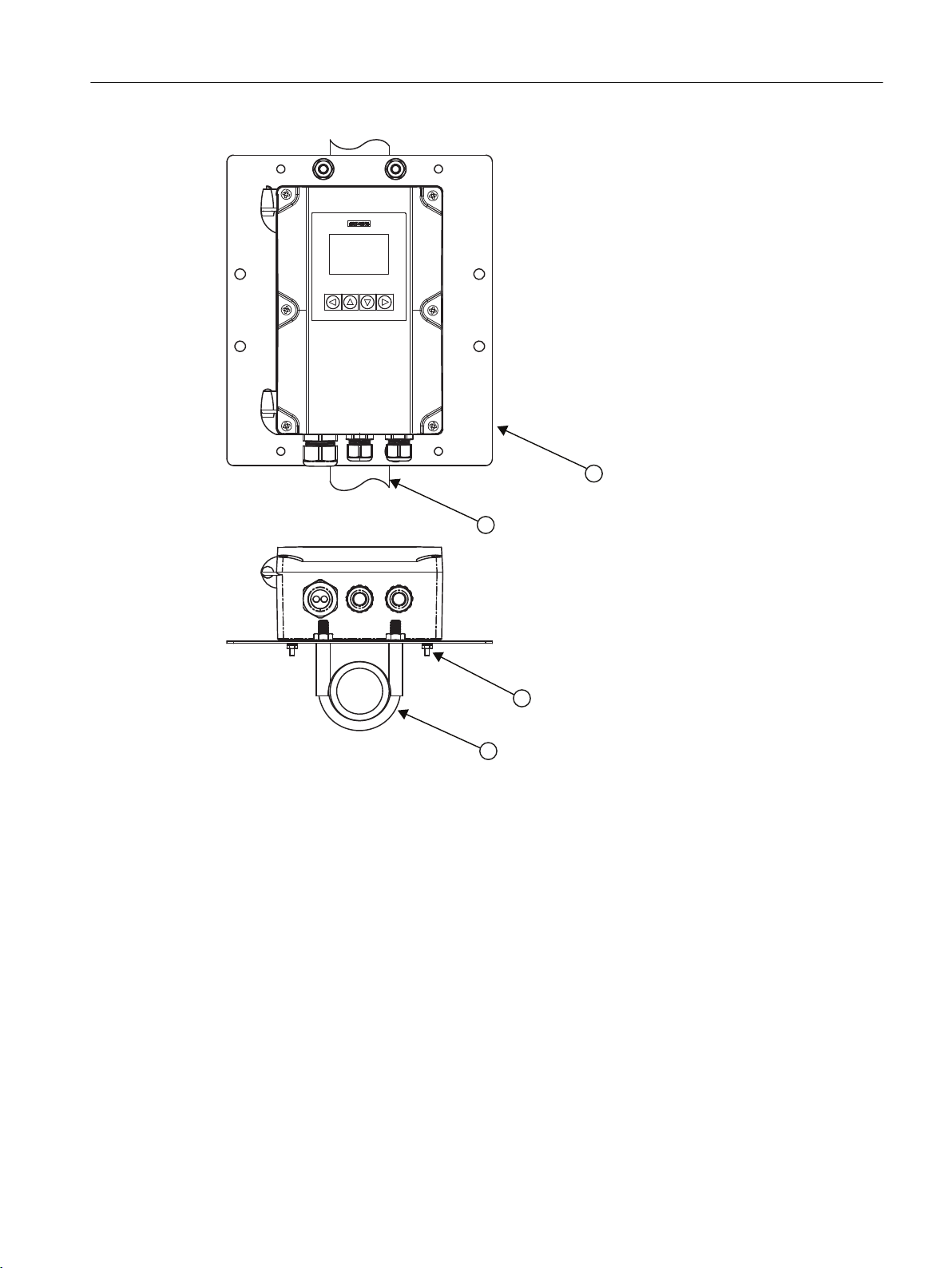

The SITRANS FST020 is available as:

Wall mount housings: AC and DC

Figure 3-1 DC Wall Mount housing shown

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 15

Page 16

Description

3.3 Features

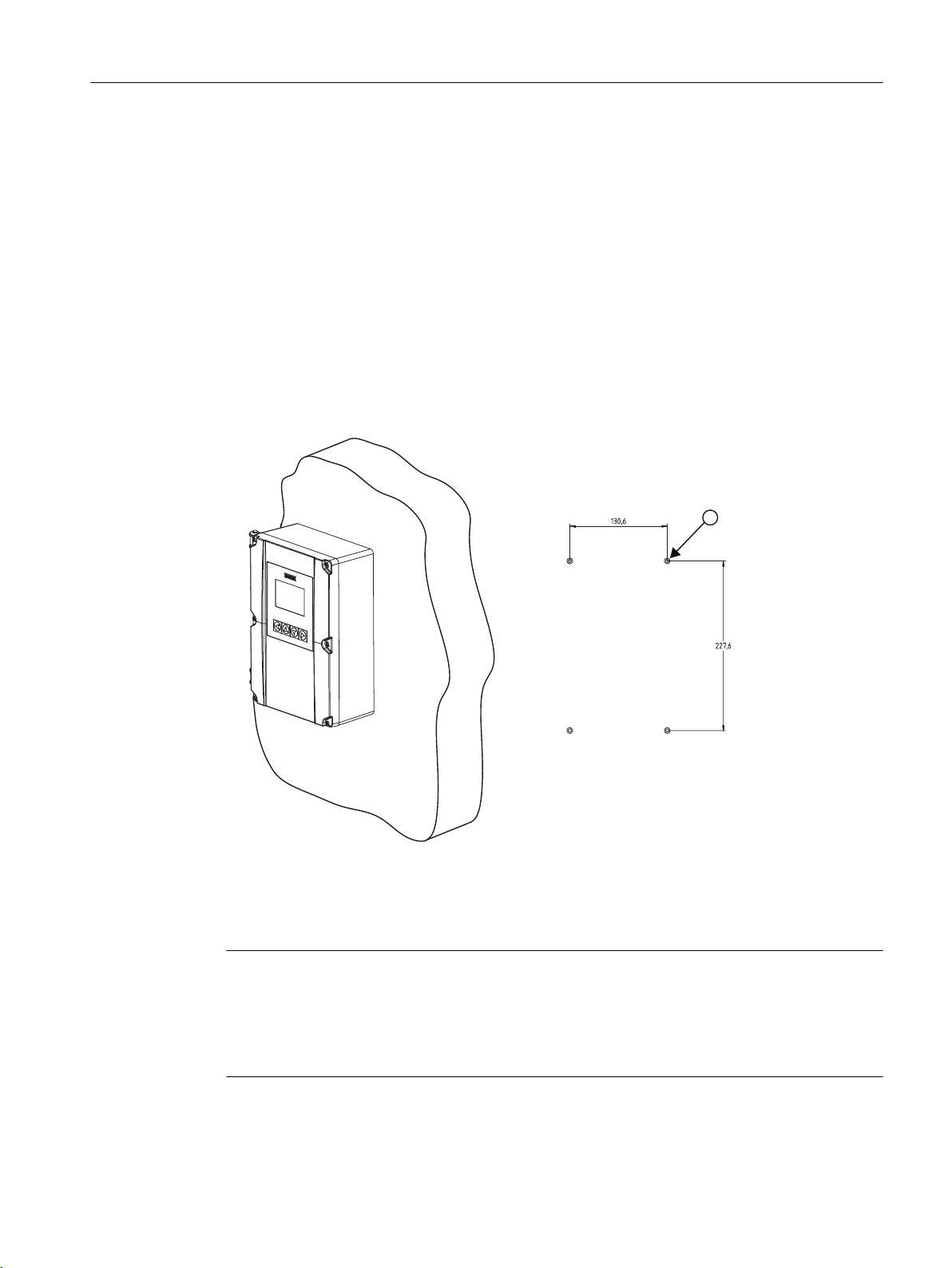

Pipe mount kit

The Pipe kit is CQO:1012NMB-1.

Figure 3-2 Pipe Mounting shown with mounting plate

3.3 Features

● Wall mount IP65 enclosure

● Full graphical local display

● SensorFlash (SD card) for memory backup, Datalogger and documentation storage

(certificates etc.)

● USB service interface

● Modbus communications

● One pulse/frequency output

● One relay

● One current output 4-20 mA

● High immunity against process noise

● Fast response to step changes in flow

● High update rate (100 Hz) on all process values

FST020 IP65 NEMA 4X

16 Operating Instructions, 09/2017, A5E41425845-AB

Page 17

Description

3.3 Features

● Measurement of:

– Volume flow

– Mass flow (with fixed density setpoint)

– Flow velocity

– Sound velocity

● Configurable upper and lower alarms and warning limits for nearly all process values

● Independent low flow cut-off settings for volume flow and mass flow

● Zero-point adjustment (initiated by host system)

● Process noise damping using digital signal processing (DSP)

● Simulation of process values

● Simulation of all outputs

● Simulation of alarms

● Enabling alarms for visibility on all outputs (HMI, status and communication)

● Comprehensive diagnostics (Siemens standard) for troubleshooting and sensor checking

● Firmware update

● Data logging in SensorFlash

● Peak indicators

● Alarm delay

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 17

Page 18

Description

3.3 Features

FST020 IP65 NEMA 4X

18 Operating Instructions, 09/2017, A5E41425845-AB

Page 19

Installing/mounting

4.1 Chapter overview (transmitter)

This chapter describes how to install the wall mount housing transmitter.

Wall mount housing

The wall mount housing transmitter can be mounted either on a wall or on a pipe (with optional

pipe mount bracket), see Installation instructions (Page 20).

4.2 Installation location requirements

4.2.1 Environment

SITRANS F flowmeters with minimum IP65/NEMA 4X enclosure rating are suitable for indoor

and outdoor installations.

Process pressure and medium temperature

If applicable, make sure that specifications for rated medium temperature (TS) plus ambient

temperature that are indicated on the device nameplate / label will not be exceeded.

4

Aggressive atmospheres

Ensure that the device is suitable for the application and that it is installed where there is no

risk of penetration of aggressive vapors.

Direct sunlight

Prevent the device from overheating or materials becoming brittle due to UV exposure by

protecting it from direct sunlight. Make sure that the maximum permissible ambient

temperature is not exceeded. Refer to the information in Technical data (Page 65).

WARNING

Electrical shock hazard

May cause death or serious injury

Disconnect power before working on this product.

Upstream / Downstream

Avoid long drop lines downstream from the sensor to prevent the meter pipe from draining.

Avoid installing the sensor upstream of a free discharge in a drop line where possible.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 19

Page 20

Installing/mounting

4.3 Installation instructions

Sensor Location in piping system

The optimum location in the system depends on the presence of excessive gas or air bubbles

in the fluid may result in erroneous measurements. Therefore, it is preferred not to install the

sensor at the highest point in the system, where gas / air bubbles will be trapped. For liquids

it is advantageous to install the sensor in low pipeline sections, at the bottom of a U-section

in the pipeline.

4.2.2 Normal environmental conditions

Normal environmental conditions

This standard applies to equipment designed to be safe at least under the following conditions:

● Indoor and outdoor use

● Altitude up to 2000 m

● Operating temperature -10 °C to 50 °C (14 °F to 122 °F)

● Maximum relative humidity 80 % for temperatures up to 31 °C decreasing linearly to 50 %

relative humidity at 40 °C (104 °F)

● Mains supply voltage fluctuations up to ±10 % of the nominal voltage

● Transient Overvoltages up to the levels of Overvoltage Category II

● Temporary Overvoltages occurring on the Mains supply.

● Pollution Degree II

4.3 Installation instructions

4.3.1 Wall mount transmitter

Wall mounting

WARNING

Hazardous voltage

May cause death or serious injury

Disconnect power before working on this device.

The transmitter can be mounted on any wall surface including wood, metal or concrete. Use

the appropriate bolts and screws as needed for your mounting application and adhere to local

codes.

FST020 IP65 NEMA 4X

20 Operating Instructions, 09/2017, A5E41425845-AB

Page 21

PP

PP

Installing/mounting

4.3 Installation instructions

Prepare holes for the four screws (M6x100 or equivalent). Screw head diameter: max. 13.5

mm; screw shaft diameter: max. 6 mm.

● Recommended mounting: Directly to wall or to electrical cabinet back panel.

● If alternate mounting surface is used it MUST support four times the weight of the unit.

Mounting the enclosure

1. Loosen the enclosure cover screws and open the cover to reveal the mounting holes.

2. Mark and drill four holes in the mounting surface for four mounting screws (supplied).

3. Using a long flat-blade screw driver, mount transmitter and tighten screws.

4. Tighten nuts (torque: 10 Nm).

5. Refer to Connecting the power supply (Page 28) and Sensor connections (Page 28) to

complete installation.

Figure 4-1 Wall mounted transmitter showing mounting hole pattern

Mounting on pipe

Note

Mounting on pipe

For mounting on pipe, see the installation instructions given in the CQO:1012NMB-1

instructions that are provided with the optional mounting bracket kit.

U-bolts and other miscellaneous hardware are not supplied with the flowmeter.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 21

Page 22

Installing/mounting

4.3 Installation instructions

For installation on 2-inch standpipe use the optional CQO:1012NMB pipe mounting kit.

Table 4-1 CQO:1012NMB-1 Mounting Kit

Description Qty

Mounting Plate 1

U-Bolt Assembly including bracket and nuts 2

8-32 x 5/8 LG cross round head screws 4

#8 Flat washer 4

#8 Split lock washers 4

8-32 Hex nut 4

1. Affix mounting plate to standpipe using the U-bolt assemblies.

2. Secure transmitter to mounting plate using #8-32 screws, washers and nuts.

3. Tighten nuts (torque: 10 Nm).

4. Refer to Connecting the power supply (Page 28) and Sensor connections (Page 28) to

complete installation.

Note

Use conduit fittings or cable glands on all cables.

FST020 IP65 NEMA 4X

22 Operating Instructions, 09/2017, A5E41425845-AB

Page 23

Installing/mounting

4.3 Installation instructions

① Mounting plate

② Stand pipe

③ Mounting hardware (see table above)

④ U-bolt assembly

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 23

Page 24

Installing/mounting

4.3 Installation instructions

FST020 IP65 NEMA 4X

24 Operating Instructions, 09/2017, A5E41425845-AB

Page 25

Connecting

This chapter describes how to wire up the transmitter for operation with a sensor.

● Transmitter power supply, communications and I/O connections (Page 28)

● Sensor connections (Page 28)

● Connecting the power supply (Page 28)

● Connecting Inputs/Outputs (Page 30)

● Connecting channel 1 (Page 31) (Modbus communication channel)

For connection of the sensor, see the relevant sensor Installation Manual.

5.1 Basic safety notes

5.1.1 Missing PE/ground connection

5

WARNING

Missing PE/ground connection

Risk of electric shock. May cause death or serious injury.

Depending on the device version, connect the power supply as follows:

● Power plug: Ensure that the used socket has a PE/ground conductor connection. Check

that the PE/ground conductor connection of the socket and power plug match each other.

● Connecting terminals: Connect the terminals according to the terminal connection

diagram. First connect the PE/ground conductor.

5.1.2 Energized devices

WARNING

Energized devices

Risk of electric shock. May cause death or serious injury.

When energized the device may be opened by qualified personnel only.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 25

Page 26

Connecting

5.3 Device nameplates

WARNING

Mains supply from building installation overvoltage category 2

A circuit breaker (max. 15 A) must be installed in close proximity to the equipment and within

easy reach of the operator. It must be marked as the disconnecting device for the equipment.

WARNING

DC connection devices

The DC power source must be isolated from mains supply.

5.2 Disconnecting device

Overvoltage Category II

Connect mains supply through a circuit breaker (max. 15 A) in close proximity to the transmitter

and within easy reach of the operator. Mark it as the disconnecting device for the transmitter.

5.3 Device nameplates

Each part of the system has one nameplate type showing the following information:

● product identification

● product specifications

● certificates and approvals

Note

Identification

Identify your device by comparing your ordering data with the information on the product

and specification nameplates.

The transmitter is identified as "Ultrasonic transmitter SITRANS FST020" and the sensor as

"Ultrasonic sensor SITRANS FSS200".

FST020 IP65 NEMA 4X

26 Operating Instructions, 09/2017, A5E41425845-AB

Page 27

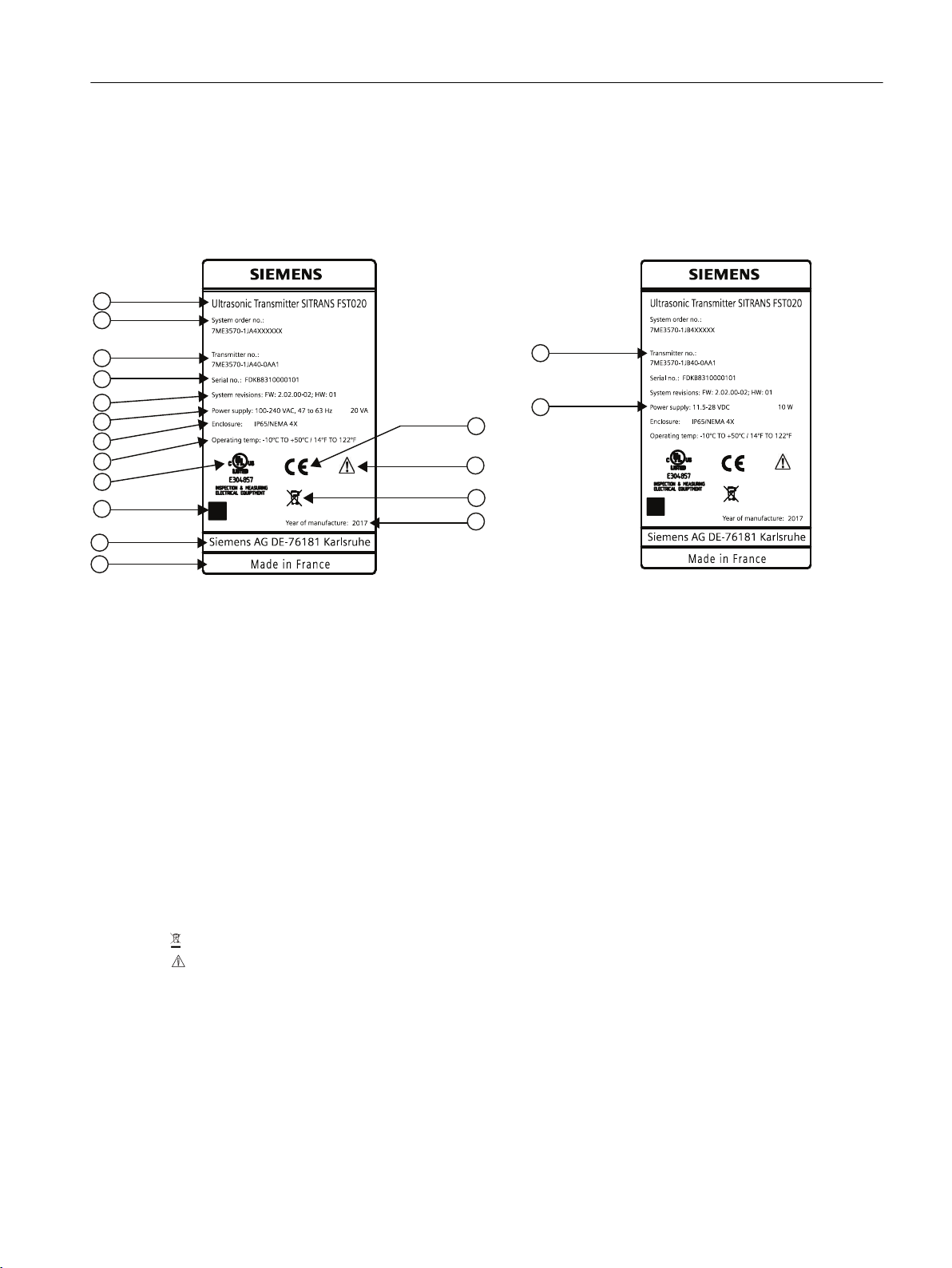

5.3.1 Device nameplate

$&'&

Transmitter nameplates

Connecting

5.3 Device nameplates

① Product name Transmitter product name

② System order no. Device-specific system order number (transmitter and sensor)

③ Transmitter order no. Transmitter replacement order numbers

④ Serial no. Transmitter serial number

⑤ System revisions System revision numbers; firmware (FW) and hardware (HW)

⑥ Power Supply Power supplies: AC and DC

⑦ Enclosure IP Degree of protection

⑧ Operating temperature Operating temperature of the device

⑨ Agency marking Specific agency identification marking

⑩ Data matrix code Product-specific QR-code

⑪ Contact information ad‐

dress

Contact address for device information

⑫ Place of manufacture Device place of manufacture

⑬ Year of Manufacture Manufacturing year. More detailed manufacturing date information is given in the serial

number (see sensor identification nameplate above)

⑭ WEEE symbol, see Disposal (Page 59)

⑮ Caution symbol

⑯ CE CE mark

Figure 5-1 Transmitter Labels: AC-DC

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 27

Page 28

Connecting

5.4 Transmitter power supply, communications and I/O connections

5.4 Transmitter power supply, communications and I/O connections

5.4.1 Sensor connections

For sensor connection, see the FSS200 Sensor installation instructions manual.

5.4.2 Connecting the power supply

Note

If the transmitter is not already mounted and cabling has not been run, proceed to Mounting

the Transmitter (Page 20) before connecting power.

WARNING

Hazardous Voltage

May cause death or serious personal injury.

Disconnect power before working on this product.

1. Using a flat-head screwdriver, loosen the six securing screws from the Keypad Enclosure

Cover and open cover.

2. To determine type of power connection refer to the following part numbers:

– 7ME3570-1HA4 = AC Power (with 500mA fuse)

– 7ME3570-1HB4 = DC Power (with 2A fuse)

3. Remove input power blind plug and fit cable gland.

4. Push cable through open gland and cable path.

5. Loosen power plug connector screws.

6. Referring to the illustration and table below, as per local electric codes, wire input power

connector for AC or DC power depending on power supply provided.

Connector pins AC DC Wire color

1 L1 + Black

2 L2N - White

3 Ground Ground Green

FST020 IP65 NEMA 4X

28 Operating Instructions, 09/2017, A5E41425845-AB

Page 29

11.5-28VD C

$&

'&

Connecting

5.4 Transmitter power supply, communications and I/O connections

7. Insert AC or DC power wires into wire entry holes and secure by tightening wire clamp

screws using a screwdriver.

– For AC - Connect ground to terminal and power to terminals L1 and L2N.

– For DC - Connect ground to terminal and power to terminals + and -.

Note

Power supply connector wires should be stripped stranded or solid conductors AWG 12-18.

① Power input (AC or DC - see inserts) ⑥ Relay

② I/O terminals TB1 ⑦ 4-20 mA

③ Modbus ⑧ I/O input cable - 30m (98ft) max length

④ Totalizer ⑨ Power input cable

⑤ Pulse ⑩ Sensor cables - 90m (300 ft) max length

Figure 5-2 Input Power Wiring

8. Plug power connector into jack.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 29

Page 30

$&

'&

Connecting

5.4 Transmitter power supply, communications and I/O connections

9. Tighten cable gland.

10.Connect the power cable to the appropriate power source (100-240 VAC @ 50/60 Hz or

11.5-28.5 VDC) and power up unit.

WARNING

Circuit limited to 15 Amps

The branch circuit must be limited to 15A or damage to the unit and death or serious injury

may result.

It is recommended that the circuit breaker be located near the transmitter.

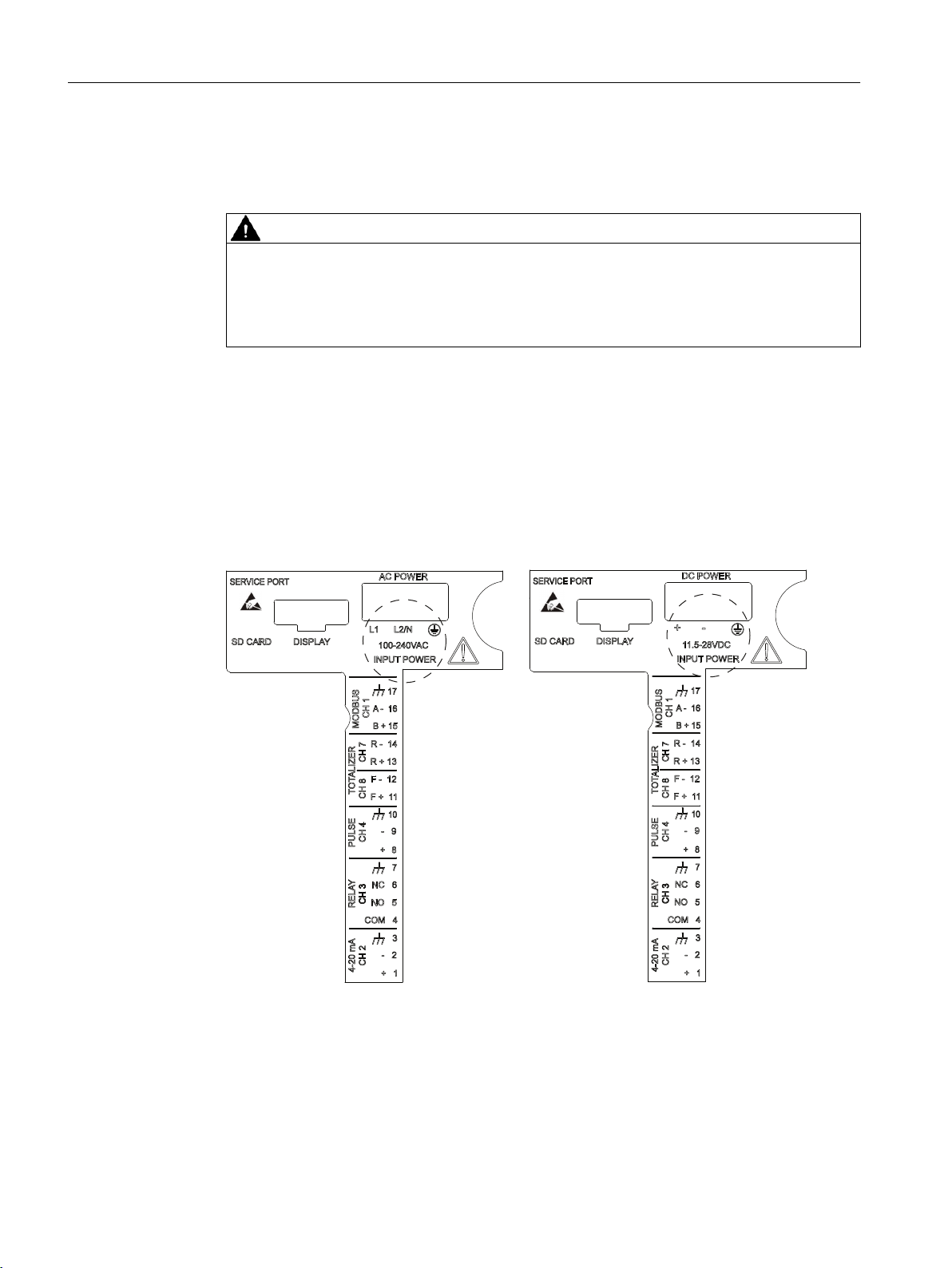

5.4.3 Connecting Inputs/Outputs

1. Remove blind plugs where required from the flowmeter case.

2. Loosen spring screws on housing lid.

3. Open housing lid.

A label showing the device configuration is placed on the PC board inside the transmitter

housing. It is either for AC or DC power depending on the flowmeter type.

Figure 5-3 Inside cover - AC and DC labels

FST020 IP65 NEMA 4X

30 Operating Instructions, 09/2017, A5E41425845-AB

Page 31

5.4.4 Connection Wiring

Terminal Block Wiring

These connection diagrams apply to the part numbers listed below.

FST020 7ME3570..._...

Figure 5-4 Terminal board channels and pin numbers

Note

4 to 20 mA current output Channel 2

Connecting

5.4 Transmitter power supply, communications and I/O connections

SITRANS FST020

It is not required to use shielded cables for the pure 4 to 20 mA current output.

Table 5-1 Input/Output Wiring

Pin# Signal Function Description

1 Io1+ Isolated Loop Supply Spannable 4-20mA output (Loop Powered) This

2 Io1- Isolated Loop Return

3 Chassis Ground Ground

4 C Common Relay Output

5 NO Normally Open Relay Output

6 NC Normally Closed Relay Output

7 Chassis Ground Ground

8 PULSE OUTPUT + Isolated Transistor Menu selection: PGEN, POS TOTAL, NEG TO‐

9 PULSE OUTPUT - Isolated Transistor

10 Chassis Ground Ground

11 NO TOT + DIGITAL INPUT + Stops Totalizer from incrementing.

12 NO TOT - DIGITAL INPUT 13 CLR TOT + DIGITAL INPUT + Clears Totalizer

14 CLR TOT - DIGITAL INPUT 15 Modbus_B Differential + Serial communication, Modbus protocol

16 Modbus _A Differential - Serial communication, Modbus protocol

17 Chassis Ground Ground

output also provides a fault indication by drop‐

ping to 2mA if assigned to flow rate and under

fault conditions.

TAL

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 31

Page 32

9

F

9

F

9

F

WRΩ

9

F

5

/

5

/

5

/

5

/

&

12

1&

,

21

PD[

P$

,

21

PLQ

PD[

P$

,

21

PLQ

PD[

P$

,21

PD[

P$

9

R

Ω

Ω

9'&

PD[

9'&

PD[

ื5/ื.വ

9

F

PD[ 9∗5

/

9& 9'&PD[

5

/

.PLQ

ื9

F

ื 9

%

$

9

FF

9

9

,+

9PLQ

9

,/

9PD[

9

LQ

PD[9WR9

5

/

9

F

Connecting

5.4 Transmitter power supply, communications and I/O connections

Wiring

① 4 - 20mA output (current source) ④ Digital input (Freeze TOT)

② Relay output ⑤ Digital input (CLR TOT)

③ Pulse output ⑥ Modbus

Isolated 4-20mA Output TB1-1/2

R = 250 Ω typical, 750 Ω maximum

Vc = 24 VDC typical / 30 VDC maximum

I = 4-20mA

RL = Loop wire resistance (both ways) plus User's input load resistance.

Figure 5-5 Typical FST020 Wiring

32 Operating Instructions, 09/2017, A5E41425845-AB

FST020 IP65 NEMA 4X

Page 33

5.4 Transmitter power supply, communications and I/O connections

Pulse output TB1-8 / TB1-9

V

= +30 VDC max.

c

RL = 3K Ω minimum

Digital Inputs TB1-11 / TB1-12 and TB1-13 / TB1-14

Vc = (10V + 0.02 x RL) max. 2 ≤ Vc ≤ 30 VDC

0 ≤ RL ≤ 1000 Ω

See also

Connecting Inputs/Outputs (Page 30)

5.4.5 Finishing the transmitter connection (wall mount housing)

Connecting

Connection check-up

1. Check individual wire and cable installations by tugging firmly.

2. Firmly tighten cable glands and insert blanking plugs in unused cable entries.

3. Close flowmeter cover.

4. Tighten the six cover securing spring screws.

Your device is now ready for commissioning.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 33

Page 34

Connecting

5.4 Transmitter power supply, communications and I/O connections

FST020 IP65 NEMA 4X

34 Operating Instructions, 09/2017, A5E41425845-AB

Page 35

Commissioning

This chapter gives instructions to commissioning your device, see Commissioning via local

display (Page 37).

Furthermore, the device can be commissioned using SIMATIC PDM, see Commissioning with

PDM (Page 175).

6.1 Basic Safety notes

CAUTION

Loss of type of protection

Damage to device if the enclosure is open or not properly closed. The type of protection

specified on the nameplate or in Technical data (Page 65) is no longer guaranteed.

● Make sure that the device is securely closed.

WARNING

6

Hot surfaces

Risk of burns resulting from hot surfaces.

● Take corresponding protective measures, for example by wearing protective gloves.

6.1.1 Hazardous contact voltage

WARNING

Hazardous contact voltage

May cause death or serious injury.

Risk of injury through hazardous contact voltage when the device is open or not completely

closed.

The degree of protection specified on the nameplate or in Technical data (Page 65)is no

longer guaranteed if the device is open or not properly closed.

● Make sure that the device is securely closed.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 35

Page 36

Commissioning

6.5 Initial startup

6.2 General requirements

Before commissioning it must be checked that:

● The device has been installed and connected in accordance with the guidelines provided

in Installing/mounting (Page 19) and Connecting (Page 25).

6.3 Power-up

Power up the device. Local display will show a screen for initial startup (Page 36).

6.4 Local display

The device is commissioned/operated with the touch keypad on the local display.

The graphic display above the keypad gives a menu-guided operation of the individual device

function/parameters. Successful operation of the key is confirmed by tactile feedback as key

is pressed.

① Full graphical display

② Touch keypad

Figure 6-1 Local display

Note

HMI timeout

If no key is pressed for 10 minutes, the display switches to show operation view. If Backlight

is set to Automatic, display backlight goes off automatically 30 seconds after the last key press.

6.5 Initial startup

The first time the device is powered up, you will be prompted to set the language. The device

always starts up showing "Language" in English. When the language has been set, you will

be prompted to set the date and time.

Before using the flow meter for the first time, essential parameters should be considered. After

confirming/changing date and time you can choose to accept the default values or start the

Quick commissioning wizard.

FST020 IP65 NEMA 4X

36 Operating Instructions, 09/2017, A5E41425845-AB

Page 37

Start

Language

Quick commissioning

Set date and time

No

Yes

Continue with Quick commissioning wizard

First startup wizard is now finished

Welcome

Commissioning

6.6 Commissioning via local display

You will be asked if you want to start the "Quick commissioning" wizard. If you choose "Yes"

(recommended), the "Quick commissioning" wizard will start. If you choose "No", you accept

the default values of the device, and the next HMI view will be the operation view 1.

6.6 Commissioning via local display

6.6.1 Chapter overview

Text Options/description

Language Set the language: English, Deutsch

Welcome Information about the "Quick commissioning" wizard

Set date and time The set date and time (real time clock) is used for all time stamps of logged

information.

Quick commissioning The "Quick commissioning" wizard comprises the most important param‐

eters/menus for quick configuration of the flowmeter.

In this chapter it is described how to commission the device via the local display using the

Quick commissioning wizard.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 37

Page 38

Start

Quick start

Quick commissioning

Sensor settings

Process values

Inputs and outputs

Copy configuration

Identification

Long tag

Location

Installation date

Next

Finished

Sensor settings

Process values

Inputs and outputs

Communication

Next

Basic configuration

Commissioning

6.6 Commissioning via local display

6.6.2 Wizards

6.6.2.1 Quick Commissioning wizard (menu item 1.1)

The Quick commissioning wizard will guide you through configuration of parameters essential

for your application. You configure parameters essential for your application by selecting the

configuration path and sub-wizards appropriate for your application.

6.6.2.2 Quick Commissioning wizard (wizard)

6.6.2.3 Sensor settings wizard (menu item 1.2)

38 Operating Instructions, 09/2017, A5E41425845-AB

Text Options/Description

Select a basic configura‐

tion wizard

Set the identification pa‐

rameters

Sensor settings, Process values, Inputs and outputs, Copy configuration

Long tag, Location, Installation date

The "Quick commissioning" wizard comprises the following subwizards:

● Sensor settings wizard (wizard) (Page 39)

● Process values wizard (wizard) (Page 44)

● Inputs/Outputs wizard (Page 45)

Each sub-wizard has its own view numbering. The sub-wizard name and the parameter name

are shown in the upper left corner of the display. The view number and the total views in the

sub-wizard are shown in the upper right corner of the display.

The Sensor settings wizard will guide you through configuration of essential parameters.

FST020 IP65 NEMA 4X

Page 39

6.6.2.4 Sensor settings wizard (wizard)

Pipe settings

Units settings

Sensor settings (1)

Yes

No

Units settings

Text Options/Description

Unit settings Select "Yes" to configure the display units.

Unit settings Set the display units of length, temperature, pressure, kinematic viscosity,

and density.

Commissioning

6.6 Commissioning via local display

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 39

Page 40

Pipe settings

Sensor settings (2)

Pipe class

Sensor settings

Pipe size

Outer diameter + wall thic kness

Circumference + wall thickness

Outer pipe diameter

Wall thickness

Custom

Custom

Liner

Wall sound velocity

Yes

No

Liner material

Liner settings

Yes

No

Pipe circumference

Inner pipe roughness

1)

Select material

Disturbed flow

Commissioning

6.6 Commissioning via local display

Text Options/Description

Pipe settings Select "Yes" to configure the pipe.

Pipe class Select the pipe class.

Pipe size Select the pips size from the options available for the selected pipe class.

Pipe circumference Enter pipe circumference. Only available if custom pipe class is selected.

Outer pipe diameter Enter outer pipe diameter. Only available if custom pipe class is selected.

Wall thickness Enter wall thickness. Only available if custom pipe class is selected.

Select material Select the pipe material.

Wall sound velocity Enter the wall sound velocity of the material. Only available if custom

material is selected.

40 Operating Instructions, 09/2017, A5E41425845-AB

FST020 IP65 NEMA 4X

Page 41

Medium settings

Yes

Sensor t ype

FSS200 high precision

FSS200 / 1011 universal

FSS200 / 991 high temperature

1011 high precision liquid

Sensor size

Sensor selection

Sensor settings

Sensor setting (3)

No

Sensor size

Commissioning

6.6 Commissioning via local display

Liner Select "Yes" to configure the liner material.

Select "No" to only configure the Inner pipe roughness.

Liner material Select the liner material.

Liner settings Set the liner sound velocity and thickness.

Disturbed flow Define the type of pipe configuration and the distance to the sensor.

Inner pipe roughness Set the inner pipe roughness.

* Select "Custom" to enter non-standard values.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 41

Text Options/Description

Sensor settings Select "Yes" to configure the sensors.

Sensor settings Select the sensor type installed (found on sensor label).

Sensor size Select the sensor size from the options list (found on sensor label).

Sensor selection Define the temperature compensation mode, the temperature class, the

spacing offset and the cable length

Page 42

Medium settings

Path settings

No

Process parameters

Sensor settings (4)

Yes

Medium settings

Custom

Commissioning

6.6 Commissioning via local display

Text Options/Description

Medium settings Select "Yes" to configure the medium.

Medium settings Select the process medium.

Process parameters Set the expected sound velocity (only available if custom process medium

is selected) and the process temperature, pressure, kinetic viscosity, and

density.

42 Operating Instructions, 09/2017, A5E41425845-AB

FST020 IP65 NEMA 4X

Page 43

Sensor settings (5)

Path settings

No

Yes

Installed paths

Save settings

Start measurement

Mounting path 1

Path 1

Path geometr y

*

**

Finished

Commissioning

6.6 Commissioning via local display

6.6.2.5 Process Values wizard (menu item 1.3)

Text Options/Description

Path settings Select "YES" to configure the path(s).

Installed paths Select the paths installed.

Save settings Moves to the next menu item.

Start measurement * for each installed path. Select the path to configure.

Path geometry Define the geometry of the path (direct or reflect mode)

Mounting path 1 Represents the spacing offset. Use Nom for most applications.

Path 1 Select "Receiver signal" to view graphical display of the receiver signal.

The Process values wizard will guide you through setup of process values for your application.

The prioritizing of the process values automatically configures the measurement views on the

display. The process value configured as first process value is set as first display view.

** Select "Next" to configure next path or to select "Next" to finish the

wizard.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 43

Page 44

1

2

3

Star t

Prioritize

1st process value

2st process value

3st process value

4st process value

5st process value

6st process value

Next

Quick start

Quick commissioning

Sensor settings

Process values

Inputs and outputs

Copy configuration

Totalizers

Totalizer

Totalizer

Process value

Mass flow

Volume flow

Standard volume flow*

Yes

No

Process value

Units

Direction

Fail-safe behavior

Next

Fail-safe behavior

Run

Hold

Memory

1st value

Volume flow

Mass flow

Flow velocity

Sound velocity

Density

Kinematic viscosity

Totalizer

Medium temperature

Units

process value

specific list

Finished

Units

Process value

specific list

Direction

Forward and backward

Forward

Backward

Hold

Activate totalizer view

Units

process value

specific list

Low flow cut-off

Next

Commissioning

6.6 Commissioning via local display

① Wizard name

② Step name / Parameter name

③ View number / Total views in wizard

6.6.2.6 Process values wizard (wizard)

44 Operating Instructions, 09/2017, A5E41425845-AB

FST020 IP65 NEMA 4X

Page 45

6.6.2.7 Inputs/Outputs wizard

The first screen in the Inputs and outputs wizard informs about the active/passive operation

availability. It shows the application possibilities of your hardware. The kind of operation

depends on the wiring.

The Inputs and outputs wizard will guide you through setup of inputs and outputs on the

available channels.

Channel 2 - output

Channel 3 - relay

Channel 4 -input/output

6.6.3 Navigating the menu structure

6.6.3.1 Chapter overview

Commissioning

6.6 Commissioning via local display

In this chapter it is described how to commission the device via the local display using the

Quick commissioning wizard.

6.6.3.2 Navigation view

The exact structure of the operating menu is explained in the Function Manual.

All items of the menu structure of the device are identified with a unique number.

Level 1 of the menu structure is standardized for all Siemens Process Instrumentation devices

and covers the following groups:

1. Quick start: Lists the most important parameters for quick configuration of the device. All

parameters in this view can be found elsewhere in the menu.

2. Setup: Contains all parameters which are needed to configure the device.

3. Maintenance and diagnostics: Contains parameters which affect the product behavior

regarding maintenance, diagnostics and service.

4. Communication: Contains parameters which describe the Modbus communication settings

of the device.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 45

Page 46

1

2

3

4

5

Commissioning

6.6 Commissioning via local display

5. Security: Contains parameters which describe all security settings of the device.

6. Language: Parameter for changing the language of the local display. Regardless of the

language setting, the term for this parameter is always the English term (Language).

① List of menu structure items

② Name of the previously selected item

③ Number of highlighted item

④ Alarm status text

⑤ Device status icon

Figure 6-2 Level 1 of the menu structure

6.6.3.3 Navigating the menu structure

You can navigate through the menu structure items in the device using the four buttons on the

display as described below.

Table 6-1 Key functions - menu structure navigation

Key Function

Return to previous item.

Select the item above.

Select the item below.

Enter the selected item.

46 Operating Instructions, 09/2017, A5E41425845-AB

FST020 IP65 NEMA 4X

Page 47

Operating

These Operating Instructions describe the operation via the local display (HMI). The device

can also be operated via various software.

7.1 Display views

There are six display views, all fully configurable. Use the and the keys to switch between

the operator views,

Four different types of views are available:

● Display of measured process values, see Reading the process values (Page 49).

● Display for totalizer operation, see Operating the totalizer (Page 51).

● Display of a list of active alarms, see Handling alarms (Page 52).

● Display of six configurable measurement/diagnostic values, see AUTOHOTSPOT.

7.2 Access control

7

You can view all items in the HMI menu but the parameters are protected against changes

through access level control. To gain access, select one of the following access levels:

● Read only

Allows no configuration. The parameter values can be viewed only (indicated by a

symbol). No PIN code required.

● User

Allows configuration and service of all parameters except calibration parameters. Default

PIN code is 2457.

● Expert

Allows configuration and service of all parameters including flow and calibration

parameters. Default PIN code is 2834.

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 47

Page 48

Operating

7.3 Operating the FST020

PIN codes can be changed in Security (5).

Note

Lost PIN code

If the PIN code is lost, provide Siemens customer support with the transmitter serial number

(see nameplate). Siemens customer support will provide a code to be entered in PIN

recovery (5.3).

Disable access level control

If logged in as Expert you can Deactivate user PIN. As User you will not be prompted to enter

the password. Enabling the access level control can be done in Activate user PIN and requires

entering the Expert password.

Auto logout function

You will not be prompted for password for 10 minutes after the last key press.

NOTICE

Device restart

Whenever the device is restarted, the access level is reset to Read only.

7.3 Operating the FST020

7.3.1 Fixed display texts

Some displayed texts are fixed, which means they will not change regardless of changed

display language.

The following tables list the fixed display texts and their corresponding process value,

diagnostic value, and compensation value names.

Table 7-1 Process values

Fixed display text Process value name

VOL.FLOW Volume flow

MASS FLOW Mass flow

FLOW VEL Flow velocity

SOUND VEL Sound velocity

DENSITY Density (Fixed value)

KIN. VISCOSITY Kinematic viscosity (Fixed value)

FST020 IP65 NEMA 4X

48 Operating Instructions, 09/2017, A5E41425845-AB

Page 49

Fixed display text Process value name

FLUID TEMP. Medium temperature (Fixed value

TOT1 Totalizer 1

Table 7-2 Diagnostic values

Fixed display text Diagnostic value name

TRN TEMP. Transmitter internal temperature

CURR. OUT (CH2) Ch2 value

REYNOLDS NO. Reynolds number

P1.SNR UP SNR up path 1

P1.SNR DOWN SNR down path 1

P1.SOUND VEL Sound velocity path 1

P1.DELTA TIME Delta time path 1

P1.ACC.BURST Path 1 percentage of bursts accepted

P1.PEAK AMP.DN Peak amplitude down path 1

P1.PEAK AMP.UP Peak amplitude up path 1

Operating

7.3 Operating the FST020

7.3.2 Reading the process values

The value of the process values can be displayed either as one or more numeric values or as

numeric value(s) in combination with a graph/bargraph. The following view types are available:

● Single value

● Three values

● Totalizer

● 1 value and graph

● 1 value and bargraph

● Six values

Table 7-3 Key functions - operator view

Key Function

No functionality

Go to the previous operator view

Go to the next operator view

Enter the menu structure access point

FST020 IP65 NEMA 4X

Operating Instructions, 09/2017, A5E41425845-AB 49

Page 50

)666

)666

)666

Operating

7.3 Operating the FST020

Single value

Three values

1 value and bargraph

Note

Bargraphs

The bargraph limit values indicate the set lower and upper alarm limits, and the vertical lines

in the bargraph indicate the set lower and upper warning limits.

1 value and graph

FST020 IP65 NEMA 4X

50 Operating Instructions, 09/2017, A5E41425845-AB

Page 51

Six values

7.3.3 Operating the totalizer

When totalizer is displayed in the main view, press to access the totalizer operation.

Operating

7.3 Operating the FST020

Table 7-4 Key functions - totalizer operation

Key Function

Exit totalizer operation

Select action to perform

Select action to perform

Perform selected action

FST020 IP65 NEMA 4X