Page 1

XG-V10WE

AN-SD1E/S422E

SERVICE MANUAL

SERVICE-ANLEITUNG

S00J4XG-V10WE

LCD PROJECTOR

LCD PROJEKTOR

XG-V10WE

MODEL

AN-SD1E

MODELL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

AN-S422E

SHARP CORPORATION

1

Page 2

XG-V10WE

AN-SD1E/S422E

• SPECIFICATIONS ............................................. 3

• NOTE TO SERVICE PERSONNEL ................... 4

• OPERATION MANUAL ...................................... 6

• REMOVING OF MAJOR PARTS ..................... 14

• RESETTING THE TOT AL LAMP TIMER ......... 19

• THE OPTICAL UNIT OUTLINE........................ 20

• CONVERGENCE AND

FOCUS ADJUSTMENT .................................. 21

• ELECTRICAL ADJUSTMENT.......................... 27

• ADJUSTING THE PC INTERFACE ................. 35

• TROUBLE SHOOTING TABLE ........................ 39

• CHASSIS LAYOUT .........................................118

• BLOCK DIAGRAM ......................................... 120

CONTENTS

Page Page

• OVERALL WIRING DIAGRAM ...................... 122

• DESCRIPTION OF SCHEMATIC DIAGRAM . 124

• WAVEFORMS ................................................ 125

• SCHEMATIC DIAGRAM ................................ 126

• PRINTED WIRING BOARD ASSEMBLIES ... 184

• PARTS LIST

Ë

ELECTRICAL PARTS............................... 197

Ë

CABINET AND MECHANICAL PARTS .... 231

Ë

ACCESSORIES PARTS ........................... 236

Ë

PACKING PARTS..................................... 236

• PACKING OF THE SET ................................. 237

• OPTIONAL BOARDS..................................... 238

Seite Seite

• TECHNISCHE DATEN..................................... 60

• HINWEISE FÜR DAS

WARTUNGSPERSONAL................................. 61

• BEDIENUNGSANLEITUNG............................. 63

• ENTFERNEN DER HAUPTTEILE ................... 71

• RÜCKSTELLEN DES LAMPEN-BETRIEBS-

ZEITZÄHLERS................................................. 76

• ÜBERSICHT DER OPTIKEINHEIT.................. 77

• EINSTELLUNG VON KONVERGENZ UND

BRENNPUNKT ................................................ 78

• ELEKTRISCHE EINSTELLUNG ...................... 84

• EINSTELLUNG DER PC-PLATINE.................. 92

• FEHLERSUCHTABELLE ................................. 96

• CHASSIS-ANORDNUNG ...............................118

INHAL T

• BLOCKSCHALTBILD ..................................... 120

• GESAMTSCHALTPLAN................................. 122

• BESCHREIBUNG DES SCHEMATISCHEN

• WELLENFORMEN......................................... 125

• SCHEMATISCHER SCHALTPLAN................ 126

• LEITERPLATTENEINHEITEN ....................... 184

• ERSATZTEILLISTE

• VERPACKEN DES GERÄTS ......................... 237

• WAHLWEISE PLATINE.................................. 238

SCHALTPLANS ............................................. 124

Ë

ELEKTRISCHE BAUTEILE ...................... 197

Ë

CEHÄUSE UND MECHANISCHE

BAUTEILE ................................................ 231

Ë

ZUBEHÖRTEILE...................................... 236

Ë

VERPACKUNGSTEILE ............................ 236

2

Page 3

Specifications

XG-V10WE

AN-SD1E/S422E

Product type

Model

Video system

Display method

LCD panel

Projection lamp

Contrast ratio

Video input signal

S-video input signal

Component input signal

Horizontal resolution

RGB input signal

Pixel clock

Vertical frequency

Horizontal frequency

Computer contr ol signal

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Power dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Laser pointer of remote control

Dimensions (approx.)

Weight (appr ox.)

Supplied accessories

Replacement parts

LCD Projector

XG-V10WE

PAL/PAL 60/PAL-M/PAL-N/SECAM/NTSC 3.58/NTSC 4.43

DTV 480i/480P/720P/1080i

LCD panel ✕ 3, RGB optical shutter method

Panel size: 46 mm (1.8") (28.7 [H] ✕ 35.8 [W] mm)

Display method: Translucent TN liquid crystal panel

Drive method: TFT (Thin Film Transistor) Active Matrix panel

No. of dots: 1,310,720 dots (1,280 [H] ✕ 1,024 [V])

200 W UHP lamp ✕ 2

400:1

BNC Connector: VIDEO (INPUT 4, 5), composite video, 1.0 Vp-p, sync negative, 75 Ω

terminated

RCA Connector: AUDIO (INPUT 4, 5), 0.5 Vrms more than 22 kΩ (stereo)

4-pin Mini DIN connector (INPUT 4, 5)

Y (luminance signal): 1.0 Vp-p, sync negative, 75 Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Ω terminated

BNC Connector (INPUT 2, 4, 5)

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

B

: 0.7 Vp-p, 75 Ω terminated

P

R

: 0.7 Vp-p, 75 Ω terminated

P

620 TV lines (video input), 720 TV lines (DTV 720P input, Dot by Dot)

PIN MINI

D-

15-

SUB CONNECTOR

RGB separate/composite sync/sync on gr een type analog input: 0

(INPUT 1), 5 BNC

CONNECTOR

(INPUT 2):

0.7 Vp-p, positive,

terminated

CONNECTOR

DVI

ORIZONTAL SYNC. SIGNAL

H

ERTICAL SYNC. SIGNAL

V

230 MHz

12

200 Hz

43

126 kHz

15

9-pin D-sub connector (RS-232C Input Port/Output Port)

5 ✕ 8 cm (1

AC 110

(29-

PIN

) (INPUT 3), RGB (DIGITAL), 250 1,000 mV, 50 Ω

: Same as above

31

32

" ✕ 3

120/220 240 V

: TTL level (positive/negative) or composite sync (Apple only)

5

32

") oval ✕ 2, 3 W + 3 W (stereo)

6.2 A/3.1 A

50/60 Hz

575 W

< 2,100 BTU/hour

C to + 40 C

++5

20

C to + 60 C

Plastic

38 kHz

Wave length: 650 nm / Max. output: 1 mW / Class II Laser Product

444.2 ✕ 196.2 ✕ 621.3 mm (W ✕ H ✕ D) (main body only)

530.1 ✕ 221.9 ✕ 643.2 mm (W ✕ H ✕ D) (including standar d lens, terminal cover,

adjustment feet and projecting par ts)

18.9 kg (main body only)

Remote control, Two AA size batteries, Power cord (1.8 m), RGB cable (3 m), PS/2 mouse

control cable (1 m), USB mouse control cable (1 m), Remote mouse receiver, Extra air

filter, Terminal cover, CD-ROM, LCD projector operation manual, LCD pr ojector quick

references, Sharp Advanced Presentation Software operation manual

Lamp unit (Lamp/cage module) (BQC-XGV10WU/1), Remote control (RRMCG1565CESA),

AA size batteries, Power cord, RGB cable (QCNW-5304CEZZ), PS/2 mouse control cable

(QCNW-5113CEZZ), USB mouse control cable (QCNW -5680CEZZ), Remote mouse

receiver (RUNTK0673CEZZ), Air filter (PFILD0110CEZZ), Terminal cover

(CCOVA1789CE01), CD-ROM (UDSKA0027CEN1), LCD projector operation manual (TINS6975CEZZ), LCD projector quick references (TINS-6981CEZZ, TINS-6982CEZZ, TINS6983CEZZ), Sharp Advanced Presentation Software operation manual (TINS-6993CEZZ)

This SHARP projector uses LCD (Liquid Crystal Display) panels. These

very sophisticated panels contain 1,310,720 pixels ( ✕ RGB) TFTs

(Thin Film Transistors). As with any high technology electr onic

equipment such as lar ge scr een TVs, video systems and video

cameras, there are certain acceptable tolerances that the equipment

must conform to.

Specifications are subject to change without notice.

This unit has some inactive TFTs within acceptable tolerances which

may result in illuminated or inactive dots on the pictur e screen. This

will not affect the picture quality or the life expectancy of the unit.

3

Page 4

XG-V10WE

5

4

AN-SD1E/S422E

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, UHP lamp, in the LCD projector

emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

234567890123456789012345678901212345678901234

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

CLMPF0064DE01/02 or BQC-XGV10WU/1 rated

100V/200W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

Since small amounts of UV-radiation are emitted from

an opening between the exhaust fans, it is recommended to place the cap of the optional lens on the

opening during servicing to avoid eye and skin ex-

posure (Fig. 1).

Note: Please obtain a lens cap before servicing a

model XG-V10WE that is received without

one.

LENS CAP

Figure 1.

4

Page 5

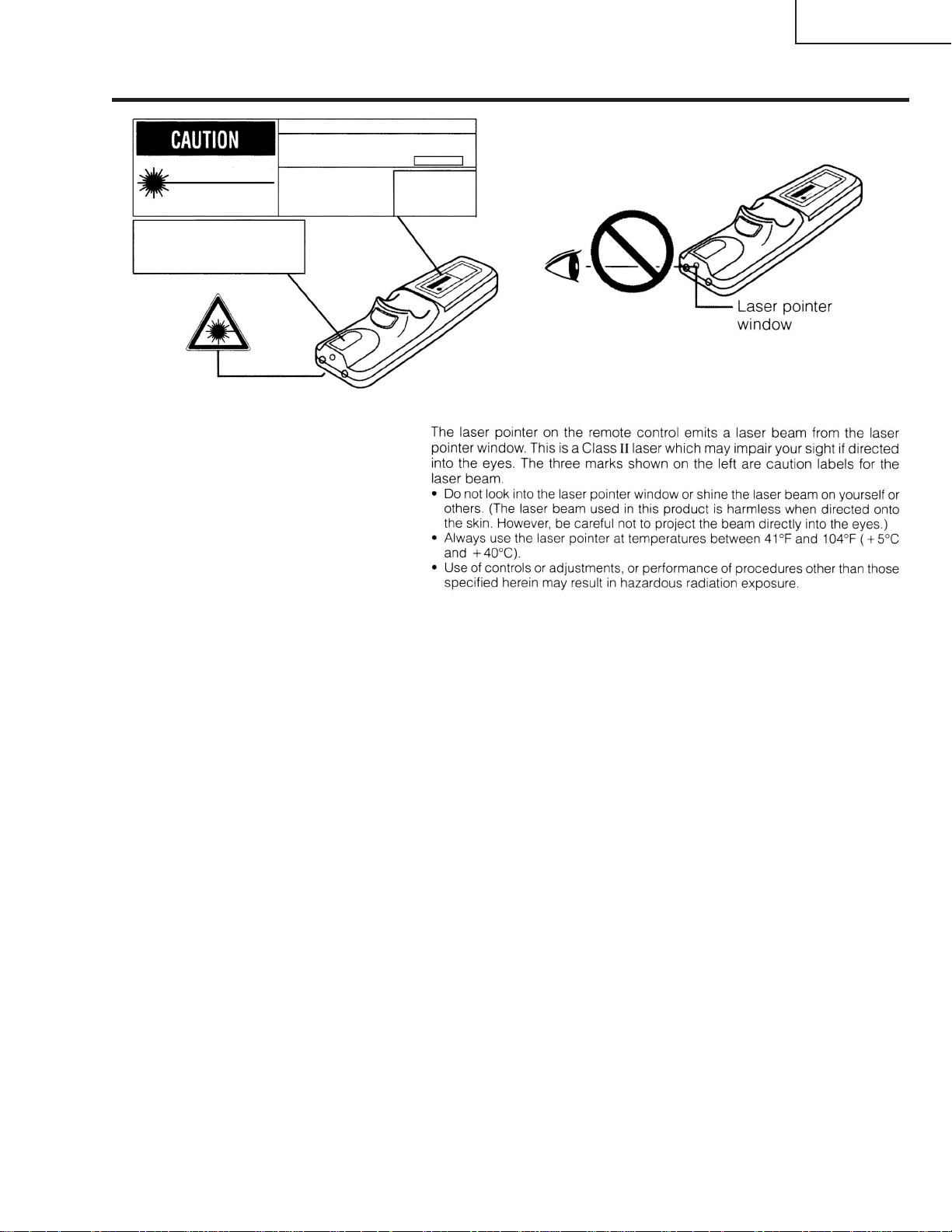

Cautions Concerning the Laser Pointer

"COMPLIES WITH 21 CFR SUBCHAPTER J"

SHARP ELECTRONICS CORPORATION

SHARP PLAZA, MAHWAH, NEW JERSEY 07430

TEL : 1-800-BE-SHARP

REMOTE CONTROL

MODEL NO. : RRMCG1564CESA

DC3V(1.5VX2PCS.)

MADE IN CHINA

FABRIQUÉ AU CHINE

LASER RADIATIONDO NOT STARE INTO BEAM

WAVE LENGTH : 650nm

MAX. OUTPUT : 1mW

CLASS II LASER PRODUCT

AVOID EXPOSURE-

LASER

RADIATION IS EMITTED

FROM THIS APERTURE.

U.S.A. ONLY

XG-V10WE

AN-SD1E/S422E

5

Page 6

XG-V10WE

AN-SD1E/S422E

Location of Controls

Projector

Front and Top View

MUTE button

POWER buttons (ON/OFF)

LENS button

ENTER button

INPUT 1, 2, 3 button

FREEZE button

ENLARGE button

UNDO button

VOLUME buttons (

MENU button

ADJUSTMENT buttons

(]/[/< /> )

INPUT 4, 5, 6 button

AUTO SYNC button

RESIZE button

GAMMA button

+ —

/)

Remote control sensor

Lens (sold separately)

Air filter (Intake vent)

Carrying handle

Adjuster

POWER indicator

LAMP 1 REPLACEMENT indicator

LAMP 2 REPLACEMENT indicator

TEMPERATURE WARNING indicator

6

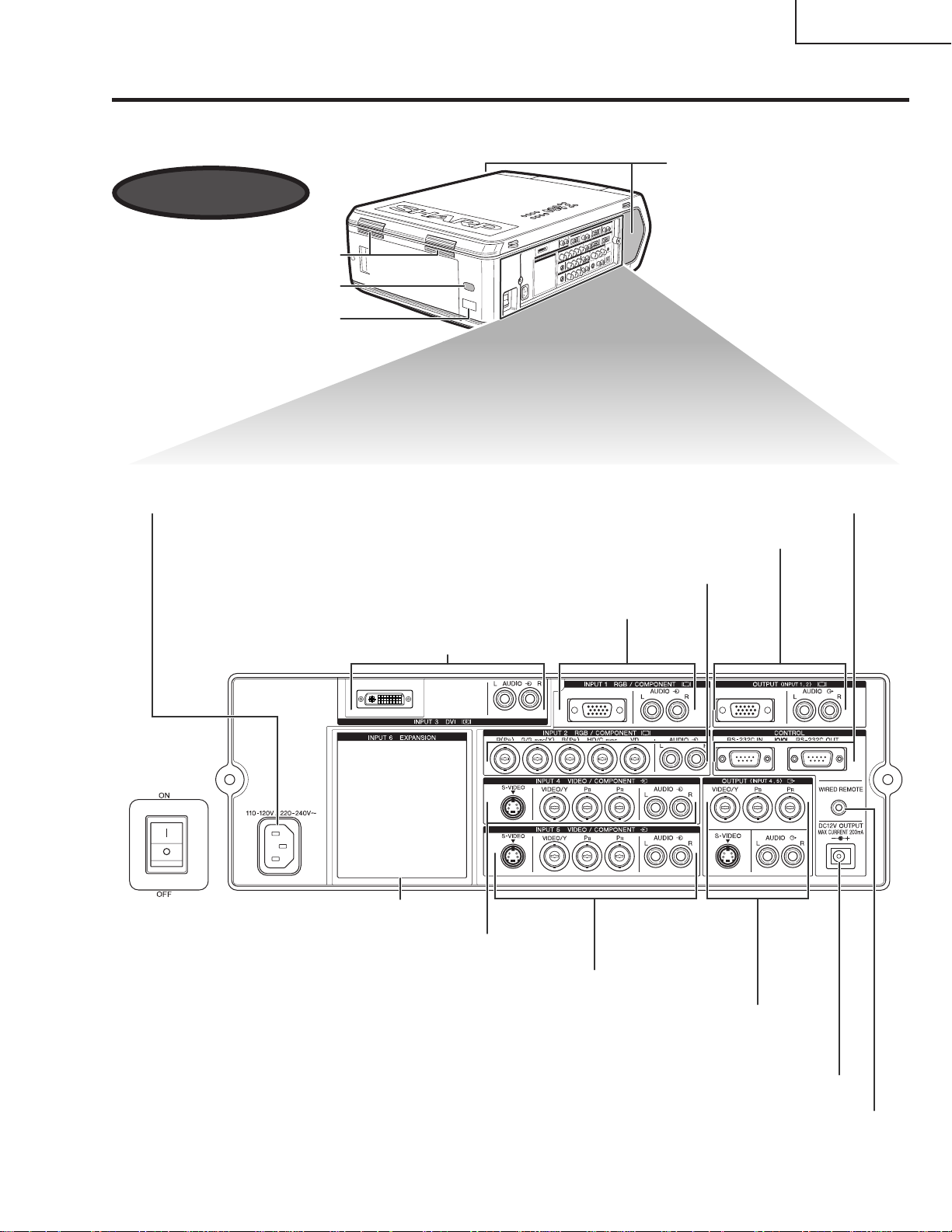

Page 7

Projector

Side and Rear View

Exhaust vent

Remote control sensor

LED display (ID No.)

XG-V10WE

AN-SD1E/S422E

Speakers

AC socket

RS-232C INPUT port

RS-232C OUTPUT port

OUTPUT port (15-pin Mini D-sub) for INPUT 1, 2/

AUDIO OUTPUT terminals for INPUT 1, 2

INPUT 2 terminals/AUDIO INPUT 2 terminals

INPUT 1 port (15-pin Mini D-sub)/

AUDIO INPUT 1 terminals

INPUT 3 port (DVI)/

AUDIO INPUT 3 terminals

INPUT 6 EXPANSION board

S-VIDEO INPUT 4 terminal (4-pin Mini DIN)/

INPUT 4 terminals/AUDIO INPUT 4 terminals

MAIN POWER switch

S-VIDEO INPUT 5 terminal (4-pin Mini DIN)/

INPUT 5 terminals/AUDIO INPUT 5 terminals

OUTPUT terminals for INPUT 4, 5/

S-VIDEO OUTPUT terminal for INPUT 4, 5 (4-pin Mini DIN)/

AUDIO OUTPUT terminals for INPUT 4, 5

DC 12V OUTPUT

WIRED REMOTE control input terminal

7

Page 8

XG-V10WE

AN-SD1E/S422E

Operating the Wireless Mouse Remote Control

Remote Control

Front View

MUTE button

POWER buttons

LENS/BLACK

SCREEN button

RIGHT-CLICK/

ENTER button

FREEZE button

ADJUSTMENT

(ON/OFF)

MOUSE/

switch

1.2.3 4.5.6

VOLUME buttons

(+/—)

LASER POINTER/

MENU button

MOUSE/

ADJUSTMENT

buttons (]/[ /</> )

INPUT 4, 5, 6 buttonINPUT 1, 2, 3 button

AUTO SYNC button

RESIZE buttonENLARGE button

GAMMA buttonTOOLS button

BACKLIGHT button

Top View

Remote control

signal transmitter

Laser

pointer

window

Rear View

LEFT-CLICK/

UNDO

button

Bottom View

Bottom View

Wired remote control

input

Inserting the batteries

Press in on the arrow

13

mark and slide in the

direction of the arrow to

remove the battery cover.

Battery

cover

Insert two AA size

2

batteries, making sure

the polarities match the

+ and – marks inside

the battery compartment.

Battery

compartment

Insert the side tabs of

the battery cover into the

slots and press the

cover in until it is

properly seated.

Battery

cover

8

Page 9

Using the Remote Control as aWireless Mouse

XG-V10WE

AN-SD1E/S422E

The remote control has the following three functions:

¥ Projector control

MOUSE/ADJUSTMENT switch

(Remote control)

¥ Wireless mouse

¥ Laser pointer

MOUSE

ADJ.

Wireless mouse/

Laser pointer

MOUSE

ADJ.

Projector control

Remote Control/Mouse Receiver Positioning

¥ The remote control can be used to control the projector within the ranges shown below.

¥ The remote mouse receiver can be used with the remote control to control the mouse functions of a connected

computer within the ranges shown below.

¥ The signal from the remote control can be reflected off a screen for easy operation. However, the effective distance of the

signal may differ due to the screen material.

Controling the Projector

Remote Control

30ß

7 m

30ß

45ß

Using the Wireless Mouse

Remote Control

30ß

45ß

30ß

Remote Control

30ß

120ß

4 m

Remote

mouse

receiver

9

Page 10

XG-V10WE

AN-SD1E/S422E

Use as a Wireless Mouse

Be sure the supplied remote mouse receiver is connected to your computer.

Slide the MOUSE/ADJUSTMENT switch to MOUSE.

MOUSE mode buttons

BLACK SCREEN

MOUSE

LASER

POINTER

LEFT-CLICK

RIGHT-CLICK

1.2.3 4.5.6

MOUSE/

ADJUSTMENT

MOUSE

ADJ.

switch

Conference Series

• For one-button mouse systems, use either the LEFT-CLICK or RIGHT-CLICK button.

• Press BACKLIGHT to turn on the backlights of the operation buttons for about five seconds.

Button name

LASER POINTER/MENU

BLACK SCREEN/LENS

RIGHT-CLICK/ENTER

MOUSE/ADJUSTMENT

LEFT-CLICK/UNDO

POWER ON/OFF

VOLUME +/–

MUTE

Position of MOUSE/ADJUSTMENT switch

LASER POINTER (GREEN)

BLACK SCREEN (GREEN)

RIGHT-CLICK (GREEN)

MOUSE (NOT LIT)

ON (NOT LIT)

MOUSE

ADJ.

MENU (RED)

LENS (RED)

ENTER (RED)

ADJUSTMENT (NOT LIT)

UNDO (NOT LIT)

ON (RED)

Button name

INPUT 1, 2, 3

INPUT 4, 5, 6

FREEZE

AUTO SYNC

ENLARGE

RESIZE

TOOLS

GAMMA

Position of MOUSE/ADJUSTMENT switch

ADJ. MOUSE

ON (RED)

10

Page 11

XG-V10WE

AN-SD1E/S422E

Use as a Laser Pointer

Slide the MOUSE/ADJUSTMENT switch to MOUSE, and press LASER POINTER ( ) to activate

the laser pointer.

LASER

POINTER

1.2.3 4.5.6

MOUSE

MOUSE/ADJUSTMENT

ADJ.

switch

Conference Series

• When the button is released, the light automatically goes off.

• For safety reasons, the laser pointer automatically goes off after 1 minute of continuous use. To turn it on, release LASER

POINTER ( ) and press again.

Wired Remote Control

When the remote control cannot be used due to the range

or positioning of the projector (rear projection, etc.), connect

3.5 mm stereo minijack cable

(sold separately)

a 3.5 mm stereo minijack cable (sold separately) from the

wired remote control input on the bottom of the remote

control to the WIRED REMOTE control input terminal on the

side of the projector.

• The laser pointer and wireless mouse functions can still be

operated wthe wired remote control.

11

Page 12

XG-V10WE

AN-SD1E/S422E

Connection Pin Assignments

INPUT 1 RGB and OUTPUT (INPUT 1, 2) Signal Input Ports:15-pin Mini D-sub female connector

5

10

15

1

6

11

RGB Input

Analog

1. Video input (red)

2. Video input

(green/sync on green)

3. Video input (blue)

4. Reserve input 1

5. Composite sync

6.Earth (red)

7.Earth (green/sync on gr

Component Input

Analog

1. P

R

(CR)

2. Y

3. P

B

(CB)

4. Not connected

5.Not connected

6.Earth (P

R

)

7.Earth (Y)

8.Earth (P

B

)

8.Earth (blue)

9.Not connected

10. GND

11. GND

12. Bi-directional data

13. Horizontal sync signal

14. Vertical sync signal

15.Data clock

9.Not connected

10. Not connected

11. Not connected

12. Not connected

13. Not connected

14. Not connected

15.Not connected

RS-232C Port: 9-pin D-sub male connector of the DIN-D-sub RS-232C cable

15

69

Pin No. Signal Name I/O Reference

1 CD Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 ER Not connected

5 SG Signal Ground Connected to internal circuit

6 DR Data Set Ready Output Not connected

7 RS Request to Send Output Connected to internal circuit

8 CS Clear to Send Input Connected to internal circuit

9 CI Not connected

DVI Port: 29-pin

Pin No. Name

1 T.M.D.S. Data 2—

2 T.M.D.S. Data 2+

C1 C2

91

16

8

C32417

C5

¥*1 Return for +5 V, Hsync. and Vsync.

2

¥*

Analog R, G and B return

3

These pins are not used on this equipment.

¥*

C4

3 T.M.D.S. Data 2/4 Shield

4 T.M.D.S. Data 4—*

5 T.M.D.S. Data 4+ *

6 DDC Clock

7 DDC Data

8 Analog Vertical Sync

9 T.M.D.S. Data 1—

10 T.M.D.S. Data 1+

11 T.M.D.S. Data 1/3 Shield

12 T.M.D.S. Data 3—*

13 T.M.D.S. Data 3+ *

14 +5 V Power

15 Ground*

1

16 Hot Plug Detect

17 T.M.D.S. Data 0—

18 T.M.D.S. Data 0—

19 T.M.D.S. Data 0/5 Shield

20 T.M.D.S. Data 5—*

21 T.M.D.S. Data 5+ *

22 T.M.D.S. Clock Shield

23 T.M.D.S. Clock+

24 T.M.D.S. Clock—

C1 Analog Red

C2 Analog Green

C3 Analog Blue

C4 Analog Horizontal sync

C5 Analog Ground*

3

3

3

3

3

3

2

12

Page 13

Dimensions

414.5

221.85

74.5

25.65 81.85 621.3

444.2

3.9

42

376

Rear View

Top View

Side View

Side View

Front View

Bottom View

Units: mm

XG-V10WE

AN-SD1E/S422E

13

Page 14

XG-V10WE

AN-SD1E/S422E

REMOVING OF MAJOR PARTS

1.Removing the intake cover, intake filter and lamp unit.

1-1. Detach the intake cover.

1-2. Detach the intake filter.

1-3. Loosen the lock screw from the lamp cover and slide the lamp cover off position.

1-4. Remove the three lock screws each from the lamp units 1 and 2, and detach these units.

Intake cover

1-3

Lamp cover

Lamp unit 1

1-4

1-4

Lamp unit 2

1-2

1-1

Intake filter

14

Page 15

XG-V10WE

AN-SD1E/S422E

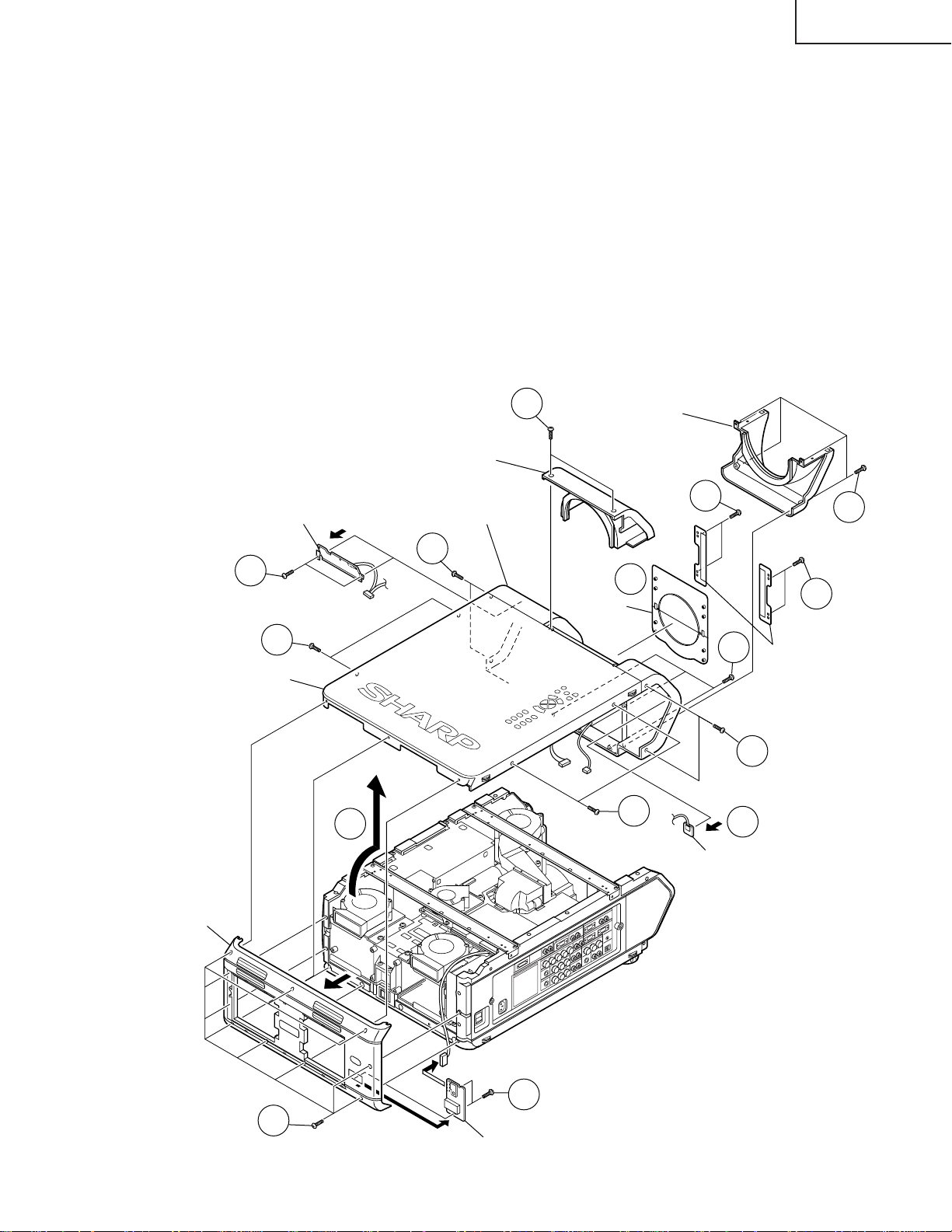

2.Removing the front, top and rear panels.

2-1. Remove the ten lock screws from the rear panel. Disconnect the connector (RD) of the remote control receiver

PWB unit 2. Then detach the rear panel.

2-2. Remove the two lock screws from the remote control receiver PWB unit 2. Detach the remote control receiver

PWB unit 2.

2-3. Remove the two lock screws from the lens cover (top) and detach the lens cover (top).

2-4. Remove the four lock screws from the lens cover (bottom) and detach the lens cover (bottom).

2-5. Remove the four lock screws from the shutter holder and detach the shutter holder.

2-6. Take out the shutter.

2-7. Remove the seven lock screws from the front panel.(Long size 2, Short size 5)

2-8. Remove the four lock screws from the top panel.

2-9. Slowly lift the back of the top panel. Disconnect the following connectors: connector (KY) of the operation

unit, connector (L) of the leaf switch, and connector (RE) of the LED PWB unit and remote control receiver

PWB unit 1. Lift and detach both the front and top panels.

2-10. Remove the two lock screws from the LED PWB unit. Detach the LED PWB unit.

2-11. Open the hooks of the remote control receiver PWB unit 1 and take out the remote control receiver PWB 1.

LED PWB unit

2-10

2-8

Top panel

Lens cover (top)

(RE)

2-9

Front panel

2-7

2-3

Lens cover (bottom)

2-6

Shutter

(KY)

(L)

2-8

2-5

2-7

2-11

2-4

2-5

Shutter holder

2-7

Rear panel

Remote control

receiver PWB unit 1

(RD)

2-2

2-1

Remote control receiver PWB unit 2

15

Page 16

XG-V10WE

AN-SD1E/S422E

3.Removing the reinforcing angles and intake fan duct assembly.

3-1. Remove the four lock screws from the front reinforcing angle and detach this angle.

3-2. Remove the four lock screws from the rear reinforcing angle and detach this angle.

3-3. Remove the five lock screws from the intake fan duct assembly and detach this assembly.

3-4. Remove the two lock screws from the intake cover and detach this cover.

3-1

Front reinforcing angle

3-1

Rear reinforcing angle

3-2

3-2

Intake cover

3-2

3-4

3-3

3-3

Intake fan duct assembly

3-3

16

Page 17

XG-V10WE

AN-SD1E/S422E

4.Removing the PWBs

4-1. Remove the two lock screws from the DVI connector.

4-2. Remove the five lock screws from the PC I/F PWB. Lift this PWB off the output PWB unit.

4-3. Remove the four lock screws from the cooling fan. Remove the lock screw from the output sub-PWB unit and

disconnect the connectors. Lift the cooling fan and the output sub-PWB unit off the output PWB unit.

4-4. Disconnect the connectors from the output PWB unit.

4-5. Remove the four stud bolts and eight lock screws from the output PWB unit. Lift and detach the output PWB

unit.

4-6. Disconnect the connector (SP) of the signal PWB unit.

4-7. Remove the eight lock screws from the side terminal board.

4-8. Remove the lock screw from the terminal cover and detach the terminal cover.

4-9. Remove the three lock screws from the grounding plate behind the terminal cover and detach the grounding

plate.

4-10. Detach the terminal board from the left-side panel. Lift the input PWB unit and the signal PWB unit off position.

Output

(F6)

(F8)

(S8)

(F7)

(TP)

(S7)

(GP)

(RP)

(BP)

(F5)

(KY)

sub-PWB

unit

(S5)

FRONT

(AZ)

(AS)

(F1)

(RE)

(L)

Cooling fan

Output sub-PWB unit

4-3

4-5

4-2

PC I/F PWB unit

4-5

4-4

(TOP VIEW)

(F4)

(S4)

(S3)

(F3)

(F2)

(RD)

(LL)

(EC)

(RL) (D) (EA)

Output

PWB unit

Output PWB unit

` Note: When reassembling, fit

the projection of the

terminal PWB shield in

the positioning hole of the

left-side panel.

4-5

4-5

4-5

4-1

`

4-8

Signal PWB unit

Input PWB unit

4-6

4-10

Left-side panel

4-7

4-9

4-7

17

Page 18

XG-V10WE

AN-SD1E/S422E

5.Removing the power/ballast PWB unit assembly.

5-1. Remove the lock screw from the socket holder (with shorter lead) for the lamp unit 1. Slide sideway and

detach the holder.

5-2. Remove the lock screw from the socket holder (with longer lead) for the lamp unit 2. Slide sideway and

detach the holder.

5-3. Disconnect the connectors from the power/ballast PWB unit assembly.

5-4. Remove the six lock screws from the power/ballast PWB unit assembly. Lift and detach this assembly.

6.Removing the inlet PWB unit assembly.

6-1. Remove the three lock screws from the left-side panel at the inlet PWB unit assembly.

6-2. Disconnect the connectors from the inlet PWB unit assembly.

6-3. Remove the two lock screws from the bottom panel at the inlet PWB unit assembly. Lift and detach this

assembly.

7.Removing the optical mechanism unit.

7-1. Remove the five lock screws from the lamp fan assembly.

7-2. Remove the seven lock screws

from the optical mechanism unit.

Lift and detach this unit.

5-1

5-3

(BB)

5-4

(EA)

Power/ballast PWB

unit assembly

(PL)

5-3

(F7)

7-1

Lamp fan assembly

Bottom panel

7-1

5-2

(F6)

7-2

7-1

Optical mechanism unit

Left-side panel

(EC)

6-3

6-2

6-1

(PA)

Inlet PWB unit assembly

18

Page 19

XG-V10WE

AN-SD1E/S422E

Resetting the TOTAL LAMP TIMER

Resetting the counter

» Draw out the lamp to be replaced. Turn on the power and the absence of the lamp is detected. Now reset the total

hour counter.

Resetting procedure

Replacing one lamp Replacing both lamps

1 Draw out the relevant lamp only. Draw out both the lamps.

2 Turn on the main power.

3 Press POWER button to LCD projector on.

4

5 Turn off the main power. Fit a new lamp into position.

» With just one of the lamps drawn out, the optical mechanism may get unstable in temperature. To avoid this,

the projector comes in the reset mode.

» For two or more projectors, their counters cannot be reset at once using the remote controller. Press the

ENTER key for resetting.

» In the process mode, the historical information is also reset.

The LED indicator at the drawn-out lamp side starts flashing.

Press the ENTER key to reset the counter. The LED indicator goes out.

End

Maintenance Indicator

TEMPERATURE

WARNING indicator

LAMP REPLACEMENT indicator

(LAMP1, LAMP2)

POWER indicator

Condition

The internal

temperature is

abnormally high.

The lamp does

not light up.

The POWER

indicator flashes

in red when the

projector is on.

Problem

· Blocked air intake.

· Clogged air filter.

· Cooling fan breakdown.

· Internal circuit failure.

· Burnt-out lamp.

· Lamp circuit failure.

· The filter cover is open.

· The lens cover is missing.

Possible Solution

· Relocate the projector to an area with

proper ventilation.

· Clean the filter.

· Take the projector to your nearest Authorized Sharp Industrial LCD Products

Dealer or Service Center for repair.

· Carefully replace the lamp.

· Take the projector to your nearest Authorized Sharp Industrial LCD Products

Dealer or Service Center for repair.

· Securely install the filter cover.

· Remove the top lens cover

(CCOVA1785CE01) off the front panel.

19

Page 20

XG-V10WE

AN-SD1E/S422E

THE OPTICAL UNIT OUTLINE

Layout of the optical system

Note: Layout for positioning the optical system.

★2 Output polarizer R

★2 Output polarizer G

Dichroic coating

(R transmission)

Dichroic coating

(G transmission)

AL-deposited face

Marking

★M2

Dichroic coating

UV absorbing glass

PBS aperture

Fly-eye lens

R-LCD

M5

L2(R)

AL-coated mirror R

RED

B/G reflector

G-LCD

Projection Lens

L2(G)

G/R Reflector

★M3

Marking

L1

Cross dichroic prism

AL-coated mirror B

G03

B-DF

GREEN

G01

PBS

(polarization beam splitter)

Marking

AL-deposited face

Dicroic coating

(B transmission)

Relay lens 1

★2 Output polarizer B

B-LCD

Input polarizer B

Relay lens 3

M6

AL-deposited face

Relay lens 2

G02

BLUE

M4

AL-coated mirror B

UHP lamp

(Light source)

Marking

★ M2 and M3 mirrors have a coat-

ing wedge (for different film thickness). Set up these mirrors, with

their markings positioned as

shown above, so that their

coated faces and both sides be

in the correct directions.

Prism array

★2 See the assemble-illustration

for determing a direction of

the output polarizer.

20

UHP lamp

(Light source)

UV-IR filter

Page 21

XG-V10WE

AN-SD1E/S422E

CONVERGENCE AND FOCUS ADJUSTMENT

» Place the set in the ceiling-mounted position, open the maintenance door, and start the

convergence and focus adjustments. Make sure the settings are complete and then turn

on the power. For adjusting the image, use the remote controller. Take the following

adjustment procedures.

1. Focusing the projection lens

(A) Replacing all the 3 LCD panels

1. Before replacing all the 3 LCD panels, project an image on the screen and bring it into focus.

2. Replace the panels with new ones. But until the focus has been completely readjusted, be careful not to

change the distance between the set and the screen, nor to move the projection lens focus and zoom

rings.

If the focus is readjusted with a different positional relation, the relation between the projection distance

and the screen size is affected. In other words, a short-distance image (40 WIDE, for example) may get

out of the focus range, or a long-distance image (300 WIDE, for example) may come out of focus.

(B) Replacing 1 or 2 of the 3 LCD panels

1. In adjusting the focus after replacement of one or two LCD panels, project an image on the screen and turn

the projection lens focus ring to get the non-replaced LCD panel into focus.

2. But until the focus has been completely adjusted for the new LCD panels, be careful not to change the

distance between the set and the screen, nor to move the projection lens focus and zoom rings.

(If the distance has been changed or the projection lens readjusted, repeat the above steps 1 and 2.)

2. Adjusting the G-LCD panel

(A) Focus adjustment. (Make this adjustment on the white-only screen.)

1. Right-and-left focus adjustment (θY direction) .

Loosen the lock screws "b" and "c" and insert the eccentric screwdriver into the notch and hole "b". Turn

the screwdriver until the right and left halves on the screen get into focus.

First get the right and left halves in balance. Then improve the accuracy while making the adjustment 2

below.

2. Top-center-bottom focus adjustment (θX and Z directions).

Loosen the lock screws "a" and "c" and insert the eccentric screwdriver into the notch and hole "a" or "c".

Turn the screwdriver until the top, center and bottom on the screen get into focus. In adjusting this top-tobottom focus, temporarily tighten the lock screw "b" to fix the θY direction adjustment.

3. Repeat the above steps 1 and 2 to finely adjust the focus. Finally tighten up all the lock screws.

Notes :

1 Carefully proceed with the focus adjustment because the adjusting directions are correlated.

2 In adjusting the convergence and focus, do not move the projection lens zoom and focus rings until the end

of all the adjustments.

(B) Convergence adjustment

» The G-LCD panel has no convergence adjustment mechanism. Use this panel as convergence adjustment

reference.

3. B-LCD panel adjustment (the same for the R-LCD panel)

(A) Focus adjustment

» T ake the same procedure as for the G-LCD panel focus adjustment. Note that the adjustment range is small

in the Z direction. If the convergence is quite different between the B-LCD and G-LCD panels, roughly adjust

the convergence first and then the focus.

(B) Convergence adjustment

» Use a crosshatch pattern signal for this adjustment.

Make the adjustment just for the G-color and the relevant color.

(1) Loosen the convergence lock screw "d".

(2) With the G-LCD panel’s screen center as reference, adjust the B-LCD panel in the X, Y and θZ directions.

(3) Finally tighten up the convergence lock screw "d".

21

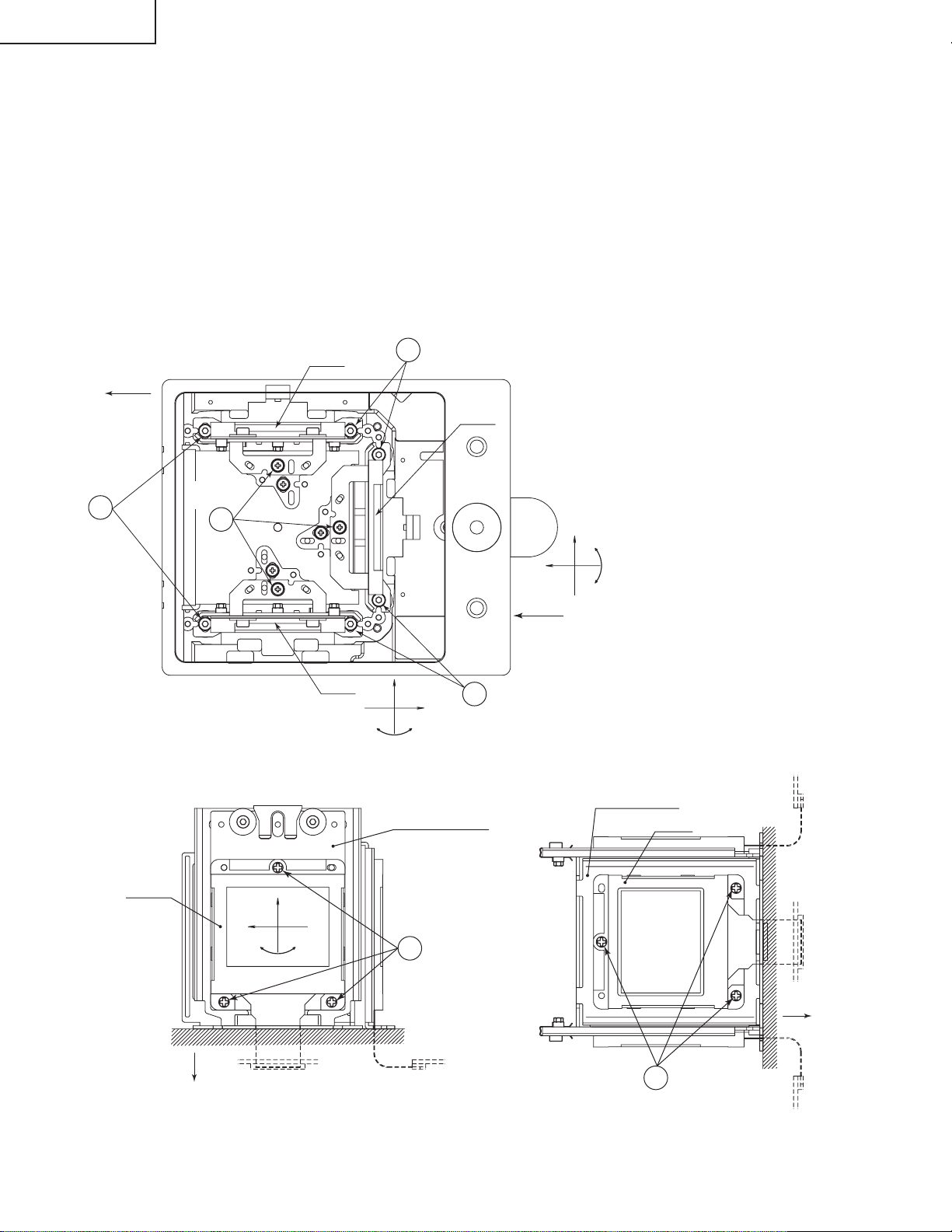

Page 22

XG-V10WE

AN-SD1E/S422E

Notes :

1 The eccentric cam is used for convergence adjustment. This means that the cam’s turning and the linear

movement are not always uniform.

2 This model is not equipped with the LCD image adjustment mechanism. This is because the dichroic prism

is used for image formation. When the LCD panels all get into the best focus, the images are almost

completely converged.

Convergence and Focus Adjustments Mechanism

BOTT OM VIEW SIDE VIEW

FRONT

Lock screw "a"

Notch and hole "a"

SIDE VIEW (from outside) SIDE VIEW (from inside)

R-LCD

B-LCD

Lock screw "c"

Notch and hole "c"

θ

X

G-LCD panel

mounting screws

G-LCD

Notch and hole "b"

Lock screw "b"

X

Y

Z

Notch and hole "c"

Z

θ

Y

Lock screw "c"

X

θ

Eccentric cam

Y

Z

TOP

G-LCD

G adjusting plate

RáB-LCD

TOP

Lock screw "d"

Y

X

θ

Z

(convergence

adjustment)

RáB-LCD panel

mounting screws

22

Page 23

Convergence and Focus Adjustments at a Glance

2

5

16

R2

50

CUT

Adjustment directions

Adjustment Direction Definition Direction of LCD panel

X direction LCD right and left

Convergence Y direction LCD top and bottom

θZ direction Rotation around Z axis LCD turning axis

Z direction LCD optical axis

Focus θX direction Rotation around X axis LCD top-to-bottom flapping

θY direction Rotation around Y axis LCD right-to-left flapping

Convergence and Focus Adjustment for the Optical Mechanism

XG-V10WE

AN-SD1E/S422E

Color Adjustment Direction

X direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

Convergence Y direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

R/B θZ direction ±1° Eccentric cam Eccentric cam adjusting wrench d Hex wrench

colors Z direction ±1.3mm

Focus θX direction ±1°

θY direction ±2.5°

Z direction ±0.4mm

G color Focus θX direction ±1° Same as for R and B colors

θY direction ±2.5°

Movement

Position Adjusting tool

Notch and hole "a" & "c"

Notch and hole "a" & "c"

Notch and hole "b" & "c"

Eccentric screwdriver a, c

Lock screw

a, c

b, c

Tightening tool

Phillips

screwdriver,

*Hex wrench

Focus Adjustments the Other Way

Lock screw Position Related direction

a Notch and hole "a" Z and θX directions

b Notch and hole "b" θY direction

c Notch and hole "c" Z, θX and θY directions

Convergence and Focus Adjusting and Tightening Tools

Tool Specific or General Tool code Configuration

Eccentric cam Specific 9DASPN-XGNV1U

adjusting wrench

80

Eccentric screwdriver Specific 9EQDRiVER-NV1A

100

Hex wrench General (redesigned) 9EQLNC-XGNV1U

Phillips screwdriver General — For M2.6 pan-head machine screw

*Hex wrench General —

23

Preferably use a 70 mm or longer

screwdriver (with a handle).

Page 24

XG-V10WE

AN-SD1E/S422E

Replacing the LCDs

Remove the top cover.

(1)Remove the six screws off the relay duct and disconnect the relay duct.

(2)Remove the two screws off the upper suction cover and detach this cover.

(3)Disconnect the LCD flat cable from the PWB connector.

(4)Place the set in the ceiling-mounted position and open the maintenance door.

(5)Remove the lock screws "b" and "c". Take out the LCD-equipped R/B adjusting board and G adjusting board.

(6)Detach the LCD panel from the adjusting board.

(7)Place a replacement LCD panel and take the above steps (1) thru (5) in the reverse order.

~ Keep in mind that the G LCD panel does not need convergence readjustment and that it has a small adjustable

range in the Z direction.

BOTT OM VIEW

Lock

R-LCD

FRONT

5

screws "c"

G-LCD

Lock

5

Lock

screws "c"

screws "b"

5

B-LCD

Z

X

θY

5

Lock

screws "c"

SIDE VIEW SIDE VIEW

R·B adjusting plate

R·B-LCD

Y

X

X

Z

`

G adjusting plate

θY

G-LCD

TOP

θZ

6

R·B-LCD panel

mounting screws

G-LCD panel

6

mounting screws

TOP

24

Page 25

XG-V10WE

AN-SD1E/S422E

1. Adjusting the mirror optical axis

The optical axis must be readjusted to correct possible eclipse that occurs with the R, G or B LCD panel.

This readjustment is usually required when an optical part in the optical mechanism has been replaced,

and may be needed when a LCD panel has been replaced.

1. Disconnect the LCD flat cable.

2. Get the lamp on. Be sure to start the cooling fan too.

(Eclipse with the R LCD panel: Screen edges appearing in cyan)

3. Loosen the lock screws of the M5 adjusting lever.

4. Watching the image on the screen, turn or slide the M5 adjusting lever until the eclipse disappears from the

screen. Now tighten up the lock screws.

(Eclipse with the G LCD panel: Screen edges appearing in magenta)

3. Loosen the lock screws of the M3 adjusting lever.

4. Watching the image on the screen, turn or slide the M3 adjusting lever until the eclipse disappears from the

screen. Now tighten up the lock screws.

(Eclipse with the B LCD panel: Screen edges appearing in yellow)

3. Loosen the lock screws of the M6 adjusting lever.

4. Watching the image on the screen, turn or slide the M6 adjusting lever until the eclipse disappears from the

screen. Now tighten up the lock screws.

2. Adjusting the orientation of polarizer

The contrast must be optimized when the polarizer or an optical mechanism part has been replaced.

1. Turn on the power.

2. If the background is blue, clear the screen and get it black.

3. Loosen the two lock screws of the polarizer (two for each plate).

4. Press the heads of the lock screws in the arrow directions until the onscreen contrast becomes best. Finally

tighten up the lock screws.

3. Adjusting the PBS

This adjustment may be required when the optical mechanism has been disassembled. Colors uneven

on the right and left halves onscreen can be corrected here. Usually there is no need to make this adjustment. It is enough to have the lamp adjusting groove in alignment.

1. Turn on the power.

2. Loosen the PBS lock screw.

3. Feed a white-only signal, or call the process mode and get the screen white only.

4. Put the eccentric screwdriver (9EQDRiVER-NV1A) in the PBS adjusting groove.

5. Watching the image on the screen, turn the eccentric screwdriver until the right-and-left colors onscreen

become most even. Finally tighten up the lock screw.

4. Adjusting the lamp optical axis

The lamp optical axis is optimized to obtain the best color evenness and brightness. Usually there is no

need to make this adjustment because the replacement lamp unit (BQC-XGV10WU/1) has been delivered

factory-adjusted.

1. Turn on the power.

2. Loosen the three lamp lock screws.

3. Feed a white-only signal, or call the process mode and get the screen white only.

4. Put the eccentric screwdriver (9EQDRiVER-NV1A) in the lamp adjusting groove.

5. Watching the image on the screen, turn the eccentric screwdriver until the right-and-left colors onscreen

become most even. Finally tighten up the lock screws.

25

Page 26

XG-V10WE

AN-SD1E/S422E

Mirror adjusting

lever lock screws

PBS lock screw

PBS adjusting groove

Lamp adjusting groove

4

1

M5 adjusting lever

R

2

G

M3 adjusting lever

4

1

M6 adjusting lever

Mirror adjusting

lever lock screws

B

1

Mirror adjusting lever

lock screws

Lamp adjusting groove

3

Lamp lock screws

Lamp lock screws

26

Page 27

XG-V10WE

AN-SD1E/S422E

ELECTRICAL ADJUSTMENT

Hook up a signal generator, or a DOSV or Mac personal computer to the projector in order to feed the

signals specified in the Adjusting conditions.

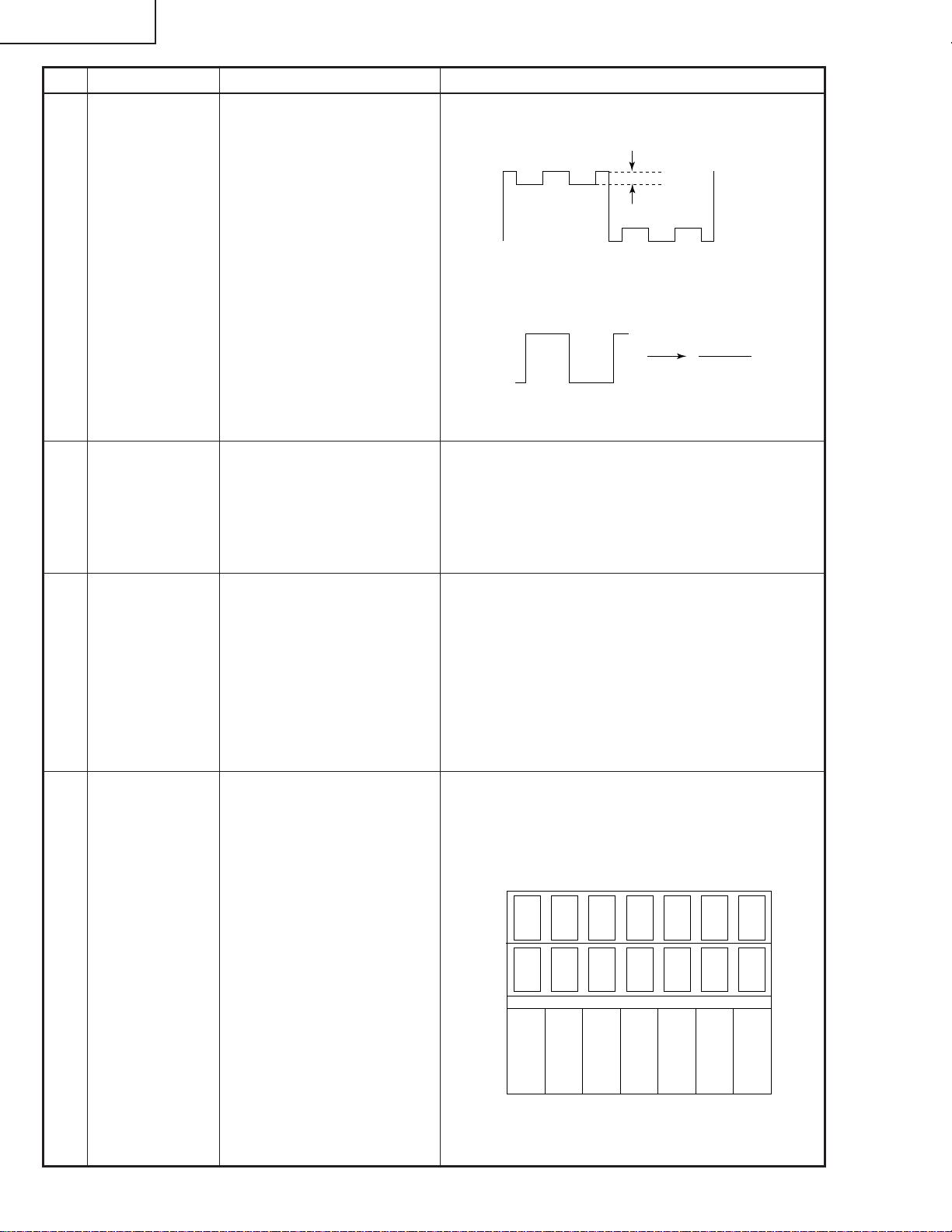

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

1. Turn on the power (with the

lamp on) and warm up the

set for 15 minutes.

» Make the following settings.

Press S2601 to call the process mode. Execute

the S2 and S4 commands on the SSS menu. With

the S2 command, all but the PC boards will be

initialized. Do not execute the S1 command

because this will get the PC boards initialized. To

readjust the PC boards, refer to "Adjusting the PC

interface" on page 35.

2 RGB drive

adjustment

3 RGB1 system

black level

signal amplitude

adjustment

1. Feed the 100% white sig-

nal.

2. Select the following group

and subjects.

Group : A/D

Subject : R-D (R)

G-D (G)

B-D (B)

1. Select the following group

and subjects.

Group : OUTPUT1

Subject : G1-BLK

G1-GAIN

For the R and B colours,

choose the following respective subjects.

R1-BLK and R1-GAIN for R

B1-BLK and B1-GAIN for B

2. Make sure the process adjustment colour bars are being displayed.

3. Connect the oscilloscope to

pin (3) (for G) of P1001.

4. Similarly connect the oscilloscope to the following for

the R and B colours.

Pin (1) of P1001 for R

Pin (5) of P1001 for B

» Using the set's control switch or the remote

controller's button, adjust the settings so that there

be some bit dropouts.

» Select G1-GAIN. Using the set's control switch or

the remote controller’s button, adjust the setting so

that the signal amplitude be 3.7 ± 0.05 Vp-p.

» Select G1-BLK. Using the set’s control switch or

the remote controller’s button, adjust the setting so

that the white to white level be 2.4 ± 0.05 Vp-p.

» Do the same for the R and B colours.

2.4Vp-p

3.7Vp-p

`The G1 settings affect all the R, G and B signals

at the same time. When the G1-BLK setting has

been changed, therefore, the R1-BLK and B1-BLK

settings are accordingly modified. Also with a

change in the G1-GAIN setting, the R1-GAIN and

B1-GAIN settings are accordingly modified. In

other words, adjust the G settings first and then

the R as well as B settings.

27

Page 28

XG-V10WE

AN-SD1E/S422E

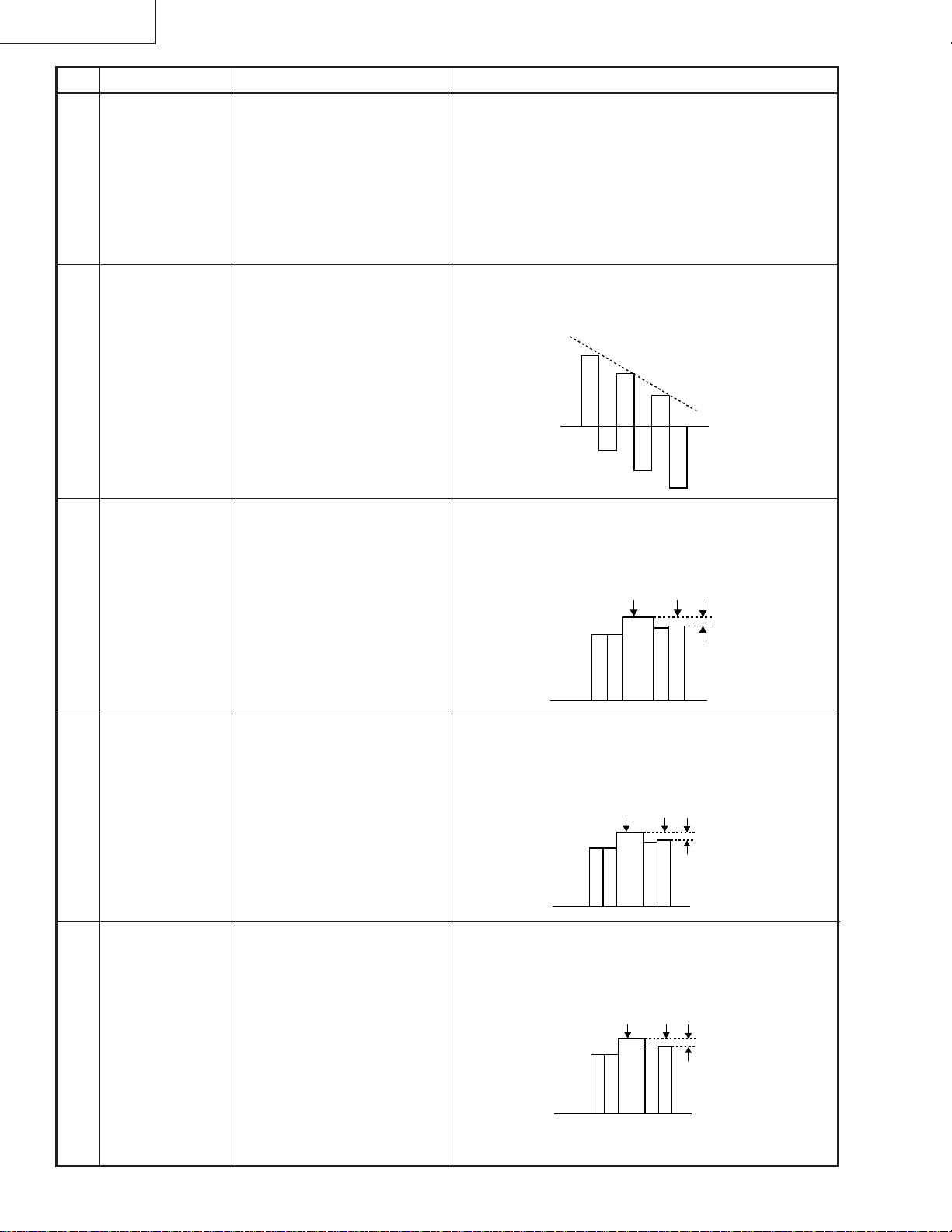

No. Adjusting point Adjusting conditions Adjusting procedure

4 RGB2 system

black level

signal amplitude

adjustment

5 Sample hold

pulse phase

checking

1. Select the following group

and subjects.

Group : OUTPUT2

Subject : R2-GAIN

R2-BLK

For the G and B colours,

choose the following respective subjects.

G2-GAIN and G2-BLK for G

B2-GAIN and B2-BLK for B

2. Connect the oscilloscope to

pin (2) (for R) of P1001.

3. Similarly connect the oscilloscope to the following for

the G and B colours.

Pin (4) of P1001 for G

Pin (6) of P1001 for B

1. Feed the SXGA-mode, 75-

Hz black signal.

2. Select the following group

and subject.

Group : OUTPUT3

Subject : SH-PHASE

» Select R2-GAIN. Adjust the setting so that the

signal component has the minimum amplitude.

» Select R2-BLK. Adjust the setting so that the wave-

form becomes a straight horizontal line.

Adjusted to

» Using the set's control switch or the remote

controller’s button, make sure the characters

OUTPUT3 are not blurry with no ghost image on

the screen. If anything blurry or a ghost image

appears onscreen, readjust the setting in the

range of 7-9.

6 RGB

countervoltage

adjustment

7 RGB tone

reproduction

adjustment

1. Feed the SXGA-mode, 60-

Hz, countervoltage adjustment signal.

2. Select the following group

and subjects.

Group : OUTPUT3

Subject : RC (R)

GC (G)

BC (B)

1. Feed the Infocom

Grayscale & Colour

Pattern signal.

2. Select the following group

and subject.

Group : OUTPUT1

Subject : G1-BLK

» Using the set's control switch or the remote

controller’s button, adjust the setting so that the

flickering be minimum.

» If there is a difference between the center and

both sides on the screen, adjust the setting to get

both sides equal to each other.

» Make sure the grayscale, shown below, is visible

up to the tone 251 (white) as well as down to the

tone 8 (black).

» If the white tone is out of spec, finely adjust the

G1-BLK setting.

4

812

249 251

28

Page 29

No. Adjusting point Adjusting conditions Adjusting procedure

XG-V10WE

AN-SD1E/S422E

8 RGB white

balance adjustment

9 Video horizontal

center adjustment

DLY checking

10 Video picture

adjustment

1. Feed the 32-step grayscale

signal. (SXGA, 60 Hz)

2. Select the following group

and subjects.

Group : OUTPUT1

Subject : R1-BLK (R)

B1-BLK (B)

1. Feed the NTSC

monoscope pattern signal.

2. Group : VIDEO 2

Subject : N358-DLY (2)

N443-DLY (0)

PAL-DLY (0)

SECAM-DLY(0)

Make sure the settings are

as above.

3. Then select the following

group and subject.

Group : VIDEO1

Subject : NTSC-H

1. Feed the split colour bar

signal.

2. Select the following group

and subject.

Group : VIDEO1

Subject : PICTURE

3. Connect the oscilloscope

between pin (1) of P801

and GND.

» Adjust the R1-BLK and B1-BLK settings to get the

tone balance to optimum.

» Using the set's control switch or the remote con-

troller’s button, adjust the setting so that the

overscan be the same at right and left.

» Using the set’s control switch or the remote con-

troller’s button, adjust the setting so that the amplitude between the black and 100% white levels be

2.3 ± 0.02 Vp-p.

2.3Vp-p

11 Video offset

adjustment

1. Feed the colour bar signal

with base band. (ON-AIR

not allowed because of its

too much noise.)

2. Select the following group

and subjects.

Group : VIDEO2

Subject : VROS (R)

VGOS (G)

VBOS (B)

Make sure there are some

bit dropouts on the screen.

If not, press the set’s control switch or the remote

controller’s mute button.

(Gamma correction is now

set for the adjustment process.)

» Using the set's control switch or the remote con-

troller’s button, adjust the settings so that the black

signal has some bit dropouts.

29

Page 30

XG-V10WE

100% White Red

100% White Red

100% White Red

AN-SD1E/S422E

No. Adjusting point Adjusting conditions Adjusting procedure

12 Video AGC

adjustment

13 Video tint

adjustment

14 NTSC colour

saturation

adjustment

1. Feed the split colour bar

signal.

2. Select the following group

and subject.

Group : VIDEO1

Subject : AGC

Make sure there are some

bit dropouts on the screen.

1. Feed the split colour bar

signal. Select the following

group and subject.

Group : VIDEO1

Subject : TINT

2. Connect the oscilloscope to

pin (4) of P801.

1. Feed the split colour bar

signal.

2. Select the following group

and subject.

Group : VIDEO1

Subject : N-COLOUR

3. Connect the oscilloscope to

pin (1) of P801.

» Using the set’s control switch or the remote

controller’s button, adjust the setting so that the

100% white signal has some bit-less.

» Using the set's control switch or the remote

controller's button, adjust the setting so that the –

(B–Y) waveform runs straight downhill.

» Using the set’s control switch or the remote

controller’s button, adjust the setting so that the

amplitude between the 100% white and red levels

be 0.20 ± 0.02 Vp-p.

15 PAL colour

saturation

adjustment

16 SECAM colour

saturation

adjustment

1. Feed the PAL colour bar

signal.

2. Select the following group

and subject.

Group : VIDEO1

Subject : P-COLOUR

3. Connect the oscilloscope to

pin (1) of P801.

1. Feed the SECAM colour

bar signal.

2. Select the following group

and subject.

Group : VIDEO1

Subject : S-COLOUR

3. Connect the oscilloscope to

pin (1) of P801.

» Using the set's control switch or the remote

controller’s button, adjust the setting so that the

amplitude between the 100% white and red levels

be 0.36 ± 0.02 Vp-p.

» Using the set's control switch or the remote

controller’s button, adjust the setting so that the

amplitude between the 100% white and red levels

be 0.50 ± 0.02 Vp-p.

30

Page 31

No. Adjusting point Adjusting conditions Adjusting procedure

XG-V10WE

AN-SD1E/S422E

17 Video input

panel signal

amplitude

adjustment

18 Video white

balance adjustment

19 DVD contrast

adjustment

1. Feed the NTSC 10-step

signal.

2. Select the following group

and subjects.

Group : VIDEO2

Subject : R1-GAIN

B1-GAIN

3. Connect the oscilloscope to

pin (1) (for R) of P1001 and

pin (3) (for G) of P1001.

4. Similarly connect the oscilloscope to the following for

the B colour.

Pin (5) of P1001 for B

Pin (3) of P1001 for G

1. Feed the NTSC

monoscope pattern signal.

2. Select the following group

and subjects.

Group : VIDEO2

Subject : R1-BLK

B1-BLK

1. Feed the 100% colour bar

signal of the 480I component signal to the G (Y) input terminal on the BNC

socket.

2. Select the following group

and subject.

Group : DVD

Subject : CONTRAST

» Select R1-GAIN. Adjust the setting so that the R

signal amplitude and the G signal amplitude be

the same.

» Do the same for the B colour.

» Using the set's control switch or the remote

controller's button, adjust the setting so that the

white balance be the same as on the monitor

screen.

» Using the set's control switch or the remote

controller's button, adjust the setting so that the

100% white signal has some bit dropouts.

20 DVD tint adjust-

ment

1. Feed the 100% colour bar

signal of the 480I component signal to the Y, Pb and

Pr input terminals on the

BNC socket. For the Y signal, feed the sync signal

only.

2. Select the following group

and subject.

Group : DVD

Subject : TINT

3. Connect the oscilloscope to

pin (2) of P801.

» Using the set's control switch or the remote

controller’s button, adjust the setting so that the

(B–Y) waveform runs straight uphill.

31

Page 32

XG-V10WE

100% White Red

AN-SD1E/S422E

No. Adjusting point Adjusting conditions Adjusting procedure

21 DVD colour

saturation

adjustment

22 DVD input panel

signal amplitude

adjustment

1. Feed the 100% colour bar

signal of the 480I component signal to the Y, Pb and

Pr input terminals on the

BNC socket.

2. Select the following group

and subject.

Group : DVD

Subject : COLOUR

3. Connect the oscilloscope to

pin (1) of P801.

1. Feed the 10-step signal to

the G (Y) input terminal on

the BNC socket.

2. Select the following group

and subjects.

Group : DVD

Subject : R1-GAIN

B1-GAIN

3. Connect the oscilloscope to

pin (1) (for R) of P1001 and

pin (3) (for G) of P1001.

4. Similarly connect the oscilloscope to the following for

the B colour.

Pin (5) of P1001 for B

Pin (3) of P1001 for G

» Using the set’s control switch or the remote

controller’s button, adjust the setting so that the

amplitude between the 100% white and red levels

be 0.10 ± 0.02 Vp-p.

» Select R1-GAIN. Adjust the setting so that the R

signal amplitude and the G signal amplitude be

the same.

» Do the same for the B colour.

23 DVD white

balance checking

24 Saw-tooth wave

correction (G),

(R)

1. Feed the NTSC

monoscope pattern signal

to the G (Y) input terminal

on the BNC socket.

2. Select the following group

and subjects.

Group : DVD

Subject : R1-BLK

B1-BLK

Make sure the lamp optical

axis has been already adjusted.

1. Feed the SXGA, 60-Hz

gray-only signal.

2. Check for uneven colour

spot on the screen.

3. Select the following group

and subject.

Group : NOKO

Subject : NOKO-G

Choose the subject NOKOR for the R colour.

» Make sure the white balance is the same as on

the monitor screen.

» If not, adjust the setting so that the white balance

be the same as on the monitor screen, using the

set's control switch or the remote controller's

button.

» When the green colour is found not uneven, turn

off the saw-tooth wave correction with S4201.

» Select NOKO-G and adjust the setting to minimize

the colour unevenness at right and left on the

screen.

For the R colour, use S4202 to turn on or off the wave

correction.

32

Page 33

No. Adjusting point Adjusting conditions Adjusting procedure

XG-V10WE

AN-SD1E/S422E

25 White balance

checking and

readjustment

26 Set-up 1. Select the following.

27 Colour-related

performance

checking

1. For the adjusting conditions, refer back to Item

Nos. 8, 19 and 24 for the

RGB, Video and DVD inputs, respectively.

DTV input

1) Feed the 720P SMPTE

(colour difference) signal.

If out of spec, take the

readjustment step below.

2) Select the following

group and subjects.

Group : DTV

Subject : CR-OFFSET

CB-OFFSET

Group : VIDEO 1

Subject : SET UP B

SET UP C

1. Feed the colour bar signal.

» Make sure the white balance is the same as on

the monitor screen. To obtain the specified white

balance, readjust the RGB, Video and DVD inputs

in this order.

» Make sure the SET UP B and SET UP C settings

are 6 and 1, respectively.

» Select the process mode L1. Check the Colour

and Tint settings.

28 Video-related

performance

checking

29 Audio-related

performance

checking

30 RGB-related

performance

checking

31 Off-timer per-

formance

checking

32 Thermistor

performance

checking

1. Feed the monoscope pattern signal.

1. Feed the stereo audio signal.

1. Feed the RGB signal.

» Select the process mode L2. Check the Picture,

Brightness and Sharpness settings.

» Select the process mode L3. Check the Bass,

Treble and Balance settings.

» Select the process mode L4. Check the Picture,

Brightness, Red, Blue, Clock, Phase, H-Pos and

V-Pos settings.

» Select the process mode OFF. Make sure that the

off-timer starts with "5" (minutes) onscreen and

counts down minute by minute each second, and

that the set turns itself off with "0" (minutes)

onscreen.

» Get the thermistor status list displayed onscreen.

33 Auto sync

performance

checking

1. Feed the phase check pattern signal.

» In the VGA, SVGA, XGA, SXGA and UXGA

modes, make sure the Clock, Phase, H-Pos and

V-Pos settings can be automatically adjusted.

33

Page 34

XG-V10WE

AN-SD1E/S422E

No. Adjusting point Adjusting conditions Adjusting procedure

34 Lens perform-

ance checking

» Using the set's control switch or the remote control-

ler, make sure the focus, zoom, keystone and lens

shift actions are as specified.

35 Delivery set-

tings

1. When the S4 delivery settings have been made, the

SET-UP signal is acceptable.

If the process mode is

» Make the following settings.

Process

adjustment

S3 "Delivery setting 3"

called up again, however,

the SET-UP signal is not

automatically accepted. In

such case, select Group:

VIDEO1 and Subject: SET

UP, change the SET UP

setting from 0 to 1, and exit

from the process mode. Or

make the S4 delivery settings again.

The methods of colour correction adjustment, after LCD panel is replaced.

When not use colour correction system.

Remote controller

setting

No. Adjusting point Adjusting conditions Adjusting procedure

1 Colour correc-

tion Rest

2 Saw-tooth wave

Correction (G),

(R)

1. Make the following choice.

Group : NOKO

Subject : CC

1. Feed the gray only RGB colour signal. (XGA 60Hz)

2. Check for uneven colour

spot on the screen.

3. Make the following choice.

Group : NOKO

» Make the following setting.

Subject : CC

Setting : 0 (colour correction OFF)

» If the colour is irregular, adjust the setting NOKO-

G or NOKO-R to minimize the right-hand and lefthand colour irregularity.

» If there is no colour irregularity, turn off the saw-

tooth correction using SW4201 (green) and

SW4202 (red).

Subject : NOKO-G

Choose the subject NOKOR for the R Colour.

34

Page 35

XG-V10WE

AN-SD1E/S422E

ADJUSTING THE PC INTERFACE (CPCi-0042CE02. PC I/F Unit)

1.Initializing the EEPROM

1) Press S2601 to call the process mode.

2) Execute the S1 command on the SSS menu. (The S1 command is used to get the PC boards initialized. Do

not carry out the S2 command because otherwise all the other adjustment data than on the PC boards would

be initialized.)

3) Make sure the program version VER.XXX on the SPECIAL menu is the latest one.

2.Adjusting the levels

2-1. Preparing the oscilloscope

1) Set the oscilloscope range to 1 Vdc/div. and 5 µs/div.

2-2. Connecting the PC interface

1) Connect the PC interface to the set and make sure the P404, P405 and P502 connectors are all tight in

position.

2) Connect a cable between the ANALOG OUTPUT terminal (signal generator) and the DSUB connector

(projector's INPUT1).

3) Set the projector's INPUT SELECT to the INPUT1 position.

4) Set the signal generator to the SXGA mode (1280 x 1024, 60 Hz, 32 tones). Adjust the output amplitude

between the black and white levels to 700 mVp-p (terminated with a 75-ohm impedance).

5) Turn on the power.

2-3. Adjusting and checking the levels

1) Press S2601 and call the process mode.

2) Adjust the SH-PHASE setting on the OUPUT3 menu to 8. (Make sure the onscreen display characters

appear crisp and clear.)

(Adjusting the A/D menu settings)

3) G-BRIGHT adjustment: Feed the black signal and adjust the G-BRIGHT setting on the A/D menu until there

are bit dropouts.

4) R-BRIGHT adjustment: Feed the black signal and adjust the R-BRIGHT setting on the A/D menu until there

are bit dropouts.

5) B-BRIGHT adjustment: Feed the black signal and adjust the B-BRIGHT setting on the A/D menu until there

are bit dropouts.

6) G-D adjustment: Feed the white signal and adjust the G-D setting on the A/D menu until there are bit

dropouts.

7) R-D adjustment: Feed the white signal and adjust the R-D setting on the A/D menu until there are bit

dropouts.

8) B-D adjustment: Feed the white signal and adjust the B-D setting on the A/D menu until there are bit

dropouts.

2-4. Adjusting the DTV settings

1) Feed the 480P Y signal to the INPUT1 terminal. Keep out the R (Pr) and B (Pb) signals.

2) G-BRIGHT adjustment: Feed the black signal and adjust the G-BRIGHT setting on the DTV menu until there

are bit dropouts.

3) CR-OFFSET adjustment: Adjust the CR-OFFSET setting to 16.

4) CB-OFFSET adjustment: Adjust the CB-OFFSET setting to 16.

5) Press S2601 to exit from the process mode.

35

Page 36

XG-V10WE

AN-SD1E/S422E

Process menu1

AD

OUTPUT1

OUTPUT2

DTV

OUTPUT3

VIDEO1

VIDEO2

DVD

NOKO

LINE

SSS

PATTERN

CVIC

LENS

SPECIAL

VIDEO2

VROS

VGOS

VBOS

R1-BLK

R1-GAIN

B1-BLK

B1-GAIN

N358 DLY

N443 DLY

PAL DLY

SECAM DLY

OUTPUT2

PSIG-H

PSIG-L

R2-BLK

R2-GAIN

G2-BLK

G2-GAIN

B2-BLK

B2-GAIN

NTSC-H

PICTURE

AGC

BRIGHT

TINT

N-COLOR

P-COLOR

S-COLOR

SET UP

SET UP B

SET UP C

VIDEO1

OUTPUT1

R1-BLK

R1-GAIN

G1-BLK

G1-GAIN

B1-BLK

B1-GAIN

OUTPUT3

RC

GC

BC

SH-PHASE

GCK-PHASE

R3-GAIN

G3-GAIN

B3-GAIN

AD

R-BRIGHT

G-BRIGHT

B-BRIGHT

R-D

B-D

G-D

DTV

G-BRIGHT

CB-OFFSET

CR-OFFSET

36

NOKO

NOKO-G

NOKO-R

CC

R-CNV-H

G-CNV-H

B-CNV-H

R-CNV-V

G-CNV-V

B-CNV-V

DVD

CONTRAST

BRIGHT

TINT

COLOR

R1-BLK

R1-GAIN

B1-BLK

B1-GAIN

Page 37

Process menu2

XG-V10WE

AN-SD1E/S422E

AD

OUTPUT1

OUTPUT2

DTV

OUTPUT3

VIDEO1

VIDEO2

DVD

NOKO

LINE

SSS

PATTERN

CVIC

LENS

SPECIAL

SPECIAL

IPL

E2PROM

ADR RD/WR

LINE

L1

L2

L3

L4

OFF

TEMP OFF

SENSER CHECK

ID CHECK

CVIC

PROGRESSIVE

ENHANCE

SCREEN

IDC

LENS

LENS AUTO

LENS TOP

LENS BOTTOM

TIME

S1

S2

S3

S4

S5

LAMP

SSS

PATTERN

RGB

RGB [50]

CROSS

RAMP

STEP

COLOR

CHR

PROGRESSIVE

MODE

LPF

LSW

PTG

LEVEL

LIMIT

FILM

THRESH

MISSTH

IDC

XEGTH

XLTH1-H

XLTH1-L

XLTH2-H

XLTH2-L

YEGTH

YLTH1-H

YLTH1-L

YLTH2-H

YLTH2-L

37

SCREEN

CUBIC-RGB

CUBIC-VIDEO

ENHANCE

BBN-RGB

BBN-VIDEO

DFC-RGB

DFC-VIDEO

Page 38

XG-V10WE

AN-SD1E/S422E

Precautions in servicing

(1) If the convergence gets out of spec during servicing, call up the process mode and select the following sub-

jects.

Group : NOKO

Subject : R-CNV-H, R-CNV-V

G-CNV-H, G-CNV-V

B-CNV-H, B-CNV-V

(H: Horizontal adjustment, V: Vertical adjustment)

Adjust the above settings in the range of 0-4. When changing each setting from the initial setting of 2, however,

the 1280 x 1024 dot display area will have a fewer number of lines.

Example 1 : When the R-CNV-H setting is changed from 2 (initial) to 4, the number of lines will be from 1280 to

1278.

Example 2 : When the R-CNV-H, G-CNV-H and B-CNV-H settings are changed to 3, 3 and 4, respectively, the

display will be 1278 x 1024 lines. But when the above settings are switched to 2, 2 and 3, respectively, the display will be 1279 x 1024 lines.

Preferably keep each setting as close to 2 as possible.

(2) When calling up the process mode, make sure the following appears onscreen.

Group : VIDEO1

Subject : SET UP B 2

SET UP C 1

Be sure to exit from this mode with the following onscreen.

Subject : SET UP 1

38

Page 39

TROUBLE SHOOTING TABLE

Checking the PWB performance

XG-V10WE

AN-SD1E/S422E

Video input in trouble

Go to "Checking the video unit

circuit".

RGB input in trouble

Feed test pattern signal from

PC.

Is specified cable connected

between PC and projector?

Yes

Is supply voltage as specified?

Yes

Does image appear?

Yes

Go to "Trouble shooting table

for PC I/F unit ".

Through-output in trouble

Through-output circuit in

trouble.

No

Use specified cable.

No

Power circuit in trouble.

No

Check the connectors, starting

from the input circuit.

Remote control in trouble

Go to "Checking the remote

control".

Checking the video system

Is the lamp on?

Yes

Is specified voltage fed to EA

connectors?

Yes

Are there signal inputs at pins (12),

(31) and (37) of SC401?

Yes

Are there signal outputs at pins (7) of

IC6014 and (7) of IC6015?

Yes

Go to "Checking IC803

(RGB signal output circuit)".

Check IC6009, IC6011,

IC6014, IC6015 and their

peripheral circuits as well

as switching circuit.

No

No

Go to "Lamp fails to light-up".

No

Check the power circuit and its parts.

No

Check the input unit circuit (IC1401,

IC1402, IC1403, IC1404, IC1405

and its peripheral circuits).

39

Page 40

XG-V10WE

AN-SD1E/S422E

Checking the video unit circuit

TROUBLE SHOOTING TABLE (Continued)

Is there video signal output at pin (7)

of IC1405?

Yes

Is there video signal input at IC4001?

Yes

Are there signal outputs at pins (6)

and (8) of IC4001?

Yes

Check the low-pass and buffer circuits

of Q6008 thru Q6014. Is the signal as

specified?

Yes

Go to "Checking IC801 (RGB signal

output circuit)".

No

Check the IC1403, IC1406 selector

switch, terminal voltage and input

circuit.

No

Check the low-pass and buffer

circuits of Q4002, Q4003 and Q4004.

No

Check IC4001 and its peripheral

circuits (bias).

No

Check Q4005 thru Q4008 and their

peripheral circuits.

Checking IC801 (RGB signal output circuit)

Go to "No colour or unusual tone",

"No Y signal" or "Out of sync".

No

Are there RGB output waveforms at

pins (31), (32) and (33) of IC803?

Yes

Are there output waveforms at pin

1 of Q6801, Q6802, Q6803?

Yes

Are there output waveforms at pin

(8), (10), (12) of SC8404?

Yes

Go to "Trouble shooting table for PC

I/F unit".

No

Check the data transfer and other

performance at pins (17) and (18) of

video IC803.

No

Check Q6801, Q6802, Q6803 and

their peripheral circuits.

No

Check IC6801, Q6807, Q6808,

Q6809 and their peripheral circuits.

40

Page 41

TROUBLE SHOOTING TABLE (Continued)

Checking the chroma and Y signals of IC801

(RGB signal output)

XG-V10WE

AN-SD1E/S422E

Are there signal inputs at pins (12),

(31) and (37) of SC401?

Yes

Are there output waveforms at pins

(7) of IC6014 (chroma signal) and

(7), (Y signal)of IC6015?

Yes

Are there signal inputs at pins (20)

(chroma signal) and (21) (Y signal)

of IC803?

Yes

Go to "Checking IC801 (RGB signal

output circuit)".

No

Go to "Checking the video unit

circuit".

No

Check the IC6009 IC6010 and IC6011

switching and their peripheral circuits.

If there is no signal at pins (1) of

IC6014 and pin (5) of IC6015 and pin

(16) of IC6010 check 3-D noise

reduction circuit (IC6009).

No

Check IC803 and its peripheral

circuits.

Checking IC806 (3-D noise reduction circuit)

and its peripheral circuits

Are there signal inputs at pins (40)

(Y signal) and (45)(chroma signal) of

IC6009?

Yes

Are there signal outputs at pins (55)

(Y signal) and (51)(chroma signal) of

IC8001?

Yes

Are there signal outputs at the

emitters of Q6010 (Y signal) and

Q6015 (chroma signal)?

Yes

Check IC6011, IC6014, IC6015 and

IC801 (RGB signal output circuit).

No

Check the buffer circuit of Q6007 thru

Q6011 as well as Q6013 thru Q6014.

No

Check IC6008, IC6010 (memory) and

their peripheral circuits.

No

Check the low-pass circuit around

Q6010, Q6012 and Q6015.

Check IC6009 (3-D noise reduction

circuit) and its peripheral circuits.

No colour or unusual tone (NTSC, PAL, PALM, PALN)

Is there chroma signal input at pin

(20) of IC801?

Yes

Are there signal outputs at pins

(46)(R-Y) and (45)(B-Y) of IC801?

Yes

Check IC804, IC805 and their

peripheral circuits.

No

Go back to the signal processing

block.

No

Check the oscillation of X801, X802,

X803 and X804 and their peripheral

circuits.

41

Page 42

XG-V10WE

AN-SD1E/S422E

TROUBLE SHOOTING TABLE (Continued)

No or unusual Y signal

Is there Y signal input at pin (21) of

IC803?

Yes

Is there Y signal output at pin (40) of

IC803?

Yes

Is there Y signal output at pin (17) of

IC804?

Yes

Check IC804 and its peripheral

circuits.

No

Go back to the signal processing

block.

No

Check IC803 and its peripheral

circuits.

No

Check IC804 and its peripheral

circuits as well as IC806 (AGC).

No or unusual horizontal sync

Is there horizontal sync pulse output

at pin (56) of IC803?

Yes

Is there horizontal sync pulse output

at pin (9) of IC802?

Yes

No

Check IC803 and its peripheral

circuits.

No

Check the pulse shaping circuit of

IC801 and IC802.

Go to "Trouble shooting table for PC

I/F unit".

No or unusual vertical sync

Is there vertical sync pulse output at

pin (4) of IC803?

Yes

Go to "Trouble shooting table for

PC I/F unit".

No

Check IC803 and its peripheral

circuits.

42

Page 43

TROUBLE SHOOTING TABLE (Continued)

Checking the output PWB unit

XG-V10WE

AN-SD1E/S422E

If there is no signal at SC6801,

go to the video system block.

If there is no signal at SC8404

and SC8405, go to "Trouble

shooting table for PC I/F unit".

Is there signal input at

SC6801?

Are voltages applied to EA

connectors and SC8404,

SC8405 and SC8502?

Yes

Are there signal outputs at

pins (17) of IC2101, IC2102,

IC2201, IC2202, IC2301,

IC2302?

Yes

Are there signal inputs at pin

(47) of IC1101, IC1102,

IC1201, IC1202, IC1301 and

IC1302?

Yes

Are there signal outputs at pins

(17), (19), (21), (28), (30) and

(32) of IC1101, IC1102,

IC1201, IC1202, IC1301 and

IC1302?

Yes

NoNo

If there is no signal at EA

connector or SC8404, SC8405

and SC8502, go to Checking

the power unitblock.

No

Check IC2101, IC2102,

IC2201, IC2202, IC2301,

IC2302 and their peripheral

circuits.

No

Check IC2101, IC2102, IC2201,

IC2202, IC2301, IC2302 and

their peripheral circuits.

No

Check IC1101, IC1102,

IC1201,IC1202, IC1301,

IC1302 and their peripheral

circuits.

If there is no signal input at

pins (1) and (32) of SC1101,

SC1201 and SC1301, check

the switching circuit and

amplifier circuit of IC1101,

IC1201, IC1301, IC1102,

IC1202, IC1302 and their

peripheral circuits.

No

Are there signal inputs at

SC1101, SC1201 and

SC1301?

Check the R, G and B panels.

Yes

Yes

No

If there is no signal input at

pins (15) and (30) of

SC1101, SC1201 and

SC1301, check IC1601

and their peripheral

circuits.

Check IC1611, IC1612,

IC1613, IC1615, IC1621,

IC1622, IC1623, IC1624

and their peripheral

circuits.

43

Page 44

XG-V10WE

AN-SD1E/S422E

TROUBLE SHOOTING TABLE (Continued)

No audio output

Are there audio signal inputs at pins

(2) and (23) of IC301?

Are there audio signal outputs at pins

(3) and (6) of IC302?

If the voltage at pin (7) of IC302 is not

as specified, check Q302, Q303 and

their peripheral circuits.

Checkig the Power Unit

No

Yes

No

Yes

Check IC302 and its peripheral

circuits, and the SP connectors and

speakers.

Check the input, the switching circuit

of IC403 and IC404, and their

peripheral circuit.

Check IC302 and its peripheral

circuits.

There is no voltage output at

EA connector.

No

Is EA connector disconnected

or loose?

No

Is AC voltage (85-264V)

applied across the BA

connector?

Yes

Is R727 broken?

Yes

Replace R727 or Q701.

Yes

Reconnect the EA connector.

No

Replace F1701.

No