Page 1

TopPage

XG-PH70X/XG-PH70X-N (1st. Edition)

SERVICE MANUAL

No. SX6Z1XGPH70X/

MULTIMEDIA PROJECTOR

XG-PH70X

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

XG-PH70X-N

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY NOTES

Precautions for using lead-free solder ..............vi

CHAPTER 1. OPERATION MANUAL

[1] SPECIFICATIONS ......................................... 1-1

[2] Operation Manual........................................... 1-2

[3] DIMENSIONS ................................................ 1-9

[4] Maintenance Indicators................................ 1-10

[5] Regarding the Lamp..................................... 1-12

CHAPTER 2. REMOVING OF MAJOR PARTS

[1]

Removing the Lamp Unit

[2] Removing the Top Cover................................ 2-2

[3] Removing the Lens Hood............................... 2-3

[4] Removing the Lens Cap................................. 2-3

[5] Removing the Lens Trim ................................ 2-4

[6] Removing the Standard Lens......................... 2-4

[7] Removing the Top Cabinet............................. 2-5

[8] Removing the Handle Bracket3 ..................... 2-6

[9] Removing the PWB Units............................... 2-7

[10]

Removing the Optical Engine and Lens Shift

[11] Removing the Terminal Unit......................... 2-10

[12] Removing the Filter Unit............................... 2-11

[13] Removing the IR (Rear) Unit........................ 2-11

[14]

Removing the Power Unit and Audio Unit

CHAPTER 3. ELECTRICAL ADJUSTMENT

[1] ELECTRICAL ADJUSTMENT........................ 3-1

[2] PC I/F adjustment method ............................. 3-3

[3] Special 232c command for factory................. 3-4

[4] SERVICE MODE............................................ 3-5

[5] Failure mode when the lamp does not light

up even when powered on............................. 3-7

................................ 2-1

.............i

........ 2-8

........ 2-12

CHAPTER 4. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE ......................4-1

CHAPTER 5. BLOCK DIAGRAM/OVERALL WIRING

DIAGRAM

[1] BLOCK DIAGRAM.........................................5-1

[2] OVERALL WIRING DIAGRAM......................5-3

CHAPTER 6. PRINTED WIRING BOARD

[1] MAIN Unit ......................................................6-1

[2] FORMATTER Unit .........................................6-5

[3] POWER Unit..................................................6-7

[4] FILTER/P.F.C CONTROL/LVPS CON-

TROL Unit......................................................6-9

[5] PC I/F Unit ...................................................6-11

[6] DIRECT OFF Unit........................................6-13

[7] AUDIO Unit..................................................6-14

[8] KEYPAD Unit...............................................6-15

[9] TERMINAL Unit ...........................................6-17

[10] IR (FRONT)/IR (REAR)/LAMP1 COVER/

LAMP2 COVER Unit/INDEX Unit ................6-18

CHAPTER 7. WAVEFORMS

[1] WAVEFORMS ...............................................7-1

CHAPTER 8. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIA-

GRAM............................................................8-1

[2] SCHEMATIC DIAGRAM................................8-2

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

XG-PH70X/XG-PH70X-N (1st. Edition)

XG-PH70X

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY NOTES

IMPORTANT SERVICE SAFETY NOTES (for USA)

Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

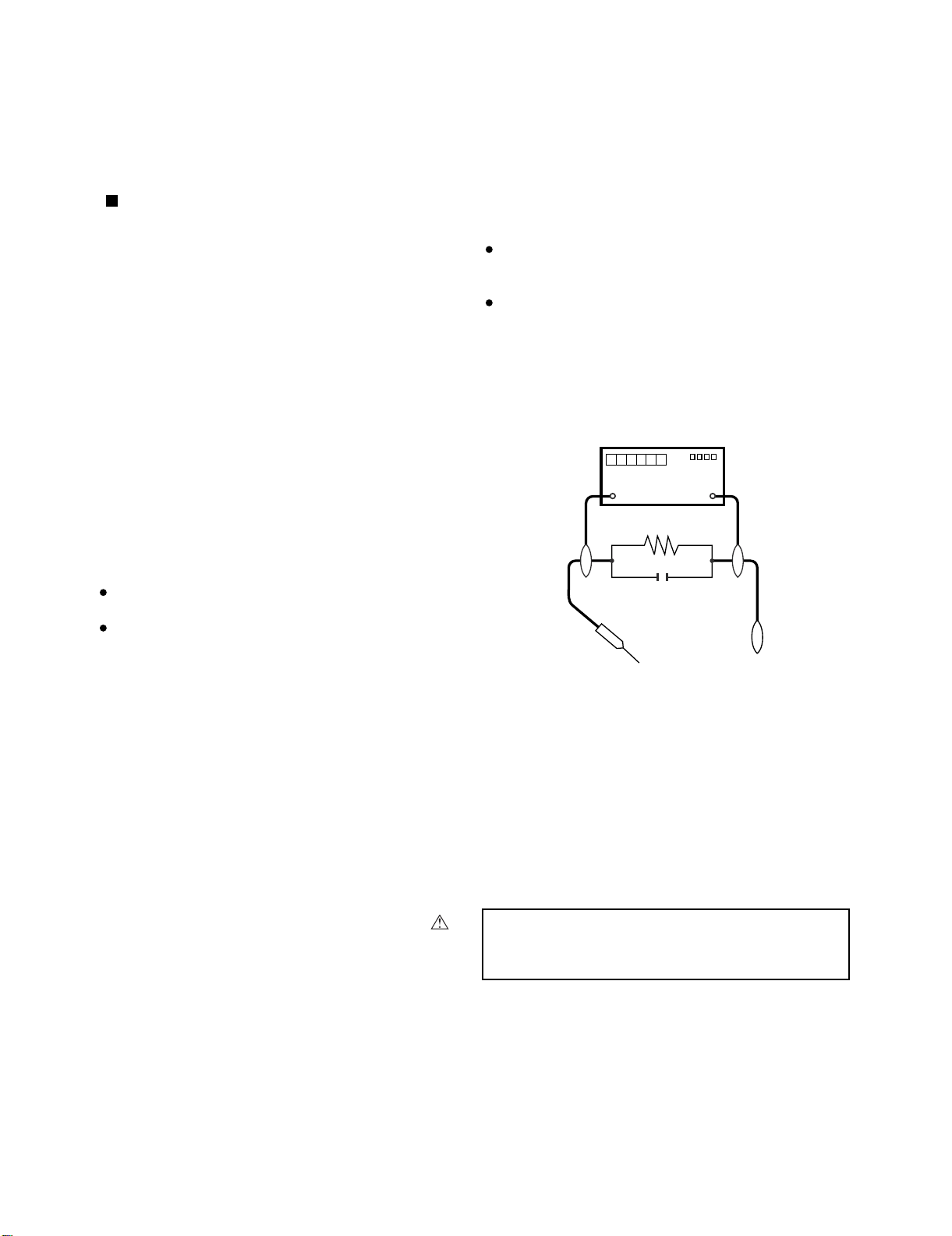

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

Service Manual

Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.4 volts RMS (this corresponds to 0.27

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in DMD™

Projector have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “ ”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

i

Page 3

XG-PH70X/XG-PH70X-N (1st. Edition)

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N'entreprendre aucune modification de tout circuit.

C'est dangereux.

2. Débrancher le récepteur avant toute réparation.

VERIFICA TIONS CONTRE L'INCEN-DIE ET

LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur .

2. Inspecter tous les dispositifs de protection comme les

boutons de commande non-métalliques, les isolants, le

dos du coffret, les couvercles ou blindages de réglage

et de compartiment, les réseaux de résistance-capacité,

les isolateurs mécaniques, etc.

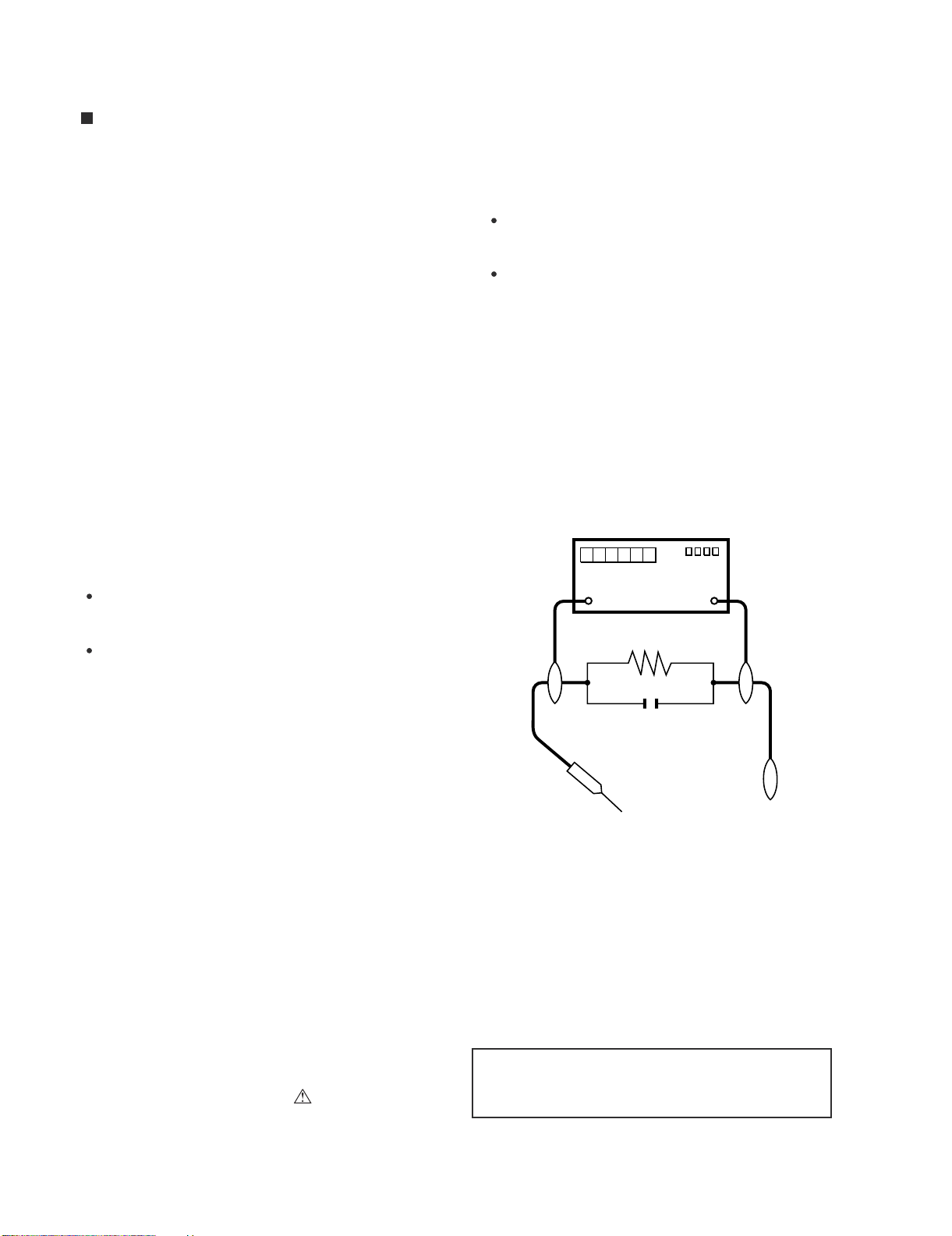

3. S'assurer qu'il n'y ait pas de danger d'électrocution en

vérifiant la fuite de courant, de la facon suivante:

Brancher le cordon d'alimentation directem-ent à une

prise de courant de 120-V. (Ne pas utiliser de tran

sformateur d'isolation pour cet essai).

A l'aide de deux fils à pinces, brancher une résistance

de 1.5 kΩ 10 watts en parallèle avec un condensateur

de 0.15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à la

terre.

Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension en travers

de la résistance.

Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au châssis

(antenne, coffret métallique, tête des vis, arbres de

commande et des boutons, écusson, etc.) et mesurer la

chute de tension CA en-travers de la résistance. Toutes

les vérifications doivent être refaites après avoir inversé

la fiche du cordon d'alimentation. (Si nécessaire, une

prise d'adpatation non polarisée peut être utilisée dans

le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.4V

(correspondante au courant CA de pointe de 0.27mA).

Dans le cas contraire, ilyaunepossibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

0.15

µ

SONDE D'ESSAI

F

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à DMD™ présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent pas

évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “ ” et hachurées dans la

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par l’usine,

indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire attention

lors de la manipulation de cette

composante sous tension.

ii

Page 4

XG-PH70X/XG-PH70X-N (1st. Edition)

NOTE TO SERVICE

PERSONNEL

//////////////////////////////////////////////////////////////

UV-RADIATION PRECAUTION

//////////////////////////////////////////////////////////////

The light source, lamp, in the pr ojector emits small

amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D'ENTRETIEN

//////////////////////////////////////////////////////////////

PRECAUTION POUR LES RADIATIONS UV

//////////////////////////////////////////////////////////////

La source de lumière, la lampe, dans le projecteur émet

de petites quantités de radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE DES

YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

Toujours porter des lunettes de soleil lors d’un entretien

1.

du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du boîtier

de lampe.

3. Do not operate for more than 2 hours with the enclosure

removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing the

lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type AN-PH7LP1/

AN-PH7LP2 rated 260W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le coffret

retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du remplacement

de la lampe.

2. Laisser l'unité refroidir pendant une heure avant de

procéder à l'entretien.

3. Ne remplacer qu'avec une lampe du même type. Type

AN-PH7LP1/AN-PH7LP2, caractéristique 260W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d'explosion. Toujours suivre les instructions

d'installation décrites ci-dessous et manipuler la lampe

avec soin.

iii

Page 5

XG-PH70X/XG-PH70X-N (1st. Edition)

////////////////////////////////////////////////////////////////

UV-RADIATION PRECAUTION (Continued)

////////////////////////////////////////////////////////////////

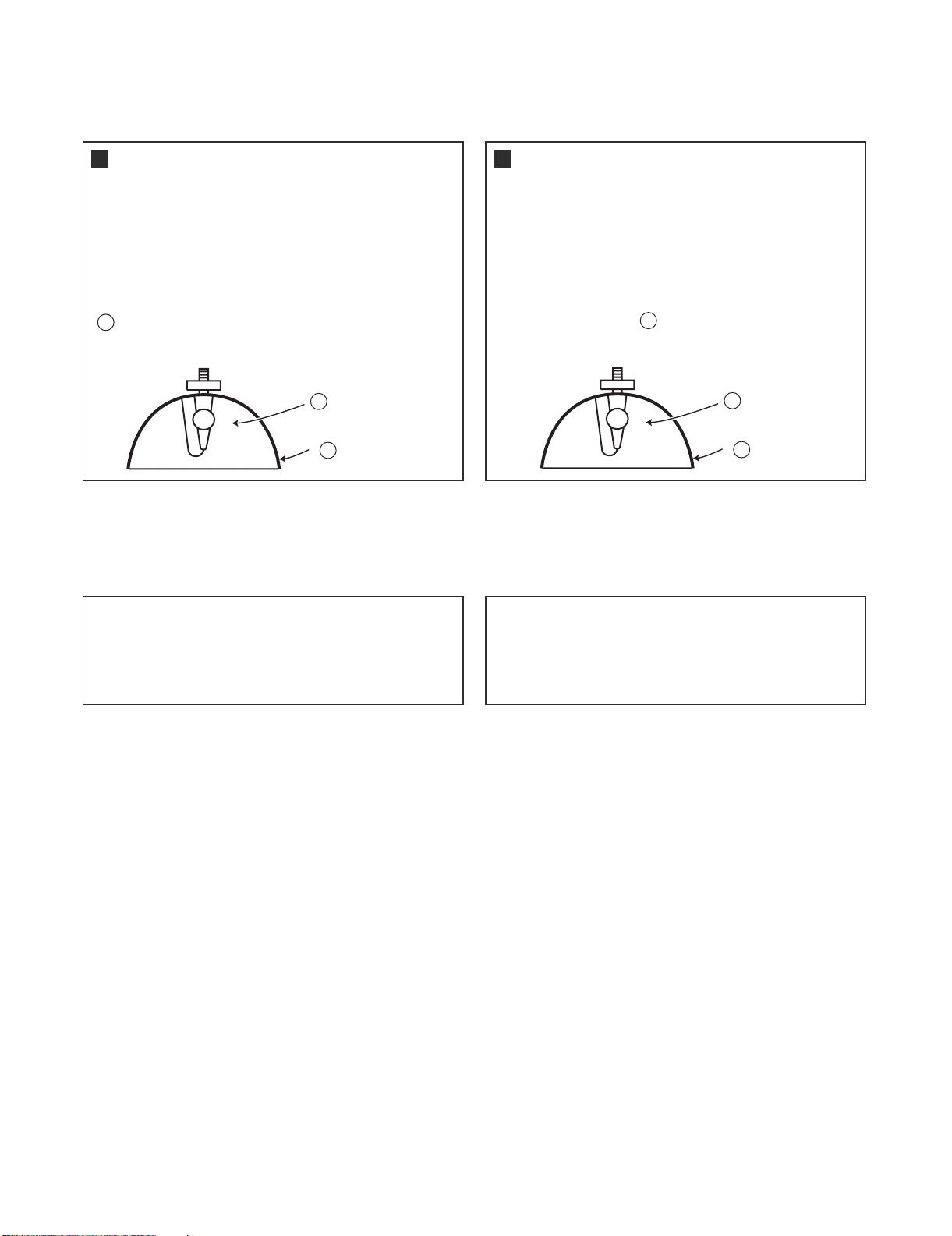

Lamp Replacement

Note:

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2

.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the devices

since the stabilizer generates high voltages at its start.

////////////////////////////////////////////////////////////////

PRECAUTION POUR LES RADIA TIONS UV (Suite)

////////////////////////////////////////////////////////////////

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur .

[N’utiliser qu’un remplacement d’origine.]

DANGER ! –– Ne jamais mettre sous tension sans la

lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

2

1

Lampe

2

Reflecteur

Since small amounts of UV-radiation are emitted

from an opening between the exhaust fans, it is recommended to place the cap of the optional lens on

the opening during servicing to avoid eye and skin

exposure.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre les ventilateurs aspirants, il est recommandé de placer le capuchon de

l’optique optionnelle sur l’ouverture pendant l’entretien

pour éviter une exposition des yeux et la peau.

iv

Page 6

XG-PH70X/XG-PH70X-N (1st. Edition)

WARNING: High brightness light source, do not stare into the beam of light, or view directly. Be especially

careful that

children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO N OT EXPOSE

THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(FILTER Unit)

8A 250V

For continued

protection against a

risk of fire, replace

only with same type

8A, AC250V fuse.

(F301)

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

directement. Ve

iller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVERTISSEMENT: AFIN D’EV

ITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ÉLECTROCUTION. NE

PASR ETIRER LES VIS Á

L’EXCEPTION DE LA VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

PRECAUTION

(Unité de Filtre)

8A 250V

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible 8A,AC250V

du même type.

(F301)

v

Page 7

XG-PH70X/XG-PH70X-N (1st. Edition)

Precautions for using lead-free solder

Employing lead-free solder

• "PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

vi

Page 8

XG-PH70X/XG-PH70X-N (1st. Edition)

XG-PH70X

CHAPTER 1. OPERATION MANUAL

[1] SPECIFICATIONS

Service Manual

Product type

Model

Video system

Display device

Standard zoom lens

Projection lamp

Component input (INPUT 1)/

output (OUTPUT) signal

Horizontal resolution

Component input (INPUT 2)

signal

RGB input (INPUT 1/2)/output

(OUTPUT) signal

RGB digital input signal (INPUT 3)

Video input signal

(INPUT 4)

S-video input signal

(INPUT 5)

Audio input signal

Audio output signal

(AUDIO OUTPUT 1

−

RS-232C terminal

LAN terminal

Pixel clock

Vertical frequency

Horizontal frequency

Audio output

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Power consumption (standby)

Heat dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

Weight (approx.)

Replacement parts

Multimedia Projector

XG-PH70X (standard zoom lens attached)/XG-PH70X-N (no lens attached)

NTSC3.58/NTSC4.43/PAL/PAL-M/PAL-N/PAL-60/SECAM/

DTV480I /DTV480P/DTV540P/DTV576I/DTV576P/DTV720P/DTV1035I /DTV1080I

0.7" DLP chip x 1

®

No. of dots: 786,432 dots (1,024 [H] x 768 [V])

1.2 x electric zoom/focus lens, F1.8−F2.0, f = 25.6−31.3 mm (standard equipment with XG-PH70X)

260 W x 2

15-pin mini D-sub connector

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

P

B: 0.7 Vp-p, 75 Ω terminated

R: 0.7 Vp-p, 75 Ω terminated

P

750 TV lines (DTV720P)

BNC connector

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

P

B: 0.7 Vp-p, 75 Ω terminated

R: 0.7 Vp-p, 75 Ω terminated

P

15-pin mini D-sub connector, 5 BNC connector: RGB separate/composite sync (TTL)/sync

on green type analog input: 0Ð0.7 Vp-p, positive, 75 Ω terminated

Horizontal sync. signal: TTL level (positive/negative) or composite sync (Apple only)

Vertical sync. signal: Same as above

DVI connector (24-pin), RGB (digital), 250

−

1,000 mV, 50 Ω (Compatible with HDCP)

RCA connector: VIDEO, composite video, 1.0 Vp-p, sync negative, 75 Ω

terminated

4-pin mini DIN connector

Y (luminance signal): 1.0 Vp-p, sync negative, 75 Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Ω terminated

φ3.5 mm stereo minijack, RCA terminal

0.5 Vrms, more than 22 kΩ

φ3.5 mm minijack

0.5 Vrms, less than 2.2 kΩ

5)

9-pin D-sub connector

8-pin RJ-45 modular connector

12

−

230 MHz

43

−

200 Hz

−

126 kHz

15

3.0 W (stereo)

3.3 cm round x 2

AC 100

−

6.6 A (AC 100 V)

240 V

−

2.7 A (AC 240 V)

50/60 Hz

650 W (when "Eco Mode" is "OFF")/570 W (when "Eco Mode" is "ON") with AC 100 V

620 W (when "Eco Mode" is "OFF")/550 W (when "Eco Mode" is "ON") with AC 240 V

0.8 W (AC 100 V)−1.1 W (AC 240 V) (When "Monitor Out" and "LAN/RS232C" are set to "Disable".)

2,440 BTU/hour (when "Eco Mode" is "OFF")/2,140 BTU/hour (when "Eco Mode" is "ON")

with AC 100 V

2,330 BTU/hour (when "Eco Mode" is "OFF")/2,070 BTU/hour (when "Eco Mode" is "ON")

with AC 240 V

41 F to 104 F (+5 C to +40 C)

−

4 F to 140 F (−20 C to +60 C)

Plastic

38 kHz

5

16

/32"x73/32"x1835/64" (410 (W) x 180 (H) x 471 (D) mm) (main body only)

5

16

/32"x737/64"x1835/64"

(410 (W) x 192.1 (H) x 471 (D) mm) (including adjustment foot

and projecting parts)

XG-PH70X: 32.9 lbs. (14.9 kg)

XG-PH70X-N: 30.3 lbs. (13.7 kg)

Remote control, Power cord for U.S., Canada, etc., Power cord for Europe, except U.K.,

Power cord for U.K., Hong Kong and Singapore, Power cord for Australia, New Zealand and

Oceania, RGB cable

, Remote mouse receiver, Cap for the standard zoom lens, Projector

manual and technical reference CD-ROM, Operation manual

As a part of policy of continuous improvement, SHARP reserves the right to make design

and specification changes for product improvement without prior notice. The performance

specification figures indicated are nominal values of production units. There may be some

deviations from these values in individual units.

1 – 1

Page 9

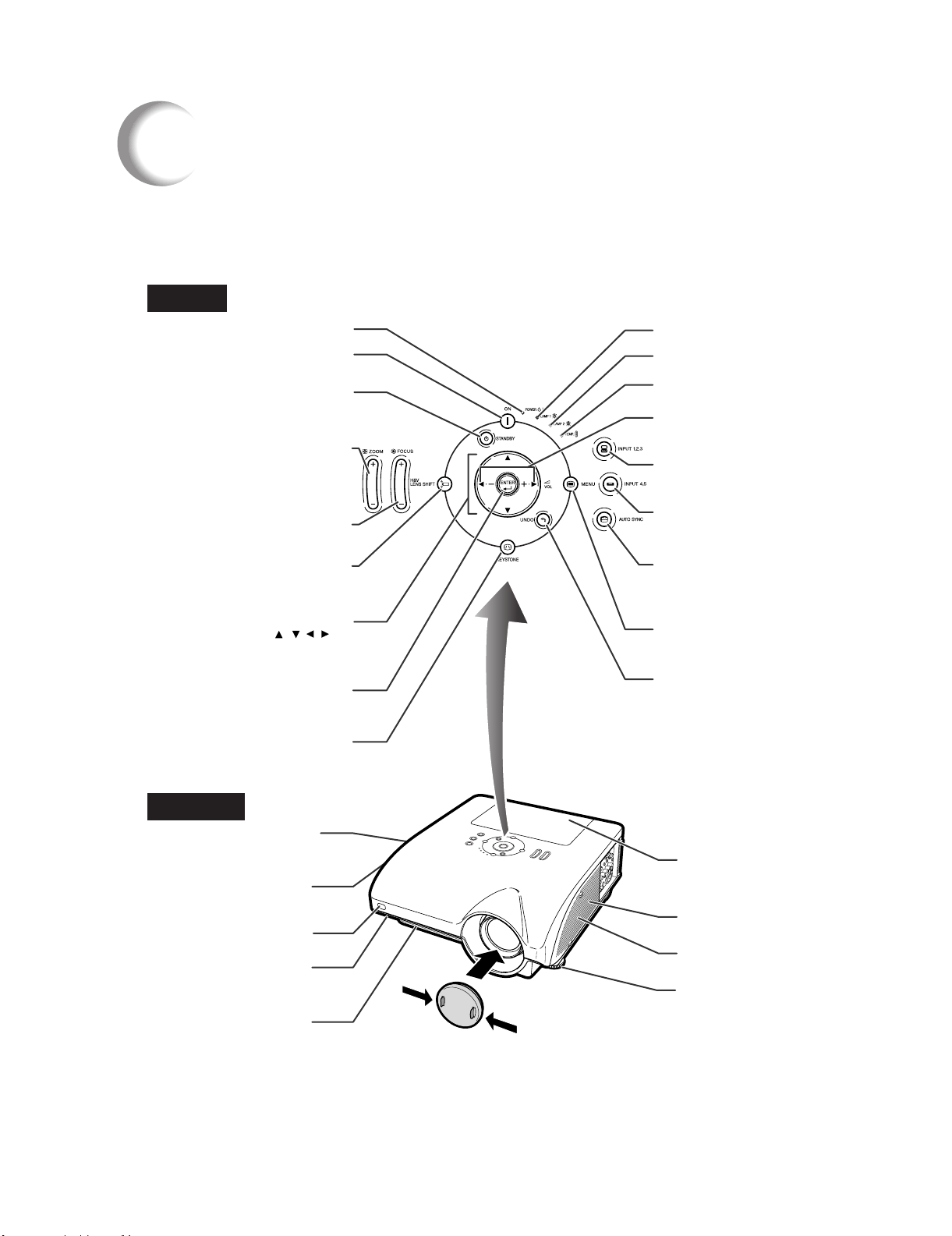

[2] Operation Manual

Part Names and Functions

Projector

Top View

XG-PH70X/XG-PH70X-N (1st. Edition)

Power indicator

ON button

For turning the power on.

STANDBY button

For putting the projector

into standby mode.

ZOOM button

For adjusting the projected

image size.

FOCUS button

For adjusting the focus.

H & V LENS SHIFT button

For shifting the lens horizontally

and vertically.

Adjustment buttons

(///)

For selecting menu items

and other settings.

ENTER button

For setting items selected

or adjusted on the menu.

KEYSTONE button

For entering the Keystone

Correction mode.

Lamp indicator 1

Lamp indicator 2

Temperature warning

indicator

Volume buttons

For adjusting the speaker

sound level.

INPUT 1, 2, 3 button

For switching input mode

1, 2 or 3.

INPUT 4, 5 button

For switching input mode

4or5.

AUTO SYNC button

For automatically

adjusting images when

connected to a computer.

MENU button

For displaying adjustment

and setting screens.

UNDO button

For undoing an operation

or returning to the previous

display.

Front View

Carrying handle

Remote control

Adjustment foot

(on the bottom of

For carrying the

projector.

Speaker

sensor

the projector)

Intake vent

Lamp unit cover

Intake vent

Speaker

Adjustment foot

(on the bottom of

the projector)

Attaching the lens cap

Push the lens cap on until it clicks

into position.

Removing the lens cap

Pull the lens cap directly outward.

1 – 2

Page 10

XG-PH70X/XG-PH70X-N (1st. Edition)

Part Names and Functions

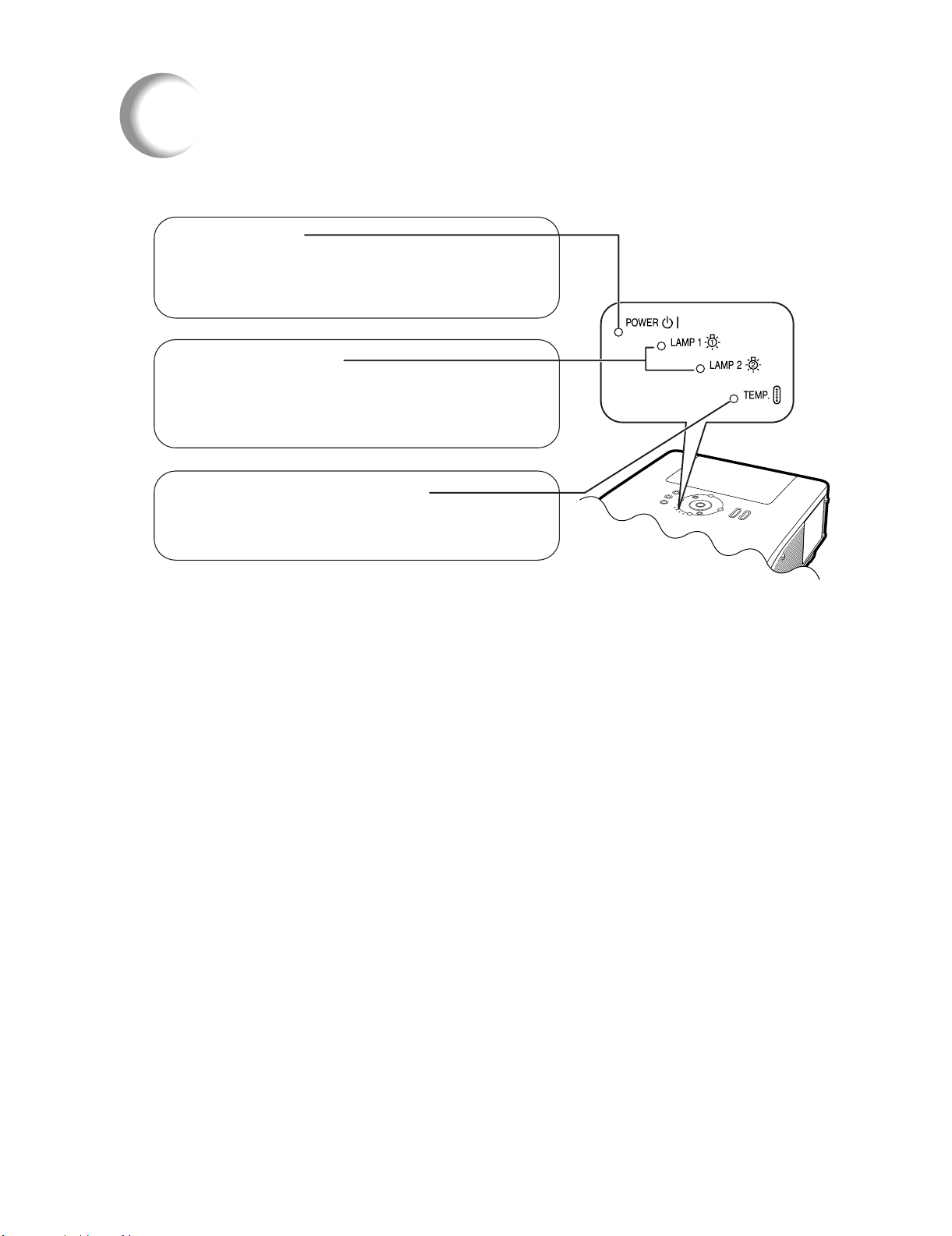

About the Indicators on the Projector

Power indicator

Red on

Green on

Red blinks

Lamp indicators 1, 2

Green on

Green blinks

Red on

Temperature warning indicator

Off

Red blinks/on

...

Normal (Standby)

...

Normal (Power on)

...

The intake vent cover is open.

...

Normal

...

The lamp is warming up.

The lamp has been shut down abnormally or

needs to be changed.

...

The internal temperature is abnormally

high.

...

Normal

...

1 – 3

Page 11

XG-PH70X/XG-PH70X-N (1st. Edition)

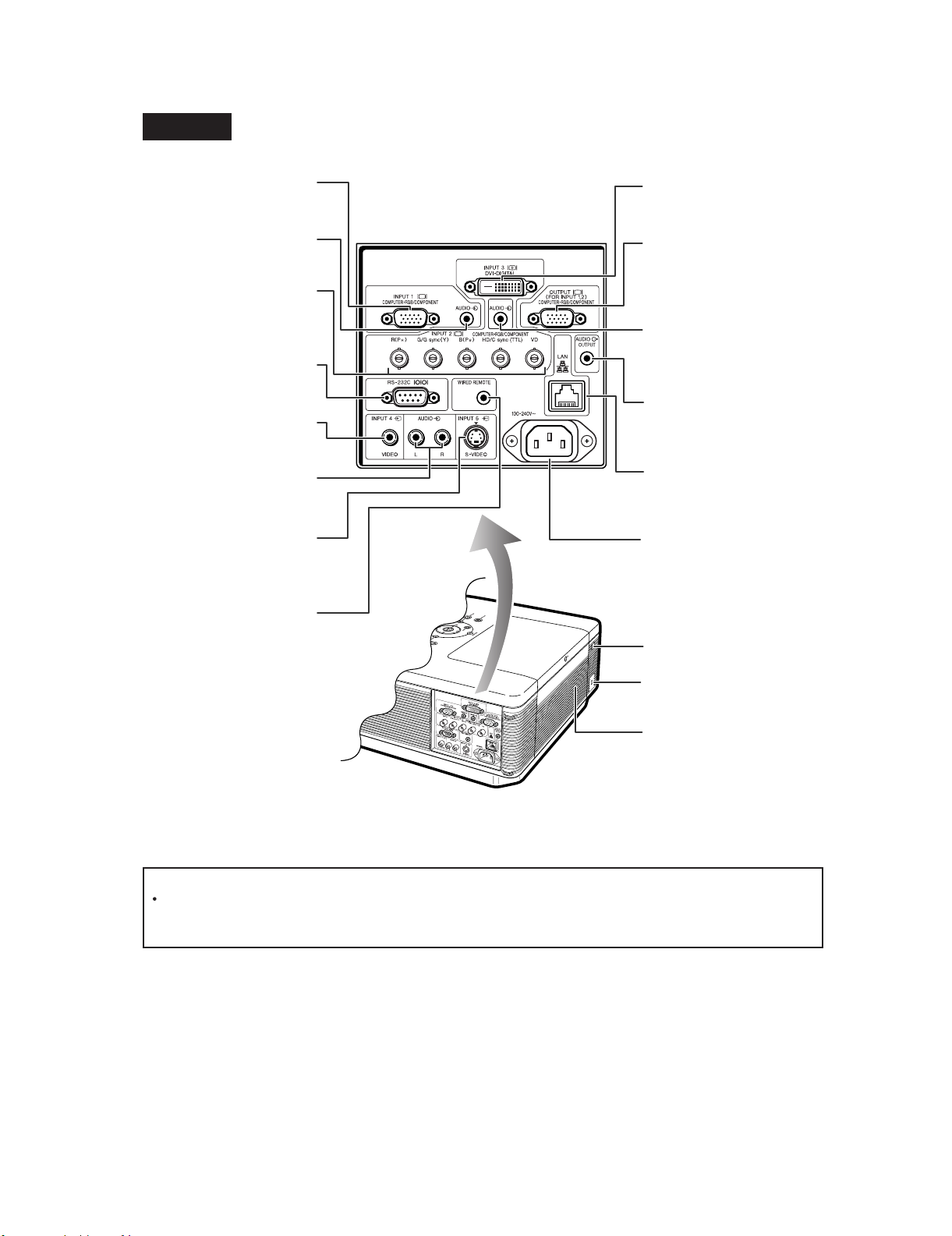

Projector (Side View)

Terminals Refer to "INPUT/OUTPUT Terminals and Connectable Main Equipment" on

INPUT 1 terminal

Terminal for computer RGB

and component signals.

AUDIO input (1) terminal

Audio input terminal for

INPUT 1.

INPUT 2 terminals

BNC terminals for computer

RGB and component

signals.

RS-232C terminal

Terminal for controlling the

projector using a computer.

INPUT 4 terminal

Terminal for connecting

video equipment.

AUDIO input (4, 5) terminals

Shared audio input terminals for

INPUT 4 and 5.

INPUT 5 terminal

Terminal for connecting

video equipment with an

S-video terminal.

WIRED REMOTE terminal

For connecting the remote

control to the projector when

the signals from the remote

control cannot reach the

remote control sensor.

INPUT 3 terminal

Terminal for DVI digital RGB

and digital component signals.

OUTPUT (FOR INPUT 1, 2)

terminal

Output terminal for computer

RGB and component signals.

Shared for INPUT 1 and 2.

AUDIO input (2, 3) terminal

Shared audio input terminal for

INPUT 2 and 3.

AUDIO OUTPUT terminal

Audio output terminal shared

for INPUT 1−5.

LAN terminal

Terminal for controlling the

projector using a computer

via network.

AC socket

Connect the supplied Power

cord.

Remote control sensor

Kensington Security

Standard connector

Exhaust vent

The speed and pitch of

the cooling fan may

change during operation

in response to internal

temperature changes.

This is normal operation

and does not indicate a

malfunction.

Using the Kensington Lock

This projector has a Kensington Security Standard connector for use with a Kensington MicroSaver Security

System. Refer to the information that came with the system for instructions on how to use it to secure the

projector.

1 – 4

Page 12

XG-PH70X/XG-PH70X-N (1st. Edition)

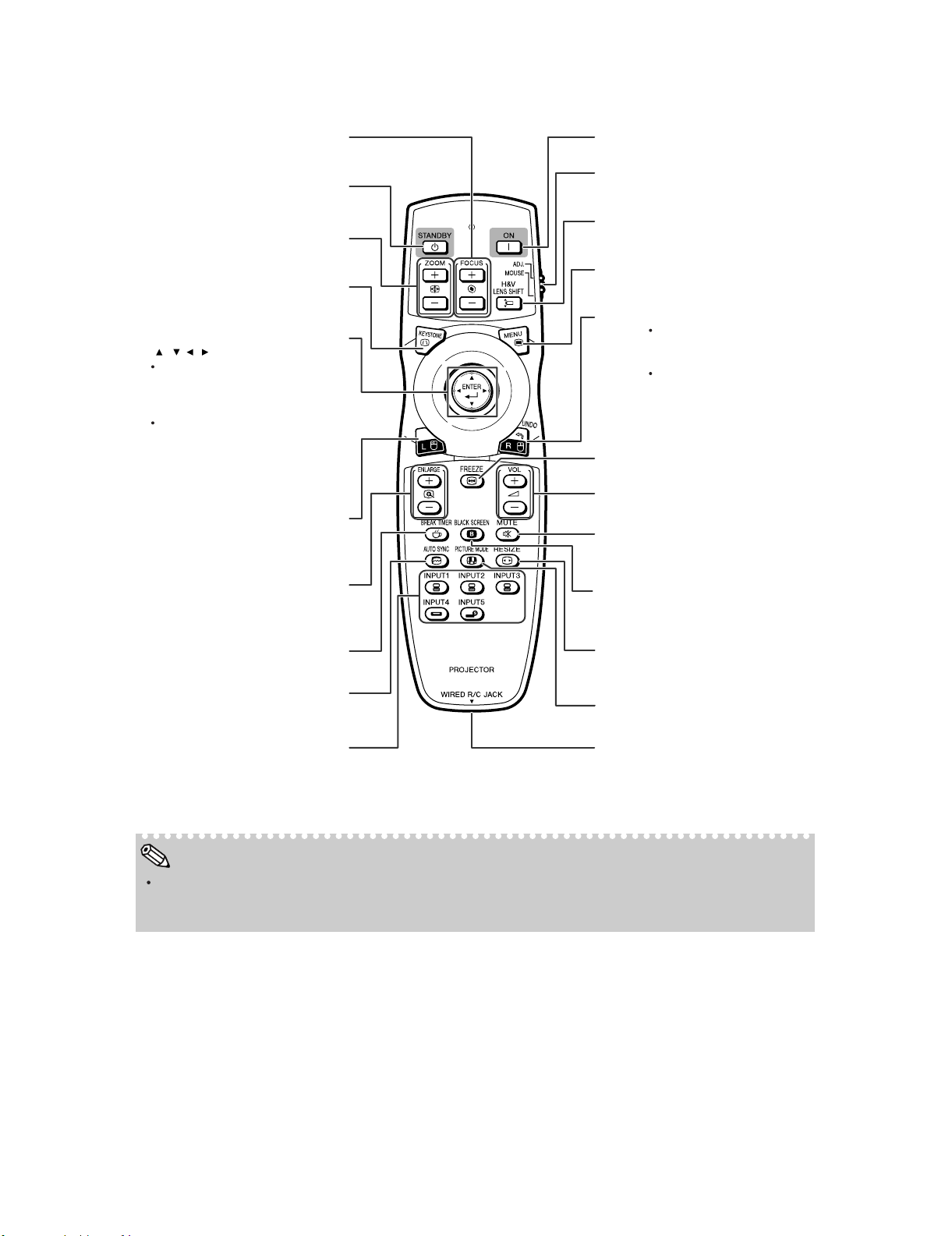

Remote Control

For bringing the projected image

into focus.

STANDBY button

FOCUS buttons

For putting the projector into

standby mode.

ZOOM buttons

For adjusting the projected

image size.

KEYSTONE button

For entering the Keystone

Correction mode.

Mouse/adjustment button

(///)

For moving the computer

cursor while the

ADJ./MOUSE switch is the

MOUSE position.

For selecting menu items

while the ADJ./MOUSE

s

witch is the ADJ. position.

ENTER button

For setting items selected or

adjusted on the menu.

L-click button

For the left click while the

ADJ./MOUSE switch is the

MOUSE position.

ENLARGE (enlarge/reduce)

buttons

For enlarging/reducing part of the

image.

BREAK TIMER button

For setting the break time.

ON button

For turning the power on.

ADJ./MOUSE switch

For switching the remote control

modes.

H & V LENS SHIFT button

For shifting the lens horizontally

and vertically.

MENU button

For displaying adjustment and

setting screens.

R-c

lick/UNDO button

For the right click while the

ADJ./MOUSE switch is the

MOUSE position.

For undoing an operation or

returning to the previous

display while the ADJ./MOUSE

switch is the ADJ. position.

FREEZE button

For freezing images.

Volume buttons

For adjusting the speaker sound level.

MUTE button

For temporarily turning off the

sound.

BLA

CK SCREEN button

For temporarily display the black

screen.

RESIZE button

F

or switching the screen size.

For automatically adjusting images

AUTO SYNC button

when connected to a computer.

INPUT 1, 2, 3, 4 and 5 buttons

For switching to the respective

input modes.

PICTURE MODE button

For switching the picture mode.

WIRED R/C JACK

For connecting the remote control

to the projector when the signals

from the remote control cannot

reach the remote control sensor.

Note

All the buttons on the remote control, except the mouse/adjustment button and the ADJ./MOUSE switch,

are made of luminous material that is visible in the dark. Visibility will diminish over time. Exposure to light

will recharge the luminous buttons.

1 – 5

Page 13

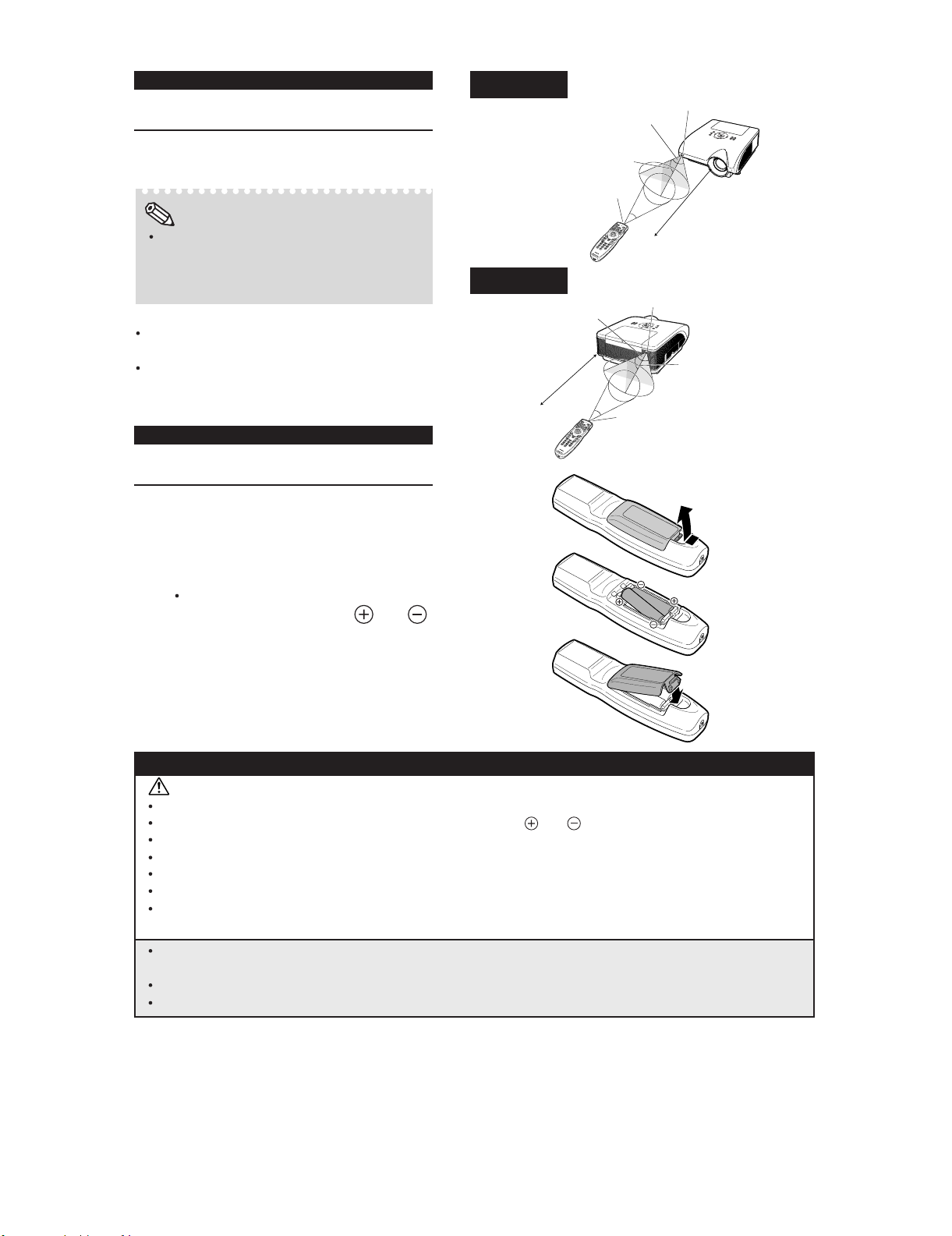

Usable Range

The remote control can be used to control the

projector within the ranges shown in the illustration.

Note

The signal from the remote control can be reflected off a screen for easy operation. However, the effective distance of the signal may

differ depending on the screen material.

When using the remote control:

Ensure that you do not drop it or expose it to

moisture or high temperature.

The remote control may malfunction under a

fluorescent lamp. In this case, move the projector away from the fluorescent lamp.

Inserting the Batteries

Front View

Remote control

signal transmitters

Rear View

23' (7 m)

XG-PH70X/XG-PH70X-N (1st. Edition)

Remote control sensor

30°

30°

30°

Remote control

Remote control sensor

30°

30°

Remote control

signal transmitters

Remote control

23' (7 m)

30°

1

Press the tab and lift open the battery

cover in the direction of the arrow

2

Insert the batteries.

Insert the batteries making sure the polarities correctly match the

marks inside the battery compartment.

3

Insert the tabs on the end of the

.

and

battery cover into their slots and

press the cover into position.

Incorrect use of the batteries may cause them to leak or explode. Please follow the precautions below.

Caution

Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type.

Insert the batteries making sure the polarities correctly match the

Batteries of different types have different properties, therefore do not mix batteries of different types.

Do not mix new and old batteries.

This may shorten the life of new batteries or may cause old batteries to leak.

Remove the batteries from the remote control once they have run out, as leaving them in can cause them to leak.

Battery fluid from leaked batteries is harmful to skin, therefore ensure you wipe them first and then remove them

using a cloth.

The batteries included with this projector may run down in a short period, depending on how they are kept.

Be sure to replace them as soon as possible with new batteries.

Remove the batteries from the remote control if you will not be using the remote control for a long time.

Comply with the rules (ordinance) of each local government when disposing of worn-out batteries.

and marks inside the battery compartment.

1 – 6

Page 14

XG-PH70X/XG-PH70X-N (1st. Edition)

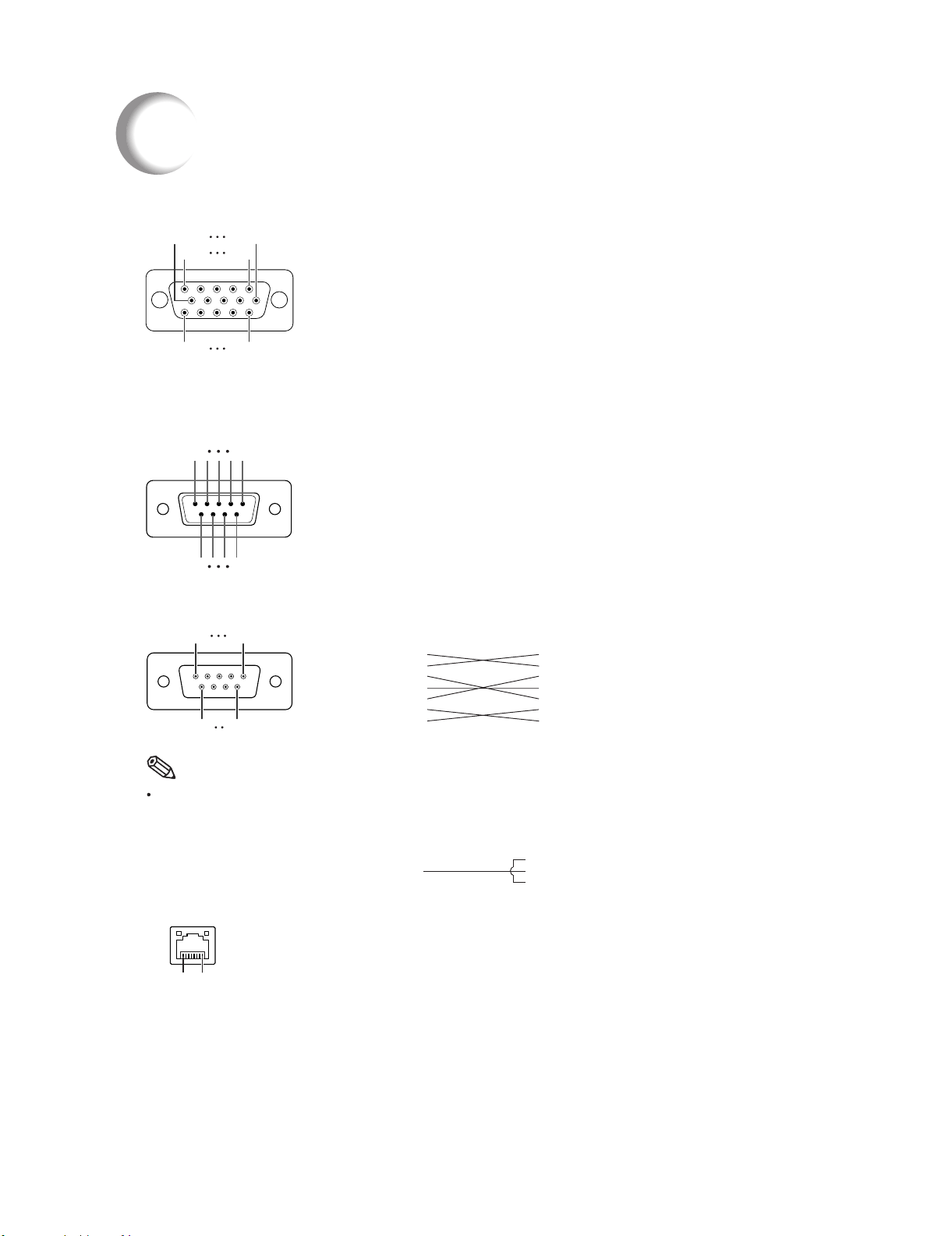

Connecting Pin Assignments

RGB Signal Terminal (INPUT 1 and OUTPUT (FOR INPUT 1, 2)): 15-pin mini D-sub female connector

10

5

15

RS-232C Terminal: 9-pin D-sub male connector

6

1

11

Pin No. Signal Name I/O Reference

51

RGB Input

1. Video input (red)

2. Video input (green/sync on green)

3. Video input (blue)

4. Not connected

5. Not connected

6. Earth (red)

7. Earth (green/sync on green)

8. Earth (blue)

9. Not connected

10. GND

11. Not connected

12. Bi-directional data

13. Horizontal sync signal: TTL level

14. Vertical sync signal: TTL level

15. Data clock

1 Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 Not connected

5 SG Signal Ground Connected to internal circuit

6 Not connected

7 RS Request to Send Connected to CS in internal circuit

8 CS Clear to Send Connected to RS in internal circuit

9 Not connected

Component Input

10. Not connected

11. Not connected

12. Not connected

13. Not connected

14. Not connected

15. Not connected

)

1. P

R(CR

2. Y

3. P

)

B(CB

4. Not connected

5. Not connected

6. Earth (P

7. Earth (Y)

8. Earth (P

9. Not connected

R

B

)

)

96

RS-232C Cable Recommended Connection: 9-pin D-sub female connector

51

96

Pin No. Signal Pin No. Signal

1CD 1 CD

2RD 2 RD

3SD 3 SD

4ER 4 ER

5SG 5 SG

6DR 6 DR

7RS 7 RS

8CS 8 CS

9CI 9 CI

Note

Depending on the controlling device used, it may be necessary to connect Pin 4 and Pin 6 on the controlling

device (e.g. computer).

Projector

Pin No.

4

5

6

Computer

Pin No.

4

5

6

LAN Terminal : 8-pin RJ-45 modular connector

Pin No. Signal Pin No. Signal

1TX+ 5

2TX− 6RX−

3RX+ 7

8...1

48

1 – 7

Page 15

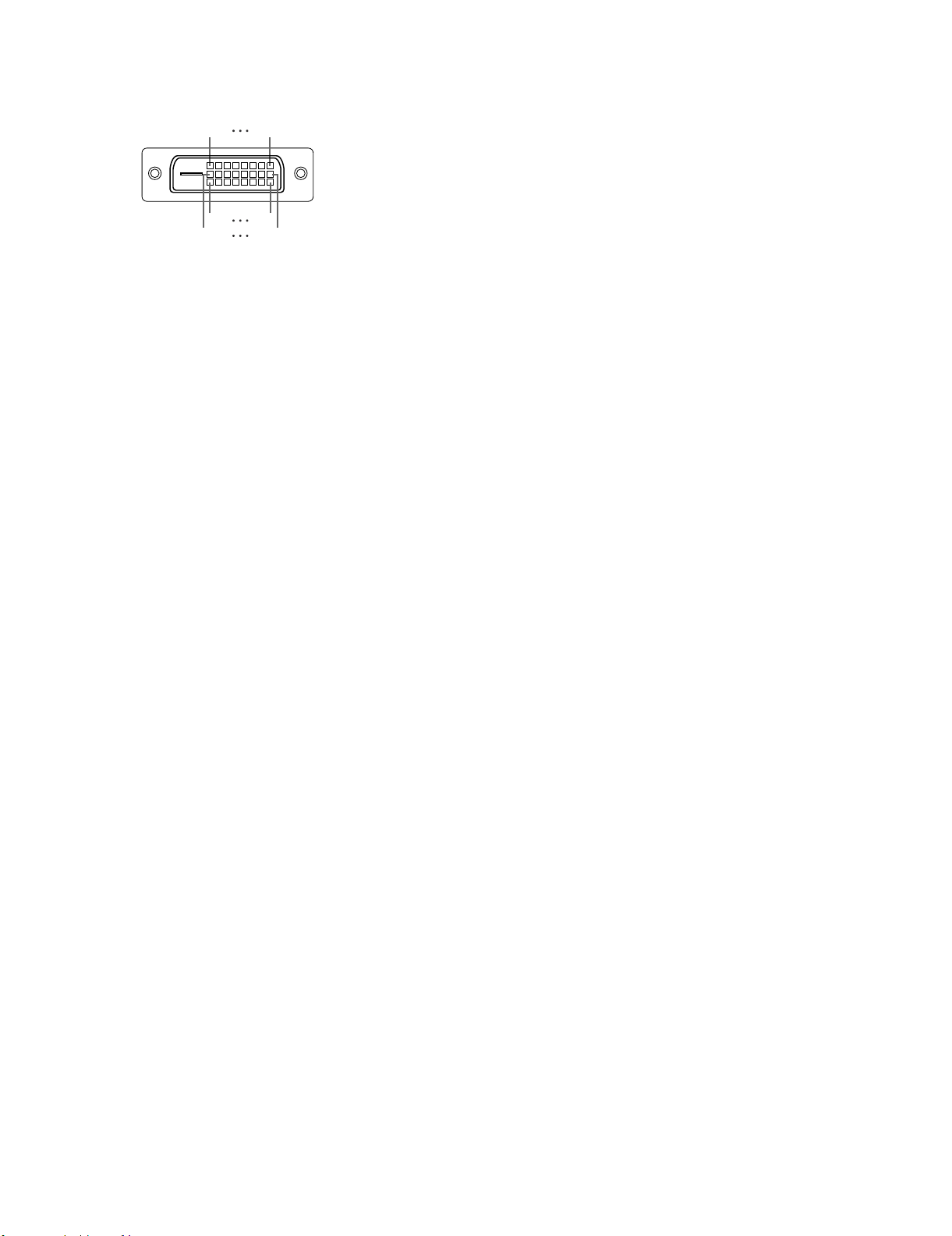

DVI digital Terminal (INPUT 3)

1724

8

16

1

9

Pin No. Signal

1 T.M.D.S. Data 2-

2 T.M.D.S. Data 2+

3 T.M.D.S. Data 2 Shield

4 Not connected

5 Not connected

6 DDC Clock

7 DDC Data

8 Not connected

9 T.M.D.S. Data 1

10 T.M.D.S. Data 1+

11 T.M.D.S. Data 1 Shield

12 Not connected

13 Not connected

14 +5 V Power

15 Ground

16 Hot Plug Detect

XG-PH70X/XG-PH70X-N (1st. Edition)

Pin No. Signal

17 T.M.D.S. Data 0-

18 T.M.D.S. Data 0+

19 T.M.D.S. Data 0 Shield

20 Not connected

21 Not connected

22 T.M.D.S. Clock Shield

23 T.M.D.S. Clock+

-

24 T.M.D.S. Clock

-

1 – 8

Page 16

XG-PH70X/XG-PH70X-N (1st. Edition)

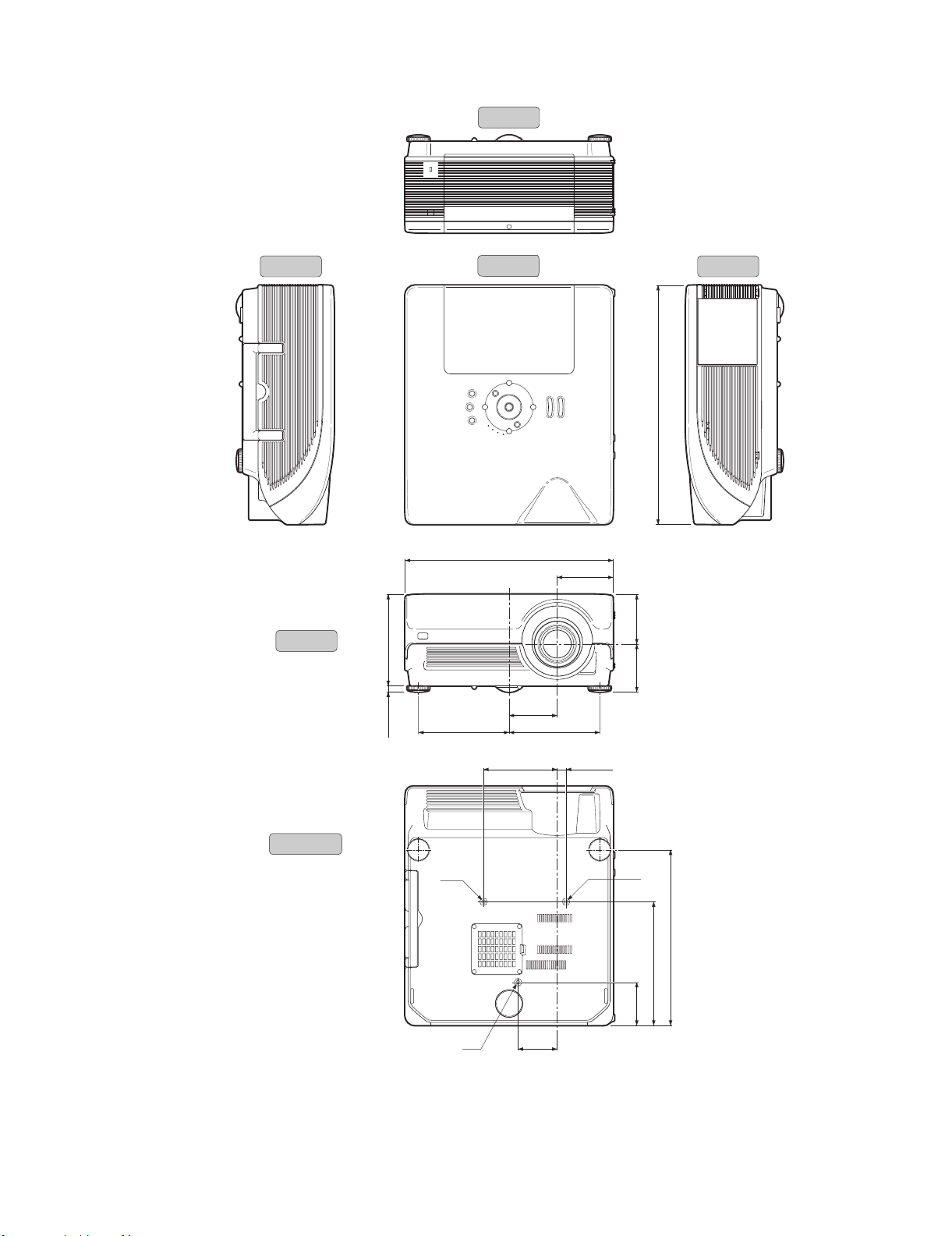

[3] DIMENSIONS

Units: inches (mm)

Side View Side View

Rear View

Top View

165/32(410)

11

4

/32(110.1)

/64 (471)

35

18

Front View

Bottom View

/32 (180)

3

7

/64 (12.1)

31

/64 (97.8)3

55

3

/32 (94.3)

23

3

3

/4(94.9)

1

7

/16(179)71/16(179)

547/64(145.5)

M4

M4

(77.27)

45

/64(17.5)

M4

/8 (346)

5

13

/64 (243.9)

39

9

/64 (85)

23

3

/

64

3

3

1 – 9

Page 17

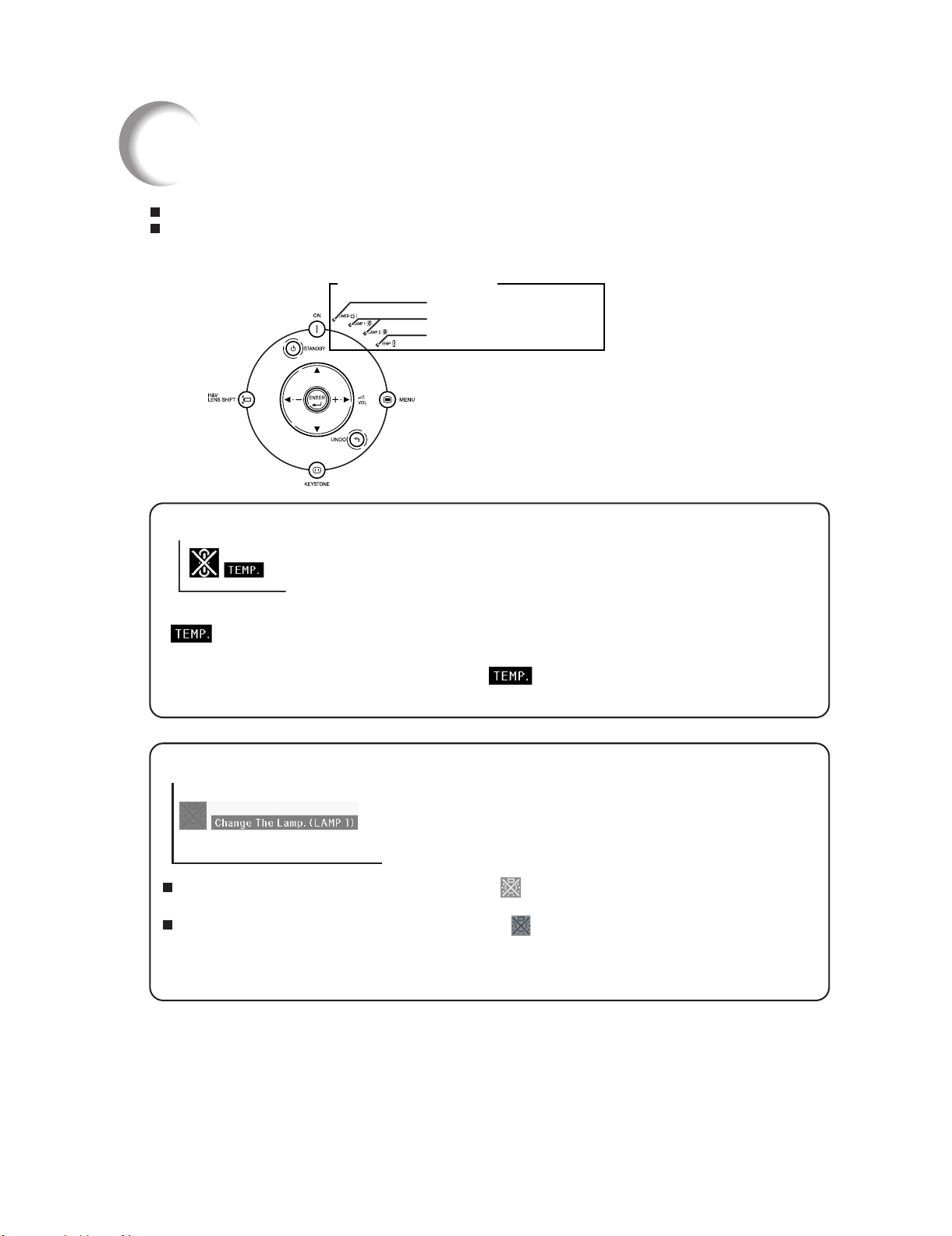

[4] Maintenance Indicators

Maintenance Indicators

The warning lights on the projector indicate problems inside the projector.

If a problem occurs, either the temperature warning indicator or the lamp indicator will illuminate

red, and the projector will enter the standby mode. After the projector has entered the standby

mode, follow the procedures given below.

XG-PH70X/XG-PH70X-N (1st. Edition)

Maintenance Indicators

Power indicator

Lamp indicators 1, 2

Temperature warning indicator

About the temperature warning indicator

If the temperature inside the projector increases, due to blockage of the air vents, or the setting location,

"

turn off and the temperature warning indicator will blink, the cooling fan will run for a further 90 seconds, and

then the projector will enter the standby mode. After "

" will illuminate in the lower left corner of the picture. If the temperature keeps on rising, the lamp will

" appears, ensure you perform the measures

About the lamp indicator

"Change The Lamp. (LAMP 2)" is displayed when the remaining life of the lamp 2 becomes 5% or less.

ı When the remaining lamp life becomes 5% or less,"

will be displayed on the screen.

ı When the percentage becomes 0%, it will change to "

this time, the lamp indicator will illuminate in red.

If you try to turn on the projector a fourth time without replacing the lamp, the lamp whose life is 0%

will not light up.

" (yellow) and "Change The Lamp. (LAMP 1/2)"

"(red), the lamp will automatically turn off. At

1 – 10

Page 18

XG-PH70X/XG-PH70X-N (1st. Edition)

Maintenance indicator

Temperature

warning

indicator

Lamp

indicators

1, 2

Power

indicator

Normal

Off

Green on

Green blinks

when the lamp

is warming up.

Green on/

Red on

Abnormal

Red on

(Standby)

Red on

Red on

(Standby)

Red

blinks

Problem

The internal

temperature is

abnormally high.

The lamp does

not illuminate.

Time to change

the lamp.

The lamp does

not illuminate.

The power

indicator blinks in

redwhenthe

projector is on.

Cause Possible solution

Relocate the projector to an area

Blocked air intake

Cooling fan breakdown

Internal circuit failure

Clogged air intake

Clogged intake vent

cover

The lamp is shut

down abnormally.

Remaining lamp life

becomes 5% or less.

Burnt-out lamp

Lamp circuit failure

The intake vent

cover is open.

with proper ventilation.

Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center for repair.

Clean the air vents and the intake

vent cover.

Disconnect the power cord from

the AC outlet, and then connect it

again.

Carefully replace the lamp.

Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center for repair.

Please exercise care when

replacing the lamp.

Securely install the cover.

If the power indicator blinks even

when the intake vent cover is

securely installed, contact your

nearest Sharp Authorized Projector

Dealer or Service Center for

advice.

Info

If the temperature warning indicator blinks and the projector enters the standby mode, the temperature

warning indicator starts to illuminate. Check whether any of the ventilation holes are blocked

and then try turning the power back on. Wait until the projector has cooled down completely before plugging

in the power cord and turning the power back on. (At least 10 minutes.)

If the power is turned off for a brief moment due to power outage or some other cause while using the

projector, and the power supply recovers immediately after that, the lamp indicator will illuminate in red

and the lamp may not be lit. In this case, unplug the power cord from the AC outlet, replace the power

cord in the AC outlet and then turn the power on again.

The cooling fan keeps the internal temperature of the projector constant and this function is controlled

automatically. The sound of the cooling fan may change during operation because the fan speed may

change and this is not a malfunction.

1 – 11

Page 19

[5] Regarding the Lamp

Regarding the Lamp

Lamp

It is recommended that the lamp units (optional: AN-PH7LP1 and AN-PH7LP2) be replaced when the

remaining lamp life becomes 5% or less, or when you notice a significant deterioration in the picture

and color quality. The lamp life (percentage) can be checked with the on-screen display.

Purchase a replacement lamp unit of type AN-PH7LP1 and AN-PH7LP2 from your place of purchase,

nearest Sharp Authorized Projector Dealer or Service Center.

IMPORTANT NOTE TO U.S. CUSTOMERS:

The lamp included with this projector is backed by a 90-day parts and labor limited warranty. All service

of this projector under warranty, including lamp replacement, must be obtained through a Sharp Authorized Projector Dealer or Service Center. For the name of the nearest Sharp Authorized Projector Dealer

or Service Center, please call toll-free: 1-888-GO-SHARP (1-888-467-4277).

Hg LAMP CONTAINS MERCURY For State Lamp Disposal Information

www.lamprecycle.org or 1-800-BE-SHARP

XG-PH70X/XG-PH70X-N (1st. Edition)

U.S.A. ONLY

Caution Concerning the Lamp

This projector utilizes a pressurized mercury lamp. A loud sound may indicate lamp failure. Lamp

failure can be attributed to numerous sources such as: excessive shock, improper cooling, surface

scratches or deterioration of the lamp due to a lapse of usage time.

The period of time up to failure largely varies depending on the individual lamp and/or the condition

and the frequency of use. It is important to note that failure can often result in the bulb cracking.

When the lamp indicator and on-screen display icon are illuminated, it is recommended that the

lamp be replaced with a new one immediately, even if the lamp appears to be operating normally.

Should the lamp break, the glass particles may spread inside the lamp cage or gas contained in the

lamp may be vented into the room from the exhaust vent. Because the gas in this lamp includes

mercury, ventilate the room well if the lamp breaks and avoid all exposure to the released gas. In

case of exposure to the gas, consult a doctor as soon as possible.

Should the lamp break, there is also a possibility that glass particles may spread inside of the

projector. In such a case, it is recommended you contact your nearest Sharp Authorized Projector

Dealer or Service Center to assure safe operation.

Replacing the Lamp

Caution

Do not remove the lamp unit from the projector right after use. The lamp will be very hot and may cause burn

or injury.

Wait at least one hour after the power cord is disconnected to allow the surface of the lamp unit to fully cool

before removing the lamp unit.

ı Carefully change the lamp by following the instructions described in this section. *If you wish, you

may have the lamp replaced at your nearest Sharp Authorized Projector Dealer or Service Center.

* If the new lamp does not illuminate after replacement, take your projector to the nearest Sharp Authorized

Projector Dealer or Service Center for repair.

1 – 12

Page 20

XG-PH70X/XG-PH70X-N (1st. Edition)

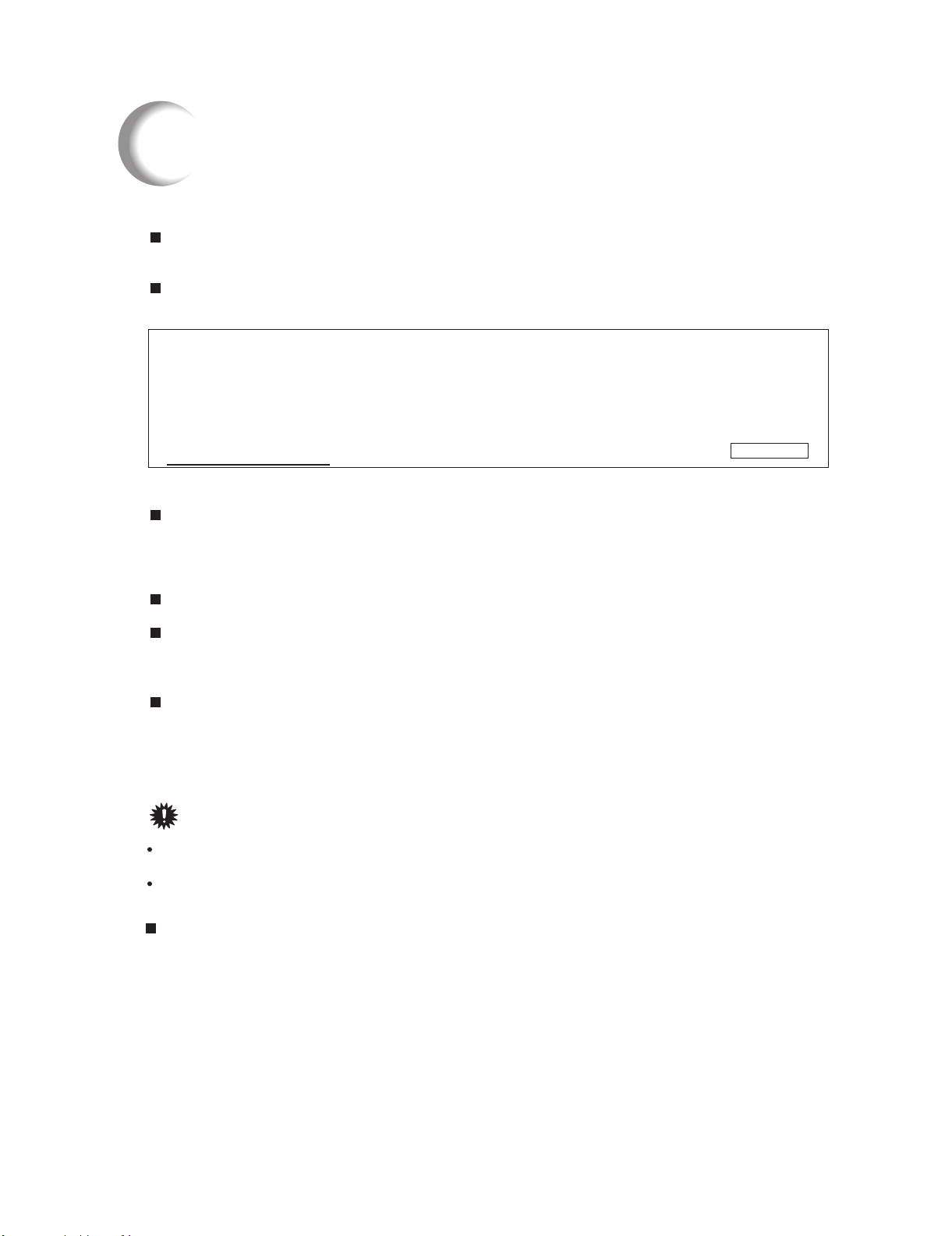

Removing and Installing

the Lamp Unit

Info

Ensure the lamp unit is removed using the

handle. Ensure the glass surface of the

lamp unit or the inside of the projector are

not touched.

To avoid injury to yourself and damage to

the lamp, make sure you carefully follow

the steps below.

Do not loosen other screws except for the

lamp unit cover and lamp unit.

(Only the silver screws are loosened.)

1

Press on the projector or

on the remote control to put

the projector into standby mode.

Wait until the cooling fan stops.

Warning!

Do not remove the lamp unit from the

projector right after use. The lamp and

parts around the lamp will be very hot

and may cause burn or injury.

Lamp unit 1

AN-PH7LP1

Optional

accessories

Lamp unit 2

AN-PH7LP2

STANDBY button

2

Disconnect the power cord.

Unplug the power cord from the AC

socket.

Leave the lamp until it has fully cooled

down (about 1 hour).

3

Remove the lamp unit cover.

Loosen the user service screw ( ) that

secures the lamp unit cover. Remove the

lamp unit cover ( ).

2

1

2

1

User service screw

1 – 13

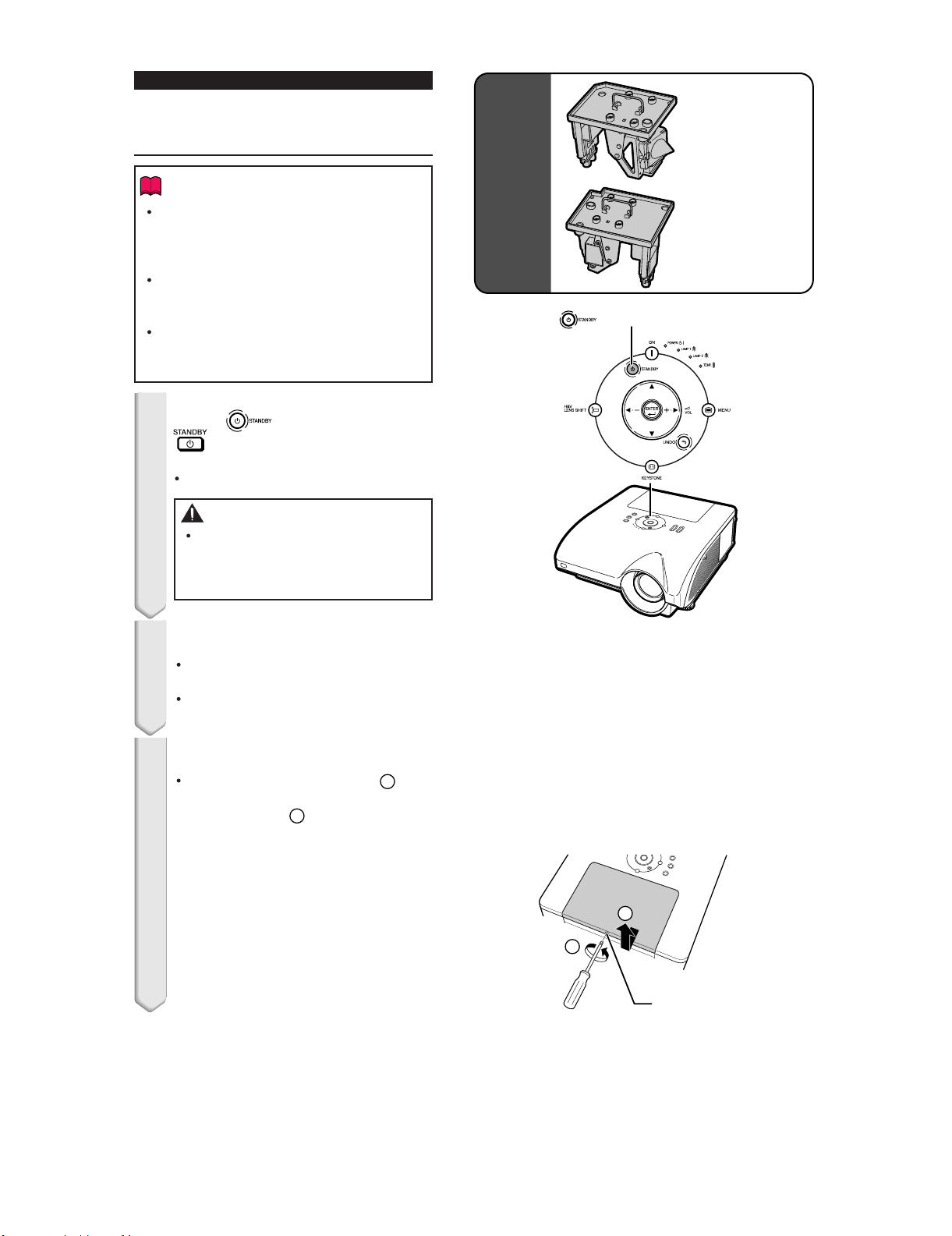

Page 21

XG-PH70X/XG-PH70X-N (1st. Edition)

Regarding the Lamp

4

Remove the lamp unit.

Loosen the securing screws (two for

each lamp) from the lamp unit. Hold the

lamp unit by the handle and pull it in the

direction of the arrow. At this time, keep

the lamp unit horizontal and do not tilt it.

5

Insert the new lamp unit.

Press the lamp unit firmly into the lamp

unit compartment. Fasten the securing

screws.

Be sure that AN-PH7LP1 and ANPH7LP2 are respective type.

6

Replace the lamp unit cover.

Align the lamp unit cover and slide it to

close. Then tighten the user service

screw to secure the lamp unit cover.

Info

If the lamp unit and lamp unit cover are not

correctly installed, the power will not turn

on, even if the power cord is connected to

the projector.

Handle

Securing screws

AN-PH7LP1

AN-PH7LP2

For Lamp 1

Compartment for

AN-PH7LP1

For Lamp 2

Compartment for

AN-PH7LP2

1 – 14

User service screw

Page 22

XG-PH70X/XG-PH70X-N (1st. Edition)

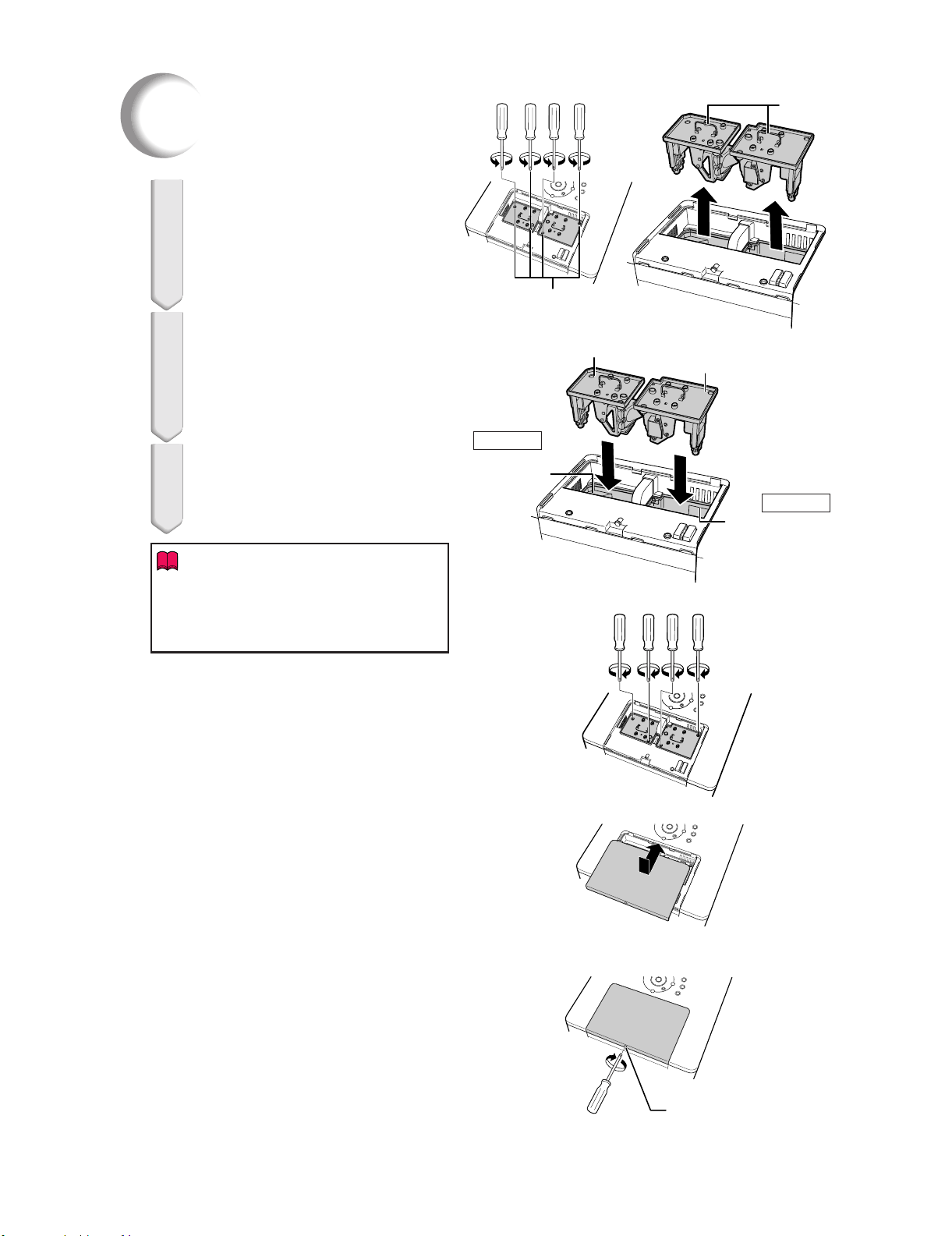

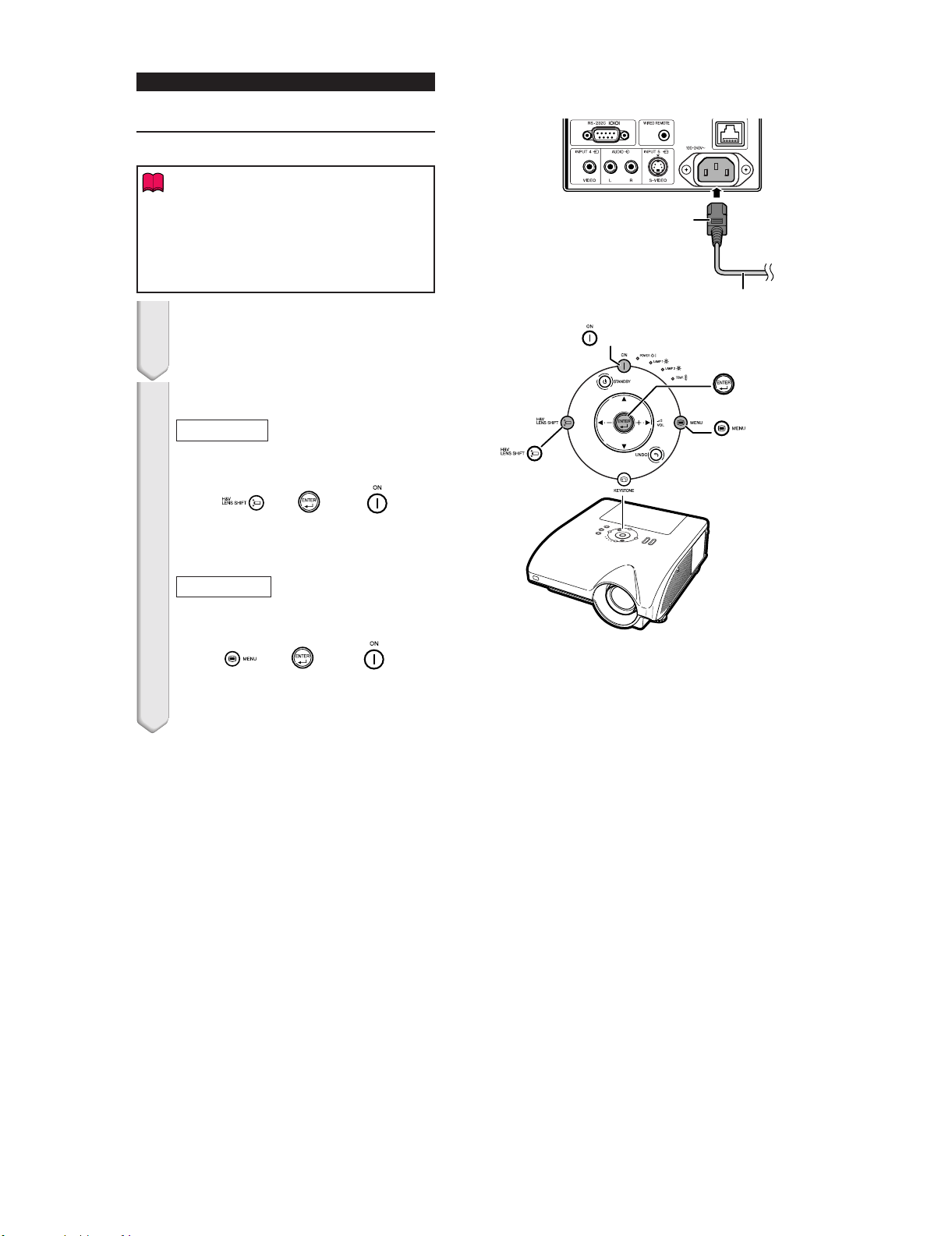

Resetting the Lamp Timer

Reset the lamp timer after replacing the lamp.

Info

Make sure to reset the lamp timer only

when replacing the lamp. If you reset the

lamp timer and continue to use the same

lamp, this may cause the lamp to become

damaged or explode.

1 Connect the power cord.

Plug the power cord into the AC socket

of the projector.

To AC socket

Power cord

ON button

2 Reset the lamp timer.

For Lamp 1

When you reset the timer for ANPH7LP1, while simultaneously holding

down

projector.

"LAMP 1 100%" is displayed, indicating

that the lamp timer is reset.

For Lamp 2

When you reset the timer for ANPH7LP2, while simultaneously holding

down

projector.

"LAMP 2 100%" is displayed, indicating

that the lamp timer is reset.

and , press on the

and , press

ENTER button

MENU button

H&V LENS

SHIFT

button

on the

1 – 15

Page 23

XG-PH70X

CHAPTER 2. REMOVING OF MAJOR PARTS

Service Manual

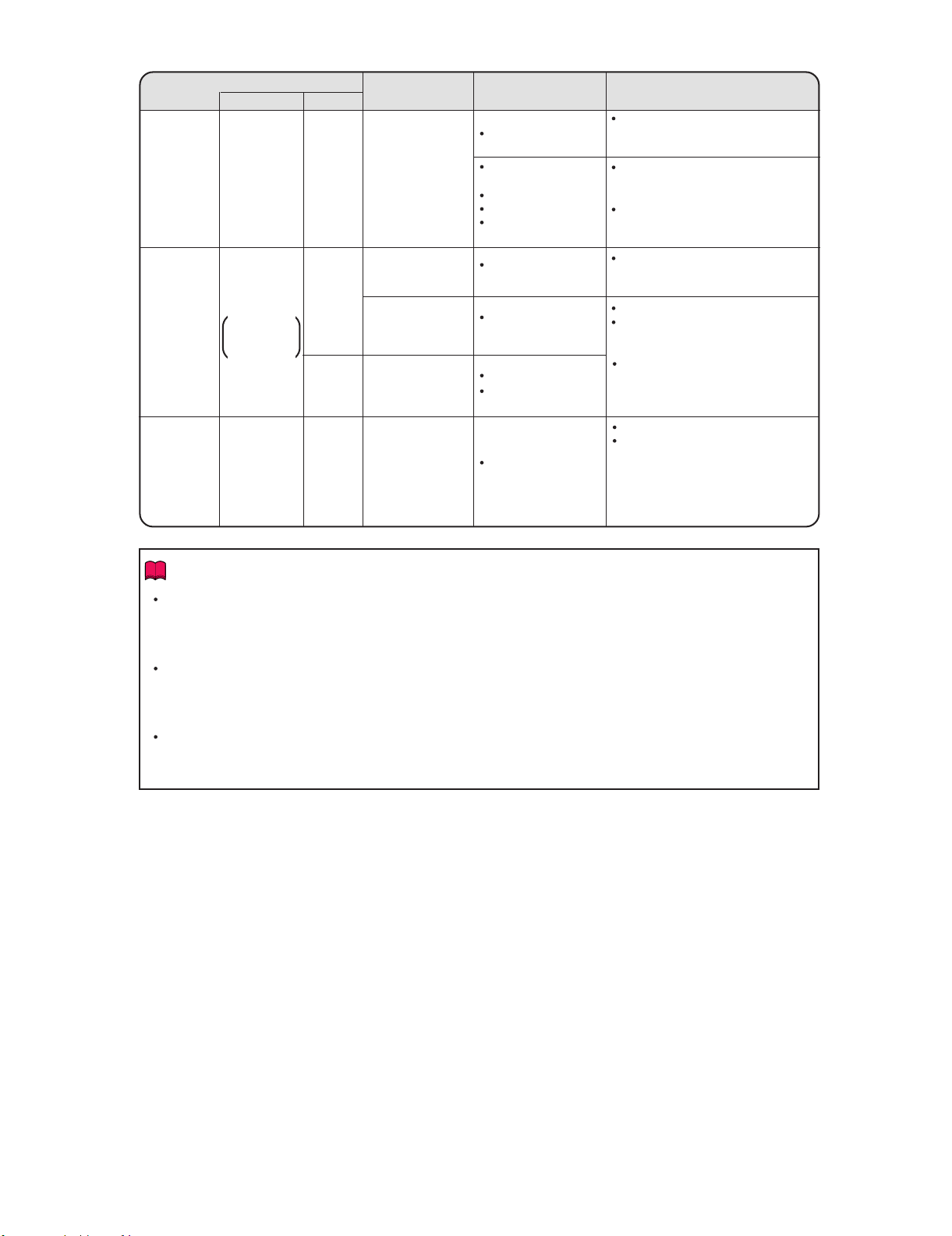

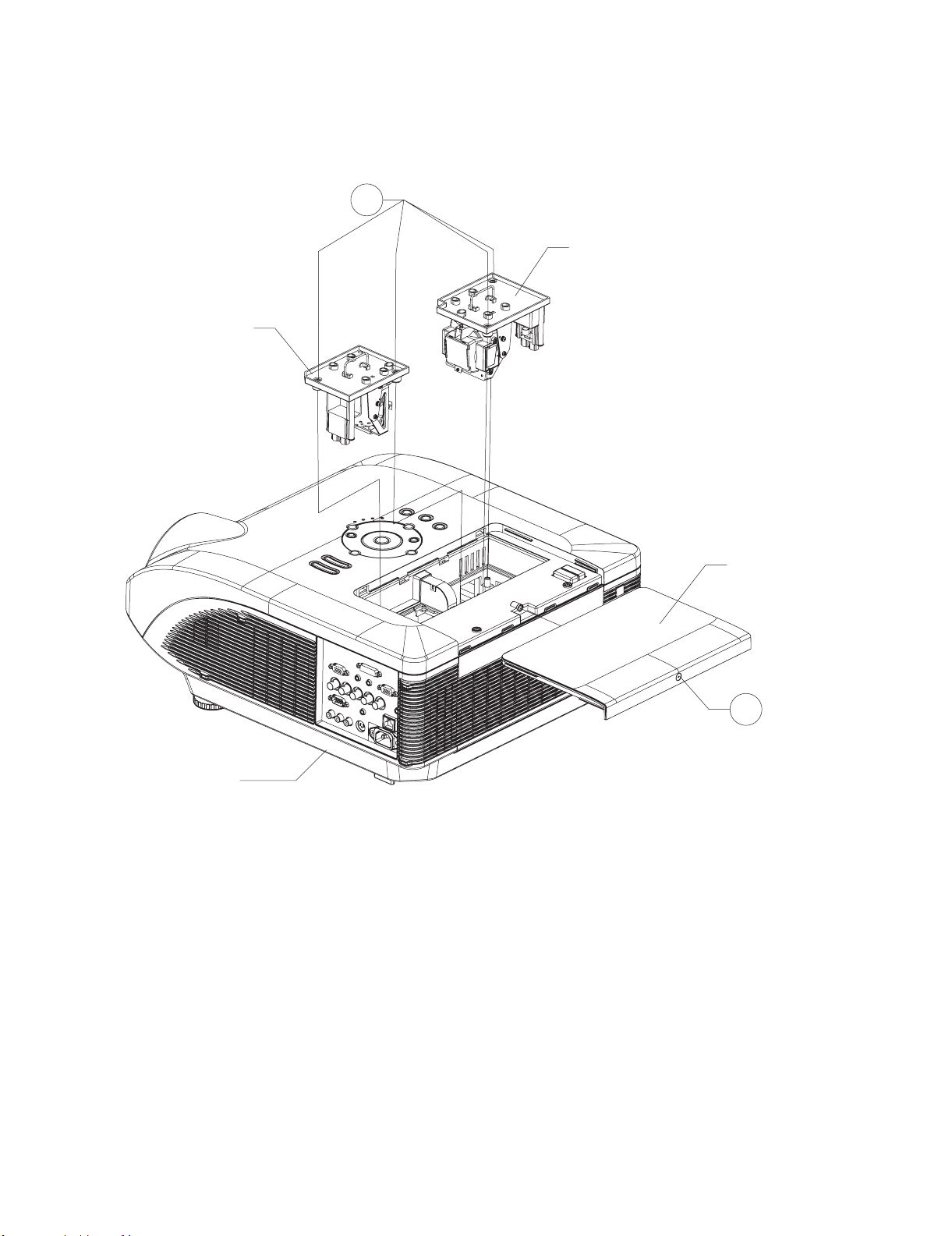

[1] Removing the Lamp Unit

1. Remove the screw from the lamp cover and detach the lamp cover.

2. Remove the four screws from the lamp units and take out the lamp units.

1-2

Lamp Unit 1

XG-PH70X/XG-PH70X-N (1st. Edition)

Lamp Unit 2

Bottom Case

Lamp Cover

1-1

2 – 1

Page 24

XG-PH70X/XG-PH70X-N (1st. Edition)

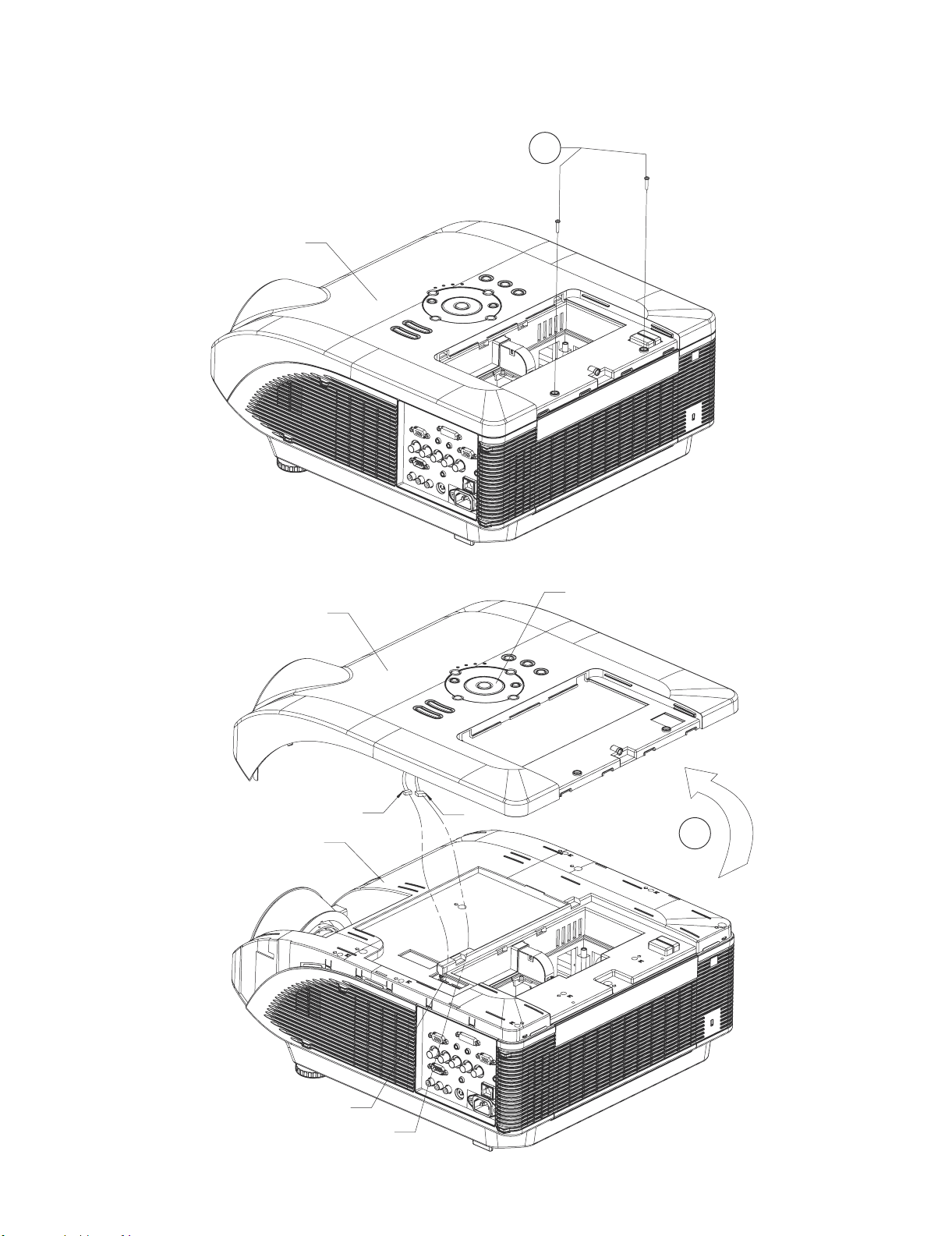

[2] Removing the Top Cover

1. Remove the two screws from the top cover.

2. Slowly lift the back of the top cover and disconnect the operation key connectors (KY1 and KY2). Pull up and off the top cover.

2-1

Top Cover

Top Cover

Top Cabinet

KY1

Operation Key

KY2

2-2

KY1

KY2

2 – 2

Page 25

XG-PH70X/XG-PH70X-N (1st. Edition)

[3] Removing the Lens Hood

* For XG-PH70X-N, the lens removal operations (sections 3 - 6) are unnecessary.

1. Slowly lift the lens hood up until it can be moved forward and then move it forward and detach the lens hood.

Top Cabinet

Lens Hood

[4] Removing the Lens Cap

1. Remove the lens cap.

3-1

Lens Cap

2 – 3

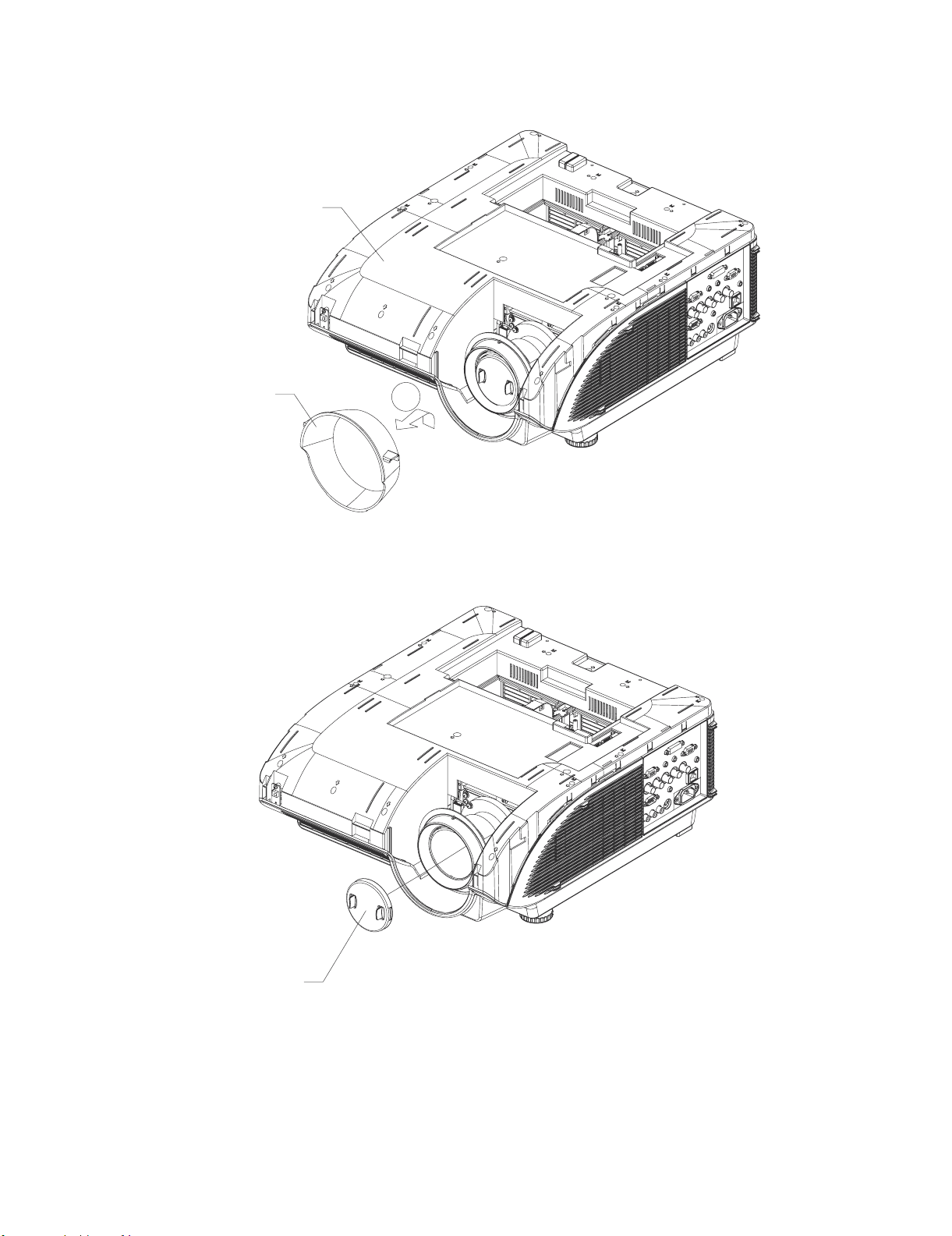

Page 26

XG-PH70X/XG-PH70X-N (1st. Edition)

[5] Removing the Lens Trim

1. Rotate the lens trim counterclockwise and then detach the lens trim.

5-1

Lens Trim

[6] Removing the Standard Lens

1. Disconnect the standard lens connector (SL).

2. Remove the three screws from the standard lens and take out the standard lens.

6-2

SL

6-1

Standard Lens

2 – 4

Page 27

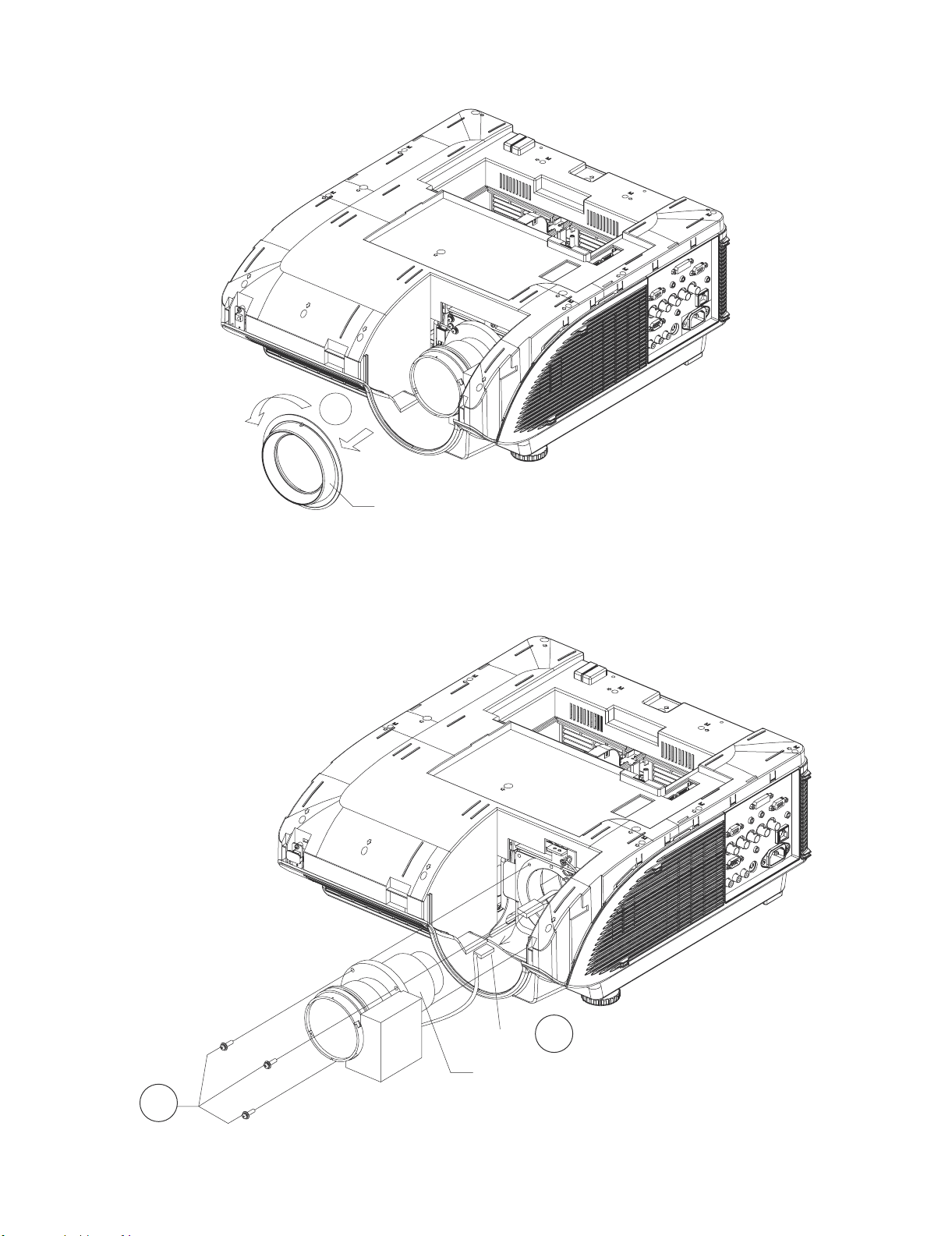

XG-PH70X/XG-PH70X-N (1st. Edition)

[7] Removing the Top Cabinet

1. Remove the screw from IR (Front) unit, take out the IR (Front) unit and then disconnect the IR (Front) unit connector (RC).

2. Remove the sixteen screws from the top cabinet and then pull up and off the top cabinet.

Top Cabinet

7-1

IR (Front) Unit

RC

7-2

Top Cabinet

2 – 5

Bottom Case

Page 28

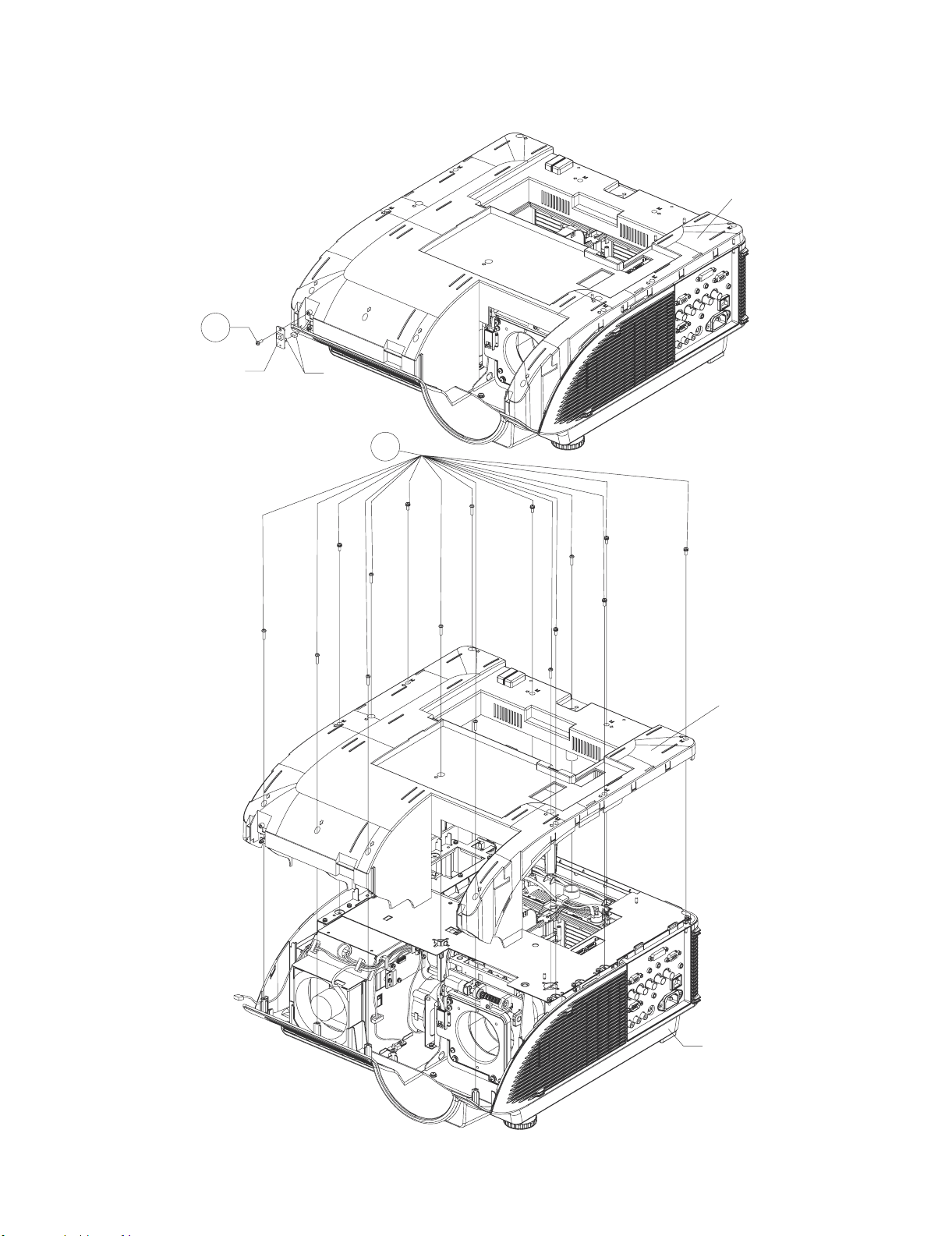

XG-PH70X/XG-PH70X-N (1st. Edition)

[8] Removing the Handle Bracket3

1. Remove the Eleven screws from the handle bracket3 and detach the handle bracket3.

8-1

Handle Bracket3

2 – 6

Page 29

[9] Removing the PWB Units

1. Disconnect all the connector from the Main Unit.

2. Remove the five screws from the Main Unit. Detach the Main Unit from the PC I/F Unit.

3. Remove the two spacers from the PC I/F Unit.

4. Remove the five spacers and the screw.

5. Disconnect the PC I/F Unit from the Terminal Unit and then detach the PC I/F Unit.

XG-PH70X/XG-PH70X-N (1st. Edition)

LSUD

LSRL

LSR

FC4

IR (Rear) Unit

FC1

FR

RC

AD

BTR

TS

BTL

PR

LSF

CW

9-2

FC3

FC5

TS

FC2

LSR

FC6

FC4

FC7

RC

LSL

9-5

LSL

FC6

RC

FC7

9-4

Main Unit

PC I/F Unit

Terminal Unit

RC

FC1

BTR

TS

PR

BTL

CW

FR

LSRL

LSUD

[Enlarged]

LSF

FC3

FC2

FC5

9-3

TS

2 – 7

Page 30

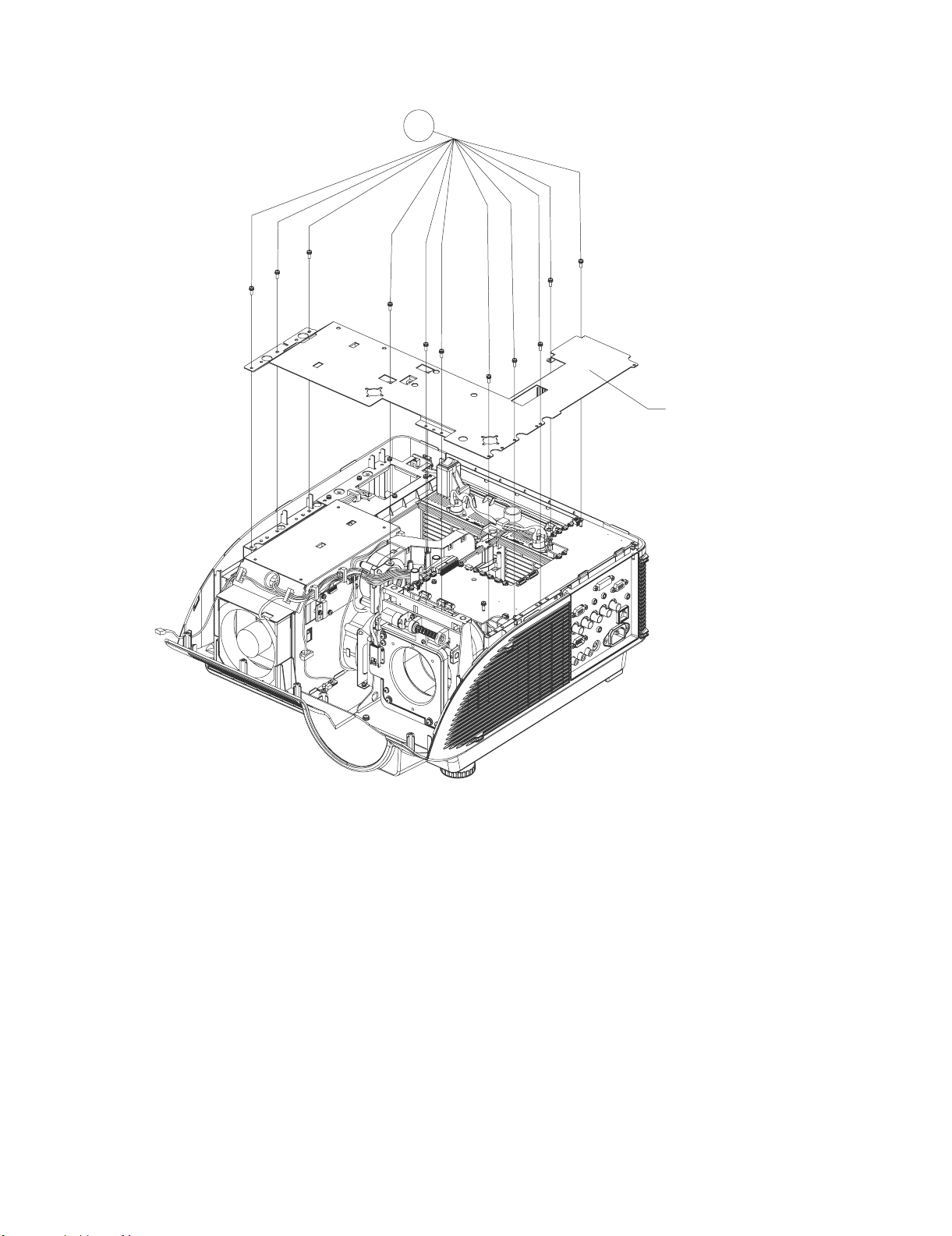

XG-PH70X/XG-PH70X-N (1st. Edition)

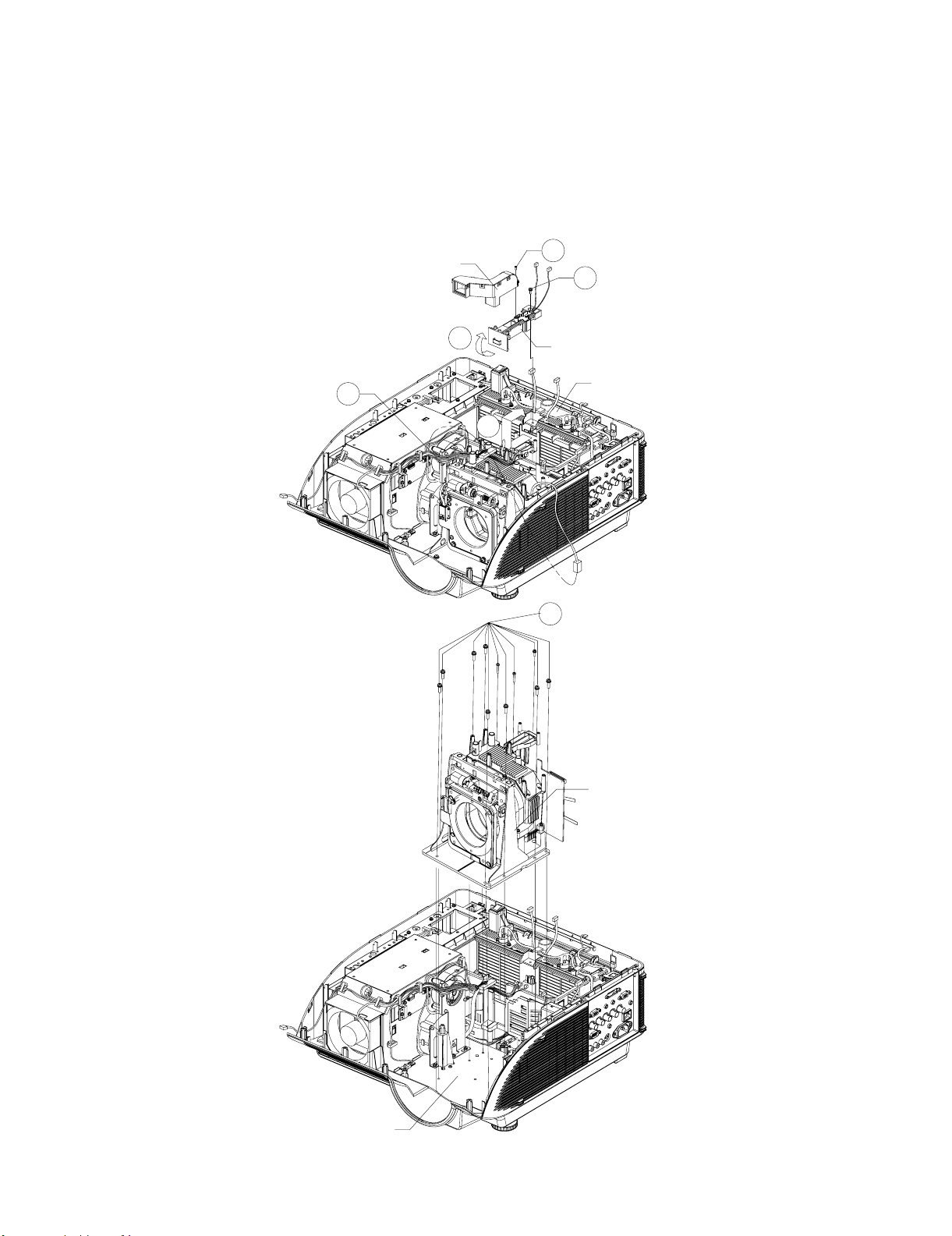

[10] Removing the Optical Engine and Lens Shift

1. Remove the screw from the rod duct and then detach the rod duct.

2. Remove the screw from the lamp channel top.

3. Unhook the front of the lamp channel top and take it out.

4. Slide the bimetal cover and detach it out.

5. Release the cable tie and then disconnect the left speaker connector.

6. Remove the eight screws from the lens shift and remove three screws from the optical engine and then lift the lens shift and optical engine out of

position.

10-5

Rod Duct

10-3

10-1

10-2

Lamp Channel Top

Bimetal Cover

10-4

10-6

Chassis

Lens Shift

2 – 8

Page 31

XG-PH70X/XG-PH70X-N (1st. Edition)

7. Remove the three screws from the optical engine and then lift the optical engine out of position.

10-6

Optical Engine

2 – 9

Page 32

XG-PH70X/XG-PH70X-N (1st. Edition)

[11] Removing the Terminal Unit

1. Remove the four screws from the terminal bracket, lift the terminal bracket and then disconnect the AC socket.

2. Remove the six spacers from the terminal unit.

3. Remove the six screws from the terminal unit and take out the terminal unit.

11-1

11-3

Terminal Unit

Chassis

11-2

Terminal Bracket

2 – 10

Page 33

XG-PH70X/XG-PH70X-N (1st. Edition)

[12] Removing the Filter Unit

1. Disconnect all the connectors from the filter unit. Remove the four screws from the filter unit and then take it out.

12-1

Filter Unit

Chassis

[13] Removing the IR (Rear) Unit

1. Disconnect all the connectors from the power unit. Remove the six screws from the Plate and then take out the Plate.

2. Remove the screw from the IR (Rear) unit and detach the IR (Rear) unit.

3. Remove the four screws from the Direct off unit and then take it out.

14-1

IR (Rear) Unit

14-2

14-1

Direct Off Unit

Power unit

Plate

14-1

PR3

PR2

PR1

PR3

PR2

PR1

Chassis

2 – 11

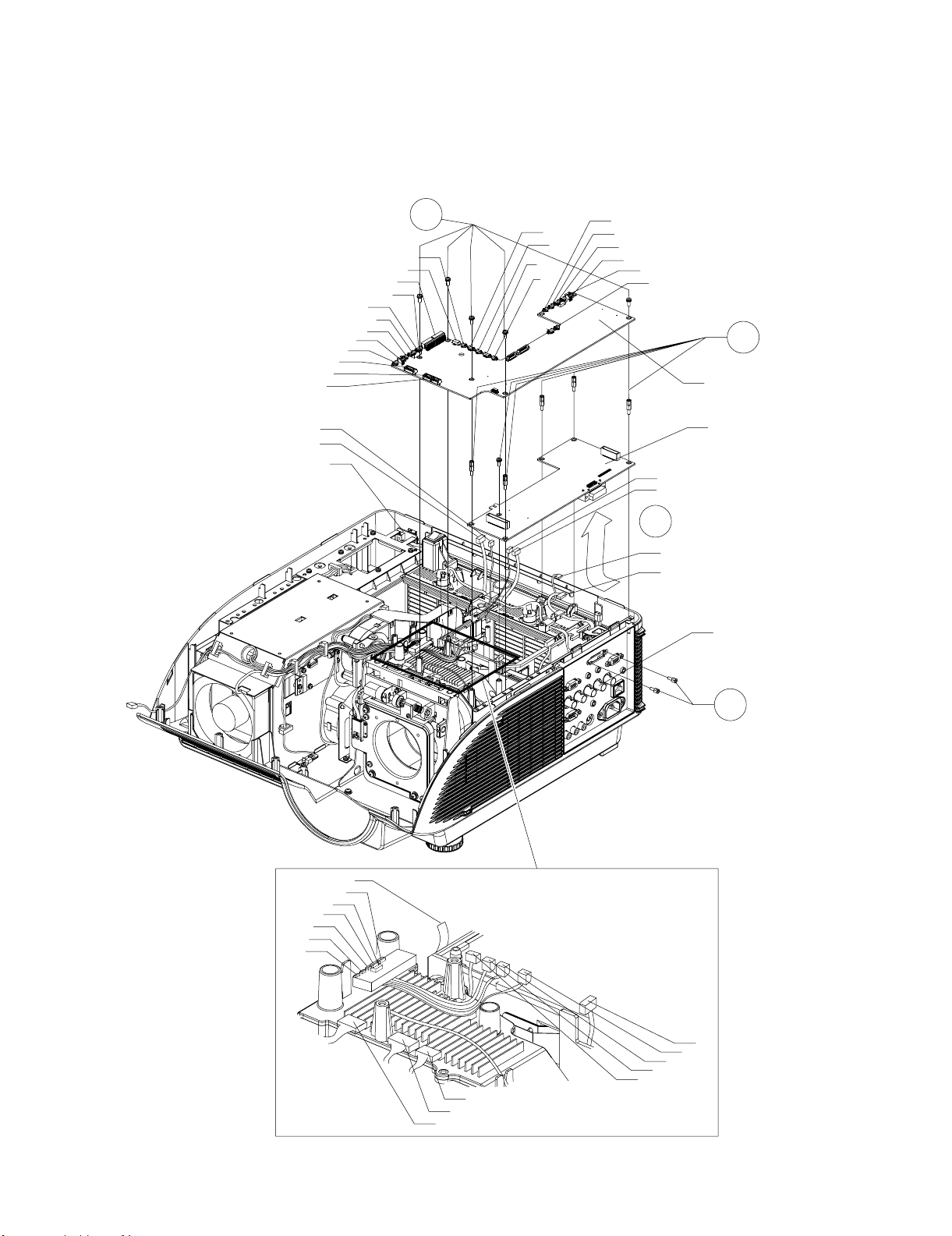

Page 34

XG-PH70X/XG-PH70X-N (1st. Edition)

[14] Removing the Power Unit and Audio Unit

1. Remove the four screws from the power unit.

2. Detach the power air guide from the power channel upper.

3. Remove the four screws from the power channel down and then disconnect the two power connector PR.

4. Remove the four screws from the power unit and then take out the power unit.

5. Remove the four screws from the holders and then disconnect the signal connectors SG.

6. Remove the four screws from the audio unit and then take out the audio unit.

Power Channel upper

Power Air Guide

Ballast Unit

Holder

14-2

14-5

SG

14-1

Power Unit

Audio Unit

14-6

Holder

14-4

Power Unit

Power Channel Down

14-3

Power Unit Insulator

Chassis

2 – 12

Page 35

XG-PH70X/XG-PH70X-N (1st. Edition)

XG-PH70X

CHAPTER 3. ELECTRICAL ADJUSTMENT

Service Manual

[1] ELECTRICAL ADJUSTMENT

– Turn on the power (lamp on state) and wait for 15 minutes for aging.

– Enter the adjustment process mode with S3602 (tact switch) on the main board.

In case that top cabinet covered S3602, you can enter by pushing key continuously in sequence.

key pad On -> Up -> Down -> Up -> Down -> Enter -> Enter -> Menu

Remote controller On -> Vol up -> Vol down -> Vol up -> Vol down -> Enter -> Enter -> Menu

* You can exit from factory mode by same method. (Or select "EXIT" in the process mode to exit.)

– Select the group to adjust with the DOWN key or the UP key, and enter the adjustment item with the ENTER key on the remote control or key pad.

– Select the adjustment item with the DOWN key or the UP key.

– Use the LEFT key or the RIGHT key for adjustment.

– To return from the adjustment item to the adjustment group, use the UNDO key or the MENU key.

– Change internal test pattern and input signal with the MUTE key

No. Adjusting point Adjusting conditions Adjusting procedure

1 Initialization of

EEPROM

2 Write MAC

address

3 Adjustment of

CW index

1. Turn on the power (the lamp lights

up) and warm up the system for 15

minutes.

2. Select the following group and

subject.

Group : SSS

Subject: S2

1. Signal input: 64 STEP color bar

signal.

2. Select the following group and

subjects.

Group : DLP

Subject : CW-INDEX

1. Press S3602 to enter the process mode.

2. Execute the S2 command on the SSS menu.

* With the S2 command, all the circuit boards than the PC board will be ini-

tialized.

NOTE: Since the PC I/F unit is initialized with S1, do not carry out S1.

The PC I/F unit is already adjusted.

When the PC I/F unit must be adjusted, in such case as S1 is carried

out by mistake, adjust it according to the "PC I/F adjustment method"

at the end of this document.

3. Wait approximately 30 seconds and when "INPUT1" appears, turn off the

power.

4. After all the fans stop, turn the power back on.

1. Read a sticker which is written mac address on main board.

2. Write MAC address by 232c serial cable. (For the procedure, refer to the

attachment.)

1. Feed the signal to INPUT 1.

2. Select subject and make adjustment so that the uniformity should be

smooth.

4 Adjustment of

DLP voltage

5-1 Adjustment of

Video brightness

5-2 Adjustment of

Video contrast

1. Read voltage rank of DLP

description.

2. Select the following group and

subjects.

Group : DLP

Subject : DMD-BIN

1. Select the following group and

subject.

Group : VIDEO

Subject : BRIGHT

1. Select the following group and

subject.

Group : VIDEO

Subject : PICTURE-SUB

R

G

B

1. Adjust DMD-BIN corresponding to the rank which has been read. (on the

main board)

Rank / setting value

B / 0

C / 1

D / 2

E / 3

* Carry out adjustment when DLP chip or PC board has been replaced

1. Check that the value is 115.

1. Check that the value is 157.

3 – 1

Page 36

XG-PH70X/XG-PH70X-N (1st. Edition)

No. Adjusting point Adjusting conditions Adjusting procedure

6 Adjustment of

component Cr/

Cb offset (1)

7 Adjustment of

component

brightness

1. Feed the color difference signal

(480i) to INPUT1

: Y 0% brightness, Cb and Cr 0%

white patterns.

2. Select the following group and

subject.

Group : COMPO

Subject : COMPO-AUTO

1. Feed the color difference signal

(480i) to INPUT1

: Y 0% brightness, Cb and Cr 0%

white patterns.

2. Select the following group and

subject.

Group : COMPO

Subject : G-BRIGHT

1. After signal input, select COMPO-AUTO for automatic adjustment.

1. Make adjustment so that some bits should be missing in the picture.

* refer to the following photo image

8 Adjustment of

component Cr/

Cb offset (2)

9 Adjustment of

RGB white balance

10 Adjustment of

sRGB white balance

11 adjustment of

video white balance

12 Adjustment of

DTV white balance

13 Factory settings 1. Select the following group and

for reference / setting

1. Feed the color difference signal

(480i) to INPUT1

: Y 0% brightness, Cb and Cr 0%

white patterns.

2. Select the following group and

subject.

Group : COMPO

Subject : CR-OFFSET

1. Feed the 50% gray pattern signal

(XGA, 60 Hz) to INPUT1.

2. Select the following group and

subject.

Group : DLP

Subjects : R1-GAIN (Red)

B1-GAIN (Blue)

1. Feed the 50% gray pattern signal

(XGA, 60 Hz) to INPUT1

2. Select the following group and

subject.

Group : DLP

Subjects : S-G1-GAIN (Green)

S-B1-GAIN (Blue)

1. Feed the 50% gray pattern signal

(NTSC, burst signal) to INPUT4.

2. Select the following group and

subject.

Group : DLPV

Subjects : V-R1-GAIN (Red)

V-B1-GAIN (Blue)

1. Feed the 50% gray pattern signal

(480i, color difference signal) to

INPUT1.

2. Select the following group and

subject.

Group : DLPV

Subjects : C-R1-GAIN (Red)

C-B1-GAIN (Blue)

subject.

Group : SSS

Subject : S4 (North America)

S3 (Europe/Asia/Australia)

S5 (Japan)

1. Reduce the CR-OFFSET value by 2 points.

1. Adjust R1-GAIN and B1-GAIN so that x-value should be 290 ±3 and y value 310 ± 3.

1. Adjust S-G1-GAIN and S-B1-GAIN so that x-value should be 313 ±5 and y value 329 ± 5.

1. Adjust V-R1-GAIN and V-B1-GAIN so that x-value should be 290 ± 3 and y value should be 310 ± 3.

1. Adjust C-R1-GAIN and C-B1-GAIN so that x-value should be 290 ± 3 and y value should be 310 ± 3.

1. Make the following settings.

PH70XU : S4 (to north America)

PH70X : S5 (to Japan)

Other : S3 (to Europe/Asia/Australia)

OSD language Video-set up level

S3 English 0IRE

S4 English 7.5IRE

S5 Japanese 0IRE

3 – 2

Page 37

XG-PH70X/XG-PH70X-N (1st. Edition)

No. Adjusting point Adjusting conditions Adjusting procedure

14 Lens shift posi-

tion

15 Turn off the

power

1. Move lens shift position

Vertical : Top position

Horizontal: Center

[2] PC I/F adjustment method

NOTE: Since the PC I/F unit is initialized with S1, do not carry out S1. The PC I/F unit is already adjusted.

When the PC I/F unit must be adjusted, in such case as S1 is carried out by mistake, adjust it according to the followings

No. Adjusting point Adjusting conditions Adjusting procedure

1 Initialization of

EEPROM

2 RGB tone repro-

duction adjustment

1. Select the following group and

subject.

Group : SSS

Subject : S1

1. Feed the window pattern signal

that has 92% (0.64Vbw) and 0%

signals (XGA/60Hz) to input 1

2. Select the following group and

subject.

Group : A/D

Subjects : AD-AUTO

1. Press S3602 to enter the process mode.

2. Execute the S2 command on the SSS menu. (By S1, all the contents of

EEPROM are initialized.)

1. After signal input, select AD-AUTO for automatic adjustment.

* When you can not prepare 92%

signal

1. Feed the window pattern signal

that has 100% (0.7Vbw) and 0%

signals.

(XGA/60Hz) to input 1

* "MUTE" key will be change to

the factory gamma

1. Select the following group and subject.

Group : A/D

Subjects : G-BRIGHT

2. Make adjustment so that some bits should be missing in black area of the

picture.

3. Select the following group and subject.

Group : A/D

Subjects : G-D

4. Make adjustment so that some bits should be missing in white area of the

picture.

5. Select the following subject.

Subjects : R-BRIGHT

6. Make adjustment so that some bits should be missing in black area of the

picture.

7. Select the following subject.

Subjects : R-D

8. Make adjustment so that some bits should be missing in white area of the

picture.

9. Select the following subject.

Subjects : B-BRIGHT

10. Make adjustment so that some bits should be missing in black area of the

picture.

11. Select the following subject.

Subjects : B-D

12. Make adjustment so that some bits should be missing in white area of the

picture.

3 – 3

Page 38

XG-PH70X/XG-PH70X-N (1st. Edition)

[3] Special 232c command for factory

How to write MAC address (Write) Send the following 232c commands in sequence

1. _ L M A 0 0 *1 *2 +"enter" key *1 the first byte

wait "OK" *2 the second byte

2. _ L M A 1 0 *3 *4 + "enter" key *3 the third byte

wait "OK" *4 the fourth byte

3. _ L M A 2 0 *5 *6 + "enter" key *5 the fifth byte

wait "OK" *6 the sixth byte

4. _ L M A 3 0 *7 *8 + "enter" key *7 the seventh byte

wait "OK" *8 the eighth byte

5. _ L M A 4 0 *9 *10 + "enter" key *9 the ninth byte

wait "OK" *10 the 10th byte

6. _ L M A 5 0 *11 *12 + "enter" key *11 the 11th byte

(Read) Send the following 232c commands

_ L M A 1 + "enter" key

MAC address will be appear on screen

*12 the 12th byte

How to write serial number (Write) Send the following 232c commands in sequence.

1. S N _ 1 1 2 3 4 + “enter” key

wait “OK”

2. S N _ 2 5 6 7 8 + “enter” key

wait “OK”

3. *1 *2 *3 *4 *5 *6 *7 *8 *9 *10 *11 *12 + “enter” key

4. *1 *2 *3 *4 *5 *6 *7 *8 *9 *10 *11 *12 + “enter” key

wait “OK”

(Read) Send the following 232c commands

S N R D 1 + “enter” key

serial number will be appear on screen

*1~*12/serial number

same data as step3

NOTE: When number of characters of the serial number is shorter than twelve characters,

please use space character ““.

for example

serial number is “1311163”

1 3 1 1 1 6 3 + “enter” key

serial number is “412311112”

4 1 2 3 1 1 1 1 2 + “enter” key

How to check projector status (Read) Send the following 232c commands

T F C K 1 + “enter” key

serial number will be appear on screen

3 – 4

Page 39

XG-PH70X/XG-PH70X-N (1st. Edition)

[4] SERVICE MODE

1. How to enter Service Mode

Select the group “Option2” by user menu and then select “service Mode”.

Enter the password “9303”

2. How to adjust in service mode

– Select the group to adjust with the DOWN key or the UP key,

and enter the adjustment item with the ENTER key on the remote control or key pad.

– Select the adjustment item with the DOWN key or the UP key.

– Use the LEFT key or the RIGHT key for adjustment.

– To return from the adjustment item to the adjustment group, use the UNDO key or the MENU key.

NOTE: – In service mode, user adjustment value will be changed to default value (Picture/CMS).

When you exit from service mode, adjustment value will change to user adjustment value.

– In service mode, the following functions will be canceled.

AV mute / sound mute / freeze / enlarge / PinP

* "standby" button on a remote controller and a operation pad is invalid in the service mode.

If you would like to turn off the power, please exit from service mode.

3. Adjustment of white balance

• Adjustment of RGB PC 1. Feed a RGB PC signal to input1

white balance 2. Select the group "DLP"

PH70X will change to input1/RGB mode automatically

group Subject initial value effective range adjustment source/mode

DLP R1-BLK 0 ±20 brightness of red INPUT1 / RGB

R1-GAIN 0 ±20 contrast of red INPUT1 / RGB

G1-BLK 0 ±20 brightness of green INPUT1 / RGB

G1-GAIN 0 ±20 contrast of green INPUT1 / RGB

B1-BLK 0 ±20 brightness of blue INPUT1 / RGB

B1-GAIN 0 ±20 contrast of blue INPUT1 / RGB

• Adjustment of video 1. Feed a video signal

white balance 2. Select the group "DLPV"

PH70X will change to input4 mode automatically

group Subject initial value effective range adjustment source/mode

DLPV V-R1-BLK 0 ±20 brightness of red INPUT4 / video

V-R1-GAIN 0 ±20 contrast of red INPUT4 / video

V-G1-BLK 0 ±20 brightness of green INPUT4 / video

V-G1-GAIN 0 ±20 contrast of green INPUT4 / video

V-B1-BLK 0 ±20 brightness of blue INPUT4 / video

V-B1-GAIN 0 ±20 contrast of blue INPUT4 / video

• Adjustment of DTV 1. Feed a component signal to input1

white balance 2. Select the group "DLPV"

PH70X will change to input1/component mode automatically

group Subject initial value effective range adjustment source/mode

DLPV C-R1-GAIN 0 ±20 contrast of red INPUT1 / component

C-G1-GAIN 0 ±20 contrast of green INPUT1 / component

C-B1-GAIN 0 ±20 contrast of blue INPUT1 / component

(memo) The adjustment value of the brightness is common to video.

3 – 5

Page 40

XG-PH70X/XG-PH70X-N (1st. Edition)

4. Adjustment of video

1. Feed a video signal

2. Select the group "VIDEO"

PH70X will change to input4 mode automatically

group Subject initial value effective range adjustment source/mode

adjustment of VIDEO VIDEO PICTURE 0 ±60 contrast INPUT4 / video

picture BRIGHT 0 ±60 brightness INPUT4 / video

adjustment of VIDEO TINT 0 ±120 tint (effected in NTSC only) INPUT4 / video

color N-COLOR 0 ±120 color saturation INPUT4 / video

setting of VIDEO gain control

AGC-CNT 0-1 auto gain control INPUT4 / video

0 : AGC On

1 : AGC Off

adjustment of delay

DLY 0 ±5 INPUT4 / video

between chroma and luminance

adjustment of VIDEO

horizontal position H-CENTER 0 ±10 INPUT4 / video

adjustment of VIDEO

low pass filter FILTER 0 ±3 filter gain INPUT4 / video

5. Others

group Subject initial value effective range adjustment source/mode

VIDEO COMP-FILTER 0 0-1 0 : filter off, 1 : filter on INPUT1 / component

switch of component

low pass filter

switch of RGB

low pass filter RGB-FILTER 0 0-1 0 : filter off, 1 : filter on INPUT1 / RGB

switch of audio delay

of internal speaker A-DELAY 0 0-1 0 : delay on, 1 : delay off INPUT4 / video

6. Initialization of adjustment value

RESET - Select this item and push ENTER key.

Value inside each item of "DLP", "DLPV" and "VIDEO" is returned to the initial value with RESET.

7. Internal test pattern

group Subject initial value effective range signal

PATTERN RGB 1 1-8 raster signal

RGB[50] 1 1-8 50% raster signal

CROSS 1 1-9 cross hatch

FOCUS 1 1-2 checkered signal

STEP 1 1-2 8step/16step

COLOR color bar

CHR 1 1-4 oblique line and vertical line

8. Firmware version

group Subject version

FIRMWARE SUB *.**

MAIN-LOADER *.**

MAIN-ZIMAGE *.**

MAIN-MTD *.**

MAIN-JFFS *.**

3 – 6

Page 41

XG-PH70X/XG-PH70X-N (1st. Edition)

9. Network setting

group Subject address

NETWORK IP ADDRESS 192.168.150.002

MAC ADDRESS **:**:**:**:**:**

10. Exit from service mode

group

EXIT - Select this item and push ENTER key.

[5] Failure mode when the lamp does not light up even when powered on

1. Status of LED

• POWER does not light up.

The sub CPU (IC3603) does not start. Check the peripheral circuits.

• POWER blinks in red.

0.5-second interval: Fan error detection.

(This unit detects the number of fan revolutions. When the fan is running more slowly than the preset lower speed limit, the

power is shut down by the protection function even if the fan does not stop completely.)

1-second interval: Bottom air filter cover (RCS) detection.

2-second interval: Communication error between sub CPU (IC3603) and main CPU (IC8003).

• LAMP LED blinks in red.

1-second interval: Lamp leaf switch detection.

(The power is not turned on if the lamp cartridge is removed from the unit.)

2. Checking the status via RS232C serial communication

Send "TFCK 1" + ENTER, "TABN 1" via 232C communication to check the status of the projector.

Return value example of the normal unit

TFCK 1

[ RCS ] Close

[ Lamp1 Leaf ] Close

[ Lamp2 Leaf ] Close

[ Main-Sub ] Communication OK.

[ Fan ] Normal

[ pwm Fan1] No error

[ pwm Fan2] No error

[ pwm Fan3] No error

[ pwm Fan4] No error

[ pwm Fan5] No error

[ pwm Fan6] No error

[ dac Fan0] No error

[ dac Fan1] No error

[ Temperature ] Normal

[ Lamp1 Non Light ] Normal

[ Lamp2 Non Light ] Normal

[ Lamp Life1 ] Normal

[ Lamp Life2 ] Normal

OK

3. Others

• The lamp does not light up if the color wheel motor does not run.

• The lamp does not light up if the thermistor sensor is not connected (e.g. breaking of wire).

• The lamp does not light up when if a communication error occurs between IC8003 and IC8025 on the PC board.

3 – 7

Page 42

XG-PH70X/XG-PH70X-N (1st. Edition)

4. Disabling of the sensors

CAUTION: When the unit is returned to a user with the sensors disabled, the cabinet may be deformed by heat because the protection function does

not work. After completion of inspection, be sure to restore the sensors to their original state.

• Temperature sensor

Mount a resistor of 10 k_ between pins 1 and 2 of CN7205 and a resistor of 12 kΩ between pins 1 and 2 of CN7005 to turn on the power with the

sensor detached. Since the unit is set to the sensor temperature fixed mode, the fan speed is fixed to low speed. After completion of inspection, be

sure to remove the resistors.

• Fan lock detection

This unit detects the pulse of the fan. When checking the operation of the PWBs without running the fan, connect the pin C8 of IC3603 (on the pin

C8 side of R3727) to GND with a jumper wire. Even if the fan does not run, the unit continues operation. Therefore the reliability of parts cannot be

maintained. After completion of inspection, be sure to remove the jumper wire.

• Air filter cover detection

Short-circuit between pins 1 and 2 of CN7001.

Since the power turns on even if the filter cover is removed, the user may be injured with the fan. After completion of inspection, be sure to restore

it to its original state.

• Lamp cartridge detection

This unit has two lamps. When turning on the lamp with one lamp cartridge removed, the cabinet may be deformed by heat. After completion of

inspection, be sure to restore the lamp cartridge to its original state.

Short-circuit between pins 1 and 2 of CN2801/CN2802.

• Color wheel motor/Photosensor

Cannot be disabled. Connect an extension jig.

3 – 8

Page 43

XG-PH70X

CHAPTER 4. TROUBLESHOOTING TABLE

Service Manual

[1] TROUBLESHOOTING TABLE

Checking the PWB Performance

DVI input in trouble Video & S-video input in

trouble

Feed the test pattern signal from PC.

Is specified cable Connected between Source

and projector?

YES YES

Is supply voltage as specified?

YES YES

Does image appear? NO Check the connectors,

NO Use specified cable. Is specified cable con-

NO Power circuit in trouble. Is supply voltage as spec-

Page 4-2, 4-3 Go to

"checking the S-Video &