Page 1

XG-C58X

XG-C68X

SERVICE MANUAL

SERVICE-ANLEITUNG

S95N2XG-C58X/

LCD PROJECTOR

LCD PROJEKTOR

XG-C58X

MODELS

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

XG-C68X

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

CONTENTS

» SPECIFICATIONS ............................................. 2

» IMPORTANT SERVICE SAFETY

NOTES (for USA)............................................... 3

» NOTE TO SERVICE PERSONNEL ................... 4

» OPERATION MANUAL...................................... 8

» DIMENSIONS .................................................. 12

» REMOVING OF MAJOR PARTS ..................... 13

» RESETTING THE TOT AL LAMP TIMER ......... 15

» THE OPTICAL UNIT OUTLINE ....................... 16

» SOFTWARE UPDATE PROCEDURE ............. 20

» ELECTRICAL ADJUSTMENT ........................... 24

» TROUBLE SHOOTING TABLE ....................... 35

» BLOCK DIAGRAM......................................... 102

» OVERALL WIRING DIAGRAM ...................... 104

» DESCRIPTION OF SCHEMATIC DIAGRAM. 106

» SCHEMATIC DIAGRAM ................................ 107

» PRINTED WIRING BOARD ASSEMBLIES... 156

» PARTS LIST

Ë

ELECTRICAL PARTS ................................ 172

Ë

CABINET AND MECHANICAL PARTS ..... 190

Ë

ACCESSORIES PARTS ............................ 196

Ë

PACKING PARTS ...................................... 196

» PACKING OF THE SET................................. 197

Page

» TECHNISCHE DATEN .................................... 53

» HINWEISE FÜR DAS

WARTUNGSPERSONAL ................................ 54

» BEDIENUNGSANLEITUNG ............................ 56

» ABMESSUNGEN............................................. 60

» AUSBAU WICHTIGER TEILE ......................... 61

» RÜCKSTELLUNG DES LAMPEN-TIMERS .... 63

» KURZBSCHREIBUNG

DER OPTIK-EINHEIT ...................................... 64

» SOFTWARE-AKTUALISIERUNGS-

VERFAHREN................................................... 68

» ELEKTRISCH EINSTELLUNG ........................ 72

» FEHLERSUCHTABELLE................................. 84

» BLOCKSCHALTBILD..................................... 102

» GESAMTSCHALTPLAN ................................ 104

» BESCHREIBUNG DES SCHEMATISCHEN .......

SCHALTPLANS ............................................. 106

» SCHEMATISCHEN SCHALTPLANS ............. 107

» LEITERPLATTENEINHEITEN ....................... 156

» ERSATZTEILLISTE

Ë

ELEKTRISCHE BAUTEILE ....................... 172

Ë

GEHÄUSE UND MECHANISCHE

BAUTEILE ................................................. 190

Ë

ZUBEHÖRTEILE ....................................... 196

Ë

VERPACKUNGSTEILE ............................. 196

» VERPACKEN DES GERÄTS......................... 197

INHALT

Seite

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

XG-C58X

XG-C68X

Specifications

Product type

Model

Video system

Display method

LCD panel

Standard lens

Projection lamp

Component input signal

(INPUT1/2)

Horizontal resolution

Computer RGB input signal

(INPUT 1/2)

Video input signal

(INPUT 3)

S-video input signal

(INPUT 4)

USB terminal

Computer control signal (RS-232C)

Horizontal frequency

Vertical frequency

Pixel clock

Audio input signal

Audio output

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Power consumption (standby)

Heat dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

Weight (approx.)

Replacement parts

LCD Projector

XG-C58X/XG-C68X

NTSC 3.58/NTSC 4.43/PAL/PAL-M/PAL-N/PAL 60/SECAM/

DTV480I/DTV480P/DTV540P/DTV576I/DTV576P/DTV720P/DTV1035I/DTV1080I

LCD panel X 3, RGB optical shutter method

Panel size: 0.99" (25.1 mm) (15 [H] X 20 [W] mm)

No. of dots: 786,432 dots (1,024 [H] X 768 [V])

1–1.27 X zoom lens, F1.7–2.2, f = 36.5–46.3 mm

SHP 310 W (Lamp unit: AN-C55LP)

15-pin mini D-sub connector

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

: 0.7 Vp-p, 75 Ω terminated

P

B

: 0.7 Vp-p, 75 Ω terminated

P

R

750 TV lines (DTV720P)

15-pin mini D-sub connector

RGB separate/sync on green type analog input: 0–0.7 Vp-p, positive, 75 Ω terminated

HORIZONTAL SYNC. SIGNAL: TTL level (positive/negative)

VERTICAL SYNC. SIGNAL: Same as above

RCA connector: VIDEO, composite video, 1.0 Vp-p, sync negative, 75 Ω

terminated

4-pin mini DIN connector

Y (luminance signal): 1.0 Vp-p, sync negative, 75 Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Ω terminated

4-pin B-type USB female connector

9-pin mini DIN connector

15–126 kHz

43–200 Hz*

12–230 MHz

ø3.5 mm minijack: AUDIO, 0.5 Vrms, more than 47 kΩ (stereo)

3.0 W (monaural)

4 cm X 7 cm

AC 120–240 V

3.4 A

50/60 Hz

405 W (Standard mode)/320 W (Low power mode) with AC 120 V

390 W (Standard mode)/315 W (Low power mode) with AC 240 V

0.5 W (AC 120 V) – 0.9 W (AC 240 V) (When “Mntr.out/RS232” is set to “OFF”)

1,522 BTU/hour (Standard mode)/1,202 BTU/hour (Low power mode) with AC 120 V

1,465 BTU/hour (Standard mode)/1,183 BTU/hour (Low power mode) with AC 240 V

41°F to 95°F (+5°C to +35°C)

–4°F to 140°F (–20°C to +60°C)

Plastic

38 kHz

3

⁄8"X 3 7⁄8"X 11 9⁄16" (390 (W) X 99 (H) X 294 (D) mm) (main body only)

15

1

⁄2"X 4 7⁄16"X 11 5⁄8" (393 (W) X 114 (H) X 303 (D) mm) (including adjustment foot

15

and projecting parts)

11.5 lbs. (5.2 kg)

Remote control, Power cord for U.S. and Canada, etc., Power cord for Europe, except U.K., Power

cord for U.K. and Singapore, RGB cable, USB cable, DIN-D-sub RS-232C adaptor, Air filter, Lens

cap, Projector manual and technical reference CD-ROM, Quick guide label, Operation manual

* Temporary noise may be visible with vertical frequencies above 100Hz if OSD functions are activated.

As a part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product improv ement without prior notice. The performance specification figures

indicated are nominal values of production units. There may be some de viations from these v alues in

individual units.

2

Page 3

XG-C58X

2

2

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

XG-C68X

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm

per volt., or higher, sensitivity to measure the AC

voltage drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary , a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in Projector have

special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

WARNING: The bimetallic component has the primary

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

conductive side exposed. Be very careful in

handling this component when the power is on.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques,

dans les projecteur à présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans

la liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

3

Page 4

XG-C58X

XG-C68X

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the projector

emits small amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIA TIONS UV

La source de lumière, la lampe métal halide,

dans le projecteur émet de petites quantités de

radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and High Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. T ype AN-C55LP

rated 80V/310W.

4. The lamp emits small amounts of UV-Radiation,

avoid direct-eye contact.

5. The high pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe haute pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type.

Type AN-C55LP caractéristique 80V/310W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe haute pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

4

Page 5

XG-C58X

4

5

XG-C68X

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

PRECAUTION POUR LES RADIATIONS UV (Suite)

234567890123456789012345678901212345678901234

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

2

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre le couvercle du conduit et le botier de la lampe,il est recommandé de

placer le CAPUCHON D'OPTIQUE sur l'ouverture

pendant l'entretien pour éviter une exposition des

yeux et la peau.

5

Page 6

XG-C58X

XG-C68X

WARNING: High brightness light source, do not stare into the beam of light, or view directly . Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET .

NO USER-SERVICEABLE P ARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within

a triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are

in the manual with the projector.

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVERTISSEMENT: AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ELECTROCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REP ARABLE

PAR L’UTILISATEUR, A L ’EXCEPTION DE L ’UNITE DE

LAMPE. POUR TOUTE REP ARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

6

Page 7

XG-C58X

XG-C68X

Precautions for using lead-free solder

1 Employing lead-free solder

"Input, Output, R/C Receiver, Fan PWB, AC INLET UNIT, POWER UNIT, BALLAST UNIT and Key PWB" of this

model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service

manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend you

to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldening bit,

contact our service station or service ranch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead solder

by 40°C, and as it has poor solder wettabillty, you may be apt to keep the soldering bit in contact with the PWB for

extended period of time. However, Since the land may be peeled of f or the maximum heat-resistance temperature of

parts may be excoeded, remove the bit from the PWB as soon as you conurm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to tum on and

off the power of the bit as required.

if a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Becareful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

7

Page 8

XG-C58X

XG-C68X

OPERATION MANUAL

Pr oj ec tor (Front and To p Vi ew )

For turning the power on.

ON button

Power indicator

Illuminates red, when the

projector is in standby.

When the power is turned

on, this indicator will

illuminate green.

STANDBY button

For putting the projector into

the standby mode.

Lamp indicator

Illuminates green indicating

normal function. Replace

the lamp when the indicator

illuminates red.

Temperature warning

indicator

When the internal

temperature rises, this

indicator will illuminate red.

UNDO button

For undoing an operation

or returning to the default

settings.

STANDBY

INPUT button

For switching input mode

1, 2, 3 or 4.

KEYSTONE button

For adjusting Keystone or

Digital Shift setting.

AUTO SYNC button

For automatically

adjusting images when

connected to a computer.

Adjustment buttons

(', ", \, |)

For selecting menu items.

VOLUME buttons

For adjusting the speaker

sound level.

MENU button

For displaying adjustment

and setting screens.

ENTER button

For setting items selected

or adjusted on the menu.

HEIGHT ADJUST

Adjustment foot

Carrying handle

button

Attaching and removing the lens cap

• Press on the two buttons of the lens cap

and attach it on the lens. Then release

the buttons to lock it in place.

• Press on the two buttons of the lens cap

and remove it from the lens.

Zoom knob

Focus ring

Intake vent

Remote control

sensor

Air filter/cooling

fan (Intake vent)

(on the bottom of

the projector)

8

Page 9

USB terminal

Terminal for

connecting a

computer using a

USB cable.

RS-232C terminal

For controlling

projector using a

computer.

AUDIO OUTPUT

terminal

Shared audio

output terminal for

INPUT 1, 2, 3 and 4.

INPUT 1 terminal

Terminal for

computer RGB and

component signals.

OUTPUT (INPUT 1, 2)

terminal

Shared computer

RGB and component

signals output

terminal

for INPUT 1 and 2.

INPUT 2 terminal

Terminal for

computer RGB and

component signals.

XG-C58X

XG-C68X

AUDIO INPUT 1, 2

terminal

Shared audio input

terminal for INPUT 1

and 2.

WIRED REMOTE

control input

terminal

INPUT 3 terminal

For connecting

video equipment.

AUDIO (L/R)

INPUT 3, 4

terminals

Shared audio input

terminals for INPUT 3

and 4.

INPUT 4 terminal

Terminal for

connecting video

equipment with an

S-video terminal.

AC socket

Exhaust vent

Kensington Security

Standard connector

Adjustment Feet

Using the Kensington Lock

This projector has a Kensington Security Standard connector for use with a Kensington

•

MicroSaver Security

System. Refer to the information that came with the system for instructions on how to use it to secure the

projector.

Carrying the projector

Before carrying the projector, fully

extend the carrying handle.

9

Page 10

XG-C58X

XG-C68X

Remo te Contro l (Front Vi ew )

For putting the projector into the

STANDBY button

standby mode.

KEYSTONE button

For adjusting Keystone or Digital

Shift setting.

ENTER button

For setting items selected or

adjusted on the menu.

UNDO button

For undoing an operation or

returning to the default settings.

ENLARGE (Enlarge/Reduce)

buttons

For enlarging or reducing part of

the image.

GAMMA button

For correcting the brightness of an

image, when the images displayed

are hard to see because of the

brightness of the room. Four

gamma modes are available to

choose from.

AUTO SYNC button

For automatically adjusting images

when connected to a computer.

INPUT buttons

For switching to the respective

input modes.

ON button

For turning the power on.

MENU button

For displaying adjustment and

setting screens.

Adjustment buttons

(', ", \, |)

For selecting menu items.

PinP button

For displaying dual pictures.

FORWARD/BACK buttons

Same function as the [Page Down]

and [Page Up] keys on a computer

keyboard when using the Remote

receiver.

FREEZE button

For freezing images.

BLACK SCREEN button

For superimposing a black screen.

RESIZE button

For switching the screen size

(NORMAL, BORDER, etc).

MUTE button

For temporarily turning off the

sound.

For adjusting the speaker sound

VOLUME buttons

level.

Remote Co ntro l (Top Vi ew )

Remote control signal transmitters

BREAK TIMER button

For displaying the break timer.

WIRED R/C JACK

For controlling the projector by

connecting the remote control to the

projector.

10

Page 11

Connection Pin Assignments

INPUT 1/2 RGB and OUTPUT Signal Terminal: 15-pin Mini D-sub female connector

RGB Input

1. Vi de o in pu t (r ed )

2. Vi de o in pu t (gr ee n/ sy nc on gre en )

3. Vi de o in pu t (blu e)

4. No t co nnected

5. No t co nnected

5

10

15

1

6

11

6. Earth (red)

7. Earth (green/sync on green)

8. Earth (blue)

9. No t co nnected

10. GND

11. Not conn ec te d

12. Bi-directional data

13. Horizontal sy nc si gn al : TTL level

14. Vertical sync si gnal : TTL level

15. Data clock

RS-232C Terminal: 9-pin Min i DIN fema le connector

Pin No. Signal Name I/O Reference

1Not connected

2RDReceive Data Input Connecte d to int ernal circ ui t

3SDSend Data Output Connected to internal circ ui t

4Not connected

5SGSignal Ground Connected to internal ci rc ui t

6Not connected

7RSRequest to send Connected to CS in internal circuit

8CSClear to send Connected to RS in internal circuit

9Not connected

Pin No. Signal Name I/O Reference

1Not connected

2RDReceive Data Input Connecte d to int ernal circ ui t

3SDSend Data Output Connected to internal circ ui t

4Not connected

5SGSignal Ground Connected to internal ci rc ui t

6Not connected

7RSRequest to send Connected to CS in internal circuit

8CSClear to send Connected to RS in internal circuit

9Not connected

9

6

5

15

8

21

69

7

3

4

9-pin D-sub male connector of the DIN-D-sub RS-232C adaptor

Component Input

1. PR (CR)

2. Y

3. P

4. No t co nnected

5. No t co nnected

6. Earth (P

7. Earth (Y)

8. Ea rth (P

9. No t co nnected

10. Not connecte d

11. Not connecte d

12. Not connecte d

13. Not connecte d

14. Not connecte d

15. Not connecte d

(CB)

B

XG-C58X

XG-C68X

)

R

)

B

No

te

•Pin 8(CS) and Pin 7(RS) are short circuited inside the projector.

RS-232C Cable recommended connection: 9-pin D-sub female connector

51

96

Pin No. Signal Pin No. Signal

1CD 1 CD

2RD 2 RD

3SD 3 SD

4ER 4 ER

5SG 5 SG

6DR 6 DR

7RS 7 RS

8CS 8 CS

9CI 9 CI

Note

•Depending on the controlling device used, it may be necessary to connect Pin 4 and Pin 6 on the controlling

device (e.g. PC).

Projector

Pin No.

4

5

6

PC

Pin No.

4

5

6

USB Terminal: 4 pin B-type USB female connector

Pin No. Signal Name

2

1

43

1VCCUSB power

2USB– USB data–

3USB+USB data+

4SGSignal Ground

11

Page 12

XG-C58X

XG-C68X

Dimensions

Units: inches (mm)

Side View Side ViewTop View

(213.3)

16

/

7

8

3

16

/

(4)

8

/

1

(294)

16

/

9

11

(5.2)

1

/16 (1.5)

Rear View

3

/8 (390)

15

5 (126.5)

1

/16 (1.5)

Front View

Bottom View

3

(99)

16

/

15

1

3

(15)

16

/

9

(124.5)

16

/

15

4

5

(104)

8

/

1

4

4

/

1

8

/

2

(7.5)

16

/

(44.5)

(54.5)

3

3

/8 (111.75)

4

15

2

/16 (75)

211/16(67.5)

M4

M4

1

/8 (80)

M4

M4

ø67.5

315/16 (100.5)91/2 (241.5)

12

Page 13

XG-C58X

2-1

2-2

2-2

2-3

Top panel

Rear panel

(Black)

XG-C68X

REMOVING OF MAJOR PARTS

1. Removal of the bottom filter cover and lamp unit cover

1-1. Detach the bottom filter cover.

1-2. Loosen the lock screw from the lamp unit cover, and detach the lamp unit cover.

1-3. Pull out the carrying handle.

1-4. Press the ~-marked spot of the upper half of the lens cover to unhook the claw, and detach the upper lens

cover.

1-5. Detach the lower half of the lens cover.

2. Removal of the top panel and rear panel

2-1. Remove the six lock screws (black) from the top panel.

2-2. Remove the eight lock screws from the rear panel and detach the rear panel.

2-2

(

:XEBS930P12000,

2-3. Slowly lift the top panel and disconnect the connector from the key PWB. Remove another screw and detach

the top panel.

2-2

:XBBS930P10000)

Lamp unit cover

1-2

1-3

Carrying handle

Lower half of the lens cover

1-4

Upper half of the lens cover

1-1

1-5

Bottom filter cover

13

Page 14

XG-C58X

4-2

4-3

4-2

Power PWB

R/C Receiver PWB

Fan PWB

Cooling Fan

4-1

4-4

4-2

XG-C68X

3. Removal of the PWBs

3-1. Remove the lock screw from the lamp socket angle. Detach the lamp socket angle.

3-2. Lift the ballast unit. Disconnect the two connectors and detach the ballast unit.

3-3. Remove the lock screw from the PWB unit cover and detach the cover.

3-4. Remove the three lock screws from the PWB assembly.

3-5. Remove the two lock screws from the cooling fan, disconnect the connector and detach the cooling fan.

3-6. Remove the lock screw from the grounding terminal, disconnect the connector and detach the AC inlet PWB.

4. Removal of the optical mechanism, fan PWB, power PWB and R/C receiver PWB

4-1. Disconnect the connector and detach the speaker unit.

4-2. Remove the eight lock screws from the optical mechanism, and take out the optical mechanism.

4-3. Remove the lock screw from the cooling fan, and detach the cooling fan and fan PWB.

4-4. Remove the four lock screws from the power PWB, and detach the power PWB.

4-5. Take out the R/C receiver PWB.

Ballast Unit

Cooling Fan

3-2

3-1

3-5

3-5

3-4

3-4

PWB Ass’y

3-6

AC Inlet PWB

3-3

PWB Unit cover

14

Page 15

RESETING THE TOTAL LAMP TIMER

1

Connect the power cord.

•

Plug the power cord into the AC sock et

of the projector.

2

Reset the lamp timer.

•

While pressing simultaneously

and

on the projector.

•

“LAMP 100%” is displayed, indicat in g

that the lamp timer is reset.

on the projecto r, press

,

ON

INPUT button

ON button

AC socket

ENTER button

XG-C58X

XG-C68X

Info

•

Make sure to reset the lamp timer on ly

UNDO button

when replacing the lamp. If you reset the

lamp timer and continue to use the same

lamp, this may cause the lamp to become

damaged or explode.

■ The warning lights on the projector indicate problems inside the projector.

■ If a problem occurs, either the temperature warning indicator or the lamp indicator will illuminate

red, and the projector will enter the standby mode. After the projector has entered the standby

mode, follow the procedures given below.

About the lamp indicator

Power indicator

Lamp indicator

Temperature warning

indicator

About the temperature warning indicator

If the temperature inside the projector increases, due to blockage

of the air vents, or the setting location, “

lower left corner of the picture. If

the temperature keeps on rising,

the lamp will turn off and the temperature warning indicator will

blink, the cooling fan will run for

further 90 seconds, then the projector will enter the standby mode.

After “

perform the following measures.

” will blink in the

” appears, be sure to

■The lamp life becomes 0%, when used

for approximately 3,000 hours with “ON”

in “Pow er Save” or when used for appro ximately 2,000 hours with “OFF” in “Power

Save”

■When the remaining lamp life becomes

5% or less, “

” will be displayed on the

screen in yellow. When the percentage

becomes 0%, “ ” will change to “ ”

(red), the lamp will automatically turn off

and then the projector will automatically

enter the standby mode. At this time , the

lamp indicator will illuminate in red.

■If you try to turn on the projector a fourth

time without replacing the lamp, the projector will not turn on.

Maintenance indicator Condition

Normal

Temperature

warning

indicator

Green on

Green

Lamp

indicator

Power

indicator

when the

lamp is

warming up

or shutting

down.

Green on/

Red on

Off

blinks

Abnormal

Abnormal

Red on/

Standby

Red blinks

Red on

Red on/

Standby

Red blinks

The internal

temperature is

abnormally high.

/

Time to change

the lamp

The lamp does

not illuminate.

The power

indicator blinks

in red when the

projector is on.

Problem Possible Solution

• Blocked air intake

• Cooling fan breakdown

• Internal circuit failure

• Clogged air intake

• Remaining lamp life

becomes 5% or

under.

• Burnt-out lamp

• Lamp circuit failure

• The filter cover, lamp

unit cover or lens

cover is open.

• Relocate the projector to an area

with proper ventilation.

•Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center

• Carefully replace the lamp.

•Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center

• Please exercise care when

replacing the lamp.

• Securely install the covers.

• If the power indicator blinks even

when the filter cover is securely

installed, contact your nearest

Sharp Authorized Projector Dealer

or Service Center for advice.

15

for repair

for repair

.

.

Page 16

XG-C58X

XG-C68X

THE OPTICAL UNIT OUTLINE

Layout for proper setup of the optical components and parts (top view)

Projection Lens

Relay lens3

M5 AL-coated mirror B M4 AL-coated mirror R

L2

L1

Relay lens 2

M3

L2

G reflector R reflector

M2

B reflector

Relay lens 1

Fly-eye lens (Output)

Fly-eye lens (Input)

Light source (Lamp)

16

Page 17

XG-C58X

XG-C68X

Adjusting the mirrors

This adjustment is needed when any of the optical parts of the optical mechanism has been replaced.

1. Disconnect the flat cables from all the LCD panels.

2. Light up the lamp.

3. Project a white-light image and check to see if there is any color tint in any direction. If any , use the M2, M4 and M5

adjusting levers.

4. Loosen the adjusting lever lock screws, make adjustments, and tighten up the lock screws.

M5 Adjusting lever

M4 Adjusting lever

Lock screws

Lock screws

Lock screws

M2 Adjusting lever

Lever D

Screw A

Screw B

Correcting color irregularities on white-only screen when replacing the lamp

If color irregularities are found at the right and left on a white-only screen after replacing the lamp, it is necessary to

readjust the optical axis of the new lamp. Take the following steps.

1. Open the lamp cover and loosen the screws A and B at the top of the lamp.

2. Using a screwdriver or the like, move the lever D in the arrow direction.

3. Temporarily fix the screws A and B, close the lamp cover, and check the white-only screen again for color

irregularities.

4. Repeat the above steps 1 and 2 until there will be no color irregularities. Now tighten up the screws A and B.

5. Finally secure the lamp cover back in position.

17

Page 18

XG-C58X

XG-C68X

Replacing the prism unit

1. Remove the four lock screws, and take the prism holder unit out of the optical unit.

2. Replace the prism unit with new one. Take the above step 1 in reverse order.

Note: Even if just one of the LCD panels is defective, it is necessary to replace the entire prism unit. Do not replace

just the defective LCD panel only. Under the present circumstances, please do not touch the display part of

LCD.

G-LCD panel

R-LCD panel

Prism unit lock screws

B-LCD panel

Optical unit

18

Page 19

XG-C58X

XG-C68X

How to Release the System Lock

Turn on the power. If the system lock is applied, the system-resetting screen appears. Press the following keys in this

order.

MENU → ENTER → ENTER → MENU → UNDO → UNDO → MENU

After pressing the MENU key first, press the remaining six keys within 10 seconds.

19

Page 20

XG-C58X

XG-C68X

SOFTWARE UPDATE PROCEDURE

Preparation

1. Install the Tera Term Pro (communication program) into PC.

1.1 Downloaded the Tera Term Pro from the Internet.

http://hp.vector.co.jp/authors/VA002416/teraterm.html

1.2 Decompress ttremp23.zip and then run setup.exe in the folder.

1.3 The Language list box appears in the dialog box.

Select English and then click Continue.

1.4 The NOTE: ~ message appears in the dialog box.

Click Continue.

1.5 The Destination Path dialog box appears.

Click Continue.

It is not necessary to change the default destination path(c:\PROGRAM FILES\TTERMPRO).

1.6 The Complete dialog box appears.

Click OK.

2. Decompress the software file for update to the suitable folder.

Loading software

1. Turn on the projector.

2. Connect the RS-232C-IN port of the projector and the RS-232C port of your PC with a DIN-D-sub RS-232C

adapter and a RS-232C serial control cable (cross type).

3. Run the Tera Term Pro (communication program).

3.1 The New connection dialog box appears, select the Serial and then select the suitable COM port.

Then click OK.

3.2 On the Tera Term Pro, select the Setup and then the Terminal.

Change Receive to CR+LF and then check Local echo.

Then click OK.

20

Page 21

3.3 Make sure that ERR is returned from the projector when you pressed the ENTER key.

4. Call the process mode.

Press the following keys in this order.

POWER ON / Adj up / Adj down / Adj up / Adj down / ENTER / ENTER / MENU

5. Select the SPECIAL on the process menu and then press the ENTER key.

6. Select the IPL2 on the sub menu and then press the ENTER key.

The lamp turns off and the projector goes into the software write mode.

7. Once unplug the AC cord and then plug it in again.

Note: Be sure to unplug the AC cord once and plug it in again.

8. On the Tera Term Pro, enter the RATE1152 and then press the ENTER key.

XG-C58X

XG-C68X

9. On the Tera Term Pro, select the Setup and then the Terminal.

Uncheck the Local echo and then click the OK button.

21

Page 22

XG-C58X

XG-C68X

10. On the Tera Term Pro, select the Setup and then the Serial port.

Change the Baud rate to 115200 and then click the OK button.

11. On the Tera Term Pro, enter the START and then press the ENTER key.

Make sure that the OK is returned from the projector and the lamp indicator is blinking in green.

12. On the Tera Term Pro, select the File and then the Send file.

Check the Binary in the Option and then select the software file for update you decompressed.

Then click open.

22

Page 23

XG-C58X

XG-C68X

13. The transfer of data starts if the setting is correct. The Bytes transferred will be counted in the dialog box.

14. Wait for several minutes until the OK is displayed two times and then the lamp indicator is illuminated in red.

If the ERR is displayed, take the steps again from the step 1.

Caution: Never turn off the projector or unplug the AC cord while transferring the data. If it is done, the projector

becomes unable to turn the power on.

In case of this, recover the projector by taking the following steps.

(1) Remove the top and the back side cabinet of the projector.

(2) Set the switch on the PC board to the WRITE side.

(3) Plug the AC cord.

(4) Take the steps again from the step 8.

(5) After transferring the data, set the switch on the PC board to the NORMAL side.

15. Unplug the AC cord.

16. Plug in the AC cord and then call the process mode.

17. From the process menu, select the SPECIAL.

Make sure that the PRG VER is changed to new version.

18. Turn off the projector.

The update is complete.

23

Page 24

XG-C58X

XG-C68X

ELECTRICAL ADJUSTMENT

No. Adjustment Items Adjustment Conditions Adjustment Procedures

1 Initialization of

EEPROM

2 Adjustment of

RGB1 black level

signal amplitude

1. Turn on the power (the lamp lights

up) and warm up the system for 15

minutes.

1. Select the following group and subjects.

Group: OUTPUT1

Subject: G1-BLK, G1-GAIN

For the color R, select the subjects

R1-BLK and R1-GAIN.

For the color B, select the subjects

B1-BLK and B1-GAIN.

2. Make sure the process adjustment

color bars are displayed.

3. For the color G, connect a oscilloscope to pin (2) of P1301.

4. For the colors R and B, connect the

oscilloscope to pin (1) of P1301 and

pin (3) of P1301, respectively.

1. Make the following settings.

Press S2601 to enter the process

mode, and execute S2 on the SSS

menu. Now the EEPROM, except for

the PC I/F unit, is initialized.

Do not execute S1, or the PC I/F unit

itself will be initialized.

(The PC I/F unit has been factoryadjusted.)

To adjust the PC I/F unit, refer to "How

to Adjust the PC I/F unit" on the

page30.

1. Select the subject G1-GAIN. Using

the set's control switch or the remote

controller button, adjust the setting

so that the signal amplitude is 4.2

Vp-p±0.05 V.

2. Select the subject G1-BLK. Using the

set's control switch or the remote

controller button, adjust the setting

so that the white-to-white level is 1.4

Vp-p±0.1 V.

3. Do the same for the other colors R

and B.

1.4Vp-p

4.2Vp-p

3 Adjustment of

PSIG

4 Checking of

sample-and-hold

pulse phase

1. Select the following group and subjects.

Group: OUTPUT2

Subject: PSIG-H, PSIG-L

Make sure the PSIG-H and PSIGL settings are 225 and 120, respectively.

1. Feed the XGA-mode 75-Hz black

signal.

2. Select the following group and sub-

ject.

Group: OUTPUT3

Subject: ENBXR-PH

ENBXG-PH

ENBXB-PH

1. Below is the waveform of PSIG.

(TP1301-2P)

PSIG-H

PSIG-L

GND

1. Check the blurring of the letters of

OUTPUT 3 and the ghost.

2. Raise the value of the ENBXR-PH

until the front ghost appears on the

left side of the letters of OSD.

3. When the value is lowered for 1 - 2

points, the front ghost disappears.

Set it to the value for 2 lowered from

the value when the front ghost

disappears.(In case that the front

ghost appears when the value of the

EMBXR-PH is 11 and disappears

when it is 10, set it to 8.)

4. Adjust the green and blue in the same

manner.

24

Page 25

No. Adjustment Items Adjustment Conditions Adjustment Procedures

XG-C58X

XG-C68X

5 Adjustment of

RGB countervoltage

6 Adjustment of

RGB gradation

reproduction

7 Adjustment of

RGB white balance

1. Feed the counter-voltage adjustment signal (XGA) prepared by the

Technical Department.

2. Select the following group and subjects.

Group: OUTPUT3

Subject: RC (R), GC (G), BC (B)

1. Feed the SMPTE pattern signal

(XGA) .

2. Select the following group and subject.

Group: OUTPUT1

Subject: G1-BLK

1. Feed the 32-step gray scale signal

(XGA, 60 Hz).

2. Select the following group and subjects.

Group: OUTPUT1

Subjects: R1-BLK (R), B1-BLK (B)

1. Using the set's control switch or the

remote controller button, adjust the

settings to minimize flickers.

2. If the results are inconsistent at the

center and on both sides onscreen,

readjust the settings to get the same

results on both sides.

1. Confirm that the 100% and 95% white

gradation as well as the 0% and 5%

black gradation are discernible.

2. If the white gradation looks dif ferently,

finely adjust the G1-BLK setting.

1. Adjust the R1-BLK and B1-BLK settings to have the specified gradation

balance (according to the standard

monitor).

8 Adjustment of

video AGC

9 Adjustment of

video brightness/

contrast

10 Adjustment of

video tint

1. Feed the NTSC 10-step gray scale

signal(with burst).

2. Select the following group and subject.

Group: VIDEO

Subject: AGC-ADJ

3. Connect the oscilloscope between

TP4501 and TP4502

1. Feed the NTSC100% window pattern signal(with burst).

2. Select the following group and subjects.

Group: VIDEO

Subject: AUTO, PICTURE/BRIGHT

1. Feed the split color bar signal.

2. Select the following group and subject.

Group: VIDEO1

Subject: TINT

1. Using the set's control switch or the

remote controller button, adjust the

setting so that the white-to-black level

is 0.72 Vp-p±0.01 V.

1. Feed the signal. Using the set's control switch or the remote controller

button, select the subject AUT O. The

setting will adjust itself.

2. And then lower the adjustment value

of the PICTURE/BRIGHT by 2 points.

3. Then adjust the PICTURE/BRIGHT

setting until the signal becomes bitless.

1. Confirm the fixed value.

Fixed value: 128

25

Page 26

XG-C58X

XG-C68X

No. Adjustment Items Adjustment Conditions Adjustment Procedures

11 Adjustment of

NTSC color

saturation

12 Adjustment of PAL

color saturation

13 Adjustment of

SECAM color

saturation

1. Feed the split color bar signal.

2. Select the following group and subject.

Group: VIDEO

Subject: N-COLOR

~ Connect the oscilloscope to pin (1)

of P1301.

1. Feed the PAL color bar signal.

2. Select the following group and subject.

Group: VIDEO

Subject: P-COLOR

~ Connect the oscilloscope to pin (1)

of P1301.

1. Feed the SECAM color bar signal.

2. Select the following group and subject.

Group: VIDEO

Subject: S-COLOR

~ Connect the oscilloscope to pin (1)

of P1301.

1. Confirm the fixed value.

Fixed value: 54

(Reference: 0.4 Vp-p)

100% White Red

1. Confirm the fixed value.

Fixed value: 51

(Reference: 0.4 Vp-p)

100% White Red

1. Confirm the fixed value.

Fixed value: 48

(Reference: 0.5 Vp-p)

100% White Red

14 Adjustment of

video white balance

15 Adjustment of

COMPO CB offset

and CR offset

16 Adjustment of

COMPO brightness

1. Feed the NTSC monoscope pattern

signal(with burst).

2. Select the following group and subjects.

Group: VIDEO

Subjects: V-R1-BLK, V-B1-BLK

1. Feed the Y-0% brightness, Cb and

Cr 0% white pattern color difference

signal (480I).

2. Select the following group and subject.

Group: COMPO

Subject: AUTO

1. Feed the 0% gray pattern signal

(480I).

2. Select the following group and subject.

Group: COMPO

Subject: G-BRIGHT

1. Using the set's control switch or the

remote controller button, adjust the

settings to have the same white balance as on the standard monitor.

1. Feed the signal. Using the set's control switch or the remote controller

button, select the subject AUT O. The

setting will adjust itself.

1. Adjust so that pixel defect occurs on

the screen.

26

Page 27

No. Adjustment Items Adjustment Conditions Adjustment Procedures

XG-C58X

XG-C68X

17 Adjustment of

COMPO white

balance

18 Automatic color

irregularity correction

19 Checking of

tracking

20 Adjustment of

sRGB white

balance

1. Feed the DTV monoscope pattern

signal.

2. Select the following group and subjects.

Group: COMPO

Subjects: C-R1-BLK, C-B1-BLK

1. Apply the automatic color correction using the automatic color irregularity correction system (ccdc).

1. Input the RGB 10-step gray-scale

(inverse vertically) signal.

2. Select the following group and subject.

Group: LINE

Subject: OPT-MECH

1. Feed the RGB 50% gray pattern

signal.

2. Select the following group and subjects.

Group: OUTPUT1

Subjects: S-R1-BLK, S-R1-GAIN, SG1-BLK, S-G1-GAIN, S-B1-BLK, SB1-GAIN

3. Have the BM-5 brightness meter and

the standard white board at hand.

1. Using the set's control switch or the

remote controller button, adjust the

settings to have the same white balance as on the standard monitor.

1. Make sure that no remarkable uneven

color remains on the screen.

Check the tracking of the gradation on

the lower side.

In case that it is bad, adjust the OPTMECH value to the optimum.

(It takes 2 - 3 seconds for changing for

selection.)

0:Red and blue up

1:Red and blue down

2:Initial value (Normal)

1. Make the S-R1-GAIN setting the

same as the R1-GAIN one.

Make the S-G1-GAIN setting the

same as the R1-GAIN one.

Make the S-B1-GAIN setting the

same as the R1-GAIN one.

Make the S-R1-BLK setting the same

as the R1-BLK one.

2. Adjust the S-B1-BLK and S-G1-BLK

settings so that the chromaticity on

the brightness meter should be as

follows.

x: .313±7/1000

y: .350±10/1000

Cautions on 3D irregular color correction adjustment

The following measurement and adjustment must be carried out:

• In a dark room (take care for stray light)

• Using diffuse reflection type (mat type) screen in the uniform conditions.

Settings of the projector must be carried out in the following conditions:

• Do not save power (to keep the lamp to the stable condition during measurement)

• Automatic search cancel (to fix INPUT1)

• INPUT1 RGB mode (cancel the component mode of INPUT 1, just in case)

(1) System setting (“setting” - “system setting”)

System optional

Simultaneous write in of 3D correction value: No (not checked)

Char transmission interval: 0 ms

Binary interval: 2 ms

27

Page 28

XG-C58X

XG-C68X

Creation of correction value by straight-line

correction coefficient: No (not checked)

Number of image captures (when adjustment,

measurement): 2 times

Number of image captures (when teaching): 4 times

(2) Teaching

Basically only one time measurement is necessary for each model for teaching, however when the optical

characteristics, etc. of the set are greatly changed, set the conditions again and measurement is necessary again according to the changes.

Measurement method of the correction coefficient

(1) Determines the standard set of C55. 1 unit (n units)

(2) Set settings are RGB mode INPUT 1.

(3) Execute teaching in the following condition setting in that standard set.

Condition setting

Model name: Newly input the model name and optical characteris-

tics Var.

Resolution: (Not related)

Correction value X direction: 29

Correction value Y direction: 22

Correction bits number: 8

Minimum adjustment value: 0

Center adjustment value: 36

Maximum adjustment value: 73

Teaching number: 5

Teaching interval: 18

Brightness change direction by adjustment value: Brightness up with adjustment value + (checked)

Adjusting points: 3-dimension (checked)

Gradation 4 (checked)

Gradation 5 (checked)

Gradation 6 (checked)

Do not check the gradations other than these.

Adjusting point (Test pattern display level)

Gradation 7: 91%

Gradation 6: 78%

Gradation 5: 65%

Gradation 4: 52%

Gradation 3: 40%

Gradation 2: 25%

Gradation 1: 13%

Gradation 0: 0%

Adjustment color: Adjustment with WHITE (checked)

(3) Color irregularity correction

Conditions setup

Correction procedure settings

Gradation 7: 2. Lower-gradation correction value to be used.

Gradation 6: 0. Correction with correction coefficient.

Gradation 5: 0. Correction with correction coefficient.

Gradation 4: 0. Correction with correction coefficient.

Gradation 3: 1. Upper-gradation correction value to be used.

28

Page 29

Gradation 2: 1. Upper-gradation correction value to be used.

Gradation 1: 1. Upper-gradation correction value to be used.

Gradation 0: 1. Upper-gradation correction value to be used.

For the model in question, select the name entered in (2) to start the color irregularity correction. If the

set has its optical characteristics rather different from the standard ones or if the set has some color

irregularity lines missing, do the teaching for that set in particular. Use its specified correction coefficients in making the adjustment.

No. Adjustment Items Adjustment Conditions Adjustment Procedures

XG-C58X

XG-C68X

21 Checking and

readjustment of

white balance

22 Checking color-

related performance

23 Checking of

picture-related

performance

24 Checking of RGB

performance

25 Checking of off-

timer performance

26 Checking of

thermistor performance

1. The adjusting conditions for each

item are as follows:

For RGB input, see Item 7.

For video input, see Item 14.

For COMPO input, see Item 17.

1. Make sure the white balance is as

specified on the standard monitor.

For readjustment, proceed in the order of RGB input, video input and

COMPO input.

1. Receive the color bar signal. 1. Select L1 in the process mode.

Check the performance of Color and

Tint.

1. Receive the monoscope pattern sig-

nal.

1. Select L2 in the process mode.

Check Picture, Brightness and Sharpness.

1. Receive the RGB signal. 1. Select L4 on the process mode.

Check Picture, Brightness, Red, Blue,

Clock, Phase, H-POS and V-POS.

1. Select OFF in the process mode.

Make sure that the off-timer starts

with 5-minute display, counts down

1 minute for 1 second, and turns off

when 0 minute is displayed.

1. Heat the thermistor with a hair dryer. 1. Make sure the temperature is displayed.

27 Automatic sync

operation

1. Receive the phase checking pattern

signal.

1. Make sure that Clock, Phase, H-POS

and V-POS can be automatically

adjusted in the VGA/S-VGA/XGA

mode.

28 Vertical line level

check

1. Receive the RGB signal. 10-step

gray-scale

1. Compare with the vertical line boundary sample, and it must be at the

boundary sample or less. In case that

it is bad, adjust the PSIG-L of the

item 3.

However, it must be within the range

of 190 - 200.

29 Factory settings 1. Make the following settings.

Destination

NorthAmerican Setting 4

Other S3

Process

adjustment

S4

Remote

controller

settings

Factory

Factory

Setting 3

29

Page 30

XG-C58X

XG-C68X

How to Adjust the PC I/F unit

1. Initialization of EEPROM

1) Press SW2601 to enter the process mode.

2) Execute S1 on the SSS menu. (By S1, the PC board alone is initialized. Do not execute S2, or all the

adjustment data, except for the PC I/F unit, is initialized.)

3) Make sure that the program version "VER. XXX" on the SPECIAL menu is the latest one.

2. Level adjustments

2-1. Setting the oscilloscope

Set the oscilloscope's range to DC1V/div and 5µ S/div.

2-2. Connecting the PC interface

1) Connect the specified cable between ANALOG OUTPUT (on the signal generator) and DSUB connector

(INPUT1 on the projector).

2) Set the projector's input selector to INPUT1.

3) Set the signal generator to XGA mode (1024x768, 60Hz, 32-step gradation). Also adjust the output

amplitude (between black and white) to 700 mVp-p (terminated with a 75-ohm impedance).

4) Turn on the power.

2-3. Adjusting items

1) Adjustment of RGB drive/gain

(1) Feed the window pattern signal that has 100% and 0% signals.

(2) Select AUTO among the A/D items in the process mode and make the adjustments.

30

Page 31

» Entering the adjustment process mode

There are following two methods.

» Press the SW2601 on the Output unit.

» Press the follwing keys in this order .

ON→Adj up→Adj down→Adj up→Adj down→ENTER→ENTER→MENU

» Adjustment mode process menu

Group Sub Group Subject

Adjust PC Image A/D R-BRIGHT

G-BRIGHT

B-BRIGHT

R-D

B-D

G-D

AD-AUTO

Adjust RGB Image OUTPUT1 R1-BLK

R1-GAIN

G1-BLK

G1-GAIN

B1-BLK

B1-GAIN

S-R1-BLK

S-R1-GAIN

S-G1-BLK

S-G1-GAIN

S-B1-BLK

S-B1-GAIN

Adjust Panel Drive OUTPUT2 PSIG-H

PSIG-L

LC-SW

LC-R-SIG

LC-G-SIG

LC-B-SIG

LC-R-LV

LC-G-LV

LC-B-LV

Adjust Commn Voltage OUTPUT3 RC

GC

BC

RCK-PHASE

GCK-PHASE

BCK-PHASE

ENBX-WIDTH

ENBXR-PH

ENBXG-PH

ENBXB-PH

DGC-SW

DGCJ-R

DGCJ-G

DGCJ-B

XG-C58X

XG-C68X

31

Page 32

XG-C58X

XG-C68X

Group Sub Group Subject

Adjust Video Image VIDEO PICTURE

BRIGHT

TINT

N-COLOR

P-COLOR

S-COLOR

AGC-CNT

AGC-ADJ

STAT-GAIN

V-R1-BLK

V-B1-BLK

VIDEO-AUTO

Adjust Component Image COMP G-BRIGHT

CB-OFFSET

CR-OFFSET

C-R1-BLK

C-B1-BLK

COMPO-AUTO

Process Mode LINE L1

L2

L4

OFF

TEMP OFF

SENSOR CHECK

TG-GAMMA

Initial Setting SSS TIME

S1

S2

S3

S4

S5

S6

Sample Pattern PATTERN RGB

RGB[50]

CROSS

FOCUS

STEP

COLOR

CHR

Adjust CVIC CVIC PROGRESSIVE MODE

IP

MDSW

PTGSW

C-TESTSW

C-ILG-LY

C-MOD-LY

C-VE-LV

ENHANCE-VIDE ENH-PLUS

ENH-MINUS

DFC

ENHANCE-HDTV ENH-PLUS

ENH-MINUS

DFC

ENHANCE-RGB MODE

ENH-GAIN

ENH-PLUS

32

Page 33

Group Sub Group Subject

Adjust CVIC CVIC SCREEN CUBIC-RGB

CUBIC-VIDEO

NR YNR-LEVEL

YNR-K

YNR-FSEL

YNR-FILSW

CNR-LEVEL

CNR-K

CNR-FSEL

CNR-FILSW

PTG TBL-NO

TESTSW

ENABLE

MV-F

VDDYP

CMS-HUE CMS-HUE-R

CMS-HUE-Y

CMS-HUE-G

CMS-HUE-C

CMS-HUE-B

CMS-HUE-M

CMS-SAT CMS-SAT-R

CMS-SAT-Y

CMS-SAT-G

CMS-SAT-C

CMS-SAT-B

CMS-SAT-M

CMS-VAL CMS-VAL-R

CMS-VAL-Y

CMS-VAL-G

CMS-VAL-C

CMS-VAL-B

CMS-VAL-M

DEGAMMA TABLE

Adust Digital Convergence CONVER CC

R-CNV-H

G-CNV-H

B-CNV-H

R-CNV-V

G-CNV-V

B-CNV-V

Vesion Cehck etc SPECIAL IPL

IPL2

E2PROM

ADR RD/WR

XG-C58X

XG-C68X

33

Page 34

XG-C58X

Adjustment jig (resistance load 25Ω)

Connecting cord (conversion cable)

Part code

RR-WZA015WJZZ

DUNTKD497WEF0

RH-iXB384WJZZ

RUNTZA018WJZZ

QCNW-E008WJZZ

Ballast microprocessor

Ballast Unit

Lamp Cable

(QCNW-D882WJQZ)

Adjustment Jig

(RUNTZA018WJZZ)

TP1

TP2

−

+

XG-C68X

[Adjustment of ballast unit output power (lamp power)]

1. List of parts requiring adjustment

When replacing the following parts, adjust the ballast unit output power (lamp power).

Part name

Cement resistor

1

Ballast Control Unit

2

3

5V regulator

4

PWM controller

5

Ref No.

R922

-IC7707

IC7704

IC7701

VHiTA78L05F-1Y

VHiM51995AF-1Y

2. Adjustment jigs

The following jigs are required for adjusting the ballast unit output power (lamp power).

Part name

1

2

Part code

3. Ballast unit output power (lamp power) adjustment method

Adjust the ballast unit output power (lamp power) in the following method.

[Setting method]

Tester

(Voltage)

XG-C58X/C68X

Projector

Connecting Cord

(QCNW-E008WJZZ)

[Adjustment method]

(1)Unplug the ballast unit lamp cable(QCNW-D882WJQZ) of the XG-C58X/C68X projector from

the lamp and connect the cable to the connecting cord (QCNW-E008WJZZ).

(2) Connect the connecting cord (QCNW-E008WJZZ) to the adjustment jig

(RUNTZA018WJZZ).

(3) Connect TP1 of the adjustment jig (RUNTZA018WJZZ) to the negative terminal of the

tester and TP2 to the positive terminal.

(4) Turn on the XG-C58X/C68X projector.

(5) Age the projector for 60 seconds or more.

(6) Adjust the volume resistor (R7728) of the ballast control PWB (DUNTKD497WEF0) so

that the voltage of the tester reaches 83± 0.5 V.

Adjustment value: 88± 0.5 V

[Cautions]

(1) Caution for electric shock: Do not touch the test points TP1 and TP2 of the adjustment

jig when supplying power since a high voltage and large current is applied to them.

(2) Caution for heat: Be careful that the resistance load of the adjustment jig produces a high

temperature when supplying power.

(3) Connection of the lamp cable: Check that the lamp cable and connecting cord (QCNW-E

008WJZZ) are connected securely.

Poor connection may cause smoking or ignition due to arc discharge.

34

Page 35

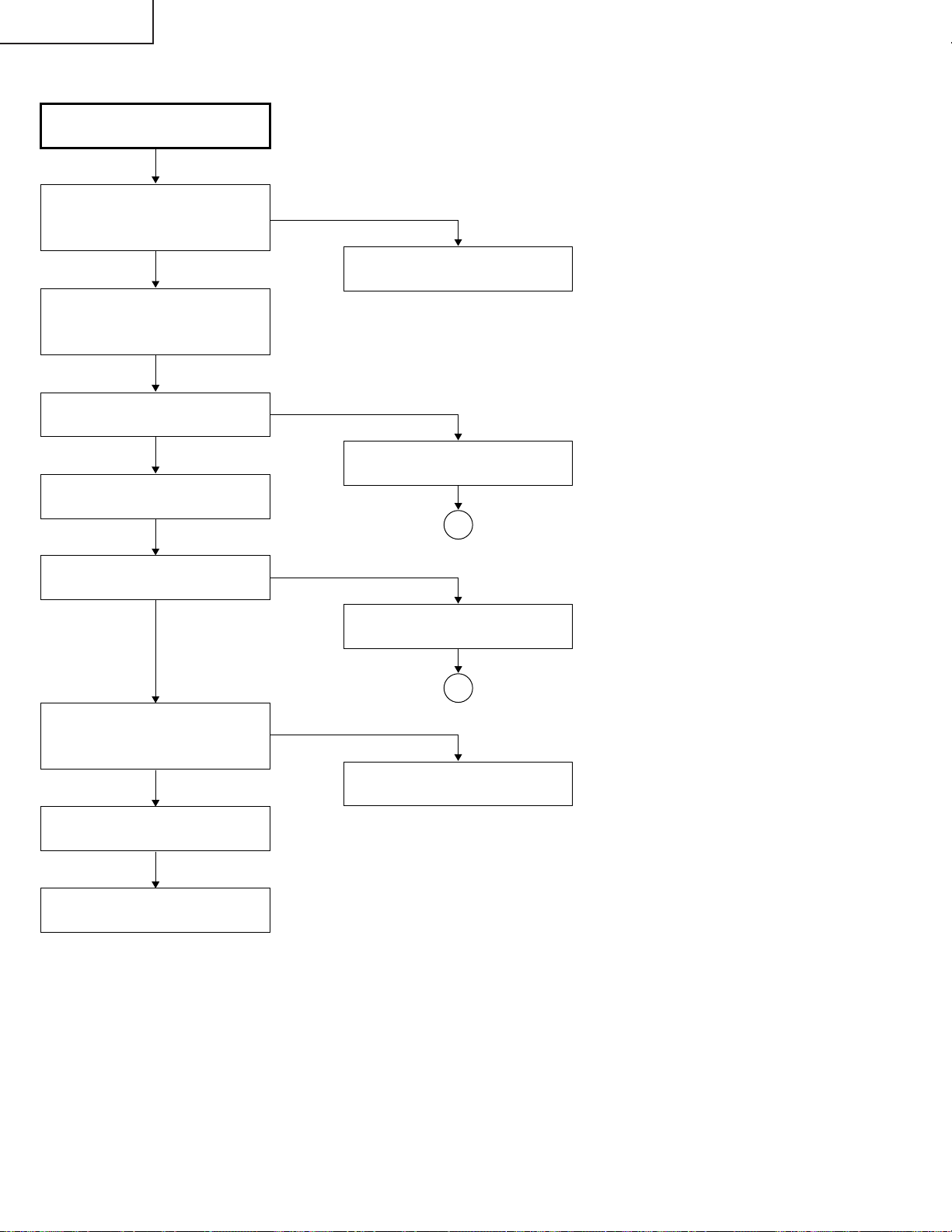

Lamp fails to light-up

XG-C58X

XG-C68X

TROUBLE SHOOTING TABLE

Turn on the power switch.

Is discharging sound heard from

lamp?

No

Is the ballast cooling fan running?

Yes

Is DC 380V pin(4) & 20V pin(1)

voltage applied between P901

connetor pins?

Yes

Is LOW LEVEL voltage applied

between pins(1) and (5) of ballast's

P7702 connector.

Yes

Replace the ballast.

Yes Yes

No

No

No No

Is the lamp out of socket?

No

Replace the lamp

Check the power supply circuits.

Check the power supply circuits.

Is the P7702 connector

disconnected?

Yes

Reconnect it into socket correctly.

Reconnect the lamp into socket.

Check the microproccessor and its

peripheral circuits.

35

Page 36

XG-C58X

XG-C68X

Checking the power unit

TROUBLE SHOOTING TABLE (Continued)

There is no voltage output at

P804

Yes

Which output voltage line fails?

BU5.3V

Is AC voltage(108~264V)applied

across the P701 connector?

Yes

Is AC voltage(108~264V)applied

across the P801 connector?

No

Is the fuse F701 open?

No

Other

No

Yes Yes

Yes

Check the Output PWB unit

Check the T804, IC802, IC804,

and their peripheral circuits.

Check the P701 or AC cord.

Is the resistor R809 open?

No

Replace Power unit.

Replace the F701.

Replace the R809.

No

Is the resistor R717 open?

No

Is the Bimetal SW open

No

Replace Inlet unit.

Yes

Replace the R717.

Yes

Push the red button of the bimetal.

36

Page 37

TROUBLE SHOOTING TABLE (Continued)

No audio output

XG-C58X

XG-C68X

Is the audio signal outputted from

the emmitor of Q306?

No

Is its signal inputted into pins(2)

and (15) of IC303?

No

Is its signal inputted into pins(12)

and (5) or pins(3) and (13) of IC302?

No

Is its signal outputted from pins(27)

and (28) or pins(29) and (30) of

P3102?

No

Is its signal inputted into pins(14)

and (15) or pins(16) and (17) of

SC3102?

No

Check the J431, J421 and their

peripheral circuits.

Yes

Yes

Yes

Yes

Yes

Check the P301 and its peripheral

circuits.

Check the IC303 and its peripheral

circuits.

Check theIC302 and its peripheral

circuits.

Check the Q304 and Q305 and its

peripheral circuits.

Check the connection between

P3102 and SC3102.

37

Page 38

XG-C58X

XG-C68X

Checking the video system

TROUBLE SHOOTING TABLE (Continued)

Is the lamp on ?

Yes

Is specified voltage EA

connectors?

Yes

Is the video signal inputted into the

pin (23) of P3102?

Yes

Is the signal outputted from the pin

(7) of IC4502?

Yes

Is the signal outputted from the pin

(5) of IC4505?

Yes

Is the signal inputted into pin (72)

of P8002?

Yes

No

No

No

No

No

No

Go to "Lamp fails to light-up".

Check power circuit and its parts.

Check the video terminal and its

peripheral circuits.

Check IC4502 and its peripheral

circuits.

Check IC4505 and its peripheral

circuits.

Check Q4501 and its peripheral

circuits.

Go to "Checking the PC I/F unit".

38

Page 39

TROUBLE SHOOTING TABLE (Continued)

Checking the S-video system

XG-C58X

XG-C68X

Is the lamp on ?

Yes

Is specified voltage EA

connectors?

Yes

Is the video signal inputted into the

pins (19) and (21) of P3102?

Yes

Is the Y-signal outputted from the

pin (7) of IC4502?

Yes

Is the C-signal outputted from the

emitter of Q4513?

Yes

Is the signal inputted into pins(72)

and (73) of P8002?

Yes

No

No

No

No

No

No

Go to "Lamp fails to light-up".

Check power circuit and its parts.

Check the video terminal and its

peripheral circuits.

Check IC4502 and its peripheral

circuits.

Check Q4513 and its peripheral

circuits.

Check Q4502 and its peripheral

circuits.

Go to "Checking the PC I/F unit".

39

Page 40

XG-C58X

XG-C68X

Checking the RGB signal.

TROUBLE SHOOTING TABLE (Continued)

Are the RGB signals outputted from

pin(16), (18) and (20) of IC3101?

Yes

Are their signals outputted from

pins(2), (6) and (10) of P3102?

Yes

Are their signals inputted into

pins(1), (5) and (25) of IC2401?

Yes

Are their signals inputted into

pins(54), (58) and (62) of P8002?

Yes

Are their signals outputted from

pin(45)-(54), pins(57)-(66) and

pins(69)-(78) of P8001?

Yes

Are their signals inputted into

IC1101, IC1201, IC1301 and

IC1401?

Yes

No

No

No

No

No

No

Check IC3101 and its peripheral

circuits.

Check SC3102, P3102 and

their peripheral circuits.

Check Q2419, Q2420 and their

peripheral circuits.

Check IC2401, Q2401, Q2402 and

Q2403 and their peripheral circuits.

Go to "Checking the PC I/F unit".

Check IC1101, IC1201, IC1301

and IC1401 and their peripheral

circuits.

Are their signals inputted into

SC1101, SC1201 and SC1301?

Yes

Check the connection of LCD

panels

And when video signal and OSD

are also not displaied, replace the

LCD panels.

40

Page 41

TROUBLE SHOOTING TABLE (Continued)

Checking the RGB Sync.

XG-C58X

XG-C68X

Are the sync inputted into pins(2)

and (4) of SC3102?

Yes

Are their signal inputted into pins(2)

and (12) of IC2404?

Yes

Are their signal inputted into

pins(63) and (66) of P8002?

Yes

Go to "Checking the PC I/F unit".

TROUBLE SHOOTING TABLE for PC I/F UNIT

Checking of PC I/F UNIT

No

No

No

Check IC3152, IC3153, IC3154,

IC3151 and their peripheral circuits.

Check P3102 and its peripheral

circuits.

Check IC2404 and its peripheral

circuits.

0

Is the user menu displayed

onscreen?

No

Check the onscreen display.

Check the RGB input.

Yes

Check the component input.

Yes

Check the video input.

Yes

Yes

End

41

Page 42

XG-C58X

XG-C68X

TROUBLE SHOOTING TABLE for PC I/F UNIT (Continued)

Checking of Onscreen Display

Is the user menu displayed

onscreen normally by the MENU

key?

No

Enter the process menu and select

PATTERN. Then select the COLOR

pattern.

Is the onscreen display color

normal?

Yes

Select the STEP signal.

Is the STEP signal as specified?

No

Yes

No problem with the onscreen

display.

No

In the process mode, make the

LCD line adjustment.

0

Yes

Rewrite the onscreen display data.

Is the signal compatible with the

STEP signal outputted at TL106

thru TL111?

Yes

Go to "Checking of GA4 and Its

Periphery".

Rewrite the onscreen display data.

0

No

IC8025 is defective.

42

Page 43

XG-C58X

XG-C68X

TROUBLE SHOOTING TABLE for PC I/F UNIT (Continued)

Checking of RGB Input

Feed the sync separation type

analog RGB signal to INPUT1.

1

Select INPUT1 using the set’s key

or the remote controller.

2

Does the picture appear?

Yes

Is the picture disturbed?

3

Do the three colors R, G and B

appear?

Carry out the AUTOSYNC process.

Is the contour of picture clear?

Is there any disturbance in the

vertical stripe pattern?

No

Yes

Yes

No

No

Go to "Confirmation of Video

Input".

Yes

Go to "Checking of Sync Signal".

No

Go to "Checking of RGB Signal".

No

Yes

IC8013, IC8025 or their periphery

is defective.

End

43

Page 44

XG-C58X

XG-C68X

TROUBLE SHOOTING TABLE for PC I/F UNIT (Continued)

Confirmation of Video Input

Make "Confirmation of Input

Signal Setting".

Is there the video signal at the land

of C8070?

Yes

Go to "Checking of Sync Signal".

IC8025 or IC8013 is defective.

Confirmation of Input Signal

Setting

Is the right item selected from input

menu?

Yes

No

No

Is there the signal at pin (55) of

SC8002 (B-to-B connector)?

Yes

Somewhere in the signal route is

defective. Check the capacitors

and resistors between SC8002

and IC8013.

The signal source or connector is

defective.

Select the right item.

No

Are the connectors connected

correctly?

Yes

End

2

No

Connect the connectors correctly.

1

44

Page 45

XG-C58X

XG-C68X

TROUBLE SHOOTING TABLE for PC I/F UNIT (Continued)

Checking of Sync Signal

Is there the vertical sync signal at

pin (11) of IC8363?

Yes

Is there the horizontal sync signal

at pin (5) of IC8363?

Yes

Is there the vertical sync signal at

TL8131?

Yes

Is there the horizontal sync signal

at TL8130?

Yes

Are both the vertical and horizontal

sync signals in appropriate timing?

No

Is the signal generator

(input source) appropriate?

No

No

Make confirmation of input signal

setting.

R8997, R8996, SC8002 or their

periphery is defective.

No

No

IC8363 is defective.

Yes

The sync signals are as specified.

End of checking.

No

Yes

R997, R996, SC8002 or their

periphery is defective.

Set the signal source

appropriately.

2

45

Page 46

XG-C58X

XG-C68X

TROUBLE SHOOTING TABLE for PC I/F UNIT (Continued)

Checking of R, G and B Signals

Is the signal type set to RGB?

Yes

Set the process mode.

Select R, G and B individually on

the pattern menu.

Go to "Checking of GA4 and Its

Periphery".

For checking the input signal, set

the signal generator to gradation

signal.

Measure the signals at TL8169,

TL8170 and TL8180 on the

oscilloscope. (MSB bit after A/D

conversion)

No

Set the signal type to RGB.

Are there the specified signals at

TL8169, TL8170 and TL8180?

Yes

IC8025 or its periphery is defective.

No

Does the signal come to C8062,

C8070 and C8078?

IC8013 or its periphery is defective.

46

No

Yes

Go to "Confirmation of Video Input".

Page 47

XG-C58X

XG-C68X

TROUBLE SHOOTING TABLE for PC I/F UNIT (Continued)

Checking of GA4 and Its Periphery

Select R, G and B individually on

the pattern menu in the process

mode.

Is picture outputted appropriately

in R, G and B?

No

Measure the signals at pins (54),

(66) and (78) of SC8001 on the

oscilloscope. These signals are

MSB of B/G/R/.

Do the oscilloscope-measured