Page 1

SERVICE MANUAL

S60A7VC-GA56Z

VIDEO CASSETTE RECORDER

VC-GA56Z

VC-GA56Z

VC-GH96Z

MODELS

In the interests of user-safety (Required by safety regulations

in some countries) the set should be restored to its original

condition and only parts identical to those specified be used.

VC-GH96Z

CONTENTS

Page

1. GENERAL INFORMATION ...........................................................................................................3

2. DISASSEMBLY AND REASSEMBLY ........................................................................................... 5

3. FUNCTION OF MAJOR MECHANICAL PARTS........................................................................... 8

4. ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF MECHANICAL UNITS ........................ 10

5. ELECTRICAL ADJUSTMENT ..................................................................................................... 29

6. MECHANISM OPERATION FLOWCHART AND TROUBLESHOOTING GUIDE ...................... 31

7. TROUBLESHOOTING ................................................................................................................ 37

8. BLOCK DIAGRAM....................................................................................................................... 48

9. SCHEMATIC DIAGRAM AND PWB FOIL PATTERN ................................................................. 57

10. PARTS LIST................................................................................................................................ 71

11. EXPLODED VIEW OF MECHANICAL PARTS ........................................................................... 79

12. PACKING OF THE SET .............................................................................................................. 83

SHARP CORPORATION

1

Page 2

VC-GA56Z

VC-GH96Z

PRECAUTIONS IN PART REPLACEMENT

When servicing the unit with power on, be careful to the section marked white all over.

This is the primary power circuit which is live.

When checking the soldering side in the tape travel mode, make sure first that the tape has been loaded and then turn

over the PWB with due care to the primary power circuit.

Make readjustment, if needed after replacement of part, with the mechanism and its PWB in position in the main frame.

(1) Start and end sensors: Q701 and Q702

Insert the sensor’s projection deep into the upper hole of the holder. Referring to the PWB, fix the sensors tight

enough.

(2) Photocoupler: IC901

Refer to the symbol on the PWB and the anode marking of the part.

(3) Cam switches A and B: D708 and D709.

Adjust the notch of the part to the white marker of the symbol on the PWB. Do not allow any looseness.

(4) Take-up and supply sensors: D707 and D706.

Be careful not to confuse the setting direction of the parts in reference to the symbols on the PWB. Do not allow

any looseness.

2

Page 3

1. GENERAL INFORMATION

1-1 FEATURES

Only for VC-GH96Z

• Hi-Fi Stereo Sound

• Built-in MTS (Multi-channel TV Sound) Decoder

Common Features

• 400 Times Rewind Speed to Fast Forward and Rewind.

• EZ Set Up

• S-VHS Quasi Playback

• Double-Azimuth 4-Heads

• 19µ Clear Picture System (in EP mode)

• HQ System for Better Resolution and Color Reproduction

• Multi-Language (English/Spanish/French) OSD (On Screen

Display) with Menu Screen Guidance

• 181-channel PLL Quartz Synthesized Random Access Tuner

with Automatic Channel Setting

• Quick Start with Full Loading Mechanism

• 1-Year, 8 Event Programmable Timer

• Simple Recording Timer

• Universal Remote Control

VC-GA56Z

VC-GH96Z

• Sharp Super Picture

• Field-Still/Variable Slow/Frame Advance

• Real-Time Counter

• Blue Screen Noise Elimination

• Auto Tracking Control System

• Digital Program Search System (DPSS)

• Skip Search

• Instant Replay

• Auto Zero Back

• Recorded Section Auto Repeat

• Full Automatic Playback

• Tamper Proof

• Up to 8 Hours of Recording and Playback (with T-160

cassette)

• Automatic Head Cleaning System

• Built in Front AV Jacks

1-2 SPECIFICATIONS

Format: VHS NTSC Standard

Video Recording System: Rotary, Slant Azimuth Two-Head Helical Scan

Number of Video Heads: 4

Video Signal Standard: NTSC Color System

Audio Recording System: 1 Stationary Head for Linear Audio

Tape Width: 12.7 mm (1/2 inch)

Tape Speed: (SP) 33.35 mm/sec. (1.31 i.p.s.)

Maximum Recording Time: (SP) 160 min. (T-160)

Channel Coverage: VHF 2-13

Antenna Input: 75 Ohm

Video Input: 0.5 to 2.0 Vp-p, 75 Ohm unbalanced

Video Output: 1.0 Vp-p, 75 Ohm unbalanced

Audio Input: –8 dBs, 47k Ohm unbalanced (0 dBs = 0.775 Vrms)

Audio Output: –8 dBs, 1k Ohm unbalanced (0 dBs = 0.775 Vrms)

Hi-Fi Audio (Only for Hi-Fi models):

Memory Backup: 24 hours

Operating Temperature: 5°C to 40°C (41°F to 104°F)

Storage Temperature: –20°C to 60°C (–4°F to 140°F)

Power Source: 110 –240 V AC, 50/60 Hz

Power Consumption: 18 W

Weight: 2.8 kg

Dimensions (approx.): 360 (W) x 92.5 (H) x 255 (D) mm

Accessories included: 75 ohm coaxial cable, Operation manual, Remote control unit, Battery (2 pcs.)

2 Rotary Heads for Hi-Fi stereo (Only Hi-Fi models)

(LP) 16.67 mm/sec. (0.66 i.p.s.) (playback only)

(EP) 11.12 mm/sec. (0.44 i.p.s.)

(EP) 480 min. (T-160)

UHF 14-69

CATV 1-125

Dynamic Range:

Frequency Response:

90 dB

20 Hz-20k Hz

AC plug adaptor (Flat ↔ Round)

Note: Specifications are subject to change without notice.

3

Page 4

VC-GA56Z

(VC-GA56Z) (VC-GH96Z)

VC-GH96Z

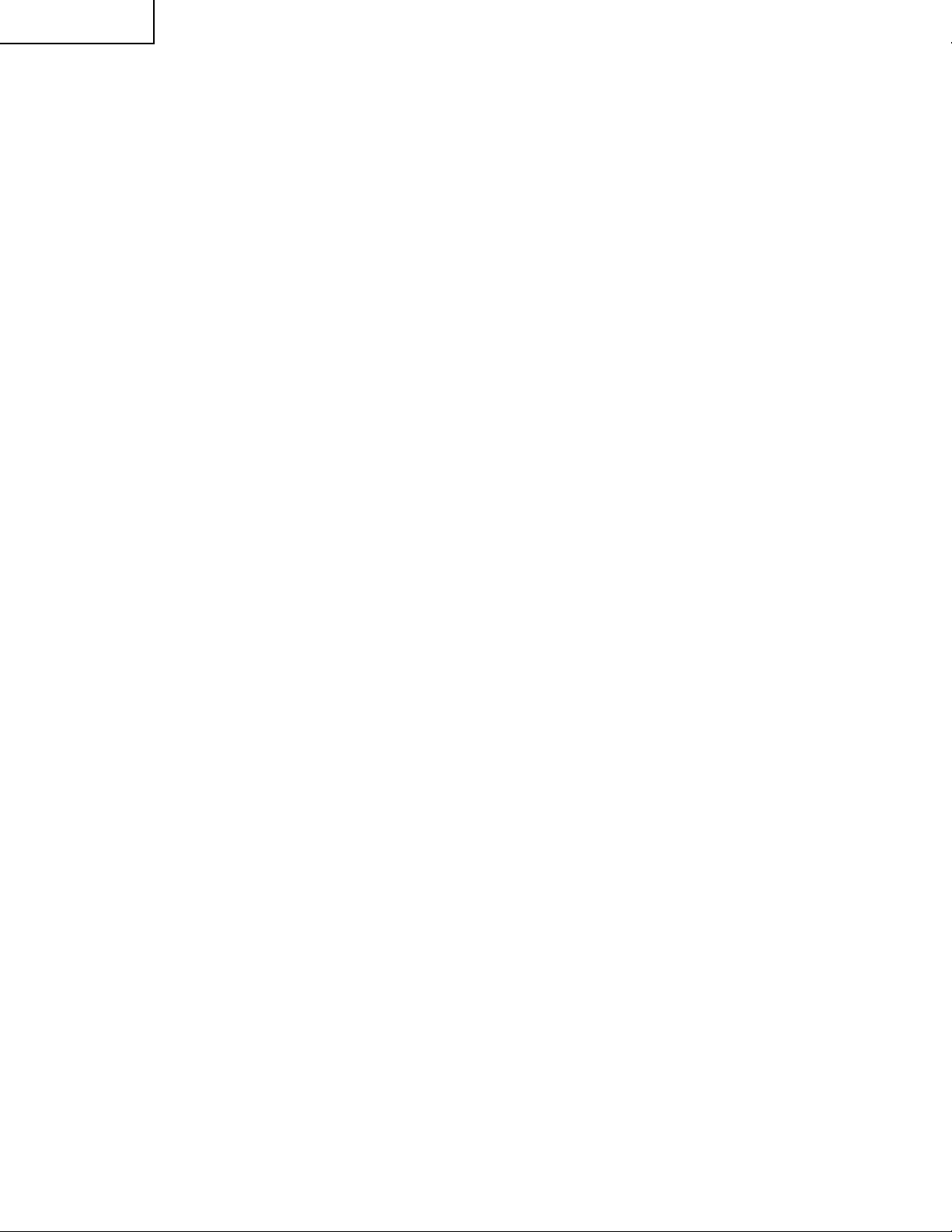

1-3 LOCATION OF MAJOR COMPONENTS AND CONTROL

4

Page 5

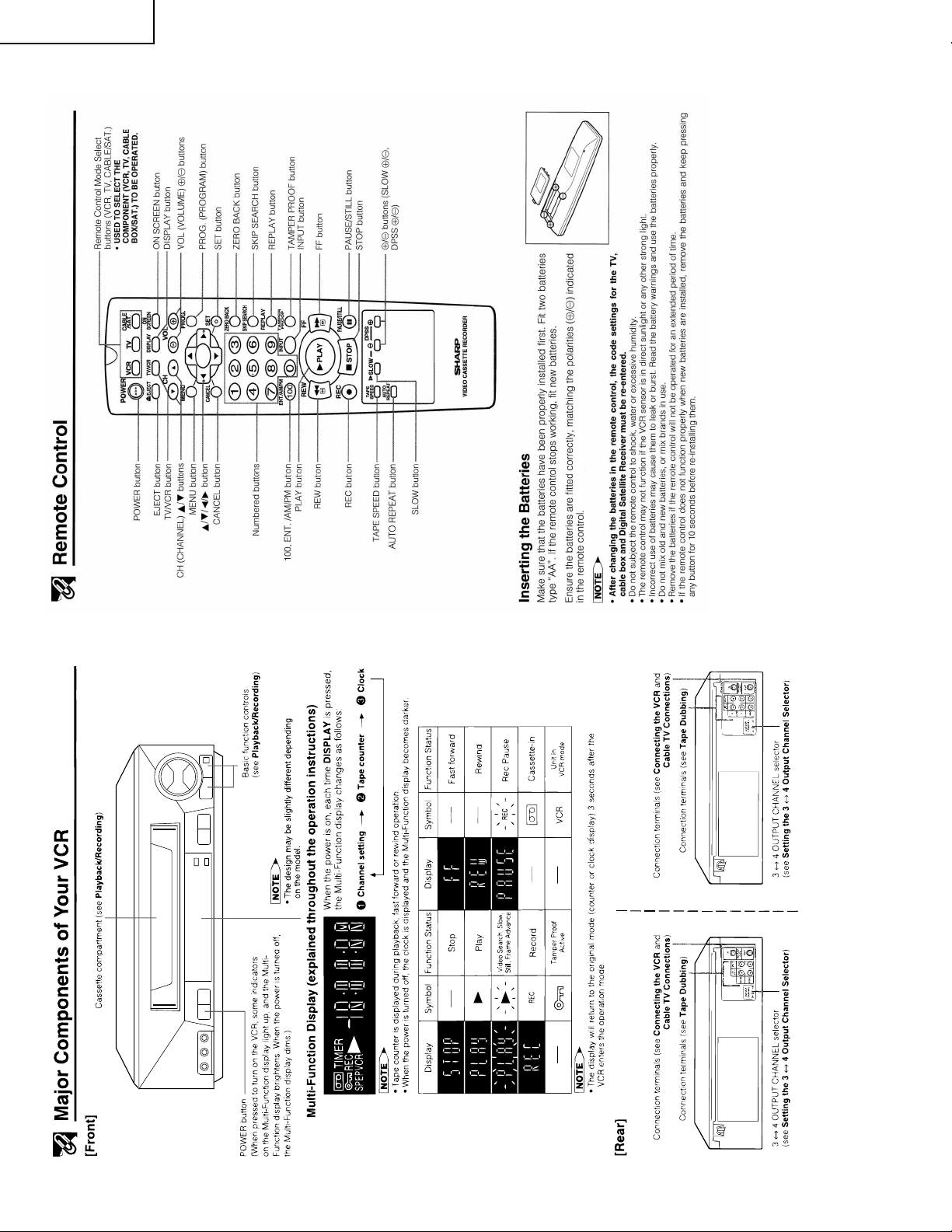

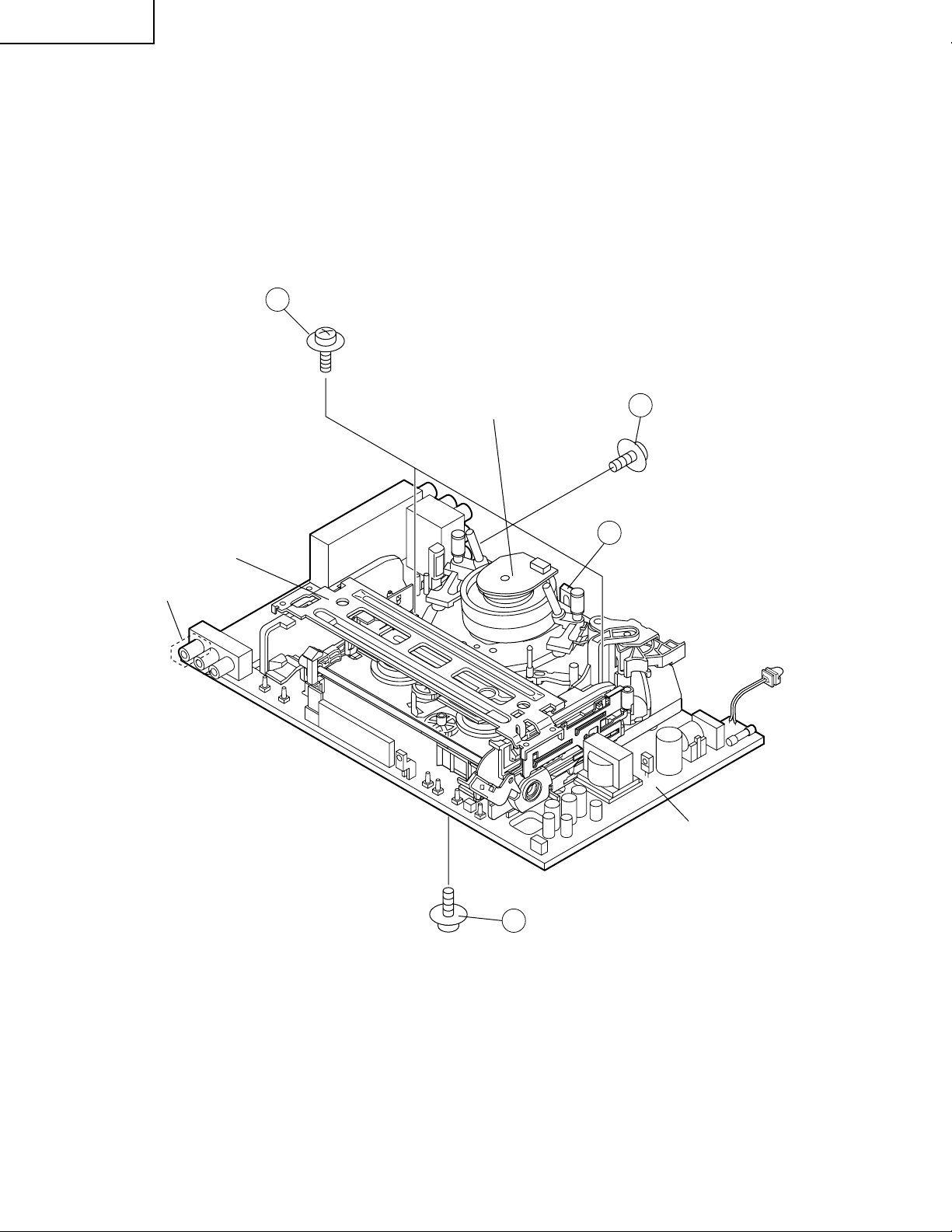

2. DISASSEMBLY AND REASSEMBLY

2-1 DISASSEMBLY OF MAJOR BLOCKS

TOP CABINET : Remove 2 screws 1.

FRONT PANEL : Remove button 2.

Remove 2 screws 3 and 7 clips 4.

OPERATION : Remove 1 screw 5.

PWB

SHIELD ANGLE : Remove 1 screw 6 with shield angle.

MECHANISM/ : Remove 1 screw 7, 1 screw 8, 2

MAIN PWB screws 9, 2 screws 0. Remove 1

screw q with antenna terminal cover.

Remove 1 screw w with top cabinet

fix angle.

ANTENNA

TERMINAL

COVER

VC-GH96Z

ANTENNA

TERMINAL

COVER

TOP CABINET

3

VC-GA56Z

VC-GA56Z

VC-GH96Z

1

SHIELD

ANGLE

10

3

C

6

FRONT PANEL

11

MECHANISM/

MAIN PWB ASSEMBLY

VC-GH96Z

11

B

A

7

B

9

A

TOP CABINET

FIX ANGLE

12

C

5

8

4

OPERATION PWB

2

MAIN FRAME

5

Page 6

VC-GA56Z

VC-GH96Z

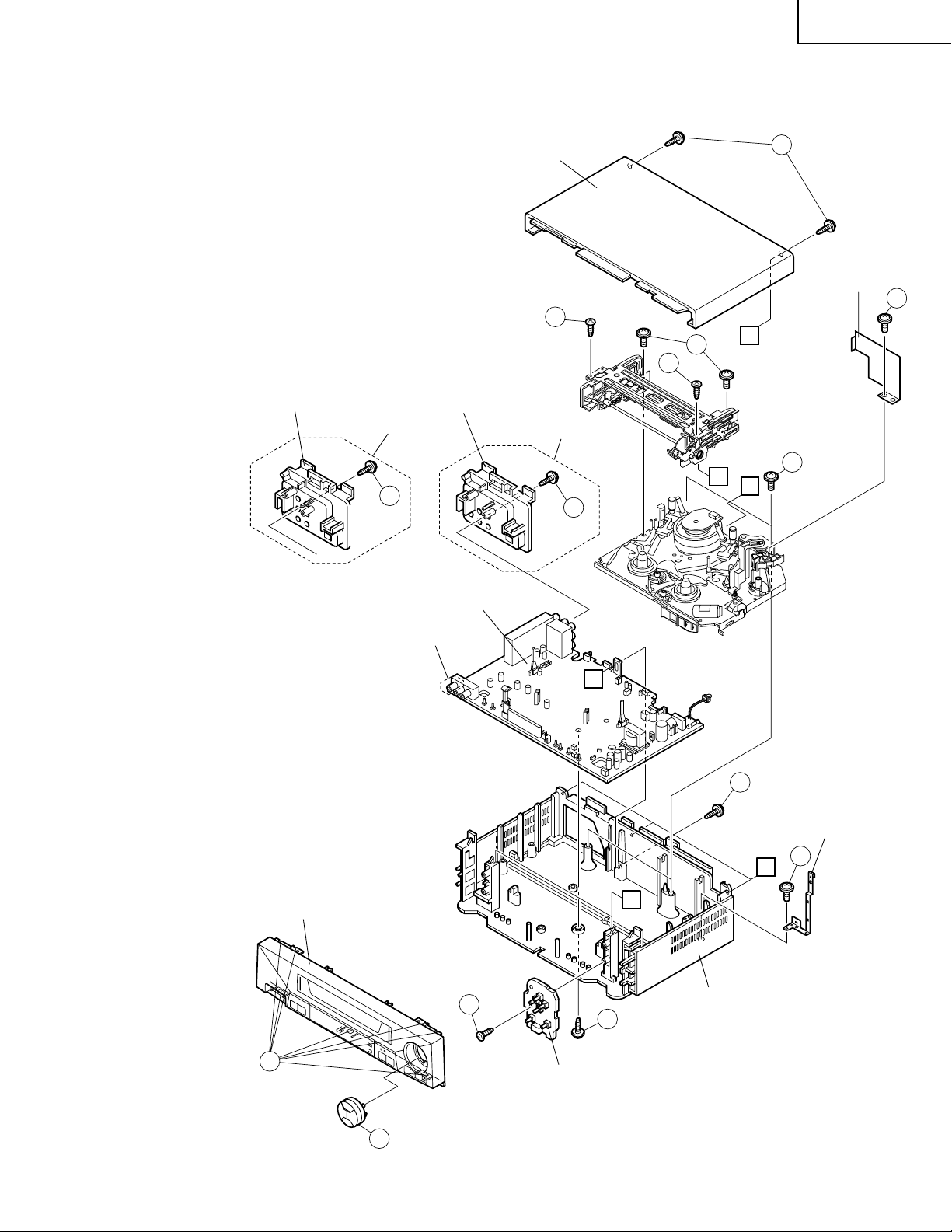

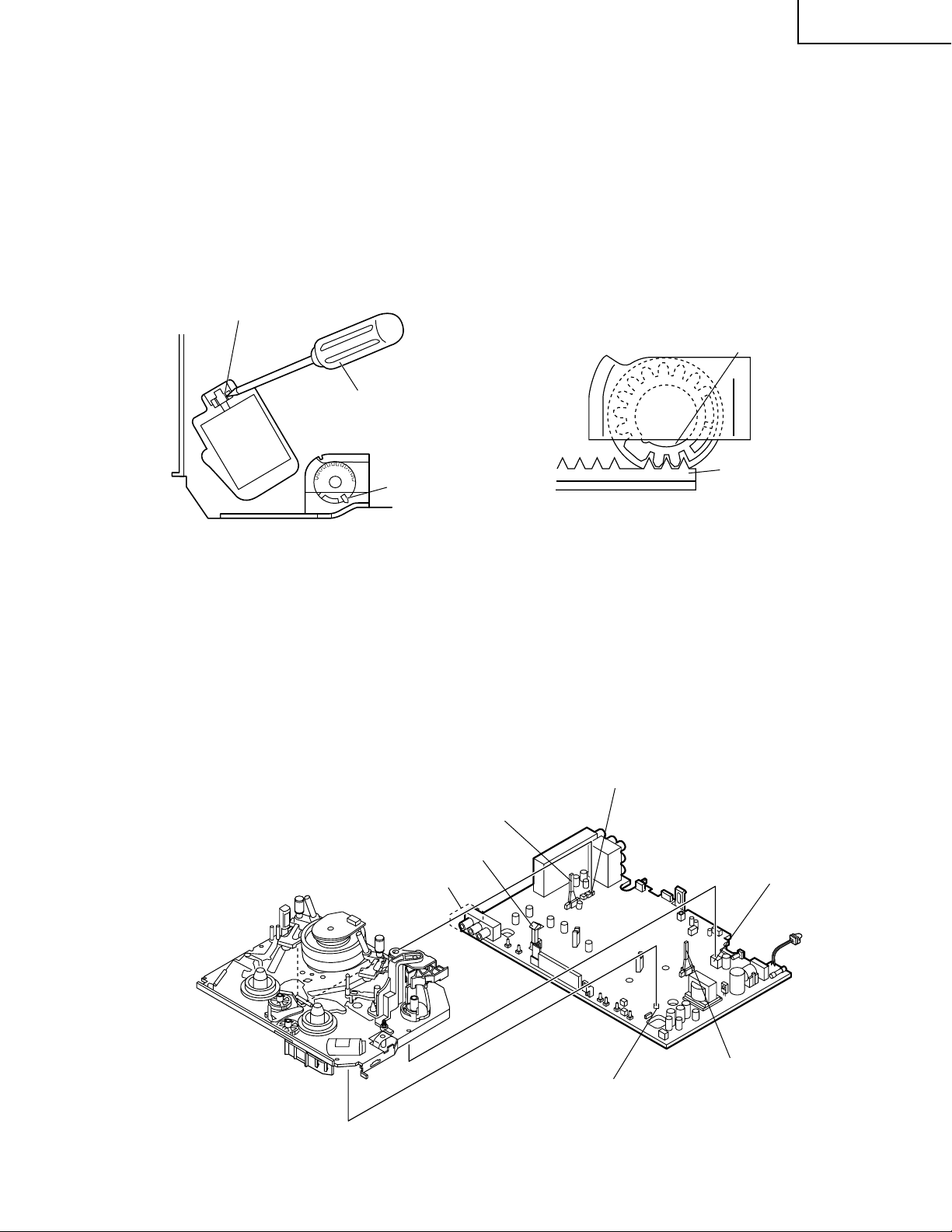

2-2 DISASSEMBLING THE MECHANISM/MAIN PWB ASSEMBLY

1. When removing the mechanism from the main PWB,

remove the antenna cover 1 screw 1, and remove the

antenna cover.

Remove the PWB bottom plate 1 screw 2.

Remove the FFC cable (AA, AD, AH) 3 which connecting the PWB and the mechanism.

Take out vertically the mechanism so that it does not

damage the adjacent parts.

4

2. Removing the mechanism and cassette housing.

Remove 2 screws 4 fixing the cassette housing to the

mechanism, and remove the cassette housing.

VC-GH96Z

CASSETTE

HOUSING

MECHANISM CHASSIS

1

3

MAIN PWB

2

6

Page 7

2-3 CARES WHEN REASSEMBLING

VC-GA56Z

VC-GH96Z

INSTALLING THE CASSETTE HOUSING

When the cassette housing is installed on the mechanism,

the initial setting is essential condition.

There are two initial setting methods, namely electrical

and mechanical.

1. Electrical initial setting

So as to perform initial setting of mechanism execute the

Step 1 of Installation of cassette housing. After ascertaining the return to the initial setting position (*1) install the

Pulley feed gear

Screwdriver

Tilt mark (*1)

cassette housing. (Conditions: When mechanism and

PWB have been installed)

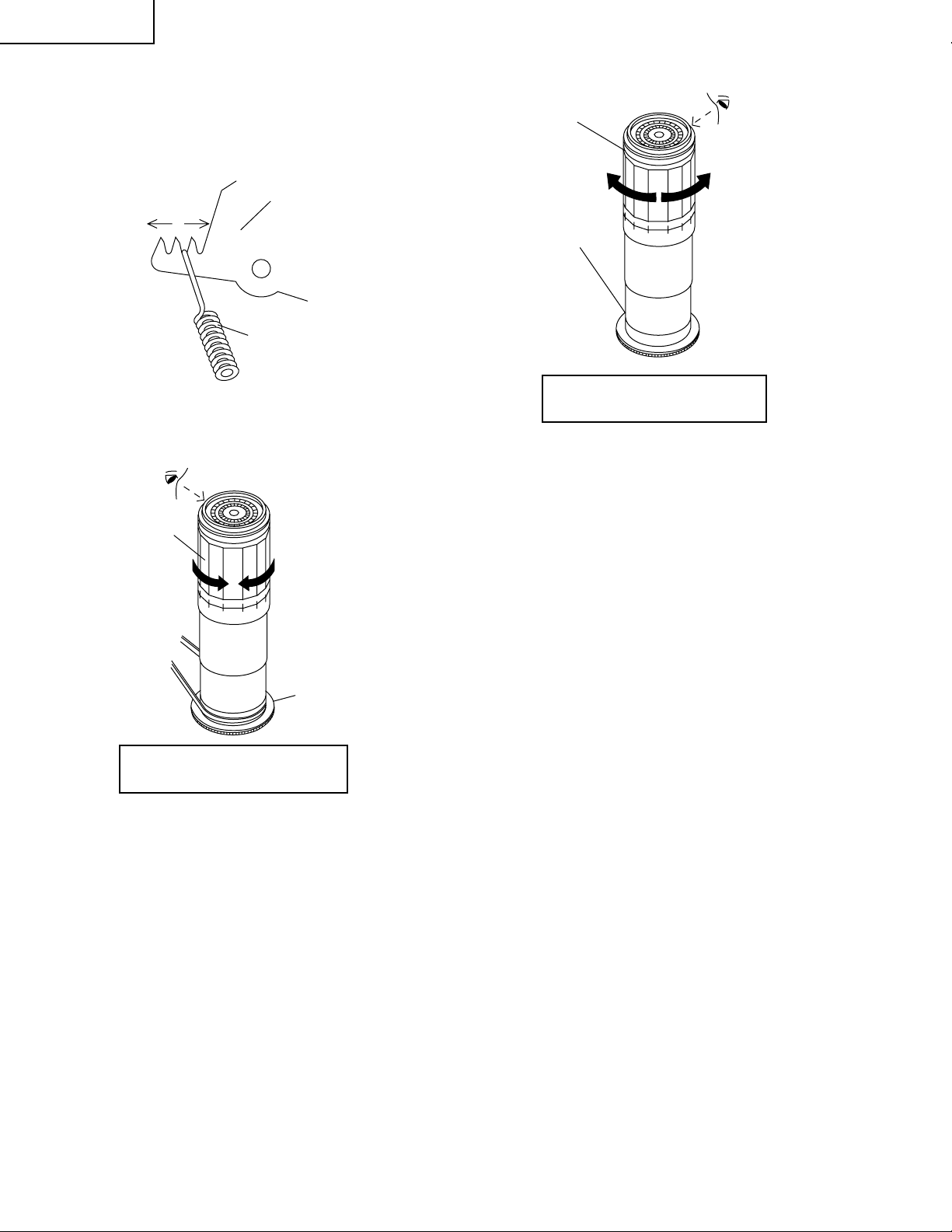

2. Mechanical initial setting

Feed the pulley feed gear of loading motor with screw

driver. After ascertaining the return to the initial set position (*1) install the cassette housing in the specified

position. (This method is applied only for the mechanism.)

Casecon

drive gear

Drive angle of

cassette housing

INSTALLING THE MECHANISM ON PWB

Lower vertically the mechanism, paying attention to the

mechanism edge, and install the mechanism with due

care so that the parts are not damaged. So as to fix the

mechanism to the main PWB install two housings. (Fit the

antenna cover to one of them. For other, fix the vicinity of

loading motor and solder joint side of main PWB.) Connect again the FFC cable (AA-MH, AD-ME, AH-MH)

between the mechanism and the main PWB.

END SENSOR

REC TIP SW

VC-GH96Z

PARTS WHICH NEED PARTICULAR CARE

When installing the mechanism chassis on the PWB unit,

take care so as to prevent deformation due to contact of

mechanism chassis with REC TIP SW.

AE CONNECTOR

AC CONNECTOR

START SENSOR

AL CONNECTOR

7

Page 8

VC-GA56Z

VC-GH96Z

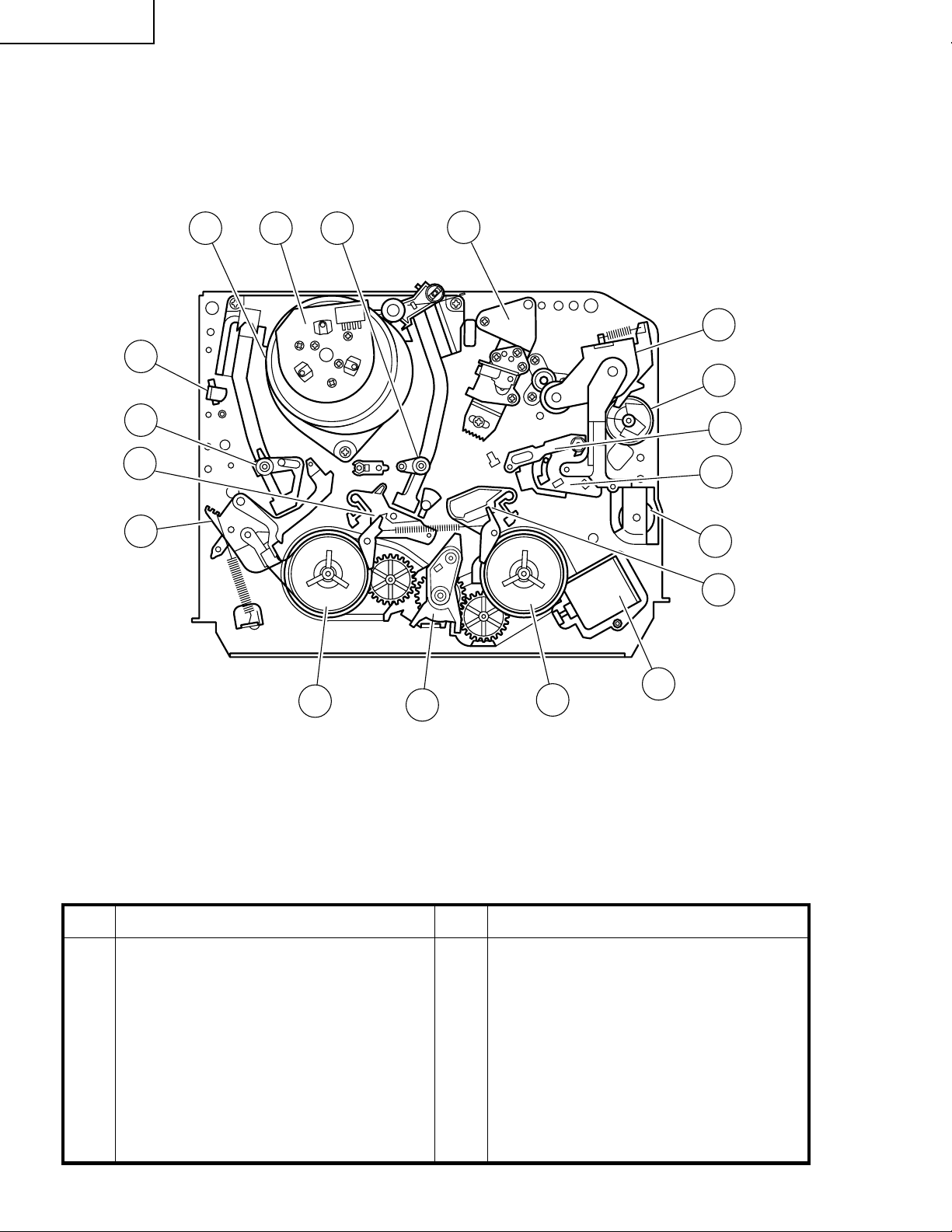

3. FUNCTION OF MAJOR MECHANICAL PARTS (TOP VIEW)

15

17

18

10

14

1

9

2

7

3

11

5

12

8

No. Function

1 Full erase head

2 Supply pole base ass’y

3 Tension arm

4 Idler wheel ass’y

5 Pinch drive lever ass’y

6 Supply reel disk

6

4

No. Function

8 Take-up main brake

9 Pinch drive cam

10 A/C head ass’y

11 Reverse guide lever ass'y

12 Casecon drive gear

13 Take-up reel disk

13

16

7 Supply main brake

14 Pinch roller lever ass’y

8

Page 9

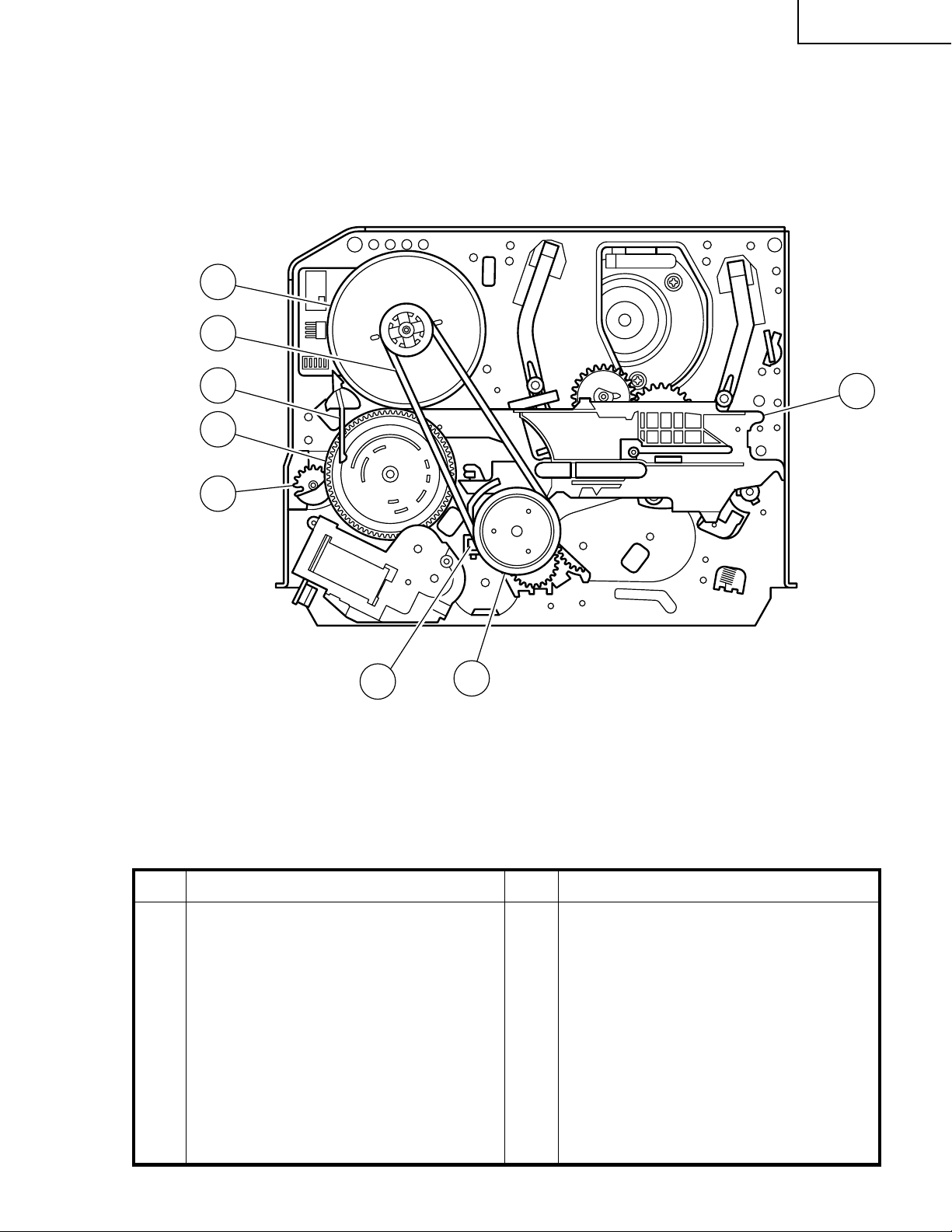

FUNCTION OF MAJOR MECHANICAL PARTS (BOTTOM VIEW)

21

22

VC-GA56Z

VC-GH96Z

19

20

12

23

26

24

No. Function

15 Drum ass’y

16 Loading motor

17 Drum drive motor

18 Take-up pole base ass’y

19 Slow brake lever

20 Master cam

21 Capstan D.D. motor

No. Function

22 Reel belt

23 Clutch lever

24 Limiter pulley ass'y

26 Shifter

9

Page 10

VC-GA56Z

VC-GH96Z

4. ADJUSTMENT, REPLA CEMENT AND ASSEMBLY OF MECHANICAL UNITS

The explanation given below relates to the on-site general service (field service) but it does not relates to the adjustment

and replacement which need high-grade equipment, jigs and skill. For example, the drum assembling, replacement

and adjustment service must be performed by the person who have finished the technical courses.

4-1 MECHANISM CONFIRMATION ADJUSTMENT JIG

So as to perform completely the mechanism adjustment prepare the following special jigs. So as to maintain the initial

performance of the machine the maintenance and check are necessary. Utmost care must be taken so that the tape

is not damaged. If adjustment needs any jig, be sure to use the required jig.

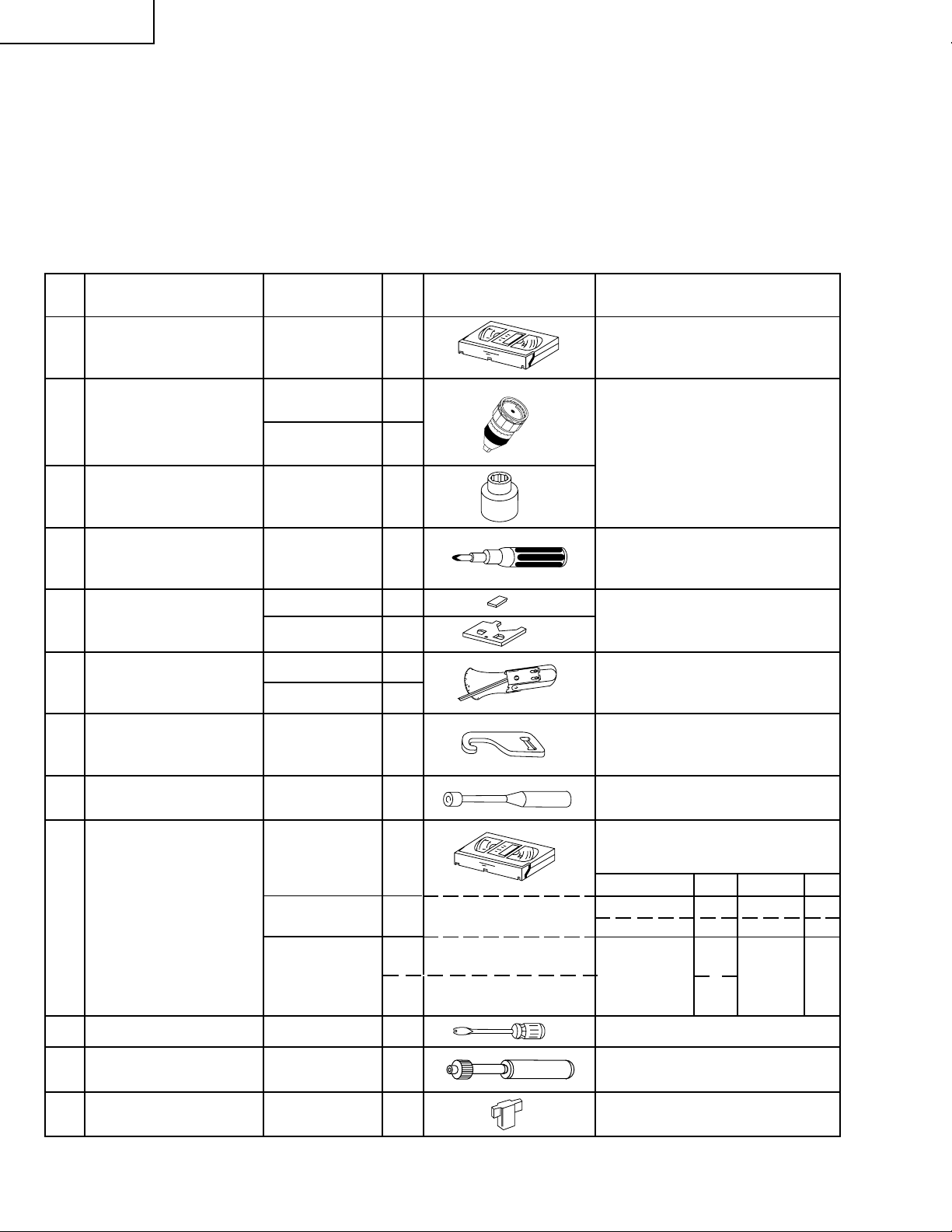

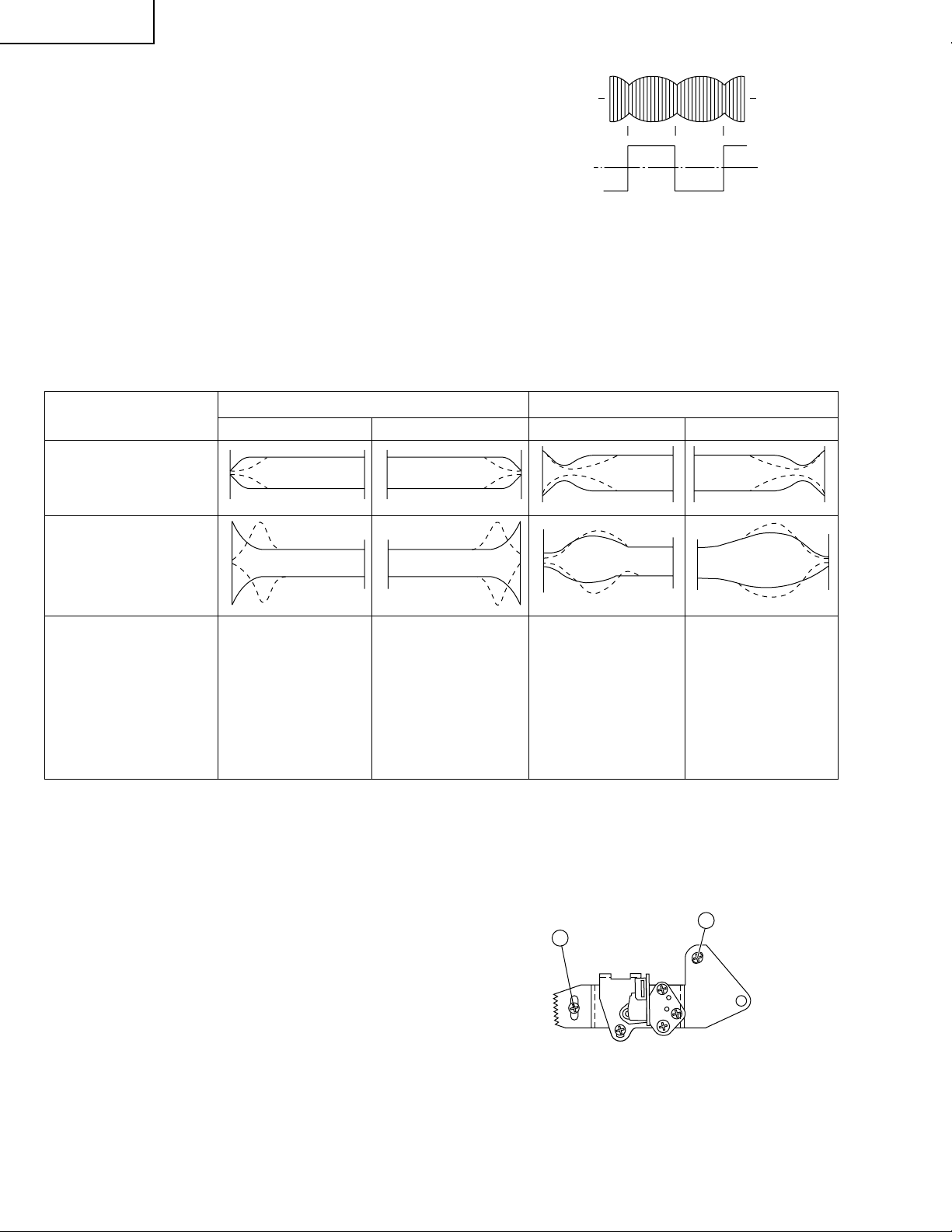

No. Jig ltem Part No. Code Configuration Remarks

This cassette torque meter is used for check-

1. Torque Cassette Meter JiGVHT-063 CZ

JiGTG0090 CM

2.

Torque Gauge

JiGTG1200 CN

3. Torque Gauge Head JiGTH0006 AW

ing and adjusting the torque of take-up for

measuring tape back tension.

These Jigs are used for checking

and adjusting the torque of take-up

and supply reel disks.

4. Torque Driver JiGTD1200 CB

Master Plane Jig and

Reel Disk Height

5.

Adjusting Jig

JiGRH0002 BR

JiGMP0001 BY

JiGSG2000 BS

Tension Gauge

6.

JiGSG0300 BF

Pinch pressing force

7. JiGADP003 BK

measuring jig

Reverse guide height

8.

adjustment box driver

9.

Alignment Tape

JiGDRiVER11055

VROATSV CD

AR

VROEFZCS BG

OR

VROEFZHS BH

When fixing any part to the threaded

hole using resin with screw, use the

jig. (Specified torque 5 kg)

These Jigs are used for checking

and adjusting the reel disk height.

There are two gauges used for the

tension measurements, 300 g and

2.0 kg.

This Jig is used with the tension

gauge. Rotary transformer clearance adjusting jig.

This Jig is used for height adjustment of the

reverse guide (for reverse guide height adjustment).

These tapes are especially used for

electrical fine adjustment.

Video Audio HiFi Audio Track

525 Monoscope 7k — 58µm

NTSC Color Bar 1k — 58µm

Black Level

(only SYNC) signal

1k

— 19µm

2.3k

Guide roller height

10. JiGDRiVERH-4 AP

adjustment driver

X value adjustment

11. JiGDRiVER-6 BM

gear driver

Reverse Guide Height

12. JiGRVGH-F18 BU

Adjusting Jig

This screwdriver is used for adjusting the

guide roller height.

For X value adjustment

This Jig is used for height

adjustment of the reverse guide.

10

Page 11

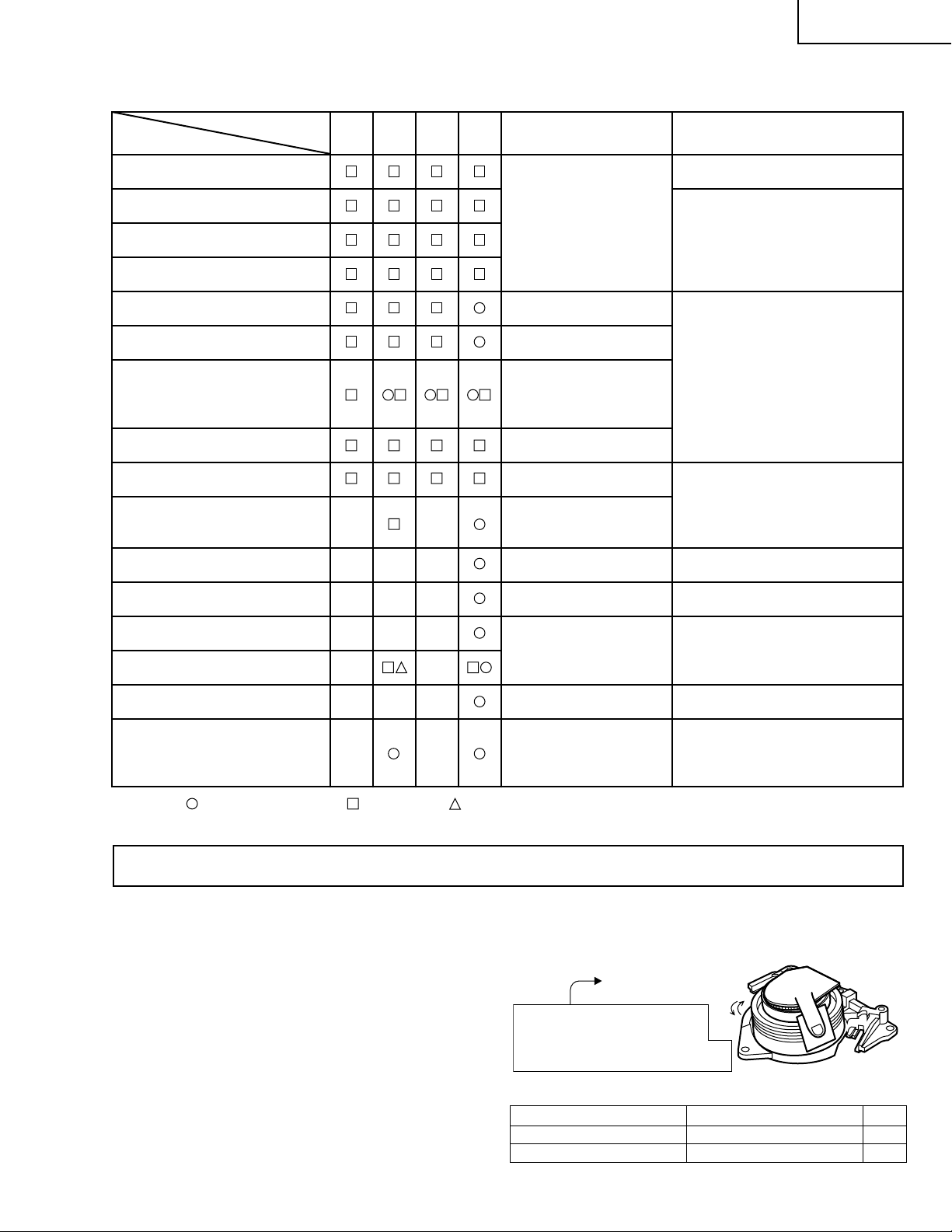

4-2 MAINTENANCE CHECK ITEMS AND EXECUTION TIME

NOTE : Part replacement. : Cleaning : Apply grease

<Specified> Cleaning liquid Industrial ethyl alcohol

* This mechanism does not need electric adjustment with variable resistor. Check parts. If any deviation is found,

clean or replace parts.

Maintained

Parts

Remarks

500

hrs.

1000

hrs.

1500

hrs.

2000

hrs.

Possible symptom

encountered

Guide roller ass’y

Sup guide shaft

Reverse guide

Slant pole on pole base

Full erase head

A/C head

Upper and lower drum ass’y

Capstan D.D. motor

Pinch roller

Reel belt

Tension band ass’y

Loading motor

Idler ass’y

Limiter pulley

Supply/take-up main brake levers

AHC (Automatic Head Cleaner)

Colour and beating

Small sound or sound

distortion

Poor S/N ratio, no colour

Poor flatness of the

envelope with alignment

tape

No tape running,

uneven colour

No tape running, tape

slack

No tape running, tape

slack, no fast forward/

rewind motion

Lateral noises Head

occasionally blocked

Abnormal rotation or significant

vibration requires replacement.

Clean tape contact part with the

specified cleaning liquid.

Clean tape contact area with the

specified cleaning liquid.

Clean rubber and rubber contact

area with the specified cleaning

liquid.

Replace the roller of the cleaner

when it wears down.

Just change the AHC roller

assembly for new one.

Screen swaying

Cassette not loaded or

unloaded

No tape running, tape

slack

Tape slack

Perform the maintenance with the regular intervals as follows so as to maintain the quality of machine.

VC-GA56Z

VC-GH96Z

Video head cleaning procedure

1. Apply one drop of cleaning liquid to the cleaning paper with the baby oiler.

2. Gently press the cleaning paper against the video head to fix your finger, and move the upper drum so that each

3. Wipe with the dry cleaning paper.

Notes :

head is passed to and fro 5 times (do not move the cleaning paper).

• Use the commercially available ethanol of Class 1 as

cleaning liquid.

• Since the video head may be damaged, do not move

up and down the cleaning paper.

• Whenever the video head is cleaned, replace the

cleaning paper.

• Do not apply this procedure for the parts other than

the video head.

Rotate the upper drum

with one hand.

Gently press the cleaning paper to

fix with your finger, and rotate the

upper drum to clean.

Move to and fro 5 times for each head.

(Do not move the cleaning paper.)

Parts Code Description Code

ZPAPRA56-001E Cleaning Paper AW

ZOiLR-02-24TE Babe Oiler (Spoit) AH

11

Page 12

VC-GA56Z

500g

Mechanism chassis

Weight to prevent

float (500g)

VC-GH96Z

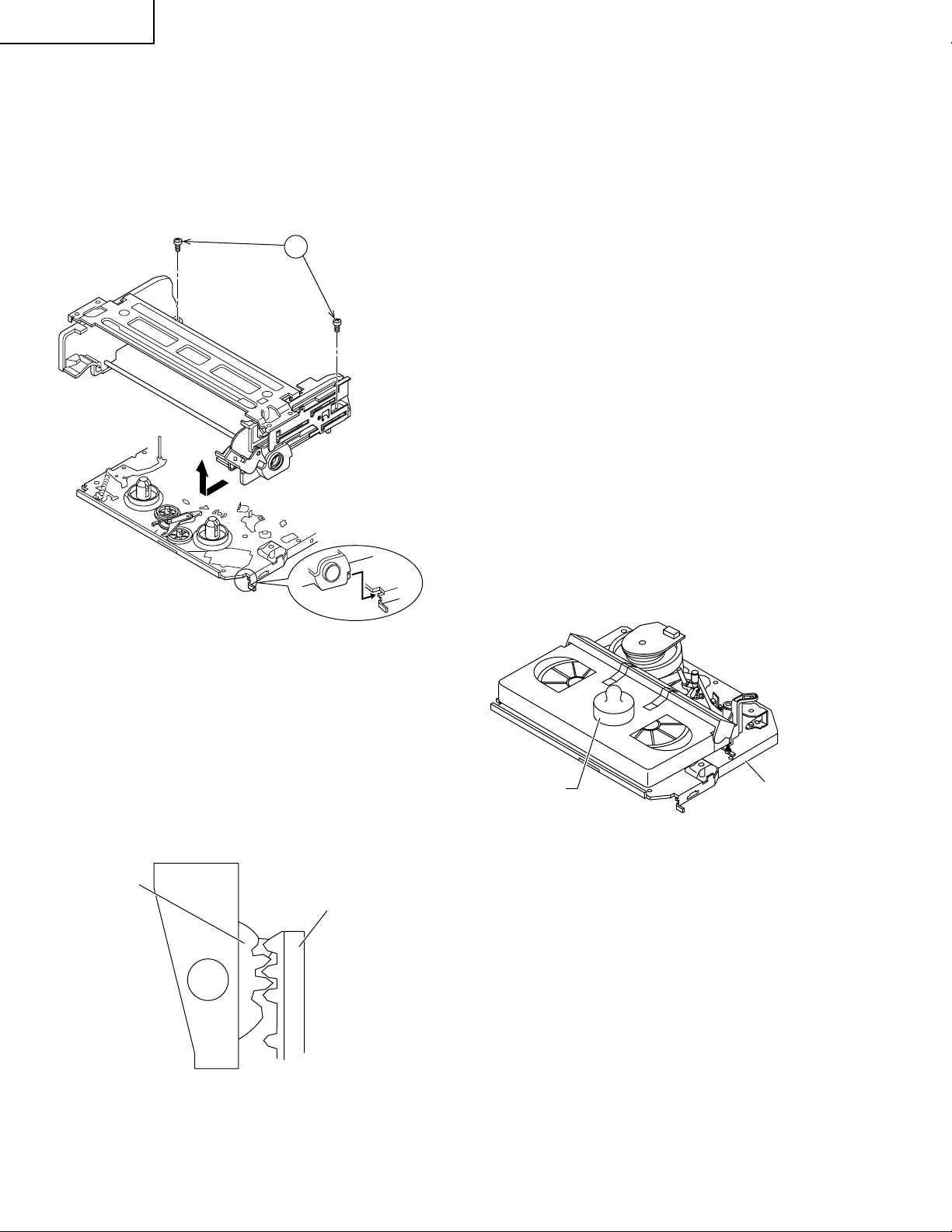

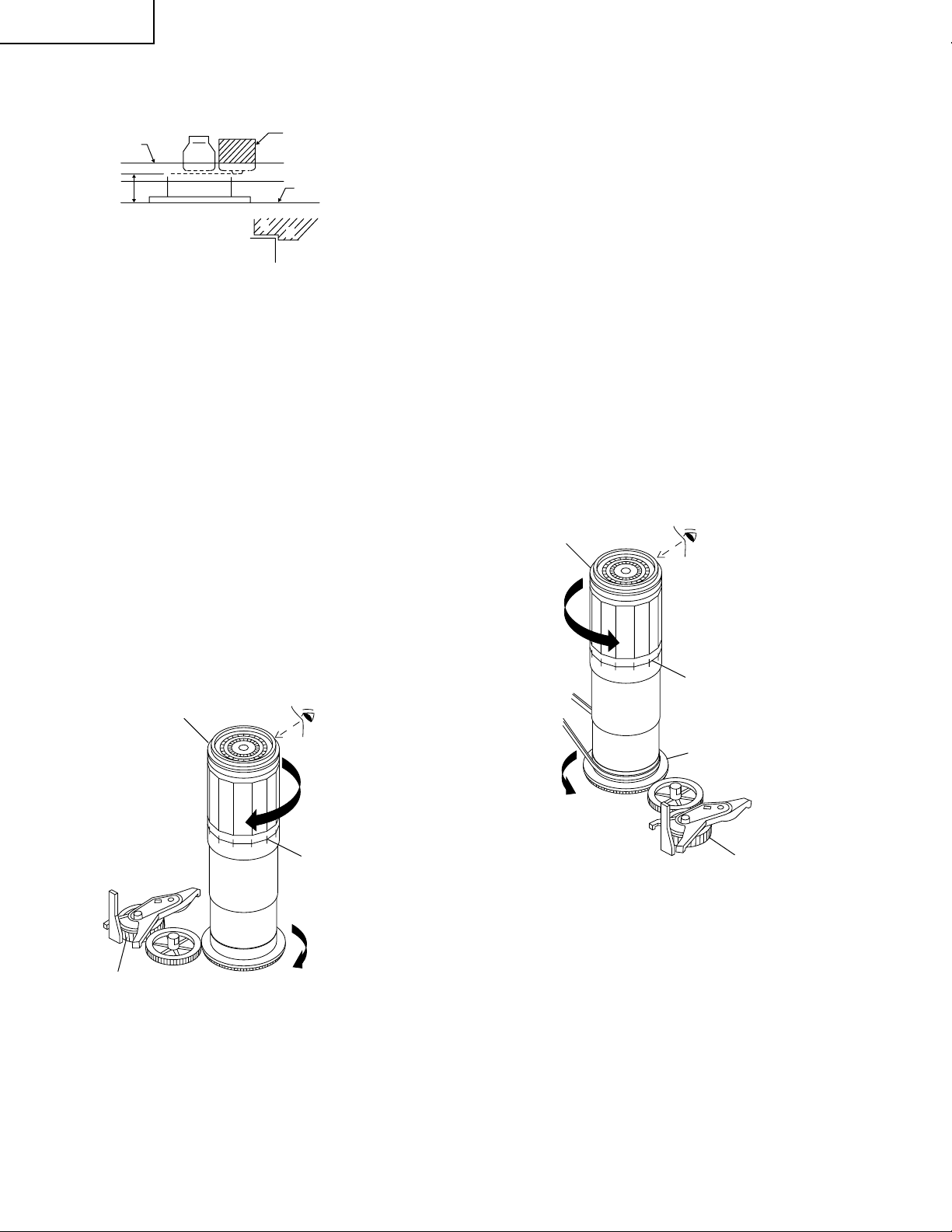

4-3. REMOVING AND INSTALLING THE CAS-

SETTE HOUSING

• Removal

1. In the cassette removing mode, remove the cassette.

2. Unplug the power cord.

3. Remove in the following numerical order.

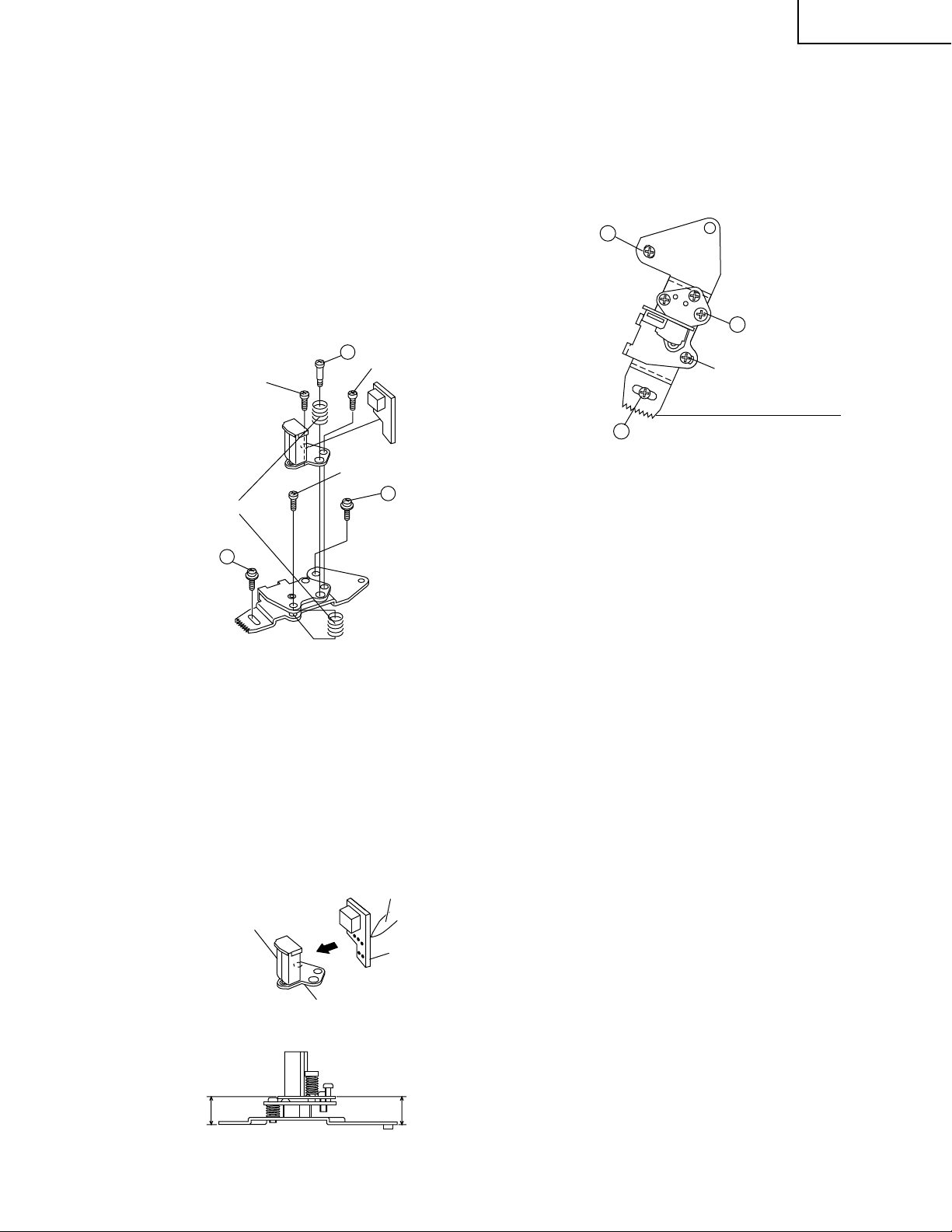

a) Remove two screws 1.

b) Slide and pull up the cassette housing control.

1

Notes:

1. When fitting the S/E sensor holder to the cassette

controller frame L/R, take care.

2. Misengagement of teeth of casecon drive gear and

drive angle gear causes malfunction. (The cassette

cannot be set, load and ejection are repeated).

3. In the case when you use the magnet screw driver,

never approach the magnet driver to the A/C head, FE

head, and drum.

4. When installing or removing, take care so that the

cassette housing control and tool do not contact the

guide pin or drum.

5. After installing the cassette housing control once perform cassette loading operation.

4-4. TO RUN A TAPE WITHOUT THE CASSETTE

HOUSING CONTROL ASSEMBLY

1. Remove the full-surface panel.

2. Short-circuit TP803 and TP802.

3. Plug in the power cord.

4. Turn off the power switch.

(The pole bases move into U.L.position.)

5. Open the lid of a cassette tape by hand.

6. Hold the lid with two pieces of vinyl tape.

7. Set the cassette tape in the mechanism chassis.

8. Stabilize the cassette tape with a weight (500g) to

prevent floating.

9. Turn on the power switch.

10. Perform running test.

Figure 4-1.

• Reassembly

1. Before installing the cassette housing control, shortcircuit TP803 and TP802 provided at operation PWB,

press the eject button. The casecon drive gear turns

and stops when the positioning mark appears. Engage

two teeth of casecon drive gear with the three teeth of

casecon drive angle gear, and set on the mechanism

chassis as shown below.

Casecon

drive gear

Casecon drive

angle gear

Figure 4-2.

Figure 4-3.

Note:

The weight should not be more than 500g.

To take out the cassette tape.

1. Turn off the power switch.

2. Take out the cassette tape.

2. Install in the reverse order of removal.

12

Page 13

VC-GA56Z

VC-GH96Z

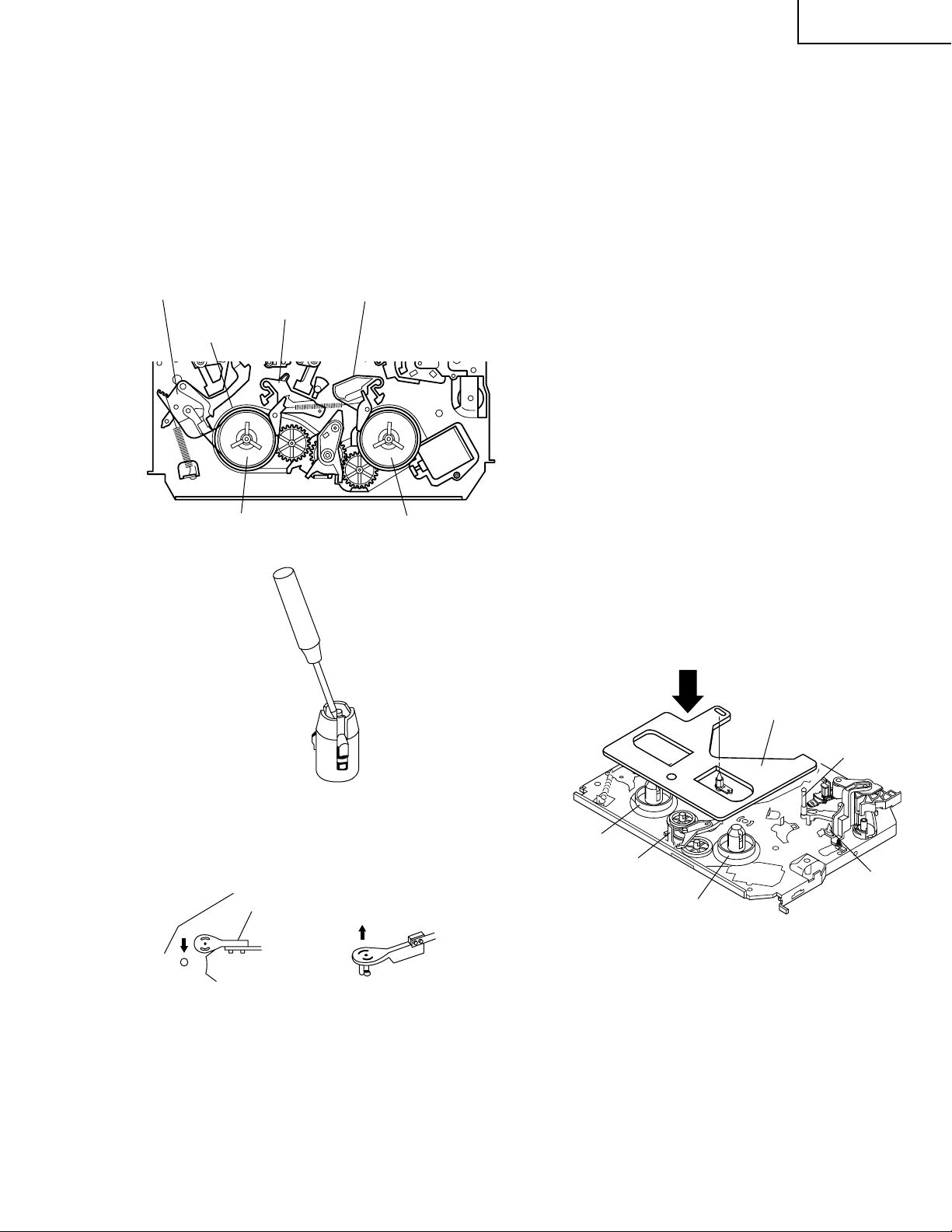

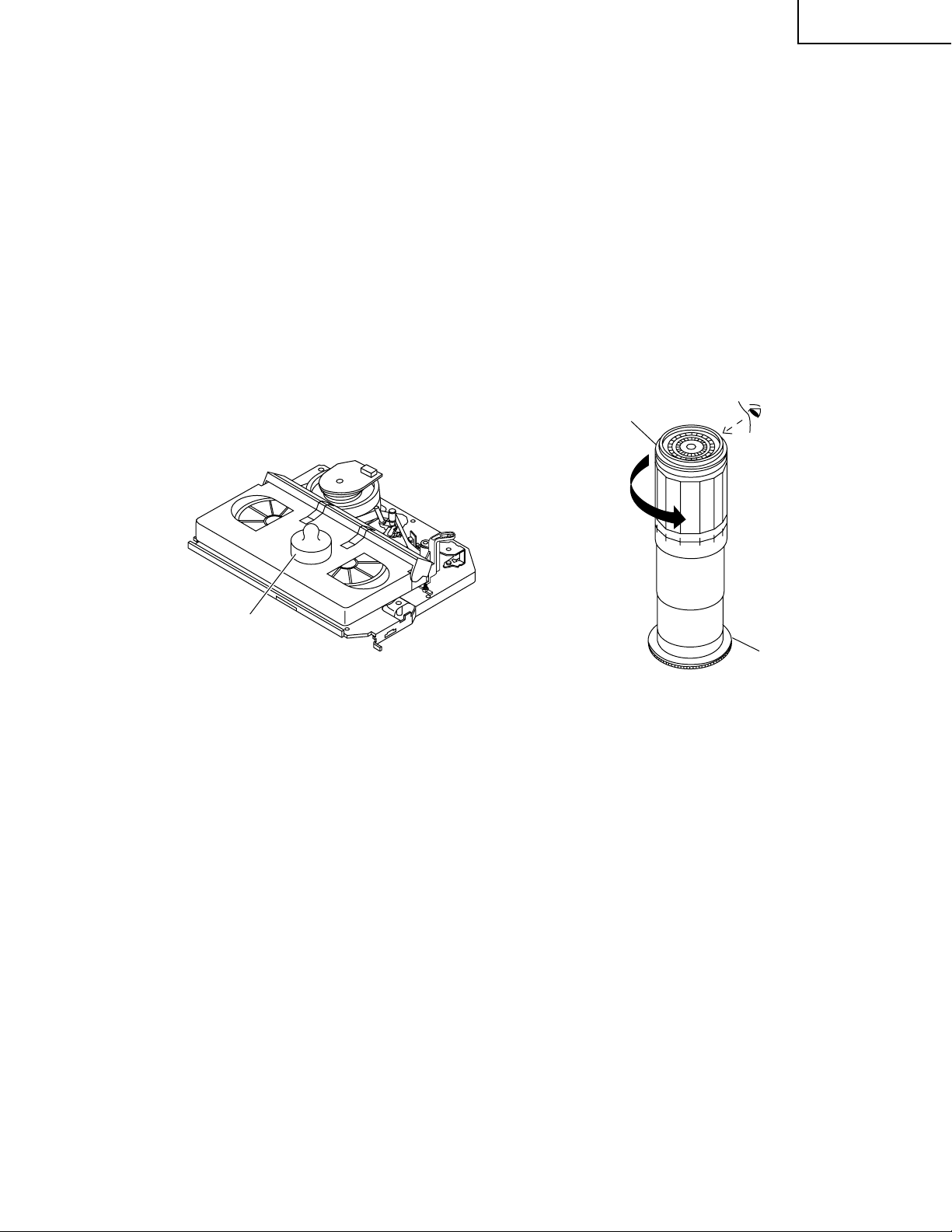

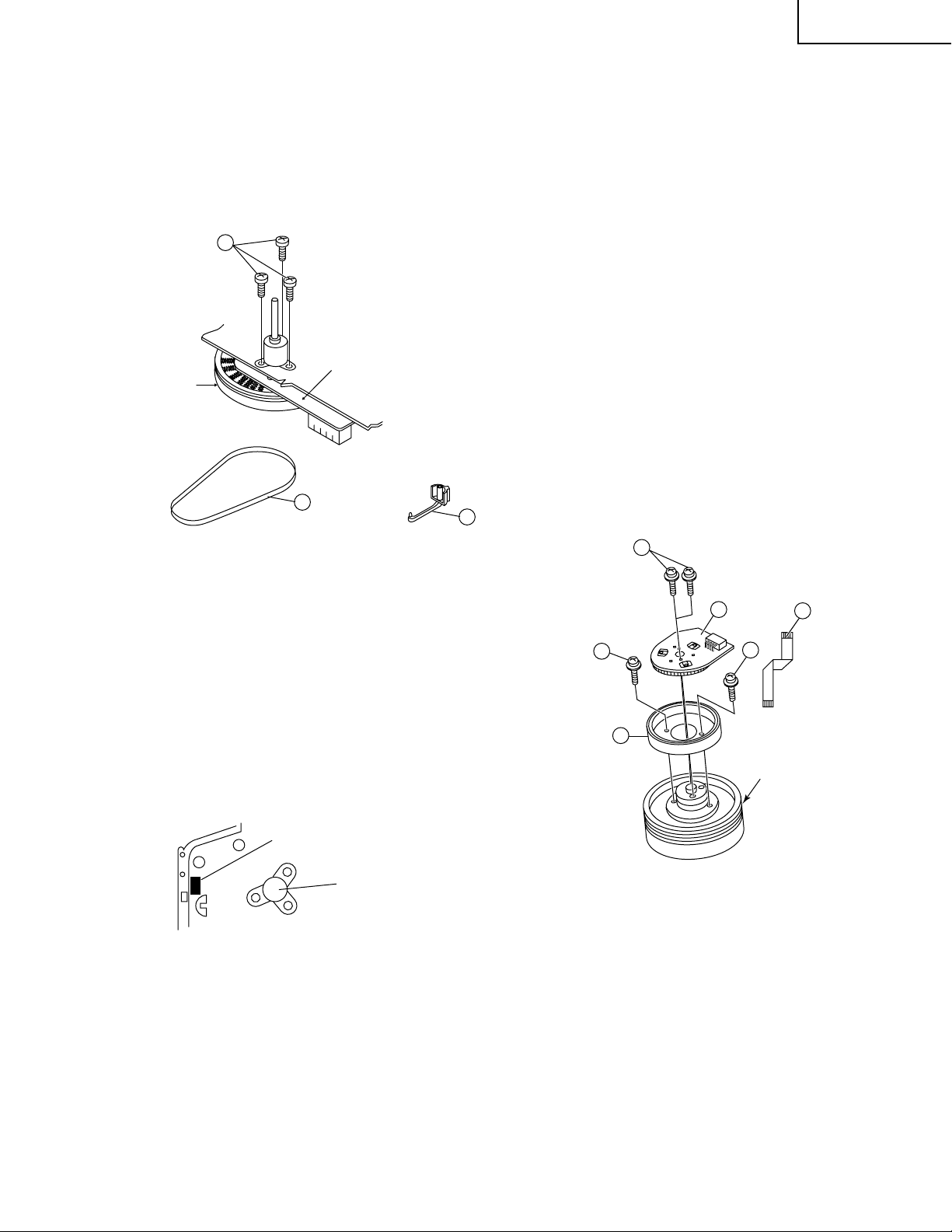

4-5. REEL DISK REPLACEMENT AND

HEIGHT CHECK

• Removal

1. Remove the cassette housing control assembly.

2. Pull the tension band out of the tension arm ass'y.

3. Remove the Supply/Take-up main brake ass'y.

4. Open the hook at the top of the reel disk, and remove

the reel disk.

Note:

Take care so that the tension band ass'y and main brake

ass'y (especially soft brake) are not deformed.

Tension arm ass'y

Supply main brake ass'y

Tension band ass'y

Supply reel disk

Take-up main brake ass'y

Take-up reel disk

4. Assemble the Supply main brake ass'y.

Notes:

1. When installing the reel disk, take due care so that the

tension band ass'y is not deformed and grease does no

adhere.

2. Do not damage the Supply main brake ass'y. Be

careful so that grease does not adhere to the brake

surface.

• Reassembly (Take-up reel disk)

1. Clean the reel disk shaft and apply grease (SC-141) to

it.

2. Align the phase of the reel disk to that of the reel relay

gear and to install a new take-up reel disk onto the

shaft.

3. Check the reel disk height and reassemble the take-up

main brake ass'y.

Note:

1. Take care so that the Take-up main brake ass'y is not

damaged. Take care so that grease does not adhere

the brake surface.

2. After reassembly, check the video search rewind back

tension (see 4-10), and check the brake torque (see 4-

14).

• Height checking and adjustment

Note:

1. Set the master plane with due care so that it does not

contact the drum.

2. When putting the master plane, shift the reverse guide

a little in the loading direction. Care must be taken

since excessive shift results in damage.

Figure 4-4.

Note:

When the tension band ass'y is pressed in the direction of

the arrow for removal, the catch is hard to be deformed.

Figure 4-5.

• Reassembly (Supply reel disk)

1. Clean the reel disk shaft and apply grease (SC-141) to

it.

2. Match the phases of reel disk and reel relay gear, and

set the new reel disk.

3. After checking the reel disk height, wind the tension

band ass'y around the reel disk, and insert into the hole

of tension arm ass'y.

Master plane

Reverse

guide

Supply reel disk

Cassette lock

release shaft

Take-up reel disk

Position

pin

Figure 4-6.

Note:

• Check that the reel disk is lower than part A but higher

than part B. If the height is not correct, readjust the reel

disk height by changing the poly-slider washer under

the reel disk.

13

Page 14

VC-GA56Z

VC-GH96Z

Note:

Whenever replacing the reel disk, perform the height

checking and adjustment.

Master plane

10 ± 0.2mm

Reel disk

Reel disk

Reel disk height

adjusting jig

Mechanism chassis

A

B

Figure 4-7.

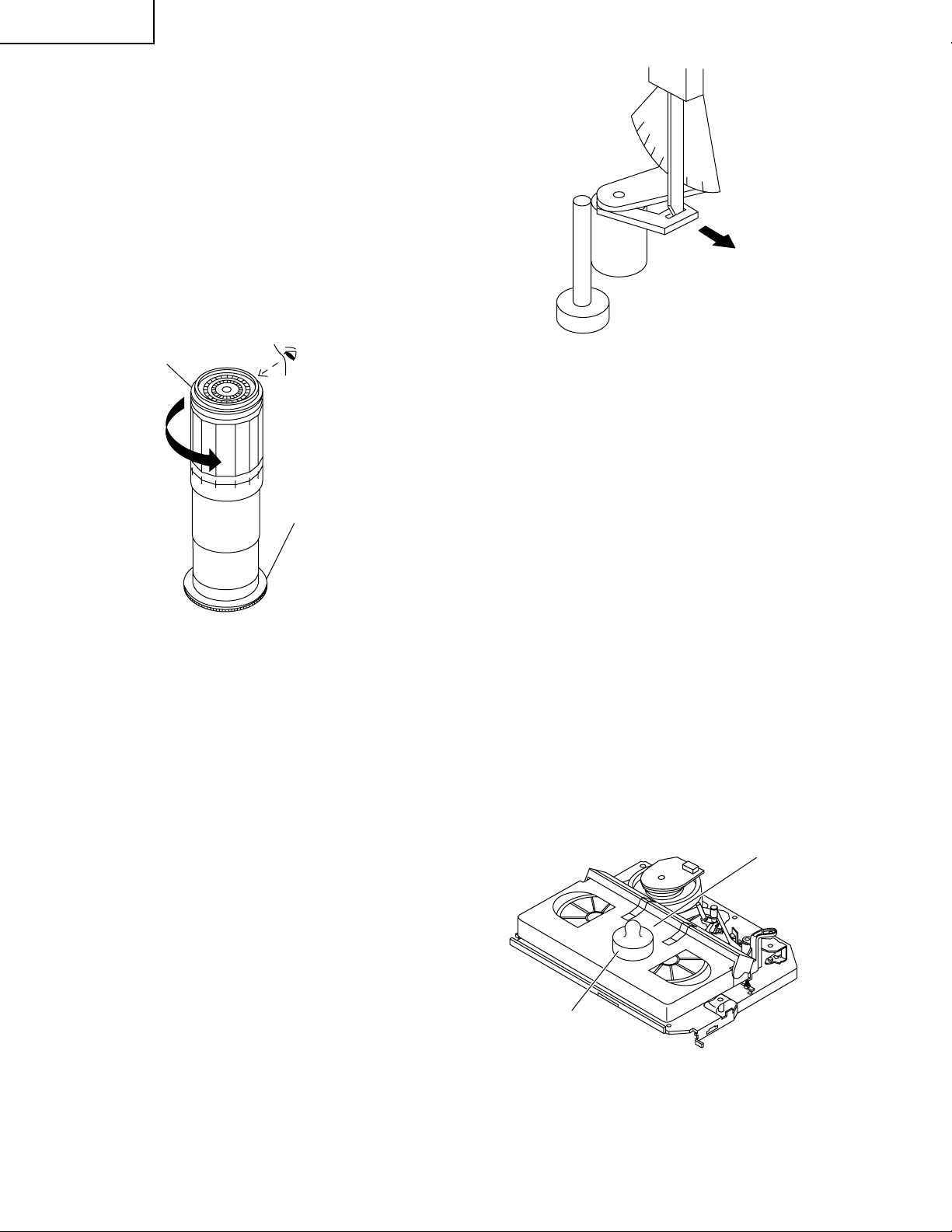

4-6. CHECKING AND ADJUSTMENT OF TAKE-

UP TORQUE IN FAST FORWARD MODE

• Remove the cassette housing control assembly.

• After short-circuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

• Setting

1. Set a torque gauge to zero on the scale. Place it on the

take-up reel disk.

2. Press the FF button.

3. To calculate the remaining capacity of the play back

mode, slowly rotate the supply reel disk, and then shift

it into the forward mode.

Notes:

1. Hold the torque gauge by hand so that it is not moved.

2. Do not keep the reel disk in lock state. Do not allow

long-time measurement.

4-7. CHECKING AND ADJUSTMENT OF

TAKE-UP TORQUE IN REWIND MODE

• Remove the cassette housing control assembly.

• After short-circuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

• Setting

1. Set a torque gauge to zero on the scale. Place it on the

supply reel disk.

2. Press the rewind button.

3. To calculate the remaining capacity, slowly rotate the

take-up reel disk, and then shift it into the rewind mode.

• Checking

1. Turn the torque gauge slowly (one rotation every 2 to

3 seconds) by hand in the CCW direction.

2. Make sure that the indication of torque gauge is not

less than 30mN·m (306gf·cm).

Torque gauge

• Checking

1. Turn the torque gauge slowly (one rotation every 2 to

3 seconds) by hand in the CW direction.

2. Make sure that the indication of torque gauge is not

less than 30mN·m (306gf·cm).

Torque gauge

30mN·m (306gf·cm)

or more

Idler ass'y

CW

The gauge is held at

its maximum value.

(Red mark)

Figure 4-8.

• Adjustment

1. If the FF winding-up torque is less than the specified

value, clean the capstan D.D. motor pulley, drive belt,

and limiter pulley with cleaning liquid, and check again.

2. If the torque is less than the set value, replace the reel

belt.

30mN·m (306gf·cm)

or more

CCW

The gauge is held at

its maximum value.

(Red mark)

Supply reel disk

Idler ass'y

Figure 4-9.

• Adjustment

1. If the rewind winding-up torque is less than the specified value, clean the capstan D.D. motor pulley, drive

belt, and limiter pulley with cleaning liquid, rewind

again, and check the winding-up torque.

2. If the winding-up torque is still out of range, replace the

drive belt.

14

Page 15

VC-GA56Z

VC-GH96Z

Notes:

1. Hold the torque gauge by hand so that it is not moved.

2. Do not keep the reel disk in lock state. Do not allow

long-time measurement.

4-8. CHECKING AND ADJUSTMENT OF TAKE-

UP TORQUE IN RECORD/PLAYBACK MODE

• Remove the cassette housing control assembly.

• After short-circuiting TP803 and TP802 provided

at operation PWB, plug in the power cord.

• Turn off the power switch.

• Open the cassette torque meter lid, and fix it with

tape.

• Load the cassette torque meter into the unit.

• Put the weight (500g) on the cassette torque meter.

• Turn on the power switch.

• Press the picture record button, and set EP picture

record mode (x3).

Set value EP6.9 ± 2.5mN·m (70 ± 25gf·cm)

4-9. CHECKING AND ADJUSTMENT OF

TAKE-UP TORQUE IN VIDEO SEARCH

REWIND MODE

• Remove the cassette housing control assembly.

• After short-circuiting TP803 and TP802 provided

at operation PWB, plug in the power cord.

• Setting

Press the playback button and rewind button to set the

video search rewinding mode.

• Checking

Place the torque gauge on the supply reel disk, and turn

it counterclockwise very slowly (one rotation every 1 to 2

seconds) and check that the torque is within the set value

14.0 ± 3.9mN⋅m. (144 ± 40gf⋅cm)

Torque gauge

CCW

500g

Cassette torque meter

Figure 4-10.

• Checking

1. Make sure that value is within the setting 6.9 ± 2.5mN·m

(70 ± 25gf·cm).

2. The winding-up torque fluctuates due to variation of

rotation torque of limiter pulley ass'y. Read the center

value of fluctuation as setting.

3. Set the EP record mode (x3) and make sure that the

winding-up torque is within setting.

• Adjustment

If the playback winding-up torque is not within the setting,

replace the limiter pulley assembly.

Note:

When the torque cassette is set, put a weight (500g) to

prevent rise.

When the cassette torque meter is taken out.

Turn off the power switch.

Supply reel disk

Figure 4-11.

Note:

Surely put the torque gauge on the reel disk to measure.

If the torque gauge is raised, accurate measurement is

impossible.

• Adjustment

If the rewinding playback winding-up torque is not within

the setting, replace the limiter pulley assembly.

Note:

The winding-up torque fluctuates due to variation of

rotation torque of supply reel disk. Read the center value

of fluctuation as setting.

15

Page 16

VC-GA56Z

VC-GH96Z

4-10. CHECKING THE VIDEO SEARCH

REWIND BACK TENSION

• Remove the cassette housing control assembly.

• After short-circuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

• Checking

1. After pressing the play button, press the rewind button,

and set the video search rewind mode.

2. Place the torque gauge on the take-up reel disk, and

turn it counterclockwise very slowly (one rotation every

2 to 3 seconds) and check that the torque is within the

set value 3.4 ± 1.5mN⋅m (35 ± 15gf⋅cm).

Torque gauge

CCW

Take-up reel disk

Figure 4-12.

Notes:

Set the torque gauge securely on the take-up reel disk.

If it is not secure, the measurement will be incorrect.

4-11. CHECKING THE PINCH ROLLER

PRESSURE

• Remove the cassette housing control assembly.

• After short-circuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

Tension gauge

Pinch roller

Capstan shaft

Tension gauge adapter

900 - 1,200gf

Figure 4-13.

1. Detach the pinch roller from the capstan shaft.

Do not separate excessively. Or the pinch lever and

pinch double action lever may disengage.

2. Engage the tension gauge adapter with the pinch roller

shaft, and pull in the arrow direction.

3. Gradually return the pinch roller, and measure the

pulling force when the pinch roller contacts the capstan

shaft.

4. Make sure that the measured value is within setting 9.0

N to 11.8 N (900 to 1,200gf).

4-12. CHECKING AND ADJUSTMENT OF

TENSION POLE POSITION

• Remove the cassette housing control assembly.

• After short-circuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

• Setting

1. Turn off the power switch.

2. Open the cassette tape (T-120), and fix with tape.

3. Set the cassette tape in loading state.

4. Put the weight (500g) on the cassette tape.

5. Turn on the power switch.

6. Make the adjustment with the beginning of a T-120

tape.

(T-120)

• Checking

Press the play button to set the playback mode.

500g

Weight to prevent

float (500g)

Figure 4-14.

• Checking

1. Set a cassette tape, push the REC button to place the

unit in the SP record mode. Now check the tension pole

position.

16

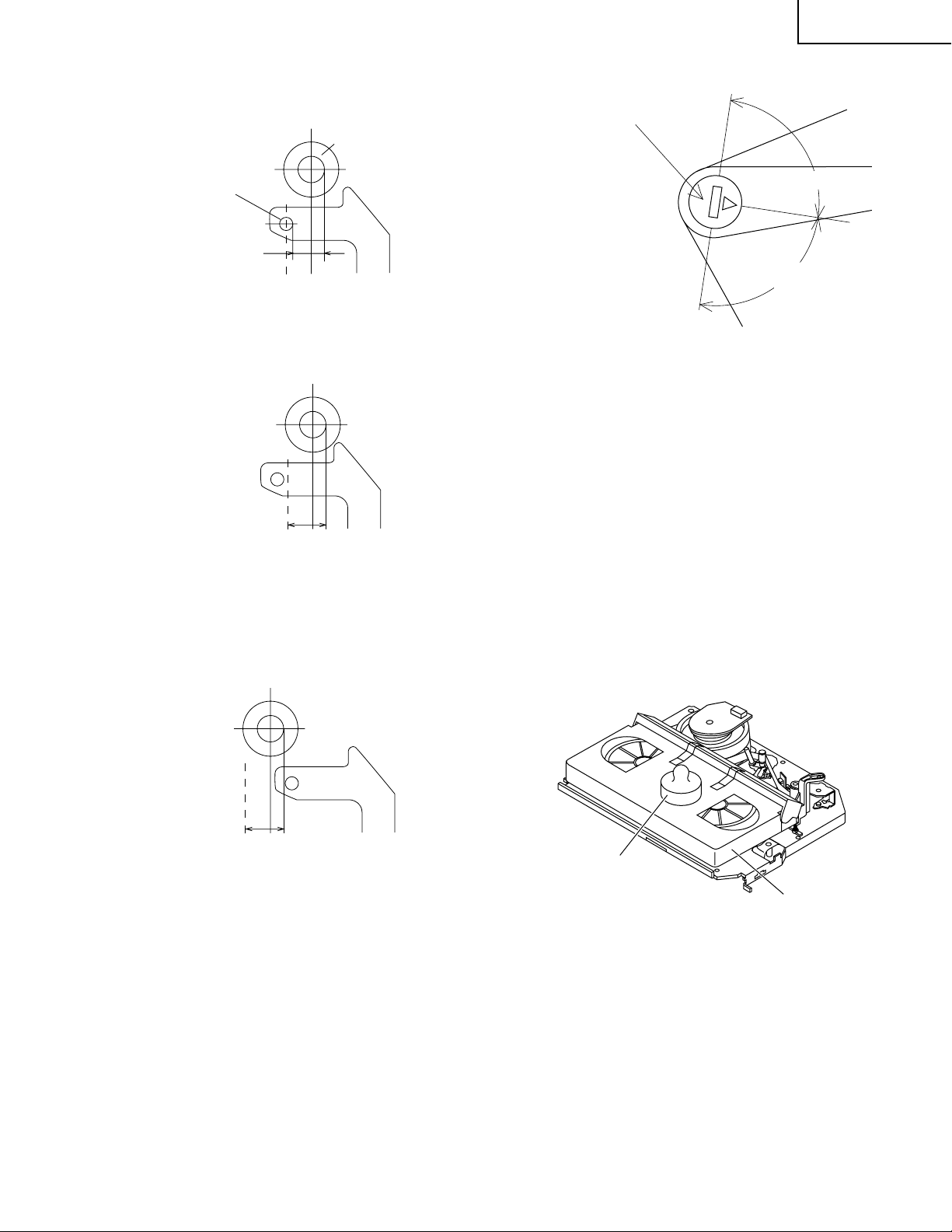

Page 17

VC-GA56Z

90°

90°

Tension pole adjuster

VC-GH96Z

2. Visually check to see if the right edge of the tension

pole is within the 2.3 ± 0.25 from the right edge of the

Sup guide shaft.

Sup guide shaft

Tension pole

2.3 ± 0.25

Make the adjustment with the beginning of a T-120 tape.

Figure 4-15.

At left side from the center line

Tension pole adjuster adjusting range

Figure 4-18.

Adjust so that the delta mark of tension pole adjuster is

within 90° range (left, right).

4-13. CHECKING AND ADJUSTMENT OF

RECORD/PLAYBACK BACK TENSION

• Remove the cassette housing control assembly.

2.3 ± 0.25

Figure 4-16.

Insert the slotted screwdriver in the tension pole adjuster,

and rotate counterclockwise.

At right side from the center line

2.3 ± 0.25

Figure 4-17.

Insert the slotted screwdriver in the tension pole adjuster,

and rotate clockwise.

• After short-circuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

• Setting

1. Turn off the power switch.

2. Open the torque cassette meter and fix with tape.

3. Set the cassette tape in loading state.

4. Put the weight (500g) on the cassette torque meter.

5. Turn on the power switch.

500g

Weight to prevent

float (500g)

Cassette torque

meter

Figure 4-19.

• Checking

1. Push the REC button to place the unit in the SP record

mode.

2. At this time ascertain that the back tension is within the

setting (36.5 to 52g·cm) by seeing the indication of

torque cassette meter.

17

Page 18

VC-GA56Z

VC-GH96Z

• Adjustment

1. If the indication of torque cassette meter is lower than

the setting, shift the tension spring engagement to the

part A.

2. If the indication of torque cassette meter is higher than

the setting, shift the tension spring engagement to the

part B.

BA

Tension arm

Tension spring

Figure 4-20.

4-14. CHECKING THE BRAKE TORQUE

• Checking the brake torque at the supply side

• Checking the brake torque at the take-up side

Torque gauge

CW

Take-up reel

disk

CCW: 4.9~13.7mN⋅m (50~140gf⋅cm)

CW: 3.9~10.8mN⋅m (40~110gf⋅cm)

CCW

Figure 4-22.

• Remove the cassette housing control assembly.

Torque gauge

CCW

CCW: 2.9~9.8mN⋅m (30~100gf⋅cm)

CW: 4.9~13.7mN⋅m (50~140gf⋅cm)

CW

Supply reel disk

Figure 4-21.

• Remove the cassette housing control assembly.

• After short-circuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

• Setting

1. Set a torque gauge to zero on the scale. Place it on the

supply reel disk.

2. Switch from the FF mode to the STOP mode.

3. Disconnect the power cord.

• After short-circuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

• Setting

1. Switch from the FF mode to the STOP mode.

2. Disconnect the power cord.

3. Set a torque gauge to zero on the scale. Place it on the

take-up reel disk.

• Checking

1. Turn the torque gauge at a rate of about one turn/2 sec

in the CCW direction/CW direction so that the reel disk

and torque gauge pointer rotates at equal speed and

make sure that the value is within the setting (CCW

direction: 4.9 to 13.7mN·m (50 to 140gf·cm), CW

direction: 3.9 to 10.8 mN·m (40 to 110gf·cm).

2. Adjustment of the brake torque at the supply side and

the take-up side

• Unless the supply side brake torque or take-up side

brake torque is within the setting, clean the felt surface

of reel disk (supply, take-up) brake lever, check again

the brake torque.

• If value cannot be set within the setting yet, replace the

main brake ass'y or main brake spring.

• Checking

Turn the torque gauge at a rate of about one turn/2 sec

in the CW direction/CCW direction with respect to the

supply reel disk so that the reel disk and torque gauge

pointer rotate at equal speed, and make sure that the

value is within the setting (CW direction: 4.9 to 13.7mN·m

(50 to 140gf·cm); CCW direction: 2.9 to 9.8mN·m (30 to

100gf·cm).

18

Page 19

VC-GA56Z

VC-GH96Z

4-15. REPLACEMENT OF A/C (Audio/Control)

HEAD

1. Remove the cassette housing control assembly.

2. In unloading state unplug the power cord.

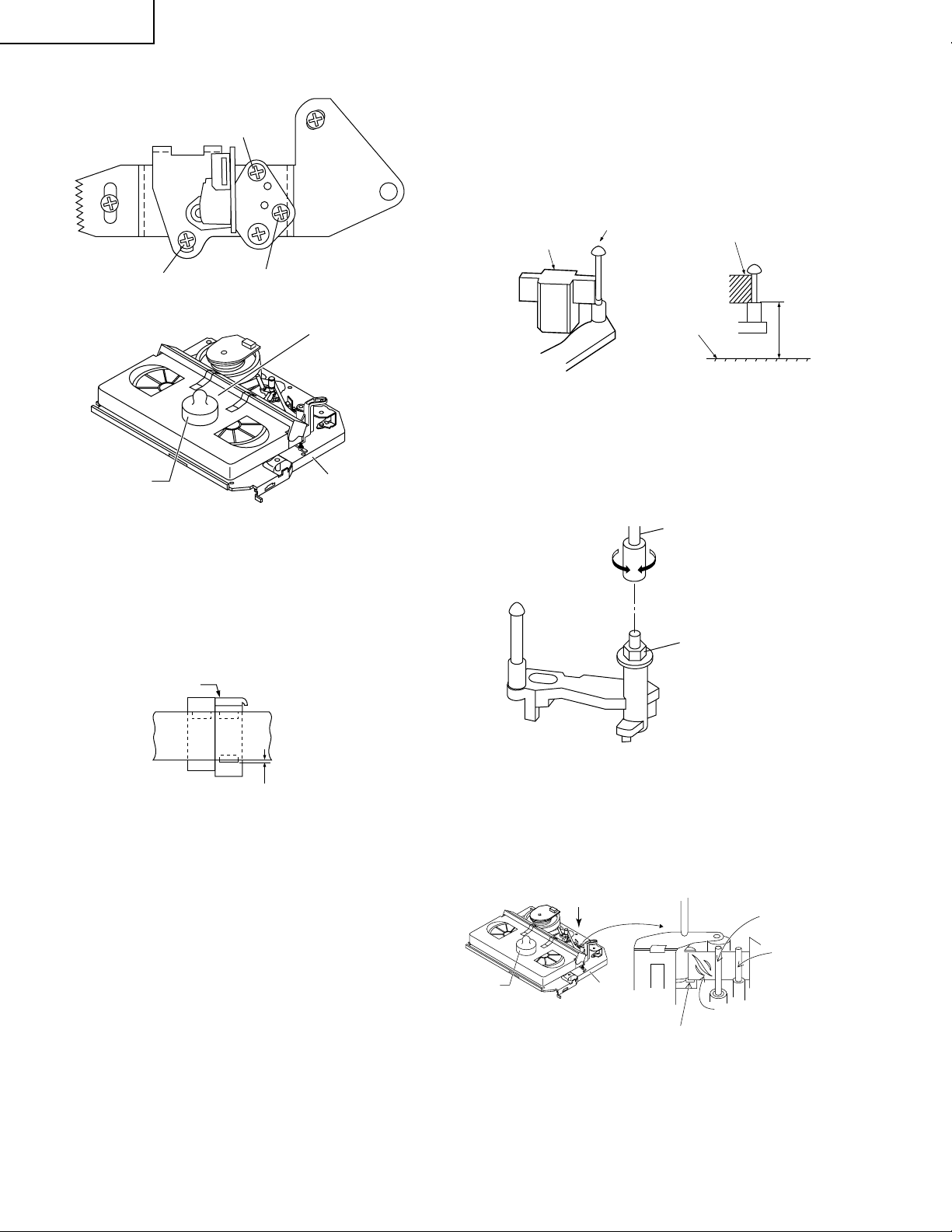

• Removal

1. Remove the screws 123, Azimuth screw, Tilt screw.

2. Unsolder the PWB fitted to the A/C head.

Notes:

1. When replacing, never touch the head. If you touched,

clean with the cleaning liquid.

2. When removing the screw 3, take care so that the

spring may out.

3

Azimuth screw

Spring

2

Tilt screw

Height screw

1

section and A/C head front section) (See the figure be-

low.)

3. Align the left end of gear of A/C head arm with the

punched mark of chassis, tentatively tighten the screws

1 and 2 so as to ensure smooth motion of A/C head

arm. Tentative tightening torque must be 0.15 to 0.20

N·m (1.5 to 2.0kgf·cm).

1

3

Height screw

Left end of A/C head arm gear

2

Punched line mark on chassis

Figure 4-25.

Note:

1. If the screws 1 and 2 are tighten tentatively too

loose, the azimuth and height of A/C head may change

when they are finally tightened. Therefore care must be

taken.

2. After completion of A/C head be sure to adjust tape

running. (Execute the running adjustment by the method

described in 4-18.)

Figure 4-23.

• Replacement

1. Solder the removed PWB to the new head assembly.

2. Adjust the height from the A/C head arm (lower surface) to the A/C head plate to 10.8mm with slide

calipers. (3 places of azimuth screw section, tilt screw

Solder

New A/C head ass'y

A/C head PWB

Never touch the head

A/C head plate

10.8mm10.8mm

Figure 4-24.

19

Page 20

VC-GA56Z

VC-GH96Z

4-16. A/C HEAD HEIGHT ROUGH ADJUSTMENT

• Setting

Azimuth screw

Height screw

500g

Weight to prevent

float (500g)

Figure 4-26.

Tilt screw

Cassette tape

Mechanism chassis

4-17. HEIGHT ADJUSTMENT OF REVERSE

GUIDE

1. Adjust the height from the mechanism chassis to the

reverse guide lower flange to 13.38 mm, using the

reverse guide height adjustment jig, in tape loading

state. (Refer to Figure 4-28 (a) (b).)

Reverse guide height

Reverse guide

adjusting jig

(a) (b)

Figure 4-28.

2. Rotate counterclockwise the reverse guide height adjustment nut 1/10 turn. (For height adjustment use the

reverse guide height adjustment box driver (JiGDRiVER

11055)).

Reverse guide height

adjusting jig

Mechanism

chassis

Box driver

13.38mm

1. Set the cassette tape in the unit.

2. Press the PLAY button to put the unit in the playback

mode.

3. Roughly adjust the height of the A/C head by turning

the height screw until the tape is in the position shown

below.

A/C head

Tape

0.3mm

Figure 4-27.

• Adjustment

Adjust the height screw visually so that the control head is

visible 0.3mm below the bottom of the tape.

CCW

Height adjusting nut

Figure 4-29.

3. Set the tape, and check for tape crease near the

reverse guide in the playback mode.

If crease is found, turn the reverse guide adjustment

nut to remove crease. (As for crease check refer to

Figure 4-30.)

500g

Weight to

prevent float (500g)

A

Mechanism

chassis

Reverse guide

Capstan

motor shaft

Fixing guide

An example of

crease near the

reverse guide

* Check for crease from the A direction.

Figure 4-30.

20

Page 21

VC-GA56Z

VC-GH96Z

4-18. ADJUSTMENT OF TAPE DRIVE TRAIN

1. Tape run rough adjustment

1 Remove the cassette housing control assembly.

2 After shortcircuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

3 Check and adjust the position of the tension pole.

(See 4-12.)

4 Check and adjust the video search rewind back

tension. (See 4-10.)

5 Connect the oscilloscope to the test point for PB

CHROMA envelope output (TP201). Set the synchronism of the oscilloscope to EXT. The PB

CHROMA signal is to be triggered by the head

switching pulse (TP202).

6 Set the alignment tape (VROATSV) to play. (Put a

500g weight on the cassette tape to prevent lift of

cassette tape.)

Guide roller

Cassette Tape

500g

Weight of 500g

Figure 4-31.

Notes:

1. Previously set the tracking control in the center position, and adjust the envelop waveform to maximum

with X value adjustment nut. Thereby the tape run

rough adjustment is facilitated.

2. Especially the outlet side envelope waveform must

have higher flatness.

Figure 4-32.

2. Adjustment of A/C head height and azimuth

1 Perform the initial setting of A/C head position by

the method stated in "4-15 Replacement 3".

2 Connect the oscilloscope to the audio output termi-

nal.

3 Using the alignment tape in which 1 kHz linear

audio signal has been recorded, adjust the height

screw so as to get max audio output.

4 Using the alignment tape in which 7 kHz linear

audio signal has been recorded, adjust the azimuth

screw so as to get max audio output.

5 The adjustment of 3 and 4 twice or three times

repeat, and finally adjust 4.

7 Press the tracking button (+), (–) and change the

envelope waveform from max to min and from min

to max. At this time make sure that the envelope

waveform changes nearly parallel.

8 Unless the envelope waveform changes nearly

parallel, adjust the height of supply side and takeup side guide roller so that the envelope waveform

changes nearly parallel. (For envelop adjustment

procedure refer to Figure 4-35.)

9 Turn the tilt screw to remove the tape crease at the

fixing guide flange.

Playback the tape and check for tape crease at the

fixing guide flange.

(1)If there is no tape crease

Turn the tilt screw clockwise so that tape crease

appears once at the flange, and then return the

tilt screw so that the crease disappears.

(2)If there is tape crease

Turn counterclockwise the tilt screw so that the

tape crease disappears.

(Reference) If the tilt screw is turned clockwise

crease appears at the lower flange.

For X value adjustment

Adjust the X value, turning the

gear-type screwdriver.

Figure 4-33.

3. Tape run adjustment

1 Connect the oscilloscope to PB CHROMA enve-

lope output test point, set oscilloscope sync to EXT,

trigger-input the PB CHROMA signal (head switching pulse).

2 Rough adjustment of X value

Tentatively fix A/C head arm screws 1 and 2 by the

method described in 4-15 "Replacement 3".

Playback the alignment tape (VROATSV) and

shortcircuit TP801 and TP802. As a result the autotracking is automatically cancelled, so that the X

value adjustment mode is set.

Move the A/C head with the X value adjustment

gear driver (JiGDRiVER-6) by the method shown in

Figure 4-33, and adjust the A/C head so as to get

the maximum envelope waveform. (Note: When

the A/C head is adjusted, adjust so that the maximum envelop waveform is obtained nearest the

position of initial setting made in 4-15.)

21

Page 22

VC-GA56Z

VC-GH96Z

3 Next, Press the tracking button (+), (–) and change

the envelope waveform from max to min and from

min to max. At this time adjust the height of supply

and take-up side guide roller with the adjustment

driver (JiGDRiVERH-4) so that the envelope waveform changes nearly parallel.

4 If the tape is lifted or sunk from the helical lead

surface, the PB CHROMA envelope waveform appears as shown in Figure 4-35.

5 Press the tracking button (+), (–) and make sure

that the envelope waveform changes nearly parallel.

6 Finally check tape crease near the reverse guide. If

tape crease is found, remove it as stated in 4-17

"HEIGHT ADJUSTMENT OF REVERSE GUIDE"

item 3.

Supply side

PB CHROMA

Envelope

CH-1 CH-2

Head switching pulse

Figure 4-34.

4. A/C head X value adjustment

1 Tentatively fix A/C head arm screws 1 and 2 by the

method described in 4-15 "Replacement 3".

2 Playback the alignment tape (VROATSV), and

shortcircuit TP801 and TP802. As a result the autotracking is automatically cancelled, so that the X

value adjustment mode is set.

When the tape is below the helical lead.When the tape is above the helical lead.

Take-up side Supply side Take-up side

Adjustment

Supply side guide roller

rotated in clockwise

direction (lowers guide

roller) to flatten

envelope.

Take-up side guide roller

rotated in clockwise

direction (lowers guide

roller) to flatten

envelope.

Figure 4-35.

3 Move the A/C head with the X value adjustment

gear driver by the method shown in Figure 4-33,

and adjust the A/C head so as to get the maximum

envelope waveform. (Note: At this time adjust so as

to get the maximum envelope waveform nearest

the A/C head position which has been set in case of

X value rough adjustment as stated in 4-18, 3- 2.)

4 Tighten finally the screws 1 and 2. Be sure to

tighten at first the screw 1 and then the screw 2.

Final tightening torque is 0.6N·m (If the screw 2 is

tightened first, the X value may deviate.)

5 Adjust the playback switching point (Refer to the

electric adjustment method.)

6 Playback the self-picture-recorded tape, and check

the flatness of envelope waveform and sound.

Supply side guide roller

rotated in counterclockwise direction (raises

guide roller) to make the

tape float above the helical

lead. The supply

side guide roller is then

rotated in the clockwise

direction to flatten the

envelope.

Take-up side guide roller

rotated in counterclockwise direction (raises

guide roller) to make the

tape float above the

helical lead. The take-up

side guide roller is then

rotated in the clockwise

direction to flatten the

envelope.

Notes:

When the A/C head X value adjustment is performed, be

sure to perform at first X value rough adjustment (refer to

4-18, 3-2).

1

2

Figure 4-36.

22

Page 23

VC-GA56Z

VC-GH96Z

4-19. REPLACEMENT OF THE CAPSTAN D.D.

(DIRECT DRIVE) MOTOR

• Removal (Follow the order of indicated numbers.)

1. Remove the reel belt 1.

2. Remove the slow brake lever 2.

3. Remove the three screws 3.

2

Capstan D.D. motor

control PWB

Capstan D.D.

motor

Reel belt

1

Slow Brake Lever

Figure 4-37-1.

2

4-20. REPLACEMENT OF DRUM D.D. MOTOR

1. Set the ejection mode.

2. Withdraw the main power plug from the socket.

• Removal ( Perform in numerical order.)

1. Disconnect the FFC cable 1.

2. Unscrew the D.D. stator assembly fixing screws 2.

3. Take out the D.D. stator assembly 3.

4. Unscrew the D.D. rotor assembly fixing screws 4.

5. Take out the D.D. rotor assembly 5.

Notes:

1. In removing the D.D. stator assembly, part of the drum

earth spring pops out of the pre-load collar.

Be careful not to lose it.

2. Install, so that the D.D. rotor ass'y and upper drum

ass'y mounting direction check holes align.

(Align the upper drum dent with the rotor hole.)

3. Be careful not to damage the upper drum or the video

head.

4. Protect the hole elements from shock due to contact

with D.D. stator or D.D. rotor ass'y.

5. After installation adjust the playback switching point for

adjustment of servo circuit.

2

D.D. stator ass'y

• Reassembly

1. Taking care so that the capstan shaft does not contact

the mechanism chassis, set its position on the mechanism chassis, and then install with the three screws.

2. Install the slow brake lever.

3. Install the reel belt.

Notes:

1. Before installing the capstan D.D. motor, confirm

whether an acetate tape (ZTAPEN120020E) is drawn

on the back of mechanism chassis.

Stick on acetate tape on the

projection part of the chassis.

Capstan Motor

Installation posltion.

MechanismChassis from the back.

Figure 4-37-2.

2. After installing the capstan D.D. motor, be sure to

rotate the capstan D.D. motor and check the movement.

3. Set the tape, and check for the tape crease near the

reverse guide in the playback mode. Adjust the A/C

head and azimuth as stated in 4-18 item 2. If crease is

found, adjust as stated in 4-17 "HEIGHT ADJUSTMENT OF REVERSE GUIDE".

3

4

5

4

D.D. rotor ass'y

1

Upper drum

Figure 4-38.

23

Page 24

VC-GA56Z

VC-GH96Z

4-21. REPLACING THE UPPER AND LOWER

DRUM ASSEMBLY

• Replacement (Perform in the numerical order)

1 Remove the motor as stated in 4-20 D.D. motor re-

placement.

2 Remove the drum earth brush ass’y 2.

3 Remove the drum base 3 from the upper and lower

drum assembly 1.

[Cares when replacing the drum]

1. Be careful so that the drum earth brush is not lost.

2. Do not touch directly the drum surface.

3. Fit gently the screwdriver to the screws.

4. Since the drum assembly is an extremely precise

assembly, it must be handled with utmost care.

5. Make sure that the drum surface is free from dust, dirt

and foreign substances.

6. After replacing the drum be sure to perform the tape

running adjustment.

After that, perform also the electrical adjustment.

• Playback switching point adjustment

• X-position adjustment and check

• Standard and x-3 slow tracking adjustment

7. After replacing the drum clean the drum.

4-22. ASSEMBLING OF PHASE MATCHING

MECHANISM COMPONENTS

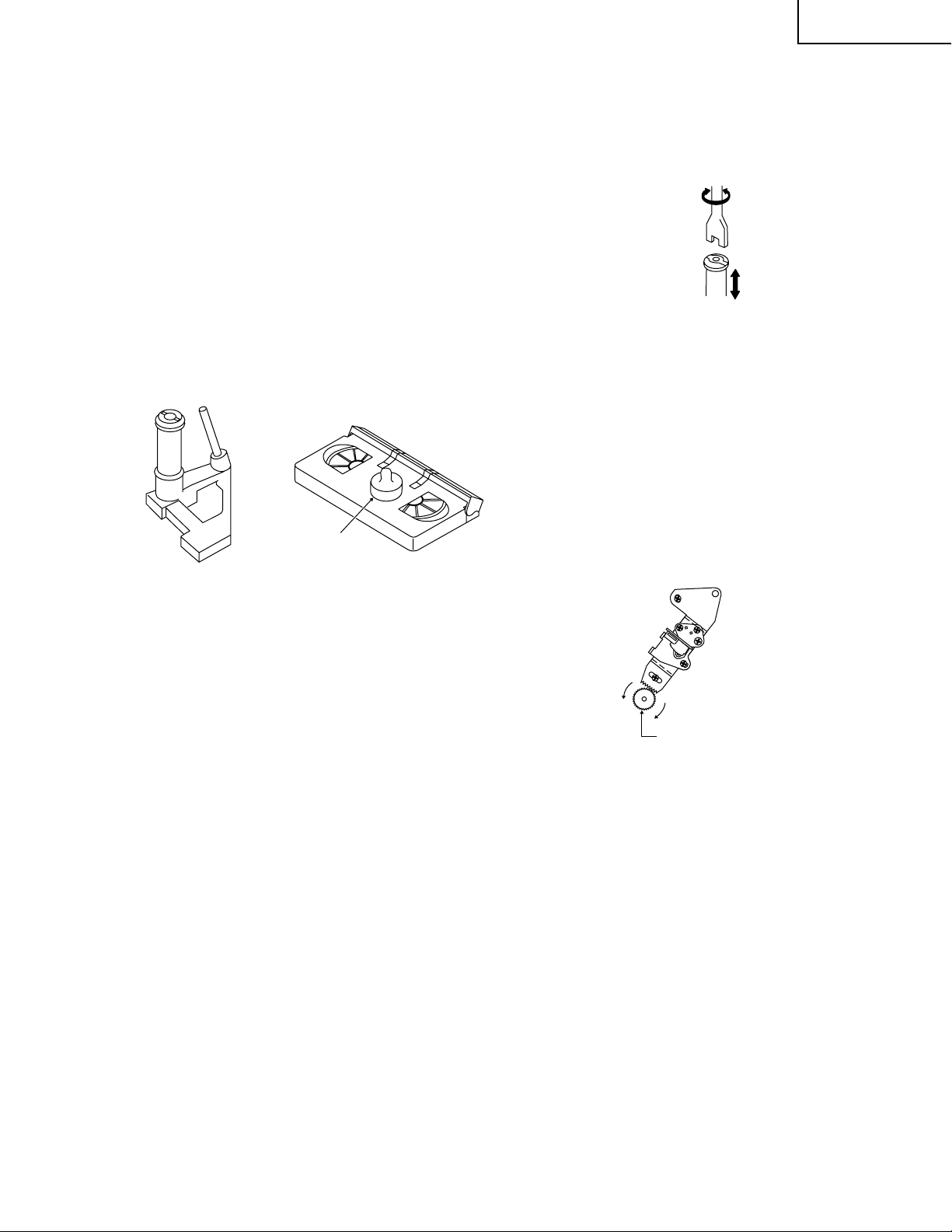

• Assemble the phase matching mechanism components in the following order.

1. Assemble the pinch roller assembly and pinch drive

cam.

2. Mounting the shifter (on the back of the mechanism

chassis).

3. Mounting the master cam (on the back of the mechanism chassis).

4. Assemble the connection gear, slow brake and loading

motor parts.

• Pinch drive cam and pinch roller assembling

method.

(Place the following parts in position in numerical order.)

(1)Reverse drive lever 1

(2)Reverse guide spring 2

(3)Reverse guide lever ass’y 3

(4)Reverse guide height adjusting nut 4

(5)Pinch drive cam 5

(6)Pinch roller ass’y 6

(7)Open lever 7

7

6

2

1

3

Figure 4-40.

4

3

1

2

5

Figure 4-39.

24

Page 25

1Insert Reverse Guide Lever Ass’y

Insert reverse guide lever ass'y

Align here.

2 Insert pinch drive cam

Turn the reverse guide lever

assembly counterclockwise

to the stopper.

Fit the pinch drive cam so that the notch of pinch

drive cam aligns with the dent of pinch drive lever

assembly.

Fit the pinch drive cam so that the notch of

pinch drive lever assembly aligns with the

half-round notch of chassis.

Pinch drive lever ass'y

Open lever

VC-GA56Z

VC-GH96Z

Figure 4-41-1.

2Insert Pinch Roller/Pinch Double Action Lever Ass’y.

Pinch Roller Double

Action Lever Ass'y

Phase Matching Point 2

3Insert Open Lever.

Figure 4-41-2.

25

Figure 4-41-3.

Page 26

VC-GA56Z

VC-GH96Z

4-23. INSTALLING THE SHIFTER

Capstan

D.D. motor

Reel pulley

(Bottom side of mechanism chassis)

Figure 4-42.

Insert

point 3

Insert

point 2

Drum

1. Make sure that the loading gear is at the PhaseMatching point 1 as shown below.

2. Install, paying attention to insert point 5 and release

point 3.

3. For the phase matching at the insert point 1, see the

Phase-Matching point 2 as shown below.

4. Finally fix the inserts 1 and 4.

Phase-Matching

point 2

Loading gear (T)

Round mark

Sifter

Half round notch

Insert

point 4

Insert

point 1

Shaft 1

Phase-matching

point 1

Shaft 1

Rotation

point 2

Shaft 1

Figure 4-43.

Shaft 4

Release

point 3

Insert

point 5

26

Page 27

VC-GA56Z

VC-GH96Z

4-24. INSTALLING THE MASTER CAM (at

REAR SIDE OF MECHANISM CHASSIS)

1. Make sure beforehand that the shifter is at the point as

shown below.

2. Place the master cam in the position as shown below.

E ring

(XRESJ30-06000)

Master cam

Fully turn

clockwise

Fully turn counterclockwise

Face the wide tooth side ward

Figure 4-44-1.

Note:

See the figure below for the phase matching between the

master cam and the casecon drive gear.

3. Finally fix with the E ring.

Master cam

4-25. REPLACEMENT OF LOADING MOTOR

• Removal

Apply grease

Apply grease

No grease

Figure 4-45.

Casecon drive gear

Round mark

When installing the master cam,

align the casecon drive gear

round mark with the half-round

notch of master cam.

Figure 4-44-2.

Half-round notch

• Replacement

Remove the loading motor, and install the replacement

loading motor as shown below.

+0

10.2 mm

–0.2

Figure 4-46.

The loading motor pressing-in must be less than 14.7 N

(1,500 gf).

Adjust the distance between motor and pulley to 10.2

+0.2

mm).

–0.2

27

Page 28

VC-GA56Z

VC-GH96Z

4-26. ASSEMBLY OF CASSETTE HOUSING

1. Drive Gear and R Drive angle ass’y

Apply grease

Figure 4-47.

MSPRT0381AJFJ

Apply grease

Apply grease

2. Synchro Gear, Drive Gear L and Drive Gear R

Top surface should be free from scratches or soil.

Drive angle

LANGF9592AJFW

Drive gear R

Frame

Figure 4-48.

28

Page 29

VC-GA56Z

P201

(TP201~204)

R701

VC-GH96Z

5. ELECTRICAL ADJUSTMENT

Notes:

• Before the adjustment:

Electrical adjustments discussed here are often required after replacement of electronic components and mechanical

parts such as video heads.

Check that the mechanism and all electric components are in good working condition prior to the adjustments,otherwise

adjustments cannot be completed.

• Instruments required:

• Color TV monitor • Dual-trace oscilloscope

• Audio signal generator • AC milli-voltmeter

• Blank video cassette tape • Alignment tape (VROEFZHS)

• Screwdriver for adjustment • Color bar generator

• RF signal generator

Figure 5-1.

29

Page 30

VC-GA56Z

VC-GH96Z

SERVO CIRCUIT ADJUSTMENT

5-1 ADJUSTMENT OF HEAD SWITCHING

POINT

Measuring Dual-trace oscilloscope

instrument

Mode Playback

Cassette Alignment tape (VROEFZHS)

Test point VIDEO OUT jack to CH2

TP202 (Sig.)~TP203 (GND) to CH1

Control R701 Head switching point adjust-

ment control

Specification 6.0 ± 0.5H (lines)

1. Remove the front panel and play the alignment tape.

2. Connect a dual-trace oscilloscope to the VIDEO OUT

jack and TP202 (Sig.) and TP203 (GND).

(Trigger the oscilloscope with the head switching pulse

on TP202.)

3. Playback the alignment tape, and then short circuit

between TP801 and TP802 on the operation PWB.

4. Adjust R701 so that the leading edge of the head

switching pulse is 6.0H (lines) ahead of the vertical

sync as shown in Figure 5-2.

5. Cancel the short circuited.

5-2 ADJUSTMENT OF FV (False Vertical

Sync) OF STILL PICTURE

Measuring Color TV monitor

instrument

Mode Playback still

Cassette Self-recorded tape (SP mode)

(See Note below 2)

Control Tracking control buttons(+) or (–)

Specification No vertical jitter of picture

1. Play a cassette which was recorded by the unit in SP

mode.

2. Press the PAUSE/STILL button to freeze the picture.

3. Look at the monitor screen and adjust (+) or (–)

TRACKING buttons so that the vertical jitter of the

picture is minimized.

4. Play and freeze the self-recorded tape in EP mode and

make sure vertical jitter of the picture is not noticeable.

Notes:

1 The FV goes back to it’s initial state when the unit is put

into the system controller reset mode due to power

failure and etc.

In this case, preset the FV once again.

2 Self-recorded tape is a cassette whose program was

recorded by the unit being adjusted.

5-3

CHECKING OF OFF TRACK

Measuring Color TV monitor

instrument

CH-2

VIDEO OUT

CH-1

HEAD

SWITCHING

PULSE

6.0 ± 0.5H (lines)

Figure 5-2.

CH-1: 1V/dev 50µsec/dev

CH-2: 1V/dev 50µsec/dev

V-sync.

Mode Playback

Cassette Self-recorded tape (EP mode)

(See Note below)

Control Tracking control buttons(+) or (–)

Specification No Poor picture and Hi-Fi sound

1. Play a cassette which was recorded by the unit in EP

mode.

2. Short circuit between TP801 and TP802 on the operation PWB to center tracking.

3. Press the tracking buttons (+) or (–) 20 times each to

bring the tracking off center. Make sure that:

1) There is nothing unusual on the playback screen.

2) There is nothing unusual in the Hi-Fi sound (for the

Hi-Fi models only).

4. Press the STOP button to quit test mode.

Note:

Self-recorded tape is a cassette whose program was

recorded by the unit being adjusted.

30

Page 31

6. MECHANISM OPERATION FLOWCHART AND TROUBLESHOOTING GUIDE

MECHANISM OPERATION FLOWCHART

31

* This flowchart describes the outline of the mechanism’s operation, but does not give its details.

G mechanical timing

Mode check

Cam mark

Mode detection outside

(D709 SW B)

Mode detection inside

(D708 SW A)

Mode detection outside

Mode detection inside

S sensor

S sensor

25

20

15

10

5

0

CA/END

CS/EJ

0 19.812 81 179 233200 265 282 316 334

10.354 12.812

EJ UL PU PU2 VSR PB SLW FF STP

0

0

1

1

1

1

Open

Close

60 120 180 240 300 380

0

0

0

CS/EJ

ULD

PU1

PU2

VSR

PB

SLOW

FF

STOP

101

0

0

0

0

1

1 or 0

Cam graph E

UL

1

1

10

Mode detection inside

sensor A

1

1

1

0

0

0

0

0

0

Mode detection outside

sensor B

0

1

1

1

1

0

1

1

0

PU1

PU2

11111010001010001000001

VSR

PB SLOW

Cassette

inserting

STOP

FF

0

0

001010001

Fullloading

CASSETTE INSERTION STOP

Insert cassette.

Double action rack slides.

Loading motor starts in normal

direction and master cam counter

clockwise.

Does mechanism position sw.

come off within 2.5 sec.?

YES

Are start/end sensors at low level

before cassette insertion ?

YES

Drum motor starts.

Tape loading.

Pinch roller comes into contact.

Cam switch is at PB position.

End

Cassette is ejected and loading

motor stops.

Start sensor close.

Loading motor turns in reverse

direction and master cam

counterclockwise.

NO

(Cassette is judged

caught halfway.)

NO

(Cassette LED or some other part

is judged defective.)

Loading motor stop.

Is drum FG pulse outputted ?

YES

End

NO

Unloading

VC-GA56Z

VC-GH96Z

Page 32

STOP REC/PLAY PLAY STILL PLAY VSR VSR PLAY

VC-GA56Z

VC-GH96Z

32

Press REC/PLAY key.

Capstan motor turns

counterclockwise.

Picture appears.

Is take-up reel sensor signal

outputted ?

YES

End

Unloading

PLAY VSF REC/PLAY STOP

Slow brake

pressing

NO

Press STILL key.

Loading motor turns in

counterclockwise direction

and master cam clockwise.

Slow brake comes into

contact with capstan motor.

Cam switch is at STILL

position.

Loading motor stops.

Capstan motor stops.

End

Pinch

roller

releasing

Idler

swinging

Pinch

roller

pressing

Press REW key.

Loading motor turns

clockwise and master

cam counterclockwise.

Release pinch roller.

Cam switch is at PU2 position.

Stop loading motor.

Turn capstan motor in

reverse direction.

Loading motor turns clockwise.

Release the supply auxiliary

brake.

Cam switch is at PU1 position.

Turn loading motor

counterclockwise.

Press PLAY Key.

Loading motor turns counterclockwise and master cam

clockwise.

Capstan motor turns

counterclockwise. PB speed.

Cam switch is at PB position.

End

Press FF key.

Set capstan motor to search

speed.

End

Press STOP key.

Capstan motor turns in

reverse direction.

Stop capstan motor.

End

Press pinch roller.

Cam switch is at VSR

position.

Stop loading motor.

Set capstan motor to search

speed.

Is take-up reel sensor signal

outputted ?

YES

End

Unloading

NO

Page 33

STOP FF/REW STOP CASSETTE EJECT

33

FF/REW

operation

Brake

function

Press FF/REW key.

Turn capstan motor in

normal or reverse direction,

after the remaining tape has

been detected.

End

FF/REW STOP

Press STOP key.

Loading motor turns counterclockwise.

Stop capstan motor.

Cam switch is at Stop

position.

Loading motor stops.

End

Tape

unloading

Cassette

eject

Press EJECT key.

Loading motor turns in clockwise and master cam

counterclockwise.

Capstan motor turns in reverse direction.

Cam switch is at UL position.

Stop loading motor.

4 supply reel pulses

outputted ?

YES

Does the take-up

reel pulse output

two edges ?

YES

Capstan motor turns

clockwise.

Loading motor turns

clockwise.

Cam switch is at

Eject position.

Loading motor

stops.

NO

NO

Capstan motor turns

clockwise.

Capstan motor turns

counterclockwise in about

2 seconds.

Capstan motor

stops.

End

VC-GA56Z

VC-GH96Z

Page 34

MECHANISM TROUBLESHOOTING

VC-GA56Z

VC-GH96Z

1. FF/REW FAILURE (NO TAPE WINDING)

Press FF key.

Is master cam at

FF position ?

YES

NO NO NO

Does loading

motor operate?

Modes changing

smoothly through

cam switch ?

Loading motor

control system

in trouble.

34

Does capstan

motor turn in FF (or

REW) direction ?

YES

NO

Are Vco 23V and

Vcc 5V applied ?

Replace the

capstan motor.

Is voltage applied

to loading motor ?

YES YES

Loading motor is

NO

damaged. Replace

it.

YES

Mode sensor

system in trouble

or master cam

malpositioned.

NO

Voltage supply

system in trouble.

YES

Voltage supply

system in trouble.

2. REC/PLAY FAILURE (MODE RELEASE)

Is the master cam

at PB position ?

YES

NO NO NO

Does loading

motor operate ?

YES YES

Modes changing

smoothly through

cam switch ?

YES

Loading motor

control system

in trouble.

NO

Does capstan

motor turn ?

YES

Are Vco 23V and

Vcc 5V applied ?

YES

Replace the

capstan motor.

Is voltage applied

to loading motor ?

Loading motor is

damaged. Replace

it.

NO

Voltage supply

system in trouble.

Voltage supply

system in trouble.

Are idler wheel

ass’y and reel disk

in mesh ?

YES

Is the pulse

outputted from reel

sensor ?

YES

The cassette tape

is presumably

damaged.

NO

Replace the idler

ass’y.

NO

Replace the reel

sensor.

Are idler wheel

ass'y and reel disk

in mesh ?

YES

Is the pulse

outputted from reel

sensor ?

YES

Check main PWB.

NO

Replace the idler

ass’y.

NO

Replace the reel

sensor.

Page 35

3. WINDING FAILURE AT VSR 4. UNUSUAL SOUND IN EACH MODE

4-i) Unusual sound in cassette

insertion and ejection mode

Is Playback

function normal ?

YES

Press REW key.

Master cam

shifting to VSR

position ?

YES

NO

NO

Go to 2. REC/

PLAY FAILURE

routine.

Go to 2. REC/

PLAY FAILURE

routine.

Is unusal sound heard during

cassette control running ?

NO

Unusual sound heard with pinch

roller lever going up or down ?

Are idler wheel

ass’y and supply

reel disk in mesh ?

YES

NO

Replace idler

gear ass’y.

Is unusual sound heard during

loading/unloading ?

NO

YES

YES

Replace cassette control ass’y.

Check pinch roller drive cam, pinch roller

drive lever and reverse guide for their actions.

Replace damaged one with new one.

35

Is supply reel disk

winding torque

normal ?

YES

Is pulse outputted

from reel sensor?

YES

Check main PWB.

NO

NO

Replace limiter

pulley ass’y.

Replace reel

sensor.

YES

Replace loading motor block.

VC-GA56Z

VC-GH96Z

Page 36

4-ii) Unusual sound in FF/REW mode

VC-GA56Z

VC-GH96Z

36

Is reel disk height as specified ?

YES

Thrust gap found at reel disk ?

YES

Drive system out of contact with any

part on main PWB ?

NO

Turn capstan motor by hand.

Unusual sound heard ?

NO

Check drive system’s gears for

damage. Replace damaged gear

with new one.

• Reel disk

• Limiter pulley ass’y

• Idler wheel ass’y

NO

NO

YES

YES

Adjust reel disk height.

Check reel disk and main chassis.

And replace defective parts.

Rearrange the parts on main PWB.

Replace capstan motor.

Page 37

7. TROUBLESHOOTING

37

Is the fuse good?

Is the normal state restored when

once unplugged power cord is

plugged again after several

seconds?

Are AT 5V voltage line normal?

Are AT 44V, AT 23V, AT 12V,

AT –24V and filament voltage lines

normal?

Is "H" level applied at pin(1) of

IC701?

Check for leak or short-circuiting of

primary circuit part.

(L901, D901~904, T901, C906,

R904, Q901~902 and etc.)

Check whether the secondary side

photocoupler circuit operates

normally.

Check whether the primary side

photocoupler output control

functions normally.

YES

YES

YES

YES

Case (1) Case (2)

When the output voltage fluctuates.

YES

YES

FLOW CHART NO.1

No power

NO

NO

NO

NO

NO

FLOW CHART NO.2

Fuse blown out.

FLOW CHART NO.3

NO

NO

The fuse blows out even when it is

replaced with new one.

See FLOW CHART NO.2

<Fuse blown out.>.

Check for leak or short-circuiting

of primary circuit part.

(L901, D901~904, T901, C906,

R904, Q901~902 and etc.)

Check each rectifier circuits and

short-circuit of secondary circuit.

Check the power failure circuit.

(Q705)

Check for short-circuiting of

rectifying diode and circuit in each

rectifying circuit of secondary circuit.

(D921~928)

Check the circuit and replace parts.

(IC901, IC903, etc.)

Check the circuit and replace parts.

(IC901, IC903, Q902, T901 and etc.)

FLOW CHART NO.4

When buzz is heard from the vicinity of power circuit.

Check for short-circuiting of circuit and rectifying diode of each rectifying circuit of secondary

circuit and check for failure of shunt regulator circuit. (D921~928, IC903, C932 and C933)

FLOW CHART NO.5

The fluorescent display tube fails light up.

Is the supply voltage of 5V feed to

pin(8) of IC801?

YES

Is the supply voltage of –24V

feed to pin(1) of IC801?

YES

Is it possible to confirm signals

FIP CS, FIP OE, FIP DATA, and

FIP CLK on the pins(2), (3), (5) and

(6) of IC801?

Are grid and segment signals

supplied to the indication tube

(DG801) from the indication

tube driver IC (IC801)?

Is supply filament voltage feed

between pin(1)/(2) and (31)/(32)

of the flourescent display tube?

Check the periphery of fluorescent

indication tube and main block.

Check that the fluorescent indication

tube is free from damages such as

crack.

YES

YES

YES

NO

NO

NO

NO

NO

NO

Check AT 5V line.

Check AT –24V line.

Check signal line between IC701

and IC801.

Replace IC801.

Check power circuit and D952.

VC-GA56Z

VC-GH96Z

Replace IC901.

Page 38

FLOW CHART NO.6

Key-in input is not received.

FLOW CHART NO.8

A cassette tape is not taken in.

VC-GA56Z

VC-GH96Z

38

Does the key switch make good

contact, when the cassette tape is

inserted?

YES

Is there the function control voltage

inputted at the pins(87) and (88)

of IC701?

YES

Check or place the peripheral circuit

of IC701.

No operation is possible from the infrared remote control.

Operation is possible from the VCR,

but no operation is possible from the

infrared remote control.

Is the supply voltage of 5V feed to

pin(3) of remote control receiver?

YES

Is "L" pulse sent out pin(1) of

receiver when the infrared remote

control is activated?

YES

Is there "L" pulse inputted at

pin(5) of IC701?

YES

Replace IC701.

NO

FLOW CHART NO.7

NO

NO

NO

Check switch contact.

Check AT 5V lines.

Replace the remote control receiver

or replace the remote control

transmitter if necessary.

Check line between remote

control receiver and pin(5) of

IC701.

Does start sensor shutter open

when the cassette tape is inserted?

YES

Does pin(79) of IC701 change from

"H" to "L" level when the cassette

tape is inserted?

YES

Does pin(11) of IC706 go to "H"

(about 4.7V) level when the cassette

tape is inserted?

YES

Does pin(13) of IC706 change to

about 10V when the cassette tape is

inserted?

YES

Is the specified voltage (about 10V)

applied at the loading motor terminal

when the cassette tape is inserted?

YES

Replace loading motor.

A cassette tape is taken in, but ejected at once.

Does the start sensor pulse at

pin(79) of IC701 change from "L" to

"H" level when the cassette tape is

loaded?

YES

Does the end sensor pulse at pin(85)

of IC701 change from "L" to "H" level

when the cassette tape is loaded?

YES

Does the master cam mode shifter

operate normally when the cassette

tape is loaded?

YES

Replace IC701.

NO

NO

NO

NO

NO

FLOW CHART NO.9

NO

NO

NO

Check start sensor shutter.

Check line start sensor and all the

way up thru to pin(79) of IC701.

Check line pin(9) of IC701 and all

the way up thru to pin(11) of IC706.

Check IC706.

Check between IC706 and loading

motor.

Check start sensor and all the way

up thru to IC701.

Check end sensor and all the way

up thru to IC701.

Check cam switch and all the way

up thru to IC701.

Page 39

FLOW CHART NO.12

The capstan motor fails to run.

Is the voltage more than about 2.6V

DC given out of pin(29) of IC701.

Check IC701.

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

Is the supply voltage of 5V feed to

pin(8) of AC connector?

Check PC 5V line.

Is the voltage more than 2.6V DC

sent in pin(4) of AC connector?

Check between the AC connector

and all the way up thru to pin(29)

of IC701.

Is the voltage at pin(3) of AC

connector 1.6~2.7V?

Check between the pin(92) of IC701

and all the way up thru to pin(3) of

AC connector.

Is the supply voltage of 12V feed to

pin(5) of AC connector?

Check AT 12V line and motor voltage

selector circuit.

Replace capstan motor.

YES

YES

YES

NO

NO

NO

FLOW CHART NO.11

No power is turned on.

Does power control(H) signal at

pin(4) of IC701 change from "L" to

"H" level?

Check IC701.

Does the base of Q951 change from

about 5.0V to 4.5V?

Check IC701 and all the way up thru

to Q951.

Is 5V sent out of the collector of

Q951?

Check Q951 and the AT 5V line.

Check peripheral circuits for poor

soldering.

FLOW CHART NO.10

The cassette tape fails to eject.

Does the capstan motor start when

the EJECT button is pressed?

See FLOW CHART NO.12.

Does the take-up reel disk turn when

the capstan motor is running?

Check reel disk and reel drive unit.

Are pulses applied at pin(2) of IC701

when the take-up reel disk is turning?

Check take-up reel sensor and all the

way up thru to IC701.

Is a "H"(about 4.7V) level applied at

pin(12) of IC706 when a reel pules

has been inputted?

Check pin(90) of IC701.

Is the voltage about 10V sent out of

pin(15) of IC706?

Check IC706.

Is the specified voltage applied at the

loading motor terminal?

Check between IC706 and all the

way up thru to the loading motor.

Dose the loading motor run? Replace loading motor.

Replace cassette cam, gear, etc.

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

39

VC-GA56Z

VC-GH96Z

Page 40

FLOW CHART NO.13

The drum motor fails to run.

FLOW CHART NO.15

No head switching pulse.

VC-GA56Z

VC-GH96Z

40

Is the voltage more than about 2.6V

DC given out of pin(46) of IC701?

YES

Is the supply voltage of 5V feed to

pin(3) of IC706?

YES

Is the voltage more than about 2.6V

applied at pin(2) of IC706?

YES

Is the supply voltage of 12V feed to

pin(21) of IC706?

YES

Check or replace drum motor.

The drum motor runs only for a few seconds.

Is drum PG signal given out of

pin(7) of IC706?

YES

NO

NO

NO

NO

FLOW CHART NO.14

NO

Check IC701.

Check PC 5V line.

Check between pin(46) of IC701

and all the way up to pin(2) of

IC706.

Check AT 12V line.

Replace IC706.

NO

Check pins (4), (5), (6) of IC706 and

periperal circuits.

YES

Check or replace drum motor.

Is the drum motor rotating?

YES

Is the drum PG signal and drum FG

signal present on pins(66) and (65)

of IC701, respectively?

YES

Are the drum PG and drum FG

signals present on pins(7) and (8) of

IC706?

NO

Check peripheral circuit of IC706.

NO

NO

YES

See FLOW CHART NO.13,14.

Are there drum PG M.M.signal at

pin(81) of IC701?

YES

Check C723 and readjust R701

(HEAD SW. POINT control.)

Replace IC701.

Could be lines between IC706

and IC701.

NO

Is drum PG signal given out of

pin(66) of IC701?

YES

Is V-H.SW.P pulse given out of

pin(23) of IC701?

YES

Replace IC701.

NO

NO

Check line between pin(7) of IC706

and all the way up thru to

pin(66) of IC701.

Check IC701.

Page 41

FLOW CHART NO.16

Drum servo does not function.

Check peripheral circuit of X701.

Is there 14.318MHz oscillation at

pins(37) and (38) of IC701?

NO

In PB mode

YES

In REC mode

Is there drum FG signal at pin(65)

of IC701?

Is there V-SYNC signal(reference)

at pin(50) of IC701?

YES

NO

NO

Check pin(50) of IC701, C770, C771,

R770 and their peripheral circuits.

Check drum FG signal line.

Is there head switching pulse at

pin(23) of IC701?

NO

See FLOW CHART NO.15.

YES

YES

Are there drum APC output at pin(34)

of IC701 and drum AFC output at

pin(32) of IC701?

NO

Replace IC701.

YES

YES