Page 1

E2?m/@:

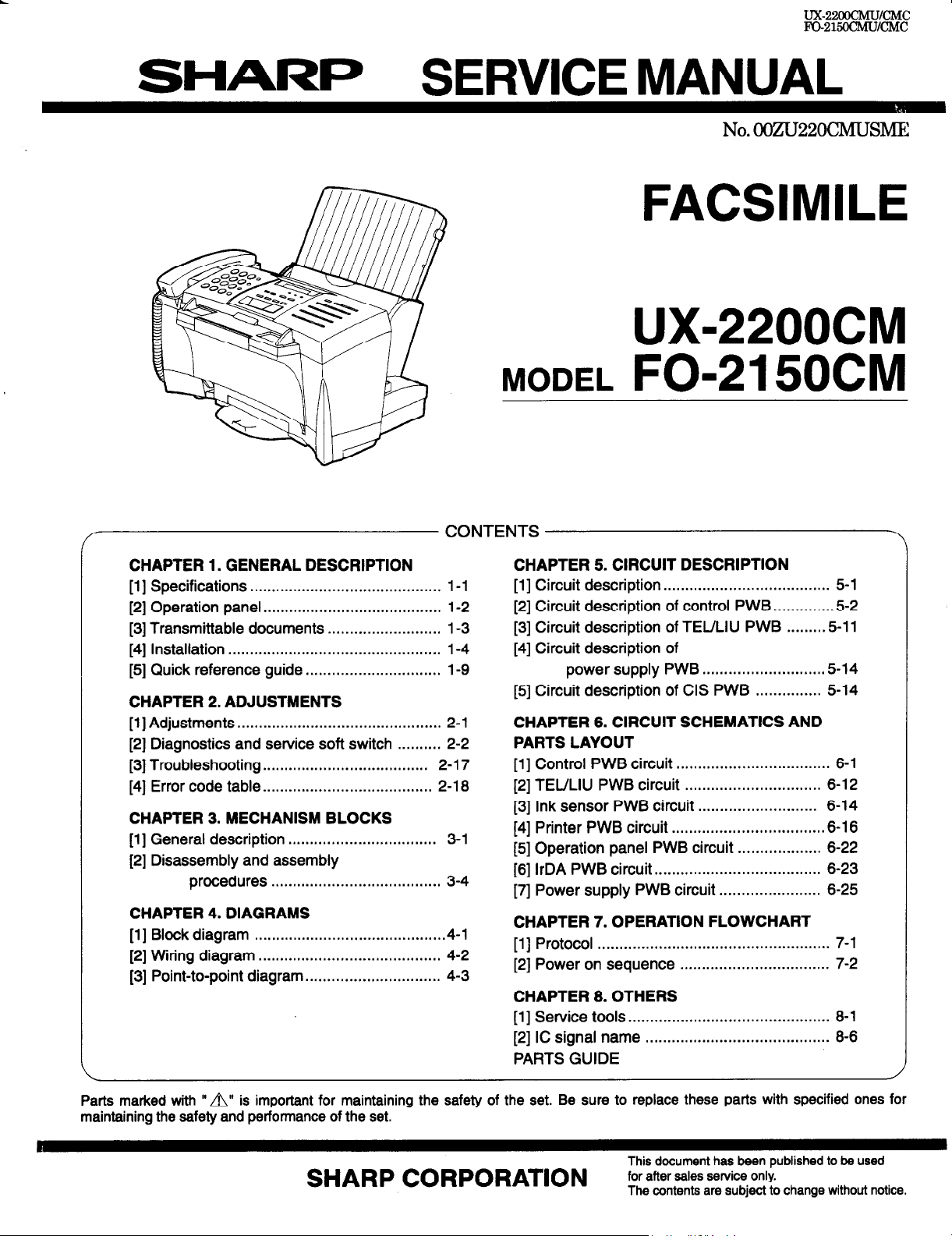

SHARI= SERVICE MANUAL

No. OOZU22OCMUShIEI

FACSIMILE

UX-2200CM

MODEL FO-2150CM

/

CHAPTER 1. GENERAL DESCRIPTION

[l] Specifications ............................................ l-1

[2] Operation panel.. ....................................... 1-2

[3] Transmittable documents .......................... l-3

[4] Installation ................................................. l-4

[5] Quick reference guide ............................... l-9

CHAPTER 2. ADJUSTMENTS

[l] Adjustments.. ............................................. 2-1 CHAPTER 6. CIRCUIT SCHEMATICS AND

[2] Diagnostics and service soft switch .......... 2-2

[3] Troubleshooting.. .................................... 2-17

[4] Error code table.. ..................................... 2-18

CHAPTER 3. MECHANISM BLOCKS

[l] General description .................................. 3-1

[2] Disassembly and assembly

procedures ....................................... 3-4

CHAPTER 4. DIAGRAMS

[l] Block diagram ........................................... .4-l

[2] Wiring diagram

[3] Point-to-point diagram.. ............................. 4-3

.......................................... 4-2

CONTENTS

CHAPTER 5. CIRCUIT DESCRIPTION

[l] Circuit description.. .................................... 5-1

[2] Circuit description of control PWB..

[3] Circuit description of TEULIU PWB

[4] Circuit description of

[5] Circuit description of CIS PWB ............... 5-14

PARTS LAYOUT

[l] Control PWB circuit.. ................................. 6-1

[2] TEULIU PWB circuit ............................... 6-12

[3] Ink sensor PWB circuit ........................... 6-14

[4] Printer PWB circuit

[5] Operation panel PWB circuit ................... 6-22

[6]

[7] Power supply PWB circuit ....................... 6-25

CHAPTER 7. OPERATION FLOWCHART

[l]

[2] Power on sequence .................................. 7-2

CHAPTER 8. OTHERS

[l] Service tools.. ............................................ 8-1

[2] IC signal name .......................................... 8-6

PARTS GUIDE

power supply PWB

IrDA PWB circuit.. .................................... 6-23

Protocol ..................................................... 7-1

...........................

................................

...........

..5-11

.......

.,.6-l 6

.5-2

.5-14

Parts marked with “A” is important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

- CAUTION FOR BATTERY REPLACEMENT -

(Danish)

ADVARSEL I

Lithiumbatteri-Eksplosionsfare ved fejlagtig handtering.

Udskiftning ml kun ske med batteri af samme fabnkat og type.

Lever det brugte batteri tilbage til leverandoren.

(English)

Caution I

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the equipment manufacturer.

Discard used batteries according to manufacturer’s

instructions.

(Finnish) VAROITUS

Pa&to voi rajjiihtaii, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Havita kaytetty paristo valmistajan ohjeiden

mukaisesti.

(French)

ATTENTION

II y a danger d’explosion s’ ii y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

meme type ou d’un type recommande par le constructeur.

Mettre au rebut les batteries usag6es conformement aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfare vid felaktigt battenbyte.

Anvand samma battentyp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera anvlnt batteri enligt fabrikantens

instruktion.

(German)

Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dijrfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batter&n verwendet werden.

Entsorgung der gebrauchten Battenen nur nach den vom

Hersteller angegebenen Anweisungen.

Page 3

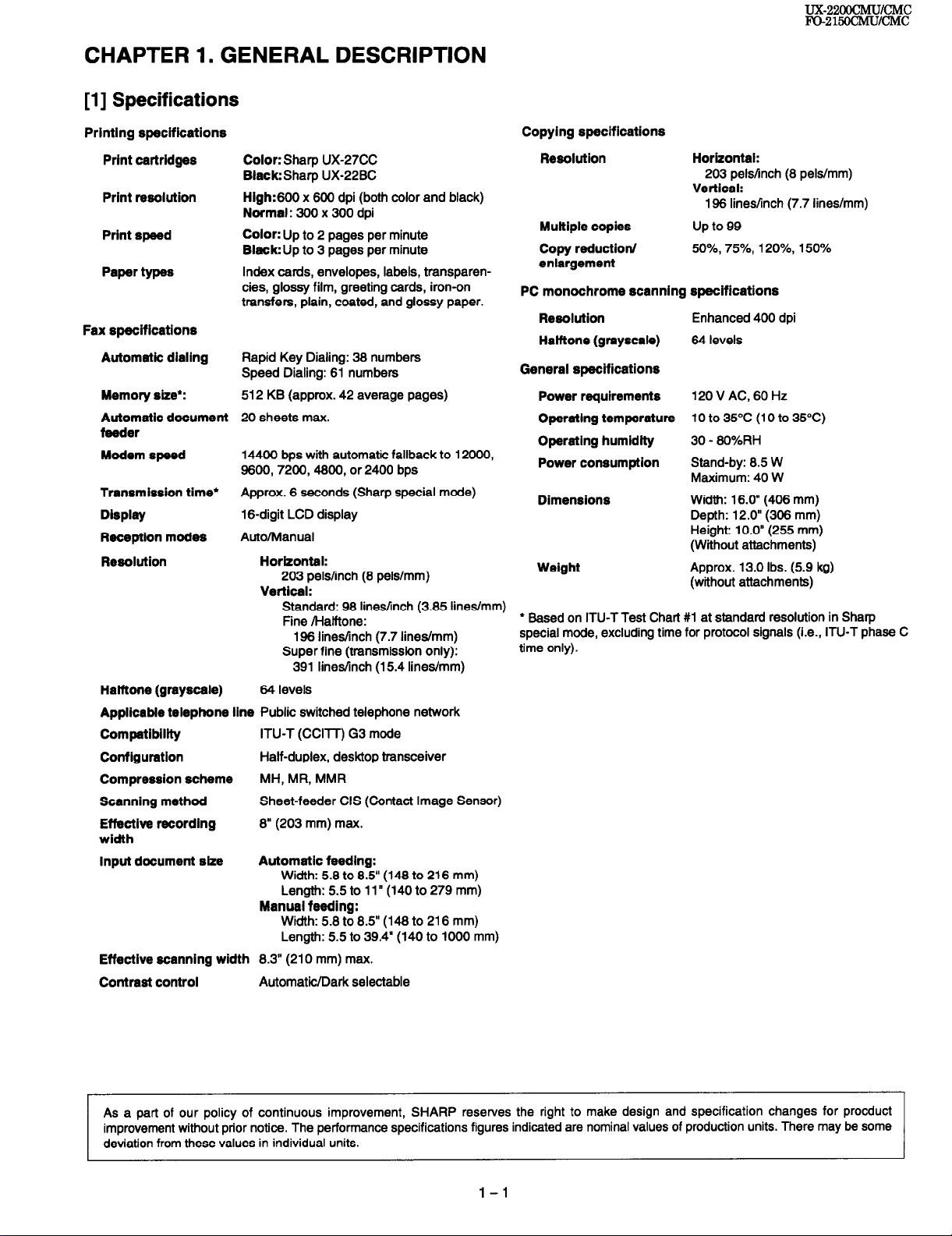

CHAPTER I. GENERAL DESCRIPTION

[l] Specifications

Printing specifications

Print cartridges

Print resolution

Print speed

Paper types

Fax specifications

Automatic dialing

Memory size’:

Automatic document

feeder

Modem speed

Transmission time*

Display

Reception modes

Resolution

Haiftone (grayscale)

Applicabie telephone line Public switched telephone network

Compatibility

Configuration

Compression scheme

Scanning method

Effective recording

width

Input document size

Effective scanning width 8.3” (210 mm) max.

Contrast control

Color: Sharp UX-27CC

Black:Sharp UX-22BC

High:600 x 600 dpi (both color and black)

Normal : 300 x 300 dpi

Color: Up to 2 pages per minute

Black: Up to 3 pages per minute

Index cards, envelopes, labels, transparencies, glossy film, greeting cards, iron-on

transfers, plain, coated, and glossy paper.

Rapid Key Dialing: 38 numbers

Speed Dialing: 61 numbers

512 KB (approx. 42 average pages)

20 sheets max.

14400 bps with automatic fallback to 12000,

9600,7200,4800, or 2400 bps

Approx. 6 seconds (Sharp special mode)

16-digit LCD display

Auto/Manual

Horizontal:

203 pels/inch (8 pels/mm)

Vertical:

Standard: 98 lines/inch (3.85 lines/mm)

Fine /Hathone:

196 lines/inch (7.7 lines/mm)

Super fine (transmission only):

391 lines/inch (15.4 lines/mm)

64 levels

ITU-T (CCllT) G3 mode

Half-duplex, desktop transceiver

MH, MR, MMR

Sheet-feeder CIS (Contact Image Sensor)

8” (203 mm) max.

Automatic feeding:

Width: 5.8 to 8.5” (148 to 216 mm)

Length: 5.5 to 11” (140 to 279 mm)

Manual feeding:

Width: 5.8 to 8.5” (148 to 216 mm)

Length: 5.5 to 39.4” (140 to 1000 mm)

Automatic/Dark selectable

Copying specifications

Resolution

Muttiple copies

Copy reductionl

enlargement

PC monochrome scanning specifications

Resolution

Haiftone (grayscale)

General specifications

Power requirements

Operating temperature 10 to 35°C (10 to 35°C)

Operating humidity

Power consumption

Dimensions

Weight

l Based on ITU-T Test Chart #1 at standard resolution in Sharp

special mode, excluding time for protocol signals (i.e., ITU-T phase C

time only).

Horizontal:

203 pels/lnch (8 pels/mm)

Vertical:

196 lines/inch (7.7 lines/mm)

up to 99

50%, 75%, 120%, 150%

Enhanced 400 dpi

64 levels

120VAC,60Hz

30 - 8O%RH

Stand-by: 8.5 W

Maximum: 40 W

Width: 16.0” (406 mm)

Depth: 12.0” (308 mm)

Height: 10.0” (255 mm)

(Wiihout attachments)

Approx. 13.0 Ibs. (5.9 kg)

(without attachments)

As a part of our policy of continuous improvement, SHARP reserves the right to make design and specification changes for procduct

improvement without prior notice. The performance specifications figures indicated are nominal values of production units. There may be some

deviation from these values in individual units.

l-l

Page 4

UX22OOCMU~~C

Fo-21gocrvlu/cMc

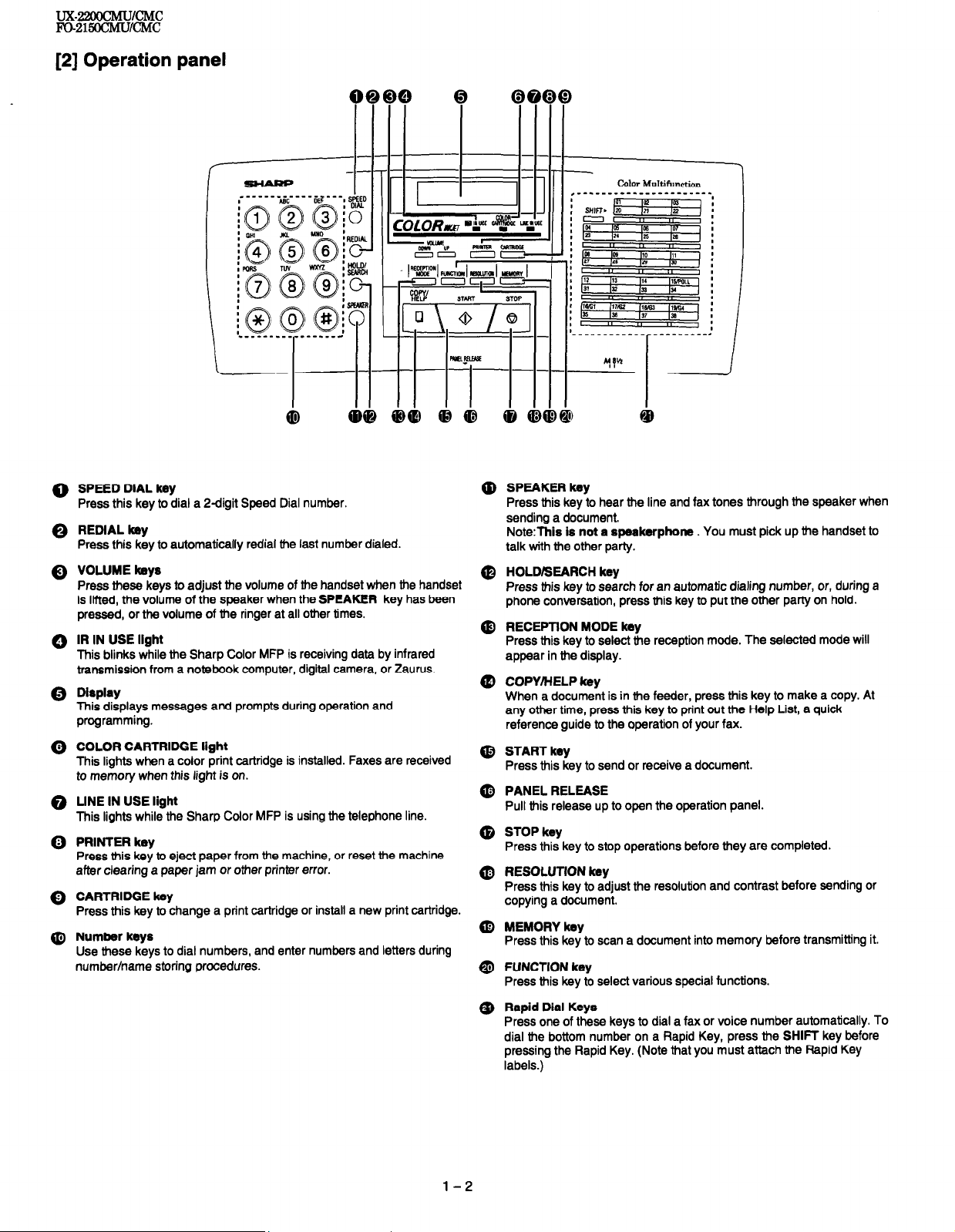

[2] Operation panel

0 SPEED DIAL key

Press this key to dial a 2digit Speed Dial number.

@ REDlALkey

Press this key to automatically redial the last number dialed.

@ VOLUME keys

Press these keys to adjust the volume of the handset when the handset

is lifted, the volume of the speaker when the SPEAKER key has been

pressed, or the volume of the ringer at all other times.

0 IR IN USE light

This blinks while the Sharp Color MFP is receiving data by infrared

transmission from a notebook computer, digital camera, or Zaurus.

0 Display

This displays messages and prompts during operation and

programming.

0 COLOR CARTRIDGE light

This lights when a color print cartridge is installed. Faxes are received

to memory when this light is on.

@ LINE IN USE light

This lights while the Sharp Color MFP is using the telephone line.

0 PRINTERkey

Press this key to eject paper from the machine, or reset the machine

after clearing a paper jam or other printer error.

0 CARTRIDGE key

Press this key to change a print cartridge or install a new print cartridge.

0 Number keys

Use these keys to dial numbers, and enter numbers and letters during

number/name storing procedures.

,_-______-_____---__--.

0 SPEAKERkey

Press this key to hear the line and fax tones through the speaker when

sending a document.

Note:This is not a speakerphone. You must pick up the handset to

talk with the other party.

@ HOLD/SEARCH key

Press this key to search for an automatic dialing number, or, during a

phone conversation, press this key to put the other party on hold.

@ RECEPTlON MODE key

Press this key to select the reception mode. The selected mode will

appear in the display.

@ COPY/HELP key

When a document is in the feeder, press this key to make a copy. At

any 0-r time, press this key to print out the Help List, a quick

reference guide to the operation of your fax.

@ START key

Press this key to send or receive a document.

@ PANEL RELEASE

Pull this release up to open the operation panel.

@ STOP key

Press this key to stop operations before they are completed.

@) RESOLUTION key

Press this key to adjust the resolution and contrast before sending or

copying a document.

@ MEMORY key

Press this key to scan a document into memory before transmitting it.

@ FUNCTION key

Press this key to select various special functions.

cO10r Multifunction

Q, Rapid Dial Keys

Press one of these keys to dial a fax or voice number automatically. To

dial the bottom number on a Rapid Key, press the SHIFT key before

pressing the Rapid Key. (Note that you must attach the Rapid Key

labels.)

l-2

Page 5

[3] Transmittable documents

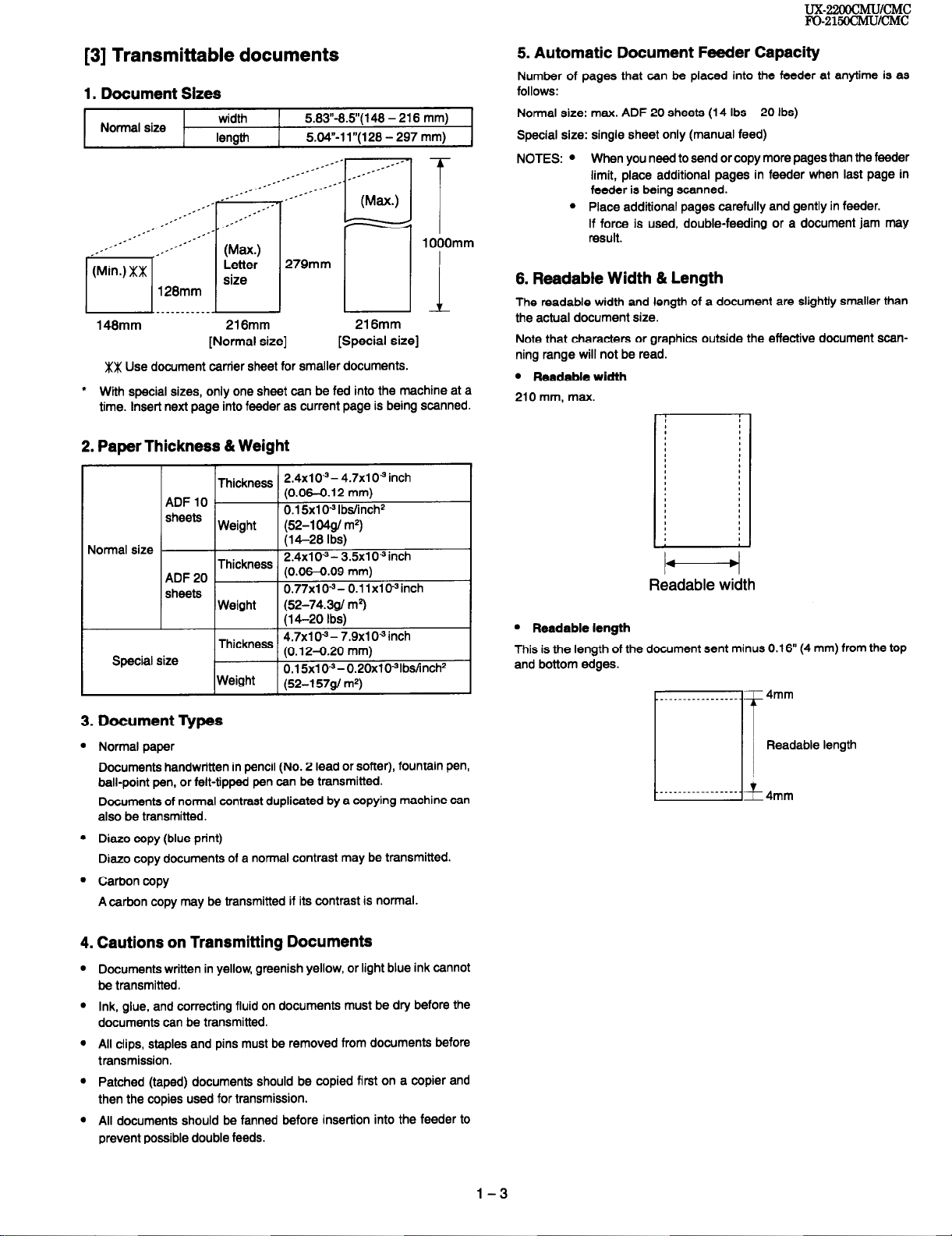

1. Document Sizes

Normal size

148mm

xx Use document carrier sheet for smaller documents.

*

With special sizes, only one sheet can be fed into the machine at a

time. Insert next page into feeder as current page is being scanned.

width

length

218mm

[Normal size]

2. Paper Thickness & Weight

1 5.63”~8.5”(146 - 216 mm)

1 5.04”-11”(126-297mm)

1 OOOmm

216mm

[Special size]

5. Automatic Document Feeder Capacity

Number of pages that can be placed into the feeder at anytime is as

follows:

Normal size: max. ADF 20 sheets (14 Ibs - 20 Ibs)

Special size: single sheet only (manual feed)

NOTES: l

f

I

When you need to send or copy more pages than the feeder

limit, place additional pages in feeder when last page in

feeder is being scanned.

l Place additional pages carefully and gently in feeder.

If force is used, double-feeding or a document jam may

result.

6. Readable Width & Length

The readable width and length of a document are slightly smaller than

the actual document size.

Note that characters or graphics outside the effective document scanning range will not be read.

l Readable width

210 mm, max.

2.4x103- 4.7x1 O9 inch

(0.06-0.12 mm)

0.15x1091bs/inch2

(52-l 04g/ m*)

(14-26 Ibs)

2.4x1 03- 3.5x1 O3 inch

(0.06-0.09 mm)

0.77x10J- 0.1 1x103inch

(52-74.3g/ m’)

(14-20 Ibs)

4.7x10*-7.9x105inch

(0.124.20 mm)

0.15x103-0.20x1031bs/inch2

I ’

I I

Normal size

Special size

ADF 10

sheets

ADF 20

sheets

Thickness

Weight

Thickness

Weight

Thickness

1 Weight t (52-l 57o/ m2)

I

3. Document vpes

Normal paper

Documents handwritten in pencil (No. 2 lead or softer), fountain pen,

ball-point pen, or felt-tipped pen can be transmitted.

Documents of normal contrast duplicated by a copying machine can

also be transmitted.

Diazo copy (blue print)

Diazo copy documents of a normal contrast may be transmitted.

Carbon copy

A carbon copy may be transmitted if its contrast is normal.

L

3

I4

Readable width

l Readable length

This is the length of the document sent minus 0.16” (4 mm) from the top

and bottom edges.

- 4mm

_

Readable length

4mm

4. Cautions on Transmitting Documents

Documents written in yellow, greenish yellow, or light blue ink cannot

be transmitted.

Ink, glue, and correcting fluid on documents must be dry before the

documents can be transmitted.

All clips, staples and pins must be removed from documents before

transmission.

Patched (taped) documents should be copied first on a copier and

then the copies used for transmission.

All documents should be fanned before insertion into the feeder to

prevent possible double feeds.

l-3

Page 6

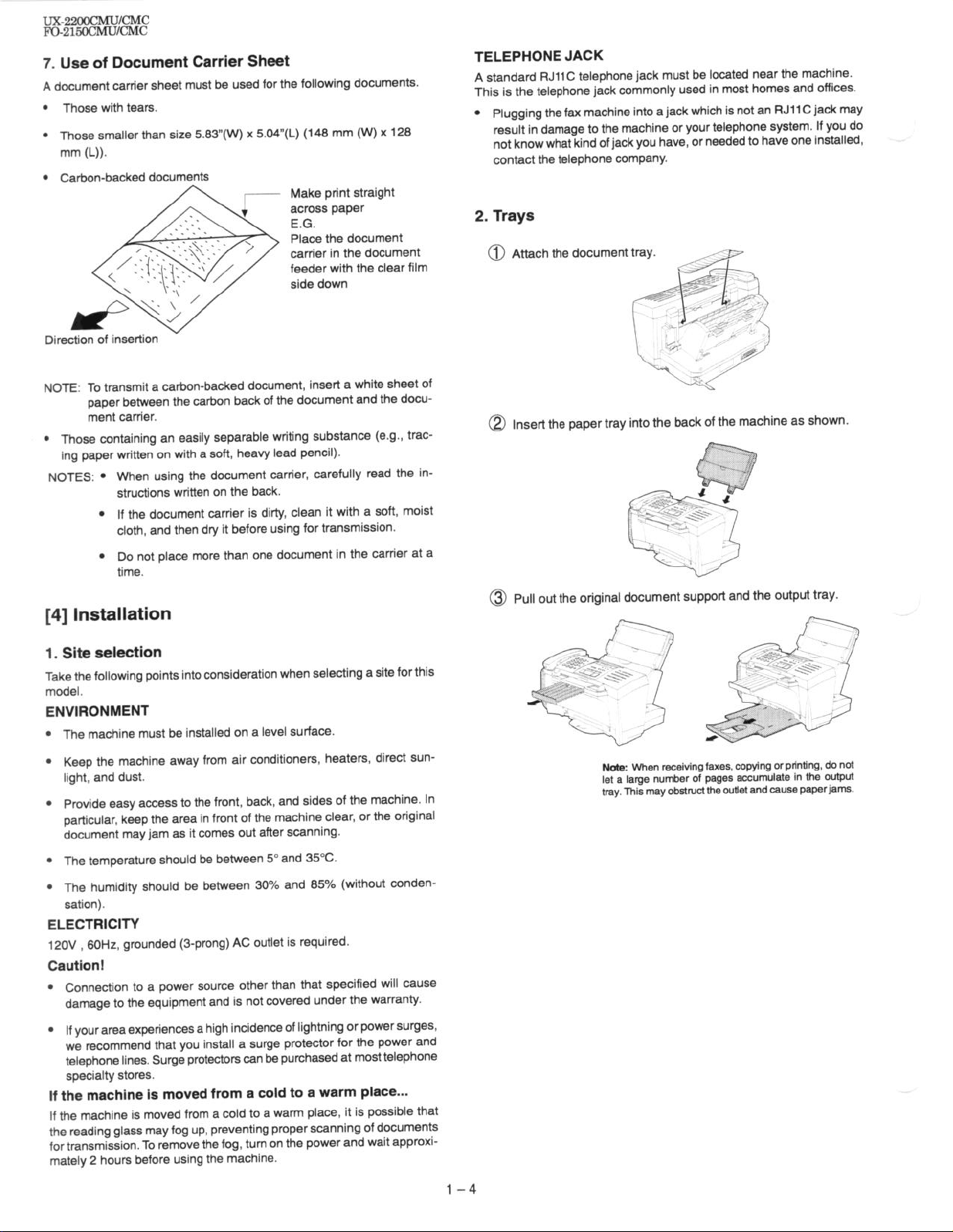

7. Use of Document Carrier Sheet

A document carrier sheet must be used for the following documents.

Those with tears.

Those smaller than size 5.83”(W) x 5.04”(L) (148 mm (W) x 128

mm (L)).

Carbon-backed documents

Make print straight

across paper

E.G.

Place the document

carrier in the document

feeder with the clear film

side down

DirectIon of lnsertlon

NOTE: To transmit a carbon-backed document, insert a white sheet of

paper between the carbon back of the document and the document carrier.

l Those containing an easily separable writing substance (e.g., trac-

ing paper written on with a soft, heavy lead pencil).

NOTES: l When using the document carrier, carefully read the in-

structions written on the back.

l If the document carrier is dirty, clean it with a soft, moist

cloth, and then dry it before using for transmission.

TELEPHONE JACK

A standard RJllC telephone jack must be located near the machine.

This is the telephone jack commonly used in most homes and offices.

l Plugging the fax machine into a jack which is not an RJll C jack may

result in damage to the machine or your telephone system. If you do

not know what kind of jack you have, or needed to have one installed,

contact the telephone company.

2. Trays

@ Attach the document tray.

@ Insert the paper tray into the back of the machine as shown.

l Do not place more than one document in the carrier at a

time.

[4] Installation

1. Site selection

Take the following points into consideration when selecting a site for this

model.

ENVIRONMENT

The machine must be installed on a level surface.

Keep the machine away from air conditioners, heaters, direct sunlight, and dust.

Provide easy access to the front, back, and sides of the machine. In

particular, keep the area in front of the machine clear, or the original

document may jam as it comes out after scanning.

The temperature should be between 5” and 35°C.

The humidity should be between 30% and 85% (without condensation).

ELECTRICITY

12OV ,60Hz, grounded (3-prong) AC outlet is required.

Caution!

Connection to a power source other than that specified will cause

damage to the equipment and is not covered under the warranty.

@ Pull out the original document support and the output tray.

Nde: When receiving faxes, copying or ptlnting, do not

let a large number of pages accumulate in the output

tray. This may obstruct the outlet and cause paparjams.

If your area experiences a high incidence of lightning or power surges,

we recommend that you install a surge protector for the power and

telephone lines. Surge protectors can be purchased at most telephone

specialty stores.

If the machine is moved from a cold to a warm place...

If the machine is moved from a cold to a warm place, it is possible that

the reading glass may fog up, preventing proper scanning of documents

for transmission. To remove the fog, turn on the power and wait approxi-

mately 2 hours before using the machine.

l-4

Page 7

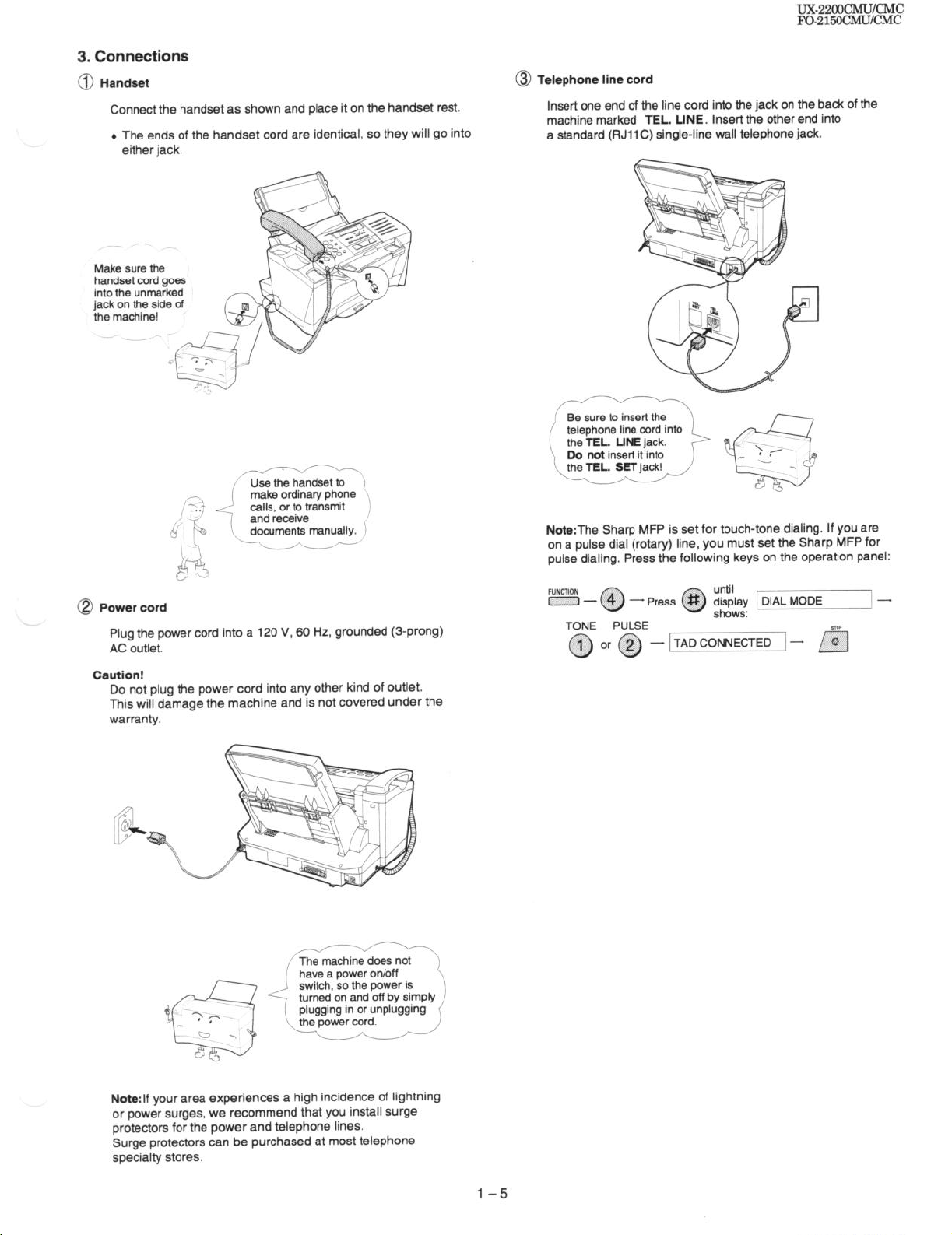

3. Connections

Handset

0

Connect the handset as shown and place it on the handset rest.

+ The ends of the handset cord are identical, so they will go into

either jack.

Make sure the

handset cord goes

into the unmarked

jack on the side of

the machine!

ux-22oocMuIcMc

FO-215ocMuKMc

@ Telephone line cord

Insert one end of the line cord into the jack on the back of the

machine marked TEL. LINE. Insert the other end into

a standard (RJllC) single-line wall telephone jack.

make ordinary phone

Q Power cord

Plug the power cord into a 120 V, SO Hz, grounded (3-prong)

AC outlet.

Caution!

Do not plug the power cord into any other kind of outlet.

This will damage the machine and is not covered under the

warranty.

Note:The Sharp MFP is set for touch-tone dialing. If you are

on a pulse dial (rotary) line, you must set the Sharp MFP for

pulse dialing. Press the following keys on the operation panel:

until

0

shows:

=-G9

TONE PULSE

@or@ I

-Press # display DIAL MODE

- TAD CONNECTED

-

Note:lf your area experiences a high incidence of lightning

or power surges, we recommend that you install surge

protectors for the power and telephone lines.

Surge protectors can be purchased at most telephone

specialty stores.

l-5

Page 8

uxs2goCMuKJMc

Fo-215oCMu/Ch,K

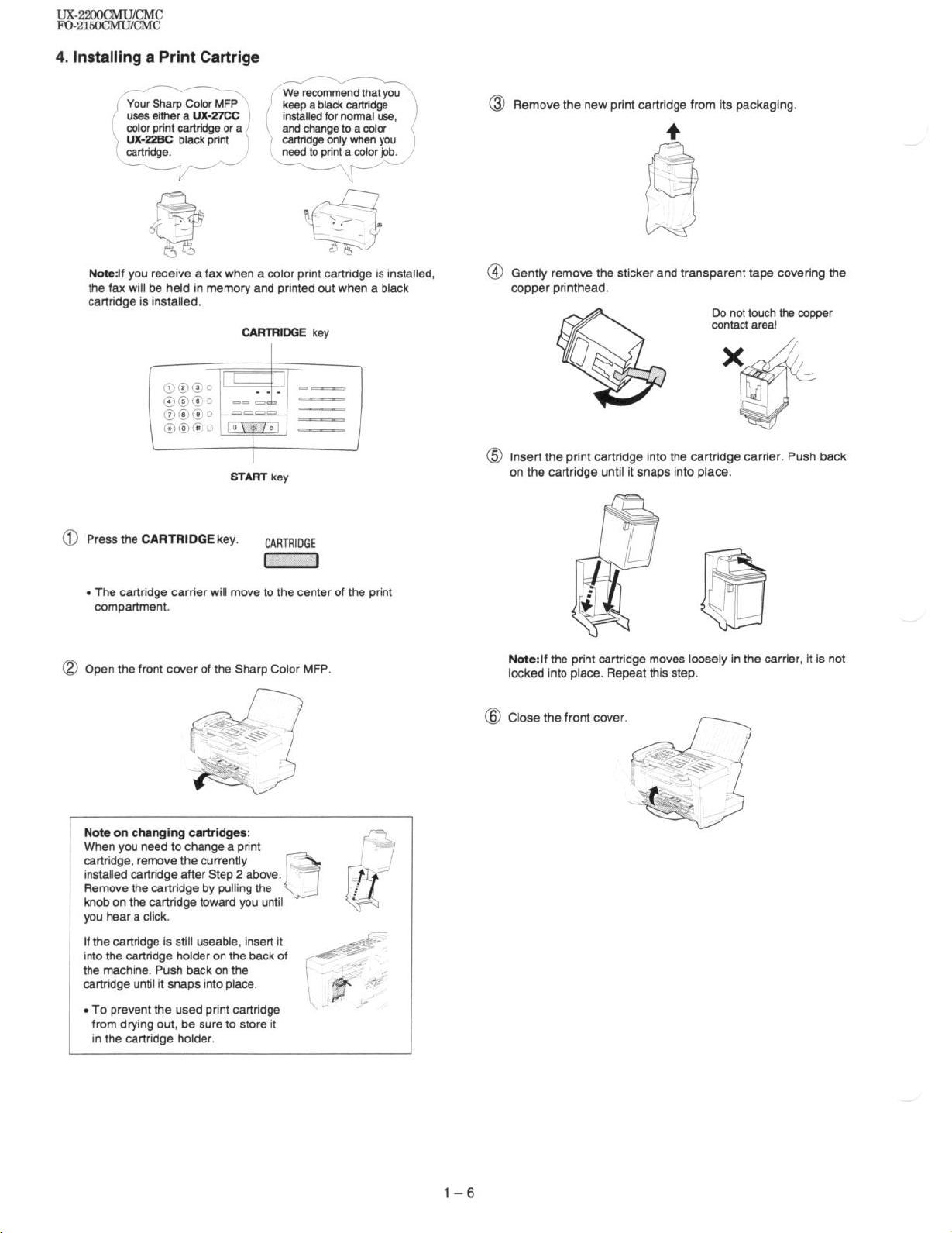

4. Installing a Print Cartrige

.-f----l

Your Sham Color MFP

uses either a UX-27CC

cOlor print cartridge or a

\ UX-22BC black print

i I cartridge.

- 7/“‘-

Noterlf you receive a fax when a color print cartridge is installed,

the fax will be held in memory and printed out when a black

cartridge is installed.

0 Press the CARTRIDGE key.

1’ We recommend that you

keep a black cartridge

installed for normal use,

and change to a color

cartridge only when you

need to print a color job.

L-~

CARTRIDGE key

CARTRIDGE

I

1

Remove the new print cartridge from its packaging.

0

4

@ Gently remove the sticker and transparent tape covering the

copper printhead.

Do not touch the copper

@ Insert the print cartridge into the cartridge carrier. Push back

on the cartridge until it snaps into place.

. The cartridge carrier will move to the center of the print

compartment.

Q Open the front cover of the Sharp Color MFP.

Note on changing cartridges:

When you need to change a print

cartridge, remove the currently

installed cartridge after Step 2 above.

Remove the cartridge by pulling the

knob on the cartridge toward you until

you hear a click.

If the cartridge is still useable, insert it

into the cartridge holder on the back of

the machine. Push back on the

cartridge until it snaps into place.

. To prevent the used print cartridge

from drying out, be sure to store it

in the cartridge holder.

Note: If the print cartridge moves loosely in the carrier, it is not

locked into place. Repeat this step.

@ Close the front cover.

l-6

Page 9

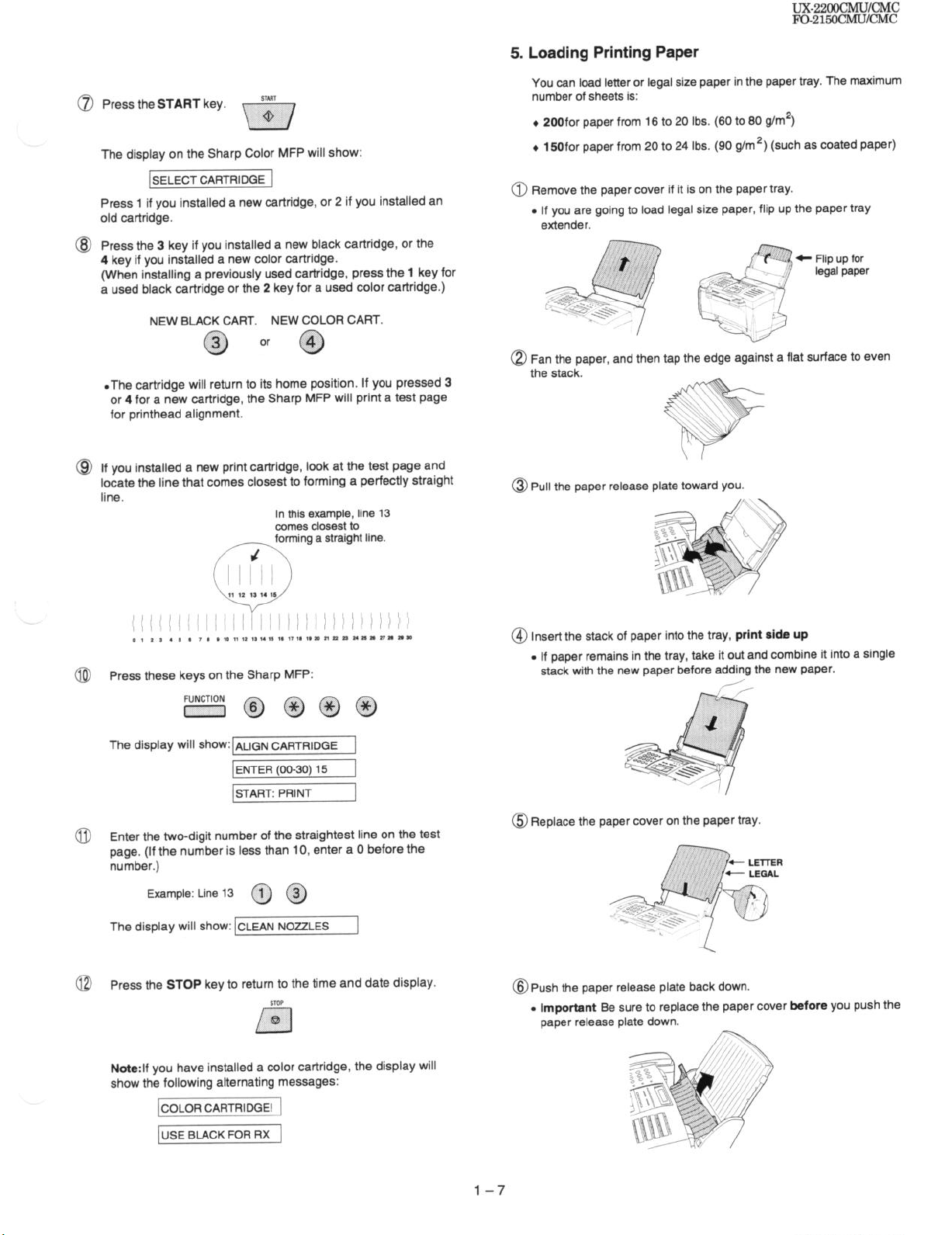

@ Press the START key.

The display on the Sharp Color MFP will show:

SELECT CARTRIDGE

Press 1 if you installed a new cartridge, or 2 if you installed an

old cartridge.

Press the 3 key if you installed a new black cartridge, or the

4 key if you installed a new color cartridge.

(When installing a previously used cartridge, press the 1 key for

a used black cartridge or the 2 key for a used color cartridge.)

UX-ZZOOCMU/CMC

FO-215ochIu/cMc

5. Loading Printing Paper

You can load letter or legal size paper in the paper tray. The maximum

number of sheets is:

4 266for paper from 16 to 20 Ibs. (60 to 60 g!m2)

l 15Ofor paper from 20 to 24 Ibs. (90 g/m2) (such as coated paper)

@ Remove the paper cover if it is on the paper tray.

. If you are going to load legal size paper, flip up the paper tray

extender.

NEW BLACK CART.

3

0

*The cartridge will return to its home position, If you pressed 3

or 4 for a new cartridge, the Sharp MFP will print a test page

for printhead alignment.

If you installed a new print cartridge, look at the test page and

locate the line that comes closest to foning a perfectly straight

line.

Aming a straight line.

Press these keys on the Sharp MFP:

The display will show: ALiGN CARTRIDGE

NEW COLOR CART.

or

4

0

In this example, line 13

comes closest to

ENTER (00-30) 15

START: PRINT

Q Fan the paper, and then tap the edge against a flat surface to even

the stack.

@Pull the paper release plate toward you.

@ Insert the stack of paper into the tray, print side up

. If paper remains in the tray, take it out and combine it into a single

stack with the new paper before adding the new paper.

Enter the two-digit number of the straightest line on the test

page. (If the number is less than 10, enter a 0 before the

number.)

Example: Line 13 @ @

The display will show: ICLEAN NOZZLES

Press the STOP key to return to the time and date display.

STOP

0

/

Note:lf you have installed a color cartridge, the display will

show the following alternating messages:

ICOLOR CARTRIDGE1 1

USE BLACK FOR RX 1

]

@Replace the paper cover on the paper tray.

@Push the paper release plate back down

. Important Be sure to replace the paper cover before you push the

paper release plate down.

l-7

Page 10

ux-22oOcMUt~c

FO-215ocMu/cMc

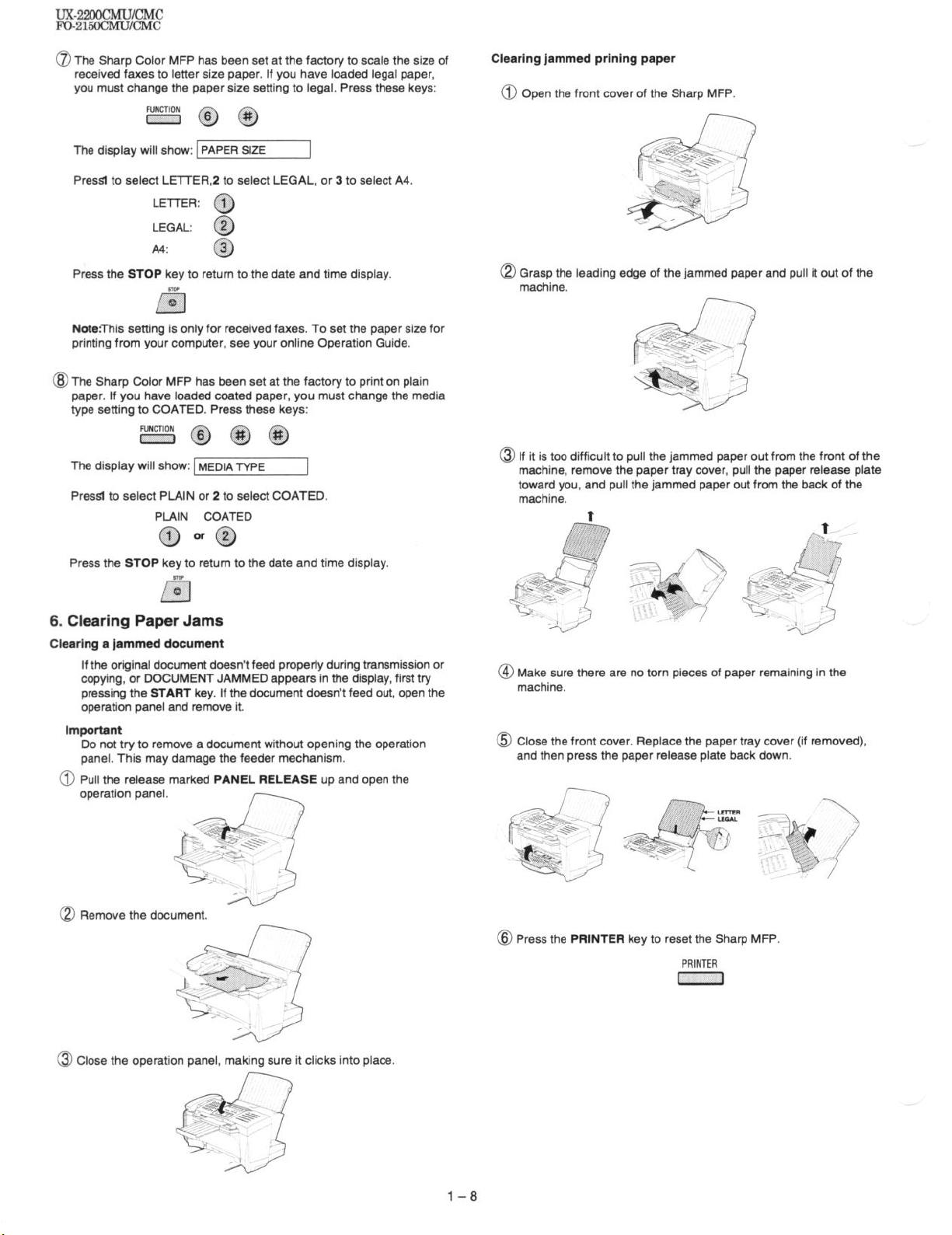

0 The Sharp Color MFP has been set at the factory to scale the size of

received faxes to letter size paper. If you have loaded legal paper,

you must change the paper size setting to legal. Press these keys:

The display will show: 1 PAPER SIZE

Presst to select LETTER,2 to select LEGAL, or 3 to select A4.

LETTER: @

LEGAL:

A4:

Press the STOP key to return to the date and time display.

Kl

Note:This setting is only for received faxes. To set the paper size for

printrng from your computer, see your online Operation Guide.

@ The Sharp Color MFP has been set at the factory to print on plain

paper. If you have loaded coated paper, you must change the media

type setting to COATED. Press these keys:

The display will show: MEDIATYPE

Presst to select PLAIN or 2 to select COATED.

PLAIN COATED

0

@

I

Clearing jammed prlnlng paper

@ Open the front cover of the Sharp MFP.

Q Grasp the leading edge of the jammed paper and pull it out of the

machine.

@ If it is too difficult to pull the jammed paper out from the front of the

machine, remove the paper tray cover, pull the paper release plate

toward you, and pull the jammed paper out from the back of the

machine.

t

Press the STOP key to return to the date and time display.

KI

6. Clearing Paper Jams

Clearing a jammed document

If the original document doesn’t feed properly during transmission or

copying, or DOCUMENT JAMMED appears in the display, first try

pressing the START key. If the document doesn’t feed out, open the

operation panel and remove it.

Important

Do not try to remove a document without opening the operation

panel. This may damage the feeder mechanism.

0 Pull the release marked PANEL RELEASE up and open the

operation panel.

document.

Q Remove

the

@ Make sure there are no torn pieces of paper remaining in the

machine.

@ Close the front cover. Replace the paper tray cover (if removed),

and then press the paper release plate back down.

@ Press the PRINTER key to reset the Sharp MFP.

PRINTER

0 Close the operation panel, making sure it clicks into place.

l-8

Page 11

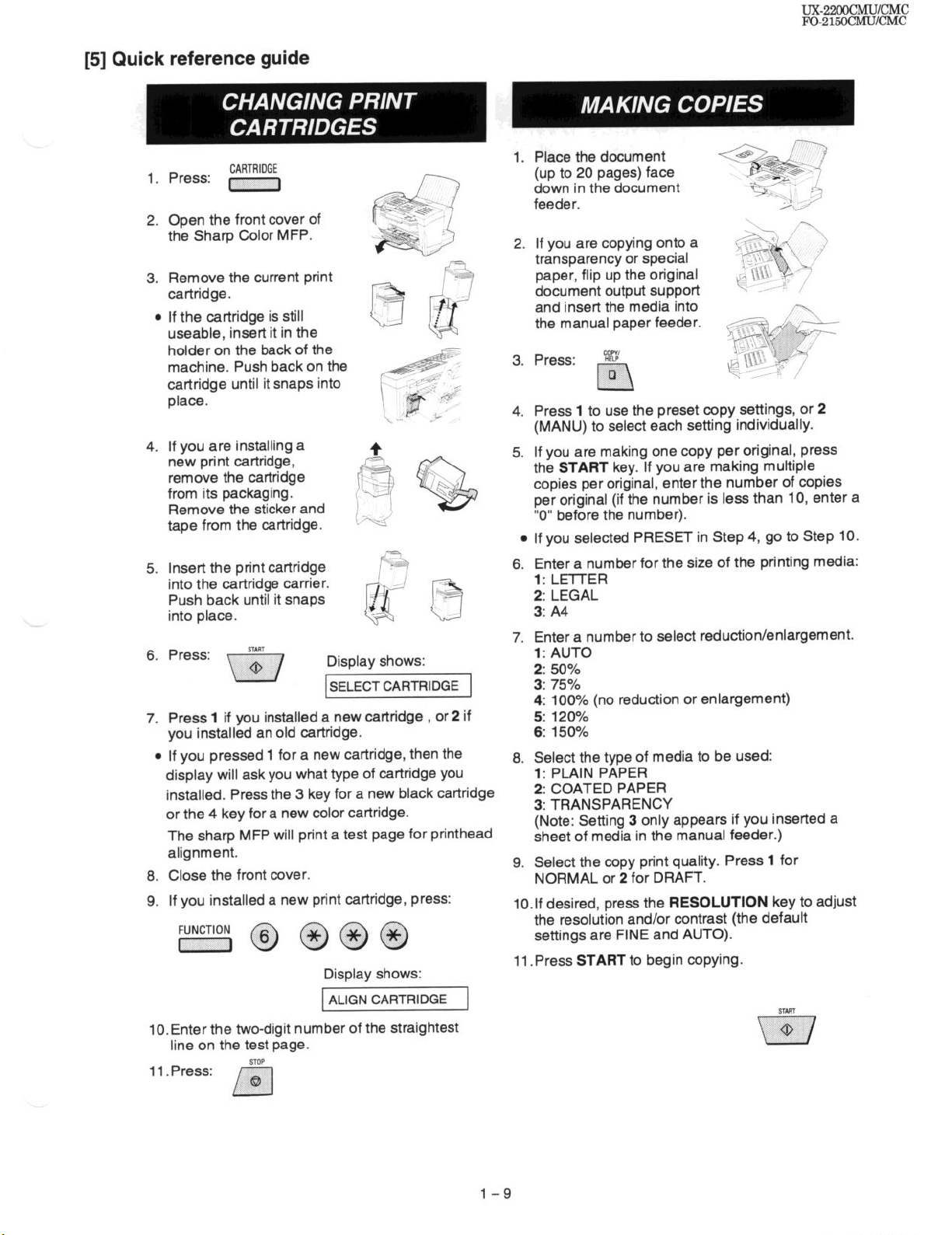

[5] Quick reference guide

Press: r-r

1.

Open the front cover of

2.

the Sharp Color MFP.

Remove the current print

3.

cartridge.

l

If the cartridge is still

useable, insert it in the

holder on the back of the

machine. Push backon the

cartridge until it snaps into

place.

If you are installing a

4.

new print cartridge,

remove the cartridge

from its packaging.

Remove the sticker and

tape from the cartridge.

Insert the print cartridge

5.

into the cartridge carrier.

Push back until it snaps

into place.

Press:

6.

Press 1 if you installed a new cartridge , or 2 if

7.

you installed an old cartridge.

0

If you pressed 1 for a new cartridge, then the

display will ask you what type of cartridge you

installed. Press the 3 key for a new black cartridge

or the 4 key for a new color cartridge.

The sharp MFP will print a test page for printhead

alignment.

8. Close the front cover.

9. If you installed a new print cartridge, press:

CARTRIDGE

I

1

Display shows:

SELECT CARTRIDGE

Display shows:

ALIGN CARTRIDGE

ux-22o0cMu/cMc

FG-215ocMuKhK

Place the document

1.

(up to 20 pages) face

down in the document

feeder.

If you are copying onto a

2.

transparency or special

paper, flip up the original

document output support i _ ,’

and insert the media into

the manual paper feeder.

Press: ?XV

3.

Press 1 to use the preset copy settings, or 2

4.

(MANU) to select each setting individually.

If you are making one copy per original, press

5.

the START key. If you are making multiple

copies per original, enter the number of copies

per original (if the number is less than 10, enter a

“0” before the number).

l If you selected PRESET in Step 4, go to Step 10.

Enter a number for the size of the printing media:

6.

1: LmER

2: LEGAL

3: A4

Enter a number to select reduction/enlargement.

7.

1: AUTO

2: 50%

3: 75%

4: 100% (no reduction or enlargement)

5: 120%

6: 150%

Select the type of media to be used:

8.

1: PLAIN PAPER

2: COATED PAPER

3: TRANSPARENCY

(Note: Setting 3 only appears if you inserted a

sheet of media in the manual feeder.)

Select the copy print quality. Press 1 for

9.

NORMAL or 2 for DRAFT.

lO.lf desired, press the RESOLUTION key to adjust

the resolution and/or contrast (the default

settings are FINE and AUTO).

11 .Press START to begin copying.

I

/1

lO.Enter the two-digit number of the straightest

line on the test page.

11. Press:

STOP

D

n

l-9

Page 12

ux-22OoCMu/Ch,rc

lQ21m/cMc

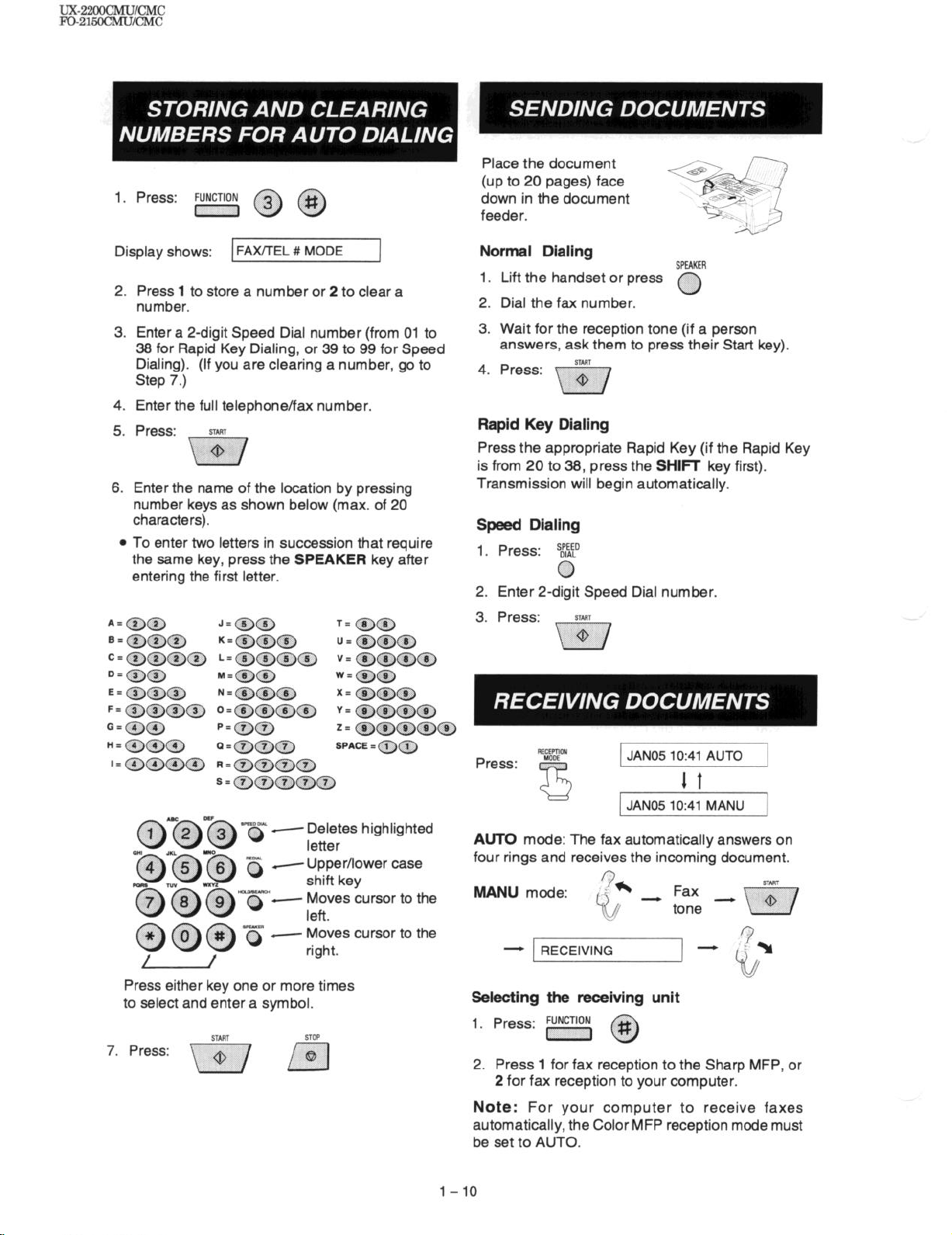

1. Press: FUNCTION

II@@

Place the document

(up to 20 pages) face

down in the document

feeder.

Display shows:

2.

Press 1 to store a number or 2 to clear a

FAX/TEL # MODE

number.

3.

Enter a P-digit Speed Dial number (from 01 to

36 for Rapid Key Dialing, or 39 to 99 for Speed

Dialing). (If you are clearing a number, go to

Step 7.)

4.

Enter the full telephone/fax number.

5.

Press: SORT

\$/

6.

Enter the name of the location by pressing

number keys as shown below (max. of 20

characters).

a

To enter two letters in succession that require

the same key, press the SPEAKER key after

entering the first letter.

Normal Dialing

Lift the handset or press

1.

SPEAKER

0

2. Dial the fax number.

3. Wait for the reception tone (if a person

answers, ask them to press their Start key).

4. Press:

START

m

Rapid Key Dialing

Press the appropriate Rapid Key (if the Rapid Key

is from 20 to 36, press the SHIFT key first).

Transmission will begin automatically.

Speed Dialing

1. Press: s&tD

0

2. Enter 2-digit Speed Dial number.

3. Press:

@

i”“r

@-@w@ 3 -E;y highlighted

4 Upper/lower case

._...

- Moves cursor to the

@ @@ ’

/

I

/

,

right.

Press either key one or more times

to select and enter a symbol.

START

STOP

7. Press:

m /Xl

Press:

REt%Em

JAN05 lo:41 AUTO

1 t

JAN05 lo:41 MANU

AUTO mode: The fax automatically answers on

four rings and receives the incoming document.

%b

Q/

._

/

_ Fax

tone - G?

MANU mode:

- RECEIVING

Selecting the receiving unit

1. Press: in, @

Press 1 for fax reception to the Sharp MFP, or

2.

2 for fax reception to your computer.

Note: For your computer to receive faxes

automatically, the Color MFP reception mode must

be set to AUTO.

l-10

Page 13

CHAPTER 2. ADJUSTMENTS

[l] Adjustments

General

Since the following adjustments and settings are provided for this model,

make adjustments and/or setup as necessary.

1. Adjustments

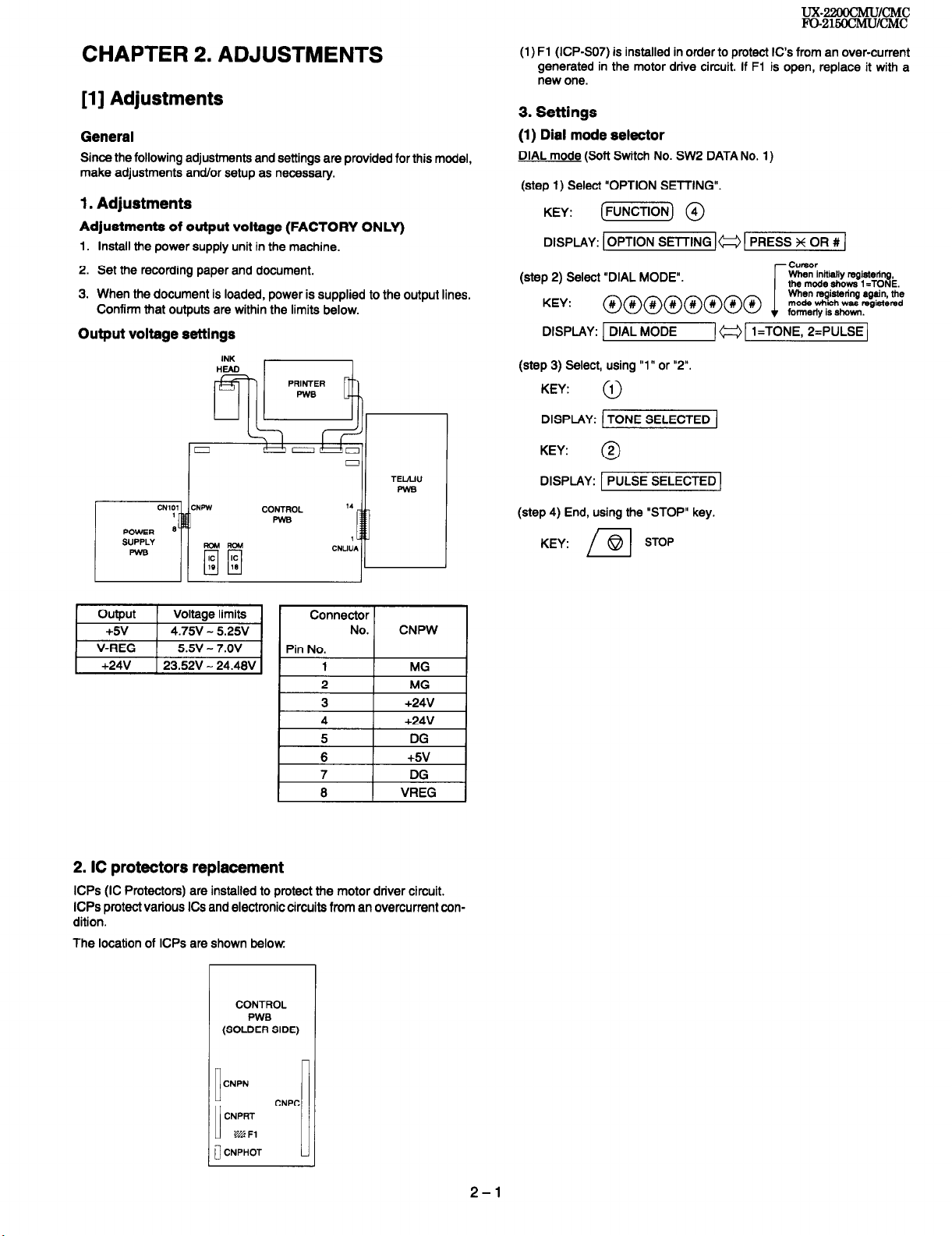

Adjustments of output voltage (FACTORY ONLY)

1. Install the power supply unit in the machine.

2. Set the recording paper and document.

3. When the document is loaded, power is supplied to the output lines.

Confirm that outputs are within the limits below.

Output voltage settings

(1) Fl (ICPSO7) is installed in order to protect It’s from an over-current

generated in the motor drive circuit. If Fl is open, replace it with a

new one.

3. Settings (1) Dial mode selector

DIAL mode (Soft Switch No. SW2 DATA No. 1)

(step 1) Select “OPTION SETTING”.

KEY: (-1 @

DISPLAY: 1 OPTION SETTING )w 1 PRESS X OR # 1

CWSOr

(step 2) Select “DIAL MODE”.

When initially registering.

the mode shows 1 =TONE.

i

DISPLAY: 1 DIAL MODE

(step 3) Select, using “1’ or “2”.

KEY:

DISPLAY: 1 TONE SELECTED 1

0

TELAIU

PWB

I/

Connector

I

No. CNPW

2. IC protectors replacement

ICPs (IC Protectors) are installed to protect the motor driver circuit.

ICPs protect various ICs and electronic circuits from an overcurrent con-

KEY:

DISPLAY: 1 PULSE SELECTED1

(step 4) End, using the “STOP” key.

KEY:

0

STOP

The location of ICPs are shown below

CONTROL

PWB

(SOLDER SIDE)

CNPN

I

CNPRT

LB Fl

CNPHOT

Ii] u

CNPC

2-l

Page 14

UX--/CMC!

lW-215oCMu/cMc

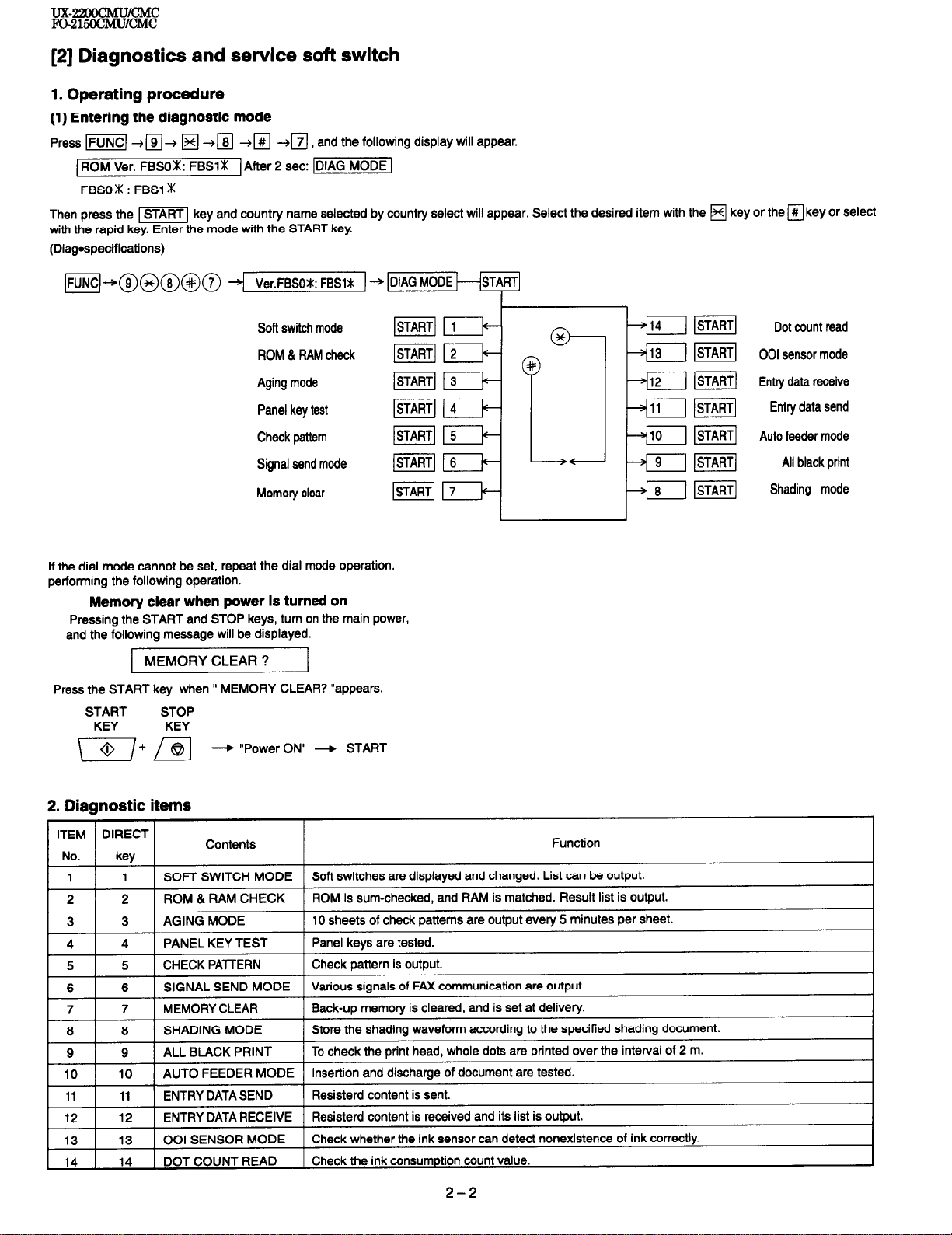

[2] Diagnostics and service soft switch

1. Operating procedure

(1) Enterlng the diagnostic mode

Press w[ --f q + q -tm +m +a , and the following display will appear.

1 ROM Ver. FBSOX: FBSlm

FBSO m : FBSl m

Then press the m key and country name selected by country select will appear. Select the desired item with the H key or the q key or select

with the rapid key. Enter the mode with the START key

(Diagqecifications)

m-*@@@@@ 4 Ver.FBSOt: FBSlt ) +

/After 2 set: -1

Soft switch mode

ROM & RAM check

Aging mode

Panel key test

Check pattern

Signal send mode

Memory clear

If the dial mode cannot be set, repeat the dial mode operation,

performing the following operation.

Memory clear when power is turned on

Pressing the START and STOP keys, turn on the main power,

and the following message will be displayed.

MEMORY CLEAR ?

Press the START key when I’ MEMORY CLEAR? “appears.

START

KEY

STOP

KEY

-+ “Power ON” -+ START

pGiq

j-K@

/Gq

ml

lsTARTj

$iq

m

Dot count read

001 sensor mode

Entry data receive

Entry data send

Auto feeder mode

All black print

Shading mode

2. Diagnostic items

Function

Page 15

UX-22oocMu/cMC

FC-215OCMLJ/CMc

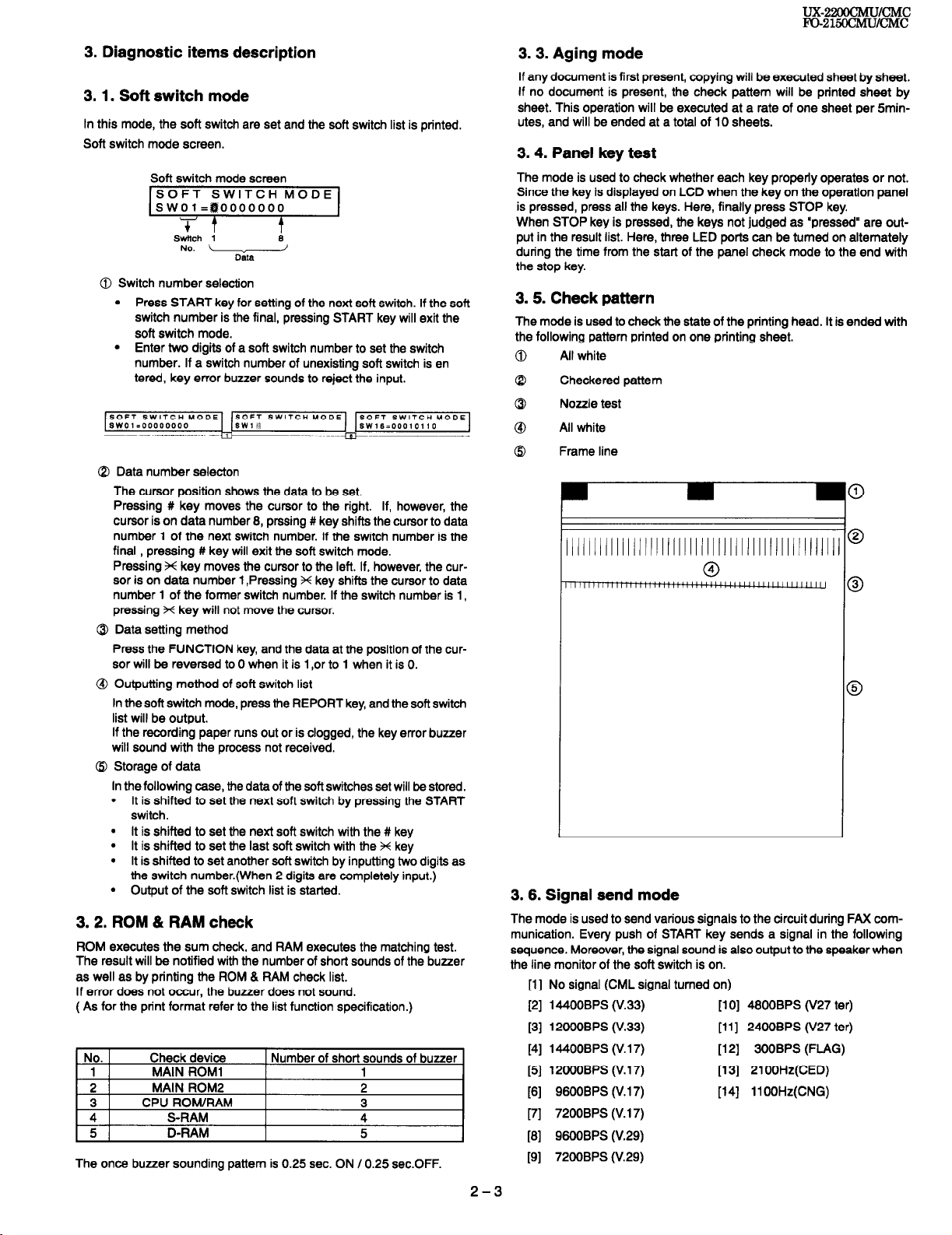

3. Diagnostic items description

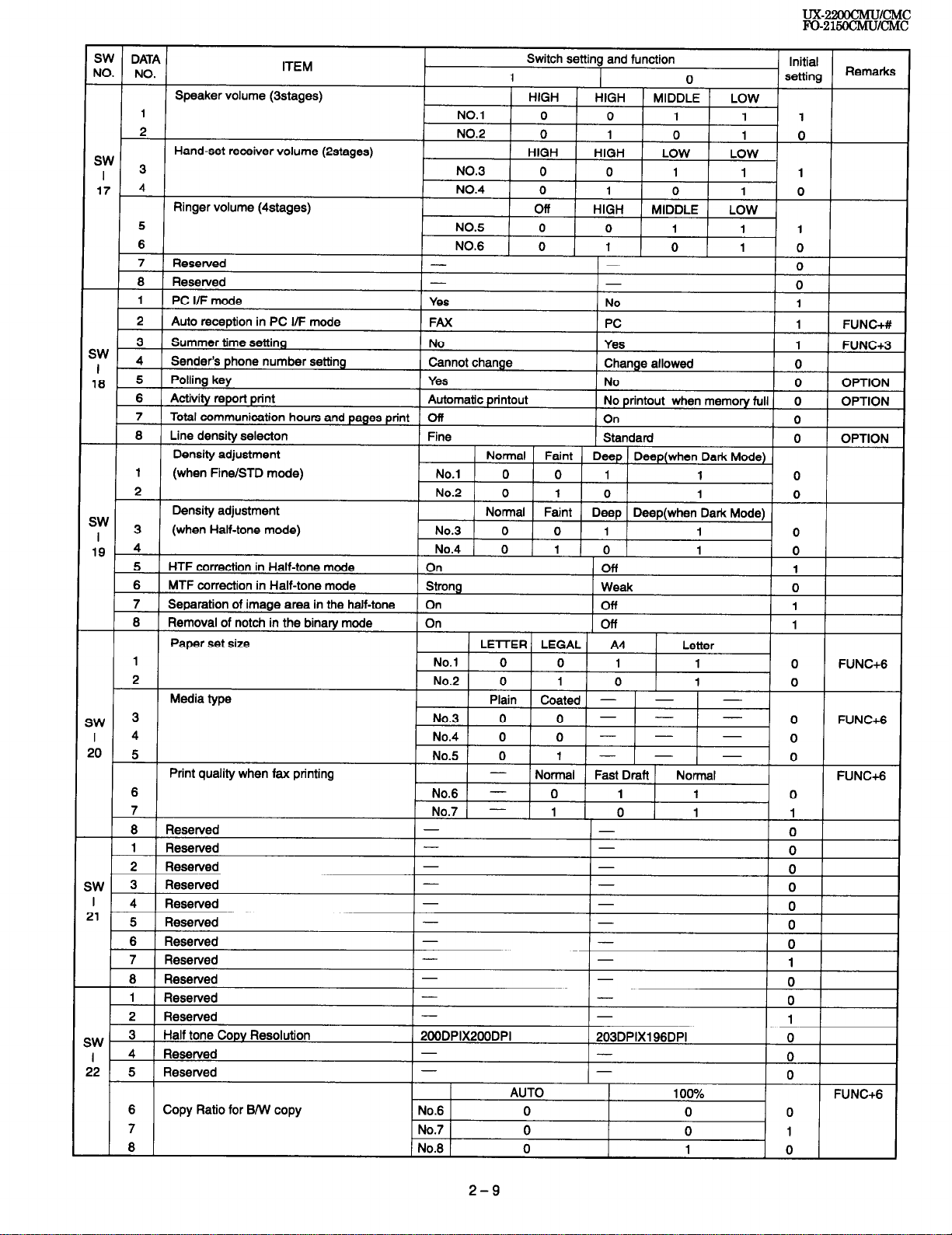

3.1. Soft switch mode

In this mode, the soft switch are set and the soft switch list is printed.

Soft switch mode screen.

Soft switch mode screen

1-1

Swkh 1

No. 4

0 Switch number selection

l Press START key for setting of the next soft switch. If the soft

switch number is the final, pressing START key will exit the

soft switch mode.

l Enter two digits of a soft switch number to set the switch

number. If a switch number of unexisting soft switch is en

tered, key error buzzer sounds to reject the input.

@ Data number selecton

The cursor position shows the data to be set.

Pressing # key moves the cursor to the right. If, however, the

cursor is on data number 8, prssing # key shifts the cursor to data

number 1 of the next switch number. If the switch number is the

final , pressing # key will exit the soft switch mode.

Pressing X key moves the cursor to the left. If, however, the cur-

sor is on data number 1 ,Pressing X key shifts the cursor to data

number 1 of the former switch number. If the switch number is 1,

pressing X key will not move the cursor.

Q Data setting method

Press the FUNCTION key, and the data at the position of the cursor will be reversed to 0 when it is 1 ,or to 1 when it is 0.

@I Outputting method of soft switch list

In the soft switch mode, press the REPORT key, and the soft switch

list will be output.

If the recording paper runs out or is clogged, the key error buzzer

will sound with the process not received.

@ Storage of data

In the following case, the data of the soft switches set will be stored.

l It is shifted to set the next soft switch by pressing the START

switch.

l It is shifted to set the next soft switch with the # key

l It is shifted to set the last soft switch with the X key

l It is shifted to set another soft switch by inputting two digits as

the switch number.(When 2 digits are completely input.)

l Output of the soft switch list is started.

3.2. ROM & RAM check

ROM executes the sum check, and RAM executes the matching test.

The result will be notified with the number of short sounds of the buzzer

as well as by printing the ROM & RAM check list.

If error does not occur, the buzzer does not sound.

( As for the print format refer to the list function specification.)

No. Check device

1 MAIN ROM1

2 MAIN ROM2

3 CPU ROM/RAM

4 S-RAM

5 D-RAM

The once buzzer sounding pattern is 0.25 sec. ON IO.25 sec.OFF.

Number of short sounds of buzzer

1

2

3

4

5

3.3. Aging mode

If any document is first present, copying will be executed sheet by sheet.

If no document is present, the check pattern will be printed sheet by

sheet. This operation will be executed at a rate of one sheet per 5minutes, and will be ended at a total of 10 sheets.

3.4. Panel key test

The mode is used to check whether each key properly operates or not.

Since the key is displayed on LCD when the key on the operation panel

is pressed, press all the keys. Here, finally press STOP key.

When STOP key is pressed, the keys not judged as “pressed” are output in the result list. Here, three LED ports can be turned on alternately

during the time from the start of the panel check mode to the end with

the stop key.

3.5. Check pattern

The mode is used to check the state of the printing head. It is ended with

the following pattern printed on one printing sheet.

All white

0

Checkered pattern

Q

Nozzle test

0

All white

@I

Frame line

@

ll/lI//II/IlI/llIlIIIII/IIIII/IIIIIllII//llIIIlI @

3.6. Signal send mode

The mode is used to send various signals to the circuit during FAX com-

munication. Every push of START key sends a signal in the following

sequence. Moreover, the signal sound is also output to the speaker when

the line monitor of the soft switch is on.

[1] No signal (CML signal turned on)

[2] 14400BPS (V.33) [I 0] 4800BPS (V27 ter)

[3] 12OOOBPS (V.33)

[4] 144OOBPS (V.17) [12] 300BPS (FLAG)

[5] 12OOOBPS (V.17) [13] 21 OOHz(CED)

[8] 9800BPS (V.17)

[7] 7200BPS (V.17)

[8] 9800BPS (V.29)

[9] 7200BPS (V.29)

[11] 2400BPS (V27 ter)

[14] llOOHz(CNG)

2-3

Page 16

UX-22oocMu/cMC

Fo-216ccMu/CMc

3. 7. Memory clear

This mode is used to clear the backup memory and reset to the

default settings.

3.8. Shading mode

This mode is used to store the shading waveform according to the

specified shading document.

3.9. All black print

This mode is used to check the state of the printing head and intentionally overheat it.

Press STOP key for the end.

3.10. Auto feeder mode

This mode is used to check the auto feed function by inserting and discharging the document. In this mode, the feed of the document will be

automatically tested if the document is set. Moreover, the number of fed

documents will be counted and be displayed on LCD.

3.11. Entry data send

This mode is used to send the registered data to the remote machine

and make the remote machine copy the registered information. When

this mode is used for sending, the remote machine must be set to the

entry data receive mode.

This information to be sent is as follows.

1. TELEPHONE NUMBER LIST

2. PASSCOD LIST

3. OPTION LIST

4. ANTI JUNK LIST

5. GROUP LIST

6. PRINT SET UP LIST

7. SOFT SW LIST

3.12. Entry data receive

This mode is used to receive the registered data which is sent from the

remote machine and to register the received data in the machine.When

this mode is used to receive the information, the remote machine must

be set to the entry data send mode

The information to be sent is as follows.

1, TELEPHONE NUMBER LIST

2. PASSCOD LIST

3. OPTION LIST

4. ANTI JUNK LIST

5. GROUP LIST

6. PRINT SET UP LIST

7. SOFT SW LIST

3.13.001 sensor mode

This mode is used to check whether the ink sensor can detect

nonexistence of ink correctly.

3.14. DOT COUNT READ

The black, cyan, magenta and yellow ink consumption counter value

is indicated.

2-4

Page 17

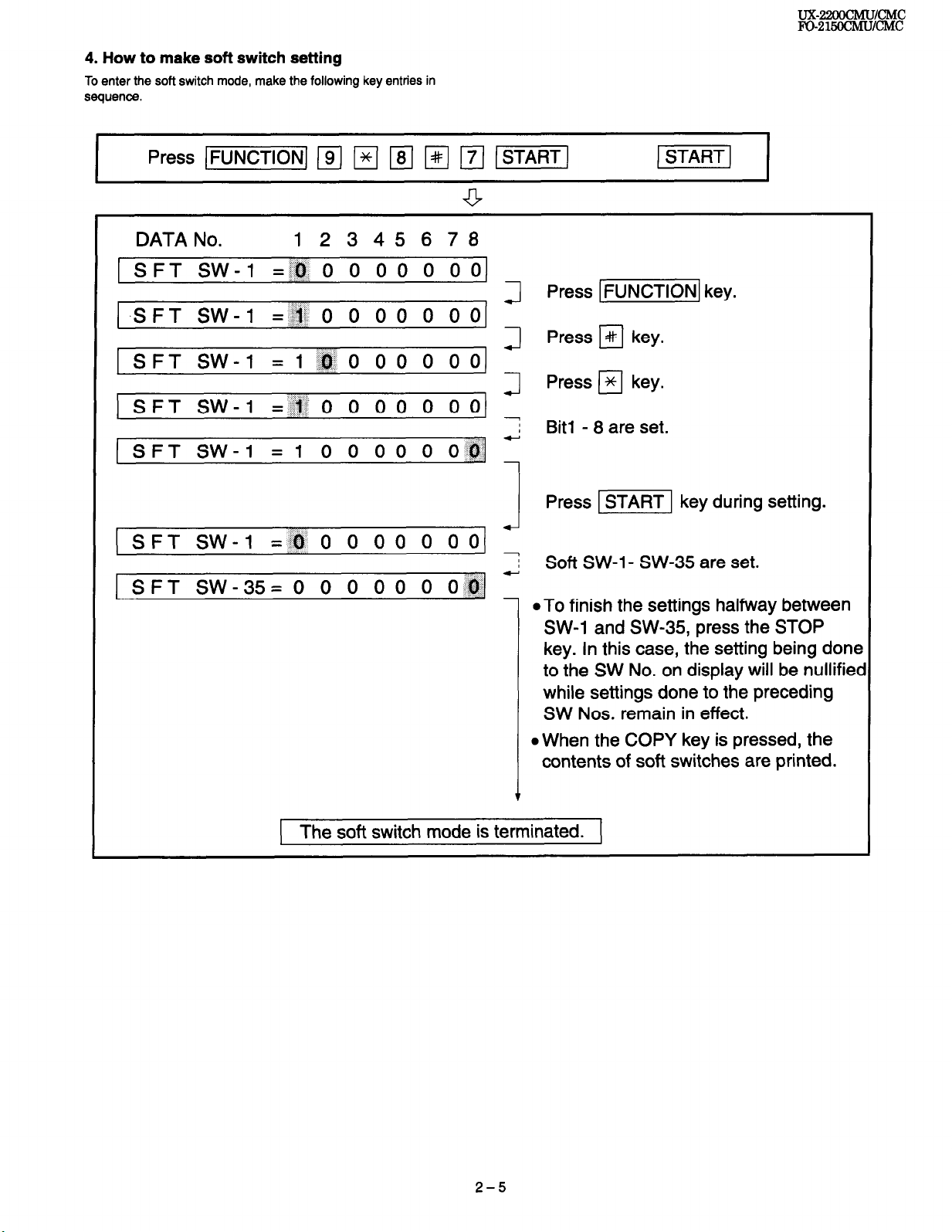

4. How to make soft switch setting

To enter the soft switch mode, make the following key entries in

sequence.

DATA No. 12345678

1 SFT SW-1 =,,.o,. 0 0 0 0 0 0 01 1 001 J

.SFT SW-1 =:+I 0 0 00 0

1 00) ~

SFT SW-1 =I:@ 0 00 0

1 Il

SFT SW-1 = ,,I 0 0 00 0 00)

1 0 /@] - SFT SW-l = 1 0 0 0 0 0

Press [FUNCTIONI key.

Press I#1 key.

Press q key.

: Bit1 - 8 are set.

UX424WCMUlCMC

FQ-215ocMulcMc

1 SFT SW-l = .;a 0 0 0 0 0 0 0

1 SFT SW-35= 0 0 0 0 0 0 O,,;ol

1 The soft switch mode is terminated. 1

Press ISTART] key during setting.

,I

2 Soft SW-l- SW-35 are set.

~ l TO finish the settings halfway between

SW-1 and SW-35, press the STOP

key. In this case, the setting being done

to the SW No. on display will be nullifiec

while settings done to the preceding

SW Nos. remain in effect.

l When the COPY key is pressed, the

contents of soft switches are printed.

2-5

Page 18

ux-22oocMu/cMC

ln215ocMu/~c

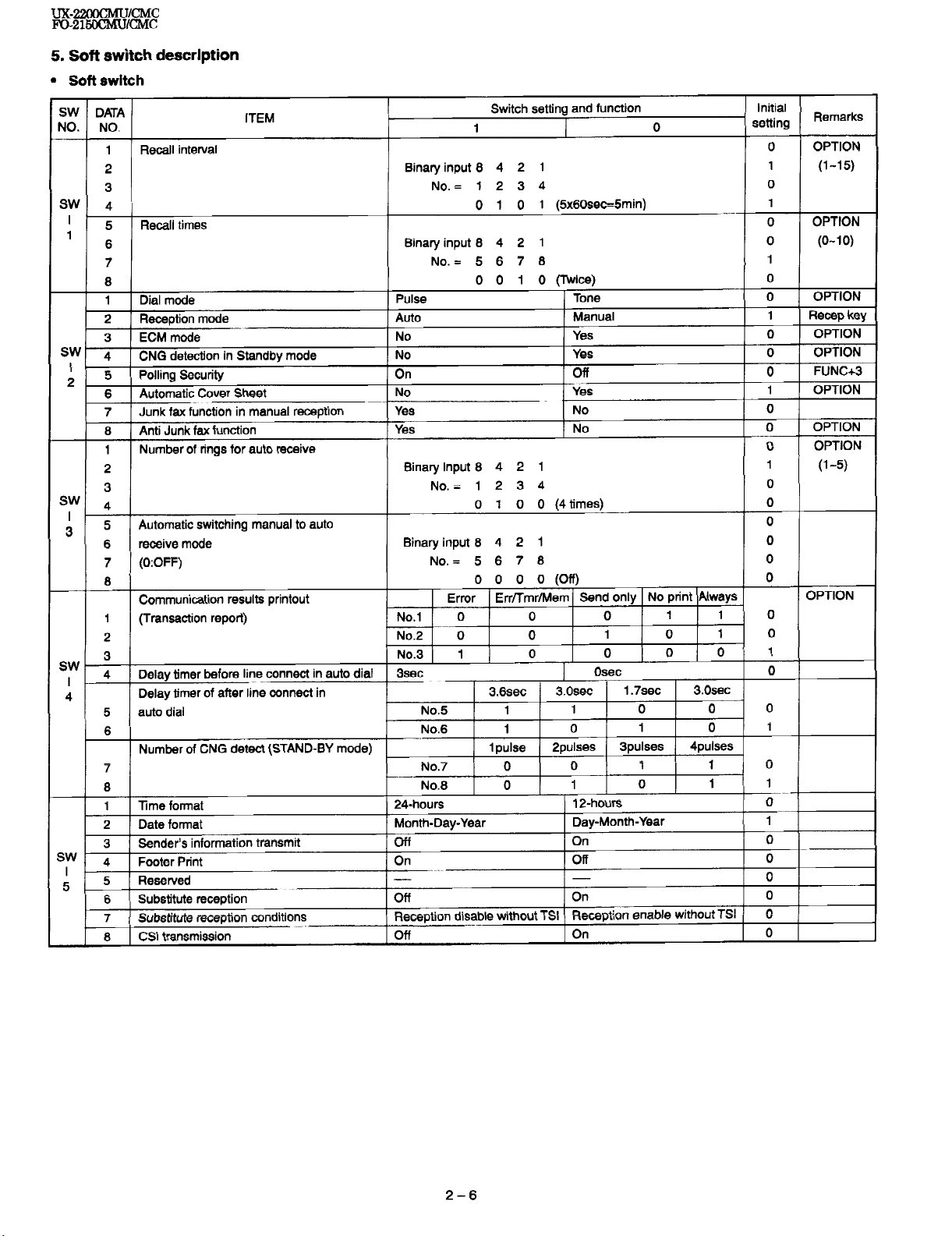

5. Soft

Soft

l

switch description

switch

input 8 4 2 1

Binary

3 4

No.= 1

2

Binary input 8 4 2 1

5 6 7 8

No. =

Binary input 8 4 2 1

No.= 1 2 3 4

(Transaction report)

Binary input 8 4 2 1

No.= 5 6 7 8

2-6

Page 19

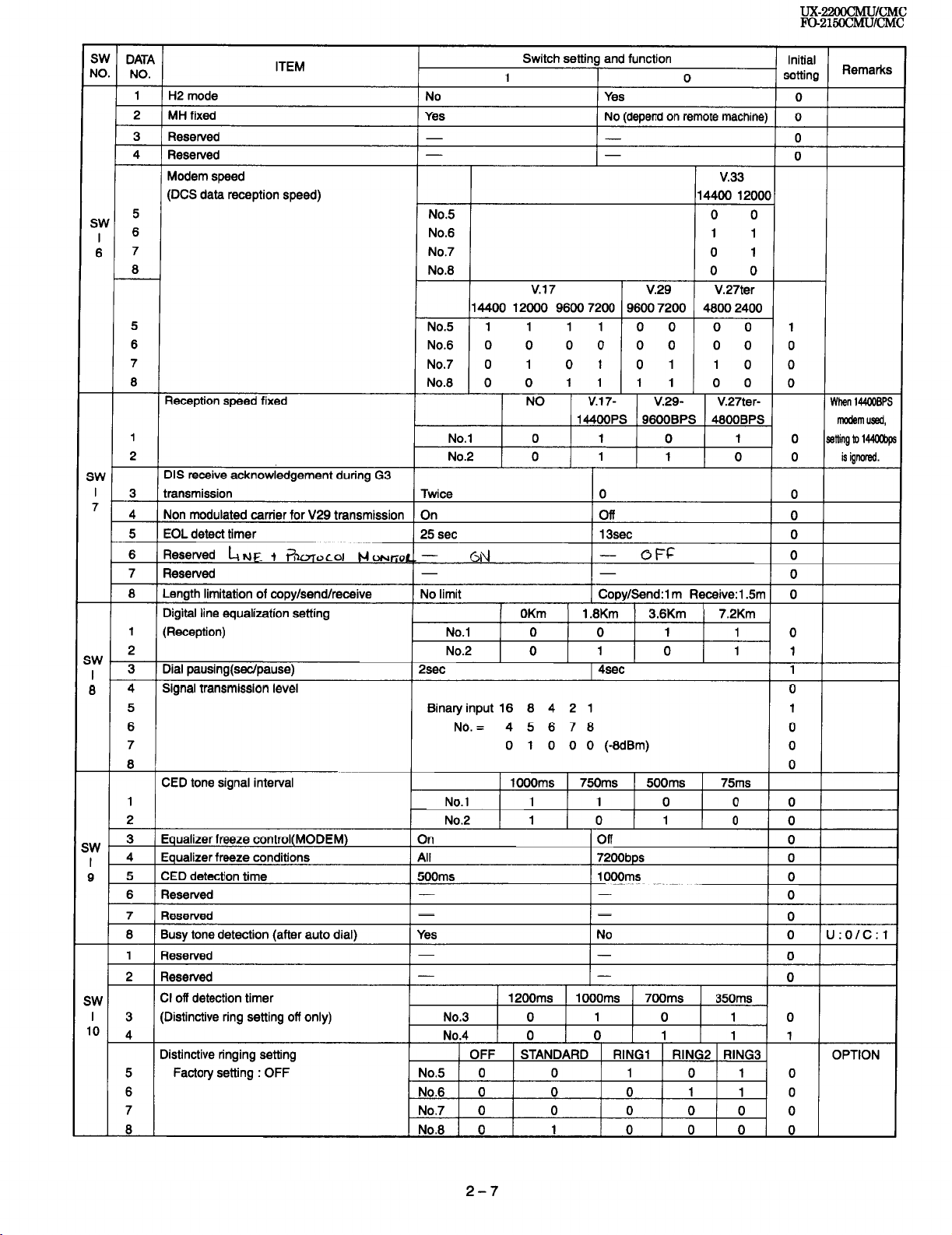

SW DATA

NO.

NO.

1

2

3

4

8

ITEM

H2

mode No

MH fixed

Reserved

Reserved

Modem

speed v.33

(DCS data

Reception

reception

speed

speed)

fixed NO

Switch

setting

1

Yes

- -

- -

No.5

No.6

No.7

No.8

v.17 v.29

14400

12000

96007200

No.5

No.6

No.7

No.8

1 1

0

0

0

0

1 0

0

1

0

1 1

v.17-

144OOPS

1

0

1

and

Yes

No

function

0

(depend

on

remote

96007200

0 0

0

0 00 0

0

1 1 0

1 1

v.29- V.27ter-

9600BPS

UXCZOOCMU~CMC

FD21-/cMc

initial

setting

machine) 0

0

0

14400

12000

0

0

1

1

0 1

0 0

V.27ter

48002400

0 0 1

0

0

0

0

45OOBPS mcdsm used,

Remarks

0

When

144WPS

(Distinctive ring setting off only)

Factory setting

:

OFF

Binary input

16 8 4 2 1

4 5 6 78

2-7

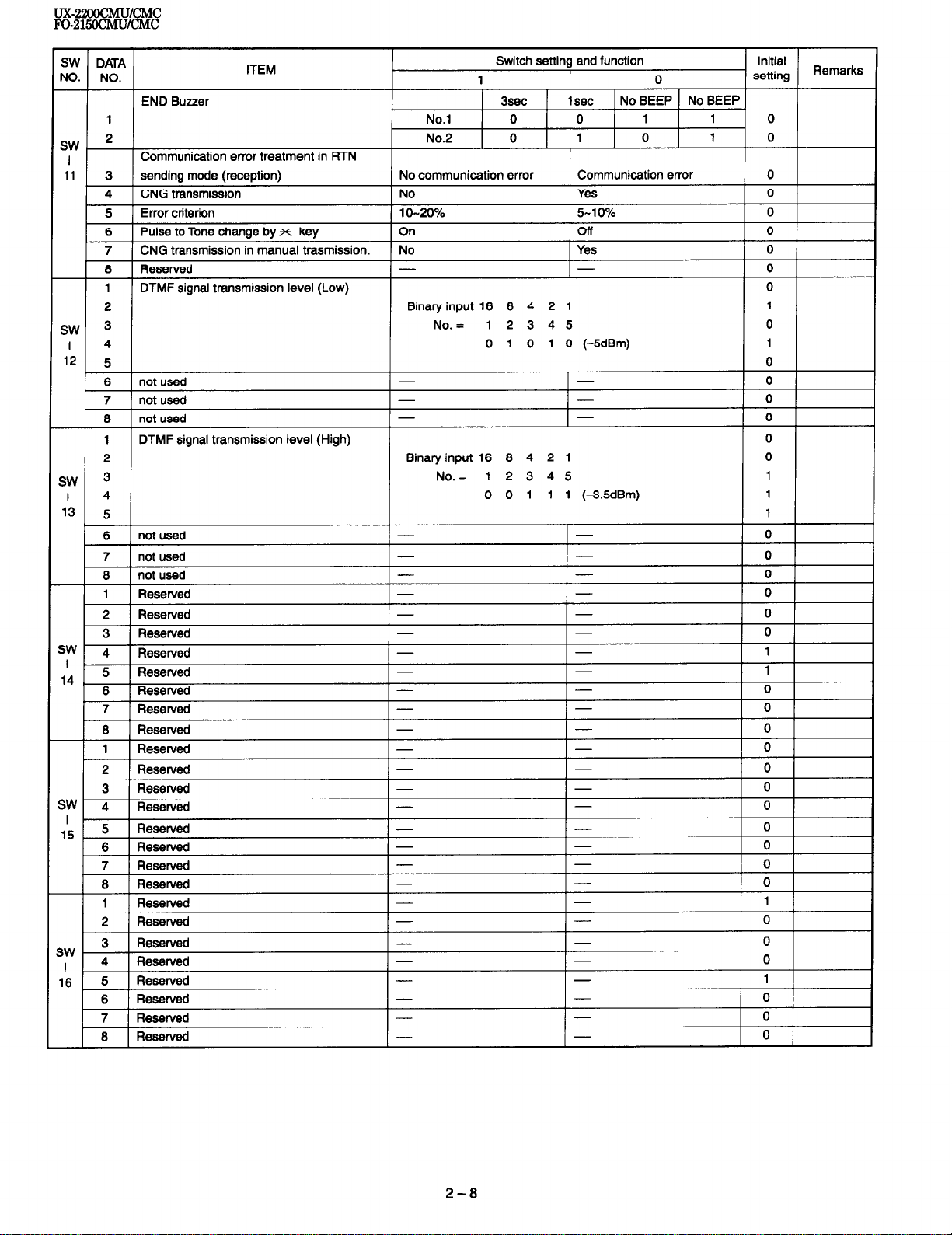

Page 20

TJX22OOCMUlCMC

F0215OCMsJ~CMc

SW

DATA

NO.

NO.

-

SW

I

11

SW

I

12

-

SW

END Buzzer

1

2

Communication error treatment in RTN

3 sending mode (reception)

4 CNG transmission

5 Error criterion

6 Pulse to Tone change bv x kev

7 CNG transmission in manual trasmission.

6 Reserved

1 DTMF signal transmission level (Low)

2

3

4

5

6 not used

ITEM

I

13

Switch setting and function

1

3sec

No.1 0

No.2 0

No communication error Communication error

No

1 O-20%

On Cff

No

-

Binary input 16 6 4 2 1

No. = 12345

0 1 0 1 0

-

Binary input 16 8 4 2 1

12345

0 0 1 1 1

1 set

0 1 1

1 0 1

Yes

5-10%

1 Yes

-

(-5dBm)

-

(-3.5dBm)

0

No BEEP No BEEP

Initial

setting

0

0

0

0

0

0

0

0

0

1

0

1

0

0

Remarks

3W

I

14

SW

I

15

SW

I

16

2-8

Page 21

Hand-set receiver volume (astages)

Fine/STD mode)

when

I 4 Reserved

!2 5 Reserved

6 Copy Ratio

7

6

for S/VI

copy

-

-

No.6

No.7

No.6

2-9

AUTO

0

0

0

-

-

100% FUNC+G

0

0

1

0

0

0

1

0

Page 22

UX-22OOCMUiCMC

Fo-216OcMu/cMc

ITEM

1 ( Resewed - - 1 0 1

2 1 Resewed - - I 0 I

SW ;

I

23 5

Resewed

Resewed

Resewed

6 1 Resewed - - 1 0 1

-

- -

-

1

Switch setting and function

1 0

-

-

7 1 Resewed - - I 1 I I

6 Resewed - - 0 I

1

Align cartridge (l-30) for color cartridge

2 Binary input 16 6 4 2 1 1

3 No. = 12345 1

4 0 1 1 1 1 (15) 1

sw

24 5 1

FAX printing with paper from manual feeder Yes No

6

7

FAX printing with color cartridge Yes

6 FAX printing when low ink detected Yes

1

Align cartridge (l-30) for black cartridge

2 Binary input 16 6 4 2 1 1

3 No. = 12345 1

SW 4 0 1 1 1 1 (15) 1

5 1

’

No

No 0

0

0

0

FUNC+G

0

0

0

FUNC+G

0

7 1 Resewed I- I- I 0 I

6 Resewed - - 0

-

SW

I

27

SW 4

DTMF detection time

1 No.1 0 0 1 1 0

2 No.2 0 1 0 1 0

3 Protection of remote reception (5 x x ) detect Yes

4 Remote reception with GE telephone Compatible 1 Not compatible 1

Remote operation code figures by external

5

6 tel (O-9) Binary input 6 4 2 1 1

7 No. = 5 6 7 6 (Data No.) 0

6 Ex 0 1 0 1 1

1 Busy tone detection ON/OFF time (Shorter duration) 350ms

Busy tone detection ON/OFF time (Longer duration)

2 No.2 0 1 0 1 1 0

Busy tone continuous sound detect time 5sec

I 5 Busy tone detect continuation sound detect No

6 Busy tone detect intermittent sound detect No Yes 0

26

Busy tone detection pulse number

7 No.7 0 0 1 1 0

6 No.8 0 1 0 1 1

50ms 60ms

1 No

1 150ms

650ms 900ms

Ppulses

4pulses Gpulses 1 Opulses

1 Osec

Yes

1OOms 120ms

2700ms 900ms

OPTION

0

0

0

1

0

OPTION

2-10

Page 23

7 ( ReSeWed

Resewed

8

1 Quiet detect

2

3

SW

4

’

30

5

Quiet

detect

6

7

8

1 Resewed

2 Resewed

;W

3 Resewed

I

31 4 Resewed

1 5

34

Reserved

6 Resewed

7 Resewed

8 Resewed

1 Resewed

2 Resewed

3 Resewed

‘w

4 Resewed

I5 5 Resewed

I

6 Resewed

7

Resewed

8 Resewed

time

start timing

-

I

1

2

Binary

input 8

4

No. = 1 2 3 4

(4sec) 0

2 1

8

(5sec)

input 8 4

Binary

No. = 5 8 7

0 1 0 0

0 1 0 1

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- -

-

-

0

OPTION

0

1

0

0

1

0

1

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0

0

0

0

0

0

n

0

0

0

0

1

0

0

0

-

0

2-11

Page 24

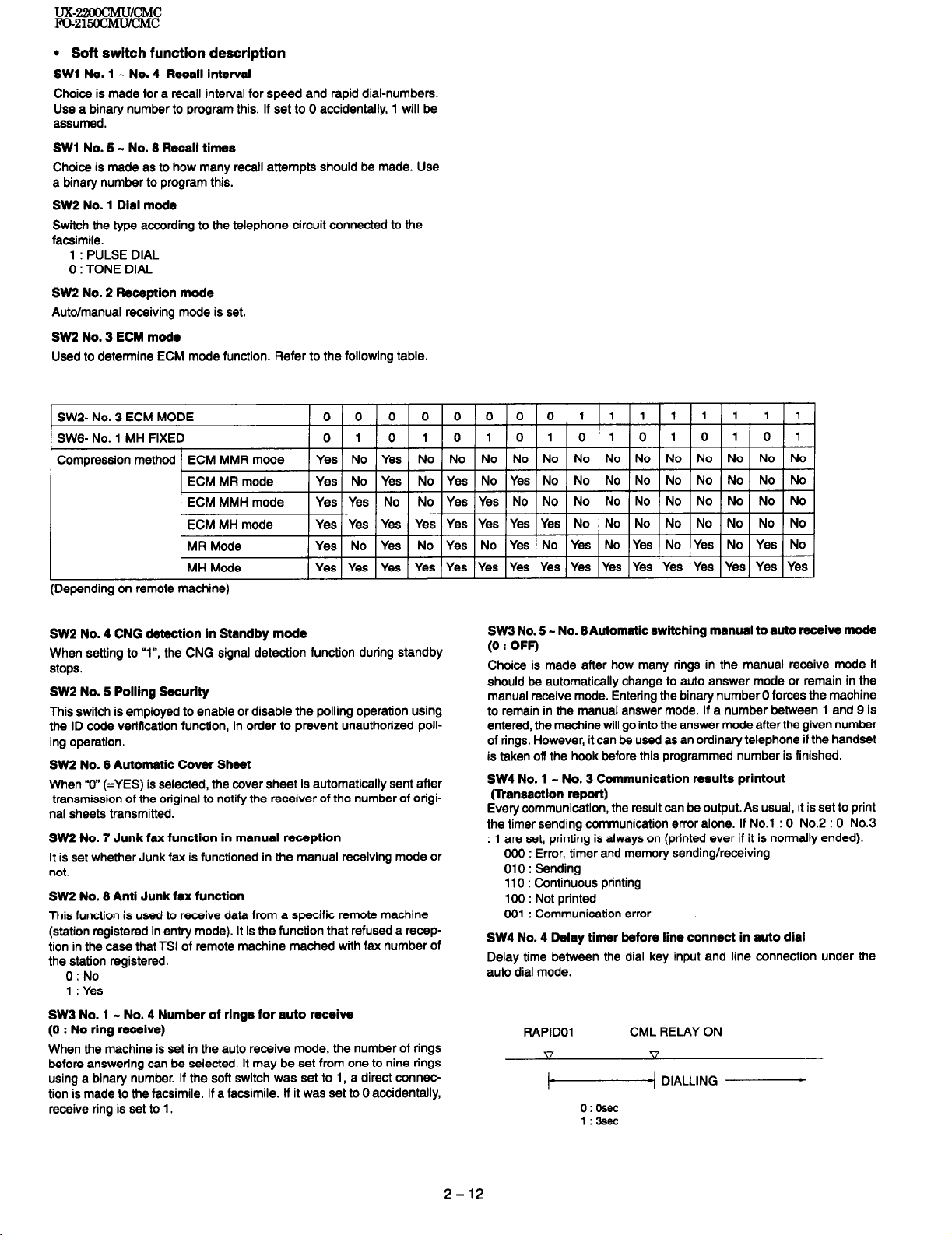

l Soft switch function description

SW1 No. 1 - No. 4 Recall interval

Choice is made for a recall interval for speed and rapid dial-numbers.

Use a binary number to program this. If set to 0 accidentally, 1 will be

assumed.

SW1 No. 5 - No. 8 Recall times

Choice is made as to how many recall attempts should be made. Use

a binary number to program this.

SW2 No. 1 Dial mode

Switch the type according to the telephone circuit connected to the

facsimile.

1 : PULSE DIAL

0 : TONE DIAL

SW2 No. 2 Reception mode

Auto/manual receiving mode is set.

SW2 No. 3 ECM mode

Used to determine ECM mode function. Refer to the following table.

ECM MMH mode

ECM MH mode

MR Mode

1 MH Mode

(Depending on remote machine)

SW2 No. 4 CNG detection in Standby mode

When setting to “l”, the CNG signal detection function during standby

stops.

SW2 No. 5 Polling Security

This switch is employed to enable or disable the polling operation using

the ID code verification function, in order to prevent unauthorlzed poll-

ing operation.

SW2 No. 8 Automatic Cover Sheet

When “0” (=YES) is selected, the cover sheet is automatically sent after

transmission of the original to notify the receiver of the number of origi-

nal sheets transmitted.

SW2 No. 7 Junk fax function in manual reception

It is set whether Junk fax is functioned in the manual receiving mode or

not.

SW2 No. 8 Anti Junk fax function

This function is used to receive data from a specific remote machine

(station registered in entry mode). It is the function that refused a reception in the case that TSI of remote machine mached with fax number of

the station registered.

0 : No

1 : Yes

SW3 No. 1 - No. 4 Number of rings for auto receive

(0 : No ring receive)

When the machine is set in the auto receive mode, the number of rings

before answering can be selected. It may be set from one to nine rings

using a binary number. If the soft switch was set to 1, a direct connection is made to the facsimile. If a facsimile. If it was set to 0 accidentally,

receive ring is set to 1.

Yes Yes No

Yes Yes Yes Yes Yes Yes Yes Yes No No No NO NO NO NO NO

Yes No Yes No Yes No Yes No Yes No Yes No Yes No Yes No

1 Yes1 Yes IYes I Yes IYes IYes IYes IYes IYes IYes IYes IYes IYes IYes Yes IYes I

No Yes Yes No No No No No No No No No NO

SW3 No. 5 - No. 8Automatic switching manual to auto receive mode

(0 : OFF)

Choice is made after how many rings in the manual receive mode it

should be automatically change to auto answer mode or remain in the

manual receive mode. Entering the binary number 0 forces the machine

to remain in the manual answer mode. If a number between 1 and 9 is

entered, the machine will go into the answer mode after the given number

of rings. However, it can be used as an ordinary telephone if the handset

is taken off the hook before this programmed number is finished.

SW4 No. 1 - No. 3 Communication results printout

(Transaction report)

Every communication, the result can be output. As usual, it is set to print

the timer sending communication error alone. If No.1 : 0 No.2 : 0 No.3

: 1 are set, printing is always on (printed ever if it is normally ended).

000 : Error, timer and memory sending/receiving

010 : Sending

110 : Continuous printing

100 : Not printed

001 : Communication error

SW4 No. 4 Delay timer before line connect in auto dial

Delay time between the dial key input and line connection under the

auto dial mode.

RAPID01

k-4 DIALLING

0 : osec

1:3sec

CML RELAY ON

2-12

Page 25

UX-22OOCMUlCMC

Fo-215OCMtJcMc

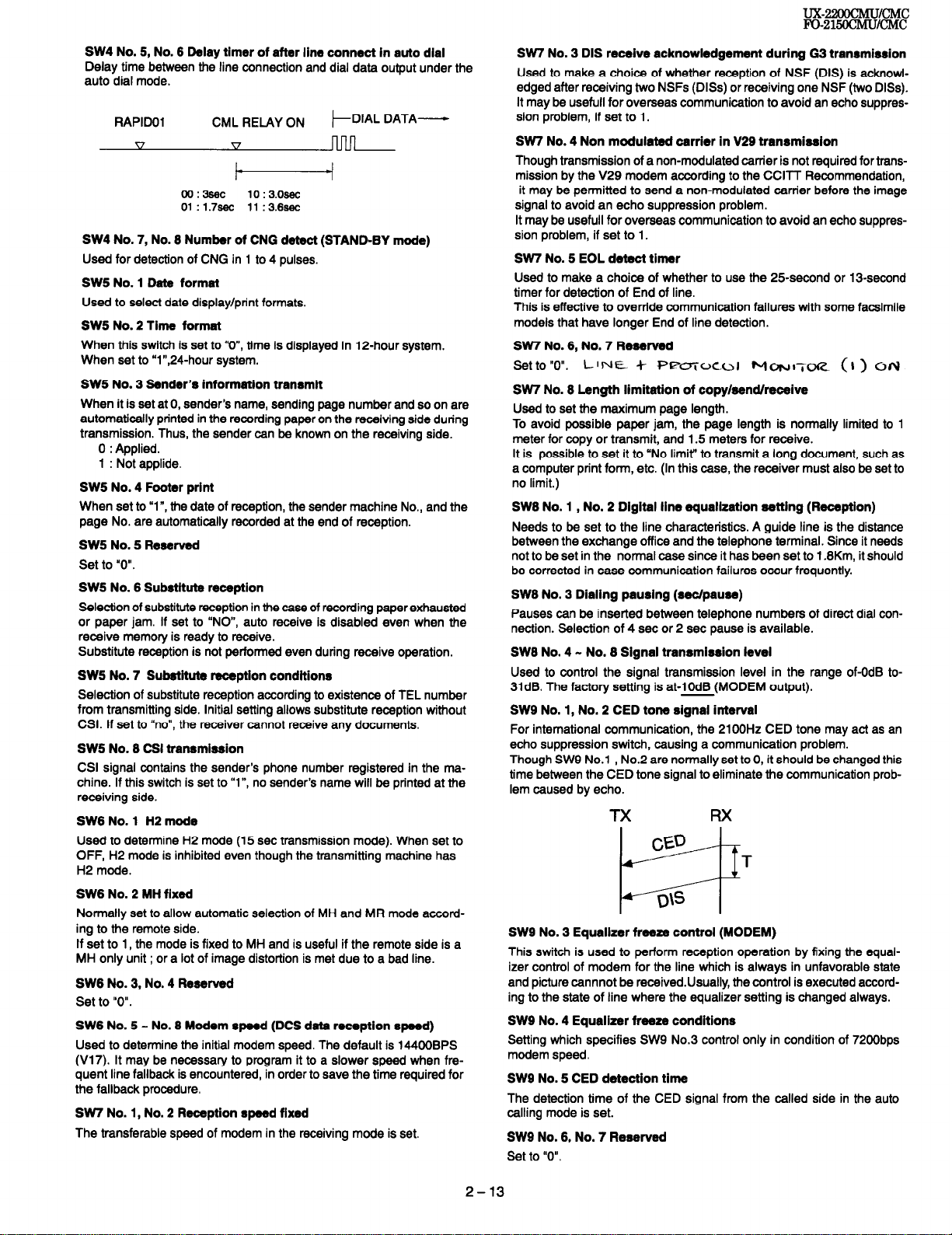

SW4 No. 5, No. 6 Delay timer of after line connect in auto dial

Delay time between the line connection and dial data output under the

auto dial mode.

RAPID01 CML RELAY ON

v V

I- -l

00:3sec

01 :1.7sec 11 :3.6sec

SW4 No. 7, No. 6 Number of CNG detect (STAND-BY mode)

Used for detection of CNG in 1 to 4 pulses.

SW5 No. 1 Dats format

Used to select date display/print formats.

SW5 No. 2 Time format

When this switch is set to “O”, time is displayed in 12-hour system.

When set to “1”,24-hour system.

SW5 No. 3 Sender’s information transmit

When it is set at 0, sender’s name, sending page number and so on are

automatically printed in the recording paper on the receiving side during

transmission. Thus, the sender can be known on the receiving side.

0 : Applied.

1 : Not applide.

SW5 No. 4 Footer print

When set to “l”, the date of reception, the sender machine No., and the

page No. are automatically recorded at the end of reception.

SW5 No. 5 Reserved

Set to ‘0”.

SW5 No. 6 Substituts reception

Selection of substitute reception in the case of recording paper exhausted

or paper jam. If set to “ND”, auto receive is disabled even when the

receive memory is ready to receive.

Substitute reception is not performed even during receive operation.

SW5 No. 7 Subsfifufe reception conditions

Selection of substitute reception according to existence of TEL number

from transmitting side. Initial setting allows substitute reception without

CSI. If set to “no”, the receiver cannot receive any documents.

SW5 No. 6 CSI transmission

CSI signal contains the sender’s phone number registered in the ma-

chine. If this switch is set to “l”, no sender’s name will be printed at the

receiving side.

SW6 No. 1 H2 mode

Used to determine H2 mode (15 set transmission mode). When set to

OFF, H2 mode is inhibited even though the transmitting machine has

H2 mode.

SW6 No. 2 MH fixed

Normally set to allow automatic selection of MH and MR mode accord-

ing to the remote side.

If set to 1, the mode is fixed to MH and is useful if the remote side is a

MH only unit ; or a lot of image distortion is met due to a bad line.

SW6 No. 3, No. 4 Reserved

Set to “0”.

SW6 No. 5 - No. 6 Modem speed (DCS data reception speed)

Used to determine the initial modem speed. The default is 144OOBPS

(V17). It may be necessary to program it to a slower speed when frequent line fallback is encountered, in order to save the time required for

the fallback procedure.

SW7 No. 1, No. 2 Reception speed fixed

The transferable speed of modem in the receiving mode is set.

10 : 3.osec

DIAL DATA-

I-

nnn

SW7 No. 3 DIS receive acknowledgement during 63 transmission

Used to make a choice of whether reception of NSF (DIS) is acknowl-

edged after receiving two NSFs (DISs) or receiving one NSF (two DISs).

It may be usefull for overseas communication to avoid an echo suppres-

sion problem, if set to 1.

SW7 No. 4 Non modulated carrier in V29 transmission

Though transmission of a non-modulated carrier is not required fortransmission by the V29 modem according to the CCllT Recommendation,

it may be permitted to send a non-modulated carrier before the image

signal to avoid an echo suppression problem.

It may be usefull for overseas communication to avoid an echo suppres-

sion problem, if set to 1.

SW7 No. 5 EOL defect timer

Used to make a choice of whether to use the 25second or 13-second

timer for detection of End of line.

This is effective to override communication failures with some facsimile

models that have longer End of line detection.

SW7 No. 6, No. 7 Reserved

Set to “0”. L’rJE + PPcriOCOl )u1oh1l~cXz (I) onl

SW7 No. 6 Length limitation of copy/send/receive

Used to set the maximum page length.

To avoid possible paper jam, the page length is normally limited to 1

meter for copy or transmit, and 1.5 meters for receive.

It is possible to set it to “No limit“ to transmit a long document, such as

a computer print form, etc. (In this case, the receiver must also be set to

no limit.)

SW6 No. 1 , No. 2 Digital line equalization setting (Reception)

Needs to be set to the line characteristics. A guide line is the distance

between the exchange office and the telephone terminal. Since it needs

not to be set in the normal case since it has been set to 1.6Km, it should

be corrected in case communication failures occur frequently.

SW6 No. 3 Dialing pausing (se&pause)

Pauses can be inserted between telephone numbers of direct dial connection. Selection of 4 set or 2 set pause is available.

SW6 No. 4 - No. 6 Signal transmission level

Used to control the signal transmission level in the range of-OdB to31dB. The factory setting is at-10dB (MODEM output).

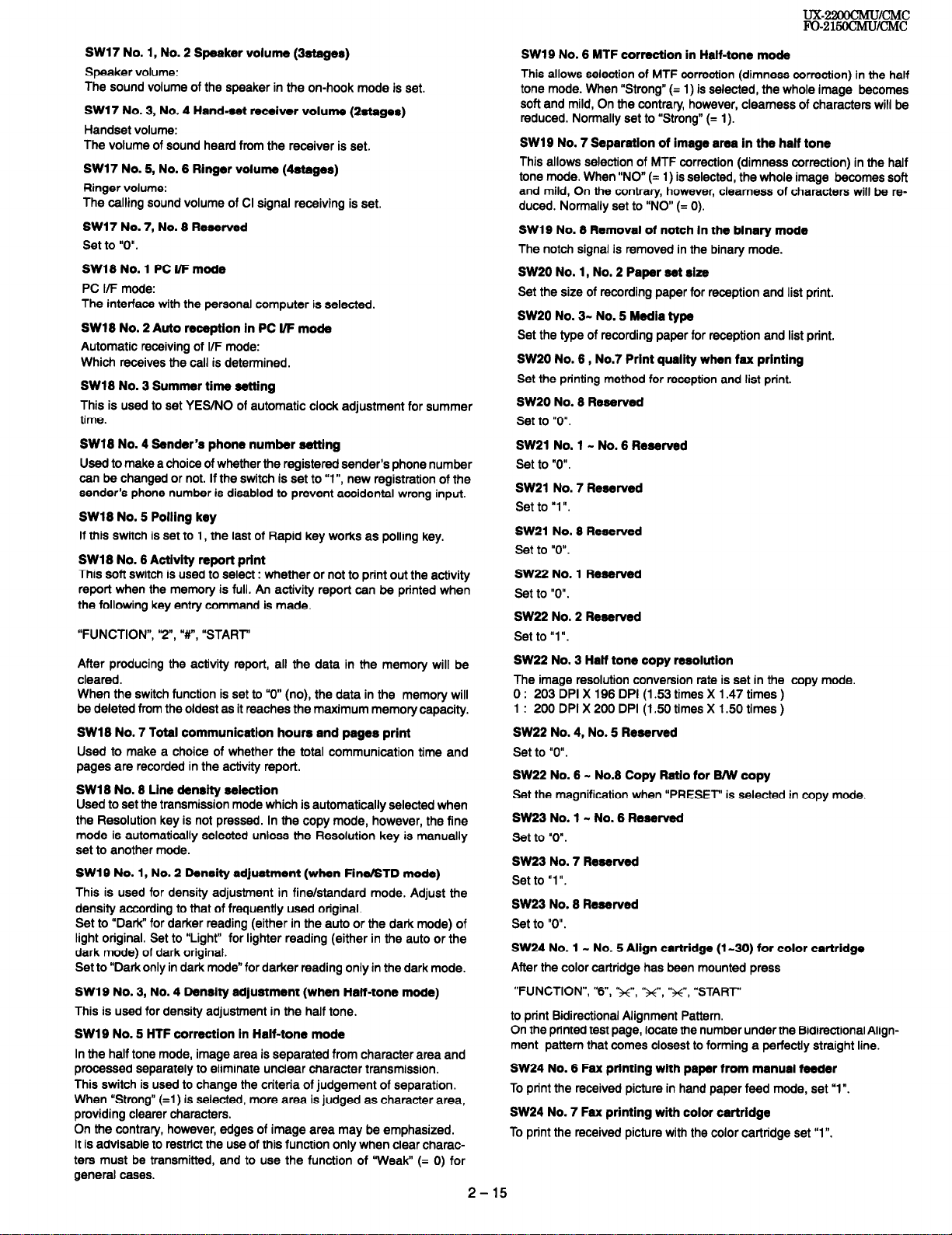

SW9 No. 1, No. 2 CED tone signal interval

For international communication, the 2100Hz CED tone may act as an

echo suppression switch, causing a communication problem.

Though SW9 No.1 , No.2 are normally set to 0, it should be changed this

time between the CED tone signal to eliminate the communication problem caused by echo.

TX RX

cw

T

INS

FP

SW9 No. 3 Equalizer freeze control (MODEM)

This switch is used to perform reception operation by fixing the equalizer control of modem for the line which is always in unfavorable state

and picture cannnot be received.Usually, the control is executed according to the state of line where the equalizer setting is changed always.

SW9 No. 4 Equalizer freeze conditions

Setting which specifies SW9 No.3 control only in condition of 7200bps

modem speed.

SW9 No. 6 CED detection time

The detection time of the CED signal from the called side in the auto

calling mode is set.

SW9 No. 6, No. 7 Resenred

Set to “0”.

2-13

Page 26

LJX-22oocMu/cMC

Fo-215clcMu/cMc

SW9 No. 8 Bwy tone detection (after auto dial)

Use to set busy tone detection in auto dialing.

SW10 No. 1, No. 2 Resewed

set to ‘0”.

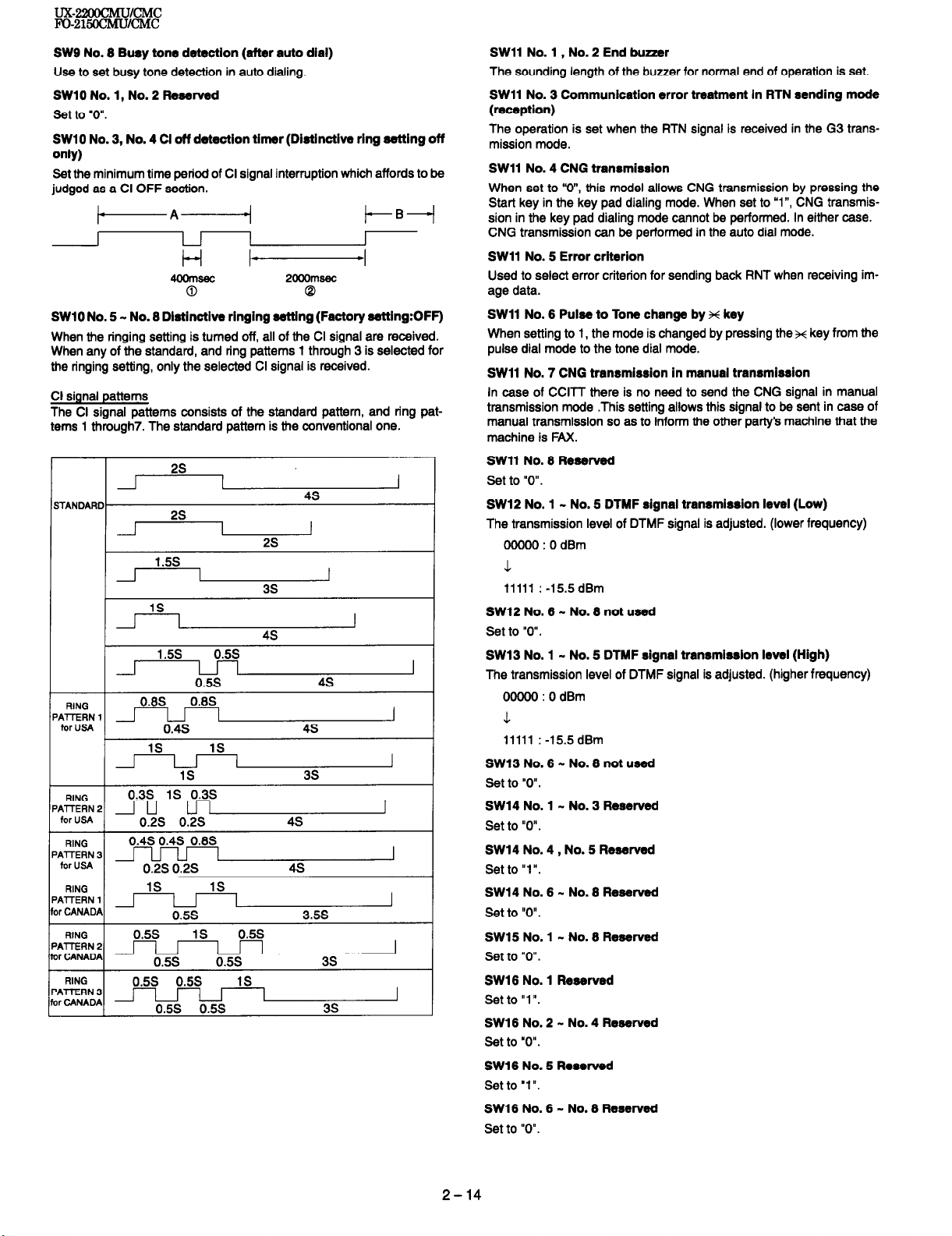

SW10 No. 3, No. 4 Cl oft detection timer (Distinctive ring setting off

only)

Set the minimum time period of Cl signal interruption which affords to be

judged as a Cl OFF section.

+------I

I-B-I

1 l-l

t-l I-

4oomsac

0 Q

SW10 No. 5 - No. 6 Distinctive ringing setting (Factory setting:OFF)

When the ringing setting is turned off, all of the Cl signal are received.

When any of the standard, and ring patterns 1 through 3 is selected for

the ringing setting, only the selected Cl signal is received.

Cl signal patterns

The Cl signal patterns

terns 1 through7. The standard pattern is the conventional one.

2s

iTANDARD

of the standard

2000msec

4s

I

and ring pat-

Fe--d

RING

'ATERN 1

for USA

RING

‘AlTERN 1 u

for USA

RING

AlTERN 3 1

for USA

RING

AlTERN

11 CANADA

RING

AllERN 2

,r CANADA

RING

AllERN 3

lr CANADA

OXIS

0.3s 1s 0.3s

0.2s 0.2s 4s

0.4s 0.4s O.&S

0.2s 0.2s 4s

1

0.5s 1s

0.5s 0.5s 1s

0.8s

0.4s

1s 1s

1s

1s 1s

0.5s

0.5s 0.5s

0.5s 0.5s

0.5s

4s

3s

3.5s

I

3s

3s

SW11 No. 1, No. 2 End buzzer

The sounding length of the buzzer for normal end of operation is set.

SW11 No. 3 Communication error treatment in RTN sending mode

(reception)

The operation is set when the RTN signal is received in the G3 trans-

mission mode.

SW11 No. 4 CNG transmission

When set to “O”, this model allows CNG transmission by pressing the

Start key in the key pad dialing mode. When set to “l”, CNG transmission in the key pad dialing mode cannot be performed. In either case.

CNG transmission can be performed in the auto dial mode.

SW11 No. 5 Error criterion

Used to select error criterion for sending back RNT when receiving im-

age data.

SW11 No. 6 Pulse to Tone change by x key

When setting to 1, the mode is changed by pressing the % key from the

pulse dial mode to the tone dial mode.

SW11 No. 7 CNG transmission in manual transmission

In case of CCllT there is no need to send the CNG signal in manual

transmission mode .This setting allows this signal to be sent in case of

manual transmission SD as to inform the other party’s machine that the

machine is FAX.

SW11 No. 6 Reeetved

Set to “0”.

SW12 No. 1 - No. 6 DTMF signal transmission level (Low)

The transmission level of DTMF signal is adjusted. (lower frequency)

00000 : 0 dBm

J

11111 : -15.5dBm

SW12 No. 6 - No. 6 not used

Set to “0”.

SW13 No. 1 - No. 5 DTMF signal transmission level (High)

The transmission level of DTMF signal is adjusted. (higher frequency)

0OOOO:OdBm

3.

11111 : -15.5 dBm

SW13 No. 6 - No. 6 not used

Set to “0”.

SW14 No. 1 - No. 3 Reserved

Set to “0”.

SW14 No. 4, No. 5 Reserved

Set to “1”.

SW14 No. 6 - No. 6 Resewed

Set to “0”.

SW15 No. 1 - No. 6 Reserved

Set tD “0”.

SW16 No. 1 Reserved

Set to “1 I’.

SW16 No. 2 - No. 4 Reserved

set to ‘0”.

SW16 No. 5 Reserved

Set to ‘1”.

SW16 No. 6 - No. 6 Reserved

Set to “0”.

2-14

Page 27

UX-ICMC

FO-215Oc!hIuK!Mc

SW17 No. 1, No. 2 Speaker volume (3stage~r)

Speaker volume:

The sound volume of the speaker in the on-hook mode is set.

SW17 No. 3, No. 4 Hand-set receiver volume (2stages)

Handset volume:

The volume of sound heard from the receiver is set.

SW17 No. 5, No. 6 Ringer volume (4stages)

Ringer volume:

The calling sound volume of Cl signal receiving is set.

SW17 No. 7, No. 6 Reserved

Set to “0”.

SW16 No. 1 PC l/F mode

PC I/F mode:

The interface with the personal computer is selected.

SW16 No. 2 Auto reception in PC l/F mode

Automatic receiving of I/F mode:

Which receives the call is determined.

SW16 No. 3 Summer time setting

This is used to set YES/NO of automatic clock adjustment for summer

time.

SW16 No. 4 Sender’s phone number setting

Used to make a choice of whether the registered sender’s phone number

can be changed or not. If the switch is set to “l”, new registration of the

sender’s phone number is disabled to prevent accidental wrong input.

SW16 No. 5 Polling key

If this switch is set to 1, the last of Rapid key works as polling key.

SW16 No. 6 Activity report print

This soft switch is used to select : whether or not to print out the activity

report when the memory is full. An activity report can be printed when

the following key entry command is made.

“FUNCTION”, ‘Z”, “#“, “START”

After producing the activity report, all the data in the memory will be

cleared.

When the switch function is set to “0” (no), the data in the memory will

be deleted from the oldest as it reaches the maximum memory capacity.

SW16 No. 7 Total communication hours and pages print

Used to make a choice of whether the total communication time and

pages are recorded in the activity report.

SW16 No. 6 Line density selection

Used to set the transmission mode which is automatically selected when

the Resolution key is not pressed. In the copy mode, however, the fine

mode is automatically selected unless the Resolution key is manually

set to another mode.

SWlQ No. 1, No. 2 Density adjustment (when Fine/STD mode)

This is used for density adjustment in fine/standard mode. Adjust the

density according to that of frequently used original.

Set to “Dark” for darker reading (either in the auto or the dark mode) of

light original. Set to “Light” for lighter reading (either in the auto or the

dark mode) of dark original.

Set to “Dark only in dark mode” for darker reading only in the dark mode.

SW19 No. 3, No. 4 Density adjustment (when Half-tone mode)

This is used for density adjustment in the half tone.

SW19 No. 5 HTF correction in Half-tone mode

In the half tone mode, image area is separated from character area and

processed separately to eliminate unclear character transmission.

This switch is used to change the criteria of judgement of separation.

When “Strong” (=l) is selected, more area is judged as character area,

providing clearer characters.

On the contrary, however, edges of image area may be emphasized.

It is advisable to restrict the use of this function only when clear charac-

ters must be transmitted, and to use the function of ‘Weak” (= 0) for

general cases.

SW19 No. 6 MTF correction in Half-tone mode

This allows selection of MTF correction (dimness correction) in the half

tone mode. When “Strong” (= 1) is selected, the whole image becomes

soft and mild, On the contrary, however, clearness of characters will be

reduced. Normally set to “Strong” (= 1).

SW19 No. 7 Separation of image area in the half tone

This allows selection of MTF correction (dimness correction) in the half

tone mode. When “ND” (= 1) is selected, the whole image becomes soft

and mild, On the contrary, however, clearness of characters will be re-

duced. Normally set to “NO” (= 0).

SW19 No. 6 Removal of notch in the binary mode

The notch signal is removed in the binary mode.

SW20 No. 1, No. 2 Paper se4 size

Set the size of recording paper for reception and list print.

SW20 No. 3- No. 5 Media type

Set the type of recording paper for reception and list print.

SW20 No. 6 , No.7 Print quality when fax printing

Set the printing method for reception and list print.

SW20 No. 6 Reserved

Set to “0”.

SW21 No. 1 - No. 6 Reserved

Set to “0”.

SW21 No. 7 Reserved

Set to “1”.

SW21 No. 6 Reserved

Set to “0”.

SW22 No. 1 Reserved

Set to “0”.

SW22 No. 2 Reserved

Set to “1 ‘I.

SW22 No. 3 Half tone copy resolution

The image resolution conversion rate is set in the copy mode.

0 : 203 DPI X 196 DPI (1.53 times X 1.47 times )

1 : 200 DPI X 200 DPI (1.50 times X 1.50 times )

SW22 No. 4, No. 5 Reserved

Set to “0”.

SW22 No. 6 - No.6 Copy Ratio for B/W copy

Set the magnification when “PRESET’ is selected in copy mode.

SW23 No. 1 - No. 6 Reserved

Set to “0”.

SW23 No. 7 Reserved

Set to “1”.

SW23 No. 6 RoseNed

Set to “0”.

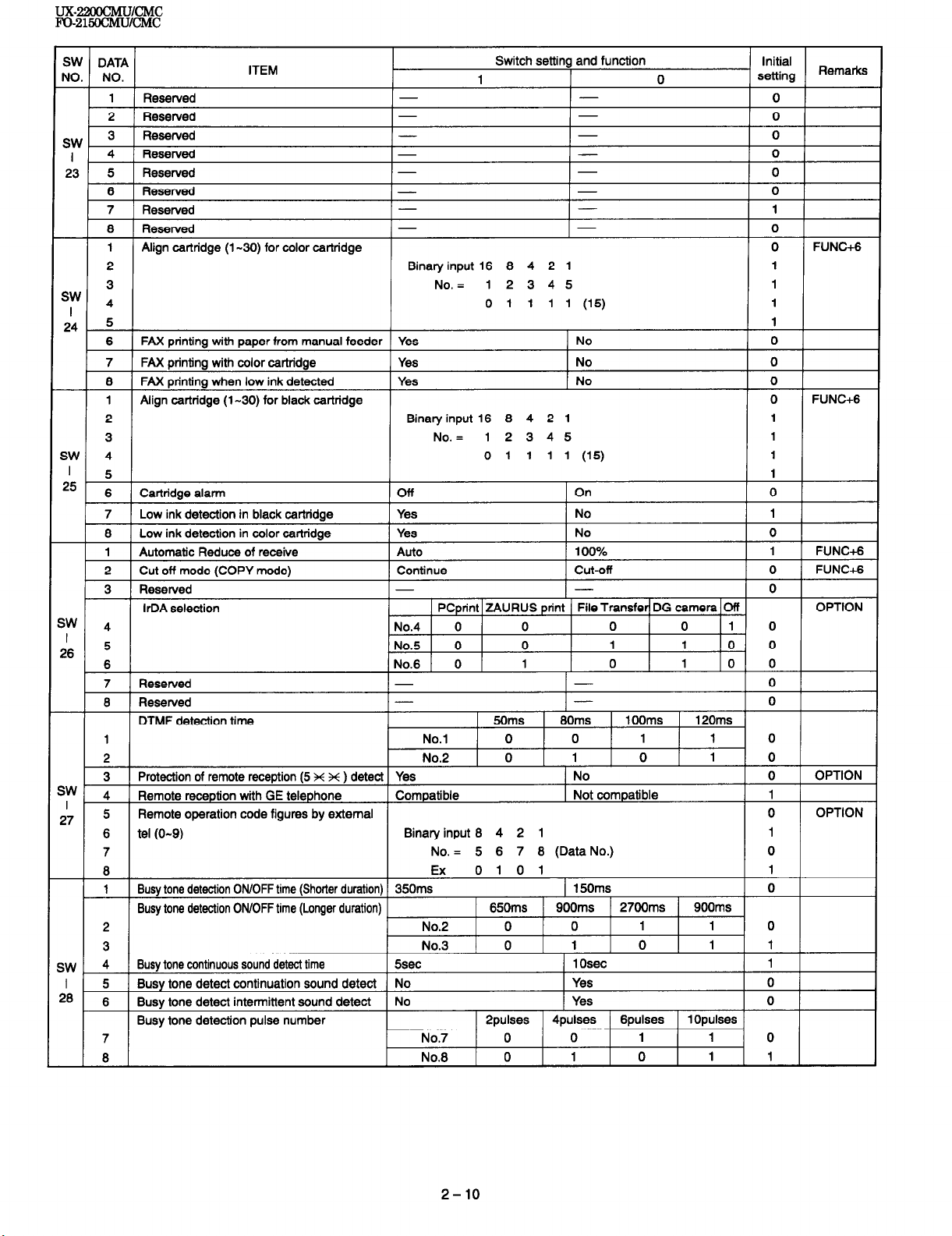

SW24 No. 1 - No. 5 Align cartridge (l-30) for color cartridge

After the color cartridge has been mounted press

“FUNCTION”, “6, ‘k”, ‘k”, ‘k”, “START’

to print Bidirectional Alignment Pattern.

On the printed test page, locate the number under the BidirectionalAlignment pattern that comes closest to forming a perfectly straight line.

SW24 No. 6 Fax prfnting wlth paper from manual feeder

To print the received picture in hand paper feed mode, set ‘1”.

SW24 No. 7 Fax printing with color cartridge

To print the received picture with the color cartridge set “1”.

2-15

Page 28

SW24 No. 8 Fax printing when low ink detected

To print the received picture in “Low Ink” state, set “1’.

SW25 No. 1 - No. 5 Align cartridge (l-30) for black cartridge

After the black cartridge has been mounted press

“FUNCTION”, “8, %“, “H”, x’, “START”

to print Bidirectional Alignment Pattern.

On the printed test page, locate the number under the Bidirectional Alignment pattern that comes closest to forming a perfectly straight line.

SW25 No. 8 Cartridge alarm

Set existence/nonexistence of alarm tone alarming the failure of return

of cartridge to the home position.

SW25 No. 7 Low ink detection in black cartridge

Set detectionlnondetection of black ink “Low ink”.

SW25 No. 8 Low ink detection in color cartridge

Set detectionlnondetection of color ink “Low ink”.

SW28 No. 1 Automatic reduce of receive

If set to 1, it is reduced automatically when receiving.

SW28 No. 2 Cut off mode (COPY mode)

Whether the excessive part is printed on the next recording paper or

discarded is selected to copy a document which is longer than the recording paper.

SW28 No. 3 Reserved

set to “0”.

SW28 No. 4 - No. 8 IrDA selection

Set the other party of Ir communication.

SW28 No. 7, No. 8 Reserved

Set to “0”.

SW27 No. 1, No. 2 DTMF detection time

Used to set detect time of DTMF (Dual Tone Multi Frequency) used in

remote reception (5 H H).

The longer the detect time is, the less the error detection is caused by

noises.

SW27 No. 3 Protection of remote reception (5 x x) detect

Used to set the function of remote reception (5 K x). When set to “l”,

the remote reception functon is disabled.

SW27 No. 4 Remote reception with GE telephone

(Corresponding to TEL made by GE) P.B.X.

“1”: Compatible with TEL mode by GE

“0”: Not compatible

l When sending (5 x xc) for remote reception with a GE manufactured

telephone remote reception may not take place because of special

specifications in their DTMF.

To overcome this, a soft SW is provided to change the modem setting to allow for remote reception.

l If this soft SW is set to “l”, other telephone sets may be adversely

affected.

SW27 No. 5 - No. 8 Remote operation code figures by external tel

(8-Q)

Remote operation codes can be changes from 0 through 9. If set to

greater than 9, it defaults to 9. The “5 x ++” is not changed.

Ex-7~ x (Default : 5 H x).

SW28 No. 1 Busy tone detection ON/OFF time (Shorter duration)

The initial value of detection is set according to electric condition.

The set value is changed according to the local switch board. (Erroneous detection of sound is reduced.)

Normally the upper limit is set to 2700msec. and the lower limit to

15Omsec.

If erroneous detection is caused by sound, etc., adjust the detection

range.

The lower limit can be set in the range of 350msec to 150msec.

SW28 No. 2, No. 3 Busy tone detection ON/OFF time

(Longer duration)

Similarly to SW-28 No.1, the set value can be varied.

The upper limit can be set in the range of 65Omsec to 2700msec.

SW28 No. 4 Busy tone continuous sound detect tima

Set detecting time busy tone for 5 seconds or as is PlT.

SW28 No. 5 Busy tone detect continuation sound detect

Used to select detection of the continuous sound of certain frequency.

SW28 No. 8 Busy tone detect intermittent sound detect

Used to select detection of the intermittent sound of certain frequency.

SW28 No. 7, No. 8 Busy tone detection pulse number

Used to set detection of Busy tone intermittent sounds.

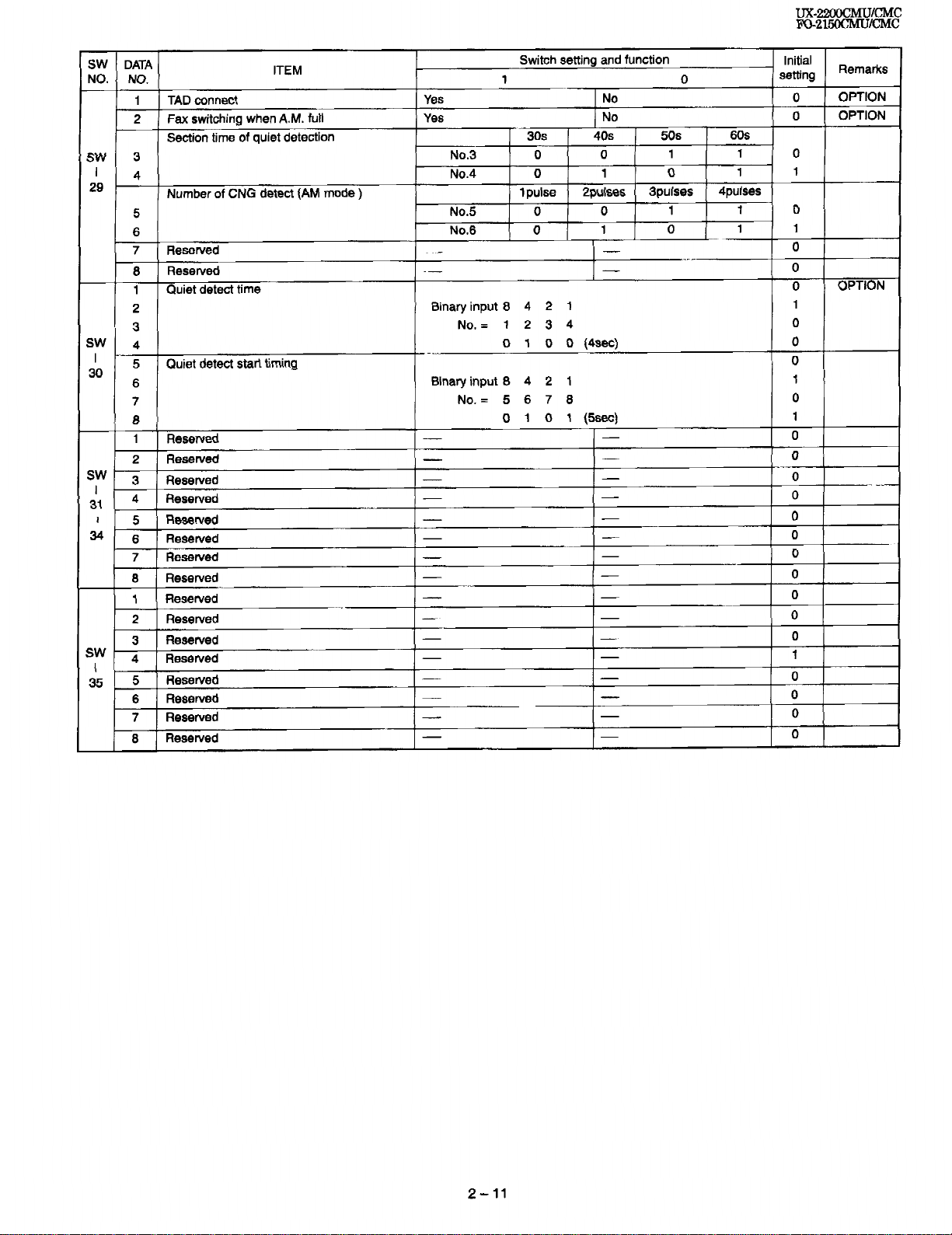

SW29 No. 1 TAD connect

When connecting the answering machine to the extension telephone

jack.

Set to “1 I’.

SW29 No. 2 Fax switching when A.M.full

If the answering machine’s memory (tape) is full and there is no re-

sponse, the machine automatically switches to Fax reception.

SW29 No. 3, No. 4 Section tims of quiet detection

The switch which sets the time from the start of detection function to the

end of the function.

SW29 No. 5, No. 6 Number of CNG detect (AM mode)

Used for detection of CNG in 1 to 4 pulses.

SW29 No. 7, No. 8 Reserved

Set to “0”.

SW38 No. 1 - No. 4 Quiet detect time

When an answering machine is connected, if a no sound state is de-

tected for a certain period of time, the machine judges it as a transmission from a facsimile machine and automatically swiches to the Fax

mode.

SW30 No. 5 - No. 8 Quiet detect start timing

Inserts a pause before commencing quiet detection.

SW31 No. 1 - No. 8 Reserved

Set to “0”.

SW32 No. 1 - No. 8 ReaeNed

Set to “0”.

SW33 No. 1 - No. 8 Reserved

Set to “0”.

SW34 No. 1 - No. 8 Reserved

Set to “0”.

SW35 No. 1 - No. 3 Reserved

Set to “0”.

SW35 No. 4 Reserved

Set to “1”.

SW35 No. 5 - No. 8 Reserved

Set to “0”.

2-16

Page 29

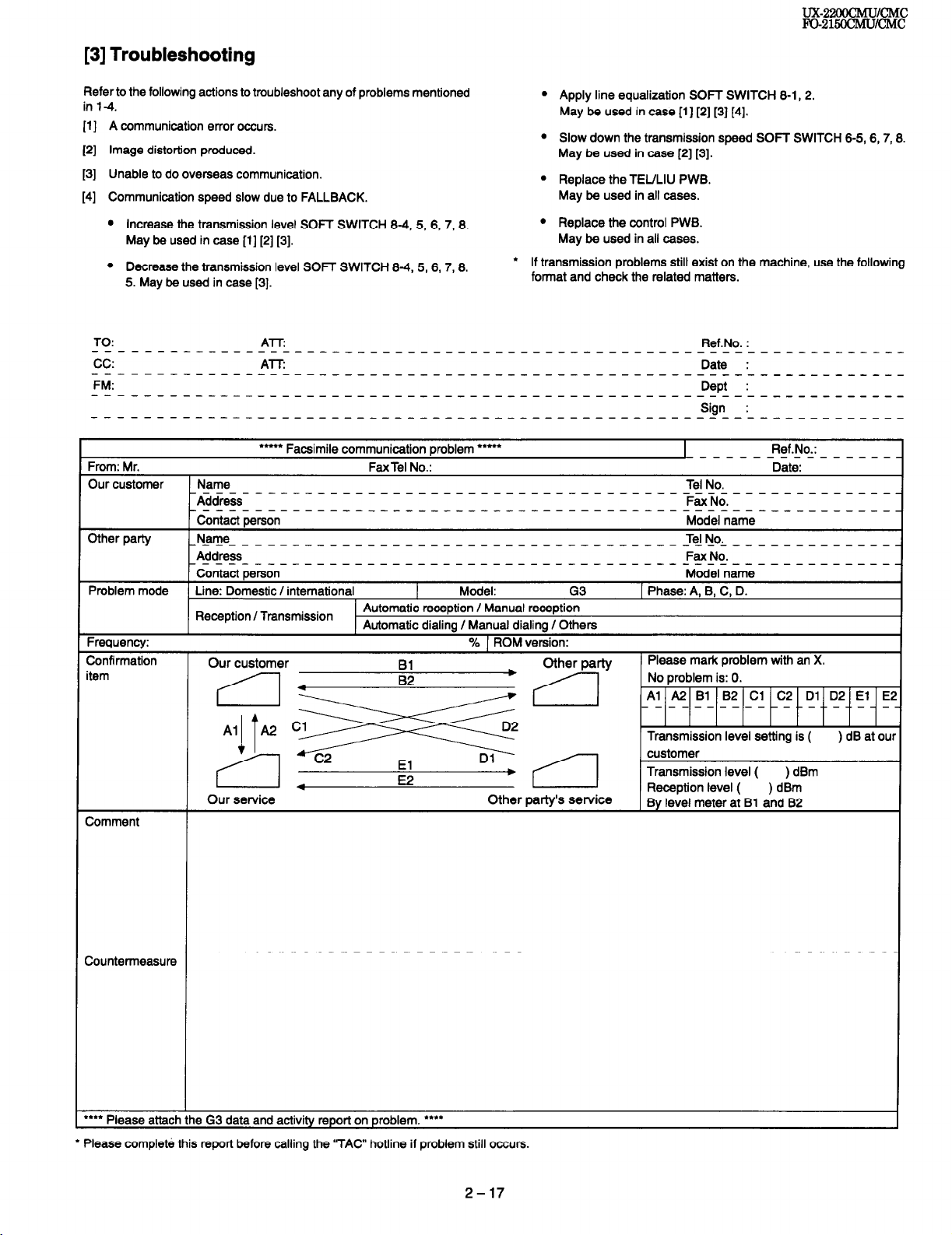

[3] Troubleshooting

UX?22WCMU~CMC

F+o-215ocMu/cMc

Refer to the following actions to troubleshoot any of problems mentioned

in 14.

[l] A communication error occurs.

[2] Image distortion produced.

[3] Unable to do overseas communication.

[4] Communication speed slow due to FALLBACK.

l Increase the transmission level SOFT SWITCH 845, 8,7,8.

May be used in case [l] [2] [3].

l Decrease the transmission level SOFT SWITCH 84,5,8,7,8.

5. May be used in case [3].

TO:

-------------------_____-----------------------cc: ATT:

--------------_-________--_-----___------------FM:

------------____________--_--_---_--------_-----

ATTI

l **** Facsimile communication problem *****

Apply line equalization SOFT SWITCH 8-1, 2.

May be used in case [l] [2] [3] [4].

Slow down the transmission speed SOFT SWITCH 6-5, 6,7,8.

May be used in case [2] [3].

Replace the TEULIU PWB.

May be used in all cases.

Replace the control PWB.

May be used in all cases.

l If transmission problems still exist on the machine, use the following

format and check the related matters.

Ref.No.

----

----

---Sign

--_-

I

---------------

Date

Dept

--------_--__

-------------

-------------

-----------_

Ref.No.:

From: Mr. FaxTel No.: Date:

Our customer

Name

-------------------------------------------------------Address

---------------------------------------------------

Contact person

Other party

_N_ame____________________________________TelNo-_____________

Address

------------------------------------------~-------------

Contact person

Problem mode Line: Domestic I international Model: G3

Reception / Transmission

Automatic reception / Manual reception

Automatic dialing / Manual dialing I Others

Tel No.

Fax No.

Model name

Fax No

Model name

1 Phase: A, B, C, D.

Frequency: % 1 ROMversion:

Confirmation

item

Our customer

Please mark problem with an X.

_-

2

Our service Other party’s service

Comment

----------------------------------------------------------------

Countermeasure

l *** Please attach the G3 data and activity report on problem. l ““*

l Please complete this report before calling the “TAC” hotline if problem still occurs.

r

Transmission level ( ) dBm

Reception level ( ) dBm

By level meter at Bl and 82

2-17

Page 30

ux-m/cMc

IV-215OCMuKMc

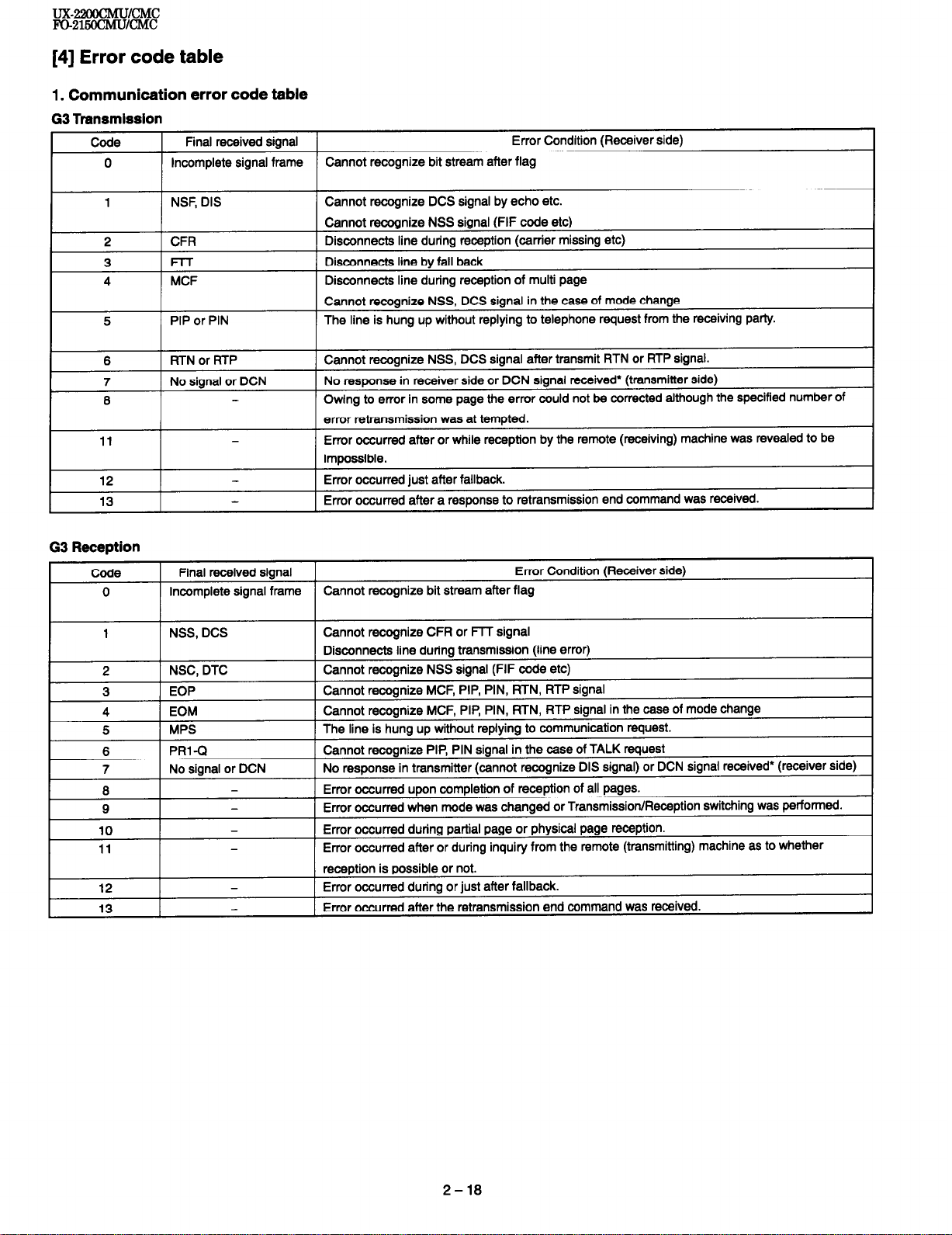

[4] Error code table

1. Communication error code table

G3 Transmission

Code

0

Final received signal Error Condition (Receiver side)

Incomplete signal frame

Cannot recognize bit stream after flag

1

2 CFR

3

4 MCF

5

6

7

3

11

12

13

G3 Reception

NSF, DIS Cannot recognize DCS signal by echo etc.

Cannot recognize NSS signal (FIF code etc)

Disconnects line during reception (carrier missing etc)

Frr

PIP or PIN

KTN or RTP

No signal or DCN

-

Disconnects line by fall back

Disconnects line during reception of multi page

Cannot recognize NSS, DCS signal in the case of mode change

The line is hung up without replying to telephone request from the receiving party.

Cannot recognize NSS, DCS signal after transmit RTN or RTP signal.

No response in receiver side or DCN signal received* (transmitter side)

Owlng to error in some page the error could not be corrected although the specified number of

error retransmission was at tempted.

Error occurred after or while reception by the remote (receiving) machine was revealed to be

impossible.

Error occurred just after fallback.

Error occurred after a response to retransmission end command was received.

Error occurred during partial page or physical page reception.

Error occurred after or during inquiry from the remote (transmitting) machine as to whether

reception is possible or not.

Error occurred during or just after fallback.

Error occurred after the retransmission end command was received.

2-18

Page 31

CHAPTER 3. MECHANISM BLOCKS

[l] General description

1. Document feed block and diagram

Separator rubber

Paper feed spring

I

3-2. Automatic document feed

1) Use of the paper feed roller and separation rubber plate ensures

error-free transport and separation of documents. The plate spring

presses the document to the paper feed roller to assure smooth feeding of the document.