Page 1

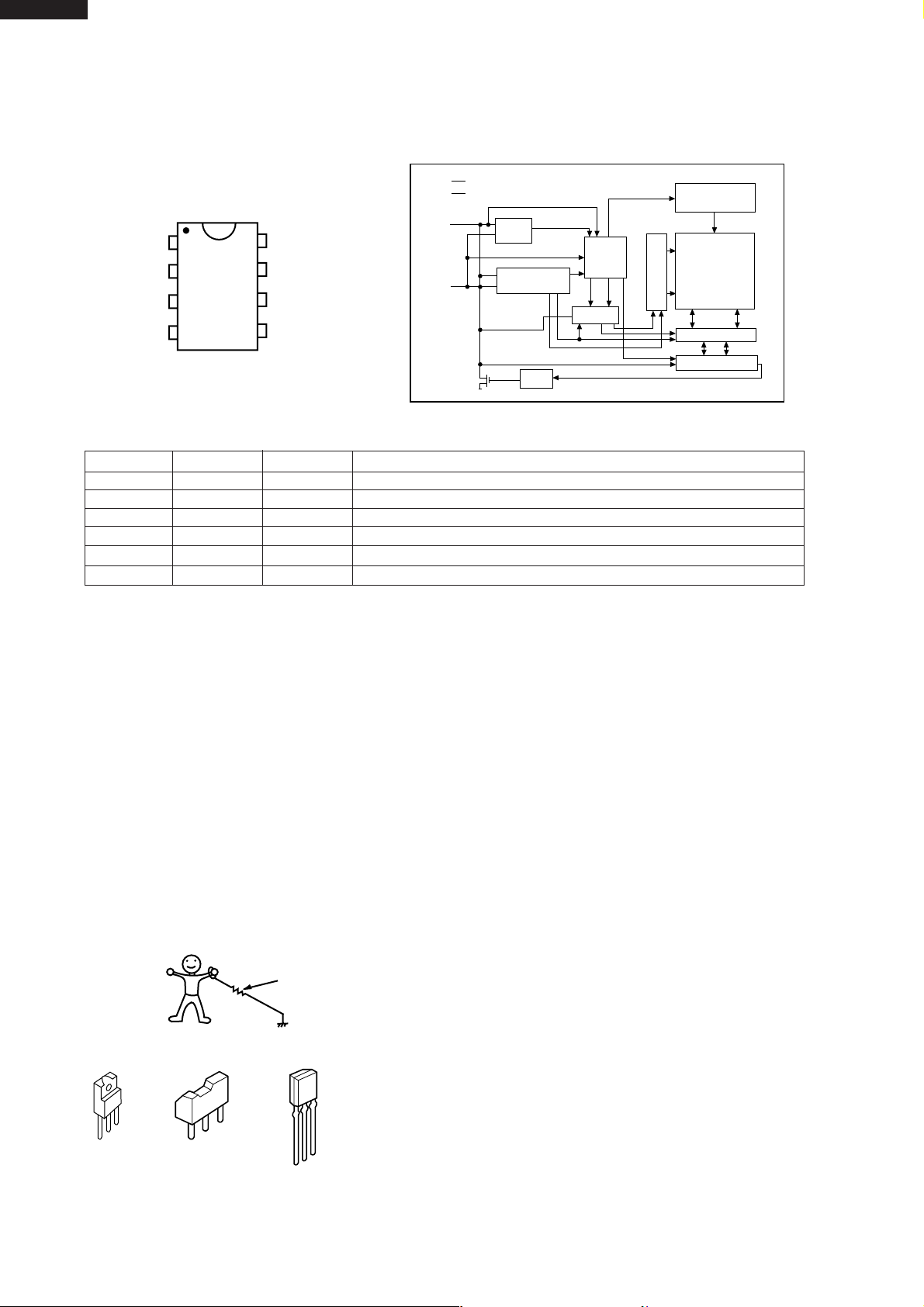

1900W/R-2

R-22AT

R-24AT

SERVICE MANUAL

SY520R24ATK//

COMMERCIAL

MICROWAVE OVEN

DOUBLE

EXPRESS

QUANTITY

DEFROST

11

1

12

2

13

3

14

4

15

5

16

6

17

7

18

8

19

9

20

4AT

POWER LEVEL

0

MANUAL/

REHEAT

STOP / CLEAR

START

SET

CHECK

VOLUME

MODELS

R-22AT

R-24AT

R-24AT

In interests of user-safety the oven should be restored to its

original condition and only parts identical to those specified

should be used.

This revised service manual is applied to

R-22AT from serial No. 050505509 and

R-24AT from serial No. 050508658.

Because many parts have been changed to improve quality of these models from May 2005 production.

And the changed parts are not interchangeable. Please use this service manual for above products.

For old products, please use old service manual (No.SX910R24ATK//) and technical reports.

TABLE OF CONTENTS

Page

SERVICING ................................................................................................................. INSIDE FRONT COVER

CAUTION, MICROWAVE RADIATION ............................................................................................................ 1

WARNING .......................................................................................................................................................... 1

PRODUCT SPECIFICATIONS ......................................................................................................................... 2

GENERAL INFORMATION ................................................................................................................................ 2

APPEARANCE VIEW ....................................................................................................................................... 3

OPERATION SEQUENCE ................................................................................................................................ 4

FUNCTION OF IMPORTANT COMPONENTS ................................................................................................ 6

TROUBLESHOOTING GUIDE .......................................................................................................................... 7

TEST PROCEDURE .......................................................................................................................................... 8

TOUCH CONTROL PANEL ASSEMBLY ........................................................................................................ 16

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE ........................................................... 24

MICROWAVE MEASUREMENT .................................................................................................................... 31

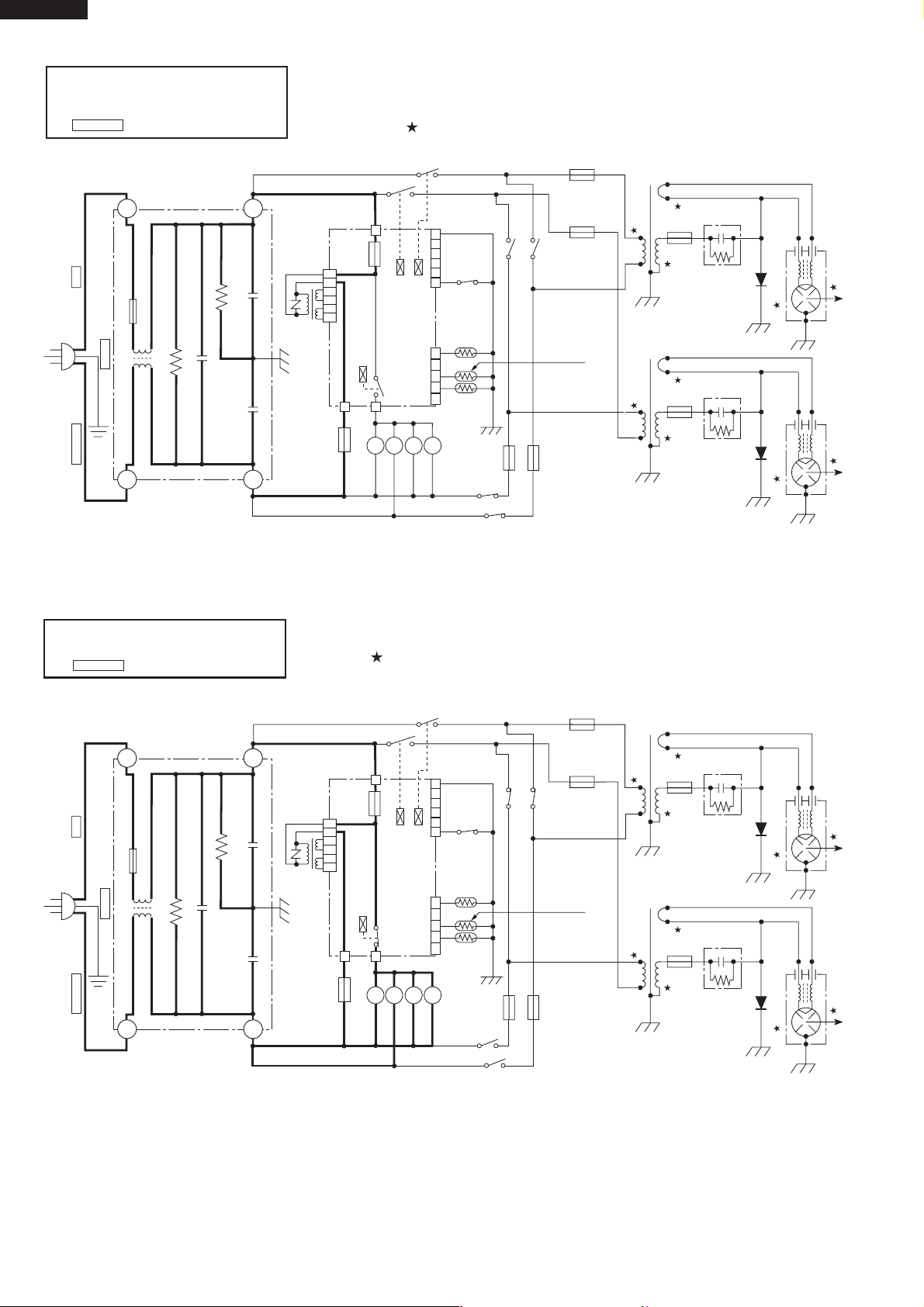

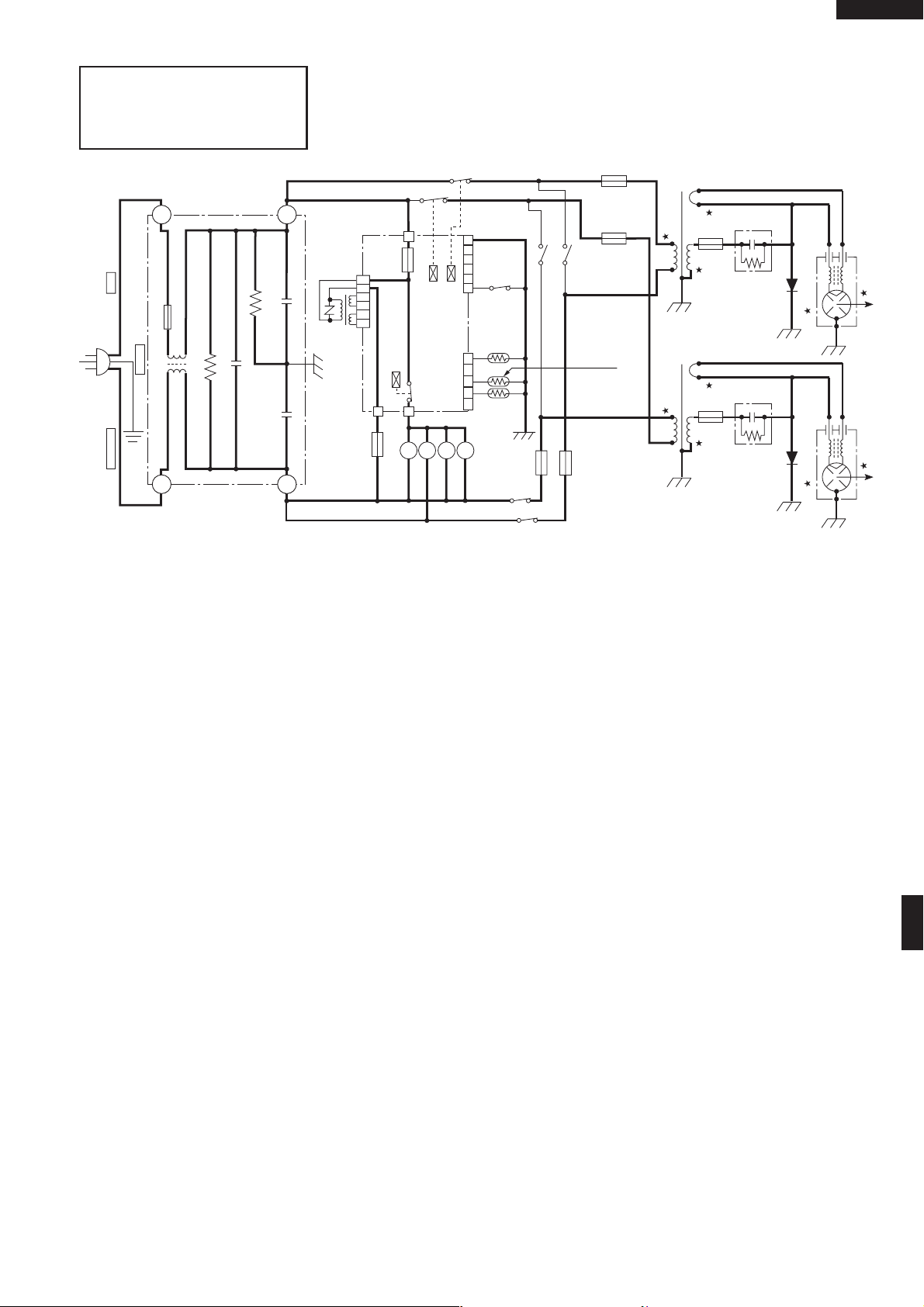

WIRING DIAGRAM ......................................................................................................................................... 32

PICTORIAL DIAGRAM ................................................................................................................................... 34

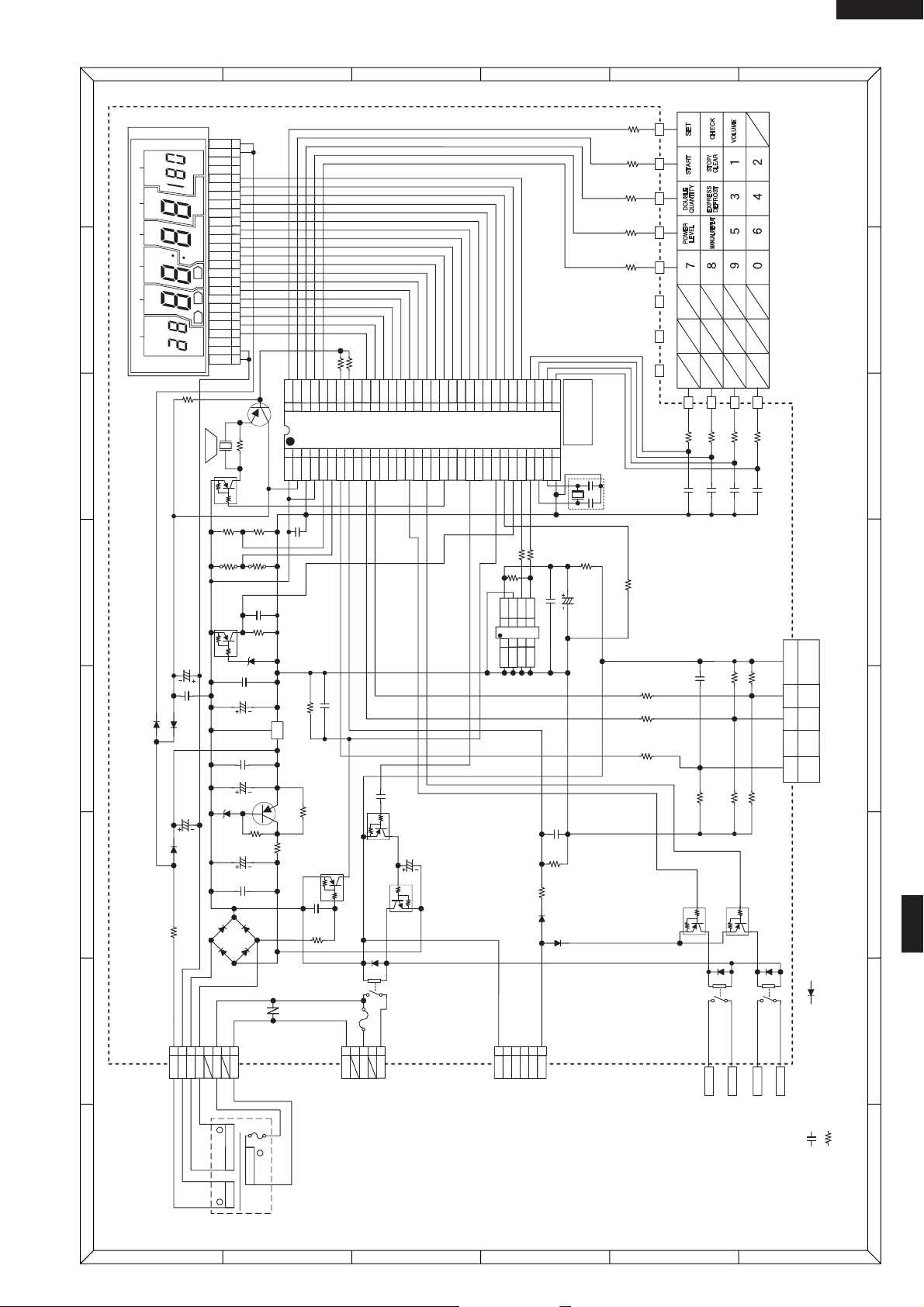

CONTROL PANEL CIRCUIT ...........................................................................................................................35

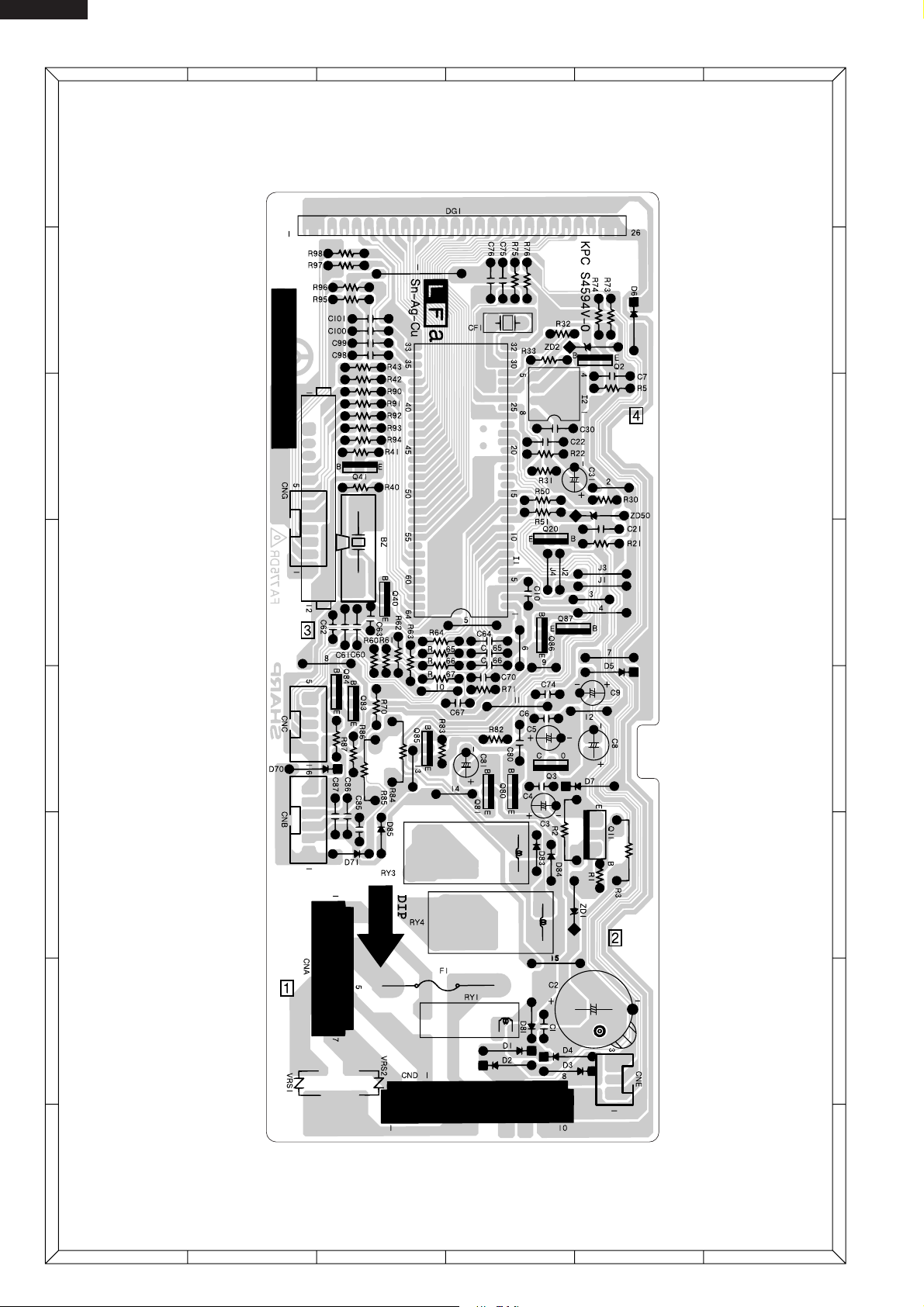

PRINTED WIRING BOARD .............................................................................................................................36

PARTS LIST ................................................................................................................................................... 37

SHARP CORPORATION

Page 2

R-22AT

R-24AT

SERVICING

WARNING TO SERVICE PERSONNEL

Microwave ovens contain circuitry capable of producing very high voltage and current. Contact with following parts

will result in electrocution.

High voltage capacitors, High voltage transformers, Magnetrons, High voltage rectifier assembly, High voltage

fuses, High voltage harness.

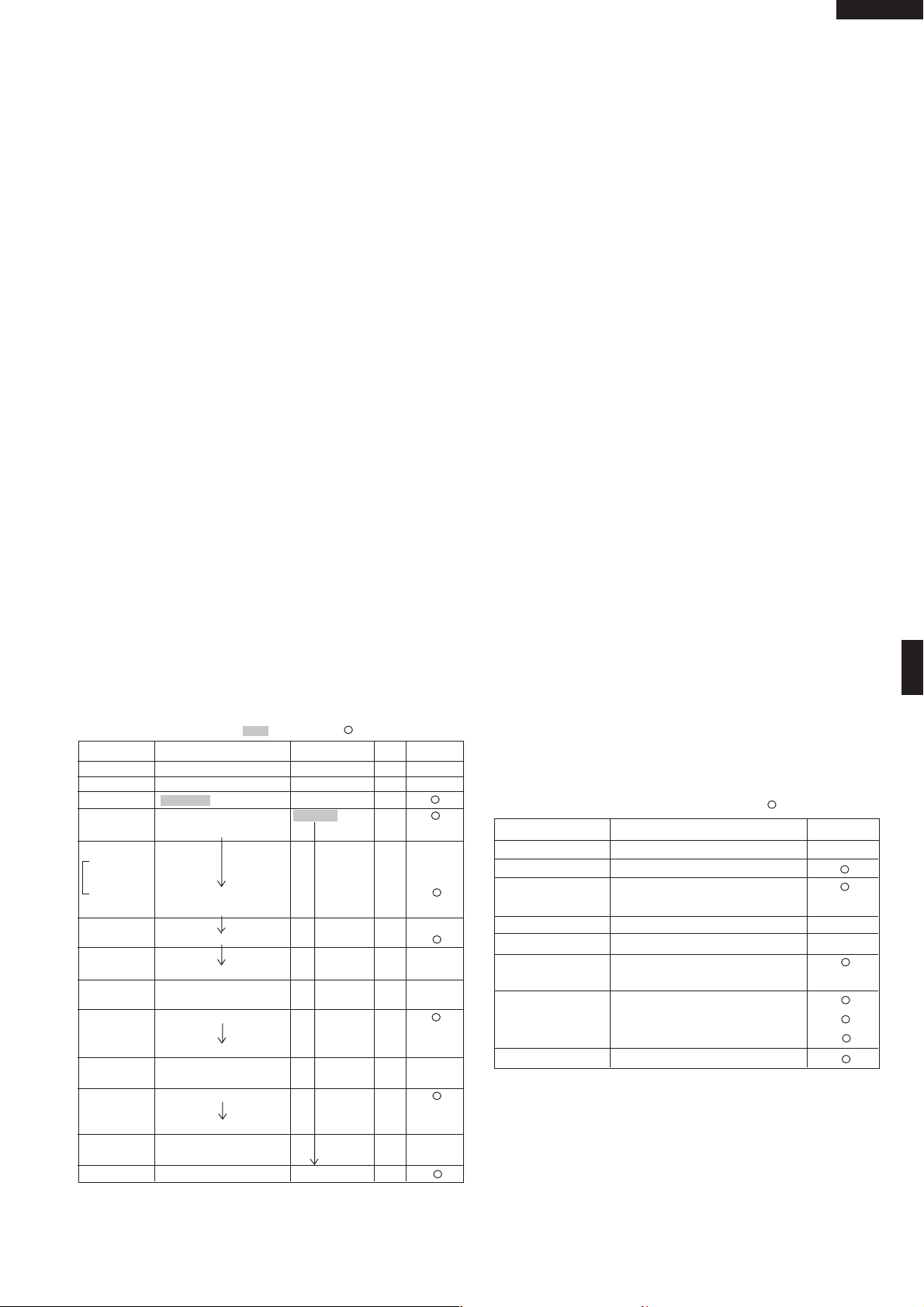

REMEMBER TO CHECK 3D

1) Disconnect the supply.

2) Door opened, and wedged open.

3) Discharge high two voltage capacitors.

WARNING: AGAINST THE CHARGE OF THE TWO

HIGH-VOLTAGE CAPACITORS.

The two high-voltage capacitors remain charged

about 60 seconds after the oven has been switched

off. Wait for 60 seconds and then short-circuit the

connection of the two high-voltage capacitors (that

is, of the connecting lead of the high-voltage rectifier) against the chassis with use of an insulated

screwdriver.

Sharp recommend that wherever possible fault-finding

is carried out with the supply disconnected. It may, in

some cases, be necessary to connect the supply after

the outer case has been removed, in this event carry out

3D checks and then disconnect the leads to the primary

of the power transformer. Ensure that these leads remain isolated from other components and the oven

chassis. (Use insulation tape if necessary.) When the

testing is completed carry out 3D checks and reconnect

the leads to the primary of the power transformer.

REMEMBER TO CHECK 4R

1) Reconnect all leads removed from components during testing.

2) Replace the outer case (cabinet).

3) Reconnect the supply.

4) Run the oven. Check all functions.

Microwave ovens should not be run empty. To test for

the presence of microwave energy within a cavity, place

a cup of cold water on the oven turntable, close the door

and set the microwave timer for one (1) minut. When the

one minute has elapsed (timer at zero) carefully check

that the water is now hot. If the water remains cold carry

out 3D checks and re-examine the connections to the

component being tested.

When all service work is completed and the oven is fully

assembled, the microwave power output should be

checked and microwave leakage test should be carried

out.

Page 3

SERVICE MANUAL

COMMERCIAL

MICROWAVE OVEN

R-22AT/ R-24AT

GENERAL IMPORTANT INFORMATION

PRODUCT SPECIFICATIONS

APPEARANCE VIEW

R-22AT

R-24AT

This Manual has been prepared to provide Sharp Corp. Service

engineers with Operation and Service Information.

It is recommended that service engineers carefully study the

entire text of this manual, so they will be qualified to render

satisfactory customer service.

CAUTION

MICROWAVE RADIATION

DO NOT BECOME EXPOSED TO RADIATION FROM

THE MICROWAVE GENERATOR OR OTHER PARTS

CONDUCTING MICROWAVE ENERGY.

Service engineers should not be exposed to the microwave

energy which may radiate from the magnetron or other

microwave generating devices if it is improperly used or

connected. All input and output microwave connections,

waveguides, flanges and gaskets must be secured. Never

operate the device without a microwave energy absorbing

load attached. Never look into an open waveguide or

antenna while the device is energized.

WARNING

Never operate the oven until the following points are ensured.

(A) The door is tightly closed.

(B) The door brackets and hinges are not defective.

(C) The door packing is not damaged.

(D) The door is not deformed or warped.

(E) There is not any other visible damage with the oven.

OPERATING SEQUENCE

FUNCTION OF IMPORTANT

COMPONENTS

SERVICING AND

TROUBLESHOOTING CHART

TEST PROCEDURE

TOUCH CONTROL PANEL

ASSEMBLY

COMPONENT REPLACEMENT

AND ADJUSTMENT PROCEDURE

MICROWAVE MEASUREMENT

Servicing and repair work must be carried out only by trained

service engineers.

All the parts marked "*" on parts list are used at voltages more

than 250V.

Removal of the outer wrap gives access to potentials above

250V.

All the parts marked "∆" on parts list may cause undue microwave exposure, by themselves, or when they are damaged,

loosened or removed.

SHARP CORPORATION

OSAKA, JAPAN

1

WIRING DIAGRAM

PARTS LIST

Page 4

R-22AT

R-24AT

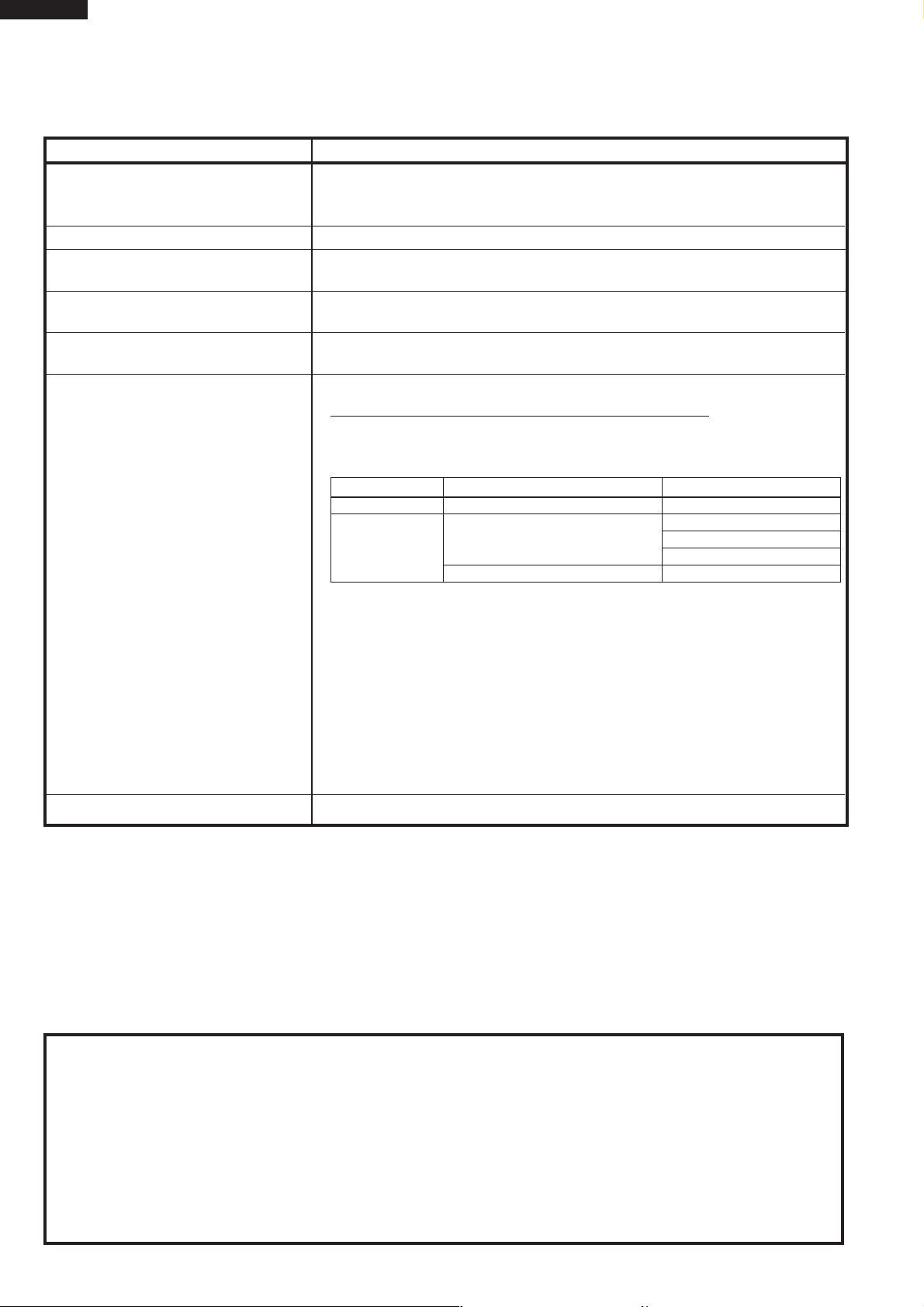

PRODUCT DESCRIPTION

SPECIFICATION

ITEM DESCRIPTION

Power Requirements 230 - 240 Volts

50 Hertz

Single phase, 3 wire earthed

Power Comsumption

Power Output

Case Dimensions Width Height Depth

Cooking Cavity Dimensions Width Height Depth

Control Complement for Touch Control System

2.4 kW Approx. 11 A [R-22AT] / 2.9 kW Approx. 13 A [R-24AT]

1500 W [R-22AT]/ 1900 W [R-24AT] nominal of RF microwave energy

(measured by method of IEC 60705)

Operating frequency 2450 MHz

510mm 335 mm 470mm

330 mm 180 mm 330mm

The combination of cooking time and microwave power

The oven can be programmed a series of up to 3 cookling stages.

The combination of microwave power and cooking time that can be input as

folllows.

Cooking Sequence Micrwave power levelthat can be iused. Cooking time that can be iused.

1 Stage only 0-100% Max. 30 minutes

0-40% all stages Max. 30 minutes any stages

2 or 3 Stage

50-100% Max. 30 minutes for 3 stages

Max. 60 minutes for 2 stages

Max. 90 minutes for 3 stages

NOTE:If the oven used with the power level above 40% on any stage, the

maximum cooking time is 30 minutes in total.

Microwave Power level

100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0%

MANUAL / REPEAT key, NUMBER keys

POWER LEVEL key, STOP / CLEAR key

START Key, DOUBLE QUANTITY key

EXPRESS DEFROST key, SET key

CHECK key, VOLUME key

CSet Weight Approx. 33 kg

GENERAL INFORMATION

WARNING

THIS APPLIANCE MUST BE EARTHED

IMPORTANT

THE WIRES IN THIS MAINS LEAD ARE COLOURED IN ACCORDANCE WITH THE FOLLOWING CODE:

GREEN-AND-YELLOW : EARTH

BLUE : NEUTRAL

BROWN : LIVE

2

Page 5

R-22AT

6

8

0

R-24AT

OVEN

1. Control panel

2. Hole for safety door latches

3. Ceramic floor

4. Splash cover

5. Oven light

6. Air intake filter

7. Air intake openings

8. Oven cavity

9. Door seals and sealing surfaces

10. Door hinges

11. Oven door with see-through window

12. Door safety latches

13. Door handle.

14. Outer cabinet

15. Removable cover over oven light bulb

16. Air vent openings

17. Power supply cord

18 Mounting plate

19 Screw for mounting plate

DISPLAY AND INDICATORS

Check indicators after the oven starts to

confirm the oven is operating as desired.

1. Heating indicator

This indicator shows cooking in progress.

2. Memory number indicator

3. Express defrost

4. Check mode indicator

5. Power level display

6. Time display

7. Filter indicator

8. Double quantity mode indicator

9. 3rd. stage indicator

10. 2nd. stage indicator

11. 1st. stage indicator

OPERATING KEYS

12. DOUBLE QUANTITY key

13. EXPRESS DEFROST key

14. NUMBER keys

15. MANUAL/ REPEAT key

16. STOP/CLEAR key

17. POWER LEVEL key

18. START key

19. SET key

20. VOLUME key

21. CHECK key

13

APPEARANCE VIEW

11

12

10

5

8

AUTO TOUCH CONTROL PANEL

12

15

17

19

11

3

4

NUMBER

2

ON

1

DOUBLE

QUANTITY

MANUAL/

REPEAT

POWER LEVEL

SET CHECK VOLUME

2

1 2 3

10

679

34

DEF

CHECK

DOUBLE

FILTER

EXPRESS

DEFROST

11

12

13

14

15

16

17

18

19

20

STOP / CLEAR

START

1

POWER

%

1

2

3

4

5

6

7

8

9

0

18

6

5

7

8

9

13

14

1

1

2

17

19

14

15

16

21

INSTALLATION INFORMATION

When this commercial microwave oven is installed near other commercial electrical appliances, connect a lead wire to

each equivalent potential terminal with equipotential marking between them (insert a lead wire between a washer and

an earth angle, and screw them), as shown in Fig. A-1, to make sure that they are at equivalent potential.

If any lead wire is not connected between them, when person touch them he/she will get a electric shock.

COMMERCIAL MICROWAVE OVEN OTHER COMMERCIAL

Equipotential marking

Lead wire

Screw

Washer

Earth angle

(Equivalent potential terminal)

Lead wire

Figure A-1

3

ELECTRICAL APPLIANCE

Equivalent

potential terminal

Page 6

R-22AT

R-24AT

OPERATION SEQUENCE

Closing the door activates all door interlock switches

(interlock switches and stop switch).

IMPORTANT

When the oven door is closed, the monitor switch contacts

COM-NC must be open. When the microwave oven is

plugged in a wall outlet (230 - 240 volts, 50Hz), the line

voltage is supplied to the control unit through the noise

filter.

Figure O-1 on page 32

1. The digital display shows .

IDLE CONDITION

When the door is opened, the contacts of the interlock

switches SW1+SW2 and stop switch SW5 open, initiating

the following:

Figure O-2 on page 32

1. A signal is input to the control unit energizing the coil of

shut-off relay RY-1.

2. The shut-off relay RY-1 contacts close completing

circuits to turn on the oven lamp, blower motor and

antenna motors.

3. If the door remains open, 60 seconds later the control

unit de-energizes shut-off relay RY-1 turning off the

oven lamp, blower motor and antenna motors.

When the door is closed, the contacts of the interlock

switches SW1+SW2 and stop switch SW5 close. With the

closing of the stop switch SW5 contacts, an additional

circuit is provided which will permit the operation of the

oven when one of the touch pads is depressed. Since the

control is enabled through the stop switch SW5, the door

must be closed before the touch pads will be effective.

When the door is closed, a full 60 second IDLE condition

is always provided for selecting and pressing the desired

touch pads. A 60 second IDLE condition will also follow the

end of each cook cycle.

MICROWAVE COOKING CONDITION

Touch MANUAL/REPEAT key and enter a desired

cooking time with the touching NUMBER key. And then

touch START key.

NOTE: The programme and the check are canceled

when any keys are not touched for more than

3 minutes during programming.

Function sequence Figure O-3 on page 33

CONNECTED COMPONENTS RELAY

Oven lamp/ Blower motor/ Antenna motors RY1

High voltage transformer T1 RY3

High voltage transformer T2 RY4

1. The line voltage is supplied to the primary winding of

the two high voltage transformers. The voltage is

converted to about 3.3 volts A.C. output on the filament

winding and high voltage of approximately 2000 volts

A.C. on the secondary winding.

2. The filament winding voltage (3.3 volts) heats the

magnetron filament and the high voltage (2000 volts) is

sent to the voltage doubling circuit, where it is doubled

to negative voltage of approximately 4000 volts D.C..

3. The 2450 MHz microwave energy produced in the

magnetron generates a wave length of 12.24 cm. This

energy is channelled through the waveguide (transport

channel) into the oven cavity, where the food is placed

to be cooked.

4. When the cooking time is up, a signal tone is heard and

the relays RY3+RY4 go back to their home position.

The circuits to the high voltage transformers T1+T2.

The relay RY1 remains and oven lamp, blower motor

and antenna motors work for 1 minute.

5. When the door is opened during a cook cycle, the

switches come to the following condition.

CONDITION

DURING DOOR OPEN

SWITCH CONTACT COOKING

Interlock switches COM-NO Closed Open

Monitor switches COM-NC Open Closed

Stop switch COM-NO Closed Open

(NO COOKING)

The circuits to the high voltage transformers T1+T2

are cut off when the interlock and stop switches

SW1+SW2+SW5 are made open. The blower motor

BM, antenna motors and oven lamp remains on even

if the oven door is opened after the cooking cycle has

been interrupted, because the relay RY1 stays closed.

Shown in the display is the remaining time, but the

program is cancelled if the oven is not started within 1

minute.

6. MONITOR SWITCH CIRCUIT

The monitor switches SW3+SW4 are mechanically

controlled by oven door, and monitors the operation of

the interlock switches SW1+SW2.

6-1. When the oven door is opened during or after the

cycle of a cooking program, the interlock switches

SW1+SW2 and stop switches SW5 must open their

contacts first. After that the contacts (COM-NC) of the

monitor switches SW3+SW4 can be closed.

6-2. When the oven door is closed, the contacts (COM-

NC) of the monitor switches SW3+SW4 must be

opened first. After that the contacts (COM-NO) of the

interlock switches SW1+SW2 and stop switch SW5

must be closed.

6-3. When the oven door is opened and the contacts of the

interlock switch SW1 (or SW2) remain closed, remains closed, the fuse F1 F10A (or F2 F10A) will

blow, because the monitor switch SW3 (or SW4) is

closed and a short circuit is caused.

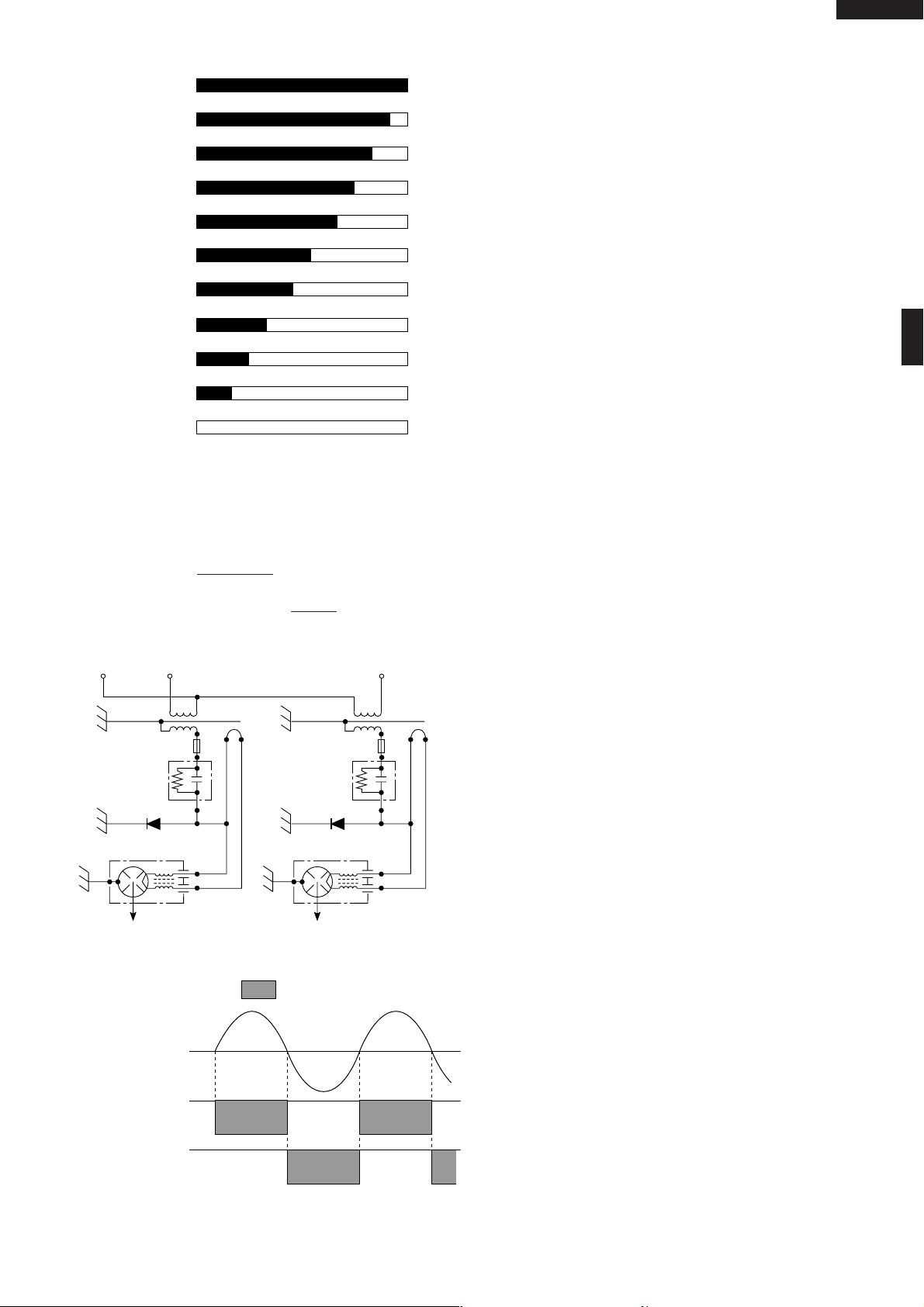

MICROWAVE VARIABLE COOKING

When the microwave oven is preset for variable cooking

power, the line voltage is supplied to the high voltage

transformers T1+T2 intermittently within a 48 second time

base through the contacts of the relays RY3+RY4.

The following levels of microwaves power are given.

4

Page 7

48 sec. ON

Number key

44sec. ON

Number key 9

40 sec. ON

Number key 8

36 sec. ON

Number key 7

32 sec. ON

Number key 6

26 sec. ON

Number key 5

22 sec. ON

Number key 4

16 sec. ON

Number key 3

12 sec. ON

Number key 2

8 sec. ON

Number key 1

0 sec. ON

Number key 0

NOTE: The ON/OFF time ratio does not exactly corre-

spond to the percentage of microwave power,

because approx. 3 seconds are needed for heating up the magnetron filament.

R-22AT

R-24AT

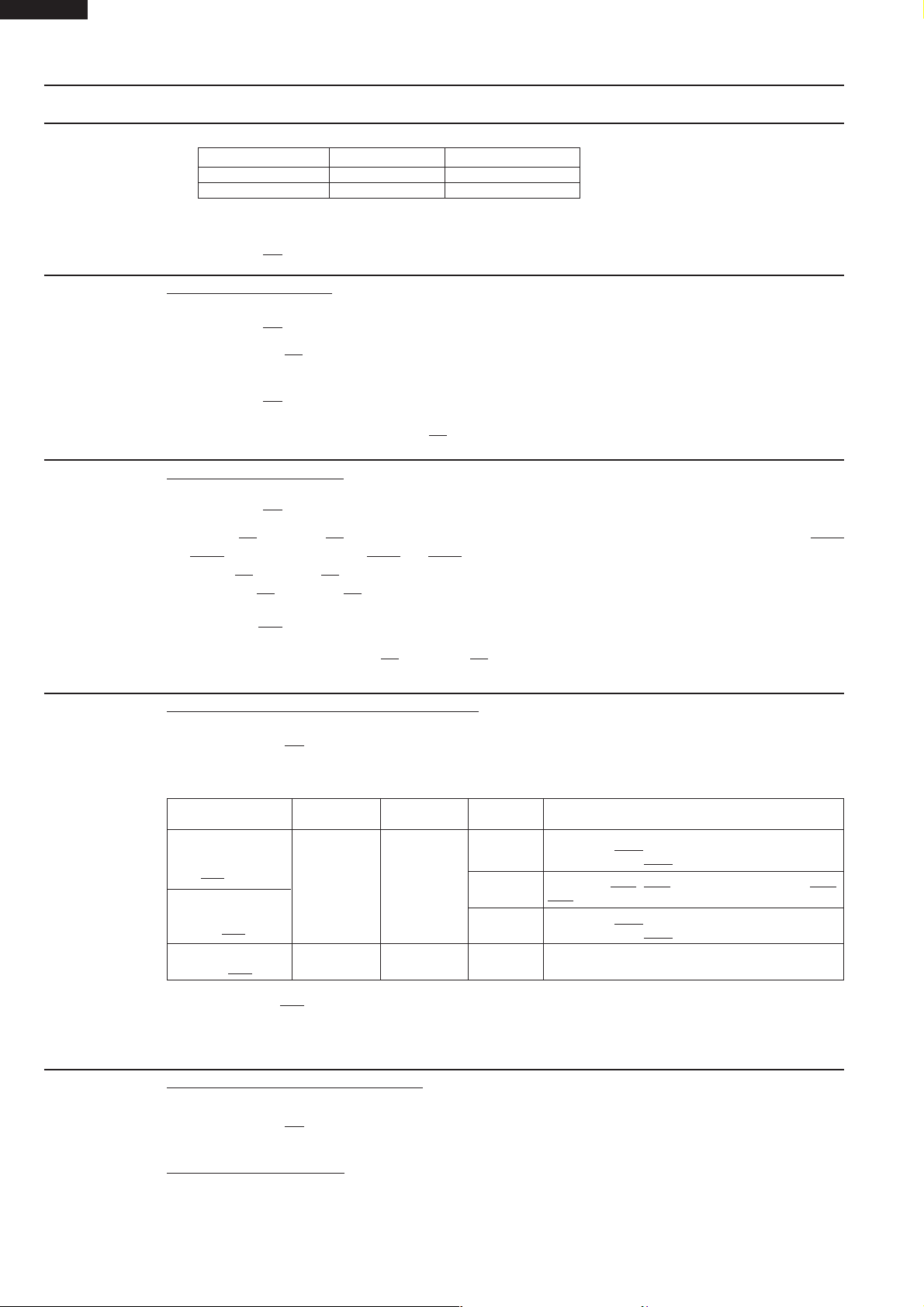

TWO MAGNETRON OPERATION SYSTEM

Two magnetrons MG1+MG2 are equipped in order to get

higher microwave power output. The primary windings of

the high voltage transformers T1+T2 are connected so

that each magnetron can be oscillated alternatively according to the frequency of the power supply. Refer to the

Figure B-1 and B-2.

T2: HIGH VOLTAGE

TRANSFORMER

(REAR)

H. V. FUSE H. V. FUSE

H. V. RECTIFIER

MG2: MAGNETRON (LOWER)

C2: H.V. CAPACITOR

H. V. RECTIFIER

Figure B-1. High Voltage Circuit

OPERATION OF

MAGNETRON

MG1: MAGNETRON (UPPER)

T1: HIGH VOLTAGE

TRANSFORMER

(FRONT)

C1: H.V. CAPACITOR

COMMERCIAL

FREQUENCY

(50HZ)

POWER OUTPUT

BY MAGNETRON T1

POWER OUTPUT

BY MAGNETRON T2

Figure B-2. Operation of Magnetron

5

Page 8

R-22AT

R-24AT

FUNCTION OF IMPORTANT COMPONENTS

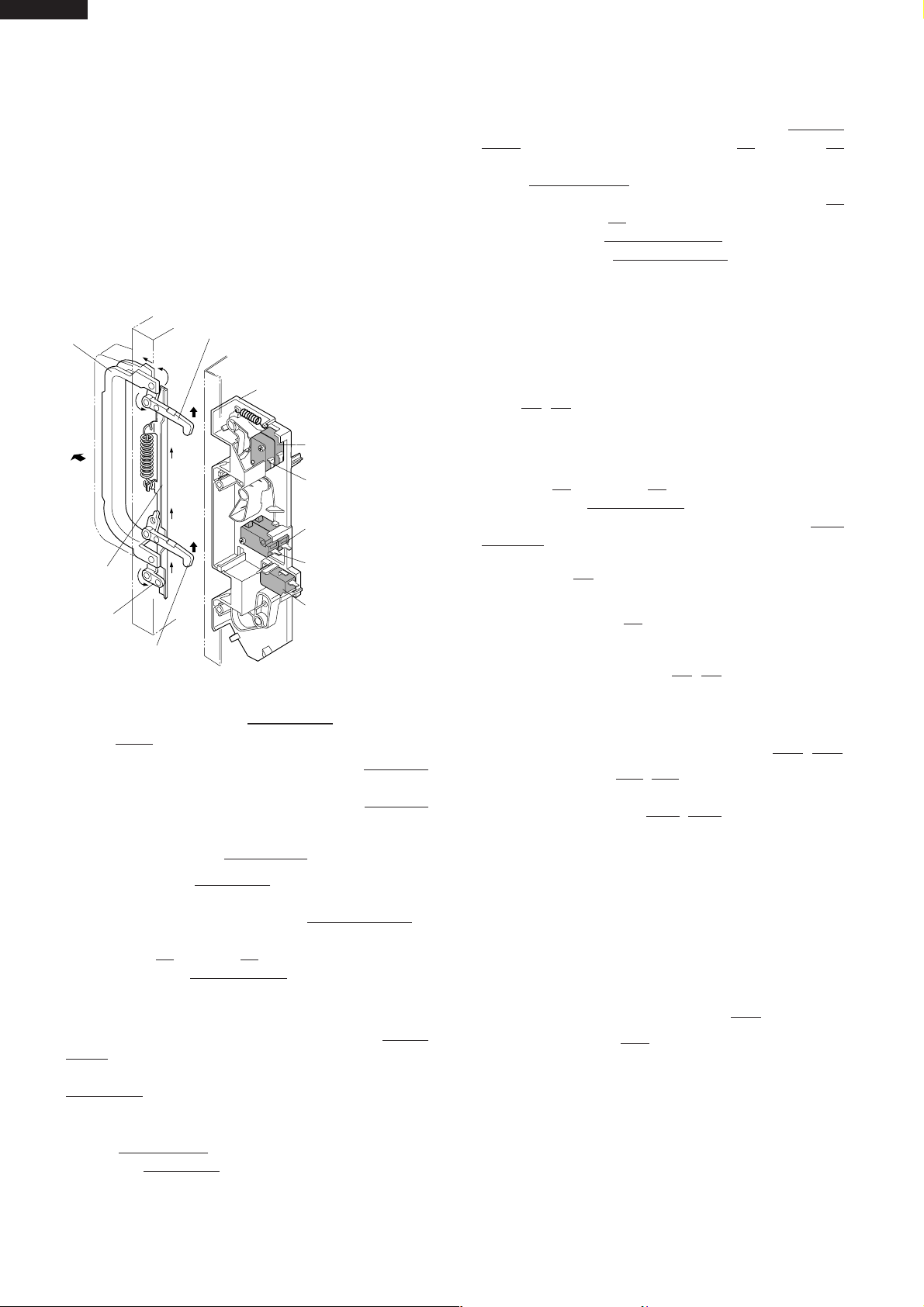

DOOR OPEN MECHANISM

1. The door release lever is pulled.

2. The upper latch head is lifted up by the linked door

release lever.

3. The head lever is lifted up by the door release lever.

4. The joint lever is lifted up by the head lever.

5. The lower latch head is lifted up by the joint lever.

6. Now both latch heads are lifted up, so they can be

released from the latch hook.

7. Now the door can be opened.

Door release

lever

Joint lever

Head lever

Latch head

Latch head

Latch hook

SW4: Monitor switch

(Oven side)

SW3: Monitor switch

SW2: Interlock switch

(Oven side)

SW1: Interlock switch

SW5: Stop switch

Figure D-1. Door Open Mechanism

INTERLOCK SWITCHES SW1, SW2 AND STOP

SWITCH SW5

1. When the oven door is closed, the contacts COM-NO

must be closed.

2. When the oven door is opened, the contacts COM-NO

must be opened.

MONITOR SWITCHES SW3, SW4

The monitor switches SW3, SW4 are activated (the contacts opened) the upper latch head and switch lever A

while the door is closed. The switch SW3 (or SW4) is

intended to render the oven inoperative by means of

blowing the fuse F1 F10A (or F2 F10A) when the contacts

of the interlock switch SW1 (or SW2) fail to open when the

door is opened.

Function

1. When the door is opened, the monitor switches SW3

+SW4 contacts close (to the ON condition) due to their

being normally closed. At this time the interlock switch

SW1+SW2 are in the OFF condition (contacts open)

due to their being normally open contact switches.

2. As the door goes to a closed position, the monitor

switches SW3+SW4 contacts are opened and interlock switch SW1+SW2 contacts are closed (On opening the door, each of these switches operate inversely.)

3. If the door is opened and the interlock switch SW1 (or

SW2) contacts fail to open, the fuse F1 F10A (or F2

F10A) blows simultaneously with closing of the monitor

switch SW3 (or SW4) contacts.

CAUTION:BEFORE REPLACING A BLOWN FUSE F1

F10A (OR F2 F10A) TEST THE INTERLOCK

SWITCH SW1 (OR SW2) AND MONITOR

SWITCHE SW3 (OR SW4) FOR PROPER

OPERATION. (REFER TO CHAPTER “TEST

PROCEDURE”).

NOISE FILTER

The noise filter assembly prevents radio frequency interference that might flow back in the power circuit.

FUSES F1, F2 F10A 250V

1. If the wire harness or electrical components are shortcircuited, this fuse blows to prevent an electric shock or

fire hazard.

2. The fuse F1 F10A (or F2 F10A) also blows when

interlock switch SW1 (or SW2) remains closed with the

oven door open and when the monitor switches SW3

(or SW4) closes.

WEAK POINT F3

If the wire harness or electrical components make a shortcircuit, this weak point F3 blows to prevent an electric

shock or fire hazard.

HIGH VOLTAGE FUSE(S) F4, F5

The high voltage fuse blows when the high voltage rectifier

or the magnetron is shorted.

MAGNETRON TEMPERATURE FUSES TF1, TF2

The temperature fuses TF1, TF2 located on the top of the

upper and lower waveguide, are designed to prevent

damage to the magnetrons MG1, MG2. If an over heated

condition develops in the tube due to blower motor failure,

obstructed air ducts, dirty or blocked air intake, etc., the

circuit to the magnetrons are interrupted. Under normal

operation, the temperature fuses remains closed. However, when abnormally high temperatures are generated

within the magnetrons, the temperature fuses will open at

150˚C causing the microwave energy to stop. The defective temperature fuses must be replaced with new rated

ones.

EXHAUST TEMPERATURE FUSE TF3

The temperature fuse TF3, located on the side of the

exhaust duct assembly, is designed to prevent damage to

the oven by fire. If the food load is overcooked, by either

error in cook time or defect in the control unit, the temperature fuse will open. Under normal operation, the oven

temperature fuse remains closed. However, when abnormally high temperatures are generated within the oven

cavity, the oven temperature fuse will open at 120˚C,

causing the oven to shut down. The defective temperature

fuse must be replaced with new rated one.

6

Page 9

R-22AT

R-24AT

EXHAUST OVEN THERMISTOR TH3

The thermistor is a negative temperature coefficient type.

The temperature in the exhaust duct is detected through

the resistance of the thermistor.

If the temperature is high, the control panel will display

“EE7” and the oven will stop to avoid overheating and

catching fire.

If the thermistor is open, the control panel will display

"EE6" and the oven will stop.

MAGNETRON THERMISTORS TH1, TH2

The thermistor is a negative temperature coefficient type.

The air temperature around the magnetron is detected

through the resistance of the thermistor.

If the temperature is high, the control panel will display

"EE17" and the oven will stop to protect the lower magnetron against overheat.

If the magnetron thermistor is open, the control panel will

display "EE16" and the oven will stop.

If the magnetron thermistor is short, the control panel will

display "EE19" and the oven will stop.

BLOWER MOTOR BM

The blower motor BM drives a blade which draws external

cool air into the oven. This cool air is directed through the

air vanes surrounding the magnetrons and cools the

magnetrons. This air is channelled through the oven cavity

to remove steam and vapours given off from the heating

foods. It is then exhausted through the exhausting air

vents at the oven cavity.

ANTENNA MOTORS SM

The upper and lower antenna motors SM drive stirrer

antennas.

OVEN LAMP OL

The oven cavity light illuminates the interior of the oven so

that food being cooked can be examined visually through the

door window without having to open the door. The oven lamp

is on during the cooking cycle and idle condition.

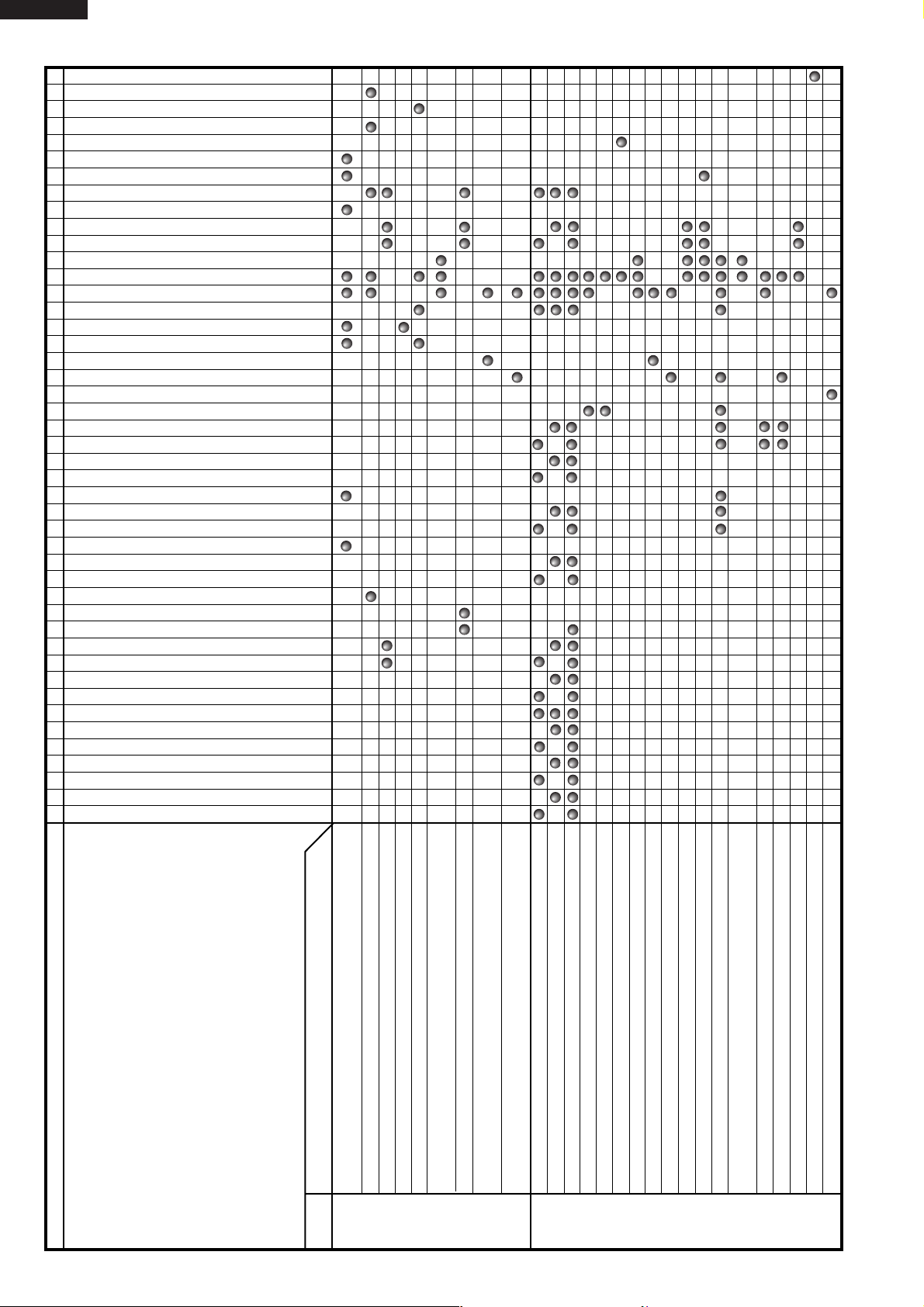

TROUBLESHOOTING GUIDE

When troubleshooting the microwave oven, it is helpful to follow the Sequence of Operation in performing the checks.

Many of the possible causes of trouble will require that a specific test be performed. These tests are given a procedure

letter which will be found in the “Test Procedure”section.

IMPORTANT: If the oven becomes inoperative because of a blown fuse F1 F10A (or F2 F10A) in the interlock switch

SW1 (or SW2) - monitor switches SW3 (or SW4) , check the interlock switch SW1 (or SW2) and monitor

switches SW3 (or SW4) before replacing the fuse F1 F10A (or F2 F10A).

7

Page 10

R-22AT

R-24AT

EEP ROM I-2

N KEY UNIT

TOUCH CONTROL TRANSFORMER T3

Due to programme lock

Over the max. cooking time

No power at wall outlet

HOME FUSE or BREAKER

Mis adjustment of switches

P FUSE 2.5A

O RELAY RY-4

O RELAY RY-3

O RELAY RY-1

M TOUCH CONTROL PANEL

Opened wire harness

Shorted wire harness

POWER SUPPLY CORD

K NOISE FILTER

OVEN LAMP OR SOCKET

J BLOWER MOTOR BM

J ANTENNA MOTORS SM

I EXHAUST THERMISTOR TH3

I MAGNETRON THERMISTOR (Lower) TH2

I MAGNETRON THERMISTOR (Upper) TH1

L HIGH VOLTAGE FUSE F5

L HIGH VOLTAGE FUSE F4

H EXHAUST TEMPERATURE FUSE TF3

H MAGNETRON TEMPERATURE FUSE TF2

H MAGNETRON TEMPERATURE FUSE TF1

F WEAK POINT F3

G FUSE F10A F2

G FUSE F10A F1

E STOP SWITCH SW5

E MONITOR SWITCH SW4

E MONITOR SWITCH SW3

E NTERLOCK SWITCH SW2

D INTERLOCK SWITCH SW1

D H.V. CAPACITOR C2

D H.V. CAPACITOR C1

H.V. WIRE HARNESS

C H.V. RECTIFIER ASSEMBLY FOR MG2

C H.V. RECTIFIER ASSEMBLY FOR MG1

B HIGH VOLTAGE TRANSFORMER T2 (Rear)

B HIGH VOLTAGE TRANSFORMER T1 (Front)

A MAGNETRON MG2 (Lower)

A MAGNETRON MG1 (Upper)

TESTPROCEDURE

AND

POSSIBLE CAUSE

DEFECTIVE PARTS

PROBLEM

“ . “ does not appear on display when power cord is plugged into

wall outlet.

Control panel can not accept key in.

Fuse F1 or F2 blows when the door is opened.

Home fuse blows when power cord is plugged into wall outlet.

Weak point F3 blows when power cord is plugged into wall outlet.

Oven lamp, fan motor and antenna motors do not work for 1

minute when the door is opened or after cooking.

Fuse F1 or F2 blows when power cord is plugged into wall outlet.

Oven lamp does not light when door is opened. (Blower and antenna

motors work)

Blower motor does not work when door is opened. (Oven lamp

lights and antenna motors work)

“EE 1” (Magnetron MG1 failure)

“EE 2” (Magnetron MG2 failure)

“EE 3” (Magnetron MG1 and MG2 failure)

“EE 6” (Exhaust thermistoropen)

“EE 7” (Exhaust air temperature is high)

“EE 9” (Exceeded max. heating time)

Oven lamp, blower motor and antenna motors do not work.

OFF

CONDITION

CONDITION

8

Oven lamp does not work.

Blower motor does not work.

Oven does not stop after end of cooking cycle.

Home fuse blows when starting the oven.

Oven goes into cook cycle but shuts down before end of cooking cycle.

It passed more than 1 minute after cooking but oven lamp, blower

motor and stirrer motors do not stop.

“EE 16” (Thermistor of magnetron are open.)

“EE 17” (Magnetron temperature is high.)

“EE 19” (Magnetron thermistor short)

“EE 10” (Fault of memory)

Antenna motors do not work.

ON

CONDITION

Page 11

TEST PROCEDURES

PROCEDURE

LETTER COMPONENT TEST

A MAGNETRON TEST

NEVER TOUCH ANY PART IN THE CIRCUIT WITH YOUR HAND OR AN INSULATED TOOL

WHILE THE OVEN IS IN OPERATION.

R-22AT

R-24AT

CARRY OUT

3D CHECKS.

Isolate the magnetron from high voltage circuit by removing all leads connected to filament terminal.

To test for an open circuit filament use an ohmmeter to make a continuity test between the magnetron

filament terminals, the meter should show a reading of less than 1 ohm.

To test for short circuit filament to anode condition, connect ohmmeter between one of the filament

terminals and the case of the magnetron (ground). This test should be indicated an infinite resistance.

If a low or zero resistance reading is obtained then the magnetron should be replaced.

MICROWAVE OUTPUT POWER (1 litre water load)

The following test procedure should be carried out with the microwave oven in a fully assembled

condition (outer case fitted). Microwave output power from the magnetron can be measured by way

of IEC 60705, i.e. it is measured by how much power the water load can absorb. To measure the

microwave output power in the microwave oven, the relation of calorie and watt is used. When P(W)

heating works for t(second), approximately P x t/4.187 calorie is generated. On the other hand, if the

temperature of the water with V(ml) rises ∆T (°C) during this microwave heating period, the calorie of

the water is V x ∆T.

The formula is as follows;

P x t / 4.187 = V x ∆ T+ 0.55 x mc (T2-T0) P (W) = 4.187 x V x ∆T / t + 0.55 x mc (T2-T0)/t

Our condition for water load is as follows:

Room temperature (T0) ...... around 20°C Power supply Voltage .............. Rated voltage

Water load ..................................... 1000 g Initial temperature (T1) ...................... 10±1°C

Heating time ................

28 sec. [R-22AT] / 22sec. [R-24AT]

Mass of container (mc) .....

330 g

T2 ......... Final Temperature P = 150 x ∆T [R-22AT] / P = 190 x ∆T [R-24AT]

Measuring condition:

1. Container

The water container must be a cylindrical borosilicate glass vessel having a maximum material

thickness of 3 mm and an outside diameter of approximately 190 mm.

2. Temperature of the oven and vessel

The oven and the empty vessel are at ambient temperature prior to the start the test.

3. Temperature of the water

The initial temperature of the water is (10±1)°C.

4. Select the initial and final water temperature so that the maximum difference between the final water

temperature and the ambient temperature is 5°C.

5. Select stirring devices and measuring instruments in order to minimize addition or removal of heat.

6. The graduation of the thermometer must be scaled by 0.1°C at minimum and be an accurate

thermometer.

7. The water load must be (1000±5) g.

8. “t” is measured while the microwave generator is operating at full power. Magnetron filament heatup time is not included.

NOTE: The operation time of the microwave oven is “t + 3” sec. (3 sec. is magnetron filament heat-up time.)

Measuring method:

1. Measure the initial temperature of the water before the water is added to the vessel.

(Example: The initial temperature T1 = 11°C)

2. Add the 1 litre water to the vessel.

3. Place the load on the centre of the shelf.

4. Operate the microwave oven at HIGH until the temperature of the water rises by a value ∆ T of

(10 ± 2) K.

5. Stir the water to equalize temperature throughout the vessel.

6. Measure the final water temperature. (Example: The final temperature T2 = 21°C)

7. Calculate the microwave power output P in watts from above formula.

9

Page 12

R-22AT

R-24AT

TEST PROCEDURES

PROCEDURE

LETTER COMPONENT TEST

Room temperature ................................................................................................. T0 = 21°C

Initial temperature .................................................................................................. T1 = 11°C

Temperature after (28 + 3) = 31 sec [for R-22AT].................................................. T2 = 21°C

Temperature after (22 + 3) = 25 sec [for R-24AT].................................................. T2 = 21°C

Temperature difference Cold-Warm...................................................................... ∆T1 = 10˚C

Measured output power

The equation is “P = 150 x ∆T” [for R-22AT] ........................... P = 150 x 10°C = 1500 Watts

The equation is “P = 190 x ∆T” [for R-24AT] ........................... P = 190 x 10°C = 1900 Watts

JUDGMENT: The measured output power should be within the range of ± 15 % of the rated output

power.

CAUTION: 1° C CORRESPONDS TO 150 WATTS [R-22AT]/ 190 WATTS [R-24AT]. REPEAT

MEASUREMENT IF THE POWER IS INSUFFICIENT.

1000g

1000g

T1˚C

1000g

T2˚C

Heat up for 31 sec. for R-22AT

Heat up for 25 sec. for R-24AT

MICROWAVE OUTPUT POWER (2000 cc alternative method)

The power output of this oven is rated using the method specified by IEC 60705. Full details of how

to curry out this procedure can be found in the Sharp Technical Training notes which is available from

Sharp Parts Centre (part number SERV-LITMW01).

The IEC-60705 procedure must be carried out using laboratory-type procedures and equipment.

These requirements make the procedure unsuitable for routine performance checks.

NOTE: The following test method gives an indication of the output power only, it cannot be used to

establish the actual/rated output power. If the true output power is required, then the IEC60705

test method must be used.

Alternative simplified method:

1. Place 2 litres of cold water (between 12°C and 20°C) in a suitable container.

2. Stir the water and measure the temperature in °C. Note temperature as T1.

3. Place the container in the microwave and heat the water for 56 sec. [R-22AT]/ 44 sec. [R-24AT] on

fill power.

4. When the 56 sec. [R-22AT]/ 44 sec. [R-24AT] is completed, remove the container and stir the water.

Note temperature as T2.

5. Calculate the output power using the following formula:

R.F. Power Output = (T2 - T1) x 150 for R-22AT.

R.F. Power Output = (T2 - T1) x 190 for R-24AT.

NOTE: The result from this test should be within the allowance of 2000cc alternative method.

(±10%).

MICROWAVE LEAKAGE TEST

This oven should be tested for microwave leakage on completion of any repair or adjustment, following

the procedure described in the Sharp Technical Training notes (part number SERV-LITMW01). The

maximum leakage permitted in BS EN 60335-2-25 is 50W/m2 (equivalent to 5W/m2), however it is not

normal to detect any significant leakage, therefore, any leakage which is detected should be

investigated.

It is essential that only leakage detectors with current calibration traceable to National Physical

Laboratories are used.

Suitable leakage detectors: CELTEC A100

APOLLO X1

10

Page 13

TEST PROCEDURES

PROCEDURE

LETTER COMPONENT TEST

B HIGH VOLTAGE TRANSFORMER TEST

WARNING: High voltage and large currents are present at the secondary winding and

filament winding of the high voltage transformer. It is very dangerous to work

near this part when the oven is on. NEVER make any voltage measurements

of the high-voltage circuits, including the magnetron filament.

CARRY OUT 3D CHECKS.

Disconnect the leads to the primary winding of the high voltage transformer. Disconnect the filament

and secondary winding connections from the rest of the HV circuitry. Using an ohmmeter, set on a low

range, it is possible to check the continuity of all three windings. The following readings should be

obtained:

R-22AT R-24AT

a. Primary winding approximately 1.8 Ω approximately 1.2 Ω

b. Secondary winding approximately 75 Ω approximately 75 Ω

c. Filament winding less than 1 Ω

If the readings obtained are not stated as above, then the high voltage transformer is probably faulty

and should be replaced.

CARRY OUT 4R CHECKS.

R-22AT

R-24AT

C HIGH VOLTAGE RECTIFIER ASSEMBLY TEST

CARRY OUT 3D CHECKS.

Isolate the high voltage rectifier assembly from the HV circuit. The high voltage rectifier can be tested

using an ohmmeter set to its highest range. Connect the ohmmeter across the terminal B+C of the high

voltage rectifier and note the reading obtained. Reverse the meter leads and note this second reading.

The normal resistance is infinite in one direction and more than 100 kΩ in the other direction.

CARRY OUT 4R CHECKS.

NOTE: FOR MEASUREMENT OF THE RESISTANCE OF THE RECTIFIER, THE BATTERIES OF

THE MEASURING INSTRUMENT MUST HAVE A VOLTAGE AT LEAST 6 VOLTS, BECAUSE OTHERWISE AN INFINITE RESISTANCE MIGHT BE SHOWN IN BOTH DIRECTIONS.

D HIGH VOLTAGE CAPACITOR TEST

CARRY OUT 3D CHECKS.

A. Isolate the high voltage capacitor from the circuit.

B. Continuity check must be carried out with measuring instrument which is set to the highest

resistance range.

C. A normal capacitor shows continuity for a short time (kick) and then a resistance of about 10MΩ

after it has been charged.

D. A short-circuited capacitor shows continuity all the time.

E. An open capacitor constantly shows a resistance about 10 MΩ because of its internal 10MΩ

resistance.

F. When the internal wire is opened in the high voltage capacitor shows an infinite resistance.

G. The resistance across all the terminals and the chassis must be infinite when the capacitor is

normal.

If incorrect reading are obtained, the high voltage capacitor must be replaced.

B

HIGH VOLTAGE RECTIFIER

C

CARRY OUT 4R CHECKS.

E SWITCH TEST

CARRY OUT 3D CHECKS.

Isolate the switch to be tested and using an ohmmeter check between the terminals as described in

the following table.

11

Page 14

R-22AT

R-24AT

TEST PROCEDURES

PROCEDURE

LETTER COMPONENT TEST

Table: Terminal Connection of Switch

Plunger Operation COM to NO COM to NC

Released Open circuit Short circuit

Depressed Short circuit Open circuit

If incorrect readings are obtained, make the necessary switch adjustment or replace the switch.

CARRY OUT 4R CHECKS.

F WEAK POINT F3 TEST

CARRY OUT 3D CHECKS.

If the weak point F3 is blown, there could be a shorts or grounds in electrical parts or wire harness.

Check them and replace the defective parts or repair the wire harness.

CARRY OUT 4R CHECKS.

CAUTION: Only replace weak point F3 with the correct value replacement.

G FUSE F1, F2 F10A TEST

COM; Common terminal,

NO; Normally open terminal

NC; Normally close terminal

CARRY OUT 3D CHECKS.

If the fuse F1 F10A (or F2 F10A) is blown when the door is opened, check the interlock switch SW1

(or SW2) and monitor switch SW3 (or SW4).

If thefuse F1 F10A (or F2 F10A) is blown by incorrect door switching replace the defective switch(s)

and the fuse F1 F10A (or F2 F10A).

CARRY OUT 4R CHECKS.

CAUTION: Only replace fuse F1 F10A (or F2 F10A) with the correct value replacement.

H TEMPERATURE FUSE TF1, TF2, TF3 TEST

1. CARRY OUT 3D CHECKS.

2. A continuity check across the temperature fuse terminals should indicate a closed circuit unless the

temperature of the temperature fuse reaches specfied temperature as shown below.

Open Close Display or

temperature temperature Condition Check point

Magnetron temperature fuse (Upper)

TF1

Magnetron temperature fuse

(Lower)

Exhaust temperature fuse

TF2

TF3

150˚C

120˚C

Non resetable

type

Non resetable

type

EE1

EE3

EE2

Oven shut

off

Magnetron

Test magnetron

Magnetron MG1, MG2 Failure: Test magnetron MG1,

MG2. Check blower motor and ventilation opening.

Magnetron MG2 Failure:

Test magnetron

Food has been burned in oven.

Temperature of oven inside is very high.

MG1 Failure:

MG1 and Blower motor.

MG2 and Blower motor.

3. CARRY OUT 4R CHECKS.

CAUTION: IF THE temperature fuse INDICATES AN OPEN CIRCUIT AT ROOM TEMPERATURE,

REPLACE temperature fuse.

I THERMISTOR TH1, TH2, TH3 TEST

1. CARRY OUT 3D CHECKS.

2. Follow the procedures below for each thermistor.

2-1. THERMISTOR TEST

Disconnect the connector of the thermistor from the switch harness. Measure the resistance of the

magnetron thermistor with an ohmmeter. Connect the ohmmeter leads to the leads of the thermistor.

Resistance: Approx. 500 kΩ -- 1 MΩ

12

Page 15

TEST PROCEDURES

PROCEDURE

LETTER COMPONENT TEST

If the meter does not indicate above resistance, replace the thermistor.

3. CARRY OUT

4R CHECKS.

J MOTOR WINDING TEST

CARRY OUT 3D CHECKS.

Disconnect the leads from the motor. Using an ohmmeter, check the resistance between the two

terminals.

Resistance of Blower motor should be approximately 60Ω.

Resistance of Antenna motor should be approximately 8.8 kΩ.

If incorrect readings are obtained, replace the motor.

CARRY OUT 4R CHECKS.

K NOISE FILTER TEST

CARRY OUT 3D CHECKS.

Disconnect the leads from the terminals of noise filter. Using an ohmmeter, check between the

terminals as described in the following table.

MEASURING POINT INDICATION OF OHMMETER

Between N and L Approx. 680 kΩ

Between terminal N and WHIT Short circuit

Between terminal L and BLK Short circuit

If incorrect readings are absorbed, replace the noise filter.

CARRY OUT 4R CHECKS.

N

LINE CROSS CAPACITOR 0.22µF/ AC250V

LINE CROSS CAPACITOR

10000 pF/ AC250V

WHT

NOISE FILTER

F3 : WEAK POINT

NOISE SUPPRESSION COIL

DISCHARGE RESISTOR 680 kΩ 1/2W

DISCHARGE RESISTOR 10 MΩ 1/2W

LINE CROSS CAPACITOR

10000 pF/ AC250V

R-22AT

R-24AT

L

BLK

L HIGH VOLTAGE FUSE F4, F5 TEST

CARRY OUT 3D CHECKS.

If the high voltage fuse F4 (or F5) is blown, there could be a short in the high voltage rectifier or the magnetron

MG1 (or MG2). Check them and replace the defective parts and the high voltage fuse F4 (or F5).

CARRY OUT 4R CHECKS.

CAUTION: Only replace high voltage fuse with the correct value replacement.

M TOUCH CONTROL PANEL ASSEMBLY TEST

The touch control panel consists of circuits including semiconductors such as LSI, IC, etc. Therefore,

unlike conventional microwave ovens, proper maintenance cannot be performed with only a voltmeter

and ohmmeter. In this service manual, the touch control panel assembly is divided into two units,

Control Unit and Key Unit, troubleshooting by unit replacement is described according to the symptoms

indicated.

1. Key Unit Note : Check key unit ribbon connection before replacement.

The following symptoms indicate a defective key unit. Replace the key unit.

a) When touching the pads, a certain pad produces no signal at all.

b) When touching the pads, sometimes a pad produces no signal.

2. Control Unit

The following symptoms may indicate a defective control unit. Replacing the control unit. Before

replacing the control unit, perform the key unit test (Procedure N) to determine if control unit is faulty.

2-1 Programming problems.

a) When touching the pads, a certain group of pads do not produce a signal.

2-2 Display problems.

a) For a certain digit, all or some segments do not light up.

b) For a certain digit, brightness is low.

c) Only one indicator does not light.

d) The corresponding segments of all digits do not light up; or they continue to light up.

e) Wrong figure appears.

13

Page 16

R-22AT

R-24AT

TEST PROCEDURES

PROCEDURE

LETTER COMPONENT TEST

f) A certain group of indicators do not light up.

g) The figure of all digits flicker.

2-3 Other possible problems caused by defective control unit.

a) Buzzer does not sound or continues to sound.

b) Cooking is not possible.

N KEY UNIT TEST

CARRY OUT

If the display fails to clear when the STOP/CLEAR pad is depressed, first verify the flat ribbon cable

is making good contact, verify that the stop switch operates properly; that is the contacts are closed

when the door is closed and open when the door is open. If the stop switch is good, disconnect the flat

ribbon cable that connects the key unit to the control unit and make sure the stop switch is closed (either

close the door or short the stop switch connector ). Use the key unit matrix indicated on the control panel

schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad making

momentary contact. If the control unit responds by clearing with a beep, the key unit is faulty and must

be replaced. If the control unit does not respond, it is faulty and must be replaced. If a specific pad does

not respond, the above method may be used (after clearing the control unit ) to determine if the control

unit or key pad is at fault.

CARRY OUT 4R CHECKS.

O RELAY TEST

CARRY OUT 3D CHECKS.

Remove the outer case and check voltage between Pin Nos. 3 and 5 of the connector (A) on the control

unit with an A.C. voltmeter. The meter should indicate 230 - 240 volts, if not check control unit circuity.

3D CHECKS.

G9

G10

G11

G12

G1

G2 G3 G4 G5 G6 G7 G8

17

7

18

8

19

20

15

9

16

0

13

5

14

6

11

3

4

1

12

2

RY1, RY3 and RY4 Relay Test

These relays are operated by D.C. voltage.

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation.

DC. voltage indicated ............................. Defective relay.

DC. voltage not indicated ....................... Check diode which is connected to the relay coil. If

diode is good, control unit is defective.

RELAY SYMBOL OPERATIONAL VOLTAGE CONNECTED COMPONENTS

RY1 APPROX. 25.9V D.C. Oven lamp, Blower motor and Antenna motors

RY3 APPROX. 25.0V D.C. High voltage transformer (MG1)

RY4 APPROX. 25.0V D.C. High voltage transformer (MG2)

CARRY OUT 4R CHECKS.

P PROCEDURES TO BE TAKEN WHEN THE FUSE ON THE PRINTED WIRING BOARD(PWB) IS

OPEN

To protect the electronic circuits, this model is provided with a fine fuse added to the primary on

the PWB. If the fuse is open, follow the troubleshooting guide given below for repair.

Problem: POWER ON, indicator does not light up.

CARRY OUT 3D CHECKS.

14

Page 17

TEST PROCEDURES

PROCEDURE

LETTER COMPONENT TEST

STEPS OCCURRENCE CAUSE OR CORRECTION

1 The rated AC voltage is not present at Check supply voltage and oven power cord.

POWER terminal of CPU connector (CN-A).

2 The rated AC voltage is present at primary Touch control transformer or secondary circuit defective.

side of touch control transformer. Check and repair.

3 Fuse on the PWB is open. Replace the fuse with new one.

(CARRY OUT 3D CHECKS BEFORE REPAIR)

NOTE: *At the time of these repairs, make a visual inspection of the varistor for burning damage

and examine the transformer with tester for the presence of layer short-circuit (check

primary coil resistance). If any abnormal condition is detected, replace the defective parts.

CARRY OUT 4R CHECKS.

R-22AT

R-24AT

15

Page 18

R-22AT

R-24AT

TOUCH CONTROL PANEL ASSEMBLY

OUTLINE OF TOUCH CONTROL PANEL

The touch control section consists of the following units as

shown in the touch control panel circuit.

(1) Control Unit

(2) Key Unit

The principal functions of these units and the signals

communicated among them are explained below.

1. Control Unit

Signal of key touch and oven function control are all

processed by one microcomputer.

1) Power Supply Circuit

This circuit changes output voltage at the secondary

side of the touch control transformer to voltages required at each part by full wave rectifying circuit,

constant voltage circuit, etc..

2) Reset Circuit

This is an Auto-clear Circuit, i.e., a reset circuit, which

enables IC1 to be activated from initial state.

3) Power Synchronizing Signal Generating Circuit

This is a circuit for generating power synchronizing

signal by virtue of the secondary side output of touch

control transformer.

This signal is used for a basic frequency to time

processing and so on.

4) Clock Circuit

This is a circuit for controlling clock frequency required

for operating I-1.

5) I-1 (Main Processor)

This is a one-chip microcomputer, responsible for

controlling the entire control unit.

6) I-2 (Memory Processor)

This is a memory IC, responsible for memory function.

7) Display Circuit

This is a circuit for driving display tubes by I-1 output.

8) Key Input Circuit

This is a circuit for transmitting key input information to

I-1.

9) Sound-body Driving Circuit

This is a circuit for driving sound body by I-1 output.

10) Relay Driving Circuit

This is a circuit for driving output relay by I-1 output.

11) Stop Switch Circuit

This is a circuit for driving I-1 to detect door opening/

closing.

12) Exhaust Air Temperature Detecting Circuit

This is a circuit for transmitting output change of

thermistor (Exhaust thermistor) to I-1.

13) Magnetron Temperature Circuit.

(Detect Noload or Fan Lock)

This is a circuit for transmitting output change of

thermistor (Magnetron thermistor) to I-1.

2. Key Unit

The key unit is composed of a matrix circuit in which

when a key it touched, one of signals P33 - P34

generated by the LSI, is passed through the key and

returned to the LSI as one of signals P24 - P27. This

model has 20 Memory pads. When the oven is shipped,

Memory pad 1 to 10 are set as follows: fig.1.

Memory No. Cook Time Output Power

1 5 sec. 100%

2 10 sec. 100%

3 20 sec. 100%

4 30 sec. 100%

5 40 sec. 100%

6 50 sec. 100%

7 1 min. 100%

81 min. 15 sec. 100%

91 min.30 sec. 100%

02 mins. 100%

(fig. 1)

This model has a double quantity pad. When the oven

is shipped, Magnification "1.8" is preset in the double

quantity pad. This model has an defrost pad. When the

oven is shipped, defrost is set as follows: fig.2.

1STAGE 2STAGE 3STAGE

POWER 40% 30% 20%

DEFROSTING TIME 0.2T+20sec 0.13T+30sec. 0.67T-50sec.

(fig. 2)

NOTE :

"CHECK" indicator will flash at half of defrosting time.

16

Page 19

DESCRIPTION OF LSI

LSI(IXA222DR)

The I/O signal of the LSI(IXA222DR) is detailed in the following table.

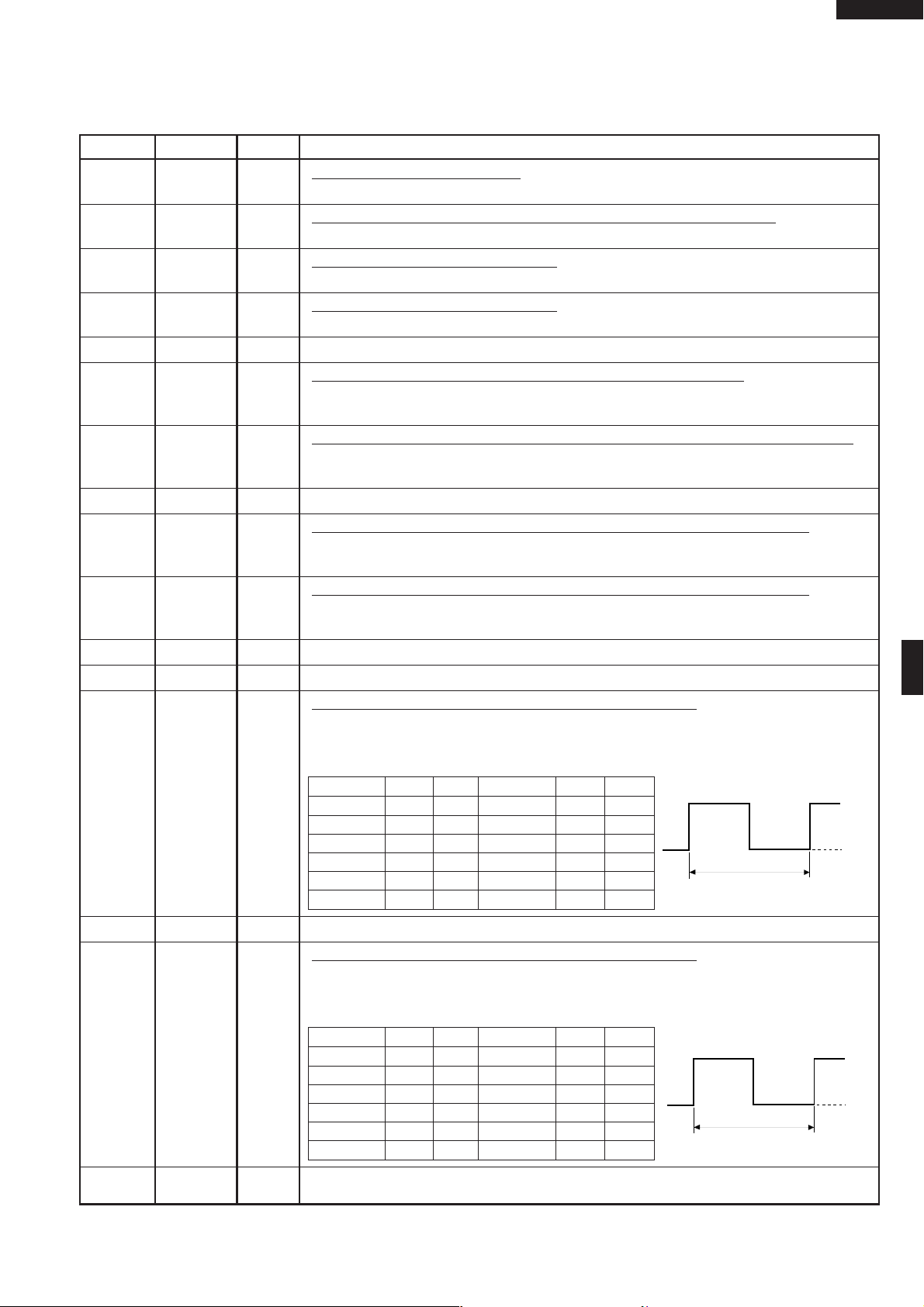

Pin No. Signal I/O Description

1 VCC IN Power source voltage: GND.

VC voltage of power source circuit input. Connected to GND.

2 VEE IN Anode (segment) of Fluorescent Display light-up voltage: -35V.

Vp voltage of power source circuit input.

3 AVSS IN Reference voltage input terminal.

A reference voltage applied to the A/D converter in the LSI. Connected to DC. (-5V)

4 VREF IN Reference voltage input terminal.

A reference voltage applied to the A/D converter in the LSI. Connected to GND.

5-6 AN7-AN6 IN Terminal to switch the specification.

7 AN5 IN Temperature measurement input: EXHAUST THERMISTOR

By inputting DC voltage corresponding to the temperature detected by the thermistor, this input is converted into temperature by the A/D converter built into the LSI.

8 AN4 IN Input signal which communicates the door open/close information to LSI.

Door closed; "H" level signal (0V).

Door opened; "L" level signal (-5.0V).

9 AN3 - Terminal not used.

10 AN2 IN Temperature measurement input: MAGNETRON THERMISTOR TH2.

By inputting DC voltage corresponding to the temperature detected by the thermistor, this input is converted into temperature by the A/D converter built into the LSI.

11 AN1 IN Temperature measurement input: MAGNETRON THERMISTOR TH1.

By inputting DC voltage corresponding to the temperature detected by the thermistor, this input is converted into temperature by the A/D converter built into the LSI.

12 AN0 - Terminal not used.

13-14 P55-P54 - Terminal not used.

15 P53 OUT Magnetron (MG1) high-voltage circuit driving signal.

To turn on and off the cook relay. In 100% power level operation, "L" level during

cooking; "H" level otherwise. In other power level operation (90, 80, 70, 60, 50, 40,

30, 20, 10 or 0%), "H" and "L" level is repeated according to power level.

R-22AT

R-24AT

Power level ON OFF Power level ON OFF

100% 48sec. 0sec. 40% 22sec. 26sec.

90% 44sec. 4sec. 30% 16sec. 32sec.

80% 40sec. 8sec. 20% 12sec. 36sec.

70% 36sec. 12sec. 10% 8sec. 40sec.

60% 32sec. 16sec. 0% 0sec. 48sec.

50% 26sec. 22sec.

16 P52 - Terminal not used.

17 P51 OUT Magnetron (MG2) high-voltage circuit driving signal.

To turn on and off the cook relay. In 100% power level operation, "L" level during

cooking; "H" level otherwise. In other power level operation (90, 80, 70, 60, 50, 40,

30, 20, 10 or 0%), "H" and "L" level is repeated according to power level.

Power level ON OFF Power level ON OFF

100% 48sec. 0sec. 40% 22sec. 26sec.

90% 44sec. 4sec. 30% 16sec. 32sec.

80% 40sec. 8sec. 20% 12sec. 36sec.

70% 36sec. 12sec. 10% 8sec. 40sec.

60% 32sec. 16sec. 0% 0sec. 48sec.

50% 26sec. 22sec.

18 P50 - Terminal not used.

OFF

OFF

48 sec.

48 sec.

ON

ON

GND

-5V

GND

-5V

17

Page 20

R-22AT

R-24AT

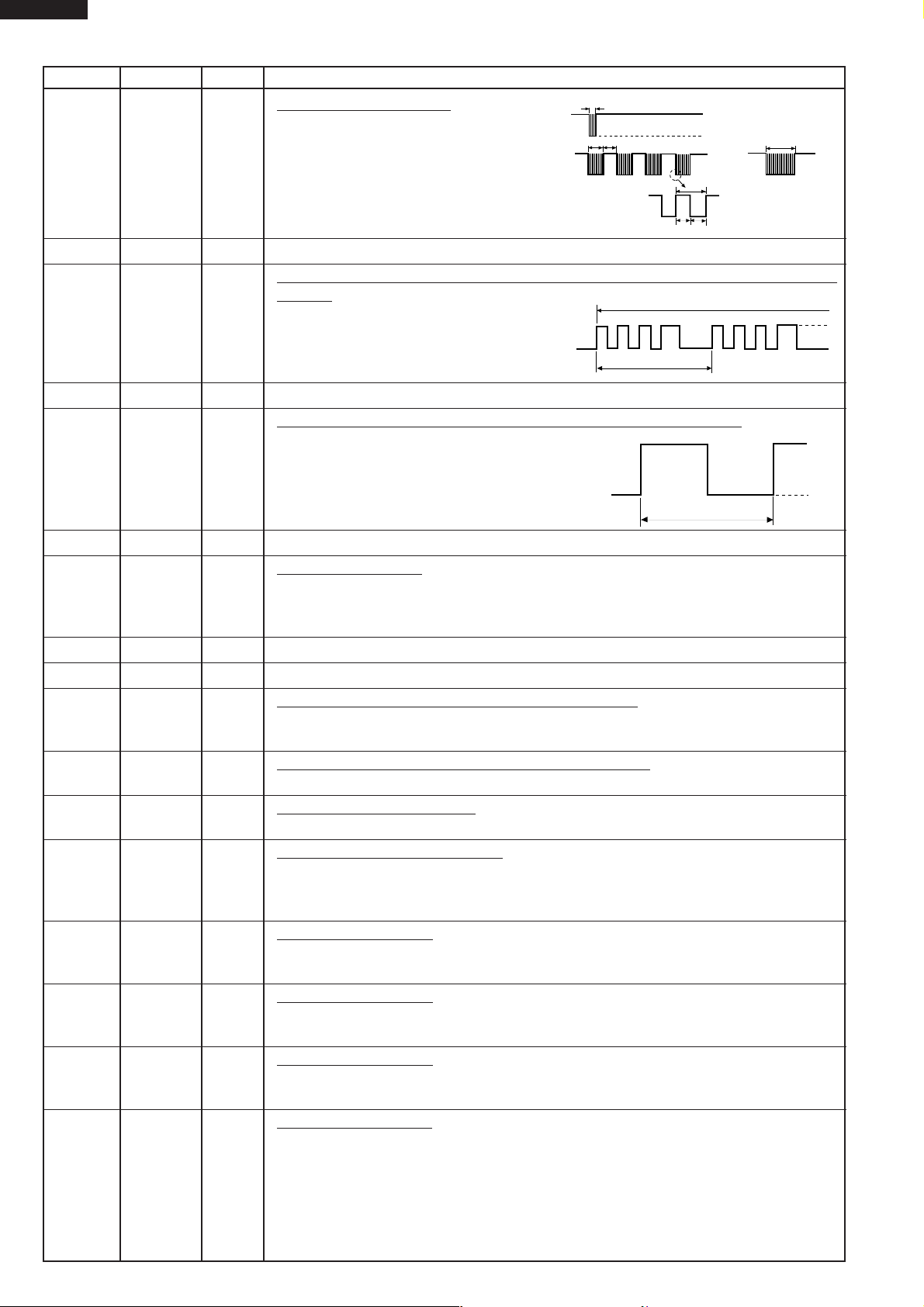

Pin No. Signal I/O Description

A

1.2 sec

B

0.12 sec

1.2 sec

GND

-5V

T

2.4 sec

C

19 P47 OUT Signal to sound buzzer.

This signal is to control the 2.5kHz

continuous signal.

A: Switch touch sound.

B: Guidance sound.

C: Completion sound.

200 sec.

200 sec.

20-21 P46-P45 - Terminal not used.

22 P44 OUT Oven lamp, Blower motor and Antenna motor driving signal (Square Waveform

: 50Hz).

To turn on and off the shut-off relay (RY1).

During cooking

The Square waveform voltage is delivered

to the RY1 relay driving circuit and relays

(RY3, RY4, COOK RELAY) control circuit.

20 msec

23-24 P43-P42 - Terminal not used.

25 INT1 IN Signal synchronized with commercial power source frequency.

This is basic timing for all time processing of LSI.

OFF

H

L

GND

26 INT0 IN Connected to VC(-5) through pull-down resistor.

27 RESET IN Auto clear terminal.

Signal is input to reset the LSI to the initial state when power is supplied. Temporarily

set to "L" level the moment power is supplied, at this time the LSI is reset. Thereafter

set at "H" level.

28 P71 OUT Memory (EEPROM) clock output.

29 P70 IN/OUT Memory (EEPROM) data input/output.

30 XIN IN Internal clock oscillation frequency setting input.

The internal clock frequency is set by inserting the ceramic filter oscillation circuit with

respect to XOUT terminal.

31 XOUT OUT Internal clock oscillation frequency control output.

Output to control oscillation input of XIN.

32 VSS IN Power source voltage: -5V.

VC voltage of power source circuit input.

33 P27 IN Signal coming from touch key.

When either one of G-12 line keys on key matrix is touched, a corresponding signal

out of P30 - P34 will be input into P27. When no key is touched, the signal is held at

"L" level.

34 P26 IN Signal similar to P27.

When either one of G-11 line keys on key matrix is touched, a corresponding signal

will be input into P26.

35 P25 IN Signal similar to P27.

When either one of G-10 line keys on key matrix is touched, a corresponding signal

will be input into P25.

36 P24 IN Signal similar to P27.

When either one of G-9 line keys on key matrix is touched, a corresponding signal

will be input into P24.

37-40 P23-P20 OUT Segment data signal.

The relation between signals and indicators are as follows:

Signal Segment Signal Segment Signal Segment

P01 ..................... k P21 ......................... h P15 ..................... d

P02 ...................... j P20 ......................... g P14 ...................... c

P03 ...................... i P17 ......................... f P13 ..................... b

P23 .................. LB P16 ......................... e P12 ..................... a

P22 .................. UB

20 msec.

ON

-5V

18

Page 21

Pin No. Signal I/O Description

41-46 P17-P12 OUT Segment data signal.

Signal similar to P23..

47-48 P11-P10 OUT Digit selection signal.

The relation between digit signal and digit

are as follows:

Digit signal Digit

P11 .................... 1st.

P10 ................... 2nd.

P07 .................... 3rd.

P06 .................... 4th.

P05 .................... 5th.

P04 .................... 6th.

§(50Hz)

§(50Hz)

P11

P10

P07

P06

GND

-31(V)

GND

-31(V)

R-22AT

R-24AT

H

L

Normally, one pulse is output in every ß

period, and input to the grid of the Fluorescent Display.

49-52 P07-P04 OUT Digit selection signal.

Signal similar to P11.

53-55 P03-P01 OUT Segment data signal.

Signal similar to P23.

56 P00 - Terminal not used.

57-58 P37-P36 OUT (Sound) Voltage level control terminal.

This terminal (P37) is to control volume level of buzzer sound with terminals P36.

Since the volume level of buzzer sound depends on voltage energized, it is control

level in 3 steps by combining signal levels for P37 and P36. Relationship of signal

level combination to sound volume level is shown in the following table, 1~3 in the

table, however, are indicated in the descending order from the maximum level of

sound volume through the minimum level.

Sound Volume P36 P37

1, (Max.) L L

2, H L

3, (Min.) L H

*At Output terminal P47, rectangular wave signal of 2.5kHz is output.

59 P35 - Terminal not used.

60 P34 OUT Key strobe signal.

Signal applied to touch-key section. A pulse signal is input to P24 - P27 terminal while

one of G-4 line keys on key matrix is touched.

61 P33 OUT Key strobe signal.

Signal applied to touch-key section. A pulse signal is input to P24 - P27 terminal while

one of G-5 line keys on key matrix is touched.

62 P32 OUT Key strobe signal.

Signal applied to touch-key section. A pulse signal is input to P24 - P27 terminal while

one of G-6 line keys on key matrix is touched.

63 P31 OUT Key strobe signal.

Signal applied to touch-key section. A pulse signal is input to P24 - P27 terminal while

one of G-7 line keys on key matrix is touched.

64 P30 OUT Key strobe signal.

Signal applied to touch-key section. A pulse signal is input to P24 - P27 terminal while

one of G-8 line keys on key matrix is touched.

P05

P04

A : 1,(Max) 20V

A

2, 13V

3,(Min) 7V

GND

-31(V)

19

Page 22

R-22AT

R-24AT

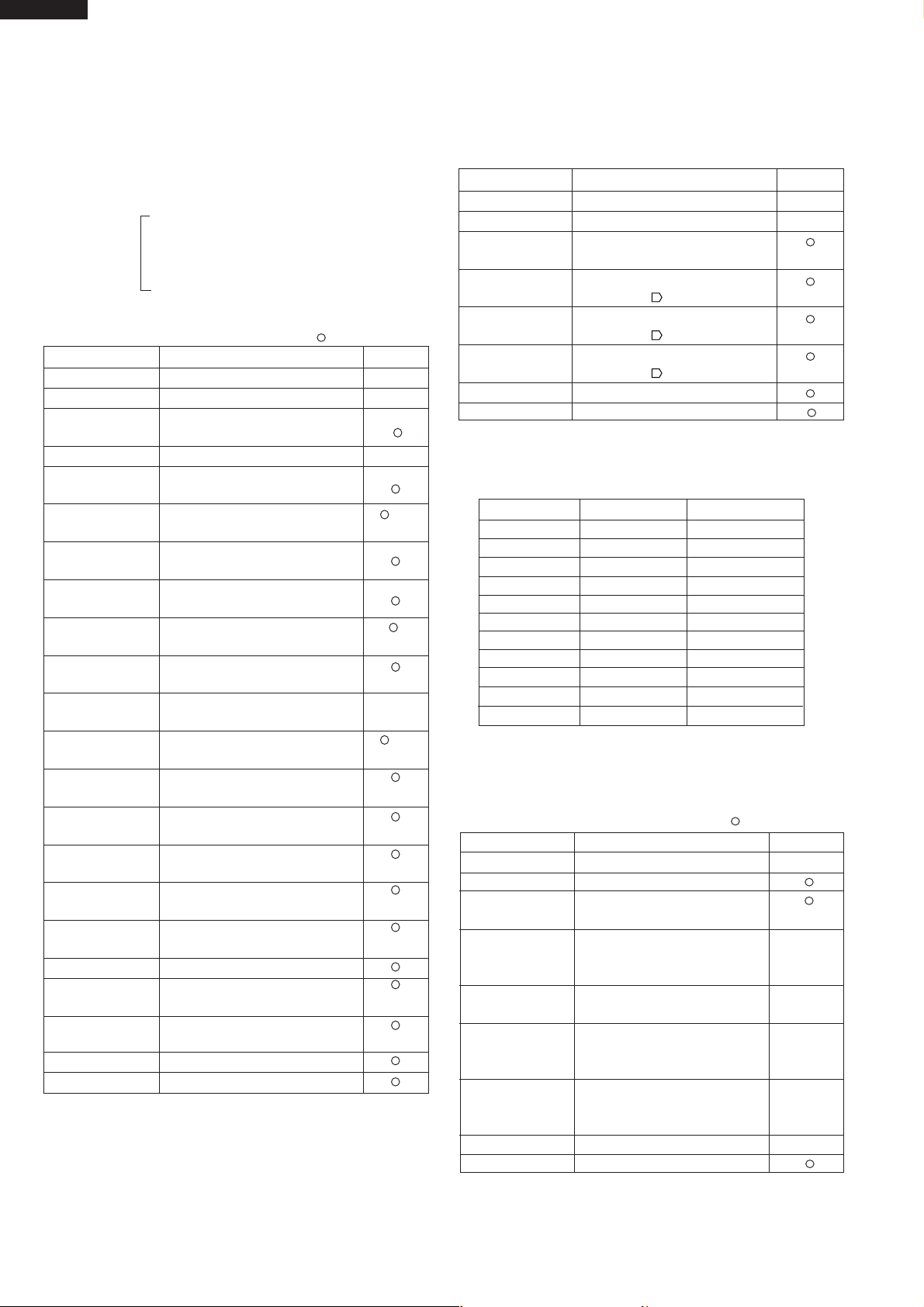

2-2 Memory IC (I-2)

CAT24WC16PI is a 4K-bit, serial memory, enabling CMOS to be erased/written electrically. This memory is constructed

with 512 registers x 8bits, enabling individual access, read and write operations to be performed. Details of input/output

signal for IC2 are as shown in the following diagram.

TOP VIEW

81

A0

A1

A2

VSS

VCC

TEST

72

SCL

63

SDA

54

Figure T-2. Relation between Pin Nos, and Signals

Pin No. Signal I/O Description

1-3 A0-A2 IN Connected to GND.

4 VSS IN Connected to VC(-5V).

5 SDA IN/OUT Serial data input/output : input/outputs data to I-1.

6 SCL IN Clock signal input : input/outputs serial data at every one pulse.

7 TEST IN Connected to VC(-5V).

8 VCC IN Connected to GND.

FUNCTIONAL DIAGRAM

(3) Vcc

(4) Vss

(5) SDA

(6) SCL

START

STOP

LOGIC

SLAVE ADDRESS

REGISTER

COMPARATOR

Dout

ACK

XDEC

5

64

1

3

CK

H.V. GENERATION

TIMING

& CONTROL

2

E PROM

512 x 8

64

YDEC

8

DATA REGISTER

Dout

START CYCLE

CONTROL

LOGIC

INC

LOAD

WORD

ADDRESS

COUNTER

R/W

PIN

SERVICING

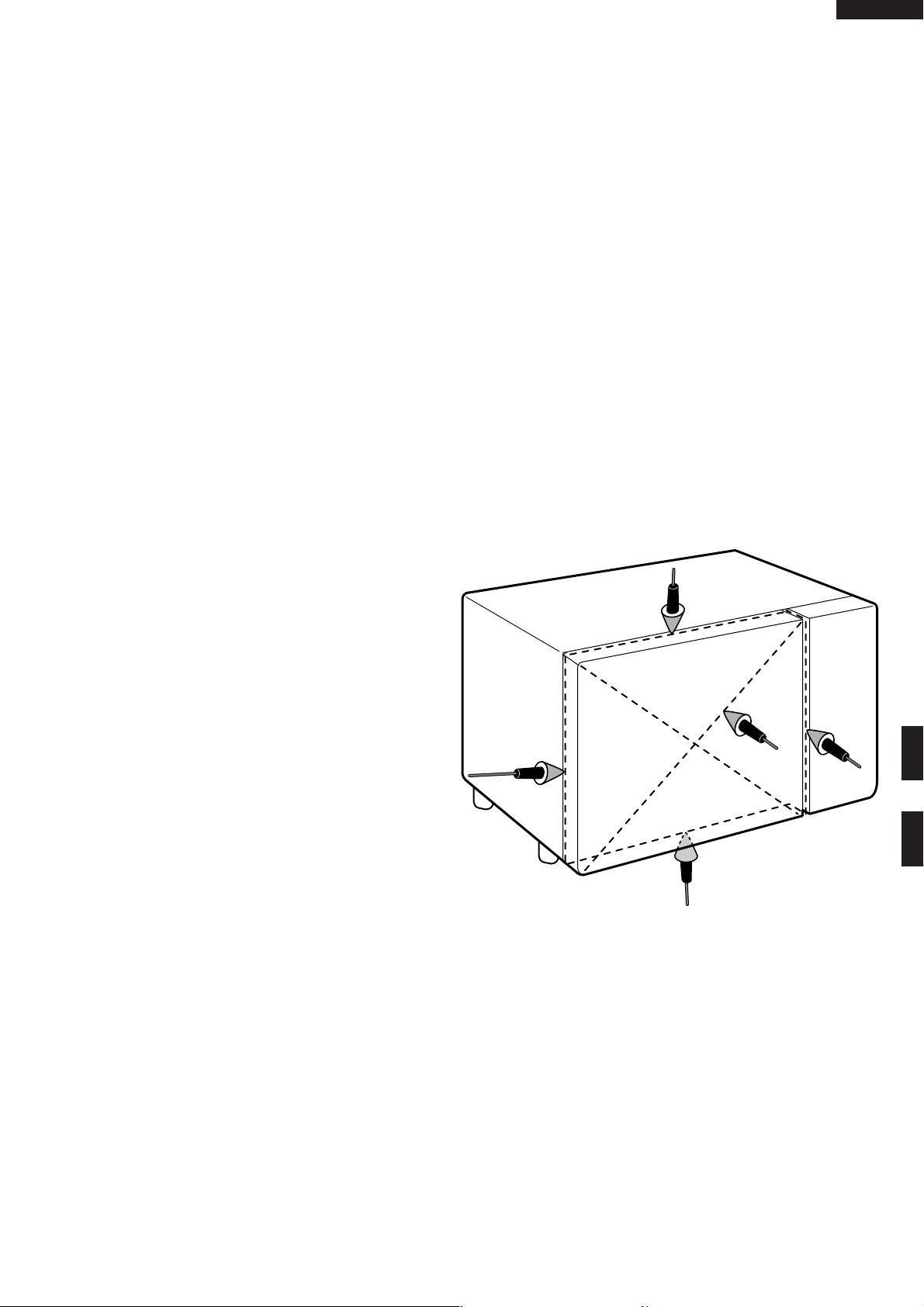

1. Precautions for Handling Electronic Components

This unit uses CMOS LSI in the integral part of the

circuits. When handling these parts, the following precautions should be strictly followed. CMOS LSI have

extremely high impedance at its input and output

terminals. For this reason, it is easily influenced by the

surrounding high voltage power source, static electricity charge in clothes, etc, and sometimes it is not fully

protected by the built-in protection circuit.

In order to protect CMOS LSI.

1) When storing and transporting, thoroughly wrap them

in aluminium foil. Also wrap all PW boards containing

them in aluminium foil.

2) When soldering, ground the technician as shown in the

figure and use grounded soldering iron and work table.

approx. 1M ohm

2. Shapes of Electronic Components

Transistor

E

B

C

KIA79L05P

DTB143ES

DTD143ES

KRA101M

3

2

1

Transistor

2SB953

Transistor

2SB1238

B

C

E

3. Servicing of Touch Control Panel

We describe the procedures to permit servicing of the

touch control panel of the microwave oven and the

precautions you must take when doing so. To perform

the servicing, power to the touch control panel is

available either from the power line of the oven itself or

from an external power source.

(1) Servicing the touch control panel with power supply of

the oven:

CAUTION: THE HIGH VOLTAGE TRANSFORMER

OF THE MICROWAVE OVEN IS STILL

LIVE DURING SERVICING PRESENTS

A HAZARD.

Therefore, when checking the performance of the

touch control panel, put the outer cabinet on the oven

to avoid touching the high voltage transformer, or

unplug the primary terminal (connector) of the high

voltage transformer to turn it off; the end of such

connector must be insulated with an insulating tape.

After servicing, be sure to replace the leads to their

original locations.

A. On some models, the power supply cord between the

touch control panel and the oven itself is so short that

the two can’t be separated. For those models, check

and repair all the controls (sensor-related ones included) of the touch control panel while keeping it

connected to the oven.

B. On some models, the power supply cord between the

touch control panel and the oven proper is long enough

that they may be separated from each other. For those

models, therefore, it is possible to check and repair the

controls of the touch control panel while keeping it

apart from the oven proper; in this case you must short

both ends of the door sensing switch (on PWB) of the

20

Page 23

R-22AT

R-24AT

touch control panel with a jumper, which brings about

an operational state that is equivalent to the oven door

being closed. As for the sensor-related controls of the

touch control panel, checking them is possible if dummy

resistor(s) with resistance equal to that of the controls

are used.

(2) Servicing the touch control panel with power supply

from an external power source:

Disconnect the touch control panel completely from

the oven proper,and short both ends of the door

sensing switch (on PWB) of the touch control

panel,which brings about an operational state that is

equivalent to the oven door being closed. Connect an

external power source to the power input terminal of

the touch control panel, then it is possible to check and

repair the controls of the touch control panel it is also

possible to check the sensor-related controls of the

touch control panel by using the dummy resistor(s).

4. Servicing Tools

Tools required to service the touch control panel assembly.

1) Soldering iron: 60W

(It is recommended to use a soldering iron with a

grounding terminal.)

2) Oscilloscope: Single beam, frequency range: DC10MHz type or more advanced model.

3) Others: Hand tools

5. Other Precautions

1) Before turning on the power source of the control unit,

remove the aluminium foil applied for preventing static

electricity.

2) Connect the connector of the key unit to the control unit

being sure that the lead wires are not twisted.

3) After aluminium foil is removed, be careful that abnormal voltage due to static electricity etc. is not applied to

the input or output terminals.

4) Attach connectors, electrolytic capacitors, etc. to PWB,

making sure that all connections are tight.

5) Be sure to use specified components where high

precision is required.

PROCEDURE FOR CHECKING/CLEARING SERVICE COUNTS OF MICROWAVE OVEN

The following procedure enables the servicer to obtain the total service counts (cook cycles) for memory cooking, manual,

repeat, double quantity cooking and defrost. The maximum capacity of the counter is 999,999 counts, above which the

counter will reset to "0". The counter will retain the total counts (will not clear) in the event of a power disruption.

1) Practice for checking total service counts

(eg; 234,567 Counts).

--- flashing / ---0.1sec. BUZZER

PAD DISPLAY INDICATOR LED PHONE

(door close) •

•

CHECK NUMBER • CHECK

CHECK #1 82 68 CHECK

(user total count)

#2

VOLUME

VOLUME

DOUBLE 2 34 56 7

QUANTITY (service total count)

1 NUMBER 1

(after 1 sec.)

45

(filter used time)

2 NUMBER 2

(after 1 sec.)

2 00

(filter lim. time)

0 (No 10) NUMBER 10

(after 1 sec.)

35 43 2

(service total cook time)

CHECK •

#2: Denotes the procedure for the servicer to disable

checking/clearing. This procedure is instructed to service personnel only and is excluded from the operation

manual.

2) Practice for clearing Service's counts

" " : Flicker / : 0.1 sec BUZZER

PAD ORDER DISPLAY PHONE

(Door close) •

CHECK "NUMBER" • CHECK

CHECK 82 68 "CHECK"

(User's Total Counts)

#1 VOLUME 82 68 "CHECK"

VOLUME 82 68 "CHECK"

DOUBLE QUANTITY 2 34 56 7 "CHECK"

(Total Counts Service)

SET 0 "CHECK"

00 "CHECK"

SET 0 "CHECK"

CHECK •

#1: Denotes the procedure for the servicer to disable

clearing. This procedure is instructed to service personnel only and is excluded from the operation manual.

#1: Denotes total service counts within the reach of user,

of which checking and clearing practices are described in this instruction manual.

21

Page 24

R-22AT

R-24AT

PROCEDURE FOR ENTERING TO I-2

When the control unit or I-2 is exchanged, re-enter the

constants of EXPRESS DEFROST, the memory information

and the EEPROM data, referring to the following procedures.

If not so, the oven will not operate correctly.

1) How to enter the contents of EXPRESS DEFROST

T = STG1 + STG2 + STG3

Constants STG = A x T + B

of EXPRESS STG1 = 0.20 x T + 20 Power level 50%

DEFROST STG2 = 0.13 x T + 30 Power level 30%

STG3 = 0.67 x T - 50 Power level 20%

Suppose above constants are entered.

" " : Flicker / : 0.1 sec BUZZER

PAD ORDER DISPLAY PHONE

(Door close) •

SET •

SET "NUMBER" •

(within 2 sec.)

#1 START "NUMBER" •

EXPRESS

DEFROST

2,0 1 0.20 DEF x 2

MANUAL/ 1 0 DEF

REPEAT #2 (+ - B)

21 20 DEF

POWER DEF "POWER"

LEVEL 1 20 100%

512050%

MANUAL/ 2 0.00 DEF

REPEAT

1, 3 2 0.13 DEF x 2

MANUAL/ 2 0 DEF

REPEAT

3230 DEF

POWER DEF "POWER"

LEVEL 2 30 100%

323030%

MANUAL/ 3 0 DEF

REPEAT

#3 5 3 5 DEF

POWER DEF "POWER"

LEVEL 3 5 100%

23520%

SET 4 • DEF

SET •

1 0.00 DEF

(A)

DEF POWER

(A)

(+ - B)

DEF POWER

DEF POWER

#1: No key entry signal.

#2: To set-B, touch the MANUAL/REPEAT key.

#3: Ex. "CHECK" will flash and the oven will beep after

50% of EXPRESS DEFROST time has lapsed when

5 key is entered during actual cooking.

2) How to enter the memory information

Example : Suppose cooking time 5 sec. and output power

100% are entered into the memory pad 1.

PAD ORDER DISPLAY PHONE

(Door close) •

SET •

SET "NUMBER" •

(within 2 sec.)

1 NUMBER 1 •

1

MANUAL/ NUMBER 1 • 0

REPEAT

5 NUMBER 1 • 5

SET "NUMBER" •

SET •

1

1

Enter the memory information into the memory pads 1 ~ 10

referring to above example. The memory information are

given below.

Memory No. Cook Time Output Power

15 sec. 100%

2 10 sec. 100%

3 20 sec. 100%

4 30 sec. 100%

5 40 sec. 100%

6 50 sec. 100%

7 1 min. 100%

81 min.15 sec. 100%

91 min.30 sec. 100%

10 2 min. 100%

11-20 0 sec.

OTHER CHECKING AND CLEARING PROCEDURE FOR

1) To check the contents of EXPRESS DEFROST.

" " : Flicker / : 0.1 sec BUZZER

PAD ORDER DISPLAY PHONE

(Door close) •

CHECK "NUMBER" • CHECK

EXPRESS 1 0.20 DEF CHECK

DEFROST (A)

DEF CHECK

1 20 POWER

(+ - B) 50%

2 0.13 DEF CHECK

(A)

DEF CHECK

2 30 POWER

(+ - B) 30%

DEF CHECK

3 5 POWER

20%

(Repeat)

CHECK •

#1: No key entry signal.

22

Page 25

2) How to clear all counter(user and service) and total

cooking time and used time of filter.

PAD ORDER DISPLAY PHONE

(Door close) •

SET •

SET "NUMBER" •

DOUBLE "NUMBER" • DOUBLE

QUANTITY

CHECK "NUMBER" • DOUBLE

SIGNAL "NUMBER" • DOUBLE

SET •

R-22AT

R-24AT

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

The "Main PWB" of this model employs lead-free solder. This is indicated by the "LF" symbol printed on the PWB

and in the service manual. The suffix letter indicates the alloy type of the solder.

Example:

Sn-Ag-Cu

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free wire solder

When repairing a PWB with the "LF" symbol, only lead-free solder should be used. (Using normal tin/lead alloy solder

may result in cold soldered joints and damage to printed patterns.)

As the melting point of lead-free solder is approximately 40˚C higher than tin/lead alloy solder, it is recommend that

a dedicated bit is used, and that the iron temperature is adjusted accordingly.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is higher and has poorer wettability, (flow), to prevent damage

to the land of the PWB, extreme care should be taken not to leave the bit in contact with the PWB for an extended

period of time. Remove the bit as soon as a good flow is achieved. The high content of tin in lead free solder will cause

premature corrosion of the bit. To reduce wear on the bit, reduce the temperature or turn off the iron when it is not

required.

Leaving different types of solder on the bit will cause contamination of the different alloys, which will alter their

characteristics, making good soldering more difficult. It will be necessary to clean and replace bits more often when

using lead-free solder. To reduce bit wear, care should be taken to clean the bit thoroughly after each use.

23

Page 26

R-22AT

R-24AT

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

WARNING: Avoid possible exposure to microwave energy. Please follow the instructions below before

operating the oven.

1. Disconnect the oven from power supply.

2. Make sure that a definite “click” can be heard when the

microwave oven door is unlatched. (Hold the door in a

closed position with one hand, then grip the door

handle and the door lever assembly with the other, this

causes the latch leads to rise, it is then possible to hear

a “click” as the door switches operate.)

3. Visually check the door and cavity face plate for damage (dents, cracks, signs of arcing etc.).

Carry out any remedial work that is necessary before

operating the oven.

Do not operate the oven if any of the following conditions

exist;

Please refer to ‘OVEN PARTS, CABINET PARTS, CONTROL PANEL PARTS, DOOR PARTS’, when carrying out any

of the following removal procedures:

1. Door does not close firmly.

2. Door hinge, support or latch hook is damaged.

3. The door gasket or seal is damaged.

4. The door is bent or warped.

5. There are defective parts in the door interlock system.

6. There are defective parts in the microwave generating

and transmission assembly.

7. There is visible damage to the oven.

Do not operate the oven:

1. Without the RF gasket (Magnetron).

2. If the wave guide or oven cavity are not intact.

3. If the door is not closed.

4. If the outer case (cabinet) is not fitted.

WARNING FOR WIRING

To prevent an electric shock, take the following

precautions.

1. Before wiring,

1) Disconnect the power supply cord.

2) Open the door and block it open.

3) Discharge the two high voltage capacitors and

wait for 60 seconds.

2. Don’t let the wire leads touch to the followiong parts;

1) High voltage parts:

Magnetron, High voltage transformer, High voltage capacitor, High voltage rectifier assembly and

High voltage fuse.