Page 1

R

SERVICE MANUAL

COOKING CONTROL

WITH COOK & DEFROST GUIDE

S1892R211M///

ILLUMINATED

TIMER

3

2

4

1

5

6

0

2.0

7

8

9

30

10

30

11

25

12

20

0.7

13

14

15

1.0

(KG)

E

R-211

MICROWAVE OVEN

MODEL

R-211(W)/(BL)M

R-211(G)M

R-211(B)M

In the interests of user-safety the oven should be restored

to its original condition and only parts identical to those

specified should be used.

TABLE OF CONTENTS

Page

SERVICING ...................................................................................................................................... 2

CAUTION, MICROWAVE RADIATION............................................................................................. 3

WARNING......................................................................................................................................... 3

PRODUCT DESCRIPTION............................................................................................................... 3

OPERATING SEQUENCE................................................................................................................ 4

DOOR SWITCHES ........................................................................................................................... 4

OUTPUT POWER TEST PROCEDURE........................................................................................... 5

TEST PROCEDURES....................................................................................................................... 6

DIGITAL ANALOGUE CONTROL PANEL ASSEMBLY ................................................................... 8

COMPONENT REPLACEMENT....................................................................................................... 12

SCHEMATIC DIAGRAM ................................................................................................................... 13

WIRING DIAGRAM ........................................................................................................................... 14

PARTS LIST...................................................................................................................................... 17

EXPLODED ILLUSTRATION............................................................................................................ 20

SHARP CORPORATION

211M -

1

Page 2

SERVICING

WARNING TO SERVICE PERSONNEL

Microwave ovens contain circuitry capable of producing very high voltage and current. Contact with following parts

will result in electrocution:High voltage capacitor, High voltage transformer, Magnetron, High voltage rectifier, High voltage harness.

REMEMBER TO CHECK 3D

1) Disconnect the supply.

2) Door opened, and wedged open.

3) Discharge high voltage capacitor.

WARNING AGAINST THE CHARGE OF THE HIGH-VOLTAGE CAPACITOR

The high-voltage capacitor remains charged about 60 seconds after the oven has been switched off. Wait for 60

seconds and then short-circuit the connection of the high-voltage capacitor (that is, of the connecting lead of the

high-voltage rectifier) against the chassis using a screwdriver with an insulated handle.

Sharp recommend that wherever possible, fault-finding is carried out with the supply disconnected. In some

cases, it may be necessary to connect the supply with the cover removed to carry out fault investigation in the

control circuitry. In such cases, the high voltage circuit should be disabled as described below to reduce the

hazards:-

• Carry out 3D checks (see above).

• Disconnect the supply leads from the high voltage transformer, making a note of the polarity. Insulate the

connectors, ensuring they are positioned away from the transformer and fastened there.

• Connect any relevant test equipment e.g. voltmeter.

• Reconnect the oven to the supply, then close the door.

• Note the results of the test, taking care to keep clear of the operational oven.

• Carry out 3D checks (see above).

• Reconnect the leads to the transformer. Take care to observe correct polarity.

• Carry out 4R checks (see below).

Microwave ovens should not be used without a load. To test for the presence of microwave energy within a cavity,

place a cup of cold water on the oven turntable, close the door and set the microwave timer for one (1) minute, set the

power level to HIGH (100%) and push the start key. When the one (1) minute has elapsed (timer at zero) carefully check

that the water is now hot.

AFTER REPAIR REMEMBER TO CHECK 4R

1) Reconnect all leads removed from components during testing.

2) Replace the outer case (cabinet).

3) Reconnect the supply.

4) Run the oven. Check all functions.

When all service work is completed, and the oven is fully assembled, the microwave power output should be checked

and microwave leakage test carried out.

IMPORTANT: If the oven becomes inoperative because of a blown fuse F8A in the 1st latch switch - monitor switch

circuit, check the 1st latch switch and monitor switch before replacing the fuse F1.

211M -

2

Page 3

CAUTION / WARNING

CAUTION

MICROWAVE RADIATION

Do not become exposed to radiation from the

magnetron or other parts conducting microwave energy. All input and output microwave connections,

waveguides, flanges and gaskets must be secured.

Never operate the device without a microwave energy absorbing load attached. Never look into an

open waveguide or antenna while the device is energized.

Servicing and repair work must be carried out only by

trained service engineers.

The parts marked '*' on the parts list and schematic

diagram have voltages in excess of 250V.

Removal of the outer wrap gives access to potential

above 250V.

All the parts marked "∆" on the parts list may cause

undue microwave exposure, by themselves, or when

they are damaged, loosened or removed.

WARNING

WARNING

THIS APPLIANCE MUST BE EARTHED. THE WIRES IN THIS MAINS LEAD ARE COLOURED IN

ACCORDANCE WITH THE FOLLOWING CODE:

GREEN-AND-YELLOW : EARTH BLUE : NEUTRAL BROWN : LIVE

If the mains lead is replaced, only part number QACCBA030WRE2 should be used

PRODUCT DESCRIPTION

SPECIFICATION

Power Requirements 230-240 Volts 50 Hertz Single phase, 3 wire grounded

Power Consumption 1.24kW

Power Output 800 watts nominal of RF microwave energy (measured by way of IEC 705)

Operating frequency of 2450 MHz

Case Dimensions Width 449 mm Height 282 mm including foot Depth 369 mm

Cooking Cavity Dimensions Width 290 mm Height 194 mm Depth 313 mm

Turntable diameter 272 mm

Control Complement DIGI/ANA

Microwave Power for Variable Cooking

Repetition Rate :

HIGH .................... Full power throughout the cooking time

MEDIUM HIGH..... approx. 70% of Full Power

MEDIUM............... approx. 50% of Full Power

MEDIUM LOW ..... approx. 30% of Full Power

LOW ..................... approx. 10% of Full Power

Set Weight Approx. 13.3 kg

211M -

3

Page 4

OPERATING SEQUENCE

OFF CONDITION

Closing the door activates all door interlock switches (monitored latch switch and latch switch).

IMPORTANT

When the timer knob is at "0" the oven is in the OFF

condition.

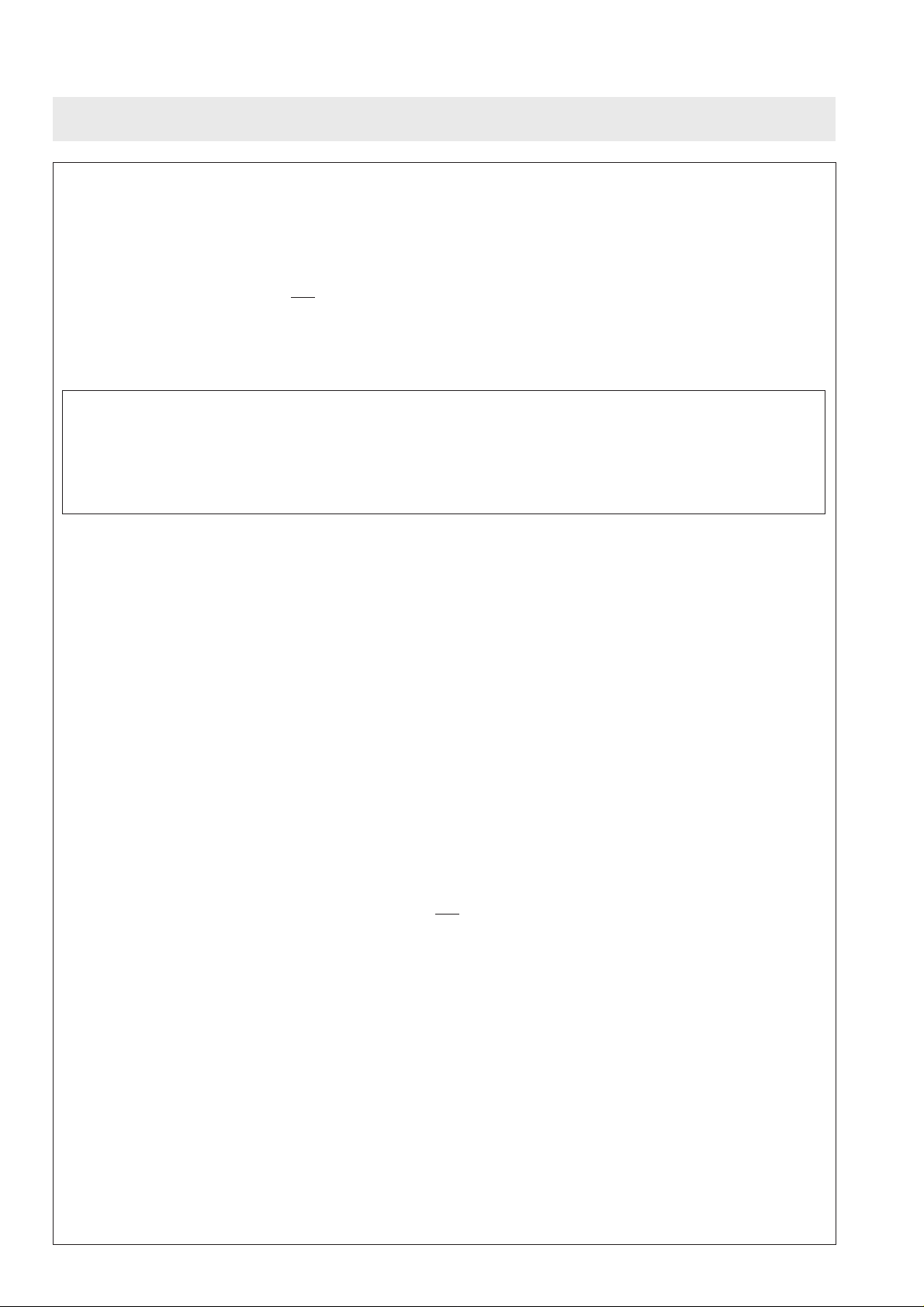

HIGH, MEDIUM HIGH, MEDIUM, MEDIUM

LOW, LOW COOKING

When the microwave oven is preset for variable cooking

power, the line voltage is supplied to the power transformer

intermittently within a 26-second time base through the

relay contact which is coupled with the current-limiting relay

(RY2). The following levels of microwave power are given.

SETTING

26 sec. ON

HIGH

20 sec. ON

MEDIUM HIGH

14 sec. ON

MEDIUM

8 sec. ON

MEDIUM LOW

4 sec. ON

LOW

6 sec. OFF

12 sec. OFF

18 sec. OFF

22 sec. OFF

NOTE: The ON/OFF time ratio does not exactly correspond

to the percentage of microwave power, because

approx. 3 seconds are needed for heating up the

magnetron filament.

Approx. 100% = 800 Watts

Approx. 70% = 560 Watts

Approx. 50% = 400 Watts

Approx. 30% = 240 Watts

Approx. 10% = 80 Watts

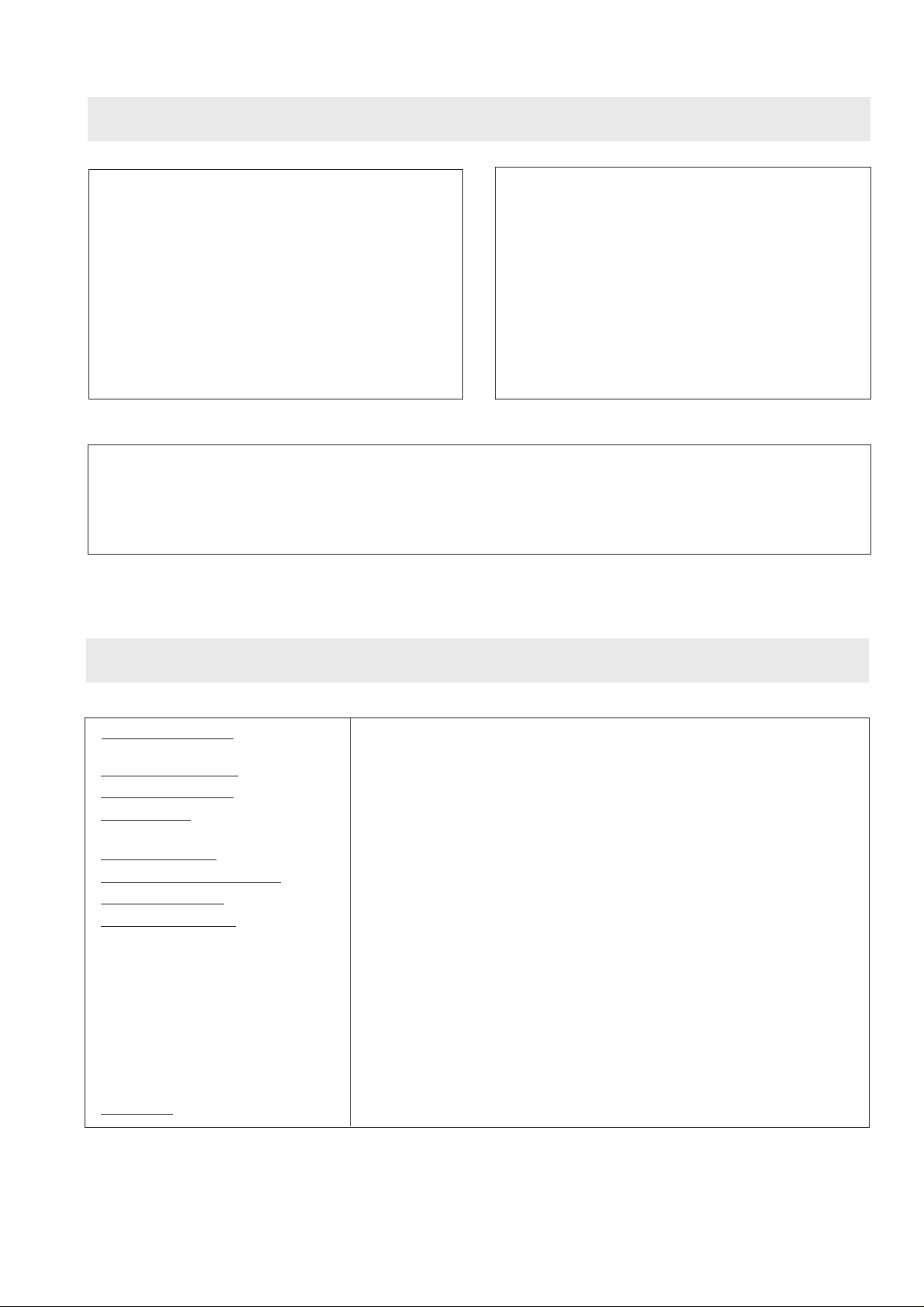

DOOR SWITCHES

DOOR OPEN MECHANISM

LATCH HOOK

DOOR

LATCH

HEADS

DOOR OPEN BUTTON

SW2: MONITOR

SWITCH

SW1: MONITORED

LATCH SWITCH

SW3: STOP SWITCH

OPEN LEVER

MONITORED LATCH SWITCH (SW1)

STOP SWITCH (SW3)

1. When the oven door is closed, the contacts (COM - NO)

must be closed.

2. When the oven door is opened, the contacts (COM NO) must be opened.

MONITOR SWITCH (SW2)

1. When the oven door is closed, the contacts (COM - NC)

must be opened.

2. When the oven door is opened, the contacts (COM NC) must be closed.

3. If the oven door is opened and the contacts (COM - NO)

of the monitored latch switch (SW1) fail to open, the fuse

F8A blows simultaneously with closing the contacts

(COM - NC) of the monitor switch (SW2).

CAUTION: BEFORE REPLACING A BLOWN FUSE (F1)

TEST THE MONITORED LATCH SWITCH

(SW1), + MONITOR SWITCH (SW2) FOR

PROPER OPERATION.

Figure D-1. Door Open Mechanism

211M -

4

Page 5

OUTPUT POWER TEST PROCEDURE

MICROWAVE OUTPUT POWER (IEC-705)

The power output of this oven is rated using the method specified by IEC-705. Full details of how to carry out this

procedure can be found in the Sharp Technical Training notes which is available from Sharp Parts Centre

(part number SERV-LITMW01).

Using this procedure, the heating time to raise 1000g of water by 10°C is approximately 50 seconds.

The IEC-705 procedure must be carried out using laboratory-type procedures and equipment. These requirements

make the procedure unsuitable for routing performance checks. An indication of the power being produced by the oven

can however be obtained using the procedure given below.

Alternative simplified method:

1. Place 2 litres of cold water (between 12°C and 20°C) in a suitable container.

2. Stir the water and measure the temperature in °C. Note temperature as T1.

3. Place the container in the microwave and heat the water for 2 minutes on full power.

4. When the 2 minutes is completed, remove the container and stir the water. Note the water temperature as T2.

5. Calculate the output power using the following formula:

R.F. Power Output = (T2 - T1) x 70.

Note: The result from this test should be within 10% of the power rating stated on the rating label.

MICROWAVE LEAKAGE TEST

This oven should be tested for microwave leakage on completion of any repair or adjustment, following the procedure

described in the Sharp Technical Training notes (part number SERV-LITMW01). The maximum leakage permitted in

BS EN 60335-2-25 is 50W/m

2

(equivalent to 5mW/cm2), however it is not normal to detect any significant leakage,

therefore, any leakage which is detected should be investigated.

It is essential that only leakage detectors with current calibration traceable to the National Physical Laboratories are used.

Suitable leakage detectors : CELTEC A100

APOLLO X1

211M -

5

Page 6

TEST PROCEDURES

COMPONENT TEST

CONTROL PANEL ASSEMBLY TEST

The control panel consists of circuits including semiconductors such as LSI, ICs, etc. Therefore, unlike conventional

microwave ovens, proper maintenance can not be performed with only a voltmeter and ohmmeter.

In this service manual, troubleshooting by replacement is described according to the symptoms indicated.

1. Control Panel

The following symptoms indicate a defective control unit.

1-1 In connection with LEDs

a) At a certain LED, all or some LEDs do not light up.

b) At a certain LED, brightness is low.

c) Only one LED does not light up.

d) All or some LEDs continue to light up.

e) A certain group of LEDs do not light up.

f) The LEDs flicker.

1-2 Other possible troubles caused by defective control unit.

a) Buzzer does not sound or continues to sound.

b) Cooking is not possible.

c) Cooking time can not be set.

d) Power level can not be set.

RELAY TEST

CARRY OUT

3D CHECKS.

Remove the outer case and check voltage between Pin Nos. 3 and 5 of the 3 pin connector (A) on the control unit with an

A.C. voltmeter.

The meter should indicate 230-240 volts, if not check oven circuit.

Relay Test

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation. convection cooking operation

or grill operation.

DC. voltage indicated.............Defective relay.

DC. voltage not indicated....... Check diode which is connected to the relay coil. If diode is good, control unit is defective.

RELAY SYMBOL OPERATIONAL VOLTAGE CONNECTED COMPONENTS

RY1 Approx. 12.0V D.C. Oven lamp / Turntable motor / Fan motor

RY2 Approx. 12.0V D.C. High voltage transformer

CARRY OUT 4R CHECKS.

211M -

6

Page 7

TEST PROCEDURES

COMPONENT TEST

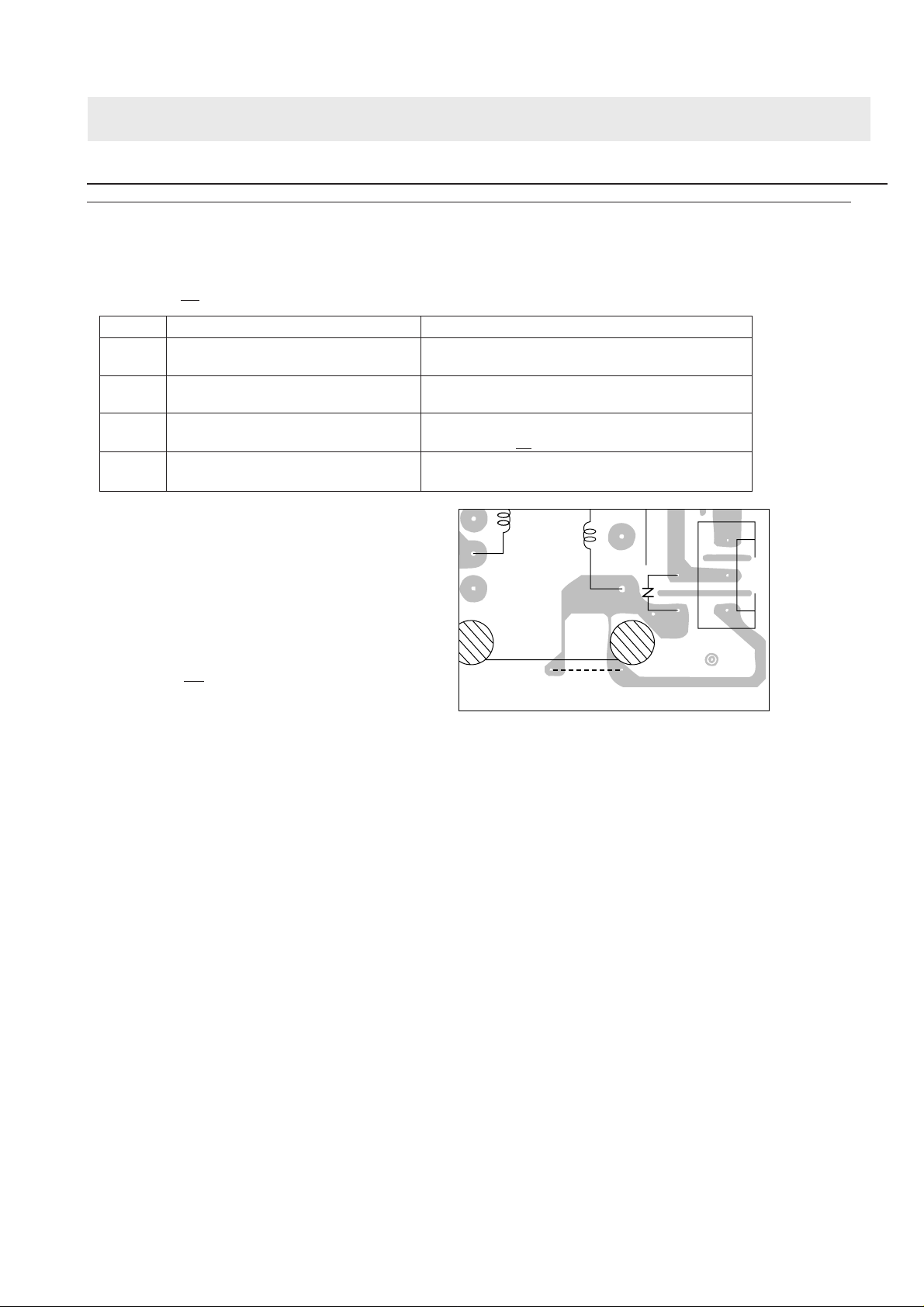

PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE PRINTED WIRING BOARD (PWB) IS OPEN.

To protect the electronic circuits, this model is provided with a fine foil pattern added to the input circuit on the PWB, this foil

pattern acts as a fuse. If the foil pattern is open, follow the troubleshooting guide given below for repair.

Problem: POWER ON, indicator does not light up.

CARRY OUT

STEPS OCCURRENCE CAUSE OR CORRECTION

1 The rated AC voltage is not present at Check supply voltage and oven power cord.

2 The rated AC voltage is present at primary Low voltage transformer or secondary circuit defective.

3 Only pattern at "a" is broken. *Insert jumper wire J1 and solder.

4 Pattern at "a" and "b" are broken. *Insert the coil RCILF2003YAZZ between "c" and "d".

NOTE: *At the time of these repairs, make a

3D CHECKS.

Power terminal of CPU connector (CN-A).

side of low voltage transformer. Check and repair.

(CARRY OUT 3D CHECKS BEFORE REPAIR)

(CARRY OUT 3D CHECKS BEFORE REPAIR)

S

P

visual inspection of the varistor for burning damage and examine the transformer

with tester for the presence of layer short

circuit (check primary coil resistance).

If any abnormal condition is detected,

(J1)

ab

c

replace the defective parts.

CARRY OUT 4R CHECKS.

VRS1

d

CN - A

15

211M -

7

Page 8

DIGITAL ANALOGUE CONTROL PANEL

OUTLINE OF CONTROL PANEL

Control Unit

Control unit consists of LSI, power source circuit, synchronizing signal circuit, ACL circuit, buzzer circuit, encoder

circuit, indicator circuit and potentiometer circuit.

1) LSI

This LSI controls the encoder signal, potentiometer

signal, relay driving signal for oven function, buzzer

signal and LED signal.

2) Power Source Circuit

This circuit generates voltage necessary in the control

unit.

Symbol Voltage Application

VC -5.0V LSI(I-1)

VR -12.0V RELAY(RY1,2)

5) Buzzer Circuit

The buzzer is responsive to signals from the LSI to

emit audible sounds (key touch sound and

completion sound).

6) Door Sensing Switch (Stop Switch)

A switch to "tell" the LSI if the door is open or closed.

7) Relay Circuit

To drive the magnetron, heating element, fan motor,

turntable motor and light the oven lamp.

8) Encoder

The encoder generates the pulse signal, and the

pulse signal is sent to the LSI.

9) Indicator Circuit

Indicator elements are the Light-emitting diodes

(LD1-LD24).

3) Synchronizing Signal Circuit

The power source synchronizing signal is available in

order to compose a basic standard time in the clock

circuit. It accompanies a very small error because it

works on commercial frequency.

4) ACL

A circuit to generate a signals which resets the LSI to

the initial state when power is supplied.

10) Potentiometer Circuit

The circuit makes setting of the power level by

variable resistance.

211M -

8

Page 9

DIGITAL ANALOGUE CONTROL PANEL

DESCRIPTION OF LSI

LSI(IZA882DR)

The I/O signal of the LSI(IZA882DR) are detailed in the following table.

Pin No. Signal I/O Description

1 RST IN Auto clear terminal.

Signal is input to reset the LSI to the initial state when power is applied.

Temporarily set to "L" level the moment power is applied, at this time the LSI is

reset. Thereafter set at "H" level.

2 INT IN Signal coming from encoder.

When the encoder is turned, the contacts of encoder make pulse signals. And

pulse signals are input into INT.

3 AVSS IN A/D converter power source voltage.

The power source voltage to drive the A/D converter in the LSI. Connected to

VC.

4 VREF IN Reference voltage input terminal.

A reference voltage is applied to the A/D converter in the LSI.

5K0INSignal coming from potentiometer.

By inputting DC voltage corresponding to the power level set by the potentiometer,

this input is converted into the power level by the A/D converter built into the LSI.

6K1INTerminal to change functions according to the model.

Signal in accordance with the model in operation is applied to set up its function.

7 AVDD IN A/D converter power source voltage.

The power source voltage to drive the A/D converter in the LSI.

8 NC No connection terminal.

9 S0 OUT Digit selection signal.

Signal is input to the anodes of the light-emitting diodes (LD19 - LD24).

10 S1 OUT Digit selection signal.

Signal is input to the anodes of the light-emitting diodes (LD13 - LD18).

11 S2 OUT Digit selection signal.

Signal is input to the anodes of the light-emitting diodes (LD7 - LD12).

12 S3 OUT Digit selection signal.

Signal is input to the anodes of the light-emitting diodes (LD1 - LD6).

13-14 NC No connection terminal.

15 D0 OUT Segment data signal.

Signal is input to the cathodes of the light-emitting diodes (LD1, LD7, LD13 and

LD19).

16 D1 OUT Segment data signal.

Signal is input to the cathodes of the light-emitting diodes (LD2, LD8, LD14 and

LD20).

17 CNVS IN Reference voltage input terminal.

A reference voltage is applied to the A/D converter in the LSI. Connected to VC.

18 VSS IN Power source voltage: -5V.

The power source voltage to drive the LSI is input to VSS terminal. Connected

to VC.

19 D2 OUT Segment data signal.

Signal is input to the cathodes of the light-emitting diodes (LD3, LD9, LD15 and

LD21).

20 D3 OUT Segment data signal.

Signal is input to the cathodes of the light-emitting diodes (LD4, LD10, LD16 and

LD22).

21 D4 OUT Segment data signal.

Signal is input to the cathodes of the light-emitting diodes (LD5, LD11, LD17 and

LD23).

22 D5 OUT Segment data signal.

Signal is input to the cathodes of the light-emitting diodes (LD6, LD12, LD18 and

LD24).

211M -

9

Page 10

DIGITAL ANALOGUE CONTROL PANEL

Pin No. Signal I/O Description

23 D6 OUT Magnetron high-voltage circuit driving signal.

To turn on and off the cook relay (RY2).

In 100% POWER operation, the signals hold "L" level during microwave

cooking and "H" level while not cooking. In other cooking modes (70%, 50%,

30%, 10%) the signal turns to "H" level

and "L" level in repetition according to

the power level.

24 D7 IN/OUT Terminal not used.

25 D8 OUT Oven lamp, turntable motor and fan motor driving signal(Square Wave-

form : 50Hz).

To turn on and off shut-off relay

20 msec

(RY1). The square waveform

voltage is delivered to the relay

(RY1) driving circuit and

During cooking

relay(RY2) control circuit.

26 NC No connection terminal.

27 F0 IN Input signal which communicates the door open/close information to LSI.

ON/OFF time ratio in Micro

cooking

(a. 32second time base)

MICRO ON OFF

COOK

100% 32sec. 0sec.

70% 24sec. 8sec.

50% 18sec. 14sec.

30% 12sec. 20sec.

10% 6sec. 26sec.

H

L

Door closed; "H" level signal.

Door opened; "L" level signal.

28 F1 Terminal not used.

29 F2 IN Signal to synchronize LSI with commercial power source frequency.

This is basic timing for all real time

processing of LSI.

20 msec

H : GND

L (-5V)

30 F3 IN Signal coming from encoder.

Signal similar to INT. Pulse signals are input into F3.

31-32 NC No connection terminal.

33 XOUT OUT Internal clock oscillation frequency control output.

Output to control oscillation input of XOUT.

34 XIN IN Internal clock oscillation frequency input setting.

The internal clock frequency is set by inserting the ceramic filter oscillation

circuit with respect to XIN terminal.

35 CNTR OUT Signal to sound buzzer.

A: key touch sound.

B: Completion sound.

0.12 sec

A

2.4 sec

B

H: GND

L: -5V

36 VDD IN Power source voltage: 0V.

The power source voltage to drive the LSI is input to VDD terminal.

211M -

10

Page 11

approx. 1M ohm

DIGITAL ANALOGUE CONTROL PANEL

SERVICING

1. Precautions for Handling Electronic Components

This unit uses CMOS LSI in the integral part of the

circuits. When handling these parts, the following

precautions should be strictly followed. CMOS LSI have

extremely high impedance at its input and output

terminals. For this reason, it is easily influenced by the

surrounding high voltage power source, static electricity

charge in clothes, etc., and sometimes it is not fully

protected by the built-in protection circuit.

In order to protect CMOS LSI.

1) When storing and transporting, thoroughly wrap

them in aluminium foil. Also wrap PW boards

containing them in aluminium foil.

2) When soldering, ground the technician as shown in

the figure and use grounded soldering iron and work

table.

2. Shapes of Electronic Components

B

C

Transistor

DTA123ES

DTA143ES

DTD143ES

KRA101M

KRA222M

B

C

E

Transistor

2SB1238

E

3. Servicing of Touch Control Panel

We describe the procedures to permit servicing of the

touch control panel of the microwave oven and the

precautions you must take when doing so.

To perform the servicing, power to the touch control

panel is available either from the power line of the oven

itself or from an external power source.

(1) Servicing the touch control panel with power

supply of the oven :

CAUTION:

THE HIGH VOLTAGE TRANSFORMER OF THE

MICROWAVE OVEN IS STILL LIVE DURING

SERVICING AND PRESENTS A HAZARD .

Therefore, when checking the performance of the

touch control panel, put the outer cabinet on the

oven to avoid touching the high voltage transformer,

or unplug the primary terminal (connector) of the

high voltage transformer to turn it off; the end of

such connector must be insulated with an insulating

tape. After servicing, be sure to replace the leads to

their original locations.

A. On some models, the power supply cord

between the touch control panel and the oven

itself is so short that the two can't be separated.

For those models, check and repair all the

controls (sensor-related ones included) of the

touch control panel while keeping it connected

to the oven.

B. On some models, the power supply cord

between the touch control panel and the oven

proper is so long enough that they may be

separated from each other. For those models,

therefore, it is possible to check and repair the

controls of the touch control panel while keeping

it apart from the oven proper; in this case you

must short both ends of the door sensing switch

(on PWB) of the touch control panel with a

jumper, which brings about an operational state

that is equivalent to the oven door being closed.

As for the sensor-related controls of the touch

control panel, checking them is possible if the

dummy resistor(s) with resistance equal to that

of the controls are used.

(2) Servicing the touch control panel with power

supply from an external power source:

Disconnect the touch control panel completely from

the oven proper, and short both ends of the door

sensing switch (on PWB) of the touch control panel,

which brings about an operational state that is

equivalent to the oven door being closed. Connect

an external power source to the power input

terminal of the touch control panel, then it is

possible to check and repair the controls of the

touch control panel; it is also possible to check the

sensor-related controls of the touch control panel by

using the dummy resistor(s).

4. Servicing Tools

Tools required to service the touch control panel

assembly.

1) Soldering iron: 30W

(It is recommended to use a soldering iron with a

grounding terminal.)

2) Oscilloscope: Single beam, frequency range: DC 10MHz type or more advanced model.

3) Others: Hand tools

5. Other Precautions

1) Before turning on the power source of the control

unit, remove the aluminium foil applied for

preventing static electricity.

2) Connect the connector of the key unit to the control

unit being sure that the lead wires are not twisted.

3) After aluminium foil is removed, be careful that

abnormal voltage due to static electricity etc. is not

applied to the input or output terminals.

4) Attach connectors, electrolytic capacitors, etc. to

PWB, making sure that all connections are tight.

5) Be sure to use specified components where high

precision is required.

211M -

11

Page 12

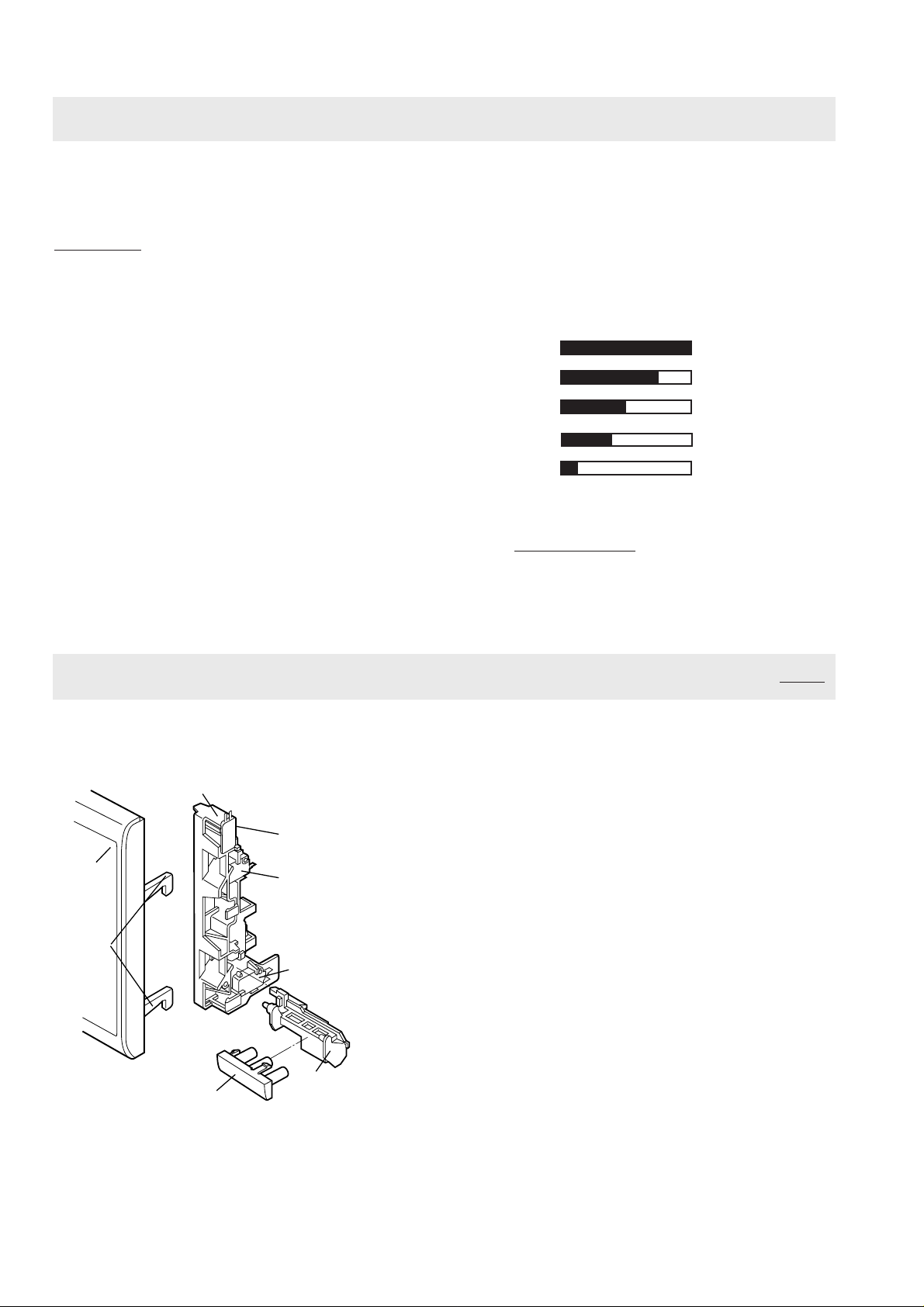

COMPONENT REPLACEMENT

DOOR REPLACEMENT

1. CARRY OUT 3D CHECKS.

2. Remove choke cover taking care not to break

clips by inserting an iron plate (thickness of about

0.5mm) or flat type screw driver into the gap between

the choke cover and door panel to free the engaged

part.

3. Remove door assembly by lifting and easing

it forward.

4. On re-installation make sure the door is

parallel with the bottom line of the oven face

plate and the latch head pass through the

latch holes correctly.

5. CARRY OUT 4R CHECKS.

NOTE : After any service to the door, the

approved microwave survey meter should be

used to assure in compliance with proper

microwave radiation standards.

OUTER CASE

CABINET

DOOR ASSEMBLY

INNER DOOR FILM

Removal

1. Tear the door film from the door panel.

2. Now the door film is free.

Installation

1. Tear away the backing film.

2. Put the pasted side of the door film on the door

panel.

Door film

Backing film

Finger tab

LATCH HEADS

Figure C-6. Door Assembly Replacement and

Adjustment

LATCH HEAD REMOVAL

1. Remove the choke as described in door

replacement.

2. Unhook the spring and lift the latch head clear.

3. Replacement, the reverse of the above.

MONITORED LATCH SWITCH, LATCH

SWITCH, AND MONITOR SWITCH REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the leads from all switches.

3. Remove the one (1) screw holding the latch hook to the

oven cavity.

4. Remove the latch hook.

5. Push the retaining tab slightly and remove the switch.

OUTER DOOR FILM

Removal

1. Remove the door film from the clips on the door frame.

Installation

1. Attach the door film to the clips on the door frame.

LATCH HOOK

Post

SW2: MONITOR

SWITCH

Tab

Post

SW1: MONITORED

LATCH SWITCH

Tab

211M -

12

Post

SW3: STOP

SWITCH

Tab

Figure C-4. Switches

Page 13

SCHEMATIC DIAGRAM

CIRCUIT SUBJECT TO

CHANGE

WITHOUT NOTICE.

DOOR CLOSED

COOK OFF

MICROWAVE CONDITION

R-211 () M 230-240V~50Hz

R-211 () 230V~50Hz

BLU /18 BRN /18

NOISE FILTER

UNIT

MONIT'D

LATCH

SWITCH

SW1

EARTH

NOSIE SUPPRESSION COIL

0. 0033 µF /250V 0. 0033 µF /250V

A5

B1

NO

NO

STOP

SWITCH

SW3

B2

G-Y /18

0. 22 µF /250V

680KΩ/0. 5W

VRS1

T1

RY1

RY2

RY2

10M/0 .5W

A3

COM

NO

LN

F1

OVEN

THERMAL

CUT-OUT

125 C

MONITOR

SWITCH

SW2

NO NO

R-211()M 0. 88µF 2100VAC

R-211() 0. 91µF 2100VAC

NOTE: INDICATES COMPONENTS

*

WITH POTENTIALS ABOVE

250V.

COM

H.V. CAPACITOR

FAN

MOTOR

OVEN

LIGHT

TURNTABLE

MOTOR

*

FM

OL

TTM

A1

POWER TRANSFORMER WITH 150 C

THERMOSTAT IN PRIMARY WINDING

MAGNETRON

*H.V. RECTIFIER *

*

211M -

13

Page 14

WIRING DIAGRAM

MOTOR

TURNTABLE

H.V

RECTIFIER

H.V CAPACITOR

LIVE

BRN

BLU

NEUTRAL

EARTH

NOISE

FAN

LAMP

OVEN

G/Y

LN

MOTOR

POWER CORD

FILTER

UNIT

BLU

BLU

BLU

WHT

WHT

WHT

RED

WHT

WHT

WHT

RED

H.V COMPONENTS

MAGNETRON

RED

BLU

OVEN

THERMAL

CUT-OUT

TRANSFORMER

H.V

WHT

BLU

RED

Figure S-1. Pictorial Diagram

MONITOR

SW2:

SWITCH

WHT

BLU

BLU

BLU

BLU

WHT

WHT

WHT

SW1:

SWITCH

MONITORED

LATCH

CONTROL

PANEL

211M -

CN-B

14

RED

BLU

BLU

BLU

WHT

SW3:

STOP

SWITCH

RELAY 2

BLU

CN-A

RED

WHT

BLU

WHT

NOTE: Most of the terminals are

Positive - Lock Type.

Page 15

WIRING DIAGRAM

B 1

SWITCH

B 2

D30

0V

Q2

DTA123ES

C6

T1

Q40

KRA101M

R6 4.7k

D3

(A)

SP1

R40 3.3k

+

ZD1 HZ6A3

+

D1

CN-A

D20

–

–

R7 10k

D2

10G471K

VRS1

c

AC

OVEN LAMP

FAN MOTOR

TURNTABLE

A 3

KRA101M

–

R20 4.7k

S0

S111S212S3

10

A 1

RY1

Q21

+

C20 0.1µ/50v

I-1 M34225M1

13NC14NC15D016D117

WH-A

MOTOR

DTD143ES

VSS

CNVS

18

(A)

+

ZD3 HZ12A3

–

C21 10µ/35v

Q10 2SB1238

R10 1k 1/2w

: IF NOT SPECIFIED 1/4w ± 5%

: IF NOT SPECIFIED 1SS270A

: IF NOT SPECIFIED 0.01µF / 16v

150

LD6LD12LD18LD24

R55

150

LD5LD11LD17LD23

R54

150

LD4LD10LD16LD22

R53

150

LD3LD9LD15LD21

R52

150

LD2LD8LD14LD20

R51

150LD1LD7LD13LD19

R50

KRA222M

Q53

KRA222M

Q52

KRA222M

Q51

KRA222M

Q50

R63 100k

R62 100k

CBA

C61

C60

R60 4.7k

R61 4.7k

SW1

Figure S-2. Control Panel Circuit

HIGH

VOLTAGE

TRANSFORMER

NO

COM

RY2

D22D21

(JD)

(JC)

Q22

DTA143ES

R30 4.7k

C30

ZD2 HZ4A2

R5 4.7k

4MHz

CF1

VC

Q1 2SB1238

R1 100 2w

(JB)

(JA)

D5

C5 0.1µ/50v

C4 47µ/16 v

C3

R4 2k 1/2w

C2 0.1µ/50v

C1 470µ/35v

D4

D1-D4

IN4005E

d

ab

(J1)

A 5

AC

Q20

R31 47k

36

35

34

33NC32NC31F330F229F128F027NC26D825D724D623D522D421D320D219

XIN

VDD

CNTR

XOUT

INT

RST

VREF

AVSS

AVDD

1

2

3

4

5K06K17

8NC9

VR1

211M -

15

Page 16

WIRING DIAGRAM

LD2

LD1

LD3

LD4

LD5

LD6

LD7

LD8

1

2

3

4

5

LD9

LD10

LD11

6

LD12

LD13

Q50

B

E

SP1

C2

E

B

26

ZD2

Q2

C1

R6

D4

D3

LD24

LD23

11

9

Q51

12

25242322212019

(JA)

(JB)

32

R5

C3

33

38

R4

R40

B

Q1

R1

ZD1

C6

S

8

,F

31

C4

40

R7

LD22

E

B

EEQ21

(JE)

ZD3

Q52

35

B

P

ABC

LD21

Q53

E

B

30

Q40

E

B

C21

B

E

Q10

R22

39

R10

(JD)

R21

SW1

R60

R61

LD18

LD19

LD20

10

R50

R51

Q20

E

(JC)

D21

C61

C5

R30

1

R20

CN - B

RY1

VRS1

CN - A

R52

CF1

2

18

D30

29

C30

C20

D23

D22

E

B

34

37

LD14

LD15

LD16

LD17

7

R63

R53

R54

R55

R62

C60

1314151617

27

28

D5

R31

36

B

Q23

B

Q22

E

D20

RY3

GRILL MICRO

DIP

RY2

41

WH - A

15

VR1

WH - A

D2

D1

T1

(J1)

Figure S-3. Printed Wiring Board

211M -

16

Page 17

P ART LIST

Note: The parts marked “ * ” are used in voltage more than 250V. The parts marked ∆ may cause undue microwave exposure

“§” MARK: SPARE PARTS-DELIVERY SECTION

ELECTRICAL PARTS

REF NO PART NO S DESCRIPTION Q'TY CODE

1-1 RH-DZA048WRE0 U H.V. rectifier 1 AM *

1-2 FPWBFA308WRE1 U Noise filter 1 AQ

1-3 QACCBA030WRE2 U Power supply cord 1 AQ

1-4 RV-MZA270WRE0 U Magnetron 1 BG *∆

1-5 RC-QZA221WRE0 U High voltage capacitor 1 AT

1-6 QSW-MA110WRE0 J Monitored latch switch/Stop switch 2 AK

1-7 QSW-MA112WRE0 J Monitor swith 1 AN

1-8 RMOTEA360WRE0 U Fan motor 1 AU

1-9 QFS-CA024WREO U Fuse F8A 1 AC

1-10 RLMPTA066WRE0 U Oven lamp 1 AK

1-11 FMOTDA056WRKO J Turntable motor assy 1 AR

1-13 RTHM-A096WRE0 U Thermal cut-out 125°C (Oven) 1 AL

1-14 RTRN-A009UREO U Power transformer 1 BH *

CABINET PARTS

REF NO PART NO S DESCRIPTION Q'TY CODE

2-1 GCABUA001URP0 U Outer case cabinet (B) 1 AT ∆

2-1 GCABUA573WRT0 U Outer case cabinet (W) 1 AT ∆

2-1 GCABUA003URP0 U Outer case cabinet (G) 1 AT ∆

2-1 GCABUA009URP0 U Outer case cabinet (BL) 1 AT ∆

2-2 GLEGPA057WRE0 U Foot 2 AB

CONTROL PANEL PARTS

REF NO PART NO S DESCRIPTION Q'TY CODE

3- 1 DPWBFB785WRK0 J Control unit 1

3- 1A QCNCMA430DRE0 J 3-pin connector (CN-A) 1 AG

3- 1B QCNCMA414DRE0 J 2-pin connector (CN-B) 1 AB

3- 1C FW-VZA234DRE0 J Lead wire (WH-A) 1 AD

3- 1D LHLD-A004URF0 J LED holder 1 AC

C1 VCEAB31VW477M J Capacitor 470 uF 35V 1 AC

C2 RC-KZA087DRE0 J Capacitor 0.1 uF 50V 1 AA

C3 VCKYD11CY103N J Capacitor 0.01 uF 16V 1 AA

C4 VCEAB31CW476M J Capacitor 47 uF 16V 1 AA

C5 RC-KZA087DRE0 J Capacitor 0.1 uF 50V 1 AA

C6 VCKYD11CY103N J Capacitor 0.01 uF 16V 1 AA

C20 VCEAB31HW104M J Capacitor 0.1 uF 50V 1 AM

C21 VCEAB31VW106M J Capacitor 10 uF 35V 1 AA

C30 VCKYD11CY103N J Capacitor 0.01 uF 16V 1 AA

C60-61 VCKYD11CY103N J Capacitor 0.01 uF 16V 2 AA

CF1 RCRS-A012DRE0 J Ceramic resonator (CST4.00MGW) 1 AD

D1-4 VHD1N4005E1-2 J Diode (1N4005E) 4 AB

D5 VHD1SS270A/-1 J Diode (1SS270ATA) 1 AA

D20-22 VHD1SS270A/-1 J Diode (1SS270ATA) 3 AA

D30 VHD1SS270A/-1 J Diode (1SS270ATA) 1 AA

I-1 RH-IZA882DRE0 J LSI 1 AK

LD1-24 VHPLTL1CHE/-3 J Light emitting diode (LED) 24 AD

Q1 VS2SB1238//-3 J Transistor (2SB1238) 1 AA

Q2 VSDTA123ES/-3 J Transistor (DTA123ES) 1 AA

Q10 VS2SB1238//-3 J Transistor (2SB1238) 1 AA

Q20 VSKRA101M//-3 J Transistor (KRA101M) 1 AB

Q21 VSDTD143ES/-3 J Transistor (DTD143ES) 1 AC

Q22 VSDTA143ES/1B J Transistor (DTA143ES) 1 AA

Q40 VSKRA101M//-3 J Transistor (KRA101M) 1 AB

Q50-53 VSKRA222M//-3 J Transistor (KRA222M) 4 AB

R1 VRS-L63DA101J J Resistor 100 ohm 2W 1 AD

R4 VRD-B12HF202J J Resistor 2.0k ohm 1/2W 1 AB

R5-6 VRD-B12EF472J J Resistor 4.7k ohm 1/4W 2 AA

R7 VRD-B12EF103J J Resistor 10k ohm 1/4W 1 AA

R10 VRD-B12HF102J J Resistor 1.0k ohm 1/2W 1 AA

211M -

17

Page 18

PART LIST

CONTROL PANEL PARTS

REF NO PART NO S DESCRIPTION Q'TY CODE

R20 VRD-B12EF472J J Resistor 4.7k ohm 1/4W 1 AA

R30 VRD-B12EF472J J Resistor 4.7k ohm 1/4W 1 AA

R31 VRD-B12EF473J J Resistor 47k ohm 1/4W 1 AA

R40 VRD-B12EF332J J Resistor 3.3k ohm 1/4W 1 AA

R50-55 VRD-B12EF151J J Resistor 150 ohm 1/4W 6 AA

R60-61 VRD-B12EF472J J Resistor 4.7k ohm 1/4W 2 AA

R62-63 VRD-B12EF104J J Resistor 100k ohm 1/4W 2 AA

RY1 RRLY-A111DRE0 J Relay (JV12S-KT) 1 AL

RY2 RRLY-A105DRE0 J Relay (OMIF-S-112LM) 1 AN

SP1 RALM-A014DRE0 J Buzzer (PKM22EPT) 1 AG

SW1 RVR-BA018WRE0 J Rotary encoder 1 AL

T1 RTRNPA121DRE0 J Transformer 1 AT

VR1 RVR-BA013DRE0 J Potention meter 1 AF

VRS1 RH-VZA032DRE0 J Varistor (10G471K) 1 AE

ZD1 VHEHZ6A3///-1 J Zener diode (HZ6A3) 1 AC

ZD2 VHEHZ4A2///-1 J Zener diode (HZ4A2) 1 AA

ZD3 VHEHZ12A3//-1 J Zener diode (HZ12A3) 1 AA

3- 2 HPNLCG001URR0 U Control panel [R-211(G)M] 1 AP

3- 2 HPNLCL001URR0 U Control panel [R-211(BL)M] 1 AP

3- 2 HPNLCW002URR0 U Control panel [R-211(W)M] 1 AP

3- 2 HPNLCB001URR0 U Control panel print (R-211(B)M) 1 AP

3- 3 JBTN-A011URF0 U Open button [R-211(G)M] 1 AE

3- 3 JBTN-A073URF0 U Open button [R-211(BL)M] 1 AE

3- 3 JBTN-A001URF0 U Open button (R-211(B)M) 1 AE

3- 3 JBTN-B009WRF0 U Open button [R-211(W)M] 1 AE

3- 4 MSPRCA045WRE0 U Spring 2 AA

3- 5 GMADIA011URR0 U Timer display plate 1 AE

3- 6 JKNBKG001URF0 U Timer knob [R-211(G)M] 1 AE

3- 6 JKNBKL001URF0 U Timer knob [R-211(BL)M] 1 AE

3- 6 JKNBKW001URF0 U Timer knob [R-211(W)M] 1 AE

3- 6 JKNBKB001URF0 U Timer knob (R-211(B)M) 1 AE

3- 7 JKNBKG002URF0 U Vari knob [R-211(G)M] 1 AD

3- 7 JKNBKL002URF0 U Vari knob [R-211(BL)M] 1 AD

3- 7 JKNBKB002URF0 U Vari knob (R-211(B)M) 1 AD

3- 7 JKNBKW002URF0 U Vari knob (R-211(W)M) 1 AD

3- 8 LSTPPA008URF0 U Stopper 1 AB

3- 9 XEPSD30P10XS0 U Self tapping screw 5 AA

3- 10 PCLI-A001URE0 U Harness clip 1 AC

OVEN PARTS

REF NO PART NO S DESCRIPTION Q'TY CODE

4-1 DOVN-A005URT0 U Oven cavity 1 BA

4-2 LBNDKA111WRP0 U Capacitor holder 1 AD

4-3 PHOK-A092WRF4 U Latch hook 1 AH

4-4 NFANJA029WRE0 U Fan blade 1 AM

4-5 PDUC-A638WRF2 U Fan duct 1 AE

4-6 LANGFA169WRP5 U Chassis support 1 AE

4-7 PPACGA126WRE0 U Seal packing 1 AC

4-8 MLEVFA078WRF0 U Open lever 1 AE

4-9 PCOVPA309WRE0 U Waveguide cover 1 AC

4-10 PDUC-A581WRF3 U Air intake duct 1 AE

4-11 GDAI-A280WRP1 U Base plate 1 AQ

4-12 PCUSGA001URP0 U HVT cushion 1 AB

4-13 PSPAGA001WRE0 U Vibration Proof Cushion 1 AA

211M -

18

Page 19

P ART LIST

Note: The parts marked “*” are used in voltage more than 250V. The parts marked ∆ may cause undue microwave exposure

“§” MARK: SPARE PARTS-DELIVERY SECTION

DOOR PARTS

REF NO PART NO S DESCRIPTION Q'TY CODE

5 CDORFB001URK0 U Door assembly (B) 1 BB ∆

5 CDORFW001URK0 U Door assembly (W) 1 BB ∆

5 CDORFG002URK0 U Door assembly (G) 1 BB ∆

5 CDORFL001URK0 U Door assembly (BL) 1 BB ∆

5-1 FDORFA299WRT0 U Door panel assembly 1 AU

5-2 GCOVHA366WRF0 U Choke cover 1 AG

5-3 GWAKPA001URF0 U Door frame (B) 1 AP ∆

5-3 GWAKPA427WRF0 U Door frame (W) 1 AP ∆

5-3 GWAKPA009URF0 U Door frame (G) 1 AP ∆

5-3 GWAKPA025URF0 U Door frame (BL) 1 AP ∆

5-4 PSHEPA560WRE1 U Outer sealer film 1 AE

5-5 LSTPPA158WRF0 U Latch head 1 AD

5-6 MSPRTA141WRE0 U Latch spring 1 AA

5-7 PSHEPA482WRE0 U Inner Sealer film 1 AH

5-8 XEBSD30P06000 U Self tapping screw 4 AA

MISCELLANEOUS

REF NO PART NO S DESCRIPTION Q'TY CODE

6-1 FROLPA070WRK2 U Roller stay 1 AM

6-2 NTNT-A034WRF0 U Turntable 1 AN

6-3 TINS-A069URRO U Operation Manual/Cookery book 1 AM

6-4 QW-QZA191WRE0 U H.V. wire A 1 AF *

6-5 QW-QZA001URE0 U H.V. wire B 1 AE *

6-6 FW-VZA041UREO U Main wire harness 1 AR

SCREW, NUT AND WASHER

REF NO PART NO S DESCRIPTION Q'TY CODE

7-1 XOTSD40P12RV0 J Screw 4mm x 12mm 12 AA

7-2 XHTSD40P08RV0 J Screw 4mm x 8mm 5 AA

7-3 LX-LZA011WRE0 U Rivet 1 AB

7-4 Not applicable to this model

7-5 XFPSD40P06000 J Screw 4mm x 8mm 2 AA

7-7 XOTSE40P12000 J Screw 4mm x 12mm (Chrome) 2 AA

7-7 XOTSF40P12000 J Screw 4mm x 12mm (Black) 2 AA

7-8 LX-CZA063WRE0 U HVT screw 4 AA

7-9 XHPSD40P08K00 J Screw 1 AA

7-10 LX-CZA030WRE0 J Screw 1 AA

7-11 LX-NZA026WRE0 U M4 Nyloc nut 1 AA

7-12 XOTSD40P10000 J Self tapping screw 2 AA

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

211M -

19

Page 20

EXPLODED ILLUSTRATION

CABINET AND UNIT CHASSIS PARTS

1-10

4-10

1-4

7-3

1-13

7-7

7-1

2-1

7-2

1-3

7-11

7-1

7-1

7-7

7-2

7-12

4-1

4-9

4-7

1-11

7-5

4-11

7-1

2-2

7-1

7-1

NOTE: In the event of removing the

turntable motor cover this part should be

refitted using screw connection:

LX-CZA030WRE0

1-14

4-8

2-2

7-1

4-13

4-3

7-12

4-12

7-1

1-6

7-8

4-5

x2

x4

7-2

1-5

1-6

1-7

1-1

4-2

6-2

7-2

1-8

1-9

7-9

4-4

1-2

3-10

4-6

7-5

7-2

6-1

211M -

20

Page 21

EXPLODED ILLUSTRATION

CONTROL PANEL PARTS

3 - 7

3 - 6

3 - 3

DOOR PARTS

3 - 4

3 - 9

3 - 9

3 - 9

3 - 2

3 - 8

3 - 1

3-1D

3 - 5

3 - 4

5

5-4

5-8

5-5

5-6

x4

5-2

5-7

5-1

5-3

211M -

21

Page 22

EXPLODED ILLUSTRATION

6-4

6-4

6-6

6-6

Actual wire harness may be different than illustration.

6-5

6-5

PACKING AND ACCESSORIES

ROLLER STAY

TRAY PAD

SPADPA496WRE1

DOOR PROTECTION SHEET

SPADPA531WRE0

INTO THE OVEN CAVITY (DIAGONALLY)

TURNTABLE TRAY

PACKING PAD KIT

CPADBA186WRKO

POLYETHYLENG BAG

SSAKHA047WRE0

INTO THE

OVEN CAVITY

UNDERNEATH

TRAY PACK

TRAY PAD

SPADPA496WRE1

Not replaceable items.

211M -

22

PACKING CASE

R-211M(W): SPAKCA154URR0

R-211M(B): SPAKCA155URR0

R-211M(G): SPAKCA157URR0

R-211M(BL): SPAKCA159URR0

Page 23

R

211M -

SHARP COPORATION

Printed in U.K.

23

Loading...

Loading...