PC3H4/PC3Q64Q

PC3H4/PC3Q64Q

■ Features

1. AC input type

2. Half pitch type (lead pitch : 1.27mm)

3. Isolation voltage between input and output

(Viso: 2 500Vrms)

4. Applicable to infrared ray reflow

(230˚C, for MAX. 30s)

5. High reliability

6. Taping package

PC3H4 (1ch), PC3Q64Q (4ch)

7. Recognized by UL, file No. E64380

Approved by VDE, No.5922UG

■ Applications

1. Programmable controllers

■ Package Specifications

Model No.

PC3H4

PC3Q64Q

Taping reel diameter 330mm (3 000pcs.)

Taping reel diameter 330mm (1 000pcs.)

■ Absolute Maximum Ratings

Parameter Rating

Forward current

*1

Peak forward current

InputOutput

Power dissipation

Collector-emitter

voltage

Emitter-collector voltage

Collector current

Collector power dissipation

Total power dissipation

*2

Isolation voltage

Operating temperature

Storage temperature

*3

Soldering temperature

*1 Pulse width<=100µs, Duty ratio : 0.001

*2 AC for 1min, 40 to 60%RH, f=60Hz

*3 For 10s

Taping specifications

PC3H4

PC3Q64Q

Symbol

I

F

IFM

P

V

CEO

VCEO

VECO

IC

PC

Ptot

Viso

Topr

Tstg

Tsol

±50

±1

70

70

35 V

6

50

150

170

2.5

−30 to +100

−40 to +125

260

Soldering area

(Ta=25˚C)

Unit

mA

A

mW

V

V

mA

mW

mW

kV

rms

˚C

˚C

˚C

0.2mm or more

Mini-falt Package AC Input Type

Half Pitch Photocoupler

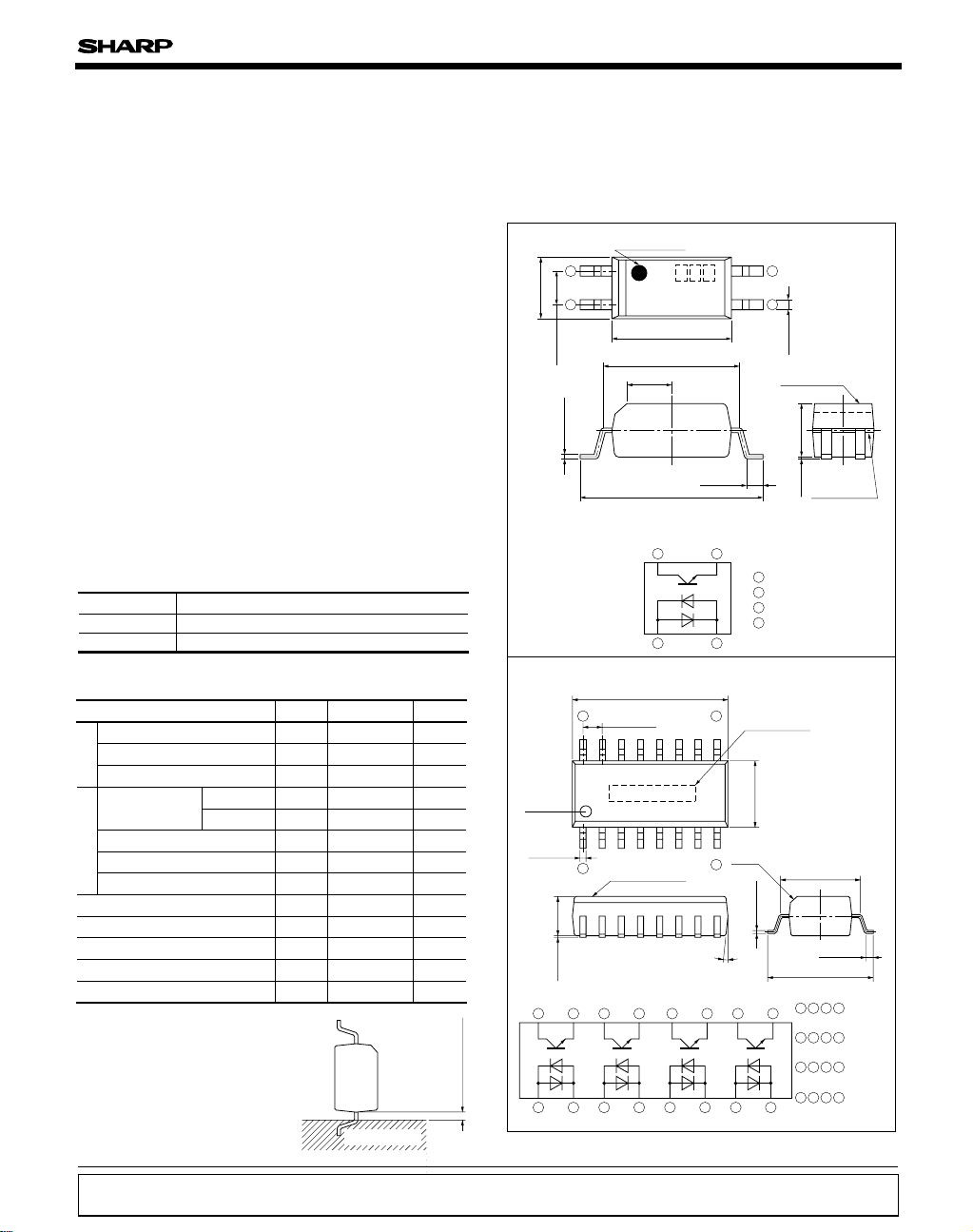

■ Outline Dimensions

PC3H4

±0.3

2.6

±0.25

1.27

±0.05

❈ ( ) : Reference dimensions

PC3Q64Q

Primary

Side

mark

±

0.1

0.4

0.2

±

2.6

0.1

±

0.1

16 15 14 13 12 11 10

12345678

Anode mark

1

2

0.2

16

1

Internal connection diagram

S

3H4

±0.2

4.4

±0.3

5.3

(1.7)

+0.2

7.0

−0.7

Internal connection diagram

±

0.3

10.3

±

0.25

1.27

Epoxy resin

0.5

+0.4

−0.2

34

21

9

8

6°

Model No.

0.2

±

4.4

C0.4

0.05

±

0.2

1

2

3

4

4

3

±0.1

0.4

Epoxy resin

±0.2

2.0

±0.1

Parting line

0.1

Anode

Cathode

Emitter

Collector

5.3

7.0

1 3 5 7

9

Anode/Cathode

2468

Anode/Cathode

9

11 13 15

Emitter

10 12 14 16

Collector

(Unit : mm)

±

0.3

+0.4

0.5

−0.2

+0.2

−0.7

Notice In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP

devices shown in catalogs, data books, etc. Contact SHARP in order to obtain the latest device specification sheets before using any SHARP device.

Internet Internet address for Electronic Components Group http://www.sharp.co.jp/ecg/

PC3H4/PC3Q64Q

■ Electro-optical Characteristics

Parameter Conditions

Input

Output

Transfer

charac-

teristics

Forward voltage I

Terminal capacitance

Collector dark current

Collector-emitter I

breakdown voltage

PC3H4

PC3Q64Q

PC3H4

PC3Q64Q

Emitter-collector

breakdown voltage

Collector current

Collector-emitter

saturation voltage

Isolation resistance

Floating capacitance V=0, f=1MHz

Response time

Rise time

Fall time

Symbol

V

F

Ct

ICEO

BVCEO

BVECO

IC

VCE(sat)

RISO

Cf

tr

tf

(Ta=25˚C)

TYP.

1.2

30

−

− −

− −

−

−

0.1

11

0.6

4

3

MAX.

1.4

250

100

−

4.0

0.2

−

1.0

18

18

MIN.

70

35

0.2

5×10

−

−

−

6

−

10

1×10

F=±20mA

V=0, f=1kHz

V

CE=50V, IF=0

V

CE=20V, IF=0 − − 100ICEO nA

C=0.1mA, IF=0

IC=0.1mA, IF=0BVCEO

E=10µA, IF=0

I

F=±1mA

I

V

CE=5V

F=±20mA

I

I

C=1mA

DC500V

40 to 60%RH

−

V

CE=2V

IC=2mA

R

L=100Ω

−

−

Unit

V

pF

nA

V

V

V

mA

V

Ω

pF

µs

µs

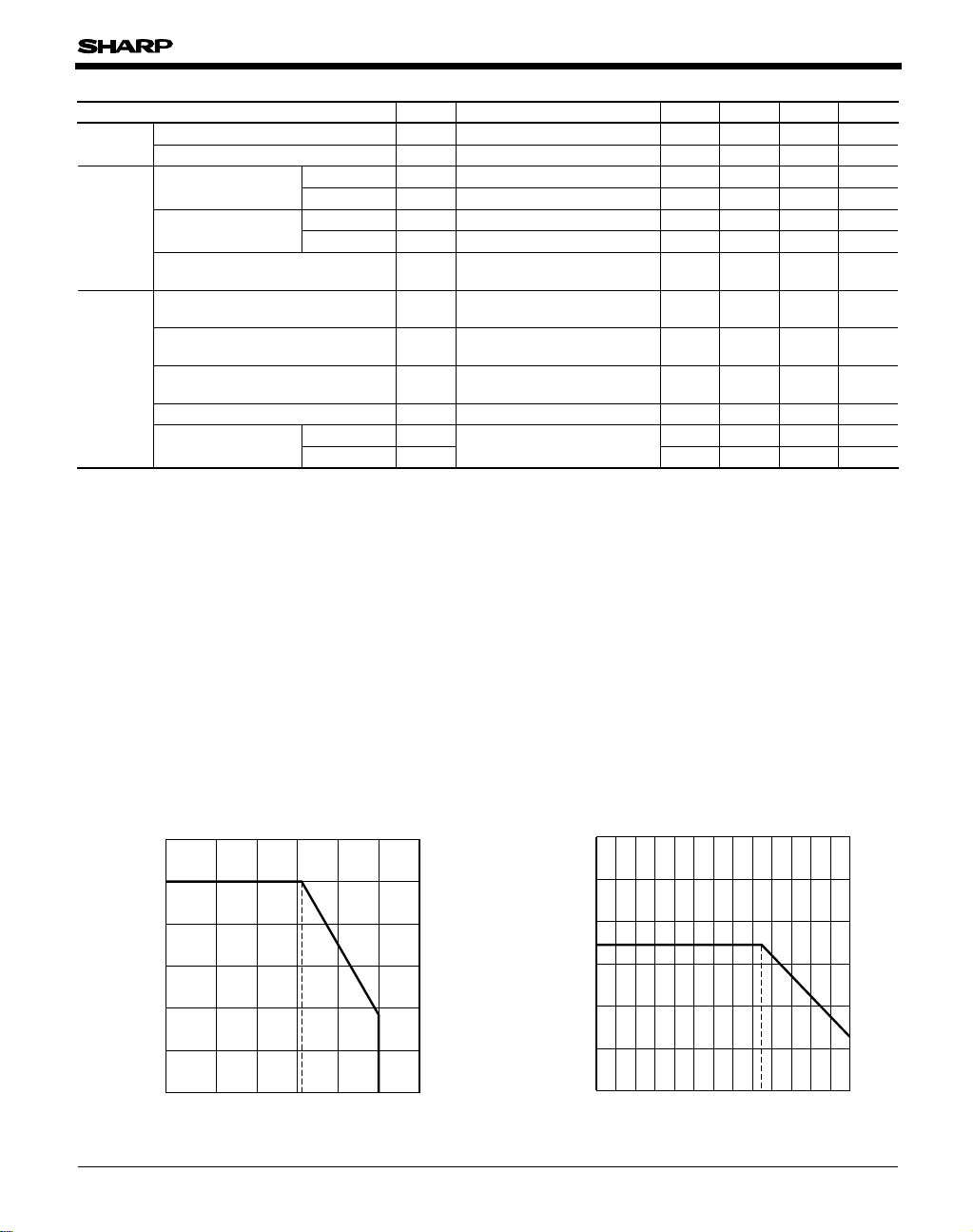

Fig.1 Forward Current vs. Ambient

Temperature

60

50

40

(mA)

F

30

20

Forward current I

10

0

−30 0 25 75 100 1255550

Ambient temperature T

(°C)

a

Fig.2 Diode Power Dissipation vs. Ambient

Temperature

100

80

70

60

40

Diode power dissipation P (mW)

20

0

−30 0 55 10050

Ambient temperature T

(°C)

a

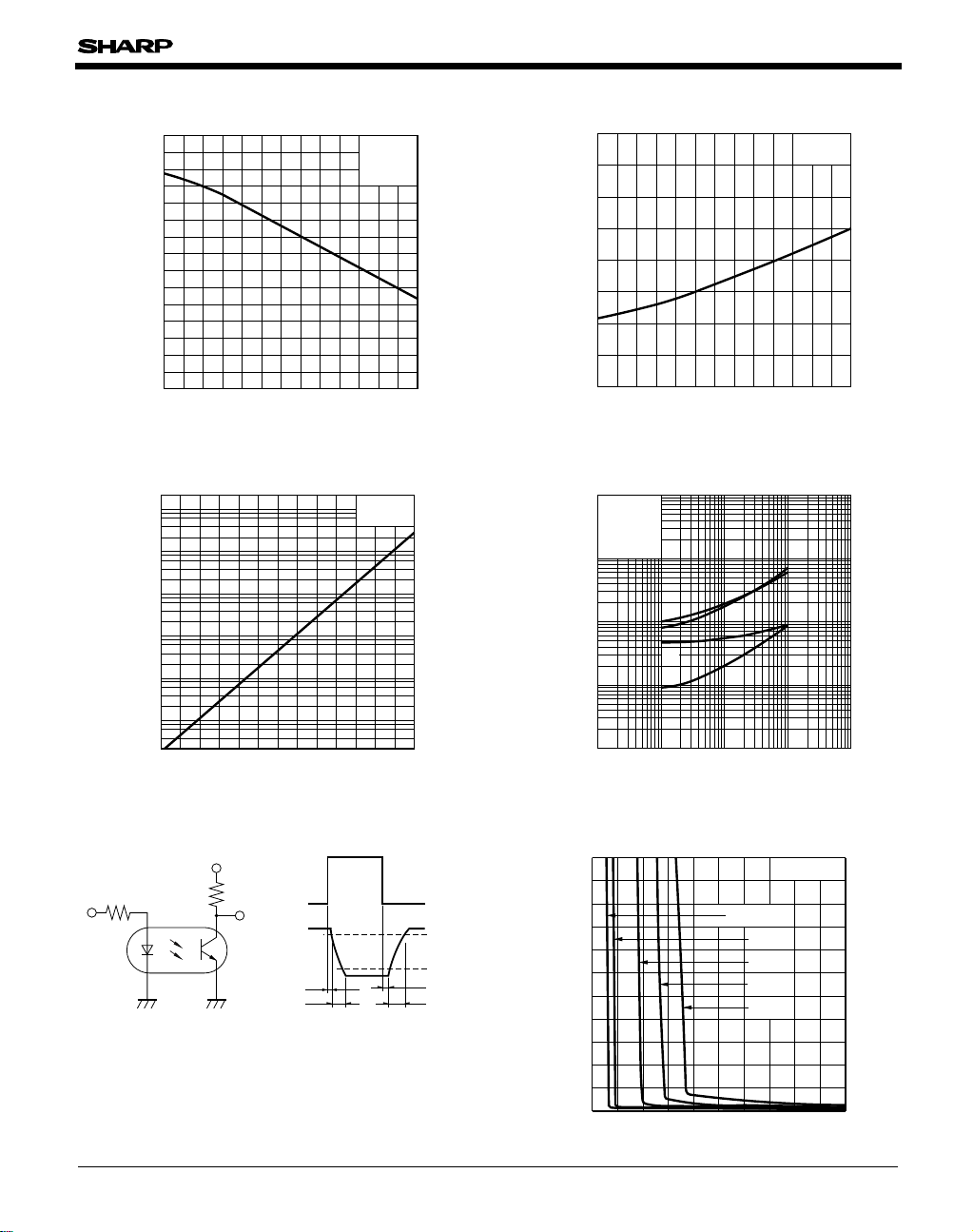

PC3H4/PC3Q64Q

Fig.3 Collector Power Dissipation vs.

Ambient Temperature

200

(mW)

150

C

100

50

Collector power dissipation P

0

−30 0 25 50 75 100 125

10000

5000

2000

(mA)

1000

FM

500

200

100

50

Peak forward current I

20

10

5

5 210

Ambient temperature T

−3

5 210

−2

Duty ratio

(°C)

a

Pulse width<=100µs

=25°C

T

a

−1

5 210

5 1

Fig.7 Current Transfer Ratio vs. Forward

Current

500

400

300

200

Current transfer ratio CTR (%)

100

0

0.1 1 10 100

Forward current I

(mA)

F

VCE=5V

=25°C

T

a

Fig.4 Total Power Dissipation vs. Ambient

Temperature

250

200

(mW)

tot

170

150

100

Power dissipation P

50

0

−30 0 25 50 75 100

Ambient temperature T

(°C)

a

Fig.6 Forward Current vs. Forward VoltageFig.5 Peak Forward Current vs. Duty Ratio

500

200

100

50

(mA)

F

20

10

5

Forward current I

1

Ta=75˚C

50˚C

020.5 1.0 1.5 2.0 2.5 3.0 3.5

Forward voltage V

25˚C

0˚C

−25˚C

(V)

F

Fig.8 Collector Current vs. Collector-emitter

Voltage

50

40

(mA)

C

30

20

Collector current I

10

0

0 2 4 6 8 10

PC (MAX.)

IF=30mA

20mA

10mA

Collector-emitter voltage V

5mA

CE

T

1mA

(V)

=25°C

a

PC3H4/PC3Q64Q

Fig.9 Relative Current Transfer Ratio vs.

Ambient Temperature

150

100

50

Relative current transfer ratio (%)

0

−30 0 20 40 60 80 100

Ambient temperature T

a

(°C)

I

F

V

=1mA

=5V

CE

Temperature

−5

10

5

−6

10

5

(A)

−7

CEO

10

5

−8

10

5

−9

10

5

Collector dark current I

−10

10

5

−11

10

−30 0 20 40 60 80 100

Ambient temperature T

a

(°C)

V

=20V

CE

Fig.10 Collector-emitter Saturation

Voltage vs. Ambient Temperature

0.16

0.14

0.12

0.10

(sat) (V)

CE

0.08

0.06

voltage V

Collector-emitter saturation

0.04

0.02

0.00

−30 0 20 40 60 80 100

Ambient temperaturet T

(°C)

a

I

=20mA

F

IC=1mA

Fig.12 Response Time vs. Load ResistanceFig.11 Collector Dark Current vs. Ambient

1000

Response time (µs)

=2V

V

CE

500

=2mA

I

C

=25°C

T

200

a

100

50

20

10

5

2

1

t

r

t

d

t

f

t

s

0.5

0.2

0.1

0.01 0.1 1 10 100

Load resistance RL (kΩ)

Fig.13 Test Circuit For Response Time

V

CC

R

L

Output

Input

Output

t

d

t

r

t

t

Input

R

D

Fig.14 Collector-emitter Saturation Voltage

vs. Forward Current

=0.5mA

I

C

F

Ta=25°C

1mA

3mA

5mA

7mA

(mA)

10

10%

90%

s

f

8

6

(sat) (V)

CE

V

4

2

Collector-emitter saturation voltage

0

0 2 4 6 8 10

Forward current I

Fig.5 Reflow Soldering

Only one time soldering is recommended within the temperature

profile shown below.

230°C

200°C

180°C

PC3H4/PC3Q64Q

25°C

2min

30s

1min

1.5min

■ Precautions for Use

Please refer to the chapter "Precautions for Use".

1min

Loading...

Loading...