‘REPARED BY: DATE

1. This specification sheets include the contents under the copyright of

Sharp Corporation (“Sharp”). Please keep them with reasonable care as

important information.

them \;i’thout Sharp’s consent,

SPEC No.

PILE No.

SHARP

ELECTRONIC COMPONENTS CROUP

SHARP CORPORATION

SPECIFICATION

Please don’t reproduce or cause anyone reproduce

ISSUE

PACE

REPRESENTATIVE DIVISION

0 PHOTOVOLTAICS DIV.

baOPTO-ELECTRONIC DEVICES DI’

0 ELECTRONIC COMPONENTS DIV.

0

0

ED-93032

April 9, 1993

12 Pages

2.

?lease obey the instructions mentioned below for actual use of this device.

( :; This device is designed for general electronic equipment.

Main uses of this device are as follows;

. Computer

* Measuring equipment

* Home appliance, etc.

c

(2) Please take proper steps in order to maintain reliabflity and safety,

in case this device is used for the uses mentioned belov which require

high reliability.

-Unit concerning control and safety of a vehicle (air plane, train,

automobile etc.)

*Fire box and burglar alarm box

[

0) Please don’t use for the uses mentioned below which require

extremely high reliability

element), etc.

0 CUSTC.LIER’S APPROVAL

l

OA equipment -Telecommunication equipment (Terminal)

*Tooling machine .AV equipment

*Gas leak detection breaker

*Other safety equipment, etc.

.Telecommunication equipment (Trunk)

. Medical equipment (relating to any fatal

PRESENTED

BY

* Traffic signal

I

3

1

DATE

T. Fla tsrimura ,

Department General Manager of

Engineering Dept., TI

Opto-Electronic Devices Div.

ELECOM Group

SHARP CORPORATION BY

1.

Application

This specification applies to the outline and characteristics of

photocoupler Model No. PC3Q64.

2.

Outline

Refer to the attached drawing No. CY5888K02.

3. Ratings and characteristics

3.1 Absolute maximum ratings

PAGE

Ta=25'C

1

*l Forward current

, Input

1

I I

!Output

,

I

*2 Peak forward current

*l Power dissipation

*l Collector power dissipation PC I 150

*l Total power dissipation

Parameter Symbol Rating j Unit

IF /

IFM

! p i

!

Collector-emitter voltage

Emitter-collector voltage

Collector current

Operating temperature

VCEO 1

VECO 1

Ic

I

+50 ; mA

i

I

21

70

35

6

50 ;mt;

1

A I

!

j mW

I

1

V

i vi

, i

! mW i

I

(

I

*1 The derating factors of absolute maximum rating due to ambient

temperature are shown in Fig. 1 'L 4.

*2 Pulse width 5 lOOps, Cuty ratio : 0.001 (Refer to Fig. 5)

*3 AC for 1 min., 40 "u 60%RH, f=60Hz

*4 For 10 s

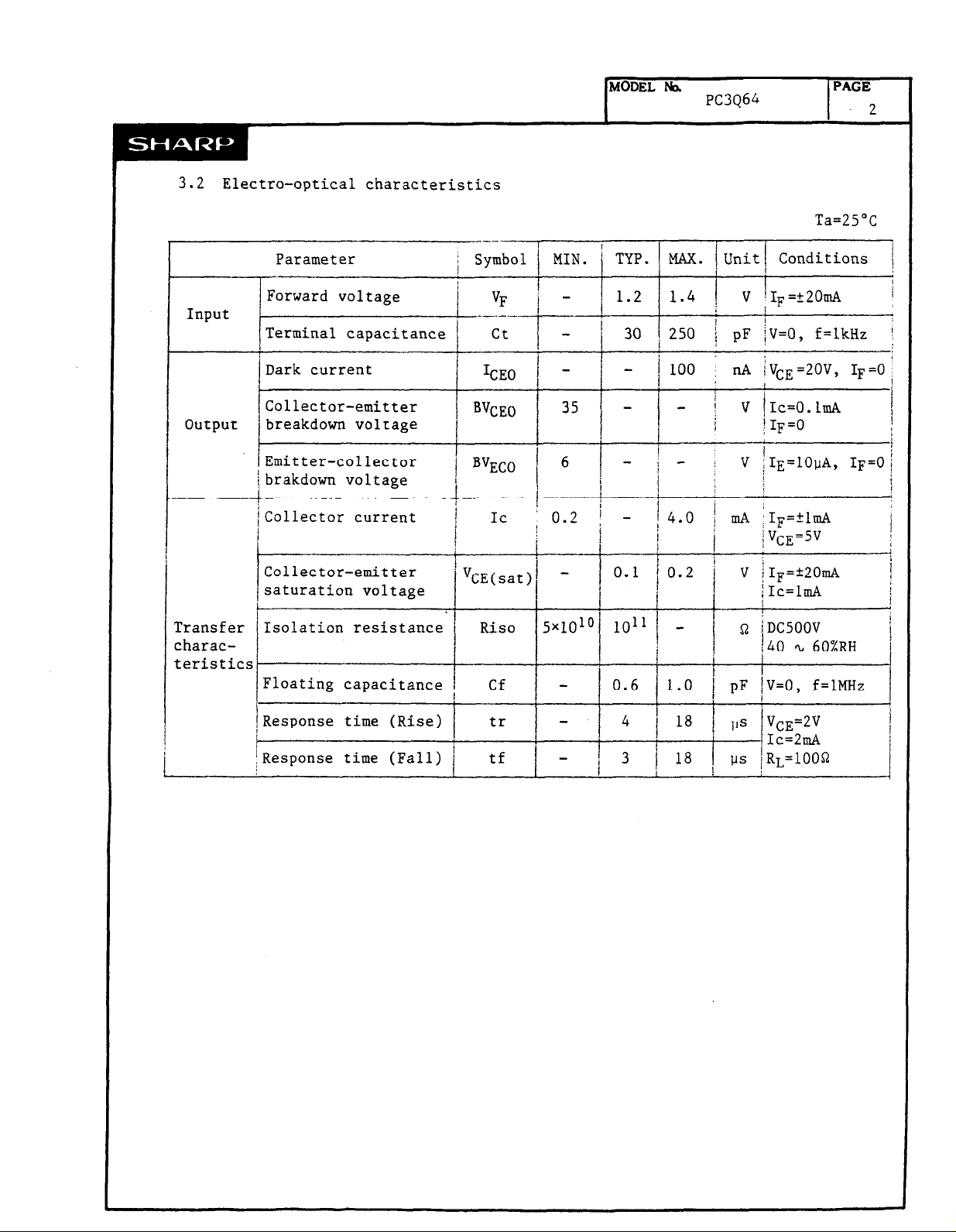

3.2 Electra-optical characteristics

Ta=25"C

Input

output

Transfer

characteristics

Parameter

Forward voltage

Terminal capacitance

Dark current

Collector-emitter

breakdown voltage

Emitter-collector / BVECO 1 6 brakdown voltage

Collector current 1 Ic

Collector-emitter

saturation voltage

j Symbol MIN. ' TYP.

/

"F -

___-._./

j ct - I 1 30 j 250 i pF $=O, f=lkHz j

'CEO

BVCEO

i- /-

I

35 - - 1 v /Ic=O.lmA

I

I

/

0.2 j - ] 4.0 / d &=tld

I

'"CE(sat)

i- 1

1

j

1.2 1.4 : " 'IF='2Oti

0.1 j 0.2 / " i1F=+20ti

MAX. 1 Unit/ Conditions /

f

I

1 100

; d &E=20", IF=0

,

I j IF=0

1 - ; " ;I~=l@ki, IF=0 1

/ ;

j

I

I

/"CE=5" ;

! ' /Ic=lmA

1

Isolation resistance Riso 5x1010 loll / - 1 $rj iDC500V

/40 ?r 60%RH

I

Ic=2mA

I

Floating capacitance i Cf -

I / 1

Response time (Rise)

tr -

Response time (Fall) 1 tf

I

0.6

I

' 4

- 1 3

I

1

1.0 i pF fV=O, f=lMHz

1 18 j ,,s VCE=2V

I

j 18 1 / , us lRL=lOOO

I

I

I

I

1

1

I

/

i

I

IMODEL No.

I

4. Reliability

Refer to the attached sheet, Page 7.

5. Incoming inspection

Refer to the attached sheet, Page 8.

6. Supplements

6.1 Isolation voltage shall be measured in the following method.

(1) Short between anode and cathode on the primary side and

between collector and Emitter on the secondary side.

(2) The dielectric withstand tester with zero-cross circuit shall

be used,

pc3Q64

(PAGE

I

3

(3) The waveform of applied voltage shall be a sine wave.

(It is recommended that the isolation voltage be measured

in insulation oil)

6.2 This product is AC input type.

6.3 (I) This product is not designed as radiation hardened.

(2) This product is assembled with electrical input and output.

(3) This product incorporates non coherent light emitting diode.

6.4 Package specifications

Refer to the attached sheet, Page 9 to 11.

6.5 UL : Under preparation

Notes

7.

7.1 For cleaning

* Cleaning conditions:

jh4ODEL No.

I

PC3Q64

1 PAGE

I

.

4

(1) Solvent cleaning:

Solvent te perature 45°C or less

Immersion 3 min. or less

(2) Ultrasonic cleaning:

Affection to device by ultrasonic cleaning has

different affection by cleaning bath size,

ultrasonic power output, cleaning

or device mounting condition etc- If user

carries out ultrasonic cleaning, user should

select fit condition that doesn't occur defect.

* The cleaning shall be carried out with solvent below.

Solvent: Ethyl alcohol, Methyl alcohol, Isopropyl alcohol

Freon TE.TF, Daiflon-solvent S3-E

Please refrain from using Chloro Fluoro Carbon type solvent to clean

devices as much as possible since it is restricted to protect the

ozonosphere. Before you use alternative solvent you are requested

to confirm that it does not damage package resin.

7.2 On mounting

In mounting this device, please perform soldering reflow satisfied

with the conditions indicated in page 12. And please pay attention

not to occur the temperature rising of the package sectionally.

time,

PWB size

8. Others

Any doubt as to this specification shall be determined in good faith

upon mutual consultation of the both parties.

SHARI=

Date code *l

I---

iurr

lax. 0.2 Pin Nos*

-i I 1

connection diagram

PC3Q64 Page 5

and internal

Q

d

l tl

W

I

P C 3 Q.6 4

Epoxy resin

.’

l-t

T

m

d

$1

4

-.-

-cu

d

-

e Q@ @Qa aDQ!J @

Date code is composed of 2-digit number marked according

to DIN standard and the,following weekly code .

First week :1

Second week : 2

Third weed : 3

Fouth week : 4

Fifth, Sixth week : 5

UNIT :l/lmm

PC3Q64

Name Outline Dimensions

rawin

0.

cy5888KO2

1

SHARP

Page 6

Fig. 1 Forward current vs.

ambient temperature

-‘Tr 0

Ambient2~empe~~tu~~ '!'~"(oC)

3 Collector power dissipation

Fig .

-

vs. ambient temperature

.a

Fig. 2 Diode power dissipation

vs. ambient temperature

4

.2 55 75

n

-

Ambitnt fzmperature Ta ("C)

Fig. 4 Total power dissipation

ambient temperature

vs.

100

200

150

100 -

-30

Ambiint ?zrnpe?\tuJ: T'aoo(“C)

5 Peak forward current

VS.

duty ratio

\

\

Pulse width S 100~

Ta = 25C

100 --

50 --

150 1

“l

*

Duty ratio

4. Reliability

The reliability of products shall be satisfied with items listed below.

!

/

Test Items

I

PC3Q64

7

I

Confidence level : 90%, LTPD : 10%/20%

Test Conditions Failure Samples (n)l

Judgement

Defective(C)

] Criteria

j Solderability *l i 23O"C, 5 s

Soldering heat *2 i 260°C, 10 s

Terminal strength

(Bending)

Mechanical shock

' Weight : lNtO.lkgf]

*3 , 1 time/each terminal

I

1 15000m/s2{1500G], 0.5ms

/ 3 times/?X, ?Y, ?Z direction

/

Variable frequency i 100 2, 2000 s 100 Hz/4 min.

vibration

j 4 times/X,Y,Z direction

1 200m/s2t20G]

Temperature

: 1 cycle -40°C Q, +125"C

cycling (30min.) (30min.) j

j 20 cycle test

i

High temp. and high i +85"C, 85%RH, 500h

humidity storage

I

High temp. storage 1 +125"C, lOOOh

Low temp. storage i -4O"C, lOOOh

-

Operation life

/

' Ta=25"C, IF=?5OmA

Ptot=l-/OmW, lOOOh

/

,

I

!

1

; VF > u x 1.2 n=ll, C=O

I

/

CEO ‘, u x 2

j I

I

IC <

L x 0.7

'CE(sat)

n=ll, C=O

n=ll, C=O

1 n=ll, C=O

i

] n=ll, C=O

9

>ux1.2 1

!

i n=22, C=()

!

,

jU: Upper

specification. n=22, C=O

i

limit

I

n=22, C=O

:L: Lower

specification n=22, C=O

/

limit

I

I

n=22, C=O

!

*1 Solder shall adhere at the area of 95% or more of immersed portion of

lead and pin hole or other holes shall not be concentrated on one portion.

*2 The lead pin depth dipped into solder shall be away 0.2mm from the

root of lead pins.

(Refer to the below)

*3 Terminal bending direction is shown below.

Weight :

lNfO.lkgf)

Incoming inspection

5.

5.1 Inspection items

(1) Electrical characteristics

IMODEL rb.

I

PC3Q64

IPAGE

8

I

VFY ICE09 VCE(sat

(2) Aplpearance

5.2 Sampling method and Inspection level

A single sampling plan, normal inspection level II based on

MIL-STD-105D is applied. The AQL according to the inspection

items

Defect 1

Major

defect Unreadable marking ! inspection II j 0.1

Minor Appearance defect except Normal

defect

are shown below.

Inspection item

Electrical characteristics i

the above mensioned. inspection II j 0.4

J, Ic, Riso, Viso

I

1 Inspection level AQL(%)

!

I

1

Normal

I

!

!

I

6.2

Package specifications

MODEL Noa

pc3Q64

PAGE

9

6.2.1

(1)

(2)

(3)

(4)

(5)

Taping conditions (Refer to the attached sheet, Page 10)

Tape structure and Dimensions

The tape shall have a structure in which a cover tape is sealed heat-

pressed on the carrier tape of hard vinylchloride to protect against

static electricity.

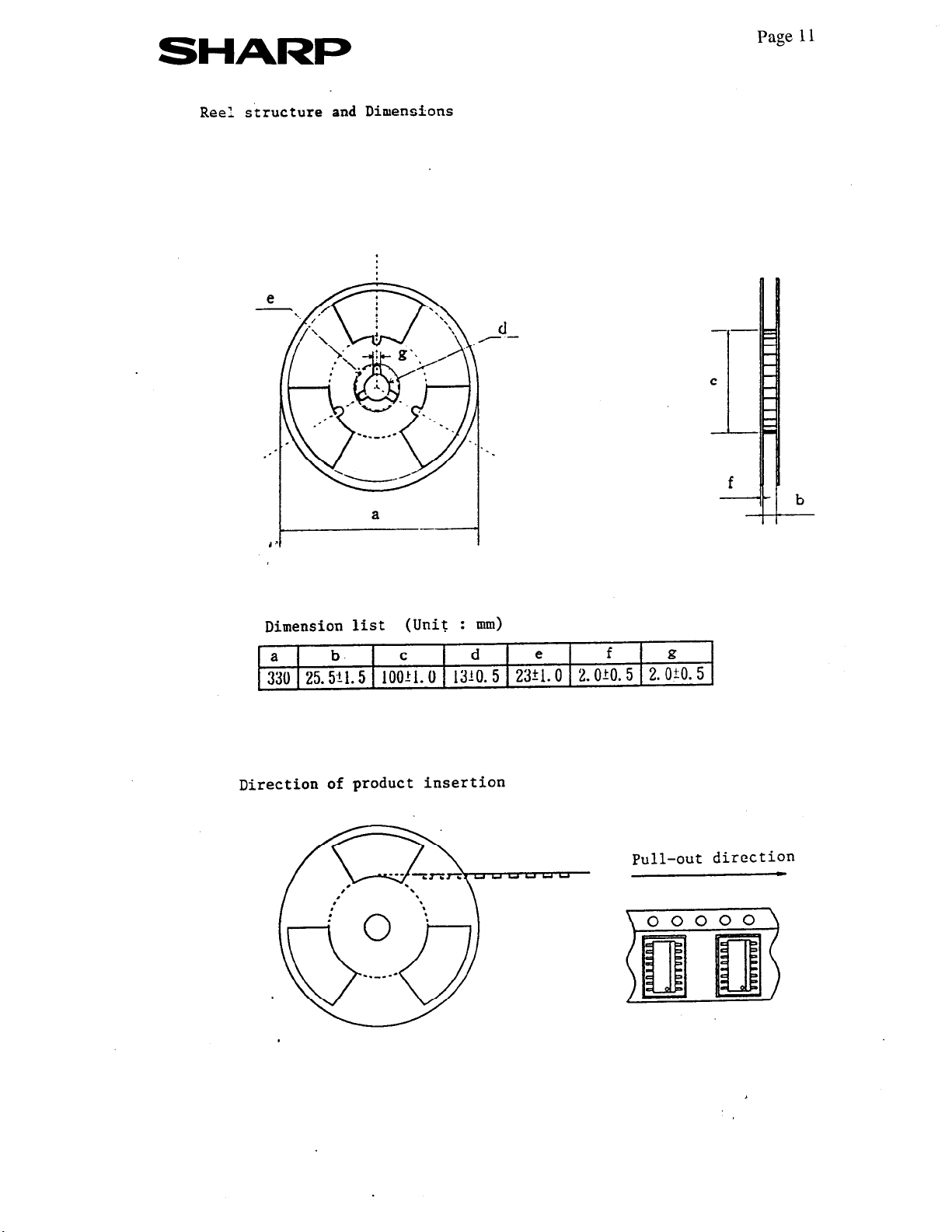

Reel structure and Dimensions (Refer to the attached sheet, Page 11)

The taping reel shall be of corrugated cardboard with its dimensions

as shown in the attached drawing.

Direction of product insertion (Refer to the attached sheet, Page 11)

Product direction in carrier tape shall direct to the anode mark at

the hole side on the tape.

Joint of tape

The cover tape and carrier tape in one reel sha

The way to repair taped failure devices

The way to repair tap’ed failure devices cut a bottom of carrier tape

with a cutter,

shall be sealed with adhesive tape.

and after replacing to good devices, the cutting portion

11 be joint less.

4

6.2.2

6.2.3

6.2.4

6 - -2.3

6.2.6

Adhesiveness of cover tape

The exfoliation force between carrier tape and cover tape shall be

0.2Ni20gf)s lN{lOOgf]for the angle from 160” to 180”.

Rolling method and quanfity

Wind the tape back on the reel so that the cover tape will be outside

the tape.

leader of the tape and fix the both ends with adh sive tape.

One reel shall contain 1000

Marking

The outer packaging case shall be marked with following information.

* Model No. * Number of pieces delivered

Storage condition

Taped procuts shall be stored at the tempera ure lower than

5 ‘L 30°C and the humidities lower than 70ZRH.

Safety protection during shipping

There shall be no deformation of component or degradation of electrical

characteristecs due to shipping.

Attach more than 20cm of blank tape to the trailer and the

PCS.

* Production date

SHARI=

Tape structure and Dimensions

Page

10

I

-

Dimension list

1 A i C t D

I 24. oto. 3 I 11. 5?0. 1 I 1.75+0. 1

1 0.4io. 05

I 3. oio. 1

(Unit :‘mm)

I

7.4iO.l

5” max

E F

12.OYJ.l 2.0+0.1 4.WO.I )1.5’>’ LO. 8+-O. 1

G

Ii I

SHARI=

Reel structure and DimensTons

Page 11

Dimension list (Unit : mm)

a b.

330 25.5Al.5 lO;!l. 0 1310. 5 23:l. 0 2.010.5 2. Ok 5

Direction of product insertion

d

f

Pull-out direction

Precautions for Soldering Photocouplers

I. If solder reflow:

MODEL I’b. PAGE

PC3Q64 12

It is recommended that only one

temperature and the time within

shown in the figure.

,

L--

2 min.

--__-_-- --; ,

Ii37 c

*

!

'1.5 min.

soldering be done at the

the temperature profile as

i;

1 min.

1

‘!

1 min:' i

Other precautions

2.

An infrared lamp used to heat up for soldering may cause a

localized temperature rise in the resin. So keep the package

temperature within that specified in Item 1.

Also avoid immersing

the resin part in the solder.

Loading...

Loading...