Page 1

SERVICE MANUAL

CODE: 00ZMXM310/S1E

DIGITAL MULTIFUNCTIONAL

SYSTEM

MX-M260/M310

MODEL

CONTENTS

NOTE FOR SERVICING

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] CONSUMABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 4-1

[5] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

MX-M260N/M310N

[7] SELF DIAG AND TROUBLE CODE . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] FIRMWARE UPDATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

NOTE FOR SERVICING

1. Warning for servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

2. Precautions for servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

3. Note for installing site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

4. Note for repairing/replacing the LSU . . . . . . . . . . . . . . . . . . . . ii

[1] PRODUCT OUTLINE

1. Line of machines and options . . . . . . . . . . . . . . . . . . . . . . 1 - 1

2. Combination of options list. . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

[2] SPECIFICATIONS

1. Basic function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[3] CONSUMABLE PARTS

1. Supply system table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

2. Maintenance parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

3. Developer/Drum life end definition. . . . . . . . . . . . . . . . . . . 3 - 3

4. Production number identification . . . . . . . . . . . . . . . . . . . . 3 - 4

5. Environment conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

2. Internal structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

3. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

4. RSPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

5. Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

6. Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

7. Solenoid/Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

8. Drive motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

9. Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

10. Fan/Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

11. PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

12. Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

[5] ADJUSTMENTS

1. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

2. Details of adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

[6] SIMULATION

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

2. Simulation code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

3. Details of simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

[7] SELF DIAG AND TROUBLE CODE

1. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

2. Details of trouble code . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

[8] MAINTENANCE

1. Maintenance list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

2. Details of Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 3

3. Other related items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

[9] FIRMWARE UPDATE

1. Firmware update procedure . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

2. Actual wiring chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

3. Signal list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Page 3

NOTE FOR SERVICING

This Service Manual uses some photographs to assure safe operation.

Please understand the meanings of photographs before servicing.

WARNING: If this WARNING should be ignored, a serious danger

to life or a serious injury may result.

CAUTION: If this CAUTION should be ignored, injury or damage

to property could result.

1. Warning for servicing

1) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Avoid complex wiring, which may lead to a fire or an electric shock.

2) If there is any abnormality such as smoke or an abnormal smell,

interrupt the job and disconnect the power plug.

It may cause a fire or an electric shock.

3) Be sure the machine is properly grounded. Failure to ground the

machine properly may result in an electric shock or fire.

To protect the machine and the power unit from lightening, grounding must be made.

4) When connecting the ground wire, never connect it to the following

points as it may cause an explosion, fire, or an electric shock:

• Gas tube

• Lightning conductor

• A water pipe or a water faucet, which is not recognized as a

grounding object by the authorities.

• Grounding wire for telephone line

5) Do not damage, break, or stress the power cord. Do not put heavy

objects on the power cord. Do not bend or pull the cord forcefully. It

may cause a fire or electric shock.

6) Keep the power cable away from a heat source.

Do not insert the power plug with dust on it into a power outlet.

It may cause a fire or an electric shock.

7) Do not put a receptacle with water in it or a metal piece which may

drop inside the machine.

It may cause a fire or an electric shock.

8) Do not touch the power plug, insert a telephone jack, perform service or operate the machine with wet or oil hands. It may cause an

electric shock.

2. Precautions for servicing

1) When servicing, disconnect the power plug, the printer cable, the

network cable, and the telephone line from the machine, except

when performing the communication test, etc.

It may cause an injury or an electric shock.

2) There is a high temperature area inside the machine. Use extreme

care when servicing.

3) There is a high voltage section inside the machine which may

cause an electric shock . Be careful when servicing.

4) Do not disassemble the laser unit. Do not insert a reflective material such as a screwdriver in the laser beam path.

It may damage eyes by reflection of laser beams.

5) When servicing the machine while operating, be careful not to

make contact with chains, belts, gear, and any other moving parts.

6) Do not leave the machine with the cabinet disassembled.

Do not allow any person other than a serviceman to touch inside

the machine. It may cause an electric shock, a burn, or an injury.

7) When servicing, do not breathe toner, developer, and ink excessively. Do not get them in the eyes.

If toner, developer, or ink enters you eyes, wash it away with water

immediately, and consult a doctor if necessary.

8) The machine has got sharp edges inside. Be careful not to damage fingers when servicing.

9) Do not throw toner or a toner cartridge in a fire. Otherwise, toner

may pop and burn you.

10) When replacing the lithium battery on the PWB, use only the specified battery. If a battery of different specification is used, it may not

be compatible and cause breakdown or malfunction of the

machine.

11) When carrying an electric unit or a PWB, use an anti-static (electricity) bag. Failure to do so may cause component failure or

machine malfunction.

MX-M260/M310/M260N/M310N NOTE FOR SERVICING - i

Page 4

3. Note for installing site

Do not install the machine at the following sites.

1) Place of high temperature, high humidity, low temperature, low

humidity, place under an extreme change in temperature and

humidity.

Paper may get damp and form dews inside the machine, causing

paper jam or copy dirt.

For operating and storing conditions, refer to the specifications

described later.

2) Place of much vibrations

It may cause a breakdown.

3) Poorly ventilated place

An electro-static type copier will produce ozone inside it.

The quantity of ozone produced is designed to a low level so as not

to affect human bodies. However, continuous use of such a

machine may produce a smell of ozone. Install the machine in a

well ventilated place, and ventilate occasionally.

4) Place of direct sunlight.

Plastic parts and ink may be deformed, discolored, or may undergo

qualitative change.

It may cause a breakdown or copy dirt.

5) Place which is full of organic gases such as ammonium

The organic photoconductor (OPC) drum used in the machine may

undergo qualitative change due to organic gases such as ammonium.

Installation of this machine near a diazo-type copier may result in

dirt copy.

6) Place of much dust

When dusts enter the machine, it may cause a breakdown or copy

dirt.

7) Place near a wall

Some machine require intake and exhaust of air.

If intake and exhaust of air are not properly performed, copy dirt or

a breakdown may be resulted.

8) Unstable or slant surface

If the machine drops or fall down, it may cause an injury or a breakdown.

If there are optional paper desk and the copier desk specified, it is

recommendable to use them.

When using the optional desk, be sure to fix the adjuster and lock

the casters.

4. Note for repairing/replacing the LSU

When repairing or replacing, be sure to observe the following items.

1) When repairing or replacing the LSU, be sure to disconnect the

power plug from the power outlet.

2) When repairing or replacing the LSU, follow the procedures

described in this Service Manual.

3) When checking the operations after repairing the LSU, keep all the

parts including the cover installed and perform the operation

check.

4) Do not modify the LSU.

5) When visually checking the inside of the machine for the operation

check, be careful not to allow laser beams to enter the eyes.

If the above precaution is neglected or an undesignated work is performed, safety may not be assured.

MX-M260/M310/M260N/M310N NOTE FOR SERVICING - ii

Page 5

[1] PRODUCT OUTLINE

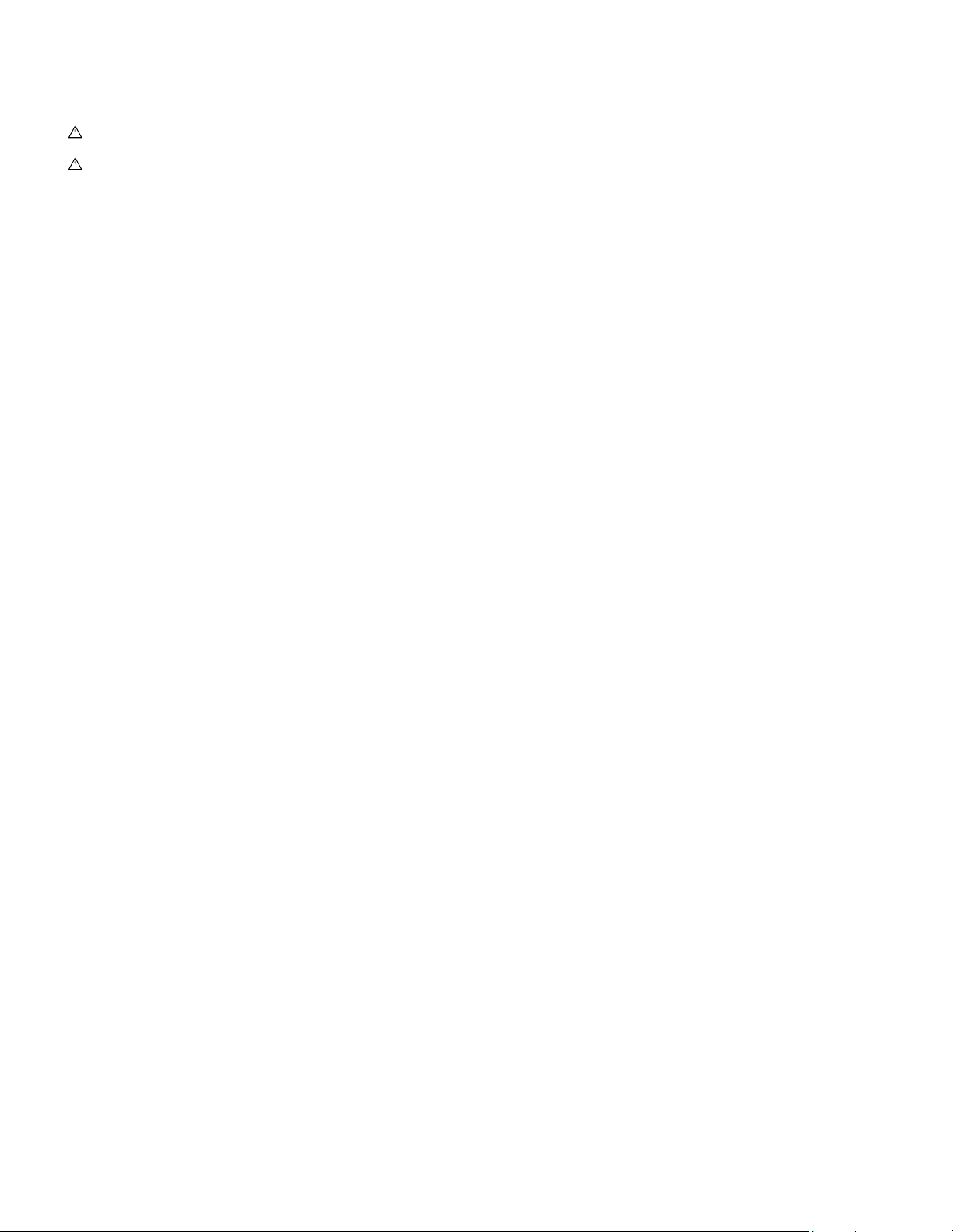

1. Line of machines and options

Job separator tray

[MX-TR11]

Staple cartridge

[MX-SCX1]

Finisher

[MX-FN13]

Exit tray

[MX-TE10]

Document cover

[MX-VR10]

[RSPF]

Copier/Printer (SPLC) model

(North America only)

[MX-M260/M310]

Reversing single pass feeder

[MX-RP10]

Copier/Printer (PCL)

Network model

[MX-M260N/M310N]

Copier/Printer (SPLC) model

[MX-M260/M310]

Data security kit

(Commercial version)

[AR-FR17U]

(For 26cpm)

[AR-FR18U]

(For 31cpm)

Application integration

module kit

[MX-AMX1]

FAX expantion kit

[AR-FX7]

Sharpdesk

license kit

[MX-USX1/

MX-USX5/

MX-US10/

MX-US50/

MX-USA0]

Machine stand

(Large)

[MX-DS11] [MX-DS12]

Machine stand

(Small)

[AR-SM5](256MB)

[AR-SM6](512MB)

Network scanner

expantion kit

Paper feed unit

(500 Sheets)

[MX-M260/M310]

FAX memory (8MB)

[AR-MM9]

Barcode font kit Flash ROM kit

Printer expantion kitExpantion memory board

[MX-PB12]

[AR-PF1] [AR-PF2]

Paper feed unit

(500x2 Sheets)

[MX-DE11][MX-DE10]

PS3 expantion kit

[MX-PK10][MX-NSX1]

MX-M260/M310/M260N/M310N PRODUCT OUTLINE 1 - 1

Page 6

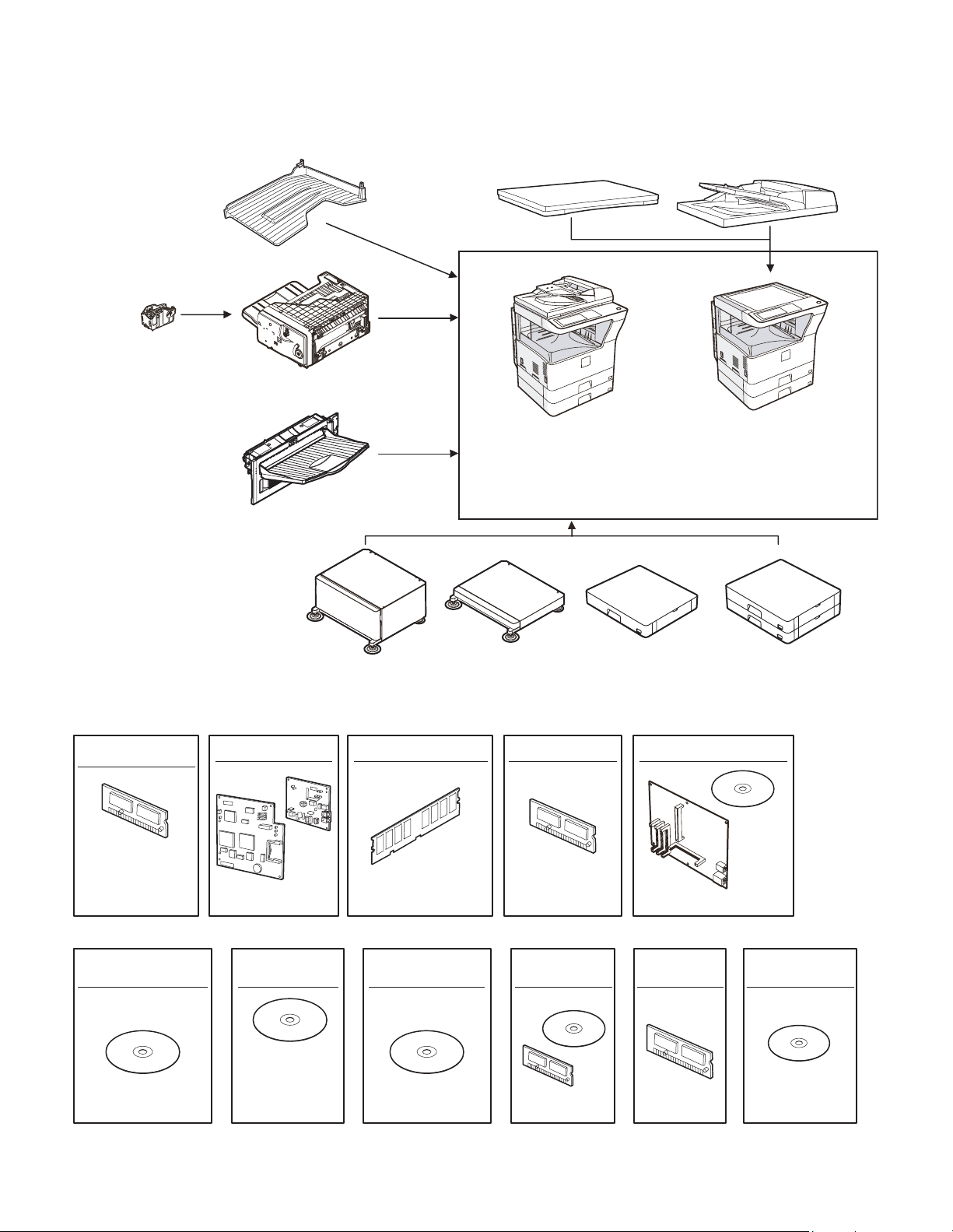

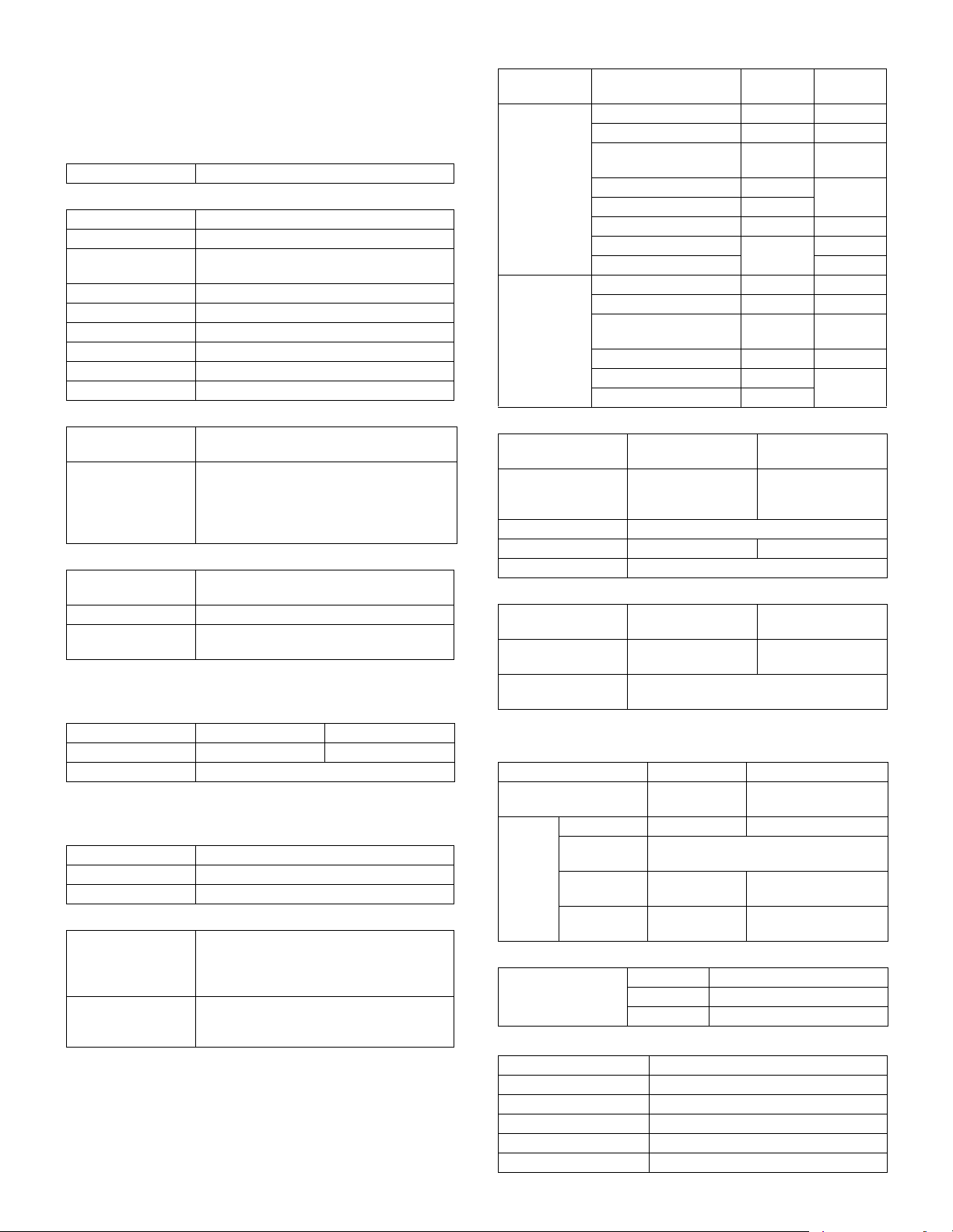

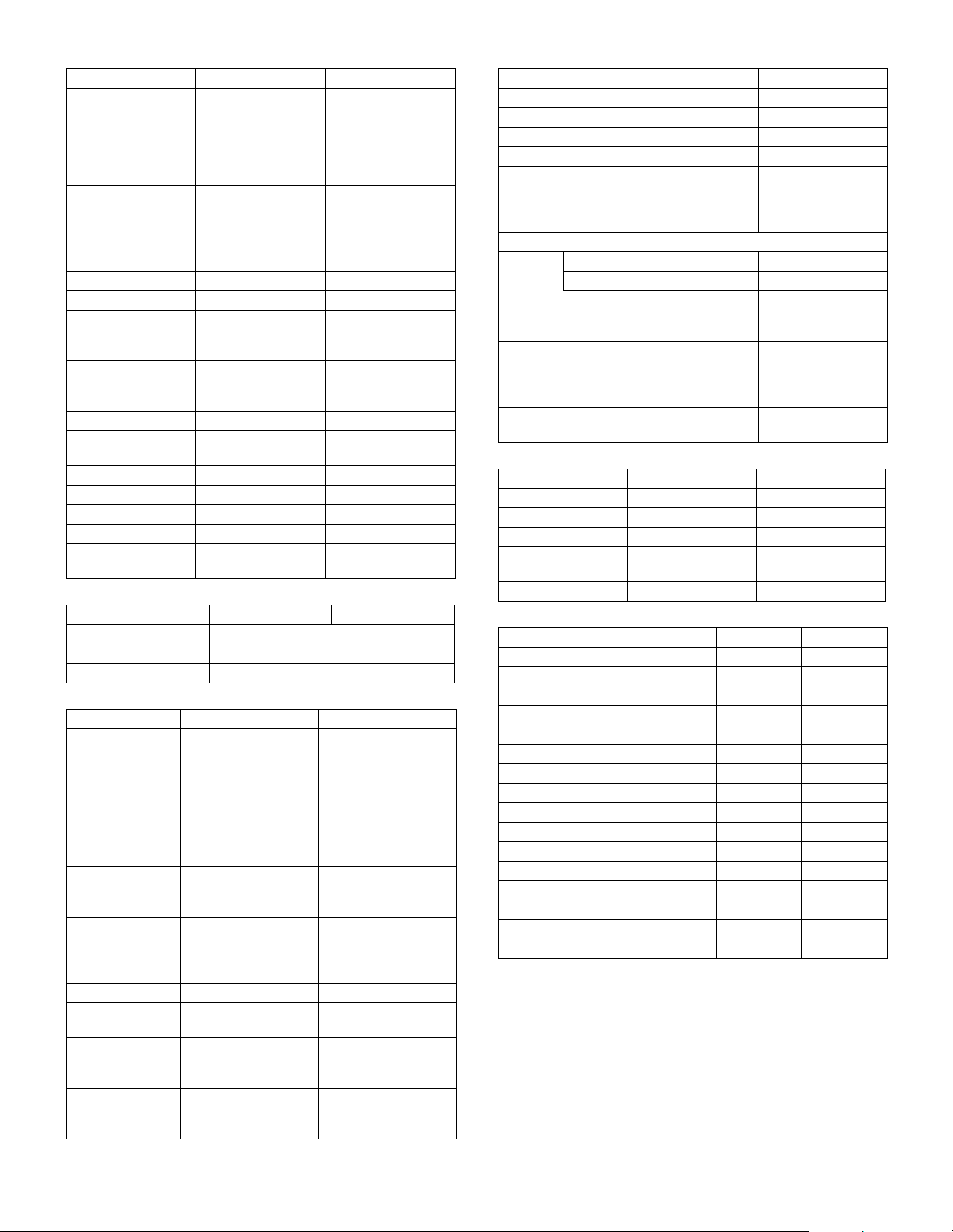

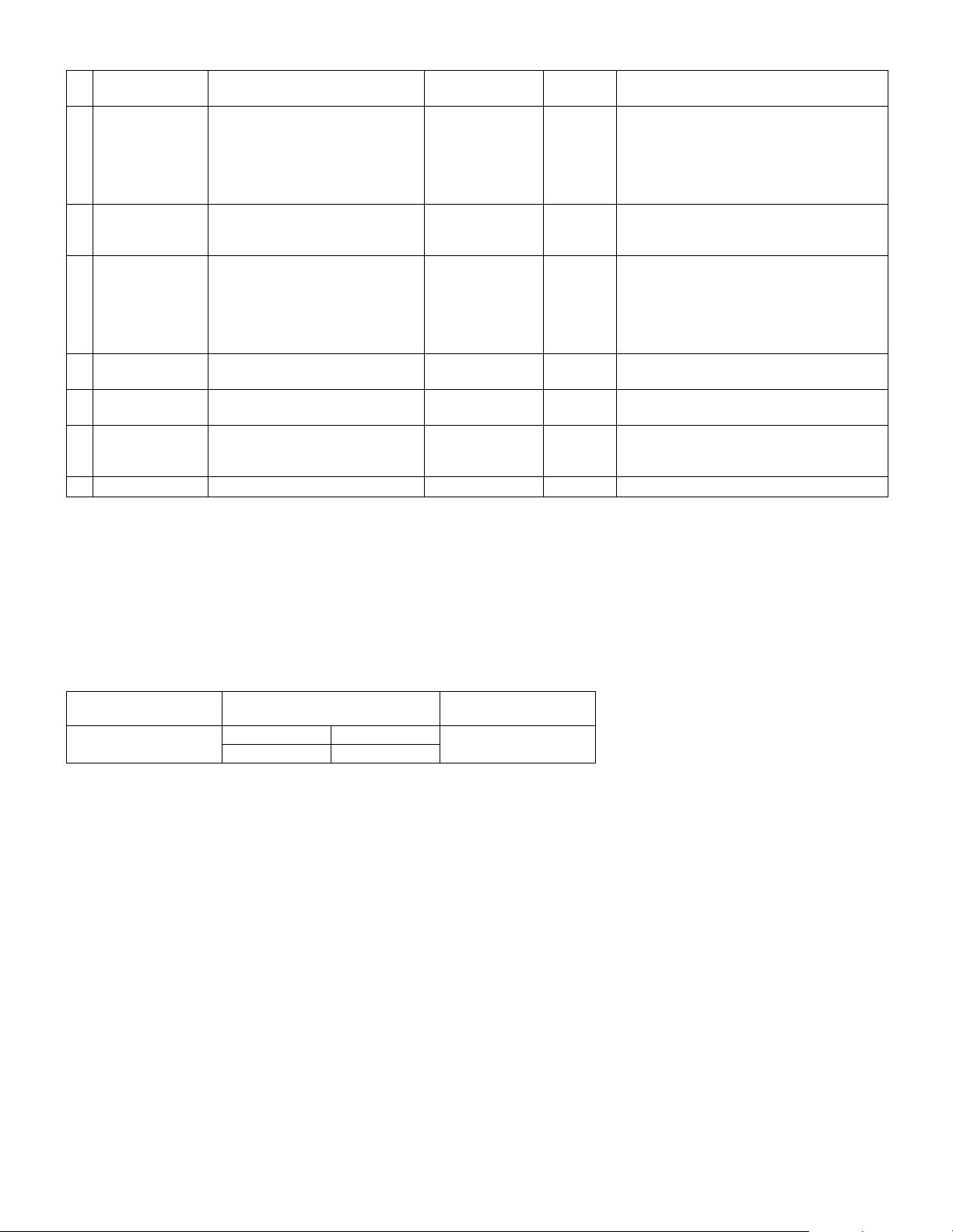

2. Combination of options list

F : Installable

✕: Not available

Section

Automatic document

feeder and OC

Paper feed system Paper feed unit (500 sheets) MX-DE10 FF

Machine stand Machine stand (Large) MX-DS11 FF

Paper exit system Finisher MX-FN13 FF

FAX system FAX expansion kit AR-FX7 FF

Printer system Printer expansion kit MX-PB12 F Standard

Memory board 256MB expansion memory board AR-SM5 FF

Software Network scanner expansion kit MX-NSX1 FF

Data security Data security kit (Commercial version) MX-FR17U FFFor 26cpm

Document feeder MX-RP10 FFStandard for North America

Document cover MX-VR10 FFUnavailable for North America

Paper feed unit (500 x 2 sheets) MX-DE11 FF

Staple cartridge MX-SCX1 FF

Job separator tray MX-TR11 FF

Exit tray MX-TE10 FFRequires installation of the

FAX memory (8MB) AR-MM9 FF

PS3 expansion kit MX-PK10 FF

Barcode font kit AR-PF1 FF

Flash ROM kit AR-PF2 FF

512MB expansion memory board AR-SM6 FF

Sharpdesk 1 license kit MX-USX1 FF

Sharpdesk 5 license kit MX-USX5 FF

Sharpdesk 10 license kit MX-US10 FF

Sharpdesk 50 license kit MX-US50 FF

Sharpdesk 100 license kit MX-USA0 FF

Application integration module kit MX-AMX1 FF

Option Main unit Model

Item Model MX-M260/M310 MX-M260N/M310N

(Small) MX-DS12 FF

MX-FN13.

MX-FR18U FFFor 31cpm

Note

MX-M260/M310/M260N/M310N PRODUCT OUTLINE 1 - 2

Page 7

[2] SPECIFICATIONS

1. Basic function

A. Base engine

(1) Type

Type Desktop

(2) Engine composition

Photoconductor kind OPC drum (Drum dia. 30mm)

Copying method Electronic photo (Laser)

Developing system Dry, 2-component magnetic brush

Charging system Sawtooth charging

Transfer system Transfer roller system

Cleaning system Contact blade system

Fusing system Heat roller

Toner supply method Toner supply by front cover open

Waste toner disposal Toner cartridge collection

(3) Dimensions / Weight

External dimensions

(W x D x H)

Occupied

dimensions (W x D)

(when the manual

paper feed tray is

extended)

(4) Warmup

Warm-up time 23 sec or less (26-sheet model)

Pre-heat Yes

Jam recovery time About 10sec, excluding fusing warmup, toner

Conditions: Leaving for 60 sec after door open, standard conditions,

polygon stop.

(5) First copy time

Platen 4.8 sec or less 4.5 sec or less

RSPF 9.3 sec or less

∗ Measuring conditions: When paper of A4 or 8.5” x 11” is fed from the

machine tray, with the polygon rotating.

(6) Engine resolution

Writing resolution 600 x 600dpi

Smoothing (Print) 1200dpi (equivalent) x 600dpi

Gradation Writing: Binary

(7) Printable range

Max. print size AB series: 416 x 293mm

Void area image loss Lead edge 4.0mm or less

development

OC model: 623 x 628 x 668mm

RSPF model: 623 x 628 x 788mm

898 x 628mm

25 sec or less (31-sheet model)

control, etc.

26-sheet model 31-sheet model

(600dpi: 9826dot x 6920dot)

Inch series: 428 x 275mm

(600dpi: 10110dot x 6496dot)

Rear edge 4.0mm or less

Total of lead/rear edges 4mm±1mm

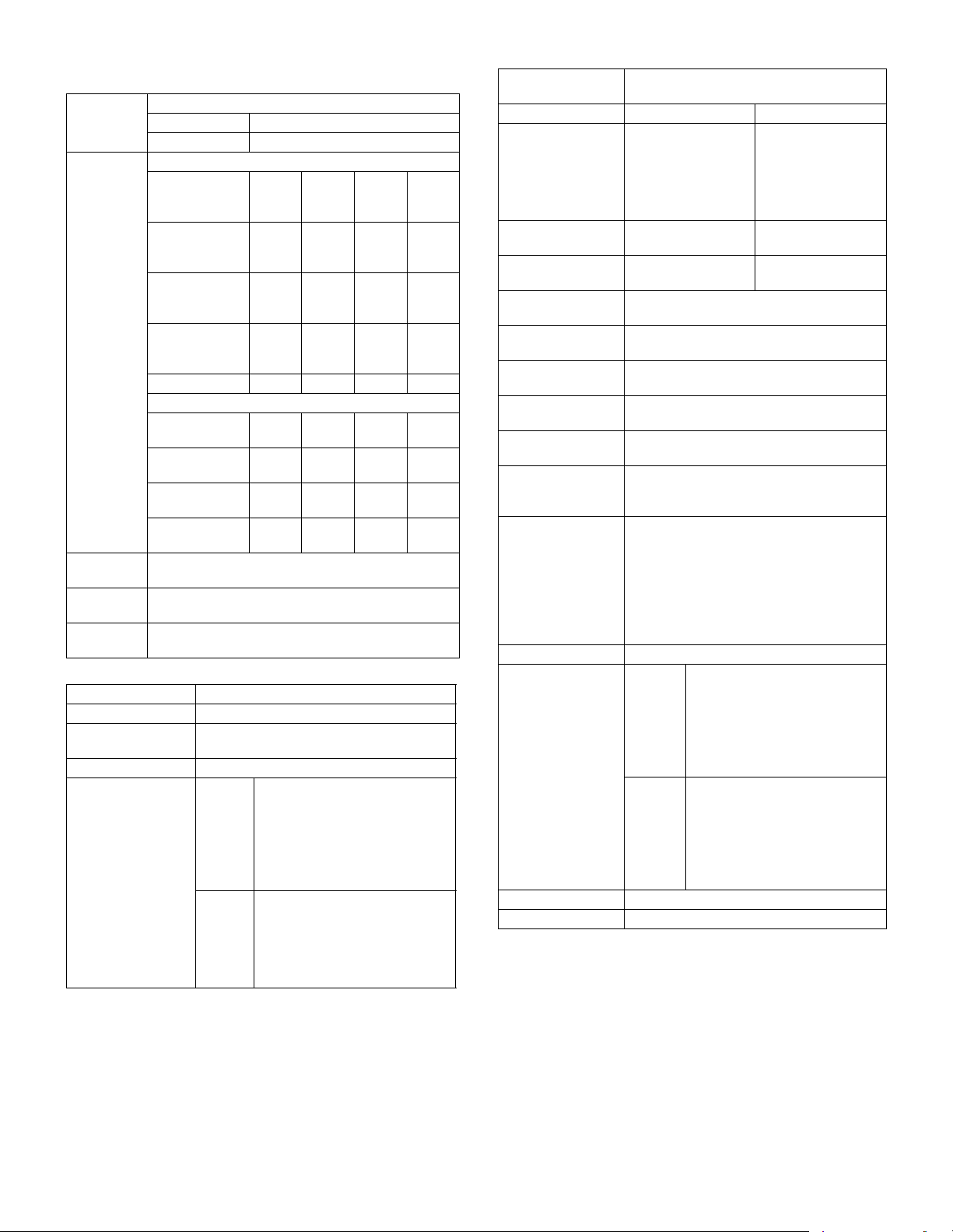

(8) Engine speed (ppm)

Tray Paper size

Tray 1- 4 A 3 15 17

B4/8.5 x 13 17 20

A4/B5/A5/8.5 x 11/

5.5 x 8.5/16K

A4R/8.5 x 11R/16KR 18 24

B5R 21

11 x 17 14 17

8.5 x 14 16 20

8K 19

Manual paper

feed

A3 14 17

B4/8.5 x 13 17 20

A4/B5/A5/8.5 x 11/

5.5 x 8.5/16K

A4R/8.5 x 11R/16KR 19 23

11 x 17 14 16

8.5 x 14 16

26-sheet

model

26 31

23 27

31-sheet

model

(9) Power source

Ex Japan in

100V system

Voltage/Current 110V 15A

120V±10% 15A

127V 12A

Frequency 50/60Hz

Power source code Fixed type Inlet type

Power switch 1 power source

Ex Japan in

200V system

220 - 240V 8A

(10) Power consumption

Maximum rated

power consumption

Shift time to sleep

mode

Ex Japan in

100V system

1.44kw 1.45kw

Default (1 minute)

Ex Japan in

200V system

B. Controller board

(1) Controller board

SPLC board PCL board

CPU --- TMPR4937

Interface Ethernet No 10Base-T/100Base-TX

USB 2.0

Device

Memory No 64MB (Standard)

Memory

expansion slot

--- 1 slot (144 pin DIMM

(64bit, 300MHz)

Full Speed 1slot

+ 256MB x 1

compatible)

(2) Memory

Local Memory Standard 32MB

Expansion 512MB x 2

Max. 1056MB

C. Operation panel

Type Dot matrix LCD, touch panel

Size Monochrome H-VGA 8.1”

Display dot number 640 x 240 (H-VGA)

LCD drive display area 192 x 72mm

LCD backlight Fluorescent lamp backlight system

LCD contrast adjustment Yes

MX-M260/M310/M260N/M310N SPECIFICATIONS 2 - 1

Page 8

D. Scanner section

(1) Resolution/Gradation

Reading

resolution

(dpi)

Transmission

resolusion

(dpi)

Reading

gradation

Exposure

lamp

Output

gradation

Platen 400 x 600dpi

RSPF 400 x 600dpi

Select mode Normal

Input resolution:OC203.2

Input resolution:

RSPF

Transmission

resolution

Half tone No Yes Yes Yes

Select mode 200 x

Input resolution:OC600 x

Input resolution:

RSPF

Transmission

resolution

256 gradations

Electrodeless xenon lamp

Binary

(2) Document table

Type Document table fixed type (Flat bed)

Scanning area 297 x 431.8mm

Original standard

position

Detection Yes

Detection size Inch

Left bottom reference

series

AB

series

Copy mode

FAX transmission mode

Fine

text

293.4

203.2

293.4

203.2

97.8

Scanner mode

200

600

600 x

367

200 x

200

Automatic setting

11 x 17, 8.5 x 14, 8.5 x 11,

8.5 x 11R, 5.5 x 8.5

Manual setting

11 x 17, 8.5 x 14, 8.5 x 13 (216 x

330), 8.5 x 11, 8.5 x 11R,

5.5 x 8.5, A3, A4, A4R

Automatic setting

A3, B4, A4, A4R, A5

Manual setting

11 x 17, 8.5 x 14, 8.5 x 13 (216 x

330), 8.5 x 11, 8.5 x 11R, A3, B4,

A4, A4R, A5

text

203.2

x

293.4

203.2

x

293.4

203.2

x

195.6

300 x

300

600 x

600

600 x

367

300 x

300

Super

fine

text

203.2

x

391.2

203.2

x

391.2

203.2

x

391

400 x

400

600 x

600

600 x

367

400 x

400

(3) Automatic document feeder

Ty pe RS P F

(Automatic duplex document feeder unit)

Scan speed When in single copy When in duplex copy

Copy 31-sheet model:

Ultra

fine

text

406.4

x

x

x

x

586.7

406.4

x

586.7

406.4

x

391

600 x

600

600 x

600

600 x

367

600 x

600

Fax 40 sheets/min

Scanner 31 sheets/min

Document set

direction

Document standard

position

Document transport

system

Document size AB series: A3 - A5,0

Document weight Single face: 35 - 128g/m

Max. loading

capacity of

documents

Transport disable

document

Detection Yes

Detection size Inch

Multi copy S-S, S-D, D-D, D-S

Mixed paper feed Enable (Same width only)

27 sheets/min

(400 x 600dpi)

26-sheet model:

26 sheets/min

(400 x 600dpi)

(Normal text, A4R)

(300 x 300dpi)

Face-up reference

Center reference

Sheet through system

Inch series: 11 x 17 - 5.5 x 8.5

Duplex: 52 - 105g/m

100 sheets (90g/m

Paper thickness of 13mm or less can be set.

OHP, perforated documents, photo,

catalogue, second original sheet, tracing

paper, carbon paper, heat-sensitive paper,

wrinkled paper, folded or broken paper,

pasted or cut-away paper, documents of

many perforated holes (2-hole, 3-hole

documents can be used), document printed

by an ink ribbon

series

AB

series

Automatic setting

11 x 17, 8.5 x 14, 8.5 x 11,

8.5 x 11R, 5.5 x 8.5, A3, A4

Manual setting

11 x 17, 8.5 x 14, 8.5 x 13 (216 x

330), 8.5 x 11, 8.5 x 11R,

5.5 x 8.5, A3, A4, A4R

Automatic setting

11 x 17, 8.5 x 11, A3, B4, A4,

A4R, B5, B5R, A5

Manual setting

11 x 17, 8.5 x 14, 8.5 x 13 (216 x

330), 8.5 x 11, 8.5 x 11R, A3, B4,

A4, A4R, A5

31-sheet model:

17 side/min

(400 x 600dpi)

26-sheet model:

14 side/min

(400 x 600dpi)

17 sheets/min

(Normal text, A4R)

16 sheets/min

(300 x 300dpi)

2

, 9 - 34 lbs,

2

, 13.9 - 28 lbs

2

)

MX-M260/M310/M260N/M310N SPECIFICATIONS 2 - 2

Page 9

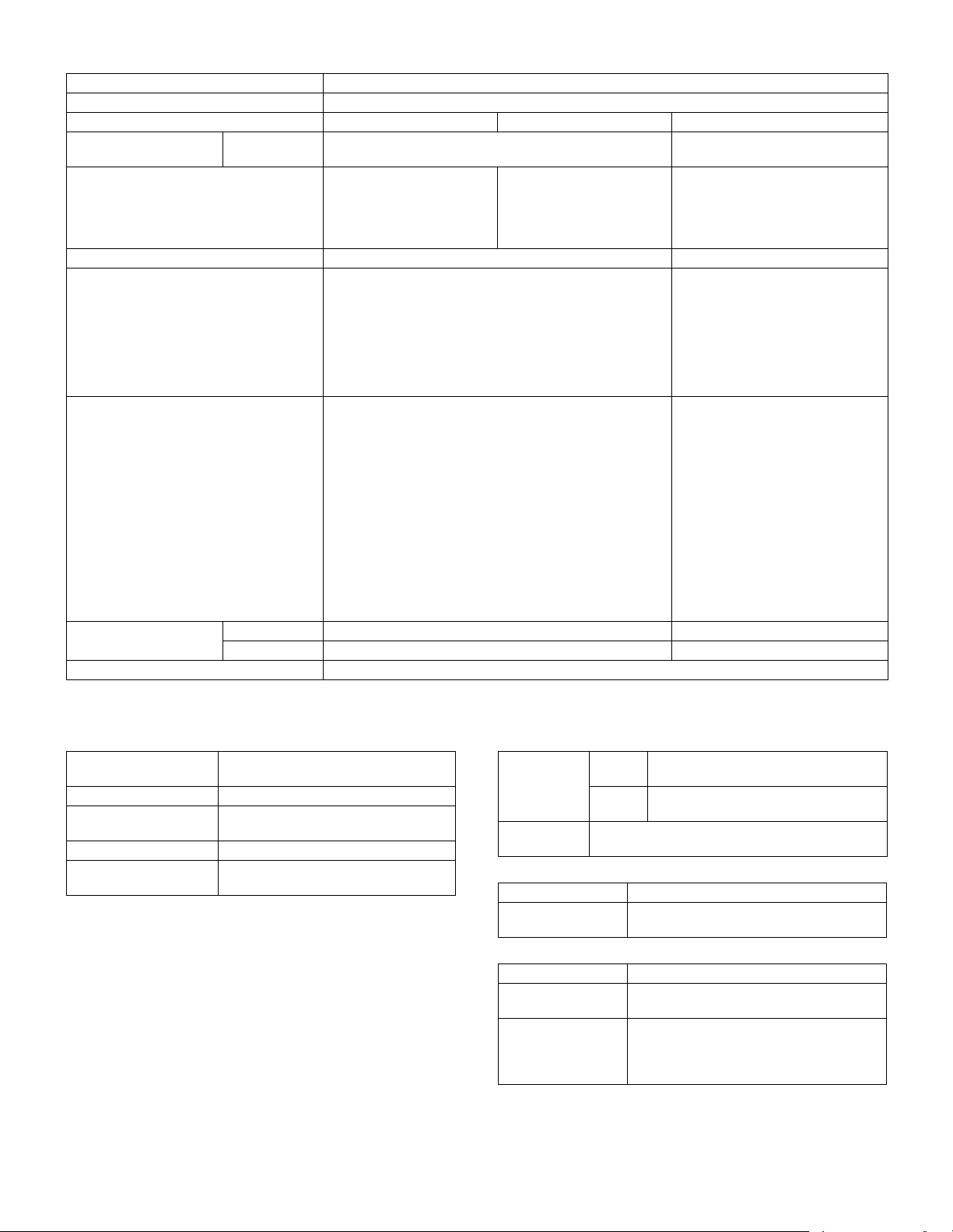

E. Paper feed section

Type Paper feed tray + Multi manual paper feed (Expanded up to 4 trays by installing options.)

Paper feed method Paper is fed from the above by the front loading system.

Details of paper feed section Tray1 Tray2 Manual paper feed tray

Paper capacity Standard paper

(80g/m

2

)

Paper size A3, B4, A4, A4R, B5, B5R,

A5, 11 x 17, 8.5 x 14,

8.5 x 13, 8.5 x 11, 8.5x11R,

5.5 x 8.5, 8K, 16K, 16KR

Paper size detection No Yes

2

Allowable paper type and weight for paper

56 - 105g/m

/15 - 28lbs Bond Multi paper feed:

feed

Paper type Standard paper (56 - 80g/m

Normal paper (60 - 105g/m

Letterhead

Color paper

Paper size setting when

shipping

Inch series 8.5 x 11 ---

AB series A4 ---

Paper remaining detection No (paper presence only)

∗ 1: Supported envelope kinds: Commercial10 (4 - 1/8” x 9 - 1/2”), International DL (110mm x 220mm), International C5 (162mm x 229mm)

F. Paper exit section

(1) Center tray of main unit

Paper exit position/

system

Paper exit capacity 500 sheets (A4, 8.5 x 11, 80g/m

Paper exit paper size/

kind

Shifter function Yes (Except for North America)

Paper remaining

detection for paper exit

Main unit top surface face-down paper

exit

2

paper)

All kinds of paper which can be fed

Ye s

500 sheets 100 sheets

A3, B4, A4, A4R, B5R,

11 x 17, 8.5 x 14 (216 x 356),

8.5 x 13 (216 x 330),

8.5 x 11, 8.5 x 11R, 8K, 16KR

A3, B4, A4, A4R, B5, B5R, A5R, A5,

B6R, 11 x 17, 8.5 x 14 (216 x 356),

8.5 x 13 (216 x 330), 8.5 x 11,

8.5 x 11R, 7.25 x 10.5R, 5.5 x 8.5,

8K, 16K, 16KR, A6R, Envelope*

Standard paper (56 - 128g/m

Special paper, heavy paper (max.

2

200g/m

)

Single paper feed:

Standard paper, special paper,

second original, heavy paper (max.

2

), 56- 200g/m2 (14 - 54lbs)

2

)

2

)

200g/m

• Standard paper: 100 sheets

(56 - 80g/m2)

• Recycled paper/coarse paper:

100 sheets

• Postcard/Double postcard

(without fold): 30 sheets

• Heavy paper (max. 200g/m

30 sheets

• OHP/Label sheet/gift wrapping

paper: 40 sheets

• Label sheet: 40 sheets

• Envelope (AB series: 10 sheets,

Inch series: 5 sheets)

G. Copy functions

(1) Copy magnification ratio

Copy

magnification

ratio

Zoom 25 - 400%

(2) Density/copy image quality process

Exposure mode Binary: Automatic, Text, Text/Photo, Photo

Number of manual

steps

(3) Duplex

System Switchback system

Paper size A3, B4, A4, A4R, B5, B5R, A5, 11 x 17,

Type and weight of

paper which can be

passed

AB

series

Inch

series

25%, 50%, 70%, 81%, 86%, 100%,

115%, 122%, 141%, 200%, 400%

25%, 50%, 64%, 77%, 100%, 121%,

129%, 200%, 400%

(Restriction by the document feeder unit: 50 - 200%)

5 steps

8.5 x 14, 8.5 x 13, 8.5 x 11, 8.5 x 11R

2

56 - 105g/m

/15 - 21.3 lbs Bond

Duplex print from manual paper feed can be

made. (Except for heavy paper, OHP sheet,

and other special paper)

1

2

)

2

):

MX-M260/M310/M260N/M310N SPECIFICATIONS 2 - 3

Page 10

(4) Copy functions

Automatic paper selection

Automatic magnification ratio selection

Vertical/horizontal independent magnification ratio

Paper type selection

Auto tray switching

Rotation copy

Electronic sort

Job reservation (only during warm-up)

Tray installation priority

Program call-out/registration (10 items)

Preheat function

Auto power shut off function

User management (100 items)

Mixed documents feed (MIX only)

Binding margin (Left/Right/Upper)

Edge erase/Center erase (Center/Edge/Center + Edge)

1 set 2 copy

Cover paper/Insert paper/Tab insert paper (Cover/Back cover only)

Multi shot (2 in 1/4 in 1) (Centering available)

Card shot (Centering available)

Half binding (Centering available)

Duplex copy direction switching

Large volume document mode

Black/white reverse (except for UK)

Stream feeding mode (ON/OFF switch by the system setting)

H. Printer function

(1) Platform

• IBM PC/AT

•Macintosh

(2) Support OS

OS SPLC

Windows 2000

XP

XP x64 No

Server

2003

Server

2003 x64

Vista

Vista x64

Server

2008

Server

2008 x64

Mac 9.0 - 9.2.2

X 10.2.8

X 10.3.9

X 10.4.11

X 10.5 -

10.5.6

Custom

PCL6

Ye s

No

Ye s

No

Custom

PCL5e

Ye s

No No

Custom

Ye s

Ye s

No

Ye s

No

PS

Ye s

PPD

Ye s

(3) PDL emulation/Font

Emulation Built-in fonts Option font

PCL5e

compatible/

PCL6

compatible

ESC/P

(VP-1100)

compatible

Postscript3

compatible

European outline font

= 80 typefaces

Line printer font (BMP)

= 1 typeface

European BMP font

= 2 typefaces

(Roman, San-serif)

Barcode font

= 28 typefaces

European outline font

= 136 typefaces

(4) Print channel

Support print

channel

• PSERVER/RPRINT for netware environment

•LPR

•IPP

• PAP : EtherTalk (AppleTalk)

• FTP

•NetBEUI

• Raw Port (Port 9100)

•USB 2.0

• HTTP (Web Submit Print)

• POP3 (E-Mail To Print)

• HTTPS

(5) Environment setting

Setting item Outline

Default setting Basic setting for using the printer, such as

SPDL Setting of SPDL symbol and fonts

PS Setting of print Enable/Disable in case of PS

the number of copies, the printing direction.

error

I. Image send function

(1) Mode

Scanner • Scan to e-mail

• Scan to Desktop

• Scan to FTP

Fax • Fax

(2) Support system

Mode Scanner Fax

Corresponding

server/protocol

(3) Support image

Mode Scanner Fax

File format • TIFF

Compression system • Non-compression

SMTP

FTP (TCP/IP)

•PDF

•G3 = MH

•G4 = MMR

---

---

•MH

•MR

•MMR

•JBIG

MX-M260/M310/M260N/M310N SPECIFICATIONS 2 - 4

Page 11

(4) Number of registration items

Item Scanner Fax

One-touch/ Group 200 items

(max. 100 items for

one group)

Program No 8 items

Memory box No Bulletin Board/

Sender registration --- 20 items

Sender list 200 items No

Item name

(Detailed setting of

transmission)

File name

(Detailed setting of

transmission)

Meta data set list 10 items No

Receive rejection

number

Polling allow number No 10 items

ID number No 10 items

System number No 1 item

Interface ID code No 10 items

Confidential box

number

Direct input only

(Default or direct

input)

30 items No

No 50 items

No 10 items

500 items

(max. 200 items for

one group)

∗ Max. 500 items in

total with 200 items

of groups

Confidential/Relay

broadcast, each 10

items

No

(5) Image process

Mode Scanner Fax

Document scan color Black/White only

Half tone reproductions Equivalent of 256 steps

Density adjustment Auto + 5 steps

(6) Address specification

Mode Scanner Fax

Address

specification

Number of Onetouch address key

registration

Number of

addresses to be

registered in a

group (1 key)

Program ✕ 8 items

Direct address

input

Chain dial ✕❍

Resend ✕ The latest single

• Specified by onetouch, group, or direct

address input.

• Input from the soft

keyboard

• Selection from

LDAP server

• Resend

Max. (number of keys):

200 items

Max. 100 items Number of addresses

Input from the soft

keyboard

• Specified by onetouch, group, or direct

address input.

500 items (including

the group dial)

registered to 1 group

(1 key) :

max. 200 items

Input with 10 key,

# key, ∗key

(Supported by the

pause key)

destination is called

out.

(7) Send function

Mode Scanner Fax

Memory send ✕❍

Onhook ✕❍

Quick online send ✕❍

Direct transmission ✕❍

Auto reductions end

(Auto magnification

ratio send)

Rotation send ❍

Recall

mode

Long document send ✕❍

No. of registration

items of senders

Error ✕❍

Busy ✕❍

Max. 200 items ✕

✕❍

A33B4,

A33A4,

B43A4

No. of times and time

are set by the system

setting.

Max. 1000mm

(except for ultra fine

mode)

(8) Receive function

Mode Scanner Fax

Automatic reception ✕❍

Manual reception ✕❍

Memory reception ✕❍

Fixed size reduction

reception

Rotation reception ✕❍

✕❍

(9) Report/List function

Mode Scanner Fax

Communication record table ✕❍

Communication reservation table ✕❍

Bulletin board check table ✕❍

ID sender table * ✕❍

Confidential reception check table ✕❍

One-touch dial list ✕❍

Group list ✕❍

Program list ✕❍

Telephone number list ✕❍

Interface group list ✕❍

System setting list (FAX) ✕❍

F code memory box list ✕❍

User management record table (Fax) ✕❍

Rejection number list ✕❍

Confidential ID table ✕❍

Web setting list ❍✕

∗ The sender table is printed as the ID sender table.

MX-M260/M310/M260N/M310N SPECIFICATIONS 2 - 5

Page 12

(10) Other functions

Mode Scanner Fax

Time specification ✕❍

Poling receive ✕❍

Cover paper adding

✕❍

function

Page division ✕❍

Send message ✕❍

Program ❍

Sender selection ✕❍

Thin film scan ❍

Communication

✕❍

result table

(11) Record size

Mode Scanner Fax

Max. record width --- 293mm

Record size --- A3 - A5/

11 x 17 - 5.5 x 8.5

(12) Sound setting

Mode Item System setting

Onhook sound Sound volume setting ❍

Call-out sound

Sound volume setting ❍

volume

Line monitor sound Sound volume setting ❍

Communication end

sound

Sound volume ❍

Sound pattern ❍

Communication end

❍

sounding time

(13) PC-FAX function

Operation OS • Windows 2000

• Windows XP/XP x64

• Windows Vista/Vista x64

• Windows Server 2003 */

Server 2003 x64*

• Windows Server 2008 */

Server 2008 x64*

∗ No support for PC-Fax on SPCL CD-

ROM.

PC IBM PC/AT compatible machine

CPU Pentium II 300MHz or above

Monitor Image resolution 640 x 480 pixel or above

Memory 64MB or more

HDD Empty capacity of 50MB or above

Interface USB2.0

Communication

protocol

No. of colors 256 colors or above

10/100BASE-TX

LPR/lp

Port 9100 (RAW)

IPP

Functions PC-FAX send ❍

(When FAX is installed)

Max. number of FAX number digits 40

digits (excluding the sub address and

pass code)

Resolution 200 x 100dpi/200 x 200dpi/200 x 400dpi/

400 x 400dpi

Send

document size

Compression

A3/B4/A4/A5/B5/11 x 17/8.5 x 14/

8.5 x 11/5.5 x 8.5/8.5 x 13/8k/16k

MH/MMR/MR

system

Broadcast

send

(Max. 200 items)

F-code send ❍ Sub

address

Pass code ❍

Telephone

book

registration,

send function

Covering letter

attachment

(Disable when broadcasting)

function

Covering letter

making

function

Sender print ❍

(Editing senders is disabled.)

Preview ❍

J. Environmental conditions

(Humidity)

85%

60%

20%

10 C 30 C 35 C

(Temperature)

Standard environmental

conditions

Usage environmental

conditions

Temperature 20 - 25°C

Humidity 65 ± 5%RH

Temperature 10 - 35°C

Humidity 20 - 85%RH

Atmospheric

pressure

❍

❍

Max.

20 digit

Max.

20 digit

❍

❍

❍

590 - 1013 hPa

(height: 0 - 2000m)

MX-M260/M310/M260N/M310N SPECIFICATIONS 2 - 6

Page 13

[3] CONSUMABLE PARTS

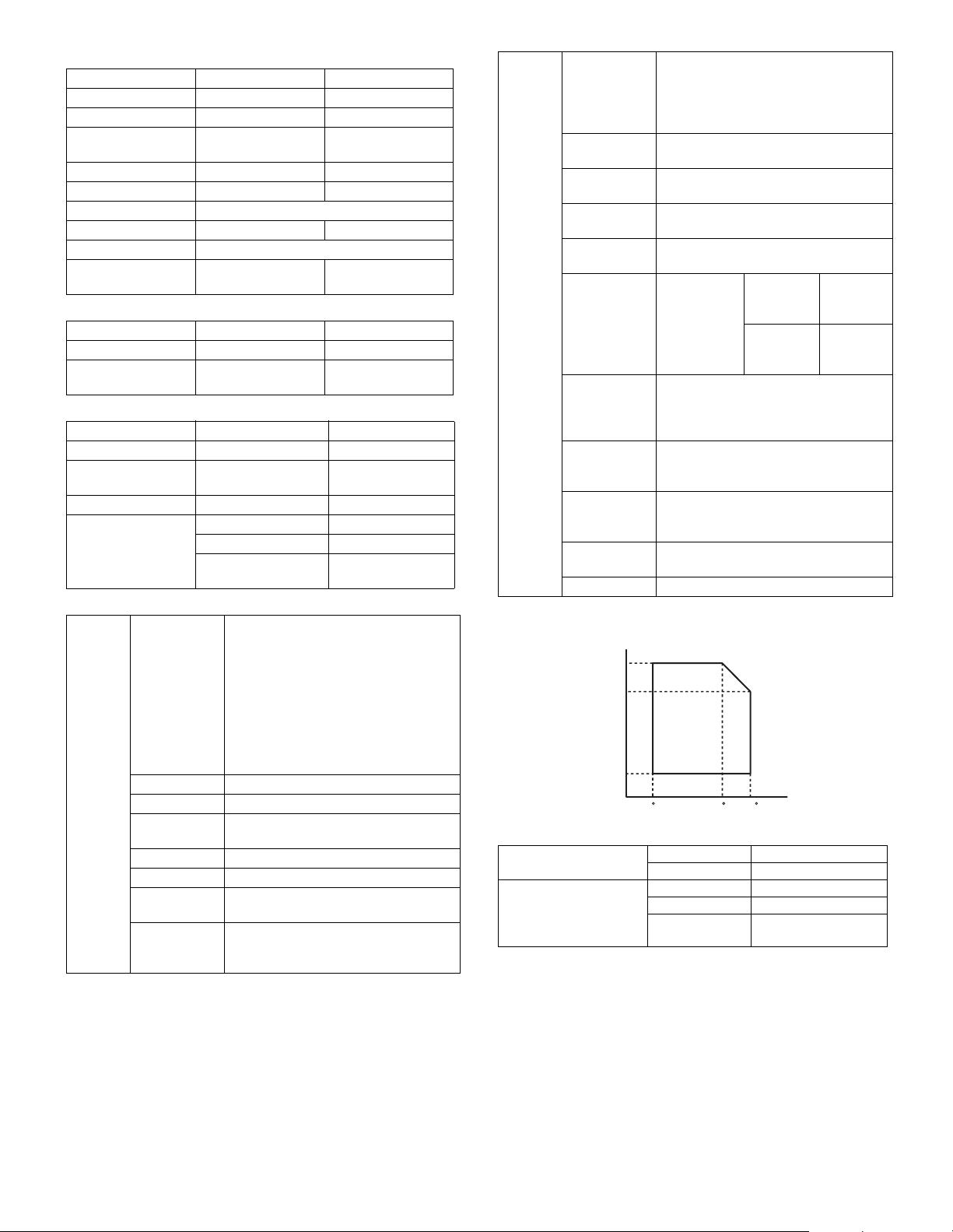

1. Supply system table

A. SEC/ SECL/ LAG

No. Item Content Life Model name Remarks

1 Toner cartridge

(black)

2 Developer (black) Developer

3 Drum Drum ×1 26cpm: 75K

B. Brazil

No. Item Content Life Model name Remarks

1 Toner cartridge

(black)

2 Developer (black) Developer

3 Drum Drum ×1 26cpm: 75K

C. Europe/ East Europe/ Russia / Australia/ New Zealand

No. Item Content Life Model name Remarks

1 Toner cartridge

(black)

2 Developer (black) Developer

3 Drum Drum ×1 26cpm: 75K

D. Asia affiliates

No. Item Content Life Model name Remarks

1 Toner cartridge

(black)

2 Developer (black) Developer

3 Drum Drum ×1 26cpm: 75K

E. Hong Kong

No. Item Content Life Model name Remarks

1 Toner cartridge

(black)

2 Developer (black) Developer

3 Drum Drum ×1 26cpm: 75K

F. SMEF/ Israel/ Philippines/ Taiwan/ Agent

No. Item Content Life Model name Remarks

1 Toner cartridge

(black)

2 Developer (black) Developer

3 Drum Drum ×1 26cpm: 75K

Toner cartridge (With IC chip)

(Toner; Net 700g)

(Developer; Net 300g)

Toner cartridge (With IC chip)

(Toner; Net 700g)

(Developer; Net 300g)

Toner cartridge (With IC chip)

(Toner; Net 700g)

(Developer; Net 300g)

Toner cartridge (With IC chip)

(Toner; Net 700g)

(Developer; Net 300g)

Toner cartridge (With IC chip)

(Toner; Net 700g)

(Developer; Net 300g)

Toner cartridge (With IC chip)

(Toner; Net 700g)

(Developer; Net 300g)

×1 25K MX-312NT Life setting by A4 (8.5"×11") 6% document

×1 26cpm: 75K

31cpm: 100K

31cpm: 100K

×1 25K MX-312BT Life setting by A4 (8.5"×11") 6% document

×1 26cpm: 75K

31cpm: 100K

31cpm: 100K

×1 25K MX-312GT Life setting by A4 (8.5"×11") 6% document

×1 26cpm: 75K

31cpm: 100K

31cpm: 100K

×1 25K MX-312AT Life setting by A4 (8.5"×11") 6% document

×1 26cpm: 75K

31cpm: 100K

31cpm: 100K

×1 25K MX-312AT Life setting by A4 (8.5"×11") 6% document

×1 26cpm: 75K

31cpm: 100K

31cpm: 100K

×1 25K MX-312FT Life setting by A4 (8.5"×11") 6% document

×1 26cpm: 75K

31cpm: 100K

31cpm: 100K

MX-312NV

MX-312NR

MX-312NV

MX-312NR

MX-312GV

MX-312GR

MX-312AV

MX-312AR

MX-312AV

MX-312AR

MX-312FV

MX-312FR

MX-M260/M310/M260N/M310N CONSUMABLE PARTS 3 - 1

Page 14

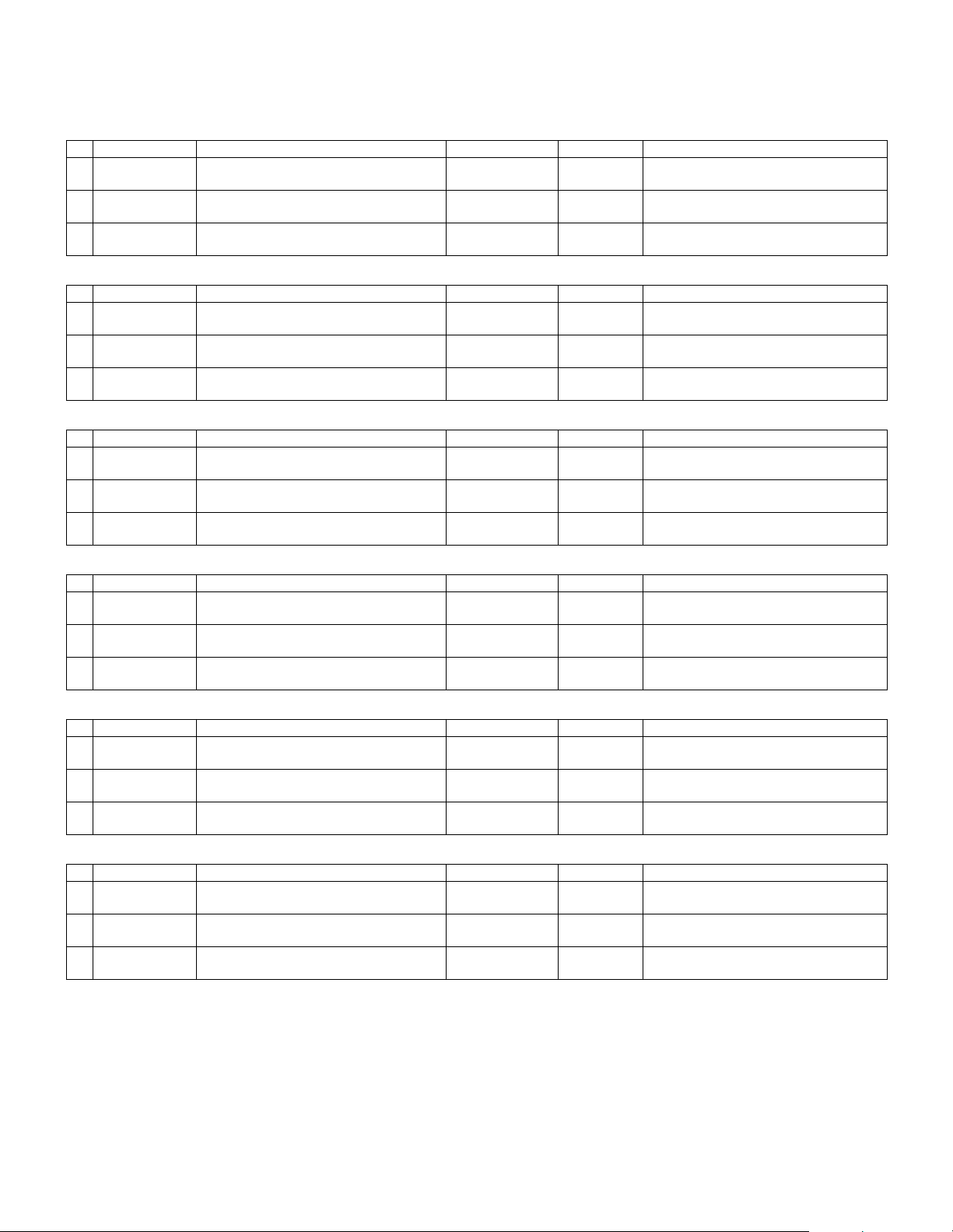

2. Maintenance parts list

A. SIICA/ SECL/ LAG (MX-M260/M310)

No. Item Content Life

1 Upper heat roller kit Upper heat roller

2 Lower heat roller kit Lower heat roller

3 150K maintenance

kit

4 MC unit MC unit ×10 26cpm: 75K (×10)

5 Cleaner blade Cleaner blade ×10 26cpm: 75K (×10)

6 Drum frame unit Drum frame unit ×1 26cpm: 225K

7 Transfer roller unit Transfer roller unit ×1 150K MX-311TX

8 Paper feed roller kit Paper feed roller kit ×1 100K MX-311RT

9 Fusing unit Fusing unit (120V heater lamp) ×1 150K MX-311FU

10 Staple cartridge Staple cartridge ×3 5000 staples ×3 MX-SCX1

Fuser gear

Upper heat roller bearing

Upper cleaning pad

Fusing separation pawl (upper)

Thermistor cleaning pad

Fusing separation pawl (lower)

Fuser bearing (lower)

Drum separation pawl unit

Transfer roller unit

DV blabe

DV side sheet F

DV side sheet R

Toner filter unit

×1

×1

×2

×1

×4

×2

×1

×4

×2

×2

×1

×1

×1

×1

×1

150K AR-310UH

300K MX-311LH

150K MX-311KA

31cpm: 100K (×10)

31cpm: 100K (×10)

31cpm: 300K

Model

name

MX-311MC

MX-311CB

MX-311DU

Remarks

∗ The life of the toner reception seat attached to

the drum frame is 300K, and it can be used up

to 3 times. (Supplied as a drum frame unit.)

∗ The other maintenance parts than the above are supplied as service parts.

B. SEGA/ SUK/ SCA/ SCNZ/ SEA/ SEES/ SEZ/ SEIS/ SEB/ SEN/ SEF/ SMEF/ Russia/ Special country

(MX-M260/M310)

No. Item Content Life

1 Upper heat roller kit Upper heat roller

Fuser gear

Upper heat roller bearing

Upper cleaning pad

Fusing separation pawl (upper)

Thermistor cleaning pad

2 Lower heat roller kit Lower heat roller

Fusing separation pawl (lower)

Fuser bearing (lower)

3 150K PM kit Drum separation pawl unit

Transfer roller unit

DV blade

DV side sheet F

DV side sheet R

Toner filter unit

4 MC unit MC unit ×10 26cpm: 75K (×10)

5 Cleaner blade Cleaner blade ×10 26cpm: 75K (×10)

6 Drum frame unit Drum frame unit ×1 26cpm: 225K

7 Transfer roller unit Transfer roller unit ×1 150K MX-311TX

8 Staple cartridge Staple cartridge ×3 5000 staples ×3 MX-SCX1

∗ The other maintenance parts than the above are supplied as service parts.

×1

×1

×2

×1

×4

×2

×1

×4

×2

×2

×1

×1

×1

×1

×1

150K AR-310UH

300K MX-311LH

150K MX-311KA

31cpm: 100K (×10)

31cpm: 100K (×10)

31cpm: 300K

Model

name

MX-311MC

MX-311CB

MX-311DU

Remarks

∗ The life of the toner reception seat attached to

the drum frame is 300K, and it can be used up

to 3 times. (Supplied as a drum frame unit.)

MX-M260/M310/M260N/M310N CONSUMABLE PARTS 3 - 2

Page 15

C. STCL/ SRH/ SRS/ SRSSC/ SBI/ Agent (MX-M260/M310/M260N/M310N)

No. Item Content Life

1 Upper heat roller kit Upper heat roller

Fuser gear

Upper heat roller bearing

Upper cleaning pad

Fusing separation pawl (upper)

Thermistor cleaning pad

2 Lower heat roller kit Lower heat roller

Fusing separation pawl (lower)

Fuser bearing (lower)

3 150K PM kit Drum separation pawl unit

Transfer roller unit

DV blade

DV side sheet F

DV side sheet R

Toner filter unit

4 MC unit MC unit ×10 26cpm: 75K (×10)

5 Cleaner blade Cleaner blade ×10 26cpm: 75K (×10)

6 Drum frame unit Drum frame unit ×1 26cpm: 225K

7 Staple cartridge Staple cartridge ×3 5000 staples ×3 MX-SCX1

∗ The other maintenance parts than the above are supplied as service parts.

×1

×1

×2

×1

×4

×2

×1

×4

×2

×2

×1

×1

×1

×1

×1

150K AR-310UH

300K MX-311LH

150K MX-311KA

31cpm: 100K (×10)

31cpm: 100K (×10)

31cpm: 300K

Model

name

MX-311MC

MX-311CB

MX-311DU

Remarks

∗ The life of the toner reception seat attached to

the drum frame is 300K, and it can be used up

to 3 times. (Supplied as a drum frame unit.)

3. Developer/Drum life end definition

When the developer/drum counter reaches the specified level.

When the developer/drum rpm reaches the specified level.

When either of the above reached the specified level, it is judged as life end.

In an actual case, when correction or warm-up operation is performed as well as output operation, the developer and the drum rotates.

Therefore, the developer/drum consuming level cannot be determined only by the copy/print quantity. When, therefore, the rpm reaches the specified

level, it is judged as life end.

To check the drum and developer life, use SIM22-1.

Developer/drum counter

Developer/drum 26cpm model 31cpm model 550K

75K 100K

Number of rotations

(Rotations)

MX-M260/M310/M260N/M310N CONSUMABLE PARTS 3 - 3

Page 16

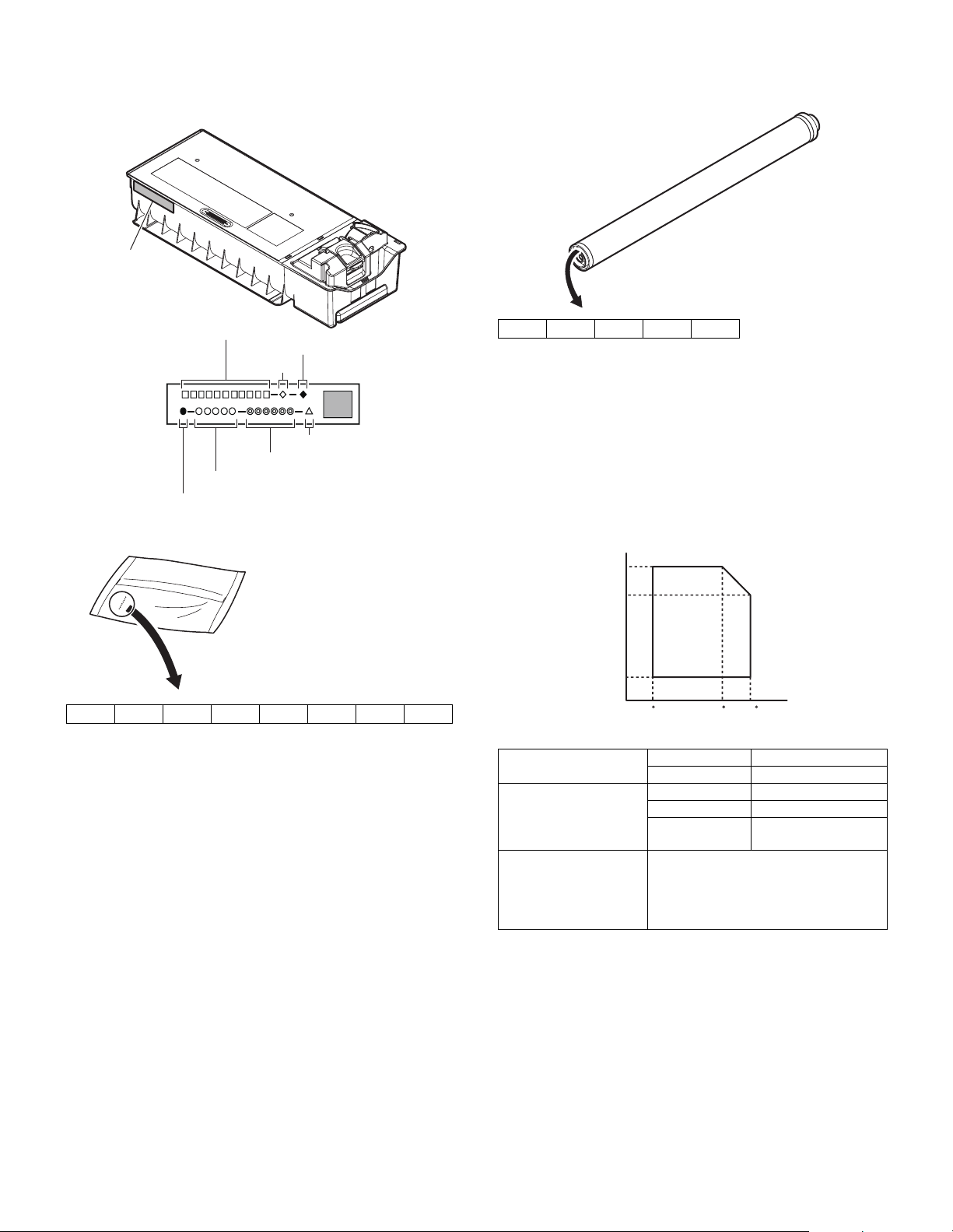

4. Production number identification

<Toner cartridge>

The label on the toner cartridge shows the date of production.

Label position

<Drum>

The laser print indicates the model conformity code and the date (year,

month, day) of production.

Internal product name

Incompatibility

Destination

Version No.

Production year/month/day (6 digits)

Serial No. in production day (5 digits)

Production place (1 digits)

<Developer>

12345678

The lot number is of 8 digits. Each digit indicates the content as follows.

The number is printed on the right under side of the back surface of the

developer bag.

1 Alphabet

Indicates the production factory.

2 Number

Indicates the production year.

3, 4 Number

Indicates the production month.

5, 6 Number

Indicates the production day.

7 Hyphen

8 Number

Indicates the production lot.

12345

1 Alphabet

Indicates the model conformity code. L for this model.

2 Number

Indicates the end digit of the production year.

3 Number or X, Y, Z

Indicates the month of packing.

X stands for October, Y November, and Z December.

4, 5 Number

Indicates the day of the month of packing.

5. Environment conditions

(Humidity)

85%

60%

20%

10 C 30 C 35 C

(Temperature)

Standard environmental

conditions

Usage environmental

conditions

Storage period Toner/Developer: 24 months from the

Temperature 20 - 25°C

Humidity 65 ± 5%RH

Temperature 10 - 35°C

Humidity 20 - 85%RH

Atmospheric

pressure

manufactured month (Production lot)

under unsealed state

Drum: 36 months from the manufactured

month under unsealed state

590 - 1013 hPa

(height: 0 - 2000m)

MX-M260/M310/M260N/M310N CONSUMABLE PARTS 3 - 4

Page 17

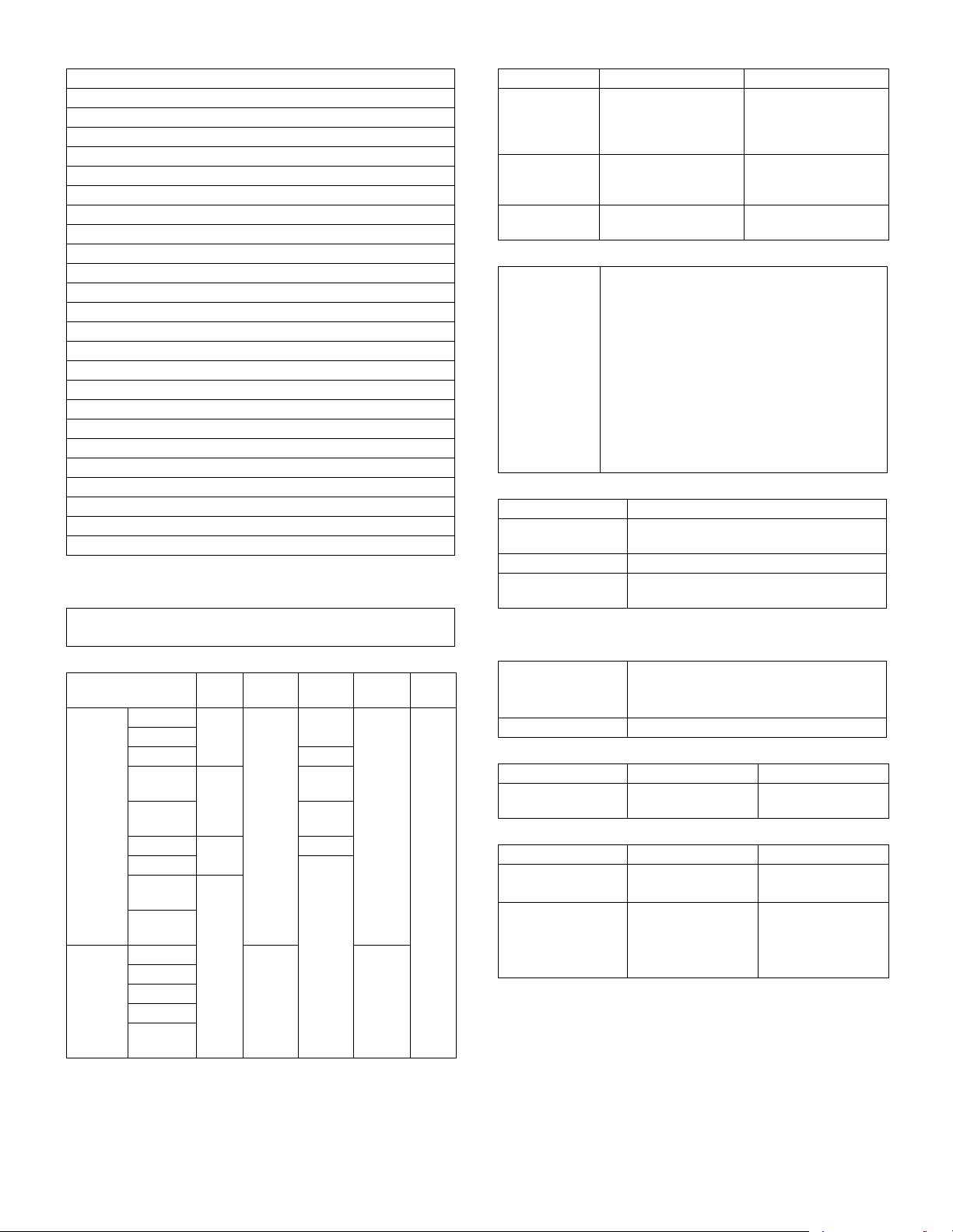

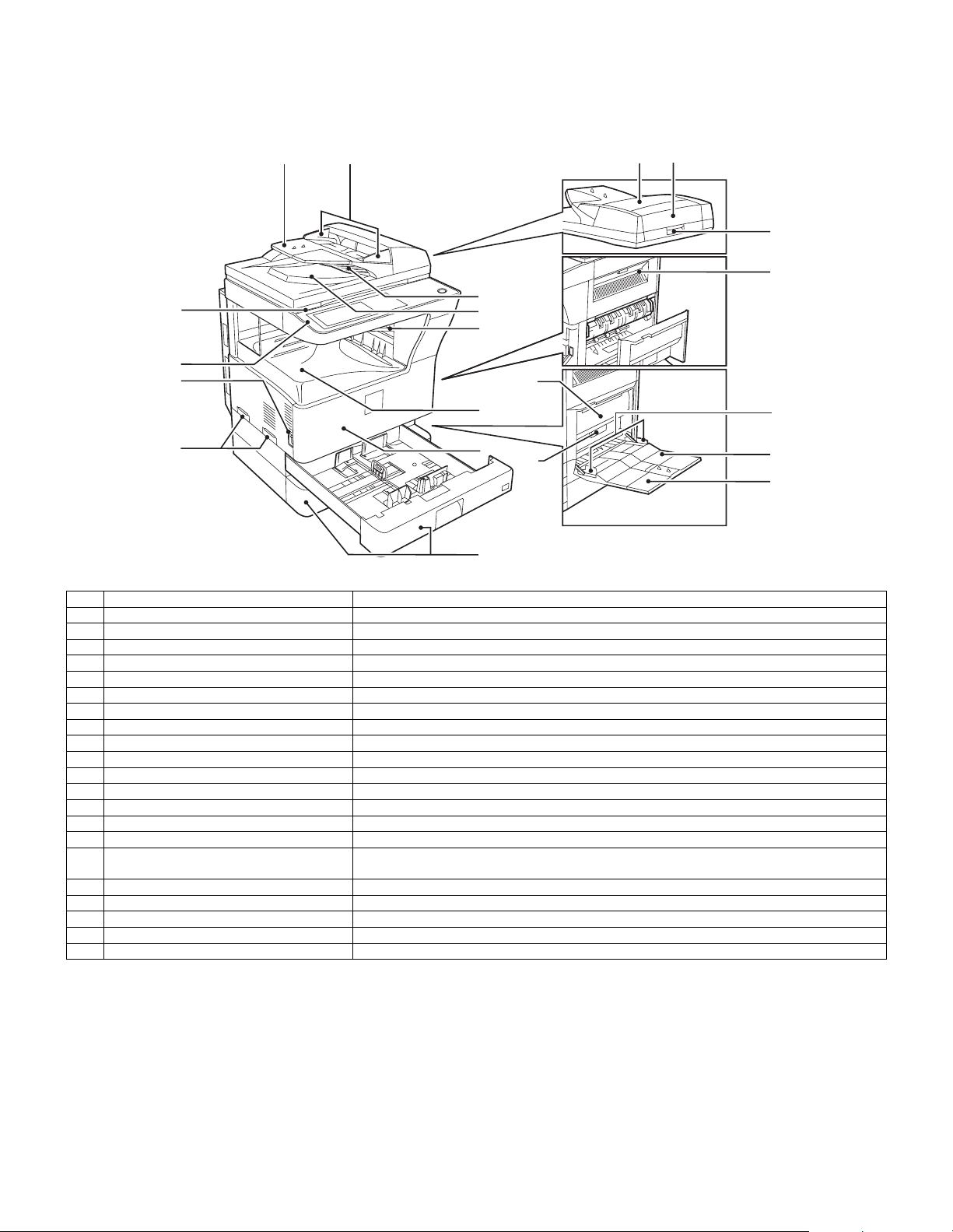

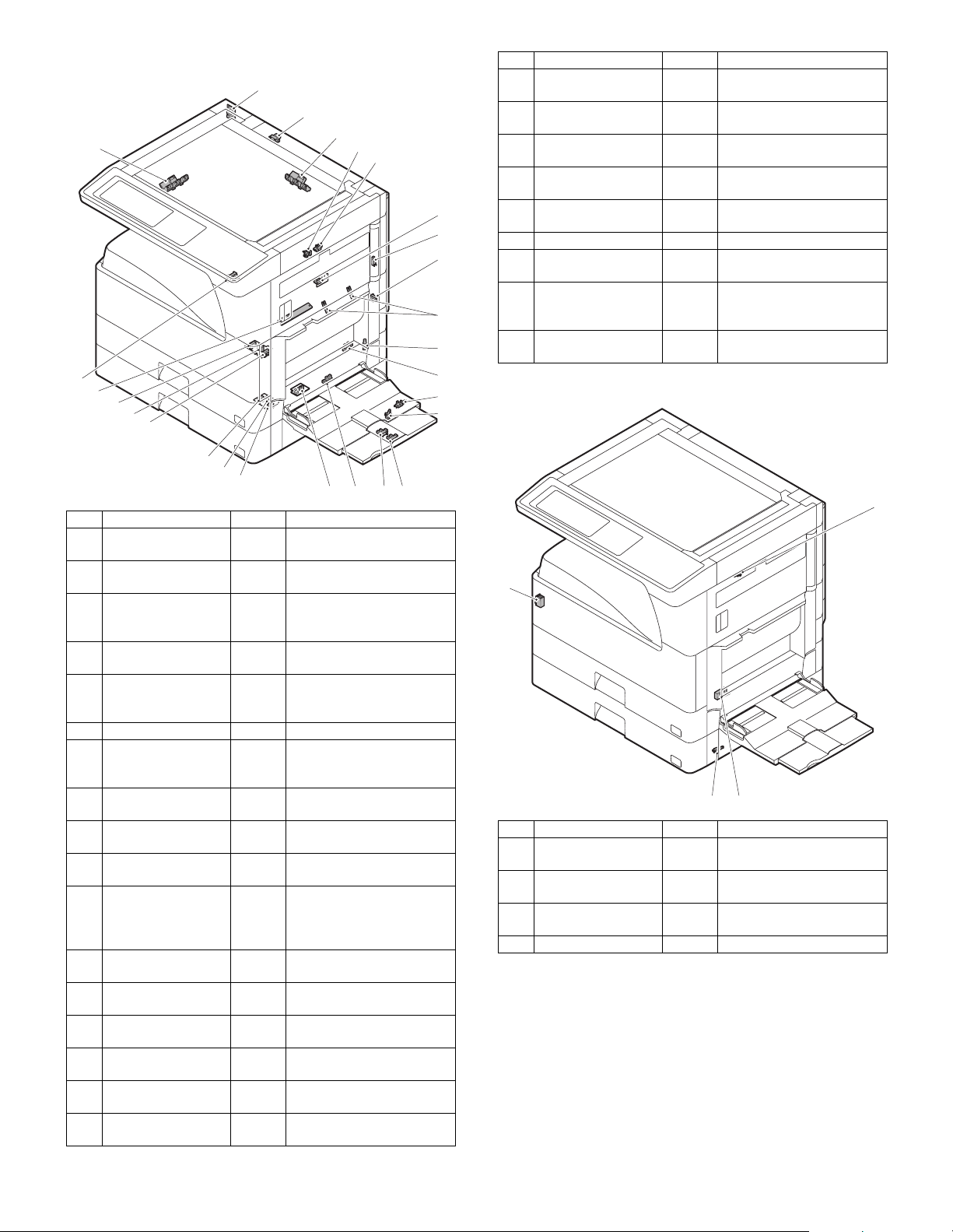

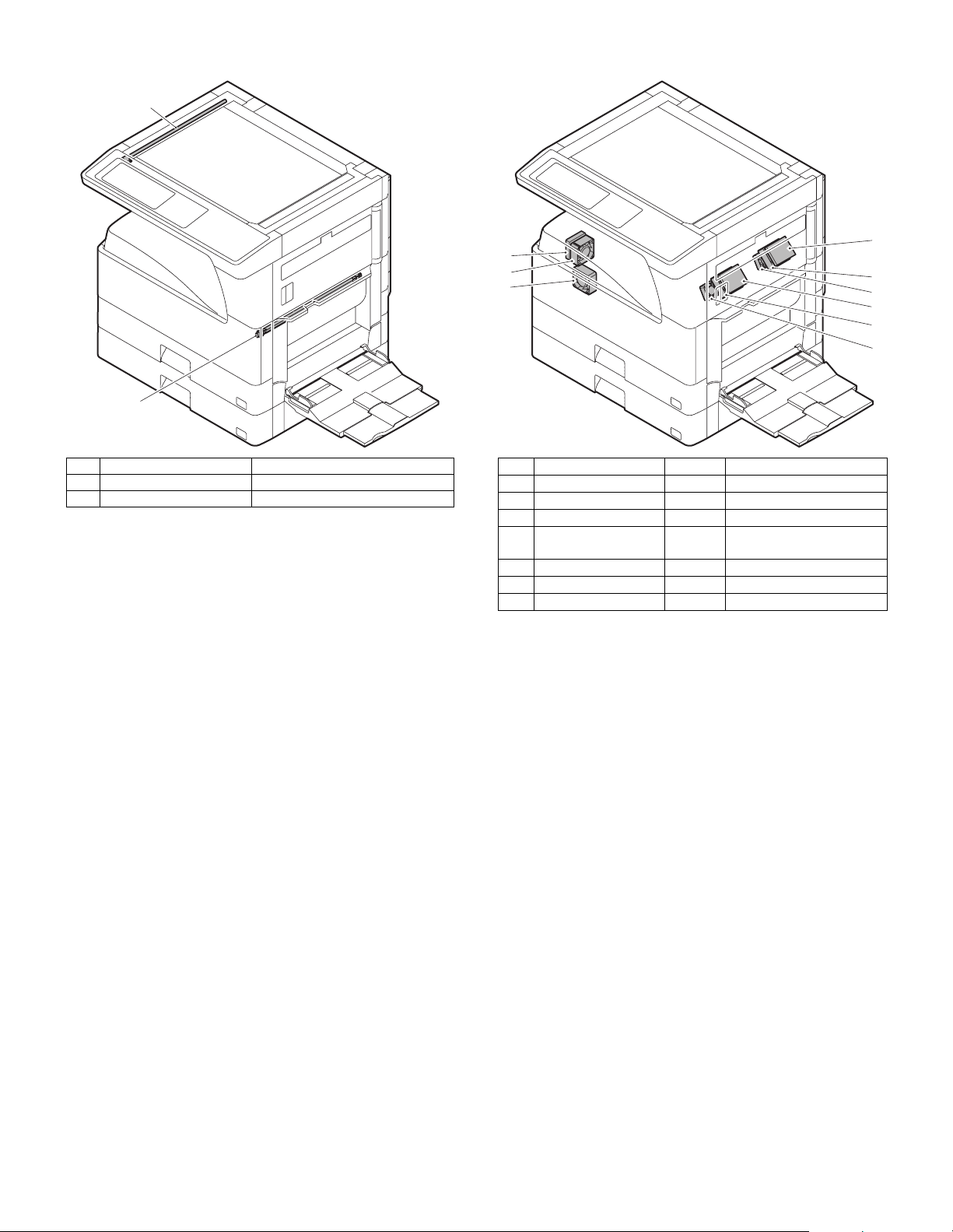

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

1

8

11

9

10

No. Name Function/Operation

1 Document feeder tray Place the original(s) that you wish to scan face up here.

2 Original guides Adjust to the size of the originals.

3 Document feeder cover Open to remove misfed originals.

4 Reversing tray Pull out to remove misfed originals.

5 Exit area Originals exit the machine here after copying.

6 Document transport cover Open to remove misfed originals.

7 Document transport cover knob Pull to open the document transport cover.

8 Document glass Place an original that you wish to scan face down here.

9 Power switch Press to turn the machine power on and off.

10 Handles Use to move the machine.

11 Operation panel Contains operation keys and the touch panel.

12 Job separator tray (Upper tray) (optional) Print jobs and received faxes are delivered to this tray.

13 Center tray Finished copies are delivered to the center tray.

14 Front cover Open to remove paper misfeeds and perform machine maintenance.

15 Paper trays Each tray holds 500 sheets of copy paper.

16 Upper right side cover Open to remove misfeeds when an optional job separator tray kit or a optional finisher is

17 Side cover Open to remove misfeeds.

18 Side cover handle Pull to open the side cover.

19 Bypass tray paper guides Adjust to the width of the paper.

20 Bypass tray Regular paper and special paper (such as transparency film) can be fed from the bypass tray.

21 Bypass tray extension Pull out the bypass tray extension before placing paper in the bypass tray.

2

installed.

15

12

13

14

36

7

16

4

5

17

19

18

20

21

MX-M260/M310/M260N/M310N EXTERNAL VIEW AND INTERNAL STRUCTURE 4 - 1

Page 18

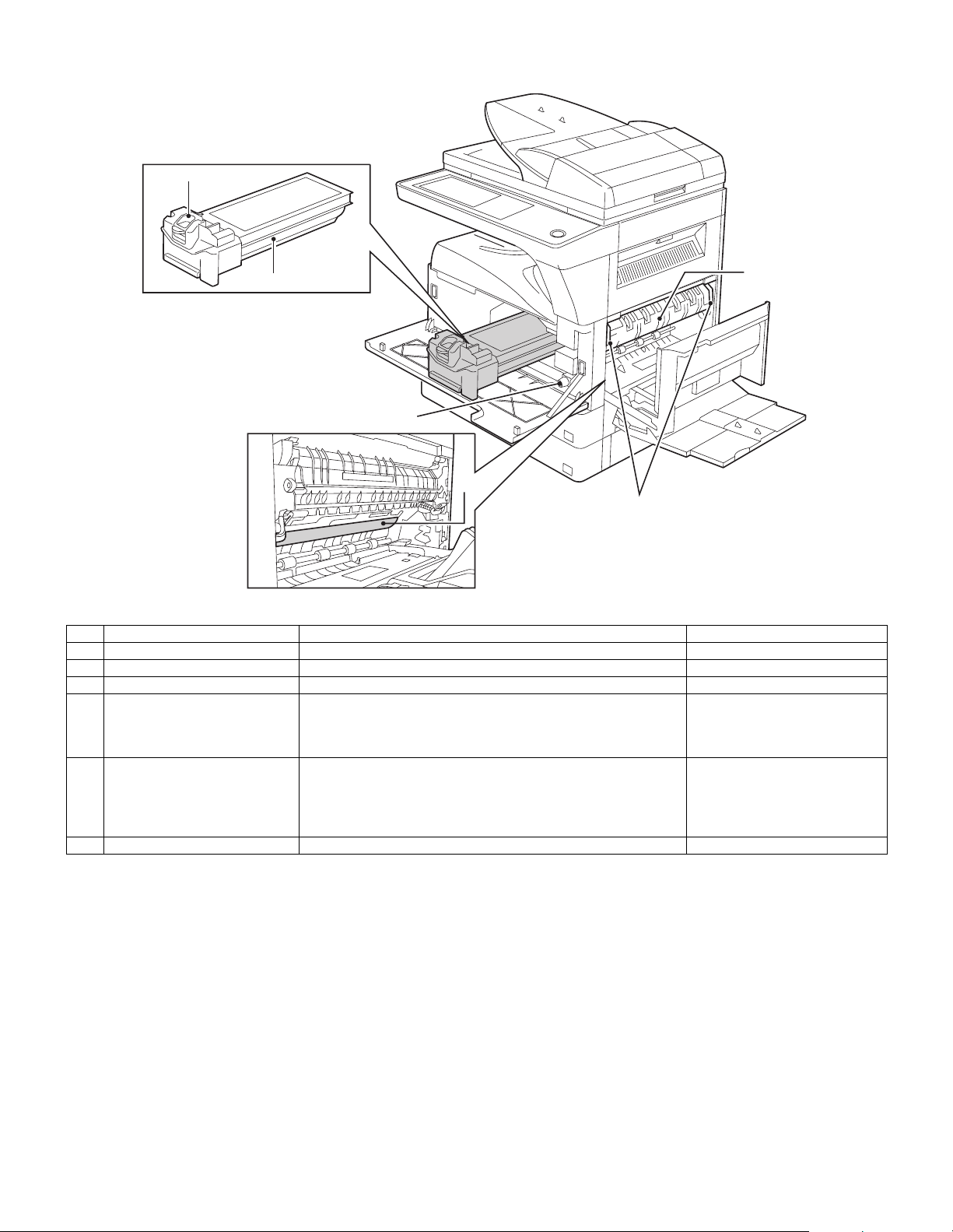

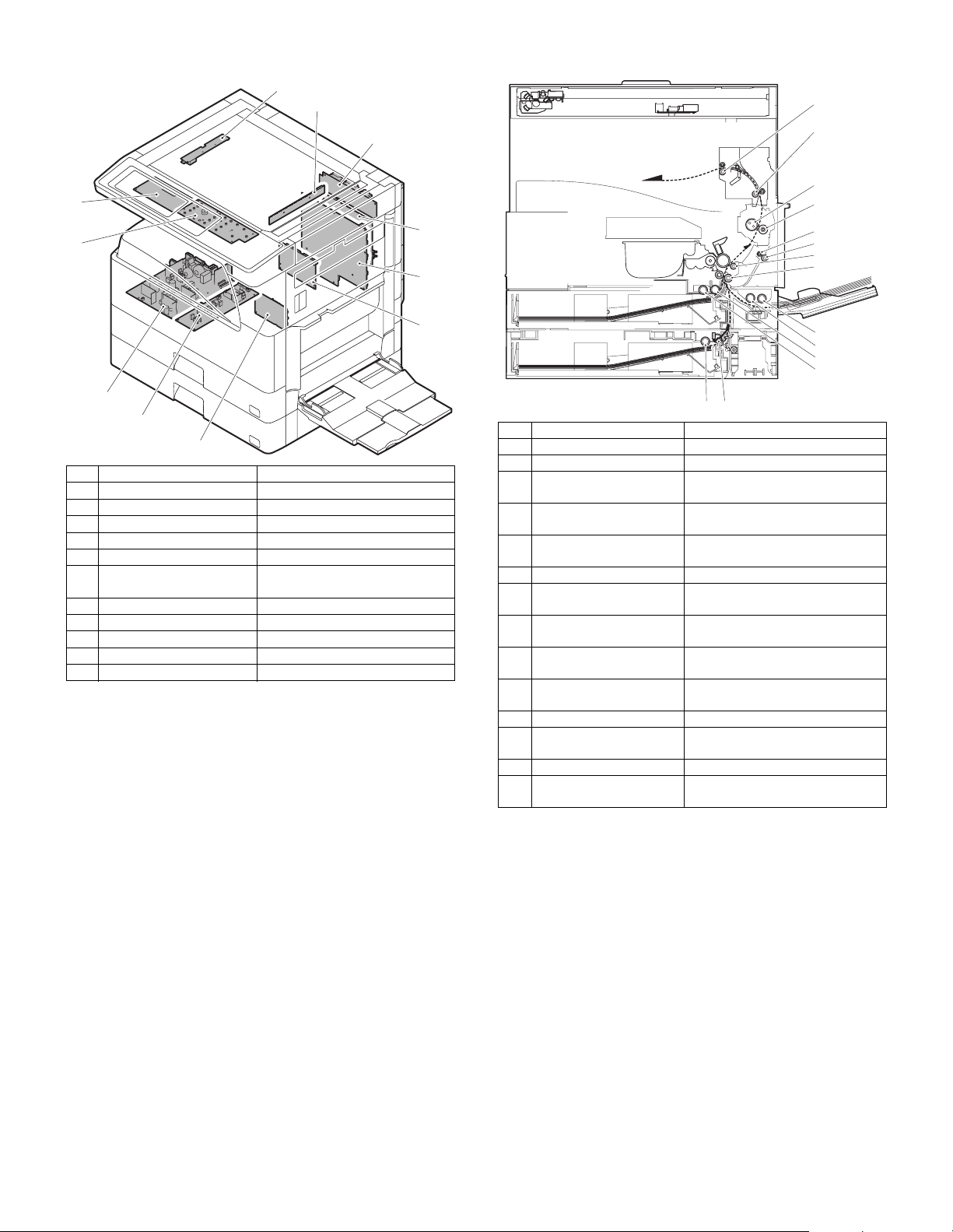

2. Internal structure

1

2

3

4

5

No. Name Function/Operation Note

1 Toner cartridge lock release lever Use to unlock the toner car tridge.

2 Toner cartridge Contains toner.

3 Roller rotating knob Turn to remove misfed paper.

4 Photoconductive drum Copy images are formed on the photoconductive drum. Do not touch the photoconductive

drum (green portion). Doing so

may damage the drum and cause

smudges on copies.

5 Fusing unit release levers To remove a paper misfeed in the fusing unit, push up on these

levers and remove the paper.

6 Fusing unit paper guide Open to remove misfed paper.

The fusing unit is hot.

Do not touch the fusing unit when

removing misfed paper.

Doing so may cause a burn or

injury.

6

MX-M260/M310/M260N/M310N EXTERNAL VIEW AND INTERNAL STRUCTURE 4 - 2

Page 19

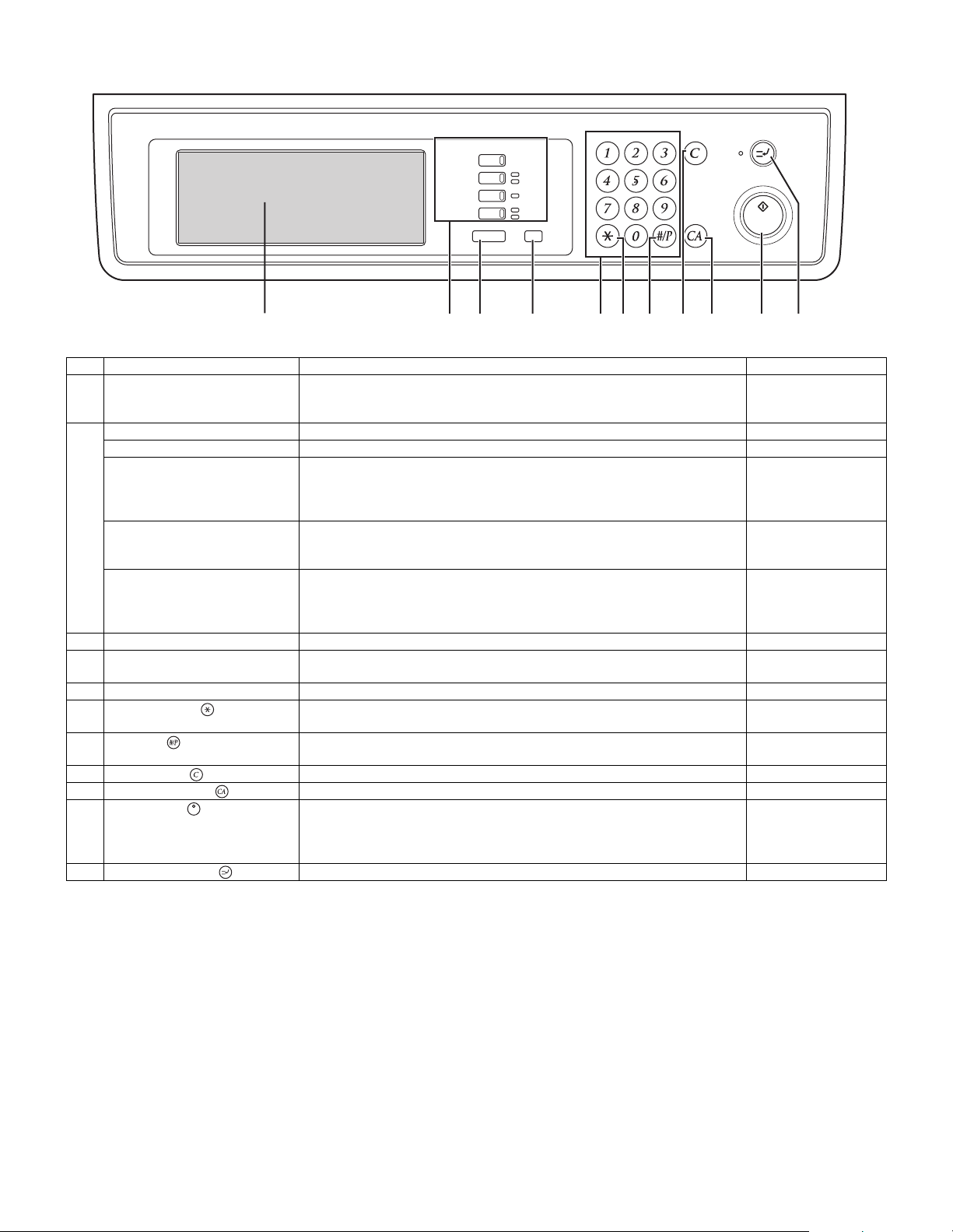

3. Operation panel

COPY

PRINT

SCAN

FAX

JOB STATUS

ON LINE

DATA

DATA

LINE

DATA

SYSTEM SETTINGS

LOGOUT

1234567891011

No. Name Function/Operation Note

1 Touch panel The machine status, messages and touch keys are displayed on the panel.

The display will show the status of printing, copying or network scanning

according to the mode that is selected. For details see the next page.

2 Mode select keys and indicators Use to change modes and the corresponding display on the touch panel.

[COPY] key Press to select copy mode.

[PRINT] key/ONLINE indicator/

DATA indicator

[PRINT] key: Press to select print mode.

• ONLINE indicator: Print jobs can be received when this indicator is lit.

• DATA indicator: A print job is in memory. The indicator lights steadily while

the job is held in memory, and blinks while the job is printed.

[SCAN] key/DATA indicator [SCAN] key: Press to select network scan mode when the network scanner

option is installed.

• DATA indicator: Lights steadily or blinks while a scanned image is being sent.

[FAX] key/LINE indicator/

DATA indicator

[FAX] key: Press to select fax mode when the fax option is installed.

• LINE indicator : This lights up while faxes are being sent or received.

When the network

scanner option is

installed.

When the fax option is

installed.

• DATA indicator: Blinks when a fax has been received to memory and lights

steadily when a fax is waiting in memory for transmission.

3 [JOB STATUS] key Press to display the current job status.

4 [SYSTEM SETTINGS] key Use to adjust various settings of the machine including the contrast of the touch

panel and administrator settings.

5 Numeric keys Use to enter numeric values for various settings.

6 [LOGOUT] key ( ) When auditing mode is enabled, press this key after finishing a job to return the

machine to account number entry standby.

7 [#/P] key ( ) Use this key to execute a job program in copy mode.

The key is also used to dial in fax mode.

8 [CLEAR] key ( ) Press to clear a copy number setting or cancel a job.

9 [CLEAR ALL] key ( ) Resets the settings to the initial settings.

10 [START] key ( ) Press in copy mode, scanner mode, or fax mode to begin copying, network

scanning, or faxing.

This key blinks when auto power shut mode has activated. Press the key to

return to normal operation.

11 [INTERRUPT] key ( ) Use to perform an interrupt copy job.

MX-M260/M310/M260N/M310N EXTERNAL VIEW AND INTERNAL STRUCTURE 4 - 3

Page 20

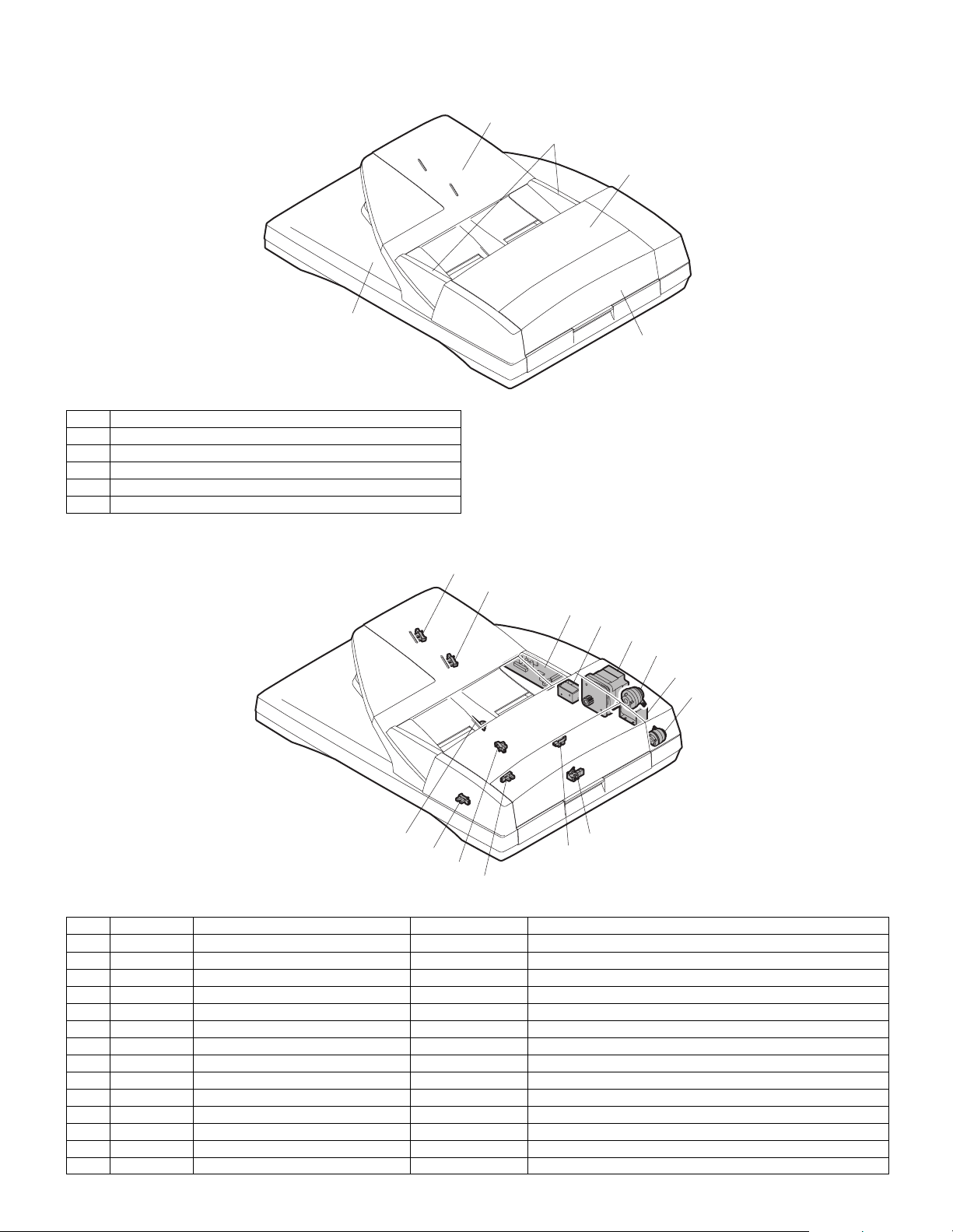

4. RSPF

A. External view

No. Name

1 Document set tray

2 Document guide

3 Document feed section cover

4 Document transport section cover

5 Document exit section

1

2

3

5

4

B. Internal structure

11

10

9

8

7

3

5

6

14

12

13

4

1

2

No. Code Name Type Function/Operation

1 EMPS Document set sensor Photo transmission Detects presence of documents.

2 FGOD Open/close sensor Photo transmission Detects open/close of the paper feed unit.

3 DFCL Paper feed clutch — —

4 DFD Paper entry sensor Photo transmission Detects presence of documents.

5 RSOL Pressure release solenoid — —

6 CLH Transport clutch — —

7 DTM SPF motor Stepping motor Drives document feed on the tray, transport, and paper exit roller.

8 GSOL Gate solenoid — —

9 — Interface PWB — —

10 DLS1 Document length detection SW (Short) Photo transmission Detects the document length on the tray.

11 DLS2 Document length detection SW (Long) Photo transmission Detects the document length on the tray.

12 OPCLS Book sensor Photo transmission Detects the SPF float.

13 RDD Paper exit sensor Photo transmission Detects presence of documents.

14 SWD Document width sensor Volume Detects the document width on the tray.

MX-M260/M310/M260N/M310N EXTERNAL VIEW AND INTERNAL STRUCTURE 4 - 4

Page 21

5. Sensor

1

2

25

24

23

22

21

20

19

18

17

No. Name Code Function and operation

1 Mirror home position

sensor

2 Document cover

sensor

3 Document size

sensor

4 2nd paper exit sensor

(Option)

5 2nd paper exit full

detection sensor

(Option)

6 1st paper exit sensor POD1 1st paper exit detection

7 Shifter home position

sensor (Except North

America)

8 Paper exit sensor

(DUP side)

9 Thermistor Fusing temperature

10 1st tray (paper tray)

detection

11 Manual feed paper

entry sensor

12 Manual paper feed

tray empty sensor 2

13 Manual paper feed

tray empty sensor 1

14 Manual feed length

detection sensor 1

15 Manual feed length

detection sensor 2

16 Manual feed paper

empty sensor

17 2nd tray paper pass

sensor

MHPS Mirror (scanner) home

position detection

OCSW Document cover open/close

detection

DSIN3 Document size detection

(Inch series: PD3, 4)

(AB series: PD4, 5)

POD2 2nd paper exit detection

TOPF 2nd paper exit section full

detection

SFTHP Shifter home position sensor

detection

PPD2 Paper exit detection

detection

CD1 1st tray (paper tray) empty

detection

PPD1L Sensor of paper entry from

the manual paper feed tray,

the 2nd/multi-tray desk, or

the DUP

MPLS2 Manual feed tray position

detection

MPLS1 Manual feed tray position

detection

MPLD1 Manual feed paper length

detection

MPLD2 Manual feed paper length

detection

MPED Manual feed paper empty

detection

PFD2 2nd tray paper pass

3

4

5

14151626

6

7

8

10

11

12

13

No. Name Code Function and operation

18 2nd tray paper upper

limit detection sensor

19 2nd tray paper empty

sensor

20 1st tray paper pass

sensor

21 1st tray paper upper

limit detection sensor

22 1st tray paper empty

sensor

23 Toner sensor Toner density detection

24 Center tray paper

YES/NO sensor

25 Document size sensor DSIN0 Document size detection

9

26 Reverse pass paper

detection sensor

LUD2 2nd tray paper upper limit

detection

PED2 2nd tray paper empty

detection

PPD1H 1st tray paper pass

LUD1 1st tray paper upper limit

detection

PED1 1st tray paper empty

detection

LOEMP Center tray paper YES/NO

DUP2

detection

(Inch series: PD1, 2)

(AB series: PD1 – 3)

Reverse pass detection

6. Switch

1

4

23

No. Name Code Function and operation

1 Right cabinet door

switch (Option)

2 Door switch DSWR1 Front door and side door

3 2nd right door switch DSWR2 Side door open/close

4 Main switch PSSW Main power switch

DSWR0 Right cabinet door open/

close detection

open/close detection

detection

MX-M260/M310/M260N/M310N EXTERNAL VIEW AND INTERNAL STRUCTURE 4 - 5

Page 22

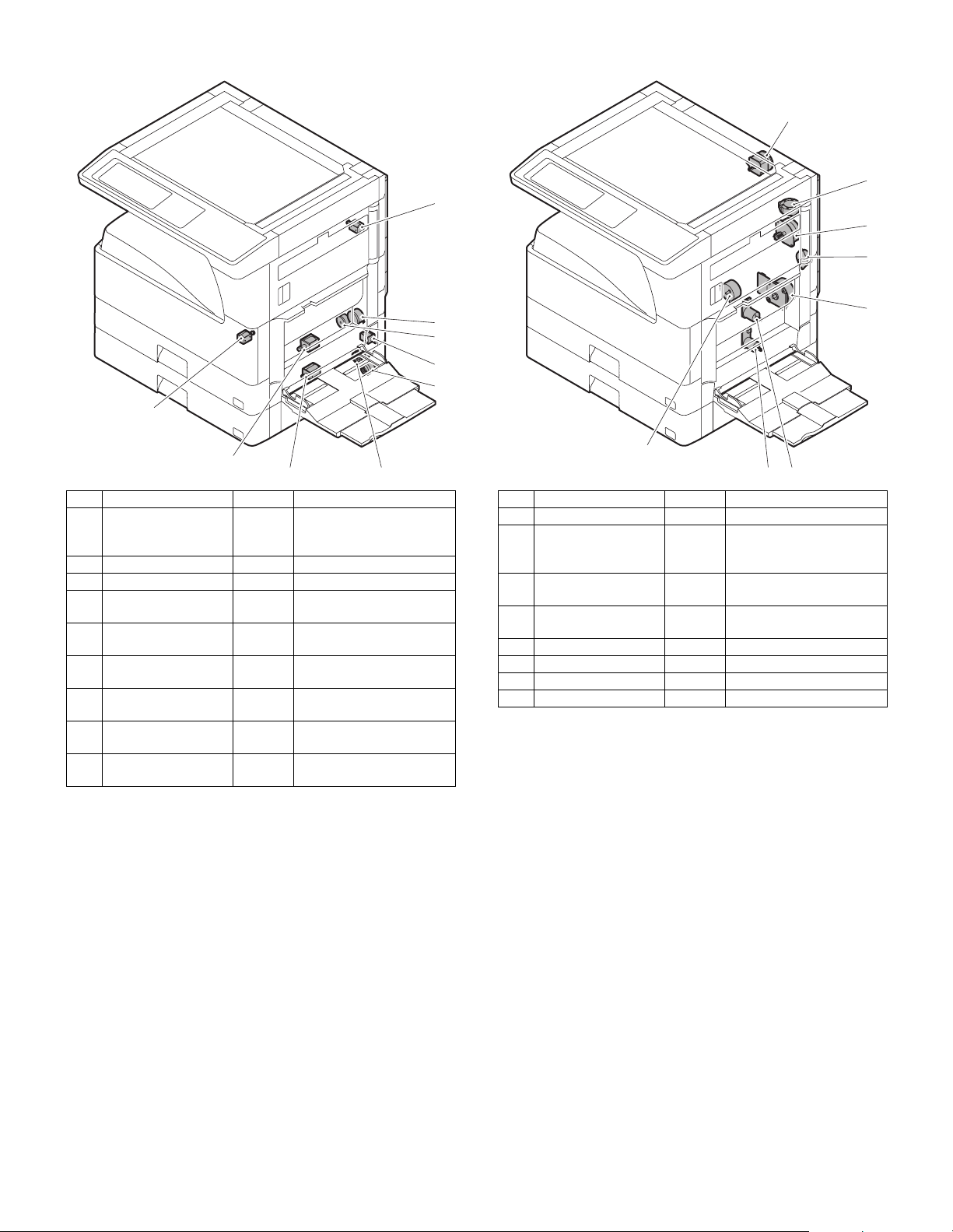

7. Solenoid/Clutch 8. Drive motor

1

1

2

4

5

9

8

No. Name Code Function and operation

1 Paper exit gate

switching solenoid

(Option)

2 PS clutch RRC Main unit paper feed

3 Paper feed clutch CPFS1 Paper feed roller drive

4 Manual paper feed

solenoid

5 Paper feed transfer

clutch

6 2nd tray paper feed

clutch

7 2nd tray paper feed

solenoid

8 Paper feed solenoid CPFC1 Solenoid for the paper feed

9 Separation pawl

solenoid

7

OGS Paper exit gate switcher

MPFS Manual paper feed

solenoid

TRC2 Paper feed transfer clutch

CPFS2

CPFC2 Solenoid for the paper feed

from the tray

from the tray

PSPS Separation pawl operation

solenoid

6

2

3

4

5

9

7

8

No. Name Code Function and operation

1 Mirror motor MIRM Optical mirror base drive

2 Shifter motor

(Except North

America)

4 Duplex motor DPXM Duplex paper switching

5 DUP-2 motor Reverse pass for paper

6 Main motor MM Main drive

7 Tray lift-up motor LUM1 Tray paper lift-up

8 Tray lift-up motor LUM2 Tray paper lift-up

9 Toner motor TM Toner supply

SFTM Shifter drive

and exit motor

transport

6

MX-M260/M310/M260N/M310N EXTERNAL VIEW AND INTERNAL STRUCTURE 4 - 6

Page 23

9. Lamp 10. Fan/Filter

1

7

2

3

2

6

1

5

6

1

4

No. Name Function and operation

1 Copy lamp Image radiation lamp

2 Heater lamp Fusing heat lamp

No. Name Code Function and operation

1 Cooling fan VFM Cools the inside of the unit.

2 Exhaust fan motor DCFM Cools the inside of the unit.

3 Intake fan motor DCFM2

4 Fusing paper exit fan VFM2 Cools the inside of the unit.

(31 sheet model)

5 Fusing paper exit fan VFM2 Cools the inside of the unit.

6 Ozon filter

7 Ozon filter

MX-M260/M310/M260N/M310N EXTERNAL VIEW AND INTERNAL STRUCTURE 4 - 7

Page 24

11. PWB 12. Roller

1

2

3

11

10

8

9

7

No. Name Function and operation

1 Inverter PWB Copy lamp control

2 CCD PWB For image scanning (read)

3 Option connector PWB

4 IMC PWB Image process

5 MCU PWB Main unit control

6 Mother board Connection with FAX PWB and

PCL PWB

7 Tray interface PWB 2nd tray control

8 DC power supply PWB DC voltage control

9 High voltage PWB High voltage control

10 KEY PWB

11 OPU PWB Operation panel control

1

2

3

4

4

5

6

1314

5

6

7

8

9

10

11

12

No. Name Function and operation

1 Paper exit roller Paper exit roller

2 Transport roller Paper transport roller

3 Upper heat roller Fuses toner on paper.

(with the Teflon roller)

4 Lower heat roller Fuses toner on paper.

(with the silicone rubber roller)

5 DUP transport follower

Duplex paper transport

roller

6 DUP transport roller Duplex paper transport

7 Transport roller Transfer images on the drum onto

paper.

8 Resist roller Synchronize the paper lead edge

with the image lead edge.

9 Manual paper feed roller Picks up papers in manual paper

feed port.

10 Manual feed transport

roller

Transports paper from the manual

paper feed port.

11 1st tray pick-up roller Picks up paper from the tray.

12 1st tray paper feed roller Transports the picked up paper to

RESIST section.

13 2nd tray pick-up roller Picks up paper from the tray.

14 2nd tray paper feed roller Transports the picked up paper to

RESIST section.

MX-M260/M310/M260N/M310N EXTERNAL VIEW AND INTERNAL STRUCTURE 4 - 8

Page 25

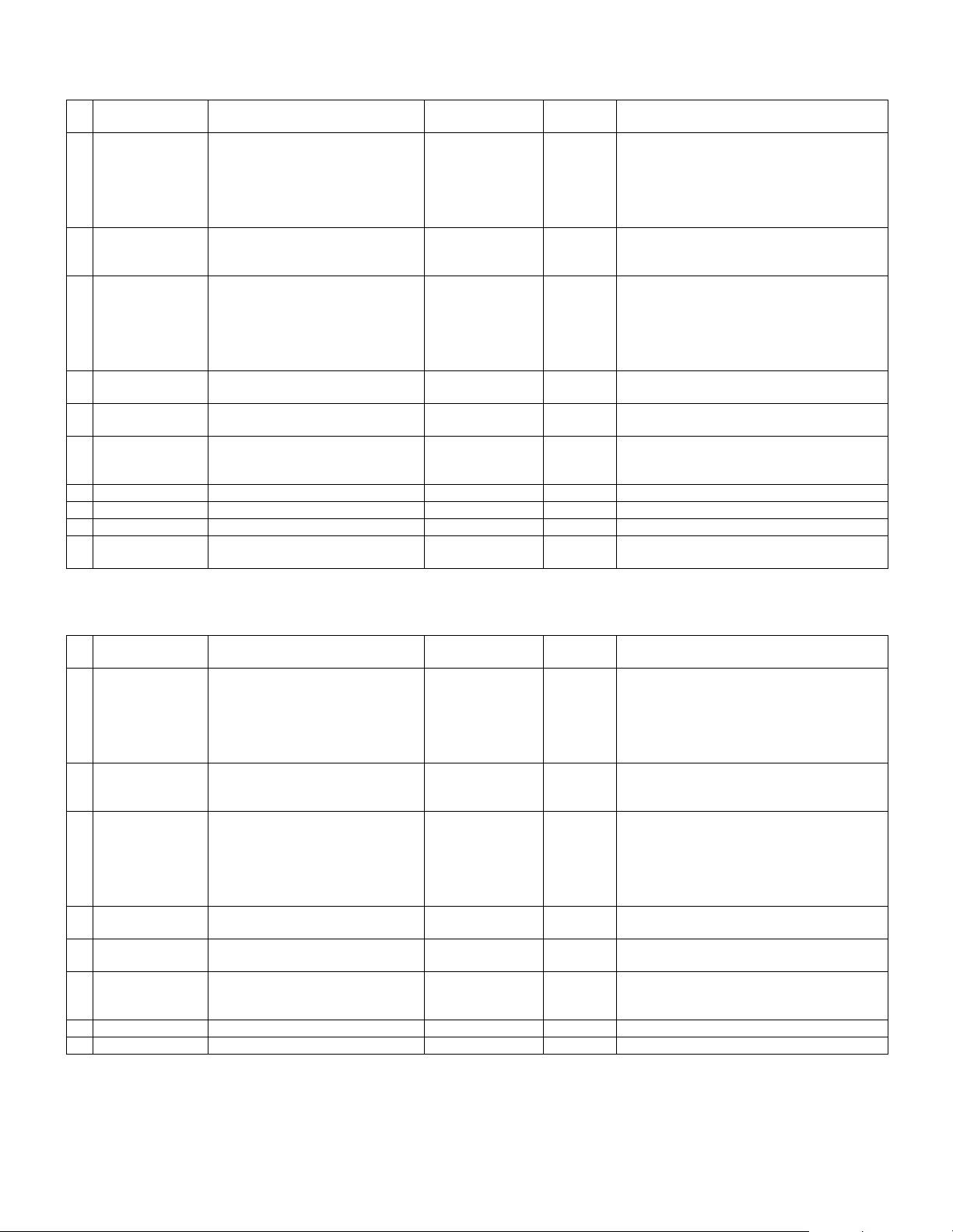

[5] ADJUSTMENTS

1. Adjustment item list

A Process section (1) Developing doctor gap adjustment Developing doctor gap adjustment

B Mechanism section (1) Print start position adjustment SIM50-5

C Image density

Section Adjustment item Adjustment procedure/SIM No.

(2) MG roller main pole position adjustment MG roller main pole position adjustment

(3) Developing bias voltage adjustment SIM8-1

(4) Grid bias voltage adjustment SIM8-2

(2) RSPF image lead edge position adjustment SIM50-6

(3) Rear edge void adjustment SIM50-1

(4) Paper off center adjustment SIM50-10

(5) Left edge void area adjustment SIM50-1-8

(6) Main scanning direction (FR direction) distortion

balance adjustment

(7) Sub scanning direction (scanning direction)

distortion adjustment

(8) Main scanning direction (FR direction) distortion

balance adjustment

(9) Main scanning direction (FR direction)

magnification ratio adjustment

(10) Sub scanning direction (scanning direction)

magnification ratio adjustment

(11) Off center adjustment (RSPF mode) SIM50-12

(12) OC (RSPF) open/close detection position

adjustment

(13) Original sensor adjustment SIM41-2, 41-4 (41-1)

(14) RSPF white correction pixel position adjustment

(required in an RSPF model when replacing the

lens unit)

(15) RSPF scan position auto adjustment SIM53-8

(1) Copy mode SIM46-2

(exposure) adjustment

No. 2/3 mirror base unit installing position

adjustment

Copy lamp unit installing position adjustment

Winding pulley position adjustment

Rail height adjustment

SIM48-1-1

a OC mode in copying (SIM 48-1-2)

b RSPF sub scanning direction magnification ratio

(SIM48-1-3, 48-1-4)

SIM41-3

SIM63-7

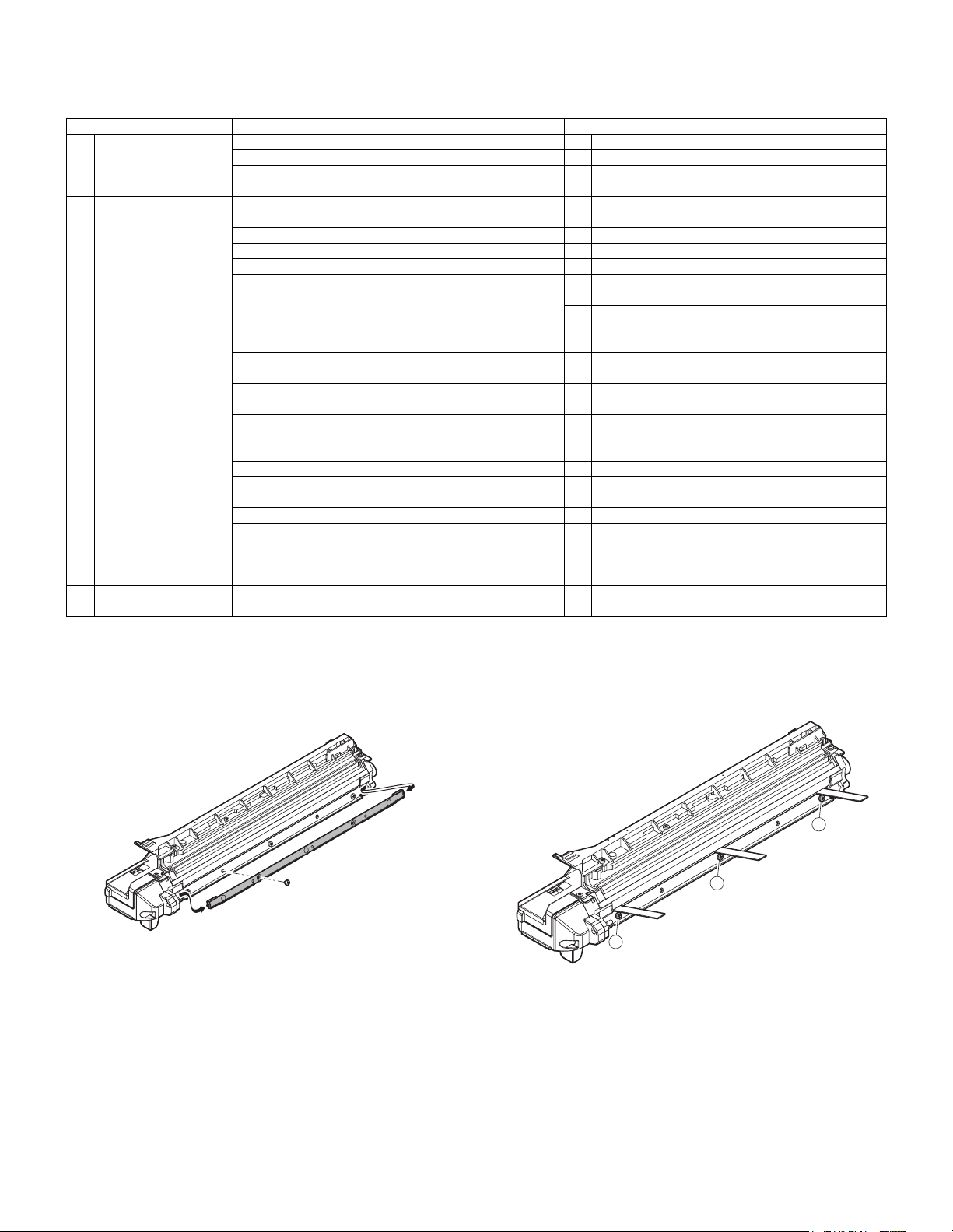

2. Details of adjustment

A. Process section

(1) Developing doctor gap adjustment

1) Remove the doctor cover.

2) Loosen the developing doctor fixing screw A.

3) Insert a thickness gauge of 1.5mm to the positions of three screws

on the developing docter as shown.

R

A

C

A

F

A

4) Tighten the developing doctor fixing screw.

5) Check the clearance of the developing doctor. If it is within the

specified range, then fix the doctor fixing screw with screw lock.

∗ When inserting a thickness gauge, be careful not to scratch the

developing doctor and the MG roller.

<Adjustment specification>

Developing doctor gap

F/C/R: 1.5

+0.1mm

-0.15mm

MX-M260/M310/M260N/M310N ADJUSTMENTS 5 - 1

Page 26

(2) MG roller main pole position adjustment

1) Put the developing unit on a flat surface.

2) Tie a needle or pin on a string.

3) Hold the string and bring the needle close to the MG roller horizontally. (Do not use paper clip, which is too heavy to make a correct

adjustment.) (Put the developing unit horizontally for this adjustment.)

4) Do not bring the needle into contact with the MG roller, but bring it

to a position 2 or 3mm apart from the MG roller. Mark the point on

the MG roller which is on the extension line from the needle tip.

5) Measure the distance from the marking position to the top of the

doctor plate of the developing unit to insure that it is 9.1mm.

If the distance is not within the specified range, loosen the fixing

screw A of the main pole adjustment plate, and move the adjustment plate in the arrow direction to adjust.

A

9.1mm

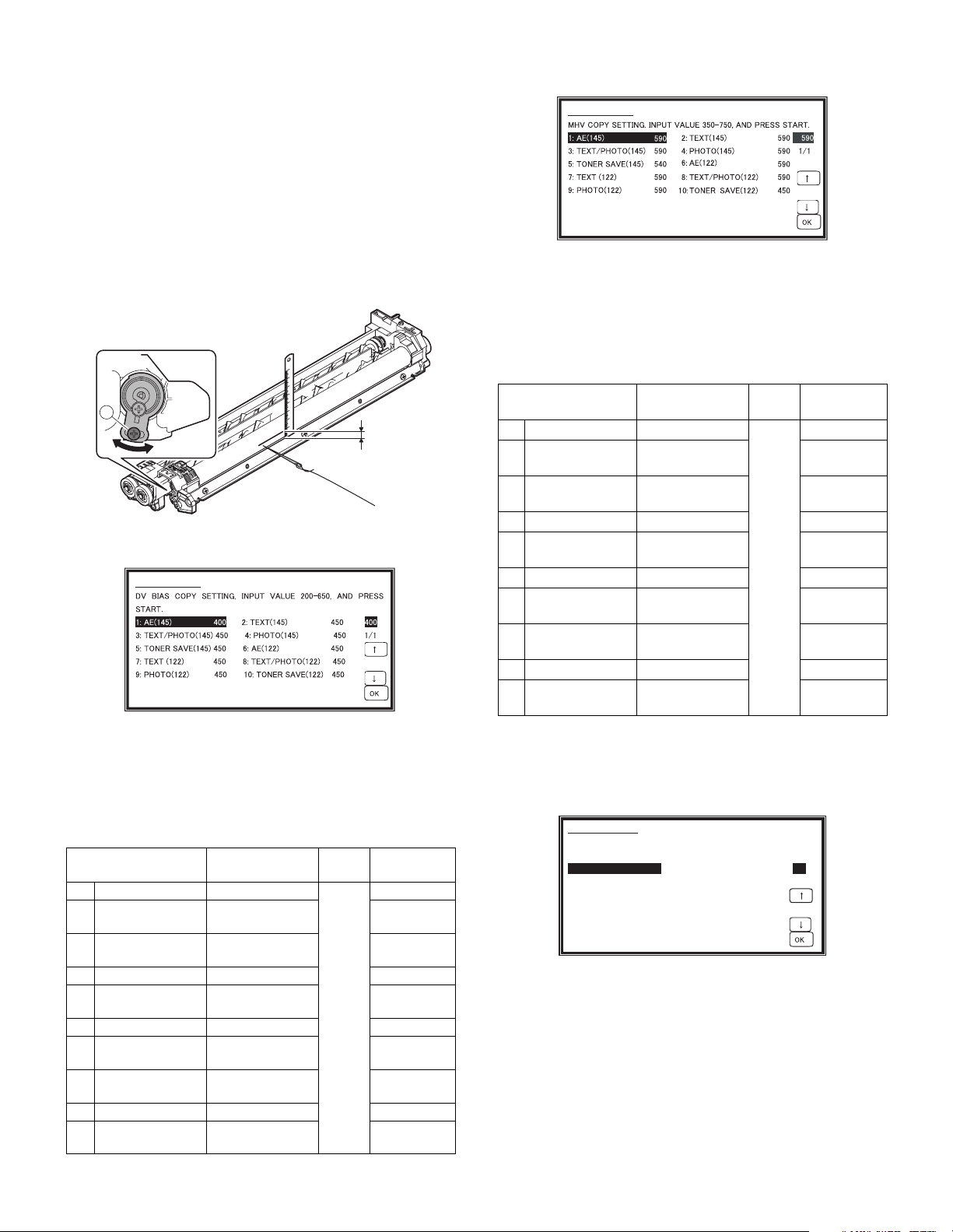

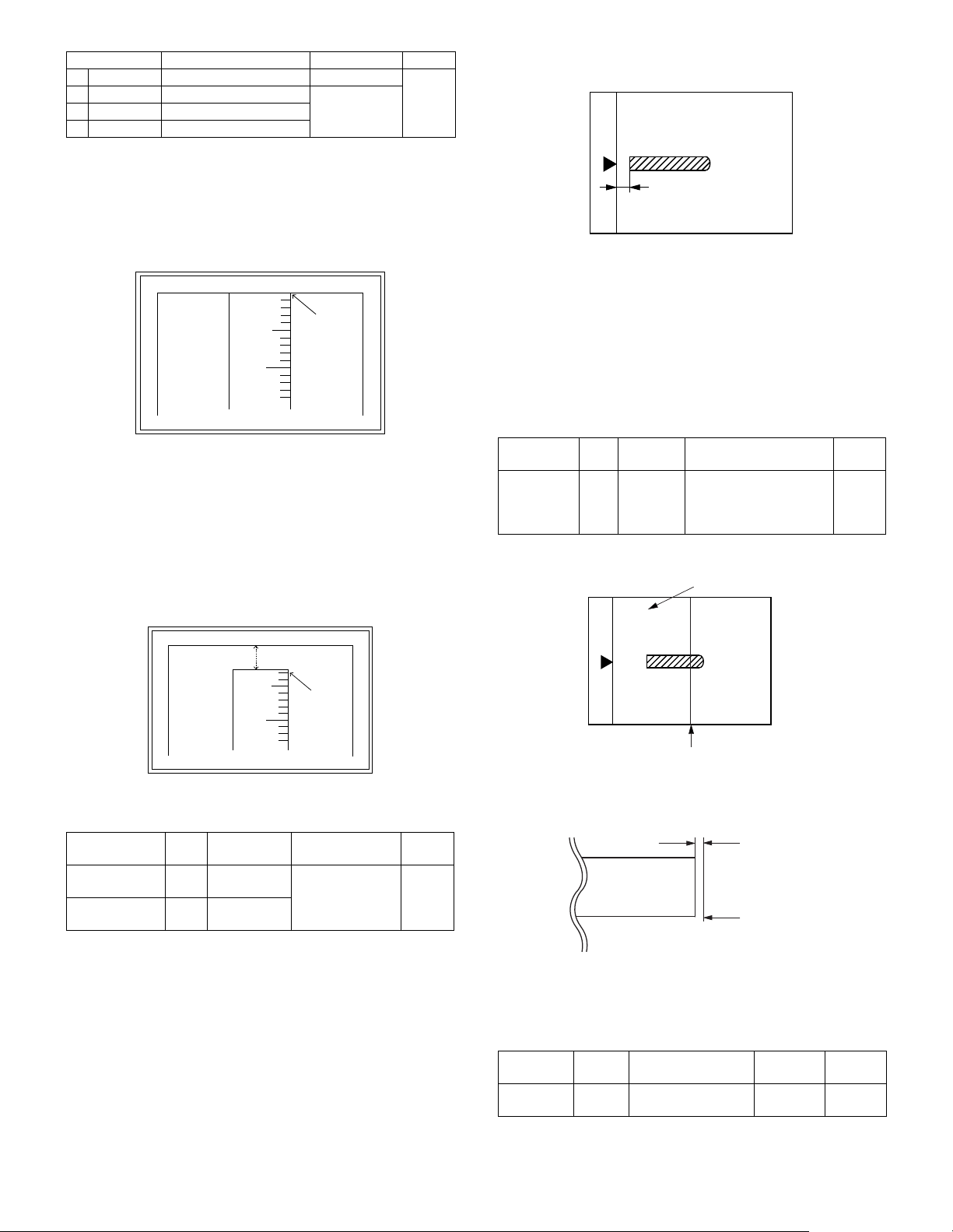

(3) Developing bias voltage adjustment (SIM 8-1)

1) Execute SIM 8-1.

2) Touch the exposure mode to be changed.

3) Enter the set value with the 10-key.

4) Press the [START] key.

<Adjustment specification>

1 AE (145) AE (145mm/s)

2 TEXT (145)

3

4 PHOTO (145) Photo (145mm/s) 450

5

6 AE (122) AE (122mm/s) 450

7 TEXT (122)

8

9 PHOTO (122) Photo (122mm/s) 450

10

Min. unit: –10V increment

SIMULATION 8-1

SIMULATION 8-1

DV BIAS COPY SETTING. INPUT VALUE 200-550, AND PRESS

START.

1: AE 426

2: TEXT 450

3: TEXT/PHOTO 450

4: PHOTO 450

5: SUPER/PHOTO 400

6: TONER SAVE 376

426

1/1

The current set value is displayed.

Output is made with the entered value, and the display returns to

the original state.

Item Content

Setting

range

Default

450

TEXT/PHOTO

(145)

TONER SAVE

(145)

Character

(145mm/s)

Character/Photo

(145mm/s)

Toner save

(145mm/s)

200-

450

450

400

650

TEXT/PHOTO

(122)

TONER SAVE

(122)

Character

(122mm/s)

Character/Photo

(122mm/s)

Toner save

(122mm/s)

450

450

400

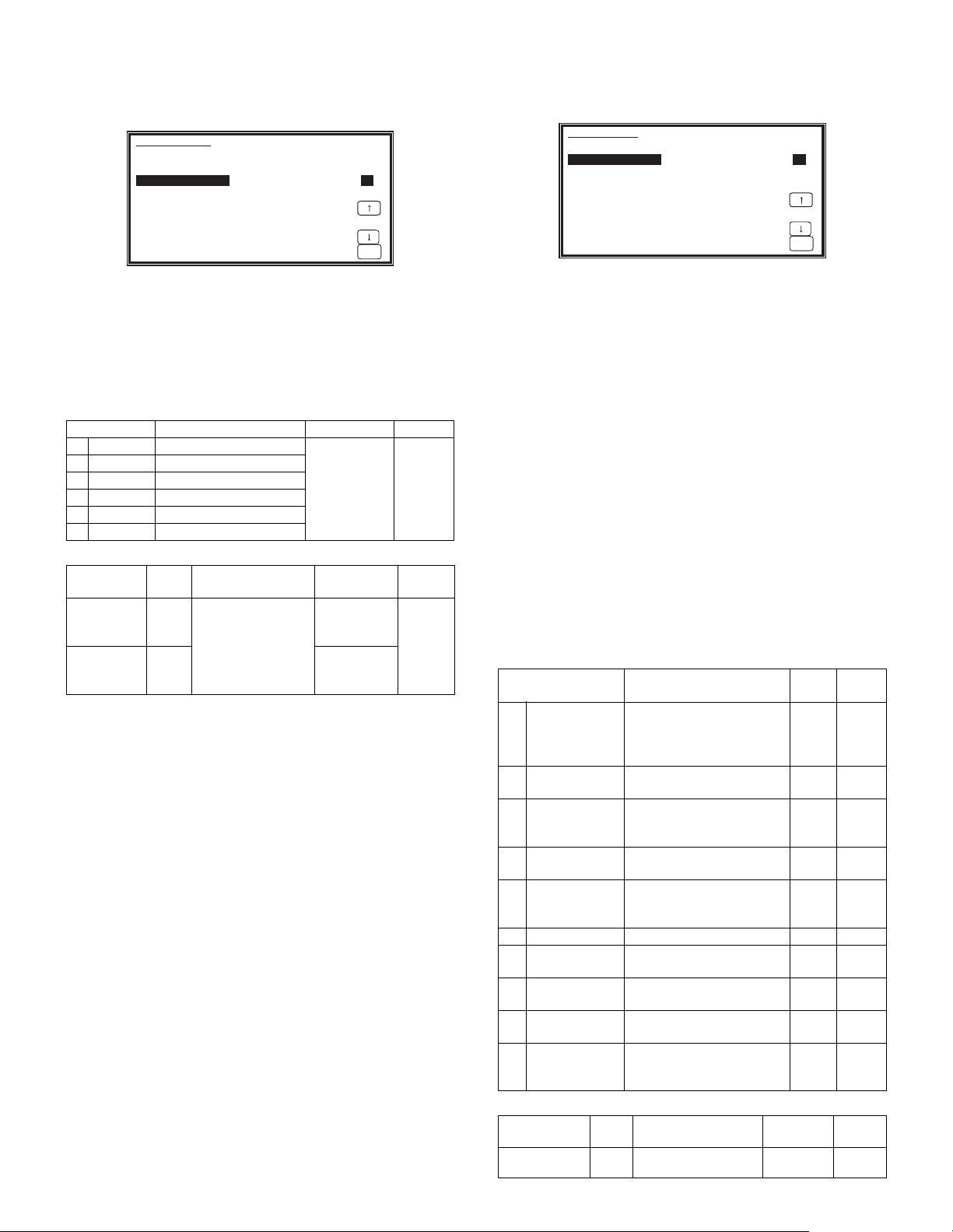

(4) Grid bias voltage adjustment (SIM 8-2)

1) Execute SIM 8-2.

SIMULATION 8-2

2) Touch the exposure mode to be changed.

The current set value is displayed.

3) Enter the set value with the 10-key.

4) Press the [START] key.

Output is made with the entered value for 30sec, and the display

returns to the original state.

<Adjustment specification>

Item Content

1 AE (145) AE (145mm/s)

2 TEXT (145)

TEXT/PHOTO

3

(145)

Character

(145mm/s)

Character/Photo

(145mm/s)

Setting

range

Default

590

590

590

4 PHOTO (145) Photo (145mm/s) 590

TONER SAVE

5

(145)

6 AE (122) AE (122mm/s) 590

7 TEXT (122)

TEXT/PHOTO

8

(122)

Toner save

(145mm/s)

Character

(122mm/s)

Character/Photo

(122mm/s)

350-

750

540

590

590

9 PHOTO (122) Photo (122mm/s) 590

TONER SAVE

10

(122)

Toner save

(122mm/s)

540

Min. unit: –10V increment

B. Mechanism section

(1) Print start position adjustment

1) Execute SIM 50-5.

SIMULATION 50-5

LEAD EDGE ADJUSTMENT(PRINT). INPUT VALUE 0-99, AND PRESS

START.

1: TRAY1 53

2: OPTION 53

3: MANUAL 53

4: DUPLEX 53

2) Touch the item to be adjusted.

The item and the currently set value are highlighted.

3) Press the [P] key.

The display is shifted to the copy menu.

4) Select the paper feed tray, the print density, and the duplex mode.

Enter the adjustment value with the 10-key.

5) Press the [START] key.

Copying is started.

53

1/1

MX-M260/M310/M260N/M310N ADJUSTMENTS 5 - 2

Page 27

Item Content Setting range Default

1TRAY1

2OPTION

3MANUAL

4DUPLEX

1st tray 0-99

Option tray

Manual feed

1-99

Back print

53

6) Measure the distance H between the paper lead edge and the

image print start position. Set the image print start position set

value again.

• 1 step of the set value corresponds to about 0.127mm shift.

• Calculate the set value from the formula below.

99 – H/0.127 (mm) = Image print start position set value

<H: Print start position measurement value (mm)>

0mm

5

10

∗ Fit the print edge with the paper edge, and perform the lead

0mm

edge adjustment.

Example:99 – 5/0.127 = 99 – 39.4 = about 59

Note : FIf the set value is not obtained from the above formula, per-

form the fine adjustment.

7) Execute SIM 50-1-2 to adjust the main tray lead edge void.

• 1 step of the set value corresponds to about 0.127mm shift.

• Calculate the set value from the formula below.

B/0.127 (mm) = Lead edge void adjustment value

<B: Lead edge void (mm)>

(2) RSPF image lead edge position adjustment

1) Set a scale on the OC table as shown below.

Note: Since the printed copy is used as a test chart, put the scale in

paralleled with the edge lines.

2) Make a copy, then use the copy output as an original to make an

RSPF copy again.

3) Check the copy output. If necessary, perform the following adjustment procedures.

4) Execute SIM 50-6.

5) Set the RSPF lead edge position set value so that the same image

is obtained as that obtained in the previous OC image lead edge

position adjustment.

<Adjustment specification>

Adjustment

mode

RSPF

image lead

edge

SIM Set value Spec value

50-6 1 step:

0.127mm

shift

Lead edge void:

1 – 4mm

Image loss: 3mm or less

Setting

range

1 – 99

position

(3) Rear edge void adjustment

1) Set a scale as shown in the figure below.

A4 (8.5" x 11")

2.5mm

5

10

2.5mm

Example: When setting the lead edge void to 2.5mm:

2.5 /0.127 = about 20

<Adjustment specification>

Adjustment

mode

Main tray lead

edge void

Print start

position

SIM Set value Spec value

50-1-2B/0.127 Lead edge void:

1 – 4mm

50-5 99 – H/0.127

Image loss: 3mm

or less

[H: Print start position measurement value (mm),

B: Lead edge void (mm)]

Setting

range

1 – 99

Paper rear edge

2) Set the document size to A4 (8.5" x 11"), and make a copy at

100%.

3) If an adjustment is required, follow the procedures below.

Void amount (Standard value: 4mm or less)

Scale image

Paper rear edge

4) Execute SIM 50-1 and set the density mode to DEN-B. The currently set adjustment value is displayed.

5) Enter the set value and press the start key.

The correction value is stored and a copy is made.

<Adjustment specification>

Adjustment

mode

Rear edge

void

SIM Set value

50-1-6

1 step: 0.127mm

shift

Spec

value

4mm or

less

Setting

range

1 – 99

MX-M260/M310/M260N/M310N ADJUSTMENTS 5 - 3

Page 28

(4) Paper off center adjustment

1) Set a test chart (UKOG-0089CSZZ) on the document table.

2) Select a paper feed port and make a copy.

3) Execute SIM 50-10.

SIMULATION 50-10

PRINT OFF-CENTER ADJUSTMENT. INPUT VALUE 1-99, AND

PRESS START.

1: BYPASS 50

2: TRAY1 50

3: TRAY2 50

4: TRAY3 50

5: TRAY4 50

6: DUPLEX 50

4) Touch the item to be adjusted.

The item and the currently set value are highlighted.

5) Press the [START] key.

The display is shifted to the copy menu.

6) Select the paper feed tray and the print density.

Enter the adjustment value with the 10-key.

7) Press the [START] key.

Copying is started.

Item Content Setting range Default

1

2

3

4

5

6

BYPASS

TRAY1

TRAY2

TRAY3

TRAY4

DUPLEX

Manual paper feed

1st tray

2nd tray

3rd tray

4th tray

Back print

<Adjustment specification>

Adjustment

mode

Paper off

center

SIM Set value Spec value

50-10-2Add 1: 0.127mm

shift to R side.

Reduce 1:

Second

print surface

50-10

0.127mm shift to L

-6

side.

off-center

50

1/1

OK

1-99 50

Single:

Center

±2.0mm

Duplex:

Center

±2.5mm

Setting

range

1 – 99

(5) Left edge void area adjustment

Note: Before performing this adjustment, be sure to check that the

paper off center adjustment (SIM 50-10) is completed.

1) Execute SIM 50-1.

SIMULATION 50-1

LEAD EDGE ADJUSTMENT. INPUT VALUE 1-99, AND PRESS START.

1: RRC-A 43 2: DEN-A 18

3: DEN-A -MANUAL 18 4: DEN-A -OPTION 18

5: DEN-A -DUPLEX 18 6: DEN-B 3

7: DEN-B-DUP 50 8: SIDE VOID 18

9: SIDE VOID-DUP 18 10: LOSS(OC) 3

2) Note down the adjustment value of SIM 50-5 (Items 1, 2, 3, 4), and

change the value to 99.

3) Set SIM 50-1 (Items 2, 3, 4, 5) to 1. (By setting to 1, there is no

void.)

4) Place a chart with a clear lead edge (or a ruler) on the OC document table.

5) Use SIM 50-1 (Item 1) to execute test print. Check the print out and

adjust so that the lead edge image is printed. (1 – 99: About

0.127mm/Step)

6) Reset the adjustment values of SIM 50-5 (Items 1, 2, 3, 4) to the

original values, and execute test print. Check the print out and

adjust so that the lead edge image is printed on the lead edge of

paper. (1 – 99: About 0.127mm/Step).

7) Adjust SIM 50-1 (Items 2, 3, 4, 5) so that the lead edge void on the

print out is the specified value. (1 – 99: About 0.127mm/Step)

8) Similar to procedure 7, adjust SIM 50-1 (Item 6, 7) so that the rear

edge void is the specified value. (1 – 99: About 0.127mm/Step)

9) Similar to procedure 7, adjust SIM 50-1 (Item 8, 9) so that the left

edge void is the specified value. (1 – 99: About 0.127mm/Step)

10) Make an enlargement copy (400%), and check that there is no

shade of the cabinet printed at the lead edge.

11) If there is a shade printed at the lead edge in procedure 9, adjust

SIM 50-1 (Item 10). (1 – 5: About 0.677mm)

* If there is no problem, set to 3.

Item Content

1

RRC-A

Original scan start position

adjustment

Lead edge position

adjustment value (OC)

2

DEN-A

Lead edge cancel

adjustment (Main tray)

3

DEN-A-MANUAL

Lead edge cancel

adjustment

(Manual feed tray)

DEN-A-OPTION

4

Lead edge cancel

adjustment (Option tray)

5

DEN-A-DUPLEX

Lead edge cancel

adjustment

(back of the machine)

DEN-B

6

7

DEN-B-DUP

Rear edge void adjustment 1-99 30

Rear edge void adjustment

(Duplex)

8

SIDE VOID

Left edge void adjustment

(First print surface)

9

SIDE VOID-DUP

Left edge void adjustment

(Duplex)

10

LOSS(OC)

Image loss amount

adjustment (Lead edge

image loss set value) (OC)

<Adjustment specification>

Adjustment

mode

SIM Set value

Left edge void 50-1-81 step: 0.127mm

shift

43

1/1

OK

Setting

range

Default

1-99 43

1-99 18

1-99 18

1-99 18

1-99 18

1-99 50

1-99 18

1-99 18

1-5 3

Spec

value

Setting

range

0.5 – 4mm 1 – 99

MX-M260/M310/M260N/M310N ADJUSTMENTS 5 - 4

Page 29

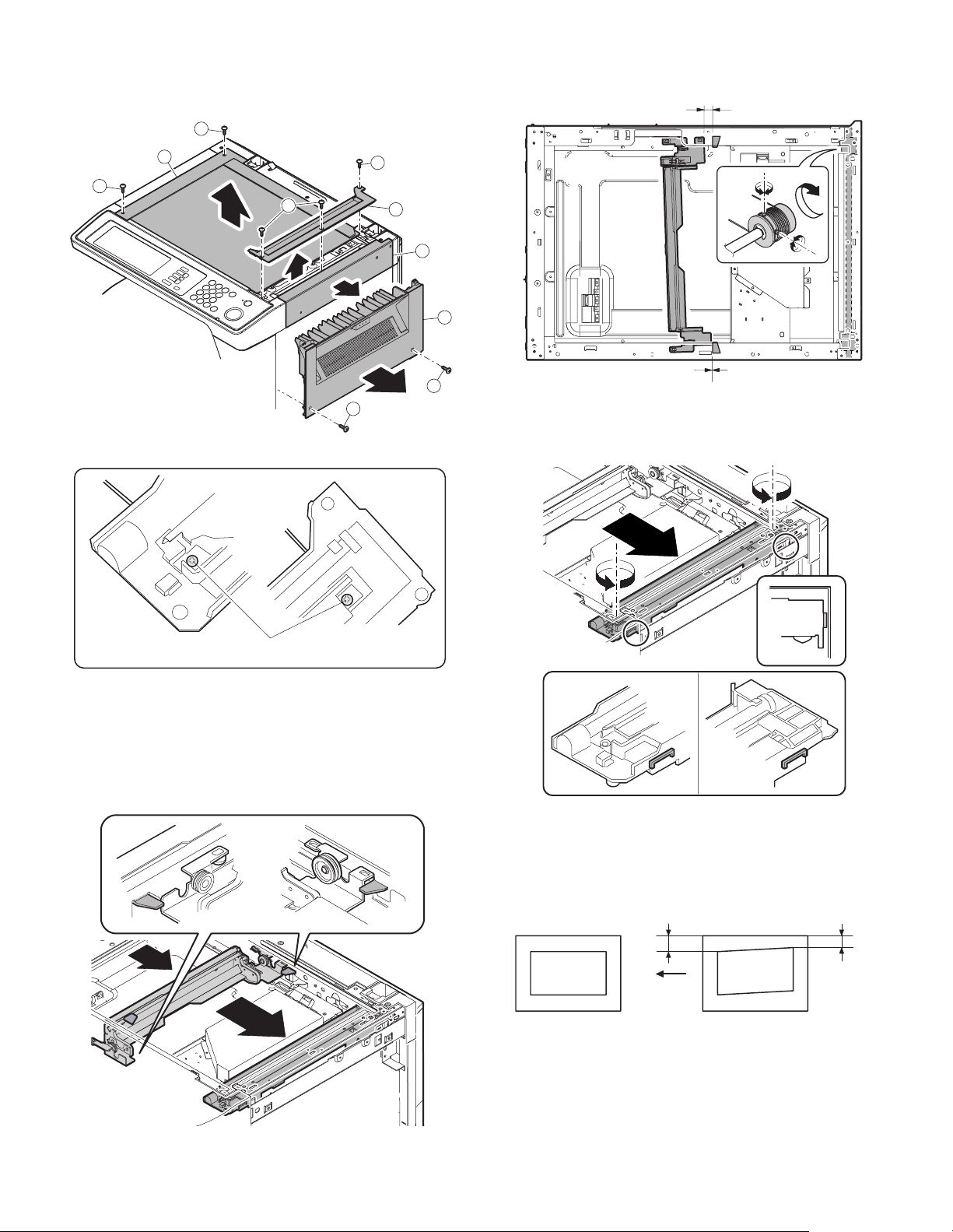

(6) Main scanning direction (FR direction) distortion

balance adjustment

1) Remove the OC glass, the right cabinet and the upper right side

cover.

1

5) Without moving the scanner drive pulley shaft, manually turn the

scanner drive pulley until the positioning plate is brought into contact with No. 2/3 mirror base unit, then fix the scanner drive pulley.

3

1

1

2) Loosen the copy lamp unit wire fixing screw.

1

2

6

5

4

4

6) Put No. 2/3 mirror base unit on the positioning plate again, push

the projections on the front frame side and the rear frame side of

the copy lamp unit to the corner frame, and tighten the wire fixing

screw.

Wire fixing screw

3) Manually turn the mirror base drive pulley and bring No. 2/3 mirror

base unit into contact with the positioning plate.

At that time, if the front frame side and the rear frame side of No. 2/

3 mirror base unit are brought into contact with the positioning

plate at the same time, the mirror base unit parallelism is proper.

If one of them is in contact with the positioning plate, perform the

adjustment of 4).

(7) Sub scanning direction (scanning direction) distortion

adjustment (Winding pulley position adjustment)

This adjustment must be performed in the following cases:

• When the mirror base drive wire is replaced.

• When the lamp unit, or No. 2/3 mirror holder is replaced.

• When a copy as shown is made.

La

Paper exit

direction

Original Copy

Lb

4) Loosen the set screw of the scanner drive pulley which is not in

contact with No. 2/3 mirror base unit positioning plate.

MX-M260/M310/M260N/M310N ADJUSTMENTS 5 - 5

Page 30

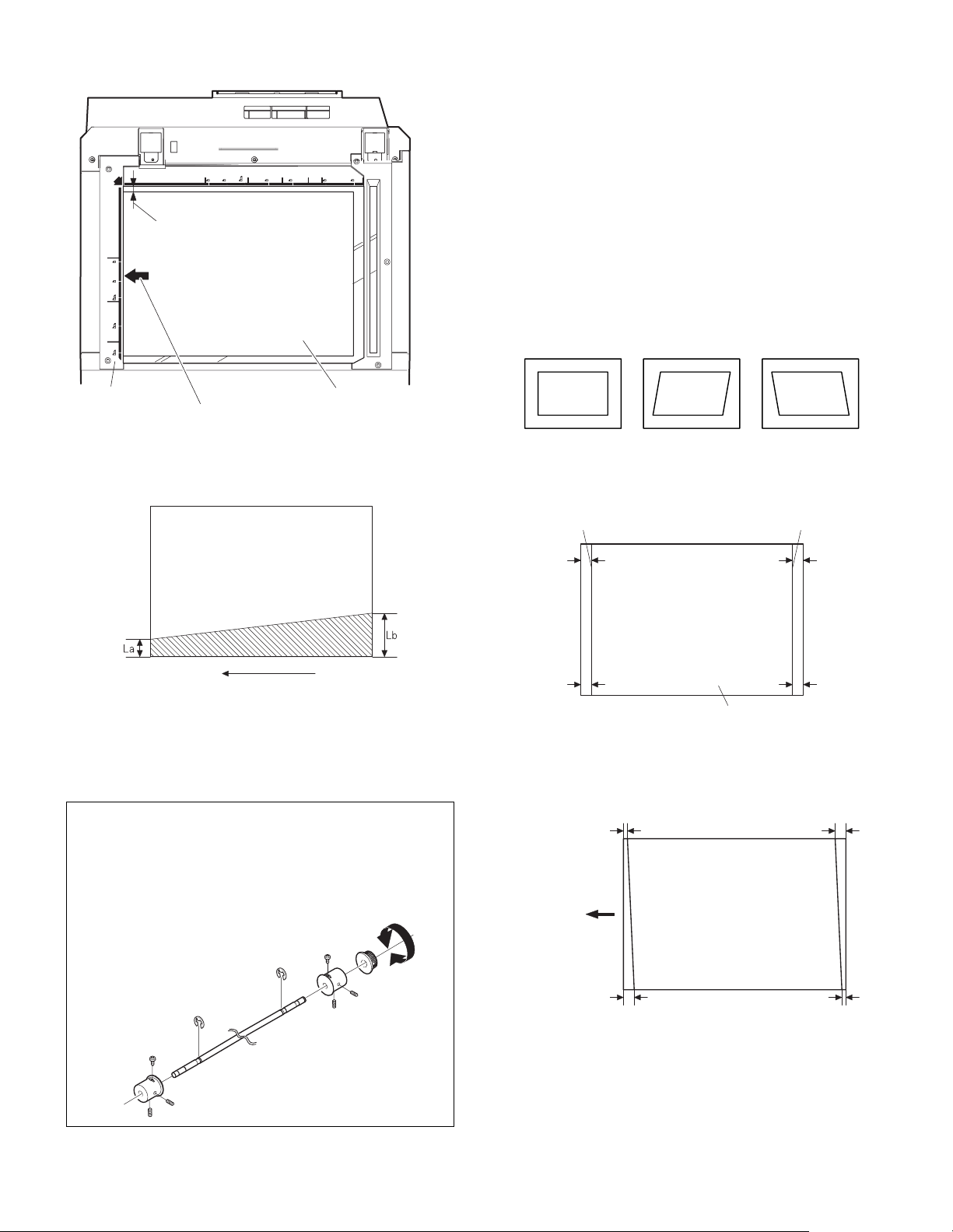

1) Set A3 (11" x 17") white paper on the original table as shown

below.

Place a little clearance from

the rear side original guide.

<Adjustment specification>

La = Lb

6) Execute the main scanning direction (FR) distortion balance

adjustment previously described in 2) again.

(8) Main scanning direction (FR direction) distortion

balance adjustment (Rail height adjustment)

When there is no skew copy in the mirror base scanning direction and

there is no horizontal error (right angle to the scanning direction), the

adjustment can be made by adjusting the No. 2/3 mirror base unit rail

height.

Before performing this adjustment, be sure to perform the horizontal