BOOKLET MAKER MX-BMX1

Operating Instruction

Stapler Folder Reference

Read this manual carefully before you use this product and keep it handy for future

reference.

For safety, please follow the instructions in this manual.

15 October 2010

Part no: #####

Doc no: x04090

rev , 15 October 2010

Warning:

This is a Class A product. In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

The product (System) which is connected to this machine will be class A

Note

The domestic environment is an environment where the use of broadcast radio and television

recievers may be expected within a distance of 10 m of the apparatus concerned.

Introduction

This manual contains instructions on the operation and maitenance of this machine. To get

the maximum versatility from this machine all operators should carefully read and follow

the instructions in this manual. Keep this manual in a handy place near the machine.

Please read the Safety Information before using this machine. It contains information related to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS.

How to read this manual

Notation conventions

Whenever necessary, the following points for attention are indicated in this manual.

WARNING:

Indicates a potentially hazardous situation which, if instructions are not followed, could

result in death or serious injury.

CAUTION:

Indicates a potentiality hazardous situation which, if instructions are not followed, may

result in minor or moderate injury or damage to machine or property.

Note

This sign refers to:

Remarks for making the operation much easier. You get practical hints or knowledge to

•

assist you in the machine operation such as:

Preparations required before operating

•

How to prevent papers from being misfed or damaged

•

Precautions required or actions to take after misoperation

•

Limitations like numerical limits, functions that cannot be used together or conditions,

•

under which a particular function cannot be used or obtained.

Information.

•

[ ]

Keys that appear on the machine’s display panel.

Safety Information

When using this machine, following safety precautions should always be followed.

Safety during operation

WARNING:

To avoid hazardous situations like for instance electric shock or danger while exposed

•

to moving, rotating or cutting devices, do not remove any covers, guards or screws

other than those specied in this manual.

Turn off the power and disconnect the power plug (by pulling the plug, not the cable) if

•

any of the following conditions exists:

You drop objects or spill something into the equipment.

•

You suspect that your equipment needs service or repair.

•

Your equipment’s covers has been damaged.

•

You notice unusual noises or odours when operating the equipment.

•

If the power cable or plug becomes worn out or otherwise damaged.

•

Before cleaning and care (unless otherwise specically instructed).

•

Electromagnetic compliance:

•

This is a Class A product. In a domestic environment this product may cause radio

•

interference in which case the user may be required to take adequate measures.

The product (System) which is connected to this machine will be class A.

•

General safety

WARNING:

Always connect the equipment to a properly grounded power source (wall outlet). If in

•

doubt, have the power source checked by a qualied electrician.

Improper grounding of the equipment can result in electrical shock. Never connect the

•

machine to a power source that lacks a ground connection terminal. This machine is

destined for specic purpose only. Any use going beyond this specic purpose is regarded as beyond the determination. The manufacturer will not be liable for damages

resulting from any use beyond the determination, unallowed operation, respectively.

The user alone bears the risk.

Do not make arbitrary changes or modications to the machine. The manufacturer will

•

not be liable for modications made at the machine on your own and damages resulting thereof. EC declaration of conformity and the mark CE will be invalidated, if you

make changes at the machine or at the individual components.

Do not override or bypass electrical or mechanical interlock devices.

•

The machine is to be used only by authorized and instructed persons. The responsibil-

•

ities on operating the machine have to be strictly laid down and observed so that there

are no unclear competences regarding safety aspects.

Vent holes serve for air circulation to protect the machine from overheating. Make sure

•

that the holes are not covered.

Do not expose ngers or other parts of the body to moving, rotating or cutting devices

•

such as for instance between upper and lower trimmer knives.

Allways locate the equipment on a solid support surface with adequate strength tor

•

the weight of the machine.

General safety, continued

CAUTION:

The machine and its peripherals must be installed and maintained by a customer service repre-

•

sentative who has completed the training course on those models.

Allways follow all warnings marked on, or supplied with, the equipment.

•

When you disconnect the power plug from the wall outlet, allways pull the plug (not the cable).

•

Disconnect the power cord before you move the machine. While moving the machine, allways

•

exercise care and make sure that the power cord will not be damaged under the machine.

Allways contact service if relocating the equipment.

•

Do not move the machine while the machine is running.

•

Do not open covers while the machine is running.

•

Do not switch of the power while the machine is running. Make sure the machine cycle has

•

ended.

Lay the power cord in a way that nobody will stumble over it. Do not place things on the cord.

•

Never attempt any maintenace function that is not specically described in this documentation.

•

Always keep magnets and all devices with strong magnetic elds away from the machine.

•

If the place of installation is air-conditioned or heated, do not place the the machine where it

•

will be:

Subject to sudden temperature changes.

•

Directly exposed to cool air from an air-conditioner.

•

Directly exposed to heat from a heater.

•

If the machine is not used over an extended period of time it should be unplugged to prevent

•

damage in the case of overload.

Note

The indications like front and rear, left and right refer to the paper transport direction.

•

The operator manual always has to be available at the place of use of the machine.

•

In the interest of technical development the company reserves the right to make alterations to

•

specications without prior notice!

Page intentionally blank.

TABLE OF CONTENTS

What You Can Do With This Machine ............................................................................................9

Guide To Components .................................................................................................................. 11

Booklet Maker ............................................................................................................................................11

Options ...........................................................................................................................................13

Cover Feeder .............................................................................................................................................14

Trimmer ......................................................................................................................................................15

Book Folder ................................................................................................................................................17

Control Panel ................................................................................................................................. 19

1. Basics ...............................................................................................21

Docking / Undocking ..................................................................................................................... 21

Docking the Booklet Maker ........................................................................................................................21

Undocking the Booklet Maker ....................................................................................................................22

Turning On / Off the Main Power .................................................................................................. 23

Booklet Maker, Cover Feeder, Trimmer and Book Folder ..........................................................................23

Check staples, Staple cartridge and stapler head......................................................................24

Removing stapler head ..............................................................................................................................24

Removing staple cartridge ..........................................................................................................................24

Installing stapler head, staple cartridge / clearing staple jam ..................................................................... 25

Emptying the trim bin ....................................................................................................................26

2. Making Booklets ..............................................................................27

Changing settings ......................................................................................................................... 27

General procedure .....................................................................................................................................27

Setting Paper Size ......................................................................................................................................27

Selecting standard paper sizes ..........................................................................................27

Custom paper size ...............................................................................................................28

Stapling ......................................................................................................................................................28

Selecting stapling On or Off ................................................................................................28

Trimming .....................................................................................................................................................29

Selecting trimming On or Off .............................................................................................. 29

Adjusting the cutting margin ..............................................................................................30

Covers ........................................................................................................................................................30

Selecting Cover Feeder Mode ............................................................................................. 30

Loading covers .....................................................................................................................31

Book Folding ..............................................................................................................................................31

General .................................................................................................................................. 31

Setting Mode ..............................................................................................................................................32

Procedure .............................................................................................................................32

On-line/Off-line ...............................................................................................................................33

Off-line mode ..............................................................................................................................................33

On-line mode ..............................................................................................................................................33

Begin On-line Production ............................................................................................................. 34

3. Tools .................................................................................................35

The Tools Screen ........................................................................................................................... 35

Units ...........................................................................................................................................................35

Software version .........................................................................................................................................35

Language ...................................................................................................................................................36

Air Separation .............................................................................................................................................37

Double Sheet Detection .............................................................................................................................37

Service access ...........................................................................................................................................38

4. Jobs ..................................................................................................39

Storing and deleting jobs .............................................................................................................39

Storing a new Job .......................................................................................................................................39

Recalling a Job ...........................................................................................................................................40

7

5. Clearing Misfeed(s) .........................................................................41

Clearing misfeed(s) .......................................................................................................................................................... 41

General ......................................................................................................................................................................... 41

Booklet Maker ................................................................................................................................................................... 42

Clearing misfeed(s) ....................................................................................................................................................... 42

Inside the Booklet Maker ......................................................................................................................................42

Trimmer ............................................................................................................................................................................. 43

Clearing misfeed(s) ....................................................................................................................................................... 43

Clearing misfeed in input area .............................................................................................................................43

Clearing misfeed in exit area ...............................................................................................................................44

Cover Feeder.....................................................................................................................................................................45

Clearing misfeed(s) in vertical transport area ............................................................................................................... 45

Book Folder ....................................................................................................................................................................... 46

Clearing misfeed(s) ....................................................................................................................................................... 46

Inside the Book Folder .........................................................................................................................................46

Exit area .................................................................................................................................................................46

6. Troubleshooting ..............................................................................47

Fault codes........................................................................................................................................................................47

General ......................................................................................................................................................................... 47

General fault codes ....................................................................................................................................................... 48

Clear Misfeed(s) ....................................................................................................................................................48

Close cover(s) .......................................................................................................................................................48

Booklet maker fault codes ............................................................................................................................................49

Check staples ........................................................................................................................................................ 49

Set too thick ........................................................................................................................................................... 49

Oil clinchers ........................................................................................................................................................... 49

Remove purged sets .............................................................................................................................................49

Illegal feed mode ................................................................................................................................................... 49

Stacker full .............................................................................................................................................................49

Trimmer fault codes ...................................................................................................................................................... 49

Trim bin full ............................................................................................................................................................ 50

Close trimmer belts ............................................................................................................................................... 50

Cover feeder fault codes ............................................................................................................................................... 50

Misfeed ...................................................................................................................................................................50

Double feed ............................................................................................................................................................ 50

Load covers ........................................................................................................................................................... 50

Book Folder fault codes ................................................................................................................................................ 51

Feed errors ............................................................................................................................................................51

7. REMARKS ........................................................................................53

Do’s And Don’ts ................................................................................................................................................................53

Where to put Your Machine ............................................................................................................................................. 54

Machine environment ...................................................................................................................................................54

Power connection .........................................................................................................................................................54

Access to machine ........................................................................................................................................................ 55

Maintaining Your Machines ............................................................................................................................................. 56

Booklet Maker ............................................................................................................................................................... 56

Oil Clinchers and Stapler heads .......................................................................................................................... 56

Cover Feeder ................................................................................................................................................................ 58

Cleaning feed rollers and paper separator pad .................................................................................................. 58

Book Folder ..................................................................................................................................................................59

Cleaning feed belts ...............................................................................................................................................59

8. Specication ...................................................................................61

Machine Specications .................................................................................................................................................... 61

Booklet Maker BK5010e ............................................................................................................................................... 61

Cover Feeder CF5010 (option) ..................................................................................................................................... 62

Trimmer TR5010e (option) ............................................................................................................................................62

Book Folder BF5010e (option) ...................................................................................................................................... 63

System Certications .................................................................................................................................................... 63

Set Size Guide .............................................................................................................................................................. 64

INDEX....................................................................................................65

8

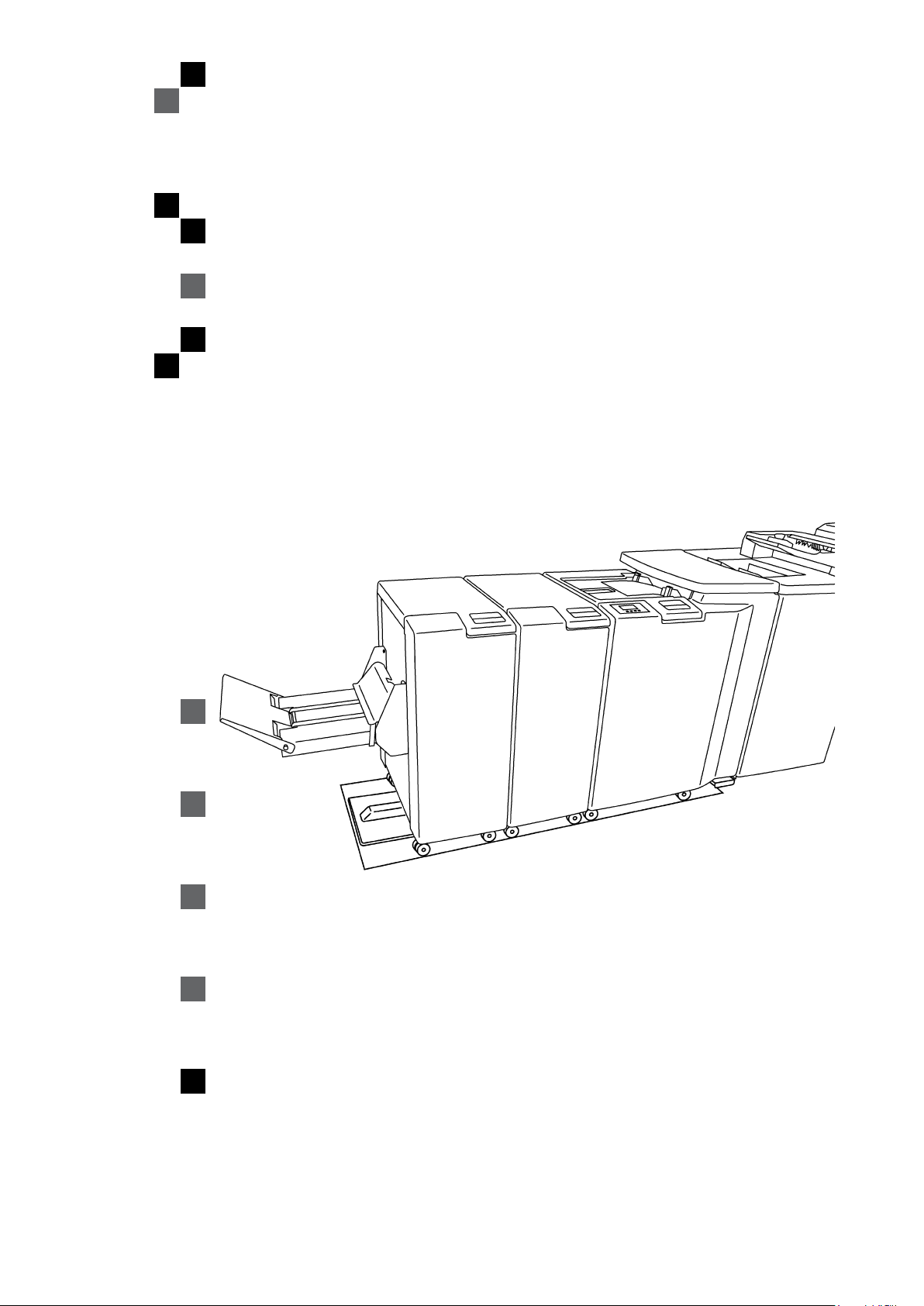

What You Can Do With This Machine

MX-TMX1 Trimmer (option)

MX-FDX2 Book Folder (option)

MX-CFX1 Cover Feeder (option)

Belt Stacker

The Booklet Maker MX-BMX1, Trimmer MX-TMX1, Book Folder MX-FDX2 and Cover Feeder

MX-CFX1 forms a booklet making system that works online with the Copier.

The print-outs from the Copier are collected in the nisher and then transported into the

MX-BMX1 Booklet Maker to the staple area. From the MX-CFX1 Cover Feeder (optional),

if present, any type of covers, colored or black and whites, can be added to the printed set.

The Booklet Maker now jogs and then staples the set. The set is then transported further to

the folding area where the set is folded into a booklet and then fed out to the belt stacker.

When a larger number of sheets are folded an effect called creeping occurs. In order to

rectify creep, the MX-TMX1 Trimmer (optional) can be attached after the Booklet Maker. The

booklets are then transported from the Booklet Maker into the Trimmer where the trail edge

will be cut off. If a MX-TMX1 Trimmer is installed to the MX-BMX1 Booklet Maker, you can

can attach the MX-FDX2 Book Folder (optional). The printouts, which have been stapled,

folded and trimmed will be fed into the MX-FDX2. The MX-FDX2 will atten the spine of the

booklet square. The booklets will, after passing the MX-FDX2, have the look of a perfect

bound book. The booklets are then fed out to the Belt Stacker.

To facilitate undocking, a MX-BMX1 Rail unit (optional) can be installed under the Booklet

Maker. Undocked or off-line, the Booklet Maker can be used as a stand-alone unit for hand

feeding.

MX-BMX1 Booklet MakerMX-BMX1 Rail unit(option)

9

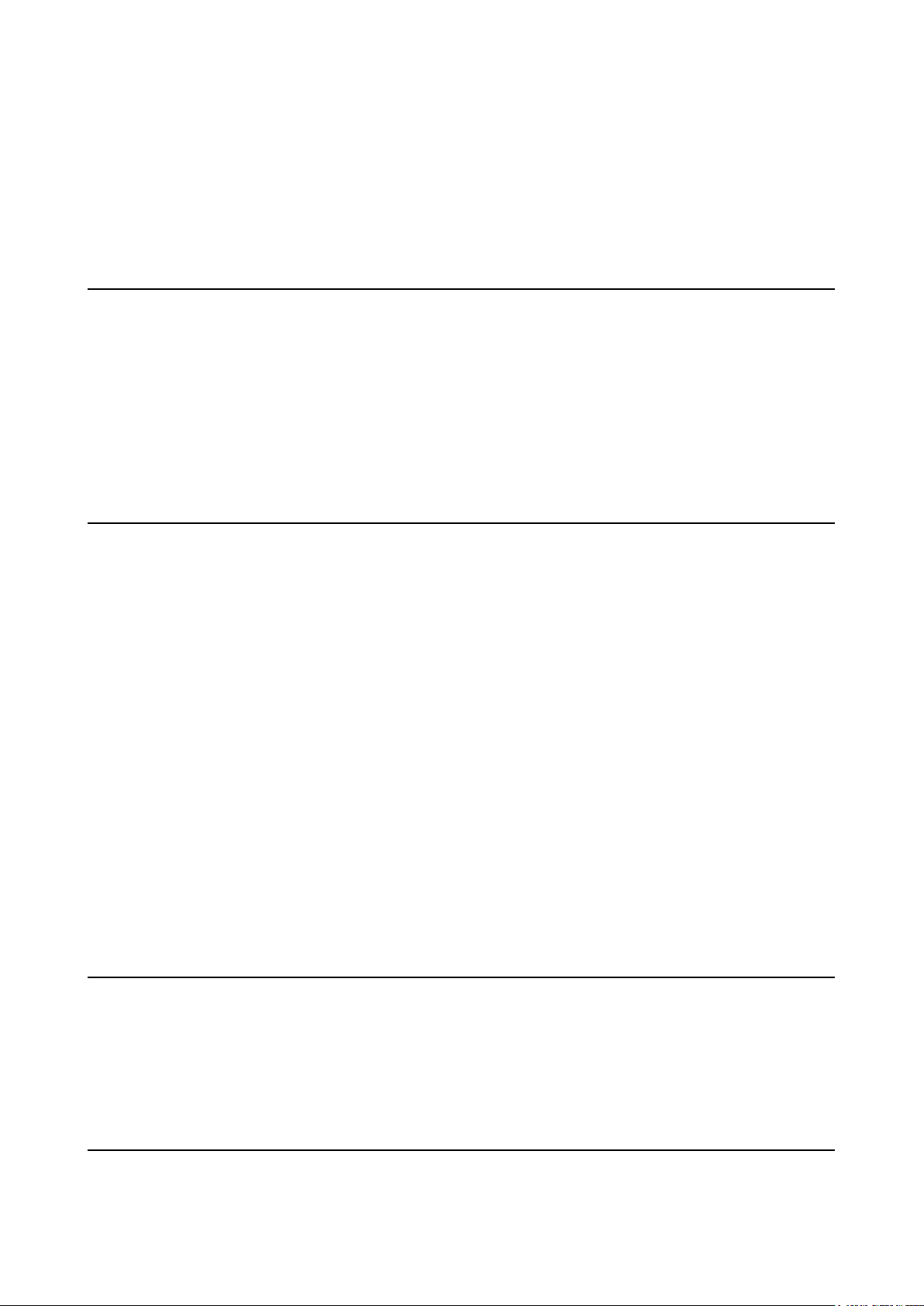

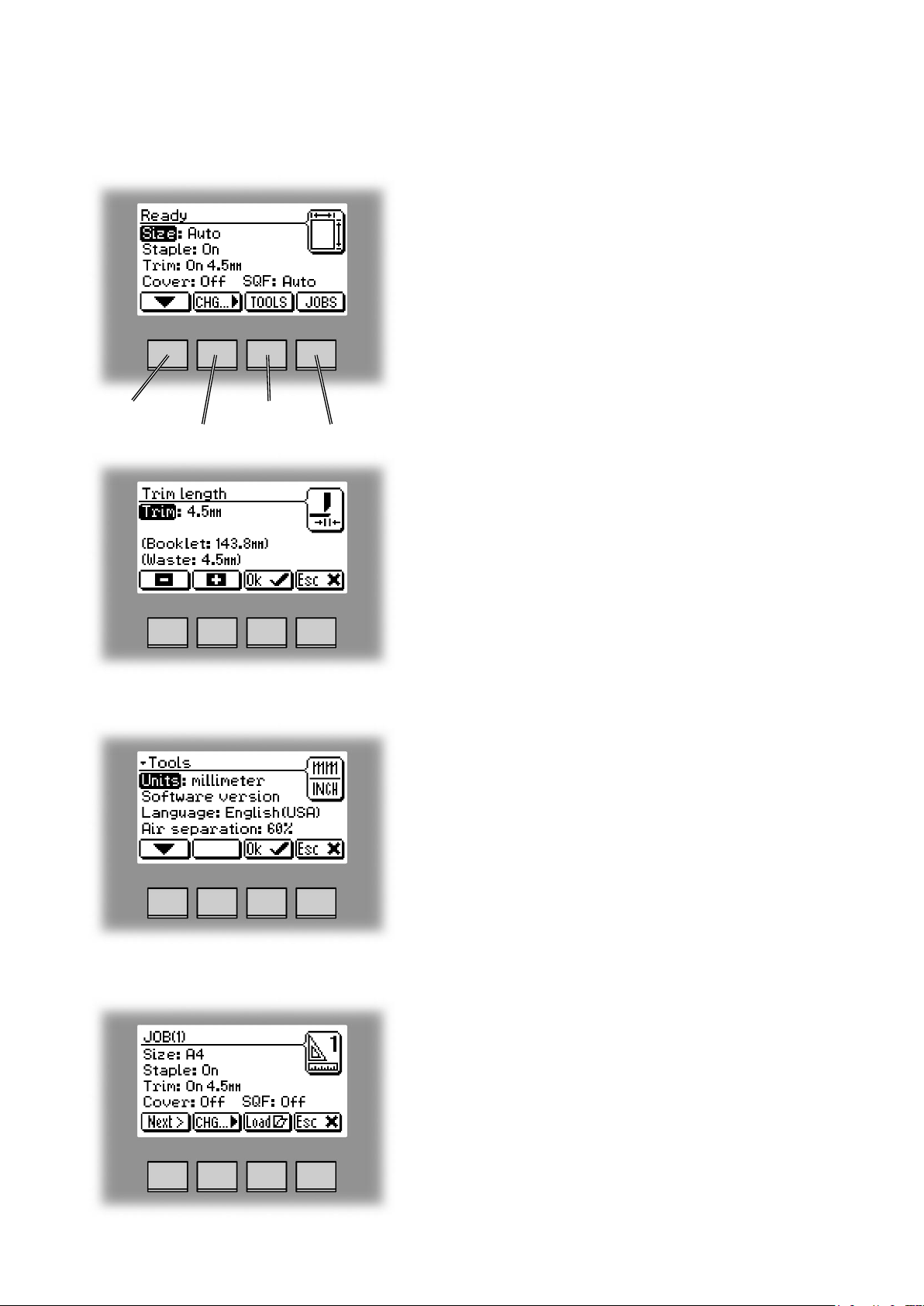

The MX-BMX1 Booklet making system is controlled from a single control panel on the Booklet

Maker. The control panel has only four buttons which will allow you to easily set up, adjust

and operate the complete system.

The buttons are multi functional, meaning that the

function of each button depends on the information

displayed.

For example: Pressing button 3 from the Ready screen

takes you to the Tools screen.

Example 2: In this screen, button 3 has no function.

Button: 1 2 3 4

Button: 1 2 3 4

Example 3: Pressing button 3 here will load the stored

Job (4).

Example 4: In this screen pressing button 3 will save

the current settings for job No 1. The asterisk on the

rst row shows that the settings for Job (1) has been

changed, but not yet saved.

Button: 1 2 3 4

10

Guide To Components

Booklet Maker

1

2

3

8

9

4

5

6

7

1 Top cover

2 Control panel

3 Main power switch

4 Infeed assembly

5 Exit tray storing shelf

6 Base

7 Docking assembly

8 Belt Stacker

9 Belt Stacker Cover

11

Booklet Maker, continues

8

COM Copier

8 Connections

9 Fold stop gate

Terminator/

COM MX-TMX1TerminatorStacker

9

POW MX-FDX2

Main Power

Interlock jumper

12

Interlock jumper/

POW MX-TMX1

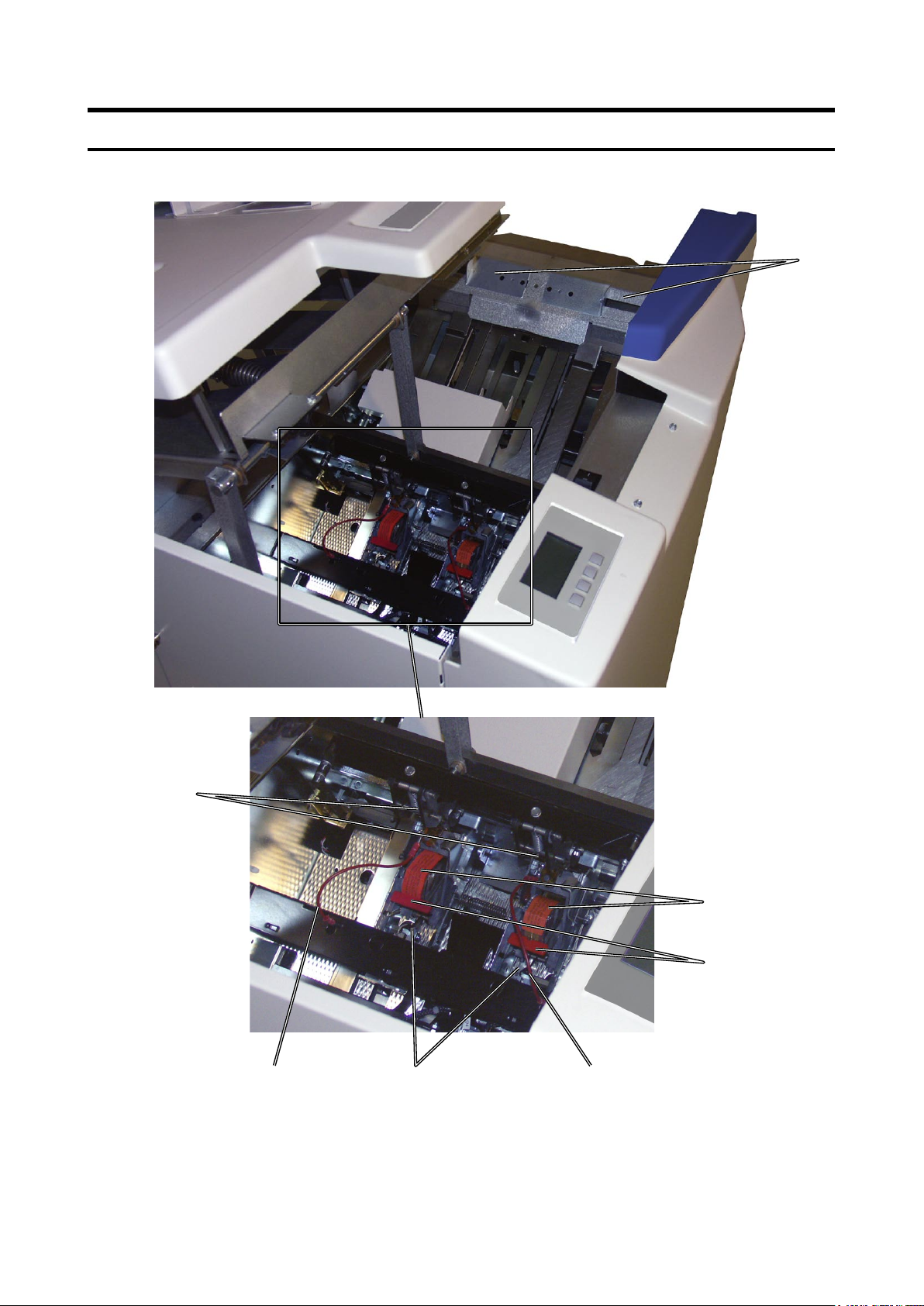

Booklet Maker, continues

6

1

5

1 Stapler heads

2 Staple cartridges

3 Cartridge locking levers

2

3

4 5

4 Stapler release latches

5 Staple detection leads

6 Hand feeding paper guides

13

Options

Cover Feeder

1

2

3

4

1 Loading capacity mark

2 Rear side guide

3 Paper orientation label

4 Feed roller assembly

5

6

7

5 Paper separator pad (also see

page 52)

6 Air nozzle (2x)

7 Front side guide

8 Jam clearance bafe

14

8

Trimmer

1

2

3

4

1 Top cover

2 Trim bin

3 Base

4 Connections

COM MX-BMX1

Stacker COM MX-BMX1 Terminator/

Power from

MX-BMX1

Com MX-FDX2

15

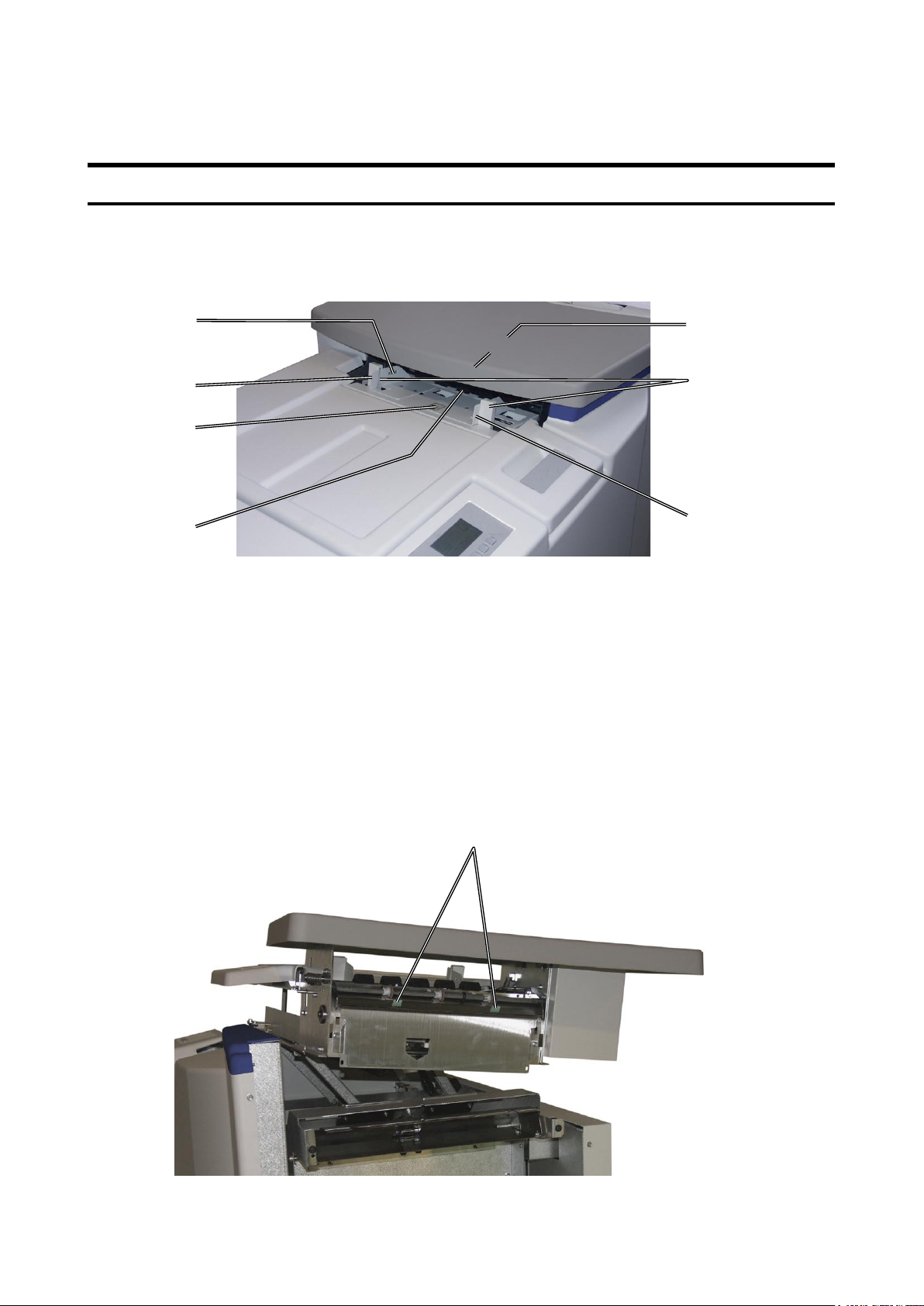

Trimmer, continues

The Trimmer interior has parts that you will come in contact with if a misfeed occurs.

6

1

7

2

3

4

5

Trimmer, top view

1 Set counter

2 Trimmer stop

3 Outfeed latch

4 Exit compressing brackets

5 Transport belt

9

8

6 Infeed roller shaft

7 Trimmer fan

8 Upper knife

9 Infeed latch

16

Book Folder

1

2

3

1 Top cover

2 Trim bin

3 Base

4 Connections

Terminator

4

StackerCOM MX-FDX2

POW MX-FDX2

17

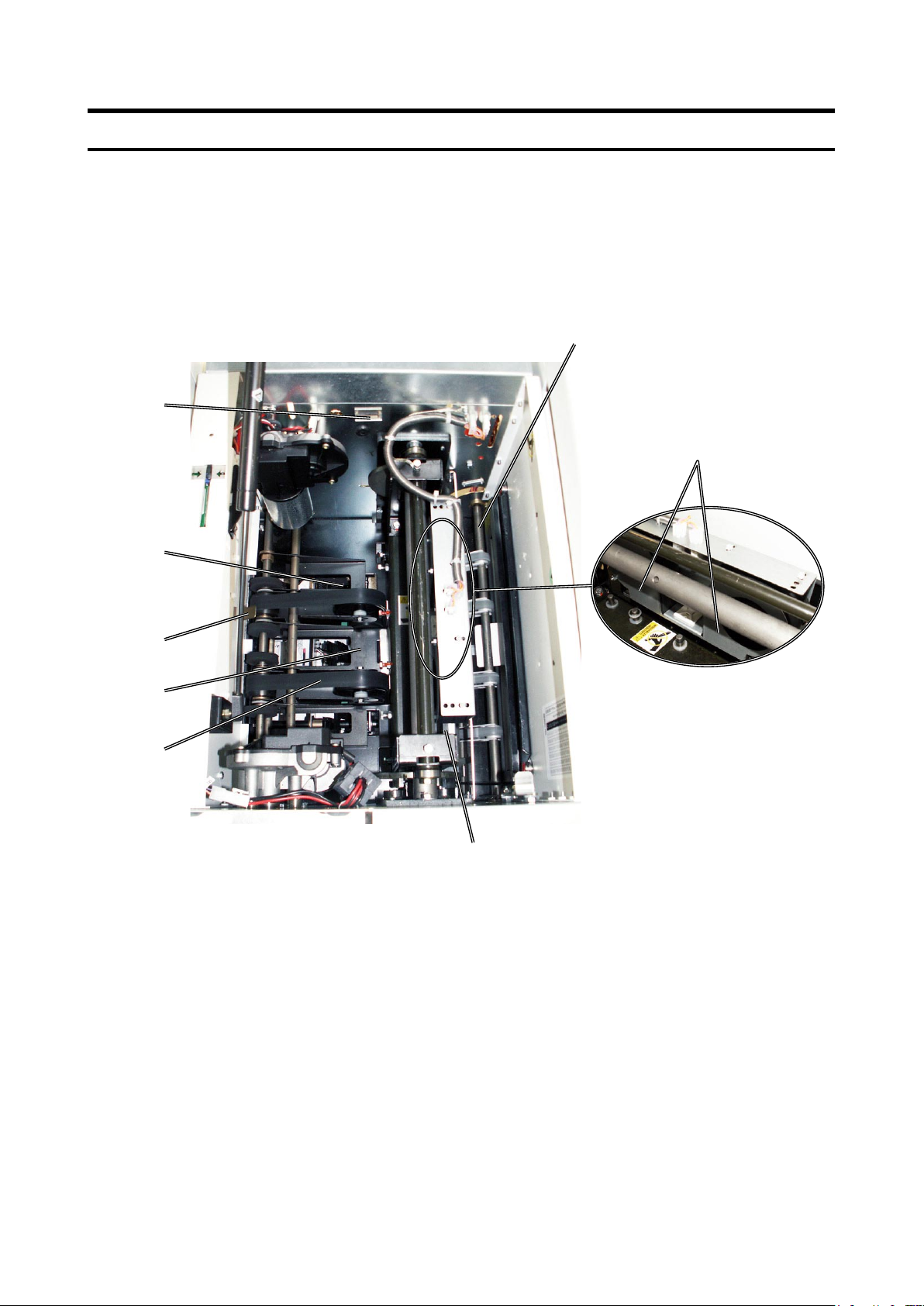

Book Folder, continues

The Book Folder interior has parts that you will come in contact with if a misfeed occur.

1

Book Folder, top view,

Upper feed belts in lifted up

2

18

1 Lower feed belts

2 Upper feed belts

Control Panel

The Ready screen.

When the system power is switched on the Ready

screen will be shown. Here you will nd information

showing the actual set up. From this screen you can

also access other screens, that will help you operate

the complete MX-BMX1 Booklet making system.

arrow button

change button

tools button

jobs button

Changing settings.

To change or adjust settings; Select an item in the

Ready screen with the [arrow] button and press the

[Change] button. For example you can ne adjust the

trimming, turn off the cover feeder or set the Book

Folder to the correct mode. Explore all settings more

thoroughly in section 2. Making Booklets.

The Tools screen.

Pressing the [Tools] button in the Ready screen takes

you to the tools screen. Here you will nd all the

necessary tools for a troublefree operation. From here

you can change the display language, set units from

millimeters to inches and more. See section 3. Tools.

for how to get around in the Tools screen.

The Jobs screen.

Pressing the [Jobs] button in the Ready screen opens

the Jobs screen. From here you can load, customize

and save job settings. These procedures are described

in section 4. Jobs.

19

The Processing screen.

This screen is shown when the machine is busy working.

If the machine is used in off-line mode you do not have

to wait for the Ready screen before handfeeding the

next set.

The Please wait screen.

While the machine sometimes needs time to perform

changes in settings, the Please wait screen will be

shown. The machine will automatically return to the

Ready screen after changes have been implemented.

20

1. Basics

7

6

ON

5

7

6

ON

5

Docking / Undocking

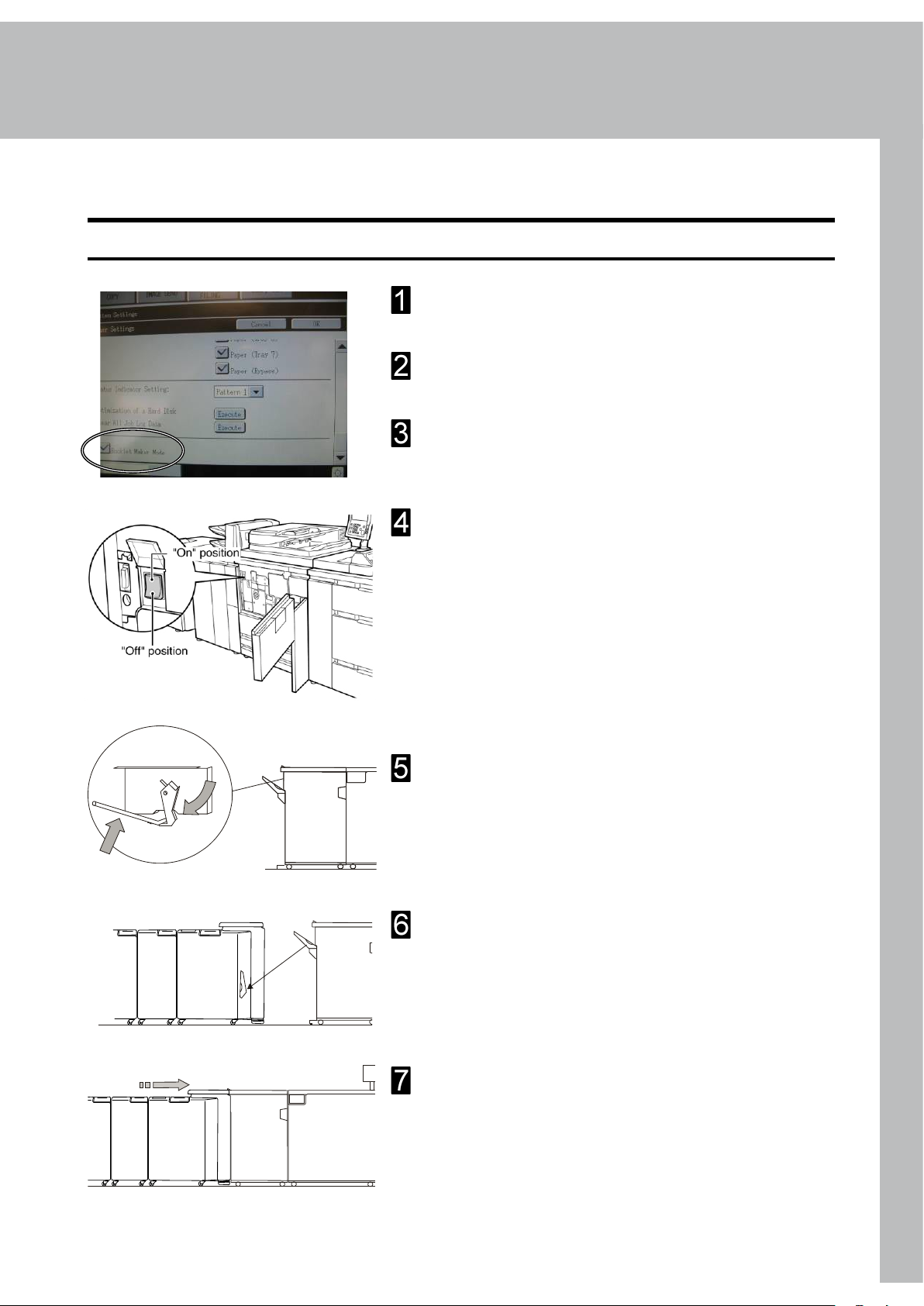

Docking the Booklet Maker

Make sure the copier is in normal copy mode and

the booklet maker is turned off.

Make a single staple 2 page copy to ensure that

the exit tray is in the correct position.

Go to [System Settings], [Device Control] and [Other

Settings]. Scroll down to “Booklet Maker Mode” and

tick the box. Press [Ok] in the box that appears.

Switch the MX-M850/M950/M1100 off using the

power switch inside the front cover.

Lift up the Exit arm catcher and set the Exit paper

arm in the upper position.

Remove the Exit tray from the Finisher and put it

on the shelf on the Booklet Maker

Move the Booklet Maker up to the copier and dock it.

continued on next page

21

1

Switch on the booklet maker and wait until the unit

comes to “Ready”.

Switch the MX-M850/M950/M1100 on using the

power switch inside the front cover.

The Copier is now in Booklet maker mode and

the booklet making system is present in the

Copier display panel.

Make sure the Booklet Maker is in “Auto” mode.

22

Undocking the Booklet Maker

7

6

5

7

6

5

Go to [System Settings], [Device Control] and

[Other Settings]. Scroll down to “Booklet Maker

Mode” mode and un-tick the box. Press [Ok] in the

box that appears.

Switch the MX-M850/M950/M1100 off using the

power switch inside the front cover.

1

Turn off the booklet maker.

Push in the latch on the docking assembly and move

the Booklet Maker away from the Copier.

Note

Be careful not to damage the communication cable

continued on next page

23

1

Take the Exit tray from the shelf on the Booklet

Maker, and install it on the Finisher.

Lift up the Exit arm catcher and move the Exit paper

arm to the lower position.

Switch the MX-M850/M950/M1100 on using the

power switch inside the front cover.

The Copier is now in Copier mode.

24

Turning On / Off the Main Power

Booklet Maker, Cover Feeder, Trimmer and Book Folder

1

1

2

Plug the Booklet Maker powercord into the wall

outlet.

Cover Feeder (optional), Trimmer (optional) and

Book Folder (optional) are powered from the

Booklet Maker.

Open the Top cover (1).

Set main power switch (2) on Booklet Maker to ON

position.

Note

The main power switch also controls Cover Feeder

(optional), Trimmer (optional) and Book Folder

(optional).

Close the Top cover.

25

1

Check staples, Staple cartridge and stapler head

Removing stapler head

Open the top cover.

Remove the set of paper.

Disconnect the staple indication lead (A) from the

socket.

Hold the stapler head in place, press the release

latch (B) to release the rear end of the stapler head

and lift up this end.

Lift out the head, allowing it to rotate around the

front end. The stapler assembly is spring loaded

and will follow the rotation of the stapler.

AB

Removing staple cartridge

C

The staple cartridges, containing approximately 5000

staples per cartridge. Cartridge may be removed either

for renewal or for jam clearance.

Raise the handle (C) on the staple cartridge locking

lever.

Remove the staple cartridge from the stapler head

by sliding it away from the stapler head.

26

Installing stapler head, staple cartridge / clearing staple jam

Look inside stapler head for jammed staples in the area

of the staple actuator. Remove staples if any.

Position the stapler head on the edge of a rm surface

(for example the top of a table).

While securely holding the head, actuate the Stapler

up and down through full travel. Perform this operation

without staple cartridge

Renewing or reinstalling the staple cartridge, pull 25

mm (1 inch) of staples out of the cartridge and tear the

staples downward starting at one side pulling away

from you. The staple tear line is indicated by an arrow

on the side of the cartridge.

Insert the cartridge into the stapler head with the end

of the staples facing toward the head of the stapler

mechanism. Push it rmly ahead.

Hold the staple cartridge rmly in place and push down

the cartridge locking lever.

IMPORTANT

Keep holding (pushing) the staple cartridge into place

while pushing down the cartridge locking lever.

1

D

While securely holding the head, actuate the Stapler up

and down through full travel. Perform this operation with

staple cartridge. Repeat this a few times to ensure that

the staples are ejected at each down movement.

Reinstall the stapler head by inserting the pin at the top of

the stapler head into the stapler retraction swing arm (D).

While rotating the stapler head, insert the pin located

at the rear end of the stapler head into the slots in the

frame of the stapler head assembly. Press down the

rear end of the stapler head until the release lever snaps

into place, locking the stapler head in position.

Press down the front end of the stapler head until it

snaps in position under the frame assembly.

Reconnect the staple indication lead (A), see previous

page.

Close the top cover and press the [Esc] button. The

booklet maker will automatically go to Ready mode. If

not and/or error message persists, hand feed a four

sheet set of paper. The booklet maker will automatically

cycle and advance staples until both stapler heads are

driving staples. The booklet maker will automatically go

to Ready mode.

27

1

Emptying the trim bin

Remove the trim bin by lifting it and pulling it out.

trim bin, no Book Folder installed

28

trim bin, with Book Folder installed

2. Making Booklets

Changing settings

General procedure

Changing of settings can be performed in two ways. Temporary, which means that the changes

will remain until a new job is loaded or permanent, which means that the changes will be

stored as a job. This job can later be recalled.

Procedure for temporary changes:

From the Ready screen, select the option you wish to change and press the [Change] button.

Conrm changes by pressing the [OK] button.

Procedure for permanent changes:

From the Ready screen, press the [Jobs] button to reach the Jobs screen. Select the Job you

want to change by pressing the [Next] button and then press the [Change] button.

Note

Choose either of the above mentioned procedures when changing size, stapling, trimming,

covers or book folding as follows.

Setting Paper Size

Selecting standard paper sizes

From the Ready screen, select Size and press the

[Change] button.

Select Auto or any standard paper size with the [arrow]

button and press the [OK] button. Selecting Auto means

that the booklet maker will automatically adjust to the

same paper size (A4, A3, 8.5”x11”, 8.5”x14”, 11”x17”

or B4) as the copier.

For other paper sizes, follow “Custom paper size” as

described on the next page.

29

2

Custom paper size

Select Size and press the [Change] button to display

the preprogrammed paper sizes.

Scroll down to Custom sizes, by pressing the [arrow]

button, and press the [OK] button. Select the custom

paper size you want to use and press the [OK]

button.

If you want to adjust, select the custom paper size you

want to change and press the [Change] button. Select

Width or Length with the [arrow] button and press the

[Change] button.

Stapling

Selecting stapling On or Off

The paper size can now be changed in increments of

0.1 mm or approx.. 0.01 inches. Press the [OK] button

to conrm.

Four different custom paper sizes can be stored.

From the Ready screen, select Staple and press the

[Change] button.

30

Selecting stapling On or Off, continues

If stapling was On, the rst choice will be Off and vice

versa.

Select On or Off with the [arrow] button and press the

[OK] button.

Trimming

Selecting trimming On or Off

2

From the Ready screen, select Trim and press the

[Change] button.

If trimming was On, the rst choice will be Off and vice

versa.

Select On or Off with the [arrow] button and press the

[OK] button.

31

2

Adjusting the cutting margin

Select Trim and press the [Change] button. Select

Trim length and press the [OK] button. Press the [+]

or [-] buttons to ne adjust in increments of 0.5 mm or

0.02 inches. The trimmed booklet size and waste are

displayed. Press the [OK] button to conrm.

Covers

Selecting Cover Feeder Mode

From the Ready screen, select Cover and press the

[Change] button.

Select On if you want the cover feeder to automatically

feed one cover to each set from the copier, or if you

are manually feeding a set.

Select Off if no covers are to be fed.

Select Feed if you want to fold only one sheet in

sequence.

Press the [OK] button to conrm.

32

Selecting Cover Feeder Mode, continues

The Purge mode is used when you want to completely

empty the Cover Feeder from covers.

Remove all cover sheets from the bin.

Select Purge and press the [Run] button. The prefed

cover sheet will now be fed into the Booklet Maker

to the stapling area, but without being stapled.

Open the Top Cover and remove the cover sheet.

Note

If you open and close the Top Cover without removing

the cover sheet, the cover sheet will be stapled and

folded and then fed to the stacker.

Loading covers

2

B

A

Make sure that the cover sheets are well fanned to

avoid misfeeds or double-feeds.

Align the cover sheets well to achieve a reliable

feeding operation and good nishing results.

When using printed covers make sure that the ink

has completely dried, to avoid smearing.

Press on top of either air nozzle (A) to lower the

paper bin. Load the covers facing downwards into

the paper bin.

Move the adjustable side guides (B) up against the

cover sheets until there is no clearance.

33

Book Folding

General

The Book Folder has six different settings. It can be set to [Auto], [Mode 1], [Mode 2],

[Mode 3], [Mode 4] or [Off].

2

In [Auto] mode, the Booklet Maker detects how many sheets there are in the booklet, and

automatically set the Book Folder to the correct mode.

Note

When the Book Folder is set to [Auto] and the booklet has less than approximately 6 sheets/

booklet, the Book Folder will bypass the Square folding action, transporting the booklet out

to the Belt stacker.

Use the manual modes to override the auto function. There are four different manual modes

to select from.

Mode 1: Approximately 6 to 11 sheets. Decreased amount of square forming.

Mode 2: Approximately 12 to 16 sheets. Medium amount of square forming.

Mode 3: Approximately 17 to 23 sheets. Increased amount of square forming.

Mode 4: Approximately 24 to 30 sheets. Maximum amount of square forming.

Select [Off] to bypass the Book Folder

Setting Mode

Procedure

34

From the Ready screen, scroll down to MX-FDX2 and

press the [Change] button.

Select [Auto], [Mode 1], [Mode 2], [Mode 3], [Mode

4] or [Off] with the [arrow] button and press the [OK]

button.

On-line/Off-line

The Booklet maker can be operated in two modes. On-line mode, when used together with

the copier, or off-line mode, working as a stand-alone unit.

Off-line mode

Follow “Undocking the Booklet maker” in section 1. Basics.

Adjust the hand feeding paper guides to the correct paper size.

Turn on the Booklet maker.

The Booklet maker is now in stand-by and will start automatically when a set is fed into the

Booklet maker. If settings need to be changed, follow “Changing settings” earlier in this

section.

2

On-line mode

Follow “Docking the Booklet maker” in section 1. Basics.

35

Begin On-line Production

Make sure that the Booklet making system (A) is present on the copier control panel.

Make sure that the Booklet maker system is set according to [Auto].

Select correct paper tray (A4R or A3) (B).

2

Select [Special modes] (C).

Select [Quantity] (D).

Press the Start button [ ] (E).

A. Booklet making system

B. Paper tray

C. Special modes

36

D. Quantity

E. Start button

3. Tools

The Tools Screen

The Tools screen.

From the Ready screen, press the [Tools] button to get to the Tools screen. Here you will nd

all the necessary tools for troublefree operation.

Units

From this screen you can change units, between

millimeters and inches. Select Units with the [arrow]

button and press the [OK] button.

Software version

Select the millimeters or inch units and then press the

[OK] button.

Select Software version with the [arrow] button and

press the [OK] button. This screen, and sub screens

show the software version for the different modules in

the booklet making system.

37

3

Software version, continues

Select the module in the system for which you want

to check the software version and press the [OK]

button.

This screen will show software version(s) in the selected

module.

Language

From this screen you can change the language in the

user interface.

Select Language with the [arrow] button and press the

[OK] button.

Select desired language with the [arrow] button and

press the [OK] button.

38

Air Separation

From this screen you can increase or decrease the Air

separation. This screen will only be shown if a Cover

Feeder is present. Select Air separation with the [arrow]

button and press the [OK] button.

3

You might want to increase the Air ow when running

thick, heavy covers.

Set the desired speed in increments of 10% with the [+]

or [-] buttons and press the [OK] button. Normal user

(default) setting is 60%.

Double Sheet Detection

From this screen you can turn the double sheet

detection On or Off. Select Double sheet det. with the

[arrow] button and press the [OK] button.

Normally double sheet detection should be set to On.

However, if you experience “false double sheet feeds”,

for example when running covers that are thick, with

dark print or with mixed prints on the covers, the double

sheet detection can be set to Off.

39

3

Service access

This screen is for authorized service personnel only

and is password protected.

40

4. Jobs

Storing and deleting jobs

The Booklet Maker has a maximum storage capacity of 10 different jobs. It is not possible

to delete jobs, therefore when you need to store a new job, an old job must be overwritten.

To make temporary changes in the actual job settings or temporary changes of a stored job,

see section 2. Making Booklets.

Storing a new Job

To store a new job or add new settings to an existing

job you need to start from the Jobs screen. From the

Ready screen press the [Jobs] button to enter the Jobs

screen.

Select an already stored job by pressing the [Next]

button. Then press the [Change] button.

Select the option you want to change with the [arrow]

button and then press the [Change] button. See section

2. Making Booklets for how to set up each separate

option.

After changing the options press the [OK] button to

accept the changes you just made.

Continued on next page.

41

Storing a new Job, continues

To store the job, press the [Save] button.

4

If you want to run the actual job, press the [Load] button.

The booklet maker will then automatically setup that

specic job and return to the Ready screen.

Recalling a Job

To recall a stored job press the [Jobs] button from the

Ready screen to enter the Jobs screen.

Select the desired job by pressing the [Next] button.

Then press the [Load] button. The booklet maker will

then automatically setup that specic job and return to

the Ready screen.

42

5. Clearing Misfeed(s)

Clearing misfeed(s)

General

If a misfeed condition should occur, it is indicated on the Booklet Maker display. The message

“Clear Misfeed(s)”, an error code and the location of the misfeed is displayed.

See examples below.

Misfeeds in the Booklet Maker are indicated

as area A, B or C and by the error code BK-

XXX.

Misfeeds in the Book Folder are indicated as

area E and by the error code SF-XXX.

43

5

Booklet Maker

Clearing misfeed(s)

Inside the Booklet Maker

To clear a misfeed indicated in Area A or B

Open the top cover.

Remove misfed sheets.

Close the top cover.

To clear a misfeed indicated in Area C

Open the top cover.

Close top cover.

If misfeed condition remains:

Switch off the main power.

Switch on the main power.

If misfeed condition remains:

Switch off the main power.

If a Trimmer is installed, rst remove the trim bin to

get access to the fold stop. By hand, pull down the

fold stop (page 8, item 9).

Remove misfed sheets.

44

Push the fold stop back into the upper position.

Switch on the main power.

Trimmer

Clearing misfeed(s)

The upper trimmer blade on the trimmer is protected by a knife protection plate that moves

away during the cutting stroke. Jams can occur in the input area or the exit area.

WARNING:

Never put ngers or other parts of the body between the upper and lower trimmer knives.

Clearing misfeed in input area

Raise the infeed roller shaft (A) by lifting latch (B).

Remove the misfed sheets in the infeed area.

After the misfed sheets are removed, lower the latch (B) and place the infeed roller shaft

into operating position.

5

A

B

45

5

Clearing misfeed(s), continues

Clearing misfeed in exit area

Lift the exit compressing brackets (A).

Secure them under the latch (B).

Remove the misfed sheets from the exit area.

After the misfed sheets are removed, lift up the latch (B) and place the compressing

brackets in operating position.

A

B

46

Cover Feeder

Clearing misfeed(s) in vertical transport area

Open the Top Cover.

Lift the jam clearance bafe (A).

Remove the misfed cover.

Put the jam clearance bafe back in normal position.

5

A

47

Book Folder

Clearing misfeed(s)

Inside the Book Folder

5

Exit area

B

A

B

A

Open the top cover.

Lift up both upper feed belts (A).

Note

Press the green dots (B) on the latches to release.

Remove the misfeeds.

Place the upper feed belts in normal position.

Close the top cover.

Open the top cover.

Remove the misfeeds through the jam clearance

area (A).

Close the top cover.

48

6. Troubleshooting

Fault codes

General

When there is a misfeed or fault condition in the booklet maker system, a message will

be displayed on the Booklet Maker. In case there is a problem that can be rectied by the

operator, a fault code and an explanation will be displayed.

Fault codes that can be rectied by the operator:

Booklet Maker: BM-201 to BM-212, BM-220, BM-401 and BM-502

Trimmer: TM-201 to TM-205, TM-401 and TM-503

Cover Feeder: CF-201 to CF-205, CF-401, CF-501 and CF-502

Book Folder: SF-201 to SF-206.

BM-201 to BM-210 indicates “Clear Misfeed(s)” in the Booklet maker

BM-211 indicates that the set is too thick to be folded

BM-212 indicates “Remove purged sets”

BM-220 indicates “Illegal feed mode”

BM-401 indicates “Check staple(s)” in the Booklet maker

BM-502 indicates “Stacker full”

TM-201 to TM-204 indicates “Clear Misfeed(s)” in the Trimmer

TM-205 indicates “Close trimmer belts”

TM-401 indicates “Empty Trim bin” in the Trimmer

TM-503 indicates “Stacker full”

CF-201 to CF-205 indicates “Clear Misfeed(s)” in the Cover feeder

CF-401 indicates “Out of covers” when there is no more

cover sheets in the Cover feeder. How to clear,

see Cover feeder fault codes

CF-501 indicates “Cover low” when the Cover feeder is

almost out of Covers. How to clear, see Cover feeder

fault codes

CF-502 indicates that there is a format mismatch between the

cover sheets and the sheets sent from the copier.

SF-201 to SF-206 indicates “Clear Misfeed(s)” in the Book Folder

Note

If procedures in this manual do not rectify the problem an authorized technician will be

needed.

49

General fault codes

Clear Misfeed(s)

Close cover(s)

In general, fault codes indicate a misfeed condition.

When a misfeed occurs, the message “Clear Misfeed(s)”,

a code and the jam area will be displayed. See section

5. Clearing Misfeeds, for how to clear a misfeed.

6

When the message “Close Cover(s)” is displayed any

of the interlock switches are actuated.

Check that the top cover is in down position.

Make sure that the cover of the Belt Stacker is in

normal position, see section 5, Clearing Misfeeds,

Exit area.

50

Booklet maker fault codes

Check staples

This message will be displayed when a staple cartridge is empty or when stapling could not

be performed. Check in the following order:

– If a staple cartridge is empty, replace according to section 1. Basics.

– If staple cartridges are OK; remove the set and check that the number of sheets is within

specications.

– If staple cartridges are OK and set is within specications; remove and check stapler head

according to section 1. Basics.

Set too thick

This message will be displayed when the set sent from the copier is outside Booklet Maker

specications. Open the top cover, remove the set and close the top cover.

Oil clinchers

This message will be displayed every 20 000 stapling cycles. The purpose is to remind the

operator to maintain stapler head and clinchers. If not doing that every 20 000 there is a great

risk of a costly mechanical breakdown. See section Maintaining Your Machines on page 52

for procedure.

6

Remove purged sets

This message will be displayed when the purged set is in the infeed area. Open the top cover,

remove the set and close the top cover.

Illegal feed mode

If this message is displayed, contact customer support.

Stacker full

This message will be displayed when the Stacker is full. Empty Stacker.

Trimmer fault codes

Note

During poor environmental conditions waste from the trimming operation may be transported

through the system.

To improve the situation the trim margin may be increased and thereby ensuring that

The waste is transported into the waste bin.

51

6

Trim bin full

This message will be displayed when the trim bin is full or when a trim strip, due to static

electricity, is prevented from falling down into the trim bin. Empty the trim bin and remove loose

trim strips from inside the Trimmer. See section 1. Basics for how to remove the trim bin.

Close trimmer belts

This message will be displayed when the belts at the outfeed area of the Trimmer is not in

correct position. Open cover and set Trimmer belts to their lower position. Close cover.

Cover feeder fault codes

Misfeed

This message will be displayed when the Cover feeder could not feed a cover from the paper

bin. Check cover loading according to section 2. Making Booklets. If problem persists, clean

separator pad according to section 7. REMARKS.

Double feed

This message will be displayed when the Cover Feeder detects that more than one cover

was fed from the cover bin. If more than one cover was fed, check cover loading according to

section 2. Making Booklets. If the covers that are fed are thick, with dark print or with mixed

prints on the covers, double feeding may be displayed even if that is not the case. Turn off

double sheet detection according to section 3. Tools.

Load covers

Code CF-501 is displayed when covers run low.

If you wish to continue production:

Load more cover sheets according to section 2. Making Booklets.

Code CF-501 will extinguish and copier will start.

If you wish to continue production, using up the cover sheets that are loaded:

Press ESC. Code CF-501 will extinguish and copier will start.

Code CF-401 is displayed when covers are empty.

If you wish to continue production:

Load more cover sheets according to section 2. Making Booklets.

If cover job is nished and you wish to run a new job without covers:

Select Cover Off in the Cover menu.

Open and Close MX-BMX1 Top Cover.

52

Book Folder fault codes

Feed errors

If feed errors occur, the feed belts needs to be cleaned or the pressure on the upper feed

belts needs to be increased. To clean the feed belts, see section 7, REMARKS Maintaining

Your Machine. To increase the pressure on the upper feed belts follow this procedure.

Open the top cover.

Place both springs in the upper position.

Close the top cover.

6

Spring in normal position Spring in upper position

53

6

Page intentionally blank.

54

7. REMARKS

Do’s And Don’ts

• Always follow all warnings marked on, or supplied with, the equipment.

• Always exercise care in moving or relocating the equipment.

Caution:

• Unplug the powercord from the wall outlet and machine before you move or relocate

the equipment.

• Do not remove the covers or guards that are fastened with screws.

• Do not override or bypass electrical or mechanical interlock devices.

• Do not operate the equipment if you notice unusual noises or odors. Disconnect the

powercord from the power source and call your authorized technician to

correct the problem.

Warning:

• Do not put ngers or other parts of the body between the upper and lower trimmer

knives.

• Do not switch off the main power switch while machine is running. Make sure machine

cycle has ended.

• Do not open covers while machine is running.

• Do not move machine while machine is running.

55

Where to put Your Machine

Machine environment

• Always locate the equipment on a solid support surface with adequate strength for the

weight of the machine.

• Always keep magnets and all devices with strong magnetic elds away from the

machine.

If the place of installation is air-conditioned or heated, do not place the machine where it

will be:

• Subjected to sudden temperature changes.

• Directly exposed to cool air from air-conditioner.

• Directly exposed to heat from heater.

7

Power connection

• Always connect the equipment to a properly grounded power source. If in

doubt, have the power source checked by a qualied electrician.

• WARNING: Improper grounding of the equipment can result in electrical shock.

• Never connect the machine to a power source that lacks a ground connection

terminal.

56

Access to machine

Place the machine near the power source, providing clearance as shown.

1

2

1. Left: more than 400 mm / 15 3/4”.

2. Front: more than 555 mm / 21 7/8”

3. Right: more than 400 mm / 15 3/4” (off-line use).

3

7

57

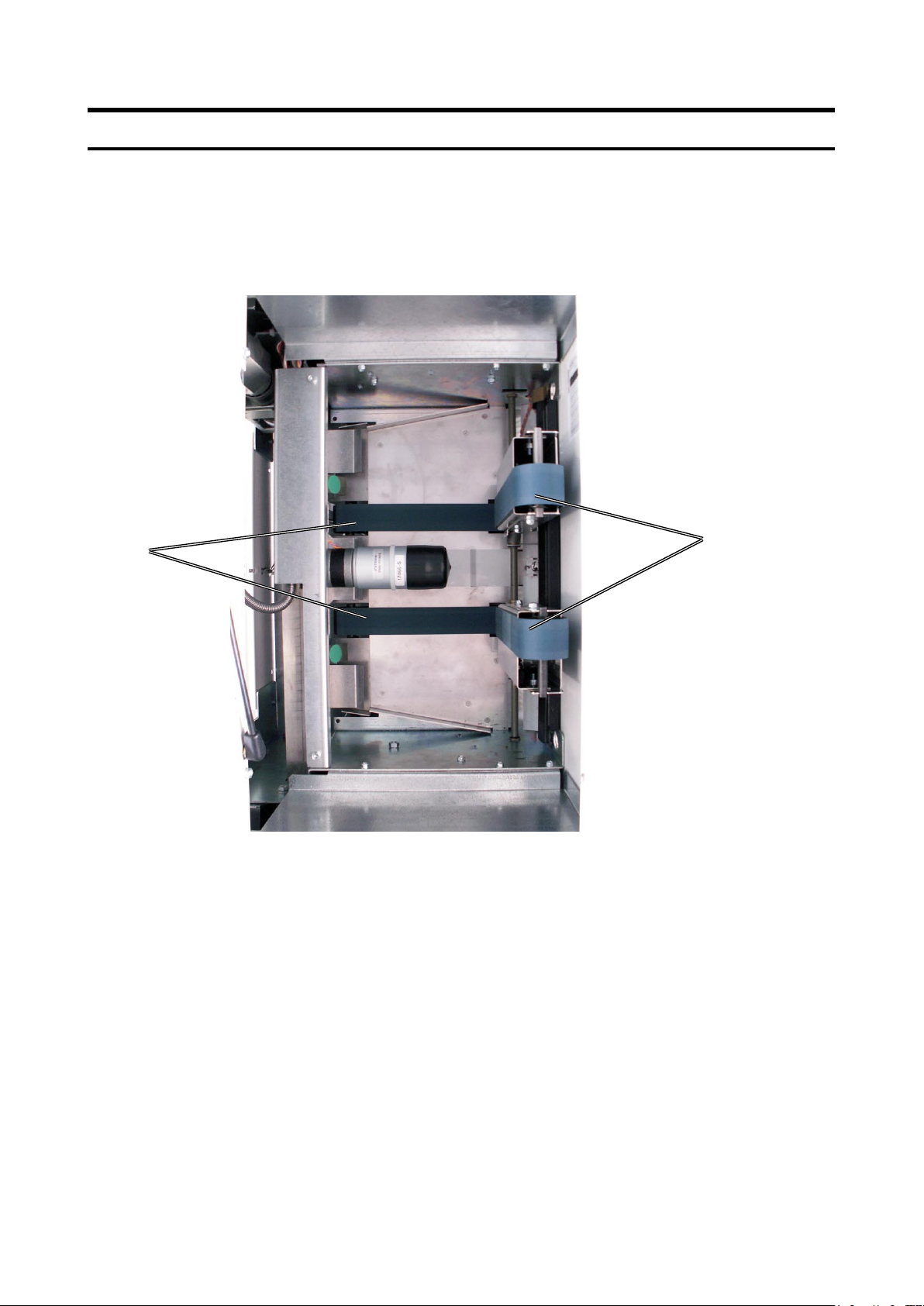

Maintaining Your Machines

Never attempt any maintenance function that is not specifically described in this

documentation.

Booklet Maker

Oil Clinchers and Stapler heads

The clinchers must be oiled every 20 000 stapling cycles to avoid mechanical breakdown.

7

close-up of clincher

lever

Stapling area,

view from infeed

close-up of

clincher

BB

close-up of clincher

lever

58

A

Open the top cover.

Put a couple of drops of oil in each clincher (A).

To get rid of excessive oil:

Push down clincher (B) lever a couple of times.

Push down clincher lever (B) while wiping of excessive oil with a dry cloth.

Run a few blank booklets.

When clinchers have beed lubricated, the error message must be reset:

Switch of the main power switch on the machine.

Press and hold the two innermost buttons on the UI, buttons 2 and 3.

Switch on the main power switch and release the buttons after 2 seconds.

7

The stapler heads must be oiled every 20 000 stapling cycles to avoid mechanical

breakdown.

C

Remove the Stapler heads according to section 1, BASICS Check staples, Staple cartridge

and Stapler head.

Put a couple of drops of oil on each side of the drive post (C).

Cycle the Stapler head a couple of times before installing it again.

59

Cover Feeder

Cleaning feed rollers and paper separator pad

The Feed rollers need to be cleaned regularly when in use, and if the unit has not been used

for a period of time. How often this should be done, depends on the paper type and print

quality.

An increasing number of misfeeds, or double feeds, is one indication of the need to clean

the Feed Rollers.

Remove the feed roller assembly by pressing it to the front of unit (A). The left end of the

feed roller assembly will now be released (B) and the assembly can be removed.

Clean the Feed rollers and the Paper separator pad with water and a clean lint free

cloth.

7

Press toward front.

Lift out this

side

Paper separator pad

A

60

B

Feed rollers

Showed with Top cover upper part

removed for clarity.

Book Folder

Cleaning feed belts

The Feed belts need to be cleaned regularly when in use, and if the unit has not been used

for a period of time. How often this should be done, depends on the paper type and print

quality.

An increasing number of misfeeds is one indication of the need to clean the Feed belts. Clean

the feed belts with water and a lint free cloth.

Open the top cover.

Clean the upper feed belts (A). The upper feed belts can easily be rotated in either

direction.

Lift up the upper feed belts to access the lower feed belts.

Clean the lower feed belts (B). Rotate the lower feed belts towards the outfeed side for

complete cleaning.

Place the upper feed belts in normal position.

Close the top cover.

A

B

7

Upper feed belts in normal position.

Upper feed belts lifted up.

61

7

Page intentionally blank.

62

8. Specication

Machine Specications

Booklet Maker MX-BMX1

Major Specications

Specications Remarks

Speed (Online usage) Maintains engine speed (actual depends if

engine is 90, 110 or 135 ppm version).

Maximum Speed 1800 booklets / hour (A4 / 8.5x11”)

1800 booklets / hour (A3 / 11x17”)

Standard Paper Sizes A4, A3, B4, 8.5x11”, 8.5x14”, 11x17 Custom sizes are available

Paper Size (Minimum) Width 206mm / 8.1”

Length 275mm / 10.8”

Paper Size (Maximum) Width 320mm / 12.6”

Length 457.2mm / 18”

Paper Weight (Minimum) 64gsm/16 lb. Bond

Paper Weight (Maximum) 300gsm / 172 lb. Index / 115 lb. Cover Engine Duplex: 216 gsm

Input / Output Sheets 1 – 30 Sheets (80 gsm / 20 lb. Bond) Stapled

Input / Output Sheets 1 – 2 Sheets Non Stapled Folding

Off-line Use Possible Stitch / Fold (2 staples)

Weight 130 kg / 286.6 lb

Dimensions (L x H x D) 1420 x 970 x 700 mm / 55.9 x 38.2 x 27.6” Incl. Base and Stacker

Power Source 100 / 110 / 115 / 127 / 220 / 230 50-60Hz + - 10%

Actual speed in number of booklets (per min / hour) depends on

number of sheets per booklet.

Power consumption 250 W or less Continuous Operations

63

Cover Feeder MX-CFX1 (option)

Specications Remarks

Maximum Speed Same as MX-BMX1 A3/11x17” or bigger paper

sizes, need two sheet sets as

inlet at least

Standard Paper Sizes Same as MX-BMX1

Paper Weight (Minimum) 70 gsm / 18 lb. Bond

Paper Weight (Maximum) Same as MX-BMX1

Cover Feeder Capacity 20 mm (approx 200 sheets of 80 gsm paper)

13/16” (approx 200 sheets of 20 lb. Bond paper)

Off-line Use Possible (Together with Booklet maker)

Weight 7 kg / 15.4 lb or less

Dimensions (L x H x D) 310 x 190 x 530 mm / 12.2 x 7.5 x 20.9”

Power Source From MX-BMX1

8

Trimmer MX-TMX1 (option)

Specications Remarks

Speed Same as MX-BMX1

Standard Paper Sizes Same as MX-BMX1 Custom sizes are available

Default trim length 4.5 mm / (11/64”) Adjustable in 0.5 mm steps

Minimum trimming 1 mm / (0.0394 in)* Adjustable in 0.5 mm steps

Maximum trimming 16 mm (0.63”) Adjustable in 0.5 mm steps

Paper Weight (Minimum) Same as MX-BMX1

Paper Weight (Maximum) Same as MX-BMX1 Engine Duplex: 216 gsm

Input / Output Sheets Same as MX-BMX1

Input / Output Sheets Same as MX-BMX1

Off-line Use Possible (Together with Booklet maker)

Weight 65 kg / 143.3 lb or less

Dimensions (L x H x D) 360 x 900 x 620 mm / 14.2 x 35.4 x 24.4”

Power Source From MX-BMX1

* When trimming SRA3 (450 mm) Booklets minimum trimming is 5 mm, when trimming 18” Booklets mini-

mum trimming is 9 mm.

64

Book Folder MX-FDX2 (option)

Specications Remarks

Speed Same as MX-BMX1

Standard Paper Sizes Same as MX-BMX1 Custom sizes are available

Paper Weight (Minimum) Same as MX-BMX1

Paper Weight (Maximum) Same as MX-BMX1

Input / Output Sheets Same as MX-BMX1

Input / Output Sheets Same as MX-BMX1

Off-line Use Possible (Together with Booklet maker &

Trimmer)

Weight 52 kg / 114.6 lb

Dimensions 360 x 900 x 620 mm / 14.2 x 35.4 x 24.4”

Power Source From MX-BMX1

System Certications

The system complies with the following directives:

EU Directive 2006/95/EC Low Voltage Directive

EU Directive 2004/108/EC EMC Directive, Class A equipment

EU Directive 2002/95/EC RoHS Directive

EU Directive 2002/96/EC WEEE Directive

Turkey RoHS Regulation of May 30, 2008

China RoHS, Standards SJ/T 11363-2006 and SJ/T 11364-2006

Certication Description Certica-

tion Body

EN 60950-1:2001 + A11:2004, 1st Edition

IEC 60950-1:2001, 1st Edition

UL 60950-1:2003, 1st Edition

CSA C22.2 No. 60950-1: 2003, 1st Edition

Information Technology

Equipment Safety – Part 1: General Requirements

UL (Underwriters

Laboratories, Inc.)

8

EN 55022:2006 + A1:2007, Class A

EN 61000-3-2:2006

EN 61000-3-3:1995 + A1:2001 + A2:2005

FCC Part 15 (2004) Subpart B, Class A

EN 55024:1998 + A1:2001 + A2:2003 EMC – immunity Intertek ETL

EMC – emission Intertek ETL

SEMKO

SEMKO

65

BK 5010e System Set Size Guide

8

Note

1. For cover jobs, deduct 2 sheets.

2. Area coverage:

Low = Text only

High = Pictures

Full = Maximum coverage

Paper weight

Bond Offset Cover Tag Index Gsm

20 50 28 46 42 80

24 60 33 56 50 90

28 70 39 64 58 100

29 73 40 62 60 110

31 81 45 73 66 120

35 90 48 80 74 130

36 90 50 82 75 140

39 100 54 90 81 150

43 110 60 100 90 160

44 110 61 102 92 170

47

50 128 70 115 104 190

53 135 74 122 110 200

54 137 75 125 113 210

58 146 80 134 120 220

62 156 85 142 128 230

65 165 90 150 135 240

67 170

70 177 97

72

76

80 201 110 184 166 290

82 208 114 189 170 300

120 65 108 97 180

93 156 140 250

161 145 260

183 100 166 150 270

192 105 175 158 280

Paper size

<A3 >A3

Grain direction Grain direction

Short Long Short Long

Area coverage Area coverage Area coverage Area coverage

Low High Full Low High Full Low High Full Low High Full

30 25 22 27 22 20 27 22 20 24 17 14

23 21 24 20 18 24 20 18 21 17 14

27

24 21 19 21 19 17 21 19 17 19 16 14

22 20 18 19 17 16 19 17 16 17 16 14

20 19 17 17 16 15 17 16 15 15 15 13

18 17 16 16 15 14 16 15 14 14 13 12

16 14 15 14 13 15 14 13 13 12 11

17

15 15 13 14 13 12 14 13 12 12 11 10

14 14 12 13 12 11 13 12 11 11 11 9

13 13 12 12 11 10 12 11 10 10 10 9

12 12 11 11 10 10 11 10 10 10 9 8

12 11 10 10 10 9 10 10 9 9 9 8

11 10 10 10 9 8 10 9 8 9 8 7

10 10 9 9 9 8 9 9 8 8 8 7

10 9 9 9 8 8 9 8 8 8 7 6

9 9 8 8 8 7 8 8 7 7 7 6

9 8 8 8 7 7 8 7 7 7 7 6

8 8 7 7 7 6 7 7 6 7 6 5

8 8 7 7 7 6 7 7 6 6 6 5

8 7 7 7 6 6 7 6 6 6 6 5

7 7 6 6 6 6 6 6 6 6 5 5

7 7 6 6 6 6 6 6 6 5 5 4

7 6 5 6 5 5 6 6 5 5 5 4

66

INDEX

A

Access to machine 55

Air Separation, adjusting 37

B

Docking the Booklet Maker 21

Undocking the Booklet Maker 22

Basics 21

Begin On-line Production 34

Book Folder 17

cleaning feed belts 59

fault codes 51

Book Folding, setting mode 32

Booklet Maker 11

fault codes 49

Booklets, making 27

C

Changing settings 27

Clearing Misfeed(s) 41

Control Panel 19

Cover Feeder 14

Cleaning feed rollers and paper separator pad 58

fault codes 50

selecting mode 30

Covers 30

loading 31

Custom paper size 28

Cutting margin

adjusting 30

D

Do’s And Don’ts 53

Docking 21

Double Sheet Detection 37

Maintaining Your Machines 56

Making Booklets 27

Misfeed(s)

clearing 41

O

Options 13

P

The Please wait screen 20

The Processing screen 20

Turning On / Off the Main Power 23

Paper Size

setting 27

Paper size

custom 28

Power connection 54

R

REMARKS 53

S

Service access 38

Setting Paper Size 27

Settings, changing 27

Software version 35

Specication 61

Staple cartridge

install 25

remove 24

Stapler head

install 25

remove 24

Staples

check 24

clearing jam 25

Stapling

on / off 28

F

Fault codes 47

Book Folder 51

Booklet Maker 49

Cover Feeder 50

general 47

Trimmer 49

G

General fault codes 47

Guide To Components 11

J

The Jobs screen 19

Jobs

storing & deleting 39

L

Language

selecting 36

M

Turning On / Off the Main Power 23

Machine

environment 54

specications 61

T

Turning On / Off the Main Power 23

The Jobs screen 19

The Ready screen 19

The Tools screen 19

Tools 35

Trim bin

emptying 26

Trimmer 15

Trimmer fault codes 49

Trimming.See also Cutting margin

on / off 30

Troubleshooting 47

Turning Off the Main Power 23

Turning On the Main Power 23

U

Undocking 21

Units

selecting 35

W

What You Can Do with This Machine 9

Where to put Your Machine 54

67

Loading...

Loading...