Page 1

SERVICE MANUAL

COMBINATION LIQUID CRYSTAL

TELEVISION AND DVD/CD PLAYER

S68ONLC32DV24

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

CONTENTS

CAUTION .............................................................................................................................

•

IMPORTANT SAFEGUARDS ..............................................................................................

•

WHEN REPLACING DVD DECK.........................................................................................

•

DISC REMOVAL METHOD AT NO POWER SUPPLY........................................................

•

PARENTAL CONTROL-RATING.........................................................................................

•

ABOUT LEAD FREE SOLDER (PbF) ..................................................................................

•

GENERAL SPECIFICATIONS .............................................................................................

•

DISASSEMBLY INSTRUCTIONS........................................................................................

•

SERVICE MODE LIST .........................................................................................................

•

SERVICING FIXTURES AND TOOLS.................................................................................

•

RE-WRITE FOR DVD FIRMWARE......................................................................................

•

WHEN REPLACING EEPROM (MEMORY) IC....................................................................

•

ELECTRICAL ADJUSTMENTS ...........................................................................................

•

TROUBLESHOOTING GUIDE.............................................................................................

•

BLOCK DIAGRAM ...............................................................................................................

•

PRINTED CIRCUIT BOARDS..............................................................................................

•

SCHEMATIC DIAGRAMS....................................................................................................

•

WAVEFORMS......................................................................................................................

•

MECHANICAL EXPLODED VIEWS ....................................................................................

•

DVD DECK EXPLODED VIEWS .........................................................................................

•

REPLACEMENT PARTS LIST.............................................................................................

•

LC-32DV24U

Page

A1-1

A1-2~A1-4

A1-5

A1-6

A1-6

A1-7

A2-1~A2-7

B1-1~B3-2

C-1

C-2

C-2

C-3

D-1~D-6

E-1~E-9

F-1~F-8

G-1~G-10

H-1~H-52

I-1, I-2

J1-1~J1-4

J2-1

K1-1~K3-8

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 2

CAUTION

THIS

LCD COLOR TELEVISION

TO ENSURE PROPER USE OF THIS PRODUCT, PLEASE READ THIS SERVICE MANUAL CAREFULLY AND RETAIN FOR FUTURE REFERENCE. SHOULD THE UNIT REQUIRE MAINTENANCE,

CONTACT AN AUTHORIZED SERVICE LOCATION-SEE SERVICE PROCEDURE.

USE OF CONTROLS, ADJUSTMENTS OR THE PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS LASER RADIATION EXPOSURE.

TO PREVENT DIRECT EXPOSURE TO LASER BEAM, DO NOT TRY TO OPEN THE ENCLOSURE.

VISIBLE LASER RADIATION MAY BE PRESENT WHEN THE ENCLOSURE IS OPENED. DO NOT

STARE INTO BEAM.

Location of the required Marking

The rating sheet and the safety caution are on the rear of the unit.

EMPLOYS A LASER SYSTEM.

CERTIFICATION: COMPLIES WITH FDA

RADIATION PERFORMANCE STANDARDS,

21 CFR SUBCHAPTER J.

PREPARATION OF SERVICING

The laser diode used for a pickup head may be destroyed with external static electricity.

Moreover, even if it is operating normally after repair, when static electricity discharge is received at the

time of repair, the life of the product may be shortened.

Please perform the following measure against static electricity, be careful of destruction of a laser diode

at the time of repair.

• Place the unit on a workstation equipped to protect against static electricity, such as conductive mat.

• Soldering iron with ground wire or ceramic type is used.

• A worker needs to use a ground conductive wrist strap for body.

A1-1

Page 3

IMPORTANT SAFEGUARDS

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with dry cloth.

7) Do not block any ventilation openings. Install in accordance with the manufacturer's instructions.

8) Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including

amplifiers) that produce heat.

9) Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding type plug has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. If the provided plug does not fit into your outlet,

consult an electrician for replacement of the obsolete outlet.

10) Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles, and

the point where they exit from the apparatus.

11) Only use attachments/accessories specified by the manufacturer.

12) Use only with the cart, stand, tripod, bracket, or table specified by the

manufacturer, or sold with the apparatus. When a cart is used, use caution when

moving the cart/apparatus combination to avoid injury from tip-over.

13) Unplug this apparatus during lightning storms or when unused for long periods

of time.

14) Refer all servicing to qualified service personnel. Servicing is required when the

apparatus has been damaged in any way, such as power-supply cord or plug is

damaged, liquid has been spilled or objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, does not operate normally, or has been dropped.

15) Apparatus shall not be exposed to dripping or splashing and that no objects filled with liquids, such a vases,

shall be placed on the apparatus.

16) An outside antenna system should not be located in the vicinity of overhead power lines or other electric

light or power circuits, or where it can fall into such power lines or circuits. When installing an outside

antenna system, extreme care should be taken to keep from touching such power lines or circuits, as

contact with them might be fatal.

17) Do not overload wall outlets and extension cords, as this can result in a risk of fire or electric shock.

18) Do not push objects through any openings in this unit, as they may touch dangerous voltage points or short

out parts that could result in fire or electric shock. Never spill or spray any type of liquid into the unit.

PORT ABLE CART WARNING

(symbol provided by RETAC)

S3126A

A1-2

Page 4

IMPORTANT SAFEGUARDS (CONTINUED)

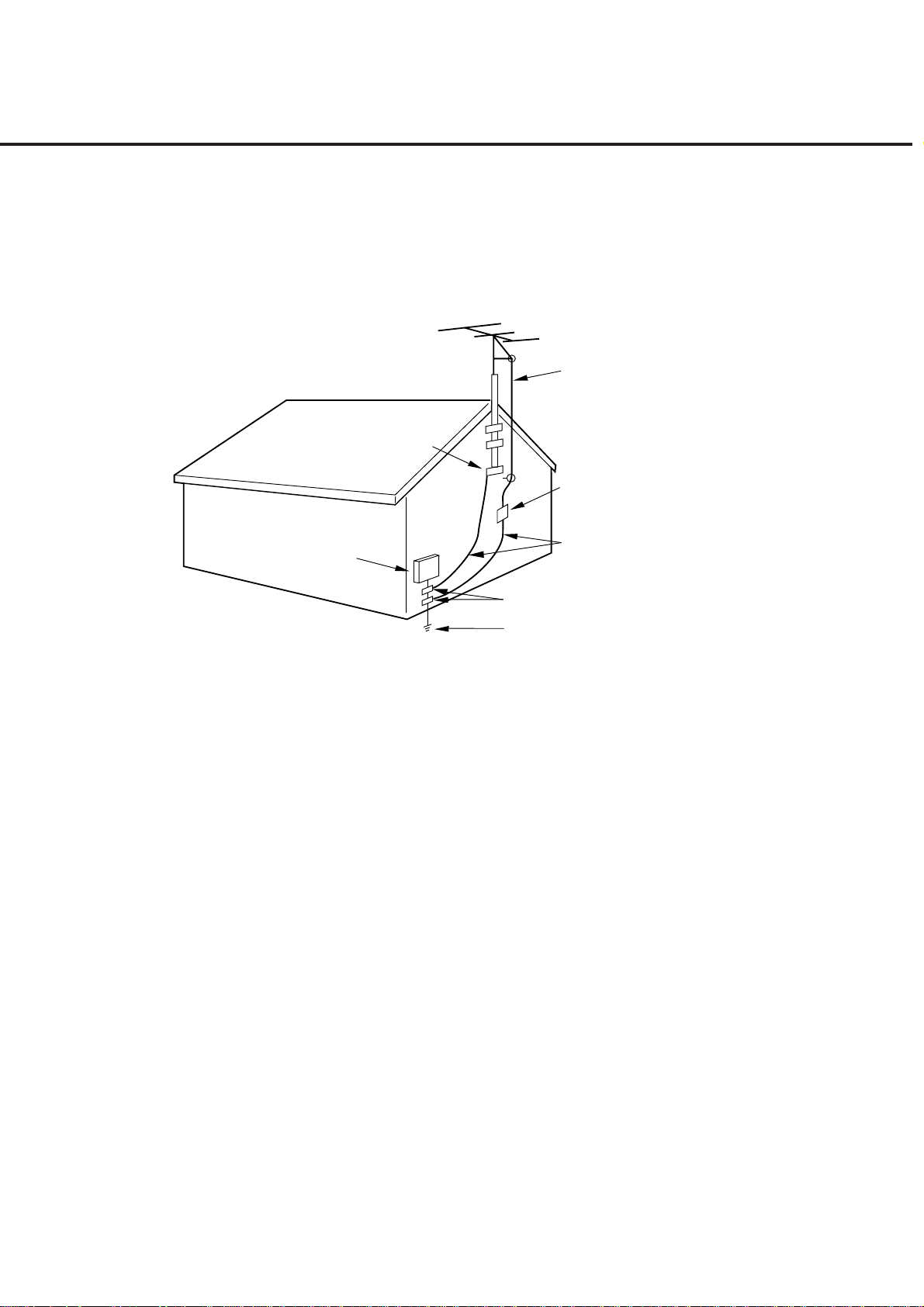

19) If an outside antenna or cable system is connected to the unit, be sure the antenna or cable system is

grounded to provide some protection against voltage surges and built-up static charges, Section 810 of

the National Electrical Code, ANSI/NFPA 70, provides information with respect to proper grounding of the

mast and supporting structure, grounding of the lead-in wire to an antenna discharge unit, size of grounding conductors, location of antenna discharge unit, connection to grounding electrodes, and requirements

for the grounding electrode.

EXAMPLE OF ANTENNA GROUNDING AS PER THE

NATIONAL ELECTRICAL CODE

ANTENNA

LEAD IN WIRE

GROUND

CLAMP

ANTENNA

DISCHARGE UNIT

(NEC SECTION 810-20)

ELECTRIC SERVICE

EQUIPMENT

GROUND CLAMPS

NEC-NATIONAL ELECTRICAL CODE

S2898A

20) When replacement parts are required, be sure the service technician uses replacement parts specified by

the manufacturer or those that have the same characteristics as the original part.

Unauthorized substitutions may result in fire, electric shock or other hazards.

21) Upon completion of any service or repairs to this unit, ask the service technician to perform safety checks

to determine that the unit is in proper operating condition.

22) Keep your fingers clear of the disc slot as it is closing. It may cause injury.

23) When you connect the product to other equipment, turn off the power and unplug all of the equipment

from the wall outlet. Failure to do so may cause an electric shock and serious personal injury. Read the

owner's manual of the other equipment carefully and follow the instructions when making any connections.

24) Reduce the volume to the minimum level before you turn on the product. Otherwise, sudden high volume

sound may cause hearing or speaker damage.

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250, PART H)

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

A1-3

Page 5

IMPORTANT SAFEGUARDS (CONTINUED)

25) Do not allow the product to output distorted sound for an extended period of time. It may cause speaker

overheating and fire.

26) When you use the headphones, keep the volume at a moderate level. If you use the headphones continuously with high volume sound, it may cause hearing damage.

27) Do not look into the opening of the disc slot or ventilation opening of the product to see the source of the

laser beam. It may cause eye damage.

28) Do not use a cracked, deformed, or repaired disc. These discs are easily broken and may cause serious

personal injury and product malfunction.

29) This reminder is provided to call the cable TV system installer's attention to Article 820-40 of the NEC that

provides guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding system of the building, as close to the point of cable entry as practical.

CONDENSATION

Moisture will form in the operating section of the player if the player is brought from cool surroundings into a

warm room or if the temperature of the room rises suddenly. When this happens, player's performance will

be impaired.

To prevent this, let the player stand in its new surroundings for about an hour before switching it on, or

make sure that the room temperature rises gradually.

Condensation may also form during the summer if the player is exposed to the breeze from an air conditioner. In such cases, change the location of the player.

HOW TO HANDLE THE LCD PANEL

• Do not press hard or jolt the LCD panel. It may cause the LCD panel glass to break and injury may occur.

• If the LCD panel is broken, make absolutely sure that you do not touch the liquid in the panel. This may

cause skin inflammation.

If the liquid gets in your mouth, immediately gargle and consult with your doctor. Also, if the liquid gets in

your eyes or touches your skin, consult with your doctor after rinsing for at least 15 minutes or longer in clean

water.

A1-4

Page 6

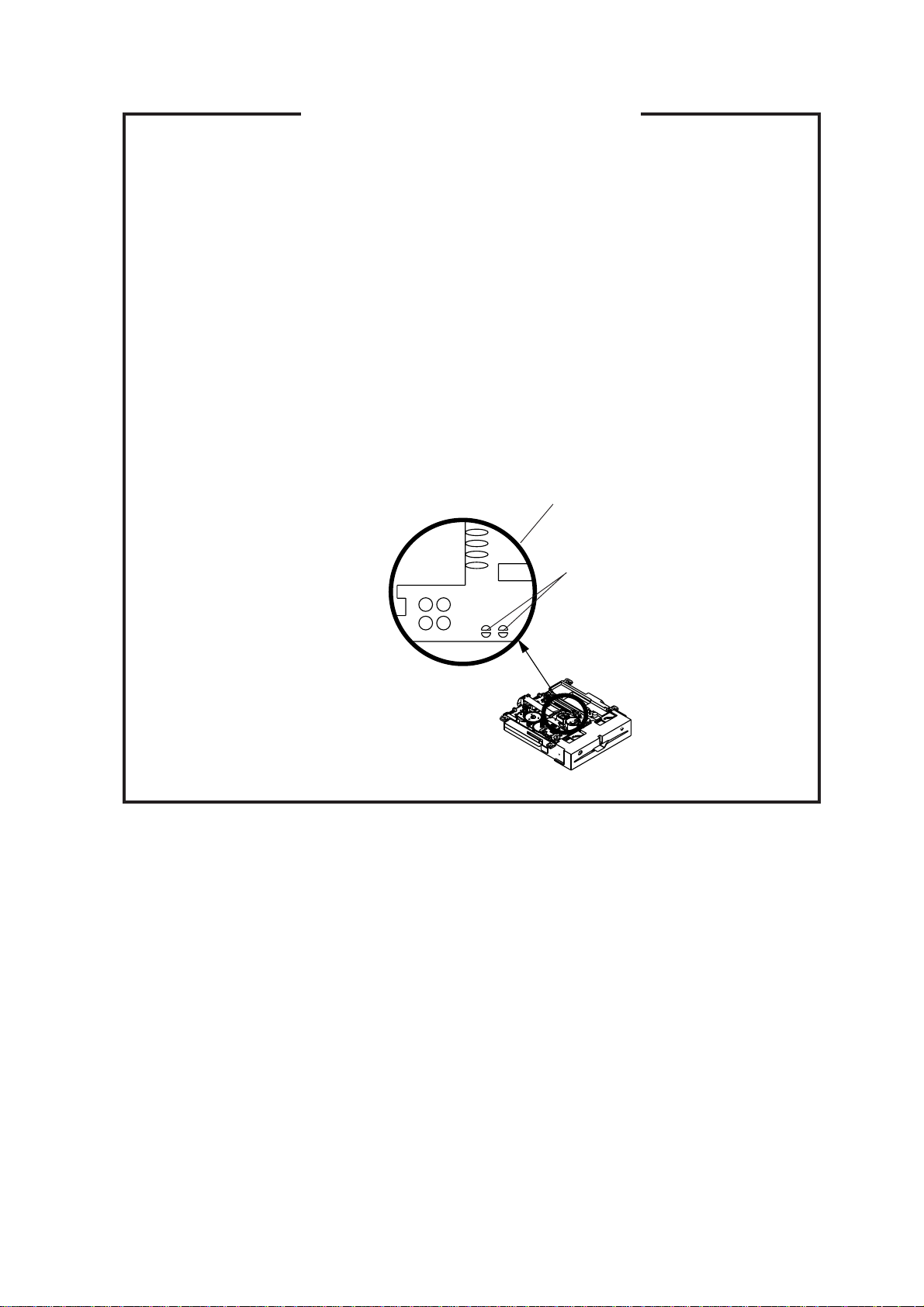

WHEN REPLACING DVD DECK

[ When removing the DVD Deck ]

Before removing Pick Up PCB and DVD MT PCB connector, the short circuit the position shown in Fig.

1 using a soldering iron. If you remove the DVD Deck with no soldering, the Laser may be damaged.

[ When installing the DVD Deck ]

Remove all the soldering on the short circuit position after the connection of Pick Up PCB and DVD

MT PCB connector.

NOTE

•

Before your operation, please read “PREPARATION OF SERVICING”.

•

Use the Lead Free solder.

•

Manual soldering conditions

• Soldering temperature: 320 ± 20

• Soldering time: Within 3 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

When Soldering/Removing of solder, use the draw in equipment over the Pick Up Unit to keep the

•

Flux smoke away from it.

o

C

Pick Up PCB

Fig. 1

Short circuit using a

soldering iron.

A1-5

Page 7

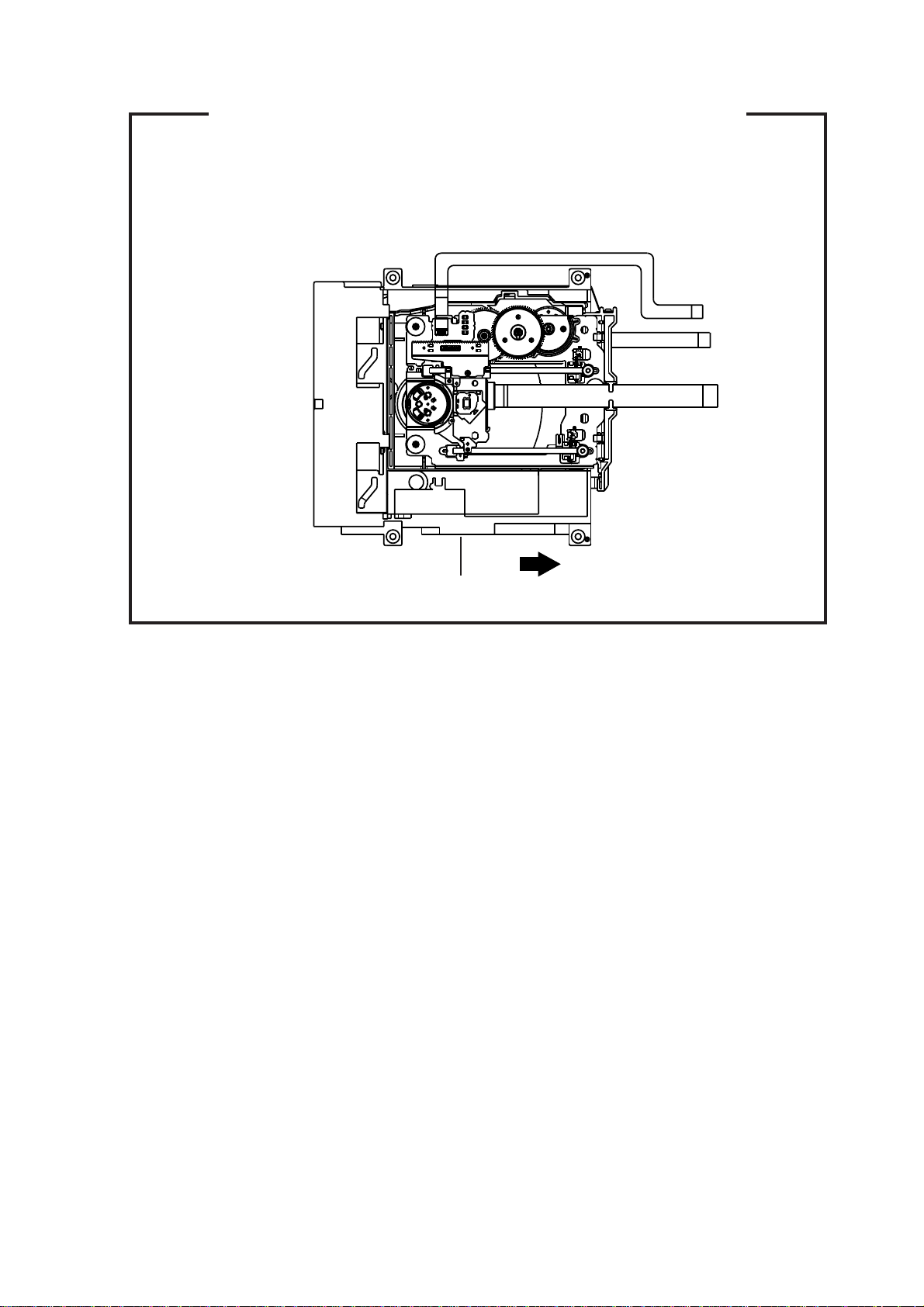

DISC REMOVAL METHOD AT NO POWER SUPPLY

1.

Remove the Back Cabinet and Angle Deck. (Refer to item 1 of the DISASSEMBLY INSTRUCTIONS.)

2.

Slide the Belt Loading toward the arrow direction by hand to release the lock. (Refer to Fig. 1)

3.

Take out the Disc from the DVD Deck. Be careful not to scratch on the Disc.

DVD Deck

Belt Loading

Fig. 1

PARENTAL CONTROL - RATING LEVEL

4 DIGIT PASSWORD CANCELLATION

If the stored 4 digit password in the Rating Level menu needs to be cancelled, please follow the steps below.

1.

Turn Unit ON.

2.

Set the DVD to the Stop Mode.

3.

Check that “No disc” is displayed on the screen.

4.

Press and hold the “STOP” button on the top panel.

5.

Simultaneously press and hold the “7” key on the remote control unit.

6.

Hold both keys for more than 2 seconds.

7.

The On Screen Display message “PASSWORD CLEAR” will appear.

8.

The 4 digit password has now been cleared.

A1-6

Page 8

ABOUT LEAD FREE SOLDER (PbF)

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a PbF printing on the PCB.

(Please refer to figures.)

Caution:

Pb free solder has a higher melting point than standard solder;

•

Typically the melting point is 86°F~104°F(30°C~40°C) higher.

Please use a soldering iron with temperature control and adjust it to 650°F ± 20°F (350°C ± 10°C).

In case of using high temperature soldering iron, please be careful not to heat too long.

Pb free solder will tend to splash when heated too high (about 1100°F/ 600°C).

•

All products with the printed circuit board with PbF printing must be serviced with lead free solder.

•

When soldering or unsoldering, completely remove all of the solder from the pins or solder area,

and be sure to heat the soldering points with the lead free solder until it melts sufficiently.

Recommendations

Recommended lead free solder composition is Sn-3.0Ag-0.5Cu.

A1-7

Page 9

GENERAL SPECIFICATIONS

Intermediate

at CD 4 Hz - 20 KHz

<

G-1 TV LCD LCD Size / Visual Size 31.5 inch / 800.4mmV

System LCD Type Color TFT LCD

Color System NTSC

Speaker 2 Speaker

Sound Output Max 5.0W + 5.0W

G-2 DVD System Color System NTSC

Disc DVD, CD-DA, CD-R/RW

Disc Diameter 120 mm , 80 mm

Drive DSM-2

Search speed Fwd 4 step

Slow speed Fwd 1/7 -1/2 times

G-3 Tuning Broadcasting System Analog US System M

System Digital ATSC(8VSB)/QAM

Tuner and System 1Tuner

Receive CH Destination US (W/CABLE)

Digital 44.00MHz

Frequency Analog Picture(FP) 45.75MHz

Preset CH No

Stereo/Dual TV Sound US-Stereo

Tuner Sound Muting Yes

G-4 Signal Video Signal Input Level 1 V p-p/75 ohm

RGB Signal Output Level -Audio Signal Input Level 0.85 V p-p/50k ohm

Number of Pixels 1366(H) x 768(V)

View Range Left/Right 88/88 degree

Up/Down 88/88 degree

Bright Dot n=2

Zero Bright Dot Ratio --

Position Front

Size 1.6 x 4.8 inch

Impedance 8 ohm

10%(Typical) ---

DVD-R/RW (Video Format Only)

Actual 2-45 times (DVD)

4-40 times (CD)

Rev 4 step

Actual 2-45 times (DVD)

4-40 times (CD)

Actual --

Rev 1/7 -1/2 times

Actual --

CH Coverage 2~69, 4A, A-5~A-1, A~I, J~W, W+1~W+84

Sound(FS) 41.25MHz

FP-FS 4.50MHz

Output Level -S/N Ratio (Weighted) -Horizontal Resolution at DVD Mode --

--

Output Level at DVD 0.56 V p-p/ 1k ohm (-20dBFs, 0dBFs=5.6 V p-p)

at TV 0-1.7 V p-p/1k ohm

Digital Output Level 0.5 V p-p/75 ohm

S/N Ratio at DVD (Weighted) 85dB

Harmonic Distortion 0.02% (1KHz)

Frequency Response : at DVD 4 Hz - 44 KHz (96KHz)

at Video CD --

at SVCD --

A2-1

Page 10

GENERAL SPECIFICATIONS

+5oC ~ +40oC

-20oC ~ +60oC

Timer Back-up (at Power Off Mode) more than -- Min Sec

G-5 Power Power Source AC 120V, 60Hz

Power Consumption at AC 170W at 120V 60Hz

Protector Power Fuse Yes

G-6 Regulation Safety UL(UL6500_2nd)/CSA(E60065_00)

G-7 Temperature Operation

G-8 Operating Humidity Less than 80% RH

G-9 Clock and Clock No

Timer Sleep Timer Max Time 120 Min

On Timer Program No

Off Timer Program No

Game Timer No

Wake Up Timer No

DC --

at DC -Stand by (at AC) 0.8W at 120V 60Hz

Energy Star Yes

Per Year -- kWh/Year

Safety Circuit Yes

IC Protector(Micro Fuse) Yes

Radiation FCC / IC

Laser DHHS

Storage

Space Around Unit 100 mm(4inch)

A2-2

Page 11

GENERAL SPECIFICATIONS

POWER Yes

DISPLAY Yes

SLEEP Yes

VIEW MODE Yes

INPUT SELECT Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

MUTE Yes

AUDIO Yes

VOL+ Yes

VOL- Yes

CH+ Yes

CH- Yes

LEFT/SLOW- Yes

ENTER Yes

RIGHT/SLOW+ Yes

UP Yes

DOWN Yes

SETUP/TV MENU Yes

EXIT/CANCEL Yes

RETURN Yes

/SUBTITLE Yes

TV/DVD Yes

OPEN/CLOSE(EJECT) Yes

FWD(SEARCH+) Yes

REV(SEARCH-) Yes

SKIP+ Yes

SKIP- Yes

PAUSE/STILL Yes

PLAY Yes

STOP Yes

PLAY MODE Yes

ANGLE Yes

ZOOM Yes

DVD MENU Yes

TOP MENU Yes

REPEAT A-B Yes

MARKER Yes

DIRECT SKIP(JUMP) Yes

FREEZE No

.

G-10 Remote Unit RC-MR

Control Glow in Dark Remocon No

Remocon Format SHARP

Format TV:SHARP, DVD:KASEIKYO

Custom Code TV:SHARP 15bit, DVD:KASEIKYO 48bit

Power Source Voltage(D.C) 3V

UM size x pcs UM-3 x 2 pcs

Total Keys 47 Keys

Keys

A2-3

Page 12

GENERAL SPECIFICATIONS

Yes

Spanish

Yes

Yes

No

No

No

WXGA+ (1440x900) No

G-11 Features Auto Shut Off Yes

(TV) Auto Search No

Power On Memory Yes

Comb Filter Yes

Game Position No

Auto Setup(Language/CH Program) No

Picture Setting(TV) Yes

AV Mode(Picture Preference) Yes

Brightness , Contrast , Color Yes

Tint Yes

Sharpness Yes

Color Temperature Yes

DNR Yes

Cable Clear No

Picture Setting(PC) Yes

HOR Position , VER Position Yes

Phase, Clock Yes

Red, Green, Blue No

Auto Adjust No

Backlight No

Audio MTS Yes

Tone Control (Bass/Treble/Balance) Yes

Stable Sound No

Surround No

BBE No

SRS WOW (SRS 3D/Focus/Tru Bass) No

Variable Audio Out Yes

Tuning CH Program Yes

Air/Cable Yes

ADD/DELETE Yes

Label CH Label Yes

Video Label Yes

Favorite CH No

V-Chip Yes

Type USA/CANADA Type

RRT Setup

Lock Hotel Lock No

Channel Lock No

Video Lock No

Panel Lock No

Menu Language

3 -D

English

French

Closed Caption

CC Advanced

View Mode (Picture Size) Yes

Picture Scroll

Film Mode Yes

Aspect

Backlight Yes

PFC(Power Factor circuit)

Freeze frame No

PIP/POP No

Direct Input Selection Yes

Digital Out Dolby Digital Yes

PC Monitor Input Yes

MPEG No

PCM No

DTS No

VGA (640x480) Yes (60Hz)

VGA (720x400) Yes (70Hz)

WVGA (848x480) No

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) Yes (60Hz)

WXGA (1360x768) Yes (60Hz)

SXGA (1280x1024) No

A2-4

Page 13

GENERAL SPECIFICATIONS

No

Audio DAC 192kHz / 24bit

HDMI Input Yes

Component Input Yes

Wall Mount Size W x H(mm) Yes (200 x 200)

Features Video CD Playback No

(DVD) SVCD Playback

MP3 Playback Yes

JPEG Yes

WMA Yes

Digital Out (Dolby Digital) Yes

Down Mix Out (Dolby Digital) Yes

Closed Caption Yes

Screen Saver No

TV Screen

VGA (640×480) Yes (60Hz)

720×480i (4:3) Yes (60Hz)

720×480i (16:9) Yes (60Hz)

720×480p (4:3) Yes (60Hz)

720×480p (16:9) Yes (60Hz)

720×576i (4:3) No

720×576i (16:9) No

720×576p (4:3) No

720×576p (16:9) No

1280×720p Yes (60Hz)

1920×1080i Yes (60Hz)

CEC (ORION Standard) No

Deep Color No

xvYCC No

720×480i (4:3) Yes (60Hz)

720×480i (16:9) Yes (60Hz)

720×480p (4:3) Yes (60Hz)

720×480p (16:9) Yes (60Hz)

720×576i (4:3) No

720×576i (16:9) No

720×576p (4:3) No

720×576p (16:9) No

1280×720p Yes (60Hz)

1920×1080i Yes (60Hz)

Screw Size M6 x 10

(MPEG) Yes

(PCM) Yes

(DTS) Yes

(DTS) No

4:3 (Letter Box, Pan Scan) Yes

16:9 (Wide) Yes

A2-5

Page 14

GENERAL SPECIFICATIONS

No

No

No

No

No

No

No

No

No

No

Dew/AHC Caution Sheet

No

No

No

No

No

No

No

On Timer No

G-12 Accessories Owner's Manual Language English/French/Spanish

Remote Control Unit Yes

Rod Antenna

Loop Antenna

U/V Mixer

DC Car Cord (Center+)

Guarantee Card

Warning Sheet

Circuit Diagram

Antenna Change Plug

Service Facility List

Important Safeguard

Quick Set-up Sheet

Battery Yes

AC Adapter

AC Cord (for AC Adapter)

AC Cord (Flat Polarity Plugs) Yes

Cable Cramp Yes

Stand Yes

Stand Screw Yes

Hexagon Wrench Yes

AV Cord (2Pin-1Pin)

Registration Card (NDL Card) Yes

300 to 75ohm Antenna Adapter

Sheet Information (Return) No

Sheet Information (HDMI)

Sheet Information (CEA) Yes

Sheet Information(FCC) Yes

Cleaning Cloth No

G-13 Interface Switch Top Power (Tact) Yes

Rear Main Power SW No

Indicator Power/Stand-By Yes (Green / Red)

w/Guarantee Card Yes

Poles -Terminal --

Terminal --

UM size x pcs UM-3 x 2 pcs

OEM Brand No

Channel Up Yes

Channel Down Yes

Volume Up Yes

Volume Down Yes

Menu No

Play Yes

Eject Yes

Skip+, Search+ Yes

Skip-, Search- Yes

Still/Pause No

Stop Yes

Main Power SW No

Input Select Yes

Power Wake Up No

A2-6

Page 15

GENERAL SPECIFICATIONS

Sets/40' container

Rohs Yes

Terminals Side Video Input 1 RCA x 1

G-14 Set Size Approx. W x D x H (mm) 797 x 243 x 583

G-15 Weight Net (Approx.) 14.5kg (32.4lbs)

G-16 Carton Master Carton No

Gift Box Material Double/Brown

Drop Test 1 Corner / 3 Edges / 5 Surfaces

Container Stuffing (40' container) 321

w/Pallet No

w/Wrapping No

G-17 Material Cabinet Front PC+ABS 94V0 NON-HALOGEN

PCB Non-Halogen Demand No

G-18 Environment Environmental standard requirement Green procurement of SHARP

Pb-free Phase3(Phase3A)

Audio Input 1 RCA x 2(L/MONO, R)

S - Input 1

Video Input 2 RCA x 1

Audio Input 2 RCA x 2(L/MONO, R)

S - Input 2 No

Video Output No

Audio Output

Component Input 1

Analog Audio Video Input 2 Audio Input Alternative

Component Input 2 No

Analog Audio No

HDMI Input 1

Analog Audio PC Monitor Audio Input Alternative

HDMI Input 2 No

Analog Audio No

Sub Woofer Out No

PC Monitor Input

Analog Audio

Digital Audio Output Coaxial

DC Jack (Center +) No

VHF/UHF Antenna Input

Video Input 3 No

Audio Input 3 No

S - Input 3 No

Other Terminal No

AC Inlet

w/o Handle, Stand Approx. W x D x H (mm)

Net w/o Handle, Stand (Approx.) 13.0kg (29.2lbs)

Gross (Approx.) 17.5kg (39.0lbs)

Content --- Sets

Material --- / --Dimensions W x D x H(mm) --Description of Origin ---

W/Color Photo Label No

W/Handle No

Dimensions W x D x H(mm) 900 x 286 x 659

Description of Origin Yes

Height (cm) 32

Rear PS 94V0 NON-DECABROM

Jack Panel --

Eyelet Demand Yes

Measures for Whisker Yes

Yes

RCA x 2 (Variable) (L, R)

RCA x 3

Yes

Yes

Mini Pin Jack( 3.5), STEREO

F Type

Yes

797 x 116 x 534

A2-7

Page 16

DISASSEMBLY INSTRUCTIONS

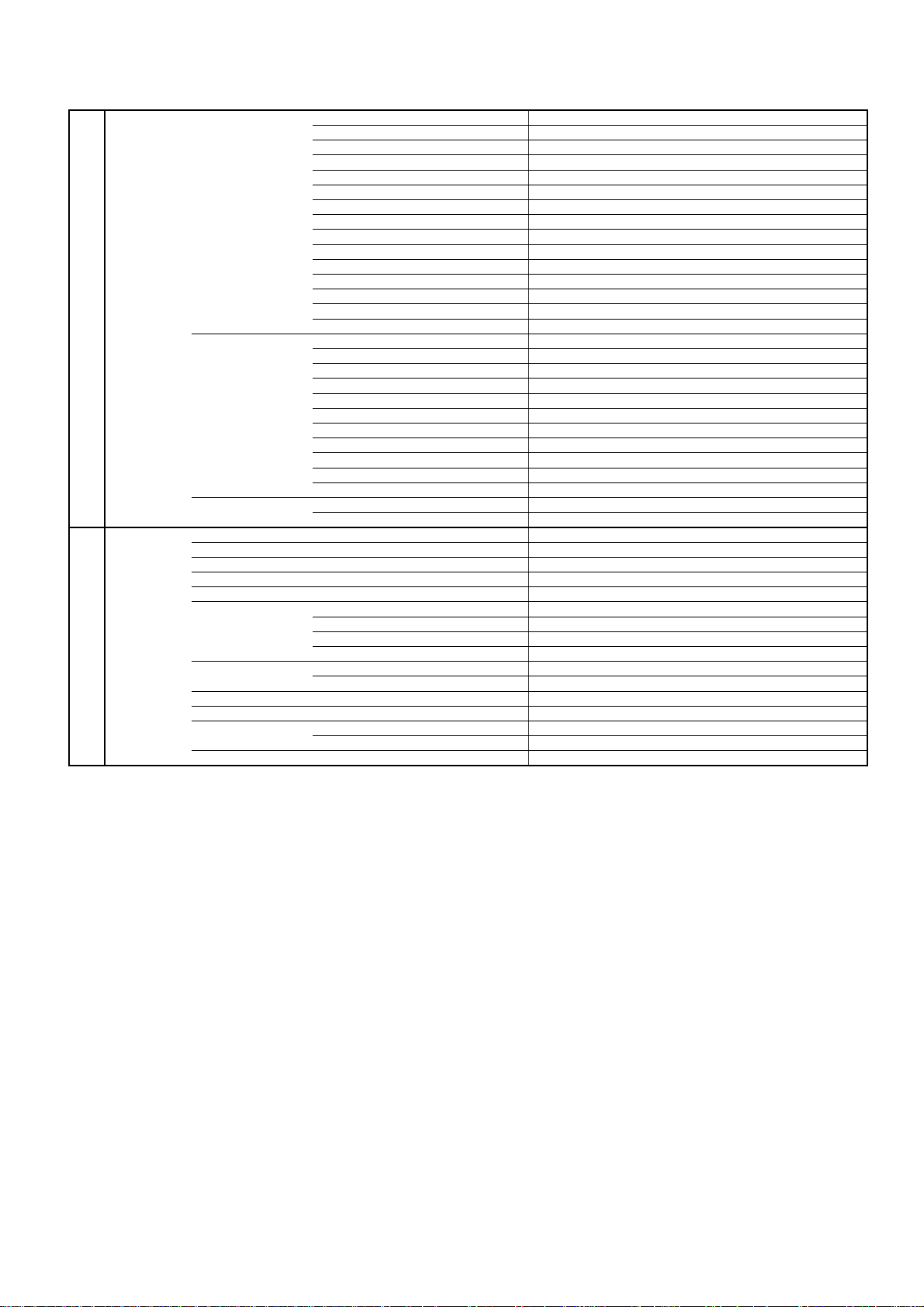

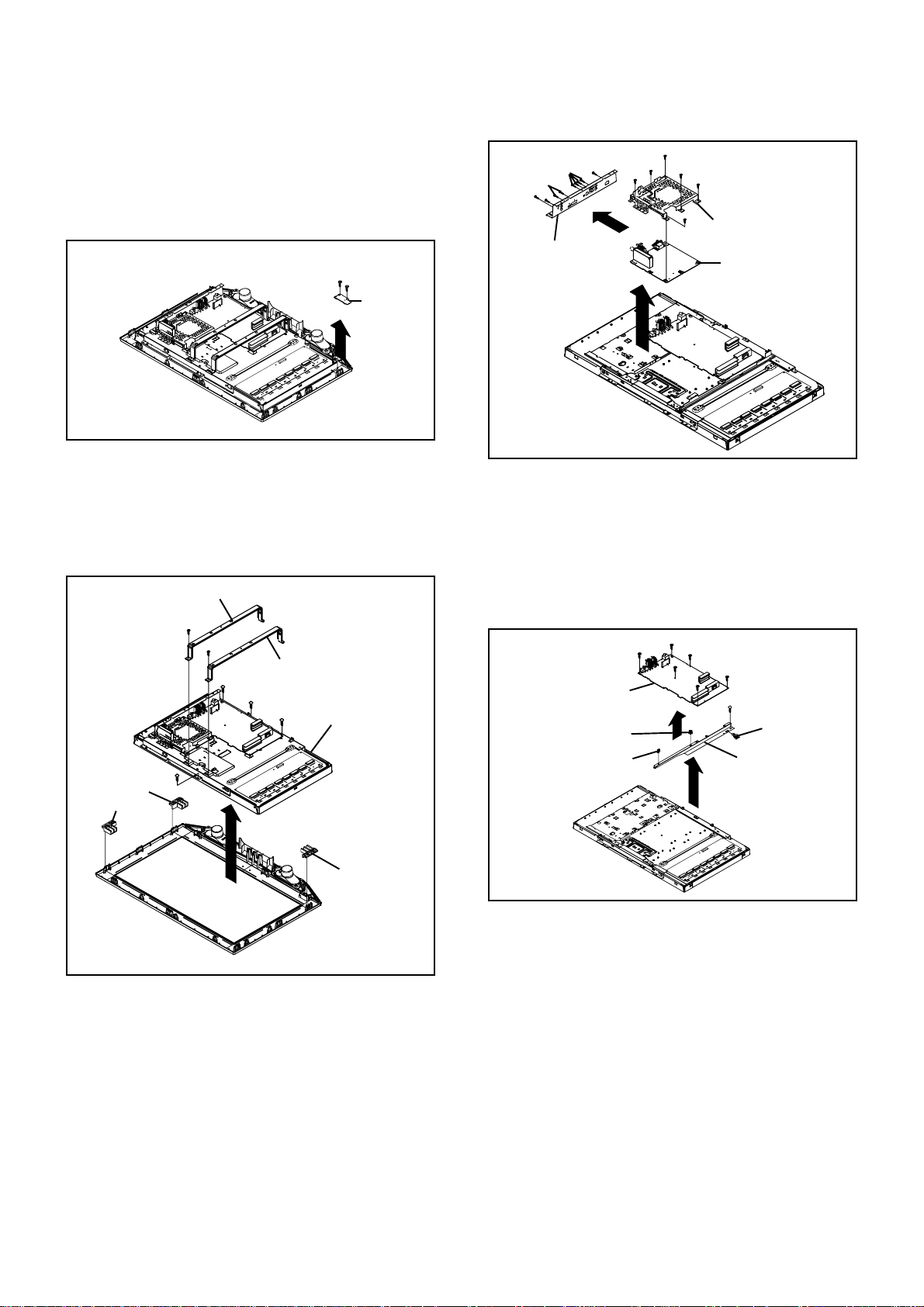

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

CAUTION

Be careful not to remove the FFC cable forcibly, because

the FFC cable may be damaged.

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the 13 screws (1).

2.

Remove the 7 screws (2).

3.

Remove the Back Cabinet in the direction of arrow.

(1)

(2)

(2)

(2)

(1)

(2)

(2)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Back Cabinet

(1)

(2)

(1)

(1)

(2)

(1)

NOTE

Before your operation, please read "PREPARATION

1.

OF SERVICING".

Use the Lead Free solder.

2.

Manual soldering conditions

3.

• Soldering temperature: 320 ± 20

o

C

• Soldering time: Within 3 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

When Soldering/Removing of solder, use the drawing

4.

equipment over the Pick Up Unit to keep the Flux

smoke away from it.

When installing the DVD Deck, remove all the soldering

5.

on the short circuit position after the connection of Pick

Up PCB and DVD MT PCB connector.

(2)

(2)

(6)

(3)

(5)

(C)

(4)

(D)

(1)

(5)

(B)

Angle DVD-1

(4)

(A)

DVD Deck

Pick Up PCB

Short circuit using

a soldering iron.

DVD MT PCB

Angle MPEG

(6)

(6)

(E)

Heat Sink

(6)

Fig. 1-1

1-2: DVD MT PCB/DVD DECK (Refer to Fig. 1-2)

1.

Short circuit the position shown in Fig. 1-2 using a

soldering iron. If you remove the DVD Deck with no

soldering, the Laser may be damaged.

2.

Disconnect the following connectors:

(CP403 and CP4301).

3.

Remove the screw (1).

4.

Remove the DVD Deck in the direction of arrow (A).

5.

Remove the 2 screws (2).

6.

Remove the screw (3).

7.

Remove the Angle DVD-1 in the direction of arrow (B).

8.

Remove the 2 screws (4).

9.

Remove the Heat Sink in the direction of arrow (C).

10.

Remove the 2 screws (5).

11.

Remove the Angle MPEG in the direction of arrow (D).

12.

Disconnect the following connectors:

(CP2301, CP2302 and CP2303).

13.

Remove the 4 screws (6).

14.

Remove the DVD MT PCB in the direction of arrow (E).

Fig. 1-2

OPERATION PCB/OPERATION2 PCB and

1-3:

ANGLE HINGE (Refer to Fig. 1-3)

1.

Disconnect the following connector: (CP6202).

2.

Remove the Plate Button Ass'y in the direction of

arrow (A).

3.

Remove the 6 screws (1).

4.

Remove the Operation PCB and Operation 2 PCB in the

direction of arrow (B).

5.

Remove the 2 screws (2).

6.

Remove the 5 screws (3).

7.

Remove the Angle Hinge in the direction of arrow (C).

(1)

Operation 2 PCB

(B)

Plate Button Ass'y

(A)

(1)

(1)

Operation PCB

(C)

(A)

(1)

(3)

(1)

(3)

(1)

(3)

(2)

(2)

(3)

(3)

B1-1

Angle Hinge

Fig. 1-3

Page 17

DISASSEMBLY INSTRUCTIONS

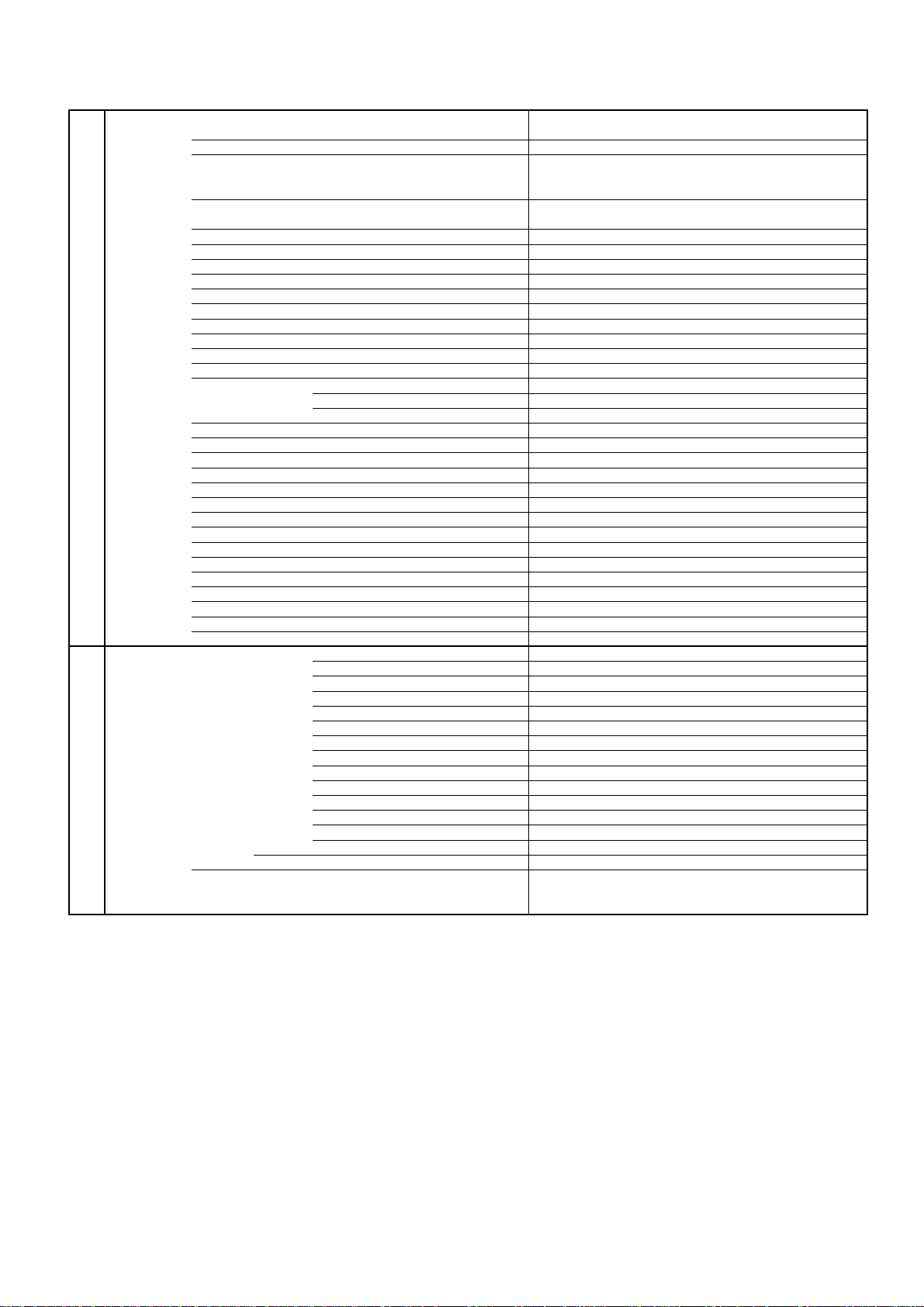

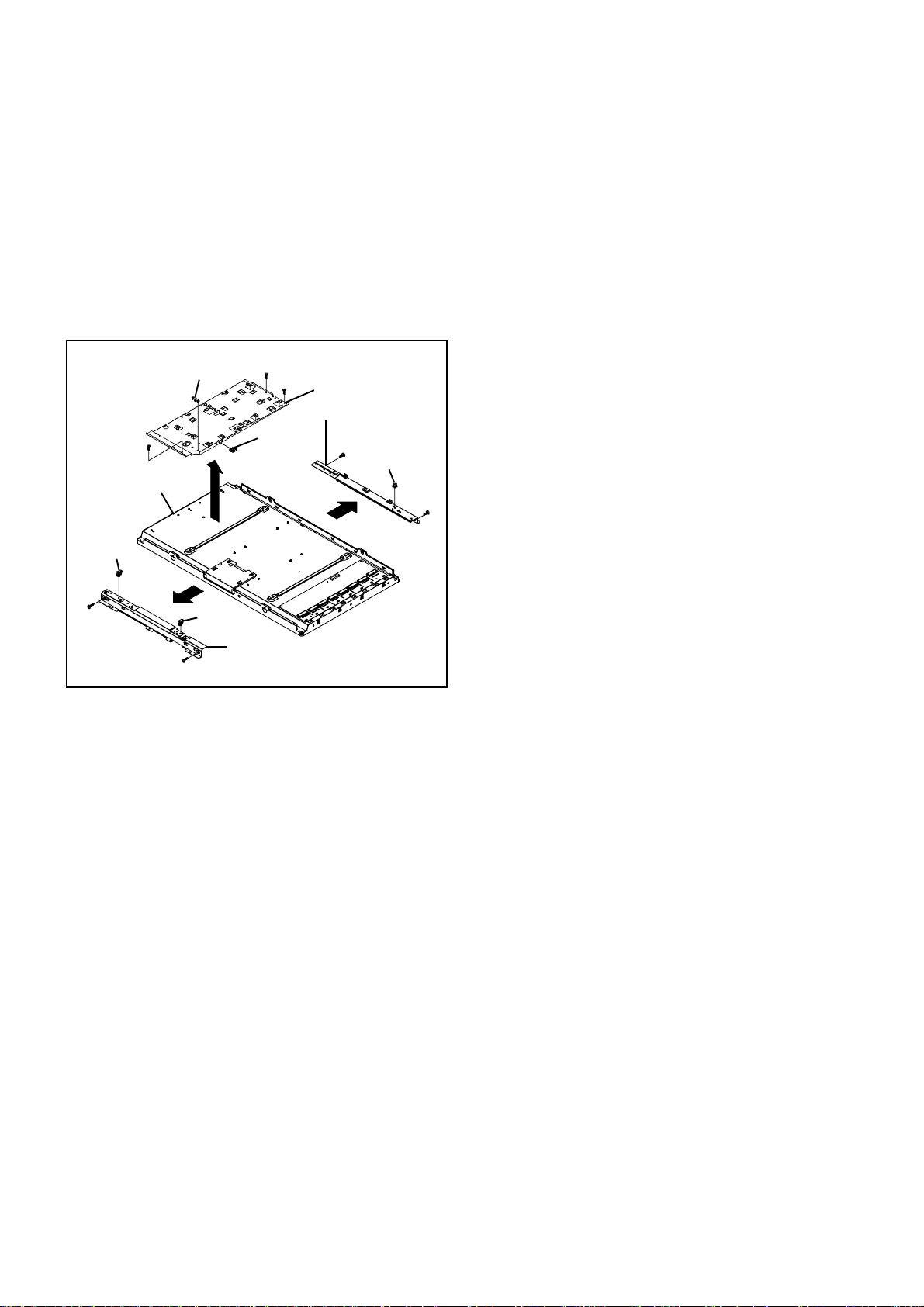

1-4: REMOCON PCB (Refer to Fig. 1-4)

1.

Disconnect the following connector:

(CP4201).

2.

Remove the 2 screws (1).

3.

Remove the Remocon PCB in the direction of arrow.

(1)

(1)

Remocon PCB

1-5: LCD BLOCK (Refer to Fig. 1-5)

1.

Remove the Holder Panel-1 and Holder Panel-2.

2.

Remove the 4 screws (1).

3.

Remove the LCD Block in the direction of arrow.

4.

Remove the 2 screws (2).

5.

Remove the Angle Main.

Angle Main

(2)

(2)

Angle Main

(1)

(1)

(1)

LCD Block

Holder Panel-2

Holder Panel-1

(1)

Fig. 1-4

(5)

(A)

(B)

(5)

(5)

(5)

(5)

(5)

Shield Digital

Digital PCB

(4)

Plate Jack

(2)

(3)

(2)

(1)

1-7: POWER PCB (Refer to Fig. 1-7)

1.

Disconnect the following connectors:

(CP302 and CP406).

2.

Remove the Holder Wire and Spring Earth.

3.

Remove the 6 screws (1).

4.

Remove the Power PCB in the direction of arrow (A).

5.

Remove the screw (2).

6.

Remove the Angle PCB-1 in the direction of arrow (B).

(1)

(1)

Power PCB

Holder Wire

Holder Wire

(1)

(1)

(A)

(1)

(1)

(2)

Spring Earth

Angle PCB-1

(B)

Fig. 1-6

Holder Panel-2

1-6: DIGITAL PCB (Refer to Fig. 1-6)

1.

Disconnect the following connectors:

(CP2804, CP3001 and CP4302).

2.

Remove the screw (1).

3.

Remove the 5 screws (2).

4.

Remove the 2 screws (3).

5.

Remove the screw (4).

6.

Remove the Plate Jack in the direction of arrow (A).

7.

Remove the 6 screws (5).

8.

Remove the Digital PCB and Shield Digital in the

direction of arrow (B).

Fig. 1-7

Fig. 1-5

B1-2

Page 18

DISASSEMBLY INSTRUCTIONS

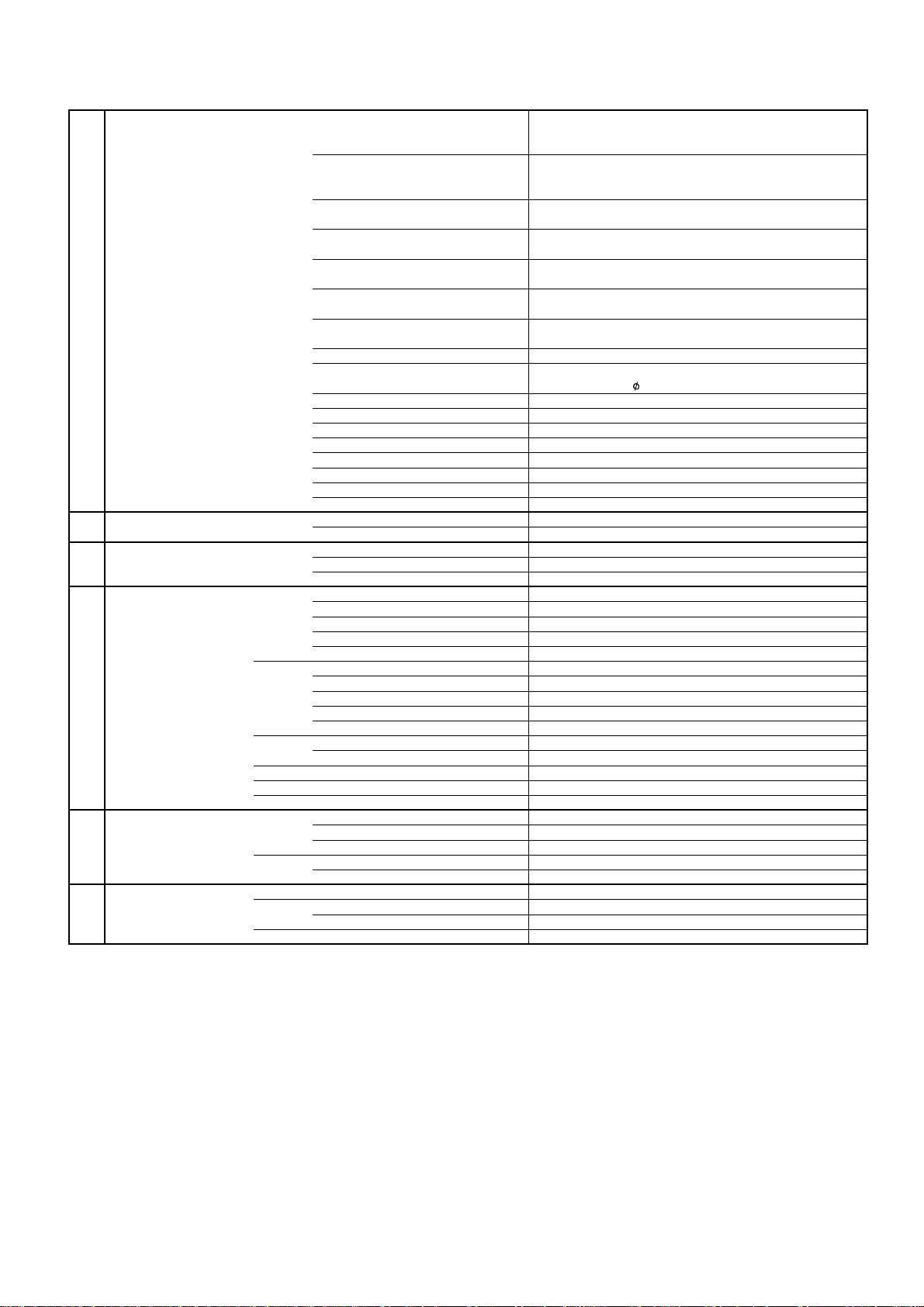

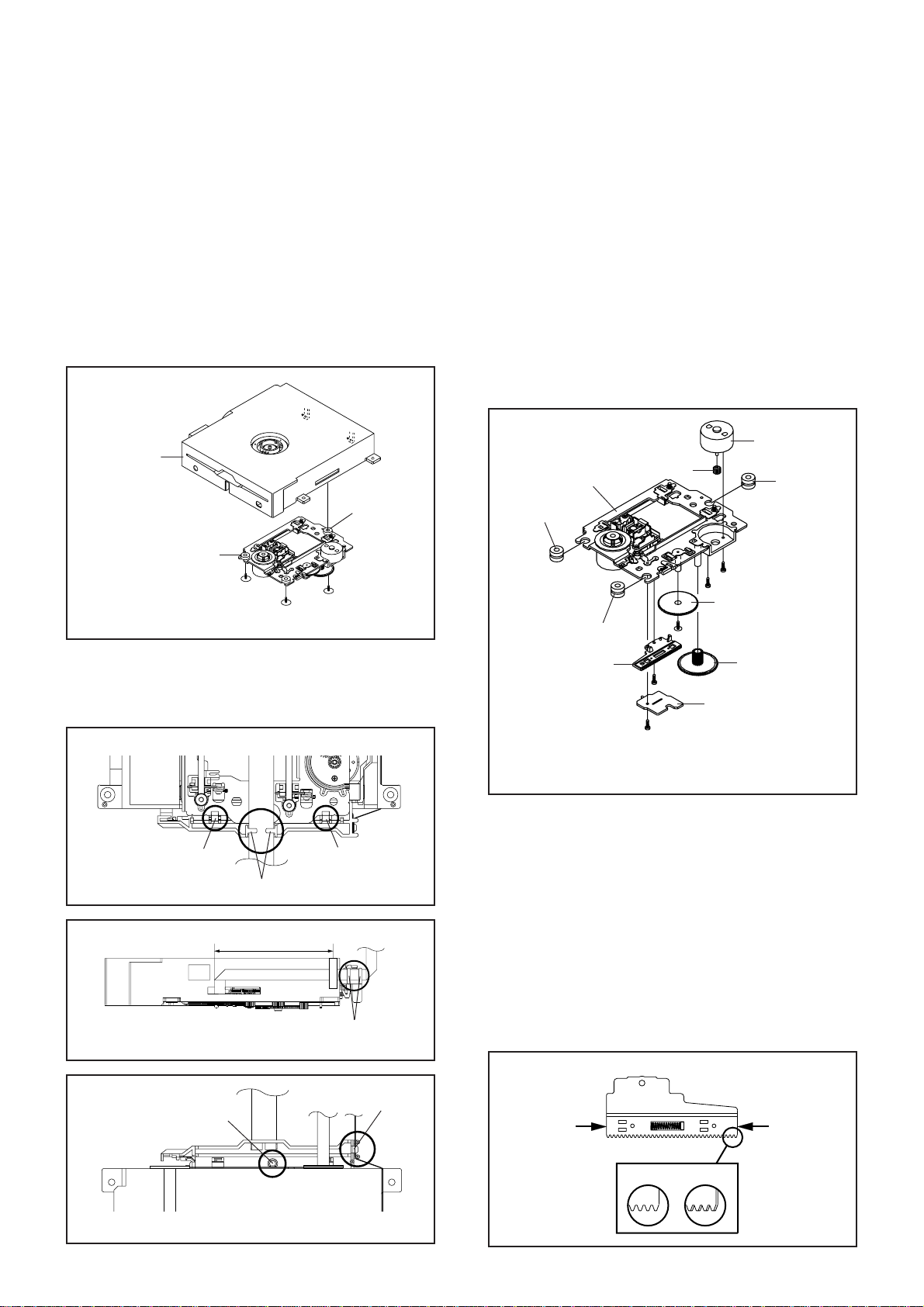

1-8: ANGLE LCD TOP/ANGLE LCD BOTTOM AND

ANGLE PCB-2 ASS'Y (Refer to Fig. 1-8)

1.

Remove the 3 screws (1).

2.

Remove the Angle Pcb-2 Ass'y and Holder Wire in the

direction of arrow (A).

3.

Remove the 2 screws (2).

4.

Remove the Angle Lcd Bottom and Holder Wire in the

direction of arrow (B).

5.

Remove the 2 screws (3).

6.

Remove the Angle Lcd Top and Holder Wire in the

direction of arrow (C).

Holder Wire

(3)

(1)

LCD Panel

Holder Wire

(C)

(3)

(A)

Holder Wire

Angle Lcd Top

(1)

(1)

Angle Lcd Bottom

Holder Wire

Angle Pcb-2 Ass'y

(2)

Holder Wire

(B)

(2)

Fig. 1-8

B1-3

Page 19

DISASSEMBLY INSTRUCTIONS

2. REMOVAL OF DVD DECK PARTS

NOTE

1. Disassemble only the DVD DECK PARTS parts listed

here. Minute adjustments are needed if the

disassembly is done. If the repair is needed except

listed parts, replace the DVD MECHA ASS'Y.

2-1: TRAVERSE ASS'Y (Refer to Fig. 2-1-A)

Remove the 3 screws (1).

1.

Unlock the 2 supports (2).

2.

Remove the Insulator (R) from the Loader Sub Ass'y.

3.

Remove the Traverse Ass'y.

4.

(2)

Loader Sub Ass'y

(2)

2-2:

SWITCH PCB ASS'Y/GEAR MIDDLE/GEAR FEED/RACK

FEED ASS'Y/FEED MOTOR (Refer to Fig. 2-2-A)

Remove the Insulator (F).

1.

Remove the Insulator (R).

2.

Unlock the support (1).

3.

Remove the Gear Middle.

4.

Remove the screw (2).

5.

Remove the Rack Feed Ass'y.

6.

Remove the screw (3).

7.

Remove the Switch PCB Ass'y.

8.

Remove the screw (4).

9.

Remove the Gear Feed.

10.

Remove the 2 screws (5).

11.

Remove the Feed Motor.

12.

Remove the Gear Motor.

13.

Feed Motor

Traverse Ass'y

Gear Motor

Insulator (R)

Insulator (R)

Traverse Ass'y

(1)

• Screw Torque: 2.0 ± 0.3kgf•cm

(1)

(1)

Fig. 2-1-A

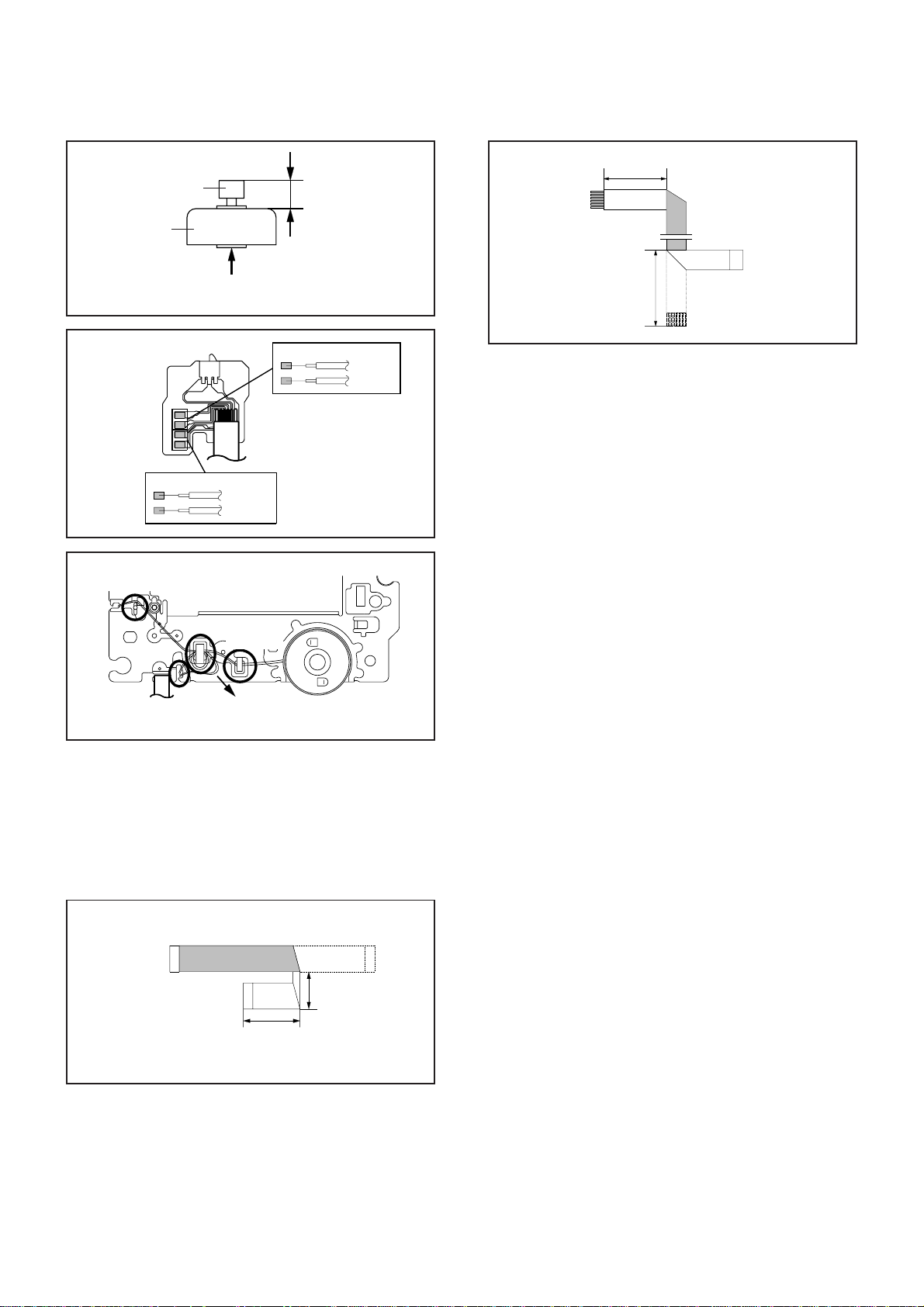

NOTE

1. In case of the Traverse Ass'y installation, hook the wire

on the Loader Ass'y as shown Fig. 2-1-B to Fig. 2-1-D.

Loader Ass'y (Bottom Side)

Check Lock Check Lock

Check Hook

80 ± 5mm

Loader Ass'y

Fig. 2-1-B

Check Hook

Fig. 2-1-C

Insulator (F)

(1)

Insulator (F)

Rack Feed Ass'y

(2)

(3)

• Screw Torque: 1.3 ± 0.3kgf•cm (Screw (2))

• Screw Torque: 3.0 ± 0.3kgf•cm (Screw (3))

• Screw Torque: 1.0 ± 0.3kgf•cm (Screw (4), (5))

(5)

(5)

Gear Feed

(4)

Gear Middle

Switch PCB Ass'y

Fig. 2-2-A

NOTE

1.

When installing the Rack Feed Ass'y, push both ends to

align the teeth as shown Fig. 2-2-B. Then install it.

2.

In case of the Gear Motor installation, check if the value

of the Fig. 2-2-C is correct.

3.

When installing the wire of the Switch PCB Ass'y, install

it correctly as Fig. 2-2-D.

Manual soldering conditions

• Soldering temperature: 320 ± 20

o

C

• Soldering time: Within 3 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

After the assembly of the Traverse Ass'y, hook the wire

4.

on the Traverse Ass'y as shown Fig. 2-2-E.

Rack Feed Ass'y

Check Hook

Loader Ass'y (Top Side)

Check Hook

Fig. 2-1-D

B2-1

Push

Push

[OK] [NG]

Fig. 2-2-B

Page 20

DISASSEMBLY INSTRUCTIONS

Feed Motor

Check Hook

Gear Motor

Safety surface for pressing

of the insert.

Switch PCB Ass'y

~ SPINDLE MOTOR ~

YELLOW (2)

GREEN (1)

Traverse Ass'y

8.0 ± 0.2mm

Fig. 2-2-C

~ FEED MOTOR ~

WHITE (4)

BROWN (3)

• Install wire from (1) to (4) in order.

Fig. 2-2-D

[ 6 pin FFC ]

40 ± 1mm

Fold

Fold

60 ± 1mm

Fig. 2-3-B

Check Hook

Check Hook

Check Hook

• Loosen the wire in the direction of the arrow.

Fig. 2-2-E

2-3: FFC WIRE HANDLING

1.

When installing the FFC, fold it correctly and install it as

shown from Fig. 2-3-A to Fig. 2-3-B.

NOTE

Do not make the folding lines except the specified

1.

positions for the FFC.

[ 24 pin FFC ]

o

20 ± 1mm

To Pick Up PCB

Fold it by 90

Printing Surface

30 ± 1mm

Fig. 2-3-A

B2-2

Page 21

DISASSEMBLY INSTRUCTIONS

3.

REMOVAL AND INSTALLATION OF

FLAT PACKAGE IC

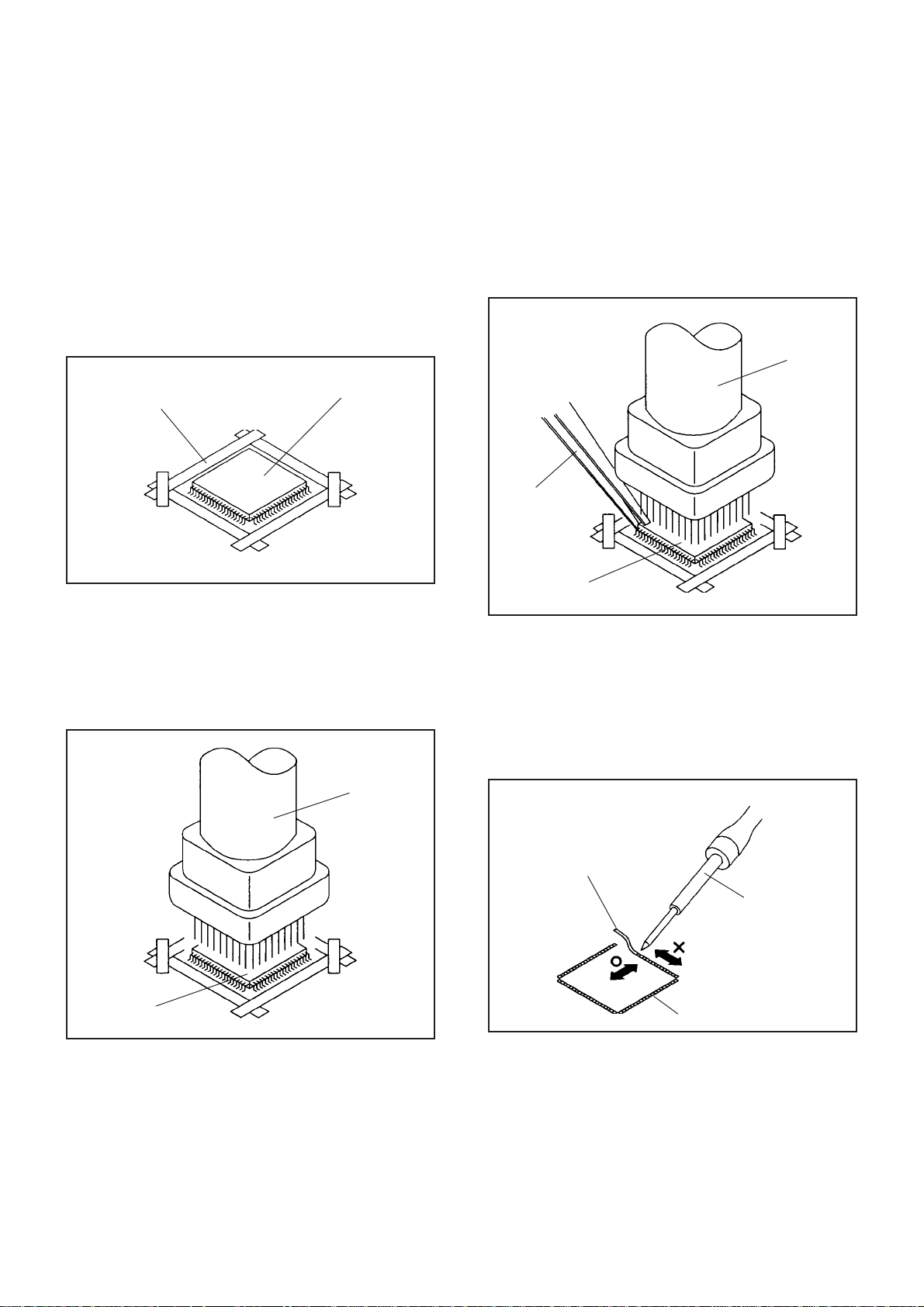

REMOVAL

Put Masking Tape (cotton tape) around the Flat Package

1.

IC to protect other parts from any damage.

(Refer to Fig. 3-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

When IC starts moving back and forth easily after

3.

desoldering completely, pickup the corner of the IC using

tweezers and remove the IC by moving with the IC

desoldering machine. (Refer to Fig. 3-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering

machine

Masking Tape

(Cotton Tape)

Heat the IC leads using a blower type IC desoldering

2.

IC

machine. (Refer to Fig. 3-2.)

NOTE

Do not rotate or move the IC back and forth , until IC

can move back and forth easily after desoldering the

leads completely.

Blower type IC

desoldering machine

Fig. 3-1

Tweezers

IC

Peel off the Masking Tape.4.

Absorb the solder left on the pattern using the Braided

5.

Shield Wire. (Refer to Fig. 3-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 3-3

Braided Shield Wire

Soldering Iron

IC

Fig. 3-2

IC pattern

Fig. 3-4

B3-1

Page 22

DISASSEMBLY INSTRUCTIONS

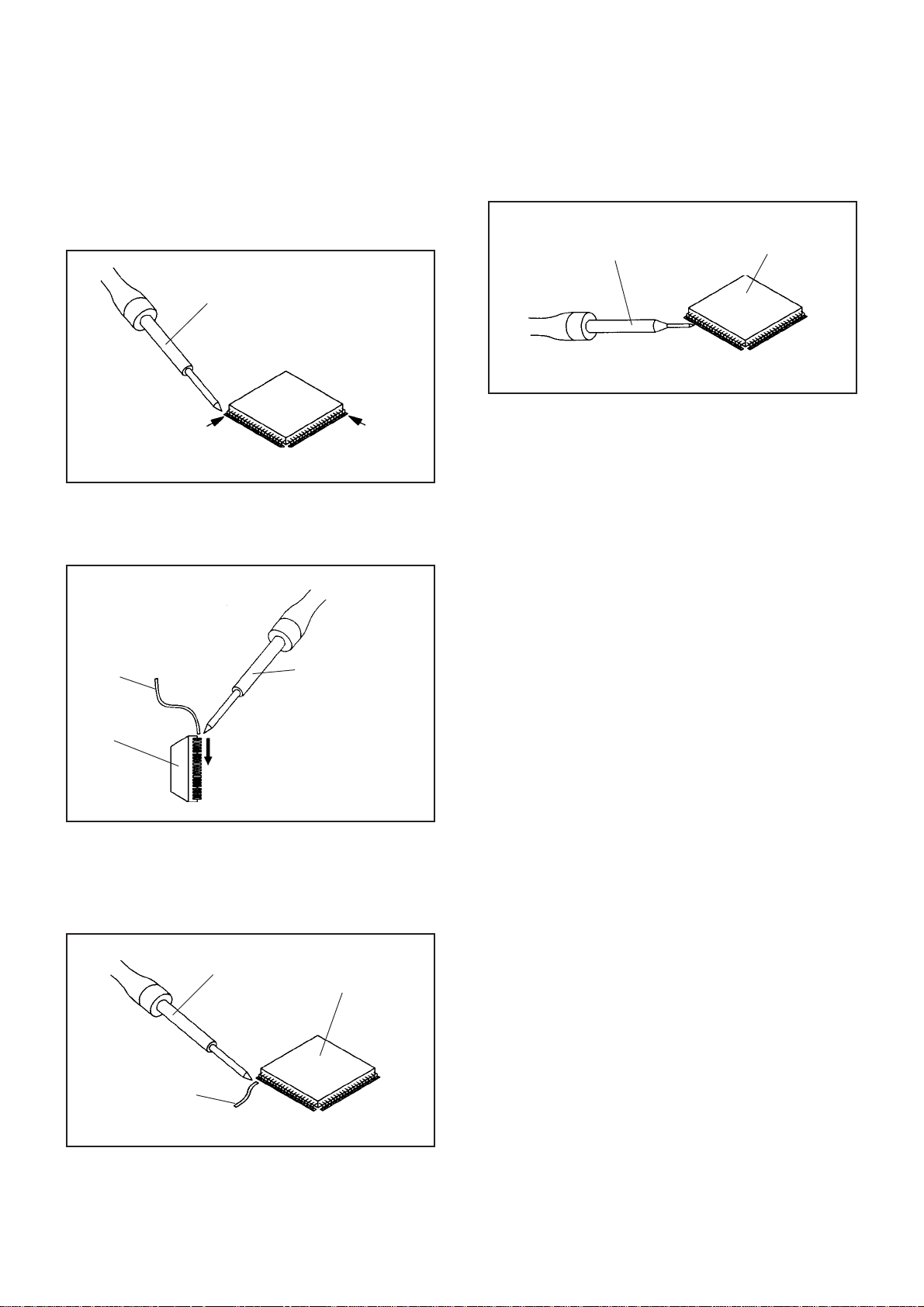

INSTALLATION

Take care of the polarity of new IC and then install the

1.

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 3-5.)

Soldering Iron

Solder temporarily

Supply the solder from the upper position of IC leads

2.

Solder temporarily

sliding to the lower position of the IC leads.

(Refer to Fig. 3-6.)

Fig. 3-5

When bridge-soldering between terminals and/or the

4.

soldering amount are not enough, resolder using a Thintip Soldering Iron. (Refer to Fig. 3-8.)

Thin-tip Soldering Iron

IC

Fig. 3-8

Finally, confirm the soldering status on four sides of the

5.

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

damaged. So, always be sure to replace the IC in this

case.

Soldering IronSolder

IC

Absorb the solder left on the lead using the Braided

3.

Supply soldering

from upper position

to lower position

Shield Wire. (Refer to Fig. 3-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 3-6

Fig. 3-7

B3-2

Page 23

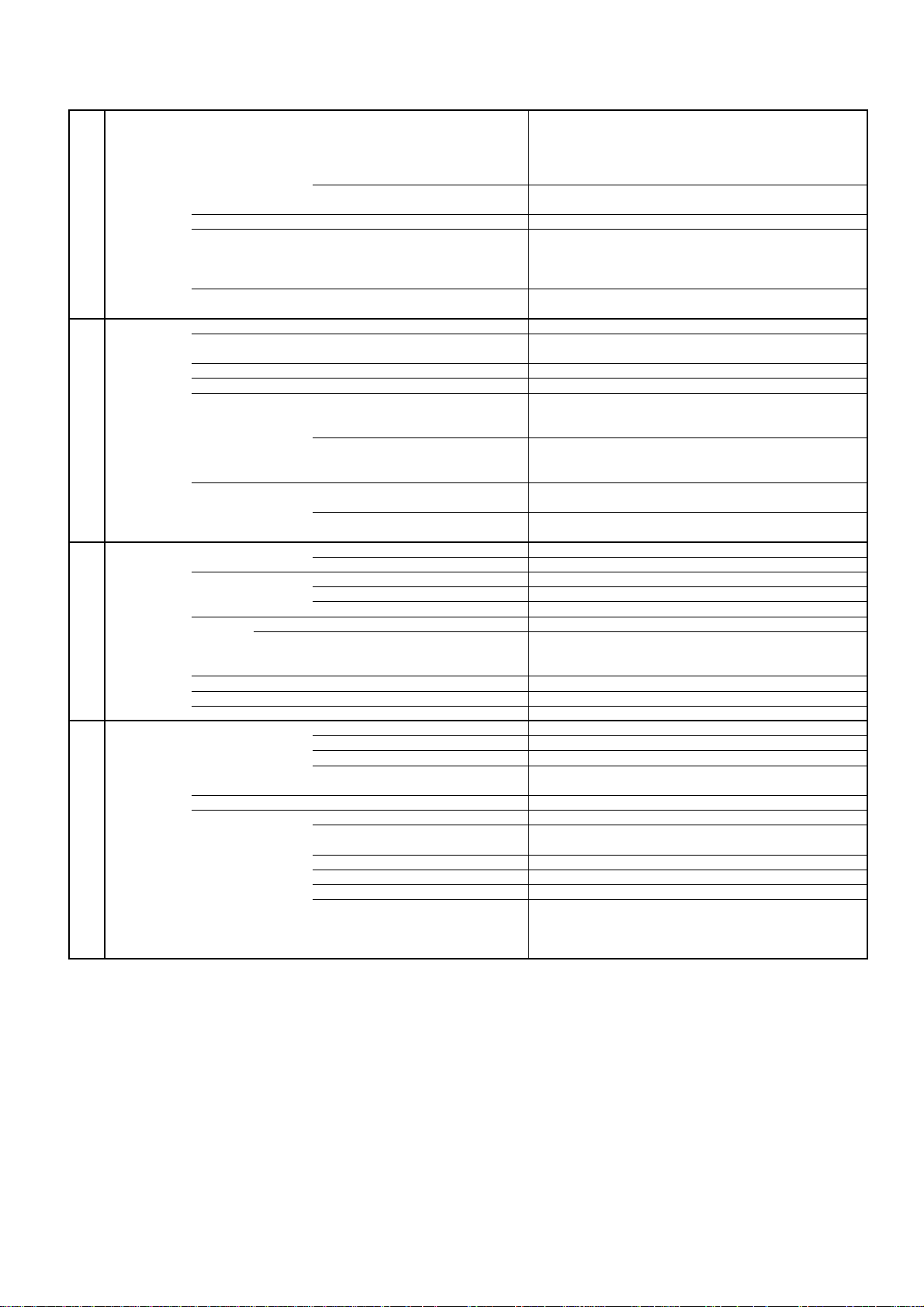

SERVICE MODE LIST

This unit is provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter to the SERVICE MODE function, press and hold both buttons simultaneously on the main unit and on the remote

control for more than a the standard time in the appropriate condition. (See below chart.)

Set

Condition

TV mode

TV mode

DVD mode

(No disc)

DVD mode

(No disc)

ALL mode

ALL mode

ALL mode

Set Key Operations

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

Remocon

Key

0 2 sec.

1 2 sec.

4 2 sec.

5 2 sec.

6 2 sec.

8

9 2 sec.

Standard

Time

2 sec.

Releasing of V-CHIP PASSWORD.

Initialization of factory TV data.

NOTE:

D VD Write mode.

Refer to the "RE-WRITE FOR DVD FIRMWARE".

POWER ON total hours are displayed on the screen.

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Check of the SUM DATA and MICON VERSION on the screen.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display

Adjustment).

If you set factory initialization, the memories are reset such

as the channel setting, and the POWER ON total hours.

Initialization of factory DVD data.

DVD mode

(No disc)

DVD mode

(No disc)

STOP 1 2 sec.

STOP 7 2 sec.

Check of the firmware version.

DVD

Refer to the "RE-WRITE FOR DVD FIRMWARE".

Releasing of PARENTAL LOCK.

Refer to the "PARENTAL CONTROL - RATING LEVEL".

C-1

Page 24

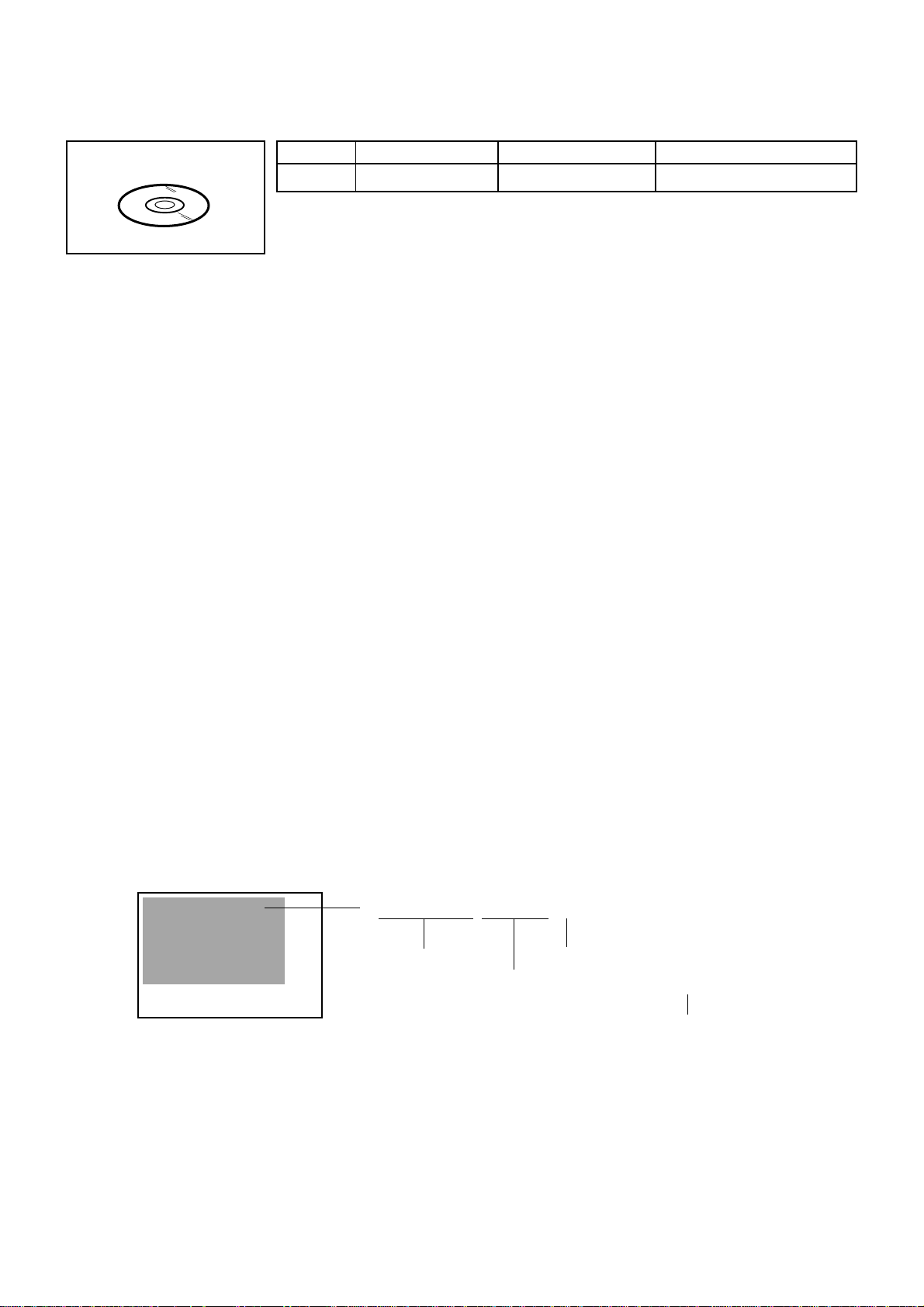

SERVICING FIXTURES AND TOOLS

JG176 Up-Date Disc

Ref. No.

JG176

Part No.

APJG176140

Parts Name

Up-Date Disc

Up-Date of the Firmware

Remarks

RE-WRITE FOR DVD FIRMWARE

Turn on the power, and set the DVD mode.

1.

Confirm that the "No Disc" will be appeared on the screen.

2.

Press both VOL. DOWN button on the set and Channel button (5) on the remote control for more than 2 seconds.

3.

Press VOL. UP/DOWN button on the unit to check if all the keys on the unit do not function.

4.

NOTE: To check if DVD Write mode is set.

When inserting Up-Date Disc at Non DVD Write mode, the read error will happen.

Insert the Up-Date Disc. (Refer to SERVICING FIXTURE AND TOOLS)

5.

Automatic read will start and "Firmware upgrade Please Wait" will be displayed on the screen.

6.

At this time, the horizontal noise lines may appear. But no problem.

NOTE: Do not turn off the unit on the way or operate the keys on the unit and remocon.

Up-Date error will happen and can not be done with the Up-Date of Up-Date Disc.

After the Up-Date, Logo screen will appear.

7.

Unplug the AC cord, then plug it in.

8.

After the write, set to the initializing of shipping.

Turn on the power, and set the DVD mode.

9.

Press both VOL. DOWN button on the set and Channel button (4) on the remote control for more than 2 seconds.

10.

The "INITIALIZE 5 ---> COMPLETE" will appear on the screen.

Then unplug the AC cord, and plug it in.

11.

CHECK FOR THE FIRMWARE VERSION

Turn on the power, and set the DVD mode.

12.

Press both Channel button (1) on the remote control and the STOP button on the set for more than 2 seconds.

13.

Firmware version will be displayed on the top left of the screen.

Turn off the power

14.

F/W V er . ADLLA8415A

Initialize: Complete

Laser drive time

DVD LD: 0Hour

CD LD : 0Hour

When the changed version displays, the Re-write will be completed.

A D L L A 8 4 1 5 A

Fixed

Release date (Example: 2008.04.15)

Released times on the same date

A = October

B = November

C = December

C-2

Page 25

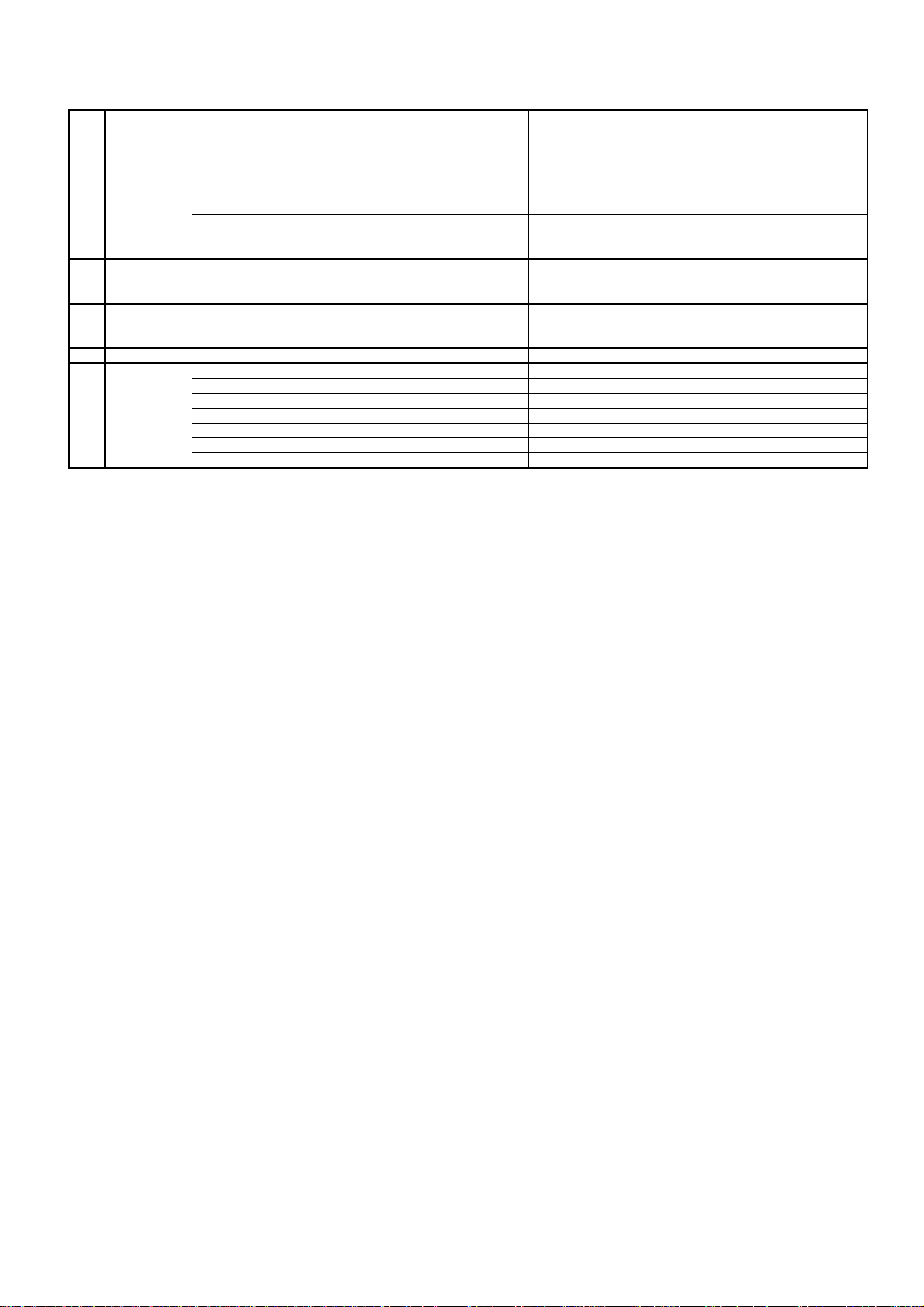

WHEN REPLACING EEPROM (MEMORY) IC

CONFIRMATION OF CHECK SUM, POWER ON TOTAL HOURS AND MICON VERSION

Initial total of MEMORY IC, POWER ON total hours and MICON VERSIONcan be checked on the screen. Total hours are

displayed in 16 system of notation.

NOTE:

1.

2.

3.

4.

NOTE:

If you set a factory initialization, the total hours is reset to "0".

Please refer to "CONFIRMATION OF INITIAL DATA" when SUM DATA is not corresponding.

Turn on the POWER, and set to the ALL mode.

Set the VOLUME to minimum.

Press both VOL. DOWN button on the set and Channel button (8) on the remote control for more than 2 seconds.

After the confirmation of each check sum, turn off the power.

The each item value might be different according to each set.

Sub Micon check version

Main Micon check version

EEPROM check version

Parameter

CHECK SUM: 3D05

LCD PWR ON: 0000

SUB: DA0E783212

DTV: CA12E86111

EEPROM: W50X02PM00

Picture: _dispSmartPic

Initial setting data check sum.

POWER ON total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

FIG. 1

CONFIRMATION OF INITIAL DATA

If a service repair is under taken where it has been required to change the MEMORY IC, the following steps should be taken

to ensure correct data settings while making reference to INITIAL SETTING TABLE (Attached "INITIAL DATA").

Turn on the POWER, and set to the ALL mode.

1.

Set the VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 2 seconds.

3.

ADDRESS and DATA should appear as FIG 2.

NOTE: No need to set data other position than 7200~73FF.

ADDRESS DATA

INIT : 0001 008A

SUB: DA0E783212

DTV: CA12E86111

EEPROM: W50X02PM00

FIG. 2

ADDRESS is now selected and should "blink". Using the UP/DOWN buton on the remote, step through the ADDRESS

4.

until required ADDRESS to be changed is reached.

Press LEFT/RIGHT button to select DATA. When DATA is selected, it will "blink".

5.

Again, step through the DATA using UP/DOWN button until required DATA value has been selected.

6.

Pressing LEFT/RIGHT button will take you back to ADDRESS for further selection if necessary.

7.

Repeat steps 4 to 6 until all data has been checked.

8.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

After the data input, set to the initializing of shipping.

Turn on the Power.

9.

Set the VOLUME to minimum.

10.

Press both VOL. DOWN button on the set and Channel button (1) on the remote control for more than 2 seconds.

11.

After the finishing of the initializing of shipping, the unit will turn off automatically.

12.

The unit will now have the correct DATA for the new MEMORY IC.

C-3

Page 26

ELECTRICAL ADJUSTMENTS

1. ADJUSTMENT PROCEDURE

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

•

Use an isolation transformer when performing any

service on this chassis.

•

When removing a PCB or related component, after

unfastening or changing a wire, be sure to put the wire

back in its original position.

•

When you exchange IC and Transistor with a heat sink,

apply silicon grease on the contact section of the heat

sink. Before applying new silicon grease, remove all the

old silicon grease. (Old grease may cause damages to

the IC and Transistor).

Prepare the following measurement tools for electrical

adjustments.

1. Pattern Generator

On-Screen Display Adjustment

1.2.Set the VOLUME to minimum.

Press the VOL. DOWN button on the set and the

channel button (9) on the remote control for more than

2 seconds to display adjustment mode on the screen as

shown in Fig. 1-1.

TV

S.Strech

480i

Function

3.

Use the CH. UP/DOWN button or Channel button (0-9)

03 R DRIVE (N)

8

on the remote control to select the options shown in

Fig. 1-2.

4.

Press the SETUP/TV MENU button on the remote control

to end the adjustments.

5.

To display the adjustment screen for TV, AV,

COMPONENT, HDMI and PC mode, press the INPUT

button on the remote control.

6.

To display the adjustment screen for DVD mode, press

the TV/DVD button on the remote control.

7.

Receive the DIGITAL broadcasting.

8.

To display the adjustment screen for DTV mode, select

the digital channel.

9.

Press the VOL.DOWN button on the set and the channel

(9) on the remote control for more than 2 seconds.

Step No.

Fig. 1-1

NO.

FUNCTION

NO.

R DRIVE(N)

03

R CUTOFF(N)

04

G DRIVE(N)

05

G CUTOFF(N)

06

B DRIVE(N)

07

B CUTOFF(N)

08

R DRIVE(C)

09

R CUTOFF(C)

10

G DRIVE(C)

11

G CUTOFF(C)

12

B DRIVE(C)

13

B CUTOFF(C)

14

R DRIVE(W)

15

R CUTOFF(W)

16

G DRIVE(W)

17

G CUTOFF(W)

18

B DRIVE(W)

19

B CUTOFF(W)

20

BAK LIGHT CENT

29

BAK LIGHT MAX

30

FUNCTION

31

BAK LIGHT MIN

32

BRIGHTNESS CENT

33

BRIGHTNESS MAX

34

BRIGHTNESS MIN

35

TINT

36

SHARP H1 MAX

37

SHARP H1 MIN

38

SHARP H2 MAX

39

SHARP H2 MIN

40

SHARP V1 MAX

41

SHARP V1 MIN

42

CONTRAST CENTER

43

CONTRAST MAX

44

CONTRAST MIN

45

COLOR CENTER

46

COLOR MAX

47

COLOR MIN

50

CONTRAST 40

Fig. 1-2

2. BASIC ADJUSTMENTS

2-1: WHITE BALANCE

1.

Place the set in Aging Test for more than 15 minutes.

2.

Receive the gray scale pattern from the Pattern

Generator.

3.

Press the INPUT button on the remote control to set to

the AV mode.

4.

Using the remote control, set the brightness and

contrast to normal position.

5.

Activate the adjustment mode display of Fig. 1-2 and

press the channel button (03) on the remote control to

select "R DRIVE(N)".

6.

Press the CH. UP/DOWN button on the remote control

to select the "R DRIVE (N)", "R CUTOFF (N)",

"B DRIVE (N)", "B CUTOFF (N)", "R DRIVE (C)",

"R CUTOFF (C)", "B DRIVE (C)", "B CUTOFF (C)",

"R DRIVE (W)","R CUTOFF (W), "B DRIVE (W)" or

"B CUTOFF(W)".

7.

Adjust the LEFT/RIGHT button on the remote control

to whiten the R DRIVE (N), R CUTOFF (N),

B DRIVE (N), B CUTOFF (N), R DRIVE (C),

R CUTOFF (C), B DRIVE (C), B CUTOFF (C),

R DRIVE (W) ,R CUTOFF (W), B DRIVE (W) and

B CUTOFF(W) at each step tone sections equally.

8.

Perform the above adjustments 6 and 7 until the white

color is achieved.

D-1

Page 27

ELECTRICAL ADJUSTMENTS

1.

Receive the monoscope pattern. (RF Input)

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (32) on the remote control to

select "BRIGHTNESS CENT".

4.

Press the LEFT/RIGHT button on the remote control until

the brightness cent step No. becomes "115".

5.

Check if the picture is normal.

6.

Receive the monoscope pattern. (VIDEO Input)

7.

Press the INPUT button on the remote control to set to

the AV mode.

8.

Using the remote control, set the brightness and contrast

to normal position.

9.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (32) on the remote control to

select "BRIGHTNESS CENT".

10.

Press the LEFT/RIGHT button on the remote control until

the brightness cent step No. becomes "113".

11.

Check if the picture is normal.

12.

Receive the monoscope pattern. (S-VIDEO Input)

13.

Press the INPUT button on the remote control to set to

the AV(Y/C) mode. Then perform the above adjustments

8~11.

14.

Playback the DVD(480i) disc. (COMPONENT Input)

15.

Press the INPUT button on the remote control to set to

the COMPONENT mode.

16.

Using the remote control, set the brightness and contrast

to normal position.

17.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (32) on the remote control to

select "BRIGHTNESS CENT".

18.

Press the LEFT/RIGHT button on the remote control

until the brightness cent step No. becomes "117".

19.

Check if the picture is normal.

20.

Playback the DVD(480i) disc. (HDMI Input)

21.

Press the INPUT button on the remote control to set to

the HDMI mode.

22.

Using the remote control, set the brightness and contrast

to normal position.

23.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (32) on the remote control to

select "BRIGHTNESS CENT".

24.

Press the LEFT/RIGHT button on the remote control until

the brightness cent step No. becomes "129".

25.

Check if the picture is normal.

26.

Playback the DVD disc. (DVD Input)

27.

Press the TV/DVD button on the remote control to set to

the DVD mode.

28.

Using the remote control, set the brightness and contrast

to normal position.

29.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (32) on the remote control to

select "BRIGHTNESS CENT".

30.

Press the LEFT/RIGHT button on the remote control until

the brightness cent step No. becomes "113".

31.

Check if the picture is normal.

2-3: CONTRAST MAX2-2: BRIGHT CENT

1.

Receive the monoscope pattern. (RF Input)

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (43) on the remote control to

select "CONTRAST MAX".

4.

Press the LEFT/RIGHT button on the remote control until

the contrast max step No. becomes "146".

5.

Check if the picture is normal.

6.

Receive the monoscope pattern. (VIDEO Input)

7.

Press the INPUT button on the remote control to set to

the AV mode.

8.

Using the remote control, set the brightness and contrast

to normal position.

9.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (43) on the remote control to

select "CONTRAST MAX".

10.

Press the LEFT/RIGHT button on the remote control until

the contrast max step No. becomes "162".

11.

Check if the picture is normal.

12.

Receive the monoscope pattern. (S-VIDEO Input)

13.

Press the INPUT button on the remote control to set to

the AV(Y/C) mode. Then perform the above adjustments

8~11.

14.

Playback the DVD(480i) disc. (COMPONENT Input)

15.

Press the INPUT button on the remote control to set to

the COMPONENT mode.

16.

Using the remote control, set the brightness and contrast

to normal position.

17.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (43) on the remote control to

select "CONTRAST MAX".

18.

Press the LEFT/RIGHT button on the remote control

until the contrast max step No. becomes "134".

19.

Check if the picture is normal.

20.

Playback the DVD(480i) disc. (HDMI Input)

21.

Press the INPUT button on the remote control to set to

the HDMI mode.

22.

Using the remote control, set the brightness and contrast

to normal position.

23.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (43) on the remote control to

select "CONTRAST MAX".

24.

Press the LEFT/RIGHT button on the remote control until

the contrast max step No. becomes "130".

25.

Check if the picture is normal.

26.

Playback the DVD disc. (DVD Input)

27.

Press the TV/DVD button on the remote control to set to

the DVD mode.

28.

Using the remote control, set the brightness and contrast

to normal position.

29.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (43) on the remote control to

select "CONTRAST MAX".

30.

Press the LEFT/RIGHT button on the remote control until

the contrast max step No. becomes "174".

31.

Check if the picture is normal.

D-2

Page 28

ELECTRICAL ADJUSTMENTS

2-4: CONTRAST CENTER 2-5: CONTRAST 40

1.

Receive the monoscope pattern. (RF Input)

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (42) on the remote control to

select "CONTRAST CENTER".

4.

Press the LEFT/RIGHT button on the remote control until

the contrast cent step No. becomes "107".

5.

Check if the picture is normal.

6.

Receive the monoscope pattern. (VIDEO Input)

7.

Press the INPUT button on the remote control to set to

the AV mode.

8.

Using the remote control, set the brightness and contrast

to normal position.

9.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (42) on the remote control to

select "CONTRAST CENTER".

10.

Press the LEFT/RIGHT button on the remote control until

the contrast cent step No. becomes "117".

11.

Check if the picture is normal.

12.

Receive the monoscope pattern. (S-VIDEO Input)

13.

Press the INPUT button on the remote control to set to

the AV(Y/C) mode. Then perform the above adjustments

8~11.

14.

Playback the DVD(480i) disc. (COMPONENT Input)

15.

Press the INPUT button on the remote control to set to

the COMPONENT mode.

16.

Using the remote control, set the brightness and contrast

to normal position.

17.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (42) on the remote control to

select "CONTRAST CENTER".

18.

Press the LEFT/RIGHT button on the remote control

until the contrast cent step No. becomes "99".

19.

Check if the picture is normal.

20.

Playback the DVD(480i) disc. (HDMI Input)

21.

Press the INPUT button on the remote control to set to

the HDMI mode.

22.

Using the remote control, set the brightness and contrast

to normal position.

23.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (42) on the remote control to

select "CONTRAST CENTER".

24.

Press the LEFT/RIGHT button on the remote control until

the contrast cent step No. becomes "96".

25.

Check if the picture is normal.

26.

Playback the DVD disc. (DVD Input)

27.

Press the TV/DVD button on the remote control to set to

the DVD mode.

28.

Using the remote control, set the brightness and contrast

to normal position.

29.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (42) on the remote control to

select "CONTRAST CENTER".

30.

Press the LEFT/RIGHT button on the remote control until

the contrast cent step No. becomes "127".

31.

Check if the picture is normal.

1.

Receive the monoscope pattern. (RF Input)

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (50) on the remote control to

select "CONTRAST 40".

4.

Press the LEFT/RIGHT button on the remote control until

the contrast 40 step No. becomes "139".

5.

Check if the picture is normal.

6.

Receive the monoscope pattern. (VIDEO Input)

7.

Press the INPUT button on the remote control to set to

the AV mode.

8.

Using the remote control, set the brightness and contrast

to normal position.

9.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (50) on the remote control to

select "CONTRAST 40".

10.

Press the LEFT/RIGHT button on the remote control until

the contrast 40 step No. becomes "154".

11.

Check if the picture is normal.

12.

Receive the monoscope pattern. (S-VIDEO Input)

13.

Press the INPUT button on the remote control to set to

the AV(Y/C) mode. Then perform the above adjustments

8~11.

14.

Playback the DVD(480i) disc. (COMPONENT Input)

15.

Press the INPUT button on the remote control to set to

the COMPONENT mode.

16.

Using the remote control, set the brightness and contrast

to normal position.

17.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (50) on the remote control to

select "CONTRAST 40".

18.

Press the LEFT/RIGHT button on the remote control

until the contrast 40 step No. becomes "130".

19.

Check if the picture is normal.

20.

Playback the DVD(480i) disc. (HDMI Input)

21.

Press the INPUT button on the remote control to set to

the HDMI mode.

22.

Using the remote control, set the brightness and contrast

to normal position.

23.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (50) on the remote control to

select "CONTRAST 40".

24.

Press the LEFT/RIGHT button on the remote control until

the contrast 40 step No. becomes "124".

25.

Check if the picture is normal.

26.

Playback the DVD disc. (DVD Input)

27.

Press the TV/DVD button on the remote control to set to

the DVD mode.

28.

Using the remote control, set the brightness and contrast

to normal position.

29.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (50) on the remote control to

select "CONTRAST 40".

30.

Press the LEFT/RIGHT button on the remote control until

the contrast 40 step No. becomes "165".

31.

Check if the picture is normal.

D-3

Page 29

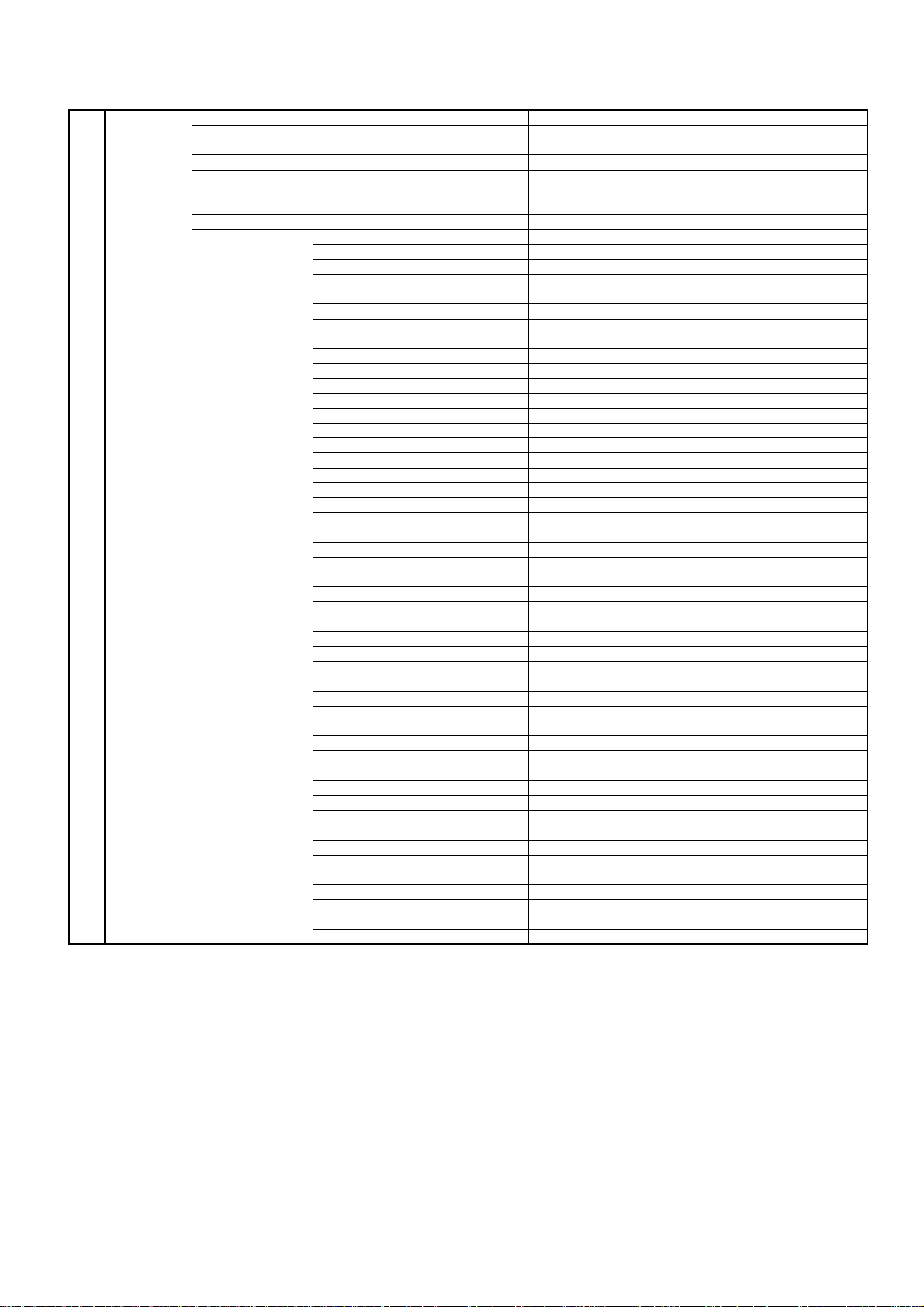

2-6: Confirmation of Fixed Value (Step No.)

Please check if the fixed values of each of the adjustment item is set correctly referring below. (TV/AV/COMPONENT/HDMI/DVD/PC/DTV)

Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No.

INVERSION

× × × × × × × × × × × × ×

× × × × × × ×

× × × ×

NOTE: For the step no. with * mark, please adjust it according to the situation of the set. For the step no. with x mark, no use.

ELECTRICAL ADJUSTMENTS

FUNCTIONNO.

1 H POSI OSD × × × × × × × × × × × × × × × × × × × × × × × ×

2 V POSI OSD × × × × × × × × × × × × × × × × × × × × × × × ×

3 R.DRIVE (N) * * * * * * * * * * * * * *

4 R CUTOFF (N) * * * * * * * * * * * * * *

5 G DRIVE (N) 0 0 0 0 0 0 0 0 0 0 0 0 0 0

6 G CUTOFF(N) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

7 B DRIVE (N) * * * * * * * * * * * * * *

8 B CUTOFF (N) * * * * * * * * * * * * * *

9 R.DRIVE (C) * * * * * * * * * * * * * *

10 R CUTOFF (C) * * * * * * * * * * * * * *

11 G DRIVE (C) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

12 G CUTOFF (C) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

13 B DRIVE (C) * * * * * * * * * * * * * *

14 B CUTOFF (C) * * * * * * * * * * * * * *

15 R.DRIVE (W) * * * * * * * * * * * * * *

16 R CUTOFF (W) * * * * * * * * * * * * * *

17 G DRIVE (W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

18 G CUTOFF (W) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

19 B DRIVE (W) * * * * * * * * * * * * * *

20 B CUTOFF (W) * * * * * * * * * * * * * *

21 H POSI CENTER × × × × × × × × × × × × ×

22 H POSI MAX × × × × × × × × × × × × ×

23 H POSI MIN × × × × × × × × × × × × ×

24 V POSI CENTER × × × × × × × × × × × × ×

25 V POSI MAX × × × × × × × × × × × × ×

26 V POSI MIN × × × × × × × × × × × × ×

27 H POSI 50 × × × × × × × × × × × × ×

28 V POSI 50 × × × × × × × × × × × × ×

29 BAK LIGHT CENT 50 50 50 50 50 50 50 50 50 50 50 50 50

30 BAK LIGHT MAX 100 100 100 100 100 100 100 100 100 100 100 100 100

31 BAK LIGHT MIN 0 0 0 0 0 0 0 0 0 0 0 0 0

32 BRIGHT CENT 115 113 113 117 130 129 130 129 129 129 129 129 113 128 128 128 128 128 128 128 129 129 129 129

33 BRIGHT MAX 200 200 200 200 200 200 200 180 180 160 160 180 200 140 140 140 140 140 140 140 200 200 200 200

34 BRIGHT MIN 60 60 60 60 60 60 60 60 60 60 60 60 60 110 110 110 110 110 110 110 60 60 60 60

35 TINT 122 113 113 119 119 116 116 120 120 120 120 120 113 128 128 128 128 128 128 128 130 130 130 130

36 SHARP H1 MAX 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511

37 SHARP H1 MIN 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

38 SHARP H2 MAX 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511

39 SHARP H2 MIN 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

40 SHARP V1 MAX 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511 511

41 SHARP V1 MIN 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

42 CONT CENTER * * * * * * * * * * * * * * * * * * * * * * * *

43 CONT MAX * * * * * * * * * * * * * * * * * * * * * * * *

44 CONT MIN 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60

45 COLOR CENT 120 107 100 122 142 138 138 123 123 123 123 123 127 128 128 128 128 128 128 128 123 123 123 123

46 COLOR MAX 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255

47 COLOR MIN 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

48 H.POZI TEXT × × × × × × × × × × × × ×

49 VPOZI TEXT × × × × × × × × × × × × ×

50 CONT 40 * * * * * * * * * * * * * *

51

52

BRIGHT (NTSC) × × × × × × × × × × × × ×

BRIGHT (PAL) × × × × × × × × × × × × ×

BRIGHT (SECAM) × × × × × × × × × × × × ×

53

CONTRAST (NTSC) × × × × × × × × × × × × ×

CONTRAST (PAL) × × × × × × × × × × × × ×

CONTRAST (SECAM) × × × × × × × × × × × × ×

TV

CVBS Y/C 480i/576i 480p/576p 720p 1080i 480i/576i 480p/576p 720p 1080i VGA 640*480 720*400 800*600 1024*768 1280*768 1280*720 1360*768 480i 480p 720p 1080i

DVD

* * * * * *

* * * * * *

0 0 0 0 0 0

* * * * * *

* * * * * *

* * * * * *

* * * * * *

* * * * * *

* * * * * *

* * * * * *

* * * * * *

* * * * * *

* * * * * *

× × × × × × ×

× × × × × × ×

× × × × × × ×

× × × × × × ×

× × × × × × ×

× × × × × × ×

× × × × × × ×

× × × × × × ×

50 50 50 50 50 50 50

100 100 100 100 100 100 100

0 0 0 0 0 0 0

× × × × × × ×

× × × × × × ×

* * * * * *

× × × × × × ×

× × × × × × ×

× × × × × × ×

× × × × × × ×

× × × × × × ×

× × × × × × ×

PCHDMIAV COMPONENT DTV

* * * *

* * * *

0 0 0 0

* * * *

* * * *

* * * *

* * * *

0

0

0 0 0 0

0 0 0 0

* * * *

* * * *

* * * *

* * * *

* * * *

* * * *

× × × ×

× × × ×

× × × ×

× × × ×

× × × ×

× × × ×

× × × ×

× × × ×

50 50 50 50

100 100 100 100

0 0 0 0

× × × ×

× × × ×

* * * *

× × × ×

× × × ×

× × × ×

× × × ×

× × × ×

× × × ×

D-4 D-5

Page 30

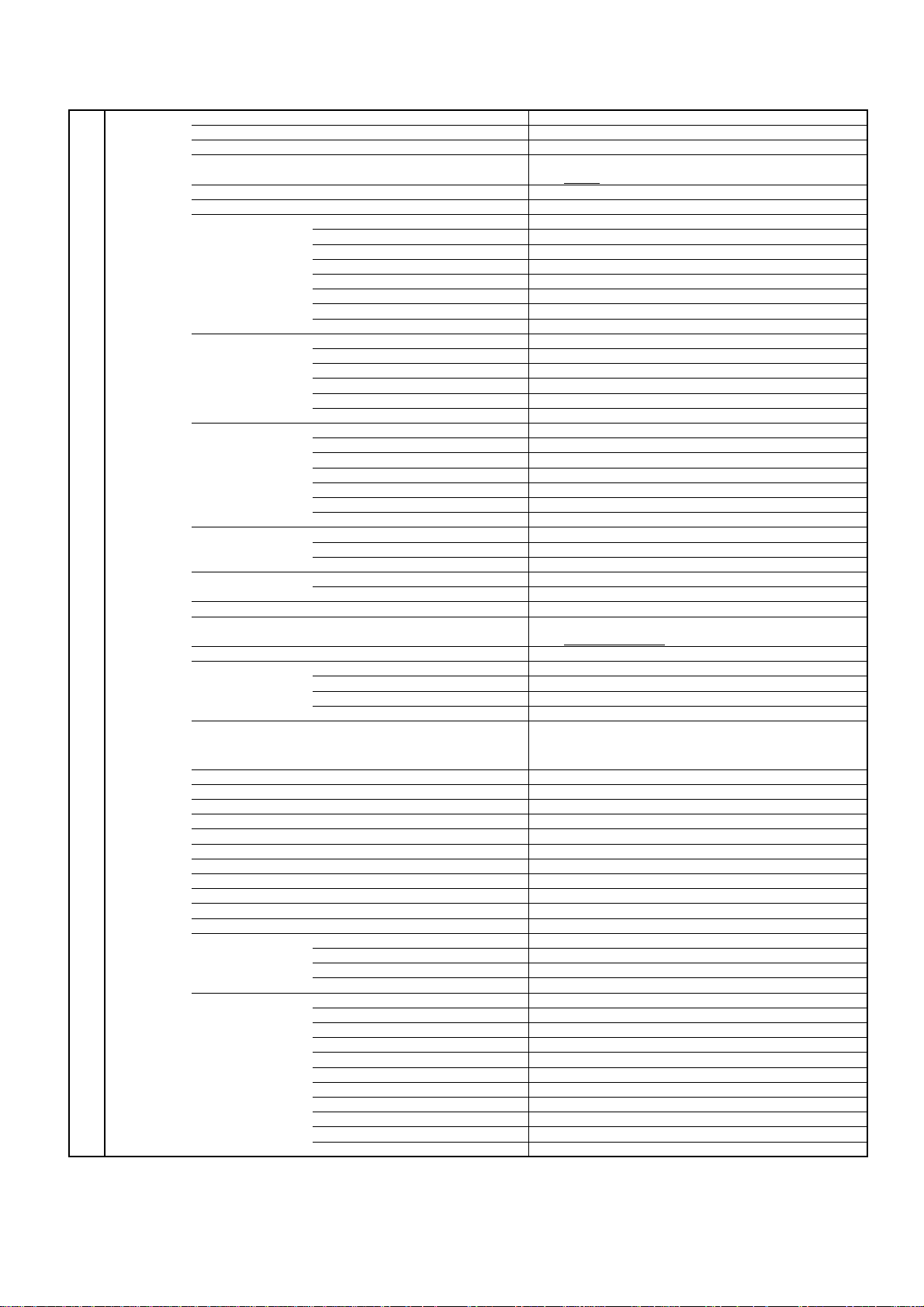

ELECTRICAL ADJUSTMENTS

CP8501

CD2804

CD8501

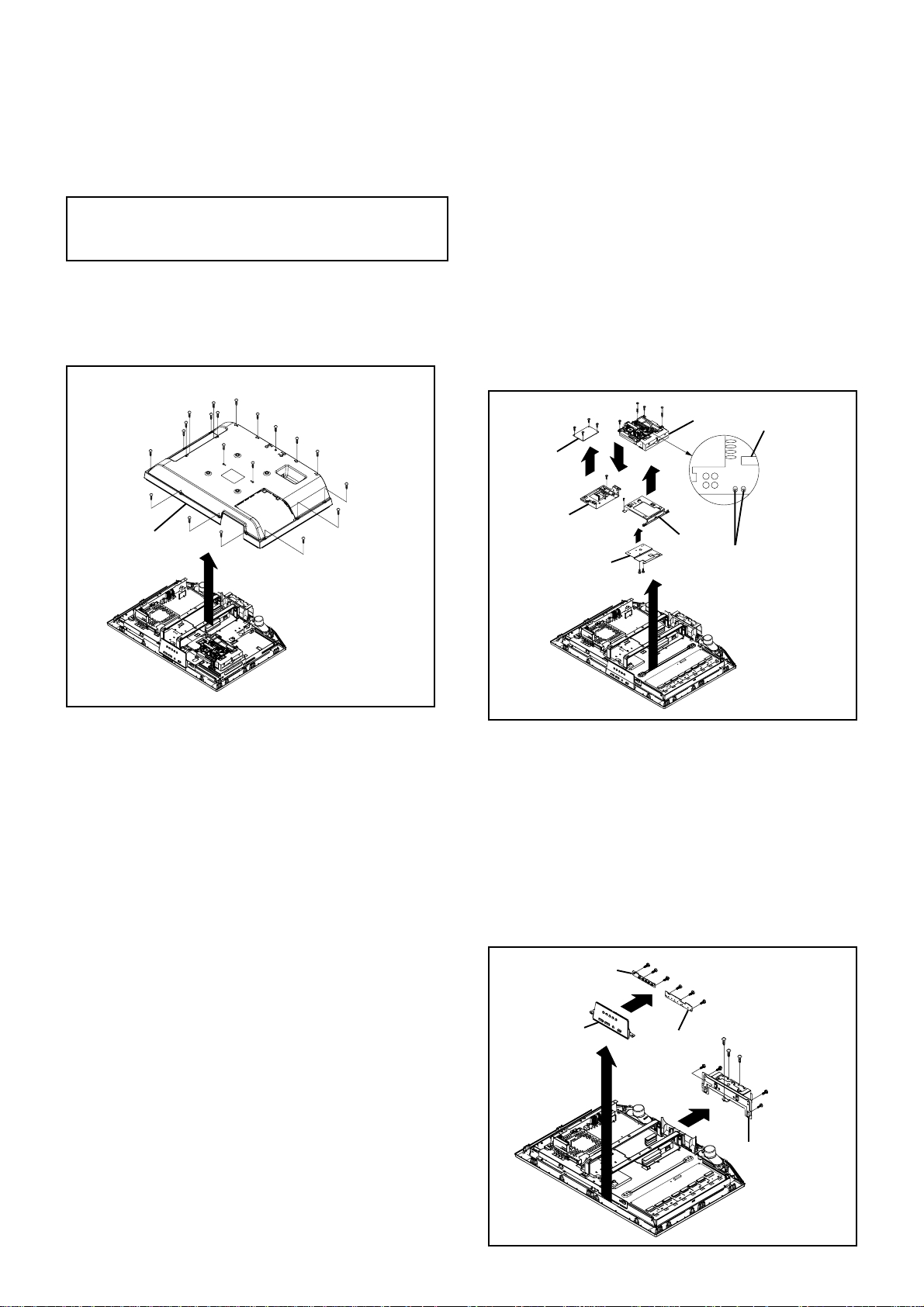

3. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

LCD PANEL

OPERATION 2 PCB

CP2251

OPERATION PCB

CP2204

CP2203

CD2202

DIGITAL PCB

DVD DECK

CD406

REMOCON PCB

CP2201

OS2201

CD2301

CD2001

CP2303

DVD MT PCB

CP403

CP406

CP2302

CP2301

CP8502

CD8502

CP4301

CP6202

CP2804

CP3001

CP401

CP4302

CP4203

TU5801

J4301

CP3601

CP4303

J4201

J4202

J4206

J4205

J4203

CD2201

CD301

SPEAKER

CP4201

CP302

D-6

POWER PCB

J401

AC IN

CD3805

Page 31

(LCD SECTION)

POWER DOES NOT TURN ON

TROUBLESHOOTING GUIDE

Is F401 broken?

No

Is there voltage at pin

1 of IC402 6V?

Yes

Is R412 broken?

No

Is there voltage at

pin 10 of IC401 19V?

Yes

No

Yes

No

Change F401.

Check IC402 and peripheral

circuit.

Change R412.

Check IC401 and peripheral

circuit.

Yes

Change DIGITAL PCB.

E-1

Page 32

THE PICTURE APPEARS,

BUT THE AUDIO DOES NOT

APPEARS. (AT RF MODE)

TROUBLESHOOTING GUIDE

Is CP302 connected?

Yes

Is there signal at

pins 1 and 4 of

No

Is there signal at pins 2

and 5 of IC302?

No

Is there signal at pins

AA3 and AA4 of

IC2801?

No

Yes

Yes

Yes

Connect CP302.

Change SP301 and SP302.

Check IC302 and peripheral

circuit.

Check Connection of CP4302.

No

Is there signal at pins 1

and 2 of IC6551?

No

Is there signal at pin

3 of IC6552, IC6553?

No

Is there signal at pin

5 of TU5801?

No

Change TU5801.

Yes

Yes

Yes

Check IC6551 and

peripheral circuit.

Check IC6552, IC6553 and

peripheral circuit.

Check IC5801 and peripheral

circuit.

E-2

Page 33

THE PICTURE DOES NOT

APPEAR

TROUBLESHOOTING GUIDE

Does backlight shine?

Yes

Is CD2804 connected?

Yes

Is there voltage at

pins 1, 2, 3, 4 and 5

of CP2804 5V?

Yes

Is there signal at pins

13, 14, 16, 17, 19, 20,

22, 23, 25 and 26 of

CP2804?

No No

No

No

Yes

Is there voltage at pins 1,

2, 3, 4 and 5 of CP406

24V?

Yes

Connected CD2804.

Check IC407 and

peripheral circuit.

Check IC401, T401, D437

and peripheral circuit.

Change V2301 (PANEL).

No

Change DIGITAL PCB.

E-3

Page 34

THE COLOR DOES NOT

APPEAR

TROUBLESHOOTING GUIDE

Is setting of color

normal?

Yes

Is the color signal

received?

Yes

Is there color signal

at IC2801?

Yes

Change DIGITAL PCB.

No

No

No

Adjust the color.

Receive the color signal.

Check IC2801 and

peripheral circuit.

E-4

Page 35

(DVD SECTION)

DOES NOT DISPLAY DVD

PICTURE

TROUBLESHOOTING GUIDE

Does this display

logo picture?

No

Is there signal at

pins 149 and 151 of

IC4001?

No

Does IC4001 gets

P.CON+3.3V and

P.CON+1.8V?

No

Check P.CON+3.3V

and P.CON+1.8V line.

Yes

Yes

Yes

Check the disc.

Check pins 8 and 10 of

CP8501 and peripheral circuit.

Change IC4001.

E-5

Page 36

DISC DOES NOT EJECT

TROUBLESHOOTING GUIDE

Does OSD appear

on the screen?

Yes

Does this eject disc at

change DVD DECK?

Yes

Change DVD DECK.

No No

No

Is remote key set

effectively?

Yes

Check pins 138 and 139

of IC4001 and peripheral

circuit.

Is there signal at pins 4

and 5 of CP2302?

Yes

Is there signal at pins 1

and 2 of CP2302?

No

No

Check pins J18 and J19 of

IC2801 and peripheral

circuit.

Check IC4001 and

peripheral circuit.

Change IC2301.

Yes

Change IC4001.

E-6

Page 37

TROUBLESHOOTING GUIDE

DOES NOT PLAY DVD

Does this display

"INCORRECT DISC"?

No

Does this display

reading mark?

Yes

Yes

No

Does CD2001 connect

with CP2301 correctly?

No

Connect CD2001.

Change IC4001.

Yes

Change DVD DECK.

No

Is the voltage

between JG017 and

JG018 less than 0.6V?

Yes

Does disc rotate?

Yes

Change IC4001.

No

Change DVD DECK.

E-7

Page 38

TROUBLESHOOTING GUIDE

DOES NOT PLAY CD

Does this display

"INCORRECT DISC"?

No

Does this display

reading mark?

Yes

Yes

No

Does CD2001 connect

with CP2301 correctly?

No

Connect CD2001.

Change IC4001.

Yes

Change DVD DECK.

No

Is the voltage

between JG019 and

JG018 less than 0.6V?

Yes

Does disc rotate?

Yes

Change IC4001.

No

Change DVD DECK.

E-8

Page 39

NO SOUND DVD/CD ANALOG

AUDIO

TROUBLESHOOTING GUIDE

Is there signal at pins

113, 114, 115 and

116 of IC4001?

Yes

Is there signal at pins 1

and 7 of IC8501?

Yes

Does CD8501 connected?

Yes

Change DIGITAL PCB.

No

No

No

Change IC4001.

Check pins 1 and 7 of IC8501

and peripheral circuit.

Connected CD8501.

NO SOUND DVD/CD DIGITAL

AUDIO

Is there signal at pin1

of CP8501?

No

Is there signal at

pin122 of IC4001?

No

Change IC4001.

Yes

Yes

Change DIGITAL PCB.

Check line circuit IC4001

to CP8501.

E-9

Page 40

A.... P.CON +12V

B.... P.CON +6V

C.... P.CON +3.3V

D.... P.CON +1.8V

E.... P.CON +A5V

DVD BLOCK DIAGRAM

DVD LOADER

E

B

C,D

DSM2

LCD BLOCK

OPU

SPINDLE/

STEPING/

SLED

MOTOR

MD_DVD, MD_CD

RF, A, B, C, D, E, F

DVD_CD, DVD_LD, CD_LD

TR+/-, FO+/-,

MOT_LD+/-,

MOT_SLED+/MOT_SPDL+/-

HOME, TIN_SW, TOUT_SW

C

Motor Drive

IC2301

LA6565VR-TLM-E

SST39VF1601-70-4C-EKE

SPINDLE/SLED/

FOCUS/TRACK_PWM,

TRAY_CLOSE/OPEN

SPDL_SENS+/-

HA0~A19,

HD0~D15,

MEMCS0, RD, WR

FLASH 16M

IC4007

MPEG/MICON/DSP/RF_AMP

IC4001

ZR36966ELCG-D-G

SD_A0~A11

SD_D0~D15

RAMDQM, CLK, CKE, WE#, CAS#,

CS0#, CS1#, RAS# SD_BA0

APWM_L+/-,

APWM_R+/-

64M SDRAM

IC4005

M12L64164A-7TG

AUDIO AMP

IC8501

NJM4565M(TE1)

A

C

DUPRD1

DUPTD1

TIN_SW

SPDIF

DAC_VIDEO_C/D

DAC_VIDEO_A

RESET

SYS_MUTE

DVD_AUDIO_L

DVD_AUDIO_R

TX

RX

START_SW

SPDIF-134

C_VIDEO

Y_VIDEO

DVD RESET

ZERO

DVD_A_OUT_L

DVD_A_OUT_R

F-1 F-2

Page 41

POWER BLOCK DIAGRAM

A

A

C IN

CD3805

J401

POWER

IC401 MP3A5038

Q2g

Vcc Q1d

20

10 18

L401 L402

1

3

D405

C403

FB

13

+

P.GND

8

2

4

D407

C404

VW

15

1

3

+

Q2d

22 23

D415

2

4

POWER

IC402

MIP2F4

D Vcc FB

2 1

4

5

Vcc SW

Vdd

TRANSFORMER

T402

1

+

C455

PS2561AL1-1-V(W)

TRANSFORMER

T401

7

5

2

9

8

3

7

5

FEED BACK

IC410

431

41

10

8

13

14

15

1

2

23

POWER SW

IC406

PS2561AL1-1-V(W)

Q416

Q417

REGULATOR

IC404 KIA431A-AT

1 3

SW

SW

SOUND +B

SW

CP401__1.TUNER+30VQ409

CP401__7.8. AT+5V

CP401__2. POWER FAIL

CP401__6.P.CON+5V

CP401__3.

SYS_POWER_H

CP401__18.SW+12V

CP406__1,2,3,4,5. +24V

SOUND AMP

IC302

N17808B

IC407

DC/DC(5V)

LA5779-E

CP401__11,12. LCD+B

FEED BACK

IC408

PS2561AL1-1-V(W)

41

23

SW

3 1

REGULATOR