Page 1

TopPage

LC-32A47L(A)

SERVICE MANUAL

No. S89C1LC32A47A

LCD COLOR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should

be restored to its original condition and only parts identical to those specified should be used.

LC-32A47L(A)

OUTLINE

This manual has been issued to cover the modifications of some parts in reference to the redesigned LCD panel

module of Model LC-32A47L.

In this Service Manual, the modifications from Model LC-32A47L (No. S79A4LC32A47L) are focused on. For what

is left out herein, please refer back to the Service Manual of the previous model LC-32A47L (No. S79A4LC32A47L).

This Service Manual should be referred to as from the July 2009 production units (serial numbers: ****51112 and on).

CONTENTS

OUTLINE AND DIFFERENCES FROM BASE MODEL

OUTLINE.................................................................... i

DIFFERENCES FROM BASE MODEL..................... ii

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY

PRECAUTION...........................................................iii

PRECAUTIONS A PRENDRE LORS DE LA

REPARATION .......................................................... iv

PRECAUTIONS FOR USING LEAD-FREE

SOLDER ................................................................... v

CHAPTER 1. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ...........................1-1

CHAPTER 3. OVERALL WIRING/BLOCK DIAGRAM

[1] OVERALL WIRING DIAGRAM ..............................3-1

[2] SYSTEM BLOCK DIAGRAM .................................3-2

CHAPTER 4. PRINTED WIRING BOARD ASSEMBLIES

[1] MAIN Unit...............................................................4-1

CHAPTER 5. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIAGRAM.........5-1

[2] MAIN Unit...............................................................5-2

Parts Guide

CHAPTER 2. ADJUSTMENT

[1] ADJUSTMENT PROCEDURE ...............................2-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-32A47L(A)

LC-32A47L(A)

OUTLINE AND DIFFERENCES FROM BASE MODEL

Service Manual

OUTLINE

This manual has been issued to cover the modifications of some parts in reference to the redesigned LCD panel module of Model LC-32A47L.

In this Service Manual, the modifications from Model LC-32A47L (No. S79A4LC32A47L) are focused on. For what is left out herein, please refer back

to the Service Manual of the previous model LC-32A47L (No. S79A4LC32A47L).

This Service Manual should be referred to as from the July 2009 production units (serial numbers: ****51112 and on).

Identifying the models with the redesigned LCD panel module

• The models with the redesigned LCD panel module have the “ ” marking added at the end of the model number given on the “Model Label”.

• The models with the redesigned LCD panel module have the “ ” marking in “No. Label” applied on the packing case.

• The models with the redesigned LCD panel module have the “ ” marking in “Back Serial No. Label”.

Interchangeability

• The previous and redesigned LCD panel modules are not interchangeable with each other.

• The redesigned LCD panel module is applicable only on the sets that have been manufactured since July 2009.

Models with the redesigned LCD panel module

Model Label

Add

MODEL NO.

LC-32A47L M0015094

****51112SERIAL NO.

A

No. Label of the packing case (Top)

MODEL NO. LC-32A47L M0015094

****51112SERIAL NO.

No. Label of the packing case (Side)

Add

LC-32A47L

SERIAL NO.

N'DE SERIE

****51112

Back Serial No. Label

Add

A

Add

A

i

Page 3

DIFFERENCES FROM BASE MODEL

LIST OF CHANGED PARTS

LC-32A47L(A)

Ref. No. Description

PRINTED WIRING BOARD ASSEMBLIES

MAIN Unit DUNTKF030FM11 DUNTKF030FM26 D Some internal parts changed

KEY Unit DUNTKF069FM06 ← ——

LED Unit DUNTKF115FM03 ← ——

POWER Unit RDENCA363WJQZ ← ——

LCD PANEL

32” LCD Panel Module Unit R1LK315T3LZ94 R1LK315T3LF22Z D Change (Unit Replacement Item)

MAIN Unit

D9602 Diode — VHDRB056L40-1Y — Add

FB2601 Ferrite Bead — RBLN-A375WJQZY — Add

FB2602 Ferrite Bead — RBLN-A375WJQZY — Add

FB2615 Ferrite Bead — RBLN-A375WJQZY — Add

FB2633 Ferrite Bead — RBLN-A375WJQZY — Add

FB2634 Ferrite Bead — RBLN-A375WJQZY — Add

FB2635 Ferrite Bead — RBLN-A375WJQZY — Add

FB2636 Ferrite Bead — RBLN-A375WJQZY — Add

FB2637 Ferrite Bead — RBLN-A375WJQZY — Add

P2602 Plug — QPLGNA349WJZZY — Add

Q9602 Transistor — VSMCH6305++-1Y — Add

Q9606 Transistor — VSRT1N141U/-1Y — Add

R9639 Resistor — VRS-CZ1JF104JY — Add

R9640 Resistor — VRS-CZ1JF104JY — Add

LC-32A47L

(No. S79A4LC32A47L)

LC-32A47L(A)

(No. S89C1LC32A47A)

Interchange-

ability

Note

CABINET AND MECHANICAL PARTS

Please refer to a Parts list

PACKING PARTS, ACCESSORIES AND SERVICE JIGS

Please refer to a Parts list

Completely interchangeableA:

Interchangeable from

B:

OLD to NEW

Interchangeability

=

NEWOLD

ψ

NEWOLD

Interchangeable from

C:

NEWtoOLD

Not interchangeableD:

NEW OLD

ψ

X

OLDNEW

ii

Page 4

LC-32A47L(A)

LC-32A47L(A)

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CON T I NUE D PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F701 (250V 5A)

F702 (250V 5A)

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

F721 (250V 2A)

F4731 (250V 2A)

DVM

BEFORE RETURNING THE RECEIVER (Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 110~240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

iii

Page 5

LC-32A47L(A)

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

•

AVERTISSEMENT

1.

N'entreprendre aucune modification de tout circuit. C'est dangereux.

2.

Débrancher le récepteur avant toute réparation.

PRECAUTION: POUR LA PROTECTION CONTINUE CONTRE LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE

F701 (250V 5A)

F702 (250V 5A)

F721 (250V 2A)

F4731 (250V 2A)

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer les vérifications suivantes.

3.

Inspecter tous les faisceaux de câbles pour s'assurer que les fils

ne soient pas pincés ou qu'un outil ne soit pas placé entre le châssis et les autres pièces métalliques du récepteur.

4.

Inspecter tous les dispositifs de protection comme les boutons de

commande non-métalliques, les isolants, le dos du coffret, les couvercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

5.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

fuite de courant, de la facon suivante:

• Brancher le cordon d'alimentation directem-ent à une prise de courant de 110~240V. (Ne pas utiliser de transformateur d'isolation

pour cet essai).

A l'aide de deux fils à pinces, brancher une résistance de 1.5 kΩ

10 watts en parallèle avec un condensateur de 0.15µF en série

avec toutes les pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise de terre

branchée à la terre.

•

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000Ω/V pour

mesurer la chute de tension en travers de la résistance.

•

Toucher avec la sonde d'essai les pièces métalliques exposées qui

présentent une voie de retour au châssis (antenne, coffret métallique, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise

d'adpatation non polarisée peut être utilisée dans le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.75V (correspondante au courant CA de pointe de 0.5mA).

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de rendre le récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

µ

F

0.15

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans les téléviseur ACL présentent des caractéristiques spéciales relatives à la sécurité, qui ne sont souvent pas évidentes à vue. Le degré de protection ne peut pas être nécessairement augmentée en utilisant des

pièces de remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans la

liste des pièces de remplacement et les diagrammes schématiques.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Pour assurer la protection, ces pièces doivent être identiques à celles

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pas

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incendies, radiations X ou autres accidents.

iv

Page 6

LC-32A47L(A)

PRECAUTIONS FOR USING LEAD-FREE SOLDER

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

PARTS CODE

ZHNDAi123250E BL J φ0.3mm 250g (1roll)

ZHNDAi126500E BK J φ0.6mm 500g (1roll)

ZHNDAi12801KE BM J φ1.0mm 1kg (1roll)

PRICE

RANK

PART

DELIVERY

DESCRIPTION

v

Page 7

LC-32A47L(A)

CHAPTER 1. REMOVING OF MAJOR PARTS

Service Manual

[1] REMOVING OF MAJOR PARTS

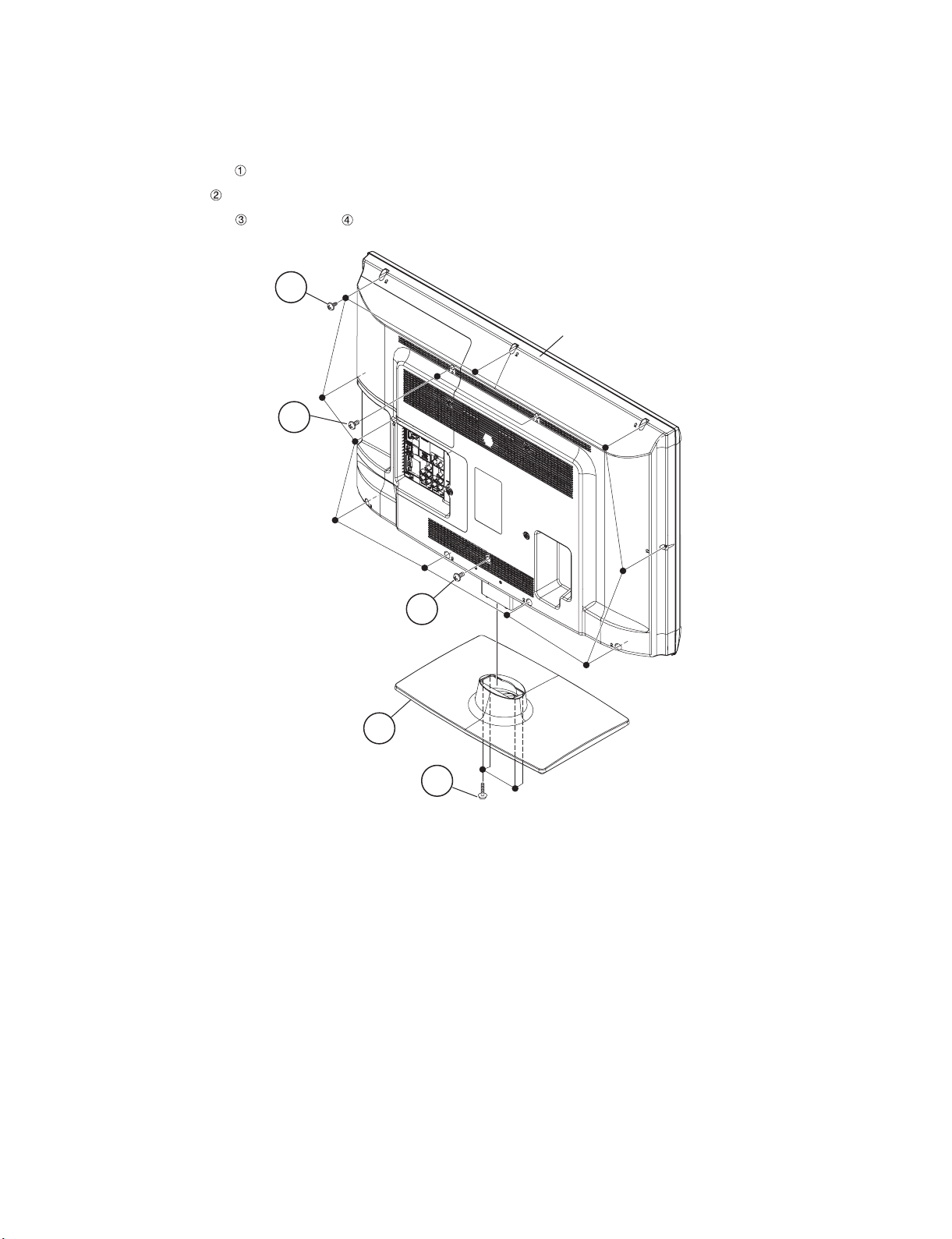

1. Removing of Stand Unit and Rear Cabinet Ass’y.

1. Remove the 4 lock screws .

2. Detach the Stand Unit .

3. Remove the 3 lock screws , 10 lock screws and detach the Rear Cabinet Ass’y.

4

Rear Cabinet Ass'y

3

LC-32A47L(A)

Stand Unit

3

2

1

1 – 1

Page 8

LC-32A47L(A)

2. Removing of Speaker L/R, Control Button Ass’y, Front Cabinet Ass’y, LED Unit and KEY Unit.

1. Disconnect the following connectors from the Main Unit. (RA, SP)

2. Detach the Speaker-L and Speaker-R .

3. Detach the LED Unit .

4. Disconnect the following connector from the LED Unit. (RA)

5. Remove the Control Button Ass’y.

6. Detach the KEY Unit from the Control Button and disconnect the connection cord from the KM connector.

7. Remove the 4 lock screws , 6 hooks and detach the Front Cabinet Ass’y.

6

Front Cabinet Ass'y

4Control Button

Control Button Ass'y

5KEY Unit

[KM]

7

7

[RA] [SP]

7

7

[RA]

3LED Unit

6

[SP]

7

7

2 Speaker-LSpeaker-R

1 – 2

1

Page 9

3. Removing of Main PWB Shield and Side Cover Ass’y.

1. Remove the 2 lock screws and detach the Side Cover Ass’y .

2. Remove the 2 lock Shafts , 2 lock screws , 6 lock screws and detach the Main PWB Shield .

3. Disconnect the following connector from the Main Unit. (KM)

1

LC-32A47L(A)

4

5

Main PWB Shield

6

2Side Cover Ass'y

3

[KM]

1 – 3

Page 10

LC-32A47L(A)

4. Removing of Support Angle and Connectors.

1. Remove the 4 lock screws and detach the Support Angle .

2. Disconnect the following connectors from the Main Unit. (PD, LB1, LP, LW)

3. Disconnect the following connectors from the Power Unit. (PD, LB1, LB2)

4. Disconnect the following connector from the Inverter Unit. (CN101)

5. Disconnect the following connector from the LCD Control Unit. (CN1)

POWER Unit INVERTER UnitLCD CONTROL UnitMAIN Unit

[CN101]

[PD]

[LB1]

[LP]

[LW]

[CN1]

2

Support Angle

(Stand Support)

1

[LB1]

[PD]

POWER UnitMAIN Unit

[LB2]

1 – 4

Page 11

LC-32A47L(A)

5. Removing of POWER Unit, MAIN Unit, Power PWB Angle, Main PWB Angle R/L/M and LCD Fix Angle-T/B.

1. Remove the 6 lock screws and detach the POWER Unit .

2. Remove the 8 lock screws and detach the MAIN Unit .

3. Remove the 10 lock screws and detach the Power PWB Angle , Main PWB Angle R , Main PWB Angle L and Main PWB Angle M .

4. Remove the 6 lock screws and detach the LCD Fix Angle-T and LCD Fix Angle-B .

32" LCD Panel Module Unit

11 LCD Fix Angle-T

10

8Main PWB Angle L

9Main PWB Angle M

6 Power PWB Angle

7Main PWB Angle R

12 LCD Fix Angle-B

5

POWER Unit

2

1

3

4 MAIN Unit

1 – 5

Page 12

LC-32A47L(A)

LC-32A47L(A)

CHAPTER 2. ADJUSTMENT

[1] ADJUSTMENT PROCEDURE

1. Adjustment of white balance

Adjustment item Adjustment conditions Adjustment procedure

1 Setting Backlight: +16

(MAX)

2 Automatic

adjustment

execution

Service Manual

For detailed adjustment procedure refer to “Kameyama Model Integral WB Adjustment

Specifications”.

1) Make the following settings for the set.

AV MODE: [DYNAMIC]

Backlight: +16

Aging time: Min. 60 minutes

2) Connect the white balance adjustment tool to the set.

3) The cross is displayed by execute command of RS232C and the probe position is set

to the center of the screen (please attention the operation manual of CA210).

4) The cross is disappeared by execute command of RS232C.

Adjusting the picture by execute command of RS232C

[Adjustment procedure]

1) Using the remote controller, transmit the “monitor adjustment process” code.

2) Set the 2nd point to the specified gradation level, With the strongest color being fixed,

turn down the R,G and B settings to their reference levels.

3) Set the 1st point to the specified gradation level.

Correct the G setting (388 x 2nd point G setting /875) (rounded off), and make the R

and B settings to their reference levels.

*Initial R, G and B settings at point 2: Gradation level set at 875

* Initial R and B settings at points 1: Correct the setting same remainder of RGB setting

at each point (This is because the adjustment is made to achieve the same remainder of

RGB setting/4 at each point).

[Adjustment value]

As per the “standard set” submitted by Engineering Department.

[Adjustment reference] Instrument: [Minolta CA-210] Engineering instrument.

Level Reference Adj. spec Ins. spec

Point 2 875

Point 1 388

Note Set conditions for inspection

X=0.272

y=0.277

X=0.272

y=0.277

AV MODE: [DYNAMIC] (Reset)

Aging Time: Min. 60 minutes

±0.001 ±0.002

±0.004 ±0.008

2 – 1

Page 13

LC-32A47L(A)

2. Model number ID plug

Model numbers are identified by inserting the destination ID plug (QCNCMA275WJQZ) in its specified slot of the destination ID connector SC9003

(QCNCWA715WJQZY).

1

4

PC Audio IN

V/LR

USB

112

SC9003

HDMI

Analog RGB

C5

MAIN Unit

L/R out

115

DDR

Position

TUNER

11014

Destination ID connector locations

SC9003

LC-32A47L(A)

1

41

Plug locations

㪛㪼㫊㫋㫀㫅㪸㫋㫀㫆㫅㩷㪠㪛㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉 㪛㪼㫊㫋㫀㫅㪸㫋㫀㫆㫅㩷㪠㪛㩷㫇㫃㫌㪾

䋨㪨㪚㪥㪚㪮㪘㪎㪈㪌㪮㪡㪨㪱㪰䋩 䋨㪨㪚㪥㪚㪤㪘㪉㪎㪌㪮㪡㪨㪱䋩

2 – 2

Page 14

LC-32A47L(A)

MEMO

2 – 3

Page 15

LC-32A47L(A)

CHAPTER 3. OVERALL WIRING/BLOCK DIAGRAM

[1] OVERALL WIRING DIAGRAM

OVERALL WIRING DIAGRAM

I

H

G

Service Manual

QCNW-J639WJQZ

QCNW-J171WJQZ

32" LCD Panel

12

LC-32A47L(A)

41

[LB1]

1

[PD]

1

14

[LB2]

QCNW-J630WJPZ

F

QCNW-J170WJQZ

12 1 61

4

[PD]

[LB1]

1

[KM]

SC9003

C5

15 1

[LP]

[LW]

41

1

QCNW-J834WJPZ

POWER

Unit

1

14

INV

Unit

CN101

E

HDMI

MAIN Unit

DDR

Position

TUNER

D

KEY Unit

C

PC Audio IN

V/ LR

USB

Analog RGB

L/R Output

[RA]

[SP]

110

14

[KM]

4

1

B

7

1

[RA]

LED Unit

QCNW-J173WJQZ

[LW / LP]

30 1

CN1

LCD Cont Unit

QCNW-J174WJQZ

A

12345678910111213141516171819

3 – 1

20 21 22

Page 16

LC-32A47L(A)

[2] SYSTEM BLOCK DIAGRAM

SYSTEM BLOCK DIAGRAM

I

INPUT

1

Vert. Insert

INPUT

2

Vert. Insert

H

G

F

INPUT

3

Vert. Insert

Vert. Insert

RF IN

Vert. Insert

E

Vert. Insert

D

C

INPUT

4/5

Vert. Insert

INPUT

4

Vert. Insert

INPUT

6

Vert. Insert

INPUT

5

Vert. Insert

Vert. Insert

SP

LR

Component

SVideo

LR

Component

CVBS/LR

[SP]

P2701

EXT-SP

Audio Out

RS-232C

RGB/HDMI

Audio

(Mini Plug)

D-SUB

RGB

HDMI 2

HDMI 3

HDMI 4

Input1 CVBS deleted

L/R

YPbPr

S-Video

L/R

YPbPr

CVBS

L/R

L/R

+5V

TU1101

Analog/

Digital

AGC

The WXGA

machine unmounts .

Tuner

SIF

D_IF

CVBS

I2C

No.9 pin RC Passthrough

RGB_LR

PCIN_H/V

PCIN_R/G/B

The WXGA

machine unmounts .

AFT

IC602

EEPROM

UR13V

IC2701

SP AMP

YDA148QZ

Disclete

Mute

UCOM_RS

DDC1 not supported

P9001

Disclete

Mute

AMP_MUTE

STANDBY

PROTECT

IC1609

In0

TMDS-SW

SII9187

In1

In2

In3

TUN_SDA_C5/TUN_SCL_C5(100KHz 5V)

LINE_OUT_L/R

A9V +3.3V

OUT1

IC1301

Audio DAC

AK4341ET

I2S

LINE_MCLK/BCLK/DAT/LRCLK

+3.3V

B

J8001

Service

Horiz. Insert

USB

A

MAIN

VCOM_SDA

VCOM_SCL

N_LINE_DAC_RST

P2602

(100KHz)

HDMI_MUTE

Vbrt

IC2602

DAC

M62332FP

P2603

+3.3V

I2C_SDA/I2S_SCL

25.000MHz

X8001

X'tal

SPOUT_L/R

N_CPU_RST

I2C

TUN_I2C

I2C_0

D_IF in

SIF

AGC

RGB in

H/V

HDMIin

I2S

RESET

N_DBG_RST

N_SRESET

P8001

Connector

for Software

Writing

IC503

A-SW

BU+3.3V

IC9002

SUB-SW

HC2G66DP

AUDIO

CVBS

IC8001

RH-IXC677WJQZQ

DTV-C5 for WXGA

Digital AV decode & Main CPU

50MHz

IC8451

64Mbit

UART-B

+3.3V

Serial FLASH

Serial FLASH

YPbPr

S-Video

zz

UART-A

USB

LCD PANEL

SHIP_EN,PNEL_EN

DETECT

BU+3.3V

IC2001

Reset

RST_H8FLS_CPLD

FLAS_W_CPLD

From CPU

WEITE_BUF

DET_T-CON POW

BU+3.3V

BU+3.3V

IC8454

EEPROM

256kbit

I2C_SDA_UCOM

I2C_SCL_UCOM

Thermister

+3.3V

+1.8V

LVDS OUT

+1.2V

CNVss

SC9003

Connector for

Model Detect

IC8251

DDR2(800)

512Mb*1

P8001

Connector for

Debugging

IC2004

Gate

7WH126FU

16MHz

Xtal

MODEL_A[1-0]

PM_REQ, CBOOTS

RxD,TxD

RxD,TxD

THERMO

16MHz

N_SRESET

[KM] P2002(4p)

[KM] P151 (4p)

IC2002

R8C/2A

IXC165WJ

UART

Monitor Micom

I2C

AFT

A/D

A/D

I/O

I/O

I/O

KEY1,KEY2,STANDBYPOW

KEY

MENU

POWER

INPUT SELECT

Ch-Up/Down

Vol-Up/Down

FRAME,R/L,U/D,TEMP[3:0],O/S_SET

I/O

STB

I/O

ERR_PNL

AC_DET

I/O

DET_10V

INT0

I/O

A/D

OPC

R/C

OPC_LED,POW_LED_R,POW_LED_G,LED_YOYAKU, ILL_LED

BU+3.3V

[RA] P2003(10p)

[RA] P101(7p)

LED

R/C

OPC

POW_LED

From CPU

BackUp Line

Power Circuit

STB_CPU

DET_13V,DET_

BU+5V

BU+3.3V

MAIN Line

A9V

5V

D3.3V

D2.6V

D1.2V

ROMSEL0

PS_ON

AC_DET

From CPU

The WXGA

machine unmounts .

VCOM_SDA

VCOM_SCL

Von

Vbrt

SYNC_DET

VCOM_WP

LCDC-EN

UR13V

BU5V

PNL_ON

P2601

[LW]

(41 pin FFC)

[LB1]

P2603

[LP] P2602

[PD] P9601(12 pin)

(6 pin)

(15 pin)

CN1

[LW / LP]

[LB1]

[PD]

(30 pin FFC)

(4 pin)

(12 pin)

POWER

[LB2]

CN101

(14 pin)

(14 pin)

12345678910111213141516171819

3 – 2

20 21 22

Page 17

LC-32A47L(A)

CHAPTER 4. PRINTED WIRING BOARD ASSEMBLIES

[1] MAIN Unit

LC-32A47L(A)

Service Manual

I

MAIN Unit

(Side-A)

H

G

F

E

D

C

B

A

12345678910111213141516171819

4 – 1

20 21 22

Page 18

LC-32A47L(A)

I

MAIN Unit

(Side-A Chip)

H

G

F

E

D

C

B

A

R2635

Q2603

SC9301

R2602

C2710

FD1

LUG1105

L2606

L2601

L2607

L2602

L2608

L2611

L2603

L2609

L2604

FB2706

L2605

LUG1103

R1102

R1101

C1135

C1110

R1117

P2601

LUG1104

C1334

C1336

C2726 C2725

R1142

R1143

R1103C1136

C1132 C2730

C1131

C1108

R1106

R1104

FB1102

C1102

C1134 C1101

BAR3

BAR1

FB1101

VER1

L2610

L2612

L2701

L2702

LF3

FB517

R8088

C8139

R8058

D505

J502

C8140

R574

R8024

C8137

R8057

D611

SG2508

R8068

R575

SG2507

C8141R8067

D610

Q1310

R1334

R1342

C534

R8022

C1309

R1344

SG2505

SG2506

R9007

R9003

R1310

R1340

J507

R548 C1307

FB509

Q1311

P2501

SG2504

R1128

C1119

C1116

R1343R1339R1345

C1306

C535

R547

FB508

SG2502

SG2503

R1125

D9618

R546

FB507

SG2501

RDA8001

D8001

R8059

Q9609

R577

R576

IC8001

R8062

FB518

R8060

R545

FB2516

R8070

R1304

J508

FB519

FB2515

R1302

Q1301

J503

R578

Q2502

FB2517

C9008 C9006

L9601

R1654

R1653

IC9003

R9017

R9016

SC1604

C533

J506

R1684

C1637C1634

Q1614

R582

C525

R1688

IC1613

FB515 R571

J505

IC503

C627

C9001

D9610

R1692

R583

C541

C526

C9007 C9009 C9002L9603

C9632

IC9608

FB516 R573

R557

R558

C9634

Q509

Q510

R581

FB513

FB514

R560

R559

C537

C528

R579

C527

R568

R580

R567

R549

IC502

C538

R552

R8080

R8081

D8002

C9628

Q508

R569

Q507

R570

FB512

J504

C9630

R9647R9648R9649

R555

R551 R556

FB511

Q8001

C532

C531

R561 R563

LUG1108

Q2501

D514

IC9606

LUG1107

C524

R562 R564

C523

C520

R550

FB510

R2505

D513

R543

R9633

C635

D509 D510

C512

R544

FB506

C513

R542

R8083

TP8011

D9619

D506

R541

FB505

R9631

Q9608

R8086 FB8022 Q8002R8082

C8920

R1134

R1141

C1126

C1129

L1105

C1128

C634

C511

TP8010

R8087

R8017

C8919

C8095

C8081

C8072

C8063

C8054

C8036

C8031

R1135

L1104

C1130

R1133

C1103

R1140

L1107

C1125

C1127

D501

TP8009

C8088

C8083

C8080

C8066

C8064

C8044

C8037

C8032

C8029

R1145 R8001

R1144 R8002

L1106

R8069

C8096

R8015

C633

R2026

R2025

R2015

R2013

R2027

C2009

LUG1106

R2005

IC9002

R2028

R9015

R9033

P2002

LUG1101

SC1601

J501

J8001

R9032

C9004

R2002

R9031

FB501

R501

C502

R504

R505

R513

R512

FB503 FB502

C510

Q604

C641

C642

R639

D607 D608

LUG1102

IC1601

R660

D601

C637 R503

R641

R8020

C8150

C501

C509

R662

R8004

FB8004

IC2004

D508

C624

C625

C626

C620

C616

R636

R659

R661

C8918

C8138

FB8001

VA8001VA8002

FD2

IC602

R8085R8084

C9635

IC1602

IC8003

IC1603

IC601

IC9609

SC9003

R635

R658

C2001

R1667R1675

C640

KOUJO1

C615

R626

R619

J601

C614

FB605

R620

R622

D606

C639

R613

SC601

R624

R617

L501

C612

FB604

C2010

R2016

C602

R618

R625

D605

SC1602

SC1603

R606

C603

R603

FB602

R610

C638

R605

C604

R604

R623

R615

C610

C601

C619

C618

C617

FB603

R616

R627

D604

D2003

C606

C605

FB601

Q603

Q601 Q602

R609

D602

FB606

FB607

C607

R607

R608

R630

R633

C9003

R631R634

R629

R632

R9002

R9001

FB9003

FB9004

R611

TH2001

SC9002

R9024

Q9001

D9007

C608

IC9001

D603

R612

R9022

D9002

P9601

IC1609

D1601

R9020

L1601

D9001

R1710

D1306

L1602

R1641

R1642

R1602

R9021

SC9001

D9609

C9633

L1603

R1676C1625

D1619

D9005

R1646

R1711

L9602

L1604

R1644

IC1604

R1645

R1669

C1626

R1712

L9604

D9614

R1657

R1660

R1661

R1678

C1628

C1629

C1630

R1677

R1715

R1658

R1714

C1622

D1620

R1611

R1713

R1680

C1621

FB9002FB9001

R1718

R1651

R1679

D1623

R1610

R1716

D1622

R1652

R1656

D9604

R1655

C536

R9632

FB2520

D2505

R2512

R2513

FB2519

IC8251

R9630

R2012

FB2518

C9629

C631 C632

C630

R2510

D504

D503

D502

TL2041

D2504

D2506

R8019

LF1

R8010

IC9607

R2017

R8012

C8082

R8013

R8031

R8030

C8070

Q2002

FB2005

R8025

R8251

R8253 R8252

R8263

C9631

FB2006

X8001

R8262

FB2014

P2603

R8006

R2075

FB2007

P2003

R2623

R8064

R8061

R8035

R8008

R8007

FB2008

C2606

TP8013

R8065

FB2009

D9602

FB2010

C2731

FB2011

C8461

R8474

C2727 C2728

FB2012

FB2013

R8475

C8460C8462

P8001

P9001

R1323

L2704

L2703

R2607C2608

IC8454

C1314

Q1304

R2611 R2606

R1337 D1311

R1336

IC2601

R1338

R8455

R8452

R8451

R8454

R1335 Q1309

R2619R2620R2612

P2602

IC2603

D1313

D1304

R2753

R2717

C2748

R2715R2754

C2601

C2602

R1322

R1324

Q1305

C2723 C2716

TU1101

P2701

C2705

C2706

C2707

R2741

C2713

IC2701

R2742

Q2704

FB9613

Q9606R9639R9640

R2752

Q9602

R2731

C2704

R2730

R2725

R2601

C2712

R2726

C2711

C2724 C2717

12345678910111213141516171819

4 – 2

20 21 22

Page 19

I

H

G

LC-32A47L(A)

MAIN Unit

(Side-B)

F

E

D

C

B

A

12345678910111213141516171819

4 – 3

20 21 22

Page 20

LC-32A47L(A)

I

MAIN Unit

(Side-B Chip)

H

G

F

E

D

C

B

A

R1321

R1325

C1327

C1325

TL1108

TL1102

LF5

C1331

R1331

C1330

TL2624

TL2623

TL2625

TL2626

TL2627

TL2628

TL2639

R2616

TL2651

R1327

IC1305

R1326

R1328

FD3

TL2640

TL2603

R2615FB2632

TL2643

TL2647

TL2646

C1329

R1316

FB2604

FB2605

FB2606

FB2607

FB2608

TL2641

TL2642

TL2644

TL2645

TL2602

R1319

R1320

C1328

C1321

TL1114

TL1112

TL1116

TL1115

TL1119

TL1121

TL1120

TL1111

TL1110

TL1101

TL1107

FB2622

FB2624

FB2626

FB2627

FB2629

R1354R1353

C1338

C1337

R1359

R1355

FB2621

FB2623

FB2625

FB2630

FB2628

FB2631

R9305

R1356R1358

R1357

Q1313

Q1314

TL2669

R2603

D9613

R9308

TL2613

FB2637

R2636

D9302

D9303

R1360

TL2612

FB2636

D9304

R9301

C9304

TL2611

TL9302

IC9301C9303

C9301

C1322

C1124

C1123

L1108

R1107

C1122

R1130

TL2608

FB2635

TL9301

C9302

R1329

R1365

C1113

Q1104

TL2606

TL2607

FB2634

R9319D9301

Q1306

R1361R1317

Q1103

R1129

R1109

D2704

TL2604

FB2615

FB2633

LUG1110

R1330

R1362R1318

R1111

R1146

C1133

C2741

TL2701

TL2638

FB2601

R8014

R1315

R1366

R1116

R1112

R1108

CF1101

FB2702

TL2673

R1314

C1323

R1372

C1137

C2745

D2703

R2604

R8457

D1310

D1314

Q1307

TL1103

FB2602

R8453

R1305

C1303

C2740

TL2702

TL2648

FB2612

R8037

R8039

R8041

R1308R1341

R1122

R1110

C1107

FB2703

D2702

TL2650

TL2649

FB2614

TL8001

TL8002

TL8010

C2744

TL2703

TL2671

FB2616

IC8451

R1303

TL8011

R8043

R8044

R1121

C1112

R1113

R1114

R1115

C2743

TL2670

FB2617

D1312

D1305

TL8003

R8045

TL8012

FB2704

D2701

FB2611

FB2610

R8036

TL8004

TL8013

R1120

R1118

C2738

C8451

R1307

R8073

TL8005

TL8018

TL9023

D9008

Q1102

Q1101

R1119

C2742

TL2704

R2639

TL8455

TL8454

TL8456

D1303

D1301

R8038

TL8007

TL8006

TL8014

TL8015

TL9022

FB2705

R8456

R1306

R8075

TL8008

TL8020

D9006

TL2016

D1307

D1302

TL8009

C8132R8040

TL8016

TL9021

C2737

TL2028

D2601

R8078

TL8019

D9004

TL2026

FB2618

IC2602

R8077

R8074

TL2025

R2610R2605

R8042

R8079

R8046

TL8017

TL2609

FB2609

R2621

Q2602

R8076

Q8003

TL2023

TL2024

TL2605

FB2620

R2608

R2609

R8090

TL2621

R2631

C2603

Q2601

R8089

C9638

TL2022

TL2610

FB2613

C2609

C2607

R8063

TL2021

TL2020

TL2672

R2640FB2619

C8252

TL2019

R8259

R8254

C8263

TL9618

TL2018

R8023

R8016

R8071

C8264

C8262

C8269

R8264

TL2017

R8066

FB8023

R8258

R8260

R8261

R8255

R8256

R8257

LUG1111

R8267

C8270

R8265

TL517

R9010

C8265

C8257

C8260

C8267

TL516

TL515

R8032

R9011

R8018

C8077

C8011

C8015

C8009

C8255

R8021

R8268

C8254C8256

C8253

C8010

R8266

TL2509

C8062

FL8019

C8261

C8251C8258

C1301R1301

C1305

R8053

C8102C8126

C8075C8087

C8028

C8268

C8266

C1316

TL521

TL524

TL526

TL2508

C8125

FL8018

C8065

C8035

C8018

C8026

C8259

TL553

TL2507

C8121

C8013

C8076

C8043R8003

IC1301

C8014

R8005

TL2505

R8033

C8120

FL8017

C8055

C8004

TL8067

C1302

TL552

TL551

TL550

TL2506

C8012

FL8016

FL8015

C8027

C1304

TL522

C8114C8119

FB8003

C1315

TL523

FB2514

TL2501

R8027C8127C8109

R8029

C8118

C8023

R8048

R8047

TL8021

TL525

TL527

C8071

R8028

C8111

C8110

FL8021

FL8022

C8022

R8049

TL2502

FL8020

C8091

C8092

R8052

FB8024

FB8002

C8001

C8094

R8034

C8124

C8047

C8017

C8008

C8007

C8113

C8123

C8073

C8041

FB8017

C8021

C8006

FB8016

C8103

TL511

TL513

R8011

C8078

C8067

C8057

C8005

C8129

C8128

C8112

TL1625

TL1626

C8003

C8016

FB8014

C8131

FB8019

C8089

C8058

FB8015

C1121

C8079

R8009

TL549

TL548

LF2

R2506

C2504

TL2504

FB8021

C8040

R1137

TL8068

C2503

FB8018

FB8020

C8045

C8046

R1138

C8134

TL512

TL514

D2502

R2507

FB8013

C1120

R8050

TL520TL518

TL519

D2503

R2508R2509

IC2502

TL9620

C8142

R8055

C8136

C8133

TL2503

R8056

C8135

R8051

C8143

TL528

TL531

TL533

R1371

R1373

R1368

C1341

IC1307

R1370

TL547

R2501

TL546

TL529

TL530

TL545

C2502

R2511

C1342R1367

TL532

TL534

D2501

R1369

IC1306

R657

Q605

R2502

Q606

C628

R599

R656

R654

C9622R9623

R2503

IC2501

C629

R600

R9625

R9629

D9611

D9612

R644

R643

R8072

R655

C9618

C9621

R9627

TL9619

R572

TL541

TL537

TL535

R9622IC9605

C9626

C2501

R2504

D1625

Q1617

D1626

Q1618

D1627

Q1619

D1628

R1700

R1701

R1706

R1707

D511

R1702

Q1620

R1703

TL1606

R9006R9035

R9619C9616

C9615

C9624

TL1634

TL542

TL540

R9004

R9009

C9608R9606

D9617

D9606

D9607

TL1627

R9608

R9610

C1639R1697

R9609

Q9604

TL544

TL538

TL536

C9606

C9607

R9613

R1696

Q1312

TL539

R1695

IC1614

R9605IC9602

R9614

R1694

TL9613

C9603

C9611

R1333

TL9615

R9616

Q9605

D1624

Q1616

IC1304

L1301

TL543

R9602C9604

C9609

TL1602

C1311

FB9604

D9605

TL9621

Q1622

Q1621

R1601

R1605

C1310

TL9601

D9615C9620R9621

R1699

Q1615

D1630

D1629

C1312R1311R1374

BAR2

R9624

R9628

D9608

D1621

R1617

TL1611

TL9602

FB9601

C9617

R9626

TL9617

D9601

R1705

R1708R1709

D1611

FB9602

FB9603

IC9604

C9619

C9627

C9610

R9612

R1698

R1704

TL1615

TL9010

TL9004

TL9007

TL9603

R9615

R9620

C9605

R1619

C9613

C9625

Q9601Q9603

R9601

R1717

D1606

TL9604

R9617

R9618C9614

C9623

R9603

D1615

IC9603

D9603

C1619

TL9605

R9641

C9637

R9637

R9636

TL9019

C1617

FB9605

TL9606

TL9616

IC9611

TL9013

R9018

TL9011

R9023

C1640

C1615

C1614

TL1302

TL1304

TL1303

TL9009

TL9006

TL9008

FB9606

TL9607

R9013

TL9012

TL9003

IC1610

D1609

TL1608

TL1614

C9612

R9019

R9026

C1616

R1685

FB9607

TL9608

R2029

R9025

TL9005

C1613

C1601

FB1605

D1613

R1614

FB9611

IC2007

C2024

R9607R9611

C1618

C1638

TL1628

R1616

TL611

R9645

R9642R9643

R2041

R2018

C1620

R1640

Q1610

D1617

D1614

TL612

FB9608

D9616

R2031

R2006

R1639

R1689

R1693

TL1631

TL1616

TL613

TL9610

TL9609

Q9607

R2014

R2004

C2015

R2001

C1635

D1616

R9646

R9644

TL2001

R2024

FB9609

TL9612

R2023

Q1609

Q1611

TL1617

R1620R1621

TL1613

FB9610

R2046

R2049

R9005

R9008

IC2002

R1638

D1607

BAR4

TL9611

Q2006

R2003

R2007

C2016

R2019

TL616

TL601

TL602

TL614

FB9612

R2047

C2005

R2022

C2014

C2012

TL603

R2009

R2048

IC9601

C2004

R2010

C2013

TP2001

R8026

R2042

C1623

D1618

TL1605

TL1609

C9601

R2044R2008

TP2002

Q1623R1665

TL610

TL604

R1663

R1604TL1603

C9602

C2003

R2030

R2011

R2033

C2006

TL1604

TL9614

TL2015

IC2001

TL9018

R2032

R2034R2036

R1606

TL609

TL608

TL607

R2020

R1603

TL606

TL605

TL615

R9012

FL2001

R2021

C2007

X2001

TL9014

R1607

C2002

TL9017

TL9016

TL9015

R9030

R1690

TL8059

R9029

R9027

R9014

R1691

R1687

D1608

IC1612

R1686

R9028

TL9020

C1631

TL618

TL8061

TL8060

TL8062

R9604

TL1601

TL1633

C1633

TL1629

TL8058

TL8063

TL8064

TL8065

TL8066

FD4

R1683

TL1632

D1612

D1610

R1682

IC1611

Q1613

TL617

R1609

TL1610

Q1612

R1608

FB2004

FB2003

FB2002

TL1630

R1615R1618

TL1607

TL2004

TL2003

C1632C1636

TL501

LUG1109

TL2005

TL2002

TL9024

TL503

TL502

TL505

TL507

FB2001

TL504

TL506

12345678910111213141516171819

4 – 4

20 21 22

Page 21

LC-32A47L(A)

CHAPTER 5. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIAGRAM

1. VOLTAGE MEASUREMENT CONDITION:

1) The voltages at test points are measured on exclusive AC adaptor and the stable supply voltage of AC 110~240V. Signals are fed by a color bar signal

generator for servicing purpose and the above voltages are measured with a 20k ohm/V tester.

2. INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1) The unit of resistance "Ω" is omitted.

(K=kΩ=1000Ω, M=MΩ).

2) All resistors are ± 5%, unless otherwise noted.

(K= ± 10%, F= ± 1%, D= ± 0.5%)

3) All resistors are 1/16W, unless otherwise noted.

CAPACITOR

1) All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2) All capacitors are 50V, unless otherwise noted.

CAUTION:

This circuit diagram is original one, therefore there may be a slight

difference from yours.

LC-32A47L(A)

Service Manual

SAFETY NOTES:

1) DISCONNECT THE AC PLUG FROM THE AC OUTLET

BEFORE REPLACING PARTS.

2) SEMICONDUCTOR HEAT SINKS SHOULD BE REGARDED AS

POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS

OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH " " ( ) ARE IMPORTANT

FOR MAINTAINING THE SAFETY OF THE SET. BE SURE TO

REPLACE THESE PARTS WITH SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE OF THE SET.

AVIS DE SECURITE IMPORTANT:

LES PIECES MARQUEES " " ( ) SONT IMPORTANTES POUR MAINTENIR LA SECURITE DE L'APPAREIL.

NE REMPLACER CES PIEDES QUE PAR DES PIECES DONT LE

NUMERO EST SPECIFIE POUR MAINTENIR LA SECURITE ET

PROTEGER LE BON FONCTIONNEMENT DE L'APPAREIL.

5 – 1

Page 22

LC-32A47L(A)

[2] MAIN Unit

•MAIN Unit-6/13

I

H

G

F

E

D

C

B

A

TO_MAIN13(POWER1)

TO_MAIN8(CPU)

LV0OUT0M

LV0OUT0P

LV0OUT1M

LV0OUT1P

LV0OUT2M

LV0OUT2P

LV0CKOM

LV0CKOP

LV0OUT3M

LV0OUT3P

TO_MAIN7(UCOM)

DET_PNL12V

DET_SYNC

TO_MAIN11(EXBUS)

TO_MAIN8(CPU)

PNL_PWM2

TO_MAIN12(CONN)

D3.3V

PNL_12V

FRAME

ROMSEL0

TEMP3

TEMP2

TEMP1

O_S_SET

ERR_PNL

SHIP_EN

SHIP_EN

PNL_EN

PNL_PWM

I2C_SCL

I2C_SDA

MAIN6 (PANEL)

5V

L2606

FA154WJ

1

L2601

FA154WJ

1

3

2

4

L2602

FA154WJ

1

3

2

4

L_R

U_D

VON

3

2

4

L2607

FA154WJ

1

3

2

4

L2608

FA154WJ

1

3

2

4

R2606

0

R2607

0

R2613

R2614

0

0

100K

R2636

1234567

*IC2602

R2601

8

M62332FP

*C2609

0.1u

10V

R2602

22K

1234567

5.0

8

7

6

5

22K

8

R2603

F

22K

Q2603

KRC404E

AO1

1

Vcc

NC

2

SCL

NC

3

SDA

NC

4

GND

R2635

10K

*R2621

10K

R2639

100K

MAIN UNIT 6/13

DUNTKF030WE

(PWBXF030WJ)

FB2604

A375WJQZ

FB2605

A375WJQZ

FB2606

A375WJQZ

FB2607

A375WJQZ

FB2608

A375WJQZ

FB2621

A074WJ

FB2622

A074WJ

FB2623

A074WJ

FB2624

A074WJ

FB2625

A074WJ

FB2626

A074WJ

FB2627

A074WJ

FB2628

A074WJ

FB2629

A074WJ

FB2630

A074WJ

FB2631

A074WJ

FB2613

A074WJ

FB2619

A074WJ

FB2620

A074WJ

FB2609

A204WJ

FB2618

A074WJ

C2606

0.1u

CZB

*FB2602

A375WJQZ

*FB2601

A375WJQZ

*FB2615

A375WJQZ

*FB2633

A375WJQZ

*FB2634

A375WJQZ

*FB2635

A375WJQZ

*FB2636

A375WJQZ

*FB2637

A375WJQZ

LW

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

LB1

6

5

4

3

2

1

LP

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

TA1-

TA1+

TB1-

TB1+

TC1-

TC1+

GND

TCLK1-

TCLK1+

TD1-

TD1+

TE1-

TE1+

GND

TA2-

TA2+

TB2-

TB2+

TC2-

TC2+

GND

TCLK2-

TCLK2+

TD2-

TD2+

TE2-

TE2+

GND

LVDS_SEL

R/L

U/D

HV_MODE

ROMSEL1

ROMSEL0

TEMP3

TEMP2

TEMP1

PE

OS_EN

SHIP_EN

P2603

NA340WJ

OFL2

BRT

ERR

OFL1

VON

GND

*P2602

NA349WJ

DET

LCD_EN

VCOM_SDA

VCOM_SCL

VCOM_WP

COND_DET

TEST_MODE

GND

GND

GND

GND

VCC

VCC

VCC

VCC

P2601

WA659WJQZ

TO LCDCONT

TO LCDCONT

TO INV

->

<-

->

->

<-

->

<->

<->

->

->

->

12345678910111213141516171819

5 – 2

20 21 22

Page 23

• MAIN Unit-13/13

I

H

G

F

E

D

C

B

A

MAIN UNIT 13/13

DUNTKF030WE

(PWBXF030WJ)

P9601

NA181WJ

To Power Unit

PD

UR13V

UR13V

UR13V

UR13V

GND

GND

GND

GND

AC_DET/NC

PS_ON

BU5V

PNL_ON

*Q9602

MCH6305

123

CZ

TO MAIN7(UCOM)

TO MAIN3(AMP_IF)

TO MAIN6(PANEL)

TO MAIN8(CPU)

VS

D3.3V

BU3.3V

AC_DET

DET_13V

SMPOW

AC_DET

PNL_12V

SMPOWHOLD

456

*R9639

100K

RT1N141U

5V

1

2

3

4

5

6

7

8

9

10

11

12

VHD

*D9602

RB056L40

*R9640

100K

CZ

KZA520WJQZ

IC9601

TCR5SB33

4.7u

KZA403WJPZ

*Q9606

D9601

D9613

C9601

1u 10V

C9602

R9607

47K

D9615

*FB9610

A074WJ

6.3V

FB9601

A375WJQZ

FB9602

A375WJQZ

FB9603

A375WJQZ

FB9604

A375WJQZ

FB9605

A375WJQZ

FB9606

A375WJQZ

FB9607

A375WJQZ

FB9611

A375WJQZ

*FB9608

A074WJ

FB9609

A074WJ

*FB9612

A375WJQZ

3

4

F

VHD

MA111G

VHD

MA111G

VHD

MA111G

GND_B

ON

NC

R9611

4.7K CZ

LC-32A47L(A)

MAIN13 (POWER)

*R9636

27K

CZ

*R9637

10KCZF

*R9645

1K

CZ

R9605

C9603

0.01u

CZB

25V

5.6K

C9607

CZB

7EN8

SS

1000P

COMP

5FB6

0.796

R9608

10K

F

R9609

47K

IC9602

R9610

6.8K

F

LV5893M

GND

Vin

1BS2

R9601

10K

R9603

3SW4

L9601

PA898WJ

CZB

C9608

1000P

R9606

4.7

456

C9605

0.01u

25V

CZ

1K

CZ

VHD

D9603

MA111G

1.9A,77m

KZA510WJPZ

D9604

D1FH3

CZ

Q9603

RN4982

456

15uH

C9609

10u

16V

5.1V 1440mA

D9605

MA111G

12 3

C9610

1u

10V

KZA520WJQZ

C9611

10u

16V

KZA510WJPZ

VHD

R9612

4.7K

CZ

D9607

MA111G

C9604

0.1u

25V

CYB

R9602

39

C9606

10u

16V

KZA510WJPZ

1

*R9646

VHD

0

CZ

D9614

MA111G

Q9601

RN4982

12 3

VIn2GND

Vout

5

KTC3875SG

VS

Q9605

D1.2V

R9613

4.7K

CZ

D9606

EXA523WJ

5.6V

R9614

IC9603

PQ1LAX95

3

On

Vin5Vout

4

10K

F

R9615

5.6K CZ

1

2

GND

Vadj

C9612

1u

KZA520WJQZ

Q9604

RT1N141U

1PS226

3

10V

VS

D9608

R9616

3.9K

CZ

R9617

33K

R9641

2.2K

R9622

4.7K

R9625

C9621

4700P

25V

0.796

5FB6

COMP

GND

C9622

1000P

IC9608

PQ1LA335

Nr

1

2

GND

3

On

0.796

5FB6

GND

D9609

D1FS4A

10K

IC9605

LV5893M

R9623

4.7

R9624

10K

F

R9626

IC9604

LV5893M

VHD

F

R9627

27K

L9603

D9610

D1FS4A

VHD

*IC9606

PQ1LA185

5.6K

L9602

15uH

PA898WJ

1.9A,77m

KZA510WJPZ

F

15uH

PA898WJ

Vout

Vin

C9629

0.1u

R9628

330

F

CIL

C9623

10u

16V

R9629

4.7K

1.9A,77m

C9624

10u

16V

KZA510WJPZ

5

4

10V

CZB

D1.26V 680mA

C9625

10u

16V

KZA510WJPZ

KZA510WJPZ

C9626

10u

16V

KZA510WJPZ

2

3

GND

On

Vin5Vout

4

IC9607

MM3441JF

CE

5

Sub

6

7

Vin

C9627

10u

Vadj

R9630

16V

3.32V 700mA

1

NC

GND

NC

Vout

1

1/2W

TWF

D9611

EXA512WJ

4V

D9612

MA111G

*C9628

0.01u

25V

CZB

C9630

1u

10V

KZA520WJQZ

4

3

2

1

R9632

1/2W

1

TWF

22k

3

Q9609

RN2408

L9604

100uH

PA903WJ

0.7A,0.5

R9631

1

1/2W

TWF

22k

3

Q9608

RN2408

A1.8V 220mA

C9638

100u

4V

ARC

C9631

1u

10V

KZA520WJQZ

D1.8V 380mA

47k

D9618

MA111G

C9633

10u 16V

KZA510WJPZ

R9633

1

TWF

47k

D9619

MA111G

1

2

1/2W

1

2

39

C9618

10u

16V

KZA403WJPZ

8

SS

1BS2

10u

16V

25V

SS

1BS2

C9634

4.7u

CZB

7

CZB

7EN8

Vin

3SW4

CZB

6.3V

R9620

4.7K

C9619

4700P

25V

NC

EN

COMP

Vin

3SW4

C9615

0.01u

CZB

CYB

C9616

0.1u

25V

R9619

KZA510WJPZ

C9632

0.01u

CZB

C9613

0.01u

25V

CZB

C9614

0.1u

25V

CYB

R9618

2

39

1

J

C9617

KZA510WJPZ

TO MAIN1(TUNER)

A9V

A5V

A3.3V

TO MAIN2(A_TERM)

A9V

5V

A5V

D3.3V

TO MAIN3(AMP_IF)

UR13V

A9V

A5V

D3.3V

TO MAIN4(AMP)

UR13V

TO MAIN14(SP_IF)

5V

D3.3V

BU3.3V

TO MAIN5(HDMI_SW1)

5V

BU3.3V

D3.3V

TO MAIN6(PANEL)

5V

D3.3V

TO MAIN10(EPROM)

BU3.3V

D3.3V

TO MAIN11(EXBUS)

D3.3V

TO MAIN12(CONN)

D3.3V

BU3.3V

BU5V

5V

TO_MAIN9(DDR)

D1.8V

TO MAIN8(CPU)

BU3.3V

PNL_ON

D3.3V

A1.8V

D1.8V

5V

D1.2V

A3.3V

USB 500mA

120mA

400mA

380mA

300mA

1030mA

180mA

12345678910111213141516171819

5 – 3

20 21 22

Page 24

LC-32A47L(A)

5 – 4

Page 25

PartsGuide

LC-32A47L(A)

PARTS GUIDE

No. S89C1LC32A47A

LCD COLOR TELEVISION

Note:

The reference numbers on the PWB are arranged

in alphabetical order.

[1] PRINTED WIRING BOARD ASSEMBLIES

[2] LCD PANEL

[3] DUNTKF030FM26 (MAIN Unit)

[4] CABINET AND MECHANICAL PARTS

MODEL

CONTENTS

LC-32A47L(A)

[5] SUPPLIED ACCESSORIES

[6] PACKING PARTS

(NOT REPLACEMENT ITEM)

[7] SERVICE JIGS (USE FOR SERVICING)

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 26

LC-32A47L(A)

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

[1] PRINTED WIRING BOARD ASSEMBLIES

N DUNTKF030FM26 BX N X MAIN Unit

N DUNTKF069FM06 AH N X KEY Unit

N DUNTKF115FM03 AM X LED Unit

!

N RDENCA363WJQZ BN N X POWER Unit

[2] LCD PANEL

N R1LK315T3LF22Z CZ N X 32" LCD Panel Module Unit

[3] DUNTKF030FM26 (MAIN Unit)

D9602 VHDRB056L40-1Y AC J Diode, RB056L-40TE25

FB2601 RBLN-A375WJQZY AA J Ferrite Bead

FB2602 RBLN-A375WJQZY AA J Ferrite Bead

FB2615 RBLN-A375WJQZY AA J Ferrite Bead

FB2633 RBLN-A375WJQZY AA J Ferrite Bead

FB2634 RBLN-A375WJQZY AA J Ferrite Bead

FB2635 RBLN-A375WJQZY AA J Ferrite Bead

FB2636 RBLN-A375WJQZY AA J Ferrite Bead

FB2637 RBLN-A375WJQZY AA J Ferrite Bead

P2602 QPLGNA349WJZZY AE J Plug

Q9602 VSMCH6305++-1Y AE J Transistor, MCH6305-TL-E

Q9606 VSRT1N141U/-1Y AB N J Transistor, RT1N141U-T111-1

R9639 VRS-CZ1JF104JY AA J Resistor, 100k 1/16W Metal Oxide

R9640 VRS-CZ1JF104JY AA J Resistor, 100k 1/16W Metal Oxide

DESCRIPTION

2

Page 27

[4] CABINET AND MECHANICAL PARTS

28

1-6

1-6

33

32

1-7

1-1

1-7

25

7

40

17

41

9

41

41

41

16

41

1-2

1

8

41

15

10

17

35

35

41

5

36

18

41

13

12

14

11

11

41

30

22

41

41

29

31

41

41

24

3-1

3

3-2

41

37

19

26

27

34

4

2-1

2

39

42

6

42

2-2

2-3

2-3

2-2

20

35

16

35

40

LC-32A47L(A)

3

Page 28

LC-32A47L(A)

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

[4] CABINET AND MECHANICAL PARTS

1 CCABAC469WJ31 BG N X Front Cabinet Ass'y

1-1 Not Available - N - Front Cabinet

1-2 Not Available - - LED Decoration

1-6 Not Available - - Spacer, x2

1-7 PSPAHB408WJZZ AC X Spacer, x2

2 CCABBB638WJ01 BG N X Rear Cabinet Ass'y

2-1 Not Available - N - Rear Cabinet

2-2 Not Available - - VESA Angle, x4

2-3 XEBSN30P08000 AA J Screw, x4

3 CCOVAD295WJ03 AL X Side AV Cover Ass'y

3-1 Not Available - - Side Terminal Cover

3-2 Not Available - N - Side Terminal Label

4 GCOVAD297WJ3A AD X Bass Cone Cover

5 GDAI-A548WJ3A AM X Stand Support

6 HINDPD489WJSA AD N X Model Label

7 JBTN-A812WJ3A AF X Control Button

8 LANGKC126WJFW AN X Support Angle

9 LANGKC275WJFW AP N X LCD Fix Angle-T

10 LANGKC276WJFW AR N X LCD Fix Angle-B

11 LANGKC277WJFW AF N X Power PWB Angle, x2

12 LANGKC278WJFW AF N X Main PWB Angle M

13 LANGKC279WJFW AG N X Main PWB Angle L

14 LANGKC280WJFW AG N X Main PWB Angle R

15 LHLDWA143WJKZ AC J Wire Holder

16 LHLDWA151WJKZ AB J Wire Holder, x2

17 LHLDWA175WJUZ AC J Wire Holder, x8

18 LHLDWA176WJUZ AC J Wire Holder

19 NSFTZA284WJFW AC J Shaft, x2

20 TLABK0023TAZZ AA J Bar Code Label

22 PSLDMB577WJFW AN N X Main PWB Shield

24 QCNCMA275WJQZ AC J Model Selector

25 QCNW-J170WJQZ AF N X Connecting Cord (KM)

26 QCNW-J171WJQZ AL N X Connecting Cord (PD)

27 QCNW-J173WJQZ AK N X

28 QCNW-J174WJQZ AG N X Connecting Cord (SP)

29 QCNW-J834WJPZ AV N X Connecting Cord (LW)

30 QCNW-J630WJPZ AK N X Connecting Cord (LB2)

31 QCNW-J639WJQZ AF N X Connecting Cord (LB1)

32 RSP-ZA391WJZZ AP N J Speaker-L

33 RSP-ZA392WJZZ AP N J Speaker-R

34 TLABNB037WJZZ AC X Back Serial No. Label

35 XBBS940P05000 AB J Screw, x6 (for Panel)

36 XBPS740P55KS0 AC X Screw, x4 (for Support)

37 XBPS830P06000 AA J Screw, x2 (for HDMI)

39 XEBS940P16000 AB J Screw, x10 (for Cabinet)

40 XEBSN40P10000 AB J Screw, x4

41 XHPS830P06WS0 AA J Screw, x38

42 XHPS830P10WS0 AB J Screw, x3

Connecting Cord (RA)

DESCRIPTION

4

Page 29

[5] SUPPLIED ACCESSORIES

LC-32A47L(A)

X4

Screw Ass'y

X7

X5

X2X1

X3

X6

"AA" size battery

NO. PARTS CODE

[5] SUPPLIED ACCESSORIES

X1 RRMCGA667WJSA AN N X Remote Control Unit

!

X2 QACCZA070WJPZ AK J AC Cord

X3 CDAI-A549WJ02 BC N X Stand Unit

X4 CX-BZA329WJ01 AD N X Screw Ass'y

X5 TINS-E169WJN1 AE N X Operation Manual (English)

X6 TINS-E170WJN1 AE N X Operation Manual (Spanish)

X7 Not Available - - "AA" Size Battery

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

DESCRIPTION

5

Page 30

LC-32A47L(A)

[6] PACKING PARTS (NOT REPLACEMENT ITEM)

S4

S2

S3

X1

X5

X6

S6

S1

S5

S5

S5

S8

X4

X7

S7

X2

S5

S9

S9

6

Page 31

LC-32A47L(A)

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

[6] PACKING PARTS (NOT REPLACEMENT ITEM)

S1 SPAKCF243WJZZ - N - Packing Case

S2 SPAKAA373WJZZ - - Cover Sheet

S3 SPAKPB045WJZZ - N - Wrapping Paper

S4 SPAKPB385WJZZ - N - Mirror Mat Base

S5 SPAKXC400WJZZ - N - Packing Add.

S6 SSAKA0101GJZZ - - Polyethylene Bag

S7 SSAKAA032WJZZ - - Polyethylene Bag

S8 SSAKHA051WJZZ - N - Polyethylene Bag

S9 TLABKA009WJZZ - - Case No. Label

[7] SERVICE JIGS (USE FOR SERVICING)

N QCNW-J832WJPZ N J Connecting Cord (L=700mm)

N Main - LCD Control Unit (LW)

N QCNW-J277WJQZ J Connecting Cord (L=700mm)

N Power - Inverter Unit (LB2)

DESCRIPTION

7

Page 32

LC-32A47L(A)

COPYRIGHT 2009 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

Aug. 2009

SH. KD

SHARP CORPORATION

AV Systems Group

CS Promotion Center

Yaita, Tochigi 329-2193, Japan

Loading...

Loading...