Page 1

LC-121M2U

LC-150M2U

SERVICE MANUAL

LCD AV MONITOR

SERVICE MANUAL

SX8Z8LC-121M2U

LCD AV MONITOR

LC-121M2U

LC-121M2U

LC-121M2U

LC-150M2U

LC-150M2U

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original

condition and only parts identical to those specified be used.

1. IMPORTANT SERVICE SAFETY PRECAUTION .................................................................................... 2

MODELS LC-121M2U/150M2U

2. SPECIFICATIONS ................................................................................................................................... 4

3. PART NAMES.......................................................................................................................................... 5

4. DISASSEMBLY OF THE SET.................................................................................................................. 6

5. ADJUSTING PROCEDURE OF EACH SECTION ................................................................................... 8

6. INTEGRATED CIRCUIT TERMINAL ARRANGEMENTS ........................................................................ 19

7. TROUBLE SHOOTING TABLE................................................................................................................ 24

8. CHASSIS LAYOUT .................................................................................................................................. 29

9. SCHEMATIC DIAGRAM .......................................................................................................................... 32

10. BLOCK DIAGRAM ................................................................................................................................... 47

11. PRINTED WIRING BOARD ASSEMBLIES .............................................................................................. 49

12. REPLACEMENT PARTS LIST ................................................................................................................. 54

13. PACKING OF THE SET ........................................................................................................................... 65

MODELS

CONTENTS

LC-150M2U

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

LC-121M2U

LC-150M2U

1. IMPORTANT SERVICE SAFETY PRECAUTION

æ Service work should be perfomed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines which follow:

LC-121M2U

LC-150M2U

WARNING

1. For continued safety, no modification of any

circuit should be attempted.

2. Disconnect AC power before servicing.

CAUTION

FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE, REPLACE

ONLY WITH SAME TYPE F701, F703 (1.6A

125V), F702 (2.5A 125V).

5A 125V

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user,

perform the following safety checks:

1. Inspect all lead dress to make certain that leads

are not pinched, and check that hardware is not

lodged between the chassis and other metal

parts in the receiver.

2. Inspect all protective devices such as non-metallic control knobs, insulation materials, cabinet

backs, adjustment and compartment covers or

shields, isolation resistor-capacitor networks,

mechanical insulators, etc.

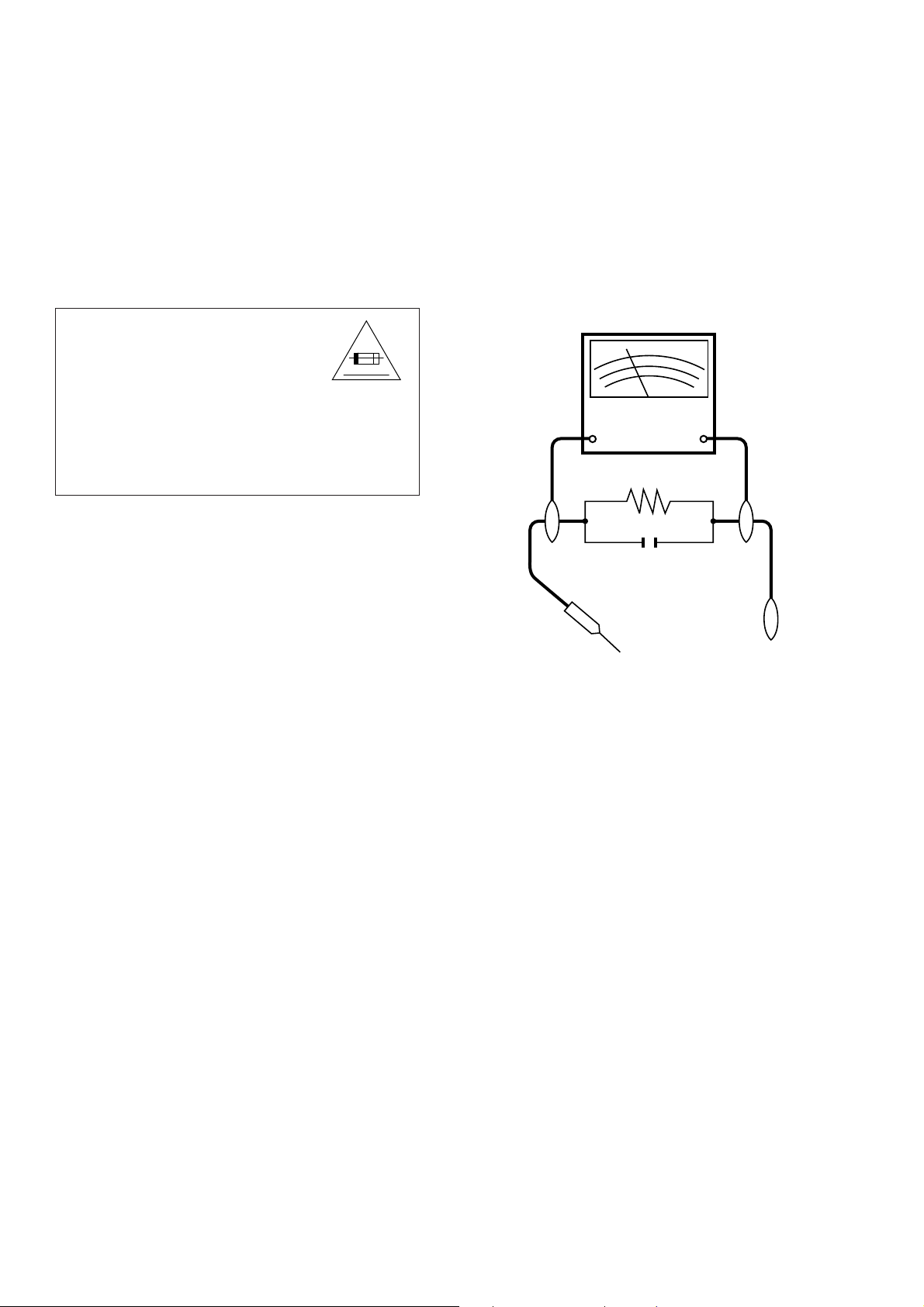

3. To be sure that no shock hazard exists, check for

current in the following manner.

• Plug the AC Adapter directly into a 120-volt AC

outlet, and connect the DC power cable into the

monitor's DC jack. (Do not use an isolation

transformer for this test).

• Using two clip leads, connect a 1.5k ohm, 10

watt resistor paralleled by a 0.15µF capacitor in

series with all exposed metal cabinet parts and

a known earth ground, such as electrical conduit

or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per

volt, or higher, sensitivity or measure the AC

voltage drop across the resisor.

• Connect the resistor connection to all exposed

metal parts having a return path to the chassis

(antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage drop across the resistor.

All checks must be repeated with the AC Adaptor plug connection reversed.(If necessary, a

nonpolarized adaptor plug must be used only for

the purpose of completing these checks.)

Any reading of 0.3V RMS(this corresponds

to 0.2 milliamp. AC.) or more is excessive and

indicates a potential shock hazard which must

be corrected before returning the receiver to

the owner.

DVM

AC SCALE

1.5k ohms.

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD monitor

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by

“ å” and shaded areas in the

and Schematic Diagrams

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock. fire. or other hazards.

Replacement Parts Lists

.

2

Page 3

LC-121M2U

LC-150M2U

1. PRECAUTIONS A PRENDRE LORS DE LA REPARATION

ÆÆ

Æ Ne peut effectuer la réparation qu’ un technicien spécialisé qui s’est parfaitement

ÆÆ

accoutumé à toute vérification de sécurité et aux conseils suivants.

LC-121M2U

LC-150M2U

AVERTISSEMENT

1. N’entreprendre aucune modification de tout circuit.

C’est dangereux.

2. Débrancher le récepteur avant toute réparation.

PRECAUTION

POUR LA PROTECTION CONTINUE

CONTRE LES RISQUES D’INCENDIE,

REMPLACER LE FUSIBLE PAR UN FUSIBLE

DE MEME TYPE F701, F703 (1.6A 125V), F702

(2.5A 125V).

5A 125V

VERIFICATIONS CONTRE L’INCENDIE ET LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l’utilisateur,

effectuer les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour

s’assurer que les fils ne soient pas pincés ou

qu’un outil ne soit pas placé entre le châssis et

les autres pièces métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme

les boutons de commande non-métalliques, les

isolants, le dos du coffret, les couvercles ou

blindages de réglage et de compartiment, les

réseaux de résistance-capacité, les isolateurs

mécaniques, etc.

3. S’assurer qu’il n’y ait pas de danger

d’électrocution en vérifiant la fuite de courant, de

la facon suivante:

• Brancher l’adaptateur CA dans la prise CA de

120 V et le câble d’alimentation CC dans le jack

du moniteur. (Ne pas utiliser un transformateur

pour cet essai.)

• A l’aide de deux fils à pinces, brancher une

résistance de 1,5kΩ 10 watts en paralléle avec

un condensateur de 0,15µF en série avec toutes

les pièces métalliques exposées du coffret et

une terre connue comme une conduite électrique

ou une prise de terre branchée à la terre.

• Utiliser un voltmètre CA d’une sensibilité d’au

moins 5000Ω/V pour mesurer la chute de tension en travers de la résistance.

• Raccordez la résistance à toutes les pièces

exposées qui ont un chemin de retour au châssis

(antenne, coffret métallique, têtes de vis, boutons, arbres de commande, emblème, etc) et

mesurez une chute de tension CA à travers la

résistance.

Il faut répéter les vérifications en inversant la

connexion de la fiche de l'adaptateur CA (S'il

y a lieu, utilisez une fiche non polarisée pour

seulement compléter ces vérifications.)

Une valeur de 0,3 V RMS ou plus (correspond

à 0,2 mA C.A.) est excessive et implique un

danger de secousse électrique, qui devra être

supprimé avant de retourner l'appareil à

l'utilisateur.

DVM

Echelle CA

1.5 k ohm

10W

0,15 µF

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les téléviseurs présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes

à vue. Le degré de protection ne peut pas être

nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

pièces électriques qui présentent ces particularités sont

identifiées par la marque “ å” et hachurées dans la liste

des pièces de remplacement et les diagrammes

schématiques.

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d’origine.

L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies, radiations X ou autres accidents.

3

Page 4

LC-121M2U

LC-150M2U

2. SPECIFICATIONS

Number of Picture Elements: 921,600 (480 (V) × 640 (H) × 3 (RBG) )

Connected Terminals: Input: DC12V, VHS, S-VHS, Audio and DVD

Power Consumption (Approx.): 38 W (Connected to AC Adapter) (LC-121M2U)

Operating Temparature: –10°C~40°C

LC-121M2U

LC-150M2U

Type: LCD display unit (LCD color AV monitor)

Size: 12.1" type (184.3 mm × 245.8 mm) (LC-121M2U)

15" type (305.3 mm × 229.0 mm) (LC-150M2U)

Display System: Transmitting type TN liquid crystal panel.

Driving System: TFT (Thin Film Transistor) active matrix system

Speaker Output: 0.7 W × 2 (Front)

2 W × 1 (Rear)

Speaker: 30 mm × 40 mm (Elliptic) × 2 (Front)

65 mm (Round) × 1 (Rear)

Light Source: Internal Light (Built-in fluorescent lamp)

Output: VHS, S-VHS, Audio and Headphone

Power Source: AC 100~240·50/60Hz (Connected to AC Adapter)

40 W (Connected to AC Adapter) (LC-150M2U)

Dimensions: 297.4 mm (W) × 264.6 mm (H) × 87 mm (D) (Includes Set Stand)

(LC-121M2U)

357.0 mm (W) × 309.2 mm (H) × 87 mm (D) (Includes Set Stand)

(LC-150M2U)

297.4 mm (W) × 264.6 mm (H) × 62.5 mm (D) (Not Include Set Stand)

(LC-121M2U)

357.0 mm (W) × 309.2 mm (H) × 62.5 mm (D) (Not Include Set Stand)

(LC-150M2U)

Weight (Approx.): 2.9 kg (LC-121M2U)

3.6 kg (LC-150M2U)

Accessories: Operation Manual, Guarantee Card, AC Adapter, Remote Control,

Set Stand Mounting Screws, Wall mounting set angle and Batteries

(AAA size x 2)

Specifications are subject to changed without prior notice.

4

Page 5

LC-121M2U

LC-150M2U

3. PART NAMES

LC-121M2U

LC-150M2U

5

Page 6

LC-121M2U

LC-150M2U

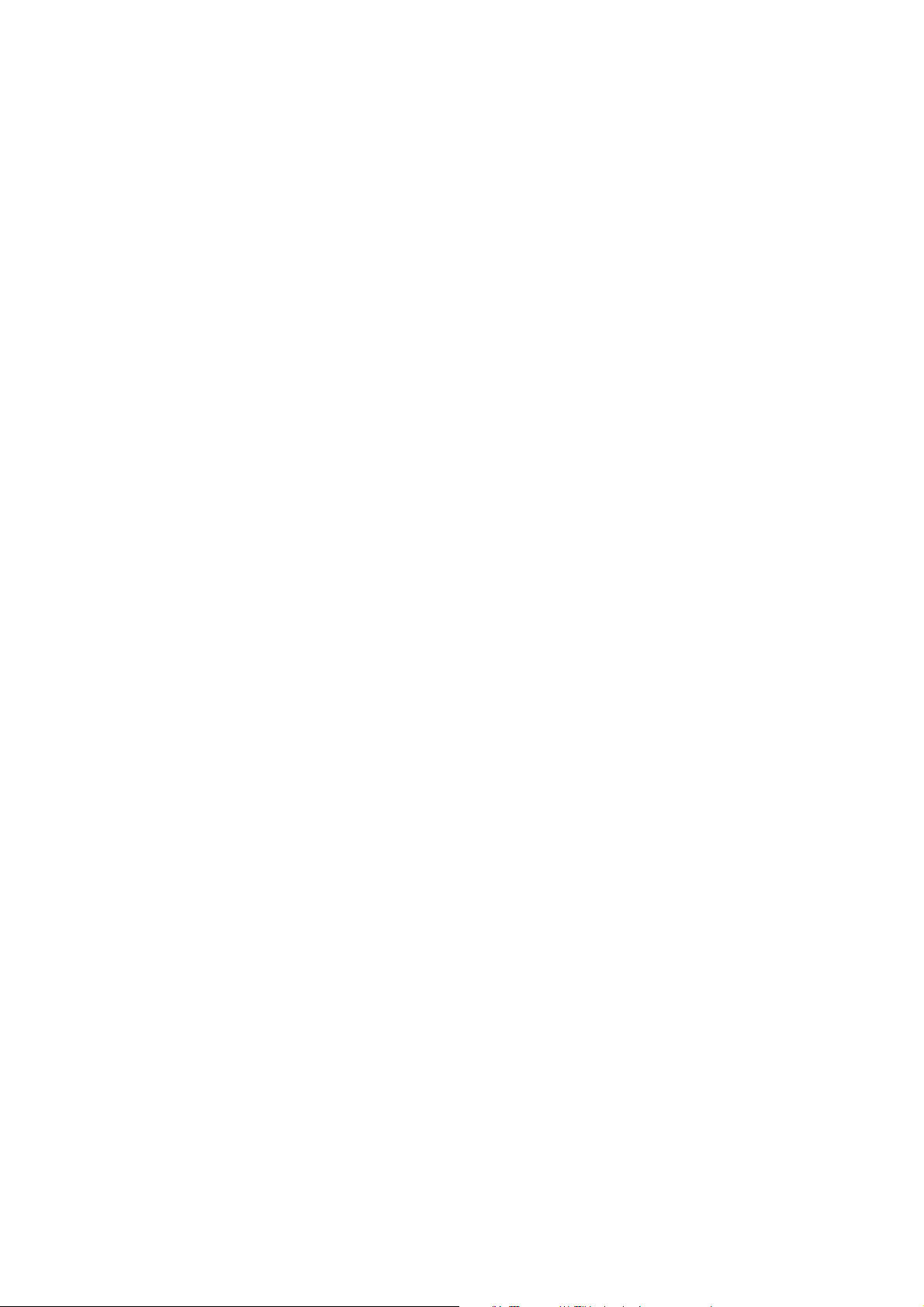

4. DISASSEMBLY OF THE SET

LC-121M2U

LC-150M2U

1. Remove four screws (1).

2. Opening six claws ( a ), release the cabinet B.

Remove the wire holder ( b ) and disconnect each

connectors (2~6).

Remove the cabinet B.

3. Remove two screws (7) which mounting the LCD

display unit.

4. Remove soldering of copper-foil tape (8) .

5. Disconnect each connectors (9~e) from the LCD

display unit.

6. Remove the cabinet A.

Push

1

a

a

a

a

a

7. Remove four screws (r) which mounting the main

PWB unit.

8. Remove one screw (t) and remove the remote control

receptor PWB.

9. Remove five screws (y) and GND cable.

10.Remove ten screws (u) and remove the terminal

cover.

11.Remove two screws (i) and remove the switch PWB.

Cabinet B

Cabinet B

5

Cabinet A

c WH

2

b WH

3

a

a

1

8

4

6

r

y

Cable

q

0

w

7

e

7

9

u

u

i

t

Cabinet A

CCABA2338CE02 GCABA2338CEKA (LC-121M2U)

CCABA2343CE02 GCABA2343CEKA (LC-150M2U)

Cabinet B

CCABB2246CE02 GCABB2246CEKA (LC-121M2U)

CCABB2249CE02 GCABB2249CEKA (LC-150M2U)

6

Page 7

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

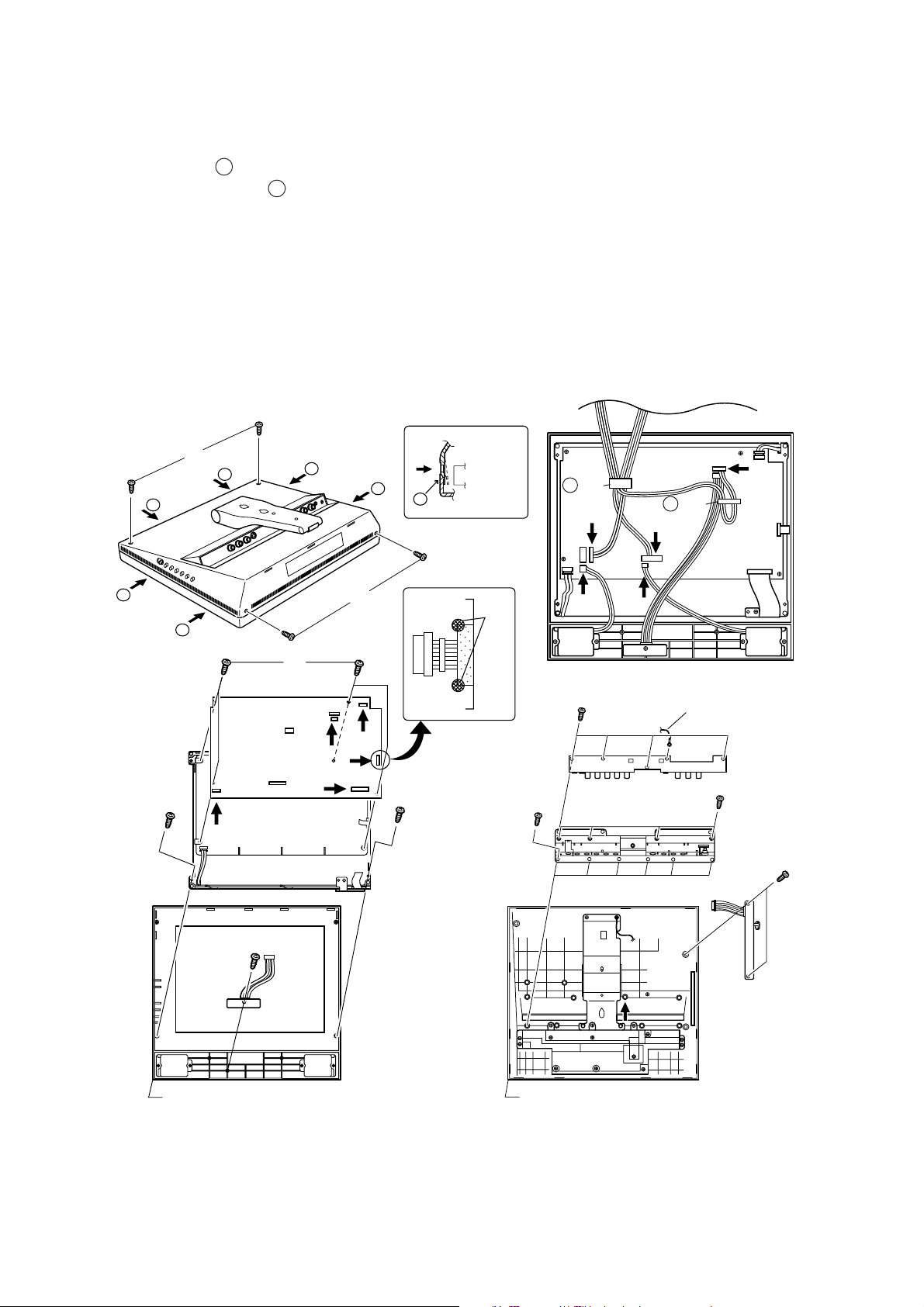

12.Remove one screw (o) and remove the SOS shield

angle.

13. Remove four screws (p) which mounting the LCD

display unit.

14.Spread bites of the LCD unit (a) out to be off from

claws.

15.Remove the Lamp unit (s).

o

p

p

Holder

LHLDZ2082CEKZ (LC-121M2U)

LHLDZ2085CEKZ (LC-150M2U)

s

a

7

Page 8

LC-121M2U

LC-150M2U

5. ADJUSTING PROCEDURE OF EACH SECTION

The best adjustment is made before shipping. If any position deviation is found or after part replace is performed, adjust

as follows.

5-1. Preparation for adjustment

(1)Use the exclusive-use AC adapter or stable DC power supply.

AC adapter: UADP-0183CEZZ

DC power supply: 12 ± 0.5V

5-2. Special mode setting procedure

(1)After initialization of E2PROM the mode is changed to the adjustment mode.

[Procedure]

Connect TP2007 and TP2008 to GND, and turn on the power.

[Description]

• The initialization of microcomputer is as follows.

• AV position, DAC data, G/A data, and video chroma data adjustment values are taken as defaults.

(2)Change to adjustment mode

[Procedure]

Short-circuit TP2007 to GND, and turn on the power.

Or short-circuit TP2008 to GND, and turn on the power.

Or holding down the [AV INPUT] key and [MENU] key, turn on the main power, and simultaneously press the (inspection

process) [SELECT "] key and [VOL– ] key to change the mode to the adjustment mode.

LC-121M2U

LC-150M2U

[Description]

The manual adjustment or adjustment through communication with the automatic machine is performed.

(3)Inspection mode

[Procedure]

Holding down the [AV INPUT] key and [MENU] key, turn on the power.

[Description]

• In the ordinary menu select “PICTURE” with the [SELECT] key, and decide with the [VOL] key. Then select

“CONTRAST”, “TINT (only NTSC)”, “COLOR”, “BLACK LEVEL”, “SHARPNESS”, “RED” , and “BLUE” with the

[SELECT] key, and decide with the [VOL] key. After that, adjust values with the [VOL] key.

• In the ordinary menu select “SOUND” with the [SELECT] key, and decide with the [VOL] key. Then, select “TREBLE”,

“BASS”, and “BALANCE” with the [SELECT] key, and decide with the [VOL] key. After that adjust values with the [VOL]

key.

• VOLUME, CONTRAST, TINT (only NTSC), COLOR, BLACK LEVEL, SHARPNESS, RED, BLUE, TREBLE, BASS,

and BALANCE change as follows.

ûMin.Û ûCenterÛ ûMax.Û

(4)Shipping setting mode

[Procedure]

Holding down the [AV INPUT] key and [MENU] key, turn on the main power, and simultaneously press the (inspection

process) [SELECT '] key and [VOL+] key to change the mode to the adjustment mode.

[Description]

User adjustment and other values are taken as defaults.

If AV1 is indicated as SETTING COMPLETE, setting has been completed.

8

Page 9

LC-121M2U

LC-150M2U

5-3. Cancel of special mode

Turn off the main unit power.

5-4. Preparation adjustment

(1)Use the exclusive-use AC adapter or stable DC power supply.

AC adapter: UADP-0183CEZZ

DC power supply: 12 ± 0.5V

5-5. OSD menu indication and items in case of manual adjustment

Adjusting range

Page Item Minimum Maximum Initial Remarks

1 + B – ADJ 0 255 128

MODEL M2H F2/M2H/M2U/M2E

TUNER OFF 1/2/OFF

AUDIO MULTIPLEX OFF OFF/ON

BOOSTER 0 0/1/2/3

SYSTEM AUTO N358/N443/PAL/PAL-M/SECAM/AUTO

COPY GUARD ON OFF/ON

CH MEMORY OFF OFF/12/16

SECAM ON OFF/ON

MULTI LANG. OFF OFF/ON

TIMER OFF OFF/ON

The Ver. No. will be displayed on the lowest part of lines.

2 TA1276 DATA ~~~~

COM 0 255 128

NTSC/PALM OSC 0 255 128

N358 BRIGHTNESS 0 255 170

R CUTOFF 0 255 80

B CUTOFF 0 255 80

N358UNICOLOR 0 127 80

R DRIVE 0 127 64

B DRIVE 0 127 64

N358SCOLOR 0 31 25

N358TINT 0 127 74

DATA COPY WAIT WAIT/SEND

3 N358 R-Y PHASE 0 3 2

N358 B-Y PHASE 0 3 1

N443 BRIGHTNESS 0 255 170

N443 UNICOLOR 0 127 80

N443 SCOLOR 0 31 25

N443TINT 0 127 74

PAL-M BRIGHTNESS 0 255 170

PAL-M UNICOLOR 0 127 80

PAL-M SCOLOR 0 31 25

PAL-M TINT 0 127 74

R-ADJ 0 255 128

One blank line.

LC-121M2U

LC-150M2U

9

Page 10

LC-121M2U

LC-150M2U

4 PAL/SECAM OSC 0 255 128

5 DVD NT BRIGHTNESS 0 255 170

6 TEST PATTERN OFF ON/OFF

7 N443 R-YPHASE 0 3 2 Fixed

PAL BRIGHTNESS 0 255 170

PAL UNICOLOR 0 127 80

PAL SCOLOR 0 31 25

PAL TINT 0 127 74

BELL F0 0 255 120

B-Y BLACK LEVEL 0 15 8

R-Y BLACK LEVEL 0 15 8

SECAM BRIGHTNESS 0 255 170

SECAM UNICOLOR 0 127 80

SECAM COLOR 0 127 75

SECAM TINT 0 127 74

DVD NT UNICOLOR 0 127 80

DVD NT COLOR 0 127 75

DVD NT TINT 0 127 74

DVD NT R-YPHASE 0 3 2

DVD NT B-YPHASE 0 3 3

DVD PAL BRIGHTNESS

DVD PAL UNICOLOR 0 127 80

DVD PAL COLOR 0 127 75

DVD PAL TINT 0 127 74

I2C DATA 000000

I2C DATA WAIT WAIT/SEND

G/A DATA 0000

G/A DATA WAIT WAIT/SEND

DIGITAL SYNC SEP. 0 FF 87 Fixed

AV NTSC H 0 7F 18 Fixed

DVD NTSC H 0 7F 1C Fixed

AV PAL H 0 7F 11 Fixed

DVD PAL H 0 7F 15 Fixed

AV SECAM H 0 7F 0E Fixed

NT/PALM V 1 1F 0C Fixed

PAL V 1 1F 0B Fixed

SECAM V 1 1F 0B Fixed

N443 B-YPHASE 0 3 1 Fixed

PAL R-YPHASE 0 3 2 Fixed

PAL B-YPHASE 0 3 1 Fixed

PAL-M R-YPHASE 0 3 2 Fixed

PAL-M B-YPHASE 0 3 1 Fixed

SECAM R-YPHASE 0 3 2 Fixed

SECAM B-YPHASE 0 3 1 Fixed

DVD PAL R-YPHASE 0 3 2 Fixed

DVD PAL B-YPHASE 0 3 1 Fixed

COLOR 0 127 60 Fixed

SCONT 0 31 18 Fixed

0 255 170

LC-121M2U

LC-150M2U

10

Page 11

LC-121M2U

LC-150M2U

8 DAC 2 1ch 0 255 0 Fixed

DAC 2 2ch 0 255 0 Fixed

DAC 2 3ch 0 255 0 Fixed

DAC 2 4ch 0 255 0 Fixed

DAC 2 5ch 0 255 0 Fixed

DAC 2 6ch 0 255 0 Fixed

DAC 2 7ch 0 255 0 Fixed

DAC 2 8ch 0 255 0 Fixed

DAC 2 9ch 0 255 0 Fixed

DAC 2 10ch 0 255 0 Fixed

DAC 2 11ch 0 255 0 Fixed

DAC 2 12ch 0 255 0 Fixed

5-6. Service Adjusting

5-6-1. Basic Adjustment

1 +B Adjustment 1. Connect the DC voltmeter to 1. Adjust +B-ADJ to 5.1V ± 0.05V.

LC-121M2U

LC-150M2U

Adjustment Adjusting conditions Adjusting method

TP1104 ( DAC 9ch )

2 Model setup 1. Select the model "M2U". When M2U is selected, the item

settings are as follows.

TUNER OFF

AUDIO MULTIPLEX OFF

BOOSTER 0

SYSTEM AUTO

COPY GUARD ON

CH MEMORY OFF

SECAM ON

MULTI LANG. OFF

TIMER OFF

3 Counter-bias adjustment 1. Set the AV1 mode to set signal 1. Adjust COM so as to minimize the

noninput state. waveform peak-peak.

2. Fit the specified adjusting instrument (DAC7ch)

to the screen center.

3. Observe the adjusting instrument

output on the oscilloscope.

4 NTSC / PAL-MOSC 1. Input the monoscope pattern of 1. Adjust NTSC/PALM OSC so as to

adjustment NTSC into AV1. get the normal screen.

(DAC8ch)

11

Page 12

LC-121M2U

LC-150M2U

5-6-2. AV input Adjustment

Adjustment Adjustment conditions Adjustment method

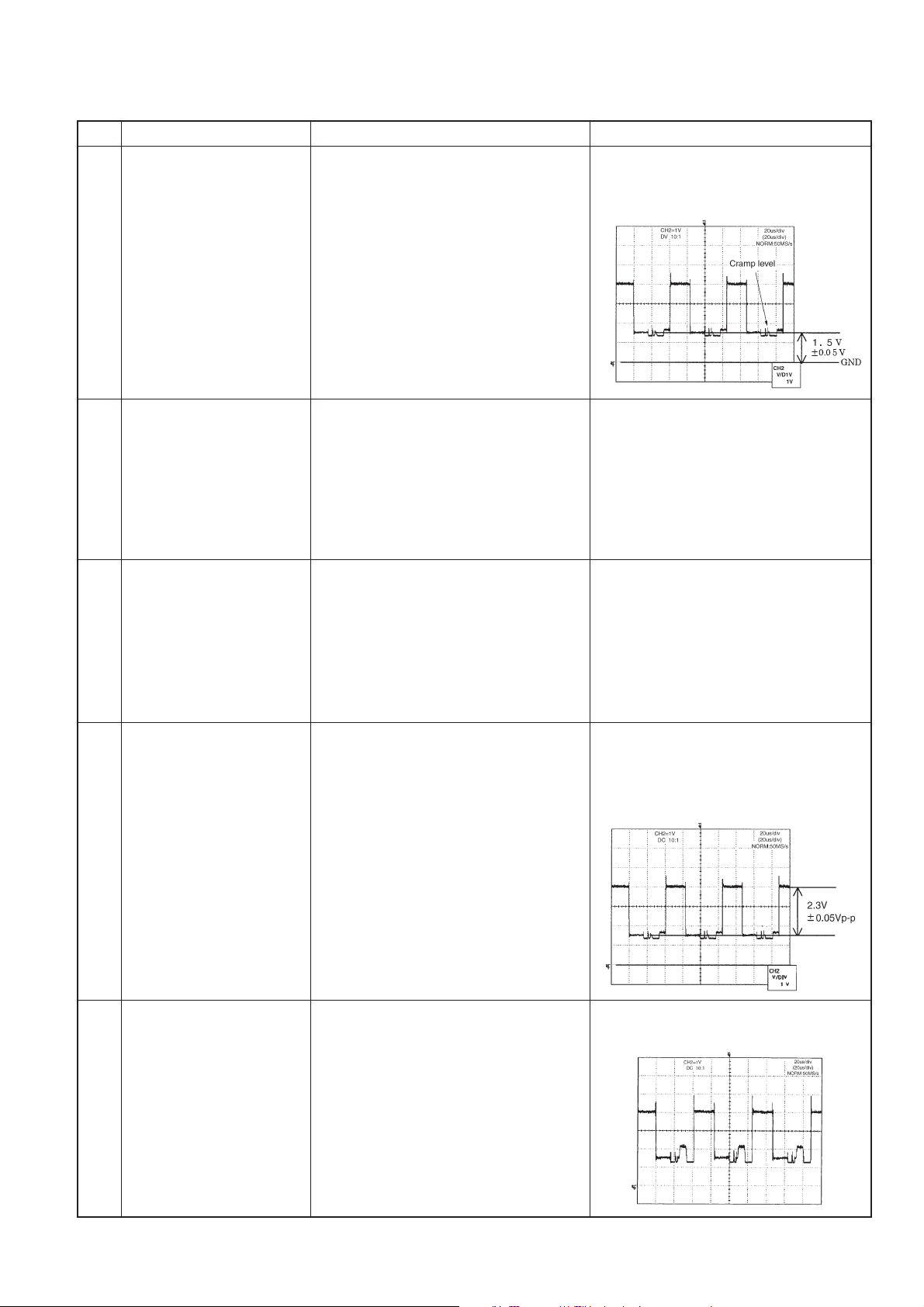

1 Brightness adjustment 1. Input the standard color bar signal 1. Adjust N358 BRIGHTNESS, and

(N358) (the same pattern as that of JPN-8CH) adjust the black level of G output so

2 R-cut off adjustment 1. Input the standard color bar signal 1. Adjust R CUTOFF so as to equalize

3 B-cut off adjustment 1. Input the standard color bar signal 1. Adjust B CUTOFF so as to equalize

4 Unicolor adjustment 1. Input the standard color bar signal 1. Adjust N358UNICOLOR, and

(N358) (the same pattern as that of JPN- adjust so as to get 100% white-

LC-121M2U

LC-150M2U

of N358 into AV1. as to get DC 1.5±0.05V.

2. Connect the oscilloscope to TP821

(IC803, pin7, G output).

(the same pattern as that of JPN-8CH) the black levels of green and red.

of N358 into AV1.

2. Connect the oscilloscope to TP821

(IC803, pin7, G output).

3. Connect the oscilloscope to TP819

(IC803, pin1, R output).

(the same pattern as that of JPN-8CH) the black levels of green and blue.

of N358 into AV1.

2. Connect the oscilloscope to TP821

(IC803, pin7, G output).

3. Connect the oscilloscope to TP820

(IC803, pin8, B output).

8CH) of N358 into AV1. black level video component equal

2. Connect the oscilloscope to TP821 to 2.3±0.05Vp-p.

(IC803, pin7, G output).

5 R DRIVE adjustment 1. Input the standard color bar signal 1. Adjust so as to get 100% white level

(the same pattern as that of JPN- identical with that of green.

8CH) of N358 into AV1.

2. Connect CH1 of oscilloscope to

TP821 (G output).

3. Connect CH2 of oscilloscope to

TP819 (R output).

12

Page 13

LC-121M2U

LC-150M2U

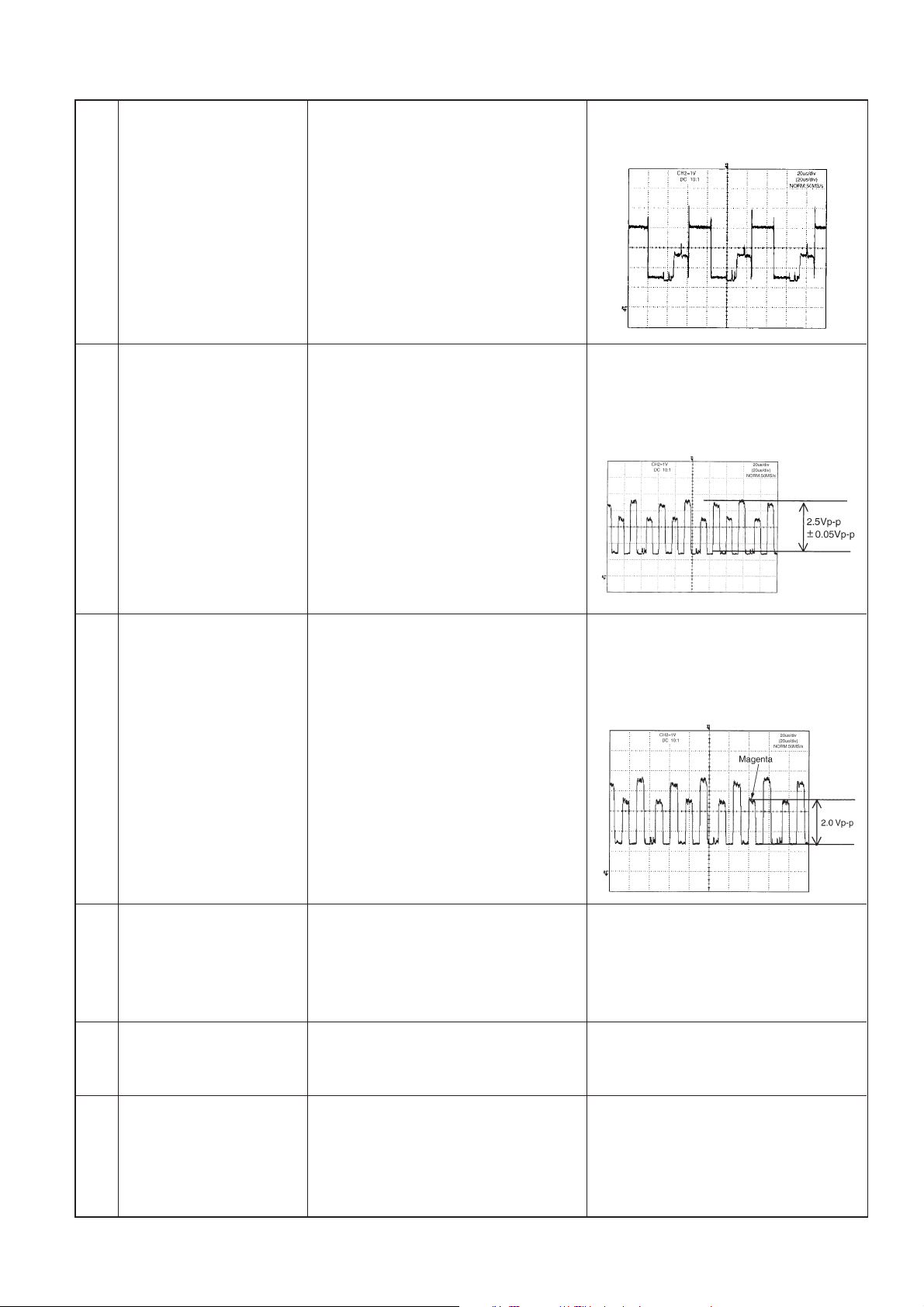

6 B DRIVE adjustment 1. Input the standard color bar signal 1. Adjust so as to get 100% white level

7 Color level adjustment 1. Input the standard color bar signal Adjust N358 SCOLOR so as to get the

LC-121M2U

LC-150M2U

(the same pattern as that of JPN- identical with that of green.

8CH) of N358 into AV1.

2. Connect CH1 of oscilloscope to

TP821 (G output).

3. Connect CH2 of oscilloscope to

TP820 (B output).

(N358) (the same pattern as that of JPN- color bar signal blue amplitude

8CH) of N358 into AV1. (black level - peak level) equal to 2.5V

2. Connect the oscilloscope to TP820 ± 0.05Vp-p.

(B output).

8 Tint adjustment 1. Input the standard color bar signal 1. Adjust N358 TINT so as to get the

(N358) (the same pattern as that of JPN- color bar signal magenta amplitude

8CH) of N358 into AV1. (black level-peak level) equal to 2.0

2. Connect the oscilloscope to TP820 ± 0.05Vp-p.

(B output).

9 N443/PAL-M adjustment 1. Position the cursor on DATA COPY 1. The indication changes from WAIT

and press VOL key. to SEND, and after the lapse of one

second WAIT is restored. Thus, N443,

PAL-M adjustment is completed.

10 4V adjustment 1. Connect the DC voltmeter to TP1110 1. Adjust R-ADJ to 4.0V ± 0.05V.

( DAC 6ch )

11 PAL/SECAM OSC 1. Input the monoscope pattern of PAL 1. Adjust PAL/SECAM OSC so as to

adjustment into AV1. get the normal screen.

(DAC8ch)

13

Page 14

LC-121M2U

LC-150M2U

12 Brightness adjustment 1. Input the standard color bar signal 1. Adjust PAL BRIGHTNESS, and

13 Unicolor adjustment 1. Input the standard color bar signal 1. Adjust PAL UNICOLOR, and adjust

LC-121M2U

LC-150M2U

(PAL) of PAL into AV1. adjust the black level of G output

2. Connect oscilloscope to TP821 so as to get DC 1.5 ±0.05V.

(IC803, pin7, G output).

(PAL) of PAL into AV1. so as to get 100% white-black level

2. Connect oscilloscope to TP821 video component equal to 2.3±0.05

(IC803, pin7 , G output ). Vp-p.

14 Color level adjustment 1. Input the standard color bar signal Adjust PAL SCOLOR so as to get the

(PAL) (the same pattern as that of E-12CH) color bar signal blue amplitude

of PAL into AV1. (black level - peak level) equal to 2.5V

2. Connect the oscilloscope to TP820 ±0.05Vp-p.

(B output).

15 Tint adjustment 1. Input the standard color bar signal 1. Adjust PAL TINT so as to get the color

(PAL) (the same pattern as that of E-12CH) bar signal magenta amplitude (black

of PAL into AV1. level-peak level) equal to 2.0±

2. Connect the oscilloscope to TP820 0.05Vp-p.

(B output).

14

Page 15

LC-121M2U

LC-150M2U

16 BELL f0 adjustment 1. Connect the oscilloscope to 1. Adjust BELL f0 so as to minimize the

17 Brightness adjustment 1. Input the standard color bar signal 1. Adjust SECAM BRIGHTNESS, and

18 Unicolor adjustment 1. Input the standard color bar signal 1. Adjust SECAM UNICOLOR, and

LC-121M2U

LC-150M2U

TP2851. a-level.

(SECAM) (the same pattern as that of E-10CH) adjust the black level of G output to

of SECAM into AV1. DC 1.5±0.05V.

2. Connect oscilloscope to TP821

(IC803, pin7, G output).

(SECAM) (the same pattern as that of E-10CH) adjust so as to get 100% white-black

of SECAM into AV1. level video component equal to 2.3±

2. Connect oscilloscope to TP821 0.05Vp-p.

(IC803, pin7, G output ).

19 Color level adjustment 1. Input the standard color bar signal Adjust SECAM COLOR so as to get

(SECAM) (the same pattern as that of E-10CH) the color bar signal blue amplitude

of SECAM into AV1. (black level - peak level) equal to 2.5V

2. Connect the oscilloscope to TP820 ±0.05Vp-p.

(B output).

20 Tint adjustment 1. Input the standard color bar signal 1. Adjust SECAM TINT so as to get

(SECAM) (the same pattern as that of E-10CH) the color bar signal magenta amplitude

of SECAM into AV1. (black level - peak level) equal to 2.0V

2. Connect the oscilloscope to TP820 ±0.05Vp-p.

(B output).

15

Page 16

LC-121M2U

LC-150M2U

5-6-3. Component input Adjustment

Adjustment Adjusting conditions Adjusting method

1 Brightness adjustment 1. From SG, input the 100% white color Adjust DVD NT BRIGHTNESS, and

(NTSC) bar signal of NTSC into conponent adjust the black level of G output so

2 Unicolor adjustment 1. From SG, input the 100% white color Adjust DVD NT UNICOLOR, and

(NTSC) bar signal of NTSC into conponent adjust so as to get 100% white-

LC-121M2U

LC-150M2U

terminal. as to get DC 1.5±0.05V.

2. Connect oscilloscope to TP821

(IC803, pin7, G output).

terminal. black level video component equal

2. Connect oscilloscope to TP820 to 2.3±0.05Vp-p.

(IC803, pin8).

3 Color level adjustment 1. From SG, input the 100% white color Adjust DVD NT COLOR so as to get

(NTSC) bar signal of NTSC into conponent the color bar signal blue amplitude

terminal. (black level - peak level) equal to

2. Connect the oscilloscope to TP820 2.8V±0.05Vp-p.

(B output).

4 Tint adjustment 1. From SG, input the 100% white color Adjust DVD NT TINT so as to get the

(NTSC) bar signal of NTSC into conponent color bar signal magenta amplitude

terminal. (black level - peak level) equal to 2.3V

2. Connect the oscilloscope to TP820 ±0.05Vp-p.

(B output).

16

Page 17

LC-121M2U

LC-150M2U

5 Brightness adjustment 1. From SG, input the 100% white color Adjust DVD PAL BRIGHTNESS, and

6 Unicolor adjustment 1. From SG, input the 100% white color Adjust DVD PAL UNICOLOR, and

LC-121M2U

LC-150M2U

(PAL) bar signal of PAL into conponent adjust the black level of G output so

terminal. as to get DC 1.5±0.05V.

2. Connect oscilloscope to TP821

(IC803, pin7, G output).

(PAL) bar signal of PAL into conponent adjust so as to get 100% white-

terminal. black level video component equal

2. Connect oscilloscope to TP820 to 2.3±0.05Vp-p.

(IC803, pin8, B output).

7 Color level adjustment 1. From SG, input the 100% white color Adjust DVD PAL COLOR so as to get

(PAL) bar signal of PAL into conponent the color bar signal blue amplitude

terminal. (black level - peak level) equal to

2. Connect the oscilloscope to TP820 2.8V±0.05Vp-p.

(B output).

8 Tint adjustment 1. From SG, input the 100% white color Adjust DVD PAL TINT so as to get

(PAL) bar signal of PAL into conponent the color bar signal magenta amplitude

terminal. (black level - peak level) equal to

2. Connect the oscilloscope to TP820 2.3V±0.05Vp-p.

(B output).

9 Tint adjustment Position the cursor on N358 TINT. Lower unconditionally the value by

10 points.

17

Page 18

LC-121M2U

LC-150M2U

5-7. Shipping setting

(1)[Procedure]

Holding down the [AV INPUT] key and [MENU] key, turn on the main power, and simultaneously press the (inspection

process) [SELECT '] key and [VOL+] key to change the mode to the adjustment mode.

(2)[Indication]

AV1 is indicated as SETTING COMPLETE.

(3)[Description]

Mode is memorized as SETTING COMPLETE.

Menu setting descriptions are as follows.

VOLUME 30

CONTRAST 30 (AV1 / AV2 / COMPONENT)

TINT 0 (AV1 / AV2 / COMPONENT) (ONLY NTSC)

COLOR 0 (AV1 / AV2 / COMPONENT)

SHARPNESS 0 (AV1 / AV2 / COMPONENT)

RED 0 (AV1 / AV2 / COMPONENT)

BLUE 0 (AV1 / AV2 / COMPONENT)

COLOR SYSTEM AUTO (AV1 / AV2 / COMPONENT)

TREBLE 0

BASS 0

BALANCE 0

BRIGHTNESS BRIGHT

UPSIDE NORMAL

RIGHT / LEFT NORMAL

AV2 IN / OUT IN

LC-121M2U

LC-150M2U

AV1

SETTING COMPLETE

18

Page 19

LC-121M2U

LC-150M2U

6. INTEGRATED CIRCUIT TERMINAL ARRANGEMENTS

1. IC2001 (QFP, 80pins)

Terminal No. Terminal name I/O Function

1 N. C –

2 N. C –

3 KEY3 I Key input 3

4 KEY4 I Key input 4

5 HPDET I Headphon input pickup

6 M O Audio selection 1

7 S O Audio selection 2

8 MONO O Forced monophonic

9 FSMUT O Front speaker MUTE output

10 RSMUT O Rear speaker MUTE output

11 N. C –

12 N. C –

13 CSYNC I Composite sync signal input

14 IFAGC I IFAGC input

15 PLCS O TV PLL chip select output

16 MRDY I I2C bus opening/connection selection input

17 PLLD I TV-PLL lock signal input

18 LMUTE O Lineout-Mute output

19 SCLK I/O Serial clock signal

20 SOUT O Serial data output

21 AFT I AFT voltage input

22 AGC I AGC input voltage

23 SCL I/O I2C bus serial clock line

24 SDA I/O I2C bus serial data line

25 N. C –

26 N. C –

27 CNV s s GND connection

28 φ O Timing output

29 RESET I Change to “Reset mode” in “L” state

30 Xin I Microcomputer oscillator connection

31 Xout O Microcomputer oscillator connection

32 V s s I GND

33 PSW I Power switch input

34 POW O DC/DC control output

35 COCS O G/A chip selection output

36 DACS O D/A chip selection output

37 BOOST O Booster selection output

38 BOOLV O Booster level selection output

39 N. C –

40 N. C –

41 DA2CS O D/A 2 chip selection output

42 AV1/AV2 O Analog SW selection 1

43 AV/S O Analog SW selection 2

44 Y/COM O Analog SW selection 3

45 IN/OUT O Analog SW selection 4

46 REQ O “H” in [ADJUSTMENT] mode, “L” in other modes.

LC-121M2U

LC-150M2U

19

Page 20

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

Terminal No. Terminal name I/O Function

47 Empty I

48 STB O Micro computer power off output

49 SECAM O “H” in SECAM mode, “L” in other modes.

50 PAL O “H” in PAL mode, “L” in other modes.

51 N. C –

52 N. C –

53 N. C –

54 SAFE I Parking input

55 Empty I

56 Empty I

57 Empty I

58 Empty I

59 Empty I

60 Empty I

61 N. C I

62 BLK OSD blanking output

63 N. C I

64 N. C –

65 N. C –

66 BOUT O B signal output

67 GOUT O G signal output

68 ROUT O R signal output

69 Vsync I OSD virtical sync signal input

70 Hsync I OSD horizontal sync signal input

71 N. C –

72 V c c I Positive voltage power terminal

73 N. C –

74 OSC1 OSD clock

75 OSC2 OSD clock

76 N. C –

77 KEY 1 I Key input1

78 KEY 2 I Key input2

79 IREM I Ir Remotecontrol input

80 ST/MT I Broadcast mode input

20

Page 21

LC-121M2U

LC-150M2U

2. IC1201 (QFP, 128pins)

Terminal No. Voltage I/O Signal name Function

1 5.0V I OSD_BK OSD Blanking input

2 5.0V I OSD_R OSD R input

3 5.0V I OSD_G OSD G input

4 5.0V I OSD_B OSD B input

5 5.0V O OSDVD OSD V output

6 5.0V O OSDHD OSD H output

7 5.0V O OSDCK OSD clock output

8 5.0V O VCIHD Horizontal sync output(VCI)

9 5.0V GND

10 5.0V VCC

11 5.0V O OFL PWM output (Inverter)

12 5.0V I MP_DA 3-wire serial data input

13 5.0V I MP_CK 3-wire serial clock input

14 5.0V I MP_CS 3-wire serial chip selection input

15 5.0V I TVAV Copy guard ON/OFF input

16 5.0V I FREE Inside/outside sync selection input

17 5.0V I CSYNC Composit signal input

18 5.0V O PDP PLL control signal output

19 5.0V GND

20 5.0V I OSCI PLL ocsillation input

21 5.0V O OSCO PLL ocsillation output

22 5.0V VCC

23 5.0V GND

24 5.0V O OHSYN Sync separation output

25 5.0V O DVDO Digital sync separation output

26 5.0V I VSYN Virtical sync signal input

27 5.0V I GST Reset input

28 5.0V GND

29 5.0V O REV Graduation power control signal output 1

30 5.0V O REVV0 Graduation power control signal output 2

31 5.0V O GSP1 Gate driver controll signal output 1

32 5.0V O GCK Gate driver controll signal output 2

33 3.3V GND

34 3.3V O OOR7 R output 7 (MSB)

35 3.3V O OOR6 R output 6

36 3.3V O OOR5 R output 5

37 3.3V O OOR4 R output 4

38 3.3V O OOR3 R output 3

39 3.3V O OOR2 R output 2

40 3.3V O OOR1 R output 1

41 3.3V O OOR0 R output 0 (LSB)

42 3.3V GND

43 3.3V O OOG7 G output 7 (MSB)

44 3.3V O OOG6 G output 6

45 3.3V O OOG5 G output 5

46 3.3V O OOG4 G output 4

47 3.3V O OOG3 G output 3

48 3.3V O OOG2 G output 2

LC-121M2U

LC-150M2U

21

Page 22

LC-121M2U

LC-150M2U

Terminal No. Voltage I/O Signal name Function

LC-121M2U

LC-150M2U

49 3.3V GND

50 3.3V VCC

51 3.3V O HDCK SOURCE driver control signal output 1

52 3.3V O OCK SOURCE driver control signal output 2

53 3.3V GND

54 3.3V O OOG1 G output 1

55 3.3V O OOG0 G output 0 (LSB)

56 3.3V O OOB7 B output 7 (MSB)

57 3.3V O OOB6 B output 6

58 3.3V O OOB5 B output 5

59 3.3V O OOB4 B output 4

60 3.3V GND

61 3.3V O OOB3 B output 3

62 3.3V O OOB2 B output 2

63 3.3V O OOB1 B output 1

64 3.3V O OOB0 B output 0 (LSB)

65 3.3V GND

66 3.3V O SPLS SOURCE driver control signal output 3

67 3.3V O SPRS SOURCE driver control signal output 4

68 3.3V O LBR SOURCE driver control signal output 5

69 3.3V O HGO SOURCE driver control signal output 6

70 3.3V I NBH CCW/CW inversion input

H:Inversion, L:Normal rotation

71 3.3V I NTSC NTSC/PAL selection input H:PAL, L:NTSC

72 3.3V GND

73 3.3V O TM0 Gate driver control signal output 3

74 3.3V O TM1 Test output 1

75 3.3V O TM2 Test output 2

76 3.3V VCC

77 3.3V GND

78 3.3V I R0 R input 0 (LSB)

79 3.3V I R1 R input 1

80 3.3V I R2 R input 2

81 3.3V I R3 R input 3

82 3.3V I R4 R input 4

83 3.3V I R5 R input 5

84 3.3V I R6 R input 6

85 3.3V I R7 R input 7 (MSB)

86 3.3V GND

87 3.3V I G0 G input 0 (LSB)

88 3.3V I G1 G input 1

89 3.3V I G2 G input 2

90 3.3V I G3 G input 3

91 3.3V I G4 G input 4

92 3.3V I G5 G input 5

93 3.3V I G6 G input 6

94 3.3V I G7 G input 7 (MSB)

95 3.3V O TM3 Test output 3

96 3.3V O TM4 Test output 4

22

Page 23

LC-121M2U

LC-150M2U

Terminal No. Voltage I/O Signal name Function

LC-121M2U

LC-150M2U

97 3.3V GND

98 3.3V I TST8 Test input 8

99 3.3V I TST7 Test input 7

100 3.3V I TST6 Test input 6

101 3.3V I TST5 Test input 5

102 3.3V I TST4 Test input 4

103 3.3V I TST3 Test input 3

104 3.3V I TST2 Test input 2

105 3.3V I TST1 Test output 1

106 3.3V I TSH VCI horisontal sync signal input

107 3.3V GND

108 3.3V O ADCK A/D converter clock output

109 3.3V I TST9 GND

110 3.3V I PMODE Sync signal

Positive polarity/Negative polarity selection input

H:Positive polarity L:Negative polarity

111 3.3V I DINV Input signal

Primary colors/complementary colors selection input

H:Complementary colors input,

L:Primary colors input

112 3.3V VCC

113 3.3V GND

114 3.3V I B 0 B input 0 (LSB)

115 3.3V I B 1 B input 1

116 3.3V I B 2 B input 2

117 3.3V I B 3 B input 3

118 3.3V I B 4 B input 4

119 3.3V I B 5 B input 5

120 3.3V I B 6 B input 6

121 3.3V I B 7 B input 7 (MSB)

122 3.3V GND

123 3.3V O OCVD Virtical synchro signal output

124 3.3V I TSV Virtical synchro signal input

125 3.3V O MASK

126 3.3V O OSCO2 Clock output (No use)

127 3.3V I OSCI2 Clock input (No use)

128 3.3V GND

23

Page 24

LC-121M2U

No picture, No sound

Do F701 and F703 function?

Check T701's secondary load.

Check IC702, Q702, L701

and their peripheral parts.

Remove F701 and F703, and

check the load side.

Is there short-circuiting?

Is there short-circuiting of T701

primary side periphery, Q701

and S701?

Replace F701 and F703.

YES

NO

YES

YES

YES

NO

NO

Check Q751, Q752, Q753,

Q754, T751, T752 and their

peripheral parts.

Check Q703 and its peripheral

parts.

Replace the fluorecent lamp

with new one and check again.

Is primary oscillator waveform

of T751 and T752 normal ?

Does Q703 function?

Does output voltage +9V

appear?

Does F702 function?

Fluorecent lamp failure to light up.

YES

YES

YES

NO

NO

NO

Are T701's secondary outputs,

+30V, +23V, +9V, +5.1V and

-5.5V normal?

Is T701's primary oscillator

waveform normal?

LC-150M2U

7. TR OUBLESHOO TING

LC-121M2U

LC-150M2U

24

Page 25

LC-121M2U

Check IC406, IC403 and their peripheral parts.

No picture (AV1, AV2 and Component)

Is output voltages

at pins 3,5 and 6 of

IC406 normal?

Is input voltages at

pins 51,52 and 53

of IC801 normal?

Is output voltages at

pins 41,42 and 43

of IC801 normal?

Is output voltages

at pins 1,7 and 8 of

IC803 normal?

No picture (AV1, AV2)

Replace LCD module with new one and check again.

Replace cables with new one and check again.

No picture

Check the in/output

of IC406 and its

peripheral parts.

No picture (AV1/AV2)

No picture (Component)

Is signal input into the pin

13 of IC2001?

Check IC406 and

its peripheral parts.

Check IC801 and

its peripheral parts.

Check IC803 and

its peripheral parts.

Is in/output voltages of IC1001 normal?

Is in/output voltages of IC1201 normal?

Are voltages and waveform of the LCD module connecting connector normal?

Aren't cables break down?

Is in/output voltages

of IC401 normal?

Check IC401 and

its peripheral parts.

Is output voltage at pin 18 of IC801 normal?

Is input voltages at pins 33 and 15 of

IC801 normal?

Check IC401 and

its peripheral parts.

Is output voltages

at pins 23 and 25

of IC851 normal?

Check IC851,

Q852, Q854, Q857

and their peripheral

parts.

Check IC403,

IC405 and their

peripheral parts.

Check IC801 and

its peripheral parts.

Are output voltages

at pin 7 of IC403 and

it of IC405 normal?

Check Q801, Q802

and their peripheral

parts.

Is input voltages

at pins 13 and 15

of IC801 normal?

Is output voltages

at pins 4,5 and 6

of IC801 normal?

Check in/output voltages of IC406

and its peripheral parts.

NO

No picture apears (AV1)

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

Check Q401~Q406 and

their peripheral parts.

Check peripheral

parts.

YES YES

NO

NO

YES

YES

YES

YES

YES

LC-150M2U

LC-121M2U

LC-150M2U

25

Page 26

LC-121M2U

No sound

Check speaker

unit and its

peripheral parts.

Check IC305 and

its peripheral

parts.

Check IC704,

Q704, Q706 and

their peripheral

parts.

Check IC310,

IC311 and their

peripheral parts.

Are output at pin

7 of IC310 and it

of IC311 normal?

Check speaker

unit and its

peripheral parts.

Check IC312 and

its peripheral

parts.

Is output at pins

3 and 5 of IC308

normal?

Is output at pins

10 and 17 of

IC305 normal?

Check IC305

and its peripheral

parts.

Check IC308

and its peripheral

parts.

Is the pin 18 of

IC2001 in Low

state?

Is output at pins

7 and 18 of

IC312 normal?

Is output at pins

10,14 and 17 of

IC305 normal?

Is 13V input at

pin 9 of IC305

as specified?

Is the pin 9 of

IC2001 in Low

state?

Muting is applied.

Check the

FSMUT line.

YES

YES

YES

YES

YES

YES

YES

YES

Check IC302,

Q301, Q302

and their

peripheral parts.

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

Check IC305

and its

peripherals.

Check Q306,

Q307, IC304 and

their peripherals.

NO

NO

YES

Muting is applied.

Check the

LMUTE line.

No sound (Front

and rear speaker)

No sound

(AV1 output)

No sound

(Front speaker)

Check speaker

and its

peripherals.

Are Q306, Q307

and IC304

normal?

Is output at pin

14 of IC305

normal?

Is the pin 10 of

IC2001 in Low

state?

YES

YES

YES

YES

No sound

(Rear speaker)

LC-150M2U

LC-121M2U

LC-150M2U

26

Page 27

LC-121M2U

Check in/output voltages of IC406.

YES

No color appears

No color (AV1, AV2 and Component)

Is output voltages

at pins 3 and 6 of

IC406 normal?

Check peripherals.

Are these voltages

as follows of IC801

normal?

pins 51 and 52

(input)

pins 41, 42 and

43 (output)

Check IC801 and

its peripheral

parts.

No color (AV1, AV2)

Is output voltages

at pin 7 of IC405

normal?

Is input voltages

at pin 13 of

IC801 normal?

Is output voltages

at pins 5 and 6 of

IC801 normal?

Check in/output

voltages of IC406.

Check IC405 and

its peripheral

parts.

Check peripherals.

No color (Component)

YES

YES

YES

NO

NO

NO

NO

NO

Check IC801 and

its peripheral

parts.

LC-150M2U

LC-121M2U

LC-150M2U

27

Page 28

LC-121M2U

No color appears

(N358)

Is 3.5795 MHz

input into the

pin 10 of IC801?

Check X801 and

its peripheral

parts.

No color appears

(N443,PAL)

YES

Is the C/Y signals at pins 13 and 15 of IC801 normal ?

Is the output at pins 10 and 11 of IC2802 normal ?

NO

Check X802 and

its peripheral

parts.

NO

Is 4.4336 MHz

input into the

pin 8 of IC801?

YES

YES

Check

Peripheral

parts of IC853.

NO

Is the composite

signal which is

input into the pins

13 and 15 of

IC801 normal?

Check Peripheral

parts of IC853.

NO

YES

Is 4 MHz input

into the pin 8 of

IC2802?

Check X2850

and its peripheral

parts.

NO

YES

Check Peripheral

parts of IC2802.

NO

Is the output at pins 29 and 30 of IC2801 normal ?

Is the output at pins 51 and 52 of IC801 normal ?

Check Peripheral parts of IC801.

YES

Check Peripheral

parts of IC2801.

YES

YES

NO

Check Peripheral

parts of IC406.

NO

No color appears

(PAL-M)

Check X803 and

its peripheral

parts.

NO

Is 3.5756 MHz

input into the

pin 9 of IC801?

YES

No color appears

(SECAM)

Check X802 and

its peripheral

parts.

NO

Is 4.4336 MHz

input into the

pin 8 of IC801?

YES

LC-150M2U

LC-121M2U

LC-150M2U

28

Page 29

LC-121M2U

LC-150M2U

8. CHASSIS LAYOUT

LC-121M2U

LC-150M2U

H

G

F

IC305 Power AMP.

P303

P752

P403

IC2801

1H Dilay system

SECAM decoder

IC2802

X2850

IC853

Digital comb filter

P402

P302

F703 1.6A 125V

IC801 Chroma decoder

RED

BLUE

X802

T701

DC/DC Transformer

BLACK

X803

X801

F701

125V 1.6A

F702 2.5A 125V

TP805

TP1106

TP1112

TP804

TP1111

P2002

P2001

P801

Micon

IC2001

P751

T751

T752

Inverter transformer

SC1202

IC1201

Controller

SC1201

E

D

IC312

Audio control

C

B

IC1001

AD converter

A

123456

29

Page 30

LC-121M2U

LC-150M2U

• DESCRIPTION OF SCHEMATIC DIAGRAM

1. When the exclusive-use AC adapter is used, the color bar signal of color bar generator for service is input

to get the normal screen. When the audio is minimized, the voltage value is measured with the 20 kΩ/V tester.

2. When the exclusive-use AC adapter is used, the color density, lightness and color hue are set to the center

position, and the signal of color bar generator for service is observed to get waveform.

The waveform test point is indicated with the mark ( ) in the wiring diagram.

3. Indication of resistors and capacitors

[Resistor]

Unit: Nonindication ··· Ω, K ··· kΩ,

M ··· MΩ

Error: Nonindication ··· ±10%

J ··· ±5%

F ··· ±1%

D ··· ±0.5%

[Capacitor]

Unit: Nonindication or µ ··· µF,

P or p ··· pF

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH " å"

IMPORTANT FOR MAINTAINING THE SAFETY

OF THE SET.

BE SURE TO REPLACE THESE PARTS WITH

SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE OF THE SET.

( )

CAUTION:

This circuit diagram is original one, therefore there

may be a slight difference from yours.

LC-121M2U

LC-150M2U

ARE

[Item]

Nonindication Carbon-film resistor Nonindication Ceramic capacitor

C Solid resistor ML Mylar capacitor

S Metal-oxide-film resistor PF Polypropylene

N Metal-film resistor film capacitor

W Cement resistor TA Tantalum capacitor

T Special resistor ST Styrol capacitor

• WA VEFORMS

1 TP804 CSYNC

Resistor Capacitor

2 TP820 B output

3 TP819 R output

4 TP821 G output

5 TP1107 VCOM

6 TP1108 VO

30

Page 31

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

31

Page 32

LC-121M2U

LC-150M2U

9. SCHEMATIC DIAGRAM: JACK UNIT

H

G

F

LC-121M2U

LC-150M2U

E

D

C

B

A

123456

32

Page 33

SCHEMATIC DIAGRAM: MAIN CIRCUIT (1)

H

G

F

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

E

D

C

B

A

123456

33

7 8 9 10 11 12

34

Page 34

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

SCHEMATIC DIAGRAM: MAIN CIRCUIT (2), REMOTE CONTROL UNIT, SWITCH UNIT (LC-121M2U)

H

G

F

E

D

C

B

A

123456

35

7 8 9 10 11 12

36

Page 35

LC-121M2U

LC-150M2U

H

G

F

E

H

G

F

E

D

C

B

A

D

C

B

A

13 14 15 16 17 18

123456

37

Page 36

LC-121M2U

LC-150M2U

SCHEMATIC DIAGRAM: MAIN CIRCUIT (2), REMOTE CONTROL UNIT, SWITCH UNIT

(LC-150M2U)

H

G

F

E

D

C

B

A

123456

38

Page 37

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

H

G

F

E

H

G

F

E

D

C

B

A

D

C

B

A

123456

121110987

39

7 8 9 10 11 12

181716151413

40

Page 38

SCHEMATIC DIAGRAM: MAIN CIRCUIT (3) (LC-121M2U)

H

G

F

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

E

D

C

B

A

123456

41

7 8 9 10 11 12

42

Page 39

LC-121M2U

LC-150M2U

H

G

F

E

H

G

F

E

D

C

B

A

D

C

B

A

13 14 15 16 17 18

123456

43

Page 40

LC-121M2U

LC-150M2U

SCHEMATIC DIAGRAM: MAIN CIRCUIT (3) (LC-150M2U)

H

G

F

E

D

C

B

A

123456

44

Page 41

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

H

G

F

E

H

G

F

E

D

C

B

A

D

C

B

A

123456

121110987

45

7 8 9 10 11 12

181716151413

46

Page 42

10. BLOCK DIAGRAM

H

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

IC310,311

Audio selection

IC312

Sound control

G

AV2 SOUND L,R

AV1 SOUND L,R

COMPONENT SOUND L,R

L

IC308

12V

IC305

Audio

Amplifer

13V

Q703

Speaker

R

Lateral

inversion

Q306,307

MIX

IC304

BPF

Switch

F

IC704

PWM control

E

AV2 input

AV1 input

D

COMPONENT input

AV2 picture

AV1 picture

Y,Cb,Cr

S picture

IC401

AV1/AV2 selection

IC406

Y/color

difference

input selection

Digital comb filter

AV color difference signal

IC851

Y/C input selection

IH

Dilay

IC407

S switch

IC403,405

SECAM

Decoder

IC801

Decoder

R,G,B R,G,B

IC802

Video amplfer

IC1002

Reference

IC1001

AD convert

IC2002

D/A converter

IC1205

PLL control

IC1201

LCD controller

Graduation

power for

LCD

IC1101

IC1127

LCD panel

C

Q702

Switch

B

IC762

12V

IN

DC/DC

T701

OUT

30V

23V

9V

5.1V

-5.5V

IC703

3.3V

IC2001

Micon

IC701

5V

IC2003

2

E

PROM

IC2004

Reset

PWM control

12V

Q703

Switch

9V

DC/AC

T751,752

A

123456

47

7 8 9 10 11 12

48

Page 43

11. PRINTED WIRING BOARD ASSEMBLIES

MAIN UNIIT (Component Side)

H

G

F

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

E

D

C

B

A

123456

49

7 8 9 10 11 12

50

Page 44

MAIN UNIIT (Wiring Side)

H

G

F

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

E

D

C

B

A

123456

51

7 8 9 10 11 12

52

Page 45

JACK/REMOTE CONTROL RECEPTOR/SWITCH UNIT

LC-121M2U

LC-150M2U

H

JACK P.W.B.

Component Side Wiring Side

G

F

E

REMOTE CONTROL RECEPTOR UNIT

Component Side

Wiring Side

SWITCH UNIT

Component Side Wiring Side

D

C

B

A

123456

53

Page 46

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

Ref. No. Part No. ★ Description Code

12. PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics identified in this manual: electrical components having

such features are identified by

Lists and schematic diagrams.

The use of a substitute replacement part which does not have

the same safety characteristics as the factory recommended

replacement parts shown in this service manual may create

shock, fire or other hazards.

“

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish

the following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

in USA : Contact your nearest SHARP Parts Distributor to order. For

Ref. No. Part No. ★ Description Code

location of SHARP Parts Distributor, Please call Toll-Free:

1-800-BE SHARP

MARK★: SPARE PARTS-DELIVERY SECTION

“å”

in the Replacement Parts

”

LCD MODULE UNIT

RLCDT0040CEZZ J LCD Module Unit DD

RLCDT0043CEZZ J LCD Module Unit DQ

(LC-121M2U)

(LC-150M2U)

LAMP UNIT

å KLMP-0073CEZZ J Lamp Unit(LC-121M2U) AZ

å KLMP-0075CEZZ J Lamp Unit(LC-150M2U) AZ

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTK9775DE01 – Main Unit(LC-121M2U) —

DUNTK9775DE02 – Main Unit(LC-150M2U) —

RUNTK0633CEZZ – Jack Unit —

RUNTK0634CEZZ – Remote Control Unit —

RUNTK0635CEZZ – Switch Unit —

Ref. No. Part No. ★ Description Code

12. LISTE DES PIECES

CHANGE DES PIECES

Les pi`eces de rechange qui pr élelesentent ces caract éleristiques sp

éleciales de s élecurit éle, sont identifi élees dans ce manuel : les

pi`eces élelectriques qui pr élesentent ces particularit éles, sont rep

éle élee par la marque å et sont hachur élees dans les listes de

pi`eces et dans les diagrammes sch élematiques.

La substitution d'une pi`ece de rechange par une autre qui ne pr é

Lesente pas les m éoemes caract éLeristuques de s élecurit éle que

la pi`ece recommand élee parl'usine et dans ce manuel de service,

peut provoquer une élLelectrocution, un incendie ou toutautre sinistre.

“

COMMENT COMMANDER LES PIECES DE RECHANGE

Pour que votre commande soit rapidement et correctement remplie,

veuillez fournir les renseignements suivants.

1. NUMERO DU MODELE 2. NO. DE REF

3. NO. DE PIECE 4. DESCRIPTION

in CANADA : Contact SHARP Electronics of Canada Limited Phone

(416) 890-2100

MARK★: SPARE PARTS-DELIVERY SECTION

Ref. No. Part No. ★ Description Code

”

DUNTK9775DE01 (LC-121M2U)

DUNTK9775DE02 (LC-150M2U)

MAIN UNIT

IC302 VHiTC4053BF-1 J TC4053BF AG

IC304 VHiNJM4560M-1 J NJM4560M AG

IC305 VHiTA8218AH-1 J TA8218AH AP

IC308 VHiNJM2283F-1 J NJM2283M AF

IC310 VHiMM1113XF1E J MM1113XFBE AE

IC311 VHiMM1113XF1E J MM1113XFBE AE

IC312 VHiTA8184F/-1 J TA8184F AN

IC401 VHiNJM2246M-1 J NJM2246M AF

IC403 VHiNJM2235M-1 J NJM2235M AE

IC405 VHiNJ2233BM-1 J NJM2233BM AE

IC406 VHiNJM2283F-1 J NJM2283M AF

IC407 VHiTC4W53U/-1 J TC4W53FU AF

IC701 VHiAN8005M/-1 J AN8005M AD

IC702 VHiFA7611CE-1 J FA7611CE AL

IC703 VHiPQ20VZ11-1 J PQ20VZ11 AH

IC704 VHiFA7610N/-1 J FA7610N AK

IC801 RH-iX3113CEZZ J TA1276AN AZ

IC802 VHiNJM4560M-1 J NJM4560M AG

IC803 VHiNJM2138M-1 J NJM2138M-TE1 AN

IC852 VHiMM1031XM-1 J MM1031XMR AF

IC853 VHiTC9090AF-1 J TC9090AF AV

IC855 VHiMM1031XM-1 J MM1031XMR AF

IC1001 VHiTLC5733A-1 J TLC5733AIPM AY

IC1002 VHiNJM4560M-1 J NJM4560M AG

IC1101 VHiLF353M//-1 J LF353M AG

IC1103 VHi10324AFV-1 J BA10324AFV-E1 AF

IC1104 VHiNJM3414V-1 J NJM3414AV AF

IC1109 VHiTC7W04U/-1 J TC7W04FU(LC-150M2U) AD

IC1110 VHiTC4053BF-1 J TC4053BF AG

IC1112 VHiTC4053BF-1 J TC4053BF AG

IC1126 VHiNJM3414V-1 J NJM3414AV AF

IC1127 VHiNJM3414V-1 J NJM3414AV AF

IC1201 RH-iX3121CEZZ J LR38553 AW

IC1205 VHiNJM4560M-1 J NJM4560M AG

IC1206 VHiPST529DM-1 J PST529DMT AE

IC2001 RH-iX3202CEZZ J M37207MF-125FP AW

IC2002 VHiMB8346BV-1 J MB88346BPFV AN

IC2003 VHi24LC4BiN-1 J 24LC04BT-I/SN AL

IC2004 VHiPST529DM-1 J PST529DMT AE

INTEGRATED CIRCUITS

54

Page 47

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

Ref. No. Part No. ★ Description Code

DUNTK9775DE01 (LC-121M2U)

DUNTK9775DE02 (LC-150M2U)

MAIN UNIT (Continued)

IC2005 VHiTC4W66F/-1 J TC4W66F AE

IC2801 VHiTA8772AN-1 J TA8772AN AV

IC2802 VHiTA1229N/-1 J TA1229N AX

TRANSISTORS

Q301 VS2SC2412KQ-1 J Transistor AA

Q302 VS2SC2412KQ-1 J Transistor AA

Q303 VSUMG4/////-1 J Transistor AC

Q304 VSUMG4/////-1 J Transistor AC

Q305 VSDTC114EE/-1 J Transistor AB

Q306 VS2SC2412KQ-1 J Transistor AA

Q307 VS2SC2412KQ-1 J Transistor AA

Q401 VSDTC114EE/-1 J Transistor AB

Q402 VS2SC2412KQ-1 J Transistor AA

Q403 VS2SC2412KQ-1 J Transistor AA

Q404 VS2SC2412KQ-1 J Transistor AA

Q405 VS2SC2412KQ-1 J Transistor AA

Q406 VS2SK1467//-1 J Transistor AE

Q407 VS2SK1467//-1 J Transistor AE

Q701 VS2SB1590KQ-1 J Transistor AC

Q702 VS2SD1803ST1E J Transistor AE

Q703 VS2SB1182//2E J Transistor AE

Q704 VS2SB1132Q/-1 J Transistor AC

Q705 VSDTC144EE/-1 J Transistor AA

Q706 VS2SD1803ST1E J Transistor AE

Q707 VSDTC144EE/-1 J Transistor AA

Q708 VS2SB1590KQ-1 J Transistor AC

Q709 VSDTC144EE/-1 J Transistor AA

Q751 VS2SC3518K/3E J Transistor AE

Q752 VS2SC3518K/3E J Transistor AE

Q753 VS2SA1037KQ-1 J Transistor AA

Q754 VSDTC114YE/-1 J Transistor AB

Q801 VS2SC2412KQ-1 J Transistor AA

Q802 VS2SC2412KQ-1 J Transistor AA

Q852 VS2SA1037KQ-1 J Transistor AA

Q854 VS2SA1037KQ-1 J Transistor AA

Q857 VS2SA1037KQ-1 J Transistor AA

Q1001 VS2SA1037KQ-1 J Transistor AA

Q1002 VS2SC2412KQ-1 J Transistor AA

Q1101 VS2SC4520S/-1 J Transistor AF

Q1102 VS2SA1729R/-1 J Transistor AK

Q1103 VSUPA606T//-1 J Transistor AD

Q1201 VS2SA1037KQ-1 J Transistor AA

Q1202 VS2SC2412KQ-1 J Transistor AA

Q1207 VSDTC144EE/-1 J Transistor AA

Q1208 VSDTC144EE/-1 J Transistor AA

Q2801 VS2SC2412KQ-1 J Transistor AA

Q2802 VS2SC2412KQ-1 J Transistor AA

DIODES AND LED’S

D701 VHDDE5SC4M/-1 J Diode AF

D702 VHDSC8024//-1 J Diode AC

D704 VHD1SS250//1E J Diode AB

D705 VHDSC8024//-1 J Diode AC

D706 VHDSC8024//-1 J Diode AC

D707 VHDDAN222//-1 J Diode AA

D709 VHDSC8024//-1 J Diode AC

D710 VHDDAN222//-1 J Diode AA

D711 RH-EX0855CEZZ J Zener Diode AD

D712 VHDD3FS4A//-1 J Diode AG

D801 VHDDAN222//-1 J Diode AA

D802 VHDDAN222//-1 J Diode AA

D1101 VHDDAN222//-1 J Diode AA

D1201 VHDMA335Q//-1 J Diode AD

D1202 VHDDAN222//-1 J Diode AA

D1203 RH-EX0849CEZZ J Zener Diode AC

D1204 VHDDAN222//-1 J Diode AA

D1205 RH-EX0227CEZZ J Zener Diode AB

D1206 VHD1SS294//-1 J Diode AC

D1207 RH-EX0590CEZZ J Zener Diode AB

D2004 VHDDAN222//-1 J Diode AA

Ref. No. Part No. ★ Description Code

D2006 VHDiMN10///-1 J Diode AB

PACKAGED CIRCUITS

X801 RCRSB0262CEZZ J Crystal AG

X802 RCRSB0263CEZZ J Crystal AG

X803 RCRSB0261CEZZ J Crystal AG

X2850 RCRSB0273CEZZ J Crystal AF

COILS

CF801 RFiLA0034CEZZ J Filter AD

CF2001 RFiLC0056TAZZ J Filter AE

FL802 RFiLC0437CEZZ J Filter AD

FL803 RFiLC0274CEZZ J Filter AG

L301 RCiLC0135CEZZ J Coil AF

L302 VP-MK102J0000 J Peaking 1000µHAB

L303 VP-MK102J0000 J Peaking 1000µHAB

L401 VP-1M220J2R9N J Peaking 22µHAC

L701 RCiLC0085CEZZ J Coil AF

L702 RCiLC0130CEZZ J Coil AG

L703 RCiLC0130CEZZ J Coil(LC-121M2U) AG

L703 RCiLC0142CEZZ J Coil(LC-150M2U) AG

L704 RCiLC0055CEZZ J Coil AD

L706 RCiLC0055CEZZ J Coil AD

L707 RCiLC0085CEZZ J Coil AF

L708 RCiLC0108CEZZ J Coil AF

L751 RCiLC0109CEZZ J Coil AF

L752 RCiLC0109CEZZ J Coil AF

L805 RCiLC0055CEZZ J Coil AD

L806 RCiLC0055CEZZ J Coil AD

L807 VP-1M101J7R7N J Peaking 100µHAC

L808 VP-1M101J7R7N J Peaking 100µHAC

L809 VP-1M101J7R7N J Peaking 100µHAC

L810 VP-1M270J3R8N J Peaking 27µHAC

L811 VP-1M101J7R7N J Peaking 100µHAC

L1001 VP-1M470J5R4N J Peaking 47µHAC

L1121 VP-1M101J7R7N J Peaking 100µHAC

L1201 VP-1M470J5R4N J Peaking 47µHAC

L1204 RCiLP0255TAZZ J Coil AD

L1206 VP-1M470J5R4N J Peaking 47µHAC

L1207 VP-1M470J5R4N J Peaking 47µHAC

L1208 VP-1M470J5R4N J Peaking 47µHAC

L2001 VP-1M470J5R4N J Peaking 47µHAC

L2002 VP-1M470J5R4N J Peaking 47µHAC

L2850 VP-1M270J3R8N J Peaking 27µHAC

TRANSFORMERS

å T701 RTRNZ0737CEZZ J Transformer AM

å T751 RTRNZ0742CEZZ J Transformer AN

å T752 RTRNZ0742CEZZ J Transformer AN

CAPACITORS

C301 VCEAPH1CN106M J 10 16V Electrolytic AD

C302 VCEAPH1CN106M J 10 16V Electrolytic AD

C303 VCEAPH1CN106M J 10 16V Electrolytic AD

C304 VCEAPH1CN106M J 10 16V Electrolytic AD

C305 VCEAPH1CN106M J 10 16V Electrolytic AD

C306 VCEAPH1CN106M J 10 16V Electrolytic AD

C325 VCKYTV1CF105Z J 1 16V Ceramic AB

C326 VCKYTV1CF105Z J 1 16V Ceramic AB

C327 VCEAPF1CW106M J 10 16V Electrolytic AB

C328 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C329 VCEAPH1CW106M J 10 16V Electrolytic AB

C330 VCEAPH1CW106M J 10 16V Electrolytic AB

C331 VCEAPF1CW106M J 10 16V Electrolytic AB

C332 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C335 VCEAPH1CW106M J 10 16V Electrolytic AB

C339 VCEAPF1CW226M J 22 16V Electrolytic AB

C340 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C341 VCEAPH1CW106M J 10 16V Electrolytic AB

C342 VCEAPH1CW106M J 10 16V Electrolytic AB

C343 VCEAPF1CW476M J 47 16V Electrolytic AC

C344 VCEAPF1CW476M J 47 16V Electrolytic AC

C345 VCEAPH1CW106M J 10 16V Electrolytic AB

C346 VCEAPF1CW476M J 47 16V Electrolytic AC

C347 VCEAPK1CN107M J 100 16V Electrolytic AD

55

Page 48

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

Ref. No. Part No. ★ Description Code

DUNTK9775DE01 (LC-121M2U)

DUNTK9775DE02 (LC-150M2U)

MAIN UNIT (Continued)

C348 VCEA2A1CW108M J 1000 16V Electrolytic AB

C349 VCKYTV1CF105Z J 1 16V Ceramic AB

C350 VCKYTV1HF104Z J 0.1 50V Ceramic AA

C351 VCKYTV1HF104Z J 0.1 50V Ceramic AA

C352 RC-EZ0774CEZZ J 220 25V Electrolytic AD

C353 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C354 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C355 VCKYTV1HF104Z J 0.1 50V Ceramic AA

C356 VCEA2A1AW228M J 2200 10V Electrolytic AC

C357 RC-EZ0774CEZZ J 220 25V Electrolytic AD

C380 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C381 VCEAPF1CW106M J 10 16V Electrolytic AB

C382 VCKYCY1EB223K J 0.022 25V Ceramic AA

C383 VCKYCY1EB223K J 0.022 25V Ceramic AA

C384 VCKYCY1HB102K J 1000p 50V Ceramic AA

C385 VCKYCY1HB102K J 1000p 50V Ceramic AA

C386 VCKYCY1HB102K J 1000p 50V Ceramic AA

C387 VCKYCY1HB222K J 2200p 50V Ceramic AA

C388 VCKYCY1HB222K J 2200p 50V Ceramic AA

C389 VCEAPF1CW106M J 10 16V Electrolytic AB

C390 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C391 VCEA2A0JW108M J 1000 6.3V Electrolytic AB

C392 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C401 RC-EZ0210TAZZ J 220 16V Electrolytic AC

C402 VCKYCY1AF105Z J 1 10V Ceramic AC

C403 VCKYCY1AF105Z J 1 10V Ceramic AC

C405 VCKYCY1AF105Z J 1 10V Ceramic AC

C409 VCKYCY1AF105Z J 1 10V Ceramic AC

C410 VCKYCY1AF105Z J 1 10V Ceramic AC

C411 VCKYCY1AF105Z J 1 10V Ceramic AC

C412 VCKYCY1AF105Z J 1 10V Ceramic AC

C414 VCEAPF1AW336M J 33 10V Electrolytic AC

C415 VCEAPF1AW336M J 33 10V Electrolytic AC

C416 VCEAPF1AW336M J 33 10V Electrolytic AC

C417 VCEAPF1AW336M J 33 10V Electrolytic AC

C418 VCKYTV1CF105Z J 1 16V Ceramic AB

C419 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C420 VCEAPF1AW336M J 33 10V Electrolytic AC

C421 VCEAPF1AW336M J 33 10V Electrolytic AC

C422 VCKYCY1AF105Z J 1 10V Ceramic AC

C431 VCKYCY1AF105Z J 1 10V Ceramic AC

C433 VCEAPF0GW107M J 100 4V Electrolytic AC

C434 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C435 VCKYCY1HB102K J 1000p 50V Ceramic AA

C437 VCEAPF1AW336M J 33 10V Electrolytic AC

C701 VCEA2A1CW108M J 1000 16V Electrolytic AB

C702 VCKYTV1CF105Z J 1 16V Ceramic AB

C703 VCEAPF1CW226M J 22 16V Electrolytic AB

C704 VCKYTV1CF105Z J 1 16V Ceramic AB

C705 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C706 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C707 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C708 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C709 VCKYTV1CF684Z J 0.68 16V Ceramic AB

C710 VCEAPT1CN226M J 22 16V Electrolytic AC

C711 VCKYCY1EB103K J 0.01 25V Ceramic AA

C712 VCKYCY1EB223K J 0.022 25V Ceramic AA

C713 VCFRED1HM222G J 2200p 50V AD

C714 VCEAPF1CN106M J 10 16V Electrolytic AD

C715 VCKYCY1HB222K J 2200p 50V Ceramic AA

C716 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C717 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C718 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C719 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C720 VCKYTV1CF684Z J 0.68 16V Ceramic AB

C724 VCEAPW1VN476M J 47 35V Electrolytic AE

C725 VCKYTV1HF104Z J 0.1 50V Ceramic AA

C728 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C729 VCKYTV1CF105Z J 1 16V Ceramic AB

C730 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C731 VCCCCY1HH181J J 180p 50V Ceramic AA

Ref. No. Part No. ★ Description Code

C732 VCEAPW0JN477M J 470 6.3V Electrolytic AE

C733 VCEAPW0JN477M J 470 6.3V Electrolytic AE

C734 VCKYTV1CF105Z J 1 16V Ceramic AB

C735 VCEAPW0JN477M J 470 6.3V Electrolytic AE

C737 VCEAPT1AN107M J 100 10V Electrolytic AD

C738 VCKYTV1CF105Z J 1 16V Ceramic AB

C741 VCKYTV1CF105Z J 1 16V Ceramic AB

C742 VCEAPT1AN476M J 47 10V Electrolytic AD

C743 VCKYTV1CF105Z J 1 16V Ceramic AB

C744 VCEAPT0JN476M J 47 6.3V Electrolytic AC

C746 VCEAPF1CN106M J 10 16V Electrolytic AD

C747 VCFRED1HM222G J 2200p 50V AD

C748 VCKYCY1HB102K J 1000p 50V Ceramic AA

C749 RC-EZ0538CEZZ J 150 16V Electrolytic AE

C751 VCEAPW1CN477M J 470 16V Electrolytic AE

C752 RC-FZ0161CEZZ J 0.22

C752 RC-FZ0376CEZZ J 0.27 50V Mylar AH

C755 VCKYCY1EF683Z J 0.068 25V Ceramic AA

C757 VCKYCY1HF103Z J 0.01 50V Ceramic AA

C758 VCKYTV1HF103Z J 0.01 50V Ceramic AA

C760 VCKYTV1HB473K J 0.047 50V Ceramic AA

C761 VCKYTV1HB473K J 0.047 50V Ceramic AA

C780 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C781 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C782 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C783 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C784 VCKYTV1CF105Z J 1 16V Ceramic AB

C787 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C788 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C789 VCEA4A1CN108M J 1000 16V Electrolytic AD

C790 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C791 VCKYTV1CF105Z J 1 16V Ceramic AB

C802 VCKYCY1HB222K J 2200p 50V Ceramic AA

C803 VCCCCY1HH120J J 12p 50V Ceramic AA

C804 VCEAPH1HW224M J 0.22 50V Electrolytic AB

C805 VCEAPK1CN107M J 100 16V Electrolytic AD

C806 VCKYCY1HF103Z J 0.01 50V Ceramic AA

C807 VCKYCY1HF103Z J 0.01 50V Ceramic AA

C808 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C809 VCEAPH1HW225M J 2.2 50V Electrolytic AB

C810 VCKYCY1EB223K J 0.022 25V Ceramic AA

C812 VCEAPH1HW225M J 2.2 50V Electrolytic AB

C813 VCEAPK1CN107M J 100 16V Electrolytic AD

C814 VCKYCY1HF103Z J 0.01 50V Ceramic AA

C815 VCKYCY1HF103Z J 0.01 50V Ceramic AA

C816 VCEAPF1CN106M J 10 16V Electrolytic AD

C817 VCEAPF1CW476M J 47 16V Electrolytic AC

C818 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C819 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C823 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C824 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C825 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C826 VCKYCY1HF103Z J 0.01 50V Ceramic AA

C827 VCEAPK1CN107M J 100 16V Electrolytic AD

C828 VCKYCY1AF105Z J 1 10V Ceramic AC

C829 VCKYCY1HF103Z J 0.01 50V Ceramic AA

C830 VCEAPK1CN107M J 100 16V Electrolytic AD

C831 VCEAPH1HW225M J 2.2 50V Electrolytic AB

C832 VCEAPH1HW105M J 1 50V Electrolytic AB

C833 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C834 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C835 VCEAPF1CW476M J 47 16V Electrolytic AC

C836 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C837 VCEAPF1CW476M J 47 16V Electrolytic AC

C838 VCKYTV1CF104Z J 0.1 16V Ceramic AA

C839 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C841 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C846 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C858 VCEAPF1AW476M J 47 10V Electrolytic AB

C861 VCEA4A0JN108M J 1000 6.3V Electrolytic AD

C870 VCEAPF1AW476M J 47 10V Electrolytic AB

C871 VCEAPF1AW476M J 47 10V Electrolytic AB

C875 VCCCCY1HH270J J 27p 50V Ceramic AA

50V Mylar

(LC-121M2U)

(LC-150M2U)

AF

56

Page 49

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

Ref. No. Part No. ★ Description Code

DUNTK9775DE01 (LC-121M2U)

DUNTK9775DE02 (LC-150M2U)

MAIN UNIT (Continued)

C876 VCCCCY1HH270J J 27p 50V Ceramic AA

C877 VCCCCY1HH270J J 27p 50V Ceramic AA

C878 VCCCCY1HH270J J 27p 50V Ceramic AA

C879 VCCCCY1HH270J J 27p 50V Ceramic AA

C880 VCCCCY1HH270J J 27p 50V Ceramic AA

C881 VCKYCY1CF474Z J 0.47 16V Ceramic AB

C882 VCKYCY1CF474Z J 0.47 16V Ceramic AB

C883 VCKYCY1CF474Z J 0.47 16V Ceramic AB

C884 VCKYCY1AF105Z J 1 10V Ceramic AC

C885 VCKYTV1AB105K J 1 10V Ceramic AD

C886 VCKYTV1AB105K J 1 10V Ceramic AD

C891 VCKYCY1AF105Z J 1 10V Ceramic AC

C892 VCKYCY1AF105Z J 1 10V Ceramic AC

C893 VCCCCY1HH120J J 12p 50V Ceramic AA

C894 VCCCCY1HH120J J 12p 50V Ceramic AA

C895 VCCCCY1HH1R0C J 1p 50V Ceramic AA

C896 VCKYCY1AF105Z J 1 10V Ceramic AC

C897 VCKYCY1AF105Z J 1 10V Ceramic AC

C950 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C951 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C952 VCEAPH1CW106M J 10 16V Electrolytic AB

C953 VCEAPH1CW106M J 10 16V Electrolytic AB

C954 VCFRED1HM822J J 8200p 50V AD

C955 VCFYEC1CM334J J 0.33 16V AE

C956 VCEAPH1CW106M J 10 16V Electrolytic AB

C957 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C958 VCEAPF1CW476M J 47 16V Electrolytic AC

C959 VCEAPF1CW476M J 47 16V Electrolytic AC

C960 VCFRED1HM822J J 8200p 50V AD

C961 VCFYEC1CM334J J 0.33 16V AE

C962 VCEAPH1CW106M J 10 16V Electrolytic AB

C963 VCEAPH0JW226M J 22 6.3V Electrolytic AB

C964 VCEAPH0JW226M J 22 6.3V Electrolytic AB

C965 VCEAPH1CW106M J 10 16V Electrolytic AB

C966 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C967 VCKYTV1CF105Z J 1 16V Ceramic AB

C968 VCKYTV1CF105Z J 1 16V Ceramic AB

C969 VCKYTV1CF105Z J 1 16V Ceramic AB

C970 VCKYTV1CF105Z J 1 16V Ceramic AB

C971 VCKYTV1CF105Z J 1 16V Ceramic AB

C972 VCKYTV1CF105Z J 1 16V Ceramic AB

C973 VCKYTV1CF105Z J 1 16V Ceramic AB

C1005 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1006 VCCCCY1HH101J J 100p 50V Ceramic AA

C1007 VCCCCY1HH101J J 100p 50V Ceramic AA

C1008 VCCCCY1HH101J J 100p 50V Ceramic AA

C1009 VCCCCY1HH101J J 100p 50V Ceramic AA

C1010 VCCCCY1HH101J J 100p 50V Ceramic AA

C1011 VCCCCY1HH101J J 100p 50V Ceramic AA

C1012 VCCCCY1HH101J J 100p 50V Ceramic AA

C1013 VCCCCY1HH101J J 100p 50V Ceramic AA

C1015 VCEAPF0JW476M J 47 6.3V Electrolytic AB

C1016 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1017 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1020 VCKYCY1AF105Z J 1 10V Ceramic AC

C1022 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1023 VCKYCY1AF105Z J 1 10V Ceramic AC

C1024 VCCCCY1HH101J J 100p 50V Ceramic AA

C1025 VCCCCY1HH101J J 100p 50V Ceramic AA

C1026 VCCCCY1HH101J J 100p 50V Ceramic AA

C1027 VCCCCY1HH101J J 100p 50V Ceramic AA

C1029 VCKYCY1AF105Z J 1 10V Ceramic AC

C1030 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1031 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1032 VCCCCY1HH101J J 100p 50V Ceramic AA

C1033 VCCCCY1HH101J J 100p 50V Ceramic AA

C1034 VCCCCY1HH101J J 100p 50V Ceramic AA

C1035 VCCCCY1HH101J J 100p 50V Ceramic AA

C1036 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1037 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1038 VCEAPF0GW476M J 47 4V Electrolytic AB

Ref. No. Part No. ★ Description Code

C1039 VCCCCY1HH101J J 100p 50V Ceramic AA

C1040 VCCCCY1HH101J J 100p 50V Ceramic AA

C1041 VCCCCY1HH101J J 100p 50V Ceramic AA

C1042 VCCCCY1HH101J J 100p 50V Ceramic AA

C1043 VCCCCY1HH101J J 100p 50V Ceramic AA

C1044 VCCCCY1HH101J J 100p 50V Ceramic AA

C1045 VCCCCY1HH101J J 100p 50V Ceramic AA

C1046 VCCCCY1HH101J J 100p 50V Ceramic AA

C1048 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1050 VCEAPF0GW107M J 100 4V Electrolytic AC

C1051 VCEAPF0JN107M J 100 6.3V Electrolytic AD

C1052 VCEAPF1AN336M J 33 10V Electrolytic AD

C1053 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1054 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1055 VCKYTV1CF105Z J 1 16V Ceramic AB

C1056 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1057 VCKYCY1AF105Z J 1 10V Ceramic AC

C1058 VCEAPW0JN476M J 47 6.3V Electrolytic AD

C1059 VCEAPW0JN476M J 47 6.3V Electrolytic AD

C1060 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1061 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1062 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1063 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1064 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1065 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1101 VCKYTV1CF105Z J 1 16V Ceramic AB

C1102 VCKYTV1CF105Z J 1 16V Ceramic AB

C1103 VCEAPH1CW106M J 10 16V Electrolytic AB

C1104 VCKYTV1CF105Z J 1 16V Ceramic AB

C1105 VCKYTV1CF105Z J 1 16V Ceramic AB

C1108 VCKYTV1CF105Z J 1 16V Ceramic AB

C1131 VCEAPW1CN107M J 100 16V Electrolytic AE

C1132 VCEAPW1CN107M J 100 16V Electrolytic AE

C1133 VCEAPW0JN107M J 100 6.3V Electrolytic AE

C1134 VCEAPW0JN107M J 100 6.3V Electrolytic AE

C1136 VCEAPW0JN107M J 100 6.3V Electrolytic AE

C1138 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1139 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1170 VCKYCY1AF105Z J 1 10V Ceramic AC

C1171 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1172 VCEAPH1CW106M J 10 16V Electrolytic AB

C1173 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1174 VCKYCY1CF104Z J 0.1 16V Ceramic AA

C1175 VCKYCY1CF104Z J 0.1 16V Ceramic AA