sharp FO-IS125N Service Manual

TopPage

MODEL SELECTION CODE DESTINATION

FO-IS125N

U

U.S.A.

FO-IS125N

SERVICE MANUAL

No. 00ZFIS125NSME

FACSIMILE

CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

[1] Caution........................................................... 1-1

[2] Specifications ................................................. 1-3

[3] Operation panel.............................................. 1-5

[4] Transmittable documents ............................... 1-6

[5] Installation ...................................................... 1-7

[6] Clearing paper jams..................................... 1-11

CHAPTER 2. ADJUSTMENTS

[1] Adjustments ................................................... 2-1

[2] Diagnostics and service soft switch ............... 2-7

[3] Troubleshooting ........................................... 2-56

[4] Error code table............................................ 2-57

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Mechanical description................................... 3-1

[2] Disassembly and assembly procedures....... 3-13

MODEL

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Circuit description ..........................................5-1

[2] Circuit description of control PWB .................5-2

[3] Circuit description of power supply PWB......5-26

[4] Circuit description of CIS unit ......................5-27

[5] Circuit description of

operation panel PWB...................................5-27

[6] Data flow chart.............................................5-28

[7] Troubleshooting...........................................5-29

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Control PWB circuit .......................................6-1

[2] Power Supply PWB circuit...........................6-16

[3] High Voltage PWB circuit.............................6-18

[4] Operation Panel/

Hook Switch PWB circuit .............................6-21

FO-IS125N

CHAPTER 4. DIADRAMS

[1] Block diagram ................................................ 4-1

[2] Wiring diagram ............................................... 4-2

[3] Point-to-point diagram.................................... 4-3

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

CHAPTER 7. OTHER

[1] Protocol .........................................................7-1

[2] Power on sequence.......................................7-2

[3] Rewriting version up the FLASH ROM ..........7-3

Parts Guide

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

FO-IS125N

FO-IS125N

CHAPTER 1. GENERAL DESCRIPTION

Service Manual

[1] Caution

1. Laser caution

This laser facsimile is a class 1 laser product that complies with 21CFR 1040.10 and 1040.11 of the CDRH or IEC60825-1 standard. This means that

this machine dose not produce a hazardous laser radiation. The use of controls, adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

This laser radiation isn't a danger to the skin, but when an exact focusing of the laser beam is achieved on the eyes retina, there is danger of spot

damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time of servicing.

1) When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged as a unit, not an individual part.

2) Do not look into the machine with the main switch turned on after removing the toner/developer unit and drum cartridge.

3) Do not look into the laser beam exposure slit of the laser optical unit with the connector connected when removing and installing the optical system.

4) The cover of Laser Printer Unit contains the safety interlock switch.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot.

Laser Wave Length : 780 nm +15/-10 nm

Laser Pulse Times : 12.00 µs/7 mm

Laser Output Power : 0.15 mW ± 0.04mW

2. Life of consumable

Section Part Estimated Life Replaced by

Toner cartridge Replacement cartridge (FO-25ND) 3,000 prints (at Letter/5% chart) User

Drum cartridge Replacement cartridge (FO-25DR) 20,000 prints (at Letter/5% chart) User

Paper feed Transfer roller (Refer to the P/G No. 1-27)

(NROLR2565XHZZ)

Fuser Fusing unit (Refer to the P/G No. 6-901)

(CFRM-2265XH04)

Paper transport Feed roller (Refer to the P/G No. 3-25)

(NROLR2562XHZZ)

Unit FO-IS125N 5 years or 50,000 prints of early either -

50,000 prints Service Engineer

50,000 prints Service Engineer

Cleaning as needed -

1 – 1

3. Caution for Battery replacement

FO-IS125N

(Danish) ADVARSEL !

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the equipment manufacturer.

Discard used batteries according to manufacturer's instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

4. Precautions for using Lead-Free Solder

1. Employing lead-free solder

This model employs lead-free solder.

This is indicated by the "LF" symbol printed on the PWB and in the service manual.

The suffix letter indicates the alloy type of the solder.

Example:

(French) ATTENTION

Il y a danger d'explosion s' il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d'un type recommandé par le constructeur.

Mettre au rébut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfare vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anweisungen.

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free solder

When repairing a PWB with the "LF" symbol, only lead-free solder should be used. (Using normal tin/lead alloy solder may

result in cold soldered joints and damage to printed patterns.)

As the melting point of lead-free solder is approximately 40°C higher than tin/lead alloy solder, it is recommended that a

dedicated bit is used, and that the iron temperature is adjusted accordingly.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is higher and has poorer melting point (flow), to prevent damage to the

land of the PWB, extreme care should be taken not to leave the bit in contact with the PWB for an extended period of time.

Remove the bit as soon as a good flow is achieved.

The high content of tin in lead free solder will cause premature corrosion of the bit.

To reduce wear on the bit, reduce the temperature or turn off the iron when it is not required.

Leaving different types of solder on the bit will cause contamination of the different alloys, which will alter their

characteristics, making good soldering more difficult.

It will be necessary to clean and replace bits more often when using lead-free solder. To reduce bit wear, care should be

taken to clean the bit thoroughly after each use.

1 – 2

FO-IS125N

[2] Specifications

Print specifications

Toner cartridge yield* (continuous printing, 5% page coverage, letter paper):

Drum cartridge yield* (continuous printing, 5% page coverage, letter paper):

Paper tray capacity: Letter: Approx. 250 sheets (20-lb. copier paper at room temperature; maximum stack height should

Printer type: Laser

Print resolution: 600 x 600 dpi (dots per inch)

Effective printing width: 8.2" (208 mm) max.

PC print speed: 12 ppm (pages per minute)

*The yields may vary depending on coverage and operating conditions.

Fax specifications

Memory capacity*: Approximately 500 average pages

Modem speed: 33,600 bps with auto fallback to lower speeds.

Transmission time*: Approx. 3 seconds

Compatibility: ITU-T (CCITT) Super G3, G3 mode

Compression scheme: MR, MH, MMR

Applicable telephone line: Public switched telephone network

Reception modes: AUTO, MANUAL

Scanning resolution: Horizontal: 203 lines/inch (8 lines/mm)

Halftone (grayscale): 64 levels

Contrast control: Automatic/Dark selectable

*Based on Sharp Standard Chart at standard resolution, excluding time for protocol signals (i.e.,ITU-T phase C time only).

Initial starter cartridge (included with machine): Approx. 1500 pages

Replacement cartridge (FO-25ND): Approx. 3000 pages

Initial starter cartridge (included with machine): 20,000 pages (average)

Replacement cartridge (FO-25DR): 20,000 pages (average)

not be higher than the line on the tray)

Legal: 100 sheets

Recommended paper weight: 20-lb. Copy Bond

Ver ti ca l:

Standard: 98 lines/inch (3.85 lines/mm)

Fine /Halftone: 196 lines/inch (7.7 lines/mm)

Super fine: 391 lines/inch (15.4 lines/mm)

Network and general specifications

Automatic document feeder: Letter/A4: 30 sheets max. (20-lb. paper)

Legal: 5 sheets max.

Input document size: Automatic feeding:

Width: 5.8" to 8.5" (148 to 216 mm)

Length (30 sheets): 5.5" to 11" (140 to 279 mm)

Length (5 sheets): 5.5" to 14" (140 to 356 mm)

Manual feeding:

Width: 2.75" to 8.5" (70 to 216 mm)

Length: 5.5" to 14" (140 to 356 mm)

Effective scanning width: 8.2" (208 mm) max.

Storable transmission destinations: Rapid Keys: 36

Telephone function: Yes (cannot be used if power fails)

Copy function: Single/Multi/Sort (up to 99 copies per page)

Network interface: 10 Base-T, 100 Base-TX

Network frame type: IEEE802.2/IEEE802.3 Ethernet II

Network protocol: TCP/IP

Supported operating systems:

Scan to E-mail: Ye s

Scan to Network Folder: Yes

Global Address Search: Yes (requires LDAP server)

User authentication: Yes

File formats: TIFF (G4), PDF (G4)

Display: LCD display, 20 digits x 2 lines

Power requirements: 120 V AC, 60 Hz

Power consumption: Standby: 8.6 W, Maximum: 690 W

Operating temperature: 50 - 86°F (10 - 30°C)

Humidity: 25 - 85% RH

Speed Dial numbers: 114

Windows

(Printer driver also supports Windows

®

2000, XP, Vista

®

Server 2003)

1 – 3

FO-IS125N

Dimensions (without attachments): Width: 16.8" (426 mm)

Depth: 16.1" (410 mm)

Height: 8.2" (208 mm)

Weight (with attachments): Approx. 15.6 lbs. (7.1 kg)

As a part of our policy of continuous improvement, SHARP reserves the right to make design and specification changes for product improvement

without prior notice. The performance specification figures indicated are nominal values of production units. There may be some deviations from

these values in individual units.

Tradmark information

• Microsoft, Windows and Internet Explorer are trademarks of Microsoft Corporation in the U.S.A. and other countries.

1 – 4

FO-IS125N

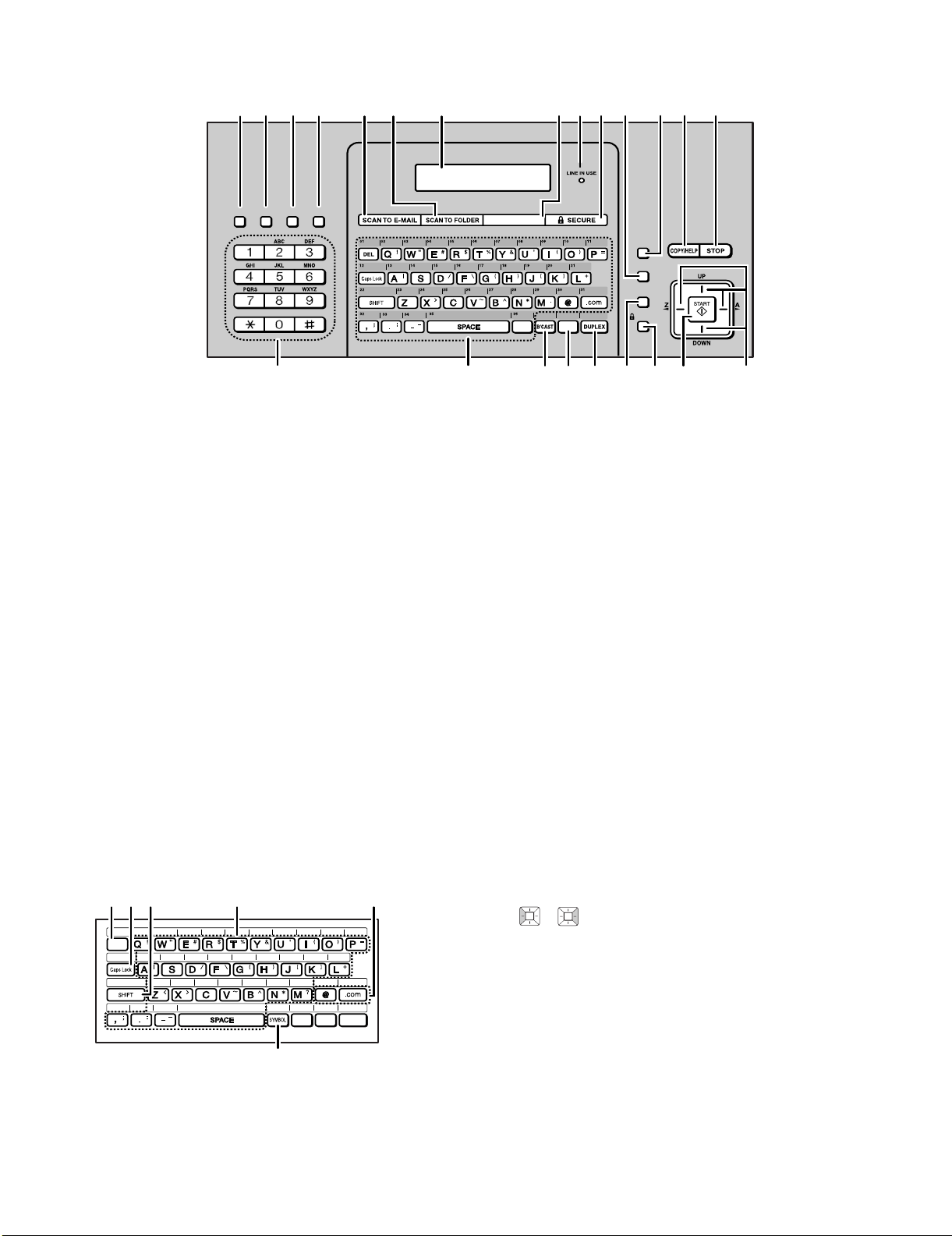

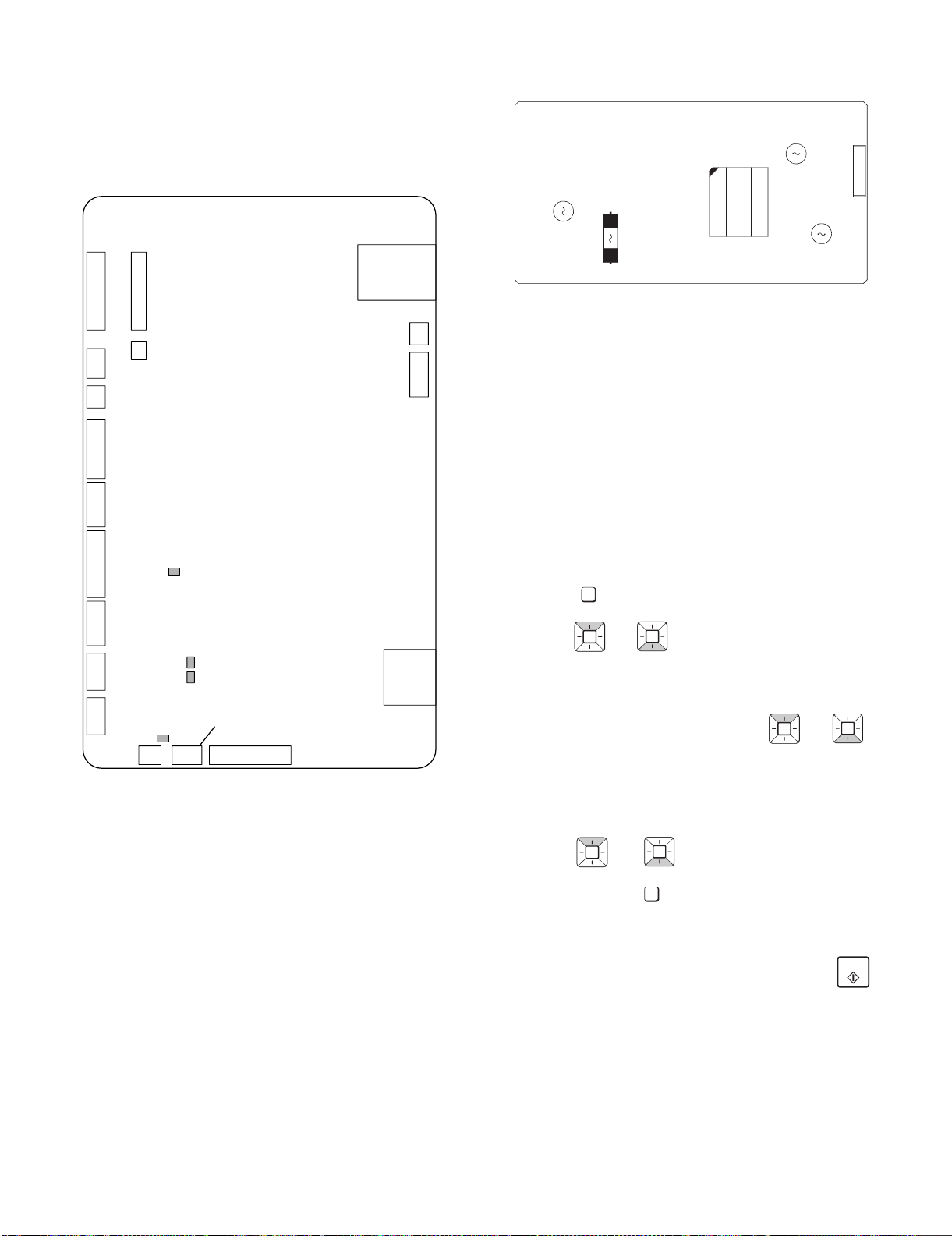

[3] Operation panel

1

SPEAKER

23

SPEED DIAL REDIAL

HOLD

456 7 89

GLOBAL ADDRESS

SYMBOL

10 11

INFO

FUNCTION

RECEPTION

RESOLUTION

RELEASE

1312

14

15 18

Note: Affix the Rapid Key labels as shown above.

1. SPEAKER key:

through the speaker when faxing. Note: This is not a

speakerphone. It cannot be used for speaking.

2. HOLD key:

3. SPEED DIAL key:

destination stored in a 3-digit Speed Dial number.

4. REDIAL key:

number dialed.

5. SCAN TO E-MAIL key:

an e-mail recipient.

6. SCAN TO FOLDER key:

a folder on a computer on the same network as the machine,

or to an FTP server.

7. Display:

the machine.

This displays messages to help you operate

8. GLOBAL ADDRESS key:

destination in a global address book on an LDAP server.

9. LINE IN USE light key:

is using the phone line to send or receive a fax.

10. SECURE key:

functions of the machine.

11. RECEPTION key:

(AUOT or MANUAL) for receiving faxes. The selected mode

will appear the the display.

12. FUNCTION key:

keys to select special functions and settings.

Press to listen to the line and fax tones

Press to put a phone call on hold.

Press to select a fax or e-mail

Press to automatically redial the last

Press to send a document to

Press to send a document to

Press to search for a

This lights up when the machine

Press to set up and use the security

Press to select the reception mode

Press this key followed by the arrow

1716

13. COPY/HELP key:

press to make a copy. At any other time, press to print the

Help List.

14. STOP key:

completed.

15. Number key:

numbers when storing transmission destinations.

Press to cancel an operation before it is

20 21

19

When a document is in the feeder,

Use these keys to dial numbers, and enter

16. Rapid keys/Letter keys:

address, on network folder can be stored in each of these keys

for one-touch selection (attach the Rapid Key labels). When

entering text, the keys are used as letter keys.

17. BROADCAST key:

mail destinations.

18. INFO key:

information.

Press to check various types of machine

19. DUPLEX key:

transmission and copying.

20. RESOLUTION key:

is in the feeder, press to adjust the scanning resolution for

transmission.

21. RELEASE key:

memory instead of being printed out because the Secure Fax

function has been activated, press this key to enter the Secure

code and print out the fax.

22. START key:

23. Arrow key:

and to search for stored destinations.

Use to scroll through and select settings,

Press to send to multiple fax or e-

Use to scan two-sided documents for

When a document

When a fax has been received to

Press after dialing to send a fax.

22

A fax number, e-mail

23

Letter keys

3

14

2

DEL

6

B'CAST

INFO

DUPLEX

1. DEL key:

cursor. When the cursor is to the right of a line of text, press to

5

backspace and clear characters. (The cursor can be moved by

pressing or .) To delete all entered characters, hold

down until all characters are cleared.

2. Caps Lock key:

again to return to lower case letter entry.

3. SHIFT key:

temporarily change case.

4. Letter keys:

5. @ key, .com key:

".com" when entering an e-mail address.

6. SYMBOL key:

enter the symbol that appears on the right side of the key.

Press to delete the character marked by the

Press to enter upper case letters. Press

Hold down while pressing a letter key to

Use to enter letters.

Press to conveniently enter "@" and

Hold down while pressing a letter key to

1 – 5

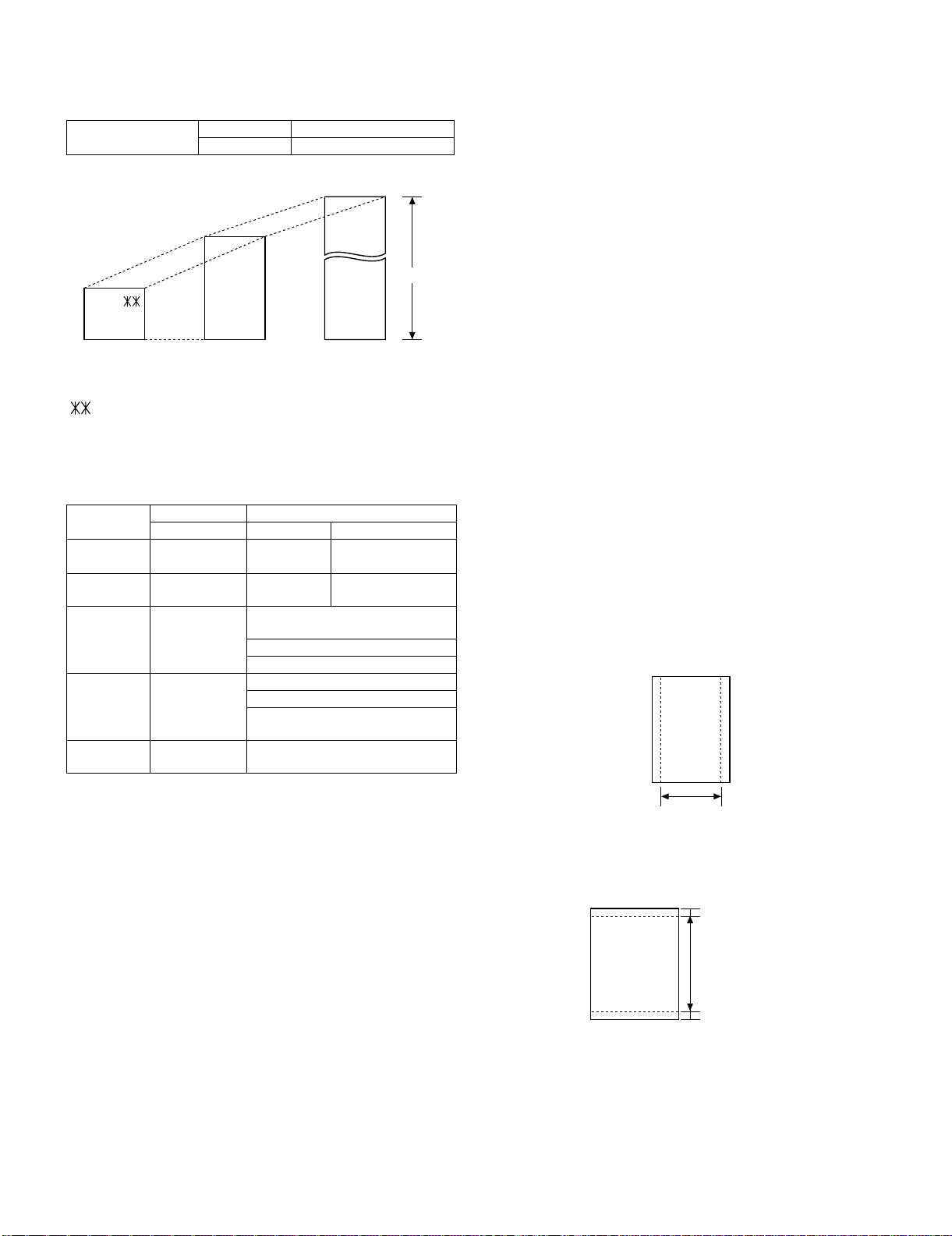

[4] Transmittable documents

h

1. Document Sizes

Normal size Width 148 - 216 mm

Length 140 - 297 mm

(Max.)

FO-IS125N

4. Cautions on Transmitting Documents

• Documents written in yellow, greenish yellow, or light blue ink cannot be transmitted.

• Ink, glue, and correcting fluid on documents must be dry before the

documents can be transmitted.

• All clips, staples and pins must be removed from documents before

transmission.

• Patched (taped) documents should be copied first on a copier and

then the copies used for transmission.

• All documents should be fanned before insertion into the feeder to

prevent possible double feeds.

(Max.)

(Min.)

140mm

70mm

[Special size]

Use document carrier sheet for smaller documents.

• With special sizes, only one sheet can be fed into the machine at a

time. Insert next page into feeder as current page is being scanned.

A4 size

216mm

[Normal size]

297mm

216mm

[Special size]

356mm

2. Paper Thickness & Weight

Product specifications

Weight

indication

Thickness

indication

Document

size

Number of

ADF sheets

Paper

quality

Indication Lower Limit Upper Limit

Metric system

indication

Metric system

indication

Document size

Range

Document size

Weight

Kind Paper of fine quality/bond paper/

2

52g/m

0.06mm 0.1mm

Minimum (148mm x 70mm)

A4 (210mm x 297mm)

Letter (216mm x 279mm)

Legal (216mm x 356mm)

Minimum ~ Letter/A4 size 30sheets

Legal 5 sheets

More than 90 kg

Below 135 kg 1 sheet

Kent paper

80g/m

2

5. Automatic Document Feeder Capacity

Number of pages that can be placed into the feeder at as follows:

Letter/A4: 30 sheets max. (20lb. paper)

Legal: 5 sheets max.

• Temperature: 50 ~ 86°F (10 ~ 30°C)

• Humidity: 25 ~ 85%

NOTE: • When you need to send or copy more pages than the

feeder limit, place additional pages in feeder when last

page in feeder is being scanned.

• Place additional pages carefully and gently in feeder. If

force is used, double-feeding or a document jam may

result.

6. Readable Width & Length

The readable width and length of a document are slightly smaller than

the actual document size.

Note that characters or graphics outside the effective document scanning range will not be read.

• Readable width

8.2” (208mm), max

3. Document Types

• Normal paper

Documents handwritten in pencil (No. 2 lead or softer), fountain

pen, ball-point pen, or felt-tipped pen can be transmitted.

Documents of normal contrast duplicated by a copying machine

can also be transmitted.

• Diazo copy (blue print)

• Diazo copy documents of a normal contrast may be transmitted.

• Carbon copy

A carbon copy may be transmitted if its contrast is normal.

Readable widt

• Readable length

This is the length of the document sent minus 0.16”(4mm) from the

top and bottom edges.

0.16"(4mm)

Readable length

0.16"(4mm)

1 – 6

FO-IS125N

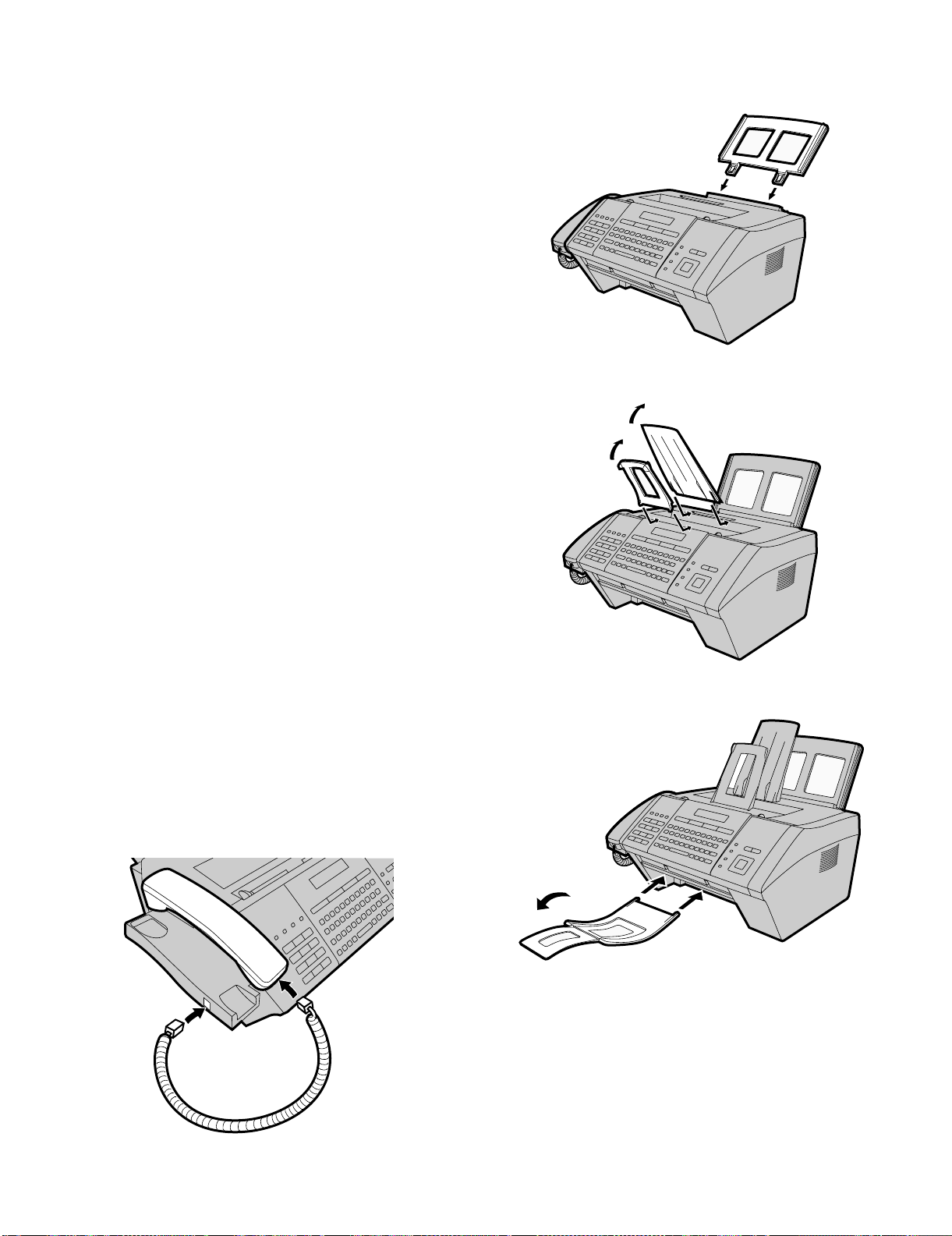

[5] Installation

1. Site selection

Take the following points into consideration when selecting a site for

this model.

ENVIRONMENT

• The machine must be installed on a level surface.

• Keep the machine away from air conditioners, heaters, direct sunlight, and dust.

• Provide easy access to the front, back, and sides of the machine.

In particular, keep the area in front of the machine clear, or the original document may jam as it comes out after scanning.

• The temperature should be between 50 - 86°F (10 - 30°C).

• The humidity should be between 25% and 80% (without condensation).

ELECTRICITY

AC 120 V, 60Hz, grounded AC (3-prong) outlet is required.

Caution!

• Connection to a power source other than that specified will cause

damage to the equipment and is not covered under the warranty.

• If your area experiences a high incidence of lightning or power

surges, we recommend that you install a surge protector for the

power and telephone lines. Surge protectors can be purchased at

most telephone specialty stores.

If the machine is moved from a cold to a warm place...

Condensation may form on the reading glass if machine is moved from

a cold to a warm place, this will prevent proper scanning of documents

for transmission. Turn on the power and wait approximately 2 hours

before using machine.

TELEPHONE JACK

A standard telephone jack must be located near the machine. This is

the telephone jack commonly used in most homes and offices.

• The language is unclear in this part. Perhaps it could say:

"Plugging the fax machine into a jack which is not a standard analog telephone jack, may result in damage to the machine or your

telephone system."

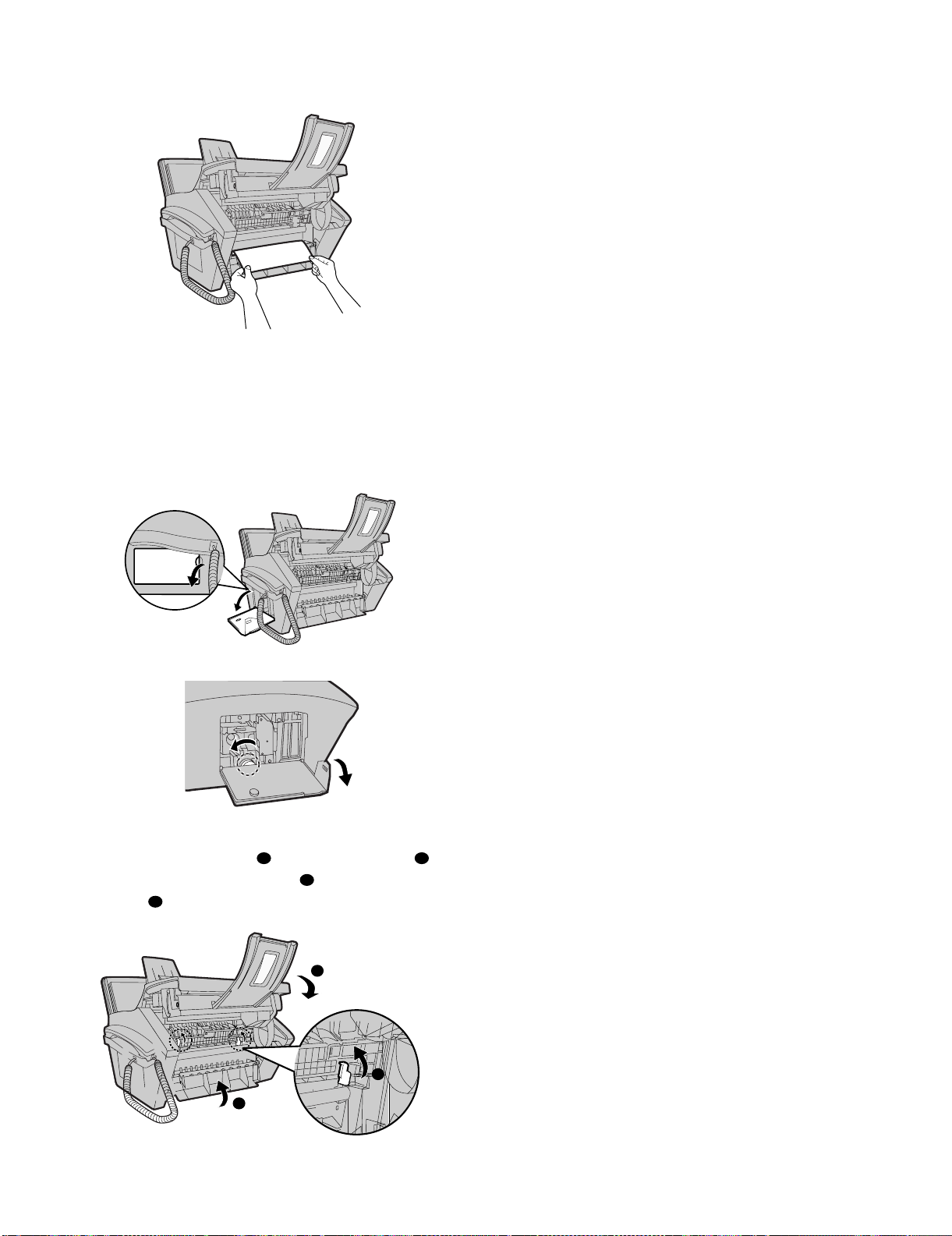

3. Attaching the tray

1) Attach the paper tray.

2) Attach the document feeder tray and the received document tray.

Insert the trays at an

angle and rotate back.

3) Attach the document exit tray.

After inserting the tray,

flip out the extension.

2. Connecting the handset

1 – 7

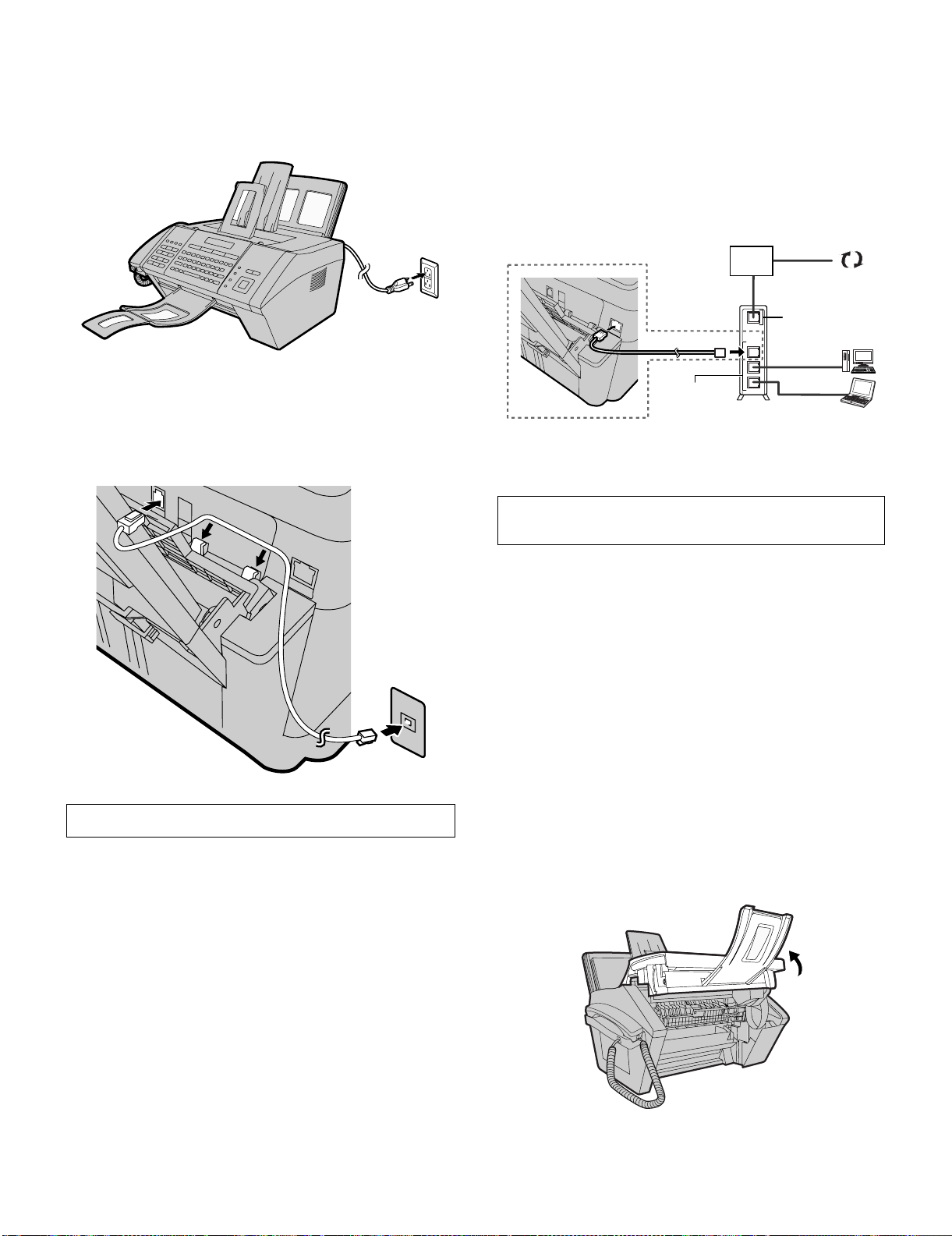

4. Connecting the power cord

Cable/DSL

modem

Router

LAN ports

(Hub/Switch)

LAN cable

LAN cable

LAN cable

LAN cable

WAN port

Internet

Plug the power cord into a 120 V, 60 Hz, grounded AC (3-prong) outlet.

• Do not plug the power cord into any other kind of outlet. This will

damage the machine and is not covered under the warranty.

5. Connecting the telephone line cord

Insert one end of the line cord into the socket on the back of the

machine marked TEL. LINE. Insert the other end into a wall telephone

socket.

FO-IS125N

7. Connecting the machine to your network

To use the Scan to E-mail and Scan to Folder functions, and to use the

machine as a printer, you must connect the machine to an Ethernet

network. In addition, to use Scan to E-mail, the network must have an

Internet connection. A typical setup is shown below.

The machine is connected using an Ethernet cable (not included).

Please purchase a 10Base-T/100Base-TX straight-through (regular)

cable.

Connect one end of the cable to the LAN port on the machine. Connect the other end to a LAN port on your switch or hub.

• If you are uncertain which port to connect the cable to, see the

manual for the router, switch or hub.

• The connections can be made with all devices powered on.

The machine is initially set for tone dialing. If you are on a pulse dial

line, change the “DIAL MODE” setting.

6. Affixing the rapid key labels

Affix each strip of Rapid Key labels above each row of letter keys as

shown in the panel illustration.

To communicate on your network, the machine must have an IP

address. To set the machine’s IP address and configure other network settings.

8. Installing the toner cartridge and drum cartridge

The laser printer in the machine uses a toner cartridge and a drum cartridge.

• The starter toner cartridge included with the machine can print

approximately 1500 letter-size pages at 5% page coverage.

• When replacing the toner cartridge, use a SHARP FO-25ND toner

cartridge. One cartridge can print about 3000 letter-size pages at

5% coverage.

• The drum cartridge can print approximately 20,000 letter-size

pages. When replacing the drum cartridge, use a SHARP FO-

25DR drum cartridge.

Follow the steps below to install the toner cartridge and the drum cartridge.

Note: The quality of the toner cartridge is guaranteed for 18 months

after the date of manufacture indicated on the package. The quality of

the drum cartridge is guaranteed for 24 months after the date of manufacture indicated on the package.

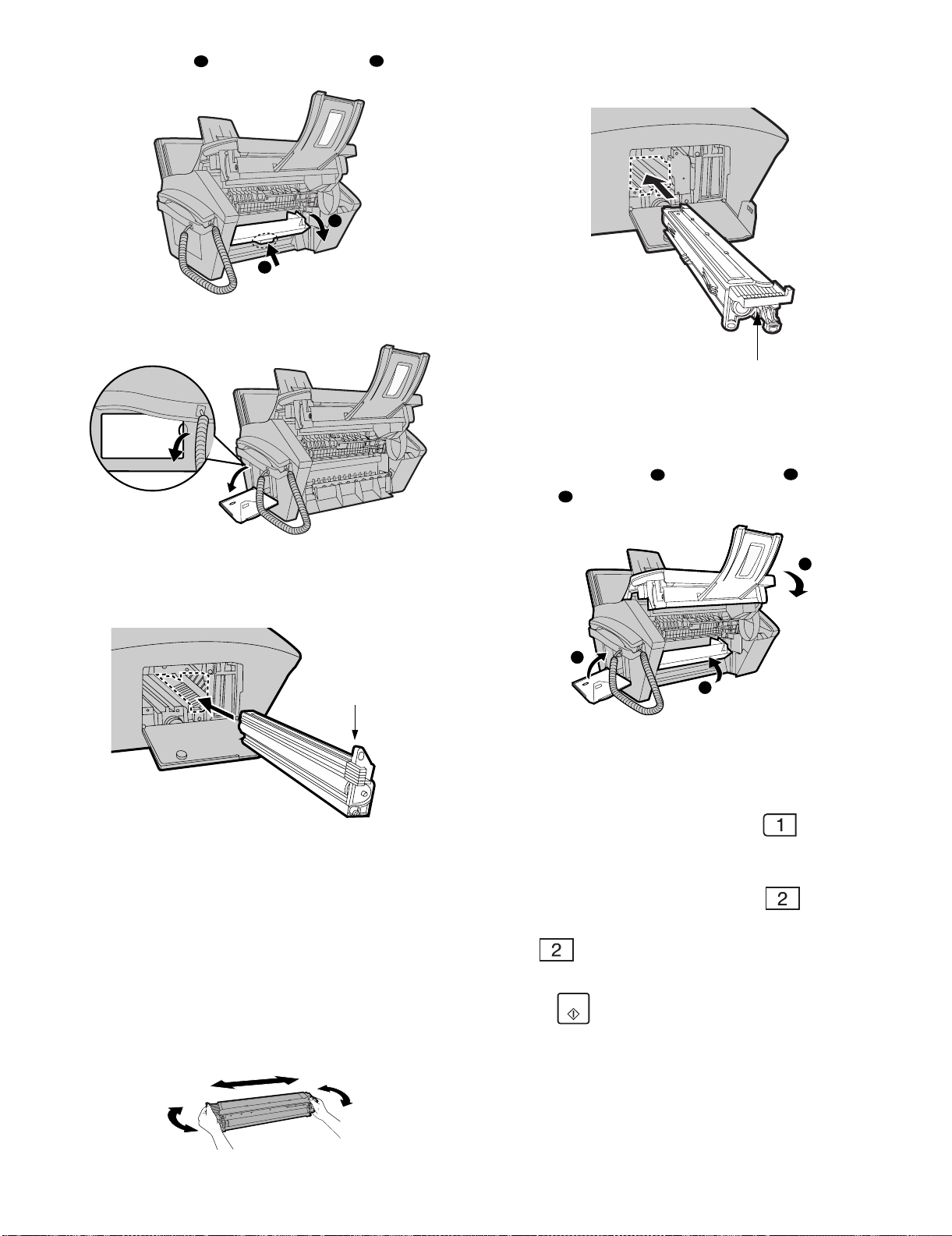

1) Open the top cover of the machine.

Caution! The fusing unit inside the print compartment becomes

very hot during operation. Do not touch the inside of the print compartment after the machine has been in operation.

1 – 8

FO-IS125N

START

2) Press the release ( ) and open the front cover ( ).

3) Open the side cover.

1

1

2

2

7) Grasp the cartridge handle and insert the toner cartridge into the

print compartment, sliding it along the guides.

Grasp this handle to

insert the cartridge.

• Make sure the cartridge “clicks” into place.

• Do not touch the roller in the toner cartridge.

8) Close the side cover ( ), the front cover ( ), and the top

cover ( ).

3

1

2

4) Remove the new drum cartridge from its packaging.

5) Insert the drum cartridge into the print compartment, sliding it along

the guides.

Grasp this

handle to

push the

cartridge in.

• Do not touch or allow other objects to contact the drum (the

green cylinder). This may damage the drum. If fingerprints, dust,

or other contaminants get on the drum, wipe it gently with a

clean cloth.

• Exposure to light for more than several minutes will damage the

drum. Be sure to insert the drum cartridge promptly into the

machine.

• If you find it necessary to leave the cartridge out of the machine

for more than several minutes, wrap the cartridge in black

paper.

6) Remove the new toner cartridge from its packaging. Shake the cartridge side to side four or five times to distribute the toner evenly

within the cartridge.

3

1

2

• Make sure the side cover is completely closed. Otherwise, light

may enter the print compartment and damage the drum.

• The display will show: [TONER EXCHANGED?] / [1 = NEW, 2 =

OLD]

9) If you installed a new toner cartridge, press to select NEW

(this will reset the toner counter to zero).

• If you temporarily removed and then replaced an old toner car-

tridge for maintenance or other reason, press to con-

tinue using the previous toner count. (Note: Be sure to press

or the machine will not alert you when the toner car-

tridge is out of toner.)

10)Press .

11)If you installed a new drum cartridge, reset the drum counter as

explained below.

1 – 9

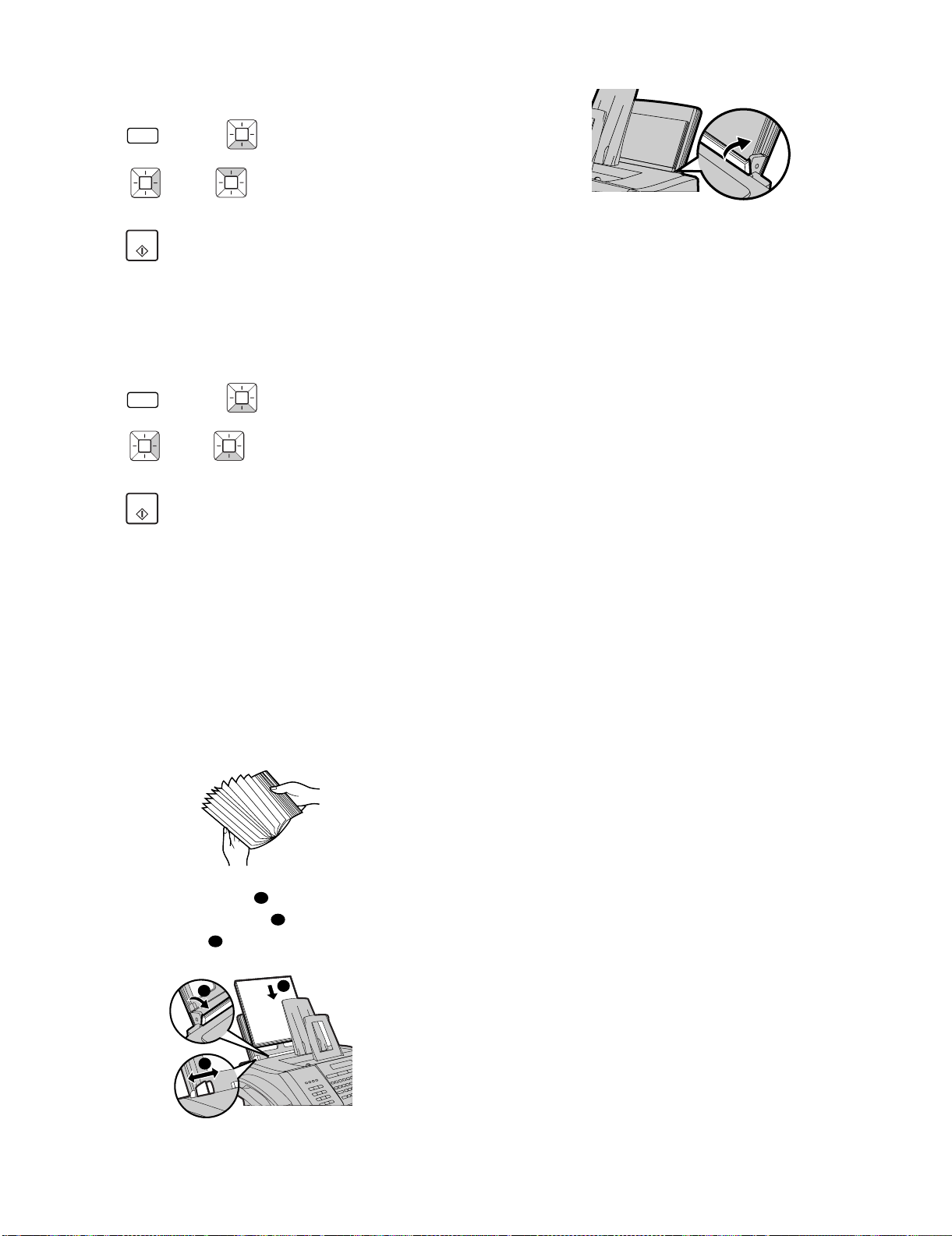

9. Resetting the drum counter

Each time you install a new drum cartridge, follow the steps below to

reset the drum counter to zero.

FO-IS125N

3) Push the paper plate back.

1) Press and then until [LIFE] appears in the display.

INFO

2) Press , then until [CLEAR DRUM COUNTER]

appears.

3) Press .

START

10. Manually resetting the toner counter

When a new toner cartridge is installed, the toner counter is reset in

Step 9 on the previous page. The procedure below is normally not necessary; however, it can be used in the event that you need to reset the

toner counter manually.

1) Press and then until [LIFE] appears in the display.

INFO

2) Press , then until [CLEAR TONER COUNTER]

appears.

3) Press .

START

11. Loading printing paper

You can load letter or legal size paper in the paper tray.

Maximum number of sheets

(20-lb. copy bond paper at room temperature)

Letter: Approx. 250 sheets

Legal size: 100 sheets

Caution! Do not use the blank side of paper that has already been

printed on.

1) Fan the paper, and then tap the edges against a flat surface to

even the stack.

• If you loaded legal size paper (or you changed the paper size),

change the paper size setting as explained.

2) Pull the paper plate forward . Squeeze the paper guide and

adjust it to the width of the paper . Insert the stack of paper into

the tray, print side up .

1

2

1

2

3

3

• Maximum stack height should not be higher than the line on the

paper guide.

1 – 10

FO-IS125N

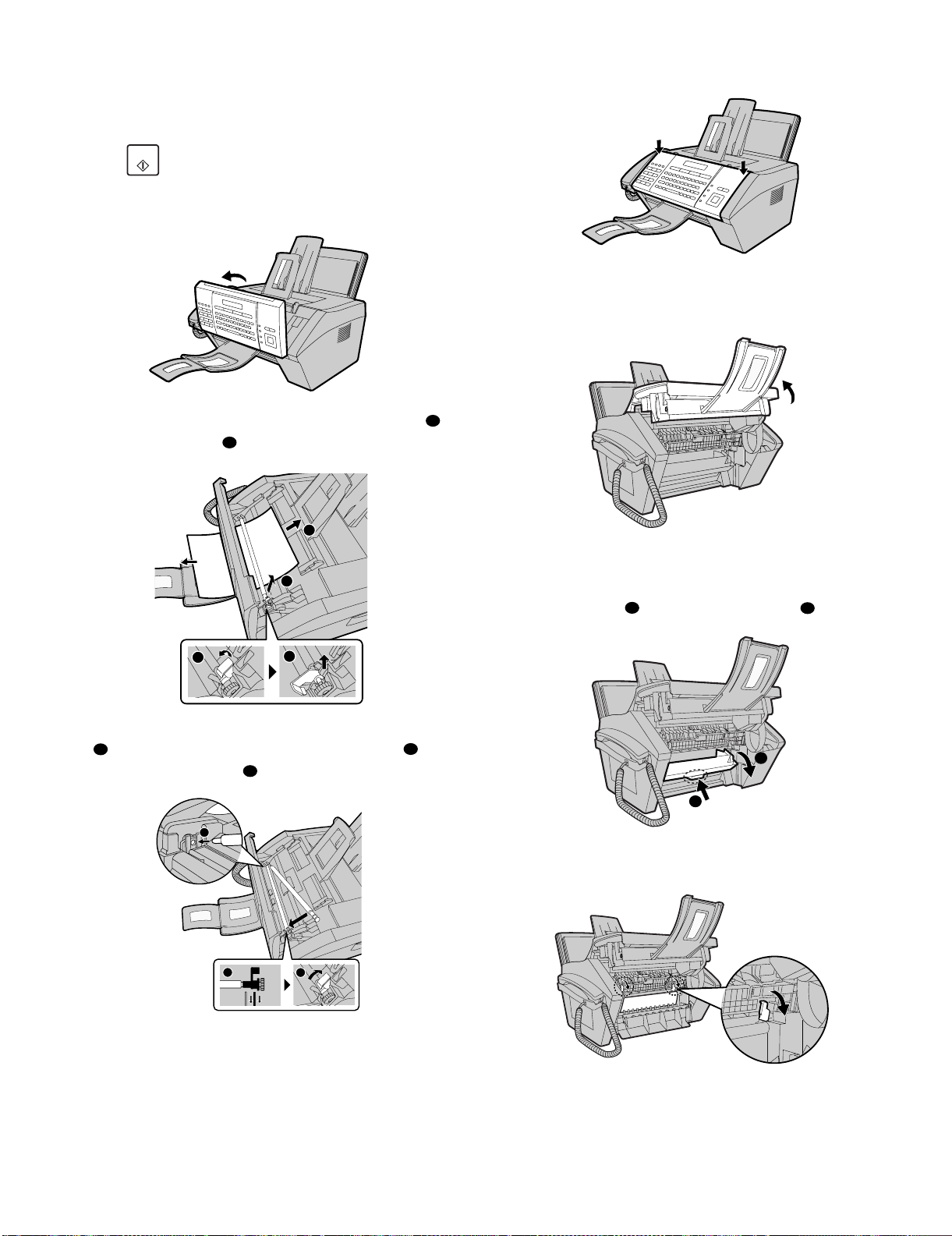

[6] Clearing paper jams

1. Clearing a jammed document

If the original document doesn’t feed properly during transmission or

copying, or [DOCUMENT JAMMED] appears in the display, first try

pressing . If the document doesn't feed out, remove it as

explained below.

1) Open the operation panel.

START

4) Close the operation panel, pressing down firmly on both sides to

make sure it clicks into place.

2. Clearing jammed printing paper

1) Open the top cover of the machine.

2) Rotate the lever so that it points straight up and pull it up ( ).

Remove the document ( ).

2

2

1

1

2

1

3) Make sure the left end of the roller is inserted correctly in its holder

( ), and then push the right end of the roller down ( ) and

1

rotate the lever back down ( ).

3

1

2

• Caution! The fusing unit inside the print compartment becomes

very hot during operation. Do not touch the inside of the print

compartment after the machine has been in operation.

2) Press the release ( ) and open the front cover ( ).

1

1

2

2

3) Push the two heater roller release levers down to release the

heater roller.

2

3

1 – 11

4) If the jammed paper is protruding from the front of the machine,

gently pull it out. Take care not to tear the paper or leave any torn

pieces of paper in the print compartment.

• If this clears the jam, go to Step 5.

• If you are unable to clear the jam in this way, go to Step 4.

• Take care not to touch or allow other objects to contact the drum

(the green cylinder). This may damage the drum.

5) If the jammed page cannot be pulled out directly, open the side

cover and rotate the white knob in the direction shown to feed out

the jammed paper.

FO-IS125N

6) After the jammed paper has been removed, push the two heater

roller release levers back up ( ), close the side cover ( ) (if

you opened it), close the front cover ( ) and then the close the

top cover ( ).

4

1 2

3

3

1

2

1 – 12

FO-IS125N

FO-IS125N

CHAPTER 2. ADJUSTMENTS

[1] Adjustments

1. General description

Since the following adjustments and settings are provided for this

model, make adjustments and/or setup as necessary.

2. Adjustments of output voltage (FACTORY ONLY)

1. Install the power supply unit in the machine.

2. Set the recording paper and document.

3. When the document is loaded, power is supplied to the output

lines. Confirm that outputs are within the limits below.

2.1. Output voltage settings

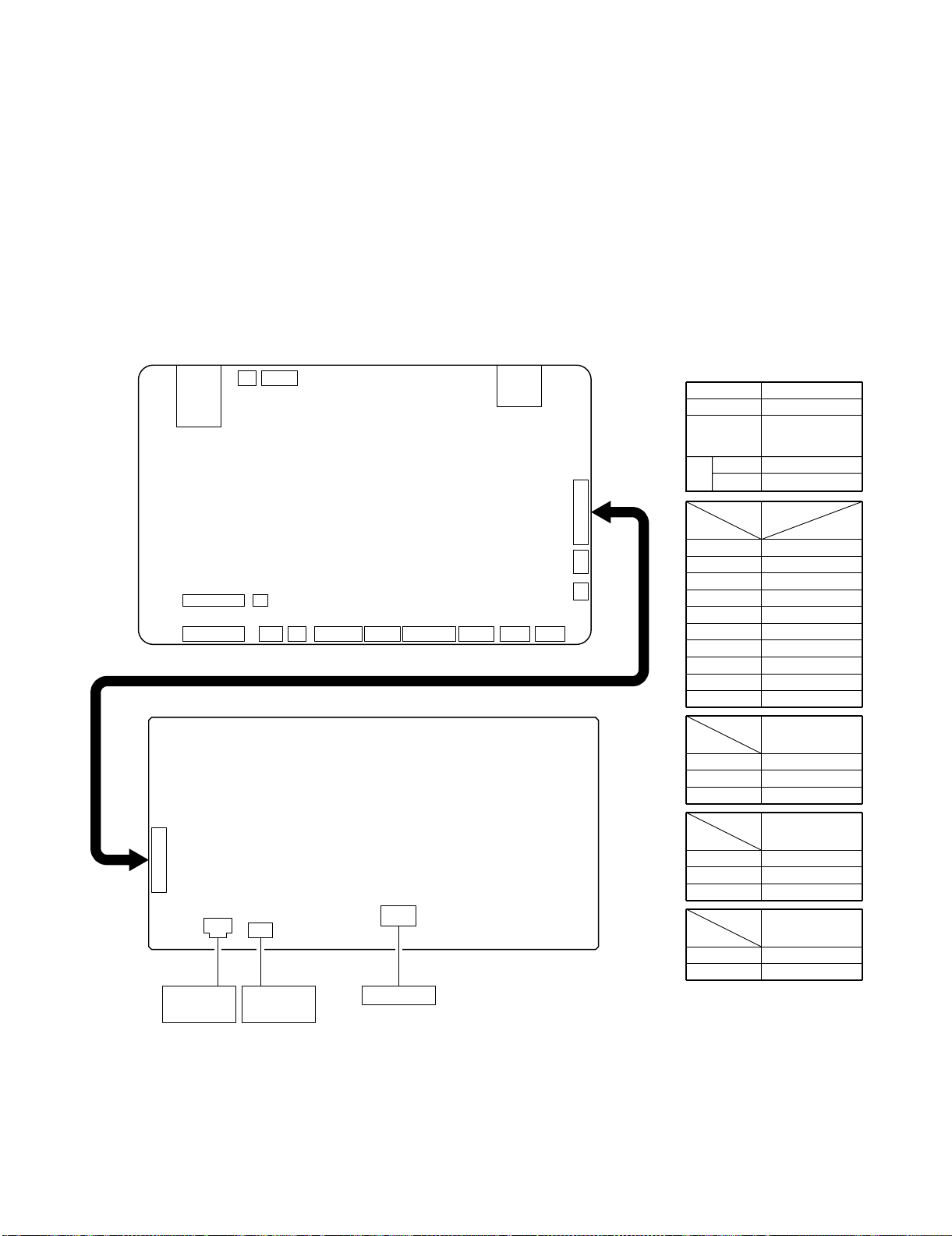

CNLAN

CNTNR

10

CN3

1

CN2

INTERLOCK

SWITCH

CNSP

CNTEL

CONTROL PWB(TOP SIDE)

CNPN

CNPIN

CNPOUT

CNRTH

CNCIS

CNHV

POWER SUPPLY PWB(TOP SIDE)

CN1

21

31

CN5

THERMAL

FUSE-2

21

FUSING UNIT

CNLSR

Service Manual

CNLNJ

10

1

CNFM

CNPM

CNMM

CNTXM

CNSL CNPW

Output Voltage limits

+24VSUB 23.04V~24.96V

+24VMAIN 23.04V~24.96V

STAND BY

Ach

RATED

Connector

Pin No. CN3

10

Connector

Pin No.

Connector

Pin No.

Connector

Pin No.

(INTERLOCK

SWITCH OFF: 0V)

4.3V~5.9V

4.3V~6.3V

CNPW

1 +24VSUB

2MG

3MG

4 +24VMAIN

5 +24VMAIN

6DG

7 Ach(4VD)

8DG

9 HEATER ON

ZC

CN5

+24VMAIN

1

N.C.

2

+24VS

3

CN1

AC NEUTRAL

1

N.C.

2

AC LIVE

3

CN2

+24VSUB

1

+24VMAIN

2

2 – 1

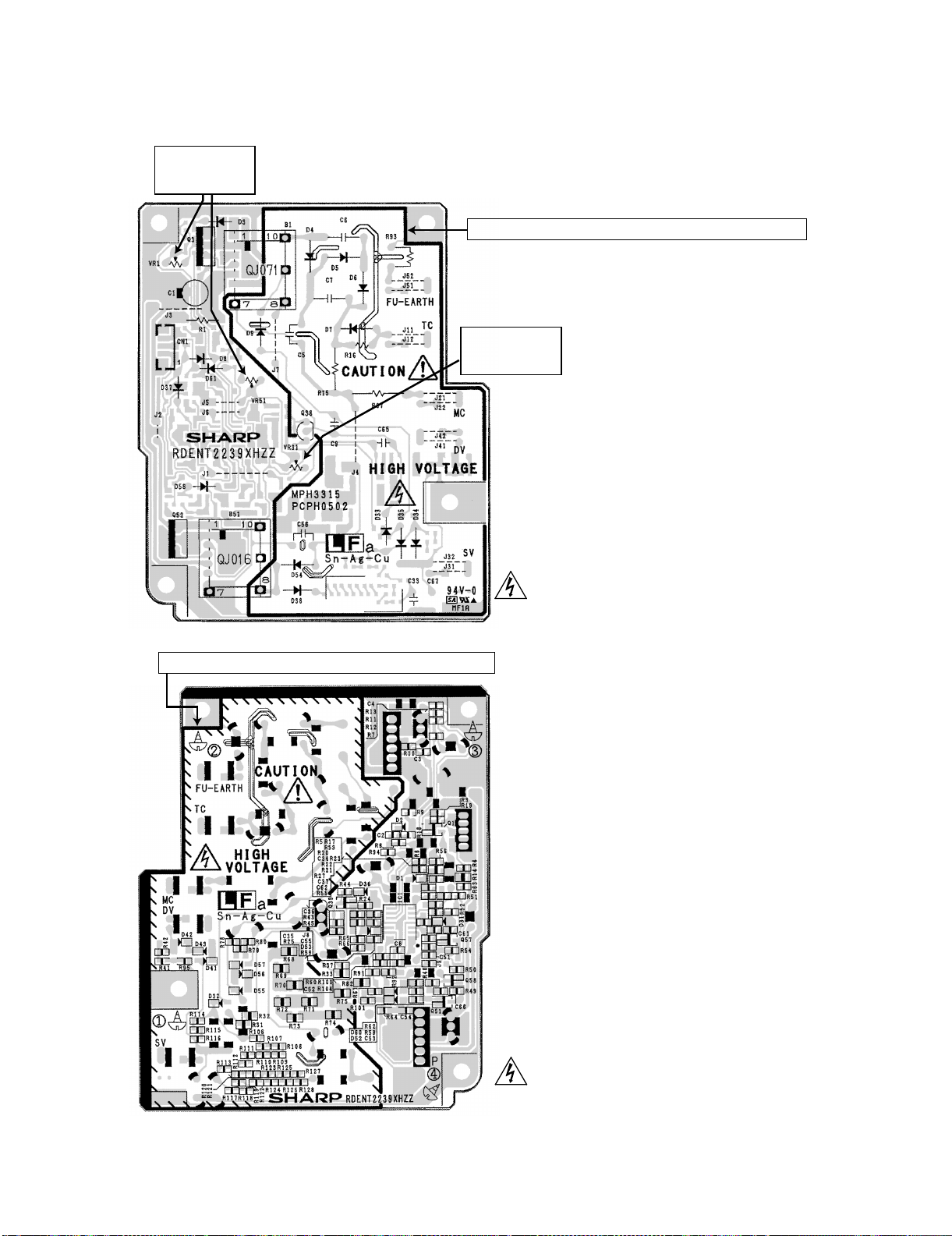

3. High voltage power check

3.1. General

Note: Since the parts of this PWB cannot be supplied, change it as a unit.

CAUTION

DO NOT TOUCH!

(VR1, VR51)

FO-IS125N

CAUTION HIGH VOLTAGE AREA MAX. 4000V (THICK LINE)

CAUTION

DO NOT TOUCH!

(VR31)

CAUTION HIGH VOLTAGE AREA MAX. 4000V (THICK LINE)

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by

anyone other than a qualified serviceperson.

There are many high voltage parts inside the unit,

and touching them is dangerous.

2 – 2

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by

anyone other than a qualified serviceperson.

There are many high voltage parts inside the unit,

and touching them is dangerous.

FO-IS125N

3.2. MC Voltage Check Point

GND (-)

(J3 or Chassis Frame)

MC Voltage Check Point (-)

(There is danger of an electric shock!)

Use Measuring instrument:

Input Resistance : more than 100 MΩ

Maximum Voltage : more than 2 kV

VOLTAGE

MC:-950V±20V(PRINTING)

MC:-850V±20V(CLEANING)

1) MC Voltage

Voltage(v)

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by anyone other than

a qualified serviceperson. There are many high voltage parts inside

the unit, and touching them is dangerous.

300Hz

Time(s)

Type

-570V

-950V

-1330V

Tolerance

± 67V

± 20V

± 67V

2 – 3

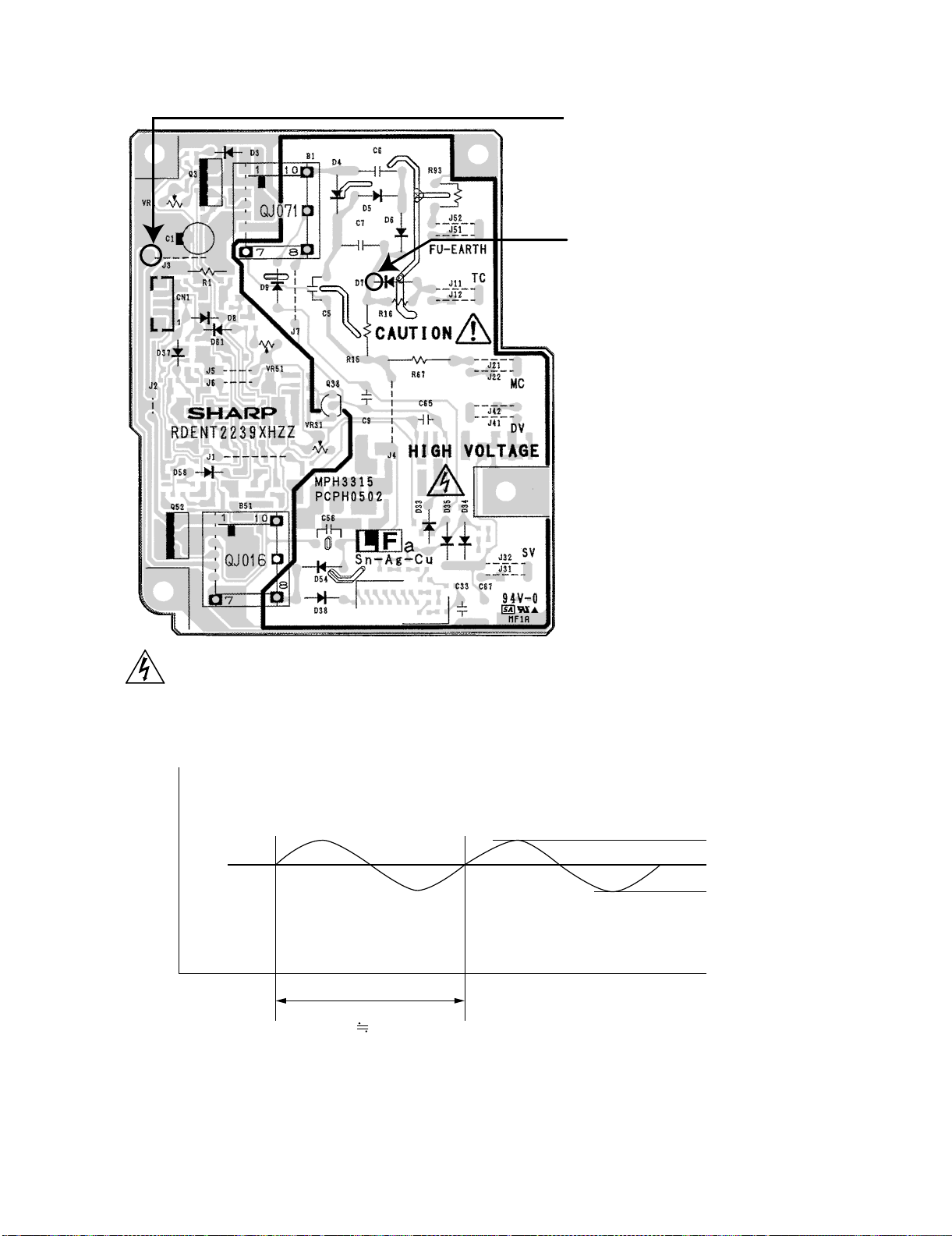

3.3. TC Voltage Check Point

FO-IS125N

GND (-)

(J3 or Chassis Frame)

TC Voltage Check Point (+)

(There is danger of an electric shock!)

Use High Voltage Tester:

Requirement of Measuring instrument:

Input Resistance : more than 100 MΩ

Maximum Voltage : more than 5 kV

VOLTAGE

TC(+):+3600V±72V(PRINTING)

TC(-):-500V±50V(CLEANING)

1) TC Voltage

Voltage(v)

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by anyone other than

a qualified serviceperson. There are many high voltage parts inside

the unit, and touching them is dangerous.

300Hz

Type

-3980V

-3600V

-3220V

Time(s)

Tolerance

± 72V

2 – 4

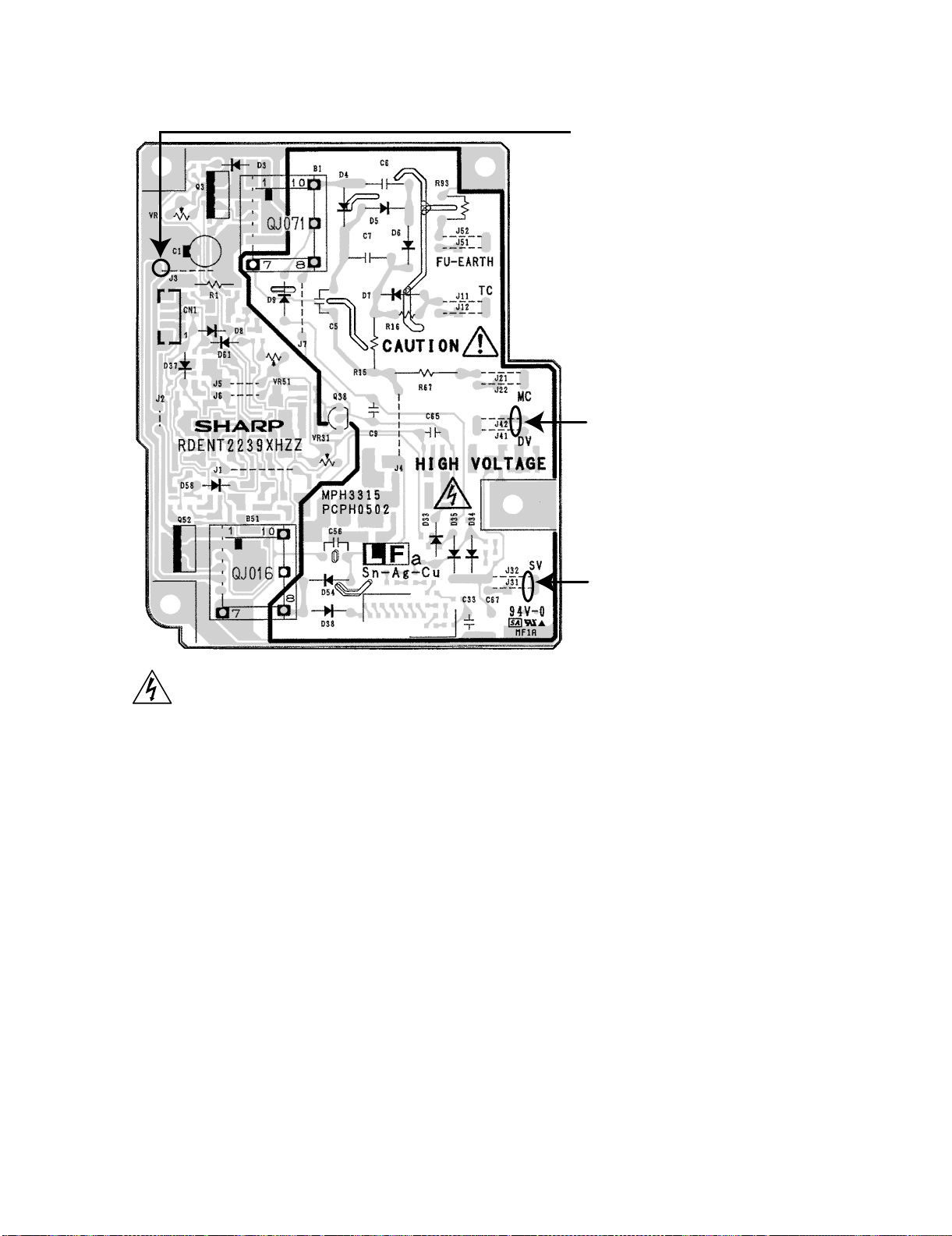

FO-IS125N

3.4. SV/DV Voltage Check Point and SV (-) Voltage Adjustment Volume

GND (-)

(J3 or Chassis Frame)

DV Voltage Check Point (+)

VOLTAGE

DV(+):+300V±5V(CLEANING)

DV(-):-200V±5V(PRINTING)

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by anyone other than

a qualified serviceperson. There are many high voltage parts inside

the unit, and touching them is dangerous.

SV Voltage Check Point (+)

VOLTAGE

SV(+):+300V±15V(CLEANING)

SV(-):-400V±15V(PRINTING)

2 – 5

4. IC Protectors Replacement

START

ICPs (IC Protectors) are installed to protect the Optical (LSU) unit,

Printer motor drive circuit, Solenoid drive circuit and Scanner motor

drive circuit. ICPs protect various ICs and electronic circuits from an

overcurrent condition.

The location of ICPs are shown below:

F300:Top side F500/F501/F600:Bottom side

CNLAN

CNPN

CNTNR

CNSP

CNPIN

CNPOUT

CNTEL

CNRTH

CNCIS

CONTROL

CNHV

CNLSR

PWB(TOP SIDE)

F300

FO-IS125N

5. Power Supply Unit Replacement

[SECONDARY]

1

CN3

[PRIMARY]

F2

F1

T1

TRANSFORMER

1) F1 (K7135AS007): AC250V/10A is installed in order to protect

overcurrent by heater circuit breakdown.

2) F2 (K7144AR005): HTM250V/4A is installed in order to protect

overcurrent by primary circuit breakdown.

3) F101 (K7144AR005): HTM250V/4A is installed in order to protect

overcurrent by breakdown of +24V line.

4) F301 (K7144AR002): HTM250V/2A is installed in order to protect

overcurrent by breakdown of Ach line.

Caution: Don’t use fuse except for rating above.

6. Volume Adjustment

You can adjust the volume of the speaker, handset, and ringer using

the up and down arrow keys.

1. Speaker volume

1) Press .

SPEAKER

F101

F301

CNPM

F500

CNMM

CNLNJ

F600

CNTXM

F501

CNFM

CNSL CNPW

1) F300 (KAB5002 251) is installed in order to protect IC’s from an

overcurrent generated in the IC302 circuit. If F300 is open, replace

it with a new one.

2) F500 (KAB2402 402) is installed in order to protect IC’s from an

overcurrent generated in the Printer motor drive circuit. If F500 is

open, replace it with a new one.

3) F501 (KAB5002 321) is installed in order to protect IC’s from an

overcurrent generated in the Solenoid driver circuit. If F501 is open,

replace it with a new one.

4) F600 (KAB3202 801) is installed in order to protect IC’s from an

overcurrent generated in the Scanner motor drive circuit. If F5 is

open, replace it with a new one.

Replacement parts

KAB3202 801 (Sharp code: QFS-L1037YCZZ)

KAB5002 251 (Sharp code: QFS-L2021XHZZ)

KAB2402 402 (Sharp code: QFS-L2025XHZZ)

KAB5002 321 (Sharp code: QPRTR2001XHZZ)

2) Press or to select HIGH, MIDDLE, or LOW.

• To turn off the speaker, press again.

2. Handset

1) When talking through the handset, press or to

select HIGH, MIDDLE, or LOW.

• Note: The volume reverts to MIDDLE each time you replace

the handset.

3. Ringer

1) Press or to select HIGH, MIDDLE, LOW or

OFF. (Make sure has not been pressed, the handset is

not lifted, and a document is not loaded in the feeder.)

• The ringer will ring once at the selected level.

2) If you selected “OFF OK?” to turn off the ringer, press .

SPEAKER

2 – 6

FO-IS125N

SOFT SWITCH MODE

SW123=00100100

Switch No.

12345678:DataNo.

SW =

SW1 =

[1] key

SW12 =

[2] key

SW123=00100100

[3] key

Cursor position

SW124=00000000

[START] key

SW125=00000000

SW123=01100000

[START] key

SW123=01100000

SW123=01100000

[>] or [#] key

SW124=00000000

With the cursor on data 8

[>] or [#] key

SW124=00000000

[>] or [#] key

SW124=00000000

SW124=00000000

[<] or [ ] key

SW123=01100000

With the cursor on data 1

[<] or [ ] key

SW123=01100000

[<] or [ ] key

SW124=00000000

[UP] or [4] key

SW123=01100000

SW125=00000000

[UP] or [4] key

SW124=00000000

[DOWN] or [6] key

SW125=00000000

SW123=01100000

[DOWN] or [6] key

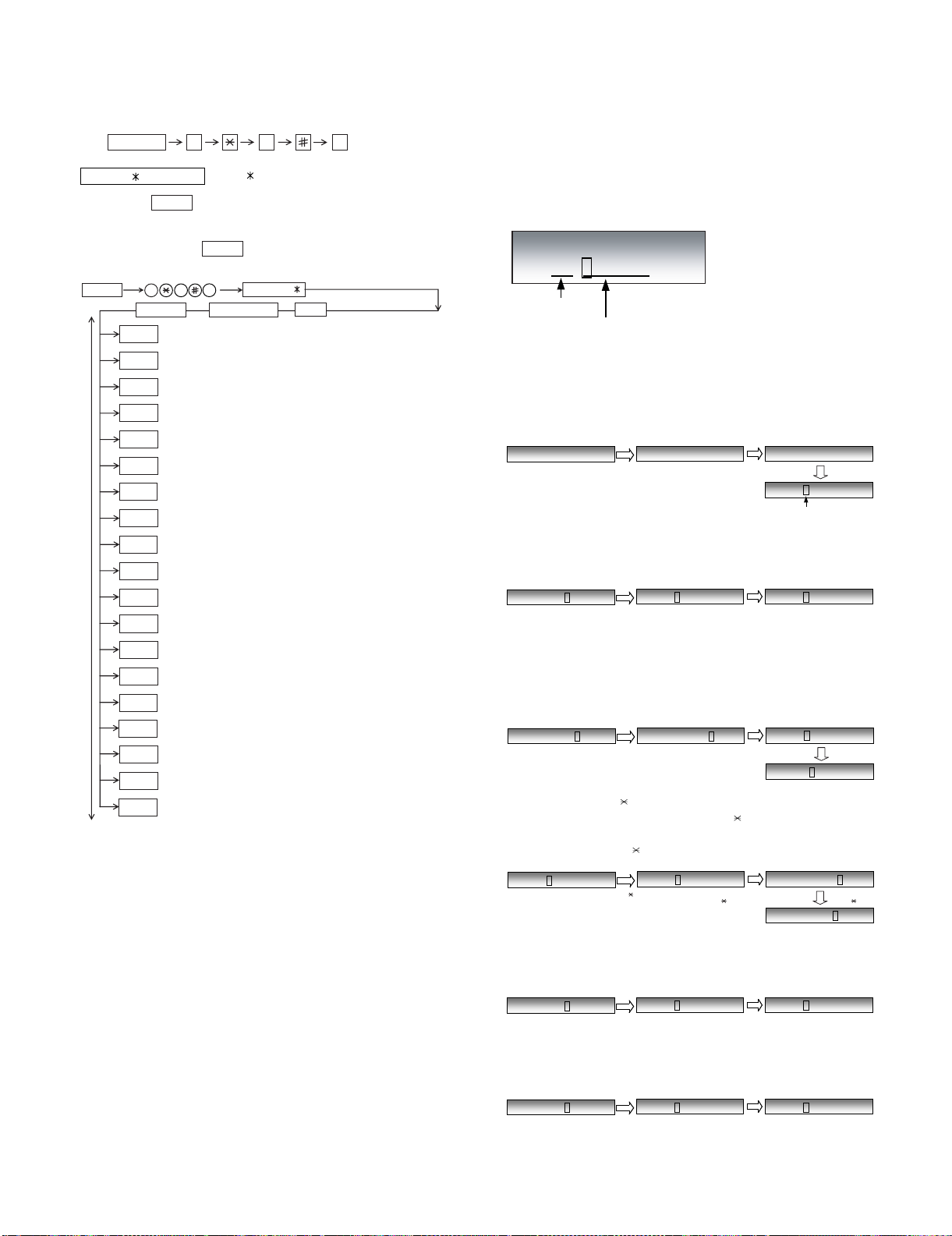

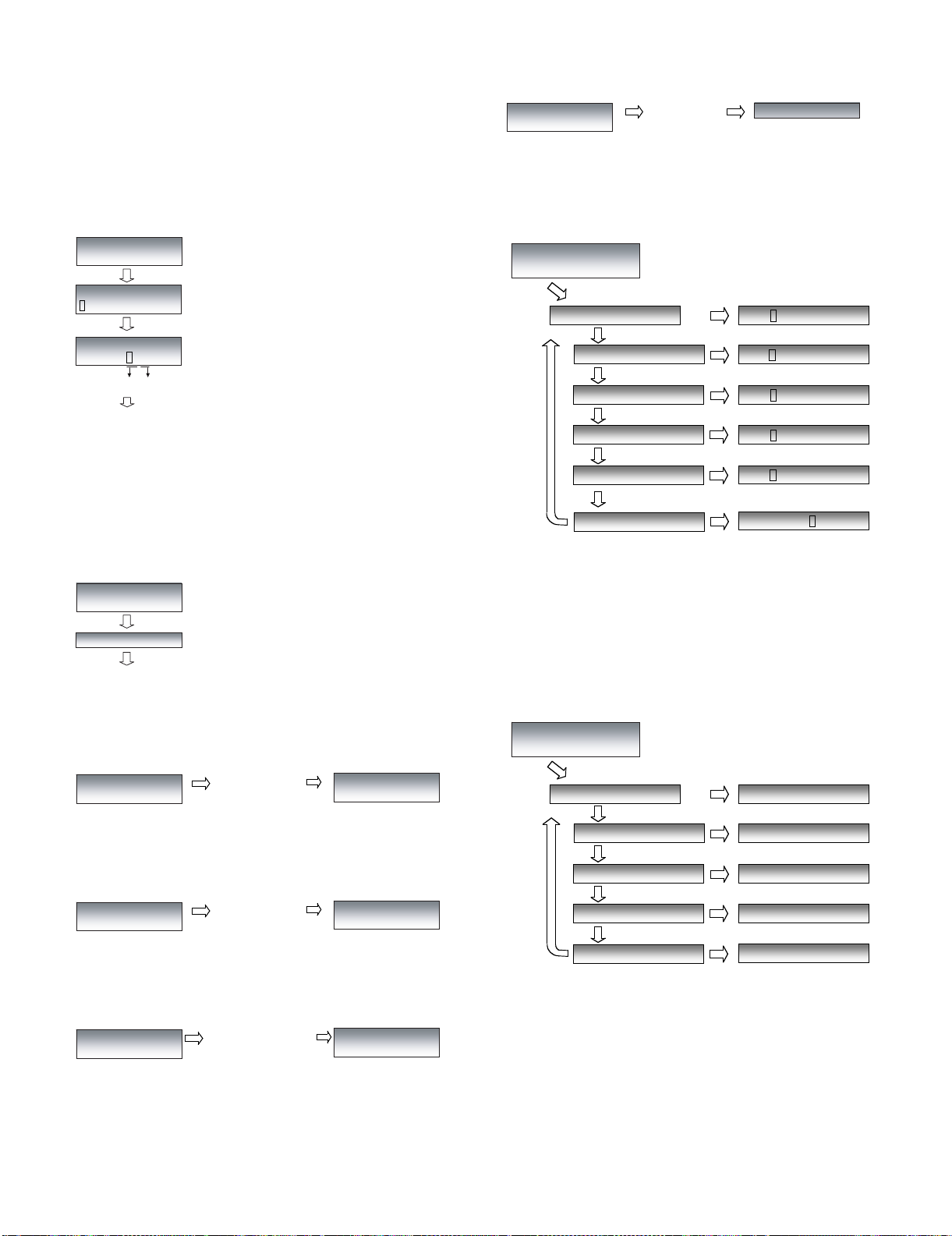

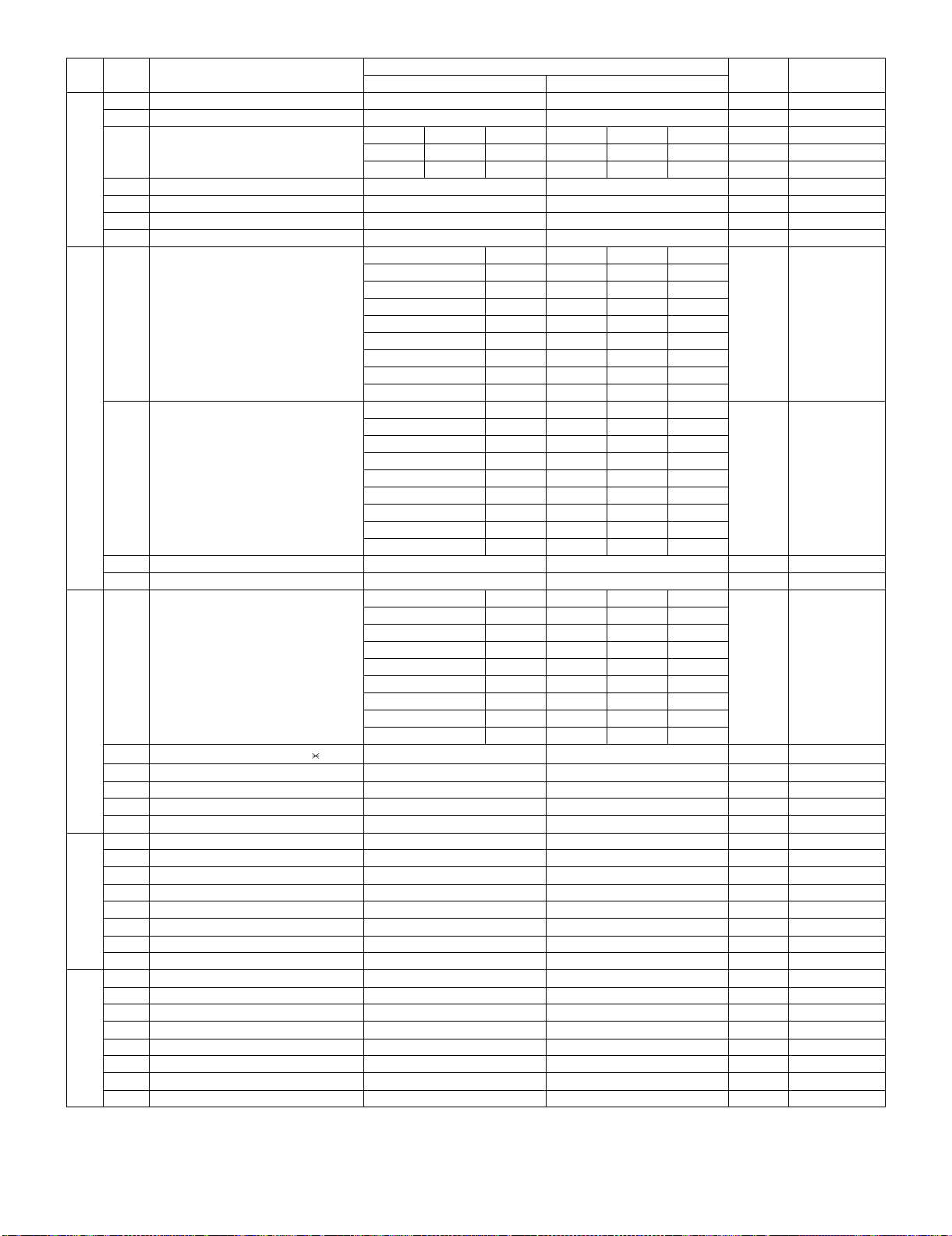

[2] Diagnostics and service soft switch

1. Entering the diagnostic mode 2. Diagnostic items description

2.1. SOFT SWITCH MODE

FUNCTION

Press

display will appear

ROM:TF78

Then press the

Select the desired item with the

with the rapid key.

Enter the mode with the

(Diag

•

specifications)

FUNCTION

UP

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

DOWN

9 8

alternately.

START

key.

START

9 8

7

COUNTRY NAMEDIAG MODE

SOFT SWITCH MODE

ROM & RAM CHECK

AGING MODE

PANEL KEY TEST

CHECK PATTERN

SIGNAL SEND MODE

SIGNAL SEND MODE2

MEMORY CLEAR

SHADING MODE

AUTO FEEDER MODE

FLASH MEM. CHECK

MEMORY SET MODE

CIS ADJUST

SHARP CHART MODE

5% CHART

ASF AGING

PASSCODE LIST

LIFE SET MODE

LIFE CLR MODE

7

, and

: ROM version

and the key or select

UP DOWN

key

key.

ROM:TF78

START

the

following

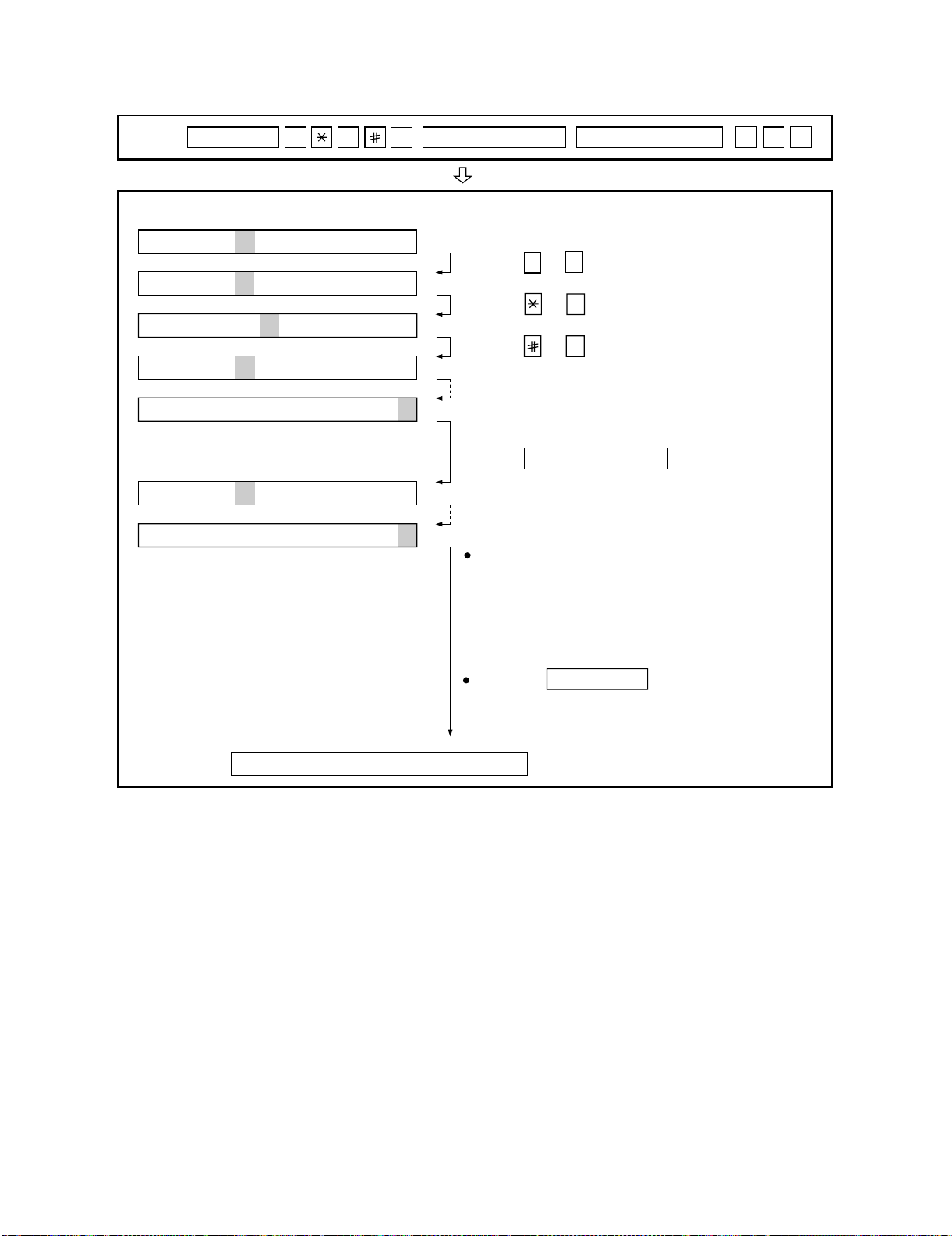

In this mode, the soft switches are set and the soft switch list is printed.

2.1.1 Operation

Soft switch mode screen

2.1.2 Switch number selection and data setting

1. Enter three digits of a soft switch number to set the switch number.

Of a switch number of unexacting soft switch is entered, key error

buzzer sounds to reject the input.

2. Press [START] key moves the cursor to the data number 1 of the

former soft switch. If the switch number is the final, pressing

[START] key will exit the soft switch mode.

3. Data number selection

a) Pressing [>] or [#] key moves the cursor to the right. If the cursor

is on data number 8, pressing [>] or [#] key shifts the cursor to data

number 1 of the next switch number. If the switch number is the

final, pressing [>] or [#] key will exit the soft switch mode.

b) Pressing [<] or [ ] key moves the cursor to the left. If the cursor

is on data number 1, pressing [<] or [ ] key shifts the cursor to

data number 8 of the former switch number. If the switch number is

001, pressing [<] or [ ] key do not move the cursor.

c) Pressing [UP] or [4] key moves the cursor to the data number 1

of the next soft switch. If the switch number is 001, pressing [UP] or

[4] key shifts the cursor to data number 1.

d) Pressing [DOWN] or [6] key moves the cursor to the data number 1 of the former soft switch. If the switch number is the final,

pressing [down] or [6] key will exit the soft switch mode.

2 – 7

e) Pressing [8] key moves the cursor to the data number 1 of the

To finish this mode, press [STOP] key

1

[1] key

[2]Key

2

SPEAKER

Go to a) or b).

..... (other key)

[SPEAKER] key

PANEL KEY TEST

Start by pressing the

[START] key

PRINTING

DIAG MODE

CHECK PATTERN

10th former soft switch.

SW123=01100000

SW113=00011010

[8] key

SW103=00000000

[8] key

f) Pressing [2] key moves the cursor to the data number 1 of the

10th next soft switch.

FO-IS125N

2.4. PANEL KEY TEST

This is used to check whether each key is normally operated or not.

After the test, the test result will be printed.

Press any key except [STOP] key. At this time, the name of each key

will be displayed every push of the key.

SW123=01100000

SW133=01000000

[2] key

SW143=01100000

[2] key

2.1.3 Data setting

Press the [1] key, and the data to the position of the cursor will be

changed to 1.

Press the [0] key, and the data to the position of the cursor will be

changed to 0.

2.1.4 Outputting method of soft switch list

In the soft switch mode, press [COPY/HELP] key, and the soft switch

list will be printed.

2.1.5 Storage of data

In the following cases, the data if the soft switches set will be stored.

• It is shifted to set the next soft switch by pressing [START] key.

• If is shifted to set the former soft switch with the [<] or [UP] or [4]

key.

• It is shifted to set the next soft switch with the [>] or [DOWN] or [6]

key.

• If is shifted to set the 10th former soft switch with the [8] key.

• It is shifted to set the 10th next soft switch with the [2] key.

2.2. ROM & RAM CHECK

To check the sum value of Firmware or RAM.

No. Device Alarm Buzzer Remarks

1

2 SDRAM 3 times <Short

ROM

(PROGRAM FLASH)

Main

1 time <Short

sound>

sounds>

a) When all keys can be inputted, the following message will be displayed.

ALL KEY OK !!

Then the screen will be all displayed in black (refer to (2))and the test

result will be printed.

b) If any key skipped, the following message will be displayed.

KEY ERROR !!

A key name that is not pressed yet is displayed so that this test can be

continued.

At that time, pressing the [STOP] key will exit this mode. And the result

will be printed.

After pressing the [STOP] key, the whole black screen appears and

the LED lights.

2.2.1 Display

2.2.2 Result printing

After checking, the results print starts.

2.3. AGING MODE

A total of 10 sheets of check patterns are printed at 1-hour intervals.

This mode is exited when executed to the end (after 9 hours) or by

pressing the [STOP] key.

DIAG MODE

ROM & RAM CHECK

DIAG MODE

AGING MODE

Start checking by

pressing [START] key

WAIT A MOMENT

Start by pressing

the [START] key

SDRAM : OK

PRINTING

1 sheet of check pattern is printed

AGING MODE

Display during the aging

mode interval

2.5. CHECK PATTERN

1 sheet of check patterns is printed.

2 – 8

FO-IS125N

Start by pressing

the [START] key

MEMORY CLEARING

PRINTING

DIAG MODE

MEMORY CLEAR

Start by pressing

the [START] key

TOTAL SHADING

DIAG MODE

SHADING MODE

[START] key

without document

DIAG MODE

AUTO FEEDER MODE

Only the sensor that is activated is displayed.

AUTO FEEDER MODE

A4 (A4 ) 1

AUTO FEEDER MODE

A4 (A4 ORG) 1

AUTO FEEDER MODE

()1

Set document

[START] key without document

Used to display the number of fed sheets.

AUTO FEEDER MODE

()0

WAIT A MOMENT

DIAG MODE

FLASH MEM. CHECK

FLASH CHECK

PRESS START or STOP

[START] key

[STOP] key

Next daig mode

[START] key

PRINTING

Start

2.6. SIGNAL SEND MODE

The specified signals are transmitted in the following sequence to

check the modem.

1. Press the [START] key, and no signals with the loop state starts.

[1] No signals (making the loop) [7] 7200BPS (V. 29)

[2] 14400BPS (V. 17) [8] 4800BPS (V. 27ter)

[3] 12000BPS (V. 17) [9] 2400BPS (V. 27ter)

[4] 9600BPS (V. 17) [10] 300BPS (FLAG)

[5] 7200BPS (V. 17) [11] 2100Hz (CED)

[6] 9600BPS (V. 29) [12] 1100Hz (CNG)

DIAG MODE

SIGNAL SEND MODE

[START] Key

[START] Key

SIG SEND MODE

V. 17 7200bps V. 17 9600bps

[START] Key

V. 29 9600bps V. 29 7200bps

2100 Hz (CED TONE) FLAG (300bps)

[START] Key

1100 Hz (CNG)

CML ON

[START] Key

[START] Key

[START] Key

[START] Key

V. 17 14400bps

[START] Key

[START] Key

V. 17 12000bps

[START] Key

V. 27ter 4800bps

[START] Key

[START] Key

V. 27ter 2400bps

2.8. MEMORY CLEAR

Clear the back-up memory including the soft switches, registration

data. After executing this mode, the memory clear report is printed.

Note: The printer/scanner life information is not cleared.

2.9. SHADING MODE

Shading waveforms are stored.

Set a shading sheet and press the [START] key to start shading.

2.10. AUTO FEEDER MODE

Inserting and discharging the document can check the auto feeder.

1. The information of document sensor (A4 sensor) and ORG sensor

is displayed when the documents are inserted to the Auto Feeder.

Press the [START] key, and feeding documents is started.

2. Pressing the [START] key during transmitting CNG signal, or pressing the [STOP] key will stop the output of signal and exit the mode.

2.7. SIGNAL SEND MODE2

A V.34 & V.8 related signal send mode. The check of the modem and

other devices is performed by sending these specific signals.

1. When pressing the [START] key, it turns into the no-signal state

(make loop). Then signals are sent in the following order by pressing the [START] key.

[1] No signals (making the loop) [9] 16800bps (V. 34)

[2] 33600bps (V. 34bis) [10] 14400bps (V. 34)

[3] 31200bps (V. 34bis) [11] 12000bps (V. 34)

[4] 28800bps (V. 34) [12] 9600bps (V. 34)

[5] 26400bps (V. 34) [13] 7200bps (V. 34)

[6] 24000bps (V. 34) [14] 4800bps (V. 34)

[7] 21600bps (V. 34) [15] 2400bps (V. 34)

[8] 19200bps (V. 34) [16] 0-300bps (V. 21)

DIAG MODE

SIGNAL SEND MODE2

V. 34 26400bps V. 34 28800bps

V. 34 24000bps V. 34 21600bps

V. 34 12000bps V. 34 14400bps

V. 34 9600bps

V. 8 ANSam V. 21 0 - 300bps

2. When pressing the [START] after sending the ANSam signal or the

[STOP] key while executing the mode, the signal output is stopped

and the indication before starting the next mode (MEMORY

CLEAR) appears.

[START] Key

[START] Key

[START] Key

CML ON

[START] Key

[START] Key

[START] Key

[START] Key

V. 34 7200bps

[START] Key

[17] ANSam

[START] Key

V. 34 33600bps

[START] Key

V. 34 31200bps

[START] Key

V. 34 19200bps

[START] Key

V. 34 16800bps

[START] Key

V. 34 4800bps

[START] Key

V. 34 2400bps

2. Press [STOP] key to exit the mode.

2.11. FLASH MEM. CHECK

Read/write of the flash memory is checked.

The result is printed after completion of check.

Be sure to clear the memory after execution.

[START] Key

[START] Key

[START] Key

2 – 9

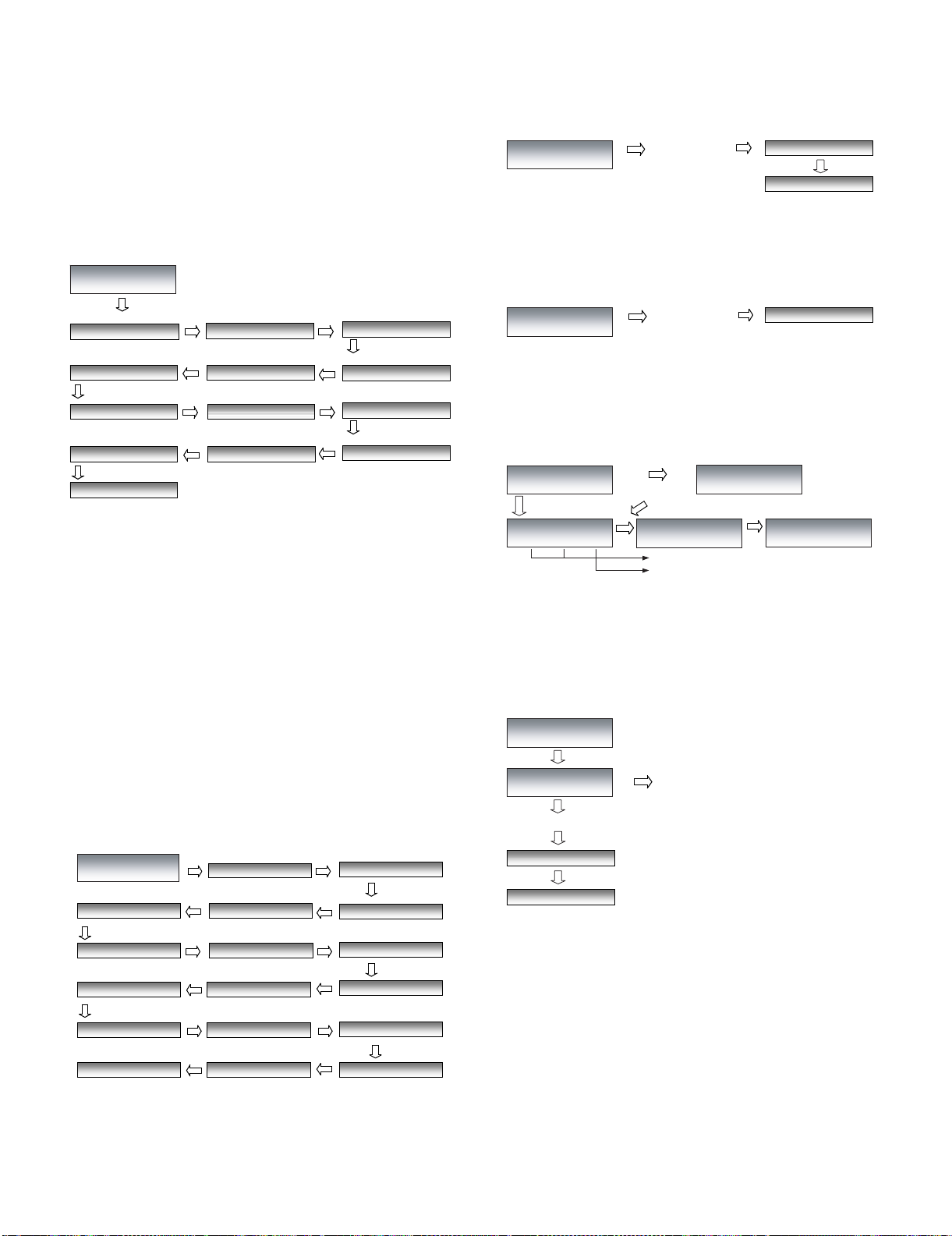

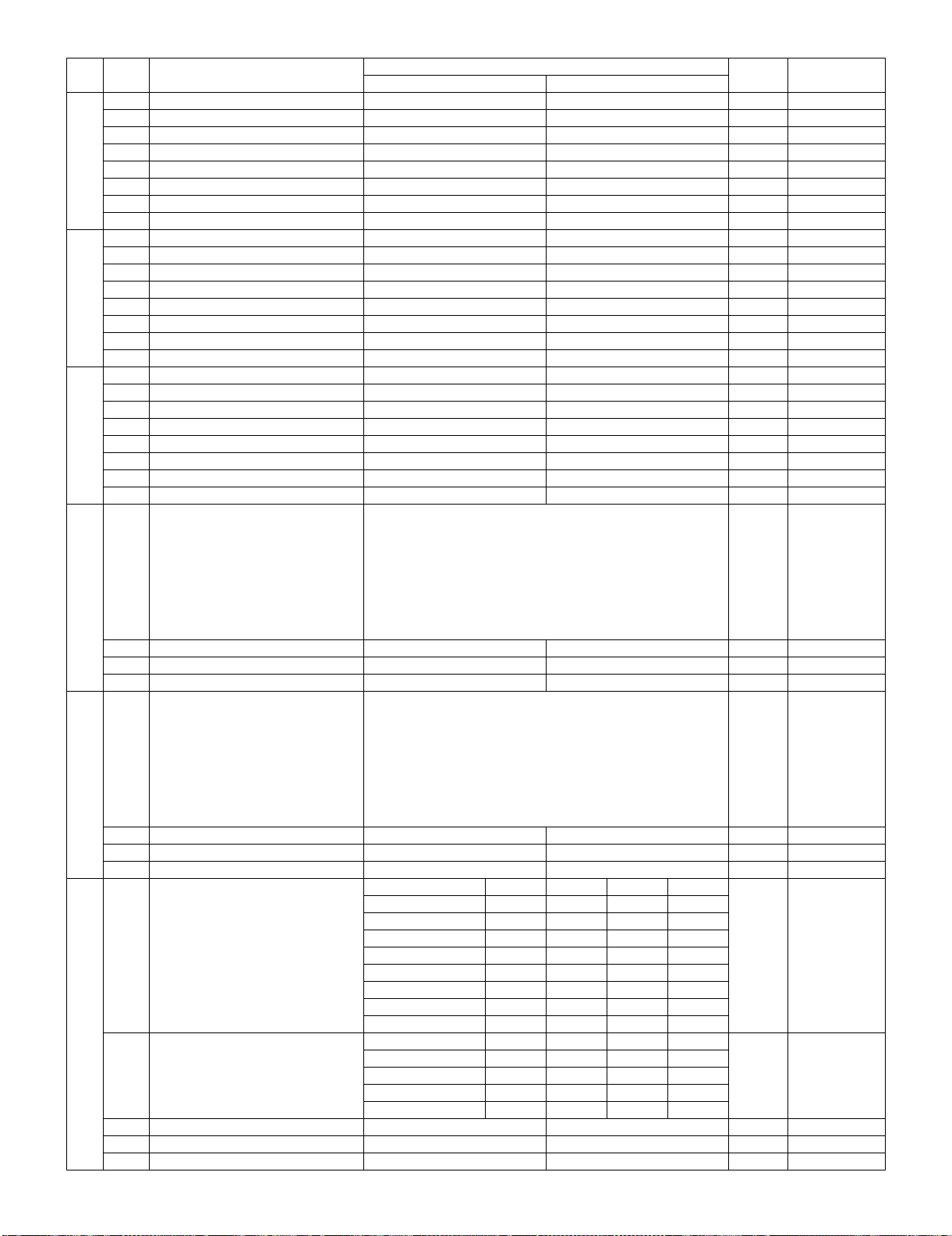

2.12. MEMORY SET MODE

Start by pressing

the [START] key

PRINTING

DIAG MODE

PASSCODE LIST

[START] Key

LIFE=0000000231

LIFE=0000000231

LIFE=0000000099

DOT COUNT=1234567890

[START] Key

SCAN

PRINT

DRUM

TONER PAGE

TONER DOTCOUNT

[START] Key

[START] Key

[START] Key

[START] Key

[DOWN] Key

[DOWN] Key

[DOWN] Key

[DOWN] Key

LIFE=0000000231

JAM=0000000001

SCAN JAM

[START] Key

[DOWN] Key

DIAG MODE

LIFE MODE

[START] Key

CLEARED

CLEARED

CLEARED

[START] Key

ALL

PRINT

DRUM

TONER

[START] Key

[START] Key

[START] Key

[DOWN] Key

[DOWN] Key

[DOWN] Key

CLEARED

CLEARED

SCAN

[START] Key

[DOWN] Key

DIAG MODE

LIFE CLR MODE

When clearing "TONER",

"TONER PAGE" and

"TONER DOT COUNT" are

also cleared.

It is possible to read or write the memory contents.

When 8 digits of physical address are entered, the data of that address

is displayed.

When 2 digits of data are entered after entering 8 digits of address and

a key is pressed, the contents can be rewritten.

Rewriting is enabled only in the range of addresses 00000000 to

007FFFFF.

If the memory is rewritten, the machine may malfunction.

DIAG MODE

MEMORY SET MODE

[START/MEMORY] key

MEMORY SET MODE

xxxxxxxx= [ ]

Entry of memory address (8 digits)

MEMORY SET MODE

1234ABCD=4C [L]

Character

Hex

code

number

• Change of memory contents: 2-digit entry in hex number

• Move down the address of the referenced memory by one: [<] or [UP] key

• Move up the address of the referenced memory by one: [>] or [DOWN] key

• Dump list print: [COPY/HELP] key

• Back to the address entry screen: [STOP] key

Press the [STOP] key on the address entry screen to exit the mode.

Address entry screen

The contents of the memory are displayed

in hex number and character code.

FO-IS125N

2.17. PASSCODE LIST

Used to print the passcode (SECURE FAX, etc.).

2.18. LIFE SET MODE

A mode for checking or setting the life value of each operation. Enter

the count value (10-digit number) of the set life using the numeric keypad.

2.13. CIS ADJUST

In this mode, the position of Scanner motor is moved from the home

position up to the specified value. And document reading lamp is

turned on.

DIAG MODE

CIS ADJUST

[START] key

CIS ADJUST MODE

The motor will move to the specified position and the reading lamp is lit on.

[START] key

Press the [STOP] key to exit the mode.

2.14. SHARP CHART MODE

SHARP CHART is printed continuously.

DIAG MODE

SHARP CHART MODE

Start by pressing the

[START] key

SHARP CHART AGING

TOTAL PAGE 1

Press the [STOP] key for interruption.

2.15. 5% CHART

5% CHART is printed continuously.

DIAG MODE

5% CHART

Start by pressing the

[START] key

Press the [STOP] key for interruption.

2.16. ASF AGING

The recording paper is fed continuously.

DIAG MODE

ASF AGING

Press the [STOP] key for interruption.

Start by pressing the

[START] key

5% CHART AGING

TOTAL PAGE 1

ASF AGING

This counter shows the printer usage status (number of printed sheets

after starting use, etc.). The counter cannot be reset by normal memory clear. Therefore, if the memory contents on the control PWB are

destroyed when repairing it, this counter setting must be cleared in

addition to normal memory clear.

Press the [STOP] key to exit the mode.

2.19. LIFE CLR MODE

A mode for clearing the life value.

2 – 10

FO-IS125N

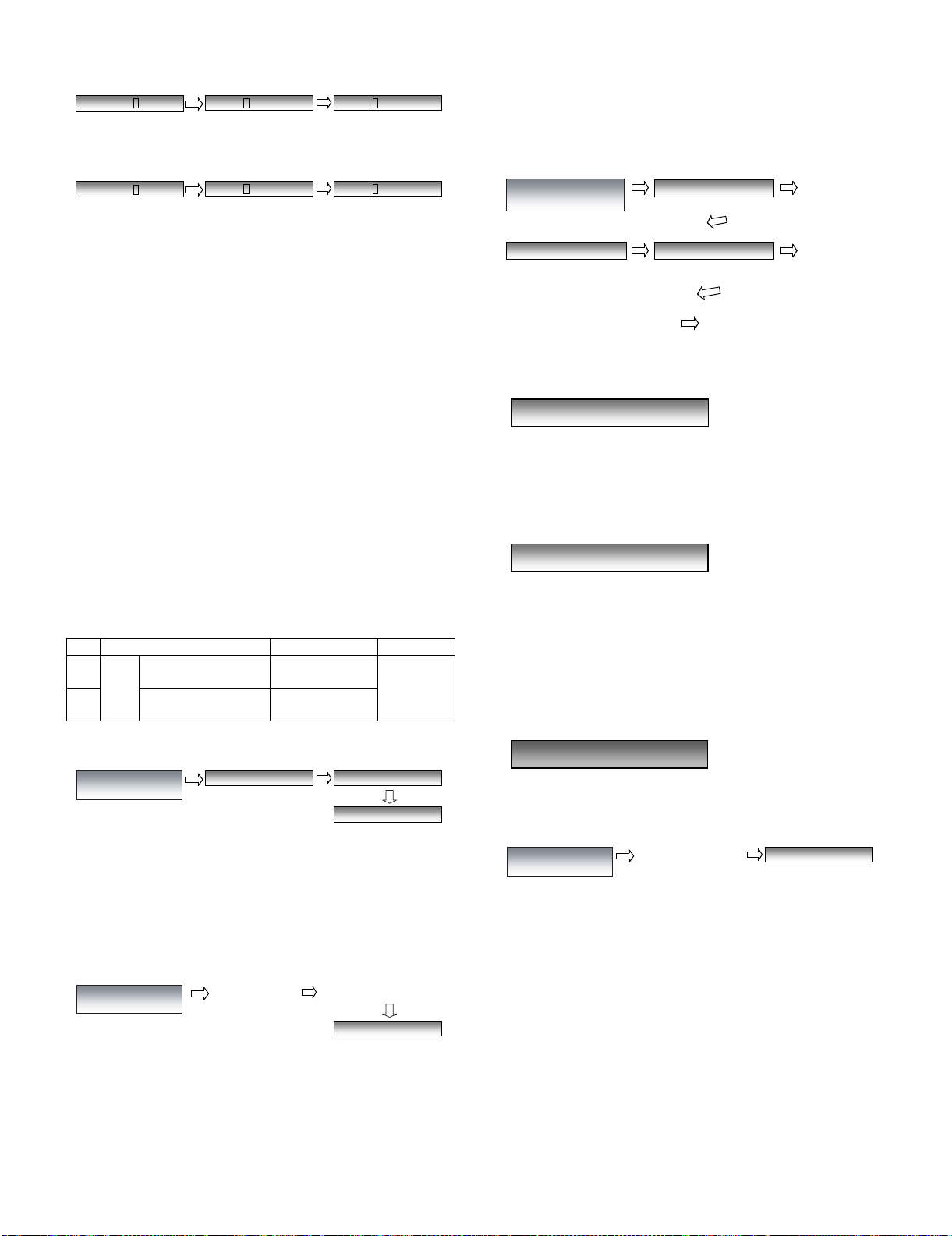

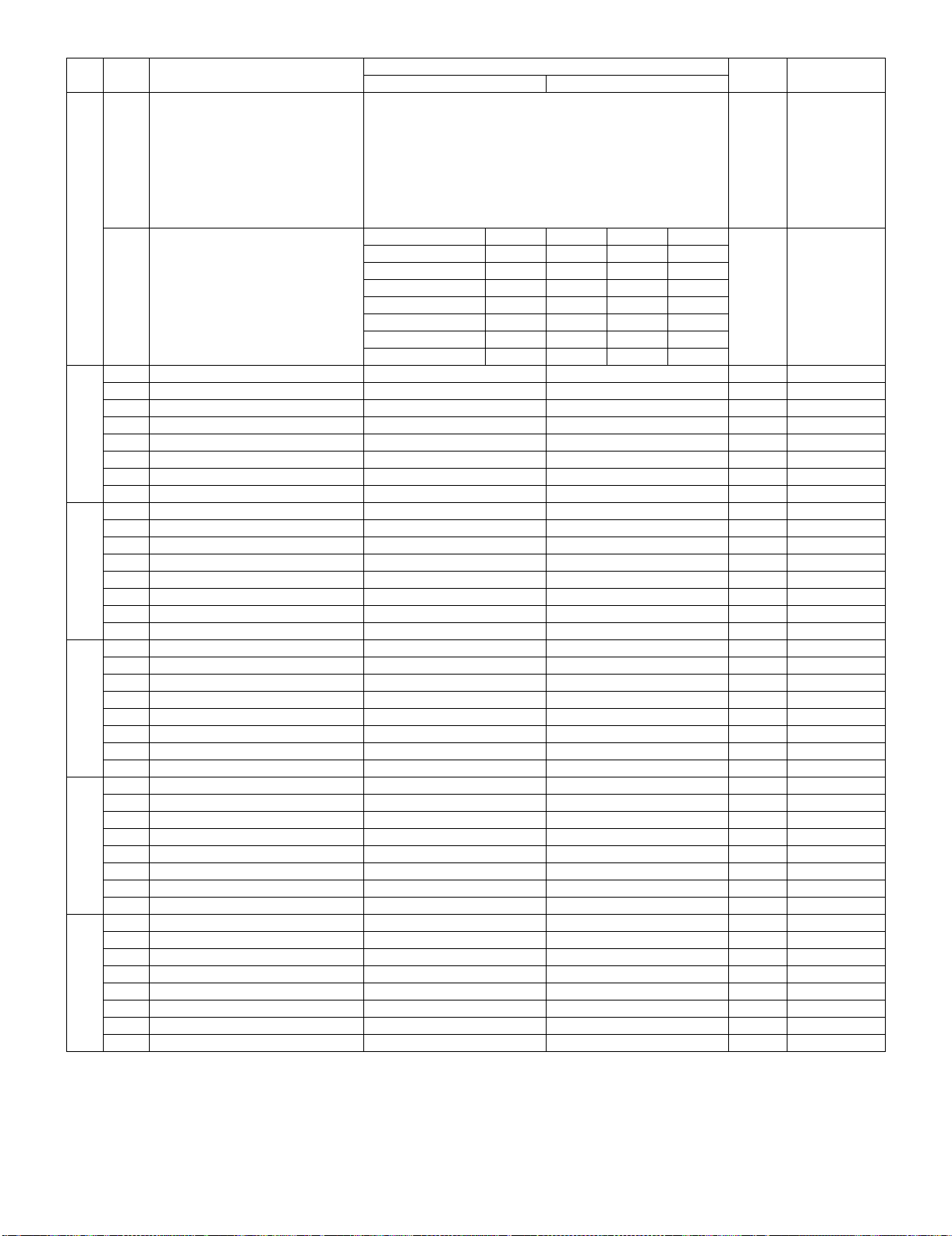

3. How to make soft switch setting

To enter the soft switch mode, press the following key entries in sequence.

Press

FUNCTION

9 8 STARTSTART

DATA No. 1 2 3 4 5 6 7 8

SW001 = 0 0 0 0 0 0 0 0

SW001 = 1 0 0 0 0 0 0 0

SW001 = 1 0 0 0 0 0 0 0

SW001 = 1 0 0 0 0 0 0 0

SW001 = 1 0 0 0 0 0 0 0

SW002 = 0 0 0 0 0 0 0 0

SW300 = 0 0 0 0 0 0 0 0

7

Press 1 or key.

Press or key.

Press or key.

Bit1 - 8 are set.

Press key during setting.

Soft SW002 - SW300 are set.

To finish the settings halfway between

SW001 and SW300, press the STOP

key. In this case, the setting being done

to the SW No. on display will be nullified

while settings done to the preceding

SW No. remain in effect.

When the COPY/HELP key is pressed, the

contents of soft switches are printed.

0

<

>

START

0

1

0

The soft switch mode is terminated.

2 – 11

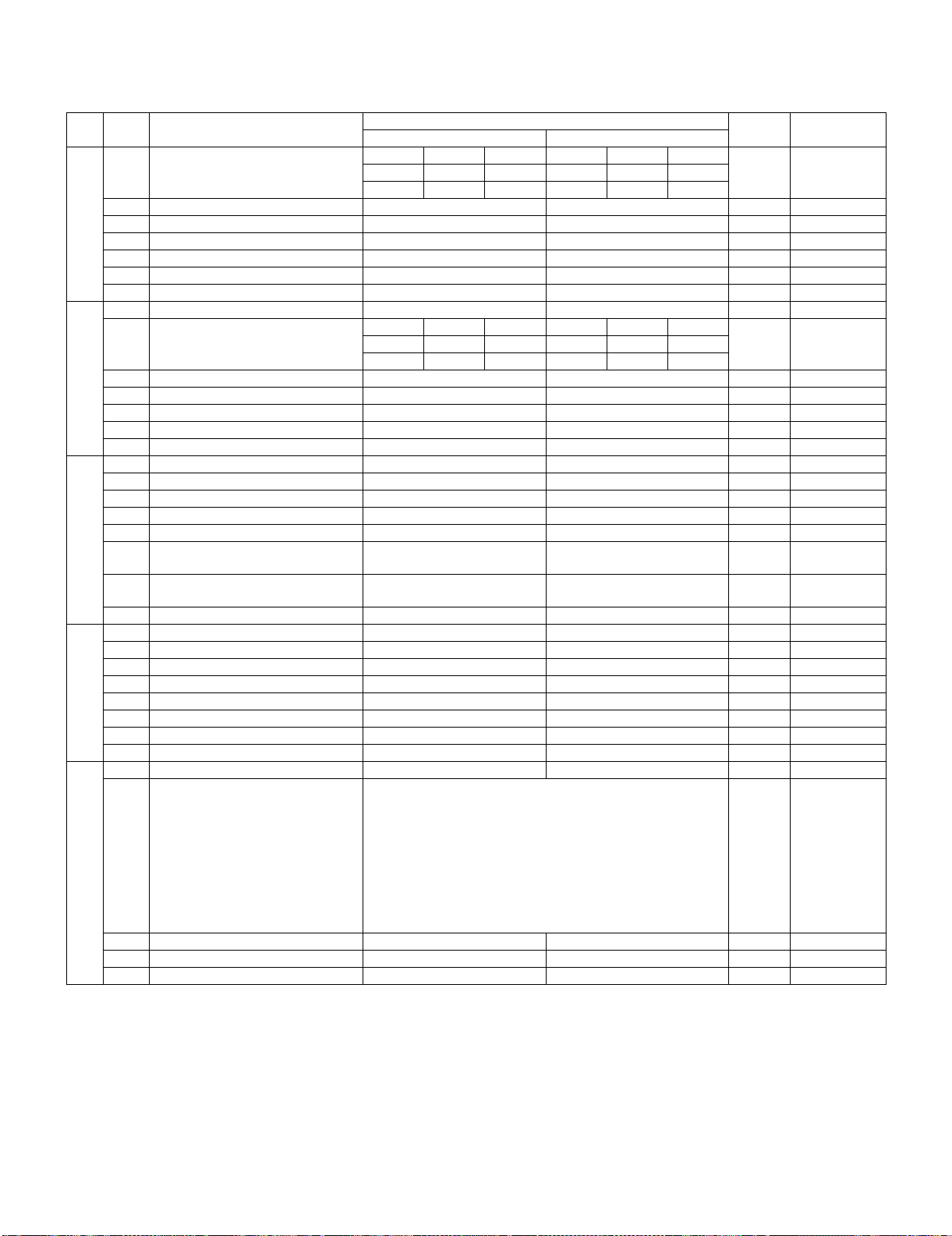

4. Soft switch description

4.1. Soft switch

FO-IS125N

SW

NO.

SW

1

SW

2

SW

3

SW

4

SW

5

DATA

NO.

Receive mode AUTO MANU.

1

2

3Reserved 1

4Reserved 0

5Reserved 0

6Reserved 0

7 Sort copy function Yes (Sort) No 0 OPTION

8Reserved 0

1 Forced 4800BPS reception Yes No 0

CED tone signal interval 75ms 500ms 750ms 1000ms

2

3

4Reserved 0

5Reserved 0

6Reserved 0

7 Footer print Yes No 0

8Reserved 0

1Reserved 0

2 CSI transmission Not transmitted Transmitted 0

3 Action when RTN is received No communication error Communication error 0

4Reserved 1

5 Pulse format N+1 N 0

6 DIS receive acknowledgement dur-

ing G3 transmission

7 Non-modulation carrier for V29

transmission mode

8 Default file format for network scan PDF TIFF 0 e-mail setting

1 Protocol monitor Yes No 0

2 Line monitor Yes No 0

3Reserved 0

4 Sender's information transmit No Yes 0

5Reserved 0

6Reserved 0

7 H2 mode No Yes 0

8 ECM mode No Yes 0

1 ECM MMR mode No Yes 0

Signal transmission level 1

2

3

4

5

ITEM

No.1 0 0

No.2 0 1

No.20011

No.30101

Twice NSF: Once

Yes No 0

Switch setting and function

10

DIS: Twice

Binary input

No. = 8 4 2 1

2345(DataNo.)

EX1101

eg. -13dBm

Initial

setting

RECEPTION

0

0

0

0

0

1

0

1

Remarks

key

6Reserved 0

7Reserved 1

8 Key tone Off On 0 OPTION

2 – 12

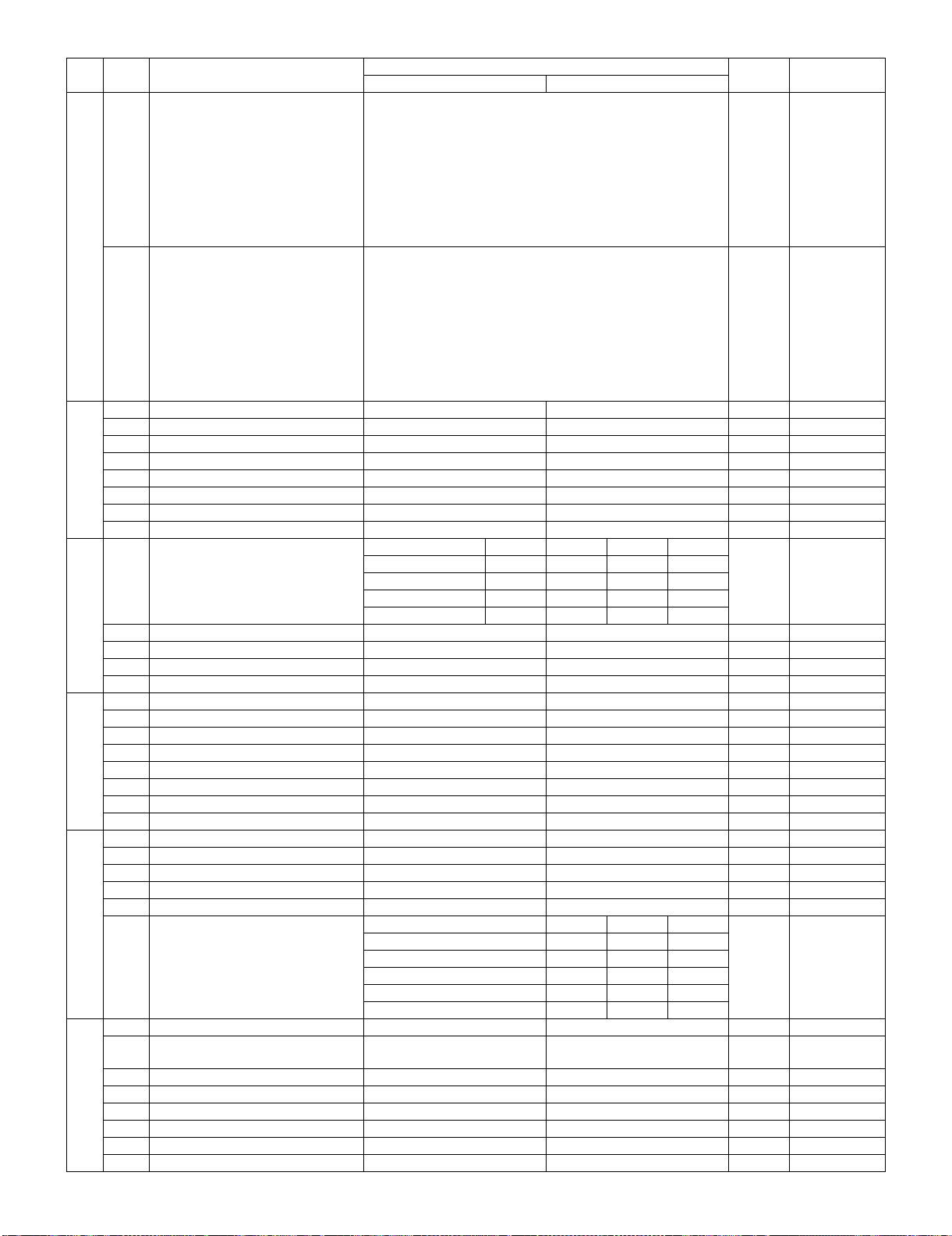

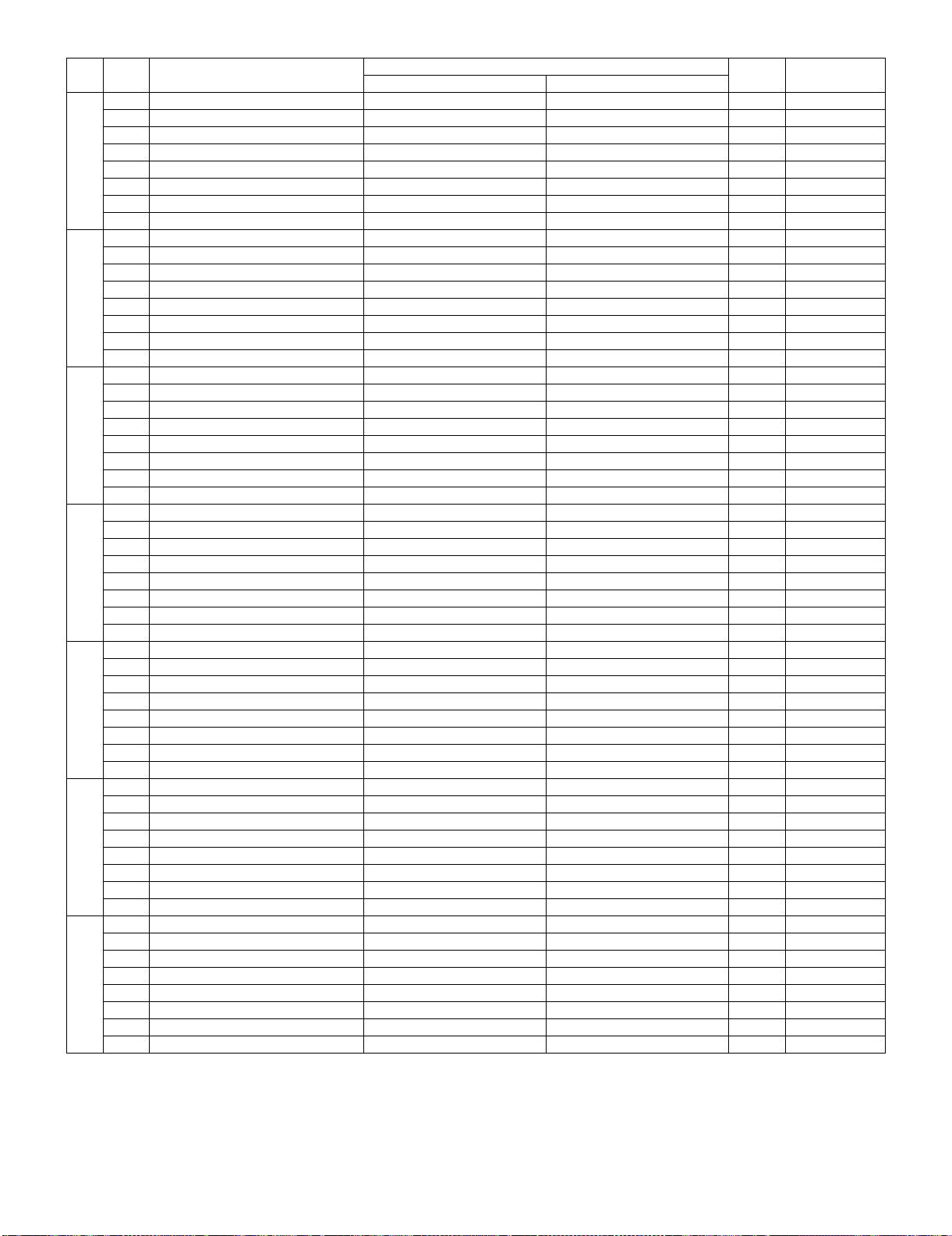

FO-IS125N

SW

NO.

SW

6

SW

7

SW

8

SW

9

SW

10

SW

11

DATA

NO.

Recall interval (FAX) 0

1

2

3

4

Recall times (FAX) 0

5

6

7

8

1Reserved 0

2Reserved 0

3 Dial mode Pulse Tone 0

4Reserved 1

5Reserved 0

6 CNG detection Yes No 1

7 Number of CNG detection 3 pulses 2 pulses 0

8 Time format 24hours 12hours-AM/PM 0

Modem speed(Except V.34 mode) No. 1 No.2 No. 3 No. 4

1

2

3

4

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 1

2Reserved 1

3Reserved 0

4Reserved 0

5Reserved 1

6 Polling key setting Yes No 0 OPTION

7 Polling security Yes No 1 ENTRY mode

8 Date format Month-Day-Year Day-Month-Year 1

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

Communication results printout No. 6 No. 7 No. 8

6

7

8

1Reserved 0

2 Activate receive fax to e-mail On Off 0 Fax to e-mail/

3 Activate secure receive On Off 0 SECURITY

4Reserved 0

5Reserved 0

6Call restriction 0 SECURITY

7Reserved 0

8Reserved 0

ITEM

V.29 9600bps 0 0 0 1

V.29 7200bps 0 0 1 1

V.27ter 4800bps 0 0 1 0

V.27ter 2400bps 0 0 0 0

Error Only 0 0 1

Error/Memory 0 0 0

Transmission 0 1 0

Not Printed 1 0 0

Every Time 1 1 0

Switch setting and function

10

Binary input

No. = 8 4 2 1

1234(DataNo.)

EX0101

eg. 3 minutes

Binary input

No. = 8 4 2 1

5678(DataNo.)

EX0011

eg. 5 times

Initial

setting

1

0

1

0

1

1

1

0

0

0

0

0

1

Remarks

Setting:

N = 1 to 9

Setting:

N = 1 to 9

OPTION

Folder

2 – 13

FO-IS125N

SW

NO.

SW

12

SW

13

SW

14

SW

15

SW

16

DATA

NO.

1Reserved 0

2Reserved 0

EOL detection timer

3

4

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

DTMF ON time No. 1 No. 2 No. 3

1

2

3

DTMF OFF time No. 4 No. 5 No. 6

4

5

6

7 Make/Break ratio in DP 40/60 33/67 1

8Reserved 0

Inter digit pause time No. 1 No. 2 No. 3

1

2

3

4

Change to PB from DP by " " Key

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 1

3Reserved 1

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

ITEM

No. 30011 0

No. 40100 0

70ms 0 0 0

90ms 0 0 1

95ms 0 1 0

100ms 0 1 1

110ms 1 0 0

120ms 1 0 1

140ms 1 1 0

150ms 1 1 1

100ms 0 0 0

110ms 0 0 1

120ms 0 1 0

135ms 0 1 1

140ms 1 0 0

150ms 1 0 1

180ms 1 1 0

200ms 1 1 1

800ms 0 0 0

840ms 0 0 1

880ms 0 1 0

900ms 0 1 1

1000ms 1 0 0

Not used 1 0 1

Not used 1 1 0

Not used 1 1 1

Yes N o

Switch setting and function

10

13sec 25sec 5sec 5sec 0

Initial

setting

0

1

1

0

1

0

0

0

0

1

Remarks

2 – 14

FO-IS125N

SW

NO.

SW

17

SW

18

SW

19

DATA

NO.

1Reserved 1

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7 Automatic reduce of receive 100% Auto 0 OPTION

8Reserved 0

1Reserved 1

2Reserved 0

3Reserved 1

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 1

7Reserved 0

8 Send hold Yes No 0 SECURITY

DTMF output level (High)

ITEM

Switch setting and function

10

Initial

setting

Remarks

SW

20

SW

21

SW

22

Binary input

1

2

3

4

5

6Reserved 0

7Reserved 0

8Reserved 0

DTMF output level (Low)

1

2

3

4

5

6Reserved 0

7Reserved 0

8Reserved 0

Dial tone detection frequency No. 1 No. 2 No. 3

1

2

3

Busy tone detection frequency No. 4 No. 5

4

5

6Reserved 0

7Reserved 0

8Reserved 0

No.= 168421

1 2 3 4 5 (Data No.)

EX0 1101

eg. Signal transmission level is set to -10dBm

Binary input

No.= 168421

1 2 3 4 5 (Data No.)

EX1 0001

eg. Signal transmission level is set to -10dBm

280 - 520Hz 0 0 0

380 - 500Hz 0 0 1

300 - 600Hz 1 0 0

Reserved 010

Reserved 011

Reserved 101

Reserved 110

Reserved 111

520 - 640Hz 0 0

300 - 600Hz 0 1

380 - 500Hz 1 0

520 - 640Hz 1 1

0

1

1

0

1

1

0

0

0

1

0

0

1

0

0

2 – 15

FO-IS125N

SW

NO.

SW

23

SW

24

SW

25

SW

26

SW

27

SW

28

DATA

NO.

Number of rings for auto-receive

(0:No ring receive)

1

2

3

4

Distinctive ring No. 5 No. 6 No. 7 No. 8

5

6

7

8

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 1

7Reserved 1

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

ITEM

OFF 0000

STD 0001

RING1 1000

RING2 0100

RING3 1100

RING4 0010

RING5 1010

Switch setting and function

10

Binary input

No. = 8 4 2 1

1234(DataNo.)

EX0100

eg. Number of rings for auto-receive is set to 1.

Initial

setting

0

1

0

0

0

0

0

0

0

Remarks

2 – 16

FO-IS125N

SW

NO.

SW

29

SW

30

SW

31

SW

32

SW

33

SW

34

SW

35

DATA

NO.

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 1

2Reserved 1

3Reserved 1

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 1

4Reserved 1

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 1

2Reserved 1

3Reserved 1

4Reserved 1

5Reserved 0

6Reserved 1

7Reserved 0

8Reserved 0

ITEM

Switch setting and function

10

Initial

setting

Remarks

2 – 17

Loading...

Loading...