Page 1

OPTION

Toner cartridge: FO-50ND

Drum cartridge: FO-47DR

Option memory: FO-8MK

Verification stamp: FO-45VS

Paper cassette (2nd): FO-CS2

LAN Network interface kit: FO-LN1

Network printer kit: FO-NP1

Network scanner kit: FO-NS2

Dual line kit: FO-60DL

NOTE:

• FO-NP1 (Network Printer Kit) and FO-60DL (Dual Line Kit) can not

be mounted simultaneously.

• FO-LN1 (LAN Network Interface Kit) and FO-60DL (Dual Line Kit)

can be mounted simultaneously. However, multi-operation of

2 line communication and network scan is not possible.

TopPage

FO-DC635U

SERVICE MANUAL

No. 00ZFDC635USME

FACSIMILE

MODEL

MODEL SELECTION CODE DESTINATION

FO-DC635 U U.S.A./Canada

Chapters 1, 2, 3, 7 and 8 of this manual are omitted because they are partly common to the FO-4470U/

FO-DC535U. Please refer to previous service manual (00ZFO4470USME) / (00ZFDC535USME) for these

chapters.

FO-DC635U

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

– 0 –

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

FO-DC635U

CHAPTER 1. GENERAL DESCRIPTION

[1] Caution........................................................... 1-1

[2] Specifications ................................................. 1-3

[3] Operation panel.............................................. 1-4

[4] Transmittable documents............................... 1-6

[5] Installation...................................................... 1-7

CHAPTER 2. ADJUSTMENTS

[1] Adjustments ................................................... 2-1

[2] Diagnostics and service soft switches............ 2-3

[3] Troubleshooting ........................................... 2-40

[4] Error code table............................................ 2-40

[5] Overseas communication mode .................. 2-40

[6] Administrator mode in the personal book

function ........................................................ 2-40

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Mechanical description .................................. 3-1

[2] Printer description .......................................... 3-1

[3] Disassembly and assembly procedures........ 3-1

[4] How to install the verification stamp (FO-

45VS) ............................................................. 3-2

CONTENTS

[2] Circuit description of control PWB ................. 5-1

[3] Circuit description of CIS unit ......................5-15

[4] Circuit description of LIU PWB ....................5-16

[5] Circuit description of operation panel PWB......5-18

[6] Circuit description of power supply PWB......5-19

[7] Circuit description of Dual Line Kit (Option:

FO-60DL).....................................................5-20

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Control PWB circuit .......................................6-1

[2] LIU PWB circuit ........................................... 6-18

[3] Printer PWB circuit ......................................6-21

[4] Power Supply PWB circuit........................... 6-25

[5] Operation Panel PWB circuit .......................6-27

[6] LCD Relay PWB circuit................................6-31

[7] 1st Paper Cassette PWB circuit ..................6-32

CHAPTER 7. OPERATION FLOWCHART

[1] G3 Protocol.................................................... 7-1

[2] Super G3 Protocol ......................................... 7-1

[3] Power on sequence....................................... 7-1

CHAPTER 4. DIAGRAMS

[1] Block diagram ................................................ 4-1

[2] Wiring diagram............................................... 4-2

[3] Point-to-point diagram.................................... 4-3

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Circuit description .......................................... 5-1

CHAPTER 8. OTHER

[1] Service tools .................................................. 8-1

[2] Rewriting version up the FLASH ROM ..........8-1

Parts Guide

– i –

Page 3

- MEMO -

FO-DC635U

– ii –

Page 4

FO-DC635U

FO-DC635U

CHAPTER 1. GENERAL DESCRIPTION

Service Manual

[1] Caution

1. Laser caution

This laser printer is a class 1 laser product that complies with 21CFR 1040.10 and 1040.11 of the CDRH or IEC60825-1 standard. This means that

this machine does not produce a hazardous laser radiation. The use of controls, adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

This laser radiation is not a danger to the skin, but when an exact focusing of the laser beam is achieved on the eyes retina, there is danger of spot

damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time of servicing.

1) When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged as a unit, not an individual part.

2) Do not look into the machine with the main switch turned on after removing the toner/developer unit and drum cartridge.

3) Do not look into the laser beam exposure slit of the laser optical unit with the connector connected when removing and installing the optical system.

4) The cover of Laser Printer Unit contains the safety interlock switch.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot.

Laser Wave Length : 770 nm -810 nm

Laser Pulse Times : 51.3 ns

Laser Output Power Max : 5 mW

2. Life of consumable

Section Part Estimated Life Replaced by

Toner cartridge Replacement cartridge

(FO-50ND)

Drum cartridge Replacement cartridge (FO-47DR) 20,000 prints (at Letter/4%

Paper feed Transfer roller (Refer to the P/G No. 10-8)

(0KW4127410302)

Fusing unit Fusing unit (Refer to the P/G No. 9-14)

(0KW4127036001)

Paper transport Paper transfer roller (Refer to the P/G No. 8-6)

(0KW4127300101)

Unit FO-DC635 5 years or 75,000 prints of

6,000 prints (at Letter/4%

chart)

chart)

50,000 prints Service Engineer

50,000 prints Service Engineer

Cleaning as needed ———————

early either

User

User

———————

1 – 1

Page 5

3. Caution for Battery replacement

FO-DC635U

(Danish) ADVARSEL !

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the equipment manufacturer.

Discard used batteries according to manufacturer's instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

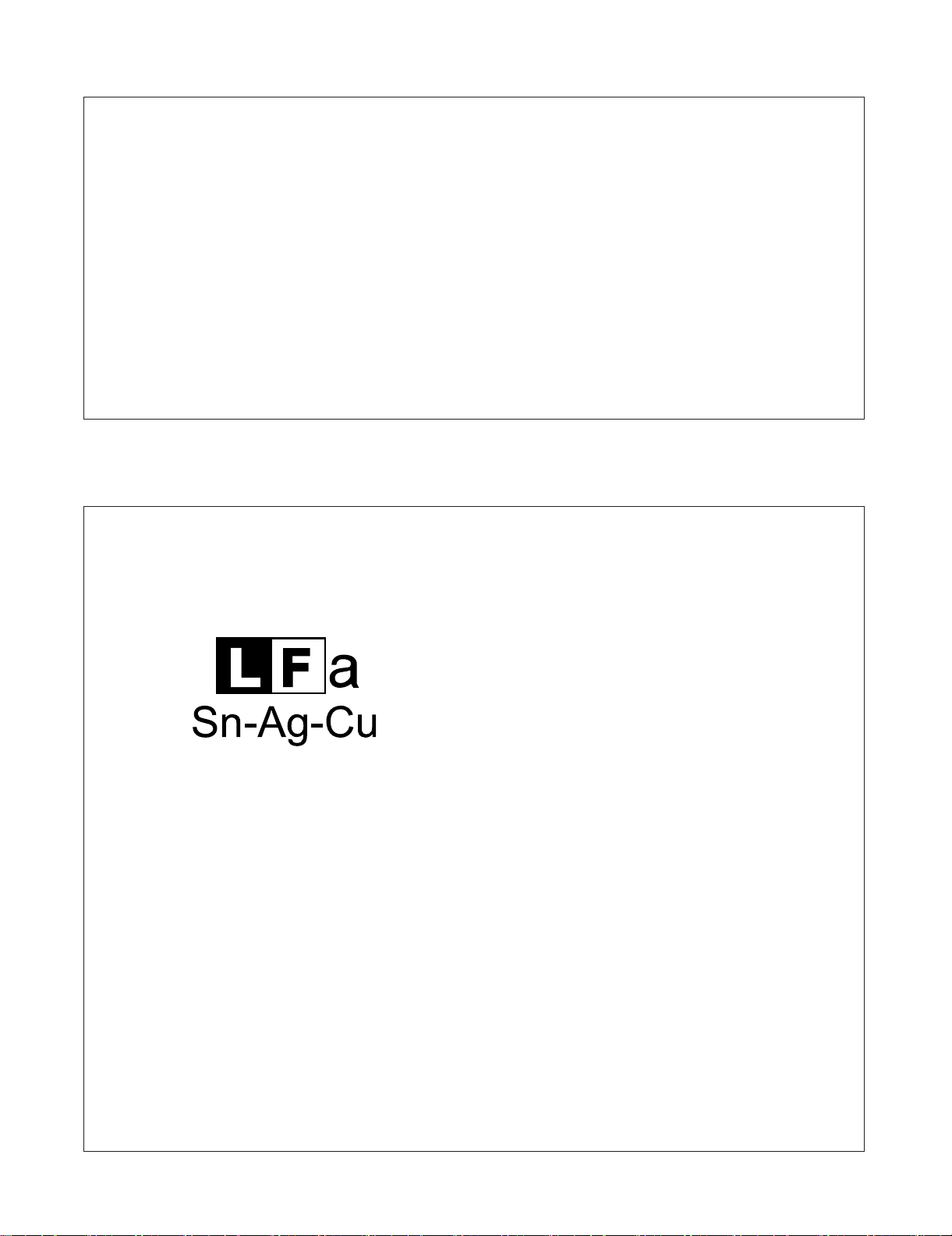

4. Precautions for using Lead-Free Solder

1. Employing lead-free solder

This model employs lead-free solder.

This is indicated by the "LF" symbol printed on the PWB and in the service manual.

The suffix letter indicates the alloy type of the solder.

Example:

(French) ATTENTION

Il y a danger d'explosion s' il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d'un type recommandé par le constructeur.

Mettre au rébut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfare vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anweisungen.

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free solder

When repairing a PWB with the "LF" symbol, only lead-free solder should be used. (Using normal tin/lead alloy solder may

result in cold soldered joints and damage to printed patterns.)

As the melting point of lead-free solder is approximately 40°C higher than tin/lead alloy solder, it is recommended that a

dedicated bit is used, and that the iron temperature is adjusted accordingly.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is higher and has poorer melting point (flow), to prevent damage to the

land of the PWB, extreme care should be taken not to leave the bit in contact with the PWB for an extended period of time.

Remove the bit as soon as a good flow is achieved.

The high content of tin in lead free solder will cause premature corrosion of the bit.

To reduce wear on the bit, reduce the temperature or turn off the iron when it is not required.

Leaving different types of solder on the bit will cause contamination of the different alloys, which will alter their

characteristics, making good soldering more difficult.

It will be necessary to clean and replace bits more often when using lead-free solder. Toreduce bit wear, care should be

taken to clean the bit thoroughly after each use.

1 – 2

Page 6

FO-DC635U

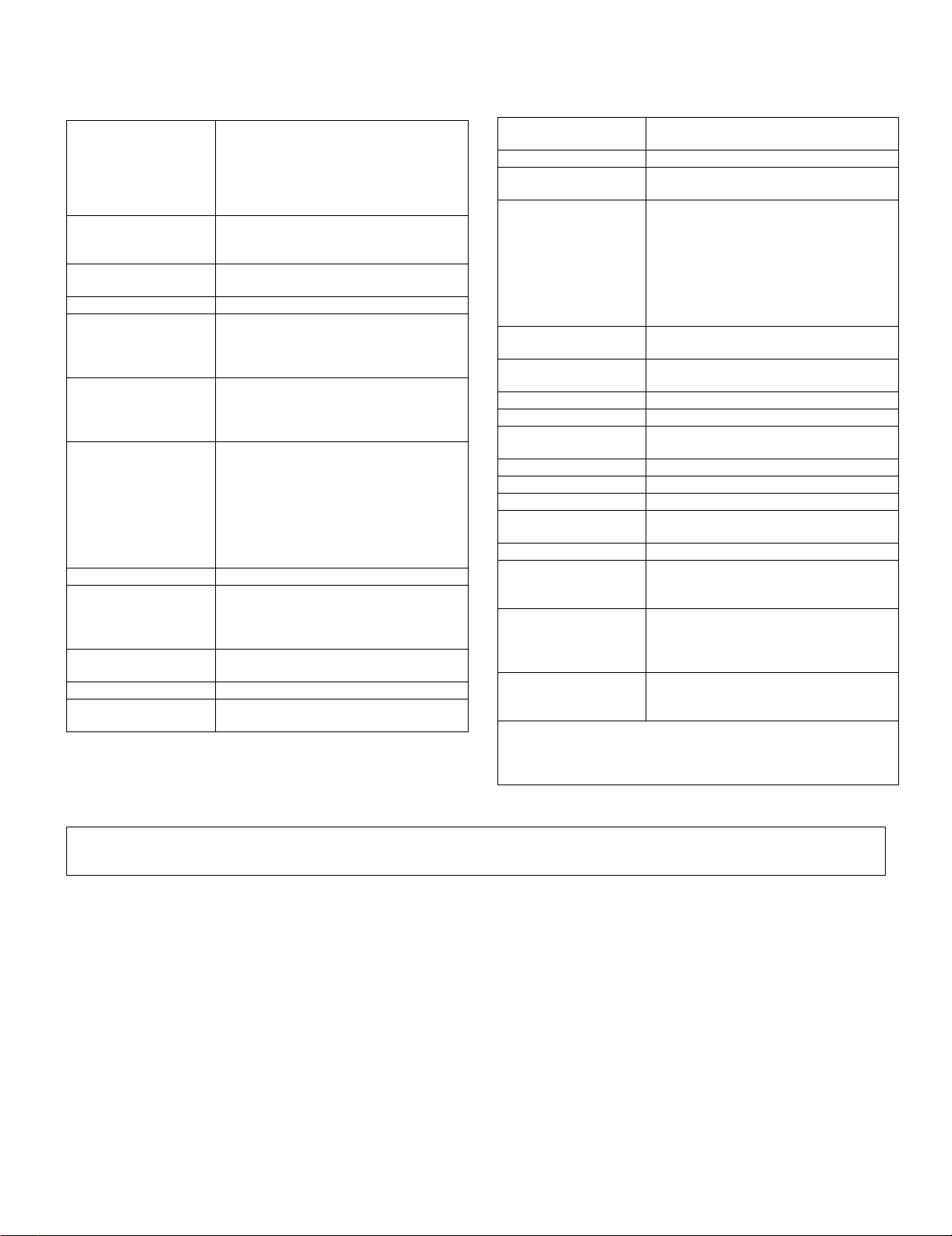

[2] Specifications

1. GENERAL

Automatic dialing: Conventional Auto Dialing:

Memory size*: 16 MB (approx. 500 pages)

Modem speed: 33,600 bps (max.) with automatic fallback

Transmission time*: Approx. 2 seconds

Toner cartridge yield**:

(continuous printing,

4% page coverage, letter paper)

Drum cartridge yield**:

(continuous printing,

4% page coverage, letter paper)

Resolution: Standard: 203 x 98 lines/inch

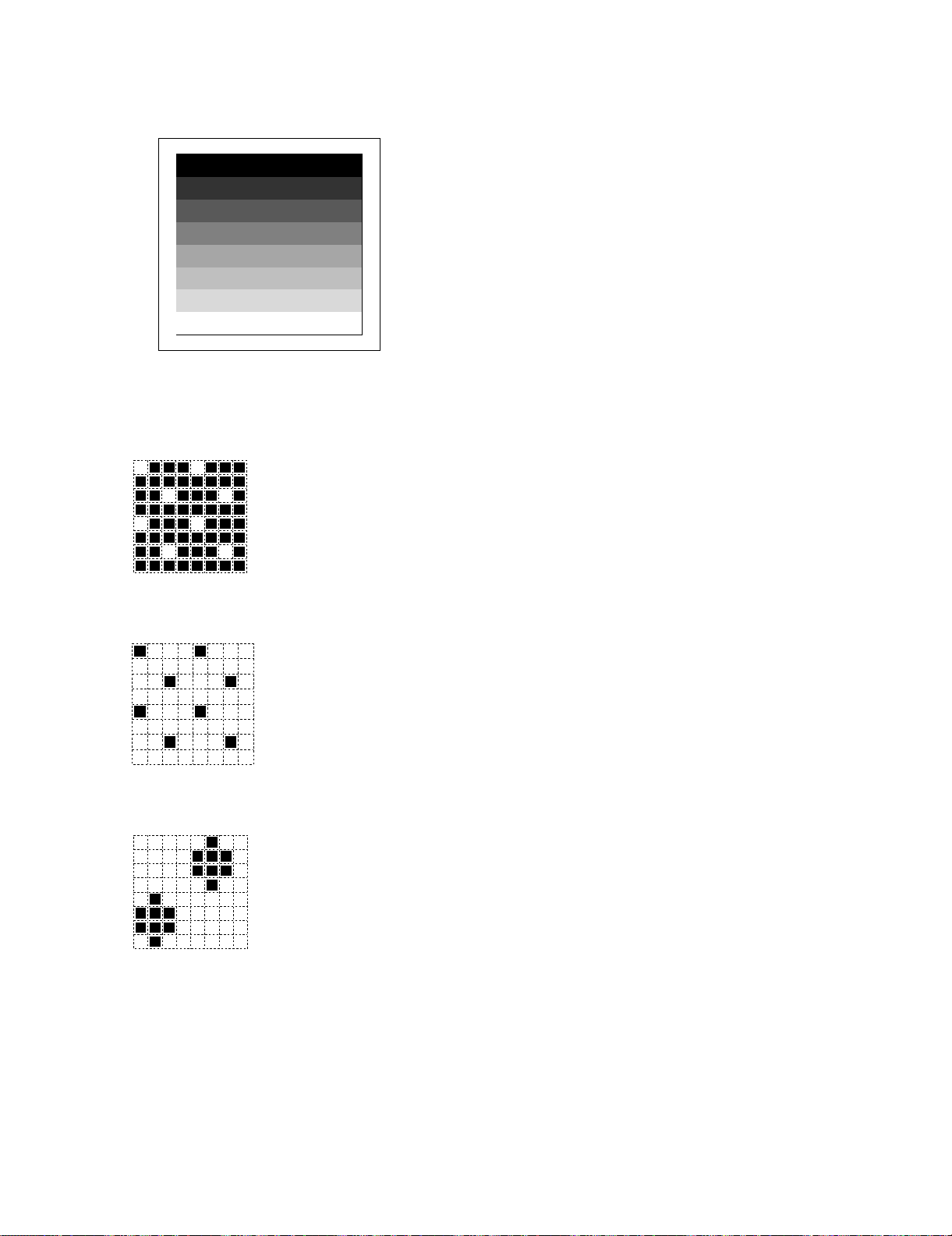

Halftone (grayscale): 64 levels

Automatic document

feeder:

Paper capacity: 750 sheets (20 lb) (500-sheet cassette ava-

Compression scheme: MMR, MR, MH, Sharp (H2), JBIG

Applicable telephone

line:

Rapid Key Dialing: 59 numbers, Speed

Dialing: 200 numbers

Personal Auto Dial Books: 40 books (59

Rapid Keys, 16 Speed Dial numbers per

book)

Optional memory: FO-8MK (8 MB;approx.

500 pages)

to lower speeds

Initial starter cartridge (included with

machine): Approx. 3000 pages

Replacement cartridge (FO-50ND):

Approx. 6000 pages

Initial starter cartridge (included with

machine): 20,000 pages (avg.)

Replacement cartridge (FO-47DR):

20,000 pages (avg.)

(8 x 3.85 lines/mm)

Fine/Halftone: 203 x 196 lines/inch

(8 x 7.7 lines/mm)

Super fine: 203 x 391 lines/inch

(8 x 15.4 lines/mm)

Ultra fine: 406 x391 lines/inch

(16 x 15.4 lines/mm)

Letter paper (20 lb): Max. 50 pages

Legal paper: Max. 20 pages (Note: 11” x

17” paper must be loaded one page at a

time.)

iable as option)

Public switched telephone network

Applicable telephone

line:

Compatibility: ITU-T (CCITT) G3 mode, Super G3 mode

Printing resolution: Horizontal: 406 lines/inch (16 lines/mm)

Input document size: Automatic feeding:

Effective scanning

width:

Effective printing

width:

Printing speed: 16 ppm

Reception modes: Auto/Manual

Instascan speed: 1.3 sec/page (letter paper; scan time only,

Full Dual Access: Yes

Copy function: Single/Multi/Sort (99 copies/page)

Power requirements: 120 V AC, 60 Hz

Operating tempera-

ture:

Humidity: 20 to 85% RH

Power consumption: Stand-by: 9 W

Dimensions: Width:21.5” (546 mm)

Weight: Approx. 48.5 lbs. (22.0 kg)

*Based on Sharp Standard Chart at standard resolution, excluding time

for protocol signals (i.e., ITU-T phase C time only).

**The yields may vary depending on coverage and operating conditions.

Public switched telephone network

Vertical: 391 lines/inch (15.4 lines/mm)

Width: 5.8 to 10.1” (148 to 257mm)

Length: 5.0 to 14.3” (128 to 364 mm)

Manual feeding:

Width: 5.8 to 11.0” (148 to 279 mm),

Length: 5.0 to 38.0” (128 to 966 mm)

(mazimum length 19” (483 mm) when ultra

fine resolution is used.)

10” (257 mm) max.

8.0” (203 mm) max.

excludes document feeding time)

50 - 86°F(10 - 30°C)

Stand-by (all options installed): 16W

Maximum: 800 W

Depth: 16.2” (412 mm)

Height: 17.0” (431 mm)

(Not including paper tray or attachments)

(Not including supplies paper tray or attachments)

As a part of our policy of continuous improvement, SHARP reserves the right to make design and specification changes for product improvement

without prior notice. The performance specifications figures indicated are nominal values of production units. There may be some deviations from

these values in individual units.

1 – 3

Page 7

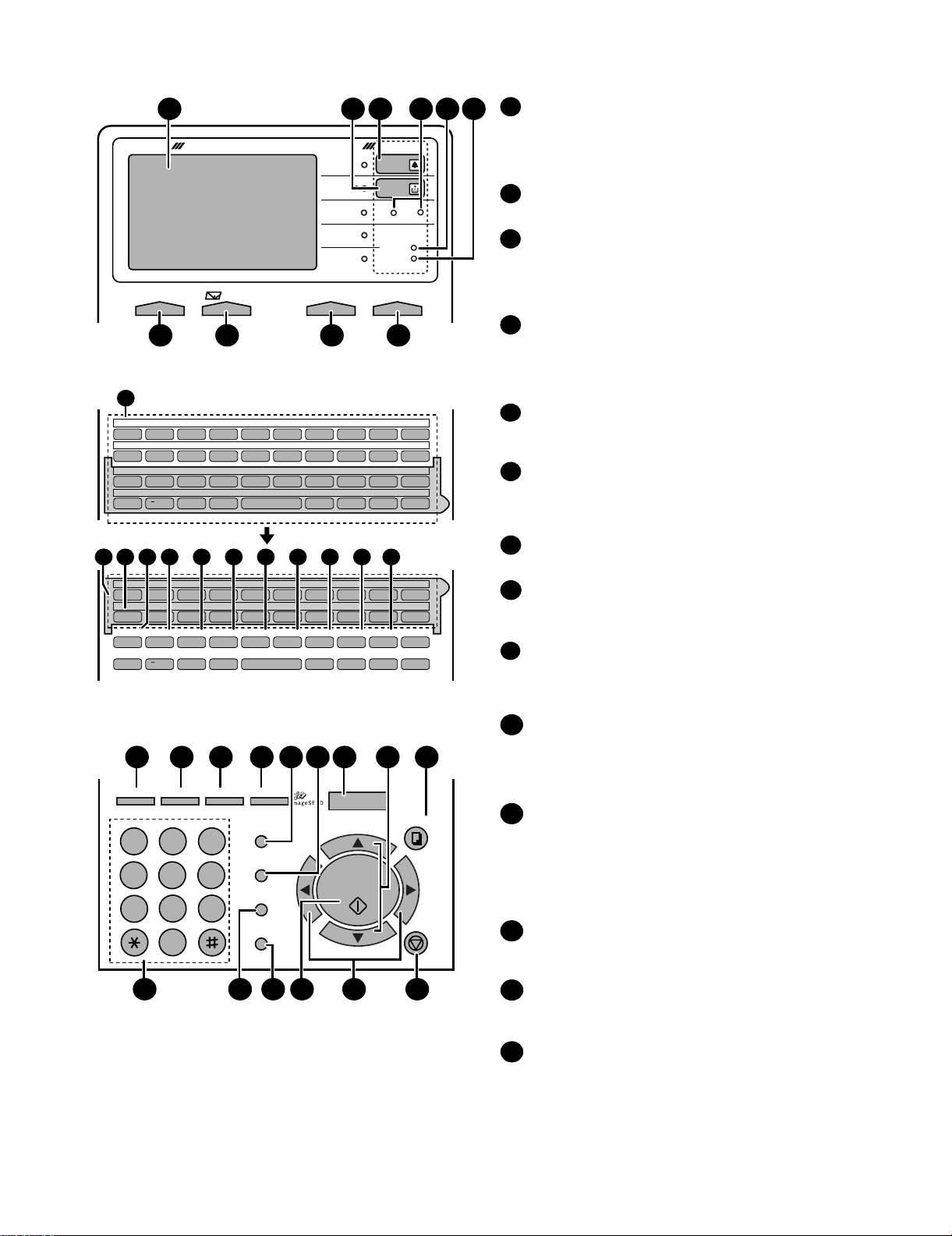

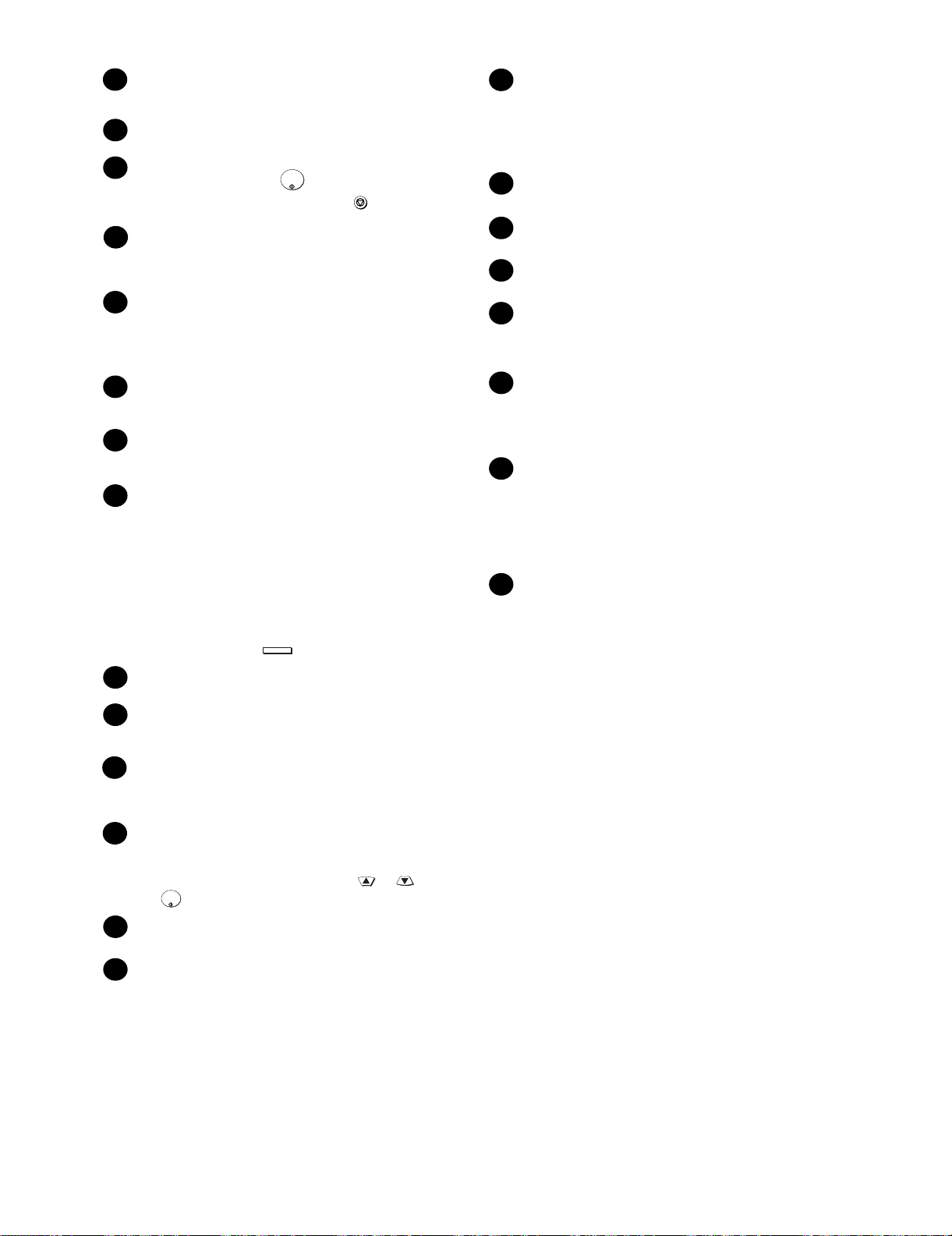

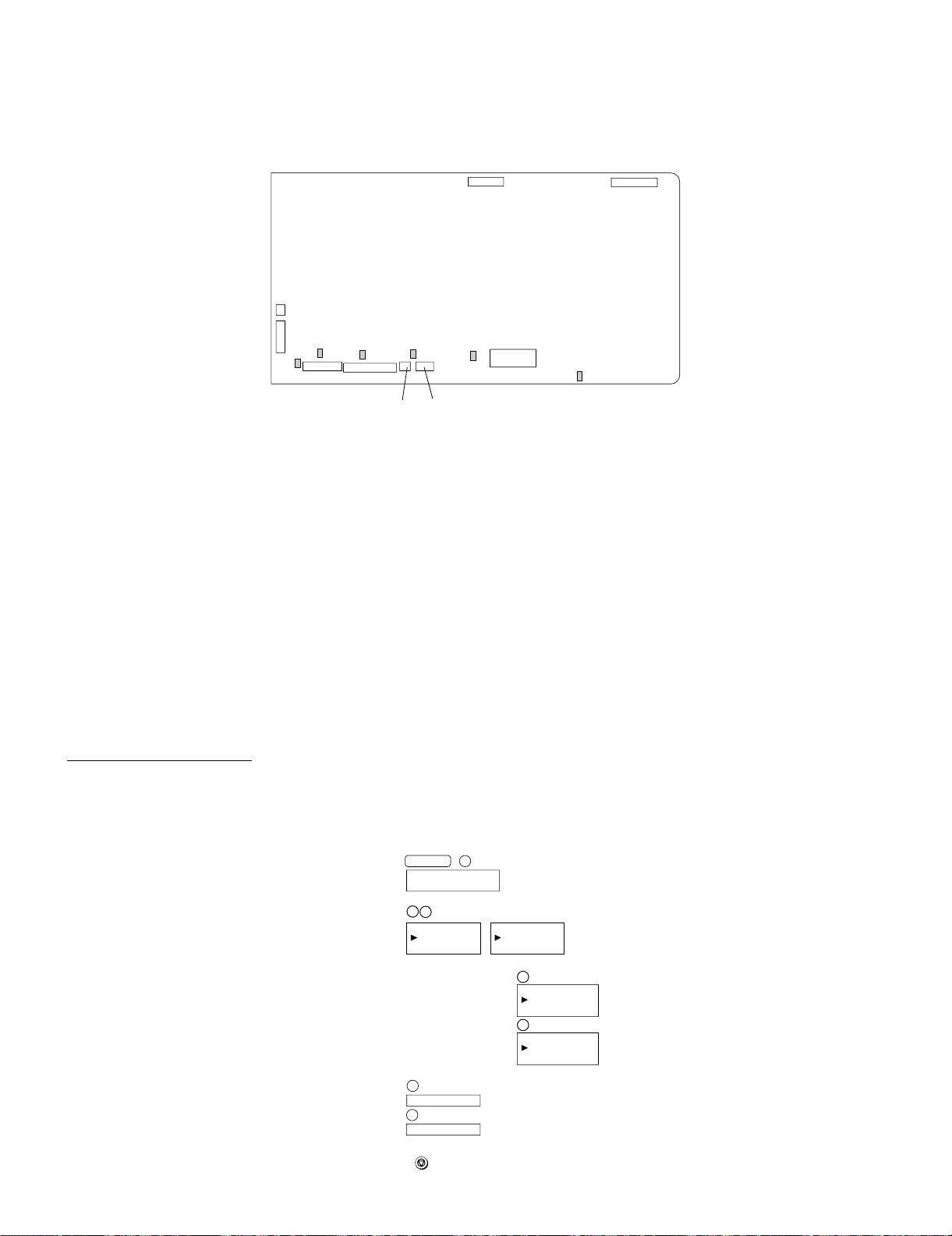

[3] Operation panel

1

DOCUMENT COMMUNICATION SYSTEM

CONTRAST RESOLUTIONe-mail ON LINE

7

11

01 02 03 04 05 06 07 08 09 10

Q/! W/" E/# R/$ T/% Y/& U/' I/( O/) P/=

11 12 13 14 15 16 17 18 19 20

SYMBOL

A/|S D F G/{ H/} J/[ K/] L/+

21 22 23 24 25 26 27 28 29 30

Caps Lock

Z/< X/> C V B N/* M/? @ .com

31 32 33 34 35 36 37 38 39

/^ // \ ;/:

SHIFT

11

40 41 42 43 44 45 46 47 48 49

50 51 52 53 54 55 56 57 58 59

SYMBOL

PAGECOUNTER

Caps Lock

GHI

PQRS

14 15 16 17 18 19 2012 13

Q/! W/" E/# R/$ T/% Y/& U/' I/( O/) P/=

A/|S D F G/{ H/} J/[ K/] L/+

CONFIDENTIAL

TIMER

Z/< X/> C V B N/* M/? @ .com

SHIFT

/^ // \ ;/:

COVER SHEET

22 2923 24 25 30282726

JOB STATUS

DUPLEX SCAN

ABC1DEF

PRIORITY

2 3

JKL

MNO

4

5

TUV

7

OPER

6

WXYZ

9

8

0

31 35 3632 3433

3 5 62

4

HALF TONE

STANDARD

SUPER FINE

ULTRA FINE

FINE

ALARM

TONER

Network

DATA

ON LINE

FAX2FAX1

98 10

Space

LIFE

MEM.STATUS

Space

BROADCAST

PERSONAL

BOOK

SPEED DIAL

ZA

REDIAL

GAB SEARCH

SPEAKER

_

REPORT

_

- ./, DEL

21

LINE

DOCUMENT

- ./, DEL

MENU

UP

START/

ENTER

DOWN

COPY

STOP

Display

1

This displays messages and prompts to help you operate

the machine. The backlight turns on whenever a key is

touched, and then automatically turns off after a preset time

if no further operations are performed. The display can be

tilted to the desired angle for easy viewing.

TONER indicator

2

This blinks when the toner cartridge nears empty, and lights

steadily when the toner cartridge needs replacement.

ALARM indicator

3

This blinks when one of the paper sources is empty, or the

drum cartridge is near or at the end of its life. This lights

steadily when all paper sources are empty, the print

compartment cover is open, or a paper jam has occurred.

A message will appear in the display to indicate the problem.

FAX1 / FAX2 lights

4

When the dual line option is installed, FAX 1 lights when

Line 1 is being used and FAX 2 lights when Line 2 is being

used. When the dual line option is not installed, only FAX 1

lights when the telephone line is being used (the FAX 2

light does not operate).

DATA light

5

This blinks when the machine is receiving a print job over

the network (only when the network printer option is

installed).

ON LINE light (printer option only)

6

When this light is on, the machine can receive data (print

jobs) over the network. The light is turned on or off with the

ON LINE key. (Only available when the network printer

option is installed).

CONTRAST key

7

Press this key to adjust the contrast before sending or

copying a document.

E-mail key

8

Press this key to send a scanned document to an e-mail

recipient. (Only available when the network scanner option

is installed).

RESOLUTION key

9

Press this key to adjust the resolution before sending or

copying a document. An indicator will light next to the

selected setting (HALFTONE, STANDARD, FINE, SUPER

FINE or ULTRA FINE).

ON LINE key (printer option only)

10

Press this key to select whether the machine is online or

off-line (the ON LINE light is on when the machine is

online). The machine must be online to receive print

jobs over the network. (Only available when the network

printer option is installed).

Rapid Dial Keys

11

Press one of these keys to dial a fax number automatically,

or specify an e-mail recipient if the network scanner option

is installed. Note that you must attach the Rapid Key labels.

When navigating through the display menu, a Rapid Key

can also be pressed in place of the numeric keys to enter

a two-digit number (for example, you can press Rapid Key

01 to enter the number "01").

SYMBOL key

12

When entering a name, press this key to enter the symbol

on a letter key (the character to the right of the slash).

Press the key again to turn off symbol entry mode.

PAGE COUNTER key

13

Press this key to include a slash and the total number of

pages after each page number on the pages of a

transmitted document.

CONFIDENTIAL key

14

Press this key to send or print out a confidential document.

FO-DC635U

1 – 4

Page 8

FO-DC635U

d

TIMER key

15

Press this key to set a fax operation to be performed

automatically at a later time.

COVER SHEET key

16

Press this key to include a cover sheet when sending a fax.

LIFE key

17

Press this key, followed by , to check the total number of

pages printed by the fax machine. (Press to return to the

data and time display.

MEM. STATUS key

18

Press this key to check the status of fax transmission jobs,

copy jobs, and fax receptions. This key can also be used to

cancel a job.

19

REPORT key

Press this key before sending a fax (on a Scan to E-mail/FTP/

Desktop transmission when the network scanner option is

installed) to have a transaction report printed out after the

transmission is finished.

DOCUMENT key

20

Press this key to transmit a document directly from the feeder

without reading it into memory.

LINE key

21

When the dual line option has been installed, press this key

before dialing to select the line.

JOB STATUS key

22

Press this key to display the FAX-STATUS screen, which

shows information on the fax job that is currently in progress.

If the dual line option is installed, the fax status will appear

separately for each line. If the network printer option is

installed, the NETWORK PRINT STATUS screen showing

information on current printer activity will appear following

the FAX STATUS screen (note that "IDLE" will appear if a

print job has been executed but is not yet being printed).

To move through each of the screens and return to the date

and time display, press one or more times as needed.

JOB STATUS

START/

ENTER

STOP

29

UP and DOWN arrow keys

Volume setting: Press these keys to change the speaker

volume when the SPEAKER key has been pressed, or the

ringer volume at any other time.

MENU key settings: Press these keys after pressing the

MENU key to scroll through the MENU key settings.

30

COPY key

Press this key to make a copy of a document that is in the fee

31

Dial keypad (numeric keys)

Use these keys to dial and program fax numbers.

REDIAL key

32

Press this key to automatically redial the last number dialed.

SPEAKER key

33

Press this key when faxing a document by Normal Dialing to

listen to the line and verify the response of the receiving fax

machine.

START/ENTER key

34

Press this key to begin fax transmission when using Speed

Dialing, Direct Keypad Dialing, or Normal Dialing. This key is

also used to select settings in the MENU key menu and

complete entries when storing names and numbers.

Left and right arrow keys

35

Press these keys to search for an auto-dial number when

sending a document. If the network scanner option is installed

and your network has an LDAP server, the left arrow key

(GAB SEARCH) can be pressed to search for a destination on

the LDAP server. (Note: "GAB" stands for "Global Address

Book".)

36

STOP key

Press this key to cancel an operation before it is completed.

DUPLEX SCAN key

23

Press this key to transmit or copy a two-sided document.

PRIORITY key

24

Press this key when you need to transmit a document ahead

of other documents waiting in memory for transmission.

BROADCAST key

25

Press this key to send a document to a group of fax

machines, or to a group of e-mail recipients if the network

scanner option is installed.

26

PERSONAL BOOK

Press this key to use or store an auto-dial number in a

personal book. If the book has a passcode, enter the

passcode; otherwise, select the book with or and

START/

ENTER

press .

27

SPEED DIAL key

Press this key to dial a Speed Dial number.

MENU key

28

Press this key to select special functions and setting.

1 – 5

Page 9

[4] Transmittable documents

1. Document Sizes

Normal size Width 5.8” - 10.1”(148 - 257 mm)

Length 5.0” - 14.3”(128 - 364 mm)

(Max.)

80g/m

966mm

2

(Max.)

(Min.)

364mm

128mm

148mm 257mm

[Normal size]

• With special sizes, only one sheet can be fed into the machine at a

time. Insert next page into feeder as current page is being scanned.

279mm

[Special size]

2. Paper Thickness & Weight

Product specifications

Indication Lower Limit Upper Limit

Weight indication

Thickness

indication

Document

size

Number of

ADF sheets

Paper quality

Japanese indication Size 4 x 6

Metric system

indication

American indication LB system indication

Metric system

indication

Inch system

indication

Document size

Range

Document size

Weight

Kind Paper of fine quality/bond paper/

45kg paper 70kg paper

2

52g/m

14 LB 20 LB

0.06mm 0.1mm

0.0024" 0.0035"

(148mm x 128mm) ~

W letter (279mm x 483mm)

A4 (210mm x 297mm)

Letter (216mm x 279mm)

B6 ~ Letter/A4 size 50sheets

B4 size/Legal 20sheets

W letter size 1sheet

90 kg (104g/m

135 kg (157g/m

Kent paper

2

) or more

2

) or less 1sheet

3. Document Types

• Normal paper

Documents handwritten in pencil (No. 2 lead or softer), fountain

pen, ball-point pen, or felt-tipped pen can be transmitted.

Documents of normal contrast duplicated by a copying machine

can also be transmitted.

• Diazo copy (blue print)

Diazo copy documents of a normal contrast may be transmitted.

• Carbon copy

A carbon copy may be transmitted if its contrast is normal.

FO-DC635U

4. Cautions on Transmitting Documents

• Documents written in yellow, greenish yellow, or light blue ink cannot be transmitted.

• Ink, glue, and correcting fluid on documents must be dry before the

documents can be transmitted.

• All clips, staples and pins must be removed from documents before

transmission.

• Patched (taped) documents should be copied first on a copier and

then the copies used for transmission.

• All documents should be fanned before insertion into the feeder to

prevent possible double feeds.

5. Automatic Document Feeder Capacity

Number of pages that can be placed into the feeder at anytime is as

follows:

Normal size: max. 50 sheets (14 lbs - 20 lbs)

Special size: single sheet only (manual feed)

NOTE: • If you need to send or copy more 50 pages, place the addi-

tional pages and carefully in the feeder just before the last

page is scanned. Do not try to force them in, as this may

cause double-feeding or jamming.

• If your document consists of several large or thick pages

which must be loaded one at a time, insert each page into the

feeder as the previous page is being scanned. Insert gently to

prevent double feeding.

6. Readable Width & Length

The readable width and length of a document are slightly smaller than

the actual document size.

Note that characters or graphics outside the effective document scanning range will not be read.

• Readable width

10” (257mm), max

Readable width

• Readable length

This is the length of the document sent minus 0.16” (4mm) from the

top and bottom edges.

0.16" (4mm)

Readable length

0.16" (4mm)

1 – 6

Page 10

FO-DC635U

[5] Installation

1. Site selection

Take the following points into consideration when selecting a site for

this model.

ENVIRONMENT

• The machine must be installed on a level surface.

• Keep the machine away from air conditioners, heaters, direct sunlight, and dust.

• Provide easy access to the front, back, and sides of the machine.

In particular, keep the area in front of the machine clear, or the original document may jam as it comes out after scanning.

• The temperature should be between 50 - 86°F (10 - 30°C).

• The humidity should be between 20% and 85% (without condensation).

ELECTRICITY

AC 120V, 60Hz, grounded AC (3-prong) outlet.

Caution!

• Connection to a power source other than that specified will cause

damage to the equipment and is not covered under the warranty.

• If your area experiences a high incidence of lightning or power

surges, we recommend that you install a surge protector for the

power and telephone lines. Surge protectors can be purchased at

most telephone specialty stores.

TELEPHONE JACK

A standard telephone jack must be located near the machine. This is

the telephone jack commonly used in most homes and offices.

• Plugging the fax machine into a jack which is not an RJ11C jack

may result in damage to the machine or your telephone system. If

you do not know what kind of jack you have, or need to have one

installed, contact the telephone company.

If the machine is moved from a cold to a warm place...

If the machine is moved from a cold to a warm place, it is possible that

the reading glass may fog up, preventing proper scanning of documents for transmission. To remove the fog, turn on the power and wait

approximately 2 hours before using the machine.

2) Connecting the telephone line cord

Insert one end of the line cord into the jack on the back of the

machine marked TEL. LINE. Insert the other end into a standard

(RJ11C) single-line wall telephone jack.

Note: The fax machine is set for touch-tone dialing. If you are on a

pulse dial (rotary) line, you must set the fax machine for pulse dialing by changing Option Setting 22.

3) Attaching the ADF exit tray

Insert the protrusion on the right side of the machine into the hole in

the right side of the ADF exit tray , then bend the tray

slightly and insert so that the protrusion on the left side of the

machine goes into the hole on the left side of the ADF exit tray

. Pull out the tray extension .

2

2

1

3

1

3

2. Assembly and connections

1) Connecting the power cord

Connect the female end of the power cord to the fax machine as

shown. Insert the male end into a 120 V, 60 Hz, grounded (3-prong)

AC outlet.

Important!: The fax machine requires its own dedicated power outlet. The power outlet must not be shared with any other devices. In

particular, do not use an extension cord to connect multiple devices

to the outlet.

Note: If your area experiences a high incidence of lightning or

power surges, we recommend that you install surge protectors for

the power and telephone lines. Surge protectors can be purchased

at most telephone specialty stores.

Press the power

switch to turn on

the power.

4) Attaching the received document tray

Slide the received document tray into the machine as shown. When

it stops, lift the end slightly and push in so that the tray locks into

place.

Important!: The received document tray must be attached for the

fax machine to operate properly.

1 – 7

Page 11

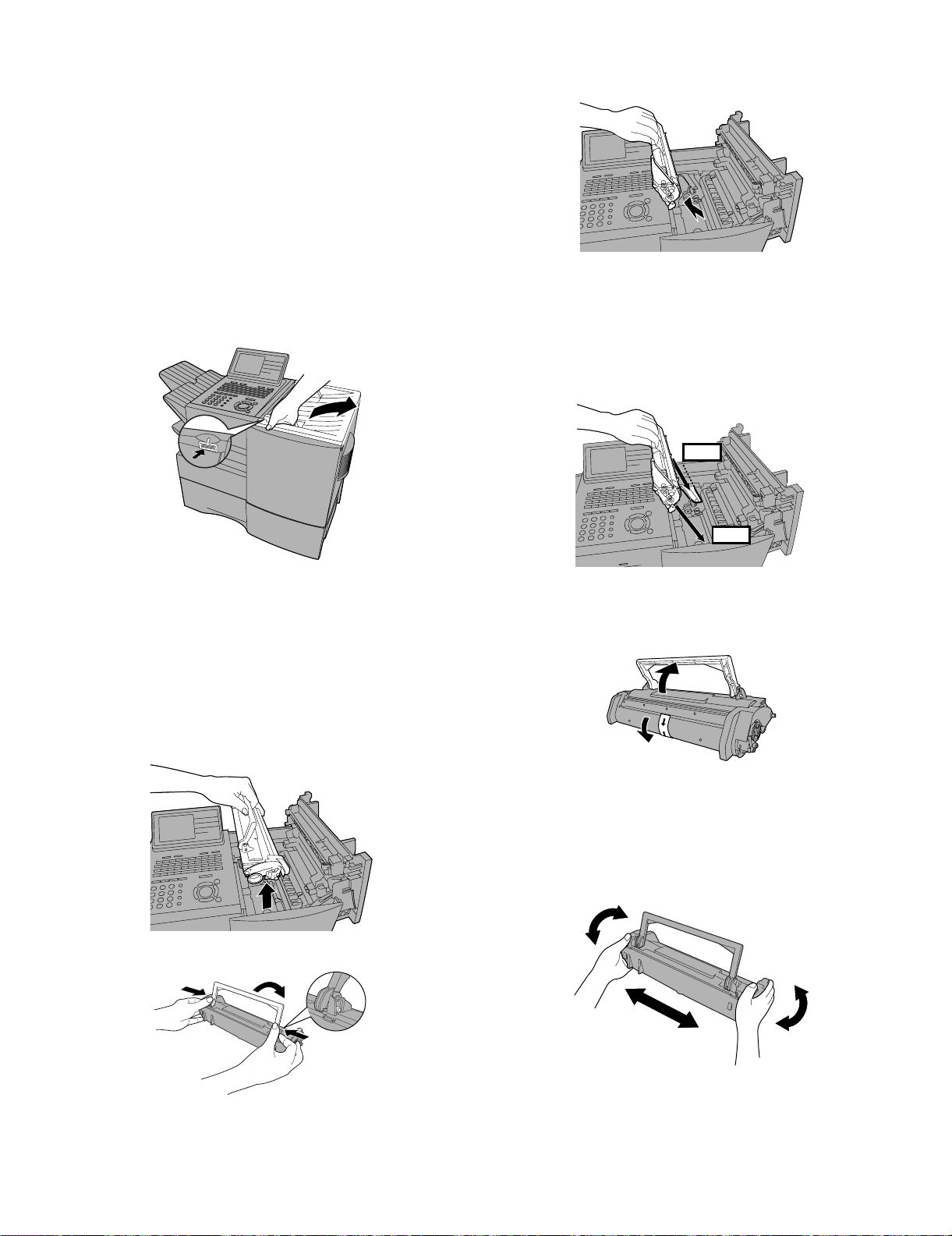

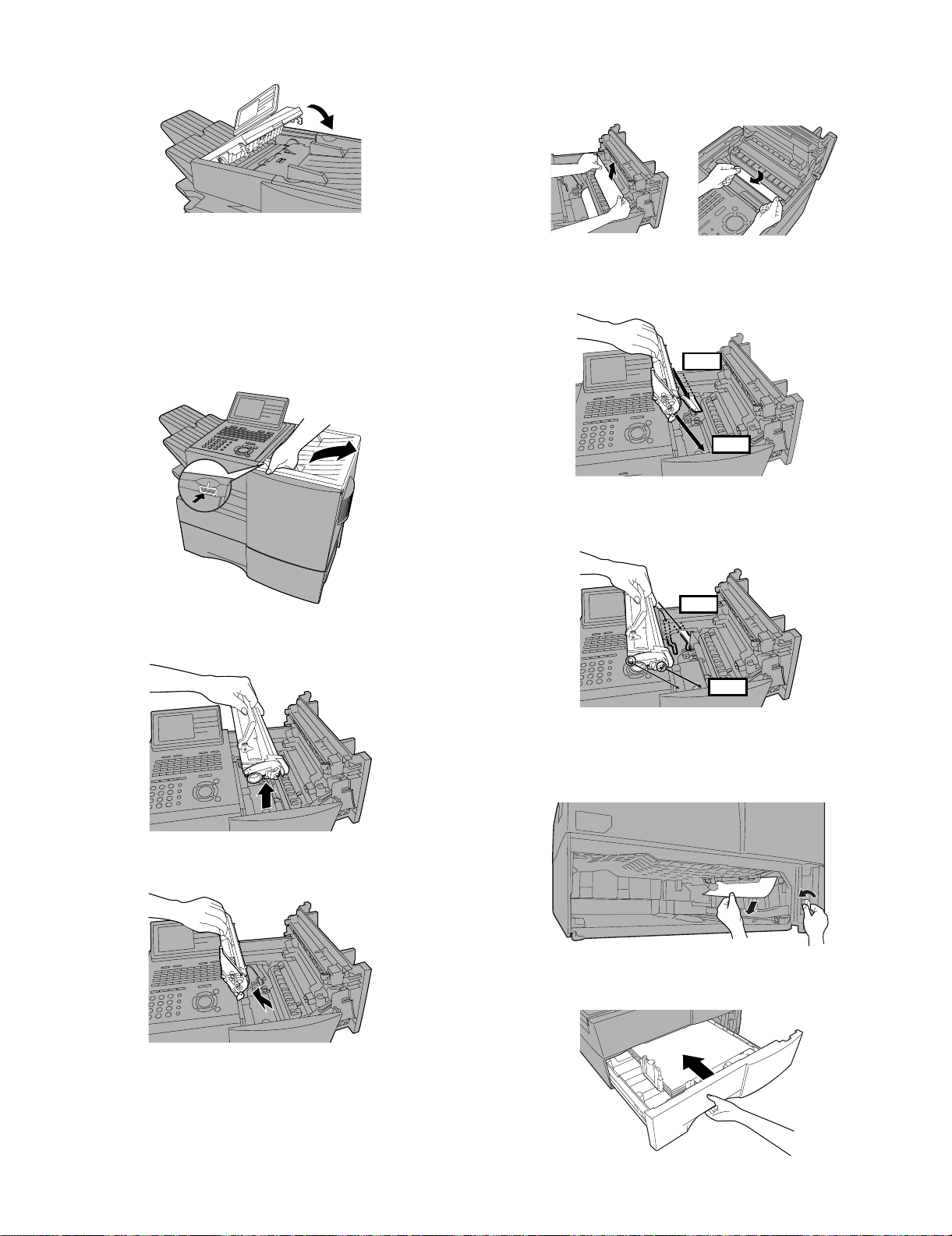

3. Installing the print cartridges (Toner cartridge:

FO-50ND)(Drum cartridge: FO-47DR)

Follow the steps below to install or replace the toner and drum cartridges.

• The initial starter toner cartridge included with the fax machine can

print approximately 3000 letter-size pages (4% coverage of each

page; continuous printing).

• The replacement toner cartridge (FO-50ND) can print approximately 6000 letter-size pages.

• The drum cartridge (FO-47DR) can print approximately 20,000 letter-size pages.

1) Press the cover release to open the print compartment cover.

• Caution! The fusing unit inside the print compartment becomes

very hot during operation. Be careful not to touch the inside of the

compartment.

FO-DC635U

3) If you are replacing the drum cartridge, remove the old cartridge

and dispose of it according to local regulations.

4) Remove the new drum cartridge from its packaging. Insert the drum

cartridge into the print compartment.

• Caution! Excessive exposure to light will damage the drum car-

tridge. Install the cartridge promptly after removing it from its

packaging.

• Make sure the drum cartridge is inserted in as far as it will go.

BLUE

2) If you are replacing the toner cartridge, remove the old cartridge

and dispose of it according to local regulations.

Go directly to STEP 5 if you are only replacing the toner cartridge

and not the drum cartridge.

To make the cartridge more compact for disposal, press the buttons

on the ends of the handle and fold the handle down.

• If you are replacing the drum cartridge but not the toner car-

tridge, remove the toner cartridge and place it on a sheet of

paper.

GREEN

5) If you are installing a new toner cartridge, remove the new toner

cartridge from its packaging. Remove the tape from the cartridge

and then open the cartridge handle so that it stands straight up.

6) Shake as indicated by the arrows to distribute the toner evenly

within the cartridge.

• If the toner is still lumpy after shaking, the gears in the cartridge

may make a noticeable sound when the print compartment

cover is closed after installing the cartridge. This is normal and

does not indicate a problem.

1 – 8

Page 12

FO-DC635U

Red line

7) Hold the toner cartridge by the handle and insert it into the print

compartment.

• Make sure the toner cartridge clicks into place.

• The handle can be left standing up.

11)When to replace the drum cartridge

When the drum cartridge nears the end of its life, the ALARM indicator on the operation panel will blink and REPLACE DRUM CARTRIDGE will appear in the display. (this message first appears

when approximately 1000 pages before the drum needs replacement). Use the following replacement drum cartridge.

Sharp FO-47DR drum cartridge

BLUE

GREEN

8) Close the print compartment cover.

9) Reset the drum counter by pressing (flip up the Rapid Key

LIFE

V

overlay), or until DRUM COUNTER CLEAR is selected

in the display, and then .

START/

ENTER

• Note: The toner counter automatically resets each time you

replace the toner cartridge. There is normally no need to reset

the toner counter manually. Should you find it necessary to

manually reset the toner counter, press (flip up the

LIFE

V

Rapid Key overlay), or until TONER COUNTER

CLEAR is selected, and then .

START/

ENTER

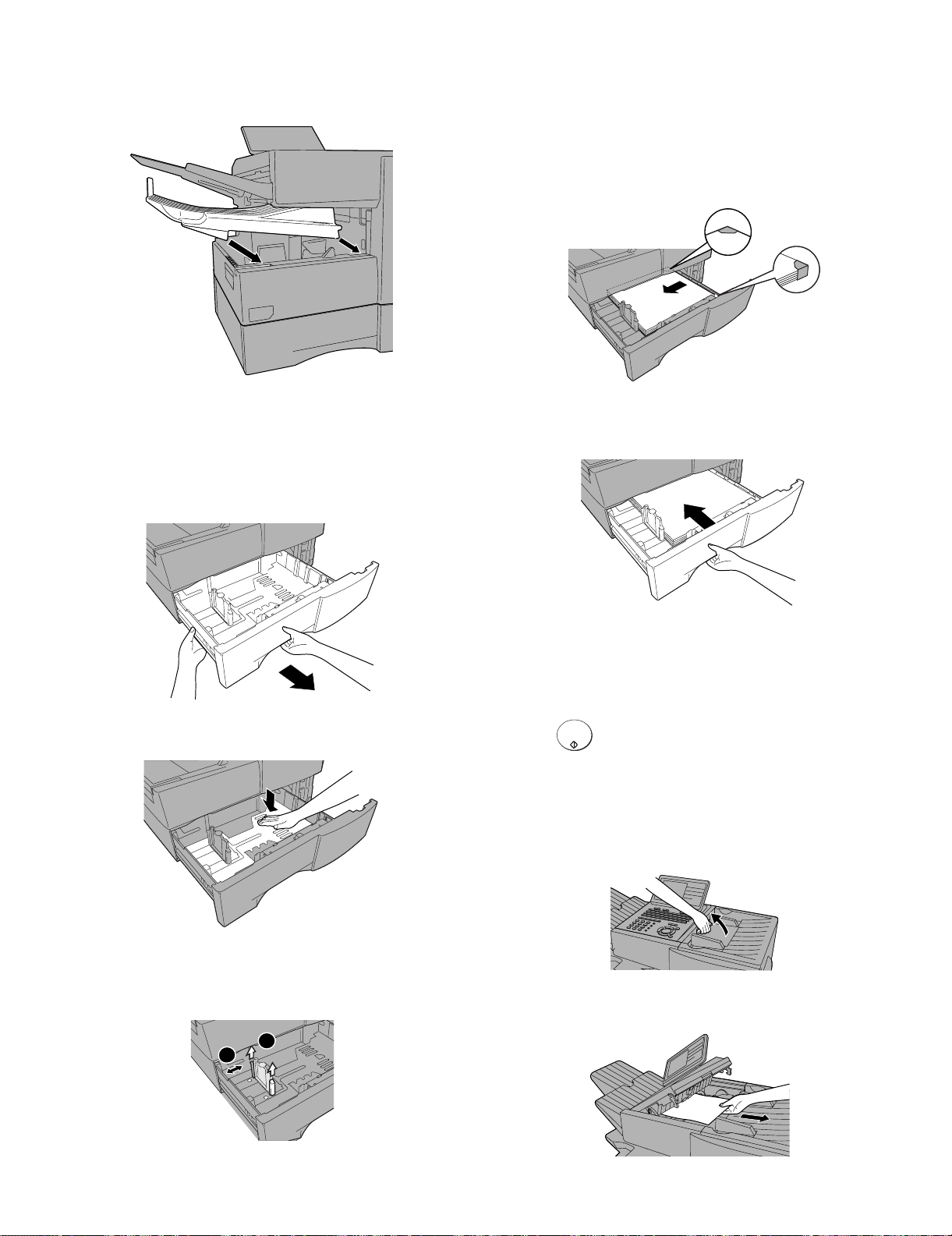

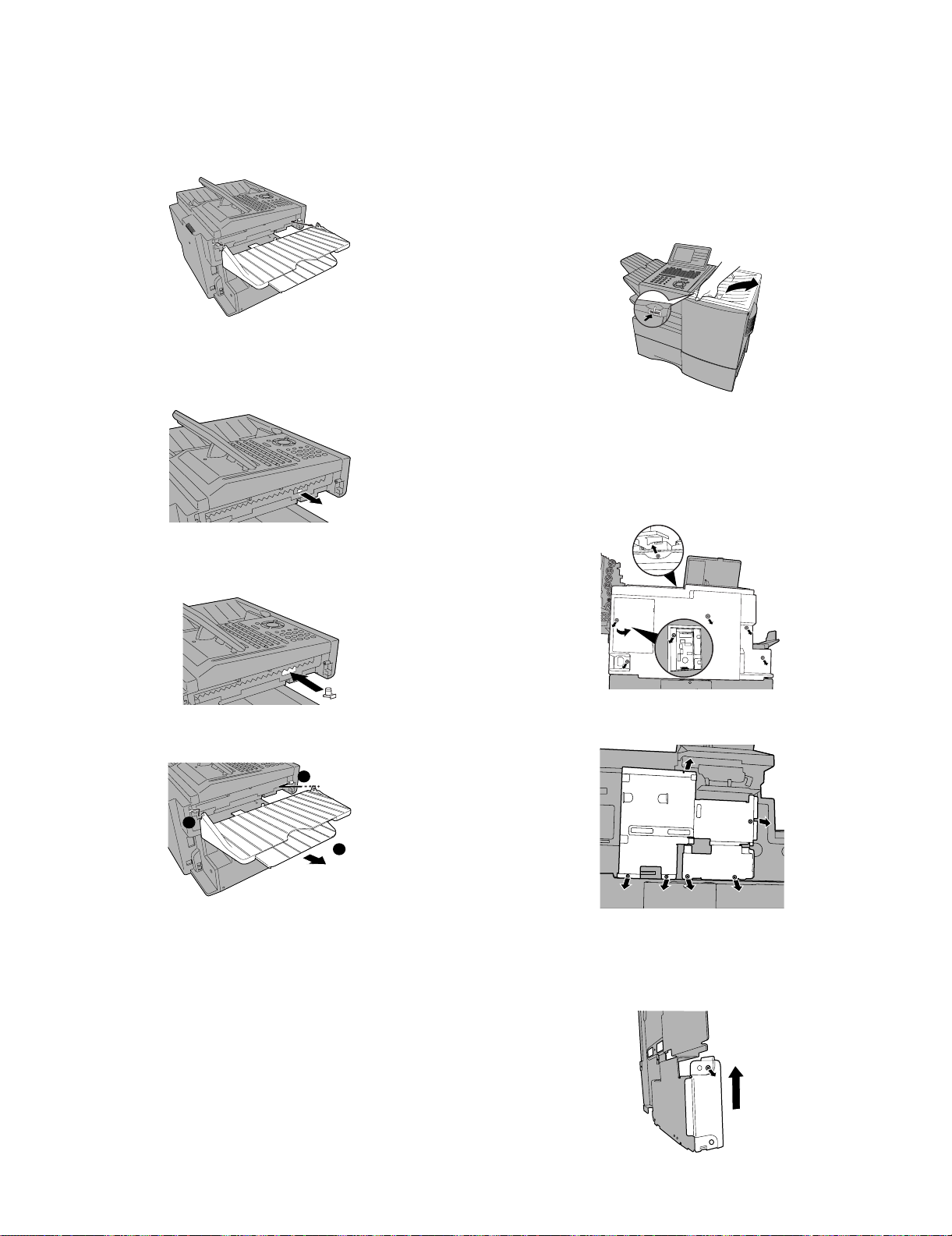

4. Loading printing paper

You can load up to 250 sheets of letter or legal paper (max. 20 lbs.) in

the paper tray. Depending on the model, a paper cassette is also

included as a standard fearure or available as an option. Up to 500

sheets of letter or legal paper can be loaded in the paper cassette.

• One paper cassette is inclued as a standard feature. A second

paper cassette is available as an option. To have a second cassette

installed, consult your dealer.

Important: Do not use the back side of paper that has already

been printed on.

Note: If you need to add paper to the tray or cassette while paper

still remains, remove the remaining paper and combine it into a single stack with the new paper.

Loading paper in the paper tray

1) Remove the received document tray.

2) Insert a stack of paper into the tray, print side up.

• Important! The stack of paper must not be higher than the red

line on the paper tray.

Note: The print compartment cover may become noticeably

warm if a large number of pages are successively printed. This

is normal and does not indicate a problem in the machine.

10)When to replace the toner cartridge

When the toner cartridge nears empty (about 100 pages can still be

printed), the toner cartridge indicator on the operation panel will

blink. When the toner cartridge is empty, the toner cartridge indicator will light steadily and REPLACE TONER CARTRIDGE will

appear in the display. Printing will no longer be possible. Use the

following replacement toner cartridge.

Sharp FO-50ND toner cartridge

Hint: When the toner cartridge nears empty, try taking it out of the

machine and shaking it. This may increase the number of pages

that can be printed before the toner runs out.

3) Squeeze the paper guide and move it to match the length of the

paper you are loading.

Attach a letter or

legal label here to

indicate the paper size.

1 – 9

Page 13

4) Replace the received document tray.

• The received document tray must be attached for the machine

to operate properly.

FO-DC635U

4) Place a stack of paper in the cassette, print side up.

• Make sure the stack of paper is not higher than the two tabs on

the paper guide and the two metal tabs. If it is, remove some of

the paper.

• If you find it difficult to load the paper, remove the cassette from

the machine. (Pull the cassette out as far as it will go, grasp the

left side of the cassette with your left hand, and then lift it up and

out with both hands.)

5. Loading paper in the paper cassette

Note: To use A4 paper in the paper cassette, you must have a service

technician adjust the cassette.

1) Grasp the hand-hold on the cassette and pull the cassette out until

it stops.

2) Push the pressure plate down until it locks into position.

5) Push the cassette back into the machine, making sure it clicks into

place.

6. Clearing paper jams

Clearing a jammed document

If the original document doesn’t feed properly during transmission or

copying, or REMOVE ORIGINAL(S) appears in the display, fist try

START/

pressing . If the document doesn’t feed out, open the opera-

tion panel and remove it.

Important: Do not try to remove a document without opening the operation panel. This may damage the feeder mechanism.

1) Open the operation panel.

ENTER

• Squeeze the release marked PANEL RELEASE and pull up.

3) Squeeze the paper guide and pull up to move it to the appropriate

holes for the length of the paper. Push the guide down into the

holes.

1

2

2) Remove the document.

1 – 10

Page 14

FO-DC635U

3) Close the operation panel, making sure it clicks into place.

4) Remove the jammed paper.

• Make sure no torn pieces of paper remain in the print compartment and rollers.

OR

7. Clearing a jammed printing paper

If the printing paper jams, PAPER JAM will appear in the display. Follow the steps below to clear the jam.

1) Press the green release and open the print compartment cover.

• Caution! The fusing unit inside the print compartment becomes

very hot during operation. Be careful not to touch the inside of

the compartment.

2) Remove the toner cartridge and place it on a sheet of paper.

5) Replace the drum cartridge.

• Make sure the drum cartridge is inserted in as far as it will go.

BLUE

GREEN

6) Replace the toner cartridge and then close the print compartment

cover.

BLUE

GREEN

3) Remove the drum cartridge.

7) If you have a paper cassette and the display still indicates that

paper is jammed, pull out the cassette and remove the jammed

paper.

8) Replace the paper cassette.

1 – 11

Page 15

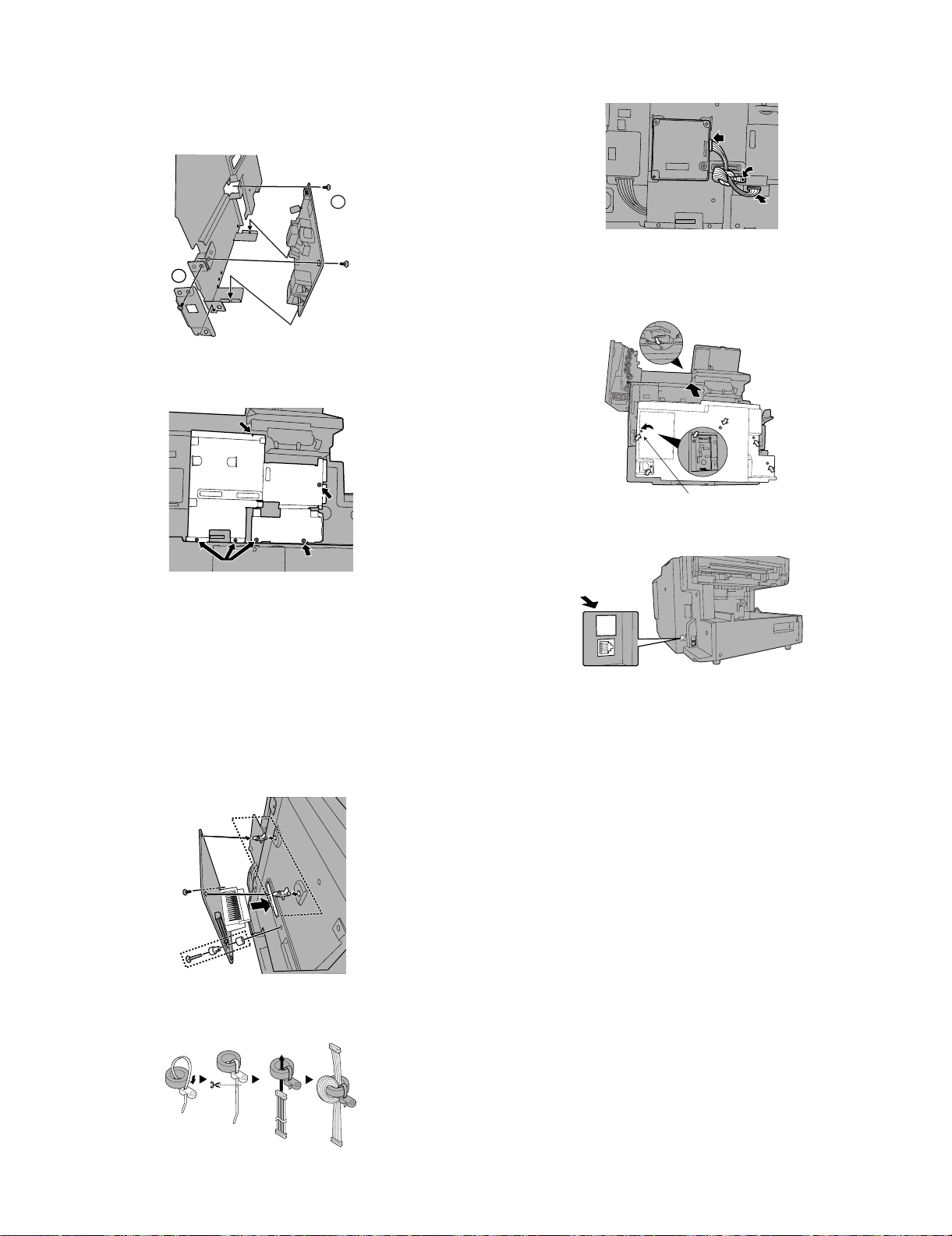

8. Replacing the Verification Stamp (FO-45VS)

If you are using the Verification Stamp function, you will need to

replace the ink cartridge in the stamp unit when it runs out of ink (when

the stamped mark on original documents becomes faint). A new ink

cartridge can be obtained from your dealer.

1) Remove the ADF exit tray.

2) Press down on the protruding tab of the green ink cartridge and pull

the cartridge out with your fingers.

FO-DC635U

9. Installing the Dual Line Kit (FO-60DL)

Note: The FO-60DL Dual Line Kit cannot be installed if the FO-NP1

Network Printer Kit is installed.

Important! The following procedure is to be performed only by a qualified service technician. Be sure to turn off the power, unplug the

power cord, and unplug the telephone line before proceeding. In addition, touch a grounded piece of metal to discharge any static electricity

that may be on your body. Make sure that an extension phone is not

connected to the machine.

1) Press the cover release to open the print compartment cover.

2) Remove 6 screws from the rear cover.

(Remember which screw secures the small cover on the left side of

the rear cover, as it must be replaced in the same position).

Remove the small cover, and then remove the screw underneath.

Remove the rear cover.

3) Insert the new ink cartridge into the machine (make sure that the

tab is facing out).

4) Replace the ADF exit tray.

1

2

3

3) Remove 6 screws and then remove the metal plate.

4) Remove the screw that holds the small side plate to metal plate

that was removed Step 3. Slide the small side plate up and remove

it from the metal plate. (Note: The small side plate is not no longer

needed, however, the screw is used again in “b” of Step 5.)

1 – 12

Page 16

FO-DC635U

For plastic

5) a: Attach the LIU board to the metal plate, positioning the modular

jacks as shown. The bottom edge of the board should fit into the

slots indicated by the arrows. Secure the LIU board with two of the

6 mm screws.

b: Attach the provided metal side plate.

a

b

6) Replace the metal plate and secure with screws in the order

shown.

1

9) Connect the cable to the LIU board and the dual line control board.

Secure the core band with the 10 mm screw.

10)Replace the rear cover.

(Be sure to replace the screw that secures the small cover in the

same position, as it is for plastic.)

3

4

7) Attach the dual line control board.

a: Insert the bushing into the hole in the dual line control board from

the outer side and secure it with the collar on the inner side.

b: Insert the winged end of the pin spacers into the metal plate, with

wings extended out vertically.

c: Attach the board so that the connector inserts into the connector

in the metal plate. Make sure that the pin spacers go into the holes

in the board. Secure the board with the 18 mm screw (which goes

into the bushing) and the remaining 6 mm screw. Tighten the

screws in the order shown.

b

c

2

a

1

2

11)Affix the “”LINE 2” label above the new jack.

LINE 2

8) Fasten the band to the core as shown and cut off the excess end.

Insert the cable through the core and wind it around the core twice.

1 – 13

Page 17

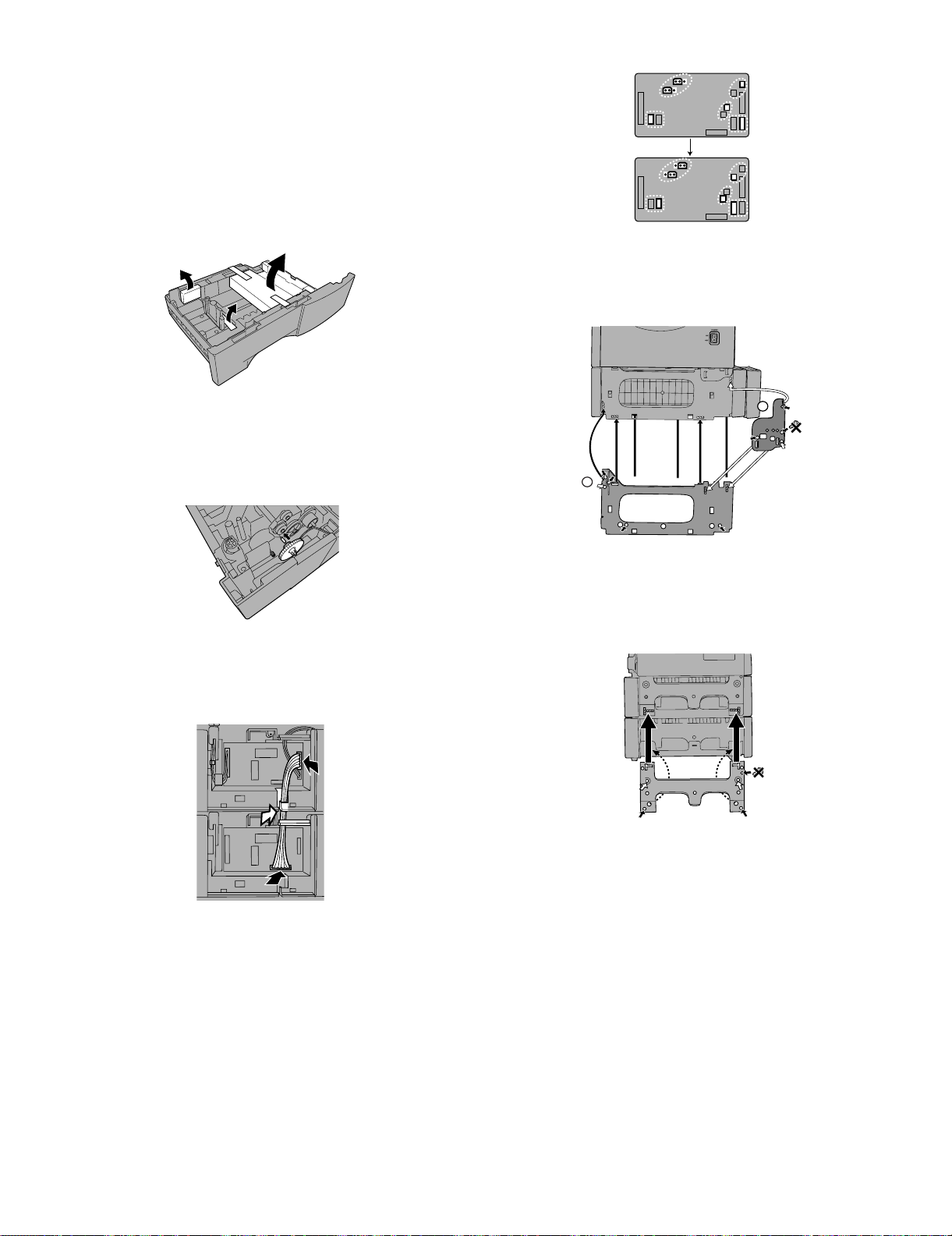

10. Installing the paper cassette option FO-CS2

(2nd)

Important! Be sure to turn off the power and unplug the power cord

before proceeding.

1) Remove the packing material and tape from the second paper cassette.

2) Remove the covers from the sides of the first cassette (the cassette

already installed on the machine), using a flat-head screwdriver to

pry each of the catches at the bottom of the covers free (2 on the

right cover, 3 on the left cover).

FO-DC635U

6) Attach the large support plate and then the small support plate to

the right side of the cassettes. Use 6 mm screws for the holes

marked with “A”, and 10 mm screws for the holes marked with “P”.

Secure the screws in the order indicated by the numbers.

3) Insert the green gear into the second cassette as shown. The side

of the gear that has the small secondary gear should face the

inside of the cassette, and should fit onto the metal shaft. Push the

gear in until the tab on the outer side goes into the slot on the metal

shaft. (Note: The gear is only used in the second cassette.)

4) Place the machine on top of the second cassette, and remove the

small cover from the rear of the first cassette. Connect the 10-pin

cable as shown, and insert it behind the guide indicated by the

white arrow.

2

A4

A4

P4

A3

1

A3

P3

A2

A1

7) Attach the support plate to the left side of the cassette. Use 6 mm

screws for holes marked with “A”, and 10 mm screws for holes

marked with “P”, securing the screws in the order indicated by the

numbers. (Note that the top hole on the right does not require a

screw.)

A4

P6

A2

A3

P5

A1

8) Attach the side covers to the first and second cassettes (refer to

steps 9 and 11 on the previous pages).

5) Change the positions of the connectors on the circuit board of the

second cassette as shown (do not change the connectors on the

first cassette). Replace the small cover on the rear of the first cassette, and attach the provided small cover on the rear of the second

cassette. (For the reconnection, see page 1-15.)

1 – 14

Page 18

FO-DC635U

11. Caution when installing paper cassette option FO-CS2(2nd) to FO-DC635

When installing the option FO-CS2 to FO-DC635U as a 2nd paper cassette, the short pins and cables on the paper cassette PWB must be reconnected.

FO-DC635

+

FO-CS2

CAUTION

Connect 1 pin and 2 pin

-- -:@:H:9:N

1st Paper Cassette

2nd Paper Cassette

From the Motor

Connecting position of each cable when

installing Paper Cassette Option FO-CS2(2nd)

to FO-DC635.

1st paper cassette (CN6)/2nd paper cassette (CN7) cable

From the Solenoid

From the Paper

size sensor

From the

Cassette sensor

1 – 15

Page 19

12. Quick reference guide

START/

ENTER

START/

ENTER

START/

ENTER

STOP

12.1. SENDING FAXES

Place your document (up to 50 letter-size pages) face down in the document feeder.

FO-DC635U

To store a Speed Dial number, press and enter a number

from 1 to 200 (press if you entered a 3-digits).

START/

ENTER

(If clearing a number, select it as explained above and then press

STOP

and .)

6) If the network scanner option is installed, SELECT DESTINATION

TYPE will appear. Make sure that FAX is selected and press

SPEED DIAL

(Note: For Normal Dialing and Direct Keypad Dialing, you can also

load the document after dialing the number.)

RESOLUTION

Press or if needed.

CONTRAST

12.1.1 Normal Dialing

1) Lift extension phone or press .

2) Dial the fax number (if using an extension phone, dial on the extension phone keypad).

3) Wait for the reception tone (if a person answers, ask them to press

their Start key).

START/

4) Press .

ENTER

SPEAKER

12.1.2 Rapid Key Dialing

1) Press the desired Rapid Key.

12.1.3 Speed Dialing

1) Press and enter the desired Speed Dial number (press

SPEED DIAL

START/

if you entered a 3-digits number).

ENTER

.

7) Enter the full fax number and press .

8) Enter a name by pressing the letter keys and press .

START/

ENTER

START/

ENTER

9) Select YES if this is a Chain Dial number or NO if not, and press

.

10)If the dual-line option is installed, select LINE-1, LINE-2, or AUTO

and press .

START/

ENTER

11)Press repeatedly to exit.

START/

2) Press .

ENTER

12.1.4 Direct Keypad Dialing

1) Dial the fax number.

START/

2) Press .

ENTER

12.2. STORING AUTO DIAL NUMBERS

1) Press and then or until ENTRY MODE is

selected in the display.

2) Press . Make sure that DESTINATION SETTING is

selected.

3) Press . Make sure that SET is selected. (To clear a num-

ber, select CLEAR.)

4) Press .

5) To store a Rapid Key number, press the desired Rapid Key.

MENU

START/

ENTER

START/

ENTER

START/

ENTER

1 – 16

Page 20

FO-DC635U

FO-DC635U

CHAPTER 2. ADJUSTMENTS

[1] Adjustments

General

Since the following adjustments and settings are provided for this

model, make adjustments and/or setup as necessary.

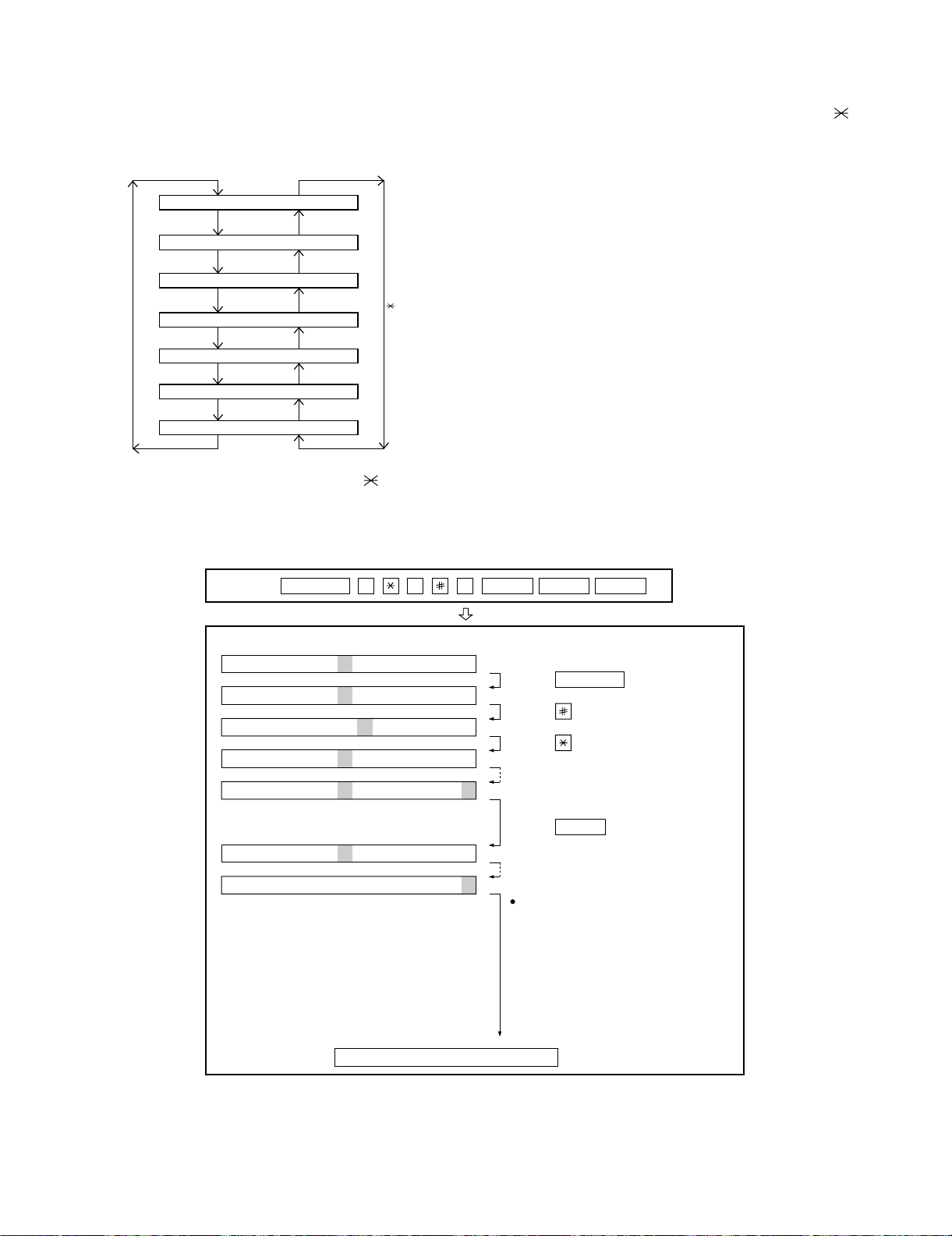

1. Adjustments

Adjustments of output voltage (FACTORY ONLY)

1. Install the power supply unit in the machine.

2. Set the recording paper and document.

3. When the document is loaded, power is supplied to the output

lines. Confirm that outputs are within the limits below.

Output voltage settings

POWER

SUPPLY

PWB

1

1

CN5

HIGH VOLTAGE

PWB

12

CN1

VR51

CN1

8

1

10

Service Manual

CONTROL PWB

CNPW1

112

8

10

CN7

CN4

1

1

CNPRT1

130

130

CN1

PRINTER PWB

Output Voltage limits Note

+5V MAIN 4.947V~5.25V CN5 7pin ↔ 8pin

+24V SUB 23.04V~24.96V CN5 1pin ↔ 2pin

Connector CN4

No.

Pin No. CN1

111+5V

210CHLREM

3TVR

4TMONV

5TMONI

6BVR

7VREM

8 C MON

9MG

10 2 +24V

9

8

7

6

5

4

3

Connector CN5

No.

Pin No. CNPW1

1 +24V SUB

2MG

3MG

4MG

5 +24V MAIN

6 +24V MAIN

7 +5V MAIN

8DG

9DG

10 DG

11 +5V MAIN

12 +5V MAIN

Connector CN1

No.

Pin No. CN7

1 +24V MAIN

2MG

3DG

4DG

5 +5V MAIN

6 +5V MAIN

7 HEATER ON

8 H-RELAY OFF

[DO NOT TOUCH!]

Fig. 1

2 – 1

Page 21

2. IC protectors replacement

ICPs (IC Protectors) are installed to protect the CIS unit, panel PWB

unit, TX motor drive circuit and verification stamp drive circuit. ICPs

protect various ICs and electronic circuits from an overcurrent condition.

The location of ICPs are shown below:

FO-DC635U

CONTROL PWB

(TOP SIDE)

1

CNSP1

2

1

CNSEN1

8

F1

CNCIS1

10 1

F2

27

F5 F100

228

CNPN1

1

CNSTP1

1214

CNTXM1

1) F1 (ICP-S0.5) F2 (ICP-S1.0) is installed in order to protect IC’s

from an overcurrent generated in the CIS unit. If F1 or F2 are open,

replace it with a new one.

2) F5 (ICP-S1.0) is installed in order to protect IC’s from an overcurrent generated in the panel PWB unit. If F5 is open, replace it with a

new one.

3) F100 (ICP-S1.0) is installed in order to protect IC’s from an overcurrent generated in the verification stamp drive circuit. If F100 is

open, replace it with a new one.

4) F101 (ICP-S1.8) is installed in order to protect IC’s from an overcurrent generated in the TX motor drive circuit. If F101 is open,

replace it with a new one.

F102

12 1

CNPW1

CNLIU1

F101

IC3

F1/F2/F5:Top side

F100/F101/F102:Bottom side

Fig.2

5) F102 (ICP-S0.7) is installed in order to protect IC’s from an overcurrent generated in the LCD drive circuit. If F102 is open, replace

it with a new one.

In addition to the replacement of F1, F2, F5, F100, F101 andF102

the factor causing F1, F2, F5, F100, F101 and F102 to open must

also be repaired. If not, F1, F2, F5, F100, F101 and F102 will open

again.

Replacement parts

ICP-S0.5 (Sharp code: VHViCPS05//-1)

ICP-S0.7 (Sharp code: VHViCPS07//-1)

CP-S1.0 (Sharp code: VHViCPS10//-1)

CP-S1.8 (Sharp code: VHViCPS18//-1)

3. Settings

3.1. Dial mode selector

OPTION SETTING: DIAL MODE (Soft Switch No. SW2 DATA No.1)

Use this to set the fax machine to the type of telephone line you are

on.

• The factory setting is "TONE".

(step 1) Select "OPTIONAL SETTING".

KEY:

DISPLAY:

(step 2) Select "DIAL MODE".

(step 2) Select "DIAL MODE".

KEY:

KEY:

DISPLAY:

DISPLAY:

(step 3) Select, using "1" or "2".

KEY:

DISPLAY: TONE SELECTED

KEY:

DISPLAY:

(step 4) End, using the "STOP" key.

KEY:

MENU 4

OPTIONAL SETTING MODE

2

2

2

2

22: DIAL MODE

22: DIAL MODE

1=TONE

2=PULSE

1

2

PULSE SELECTED

STOP

<With optional line unit>

22: DIAL MODE

1=LINE-1

2=LINE-2

Select line using "1" or "2"

KEY:

1

DISPLAY:

DIAL MODE(LINE-1)

1=TONE

KEY:

DISPLAY:

2=PULSE

2

DIAL MODE(LINE-2)

1=TONE

2=PULSE

2 – 2

Page 22

FO-DC635U

Press

, and

the

following

display will appear.

MENU

9 8

6

PCU ROM VER.:

(Diag¥specifications)

MENU

9 8 6

START

01

AREA PRINT MODE 1

START

02

CHECK PATTERN 1

START

03

CHECK PATTERN 2

START04

CHECK PATTERN 3

START05

CHECK PATTERN 4

START06

PAPER FEED AGING 1

START07

PAPER FEED AGING 2

START

START

08

BIAS ADJUST MODE2

START

09

LIFE SET MODE

START

START

Then press the

key. Select the desired item with the

key and the key or select with the rapid key.

Enter the mode with the key.

START10

LIFE ALL CLEAR

START11

LIFE ENTRY MODE

PCU ROM Ver.:

START12

LIFE CLEAR MODE

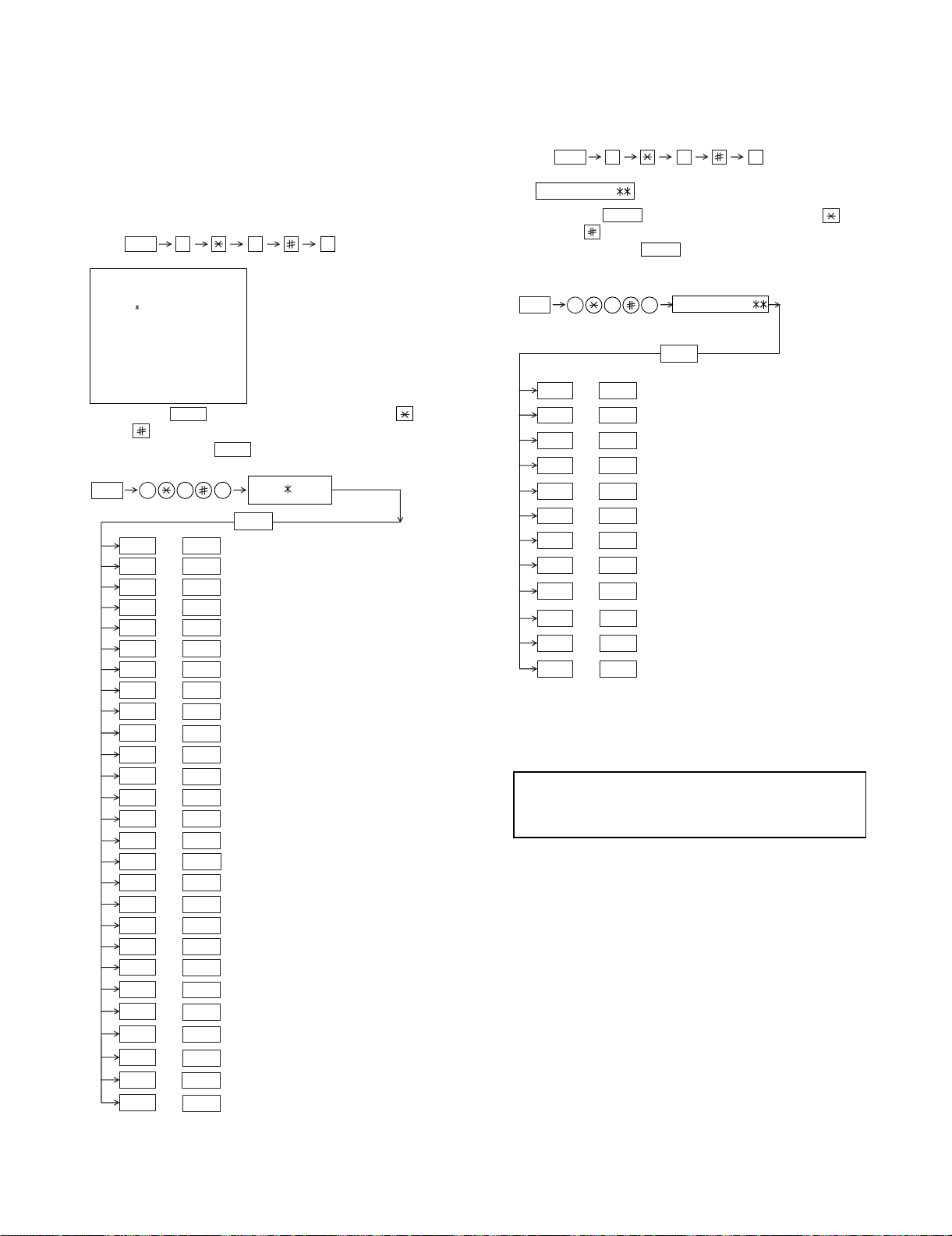

[2] Diagnostics and service soft switches

1. Operating procedure

Two kinds of diagnoses are supported.

1.1. Fax diagnosis

This diagnosis is concerned with the main body of fax which is used

for production and service support.

Entering the diagnostic mode

1.2. Print diagnosis

This diagnosis is concerned with the print which is used for production

and service support.

Entering the diagnostic mode

Press

MENU

9 8

display will appear.

FAX

:TF23

NIC:x.xxx

PRN:xxxx

PRN

MEMORY

GAA:ESx GAB:ESx

Then press the

SIZE=16(MB)

START

key. Select the desired item with the

and the key or select with the rapid key.

Enter the mode with the

(Diag

¥

specifications)

MENU

9 8 7

B PRINT AREA

C ROM & RAM CHECK

D AUTO FEEDER MODE

E AGING MODE

F PANEL CHECK MODE

G OPTICAL ADJUST MODE

H PRODUCT CHECK

I

J

K

L

M

N

O CONF. PASSCODE

P

Q

R

S

T

U

V

W

X

Y

Z

@

*: FONT LIST PRINT MODE can be used only when the

network function is effective.

START

STARTA SOFT SWITCH MODE

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

7

,and

1stLine

nd

2

Line

rd

3

Line F/W version

th

4

Line NIC board version

th

5

Line PCL board version

th

Line

6

th

7

Line Memory size

th

8

Line GATE arrayA/B version

th

9

Line

key.

TF23

START

SIGNAL SEND MODE

COMM. CHECK MODE

MEMORY CLEAR MODE

FLASH MEMORY CHECK

ALL FAX/TEL. ENTRY MODE

DEPT. PASSCODE

SIGNAL SEND MODE 2

MEMORY SET MODE

STAMP AGING MODE

DIAL TEST MODE

COPY DIAG MODE

LCD CHECK MODE

PERSONAL BOOK LIST

FONT LIST PRINT MODE(*)

NO FUNCTION

NO FUNCTION

ADMIN PASSWORD

PRINT HOLD CODE

the

following

key

Memory clear when power is turned on

Pressing the STOP keys, turn on the main power, and the following

message will be displayed.

MEMORY CLEAR ?

1 = ALL , 2 = IMAGE , 3 = NO

1 = All the data will be deleted including initially registered data.

2 = Delete the image file to be used in transmission. This will delete all

the data related to communication such as reserved transmission or

intercepting. However, the data initially registered will not be deleted.

3 = Memory will not be cleared and the machine enters stand-by

mode.

2 – 3

Page 23

2. Diagnostic items description

ROM SRM DRM1 DRM2

••••

ROM SRM DRM1 DRM2

PPP E

Display during check Display after check

P=PASS E=ERROR

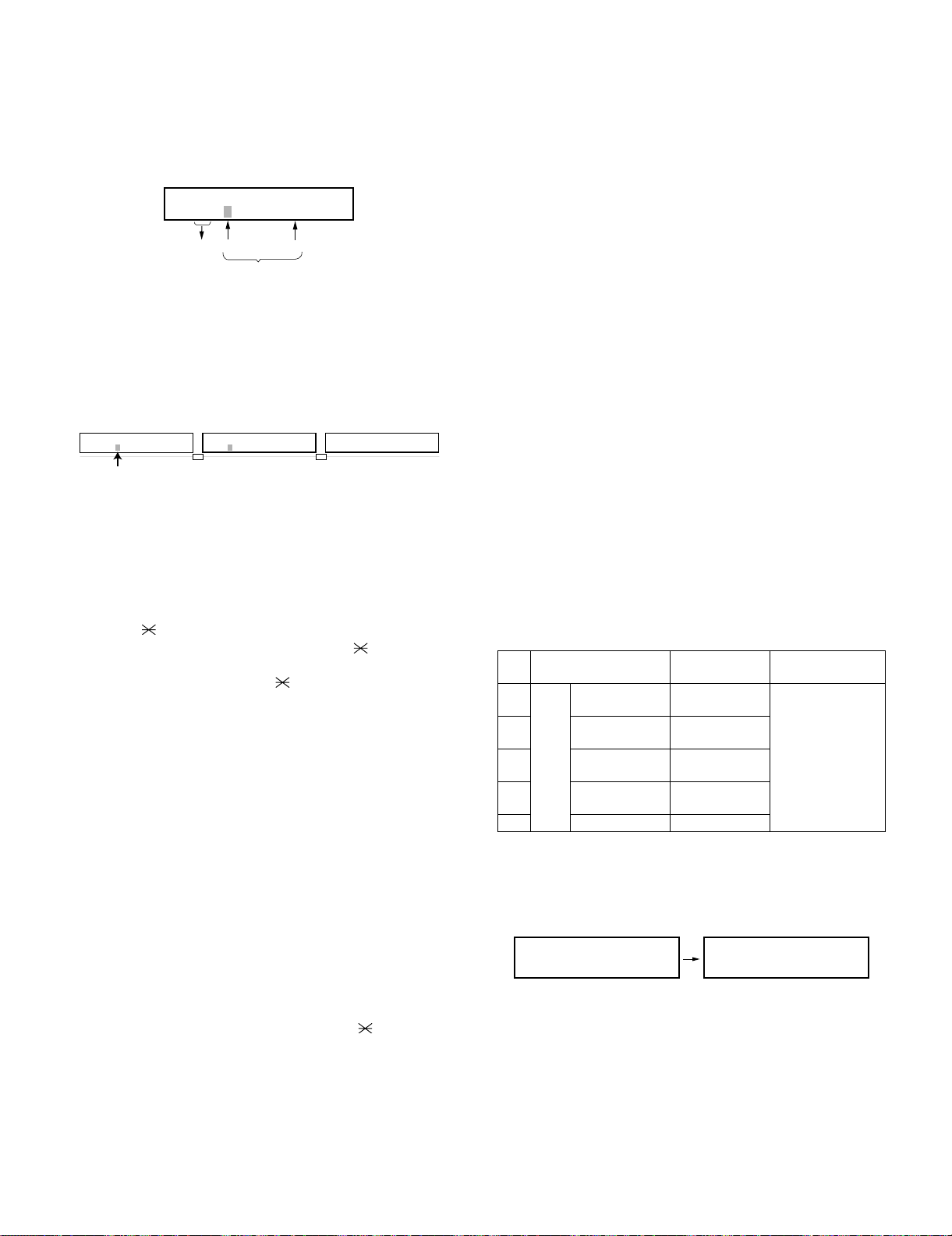

2.1. Fax diagnosis

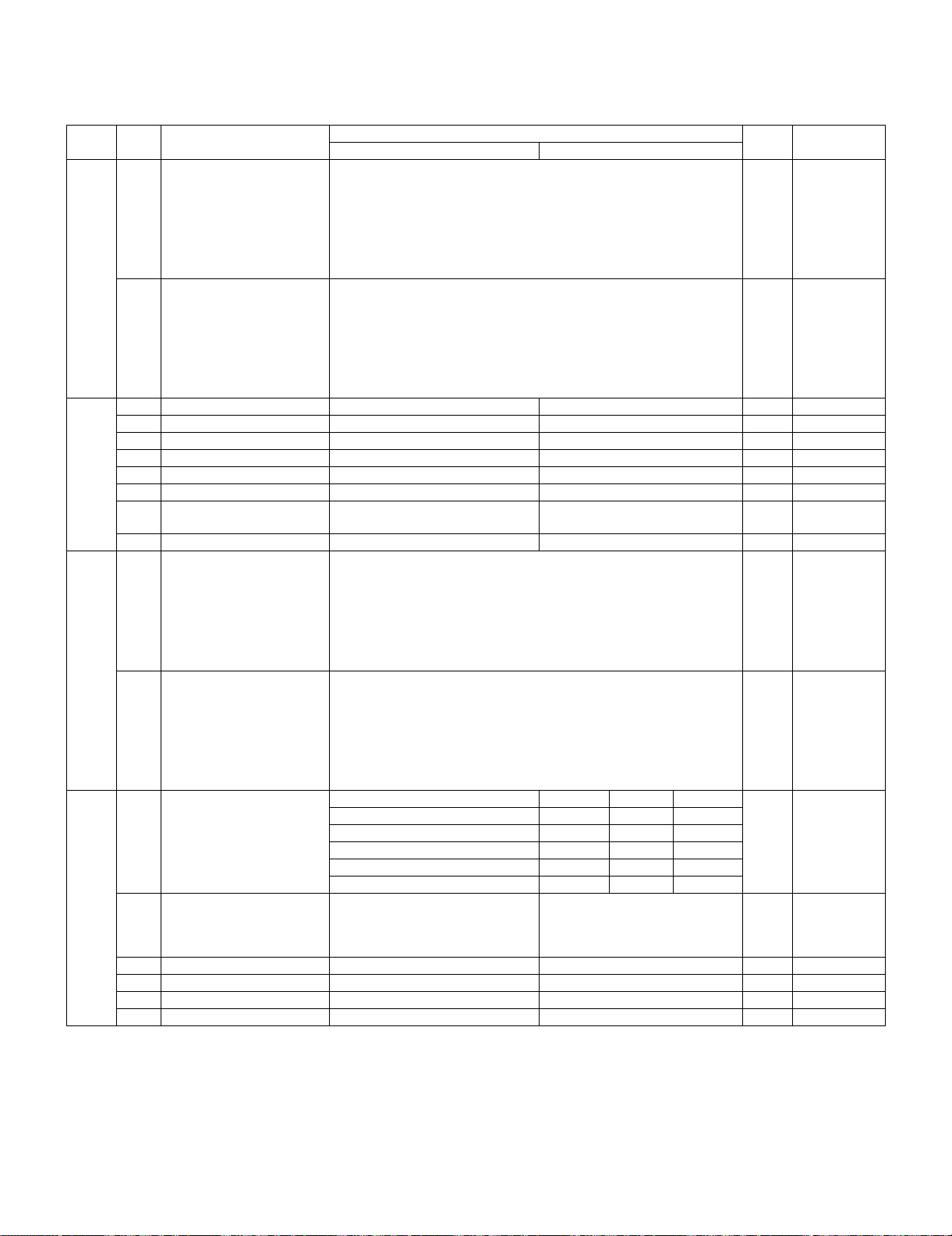

2.1.1 (A) Soft switch mode

In this mode, the soft switch are set and the soft switch list is printed.

Soft switch mode screen

SOFT SWITCH MODE

SW01=00000000

1234567 :DATA No.

Switch

No.

1. Switch number selection

• Press START key for setting of the next soft switch. If the soft

switch number is the final, pressing START key will exit the soft

switch mode.

• Enter two digits of a soft switch number to set the switch number. If a switch number of nonexistent soft switch is entered, key

error buzzer sounds to reject the input.

SOFT SWITCH MODE

SW01=00000000

Cursor

1 6

2. Data number selection

The cursor position shows the data to be set.

Pressing # key or → key moves the cursor to the right. If, however,

the cursor is on data number 8, pressing # key or → key shifts the

cursor to data number 1 of the next switch number. If the switch

number is the final, pressing # key or → key will exit the soft switch

mode.

Pressing key or ← key moves the cursor to the left. If, how-

ever, the cursor is on data number 1, pressing key or ← key

shifts the cursor to data number 1 of the former switch number. If

the switch number is 1, pressing key or ← key will not move

the cursor and the error buzzer will sound.

3. Data setting method

Press the MENU key, and the data at the position of the cursor will

be reversed to 0 when it is 1, or to 1 when it is 0. (If the soft switch

can be changed at the bit (Refer to 6.), the error buzzer will sound

with the process not received.)

4. Outputting method of soft switch list

In the soft switch mode, press the REPORT key, and the soft switch

list will be output.

If the recording paper runs out or is clogged, the key error buzzer

will sound with the process not received.

5. Storage of data

In the following case, the data of the soft switches set will be

stored.

• It is shifted to set the next soft switch by pressing the START

switch.

• It is shifted to set the next soft switch with the [#] key.

• It is shifted to set the last soft switch with the [ ] key.

• It is shifted to set another soft switch by inputting two digits as

the switch number. (When 2 digits are completely input.)

• Output of the soft switch list is started.

6. Inhibition of data change

(This is also applicable for the optional setting.)

In the following case, it is inhibited to change the data with the key

error buzzer.

Data

ENTER LAST DIGIT

SW1

8

SOFT SWITCH MODE

SW16=00010110

FO-DC635U

• Switching ON/OFF of ECM during the use of image memory.

• OFF to ON of telephone billing function which is using the image

memory is used (Note: In the existing set, the telephone billing

code function is specified from OFF to ON when the timer system communication (including the batch communication) is set.)

Here, the memory is usable when the telephone billing code

function is on. It can be set from ON to OFF while the memory is

used. However, if setting is practically changed even once, it

can not be returned from OFF to ON.

• OFF to ON of department control function during use of image

memory.

(Note: In the existing set, the department control function is set

from OFF to ON when the timer communication (including the

batch sending) or the memory hold is set.)

• ON to OFF of continuous serial polling function when the continuous serial polling is started.

(Note: In the existing set, "ON to OFF of the continuous serial

polling function when the continuous serial polling is registered"

has been applied, but the conditions are now moderated. However, registration is impossible to the program of the new continuous serial polling when the continuous serial polling function is

OFF.)

• In addition, change of all soft switches during communication.

2.1.2 (B) Print area

According to the size of the specified sheet, the effective printing area

is printed.

2.1.3 (C) ROM & RAM check

This is an item to check if the loaded memory device acts normally.

• The memory devices shown in the following table are checked.

• In case that an error occurs in the device check, the alarm buzzer

shown in the table sounds.

Check device and alarm buzzer

No. Device checked Number of

1

ROM (PROGRAM FLASH)

2 SRAM <Short sounds>

3 D-RAM1 (*1) <Short sounds>

Main

4 D-RAM2 (*2) <Short sounds>

5— —

*1: Work memory (SDRAM 8MB)

*2: Page memory (SDRAM 16MB)

(Example of display) In case that DRAM2 is erroneous.

• After the check is complete, the result is outputted.

• In case that an NIC and a PCL board are mounted, the version

information of the board is also printed on the result.

2 – 4

buzzer sound

<Short sound>

1 time

2 times

3 times

4 times

<Short sound>:

0.5 sec.ON / 0.5

sec.OFF

<Long sounds>:

1.0 sec.ON / 0.5

sec.OFF

Remarks

Page 24

FO-DC635U

2.1.4 (D) Auto feeder mode

By executing the document insertion and discharge, the automatic

feeding function can be checked. And the document sensor can be

checked as well.

1. Set the document

Before pressing the “START” key, only the document sensor check

is carried out. And as the document sensor is ON, the document

size (A4/B4) and the sensor information (A4/B4/ORG) are displayed.

AUTO FEEDER MODE

()

After setup of the document

AUTO FEEDER MODE

B4 (A4 B4 ORG)

Only the sensor which is

activated (fallen down) is displayed.)

The paper sheet size (A4/B4) is

displayed.

2. The automatic feeding starts by pressing the “START” key. This

mode ends when the document ends, and the result is printed.

2.1.5 (E) Aging mode

This is a mode to execute the copying action and the check pattern

printing action once every 60 minutes and continue the action until 10

sheets are outputted in total.

1. The printing action on the 1st sheet starts by pressing down the

“START” key and entering the mode. When document is set at the

time of the mode start-up the copy action is carried out, and when

the document is not set the “check pattern 1” of the print dialog is

printed.

2. The number of printouts is displayed after printing.

2.1.6 (F) Panel check mode

This is to check that each key acts normally and this is displayed on

the LCD according to the key input. And during execution, the document reading lamp is ON. After inspection start, the LEDs light on

sequentially. At the mode end with the “STOP” key, all of them go OFF.

As to the test result, it is printed out after the mode end.

When the “NUMERIC” key is pressed during the panel check execution, sending of the DTMF signal corresponding to the key starts, and

when another key is pressed sending of the DTMF signal stops.

(Softswitch change is required. SW80 No.6: 0 →1)

• After inputting all the keys, input the “STOP” key at last, and then

the result is displayed.

a) In case that all the keys are pressed.

PANEL CHECK MODE

ALL KEY OK !!

• Until the STOP key is pressed, all black 4-split sequential display is

performed.

• After the mode end, the test result is printed.

b) In case that there is a key that is not pressed.

2.1.7 (G) Optical adjust mode

The optical system is adjusted.

• By pressing down the “START” key, the document reading lamp

“100%: ON” is turned ON.

2.1.8 (H) Product check

This is a dialog used in the production process and a mode to execute

a specific mode in the series of the flow. After the mode end, the rest

result as to the checked items is printed.

• After moving to the mode, the following actions are sequentially

executed.

1. Memory clear (Same as Diagnosis K)

2. Panel check (Same as Diagnosis F)

3. ROM & RAM test check (Same as the Diagnosis C)

4. Test result print

Memory clear printing

Panel check result printing

ROM & RAM test result printing

5. Print area (The specification of each item is the same as the specification of the simple mode.)

2.1.9 (I) Signal send mode

It can be used to check the modem. When the START key is pressed,

silence signal (make loop) will be executed. The following signals are

sent by pressing the START key thereafter.

[1] No signals (mark loop) [9] 9600bps (V. 29)

[2] 4800bps (V27ter) [10] 7200bps (V. 29)

[3] 14400bps (V. 33) [11] 4800bps (V.29ter)

[4] 12000bps (V. 33) [12] 2400bps (V.29ter)

[5] 14400bps (V. 17) [13] 300bps (FLAG)

[6] 12000bps (V. 17) [14] 2100Hz (CED)

[7] 9600bps (V. 17) [15] 1100Hz (CNG)

[8] 7200bps (V. 17)

2.1.10 (J) Comm. check mode

1. Turn on the Line Monitor. (SW7 No.7, SW29 No.7)

2. Turn off the Cover Sheet Function. (SW2 No.6, SW24 No.6)

3. Set Line Equivalence at 0 km. (SW8 No.1/No.2, SW30 No.1/No.2)

4. Set the copy cut off mode (SW75 No.2) to “Continue”

5. Set the ringer volume (SW62 No.5/No. 6) to OFF.

After the check, it is necessary to be sure to return the afore mentioned soft switches into the initial state. (Clear the memory with the

diagnosis.)

2.1.11 (K) Memory clear mode

Clear the back-up memory to initialize the soft switches. The Flash

Memory will be initialized. Then, the initialized list be output.

1. Memory clear is executed.

2. The result that says initialized is printed.

NOTE: The life counter, and the adjustment values of the top void and

the large LCD contrast are not cleared.

PANEL CHECK MODE

KEY ERROR !!

• Until the STOP key is pressed, all black 4-split sequential display is

performed.

• After the mode end, the test result is printed.

2 – 5

Page 25

2.1.12 (L) Flash Memory check

This is a mode to check that the flash memory acts normally. The flash

memories shown in the following table are checked.

No. Flash memory Number of

buzzer sound

1NQR-Flash

(Standard)

2 NAND-Flash

(Standard)

3 NAND-Flash

(Option)

4— —

5— —

• NAND-Flash (optional) is valid only when the optional memory is

mounted.

1. The NOR flash memory test is executed.

NOR FLASH CHECK

S -———————E

2. The concerned alarm buzzer sounds only when the error occurs.

3. The NAND flash memory test is executed.

NAND FLASH CHECK

S -———————E

4. The concerned alarm buzzer sounds only when the error occurs.

5. The result is printed.

NOTE: • During operation of this diagnosis, dual operation is not

possible at all.

• If this is excessively repeated, it will shorten the life of the

flash memory.

<Long sound>

1 time

<Long sounds>

2 times

<Long sounds>

3 times

Remarks

<Short sound>:

0.5 sec.ON / 0.5

sec.OFF

<Long sounds>:

1.0 sec.ON / 0.5

sec.OFF

2.1.13 (M) All FAX/TEL. entry mode

This is a function to copy the FAX and TEL numbers registered in the

one-touch dialing (RAPID) key [01] to the all one-touch dialing

(RAPID) key and the all abbreviated number (SPEED DIAL) to simplify

the FAX and TEL number registration at the time of aging. (Only the EMAIL can be used for the network models.)

1. Copy the FAX/TEL number or the E-MAIL stored in the RAPID key

[01] to all RAPID keys.

2. Copy the FAX/TEL number or the E-MAIL stored in the RAPID key

[01] to all SPEED DIAL numbers.

3. If the chain dial is not set for the RAPID key, or RAPID key [01]

stores the E-MAIL, the RAPID keys [02] – [59] and all SPEED DIAL

numbers are stored in the group number [01].

4. Enter all registered one-touch send (RAPID) keys and speed dial

numbers (SPEED DIAL) on the personal books [01] - [10]. Following this, set the password registration and the password setting to

ON, and set the TTI setting to OFF.

The call-receiver names and book names are specified as follows:

Rapid R XX XX : Rapid key send

SPEED DIAL S XXX XXX : Speed dial number

Personal book BOOK XX XX : Book number

FO-DC635U

NOTE: Before entering this mode, a FAX/TEL number or an E-MAIL

must be stored in the RAPID key [01]. (This program will not

be executed if there is no data stored, or otherwise a program

or a group is registered.)

2.1.14 (N) Dept. passcode

The department passcode list is printed.

2.1.15 (O) Conf. passcode

The confidential passcode list is printed. Differing from printing of one

box alone soon after registration, the confidential passcodes of all

boxes are printed.

2.1.16 (P) Signal send mode 2

The signals concerned with V.34 & V.8 are checked. It can be used to

check the modem. When the START key is pressed, silence signal

(make loop) will be executed. The following signals are sent by pressing the START key thereafter.

[1] No signals (mark loop) [10] 14400BPS (V. 34)

[2] 33600BPS (V. 34) [11] 12000BPS (V. 34)

[3] 31200BPS (V. 34) [12] 9600BPS (V. 34)

[4] 28800BPS (V. 34) [13] 7200BPS (V. 34)

[5] 26400BPS (V. 34) [14] 4800BPS (V. 34)

[6] 24000BPS (V. 34) [15] 2400BPS (V. 34)

[7] 21600BPS (V. 34) [16] 0 - 300BPS (V. 34)

[8] 19200BPS (V. 34) [17] ANSam

[9] 16800BPS (V. 34)

2.1.17 (Q) Memory set mode

The set and dump list of the memory content is output.

MEMORY SET MODE

AD = 00000000

Cursor

• The address (8 digits (P) generally including the bank information is

input, and the data of 2 digits is continuously input. Inputting is

done in the hexadecimal mode. The ten-key is used for 0 through

9, and the alphabetic keys A (RAPID 01 through 06) are used for A

through F.

MEMORY SET MODE

AD = A02800F6 DATA = 0B

• During data inputting, the address can be moved forward and back-

ward one byte by one byte with " " and "#". (The address prior

to the address 0 is looped as the maximum address.)

• The Validity of the address is not checked. Accordingly, writing/

reading operations are possible in the address of the memory not

assigned, the address of ROM and so on. (However, as practical,

writing is not done, and the data content runs short each reading.)

Though writing is possible in the flash memory, a little time is

required. It is also necessary to take care that the life of the flash

memory is excessively shortened if much data is written in the flash

memory. Since it may run away depending the written content, take

minute care for the writing address.

(The letters after 16th letter of the call-receiver’s name registered in

the one-touch dialing [01] are cut off.)

2 – 6

Page 26

FO-DC635U

U:LCD CHECK MODE

1=CONT.ADJ 2=TEST DISP

CONTRAST=-9 TEMP=+25

A

HHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHH

• When the REPORT key is input, the memory dump list is produced

from the displayed address (here, it is limited at the 16-byte boundary address (address with end 0) which does not exceed the specified address and is just in front.). The dump list is output to a maximum of 99 pages. If any data of one page can be repeatedly developed and printed, the list is sufficient. But it is not desired that the

content of plural pages are developed in the memory once and are

then printed. If the STOP key is pressed, it will pass to the diagnosis after the page which is now being printed is completed printed.

If the address exceeds the maximum address, it will return to the

address 0 and printing will be continued.

2.1.18 (R) Stamp aging mode

This is a mode to execute the continuous drive aging of the Verification

stamp.

1. Set the document and press down the “START” key and the continuous drive of the Verification stamp starts.

2. Send the document at the interval of 10 mm and stamp the Verification stamp continuously. The total number of times of Verification

stamp printing after entering this mode is displayed on the display.

• Displayed screen during execution.

STAMP AGING

TIMES = 13 PAGES = 1

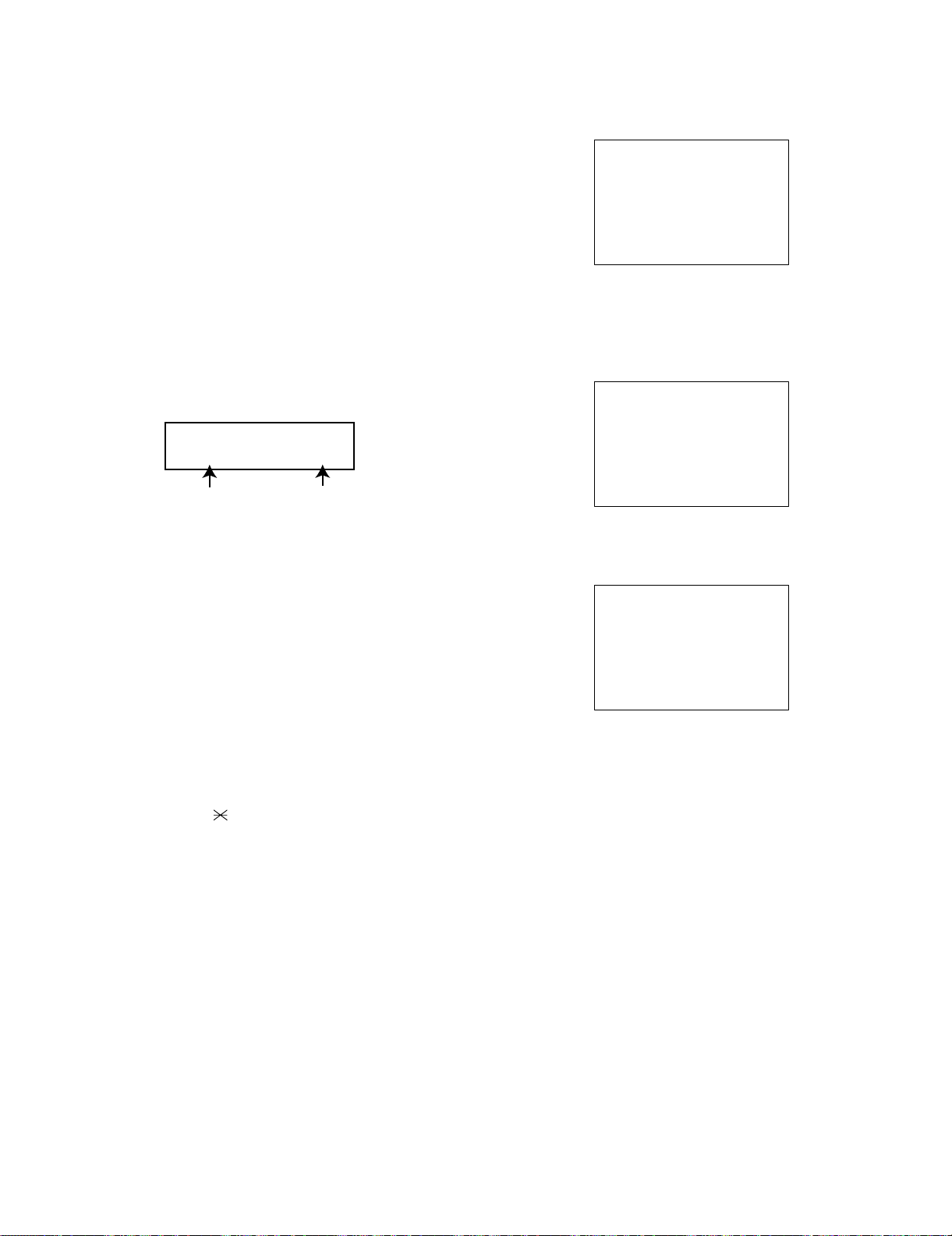

2.1.21 (U) LCD check mode

This is an item to check that the LCD acts normally.

1. The screen for selecting the contrast adjustment mode and the “H”

display mode appears.

2. Select the mode using the “←” or “→” keys or otherwise dial keys

“1” or “2”.

[When the contrast adjustment mode is selected]

3. Adjust with the “←” or “→” keys so that both right and left halves of

the “A” can be recognized.

Print total number

of times

3. By pressing down the “STOP” key during the action, or when no

more document is left, the continuous drive of the Verification

stamp stops.

NOTE: • In case that the document is not set, this cannot be exe-

cuted.

• The normal action aging that one Verification stamp is

pressed on one sheet of document is executed in the normal copying.

2.1.19 (S) Dial test mode

The mode is used to inspect whether dialing is accurate in two kinds of

dial modes. All data which can be dialed in this mode are automatically

called up in both PB mode and DP mode.

[In case that 2 line optional is not mounted.]

1. Turn on CML, and dial the following in the PB mode.

1, 2, 3, 4, 5, 6, 7, 8, 9, , 0, #

2. Dial the following in the DP mode.

1, 5, 9, 0

3. After dialing, turn off CML.

NOTE: This mode uses the ordinary auto dial. (Accordingly, the signal

sending time and minimum pause are all the same as ordinary. The

measurement result in this mode is completely all the same as in the

ordinary dial mode.)

2.1.20 (T) Copy diag mode

This mode is for automatic mode selection of copy to reduce the time

for treatment at the time of production.

1. Set 2 sheets of document. (No problem if there are 2 sheets or

more.)

2. 3 sheet continuous copy:

1st sheet in the FINE AUTO

2nd sheet and after that are copied in the H-TONE DARK.

NOTE: Input of the image quality and the darkness keys is invalid in

this mode.

Page number

[When the “H” display mode is selected]

4. Turn on the backlight so that the whole screen shows “H“. (26 letters x 9 lines)

2.1.22 (V) Personal book list

The PASSCODE of the personal book 00 to 10 are output.

2.1.23 (W) Font list print mode [Only when network func-

tion is mounted]

The font list that can be used in the network function is printed.

2.1.24 (X) No function

2.1.25 (Y) No function

2.1.26 (Z) ADMIN PASSWORD

Print the admin password.

2.1.27 (@)Print hold code

Print the pass code of PRINT HOLD.

2 – 7

Page 27

2.2. Print diagnosis

2.2.1 Rapid key 01: Area print mode 1

The effective printing area frame is printed in the specified sheet size.

1

2

3

4

5

6

7

8

The data pattern used here are as follows and 1 data 30 mm is printed.

1. [Full black pattern]

2. [Intermediate tone 2 pattern]

The left pattern is repeated.

3. [Intermediate tone 1 pattern]

The left pattern is repeated.

4. [Mesh point pattern]

The left pattern is repeated.

FO-DC635U

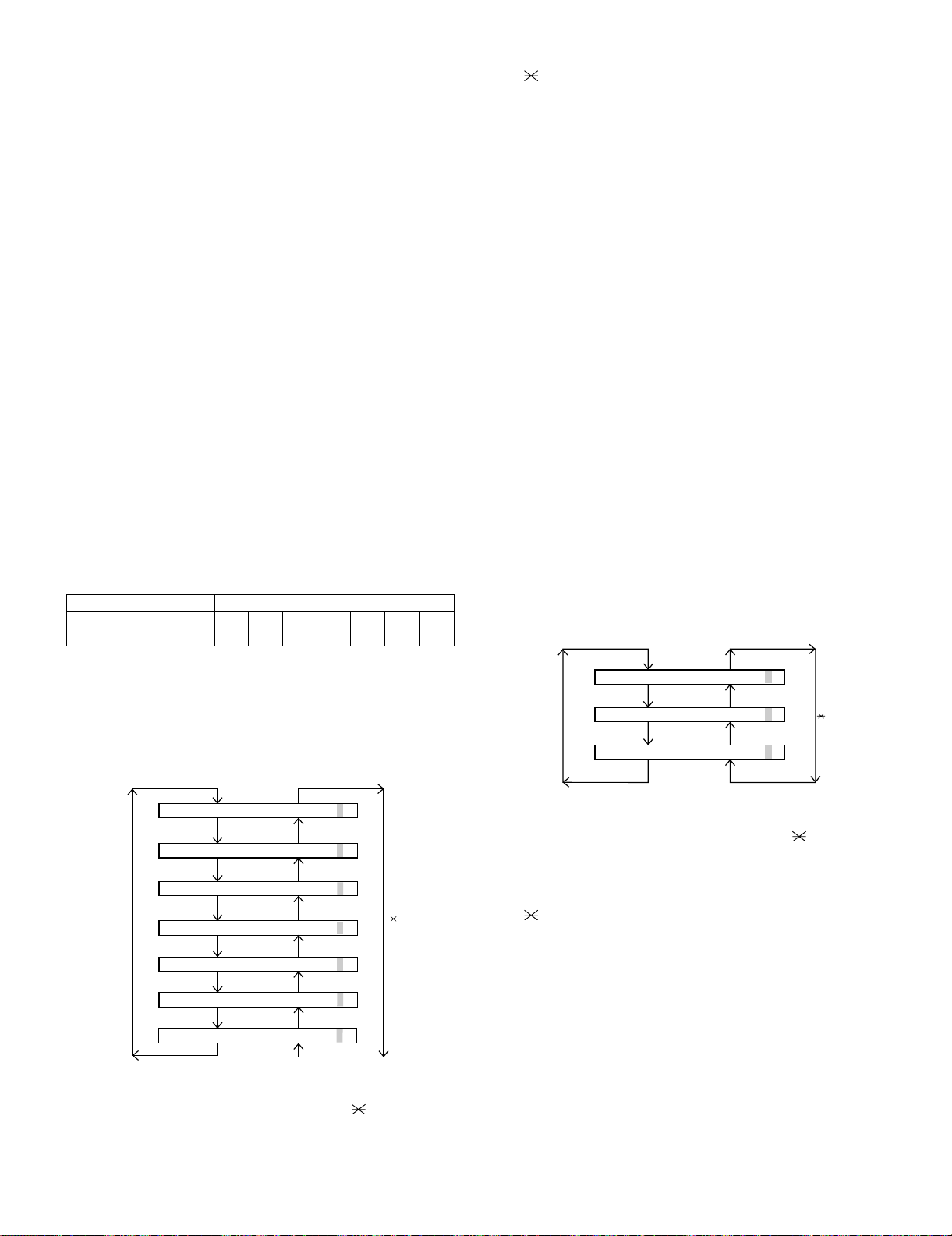

2.2.2 Rapid key 02: Check pattern 1

The lateral stripe 2 pattern is printed on one sheet.

(Black 2 line and white 2 line are repeated.)

2.2.3 Rapid key 03: Check pattern 2

The lateral stripe 2 pattern is printed on multiple pages.

Press the STOP key to end the printing.

2.2.4 Rapid key 04: Check pattern 3

The intermediate tone 1 is printed on one sheet.

2.2.5 Rapid key 05: Check pattern 4

In this mode, 1 sheet is printed as to the square frame pattern for the

skew measurement.

2.2.6 Rapid key 06: Paper feed aging 1

The mode is used for aging related to the printing. In this mode, the following modes are provided.

1. Blank paper aging mode (ALL WHITE AGING)

2. Whole black print aging mode (ALL BLACK AGING)

3. 5% printing aging mode (5% AGING)

4. 4% printing aging mode (4% AGING)