Page 1

SERVICE MANUAL

No. 00ZFO5500USME

FACSIMILE

MODEL FO-5500

FO-5500U/C

This service manual FO-5500U/C is applied to the optional type (FO-45UC) equipped with the 3rd transport unit of FO6500U/C. The performance and operation are not different from the old ones. Since only the areas which are changed

from those of FO-6500U/C are described, use the existing service manual (00ZFO6500USME) of FO-6500U/C together

for the other areas.

CAUTION

This laser printer is a class 1 laser product that complies with 21CFR 1040.10 and 1040.11 of the CDRH standard. This means

that this machine does not produce a hazardous laser radiation. The use of controls, adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This laser radiation is not a danger to the skin, but when an exact focusing of the laser beam is achieved on the eyes retina, there is

danger of spot damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time of servicing.

1) When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged as a unit, not an individual part.

2) Do not look into the machine with the main switch turned on after removing the toner/developer unit and drum cartridge.

3) Do not look into the laser beam exposure slit of the laser optical unit with the connector connected when removing and installing

the optical system.

4) The cover of Laser Printer Unit contains the safety interlock switch.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot.

Laser Wave Length : 770-810 mm

Laser Pulse Times : 49.2 µs

Laser Output Power : 0.5 mW

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

FO-5500U/C

CONTENTS

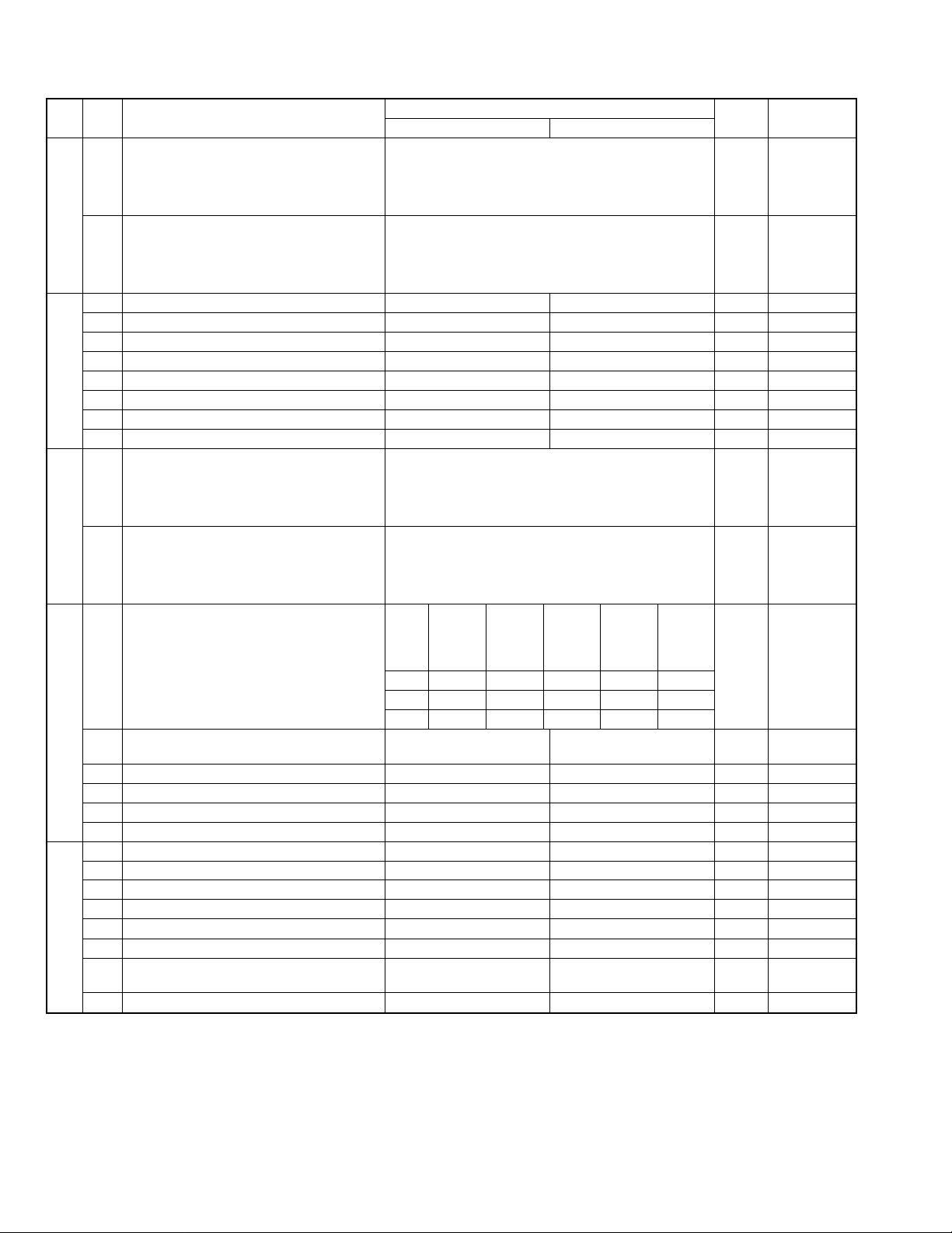

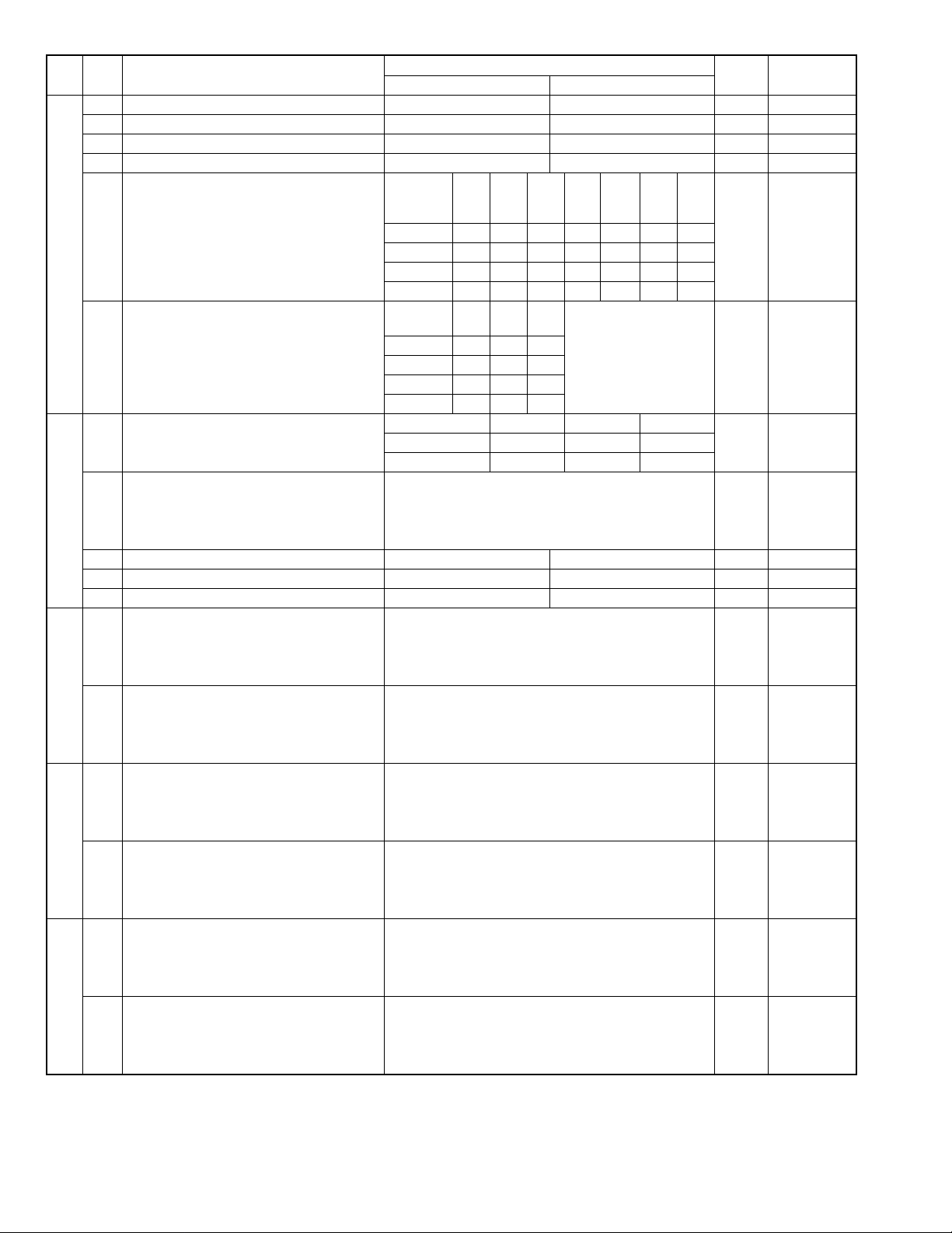

CHAPTER 1. GENERAL DESCRIPTION

[1] Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

[3] Transmittable Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

[4] Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

[5] Quick reference guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

CHAPTER 2. ADJUSTMENTS

[1] Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[2] Diagnostics and service soft switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

[3] Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

[4] Error code table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

CHAPTER 4. DIAGRAMS

[1] Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[2] Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

[3] Point to point diagram and connector signal name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

CHAPTER 6. CIRCUIT SCHEMA TICS AND PARTS LA YOUT

[1] Control PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[2] TEL/LIU PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

[3] Power supply PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

[4] Operation panel PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

[5] CCD PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

[6] RS232C I/F PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

[7] Printer control PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

PARTS GUIDE

Note: Since the following contents are the same as those of the base model FO-6500U/C, refer to the Service

Manual for the base model FO-6500U/C.

CONTENTS

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Mechanical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[2] Printer description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

[3] Disassembly/assembly procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[2] Circuit description of control PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[3] Circuit description of TEL/LIU PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

[4] Circuit description of CCD PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

[5] Circuit description of operation PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

[6] Circuit description of power supply PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

[7] Circuit description of RS232C I/F PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

CHAPTER 7. OPERATION FLOWCHART

[1] Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[2] Power on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

CHAPTER 8. OTHERS

[1] Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[2] IC signal name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Page 3

CHAPTER 1. GENERAL DESCRIPTION

[1] Specifications

FO-5500U/C

• GENERAL

Applicable telephone

line:

Compatibility: ITU-T (CCITT) G3 mode

Configuration: Half-duplex, desktop transceiver

Compression scheme: MH, MR, MMR and Sharp special mode

Memory size*: 1 MB (approx. 50 average pages)

Memory option: 1 MB/2 MB/4 MB Flash Memory

Scanning method: Flat-bed, solid-state CCD

Resolution: Horizontal:

Printing density: Horizontal:

Reception modes: Auto/Manual switching

Modem speed: 14400 bps with automatic fallback to

Transmission time*: Approx. 6 seconds

Input document size: Automatic feeding:

Paper size: Width – 8.5" (216 mm)

Paper capacity: 650 sheets

Automatic document

feeder:

Public switched telephone network/PBX

203 lines/inch ( 8 dot s/m m )

Vertical:

Standard – 98 lines/inch (3.85

lines/mm)

Fine/Halftone – 196 lines/inch (7.7

lines/mm)

Super fine – 392 lines/inch (15.4

lines/mm)

406 lines/inch (16 lines/mm)

Vertical:

391 lines/inch (15.4 lines/mm)

12000, 9600, 7200, 4800, or 2400 bps

(Sharp special mode)

Width – 5.8 to 10.1" (148 to 256 mm)

Length – 5.0 to 14.3" (128 to 364 mm)

Manual feeding:

Width – 5.8 to 11.0" (148 to 280 mm)

Length – 5.0 to 17.0" (128 to 432 mm)

Length – 11-14" (280-356 mm)

50 documents max.

Effectiv e sc ann ing wi dth: 10.1" (256 mm)

Effective recording width: 8.0" (203 mm)

Copy function: Single/Multi-copy/Sort-copy

(99 copies/page)

Telephone function: Standard (cannot be used if power

fails)

Halftone (gray scale): 64 levels

Power requi rement s : 120 V AC, 60 Hz

Oper ating environment: 50-86°F (10-30°C), 20 to 85% RH

Power consumptio n: Stand-by: 10 W at AC 120 V

Maximum: 400 W at AC 120 V

Dimensions: Width: 13.8" (351 mm)

Depth: 22.9" (582 mm)

Height: 13.7" (349 mm)

Weight: Approx. 40.8 lbs. (18.5 kg)

• PRINTER SECTION

Type: Desktop, Laser Beam Printer

Print syst e m: Electrostatic Dry Powdered Imaging

System

Exposure system: Laser Diode + Polygon Mirror

Scanning

Resolution: Horizontal: 406 (dot/inch)

Vertical: 391 (dot/inch)

Print speed: 6 pages per minute (A4 size paper)

First print time: Within 19 seconds (face down)

Warming-up time: Within 40 sec.

Oper ating environment: Temperature: 10-30˚C

Humidity: 20-80%RH

Toner cartri d ge life: 3,000 prints or more (when black-to-

white ratio on print is 5% or less)

Drum cartridge life: 20,000 prints or more (when black-

to-white ratio on print is 5% or less)

* Based on ITU-T (CCITT) Test Chart #1 at standard resolution in

Sharp special mode, excluding time for protocol signals (i.e., ITUT phase C time only).

<IMPORTANT PLEASE READ FIRST>

To avoid problems with supplies, please don’t use supplies from other units. Please use new supplies, when supply changes are required.

1 – 1

Page 4

FO-5500U/C

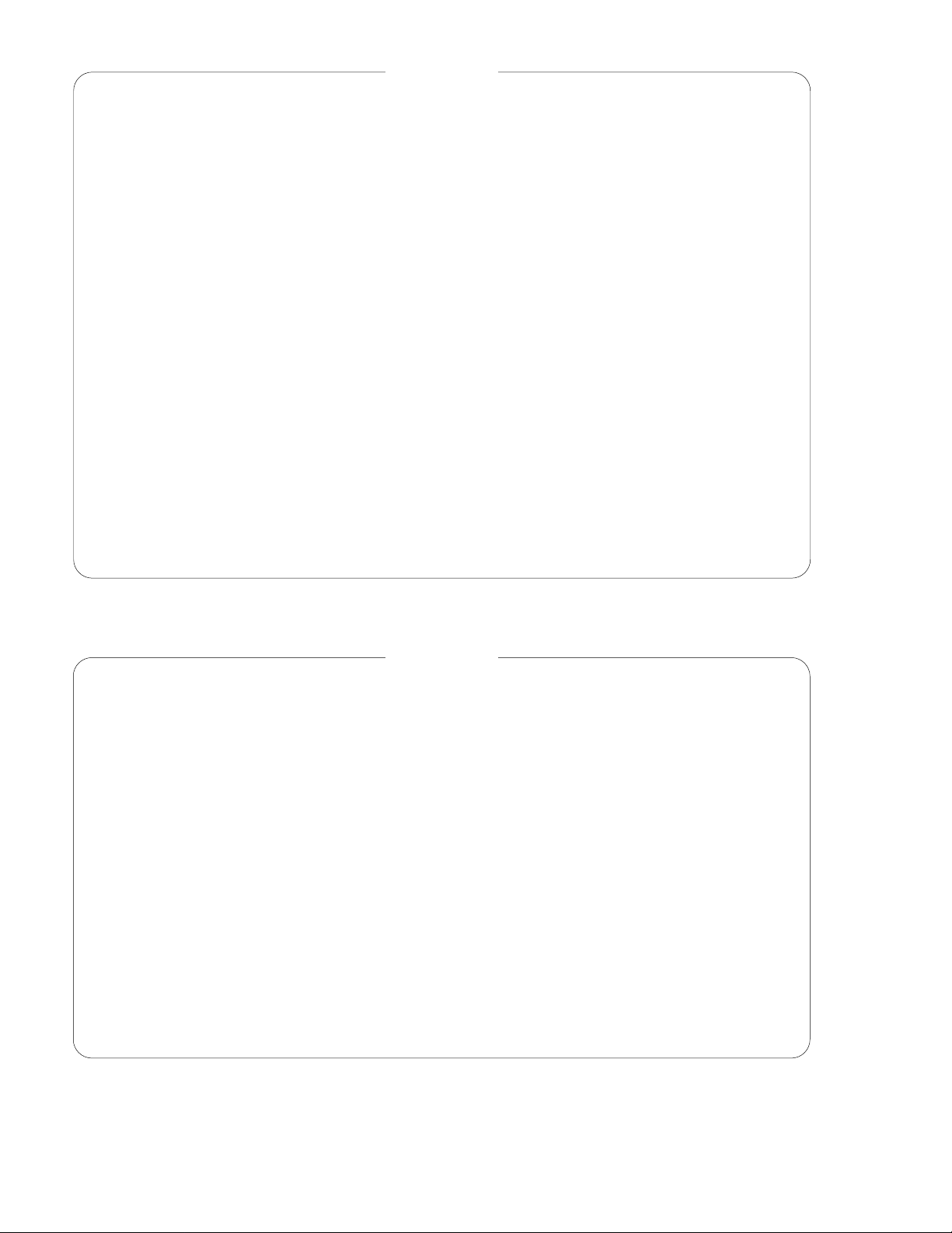

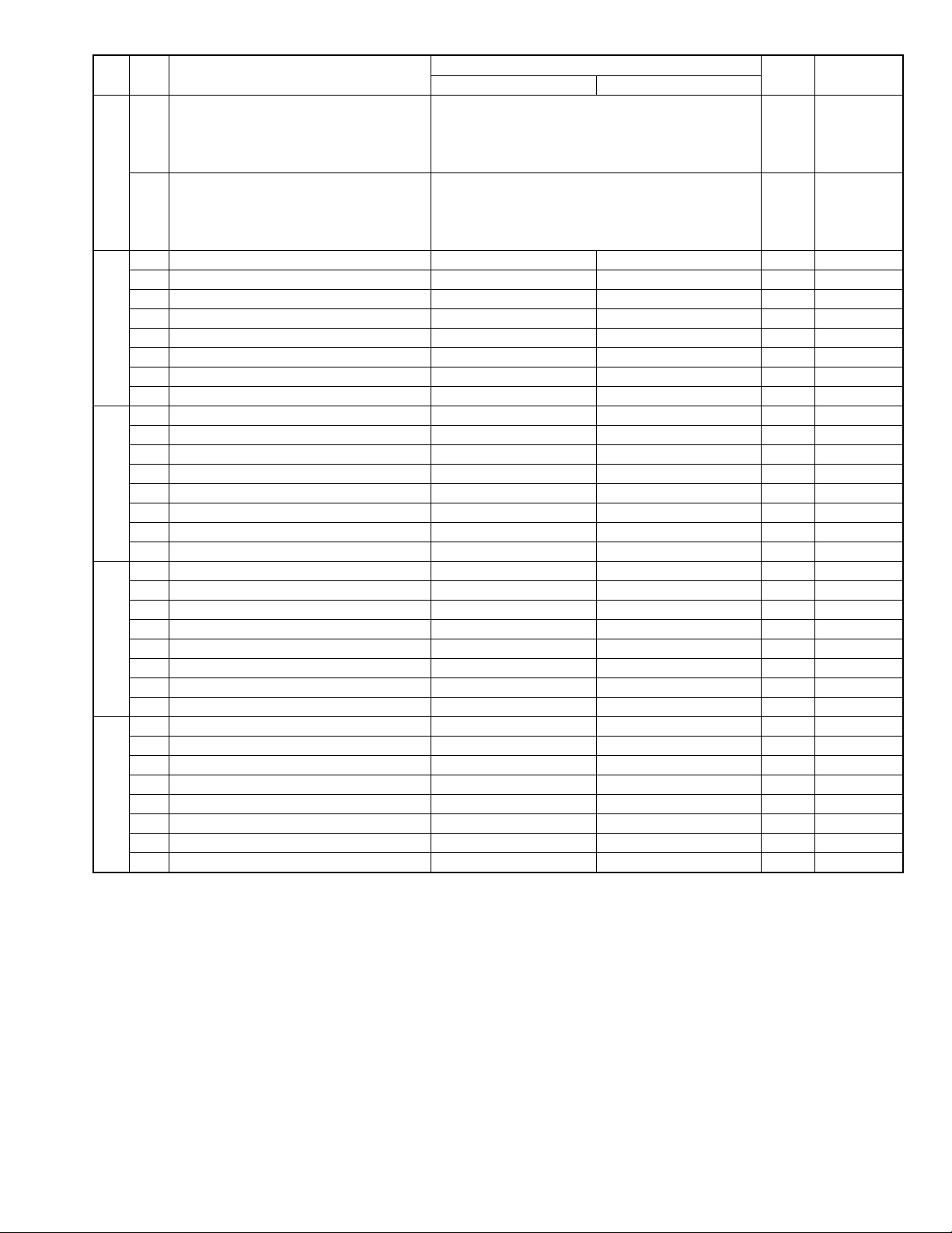

[2] Operation panel (1)

LINE STATUS light

This lights when the fax machine

is using the telephone line.

Display

This displays various

messages during

operation and

programming.

Service indicator

This lights when a

problem occurs which

must be fixed by a

service engineer.

Drum cartridge indicator

This blinks when the drum

cartridge nears the end of

its life, and lights steadily

when the drum cartridge

needs replacement.

CHANGEOVER key

Two types of information appear in the display: prompts related to

operations you are performing, and information about how the fax

is using the telephone line (transmitting, receiving, etc.). Press this

key to switch between the two types of information.

Toner cartridge indicator

This blinks when toner nears

empty, and lights steadily

when the toner/developer

cartridge needs replacement.

LINE-STATUS RESOLUTION

IN USE STANDARD

FINE

SUPER FINE

HALF TONE

CHANGEOVER

Paper out indicator

This blinks when one of the

paper sources (cassette) is out

of paper, and lights steadily when

all sources are out of paper.

RESOLUTION key

Press this key to

adjust the resolution

before sending or

copying a document.

SPEED DIAL key

Press this key to dial

a Speed Dial number.

Telephone dial keypad

(numeric keys)

Use these keys to dial

and program numbers.

REDIAL key

Press this key to automatically

redial the last number dialed.

SPEAKER key

Press this key to dial a

number without picking

up the handset.

FUNCTION key

Press this key to select

various special functions.

BROADCAST key

Press this key to send a

document to a group of

receiving fax machines.

ABC

123

GHI

456

PRS

789

DEF

JKL MNO

TUV WXY

OPER

0

STOP key

Press this key to

stop operations

before they are

completed.

COVER SHEET key

Press this key to include

a cover sheet with a

transmitted document.

COPY key

Press this key to make

a copy of a document.

FUNCTION

SPEED DIAL

REDIAL

SPEAKER

COPY REPORT DOCUMENT

BROADCAST

STOP START

START key

Press this key to

send or receive

a document

REPORT key

Press this key to print out

a report on the transaction

just completed.

DOCUMENT key

Press this key to transmit

a document without

reading it into memory.

COVER SHEET

PRIORITY

PRIORITY key

Press this key when

you want to transmit

a document ahead of

other documents which

.

are waiting in memory

for transmission.

1 – 2

Page 5

Operation panel (2)

Rapid Dial keys

Press one of these keys to dial a fax

or voice number automatically. (these

keys also serve as letter entry keys

when storing a name).

PAGE COUNTER key

Press this key to have a slash and

the total number of pages added

after each page number on the

pages of a transmitted document.

CONTRAST key

Press this key to adjust the

contrast before sending or

copying a document.

TIMER key

Press this key to set an

operation to be performed

automatically at a later time.

CONFIDENTIAL key

Press this key to send or

print out a confidential

document.

FO-5500U/C

RELAY key

Press this key to send a document

to another fax machine and have

that machine in turn send the

document to a number of end

receiving machines.

LIFE key

Press this key, followed

by the "1" key, to check

the total number of pages

printed by the fax machine.

MEM. STATUS key

Press this key to

see what documents

have been scanned

into memory for

transmission.

01

02

A

09

I

17

Q

25

Y

SPACE key

Press this key to enter a

space when storing a name.

SHIFT key

Press this key to switch

between upper and

lower case when storing

a name.

03

B

C

10

11

J

K

18

19

R

S

27 28 29 30 31 32

26

Z

04

05

D

12

L

20

T

SP key

Press this key to enter

symbols when storing

a name.

06

E

F

13

14

M

N

21

22

U

V

CLEARSPSHIFTSPACE

CLEAR key

Press this key to clear

mistakes when storing

names and numbers.

07

08

G

H

15

16

O

P

23

24

W

X

key, key

Press these keys to move

the cursor forward and

backward when storing

names and numbers.

(Flip up the

Rapid Key

overlay)

33

34

A

41

I

CONTRAST

Q

DUPLEX SCAN

Y

DUPLEX SCAN key

Press this key to transmit

or copy two-sided

documents.

35

B

C

42

43

J

K

PAGE COUNTER

CONFIDENTIAL

R

S

Z

UP and DOWN key

Press these keys to adjust

the volume of the handset

when the handset is lifted,

the volume of the speaker

when the SPEAKER key

has been pressed, or the

volume of the ringer at all

other times.

36

D

44

L

TIMER

T

37

E

45

M

RELAY

U

38

39

F

G

46

47

N

O

MEM.STATUS

LIFE

V

W

DOWN UP

CLEARSPSHIFTSPACE

SEARCH DIAL key

Press this key to

search by name for

a number stored

for automatic

dialing.

40

H

48

P

SEARCH DIAL

X

1 – 3

Page 6

FO-5500U/C

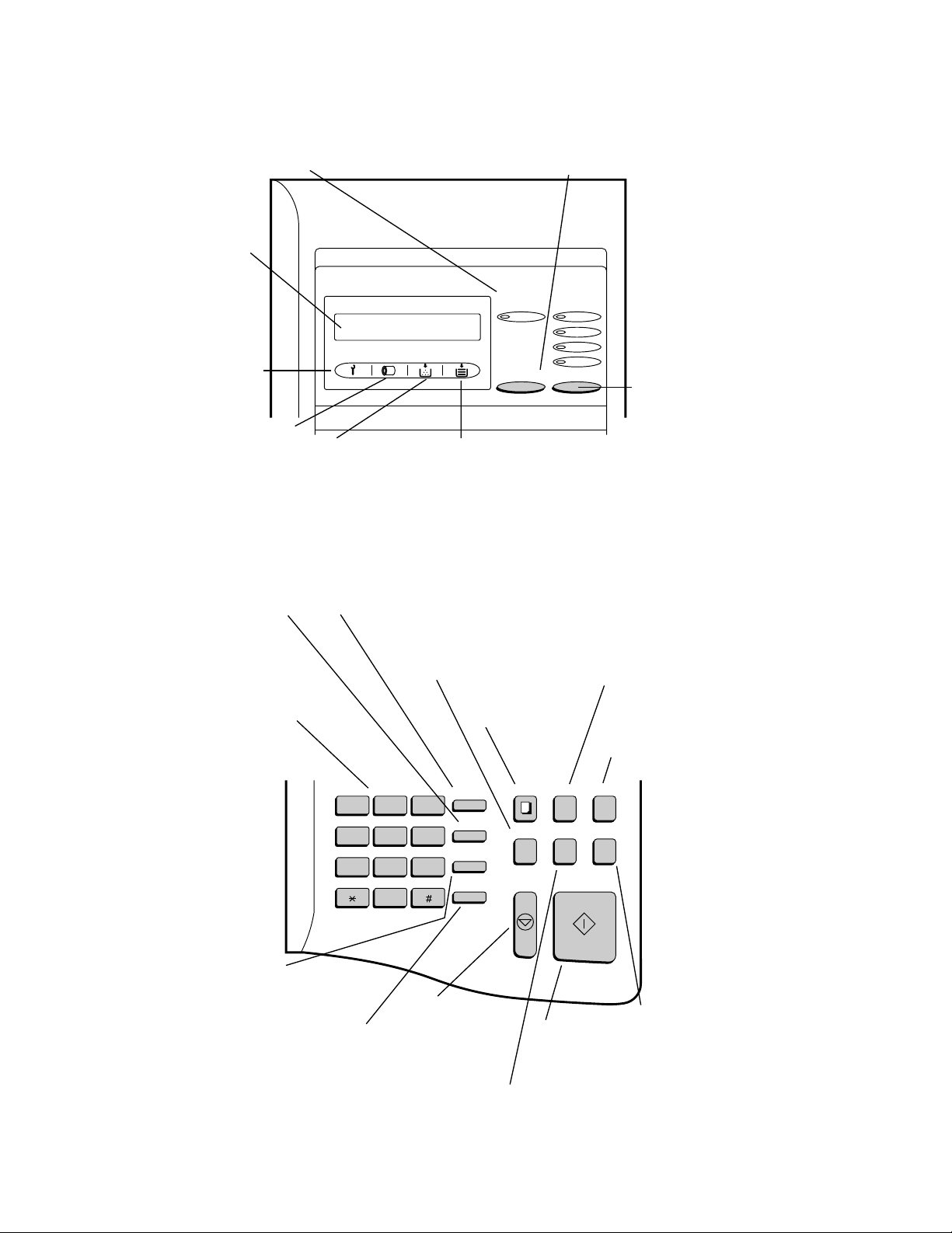

[3] Transmittable documents

1. Document Sizes

Normal size

(Min.)

128mm

148mm 216mm

Use document carrier sheet for smaller documents.

* With special sizes, only one sheet can be fed into the machine at

a time. Insert next page into feeder as current page is being

scanned.

2. Paper Thickness & Weight

Weight

indication

Thickness

indication

Document

size

Number of

ADF sheets

Paper

quality

Japanese indication

Size 4 × 6

Metric system

indication

American indication

LB system indication

Metric system

indication

Inch system indication 0.0024" 0.0035"

Document size

Range

Document size

Weight

Kind Paper of fine quality/bond paper/Kent

width 5.83" – 8.5" (148 – 216 mm)

length 5.04" – 11" (128 – 279 mm)

(Max.)

80g/m

432mm

2

(Max.)

Letter size

[Normal size]

Indication Lower Limit Upper Limit

279mm

216mm

[Special size]

Product specifications

45kg paper 70kg paper

2

52g/m

14 LB 20 LB

0.06mm 0.1mm

(148mm × 128mm) ~

W letter (279.4mm × 432mm)

A4 (210mm × 297mm)

Letter (216mm × 279mm)

B6 ~ Letter/ A4 size 50 shee ts

B4 size/Legal 20 sh eets

W letter size 1 sheet

90 kg (104g/m2) or more

135 kg (157g/m2) or less 1 sheet

paper

4. Cautions on Transmitting Documents

• Documents written in yellow, greenish yellow, or light blue ink

cannot be transmitted.

• Ink, glue, and correcting fluid on documents must be dry before the

documents can be transmitted.

• All clips, staples and pins must be removed from documents be-

fore transmission.

• Patched (taped) documents should be copied first on a copier and

then the copies used for transmission.

• All documents should be fanned before insertion into the feeder to

prevent possible double feeds.

5. Automatic Document Feeder Capacity

Number of pages that can be placed into the feeder at anytime is as

follows:

Normal size: max. 50 sheets (14 lbs – 20 lbs)

Special size: single sheet only (manual feed)

NOTES: • When you need to send or copy more pages than the

feeder limit, place additional pages in feeder when last

page in feeder is being scanned.

• Place additional pages carefully and gently in feeder.

If force is used, double-feeding or a document jam may

result.

6. Readable Width & Length

The readable width and length of a document are slightly smaller than

the actual document size.

Note that characters or graphics outside the effective document scanning range will not be read.

• Readable width

8.3" (208 mm) max.

Readable width

• Readable length

This is the length of the document sent minus 0.16" (4 mm) from the

top and bottom edges.

3. Document Types

• Normal paper

Documents handwritten in pencil (No. 2 lead or softer), fountain

pen, ball point pen, or felt-tipped pen can be transmitted.

Documents of normal contrast duplicated by a copying machine

can also be transmitted.

• Diazo copy (blueprint)

Diazo copy documents of a normal contrast may be transmitted.

• Carbon copy

A carbon copy may be transmitted if its contrast is normal.

4mm

Readable length

4mm

1 – 4

Page 7

FO-5500U/C

7. Use of Document Carrier Sheet

A document carrier sheet must be used for the following documents.

• Those with tears.

• Those smaller than size 5.83" (W) × 5.04" (L) (148 mm (W) × 128

mm (L)).

• Carbon-backed documents

Make print straight

across paper

E.G.

Place the document

carrier in the document

feeder with the clear film

side down

Direction of insertion

NOTE: To transmit a carbon-backed document, insert a white

sheet of paper between the carbon back of the document

and the document carrier.

• Those containing an easily separable writing substance (e.g., trac-

ing paper written on with a soft, heavy lead pencil).

NOTES: • When using the document carrier, carefully read the in-

structions written on the back.

• If the document carrier is dirty, clean it with a soft, moist

cloth, and then dry it before using for transmission.

• Do not place more than one document in the carrier at a

time.

• The thickness of document which can be held with the carrier

sheet is up to 20 lb.

TELEPHONE JACK

A standard RJ11C telephone jack must be located near the machine.

This is the telephone jack commonly used in most homes and offices.

• Plugging the fax machine into a jack which is not an RJ11C jack

may result in damage to the machine or your telephone system. If

you do not know what kind of jack you have, or need to have one

installed, contact the telephone company.

If the machine is moved from a cold to a warm place...

If the machine is moved from a cold to a warm place, it is possible

that the reading glass may fog up, preventing proper scanning of

documents for transmission. To remove the fog, turn on the power

and wait approximately 2 hours before using the machine.

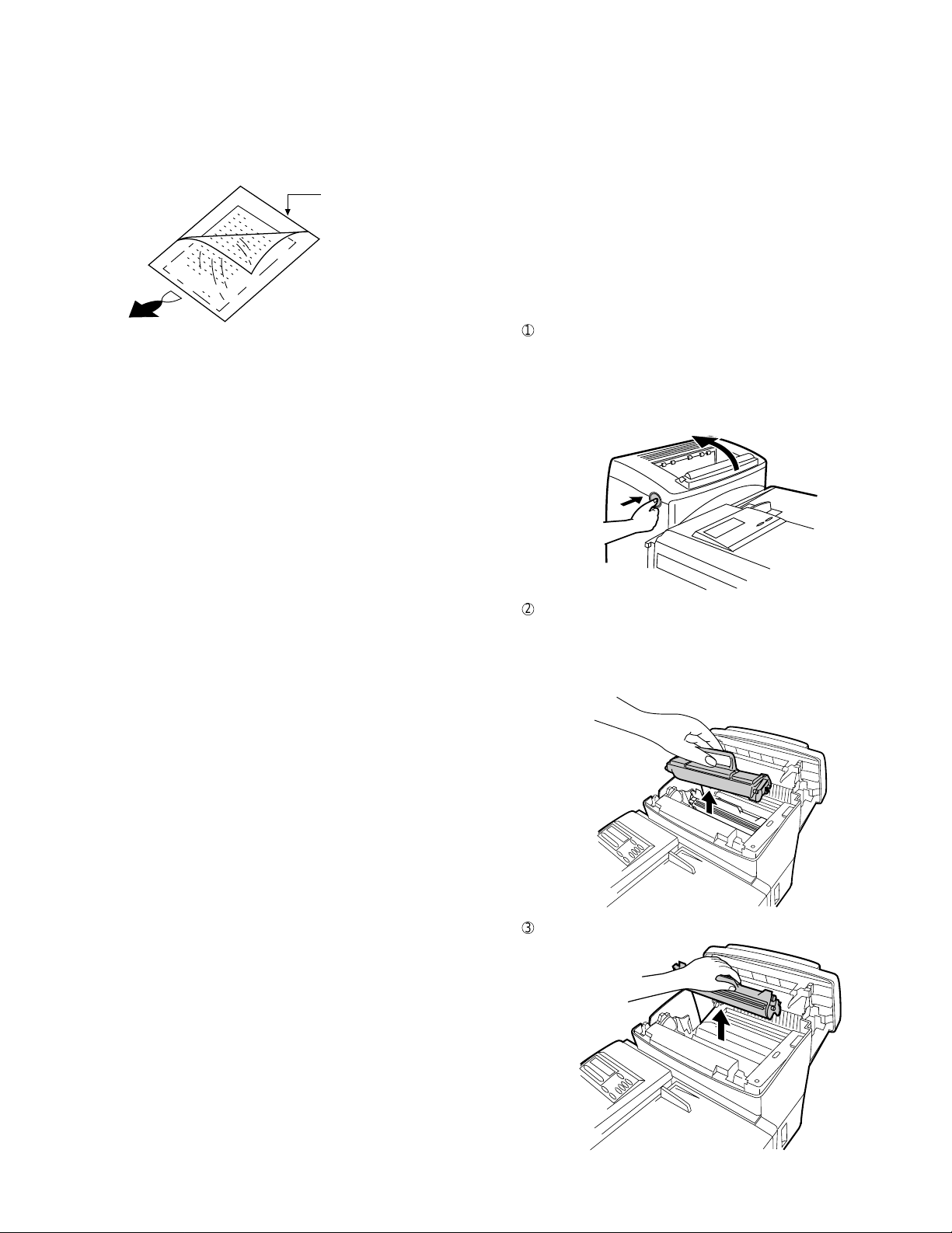

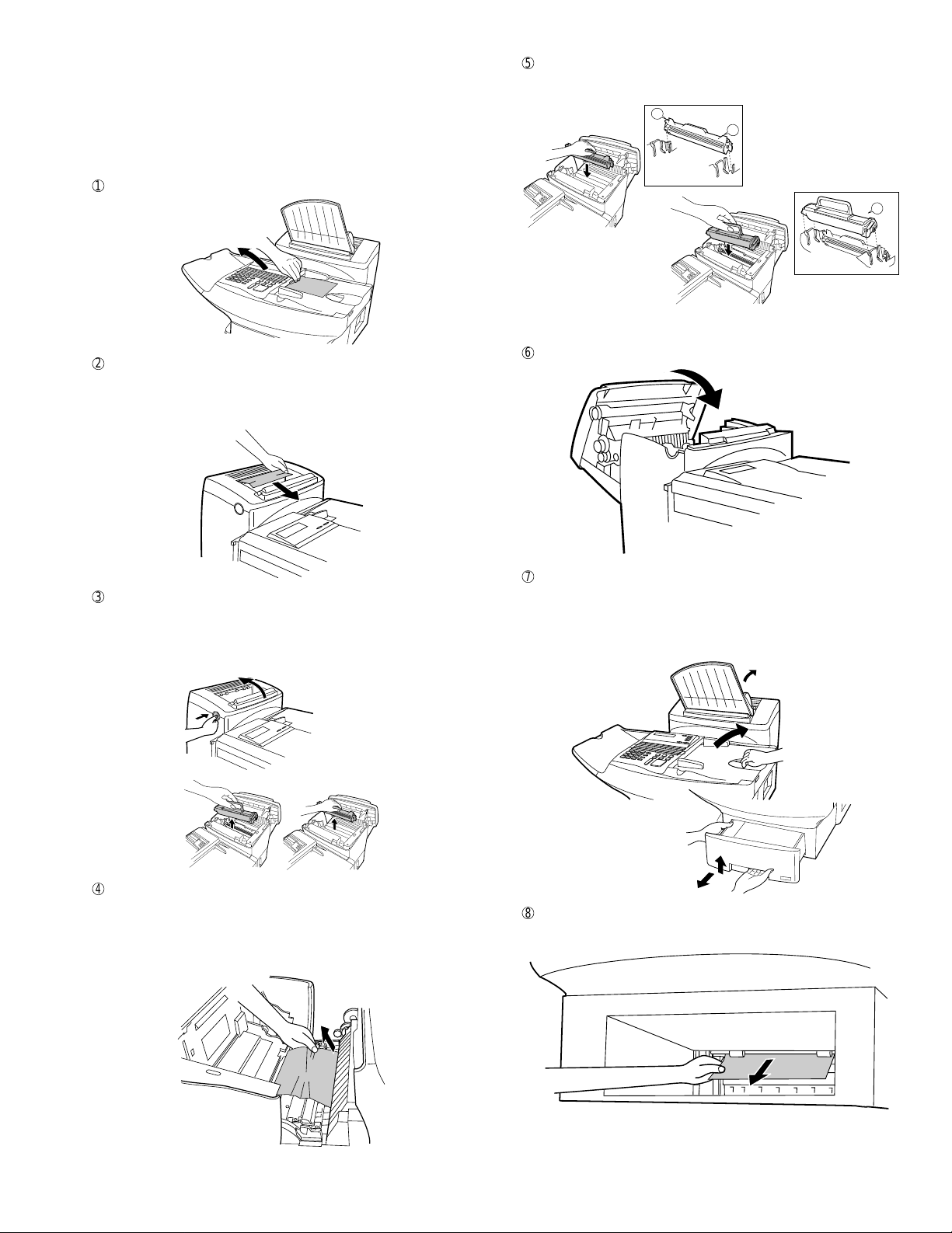

2. Installing the printer cartridges (Toner

cartridge: FO-45ND/Drum cartridge: FO-45DR)

1

Press the button on the side of the printer compartment, and open

the printer cover.

• Caution! The ribs on the bottom of the inside of the printer

cover become very hot during printing. Be careful not to touch

them.

• If you are installing the cartridges for the first time, go to Step 4.

[4] Installation

1. Site selection

Take the following points into consideration when selecting a site for

this model.

ENVIRONMENT

• The machine must be installed on a level surface.

• Keep the machine away from air conditioners, heaters, direct sun-

light, and dust.

• Provide easy access to the front, back, and sides of the machine.

In particular, keep the area in front of the machine clear, or the

original document may jam as it comes out after scanning.

• The temperature should be between 41° and 95°F (10° and 35°C).

• The humidity should be between 30% and 85% (without condensa-

tion).

ELECTRICITY

A 120 V, 60 Hz, grounded (3-prong) AC outlet is required.

Caution!

• Connection to a power source other than that specified will cause

damage to the equipment and is not covered under the warranty.

• If your area experiences a high incidence of lightning or power

surges, we recommend that you install a surge protector for the

power and telephone lines. Surge protectors can be purchased at

most telephone specialty stores.

2

If you are replacing the cartridges, grasp the handle on the toner

cartridge, and pull the toner cartridge out of the compartment.

• If you are only replacing the drum cartridge, place the toner

cartridge on a piece of paper on a horizontal surface.

• If you are only replacing the toner cartridge, go to Step 6.

3

Pull the old drum cartridge out of the compartment.

1 – 5

Page 8

FO-5500U/C

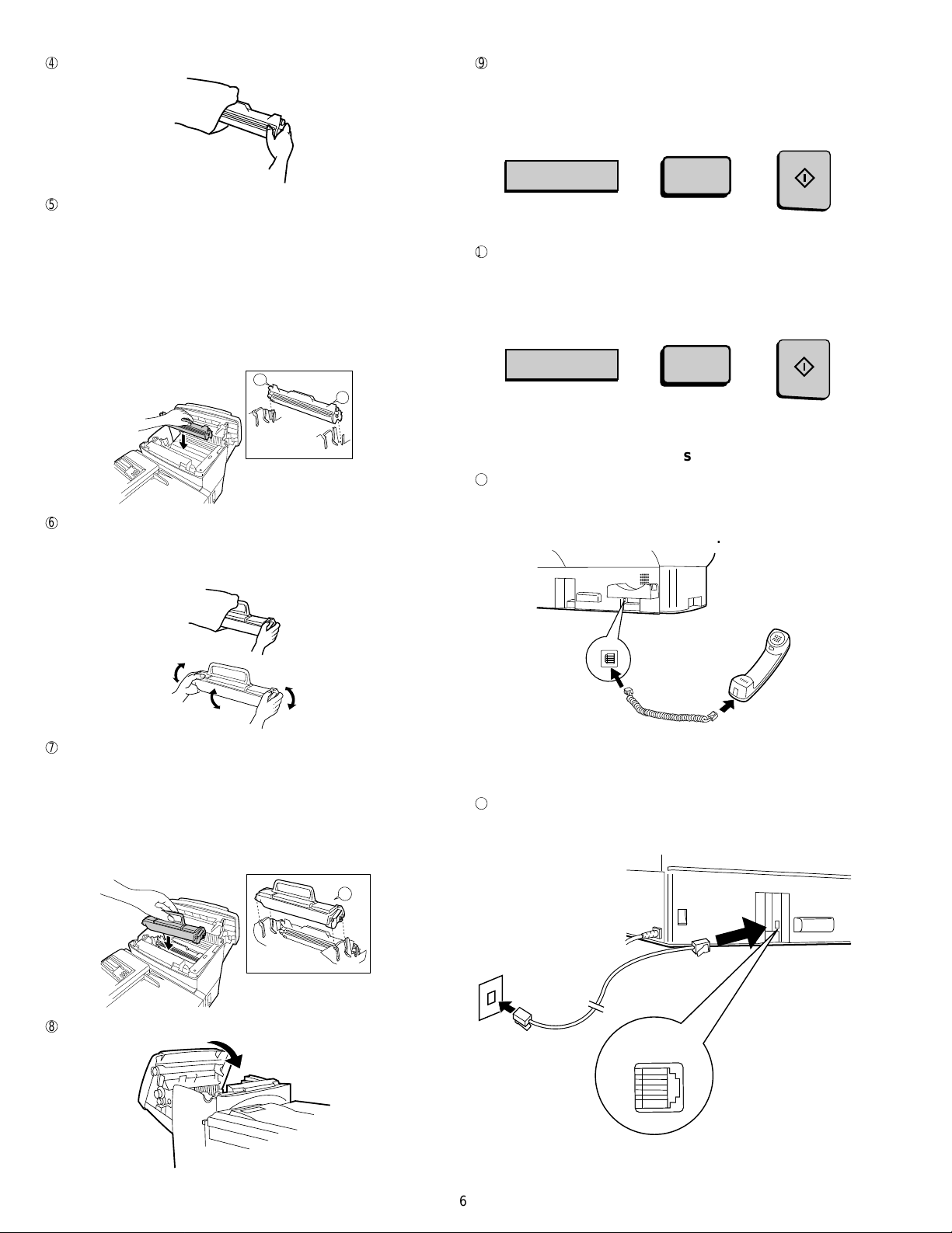

4

Remove the new drum cartridge from its packaging.

9

If you replaced the toner cartridge, reset the toner counter by

pressing the LIFE key (flip up the Rapid Key overlay if necessary),

the "2" key, and the START key.

5

Align the arrowhead on the right side of the drum cartridge (the

right side is marked "R") with the arrowhead pointing down which

is marked on the right side of the compartment, and insert the

cartridge into the compartment so that the ends of the cartridge

move along the guides on the sides of the compartment. Make

sure the cartridge is set firmly in place.

• Place the old drum cartridge (if you removed one) in the empty

drum cartridge bag, seal the bag, and dispose of it in a way that

conforms to any local regulations that may exist in your area.

• If you are not replacing the toner cartridge, go to Step 7.

L

R1

Left

Right

6

Remove the new toner cartridge from its packing, and shake several times as shown.

• This ensures that the toner is well distributed inside the car-

tridge.

LIFE

V

F

If you replaced the drum cartridge, reset the drum counter by

pressing the LIFE key (flip up the Rapid Key overlay if necessary),

the "3" key, and the START key.

2

LIFE

V

3

START

START

3. Assembly and connections

1

Connect the handset cord to the handset and the fax as shown.

• The ends of the handset cord are identical, so they will go into

either jack.

Place the handset on the handset rest.

7

Hold the handle of the toner cartridge so that the "2" marked on

the cartridge is to the right, and insert the cartridge into the compartment so that the two knobs on each side of the cartridge move

along the two guides on each side of the compartment.

Press the handle down so that the cartridge sets into place.

• Place the old toner cartridge (if you removed one) in the empty

toner cartridge bag, seal the bag, and dispose of it in a way that

conforms to any local regulations that may exist in your area.

2

Left

Right

8

Close the printer cover.

Use the handset to make ordinary

phone calls, or to transmit and receive documents manually.

2

Plug one end of the telephone line cord into the jack on the fax

marked "LINE". Plug the other end into a standard (RJ11C) telephone wall jack.

TEL.

LINE

1 – 6

Page 9

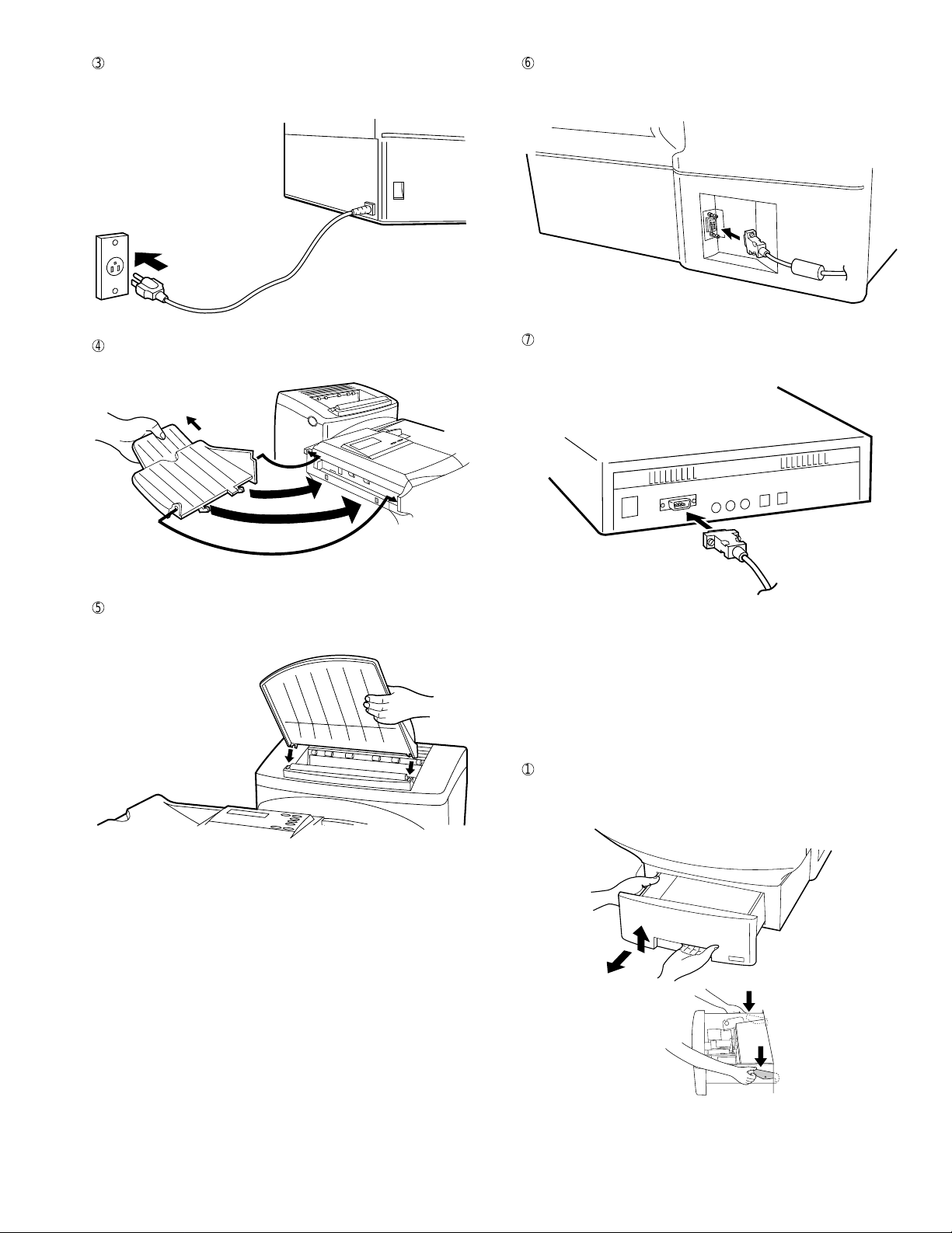

3

Plug the power cord into a 120V, 60Hz, grounded (3-prong) AC

outlet.

Press the power switch to turn on the power.

4

Attach the original document OUT tray by inserting the tabs into

the holes in the fax as shown.

FO-5500U/C

6

Insert the male end of the PC interface cable into the port on the

right side of fax as shown. Tighten the attached screws with a

screwdriver.

7

Insert the female end of the PC interface cable into the serial

(RS-232C) port on your computer.

Tighten the attached screws with a screwdriver.

5

Attach the received document tray by inserting the tabs into the

holes in the fax as shown.

4. Loading printing paper

The paper cassettes and the paper tray hold the paper on which

received documents are printed. If needed, a second cassette is

available as an option from your dealer.

The paper cassette can hold 500 sheets of either legal or letter size

paper. The paper tray can hold 150 sheets of either legal or letter size

paper.

1

Grasp the hand hold on the cassette as shown, lift the cassette

slightly, and then pull it out as far as it will go. Do not force.

Push down on green levers on both sides of the cassette tray as

shown, and then pull it completely out of the fax using both hands.

1 – 7

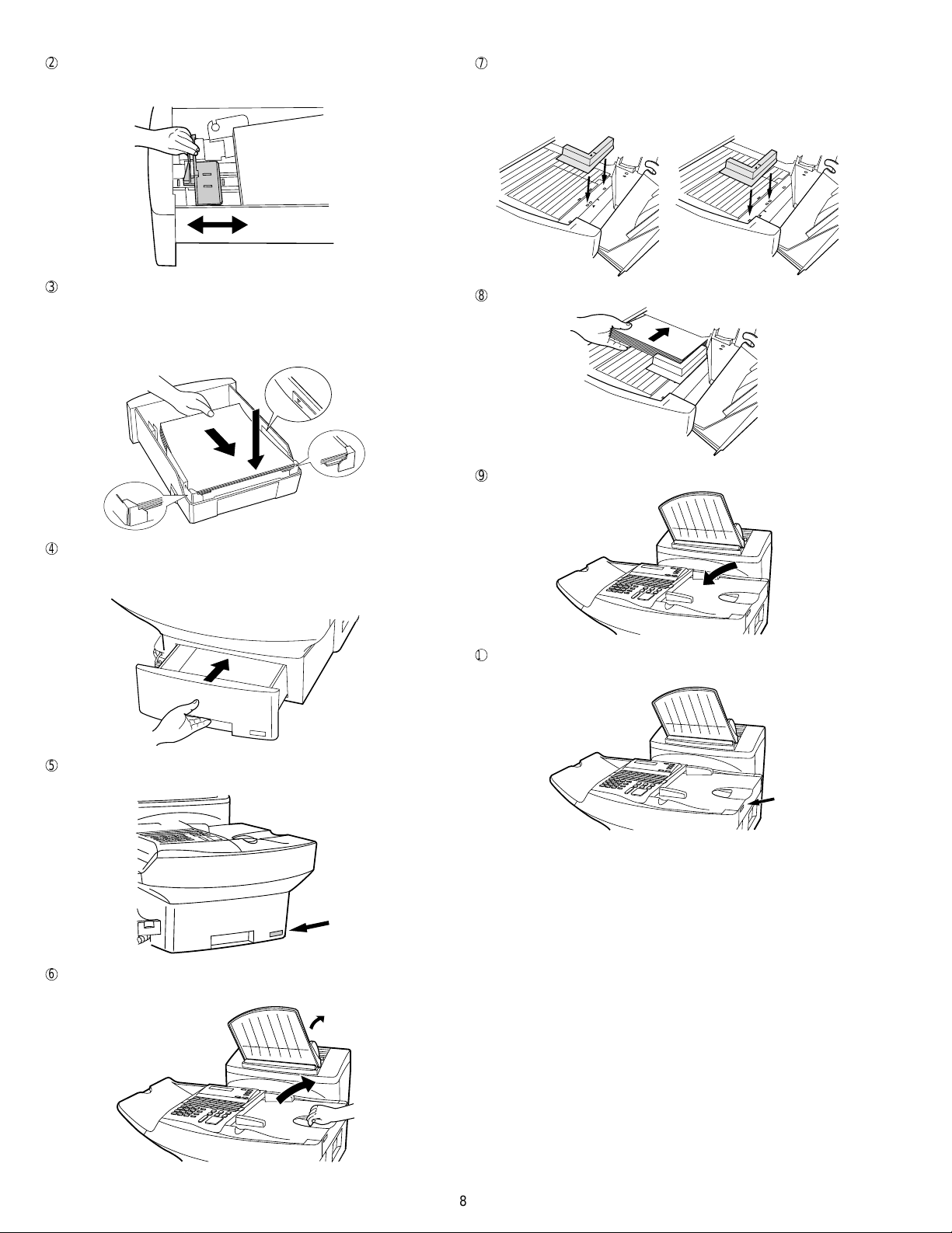

Page 10

FO-5500U/C

2

Pinch the ends of the paper guide together, and move the guide to

the appropriate position depending on whether you are loading

letter or legal size paper.

7

Move the paper guide to the appropriate position depending on

whether you are loading letter or legal paper.

• To remove the paper guide, press its inner side at the arrow

marks and lift.

LETTER LEGAL

3

Place a stack of paper on the pressure plate, press it down, and

insert the two far corners of the paper under the paper holders as

shown.

• Make sure the stack of paper is not higher than the tabs at the

top of the paper guide. If it is, remove some of the paper.

4

Put the cassette back in the fax.

• Push down on green levers on sides of cassette for it to go all

the way in.

LTR

8

Place the paper in the tray.

9

Close the original document IN tray.

LGL

5

If desired, attach a letter or legal sticker as appropriate to the

cassette.

6

Rotate the received document tray back. Grasp the hand hold on

the original document IN tray as shown, and open it.

F

If desired, attach a letter or legal sticker as appropriate to the fax

as shown.

1 – 8

Page 11

5. Clearing paper jams

If a document doesn’t feed through the scanner properly during transmission or copying, or DOCUMENT JAM appears in the display, first

try pressing the START key. If the document doesn’t come out of the

feeder, open the operation panel by squeezing the operation panel

release on the right side of the operation panel (marked "PULL UP"),

and gently pull out document.

1

5

Replace the drum cartridge, and then the toner cartridge.

L

R1

Left

Right

FO-5500U/C

2

If the leading edge of the document is protruding from the printer

2

compartment outlet, try pulling it out.

• If you are unable to clear the paper jam in this way, continue

with the following steps.

3

Open the printer cover and remove the toner cartridge and drum

cartridge.

• Caution! The ribs on the bottom of the inside of the printer

cover become very hot during printing. Be careful not to touch

them.

Left

6

Close the printer cover.

7

If you didn’t find any paper in the printer compartment, or if

Right

PAPER JAM still appears in the display after you close the printer

cover, check each paper cassette and the paper tray.

• To check the paper tray, grasp the hand hold on the original

document IN tray and rotate the tray up.

4

Gently pull the paper out of the compartment.

• If the leading edge of the paper has entered the fusing unit, first

pull the leading edge out of the fusing unit, then pull the paper

out of the compartment.

• Be sure to remove any torn pieced of paper.

1 – 9

8

Gently pull out any jammed paper you find, and then replace the

cassette or close the original document IN tray.

Page 12

FO-5500U/C

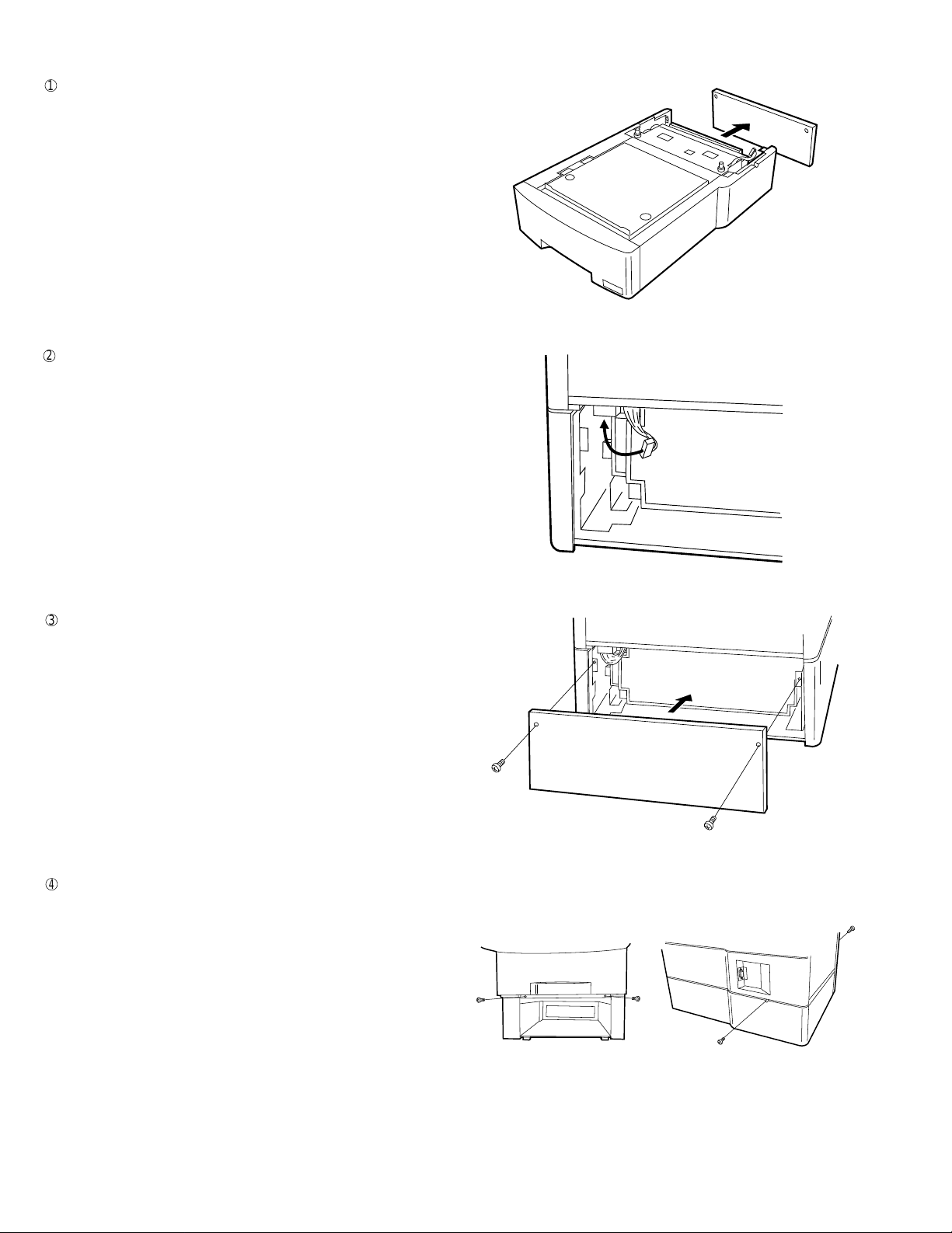

6. Installing an option cassette (FO-45UC)

1

Remove the two screws on the rear side of the optional cassette,

and then remove the rear plate of the optional cassette.

2

Place the fax machine on top of the optional cassette. Connect the

connector on the optional cassette to the wire connector on the

bottom of the fax.

3

Replace the rear plate on the optional cassette, and secure it with

the two screws.

4

Secure the optional cassette to the fax machine with two screws

on the front and one screw on each side.

1 – 10

Page 13

FO-5500U/C

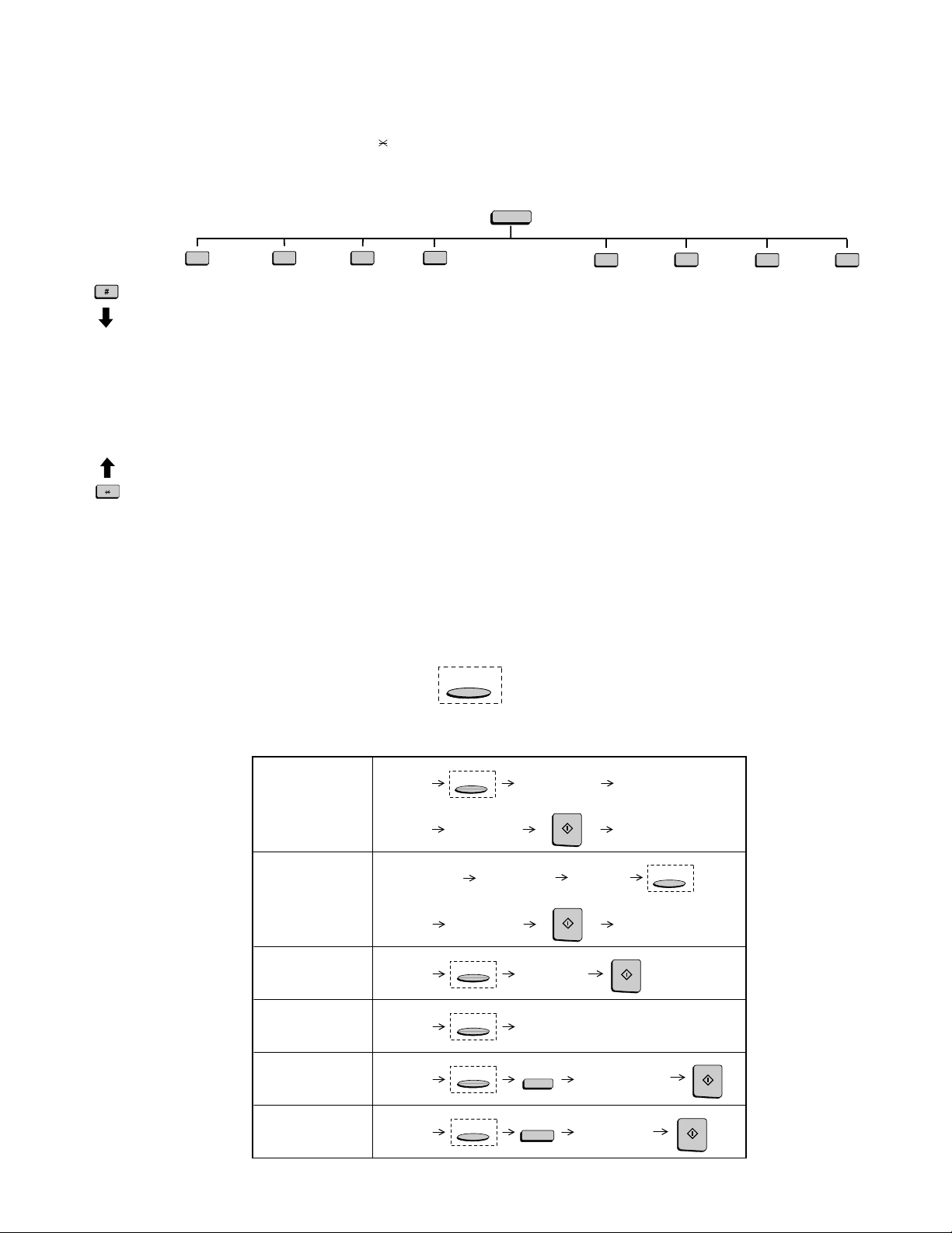

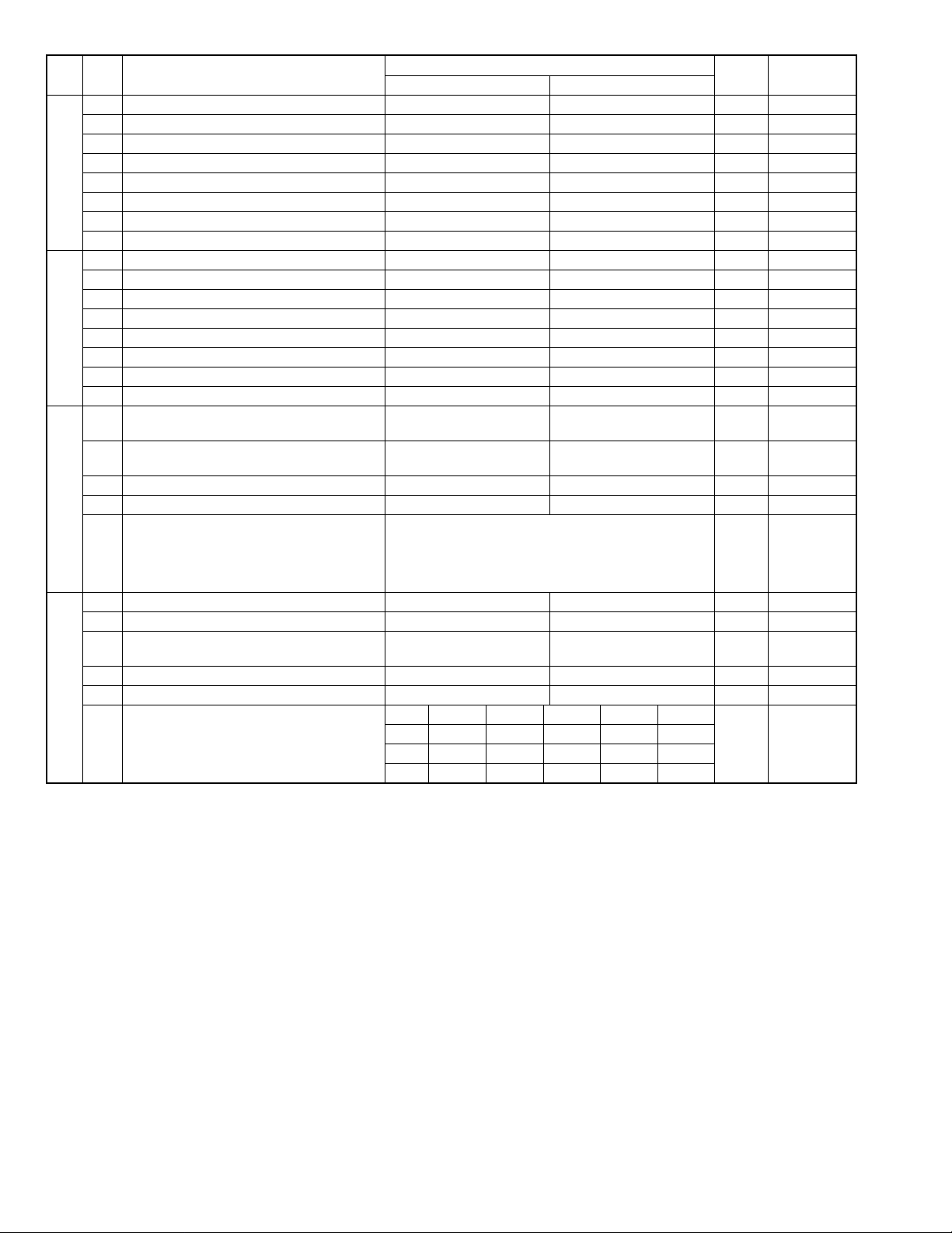

[5] Quick reference guide

FUNCTION key menu

The following chart shows the layout of the functions and settings accessed by pressing the FUNCTION key. First press the FUNCTION key, the

appropriate nu meric key as shown, and then "#" or " " until the d esired item appears.

Instructions for making each setting appear in the display. If you have any difficulty, refer to the detailed instructions on the page shown below the

setting.

FUNCTION

1

Reception

Mode

2

Listing Mode

Activity Report

Timer List

Telephone

Number List

Relay Group List

Passcode List

Option Setting

Program/Group

List

Batch

Transmission List

Department

Usage List

Confidential

Reception List

Anti Junk Fax

Number List

3

Entry Mode

Fax/Tel

Numbers for

Auto Dialing

Passcode Number

Own Number and

Name Set

Date and Time

Set

ID Number

System Number

Store Junk Fax

Number

Department

Code Mode

Optional Settings

Fine Resolution

Priority

Number of Rings to

Auto Answer Mode

Auto Listing

Transaction Report

Print Select

Recall Times

Recall Wait Interval

Security Selection

ECM

Auto cover Sheet

Memory Scanning

Copy Reduce

Copy Cut-off

Receive Reduce

Image Memory

Print

Cassette Selection

Cassette

Changeover

Note: Steps which are optional are enclosed in a dotted frame:

4

RESOLUTION

Retransmission

Times

Retransmission

Interval

Heater Mode

Junk Fax Check

Alarm Buzzer

Dial Mode

Quick on Line

Multi TTI

Beep Length

Tel. Billing Code

Department Code

Mode

Distinctive Ringing

Verification Stamp

Print Hold

PC-Interface Mode

Receive Unit

6

Print Hold

Mode

Hold Data Print

Print Hold Code

Set

Print Hold Code

Clear

7

Program/Group

Mode

Program Entry

Mode

Group Entry

Mode

8

Serial Polling

Mode

9

Memory Polling

Mode

Memory Polling Set

Memory Polling

Clear

Transmitting documents

Normal Dialing (1)

Normal Dialing (2)

Direct Keypad

Dialing

Rapid Key Dialing

Speed Dialing

Redialing

Load

document

Lift handset

or

press SPEAKER

Load

document

Load

document

Load

document

Load

document

RESOLUTION

Wait for

reception tone

Dial (press

numeric keys)

Wait for

reception tone

RESOLUTION

RESOLUTION

RESOLUTION

RESOLUTION

Lift handset

or

press SPEAKER

START

Load

document

START

Dial (press

numeric keys)

Press Rapid

key

Enter Speed Dial number

SPEED DIAL

REDIAL

(press numeric keys, -if less

than 3 digits, press START

to complete entry)

Dial (press

numeric keys)

Hang up

Hang up

START

Wait for

reception tone

RESOLUTION

START

START

1 – 11

Page 14

FO-5500U/C

M E M O

1 – 12

Page 15

FO-5500U/C

CHAPTER 2. ADJUSTMENTS

[1] Adjus tmen ts

General

Since the following adjustments and settings are provided for this

model, make adjustments and/or setup as necessary.

1. Adjustments

Adjustments of output voltage (FACTORY ONLY)

1. Install the power supply unit in the machine.

2. Set the recording paper and document.

3. When the document is loaded, power is supplied to the output

lines. Confirm that outputs are within the limits below.

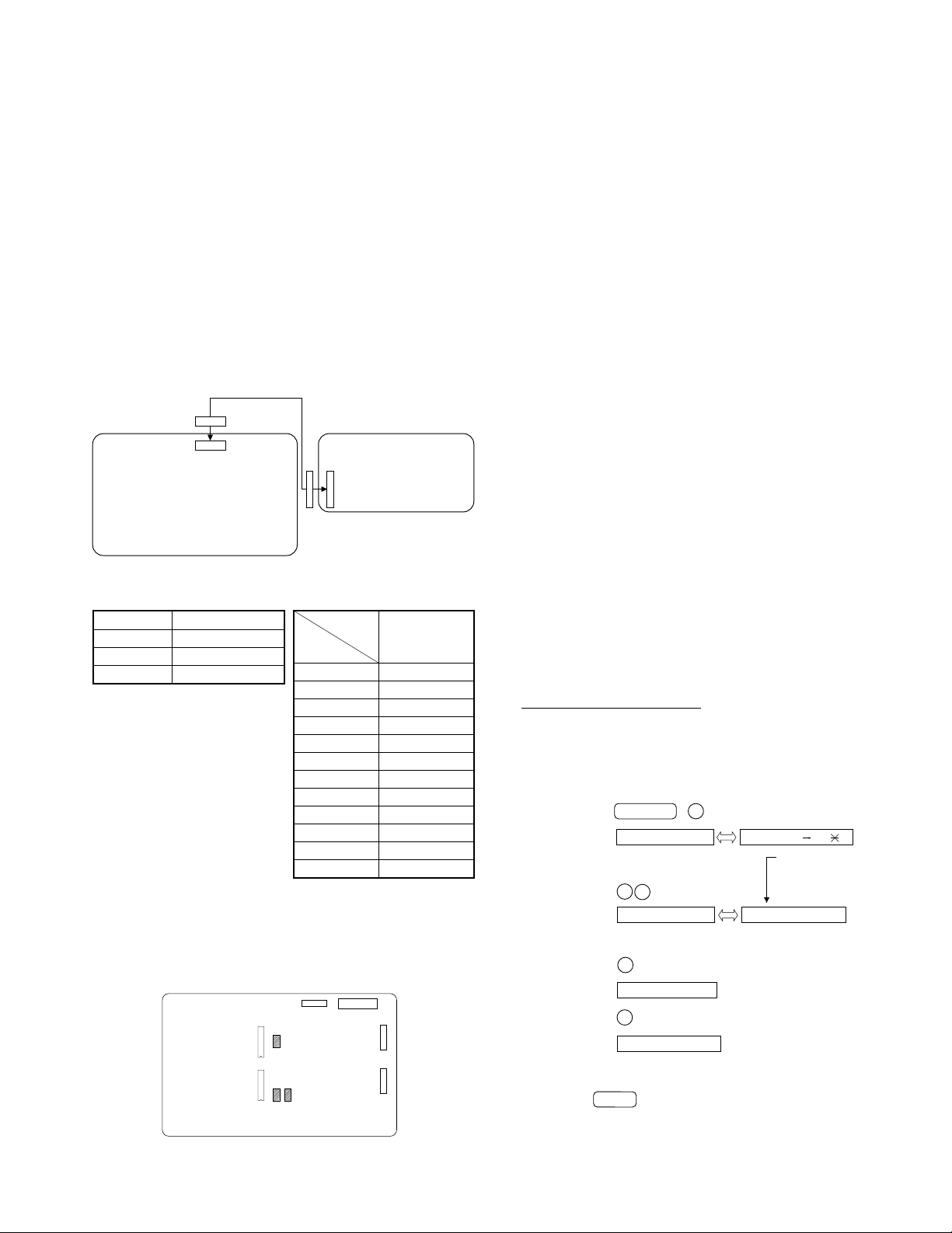

Output voltage settings

CNPRT

No.

CNRS

POWER SUPPLY

PWB

CNPW

CNPW

CONTROL

PWB

CNPW

Fig. 1

Output Voltage limits

Connector

+5V 4.75V~5.25V

+12V 11.5V~12.5V

VM (+24V) 23.04V~24.96V

Pin No.

1VM

2VM

3VM

4MG

5MG

6MG

7 +5V

8 +5V

9DG

10 DG

11 +12V

12 AG

2. IC protectors replacement

ICPs (IC Protectors) are installed to protect the TX motor drive circuit

and verification stamp drive circuit. ICPs protect various ICs and electronic circuits from an overcurrent condition.

The location of ICPs are shown below:

CONTROL

PWB

(TOP SIDE)

IC17

CNPW

F1

(1) F3 (CCP2E20) is installed in order to protect IC’s from and

overcurrent generated in the verification stamp drive circuit. If F3

is open, replace it with a new one.

(2) F1, F2 (CCP2E30) is installed in order to protect IC’s from an

overcurrent generated in the TX motor drive circuit. If F1, F2 is

open, replace it with a new one.

In addition to the replacement of F1, F2 and F3, the factor

causing F1, F2 and F3 to open must also be repaired. If not, F1,

F2 and F3 will open again.

Replacement parts

CCP2E20 (Sharp code: VHVCCP2E20/-1)

CCP2E30 (Sharp code: VHVCCP2E30/-1)

3. Volume adjustment

You can adjust the volume of the speaker, handset, and ringer using

the UP and DOWN keys on the operation panel (flip up the Rapid Key

overlay to access the keys).

Speaker

The speaker has 3 volume levels: HIGH, MIDDLE, and LOW. To

adjust the volume of the speaker, press the SPEAKER key and then

press the UP or DOWN key until the desired level appears in the

display. Press the SPEAKER key again to turn the speaker off.

Handset

The handset receiver has 3 volume levels: HIGH, MIDDLE, and LOW.

To adjust the volume of the handset receiver, lift the handset and

then press the UP or DOWN key until the desired level appears in the

display.

Ringer

The ringer has 4 volume levels: HIGH, MIDDLE, LOW, and OFF. To

adjust the volume of the ringer, press the UP or DOWN key until the

desired level appears in the display (make sure the SPEAKER has

not been pressed and the handset is not lifted). The fax will ring at the

new volume level each time you change the level. If you select OFF,

press the START key to confirm your selection.

4. Settings

(1) Dial mode selector

OPTION SETTING: DIAL MODE (Soft Switch No. SW2 DATA No. 1)

Use this to set the fax machine to the type of telephone line you are

on.

• The factory setting is "TONE".

(step 1) Select "OPTION SETTING".

KEY:

DISPLAY:

(step 2) Select "DIAL MODE".

KEY:

DISPLAY:

(step 3) Select, using "1" or "2".

KEY:

DISPLAY: TONE SELECTED

KEY:

DISPLAY:

FUNCTION 4

OPTION SETTING ENTER #01 33, ,#

Cursor

When initially registering,

the mode shows 1=TONE.

When registering again, the

3

2

DIAL MODE

1

2

PULSE SELECTED

mode which was registered

formerly is shown.

1=TONE, 2=PULSE

IC13

F3

F2

Fig. 2

CNPN

2 – 1

(step 4) End, using the "STOP" key.

KEY:

STOP

Page 16

FO-5500U/C

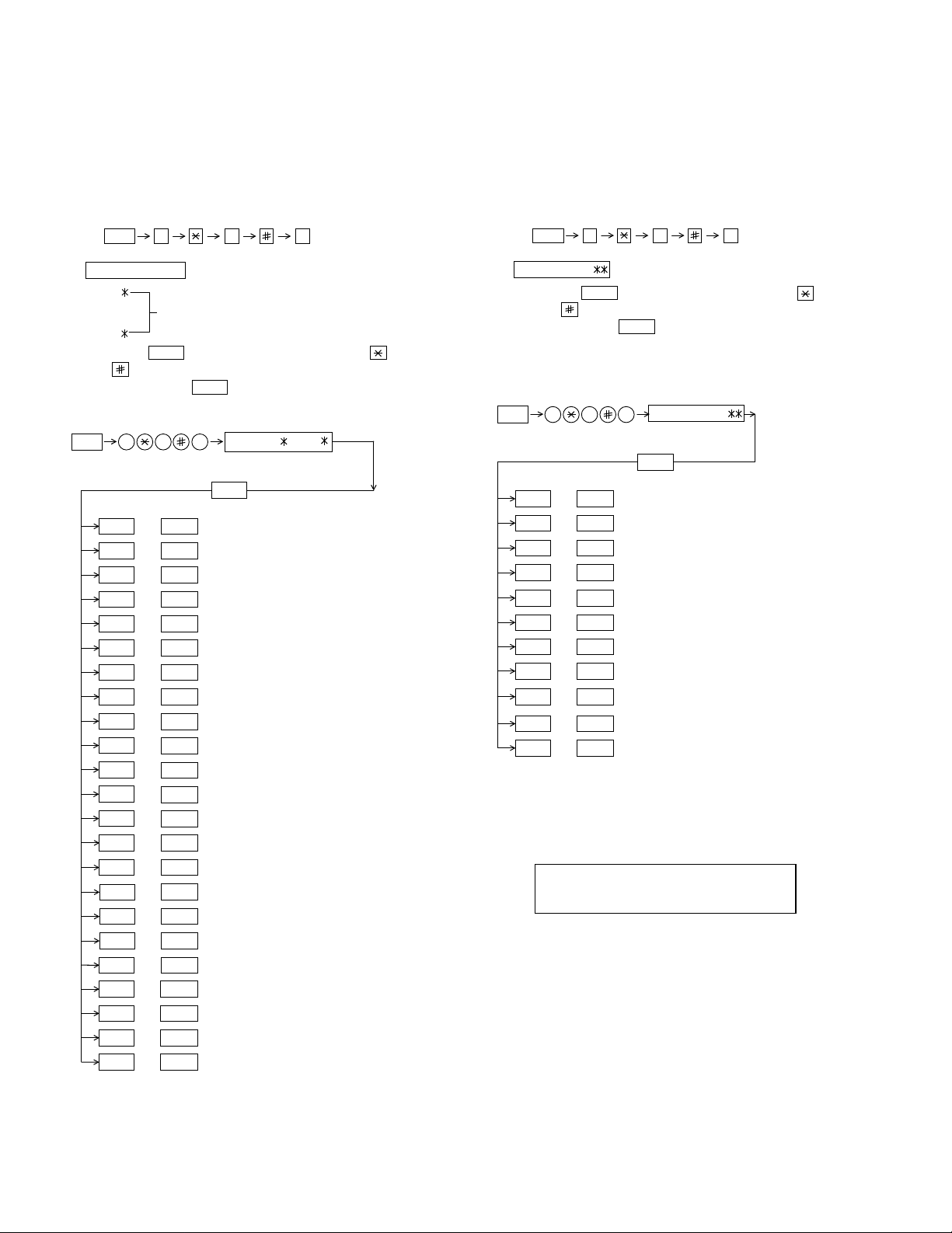

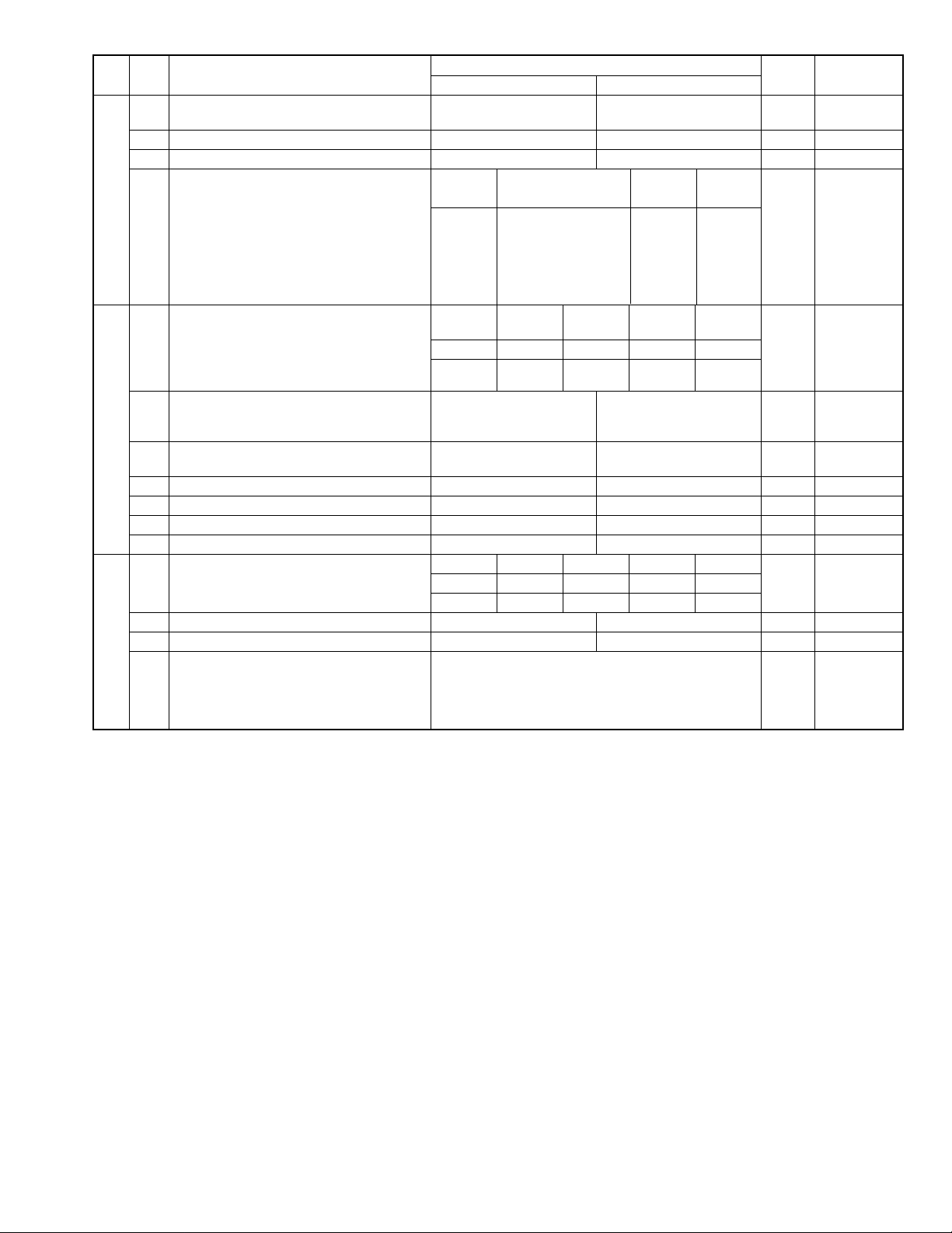

[2] Diagnostics and service soft switch

1. Operating procedure

Two kinds of diagnoses are supported.

1-1. Fax diagnosis

This diagnosis is concerned with the main body of fax which is

used for production and service support.

Entering the diagnostic mode

1-2. Print diagnosis

This diagnosis is concerned with the print which is used for production and service support.

Entering the diagnostic mode

Press

FUNC

9 8

display will appear.

ROM: XXXXX

XXXXX

FAN0

Identical

FAN1

START

Then press the

key. Select the desired item with the

and the key or select with the rapid key.

START

Enter the mode with the

•

specifications)

(Diag

FUNC

9 8 7

START01 SOFT SWITCH MODE

02 PRINT AREA

03 ROM & RAM CHECK

04 AUTO FEEDER MODE

05 AGING MODE

06 PANEL CHECK MODE

07 OPTICAL ADJUST MODE

08 PRODUCT CHECK

09

10

11

12

13

14 RS232C CHECK MODE

15

16 CONF. PASSCODE

17 PRINT HOLD CODE

18 MEMORY SET MODE

19 MOTOR AGING

20 STAMP AGING

21 SCANNER SET MODE

22 DIAL TEST MODE

23 COPY DIAG MODE

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

key.

ROM:

FAN0 FAN1

START

SIGNAL SEND MODE

COMM. CHECK MODE

MEMORY CLEAR

FLASH MEMORY

ALL FAX/TEL ENTRY MODE

DEPT. PASSCODE

7

the

, and

following

Press

FUNC

9 8

6

the

, and

following

display will appear.

PCU ROM Ver.:

START

Then press the

key. Select the desired item with the

key and the key or select with the rapidkey.

START

START

START

START04

START05

START06

START07

START

START

START10

START11

START

PCU ROM Ver.:

START

AREA PRINT MODE

CHECK PATTERN 1

CHECK PATTERN 2

CHECK PATTERN 3

PAPER FEED AGING

BIAS ADJUST MODE

LIFE SET MODE

LIFE ALL CLEAR

LIFE ENTRY MODE

TOP ADJUST MODE

LIFE CLEAR MODE

key

Enterthe modewith the key.

(Diag•specifications)

FUNC

9 8 6

01

02

03

08

09

3) Memory clear when power is turned on

Pressing the START and STOP keys, turn on the main power, and

the following message will be displayed.

MEMORY CLEAR

EXECUTE ? 1 = YES , 2 = NO

Here, when 1: YES is selected, the memory will be cleared to be

ready for operation.

If 2: NO is selected, it will continue ready for operation as it is.

2 – 2

Page 17

FO-5500U/C

2. Diagnostic items description

2-1. Fax diagnosis

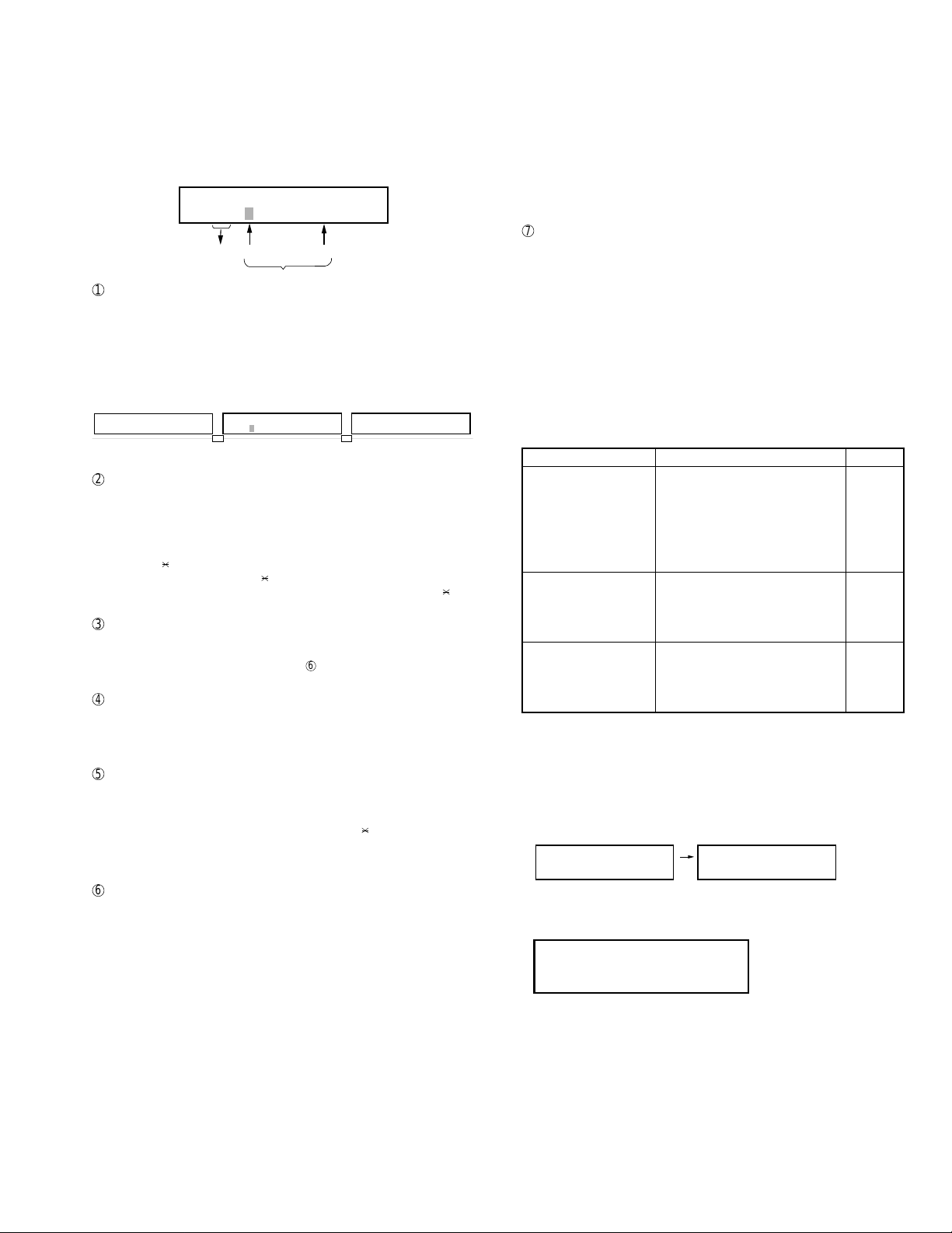

1) Soft switch mode

In this mode, the soft switch are set and the soft switch list is printed.

Soft switch mode screen

Soft switch mode screen

S O F T S W I T C H M O D E

S W 0 1 = 0 0 0 0 0 0 0 0

8

1

Switch number selection

Switch

No.

1

Data

• Press START key for setting of the next soft switch. If the soft switch

number is the final, pressing START key will exit the soft switch

mode.

• Enter two digits of a soft switch number to set the switch number. If

a switch number of unexisting soft switch is entered, key error

buzzer sounds to reject the input.

S O F T S W I T C H M O D E

S W 0 1 = 0 0 0 0 0 0 0 0

2

Data number selection

S O F T S W I T C H M O D E

S W 1

1 6

S O F T S W I T C H M O D E

S W 1 6 = 0 0 0 1 0 1 1 0

The cursor position shows the data to be set.

Pressing # key moves the cursor to the right. If, however, the cursor is

on data number 8, pressing # key shifts the cursor to data number 1 of

the next switch number. If the switch number is the final, pressing # key

will exit the soft switch mode.

Pressing key moves the cursor to the left. If, however, the cursor is

on data number 1, pressing key shifts the cursor to data number 1

of the former switch number. If the switch number is 1, pressing key

will not move the cursor.

3

Data setting method

Press the FUNCTION key, and the data at the position of the cursor

will be reversed to 0 when it is 1, or to 1 when it is 0. (If the soft switch

can be changed at the bit (Refer to 6.), the error buzzer will sound

with the process not received.)

4

Outputting method of soft switch list

In the soft switch mode, press the REPORT key, and the soft switch list

will be output.

If the recording paper runs out or is clogged, the key error buzzer will

sound with the process not received.

5

Storage of data

In the following case, the data of the soft switches set will be stored.

• It is shifted to set the next soft switch by pressing the START switch.

• It is shifted to set the next soft switch with the [#] key.

• It is shifted to set the last soft switch with the [ ] key.

• It is shifted to set another soft switch by inputting two digits as the

switch number. (When 2 digits are completely input.)

• Output of the soft switch list is started.

6

Inhibition of data change

(This is also applicable for the optional setting.)

In the following case, it is inhibited to change the data with the key

error buzzer.

• When the print hold bus code is not registered, the print hold func-

tion is turned from OFF to ON.

• When the print hold function is on, the print hold bus code is

cleared.

• When the memory is used because of substitutive receiving, etc, the

print hold function is mutually turned on/off.

• OFF to ON of telephone billing function which is using the image

memory is used (Note: In the existing set, the telephone billing code

function is specified from OFF to ON when the timer system communication (including the batch communication) is set.)

Here, the memory is usable when the telephone billing code function is on. It can be set from ON to OFF while the memory is used.

However, if setting is practically changed even once, it can not be

returned from OFF to ON.

• OFF to ON of multi TTI function and telephone billing code function

when the department control function is OFF.

• OFF to ON of department control function during use of image

memory.

(Note: In the existing set, the department control function is set from

OFF to ON when the timer communication (including the batch

sending) or the memory hold is set.)

• ON to OFF of continuous serial polling function when the continuous

serial polling is started.

(Note: In the existing set, "ON to OFF of the continuous serial

polling function when the continuous serial polling is registered" has

been applied, but the conditions are now moderated. However, registration is impossible to the program of the new continuous serial

polling when the continuous serial polling function is OFF.)

7

Linked change of data (This is the same even in the optional setting.)

• When the department control function is off, the multi TTI function

and telephone billing code function are turned off.

2) Print area

According to the size of the specified sheet, the effective printing area is

printed.

3) ROM & RAM check

The sum value of ROM, the work and the back-up RAM are checked.

The RS-232C interface is also checked. If any error occurs, the buzzer will

inform it. (Refer to the following table). Finally, the result will be printed.

This diagnosis does not check the flash memory. The flash memory is

checked with the flash memory test.

Number of buzzer sounds Device checked Remarks

1 time <Short sound> ROM1 Main

2 times <Short sounds> ROM2 Main

3 times <Short sounds> Integrated ROM/RAM Main

4 times <Short sounds> D-RAM Main

5 times <Short sounds> S-RAM Main

*6 times <Short sounds> S-RAM (on the optional memory) Main

1 time <Long sound> ROM Sub 1

2 times <Long sounds> Integrated ROM/RAM Sub 1

3 times <Long sounds> D-RAM Sub 1

4 times <Long sounds> Dual port RAM1 Sub 1

5 times <Long sounds> ROM Sub 2

6 times <Long sounds> Integrated ROM/RAM Sub 2

7 times <Long sounds> D-RAM Sub 2

8 times <Long sounds> Dual port RAM2 Sub 2

* As practical, it is judged that the optional memory is not installed if any

error occurs. Therefore, it does sometimes not sound.

For the short and long sounds, one pattern is as follows.

Main system: 0.25 seconds ON/0.25 seconds OFF

Sub system: 1.00 second ON/0.25 seconds OFF

The execution state of checking is as follows. Moreover, the list of the

check result is output after checking is ended.

Display during check

ROM CPU SRAM DRM DPR

• • • • • •

<Relationship between display and memory>

Display after check

ROM CPU SRAM DRM DPR

PP P E P

P=PASS E=ERROR

ROM/RAM

check list

output

ROM CPU SRAM DRM DPR

• • • • • •

DRAM (4Mbit)

SRAM (512Kbit x 2)

ROM (4Mbit x 2)

• When the option is installed, two SRAMs

are added every option.

(The type without the optional unit is shown.)

The check result of RS-232C interface board is listed and printed together

with the check result of ROM&RAM.

2 – 3

Page 18

FO-5500U/C

4) Auto feeder mode

The auto feed function can be checked by inserting and discharging

the document.

Check of auto feed function

After this mode is activated, set up the document, and press the

START key, and it will be automatically fed. (Before the START key is

pressed, the document sensor alone is activated.)

Moreover, the document size (A4/B4) and sensor information

(A4/B4/ORG) are displayed when the document sensor is turned.

04 : AUTO FEEDER MODE

()

After setup of the document

04 : AUTO FEEDER MODE

B4 (A4 B4 ORG)

Only the sensor which is

activated (fallen down) is displayed.)

The paper sheet size (A4/B4) is

displayed.

5) Aging mode

If any document is set up in the first state (when started), copying will

be executed. If it is not set up, "check pattern 1" of the print diagnosis

is output at the intervals of 1 time/60 minutes. (A total of 10 sheets

are output.)

6) Panel check mode

This is used to check whether each key is normally operated or not.

According to the key input, LCD is displayed. Moreover, during execution, the document reading lamp is turned on.

1

When [PANEL CHECK MODE] is displayed, press the [START]

key.

The test will be started. When the test is started, LEDs will sequentially come on (the lighting sequence and speed are separately specified). It can be checked whether all LEDs are all lit or

not.

2

Press any other key except [STOP] key.

At this time, the name of each key will be displayed every push of

the key.

3

Finally press the [STOP] key.

If all keys can be input, the key input "ALL KEY OK!!" will be

displayed when the STOP key is ended.

The screen will be all displayed in black, and the test result will be

printed.

In this test, it is okayed if all the other keys except [STOP] key have

been pressed from start of the test to its end (the [STOP] key is

pressed). If any key is skipped, it will be regarded as "KEY ERROR!!",

and the name of the key not pressed will be printed on the list as the

result. This will complete printing.

Some two keys may be interchanged in the hardware. In this case, it

is necessary to check the display when pressing the key.

7) Optical adjust mode

The document reading lamp is turned on.

8) Product check

The diagnosis is used in the production process.

After shift to the mode, the following operations are sequentially executed. At this time, the sensor of read-error can be checked by feeding the B3 document. Set up one short document of B4 size.

1

Memory clear (Same as Diagnosis 11)

2

Panel test (Same as Diagnosis 06)

3

Document feed

4

ROM & RAM test, RS-232C interface board check (Same as the

diagnosis 03)

5

Flash memory test mode (Same as Diagnosis 12)

6

Registration of fixed data

Registration of rapid key No. and other data necessary for production.

The registered data are shown in the following table. The chain

dial is not set for any destination.

Rapid

No.

FAX

No.

Rapid

No.

FAX

No.

Rapid

No.

FAX

No.

Rapid

No.

FAX

No.

01 20 06 25 11 1 21 01

02 21 07 26 12 2 22 02

03 22 08 27 13 3 23 03

04 23 09 28 14 4 24 04

05 24 10 29 15 5 25 05

7

Transmission check (Same as Diagnosis 10)

The soft switches necessary for production are set.

8

Test result print (two sheets)

• AUTO FEEDER CHECK LIST

• FLASH MEMORY CHECK LIST

Memory clear printing

Panel test result printing

ROM&RAM test result printing

Check result printing of RS-232C interface board

9

Print area printing (one sheet)

9) Signal send mode

After shift to the mode, press the START key, and the signals will be

transmitted in the following sequence.

It can be used to check the modem and so on.

[ 1] No signals

[ 2] 4800BPS (V27ter)

[ 3] 33600BPS (V. 34)

[ 4] 31200BPS (V. 34)

[ 5] 28800BPS (V. 34)

[ 6] 26400BPS (V. 34)

[ 7] 24000BPS (V. 34)

[ 8] 21600BPS (V. 34)

[ 9] 19200BPS (V. 34)

[10] 16800BPS (V. 34)

[11] 14400BPS (V. 34)

[12] 12000BPS (V. 34)

[13] 9600BPS (V. 34)

[14] 7200BPS (V. 34)

[15] 4800BPS (V. 34)

[16] 2400BPS (V. 34)

[17] 14400BPS (V. 33)

[18] 12000BPS (V. 33)

[19] 14400BPS (V. 17)

[20] 12000BPS (V. 17)

[21] 9600BPS (V. 17)

[22] 7200BPS (V. 17)

[23] 9600BPS (V. 29)

[24] 7200BPS (V. 29)

[25] 4800BPS (V27ter)

[26] 2400BPS (V27ter)

[27] 300BPS (FLAG)

[28] 2100H z (CED)

[29] 1100Hz (CNG)

This content is executed on the

28,800 bps machine alone.

Note: Since 28,800 bps is not

specified, the contents of

the items may be changed.

2 – 4

Page 19

FO-5500U/C

10) Comm. check mode

Turn on the line monitor.

1

2

Set 0 km at the line equivalence.

3

Bring the copy mode into the continuity mode.

4

It is set to shift into the diagnosis mode when the SPEED key

alone is pressed.

After the check, it is necessary to be sure to return the aforementioned soft switches into the initial state.

(Clear the memory with the diagnosis.)

11) Memory clear

Clear the back-up memory to initialize the soft switches.

The flash memory will be initialized. Then, the initialized list be output.

12) Flash memory

The flash memory is checked.

The ordinary memories (ROM, SRAM, DRAM) are checked in the

ROM&RAM check process. The write/read test is taken every block to

print the result.

When an error occurs, the following error buzzer will sound.

Number of buzzer sounds Check device

7 times <Short sounds> Page memory

8 times <Short sounds> Flash memory

9 times <Short sounds> Flash memory (optional)

During operation of this diagnosis, dual operation is not possible at

all.

If this is excessively repeated, it will shorten the life of the flash

memory.

13) All FAX/TEL. entry mode

Before entry into the diagnosis, the reference destination number is

first written into the Rapid key number 01 in the FAX number registration mode.

1

The diagnosis mode is activated. If any number is not registered in

the Rapid key number 01 or any program or group is registered,

the diagnosis will be passed without any execution.

2

The FAX/TEL number (including the substitutive one) of the Rapid

key number 01 is copied into the Rapid key numbers 02 thru 48.

3

The FAX number of the Rapid key number 01 is copied into the

speed key numbers 001 thru 150.

4

If any chain dial is not set in the Rapid key number 01, the Rapid

key numbers 02 thru 48 and speed key numbers 001 thru 150 are

registered in the group number.

If any chain dial is set, any group will not be produced but the

chain dial setting alone of the Rapid dial will be canceled.

(In all other Rapid key numbers except 01, the chain dial is kept

as it is set.)

14) RS-232C check mode

RS-232C interface board is checked.

When the interface board is installed, the result will be printed after

the check.

15) Dept. passcode

The department passcode list is printed.

16) Conf. passcode

The confidential passcode list is printed.

Differing from printing of one box alone soon after registration, the

confidential passcodes of all boxes are printed.

17) Print hold code

The print lockout passcode No. is printed.

18) Memory set mode

The set and dump list of the memory content is output.

• The address (8 digits (P) generally including the bank information

is input, and the data of 2 digits is continuously input.

Inputting is done in the hexadecimal mode. The ten-key is used for

0 thru 9, and the alphabetic keys A (RAPID01 thru 06) are used for

A thru F.

• During data inputting, the address can be moved forward and

backward one byte by one byte with " " and "#". (The address

prior to the address 0 is looped as the maximum address.)

• The Validity of the address is not checked. Accordingly, writ-

ing/reading operations are possible in the address of the memory

not assigned, the address of ROM and so on.

(However, as practical, writing is not done, and the data content

runs short each reading.)

Though writing is possible in the flash memory, a little time is

required.

It is also necessary to take care that the life of the flash memory is

excessively shortened if much data is written in the flash memory.

Since it may run away depending the written content, take minute

care for the writing address.

• When the REPORT key is input, the memory dump list is produced

from the displayed address (here, it is limited at the 16-byte boundary address (address with end 0) which does not exceed the specified address and is just in front.). The dump list is output to a

maximum of 99 pages. If any data of one page can be repeatedly

developed and printed, the list is sufficient. But it is not desired that

the content of plural pages are developed in the memory once and

are then printed. If the STOP key is pressed, it will pass to the

diagnosis after the page which is now being printed is completed

printed.

If the address exceeds the maximum address, it will return to the

address 0 and printing will be continued.

(16th and subsequential letters of the destination name registered in

the Rapid No. 01 will be discarded.)

2 – 5

Page 20

FO-5500U/C

19) Motor aging

• Whether a document is present or not, the motor in the sending

system is kept in rotation until the STOP key is pressed.

• The image quality selection key can be input during stop alone to

set the rotation speed for the image quality.

(Here, the speed for FINE is selected when the intermediate tone

is specified.)

• The image quality for default at the start of execution is STD

regardless of the image quality selection priority of the main body.

• For rotation, the ten key "1" selects the 1-2 phase excitation, "2"

selects the 2-phase excitation and "3" selects the micro step. It can

not be changed during rotation. The 1-2 phase excitation is set as

default.

20) Stamp aging

• It is impossible if any document is not set up.

• The document is fed at the 10 mm intervals, and is continuously

stamped.

• The total number of stamps from entry of the mode is displayed on

the screen.

• The ordinary operation aging which stamps a finish every docu-

ment is executed in the ordinary copying mode.

21) Scanner set mode

• The reading width and motor drive conditions are set.

<Reading width>

1. Top margin

2. Bottom margin

3. Left adjustment (The left position alone is specified.)

Specify the above values.

• Select the above items 1, 2 and 3 with the [ ] and [#] keys, and

set the values with the [←] and [→] keys. The values can be set in

the range of +3.0 mm to -3.0 mm at the 0.1 mm intervals. While

the [←]/[→] key is continuously pressed one second or more, the

setting value is automatically increased/decreased (in the range

between the upper and lower limits).

• Input the quality selection key, and the value will be respectively

set corresponding to the selected image quality. Here, the intermediate tone is the same as for the setting value of FINE.

• ±0.0 mm is default for all.

<Drive conditions of motor>

4. Motor

5. Phase

6. Slow-up

7. Slow-down

Specify the above values.

• Select the above items d thru g with the [ ] and [#] keys, and

select the setting value with the ten-key.

Setting values

4. 6 steps

5. Selection of one mode from 1-2 phase, 2-phase and micro step

6. 3 steps

7. 3 steps

• Input the quality selection key, and the value will be respectively

set corresponding to the selected image quality. Here, the intermediate tone is the same as for the setting value of FINE.

1. TOP

2. BOTTOM

3. LEFT

4. MOTOR

5. PHASE

6. SLOW UP

7. SLOW DOWN

22) Dial test mode

The mode is used to inspect whether dialing is accurate in two kinds

of dial modes or not. All data which can be dialed in this mode are

automatically called up in both PB mode and DP mode.

When this mode is activated, the following operations will be automatically executed to their ends. Whether the dialed content is right or not

is judged with the external instrument which is connected to the line

cable.

1

After shift to the FAX diagnosis mode, press RAPID 22.

(Also switch the display with the [ ] and [#] keys.)

2

Press the START key.

3

Turn on CML, and dial the following in the PB mode.

1, 2, 3, 4, 5, 6, 7, 8, 0, , 0, #

4

Turn off CML 500 mS alone.

5

Dial the following in the DP mode.

1, 5, 9, 0

6

After dialing, turn off CML.

This mode uses the ordinary auto dial. (Accordingly, the signal sending time and minimum pause are all the same as ordinary.

The measurement result in this mode is completely all the same as in

the ordinary dial mode.

Moreover, the same process as above is also done in the dial test

mode which is executed in the product check mode.

23) Copy diag mode

In order to shorten the process time during production, this mode is

used to automatically switch the copy mode. Three menus are provided.

1. 1Set up two documents. (In case of two documents or more,

there is no problem.

2Press the START key.

3Copy 1st document in the fine mode/density AUTO. (One

sheet is printed in the ordinary copy mode.)

4Copy 2nd (subsequential) document in the intermediate

tone mode/density DARK. (In the ordinary copying mode,

one sheet is printed when the RESOLUTION key is pressed

three times.)

When copy test is tried during production or is checked in two modes

(fine and intermediate tones), this mode is provided to reduce the

troublesome work which makes the operator stand aside to change

the mode. Accordingly, the fine and intermediate tones are merely

switched, and the mode is not switched to another mode. (Input of the

image quality/density key is invalid.)

2. Try the copy in the mode fixed at COPY REDUCE 95% and

fine mode/density AUTO. At this time, don’t change the soft

key of COPY REDUCE. (Input of the image quality/density key

is invalid.

3. Continuously try the above items 1 and 2.

2 – 6

Page 21

FO-5500U/C

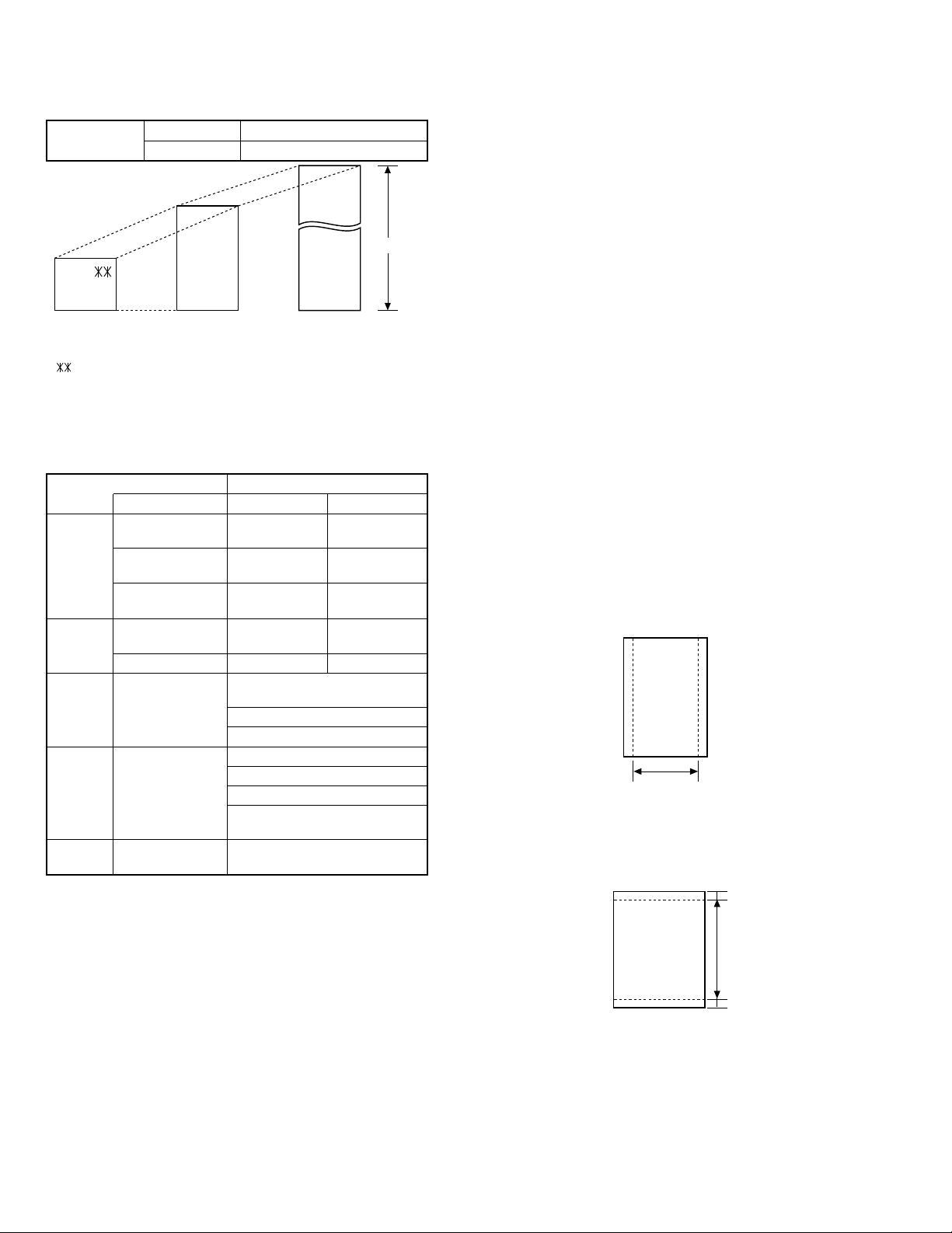

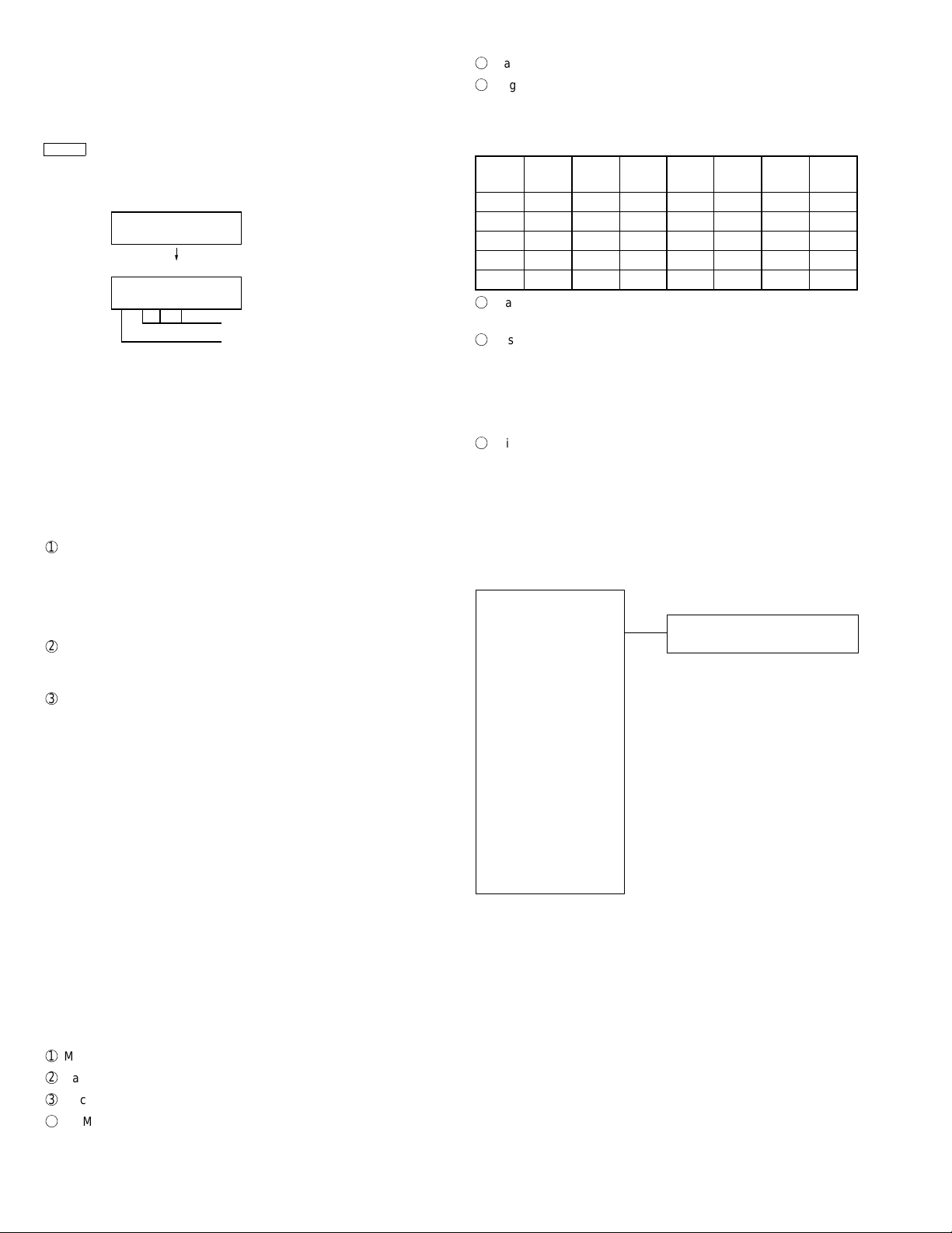

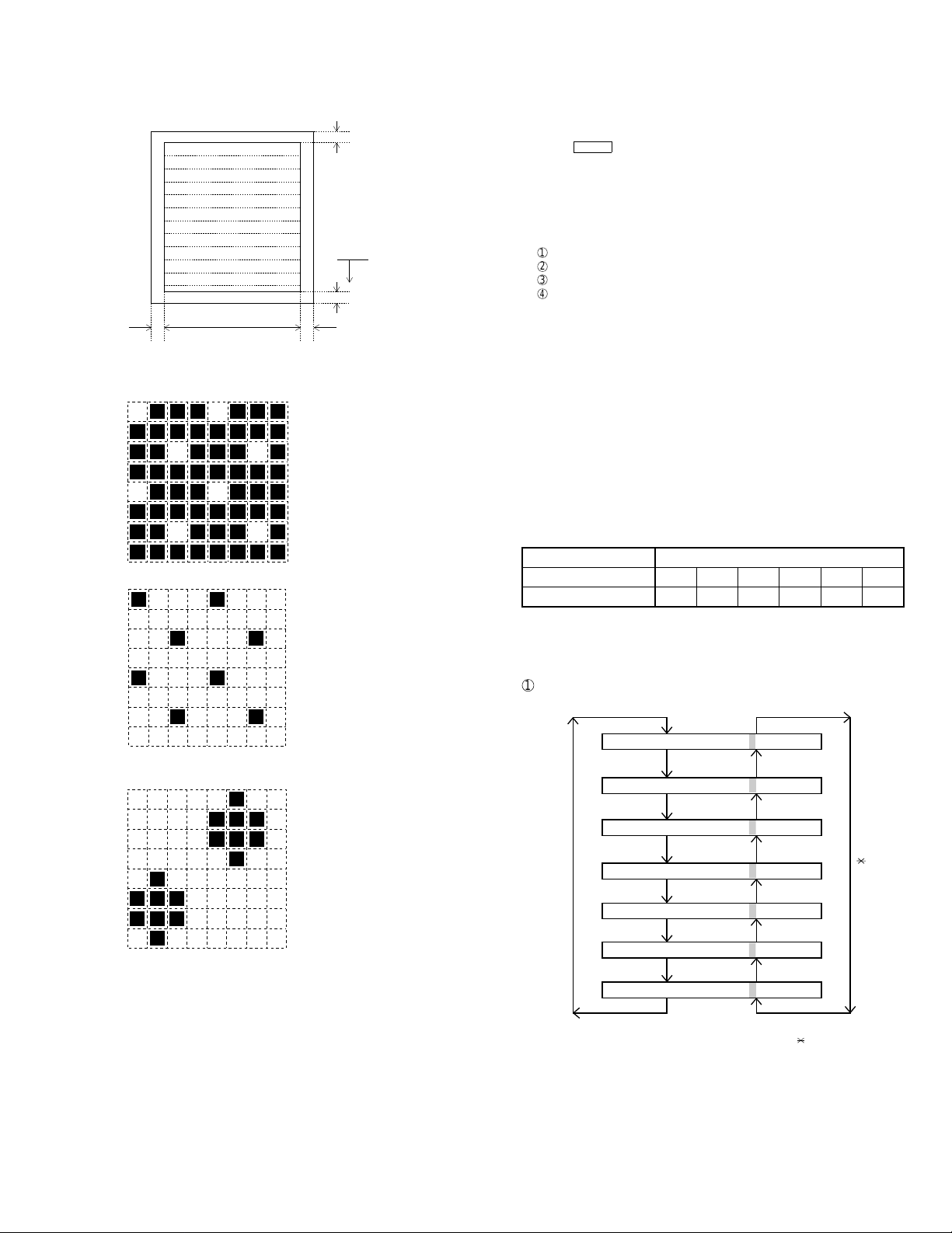

2-2. Print diagnosis

Rapid key 01: Area print mode

The effective printing area frame is printed in the specified sheet size.

+ 1

4mm

1. Full Black pattern

2. Intermediate tone 2 pattern

3. Intermediate tone 1 pattern

4. Mesh point pattern

5. Longitudinal strip 2 pattern

6. Lateral strip 2 pattern

7. Longitudinal strip 1 pattern

8. Lateral strip 1 pattern

9. Full white pattern

208mm

4mm ± 2

1. [Full black pattern]

2. [Intermediate tone 2 pattern]

3. [Intermediate tone 1 pattern]

4mm

The left pattern is repeated.

The left pattern is repeated.

- 2

pattern is repeated.

5mm

Rapid key 02: Check pattern 1

The lateral stripe 2 pattern is printed on one sheet.

(Black 2 line and white 2 line are repeated.)

Rapid key 03: Check pattern 2

The lateral stripe 2 pattern is printed on multiple pages.

Press the STOP key to end the printing.

Rapid key 04: Check pattern 3

The intermediate tone 1 is printed on one sheet.

Rapid key 05: Paper feed aging

The mode is used for aging related to the printing. In this mode, the

following modes are provided.

1 Blank paper aging mode (ALL WHITE AGING)

2 Whole black print aging mode (ALL BLACK AGING)

3 5% printing aging mode (5% AGIN G)

4 4% printing aging mode (4% AGIN G)

After selecting the paper-pass aging mode in the print diagnosis mode,

input the number of each mode above with the ten-key, and the mode will

be executed. The detailed specifications of each mode are described as

follows. Here, the operation in each mode is stopped only when the STOP

key is pressed by the operator or a printing-impossible error occurs.

• Blank paper aging mode

In the mode, printing is continued in the whole white (white paper) printing

pattern until the STOP key is pressed by the operator. (In the printing area)

• Whole black printing aging mode

In the mode, printing is continued in the whole black (whole black) printing

pattern until the STOP key is pressed by the operator. (In the printing area)

Rapid key 6: Bias adjust mode

The mode is used to adjust the printing density of the printed image. The

image printing density is adjustable in six steps of 1 to 6.

For details, refer to the following table. (For selection, use the keys 1 thru

6.)

Image printing density Thin ←→Thick

123456

Default value O

Rapid key 7: Life set mode

The mode is used to set the life counter of the printer and the counter of

the auto feeder at desired values. For setting, proceed with the following

procedure.

1

When the life counter setting mode is selected, the following will be is

displayed.

4. [Mesh point pattern]

The left pattern is repeated.

5. [Longitudinal strip 2 pattern]

Black 2 dot and white 2 dot are repeated in line.

6. [Lateral strip 2 pattern]

Black 2 line and white 2 line are repeated.

7. [Longitudinal strip 1 pattern]

Black 1 dot and white 1 dot are repaeted in line.

8. [Lateral strip 1 pattern]

Black 1 line and white 1 line are repeated.

9. [Full White pattern]

LIFE

LIFE

IFE1

= 00123

0

= 00123

0

= 00123

0

= 00123

0

= 00123

0

0

0

# key

MACHINE

DRUM

L

LIFE2

LIFE3

FEEDER L I FE= 00123

TONER LIFE= 00123

The cursor blinks at the top data.

Seven counters can be selected with the "#" and " " keys.

key

2 – 7

Page 22

FO-5500U/C

2

In the state 1, input a desired setting number of 6 digits with the

ten-key.

3

After input of 6 digits, shift to another counter with the "#" and " " keys

as necessary. When all necessary counters are completely input, press

the START key.

4

"STORED" will be displayed with the set values stored into the mem-

ory. For checking, retry this mode.

Note:

The counter shows the operational state of the printer (how many sheets

have been printed since start of use? and others). The ordinary memory

does not reset the counter. For clearing, set 0 in this mode or use the life

counter clear mode in Item 3-9. (Accordingly, it is necessary to reset the

counter or do the clear process in addition to the ordinary memory clear if

the content in the memory on the control PWB is broken because of PWB

repair, etc. (In the production stage, it is necessary to execute this in the

last process.)

Rapid key 08: Life all clear

The mode is used to clear the life counter of the printer of the counter

of the auto feeder.

Note: The counter shows the operational state of the printer (e.g.

how many sheets have been printed since start of use?). The

ordinary memory does not reset the counter. For clearing, set

0 in the mode 8 or execute this mode. (Accordingly, it is necessary to reset this counter in addition to the ordinary memory

clear if the content in the memory on the control PWB is

broken because of PWB repair, etc. (In the production stage, it

is necessary to execute this in the last process.)

Rapid key 10: Top adjust mode

As the method to adjust the top margin for printing, adjust top-margin

adjusting VR on the PWB. If this mode is used at this time, adjustment is possible without the printing test every time when VR is

turned.

For the practical use, determine the adjusting value on the basis of

the old data, and adjust to the determined value in this mode. Then,

check it with the printing test.

Rapid key 11: Life clear mode

The mode is used to respectively clear the life counter of the printer

and the counter of the auto feeder. For setting, proceed with the

following procedure.

1

When the life counter clearing mode is selected, the following will

be is displayed.

MACHINE

DRUM

# key

LIFE

LIFE

L

IFE1

LIFE2

LEAR

C

LEAR

C

LEAR

C

LEAR

C

key

Rapid key 09: Life entry mode

(For Serviceman temporary counter)

The mode is used to set a desired value for the judgment value

(alarm judgment counter value) of the general purpose life counters 1

thru 3 of the printer. If the life of a consumable part (developer,

imprinter, etc) is set, the model which has the error display and RMS

function will inform RMS when the counter reaches the set value.

For setting, proceed with the following procedure.

1

When the life counter setting mode is selected, the following will

be displayed.

LI FE1= 00000

# key

LI FE2= 00000

LI FE3= 00000

The cursor blinks at the top data.

Three counters can be selected with the "#" and " " keys.

2

In the state 1, input a desired setting number of 6 digits with the

ten-key.

3

After input of 6 digits, shift to another counter with the "#" and " "

keys as necessary. When all necessary counters are completely

input, press the START key.

4

"STORED" will be displayed with the set values stored into the

memory. For checking, retry this mode.

Note: The counter shows the operational state of the printer (how

many sheets have been printed since start of use? and others). The ordinary memory does not reset the counter. For

clearing, set 0 in this mode or use the life counter clear mode

in Item 3-9. (Accordingly, it is necessary to reset the counter or

do the clear process in addition to the ordinary memory clear if

the content in the memory on the control PWB is broken because of PWB repair, etc. (In the production stage, it is necessary to execute this in the last process.)

0

0

0

key

LIFE3

FEEDER L I FE LEAR

TONER L I FE LEAR

LEAR

C

C

C

Seven counters can be selected with the "#" and " " keys.

2

In the state 1, input the CLEAR key, and the counter will be

respectively cleared.

3

After one clear, move the cursor to another counter with the "#"

and " " keys as necessary, and then press the CLEAR key.

When the necessary counters are completely cleared, press the

STOP key.

2 – 8

Page 23

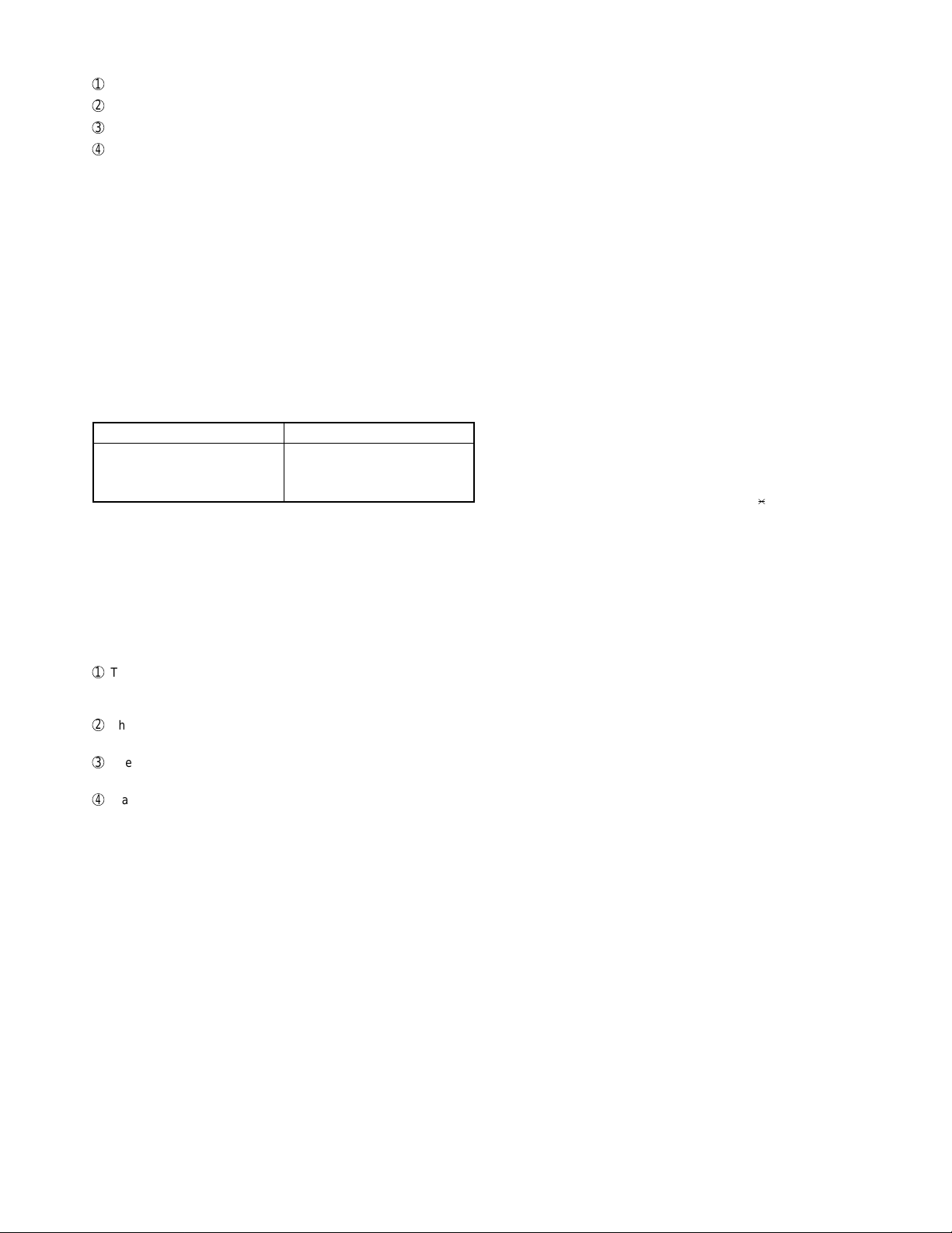

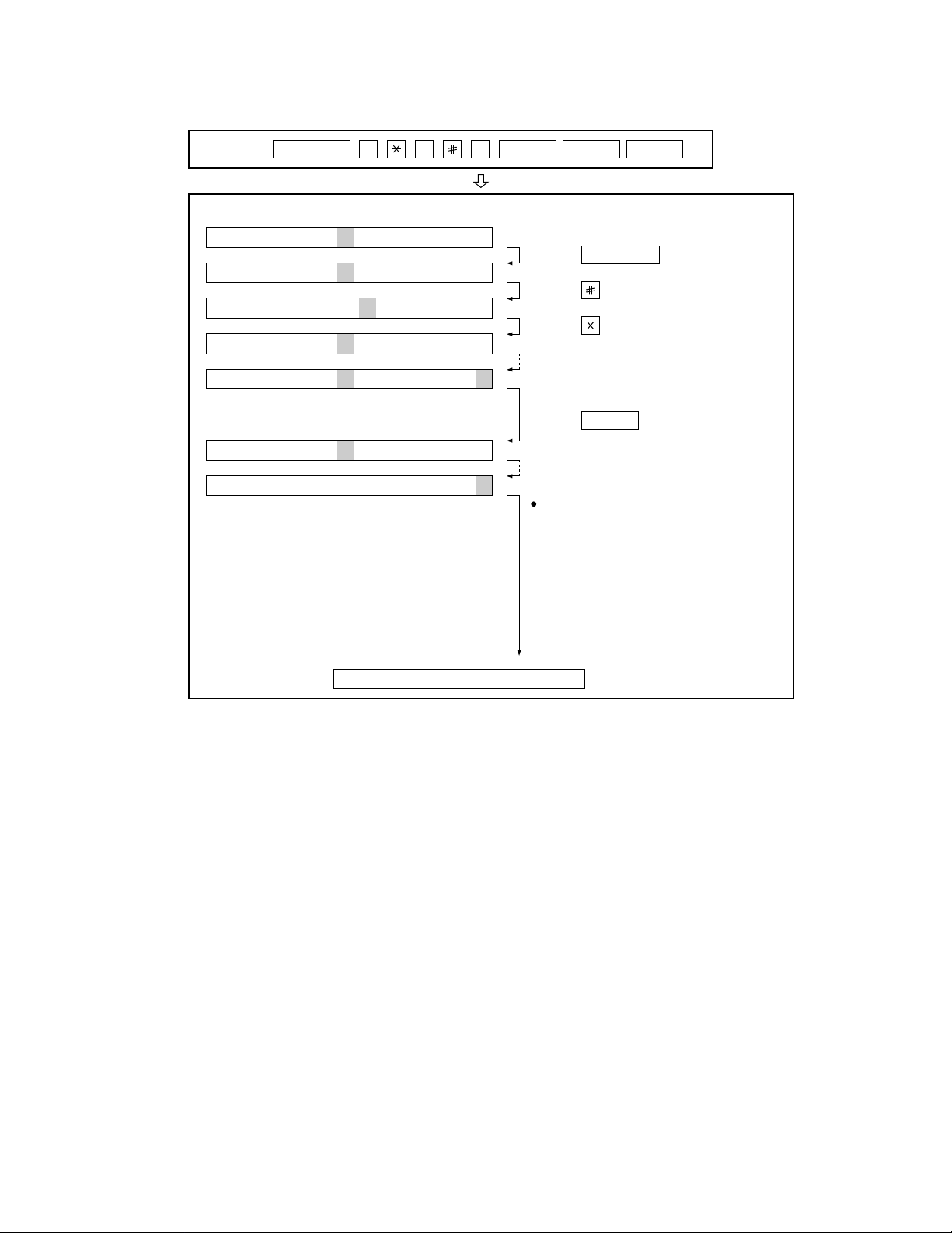

3. How to make soft switch setting

To enter the softswitch mode, make the following key entries in sequence.

FO-5500U/C

Press

FUNCTION

9 8 7 START 0 1START

S F T S W 1 = 0 0 0 0 0 0 0 0

S F T S W 1 = 1 0 0 0 0 0 0 0

S F T S W 1 = 1 0 0 0 0 0 0 0

S F T S W 1 = 1 0 0 0 0 0 0 0

S F T S W 1 = 1 0 0 0 0 0 0 0

S F T S W 2 = 0 0 0 0 0 0 0 0

S F T S W 99 = 0 0 0 0 0 0 0 0

Press FUNCTION key.

Press key.

Press key.

Bit1 - 8 are set.

Press key during setting.

START

Soft SW2 - 99 are set.

To finish the settings halfway between

SW 1 and SW99, press the STOP key.

In this case, the setting being done to

the SW No. on display will be nullified

while settings done to the preceding

SW Nos. remain in effect.

The soft switch mode is terminated.

2 – 9

Page 24

FO-5500U/C

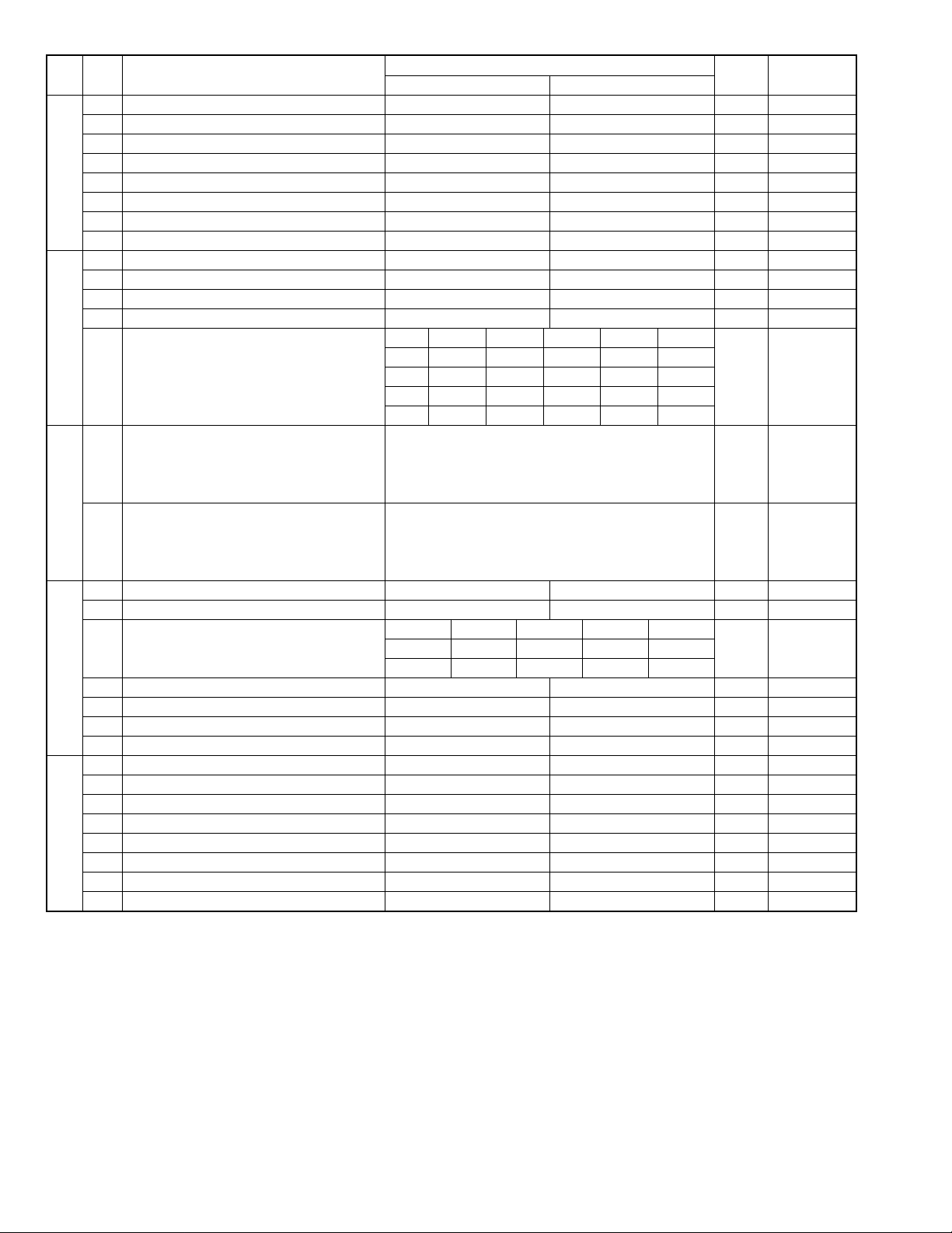

4. Soft switch description

• Soft switch

SW

DATA

NO.

NO.

1 Recall interval Binary input 8 4 2 1 0 OPTION

2 No. = 1 2 3 4 (Data No.) 1 Set to 1~15

3EX01010

SW1

SW2

SW3

SW4

SW5

4 eg. Recall interval is set to 5 min. 1

5 Recall attempts Binary input 8 4 2 1 0 OPTION

6 No. = 5 6 7 8 (Data No.) 0

7 EX 0 0 1 0 1 Set to 1~15

8 eg. Recall attempt times is set to 2 times. 0

1 Dialing mode PULSE TONE 0

2 Receive mode AUTO MANUAL 1

3 ECM mode Off On 0 OPTION

4 Reserved 0

5 Polling security On Off 1 OPTION

6 Auto cover sheet No Yes 1 OPTION

7 JUNK-FAX function in manual reception Yes No 0

8 JUNK-FAX function Yes No 0 OPTION

1 Number of rings for auto-receive

(0: No ring receive)

2 No. = 1 2 3 4 (Data No.) 0 Set to 0~15

3EX00010

4 eg. Number of rings for auto receive is set to 1. 1

5 Switch to auto-receive from manual receive

(0: No switch)

6 No. = 5 6 7 8 (Data No.) 0 Set to 0~15

7EX00000

8 eg. Switch to auto receive is set to disable. 0

Communication results printout Printed at

1 No. 1 0 0 0 1 1 0

2 No. 2 0 0 1 0 1 0

3 No. 3 1 0 0 0 0 1

4 Image addition function to the communication

result table (for memory transmission only)

5 Reserved 0

6 TEL billing code function On Off 0 OPTION

7 Billing code position Before After 1 OPTION

8 Multi-TTI feature On Off 0 OPTION

1 Time display format 24 hours 12 hours-AM/PM 0

2 Date display format Month-Day-Year Day-Month-Year 1

3 Header print Off On 0

4 Footer print On Off 0

5 Relay data output No Yes 0

6 Substitute reception Off On 0

7 Substitute reception conditions Reception disable without

8 CSI transmission Off On 0

ITEM

Switch setting and function

10

Initial

setting

Remarks

Binary input 8 4 2 1 0 OPTION

Binary input 8 4 2 1 0 OPTION

error only

Printed at

error/timer/

memory

only

Printed at

transmission mode

only

Not printed Printed

every time

OPTION

On Off 1 OPTION

TSI

Reception enable without

TSI

0

2 – 10

Page 25

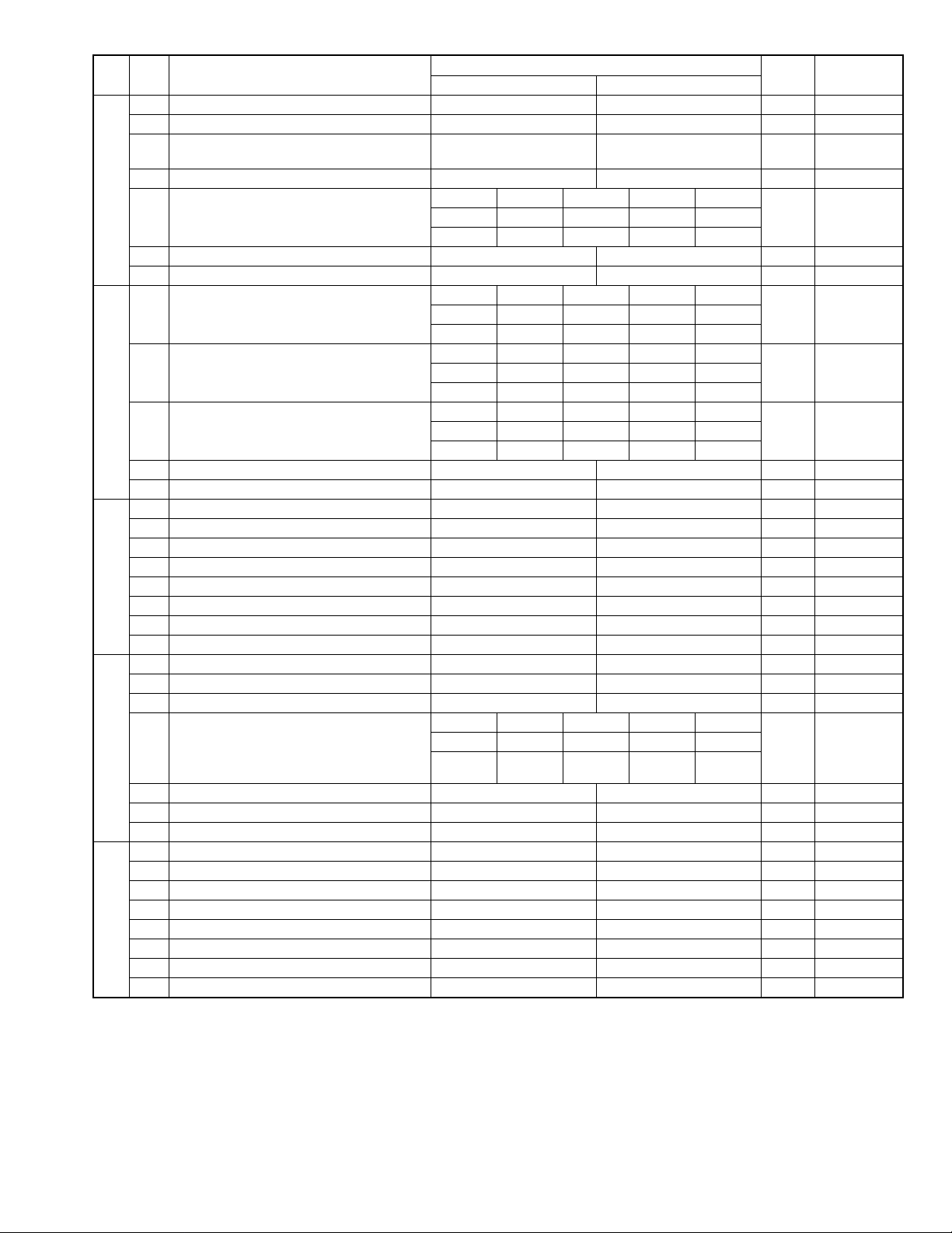

FO-5500U/C

SW

DATA

NO.

NO.

1 MH fixed Yes No (depend on remote

2 H2 mode No Yes 0

3 Reserved 0

SW6

SW7

SW8

Modem speed

(DCS data reception speed)

4 No. 4 00000000

5 No. 5 11110000

6 No. 6 00000000

7 No. 7 01010110

8 No. 8 00111100

Reception speed fixed NO V. 17-

1 No. 1 0 1 0 1 0

2

3 DIS receive acknowledge in G3 transmission Twice Once in NSF reception,

4 Non-modulated carrier in V.29 transmission

mode

5 EOL detection timer 25sec 13sec 0

6 Reserved 0

7 Reserved 0