Page 1

SERVICE MANUAL

No. 00ZFO4400USME

FACSIMILE

FO-4400U

FO-CS1

MODEL

MODEL SELECTION CODE DESTINATION

FO-4400 U U.S.A./Canada

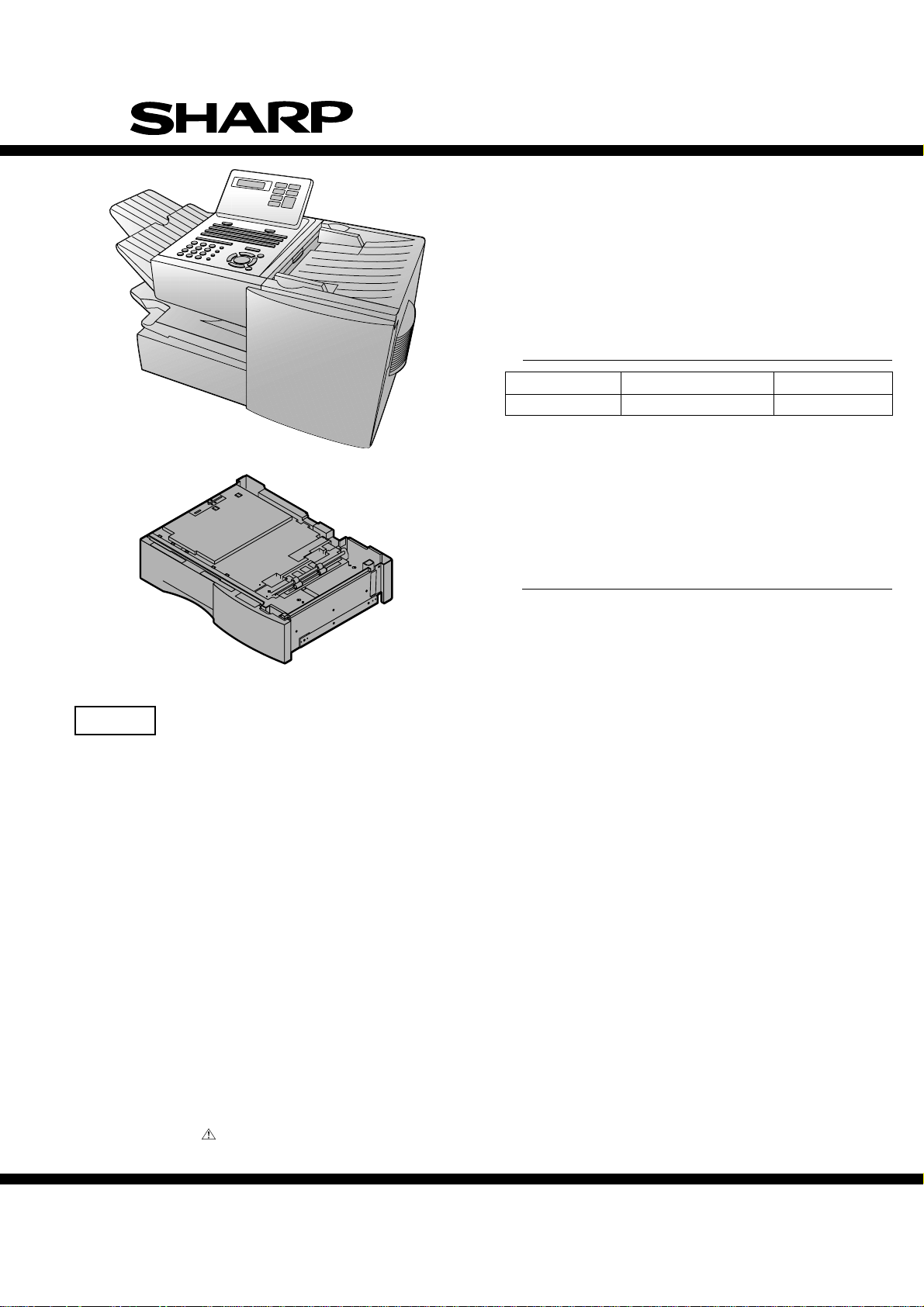

Illustration: FO-4400

FO-4400

OPTION:PAPER CASSETTE

MODEL

Illustration: FO-CS1

CAUTION

This laser printer is a class 1 laser product that complies with 21CFR 1040.10 and 1040.11 of the CDRH or IEC60825-1 standard. This

means that this machine does not produce a hazardous laser radiation. The use of controls, adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This laser radiation is not a danger to the skin, but when an exact focusing of the laser beam is achieved on the eyes retina, there is

danger of spot damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time of servicing.

1) When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged as a unit, not an individual part.

2) Do not look into the machine with the main switch turned on after removing the toner/developer unit and drum cartridge.

3) Do not look into the laser beam exposure slit of the laser optical unit with the connector connected when removing and installing the

optical system.

4) The cover of Laser Printer Unit contains the safety interlock switch.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot.

FO-CS1

OPTION

Toner cartridge: FO-50ND

Drum cartridge: FO-47DR

Option memory: FO-8MK

Verification stamp: FO-45VS

Paper cassette: FO-CS1

Laser Wave Length : 770-795 nm

Laser Pulse Times

Laser Output Power : 5 mW

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

: 51.3 ns

SHARP CORPORATION

1 - 1

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

FO-4400U

FO-CS1

• CAUTION FOR BATTERY REPLACEMENT

• PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] Life of consumable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[3] Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

[4] Transmittable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

[5] Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

[6] Quick reference guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

CHAPTER 2. ADJUSTMENTS

[1] Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[2] Diagnostics and service soft switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

[3] Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

[4] Error code table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

[5] Overseas communication mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

[6] Administrator mode in the personal book function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Mechanical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[2] Printer description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

[3] Disassembly and assembly procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

[4] How to install the verification stamp (FO-45VS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

CONTENTS

CHAPTER 4. DIAGRAMS

[1] Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[2] Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

[3] Point-to-point diagram and connector signal name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[2] Circuit description of control PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[3] Circuit description of CIS unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

[4] Circuit description of LIU PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

[5] Circuit description of operation panel PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

[6] Circuit description of power supply PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Control PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[2] LIU PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

[3] Printer PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

[4] Power supply PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

[5] Operation panel PWB circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

[6] 2nd paper cassette PWB circuit (FO-CS1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

CHAPTER 7. OPERATION FLOWCHART

[1] G3 protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[2] Super G3 protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

[3] Power on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

CHAPTER 8. OTHERS

[1] Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[2] Rewriting version up the FLASH ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

P ARTS GUIDE

1 – 2

Page 3

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the equipment manufacturer.

Discard used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

PRECAUTIONS FOR USING LEAD-FREE SOLDER

FO-4400U

FO-CS1

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type recommandé par le constructeur.

Mettre au rébut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfare vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anweisungen.

11

1

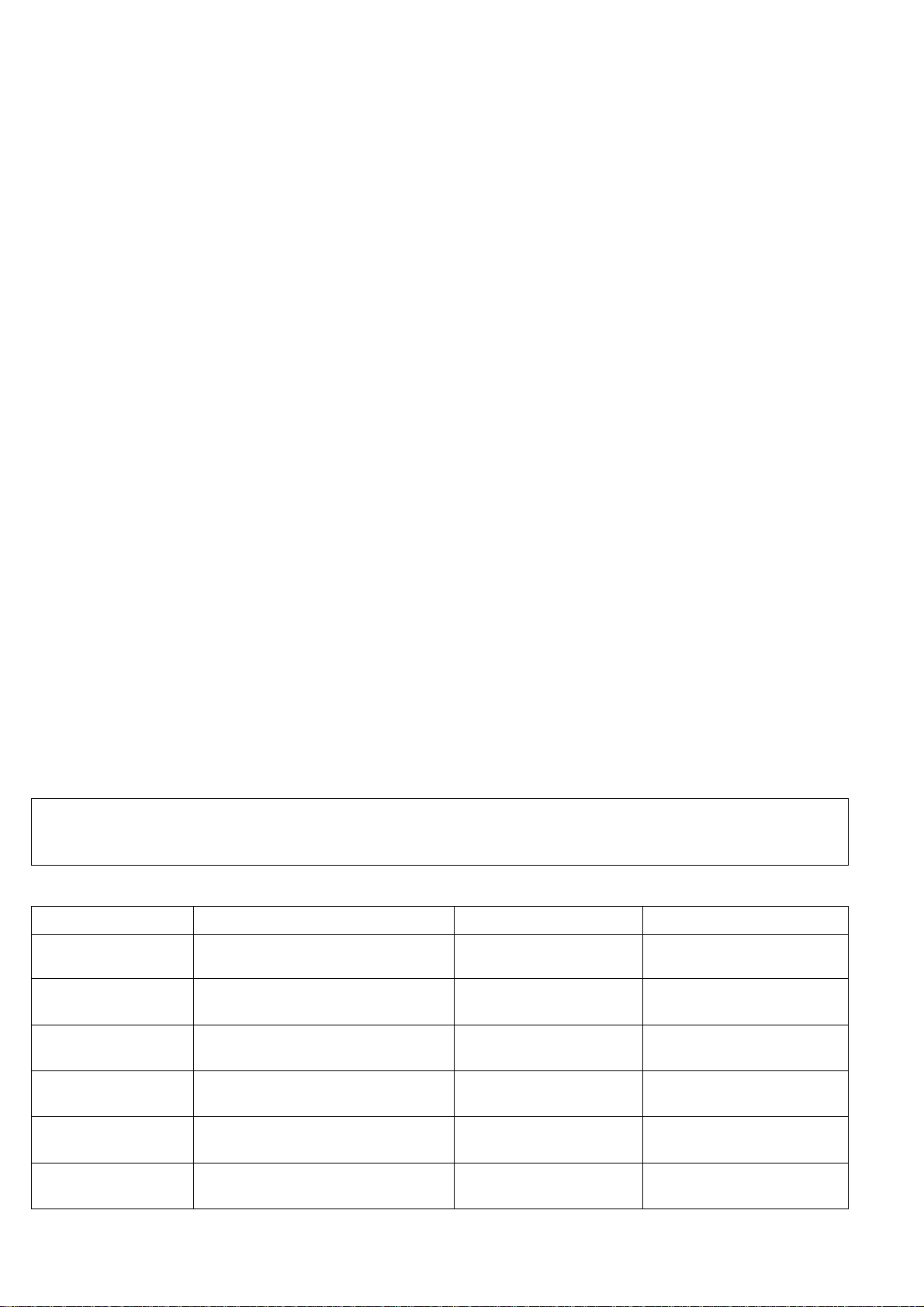

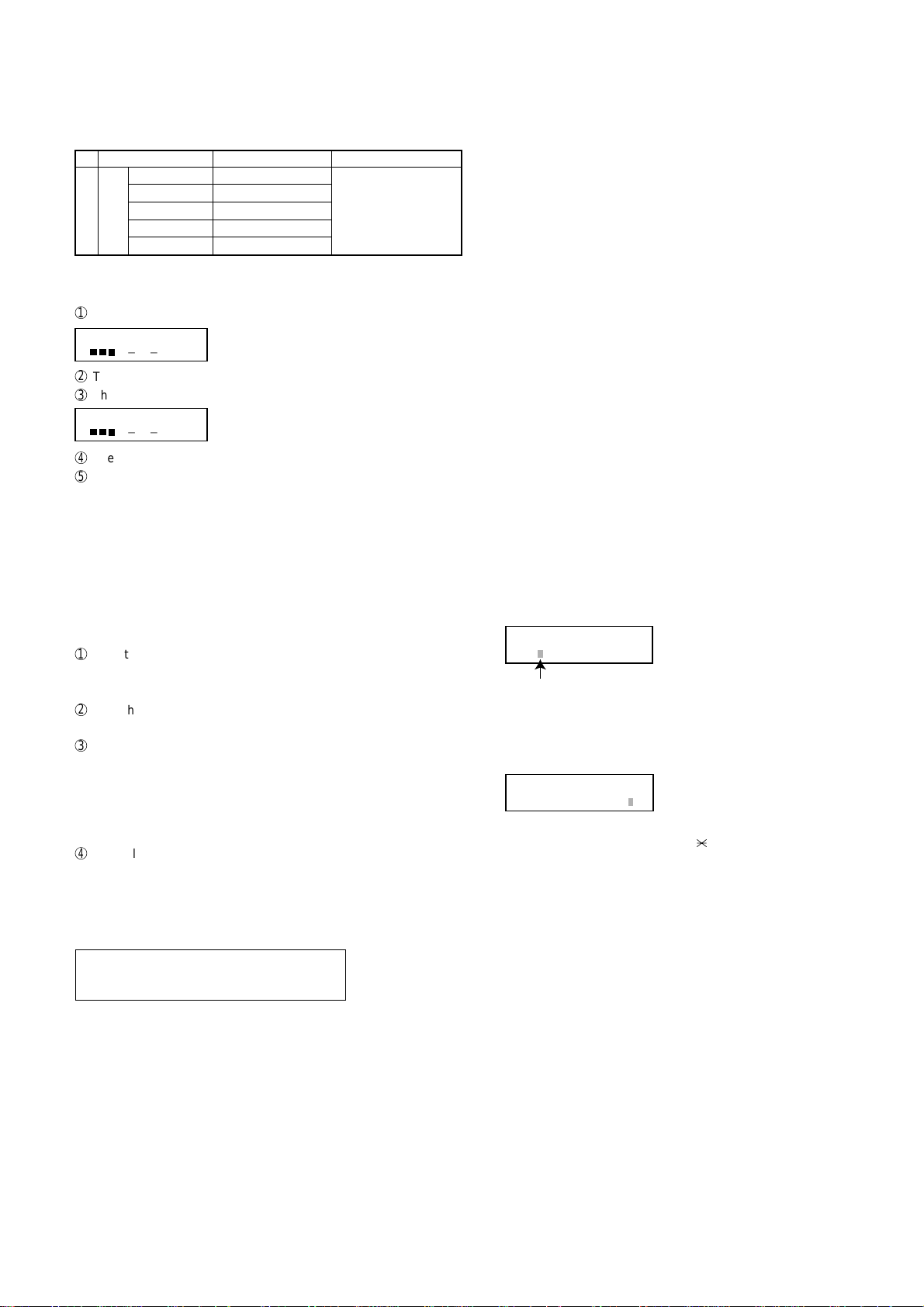

Employing lead-free solder

11

The Power supply PWB of this model employs lead-free solder. This is indicated by the “LF” symbol printed on the PWB

and in the service manual.

The suffix letter indicates the alloy type of the solder.

Example:

Indicates lead-free solder of tin, silver and copper.

22

2

Using lead-free solder

22

When repairing a PWB with the “LF” symbol, only lead-free solder should be used. (Using normal tin/lead alloy solder may

result in cold soldered joints and damage to printed patterns.)

As the melting point of lead-free solder is approximately 40ºC higher than tin/lead alloy solder, it is recommended that a

dedicated bit is used, and that the iron temperature is adjusted accordingly.

33

3

Soldering

33

As the melting point of lead-free solder (Sn-Ag-Cu) is higher and has poorer wettability (flow), to prevent damage to the land

of the PWB, extreme care should be taken not to leave the bit in contact with the PWB for an extended period of time.

Remove the bit as soon as a good flow is achieved.

The high content of tin in lead free solder will cause premature corrosion of the bit.

To reduce wear on the bit, reduce the temperature or turn off the iron when it is not required.

Leaving different types of solder on the bit will cause contamination of the different alloys, which will alter their

characteristics, making good soldering more difficult.

It will be necessary to clean and replace bits more often when using lead-free solder. To reduce bit wear, care should be

taken to clean the bit thoroughly after each use.

1 - 3

Page 4

FO-4400U

FO-CS1

CHAPTER 1. GENERAL DESCRIPTION

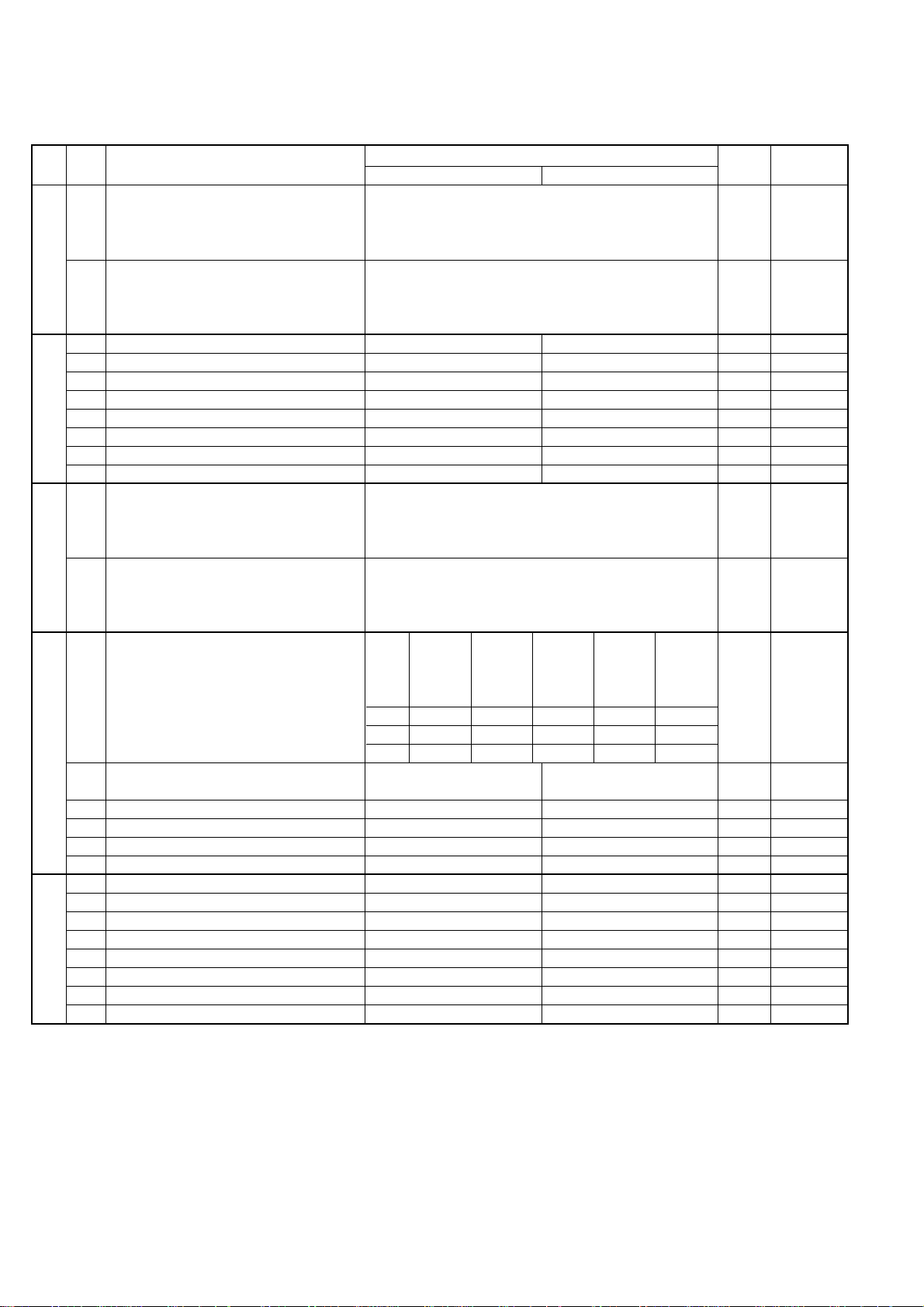

[1] Specifications

• GENERAL

Automatic dialing: Conventional Auto Dialing:

Rapid Key Dialing: 59 numbers

Speed Dialing: 75 numbers

Personal Auto Dial Books: 10 books

(59 Rapid Keys, 16 Speed Dial

numbers per book)

Memory size* : 2 MB (approx. 124 pages)

Optional memory: FO-8MK (8 MB;

approx. 500 pages)

Modem speed: 33,600 bps (max.) with automatic

fallback to lower speeds

Transmission time* : Approx. 3 seconds

Toner cartridge yield: Initial starter cartridge (included with

(continuous printing, fax machine): Approx. 3000 pages

4% page coverage, Replacement cartridge (FO-50ND):

letter paper) Approx. 6000 pages

Drum cartridge yield: Initial starter cartridge (included with

fax machine): 20,000 pages (avg.)

Replacement cartridge (FO-47DR):

20,000 pages (avg.)

Resolution: Horizontal:

203 pixels/inch (8 dots/mm)

Vertical:

Standard: 98 lines/inch (3.85 lines/mm)

Fine/Halftone: 196 lines/inch

(7.7 lines/mm)

Super fine: 391 lines/inch (15.4 lines/mm)

Automatic document feeder: Letter paper (20 lb): Max. 50 pages

Legal paper: Max. 20 pages

(Note: 11” x 17” paper must be loaded

one page at a time.)

Paper capacity: 250 sheets (20 lb)

(500-sheet cassette available as option)

Compression scheme: MMR, MR, MH, Sharp (H2)

Halftone (grayscale): 64 levels

Applicable telephone line: Public switched telephone network

Compatibility: ITU-T (CCITT) G3 mode, Super G3

mode

Printing resolution: Horizontal: 406 lines/inch (16 lines/mm)

Vertical: 391 lines/inch (15.4 lines/mm)

Input document size: Automatic feeding:

Width: 5.8 to 10.1” (148 to 256mm)

Length: 5.0 to 14.3” (128 to 364 mm)

Manual feeding:

Width: 5.8 to 11.0” (148 to 279 mm)

Length: 5.0 to 19.0” (128 to 483 mm)

Effective scanning width: 8.2” (208 mm) max.

Effective printing width: 8.0” (203 mm) max.

Reception modes: Auto/Manual

Instascan speed: 1.3 sec/page (letter paper; scan time

only, excludes document feeding time)

Full Dual Access: Yes

Copy function: Single/Multi/Sort (99 copies/page)

Power requirements: 120 V AC, 60 Hz

Operating temperature: 50 - 86°F(10 - 30°C)

Humidity: 20 to 85 % RH

Power consumption: Stand-by: 9 W

Maximum: 760 W

Dimensions: Width: 21.5” (546 mm)

Depth: 16.2” (412 mm)

Height: 13.6” (346 mm)

(Not including paper tray or attachments)

Weight: Approx. 31.3 lbs. (14.2 kg)

(Not including supplies paper tray or

attachments)

* Based on ITU-T Test Chart #1 at standard resolution, excluding time for

protocol signals (i.e., ITU-T phase C time only).

<IMPORTANT PLEASE READ FIRST>

To avoid problems with supplies, please don’t use supplies from other units. Please use new supplies, when supply changes are required.

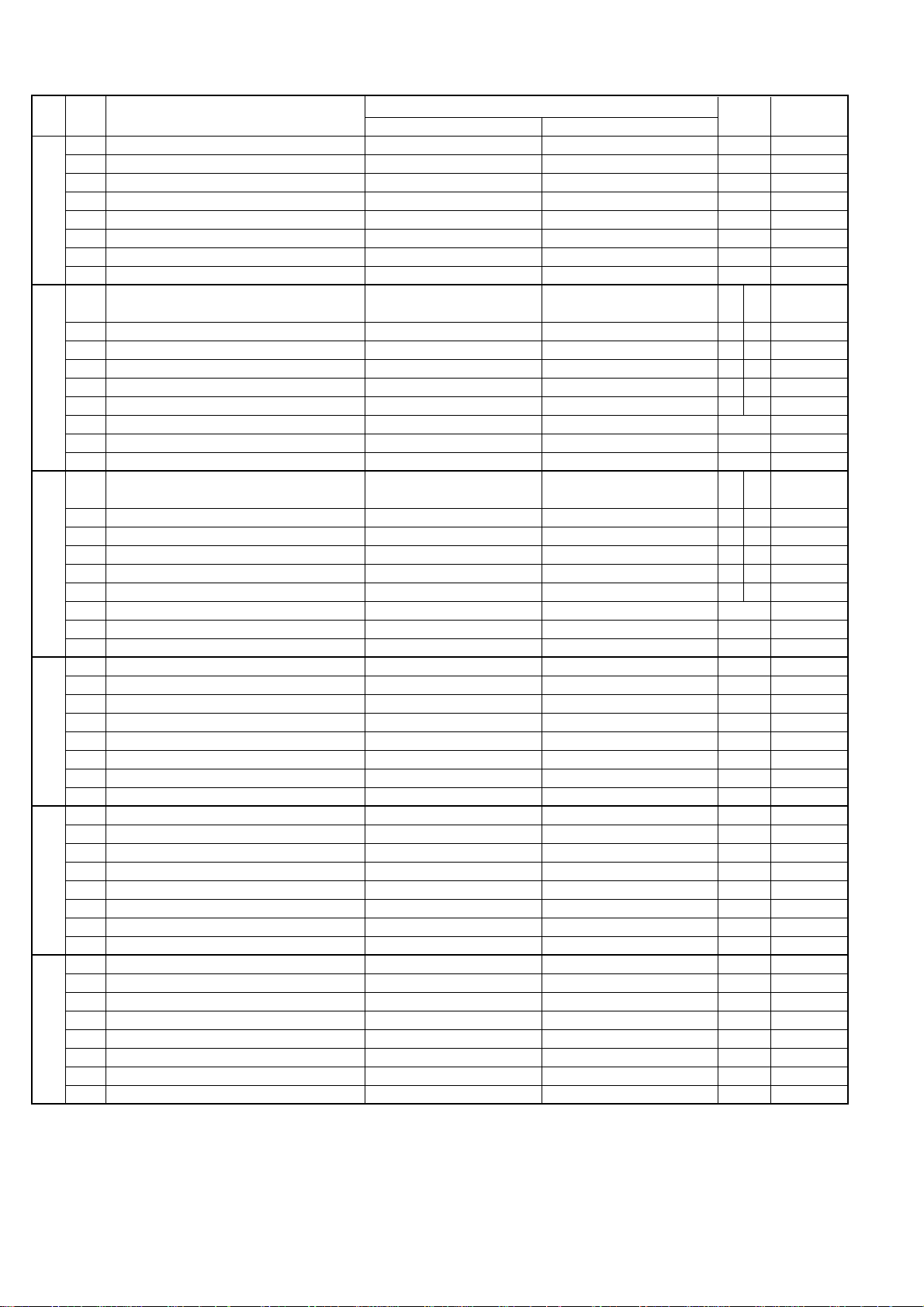

[2] Life of consumable

Section Part Estimated Life Replaced by

Toner cartridge Replacement cartridge 6,000 prints User

(FO-50ND) (at Letter/4% chart)

Drum cartridge Replacement cartridge 20,000 prints User

(FO-47DR) (at Letter/4% chart)

Paper feed Transfer roller

(0KW4127410302)

Fuser Fusing unit

(0KW4127035501)

Paper transport

Paper transfer roller (Refer to the P/G No. 8-6)

(0KW4127300101)

Unit FO-4400 5 years or 75,000 prints ———————

(Refer to the P/G No. 10-8)

(Refer to the P/G No. 9-14)

1 – 1

50,000 prints Service Engineer

50,000 prints Service Engineer

Cleaning as needed ———————

of early either

Page 5

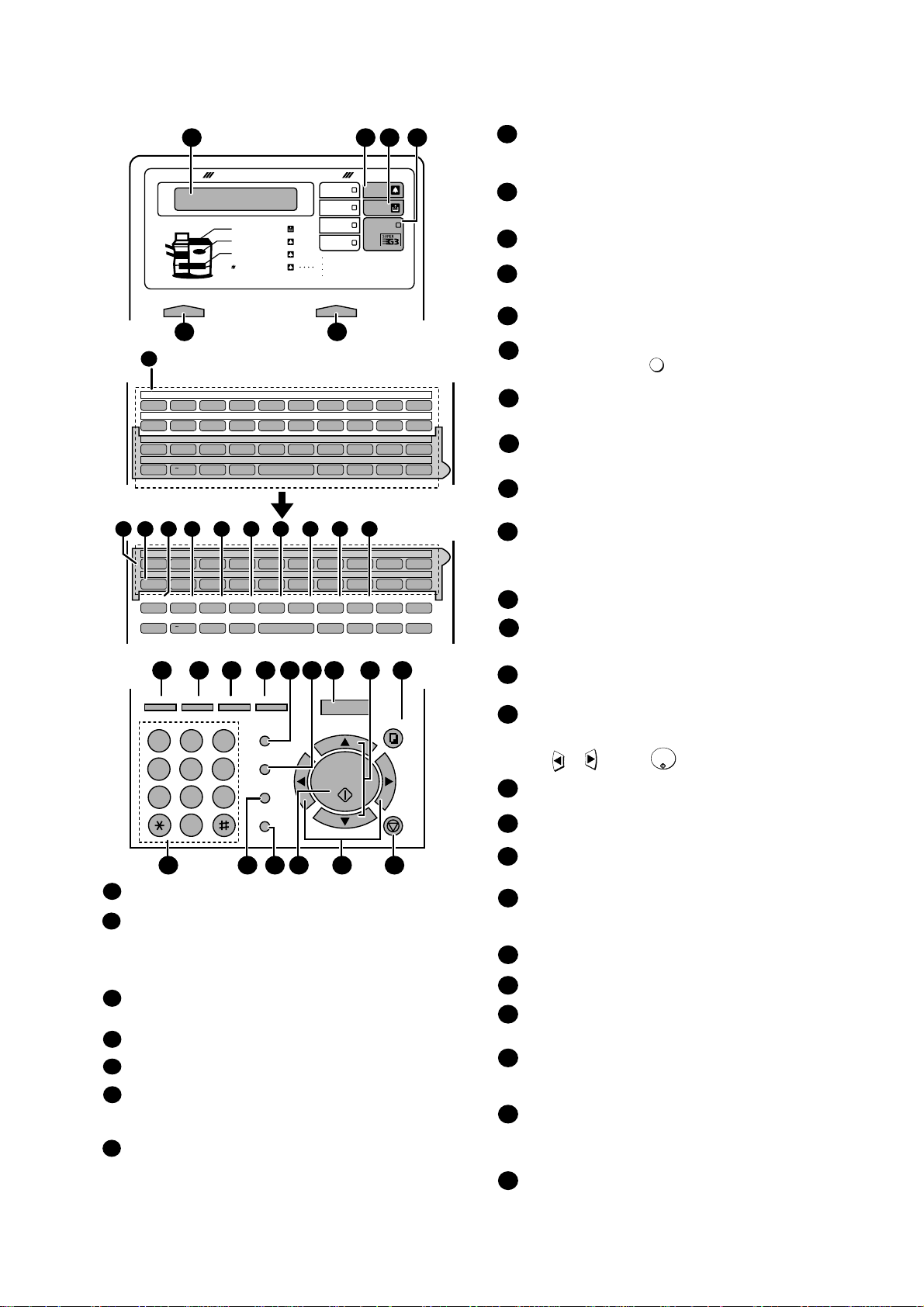

[3] Operation panel

Q / ! W / " E / # R / $ T / % Y / & U / ' I / ( O / ) P / =

SYMBOL

A / |S D F G / { H / } J / [ K / ] L / +

Caps Lock

Z / < X / > C V B N / * M / ? @ .com

SHIFT

/ ^

/ / \ ; / :

Space

_

- . / , DEL

Q / ! W / " E / # R / $ T / % Y / & U / ' I / ( O / ) P / =

SYMBOL

A / |S D F G / { H / } J / [ K / ] L / +

Caps Lock

PAGE COUNTER

CONFIDENTIAL

TIMER

COVER SHEET

LIFE

MEM.STATUS

REPORT

DOCUMENT

Z / < X / > C V B N / * M / ? @ .com

SHIFT

/ ^

/ / \ ; / :

Space

_

- . / , DEL

01 02 03 04 05 06 07 08 09 10

11 12 13 14 15 16 17 18 19 20

40 41 42 43 44 45 46 47 48 49

50 51 52 53 54 55 56 57 58 59

21 22 23 24 25 26 27 28 29 30

31 32 33 34 35 36 37 38 39

7

7

8 10 11 12 13 14 15 16

PLAIN PAPER LASER FACSIMILE

HALF TONE

Toner Cartridge

Drum Cartridge

Paper Supply

Paper Jam

Paper Size Error

Printer Cover Open

Out Put Tray Error

ALARM Guide

ALARM

TONER

LINE IN USE

CONTRAST RESOLUTION

STANDARD

FINE

SUPER FINE

1

5

2 3 4

6

JKL

ABC1DEF

WXYZ

9

GHI

4

5

MNO

6

PQRS

7

TUV

8

0

2 3

OPER

PERSONAL

BOOK

SPEED DIAL

REDIAL

SPEAKER

JOB STATUS

DUPLEX SCAN

PRIORITY

BROADCAST

MENU

UP

ZA

DOWN

START/

ENTER

COPY/HELP

STOP

1717 24241818 1919 2020 2525

2626 3030 31312727 2929

2323

2828

22222121

PAGE COUNTER key

Press this key to include a slash and the total number of pages after each

page number on the pages of a transmitted document.

CONFIDENTIAL key

Press this key to send or print out a confidential document.

TIMER key

Press this key to set an operation to be performed automatically at a later

time.

11

COVER SHEET key

Press this key to include a cover sheet when sending a fax.

LIFE key

Press this key, followed b y , to check the total number o f pag es printed

by the fax machine.

MEM. ST ATUS key

Press this key to chec k the status of fax transmission jobs, copy jobs, and

receptions.

fax This key can also be used to cancel a job.

REPORT key

Press this key to print out a report on the most recently completed

transmission or reception.

DOCUMENT key

Press this key to trans mit a docu ment dire ctly from t he f e eder without

it into memory .

1

15

16

13

12

14

JOB STATUS key

Two types of information appear in the display: prompts related to

operations

you are performing, and information about how the fax machine

is

using the telephone line (transmitting, receiving, etc.). Press this key to

between the two types of information.

DUPLEX SCAN key

Press this key to transmit or copy a two-sided document.

PRIORITY key

Press this key when you need to transmit a document ahead of other

documents waiting in memory for transmission.

BROADCAST key

Press this key to send a fax to a group of receiving fax machines.

17

19

20

18

PERSONAL BOOK

Press this key to use or store an auto-dial number in a personal book. If

book has a passcode, enter the passcode; otherwise, select the book

with

or and press .

SPEED DIAL key

Press this key to dial a Speed Dial number.

MENU key

Press this key to select special functions and settings.

UP and DOWN arrow keys

Volume setting: Press these keys to change the speaker volume when the

SPEAKER key has been pressed, or the ringer volume at any other time.

COPY/HELP key

When a document is in the feeder, press this key to make a copy of a

document. At any other time, press this key to print out the Help List, a

reference guide to the operation of your fax machine.

Dial keypad (numeric keys)

Use these keys to dial and program fax numbers.

REDIAL key

Press this key to automatically redial the last number dialed.

SPEAKER key

Press this key wh en trans mittin g a document b y Normal Dialing to l isten to

the

line and verify the response of the receiving fax machine.

START/ENTER key

Press this key to begin fax transmission when using Speed Dialing, Direct

Keypad Dialing, or Normal Dialing. This key i s also use d to sel ect s etting s

and

complete entries when storing names and numbers.

Left and right arrow keys

Auto-dial numbers: Press these keys to search for an auto-dial number

when sending a fax.

MENU key settings: Press these keys after pressing the MENU key to

scroll

through the MENU key settings.

STOP key

Press this key to cancel an operation before it is completed.

START/

ENTER

24

25

26

27

28

29

30

31

23

21

22

Display

This displays messages and prompts to help you operate the machine.

ALARM indicator

This blinks when one of the paper sources is empty or the drum cartridge is

near the end of its life (printing is still possible). This lights steadily when the

drum cartridge has reached the end of its lif e, all paper sources are empty, the

print compartment cover is open, or a paper jam has occurred (printing is not

possible). A message will appear in the display to indicate the problem.

TONER indicator

This blinks when the toner cartridge nears empt y, and lights steadily when

the

toner cartridge needs replacement.

LINE IN USE light

This lights when the fax machine is using the telephone line.

CONTRAST key

Press this key to adjust the contrast before sending or copying a document.

RESOLUTION key

Press this key to adj us t the res ol uti on be fore sending or copying a document.

An indicator will light next to the selected setting (HALFTONE, STANDARD,

FINE or SUPER FINE).

1

2

3

4

5

6

reading

change

the

quick

9

Rapid Dial Keys

Press one of these keys to dial a fax number automatically. (Note that you

must attach the Rapid Key labels.) When navigating through the display

menu, a Rapid Key can also be pressed in place of the numeric keys to

enter a two-digit number (for example, you can press Rapid Key 01 to enter

the number “01”).

7

10

9

SYMBOL key

When entering a name, press this key to enter the symbol on a letter key

(the character to the right of the slash). Press the key again to turn off

symbol entry mode.

8

1 – 2

FO-4400U

FO-CS1

Page 6

FO-4400U

(

)

[

]

[Sp

]

FO-CS1

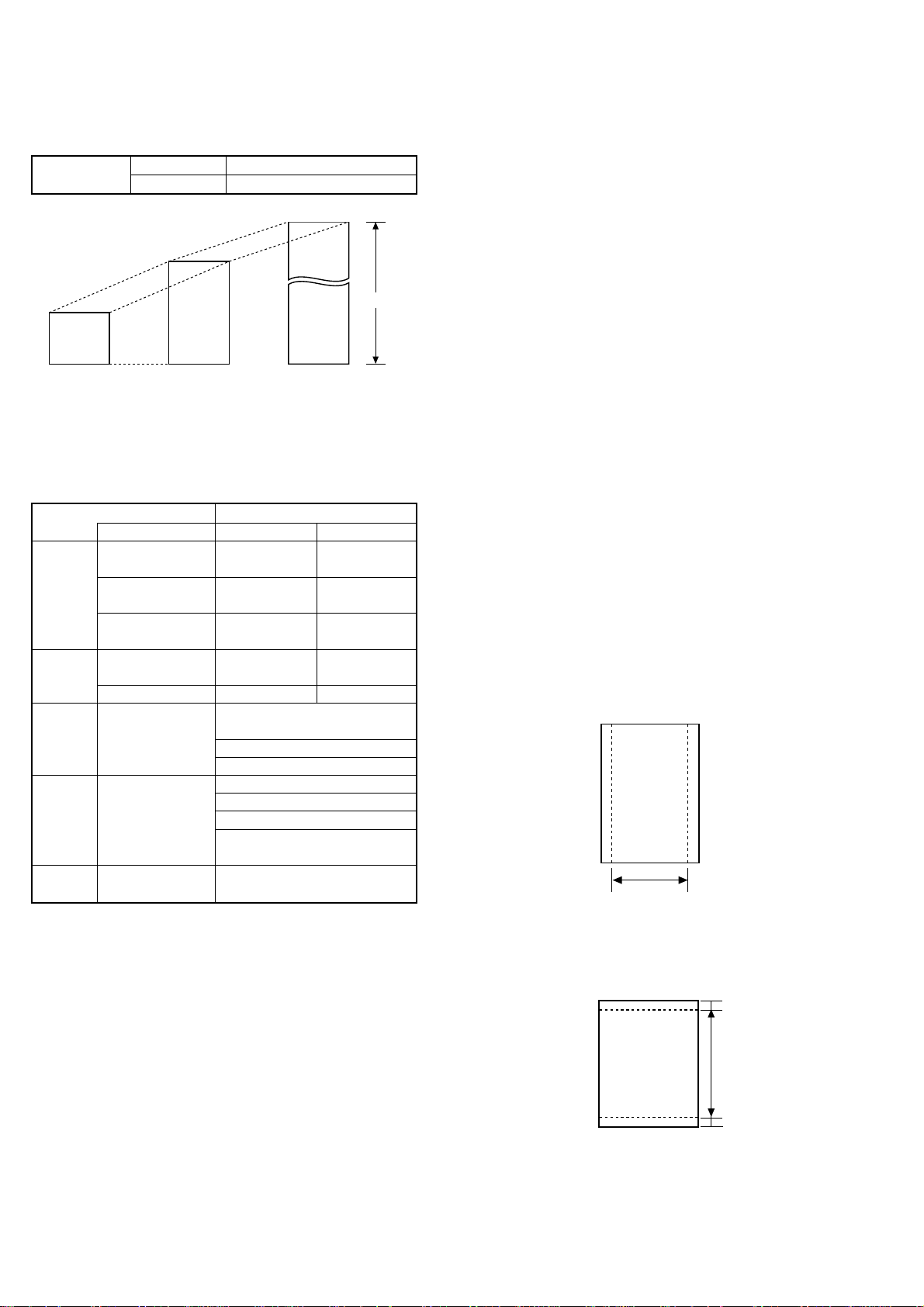

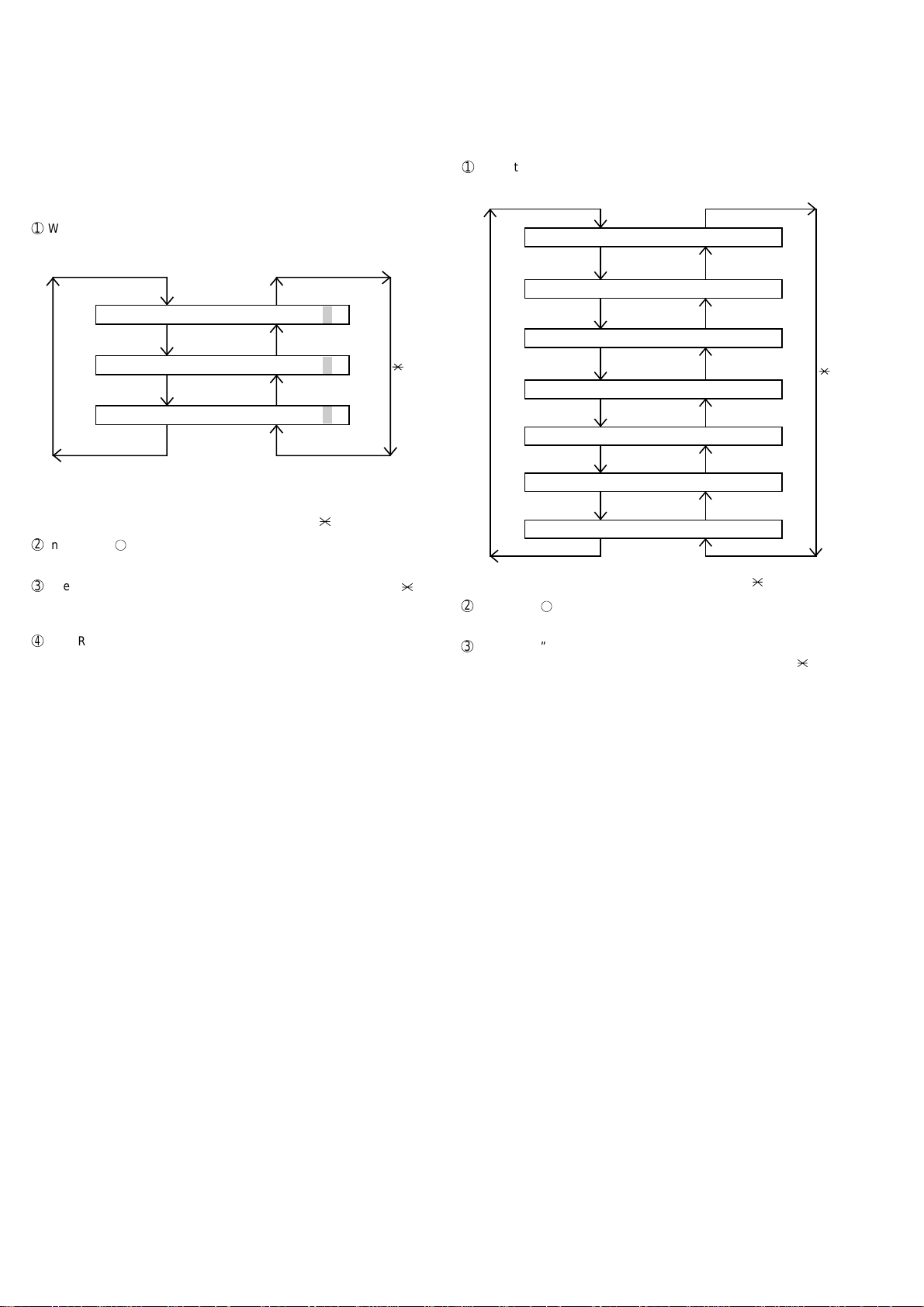

[4] Transmittable documents

1. Document Sizes

Normal size

(Min.)

128 mm

148 mm 256 mm

* With special sizes, only one sheet can be fed into the machine at a

time. Insert next page into feeder as current page is being scanned.

2. Paper Thickness & Weight

Weight Japanese indication 45kg paper 70kg paper

indication Size 4 × 6

Metric system 52g/m

indication

American indication 14 LB 20 LB

LB system indication

Thickness Metric system 0.06mm 0.1mm

indication indication

Inch system indication 0.0024

Document Document size (148mm × 128mm) ~

size Range W letter (279mm × 483mm)

Number of Document size B6 ~ Letter/A4 size 50 sheets

ADF sheets

Paper Kind Paper of fine quality/bond paper/

quality Kent paper

Weight B4 size/Legal 20 sheets

3. Document Types

• Normal paper

Documents handwritten in pencil (No. 2 lead or softer), fountain pen,

ball point pen, or felt-tipped pen can be transmitted.

Documents of normal contrast duplicated by a copying machine can

also be transmitted.

• Diazo copy (blueprint)

Diazo copy documents of a normal contrast may be transmitted.

• Carbon copy

A carbon copy may be transmitted if its contrast is normal.

width 5.8" – 10.1" (148 – 256 mm)

length 5.0" – 14.3" (128 – 364 mm)

(Max.)

80g/m

0.0035

483 mm

2

"

(Max.)

Normal size

Indication Lower Limit Upper Limit

364 mm

279 mm

ecial size

Product specifications

2

"

A4 (210mm × 297mm)

Letter (216mm × 279mm)

W letter size 1 sheet

90 kg (104g/m2) or more

135 kg (157g/m2) or less1 sheet

4. Cautions on Transmitting Documents

• Documents written in yellow, greenish yellow, or light blue ink cannot

be transmitted.

• Ink, glue, and correcting fluid on documents must be dry before the

documents can be transmitted.

• All clips, staples and pins must be removed from documents before

transmission.

• Patched (taped) documents should be copied first on a copier and

then the copies used for transmission.

• All documents should be fanned before insertion into the feeder to

prevent possible double feeds.

5. Automatic Document Feeder Capacity

Number of pages that can be placed into the feeder at anytime is as

follows:

Normal size: max. 50 sheets (14 lbs - 20 lbs)

Special size: single sheet only (manual feed)

NOTES: • If you need to send or copy more 50 pages, place the ad-

ditional pages and carefully in the feeder just before the

last page is scanned. Do not try to force them in, as this

may cause double-feeding or jamming.

• If your document consists of several large or thick pages

which must be loaded one at a time, insert each page into

the feeder as the previous page is being scanned. Insert

gently to prevent doublefeeding.

6. Readable Width & Length

The readable width and length of a document are slightly smaller than

the actual document size.

Note that characters or graphics outside the effective document scanning range will not be read.

• Readable width

8.2" (208 mm) max.

Readable width

• Readable length

This is the length of the document sent minus 0.16" (4 mm) from the top

and bottom edges.

0.16"(4mm)

Readable length

4mm

0.16"

1 – 3

Page 7

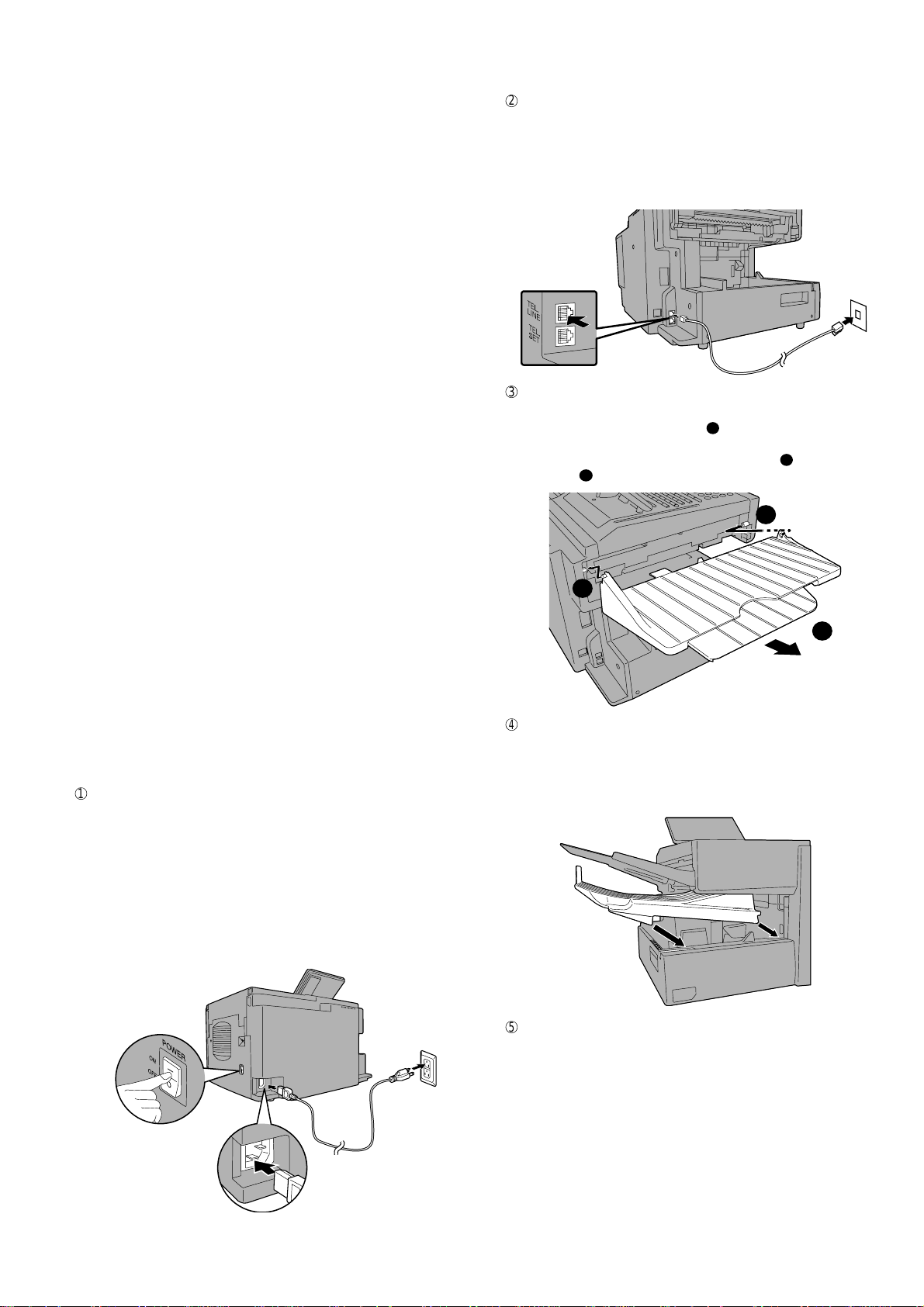

[5] Installation

1. Site selection

T ake the following points into consideration when selecting a site for this

model.

ENVIRONMENT

• The machine must be installed on a level surface.

• Keep the machine away from air conditioners, heaters, direct sun-

light, and dust.

• Provide easy access to the front, back, and sides of the machine. In

particular, keep the area in front of the machine clear, or the original

document may jam as it comes out after scanning.

• The temperature should be between 50° and 86°F (10° and 30°C).

• The humidity should be between 30% and 85% (without condensa-

tion).

ELECTRICITY

AC 120 V, 60 Hz, grounded (3-prong) AC outlet is required.

Caution!

• Connection to a power source other than that specified will cause

damage to the equipment and is not covered under the warranty.

• If your area experiences a high incidence of lightning or power surges,

we recommend that you install a surge protector for the power and

telephone lines. Surge protectors can be purchased at most telephone

specialty stores.

TELEPHONE JACK

A standard RC11C telephone jack must be located near the machine.

This is the telephone jack commonly used in most homes and offices.

• Plugging the fax machine into a jack which is not an RC11C jack may

result in damage to the machine or your telephone system. If you do

not know what kind of jack you have, or need to have one installed,

contact the telephone company.

If the machine is moved from a cold to a warm place...

If the machine is moved from a cold to a warm place, it is possible that

the reading glass may fog up, preventing proper scanning of documents

for transmission. T o remove the fog, turn on the power and wait approximately 2 hours before using the machine.

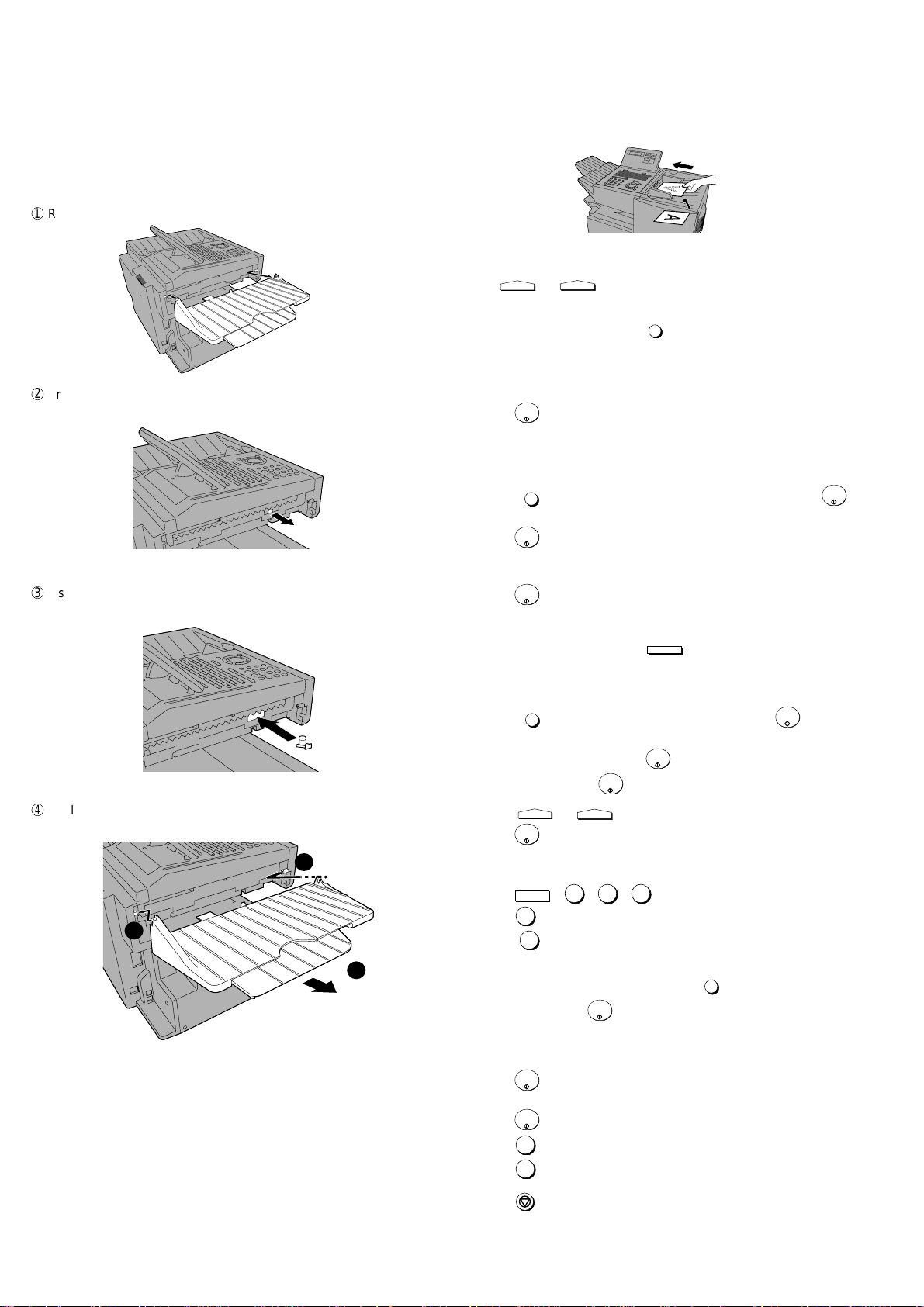

2. Assembly and connections

1

Connecting the power cord

Connect the female end of the power cord to the fax machine as

shown. Insert the male end into a 120 V, 60 Hz, grounded (3-prong)

AC outlet.

Important!: The fax machine requires its own dedicated power outlet.

The power outlet must not be shared with any other devices. In particular, do not use an extension cord to connect multiple devices to the

outlet.

Note: If your area experiences a high incidence of lightning or power

surges, we recommend that you install surge protectors for the power

and telephone lines. Surge protectors can be purchased at most telephone specialty stores.

FO-4400U

FO-CS1

2

Connecting the telephone line cord

Insert one end of the line cord into the jack on the back of the machine marked TEL. LINE. Insert the other end into a standard (RJ1 1C)

single-line wall telephone jack.

Note: The fax machine is set for touch-tone dialing. If you are on a pulse

dial (rotary) line, you must set the fax machine for pulse dialing by changing Option Setting 22.

3

Attaching the ADF exit tray

Insert the protrusion on the right side of the machine into the hole in

the right side of the ADF exit tray 1, then bend the tray slightly and

insert so that the protrusion on the left side of the machine goes into

the hole on the left side of the ADF exit tray 2. Pull out the tray

extension 3.

1

2

3

4

Attaching the received document tray

Slide the received document tray into the machine as shown. When

it stops, lift the end slightly and push in so that the tray locks into

place.

Important!: The received document tray must be attached for the fax

machine to operate properly.

Press the power

switch to turn on

the power.

1 – 4

5

Verification Stamp option (FO-45VS)

Note: This feature is available as an option. Consult your dealer if

you wish to use this feature.

When transmitting a document, you can have the fax machine stamp

each document page as it is scanned. After scanning, you can check

to see if all document have been stamped to verify that no double

feeds occurred. (A double feed occurs when two pages are fed through

the scanner at once, which means that one of the pages is not

scanned.)

To use this function, have your dealer install the Verification Stamp

option, and then set Option Setting 29 to ON.

Page 8

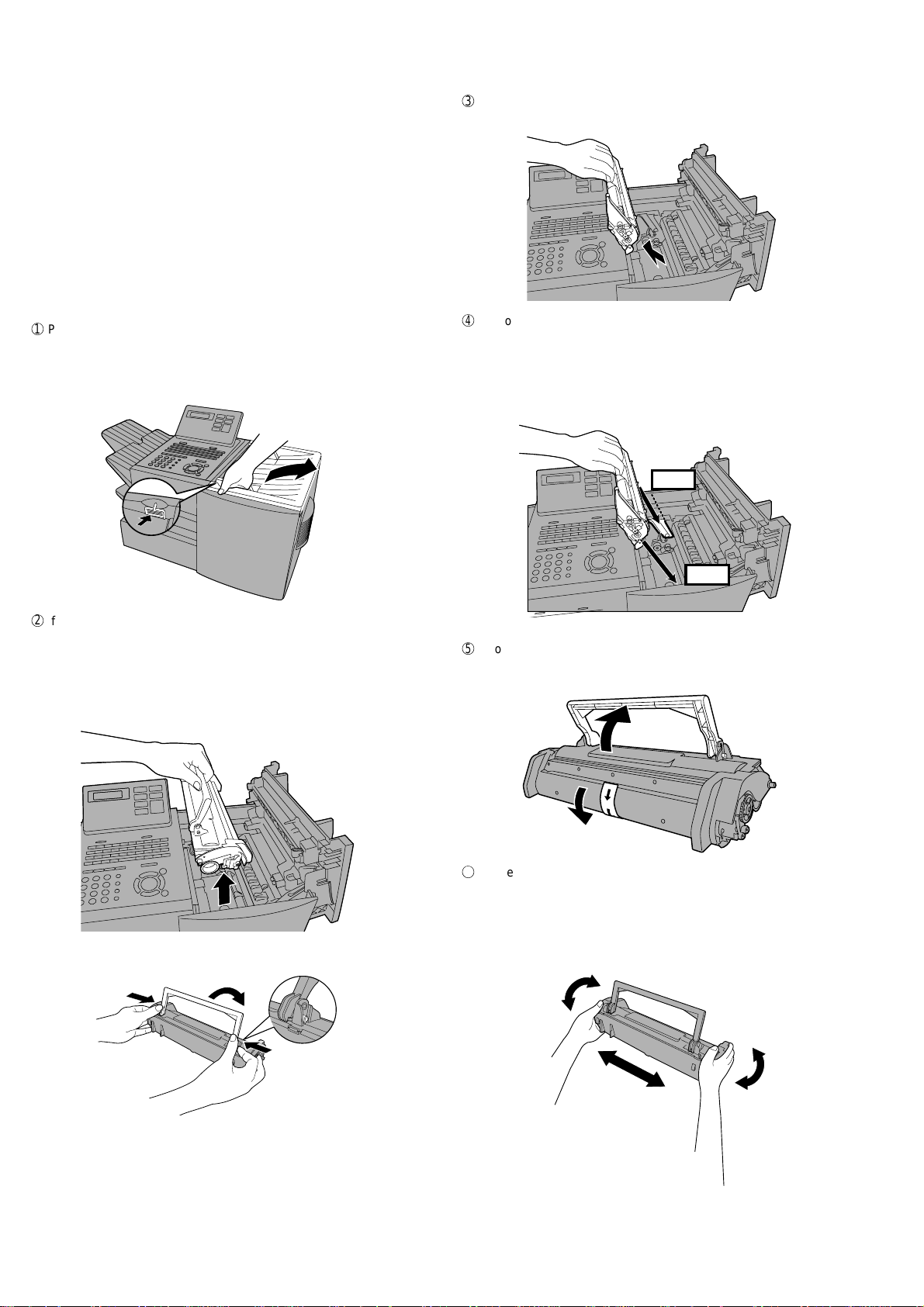

FO-4400U

FO-CS1

3. Installing the printer cartridges

(Toner cartridge: FO-50ND)

(Drum cartridge: FO-47DR)

Follow the steps below to install or replace the toner and drum cartridges.

• The initial starter toner cartridge included with the fax machine can

print approximately 3000 letter-size pages (4% coverage of each

page; continuous printing).

• The replacement toner cartridge (FO-50ND) can print approximately

6000 letter-size pages.

• The drum cartridge (FO-47DR) can print approximately 20,000 let-

ter-size pages.

1

Press the cover release to open the print compartment cover.

• Caution! The fusing unit inside the print compartment becomes

very hot during operation. Be careful not to touch the

inside of the compartment.

3

If you are replacing the drum cartridge, remove the old cartridge and

dispose of it according to local regulations.

4

Remove the new drum cartridge from its packaging. Insert the drum

cartridge into the print compartment.

• Caution! Excessive exposure to light will damage the drum

cartridge. Install the cartridge promptly after removing it

from its packaging.

• Make sure the drum cartridge is inserted in as far as it will go.

BLUE

2

If you are replacing the toner cartridge, remove the old cartridge and

dispose of it according to local regulations.

Go directly to STEP 6 if you are only replacing the toner cartridge

and not the drum cartridge.

• If you are replacing the drum cartridge but not the toner cartridge,

remove the toner cartridge and place it on a sheet of paper.

GREEN

5

If you are installing a new toner cartridge, remove the new toner cartridge from its packaging. Remove the tape from the cartridge and

then open the cartridge handle so that it stands straight up.

6

Shake as indicated by the arrows to distribute the toner evenly within

the cartridge.

• If the toner is still lumpy after shaking, the gears in the cartridge

may make a noticeable sound when the print compartment cover

is closed after installing the cartridge. This is normal and does not

indicate a problem.

To make the cartridge more compact for disposal, press the buttons on

the ends of the handle and fold the handle down.

1 – 5

Page 9

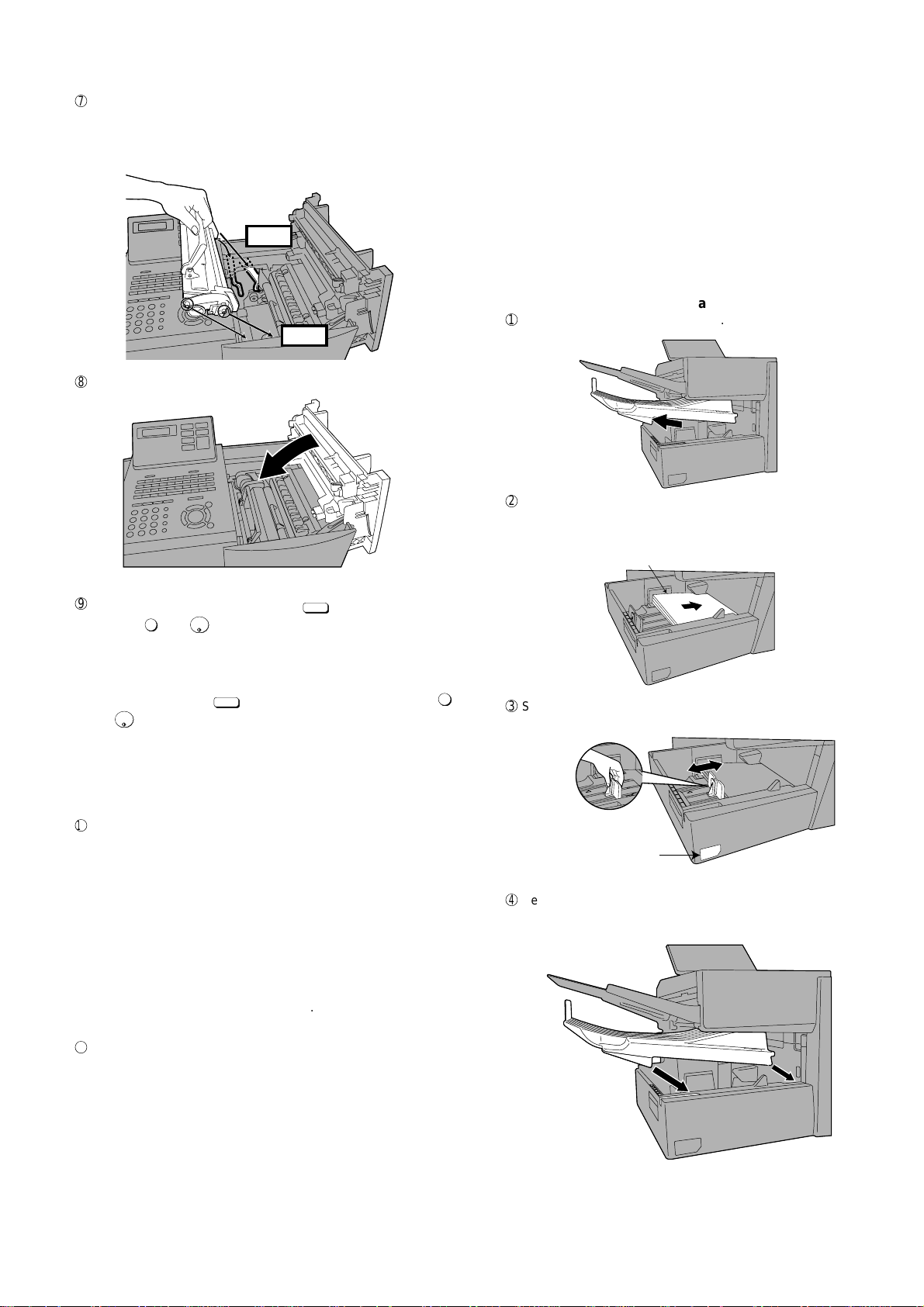

7

Red line

Attach a letter or

legal label here to

indicate the paper size.

Hold the toner cartridge by the handle and insert it into the print compartment.

• Make sure the toner cartridge clicks into place.

• The handle can be left standing up.

BLUE

GREEN

8

Close the print compartment cover.

FO-4400U

FO-CS1

4. Loading printing paper

You can load up to 250 sheets of letter or legal paper (max. 20 lbs.) in

the paper tray.

• A paper cassette is available as an option. Up to 500 sheets of letter

or legal paper can be loaded in the paper cassette. To have the cassette installed, consult your dealer.

Important: Do not use the back side of paper that has already been

printed on.

Note: If you need to add paper to the tray or cassette while paper still

remains, remove the remaining paper and combine it into a single

stack with the new paper.

Loading paper in the paper tray

Remove the received document tray.

1

2

Insert a stack of paper into the tray, print side up.

• Important! The stack of paper must not be higher than the red line

on the paper tray.

9

Reset the drum counter by pressing

overlay), 3, and

START/

ENTER

.

LIFE

(flip up the Rapid Key

V

• Note: The toner counter automatically resets each time you re-

place the toner cartridge. There is normally no need to reset the toner

counter manually . Should you find it necessary to manually reset the

toner counter, press

START/

ENTER

and

.

Note: The print compartment cover may become noticeably warm if a

large number of pages are successively printed. This is normal and does

not indicate a problem in the machine.

F

When to replace the toner cartridge

When the toner cartridge nears empty (about 100 pages can still be

printed), the toner cartridge indicator on the operation panel will blink.

When the toner cartridge is empty, the toner cartridge indicator will

light steadily and REPLACE TONER will appear in the display . Printing will no longer be possible. Use the following replacement toner

cartridge.

Sharp FO-50ND toner cartridge

Hint:

When the toner cartridge nears empty, try taking it out of the machine and shaking it. This may increase the number of pages that

can be printed before the toner runs out.

LIFE

(flip up the Rapid Key overlay), 2 ,

V

3

Squeeze the paper guide and move it to match the length of the

paper you are loading.

4

Replace the received document tray.

• The received document tray must be attached for the fax machine

to operate properly.

G

When to replace the drum cartridge

When the drum cartridge nears the end of its life, the ALARM indica-

tor on the operation panel will blink and DRUM LIFE REACHED will

appear in the display. (this message appears when approximately

1000 pages can still be printed). Use the following replacement drum

cartridge.

Sharp FO-47DR drum cartridge

1 – 6

Page 10

FO-4400U

FO-CS1

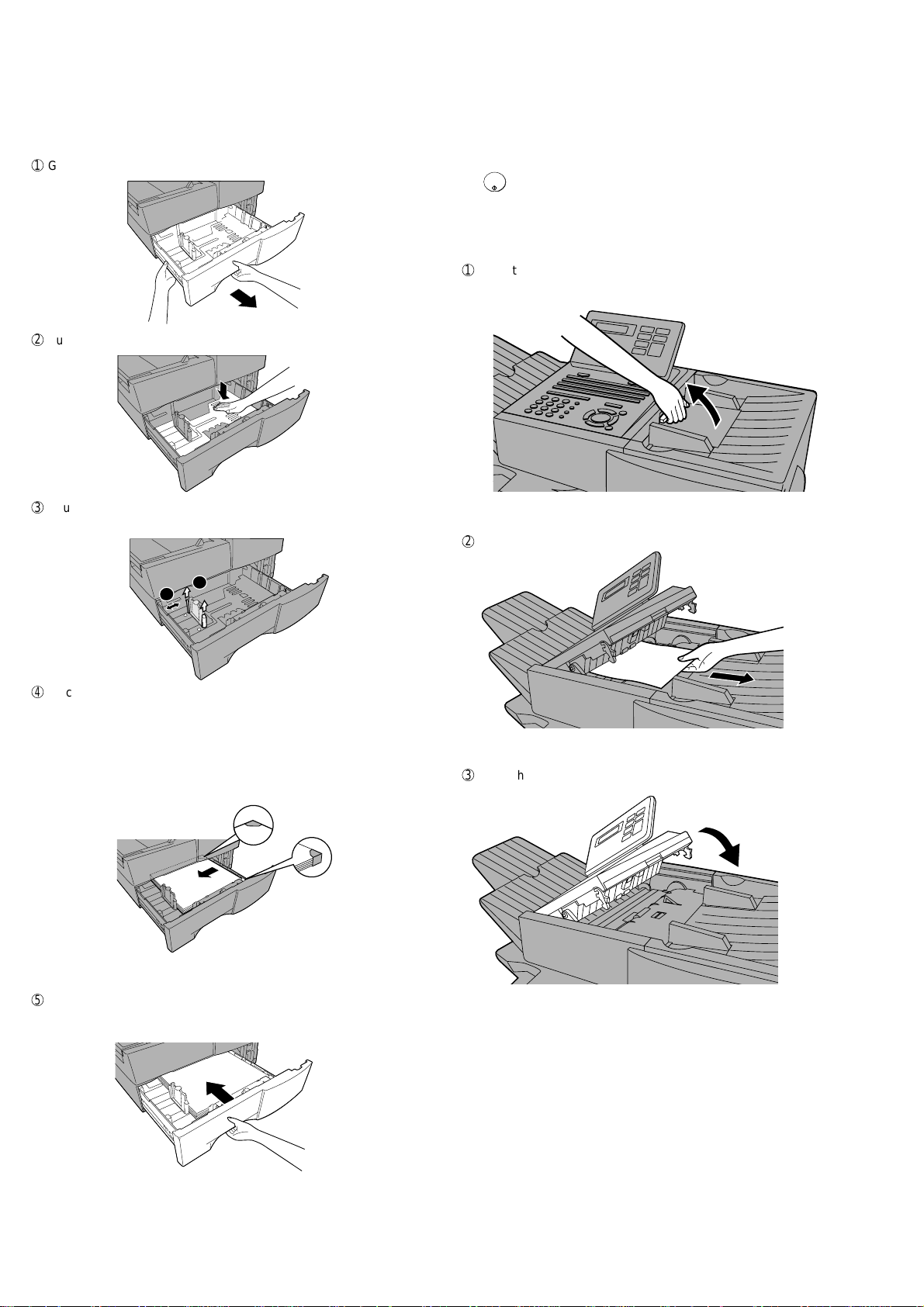

Loading paper in the paper cassette (if installed FO-CS1)

Note: To use A4 paper in the paper cassette, you must have a service

technician adjust the cassette.

1

Grasp the hand-hold on the cassette and pull the cassette out until it

stops.

2

Push the pressure plate down until it locks into position.

3

Squeeze the paper guide and pull up to move it to the appropriate

holes for the length of the paper. Push the guide down into the holes.

5. Clearing paper jams

Clearing a jammed document

If the original document doesn’t feed properly during transmission or

copying, or REMOVE ORIGINAL(S) appears in the display , fist try press-

START/

ENTER

ing

. If the document doesn’t feed out, open the operation panel

and remove it.

Important: Do not try to remove a document without opening the opera-

tion panel. This may damage the feeder mechanism.

1

Open the operation panel.

• Squeeze the release marked PANEL RELEASE and pull up.

2

Remove the document.

1

2

4

Place a stack of paper in the cassette, print side up.

• Make sure the stack of paper is not higher than the two tabs on the

paper guide and the two metal tabs. If it is, remove some of the

paper.

• If you find it difficult to load the paper, remove the cassette from the

machine. (Pull the cassette out as far as it will go, grasp the left

side of the cassette with your left hand, and then lift it up and out

with both hands.)

5

Push the cassette back into the machine, making sure it clicks into

place.

3

Close the operation panel, making sure it clicks into place.

1 – 7

Page 11

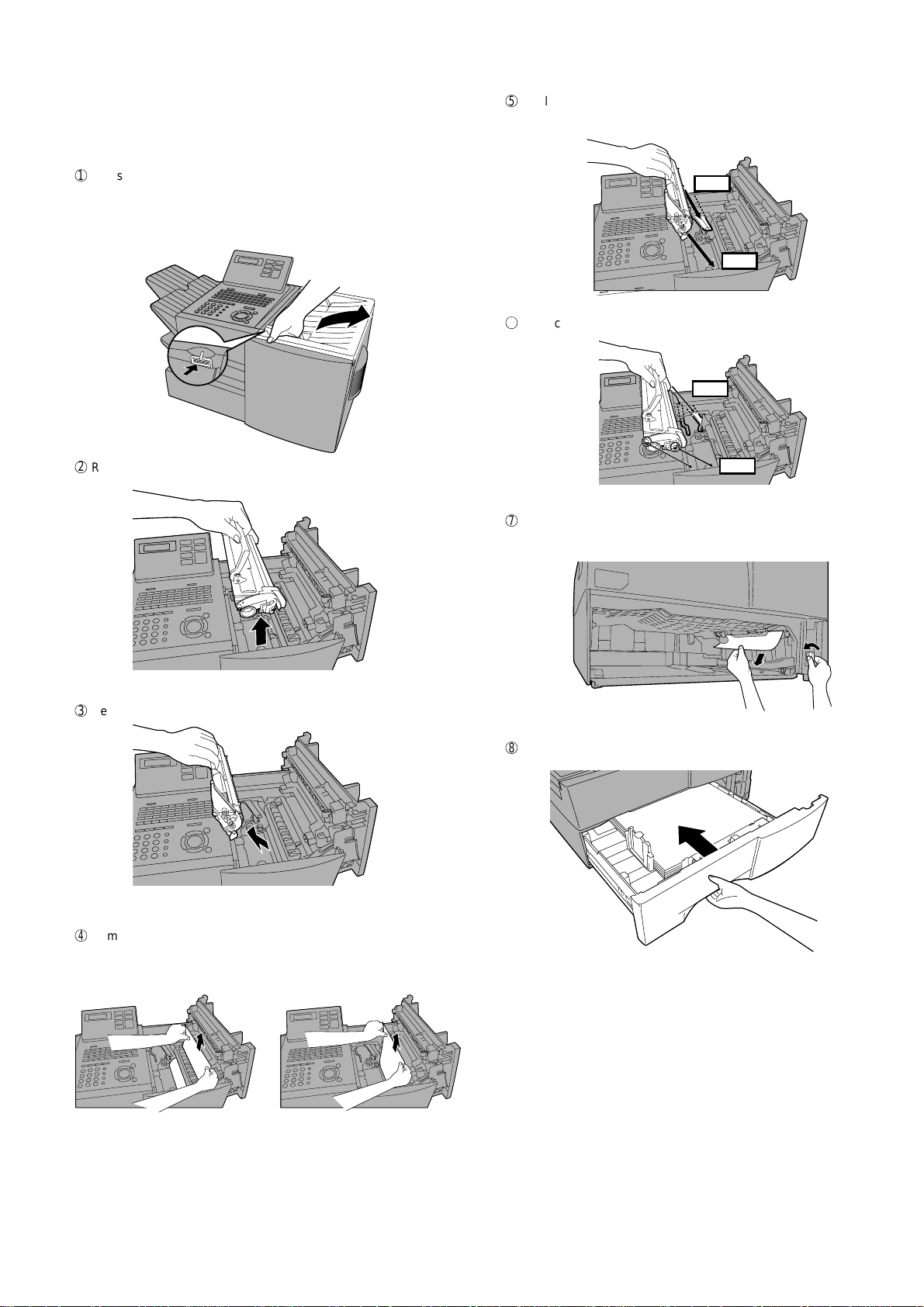

Clearing a jammed printing paper

GREEN

BLUE

If the printing paper jams, PAPER JAM will appear in the display . Follow

the steps below to clear the jam.

1

Press the green release and open the print compartment cover.

• Caution! The fusing unit inside the print compartment becomes

very hot during operation. Be careful not to touch the

inside of the compartment.

2

Remove the toner cartridge and place it on a sheet of paper.

FO-4400U

FO-CS1

5

Replace the drum cartridge.

• Make sure the drum cartridge is inserted in as far as it will go.

BLUE

GREEN

6

Replace the toner cartridge and then close the print compartment

cover.

3

Remove the drum cartridge.

4

Remove the jammed paper.

• Make sure no torn pieces of paper remain in the print compartment

and rollers.

7

If you have a paper cassette and the display still indicates that paper

is jammed, pull out the cassette and remove the jammed paper.

8

Replace the paper cassette.

OR

1 – 8

Page 12

FO-4400U

2

1

A

1

3

2

FO-CS1

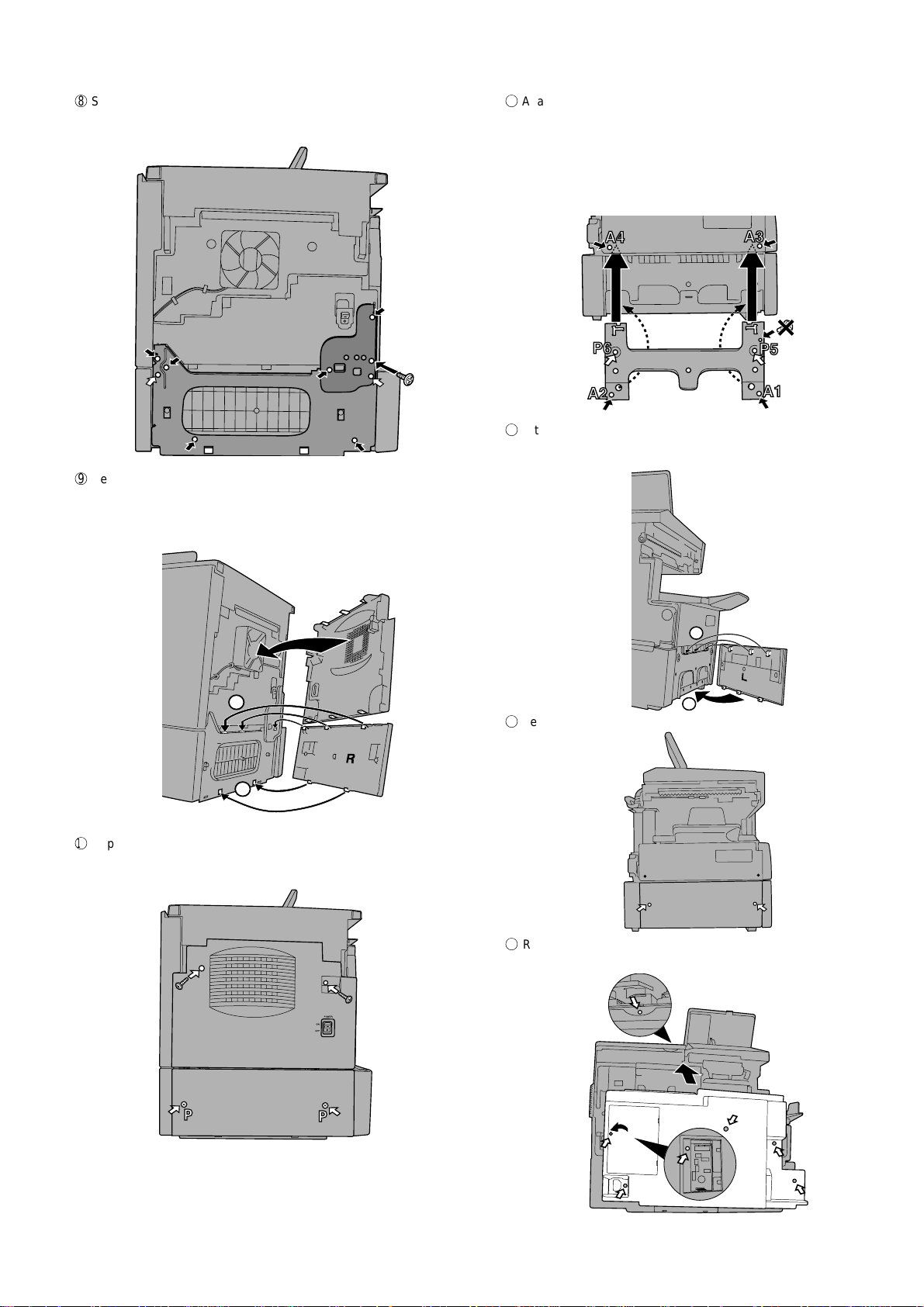

6. Installing the paper cassette (FO-CS1)

Installing the second paper cassette

Important: Be sure to turn off the power and unplug the power cord

before proceeding.

1

Press the cover release to open the print compartment cover.

2

Remove 6 screws from the rear cover.

Remove the small cover on the left side of the rear cover, and then

remove the screw underneath. Remove the rear cover.

5

Place the machine on top of the cassette.

1. Insert the cable guide into the cut-out in the edge of the metal

plate, and then fold it in half and hook the top and bottom edges

together.

2. Insert the 15pin cable through the ferrite core, and then connect

the cable to the connectors on the machine and the cassette as

shown. Position the ferrite core in the gap between the bottom

left-hand corner of the circuit board and the side of the

compartment. Insert the cable into the cable guide, and then

insert the remainder of the cable into the slot in the cassette

below the cable guide. Tie the wires with the band.

3

Remove 2 screws from the right cover of the machine.

From inside the print compartment, push the 3 tabs indicated in the

blowup out. (Note: The blowup shows the inside of the print compartment.) Insert your left index finger in between the cover and the machine as shown, and then close the print compartment cover. With

your index finger still inserted, grasp both sides of the cover and pull

it off.

4

Remove the packing material and tape from the paper cassette.

6

Replace the small cover over the circuit board and secure it with a

10 mm screw.

P

7

Attach the support plates to the right side of the machine.

1. Remove the indicated screw.(In Step 8 below, replace it in the

same hole.)

2. Mount the large plate, making sure that the guides fit into the holes

as shown.

3. Mount the small plate, making sure that the guides fit into the holes

as shown.

1 – 9

Page 13

8

P

P

Secure the plates with screws as shown. Use 6 mm screws for the

holes marked with “A”, and 10 mm screws for the holds marked with

“”P”. Secure the screws in the order indicated by the numbers.

A4

A3

A3

P3

A2

9

Replace the right side cover on the machine, inserting the tabs into

A4

A4

P4

A1

the holes.

Attach the longer cassette cover to the right side of the cassette,

inserting the tabs into the holes (first top, then bottom).

FO-4400U

FO-CS1

G

Attach the support plate to the left side of the machine, inserting the

top edges of the plate under the machine housing. Make sure that

the guides fit into the holes as shown.

Secure the plate with screws as shown. Use 6 mm screws for the

holes marked with “A”, and 10 mm screws for the holes marked with

“P”. Secure the screws in the order indicated by the numbers.

(Note that the top hole on the right does not require a screw.)

H

Attach the shorter cassette cover to the left side of the cassette, inserting the tabs into the holes (first top, then bottom).

1

2

F

Replace the screws in the side cover on the machine.

Secure the cassette cover with two 10 mm screws.

A

A

P

A

1

2

I

Secure the cassette cover with two 10 mm screws.

J

Replace the rear cover (replace the screw under the small cover on

the left side of the rear cover first, and then replace the small cover).

A

A

P

P

A

P

A

1 – 10

Page 14

FO-4400U

CONTRAST

BROADCAST

START/

ENTER

SPEAKER

FO-CS1

7. Replacing the Verification Stamp (FO-45VS)

If you are using the Verification Stamp function, you will need to replace

the ink cartridge in the stamp unit when it runs out of ink (when the

stamped mark on original documents becomes faint). A new ink cartridge can be obtained from your dealer.

1

Remove the ADF exit tray.

2

Press down on the protruding tab of the green ink cartridge and pull

the cartridge out with your fingers.

3

Insert the new ink cartridge into the machine (make sure that the tab

is facing out).

4

Replace the ADF exit tray.

[6] Quick reference guide

SENDING FAXES

Place your document (up to 50 letter-size pages) face down in the document feeder.

(Note: For Normal Dialing and Direct Keypad Dialing, you can also load

the document after dialing the number.)

RESOLUTION

Press

Normal Dialing

1. Lift extension phone or press

2. Dial the fax number (if using an extension phone, dial on the extension phone keypad).

3. Wait for the reception tone (if a person answers, ask them to press

their Start key).

4. Press

Rapid Key Dialing

1. Press the desired Rapid Key.

Speed Dialing

1. Press

if you entered a 1-digit number).

2. Press

Direct Keypad Dialing

1. Dial the fax number.

2. Press

BROADCASTING

1. Load the document and press

2. Dial destination numbers:

Press a Rapid Key.

Press a Group Key.

Press

plete entry if only one digit is entered).

Enter a full number and press

3. When finished, press

4. Press

5. Press

or

if needed.

.

START/

ENTER

.

SPEED DIAL

and enter the desired Speed Dial number (press

START/

ENTER

.

START/

ENTER

.

.

SPEED DIAL

and enter a Speed Dial number (press

START/

ENTER

.

START/

ENTER

.

RESOLUTION

START/

ENTER

CONTRAST

or

if needed.

.

START/

ENTER

to com-

1

STORING AUTO DIAL NUMBERS

1. Press

MENU

, 3 , 0 , 1 .

2. Press 1 to store a number.

2

3

(Press 2 to clear a number.)

3. To store a Rapid Key number, press the desired Rapid Key.

To store a Speed Dial number, press

START/

from 1 to 75 (press

ENTER

if you entered a 1-digit number).

SPEED DIAL

and enter a number

(If clearing a number, select it as explained above and then perform

Step 7 and 9.)

4. Enter the full fax number.

START/

5. Press

ENTER

.

6. Enter a name by pressing the letter keys.

START/

7. Press

ENTER

.

8. Press 1 if this is a Chain Dial number.

Press 2 if this is a regular number.

9. Press

STOP

repeatedly to exit.

1 – 11

Page 15

CHAPTER 2. ADJUSTMENTS

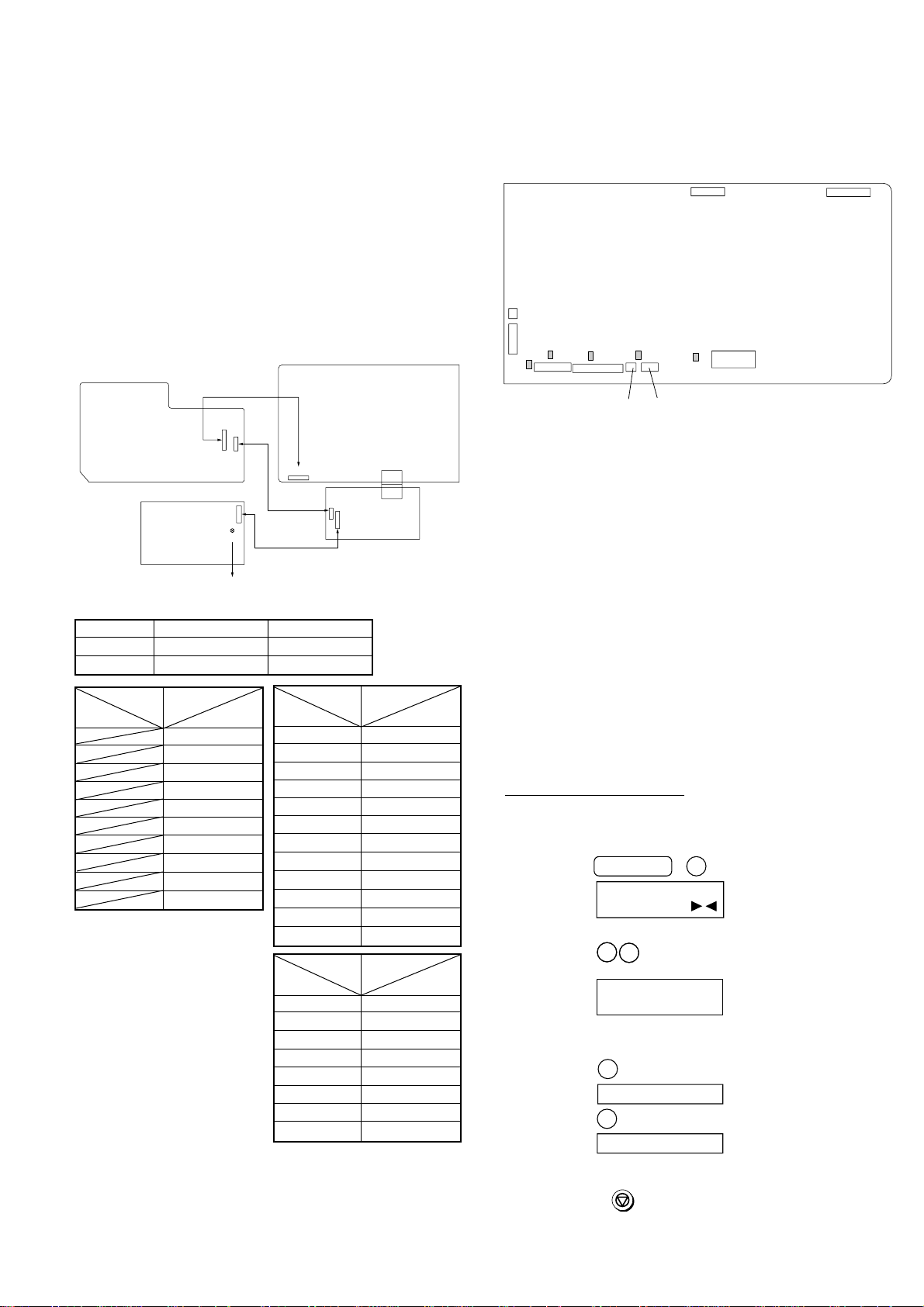

CONTROL PWB

(TOP SIDE)

CNLIU1

CNSP1

CNSEN1

CNCIS1

CNPN1

CNSTP1

F1/F2/F5:Top side

F100/F101:Bottom side

CNTXM1

IC3

1

1

8

10 1

1

1214

27

228

F1

F2

F5 F100

F101

2

CNPW1

12 1

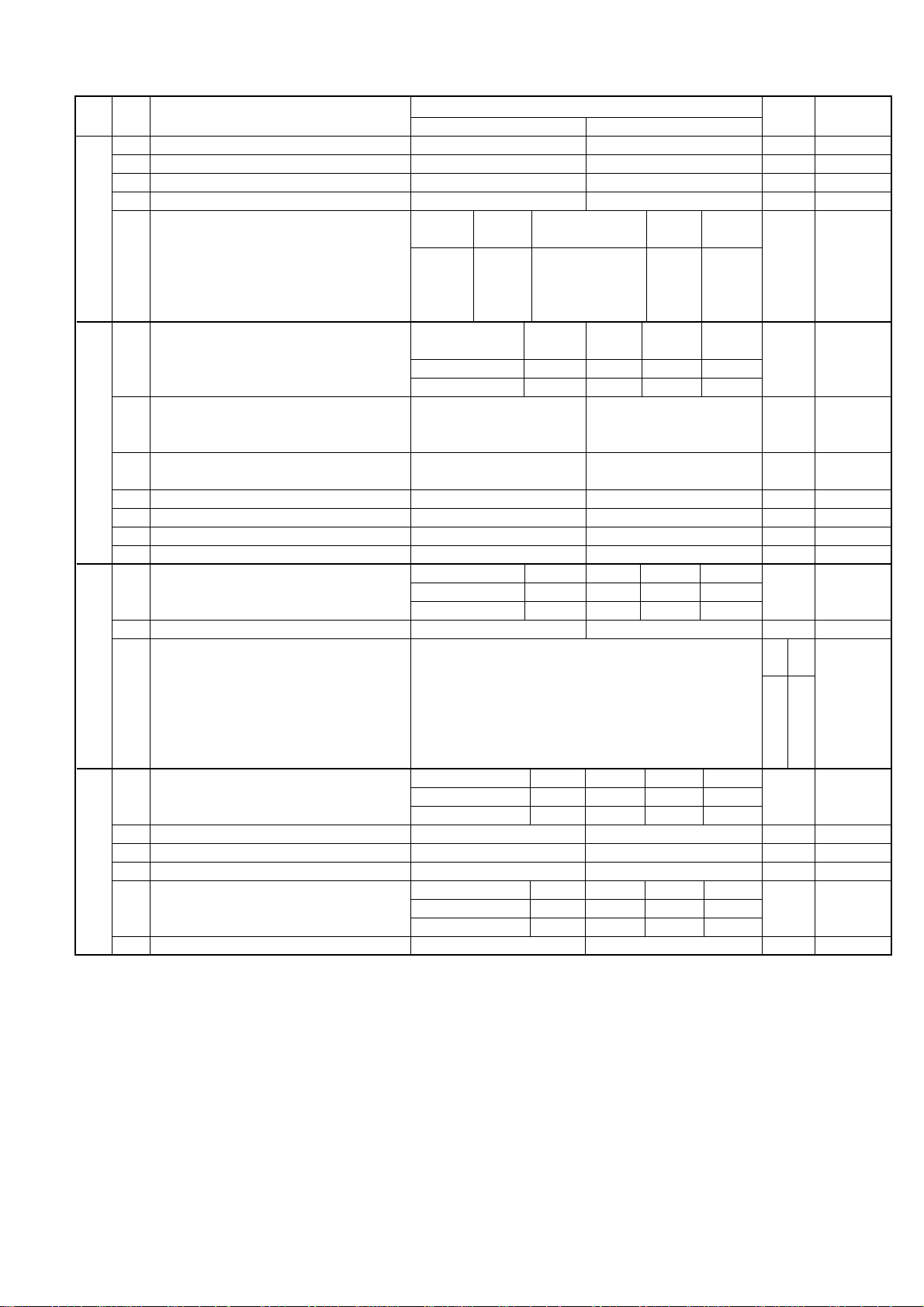

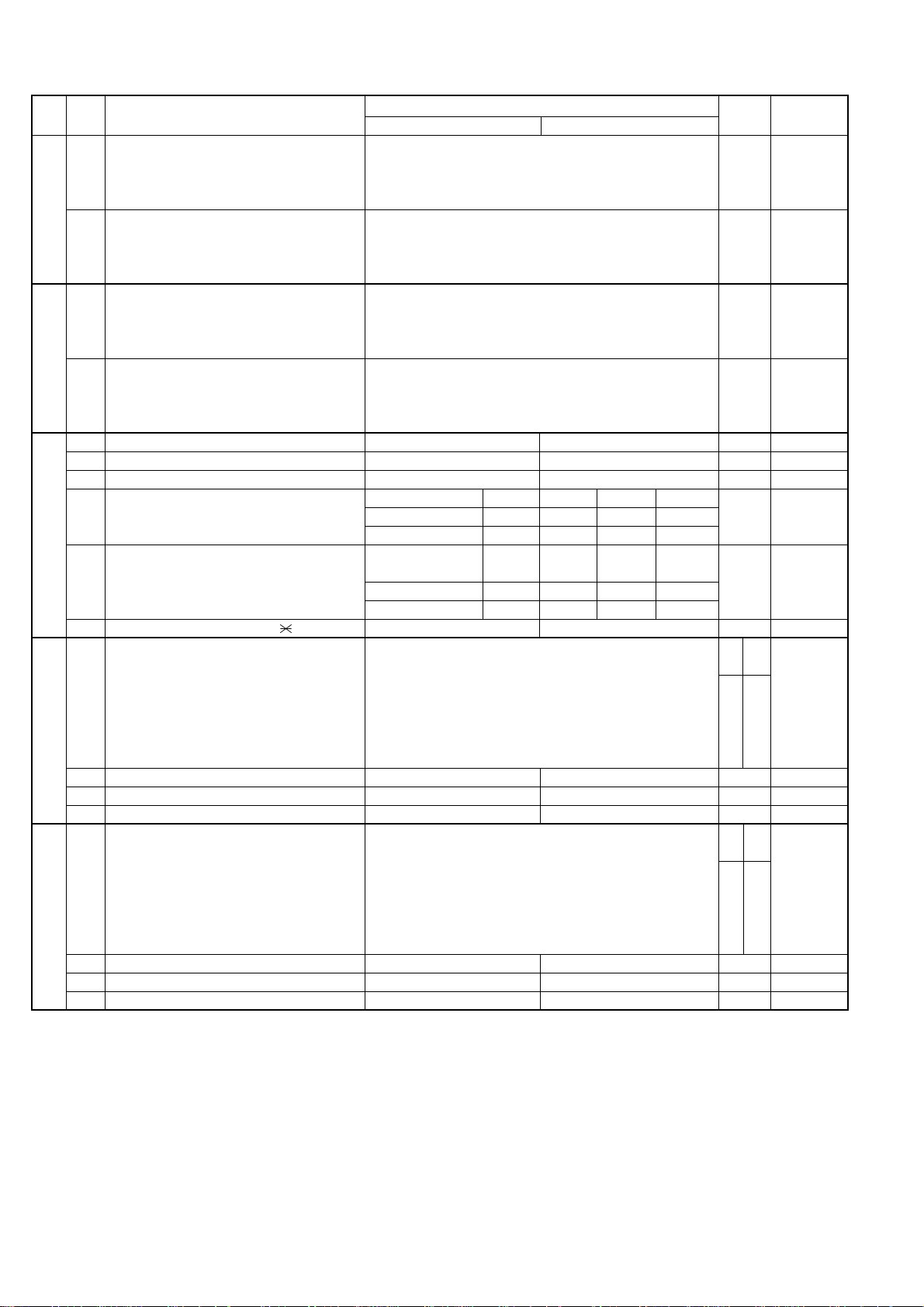

[1] Adjustments

General

Since the following adjustments and settings are provided for this model,

make adjustments and/or setup as necessary.

1. Adjustments

Adjustments of output voltage (FACTORY ONLY)

1. Install the power supply unit in the machine.

2. Set the recording paper and document.

3. When the document is loaded, power is supplied to the output lines.

Confirm that outputs are within the limits below.

Output voltage settings

FO-4400U

FO-CS1

2. IC protectors replacement

ICPs (IC Protectors) are installed to protect the CIS unit, panel PWB

unit, TX motor drive circuit and verification stamp drive circuit. ICPs protect various ICs and electronic circuits from an overcurrent condition.

The location of ICPs are shown below:

POWER

SUPPLY

PWB

Output Voltage limits Note

+5V MAIN 4.947V~5.25V CN5 7pin ↔ 8pin

+24V SUB 23.04V~24.96V CN5 1pin ↔ 2pin

Connector CN4

No.

Pin No. CN1

1 11 +5V

2 10 CH LREM

39T VR

4 8 T MON V

5 7 T MON I

6 6 B VR

7 5 V REM

8 4 C MON

93MG

10 2 +24V

HIGH VOLTAGE

PWB

CN5

[DO NOT TOUCH!]

1

1

CN1

12

CN1

VR51

8

1

10

CNPW1

112

Fig. 1

Connector CN5

No.

Pin No. CNPW1

Connector CN1

No.

Pin No. CN7

CONTROL PWB

CNPRT1

130

130

CN7

8

10

1

CN4

PRINTER PWB

1

CN1

1 +24V SUB

2MG

3MG

4MG

5 +24V MAIN

6 +24V MAIN

7 +5V MAIN

8DG

9DG

10 DG

11 +5V MAIN

12 +5V MAIN

1 +24V MAIN

2MG

3DG

4DG

5 +5V MAIN

6 +5V MAIN

7 HEATER ON

8 H-RELAY OFF

Fig. 2

(1) F1 (ICP-S0.5) F2 (ICP-S1.0) is installed in order to protect IC’s from

an overcurrent generated in the CIS unit. If F1 or F2 are open,

replace it with a new one.

(2) F5 (ICP-S1.0) is installed in order to protect IC’s from an overcurrent

generated in the panel PWB unit. If F5 is open, replace it with a

new one.

(3) F100 (ICP-S1.0) is installed in order to protect IC’s from an

overcurrent generated in the verification stamp drive circuit. If F100

is open, replace it with a new one.

(4) F101 (ICP-S1.8) is installed in order to protect IC’s from an

overcurrent generated in the TX motor drive circuit. If F101 is open,

replace it with a new one.

In addition to the replacement of F1, F2, F5, F100 and F101, the

factor causing F1, F2, F5, F100 and F101 to open must also be

repaired. If not, F1, F2, F5, F100 and F101 will open again.

Replacement parts

ICP-S0.5 (Sharp code: VHViCPS05//-1)

ICP-S1.0 (Sharp code: VHViCPS10//-1)

ICP-S1.8 (Sharp code: VHViCPS18//-1)

3. Settings

(1) Dial mode selector

OPTION SETTING: DIAL MODE (Soft Switch No. SW2 DATA No. 1)

Use this to set the fax machine to the type of telephone line you are on.

• The factory setting is "TONE".

(step 1) Select "OPTIONAL SETTING".

KEY:

DISPLAY:

(step 2) Select "DIAL MODE".

(step 2) Select "DIAL MODE".

KEY:

KEY:

DISPLAY:

DISPLAY:

(step 3) Select, using "1" or "2".

KEY:

DISPLAY: TONE SELECTED

KEY:

DISPLAY:

(step 4) End, using the "STOP" key.

KEY:

2 – 1

MENU 4

4:OPTIONAL SETTING

ENTER #(01-36, , )

2

2

2

2

22: DIAL MODE

22: DIAL MODE

1=TONE, 2=PULSE

1

2

PULSE SELECTED

STOP

Page 16

FO-4400U

FO-CS1

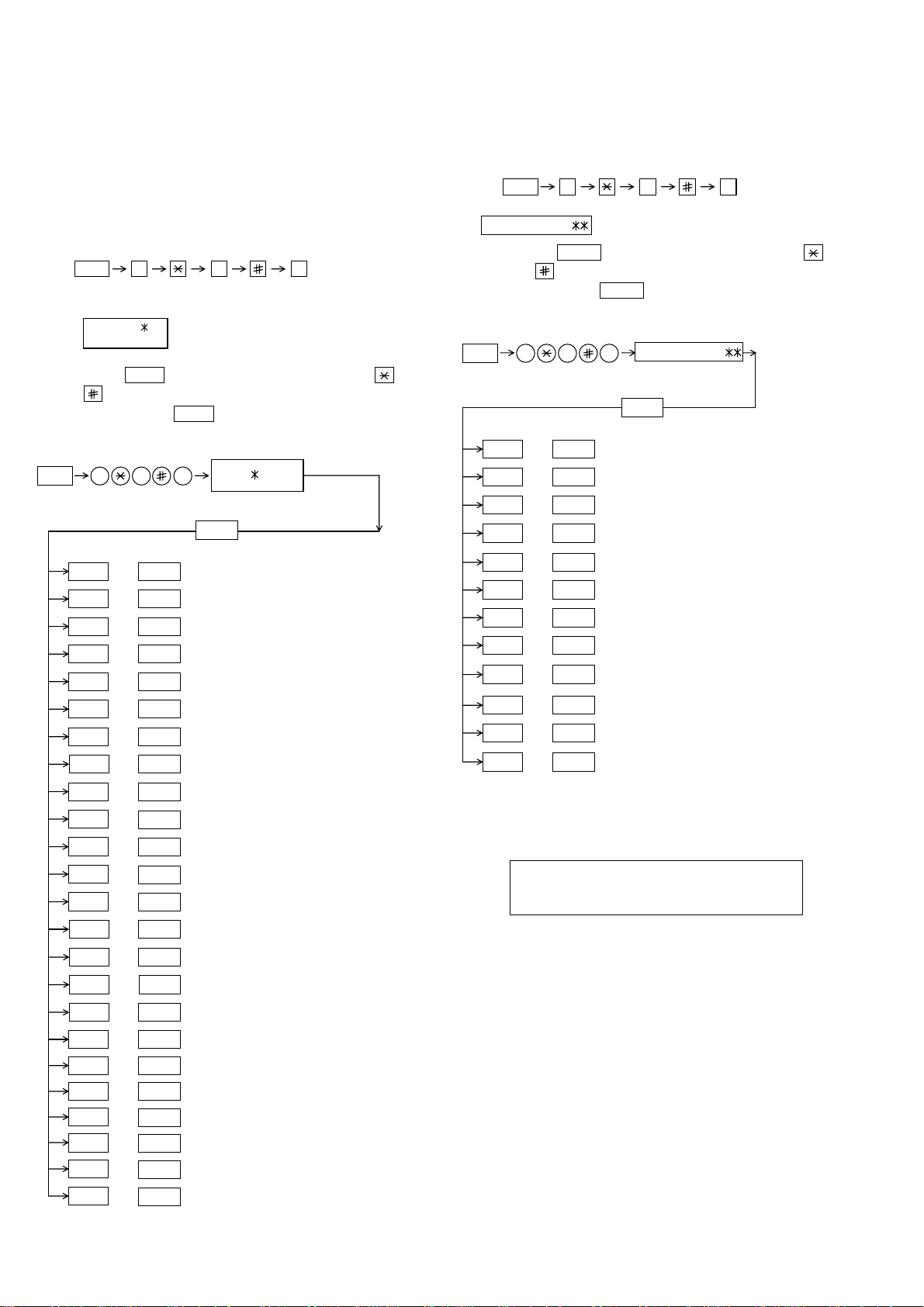

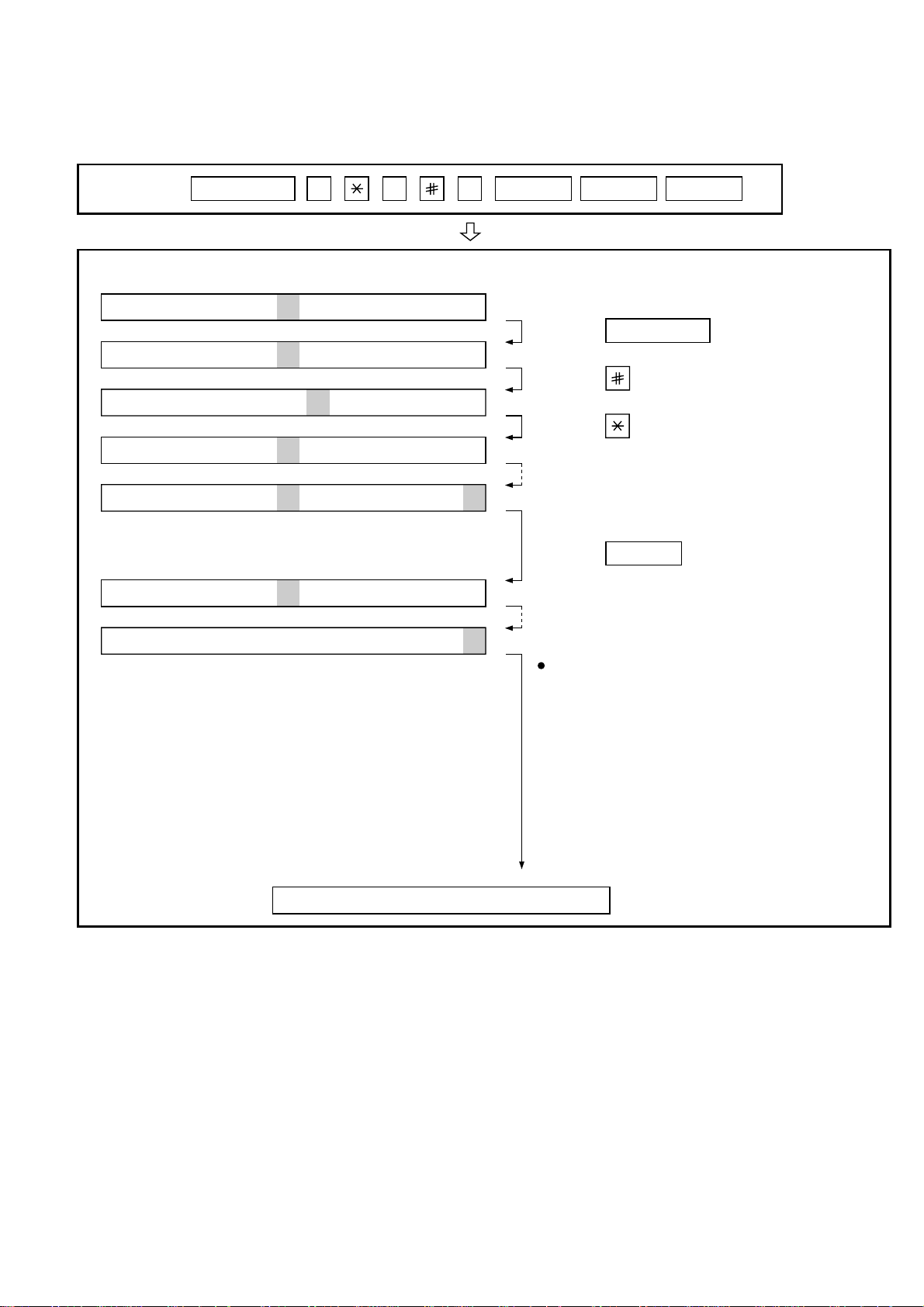

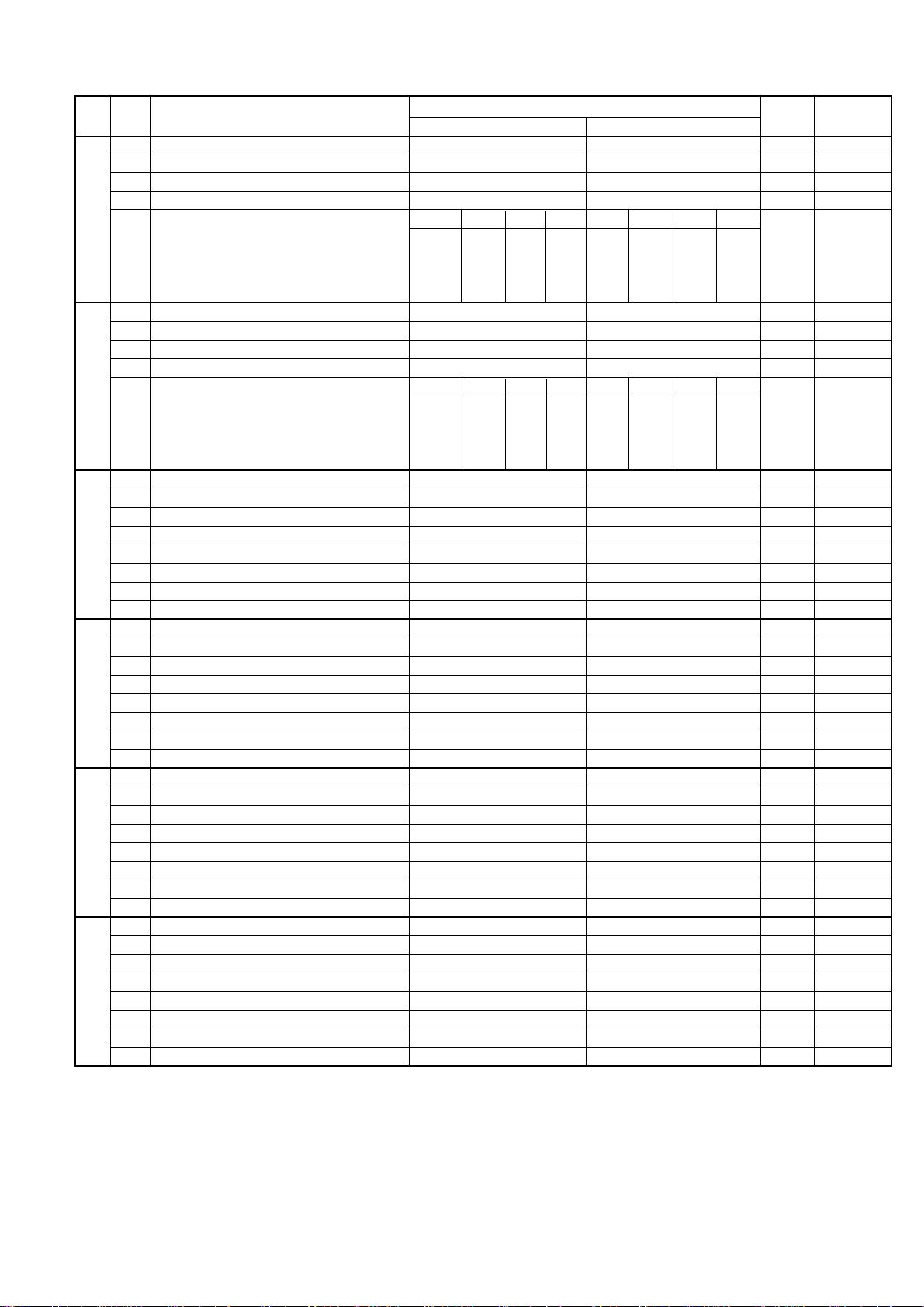

[2] Diagnostics and service soft switches

1. Operating procedure

Two kinds of diagnoses are supported.

1-1. Fax diagnosis

This diagnosis is concerned with the main body of fax which is used for

production and service support.

Entering the diagnostic mode

MENU

Press

display will appear.

MAIN:TA68

Then press the

and the key or select with the rapid key.

Enter the mode with the

(Diag

•

specifications)

MENU

9 8

START

9 8 7

7

, and

the

key. Select the desired item with the

START

key.

TA68

following

key

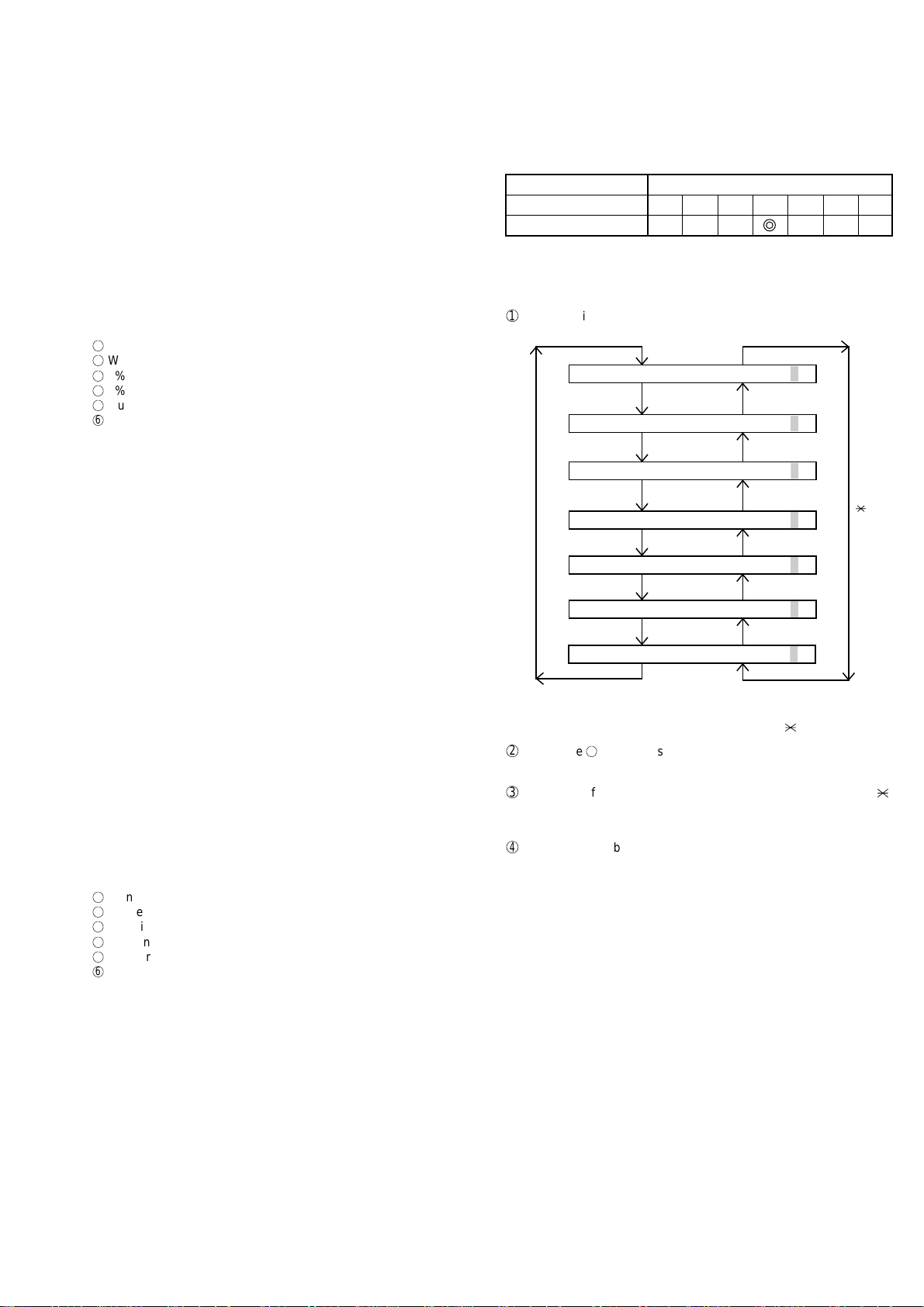

1-2. Print diagnosis

This diagnosis is concerned with the print which is used for production

and service support.

Entering the diagnostic mode

MENU

Press

display will appear.

PCU ROM VER.:

Then press the

key and the keyor select with the rapidkey.

Enterthe mode with the key.

(Diag•specifications)

MENU

01

02

9 8

START

9 8 6

START

START

6

, and

the

following

key. Select the desired item with the

START

PCU ROM Ver.:

START

AREA PRINT MODE 1

CHECK PATTERN 1

START

STARTA SOFT SWITCH MODE

B PRINT AREA

C ROM & RAM CHECK

D AUTO FEEDER MODE

E AGING MODE

F PANEL CHECK MODE

G OPTICAL ADJUST MODE

H PRODUCT CHECK

I

J

K

L

M

N

O CONF. PASSCODE

P

Q

R

S

T

U

V

W

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

START

SIGNAL SEND MODE

COMM. CHECK MODE

MEMORY CLEAR MODE

FLASH MEMORY CHECK

ALL FAX/TEL. ENTRY MODE

DEPT. PASSCODE

SIGNAL SEND MODE 2

MEMORY SET MODE

STAMP AGING MODE

DIAL TEST MODE

COPY DIAG MODE

LCD CHECK MODE

PERSONAL BOOK LIST

NO FUNCTION

03

08

09

START

START04

START05

START06

START07

START

START

START10

START11

START12

CHECK PATTERN 2

CHECK PATTERN 3

CHECK PATTERN 4

PAPER FEED AGING 1

PAPER FEED AGING 2

BIAS ADJUST MODE2

LIFE SET MODE

LIFE ALL CLEAR

LIFE ENTRY MODE

LIFE CLEAR MODE

Memory clear when power is turned on

Pressing the START and STOP keys, turn on the main power, and the

following message will be displayed.

MEMORY CLEAR ?

1 = ALL , 2 = IMAGE , 3 = NO

1 = All the data will be deleted including initially registered data.

2 = Delete the image file to be used in transmission. This will delete all

the data related to communication such as reserved transmission or

intercepting. However, the data initially registered will not be deleted.

3 = Memory will not be cleared and the machine enters stand-by mode.

X

START

NO FUNCTION

2 – 2

Page 17

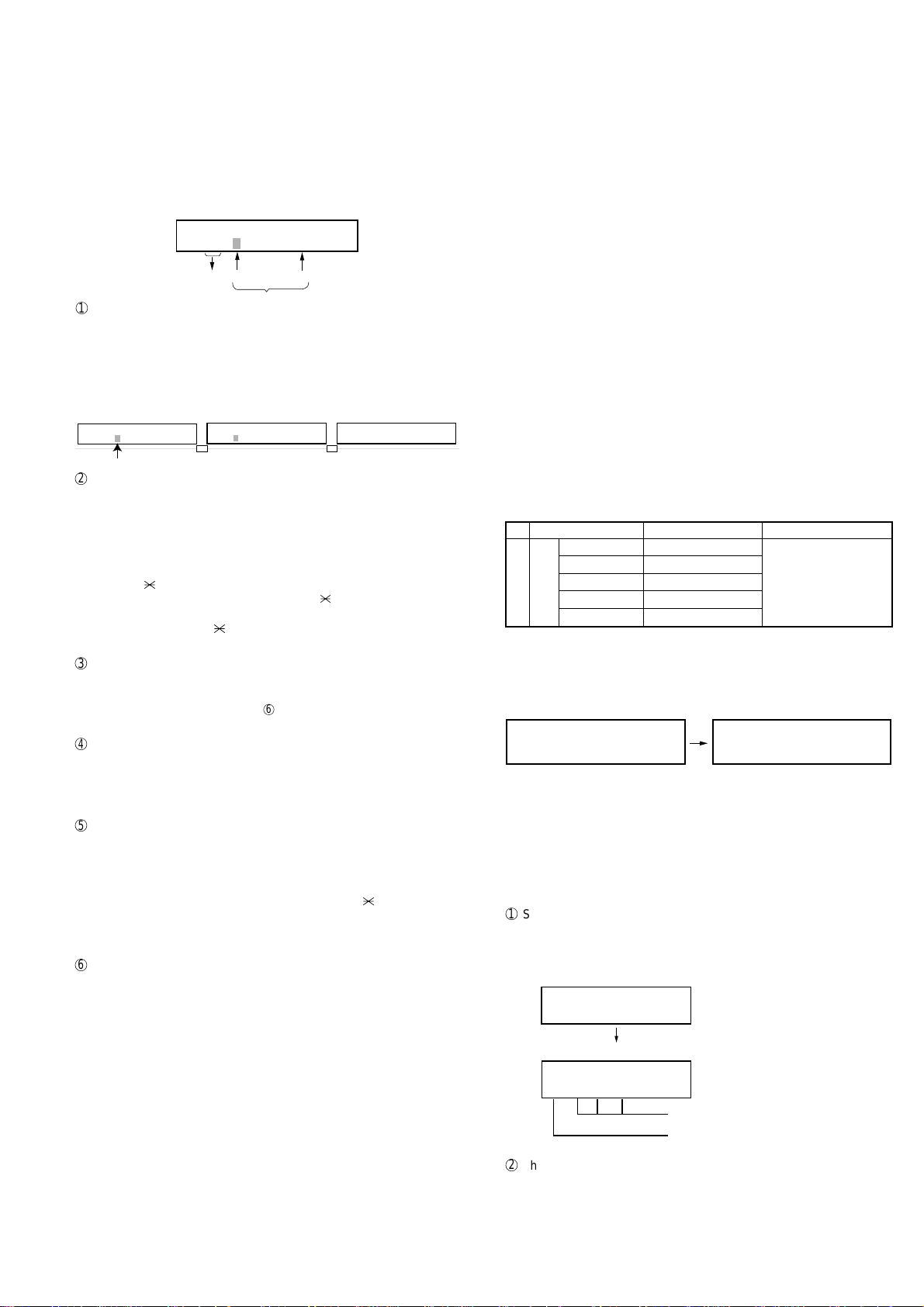

2. Diagnostic items description

ROM SRM DRM1 DRM2

• • • •

ROM SRM DRM1 DRM2

P P P E

Display during check Display after check

P=PASS E=ERROR

2-1. Fax diagnosis

A) Soft switch mode

In this mode, the soft switch are set and the soft switch list is printed.

Soft switch mode screen

S O F T S W I T C H M O D E

S W 0 1 = 0 0 0 0 0 0 0 0

8

Data

1

Switch number selection

1 2 3 4 5 6 7 :DATA No.

Switch

No.

• Press START key for setting of the next soft switch. If the soft

switch number is the final, pressing START key will exit the soft

switch mode.

• Enter two digits of a soft switch number to set the switch number.

If a switch number of nonexistent soft switch is entered, key error

buzzer sounds to reject the input.

S O F T S W I T C H M O D E

S W 0 1 = 0 0 0 0 0 0 0 0

Cursor

2

Data number selection

E N T E R L A S T D I G I T

S W 1

1 6

S O F T S W I T C H M O D E

S W 1 6 = 0 0 0 1 0 1 1 0

The cursor position shows the data to be set.

Pressing # key or → key moves the cursor to the right. If, however,

the cursor is on data number 8, pressing # key or → key shifts the

cursor to data number 1 of the next switch number. If the switch

number is the final, pressing # key or → key will exit the soft switch

mode.

Pressing key or ← key moves the cursor to the left. If, however,

the cursor is on data number 1, pressing key or ← key shifts the

cursor to data number 1 of the former switch number. If the switch

number is 1, pressing key or ← key will not move the cursor and

the error buzzer will sound.

3

Data setting method

Press the MENU key, and the data at the position of the cursor will be

reversed to 0 when it is 1, or to 1 when it is 0. (If the soft switch can

be changed at the bit (Refer to 6.), the error buzzer will sound with

the process not received.)

4

Outputting method of soft switch list

In the soft switch mode, press the REPORT key , and the soft switch

list will be output.

If the recording paper runs out or is clogged, the key error buzzer will

sound with the process not received.

5

Storage of data

In the following case, the data of the soft switches set will be stored.

• It is shifted to set the next soft switch by pressing the START

switch.

• It is shifted to set the next soft switch with the [#] key.

• It is shifted to set the last soft switch with the [ ] key.

• It is shifted to set another soft switch by inputting two digits as the

switch number. (When 2 digits are completely input.)

• Output of the soft switch list is started.

6

Inhibition of data change

(This is also applicable for the optional setting.)

In the following case, it is inhibited to change the data with the key

error buzzer.

• Switching ON/OFF of ECM during the use of image memory.

• OFF to ON of telephone billing function which is using the image

memory is used (Note: In the existing set, the telephone billing

code function is specified from OFF to ON when the timer system

communication (including the batch communication) is set.)

Here, the memory is usable when the telephone billing code function is on. It can be set from ON to OFF while the memory is

used. However, if setting is practically changed even once, it can

not be returned from OFF to ON.

FO-4400U

FO-CS1

• OFF to ON of department control function during use of image

memory.

(Note: In the existing set, the department control function is set

from OFF to ON when the timer communication (including the

batch sending) or the memory hold is set.)

• ON to OFF of continuous serial polling function when the con-

tinuous serial polling is started.

(Note: In the existing set, "ON to OFF of the continuous serial

polling function when the continuous serial polling is registered"

has been applied, but the conditions are now moderated. However, registration is impossible to the program of the new continuous serial polling when the continuous serial polling function is

OFF.)

• In addition, change of all soft switches during communication

B) Print area

According to the size of the specified sheet, the effective printing area is

printed.

C) ROM & RAM check

This is an item to check if the loaded memory device acts normally.

• The memory devices shown in the following table are checked.

• In case that an error occurs in the device check, the alarm buzzer

shown in the table sounds.

Check device and alarm buzzer

No. Device checked

1

2 SRAM <Short sounds> 2 times

3 Main D-RAM1 (*1) <Short sounds> 3 times <Long sounds>:

4 D-RAM2 (*2) <Short sounds> 4 times 1.0 sec.ON / 0.5 sec.OFF

5 ——

ROM (PROGRAM FLASH)

*1: Work memory (SDRAM 8MB)

*2: Page memory (SDRAM 8MB)

(Example of display) In case that DRAM2 is erroneous.

After the check is complete, the result is outputted.

D) Auto feeder mode

By executing the document insertion and discharge, the automatic feeding function can be checked. And the document sensor can be checked

as well.

1

Set the document

Before pressing the “START” key , only the document sensor check is

carried out. And as the document sensor is ON, the document size

(A4/B4) and the sensor information (A4/B4/ORG) are displayed.

AUTO FEEDER MODE

( )

After setup of the document

AUTO FEEDER MODE

B4 (A4 B4 ORG)

2

The automatic feeding starts by pressing the “START” key. This mode

ends when the document ends, and the result is printed.

Number of buzzer sound

<Short sound> 1 time <Short sound>:

Only the sensor which is

activated (fallen down) is displayed.)

The paper sheet size (A4/B4) is

displayed.

Remarks

0.5 sec.ON / 0.5 sec.OFF

2 – 3

Page 18

FO-4400U

FO-CS1

E) Aging mode

This is a mode to execute the copying action and the check pattern

printing action once every 60 minutes and continue the action until 10

sheets are outputted in total.

1

The printing action on the 1st sheet starts by pressing down the

“START” key and entering the mode. When document is set at the

time of the mode start-up the copy action is carried out, and when

the document is not set the “check pattern 1” of the print dialog is

printed.

2

The number of printouts is displayed after printing.

F) Panel check mode

This is to check that each key acts normally and this is displayed on the

LCD according to the key input. And during execution, the document

reading lamp is ON. After inspection start, the LEDs light on sequentially.

At the mode end with the “STOP” key, all of them go OFF. As to the test

result, it is printed out after the mode end.

When the “NUMERIC” key is pressed during the panel check execution, sending of the DTMF signal corresponding to the key starts,

and when another key is pressed sending of the DTMF signal stops.

• After inputting all the keys, input the “STOP” key at last, and then the

result is displayed.

a) In case that all the keys are pressed.

PANEL CHECK MODE

ALL KEY OK !!

• After the mode end, the test result is printed.

b) In case that there is a key that is not pressed.

PANEL CHECK MODE

KEY ERROR !!

• At the time of NG, the keys that are not pressed are displayed

sequentially, and it becomes the mode to input the key again.

• With the “STOP” key, the re-check is complete.

• After the mode end, the test result is printed.

G) Optical adjust mode

The optical system is adjusted.

• By pressing down the “START” key, the document reading lamp “100%:

ON” is turned ON.

I) Signal send mode

After shift to the mode, press the START key, and the signals will be

transmitted in the following sequence.

It can be used to check the modem and so on.

[ 1] No signals

[ 2] 4800BPS (V. 27ter)

[ 3] 14400BPS (V. 33)

[ 4] 12000BPS (V. 33)

[ 5] 14400BPS (V. 17)

[ 6] 12000BPS (V. 17)

[ 7] 9600BPS (V. 17)

[ 8] 7200BPS (V. 17)

[ 9] 9600BPS (V. 29)

[10] 7200BPS (V. 29)

[11] 4800BPS (V. 29ter)

[12] 2400BPS (V. 29ter)

[13] 300BPS (FLAG)

[14] 2100Hz (CED)

[15] 1100Hz (CNG)

J) Comm. check mode

1

Turn on the Line Monitor. (SW7 No.7, SW37 No.7)

2

Turn off the Cover Sheet Function. (SW2 No.6, SW32 No.6)

3

Set Line Equivalence at 0 km. (SW8 No.1/No.2, SW38 No.1/No.2)

After the check, it is necessary to be sure to return the aforementioned

soft switches into the initial state.

(Clear the memory with the diagnosis.)

K) Memory clear mode

Clear the back-up memory to initialize the soft switches.

The Flash Memory will be initialized. Then, the initialized list be output.

1

Memory clear is executed.

2

The result that says initialized is printed.

NOTE: The life system counter is not cleared.

H) Product check

This is a dialog used in the production process and a mode to execute a

specific mode in the series of the flow.

After the mode end, the rest result as to the checked items is printed.

• After moving to the mode, the following actions are sequentially ex-

ecuted.

1

Memory clear (Same as Diagnosis K)

2

Panel check (Same as Diagnosis F)

3

ROM & RAM test check (Same as the Diagnosis C)

4

Test result print

Memory clear printing

Panel check result printing

ROM & RAM test result printing

5

Print area (The specification of each item is the same as the specifi

cation of the simple mode.)

2 – 4

Page 19

L) Flash Memory check

This is a mode to check that the flash memory acts normally. The flash

memories shown in the following table are checked.

No. Flash memory

1

2

3

4 ——1.0 sec.ON / 0.5 sec.OFF

5 ——

NOR-Flash (Standard)

NAND-Flash (Standard)

NAND-Flash (Option)

Number of buzzer sound

<Long sound> 1 time <Short sound>:

<Long sounds> 2 times

<Long sounds> 3 times <Long sounds>:

Remarks

0.5 sec.ON / 0.5 sec.OFF

• NAND-Flash (optional) is valid only when the optional memory is

mounted.

1

The NOR flash memory test is executed.

NOR FLASH CHECK

S — — — — — — — E

2

The concerned alarm buzzer sounds only when the error occurs.

3

The NAND flash memory test is executed.

NAND FLASH CHECK

S — — — — — — — E

4

The concerned alarm buzzer sounds only when the error occurs.

5

The result is printed.

NOTE:

• During operation of this diagnosis, dual operation is not possible at all.

• If this is excessively repeated, it will shorten the life of the flash memory.

M) All FAX/TEL. entry mode

This is a function to copy the FAX and TEL numbers registered in the

one-touch dialing (RAPID) key [01] to the all one-touch dialing (RAPID)

key and the all abbreviated number (SPEED DIAL) to simplify the FAX

and TEL number registration at the time of aging.

1

Copy the Fax and Tel numbers (including agency) registered in the

one-touch dialing (RAPID) key [01] to all one-touch dialing (RAPID)

key.

2

Copy the FAX and TEL numbers registered in the one-touch dialing

(RAPID) key [01] to the all abbreviated number (SPEED DIAL).

3

In case the chain dial is not set in the one-touch dialing (RAPID) key

[01], register the one-touch dialing (dialing) keys [02] – [59] and all

abbreviated number (SPEED DIAL) to the group number [01].

In case that the chain dial is set, do not create a group, but cancel

only the chain dial setting of the one-touch dialing (RAPID) key [01].

(All except for the one-touch dialing (RAPID) key [01], chain dial is

kept set.)

4

Enter all registered one-touch send (RAPID) keys and speed dial

numbers (SPEED DIAL) on the personal books [01] - [10].

Following this, set the password registration and the password

setting to ON, and set the TTI setting to OFF.

The call-receiver names and book names are specified as follows:

Rapid R XX XX : Rapid key send

SPEED DIAL S XXX XXX

Personal book BOOK XX XX : Book number

(The letters after 16th letter of the call-receiver’s name registered in the

one-touch dialing [01] are cut off.)

NOTE: Before entering this mode, FAX and TEL numbers must be reg-

istered in the one-touch dialing (RAPID) key [01].

(In case that they are not registered, or a program or a group is

registered, it is not executed.)

N) Dept. passcode

The department passcode list is printed.

O) Conf. passcode

The confidential passcode list is printed.

Differing from printing of one box alone soon after registration, the confidential passcodes of all boxes are printed.

: Speed dial number

FO-4400U

FO-CS1

P) Signal send mode 2

The signals concerned with V.34 & V.8 are checked.

After this mode is activated, press the START key, and the signals will

be sent in the following sequence.

It can be used to check the modem.

[ 1] No signal

[ 2] 33600BPS (V. 34)

[ 3] 31200BPS (V. 34)

[ 4] 28800BPS (V. 34)

[ 5] 26400BPS (V. 34)

[ 6] 24000BPS (V. 34)

[ 7] 21600BPS (V. 34)

[ 8] 19200BPS (V. 34)

[ 9] 16800BPS (V. 34)

[10] 14400BPS (V. 34)

[11] 12000BPS (V. 34)

[12] 9600BPS (V. 34)

[13] 7200BPS (V. 34)

[14] 4800BPS (V. 34)

[15] 2400BPS (V. 34)

[16] 0 - 300BPS (V. 34)

[17] ANSam

Q) Memory set mode

The set and dump list of the memory content is output.

MEMORY SET MODE

AD = 00000000

Cursor

• The address (8 digits (P) generally including the bank information is

input, and the data of 2 digits is continuously input.

Inputting is done in the hexadecimal mode. The ten-key is used for 0

through 9, and the alphabetic keys A (RAPID 01 through 06) are

used for A through F.

MEMORY SET MODE

AD = A02800F6 DATA = 0B

• During data inputting, the address can be moved forward and back-

ward one byte by one byte with " " and "#". (The address prior to the

address 0 is looped as the maximum address.)

• The Validity of the address is not checked. Accordingly , writing/ read-

ing operations are possible in the address of the memory not assigned, the address of ROM and so on.

(However, as practical, writing is not done, and the data content runs

short each reading.)

Though writing is possible in the flash memory, a little time is required.

It is also necessary to take care that the life of the flash memory is

excessively shortened if much data is written in the flash memory.

Since it may run away depending the written content, take minute

care for the writing address.

• When the REPORT key is input, the memory dump list is produced

from the displayed address (here, it is limited at the 16-byte boundary address (address with end 0) which does not exceed the specified address and is just in front.). The dump list is output to a maximum of 99 pages. If any data of one page can be repeatedly developed and printed, the list is sufficient. But it is not desired that the

content of plural pages are developed in the memory once and are

then printed. If the STOP key is pressed, it will pass to the diagnosis

after the page which is now being printed is completed printed.

If the address exceeds the maximum address, it will return to the

address 0 and printing will be continued.

2 – 5

Page 20

FO-4400U

1

2

3

4

5

6

7

8

9

FO-CS1

R) Stamp aging mode

This is a mode to execute the continuous drive aging of the Verification

stamp.

1

Set the document and press down the “START” key and the

continuous drive of the Verification stamp starts.

2

Send the document at the interval of 10 mm and stamp the

Verification stamp continuously. The total number of times of

Verification stamp printing after entering this mode is displayed on

the display.

• Displayed screen during execution

STAMP AGING

TIMES = 13 PAGES = 1

2-2. Print diagnosis

Rapid key 01: Area print mode 1

The effective printing area frame is printed in the specified sheet size.

Print total number

of times

3

By pressing down the “STOP” key during the action, or when no

more document is left, the continuous drive of the Verification stamp

stops.

NOTE:

Page number

• In case that the document is not set, this cannot be executed.

• The normal action aging that one V erification stamp is pressed on one

sheet of document is executed in the normal copying.

S) Dial test mode

The mode is used to inspect whether dialing is accurate in two kinds of

dial modes . All data which can be dialed in this mode are automatically

called up in both PB mode and DP mode.

[In case that 2 line optional is not mounted.]

1

Turn on CML, and dial the following in the PB mode.

1, 2, 3, 4, 5, 6, 7, 8, 9, , 0, #

2

Dial the following in the DP mode.

1, 5, 9, 0

3

After dialing, turn off CML.

NOTE:

This mode uses the ordinary auto dial. (Accordingly, the signal sending

time and minimum pause are all the same as ordinary.

The measurement result in this mode is completely all the same as in

the ordinary dial mode.)

T) Copy diag mode

This mode is for automatic mode selection of copy to reduce the time for

treatment at the time of production.

1

Set 2 sheets of document. (No problem if there are 2 sheets or

more.)

2

3 sheet continuous copy: 1st sheet in the FINE AUTO

2nd sheet and after that are copied in the

H-TONE DARK.

NOTE:

Input of the image quality and the darkness keys is invalid in this mode.

The data pattern used here are as follows and 1 data 30 mm is printed.

1. [Full black pattern]

2. [Intermediate tone 2 pattern]

The left pattern is repeated.

3. [Intermediate tone 1 pattern]

The left pattern is repeated.

4. [Mesh point pattern]

The left pattern is repeated.

U) LCD check mode

This is an item to check that the LCD acts normally.

[In case of a 2 lines LCD]

Display “H” to all the digits. (20 letters x 2 lines)

HHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHH

V) Personal book list

The PASSCODE of the personal book 00 to 10 are output.

W) No function

X) No function

5. [Longitudinal strip 2 pattern]

Black 2 dot and white 2 dot are repeated in line.

6. [Lateral strip 2 pattern]

Black 2 line and white 2 line are repeated.

7. [Longitudinal strip 1 pattern]

Black 1 dot and white 1 dot are repeated in line.

8. [Lateral strip 1 pattern]

Black 1 line and white 1 line are repeated.

9. [Full White pattern]

2 – 6

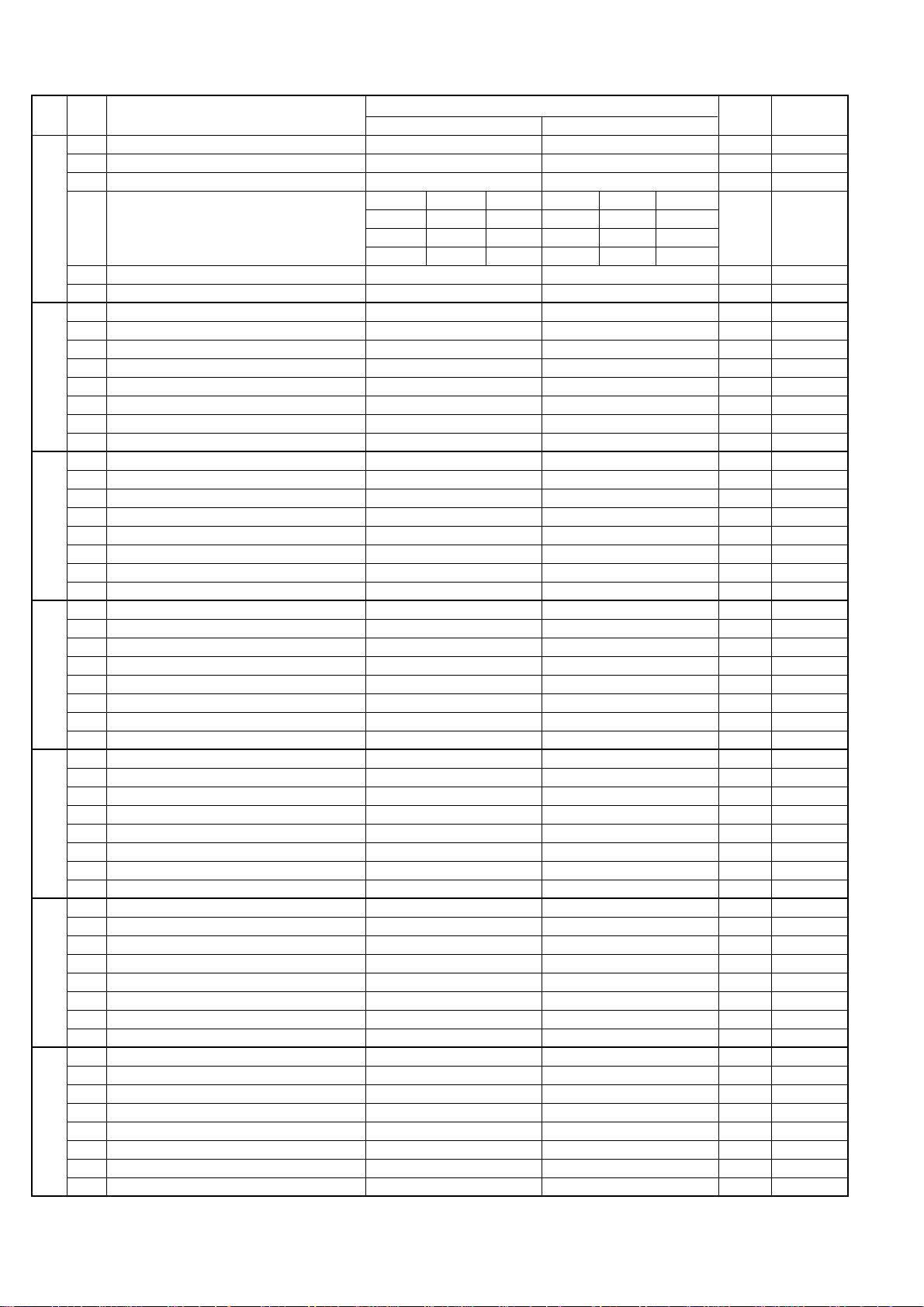

Page 21

MACH I NE

DRUM

L

LIFE

LIFE

IFE1

= 0123

FEEDER L I FE=

=

=

LIFE2

=

LIFE3

=

0

key

# key

001230

001230

001230

001230

001230

0

FEEDER L I FE= 001230

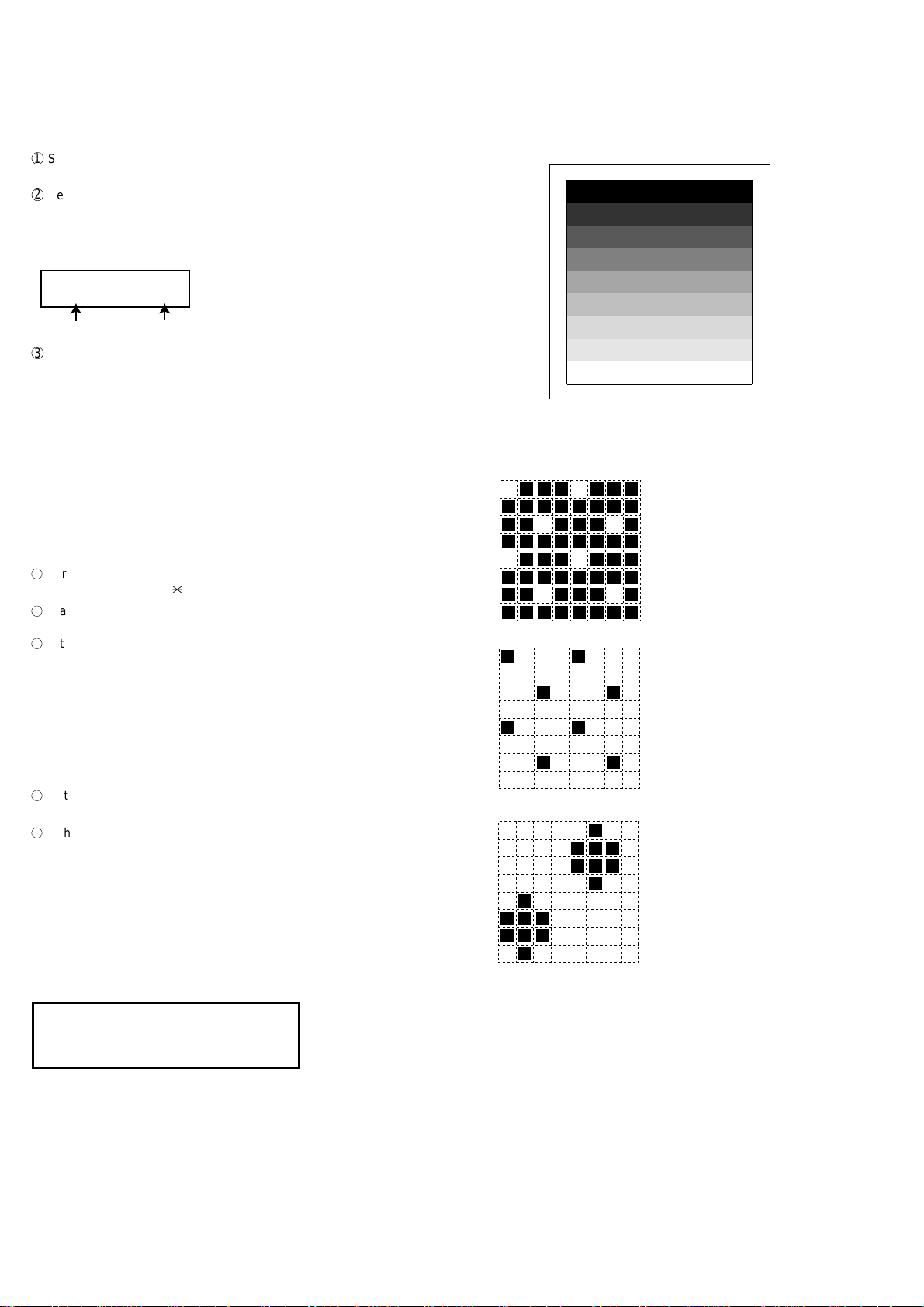

Rapid key 02: Check pattern 1

The lateral stripe 2 pattern is printed on one sheet.

(Black 2 line and white 2 line are repeated.)

Rapid key 03: Check pattern 2

The lateral stripe 2 pattern is printed on multiple pages.

Press the STOP key to end the printing.

Rapid key 04: Check pattern 3

The intermediate tone 1 is printed on one sheet.

Rapid key 05: Check pattern 4

In this mode, 1 sheet is printed as to the square frame pattern for the

skew measurement.

Rapid key 06: Paper feed aging 1

The mode is used for aging related to the printing. In this mode, the

following modes are provided.

1

Blank paper aging mode (ALL WHITE AGING)

2

Whole black print aging mode (ALL BLACK AGING)

3

5% printing aging mode (5% AGING)

4

4% printing aging mode (4% AGING)

5

Outer frame check pattern

6

4% check pattern

After selecting the paper-pass aging mode in the print diagnosis mode,

input the number of each mode above with the ten-key, and the mode

will be executed. The detailed specifications of each mode are described

as follows. Here, the operation in each mode is stopped only when the

STOP key is pressed by the operator or a printing-impossible error occurs.

• Blank paper aging mode

In the mode, printing is continued in the whole white (white paper)

printing pattern until the STOP key is pressed by the operator . (In the

printing area)

• Whole black printing aging mode

In the mode, printing is continued in the whole black (whole black)

printing pattern until the STOP key is pressed by the operator. (In the

printing area)

• 5% aging mode

In this mode, the 5% print pattern is repeatedly printed until the [STOP]

key is pressed by the operator.

• Outer frame pattern aging mode

In this mode, the outer frame check pattern is repeatedly printed until

the [STOP] key is pressed by the operator. For the outer frame, only

the frame showing the printing area is printed.

• 4% chart aging mode

In this mode, the 4% chart is repeatedly printed until the [STOP] key

is pressed by the operator.

Rapid key 07: Paper feed aging 2

This is a mode that is used for aging related to printing, and there are

following modes. And also as to the print interval 5 sec. – 12 hour can

be set.

1

Blank paper aging mode (ALL WHITE AGING)

2

Whole black print aging mode (ALL BLACK AGING)

3

5% printing aging mode (5% AGING)

4

4% printing aging mode (4% AGING)

5

Outer frame check pattern aging mode

6

4% check pattern aging mode

After entering this mode and selecting the paper feeding aging mode,

each mode is executed by inputting the number of the above each mode

with the numeric number keys and then inputting the print interval with

the numeric number keys. Refer to the paper feeding aging mode 1 for

each mode. Each mode stops the action only when the STOP key is

pressed by an operator or when an error for print impossible occurs.

FO-4400U

FO-CS1

Rapid key 08: Bias adjust mode

The mode is used to adjust the printing density of the printed image.

The image printing density is adjustable in seven steps of 1 to 7.

For details, refer to the following table. (For selection, use the keys 1

through 7.)

Image printing density Thin ←→Thick

12345 67

Default value

Rapid key 09: Life set mode

The mode is used to set the life counter of the printer and the counter of

the auto feeder at desired values. For setting, proceed with the following

procedure.

1

When the life counter setting mode is selected, the following will be

is displayed.

The cursor blinks at the top data.

Five counters can be selected with the "#" and " " keys.

2

In the state 1, input a desired setting number of 6 digits with the ten-

key.

3

After input of 6 digits, shift to another counter with the "#" and " "