Page 1

ELECTRONIC

CASH REGISTER

MODEL ER-A440

SRV Key : LKGIM7113RCZZ

PRINTER: DP730

(For "U" & "A" version)

CONTENTS

CHAPTER 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHAPTER 2. LIST OF OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CHAPTER 3. REMOVING THE TOP CABINET. . . . . . . . . . . . . . . . . . . . . . . 3

CHAPTER 4. REMOVING THE PRINTER UNIT . . . . . . . . . . . . . . . . . . . . . . 3

CHAPTER 5. REMOVING THE MAIN PWB . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHAPTER 6. REMOTE DRAWER: ER-04DW. . . . . . . . . . . . . . . . . . . . . . . . 4

CHAPTER 7. EXPANSION RAM CHIP (ER-03RA). . . . . . . . . . . . . . . . . . . . 5

CHAPTER 8. JOURNAL NEAR END SENSOR: DUNTK3677BH03 . . . . . . . 5

CHAPTER 9. KEY TOP KIT: ER-11KT7/12KT7/22KT7/11DK7G/51DK7G . . 6

Parts marked with " " is importa nt for maintaining t he safety of the set . Be sure to replace thes e parts with specifi ed

ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has bee n pu bl is hed to be used

for after sales service only.

Page 2

CHAPTER 1. GENERAL

This manual describes the ER-A440 disassembly procedures and the

option attachment procedures. For assembly procedures, reverse the

disassembly procedures. For attachment of options which do not require special descriptions, descriptions are omitted.

Note for operations

• Before operation, ground the operator’s body and perform other

necessary measure against static electricity.

• During operations, disconnect the AC cord from the outlet.

• After completion of operations, connect the connectors.

• After completion of operations, be sure to perform the master re-

set.

1. SRV. reset (Program Loop Reset)

Used to return the machine back to its operational state after a lockup has occurred.

Procedure

• Method 1

1) Unplug the AC cord from the wall outlet.

2) Set the mode switch to (SRV′) position.

3) Plug in the AC cord to the wall outlet.

4) Turn to (SRV) position from (SRV′) position.

• Method 2

1) Set the mode switch to PGM2 position.

2) Turn off the AC switch.

3) While holding down JOURNAL FEED key and RECEIPT FEED

key, Turn on the AC switch.

Note: When disassembling and reassembling always power up us-

ing method 1 only. Method 2 will not reset the CKDC8.

Note: SRV programming job#926-B must be set to "4" to allow PGM

program loop reset.

Procedure

1) Unplug the AC cord from the wall outlet.

2) Set the MODE switch to the (SRV′) position.

3) Plug in the AC cord to the wall outlet.

4) While holding down JOURNAL FEED key and RECEIPT FEED

key, turn to (SRV) position from (SRV′) position.

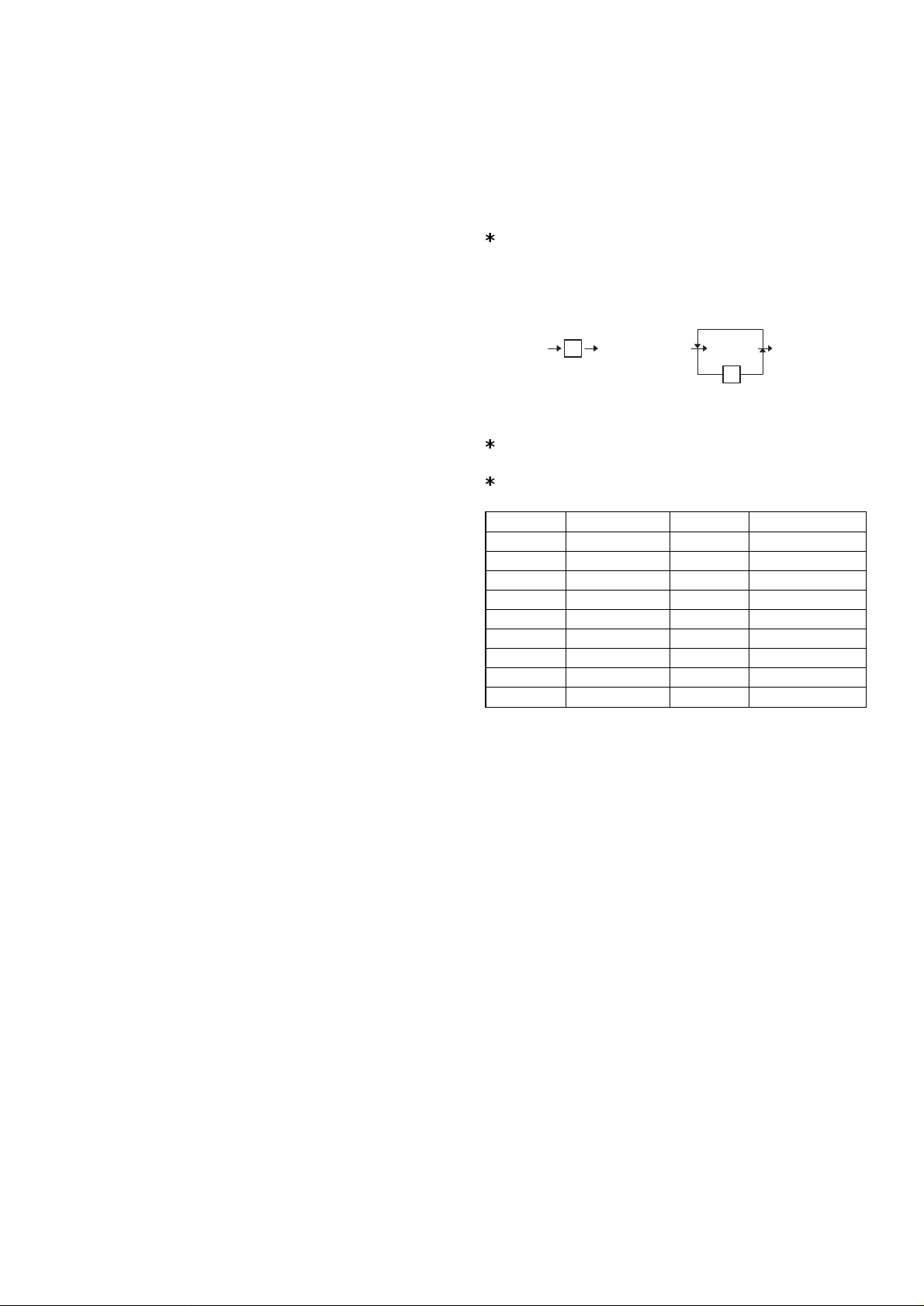

5) Key position assignment:

After the execution of MRS-2, only the RECEIPT FEED and

JOURNAL FEED keys can remain effective on key assignment.

Any key can be assigned on any key position on the main keyboard.

[key setup procedure]

0

Disable

*2

*1

complete.

MRS-2

executed

NOTES:

1: When the 0 key is pressed, the key of the key number on

display is disabled.

2: Push the key on the position to be assigned. With this, the key

of the key number on display is assigned to that key position.

Key number Key name Key number Key name

1 Numeric key "0" 10 Numeric key "9"

2 Numeric key "1" 11 Numeric key "00"

3 Numeric key "2" 12 Numeric key "000"

4 Numeric key "3" 13 Decimal point key

5 Numeric key "4" 14 CL key

6 Numeric key "5" 15 @/FOR key

7 Numeric key "6" 16 SB TL key

8 Numeric key "7" 17 CA/AT key

9 Numeric key "8"

0 Key position set Free key Free key setup

2. Master reset (Al l me mory clear)

There are two possible methods to perform a master reset.

• MRS-1

Used to clear all memory contents and return machine back to its

initial settings and return keyboard back to default keyboard layout.

Procedure

1) Unplug the AC cord from the wall outlet.

2) Set the MODE switch to the (SRV′) position.

3) Plug in the AC cord to the wall outlet.

4) While holding down JOURNAL FEED key, turn to (SRV) position

from (SRV′) position.

• MRS-2

Used to clear all memory and keyboard contents.

This reset returns all programming back to defaults. The keyboard

must be entered by hand.

This reset is used if an application needs different keyboard layout

other than that supplied by a normal MRS-1.

– 1 –

Page 3

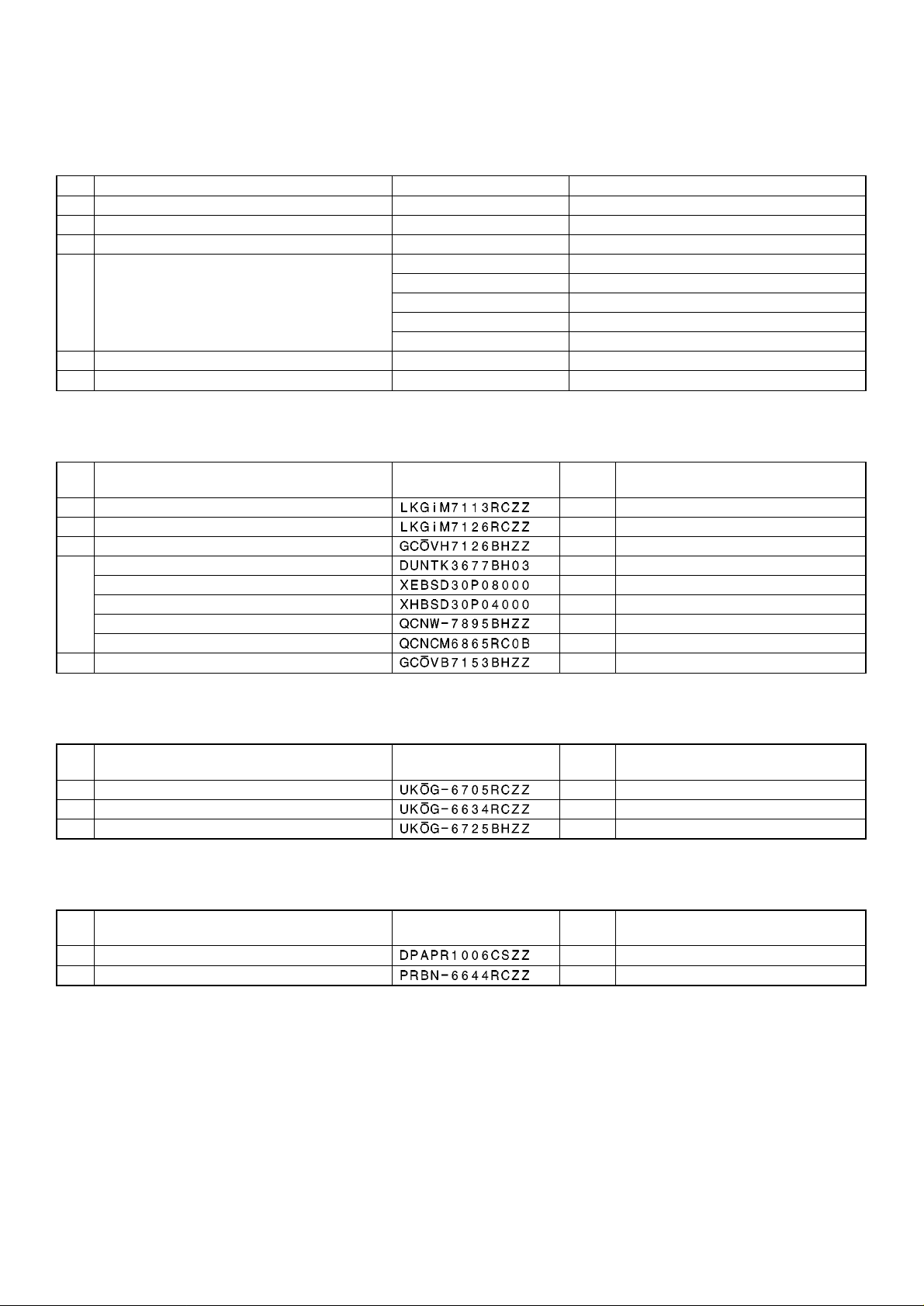

CHAPTER 2. LIST OF OPTIONS

1. Options

No. NAME MODEL DESCRIPTION

1 EXPANSION RAM CHIP ER-03RA 512K bytes RAM CHIP

2 REMOTE DRAWER ER-04DW

3 PRESETS LOADER ER-01FD/02FD FD unit

4 KEY TOP KIT ER-11KT7 1 × 1 KYE TOP UNIT

ER-12KT7 1 × 2 KYE TOP UNIT

ER-22KT7 2 × 2 KYE TOP UNIT

ER-11DK7G 1 × 1 DUMMY KYE KIT

ER-51DK7G 5 × 1 DUMMY KYE KIT

5 COIN CASE ER-55CC2 for "U" version

6 COIN CASE ER-48CC2 for "A" version

2. Service options

No. NAME PARTS CODE

1 SERVICE KEY

2 MODE KEY GRIP COVER

3 DRIP-PROOF KEYBOARD COVER

4 JOURNAL NEAR END SENSOR UNIT

Screw (Sensor unit – Top cabinet)

Screw (Sensor unit – Earth wire – Top cabinet)

Earth wire

Connector (2pin)

5 TEXT PRESET KEYBOARD COVER

3. Service tools

No. NAME PARTS CODE

1 RS-232 LOOP BACK CONNECTOR

2 KEY TOP REMOVER

32 × 2 KEY TOP INSTALLING JIG

4. Supplies

No. NAME PARTS CODE

1 ROLL PAPER

2 INK LIBBON

PRICE

RANK

AF

AL OP key only

BE Include the switch cover

BB Q’ty: 1

AA Q’ty: 1

AA Q’ty: 1

AF Q’ty: 1

AA Q’ty: 1

BH

PRICE

RANK

BU

AX

BB

PRICE

RANK

AR 5 roll /pack

AZ

DESCRIPTION

DESCRIPTION

DESCRIPTION

– 2 –

Page 4

CHAPTER 3. REMOVING THE TOP

CHAPTER 4. REMOVING THE

CABINET

1) Remove the printer cover .

2) Remove the 4 screws

1

2

.

2

Printer

PRINTER UNIT

1) Remove the top cabinet.

2) Remove the two screws

3) Remove the printer cable

4) Remove the printer unit

3

2

1

.

.

from the top cabinet.

2

3) Separate the top cabinet and the bottom cabinet.

Note: Transformer cable

tom cabinet are connected to the main PWB on the top

cabinet. Be careful when separating them from the bottom

cabinet.

4) Remove transformer cable

PWB.

5

and the drawer cable on the bot-

and drawer cable from the main

6

– 3 –

Page 5

CHAPTER 5. REMOVING THE MAIN

PWB

1) Remove the top cabinet.

2) Remove the printer unit.

3) Remove the following connector cables from the main PWB.

Dry battery cable

Pop up display cable

Note: The pop-up cable is fixed with the holder not to make

contact with the heat radiating plate on the main PWB. Be

careful of it when installing.

Mode switch cable

Keyboard cable

Front display cables

4) Remove the RS232 cable from the RS232 PWB .

5) Remove the screw

6) Remove the four screws

7) Remove the two screws

and grounding wire .

and main PWB .

and RS232 PWB .

2. Installation procedure

1) Remove the top cabinet.

2) Connect the remote drawer cable

the main PWB. (Location: CN7)

3) Use nippers to cut off drawer cable binding holder

bottom cabinet, and bind drawer cable

Screw

used in this case is an accessory of the ER-04DW.

to the drawer connector on

of the ER-04DW.

on the

11

12

10

6

13

3

4

8

9

5

1

2

9

7

CHAPTER 6. REMOTE DRAWER:

ER-04DW

CAUTION:

The drawer unit should be securely fitted to the supporting platform

to avoid instability when the drawer is open.

1

4) Use nippers to cot off the drawer cable split pin

cabinet, and attach the top cabinet.

3

2

1

of the top

4

1. Outline

The ER-A440 allows connection of one remote drawer ER-04DW.

– 4 –

Page 6

CHAPTER 7. EXPANSION RAM

CHAPTER 8. JOURNAL NEAR END

CHIP (ER-03RA)

1. Outline

ER-03RA: 512KB SRAM chip

2. Installation procedure

Before working on the installation, turn off the power switch on the

ECR and unplug the AC cord from the AC outlet.

Also save the memory contents bef ore proceeding to the installation

work.

1) Remove the top cabinet.

2) Install the ER-03RA to the IC socket on the Main PWB. (Location

No. IC14)

3) Master reset the ECR.

4) Load the data in memory which had been saved.

5) Program reset the ECR.

ER-03RA

SENSOR

(DUNTK3677BH03)

1. Parts list

To install the journal near end sensor, the following parts are

reguired.

NO. PARTS NAME PARTS CODE

JOURNAL NEAR

END SENSOR

UNIT

Screw (Sensor

unit-Top cabinet)

Screw (Sensor

unit-Earth wire-Top

cabinet)

Earth wire AF 1

Connector (2 pin) AA 1

2. Installation procedure

1) Remove the Printer cover.

2) Remove the Top cabinet.

3) Remove the Printer unit.

4) Remove the Main PWB unit.

5) Install the Sensor unit

6) Install the Earth wire

7) Fix the Earth wire

to the Top cabinet with the Screw .

to the Sensor unit with the Screw .

to the Top cabinet with the Screw.

PRICE

RANK

BB 1

AA 1

AA 1

Q’ty

2

1

4

Through the earth wire into the thins.

3

– 5 –

Page 7

8) Solder the Connector (2 pin) to the Main PWB unit. (Location:

CN8 NEJ)

Solder the connector(2pin).

2. Installation procedure

ER-22KT7

ER-12KT7

ER-11KT7

9) Connect the Sensor unit cable to the Connector (2 pin) to the

Main PWB unit. (Location: CN8 NEJ)

CHAPTER 9. KEY TOP KIT

1. Outline

The ER-A440 employs the following key top (option) to allow additional installation of the key top and change in the key layout.

MODEL NAME DESCRIPTION

ER-11KT7 1 × 1 Key top

ER-12KT7 1 × 2 Key top

ER-22KT7 2 × 2 Key top

ER-11DK7G 1 × 1 Dummy key

ER-51DK7G 5 × 1 Dummy key

ER-22KT7

ER-12KT7

ER-11KT7

– 6 –

Page 8

ER-12KT7, ER-22KT7

1) Attach two spacers to the keyboard frame.

Yellow

White

(When using 2 × 2 key top installing jig (UKOG-6725BHZZ) for

installation)

1) Remove the key label and the key cap from the key top.

2) Attach the key top so that the guide arm is under the jig.

Jig

Key top

Guide arm

3) With the jig inserted in the key top, slowly press down the key

top until the guide arm is brought into contact with the guide

holder A.

Jig

Key top

Guide arm

Yellow

White

White

Yellow

• Attach the yellow spacer to the left lower side, and the white

spacer to the right lower side.

2) The key top of the ER-12KT7 and the ER-22KT7 includes the

guide pin. Install the key top so that t he guide pin is engaged

with the spacer attached to the keyboard frame.

Guide arm

A

4) Remove the jig under the above condition 3), and press the

key top.

5) Check that the key top operates properly.

6) Install the key label and the key cap.

ER-11DK7G, ER-51DK7G

– 7 –

Page 9

COPYRIGHT 1998 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this public ation may be reproduce d,

stored in a retrieval system, or transmitted,

in any form or by any means ,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Information Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1998 May Printed in Japan

Loading...

Loading...