SHARP ERA440U Service Manual

SERVICE MANUAL

ELECTRONIC

CASH REGISTER

MODEL ER-A440

SRV Key : LKGIM7113RCZZ

PRINTER : DP-730

("U" & "A" version)

CAUTION

EXTREME CAUTION MUST BE TAKEN WHEN SERVICING THIS MACHINE. EVEN

THOUGH THE MODE SWITCH IS IN THE OFF POSITION, VOLTAGE IS STILL SUPPLIED

TO THE ENTIRE MACHINE.

WHEN WORKING ON THIS MACHINE MAKE SURE THAT THE POWER CORD IS

REMOVED FROM THE WALL OUTLET.

CONTENTS

CHAPTER 1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

CHAPTER 2. OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

CHAPTER 3. SERVICE (SRV) MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

CHAPTER 4. HARDWARE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

CHAPTER 5. TEST FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

CHAPTER 6. DOWN LOAD FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

CHAPTER 7. SERVICE PRECAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

CHAPTER 8. CIRCUIT DIAGRAM & PWB LAYOUT . . . . . . . . . . . . . . . . . . . 8-1

PARTS GUIDE

Parts marked wi th " " i s impo rtan t for mai ntai ning the saf ety of the set . Be su re to re plac e thes e part s with sp ecif ied on es

for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

CHAPTER 1. SPECIFICATIONS

1. Appearance/Rat ing

1) Rating

Power source AC 120 V ±10% 50/60Hz

Power consumption Standby: 11.5 W

Maximum: 40 W (max.)

Operating temperature 0°C~40°C (32°F~104°F)

Operating humidity 10%~90% (RH)

Physical dimensions,

including the drawer

Weight 28.7 lbs (13 kg)

2. Keyboard

420(W) ✕ 427(D) ✕ 292(H)mm

16.5(W) ✕ 16.8(D) ✕ 11.5(H)in.

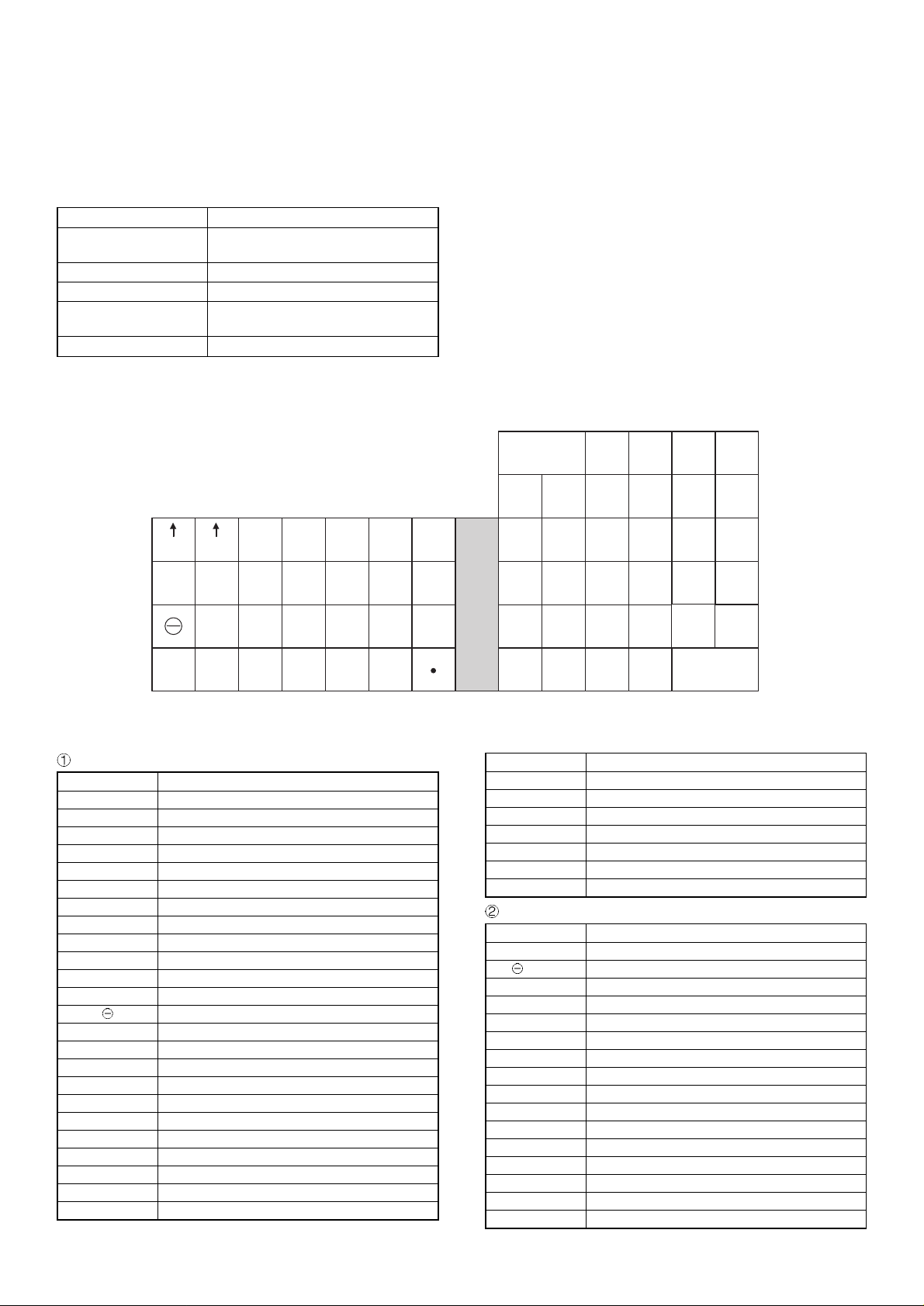

1) Standard keyboard layout

JOURNAL

WYPL2

PRINT

WYPL2

#

WYPL2

CASH

#

NS

RA

RECEIOT

PCPT

%1 %2 PO

WYPL2

2) Key top name

Standard Key Top

KEY TOP DESCRIPTION

0 to 9,00 Numeric keys

• Decimal point key

CL Clear key

@/FOR Multiplication/split-pricing key

1 to 20 Department 1 to 20 keys

↑ R Receipt Paper Feed key

↑ J Journal Paper Feed key

RCPT Receipt print & on/off key

# Non-Add Code key

AUTO 1, 2 Automatically Entry key 1, 2

CASH # Cashier code entry key

NS No Sales key

Discount key

% 1, 2 % key 1, 2

PO 1, 2 Paid Out key

RA Received on Account key

VOID Void key

PLU/SUB PLU/Subdept code entry key

SBTL Subtotal key

CH Charge key

CA/AT Cash/amount tendered

TAX1 SHIFT TAX1 shift key

TAX2 SHIFT TAX2 shift key

TAX Tax key

CL

@/

FOR

RFND

VOID

789

456

123

000

Fig. 2-1

1 – 1

PLU/SUB

AUTO1AUTO

5101520

4 9 14 19

3 8 13 18

2 7 12 17

1 6 11 16

KEY TOP DESCRIPTION

PRINT Validation print key

RFND Refund key

CONV Currency conversion key

CHK Check key

MDSE SBTL Merchandise subtotal key

FS SHIFT Food stamp shift key

FS TEND Food stamp tendered key

Optional Key Top

KEY TOP DESCRIPTION

% 3, 4 % key 3, 4

2, 3, 4 Discount key 2, 3, 4

AUTO 3 ∼ 10 Automatically entry key 3 ∼ 10

CA 2 Cash total 2 key

CH 2 ∼ 5 Charge key 2 ∼ 5

CR 3, 4 Credit key 3, 4

21 to 50 Department 21 to 50 key

TAX3 SHIFT TAX3 shift key

TAX4 SHIFT TAX4 shift key

RA2 Received on account key 2

PO2 Paid out key 2

CONV2 ∼ 4 Currency conversion key 2 ∼ 4

CHK2 Check key 2

RFND SALE Refund sales key

BIRTH Birthday key

1 to 68 Direct price lookup/Subdepartment keys

2

TAX1

SHIFT

TAX

CONV

CHK

MDSE

SBTL

CA/AT

TAX2

SHIFT

FS

SHIFT

FS

TEND

CH

SBTL

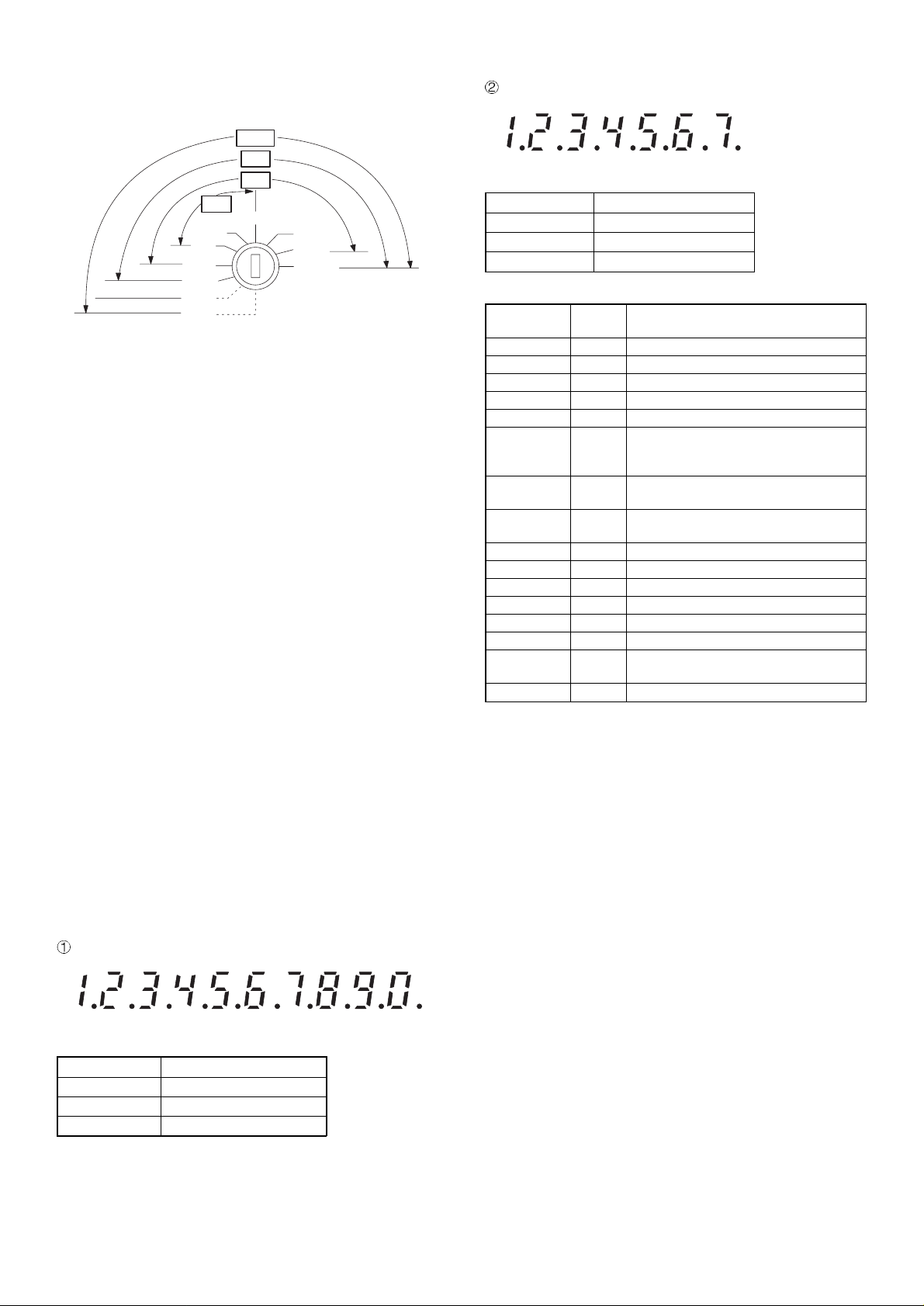

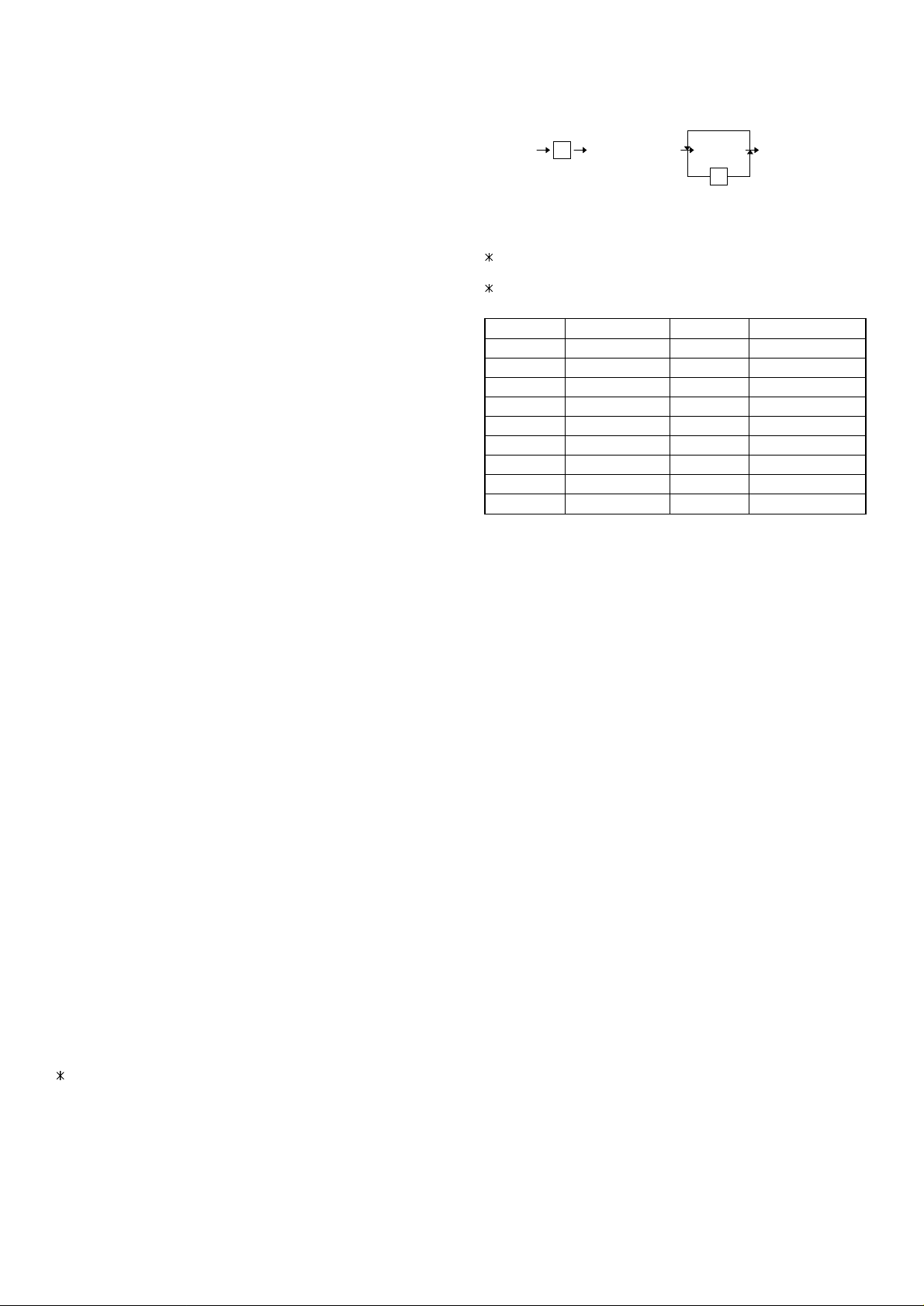

3. Mode switch

SRV

MA

SM

OP

OP,X/Z

OFF

PGM1

PGM2

(SRV)

(SRV')

* The key can be removed in the REG or OFF position.

* In the SRV’ mode, key inputs are prohibited and no display is

made.

* With the key in the off position power is not supplied to the

main PWB.

[Functions]

REG

MGR

X1/Z1

X2/Z2

Fig. 3-1

• Function for each key position

• SRV’: System reset

• SRV: Service mode (Service programming)

• PGM2: Allows programming of an item that is not changed

frequently, in addition to the PGM1 mode programming.

• PGM1: Allows programming of items frequently changed (e.g.

department, PLU pricing, and discount rate setting).

• OP, X/Z:Allows X or Z operation by servers or cashiers.

• REG: Allows registrations.

• MGR: Allows the operations, by authorized person such as a

manager (e.g. correction after transaction finished or

cancellation of entry limits), which are not permitted to

ordinary cashiers.

• X1/Z1: Allows reading and resetting of a day’s sales total.

• X2/Z2: Allows reading or resetting sales totals in a specified

period.

• OFF: Switching off the display to prevent key board entries.

(The setting turn off the AC power.)

4. Display

1) Layout

Operator display

Fig. 4-1

Customer display (Pop-up display)

Fig. 4-2

7 segment display (LED)

No. of positions 7

Color of display Yellow Green

Character size 14.2 (H) ✕ 8.0 (W) mm

Display contents

Display

Position

Amount 1-8

Minus sign 4-10 –: Floating

Error 10 E

PGM Mode 10 P

VOID Mode 10 u

CA/AT

CHK, CR

SUB TOTAL/

short tender

Change 10 C: Light up whenever the change due

Department 9-10 No zero-suppressed

PLU 5-10 No zero-suppressed

Repeat 8 Endless count, starting from 2.

Decimal point 3-1 TAB

Receipt OFF 9 (–)

Cashier No. 2-3 –xx–: free code

VP

compulsory

Sentinel 10 Light up the decimal point

10 F: Lights up when a registration is

finalized by depressing CA/AT, CHK,

CR key

10 o

amount appears in the display.

10 U: Light up when the validation printing is

compulsory

Description

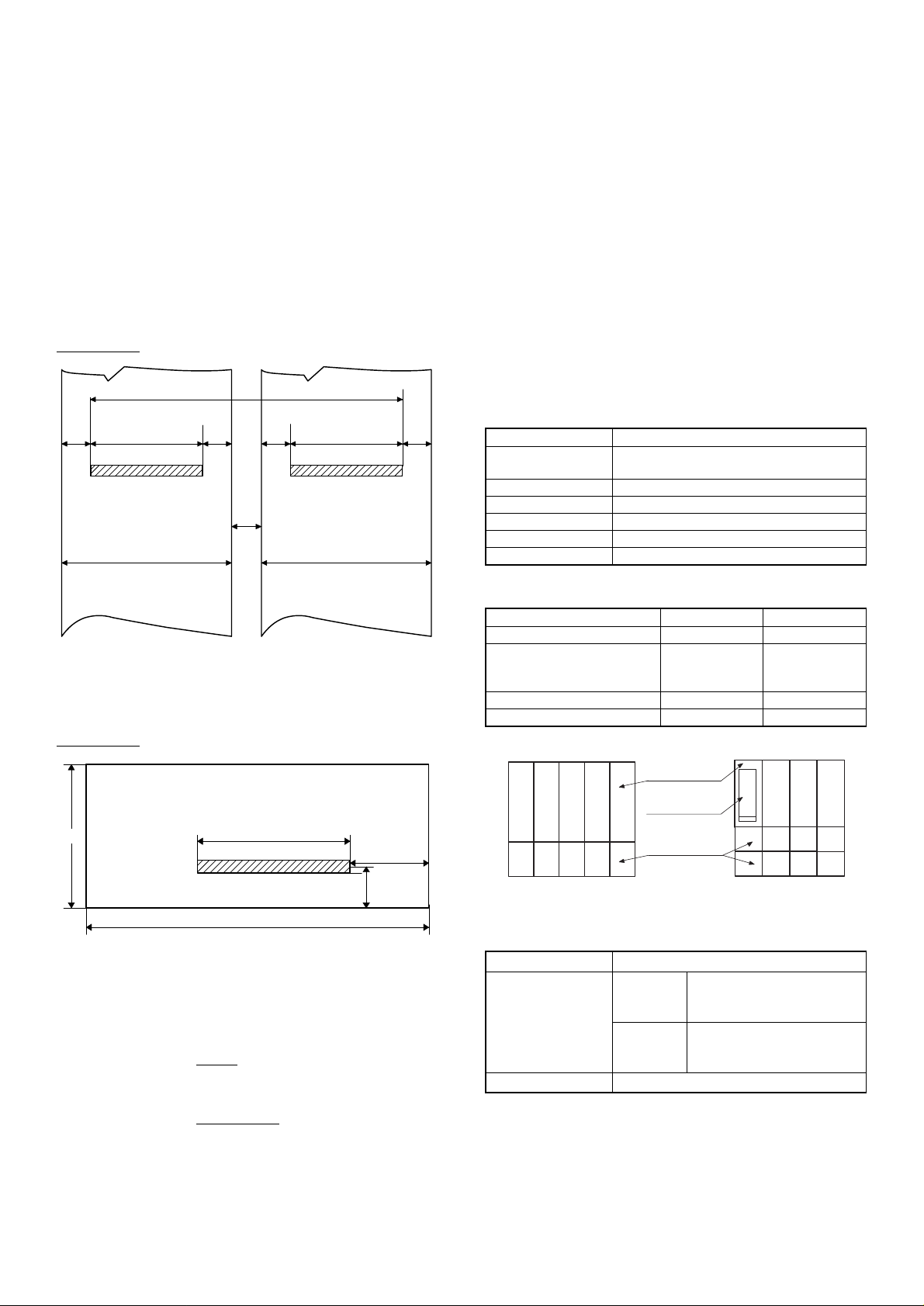

5. Printer (DP-730)

1) Specifications

Part number: DP-730

•

• No. of stations: 2

• Printing system: Mechanical serial dot

• Direction of printing: Bidirectional

• Printing capacity: Receipt – 24 characters

Journal – 24 characters

Validation – 55 characters

(one line only)

• Character size: 1.36 (W) ✕ 2.75 (H) mm at 7 ✕ 7 dots

Print pitch:

Column distance

Row distance

1.59 mm

5.08 mm

7 segment display (LED)

No. of positions 10

Color of display Yellow Green

Character size 14.2 (H) ✕ 8.0 (W) mm

• Total number of dots: Receipt – 108 dots/216 positions

Journal – 108 dots/216 positions

Validation – 248 dots/495 positions

• Font: 7 ✕ 7 dots (including half dot)

Space between characters – 1 dot (2

positions)

1 – 2

• Distance between dots: 0.353 mm (H) ✕ 0.353 mm (W)

• Journal near end sensor: Service route option

• Print speed: Approx. 3.0 lines/sec.

• Paper feed speed: Receipt – Approx. 30 lines/sec.

Journal – Approx. 30 lines/sec.

• Reliability: MCBF – 4 million lines (excluding the

print head)

Head life – 50 million characters

(at 4 dots/1 character/

1 pin)

• Validation form sensor: Not setup

2) Printing area

Receipt/journal

4) Inking

•

Ink supply system: Ink ribbon

• Form: Cartridge/Endless ribbon

• Specification: Material – Nylon

• Ribbon life: Approx. 6 million characters

• Print color: Purple (single color)

5) Logo stamp: None

6) Cutter

•

Method: Manual

6. Drawer

3.56 3.56 3.56

Validation form

70

37.87

4.2

44.5± 0. 5

RECEIPT JOURNAL

Fig. 5-1

87.08 (PRINT AREA)

87.08

37.87

44.5± 0.5

3.56

Unit : mm

20

1) Specification

(1) Drawer box and drawer

Model name SK-423

Size 420 (W) ✕ 427 (L: included lock key)

Color GRAY 368

Material Metal

Bell —

Release lever Standard equipment; Situated at the bottom

Drawer open sensor Standard equipment

✕ 112 (H: included rubber leg)

2) Money case

For "U" version For "A" version

Separation from the drawer Allowed Allowed

Separation of the coin compartments from the money

case

Bill separator — YES

Number of compartments 5B/5C 4B/8C

For "U" Version For "A" Version

Disallowed Disallowed

Bill compartments

Bill separator

Coin compartments

22

130 ~ 210

Fig. 5-2

3) Paper

•

Paper roll dimensions:44.5±0.5mm in width, 83mm in diameter

• Paper quality: Journal

Bond paper (paper thickness: 0.06 to

0.09mm, paper weight: 52.3 to 64g/m

Validation form

Thickness: 0.07 to 0.14mm

130mm or more (W) ✕

Size:

70mm or more (H)

Unit : mm

2

)

3) Lock

Location of the lock Front

Method of locking

and unlocking

Key No. SK1-1

1 – 3

5B/5C

5B/8C

Locking: Insert the drawer lock key into

the lock and turn it 90 degrees

counterclockwise.

Unlocking: Insert the drawer lock key into

the lock and turn it 90 degrees

clockwise.

CHAPTER 2. OPTIONS

1. System configuration

(NOTE1)

This symbol shows

NEW MODEL

ER-01/02FD

LOCAL PURCHASE

COMPUTER

COMMERCIAL

PRODUCT

CABLE3.5 inch FDD

ER-A440

MASTER MACHINE

ER-04DW

REMOTE DRAWER

ER-03RA

OPTION RAM

Fig. 1-1

2 – 1

2. Options

No. NAME MODEL DESCRIPTION

1 EXPANSION RAM CHIP ER-03RA 512K bytes RAM CHIP

2 REMOTE DRAWER ER-04DW

3 PRESETS LOADER ER-01FD/02FD FD unit

4 KEY TOP KIT ER-11KT7 1 × 1 KYE TOP UNIT

ER-12KT7 1 × 2 KYE TOP UNIT

ER-22KT7 2 × 2 KYE TOP UNIT

ER-11DK7G 1 × 1 DUMMY KYE KIT

ER-51DK7G 5 × 1 DUMMY KYE KIT

5 COIN CASE ER-55CC2 for "U" version

6 COIN CASE ER-48CC2 for "A" version

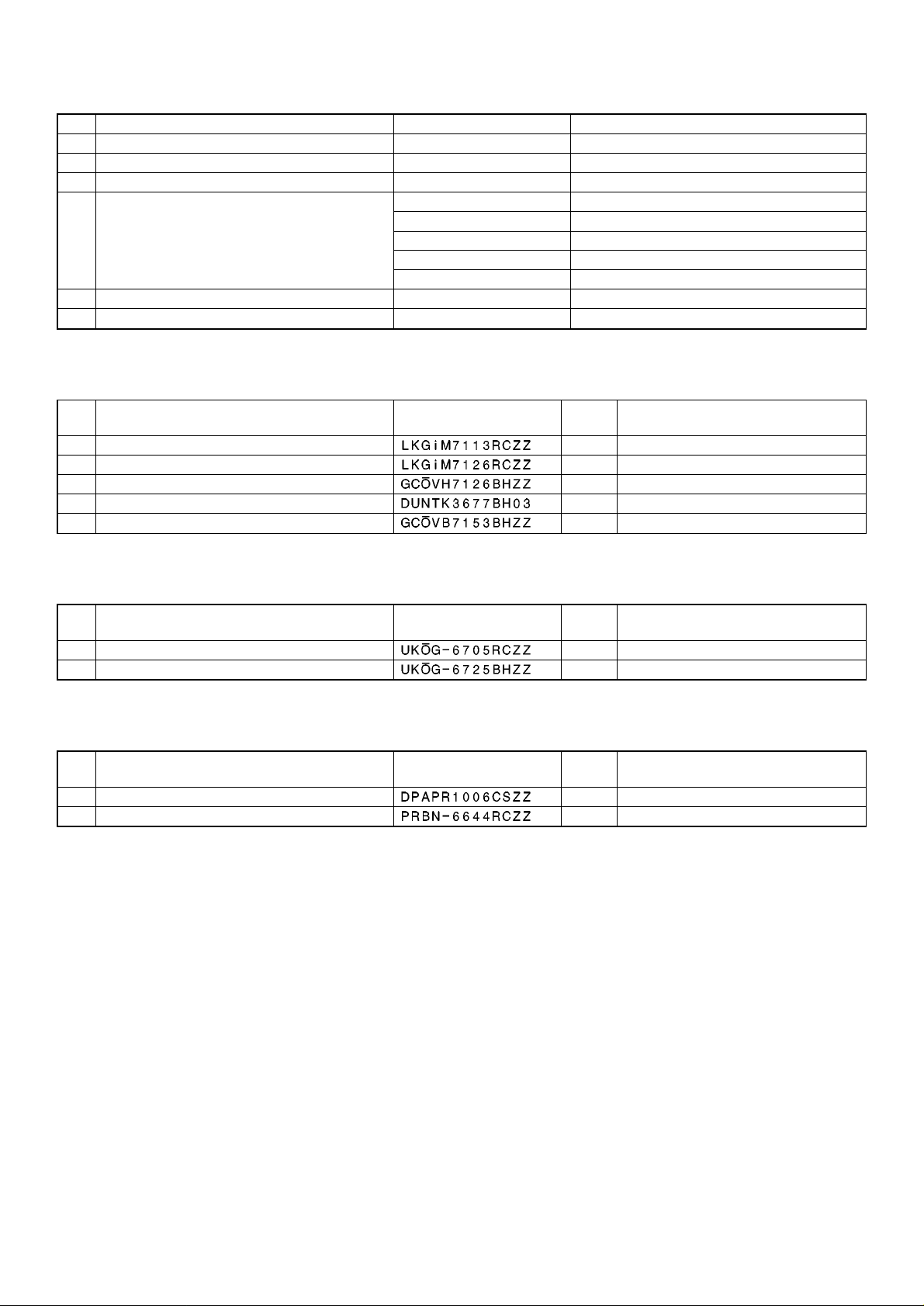

3. Service options

No. NAME PARTS CODE

1 SERVICE KEY

2 MODE KEY GRIP COVER

3 DRIP-PROOF KEYBOARD COVER

4 JOURNAL NEAR END SENSOR

5 TEXT PRESET KEYBOARD COVER

4. Service tools

No. NAME PARTS CODE

1 RS-232 LOOP BACK CONNECTOR

2 KEY TOP REMOVER

5. Supplies

No. NAME PARTS CODE

1 ROLL PAPER

2 INK LIBBON

PRICE

RANK

AF

AL OP key only

BE Include the switch cover

BB

BH

PRICE

RANK

BU

BB

PRICE

RANK

AR 5 roll/pack

AZ

DESCRIPTION

DESCRIPTION

DESCRIPTION

6. Options

For installation of the options, refer to the Installation Manual which is issued separately.

2 – 2

CHAPTER 3. SRV. RESET AND

[key setup procedure]

MASTER RESET

1. SRV. reset (Program Loop Reset)

Used to return the machine back to its operational state after a lockup has occurred.

Procedure

• Method 1

1) Unplug the AC cord from the wall outlet.

2) Set the mode switch to (SRV′) position.

3) Plug in the AC cord to the wall outlet.

4) Turn to (SRV) position from (SRV′) position.

• Method 2

1) Set the mode switch to PGM2 position.

2) Turn off the AC switch.

3) While holding down JOURNAL FEED key and RECEIPT FEED

key, Turn on the AC switch.

Note: When disassembling and reassembling always power up us-

ing method 1 only. Method 2 will not reset the CKDC8.

Note: SRV programming job#926-B must be set to "4" to allow PGM

program loop reset.

0

Disable

*2

Free key setup

complete.

*1

MRS-2

executed

NOTES:

1: When the 0 key is pressed, the key of the key number on display

is disabled.

2: Push the key on the position to be assigned. With this, the key of

the key number on display is assigned to that key position.

Key number Key name K ey number Key name

1 Numeric key "0" 10 Numeric key "9"

2 Numeric key "1" 11 Numeric key "00"

3 Numeric key "2" 12 Numeric key "000"

4 Numeric key "3" 13 Decimal point key

5 Numeric key "4" 14 CL key

6 Numeric key "5" 15 @/FOR key

7 Numeric key "6" 16 SBTL key

8 Numeric key "7" 17 CA/AT key

9 Numeric key "8"

Key position set Free key

0

2. Master reset (Al l me mory clear)

There are two possible methods to perform a master reset.

• MRS-1

Used to clear all memory contents and return machine back to its

initial settings and return keyboard back to default keyboard layout.

Procedure

1) Unplug the AC cord from the wall outlet.

2) Set the MODE switch to the (SRV′) position.

3) Plug in the AC cord to the wall outlet.

4) While holding down JOURNAL FEED key, turn t o (SRV) position

from (SRV′) position.

• MRS-2

Used to clear all memory and keyboard contents.

This reset returns all programming back to defaults. The keyboard

must be entered by hand.

This reset is used if an application needs different keyboard layout

other than that supplied by a normal MRS-1.

Procedure

1) Unplug the AC cord from the wall outlet.

2) Set the MODE switch to the (SRV′) position.

3) Plug in the AC cord to the wall outlet.

4) While holding down JOURNAL FEED key and RECEIPT FEED

key, turn to (SRV) position from (SRV′) position.

5) Key position assignment:

After the execution of MRS-2, only the RECEIPT FEED and

JOURNAL FEED keys can remain effective on key assignment.

Any key can be assigned on any key position on the main keyboard.

3 – 1

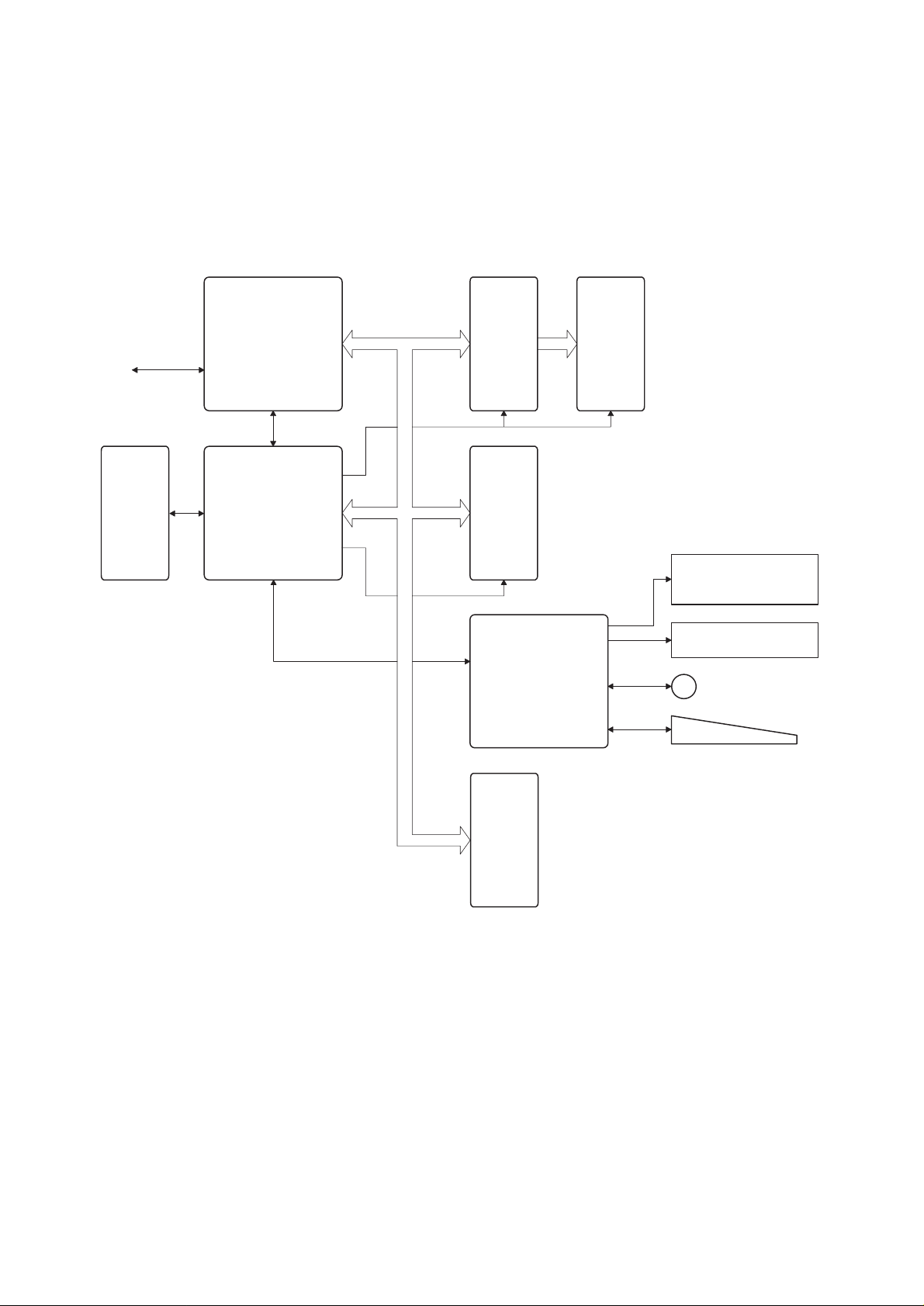

CHAPTER 4. HARDW ARE DESCRIPTION

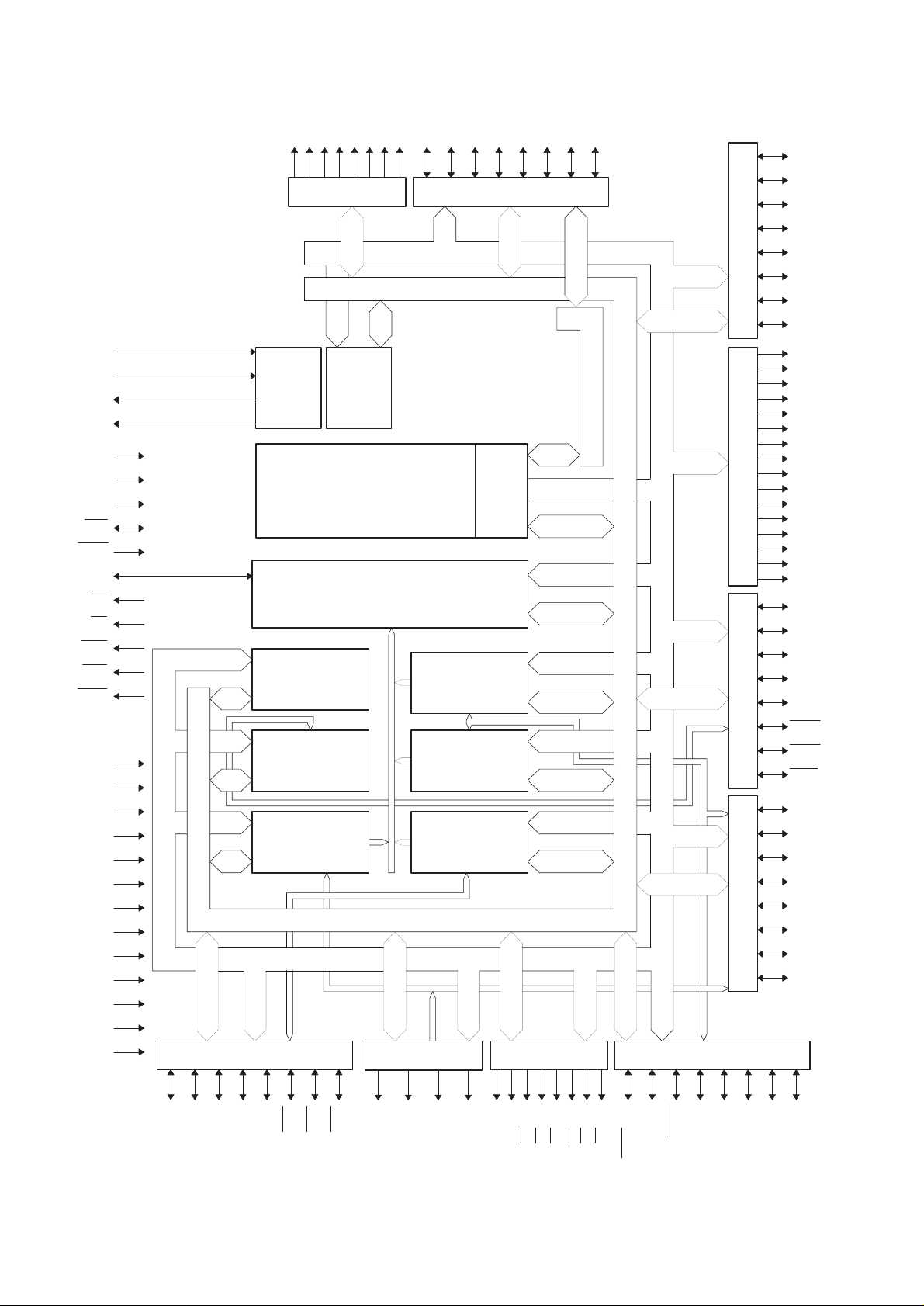

1. Hard ware block diagram

DRAWER

PRINTER

DP-730

CPU

GATE ARRAY

MPCA7

STANDARD

RAM1

RAM2

32KBx2

STANDARD

ROM

256KB

CKDC8

OPTIONAL

RAM

512KB

ER-03RA:512KB

OPERATER DISPLAY

1 LINE

7SEG 10DIG

CUSTOMER DISPLAY

1 LINE

7SEG 7DIG

SWITCH

KEY BOARD

Fig. 1-1

4 – 1

RS232

I/F

1 ports

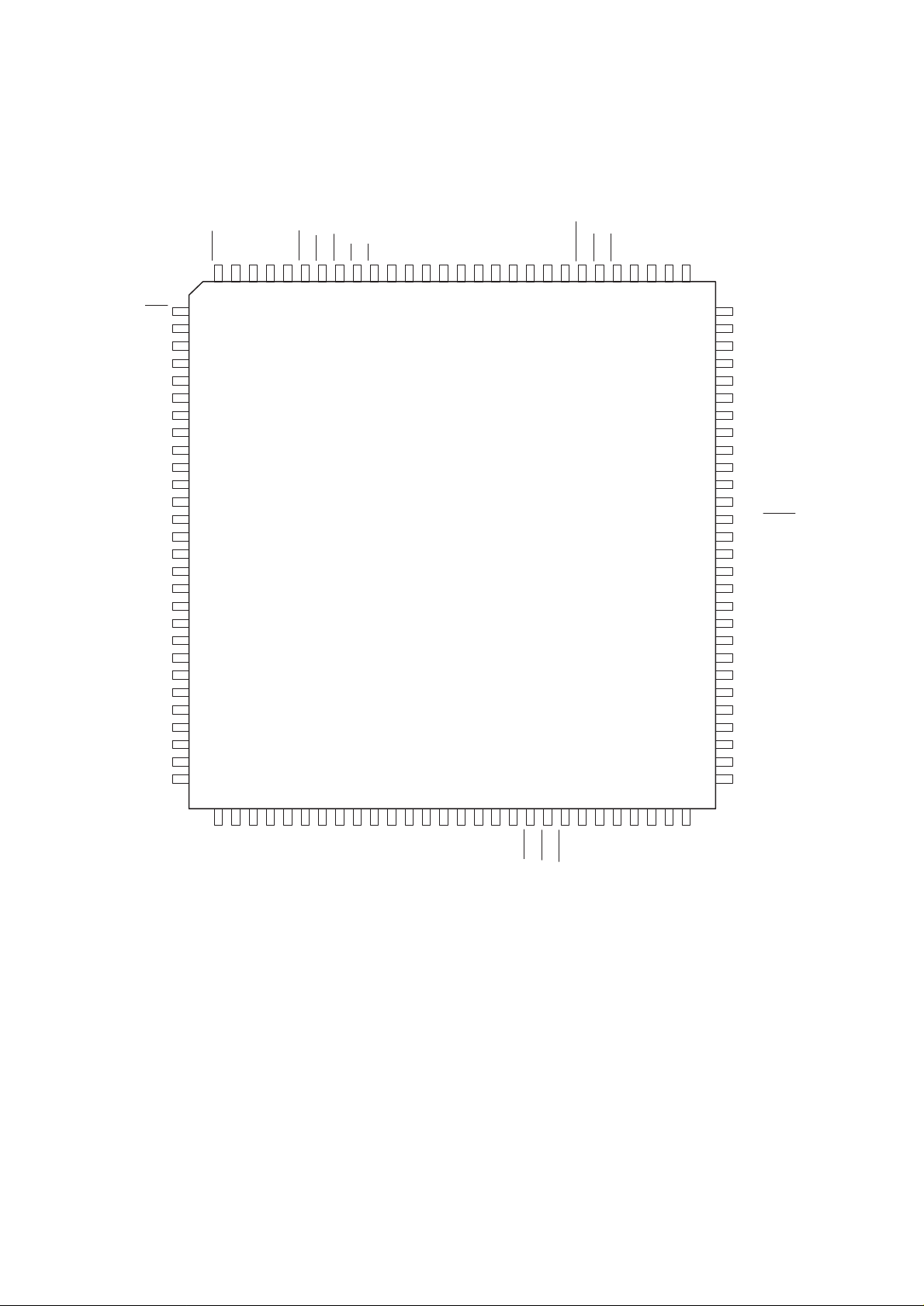

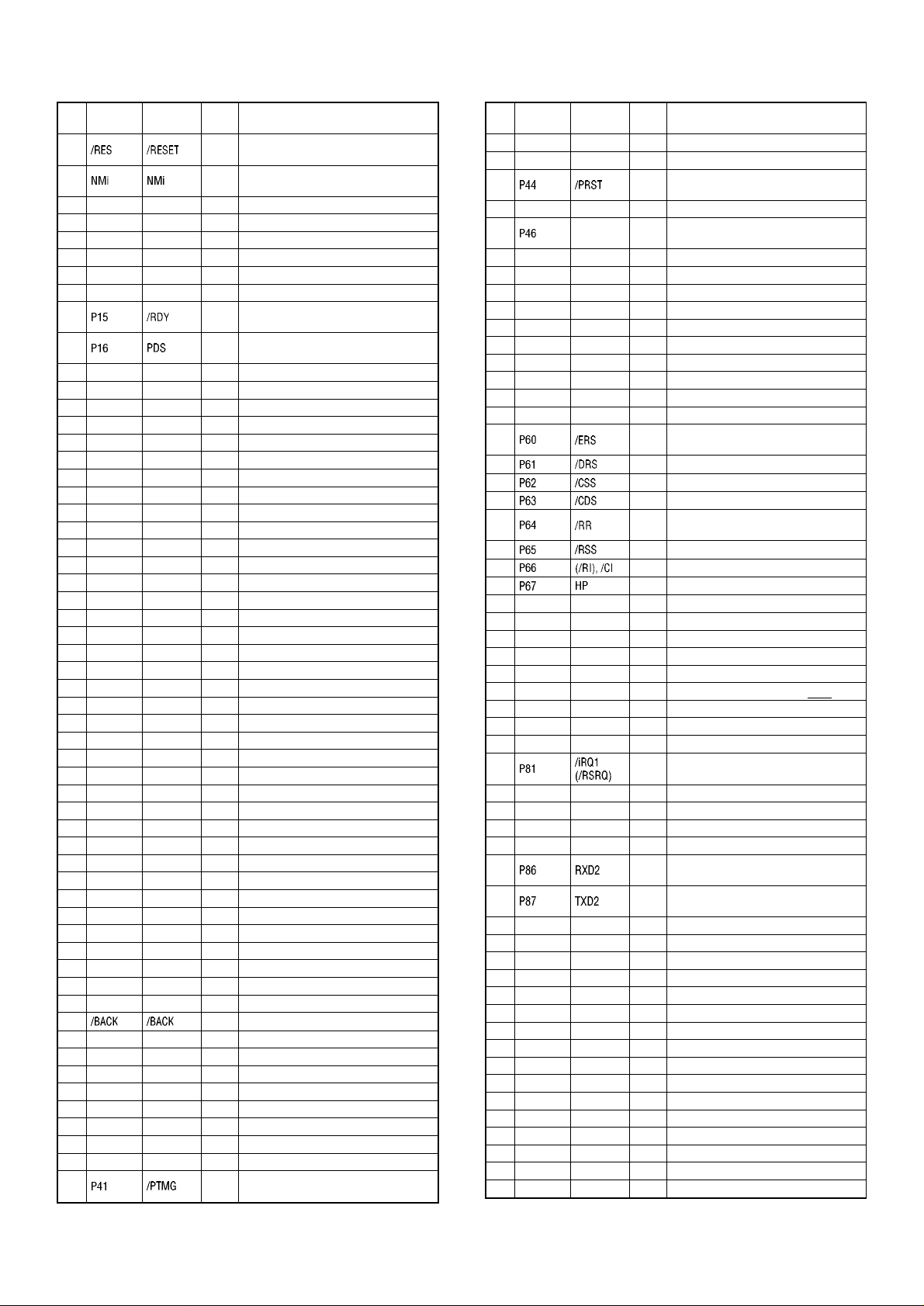

2. Description of main LSI’s

2-1. CPU (HD6415108-10)

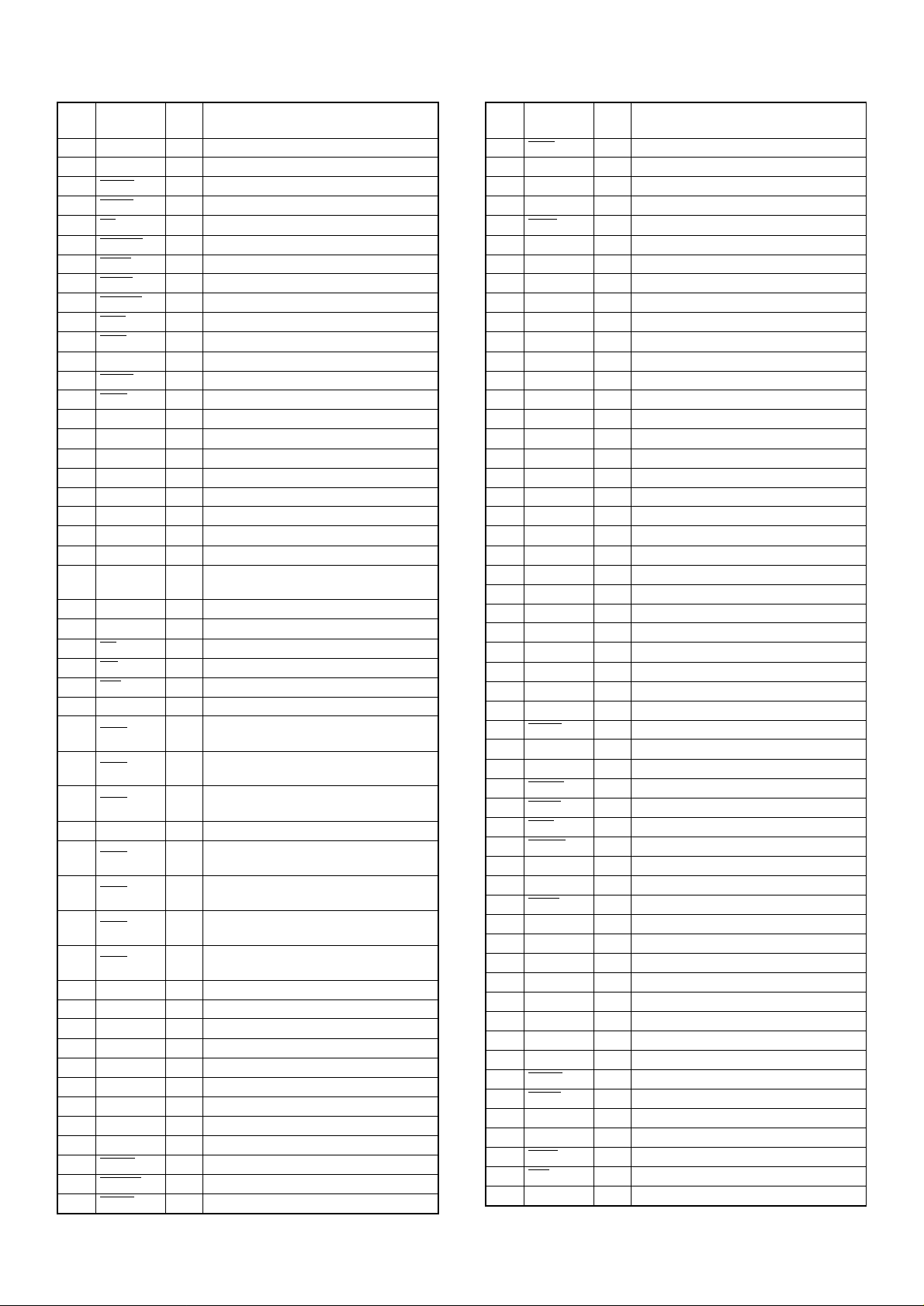

1) Pin configuration

MD2

MD1

STBY

MD0

VCC

LWR

RFSH

RD

HWR

AS

E

X

VSS

XTAL

VSS

EXTAL

TXD2

TXD1

RXD2

RXD1

SCK2

UASKC

IRQ1

IRQ0

VCC

AN3

AVCC

AN2

RES

NMI

VSS

P10

P11

P12

P13

P14

P15

P16

P17

D0

D1

D2

D3

D4

D5

D6

D7

VSS

A0

A1

A2

A3

A4

A5

A6

A7

112

111

110

109

108

107

106

105

104

103

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

293031323334353637383940414243444546474849505152535455

102

999897969594939291908988878685

101

100

56

84

83

82

81

80

78

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

AN1

AN0

AVSS

VSS

P67

P66

P65

P64

P63

P62

P61

P60

P57/STOP

P56

P55

P54

P53

P52

P51

P50

VSS

P47

P46

P45

P44

P43

P42

P41

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

VSS

A20

HD6415108-10 pin configuration

Fig. 2-1

4 – 2

A21

A22

A23

VSS

WAIT

BACK

P33

BREQ

P34

P35

P36

P37

VCC

P40

2) Block diagram

EXTAL

XTAL

X

E

MD2

MD1

MD0

RES

STBY

NMI

AS

RD

HWR

LWR

RFSH

VCC

VCC

VCC

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

AVCC

AVSS

D7D6D5D4D3

Data bus Port 1

Clock

oscillator

Watch

dog timer

H8/500 CPU DTC

Interruption controller

Refresh controller

Wait state

controller

A/D convertor

D2

P17

D1

D0

16bit free running

timer x 2ch

Serial

communication

interface x 2ch

P16

P15

8bit timer

P14

P13

P12

P11

P10

Data bus (Lower)

Data bus (Upper)

Address bus

P27/A23

P26/A22

P25/A21

P24/A20

Port 2

P23/A19

P22/A18

P21/A17

P20/A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

Address bus

A5

A4

A3

A2

A1

A0

P37

P36

P35

P34

Port 3Port 4

P33

BREQ

BACK

WAIT

P47

FTI2

P45

FTI1

P43

P42

P41/TMCI

P40

Port 5Port 6Port 7Port 8

TXD2

RXD2

TXD1

RXD1

SCK2

IRQ2

IRQ1

IRQ0

P73

AN2

AN1

Fig. 2-2

4 – 3

AN0

P67

P66

RS/P65

CS/P62

RR/P64

CD/P63

ER/P60

DR/P61

P56

STOP/P57

FMRS

P54

P53

P52

P51

P50

3) Pin description

PIN

SYMBOL

No.

1 IN

2

3 VSS VSS GND

4 P10 ERC OUT EVENT READ CANCEL (to CKDC)

5 P11 LDRQ OUT LOAD REQUEST (to CKDC)

6 P12 /SHEN IN SHIFT ENABLE (from CKDC)

7 P13 /FRES OUT FISCAL MEMORY RESET (NU)

8 P14 BUSY IN FISCAL MEMORY BUSY (NU) Pull-up

9

10

11 P17 IN GND Nu

12 D0 D0 I/O DATA BUS 0

13 D1 D1 I/O DATA BUS 1

14 D2 D2 I/O DATA BUS 2

15 D3 D3 I/O DATA BUS 3

16 D4 D4 I/O DATA BUS 4

17 D5 D5 I/O DATA BUS 5

18 D6 D6 I/O DATA BUS 6

19 D7 D7 I/O DATA BUS 7

20 VSS V SS GND

21 A0 A0 OUT ADDRESS BUS 0

22 A1 A1 OUT ADDRESS BUS 1

23 A2 A2 OUT ADDRESS BUS 2

24 A3 A3 OUT ADDRESS BUS 3

25 A4 A4 OUT ADDRESS BUS 4

26 A5 A5 OUT ADDRESS BUS 5

27 A6 A6 OUT ADDRESS BUS 6

28 A7 A7 OUT ADDRESS BUS 7

29 A8 A8 OUT ADDRESS BUS 8

30 A9 A9 OUT ADDRESS BUS 9

31 A10 A10 OUT ADDRESS BUS 10

32 A11 A11 OUT ADDRESS BUS 11

33 A12 A12 OUT ADDRESS BUS 12

34 A13 A13 OUT ADDRESS BUS 13

35 A14 A14 OUT ADDRESS BUS 14

36 A15 A15 OUT ADDRESS BUS 15

37 VSS VSS GND

38 A16 A16 OUT ADDRESS BUS 16

39 A17 A17 OUT ADDRESS BUS 17

40 A18 A18 OUT ADDRESS BUS 18

41 A19 A19 OUT ADDRESS BUS 19

42 A20 A20 OUT ADDRESS BUS 20

43 A21 A21 OUT ADDRESS BUS 21

44 A22 A22 OUT ADDRESS BUS 22

45 A23 A23 OUT ADDRESS BUS 23

46 VSS VSS GND

47 /WAIT /WAIT IN Wait signal from MPCA

48

49 /BREQ /BREQ IN Bus control request (Nu) pull-up

50 P33 DOPS IN Drawer open sencer signal

51 P34 /DR0 OUT Drawer open drive signal

52 P35 /DR1 OUT Option drawer 1 drive signal

53 P36 NU IN (Nu) GND

54 P37 NU IN (Nu) GND

55 VCC VCC +5V

56 P40 /IFV IN Slip printer enable (Nu) pull-up

57

SIGNAL

NAME

IN/

OUT

RESET INPUT from CKDC WUTH

BUFFER

NON-MASKABLE INTERRUPT INPUT

IN

FOR SSP INTERRUPT INPUT

FISCAL MEMORY READY (NU)

IN

Pull-up

POP-UP DISPLAY SENSOR (NU)

IN

Pull-up

Bus control request acknowl edge (Nu)

OUT

Printer (Dp-730) timing signal from

IN

MPCA

FUNCTION

PIN

SYMBOL

No.

58 P42 /TOF IN Slip TOF signal (Nu) pull-up

59 P43 /BOF IN Slip BOF signal (Nu) pull-up

60

61 P45 /NEJ IN Near END signal jounal

62 IN

63 P47 /NER IN Near END signal receipt

64 VSS V SS GND

65 P50 TRG1 OUT Dot pulse adjust signal

66 P51 /PSTOP OUT Nu

67 P52 /CKDCR2 OUT Nu

68 P53 OPDS IN Nu (GND)

69 P54 FVPON OUT Nu

70 P55 FMRS IN Nu (GND)

71 P56 /SLIPLMP OUT Nu

72 P57 /STOP OUT Nu

73

74

75

76

77

78

79

80

81 VSS V SS GND

82 AVSS AVSS IN GND

83 P70 VPJ IN Validation sensor journal (NU) GND

84 P71 VPR IN Validation sensor receipt (NU) GND

85 P72 VPTEST IN +24V test input

86 P73 IN Validation sense signal (Nu)

87 AVCC AVCC IN +5V

88 VCC VCC +5V

89 P80 /iRQ0 IN Interrupt signal 0 from MPCA

90

91 P82 /iRQ2 IN Interrupt signal (Nu) pull-up

92 P83 SCK2 OUT CKDC & FMC i/F sync shift clock

93 P84 RXD IN RS232C RECEIVE DATA

94 P85 TXD OUT RS232C SEND DATA

95

96

97 VSS V SS GND

98 EXTAL EXTAL IN X-TAL (14.7456MHz)

99 XTAL XTAL IN X-TAL (14.7456MHz)

100 VSS VSS GND

101 φφ OUT System clock (7.3728MHz)

102 E OUT E clock (NU)

103 /AS /AS OUT Address strobe

104 /RD /RD OUT Read

105 /HWR /WR OUT Write

106 /LWR OUT Nu

107 /RFSH /RFSH OUT Refresh cycle (NU)

108 VCC VCC +5V

109 MD0 MD0 IN +5V (MODE 3)

110 MD1 MD1 IN +5V (MODE 3)

111 MD2 MD2 IN GND (MODE 3)

112 /STBY /STBY IN +5V (Nu)

SIGNAL

NAME

IN/

OUT

Printer (Dp-730) Reset signal from

IN

MPCA

CKDC interface shift enable signal

(NU) GND

ER signal for RS232 (Equipment

OUT

Ready)

DR signal for RS232 (Data set Ready)

IN

CS signal for RS232 (Clear to Send)

IN

CD signal for RS232 (Carrier Detect)

IN

RR signal for RS232 (Ready to

OUT

Receive) (Nu)

RS signal for RS232 (Request to Send)

OUT

CI signal for RS232 (Calling Indicator)

IN

Printer (Dp-730) Home position pulse

IN

Interrupt signal from OPTION PWB

IN

CKDC, Fiscal memory unit I/F shift

IN

input data

CKDC, Fiscal memory unit I/F shift

OUT

output data

FUNCTION

GND

4 – 4

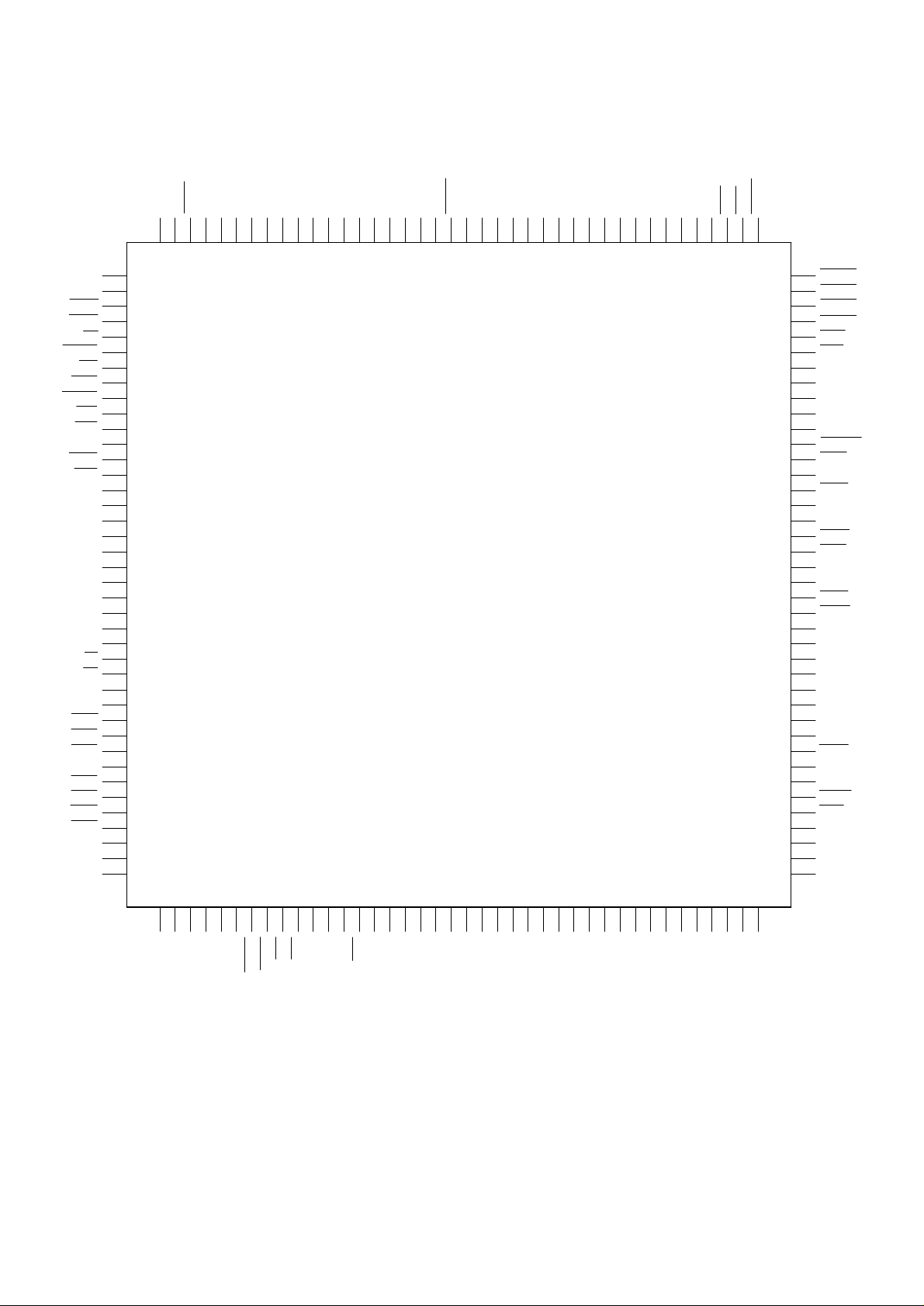

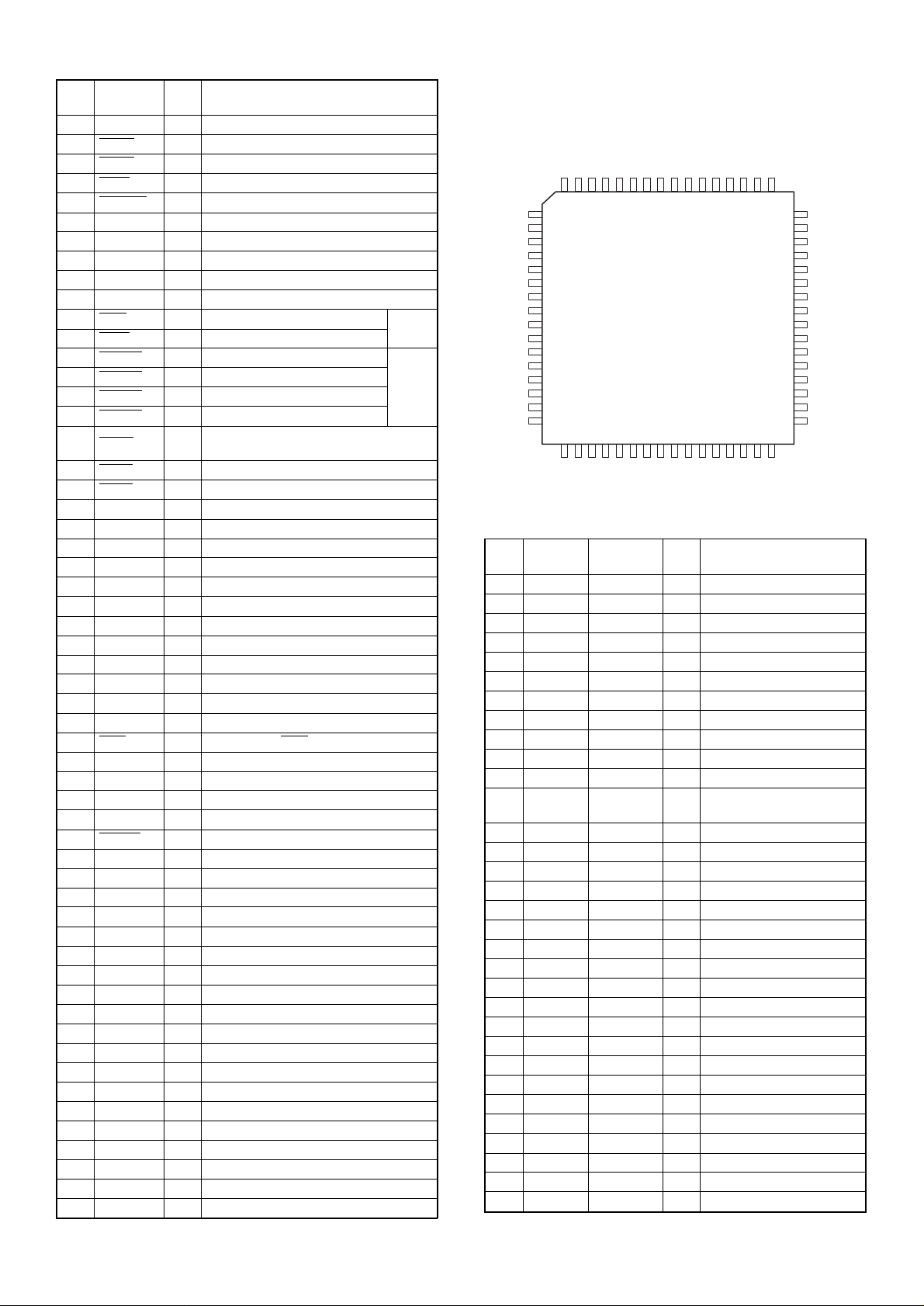

2-2. G.A (MPCA7)

1) Pin configuration

160 NU

1RF

2JF

3PCUT

4FCUT

5VF

6STAMP

SLF

PHAI

7

8SLRS

9SLMTD

10RES

11TRG

12TRG

13POFF

14INT1

15HTS1

16SCK1

17STH1

18NU

19NU

20VCC

21GND

22NU

23VRESC

24SLTMG

25SLRST

26AS

27RD

28WR

29

30SDT7

31SDT6

32SDT5

33GND

34SDT4

35SDT3

36SDT2

37SDT1

38D0

39D1

40D2

41D342GND

159 DOTEN

158 TWAIT

157 NU

43

44

156 NU

155 NU

154 NU

153 NU

45D646D747SSPRQ

48

152 STH2

151 SCK2

150 HTS2

149 SLMTR

148 SLMTS

147 SLMTD

146 RJMTR

145 RAS3

144 NU

143 GND

142 VCC

141 ASKRX

139 NU

138 NU

137 RJMTD

135 DT5

134 DT6

133 DT7

132 GND

131 DT1

130 DT2

129 DT3

127 RJTMG

126 RJRST

125 RAS1

124 RAS2

123 ROS2

122 ROS1

140 NU

136 RJMTS

128 DT4

121 OPTCS

120 EXINT0

119 EXINT1

118 EXINT2

117 EXINT3

116 WRO

115 RDO

114 RA15

113 RA16

112 GND

111 RA17

110 RA18

109 EXWAIT

108 WAIT

107 NU

106 MCR1

105 NU

104

103 RCKX

102 IRRX

101 GND

100 VCC

DAX1

99

UATX

98 UARX

97

UASCK

96

IRTX

95 RCO

94 NU

93 NU

92 NU

91 NU

90 MA15

89 TEST

88 MD0

87 MD1

86 IPLON

85 INT4

84 PRST

83 PTMG

82 TRGI

81 A23

49

50

51RXDI

52TXDI

53SCKI

54IRQ0

55A0

56A1

57A2

58A3

59A4

60A5

62VCC

63A6

61GND

64A7

65A8

66A9

69A12

67A10

68A11

70A13

71A14

72A15

74A17

75A18

76A19

77A20

78A21

79A22

73A16

80NU

D4

D5

INT2

RESET

INT3

GATE ARRAY (LZ9AH39)

MPCA7

Fig. 2-3

4 – 5

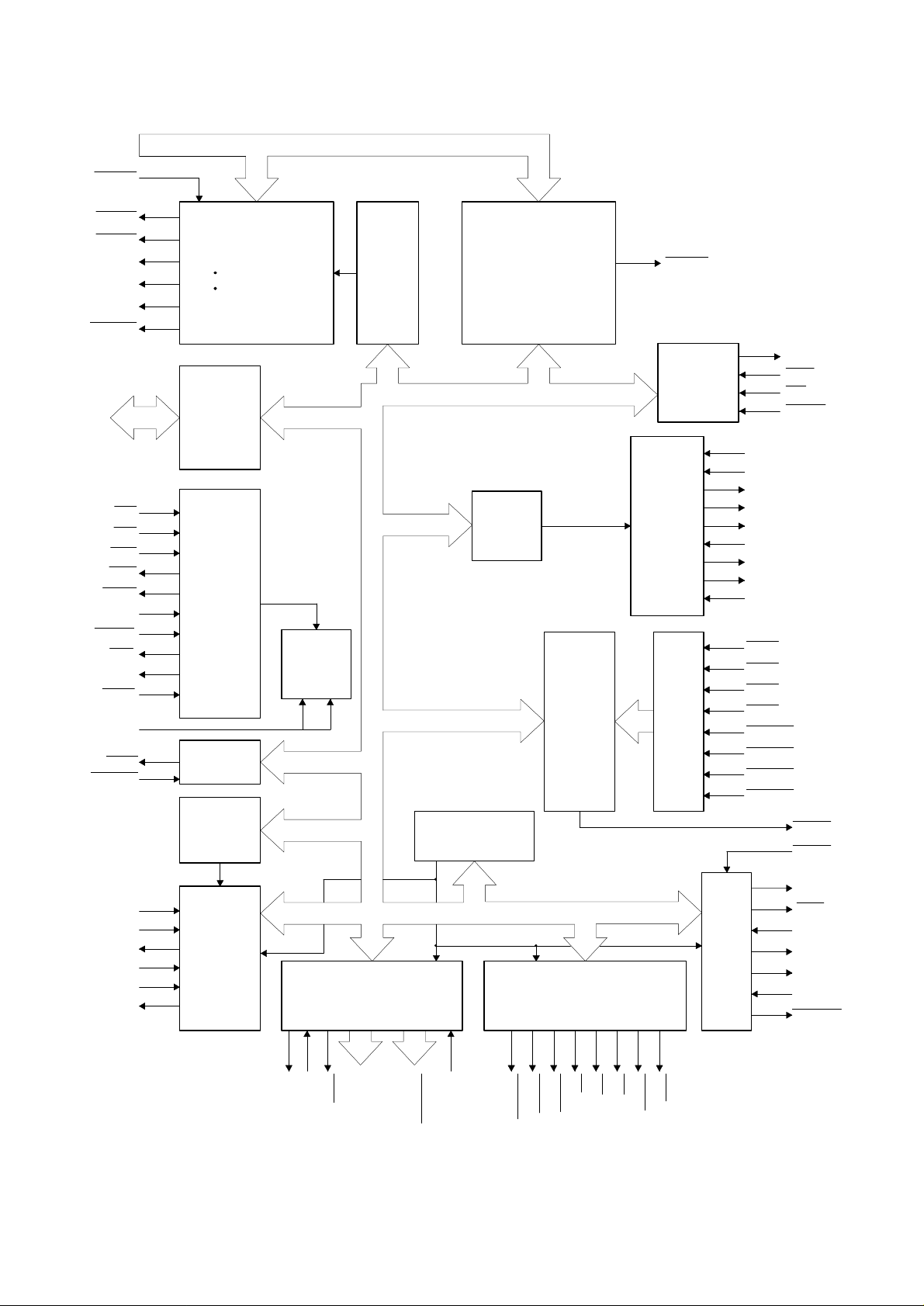

2) Block diagram

A23~A0

IRLON

ROS1

ROS2

RAS1

RAS2

RAS3

OPTCS

D0~D7

AS

RD

WR

RDO

WRO

Φ

RESET

RES

VRESC

POFF

MD0

MD1

WAIT

EXWAIT

Address decode

External CS

Internal CS

Buffer

Read/write

control

WAIT

control

Φ

Divider

RASEL

Image

control

SSP comparison register

BAR.

CHS

serial select

INTO

control

SSPRQ

I/R Control

Multiplexer

IRTX

IRRX

RCI

ASKRX

TXDI

SCKI

RXDI

HTS1

SCK1

STH1

HTS2

SCK2

STH2

INT4

INT1

INT2

INT3

EXINT0

EXINT1

EXINT2

EXINT3

CAPS

select

RJRST

SLRST

*PRST

RJTMG

SLTMG

PTMG

* Output selection with CAPS.

PRST/PTMG.

Print gate

Print pulse control

TRG

TRG

DOTEN

Print mode PMD

IRQ0

TEST

MTD

MTD

Motor

drive

Printer control port

DT1~9

SDT1~7

TRGI

PCUT

STAMP

FCUT

JF

RF

VF

SLF

SLRS

RJMTR

SLMTD

SLMTS

SLMTR

SLMTD

Fig. 2-4

4 – 6

3) Pin description

Pin

Signal

No.

name

1 RF Out Receipt side paper feed solenoid

2 JF Out Journal side paper feed solenoid

3

PCUT Out Printer partial cut signal (NU)

4

FCUT Out Printer auto cut signal (NU)

5

VF Out Multi line validation paper feed (NU)

STAMP Out Printer stamp signal (NU)

6

7

SLFS Out Slip printer paper feed singnal (NU)

8

SLRS Out Slip printer release signal (NU)

9

SLMTD Out Slip printer motor drive signal (NU)

10

RES Out Peripheral output reset

11

TRG Out Dot head trigger signal (NU)

12 TRG Out Dot head trigger signal

13

POFF In Power off signal input

14

INT1 In (NU)

15 HTS1 Out 8 bit serial port output (for CKDC8)

16 SCK1 Out Serial port shift clock output (for CKDC8)

17 ST H1 In 8 bit serial port input (for CKDC8)

18 RAS VZ — Chip select (NU)

19 — — Nu

20 VCC — +5V

21 GND — GND

22 INTMCR — Interrupt (NU)

23 VRESC Out

24 SLTMG In Slip printer timing signal (NU)

25 SLRST In Slip printer reset signal (NU)

26

AS In Address strobe

27

RD In Read strobe

28

WR In Write strobe

29 φ In (φ) System clock (7.3728 MHz)

30

SDT7 Out

31

SDT6 Out

SDT5 Out

32

33 GND — GND

34

SDT4 Out

35

SDT3 Out

SDT2 Out

36

37

SDT1 Out

38 D0 I/O Data bus 0

39 D1 I/O Data bus 1

40 D2 I/O Data bus 2

41 D3 I/O Data bus 3

42 GND — GND

43 D4 I/O Data bus 4

44 D5 I/O Data bus 5

45 D6 I/O Data bus 6

46 D7 I/O Data bus 7

47

SPRQ Out SSP interrupt request to CPU

48

RESET In MPCA reset

49

SHEN In Shift enable from CKDC8

In/

Out

Turns active when reset and power

down is met

Slip printer printhead drive signal (dot7)

(NU)

Slip printer printhead drive signal (dot6)

(NU)

Slip printer printhead drive signal (dot5)

(NU)

Slip printer printhead drive signal (dot4)

(NU)

Slip printer printhead drive signal (dot3)

(NU)

Slip printer printhead drive signal (dot2)

(NU)

Slip printer printhead drive signal (dot1)

(NU)

Function

Pin

No.

100 VCC — +5V

101 GND — GND

102

103

104 DAX1 — System clock (7.3728MHz)

Signal

name

INT3 In Interrupt signal (Nu)

50

51 RXD2 Out 8 bit serial port output to CPU

52 TXD2 In 8 bit serial port input from CPU

53 SCK2 In Serial port shift clock input from CPU.

54

IRQ0 Out Interrupt request to CPU

55 A0 In Address bus 0

56 A1 In Address bus 1

57 A2 In Address bus 2

58 A3 In Address bus 3

59 A4 In Address bus 4

60 A5 In Address bus 5

61 GND — GND

62 VCC — +5V

63 A6 In Address bus 6

64 A7 In Address bus 7

65 A8 In Address bus 8

66 A9 In Address bus 9

67 A10 In Address bus 10

68 A11 In Address bus 11

69 A12 In Address bus 12

70 A13 In Address bus 13

71 A14 In Address bus 14

72 A15 In Address bus 15

73 A16 In Address bus 16

74 A17 In Address bus 17

75 A18 In Address bus 18

76 A19 In Address bus 19

77 A20 In Address bus 20

78 A21 In Address bus 21

79 A22 In Address bus 22

80

LCDC — LCD CS (NU)

81 A23 In Address bus 23

82 TRGI In Dot pulse control/drive signal

83

PTMG Out Printer timing signal

84

PRST Out Printer reset signal

85

RDY In Ready from FMC unit

86

IPLON In To option connector (NU)

87 MD1 In Mode select input (+5V)

88 MD0 In Mode select input (GND)

89

TEST In +5V

90 MA15 — Image address 15 (NU)

91 MA18 — Nu

92 MA19 — Nu

93 RCVRDY1 — Nu

94 RCVRDY2 — Nu

95 RC0 — Remote control encord signal for CPU

96 IRTX — I/R output for LED (NU)

97 UASCK — I/R serial data shift clock (NU)

98

UARX — I/R serial data for CPU (NU)

99

UATX — I/R serial data from CPU (NU)

IRRX — I/R input from I/R unit (NU)

RCI — I/R input from I/R unit (NU)

In/

Out

Function

4 – 7

Pin

No.

Signal

name

In/

Out

Function

105 DAX2 — Nu

106

MCR1 — Nu

107

MCR2 — Nu

108

WAIT Out Wait request signal

109

EXWAIT In External wait control input signal

110 RA18 Out Nu

111 RA17 Out Nu

112 GND — GND

113 RA16 Out Nu

114 RA15 Out Nu

115

RDO Out Expansion RD signal

WRO Out Expansion WR signal

116

117

EXINT3 In Expansion interruption signal 3

EXINT2 In Expansion interruption signal 2

118

119

EXINT1 In Expansion interruption signal 1

120

EXINT0 In Expansion interruption signal 0

121

OPTCS Out

122

ROS1 Out ROM 1 chip select signal

123

ROS2 Out ROM 2 chip select signal (NU)

Chip select base signal for expansion

option

Option

Option

124 RAS2 Out RAM 2 chip select signal

125 RAS1 Out RAM 1 ship select signal

126 RJRST In Printer reset signal

127 RJTMG In Printer timing signal

128 DT4 Out Printer dot signal 4

129 DT3 Out Printer dot signal 3

130 DT2 Out Printer dot signal 2

131 DT1 Out Printer dot signal 1

132 GND — GND

133 DT7 Out Printer dot signal 7

134 DT6 Out Printer dot signal 6

135 DT5 Out Printer dot signal 5

136

MTD Out Printer motor drive signal

137 MTD Out Printer motor drive signal

138 DOT9 Out Printer dot signal 9 (NU)

139 DOT8 Out Printer dot signal 8 (NU)

140 SYNC — Nu (+5V)

141

ASKRX — I/R input from I/R unit (NU)

142 VCC — +5V

143 GND — GND

144 — — Nu

145 RAS3 Out

146 RJMTR In Printer motor lock detection signal (NU)

147 SLMTD In Nu

148 SLMTS In Nu

149 SLMTR In GND

150 HTS2 Out Seri al output to FMC unit (NU)

151 SCK2 Out Serial clock to FMC unit (NU)

152 STH2 In Serial input to FMC unit (NU) pull-up

153 — — Nu

154 — — Nu

155 — — Nu

156 — — Nu

157 — — Nu

158 LCDWT — Nu

159 DOTEN Out Dot drive enable signal

160 RASP — Nu

2-3. CKDC8

1) Pin configulation

NUNUG10G9G8G7G6G5G4G3G2G1BUZ

646362616059585756555453525150

1

DP

2

SA

3

SB

4

SC

5

SD

6

SE

7

SF

8

SG

GND

VDD

KR4

KR10

KR11

NU

HTS

STH

9

10

11

12

13

14

15

16

171819202122232425262728293031

ST0

/SCK

ST1

ST2

CKDC8

ST3

ST4

ST5

VDD

NU

GND

2) Pin assignment (CKDC8)

Pin

No.

SYMBOL

SIGNAL

NAME

1 DP DP OUT DISPLAY SEGMENT Dp

2 A SA OUT DISPLAY SEGMENT a

3 B SB OUT DISPLAY SEGMENT b

4 C SC OUT DISPLAY SEGMENT c

5 D SD OUT DISPLAY SEGMENT d

6 E SE OUT DISPLAY SEGMENT e

7 F SF OUT DISPLAY SEGMENT f

8 G SG OUT DISPLAY SEGMENT g

9 VSS0 GND GND

10 VDD0 VDD VDD

11 KR4 KR4 IN KEY RETURN 4

12 KR10 KR10 IN

13 KR11 KR11 IN KEY RETURN (MODE sw)

14 KR8 NU IN GND

15 HTS HTS IN

16 STH STH OUT

17 /SCK /SCK IN SHIFT CLOCK

18 ST0 ST0 OUT KEY STROBE 0

19 ST1 ST1 OUT KEY STROBE 1

20 ST2 ST2 OUT KEY STROBE 2

21 ST3 ST3 OUT KEY STROBE 3

22 ST4 ST4 OUT KEY STROBE 4

23 ST5 ST5 OUT KEY STROBE 5

24 VDD1 VDD VDD

25 AXSS GND GND

26 KR9 NU GND

27 KR0 KR0 IN KEY RETURN 0

28 KR1 KR1 IN KEY RETURN 1

29 KR2 KR2 IN KEY RETURN 2

30 KR3 KR3 IN KEY RETURN 3

31 KR5 KR5 IN KEY RETURN 5

32 KR6 KR6 IN KEY RETURN 6

IN/

OUT

/POFFNUST8

49

48

ST7

47

ST6

46

/RESETS

45

/SHEN

44

ERC

43

LDRQ

42

GND

41

40

39

GND

38

37

36

/RES0

35

VDD

34

GND

33

KR7

32

KR0

KR1

KR2

KR3

KR5

KR6

FUNCTION

KEY RETURN (feed clerk

MRS sw)

4 – 8

Pin

No.

SYMBOL

SIGNAL

NAME

IN/

OUT

FUNCTION

33 KR7 KR7 IN KEY RETURN 7

34 AVRF GND

35 AVDD VDD

36 /RESET /RES0 IN

37 XT2

38 XT1

32.768 KHz

39 IC GND

40 X2

41 X1

4.19 MHz

42 VSS1 GND

43 LDRQ LDRQ IN LORD REQUEST

44 ERC ERC IN EVENT READ CANCEL

45 SHEN /SHEN OUT SHIFT ENABLE

46 /RES1 /RESETS OUT SYSTEM TO RESET

47 ST6 ST6 OUT KEY STROBE 6

48 ST7 ST7 OUT KEY STROBE 7

49 ST8 ST8 OUT KEY STROBE 8

50 ST9 NU OUT KEY STROBE 9

51 /POFF /POFF IN POWER OFF

52 BUZ BUZ OUT BUZZER

53 T0 G1 OUT DISPLAY DIGIT 1

54 T1 G2 OUT DISPLAY DIGIT 2

55 T2 G3 OUT DISPLAY DIGIT 3

56 T3 G4 OUT DISPLAY DIGIT 4

57 T4 G5 OUT DISPLAY DIGIT 5

58 T5 G6 OUT DISPLAY DIGIT 6

59 T6 G7 OUT DISPLAY DIGIT 7

60 T7 G8 OUT DISPLAY DIGIT 8

61 T8 G9 OUT DISPLAY DIGIT 9

62 T9 G10 OUT DISPLAY DIGIT 10

63 T10 NU OUT DISPLAY DIGIT 11

64 ID NU OUT DISPLAY SEGMENT

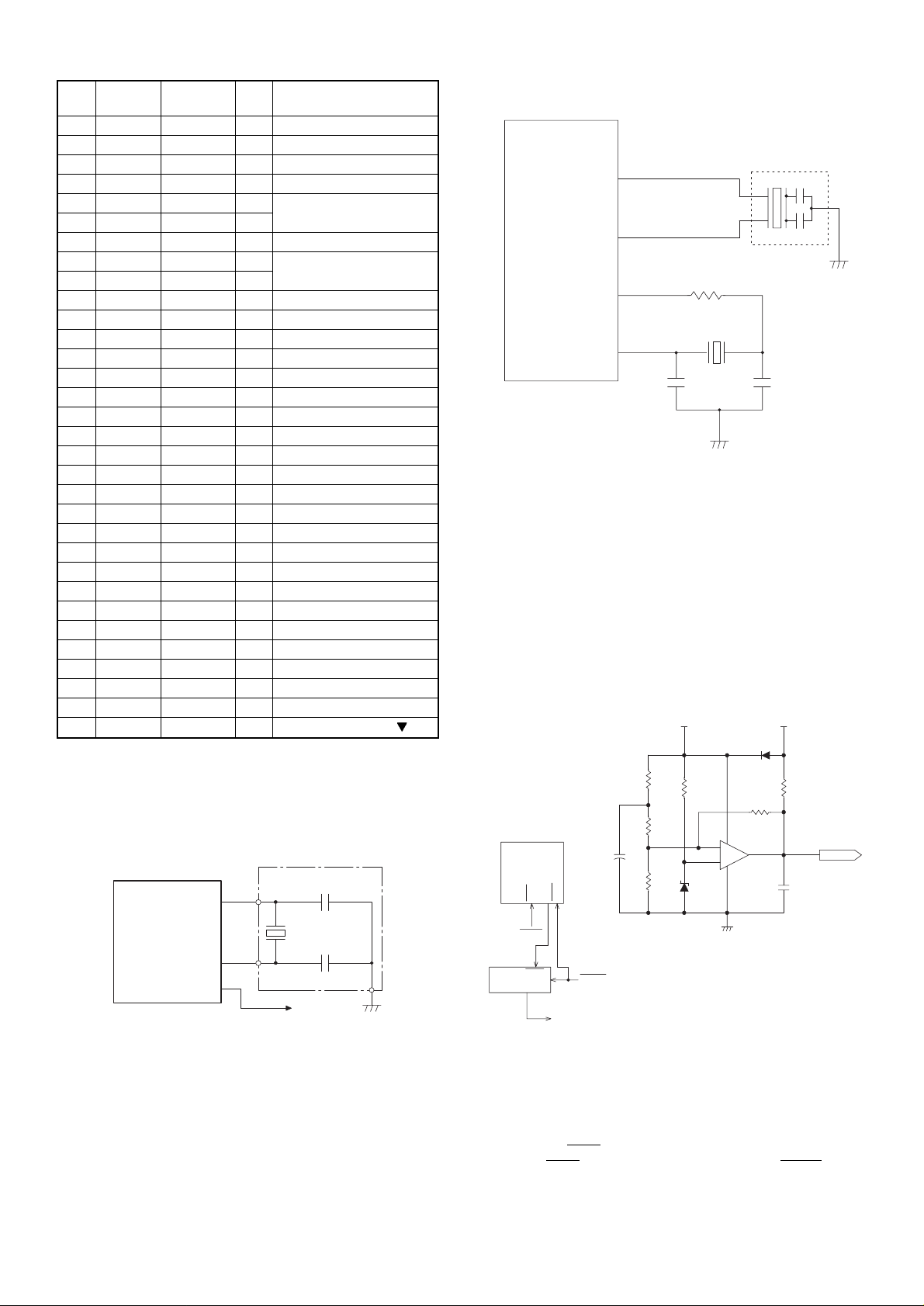

3. Clock generator

1) CPU (HD64151010FX)

X1

99

XTAL

CPU

(HD64151010FX)

EXTAL

98

101

Fig. 3-1

Basic clock is supplied from a 14.7456MHz ceramic oscillator.

The CPU contains an oscillation circuit from which the basic clock is

internally driven. If the CPU was not operating properly, the signal

does not appear on this line in most cases.

14.7456MHz

PHAI

2) CKDC8 oscillation circuit

X3

1

3

4.19MHz

C105

33P

2

CKDC 8

HD404728A91FS

XT2

XT1

40

X2

41

X1

R164

37

38

C106

18P

330K

X2

32.768KHz

Fig. 3-2

Two oscillators are connected to the CKDC8.

The main clock X3 generates 4.19MHz which is used during power

on.

When power is turned off, the CKDC8 goes into the standby mode

and the main clock stops.

The sub-clock X2 generates 32.768KHz which is primarily used to

update the internal RTC (real time clock). During the standby mode, it

keeps oscillating to update the clock and monitoring the power recovery.

4. Reset (POFF) circuit

+24V +5V

D7

1SS133

R9

2.7K

R10

56K

8

B

3

+

1

2

IC3A

4

KIA393F

C3

1000P

/POFF

CPU

MPCA7

INT0

13 48

54

POFF

89

IRQ0

72

C208

1µ 50V

IRQ0

1

RESET (FROM CKDC 8)

STOP (TO CKDC 8)

R12

8.2KG

+

R13

15KG

R14

9.1KG

R11

2.7K

ZD2

MTZ5.1A

Fig. 4-1

In order to prevent memory loss at a time of power off and power

supply failure of the ECR, the power supply condition is monitored at

all times. When a power failure is met, the CPU suspends the execution of the current program and immediately executes the power-off

program to save the data in the CPU registers in the external S-RAM

with the signal

The signal

STOP forced low to prepare for the power-off situation.

STOP is supplied to the CKDC8 as signal RESET to reset

the devices.

4 – 9