Page 1

Dealer Knowledge Book

ERA410

ERA420

ERA410

MODEL ER-A410 & ER-A420

ROM VERSION RCC2A

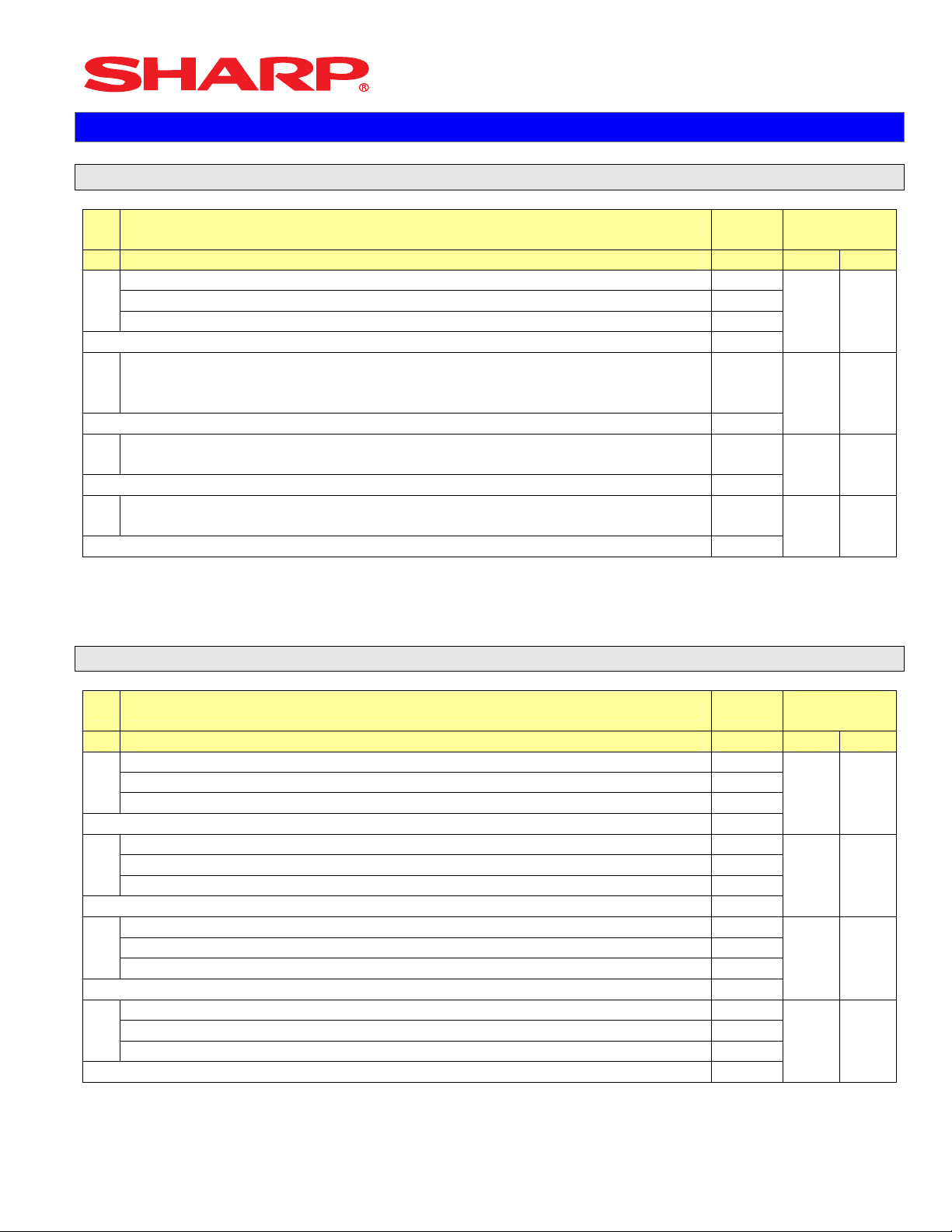

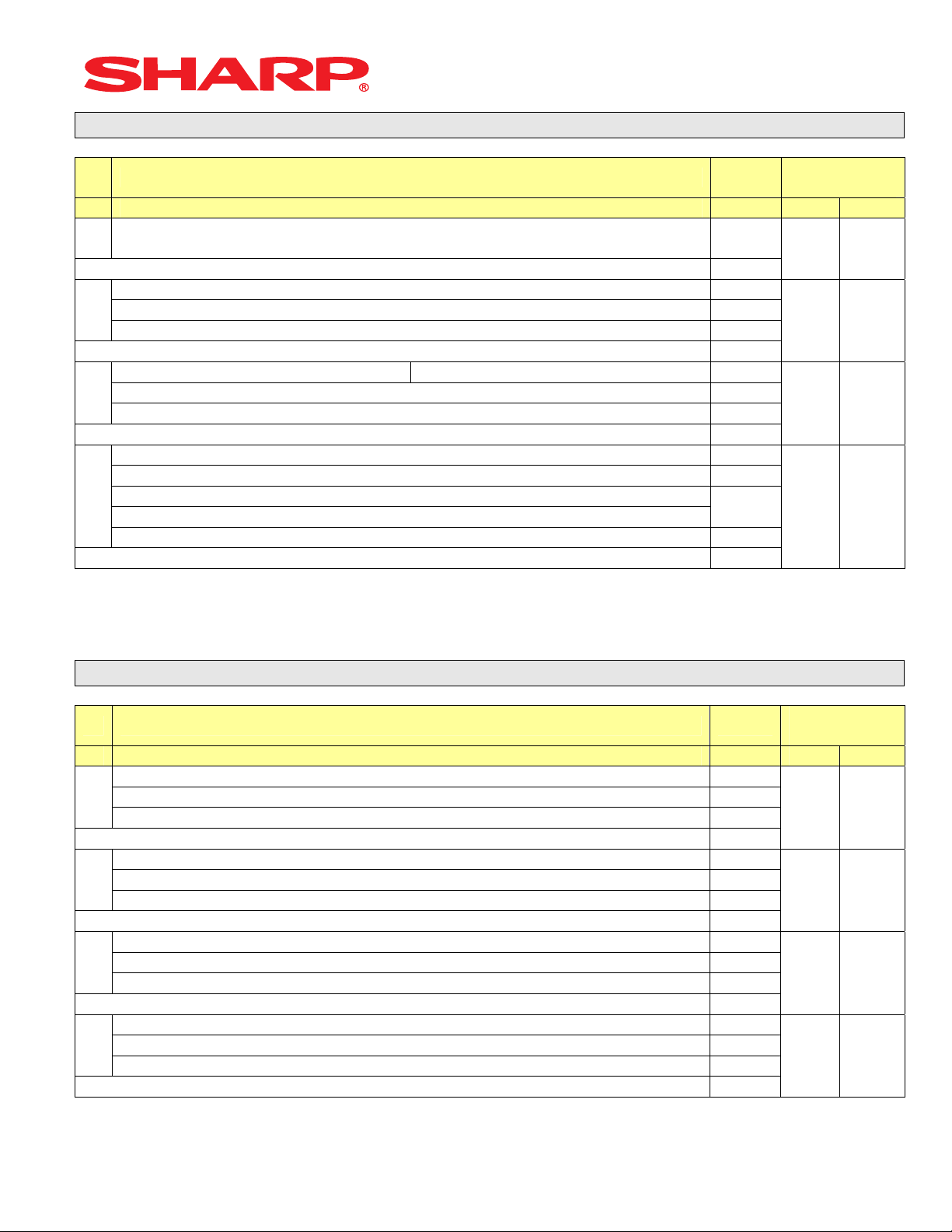

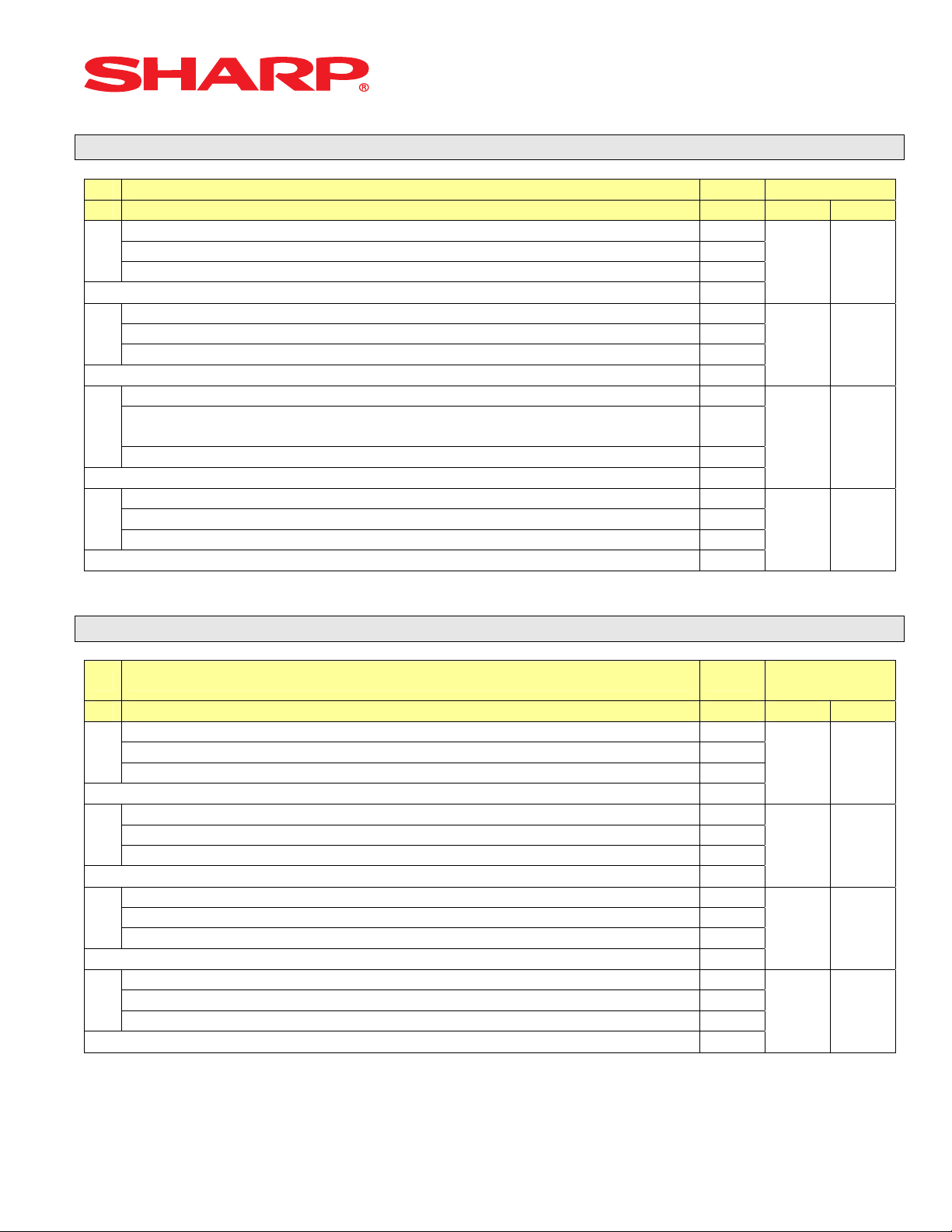

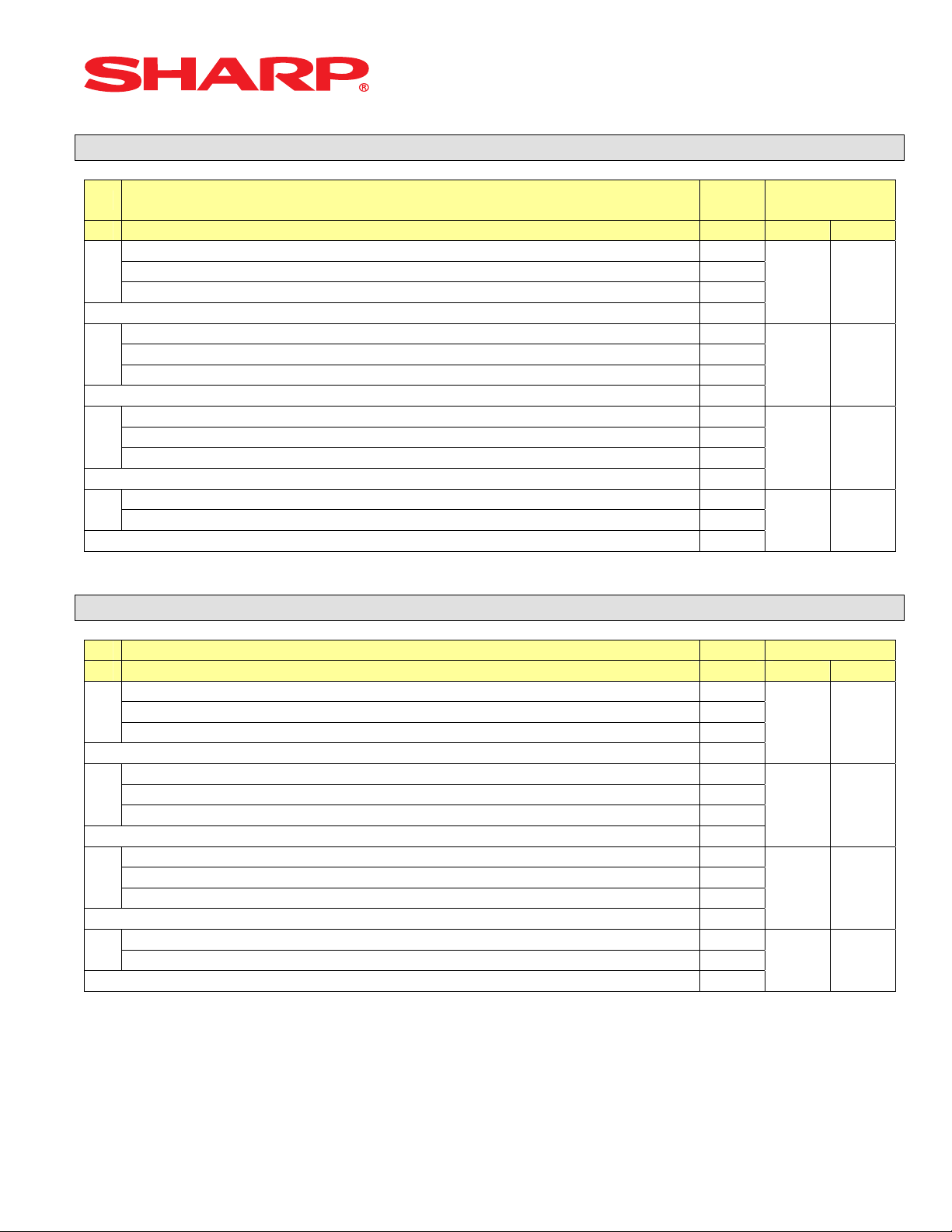

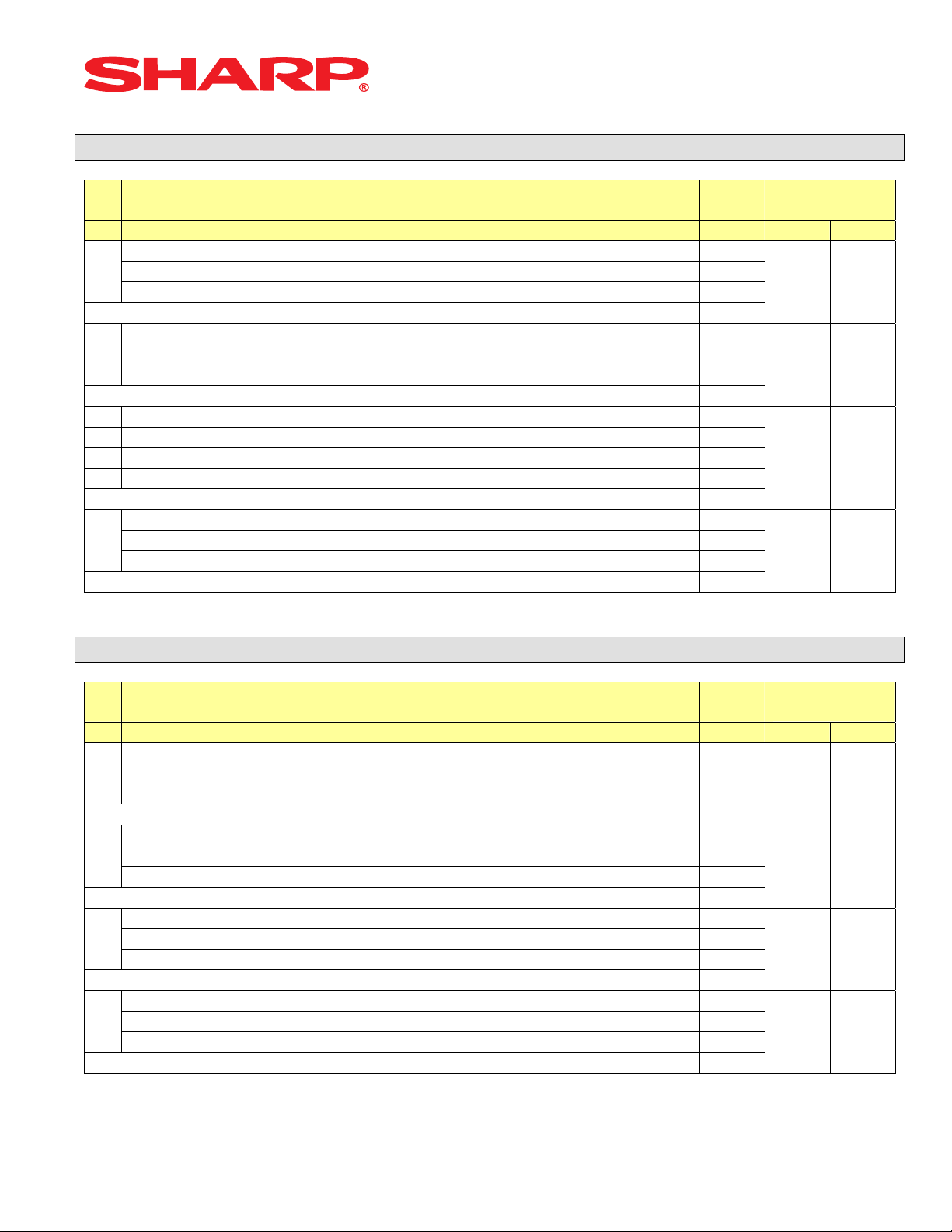

Contents

Category

Introduction …………………………………………………………………………………………………………………

SECTION 1. System Presets

Overview……………………………………………… ………………..…………………………………

Prior to Beginning……………………………………………..……………………………….………….

System Preset Job No……………………………………………………………………………………

SECTION 2. Free Key Layouts

Free Key Layout Set Up….………………………………………………………………………………

Free Key Layout Readings..……………………………………………………………..……………...

SECTION 3. File Allocation

Allocating Memory Files……………………………………………………….….……..……………….

SECTION 4. Peripherals

Peripheral Device Overview………………………………….……………….……….………………...

Coin Dispenser...…………………………………………………………...……………………………..

Scale………………………………………………………………………………………..………………

Printers…………………………………………………………………………………….……………….

Scanner…………………………………………………………………………………………………….

SECTION 5. PGM2 Mode Programming

Departments……………………………………………………………………………………………….

PLU/UPC…………………………………………………………………………………………………...

Cashiers……………………………………………………………………………………………………

Function & Media Keys…………………………………………………………………………………..

Machine Settings……………………………………………………………………………………….....

SECTION 6. COM Communication

Overview…………………………………………………………………………………………………...

Online………………………………………………………………………………………………………

RS232 Communications Set Up………………………………………………………………………...

SECTION 7. Electronic Funds Transfer

Overview…………………………………………………………………………………………………...

Data Tran 162LT Configuration………………………………………………………………………….

Cable Connection…………………………………………………………...……….……………………

EFT Related Programming…………………………………………………...………………………….

SECTION 8. Utilities

Overview…………………………………………………………………………………………………...

02FD.EXE Installation/Usage……………………………………………………………………………

SECTION 9. SSP’s …………………………...……………………………………………………..……………………..

Notice:

Except as permitted by such license, no part of the software or documentation may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, recording, or otherwise, without the prior written permission of Sharp

Electronics Corporation.

The Data Tran software and/ or documentation referred to in this manual are furnished under the license by Datacap Systems, Inc. and

may only be used or copied in accordance with the terms of such license.

Designs and specification are subject to change without notice

Pg.

iii

2

3

8

29

30

32

37

38

39

40

42

46

50

64

75

76

88

113

117

131

155

156

156

162

164

165

166

166

169

187

188

194

202

Page 2

Dealer Knowledge Book

TRADEMARKS

All trademarks and registered marks are the property of their respective holders.

DISCLAIMER

The information contained in this document is furnished without assurance of peripheral/software

compatibility between Sharp POS products and the products of the suppliers listed.

Product specifications change without notification (both Sharp’ and other supplier’s products).

Sharp POS does not undertake to update materials. It is the dealer’s responsibility to keep current

with all technical issues associated with these products.

NOTICE TO USERS

This manual is intended to assist authorized Sharp dealers, with learning and understanding how to

the install and provide support for the ER-A410 and ER-A420.Please read each section carefully as it

will provide helpful hints and recommendations that will make your time more efficient and produce

time saving results. This manual is not intended for end user customers of authorized Sharp dealers.

Designs and specification are subject to change without notice Page ii of 209

Page 3

Dealer Knowledge Book

Overview

The new ER-A410 and ER-A420 Version Up model ECRs has the following new features:

1) UPC (EAN) Codes Scanning

2) Overlapping Cashier Function (Transaction Sales Suspend Mode)

3) Remote Kitchen Printer using the following Epson models:

a. TM-T88III Thermal Printer

b. TM-U220 Black & Red Dot matrix Printer

c. TM-U230 Black & Red Dot matrix Printer

Note: The program data from the old ERA410 or ERA420 with version RACC1A are NOT

compatible with the new ER-A410 or ER-A420 version RCC2A.

PC Link version for the old ER-A410 and ER-A420 will not work with the new ER-A410 and

ER-A420 ECRs.

Designs and specification are subject to change without notice Page iii of 209

Page 4

System Presets

Section-1: System Presets

Designs and specification are subject to change without notice Page 1 of 209

Page 5

System Presets

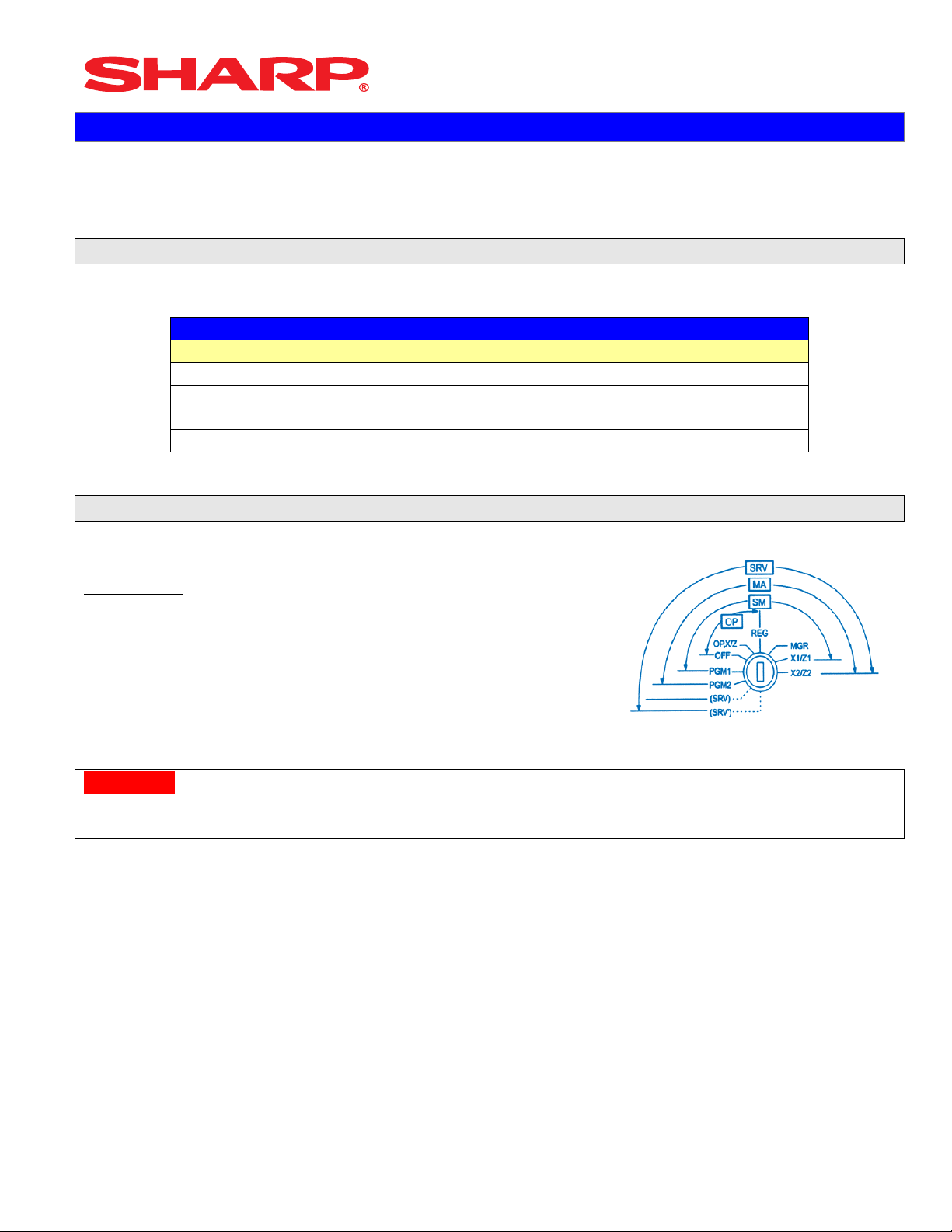

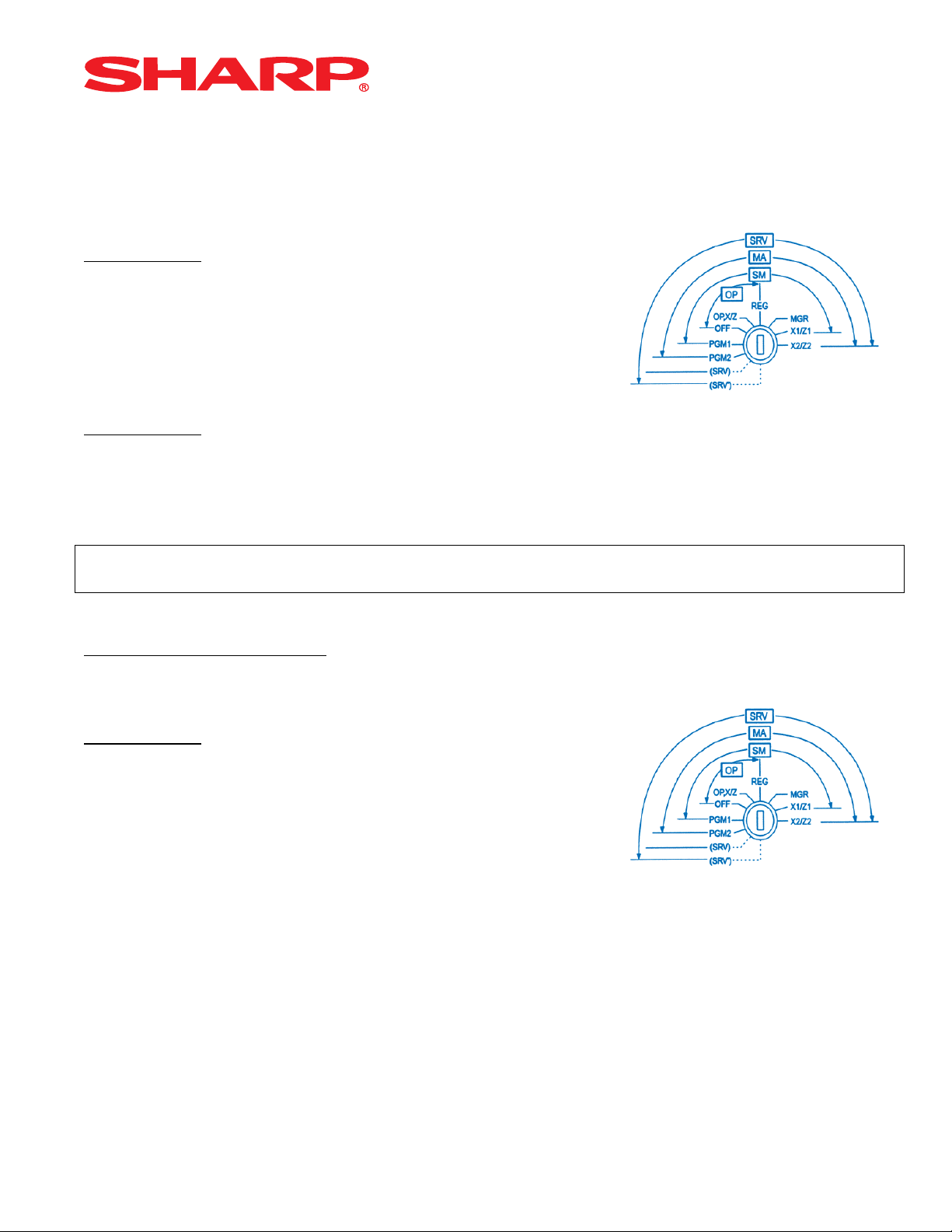

Section-1: SRV Mode Programming

SRV-mode programmings consist of service programming jobs, which define the

ERA410/ERA420 system capabilities. The service program settings are printed on the Receipt /

Journal printer.

1. SRV-mode Program Readings:

List of SRV-mode Program Reports:

SRV-Mode Related Jobs: (X = indication of availability)

Job No. Description

900 System Presets / Memory Allocation

950 Free Key – Function keys

951 Keyboard Layout – Dept & PLU Link Key Position

990 Special Service Patch Data

2. Entering the SRV-Mode

To enter SRV-mode programming

Procedure:

1) Place the mode switch to the SRV’ position

2) Place the AC power cord into the wall outlet

3) Place the AC power cord into the wall outlet

CAUTION:

Never enter the SRV mode in the middle of a transaction – severe damage may result to the sales

totals.

Designs and specification are subject to change without notice Page 2 of 209

Page 6

System Presets

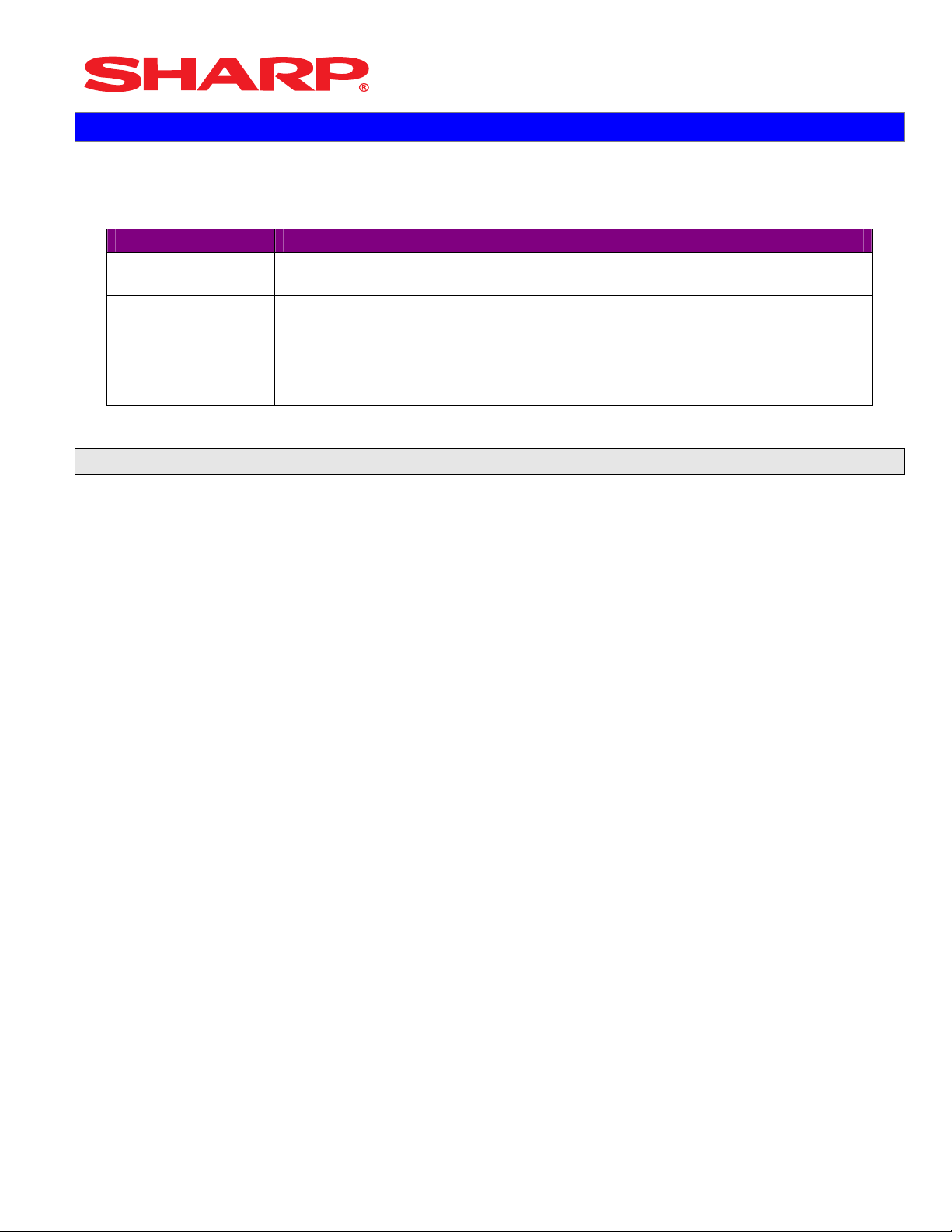

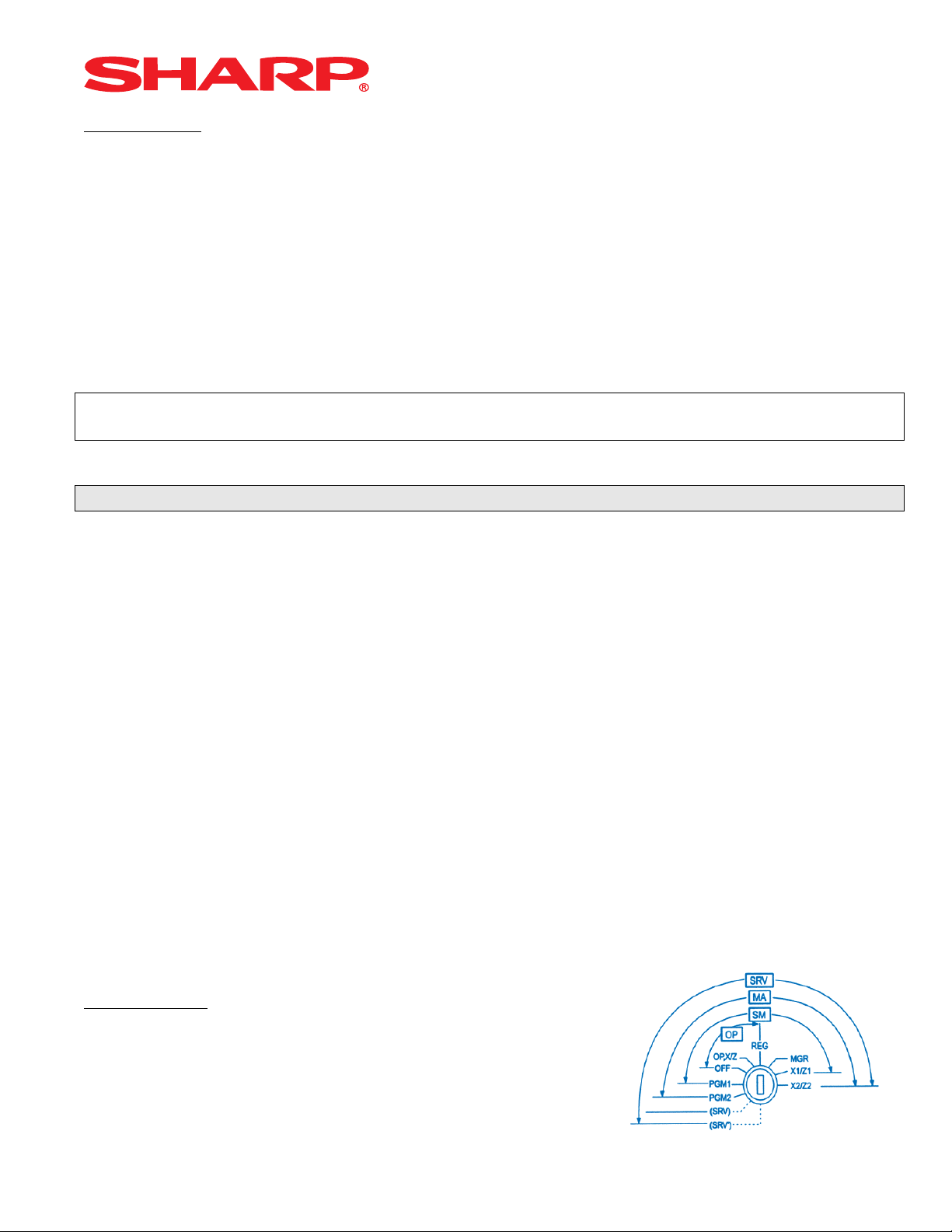

Section-2: Prior to Beginning

The ERA410/A420 POS terminal should be initialized by executing a master reset. The Program

and Master Reset operations are available in one of the following three types:

Type Description

Program Reset Initializes the hardware and resident program without clearing

memory and totalizers

Master Reset-1 Initializes the hardware and clears the entire memory – restoring

factory initial values

Master-Reset-2 Initializes the hardware and clears the entire memory – restoring

factory initial values and enabling free key layout of the ERA410/A420

“fixed keys”

1. Master Resets:

The Master Reset procedures are primarily performed during installation and setup of the ERA410

and ERA420 model cash registers. Each has an important role when installing the equipment.

Follow one the below procedures when you wish to perform a Master Reset.

1. General Rule:

Master Reset: Clears the entire memory and resumes initial values (default program).

Program Reset: Resumes the initial program without clearing memory.

There are 2 methods for performing a Master Reset operation.

1) Master Reset-1: Normal Master Reset (out of box setup)

Clears the entire memory and resumes initial values

2) Master Reset-2: Enables the ability to change the layout fixed keys in addition to executing

the Master Reset-1.

Fixed Keys: [0][1][2][3][4][5][6][7][8][9][0][00][000][.][@/FOR][SBTL][CA/AT]

IMPORTANT NOTES:

During the Master Reset initialization, the following actions should be noted:

1) ***MRS*** is displayed on the upper line of the operator display.

2) MASTER RESET*** is printed on the journal tape.

3) The buzzer will beep 3-times

Designs and specification are subject to change without notice Page 3 of 209

Page 7

System Presets

2. Master Reset-1 Operations:

There are 2 possible procedures to use in performing a Master Reset-1 operation.

Follow the below procedure when you wish to perform a program-reset (initialization)

Procedure A:

1) Place the mode switch to the SRV’ position

2) Place the AC power cord into the wall outlet

3) Depress and hold the [JOURNAL] feed key

4) Turn the mode switch from SRV’ -- > SRV position

Procedure B:

1) Remove the AC power cord from the outlet

2) Place the mode switch to the SRV position

3) Depress and hold the [JOURNAL] feed key

4) Replace the AC power cord into the wall outlet

Note:

***Procedure A must be used to reset the hardware. Procedure B cannot reset the hardware.

Master Reset-2 Operations:

There are 2 possible procedures to use in performing a Master Reset-2 operation.

Procedure A:

1) Place the mode switch to the SRV’ position

2) Place the AC power cord into the wall outlet

3) Depress and hold the [JOURNAL] & [RECEIPT] feed keys

4) Turn the mode switch from SRV’ -- > SRV position

***The operator display will show the fixed function keys (starting with the [0] key)

5) Program the Function Keys by depressing the desired location(s).

6) Once the [CA/AT] key is placed on the keyboard, ***MRS*** will be displayed and the reset

process will continued as outlined in Master Reset-1

Designs and specification are subject to change without notice Page 4 of 209

Page 8

System Presets

Procedure B:

1) Remove the AC power cord from the outlet

2) Place the mode switch to the SRV position

3) Depress and hold the [JOURNAL] & [RECEIPT] feed keys

4) Replace the AC power cord into the wall outlet

***The operator display will show the fixed function keys (starting with the [0] key)

5) Program the Function Keys by depressing the desired location(s).

6) Once the [CA/AT] key is placed on the keyboard, ***MRS*** will be displayed and the reset

process will continued as outlined in Master Reset-1

Note:

***Procedure A must be used to reset the hardware. Procedure B cannot reset the hardware.

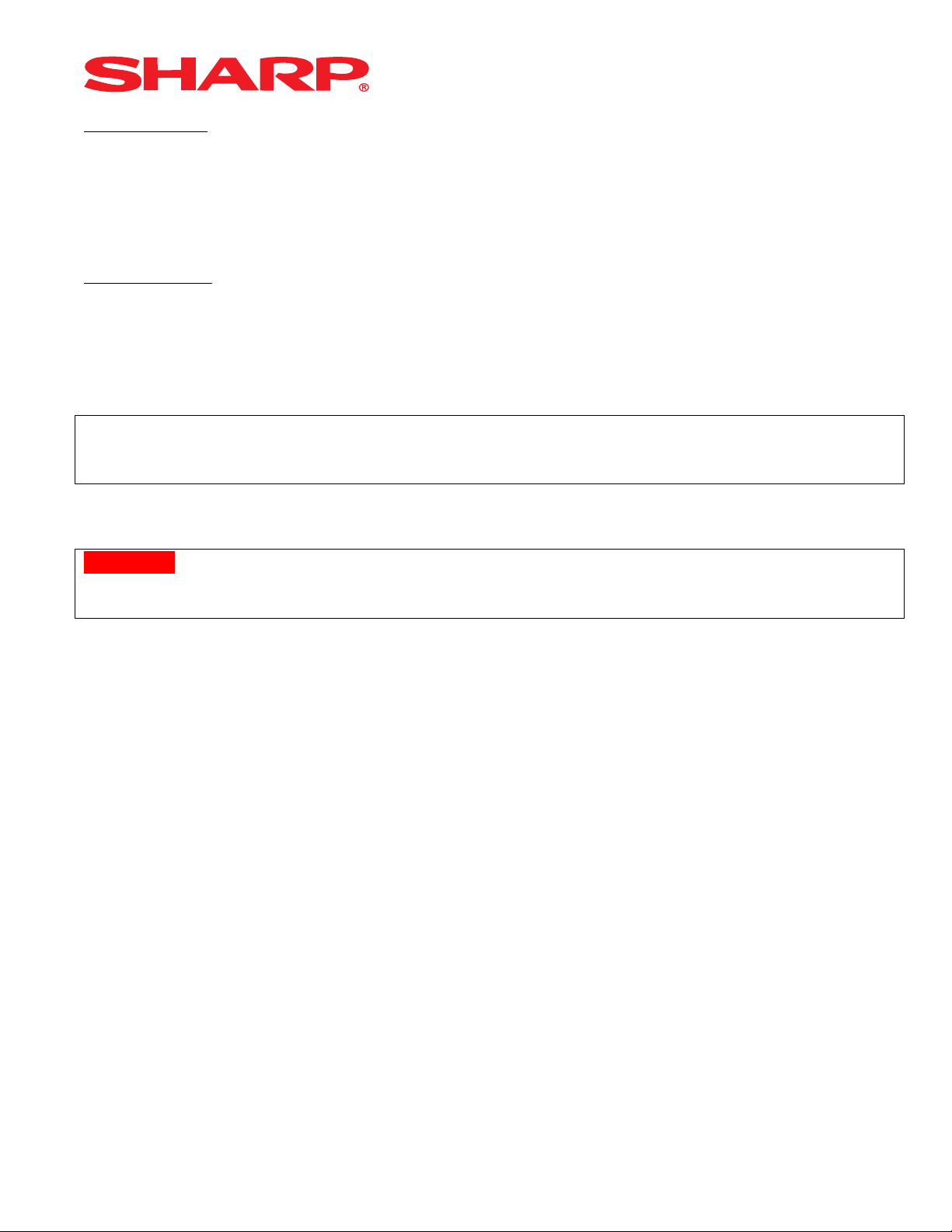

2. Program Reset:

The Program Reset (sometimes referred to as a “Service Reset”) may be achieved with or without

a [SRV] key (part no. LKGiM7113RCZZ) based on the System Preset settings.

1. General Rule:

A Program Reset should be performed under the following general conditions:

1) After the memory allocation setting has been modified

2) When a device assignment has been modified in COM port assignment

IMPORTANT NOTE:

During the Program Reset operation, PROGRAM RESET*** is printed on the journal tape

Follow the below procedure when you wish to perform a program-reset (initialization)

2. Procedures:

Base on the SRV Job#928-B setting, there may be 3 possible procedures in performing a

Program Reset.

Procedure- A:

1) Place the mode switch to the SRV’ position

2) Place the AC power cord into the wall outlet

3) Turn the mode switch from SRV’ -- > SRV position

Designs and specification are subject to change without notice Page 5 of 209

Page 9

System Presets

Procedure- B:

1) Remove the AC power cord from the outlet

2) Place the mode switch to the SRV’ position

3) Replace the AC power cord into the wall outlet

4) Turn the mode switch clockwise to the SRV position (7 o’clock)

Procedure- C: (based on SRV Job#928-B)

1) Remove the AC power cord from the outlet

2) Place the mode key in the PGM2 position

3) Depress and hold the [RECEIPT] & [JOURNAL] feed keys

4) Replace the AC power cord into the wall outlet while holding the keys

Note:

***Procedure A must be used to reset the hardware. Procedures B and C cannot reset the

hardware.

CAUTION:

Never enter the SRV mode in the middle of a transaction – severe damage may result to the sales

totals.

Designs and specification are subject to change without notice Page 6 of 209

Page 10

System Presets

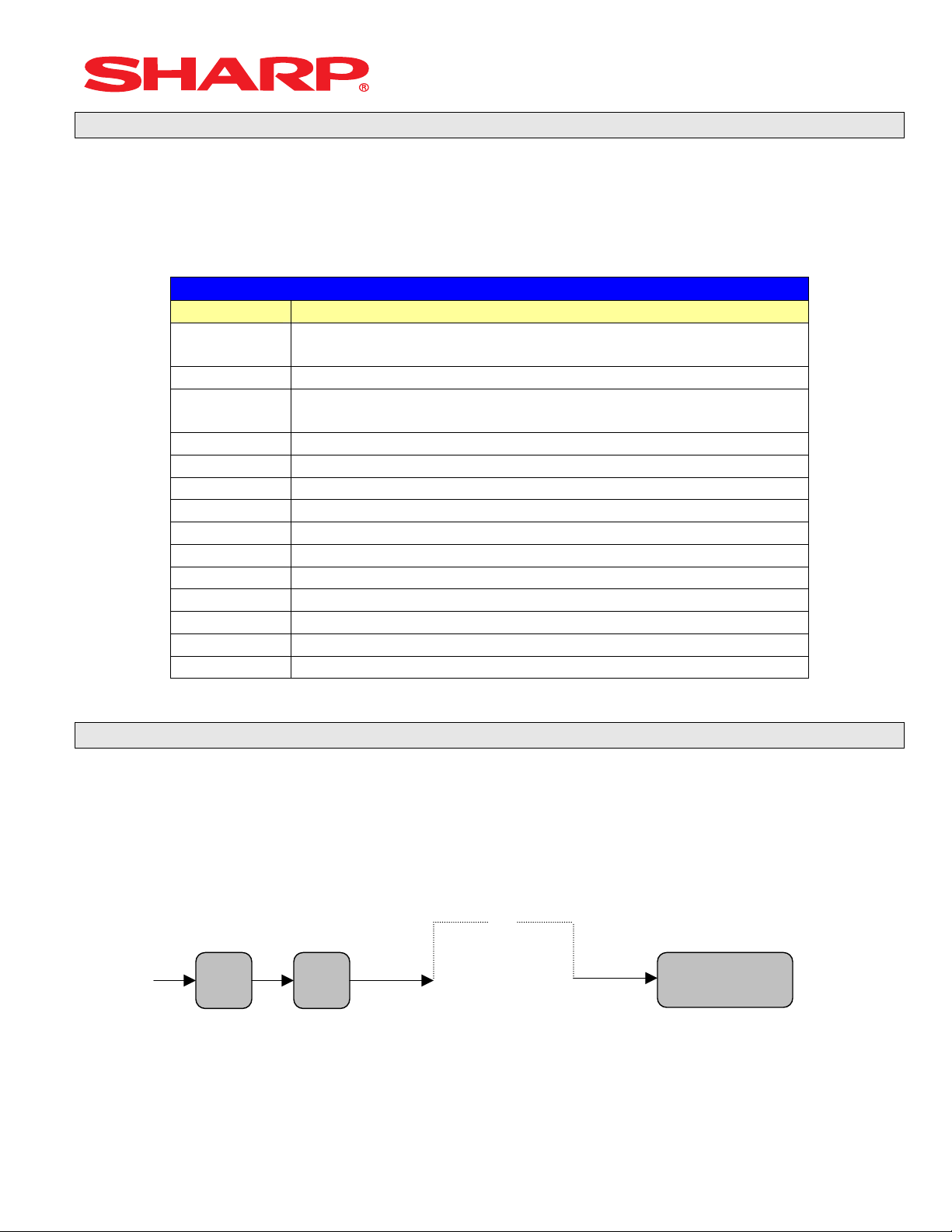

3. Recommended Set Up Procedures

To minimize unnecessary steps when installing the ERA410 and ERA420 model cash register,

please perform Job#975 (Memory Allocation), Job#900s (Service Parameters),

Job#950 (Free Key), Job#951 (Keyboard Link Position) followed by “All” PGM2 settings.

The below chart represents the SRV Job# Reference Descriptions:

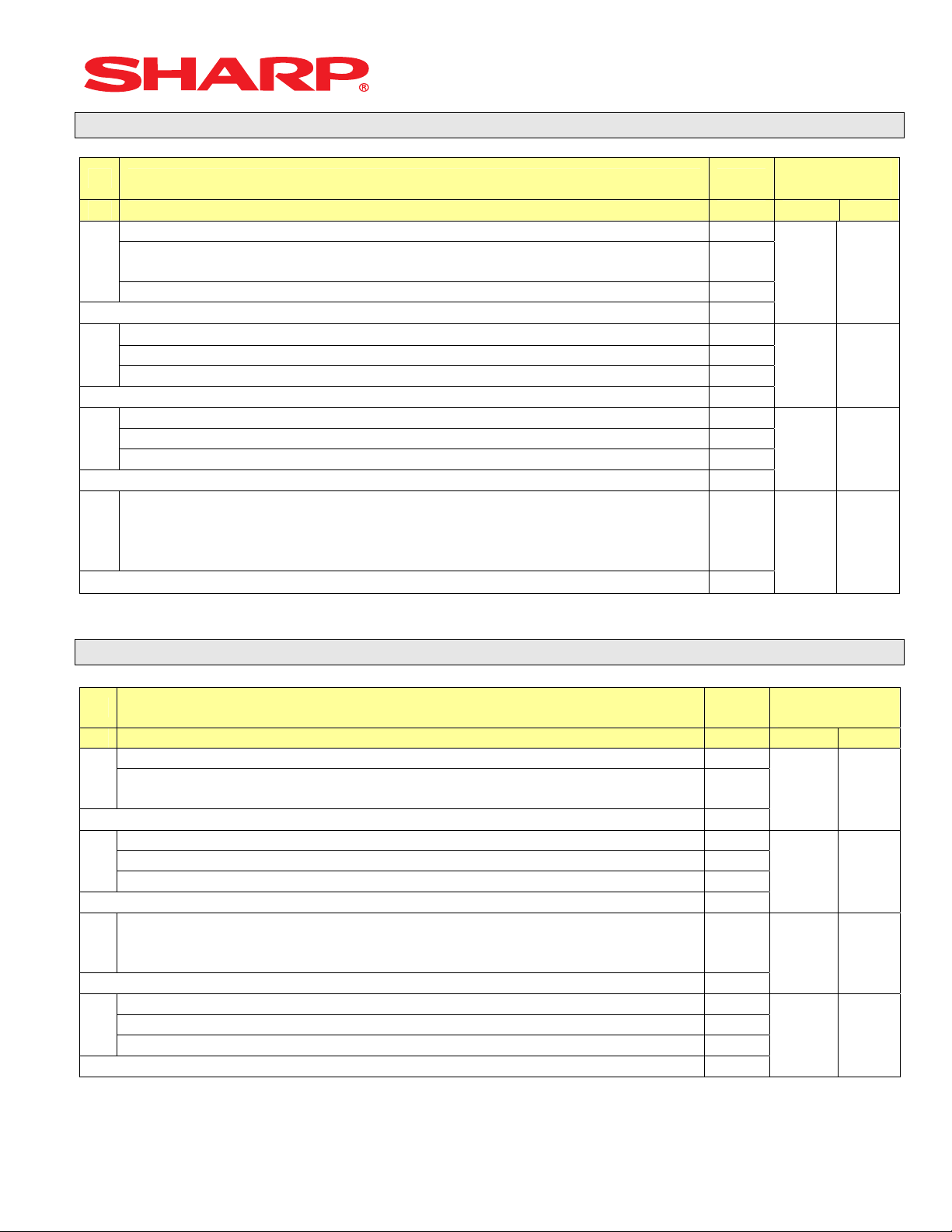

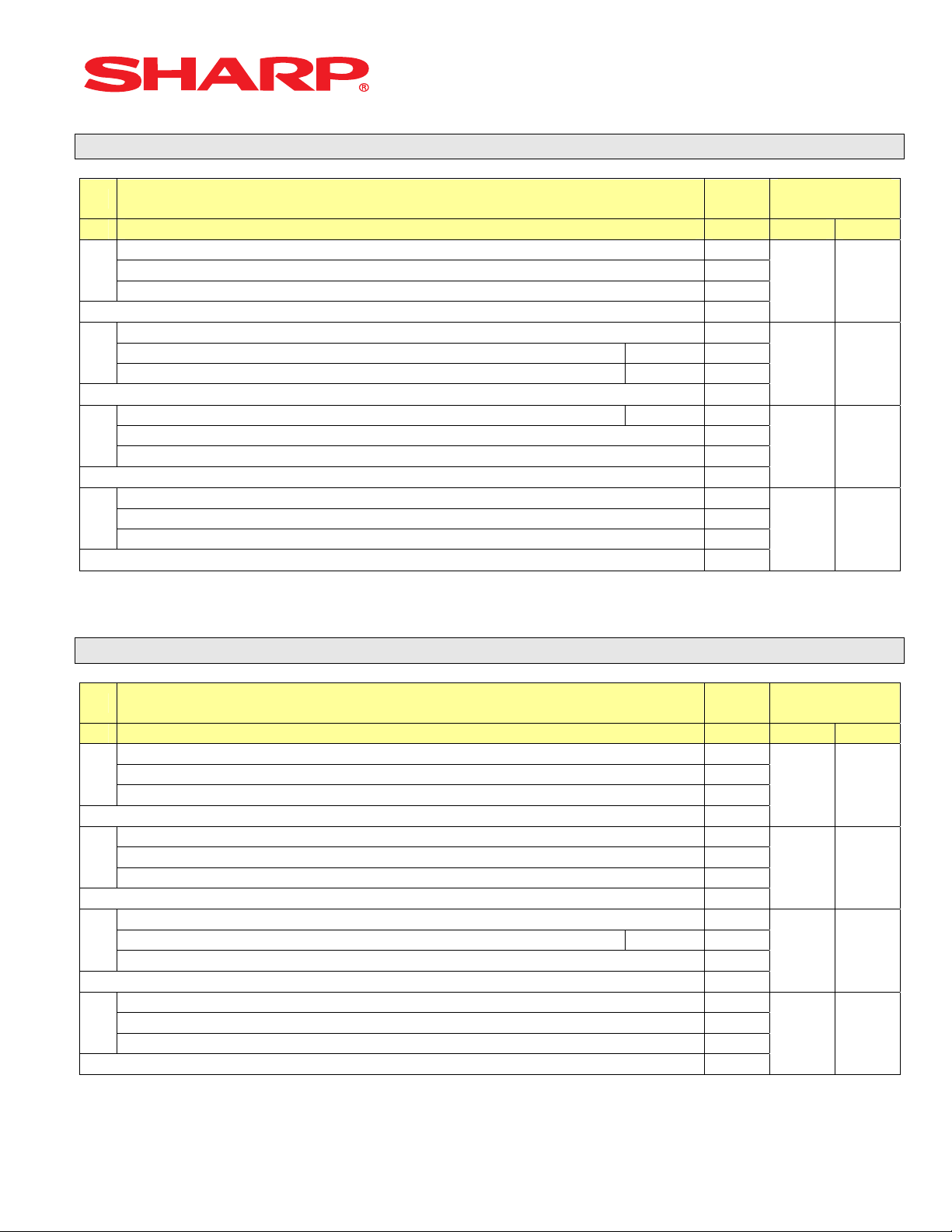

SRV-Mode Related Jobs: (X = indication of availability)

Job No. Description

901 – 929

980

930 - 939 Report Counters Z-Counters

942 – 943

969

944 PGM2 Mode Secret Code

948 Training Cashier Assignment

949 Training Mode Title Programming

950 Keyboard Layout – Function keys

951 Keyboard – Dept & PLU Keys

975 Memory File Allocation Programming

985 Euro Symbol Programming for the TM-295 Slip Printer

986 Domestic Currency Symbol Programming

987 Language Selection for Text Print

990 Special Service Patch

996, 998 Program Data Send/Receive Function

4. Service Mode Programming

System Parameters

GT Totalizers

Service mode programming is usually performed during the installation process. To change the

System Preset settings, the key operation is required:

0

XXX

[Job#]

ABCD

Designs and specification are subject to change without notice Page 7 of 209

.

@

CA/AT

Page 11

System Presets

Section-3: System Preset Job No.

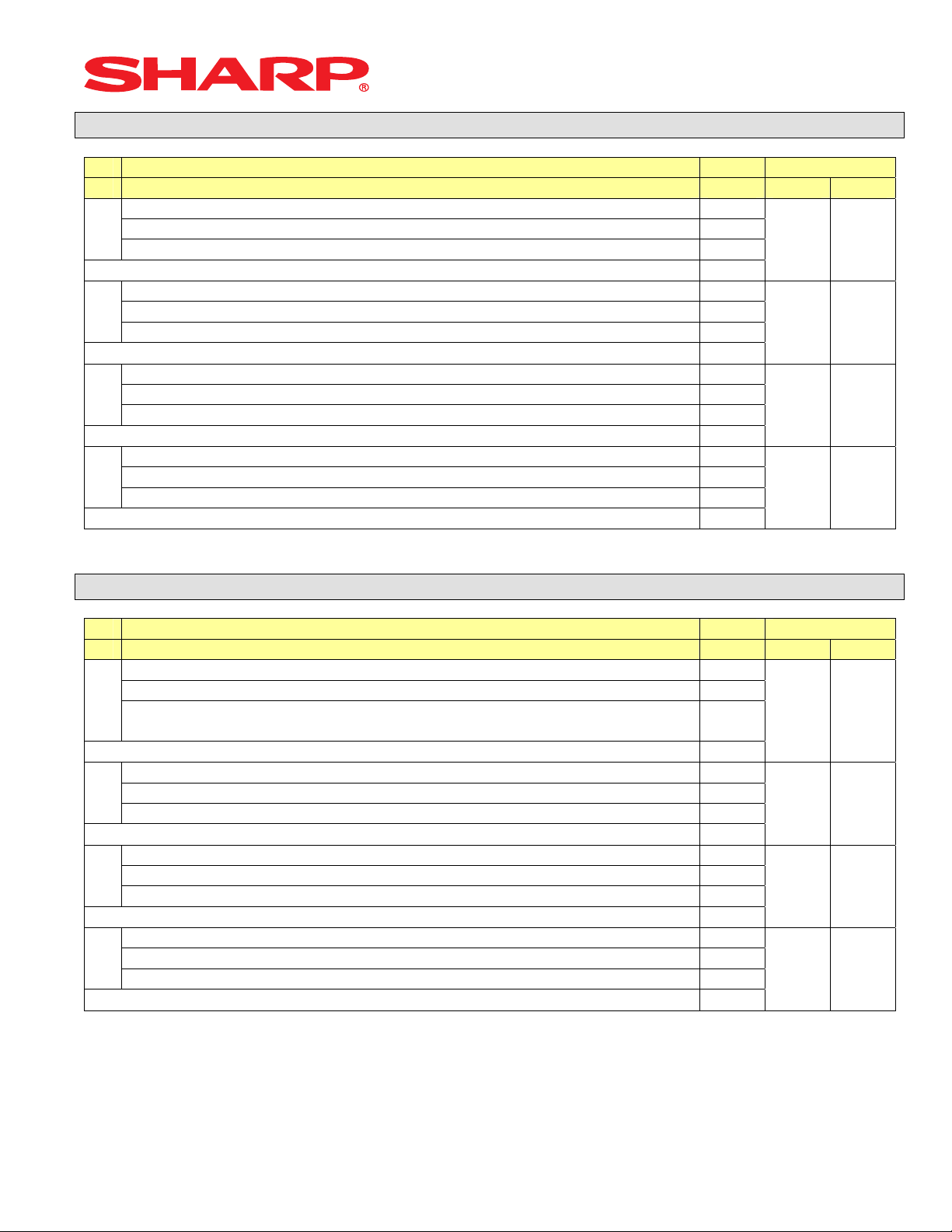

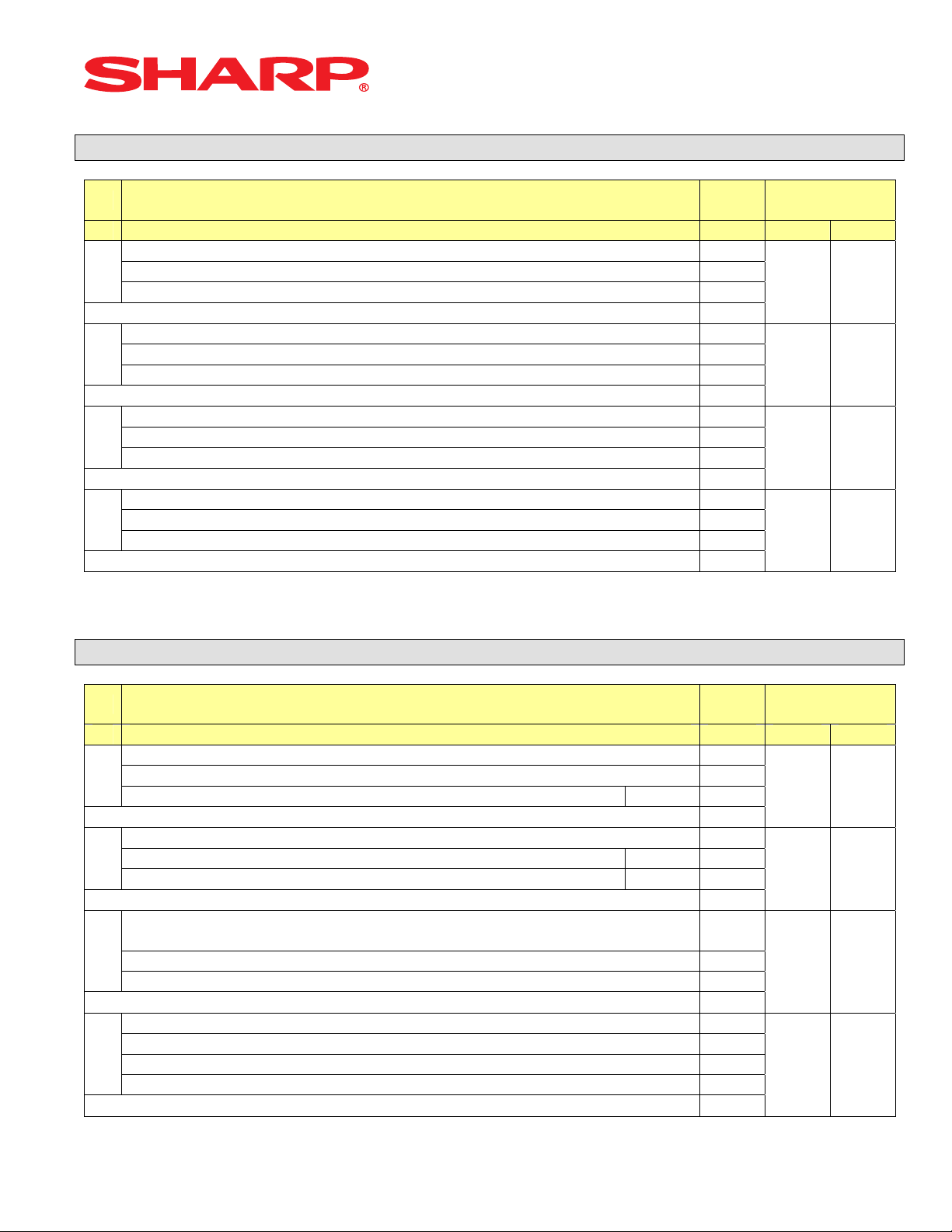

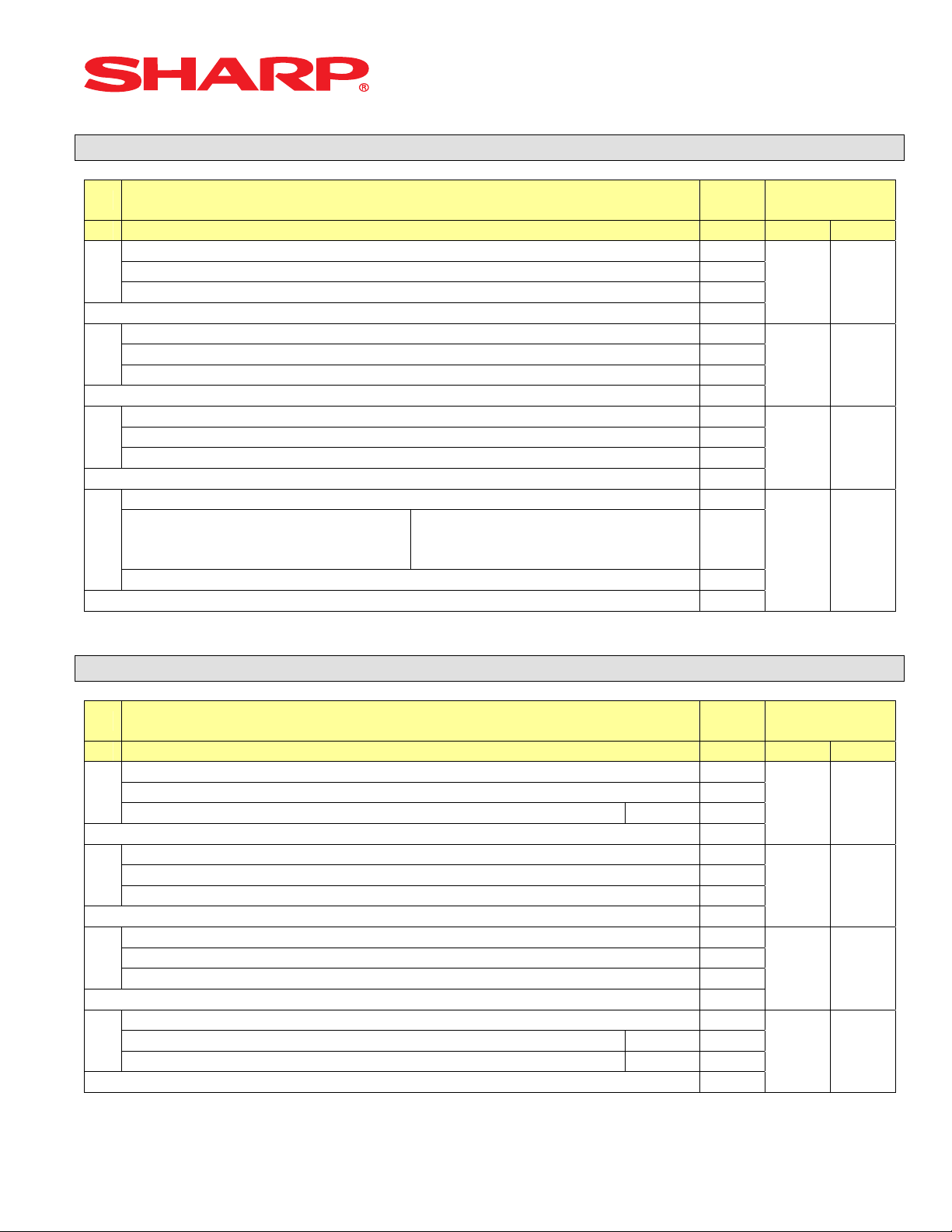

System Preset: 901

Bit Description Data

A410 A420

4/0

A

2/0

1/0

Enter SUM of Selection ----^

Tax System:

B

Auto Tax 1-4 & Manual Tax System / Canadian Tax (Type 1-10) / Canadian

Tax (Type-11: VAT-on-VAT)

Enter SUM of Selection ----^

Tax Rounding System:

C

- Singapore / Normal

Enter SUM of Selection ----^

Tab Setting:

D

- Decimal setting for display and print

Enter SUM of Selection ----^

0/6/7

8/0

3/2/1/0

MRS

Defaults

0 0

0 0

0 0

2 2

NOTE:

• 901-C: The Singapore Tax Rounding method will round the tax to the nearest nickel.

System Preset: 902

Bit Description Data

A410 A420

---- ---

A

---- ---

---

Enter SUM of Selection ----^

---- ---

B

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

C

---

---- ---

Enter SUM of Selection ----^

---- ---

D

---- ---

---- ---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

Designs and specification are subject to change without notice Page 8 of 209

Page 12

System Preset: 903

System Presets

Bit Description Data

A410 A420

ECR Data Copy (SIO) All RAM data Send/Receive Baud Rate (bps):

A

19200/9600

Enter SUM of Selection ----^

---- ---

B

Measure of Weight for Scale Entries Kg/Lb 2/0

---- ---

Enter SUM of Selection ----^

---

C

Tare Weight Entry is allowed Yes/No 2/0

Scale Weight System 1 Int. & 3 Dec./2 Int. & 2 Dec. 1/0

Enter SUM of Selection ----^

---- --Food Stamp System:

D

Food Stamp Forgiveness / Tax Payable in Food Stamps

Tax in Not Payable in Food Stamps / No Food Stamps

---- ---

Enter SUM of Selection ----^

5/4

3/2/1/0

MRS

Defaults

5 5

0 0

0 0

0 0

NOTE:

• 903-A is applicable for the 02FD.exe utility (not online communications)

• Manual Scale Entry is NOT allowed.

• To enabled Scale entries 906-D must be set = 1

System Preset: 904

Bit Description Data

A410 A420

Date is printed No/Yes 4/0

A

---- ---

---- ---

Enter SUM of Selection ----^

Consecutive No. is printed No/Yes 4/0

B

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

C

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

D

---- ---

---- ---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

904-A&B applies to Receipts, Slip, and Kitchen Print chits

Designs and specification are subject to change without notice Page 9 of 209

Page 13

System Preset: 905

System Presets

Bit Description Data

A410 A420

Tax4 Subtotal is printed on Trans. Reports No/Yes 4/0

Gross Tax4 & Refund Tax4 Totals are printed on Trans.

A

Reports

Net Tax4 Total is printed on Trans. Reports No/Yes 1/0

Enter SUM of Selection ----^

Tax is printed when the Taxable Subtotal = $0.00 Yes/No 4/0

B

Tax is printed when GST is VAT No/Yes 2/0

Tax is printed when Tax = $0.00 No/Yes 1/0

Enter SUM of Selection ----^

GST Exempt is printed on Trans. Reports No/Yes 4/0

C

Enter SUM of Selection ----^

Canadian Tax System:

D

Type10/Type9/Type8/Type7/Type6/Type5/Type4/Type3/Type2/Type1

Enter SUM of Selection ----^

No/Yes 2/0

---- ---

---- ---9/8/7/

6/5/4/

3/2/1/

0

MRS

Defaults

0 0

0 0

0 0

5 5

NOTE:

• 905-C is related to 905-D the Canadian Tax System

System Preset: 906

Bit Description Data

A410 A420

Dept. & PLU/UPC Codes are printed Yes/No 4/0

A

PLU/UPC (EAN) Stock System:

Entry is Inhibited/Error Message and Operation continues/Allowed

Enter SUM of Selection ----^

Bottle Return Function is Enabled Yes/No 4/0

B

Hash Dept. is Enabled Yes/No 2/0

---- ---

Enter SUM of Selection ----^

Multiplication System:

C

PLU/UPC (EAN) Price Look Up at Refund Entry No/Yes 4/0

D

Presetting of the Consecutive No. is Enabled No/Yes 2/0

Fractional Qty System is enabled (3 decimal places) Yes/No 1/0

Fast Food (FF sequence)/Split-Price/Successive

Multiplication/Multiplication

Enter SUM of Selection ----^

Enter SUM of Selection ----^

2/1/0

3/2/1/

0

MRS

Defaults

0 0

0 0

2 2

0 0

NOTE:

• 906-D must not be changed until after totalizers are reset (Qty 0 Æ 0.000 & vice-versus)

• Fractional entries are disabled when a SCALE is enabled in PGM2 Job #2690 programming.

Designs and specification are subject to change without notice Page 10 of 209

Page 14

System Preset: 907

System Presets

Bit Description Data

A410 A420

---- ---

A

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

B

UPC (EAN) Code Printing on Journal No/Yes 2/0

UPC (EAN) Code Printing on Receipt No/Yes 1/0

Enter SUM of Selection ----^

X Report is Enforced prior to Ind./All Cashier CCD Yes/No 4/0

C

---- 2/0

Minus Dept. and PLU/UPC (EAN) items are Enabled Yes/No 1/0

Enter SUM of Selection ----^

---- ---

D

---- ---

---- ---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

1 1

0 0

NOTE:

• To enable Coupon PLU items 907-D must be set = 1

System Preset: 908

Bit Description Data

A410 A420

GT1 is printed on the Trans.-Z Report No/Yes 4/0

A

GT2 is printed on the Trans.-Z Report No/Yes 2/0

GT3 is printed on the Trans.-Z Report No/Yes 1/0

Enter SUM of Selection ----^

GT1 is printed on the Trans.-X Report Yes/No 4/0

B

GT2 is printed on the Trans.-X Report Yes/No 2/0

GT3 is printed on the Trans.-X Report Yes/No 1/0

Enter SUM of Selection ----^

VOID-mode operations affect the Hourly Report Yes/No 4/0

C

X//Z1 Reports may taken in X2/Z2 Mode No/Yes 2/0

Consecutive No. is Reset upon a Trans.-Z Report Yes/No 1/0

Enter SUM of Selection ----^

X/Z Report Printing: Journal only/Receipt & Journal 4/0

D

---- --Trans.-Z1 Report resets the GT Yes/No 1/0

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

• 908-D: The X/Z Report printing option does not apply to Individual Cashier Report

Designs and specification are subject to change without notice Page 11 of 209

Page 15

System Preset: 909

System Presets

Bit Description Data

A410 A420

---- ---

A

Training GT is printed on the Trans.-X Report Yes/No 2/0

Training GT is printed on the Trans.-Z Report No/Yes 1/0

Enter SUM of Selection ----^

PLU/UPC (EAN) Item Data is printed on the Z Report No/Yes 4/0

B

---- ---

---- ---

Enter SUM of Selection ----^

VOID-mode & MGR VOID is printed on the Trans.-Z2 Report No/Yes 4/0

C

VOID-mode & MGR VOID is printed on the Trans.-Z1 Report No/Yes 2/0

---- ---

Enter SUM of Selection ----^

---- ---

D

---- ---

---- ---

Enter SUM of Selection ----^

MRS

Defaults

2 2

0 0

0 0

0 0

NOTE:

• 909-B: No Sales Data is printed for the PLU/UPC (EAN)-Z Report when = 4

System Preset: 910

Bit Description Data

A410 A420

---- ---

A

Overlapped Cashier Function Yes/No 1/0

---- ---

Enter SUM of Selection ----^

Cashier Code Display Appear/Hidden 2/0

Auto Sign Off at the End of the

B

Transaction

---- ---

---- ---

C

Server/Cashier Sign-on System Auto Sign-Off/Stay-Down 2/0

---- --(Fixed): Server/Cashier system is code entry 4

D

---- ---

---- ---

Yes (Everytime) / No

After Cashier Z1 Only

Enter SUM of Selection ----^

Enter SUM of Selection ----^

Enter SUM of Selection ----^

1/0

MRS

Defaults

0 0

2 2

0 0

4 4

NOTE:

• 910-A: The Cash drawer opening is based on the Individual Server preset

• 910-C: The Server stay-down system requires a manual sign-off sequence

Designs and specification are subject to change without notice Page 12 of 209

Page 16

System Preset: 911

System Presets

Bit Description Data

A410 A420

---- ---

A

---- --Fractional Qty System: Ignored/Round-Up/Round-Off 2/1/0

Enter SUM of Selection ----^

C/D Check of UPC (EAN) Yes/No 4/0

B

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

C

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

D

---- ---

---- ---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

• 911-A: Is ignored for Scale operations

Designs and specification are subject to change without notice Page 13 of 209

Page 17

System Preset: 912

System Presets

Bit Description Data

A410 A420

---- ---

A

---- --Date Print Format YYMMDD/DDMMYY/MMDDYY 2/1/0

Enter SUM of Selection ----^

---- ---

B

---- --Time Clock System 24-Hour System/12-Hour System 1/0

Enter SUM of Selection ----^

Receipt After-Transaction Format Detailed/Totals only 4/0

C

Copy Receipt Function is Enabled Yes/No 2/0

Receipt Footer Print Control By Media Preset/All Receipts 1/0

Enter SUM of Selection ----^

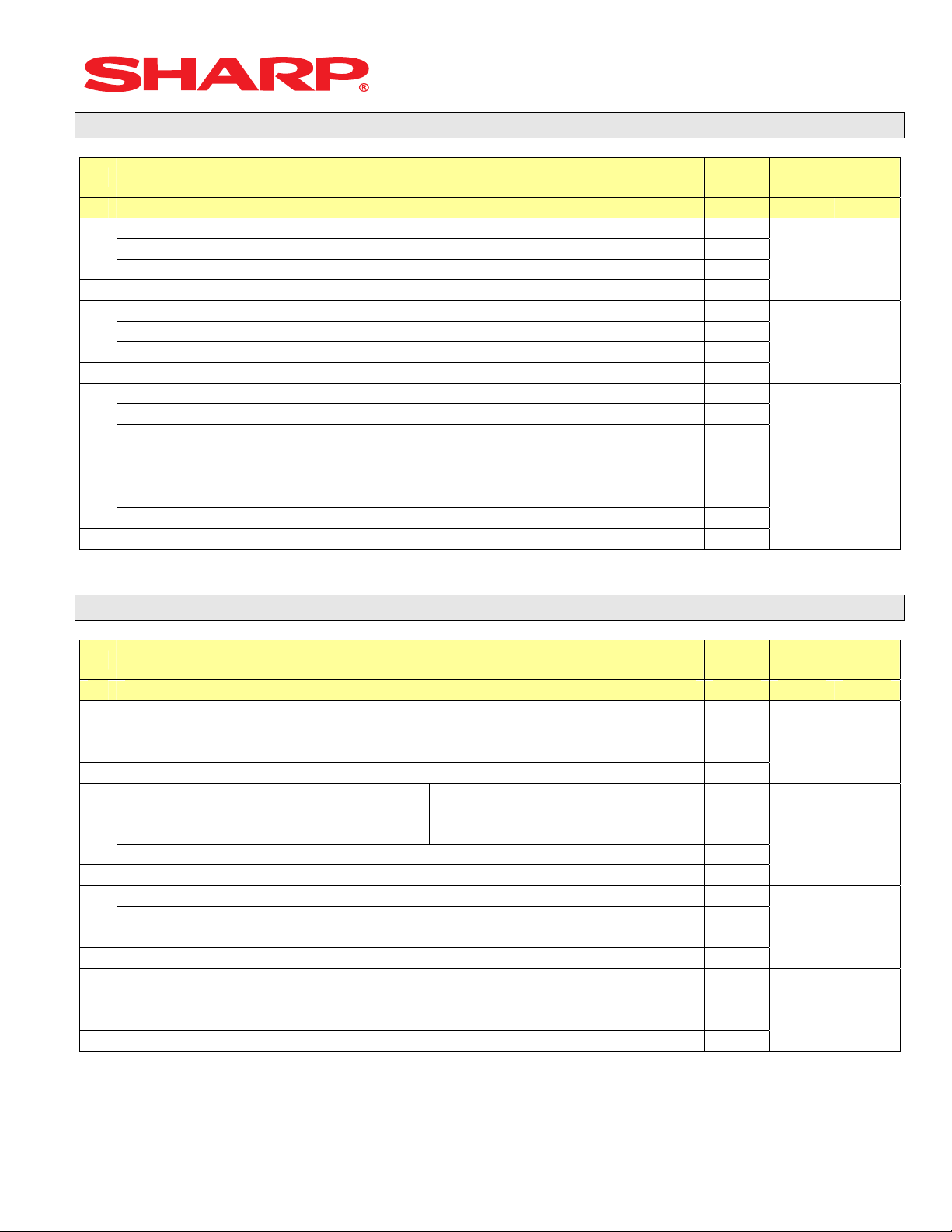

3-Line Header – No Logo Graphic Stamp 0

Graphic Logo Stamp only 1

D Logo Message Control:

Graphic Logo Stamp & 3-Line Footer 2

6-Line Header – No Stamp 3

Graphic Logo and 3-Line Header 4

3-Line Header – No Stamp/3-Line Footer 5

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

6 6

1 0

NOTE:

• 912-D: The Graphic Logo STAMP – Must use PC Link to upload Graphical Logos to the ECRs.

• 912-D: The Graphic Logo bitmap should be 288 dots (w) x 130 dots (h) and black & white only.

Designs and specification are subject to change without notice Page 14 of 209

Page 18

System Preset: 913

System Presets

Bit Description Data

A410 A420

---- ---

A

---- --VP Total Amounts Contains: Tendered Amount/Total Amount 1/0

Enter SUM of Selection ----^

Subtotal is printed when the [SBTL] key is depressed Yes/No 4/0

B

MDSE Subtotal is printed when the [MDSE] key is depressed Yes/No 2/0

Escaping Compulsory VP and SLIP print is Enabled Yes/No 1/0

Enter SUM of Selection ----^

---- ---

C

Error-Tone System

Keyboard Buffering is Enabled No/Yes 1/0

Compulsory Drawer Closed prior to operation is enabled Yes/No 4/0

D

Error System “Misoperation”/One-Shot Error Only 2/0

Key Touch-Tone is enabled No/Yes 1/0

Until [CL] is depressed/2

seconds

Enter SUM of Selection ----^

Enter SUM of Selection ----^

2/0

MRS

Defaults

0 0

1 1

0 0

4 4

NOTE:

• 913-B: The sequence for escaping “Compulsory” VP or SLIP print operations:

Æ [.] Æ [SLIP or PRINT]

System Preset: 914

Bit Description Data

A410 A420

Receipts are printed upon [NO SALE] operations No/Yes 4/0

A

The [NO SALE] function is combined with the [CASH] key Yes/No 2/0

Tax Delete function is Enabled Yes/No 1/0

Enter SUM of Selection ----^

---- ---

B

---- --The [NO SALE] function is allowed after a Non-Add No. entry Yes/No 1/0

Enter SUM of Selection ----^

---- ---

C

VOID-mode is Enabled No/Yes 2/0

Non-Add # Entry is Compulsory at the beginning of each Trans. Yes/No 1/0

Enter SUM of Selection ----^

Manual Tax entry is Enabled No/Yes 4/0

D

Check-Cashing function is Enabled Yes/No 2/0

Non-Add # Entry is Enabled No/Yes 1/0

Enter SUM of Selection ----^

MRS

Defaults

1 1

1 1

0 0

0 0

NOTE:

Designs and specification are subject to change without notice Page 15 of 209

Page 19

System Presets

System Preset: 915

Bit Description Data MRS

A410 A420

---- ---

A

---- --Fraction Treatment Disregard/Rounding Up/Rounding Off 2/1/0

Enter SUM of Selection ----^

---- ---

B

---- ---

---- ---

Enter SUM of Selection ----^

---- --SBTL (-) or SBTL (%) within the same

C

Transaction

Enter SUM of Selection ----^

---- ---

D

---- ---

---- ---

Enter SUM of Selection ----^

Once/Any No. Times 2/0

0 0

0 0

0 0

0 0

NOTE:

System Preset: 916

Bit Description Data

A410 A420

---- ---

A

---- --Print when the No. Text Characters overlap the Amount 2-Line/Truncate 1/0

Enter SUM of Selection ----^

Charge Media Finalization when the Amount = $0.00 Yes/No 4/0

B

---- --Food Stamp SBTL is Compulsory before FS-Tender Yes/No 1/0

Enter SUM of Selection ----^

Allow the MDSE SBTL to go Negative No/Yes 4/0

C

[SBTL] Entry is Compulsory before Tendering Finalization Yes/No 2/0

[SBTL] Entry is Compulsory before Direct Finalization Yes/No 1/0

Enter SUM of Selection ----^

Coupon PLU Totalizer prints on the Trans.-(X/Z) Reports No/Yes 4/0

D

NET Sales SBTL (NET1) is printed on the Trans.-(X/Z) Reports No/Yes 2/0

Check-Change Totalizer is printed on the Trans.-(X/Z) Reports No/Yes 1/0

Enter SUM of Selection ----^

MRS

Defaults

1 1

4 4

0 0

0 0

NOTE:

Designs and specification are subject to change without notice Page 16 of 209

Page 20

System Presets

System Preset: 917

Bit Description Data MRS

A410 A420

Tax1 Subtotal is printed on Trans. Reports No/Yes 4/0

A

Gross Tax1 & Refund Tax1 Totals are printed on Trans. Reports No/Yes 2/0

Net Tax1 Total is printed on Trans. Reports No/Yes 1/0

Enter SUM of Selection ----^

Tax2 Subtotal is printed on Trans. Reports No/Yes 4/0

B

Gross Tax2 & Refund Tax2 Totals are printed on Trans. Reports No/Yes 2/0

Net Tax2 Total is printed on Trans. Reports No/Yes 1/0

Enter SUM of Selection ----^

Tax3 Subtotal is printed on Trans. Reports No/Yes 4/0

C

Gross Tax3 & Refund Tax3 Totals are printed on Trans. Reports No/Yes 2/0

Net Tax1 Total is printed on Trans. Reports No/Yes 1/0

Enter SUM of Selection ----^

Total Tax is printed on the Trans.-(X/Z) Reports No/Yes 4/0

D

Gross & Ref. Manual Tax Totals are printed on Trans. Reports No/Yes 2/0

Net Manual Tax Totalizer is printed on Trans.-(X/Z) Reports No/Yes 1/0

Enter SUM of Selection ----^

0 0

0 0

0 0

0 0

NOTE:

System Preset: 918

Bit Description Data MRS

A410 A420

Assoc. PLU Text of Combo Meals is printed No/Yes 4/0

Direct-Tender for 2nd or subsequent tender is allowed Yes/No 2/0

A

Combo Meal Kitchen Printer printing is by

---- ---

B

PLU Text is printed in RED when the unit price is $0.00 Yes/No 2/0

Fractional entries allowed for non-Scalable Dept. & PLU items No/Yes 1/0

---- ---

C

Kitchen Printer output Groups Like Items No/Yes 2/0

Kitchen Printer output prints Dept. & PLU Text in Double-Sized Yes/No 1/0

D

Combo Meal’s KP/by PLU’s

KP

Enter SUM of Selection ----^

Enter SUM of Selection ----^

Enter SUM of Selection ----^

Enter SUM of Selection ----^

1/0

2 2

2 2

3 3

0 0

NOTE:

Designs and specification are subject to change without notice Page 17 of 209

Page 21

System Presets

System Preset: 919

Bit Description Data MRS

A410 A420

----

A

----

----

Enter SUM of Selection ----^

Cashier No. is Checked at PBLU Reorder No/Yes 4/0

B

---- --Guest Check Number-System Entry Manual/Auto-Generate 1/0

Enter SUM of Selection ----^

---- ---

C

[PBLU] Entry is Compulsory Yes/No 2/0

Amount Prints when PLU/UPC (EAN) Unit Price is $0.00 Yes/No 1/0

Enter SUM of Selection ----^

Normal SBTL is printed in addition to the Conversion SBTL No/Yes 4/0

D

---- --Foreign Currency Format Omit Decimal Digits/Not 1/0

Enter SUM of Selection ----^

0 0

4 4

0 0

0 0

NOTE:

System Preset: 920

Bit Description Data MRS

A410 A420

---- ---

A

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

B

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

C

---- ---

---- ---

Enter SUM of Selection ----^

---

D ----

---

---

---

Enter SUM of Selection ----^

0 0

0 0

0 0

0 0

NOTE:

Designs and specification are subject to change without notice Page 18 of 209

Page 22

System Presets

System Preset: 921

Bit Description Data MRS

A410 A420

Convert UPC-E to UPC-A Code Yes/No 4/0

A

---- ---

---- ---

Enter SUM of Selection ----^

---

B

---

---

---

C

---

---

---

D

0 0

0 0

0 0

0 0

Enter SUM of Selection ----^

NOTE:

System Preset: 922

Bit Description Data

A410 A420

---- ---

A

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

B

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

C

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

D

---- ---

---- ---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

Designs and specification are subject to change without notice Page 19 of 209

Page 23

System Preset: 923

System Presets

Bit Description Data

A410 A420

---- ---

A

---- --(Fixed) ---

Enter SUM of Selection ----^

(Fixed)

B

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

C

(Fixed) --(Fixed)

Enter SUM of Selection ----^

(Fixed) ---

D

(Fixed) ---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

System Preset: 924

Bit Description Data MRS

A410 A420

---- ---

A

---- --(Fixed) ---

Enter SUM of Selection ----^

(Fixed) ---

B

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

C

(Fixed) --(Fixed) ---

Enter SUM of Selection ----^

---

D

---

Enter SUM of Selection ----^

0 0

0 0

0 0

0 0

NOTE:

Designs and specification are subject to change without notice Page 20 of 209

Page 24

System Preset: 925

System Presets

Bit Description Data

A410 A420

---

A

---

---- ---

Enter SUM of Selection ----^

---- ---

B

---

---

Enter SUM of Selection ----^

C

Enter SUM of Selection ----^

---- ---

D

---

---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

System Preset: 926

Bit Description Data

A410 A420

---- ---

A

Direct Voids and the Voided item is printed on the KP No/Yes 2/0

Past Voids and the Voided item is printed on the KP No/Yes 1/0

Enter SUM of Selection ----^

Program Reset via PGM2-Mode is Enabled Yes/No 4/0

B

Refunded Data is sent to the KP No/Yes 2/0

---- ---

Enter SUM of Selection ----^

---

C

---

---

Enter SUM of Selection ----^

D

---- ---

---- ---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

• When REFUND Data is preset to print to the KP. It will print in RED.

• When REFUND Data is preset NOT to print to the KP. It will print in BLACK.

Designs and specification are subject to change without notice Page 21 of 209

Page 25

System Preset: 927

System Presets

Bit Description Data

A410 A420

---- ---

A

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

B

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

C

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

D

---- ---

---- ---

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

System Preset: 928

Bit Description Data

A410 A420

---- ---

A

---- --Slip Logo is printed on Slip Printer Yes/No 1/0

Enter SUM of Selection ----^

---- ---

B

Validation Message is printed on Slip for Checks & Charges Yes/No 2/0

Header Line is printed on Slip on Reorder Entries No/Yes 1/0

Enter SUM of Selection ----^

PLU/UPC (EAN) is printed on the [BILL] when the unit price =

$0.00

C

Combo Meal Individual PLU Item Text is printed on the [BILL] No/Yes 2/0

---- ---

Enter SUM of Selection ----^

Compulsory Bill Print System:

Compulsory for GLU/PBLU entries 2

D

Compulsory for every entry 1

Compulsory based on Media key preset 0

Enter SUM of Selection ----^

No/Yes 4/0

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

Designs and specification are subject to change without notice Page 22 of 209

Page 26

System Preset: 929

System Presets

Bit Description Data

---- ---

A

---- --KP Print format for Media Keys Detailed/Summary 1/0

Enter SUM of Selection ----^

---- ---

B

---- --(Fixed) 1/0

Enter SUM of Selection ----^

---- ---

C

---- ---

---

Enter SUM of Selection ----^

--Taxable Status of PLU/UPC (EAN),

D

which is SET at “Non-Taxable” by

PGM.

---- ---

Non-Taxable /

According to its Associated

Department

Enter SUM of Selection ----^

2/0

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

System Preset: 980

Bit Description Data

A410 A420

---- ---

A

---- --PLU Stock Function is Enabled Yes/No 1/0

Enter SUM of Selection ----^

---- ---

B

---- --HASH department entries are added to the Hourly Report Yes/No 1/0

Enter SUM of Selection ----^

---- ---

C

---- ---

---- ---

Enter SUM of Selection ----^

---- ---

D

RCPT Key is separate from the P/O Key Yes/No 2/0

PLU Price-2 is Enabled Yes/No 1/0

Enter SUM of Selection ----^

MRS

Defaults

0 0

0 0

0 0

0 0

NOTE:

Designs and specification are subject to change without notice Page 23 of 209

Page 27

System Presets

Reset Report Counters – Z1/Z2

All Zeros

930

939 XXXX

(4 Digits)

930: Z1 General Report Counter

931: Hourly Z1 Report Counter

934: PLU Z1 Report Counter

935: Cashier Z1 Report Counter

936: PBLU Z1 Report Counter

937: Z2 General Report Counter

939: Daily Net Z2 Report Counter

All Zeros

942

943

969 XXXXXXXXXXXXX

(13 Digits)

942: GT2 (Positive GT)

943: GT3 (Negative GT)

969: Training GT

Note: The Net GT is obtained from GT2 and GT3 calculations

MRS = 0000000000000

.

.

@

@

CASH

CASH

Designs and specification are subject to change without notice Page 24 of 209

Page 28

System Presets

Secret Code Programming

All Zeros

944

XXXX

(4 Digits)

MRS = 0000

Training Cashier Programming

All Zeros

948

XX

(2 Digits)

XX: Cashier Code

MRS = 00

Training Mode Title Programming

0

949

(Characters)

12 Char.

MRS = **TRAINING**

Designs and specification are subject to change without notice Page 25 of 209

.

.

.

@

@

@

CASH

CASH

CASH

Page 29

System Presets

Euro Symbol Programming

0

985 X

X: 0 = “spaces”

1 = Euro Symbol

MRS = 0 (spaces)

Domestic Currency Symbol

0

986 (Characters)

4 Char.

MRS = **$**

Note: The characters are entered using the programming key layout or by entering the numeric

codes shown on page 20. This symbol is printed with positive amounts of domestic currency and

will be printed to the left-side of the amount.

.

.

@

@

CASH

CASH

Designs and specification are subject to change without notice Page 26 of 209

Page 30

System Presets

Language Setting For Text

0

987 X

X: 0 = English Text

1 = French Text

2 = Spanish Text

MRS = 0 (English)

Note: The following text is changed upon the setting above:

- FUNCTION text

- CASHIER text

- MESSAGE text (e.g. Logo, etc.)

Designs and specification are subject to change without notice Page 27 of 209

.

@

CASH

Page 31

System Presets

System Preset Reading – SRV Mode

1. Procedures:

1) Place the SRV key to the SRV-Mode position

2) Enter the following sequence:

900

2. Print Out:

@ CASH

File #5 = 0 for Overlapping Cashier

File #6 = 0 for KP Buffer

Designs and specification are subject to change without notice Page 28 of 209

Page 32

Free Key Layouts

Section-2: Free Key Layouts

Designs and specification are subject to change without notice Page 29 of 209

Page 33

Free Key Layouts

Function Key Layout

MRS Defaults

950 XXX

(Function No.)

(Inhibits)

(Advances to next Function)

XXX: Function No. 1-79

: 999 (for inhibiting a key)

MRS = Standard “out-of-the-box” key layout

Note: If the “fixed” function keys are accidentally placed in the wrong position, it may become

necessary to restore the MRS default keyboard in order to continue.

Function Key Layout

951 XXX

Key No.

(Inhibits)

(Advances to next Key No.)

XXX: 1-82 (ER-A410)

: 1-119 (ER-A420)

: 999 (for inhibiting a key location)

MRS = Standard “out of box” key layout

Note: The Key No. programmed in this programming will be used in the PGM2 mode

programming for assigning direct Dept. and/or PLU keys on the keyboard

.

.

@

@

(Key on Keyboard)

@

SBTL

(Key on Keyboard)

@

SBTL

CASH

CASH

Designs and specification are subject to change without notice Page 30 of 209

Page 34

Free Key Layouts

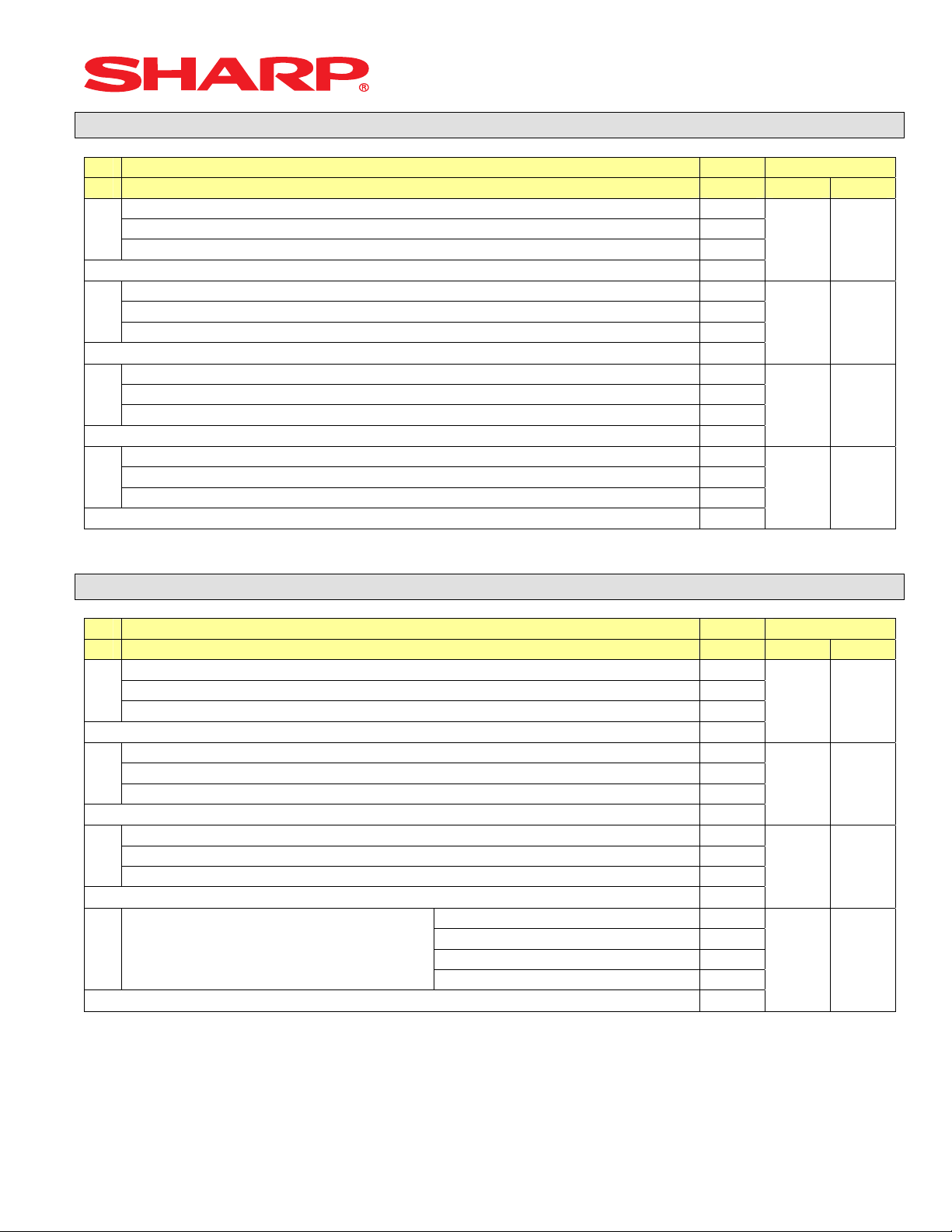

Function Key Reference Chart

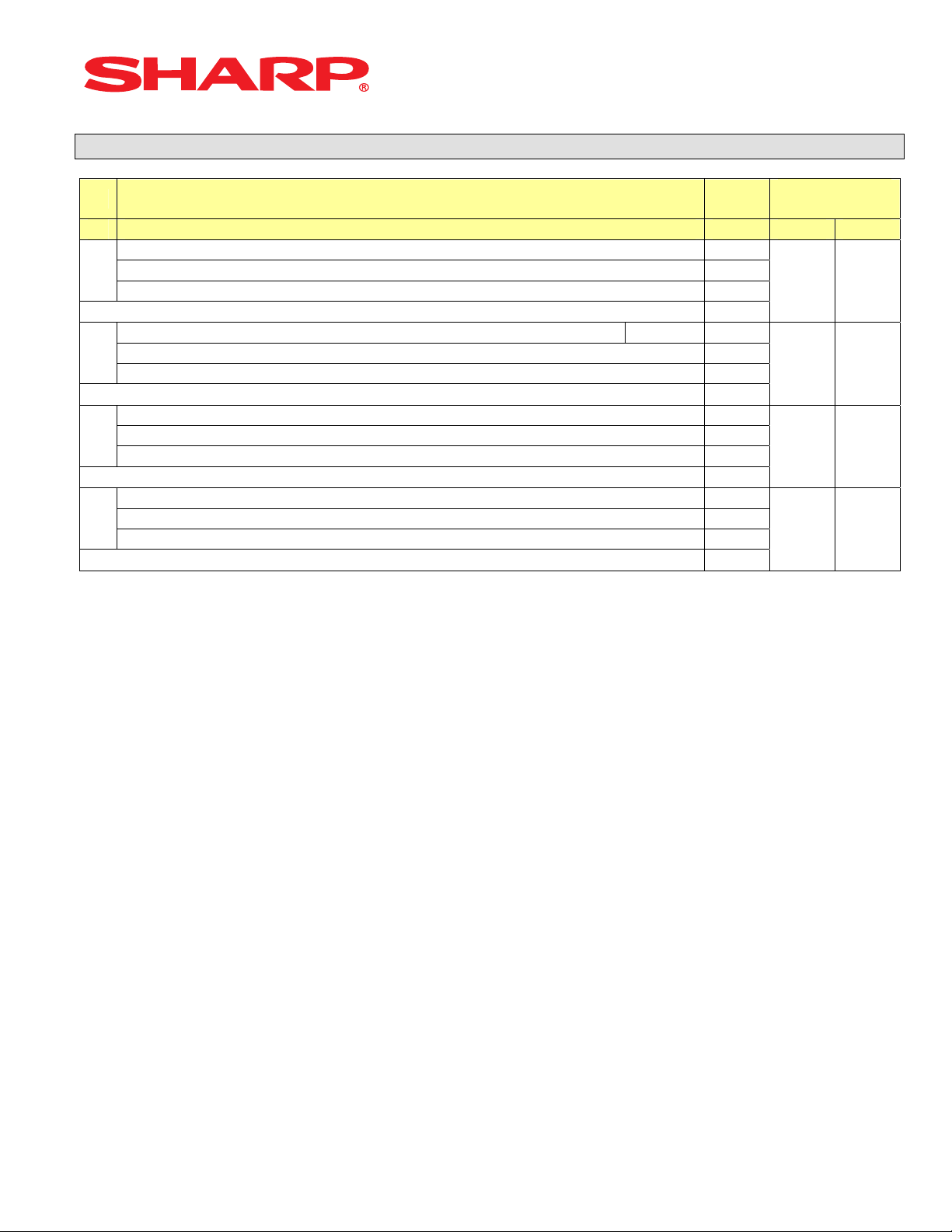

1. ER-A410

16

5

4

3

2

1

10

9

8

7

6

15

14

13

12

11

22

21

20

19

18

17

28

27

26

25

24

23

34

33

32

31

30

29

40

39

38

37

36

35

46

45

44

43

42

41

52

51

50

49

48

47

58

57

56

55

54

53

Note: The keys are fixed and cannot be assigned to Key Functions

2. ER-A420

7

6

5

4

3

2

1

14 21 28 35 42 49 56 63 70 77 84 91 98 105 112 119

13 20 27 34 41 48 55 62 69 76 83 90 97 104 111 118

12 19 26 33 40 47 54 61 68 75 82 89 96 103 110 117

11 18 25 32 39 46 53 60 67 74 81 88 95 102 109 116

10 17 24 31 38 45 52 59 66 73 80 87 94 101 108 115

9

8

16 23 30 37 44 51 58 65 72 79 86 93 100 107 114

15 22 29 36 43 50 57 64 71 78 85 92 99 106 113

Note: The keys are fixed and cannot be assigned to Key Functions

64

63

62

61

60

59

70

69

68

67

66

65

76

75

74

73

72

71

82

81

80

79

78

77

Designs and specification are subject to change without notice Page 31 of 209

Page 35

Free Key Layouts

Free Key Layout Reading – SRV Mode

2. Procedures:

1) Place the SRV key to the SRV-Mode position

2) Enter the following sequence:

950

@ CASH

Note:

Additional Function Keys:

080 – AMT

081 – REPEAT

082 – INQ

083 – NO DEL

084 – PRCHNG

Designs and specification are subject to change without notice Page 32 of 209

Page 36

Free Key Layouts

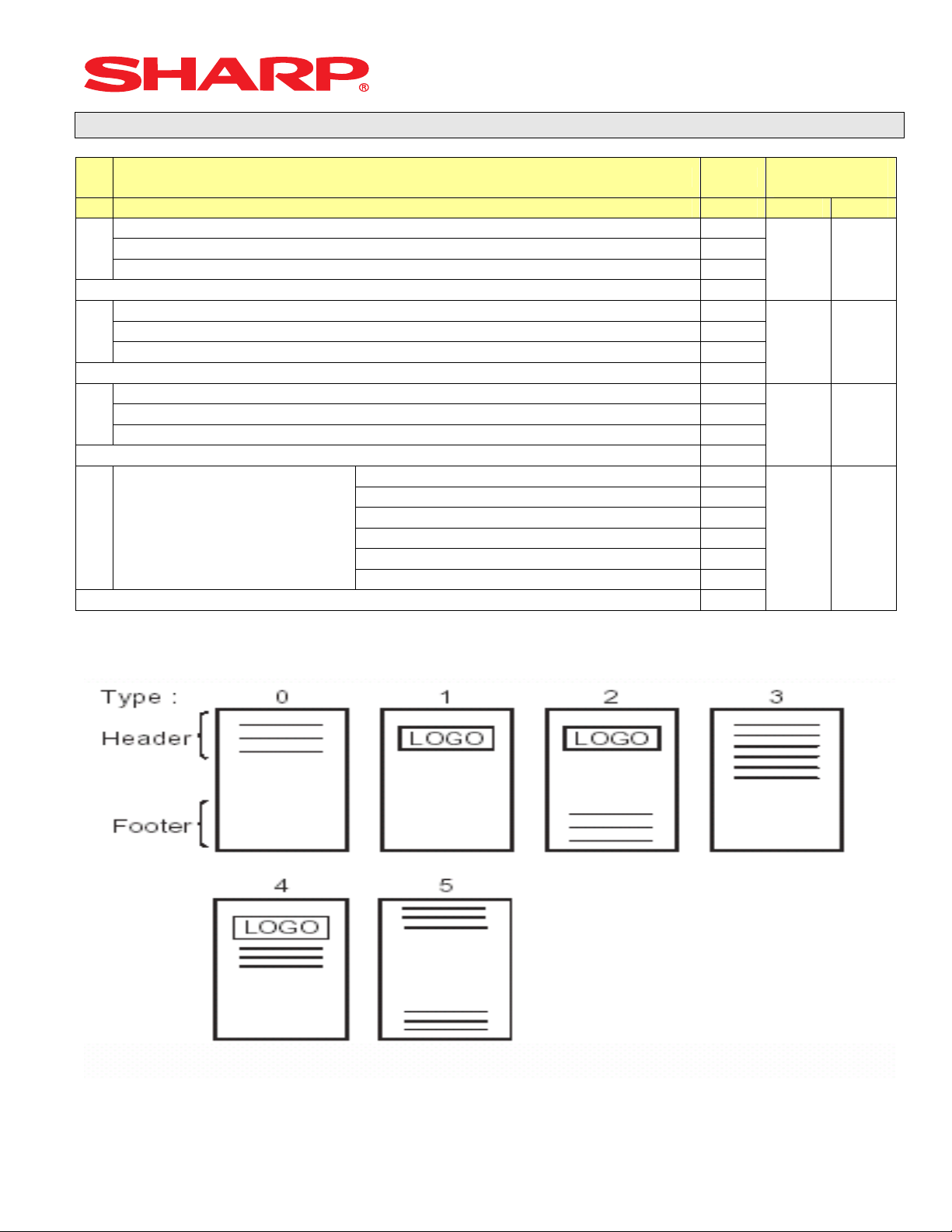

3. Keyboard No. Reference:

1) Example from the ER-A410 Key No. Layout:

16

5

4

3

2

1

10

9

8

7

6

15

14

13

12

11

22

21

20

19

18

17

28

27

26

25

24

23

34

33

32

31

30

29

40

39

38

37

36

35

46

45

44

43

42

41

52

51

50

49

48

47

58

57

56

55

54

53

Note: The keys are fixed and cannot be assigned to Key Functions

2) Example from the ER-A420 Key No. Layout:

7

6

5

4

3

2

1

14 21 28 35 42 49 56 63 70 77 84 91 98 105 112 119

13 20 27 34 41 48 55 62 69 76 83 90 97 104 111 118

12 19 26 33 40 47 54 61 68 75 82 89 96 103 110 117

11 18 25 32 39 46 53 60 67 74 81 88 95 102 109 116

10 17 24 31 38 45 52 59 66 73 80 87 94 101 108 115

9

8

16 23 30 37 44 51 58 65 72 79 86 93 100 107 114

15 22 29 36 43 50 57 64 71 78 85 92 99 106 113

Note: The keys are fixed and cannot be assigned to Key Functions

64

63

62

61

60

59

70

69

68

67

66

65

76

75

74

73

72

71

82

81

80

79

78

77

Designs and specification are subject to change without notice Page 33 of 209

Page 37

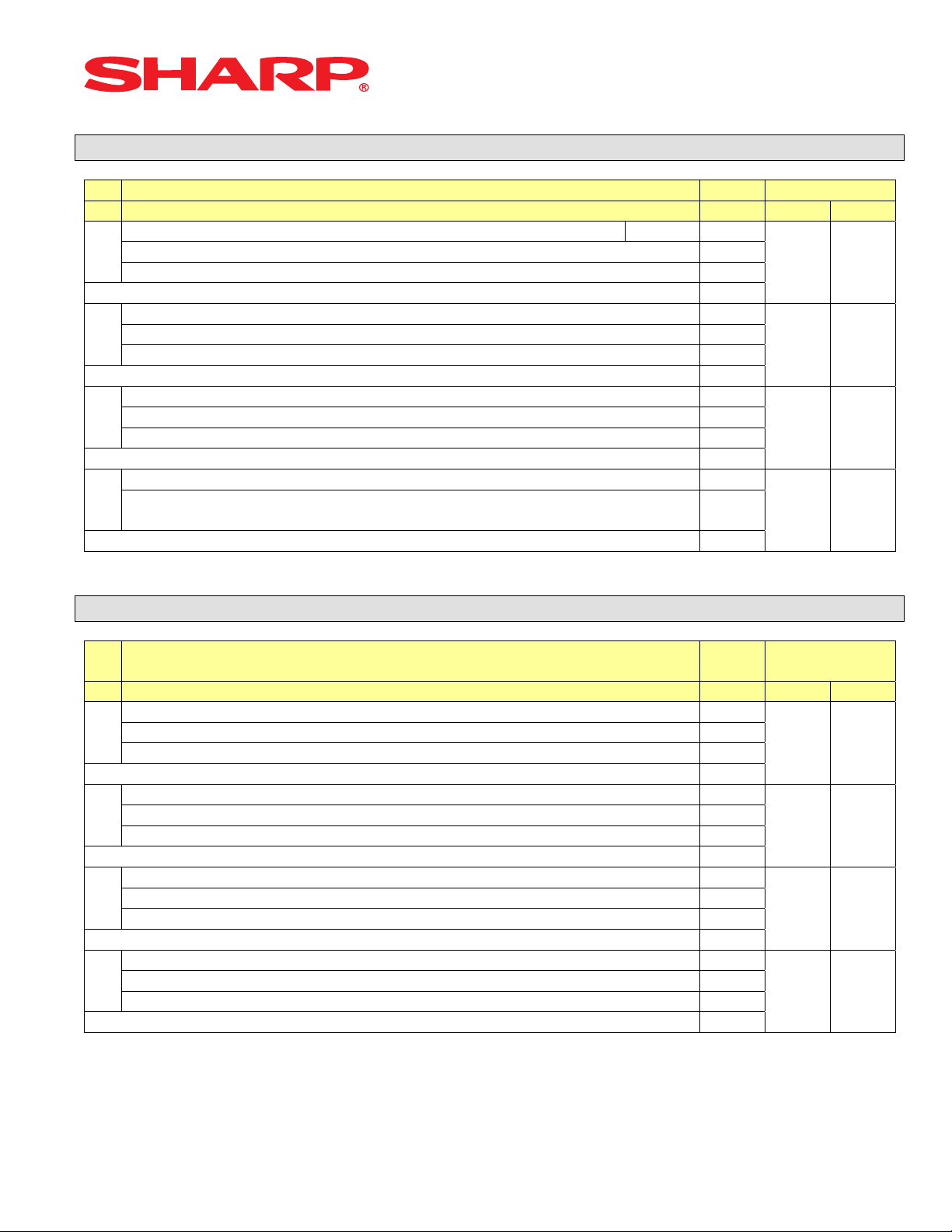

Free Key Layouts

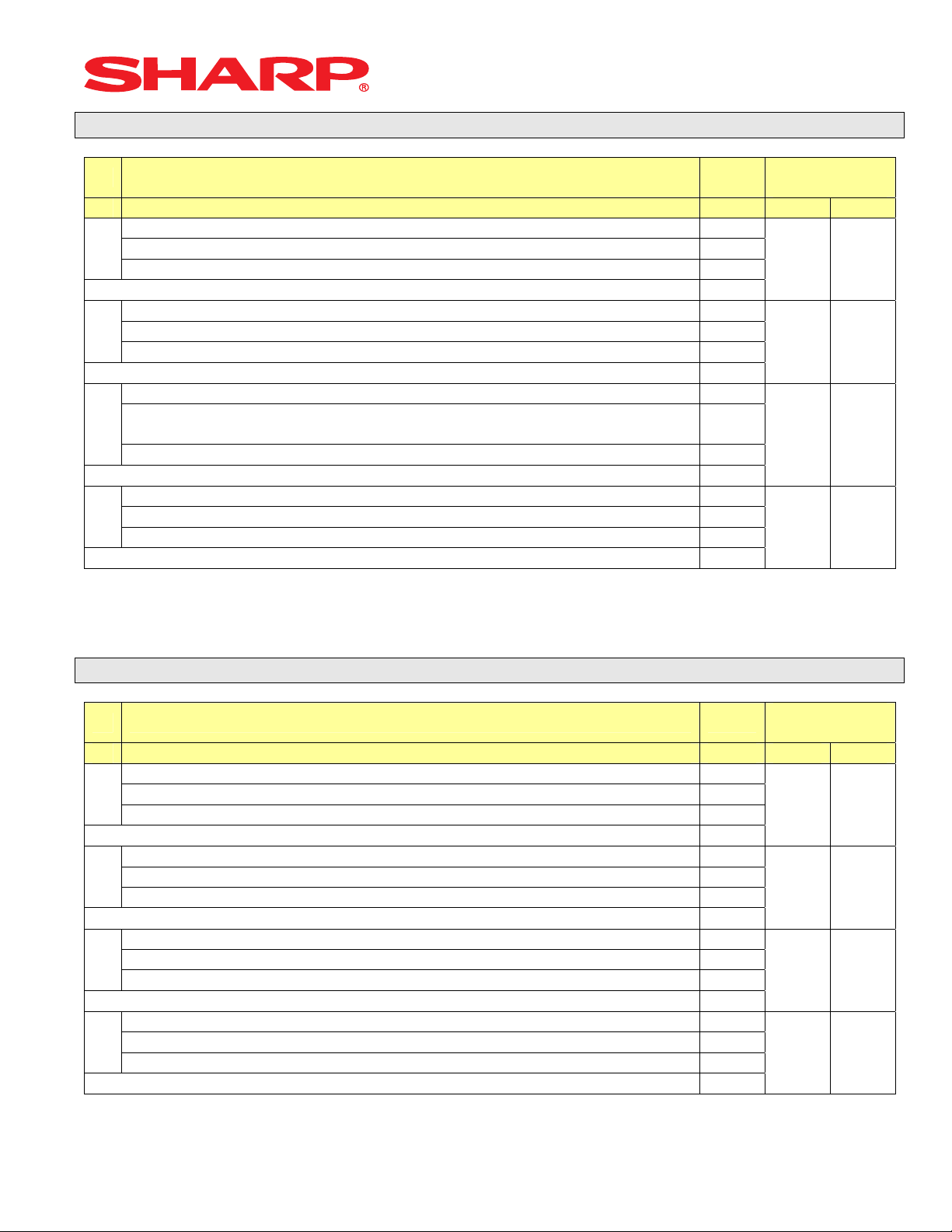

4. Reference Free Keys to Keyboard:

1) Example from the ER-A410 default Key Layout:

16

Receipt 5 Journal

10

SLIP

4

R/A

3

(-)

2

VOID

1

#/TM

9

RCPT

8

%

7

RFND

6

15

14

13

12

11

FINAL

22

@/FOR

21

20

19

18

17

PBLU

28

.

27

7

8

26

4

5

25

1

2

24

0

23

NC

34

CL

33

32

31

30

29

9

6

3

00

40

39

38

37

36

35

PLU/

46

45

44

43

42

41

SUB

52

51

50

49

48

47

SCALE

58

57

56

55

54

53

OPEN

TARE

64

63

62

61

60

59

70

69

68

67

66

65

TAX1

SHIFT

76

TAX

75

CONV

74

CHK

73

MDSE

SBTL

72

CA/AT

71

Key No.

Free Key Function

2) Example from the ER-A420 Default Key Layout:

RCPT 7 JRNL

14

6

5

4

3

2

1

13 20 27 34 41 48 55 62 69 76 83

12 19 26 33 40 47 54 61 68 75 82

11 18 25 32 39 46 53 60 67 74 81

10 17 24 31 38 45 52 59 66 73 80

9

8

21 28 35 42 49 56 63 70 77 84

16 23 30 37 44 51 58 65 72 79

15 22 29 36 43 50 57 64 71 78

L1

91

PRICE

SHIFT

90

@/FOR

89

7

88

4

87

1

86

0

85

L2

98

#/TM

97

.

96

8

95 9 102

5

94

2

93

00

92

L3

105

SCALE

104

CL

103

6

101

3

100

MDSE

SBTL

99

AUTO

112

RCPT

/PO

111

%

110

RFND

109

CH2

108

CH1

107

SBTL

106

Key No.

Free Key Function

Designs and specification are subject to change without notice Page 34 of 209

CASH

#

82

FS

SHIFT

81

FS

TEND

80

CH

79

SBTL

78

/NS

77

CASH

#

119

RA

118

(-)

117

VOID

116

TAX1

SHIFT

115

CHK

114

CA/AT

113

Page 38

Free Key Layouts

Key Location No. Reading

1. Procedure:

1) Place the SRV key to the SRV-Mode position

2) Enter the following sequence:

951

2. Print Out:

Designs and specification are subject to change without notice Page 35 of 209

@ CASH

Page 39

Free Key Layouts

3. Reference to Key Locations to Keyboard:

1) Example from the ER-A410 default Key Layout:

16

Receipt 5 Journal

10

SLIP

4

R/A

3

(-)

2

VOID

1

#/TM

9

RCPT

8

%

7

RFND

6

15

14

13

12

11

FINAL

22

@/FOR

21

20

19

18

17

PBLU

28

.

27

7

8

26

4

5

25

1

2

24

0

23

NC

34

CL

33

32

31

30

29

9

6

3

00

40

39

38

37

36

35

PLU/

46

45

44

43

42

41

SUB

52

51

50

49

48

47

SCALE

58

57

56

55

54

53

OPEN

TARE

64

63

62

61

60

59

70

69

68

67

66

65

TAX1

SHIFT

76

TAX

75

CONV

74

CHK

73

MDSE

SBTL

72

CA/AT

71

2) Example from the ER-A420 Default Key Layout:

RCPT 7 JRNL

14

6

5

4

3

2

1

13 20 27 34 41 48 55 62 69 76 83

12 19 26 33 40 47 54 61 68 75 82

11 18 25 32 39 46 53 60 67 74 81

10 17 24 31 38 45 52 59 66 73 80

9

8

21 28 35 42 49 56 63 70 77 84

16 23 30 37 44 51 58 65 72 79

15 22 29 36 43 50 57 64 71 78

L1

91

PRICE

SHIFT

90

@/FOR

89

7

88

4

87

1

86

0

85

L2

98

#/TM

97

.

96

8

95 9 102

5

94

2

93

00

92

L3

105

SCALE

104

CL

103

6

101

3

100

MDSE

SBTL

99

AUTO

112

RCPT

/PO

111

%

110

RFND

109

CH2

108

CH1

107

SBTL

106

Designs and specification are subject to change without notice Page 36 of 209

CASH

#

82

FS

SHIFT

81

FS

TEND

80

CH

79

SBTL

78

/NS

77

CASH

#

119

RA

118

(-)

117

VOID

116

TAX1

SHIFT

115

CHK

114

CA/AT

113

Page 40

File Allocation

Section-3: File Allocation

Designs and specification are subject to change without notice Page 37 of 209

Page 41

File Allocation

Memory Allocation

975 X YYYY

File No.

X: see the chart below

YYYY: see the chart below

MRS = see the chart below

Notes: (1) The maximum number for “YYYY” cannot be exceeded.

(2) The codes indicated are for PGM and REG mode operations

Departments 1 1-99 2 -digits 20 10

PLU/UPC 2 0-1500 6-digits 500 500

PBLU 3 0-999 4-digits 50 0

Cashier 4 1-20 2-digits 20 20

Number of Overlapped

KP Buffer 6 0 = Erase

.

Cashier

@

5 0: 0

Note: Same as

the number of

cashiers [**}

allocated

1 = Create

@

MRS DEFAULTS FILE NAME X YYYY Codes

ERA410 ERA420

2-digits 0 0

Same as

Reg Buffer

CASH

0 0

Designs and specification are subject to change without notice Page 38 of 209

Page 42

PERIPHERALS

Section-4: PERIPHERALS

Designs and specification are subject to change without notice Page 39 of 209

Page 43

PERIPHERALS

Overview – Cable & Communications Specifications

RS-232 connections are simple, universal and a supported data interface for the ER-A410 and

ER-A420 model ECRs. The standards for communications of 256kbps or less and line lengths of

15m (50 ft) or less will depend on the length and quality of the cable.

1. Specifications:

(1) Cable: 24 – 28 AWG, Shielded, twisted pair – (refer to the chart on the next page)

(2) Connector: D – Sub 9 pin (female type) connector.

(3) Baud Rate: (Please refer to each peripheral’s section)

2. Pin Outs:

(Please refer to each peripheral’s section)

3. ECR Pin Outs:

The DB-9 of the ER-A410 and ER-A420 follows EIA computer specifications for its pin outs as

shown below:

Designs and specification are subject to change without notice Page 40 of 209

Page 44

PERIPHERALS

4. Belden Cable Chart:

The chart below is the specs for a Belden cable that can be used for communications

RS232 Serial Cable

Maximum Distance from POS to Printer 50 ft. or less

Type Cable Twisted Pair

Wire Gauge 24 AWG / Shielded

Belden Number 9540

4. Cable Chart/Distances:

Typically, the recommended cabling distance length will be less than 25 feet when the data rate is

9600 bps or greater. If transmission errors occur, follow these procedures to determine the cause

of the problem:

1) Reduce the baud rate – when the preset is available.

2) Reduce the cable length – when the baud ate is fixed.

3) Use a cable with a lower capacitance per foot rating.

Designs and specification are subject to change without notice Page 41 of 209

Page 45

PERIPHERALS

Section – 1: Coin Dispenser

The following table shows the related PGM-Mode Job#s available for the ER-A410 and ER-A420

model ECRs when the Coin Dispenser is connected.

Scale

Mode Job# Description

2690 Channel Assignment

PGM-Mode

2510 Cashier Drawer Assignment

Note: The Telequip Transact coin dispenser is provided with the necessary connection cable as

part of the standard equipment

Designs and specification are subject to change without notice Page 42 of 209

Page 46

1. Cabling Pin Outs:

PERIPHERALS

UP-3301

D-SUB 9 (Female)

TeleQuip Coin

FG

RXD

TXD

DTR

S.G

DSR

RTS

CTS

CI

1

2

3

4

5

6

7

8

9

1

3

2

4

5

TXD

RXD

GND

2. Data Transmission:

- 7 bits ASCII code

- One Start bit

- Even Parity

- One Stop bit

- Baud Rate: 9600 bps (fixed)

3. Protocol

(ECR) (Coin)

EOT

“C”

<STX>XX<ETX><CC>

STATUS ACK

or

STATUS NAK

XX: Ten’s + ones

CC: Cents

Designs and specification are subject to change without notice Page 43 of 209

Page 47

PERIPHERALS

RS232 Channel Assignment - 2690

.

@

@

@

0002

@

SBTL

SBTL

CASH

CASH

2690

X: 1

A: Channel No for On-Line or Print All Data = 2/1/0

B: (Fixed) = 0

C: Channel No. for Scale = 2/1/0

D: Channel No. for Coin Dispenser = 2/1/0

MRS = 0000

X: 2

A: Channel No. for Scanner = 2/1/0

B: Channel No. for Kitchen Printer 1 = 2/1/0

C: Channel No. for Kitchen Printer 2 = 2/1/0

D: (Fixed) = 0

MRS = 0000

X: 3

B: Channel No. for Slip Printer = 2/1/0

C: (Fixed) = 0

D: Channel No. for CAT = 2/1/0

MRS = 0000

Channel No. 0 = No Connection

1 = RS-Port No. 1

2 = RS-Port No. 2

Note: Each Channel No. assignment may only have a single device assigned to it at any one time.

When a second or subsequent device is assigned to the same channel No., the “ENTRY

ERROR” occurs.

Channel Assignment for COIN DISPENSER:

2690 or

Designs and specification are subject to change without notice Page 44 of 209

.

0

X

ABCD

Bit No.

X : Bit No. 1- 3

ABCD : See Below

A: (Fixed) = 0

1 0001

Page 48

PERIPHERALS

Quick Steps – Coin Dispenser

To quickly setup the ER-A410/ER-A420 to interface with a coin dispenser, please refer to the

outlined procedures below:

No. Description Comments/Procedure

Step–1 Connect the Coin Dispenser CH–1 or CH–2

Step–2

Step–3

Step–4 PGM Job#2510 Verify that the Cashiers have a valid Drawer Assignment (1 or 2)

PGM Job#2690

Program Reset

2690 Æ [.] Æ [@] Æ 1 Æ @ Æ 0001 [SBTL] Æ [CA/AT] for CH–1)

or

2690 Æ [.] Æ [@] Æ 1 Æ @ Æ 0002 [SBTL] Æ [CA/AT] for CH–2)

Note: Must match the physical connection

• Place the SRV-Key counter-clockwise to 6 o’clock position

(SRV’ position)

• Count 5 seconds

• Turn SRV-Key clockwise to 7o’clock position (SRV po sit i on)

• Verify”***PROGRAM RESET has printed on the journal-side

tape.

Designs and specification are subject to change without notice Page 45 of 209

Page 49

PERIPHERALS

Section–2: Scale

The following table shows the related SRV and PGM-Mode Job#s available for the ER-A410 and

ER-A420 model ECRs when the Scale is connected.

Scale

Mode Job# Description

SRV-Mode

PGM-Mode

903–B Symbol of Scale Entry

903–C Unit of Weight for Scale Entries

906–D Fractional Quantities Entries

918–B Fractional Entries for Non-Scalable

Dept./PLU Items

950

2690 Channel Assignment

2110 Dept. Function Programming

2210 PLU Function Programming

2231 PLU Function Range Programming

2618 Scale Tare Table Programming

[SCALE] – Function #77

(OPEN TARE] – Function #78

Designs and specification are subject to change without notice Page 46 of 209

Page 50

1, Cabling Pin Outs:

PERIPHERALS

UP-3301

D-SUB 9 (Female)

Avery/NCI/Weightronix

D-SUB 9 (Female)

FG

RXD

TXD

DTR

S.G

DSR

RTS

CTS

CI

1

2

3

4

5

6

7

8

9

3

2

5

TXD

RXD

GND

2. Data Transmission:

- Bits ASCII Code

- Even Parity

- One Stop Bit

- Baud Rate: 9600 bps (fixed)

3. Protocol:

(ECR) (Scale)

COMMAND

RESPONSE

<Command> <Response>

W <STX>0XX.XX<CR>;LB

<STX>0XX.XX<CR>;KG

(Error)

<STX>Status byte><CR>

B7

Parity Bit

B6

Always

=

B5

Net Wt.

=

B4

Center

Of Zero

=

B3

Outside

Of Zero

=

Under

B2

Zero

=

B1

Out Of

Range

=

B0

Motion

Designs and specification are subject to change without notice Page 47 of 209

Page 51

PERIPHERALS

RS232 Channel Assignment - 2690

.

@

@

@

0020

@

SBTL

SBTL

CASH

CASH

2690

X: 1

A: Channel No for On-Line or Print All Data = 2/1/0

B: (Fixed) = 0

C: Channel No. for Scale = 2/1/0

D: Channel No. for Coin Dispenser = 2/1/0

MRS = 0000

X: 2

A: Channel No. for Scanner = 2/1/0

B: Channel No. for Kitchen Printer 1 = 2/1/0

C: Channel No. for Kitchen Printer 2 = 2/1/0

D: (Fixed) = 0

MRS = 0000

X: 3

B: Channel No. for Slip Printer = 2/1/0

C: (Fixed) = 0

D: Channel No. for CAT = 2/1/0

MRS = 0000

Channel No. 0 = No Connection

1 = RS-Port No. 1

2 = RS-Port No. 2

Note: Each Channel No. assignment may only have a single device assigned to it at any one time.

When a second or subsequent device is assigned to the same channel No., the “ENTRY

ERROR” occurs.

Channel Assignment for SCALE:

2690 or

Designs and specification are subject to change without notice Page 48 of 209

.

0

X

ABCD

Bit No.

X : Bit No. 1- 3

ABCD : See Below

A: (Fixed) = 0

1 0010

Page 52

PERIPHERALS

Quick Steps – Scale

To quickly setup the ER-A410/ER-A420 to interface with a Scale, please refer to the outlined

procedures below:

No. Description Comments/Procedure

Step–1 Connect the Scale CH–1 or CH–2

Step–2 SRV Job#903-B, C, D

Step–3 SRV Job#906-D 906 Æ [.] Æ [@] Æ xxx1 Æ [CA/AT]

Step–4 SRV Job#918

Step-5 SRV Job#950

Step-6

Step-7

Step-8

PGM Job #2690

Program Reset

PGM Job #2110

-and/orPGM Job#2210

903 Æ [.] Æ [@] Æ x030 Æ [CA/AT]

(For 3 Decimal Places) or

903 Æ [.] Æ [@] Æ x020 Æ [CA/AT]

(For 2 Decimal Places)

(For Fractional Entries)

918 Æ [.] Æ [@] Æ x0xx Æ [CA/AT]

(For Non-Scale Fractional Entries) or

918 Æ [.] Æ [@] Æ x1xx Æ [CA/AT]

(For Disallowing Non-Scale Fractional Entries)

• Place the [SCALE] Key (Function #77) on the keyboard

• Place the [OPEN TARE] Key (Function #78) on the keyboard

2690 Æ [.] Æ [@] Æ 1 Æ @ Æ 0010 [SBTL] Æ [CA/AT] for CH–1)

or

2690 Æ [.] Æ [@] Æ 1 Æ @ Æ 0020 [SBTL] Æ [CA/AT] for CH–2)

Note: Must match the physical connection

• Place the SRV-Key counter-clockwise to 6 o’clock position

(SRV’ position)

• Count 5 seconds

• Turn SRV-Key clockwise to 7o’clock position (SRV po sit i on)

• Verify”***PROGRAM RESET has printed on the journal-side

tape.

2110 Æ [.] Æ [@] Æ (Dept. No.) Æ @ Æ xyzxxx [SBTL] Æ [CA/AT]

–and/or-

2210 Æ [.] Æ [@] Æ (Dept. No.) Æ @ Æ xyz [SBTL] Æ [CA/AT]

Y = Tare Table No. (1–9)

Z = Scale Comp. /Enabled/Inhibited = 2/1/0

Designs and specification are subject to change without notice Page 49 of 209

Page 53

PERIPHERALS

Section–3: Slip

The following table shows the related SRV and PGM-Mode Job#s available for the ER-A410 and

ER-A420 ECRs when the Slip Printer is connected.

Slip Printer

Mode Job# Description

SRV-Mode

PGM-Mode

913–B Escape Compulsory SLIP & Validation

928–A Printing of Slip Logo

Val. Message Printing on Slip

928–B

928–C

928–D

950

2690 Channel Assignment

2320 Media Key Function Programming

2615 Validation Limitation Programming

Header Line Printing on Slip when Reorder Printing

Print PLU Items on Slip when $0.00

Set PLU Items Print on Slip

PB/NBAL Prints on Slip

Slip Print Compulsion System

[PRINT]–Function #33

[SLIP]–Function #34

Designs and specification are subject to change without notice Page 50 of 209

Page 54

PERIPHERALS

1. Cabling Pin Outs:

ECR SLIP PRINTER

9-Pin D–Sub 25-Pin D–Sub

2. Data Transmission:

- 8 Bits ASCII Code

- No Start Bit

- Non Parity

- 1 Stop Bit

- Baud Rate: 9600 bps (fixed)

*Handshaking: DTR/DSR Control

Designs and specification are subject to change without notice Page 51 of 209

Page 55

TM-U295 Switch–1Settings:

Switch Contents On Off Setting

SW1-1 Data Receive Buffer Ignored Prints “?” OFF

SW1-2 Receive Buffer Capacity 35 bytes 512 Kbytes OFF

SW1-3 Handshaking XON/XOFF DTR/DSR OFF

SW1-4 Data Word length 7 bits 8 bits OFF

SW1-5 Parity Check With Parity Without Parity OFF

SW1-6 Parity selection Even Parity Odd Parity OFF

SW1-7 Baud Rate Selection (*1) OFF

SW1-8 Baud Rate Selection (*1) OFF

SW1-9 DSR (#6) Reset Effective Invalid OFF

SW-10 Init (#25) Reset Effective Invalid ON

(*1): SW1-7, 1-8 Definitions

1200 bps ON ON

2400 bps OFF ON

4800 bps ON OFF

9600 bps OFF OFF

PERIPHERALS

ROM Version 1.08

Rate SW1-7 SW1-8

Designs and specification are subject to change without notice Page 52 of 209

Page 56

PERIPHERALS

RS232 Channel Assignment - 2690

.

@

@

@

0200

@

SBTL

SBTL

CASH

CASH

2690

X: 1

A: Channel No for On-Line or Print All Data = 2/1/0

B: (Fixed) = 0

C: Channel No. for Scale = 2/1/0

D: Channel No. for Coin Dispenser = 2/1/0

MRS = 0000

X: 2

A: Channel No. for Scanner = 2/1/0

B: Channel No. for Kitchen Printer 1 = 2/1/0

C: Channel No. for Kitchen Printer 2 = 2/1/0

D: (Fixed) = 0

MRS = 0000

X: 3

B: Channel No. for Slip Printer = 2/1/0

C: (Fixed) = 0

D: Channel No. for CAT = 2/1/0

MRS = 0000

Channel No. 0 = No Connection

1 = RS-Port No. 1

2 = RS-Port No. 2

Note: Each Channel No. assignment may only have a single device assigned to it at any one time.

When a second or subsequent device is assigned to the same channel No., the “ENTRY

ERROR” occurs.

Channel Assignment for SLIP PRINTER:

2690 or

Designs and specification are subject to change without notice Page 53 of 209

.

0

X

ABCD

Bit No.

X : Bit No. 1- 3

ABCD : See Below

A: (Fixed) = 0

3 0100

Page 57

PERIPHERALS

Quick Steps – Slip Printer

To quickly setup the ER-A410/ER-A420 to interface with an Epson TM-U295 Slip Printer, please

refer to the outlined procedures below:

No. Description Comments/Procedures

Step–1 Connect the Slip Printer CH–1 or CH–2

Step–2 SRV Job#913-B

Step–3 SRV Job#928- A, B, C, D

Step-4 SRV Job#950

Step-5

Step-6

Step-7

PGM Job #2690

Program Reset

PGM Job #2615

913 Æ [.] Æ [@] Æ x1xx Æ [CA/AT]

(For Escaping Compulsory Slip or Validation) or

913 Æ [.] Æ [@] Æ x0xx Æ [CA/AT]

(For No Escape of Compulsory Slip or Validation)

928 Æ [.] Æ [@] Æ ABCD Æ [CA/AT]

A: Slip Logo Text Prints Yes/No = 1/0

B: VP Message Prints on Slip Yes/No = 2/0

B: C: Header Line on Slip Prints Reorder No/Yes = 1/0

C: Prints $0.00 PLU Items on Slip No/Yes = 4/0

C: Prints PLU Text of Set PLU Links on Slip No/Yes = 2/0

D: Print the PB/NBAL on Slip No/Yes = 4/0

D: Compulsory Slip System PBLU Only/Every Trans/By Media

Yes/No = 2/1/0

• Place the [SLIP] Key (Function #34) on the keyboard

• Place the [PRINT] Key (Function #33) on the keyboard

2690 Æ [.] Æ [@] Æ 1 Æ @ Æ 0100 [SBTL] Æ [CA/AT] for CH–1)

or

2690 Æ [.] Æ [@] Æ 1 Æ @ Æ 0200 [SBTL] Æ [CA/AT] for CH–2)

Note: Must match the physical connection

• Place the SRV-Key counter-clockwise to 6 o’clock position

(SRV’ position)

• Count 5 seconds

• Turn SRV-Key clockwise to 7o’clock position (SRV po sit i on)

• Verify”***PROGRAM RESET has printed on the journal-side

tape.

2615 Æ [.] Æ [@] Æ VVXXAB Æ [SBTL] Æ [CA/AT]-

VV: Initial Line Feed

XX: Max Slip Line No.

A: No. of Times for Validation when set for Compulsory = 0–9

B: No. Line Feed after Tray SBTL key is depressed = 0–9

Designs and specification are subject to change without notice Page 54 of 209

Page 58

PERIPHERALS

Section–4: Remote Kitchen Printer

The following table shows the related SRV and PGM-Mode Job#s available for the ER-A410 and

ER-A420 ECRs when a Remote Printer is connected.

Remote Kitchen Printer

Mode Job# Description

SRV-Mode

PGM-Mode

918–A Output of Set PLU to KP

918–B Red Color Print on KP when PLU/UPC’s are ZERO price

items

918–C Like Items Consolidation on KP

918–C

926–A Sending Direct VOID and Past Item VOID Data to the KP

926-B Sending Refund Data to the KP

929-A KP Print Format when Finalizing (Expediter Print Format)

950

975 #6 KP Buffer

2690 Channel Assignment

2692 Kitchen Printer Programming

3653 Back Up Kitchen Printer Programming

3654 Kitchen Printer Name Programming

3655 Kitchen Printer Print Format Programming

3656 Chit Receipt Print Format Programming

2118 Department KP Print Assignment Programming

2218 PLU/UPC KP Print Assignment Programming

2328 Media Key Print Assignment Programming

Dept/PLU and UPC (EAN) Text Print on KP in Double

Size Character

[RP Send]–Function #85

Designs and specification are subject to change without notice Page 55 of 209

Page 59

PERIPHERALS

1. Cabling Pin Outs:

ECR EPSON PRINTER

9-Pin D–Sub 25-Pin D–Sub

2. Data Transmission:

- 8 Bits ASCII Code

- No Start Bit

- Non Parity

- 1 Stop Bit

- Baud Rate: 9600 bps (fixed)

*Handshaking: DTR/DSR Control

Designs and specification are subject to change without notice Page 56 of 209

Page 60

Kitchen Printer Programming - 2692

2692

X: KP No. KP2/KP1 = 2/1

A: Logo Text Print Yes/No = 1/0

B: Auto Cut Yes/No = 1/0

C: Type of Printer

TM-T88III+Logo/TM-T88III/TM-U230/TM-U220 = 3/2/1/0

Back Up Kitchen Printer Programming - 3653

3653

X: KP No. KP2/KP1 = 2/1

Y: 2nd KP (Back Up) KP2/KP1/Nothing =2/1/0

MRS = 0

.

0

X

ABC

KP No.

.

0

X

Y

KP No.

@

@

PERIPHERALS

@

@

SBTL

SBTL

CASH

CASH

Designs and specification are subject to change without notice Page 57 of 209

Page 61

Kitchen Printer Name Programming - 3654

3654

X: KP No. KP2/KP1 = 2/1

KP Name: Maximum 12 Characters

Characters can be entered by using the character keys or by character code entry. The key

sequence for entering character codes is as follows:

XXX Æ [00] key XXX: Character Code (3 digits)

MRS = Spaces

Designs and specification are subject to change without notice Page 58 of 209

.

Space

X Characters

(Max 12)

KP No.

@

PERIPHERALS

@

SBTL

CASH

Page 62

Kitchen Printer Print Format Programming - 3655

3655

X: KP No. KP2/KP1 = 2/1

A: Taxable Status Print Yes/No =1/0

B: Qty Print when Qty is “1” Yes/No =1/0

C: Dept /PLU/UPC (EAN) Code Print Yes/No =1/0

D: Unit Price Print Yes/No =1/0

E: Total Amount Print Yes/No =1/0

MRS = 00000

Note: [Taxable Status Print] = “YES” is effective when [AMOUNT] Print = “YES”

Designs and specification are subject to change without notice Page 59 of 209

.

0

X

ABCDE

KP No.

@

PERIPHERALS

@

SBTL

CASH

Page 63

Chit Receipt Format Programming - 3656

3656

A: Taxable Status Print Yes/No =1/0

B: Qty Print when Qty is “1” Yes/No =1/0

C: Dept /PLU/UPC (EAN) Code Print Yes/No =1/0

D: Unit Price Print Yes/No =1/0

E: Total Amount Print Yes/No =1/0

MRS = 00000

Note: [Taxable Status Print] = “YES” is effective when [AMOUNT] Print = “YES”

Designs and specification are subject to change without notice Page 60 of 209

.

0

ABCDE

@

PERIPHERALS

SBTL

CASH

Page 64

PERIPHERALS

RS232 Channel Assignment - 2690

.

@

@

@

0200 (KP #2)

@

SBTL

SBTL

CASH

CASH

2690

X: 1

A: Channel No for On-Line or Print All Data = 2/1/0

B: (Fixed) = 0

C: Channel No. for Scale = 2/1/0

D: Channel No. for Coin Dispenser = 2/1/0

MRS = 0000

X: 2

A: Channel No. for Scanner = 2/1/0

B: Channel No. for Kitchen Printer 1 = 2/1/0

C: Channel No. for Kitchen Printer 2 = 2/1/0

D: (Fixed) = 0

MRS = 0000

X: 3

B: Channel No. for Slip Printer = 2/1/0

C: (Fixed) = 0

D: Channel No. for CAT = 2/1/0

MRS = 0000

Channel No. 0 = No Connection

1 = RS-Port No. 1

2 = RS-Port No. 2

Note: Each Channel No. assignment may only have a single device assigned to it at any one time.

When a second or subsequent device is assigned to the same channel No., the “ENTRY

ERROR” occurs.

Channel Assignment for SCALE:

2690 or

Designs and specification are subject to change without notice Page 61 of 209

.

0

X

ABCD

Bit No.

X : Bit No. 1- 3

ABCD : See Below

A: (Fixed) = 0

2 0100 (KP#1)

Page 65

PERIPHERALS

Quick Steps – Remote Kitchen Printer

To quickly setup the ER-A410/ER-A420 to interface with a Remote Kitchen Printer, please refer to

the outlined procedures below:

No. Description Comments/Procedures

Step–1 Connect the Remote Printers KP#1 on CH–1 or KP#2 on CH–2

Step–2 SRV Job#918-A 918 Æ [.] Æ [@] Æ 4xxx Æ [CA/AT]

Output of Set PLU to KP

Step-3 SRV Job#918-B 918 Æ [.] Æ [@] Æ x2xx Æ [CA/AT]

Red Color Print on KP when PLU/UPC’s are ZERO price items

Step-4 SRV Job#918-C 918 Æ [.] Æ [@] Æ x0xx Æ [CA/AT]

Like Items Consolidation on KP

Step-5 SRV Job#918-C

Step-6 SRV Job#926-A 926 Æ [.] Æ [@] Æ 3xxx Æ [CA/AT]

Step–6 SRV Job#926-B 926 Æ [.] Æ [@] Æ x0xx Æ [CA/AT]

Step-7 SRV Job#929-A 926 Æ [.] Æ [@] Æ 1xxx Æ [CA/AT]

Step-8 SRV Job#950

Step-9 SRV Job#975 Create #6 KP Buffer

Step-10

Step-11

Step-12

Step-13

PGM Job #2690

PGM Job #2692

Program Reset

Other PGM2 Mode Programming

918 Æ [.] Æ [@] Æ x1xx Æ [CA/AT]

Dept/PLU and UPC (EAN) Text Print on KP in Double Size

Character

Sending Direct VOID and Past Item VOID Data to the KP

Sending Refund Data to the KP

Detail KP Print Format when Finalizing (Expediter Print Format)

• Place the [RP Send] Key (Function #85) on the keyboard if

required.

Note: The RP Send Key can send an item to the remote KP before

finalizing the transaction.

2690 Æ [.] Æ [@] Æ 2 Æ @ Æ 0100 [SBTL] Æ [CA/AT] for CH–1)

or

2690 Æ [.] Æ [@] Æ 2 Æ @ Æ 0200 [SBTL] Æ [CA/AT] for CH–2)

Note: Must match the physical connection

2692 Æ [.] Æ [@] Æ X Æ @ Æ ABC [SBTL] Æ [CA/AT]

X: KP No. KP2/KP1 =2/1

A: Logo Text Print Yes/No =1/0

B: Auto Cut Yes/No =1/0

C: Type of Printer

TM-T88III+Logo /TM-T88III/TM-U230/TM-U220 = 3/2/1/0

• Place the SRV-Key counter-clockwise to 6 o’clock position

(SRV’ position)

• Count 5 seconds

• Turn SRV-Key clockwise to 7o’clock position (SRV po sit i on)

• Verify”***PROGRAM RESET has printed on the journal-side

tape.

3653 Æ [.] Æ [@] Æ X Æ @ Æ Y Æ [SBTL] Æ [CA/AT]

X: KP No. KP2/KP1 = 2/1

Y: Back Up Printer KP2/KP1/Nothing = 2/1/0

3654Æ [.] Æ [@] Æ X Æ @ Æ Name (12 Max) Æ [SBTL] Æ [CA/AT

X: KP No. KP2/KP1 = 2/1

Characters can be entered by using the character keys or numeric

keys.

Designs and specification are subject to change without notice Page 62 of 209

Page 66

PERIPHERALS

Step-14

Other PGM2 Mode Programming

XXX Æ 00 Key XXX: Character Code (Digits)

3655 Æ [.] Æ [@] Æ X Æ @ Æ ABCDE Æ [SBTL] Æ [CA/AT

X: KP No. KP2/KP1 = 2/1

A: Taxable Status Print Yes/No = 1/0

B: Qty Print when Oty is 1 Yes/No = 1/0

C: Dept/PLU/UPC(EAN) Code Print Yes/No = 1/0

D: Unit Price Print Yes/No = 1/0

E: Total Amount Print Yes/No = 1/0

MRS = 00000

3656 Æ [.] Æ [@ Æ ABCDE Æ [SBTL] Æ [CA/AT

Chit Receipt Format

A: Taxable Status Print Yes/No = 1/0

B: Qty Print when Oty is 1 Yes/No = 1/0

C: Dept/PLU/UPC (EAN) Code Print Yes/No = 1/0

D: Unit Price Print Yes/No = 1/0

E: Total Amount Print Yes/No = 1/0

MRS = 00000

Note: “TAXABLE STATUS Print = YES is effective when

“AMOUNT” print = YES

Designs and specification are subject to change without notice Page 63 of 209

Page 67

PERIPHERALS

Overview: Scanner (Barcode Reader)

The new ER-A410 and ER-A420 model ECRs are capable of scanning the following UPC (EAN)

codes.

1) UPC (EAN) Available Codes:

UPC-A (Number System Character 0,2,3,4,5)

0 * * * * * “ “ “ “ “ C/D

* Maker Code “Item Code

2 “ “ “ “ “ ‘ * * * * C/D

“Item Code ‘P/C-Price Check Digit *Price

Note: Maximum Price = $99.99

3 C/D

Use for National Drug Codes or National Health Retail Item Codes

4 * * * * * * * * * * C/D

*Free Format

5 * * * * ‘ ‘ ‘ “ “ C/D

*Maker Code ‘Family Code “Coupon Price

UPC-E

UPC-E is a zero-suppressed version of UPC-A that conforms to the UPS-E Standards.

EAN 13

* * “ “ “ “ “ ‘ ‘ ‘ ‘ ‘ C/D

*Nation Code “ Maker Code ‘Item Code

EAN-13 plus Add-On

* * “ “ “ “ “ ‘ ‘ ‘ ‘ ‘ C/D

**** *

*Nation Code “Maker Code ‘Item Code *Add On Codes (5 Digits)

* * “ “ “ “ “ ‘ ‘ ‘ ‘ ‘ C/D

**

*Nation Code “Maker Code ‘Item Code *Add On Codes (2 Digits)

Designs and specification are subject to change without notice Page 64 of 209

Page 68

PERIPHERALS

EAN8

Ordinary EAN-8 Codes

40 123 12 7

AB CDE FG H

AB: Nation Code