Page 1

CODE: OOZER31001M.M

—

—

Page 2

ENGLISH .....................

DEUTSCH. .....................Seite 59

.Page 1

FRAN~AIS. ....................Page

ESPANOL, .....,...............Pagina181

119

Page 3

CONTENTS

Page

GENERAL

1.

SUMMARY OF THE ER-3100 OPTIONS

2.

BEFORE INSTALLINGOPTIONS

3.

PRINTING OUT THE SRV-MODE AND PGM-MODE PROGWS .............

4.

REMOVING THE TOP CABINET AND MAIN DRAWER

5.

Removing the top cabinet

5.1

Replacing the top cabinet

5.2

Removing the main drawer

5.3

Replacing the main drawer .................................

5.4

Rs-232c INTERFACE (ER-31RS2)

6.

6.1

Outline

6.2

Installationprocedure .....................................

*0*9**9***0*90***0******0*.*.........................

● *.***....********,****,*...**

...............

● .*****.● **..*..● *.*

.........**.......**

.......

● .*..*.*..................● *.*.*.*

...............

● .**.*.*● *.**.***● ....*.**..*.*.**....***.**.****,**

● ..***.*.*.*..**.*..*.*.● ..*

● *.**..*● .*.*.......

● **..*............*****.*..****.

1

2

4

6

10

10

11

11

12

.

14

14

15

6.3

Operationalcheck

6.4

Programming

7.

RAM MEMORY CHIP (ER-46PLI)

7.1

Outline

7.2

Installationprocedure .....................................

7.3

Operationalcheck

7.4

Programming

● *.***...*...*.● ..*....● .**.*..● *..*...● ...*....

● ****.*.● ***O.***● .9..*.................**.m● *.**.**

.......

.**.***

● **.*.*● *.**..*● .**...*..**...*● .******...

● .......● . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

● *****..● .**.*.*● .**.*..● ..*.*..● .*

.*..*.*

● ..*..*....***...***.**....

-i-

20

21

35

35

35

36

38

Page 4

8.

PRESETS LOADER

8.1

Outline *..*..*..*..*...*....*..***.**.**....m.*.*****0***.*

8.2

Installationprocedure

8.3

Operationalcheck

.**.**......*e*e**e******a**********a**e*a*.e*

● .*.*.......*.*.***m*.*me**.*me*.e***

.*.*.....******e*****m***me***e.**be***.**

Yage

42

42

42

44

8.4

8.5

8*6

9.

9.1

9.2

9.3

9.4

10.

10.1

10.2

10.3

Programming ................................................

Data sending and receiving .................................

Use of the ER-OIFD 3.5-inch floppy disk unit

REMOTE DMWER (ER-37DW3)

Outline

● ...*............● .....*...**.*..*....*.****● *******

Installationprocedure

Operationalcheck

● ***.***● ..*..,.*● **.....*● .*.****.● ******

.***..*

● *.*....● ..*..***.**.**.**● *.**.***● *

● ..*..*.● .**..*.● .**..*.● .*..

8****.**.*..*..

Modificationof the PGM-mode program .......................

MODE SWITCH (ER-31ml/~2/~3/~4/~5) ....OOO..eoeo=.oco....

Outline

Installationprocedure

Operationalcheck

.....**...........................*.*.......*.*.....

...............

● ....*.............*..*........● ....***● *.

● ......*...**.*...*..*

45

46

47

49

49

49

52

53

54

54

54

57

- ii -

Page 5

1. GENERAL

Table 1 shows all options availablefor the ER-3100 cash

1.

register.

Some options require removing the top cabinet or modifying the

2.

SRV-modeand PGM-mode programs.

Therefore,

OPTIONS” on page 4 before installingany option.

be sure to consult Section3 “BEFORE INSTALLING

–l–

Page 6

2. SUMMARYOF THE ER-31OOOPTIONS

Table 1

Name

LS-232C

Lnterface

M memory

:hip of the PLU capability.

tiodeswitch

lemote

~rawer

?resets

Loader

ER-31RS2 This option is the RS-232C

ER-46PL1

ER-31MD1

ER-31MD2

ER-31MD3

ER-31MD4

ER-31MD5

ER-37DW3

ER-OIFD

ER-52CB

Model name

interfacethat provides data

transferbetween the ER-31OOS

or between the ER-31OO and a

personal computer or kitchen

printer.

This option enables the expansiom

This option is available in

100 varieties.

A single remote drawer can be

connectedto the ER-31OO.

3.5-inch floppy disk unit

S10 interfacecable

Remarks

ER-67LC

;oin case ER-38CC

;oin case

:over

3attery

In addition to the above options, those shown in Table 2 on the next

page are optionallyavailable through the Parts Department.

ER-38cvl/cv2/cv3/cv4/cv5

ER-30BT

Level converter

–2–

Page 7

Table2

Name

Journal near-end sensor

Validationsensor

Drawer open sensor*

I

Water-proofpush-buttoncashier switch cover

Mode switch key grip cover (for the operator key)

Service key for the optionalmode switch (ER-31MD)

Service key for the standardmode switch

Drip-proof printer cover

Real key one-hole type clerk switch (four kinds)

* The standard cash drawers of the machines for some destinationsare

equippedwith no drawer open sensor.

Part code

DKIT-8226RCZZ

DKIT-8227RCZZ

DKIT-8331RCZZ

GCOVB6872RCZZ

LKGIM7126RCZZ

LKGIM7094RCZZ

LKGIM7113RCZZ

DKIT-8322Rczz

DKIT-8321RCZZ

\.

–3–

Page 8

3. BEFORE ~STALLING OPTIONS

If you install any option in the ER-31OO register already in use,

you must have a Z reading

the installation.

If the register is not reset, sales data stored in the register

may be destroyed.

Print out the SRV-mode and PGM-mode programs before installing

2.

any option.

installation.

For the printout procedure refer to Section 4 “PRINTING OUT THE

SRV-MODEAND PGM-MODE PROGRAMS” on page 6.

If you install optional expansionRAMs and/or ROM (for the

3.

ER-31RS2) in the ER-31OO registeralready in use, perform data

saving for memory protectionby using the S10 interface in

advance. After the option(s)has been installed,perform data

loading for restoringmemory contents.

LOADER” for the data saving/loadingprocedure. It is advisable

to perform the above data saving when installingother options.

As a safety measure, be sure to turn the mode switch to the OFF

4.

It may be necessary to modify each program after

performedby its user before

See Section 8 “PRESETS

performing

position and unplug

If you do not unplug the register, the transformerPm will

remain on.

The ER-31OO is equippedwith various SRV-mode functions to aid

5.

you in installing the options.

than those shown in each of the followingsections, so that data

stored is not destroyed.

To install any options other than the remote drawer and presets

6.

loader, you need to remove the top cabinet. Please read 5.1

“Removing the top cabinet”under Section 5 “REMOVING ~E TOP

CABINET AND MAIN DRAWER~ on page 10.

drawer or ER-31RS2 interfacecable,

drawer. Please read 5.3 “Removingthe main drawer” on page 11.

the registerbefore installingany

Never enter any job numbers other

To install the remote

you need to remove the main

–4–

option.

Page 9

Model

name

ER-46PLl

Removal of the

top cabinet

needed

Table3

S10 interface

needed

Modificationof

the SRV-mode and

PGM2-modeprograms

needed

*

Service key

needed

ER-31RS2

ER-31MD1

ER-31MD2

ER-31MD3

ER-31MD4

ER-31MD5

ER-37DW3

ER-52CB

ER-67LC

&

ER-OIFD

ER-38CC

ER-38CV1

IER-38cv2I

ER-38CV3

ER-38CV4

ER-38CV5

needed

needed

not needed

not needed

not needed

I

not needed

not needed

not needed

needed

needed

not needed

needed

not needed

needed

needed

needed

needed

(supplied)

needed

not needed

needed

not needed

I I I

not needed

not needed

needed

needed

(for ER-31MD)

needed

—

needed

needed

needed

Hot needed

not needed

–5–

Page 10

4.

P~~G OUT THE SRV-MODE AND PGM-MODEPROGWS

The

1.

(1) Programmodification (SRV or PGM mode)

SRV-modeand PGM-mode programmingof the ER-31OO relies on

job numbering system.

the

PGM-mode programs,follow the proceduresbelow.

For a printout of the SRV-mode and

Job number

(2) Program printout (SRV or PGM mode)

Job number~

2.

It is necessary to print out the current SRV-modeand PGM-mode

programsusing the followingproceduresbefore installingany

option.

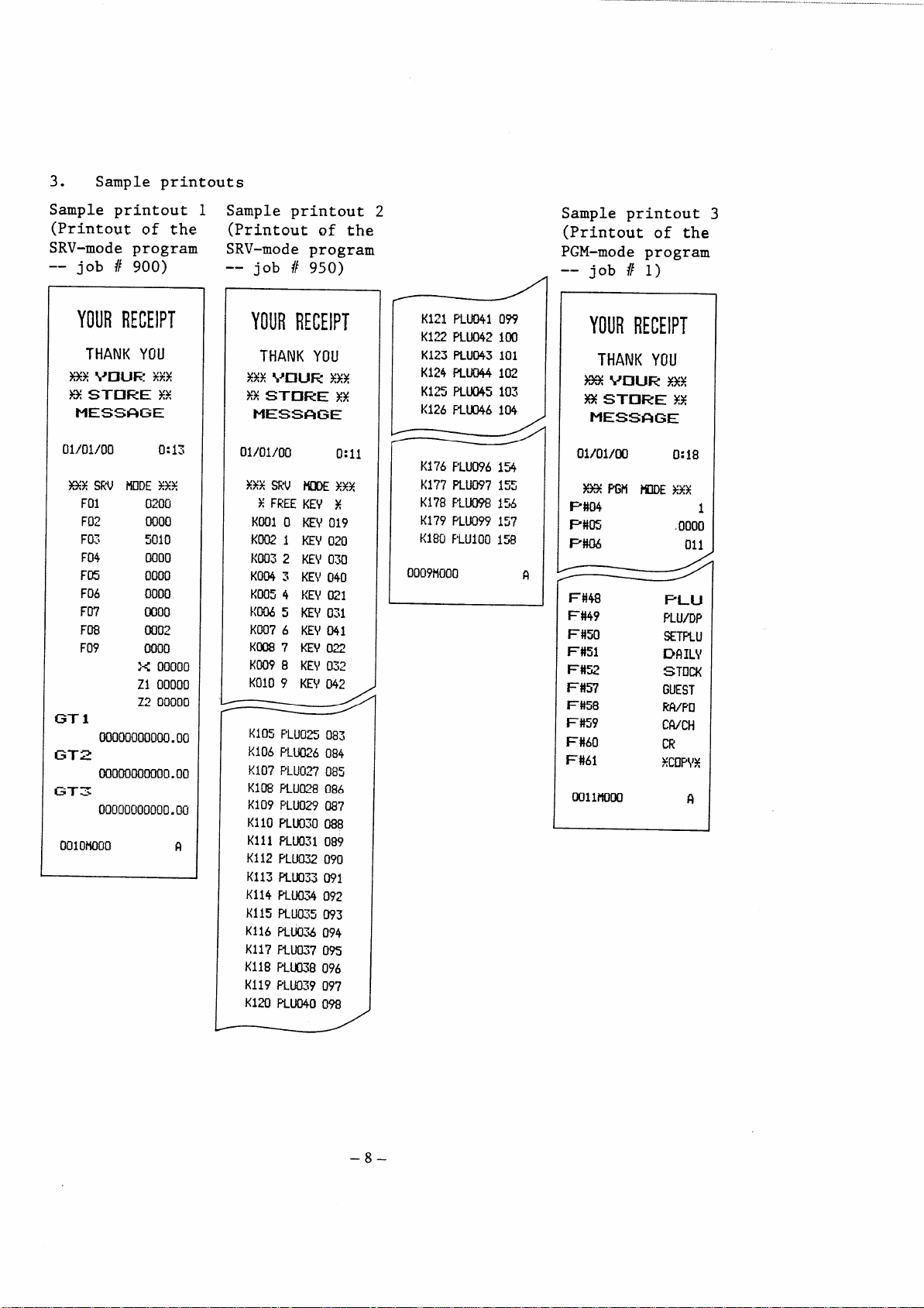

(1) Printing out the SRV-mode program

Put the service key in the mode switch and turn it to the SRV

position.

@ Full item printout of the SRV-modeprogram -- job number 900

9oo~ x ~

Refer to sample printout 1, page 8.

@ Printoutof key position codes -- job number 950

950~

Refer to sample printout 2, page 8.

(2) Printing out the PGM-mode program

Turn the mode switch to the PGM position.

—-m-m~

m—--m

E

m—-m

m

Data~TL

D

@ Printout of function information-- job number 1

1~

m~m

Refer to sample printout 3, page 8.

@ Printout of departmentalinformation-- job number 10

~~~

10

Refer to sample printout 4, page 9.

m

–6–

Page 11

@ Printout of PLU information-- job number 20

Start PLU

code

Refer to sample printout 5, page 9.

@ Printout of set PLU information--

23~

Refer to sample printout 6, page 9.

@ printout of cashier numbers --

40—~~

Refer to sample printout 7, page 9.

m—-m

m

End PLU

code

job n~mber A()

job ~um~er 23

–7–

Page 12

3. Sample printouts

Sample printout 1

(Printoutof the

SRV-modeprogram

-- job # 900)

YOURRECEIPT

01)01/00

HXSRV ~DE Y++

F(I1

Ftt2

Fo~

F04 0000

FE

F06 0000

F07

F08

F09

GT1

Ooooooooooo.oo

GT2

Ooooooooooo.oo

G-T3

00000000000.00

Oolomoo

0:13

a~fj~

0050

5010

Oooo

0000

~o~

0000

:< 00000

ZI 00000

Z2 00000

R

Sample printout 2

(printoutof the

SRV-modeprogram

-- job # 950)

YOURRECEIPT

01/01/00

K105F’LU025083

RI06F’L~96 o84

K107F’LLJ027085

K108RU028 086

KI09 PLU029087

Kl10F’LU02d088

KillF’LU031of39

K112 F’LU032090

K113 Ru033 WI

K114PLU’i 09z

mua~s093

K115

K116RU074094

K1l?F’Lu037

Kii8R1.K138096

K119PLU039097

K120F’LuD400?8

0:11

09S

K121PLU04i099

KlZPLU042im

K123FLU043101

Ki24fiU044102

K125RU045103

KI26F’LUD46104

K176F’LU09613

K177PLU097155

K17SF’LU0981%

K179FLU099157

K180

F’LU1OOIW

Ooo?tlooo

Sample printout 3

(Printoutof the

PGM-mode program

-- job # 1)

YOURRECEIPT

ol/ol/cnl

I P#04

P#m

I

I F’#06

9

F#48

F#49

F#50

F#51

F#W

1=#57

F#58

F#59

F#60

F#61

Oollmoo

0:18

1

.0000

011

–8–

Page 13

Sample printout 4

(Printoutof the

PGM-mode program

-- job # 10)

Sample printout 5

(Printoutof the

PGM-mode program

-- job # 20)

Sample printout 6 Sample printout 7

(Printoutof the

PGM-mode program

-- job # 23)

(Printoutof the

PGM-mode program

--job #40)

YOURRECEIPT

01/01/00

Y33PGN

Iml

mlPLu

Z#Gl

WLU

Mnl

mTPLu

4#al

Oo4PLu

5#Ql

WJPLU

$#01

O06PLU

7#Ql

O07PLU

8#ul

O08PLU

WI

098PLu

99#1

099PLu

lmcll

100PLU 0.00

oo18m

0:24

WE%%X

SET

-0.01

SET

-0.m

SET

-0.03

SET

-0.04

SET

-o.m

0.06

0.07

0.08

0.00

0.00

$

YOURRECEIPT

SET

-0.01

mu 10

PLu11

PLu12

PLU 13

PLu 14

SET

-0.02

PLu 8

F’LU 9

PLU 10

SET

-0.03

SET

-0.04

SET

-0.05

SET

0.00

F’LU92

PLU 9S

PLu 94

fi

YOURRECEIPT

01/01/00

0:26

–9–

Page 14

5. REMOVING THE TOP CABINET AND MAIN DRAWER

5.1 Removing the top cabinet (Fig. 1)

1. Turn the mode switch to the OFF position and unplug the cash

register.

Fix the front of the key sheet to the top cabinet by attaching

tape to two locations.

2. Raise the customer display by pulling it in the direction of the

arrow A.

Remove the two screws situated on the right and left sides of the

3.

top cabinet.

back of the cabinet.

4. Remove the top cabinet by moving it in the directions of the

arrows B, C, and D in this sequence,

Then remove the printer cover and the screw at the

(Fig. 1)

h

‘/

Fix

n

‘\

A

..

\

–lo–

Page 15

5.2 Replacing the top cabinet

Replace the top cabinet in the reverse order of removing,

When replacing the cabinet,

use care to prevent the heat sink

from catching the cables that connect the display PWB and main

Pm.

Also, prior to fixing the top cabinet make sure the interface

cable between the display PWB and the main PWB is securely

connected to the socket on the main PWB.

5.3 Removing the main drawer

1. Remove the two screws from the bottom of the drawer.

(Fig. 2)

Fig. 2

2.

Move the main unit forward (in the direction of the arrow a) and

lift upwards (the arrow b).

3.

Disconnect the drawer connectioncable and grounding strap.

(Fig. 3)

–11–

Page 16

Fig. 3

5.4 Replacing the main drawer

1. Reconnect the drawer connectioncable and grounding strap.

2.

Fit the pawls on the bottom of the main unit into the holes in

the drawer by moving the main unit in the directionof the arrow

c and move it backward (in the direction of the arrow d).

(Fig. 4)

Fig. 4

– 12–

Page 17

Secure the drawer to the main unit by using the two screws

3.

removed in step 1 of 5.3.

(Fig. 5)

I

Fig. 5

–13–

Page 18

6. RS-232C INTERFACE (ER-31RS2)

6.1

Outline

0

EIA (ElectronicsIndustriesAssociation)standard RS-232C is

associatedwith the transfer of binary serial data, control

signals, and timing signalsbetween

0

The RS-232C interfaceis one of the

the exchange of informationbetween

modems and data terminals.

devices generally used for

a computer and a peripheral

device.

0

This interface (ER-31RS2)was designed to conform to the EIA

standard,but in particularit was designed for connection

between the ER-31OO and a data processingmachine.

0

It becomes necessary to set communicationspecificationsof the

ER-31RS2 (e.g. baud rate) matched to those of the data processing

machine, when the ER-31RS2 is connectedwith a data processing

machine that is equippedwith the RS-232C2 interface.

0

The jumper-switch (Jl

- J8) on the ER-31Rs interface circuit

board must be used to choose the specifications.

0

Refer to “RS-232C Specificationbook” publishedby Engineering

Department,

ElectronicsIndustriesAssociation (EIA), for details

of RS-232C requirements.

Com~onents

The ER-31Rs2 consistsof the followingcomponents.

1) Interfaceboard unit (CPWBE6951RC06)

2) Control ROM (VH127256R223A)

Note: The version of the control ROM is indicatedby the last

characterof its part code.

(This control ROM is version A.)

3) Connectingcable (QCNW-7059RCZZ)

4) Others

A) Ferrite core (RCORF6629RCZZ)

2 pcs.

B) Connector spacer for mini pitch (PSPAB2343RCZZ)2 pcs.

Connector spacer for inch pitch (PSPAB2333RCZZ) 2 pcs.

C) Screw (XUPSD30P08000)

(XBPSD30P06KSO)

–14–

2 pcs.

2 pcs.

Page 19

D) Nut (XNESD26-20000)

2 pcs.

E) Spring washer (XWSPN26-06000)

F) Grounding cable (QCNW-6791RCZZ)

Note: If the machine is equippedwith grounding cable, it is

not necessary to connect this cable (Fig. 9).

The cable and connector to be connected to the external

equipmentneed to be procured locally.

For the connector to be attached to the ER-31RS2 connecting

cable, use either of the followingthat can be mounted on the

bottom cabinet of the ER-31OO.

0 Mini pitch DB-C6-J1O-1 (JAEmake) (SHARPpart code:

LCHSM6656RCZZ)

“ Inch pitch DB-C6-JIO-2 (JAE make) (SHARP part code:

LCHSM6657RCZZ)

Use a shielded cable for connectingcable.

6.2

Installationprocedure

Prior to installingthe ER-31RS2 perform data saving for memory

protection

by using the S10 interface. For the data

2 pcs.

1 pc.

saving

procedure,

Remove the

1.

see Section 8 “PRESETSLOADER”.

top cabinet and main drawer.

(Refer to Section 5 “

REMOVING THE TOP CABINET AND MAIN DRAWER”.)

2.

Installationof the control ROM.

Remove the RAM PWB unit from the main PWB and connect the control

ROM to the ROM3 socket on the main PWB.

(Note that the control

ROM is placed in the same directionas the ROM1 and ROM2.)

After the control ROM has been installed,replace the RAM PWB

unit.

–15–

Page 20

Servicebattery

RSTs

\

~RAM PWBunit

M

Notes: 1. The connectorsof the RAM PWB unit are both taped so

that it can resist vibrationsduring transportation.

Remove the tapes from the connectorsprior to the

installationwork and attach tapes again to the

connectorsafter completionof the installationwork.

2. Prior to removing the RAM PWB unit connect the

service

service

the RST

unit is

battery

entirelydestroyed.

battery (CKOG-6626RCZZ)to this unit and the

connector (UKOGGO056CSZZ)to the ON side of

switch for memory protection.

If the RAM PWB

removedwithout connectingthe service

and service connector,the RA.Mdata is

If this is the case, take master

resetting 1 when starting the ER-31OO.

The RAM data may be destroyed even when the above

action is taken for memory protection.

If the

ER-31OO cannot start normally after installingthe

control ROM, start it by master resetting 1.

It is advisable to perform data saving by using the

–16–

Page 21

S10 interface.

This enables RAMs to be loaded with

saved data after master resetting 1 even if their

contents are destroyed.

Master resetting 1:

Memory all clear start (masterreset start)

For master resetting 1, plug in the register,

holding down the journal feed key in the SRV mode.

3. If master reset (MRSI or MRS2) is performed at the

ER-31OO equippedwith the R22113ROM as a common ROM

after the ER-31RS2ROM has been installedin it, it

is automatica~lyloaded with SSP data to activate the

ER-31RS2 program. At this time every SSP data

already programmed is cleared.

Accordingly,it is

necessary to program the programmed SSP data again

after master reset has been performed.

If the ER-31OO is equippedwith any version other

than the R221B comon ROM, it

loaded with the SSP data; and

is not cleared. The SSP data

loaded into the ER-31OO is as

is not automatically

the programmed SSP data

that is automatically

follows:

SSP No.: ER31OO-OO1

1. 01

2. 01

3. 134

4. 244

5. 00

6. 134

7.

246

8. 00

9. 06

10. 24

11. 131

12. 01

13. 00

14. 24

15. 189

16. 183

17. 84

18.

122

–17–

Page 22

Mount the RS-232C interfaceboard unit on the bottom cabinet.

3.

Pass the two cables of the unit through the ferrite core, wind

them on the core by one turn, and connect them to the main unit.

(Fig. 7)

tecore

6629RCZZ

Fig. 7

Break off the knockout for cable hole @ on the right side of

the bottom cabinet.

4.

Remove the option mounting bracket from the rear of the bottom

cabinet and break off the knockout for cable hole @ by means of

a wire cutter or the like.

(Fig. 16 on page 49)

(Fig. 8)

v

Optionmounting

LANGK7228RCZZ

bracket,

I

Fig, 8

–18–

Page 23

Secure the 25-pin connectorof the ER-31Rs2 connectingcable to

5.

the option mounting bracket removed in step 4 above togetherwith

the groundingwire of the cable.

(Note that pin 1 faces this

side.)

When fixing the 25-pin connector,

use either of the supplied two

types of connector spacers (inch pitch type silver spacer and

mini pitch type golden spacer).

Select the one that matches the

mating connector.

@

/’-----~EsD26-2oooo

ble

Fig. 9

6.

Restore the option mounting bracket to the bottom cabinet.

7.

Connect the connectorat the other end of the connectingcable to

part @ shown in Fig. 7.

8.

Connect the mating connector to the connector secured to the

option mounting bracket from below the bottom cabinet and then ~€

fix the mating connector.

–19–

Page 24

Replace the top cabinet and drawer.

9.

(Refer to Section 5

“REMOVINGTHE TOP CABINET AND MAIN DRAWER”.) At this time draw

out the drawer cable from the bottom cabinet at the back or

through cable hole @ on its right side (see Fig. 16 on page

49).

Use care to prevent the drawer cable, groundingwire, etc.

from being caught between the bottom cabinet and the drawer.

6.3 Operationalcheck

0 Preparation

Connect the test connector to the 25-pin RS-232C connector (25P

D-sub) of the ER-31Rs2.

QCNW-7059RCZZ

MainPWB

ER-31RS2

Interface

PWB

CPWBF6951RC06

$ 0

Testconnector

UKOG-6639RCZZ

/

After connectingthe test connector (UKOG-6639RCZZ)to the 25P

D-sub, interfacePWB input and output signalsmust be connected

in followingmanner.

ER

I

,

DR

0 Start of the test

The test will start after the followingkeyboard command in the

SRV mode.

119~

Note:

n

The above command would not be acceptedunless the

ER-31RS2 control ROM (27256)is in the ROM socket (ROM3)

on the main PWB of the ER-31OO.

cause the “Check over”

print and automaticallyfinalize

The above operationwill

the check program.

–20–

Page 25

IT

‘3

119

\

Data entry with

numeric keys

I

A~B+c+D~

/

I

Sample“Checkover”print

If any print other than shown above occurs, it indicates that the

ER-31RS2 is malfunctioning.

6.4 Programming

1. Modificationof the SRV-modeprogram

0 Reprogrammingto enable or disable the ER-31Rs2 option to select

the kitchn printer or the RS-232C communicationfunction.

.—.l~.—>

909 ~ —~

In the above key operation,

data of job number 909; and for convenience,data in the fourth

column is called A, the one in the third column B,

second column C, and the one in the first column D.

Of these data, data D decideswhether to enable or disable the

ER-31RS2 option and to select the kitchen printer or the RS-232C

communicationfunction.

Kitchen printer/

RS-232C communication function

RS-232C communication function

Kitchen printer

Note:

For data D, never enter any digit other than those shown

A, B, C, and D each refer to preset

the one in the

Change the data according to Table 4.

Table 4

ER-31RS2

option

Disable

Enable

Disable

Enable

Data

o

1

2

3

in the above table.

–21–

Page 26

Data A, B, and C do not need to be changed.

same data as data A, B, and C of job number 909 shown in

Enter the

the SRV-mode program list printed

installingthe option.

2. PGM-modeprogramming

(1) Programmingto select data handling

The ER-31Rs2 has the followingfour

which can be enabled or disabledby

programming.

0 Sending of print data

0 Sending of report print data

0 Loading of RAM data

0 Dumping of RAM data

a. Programmingprocedure

Perform this programmingin the PGM

followingprocedure.

When A, B, C, and

D are all zeroes

by job number 900 before

functions

data handling functions,

the PGM-mode

mode by using the

zgo~~~~

A Sending of print data Enable/Disable

B Sending of report print data Enable/Disable

c Loading of RAM data Enable/Disable

D Dumping of RAM data Enable/Disable

‘~AB~D $ ,~

A, B, C, and D are all set to zeroes

when master resetting is taken.

Table 5

–22–

1/0

1/0

1/0

1/0

Page 27

b. Print

The contents of the programmingare printed on the

receipt/journalpaper. The print format is shown below.

The logo and date printed are the same as those printed on

the receipt.

12345678901 2345678901

#0290

SEND

SEND REPORT DATA

LOAD

DUMP RAM

PRINT

RAM DATA

DATA

DATA

YES

YES

NO

?lfisI? and ItNo!t

showthe contents

of theprogramming.

NO

(2) Programmingof master/slaveassignmentand the slave

terminalnumber

It can be specifiedby this programmingwhether to use the

ER-31OO as the master or a slave.

Also,

the terminal number

of the ER-31OO can be specifiedby this programmingwhen it

has been programmed to work as a slave.

Programmingprocedure

a.

Perform the programming in the PGM mode by using the

followingprocedure.

ABCD

is set to “0001”

(the slave terminal

number is set to

when master resetting

is taken.

–23–

“1”)

Page 28

Table 6

Automatic sending of the ER-OFF command No/Yes

A

1/0

B Master/Slave 1/0

CD Slave terminal number

Note: When B=l, key in “00” for CD.

The terminalnumber of the master is fixed at “PC”

(50H 43H).

b. Print

The contents of the programmingare printed on the

receipt/journalpaper. The print format is shown below.

The logo and date printed are the same as those printed on

the receipt.

12345678901 23456789ol

#0291

AUTOMATIC ER–OFF YES

MACHINE

TERMINAL NO.

SLAVE

05

t?~slf and ttNoIl

showthecontents

of theprogramming.

-When theER-31OOis

prograsumedas the

master,

printedin placeof

tls~~rle

(3) pr~gra~ifigOf the start and end codes

The start and end codes of the data block can each be

specifiedin up to three digits by this programming. If

“000” is specified for each of the codes, the data block is

providedwith neither the start code nor the end code.

“MASTER”

iS

–24–

Page 29

a.

Programmingprocedure

Perform the programmingin the PGM mode by using the

followingprocedure.

“000000”

292

~1 ●

3

~~

‘xxxXxx

1

Mm

St~;~d

code

code

When master resetting is taken,

“002013” is specified.

This means that the data block is

provided with the start code 02H(STX)

and the end code ODH(CR).

Enter both the codes in decimal digits.

Any figures greater than 127 cannot be specified for start

and end codes.

b. Print

The contents of the programmingare printed on the

receipt/journalpaper.

The print format is shown below.

The logo and date printed are the same as those printed on

the receipt.

12345678gc)I 2345678gol

#0292

START

END

CODE

CODE

–25–

017

003

+-The startcode

isDC1(llH)and

the endcodeis

E~(03H).

Page 30

(4) Programmingfor protocol, etc.

This programmingis intended to select “ProcedureYes” or

“ProcedureNo” for protocol, “Modem connectionyest~or

“Modem connectionNo” for modem, and

“SensingNo”

No” is selected for protocol,

can be accomplishedas a transmissionjob.

this job is performed even if

Disable” has been selected in (1) “Programmingto select

data handling functions.”

a. Programmingprocedure

Perform this programmingin the PGM mode by using the

followingprocedure.

~’

293

n

for control signals (DR and CS).

sending of print data alone

“Sending of print data

When A, B, C, and

D are all zeroes

● ~

~

A, B, C, and D are all

EABCD~

set to zeroes when master

resetting is taken.

“sensing yes” or

If “Procedure

In this case

T

z

Table 7

Modem connectionYes, procedureYes

2

I

A 1 Modem connectionNo, procedure

Modem connectionNo, procedureYes

o

B 1/0

c 1/0

D n

(o-9) and when n =

Sensing of DR signal No/Yes

I

Sensing of CS signal No/Yes

ER off time in the slave in the case

of modem connectionYes:

the ER off time is approx. 3 sec.;

1 thru 9, that time is

approxe (n x 10) sec.

–26–

Whenn=O,

NO

I

I

This selection

is valid only

when A is 1.

Page 31

b.

Print

The contents of the programmingare printed on the

receipt/journalpaper.

The print format is shown below.

The logo and date printed are the same as those printed on

the receipt.

12345678gol 2345678gol

#0293

MODEM

PROCEDURE

DR

Cs

ER–

Programmingof the terminalnumbers of slaves that are

(5)

SENSE

S“ENS E

OFF

CONNECTION

TIME

YES

NO

YES

YES

/10s

‘l~slt and ?lNoIl

showthecontents

of theprogramming.

0

connected to the master through modems.

When slaves are connectedto the master throughmodems and

the master is an ER-3100, the terminal numbers of those

slaves to which the ER-OFF command is to be sent

automaticallyneed to be listed in the master by this

programming.

a.

Programmingprocedure

Perform this programmingin the PGM mode by using the

followingprocedure.

To set the terminal no.

t. UOOII

294~~~

X

.=.

—

–27–

Page 32

b. Print

The contents of the programmingare printed on the

receipt/journalpaper.

The print format is shown below.

The logo and date printed are the same as those printed on

the receipt.

12345678901 2345678gol

#0294

SLAVE

SLAVE

SLAVE

SLAVE

TERMINAL

TERMINAL

TERMINAL

TERMINAL

+Terfi~numbers

01

02

11

12

listedinthemaster.

(6) Reading the contents of the PGM-mode programming

a. Procedure (in the PGM mode)

190~

m~m

b. Print

The contents of the programmingare printed on the

receipt/journalpaper.

next page.

The logo and date printed are the same as those

The print format is shown on the

printed on the receipt.

–28–

Page 33

12345678901 2345678901

#o190

#0290

SEND

SEND

LOAD

DUMP

#0291

AUTOMATIC ER–OFF YES

MACHINE

TERMINAL NO 05

#0292

START

END

#0293

PGM

PRINT DATA

REPORT DATA

RAM

RAM

CODE

CODE 003

DATA

DATA

SLAVE

NO

YES

YES

NO

017

MODEM

PROCEDURE NO

DR SENSE YES

Cs SENSE

ER–OFF

#0294

SLAVE TERMINAL

SLAVE TERMINAL

SLAVE

SLAVE TERMINAL

CONNECTION

TIME

TERMINAL

–29–

/10s

YES

YES

01

02

11

12

o

Page 34

3. PGM-mode programming (for the kitchen printer)

(1) Programmingto select whether to allowor disallow the data

transmissionto the kitchen printer.

The former programming

is performed, taking into account

that the kitchen printer may be disconnectedfrom the

ER-31OO due to its possible breakdown,etc.

0 Key operation

1111

0

Table8

A 1/0

Data transmission

A=

O when master resetting is taken.

Allowed/Disallowed

0 Print

12345678gQI 2345678901

#0280

KITCHEN

PRINTER

YES

l~~sll and IINOI1

showthecontents

of theprogramming.

(2) Programmingto decide whether to allow or disallow the

refund data transmissionto the kitchen printer

This programmingis intendedto decide whether to allow or

disallow the ER-31OO to send print data to the kitchen

printer when a refund entry is made.

–30–

Page 35

0 Key operation

A 1/0 Void item Send/Not Send

1111

0

Table 9

B 1/0 Refund data Send/Not Send

+

A=

O when master resetting is taken.

0 Print

12345678901 2345678901

#0281

m

REFUND DATA SEND

ITEM

SEND NO

NO

tt~s!t and tINoll

showthecontents

of theprogramming.

(3) Programming to decide whether to skip the free text,

PLU/dept.

code, unit price, and total amount in data

printing at the kitchen printer.

0 Key operation

MO()()OII

I

–31–

I

Page 36

Table 10

A 1/0 Free text Skip/Not Skip

1/0 PLU/dept.

B

1/0 Unit price Skip/Not Skip

c

1/0 Total amount Skip/Not Skip

D

code Skip/Not Skip

ABCD =

0000 when master resetting is taken.

0 Print

12345678901 23456789ol

#0282

FREE

PLU/DPT

UNIT

TOTAL AMOUNT

TEXT NO

CODE YES

PRICE

NO

YES

t!~s!l and ltNoll

showthecontents

of theprogramming.

(4) Programmingfor printing of dept./PLU data Yes/No

This programmingis intended to decide for individual

departments (or PLUS) whether to print data on the receipt,

journal, and kitchen printer.

0 Key operation

NKl: Dept. code

–32–

Page 37

Table 11

1 Receipt/journaland kitchen printer

NK2 2 Receipt/journal

3 Journal and kitchen printer

m2 =

O when master resetting is taken.

0 Print

123

#02

DPT

DPT

DPT

DPT

45678901234 56789ol

83

01 R/J&KP

02 R/J

03 J&KP

04

R/J&KP

t

Dep~code

NK2 = 1

NK2= 2

NK2= 3

(5) Reading the contents of the programming,job # 280, 281,

282, and 283

0 Key operation

–33–

Page 38

0 Print

12345678901 2345678901

#0180

#0280

KITCHEN

#0281

w

REFUND

ITEM

#0282

FREE

PLU/DPT

UNIT

TOTAL

#0283

DPT 01

DPT02

DPT 19

DPT 20

TEXT

PRICE

AMOUNT

PGM

PRINTER

SEND

DATA

CODE

SEND

R/J&KP

R/J

.

R/J&KP

R/J&KP

YES

NO

NO

NO

YES

NO

YES

Allof the

programmed

departments

are printed.

–34–

Page 39

7. RAM MEMORY CHIP (ER-46PL1)

7.1 Outline

The ER-3100 can be equipped with up to 990 PLUS by installinga

maximum of two ER-46PLI RAM memory chips.

The PLU capabilityof the ER-31OO can be expanded up to 628 PLUS

(up to 990 PLUS including standardPLUS). The first 200 PLUS can

be entered directlyby manipulatingthe PLU level shift key.

The remaining (790 PLUS) can be entered on the code entry system

(which require the entry of correspondingPLU codes and

depressionof the PLU key).

The number of additionalPLUS depends on the number of RAM memory

chips installed.

See Table 12 below.

Table 12

Stock control

No

StandardRAMs ~ _ 362 ~ - ~14

(RAMl,RAM2)

Optional RAM

memory chip

I

(RAM3)

Optional M

memory chip

(RAM4)

I

Captions in parenthesesare printed on the RAM PWB.

When installinga single chip, be sure to mount it in the RAM3

socket, not in the RAM4 socket.

7.2 Installationprocedure

1.

Prior to installingthis option,

interface for memory protection.

for the data saving procedure.

\363 -

677 -

676 I315 - 586 I

990 587 - 858

save the data by using the S10

See Section 8

Yes

I

“PRESETSLOADER”

–35–

Page 40

2.

Remove the top cabinet.

(See Section 5

“REMOVINGTHE TOP CABINET

AND MAIN DRAWER”.)

Install the optional RAM memory chip(s) on the RAM PWB unit above

3.

the main PWB.

Mount the chip(s) in the RAM socket(s)as

indicatedbelow.

0 Ist chip in the RAM3 socket

0 2nd chip in the RAM4 socket

Fig. 10

4.

Replace the top cabinet.

(See Section 5 “REMOVINGTHE TOP

CABINET AND MAIN DRAWER”.)

7.3 Operationalcheck

Test and clear the RAMs in the SRV mode.

0 RAM testing

3ox~

~ (X: 2 or 3)

–36 –

Page 41

Table 13

Test job no.

302

Test RAM no.

RAM3

303 M4

Test results are printed on the receipt and journal at the

ER-31OO cash register.

Normalprintout1 (whentheregisteris

I

El––––

(E3]

E2

El––––

——— ——

E

30X

1

30X

i

30X

fullyequippedwith RAMs,)

I

x:

or 3

2

Normalprintout2

Y

z

Y:

RAMno.of RAM thatis notmounted

or4)

(3

Errorprintout

z:

RAM

no.of mountedRAM (3 or4)

All of the RAMs mounted must be tested.

If an error printout occurs for a particularRAM, recheck to

see if the RAM is in the correct position or if the

connectorsof the RAM PWB unit correctlyconnect to those of

the main PWB.

(If the power is turned on with the M being mounted in the

reverse direction,

it may be damaged.)

0 RAM clearing

40x~~ (X: 1 or 2)

–37 –

Page 42

Table 14

Clear job no,lRAM no. INote

I

400

401

402

The above operation clears a correspondingRAM.

7.4 Programming

1.

Modificationof the SRV-modeprogram

0 Reprogrammingto select the number of optional PLUS and the code

display (DPT or PLU) for PLU entries and to enable or disable PLU

report zero-skip.

I I I

RAM2

I

W3

W4

To set A thru D

to o.

Data entry with

numeric keys

Standard RAM

I

Optional RAM

memory chip

Optional RAM

memory chip

I

In the above key operation,

preset data of job number 901; and for convenience,data in the

fourth column is called A, the one in the third column B, the one

in the second column C,

Of these data,

PLUS.

Change it according to Table 15 below.

data C serves to select the number of optional

A, B, C, and D are each refer to

and the one in the first column D.

–38–

Page 43

Table 15

No. of

PLU option option

Ms

Option RAM

Data C

No (standard)

Yes 1

Yes 2

o

W3

RAM3

0

1

2

R.AM4

Data D serves to program whether to enable or disable overlapped

clerk entry and PLU stock control

unit price zero (0) of department

Note: When the enabled PLU stock

or whether or not to print the

or PLU.

control has been disabled or

when the disabled PLU stock control has been enabled, it

is necessary to clear RAM2 thru RA.M4by jobs # 400 thru

402 prior to programmingjob # 901 above.

(This is

because the memory structurevaries depending upon the

contents of the programming for PLU stock control

(Enable/Disable).

Table 16

Overlapped

PLU stock

clerk entry control

Disable

Disable

Disable Disable

Disable

Enable

Disable Enable

Enable

Enable

Enable

Enable

Disable

Disable

Enable

Enable

–39–

Printing of

the unit price

zero (0) of

dept.

orPLU

Yes

No

Yes

No

Yes

No

Yes

No

Data D

o

1

2

3

4

5

6

7

Page 44

Note: For data C and D never enter any digits other than those

shown in Tables 15 and 16.

Data A and B do not need to be changed.

data as data A and B of job number 901 shown in the

SRV-modeprogram list priiltedby job number 900 before

installingthe option.

When you need to change data A to O, any leading zeros

need not be entered.

Example 1:

Example 2:

.

2.

PGM-modePLU programming

This programmingis described in the InstructionManual.

are asked to perform this programming,however, perform it

accordingto customer’srequirements.

The PLU programmingconsists of the followingthree jobs:

(1) Programmingof unit prices -- job number 20

If data A, B, C, and D are O, 4, 1, and 2,

enter like this:

If data A, B, C and D are O, 0, 1, and 2,

enter like this:

E+ B + E=

E“D

Enter the same

If yOU

i.

X=o

xxxxxx~”

For automatic

incrementof

PLU code

Zzz:

Xxxxxx:

(2) Programmingof departmentsto be associatedwith PLUS -- job

number 22

PLU code

Unit price;

denominationsused for unit price entry is in

cents.)

enter “600”.

enter a maximum of six digits.

If the unit price is $6.00, for example,

–40–

m—

(The

Page 45

22

X=o

For automatic

4

incrementof

PLU code

Zzz:

xx:

Programmingof text

(3)

zl~~~~

Characters:

In addition to the above perform the followingprogrammingjobs

as necessary.

For details of these jobs, consult the ER-31OO Instruction

Manual.

(4) Programmingof set PLUS -- job number 23

(S) Programming of PLUS linked to set PLUS -- job number 24

PLU code

Department code

~zzz~ x Characters

4

<

L

Zzz: PLU code

Enter a maximum of twelve charactersthrough

characterkeys.

To enter space

I

E A“

For automatic “

incrementof

PLU code

~m

I

•~

(6) Programmingof PLU stock (add type) -- job number 25

(7) Programming of PLU stock (overridetype) -- job number 26

–41–

Page 46

8. PRESETS LOADER

8.1 Outline

The presets loader option consists of the following devices:

0 ER-52CB S10 interfacecable

0 ER-67LC (ER-52Lc)level converter

0 ER-OIFD 3.5-inch floppy disk unit

The TTL-level S10 transfer function is standard for the ER-31OO

cash register.

The ER-31OO can achieve standard (TTL-level)S10 data exchange

with another ER-31OO or the ER-OIFD through the ER-52CB, and

RS-232C S10 data exchangewith a personal computer through the

ER-67LC.

This enables saving and loading of various data.

8.2 Installationprocedure

0 Installationof the ER-52CB S10 interfacecable (for data

transferbetween ER-31OOS)

Open the S10 connector cover on the left side of the ER-31OO

1.

by turning it backward and connect the one end of the

ER-52CB cable to the S10 connector.

2.

Connect the other end of the cable to the S10 connector of

the mating cash register.

Note:

After the cable is disconnectedfrom the S10

connector,be sure to close the cover to protect the

connector.

–42–

Page 47

~sIO interfacecable

ER-52CB:QCNW-6952RCZZ

Fig. 11

0 Installationof the ER-52CB S10 interface cable and ER-67LC

(ER-52LC)level converter (for data transfer between the ER-31OO

and a personal computer)

1. Connect the ER-52CB to the S10 connector of the ER-3100 and

to that of the ER-67LC.

2.

Connect the ER-67LC to the personal computer.

(Refer to the

ER-67Lc InstallationManual and the InstallationManual of

the computer.)

*TO theER-31oo

/

LS1O interfacecable

QCNW-6952RC2Z

Fig. 12

–43–

To the

personalcomputer

(ER-52Lc)

Page 48

0 Installationof the ER-52CB S10 interface cable and ER-OIFD

3.5-inchfloppy disk unit (for data transfer between the ER-31OO

and the ER-OIFD)

Refer to the ER-OIFD InstallationManual.

1.

2. Connect the ER-52CB to the S10 connectoron the left side of

the ER-31OO and to the serial interfaceconnector (@) of

the ER-OIFD (see Fig. 13).

Open the cover on the right side

3.

of the ER-OIFD and perform

its programming.

Frontview

Backview

(Refer to 8.6

b

Fig. 13

“Use of the ER-OIFD”.)

POWERLED

ON when theERO1.FDpoweris on.

ERRORLED

ON whentheFD read/writeerror

ismet.

diskinitialization.

ERRORLED

On at a datatransfererror.

Also,usedto indicatedisk

initialization.

RUNkey

Usedto startdatatransfer

betweentheEROIFDandtheECR.

3.5”FD

Serialinterfaceconnector

(~L level)

Serialinterfaceconnector

(RS232Clevel)

POWERswitch

AC adapterjack

AC adapter

Also,usedto indicate

8.3 Operationalcheck

Perform the S10 test in the SRV mode.

Testing of the ER-52cB requires the ER-52cB, loop back connector

(UKOG-6651RCZZ), and service key;

and testing of the ER-67Lc

requires the ER-67LC, ER-52cB, loop back connector

(UKOG-6639RCZZ), and service key.

–44–

Page 49

To accomplish the S10 test, perform the following key operation

in the SRV mode:

122

~m

Test results are printed on the receipt and journal at the cash

register.

I

EX––––

I

If an error printout occurs, check the S10 connector,including

the internal cablewithin the cash register, to see if it is in

position.

8.4 Programming

1. Modification of the SRV-mode program

0 Programmingof the data rate (Prior to this programmingprint out

the current SRV-modeprogram by job number 900.)

122

122

Normalprintout

I

Errorprintout

x:

1

I

El:

E2:

E3:

to 3

ER-DRerror

Transfererror (dataerror)

Time-outerror

Data entry with

numeric keys

In the above key operation,

data of job number 909; and for convenience,data in the fourth

column is called A, the one in the third COlumn B, the one in the

second column C, and the one in the first column D.

Of these data,

desired data rate according to Table 17.

data C serves to decide the data rate.

A, B, C, and D each refer to preset

Select a

–45–

Page 50

Table 17

Data rate

9600 BPS

Data C

o

4800 BPS 1

2400 BPS

1200 BPS

2

3

600 BPS 4

Note:

For data C never enter any digit other than those shown in

Table 17.

Data A, B, and D do not need to be changed. Enter the

same data as data A, B, and D of job number 909 shown in

the SRV-mode program list printed by job number 900 before

installingthe option.

If data A is O, enter data B, C, and D in this sequence

without entering this zero.

8.5 Data sending and receiving

Data transmissioncan be started after the receiver has been set

up.

Receive mode entry

1.

Turn the mode switch to the SRV position and perform the

followingkey operation:

998~

~’~

a

—

‘~w

This operation readies the ER-31OO for receiving S10 data.

When the ER-31OO enters the receive mode, the mating device,

which may be an ER-3100 cash register,ER-OIFD floppy disk unit,

or personal computer, can start S10 data transfer.

2.

Send mode entry

Turn the mode switch to the SRV position and perform the

followingkey operation:

~,

●

996

~~~

a

T

m

This operation starts the transfer of S10 data stored in every

RAM in the ER-31OO.

–46–

Page 51

8.6 Use of the ER-OIFD 3.5-inch floppy disk unit

8.6.1 Setting of the dip switches on the ER-OIFD

When using the ER-OIFD as the presets loader for the ER-31OO, set

its dip switches (shown in Fig.

Table 18

ata rate

P

9600 bps

4800 bps

t--

2400 bps

1200 bps

600 bps

F

Note: Select the same data rate as that of the ER-31OO.

1

OFF

ON OFF

DS1

4

ON

14) according to Table 18 below.

DS

6

5

ON

o~F’

ON

OFF

ON

OFF

ON

ON

OFF

OFF

7

OFF

OFF

OFF

ON

ON

8 1

OFF

OFF

2

ON

7

OFF

Fig. 14

–47–

Page 52

8.6.2 Data sending and receiving

Receiving

1.

The ER-OIFD is always in the receive mode when the power is on.

When receiving data, make sure the floppy disk is correctly set.

2. Sending

The ER-OIFD starts data transferwhen the RUN key is pressed.

Prior to pressing the RUN key, make sure that the ER-31OO is in

the receive mode and that the floppy disk is correctly set.

–48–

Page 53

9. ~MOTE DWWER (ER-37Dw3)

9.1 Outline

The ER-37DW3 is a remote drawer to be externallyconnected to the

ER-3100 cash register.

A single remote drawer may be connected to the cash register.

The remote drawer consists of the following items.

0 Drawer

0 Balancingmetal fixtures

1

2

o

Balancingmetal

fixtures(2pcs.)

9.2 Installationprocedure

1. Remove the main drawer from the cash register.

(Refer to Section 5

2. Break off the knockout for cable hole A at the side of the

bottom cabinet.

(Fig. 16)

~

“REMOVINGTHE TOP CABINET AND MAIN DRAWERn.)

Drawer

Fig. 15

o

Fig. 16

–49–

Page 54

3. Remove the fitting from part @ on the back of the bottom

cabinet.

(Fig. 17)

(Do not discard this fitting because it is later used for a

strain relief.)

Pass the remote drawer cable through the hole made at part @

4.

and connect it to the DRCN2 connector (shownin Fig. 18) on the

main PWB. Then fix the cable with the fitting removed in step 3

above. (Fig. 17)

D30P08000

f the bottom

t

Fig. 17

Fig. 18

–50–

Page 55

5. Replace the main drawer.

(Refer to 5.4 “Replacing the main

drawer” under Section 5

DRAWER”.)

At this time draw out the remote drawer cable through cable hole

A shown in Fig. 16.

o

caught by anything.

The followingdescribes the method for securing the remote drawer

6.

on a table by use of the suppliedbalancingmetal fixtures.

(1) Choose a flat table.

(2) Lay down the drawer so that the left side faces downward.

(3) With the cushion areas of the fixturesdirected to the

drawer bottom,

(lookingfrom the front) so that the drawer bottom plate can

be inserted in the U-shaped grooves of the fixtures. These

fixturesmust be fitted in the same directionand level.

(See Fig. 19)

“REMOVINGTHE TOP CABINET AND MAIN

Use care to prevent the cable from being

insert them in two holes at the left side

Insertdeepinto

thegroove.

Adhesiveface

Fig. 19

(4) Peel off the protective seal from the cushion area. The

adhesive area is then exposed.

Fig. 20

Don’t lay a table cloth on

–51–

Page 56

the table because the adhesive area may accidentallycontact

Also clean the surface of the table.

it.

Stand the drawer up, and gently press it down to fix the

(5)

adhesive face of each fixture firmly on the table.

Fig. 20)

(See

Now the drawer has been fixed tightly to the table.

(6)

you want to remove the drawer to another location,move it

to the left (lookingfrom the front) to detach it from the

fixtures. The balancingmetal fixture loses its adhesive

propertiesonce used.

9.3 Operationalcheck

Execute the drawer test in the SRV mode.

Job numbers 111 and 112

With this key operationa single drawer alone opens; and a “ ~ “

appears in the first position of the register display if the

drawer is providedwith the drawer open sensor.

appears.

The main drawers of those machines for some general

(If not, a “ [ “

agents are provided with no drawer open sensor.)

Close the open drawer by hand.

II[ ft

the

. (If the drawer is provided with no drawer open sensor,

II[ 11

in the display remainsunchanged when the drawer is

Then the “ O “

is replaced with a

In case

closed.)

After confirmingthe above drawer and display actions press a key

on the keyboard.

This will provide the “Check over” print and

then finalize the drawer test.

Table 19

11X

Job #

I

111 Main drawer (Drawer 1)

Drawer to work

Sample“Checkovert’print

(X: 1 or2)

112 Remote drawer (Drawer 2)

–52–

Page 57

The above print only shows that the drawer test has been

performedbut not whether the test result is all right or not.

Check the result yourself.

If a remote drawer is connected, test

the main drawer as well.

9.4 Modificationof the PGM-mode program

0 Drawer assignment to clerks

o

In the above key operationNKl is a clerk code (see Table 20) and

NK2 is a drawer number (see Table 21).

Table 20

NKl

1

2

3

4

Clerk

Clerk A

Clerk B

Clerk D

Clerk E

Table 21

NK2

o

1

2

Drawer

No drawer

Drawer 1

Drawer 2

–53–

Page 58

10. MODE SWITCH (ER-31MDl/MD2/MD3/MD4/MD5)

10.1 Outline

The ER-31OO cash register can be equippedwith an optional mode

switch for more strict control of individualECRS.

switch is available in 100 varieties.

equally divided into five groups, which are given the model names

ER-31MD1 thru ER-31MD5 respectively.

When installingtwo or more optionalmode switcheswithin a

store, use those that are different in key number (see Fig. 21).

0 Howto readthekey

Keyname

/

Keyno.

identificationnmber

These varieties are

xxx

\ /00\ /

Keyno.

001

to

100

This mode

Key type

C)l+op

03+SM

05+MA

v

Key

Modeswitch

Fig. 21

10.2 Installationprocedure

1. Remove the top cabinet.

CABINET AND MAIN DRAWER”.)

2. Disconnect the connectorsat the inside of the top cabinet and

remove the keyboard unit and switch unit.

(Refer to Section 5 “REMOVING THE TOP

(Fig. 22)

–54–

Page 59

Fig. 22

3* Remove the M3 countersunktappingscrews and spring washers from

the standard mode switch and then remove the mode switch from the

switch mounting bracket of the switch unit.

switch

unit

~ Lm,,D30p06000

M3 countersunk

tappingscrew

Fig. 23

(Fig. 23)

–55 –

Page 60

4. Install the optional mode switch by using the screws removed in

step 3.

(The spring washers do not need to be used.) (Fig. 24)

tionalmodeswitch

/w

Fig. 24

Replace the switch unit and keyboard unit in the reverse order of

5.

removing and then connect securely the connectorsdisconnectedin

step 2.

(Fig. 25)

–56–

Page 61

To the remotedisplay

RemotedisplayconnectorCN1 RemotedisplayconnectorCN2

To the

— -. /

Xo thenoisefilter

‘ransfomer %

“1OtnemainN5

mainPWB

CPUconnectorCN

Modeswitchz

f

DisplayPWB

11 I1

u~

II

,KeyboardconnectorCN2

KeyboardconnectorCNl

%

4-gangpush-button

eh + OF ew4 t-h

r.s

I

i

II >11

+,

frompin @

1

Colorof theconnector:

‘E

Colorof theconnector:Black

J

Beige

Fig. 25

Replace the top cabinet.

6.

cabinet”

under Section 5

(Refer to 5.2 “Replacing

“REMOVINGTHE TOP CABINET

DRAWER”.)

Operationalcheck

10.3

This check requires the service key (LKGIM7094Rczz)for the

optionalmode switch.

–57 –

the top

AND MAIN

Page 62

Check the mode switch in the SRV mode to see if it functions

normally.

Perform the followingkey operation:

lo6~TL

With this key operation the code that correspondsto the mode

currentlyselected by the mode switch appears on the register

display.

sequence shown in the table below to see if correspondingmode

codes

Checking sequence

Mode switch position

Mode code on the 9 0 1 2 E 3 4 5 6 7

display

appear on the display.

D

Turn the mode switch to respectivepositions in the

11 10 9 8 7 6 5 4 3 2 1

//7/-

/~/~

(SRV) (s)

Table 22

1 2 3 4 5 6

PGM ~

& OP x/z REG xl Z1 x2/z2

Y

Y: Oto 7, 9, E, F

7 8 9 10

(“OEH”appears on the display when the mode switch is between two

positions and

When the mode switch is turned back to the (SRV) position after

turned to the X2/Z2 position, the “Check over” print occurs and

the operationalcheck comes to an end.

If any code other than those shown above with the

“OEH” appears on the display during checking,the

check terminateswith an error print.

I

“OFH” appearswhen a “double code” error occurs.)

exceptionof

operational

106

Normalprint

–58–

E–––––

106

Errorprint

Page 63

Page 64

SHARPCORPORATION

OSAKA, JAPAN

Loading...

Loading...