Page 1

ER+3RP

SHARP SERVICEMANUAL

CODE:OOZER03RPSM-E

RemotePrinter

MODEL ER-03Rp

OPTION FOR ER-52BR . ER=8700

ER-4100 9ER”3300

ER-3310

IN LINE SYSTEM

CONTENTS

General . . . . . . . . . . . .

1.

2.

Specifications . . . . . . .

Setting of Dip switches

3.

Disassembly procedure . . . .

4

Circuit description . . . . . . . . .

5

Printer unit description . . . . .

6

7

Overview and operating principle of the printer . . . . . . . . . . . . . . . . . . . . 10

8.

Troubleshooting

Disassembly and

9.

10.

Test Function (SWI-7: ON) .

. . . . . . . . . .

reassembly

. . . . .

. . . . .

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

\

1

1

2

3

4

9

14

18

30

11.

Special service tool . . . . . . . .

12.

Circuit diagram . . . . . . . . . . .

~“*~~ ~~~~~~A~lON foraftersaiesserviceonly.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

This document has been published to be used

The contents are subject to change without notice.

Page 2

Page 3

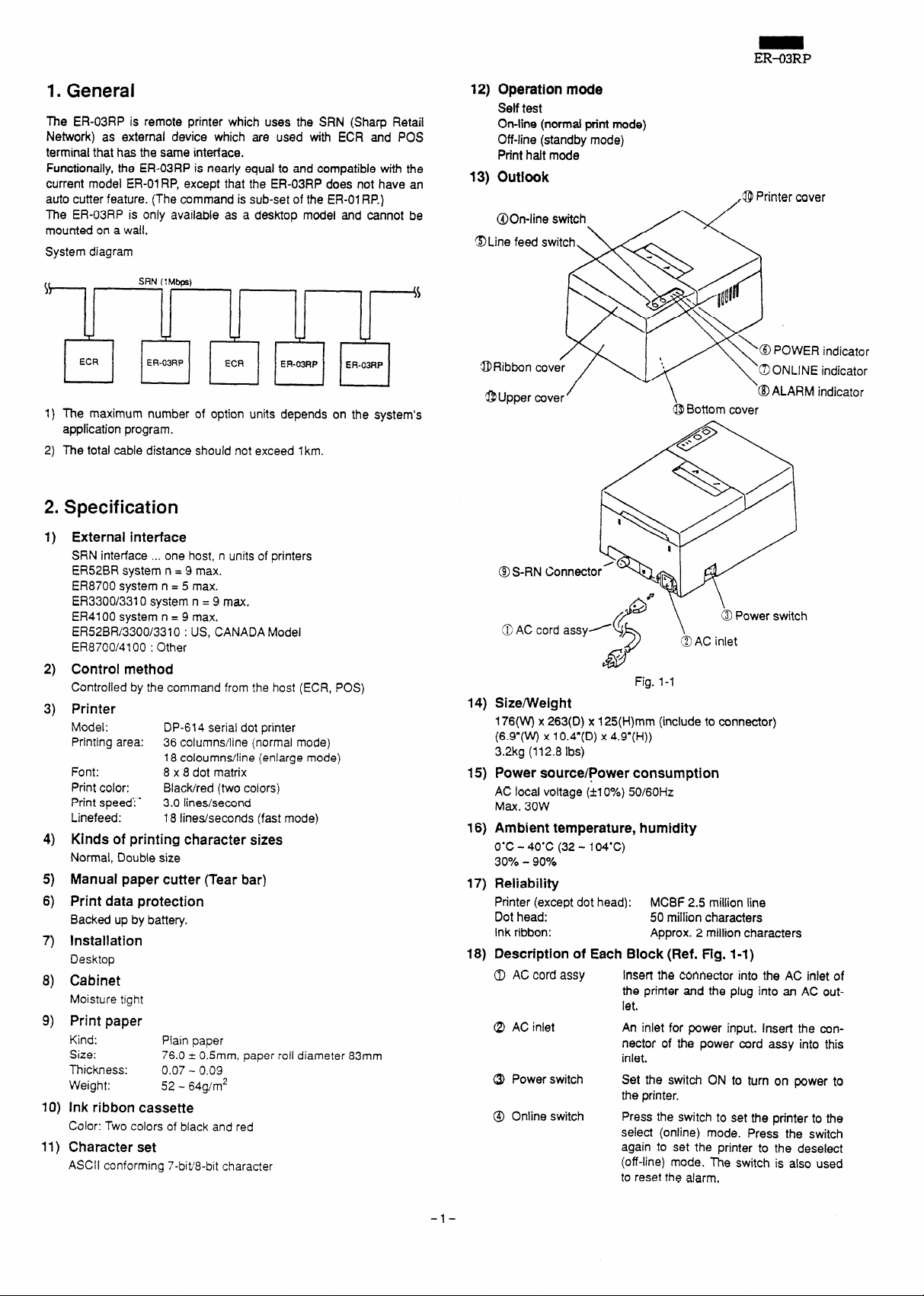

1. General

The ER-03RP is remote printer which uses the SRN (Sharp Retail

Network) as external device which are used with ECR and POS

terminal that has the same interface.

Functionally, the ER-03RP is nearly equal to and compatible with the

cument model ER-01RP, except that the ER-03RP does not have an

auto cutter feature. (The command is sub-set of the ER-01RP.)

The ER-03RP is only available as a desktop model and cannot be

mounted on a wail.

System diagram

12)

Operationmode

Self test

(normalprintmode)

On-line

Off-line (standby mode)

Print hait mode

13)

outlook

@On-line switch.

@Line feed switch. \/. \

<opnntermver

ER43RP

,.

1) The maximum number of option units depends

application program.

2) The total cable distance should not exceed lkm.

(

2.

Specification

External interface

1)

SRN interface ... one host, n units of printers

ER525R system n = 9 max.

ER8700 system n = 5 max.

ER3300/331Osystem n = 9 max.

ER4100 system n = 9 max.

ER52BR/3300/3310 : US, CANADA Model

ER8700/4100 : Other

2)

Control method

Controlled by the command from the host (ECR,

Printer

3)

Model: DP-614 serial dot printer

Printing area: 36 columns/line (normal mode)

Font:

Print color:

Print speed”:”

Linefeed:

4)

Kinds of printing character sizes

Normal, Double size

Manual paper cutter (Tear bar)

5)

6)

Print data protection

Backed up by battery.

Installation

7)

Desktop

Cabinet

8)

Moisture tight

Print paper

9)

Kind: Piain paper

Size:

Thickness: 0.07- 0.0’3

Weight: 52- 64g/m2

Ink ribbon cassette

10)

Color: Two colors of black and red

11)

Character set

ASCII conforming 7-bit’8-bit character

SRN(lMbrs\

18 coloumns/line (enlarge mode)

8 x 8 dot matrix

Black/red (two colors)

3.0 lines/second

18 lines/seconds (fast mode)

76.0 ~ 0.5mm, paper roll diameter 83mm

on the system’s

Pos)

.

~ ‘~WER indicator

QRibbon cover

“~\::;:;;::;r

@Upper cover

OS-RN

.9

@AC cord assy~

Size/Weight

14)

176(W)

x 263(D) x 125(H)mm (include to connector)

(6.9”(W)

3.2kg (112.8 Ibs)

15)

Power source/Power consumption

AC local voltage (*1O%)50/60Hz

Max. 30W

16)

Ambient temperature, humidity

O“C-

30Y0- 90%

17)

Reiiabiiity

Printer (except dot head):

Dot head:

Ink ribbon:

18)

Description of Each Block (Ref. Fig. l-l)

0 AC cord assy

Q) AC inlet

@ Power switch

@ Online switch

X 10.4”(D) X 4.9”(H))

40”C (32 - 104”C)

$\

/

&

Insert the connector into the AC inlet of

the printer and the plug into an AC outlet.

An inlet for power input. Insert the connector of the power cord assy into this

inlet.

Set the switch ON to turn on power to

the printer.

Press the switch to set the printer to the

select (online) mode. Press the switch

again to set the printer to the deselect

(off-line) mode. The switch is also used

to reset the alarm,

@Bottom cover

\

@ Power switch

~ AC inlet

Fig. 1-1

MCBF 2.5 million line

50 million characters

Approx. 2 million characters

-1-

Page 4

ER-Q3RP

When the switch is pressed during the

printer operation, the printer is set to the

deselect mode after pfinting the current

line.

Setting the power switch ON with the online switch held down will initiate the

master reset operation.

Line feed switch

POWER indicator

(yellow green)

ONLINE indicator

(yellow green)

ALARM indicator

(red)

Connector

Printer cover

Ribbon cover

Upper cover

Bottom rover

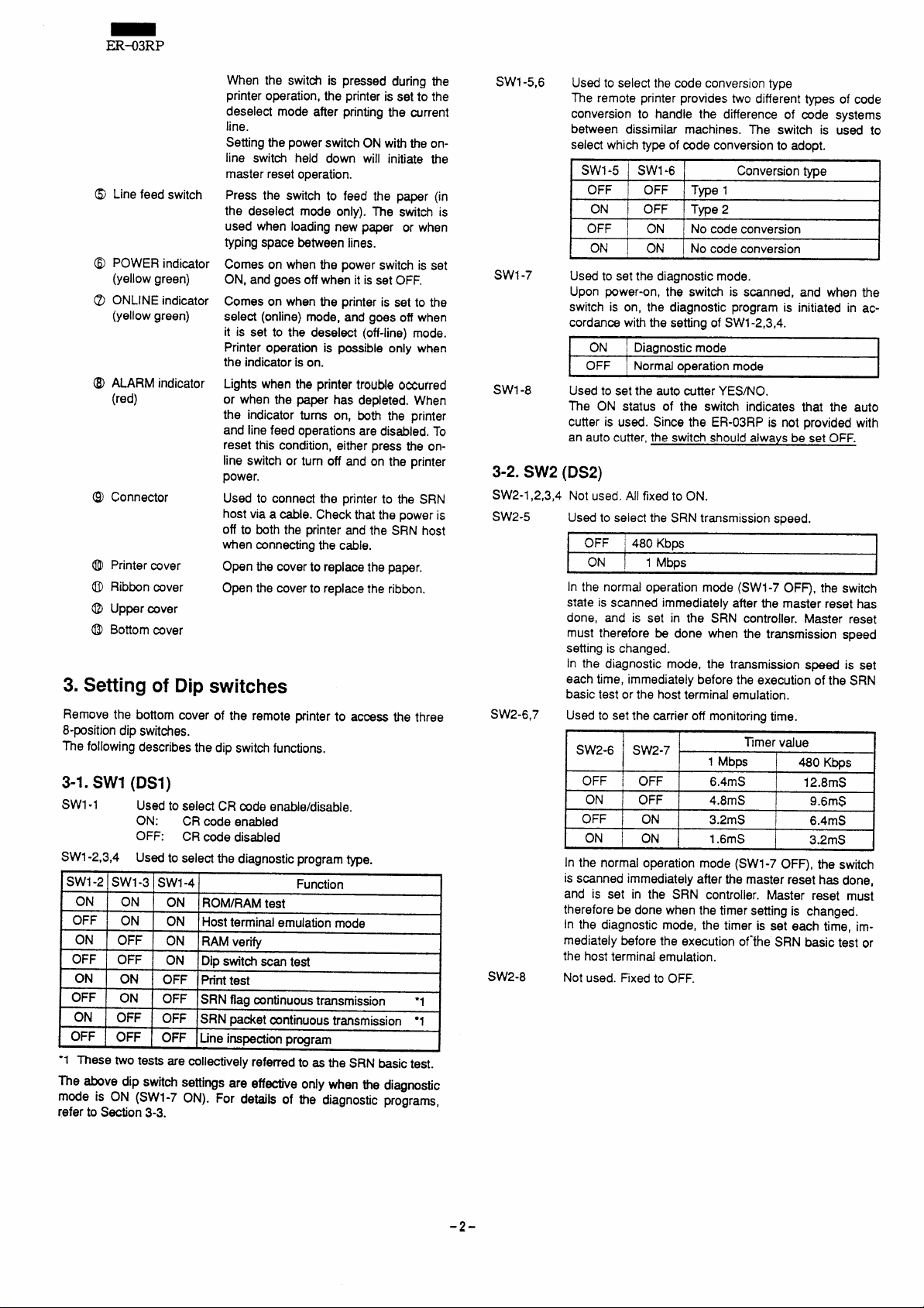

Setting of Dip

Remove the bottom cover of the remote printer to acoess the three

8-position dip switches.

The following describes the dip switch functions.

Press the switch to feed the paper (in

the deseiect mode only). The switch is

used when loading new paper or when

typing space between lines.

Comes on when the power switch is set

ON, and goes off when it is set OFF.

Comes on when the printer is set to the

select (online) mode, and goes off when

it is set to the deselect (off-line) mode.

Printer operation is possible only when

the indicator is on.

Lights when the printer trouble O@ufred

or when the paper has depleted. When

the indicator turns on, both the printer

and line feed operations are disabled. To

reset this condition, either press the online switch or turn off and on the printer

power.

Used to connect the printer to the SRN

host via a cable. Check that the power is

off to both the printer and the SRN host

when connecting the cable.

Open the coverto replace the paper.

Open the coverto replace the ribbon.

switches

3-1. SWI (DSI)

Swl “1

SWI-2,3,4 Used to select the diagnostic program type.

Swl -2 SW1-3 SW1-4

ON ON

OFF

ON

OFF OFF

ON

OFF ON

ON OFF OFF

OFF OFF

●1 These two tests are collectively referred to as the SRN basic test.

The above dip switch settings are effective only when the diagnostic

mode is ON (SW1-7 ON). For deals of the diagnostic programs,

refer to Section 3-3.

Used to select CR mde enable/disable.

ON:

OFF:

ON

OFF ON RAM verifv

,

ON

CR code enabled

CR code disabled

ON

ROMIRAM test

ON

Hostterminal emulation mode

ON

Dip sw-tch’scantest

OFF

Print test

OFF

SRN flag continuous transmission *I

SRN packet continuous transmission

OFF

Line inspection program

Function

●1

SWI -5,6

Swl -7

SWI -8

Used to select the code conversion type

The remote printer provides two different types of code

conversion to handie the difference of code systems

between dissimilar machines. The switch is used to

select which type of code conversion to adopt.

Swl -5 SW1+6

OFF OFF

ON

OFF

ON

Used to set the diagnostic mode.

Upon power-on, the switch is scanned, and when the

switch is on, the diagnostic program is initiated in accordance with the setting of SW1-2,3,4.

ON I Diagnostic mode

OFF ~Normal operation mode

Used to set the auto cutter YES/NO.

The ON status of the switch indicates that the auto

cutter is used. Since the ER-03RP is not provided with

an auto cutter, the switch should always be set OFF.

OFF

ON No code conversion

, ON

Conversion type

Type 1

Type 2

No code conversion

3-2. SW2 (DS2)

SW2-1,2,3,4

SW2-5

SW2-6,7

SW2-8

L

Not used. All fixed to ON.

Used to select the SRN transmission speed.

OFF ~480 Kbps

ON

In the normal operation mode (SW1-7 OFF), the switch

state is scanned immediately after the master reset has

done, and is set in the SRN controller. Master reset

must therefore be done when the transmission speed

setting is changed.

in the diagnostic mode, the transmission speed is set

each time, immediately before the execution of the SRN

basic test or the host terminal emulation.

Used to set the carrier off monitoring time.

SW2-6 SW2-7

OFF i OFF

ON

OFF ‘ ON

ON

In the normal operation mode (SW1-7 OFF), the switch

is scanned immediately after the master reset has done,

and is set in the SRN controller. Master reset must

therefore be done when the timer setting is changed.

In the diagnostic mode, the timer is set each time, immediately before the execution of-the SRN basic test or

the host terminal emulation.

Not used. Fixed to OFF.

1 Mbps

OFF

ON

Tmer value

1 Mbps

6.4mS 12.8mS

4.8mS 9.6mS

3.2mS ]

1.6mS

480 Kbps

6.4mS

3.2mS

-2-

Page 5

ER-03RP

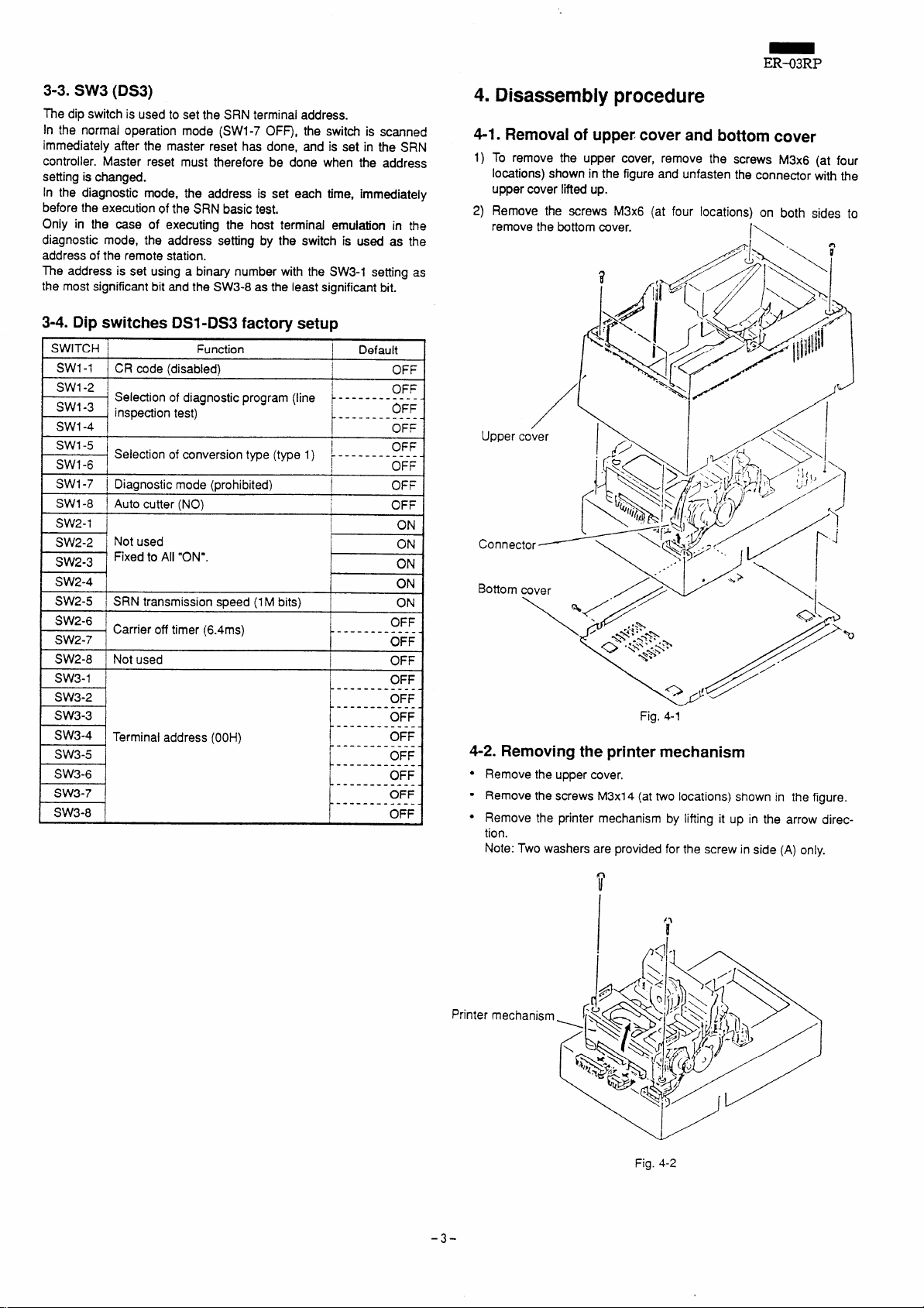

3-3. SW3 (DS3)

The dip switch is used to set the SRN terminal address.

In the normal operation mode (SW1-7 OFF), the switch is scanned

immediately after the master reset has done, and is set in the SRN

controller. Master reset must therefore be done when the address

setting is changed.

In the diagnostic mode, the address is set each time, immediately

before the executi~n of the SRN basic test.

Only in the case of executing the host terminal emulation in the

diagnostic mode, the address setting by the switch is used

address of the remote station.

The address is set using a binary number with the SW3-1 setting as

the most significant bit and the SW3-8 as the least significant bit.

as the

3-4. Dip switches DS1-DS3 factory setup

SWITCH

Swl -1 CR code (disabled)

SW1-2 I

Swl -3

SW1-4 I ‘ ‘

I

SW1-5 i

SWI-6 ~

SWI-7 \ Diagnostic mode (prohibited)

SW1-8 ! Auto cutter (NO)

I

I sw2-1 I

SW2-2

SW2-3

R

I

Selection of diagnostic program (line

inspection test) ------------

1

+Selection of conversion type (type 1) ,

Not used

Fixed to All “ON”.

I

Function Default

I

~--------:;:-

[

~

~-----------,

I

,

I

I

R

I

OFF

OFF

OFF

OFF

OFF

OFF

ON I

4. Disassembly procedure

4-1. Removal of upper cover and bottom cover

To remove the upper cover, remove the screws M3x6 (at four

1)

locations) shown in the figure and unfasten the connector with the

upper cover lifted up.

2)

Remove the screws M3x6 (at four locations) on both sides to

remove the bottom cover.

I

l\

SW2-5 I SRN transmission speed (1M bits) ~

$W2-6 I

SW2-7

SW2-8

SW3-1 I

t

1

I SW3-3 I

I

SW3-4 Terminal address (OOH)

SW3-5

H

I SW3-6 I

i

I

SW3-8 I

I

Carrier off timer (6.4ms)

Not used

I

1

I

I

/

]

.-_----_----

I

!

I

I

I

L------------4

~.

L------------A

L------------q

-------_----

1

L----.---95:

I

L------------q

!-------------+

~

ON

OFF

OFF

OFF

OFF

OFF I

OFF

OFF I

OFF ]

Fig, 4-1

I

4-2. Removing the printer mechanism

● Remove the upper cover.

● Remove the screws M3x14 (at two locations) shown in the figure.

● Remove the printer mechanism by lifting it up in the arrow direc-

tion.

Note: Two washers are provided for the screw in side (A) only.

Printer

-3-

Fig. %2

Page 6

ER-03RP

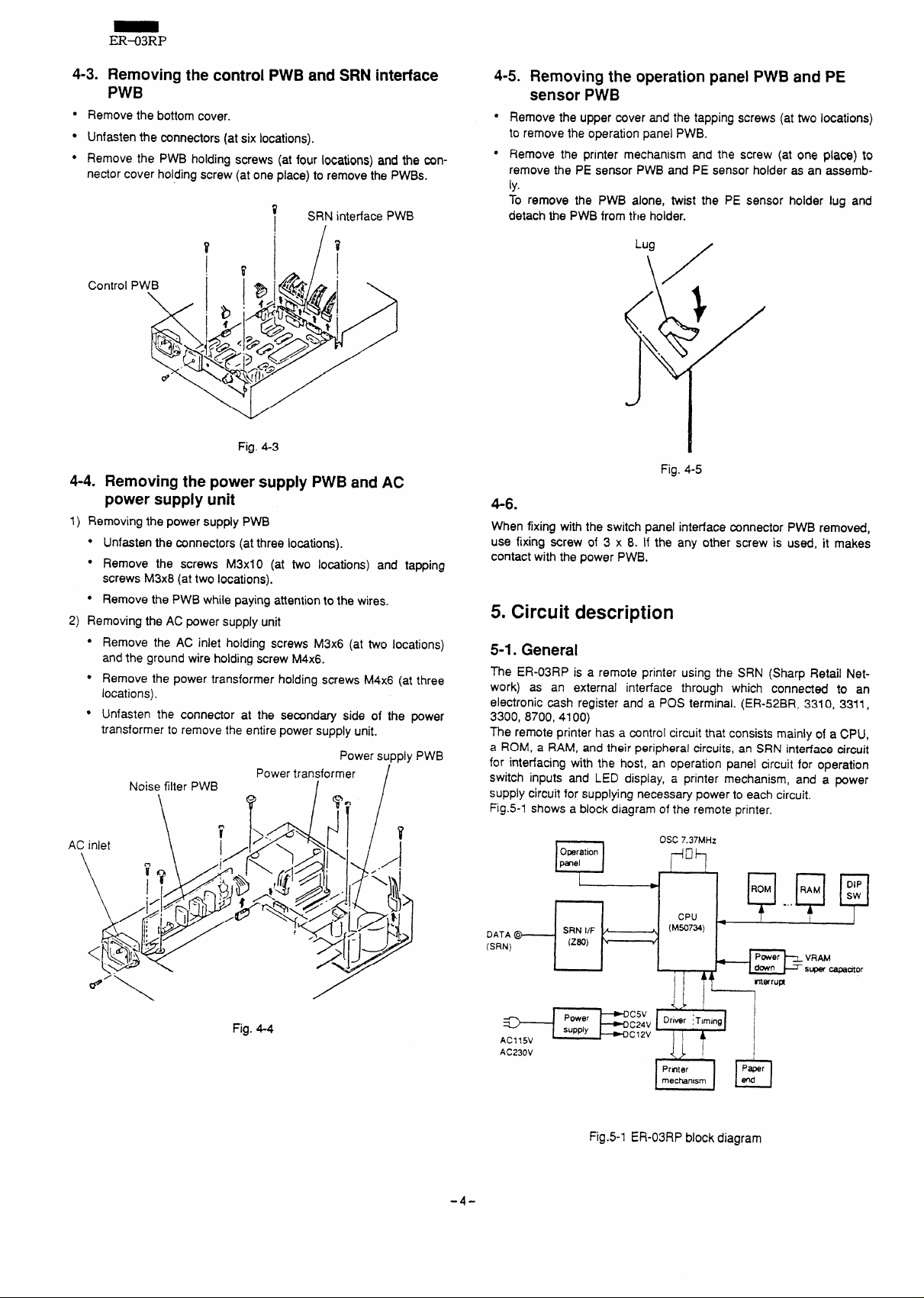

4-3. Removing the control PWB and SRN interface

PWB

●

Remove the bottom cover.

●

Unfasten the mnnectors (at six locations).

●

Remove the PWB holdina screws (at four locati~ns) and the connector cover holding scre; (at one place) to remove the PWBS.

?

SRN interface PWB

Control

Fig. 4-3

4-4. Removing the power supply PWB and AC

power supply unit

Removing the power supply PWB

1)

● Unfasten the connectors (atthree locations).

● Remove the screws M3x1O (at two locations) and tapping

screws M3x8 (attwo locations).

● Remove the PWB while paying attention to the wires.

2) Removing the AC power supply unit

●

Remove the AC inlet holding screws M3x6 (at two locations)

and the ground wire holding screw M4x6.

●

Remove the power transformer holding screws M4x6 (at three

locations).

●

Unfasten the connector at the secondary side of the power

transformer to remove the entire power supply unit.

Power supply PWB

Noise filter PWB

Power transformer

/

I

4-5. Removing the operation panel PWB and PE

sensor PWB

Remove the upper cover and the tapping screws (at two locations)

to remove the operation panel PWB.

Remove the printer mechanism and the screw (at one place) to

remove the PE sensor PWB and PE sensor holder as an assemb-

ly.

To remove the PWB alone, twist the PE sensor holder lug and

detach the PWB from the holder.

Fig. 4-5

4-6.

When fixing with the switch panel intedace connector PWB removed,

use fixing screw of 3 x 8. If the any other screw is used, it makes

contact with the power PWB.

5. Circuit description

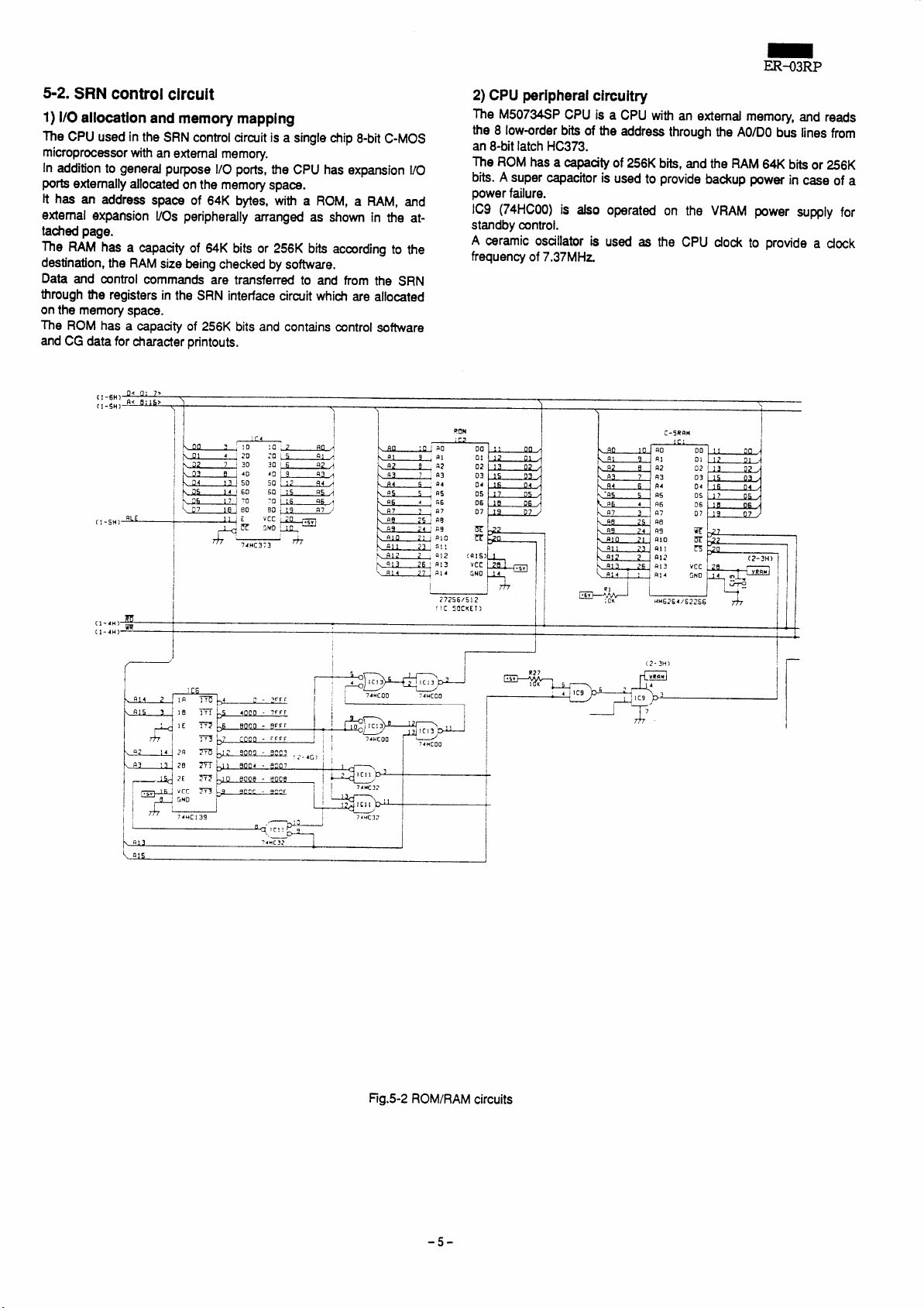

5-1. General

The ER-03RP is a remote printer using the SRN (Sharp Retail Network) as an external interface through which connected to an

electronic cash register and a POS terminal. (ER-52BR, 3310, 3311,

3300, 8700, 4100)

The remote printer has a control circuit that consists mainly of a CPU,

a ROM, a RAM, and their peripheral circuits, an SRN interface circuit

for interfacing with the host, an operation panel circuit for operation

switch inputs and LED display, a printer mechanism, and a power

supply circuit for supplying necessary power to each circuit.

Fig.5-l shows a block diagram of the remote printer.

Fig. 4-4

-4-

m.?. a

AC230V

?

Opratlon

~el

/

SRNIIF

f

I

I

Fig.5-l ER-03RP block diagram

Osc7.37MHZ

,+il

*

(MS0734)

\

I .,

&,fi

CPU

7

..I-i

ROM RAM

Pmer ~VRAM

~-

r---- . .

Page 7

ER-03RP

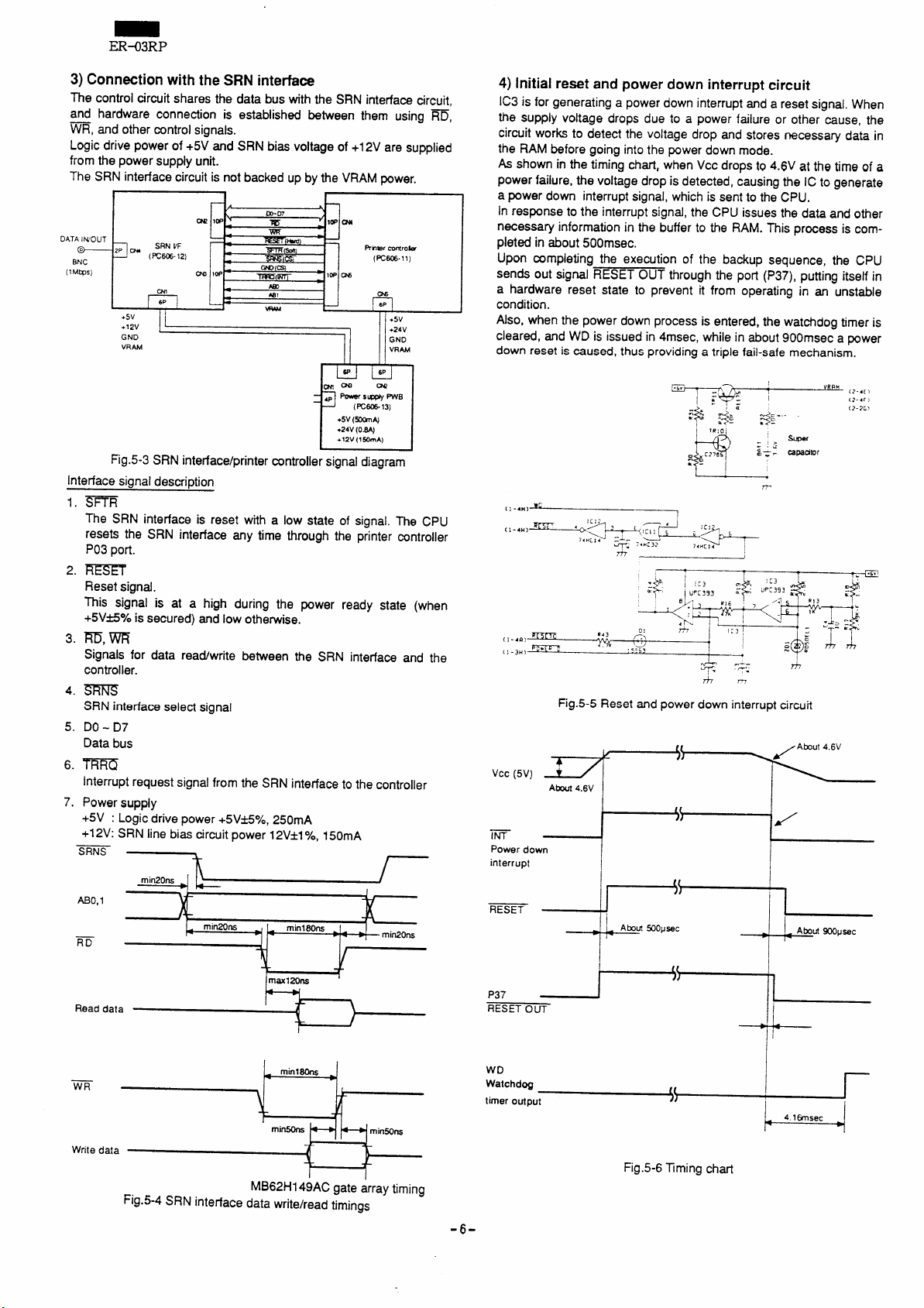

5-2. SRN control circuit

1) 1/0 allocationandmemorymapping

The CPU used in the SRN control circuit is a single chip 8-bit C-MOS

microprocessorwith an external memo~.

In addition to general purpose 1/0 ports, the CPU has expansion 1/0

PO* externally allocated on the memory space.

It has an address space of 64K bytes, w“th a ROM,

externalexpansion 1/0s peripherally manged as shown in the at-

tached page.

The RAM

destination, the RAM size being checked by software.

Data and control commands are transferred to and tiom the SRN

through the registers in the SRN interface circuit which are allocated

on the memory space.

The ROM has a capacity of 256K bits and contains control software

and CG data for character printouts.

hasa capacityof 64K bits or 256K bits according to the

a RAM, and

2) CPUperipheralcircuit~

The M50734SP CPU is a CPUwithanextemdmemory, and reads

the 8 low-order bits of the address through the AO/DObus lines from

an 8-bit latch HC373.

The ROM has

bits. A super capacitor is used to provide backup power in case of a

power failure.

IC9 (74HCOO)is also operated on the VRAM power supply for

standby control.

A ceramic osallator is used as the CPU dock to provide a dock

frequency of 7.37MHz.

acapaatyof256K bits, and the RAM 64K bits or 256K

~

( Qls

74”[00

7“F ‘

)

I

I

Fig.5-2 ROM/RAM circuits

-5-

Page 8

ER-03RP

3)ConnectionwiththeSRNinterface

The control circuit shares the data bus with the SRN interface circuit,

and hardware connection is established between them using ~,

~, and other control signals.

Logic drive power of +5V and SRN bias voltage of +12V are supplied

from the power supply unit.

The SRN interface circuit is not backed up by the VRAM power.

i

DATA INIOUT

o

~

BNC

[lM@s)

SRNIIF

2P W’u

(Wm-lz) (=606-11)

m

6P

I 1

+5V

I

Fig.5-3 SRN interface/printer wntroller signal diagram

Interface sianal descri~tion

1.

m

The SRN interface is reset with a low state of signal. The CPU

resets the SRN interface any time through the printer controller

P03 port.

2.

REsff

Reset signal.

~is signal is at a high during the power ready state (when

+5Vfie\e is secured) and low otherwise.

3.

m, m

Signals for data read/write between the SRN interface and the

controller.

4.

SRNS

SRN interface select signal

5.

DO- D7

Data bus

6.

TRRQ

Interrupt request signal from the SRN interface to the controller

7.

Power supply

+5V : Logic drive power +5V*5%, 250mA

+12V: SRN line bias circuit power 12V*1

““s 7

f

P

IWP ~

04!

IW

C#2

. -

m-07

m

m

WI

m

w

t

5-

RnWr COntrok

w

(PC6C6.13)

+5V (*N

+24V (IJm

+12V (l WA)

1

I I

t-

~m

,P - s- FWB

?“

Yo, 150mA

●5V

4)Initialresetandpowerdowninterruptcircuit

IC3 is for generating a power down interrupt and a reset signal. When

the supply voltage drops due to a power failure or other cause, the

circuit works to detect the voltage drop and stores necessary data in

the RAM before going into the power down mode.

As shown in the timing chart, when Vcc drops to 4.6V at the time of a

power failure, the voltage drop is detected, causing the IC to generate

a power down interrupt signal, which is sent to the CPU.

in response to the interrupt signal, the CPU issues the data and other

necessary information in the buffer to the RAM. This process is compieted in about 500msec.

Upon mmpieting the execution of the backup sequence, the CPU

sends out signal RESET OUT through the port (P37), putting itseif in

a hardware reset state to prevent it from operating in an unstabie

condition.

Aiso, when the power down process is entered, the watchdog timer is

cieared, and WD is issued in 4msec, whiie in about 900msec a power

down reset is caused, thus providing a tripie faii-safe mechanism,

w:

; 1-4H>

I

Fig.5-5 Reset and power down interrupt circuit

‘cc(’v)r-

Powerdown

interrupt

m

Readdata

Writedata

t

maw120n2

T

MB62H149AC gate array timing

Fig.5-4 SRN interface data write/read timinas

P37 r’~1

RESETOUT

WD

Watchdog

timeroutput

Fig.5-6 Timing chm

-6-

Page 9

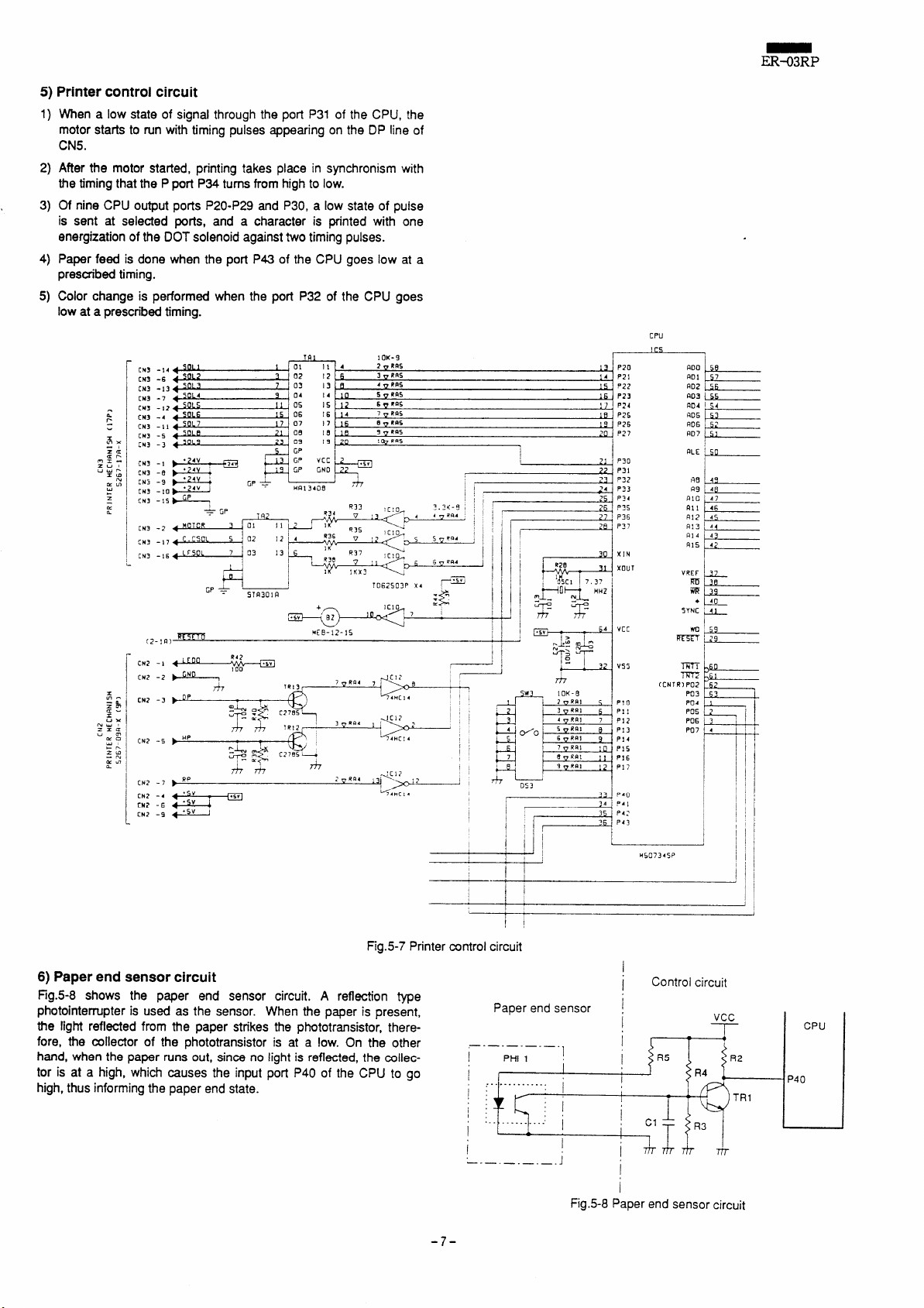

5)Printercontrolcircuit

1)

When a low state of signal through the port P31 of the CPU, the

motor starts to run with timing pulses appearing on the DP line of

CN5.

2)

After the motor statied, printing takes place in synchronism with

the timing that the Pport P34 turns from high to low.

3)

Of nine CPU output ports P20-P29 and P30, a low state of puise

is sent at selected ports, and a character is printed with one

energization of the DOT solenoid against two timing pulses.

4)

Paper feed

prescribed timing.

Color change is performed when the port P32 of the CPU goes

5)

low

is done when the port P43 of the CPU goes low at a

ataprescribed timing.

CM3 -14

CN3 -6

CH3-13

CN3-7

CM3-12

(N3 -4

CN3 -11

CN3 -5

CN3 -3

CM3 -i

CM3 -.9

,,,,,”:&;‘GpW~ ; ‘

+ 4V HRI 3408

.-

CN3 - 1s

CN3 -2

CN3 -17

CN3 -16

191

1OK-9

ER-03RP

CPU

---

P20

13

1s P23

I p24

1?,

1s P2S

P26

19

P27

20

‘ P30

21

22- P31

P32

23

i’

24 P33

XIN

X12UT

4s

d4

t

43

CN2 - I

CN2 -2

CN2 -3

CN2 -5

[N? -7

CN2 -4

CN2 .6

CN2 -9

54 HC14

Fig.5-7 Printer control circuit

6) Paperend

Fig.5-8

sensor circuit

shows

the paper end sensor circuit. A

reflection type

p~otointerrupter is used as the sensor. When the paper is present,

the light reflected from the paper strikes the phototransistor;, there-

fore, the collector of the phototransistor is at a low. On the other

hand, when the paper runs out, since no light is reflected, the collector is at a high, which causes the input port P40 of the CPU to go

high, thus informing the paper end state.

1

I

1

I

I

23

2A p.)

354

~ ~

end sensor ~

Paper

—.—.—.—.—. I

PHI 1

1

!

.,

i:

1.

I

I

—.—.—.—.—.

1

I

J

Fig.5-8 Paper end sensor circuit

V55

?!0

PI 1

P12

P13

P14

Pl!i

Pls

P17

P40

P42

1

I

1

I

I

m

0

$1

m

[CNTR) P02

P03

62

63 I

I

Control circuit

\tPP I

v Gu

-7-

Page 10

ER-03RP

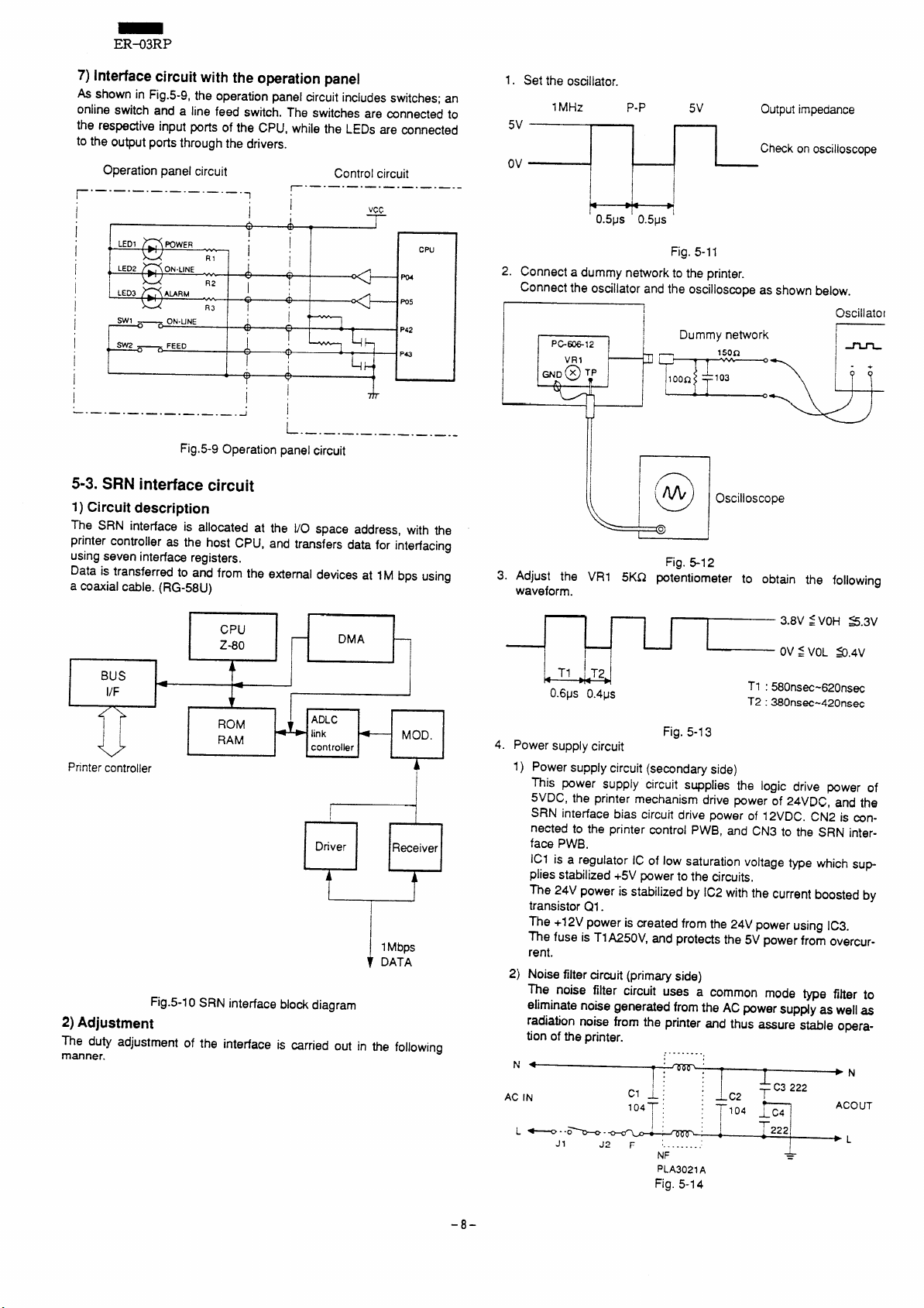

7)Interfacecircuitwiththeoperationpanel

shown in Fig.5-9, the operation panel circuit includes switches; an

As

online switch and a line feed switch. The switches are mnnected to

the respective input ports of the CPU, while the LEDs are connected

to the output ports through the drivers.

Operation panel circuit

.—.—.—.—.—.—.—.—.

r

I

,

I

LED1

nFQwER

,,

I

I

LED2

~ON-LINE

(I

LED3

~URM

i ,=.—O

I i;

-. —. —. —. —. —. —. —.—. J

ON-LINE

—

RI

R2

R3

1;

1!

w

i

“

1:

I

A

n

.

.

Y I T

L

Control circuit

.—.—.—.—.—.—.—. —.-

r

vc~

-

I

I

I

J

CPU

PD4

ms

P42

4

.—.—.—.—.—.—.—-—--

Fig.5-9 Operation panel circuit

5-3. SRN interface circuit

1) Circuit description

The SRN interface is allocated at the l/O space address, with the

printer controller as the host CPU, and transfers data

using seven interface registers.

Data is transferred to and from the external

devices at IM bps using

a coaxial cable. (RG-58U)

for interfacing

t 1 b I

CPU

Z-80

DMA

1. Set the oscillator.

1MHz

P-P

5V

Outputimpedance

5V

Checkonoscilloscope

Ov

L

P 1-

o.5ps o.5ps ‘

+

Fig. 5-11

2. Connect a dummy network to the printer.

Connect the oscillator and the oscilloscope as shown below.

PG-12

VR1

~D @ TP

[

I

Dummv network

Oscillator

I

@

3. Adjust the VR1 5KQ potentiometer to obtain the following

waveform.

Fig, 5-12

BUS

.? ‘

l/F

&

ADLC

link

controller

I

I

Driver

MOD.

A

Receiver

u

printer controller

ROM

RAM

b

TIP

[

I

1Mbps

I DATA

Fig.5-10 SRN interface block diagram

2)Adjustment

The duty adjustment of the intedace is carried out in the following

manner.

w

0.6ps 0.4ps

*

4. Power supply circuit

1)

Power supply circuit (secondary side)

Fig. 5-I 3

T1 : 580nsec-620ns~

T2 :380nsec-420nsW

This power supply circuit supplies the logic drive power of

5VDC, the printer mechanism dtive power of 24VRC, and the

SRN interface bias circuit drive

power of 12VDC. CN2 is mn-

nected to the printer control PWB, and CN3 to the SRN interface PWB.

ICI is a regulator IC of low saturation voltage type which sup

plies stabilized +5V power to the circuits,

The 24V power is stabilized by IC2 with the current boosted by

transistor Q1.

The +12V power is created from the 24V power using IC3.

The fuse is TlA250V, and protects the 5V power from overcurrent.

2)

Noise filter circuit (primary side)

The noise filter circuit uses a common mode type fiher to

eliminate noise generated from the

ACpower sup~y as well as

radiation noise from the printer and thus assure stable operation of the printer.

,.........,

●

N

AC IN

L/.~ --OL -~

JI

T :- : 1 T

cl i j j C2 ~

104 ; :

T

J2 F ‘.........’

NF

pLA3021A

‘1

: ~lo4 ~w

:J

-’- C3222

T222

i

=

➤ N

ACOUT

➤ L

Fig. 5-14

-8-

Page 11

ER-03RP

6. Printer unit description

6-1. Hints and tips in handling the printer

6-1-1. Hintsinusingtheprinter

Do not operate the printer

(1)

paper and ink ribbon. Printing without

damage the printhead and platen surface, deteriorate the print

quality, and

(2)

Do not try to move the print head by hand. Since the belt that

drives the print head is directly coupled with a gear train, the belt

and the carnage drive pipe will be subjected to overload

the print head is

and other trouble.

(3)

Since the printer uses a permanent magnet (in the motor) and

an electromagnet, avoid using the printer in a location that may

be subjected to a large amount of iron filings, dust, dirt, etc.

Printed circuit boards are mounted in the bottom of the orinter.

(4)

Take care so that the printed circuit boards do not c~me in

contact with the case or foreign materials do not adhere to the

boards.

shorten the printer life.

moved by hand, leading to timing misalignment

6-1-2. Hints in storing the printer

(1)Do not store the printer in a location where a large amount of

or dirt, high temperature, or high humidity is encountered.

dust

6-2. How to load the paper

Use paper of prescribed standard.

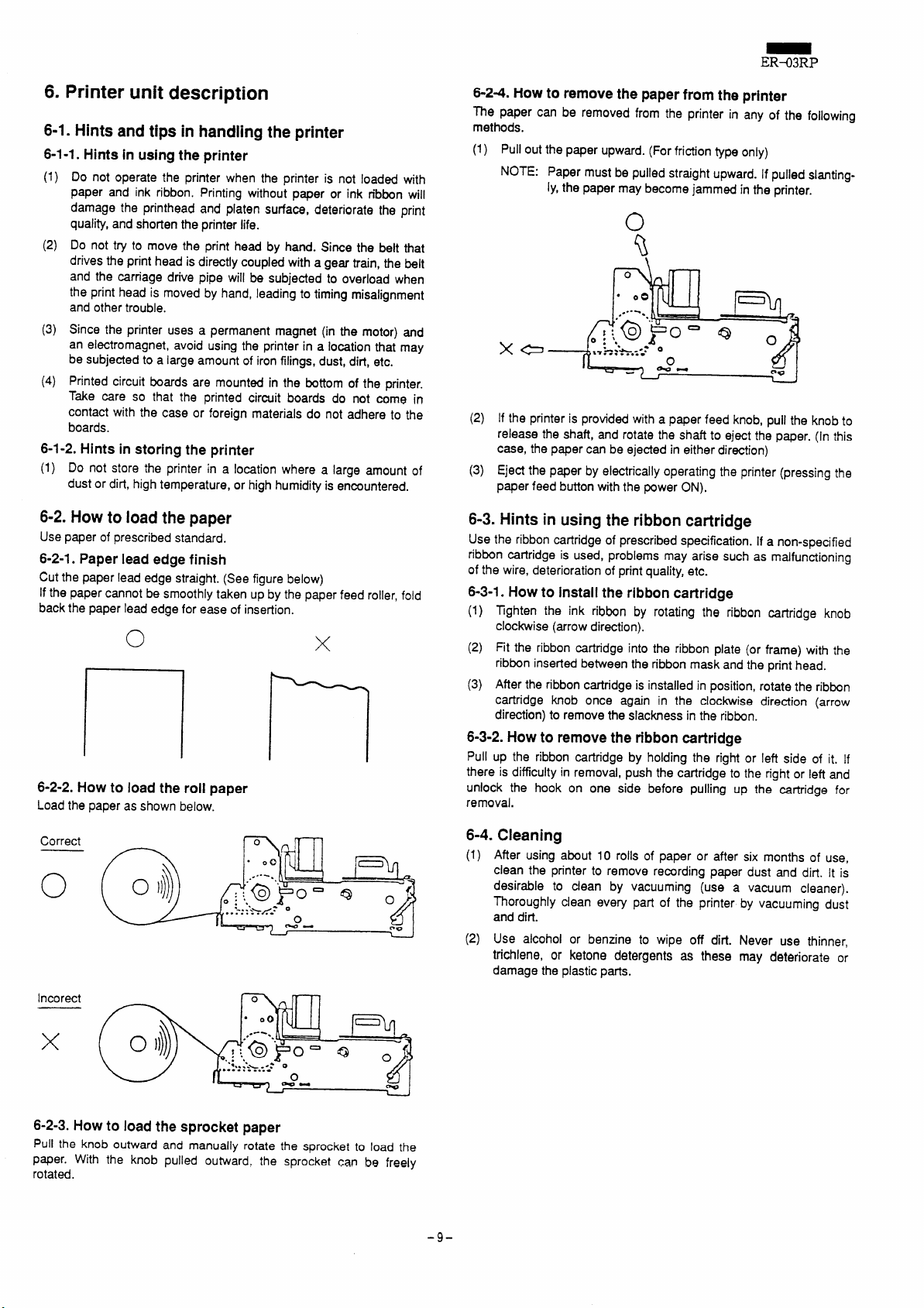

6-2-1. Paperleadedgefinish

Cut the paper lead edge straight. (See figure below)

If the paper cannot be smoothly taken up by the paper feed roller, fold

back the paper lead edge for ease of insertion.

o

6-2-2.How to loadthe rollpaper

Load the paper as shown below.

when the printer is not loaded with

paper or ink ribbon will

when

x

6-24. How

The paper can be removed from the printer in any ofthe following

methods.

(1) Pull out the paper upward. (For fridion type only)

to removethepaperfromthe printer

NOTE: Paper must be pulled straight upward. If pulled slanting-

ly,the paper may become jammed in the printer.

\

1““Qllw1I

(2) If the printer is provided with a paper feed knob, pull the knob to

release the shaft, and rotate the shaft to eject the paper. (in this

case, the paper can be ejected in either direction)

(3) Eject the paper by electrically operating the printer (pressing the

paper feed button with the power ON),

6-3. Hints in using the ribbon cartridge

Use the ribbon cartridge of prescribed specification. If a non-specified

ribbon cartridge is used, problems may arise such as malfunctioning

of the wire, deterioration of print quality, etc.

6-3-1. Howto installtheribboncartridge

Tghten the ink ribbon by rotating the ribbon cartridge knob

(1)

clockwise (arrow direction).

(2) Fit the ribbon cartridge into the ribbon plate (or frame) with the

ribbon inserted between the ribbon mask and the print head.

(3) After the ribbon cartridge is installed in position, rotate the ribbon

catiridge knob once again in the clockwise direction (arrow

direction) to remove the slackness in the ribbon.

6-3-2.Howto removetheribboncartridge

Pull up the ribbon cartridge by holding the right or left side of it. If

there is difficulty

unlock the hook on

removal.

in removal, push the cartridge to the right or left and

one side before pulling up the cartridge for

Correct

o

Incorect

x

6-2-3. How to load the sprocket paper

Pull the knob outward and manually rotate the sprocket to load the

paper. With the knob pulled outward, the sprocket can be freely

rotated.

6-4. Cleaning

(1)

(2)

-9-

After using about 10 rolls of paper or after six months of use,

clean the printer to remove recording paper dust and dirt. It is

desirable to clean by vacuuming (use a vacuum cleaner).

Thoroughly clean eve~ part of the printer by vacuuming dust

and dirt.

Use alcohol or benzine to wipe off dirt. Never use thinner,

trichlene, or ketone detergents as these may deteriorate or

damage the plastic parts.

Page 12

ER-03RP

7. Overview and operating principle of the

printer

7-1. Overview

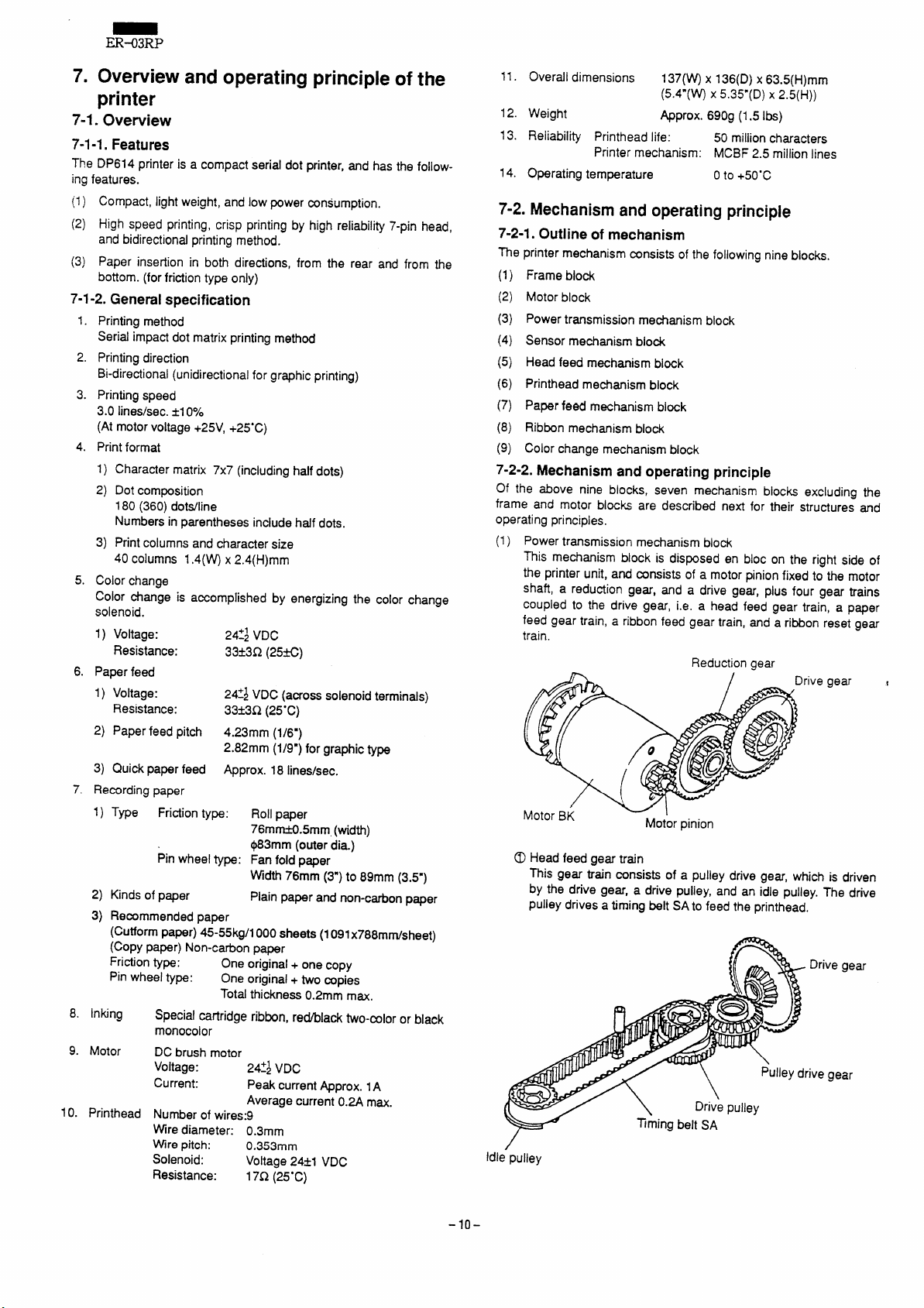

7-1-1.Features

The DP614 printer is a compact serial dot printer, and has the following features.

(1) Compact, light weight, and low power consumption.

(2) High speed printing, crisp printing by high reliability 7-pin head,

and bidirectional printing method.

(3) Paper insertion in both directions, from the rear and from the

bottom. (for friction type only)

Generalspecification

7-1-2.

1.

Printing method

Serial impact dot matrix printing method

2.

Printing direction

Bi-directional (unidirectional for graphic printing)

Printing speed

3.

3.0 iines/sec.

(At motor voltage +25V, +25*C)

4.

Print format

1) Character matrix 7x7 (including half dots)

2) Dot composition

180 (360) dots/line

Numbers in parentheses include haff dots.

3) Print columns and character size

40 columns 1,4(W) x 2.4(H)mm

5.

Color change

Color change is accomplished by energizing the color change

solenoid.

1) Voltage:

Resistance:

6.

Paper feed

1) Voltage:

Resistance:

2) Paper feed pitch

3) Quick paper feed

7.

Recording paper

1)

Type

2)

Kinds of paper

3)

Recommended paper

(Cutform paper) 45-55kg/l 000 sheets (1091x788mrn/sheet)

(Copy paper) Non-carbon paper

Friction type:

Pin wheel type:

Inking

8.

9. Motor

10. Printhead

*1 070

24ti VDC

33*3Q (25&)

24~~VDC (across solenoid termin~s)

33*3Q (25-C)

4.23mm (1/6”)

2.82mm (1/9”) for graphic type

Approx. 18 lines/see.

Friction type:

Pin wheel type: Fan fold paper

Special cartridge ribbon, red/black two-color or black

monocolor

DCbrush motor

Voltage:

Current:

Number of wires:9

Wire diameter: 0.3mm

Wire pitch:

Solenoid:

Resistance:

Roll paper

76m@.5mm, (width)

$83mm (outer dia.)

Width 76mm (3”) to 89mm (3.5”)

Plain paper and non-carbon paper

One original + one copy

One original + two copies

Total thickness 0.2mrn max.

24t4 VDC

Peak current Approx. 1A

Average current 0.2A max.

0.353mm

Voltage 24*1 VDC

17Q (25*C)

11. Overall dimensions

12. Weight

13. Reliability Printhead life:

Printer mechanism: MCBF 2.5 million lines

14. Operating temperature

137(W) x 136(D) x 63.5(H)mm

(5.4”(~

Approx. 690g (1,5 Ibs)

X 5.35”(D) X 2.5(H))

50 million characters

o to +50”C

7-2. Mechanism and operating principle

7-2-1.Outlineof mechanism

The printer mechanism mnsists of the following nine blocks.

(1)

Frame block

(2)

Motor block

(3)

Power transmission mechanism block

(4)

Sensor mechanism block

(5)

Head feed mechanism block

(6)

Printhead mechanism block

(7)

Paper feed mechanism block

(8)

Ribbon mechanism block

(9)

Color change mechanism block

Mechanismandoperatingprinciple

7-2-2.

Of the above nine biocks, seven mechanism blocks excluding the

frame and motor blocks are described next for their structures and

operating principles.

(1) Power transmission mechanism block

This mechanism block is disposed en bloc on the right side of

the printer unit, and consists of a motor pinion fixed to the motor

shaft, a reduction gear, and a drive gear, plus four gear trains

coupled to the drive gear, i.e. a head feed gear train, a paper

feed gear train, a ribbon feed gear train, and a ribbon reset gear

train.

Reduction gear

gear

@ Head feed gear train

This gear train consists of a pulley drive gear, which is driven

by the drive gear, a drive puliey, and an idle pulley. The drive

pulley drives a timing belt SA to feed the printhead.

Drive gear

ive gear

ldl~pulley

-10-

Page 13

ER-03RP

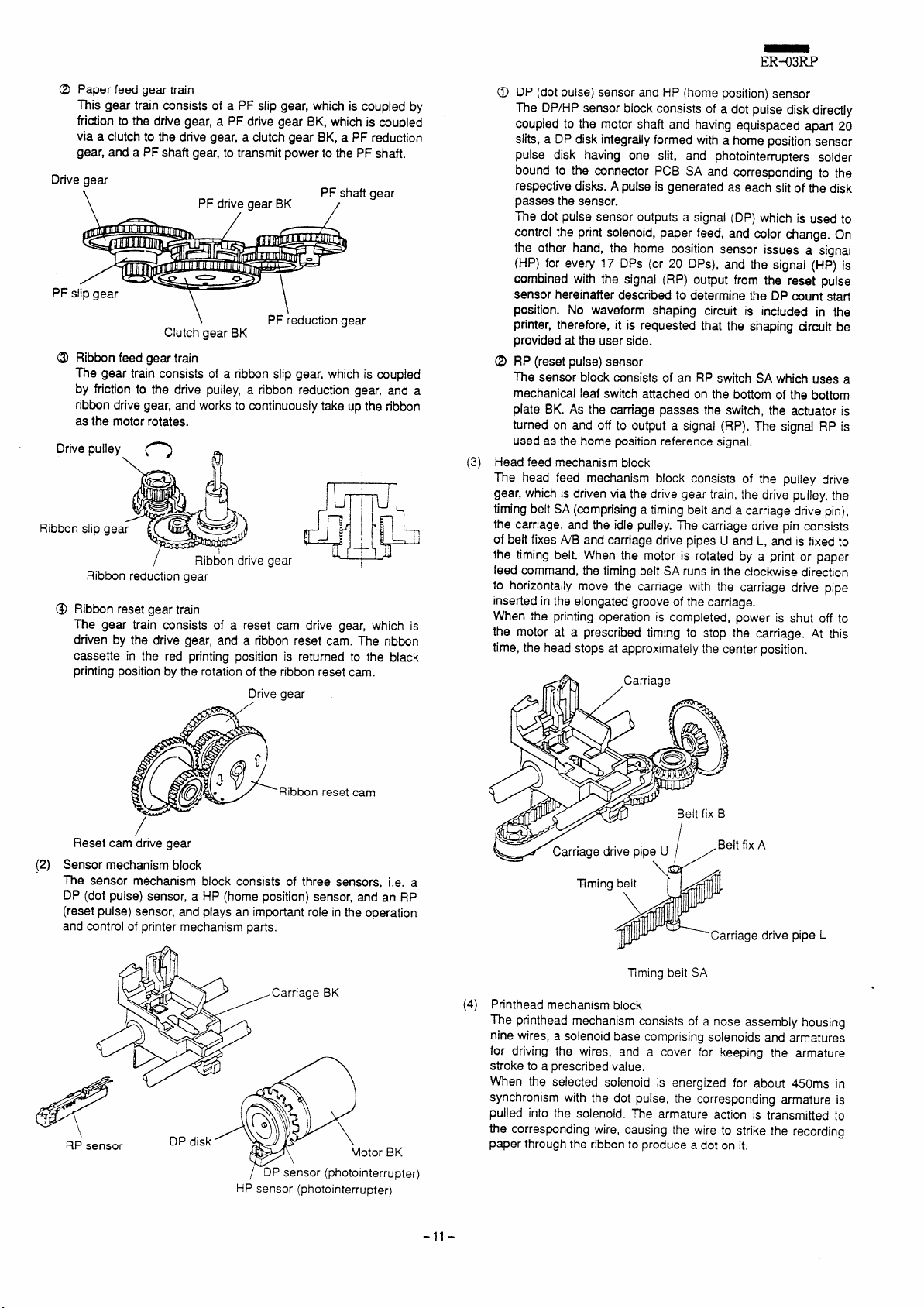

Paper feed gear train

This gear tr~n consists of a PF slip gear, which is coupled by

friction to the drive gear, a PF drive gear BK, which is coupled

via a cfutch to the drive gear, a clutch gear BK, a PF reduction

gear, and a PF shaft gear, to transmit power to the PF shaft.

Drive gear

\

Si

PF

PF drive gear

\

Clutch gear

, /

PF reduction gear

BK

BK

PF shaft gear

@ Ribbon feed gear train

The gear train consists of a ribbon slip gear, which is coupled

by friction to the drive pulley, a ribbon reduction gear, and a

ribbon drive gear, and works to continuously

take up the ribbon

asthe motor rotates.

Drive pulley

Ribbon slip gea

Ribbon reduction gear

Ribbon reset gear train

@

The gear train consists of a reset cam drive gear, which is

driven by the drive gear, and a ribbon reset cam. The ribbon

cassette in the red printing position is returned to the black

printing position by the rotation of the ribbon reset cam.

o

\

/

0

Ribbon drive

gear

Drive gear

DP (dot pulse) sensor and HP (home position) sensor

The DP/HP sensor block consists of a dot pulse disk directly

coupled to the motor shaft and having equispaced apart 20

slits, a DP disk integrally formed with

ahome position sensor

pulse disk having one slit, and photointerrupters solder

bound to the mnnector PCB SA and corresponding to the

respective disks. A pulse is generated as each slit of the disk

passes the sensor.

The dot pulse sensor outputs a signal (DP) which is used to

the print solenoid, paper feed, and mlor change. On

control

the other hand, the home pcsition sensor issues a signal

(HP) for every 17 DPs (or 20 DPs), and the signal (HP) is

combined with the signal (RP) output from the reset pulse

sensor hereinafter described to determine the DP count start

position. No waveform shaping circuit is included in the

printer, therefore, it is requested that the shaping circuit be

provided at the user side.

RP (reset pulse) sensor

The sensor

mechanical !eaf switch

block consists of an RP switch SA which uses a

attached on the bottom of the bottom

plate BK. As the cm-age passes the switch, the actuator is

turned on and off to output a signal (RP). The signaf RP is

used as the home position reference signal.

(3)

Head feed mechanism block

The head feed mechanism block consists of the pulley drive

gear, which is driven via the drive gear

train, the drive pulley, the

timing belt SA (mmprising a timing belt and a carriage drive pin),

the carriage, and the idle pulley. me carriage drive pin consists

of beit fixes WB and carriage drive pipes U and L, and is fixed to

I

the timing belt. When the motor is rotated by a print or paper

feed command, the timing belt SAruns in the clockwise direction

to horizontality move the carriage with the carriage drive pipe

inserted in the elongated groove of the carriage.

When the printing operation is completed, power

is shut off to

the motor at a prescribed timing to stop the carriage. At this

time, the head stops at approximately the center position.

Ribbon reset cam

/

cam drive gear

Reset

(2)

Sensor mechanism block

The sensor mechanism block consists of three sensors, i.e. a

DP (dot pulse) sensor, a HP (home position) sensor, and an RP

(reset pulse) sensor, and plays an important role in the operation

and control of printer mechanism parts.

HP sensor (photointerrupter)

otor BK

nterrupter)

-11-

Timing

rriage drive pipe L

SA

(4)

Printhead mechanism biock

Tming belt

The printhead mechanism tinsists of a nose assembiy housing

nine wires, a solenoid base comprising soienoids and armatures

for driving the wires, and a cover for keeping the armature

stroke to a prescribed vaiue.

When the selected soienoid is energized for about 450ms in

synchronism with the dot pulse,

the corresponding armature is

pulied into the soienoid. me armature action is transmitted to

the corresponding wire, causing the wire to strike the recording

paper through the ribbon to produce a dot on it.

Page 14

ER-03RP

Ifl /p”n’

‘T

Nose assembly/

Paper feed mechanism

(5)

The paper feed mechanism consists of the paper feed power

transmission mechanism described in 2-2-2. (l)-(2), a paper

feed solenoid which controls the clutch mechanism, a PF

lever, and a clutch cam. The

The clutch mechanism has a spring clutch, consisting of a PF

drive gear BK, a clutch gear BK, a clutch spring, and the clutch

cam, to transmit the rotation of the clutch gear BK to the PF

drive gear BK.

Two paper feed methods are available for the printer, the friction

method and the pin wheel method.

Drive

PF slips

PF slipgea’r

Clutch cam I

\Solenoid base

PF shaft is driven to feed the paper.

PF shaft

\

,=”L

‘ <i

;)

.

//

Clutch spring

o

5

stopper

spring

PF shaft gear

Paper feed

solenoid

PF trigger lever

0

\

Clutch gear BK

trigger

[Paper feed overload protection mechanism]

A safety mechanism is provided to prevent gear breakage

and motor coil burning due to the motor seizure in case

overload is applied to the PF shaft because of p~er jam,

etc. The PF slip gear is coupled by friction to the drive gear

via the PF slip spring, and is so constructed that when the PF

shah is subjected to a greater load than a prescribed torque,

it slips on the PF shaft to absorb the overload.

,Side plate R

tve gear

slip

PF

y\

[Paper release mechanism]

me PF shaft gear is coupled to the PF ratchet fixed to the

PF shaft so that the ratchet engagement is released when

the paper is pulled in the forward direction, thus allowing the

paper to be smoothly pulled out. Also, if a knob is mounted

on the PF shafi, the ratchet engagement can be released by

pulling the knob outward, thus allowing the PF shaft to be

freely rotated. In this situation, the paper can be fed in either

forward or reverse directions by rotating the knob.

slip gear

Pivot drive gear

\

0 Friction type (Type D/P61*-*F*)

The friction type consists of two PF rollers fixed to the PF

shaft, pressure rollers press-contracting the respective PF

rollers, and pressure roller springs applying pressure to the

respective pressure rollers. Paper is fed by the friction force

acting between the PF rollers and the pressure rollers, Paper

can be inserted either from the rear or from the bottom.

aft

gear

do

o

A

‘u ”Rear

t

Pressure roller spring

Bottom

PF ratchet

(6)

Ribbon mechanism block

The mechanism block consists of a ribbon cartridge in which an

endless ribbon is housed, a ribbon feed gear train, and a ribbon

drive pole SA which is driven by the ribbon feed gear train.

When the motor is in rotation, the ribbon drive pole SA is continuously rotated via the gear train, to drive the ribbon gear

contained in the ribbon cartridge so that the ribbon is continuously taken

The ribbon drive pole SA is coupled to the ribbon drive gear via

a ratchet, so that it can be rotated freely in the direction in which

the ribbon is taken up (in the forward direction). Therefore, the

cartridge knob can be rotated to take up the ribbon with the

ribbon cartridge installed in the printer.

up.

PF shaft gear

-12-

Ribbon drive gear

Page 15

The two-color ribbon cartridge (D type) is mounted on the ribbon

plate, and the mono-color type (M type) on the frame,

Mono-color ribbon cartridge mounted in position

Two-color ribbon cartridge mounted in position

ER-03RP

(7) Color change mechanism block (for Dtype only)

The mechanism block consists of a ribbon plate on which to

mount a ri~on cartridge, a color change lever,

solenoid, a ribbon reset cam, and a reset cam drive gear.

In normal operating condition, the ribbon plate is locked in position by the lower hook of the color change lever,

black ribbon area in the printing position. When the mlor change

solenoid is energized through a red print command, the color

change lever is pulled in to disengage the lower hook from the

ribbon plate. The mior change lever swings upward by the force

of the color change lever, hitting the upper hook of the color

change lever. The ribbon plate is thus retained by the upper

hook, setting the red ribbon area in the printing position for red

printing. When the printing is completed, the ribbon plate is

pulled downward by the ribbon reset cam, engaged with the

lower hook of the color change lever, and reset to the original

position (black printing position).

The timing is so set that the ribbon reset cam will be operated

when the printhead is in a non-printing area at the extreme right

or left, to avoid accidental resetting during printing.

a color change

holdingthe

change

or

solenoid

[Safety mechanism]

If the ribbon gear binds because of a ribbon jam, the motor

may be subjected to overload, causing gear tooth breakage,

motor coil burning, and other troubles. To prevent such

troubles, the ribbon slip gear is coupled by friction to the

drive pulley via the ribbon slip spring, and is so constructed

that it slips in the drive pulley when the r!bbon feed system is

subjected to overload.

Drive pull

Fixed

Ribbon slip spr

Ribbon slip g

Color ch’angespring

-\

Ribbon reset

cam

e lever

[Black printing]

uIIin

d printing]

[Resetting]

I

Fixed

-13-

Page 16

ER-03RP

8. Troubleshooting

Repairing procedure

8-1.

Repairs should be done in accordance with Section 3 “Troubleshooting chart” after acquiring working knowledge of the operating principle

and construction of the printer.

Also refer to 8-2 “Connector and wiring diagrams” which should

facilitate the check and repair work. - -

8-2. Connector and wiring diagrams

8-2-1.Connectordiagram

4286

diagram

Printhead SA

Head FPC

Connector C

SOL4

1

2

SOL2

3 SOL6

4

SOL6

5 SOL9

r

6 + 24V

7 + 241’

8 + 24V

9 SOL?

)0 Sou

11 Sou

12

SOLI

13 F CND

I

Connector PCB SA

l[y[

I I

~ i

i,

I

Ii

T

MA

5

6 \ SOL2

I

7 Soti

8 I +24V

9 + 24V

10 + 24\’

1$ PF @ii ‘

17 cc on!

cc~

10

connector B

rOcontrol biOck

1

17

Connector A

Connector PWB SA

UKOG-6669RCZZ

L

1

DP sensor

k

1

J

●

(

Y HPsensor

+w~ i

1

(F

Validation (option)

L

I

1

I

1

T

l~Jl[’~-

RP sensor paper end (op~ion)

J

-14-

Tomntrol

block

J

Wiring diagram

Page 17

8-3.Troubleshootingchart

8-3-1.Headfeedtrouble

Phenomenon

Carriage does not

move

Carriage does not stop DP/HP/RP signal

Symptom

Motor does not run Motor defective

Motor runs

Possible cause

Applied voltage to

motor not normal

Connector PCB SA

defective

Paperjam

Printhead w“re caught Check if wire gets caught. Replace printhead SA.

in ink ribbon or paper

Foreign matter caught Manually rotate motor pinion to check if

in gear wheel train or

broken gear causing

action failure

~ming belt SA and Remove carriage BK and check if

pulley out of phase carriage drive pin and pulley timing belt SA.

Carriage bearing

trouble

DP/HP/RP signal

I abnormal

abnormal and its output waveform. Also check replace sensor, or

Trouble in control block ‘ Check hardware circuit in control block

ER-Q3RP

Checking procedure

Apply rated voltage across soldered

motor leads @(red)

solder side of connector

PCB SAto &eck if motor runs.

Check voltage across pin 1 (~) and pin

2 (~) of ~nnector A on connector PCB

SA to see if applied voltage is normal.

Check for continuity between pin 1 of

connector A and motor lead (red) and PCB SA.

between pin 2 and motor lead (black).

Remove printhead and checkfor

jammed paper or foreign matter.

gear train moves smoothly. matter, etc. or replace

engagement is not out of phase.

Check if carriage rail (front and rear) is

i lubfi~ted and if ~rriage r~l moves

i smoothly when turned by hand. oil, or replace carriage

Check voltage applied to each sensor Repair control block,

and its output waveform. Also check replace sensor, or

connector PCB SAfor continuity. replace connector

Check voltage applied to each sensor

connector PCB SAfor continuity.

and wiring from control block.

and ~(black) on

I Adjust position of

I matter, etc. and apply

replace connector

Repair control block or

rectify wiring.

Remedy

Replace motor.

Repair control block.

Replace connector

Remove foreign

matter, etc.

(Also replace ribbon

cassette if wire gets

caught in ribbon)

Remove foreign

broken gear.

Remove foreign

BK and carriage rail.

PCB SA.

Repair control block.

PCB SA.

8-3-2.Printing trouble

Phenomenon

Cannot print (ail dots

or particular dots)

Symptom

Carriage motion is

normal failure

Head FPC connection

Printhead SA defective

Improper mounting of

ink ribbon I

“

DP/HP/RP signal

abnormal

Trouble in control block Check hardware circuit in control block

Connector PCB SA

defective

Foreign matter caught

in printing area

Deformation or Remove printhead SA and check ribbon

improper mounting of

ribbon mask

Possible cause Checking procedure Remedy

Check connection of FPC.

Replace printhead SA with a new one Replace printhead SA.

and check the result.

, Check mounting condition of ribbon.

Check voltage applied to each sensor Repair control block,

and its output waveform. Also check replace sensor, or

connector PCB SAfor mntinuity. replace connector

and wiring from control block.

Check for continui~ between cunnector I

A and connector B. (Refer to 8-2. Wiring

diagram)

Remove printhead SA and check printing

area for foreign matter.

mask for deformation and mounting

I condition.

-15-

Firmly insert FPCto

establish proper

connection.

‘ Mount ink ribbon

correctly.

PCB SA.

Repair control block or

rectify wiring.

Replace conne~or

PCB SA.

Remove foreign

matter.

Replace or properly

mount ribbon mask.

Page 18

Phenomenon

Printed characters too

light

3i-directional printing

nisafignment

9

Symptom ~

No ribbon feed

[ cassette.

Ribbon feed is normal

Misalignment

than 3.5 columns (17

dots)

Misalignment inside of

2 dots (misalignment

inside of 0.3mm is

within specification)

greater

Possible cause ~

~Improper mounting of

ribbon cassette

Ribbon cassette

defective

Foreign matter caught

in ribbon drive

mechanism or broken ~smoothly.

gear causing action ~

Troubie in ribbon slip ~

mechanism

Improper gap

, between printhead

I and platen

Trouble in controlblock I Check voltage ~plied from control block

Improper mounting

‘Sition OfRp sensor

Improper mounting

position of connector

PCBSA

~Check mounting condition of ribbon

1cassette.

I

! Rotate ribbon cassette

~arrow direction to check knob operation

\ and ribbon takeup condition.

t Manually rotate motor pinion

~toward you to check if gear train moves

t

I

With ribbon cassette mounted in

~position, manually rotate motor pinion in

~direction toward you to check if ink

ribbon is taken up properly.

Check gap

I platen.

~.

~as well as voltage added time.

I

i Try to shift RP sensor mounting position

I to left or right to check if bidirectional

I

prlntlng misalignment is corrected.

; Tryto shift connector PCB SAforward or

~backward to check if biairectionai

; printing misalignment is corrected.

I

Checking procedure

takeup knob in

in direction

between printhead and

Properly mount ribbon

cassette.

Replace ribbon

Remove foreign

matter, etc. and

I replace broken gear.

I I

Replace ribbon slip

mechanism.

gap.

‘ Adjust

Repair control block.

Readjust RP sensor.

Readjust connector

PCB SA.

Remedy

;-3-3.Paperfeedtrouble

Phenomenon

Cannot insert paper

I

Paper feed does not

operate at all or fails

to operate sometimes

paper feed pitch

improper

Symptom

PF coil does not pull in

PF coil puIIsin

Paper feed pitch too

great

Possible cause

paper lead edge is

bent or improperly cut ~and cut straight.

Trouble because of !

non-standard paper

Trouble because of ,

paper dust or foreign

matter

Improper loading of

paper on pin wheels

G~ between pF coil

and PF trigger lever is

too wide

PFcoil defective

Connector PCB SA

defective

Trouble in control biock ~Check hardware circuit in mntrol block

Trouble be~use of

paper jam

Gap between PF coil ,

and PFtrigger iever is i trigger iever.

too smali

Troubie in paper feed ~Check if p~er feed mechanism has not I Remove foreign

mechanism

Troubie in ciutch

mechanism

!

‘ Check that paper lead edge is not bent

Check thickness, width, and diameter of

paper used.

Check paper feed route for dust and

~foreign matter.

I

Check if guide holes of paper are

I engaged with pin wheels properly

(symmetrically and without beingstretched too tight or compressed too

i loose).

~Check gap between Pi mil and PF

trigger lever.

,

I Check resistance of PF coil.

~(Specification: Approx. 30Q)

~Checkfor continuity between solder part

‘ on connector PCB SA and connector A.

: and wiring from control biock.

: Check paper feed route and paper

~ioading condition.

1

I

Check gap between PF coii and PF

~seized up because of foreign matter or

broken gear, or if PF siip mechanism is

‘ generating enough force to feed paper.

I Check ciutch gear BK, drive gear BK,

~and clutch spring for abnormal wear and

I other defects.

Checking procedure

Remedy

Insert paper properly

once again.

Use paper of

prescribed

specification.

Remove paper dust

and foreign matter.

Load paper pr.r-,.,.

I Readjust gap between

PF coil and PF trigger

I lever.

Repiace PF coii.

Repiace connector

PCB SA.

Repair control block or

I rectify wiring.

i Rectify paper feed

route and ioad paper

I correctiy.

Readjust gap between

PF coii and PF trigger

I iever.

matter, repiace broken

gear, or repiace PF

siip mechanism.

Repiace defective

parts.

‘nnQrlv

-16-

Page 19

8-3-4.

Ribbonfeedtrouble

Phenomenon

No ribbon feed

8-3-5. Color changetrouble

Phenomenon

No red printing

No color change

Symptom

Symptom Possibie cause

Possible cause

Improper mounting of

ribbon cassette

Ribbon cassette

defea”ve

Foreign matter caught

in ribbon drive

mechanism or broken

gear causing action

failure

Trouble in ribbon siip

mechanism

I Maladjustment of

color change timing

I

ER-03RP

Checking procedure

Check mounting condition of ribbon Properly mount ribbon

cassette. cassette.

Rotate ribbon cassette takeup knob in

arrow direction to check knob operation

and ribbon takeup condition.

Manually rotate motor pinion in direction

toward you to check if gear train moves

smoothly.

With ribbon cassette mounted in Replace ribbon

position, manuaily rotate motor pinion in I

direction toward you to check if ink

ribbon is taken

With prfnthead positioned at extreme left,

check if registration mark (0)on ribbon

reset cam is aligned with engaging

position with reset cam drive gear.

up properly.

Checkinq orocedure

I

!

~Realign registration

! mark.

Remedy

Replace ribbon

cassene.

Remove foreign

matter, etc. and

replace broken gear.

slip

mechanism.

Remedv

Mixed coior printing

Mixed coior printing /

I

‘ Maladjustment of CC

=

defective

Trouble in control block

I

I

I Maladjustment of

! mior change timing

I

I

I

Ribbn mask sh~e

\

1defective

/

I

b

I faiiure

+eset cam drive gear Ribkn reset cam ~

With CC lever puiled in CC coii, check

gap between ribbon plate and CC lever.

Check resistance of CC roil.

(Specification: Approx. 30Q)

Check for continuity between soider part

on connector PCB SAand connector A.

Check hardware circuit in controi block

and wiring from control block.

With printhead positioned at extreme left, / Readjust registration

check if registration

reset cam is aligned with engaging

position with reset cam drive gear.

+ 0+

cm

Reset cam drive gear Rib&n reset cam

With paper and ribbon loaded in position, ~Replace ribbon mask.

carefully move ribbon piate up and down ~

to check if ribbon does not catch ribbon ~

mask.

Check if CC lever operates smoothiy. ~Replace parts or

mark (0)on ribbon

Registration

mark

A

~Readjust gap.

I Replace CC coil.

Repiace connector

PCB SA.

I Repair control block

I and rectify wiring.

mark.

I

~make corrections.

-17-

Page 20

ER--O3RP

9. Disassembly and reassembly

Observe the following precautions in maintenance.

PRECAUTIONS

~

When the printer is operating satisfactorily, do not try to dis-

(1)

assemble, reassemble, or adjust the printer mechanism

without proper reasons. Exercise particular care not to loosen

the mounting screws on each part by accident.

After finishing inspection, always check the parts before

(2)

power-on to confirm that there is no abnormality.

Never try to print without paper and ribbon loaded in the

(3)

printer.

Check that the paper is loaded properly.

(4)

Care must be taken in maintenance so that parts, saews

(5)

used for maintenance will not be left in the printer.

When handling printed circuit boards, avoid using gloves that

(6)

tend to generate static electricity.

Do not place printed circuit boards directly on the printer or

(7)

the floor.

In disassembly and reassembly, check the leads and cords

(8)

for damage and avoid such wiring as to cause strain to them.

9-1. List of maintenance tools

Phillips screwdriver (large size) for 3mm size

1.

2.

Normal screwdriver (small size)

Tweezers

3.

4.

Belt tension gauge (dial tension gauge) 100g

Scale

5.

6.

Soldering pencil

7.

Long-nose pliers

Thickness gauge (0.5, 0.6mm)

8.

Lubricating pen

9.

10.

Screw lockpaint

11.

Oscilloscope

9-2. Disassembly process

Disassemble and reassemble the printer in acmrdance with the fol-

lowing disassembly procedure.

1. CC (mlor change) coil SA

I

&

2. Ribbon plate BK

I

(9-3-1) ~

(9-3-2)

+

3. Printhead SA

J

4. PF (paper feed) coil SA

I

I

5. Drive gear

I

t f

6. CC (color change) lever

I

7. Detent lever

I

I

I 8. Carrier biock

I S. Platen BK

10. PF (paper feed) block

11. Paper pressure roller

12. RP (reset pulse) sensor SA (9-3-12) I

+

+

&

L

&

(9-3-3)

(9-3-4) ~

(9-3-5) /

(9-3-6) ~

(9-3-7)

1

(9-3-8) I

(9-3-9) /

(9-3-1o) i

(9-3-11) i

+

~13. Connector PCB SA (9-3-13) /

-18-

&

~14, Motor BK

15. Ribbon feed block

16. Timing belt SA (9-3-16) ~

(9-3-14) /

(9-3-15) ~

\

Page 21

Parts number reference Figure

ER-03RP

-19-

1’

///1 - \—L”. —

\

‘\

\

Page 22

ER-03RP

9-3. Disassembly/reassembly procedures

Work on disassembly/reassembly of each block in accordance with

the disassembly/reassembly flow.

NOTE:

(Example) Connector PCB SA(5-2)

Reference numerals used in text

The reference nume~5-2 indicates the figure number in

the attached drawing (Fig. 9-l). Proceed with work by

referring to the drawing.

9-3-1. Disassembly/reassembly of CC (color

change) coil SA

Tools

f

Phillips screwdriver

]

~Soldering pencil

[Disassembly procedure]

1. Removethe holding screw (5-14).

Disengage the cord from the cord holder pawi.

2.

3. Unsoiled the mrd from the connector PCB SA (5-2) using the

soldering pencil.

[Reassembly procedure]

Reversethe disassembly procedure.

However,the following adjustment is necessary.

IDisassembly/reassembly flow]

~CC coil SA (Section 9-3-1)

Disassembly Reassembly

Ribbon plate BK

I

!

I

,

I

I

[Disassembly procedure]

1. Remove the CC coil holding screw (5-14) to remove the CC coil.

2. Remove the two mlor change springs (6-2).

3. Disengage the portion A while lifting up the color change lever

(6-3), and then, disengage the hinge (portion B) on the right side

of the ribbon plate (6- 1).

Pofiion

IADJusTMENTs1

Move the printhead to the center of the carriage rail so that the CC

coil core contacts the CC lever as shown by (A) in the figure below.

Move the CC coil in directions indicated by arrows + and + to adjust

the clearance betvveen the CC lever and the ribbon plate to 0,2-

0.5mm.

Scr~w lock

CC coil core

CC lever

Po~ion B

4. Slide the ribbon plate to the right, and disengage the hinge (por-

tion C) on the left side to remove the ribbon plate.

[Reassembly procedure]

Reverse the disassembly procedure.

NOTE: Take care not to deform the ribbon plate BK when reassem-

bling.

9-3-3. Disassembiy/reassembly of printhead SA

(Refer to drawing for F type)

[Disassembly procedure]

:.

Remove the flat cable from the connector. Work is made easier if

the flat cable is removed from the end.

2. With the lock lever released, extract the printhead SA (3-16) up-

ward.

[Reassembly procedure]

Reverse the disassembly procedure.

NOTE: Check that the flat cable is not in contact with the HP and DP

discs.

9-3-4. Disassembly/reassembly of PF (paper feed)

coil SA (Refer to drawing for F type)

!Tools

~Phillips screwdriver

: Soldering pencil

9-3-2. Disassembly/reassembly of ribbon plate BK

Tools

Phillips screwdriver

, Tweezers

IDisassembly/reassembly flow]

) CC coil SA (Section 9.3-1)

I

Disassembly

L

i! PFcoil SA

-20-

Reassembly

I

I

>

Page 23

[Disassemblyprocedure]

1. Remove the holding screw (5-12).

2. Disengage the cord from the ard holder pawi.

3. Unsoiled the cord from the mnnector PCB SA (5-2) using the

soldering pencil.

[Reassemblyprocedure]

Reverse the disassembly procedure.

However, the following adjustment is necessary.

=

As shown in the figure below, move the PF coil

arrows i- and PF coil SA and the PF trigger

PF trigger lever overriding the clutch cam as shown by (A).

to adjust the clearance (B) between the core of the

lever to 0.1- 0.2mm with the tip of the

in directions shown by

2m/m

ER+3RP

Remove the ribbon reset cam (4-26).

4.

Remove the ribbon reset cam drive gear (4-25).

5.

Remove the E-ting (4-14).

6.

Remove the clutch gear BK (4-12).

7.

Remove the clutch cam (4-11).

8.

Remove the clutch spring (4-13) by rotating it munterclockwise.

9.

Pry off the PF reduti.on gear (4-15) with the normal screwdriver.

10.

NOTE: Take care not to ruin the teeth of the PF reduction gear.

Remove the PF drive gear (4-10).

11.

Remove the drive gear (4-5), PF slip gear (4-6), and PF slip

12.

spring (4-7).

Remove the reduction gear (4-4).

13.

Remove the motor pinion (4-3).

14.

NOTE: The motor pinion is glued to the motor shaft. Remove

the motor pinion taking care so as not to bend the motor

shaft or ruin the teeth of the motor pinion,

[Reassemblyprocedure]

Reverse the reassembly procedure.

However, the following adjustments are necessary.

NOTE 1: Check the backlash amount for engagement of the gears.

NOTE 2: Use screw lock paint to fix the motor pinion in place.

trigger lever

PF

9-3-5. Disassembly/reassembly of drive gear

(Refer to drawing for D type)

Tools

Normal screwdriver (small size)

Tweezers

[Disassembly/reassembly flow]

CC coil SA (Section 9-3-1)

Reassembly

Ribbon plate BK (Section 9-3-2)

I

I

The following adjustment must be made when reassembling the ribbon reset cam. Adjust and assemble in acmrdance with the following

procedure.

0 ASshown in the figure below, move the carriage to the extreme

ieft end of the frame BK by manually rotating the clutch gear.

In this situation, adjust the position so that the “R” cut portion on

the pulley flange faces to

Frame~K ~~

the right.

Carriage

u

II II

portion

t

\

Pulley’flange

With the position adjusted in the above step 0, reassemble the

ribbon reset cam so that the registration mark (0) on the cam

faces the center of the reduction pivot.

Reduction pivot center

\

Ribbon reset cam registration

mark

/

Disa&embly

J

Drive gear

L

I

[Disassembly procedure]

1. Remove the E-ring (4-18).

2. Disengage the hook (frame side) of the PF trigger lever spring

(4-17), and remove the PF trigger lever (4-16) and PF trigger

spring (4-17).

Remove the E-ring (4-27).

3.

-21-

Page 24

ER-03RP

/ADJUSTMENT21

reassemble the PF reduction gear and the PF drive gear, engage

To

one of the longer teeth of the PF reduction gear with the PF drive

gear (as shown by arrow) and push it in until it snaps into place.

gear

J

PF drive gear

“3$

/Adjustment/

Reassemble the PF trigger lever with the hook A of the PF trigger

lever spring engaged with the frame.

Next, engage the hook B of the PF trigger lever spring with the PF

trigger lever using tweezers or other appropriate tool.

A

c~

, Frame

HookA

Engaged with hook B

0 ~

Lleverspring

Of PF trigger

Drive gear

Motor BK

Motor pinion

Reduction gear

i

Motor pinion

Adjusting direction

Ad

B

Pull out motor pinion in arrow

direction to disengage it from

reduction gear

/

Reduction gear

9-3-6. Disassembly/reassemblyof CC (color change)

lever

Tools

I Tweezers

I

\,

/

7

K

PF trigger leversp’ring

]ADJUSTMENT41

After reassembly, make test printing, and if misalignment is noted in

bi-directional printing, make the adjustment in accordance with the

following procedure.

<Procedure>

Adjust the reduction gear engagement with the motor pinion so

that no misalignment occurs in b~direotional printing. ‘

eMethod of adjustment

Make adjustment in accordance with the table and figures below.

Phenomenon

H H H-----H —

H H H-----H —

H H H-----H —

H H H-----H —

PF trigger lever

Methodof adjustment

Adjustengagementwith the

reduction gear by rotating

motor pinion in direction shown

by arrow

Adjust engagementwith the

reductiongear by rotatingthe

motor pinion in direction shown

by arrow B in the figure below.

Ainthefigurebelow.

the

IDisassembly/reassembly flow]

~

Drive gear (Section 9-3-5)

Disassembly Reassembly

J

I CClever

[Disassembly procedure]

1. Disengage the hook of the CC lever spring (6-4) from the frame

(l-l).

2. Remove the CC lever (6-3) and CC lever spring (6-4).

1]

[Reassemblyprocedure]

Reverse the disassembly procedure.

NOTE: As shown below, hook up the CC lever spring to the CC

spring retention hole of the frame BK, and check that the CC

[ever moves lightly with the CC spring force.

- 22%

Page 25

ER-03RP

9-3-7. Disassembiy/reassembiy of detent iever

Tools

Tweezers

IDisassembly/reassemblyflow]

Drive gear (Section 9-3-5)

I

Disassembly

Detent lever

[1

[Disassemblyprocedure]

1. Disengage the hook of the detent lever spring (4-9) from the frame

(l-l).

2. Remove the detent lever (4-8) and

[Reassemblyprocedure]

Reverse the disassembly procedure.

1:As shown below, hook up the detent lever spring to the

NOTE

square spring retention hole of the frame BK, and check

that the detent lever moves smoothly.

Reas~embly

spring.

Detent lever

[Reassemblyprocedure]

Reverse the disassembly procedure,

4-3-9. Disassembly/reassembly of platen BK

Tools

Phillipsscrewdriver

Normalscrewdriver(smallsize)

Long-nosepliers

Thicknessgauge

[Disassembly/reassemblyflow]

Printhead SA (Section 9-3-3)

L

I

I

1

“r

Reassembly

Carrier block (Section 9-3-8)

\

Disassembly

J

II Platen BK

[Disassemblyprocedure]

1. Remove the paper pressure SA (2-2) by pushing the holding

pawls in arrow direction using the normal screwdriver.

I

~1

lever spring position

Detent

NOTE 2: For graphic type, reassemble the above before reassem-

bling the PF shaft BK.

9-3-8. Disassembiy/reassembiy of carrier biock

r

~Tools

j Tweezers

I Normal screwdriver

IDisassembly/reassembly flow]

~

Printhead SA (Section 9-3-3)

L

I

Disassembly

i Carrier block

e

Reassembly

[Disassembly procedure]

1.

Move the carriage BK

rail, and

platen side.

2.

Pull out the carriage rail (3-12) to the left.

3.

Remove the carriage BKby lifting up its front side.

4.

Remove the E-ring (3-13) holding the

motor side.

Pull out the carriage rail (3-12) to the right.

5.

remove the E-ring holding the carriage rail (3-12) at the

(3-1) to the center of the printer carriage

1

carriagerail (3-12) at the

SA

Holding pawls

2. Remove the two holding screws (3-15).

3. Remove the platen BK in frontward direction.

[Reassemblyprocedure]

Reverse the disassembly procedure.

NOTE 1:

NOTE 2:

NOTE 3:

NOTE 4:

The following adjustment is necessary after reassembly.

Fit the guides of the platen BK onto the projections (on

right and left sides) of the side frame to reassemble it in

place.

Set the platen BK in the position where the widest head

gap is achieved, and temporarily fix it there with holding

screws.

When reassembling the paper pressure

BK, make sure that the holding pawls firmly engage the

frame BK.

Remove the ribbon mask (3-2) before reassembling the

carriage BK inposition.

SAinto the frame

-23-

Page 26

ER-03RP

IADJUSTMENTI

Measure the gap between the printhead and the platen with the

thickness gauge, and move the platen BK back and forth to adjust the

to 0.55mrn#.05mm at right and left ends as well as at the

gap

center.

After the adjustment, tighten the holding screws to firmly fix the platen

BK in place.

NOTE: Fit the ribbon mask after the above adjustment.

9-3-10. Disassembly/reassembly of PF (paper feed)

block

Tools

~

I Normal screwdriver (small size)

I Long-nose

Tweezers

/

pliers

1

IDisassembly/reassemblyflow]

, CC coil SA (Section 9-3-I)

Reassembly

1

‘r

I‘FcoilsA(section9-3-4) I

Disassembly

J

I PF shaft BK

[Disassembly procedure]

i.

Remove the E-ring (2-8) holding the PF shaft BK (2-5).

2.

Push the bearings (gearwheel train side) instalied on the right and

ieft sides of the frame (1-1) toward the inside to remove the PF

shaft BK (2-5), PF shaft washer (2-7), PF shaft bearing (2-6), two

pin wheel washers (2-3) (for P

(for Ptype).

Q

w.

Using the long-nose pliers, unbend the crimped edges (four locations) of the side frames holding the rear plate (2-4) and remove

the rear plate (2-4).

4.

Remove the pin wheel guides (2-14, 2-15) and the lock levers

(2-16, 2-17).

[Reassembly procedure]

Reverse the disassembly procedure.

NOTE 1:

NOTE 2:

NOTE 3:

NOTE 4:

Observe

washers. (For P type only)

Instail the pin wheels to the

right and left pin wheels are aligned with each other.

Check to ensure that the

and smoothly.

Observe the direction in which

the direction in which to assemble the pin wheel

type), and two pin wheels (2-13)

PF shaft so that the pins on the

PF shaft bearings move Iightiy

toassemblethewashers.

4-3-Il. Disassembly/reasSernbly of paper pressure

rollers

!Tools

~Tweezers

I Normal screwdriver

IDisassembly/reassembly flow]

r

~

Printhead SA (Section 9-3-3)

L

I Carrier block (S&tion 9-3-8)

~’

Disassembly

L

1

j Paper pressure rollers

‘r

I

Reassembly

\

[Disassemblyprocedure]

1. Remove the two paper pressure rollers (2-3) from the paper pres-

roller springs (2-4) using the tweezers.

sure

Insert the normal screwdriver to extract the spring upward.

2,

[Reassembly procedure]

Reverse the disassembly procedure.

However, the following adjustment is necessary.

IADJUSTMENT I

A shown

pressure roller in the arrow direction using the normal screwdriver to

see if the pressure roller moves parallel. If the balance is not good,

bend the pressure spring retainers on the bottom plate in the arrow

directions (~) to adjust the balance.

in the figure below, Iightiy press the center of the paper

Bend retainers [n arrow directions to adjust spring balance.

43-12. Disassembly/reassembly of RP sensor SA

I Tools

I Phillips screwdriver

I

1

I

II

PF shaft bearing

\

Washer

Q