Page 1

Thank You For

Purchasing This DVD

Collection! If You Did

NOT Purchase This

Document As Part Of A

DVD Collection From

RushAZ85705 on E-Bay,

This Document Has

Been Passed

Fraudulently! Please

Alert

RushTalion@Cox.Net !

Thank You Again!

Page 2

SERVICE MANUAL

CODE : 00ZAR800//A1E

DIGITAL COPIER

MODEL

CONTENTS

[ 1 ] SPECIFICATIONS•ACCESSORIES•OPTIONS•SUPPLIES. . . 1 - 1

[14] FUSER UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 1

AR-800

(Maintenance tables)

Parts marked with “ “ are important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 3

Page 4

GENERAL

The major differences between the AR-800 and the AR-650 are

described below.

1. Specifications

The major differences between the AR-800 and the AR-650

lie in the copy (print) speed and the maintenance cycle.

(Max. copy (print) speed)

AR-650: 65CPM (PPM)

AR-800: 80CPM (PPM)

The process speed is the same, but the paper feed interval

differs.

(Maintenance cycle and consumable parts replacement cycle)

AR-650: Every 400K

AR-800: Every 440K

2. Hardware

Differences between the AR-800 and the AR-650

1) The PWA-F-LGC PWB differs.

AR-650: PWA-F-LGC-300

AR-800: PWA-F-LGC-304

(Different parts): Connector, EEPROM, FLASH ROM

The above two PWBs are not compatible each other.

2) Front cabinet

3) Model badge

3. Options

The AR-P13 (printer unit) is also revised for either of two

models, the AR-650 and the AR-800.

The differences between the old and new versions are as

follows:

(AR-P13 for AR-650)

Characters printed on the packing case are in black.

Firmware version: 1.43

Software version: (CD-ROM) 1.10

(Printed on the packing case)

(AR-P13 for AR-650/800)

Characters printed on the packing case are in blue.

Firmware version: 1.44

Software version: (CD-ROM) 1.20

(Printed on the packing case)

The service documents are based on the above contents.

A. Service manual

Chapter 1. SPECIFICATIONS, ACCESSERIES, OPTIONS,

SUPPLIES

Comprehensive contents of the AR-800 and the AR-650

(Complete version)

Chapter 14. FUSER UNIT

Since the temperature control of the fusing section on page

14-5 differs between the AR-800 and the AR-650, the

temperature control of the AR-800 is added.

Only the contents of page 14-5 are described.

B. Actual wiring diagram

Since the PWA-F-LGC-304 (for AR-800) is newly employed,

the connector wiring is changed and the actual wiring

diagram is changed. The actual wiring diagram for the AR800 is newly prepared.

C. Service Handbook

Though the maintenance cycle and the consumable parts

replacement cycle differ between the AR-800 and the AR650, the contents of the Service Handbook are not changed.

Be sure to note the maintenance cycle of both models for

servicing.

AR-650: Every 400K

AR-800: Every 440K

D. Parts Guide

Only the different sections between the AR-650 and the AR800 are prepared.

Sections 1, 2, 5, 6, 13, 31, 39, 47, 62, 86, 101, 203, 204

(including the contents of both models, AR-800/AR-650)

For servicing of the AR-800, use these documents as well

as the service document of the AR-650.

4. Others

The temperature control in the fusing section differs between

the AR-650 and the AR-800.

Except the above, the AR-800 and the AR-650 are the same.

Page 5

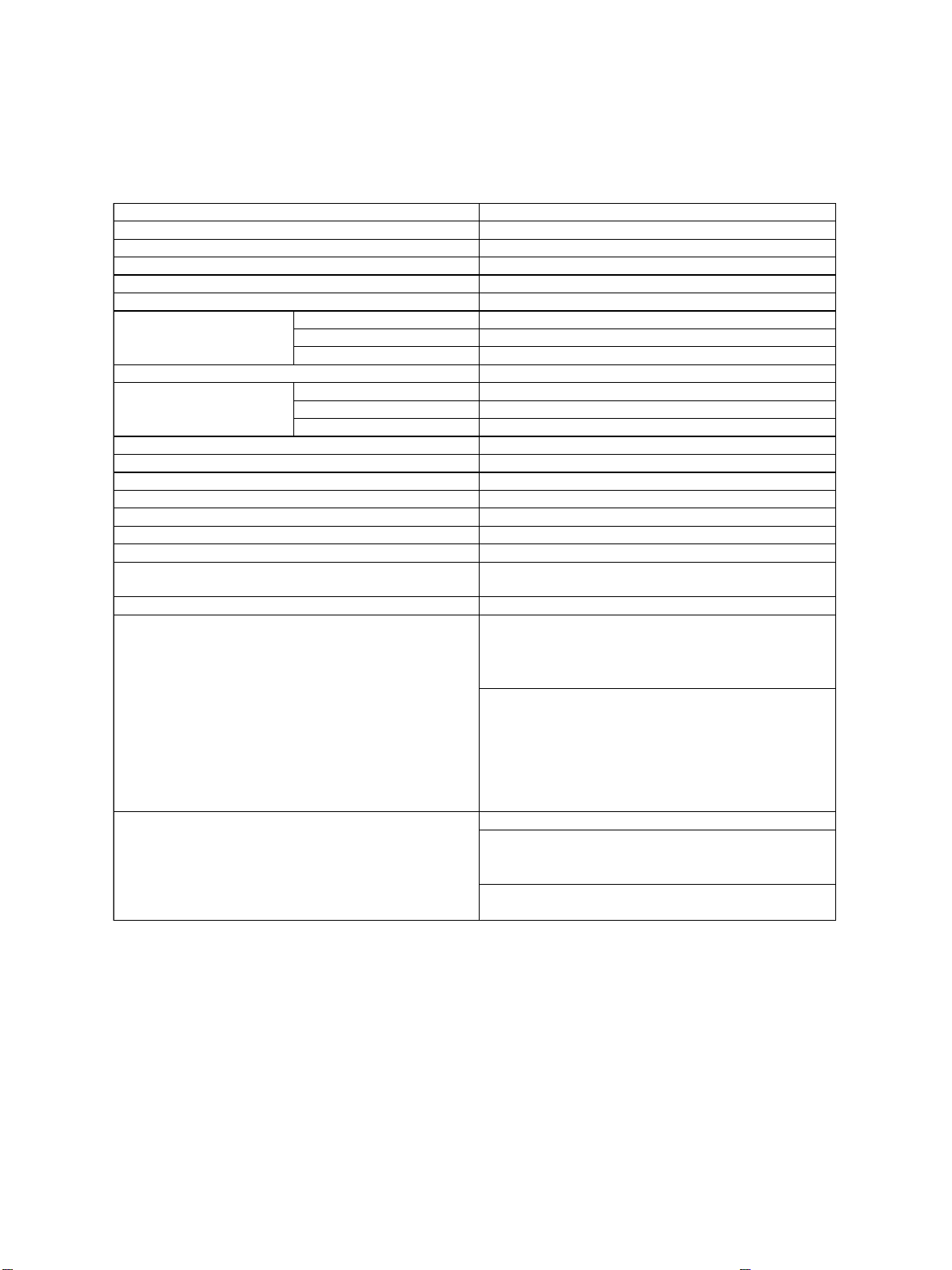

1. SPECIFICATIONS • ACCESSORIES • OPTIONS • SUPPLIES

1.1 Specifications

1. System

Copy system Indirect electronic photo system (Dry type)

Body type Console type

Original table type Fixed type (Left center reference)

Original cover RADF standard provision

Frame structure Fixed frame type

Photoconductor OPC drum (ø100)

Original scan system

Scan data output system 1-scan multi-copy system

Exposure system

Developing system 2-component magnetic brush developing system

Discharging system Photo discharging by red LED

Charging system Negative corona system (Scorotron)

Transfer system Transfer belt system

Separation system Transfer belt system

Transfer belt cleaning system Fur brush system + Blade system

Drum cleaning system Blade system + Fur brush system

Toner supply system Toner hopper system, right top side toner bottle supply

Toner density adjustment system Magnetic auto toner system

Toner empty detection system

Scan sensor CCD line sensor (7500 pixel)

Scan resolution 600 x 600dpi

Scan light source Halogen lamp (180W)

Exposure light source Semiconductor laser

Exposure resolution 600dpi

Scan system Using polygon mirror

system

1. Mechanical sensor system

Note 1: When detecting, the toner supply lamp flashes.

Fusing system

2. Electrical system (Using auto toner sensor)

Note 1: When detecting toner empty, the toner supply

lamp flashes and the message is displayed.

Heat roller system

Infrared heater (Upper) 2 pcs.

700W + 600W

Roller dia. (Upper) ø 60mm

Roller dia. (Lower) ø 60mm

1 - 1 SPECIFICATIONS

Page 6

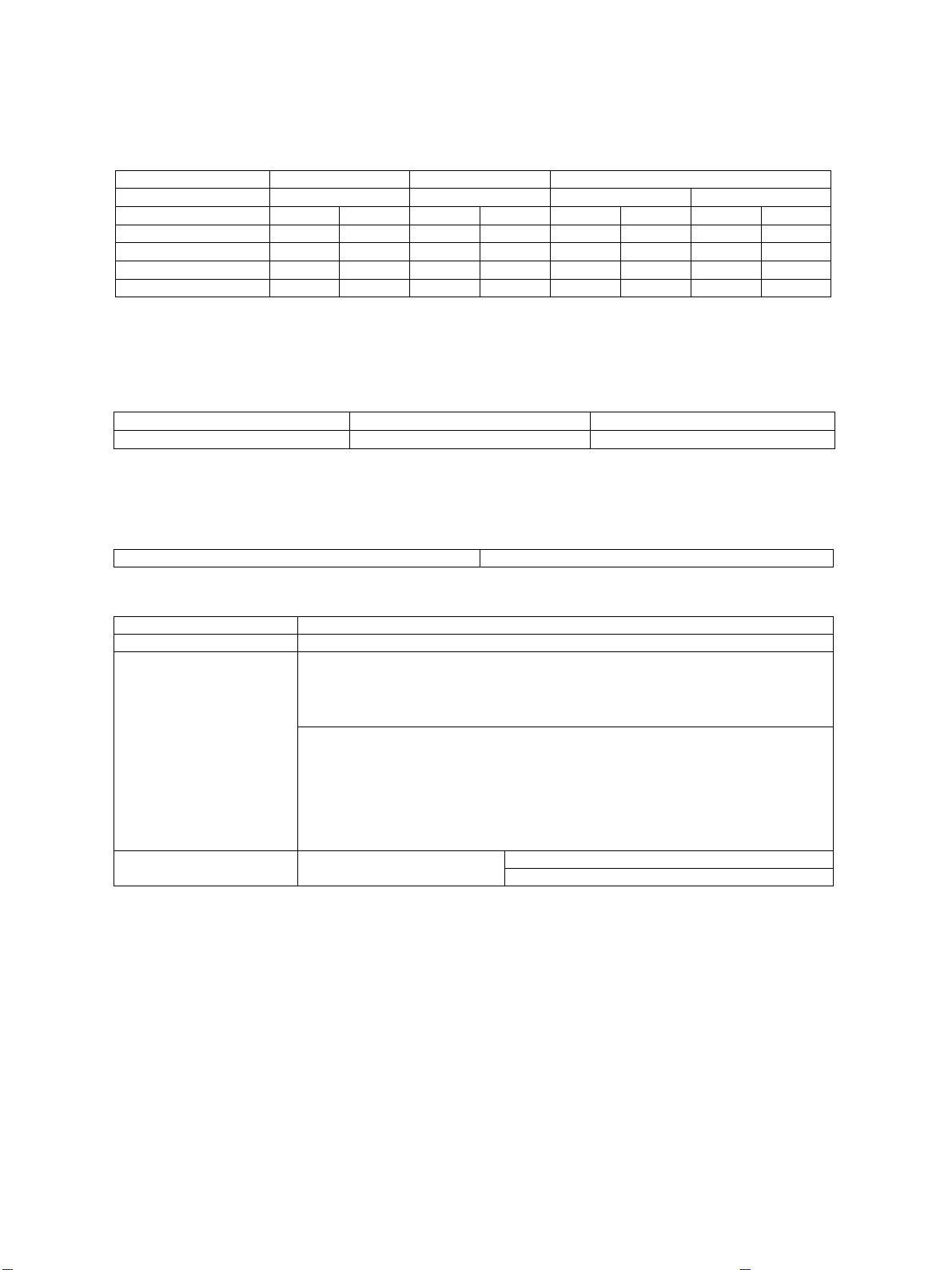

2. Basic specifications

A. Copy speed

(1) Continuous copy

Paper feed system

Paper size

A4,B5,A5-R,LT,ST-R

A4-R,B5-R,LT-R

B4,FOLIO,LG,COMP

A3,LD

AR-650

65(55)

-

-

-

LCF

AR-800

80

-

-

-

Cassette

AR-650

65

51

44

38

AR-800

74

61

52

43

Size specified

AR-650

48

42

37

33

Note 1: The above specifications are for manual feed, single and continuous copy.

Note 2: The state which is other than the toner supply mode.

(2) First copy

AR-650

First copy time

3.9sec or less

Note 1: The above specification is for manual feed, normal size, A4/LT size, LCF feed.

Note 2: When APS is not used.

B. Warming up time

Normal About 420sec at 20°C

C. Original

Max. size A3 or LD

Kind Sheet, cubic material, book

Original size detection

Glass surface: Provided

Note 1: Fixed detection system with the platen cover open

Manual feed

AR-800

48

42

37

33

3.6sec or less

Size not specified

AR-650

33

33

33

33

AR-800

AR-800

33

33

33

33

RADF: Provided

Note: The original width and length are detected in RADF feed.

Note 2: Only the first sheet is detected except when the mixed original mode is

selected.

Fixed size

auto detection

SPECIFICATIONS 1 - 2

AB series: A3,A4,A4-R,A5-R,B4,B5,B5-RAllowable original size for

LT series: LD,LG,LT,LT-R,ST-R

Page 7

D. Paper

(1) Size

Fixed size

Cassette

AB series: A3,A4,A4-R,A5-R,B4,B5,B5-R,FOLIO

LT series: LD,LG,LT,LT-R,ST-R,COM

AB series: A3,A4,A4-R,A5-R,B4,B5,B5-R,FOLIOSFB

LT series: LD,LG,LT,LT-R,ST-R,COM

LCF : A4,LT,B5

Note 1: Postcards cannot be used.

Note 2: Name cards cannot be used.

Note 3: Same surface copy cannot be used.

Note 4: Envelopes cannot be used.

Note 5: The paper width of fixed size is detected with the manual tray guide width.

Note 6: The upper stage of B5 cassette cannot be used.

Note 7: SFB mixed size paper cannot be used.

(2) Kind

Cassette

LCF

PPC paper

SFB

PPC paper

Tracing paper: Out of warranty

OHP film: Out of warranty

Label sheet: Out of warranty

Note 1: Only one sheet feed is allowed except for PPC paper.

Note: Special paper such as postcards and PPC paper with punch holes cannot be used.

(3) Weight

Cassette, LCF 64~ 80 g/m2,17~ 22 lbs

64~ 80 g/m2,17~ 22 lbs Continuous feed allowedSFB

80~157g/m

2

,22~ 41 lbs Only one sheet feed allowed

(4) Curl level

Curl level PPC paper: The highest point when paper is put on a flat surface must be 5mm or less.

1 - 3 SPECIFICATIONS

Page 8

E. Paper feed

Paper feed means

LCF

Cassettes: 3 steps (Drawers of the copier)

SFB

Capacity

LCF: 4,000 sheets (Load height: max. 415mm)

Cassette: 500 sheets (Load height: max. 55mm)

SFB: 100 sheets (Load height: max. 11mm)

Note 1: 50 sheets for SFB duplex copy.

Note 2: However, the cassette load height is displayed as

53mm.

Note 3: however, the SFB load height is displayed as 10mm.

Manual feed start Start key start

Priority feed means LCF priority

Note 1: By data input of the adjustment mode, another paper

Factory setup: LCF

priority

feed means can have priority to be selected.

Manual feed size

specification

After setting paper, press the paper size key to specify the

paper size.

Note 1: By specifying the paper size, the binding margin,

duplex edge erase, and continuous page copy can be

performed. For APS and AMS, invalid.

F. Continuous copy

No. of sheets Increment of 1 sheet up to max. 999 sheets

Input system 10-key input

Count system Reduction system

Note 1: “1”is displayed in auto clear and warming up.

G. Density adjustment

Auto density adjustment Available

Manual density adjustment 11-step adjustment (Operated with

keys on the control panel LCD)

Priority mode Auto density adjustment

Factory setup: Auto

Note 1: By data input of the adjustment

mode, selection of auto/manual is

allowed.

H. Picture quality mode

Picture process mode Standard/Photo/Text mode

Priority mode Standard mode

Note: By data input of the adjustment mode, the mode can be selected.

I. Magnification ratio

(1) Reduction and enlargement

Reduction and enlargement Auto setup system depends on selecting

size and paper size.

Note 1: A desired fixed-size series (including a different

series) can be selected: Japan A5, UNIVERSAL,

OTHER.

the original

SPECIFICATIONS 1 - 4

Page 9

(2) Selected magnification ratio

a. AB series

Paper

A3 B4 FOLIO A4 B5 A5

Original

A3 100 86 71 71 61 50

B4 115 100 82 82 71 57

FOLIO 127 110 100 90 78 63

A4 141 122 100 100 86 71

B5 163 141 115 115 100 82

A5 200 173 141 141 122 100

b.LT series

Paper

LD COMP LG LT ST

Original

LD 100 82 78 65 50

COMP 108 100 84 78 54

LG 121 100 100 78 60

LT 129 119 100 100 65

ST 200 165 154 129 100

Note 1: The above numbers show magnification ratios.

(3) Other

Zoom 20 – 400%, increment of 1%

Copy allow area display Available

Auto paper selection (APS)/Auto magnification

ratio selection

Available Factory setup: APS

priority

J. Counter display

Total counter Mechanical system 7 digits

Displayed on the control panel.

A3/LD double count mode Available (Electronic counter) Factory setup: ON

PM counter Available (Electronic counter) Factory setup:

400,000 (AR-650)

440,000 (AR-800)

Resettable counter Available (Electronic counter) Factory setup

Europe: Used.

Others: Not used.

Original counter Available (Electronic counter) Factory setup

Europe: Used.

Others: Not used.

Copy job counter Available (Electronic counter)

Print job counter Available (Electronic counter)

1 - 5 SPECIFICATIONS

Page 10

K. Charger wire cleaning

Charger wire cleaning Available (Auto cleaning system)

Note 1: The charging wire is cleaned.

L. Special functions

Interruption Available

Pre-heat

Available Key input is accepted

during warming up and in

the ready state.

Note 1: Auto pre-heat function can be set in the adjustment

mode.

Note 2: By data input of the adjustment mode, time can be

set in the increment of 5min (5 – 60min).

Factory setup (Note 2)

North America, Europe:

15min

Others: Cancel

Note 3: The fuser temperature in pre-heat can be set in the

adjustment mode.

Factory setup (Note 3); 170

C

AvailableAuto clear

Setup can be changed in the adjustment mode.

Factory setup: 45sec

(15 – 150sec, in the increment of 15sec, and cancel of

setup)

Auto off

Available

Note 1: Time up to OFF can be changed in the adjustment

mode or in the adjustment screen setup. (Max. 240min.

Only the adjustment code can be canceled.)

Note 2: Use or non-use can be selected in the adjustment

Factory setup (Note 1, 2)

North America, Europe:

90min

Others: Not used.

mode.

Note 3: For time setup, selection of User adjustment

Allow/Not Allow can be made.

Factory setup (Note 3)

North America, Europe:

Available

Others: Not Available

Self diag Available

Error code history Available

Password code Available Factory setup: OFF

Dew-prevention Available (Optional in some destinations)

Message Available

Note 1: Graphic LCD, backlight provided.

All clear Available AC key

Mode memory Available (4 modes)

Cover paper mode Available (in the following 4 modes)

(1) White cover mode

(2) Copy cover mode

(3) White cover/white back cover mode

(4) Copy cover/white back cover mode

Sheet insertion mode Available (in the following 2 modes)

(1) White paper insertion mode

(2) Copy paper insertion mode

Weekly timer Available

Pre-heat start Available

Pre-heat copy Available

Auto duplex auto

Available Factory setup: OFF

selection

SPECIFICATIONS 1 - 6

Page 11

Timer display Available Factory setup: Display

provided

Auto sort Available Factory setup: ON

Auto cassette selection Available Factory setup: Available

Paper feed means which

allow selection:

(1) LCF

(2) Cassette

Network printer Allows connection of network printer board (option).

Language selection Available (3 languages)

Note 1: Language selection of DSS display must be

initialized.

FROM update Available

Note 1: Download from PC

Performed by a

serviceman.

Adjustment code output Available (05, 08 code) Performed by a

serviceman.

Mixed original load Available

M. Edit function

Continuous page copy Available

Edge erase Available

By data of the adjustment mode, the edge erase priority

Factory setup: No

priority

mode can be selected.

Binding margin (Image shift) Available

Trimming, masking Available

2in1 Available

4in1 Available

Electronic sort Available

Magazine sort Available

Page numbering Available

Rotational copy Available

Document storage Available

Date write Available

N. Digital edit functions

Independent zoom of magnification ratio Available

Mirror image Available

Black-white reversion Available

1 - 7 SPECIFICATIONS

Page 12

O. Operation panel

Operation key

Hard key

Note 1: There are following 19 keys.

Start

0 – 9 (10 keys)

Clear

Stop

All clear

Interruption

Pre-heat

HELP

Copy

Printer

Status display

Displayed with the message display and LED.

Note 1: There are following 6 LED’s.

All clear

Interruption

Pre-heat

Copy

Printer

Timer

Message display Graphic LCD with touch panel (with backlight)

Note 1: Details of LCD

Display dot: 320 x 240 (1/4 VGA)

Display area: 115.7mm c 86.37mm

P. Environmental conditions

Normal use 10~30˚C,20~85%RH,without dew

(1)-5~10˚C,20~85%RH,without dewSpecial use

(2)30~35˚C,20~85%RH,without dew

Transit or storage with consumable parts

-10~35˚C,85%RH or less, without dew

packed together

Transit or storage without consumable parts

-40~50˚C,85%RH or less, without dew

packed together

Transit or storage of consumable parts -10~35˚C,85%RH or less, without dew

Q. Noises

Ready state 45dB(A)or less

Continuous copy 65dB(A)or less

R.

S. Conforming standards

Safety standards

1) Electrical appliances regulations (S mark)

2)UL

3)CSA

4)CDRH

5)CE mark

6)TUV

Interruption wave standards

1)VCCI

2)FCC(IC)

3)CE mark

4)C-TICK(Australia)

SPECIFICATIONS 1 - 8

Page 13

T. Power source

Power voltage,

100V-50/60Hz,115V-50/60Hz,220V-50/60Hz,230~240V-50/60Hz,240V-50Hz

frequency

Power consumption 2.0kW or less

Power cord 2m

Note 1: For 200 series, detachable.

U. External view

External dimensions

(1) Body: W920 X D742 X H1111 mm

(2) Body + Finisher: W1735 X D742 X H1111 mm

(3) Body + Finisher + DSSC: W1735 X D905 X H1111 mm

Weight Body only: 250 kg

V. Packing

External dimensions W1015 X D845 X H1290 mm (with palette)

Weight 285 kg

Packed items

Operation Manual

Drum

Operation Manual Pocket

Original feed tray

Maintenance management table (Card, sheet)

Delivery installation contract (EU only)

MSDS card (USA,UK only)

Warranty for Australia

Warranty registration (EU only)

W. Maintenance

(1) Periodic inspection

Periodic inspection interval 400,000 sheets (AR-650) 440,000 sheets (AR-800)

(2) Overhaul

Overhaul interval 800,000 sheets (AR-650) 880,000 sheets (AR-800)

1 - 9 SPECIFICATIONS

Page 14

X. Automatic original feeder

Automatic original feeder ADF conforming to duplex original (Standard provision)

(1) Functions

Functions

Loaded originals are automatically separated and fed.

a) Auto magnification ratio/Paper selection

b) Conforming to duplex original

c) SADF/ADF

Allowable original

Size: A3 – A5R, or LD – STR

Weight: 60~90g/m2(16~24 Lbs)

Kind: High quality paper

Original capacity

A4, A4R, B5, B5R, A5R, LT, LTR, STR: 60 sheets

B4, LG, COMP, FOLIO: 35 sheets

A3, LD: 30 sheets

Original process method

Setup method: The final page is at the bottom, and the front surface is up.

Paper feed method: The paper at the bottom (the last page) is fed first to

the copy section.

Paper exit method: The last page is put in face-up, and the others are

stacked on it.

Original position Center reference

Power source Supplied from the copier.

Y. Auto duplex function

(1) Auto duplex function

Applicable paper

Size

AR-650

Standard provision

A3,A4,A4-R,B4,B5,B5-R,A5-R

AR-800

LD,LG,LT,LT-R,ST-R

Paper conditions

Capacity

Weight

Curl level

64 80g/ m2 (17~22 Lbs)

5mm or less

A4,A4R,B5,LT,LT-R:60 sheets

A3,B4,LD,LG,COMP,FOLIO,B5-R,A5-R,ST-R:35 sheets

Separation system

Transfer reference

Load system

Refeed system

Refeed process speed

Jam process system

A4,B5,A5-R,LT,ST-R

A4-R,B5-R,LT-R

B4,LG

A3,LD:

65 cpm

51 cpm

44 cpm

38 cpm

Open the front cover and pull out the unit.

Separation belt system

Center reference

Face-down

Take-up from the bottom

70 cpm

57 cpm

50 cpm

42 cpm

Remove all paper in M/C.

Stack quantity

1 set

SPECIFICATIONS 1 - 10

Page 15

Z. Reverse paper exit function

Reverse paper exit Available

Process speed

A4,B5,A5-R,LT,ST-R:65cpm

A4-R,B5-R,LT-R:45cpm

B4,LG:36cpm

A3,LD:30cpm

Applicable paper

A3,B4,A4,A4-R,B5,B5-R,A5-RSize

LD,LG,LT,LT-R,ST-R

Weight

64~80g/m

2

17~22 Lbs

5mm or less (Paper feed section)Paper conditions Curl level

20mm or less (Refeed section)

Use conditions In duplex paper exit of the first set in Single Duplex mode, with an odd number of the

➔

quantity of originals.

Picture and picture quality specifications

4

A. Picture quality

Picture density 1.0 or above Original density: 1.0

Background copy 3.0 or less

Resolution

Normal: Vertical 4.0mm or above/Horizontal 4.0mm or above

Enlargement 200%: Vertical 4.5mm or above/Horizontal 4.0mm

or above

Reduction 50%: Vertical 2.0mm or above/Horizontal 1,7mm or

above

Normal: 1.0%Magnification ratio error

Enlargement 200%/Reduction 50% 1.5%

Lead edge shift Body 0 2mm, system 0 4.0mm

Side shift Body 0 3.0mm, system 0 4.0mm

±

±

±

±

±

±

Inclination Body 1.0mm or less, system 3.0mm or less/200mm

1 - 11 SPECIFICATIONS

Page 16

1.2 Accessories

Operation Manual

Drum

Operation Manual Pocket

Original feed tray

Maintenance management table (Card, sheet)

Delivery installation contract (EU only)

MSDS card (USA,UK only)

Warranty for Australia

Warranty registration (EU only)

1.3 Options

ITEM

Finisher

Finisher

Punch unit

Printer kit

Network Card(NIC)

Memory

MODEL

AR-FN8

AR-FN9

AR-PN2A

AR-PN2B

AR-PN2C

AR-PN2D

AR-P13

AR-NC4T

AR-SM3

NOTE

Finsher with Saddle Stitching

2 holes (80mm pitch) Europe

2 holes (70mm pitch) 3 holes (108mm pitch) USA/Canada

4 holes (80mm pitch) France

4 holes (70/21mm pitch) Sweden

This kit is available in two kinds.

One for the AR-650 has black characters printed on the

packing case.

The other is applicable to all the models, and has blue

characters printed on the packing case.

Expansion Memory for Printer

SPECIFICATIONS 1 - 12

Page 17

1.4 Supplies

USA/CANADA

No. Name Content Life

1 Toner (Black) Toner (AR-650NT)

240K

Toner: Net 1500g: 60K

*

2 Developer (Black) Developer

400K/440K

(Developer: Net 1500g: 400K)

*

3 Drum Drum

400K/440K

Note 1) Print on Master/individual carton:

Toner/Developer in 2 languages (English/French), DR in 4 languages (English/French/German/Spanish).

Packed with machine: DR 400K/440K Developer 400K/440K

OTHER COUNTRY

No. Name Content Life

1 Toner (Black) Toner (AR-650T)

Toner: Net 1500g:60K

2 Developer (Black) Developer

(Developer: Net 1500g: 400K)

3 Drum Drum

Note 1) Print on Master/individual carton:

4 languages (English/French/German/Spanish).

Packed with machine: DR 400K/440K Developer 400K/440K

240K

*

400K/440K

*

400K/440K

MODEL

AR-650MT

AR-650ND

AR-650DR

MODEL

AR-650LT

AR-650DV

AR-650DM

Pack Remark

1

*

Life: By A4 6% documents.

(MT=NT x 4)

*

Life for use with the AR-650: 400K

4

Life for use with the AR-800: 440K

*

Life for use with the AR-650: 400K

10

Life for use with the AR-800: 440K

Pack Remark

1

*

Life: By A4 6% documents.

(LT=T x 4)

*

Life for use with the AR-650: 400K

4

Life for use with the AR-800: 440K

*

Life for use with the AR-650: 400K

10

Life for use with the AR-800: 440K

No. ITEMS CONTENTS LIFE MODEL Pack Remark

Drum cleaning Blade x1

Drum Separation Claw x2

Drum Cleaning Roller x1

Charger Wire (Main) x1

Maintenance Kit 11

2 Maintenance Kit 2

Fusing Kit3

DF Kit4 400K/440K AR-650DF 1

5 Waste toner bottle Waste toner bottle x4 AR-650HB 1

Stapler for Finisher

6

5000 sheets

Stapler for Finisher

7

2000 sheets

Note: Maintenance parts other than above items must be ordered through the parts department using the proper part number.

Charger Wire Cleaning Pad x1

Charger Grid x1

Transfer belt x1

Transfer belt charger roller x1

Transfer belt brush roller x1

Transfer belt cleaning blade x1

Ozone filter x1

Air filter (toner filter) x1

Pick up roller for large capacity feeder x1

Feed roller for large capacity feeder x1

Separation roller for large capacity feeder x1

Heat roller upper x1

Heat roller lower x1

Heat roller scraper (upper) x1

Heat roller silicone roller (upper) x1

Heat roller cleaning roller x1

Heat roller cleaning roller (lower) x1

Heat roller cleaning roller (silicon roller ) (lower) x1

Picck up roller for Auto document Feeder x1

Feed roller for auto document feeder x1

Separation roller for auto document feeder x1

Transport belt for auto document feeder x1

Staple Cartrige x1 5000x3 SF-SC11 20

Staple Cartrige x1 2000x3 SF-SC3 40 (For AR-FN9 Saddle Stitch)

*

400K/440K

*

400K/440K AR-650LC 1

*

400K/440K AR-650FU 1

*

*

Life for use with the AR-650: 400K

1AR-650KA

Life for use with the AR-800: 440K

*

Life for use with the AR-650: 400K

Life for use with the AR-800: 440K

*

Life for use with the AR-650: 400K

Life for use with the AR-800: 440K

*

Life for use with the AR-650: 400K

Life for use with the AR-800: 440K

Cartridge for AR-FN8 and AR-FN9

Common with S55,S55N

1 - 13 SPECIFICATIONS

Page 18

1.5 System List

Staple

cartridge

Finisher

AR-FN8

AR-FN9

Supplies

Drum

Toner bag Toner

Developer

SPECIFICATIONS 1 - 14

Page 19

14. FUSER UNIT

Reference

1. The Thermistor status counter normally has a value of between 0 and 9.

• At the power on, if the heater is not turned ON and the copier goes into C41 CALL SERVICE, check the

Thermistor status counter to see if it is 2 or more. If it is 2 or more, be sure to check the thermistor and

heater lamp, and after repair, reset the Thermistor status counter (08-code 400) to 0 and then turn ON

the power switch.

•

If the counter has a value 10 or greater (11 for example), the BC-RAM or the data in it have been

destroyed by charger leakage, etc. In this case, check the guide bias, high-voltage transformers,

charger wires, etc. for any defects. Also, all the data inside BC-RAM needs to be rechecked.

2. Relationship between the output voltage and the fusing temperature.

• 200°C corresponds to approx. 2.5V and 0.25 V corresponds to approx. 40°C.

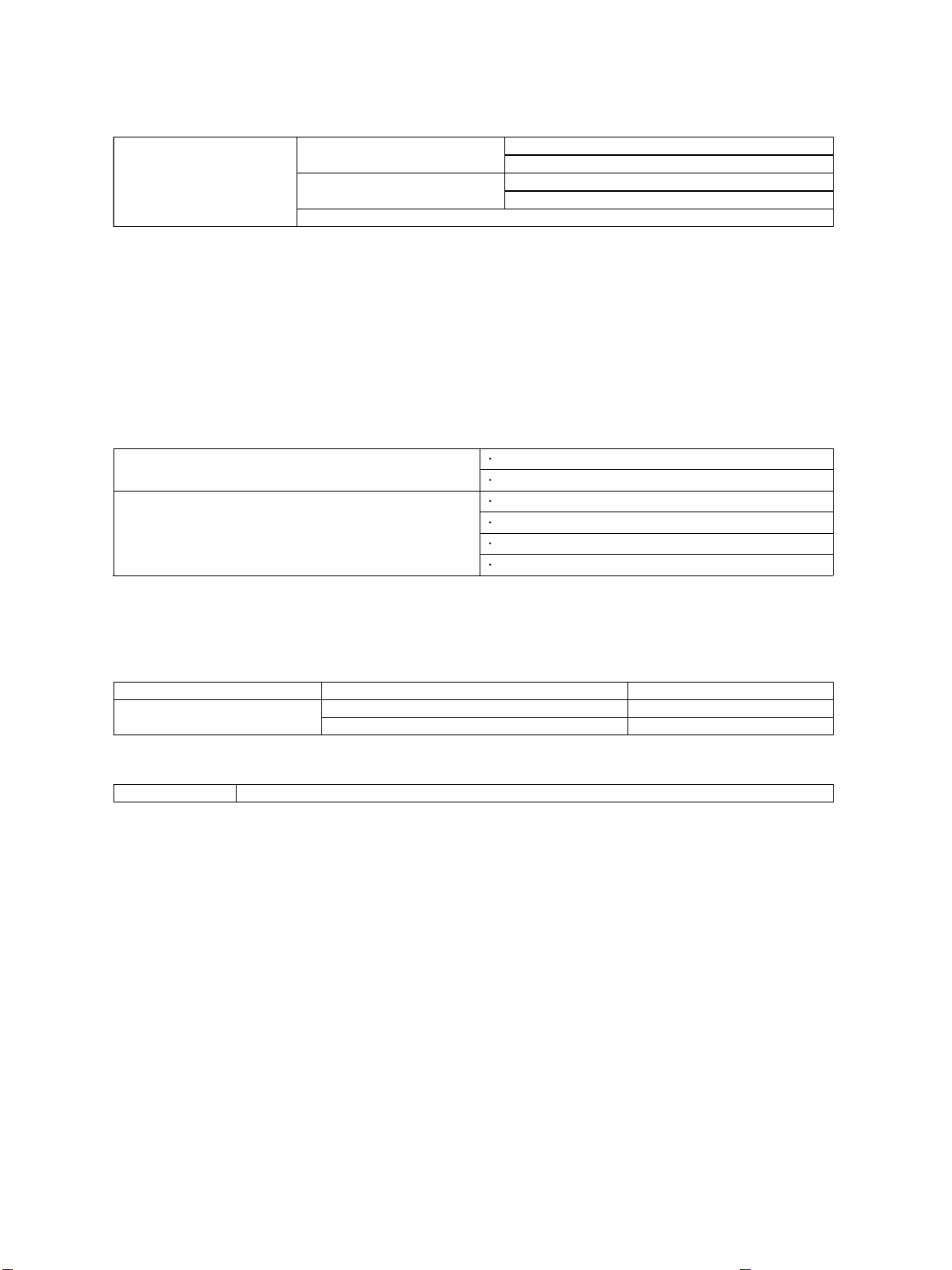

3. Relationship between heat roller surface temperature and fuser lamp operation.

(AR-650)

Temperature

Less than 200°C ON

200°C

More than 200°C OFF

Heater lamp state

Maintains previous status

(AR-800)

Temperature Fusing control

200°C or above Heater lamp OFF

170~200°C

160~170°C Copying is continued at a

160°C or below

Heater lamp ON

Normal copy speed

lower speed.

Copying is interrupted and

the machine is reset to the

ready state.

Heat roller

temperature

distribution

Warm-up Standby (200°C)

C

200

Heater lamp

ON

Warm up Standby(200 )

˚C

200

170

160

Heater lamp

Copy speed

OFF OFF

OFF

ON

0 0 0 80 65 80 65 0 80 65 0

Copying (200°C)

ON

Standby

(200 )

ON

OFF

Copying

ON

ON ON ON ON

ON ON ON ONON ON

OFF

OFF

Copying

OFF

OFF

Waiting

ON

4. Temperature control at heat roller ends

During multicopying, the temperature at each end (no paper-contact area) of the heat roller normally tends

to rise higher than the controlled temperature of the paper-contact area. Therefore, the circuit is designed so

that if the temperature in the no paper-contact area rises to 240°C, the second thermistor detects this,

causing the heater to be turned OFF immediately regardless of the temperature in the paper-contact area.

14 - 1 FUSER UNIT

Page 20

PERIODICAL MAINTENANCE (AR-800)

Inspection every 440,000 Copies

(1) Preparation

Ask the copier operator about the present machine conditions and note them down.

1

Before starting the maintenance work, make and retain a few sample copies for comparison

2

reference purposes.

3

Turn the power switch OFF and disconnect the power cord plug.

(2) The periodic inspection should be conducted in accordance with the Periodic Inspection Check list

shown below.

Perform the inspection by referring to the figures, as well as to the explanation in the Service Manual

when necessary.

(3) After the inspection has been completed, plug in the machine and turn the power switch ON, and

check the general operation of the machine by making a few copies and comparing them to those

made previously.

Inspection and Overhaul every 880,000 Copies

(1) Replace all the consumables.

(2) Check that if there is any damage to the parts in the driving section (gear, pulley, timing belt, etc.). In

principle, replace those parts at this time.

(3) Check to see if there is any damage or peeling of adhered parts (tape, Mylar sheet, etc.). Replace

any affected parts if necessary.

(4) Check that if all the switches and sensors operate properly. Replace them if they are not operating

properly.

(5) Clean the inside of the machine thoroughly.

Note: Before inspecting and overhauling the feed section of the 3-cassette feed unit, remove the

PFP upper aligning unit and PFP feed unit from the copier.

Explanation of the items in the “Remarks” column of the Periodic Inspection Check List

Periodic Inspection Check List

Symbols used in the Periodic Inspection Check List

Cleaning Lubrication Replacement Operation check Date

A

:Cleaning with alcoholL:Launa 40 110: Every 110,000 copies :Check for User’s

:Cleaning with soft Application 440: Every 440,000 copies abnormalities name

pad, cloth, or cleanerSI:Silicon Oil Same from here on after cleaning Machine

(vacuum cleaner)

MAINTENANCE

W

:White grease :

(Molycoat)

AV

:Alvania No.2

Replace in event of deformation or other damage

or No.

replacement. Inspector

Remarks

Page 21

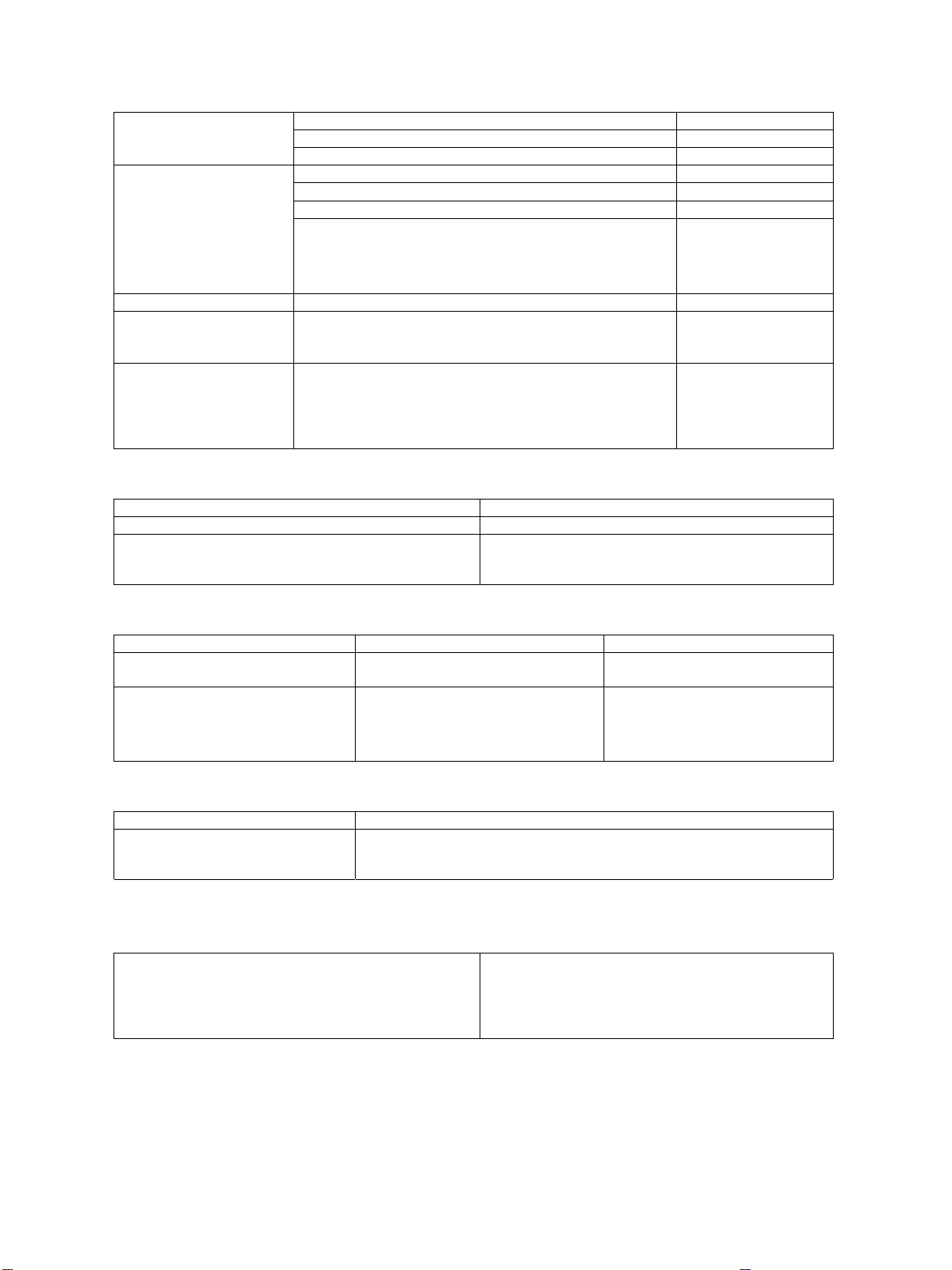

PERIODIC INSPECTION CHECK LIST

Category Item to check

1. Overall unit

2. Main blade 440

3. Toner bag 110

Cleaner

4. Recovery blade

5. Separation claw (for Drum) 440

6. Fur brush 440

7. Toner transport auger drive

8. Cleaner lower guide

8-1.

Toner adhesion amount sensor

8-2. Drum shaft bearing

9. Discharge LED

10. Drum shaft

Drum 11. Drum 440

12. Ozone filter (for exit fan) 440

13. Glass or

14. Glass holder or

15. Mirror 1

16. Mirror 2

17. Mirror 3

Scanner

18. Reflector

19. Lens

20. Exposure lamp

21. Copy area indicator

21-1. Shading glass

22. Automatic paper-size detector

23. Slide sheet (front, rear) or

24. Air filter

25. Case

26. Charger wire 440

Clean at Lubricate at Replace Check

440,000 copies 440,000 copies

W

A

A

A

x 1,000 while on

Charger

Around 30. Slit glass on the copier

laser unit

Developer

Note:

27. Terminal contact

28. Charger wire cleaner 440

29. Grid 440

31. Overall unit

31-1. Duct cover

32. Developer material 440

33. Front shield

The “Remarks” column indicates page and item numbers in the Parts List for consumab parts.

The consumable replacement cycle on the feeding system is the number of sheets fed on each feeding

source.

MAINTENANCE

Page 22

Category Item to check

Clean at Lubricate at Replace Check

440,000 copies 440,000 copies

x 1,000 while on

34. Oil seal (9 portions)

35. Guide roller or

Developer 36. Duct filter

37. Toner filter 440

38. Toner hopper drive worm gear

42. Aligning roller

43. Paper guide

Paper 44. Brush

feed 46. Paper feed system drive gears

section (tooth faces)

47. Aligning unit support bush

and pressurizing leaf spring

69. Upper heat roller (Teflon roller) 440

70. Lower heat roller (rubber roller) 440

71. Upper separation claw 440

72. Lower separation claw

73. Cleaning roller 1 440

74. Cleaning roller 2 440

Fuser unit 75. Cleaning roller 3 440

A

A

AV

W

W

W

75-1. Cleaning roller 4 440

76. Upper and lower thermistors

77. Heat roller entrance guide

78. Heat roller exit guide

79. Paper dust recovery bracket

80. Exit roller

81. Heat roller/cleaning roller drive

gear

82. Cleaning roller bush

83. Transfer belt 440

84. Transfer belt power supply 440

roller

85. Transfer belt cleaning brush 440

Transfer 86. Transfer belt drive roller

belt 87. Transfer belt follower roller

88. Transfer belt separation

auxiliary roller

89-1. Transfer belt cleaning blade 440

89-2. Flicker periphery

89-3. GCB bush and plastic bush

A

A

A

A

SI

SI

A

A

A

L

MAINTENANCE

Page 23

Category Item to check

Clean at Lubricate at Replace Check

440,000 copies 440,000 copies

x 1,000 while on

Transfer 89-4.

belt

ADU 94. ADU aligning roller

PFP 52. Paper guide

ADF 103. ADF reversal roller

Transfer belt separation

auxiliary roller bearing and GCB

90. ADU pick-up roller

91. ADU feed roller

92. ADU separation belt

93. Transport rollers 1 to 4

95. GCB bush and plastic bush

96. Drive gear tooth faces

97.

Exit/ADU switching gate and Main

unit eixt section/ADU relay roller

48. PFP pick-up roller 110

49. PFP feed roller 110

50. PFP separation roller

51. PFP aligning roller

53. Tray drive worm wheel and

gear (tooth faces)

54. PFP drive gear (tooth faces)

55. GCB bush and plastic bush

98. ADF pick-up roller 440

99. ADF feed roller 440

100. ADF separation pad 440

101. Transport belt 440

102. ADF aligning roller

104. ADF empty sensor

105. ADF aligning sensor

106. ADF size sensor

107. Exit sensor

108. ADF timing sensor

109. Transport belt cleaning brush

56. LCF pick-up roller 440

57. LCF feed roller 440

A

A

A

L

A

A

A

L

W

A

AV

110

A

W

W

L

A

A

LCF

58. LCF separation roller

59. Manual pick-up roller 110

60. Manual feed roller 110

61. Manual separation roller

62. Paper guide

63.

Paper feed system drive gears

64. GCB bush and plastic bush

65. Gear

66. Worm and worm wheel

67. Worm shaft

68. Wire pulley shaft

AV

AV

W

L

W

W

W

W

440

110

Note: When lubricating, do not allow oil to come in contact the rollers, belts and belt pulleys.

MAINTENANCE

Page 24

Page 25

SHARP CORPORATION

Digital Document Systems Group

Products Quality Assurance Department

Yamatokoriyama, Nara 639-1186, Japan

2001 November Printed in Japan N

COPYRIGHT © 2001 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

Loading...

Loading...