Page 1

SERVICE HANDBOOK

CODE : 00ZAR650//H1E

DIGITAL COPIER

MODEL

CONTENTS

[ 1 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] PERIODICAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[ 3 ] PRECAUTIONS FOR STRONG AND HANDLING SUPPLIES . . 3 - 1

[ 4 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

[ 5 ] INSTALLATION INSTRUCTIONS

FOR FIRMWARE UPDATE THROUGH PC . . . . . . . . . . . . . . . 5 - 1

[ 6 ] MANUAL FOR FIRMWARE DOWNLOAD. . . . . . . . . . . . . . . . . 6 - 1

[ 7 ] HARNESS WIRING DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Parts marked with “ “ are important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

AR-650

SHARP CORPORATION

This document has been publi shed to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

GENERAL PRECAUTIONS REGARDING THE INSTALLATION

AND SERVICE FOR THE COPIER

The installation and service should be done by a qualified service technician.

1. Transportation/Installation

• When transporting/installing the copier, move it by the casters while lifting the stoppers.

The copier is quite heavy and weighs approximately 250 kg (551 lb), therefore pay full attention

when handling it.

• Be sure to use a dedicated outlet with AC 115V or 120V/20A (220V, 230V, 240V/10A) or more for

its power source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for the copying operation, keep a minimum clearance of

80 cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) in the rear.

2. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers, the transfer belt and the highvoltage transformer.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fan, etc.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

and rotating/operating sections. Avoid exposure to laser radiation.

• Use suitable measuring instruments and tools.

• Avoid exposure to laser radiation during servicing.

− Avoid direct exposure to beam.

− Do not insert tools, parts, etc. that are reflective into the path of the laser beam.

− Remove all watches, rings, bracelets, etc. that are reflective.

3. Main Service Parts for Safety

• The breaker, door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important for safety. Be sure to handle/install them properly.

4. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug the

power cord during service”, “Hot area”, “Laser warning label” etc. to see if there is any dirt on

their surface and whether they are properly stuck to the copier.

Page 3

5. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, supplies, consumable parts and packing

materials, it is recommended to follow the relevant local regulations or rules.

6. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, toothed washers in the wrong places.

7. Basically, the machine should not be operated with any parts removed or disassembled.

8. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband, because the ICs on it may become damaged due to static electricity.

Caution: Before using the wrist band, pull out the power cord plug of the copier and make

sure that there is no uninsulated charged objects in the vicinity.

Caution : Dispose of used RAM-IC’s (including lithium battery)

according to the manufacturer’s instructions.

Vorsicht : Entsorgung des gebrauchten RAM-IC’s (inklusive

der Lithium Batterie) nach Angaben des Herstellers.

Page 4

1. ADJUSTMENT

2. PERIODICAL MAINTENANCE

3. PRECAUTIONS FOR STORING

& HANDLING SUPPLIES

4. TROUBLESHOOTING

5. INSTALLATION INSTRUCTIONS

FOR FIRMWARE UPDATE

THROUGH PC

6. MANUAL FOR FIRMWARE

DOWNLOAD

7. HARNESS WIRING DIAGRAMS

Page 5

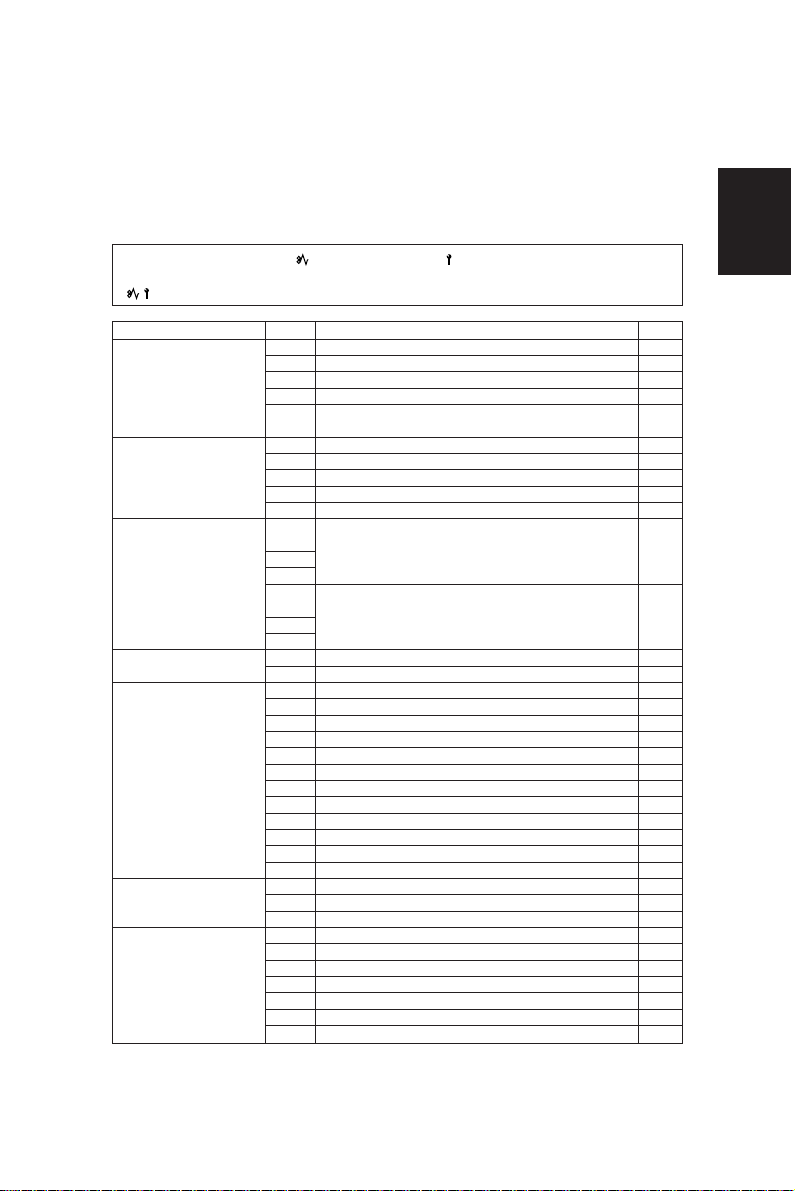

CONTENTS

1. ADJUSTMENT ...................................................................................................................... 1-1

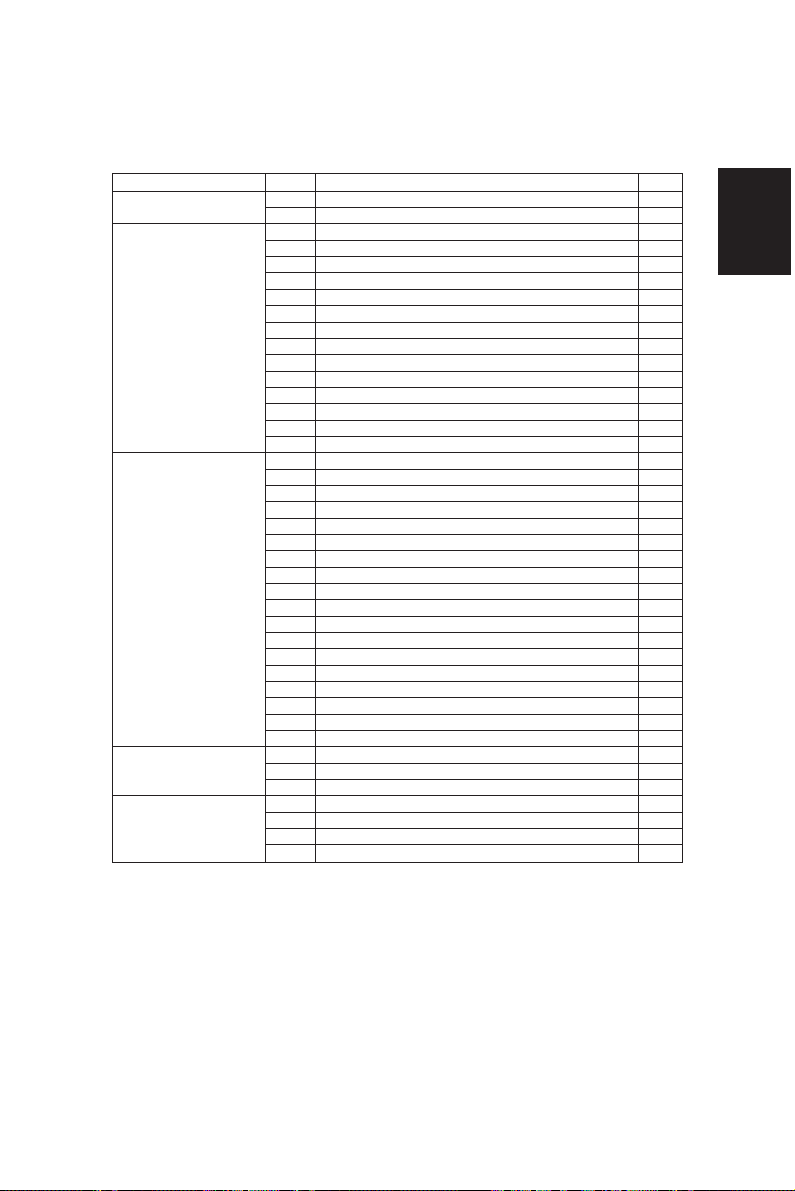

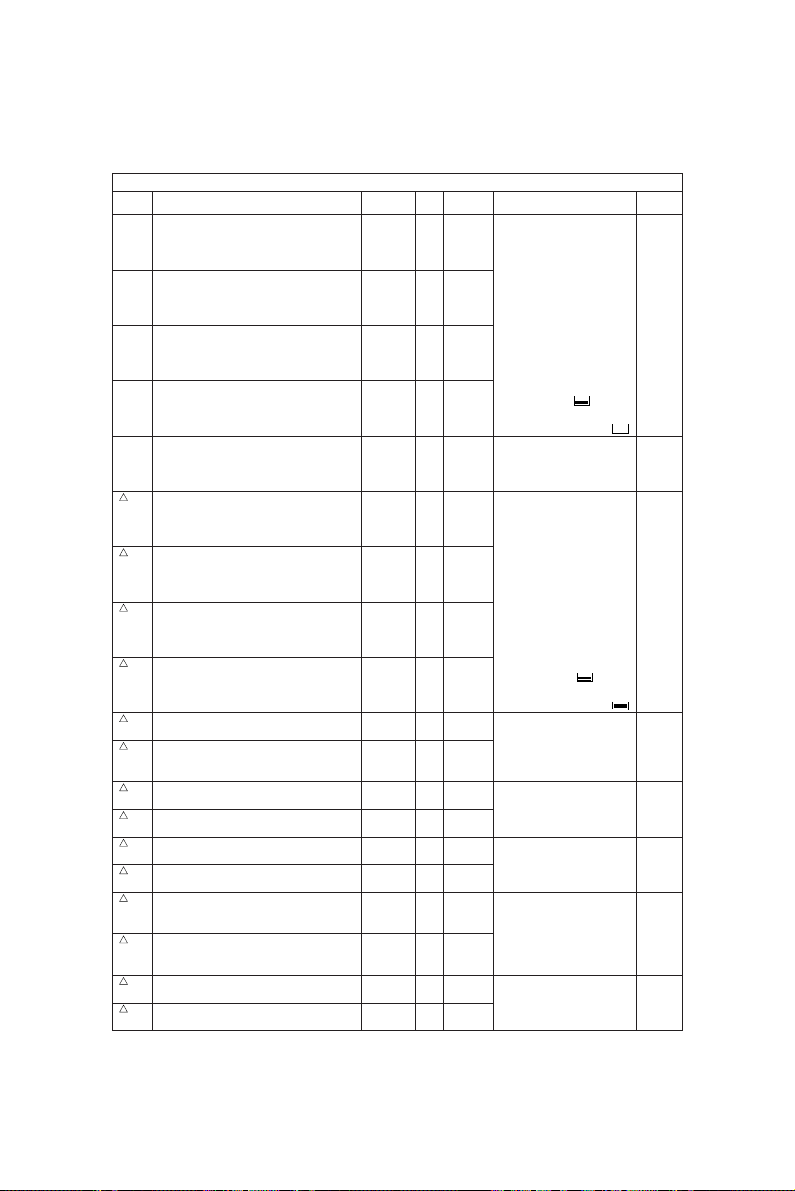

1.1 Error Codes ............................................................................................................................ 1-1

1.2 Self-Diagnostic Modes ........................................................................................................... 1-6

1.2.1 Input signal check (test mode 03) ..................................................................................... 1-8

1.2.2 Output signal check (test mode 03) .................................................................................. 1-10

1.2.3 Test print mode (test mode 04) ......................................................................................... 1-13

1.2.4 Adjustment mode (05) ...................................................................................................... 1-14

1.2.5 Setting mode (08) ............................................................................................................. 1-25

1.2.6 How to register/change ID codes (access control mode) ................................................. 1-33

1.3 Formatting the Hard Disk ....................................................................................................... 1-34

1.4 Auto-Toner Sensor Adjustment .............................................................................................. 1-35

1.5 Print Image Adjustment ......................................................................................................... 1-37

1.5.1 Adjustment of paper aligning value ................................................................................... 1-39

1.5.2 Adjusting the printer section ............................................................................................. 1-40

1.5.3 Adjusting the scanner section ........................................................................................... 1-46

1.6 Image Density ........................................................................................................................ 1-52

1.7 Automatic Adjustment of Gamma correction ......................................................................... 1-53

1.8 Sharpness (HPF) Adjustment ................................................................................................ 1-55

1.9 Data Correction ...................................................................................................................... 1-56

1.10 High-Voltage Adjustment ....................................................................................................... 1-57

1.11 Installation of Carriage Drive Wire ......................................................................................... 1-62

1.11.1 Wire tension adjustment ................................................................................................... 1-62

1.11.2 Adjustment of carriage 1 and carriage 2........................................................................... 1-62

1.11.3 Carriage drive wire assembling ......................................................................................... 1-63

1.12 Lens Unit ................................................................................................................................ 1-65

1.12.1 Adjusting the lens magnification ....................................................................................... 1-66

1.13 Adjusting Horizontal Deviation Caused by Paper Feed ......................................................... 1-68

1.14 Changing the Paper Size ....................................................................................................... 1-69

1.14.1 LCF paper sizes ................................................................................................................ 1-69

1.14.2 PFP paper sizes ............................................................................................................... 1-70

1.15 Adjustment of Duplexer.......................................................................................................... 1-71

1.15.1 Adjustment of the Stack Guide Unit .................................................................................. 1-71

1.15.2 Holding gate position adjustment...................................................................................... 1-73

1.16 Adjusting the Thickness of the Magnetic Brush (leveler) ....................................................... 1-76

1.17 Adjusting the Gap between the Drum and Sleeve ................................................................. 1-76

1.18 Adjustment of Developer Polarity Position ............................................................................. 1-76

1.19 Adjusting the Heat Roller Pressure ........................................................................................ 1-76

1.20 Setting the Heat Roller Temperature and Heat Roller Pressure ............................................ 1-77

1.21 Adjusting the Fuser Inlet Guide.............................................................................................. 1-79

CONTENTS I

Page 6

1.22 Adjustment of ADF ................................................................................................................. 1-80

1.22.1 Adjustment of skew with ADF ........................................................................................... 1-80

1.22.2 Adjustment of ADF horizontal deviation caused for ADF .................................................. 1-81

1.22.3 Adjustment of ADF leading-edge position ........................................................................ 1-82

1.22.4 Adjustment of leading-edge position for ADF (at the Time of Reversing) ......................... 1-82

1.22.5 Adjustment of magnetic catches installation..................................................................... 1-83

1.22.6 Adjustment of the separation area .................................................................................... 1-84

1.22.7 EEPROM Initialization, Sensor Adjustment and Test Mode .............................................. 1-85

1.23 Fine Adjustment of Binding Position/Folding Position ............................................................ 1-86

1.24 Adjustment of RADF Height ................................................................................................... 1-87

1.25 Flapper Solenoid Adjustment ................................................................................................. 1-88

1.26 Additional Parts when Installing the Paper Exit Tray .............................................................. 1-89

2. PERIODICAL MAINTENANCE ............................................................................................. 2-1

2.1 Inspection every 400,000 Copies ........................................................................................... 2-1

2.2

Inspection and Overhaul every 800,000 Copies ....................................................................................

2-1

2.3 Periodic Inspection Check List ...............................................................................................2-1

2.4 Periodical Maintenance Kit (For 400k) ................................................................................... 2-14

2.5 Jig List .................................................................................................................................... 2-15

3. PRECAUTIONS FOR STORING AND HANDLING SUPPLIES............................................ 3-1

3.1 Precautions for Storing Supplies ............................................................................................ 3-1

3.2 Checking and Cleaning the OPC Drum ................................................................................. 3-1

3.3 Checking and Cleaning the Drum Cleaning Blade, Transfer Belt Cleaning Blade ................. 3-2

3.4 Checking and Cleaning the Heat Roller Cleaning Roller 1, 2, 3, 4 ........................................ 3-3

3.5 Checking and Cleaning the Upper and Lower Heat Rollers................................................... 3-3

3.6 Checking and Replacing Transfer Belt ................................................................................... 3-4

3.7 Checking and Replacing Transfer Belt Power Supply Roller.................................................. 3-4

3.8 Checking and Replacing Transfer Belt Cleaning Brush.......................................................... 3-4

3.9 Replacement of maintanance parts ....................................................................................... 3-5

4. TROUBLESHOOTING........................................................................................................... 4-1

4.1 Scanner System Related Service Call ................................................................................... 4-1

4.2 Process System Related Service Call ................................................................................... 4-3

4.3 Fuser Related Service Call .................................................................................................... 4-4

4.4 Communication Related Service Call .................................................................................... 4-6

4.5 ADF Related Service Call ...................................................................................................... 4-7

4.6 Other Troubles on the ADF System........................................................................................ 4-8

4.7 Other Service Calls ................................................................................................................ 4-12

4.8 Laser Optical system Related Service Call ............................................................................ 4-13

4.9 Finisher Related Service Call ................................................................................................. 4-15

4.10 Image Quality Maintenance Control Related Troubleshooting ............................................... 4-30

II CONTENTS

Page 7

5. INSTALLATION INSTRUCTIONS FOR FIRMWARE UPDATE THROUGH PC .................... 5-1

5.1 Outline .................................................................................................................................... 5-1

5.2 System Configuration ............................................................................................................. 5-1

5.3 Preparation of PC to use a network ....................................................................................... 5-2

5.3.1 Setting Virtual Modem ......................................................................................................... 5-2

5.3.2 Using Dial-Up Networking ...................................................................................................5-6

5.3.3 Using New Connection ........................................................................................................ 5-8

5.4 Installation of FTP Server ...................................................................................................... 5-12

6. MANUAL FOR FIRMWARE DOWNLOAD ............................................................................ 6-1

[ 3 ] [ 9 ] Mode operation ........................................................................................................ 6-1

6.1 Outline .................................................................................................................................... 6-1

6.2 Preparation of PC .................................................................................................................. 6-1

6.2.1 Software Installation ............................................................................................................ 6-1

6.2.2 Preparation of Updated Files...............................................................................................6-2

6.2.3 Connection between Copier and PC ................................................................................... 6-3

6.3 Download Operation .............................................................................................................. 6-4

6.4 Screen Details ........................................................................................................................ 6-10

7. HARNESS WIRING DIAGRAMS ........................................................................................... 7-1

7.1 AC Wire Harness ................................................................................................................... 7-1

7.2 DC Wire Harness ........................................................................................................... Appendix

CONTENTS III

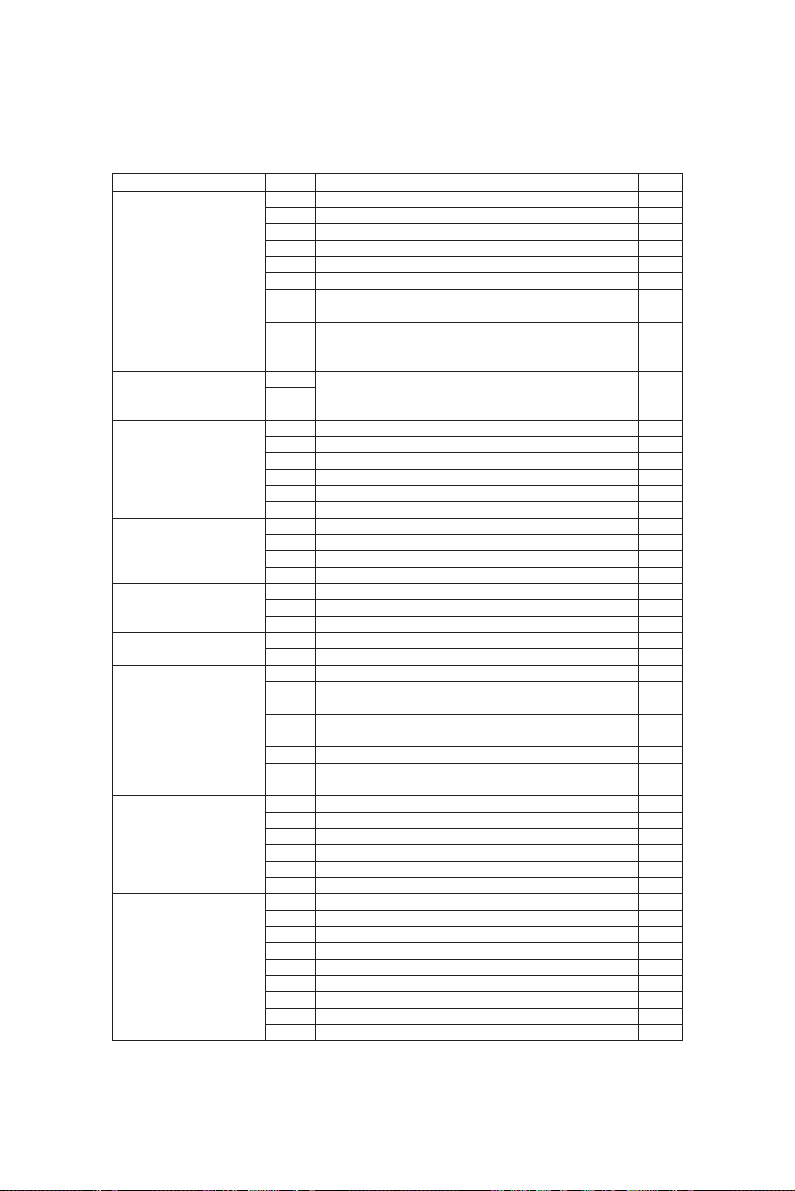

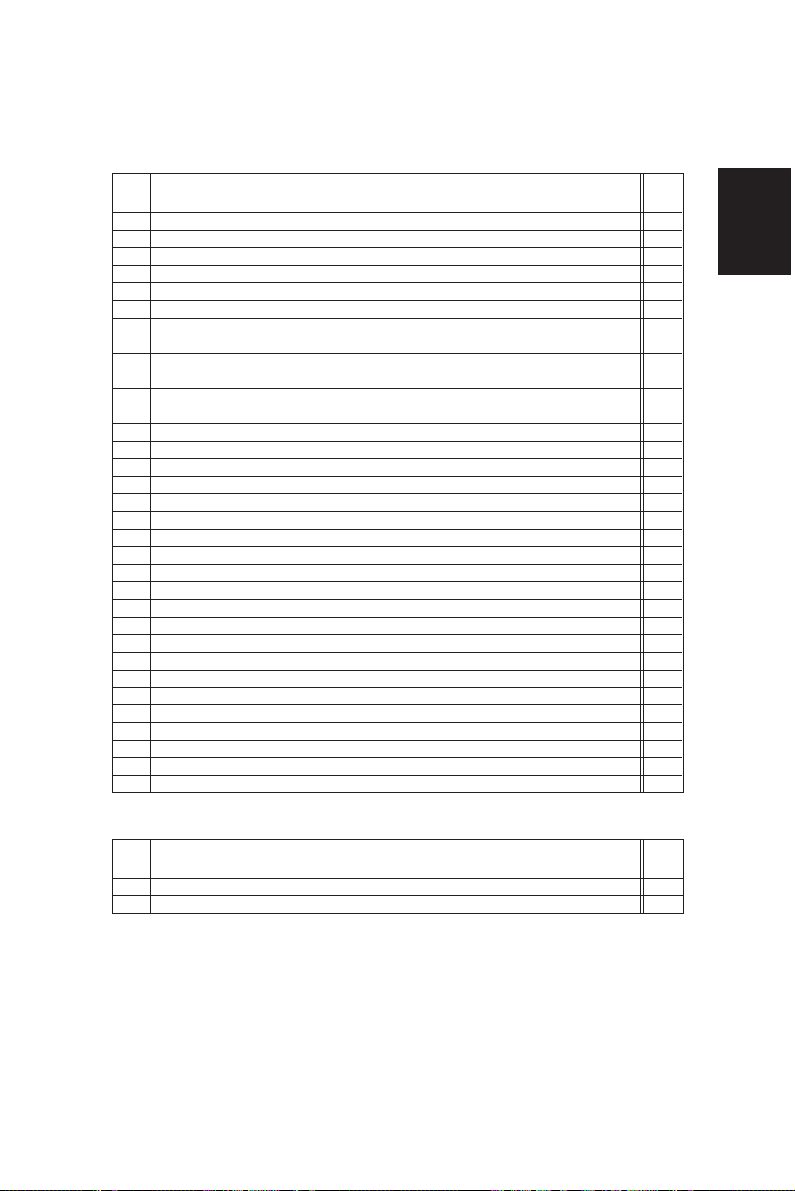

Page 8

1. ADJUSTMENT

1.1 Error Codes

When either the CLEAR PAPER ( ) or CALL FOR SERVICE ( ) symbol appears, press the CLEAR/STOP

and [8] keys simultaneously and the corresponding error code will be displayed.

/ → [C] + [8] (error code)

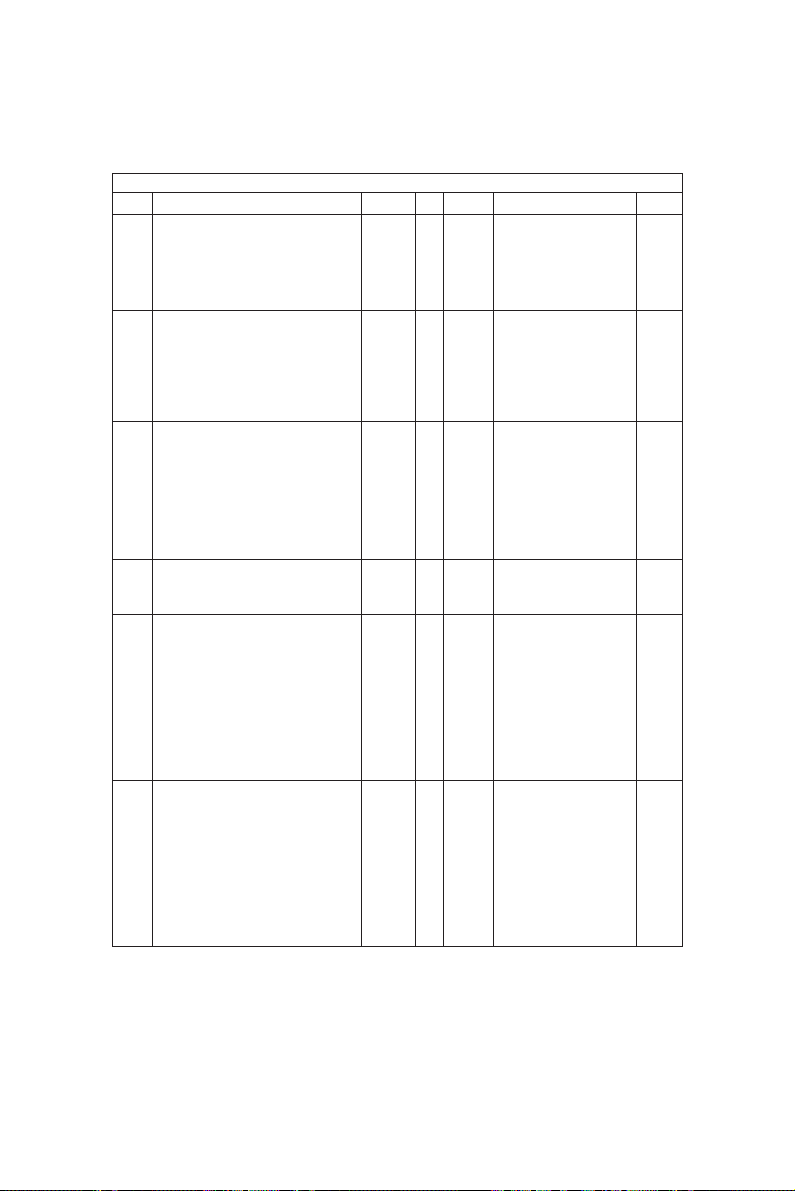

Group

Transporting jam inside the

copier 1

Paper feeding jam

Transport jam from feed for

RGT

Paper jam if some cover is

opened during copying

ADU reversal section

transport line jam

Original transporting jam

at the ADF

Paper jam at the finisher

Error code

Fuser exit switch non-arrival jam

E01

Fuser exit switch accumulation jam

E02

Paper remaining inside the copier at power ON

E03

Jam caused by HDD error

E09

Image transport ready timeout

E0A

(Image data transport error between SYS board and PLG board)

Bypass feeding jam

E12

PFP 1st cassette feeding jam

E15

PFP 2nd cassette feeding jam

E16

PFP 3rd cassette feeding jam

E17

LCF feeding jam

E19

PFP transport jam (non-arrival at RGT)

E31

E31:During upper cassette feed

E32:During middle cassette feed

E32

E33:During lower cassette feed

E33

PFP transport jam (inside the PFP)

E34

E34:During upper cassette feed

E35:During middle cassette feed

E35

E36:During lower cassette feed

E36

Copier front cover is opened during copying

E41

Exit jam processing cover is opened during copying

E47

ADU RGT non-arrival

E50

ADU transport TR1 non-arrival

E51

ADU transport TR2 non-arrival

E52

PFP upper cassette RGT non-arrival (from ADU feed)

E53

ADU feed non-arrival

E54

Paper on transport path at copy end

E55

Paper on PFP transport path after door open/close

E56

Reversal switch non-arrival jam

E57

Reversal switch accumulation jam

E58

Exit switch accumulation jam

E59

Exit switch non-arrival jam

E5A

ADU transport start timeout jam

E5B

Original feeding jam at the feed section of the ADF

E71

Original transporting jam at the transport section of the ADF

E72

Original exiting jam at the exit section of the ADF

E73

PUNCH jam

E9F

Transporting delay jam

EA1

Transporting stationary jam

EA2

Jam at power ON

EA3

Door open jam

EA4

Staple jam

EA5

Early arrival jam

EA6

Machine status

Reference

1 - 1 ADJUSTMENT

Page 9

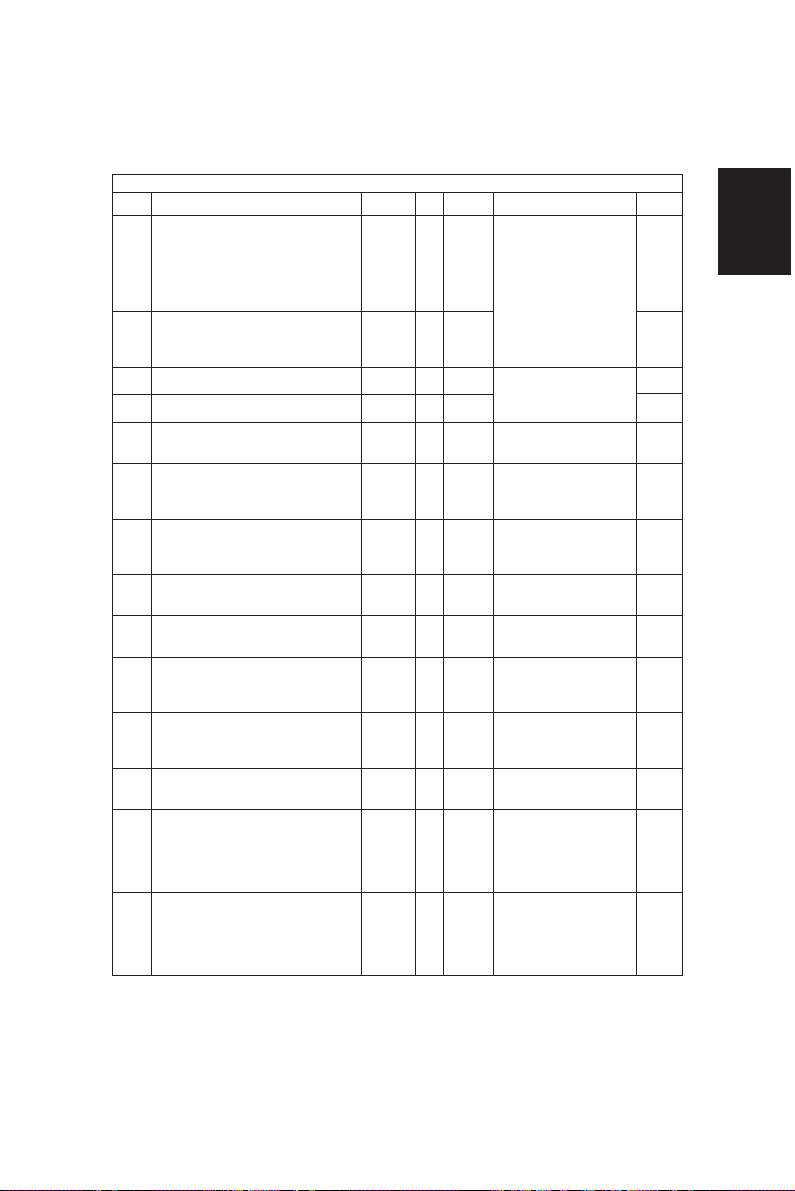

Group

Paper jam at the finisher

Copier transport jam 2

Paper feeding error

(Refer to page 1-4)

Service call from the

optical system

Process system related

service call 1

Process system related

service call 2

Fuser related

Service call from

communication

Service call ADF

Error code

EA8

Finisher saddle staple jam

EA9

Finisher saddle door open jam

EAA

Finisher saddle power ON jam

EAB

Finisher saddle transport accumulation jam

EAC

Finisher saddle transport delay jam

EAD

Print end command time-out jam

EAE

Finisher receive time-out jam

Machine status

Paper cannot be detected from the copier in a fixed-time.

Finisher ready time-out error

EB3

(Finisher cannot prepare for receiving the paper after the

leading edge of the paper reaches to RGT in a fixed-time.)

Double jam

EB5

(Residence jam occurs because of the double paper is

EB6

separated in paper feeding.)

Duplexer side guide is abnormal

C11

Duplexer stopper guide is abnormal

C12

PFP upper tray is abnormal

C15

PFP middle tray is abnormal

C16

PFP lower tray is abnormal

C17

LCF tray is abnormal

C18

Peak detection error

C26

Home switch does not turn OFF

C27

Home switch does not turn ON

C28

Scanner disconnection detection

C29

Charger cleaning operation error

C36

Transfer belt operation error

C37

Drum thermistor disconnection

C42

Brush motor lock error

CD1

Auger motor lock error

CD2

Abnormal thermistor or heater disconnection at power ON

C41

Warming up mode after disconnection judgment, or abnormal

C43

thermistor after ready

Warm-up time after detected disconnection or heater discon-

C44

nection after ready

Thermistor disconnection at HTR edge portion

C45

Lower thermistor (press roller) error after ready (Low temperature

C46

is detected because of disconnection or connector omission.)

Communication error between PFC and MCPU

C56

C57

Communication error between MCPU and IPC

C58

Communication error between IPC and the finisher

C59

Communications error between MCPU and LCPU

F07

Communications error between SYS and LGC boards

F11

Communications error between SYS and SLG boards

C72

Defective adjustment by the aligning sensor detected

C73

EEPROM defective initialization

C74

Defective adjustment by the exit/reversal sensor detected

C76

Transmission time-out error

C77

Transmission buffer full

C78

ADF power ON I/F error

C79

Reception time-out error

C80

Defective adjustment of ADF timing sensor

C93

ADF original stop signal not received

Reference

4.1

4.1

4.1

4.1

4.2

4.2

4.2

4.7

4.7

4.3

4.3

4.3

4.3

4.3

4.4

4.4

4.4

4.4

4.4

4.4

4.5

4.5

4.5

4.5

ADJUSTMENT 1 - 2

Page 10

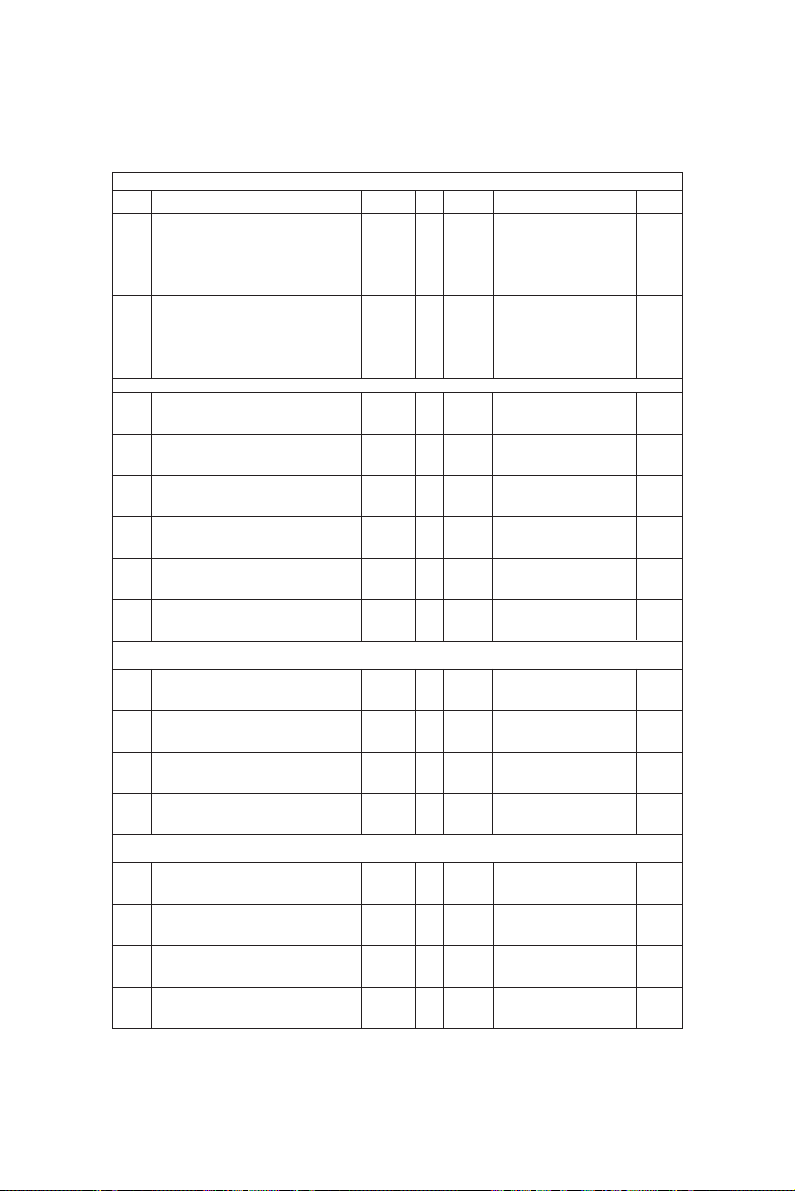

Group

Other service calls

Service call from the

laser optical

Service call from the finisher

Finisher related service call

Service call from the others

Error code

C94

M-CPU is abnormal

C99

PFC microcomputer is abnormal

CA1

Polygonal motor is abnormal

CA2

HSYNC is abnormal

CA3

Secondary scanning rough adjustment error

CA4

Primary scanning counter load error

CA5

Laser power adjustment error

CA6

Laser PWM calibration error

CA9

Image data transfer malfunction from SYS board

CAA

Secondary scanning fine adjustment error

CAB

Secondary scanning inter-page compensation error

CAC

Primary scanning dot adjustment error

CAD

Primary scanning tap adjustment error

CAE

Primary scanning tap amount measurement error

CAF

Primary scanning inter-page compensation error

CD0

Laser initialize time-out error

CB1

Transport motor is abnormal

CB2

Exit motor is abnormal

CB3

Tray elevation motor is abnormal

CB4

Alignment motor is abnormal

CB5

Staple motor is abnormal

CB6

Staple unit shift motor is abnormal

CB7

Stacking sensor is abnormal

CB8

Backup RAM data is abnormal

CB9

Saddle thrust motor is abnormal

CBA

Saddle front staple motor is abnormal

CBB

Saddle inner staple motor is abnormal

CBC

Saddle alignment motor is abnormal

CBD

Saddle guide motor is abnormal

Saddle fold motor is abnormal

CBE

Saddle positioning plate motor is abnormal

CBF

Sensor connector connection error

CC0

Microswitch error

CC1

Communications error between finisher saddle

CC2

Swing motor is abnormal

CC4

Horizontal registration motor is abnormal

CC5

Punch motor is abnormal

CC6

Power abnormality interrupt error

C92

C94

MCPU is abnormal

C99

PFC microcomputer is abnormal

F10

HDD formatting error

Machine status

Reference

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.7

4.7

4.7

4.7

1 - 3 ADJUSTMENT

Page 11

Addition to the explanation

(1) When a paper feeding error occurs:

: Error has occurred in the unit →Disabled

: No error has occurred in the unit →Enabled

: To operate continuously, error code ([C]+[8]) is not displayed.

(2) During C11 and C12 error codes

* If the mode which Duplexer is used is selected as “single-sided → duplex” or “two-sided → duplex”,

the “install the Duplexer” message is displayed and printing is not possible.

* If the mode other than the above (the Duplexer is not used) is selected, the operation can be

normally accepted.

(3) During C15, 16, 17 error codes

* If a cassette in which an error has occurred is selected:

The “Add Paper” message is displayed even if the sheet is set, and copying can be performed

when another paper cassette is selected.

* If a cassette other than the above is selected, the operation can be normally accepted.

ADJUSTMENT 1 - 4

Page 12

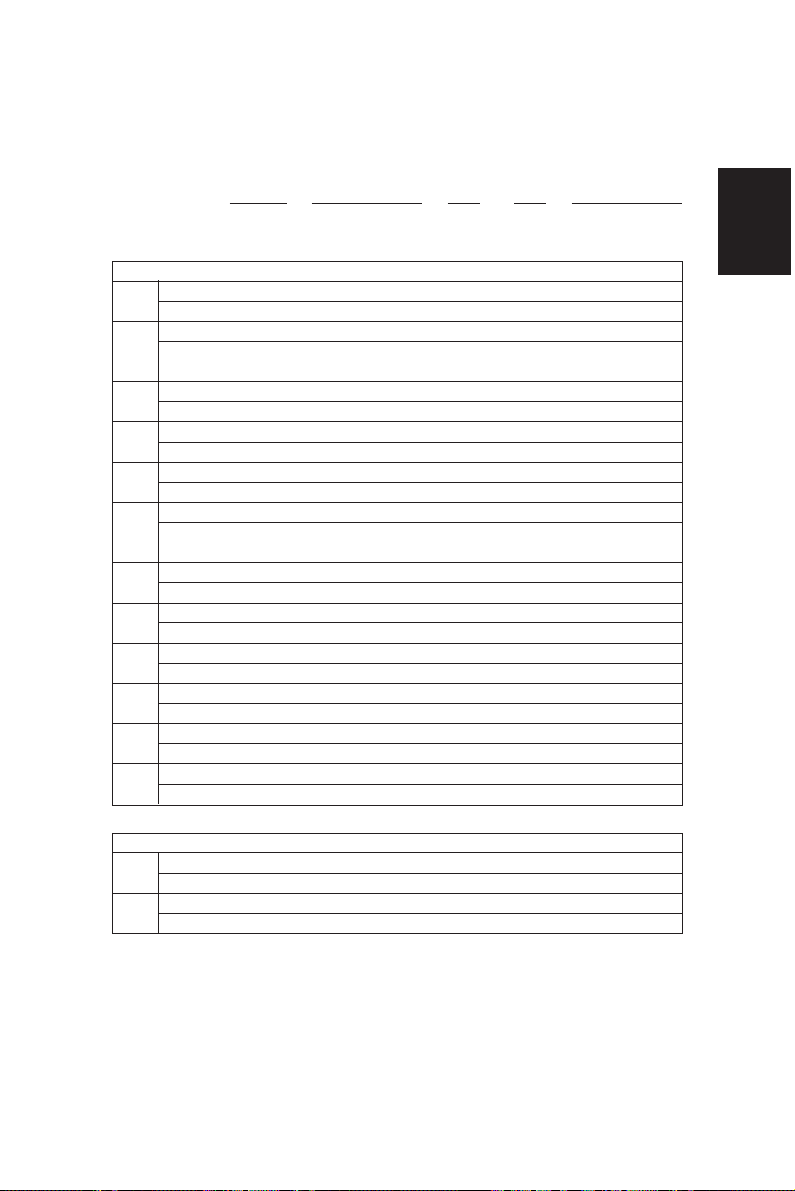

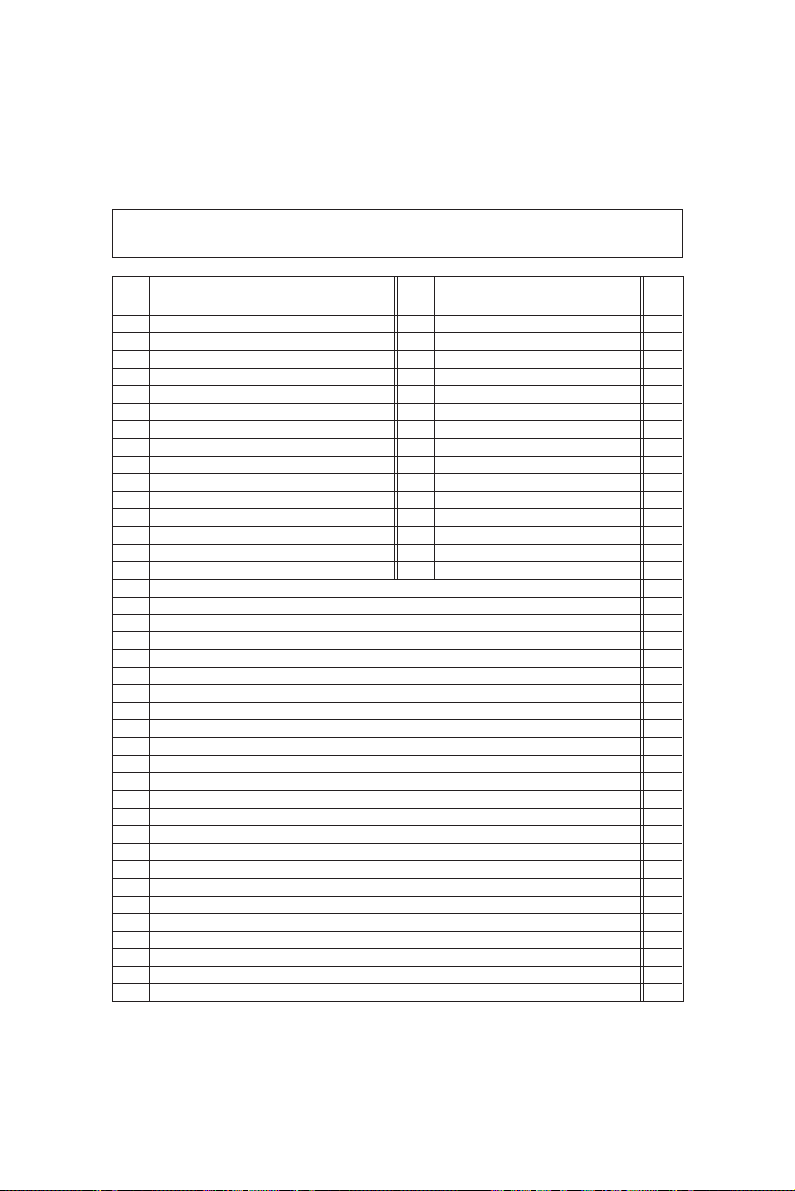

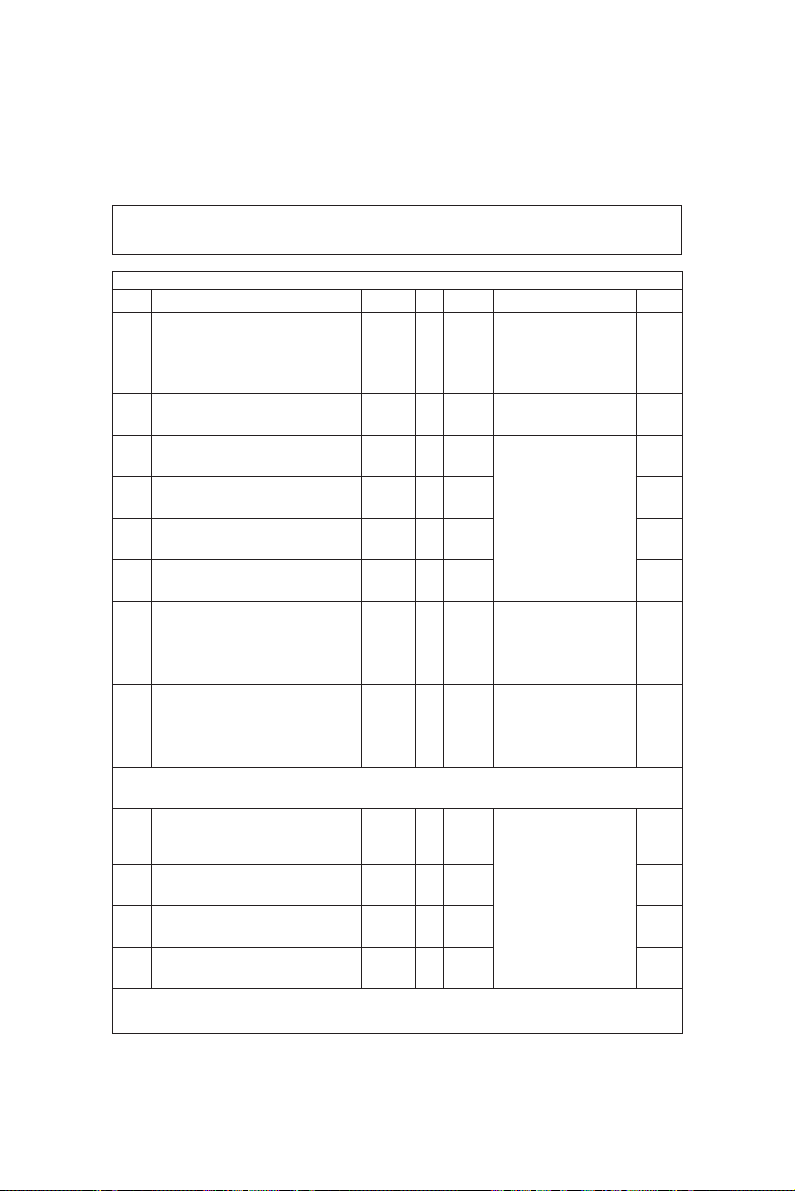

Error history (08-253)

(Display example)

Copy mode

A Paper feed cassette

0: Non-select 1: Bypass 2: LCF 3: PFP(U) 4: PFP(M) 5: PFP(L) 6: ADU

B Paper size code

0: Non-select 1: A5-R 2: ST-R 3: LT 4: A4 5: B5-R 6: LT-R 7: A4-R 8: OTHER/UNIV 9: B5

A: FOL/COM B: LG C: B4 D: LD E: A3 F: 13'LG G: 8.5*8.5

C Sort mode/Staple mode

0: Non-select 1: Group 2: Sort 7: Staple (Front) 8: Staple (2 places) 9: Staple (Rear) A: Saddle stetch

D DF mode

0: Not used 1: AUTO FEED (SADF) 2: STACK FEED

E APS/AMS mode

0: Non-select 1: APS 2: AMS

F Duplex mode

0: Non-select 1: Book 2: Two-sided/Single-sided 4: Two-sided/Duplexed

8: Single-sided/Duplexed

G Not used

0: Not used

H Image shift

0: Not used 1: Book 2: LEFT 3: RIGHT

I Editing

0: Not used 1: Masking 2: Trimming 3: Mirroring 4: Negative/Positive

J Edge-erase/Dual-page

0: Not used 1: Edge-erase 2: Dual-page 3: Edge-erase & Dual-page

K Not used

0: Not used

L Function

0: Not used 1: PPC 2: Not used 3: Not used 4: GDI 5: DSS

EA1

Error code

3 digit

9 9 0 3 2 6 1 7 5 7 3 2

YYMMDDHHMMSS

12 digit (Date, time)

6 4

MMM

3 digit

(Reproduction ratio)

NNN

3 digit

6 4

2 3 6 2 1 0 0 0 0 0 0 0

ABCDEFGHIJKL

12 digit

(Copy mode)

Reproduction ratio

MMM Primary scanning reproduction ratio (Y direction)

Hexadecimal

NNN Secondary scanning reproduction ratio (X direction)

Hexadecimal

Setting mode, code "253" displays latest 8 error data

1 - 5 ADJUSTMENT

Page 13

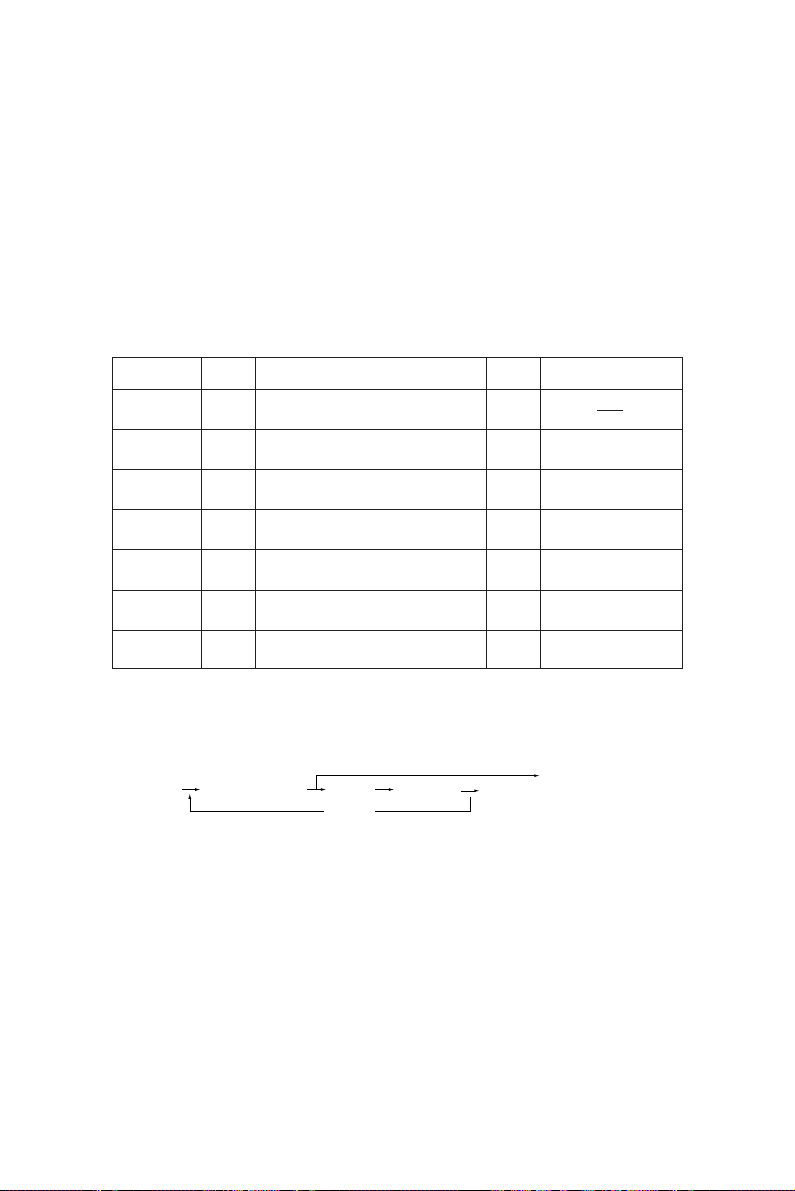

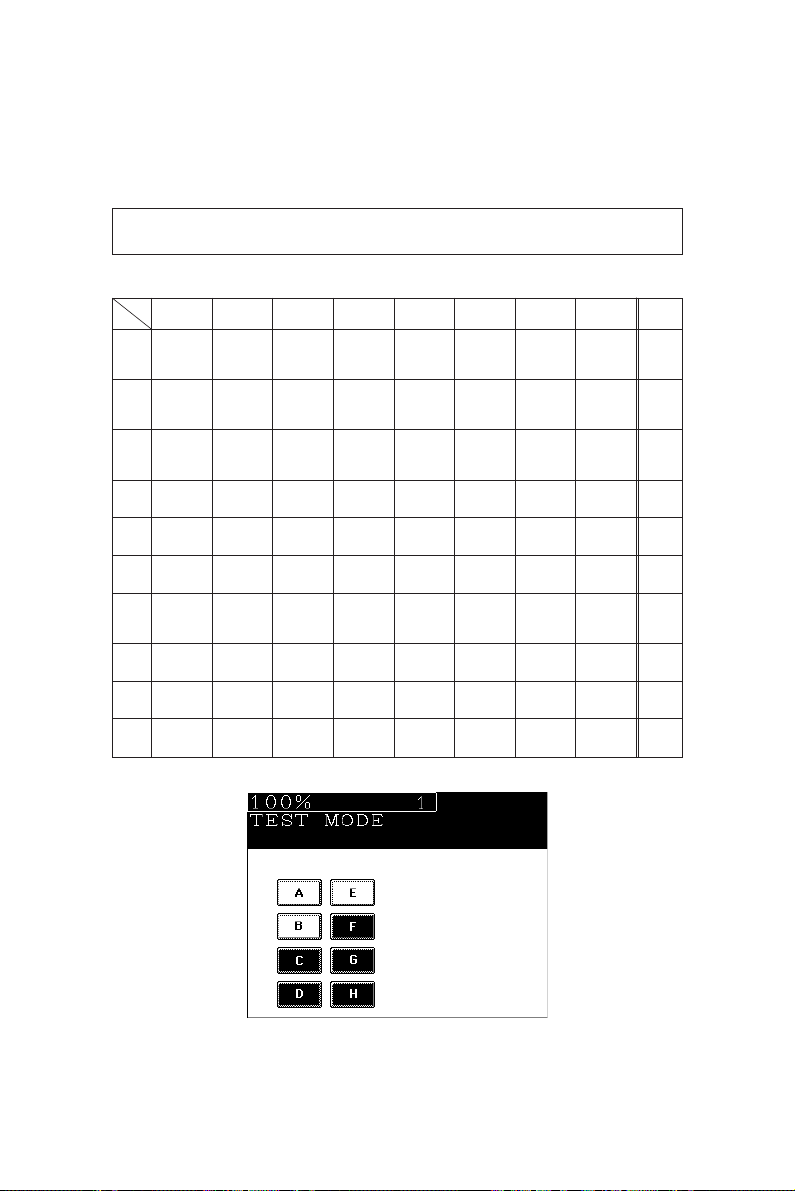

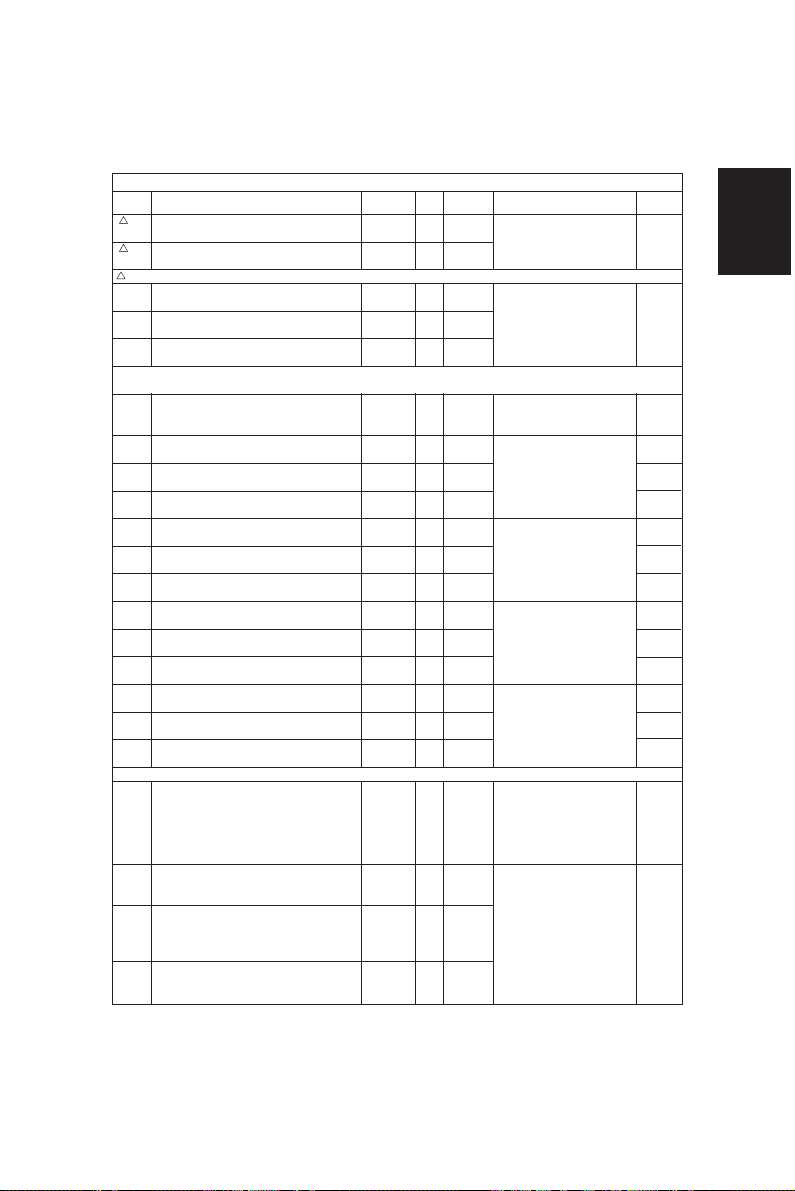

1.2 Self-Diagnostic Modes

[

]

This copier is a multi-function copier (net work printer, DSS). So, compared with conventional copiers:

1) It has more setting items in the self-diagnostic mode.

2) Setting items are related to each other.

For this reason, if normal operations are continued on the control panel (by [0] + [9] or [C] keys) when

adjustments are completed, operation trouble (e.g. machine lock) may occur due to the internal structure

of the program.

So, when the self-diagnostic mode in adjustments after unpacking, servicing or preventative maintenance, first turn the power OFF before handing the copier over to the user.

Mode

All-LEDs-lit

Test mode

Test print

mode

Adjustment

mode

Setting mode

List print

mode

Unit replace

mode

Note: To access the desired self-diagnostic mode, turn on the power switch while pressing the appropriate keys

(e.g. [0]+[5]).

Input

code method

[0]+[1]+

All LEDs on the control panel are lit, and all

[PWR]

pixels on the LCD light and go out.

[0]+[3]+

Input/output signals are checked.

[PWR]

[0]+[4]+

Test print

[PWR]

[0]+[5]+

Adjustment of items

[PWR]

[0]+[8]+

System switchover and setting of each

[PWR]

priority mode, PM counter, etc.

[9]+[START]

[6]+[START]

Printing of 05, 08 code data lists

+[PWR]

Mode for executing auto-toner adjustment

+[PWR]

and drum counter clear

Definition

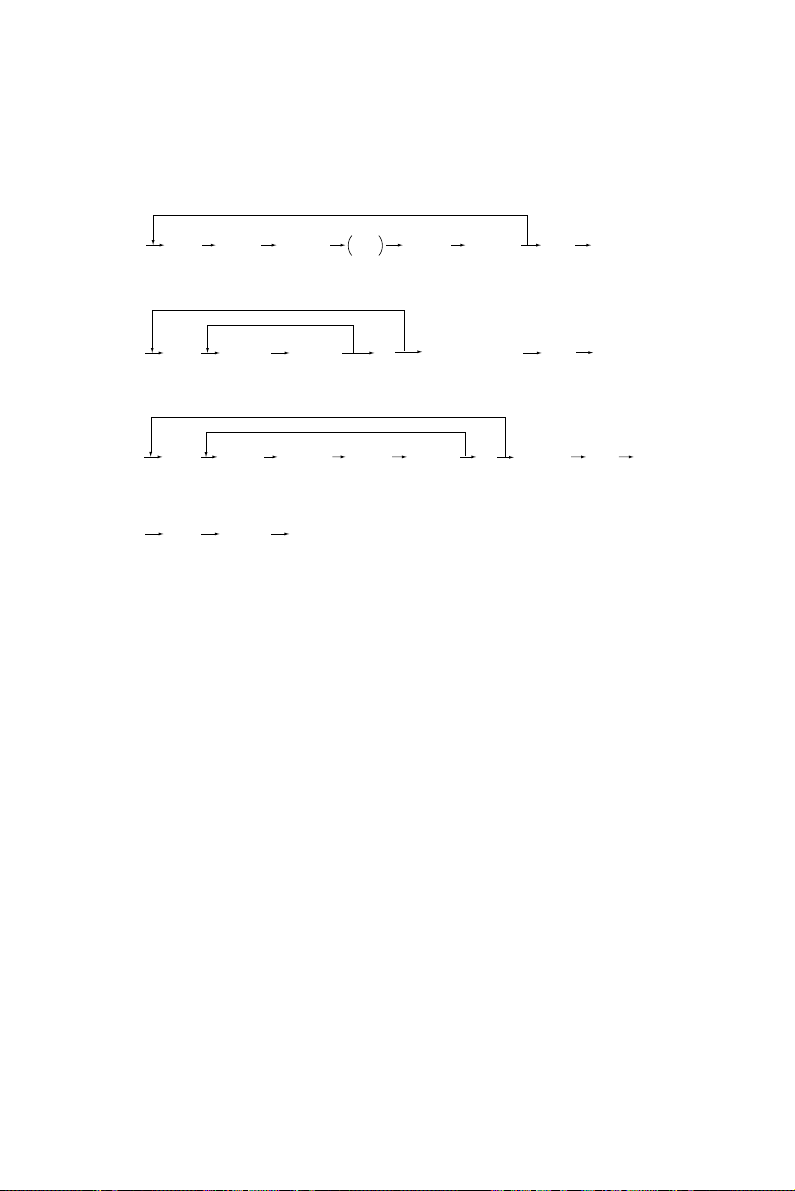

<Procedure>

• All-LEDs-lit mode (01):

[0] [1]

[PWR]

( All LEDs light ) [START]

START

(Key check) [C] Exit

Notes: 1. The mode cannot be cleared by [0]+[9] during the key check; it can be cleared only by [C].

It can be cleared by both [0]+[9] and [C] when all LEDs on the control panel are lit.

2. Key Check With LED (Press to turn LED out.)

Without LED (Press to display this in message area.)

Clearing

[C]or

[0]+[9]

[0]+[9]

[0]+[9]

[0]+[9]

[0]+[9]

[PWR]

OFF

[PWR]

OFF

Display

100% C A4

TEST MODE

100% P A4

TEST PRINT

100% A A4

TEST MODE

100% D A4

TEST MODE

100% P A4

LIST PRINT

100% K A4

TEST MODE

[C] or [0] [9] Exit

ADJUSTMENT 1 - 6

Page 14

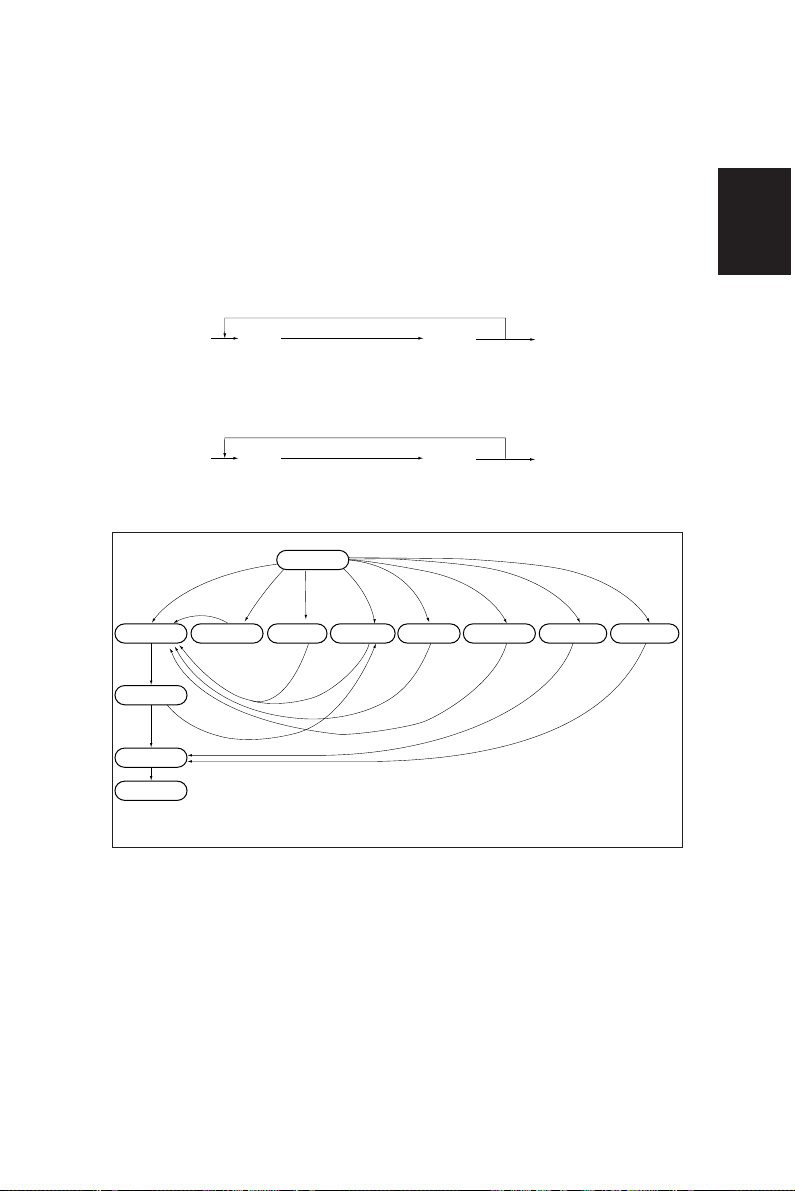

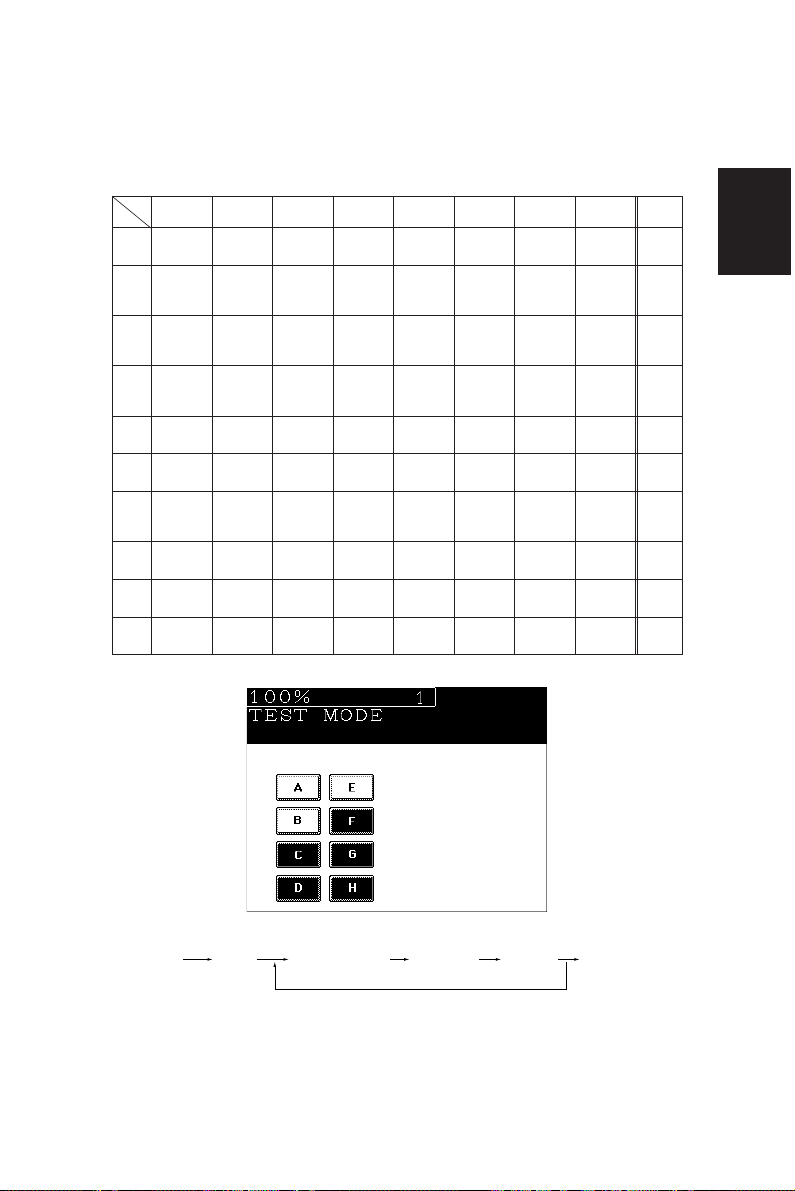

• Test mode (03): Refer to 1.2.1 and 1.2.2.

• Test print mode (04): Refer to “1.2.3 Test print mode”.

• Adjustment mode (05): Refer to “1.2.4 Adjustment mode”.

• List print mode

[9] [START]

[PWR]

(code) [START]

101: 05 adjustment code

102: 08 setting code

103: 08 setting code (For tandem)

201: Job access code

(Start of operation)

• Unit replace mode

[PWR] OFF

[6] [START]

[PWR]

(code) [START]

1: Auto-toner adjustment

2: Drum counter reset

(Start of operation)

[PWR] OFF

• Setting mode (08): Refer to “1.2.5 Setting mode”.

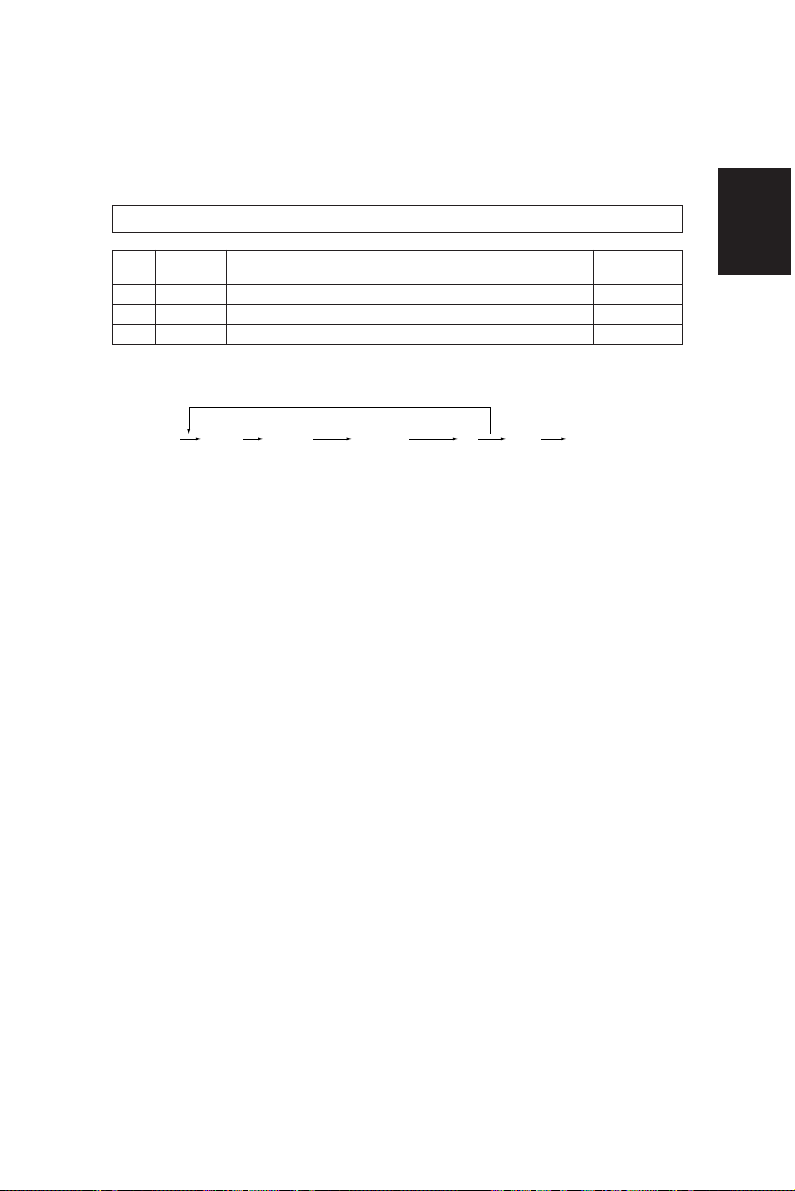

[0][1]

*2

[Power] ON

[0][3] [0][5]

Test mode

[0][8]

Adjustment mode

[0][9][0][9]

[0][4] [9][S] [6][S]

Setting mode

[0][9]

Test print mode

[0][9]

List print mode

[S]: START key ON.

[C]: CLEAR key ON.

Unit replace mode

Warming up

Standby

[Power] OFF

*3

Hand over to user

Normal

[C]

All the displays on

the control panel lit

*1

[0][5]

Quick reference chart for self-diagnostic mode

*1 When the copier is in the adjustment mode which you entered by turning the power switch ON while

pressing keys [0] and [5] simultaneously, pressing keys [0] and [9] simultaneously will set the copier

to the standby mode. In this standby mode only can the adjustment mode be accessed repeatedly

by simply entering [0] and [5].

*2 While all the displays on the control panel are lit, copying is not available. When the copier enters the

standby mode by pressing the [0] [9] or [C], copying is enabled.

*3 When the self-diagnostic mode was used, turn the power OFF, then hand over to the user.

1 - 7 ADJUSTMENT

Page 15

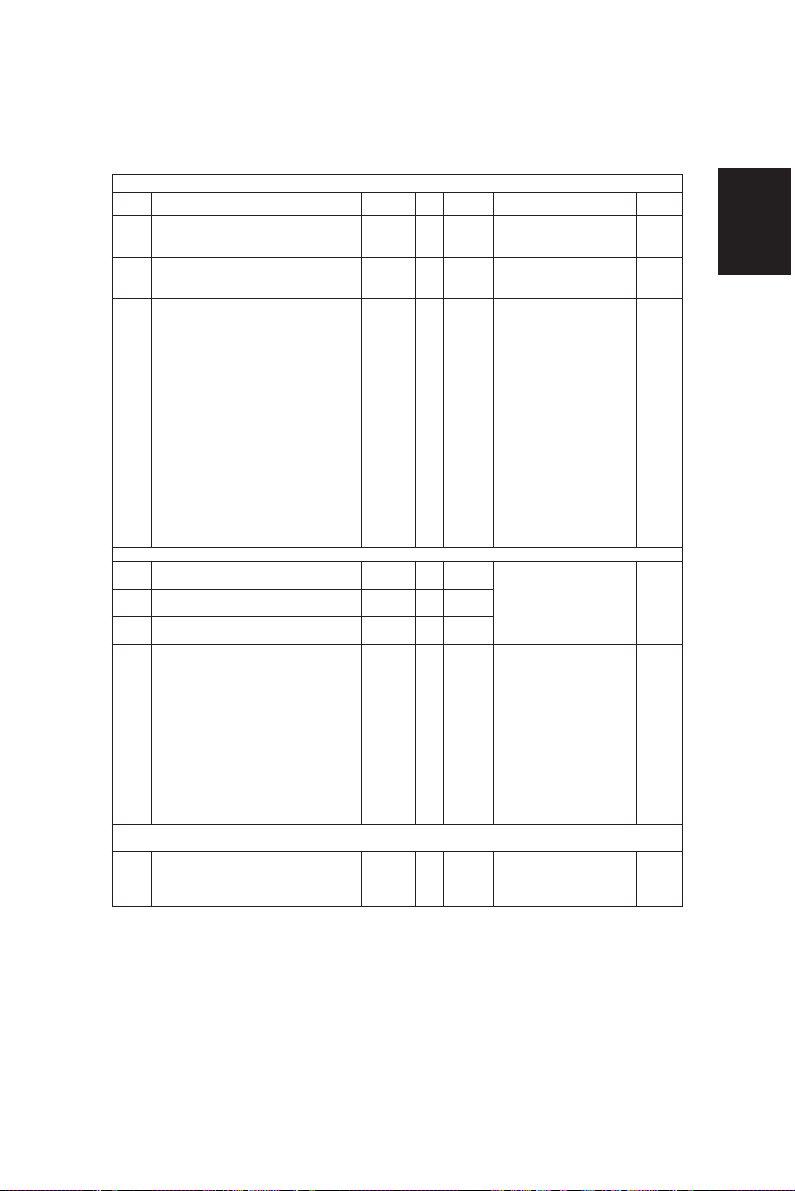

1.2.1 Input signal check (Test mode 03)

In the [0] [3] test mode, the following input signal states can be checked by pressing the corresponding

keys.

[A] When the ENERGY SAVER key is OFF (LED indicating the energy saver mode is out)

Icon

Key

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[0]

ABCDEFGH

(OFF)

(OFF)

(ON)

(ON)

–

–

–

–

–

–

Manual feed

paper width

switch 1

(OFF)

Manual feed

switch

(OFF)

ADU side

switch

(ON)

PFP middle

cassette SW

(ON)

–

–

ADU

connection

(Disconnection)

Fuser exit

switch

(OFF)

–

–

Manual feed

paper width

switch 0

ADU empty

switch

(Not empty)

PFP lower

cassette SW

Copier

paper stop

switch

Developer

unit not

mounted SW

LCF bottom

SW

(Bottom)

ADU

transport

switch 2

(ON)

–

PFP-U paper

start SW

(OFF)

PFP-M paper

start SW

(OFF)

PFP-L paper

start

SW

(OFF)

–

Front cover

SW

(OFF)

–

–

LCF door

SW

(Open)

LCF paper

start switch

(OFF)

–

PFP-U

paper

stop SW

(OFF)

PFP-M paper

stop SW

(OFF)

PFP-L

paper

stop SW

(OFF)

–

Reversal

switch

(ON)

–

–

LCF tray up

SW

(Top)

ADU feed

switch

(ON)

–

PFP-U

tray up SW

(ON)

PFP-M

tray up SW

(ON)

PFP-L

tray up SW

(ON)

–

Exit switch

(ON)

–

–

LCF empty

SW

(Not empty)

ADU

transport

switch 1

(ON)

–

PFP-U

empty SW

(OFF)

PFP-M

empty SW

(OFF)

PFP-L empty

SW

(OFF)

–

–

IPC

connection

(Disconnection)

–

Manual feed

paper width

switch 3

(OFF)

LCF switch

(Disconnection)

ADU end

switch

(ON)

–

–

–

–

Toner-full

switch

(ON)

–

–

Manual feed

paper width

switch 2

LCF tray

down key

ADU

aligning

switch

PFP upper

cassette SW

(OFF)

–

(ON)

–

–

(ON)

–

–

Remarks

–

–

–

–

–

–

–

–

–

–

Icons on the control panel in the table states are displayed as white on a black background (ON state).

ADJUSTMENT 1 - 8

Page 16

[B] When the ENERGY SAVER key is ON (LED indicating the energy saver mode is lit)

Icon

Key

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

ABCDEFGH

–

–

–

–

Platen

switch

(Close)

–

ADF size

switch 1

(ON)

–

APS

sensor 3

(OFF)

ADF size

switch 2

(ON)

–

–

–

–

–

–

–

Total

counter

connection

(Disconnection)

–

–

–

APS

sensor 2

(OFF)

ADF empty

switch

(OFF)

–

–

Auto toner

sensor

connection

(Disconnection)

–

–

–

APS

sensor 1

(OFF)

ADF cover

(Open)

–

–

–

–

–

–

APS

sensor 6

(OFF)

ADF APS

start SW

(ON)

–

–

Cleaner

connection

(Disconnection)

Key counter

connection

(Disconnection)

–

–

APS

sensor 5

(OFF)

ADF exit

sensor

(ON)

–

–

Main charger

cleaning

switch

(OFF)

Toner supply

cover switch

(Open)

Transfer belt

contact

switch

(OFF)

ADF

connection

(Disconnection)

APS

sensor 4

(OFF)

ADF timing

sensor

(ON)

–

Exit cover

switch

(Open)

Toner empty

switch

(OFF)

Transfer belt

separation

switch

(OFF)

Scanner

home SW

(OFF)

ADF

aligning

sensor

(ON)

–

–

–

Remarks

–

–

–

–

–

–

–

–

[9]

[0]

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Icons on the control panel in the table states are displayed as white on a black background (ON state).

<Procedure>

[0] [3]

[PWR]

[START] [ENERGY SAVER] [Digital keys] (LCD ON) [0] [9]

(Exit)

Note: Initialization is executed before test mode is entered.

1 - 9 ADJUSTMENT

Page 17

1.2.2 Output signal check (test mode 03)

In the [0] [3] test mode, the following output signal states can be checked by entering the corresponding codes.

Code Function Code Function

101 Drum motor ON 151 OFF 1

102 Toner motor ON 152 OFF 1

103 Polygonal motor mirror (600 dpi) ON 153 OFF 1

108 Aligning motor ON 158 OFF 1

109 Pedestal motor ON 159 OFF 1

110 ADU motor ON 160 OFF 1

111 Scraper solenoid ON 161 OFF 1

112 Developer motor ON 162 OFF 1

113 Heat roller motor ON 163 OFF 1

114 Transfer belt motor ON 164 OFF 1

115 Fur brush motor ON 165 OFF 1

116 Auger motor ON 166 OFF 1

117 Laser bias ON 167 OFF 1

118 Laser ON 168 OFF 1

119 Fuser unit motor rotating slowly ON 169 OFF 1

218 Total counter counts 2

219 Reversal fan ON/OFF 3

220 ADU transport clutch ON/OFF 3

221 ADU aligning clutch ON/OFF 3

222 ADU feed clutch ON/OFF 3

223 ADU stack clutch ON/OFF 3

226 PFP upper feed clutch ON/OFF 3

227 PFP middle feed clutch ON/OFF 3

228 PFP lower feed clutch ON/OFF 3

229 PFP upper aligning feed clutch ON/OFF 3

230 PFP middle aligning feed clutch ON/OFF 3

231 PFP lower aligning feed clutch ON/OFF 3

233 Manual feed motor ON/OFF 3

234 Manual feed pick-up solenoid ON/OFF 3

235 Discharge LED lamp ON/OFF 3

236 Exit fan, low speed ON/OFF 3

237 Exit fan, high speed ON/OFF 3

239 Main charger fan ON/OFF 3

240 Developer fan ON/OFF 3

241 Heater fan low-speed ON/OFF 3

242 Heater fan high-speed ON/OFF 3

243 Main charger wire cleaner ON (reset) 2

244 Transfer belt cam motor UP/DOWN 3

249 Developer bias -DC1 ON/OFF 3

Operation

procedure

group

ADJUSTMENT 1 - 10

Page 18

Code Function

250 Developer bias -DC2 ON/OFF 3

251 Developer bias -DC3 ON/OFF 3

252 Main Charger ON/OFF 3

255 Transfer belt cleaning brush bias ON/OFF 3

257 Duct (in/out) fan, low speed ON/OFF 3

259 Duct (in/out) fan, high speed ON/OFF 3

261 Scanning motor ON 2

(Automatically stops at the limit position, its speed is variable using the ZOOM keys.)

262 Document (indicator) motor ON 2

(Automatically stops at the limit position)

263 Exposure lamp ON 3

(Automatically goes OFF after 6 seconds, and the fan motors rotate at low speed.)

264

Scanning optical system cooling fan motor 1

265

Scanning optical system cooling fan motor 2

266 SLG PC board cooling fan motor 3 ON/OFF 3

270 LCF feed motor ON/OFF 3

271 LCF tray motor UP/DOWN 2

272 ADU side guide motor ON (reciprocating) 2

273 ADU end guide motor ON (reciprocating) 2

274 ADU/exit switching gate solenoid ON/OFF 3

275 ADU paper holding gate solenoid ON/OFF 2

277 ADU reverse clutch ON/OFF 3

278 PFP upper tray motor UP/DOWN 2

279 PFP middle tray motor UP/DOWN 2

280 PFP lower tray motor UP/DOWN 2

281 ADF pick-up roller rotation ON/OFF 3

282 ADF aligning roller rotation ON/OFF 3

283 ADF transport belt CW rotation ON/OFF 3

284 ADF transport belt CCW rotation ON/OFF 3

285 ADF reverse roller rotation ON/OFF 3

288 ADF reverse solenoid ON/OFF 3

292 Laser unit fan ON/OFF 3

295 Power off mode 4

ON/OFF 3

ON/OFF 3

Operation

procedure

group

List of System Output Check Functions

Code Function

401 Get mounted PM (page memory) size 2

402 PM (page memory) read/write check 2

1 - 11 ADJUSTMENT

Operation

procedure

group

Page 19

<Procedure>

Group (1)

[START]

(Code) Operation

[PWR]

Group (2)

[0] [3]

(Code) [START] Operation

[PWR]

Group (3)

[0] [3]

(Code) [START] Operation

[PWR]

Group (4)

[0] [3]

(Code) [START] [PWR] OFF

[PWR]

(ON)

(One-way)

(ON)

Stop

[START] Operation

code

[C] Test mode standby

[START] Operation

(OFF)

(OFF)

[C]

[0] [9] Warm-up[0] [3]

[0] [9] Warm-up

Test mode

standby

[0] [9]

Warm-up

ADJUSTMENT 1 - 12

Page 20

1.2.3 Test print mode (test mode 04)

In test mode “04”, you can print the test pattern generated by the following ASIC codes.

Code ASIC Test pattern type

111 SH Primary scanning. 33 gradations, error diffusion

113 SH Secondary scanning. 33 gradations, error diffusion

142 POPS 2 dots grid pattern (10mm Pitch)

Remarks

<Operation procedure>

[PWR]

[START](Code)[0] [4]

(Test print)

[0] [9][C] Warm-upOperation

Note: Though errors are displayed when it occurs, recovery is not carried out. This is recovered by

turning the power OFF then ON again.

1 - 13 ADJUSTMENT

Page 21

1.2.4 Adjustment mode (05)

In this mode, the following adjustment items can be corrected or changed. To access this mode, turn

the power ON while pressing the [0] and [5] keys.

CODE

200 Automatic adjustment of the Auto-toner circuit. All — —

201 Manual adjustment of the Auto-toner circuit. All 128 0-255 2

♦203 Developer High 1 adjustment Printer 104 0-255 1

Out put is NOT available for measurement.

Enter the value set in code 205-0.

♦205-0 Developer High 1 adjustment Copier 104 0-255 7

Output IS available for measurement. (Text/

Adjust by measuring the output. Photo)

♦205-1 Developer High 1 adjustment Copier 104 0-255 6

Output is NOT available for measurement. (Text)

Enter the value set in code 205-0.

♦205-2 Developer High 1 adjustment Copier 104 0-255 6

Output is NOT available for measurement. (Photo)

Enter the value set in code 205-0.

♦207 Developer High 2 adjustment All 104 0-255 2

Out put IS available for measurement.

Adjust by measuring the output.

♦216 Developer High 3 adjustment All 133 0-255 2

Output IS available for measurement.

♦Key in Code 205 press the START key, key in the Sub Code, then press the START key. For 205-0, 207 and 216 use the UP

or DOWN key to change the value, press the SET key to store or the RESET key. For codes 203, 205-1 and 205-2 key in the

value set in code 205-0, press the SET key to store or the CLEAR key to reset.

♣210-0 Charge corona grid voltage adjustment. The Copier 93 0-255 7

developer unit must be removed. (Text/

Output IS available for measurement. Adjust Photo)

by measuring the grid voltage output.

♣210-1 Charge corona grid voltage adjustment. Copier 93 0-255 6

Output is NOT available for measurement. Set (Text)

to the value set in code 210-0.

♣210-2 Charge corona grid voltage adjustment. Copier 93 0-255 6

Output is NOT available for measurement. Set (Photo)

to the value set in code 210-0.

♣212 Charge corona grid voltage adjustment. Printer 93 0-255 1

Output is NOT available for measurement. Set

to the value set in code 210-0.

♣Key in Code 210 press the START key, key in the Sub Code, then press the START key. For 210-0 use the UP or DOWN key

to change the value, press the SET key to store or the RESET key. For codes 210-1, 210-2 and 212 key in the value set in

code 210-0, press the SET key to store or the CLEAR key to reset.

ADJUSMENT MODE

05 MODE

DEFAULT

RANGE DESCRIPTION

Increasing the value increases

the sensor out put.

Output is automatically set in

the range of 2.45 - 2.55V.

Refer to the complete autotoner adjustment.

The current value of the autotoner circuit is displayed and

can be manually set.

The developer power supply

output is increased when the

value is increased.

Before performing this

adjustment refer to the

complete adjustment.

The developer bias power

supply output is increased

when the value is increased.

Before performing this

adjustment refer to the

complete adjustment.

The developer bias power

supply output is increased

when the value is increased.

Before performing this

adjustment refer to the

complete adjustment.

The charge corona power

supply output is increased

when the value is increased.

Before performing this

adjustment refer to the

complete adjustment.

Check or adjust the output

voltage using code 210-0 first,

then set the remaining codes

210-1, 210-2 and 212 to the

value set in 210-0.

PROCEDURE

GROUP

ADJUSTMENT 1 - 14

Page 22

CODE

291 Image Quality Control circuit check value, not All 0 0-255 3

adjustable.

Value indicates Status: Good or Error.

292 Image Density Sensor output check value All 0 0-1023 3

When the LED (light source) is turned OFF.

(This is the current value stored in memory

from the last time the machine performed the

Image Quality Control compensation

adjustment). It is not adjustable.

Normal value is 102 - 307.

293 Image Density Sensor output check value All 0 0-1023 3

When the LED (light source) is turned ON.

(This is the current value stored in memory

from the last time the machine performed the

Image Quality Control compensation

adjustment) not adjustable.

Normal value is 388-819.

296 Service Automatic adjustment of image All 0 0-255 3

Density Sensor LED intensity. The value

displayed is the output check value after the

light source is adjusted.

305 Leading to trailing edge image shift. Scanner All 128 0-255 1

(secondary scanning) start position deviation).

Key in the value, press SET key to store or

CLEAR key to reset.

306

CCD primary scanning start position deviation.

Key in the value, press SET key to store or

CLEAR to key to reset.

310 Exposure lamp intensity. Set to default value. All 55 30-70 1

Key in the value, press SET key to store or

CLEAR key to reset.

•335-0 Scanner acceleration curve setting (50-59%). All 2 0-2 6

•335-1 Scanner acceleration curve setting (60-79%). All 0 0-2 6

•335-2 Scanner acceleration curve setting (80-95%). All 1 0-2 6

•335-3 Scanner acceleration curve setting (96-103%). All 1 0-2 6

•335-4

Scanner acceleration curve setting (104-190%).

•335-5

Scanner acceleration curve setting (191-400%).

• Key in code 335 press the START key, key in the Sub code, then press the START key. Key in the value, press the SET key to

store or the CELAR key to reset.

ADJUSMENT MODE

05 MODE

DEFAULT

RANGE DESCRIPTION

A value of 2 or 4 indicates an

error in the image Quality

Control circuit. All other values

0-255 indicate that the Image

Quality Control circuit is

working correctly. For additional information refer to the

Image Quality Control

Troubleshooting section.

Use this code only when

checking or troubleshooting

Image Quality Control

problems. See Image Quality

Control Troubleshooting

section.

Use this code only when

checking or troubleshooting

Image Quality Control

problems. See Image Quality

Control troubleshooting

section.

Use this code only when

checking or troubleshooting

Image Quality Control problems.

The higher the number the

dirtier the sensor or the greater

the amount of drum wear.

255 = sensor is too dirty or

drum is too worn for compensation. See Image Quality Control

Troubleshooting section.

When the value is increased

by 1, the image shift

approximately 0.1213mm

towards the trailing edge of the

All 45 0-90 1

All 1 0-2 6

All 1 0-2 6

paper(machine).

When the value is increased

by 1, the image shifts

approximately 0.0423mm

towards the front side of the

paper (machine).

The exposure lamp voltage

increases or decreases

0.25V/step.

0: Acceleration ratio (1)

1: Acceleration ratio (2)

2: Acceleration ratio (3)

Adjustment corrects for blurs

in the leading 2 inches of the

copy. Set to the default values

when memory has been

corrupted. Adjust only when

replacing the scan drive motor.

PROCEDURE

GROUP

1 - 15 ADJUSTMENT

Page 23

CODE

♥340 Scanner copy length reproduction ratio Copier 128 0-255 1

adjustment.

♥350 RADF single sided original stop position. All 8 0-15 1

♥351 RADF double sided original side 2 stop All 8 0-15 1

position.

356 RADF sensor automatic adjustment and All — — 4

EEPROM initialization.

Press the START key, WAIT is displayed while

the automatic adjustment is performed.

♥401 Polygonal motor speed fine adjustment. Printer 128 0-255 1

♥405 Polygonal motor speed fine adjustment. Copier 120 0-255 1

ADJUSMENT MODE

05 MODE

DEFAULT

RANGE DESCRIPTION

Adjust the length of the copy

image to 1:1 so that it is not

stretched or compressed. Use

a millimeter scale and ledger/

A3 paper to adjust. Increasing

the value decreases the length

0.05% step(or 0.1mm/step).

The higher the value, the more

the original is fed towards the

paper feed side of the

machine.

1 step is equal to approximately 1mm change.

Test copy can be made in 05

test mode.

The higher the value, the more

the original is fed towards the

exit side of the machine.

1 step is equal to approximately 1mm change.

Test copy cannot be made in

05 test mode. Press 09 to

enter normal copy mode and

toggle back to 05 mode to

adjust.

Perform RADF EEPROM

Initialization when EEPROM,

RADF logic PWA or sensors

are replaced.

Adjust the width of the printed

image (front to rear of

machine) to 1:1, so that it is

not stretched or compressed.

When the value is increased

by 1, the width reproduction

ratio is enlarged by approximately 0.05% step (or 0.1mm/

step). After setting the value,

select LT/A4 paper, then press

the ENERGY SAVER key to

make a test print.

Adjust the width of the copied

image (front to rear) to 1:1 so

that it is not stretched or

compressed. When the value

is increased by 1, the width

reproduction ratio is enlarged

by approximately 0.05%/step

(or 0.1mm/step). After setting

the value, select LT/A4 paper,

then press the ENERGY

SAVER key to make a test

copy.

PROCEDURE

GROUP

ADJUSTMENT 1 - 16

Page 24

CODE

410 Laser write position(front to rear of machine Copier 140 0-255 1

image registration).

After adjusting code 411, key in the value set

in code 411, press the SET key to store in

memory or the CLEAR key to reset.

♥411 Laser write position (front to rear of machine Printer 140 0-255 1

image registration).

♥415 First beam laser power. Copier 103 0-255 1

♥416 First beam laser power. Printer 103 0-255 1

♥430 Copy leading edge void adjustment. Copier 24 0-255 1

♥431 Copy top edge void adjustment (rear of Copier 0 0-255 1

machine). Top of copy LT/A4 or right side edge

of ST-R/A5-R, LT-R/A4-R, Legal/B4 and

Ledger/A3.

♥432 Copy bottom edge void adjustment (front of Copier 0 0-255 1

Machine). Bottom of copy LT/A4 or left side

edge of ST-R/A5-R, LT-R/A4-R, Legal/B4 and

Ledger/A3.

♥433 Copy trailing edge void adjustment. Copier 30 0-255 1

♥435 Printed page leading edge void adjustment. Printer 24 0-255 1

♥436 Printed page top edge void adjustment (rear Printer 0 0-255 1

of machine). Top of printed page LT/A4 or

right side of ST-R/A5-R, LT-R/A4-R, Legal/B4

and Ledger/A3.

♥437 Printed page bottom edge void adjustment Printer 0 0-255 1

(front of machine). Top of printed page LT/A4

or left side edge of ST-R/A5-R, LT-R/A4-R,

Legal/B4 and Ledger/A3.

♥438 Printed page trailing edge void adjustment. Printer 0 0-255 1

♥442 Bypass registration adjustment. Image on the All 8 0-15 1

drum to the paper’s leading edge.

♥443 LCC registration adjustment. Image on the All 15 0-40 1

drum to the paper’s leading edge.

Test copy available while in the 05 Mode.

ADJUSMENT MODE

05 MODE

DEFAULT

RANGE DESCRIPTION

Always perform code 411 first,

then set the value of code 410

to the value set in code 411.

When the value is increased

by 1, the image on the drum is

shifted by 0.0423mm to the

rear of the copier(primary

scanning direction). Refer to

the complete adjustment

procedure before performing

this adjustment.

Laser power increases

2.34É W/step.

Set to 103 do not change from

the setting.

Increasing the value by 1

increases the void by

approximately 0.04233mm.

Increasing the value by 1

increases the void by

approximately 0.04233mm.

Increasing the value by 1

increases the void by approximately 0.04233mm.

Increasing the value by 1

increases the void by approximately 0.04233mm.

Increasing the value by 1

increases the void by

approximately 0.04233mm.

Increasing the value by 1

increases the void by

approximately 0.04233mm.

Increasing the value by 1

increases the void by

approximately 0.04233mm.

Increasing the value by 1

increases the void by approximately 0.04233mm.

Increasing the value by 1

shifts the image on the paper

by approximately 0.5mm

towards the paper’s leading

edge. Increasing the value

makes the paper arrive later.

Increasing the value by 1

shifts the image on the paper

by approximately 0.5mm

towards the papers’ leading

edge. Increasing the value

makes the paper arrive later.

PROCEDURE

GROUP

1 - 17 ADJUSTMENT

Page 25

CODE

♥444 PFP registration adjustment. Image on the All 8 0-15 1

drum to the paper’s leading edge.

Test copy available while in the 05 mode.

♥445 Duplexer registration adjustment. Image on All 8 0-15 1

the drum to the papers’ leading edge.

Toggle between 09 and 05 Mode to make a

test copy.

♥Key in the value, press the SET key to store or the CLEAR key to reset.

♠450-0 PFP upper paper alignment (paper buckle) All 14 0-31 6

at the main registration roller. Paper length

330mm and longer.

♠450-1 PFP upper paper alignment (paper buckle) All 8 0-31 6

at the main registration roller. Paper length

220mm to 329mm.

♠450-2 PFP upper paper alignment (paper buckle) All 5 0-31 6

at the main registration roller. Paper length

219mm and less.

♠452-0 PFP middle paper alignment (paper buckle) All 2 0-31 6

at the main registration roller. Paper length

330mm and longer.

♠452-1 PFP middle paper alignment (paper buckle) All 8 0-31 6

at the main registration roller. Paper length

220mm to 329mm.

♠452-2 PFP middle paper alignment (paper buckle) All 5 0-31 6

at the main registration roller. Paper length

219mm and less.

♠Key in Code 450 or 452 press the START key, key in the Sub Code, then press the START key. Key in the value, press SET

key to store or the CLEAR key to reset.

455 Duplexer paper alignment (paper buckle) at All 10 0-31 1

the main registration roller.

■456-0 PFP lower paper alignment (paper buckle) All 2 0-31 6

at the main registration roller. Paper length

330mm and longer.

■456-1 PFP lower paper alignment (paper buckle) All 8 0-31 6

at the main registration roller. Paper length

220mm to 329mm.

■456-2 PFP lower paper alignment (paper buckle) All 5 0-31 6

at the main registration roller. Paper length

229mm and less.

■Key in Code 456 press the START key, key in the Sub Code, then press the START key. Key in the value, press SET key to

store or the CLEAR key to reset.

#457 LCF paper alignment (paper buckle) at the All 16 0-31 1

main registration roller.

#458 Manual feed paper alignment (paper buckle) All 14 0-31 1

amount at he main registration roller.

#459 PFP upper paper alignment (paper buckle) All 4 0-15 1

at the PFP upper registration roller.

#460 PFP middle paper alignment (paper buckle) All 7 0-15 1

at the PFP middle registration roller.

ADJUSMENT MODE

05 MODE

DEFAULT

RANGE DESCRIPTION

Increasing the value by 1

shifts the image on the paper

by approximately 0.5mm

towards the papers’ leading

edge. Increasing the value

makes the paper arrive later.

Increasing he value by 1 shifts

the image on the paper by

approximately 0.5mm towards

the papers’ leading edge.

Increasing the value makes

the paper arrive later.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

PROCEDURE

GROUP

ADJUSTMENT 1 - 18

Page 26

CODE

#461 PFP lower paper alignment (paper buckle) All 7 0-15 1

at the PFP lower registration roller.

#462 Duplexer registration roller paper alignment All 4 0-15 1

(paper buckle)

464 Duplexer end guide shifting amount All 2 0-3 1

# Key in the value, press the SET key to store or the CLEAR key to reset.

▲468-0

Binding position/folding position fine adjustment

(A4-R/LT-R)

▲468-1 Binding position/folding position fine All 0 -14-14

adjustment (B4).

▲468-2

Binding position/folding position fine adjustment

(A3/LD)

469 Finisher aligning speed adjustment All 0 0-4 1

▲ Key in Code 468 press the Start key, key in the Sub Code, then press the START key. Key in the value, press SET key to

store or the CLEAR key to reset.

470 Paper remaining indicator. Automatic All — 0-31 8

adjustment for EMPTY condition. LCF and

Drawers.

ADJUSMENT MODE

05 MODE

DEFAULT

RANGE DESCRIPTION

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

Increasing the value by 1

increases the aligning (paper

buckle) by 0.9mm.

In stacking of only a few sheets

in the case of the following

values only, the end guide is

moved towards the pickup

roller compared with the

standard pickup roller position.

If the paper is a large size than

the standard one or it has

much curing or the edges are

turned, then if a jam occurs,

the position of the end guide is

lowered. This will help to

decrease the possibility of

future jams.

0: A3/LD 0~2mm, other. 0~2mm

1: A3/LD 0~2mm, other. 0~0mm

2: A3/LD 0~4mm, other. 0~2mm

3: A3/LD 0~4mm, other. 0~0mm

All 0 -14-14 6

All 0 -14-14

Position shifts to the right page

0.25mm/step.

0: High

1: Middle-high

2: Middle

3: Middle-low

4: Low

If the adjustment value is made

larger, the finisher aligning

speed becomes slower.

If the paper exiting to the

finisher becomes misaligned or

there are staple jams, then

only on these occasions these

codes should be used.

Remove all of the paper from

the LCF and PFP, then

perform the automatic

adjustment.

PROCEDURE

GROUP

1 - 19 ADJUSTMENT

Page 27

CODE

471 Paper remaining indicator. LCF manual All 4 0-31 1

adjustment for LESS than 1/2 the capacity.

Key in the value, press the START key to store

or the CLEAR key to reset.

472 Paper remaining indicator. PFP upper manual All 10 0-31

adjustment for LESS than 1/2 the capacity.

Key in the value, press the START key to

store or the CLEAR key to reset.

473 Paper remaining indicator. PFP middle All 10 0-31

manual adjustment for LESS than 1/2 the

capacity. Key in the value, press the START

key to store or the CLEAR key to reset.

474 Paper remaining indicator. PFP lower manual All 10 0-31

adjustment for LESS than 1/2 the capacity.

Key in the value, press the START key to

store or the CLEAR key to reset.

475 Paper remaining indicator. Automatic All — — 8

adjustment for FULL condition. LCF and

PFP.

476 Paper remaining indicator. LCF manual All 2 0-31 1

adjustment for MORE than 1/2 the capacity.

477 Paper remaining indicator. PFP upper manual All 2 0-31

adjustment for MORE than 1/2 the capacity.

478 Paper remaining indicator. PFP middle manual All LT 0-31

adjustment for MORE than 1/2 the capacity.

479 Paper remaining indicator. PFP lower manual All LT 0-31

adjustment for MORE than 1/2 the capacity.

481 Drum motor speed fine adjustment. Copier 128 0-255 1

482 Drum motor speed fine adjustment. Printer 120 0-255

483 Registration motor speed fine adjustment. Copier 128 0-255 1

484 Registration motor speed fine adjustment. Printer 128 0-255

485 Fuser drive motor speed fine adjustment. Copier 128 0-255 1

486 Fuser drive motor speed fine adjustment. Printer 128 0-255

487

Transfer belt drive motor speed fine adjustment.

488

Transfer belt drive motor speed fine adjustment.

489 Pedestal drive motor speed fine adjustment. Copier 128 0-255 1

490 Pedestal drive motor speed fine adjustment. Printer 128 0-255

ADJUSMENT MODE

05 MODE

DEFAULT

RANGE DESCRIPTION

Perform the manual adjustment when the remaining

amount of paper is less than

1/2. Perform adjustment code

470 first. Then adjust as

necessary.

Decrease the value in these

codes when the remaining

amount of paper indication is

slower than the actual amount

of paper.

Example: When the paper

remaining

indicator shows "

then changes suddenly to

Load 4,000 sheets of paper in

the LCC and 500 sheets in the

Drawers, then perform the

automatic adjustment.

Perform the manual adjustment when the remaining

amount of paper is greater

than 1/2. Perform adjustment

code 475 first. Then adjust as

necessary.

Increase the value in these

codes when the remaining

amount of paper indication is

size: 4

A/B

size: 8

size: 7

A/B

size: 3

Copier 128 0-255 1

Printer 132 0-255

greater than the actual amount

of paper.

Example: When the paper

remaining

indicator shows "

then changes suddenly to

Increasing the value by 1

increases the motor speed by

0.067%. Set value to 128 for

the copier and 120 for the

printer.

Increasing the value by 1

increases the motor speed by

0.097%. Set value to 128 for

the copier and printer.

Increasing the value by 1

increases the motor speed by

0.061%. Set value to 128 for

the copier and printer.

Increasing the value by 1

increases the motor speed by

0.127%/step (or 0.254mm/

step). Refer to the complete

adjustment procedure before

performing this adjustment.

Increasing the value by 1

increases the motor speed by

0.061%. Set value to 128 for

the copier and printer.

"

" "

"

" "

PROCEDURE

GROUP

ADJUSTMENT 1 - 20

Page 28

CODE

491 Duplexer drive motor speed fine adjustment. Copier 128 0-255 1

492 Duplexer drive motor speed fine adjustment. Printer 128 0-255

Key in the value, press the SET key to store or the CLEAR key to reset.

▼493-0 Developer drive motor speed fine adjustment. Copier 6 0-15 1

Set to the default value.

▼493-1 Developer drive motor speed fine adjustment. Copier 6 0-15

Set to the default value. (Text)

▼493-2 Developer drive motor speed fine adjustment. Copier 6 0-15

Set to the default value. (Photo)

▼ Key in code 493 press the START key, key in the Sub Code, then press the START key. Key in the value, press the SET key

to store or the CLEAR key to reset.

★495 Developer drive motor speed fine adjustment. Printer 6 0-15 1

★501 Manual exposure fine adjustment for the Copier 128 0-255 1

center setting. (Photo)

★503 Manual exposure fine adjustment for the Copier 128 0-255 1

center setting.

★504 Manual exposure fine adjustment for the Copier 128 0-255 1

center setting. (Text)

★505 Manual exposure fine adjustment for the Copier 20 0-255 1

lighter setting.

★506 Manual exposure fine adjustment for the Copier 10 0-255 1

lighter setting. (Photo)

★507 Manual exposure fine adjustment for the Copier 30 0-255 1

lighter setting. (Text)

★508 Manual exposure fine adjustment for the Copier 13 0-255 1

darker setting.

★509 Manual exposure fine adjustment for the Copier 20 0-255 1

darker setting. (Photo)

★510 Manual exposure fine adjustment for the Copier 12 0-255 1

darker setting. (Text)

★512 Automatic exposure fine adjustment. Copier 128 0-255 1

★514 Automatic exposure fine adjustment. Copier 128 0-255 1

★515 Automatic exposure fine adjustment. Copier 128 0-255 1

★ Key in the value, press the SET key to store or the CLEAR key to reset.

580 Image mode automatic gamma adjustment for Copier None None 5

error diffusion. The TEST PRINT must be on

the exposure glass or ERROR will occur.

593 Image mode gamma data slope correction. Copier 0 0-9 1

Data adjustment for gamma correction. (Text/Photo)

594 Image mode gamma data slope correction. Copier 0 0-9

Data adjustment for gamma correction. (Photo)

595 Image mode gamma data slope correction. Copier 0 0-9

Data adjustment for gamma correction. (Text)

ADJUSMENT MODE

05 MODE

(Text/Photo)

(Text/Photo)

(Text/ Photo)

(Text/Photo)

(Photo)

(Text/Photo)

(Text)

DEFAULT

RANGE DESCRIPTION

Increasing the value by 1

increases the motor speed by

0.148%. Set value to 128 for

the copier and the printer.

Increasing the value by 1

increases the motor speed by

3.85%. Set value to 6.

Increasing the value by 1

increases the motor speed by

3.85%. set value to 6.

Increasing the value darkens

the copy at the center setting

of manual exposure.

Increasing the value lightens

the copy at the lighter setting

of manual exposure.

Increasing the value darkens

the copy at the darker setting

of manual exposure.

Increasing the value darkens

the copy at the automatic

exposure setting.

Automatically corrects the

image quality after reading the

test print pattern.

Before performing this

adjustment refer to the

complete adjustment.

Increasing the value darkens

the image.

0: Default value is the

1-9: Slope correction (the

center value 5

(Same as set value 5).

higher the value, the

darker the image

becomes).

PROCEDURE

GROUP

1 - 21 ADJUSTMENT

Page 29

CODE

620 HPF(High Pass Filter) strength setting. Copier 1 1 Right 1

Normally set it to 1 this places the filtering in

the optimum range for the Text/Photo mode.

621 HPF(High Pass Filter) strength setting. Copier 2 2 Right 1

Normally set it to 2 this places the filtering in (Photo) digit

the optimum range for the Photo mode.

622 HPF(High Pass Filter) strength setting. Copier 3 3 Right 1

Normally set it to 3 this places the filtering in (Text) digit

the optimum range for the Text mode.

ADJUSMENT MODE

05 MODE

(Text/Photo)

DEFAULT

RANGE DESCRIPTION

Right hand digit (2nd digit

digit

entered):

1: Text/Photo (fixed at the

Left hand digit (1st digit

0-9 Left

entered):

digit

0: Default value is used

1-9: Increasing the value

Do not set to values other than

these: 1, 11, 21, 31, 41, 51,

61, 71, 81, 91.

Right hand digit (2nd digit

entered):

2: Photo (fixed at the

Left hand digit (1st digit

0-9 Left

entered):

digit

0: Default value is used

1-9: Increasing the value

Do not set to values other than

these: 2, 12, 22, 32, 42, 52,

62, 72, 82, 92.

Right hand digit (2nd digit

entered):

3: Text (fixed at the

Left hand digit (1st digit

0-9 Left

entered):

digit

0: Default value is used

1-9: Increasing the value

Do not set to values other than

these: 3, 13, 23, 33, 43, 53,

63, 73, 83, 93.

optimum level) do not

enter values other than 1

for the right hand digit.

setting enhances the

image sharpness

optimum level) do not

enter values other than

2 for the right hand digit.

setting enhances the

image sharpness

optimum level) do not

enter values other than

3 for the right hand digit.

setting enhances the

image sharpness

PROCEDURE

GROUP

ADJUSTMENT 1 - 22

Page 30

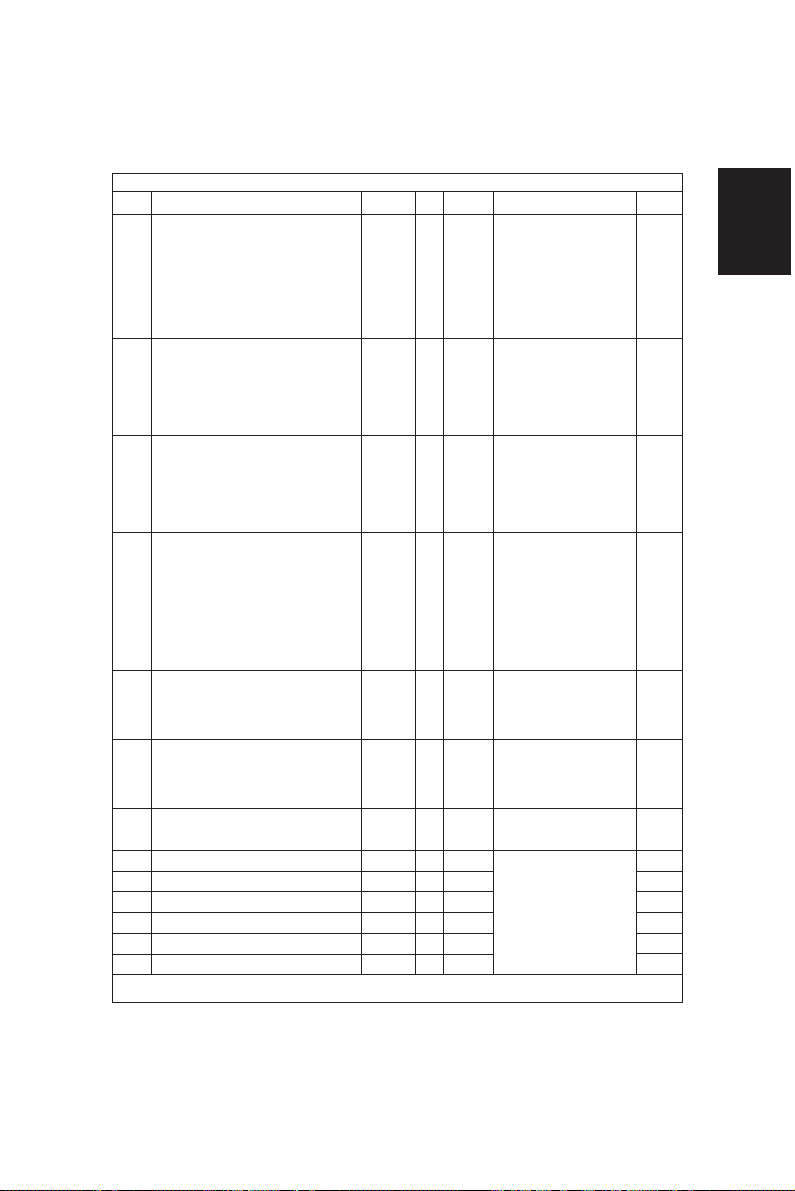

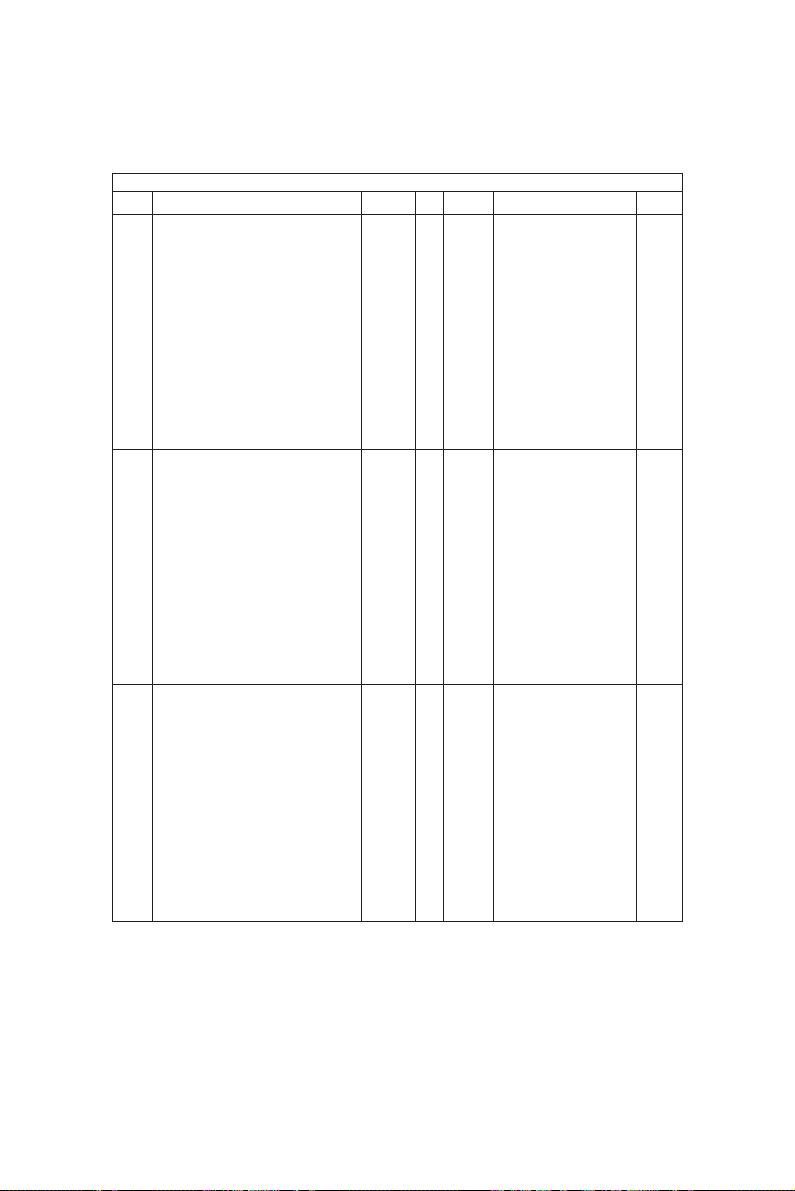

<Procedure>

Group 1

[0] [5]

[PWR]

Group 2

[0] [5]

[PWR]

Group 3

[0] [5]

[PWR]

Group 4

[Digital keys]

(Code)

[CANCEL]

(Code)

[C] or [CANCEL]

(Code)

[START]

[START][Digital keys]

[START][Digital keys]

[Digital keys]

*[FC] key

(Adjust)

[UP] or [DOWN]

(Adjust)

[SET]

or

[INT]

Setting cannot

be changed

(Set to memory)

[C]

(To correct)

[RESET]

(To correct)

[0] [9]

(Exit)

[SET]

or

[INT]

[SET]

or

[INT]

(Set to memory)

[E/S]

(Test copy)

* [FC] key is used for

"–" input

[0] [9]

(Exit)

[0] [9]

(Exit)

[0] [5]

[PWR]

Group 5

[0] [5]

[PWR]

[Digital keys]

Cassette

keys

Cassette

selection

(Code)

[START]

Digital

[E/S]

keys

pattern

Test

print

Outoput

selection

1: Code 401, 411, 442, 443, 444, 488

2: Code 580

(Adjust)

[0] [9]

(Exit)

[SET]

or

[INT]

(Memorize)

(Automatic Adjustment)

When the output pattern

selection is "1"

Digital

[START]

keys

(Code)

1 - 23 ADJUSTMENT

[Digital keys]

[0] [9]

(Exit)

Page 31

Group 6

[CANCEL]

[START]

Digital

[0] [5]

keys

[PWR]

(Code)

(When there are multiple setting items for a single item)

Digital

keys

Enter

setting

item value

(To correct)

Group 7

[CANCEL] or [C]

[CANCEL]

[0] [5]

[PWR]

keys

(Code)

(When there are multiple setting items for a single item)

[START]

Digital

Digital

keys

Enter

setting

item value

(To correct)

Group 8

[0] [5]

[PWR]

Code: 470,

475

[START][Digital keys]

[C]

(Stop)

[START]

[C]

[C]

[START]

[START]

[Digital keys]

*[FC] key

(Adjust)

[DOWN]

(Adjust)

[SET]

or

[INT]

(Memorize)

[SET]

or

[INT]

Set to

memory

[C]

(To correct)

*[FC] key is used for "–" input

[UP]

or

(To correct)

[RESET]

[0] [9]

(Exit)

[SET]

or

[INT]

Set to

memory

[E/S]

Test

copy

[E/S]

Test

copy

[0] [9]

(Exit)

[0] [9]

(Exit)

ADJUSTMENT 1 - 24

Page 32

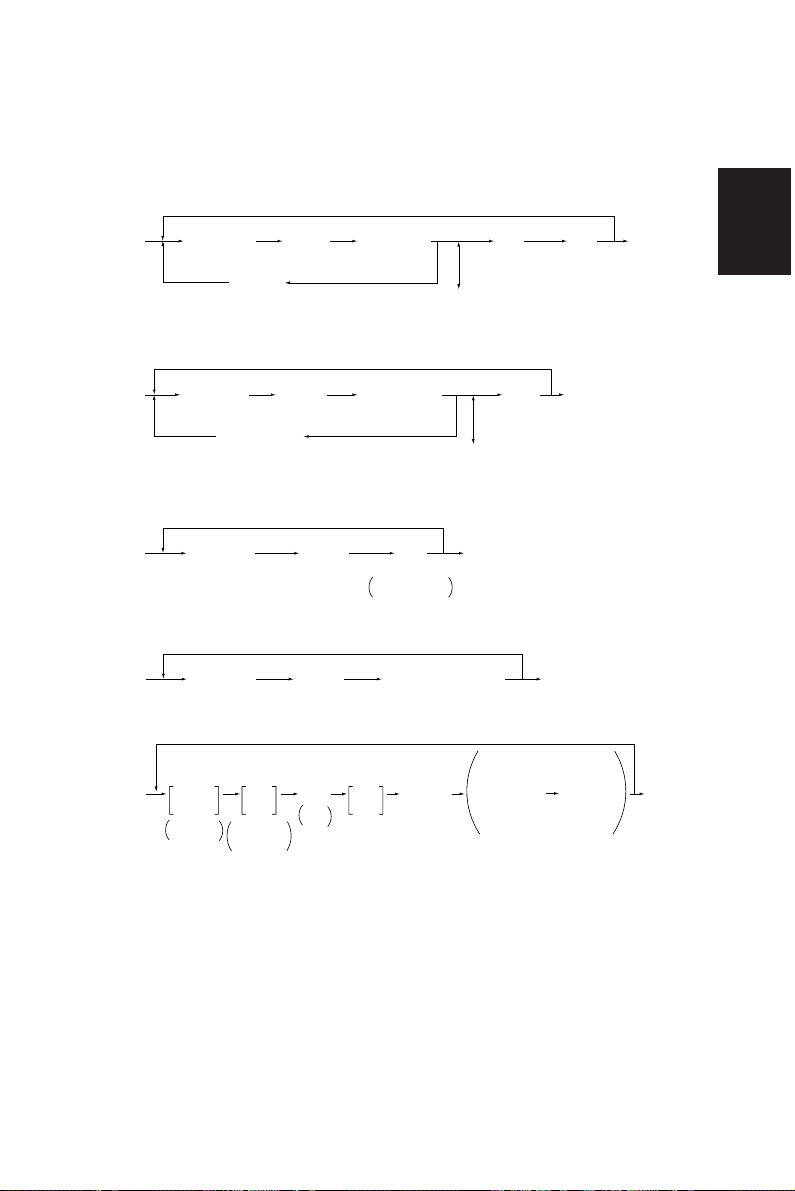

1.2.5 Setting mode (08)

In this mode, the various special modes listed in the Setting Code List can be set or changed.

<Procedure>

Group 1

[CANCEL]

[0] [8]

[PWR]

[Digital keys]

(Code)

[START]

[Digital keys]

or

[Selectable icons]

Set or change

a value.

(To correct)

[SET]

or

[INT]

(Set to memory)

[C]

[0] [9]

(Exit)

Group 2

[0] [8]

[PWR]

Group 3

[0] [8]

[PWR]

[Digital keys]

(Code)

(Code)

[START]

[CANCEL]