Page 1

2

15.Feb

TopPage

SERVICE MANUAL

CODE: 00ZAR6020/S2E

DIGITAL MULTIFUNCTIONAL

SYSTEM

AR-6020/6023

AR-6020D/6023D

AR-6020N/6023N

MODEL

CONTENTS

NOTE FOR SERVICING

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] FIRMWARE UPDATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

AR-6026N/6031N

2

[11] OPERATIONAL DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] SERVICE WEB PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

[14] TOOL LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Parts marked with " " are important for maint aining the safety of the set. Be sur e to rep lace the se parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

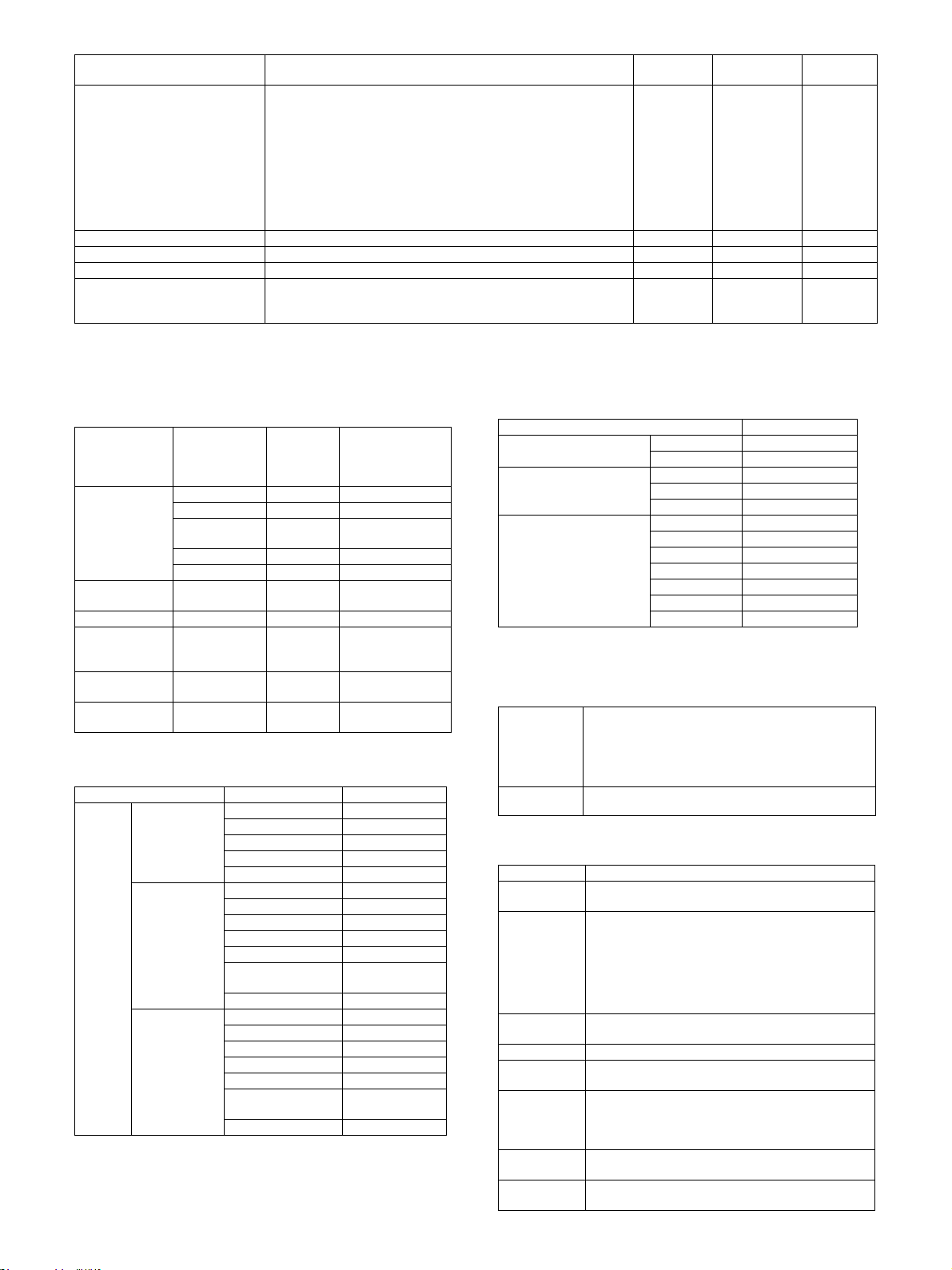

CONTENTS

NOTE FOR SERVICING

1. Precautions for servicing . . . . . . . . . . . . . . . . . . . . . . . . . i

2. Warning for servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

3. Note for installing site. . . . . . . . . . . . . . . . . . . . . . . . . . . . i

4. Note for handling PWB and electronic parts . . . . . . . . . .ii

5. Note for repairing/replacing the LSU . . . . . . . . . . . . . . . .ii

6. Note for handling the drum unit, the transfer unit,

the developing unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

[1] PRODUCT OUTLINE

1. System diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Option lis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

[2] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Copy functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

3. Printer function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

4. Image send function. . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

5. Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

6. Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

7. Dimensions and Weight. . . . . . . . . . . . . . . . . . . . . . . 2-11

8. Machine Occupied Area. . . . . . . . . . . . . . . . . . . . . . . 2-11

9. Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

[3] CONSUMABLE PARTS

1. Supply system table/Maintenance parts list. . . . . . . . .3-1

2. Maintenance parts list . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3. Environmental conditions. . . . . . . . . . . . . . . . . . . . . . .3-2

4. Production number identification . . . . . . . . . . . . . . . . . 3-2

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Internal view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

3. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4. Motor, solenoid, clutch. . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5. Sensor, switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

6. PWB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

7. Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

[5] ADJUSTMENTS

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Details of adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] SIMULATION

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

2. List of simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

3. Details of simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

[7] TROUBLESHOOTING

1. Error code list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

2. Details of error codes and countermeasures . . . . . . . .7-2

[8] FIRMWARE UPDATE

1. Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

2. Install USB Driver procedure . . . . . . . . . . . . . . . . . . . .8-1

3. Download Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

4. Receive the ROM version . . . . . . . . . . . . . . . . . . . . . .8-4

[9] MAINTENANCE

1. Necessary work for maintenance. . . . . . . . . . . . . . . . .9-1

2. Maintenance timing display . . . . . . . . . . . . . . . . . . . . .9-2

3. Maintenance list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

4. Maintenance display system . . . . . . . . . . . . . . . . . . . .9-6

5. Note for replacement of consumable parts . . . . . . . . .9-6

[10] DISASSEMBLY AND ASSEMBLY

1. Disassembly and Assembly table . . . . . . . . . . . . . . .10-1

2. Disassembly and assembly of each unit . . . . . . . . . .10-2

[11] OPERATIONAL DESCRIPTIONS

1. Operation panel section. . . . . . . . . . . . . . . . . . . . . . . 11-1

2. RSPF section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

3. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

4. Manual paper feed section. . . . . . . . . . . . . . . . . . . . . 11-8

5. Paper registration section . . . . . . . . . . . . . . . . . . . . . 11-9

6. Paper feed tray section . . . . . . . . . . . . . . . . . . . . . .11-10

7. Paper exit section. . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

8. Duplex section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

9. OPC drum section . . . . . . . . . . . . . . . . . . . . . . . . . .11-14

10. Toner supply section . . . . . . . . . . . . . . . . . . . . . . . . 11-16

11. Developing section. . . . . . . . . . . . . . . . . . . . . . . . . . 11-17

12. Transfer section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-19

13. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-21

14. Fan and filter section . . . . . . . . . . . . . . . . . . . . . . . . 11-25

[12] EL E CTR I CAL SEC T IO N

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

2. Power line diagram . . . . . . . . . . . . . . . . . . . . . . . . . .12-3

3. Actual wiring chart . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

4. Signal list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

[13] SERVICE WEB PAGE

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

2. Details and operation procedures . . . . . . . . . . . . . . .13-1

[14] TOOL LIST

1. TOOL LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

Page 3

CAUTION

DOUBLE POLE/NEUTRAL FUSING

ATTENTION.

Double pôle/fusible sur le neutre

AR-6020

NOTE FOR SERVICING

1. Precautions for servicing

1) When servicing, disconnect the power plug, the printer cable,

the network cable, and the telephone line from the machine,

except when performing the communication test, etc.

It may cause an injury or an electric shock.

2) There is a high temperature area inside the machine. Use

extreme care when servicing.

It may cause a burn.

3) There is a high voltage section inside the machine which may

cause an electric shock. Be careful when servicing.

4) Do not disassemble the laser unit. Do not insert a reflective

material such as a screwdriver in the laser beam path.

It may damage eyes by reflection of laser beams.

5) When servicing with the machine operating, be careful not to

place your hands by belts, gears, chains, and other drive components.

6) Do not leave the machine with the cabinet disassembled.

Do not allow any person other than a serviceman to touch

inside the machine. It may cause an electric shock, a burn, or

an injury.

7) When servicing, do not breathe toner, developer, and ink

excessively. Do not get them in the eyes.

If toner, developer, or ink enters you eyes, wash it away with

water immediately, and consult a doctor if necessary.

8) The machine has got sharp edges inside. Be careful not to

damage fingers when servicing.

9) Do not throw toner or a toner cartridge in a fire. Otherwise,

toner may explode and burn you.

10) When replacing the lithium battery on the PWB, use only the

specified battery.

If a battery of different specification is used, the battery may

cause malfunction or breakdown of the machine.

11) When transporting a PWB, be sure to place the PWB in an

anti-static bag.

It may cause a breakdown or malfunctions.

2. Warning for servicing

1) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Avoid complex wiring, which may lead to a fire or an electric

shock.

2) If there is any abnormality such as a smoke or an abnormal

smell, interrupt the job and disconnect the power plug.

It may cause a fire or an electric shock.

3) Be sure to connect the grounding wire. If an electric leakage

occurs without grounding, a fire or an electric shock may result.

For proper machine functionality, the machine must be

grounded.

4) When connecting the grounding wire, never connect it to the fol-

lowing points.

It may cause an explosion, a fire or an electric shock.

- Gas tube

- Lightning conductor

- A water pipe or a water faucet, which is not recognized as a

grounding object by the authorities.

- Grounding wire for telephone line

5) Do not damage, break, or twist the power cord.

Service Manual

Do not put heavy objects on the power cable. Do not forcefully

bend or pull the power cable.

It may cause a fire or an electric shock.

6) Keep the power cable away from a heat source.

Do not insert the power plug with dust on it into a power outlet.

It may cause a fire or an electric shock.

7) Do not put a metallic object or a container with water in it inside

the machine.

It may cause a fire or an electric shock.

8) With wet or oily hands, do not touch the power plug, do not perform servicing, touch the power plug, insert a telephone jack, or

operate the machine with wet or oily hands.

It may cause an electric shock.

3. Note for installing site

Do not install the machine at the following sites.

1) Place of high temperature, high humidity, low temperature,

low humidity, place under an extreme change in temperature and humidity.

Paper may get damp and form moisture inside the machine,

causing paper jam or copy dirt.

For operating condition, refer to the specifications described

later.

2) Place with a lot of vibration

It may cause a breakdown.

3) Poorly ventilated place

An electro-static type copier will produce ozone inside it.

The quantity of ozone produced is designed to a low level so as

not to affect human bodies. However, continuous use of such a

machine may produce an odor of ozone. Install the machine in a

well ventilated place.

4) Place with direct sunlight.

Plastic parts and toner may be deformed, discolored, or may

undergo qualitative change.

It may cause a breakdown or copy quality issues.

5) Place which is full of organic gases such as ammonium

The organic photoconductor (OPC) drum used in the machine

may undergo qualitative change due to organic gases such as

ammonium.

Installation of this machine near a diazo-type copier may result

in copy quality issues.

6) Place with excessive dust

When dusts enter the machine, it may cause a breakdown or

copy quality issues.

7) Place near a wall

Some machines require intake and exhaust of air.

If intake and exhaust of air are not properly performed, copy dirt

or a breakdown may be a result.

8) Unstable or slant surface

If the machine drops or falls down, it may cause an injury or a

breakdown.

If there are optional paper desks and the copier desks specified,

it is recommendable to use them.

When using the optional desk, be sure to fix the adjuster and

lock the casters.

AR-6020 NOTE FOR SERVICING - i

Page 4

4. Note for handling PWB and electronic parts

When handling the PWB and the electronic parts, be sure to

observe the following precautions in order to prevent against damage by static electricity.

1) When in transit or storing, put the parts in an anti-static bag or

an anti-static case and do not touch them with bare hands.

2) When and after removing the parts from an anti-static bag

(case), use an earth band as shown below:

- Put an earth band to your arm, and connect it to the

machine.

- When repairing or replacing an electronic part, perform the

procedure on an anti-static mat.

5. Note for repairing/replacing the LSU

When replacing, be sure to observe the following items.

1) When replacing the LSU, be sure to disconnect the power plug

from the power outlet.

2) When replacing the LSU, follow the procedures described in

this Service Manual.

3) When checking the operations after repairing the LSU, keep all

the parts including the cover installed and perform the operation check.

4) Do not modify the LSU.

5) When visually checking the inside of the machine for the operation check, be careful not to allow laser beams to enter the

eyes.

If the above precaution is neglected or an undesignated work

is performed, safety may not be assured.

6. Note for handling the OPC drum unit, the

transfer unit, and the developer unit

When handling the OPC drum unit, the transfer unit, and the developer unit, strictly observe the following items.

If these items are neglected, a trouble may be generated in the

copy and print image quality.

(OPC drum)

1) Avoid working at a place with strong lights.

2) Do not expose the OPC drum to lights including interior lights

for a long time.

3) When the OPC drum is removed from the machine, cover it

with light blocking material. (When using paper, use about 10

sheets of paper to cover it.)

4) Be careful not to attach fingerprints, oil, grease, or other foreign material on the OPC drum surface.

(Transfer unit)

5) Be careful not to attach fingerprints, oil, grease, or other foreign material on the transfer roller.

(Developer unit)

1) Be careful not to attach fingerprints, oil, grease, or other foreign material on the developer unit.

AR-6020 NOTE FOR SERVICING - ii

Page 5

[1] PRODUCT OUTLINE

-8#3

!220

!2

!2$$

!2..

-862

!2."

-8%"

!20"

PRINTER

EXPANSION KIT

MX-USX5

SHARPDESK 5 LICENSE

KIT

-80+

PS3 EXPANSION

KIT

MX-US10

SHARPDESK 10 LICENSE

KIT

MX-US50

SHARPDESK 50 LICENSE

KIT

MX-USA0

SHARPDESK 100 LICENSE

KIT

-8#3

-8#3

!2$3

!2$3

MX-USX1

SHARPDESK 1 LICENSE

KIT

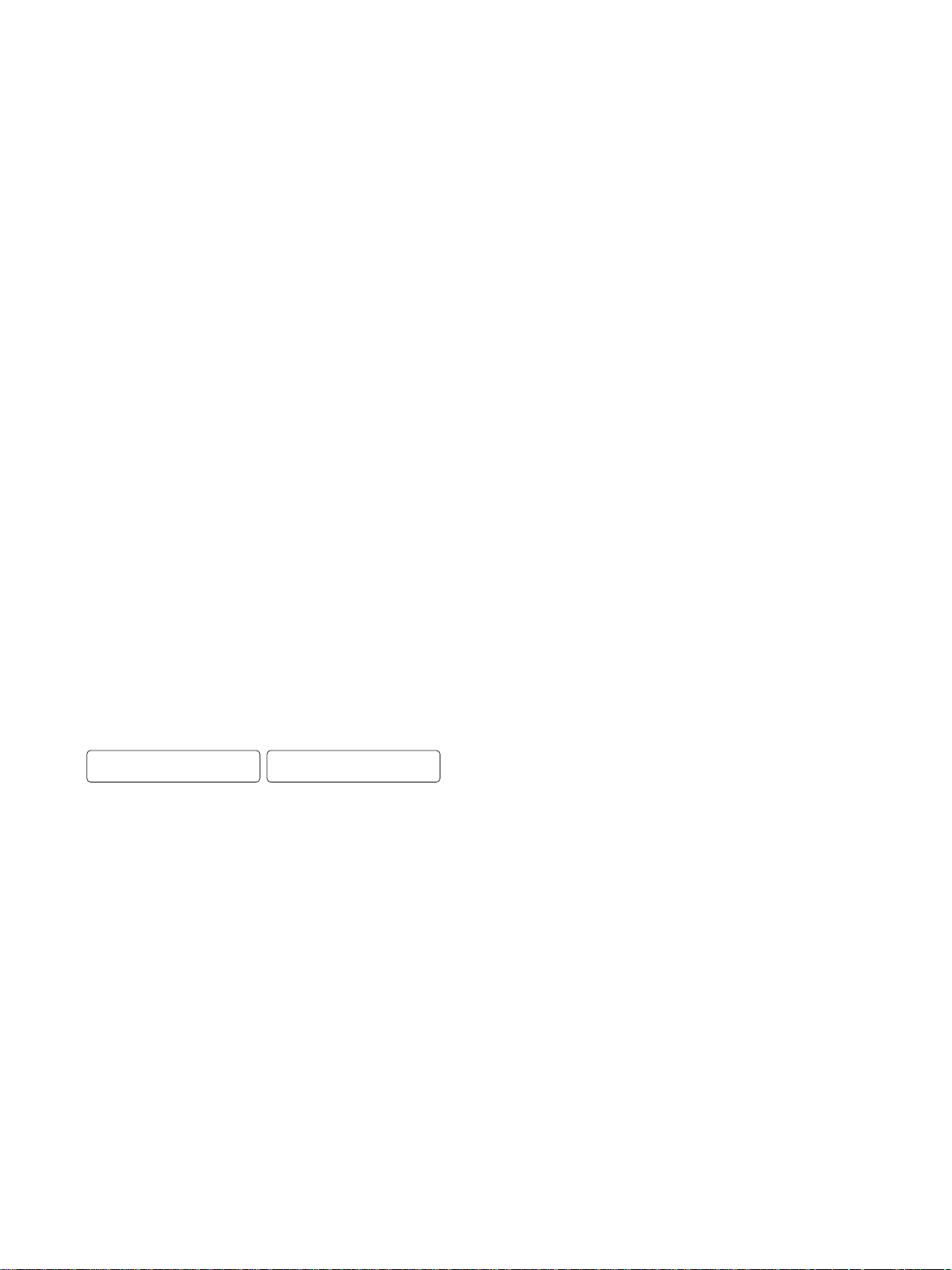

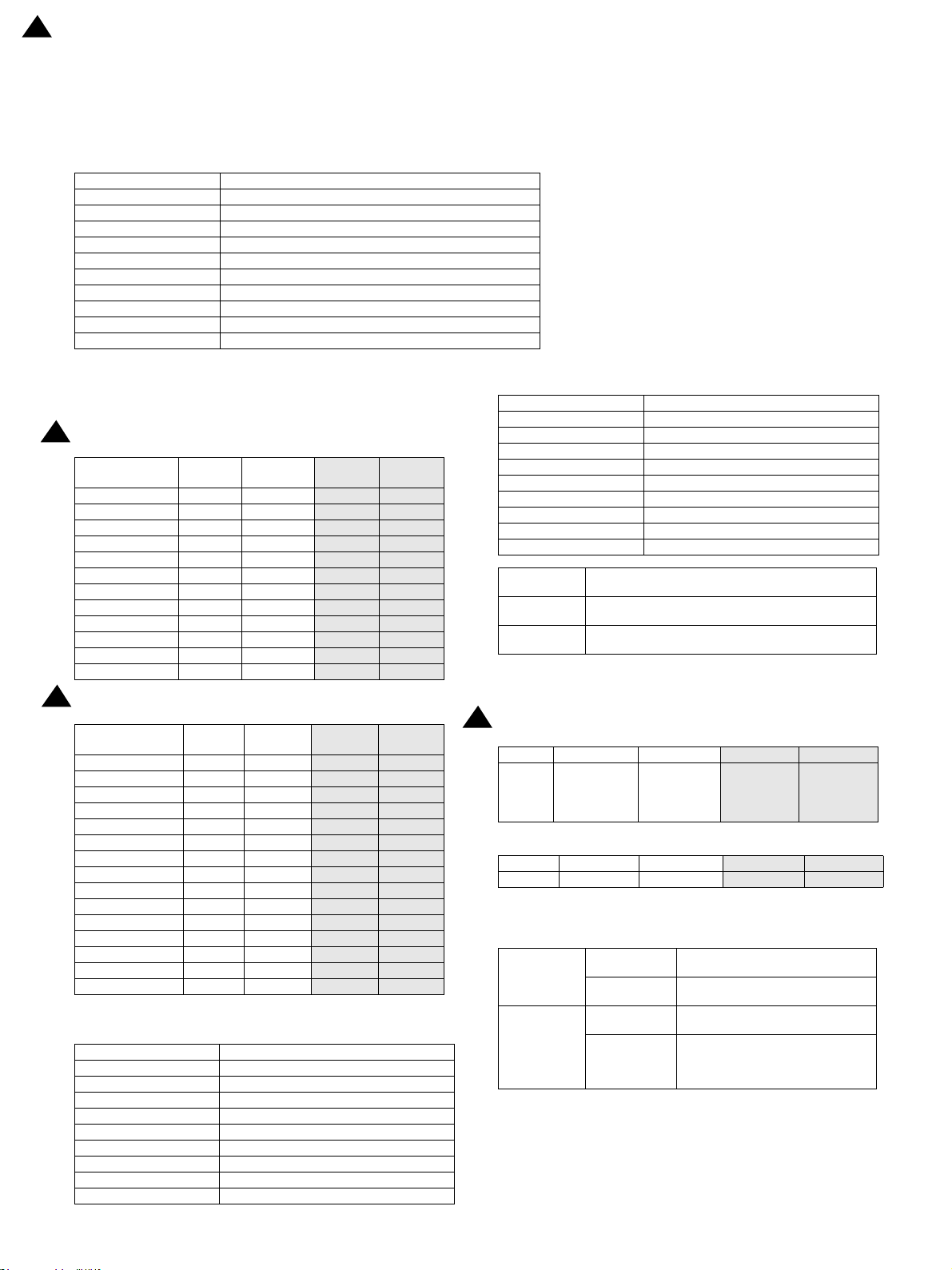

1. System diagram

A. 20/23 cpm machine

AR-6020 CONFIGURATION 1-1

Page 6

!220

!2..

-862

!2."

-8%"

!20"

PRINTER

EXPANSION KIT

MX-USX5

SHARPDESK 5 LICENSE

KIT

-80+

PS3 EXPANSION

KIT

MX-US10

SHARPDESK 10 LICENSE

KIT

MX-US50

SHARPDESK 50 LICENSE

KIT

MX-USA0

SHARPDESK 100 LICENSE

KIT

-8#3

-8#3

!2$3

!2$3

MX-USX1

SHARPDESK 1 LICENSE

KIT

15.Feb

2

2

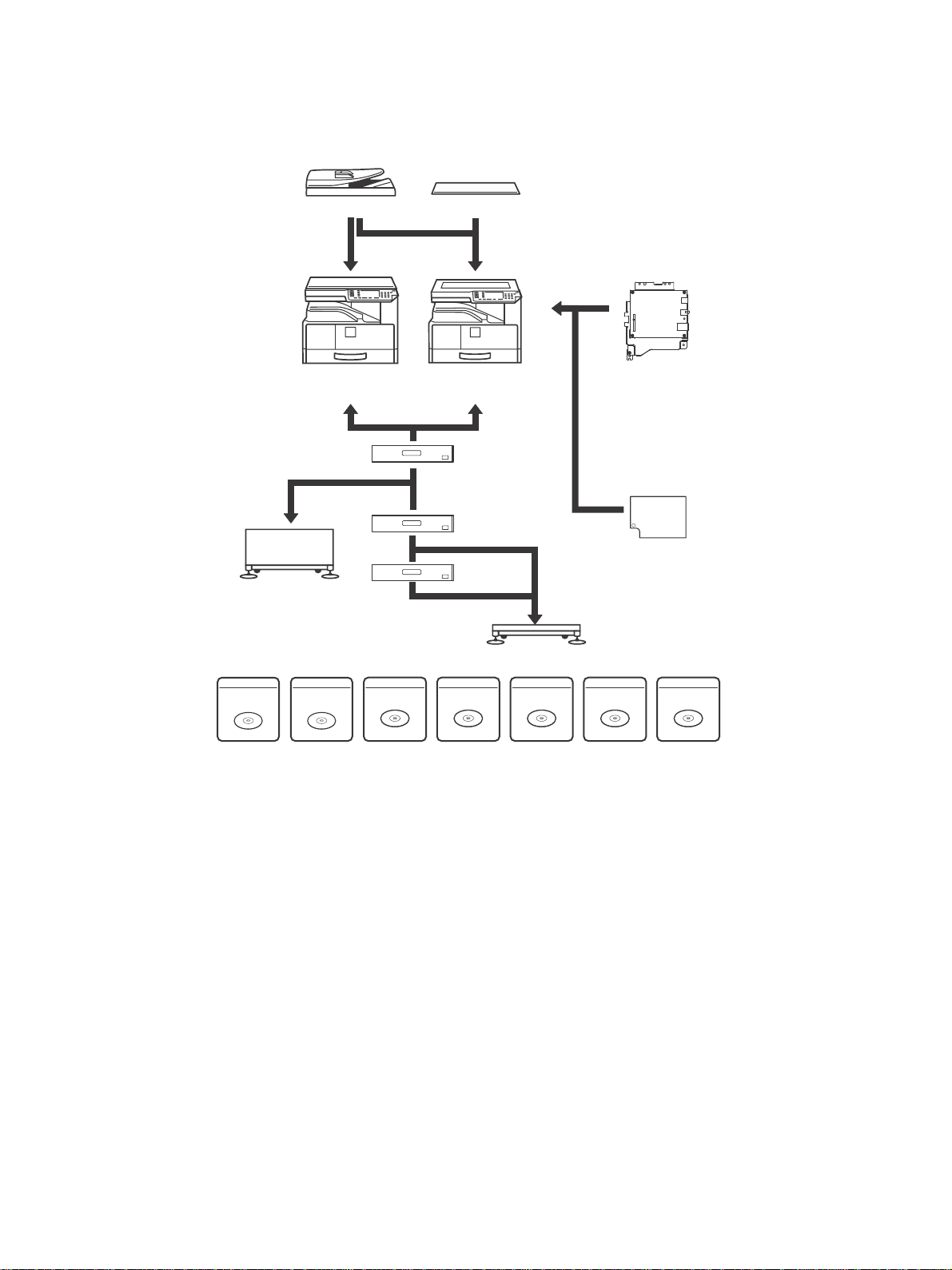

B. 26/31 cpm machine

2

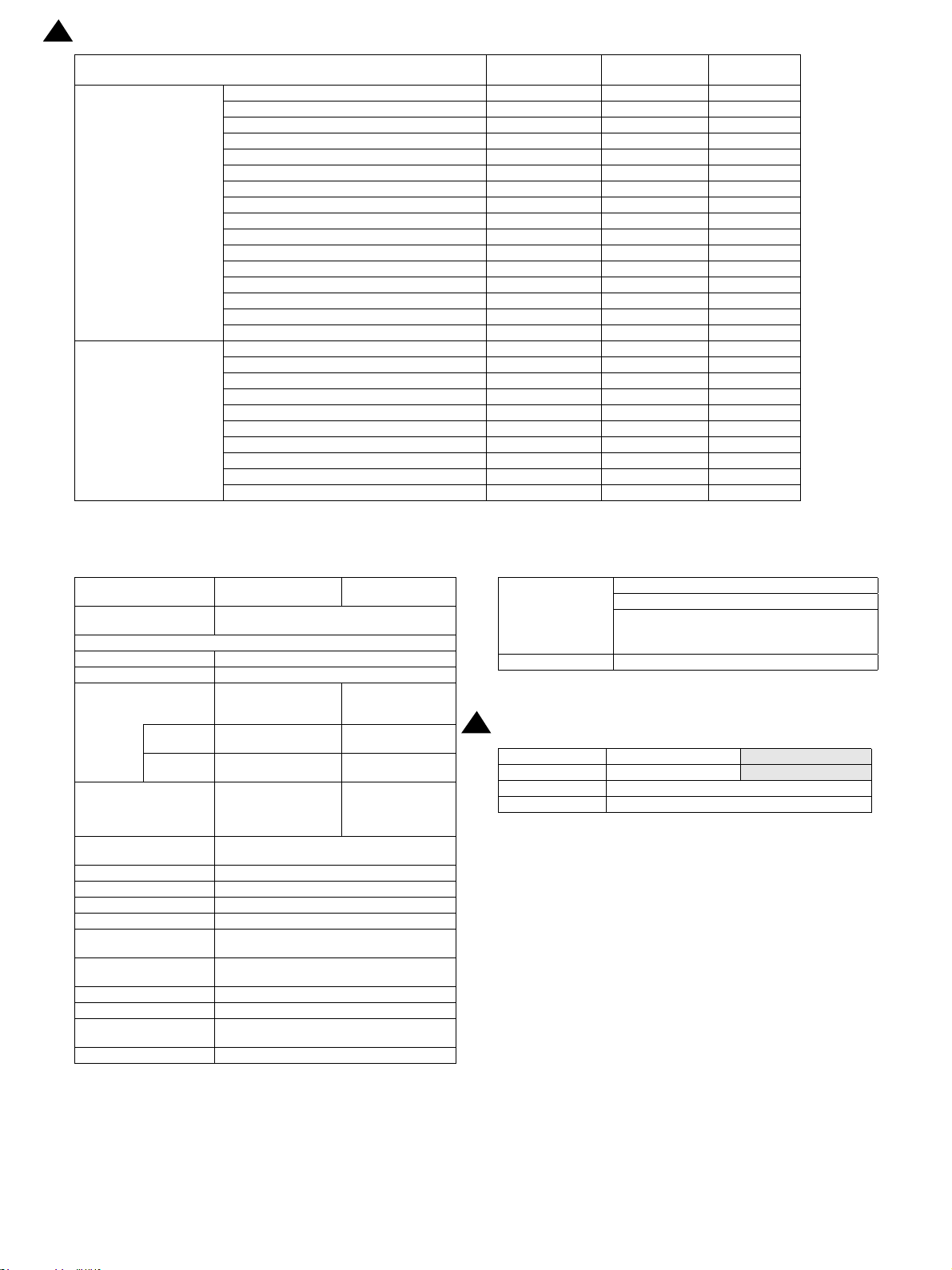

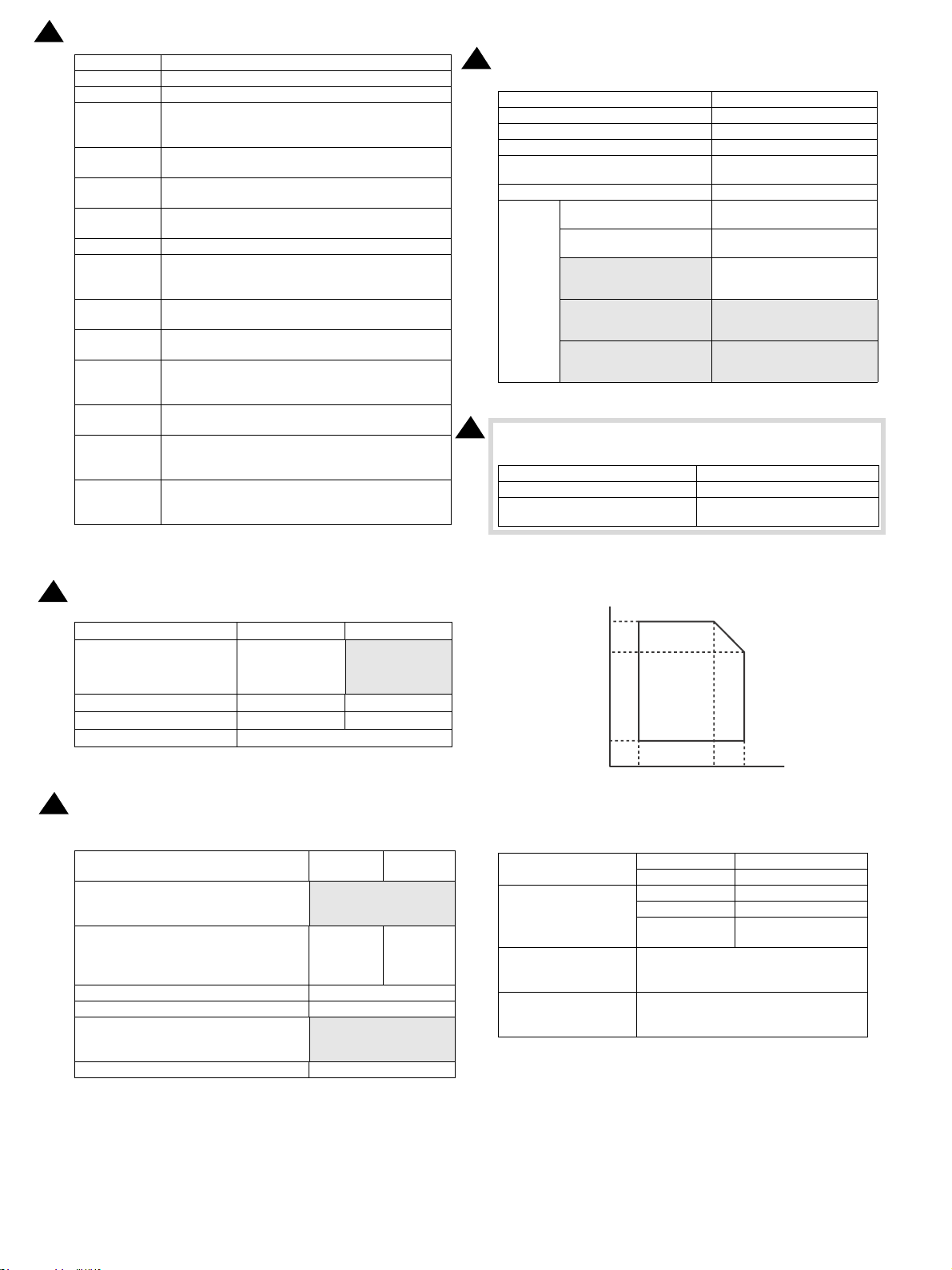

2. Option List

Document

Feed System

Paper Feed

System

Stand

Model/Option AR-6020/6023 AR-6020D/6023D AR-6020N/6023N

AR-RP11 Reversing single pass feeder (RSPF) O O O

MX-VR12 Document cover STD O O

MX-CS12 500-sheet paper feed unit O O O

MX-CS13 500-sheet paper feed unit O O O

AR-DS19 Stand (Large) O O O

AR-DS20 Stand (Small) O O O

AR-NB7 NETWORK EXPANSION KIT O O STD *1

Printer

Expansion

Application /

Solution

AR-PB10 PRINTER EXPANSION KIT

MX-EB14 EXPANSION MEMORY BOARD O O O

MX-PK10 *2 PS EXPANSION KIT O O O

MX-USX1 SHARPDESK 1 LICENSE kit O O O

MX-USX5 SHARPDESK 5 LICENSE kit O O O

MX-US10 SHARPDESK 10 LICENSE kit O O O

MX-US50 SHARPDESK 50 LICENSE kit O O O

MX-USA0 SHARPDESK 100 LICENSE kit O O O

STD: Standard

O

: Option installation enable

*1 The AR-PR10 is required for PCL (SPLC only.)

*2 S/D Model: AR-NB7A; N model: AR-PB10 is necessary.

XX

X

: Option installation disable

AR-6026N/6031N Note

O

O

STD without motor

O with motor

O

O

STD *1

O O

O

O

O

O

O

O

O

AR-6020 CONFIGURATION 1-2

Page 7

15.Feb

2

AR-6020

[2] SPECIFICATIONS

1.Basic specifications

A.Engine Composition

Photoconductor OPC Drum (φ30mm)

Recording method Electronic Photo (Laser)

Developing method Dry-type Dual component Magnetic Brush Development

Charging method Charged Saw-Tooth Method

Transfer method Transfer roller

Separation method Separation claw

Cleaning method Contact blade method

Fusing method Heat roller

Toner supply method Open the front cover and insert the cartridge

Toner supply while working Unavailable

Appearance Pastel white

Service Manual

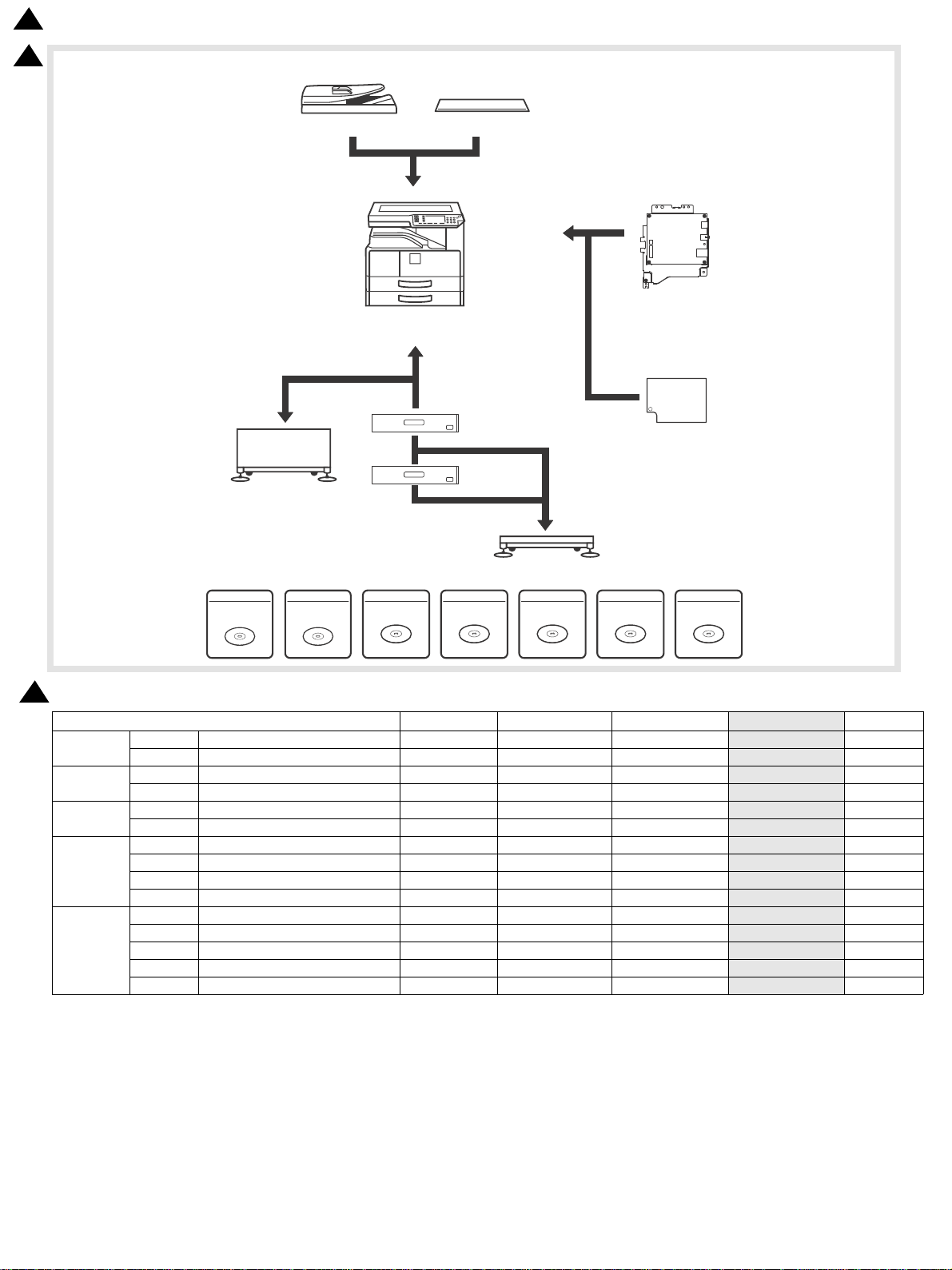

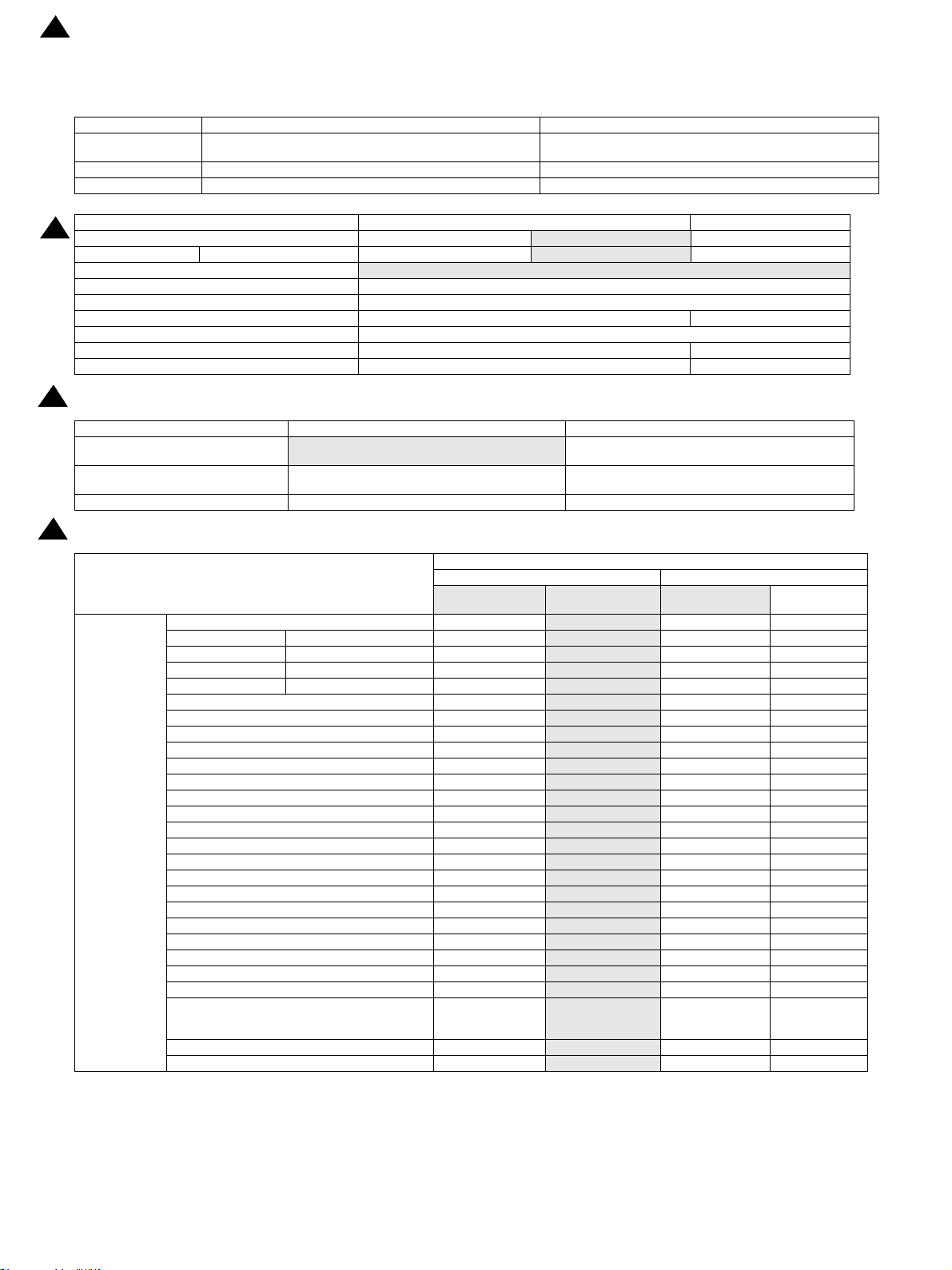

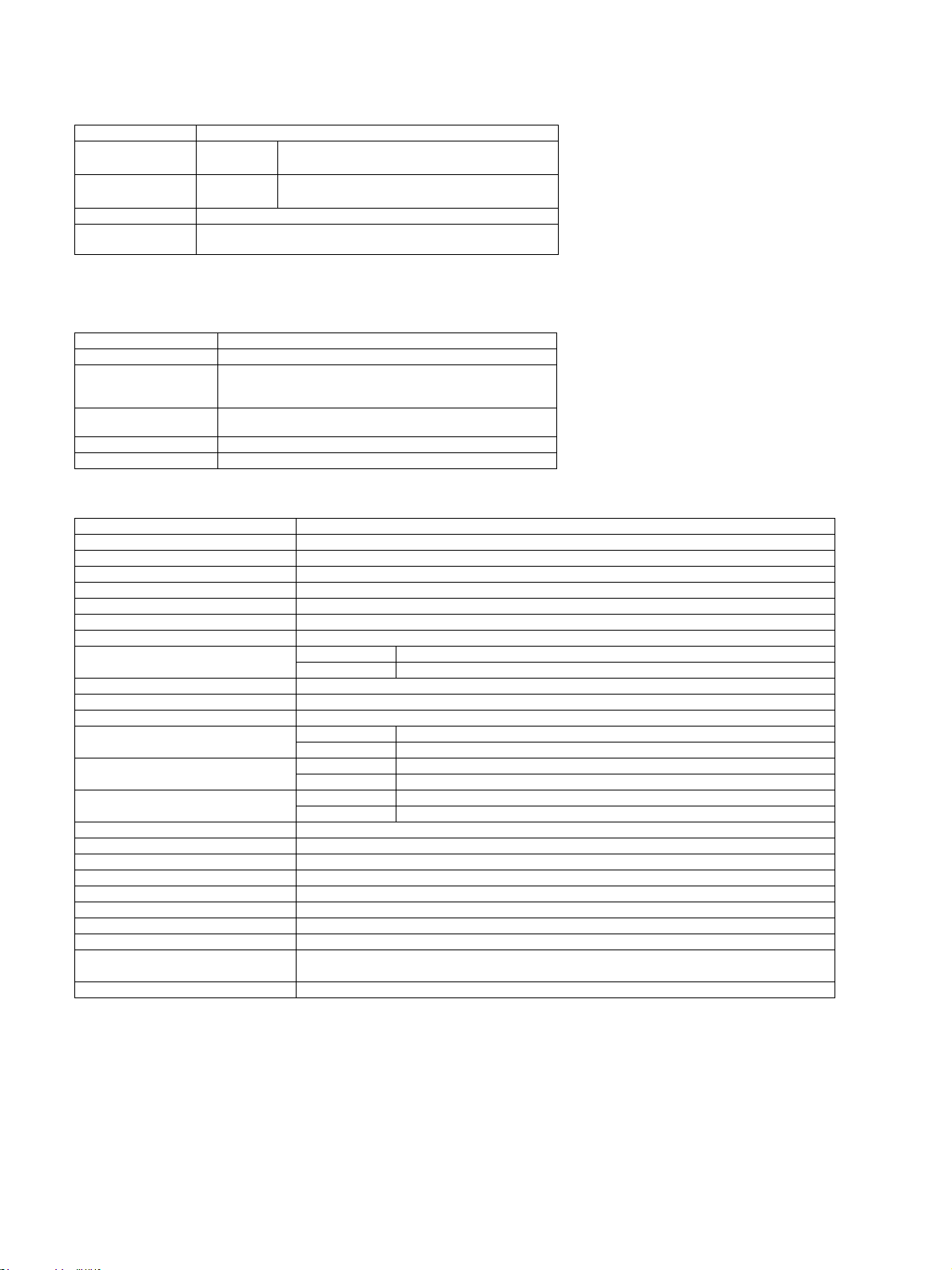

B.Engine speed (ppm)

2

(1)Tra y 1, 2

Paper size (short

edge feed)

A4/ 8.5"x11" 20ppm 23ppm

A4R 14pm 15ppm

8.5"x11"R 15ppm 16ppm

A5/ 5.5"x8.5"R 20ppm 23ppm

B5/ 16K 20ppm 23ppm

B5R 16ppm 18ppm

16KR 15ppm 16ppm

8.5x13" 12ppm 13ppm

B4/ 8.5"x14 12ppm 13ppm

A3 11ppm 12pm

11"x17" 10ppm 11ppm

8K 11ppm 12ppm

2

(2) Bypass tray

Paper size (short

edge feed)

A4 16ppm 18ppm

8.5"x11" 16ppm 18ppm

A4R/ 8.5"x11"R 10ppm 11ppm

A5 16ppm 18ppm

5.5"x8.5" 16ppm 18ppm

A5R/ 5.5"x8.5"R 16cpm 18cpm

B5 16cpm 18cpm

16K 16cpm 18cpm

B5R/ 16KR 10ppm 11ppm

8.5x13" 10ppm 11ppm

B4 10ppm 11ppm

8.5"x14 10ppm 11ppm

A3 10ppm 11ppm

11"x17" 10ppm 11ppm

8K 10ppm 11ppm

20cpm 23cpm

20cpm 23cpm

C.Printable area

A3 293x413mm

B4 253x357mm

A4 206x290mm

B5 178x250mm

A5 144x203mm

A5R 203x144mm

8K 266x383mm

16K 191x263mm

11x17 275x425mm

8.5x14 212x349mm

26cpm 31cpm

26ppm 31ppm

18ppm 23ppm

18ppm 23ppm

26ppm 31ppm

26ppm 31ppm

18ppm 23ppm

18ppm 23ppm

16ppm 20ppm

18ppm 23ppm

15ppm 17ppm

15ppm 17ppm

15ppm 17ppm

26cpm 31cpm

24ppm 29ppm

24ppm 29ppm

19ppm 25ppm

25ppm 29ppm

25ppm 29ppm

25ppm 29ppm

24ppm 29ppm

24ppm 29ppm

19ppm 25ppm

16ppm 21ppm

16ppm 21ppm

16ppm 20ppm

15ppm 18ppm

15ppm 18ppm

15ppm 17ppm

A3 293x413mm

B4 253x357mm

A4 206x290mm

8.5x13.5 212x336mm

8.5x13.4 212x333mm

8.5x13 212x323mm

8.5x11 212x272mm

5.5x8.5 136x209mm

5.5x8.5R 209x136mm

Executive 180x260mm

Void area

Image loss

Loss width

Front end: 1 to 4mm, Back end: 1 to 5mm, Both sides:

Max. 6mm

Front end: 4mm or less, Back end: 1 to 5mm, Right/Left :

Total 6mm or less

Front end/Back end: 4mm or less , Right/Left : Total

6mm or less

* When making original size/one-sided copies, the first sheet from

the bypass tray has no back end void setting.

2

D.First Copy Time

26cpm 31cpm

5.2seconds 5.2 seconds

Platen

20cpm 23cpm

A4: 6.4

seconds

LT: 6.5

seconds

A4: 6.4

seconds

LT: 6.5

seconds

First copy time from the paper feeding unit

20cpm 23cpm

Platen 12.5 seconds 12.5 seconds

26cpm 31cpm

10.9 seconds 10.9 seconds

E.Engine resolution

Resolution

Copy

Print

Copy

To ne

Print

<Writing>

600 x 600dpi

<Writing>

600 x 600dpi

<Writing>

600 x 600dpi x 1bit

<Writing>

SPLC : 600 x 600dpi x 1bit

PCL : 600 x 600dpi x 1bit

PS : 600 x 600dpi x 1bit

AR-6020 SPECIFICATIONS 2 – 1

Page 8

2

15.Feb

F. Scanner section

(1)Resolution/Gradation

Scan Resolution for

Copying (dpi)

Transmission Resolution (dpi)

Exposure Lamp White LED

Scan Levels 256 levels

Output Levels

(2)Document table

Form Fixed original glass (Flatbed)

Scan Range 297x431mm

Standard Location of Original Rear Left

Original size detection No

Heater (scanner section) No

2

G.Document feeder

Type RSPF

Scan Speed

Copy

(400x600dpi)

Fax No No

Document Glass 400x600dpi

RSPF 400x600dpi

Refer to Image Send Function.

Monochrome : 1bit

Gray scale : 8bit

Full Color : RGB each color 8bit

Monochrome(A4/

8.5x11)

20/23cpm :

Single:23sides/minute;

Duplex:11 sides/minute;

26/31cpm :

Single:23sides/minute;

Monochrome

Color(A4/8.5x11)

No

Type RSPF

Scan

Original setup direction Upward standard (1toN feeding standard)

Original setup position Center alignment

Original Transport method Sheet-through method

Original feeding order From upper sheet

Original size Standard type

Original weight

Original Stack Capacity

Not transportable original

type

Original size detection Yes

Original size to be detected Auto detection

Original feeding direction Right hand feeding

Original size Guide

Multi copy

Stamp No

1.27 msec/Line(Color), 0.423 msec/

Line(Gray scale/BW)

<Single side>

Plain paper: 50-128g/m2, 13-32 lb.bond

<Double side>

Plain paper: 50-105g/m2, 13-28 lb.bond

Max. 100 sheets (80g/m2, 21 lbs Bond) ,

or Max. height: 1/2 inch, 13mm or less

The following documents are NOT

allowed;

OHP, second original drawing, tracing

paper, carbon paper, thermal paper,

wrinkled/broken/torn document, document with cuts and pastes,

documents printed by an ink ribbon, and

perforated document except

2-punched/3-punched (Perforated document by punch unit is allowed.).

(Center) A3/A4, 11, B4/B5, 8-1/2, A4R/A5,

B5R, 5-1/2

S-S, S-D (Only Duplex model) , D-D (Only

Duplex model) D-S

Standard sheet type

A3

B4

11x17

Type *2

In ch -1 Yes Yes No N o No Ye s Ye s Ye s N o Ye s N o Yes N o N o No No No N o No No

In ch -2 Ye s N o N o No Ye s Ye s Ye s Ye s N o Ye s N o Yes N o N o No No No N o No No

In ch -3 Ye s N o N o Ye s N o Ye s Ye s Ye s N o Ye s N o Yes N o N o No No No No N o N o

AB-1 Yes Yes No No No Yes No No No Yes Yes Yes Yes Yes Yes Yes No No No No

AB -2 Ye s N o N o N o Yes Yes No N o N o Ye s Yes Yes Ye s Ye s Ye s Yes No N o N o N o

AB -3 Ye s N o N o N o Yes Yes No N o N o Ye s Yes Yes Ye s N o No Yes No Ye s Ye s Ye s

AB -4 Ye s N o N o Yes N o Ye s No N o N o Ye s Yes Ye s Yes Yes Ye s Ye s N o No N o N o

AB-5 Yes No Yes No No Yes No No No Yes Yes Yes Yes Yes Yes Yes No No No No

8.5x14

8.5x13.5

8.5x13.4

216x343)

216x340)

8.5x11

8.5x13

216x330)

5.5x8.5

8.5x11R

5.5x8.5R*1

A4

A4R

B5

B5R

A5

8K

A5R*1

16K

16KR

AR-6020 SPECIFICATIONS 2 – 2

Page 9

15.Feb

2

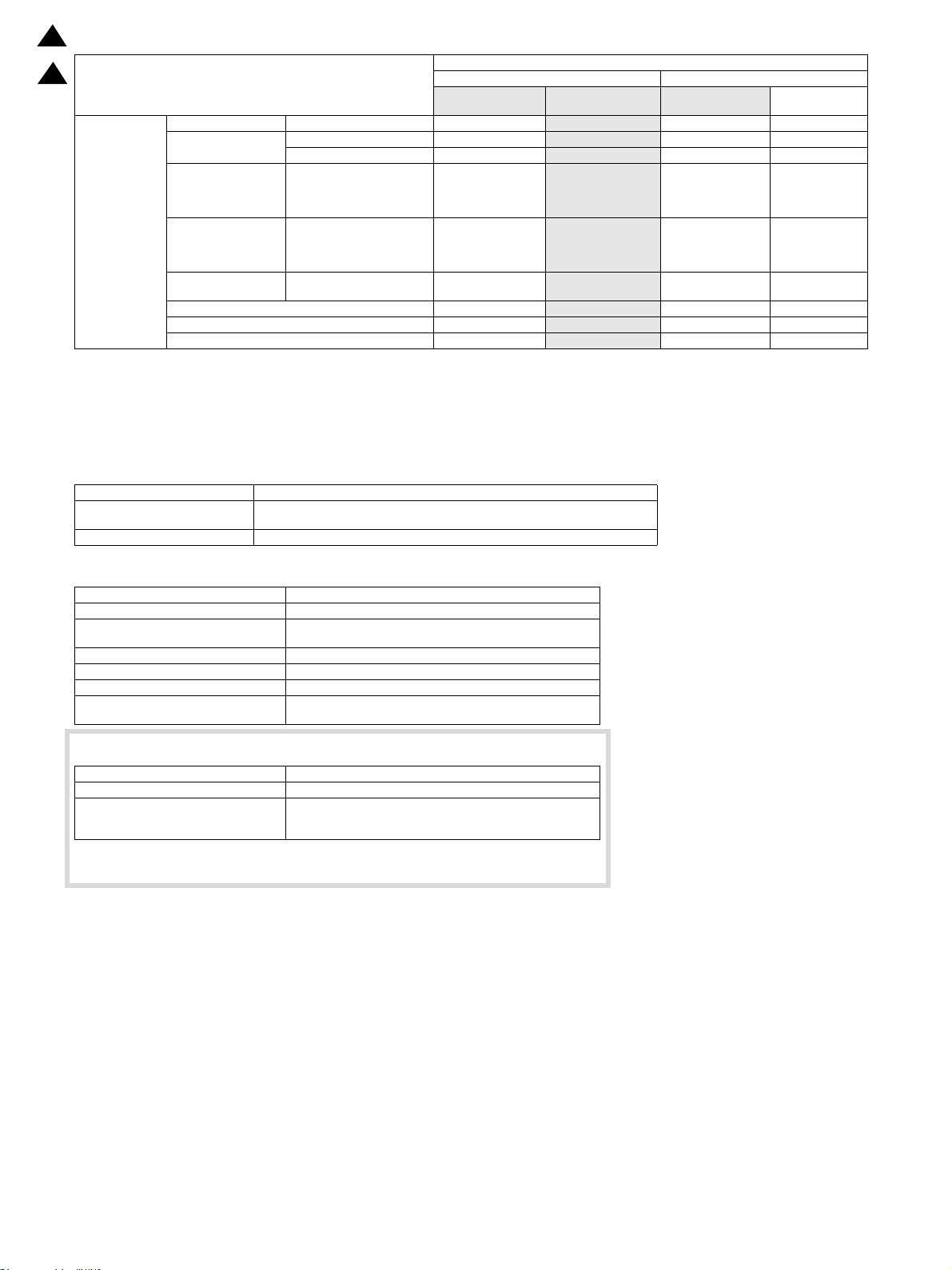

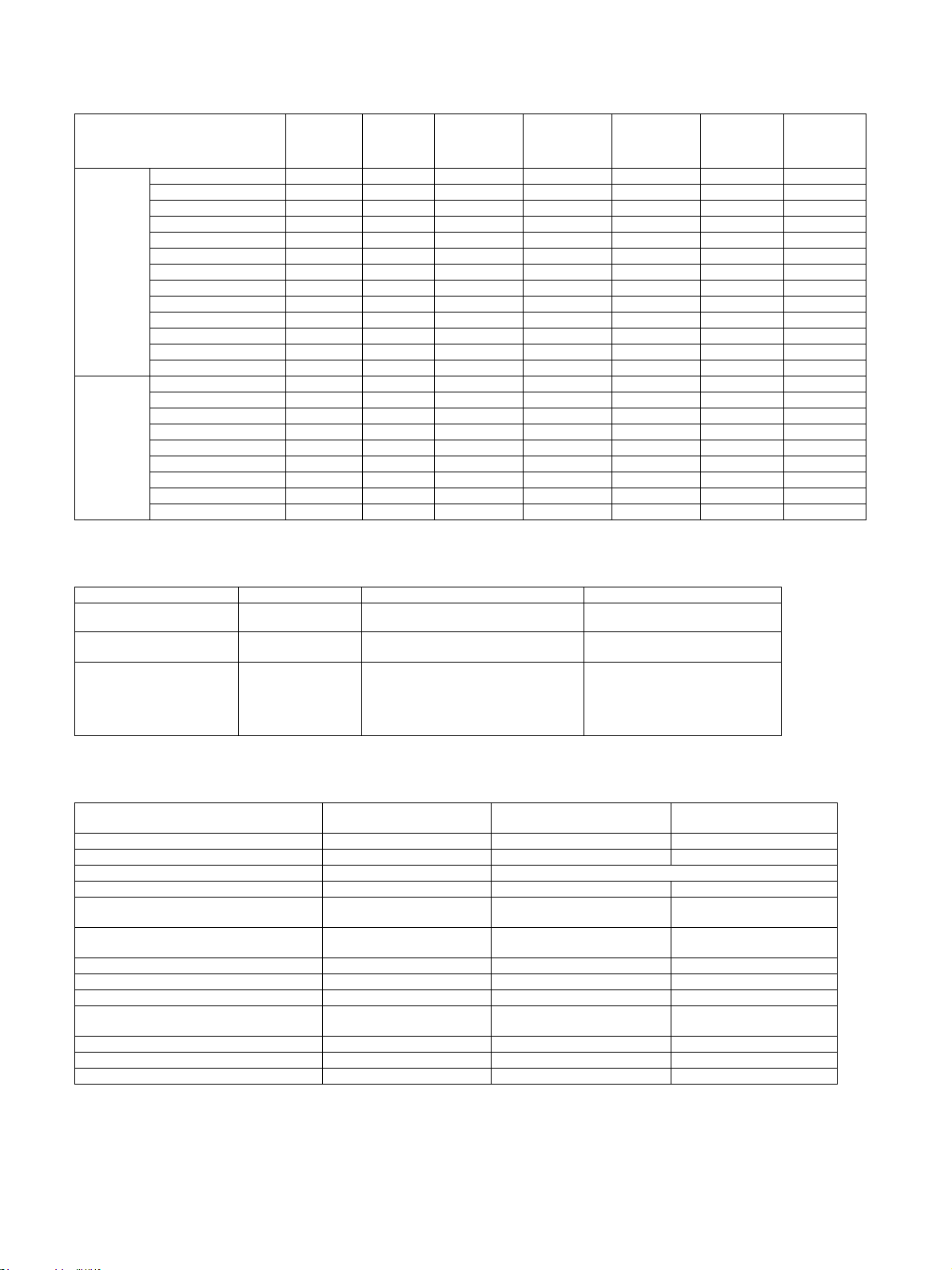

H.Paper feed section

(1)Basic specifications

20/23 cpm 26/31 cpm

Form

Paper loading method To be loaded from the upper side with front loading system To be loaded from the upper side with front loading system

Heater None. None.

Standard: 250-sheet tray x1 + Multi Bypass(100)

Max.: 250-sheet tray x1 + 500-sheet tray x3 + Multi Bypass(100)

Standard: 500-sheet tray x 2 + Multi Bypass (100)

Max: 500-sheet tray x 4 + Multi Bypass (100)

2

Paper Capacity Standard paper (80g/m2) 250 sheets

Paper size detection

Paper Type setting Yes

Paper Size change User setting

Default paper size setting AB systems: A4 Inch systems: 8.5x11 -Paper balance detection Paper empty only

Cassette handle grabbing from both direction Yes -Paper Size Indication Window Depending on Paper Size sheet --

(2)Other paper type capacities

2

Paper Type Paper Tray Bypass Tray

Plain paper

Envelope --

Others -- Single paper feed (transparency, label)

(3)Size of paper which can be fed

2

Paper Size

Item Tray Multi bypass

20/23 cpm

No

20/23 cpm : 250 sheets (80g/m2)

26/31 cpm : 500 sheets (80g/m2)

Tray (250 sheets) Tray (500 sheets) 1 Paper Feed Tray

11x 17 Yes

8.5x14 216x356mm Yes

8.5x13.5 216x343mm Yes

8.5x13.4 216x340 mm Yes

8.5x13 216x330 mm Yes

8.5x11 Yes

8.5x11R Yes

7.25x10.5 *3 No

7.25x10.5R *3 No

5.5x8.5 No

5.5x8.5R Yes

A3 Yes

B4 Yes

A4 Yes

A4R Yes

B5 Yes

B5R Yes

A5 No

A5R Yes

B6R No

A6R No

8K Yes

16K Yes

16KR Yes

Envelope*1 No

Custom No

Extra No

26/31 cpm 20/23/26/31 cpm

500 sheets x2 100 sheets

100 sheets (55-80g/m2)

(For multi paper feed, 55-128g/m2)

AB system: 10 envelopes

Inch system: 5 envelopes

Paper Feeding Section

Main unit Optional tray

(500 sheets)

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

No No Yes

No No Yes

No No Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

No No Yes

Yes Ye s Yes

No No Yes

No No Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

No No

No No Yes

No No Yes

Multi Bypass

Yes

(Single feed is

available)

AR-6020 SPECIFICATIONS 2 – 3

Page 10

15.Feb

2

2

Tray (250 sheets) Tray (500 sheets) 1 Paper Feed Tray

Thin Paper 55-59g/m2 13-16lb bond Yes

60-105g/m2 16-28lb bond Yes

Recycled Paper Yes

106-128g/m2 28 lb bond 32 lb bond

129-200g/m2 32 lb bond 110 lb C o ver

201g/m2 and above

110 lb bond and above

Paper Type

Plain Paper

Heavy paper

Heavy paper

Heavy paper

OHP paper No

Label *2 No

Tab Paper No

*1: Supporting envelope: Monarch / Com-10 / DL

*2 Recommended media: SF-4A3F

*3 It can be fed, but not display.

I.Paper exit section

(1) Duplex

Type 1 Pass, Switchback type

Transportable Paper (Fixed)

Size/Weight

Other Duplex print using the manual bypass is not possible.

Refer to the “Usable Paper Size and Weight”.

Main unit Optional tray

No

No

No

Paper Feeding Section

(500 sheets)

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

No No

No No

No No No

No No Yes

No No Yes

No No No

Multi Bypass

Yes

(A4 or less)

(Multi feed is

available)

Yes

(A4 or less)

(Multi feed is

available)

(2) Exit Capacity

Ejection part Center part of the main unit

Ejection method Face-down ejection

Paper capacity for ejection

Ejectable paper size and weight Refer to the “Usable Paper Size and Weight”.

Shifter function No

Detection of ejected paper No

Detection of full ejected paper

(The paper is counted by the software)

250 sheets

(A4/8.5x11:80g/m3)

There is no sensor to detect.

(3) Rotate Sort

Output Tray It is possible to use the Multi Bypass and each paper tray.

Output Paper Size A4/A4R, B5/B5R, 16K/16KR, 8.5”x11”/8.5”x11”R

Output Paper Type

* The output in different 90 degrees direction when using 2 papers

feed trays.

Thin paper(55-59g/m2 13-16 lb bond)

Plain paper(60-105g/m2 16-28 lb bond)

Recycled paper

AR-6020 SPECIFICATIONS 2 – 4

Page 11

(4) Usable Paper Size and Weight (Main Unit Output Tray, Duplex Section)

11x17 Yes Ye s

8.5x14 216x356mm Yes Yes

8.5x13.5 216x343mm Yes Yes

8.5x13.4 216x340 mm Yes Yes

8.5x13 216x330 mm Yes Yes

8.5x11 Yes Yes

8.5x11R Yes Yes

7.25x10.5 No Yes

7.25x10.5R No Yes

5.5x8.5 No Yes

5.5x8.5R No Yes

A3 Yes Ye s

Paper Size

Paper Type

*1: Supporting Envelope Monarch/Com-10/DL

B4 Yes Ye s

A4 Yes Ye s

A4R Yes Ye s

B5 Yes Ye s

B5R Yes Ye s

A5 No Yes

A5R Yes Ye s

B6R No Yes

A6R No Yes

8K Ye s Ye s

16K Yes Ye s

16KR Yes Ye s

Envelope*1 - Yes

Extra - Yes

Custom - Thin Paper 55-59g/m2 13-16lb bond No Yes

Plain Paper

Heavy paper 106-128g/m2 28 lb bond -32 lb bond No Yes

Heavy paper 129-200g/m2 32 lb bond -110 lb Cover No Yes

Envelope - Yes

OHP - Yes

Label - Yes

Tab Paper - -

60-105g/m2 16-28lb bond Yes Yes

Recycled Paper Yes Yes

Duplex Section

Output Section

Main Unit Output tray

(Non-Offset)

J.Operation panel

(1)Display Device

Form LCD Display with Back Light (custom LCD)

Number of Dots in display 167 segments

Color display Monochrome

LCD Drive Display Area (WxD) 51x77mm

LCD Back Light White LED backlight method

LCD Contrast Adjust No

Angle/Position Adjustment No

(2)Key

Model

Star t K ey O O O

Clear Key O O O

Clear All Key (“CA”) O O O

Basic Input Section

Mode area

Interrupt Key O O O

10 Key O O O

Power Saving Key*1 O O O

* key O O O

# key O O O

Printer Online Key O O O

Scanner Mode Key O O O

AR-6020 SPECIFICATIONS 2 – 5

Simplex model

(Standard model)

Duplex model

(D model)

N model

Page 12

2

15.Feb

Model

Function Selection Key

LED display items

Simplex model

(Standard model)

Ratio Selection Key O O O

Zoom Key O O O

Tray Selection Key O O O

Paper Size Selection Key O O O

Original Key O O O

Paper Key O O O

Exposure Setting Key O O O

Copy Image Quality Mode Selection Key O O O

2in1/4in1 Selection Key O O O

Margin Shift Selection Key O O O

E-Sort Key O O O

Edge/Center Erase Selection Key O O O

Dual Page Copy Key O O O

Duplex Mode Switch Key O O O

One-Touch Send Key(6 keys) O O O

ID Card Copy Key O O O

Interrupt LED O O O

Start Key LED O O O

Power Saving LED O O O

Exposure Setting LED O O O

Copy Image Quality Mode LED O O O

Print Online LED O O O

Scan Mode LED O O O

ID Copy LED O O O

Error LED O O O

Data LED O O O

Duplex model

*1 According to the BA, the icon of Power Saving Key can uses the key (crescent mark) to indicate.

(D model)

N model

K.Controller board

Standard model / Dmodel

CPU

Interface

IEEE1284 Parallel No

IEEE 802.1x No

Ethernet

Interface

Support

Protocol

USB 2.0(High Speed)

(Host) *1

USB 2.0(High Speed)

(Device)

USB Authentication No

ACRE Expansion I/F No

Ir-Simple I/F No

Video I/F No

Serial I/F (for coin

vender)

Parallel I/F (For Coin

Vendor etc,)

Memory Refer to Memory / Hard disk

Memory Slot No

Windows Premium Logo

acquisition

WHQL acquisition Yes

H8S/2373 (16bit 1 chip microcomputer,

24.576MHz)

1 port (When Network

Expansion Kit is

expanded)

10Base-T, 100Base-TX10Base-T, 100Base-

TCP/IP (IPv4) TCP/IP (IPv4)

1 port (Side face)

(When Network

Expansion Kit is

expanded)

1 port

No

Supported by Service boarded

No

*1 Switching to “USB Host invalid” shall be available by Sim.

N-model

1 port

TX

1 port (Side face)

L.Memory/Hard disk

64MB

Memory of MCU

board

Memory Expansion 128MB

M.Warm-up time

2

Warm up time 25 seconds or less

Preheat Yes

Jam recovery time 15 sec

* May be different depending on the environment.

Hard disk : not available

Number of sheets which can be scanned

TEST CHART B : 100 sheets

TEST CHART C : 80 sheets

20/23 cpm model

26/31 cpm model

20 seconds or less

AR-6020 SPECIFICATIONS 2 – 6

Page 13

2. Copy functions

A. Copy Ratio

Item Contents

Copy Ratio (Fixed)

Zoom

Preset Ratio None

XY Zoom

AB Series

Inch Series

Platen

R-SPF

Yes (25-400% for both horizontally and vertically, However, when R-

* It can’t be set when using the RSPF.

B. Exposure/Copy image quality processing

Item Contents

Exposure Mode Auto/Text/Photo

Resolution

Gradation

Number of manual steps 5 steps (Text/Photo)

Toner Save Mode Yes (the setting is different depending on the area)

Writing: 600 x 600 dpi

Scanning: 400 (main) x 600 (sub) dpi (Photo Mode), 400 (main) x

600 (sub) dpi (AE, Text Mode)

Writing : 2 values

Scanning: 256 gradations

C. Copy function

Item Contents

Auto Paper Selection (APS) O

Auto Magnification Selection (AMS) O

Auto Tray Switching O

Support Mixed Original X

Stream Feeding Mode O

Memory Copy (SOPM) O

Rotation Copy O

e-Sort

Rotation Sort O

Sky Shot Prevention X

XY Zoom O

Dual Page Copy

Margin Shift

Edge+Center Erase

B/W Reverse X

2in1 / 4 in 1 O

ID Card Copy O (can enlarge, because the ID Card Copy for all destinations.)

Off-set Print X

Preheat Function O(Terms can be specified by system setting)

Auto Power Shutoff O(Terms can be specified by system setting)

System Setting O

Duplex Copy O(Only for D-model/N-model)

Toner Save Mode

Account Control O(Only copy can be controlled. Number of control: 20)

25%*,50,70,81,86,100,115,122,141,200,400%*

25%*,50,64,77,95,100,121,129,141,200,400%*

25-400%(376 levels by 1%)

50-200%(151 levels by 1%)

SPF is used, 50-200%)

Sort Function O *Except for Interrupt Copy

Group Function O

OC O *Except for enlarged copy

RSPF X

AB series 10mm(5, 10, 15, 20mm)

Inch series 1/2 inch (1/4,1/2,3/4,1 inch)

AB series 10mm(5, 10, 15, 20mm)

Inch series 1/2 inch (1/4,1/2,3/4,1 inch)

O(Can be specified according to area/Settings can be changed by service

simulation)

AR-6020 SPECIFICATIONS 2 – 7

Page 14

3. Printer function

A. Driver supported OS

USB

Twain/

Button

Manager

Windows

Mac

OS *1

Server 2003 No CD-ROM No CD-ROM No CD-ROM CD-ROM

Server 2003x64 No CD-ROM No CD-ROM No CD-ROM CD-ROM

Server 2008 No CD-ROM No CD-ROM No CD-ROM CD-ROM

Server 2008x64 No CD-ROM No CD-ROM No CD-ROM CD-ROM

Vista CD-ROM CD-ROM CD-ROM CD-ROM No CD-ROM CD-ROM

Vistax64 CD-ROM CD-ROM CD-ROM CD-ROM No CD-ROM CD-ROM

Windows7 CD-ROM CD-ROM CD-ROM CD-ROM No CD-ROM CD-ROM

Windows7x64 CD-ROM CD-ROM CD-ROM CD-ROM No CD-ROM CD-ROM

Windows8 CD-ROM CD-ROM CD-ROM CD-ROM No CD-ROM CD-ROM

Windows8x64 CD-ROM CD-ROM CD-ROM CD-ROM No CD-ROM CD-ROM

Windows8.1 CD-ROM CD-ROM CD-ROM CD-ROM No CD-ROM CD-ROM

Windows8.1 x64 CD-ROM CD-ROM CD-ROM CD-ROM No CD-ROM CD-ROM

Server 2012 x64 No CD-ROM No CD-ROM No CD-ROM CD-ROM

9 No No No No No No No

X 10.2 No No No No No No No

X 10.3 No No No No No No No

X 10.4 No No No No No CD-ROM No

X 10.5 No No No No No CD-ROM No

X 10.6 No No No No No CD-ROM No

X 10.7 No No No No No CD-ROM No

X 10.8 No No No No No CD-ROM No

X 10.9 No No No No No CD-ROM No

*1 New OS is supported according to the rule of the Document Solutions Group.

B. PDL emulation/Font

Network

Twain/

SPLC

Custom

PCL6

Custom

PCL5e

Custom PS PPD

PDL(command) Overseas Resident Font Optional Font

PCL6 compatible OPT

ESC/P(VP-1100) compatible,

ESC/P_super compatible

Postscript3 compatible OPT*1 ---

--- --- ---

European outline font=80 font types

Line printer font (BMP)=1 font types

---

Japanese font

Heisei font = 2 fonts

- Heisei Mincho W3

- Heisei Kaku Gothic W5

Outline font=136 fonts

* When NW Expansion Kit and PS Expansion Kit are expanded, Nova-Light has optional font because it supports PS3.

C. Support print channel

S/D Model N Mode

USB(Device) USB1.1/USB2.0(High-Speed) --- USB1.1/USB2.0(High-Speed)

USB(Host) --- --- --Ethernet --- 10Base-T, 100Base-TX

PSERVER/RPRINT in NetWare environments --- --- ---

LPR --- ---

IPP --- ---

PAP Ether Talk (Apple Talk) --- --- --FTP --- --- --NetBEUI --- --- ---

Raw Port(Port9100) --- ---

HTTP(Web Submit Print) --- --- --POP3(E-Mail To Print) --- --- --BMLinks --- --- ---

* IPP,HTTP, and POP support SSL, but the Russia not support SSL.

Printer Expansion Kit should

be extended for N model

Print channel of UNIX LPR/

LPD command compatible

Print channel compliant with

IPP1.0

Support TCP port of No.9100

(Raw Port)

AR-6020 SPECIFICATIONS 2 – 8

Page 15

D. Direct Print

(1)File Transmission Method

Communication Method Operation Method Support

1

FTP

2 Push Print Send the print instruction from PC to MFP by FTP client software. Yes

3 WEB Page Push Print

4 E-mail Push Print

USB flash

5

drive

Shared

6

Folder

Pull Print After access to FTP service by operation panel and select the file, the printing is performed. No

It can view the data on client PC by the “send a print job” on web page, and send a print

instruction to MFP.

Send the attached data of E-mail to MFP by client PC, the printing is performed. It can enter

the print set instruction in the body of E-mail.

Pull Print

Pull Print

Connect the USB memory to MFP, and select the data in USB memory by operation panel,

the printing is performed.

After access to Shared Folder by operation panel and select the file, the printing is performed.

(2)File Format

File Type Extension Support

TIFF TIFF,TIF Yes*1

JPEG FIF,JPE,JPEG,JPG Yes*1

PCL PCL,PRN,TXT Yes*1

XPS XPS No

PDF PDF Yes*2

Encrypted PDF PDF No (only NULL password*2)

PS PS,PRN Yes*2

*1: Network expansion kit for S/D model and Print expansion kit is needed.

*2: PS expansion kit is needed.

E. Print Function

No

No

No

No

Function Contents

Bar-code Font JetCAPS BarDIMM emulation No No No

Network Tandem Print

ROPM One RIP processing enables plural numbers of printing out. Yes Yes Yes

Multi access support

Paper direction setting for duplex

printing of letter head paper or

punch paper. [Support printing on

logo paper (SEGA AOK Company)]

Driver Distribution Function

Form Overlay

Support Planet Press

Add support font

Bonjour for Macintosh environment

Layout print Various layouts fitted to different print usage are available. Yes No No

Perfect binding

Support Sharp Print System Support Print in anywhere. No No No

Support WSD The Discovery function of printer Yes Yes Yes

Rotation in 90 degrees function

Printing position adjustment for

odd/even pages

2 units of MFP is connected tandem and

writing out is performed by 2 MFP working together. Only when HDD is

installed.

Divide jobs by PC and send them to MFPs.

RIP processing shall be available during printing. And printing shall be

available during scanning.

As for papers having front/back attribute such as letter head or punching

paper, Front/back side and print order shall be corrected at duplex

printing.

The administrator can distribute driver to each client by Sharp Remote

Device Management.

Or it can use MSI to download and install.

The form is downloaded to the MFP in advance and only the data

contents is sent, then fit them into the form by MFP to print.

Support Planet Press by Object if Lune Inc. (software which performs

mapping of form (DL in advance) and variable data inside the printer.)

Support Heisei fonts No Yes No

Support Morisawa fonts No No No

A technology developed by Apple Corps. To detect the peripherals on

the network automatically and connect. It enables users for dynamic

network connection with computers, peripherals and software.

Function that performs saddle stitch print by small amount of pages to

restrain adding of thickness by plural pages binding.

When print image and size is coincide and different direction of paper is

indicated as the paper feed tray, the image is rotated 90 degrees

automatically to print. (However, direction change during job is not

available.)

Printing position of odd/even pages is adjusted. (They can be adjusted

separately.)

Value can be adjusted by the unit of mm/inch

PCL6

compatible

No No No

No No No

No No No

No No No

No No No

No No No

No Yes No

No No No

Yes Ye s Yes

No No No

PostScript3

compatible

SPLC

AR-6020 SPECIFICATIONS 2 – 9

Page 16

Function Contents

It is a function that a certain items are turned ON mandatorily, in order to

restrict the operation by user level. The target operations for restriction

are as follows;

Consideration should be taken in designing, so as to respond to

Print Policy Function

Toner Save Mode Toner Save Mode (1 step) No No No

Support RET Support simulated resolution No No No

Print density adjustment Function to switch in 5 stages. Yes Yes Yes

A4/Letter

Automatic

Switching Function

additional requests.

- User authentication every time

- Forced Retention

- Forced black and white print

- Obtain the login name of Windows

- Accounting Code

Automatic switching while output, it may not out of paper. No No No

PCL6

compatible

No No No

PostScript3

compatible

4.Image Send Function

SPLC

A.Overview of Image Send Function

(1)Mode

N model/ S/D

Mode Sub Mode S/D model

E-mail No No

FTP Server No No

Scanner

Internet Fax/

Direct SMTP

Fax - No No

USB Twain Scan

(Including Button

Manager)

Network Twain

Scan

ID Card Scan -

Network Folder

(SMB)

Desktop No No

USB Memory No Yes

-NoNo

-YesNo

-NoYes

No No

Yes (B ut to n

Manager)

(2)Support Image (N model: Standard, S/D model: NW

Expansion Kit is installed)

Mode Type Support

TIFF Yes

File Format

(B/W)

File Format

(Gray Scale)

Scanner

File Format

(Color)

PDF Yes

PDF/A No

Encrypted PDF No

XPS No

Color TIFF Yes

JPEG Yes

PDF Yes

PDF/A No

Encrypted PDF No

Compact PDF(ACRE

installed)

XPS No

Color TIFF Yes

JPEG Yes

PDF Yes

PDF/A No

Encrypted PDF No

Compact PDF(ACRE

installed)

XPS No

model

(NW Expansion

Kit is installed)

No

No

No

(3)Image Processing (N model: Standard, S/D model:

NW Expansion Kit is expanded)

Mode Scanner

Exposure adjustment

Original Type*

Resolution (Different

depending on file format/

sending method)

Auto Yes

Manual 5 levels

Text Yes

Photo Yes

Auto Yes

75x75dpi Yes

100x100dpi Yes

150x150dpi Yes

200x200dpi Yes

300x300dpi Yes

400x400dpi Yes

600x600dpi Yes

*Only can be set in the Monochrome 2 levels.

B.Push Scan (Button Manager)

(System) Shall meet the operating conditions of each OS

Hardware

Environment

Selectable

destination

basically.

(HDD) 8MB or more: 100MB or more is recommended

(Monitor) 800x600dots or more

Shall be able to display 256 colors or more.

(Other) USB port (2.0)

Sharpdesk/ E-mail software/ Fax software/ OCR software/ MS Word/ Any directory

C.Pull Scan (TWAIN)

Item Contents

Interface

Hardware

Environment

Two-sided

Scan

Color Mode B/W(Mono2)/ B/W(Error Diffusion)/Gray Scale/Full Color

Resolution

Scanning

Range

Preview

Function

Zoom Preview

Function

USB Twain: USB

Network Twain*:NIC

(System)Shall meet the operating conditions of each OS

basically.

(HDD) 8MB or more: 100MB or more is recommended

(Monitor) 800x600dots or more

Shall be able to display 256 colors or more.

(Other) USB Twain: USB Port

Network Twain*:Network Port

Yes

75dpi/ 100dpi/ 150dpi/ 200dpi/ 300dpi/ 400dpi/ 600dpi

or Custom: 50-9600dpi (simulated)

A3/ A4/ A4-R/A5-R/ B4/ B5/ B5-R/ Ledger/ Letter/

Letter-R/ Executive/ Executive-R/ Foolscap/ Invoice/

Invoice-R/ Legal/ 8.5x13.4/ 8.5x13.5(343 x216mm)/

Postcard/ 8K/ 16K/ 16K-R/ Auto/ Custom

Yes

Yes

AR-6020 SPECIFICATIONS 2 – 10

Page 17

85%

60%

20%

10°C 30°C 35°C

Humidity (RH)

Temperature

15.Feb

2

Item Contents

Rotation Scan Yes (90 / 180/ 270 degrees)

Quick Scan No

Brightness/

Contrast

Adjustment

Gamma

Adjustment

Color

Matching

Edge

Emphasis

B/W Reverse Yes

Selection of

Light Source

Color

Threshold

Setting

Addition of

Void A re a

Storing of

Setting

Contents

Keeping of

Preview Image

Unit of Display

for Scanning

Range

Notes’

Security

Feature

Auto/ Manual(-100 - +100)

Yes

None / For Printer / For CRT / For LCD / ICM

None / Normal / Sharp / Blur

Yes(Red/ Green/ Blue/ White)

Auto/ Manual (1-254)

Available (Lead Edge/Trail Edge: 2.5mm Right/Left:

3.0mm)

Yes

Yes

Pixel/ mm/ inch

No

* For N model and S/D model while the network expansion kit was

expanded.

2

7. Dimensions and Weight

1 Tray model (Floor to OC) 599(W) x 612(D) x 511(H) mm

1 Tray model (Floor to RSPF) 599(W) x 612(D) x 643(H) mm

4 Trays model (Floor to OC) 599(W) x 612(D) x 940(H)mm

Only main unit (with handle) 599(W) x 612(D) x 1012(H)mm

Main unit (with multi bypass tray

expanded)

Dimensions occupied by the machine 909(W)x 612(D) mm

Main unit (Standard model)

Main unit (Duplex model (D

model))

Main unit (Network supported duplex print model

Weight *

(20/23cpm N-model))

Network supported duplex

print 1 tray model (26/

31cpm N-model)

Network supported duplex

print 2 tray model (26/

31cpm N-model)

599(W)x 612(D) mm

27.9kg(with OC)

33.5kg(with RSPF)

28.2kg(with OC)

33.8kg(with RSPF)

28.4kg(with OC)

34.0kg(with RSPF)

30.9 kg(with OC)

36.5 kg(with RSPF))

36.8 kg(with OC)

42.4 kg(with RSPF)

* Include OPC Drum. Not include Toner/Developer.

2

8. Machine Occupied Area

Standard model/D model/N model

Only main unit (with handle) 599(W)×612 (D)

Main unit (with multi bypass tray

expanded)

909(W)×612(D)

9. Ambient conditions

2

5. Power Source

2

6. Power consumption

Overseas 100V Overseas 200V

20/23 cpm : 220-

Voltage

Frequency

Power code | Sharp model

Power Switch

The full configuration can be operated with the rated power source.

Max. power consumption *1

Power Consumption when Network/Fax

standby: 1W or less

The condition of Network standby: Limited to

connection of the TCP/IP protocol.

Time to go into preheat mode.*2 1min (Default)

Time to come back from preheat mode. 15sec

Time to go into sleep mode.

Time to come back from sleep mode. *3 25sec

100-127V 12A

50/60Hz 50/60Hz

Fixed Type (Direct) Inlet or direct

1 switch

240V 5A

26/31 cpm : 220240V 8A

Overseas

100V

20/23 cpm : 1.2kW or less

26/31 cpm : 1.45kW or

No No

15 min (Default)

After printing out, shut off

immediately (Default 1sec)

Overseas

less

200V

Under the following environmental conditions, the print quality is

guaranteed.

Standard environmental

conditions

Usage environmental

conditions

Supply transportation

environmental conditions

(Term : 2 weeks)

Supply storage

environmental conditions

(unopened)

Temperature 20 - 25 degrees C

Humidity 65 +/- 5 %RH

Temperature 10 - 35 degrees C

Humidity 20 - 85 %RH

Atmospheric

pressure

- 20 - 45 degrees C (no condensation)

- 10 - 40 degrees C (no condensation)

590 - 1013 hPa

(height: 0 - 2000m)

*1: when powered on, the thermal heater is OFF.

*2: Setting Range: 1-60 minutes (Blue Angel Standard)

*3: Revised Energy Conservation, Energy StarVer.2.0, Blue Angel

Standard

AR-6020 SPECIFICATIONS 2 – 11

Page 18

15.Feb

2

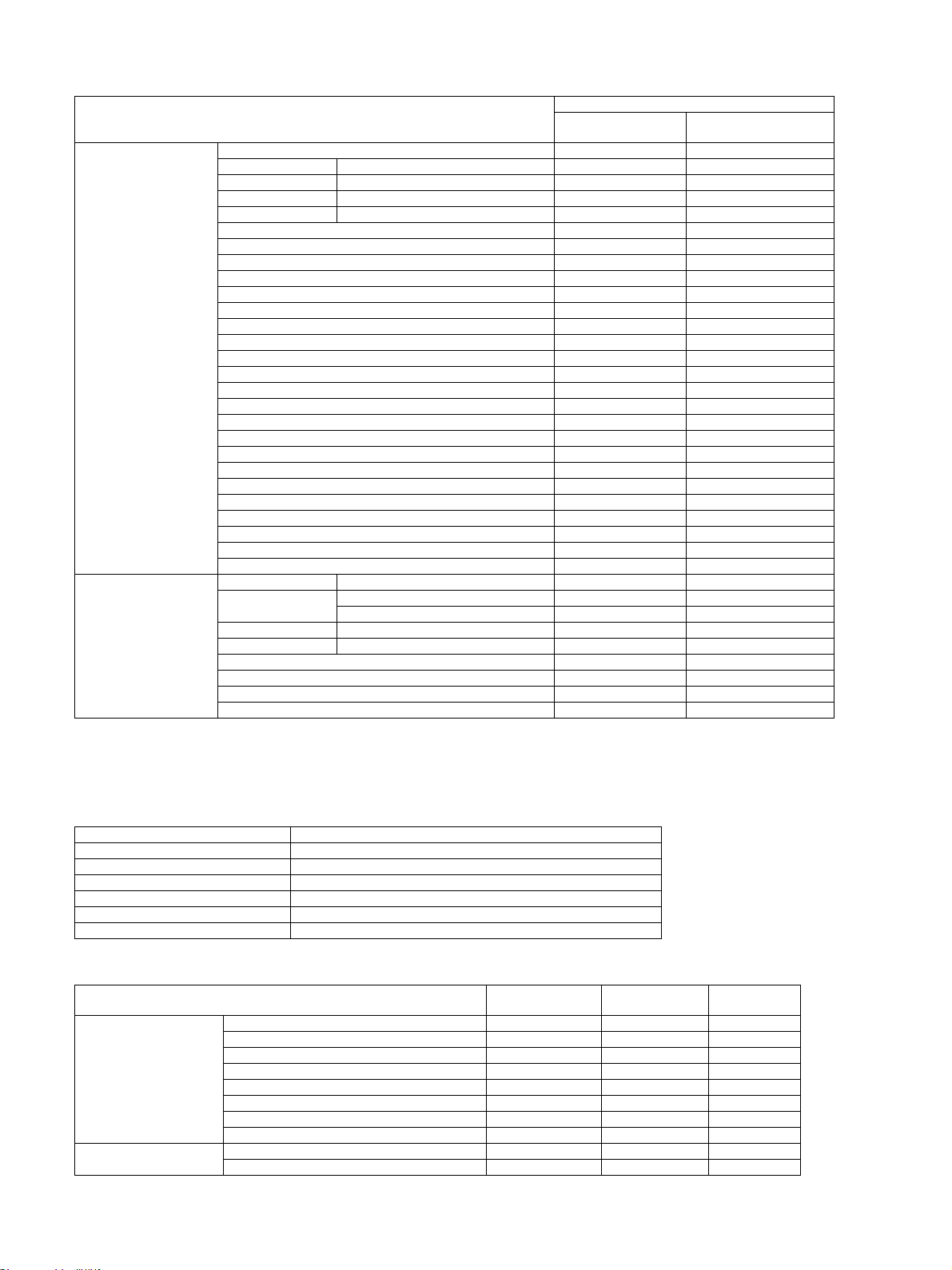

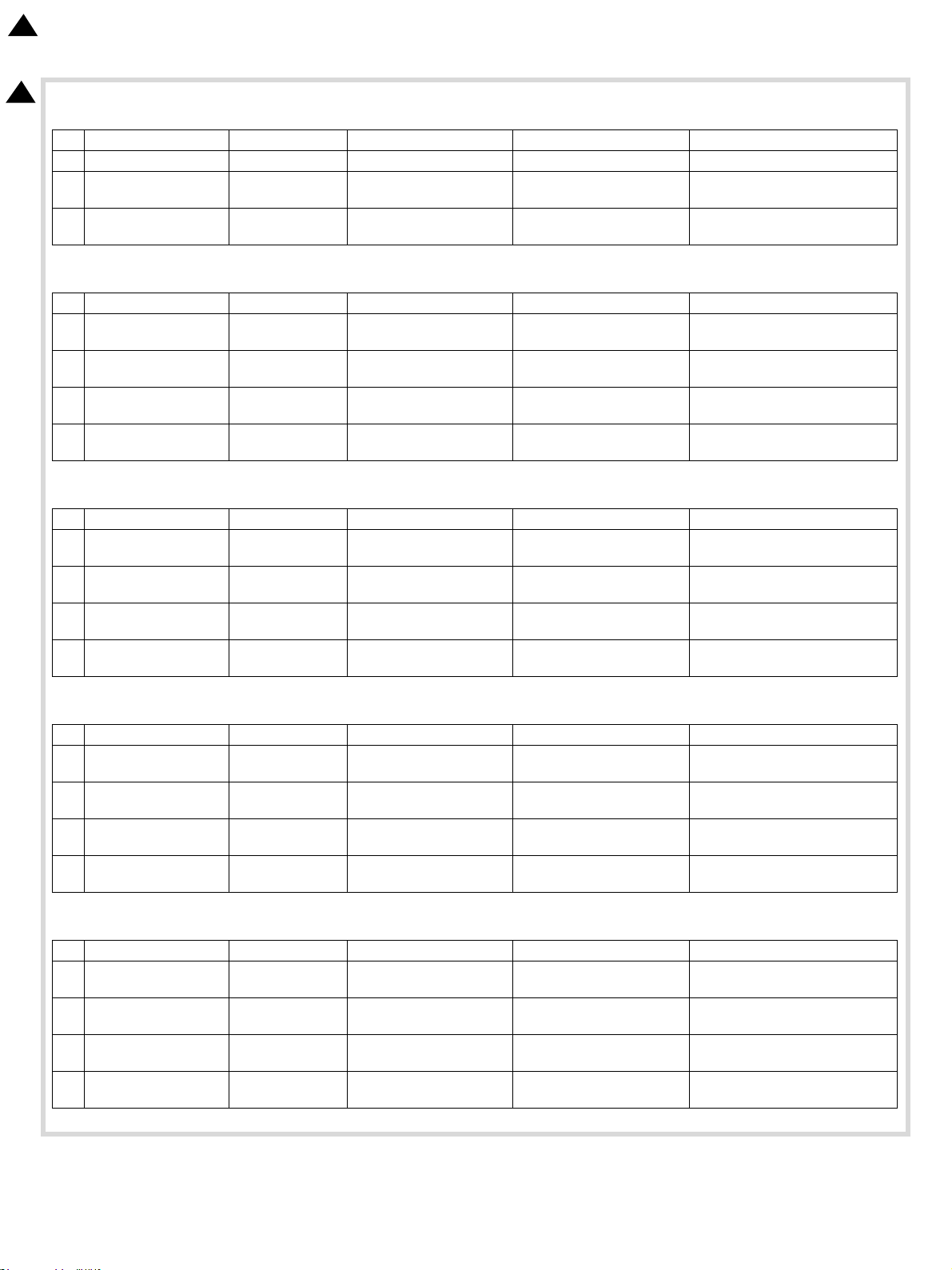

[3] CONSUMABLE PARTS

2

1.Supply system table

A. South and Central America

No. Name Product name Content Life Remark

1 Toner cartridge(Black) MX-237NT Toner cartridge x1 20K Life setting by A4 6% document

2 Developer MX-312NV Developer x1

3 Drum KIT MX-312NR Drum x1

B. Europe

No. Name Product name Content Life Remark

1 Toner cartridge(Black) MX-237GT Toner cartridge x1

2 Toner cartridge(Black) MX-238GT Toner cartridge x1

3 Developer MX-312GV Developer x1

4 Drum KIT MX-312GR Drum x1

20cpm/23cpm : 75K

26cpm/31cpm : 100K

20cpm/23cpm : 75K

26cpm/31cpm : 100K

20K

23K(Toner save mode)

8.4K

10K(Toner save mode)

20cpm/23cpm : 75K

26cpm/31cpm : 100K

20cpm/23cpm : 75K

26cpm/31cpm : 100K

Life setting by A4 6% document

Life setting by A4 6% document

C. Australia, New Zealand

No. Name Product name Content Life Remark

1 Toner cartridge(Black) MX-237GT Toner cartridge x1

2 Toner cartridge(Black) MX-238GT Toner cartridge x1

3 Developer MX-312GV Developer x1

4 Drum KIT MX-312GR Drum x1

20K

23K(Toner save mode)

8.4K

10K(Toner save mode)

20cpm/23cpm : 75K

26cpm/31cpm : 100K

20cpm/23cpm : 75K

26cpm/31cpm : 100K

Life setting by A4 6% document

Life setting by A4 6% document

D. Asia

No. Name Product name Content Life Remark

1 Toner cartridge(Black) MX-237AT Toner cartridge x1

2 Toner cartridge(Black) MX-238AT Toner cartridge x1

3 Developer MX-312AV Developer x1

4 Drum KIT MX-312AR Drum x1

20K

23K(Toner save mode)

8.4K

10K(Toner save mode)

20cpm/23cpm : 75K

26cpm/31cpm : 100K

20cpm/23cpm : 75K

26cpm/31cpm : 100K

Life setting by A4 6% document

Life setting by A4 6% document

E. Middle East, Africa (except Iran)

No. Name Product name Content Life Remark

1 Toner cartridge(Black) MX-237FT Toner cartridge x1

2 Toner cartridge(Black) MX-238FT Toner cartridge x1

3 Developer MX-312FV Developer x1

4 Drum KIT MX-312FR Drum x1

20K

23K(Toner save mode)

8.4K

10K(Toner save mode)

20cpm/23cpm : 75K

26cpm/31cpm : 100K

20cpm/23cpm : 75K

26cpm/31cpm : 100K

Life setting by A4 6% document

Life setting by A4 6% document

AR-6020 CONSUMABLE PARTS 3-1

Page 19

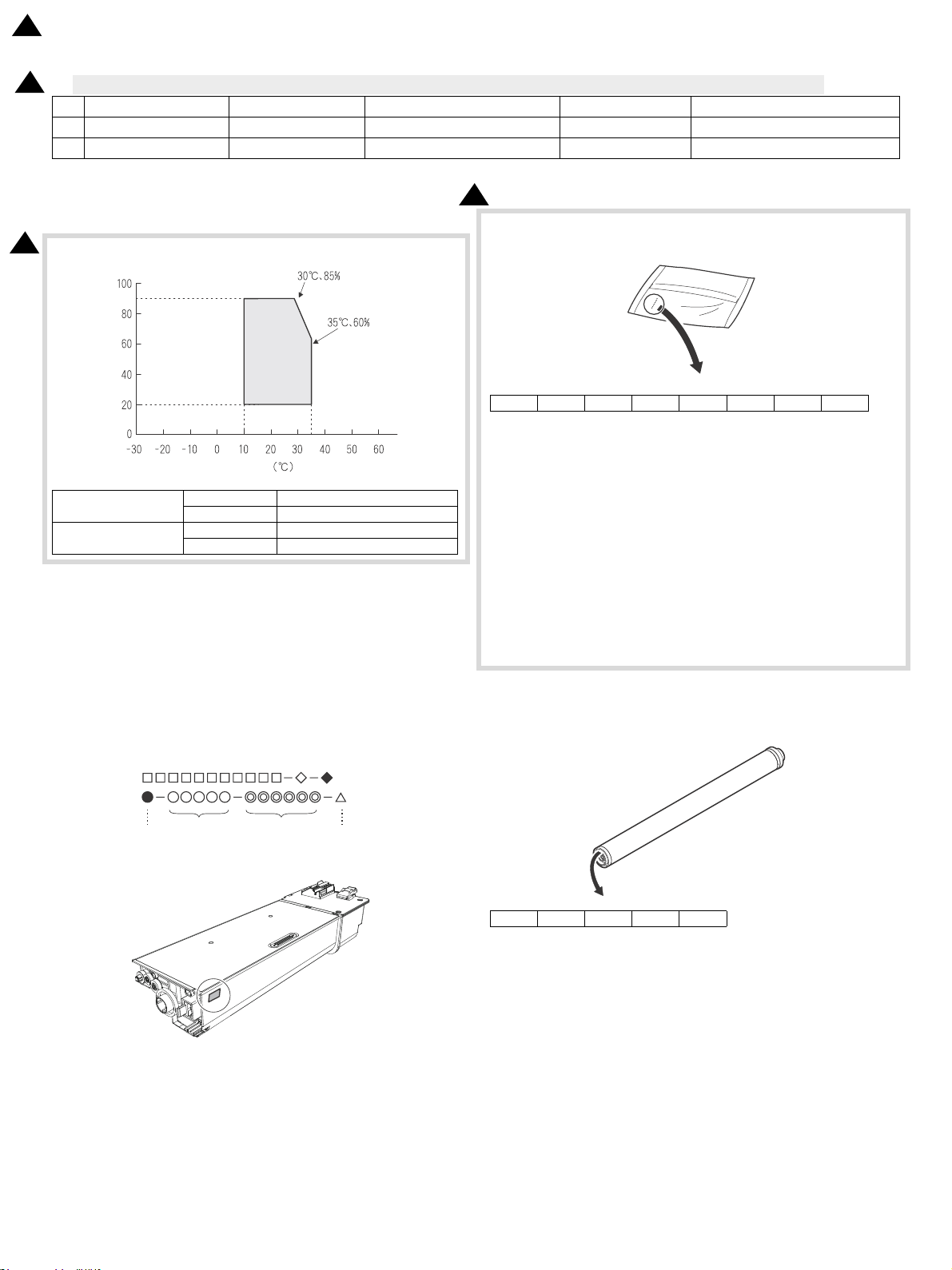

(UMIDITY

4EMPERATURE

5SEENVI

RONMENT

CONDITIONS

Ver.No.Production

place

Serial

number

Year/

Month/

Day

15.Feb

2

2.Maintenance parts list

2

A. Middle East, Africa (except Iran), Europe, Australia, New Zealand, Asia, South and Central America

No. Name Product name Content Life Remark

1 Heat roller MX-312UH Upper heat roller x1 150K

2 Toner filter MX-312TF Toner filter x1 75K

3. Environmental conditions

2

A.Use conditions

Standard environment al

conditions

Usage environmental

conditions

B.Life(packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

Temperature 20 - 25 degrees C

Humidity 65 +/- 5%RH

Temperature 10 - 35 degrees C

Humidity 20 - 85%RH

2

<Developer>

12345678

The lot numbe

r is of 8 digits. Each digit indicates the content as follows.

The number is printed on the right under side of the back surface of the

developer bag.

1 Alphabet

Indicates the production factory.

2 Number

Indicates the production year.

3, 4 Number

Indicates the production month.

5, 6 Number

Indicates the production day.

7 Hyphen

8 Number

Indicates the production lot.

4. Production number identification

<Toner cartridge>

The label on the toner cartridge shows the date of production.

<Drum>

ser print indicates the model conformity code and the date (year,

The la

month, day) of production.

12345

1 Alphabet

Indicates the model conformity code. L for this model.

2 Number

Indicates the end digit of the production year.

3 Number or X, Y, Z

Indicates the month of packing.

X stands for October, Y November, and Z December .

4, 5 Number

Indicates the day of the month of packing.

AR-6020 CONSUMABLE PARTS 3-2

Page 20

AR-6020/6023/

6020D/6023D

with Network

Expansion Kit

AR-6020N/6023N/

6026N/6031N and

AR-6020/6023/

6020D/6023D

with Network

Expansion Kit

15.Feb

2

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

2

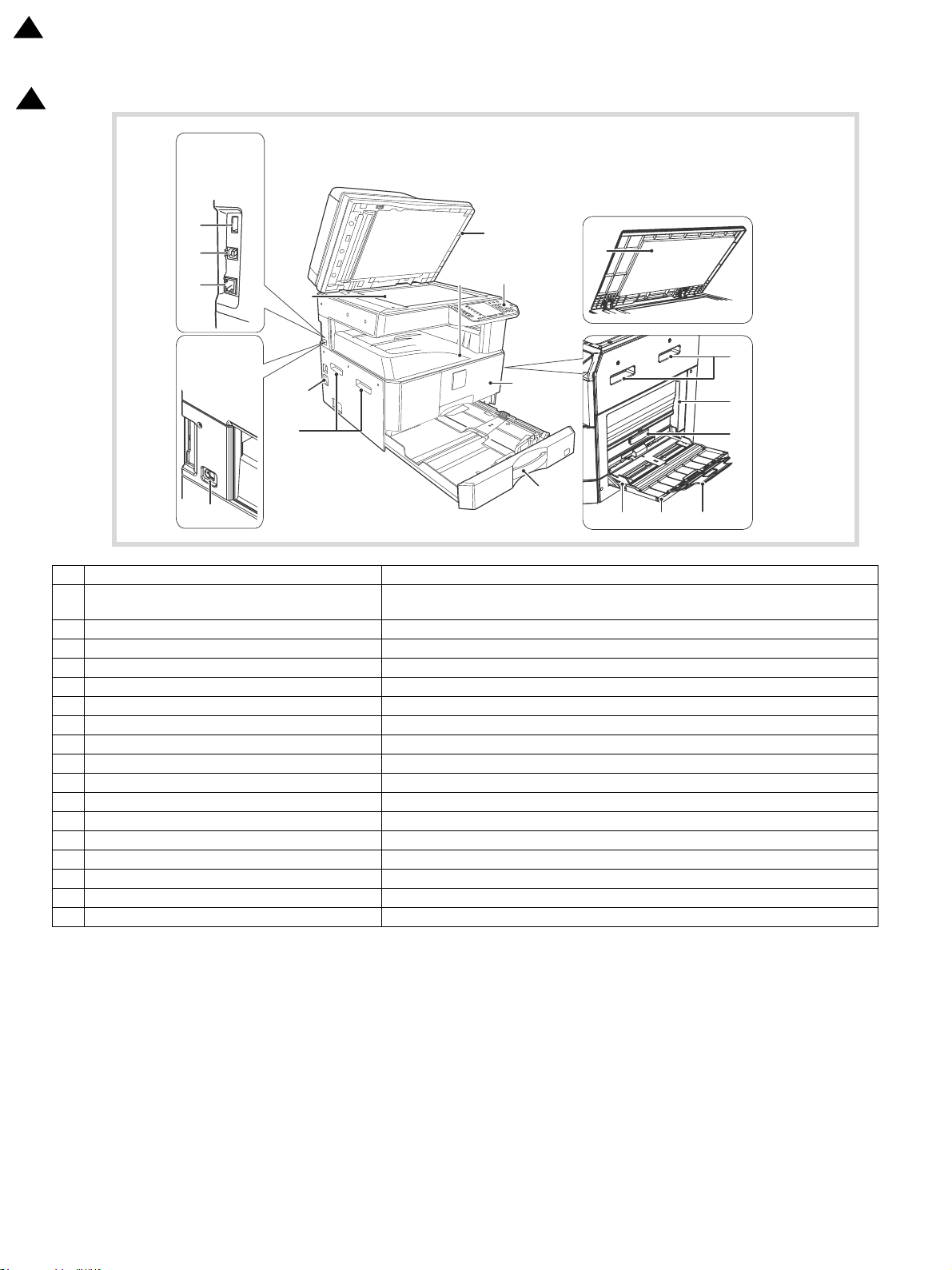

1. External view

No. Name Function/Operation

USB 2.0 connector (Type A) (when the network

1

ansion kit is installed)

exp

Connect to the USB device.

2 Glass cleaner (when the RSPF is installed) Use to clean the original scanning glass.

3 Document glass Place an original that you wish to scan face down here.

4 Handles Use to move the machine.

5 Power switch Press to turn the machine power on and off.

6 Centre tray Copies and printed pages are output to this tray.

7 Operation panel Contains operation keys and indicator lights.

8 Front cover Open to remove paper misfeeds or replace the toner cartridge.

9 Paper trays The tray holds 250 sheets of paper.

10 Document cover (when installed) Open to make a copy from the document glass.

11 Side cover Open to remove misfeed paper.

12 Side cover handle Pull to open the side cover.

13 Bypass tray guides Adjust to the width of the paper when using the bypass tray.

14 Bypass tray Special paper (heavy paper or transparency film) can be

15 Bypass tray extension Pull out when feeding large paper such as A3 and B4 (11" x 17" and 8-1/2" x 14").

16 USB 2.0 connector Connect to your computer to use the printer and scanner functions.

17 10BASE-T/100BASE-TX LAN connector Connect to your network to use the pr

inter and scanner functions.

fed from the bypass tray.

AR-6020 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-1

Page 21

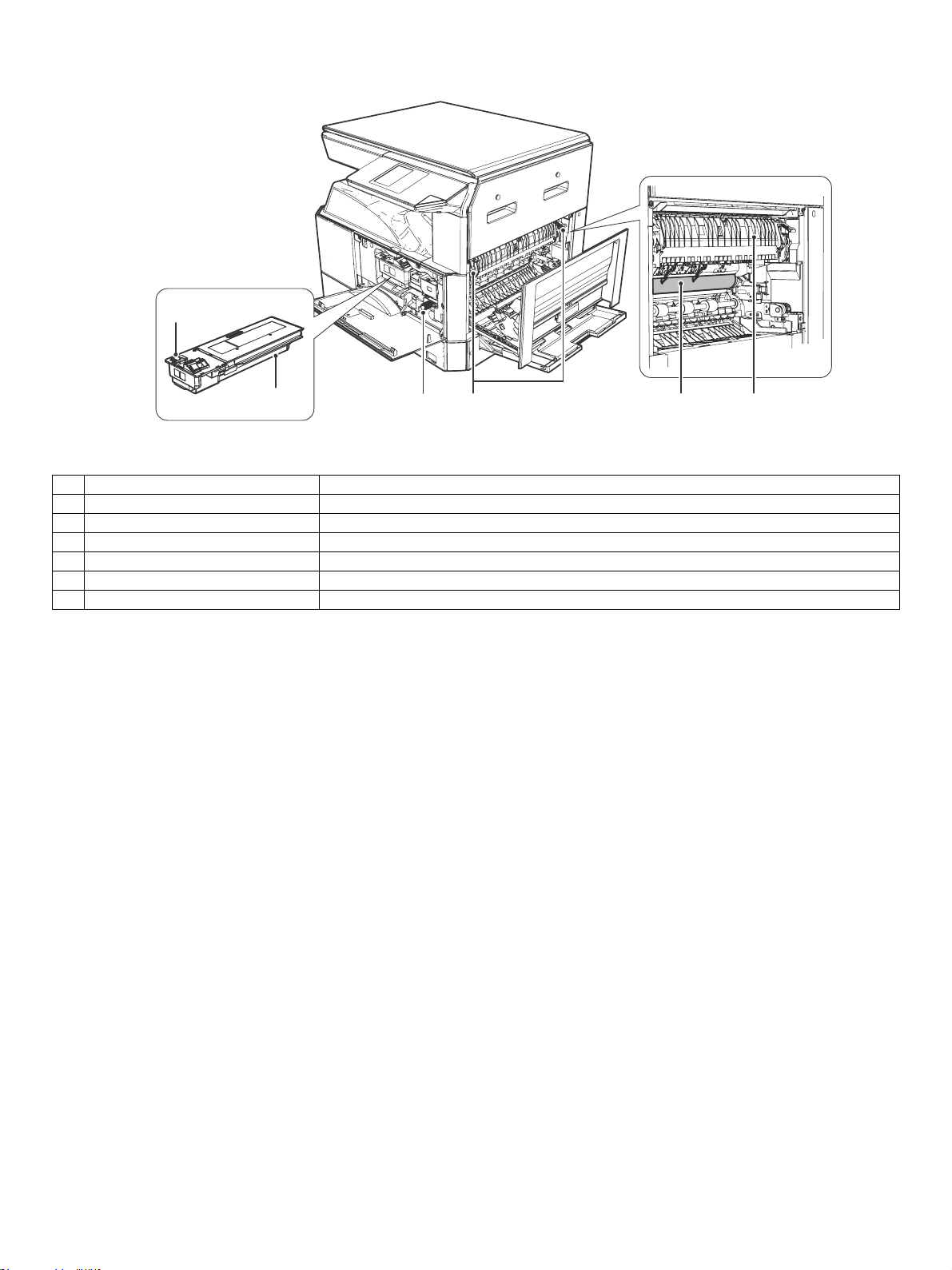

2. Internal view

No. Name Function/Operation

1 Toner cartridge lock release lever To replace the toner cartridge, pull out the to

2 Toner cartridge Contains toner.

3 Fusing unit release levers To remove the paper misfeed in the fusing unit, push down on these levers and remove the paper.

4 Roller rotating knob Rotate to remove misfeed paper.

5 Photoconductive drum Images are formed on the photoconductive drum.

6 Fusing unit paper guide Open to remove misfeed paper.

ner cartridge while pushing on this lever.

AR-6020 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-2

Page 22

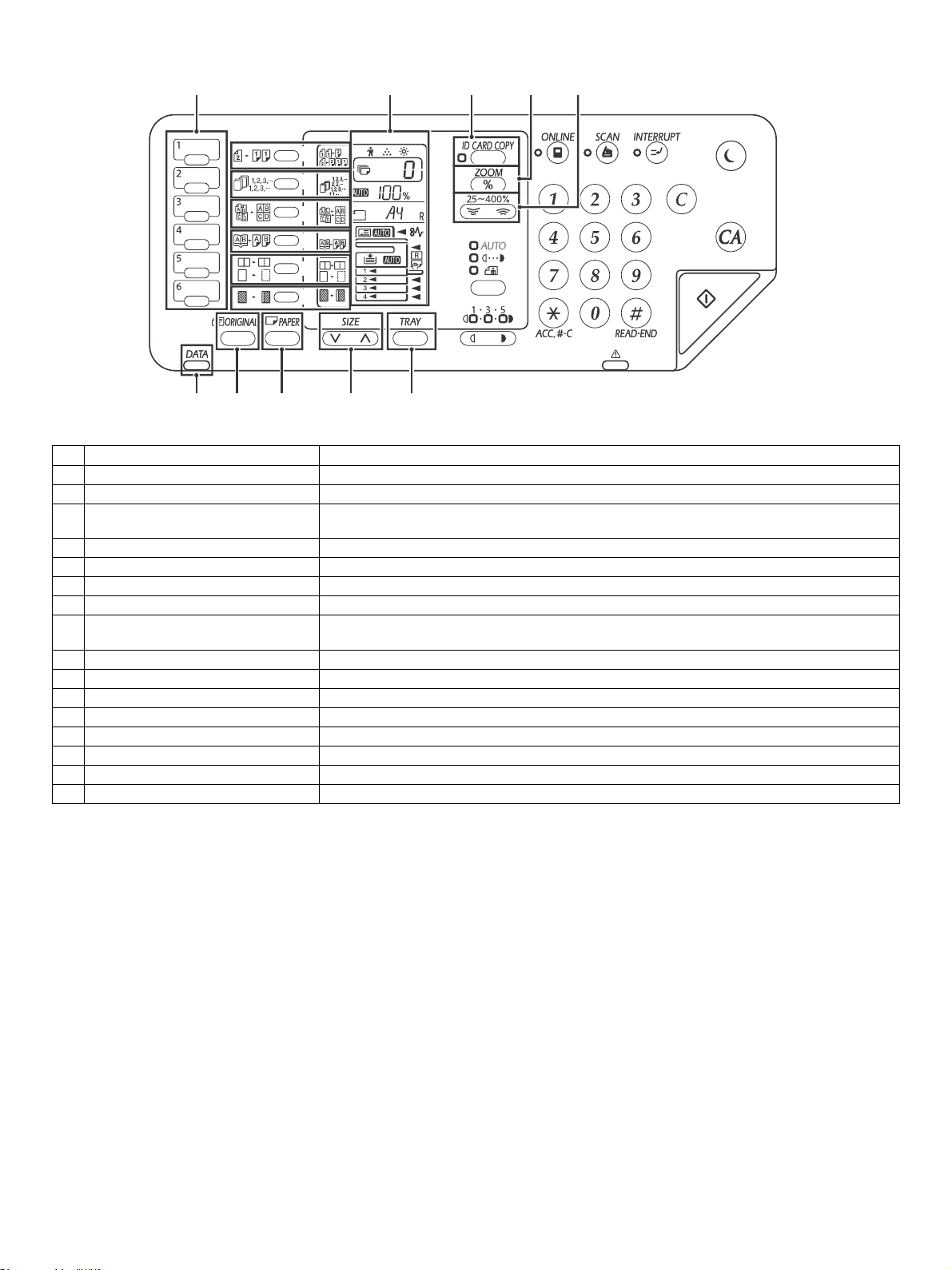

3. Operation panel

1

2

3

4

5

6

7

12 13 14 15 16

891011

No. Name Function/Operation

1 SCAN MENU key Use to scan by means of the provided Button Manager software and Scan to USB.

2 ORIGINAL TO COPY key/indicator Press to select duplex copy.

SORT/GROUP/ROTATE SORT key /

3

indicators

4 2 IN 1 / 4 IN 1 key / indicators Press to select the "2 IN 1" or "4 IN 1" mode.

5 DUAL PAGE COPY key / indicator Use to make individual copies of the two pages of an ope

6 ERASE key / indicators Press to select the "CENTER ERASE" or "ED

7 MARGIN SHIFT key / indicator Shifts text or image on the copy to leave a binding

8 Display

9 ID CARD COPY key/indicators Press to use ID Card copy.

10 Zoom key Hold down when the machine is not in use to display the copy ratio in the display.

11 Copy ratio keys Use to select any reduction or enlargement copy r

12 DATA NOTIFICATION indicator (Green) The indicator lights solidly or blinks to indicate the status of a job.

13 ORIGINAL key Use to enter the original size.

14 PAPER key Use to set the paper size in the paper trays..

15 SIZE key Use to select a paper size.

16 TRAY SETTING key Use to manually select a paper tray.

Press to select the "SORT", "GROUP" or "ROTATE SORT" mode.

n book or other two-page original.

GE + CENTER ERASE" mode.

margin on the edge of the copy.

Shows the set number of copies, as well as the copy r

an error code when an error occurs.

atio, system setting function or setting code, or

atio from 25% to 400% in increments of 1%.

AR-6020 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-3

Page 23

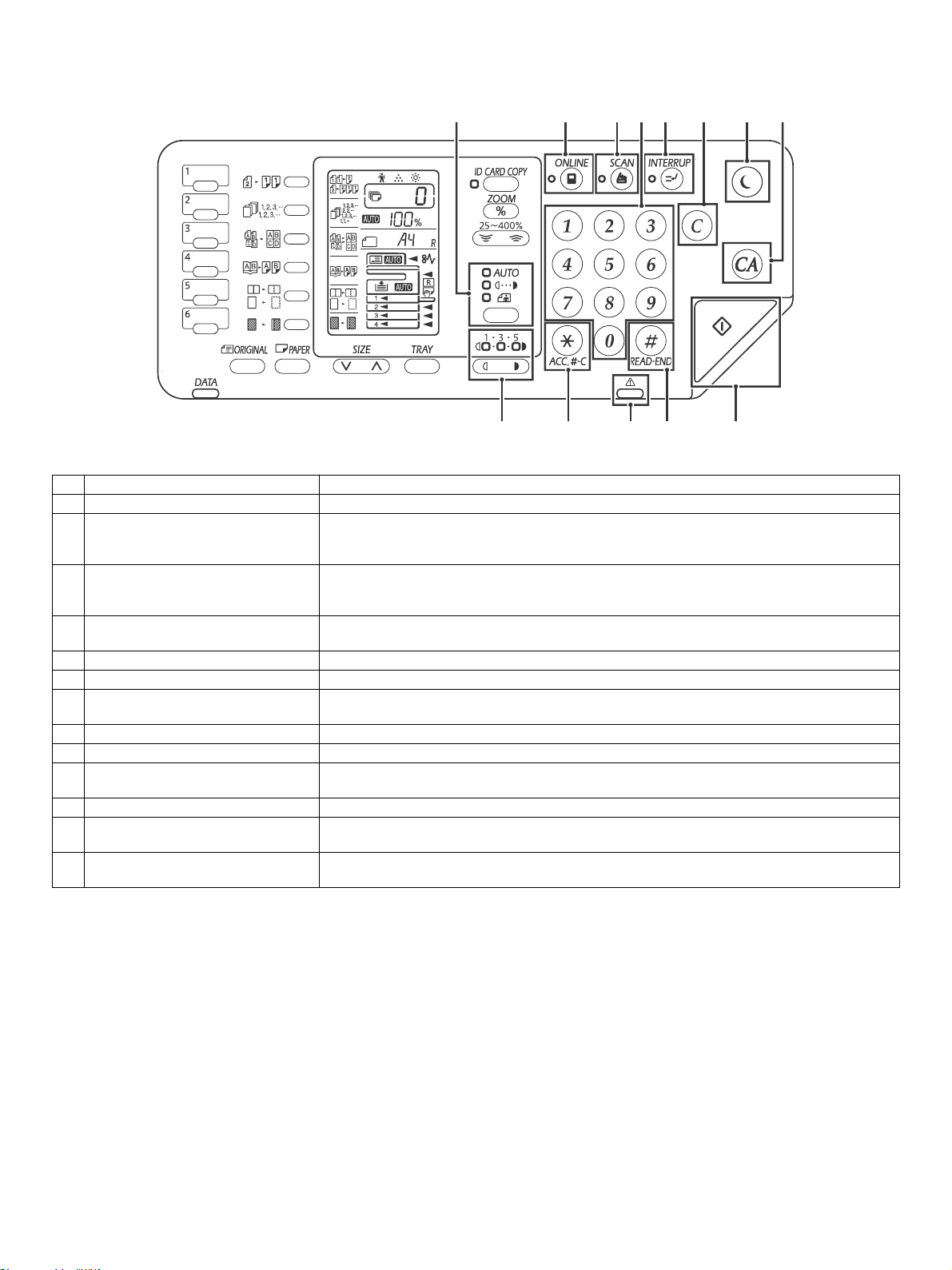

No. Name Function/Operation

13

45

9 10 11 12

26

8

7

13

1 AUTO/TEXT/PHOTO key indicators Use to select the exposure mode: "AUTO", "TEXT", or "PHOTO".

Press to toggle the machine between online and off-line. T

2 ONLINE key indicator

3 SCAN key indicator

4 Numeric keys

5 INTERRUPT key indicator Interrupts a copy run.

6 CLEAR key Clears the copy quantity display or

7 POWER SAVE key indicator

8 CLEAR ALL key Press to return the copy and scan settings to the initial settings.

9 Light and Dark keys indicators The selected exposure level indicator lights up.

10 Audit clear key

11 Error indicator Lights solidly or blinks to indicate the status of the error.

12 READ-END key

13 START key indicator

online, and goes off when the machine is off-line.

The indicator blinks while the machine is receiving pr

Press to switch the machine to scanner mode and scan by means of the provided Button Manager

sof

tware.

The indicator blinks during scanning and tr

Use to select the desired copy quantity or to

To display the total number of pages output by the machine, hold the [0] key down.

Use to switch the machine to "Auto power shut-off" mode, which is a power save function.

[Power save key] blinks when the machine is in an auto power shut-off mode.

While using the copy enabling the auditing mode, press to retur

waiting for account number-in.

Copying starts if you press this key when you che

finished scanning the original pages.

Press to make a copy. Also, press to configure the system

indicator is on.

ansmission of the scanned data.

make system setting entries.

terminates a copy run.

ck the total number of copies made and have

he indicator lights up when the machine is

int data and while printing is paused.

settings. Copying is possible when the

n the machine to the status of the

AR-6020 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-4

Page 24

<20/23/26/31 cpm>

<26/31 cpm>

15.Feb

2

4. Motor, solenoid, clutch

2

No. Name Code Function operation

1 Mirror motor MIRM Drives the optical mirror base (scanner unit).

2 Toner motor TNM_D Toner supply

3 Duplex motor ADUM Switchback operation and paper exit motor in duplex.

4 Main motor MM Drives the machine.

5 1st tray paper feed clutch C1PUC Drives the pick up roller

6 PS clutch RRC Drives the resist roller

7 Bypass tray paper transport clutch MPFC Drives the bypass tray paper transport roller.

8 Ozone exhaust fan OZFM

9 Power supply unit cooling fan PSFM Cools the Power supply unit.

2

10 Paper tray lift motor C1LUM Lifts the paper feed tray.

11 LSU cooling fan LSUFM Cools the LSU and the Developing unit.

Cools the inside of the machine and discharges the ozone.

AR-6020 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-5

Page 25

15.Feb

2

5. Sensor, switch

2

No. Name Code Function operation

1 Mirror home position sensor MHPS Detects the mirror (scanner unit) home position.

2 Side door/Front cover switch DSWR/DSWF Side door/Front cover open detection

3 Paper exit sensor (paper exit side) POD Detects paper exit.

4 Paper exit sensor (DUP side) POSD Paper tra nsport detection

5 Thermistor

6 Thermostat RDTCT Fusing section abnormally high temperature detection

7 Toner density sensor TCS Detects the toner density in the developing unit.

8 Bypass tray sensor MPED Bypass tray transport detection

9 Paper in sensor PIN Paper transport detection

10 Tray empty C1SS Tray paper entry detection

11 Power switch MAIN SW Turns ON/OFF the main power source.

12 Temperature sensor TH_RA

13 Paper feed tray 1 paper empty detector C1PED Detects paper empty in Paper feed tray 1

14 Toner motor sensor TM_COUNT Detects the rotation of the toner motor.

15 Paper width sensor MPWD

2

16 Paper feed tray upper limit detector C1LUD This detector detects when the tray in paper feed tray reaches its upper limit.

17 Temperature / humidity sensor HUD_RA/TH_RA

TH_US_IN

UM_IN

TH_

Fusing section temperature detection

Detects the temperature around the machine. This is only for 20/23cpm

chine.

ma

Detects the paper width. (Manual paper feed tray)

Detects the temperature and the humidity around the machine. This is only for

26/31cpm machine.

AR-6020 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-6

Page 26

6. PWB

1

2

4

3

7

9

5

8

6

No. Name Function operation

1 LED drive PWB Copy lamp control

2 CCD PWB Image scanning

3 MCU PWB Main control PWB

4 High voltage PWB High voltage control

5 DC PWB DC power control

6 OPE PWB Operation panel input/Display, operation p

7 USB I/F PWB Connect a USB device

8 LCD Shows various messages.

9 NNB PWB Network interface PWB

anel section control

AR-6020 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-7

Page 27

14 5 6

7

18

3 2

8

9

11

12

14

15

16

10

22

13

19 201721

19

21

19

21

<20/23/26/31 cpm> <26/31 cpm>

15.Feb

2

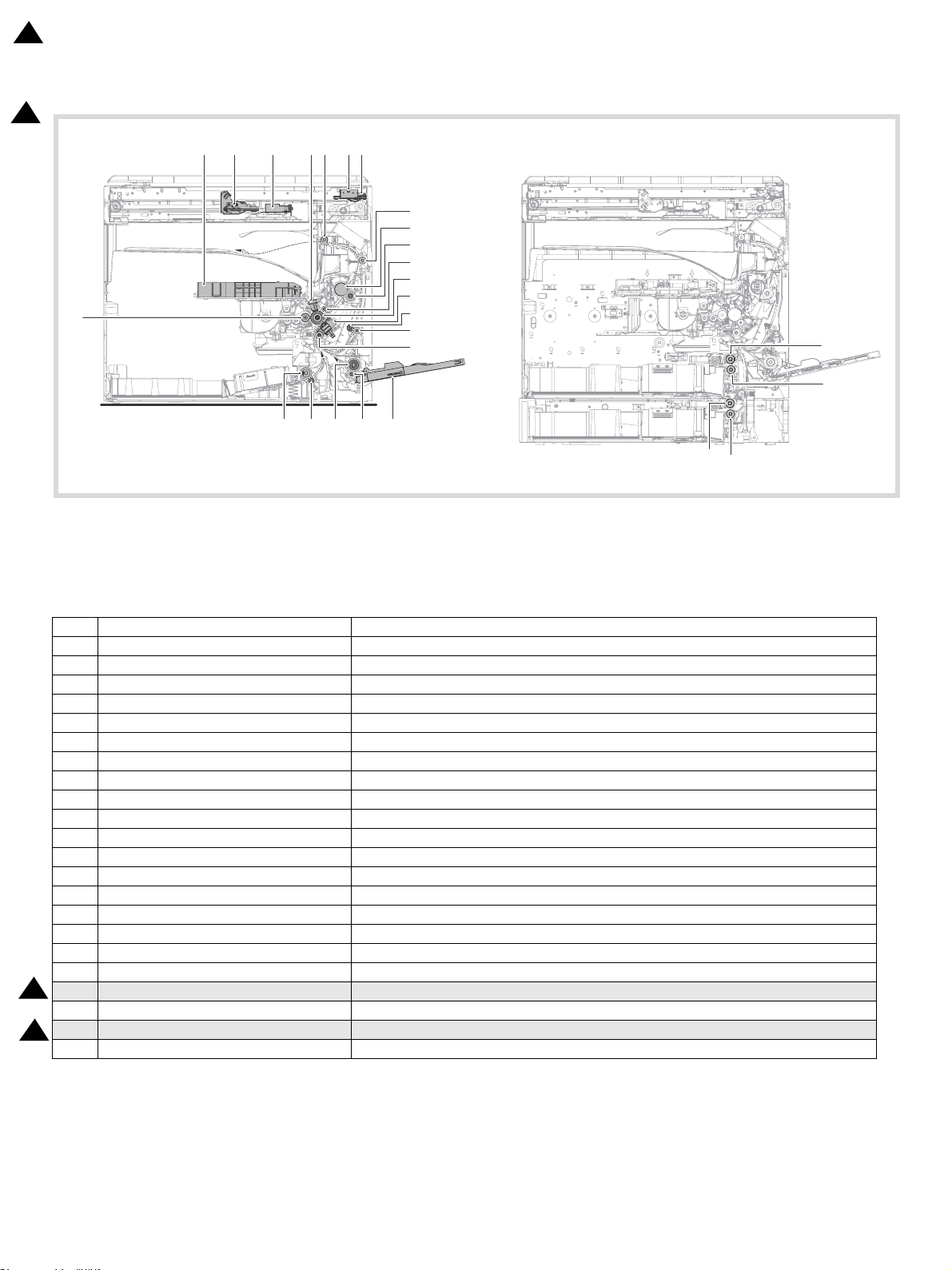

7. Cross sectional view

2

No. Name Function/Operation

1 Copy lamp Image radiation lamp

2 Copy lamp unit Operates in synchronization with No. 2/3 mir

3 LSU unit Converts image signals into laser beams to write on the drum.

4 Lens unit Reads images with the lens and the CCD.

5 MC holder unit Supplies negative charges evenly on the drum.

6 Paper exit roller Used to discharge paper.

7 Transport roller Used to transport paper.

8 Upper heat roller Fuses toner on paper (with the teflon roller).

9 Lower heat roller Fuses toner on paper (with the silicon rubber roller).

10 Waste toner transport roller Transports waste toner to the waste toner box.

11 Drum unit Forms images.

12 Transfer roller unit Transfer images (on the drum) onto paper.

13 DUP follower roller Transports paper for duplex.

14 Duplex transport roller Transports paper for duplex.

15 Resist roller Takes synchronization between the paper lead edge and the image lead edge.

16 Bypass tray Bypass tray

17 Bypass tray paper pick up roller Picks up paper in bypass tray.

18 No. 2/3 mirror unit

2

19 Tray separation roller Separates a document to prevent double-feeding.

20 Bypass tray separation roller

21 Tray paper feed roller Picks up paper from the tray.

2

22 MG roller Puts toner on the OPC drum.

Reflects the images from the copy lamp unit to the lens unit.

Separates a document to prevent double-feeding. (Bypass tray)

ror unit to radiate documents sequentially.

AR-6020 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-8

Page 28

20mm

20mm

150mm

A

A

A

DV front cover

2

3

1

AR-6020

[5] ADJUSTMENTS

Service Manual

1. General

Each adjustment item in the adjustment item list is associated with a specific Job number. Perform the adjustment procedures in the sequence

of Job numbers from the smallest to the greatest.

However, there is no need to perform all the adjustment items. Perform only the necessary adjustments according to the need.

Unnecessary adjustments can be omitted. Even in this case, however, the sequence from the smallest to the greatest Job number must be

observed.

If the above precaution should be neglected, the adjustment would not complete normally or trouble may occur.

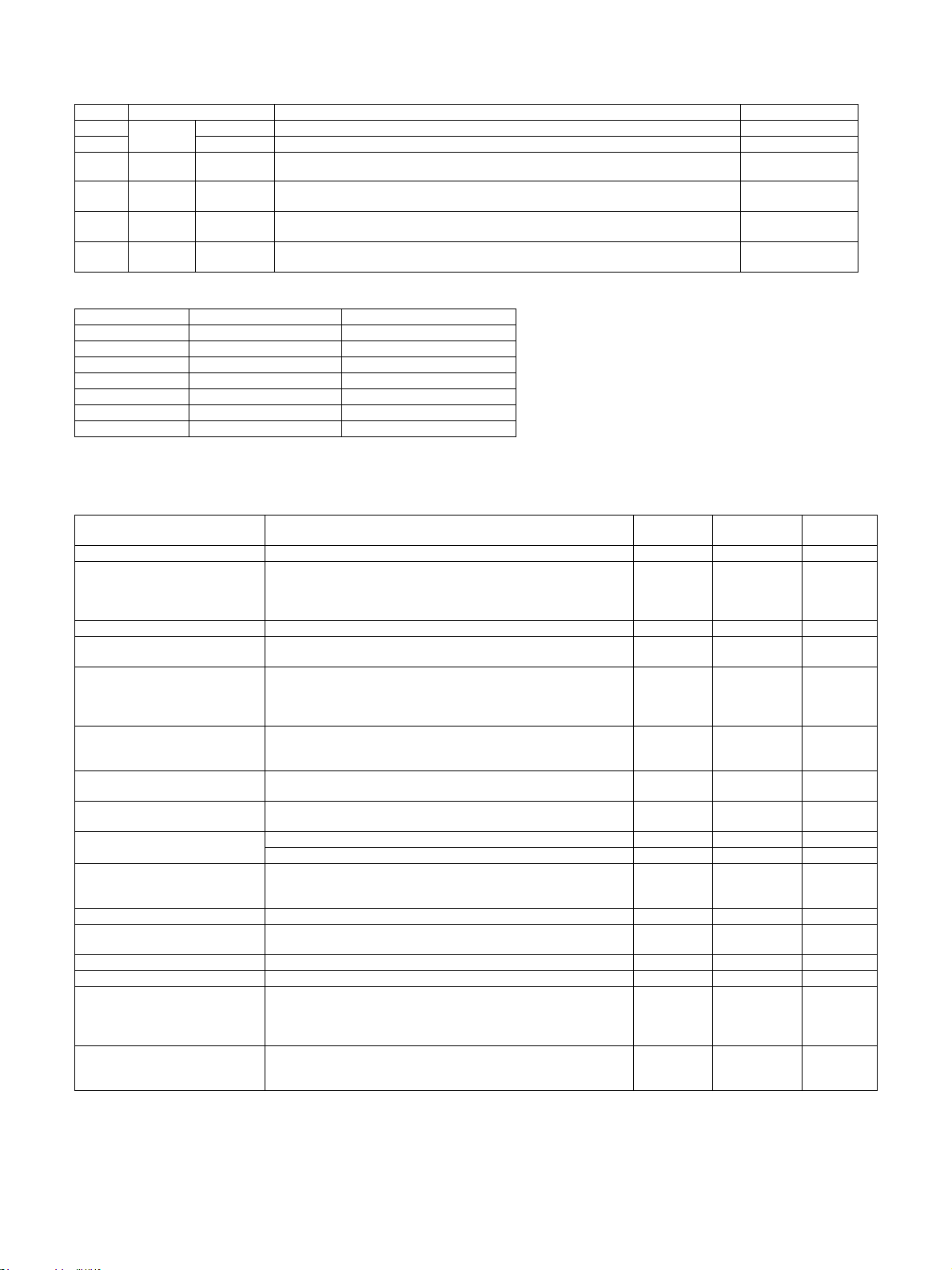

2. Adjustment item list

Job No Adjustment item list Simulation

1-A Developing doctor gap adjustment Developing doctor gap adjustment

ADJ 1 Process section

ADJ 2 Mechanism section

ADJ 3

Image density

adjustment

1-B MG roller main pole position adjustment

1-C Developing bias voltage adjustment

1-D Grid bias voltage adjustment

Lead edge image position

(1)

adjustment

RSPF copy lead edge position

(2)

2-A Image position adjustment

2-B Main scanning direction (FR direction) distortion balance adjustment

2-C Scan image (sub scanning direction) distortion adjustment Winding pulley position adjustment

2-D Main scanning direction (FR direction) magnification ratio adjustment SIM 48-1

Sub scanning direction (scan-

2-E

ning direction) magnification

ratio adjustment

2-F Off center adjustment

3-A Copy mode image density adjustment

adjustment

(3) Rear edge void adjustment SIM50-1, SIM50-19

(4) Paper off center adjustment SIM50-10

Side edge void area adjust(5)

ment

(1) OC mode in copying SIM 48-1

RSPF sub scanning direction

(2)

magnification ratio

(1) OC mode SIM 50-12

RSPF original off-center

(2)

adjustment

Mechanical off-center adjust(3)

ment

MG roller main pole position adjustment

SIM50-10

SIM50-6

SIM26-43

No. 2/3 mirror base unit installing

position adjustment

Copy lamp unit installing position

adjustment

Rail height adjustment

SIM 48-5

SIM 50-12

---

46-2

SIM

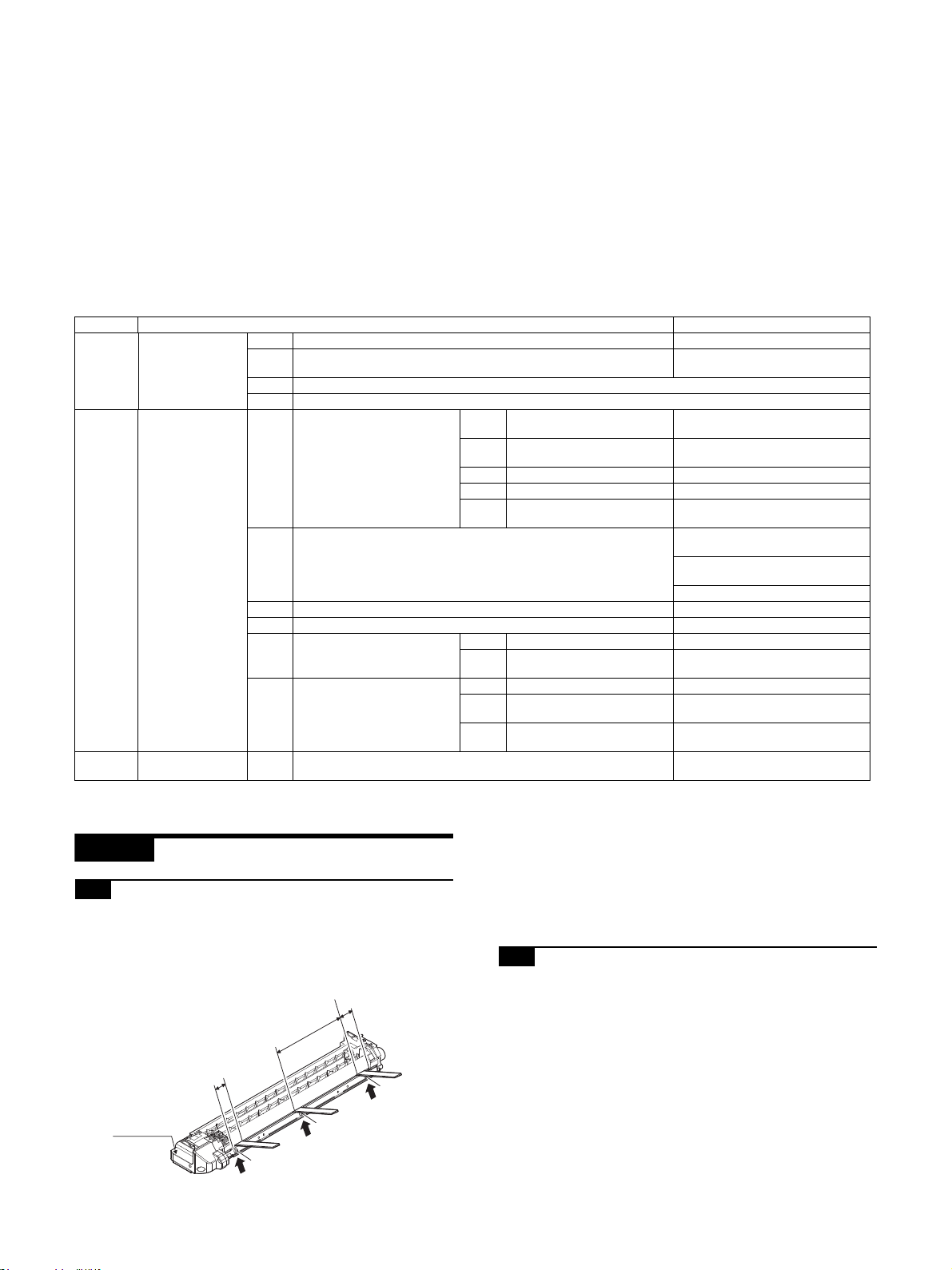

3. Details of adjustment

ADJ 1 Process sectio n

1-A Developing doctor gap adjustment

1) Loosen the developing doctor fixing screw A.

2) Insert a thickness gauge of 1.5mm to the three positions at

20mm and 150mm from the both ends of the developing doctor as shown.

AR-6020 ADJUSTMENTS 5 – 1

3) Push the developing doctor in the arrow direction, and tighten

the fixing screws of the developing doctor in the sequence of

13233.

4) Check the clearance of the developing doctor. If it is within the

specified range, then fix the doctor fixing screw with screw

lock.

* When inserting a thickness gauge, be careful not to scratch

the developing doctor and the MG roller.

1-B MG roller main pole position adjustment

1) Remove the DV front cover, and put the developing tank on a

flat surface.

2) Tie a string to a needle or a pin.

3) Hold the string and bring the needle close to the MG roller horizontally. (Do not use paper clip, which is too heavy to make a

correct adjustment.) (Put the developing unit horizontally for

this adjustment.)

4) Do not bring the needle into contact with the MG roller, but

bring it to a position 2 or 3mm apart from the MG roller. Mark

the point on the MG roller which is on the extension line from

the needle tip.

5) Measure the distance from the marking position to the top of

the doctor plate of the developing unit to insure that it is 18mm.

Page 29

If the distance is not within the specified range, loosen the fix-

2

3

4

2

3

4

ing screw A of the main pole adjustment plate, and move the

adjustment plate in the arrow direction to adjust.

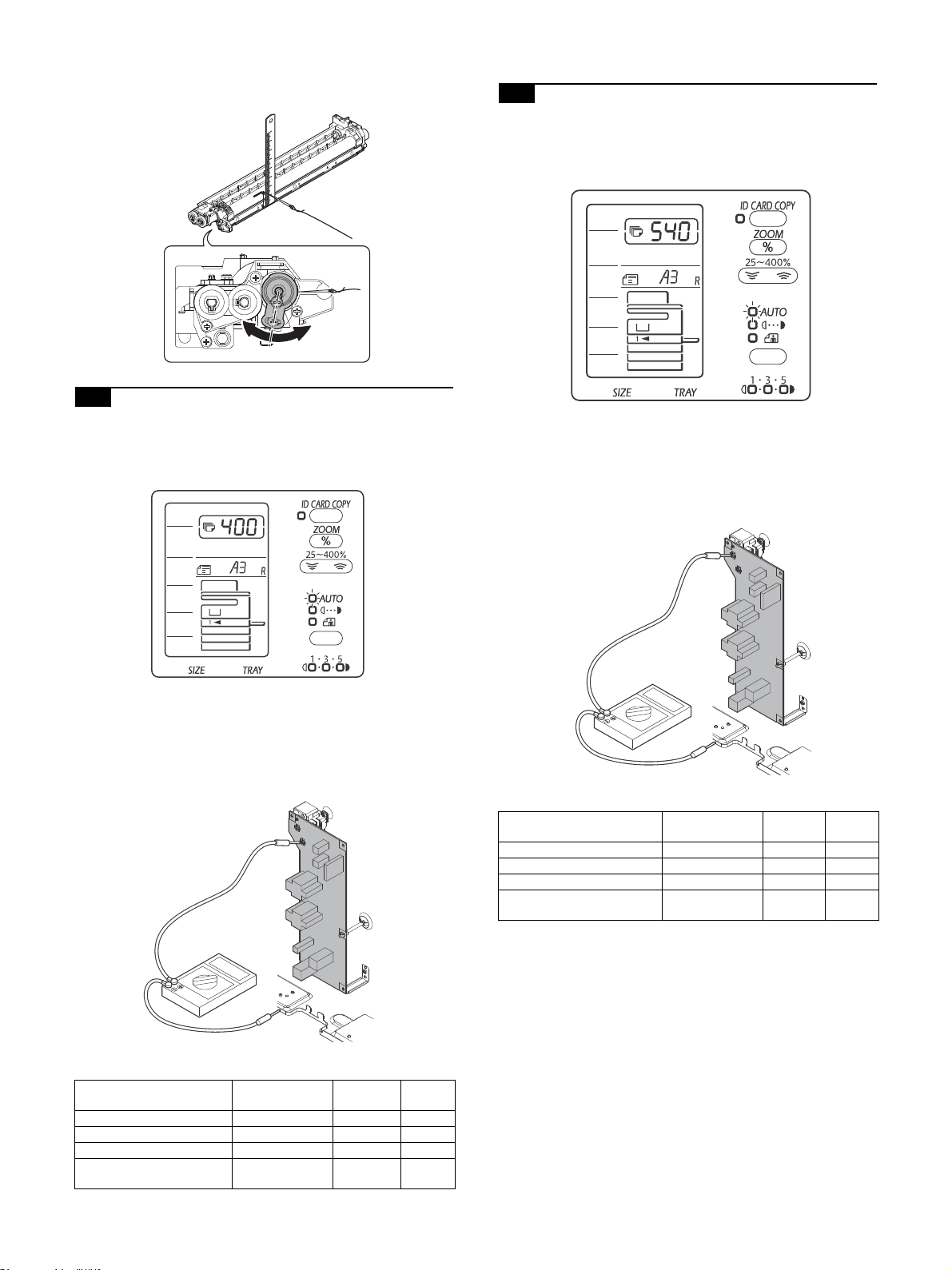

1-C Developing bias voltage adjustment

NOTE: Use a digital multi-meter with an internal resistance of

10Mohm or more.

1) Execute SIM 8-1.

1-D Grid bias voltage adjustment

NOTE: Use a digital multi-meter with an internal resistance of

10Mohm or more.

1) Execute SIM 8-2.

2) Touch the exposure mode to be changed.

The current set value is displayed.

3) Enter the set value with the 10-key.

4) Press the [START] key.

Output is made with the entered value, and the display returns

to the original state.

2) Touch the exposure mode to be changed.

The current set value is displayed.

3) Enter the set value with the 10-key.

4) Press the [START] key.

Output is made with the entered value, and the display returns

to the original state.

<SIM8-1>

LED Output mode

AUTO indicator COPY 0 - 650 400

TEXT indicator COPY-TSON 0 - 650 320

PHOTO indicator PRINTER 0 - 650 400

TEXT indicator & PHOTO

indicator

PRINTER-TSON 0 - 650 400

Setting

range

Default

<SIM8-2>

LED Output mode

AUTO indicator COPY 0 - 750 540

TEXT indicator COPY-TSON 0 - 750 460

PHOTO indicator PRINTER 0 - 750 540

TEXT indicator & PHOTO

indicator

PRINTER-TSON 0 - 750 540

Setting

range

Default

AR-6020 ADJUSTMENTS 5 – 2

Page 30

A4(8.5" x 11")

Paper rear edge

A4(8.5" x 11")

A4(8.5" x 11")

Paper rear edge

ADJ 2 Mechanism section

NOTE: If a jam error or paper empty occurs during copying in the

adjustment by the simulation, the image data is not saved,

and therefore recopying is required.

2-A Image position adjustment

2-A (1)Lead edge image position adjustment

NOTE: This adjustment executes the copy image position and the

lead edge void amount adjustment.

By adjusting the image reading start position and the print

start position (the registration roller ON timing) under the

100% printing.

<How to operate>

When this adjustment is executed, the current setting value is displayed in 2-digits. (The center value is 50.)

The switching of each setting and display can be made with pressing the [AUTO/TEXT/PHOTO] key.

When the adjustment value is entered by the [Numeric] keys and

press the [START] key, the setting value is saved and the machine

makes one copy. (The setting value range is from 1 to 99.)

When the [INTERRUPT] key is pressed, the process is interrupted

and the machine goes into the sub code input standby mode. When

the [CA] key is pressed, the simulation is terminated.

When this adjustment is executed with the original cassette tray,

the adjustment values of all cassette trays becomes the same

value.

(When the adjustment value is increased by 1, the position is

shifted by 0.1mm.)

C = 10 x R (mm)

When the C value is increased by 10, the image loss amount is

decreased in 1mm.

4) Measure the distance between the lead edge of the paper and

the image printing start position (H mm). Then, set the value

(A) by calculating with the following formula.

Paper rear edge

A = 10 x H (mm)

When the A value is increased by 10, the image lead edge

moves to the paper lead edge in 1mm.

5) Set the lead edge adjustment value (B) to 50 (2.5mm).

LED Adjustment mode

AUTO, 1st tray indicator

AUTO, 2nd tray indicator

AUTO, Bypass tray indicator

TEXT indicator

PHOTO indicator

AUTO, TEXT, PHOTO indicator

Print start position (1st tray paper feed)

Print start position (2nd tray paper feed)

Print start position (Bypass tray paper feed) *

Image lead edge void amount

Image reading start position

Image rear edge void amount

* Supported for the installed models only. Skipped for the models

without installation.

When printing is made with bypass tray, use A3 paper with the AB

destination or the W-letter with the Inch destination.

When the adjustment value of the print start position is increased

by 1, the timing of the registration roller is delayed and the printing

image is cut in 1mm. When the adjustment value of the image

reading start position is increased by 1, the image reading start

position is shifted to home position (towards you) in 1mm.

1) Enter SIM50-01 mode.

2) Set the following setting value to [1] by [Numeric] keys and

press the [START] key. Then, print one copy.

Item A: The print start position (The [AUTO] indicator lights. )

Item B: The image lead edge void amount (The [TEXT] indicator lights.)