Page 1

CODE : 00ZAR5320/A2E

DIGITAL COPIER

MODEL AR-5320D

AR-5320D

(with option installed)

CONTENTS

[ 1 ] NOTE FOR THIS SERVICE MANUAL . . . . . . . . . . . . . . . Refer to AR-M160

[ 2 ] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AR-5320D

[ 3 ] CONSUMABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AR-5320D

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . . AR-5320D

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . AR-5320D

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to AR-M160

[ 7 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AR-5320D

[ 8 ] USER PROGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AR-5320D

[ 9 ] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to AR-M160

[10] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AR-5320D

[11] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . .Refer to AR-M160

[12] FLASH ROM VERSION UP PROCEDURE . . . . . . . . . . .Refer to AR-M160

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AR-5320D

Parts marked with ““ are important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 2

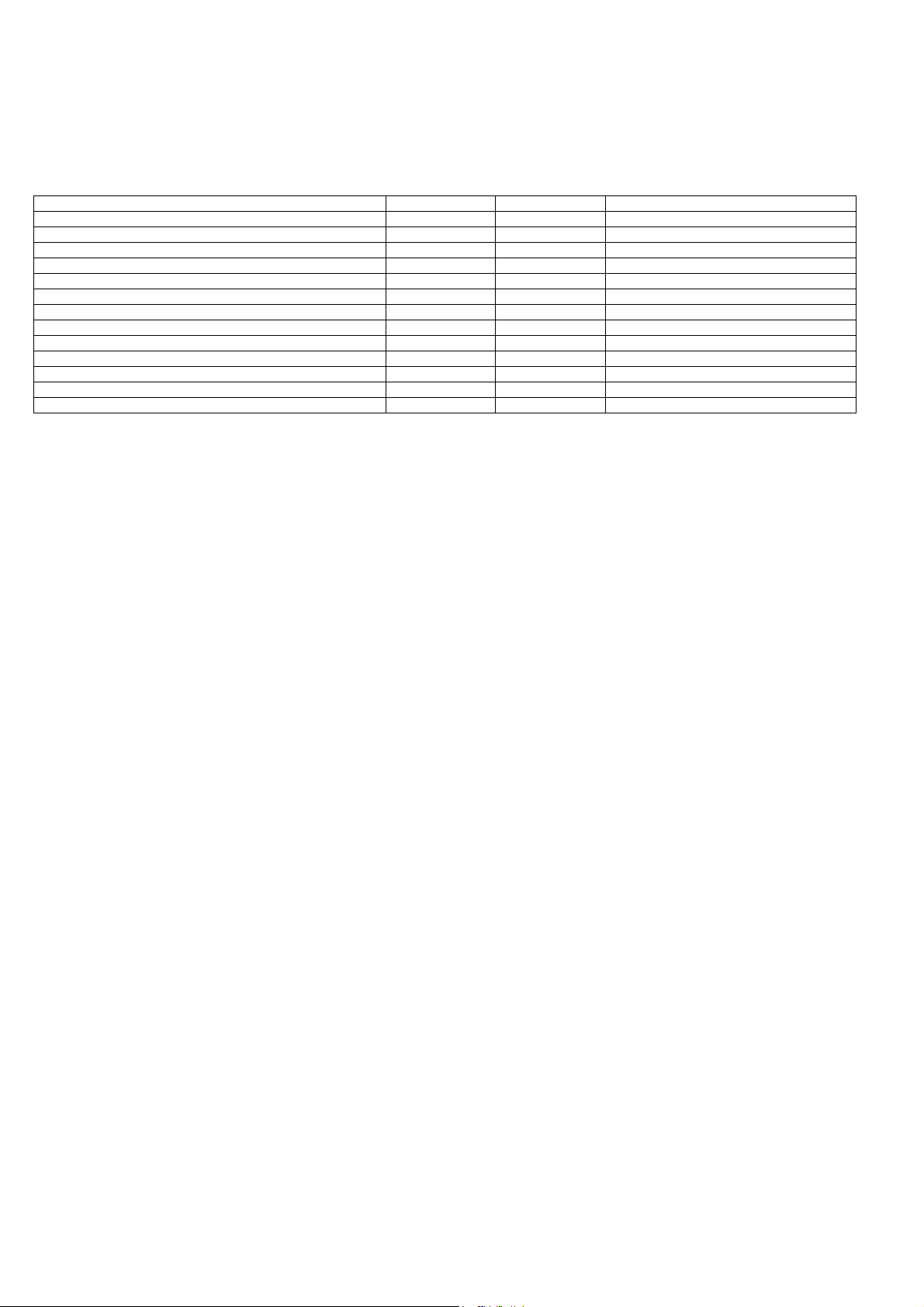

[1] NOTE FOR THIS SERVICE MANUAL

This Service Manual describes only the items related to the AR-5320D. For the other items common with the AR-M205, please refer to the AR-M160/

205 Service Manual (Document code:00ZARM205/A1E). The table below shows which document(s) should be referred to for each section. (Refer to

the document marked with O.)

[ 1 ] GENERAL O

[ 2 ] SPECIFICATIONS O

[ 3 ] CONSUMABLE PARTS O

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURES O O Appearance / Internal / Operation panel

[ 5 ] UNPACKING AND INSTALLATION O O Changing the copy paper size in the tray

[ 6 ] ADJUSTMENTS O

[ 7 ] SIMULATIONS O O

[ 8 ] USER PROGRAMS O O

[ 9 ] TROUBLE CODE LIST O

[10] MAINTENANCE O

[11] DISASSEMBLY AND ASSEMBLY O

[12] FLASH ROM VERSION UP PROCEDURE O

[13] ELECTRICAL SECTION O O Block diagram / Actual wiring diagram 1/7

Section AR-M160/M205 AR-5320D Changed item

AR-5320D NOTE FOR THIS SERVICE MANUAL 1-1

Page 3

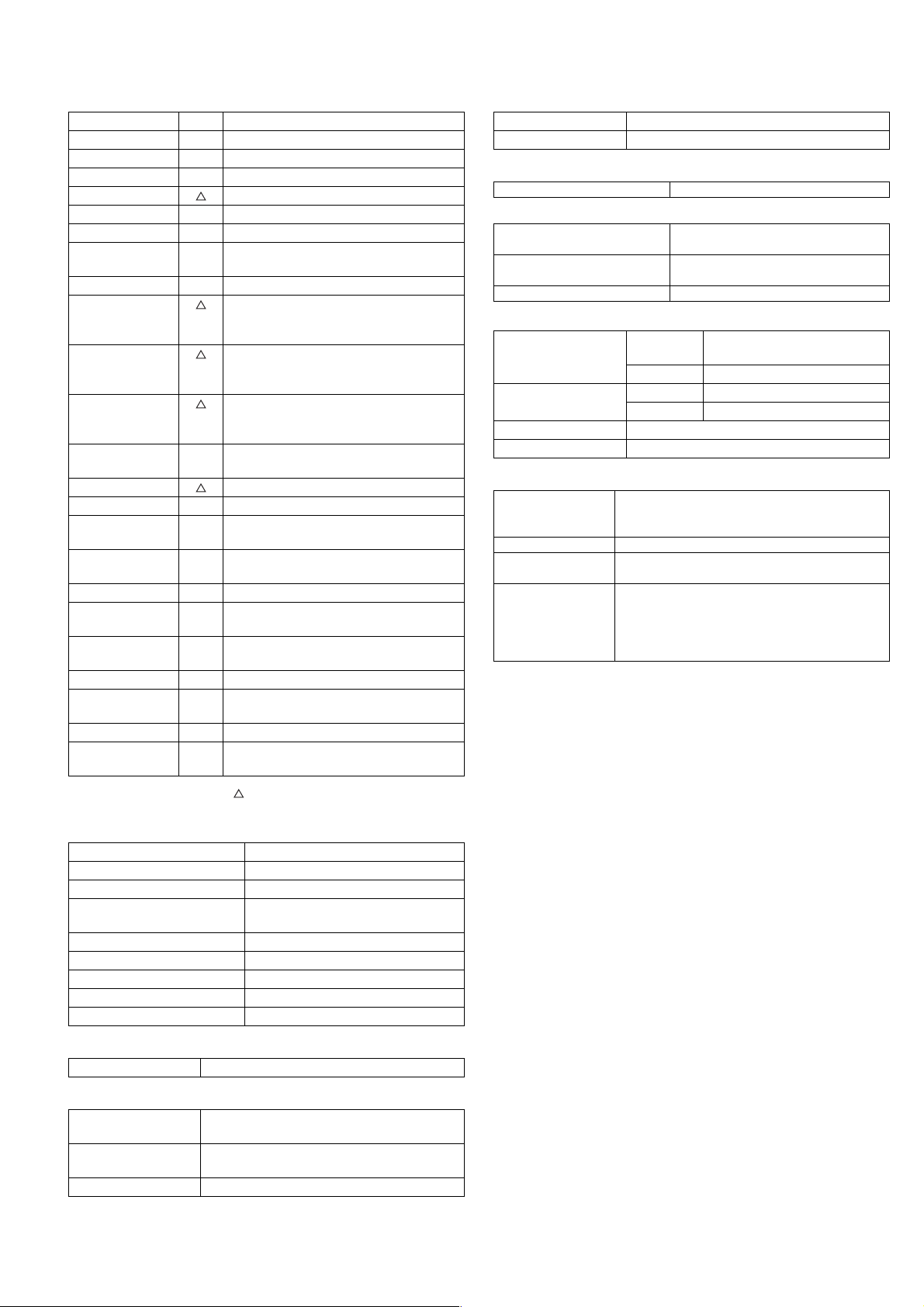

[2] SPECIFICATIONS

1. Copy mode

A. Type

Type Desk-top

Paper exit Wing less

B. Machine composition

AR-5320D 20-CPM multi function model

(1) Option

Machine Model

250 sheets paper feed unit AR-D24

250 sheets x 2 paper feed unit AR-D25

RSPF AR-RP6

Dual function board AR-EB7

256MB optional memory AR-SM5 option for AR-EB7

C. Copy speed

(1) Scan One Print many

AR-5320D Available

Condition: Copy speed in the normal copy from all the paper feed ports

including the manual paper feed port.

(2) Continuous copy speed (Sheets/min)

Paper size Normal

A3 11 11 11

B4 12 12 12

A4 20 20 20

AB

system

Inch

system

A4R 141414

B5 20 20 20

B5R 161616

11" X 17" 10 10 10

8.5" X 14" 12 12 12

8.5" X 13" 12 12 12

8.5" X 11" 20 20 20

8.5" X 11"R 15 15 15

8.5" X 5.5" 20 20 20

Enlargement

(200%)

D. First copy time

(1) Basic speed

First copy time 7.2sec (A4, 8.5" X 11"/1st tray/with OC)

(Polygon motor ready state)

E. Document

Max. document size A3, 11" X 17"

Document reference

position

Detection (Platen) None

Detection size A3, B4, A4, A4R, B5, B5R, A5

Left side center

11" X 17", 8.5" X 14", 8.5" X 13", 8.5" X 11",

8.5" X 11"R, 8.5" X 5.5"

(8.5" X 13" is detected by key input.)

Reduction

(50%)

(1) R-SPF

Standard/Option Option

AR-RP6

Document load

capacity

Document size

(Max. ~ Min.)

Document

replacement speed

Document set/Paper

feed direction

Document weight 56 ~ 90g/m·, 15 ~ 24 lbs

Document size

detection

Document mixture Copy mode: Not Available

40 sheets (Thickness 4mm or less)

A3 ~ A5

11" x 17" ~ 8.5" x 5.5"

(8.5" x 5.5", duplex is inhibited.)

20 sheets/min

(A4 , 8.5" x 11" normal copy)

Face up, Center reference,

Paper feed from the top

On the document feed tray

F. Paper feed

Copy size

(Max. ~ Min.)

Paper feed system 1 cassette + Multi manual paper feed

Paper feed capacity 250 x 2 (Paper feed tray)

Remaining quantity

detection

(1) Paper feed section of the copier

Paper feed

size

Side front Front

Paper feed

capacity

Detection Paper empty detection available, size detection

Weight 56 ~ 90g/m· (15 lbs. ~ 21 lbs.)

Special paper Recycled paper

(2) Manual paper feed section

Paper feed

size

Paper feed

capacity

Detection Size detection not available,

Weight 56 ~ 200g/m· (15 ~ 34 lbs.)

Special paper Recycled paper, OHP film, labels

Paper feed Single except for recycled paper

A3 ~ A6

11" x 17" ~ 8.5" x 5.5"

+ 100 (Multi bypass feed tray)

Cassette

section

Manual tray Only empty detection available

A3, B4, A4, A4R, B5, B5R, A5

11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11",

8.5" x 11"R, 8.5" x 5.5"

(For A5 and 8.5" x 5.5", only No. 1 tray available.)

250 sheets

(56 ~ 90g/m· equivalent) (15 ~ 21 lbs.)

(by key input)

A3 ~ A6, 11" x 17" ~ 8.5" x 5.5"

100 sheets(56 ~ 80g/m·)

paper empty detection available

Only empty detection available

AR-5320D SPECIFICATIONS 2-1

Page 4

(3) Option paper feed unit

1-step paper feed unit 2-step paper feed unit

Model AR-D24 AR-D25

Paper feed size A3, B4, A4, A4R, B5, B5R

11" x 17", 8.5" x 14", 8.5" x 13",

8.5" x 11", 8.5" x 11"R

Capacity

(56 ~ 80gm·)

Paper weight 56 ~ 90 g/m· (15 ~ 21 lbs.)

Moisture preserving

heater

Paper empty detection Available

Paper size setting User setting

External dimensions

(W x D x H)

Weight About 4.7kg About 10kg

Special paper Recycled paper

Power Supplied from the machine

About 250 sheets x

1 tray

None

Paper size detection:None

590 x 471 x 88mm 590 x 471 x 173.5mm

About 250 sheets x

2 trays

G. Job speed

S-S (1st step) 100% (document replacement rate)

Condition:With SPF/RSPF A4/Letter Normal 1st tray

H. Multi copy

Max. number of multi copy 999 sheets

I. Warm-up time

Warm-up time 45 sec

Pre-heat Available

Jam recovery Within 45 sec

J. Copy magnification ratio

Fixed

magnification

ratio

Zooming 25 ~ 400%

Independent

zooming(vertical)

Independent zooming

(horizontal)

AB system:

50, 70, 81, 86, 100, 115, 122, 141, 200%

Inch system:

50, 64, 77, 95, 100, 121, 129, 141, 200%

SPF/RSPF(50 ~ 200%)

Available (25 ~ 400%)

SPF/RSPF(50 ~ 200%)

Available (25 ~ 400%)

SPF/RSPF(50 ~ 200%)

N. Paper exit / finishing

Paper exit section

capacity

Full detection None

Finishing Dual function board:

Electronic sort

capacity

Offset function Available (by the shifter)

Staple function None

(1) Electronic sort board (Option)

Electronic sort Sorting 100 sheets of A4 standard

Rotation copy If there is paper of same size as the document,

2 in 1, 4 in 1 Copies of 2 pages or 4 pages are integrated into

Edge erase Images surrounding the document are erased

Center erase The image at the center is erased when copying.

Margin shift Binding margin is made at the left edge of the set

Memory for

electronic sort

* Memory loading

capacity

Memory expansion DIMM memory slot x 1, max. 256MB x 1 slot +

USB2.0 Standard provision of E-sort

SPLC (JBIG-GDI) Supported when E-sort is installed.

ROPM Supported when E-sort is installed.

Face down 250 sheets

Option (AR-EB7)

A4 (8.5" x 11") standard document 100 sheets

documents

Grouping 100 sheets of A4 standard

documents

the image is rotated to copy even though the

paper is set in the different direction from the

document direction.

one surface. Divided by solid lines,

(Selectable by the user program.)

when copying. (Adjustable in 5 ~ 20mm by the

user program.)

(Adjustable in 5 ~ 20mm by the user program.)

documents.

(Adjustable in 5 ~ 20mm by the user program.)

16MB

A4 standard 100 pages

16MB (Max. 272MB in total)

K. Print density

Density mode Auto / Text / Photo

No. of manual

adjustment

Resolution Writing: 600 x 600dpi

Gradation Reading: 256 gradations

Toner save mode Set by the user program

5 steps (Text / Photo)

Reading: 600 (main) x 600 (sub) (PHOTO mode)

600 (main) x 300 (sub) (AE mode)

Writing: Binary

L. Void width

Void area Lead edge 1 ~ 4mm,

rear edge 4mm or less,

both sides 4mm or less

Image loss 4mm or less

M. Auto duplex

Standard/

Option

Standard provision

(D → D / D → S enable only when RSPF is installed)

AR-5320D SPECIFICATIONS 2-2

Page 5

O. Additional functions

APS O

AMS O

Auto tray switching O

Memory copy O

Rotation copy

E-sort O Option

Rotation sort X

Independent

zooming

1 set 2 copy O Enlargement invalid/SPF invalid

Binding margin Default AB series:

Edge erase Default AB series:

Center erase Default AB series:

Black/white

reverse

2in1/4in1

Sorter O Offset function (Shifter) provided

Preheating O The conditions are set by the user

Auto shut-off O The conditions are set by the user

User programming O

Total counter O Supports Total counter, Scan counter, and

Coin vendor

support

Auditor support O (Supports I/F only.)

Duplex O (Standard provision for the model of 20-

Toner save O (Set according to the destination)

Department

management

O

10mm (5, 10, 15, 20mm)

Inch series: 1/2 inch (1/4, 1/2, 3/4, 1 inch)

10mm (5, 10, 15, 20mm)

Inch series: 1/2 inch (1/4, 1/2, 3/4, 1 inch)

10mm (5, 10, 15, 20mm)

Inch series: 1/2 inch (1/4, 1/2, 3/4, 1 inch)

X

program.

program.

Copy counter.

O (Supports I/F only.)

sheet model only)

O (Copy: 20 Dept.)

S. Power source

Voltage AC120V, 220V, 230V, 240V ±15%

Frequency 50/60Hz common

T. Power consumption

Max. power consumption 1200W

* EnergyStar conformity

Average power consumption in

operation

Power consumption when

standby

Energy consumption efficiency Less than 25W

Less than 550W

5W(Not include option)

U. Digital performance

Resolution Reading 600 x 600dpi (PHOTO mode)

Writing 600 x 600dpi

Gradation Reading 256 gradations

Writing Binary

Memory Simplex:16MB Duplex:32MB

Hard disk None

600 x 300dpi (AE mode)

V. Printing function

Print speed <Standard>12ppm

Data resolution 600dpi

Option memory 16MB (with the AR-EB7 installed)

Printer driver Two drivers for the case when the AR-EB7 is

(With the AR-EB7 installed)

20ppm

256MB (AR-SM5) can be added to the AR-EB7.

installed and when it is not are automatically

installed by plug & play.

<Standard> SHARP GDI driver

<with the AR-EB7 installed> SPLC driver

O : Available :Installation of the option is required.

X : Not available

P. Other specifications

Photoconductor type OPC (Organic Photo Conductor)

Photoconductor drum dia. 30mm

Copy lamp Cold cathode fluorescent lamp (CCFL)

Developing system Dry 2-component magnetic brush

Charging system Saw teeth charging

Transfer system (+) DC corotron

Separation system (-) DC corotron

Fusing system Heat roller

Cleaning system Contact blade

development

Q. Package form

Body Body / Accessories

R. External view

External dimensions

(W x D x H)

Occupying area

(W x D)

Weight About 36.9kg (without DV-cartridge)

590 x 577 x 520 mm

590 x 531mm

(When the manual tray is installed.)

AR-5320D SPECIFICATIONS 2-3

Page 6

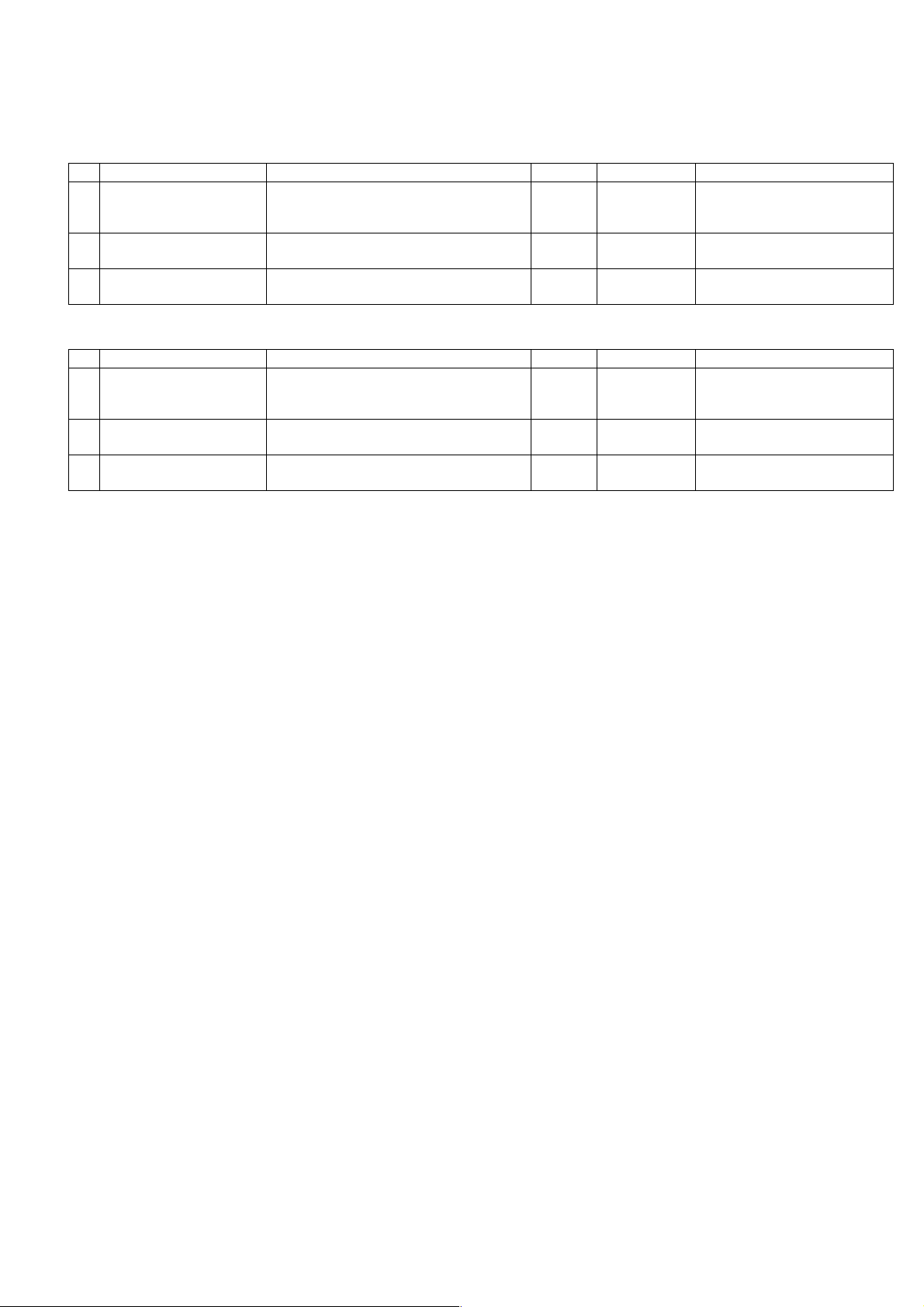

[3] CONSUMABLE PARTS

1. Supply system table

A. East Europe / Russia

NO Name Content Life Product name Remark

1 Toner cartridge(Black)

<With IC>

2 Developer Developer

3 Drum kit Drum

B. Latin America

NO Name Content Life Product name Remark

1 Toner cartridge(Black)

<With IC>

2 Developer Developer

3 Drum kit Drum

Toner

(Toner: Net Weight 537g)

Vinyl bag

(Developer : Net Weight 400g)

Drum fixing plate

Toner

(Toner: Net Weight 537g)

Vinyl bag

(Developer : Net Weight 400g)

Drum fixing plate

x10

160K AR-016LT Life setting by A4 6% document

x10

x10 500K AR-202LD LD=DV*10

x1x150K AR-202DM

x10

190K AR-016LT Life setting by A4 6% document

x10

x10 500K AR-202LD LD=DV*10

x1x150K AR-202DM

LT =T *1 0

LT =T *1 0

AR-5320D CONSUMABLE PARTS 3-1

Page 7

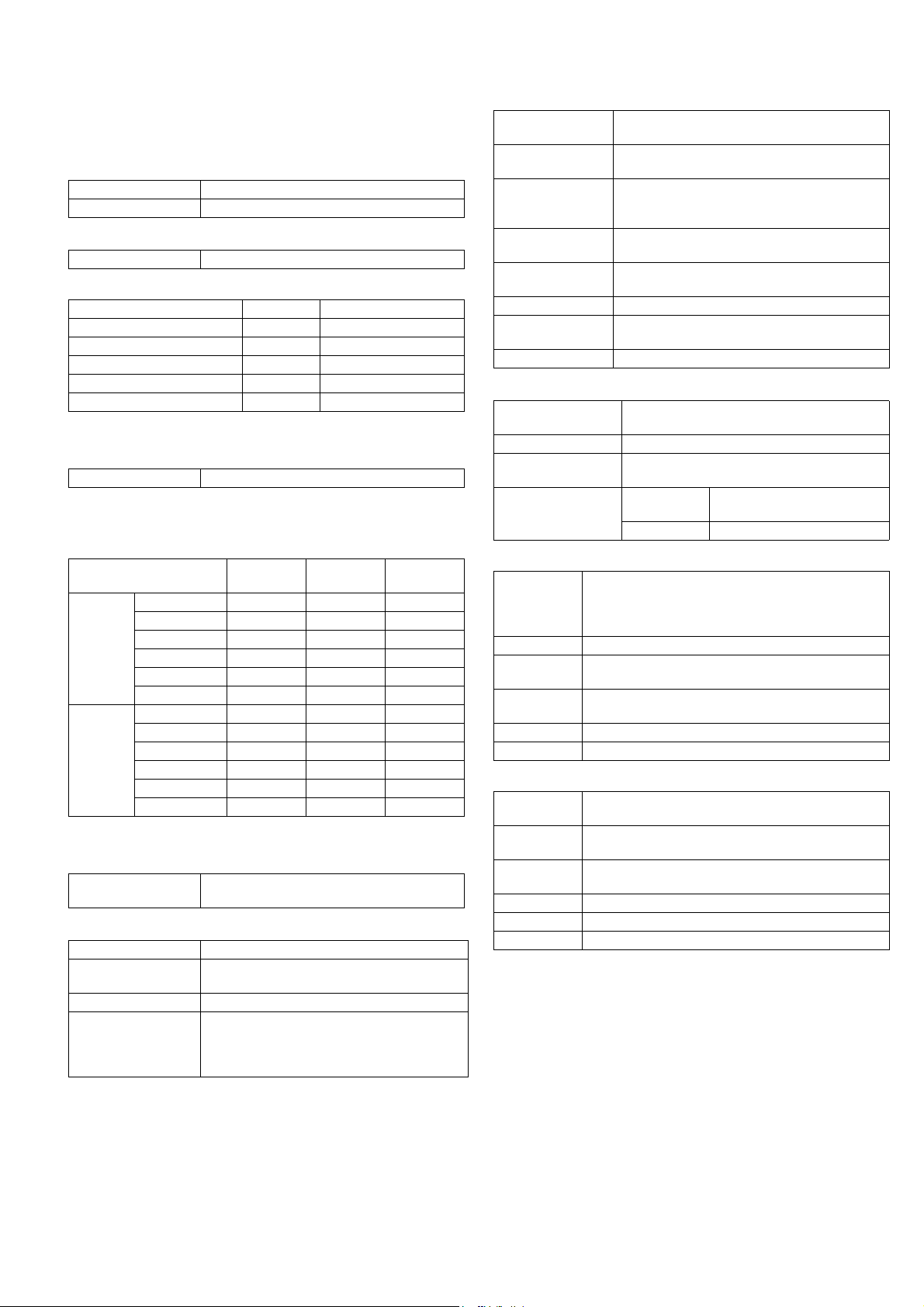

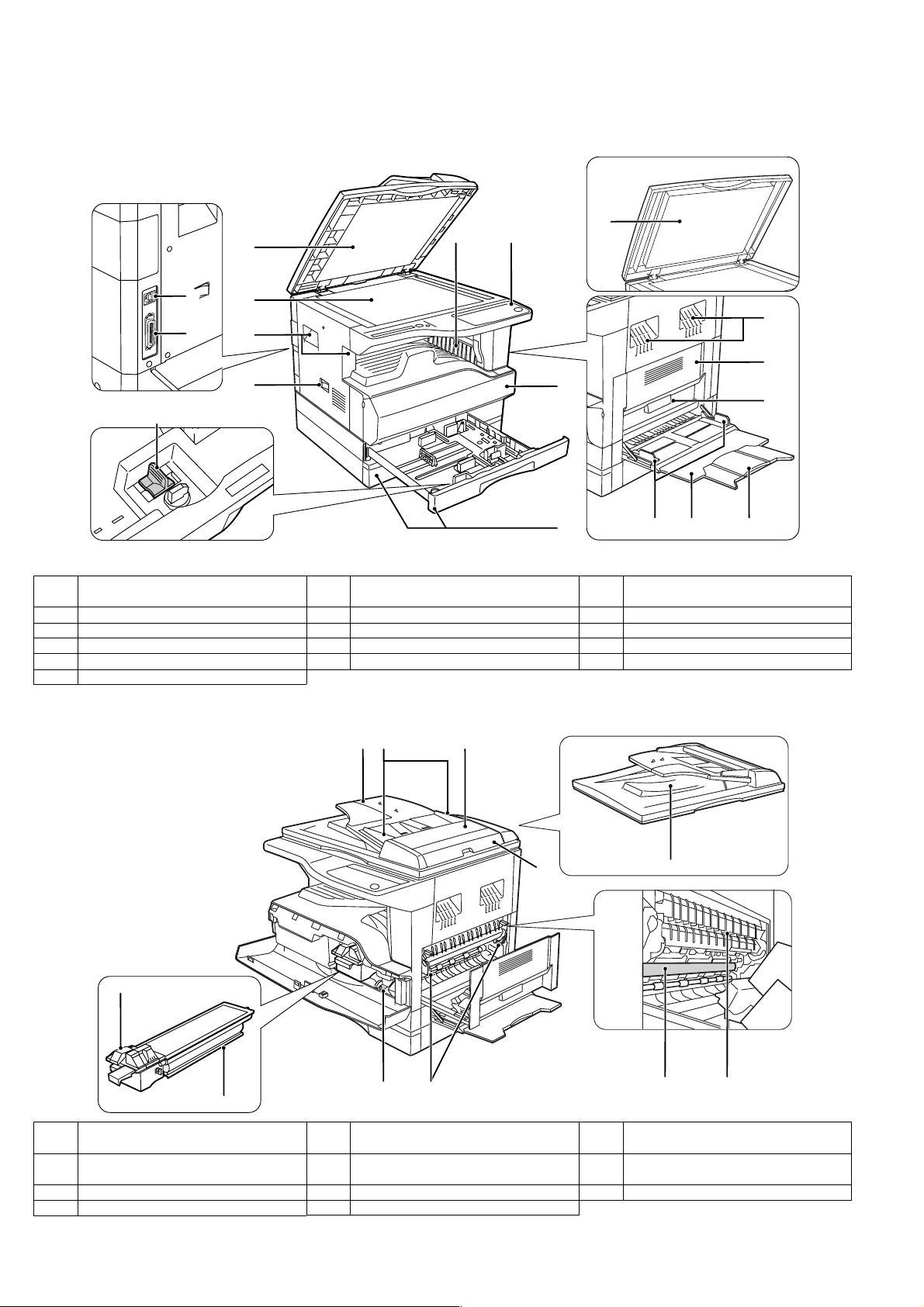

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

6 5

7

15

16

1

2

3

4

14

8

1

1 Document feeder cover (when the RSPF

is installed) /document cover

4 Power switch 5 Operation panel 6 Paper output tray

7 Front cover 8 Paper trays 9 Side cover

10 Side cover handle 11 Bypass tray guides 12 Bypass tray

13 Bypass tray extension 14 Charger cleaner 15 USB connector

16 Parallel connector

2 Document glass 3 Handles

3

9

10

131211

2. Internal

18

22

23

17 Document feeder tray

(when the RSPF is installed)

20 Right side cover

(when the RSPF is installed)

23 Toner cartridge 24 Roller rotating knob 25 Fusing unit release levers

26 Photoconductive drum 27 Fusing unit paper guide

18 Original guides

21 Exit area

24 25

(when the RSPF is installed)

(when the RSPF is installed)

1917

20

19 Feeding roller cover

22 Toner cartridge lock release lever

21

2726

(when the RSPF is installed)

AR-5320D EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-1

Page 8

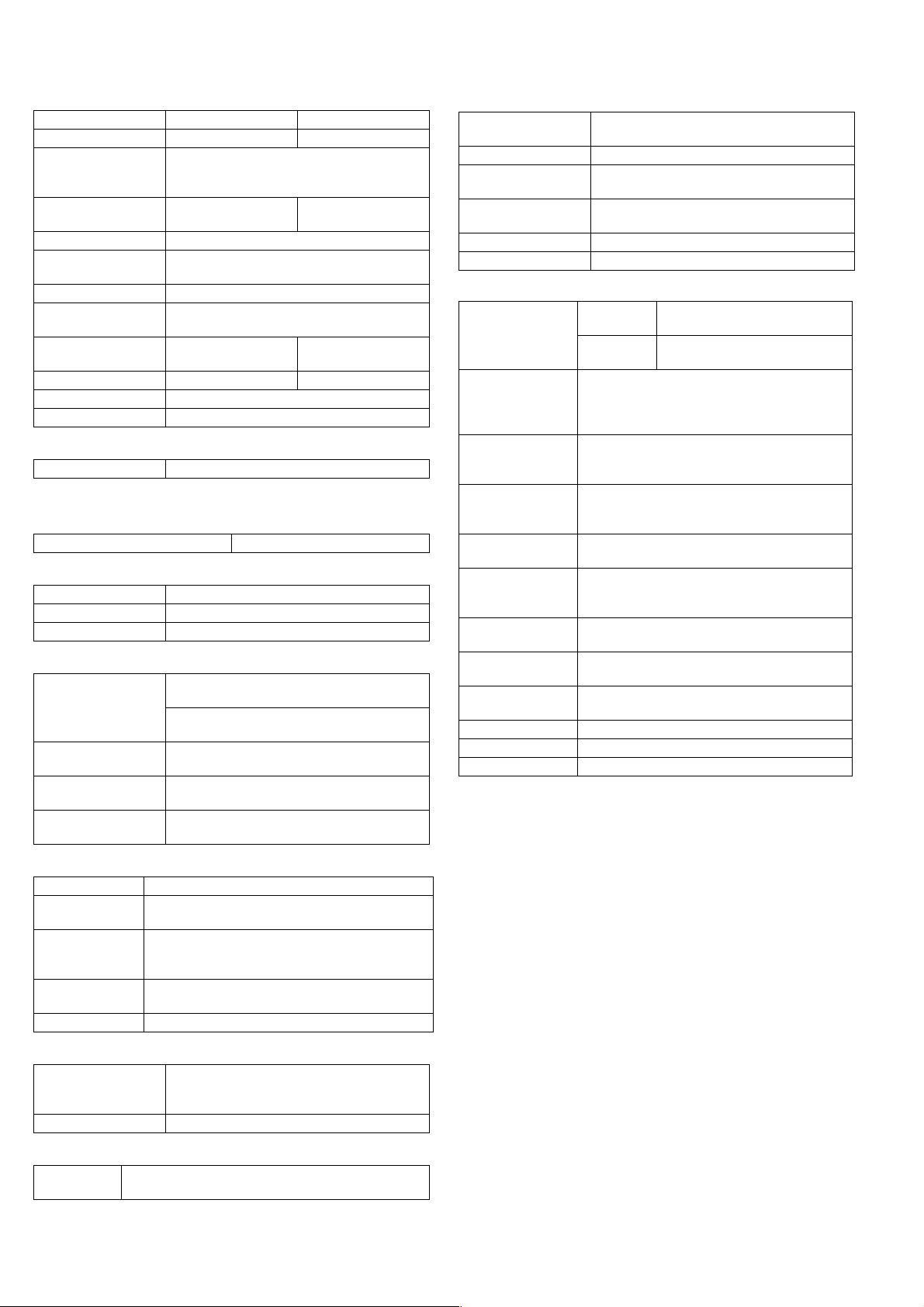

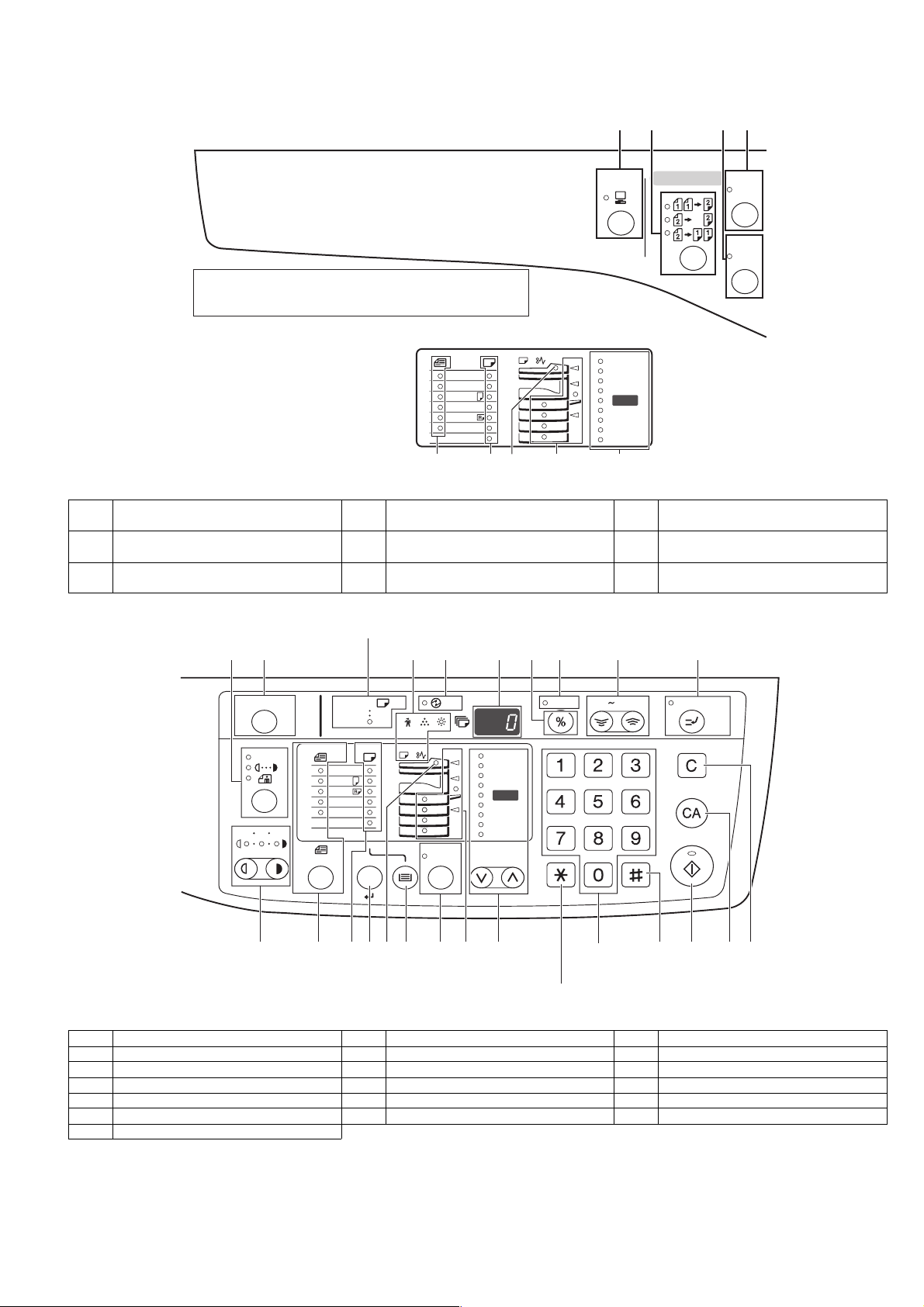

3. Operation Section

1 2 3 4

The indications of the operation panel may differ

depending on the country and the region.

The example of a display of inch series

11X17

X

14

8½

X

11

8½

X

5½

8½

X

11

8½

8½X13

EXTRA

7

8

1 ON LINE key/indicator 2 ORIGINAL TO COPY key/indicators

(Duplex model only)

4 XY-ZOOM key/indicator 5 RSPF indicator

(when the RSPF is installed)

7 ORIGINAL SIZE ENTER key /

8 PAPER SIZE indicators 9 PRESET RATIO selector keys /

ORIGINAL SIZE indicators

6

5

ON LINE

200

141

129

121

100

95

77

64

%

%

50

%

ORIGINAL TO COPY

XYZOOM

DUAL

PA G E

COPY

9

3 DUAL PAGE COPY key/indicator

6 Paper feed location / misfeed location

indicators

indicators

12

10

ACC.#-C

135

11

AU TO

20

EXTRA

ENTER

7

A3

A4

A4

A5

B4

AU TO

8

21

13

14

AU TO

%

5

22

23

6

15

200

141

122

115

100

9

16

17

ZOOM

%

%

86

81

70

50

%

18

25 400%

INTERRUPT

24 26

19

28

2725

Not used for this machine.

10 AUTO/TEXT/PHOTO key / indicators 11 AUDIT CLEAR key 12 AUTO PAPER SELECT indicator

13 Alarm indicators 14 POWER SAVE indicator 15 Display

16 Copy ratio display key 17 ZOOM indicator 18 Zoom keys

19 INTERRUPT key / indicator 20 Light and Dark keys / indicators 21 PAPER SIZE ENTER key

22 TRAY SELECT key 23 AUTO IMAGE key / indicator 24 Numeric keys

25 # key 26 START key / indicator 27 CLEAR ALL key

28 CLEAR key

AR-5320D EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-2

Page 9

[5]UNPACKING AND INSTALLATION

A3

A4

A4

A5

B4

TRA

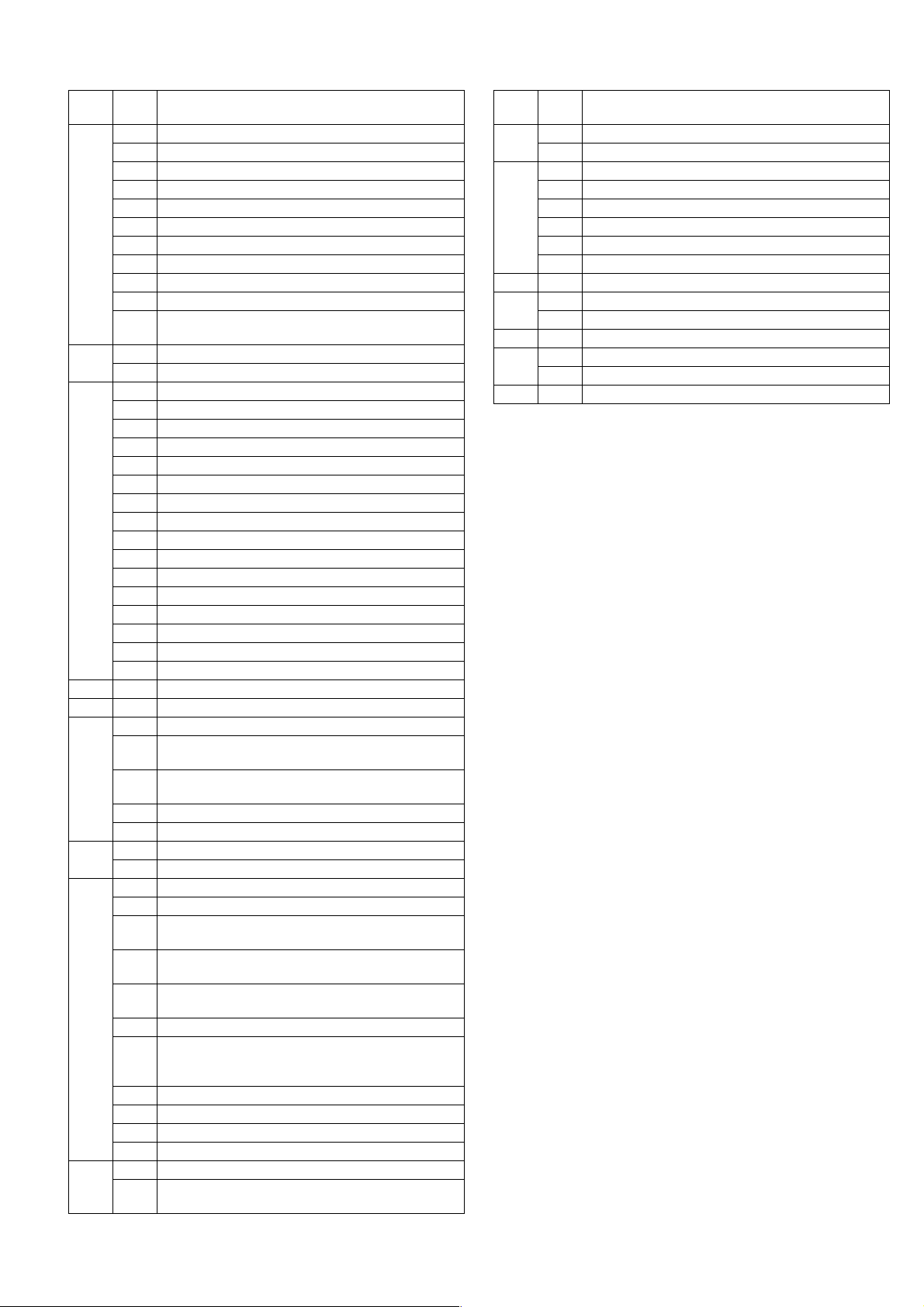

5. Changing a tray's paper size setting

Follow these steps to change a tray's paper size setting.

Note:

•The paper size setting cannot be changed when the machine has

stopped temporarily due to running out of paper or a misfeed, or during

interrupt copying.

•During printing (even in copy mode), the paper size setting cannot be

changed.

•A5 size paper can only be selected in upper paper tray.

•Do not load paper that is a different size than the paper size setting.

Copying will not be possible.

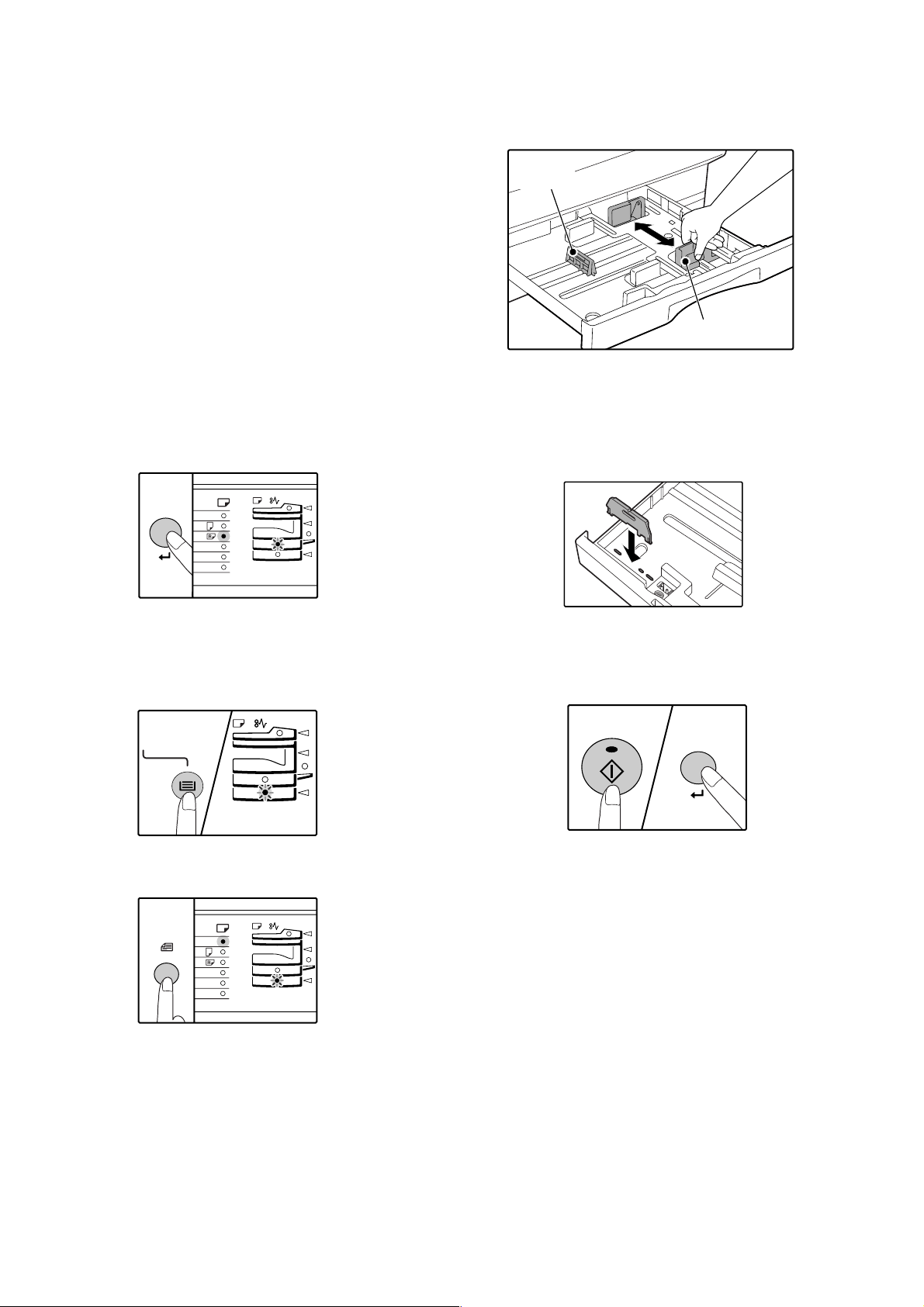

4) Squeeze the lock lever of the front guide and slide the front guide to

match the width of the paper, and move the left guide to the

appropriate slot as marked on the tray.

Left guide

Front guide

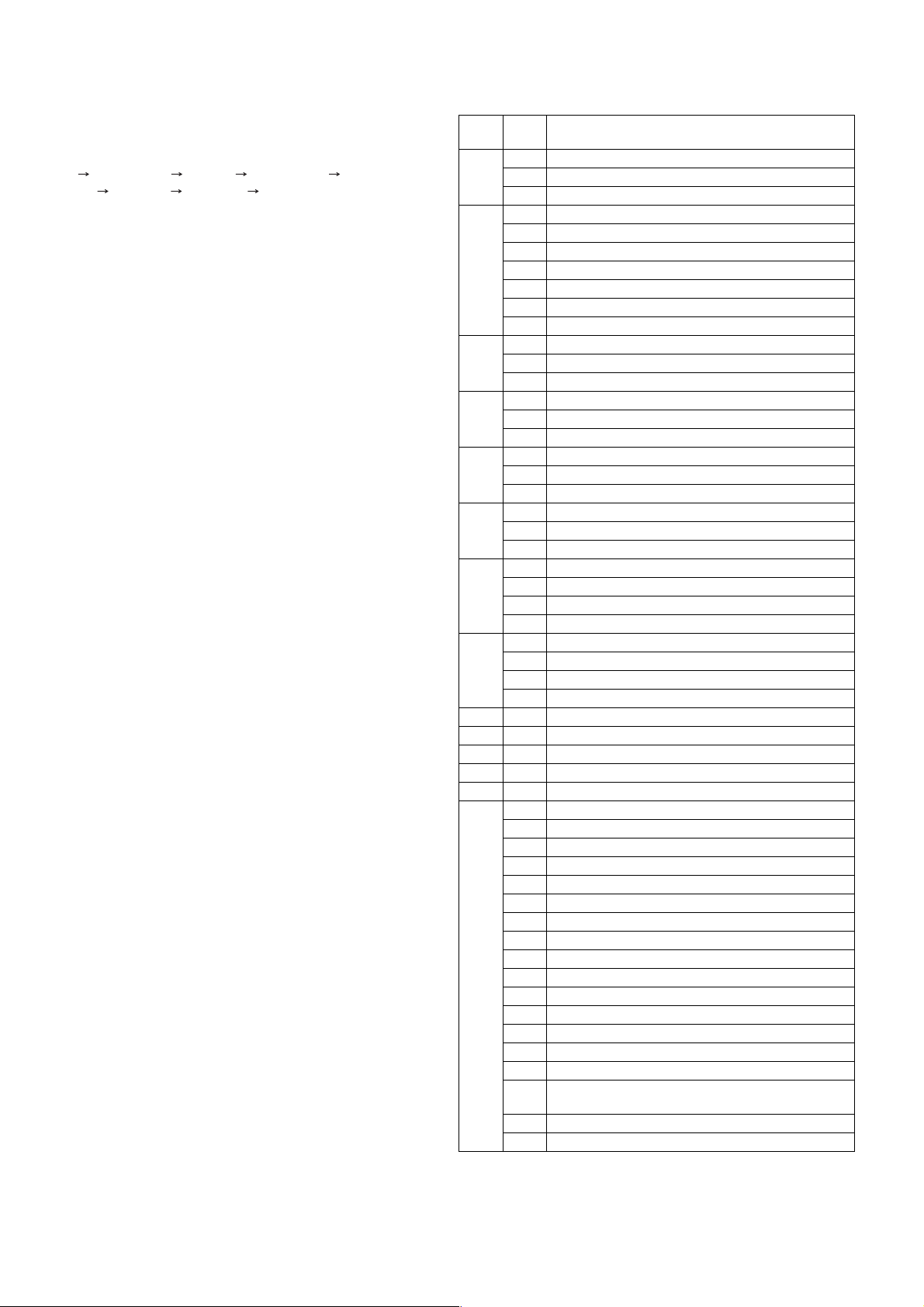

1) Hold down the [PAPER SIZE ENTER] key for more than 5 seconds

to set the selected paper size.

The currently selected paper feed location indicator will blink and the

corresponding paper size (which is currently set) indicator will light

steadily.

All other indicators will go out.

2) If the machine has two paper trays, use the [TRAY SELECT] key to

select the paper tray for which you wish to change the paper size

setting.

Each time the [TRAY SELECT] key is pressed, a paper tray will be

indicated with a blinking paper feed location indicator.

•The front guide is a slide-type guide. Grasp the locking knob on the

guide and slide the guide to the indicator line of the paper to be loaded.

•The left guide is an insert-type guide. Remove it and then insert it at the

indicator line of the paper to be loaded.

•When using 11" x 17" sized paper store the left guide in the slot at the

left front of the paper tray.

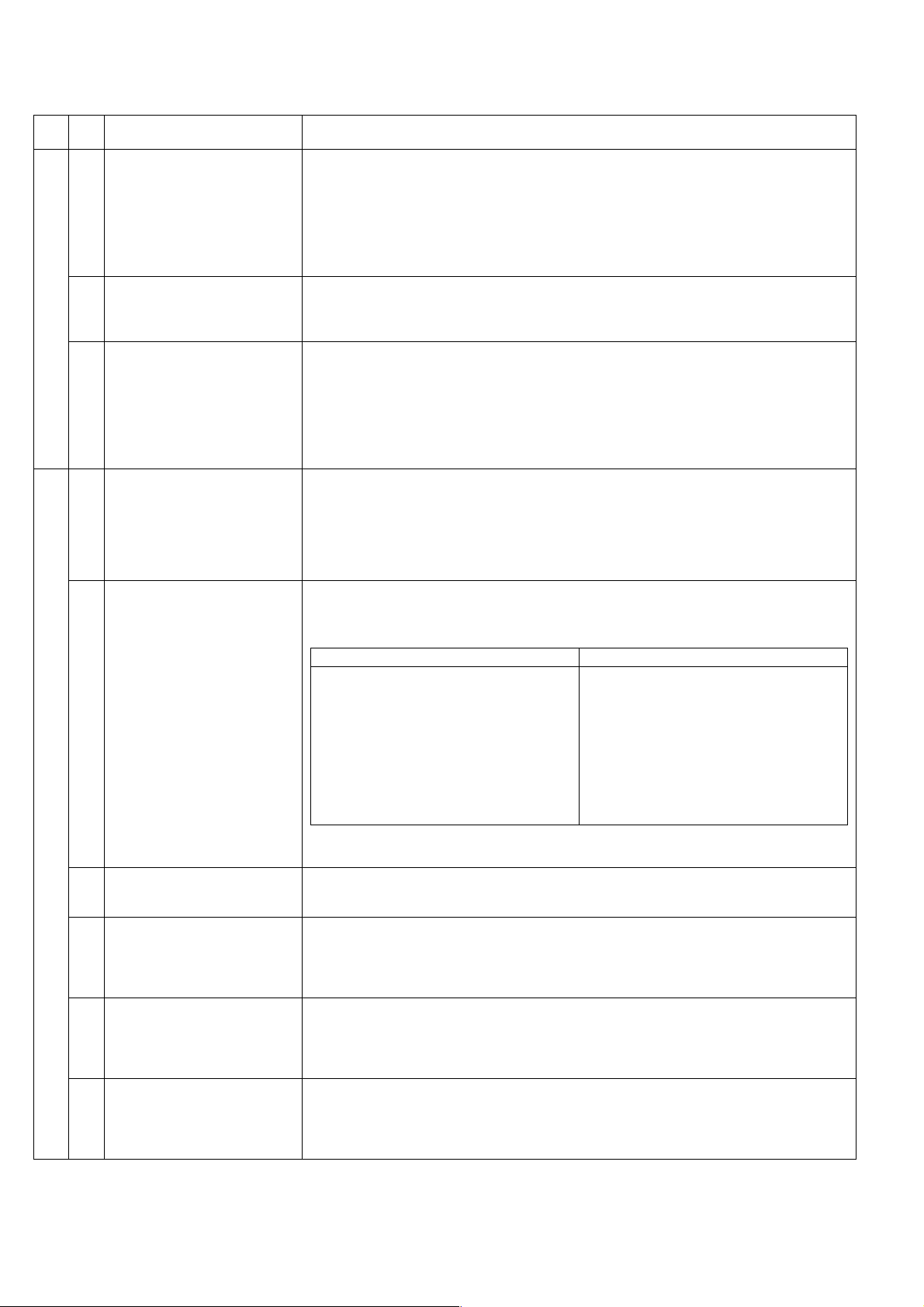

5) Press the [START] key and then the [PAPER SIZE ENTER] key.

To change the paper size setting of another tray, repeat steps 2) to 5)

after pressing the [START] key.

3) Use the [ORIGINAL SIZE ENTER] key to select the paper size.

The indicator of the selected paper size lights up.

ENTER

AR-5320D UNPACKING AND INSTALLATION 5-1

Note:Affix the paper size label for the paper size selected in step 3) to

the label position on the right end of the tray.

Important points when using the printer mode

•Make sure that the tray's paper size setting is the same as the tray's

paper size setting in the printer driver. For example, if the tray's paper

size setting is A4R, set "Setting Paper Size" to "A4-R". For more

information, see "CONFIGURING THE PRINTER DRIVER" in the

"Software Setup Guide".

Page 10

[7] SIMULATIONS

1. Entering the simulation mode

Perform the following procedure to enter the simulation mode.

"#" key Interrupt key "C" key Interrupt key

Main code Start key Sub code Start key

2. Canceling the simulation mode

When the clear all key is pressed, the simulation mode is cancelled.

When the interruption key is pressed, the process is interrupted and the

screen returns to the sub code entering display.

* After canceling the simulation mode, be sure to turn OFF/ON the

power and check the operation.

Note: If the machine is terminated by a jam error or paper empty during

copying in the adjustment by the simulation, recopying is required.

3. List of simulations

Main

Sub

code

code

01 01 Mirror scanning operation

02 Mirror home position sensor (MHPS) status display

06 Mirror scanning operation aging

02 01 Single paper feeder (SPF) aging

02 SPF sensor status display

03 SPF motor operation check

08 SPF paper feed solenoid operation check

09 RSPF reverse solenoid operation check

10 RSPF paper exit gate solenoid operation check

11 SPF PS release solenoid operation check

03 02 Shifter sensors status display

03 Shifter operation check

11 Shifter home position check

05 01 Operation panel display check

02 Fusing lamp and cooling fan operation check

03 Copy lamp lighting check

06 01 Paper feed solenoid operation check

02 Resist roller solenoid operation check

10 Main cassette semicircular roller cleaning

07 01 Warm-up display and aging with jam

06 Intermittent aging

08 Shifting with warm-up display

08 01 Developing bias output

02 Main charger output (Grid = HIGH)

03 Main charger output (Grid = LOW)

06 Transfer charger output

09 01 Duplex motor forward rotation check

02 Duplex motor reverse rotation check

04 Duplex motor RPM adjustment

05 Duplex motor switchback time adjustment

10 - Toner motor operation

14 - Trouble cancel (except for U2)

16 - U2 trouble cancel

20 01 Maintenance counter clear

21 01 Maintenance cycle setting

22 01 Maintenance counter display

02 Maintenance preset display

03 Jam memory display

04 Jam total counter display

05 Total counter display

06 Developing counter display

08 SPF counter display

09 Paper feed counter display

12 Drum counter display

13 CRUM type display

14 P-ROM version display

15 Trouble memory display

16 Duplex print counter display

17 Copy counter display

18 Printer counter display

19 Scanner mode counter display

<Not Available for AR-5320D>

21 Scanner counter display <Not Available for AR-5320D>

22 SPF jam counter display

Contents

AR-5320D SIMULATIONS 7-1

Page 11

Main

code

Sub

code

Contents

24 01 Jam total counter clear

02 Trouble memory clear

04 SPF counter clear

05 Duplex print counter clear

06 Paper feed counter clear

07 Drum counter clear

08 Copy counter clear

09 Printer counter clear

13 Scanner counter clear <Not Available for AR-5320D>

14 SPF jam total counter clear

15 Scanner mode counter clear

<Not Available for AR-5320D>

25 01 Main motor operation check

10 Polygon motor operation check

26 02 Size setting

03 Auditor setting

04 Copier duplex setting

05 Count mode setting

06 Destination setting

07 Machine condition check (CPM)

18 Toner save mode setting

30 CE mark conformity control ON/OFF

31 Auditor mode exclusive setup

36 Cancel of stop at maintenance life over

37 Cancel of stop at developer life over

38 Cancel of stop at drum life over

39 Memory capacity check

42 Transfer ON/OFF timing control setting

43 Side void amount setting

51 Copy temporary stop function setting

30 01 Paper sensor status display

42 01 Developing counter clear

43 01 Fusing temperature setting

10 Postcard paper feed cycle setting

<Not Available for AR-5320D>

11 Postcard size paper fusing temperature setting

<Not Available for AR-5320D>

12 Standby mode fusing fan rotation setting

13 Fusing paper interval control allow/inhibit setting

44 34 Transfer current setting

40 Setting of rotation time before toner supply

46 01 Copy density adjustment (300dpi)

02 Copy density adjustment (600dpi)

09 Copy exposure level adjustment, individual setting

(Text) 300dpi

10 Copy exposure level adjustment, individual setting

(Text) 600dpi

11 Copy exposure level adjustment, individual setting

(Photo) 600dpi

18 Image contrast adjustment (300dpi)

19 Exposure mode setting

(Gamma table setting/AE operation mode setting/

Photo image process setting)

20 SPF exposure correction

29 Image contrast adjustment (600dpi)

30 AE limit setting

31 Image sharpness adjustment

48 01 Main/sub scanning magnification ratio adjustment

05 SPF/RSPF mode sub scanning magnification ratio

adjustment in copying

Main

code

Sub

code

Contents

49 01 Flash ROM program writing mode

12 Standby mode fusing fan RPM setting<Additional>

50 01 Image lead edge adjustment

06 Copy lead edge position adjustment (SPF/RSPF)

10 Paper off-center adjustment

12 Document off-center adjustment

18 Memory reverse position adjustment in duplex copy

19 Rear edge void adjustment in duplex copy

51 02 Resist amount adjustment

53 08 SPF scanning position automatic adjustment

10 SPF scan position change-over setting

61 03 HSYNC output check

63 01 Shading check

07 SPF automatic correction

64 01 Self print

AR-5320D SIMULATIONS 7-2

Page 12

4. Contents of simulations

Main

Sub

code

code

01 01 Mirror scanning operation When the [START] key is pressed, the home position is checked in the first place, and the mirror

02 Mirror home position sensor

(MHPS) status display

06 Mirror scanning operation aging When the [START] key is pressed, the mirror base performs A3 full scanning at the set magnification

02 01 Single paper feeder (SPF) aging When the [START] key is pressed, the set magnification ratio is acquired and document transport

02 SPF sensor status display (In order to receive the sensor change notification, the load must be decreased.)

Contents Details of operation

base performs A3 full scanning once at the set magnification ratio speed. During this scanning, the

set magnification ratio is displayed. The mirror home position sensor status is displayed with the DV

replacement/OPC drum cartridge replacement lamp.

(The lamp lights up when the mirror is in the home position.)

During scanning, the copy lamp lights up.

When the [Interrupt] key is pressed, the operation is interrupted to go to the sub code input standby

mode.

Used to monitor the mirror home position sensor. When the sensor is ON, the DV replacement/OPC

drum cartridge replacement lamp is lighted. During that time, the display section displays the sub

code. When the [Interrupt] key is pressed, the machine goes to the sub code input standby mode.

(When the CA key is pressed, the simulation is terminated.)

ratio speed. During scanning, the set magnification ratio is displayed. After 3 seconds, the mirror

base performs full scanning again. During scanning, the set magnification ratio is displayed.

* When the [START] key is pressed again, the ready lamp turns and remains off.

The DV replacement/OPC drum cartridge replacement lamp displays the status of the mirror

home position sensor. (The lamp lights up when the mirror is in the home position.)

During aging, the copy lamp lights up. When the [Interrupt] key is pressed, the operation is

interrupted if operating, and the machine goes into the sub code input standby mode.

operation of single surface is performed in the case of SPF or document transport operation of

duplex surfaces is performed in the case of RSPF. Since, however, there is no limited condition for

this operation, it does not stop even at a paper jam. During operation, the LED on the display section

corresponding to the selected magnification ratio lights up, and the magnification ratio is displayed

on the 7-seg display. When the [Interrupt] key is pressed at that time, the machine goes to the sub

code input standby mode. When the [CA] key is pressed, the simulation is terminated.

The sensor status (ON/OFF) in the SPF can be checked with the following lamps.

When a sensor detects paper, it turns on. The open/close detection sensor turns on when the

machine is opened.

Display lamp Sensor

Toner supply lamp

Copier jam lamp

The DV replacement/OPC drum cartridge lamp

Paper empty lamp

SPF jam lamp

Manual paper feed lamp

Tray jam lamp

AE lamp

TEXT lamp

PHOTO lamp

SPF document set sensor

SPF document transport sensor

SPF unit (OC cover) open/close sensor

SPF paper exit sensor

SPF paper feed cover open/close sensor

SPF paper length sensor 1

SPF paper length sensor 2

SPF paper feed width sensor (small)

SPF paper feed width sensor (middle)

SPF paper feed width sensor (large)

When the [Interrupt] key is pressed, the machine goes to the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

03 SPF motor operation check When the [START] key is pressed, the motor rotates for 10 sec at the speed corresponding to the set

08 SPF paper feed solenoid operation

check

09 RSPF reverse solenoid operation

check

10 RSPF paper exit gate solenoid

operation check

magnification ratio. When the [Interrupt] key is pressed, the machine stops operation and goes to the

sub code input standby mode. When the [CA] key is pressed, the simulation is terminated.

The SPF paper feed solenoid (PSOL) is turned ON for 500msec and OFF for 500msec.

This operation is repeated 20 times.

After completion of the process, the machine goes to the sub code input standby mode.

When the [Interrupt] key is pressed during the process, the machine goes to the sub code input

standby mode. When the [CA] key is pressed, the simulation is terminated.

The RSPF reverse solenoid (PSOL) is turned ON for 500msec and OFF for 500msec.

This operation is repeated 20 times.

After completion of the process, the machine goes to the sub code input standby mode.

When the [Interrupt] key is pressed during the process, the machine goes to the sub code input

standby mode. When the [CA] key is pressed, the simulation is terminated.

The RSPF paper exit gate solenoid (GSOL) is turned ON for 500msec and OFF for 500msec.

This operation is repeated 20 times.

After completion of the process, the machine goes to the sub code input standby mode.

When the [Interrupt] key is pressed during the process, the machine goes to the sub code input

standby mode. When the [CA] key is pressed, the simulation is terminated.

AR-5320D SIMULATIONS 7-3

Page 13

Main

Sub

code

code

02 11 SPF PS release solenoid operation

check

Contents Details of operation

The SPF PS release solenoid (CLH) is turned ON for 500msec and OFF for 500msec. This operation

is repeated 20 times.

After completion of the process, the machine goes to the sub code input standby mode. When the

[Interrupt] key is pressed during the process, the machine goes to the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

03 02 Shifter sensors status display The shifter HP sensor is monitored. When the sensor is ON, the [Copier position jam lamp] is lighted.

During this operation, the display section displays the sub code. When the [Interrupt] key is pressed,

the machine goes to the sub code input standby mode. When the [CA] key is pressed, the simulation

is terminated.

03 Shifter operation check The shifter is reciprocated 4 times. During the process, the display section displays the sub code.

After completion of the process, the machine goes to the sub code input standby mode. When the

[Interrupt] key is pressed during the process, the machine goes to the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated. To stop the shifter, however, stop is in

the home position.

11 Shifter home position check The shifter is moved in one direction by the specified steps. The 7-seg LED displays the sub code.

While the shifter is moving, the shifter HP sensor is monitored. While the sensor is ON, the machine

position jam lamp is lighted.

3 key:

4 key:

5 key:

Step toward the front

Step toward the rear

Initial

When the [Interrupt] key is pressed during the process, the machine goes to the sub code input

standby mode. When the [CA] key is pressed, the simulation is terminated.

05 01 Operation panel display check <<LED check mode (ALL ON/Individual ON)>>

When the [START] key is pressed in the sub code input mode, all the LED's (including the 7-seg

lamps) are turned ON. After 5 sec of all ON, the machine goes to the sub code input standby mode.

When the [Mode select] key is pressed during all ON, the lighting mode is shifted to the individual ON

mode, where the LED's are individually lighted from the left top, to the left bottom, to the next line top,

to the bottom, and so on. (For the 7-seg lamps, the 3-digit lamps are lighted at once.)

After completion of lighting of all the lamps, the mode is shifted to the all ON mode.

After 5 sec of all ON mode, the machine goes to the sub code input standby mode.

Individual ON mode cycle: 300ms for ON 20ms for OFF

When the [Interrupt] key is pressed in the LCD check mode, the machine goes back to the sub code

input standby mode.

When the [CA] key is pressed, the simulation is terminated.

When the [START] key is pressed with all the lamps ON, the machine goes back to the key input

check mode.

<< Key input check mode>>

When the machine goes into the key input check mode, [- - -] is displayed on the copy quantity

display. Every time when a key on the operation panel is pressed, the input value is added on the

copy quantity display.

[- - -] [ 1] [ 2] •••.

When a key is pressed once, it is not counted again.

When the [START] key is pressed, the input number is added and displayed for 3 sec, and the

machine goes into the LED lighting check mode (LED all ON state). When the [Interrupt] key is

pressed for the first time, it is counted. When the key is pressed for the second time, the machine

goes into the sub code input mode. When the [CA] key is pressed for the first time, it is counted.

When the key is pressed for the second time, the simulation is terminated. (Note for the key input

check mode).

•Press the [START] key at the end. (When the key is pressed during the process, the machine goes

into the LED lighting check mode (all ON state).).

•When two or more keys are pressed simultaneously, they are ignored.

02 Fusing lamp and cooling fan

operation check

When the [START] key is pressed, the fusing lamp turns ON for 500ms and OFF for 500ms.

The operation is repeated 5 times. During this process, the cooling fan motor rotates.

After completion of the process, the machine goes into the sub code input standby mode.

03 Copy lamp lighting check When the [START] key is pressed, the copy lamp lights up for 5 sec. After completion of lighting, the

machine goes into the sub code input mode.

When the [Interrupt] key is pressed, the process is interrupted and the machine goes into the sub

code input standby mode. When the [CA] key is pressed, the simulation is terminated.

AR-5320D SIMULATIONS 7-4

Page 14

Main

Sub

code

code

06 01 Paper feed solenoid operation

check

Contents Details of operation

When this simulation is executed, the sub code is displayed on the 7-seg LED and the lamp

corresponding to the solenoid lights up.

Select a solenoid with the tray select key (the lamp corresponding to the solenoid lights up) and

press the [START] key, and the machine repeats operation of ON for 500ms and OFF for 500ms.

This operation is repeated 20 times.

After that, the machine goes into the sub code entry standby mode.

Display lamp Solenoid

Main cassette lamp

2nd cassette lamp

3rd cassette lamp

4th cassette lamp

Manual paper feed lamp

2nd cassette jam lamp

Machine jam lamp & 2nd cassette jam lamp

Main cassette paper feed solenoid

* 2nd cassette paper feed solenoid

* 3rd cassette paper feed solenoid

* 4th cassette paper feed solenoid

Manual paper feed solenoid

* 2nd cassette paper transport solenoid

* 3rd cassette transport solenoid

* Supported for the installed models only. Skipped for the models without installation.

02 Resist roller solenoid operation

check

When the [START] key is pressed in the sub code input state, the resist solenoid (RRS) turns ON for

500ms and OFF for 500ms. This operation is repeated 20 times.

After completion of the process, the machine goes into the sub code input standby mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

10 Cassette semi-circular roller

cleaning

First of all, remove the developer unit.

Enter the simulation code, specify the cassette to be cleaned with the tray select key, and press

START button. The main motor rotates to move the cassette semi-circular roller by half circle and

make the roller face downward.

After completion of cleaning, when INTERRUPT key is pressed, the machine goes into the sub code

entry standby mode and the roller returns to the original positions.

To clean another roller continuously, press INTERRUPT key to return the roller to the original

position, and execute the simulation again.

During the operation, the sub code is displayed on the display.

* When CA key is pressed, the simulation mode is terminated.

However, the roller returns to the original position by the initial operation.

07 01 Warm-up display and aging with

jam

Copying is repeated to make the set copy quantity. When this simulation is executed, warm-up is

started and warm-up time is counted up every second from 0 and displayed. After completion of

warm-up, warm-up time count is stopped. When the [CA] key is pressed, the ready lamp lights up.

After that, when the copy quantity is inputted with keys and the [START] key is pressed, copying is

repeated to make the set copy quantity. (Intermittent 0 sec)This simulation is canceled by turning off

the power or performing a simulation that executes hardware reset.

06 Intermittent aging Copying is repeated to make the set copy quantity. When this simulation is performed, warm-up is

performed and the ready lamp is lighted. Enter the copy quantity with the key and press the [START]

key, and copying is repeated to make the set copy quantity, the ready state remains for 3 sec, and

copying is repeated again to make the set copy quantity. These operations are repeated.

This simulation is canceled by turning off the power or performing a simulation that executes

hardware reset.

08 Shifting with warm-up display

(Shifting similar to pressing the CA

key)

When the simulation code is entered, warm-up is started and warm-up time is counted up every

second from 0 and displayed. When the [CA] key is pressed during counting up, the display section

displays "0" and count-up process stops. However, warm-up is continued.

After completion of warm-up, counting is stopped. Press the [CA] key to terminate the simulation

mode. (This simulation is similar to SIM07-01, but without the aging function.)

AR-5320D SIMULATIONS 7-5

Page 15

Main

code

Sub

code

Contents Details of operation

08 01 Developing bias output When the [START] key is pressed, the developing bias signal is turned ON for 30 sec.

However, to calculate the actual output value is calculated, execute SIM25-01.

After completion of the process, the machine goes into the sub code input standby mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

02 Main charger output (Grid = HIGH) When the [START] key is pressed, the main charger output is supplied for 30 sec in the grid voltage

HIGH mode. After completion of the process, the machine goes into the sub code input standby

mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

03 Main charger output (Grid = LOW) When the [START] key is pressed, the main charger output is supplied for 30 sec in the grid voltage

LOW mode. After completion of the process, the machine goes into the sub code input standby

mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

06 Transfer charger output Select an output mode with the [Mode select] key and press the [START] key. The transfer charger

output is delivered for 30 sec in the selected mode.

After 30 sec of transfer charger output, the machine goes into the sub code entry standby mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

Display lamp Output mode

AE mode lamp

TEXT mode lamp

AE mode lamp & PHOTO mode lamp

TEXT mode lamp & PHOTO mode lamp

AE & TEXT & PHOTO mode lamp

Normal size width: Front surface

Normal size width: Back surface

Small size width: Front surface

Small size width: Back surface

Manual paper feed mode

•Small size is Letter R (A4R) or smaller.

09 01 Duplex motor forward rotation

check

The duplex motor is driven in forward direction (in the paper exit direction) for 30 sec.

During the process, the display section displays the sub code.

After completion of the process, the machine goes into the sub code input standby mode.

When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

02 Duplex motor reverse rotation

check

The duplex motor is driven in reverse direction for 30 sec.

During the process, the display section displays the sub code.

After completion of the process, the machine goes into the sub code input standby mode.

When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

04 Duplex motor RPM adjustment When any key input is made, it is displayed on the display section.

When the [START] key is pressed, the set code data are acquired and stored in the EEPROM, and

the machine goes into the sub code input standby mode.

When, however, the [START] key is pressed outside the set range, it is not assured.

Set range: 1 - 13 Default: 4

At that time, when the [Interrupt] key is pressed, the data are not rewritten and the machine goes into

the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated without rewriting the data.

05 Duplex motor switchback time

adjustment

When any key input is made, it is displayed on the display section. When the [START] key is pressed,

the set code data are acquired and stored in the EEPROM, and the machine goes into the sub code

input standby mode.

Set range: 50 ~ 76 Default: 50

(Change quantity 1 1-2 phase 3 steps)

At that time, when the [Interrupt] key is pressed, the data are not rewritten and the machine goes into

the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated without rewriting the data.

10 - Toner motor operation When the [START] key is pressed, the toner motor is driven for 30 sec.

After completion of the process, the machine goes into the main code input standby mode.

When the [Interrupt] key is pressed, the machine goes into the main code input standby mode.

* If this simulation is executed with the toner cartridge installed, an over toner error may occur.

14 - Trouble cancel (except for U2) * Trouble to write into the EEPROM such as H trouble is canceled and hardware reset is

performed.

16 - U2 trouble cancel * U2 trouble is canceled and hardware reset is performed.

20 01 Maintenance counter clear When the [Start] key is pressed, the maintenance count value is cleared and "000000" is displayed.

(Alternate display of "000" and "000")

AR-5320D SIMULATIONS 7-6

Page 16

Main

code

Sub

code

Contents Details of operation

21 01 Maintenance cycle setting The current set maintenance cycle code is displayed (initial display), and the set data are stored.

Code Setting

0

1

2

3

4

5

5,000 sheets

7,500 sheets

10,000 sheets

25,000 sheets

50,000 sheets * Default

Free (999,999 sheets)

22 01 Maintenance counter display The maintenance counter value is displayed. (Alternate display by 3 digits)

02 Maintenance preset display (Valid

only when the destination is set to

The copy quantity corresponding to the code that is set with SIM21-01 is displayed.

(For example: 50,000 sheets)

EX Japan)

03 Jam memory display The LED of the latest jam position is lighted. Every time when the magnification ratio display key is

pressed, the jam memory data is acquired sequentially from the latest. The jam position is judged by

the acquired data and the corresponding LED is lighted. The 7-seg display indicates the jam number.

At that time, "A" is displayed on the upper first digit. When the last one is displayed, the latest one will

be displayed again. Max. 30 jams from the latest are stored. When the [Interrupt] key is pressed, the

machine goes into the sub code input standby mode. When the [CA] key is pressed, the simulation is

terminated.

04 Jam total counter display The jam total counter value is displayed. (Alternate display by 3 digits)

05 Total counter display The total counter value is displayed. (Alternate display by 3 digits)

06 Developing counter display The developing counter data is acquired and displayed on the 7-seg display. (Alternate display by 3

digits)

When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

08 SPF counter display The SPF counter value is displayed. (Alternate display by 3 digits)

09 Paper feed counter display The counter value of the selected paper feed section is acquired from each variable, the data is

displayed on the 7-seg display according to the regulations. When this simulation is executed, the

value of the first cassette is displayed first. Press the tray select key to select the paper feed tray.

When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

12 Drum counter display The drum counter and the drum rotating time are displayed.

To change the display mode, press the [Mode select] key.

Display lamp

AE mode lamp

TEXT mode lamp

Display mode

Drum counter

Drum rotating time

13 CRUM destination display When this simulation is executed, the CRUM destination set (written) in the CRUM chip is displayed.

This simulation is valid only for the models where the CRUM is valid.

7-seg display Meaning (CRUM destination) 7-seg display Meaning (CRUM destination)

00

01

02

03

Not set yet

BTA-A

BTA-B

BTA-C

04

99

12

BTA-E

Conversion

AL series

14 P-ROM version display The P-ROM version is displayed on the copy quantity display. The main code and the sub code are

alternatively displayed by 2 digits. The display interval is same as that of the counter display.

By pressing the fixed magnification ratio key, each version display is switched.

Display lamp (AB series) Display lamp (Inch series) Displayed version

141% 141% Machine program

15 Trouble memory display The trouble codes up to the latest one are acquired from the trouble memory data.

Every time when the magnification ratio display is pressed, the main code of the trouble is displayed

on the 1st ~ 2nd digit.

* The latest 20 troubles are stored in the memory.

The 3rd digit indicates the trouble history code, "A" ~ "J" (meaning of 1 ~ 10).

After "J" is displayed, "A" ~ "J" blinks. (Meaning of 11 ~ 20)

After "J" blinks (meaning of 20), "A" ~ "J" is lighted. (Returns to 1.)

When the [START] key is pressed, the sub code is displayed.

When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

* Note that when the history code blinks, the trouble code and the sub code do not blink.

16 Duplex print counter display Data is acquired from the duplex print counter variable, and is displayed.

When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

AR-5320D SIMULATIONS 7-7

Page 17

Main

code

Sub

code

Contents Details of operation

22 17 Copy counter display The copy counter value is displayed. (Alternate display by 3 digits) When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

18 Printer counter display The printer counter value is displayed. (Alternate display by 3 digits)When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

19 Scanner mode counter display

<Not Available for AR-5320D>

21 Scanner counter display

<Not Available for AR-5320D>

The scanner mode counter value is displayed. When the [Interrupt] key is pressed, the machine goes

into the sub code input standby mode. When the [CA] key is pressed, the simulation is terminated.

The scanner counter value is displayed. (Alternate display by 3 digits)When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

22 SPF jam counter display The SPF jam counter value is displayed. (Alternate display by 3 digits)When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

24 01 Jam total counter clear When the [START] key is pressed, the jam total count value is reset to zero, and zero is displayed.

02 Trouble memory clear The trouble memory and the EEPROM trouble history data are cleared and "000" is displayed on the

7-seg display. When the [Interrupt] key is pressed, the machine goes into the sub code input standby

mode. When the [CA] key is pressed, the simulation is terminated.

04 SPF counter clear When the [START] key is pressed, the SPF count value is reset to zero and displayed on the 7-seg

display. When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

05 Duplex print counter clear The duplex print count data is cleared, and zero is displayed on the 7-seg display.

When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

06 Paper feed counter clear The paper feed counter data of each paper feed section is cleared, and "000" is displayed on the 7-

seg display. When the [Interrupt] key is pressed, the machine goes into the sub code input standby

mode. When the [CA] key is pressed, the simulation is terminated.

07 Drum counter clear When the [START] key is pressed, the drum count and the drum roasting time are reset to zero, and

the drum counter value is displayed on the 7-seg LED. When the [Interrupt] key is pressed, the

machine goes into the sub code input standby mode. When the [CA] key is pressed, the simulation is

terminated.

08 Copy counter clear When the [START] key is pressed, the copy count value is reset to zero and displayed on the 7-seg

display. When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

09 Printer counter clear When the [START] key is pressed, the printer count value is reset to zero and displayed on the 7-seg

display. When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

13 Scanner counter clear When the [START] key is pressed, the scanner count value is reset to zero and displayed on the 7-

seg display. When the [Interrupt] key is pressed, the machine goes into the sub code input standby

mode. When the [CA] key is pressed, the simulation is terminated.

14 SPF jam total counter clear When the [START] key is pressed, the SPF jam total count value is reset to zero and displayed on

the 7-seg display. When the [Interrupt] key is pressed, the machine goes into the sub code input

standby mode. When the [CA] key is pressed, the simulation is terminated.

15 Scanner mode counter clear When the [START] key is pressed, the scanner mode count value is reset to zero and displayed on

the 7-seg display. When the [Interrupt] key is pressed, the machine goes into the sub code input

standby mode. When the [CA] key is pressed, the simulation is terminated.

25 01 Main motor operation check

(Cooling fan motor rotation check)

When the [START] key is pressed, the main motor (together with the duplex motor for the duplex

model) is driven for 30 sec. At that time, to save toner consumption, if the developing until is installed,

the developing bias, the main charger, and the grid are outputted. Since, in that case, laser discharge

is required when the motor stops, the polygon motor is driven simultaneously. Check if the

developing unit is installed or not. If it is not installed, the above high voltage is not outputted and only

the motor is rotated. After completion of 30 sec operation, the machine goes into the sub code input

standby mode.

* This simulation must not be executed by forcibly turning on the door open/close switch.

10 Polygon motor operation check When the [START] key is pressed, the polygon motor is rotated for 30 sec. After completion of 30 sec

operation, the machine goes into the sub code input standby mode.

AR-5320D SIMULATIONS 7-8

Page 18

Main

code

Sub

code

Contents Details of operation

26 02 Size setting Used to set Enable/Disable of the FC (8.5" x 13") size detection.

Code number Setting

0

1

FC detection Disable

FC detection Enable

* Default except for the following

* Default only for SCA/Philippines

Detection size when a document of the FC ((8.5" x 13") size is used

Unit to

be used

Destination Document size

Document SPF EX Japan AB

series (FC)

0 (Disable) 1 (Enable)

FC (8.5" x 13") B4 FC (8.5" x 13")

B4 B4 FC (8.5" x 13")

Setting

Inch series (FC) FC (8.5" x 13") LG (8.5" x 14") FC (8.5" x 13")

LG (8.5" x 14") LG (8.5" x 14") FC (8.5" x 13")

•For the other destinations, this setting is disabled.

03 Auditor setting Used to set the auditor.

Code number Mode

0

1

2

Built-in auditor mode

Coin vendor mode

Other

* When the coin vendor mode is selected, if the auditor setup is ON and the standard tray is

manual feed tray, the standard tray setup must be changed to the main cassette.

04 Copier duplex setting When this simulation is executed, the current set duplex code number is displayed. Enter the desired

code number of duplex setting and press the [START] key, and the entered code number is set.

Code number Mode

0

1

Without duplex

With duplex

* When this simulation is executed, the binding margin setup is automatically set to the default

(left side).

05 Count mode setting When any key input is made, it is displayed on the display section. When the [START] key is pressed,

the set code data are acquired and stored to the count mode set variable and in the EEPROM, and

the machine goes into the sub code input standby mode. However, if the [START] key is pressed

outside the set range, it is not assured. At that time, when the [Interrupt] key is pressed, the data are

not rewritten and the machine goes into the sub code input standby mode. When the [CA] key is

pressed, the simulation is terminated without rewriting the data.

[*1 : Total counter / Developer counter *2 : maintenance counter]

0:

1:

2:

3:

*1= Double count

*1= Single count

*1= Double count

*1= Single count

*2= Double count

*2 = Double count

*2= Single count

*2= Single count

06 Destination setting When this simulation is executed, the current set destination code number is displayed. Enter the

desired code number of the destination and press the [START] key to set the destination.

Code number Destination

0

1

2

3

4

5

6

Japan AB series

Inch series

EX Japan AB series

EX Japan inch series

EX Japan AB series (FC)

China (EX Japan AB series + China paper support)

Taiwan (EX Japan AB series + China paper support)

If this setting is changed, SIM46-19 setting is also changed accordingly.

(The paper size is also changed: AB series is changed to A4, and Inch series to Letter.

The AE limit setup is set to the default.

When the destination is changed (from Japan to EX Japan or from EX Japan to Japan),

the maintenance cycle is also set to the default accordingly.)

AR-5320D SIMULATIONS 7-9

Page 19

Main

code

Sub

code

Contents Details of operation

26 07 Machine condition check (CPM) When this simulation is executed, the current setting of the machine is displayed.

7-seg display Meaning (CPM information)

15

16

20

15CPM

16CPM

20CPM

18 Toner save mode setting Used to set ON/OFF of the toner save mode.

Code number Setting

0

1

Toner save OFF

Toner save ON

* The toner save mode of the user program is also changed accordingly.

30 CE mark conformity control ON/

OFF

When this simulation is executed, the current set code number of CE mark conformity is displayed.

Enter the desired code number of CE mark conformity and press the [START] key to set the code

number.

Code number Setting

0

1

CE mark conformity control OFF *Default for 100V system

CE mark conformity control ON

31 Auditor mode exclusive setup Used to set whether the manual fed tray can be used or not when the auditor mode is set to the coin

vendor mode.

Code number Setting

0

1

Exclusive setup OFF (Manual paper feed allowed)

Exclusive setup ON (Manual paper fed inhibited)

* When this is set to "Exclusive setup ON," if the auditor is set to the coin vendor mode and the

standard tray is set to the manual feed tray, the standard tray must be set to the main cassette.

36 Cancel of stop at maintenance life

over

Used to set stop at maintenance life over.

Code number Setting

0

1

Stop at maintenance life over

Cancel of stop at maintenance life over * Default

37 Cancel of stop at developer life

over

When this simulation is executed, the current set code number is displayed. Enter the desired code

number and press the [START] key to set the code number. The machine goes into the sub code

input state.

Code number Setting

0

1

Stop at developer life over

Cancel of stop at developer life over

38 Cancel of stop at drum life over When this simulation is executed, the current set code number is displayed. Enter the desired code

number and press the [START] key to set the code number.

Code number Setting

0

1

Stop at drum life over

Cancel of stop at drum life over

AR-5320D SIMULATIONS 7-10

Page 20

Main

code

Sub

code

Contents Details of operation

26 39 Memory capacity check When this simulation is executed, the current memory capacity is displayed.

7-seg display Meaning (Memory capacity)

42 Transfer ON/OFF timing control

setting

16

32

When this simulation is executed, the current setting value of transfer ON timing is displayed.

Enter a set value and press the [START] key to set the entered value, and the machine will go into

16MByte

32MByte

the sub code input standby mode.

When the [Mode select] key is pressed, the ON timing setting and the OFF timing setting are

alternatively selected. At that time, the setting is saved and written into the EEPROM.

Display lamp Setting mode Default

AE mode lamp

TEXT mode lamp

Transfer ON timing

Transfer OFF timing

•Setting range: 1 ~ 99

When the setting value is increased by 1, time is increased by 2ms.

•The default, 50, of transfer ON timing means "344ms passed from PS release."

The default, 50, of transfer OFF timing means "304ms passed from P-IN OFF."

43 Side void amount setting Used to set the side void amount on the both sides.

Enter a set value with the 10-key and press the [START] key, and the entered value will be saved and

the machine will go into the sub code input standby mode.

The setting range is 0 ~ 10. When the set value is increased by 1, the void amount is increased by

0.5mm. The default is 3 (= 1.5mm).

To select the setting mode, press the [Exposure mode select] key. The set value of the selected

mode is displayed on the copy quantity display. At that time, the set value is also saved.

Display lamp Setting mode

AE mode lamp

TEXT mode lamp

Side void amount (Right)

Side void amount (Left)

50

50

* When the setting value is increased by 1, time is increased by 0.5ms.

51 Copy temporary stop function

setting

When any key is pressed, it is displayed on the display section. When the [START] key is pressed,

the set code data is acquired and stored to the setting variable of sort/group copy temporary stop

function and to the EEPROM. The machine goes into the sub code input standby mode.

Code number Setting

0

1

Not stop

Stop * Default

When the [Interrupt] key is pressed at that time, the machine goes into the sub code input standby

mode without rewriting the data. When the [CA] key is pressed, the simulation mode is terminated

without rewriting the data.

* When this is set to "Stop," temporary stop is made for every 250 copies in one copy job.

30 01 Paper sensor status display The paper sensor status is displayed with the lamps on the operation panel.

* When each sensor detects paper, the corresponding lamp turns on.

Display lamp Sensor name

Developer lamp

Machine jam lamp

Toner lamp

Manual paper feed lamp

No. 1 cassette lamp

No. 2 cassette lamp

No. 3 cassette lamp

No. 4 cassette lamp

Tray jam lamp 1

Tray jam lamp 2

Paper empty lamp

Paper exit sensor

Duplex sensor

Paper entry sensor

Manual feed paper empty sensor

No. 1 tray paper empty sensor

No. 2 tray paper empty sensor

No. 3 tray paper empty sensor

No. 4 tray paper empty sensor

No. 2 tray paper feed sensor

No. 3 tray paper feed sensor

No. 4 tray paper feed sensor

42 01 Developing counter clear The developer counter data in the EEPROM is cleared and 0 is displayed on the 7-seg display.

When the [Interrupt] key is pressed at that time, the machine goes into the sub code input standby

mode. When the [CA] key is pressed, the simulation mode is terminated.

AR-5320D SIMULATIONS 7-11

Page 21

Main

Sub

code

code

43 01 Fusing temperature setting

(During normal copy)

Contents Details of operation

When the simulation is terminated, the current set value is displayed. When the [%] key is pressed,

the setting is changed. When the [START] key is pressed, the set content is written into the

EEPROM and the machine goes into the sub code input standby mode.

Set temperature (°C) Set temperature (°C)

160

165

170 * Default

175

180

10 Postcard paper feed cycle setting Used to set the paper feed cycle timing in postcard printing. (Pickup interval)[1] ~ [99]

(Center [50], Unit: 100msec)(Example: When 50, pickup interval = 100msec x 50)

11 Postcard size paper fusing

temperature setting

When this simulation is executed, the current set value is displayed. When the [%] key is pressed,

the setting is changed. When the [START] key is pressed, the set content is written into the

EEPROM and the machine goes into the sub code input standby mode.

Set temperature (°C) Set temperature (°C)

160

165

170

195 * Default

175

180

185

190

195

200

185

190

200

12 Standby mode fusing fan rotation

setting

When this simulation is executed, the current set code number is displayed. Enter the desired code

number and press the [START] key to set the code number.

Code number Setting

13 Fusing paper interval control allow/

inhibit setting

0

1

Used to set the paper feed timing of 21st and later page to A3 or WLT when multi copying or printing

paper of narrow width. (A3 or WLT depends on the destination.)

Low speed rotation *Default

High speed rotation

When this simulation is executed, the currently set code number is displayed. Enter a desired code

number and press the [START] key, and the entered code number is written into the EEPROM and

the machine goes into the sub code entry standby mode.

Code number Setting

0

1

Inhibit * Default

Allow

<Applicable paper>

1) Cassette paper feed: A4R, B5R, 8-1/2" X 14", 8-1/2" X 13", 8-1/2" X 11", A5, INV

2) Manual paper feed: A4R, B5R, 8-1/2" X 14", 8-1/2" X 13", 8-1/2" X 11", A5, INV,16KR

* A5 size for manual paper feed is valid only for EX Japan AB series.

44 34 Transfer current setting Used to set the transfer current for the front surface and that for the back surface. When this

simulation is executed, the current set value is displayed on the 7-seg display. Select the set value

with the zoom (Up/Down) keys and press the [START] key, and the set content is written into the

EEPROM and the machine goes into the sub code input standby mode. Press the [Mode select] key

to select each setting mode. At that time, the setup content is written into the EEPROM.

The set range is 90uA ~ 360uA in the increment of 10uA.

Display lamp Setting mode

AE mode lamp

TEXT mode lamp

AE mode lamp & PHOTO mode lamp

TEXT mode lamp & PHOTO mode lamp

AE & TEXT & PHOTO mode lamps

Normal size width: Front

Normal size width: Back

Small size width: Front

Small size width: Back

Manual paper feed

40 Setting of rotation time before

toner supply

* Small size paper must be Letter R (A4R) or smaller.

* For the special size of tray, use the normal size width.

Used to set the time interval between start of rotation (ready) of the main motor and start of toner

supply in previous rotation after supplying the power. [1] ~ [99] (Default [8], unit: sec)

AR-5320D SIMULATIONS 7-12

Page 22

Main

code

Sub

code

Contents Details of operation

46 01 Copy density adjustment (300dpi) Used to set the copy density for each mode.

(Operating procedure)

When this simulation is executed, warm-up and shading are operated, and the current set value is

displayed in two digits. (Default [50])

* The density LED is not lighted.

Change the set value and press the [START] key, and a copy is made according to the set value.

The greater the set value is, the darker the density is, and vise versa. In this case, only a copy at Exp.

3 can be made. When, however, the density is set darker, Exp.1 and Exp. 5 become darker, too.

If the dentistry is set lighter, Exp. 1 and Exp. 5 become lighter, too. To select a desired copy mode,

press the [Copy mode select] key. The selected copy mode set value is displayed on the copy

quantity display. (Adjustment range: 1 ~ 99)

Display lamp Copy mode

AE mode lamp

TEXT mode lamp

PHOTO mode lamp

TEXT mode lamp & PHOTO mode lamp

AE mode lamp & PHOTO mode lamp

AE mode (300dpi)

TEXT mode (300dpi)

PHOTO mode

TS mode (TEXT) (300dpi)

TS mode (AE) (300dpi)

02 Copy density adjustment (600dpi) Used to set the copy density for each mode.

(Operating procedure)

When this simulation is executed, warm-up and shading are operated, and the current set value is

displayed in two digits. (Default [50])Change the set value and press the [START] key, and a copy is

made according to the set value. The greater the set value is, the darker the density is, and vise

versa. In this case, only a copy at Exp. 3 can be made.

When, however, the density is set darker, Exp.1 and Exp. 5 become darker, too.

If the dentistry is set lighter, Exp. 1 and Exp. 5 become lighter, too.

To select a desired copy mode, press the [Copy mode select] key.

The selected copy mode set value is displayed on the copy quantity display.

(Adjustment range: 1 ~ 99)

Display lamp Copy mode

AE mode lamp

TEXT mode lamp

PHOTO mode lamp

TEXT mode lamp & PHOTO mode lamp

AE mode lamp & PHOTO mode lamp

09 Copy exposure level adjustment,

individual setting (Text) 300dpi

Used to adjust the shift amount and the inclination value for each density level (1 ~ 5) when the

exposure mode is the TEXT mode (including TS)

•The shift amount is the same as the gamma (gradation), and is used to set the overall brightness.

When the shift amount is increased, the overall brightness is decreased.

When the shift amount is decreased, the overall brightness is increased

•The inclination value changes the gamma (gradation).

When the set value is increased, the gamma is increased to increase the contrast.

(Clearer black and white images)

When the set value is decreased, the gamma is decreased to decrease the contrast.

(Increased gradation)

* Press the [%] key to switch between the shift amount and the inclination value.

The 7-seg display shows the mode.

The initial display is "Shift.

Shift is indicated as "b" (Brightness).

Inclination is indicated as "c" (Contrast).

(Example)

[b50] [%T] key [c50] [%] key [b50] [%] key [c50] •••

* Select the adjustment level with the [Density adjust] key.

The density LED displays the selected level (Exp. 1 ~ Exp. 5)

* Select TEXT or TEXT (TS) with the [Mode select] key.

Mode lamp Exposure mode to be adjusted

TEXT mode lamp

TEXT mode lamp & PHOT mode lamp

AE mode (600dpi)

TEXT mode (600dpi)

PHOTO mode

TS mode (TEXT) (600dpi)

TS mode (AE) (600dpi)

TEXT mode

TEXT (TS) mode

* Change the shift amount and the inclination value with the 10-key.

The set range is [1] ~ [99]. The default is [50].

Change the set value and press the [START] key, and a copy is made at the set value.

AR-5320D SIMULATIONS 7-13

Page 23

Main

code

Sub

code

Contents Details of operation

46 10 Copy exposure level adjustment,

individual setting (Text) 600dpi

11 Copy exposure level adjustment,

individual setting (Photo) 600dpi

Used to adjust the shift amount and the inclination value for each density level (1 ~ 5) when the

exposure mode is the TEXT mode (including TS)

•The shift amount is the same as the gamma (gradation), and is used to set the overall brightness.

When the shift amount is increased, the overall brightness is decreased.

When the shift amount is decreased, the overall brightness is increased

•The inclination value changes the gamma (gradation).

When the set value is increased, the gamma is increased to increase the contrast.

(Clearer black and white images)

When the set value is decreased, the gamma is decreased to decrease the contrast.

(Increased gradation)

* Press the [%] key to switch between the shift amount and the inclination value.

The 7-seg display shows the mode.

The initial display is "Shift.

Shift is indicated as "b" (Brightness).

Inclination is indicated as "c" (Contrast).

(Example)

[b50] [%T] key [c50] [%] key [b50] [%] key [c50] •••

* Select the adjustment level with the [Density adjust] key.

The density LED displays the selected level (Exp. 1 ~ Exp. 5)

* Select TEXT or TEXT (TS) with the [Mode select] key.

Mode lamp Exposure mode to be adjusted

TEXT mode lamp

TEXT mode lamp & PHOT mode lamp

TEXT mode

TEXT (TS) mode

* Change the shift amount and the inclination value with the 10-key.

The set range is [1] ~ [99]. The default is [50].

Change the set value and press the [START] key, and a copy is made at the set value.

Used to adjust the shift amount and the inclination value for each density level (1 ~ 5) when the

exposure mode is the PHOTO mode

•The shift amount is the same as the gamma (gradation), and is used to set the overall brightness.

When the shift amount is increased, the overall brightness is decreased.

When the shift amount is decreased, the overall brightness is increased

•The inclination value changes the gamma (gradation).

When the set value is increased, the gamma is increased to increase the contrast.

(Clearer black and white images)

When the set value is decreased, the gamma is decreased to decrease the contrast.

(Increased gradation)

* Press the [%] key to switch between the shift amount and the inclination value.

The 7-seg display shows the mode.

The initial display is "Shift."

Shift is indicated as "b" (Brightness).

Inclination is indicated as "c" (Contrast).

(Example)

[b50] [%T] key [c50] [%] key [b50] [%] key [c50] •••

* Select the adjustment level with the [Density adjust] key.

The density LED displays the selected level (Exp. 1 ~ Exp. 5)

* The [Mode select] key is invalid, and the PHOTO lamp lights up.

* Change the shift amount and the inclination value with the 10-key.

The set range is [1] ~ [99]. The default is [50].

Change the set value and press the [START] key, and a copy is made at the set value.

AR-5320D SIMULATIONS 7-14

Page 24

Main

code

Sub

code

Contents Details of operation

46 18 Image contrast adjustment

(300dpi)

Used to adjust the contrast for each mode.

(Operating procedure)

When this simulation is executed, warm-up and shading are performed, and the current set value is

displayed in two digits. (Default: 50)

* The density LED is not lighted.