Page 1

SERVICE MANUAL

CODE: 00ZAR5132FM1E

DIGITAL COPIER NO.1

MODEL AR-5132

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] OPTIONS SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] PART NAMES AND FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] UNPACKING AND INSTRATION . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] PICTURE QUALITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] DISASSEMBLY AND REASSEMBLY . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] SIMULATION AND DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MAINTENANCE AND OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 2

CAUTION

This copier machine is a class 1 laser product that complies with 21CFR 1040.10 and 1040.11 of the

CDRH standard and IEC825. This means that this machine does not produce hazardous laser

radiation. The use of controls, adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

This laser radiation is not a danger to the skin, but when an exact focusing of the laser beam is

achieved on the eye’s retina, there is the danger of spot damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time

of servicing.

1) When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged

as a unit, not as individual parts.

2) Do not look into the machine with the main switch turned on after removing the developer unit,

toner cartridge, and drum cartridge.

3) Do not look into the laser beam exposure slit of the laser optical unit with the connector connected

when removing and installing the optical system.

4) The safety interlock switch is equipped.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

LASER WAVE – LENGTH : 785 ± 15nm

Pulse times : 5.66µs/7mm

Out put power : 0.3mW ∼ 0.6mW

CAUTION

INVISIBLE LASER RADIATION,

WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

VORSICHT

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERBRÜCKT.

NICHT DEM STRAHL AUSSETZEN.

VARO !

AVATTAESSA JA SUOJALUKITUS

OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE ÄLÄ

KATSO SÄTEESEEN.

ADVARSEL

USYNLIG LASERSTRÅLNING VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER UDE AF

FUNKTION. UNDGÅ UDSAETTELSE FOR

STRÅLNING.

VARNING !

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL

ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN. – STRÅLEN ÄR

FARLIG.

Page 3

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1. Features of copying functions . . . . . . . . . 1-1

2. System outline (options) . . . . . . . . . . . . . . 1-2

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . 2-1

1. Basic specifications . . . . . . . . . . . . . . . . . 2-1

2. Consumable parts . . . . . . . . . . . . . . . . . . 2-3

[ 3 ] OPTIONS SPECIFICATIONS . . . . . . . . 3-1

[ 4 ] PART NAME AND FUNCTION . . . . . . 4-1

1. External view . . . . . . . . . . . . . . . . . . . . . . 4-1

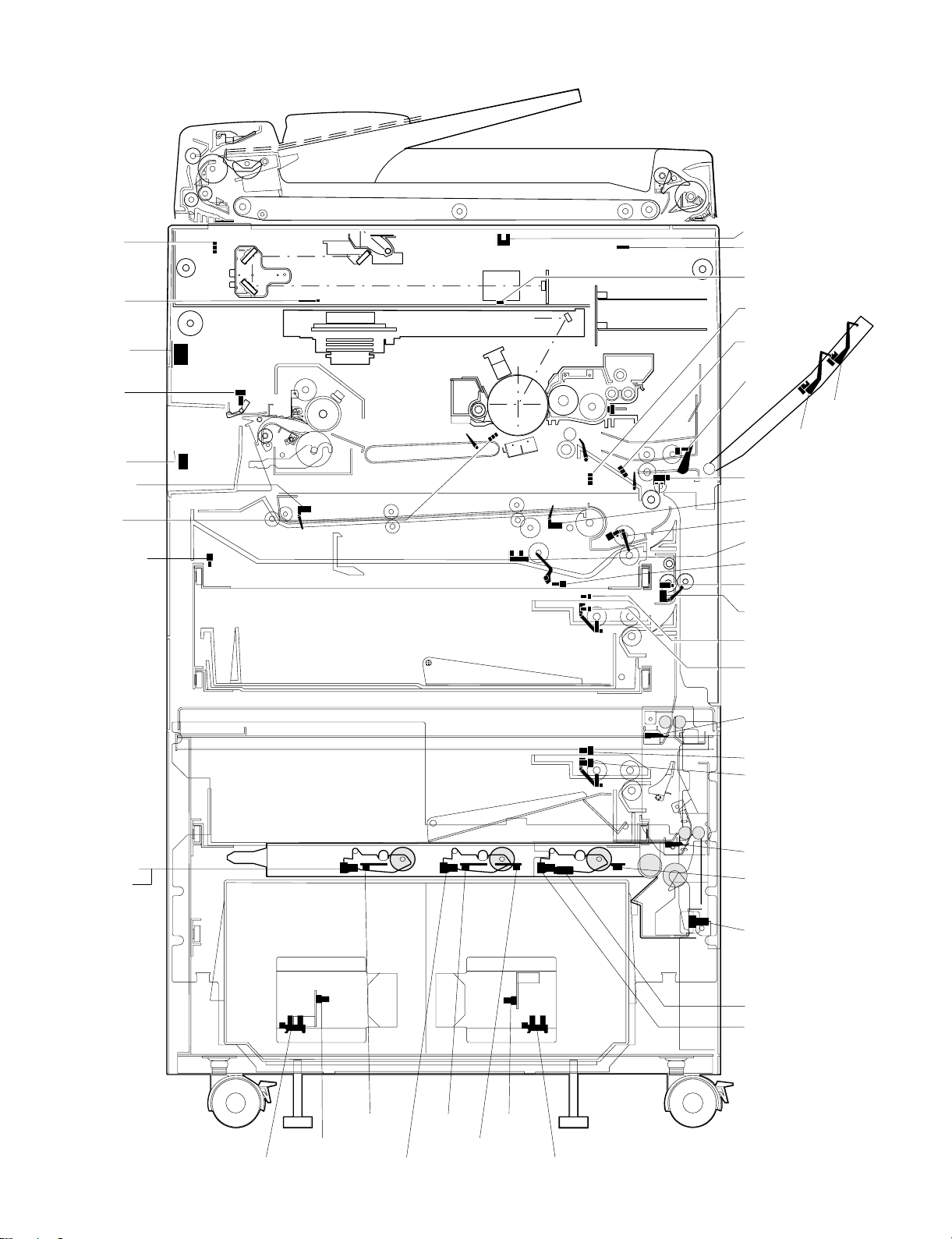

2. Internal structure . . . . . . . . . . . . . . . . . . . 4-2

3. Operation panel . . . . . . . . . . . . . . . . . . . . 4-3

4. Major parts . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

6. Clutches and solenoid . . . . . . . . . . . . . . . 4-8

7. Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

8. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . 4-10

9. Duplex copy tray . . . . . . . . . . . . . . . . . . 4-11

10. Desk unit (Major parts) . . . . . . . . . . . . . . 4-12

11. Desk unit (Sensor) . . . . . . . . . . . . . . . . . 4-13

12. RADF (Sensor) . . . . . . . . . . . . . . . . . . . . 4-14

13. RADF (Motor) . . . . . . . . . . . . . . . . . . . . . 4-15

14. RADF (Clutches and solenoid) . . . . . . . 4-15

15. RADF (PWB) . . . . . . . . . . . . . . . . . . . . . 4-16

[ 5 ] UNPACKING AND INSTALLATION .5-1

1. Use environment . . . . . . . . . . . . . . . . . . . 5-1

2. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . 5-2

3. Setting-up procedure . . . . . . . . . . . . . . . . 5-4

[ 6 ] PICTURE QUALITY ADJUSTMENT . 6-1

1. I nitial setting of process control . . . . . . . . 6-1

2. Picture quality adjustment procedure . . . 6-2

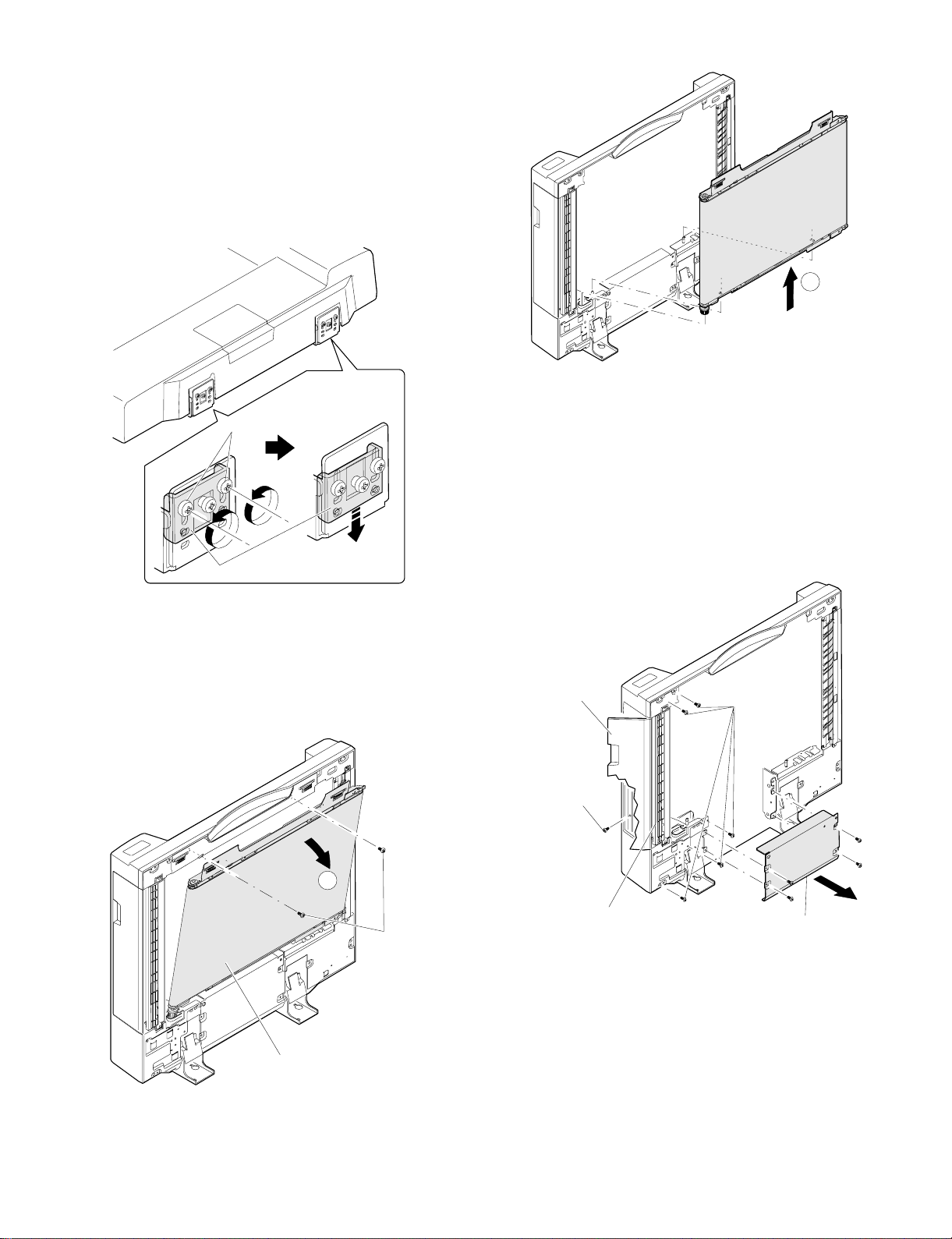

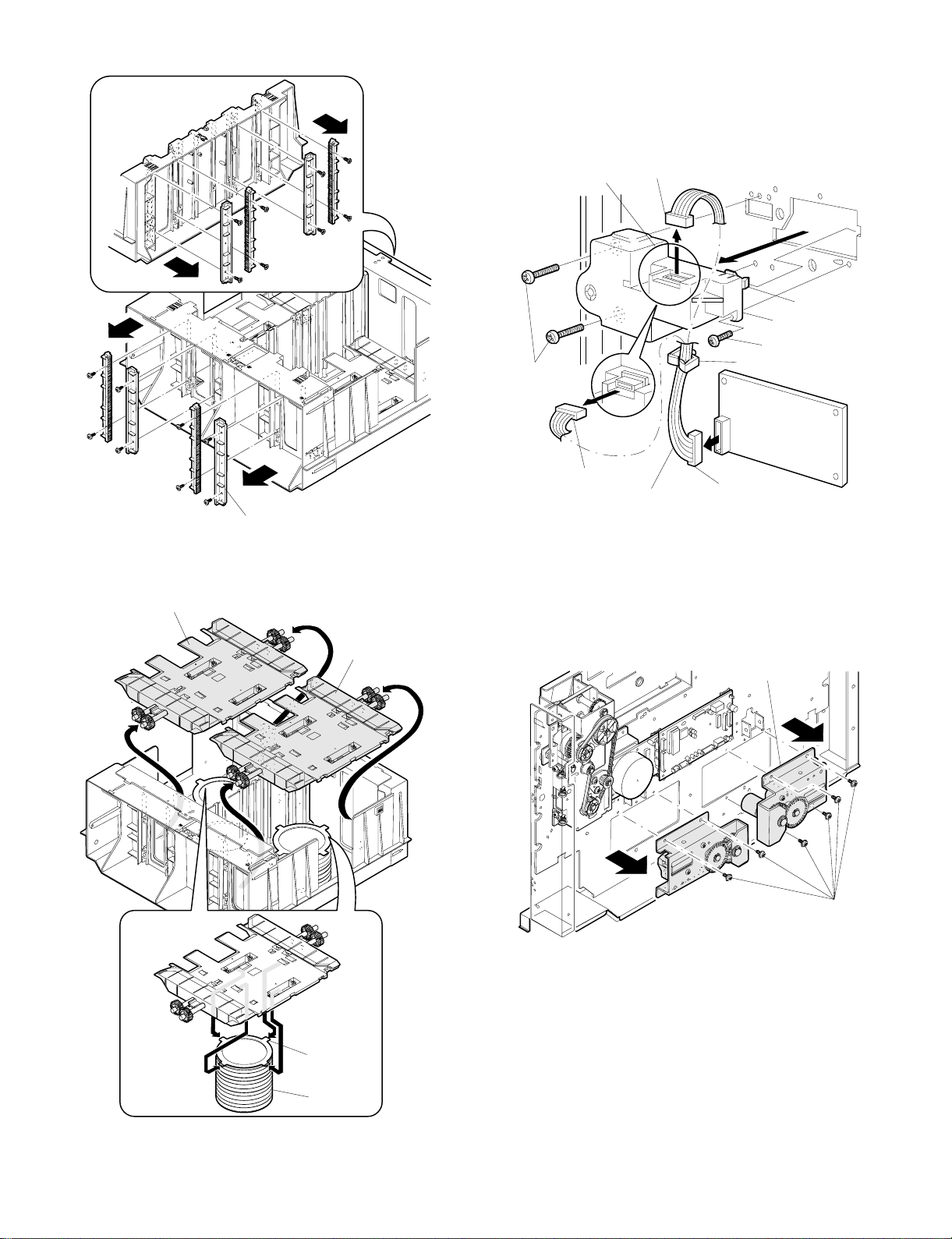

[ 7 ] DISASSEMBLY AND

REASSEMBLY . . . . . . . . . . . . . . . . . . . . . 7-1

1. Process unit . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Manual feed copy unit . . . . . . . . . . . . . . . 7-2

3. Paper feed unit . . . . . . . . . . . . . . . . . . . . . 7-3

4. Transport base unit . . . . . . . . . . . . . . . . . 7-4

5. Fusing unit . . . . . . . . . . . . . . . . . . . . . . . . 7-5

6. Auto duplex unit . . . . . . . . . . . . . . . . . . . . 7-7

7. Main components at rear frame side . . . . 7-8

8. Operation panel unit/Document size

sensor PWB (light reception side) . . . . . 7-10

9. Optical unit . . . . . . . . . . . . . . . . . . . . . . . 7-11

10. LSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

11. PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

12. RADF . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

13. DESK UNIT . . . . . . . . . . . . . . . . . . . . . . 7-26

[ 8 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 8-1

1. Developing section . . . . . . . . . . . . . . . . . . 8-1

2. Process section . . . . . . . . . . . . . . . . . . . . 8-3

3. Laser unit . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

4. Optical section . . . . . . . . . . . . . . . . . . . . . 8-7

5. Document detection section . . . . . . . . . . 8-12

6. Others . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

[ 9 ] SIMULATION AND DIAGNOSTICS . . 9-1

1. Start and end of simulations . . . . . . . . . . 9-1

2. Simulation main code input screen . . . . . 9-1

3. Simulation sub code input screen . . . . . . 9-1

4. Simulation in-progress screen . . . . . . . . . 9-1

5. Setting input activation . . . . . . . . . . . . . . . 9-2

6. Exception processing . . . . . . . . . . . . . . . . 9-2

7. Simulation list . . . . . . . . . . . . . . . . . . . . . . 9-2

8. Detail of simulation . . . . . . . . . . . . . . . . . . 9-7

9. SELF-DIAGNOSTICS . . . . . . . . . . . . . . 9-93

10. KEY OPERATOR PROGRAM . . . . . . . 9-100

11. RADF test mode . . . . . . . . . . . . . . . . . 9-106

[10] MAINTENANCE AND OTHERS . . . . 10-1

1. Maintenance intervals and items to be

serviced . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Replacing ozone filter . . . . . . . . . . . . . . 10-2

3. Oiling and greasing positions . . . . . . . . . 10-2

4. Other maintenance intervals and items

to be serviced . . . . . . . . . . . . . . . . . . . . . 10-3

Page 4

[1] GENERAL

1. Features of copying functions

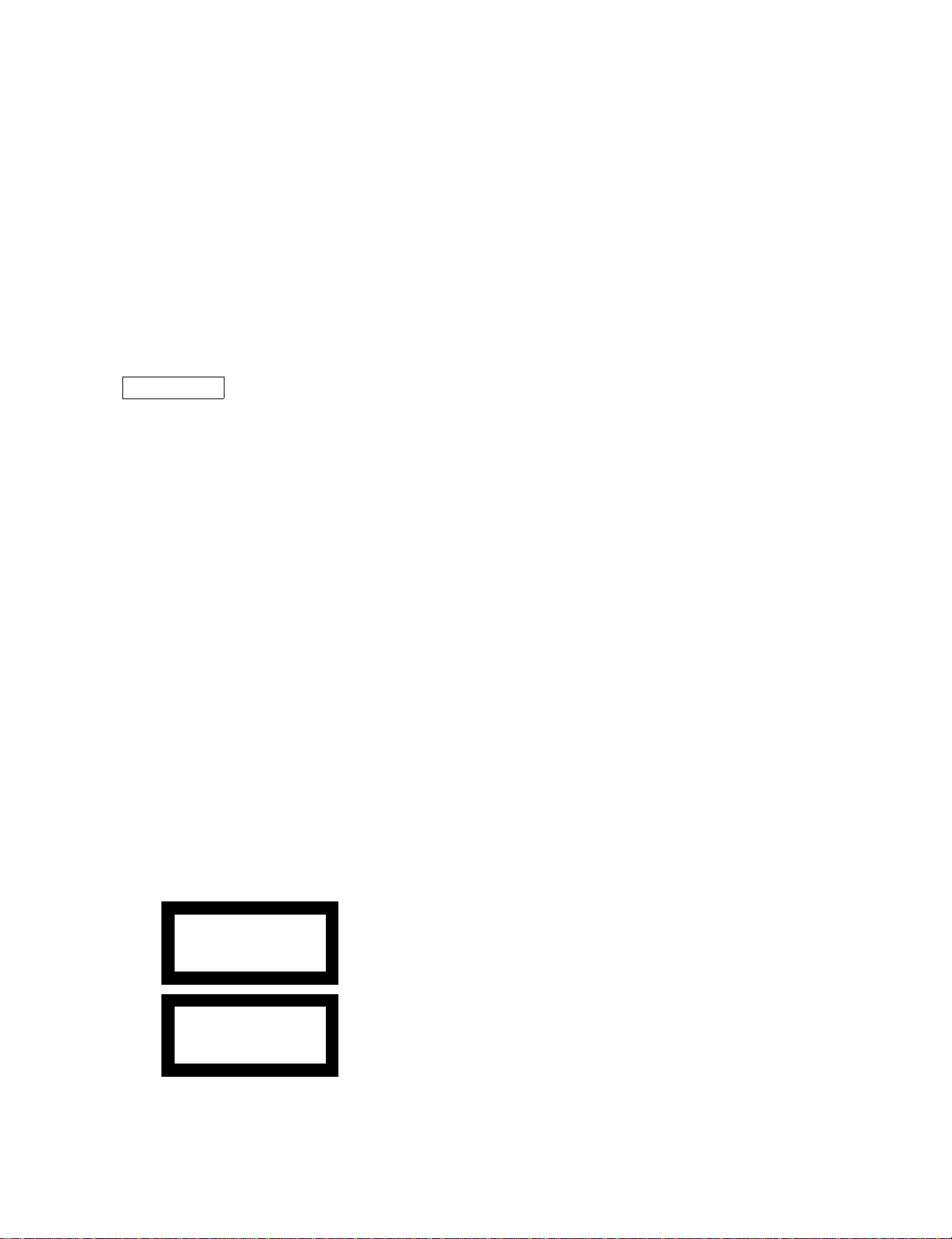

(1) Various functions in the digital system

Different from the conventional analog copiers, the original image

data scanned by the CCD sensor (which converts optical signals into

electrical signals) are converted into digital signals. With the printer kit

(option), in addition to copying functions, this machine can be connected with a computer to serve as a printer. The other features

include the independent zooming function and black-white reversing

function.

Independent z oomi ng copy

Black-white reversing copy

(6) 1-set 2-copy

The right and the left pages of a book, etc. can be copied into two

sheets of paper continuously.

(7) Edge erase copying

Shade at the copy edge can be automatically erased.

(6) Binding margin copying

Copying with binding margin can be made.

(2) Message screen

The message screen employs the LCD display with backlight, and

displays the operational descriptions and paper jam removal procedure, etc.

COPY

READY TO COPY.

COPY RATIO

100%

EXPOSURE

AUTO

AUTO PAPER

SELECT

DUPLEX

11X17

1.

1

2.

X14

8

2

1

3. 8

2

X11

0

ORIGINAL

1

X11

8

2

1

X11R

8

2

(3) Front loading paper tray

The paper trays including the two-step paper feed desk employ a

front loading system to facilitate paper loading.

(4) 351-step zooming by the electronic zooming

function

The electronic zooming function allows 351-step zooming from 50%

to 400% (1% increment).

(9) Copy conditions registration/recall

Nine sets of complicated copying procedures can be stored and

recalled when necessary.

(10) Key operator program

The key operator program is used by the key operator to set and

cancel the customer functions.

(11) Auto duplex copy

Duplex copy is made automatically.

Original Copy

(5) Paper/magnification ratio auto selection

When the desired magnification ratio is specified, the suitable paper

size is automatically selected by the original size detection function. If

the copy paper size is specified, then the suitable magnification ratio

is automatically selected.

1 – 1

Page 5

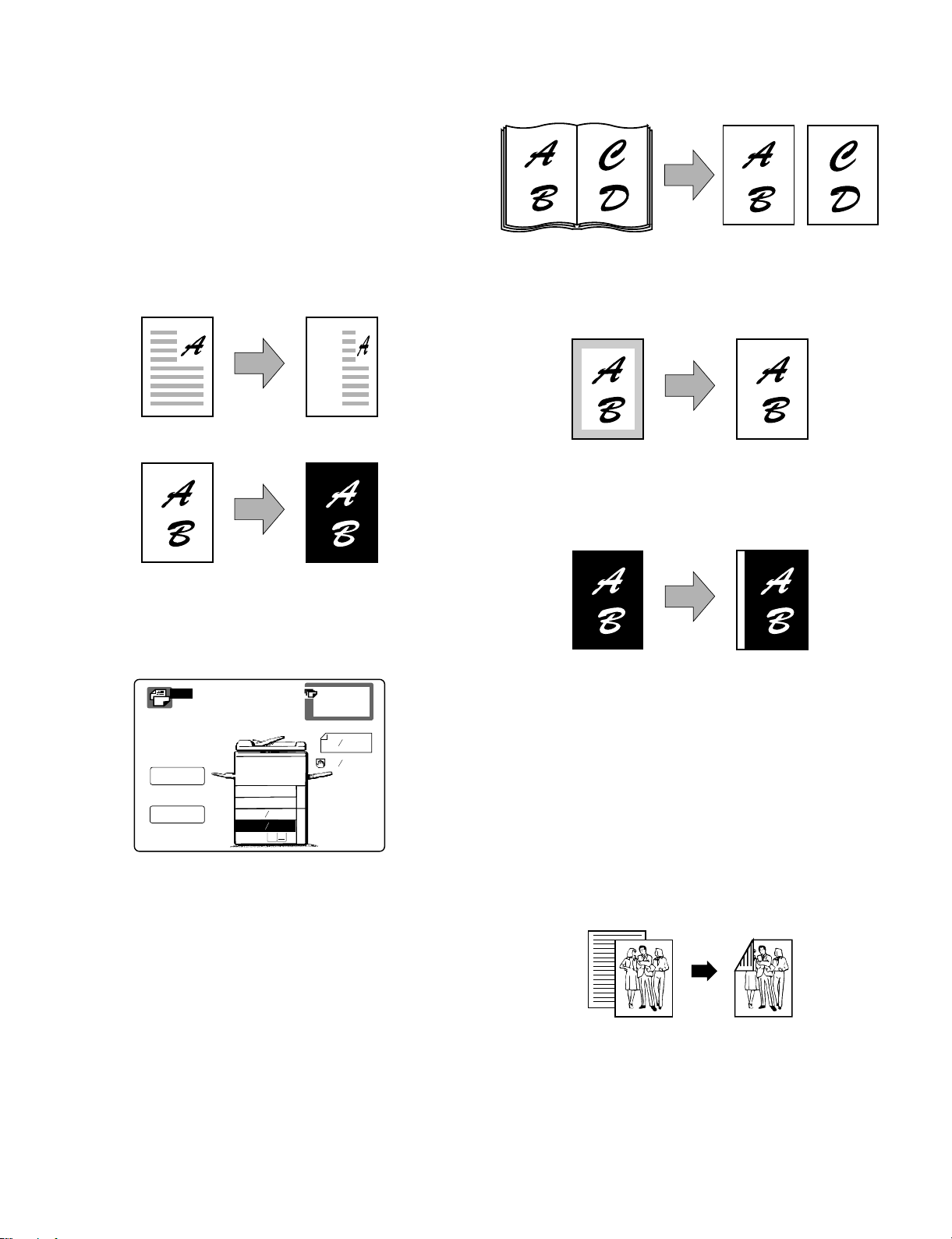

2. System outline (options)

20-bin sorter

(SF-S15)

Copied papers are sorted in the sequence

of pages or in each page automatically.

(Max. 20 sets of sorting is possible.)

Staple sorter

(SF-S53N)

Printer kit

Connected to a computer

to allow the machine to

be used as a printer.

Copied papers are sorted in the sequence

of pages or in each page automatically.

(Max. 20 sets of sorting is possible.)

The sorted papers (in the sequence of

pages) can be stapled.

1 – 2

Page 6

[2] SPECIFICATIONS

1. Basic specif icat io ns

(1) Type: Console

(The desk is standard equipment, but packaged

separately.)

(2) Copy system: Static electricity transfer, dry

copier

(3) Scanning system

Miniature optical, CCD linear sensor

Linear sequential scanning by light source

shifting

Basic scanning resolution: 400 dpi

(4) Copy speed

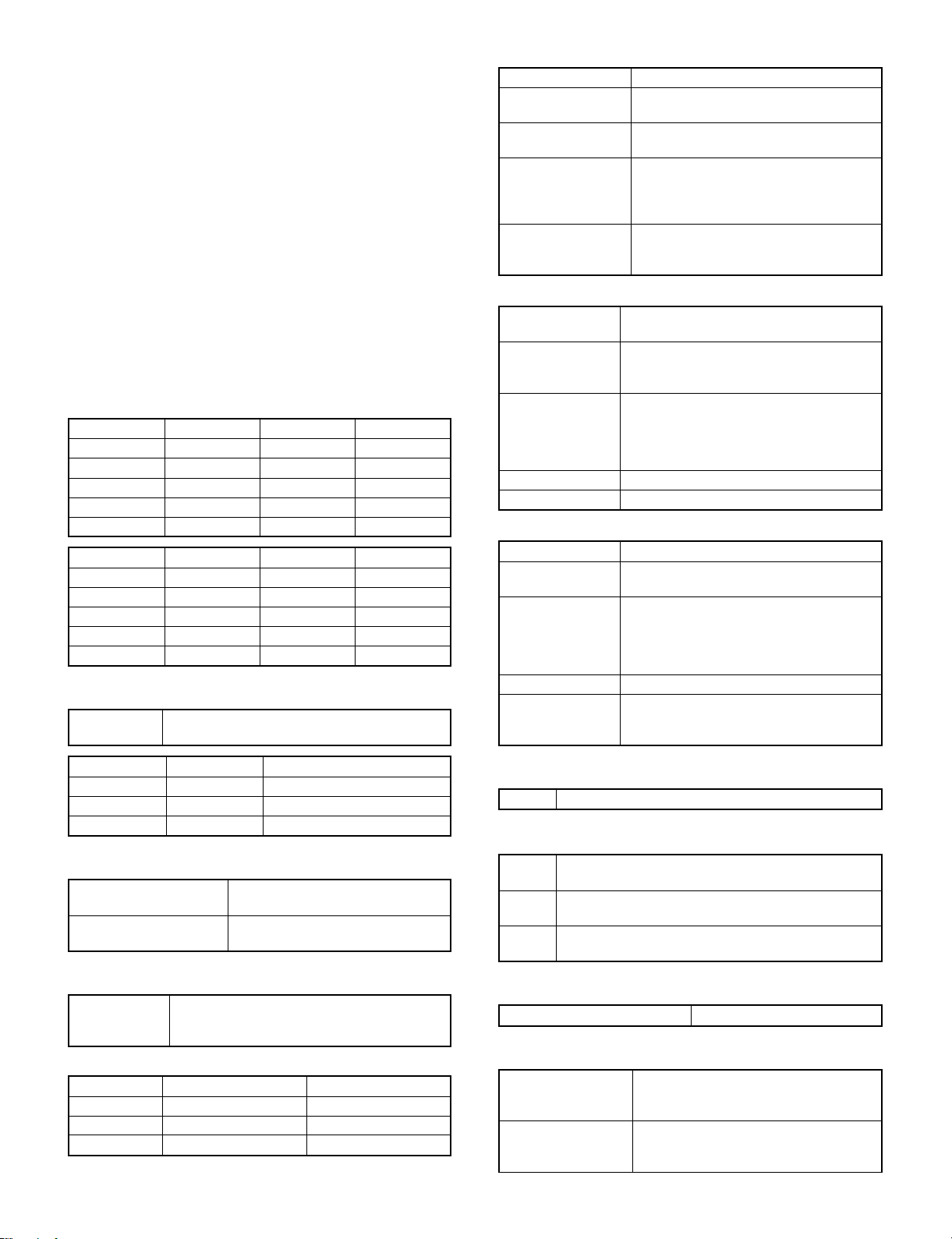

Paper size Normal Enlargement Reduction

Letter 32 17 23

W-letter 17 16 17

Legal 19 17 19

Letter-R 23 17 21

Invoice 32 17 23

Paper size Normal Enlargement Reduction

A4 32 17 23

A3 17 16 17

B4 19 17 19

A4R 23 17 21

A5 32 17 23

(5) First copy time

4.6 seconds When a sheet of A4 or letter size paper is fed

from the paper tray 1

1 Manual feed tray

Tray type Folding type (2-stage telescopic)

Copy paper size A3 ∼ A6R

Detectable paper size A3, B4, A4, A4R, A5

Feedable paper size Single feed: 56 ∼ 128 g/m

Special type of paper OHP with backing paper (backing paper is

W letter size ∼ invoice form

W-letter, Legal, Letter, Letter-R, Invoice

2

Multi feed: 56 ∼ 80 g/m2 (50 sheets)

(A4/Letter size or smaller when paper

weight is more than 104 g/m2)

removed when set), label paper, recycled

paper, blueprint paper, index paper

2 Paper tray 1/paper tray 2

Cassette type Paper tray 1: Inner type

Copy paper size A3 ∼ A5 (A5R is available only for inner type)

Size change To be performed only by service person

Paper tray 2: Integral with drawer

W letter size ∼ Invoice form

(Invoice form is available only for inner type)

• Changing regulating plate mounting position

• Moving size detection block

• Changing size display

Feedable paper size 56 ∼ 80 g/m2 (including recycled paper)

Capacity 500 sheets (total thickness: less than 54 mm)

3 Paper tray 3

Cassette type LCC (Large capacity cassette) type

Copy paper size A4

Size change To be performed only by service person

Letter

• Changing regulating plate mounting position

• Moving size detection block

• Changing size display

Feedable paper size 56 ∼ 80 g/m2 (including recycled paper)

Capacity 3000 sheets (1500 sheets for each stage)

Total thickness: less than 165 mm (Thickness

of 1500 sheets)

ADU No data ADU standard equipment

Paper tray 1 4.6 sec

Paper tray 2 5.3 sec

Paper tray 3 5.5 sec LCC

(6) Document

Max. document size 437 × 301 mm

(same for both AB/Inch systems)

Document positioning

reference point

Left center (when OC is used.)

(7) Paper feed

Paper feed port 500 sheets cassette × 2

Tray size (factory setting)

ADU ADU Standard

Paper tray 1 A3/W-letter Supplied as accessory

Paper tray 2 A4R/Legal

Paper tray 3 A4/Letter

3000 sheets cassette (LCC type)

Manual feed tray

(8) Job speed

S → S 32 sheets/min (10 documents and 1 copy per document)

Conditions: with duplex unit and without stapler

Excluding first copy.

S → D 20 surfaces/min (10 documents and 5 copies per

document)

D → D 20 surfaces/min (5 documents and 5 copies per

document)

D → S 25 surfaces/min (5 documents and 5 copies per

document)

(9) Multi copy mode

Maximum setting 999 copies

(10) Warm-up time

Power ON →

lighting of ready lamp

JAM recovery 10 sec. (reference value)

2 – 1

Approx. 90 sec.

Rated voltage input, ambient temperature

20°C, humidity 65%RH

(Varies depending on the fusing

temperature at which a paper jam occurs)

Page 7

(11) Fixed magnification

Inch series 10 steps 400, 200, 141, 129, 121, 100, 95, 77, 64, 50

AB series 10 steps 400, 200, 141, 122, 115, 100, 86, 81, 70, 50

(12) Zooming

Zooming 50 ∼ 400% Adjustable in steps of 1%

Independent zooming,

longitudinal

Independent zooming,

lateral

50 ∼ 400% Adjustable in steps of 1%

50 ∼ 400% Adjustable in steps of 1%

(13) Printing area

Paper size (mm)

A3 416 × 293

B4 360 × 253

A4 206 × 293

A4R 293 × 206

A5 144 × 206

Paper size (mm)

W Letter 428 × 275

Legal 352 × 212

Letter 212 × 275

Letter-R 275 × 212

Invoice 136 × 212

(14) Void area and image loss

Void area Less than 3 mm at leading edge, less than 3 mm at

trailing edge, less than 5 mm in the sum of both.

Image loss Less than 5 mm at leading edge, less than 5 mm at

sides of both leading and trailing edges

(at 100% magnification)

(15) ADU

Standard

Paper size A3, B4, A4, A4R, A5 (B5, B5R)

W-letter, Legal, Letter, Letter-R

Paper weight 56 ∼ 80 g/m

Capacity A4 ⋅ B5/Letter: 50 sheets

A3 ⋅ B4/W-letter, Legal: 30 sheets

Power source Supplied from the main body.

2

(16) Paper exit tray

Capacity 250 sheets

Sorter Option (For details, see optional specifications.)

(17) Additional functions

APS |

AMS |

Duplex copy |

Sorter Option

Copy condition

registration and call

Independent zooming 50 ∼ 400% in longitu dinal and lateral

1-set 2-copy Not available in enlargement mode

Binding margin Shift width: 9 mm, 3/8" (width is

Edge erase Width: 5 mm, 1/4"

Reverse video Entire surface only

Preheating function Adjustable by key operator program

Auto-power shut-off Adjustable by key operator program

Message display |

Guidance display | (images available)

Self-diagnostics |

Key operator program |

Process control |

9 copy functions

directions, each

adjustable, but binding direction is fixed)

(Setting by key operator program)

Adjustable by key operator program

(18) Machine configuration

Model

Main body AR-5132

RADF Standard

ADU Standard

DESK Standard

20 bin sorter SF-S15 Option

20 bin staple sorter SF-S53N Option

Printer kit AR-BD14 Option

(19) Other specifications

Photoconductor type OPC

OPC diameter 65 mm

Exposure lamp Halogen lamp

Developing 2-component inversion

Charging Scorotron

Transfer Corotron

Separation Corotron

Fusing Heat roller + separation pawl + cleaning roller

Cleaning Blade

(20) Appearance

Width × Depth × Height 638 × 680 × 1145 mm

Installation area (width × depth) 1236 × 680 mm

Weight About 143.9 kg

(21) Power supply

Power supply 120 V, 220 V ∼ 230 V, 240 V ±10%

Frequency 50/60 Hz

(22) Power consumption

Max. power consumption Less than 1.5 kW

2 – 2

Page 8

Package Remarks

name

Product

those supplied separately.

those supplied separately.

Fusing separation pawl (upper) × 4

Heat roller gear × 1

Fusing separation pawl (lower) × 2

Charging plate unit × 1

Drum separation pawl unit × 1

1 Drum OPC drum × 1 160 K AR-532DR 10

2 Developer (black) Developer (850 g) × 10 80 K (× 10) AR-532MD1 1 (AR-532ND1) × 10 = AR-532MD1

3 Toner (black) Toner cartridge (600 g) × 10 15 K (× 10) AR-532MT1 1 (AR-532NT1) × 10 = AR-532MT1

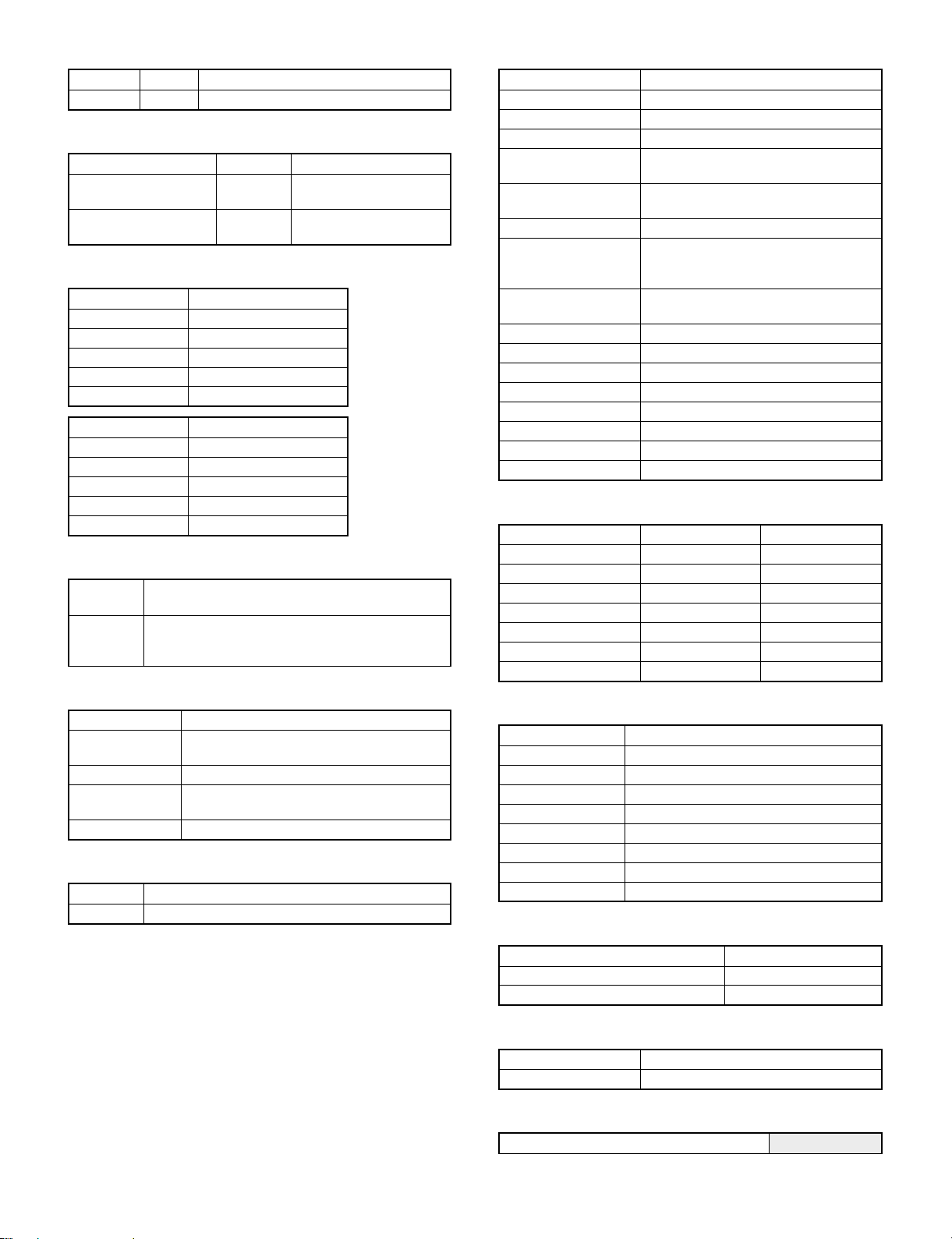

(1) SEC

NO. Name Description Life

2. Consumable parts

4 Upper heat roller kit Upper heat roller × 1 160 K AR-532UH 5 Replacement of fusing separation pawl for every 80 K should be done using

5 Lower heat roller kit Lower heat roller × 1 160 K SF-240LH 5 Replacement of fusing separation pawl for every 80 K should be done using

6 80K maintenance kit Cleaner blade × 1 80 K AR-532KA1 5

7 Cleaner blade Cleaner blade × 10 80 K (× 10) SF-222CB 1 (SF-228BL) × 10 = SF-222CB

8 Upper cleaning roller Upper cleaning roller × 10 80 K (× 10) SF-240UR 1 (SF-240RU) × 10 = SF-240UR

9 Lower cleaning roller Lower cleaning roller × 10 80 K (× 10) SF-235CR2 1 (SF-235RU) × 10 = SF-235CR2

10 Staple cartridge Staple cartridge × 5 5000 times × 5 SD-LS20 10 (SD-SC20) × 5 = SD-LS20

* When replacing parts other than those given above, use service parts.

2 – 3

Page 9

Package Remarks

name

Product

Order is received as SF-216LP.

Order is received as AR-532HG.

Order is received as SD-360LP.

Order is received as SF-240DP.

Order is received as AR-532SU.

Order is received as AR-532PU.

Order is received as SF-240BU.

Order is received as AR-532FL.

Order is received as AR-532CL.

Order is received as AR-532MC.

(2) SECL

1 Drum OPC drum × 1 160 K AR-532DR 10

2 Developer (black) Developer (850 g) × 10 80 K (× 10) AR-532MD1 1 (AR-532ND1) × 10 = AR-532MD1

NO. Name Description Life

Lower heat roller × 1

Toner receiving seal × 1

DV seal × 1

Heat roller gear × 1

3 Toner (black) Toner cartridge (600 g) × 10 15 K (× 10) AR-532MT1 1 (AR-532NT1) × 10 = AR-532MT1

4 160K maintenance kit Upper heat roller × 1 160 K AR-532KB 1

Lower cleaning roller × 1

Cleaner blade × 1

Toner recovery container × 4

Fusing separation pawl (upper) × 4

Fusing separation pawl (lower) × 2

Screen grid × 1

Charging plate unit × 1

Drum separation pawl unit × 1

5 80K maintenance kit Upper cleaning roller × 1 80 K AR-532KA 1

6 Staple cartridge Staple cartridge × 5 5000 times × 5 SD-LS20 10 (SD-SC20) × 5 = SD-LS20

7 Cleaner blade Cleaner blade × 10 80 K (× 10) SF-222CB 1 (SF-228BL) × 10 = SF-222CB

8 Upper cleaning roller Upper cleaning roller × 10 80 K (× 10) SF-240UR 1 (SF-240RU) × 10 = SF-240UR

9 Lower cleaning roller Lower cleaning roller × 10 80 K (× 10) SF-235CR2 1 (SF-235RU) × 10 = SF-235CR2

2 – 4

10 Upper heat roller Upper heat roller × 1 160 K AR-532HU 5

11 Fusing separation pawl (upper) Fusing separation pawl (upper) × 4 × 10 80 K (× 10) SF-216UP 1 SF-216LP = (SF-216MP) × 10 SF-216MP is supplied 4 pcs. for 1 copier.

12 Heat roller gear Heat roller gear × 10 160 K (× 10) AR-532HG 1 AR-532HG = (AR-532JG) × 10

13 Lower heat roller Lower heat roller × 1 160 K SF-240HR 5

14 Fusing separation pawl (lower) Fusing separation pawl (lower) × 2 × 10 80 K (× 10) SD-360LP 1 SD-360LP = (SD-360MP) × 10 SD-360MP is supplied 2 pcs. for 1 copier.

15 Drum separation pawl Drum separation pawl × 2 × 10 80 K (× 10) SF-240DP 1 SF-240DP = (SF-240EP) × 10 SF-240EP is supplied 2 pcs. for 1 copier.

16 Screen grid Screen grid × 10 80 K (× 10) AR-532SU 1 AR-532SU = (AR-532TU) × 10

17 Charging plate Charging plate × 10 80 K (× 10) AR-532PU 1 AR-532PU = (AR-532NU) × 10

18 Waste toner bottle Waste toner bottle × 1 SF-240TB 5

19 Heat insulation bushing Heat insulation bushing × 2 × 10 160 K (× 10) SF-240BU 1 SF-240BU = (SF-240DU) × 10

20 Ozone filter Ozone filter × 10 80 K (× 10) AR-532FL 1 AR-532FL = (AR-532JL) × 10

21 Copy lamp Copy lamp × 10 AR-532CL 1 AR-532CL = (AR-532DL) × 10

22 MC case MC case × 10 AR-532MC 1 AR-532MC = (AR-532NC) × 10

* When replacing parts other than those given above, use service parts.

Page 10

Package Remarks

name

Product

Order is received as SF-216UP.

Order is received as AR-532HG.

Order is received as SD-360LP.

Order is received as SF-240DP.

Order is received as AR-532SU.

Order is received as AR-532PU.

Order is received as SF-240BU.

Order is received as AR-532FL.

Order is received as AR-532CL.

Order is received as AR-532MC.

NO. Name Description Life

(3) Europe

1 Drum OPC drum × 1 160 K AR-532DM 10

2 Developer (black) Developer (850 g) × 10 80 K (× 10) AR-532LD1 1 (AR-532DV1) × 10 = AR-532LD1

3 Toner (black) Toner cartridge (600 g) × 10 15 K (× 10) AR-532LT1 1 (AR-532T1) × 10 = AR-532LT1

4 160K maintenance kit Upper heat roller × 1 160 K AR-532KB 1

Lower heat roller × 1

Toner receiving seal × 1

DV seal × 1

Heat roller gear × 1

Lower cleaning roller × 1

Cleaner blade × 1

Toner recovery container × 4

Fusing separation pawl (upper) × 4

Fusing separation pawl (lower) × 2

Screen grid × 1

Charging plate unit × 1

Drum separation pawl unit × 1

5 80K maintenance kit Upper cleaning roller × 1 80 K AR-532KA 1

6 Staple cartridge Staple cartridge × 5 5000 times × 5 SD-LS20 10 (SD-SC20) × 5 = SD-LS20

7 Cleaner blade Cleaner blade × 10 80 K (× 10) SF-222CB 1 (SF-228BL) × 10 = SF-222CB

8 Upper cleaning roller Upper cleaning roller × 10 80 K (× 10) SF-240UR 1 (SF-240RU) × 10 = SF-240UR

9 Lower cleaning roller Lower cleaning roller × 10 80 K (× 10) SF-235CR2 1 (SF-235RU) × 10 = SF-235CR2

2 – 5

10 Upper heat roller Upper heat roller × 1 160 K AR-532HU 5

11 Fusing separation pawl (upper) × 10 80 K (× 10) SF-216UP 1 SF-216UP = (SF-216TP) × 10 SF-216TP is supplied 4 pcs. for 1 copier.

12 Heat roller gear Heat roller gear × 10 160 K (× 10) AR-532HG 1 AR-532HG = (AR-532JG) × 10

13 Lower heat roller Lower heat roller × 1 160 K SF-240HR 5

14 Fusing separation pawl (lower) Fusing separation pawl (lower) × 2 × 10 80K (× 10) SD-360LP 1 SD-360LP = (SD-360MP) × 10 SD-360MP is supplied 2 pcs. for 1 copier.

15 Drum separation pawl Drum separation pawl × 2 × 10 80 K (× 10) SF-240DP 1 SF-240DP = (SF-240EP) × 10 SF-240EP is supplied 2 pcs. for 1 copier.

16 Screen grid Screen grid × 10 80 K (× 10) AR-532SU 1 AR-532SU = (AR-532TU) × 10

17 Charging plate Charging plate × 10 80 K (× 10) AR-532PU 1 AR-532PU = (AR-532NU) × 10

18 Waste toner bottle Waste toner bottle × 1 SF-240TB 5

19 Heat insulation bushing Heat insulation bushing × 2 × 10 160 K (× 10) SF-240BU 1 SF-240BU = (SF-240DU) × 10

20 Ozone filter Ozone filter × 10 80 K (× 10) AR-532FL 1 AR-532FL = (AR-532JL) × 10

21 Copy lamp Copy lamp × 10 AR-532CL 1 AR-532CL = (AR-532DL) × 10

22 MC case MC case × 10 AR-532MC 1 AR-532MC = (AR-532NC) × 10

* When replacing parts other than those given above, use service parts.

Page 11

Package Remarks

name

Product

Order is received as SF-216UP.

Order is received as AR-532HG.

Order is received as SD-360LP.

Order is received as SF-240DP.

Order is received as AR-532SU.

Order is received as AR-532PU.

Order is received as SF-240BU.

Order is received as AR-532FL.

Order is received as AR-532CL.

Order is received as AR-532MC.

(4) SCA

NO. Name Description Life

1 Drum OPC drum × 1 160 K AR-532DM 10

Lower heat roller × 1

Toner receiving seal × 1

2 Developer (black) Developer (850 g) × 10 80 K (× 10) AR-532LD1 1 (AR-532DV1) × 10 = AR-532LD1

3 Toner (black) Toner cartridge (600 g) × 10 15 K (× 10) AR-532LT1 1 (AR-532T1) × 10 = AR-532LT1

4 160K maintenance kit Upper heat roller × 1 160 K AR-532KB 1

DV seal × 1

Heat roller gear × 1

Lower cleaning roller × 1

Cleaner blade × 1

Toner recovery container × 4

Fusing separation pawl (upper) × 4

Fusing separation pawl (lower) × 2

Screen grid × 1

Charging plate unit × 1

Drum separation pawl unit × 1

5 80K maintenance kit Upper cleaning roller × 1 80 K AR-532KA 1

6 Staple cartridge Staple cartridge × 5 5000 times × 5 SD-LS20 10 (SD-SC20) × 5 = SD-LS20

7 Cleaner blade Cleaner blade × 10 80 K (× 10) SF-222CB 1 (SF-228BL) × 10 = SF-222CB

8 Upper cleaning roller Upper cleaning roller × 10 80 K (× 10) SF-240UR 1 (SF-240RU) × 10 = SF-240UR

9 Lower cleaning roller Lower cleaning roller × 10 80 K (× 10) SF-235CR2 1 (SF-235RU) × 10 = SF-235CR2

2 – 6

10 Upper heat roller Upper heat roller × 1 160 K AR-532HU 5

11 Fusing separation pawl (upper) Fusing separation pawl (upper) × 4 × 10 80 K (× 10) SF-216UP 1 SF-216UP = (SF-216TP) × 10 SF-216TP is supplied 4 pcs. for 1 copier.

12 Heat roller gear Heat roller gear × 10 160 K (× 10) AR-532HG 1 AR-532HG = (AR-532JG) × 10

13 Lower heat roller Lower heat roller × 1 160 K SF-240HR 5

14 Fusing separation pawl (lower) Fusing separation pawl (lower) × 2 × 10 80 K (× 10) SD-360LP 1 SD-360LP = (SD-360MP) × 10 SD-360MP is supplied 2 pcs. for 1 copier.

15 Drum separation pawl Drum separation pawl × 2 × 10 80 K (× 10) SF-240DP 1 SF-240DP = (SF-240EP) × 10 SF-240EP is supplied 2 pcs. for 1 copier.

16 Screen grid Screen grid × 10 80 K (× 10) AR-532SU 1 AR-532SU = (AR-532TU) × 10

17 Charging plate Charging plate × 10 80 K (× 10) AR-532PU 1 AF-532PU = (AR-532NU) × 10

18 Waste toner bottle Waste toner bottle × 1 SF-240TB 5

19 Heat insulation bushing Heat insulation bushing × 2 × 10 160 K (× 10) SF-240BU 1 SF-240BU = (SF-240DU) × 10

20 Ozone filter Ozone filter × 10 80 K (× 10) AR-532FL 1 AR-532FL = (AR-532JL) × 10

21 Copy lamp Copy lamp × 10 AR-532CL 1 AR-532CL = (AR-532DL) × 10

22 MC case MC case × 10 AR-532MC 1 AR-532MC = (AR-532NC) × 10

* When replacing parts other than those given above, use service parts.

Page 12

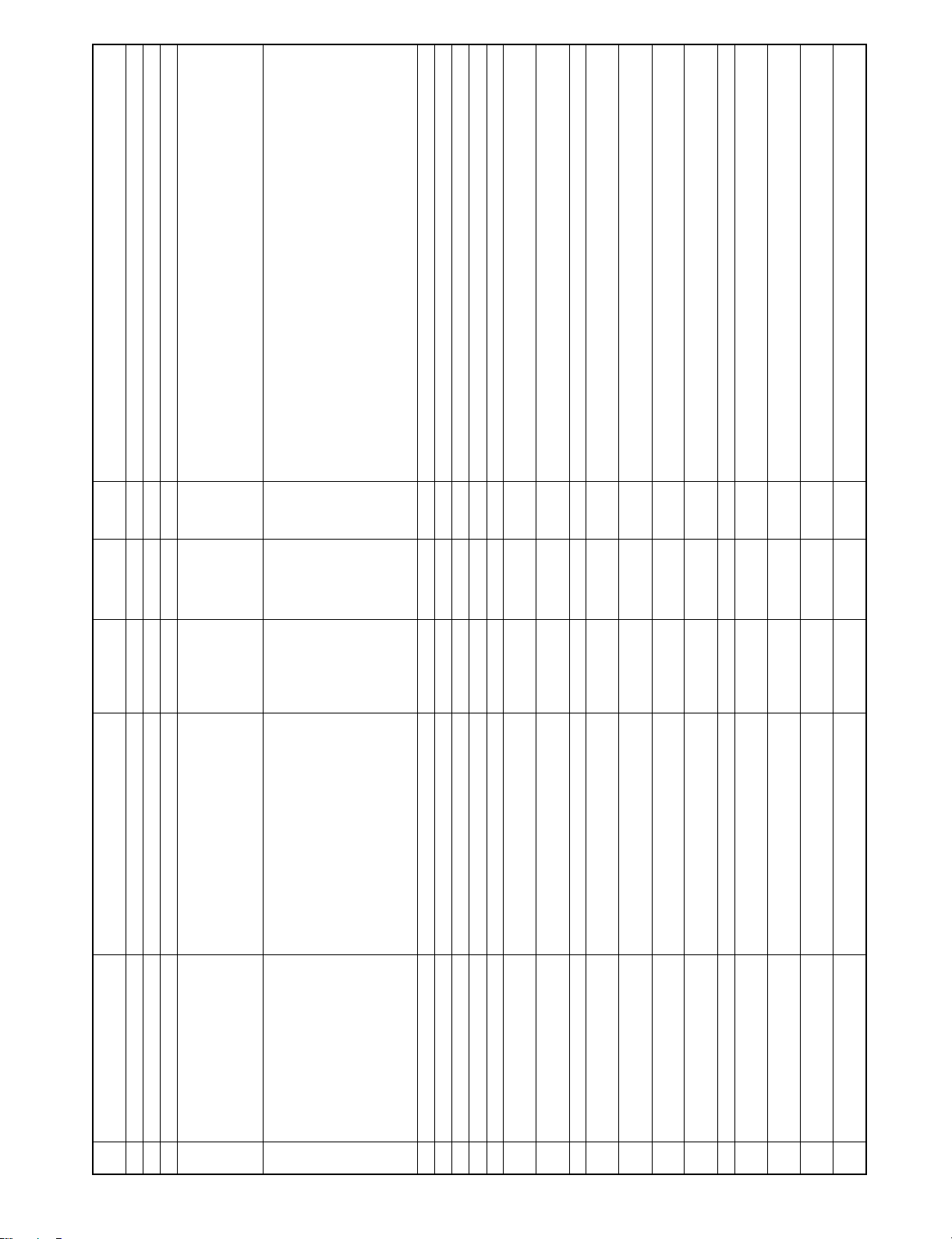

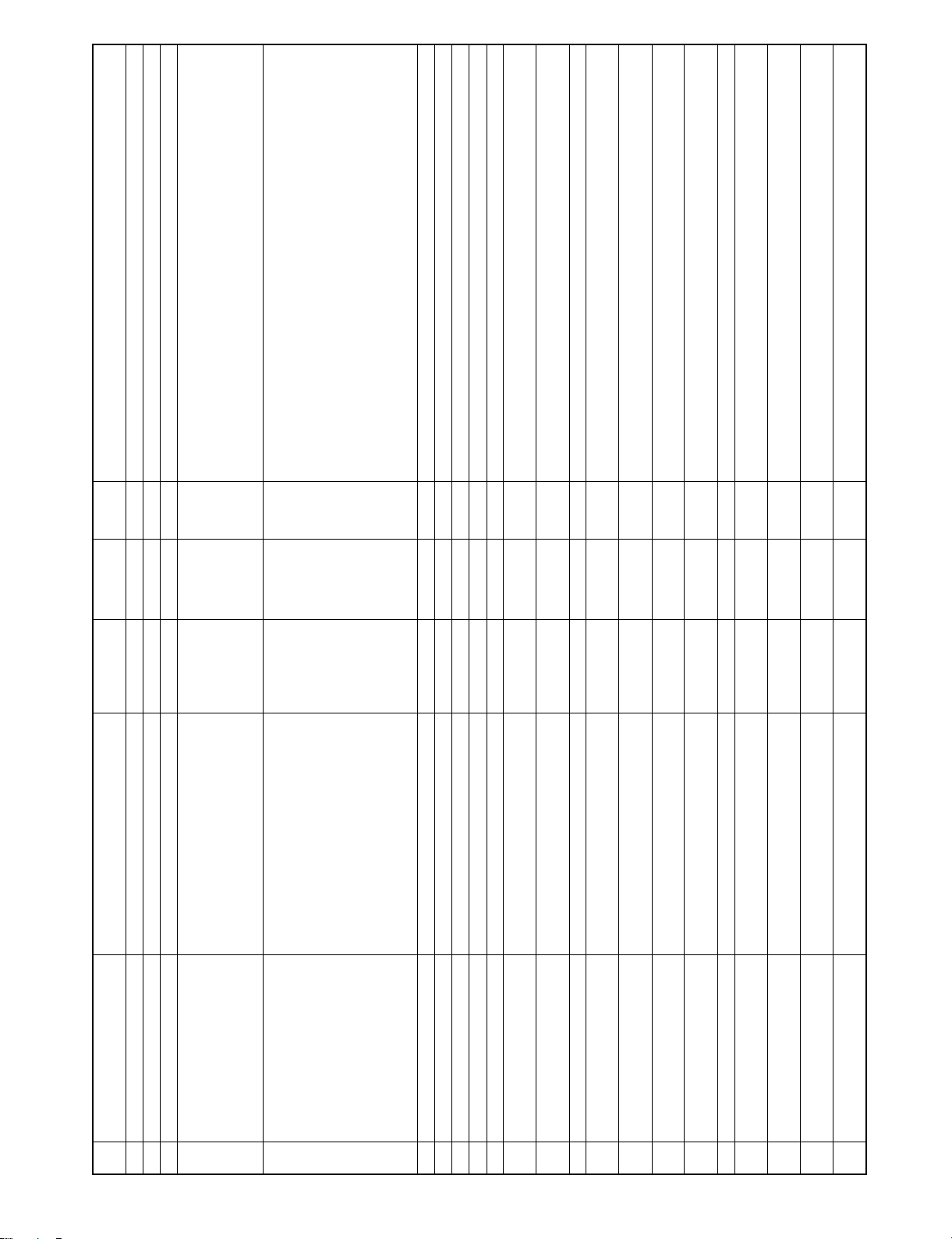

[3] OPTIONS SPECIFI C ATIONS

1. SF-S15

2. SF-S53N

Name 20-bin sorter

No. of bins 20 bins

Paper collection Copy face up

Capacity per bin Max. 50 sheets (100 sheets: Top bin)

Allowable paper size/weight

for collating

Power source Supplied from the copier.

Dimensions 500mm (W) × 520mm (D) × 957mm (H)

Weight About 13kg

Name Staple sorter

No. of bins 20 bins

Paper collection Copy face up

Capacity per bin Max. 50 sheets (250 sheets: Top bin)

Allowable paper size/weight

for collating

No. of sheets for stapling 50 sheets (80g/m2)

Power source Supplied from the copier.

Dimensions 475mm (W) × 597mm (D) × 995mm (H)

Weight About 42.1kg

Max. A3, Min.: B5 (Min. A6 for non-sort)

Non-sort: 52 ∼ 128g/m2,

Sort/Grouping: 56 ∼ 80g/m

Max.: A3, Min.: B5 (Non-sort: Min. A5),

Non-sort: 52 ∼ 128g/m2,

Sort/staple sort/grouping: 56 ∼ 89g/m

2

2

3 – 1

Page 13

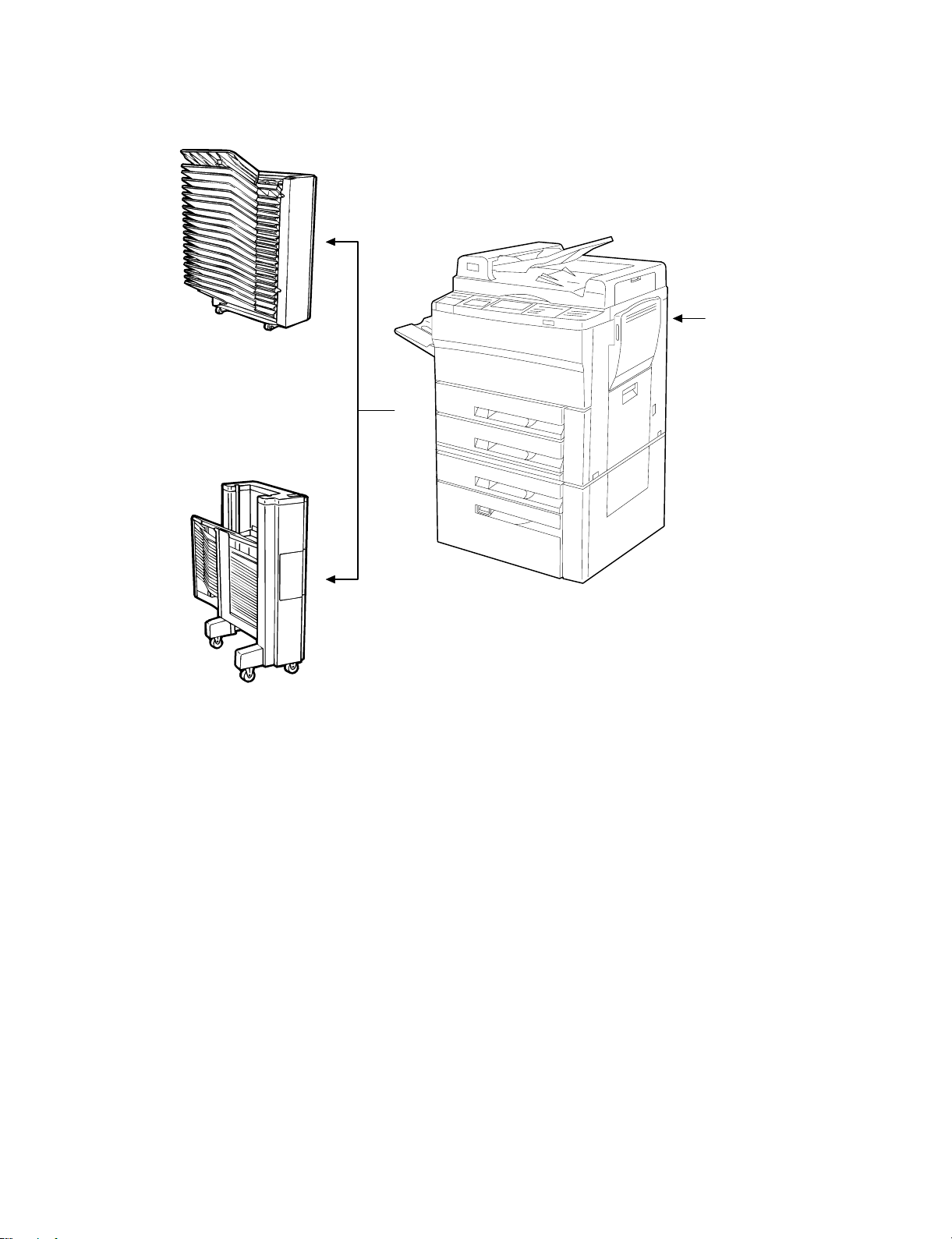

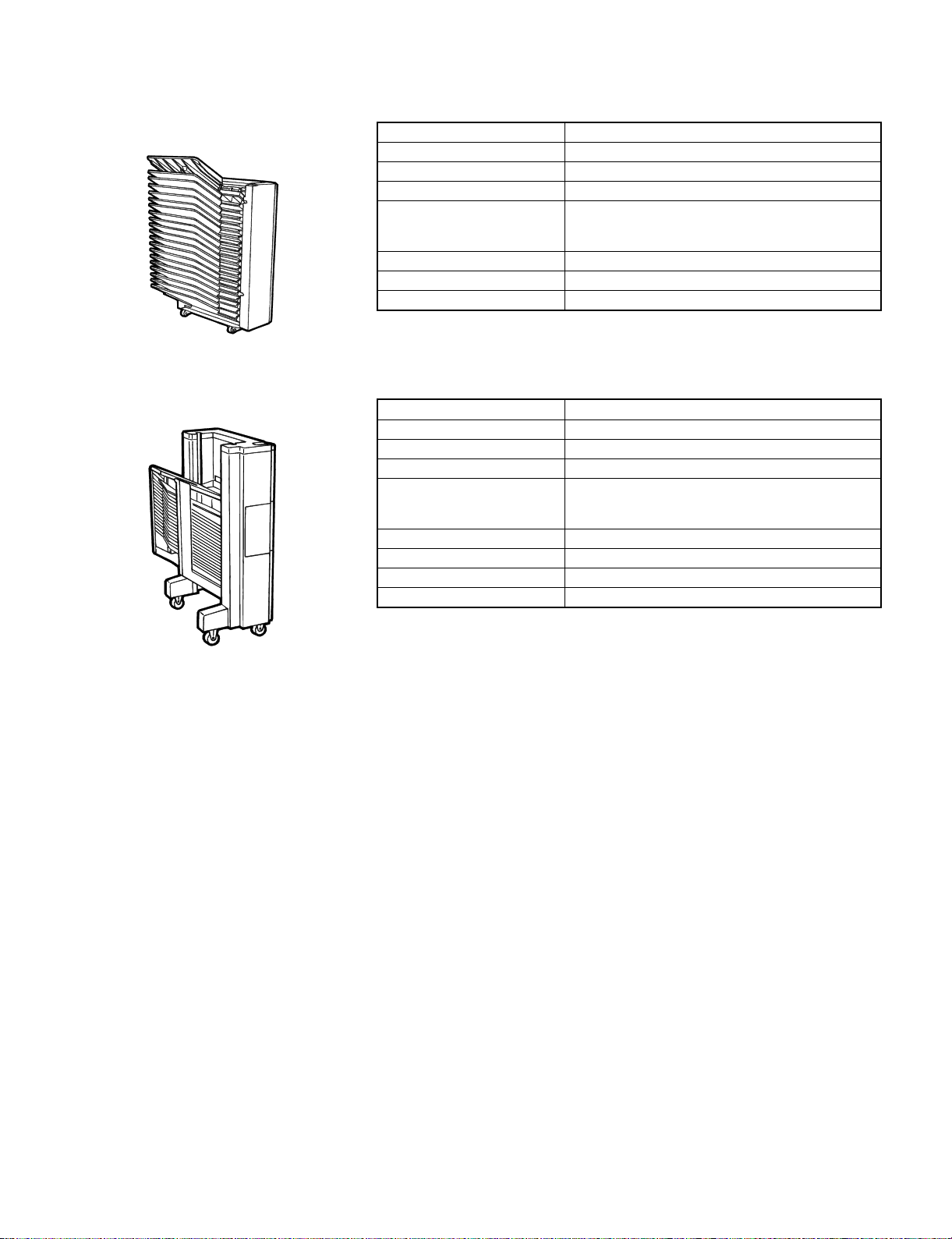

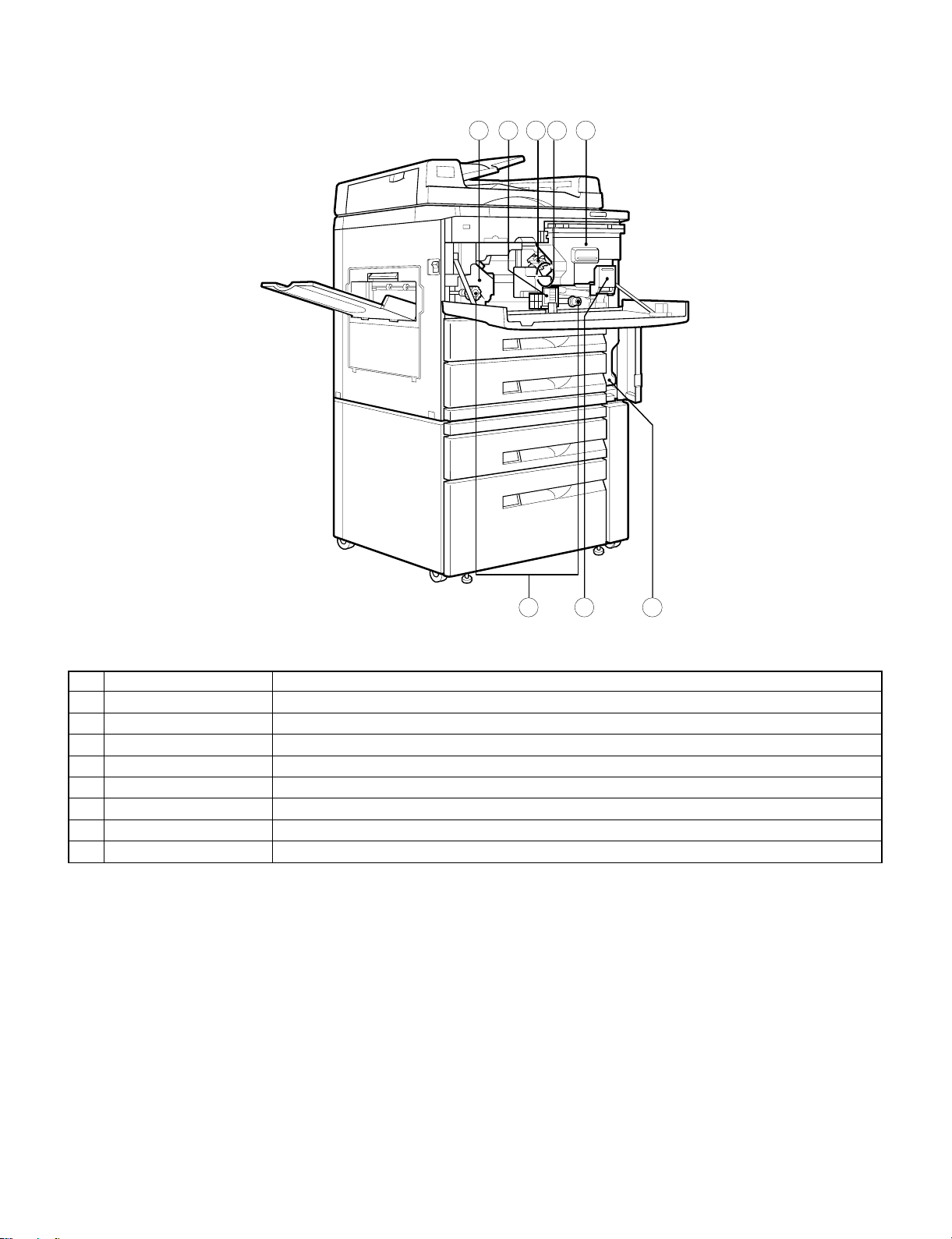

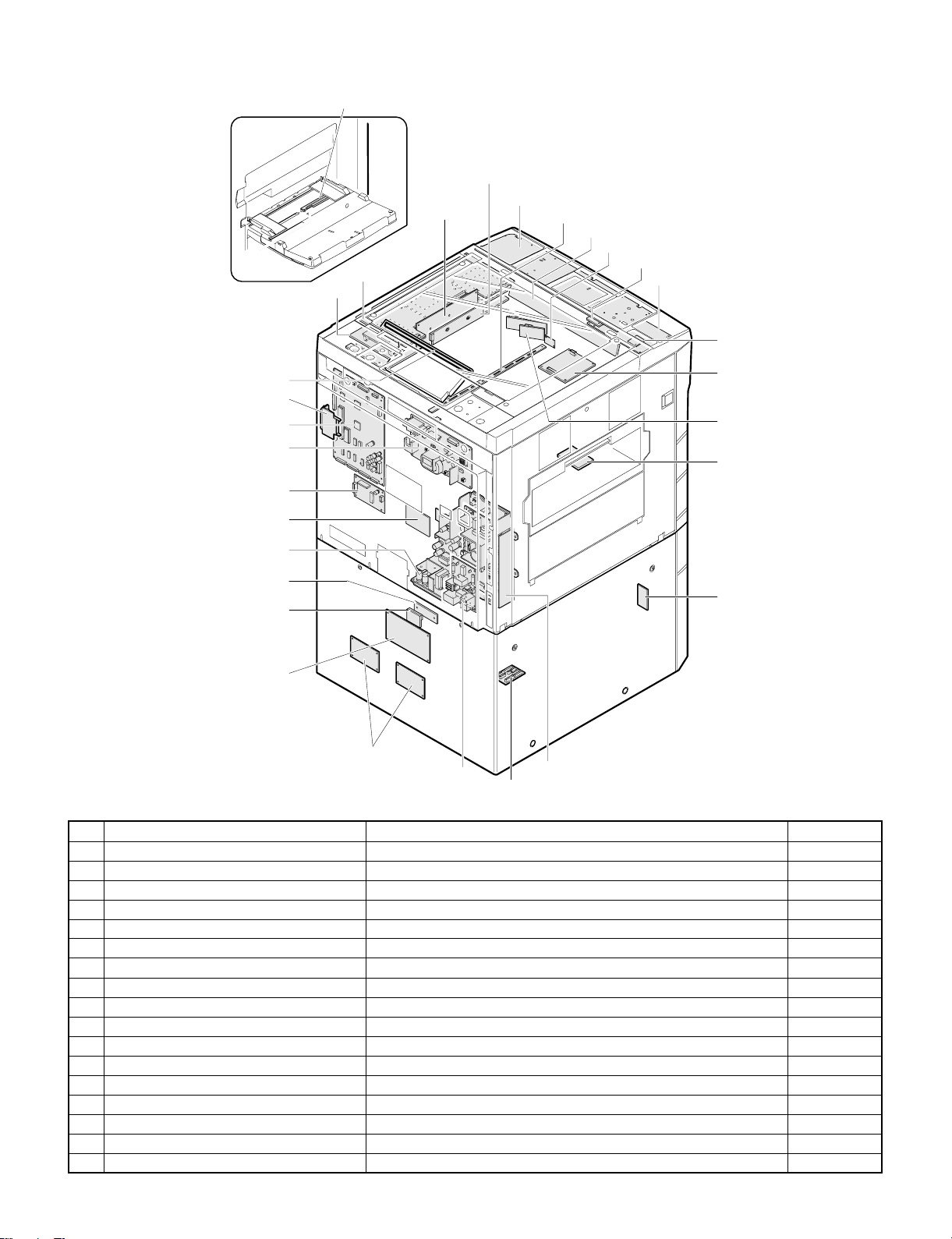

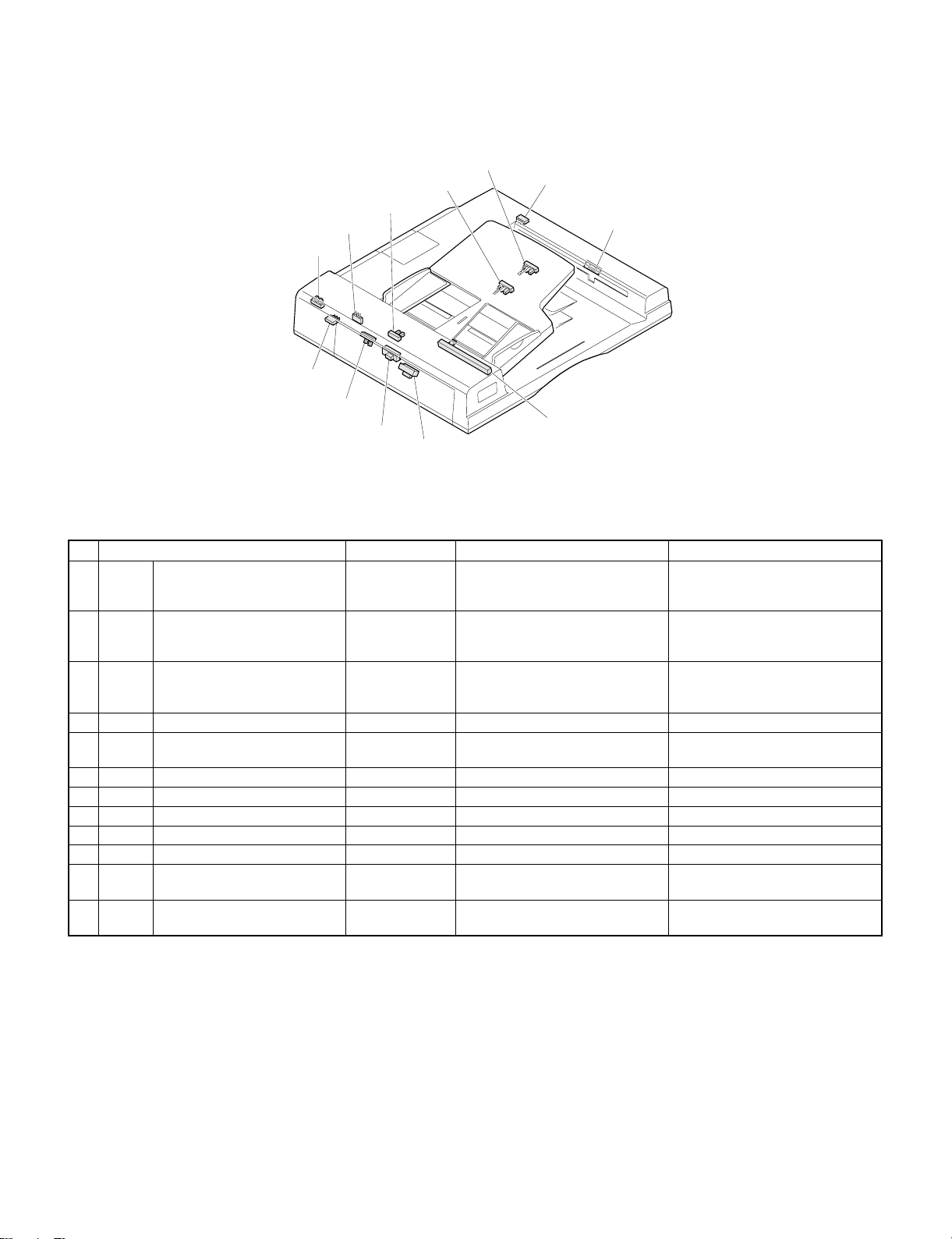

[4] PART NAME AND FUNCTION

1

2 3 4 5

6

7 8 9

10

11

12 13

14 15 16 17

18

19

20

21

22

23 24

1. External view

No. Name Function

Exit tray Finished copies are deposited in the exit tray.

1

Paper clip tray Keep paper clip here.

2

Document feeder indicator Indicate document feeder condition.

3

RADF feeding roller cover Open to remove misfed documents.

4

Operation panel All copier controls are located here for easy operation.

5

Document guides Adjust to the size of the documents.

6

Document feeder tray Holds up to 50 documents.

7

Document feeder cover Open to make copies from the document glass.

8

Document glass All documents which cannot be copied from the RADF must be copied here.

9

RADF exit area Finished documents are output here.

F

RADF exit roller cover Open to remove misfed documents.

G

Manual feed tray paper guides Adjust to the width of the copy paper.

H

Manual feed tray Special papers (including transparency film) and copy paper can be fed from the manual feed tray.

I

Exit area cover Open to remove misfed paper.

J

Power switch Press to turn copier power on and off.

K

Duplex module The duplex module provides duplex copying capability.

L

Paper tray 1 Holds 500 sheets of 20 lb. bond paper. Copy paper size can be changed by changing the inner cassette.

M

Paper tray 2 Holds 500 sheets of 20 lb. bond paper.

N

Paper tray 3 Holds A4 or letter sized paper. Tray capacity is 3,000 sheets of 20 lb. bond paper.

O

Front cover Open to remove misfeeds and to service the copier.

P

Waste toner bottle cover Open to replace the Waste toner bottle.

Q

Handles Pull out to move the copier.

R

Upper side cover Open to remove misfeeds in the paper feed area.

S

Lower side cover Open to remove misfeeds in paper tray 2 and 3.

T

4 – 1

Page 14

2. Internal structure

1 5

6 7

8

2 3 4

No. Name Function

Fusing unit Fuses toner to paper.

1

Transport level Turn to open the paper transport section.

2

Corona unit The unit is used to charge the photoconductive drum.

3

Photoconductive drum Copy images are formed on the photoconductive drum.

4

Toner hopper Contains toner.

5

Roller rotating knobs Turn to remove misfed paper.

6

Toner hopper lock lever Pull down release the toner hopper.

7

Waste toner bottle Waste toner is collected here. Replace when a message appears in the display indicating the need to do so.

8

4 – 2

Page 15

There keys are not used for

the copier features.

PRINTE R

CA

ON LINE

COPY

CLEAR ALL

START

343332313029

10 11 12 13

3 4 5 6 7 8 9

2

P

INTERRUPT

PROGRAM

?

INFORMATIO N

SCROLL DISPLAY

0

ORIGINAL

READY TO COPY.

COPY

DUAL PAGE

COPY

EDGE

ERASE

MARGIN

SHIFT

B/W

REVERSE

XY-

ZOOM

X11

X11R

2

2

1

1

8

8

AUTO PAPER

COPY RATIO

AUTO

IMAGE

2

ORIGINAL TO COPY

11

23

1

456

X11

X14

2

2

1

1

11X17

8

SELECT

DUPLEX

1.

2. 8

3.

AUTO

100%

EXPOSURE

ZOOM

122

1

2

ODD

NUMBER

PRE-COUNT

ORIGINALS

EVEN

NUMBER

(ORIGINALS)

8

7

100%

GROUP

SORTER

STAPLE

SORT

C

0/

AUDIT CLEAR

TRAY SELECT

DARK

LIGHT

EXPOSURE

AUTO

MANUAL

PHOTO

SORT

28

27262524232220 21191817

16

1514

9

Light key

Dark key

Tray and paper size display

Original size display

Paper tray select key

Ten key pad

Auditor clear key

Clear key

U

V

W

X

Y

Z

[

\

Program

Original to copy key and indicator

Sorter key and indicator

Original to copy key and indicator

Zoom key

Reduction key

Enlargement key

100% key

I

J

K

L

M

N

O

P

Clear all key

Start key and indicator

]

^

Copy ratio display

Exposure display

Exposure key

Auto paper select display

Q

R

S

T

1

the

of

adjust-

best suit

to

display

vary the contrast

to

LCD contrast control

Use the contrast control

ment

message

the room lighting conditions.

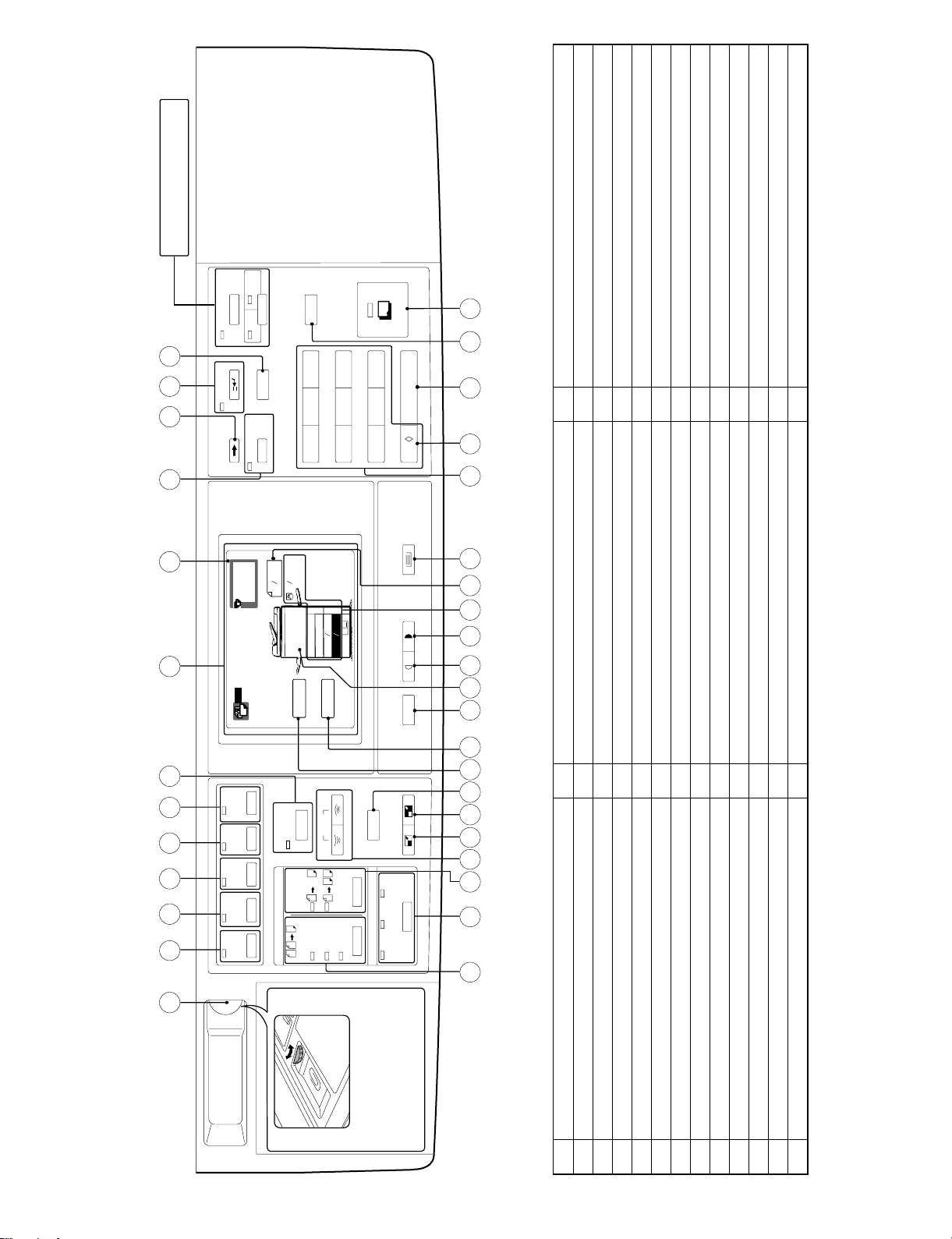

3. Operation panel

LCD contrast volume

XY-zoom

Black white reverse

Margin shift

1

2

3

No. Name No. Name No. Name

4

Edge erase

Dual page copy

Auto image

5

6

7

LCD display

Copy quantity display

Operation information

Scroll display

Interrupt key and indicator

8

9

F

G

H

4 – 3

Page 16

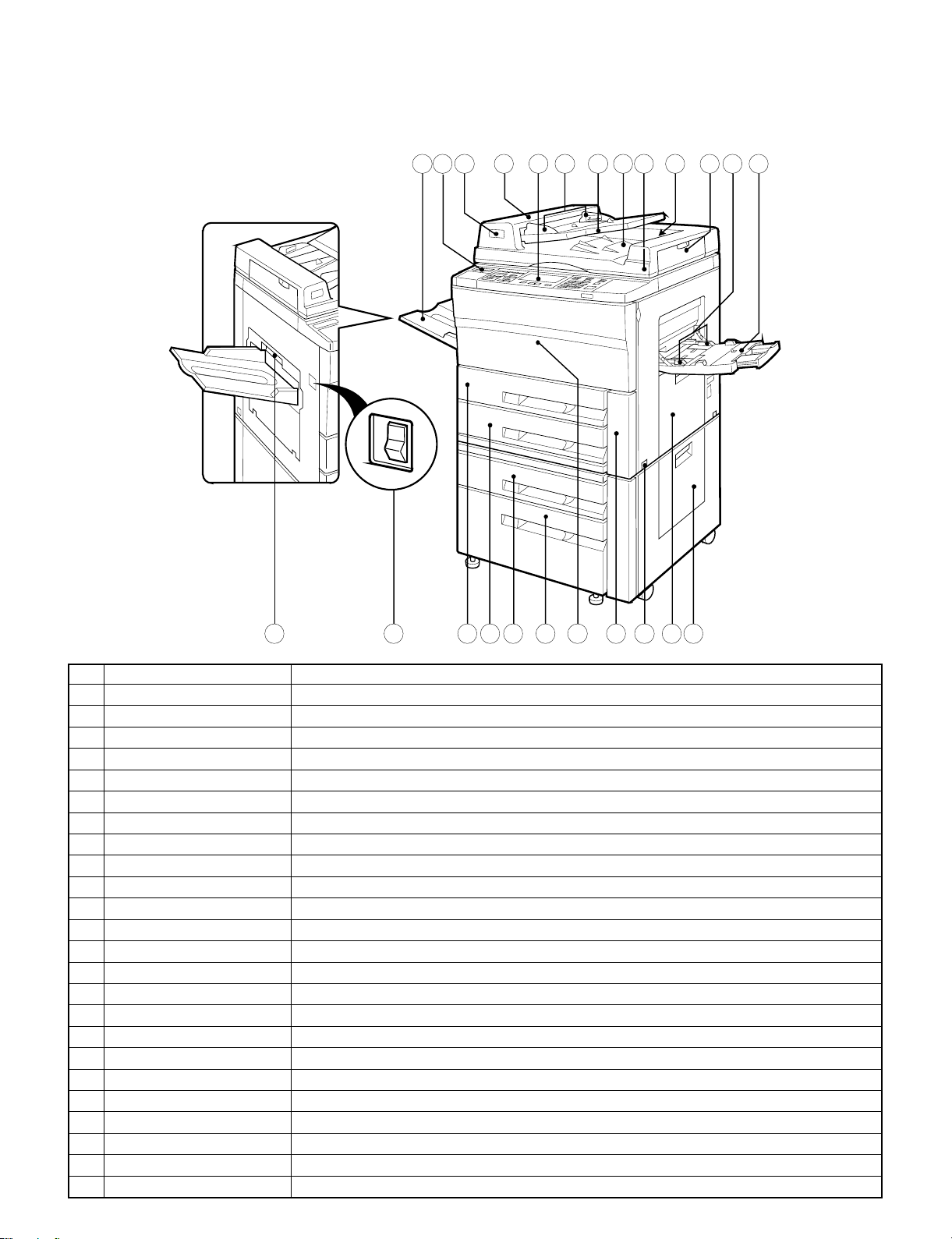

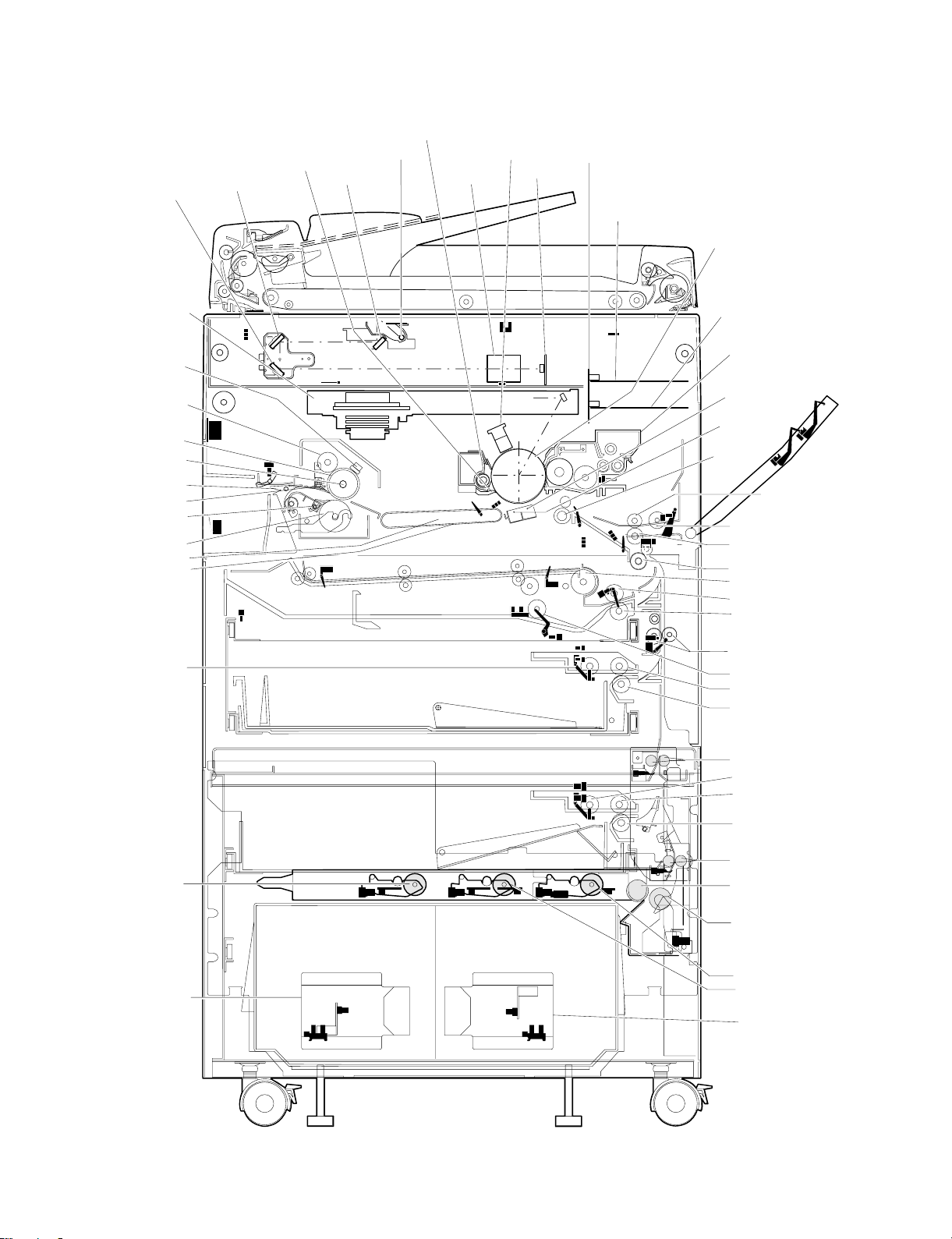

4. Major parts

3.3rd mirror

12.Drum separation unit

2.2nd mi r r or

10.Copy lamp

1.1st m ir r or

9.Cleaner unit

20.Main charger unit

16.Lens unit

24.Mother PWB

8.CCD PWB

15.ICU PWB

25.OPC drum

19.LSU

13.Fuser thermistor

50.Upper cleaning roller

51.Upper heat roller

14.Heater lamp

26.Paper exit select gate

52.Upper separation pawl

18.Lower sepatation pawl

17.Lower heat roller

46.Suction unit

45.Suction belt

28.Paper tray 1

pick-up roller

40.Printer PWB (option)

11.Developer unit

47.Transfer charger

44.Separation

charger

41.Res i st roll er

21.Manual feed pap er

feed roller

22.Manual feed pick-up roler

23.Manual feed separation roller

49.Transport roller (upper)

6.ADU reverse roller

5.ADU pi c k - u p ro l l er

7.ADU separation roller

48.Transport roler (lower)

4.ADU paper feed roller

27.Paper tray paper feed roller

29.Paper tray 1 separation roller

43.Resist roller (desk upper)

31.Paper tray 2 pick-up roler

30.Paper tray 2 paper feed roller

37.Paper tray 3

pick-up roller 2

34.Paper tray 3

lift-up unit 2

32.Paper tray 2 separation roller

42.Resist roller (desk lower)

35.Pap er tray 3 paper feed roller

38.Pap er t ra y 3 s eparation r o ller

36.Paper tray 3 pick-up roller 1

39.Paper tray 3 transport roller

33.Paper tray 3 lift-up unit 1

4 – 4

Page 17

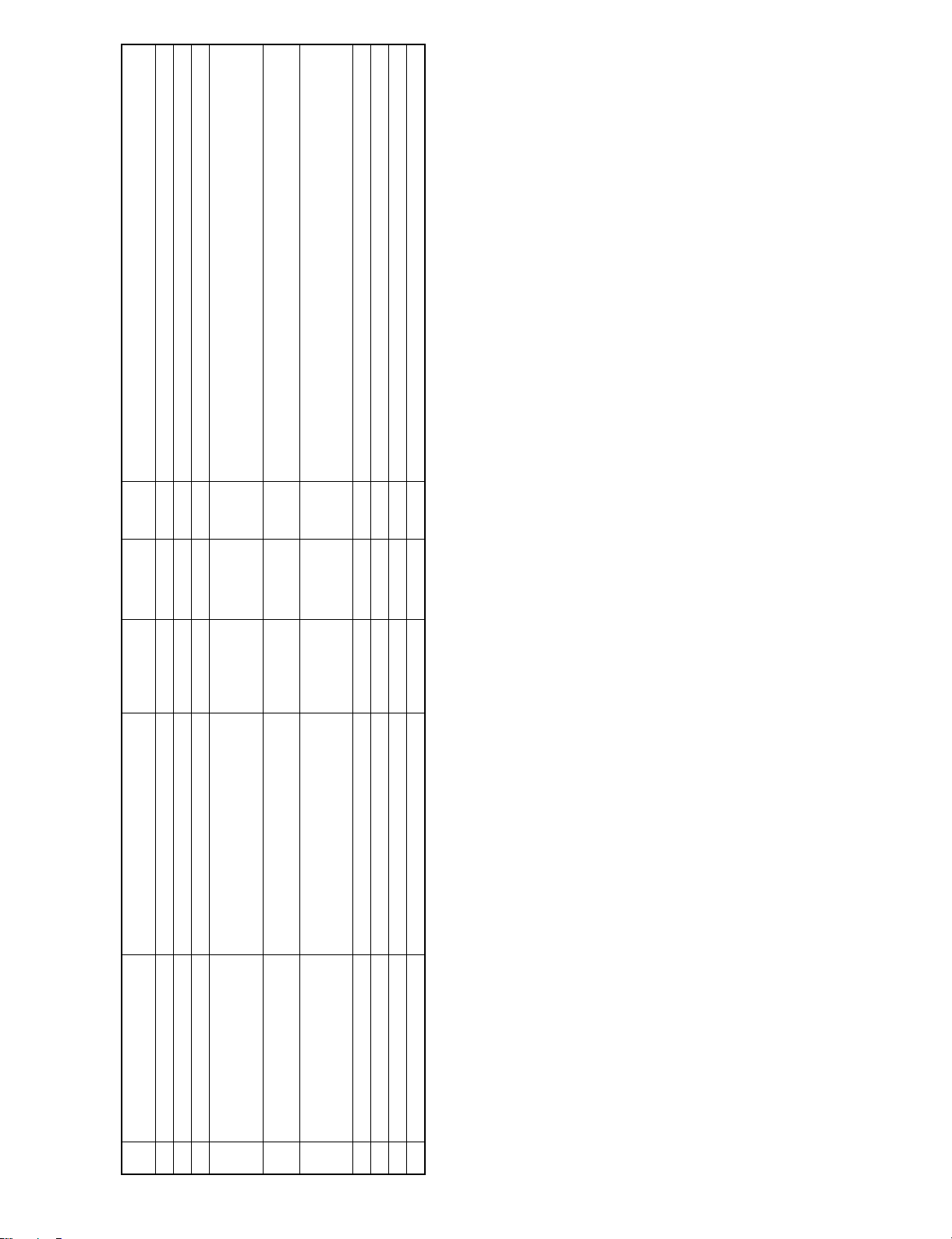

No. Part name No. Part name No. Part name

1 1st mirror 19 LSU 37 Paper tray 3 pick-up roller 2

2 2nd mirror 20 Main charger unit 38 Paper tray 3 separation roller

3 3rd mirror 21 Manual feed paper feed roller 39 Paper tray 3 transport roller

4 ADU paper feed roller 22 Manual feed pick-up roller 40 Printer PWB (Option)

5 ADU pick-up roller 23 Manual feed separation roller 41 Resist roller

6 ADU reverse roller 24 Mother PWB 42 Resist roller (desk-lower)

7 ADU separation roller 25 OPC drum 43 Resist roller (desk-upper)

8 CCD PWB 26 Paper exit select gate 44 Separation charger

9 Cleaner unit 27 Paper tray 1 paper feed roller 45 Suction belt

10 Copy lamp 28 Paper tray 1 pick-up roller 46 Suction unit

11 Developer unit 29 Paper tray 1 separation roller 47 Transfer charger

12 Drum separation unit 30 Paper tray 2 paper feed roller 48 Transport roller (lower)

13 Fuser thermistor 31 Paper tray 2 pick-up roller 49 Transport roller (upper)

14 Heater lamp 32 Paper tray 2 separation roller 50 Upper cleaning roller

15 ICU PWB 33 Paper tray 3 lift-up unit 1 51 Upper heat roller

16 Lens unit 34 Paper tray 3 lift-up unit 2 52 Upper separation pawl

17 Lower heat roller 35 Paper tray 3 paper feed roller 53

18 Lower separation pawl 36 Paper tray 3 pick-up roller 1 54

4 – 5

Page 18

5. Sensor

7.MHPS

2.CSWF

10.P-SW

15.POD

3.CSWL

21.DPPD1

18.PSD

23.DTBHPS

34.DPTD2

41.LMS2

31.DLUD2

38.E2CLK 40.LMS1

30.DLUD1

37.E1CLK

8.MPED

16.PPD1

17.PPD2

1.BD

5.IR

9.OCSW

14.PLS2

13.PLS1

19.TFD

22.DPPD2

20.DPFD

25.DTWHPS

24.DTPID

4.CSWR

12.PID

6.LUD2

11.PED3

33.DPOD1

42.LUD3

43.PED3

34.DPOD2

27.DLPD1

26.DDOP

39.F/LSW

29.DLPD332.DPE2

28.DLPD2

35.DPTD1

4 – 6

Page 19

No Section Name Function Contact / output

1 Main body BD Laser beam sensor Detection of laser beam start position

2 CSWF Door switch Front Front door open / close detection ON when closed

3 CSWL Door switch L Left door open / close detection ON when closed

4 CSWR Door switch R Right door open / close detection ON when closed

5 IR Optical communication light-receiving sensor Optical communication module for PDA/ZR

6 LUD2 Paper tray 1 lift-up sensor Detection of paper tray 1 lift-up upper limit Low when lift plate detected

7 MHPS Mirror home position sensor Detection of mirror unit home position High at home position

8 MPED Manual feed tray paper empty detector Detection of paper in manual feed tray Low when paper is detected

9 OCSW OC switch Detection of OC cover operation Low when cover is open

10 P-SW Main Power switch Main power ON / OFF

11 PED3 Paper tray 1 paper empty sensor Detection of paper in paper tray 1 Low when paper is detected

12 PID Paper in sensor Detection of paper in cassette High when paper pass over

13 PLS1 Manual feed tray paper length sensor 1 Manual feed tray paper length sensor 1 Low when detected

14 PLS2 Manual feed tray paper length sensor 2 Manual feed tray paper length sensor 2 Low when detected

15 POD Paper exit sensor Detection of paper exit from fusing section Low when paper pass over

16 PPD1 Paper pass detector 1 Paper transport detection 1 Low when paper pass over

17 PPD2 Paper pass detector 2 Paper transport detection 2 Low when paper pass over

18 PSD Paper separation detector Detection of paper separation on the OPC drum Low when paper pass over

19 TFD Waste toner sensor Waste toner bottle full detection Low when full waste toner detected

20 ADU DPFD ADU paper exit detector Detecton of paper exit from ADU High when paper pass over

21 DPPD1 ADU Paper feed sensor 1 Detection of Paper feed in ADU position 1 High when paper pass over

22 DPPD2 ADU Paper feed sensor 2 Detection of Paper feed in ADU position 2 High when paper pass over

23 DTBHPS ADU rear plate home position sensor Detection of ADU rear plate home position Low at home position

24 DTPID ADU Tray sensor Detection of paper in ADU High when paper is detected

25 DTWHPS ADU alignment plate home position sensor Detection of ADU alignment plate home position Low at home position

26 Desk unit DDOP Desk side open/close sensor Desk side door open / close detection Low when desk side door is open

27 DLPD1 Desk paper pass sensor 0 Paper transport detection 0 High when paper pass over

28 DLPD2 Paper tray 3 paper pass sensor 1 Paper transport detection 1 High when paper pass over

29 DLPD3 Paper tray 3 paper pass sensor 2 Paper transport detection 2 High when paper pass over

30 DLUD1 Paper tray 3 lift-up sensor 1 Detection of paper tray 3 lift-up upper limit High when interrupted

31 DLUD2 Paper tray 3 lift-up sensor 2 Detection of paper tray 3 lift-up upper limit High when interrupted

32 DPE2 Paper tray 3 paper empty sensor Detection of paper in paper tray 3 High when paper is detected

33 DPOD1 Desk unit resist sensor 1 Paper pass detection 1 Low when paper is detected

34 DPOD2 Desk unit resist sensor 2 Paper pass detection 2 Low when paper is detected

35 DPTD1 Paper tray 3 paper quantity sensor 1 Detection of paper quantity in paper tray 3

36 DPTD2 Paper tray 3 paper quantity sensor 2 Detection of paper quantity in paper tray 3

37 E1CLK Paper tray 3 lift-up motor 1 encoder clock detector Lift-up motor encoder clock detection Pulse output

38 E2CLK Paper tray 3 lift-up motor 2 encoder clock detector Lift-up motor encoder clock detection Pulse output

39 F/LSW Front loading open/close switch Paper tray 3 open / close detection High when open

40

41

42 LUD3 Paper tray 2 lift-up sensor Detection of paper tray 2 lift-up upper limit Low when lift plate detected

43 PED3 Paper tray 2 paper empty sensor Detection of paper in paper tray 2 Low when paper is detected

LMS1 Limit sensor 1 Prevention against excessive height of cassette

paper.

LMS2 Limit sensor 2 Prevention against excessive height of cassette

paper.

High when interrupted

High when interrupted

4 – 7

Page 20

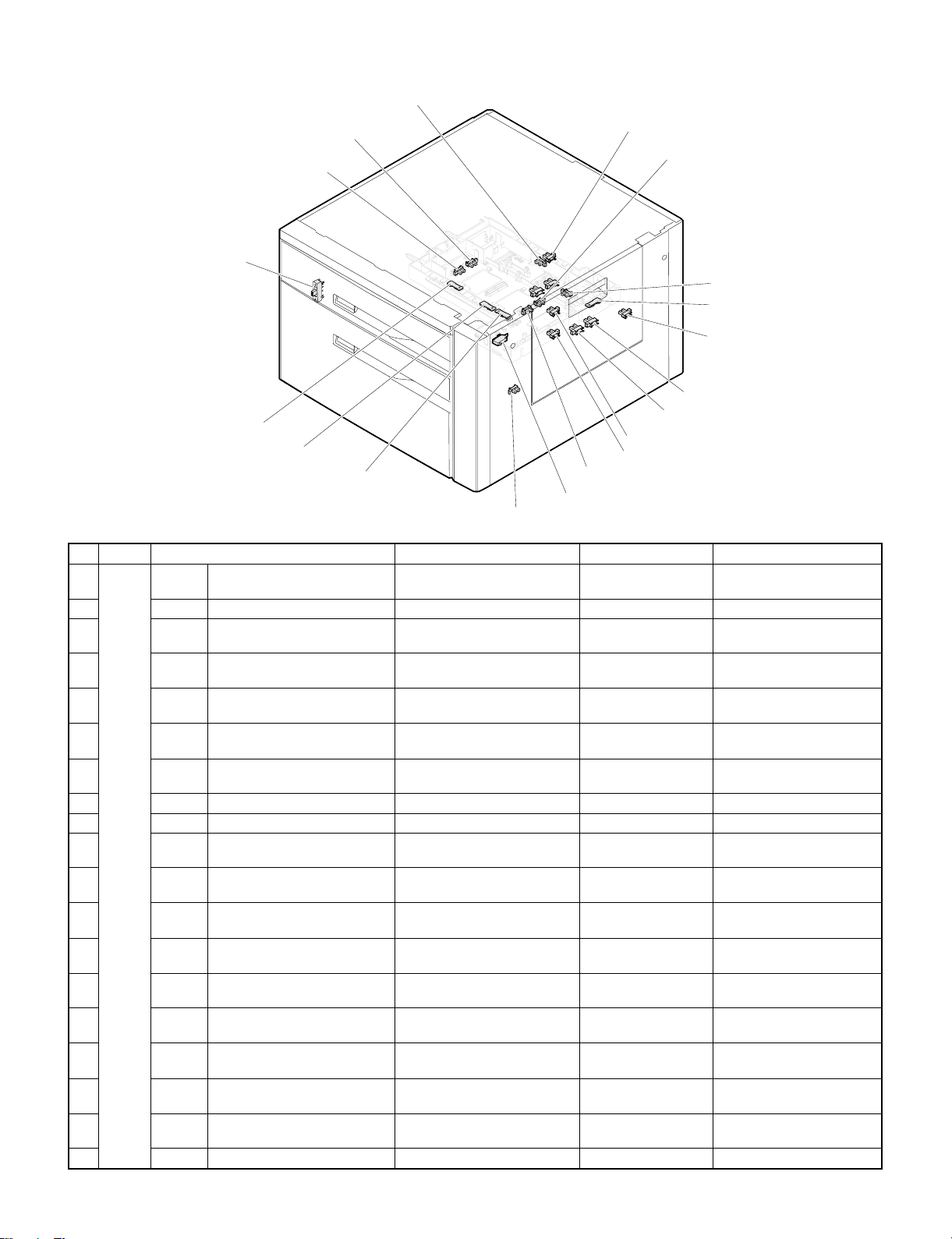

6. Clutches and solenoid

3.DGS

5.PSPS

9.DDC

6.RRC

8.TRCL

7.TRCH

4.MPFS

10.DPFC

11.DRRC

No. Section Name Function Type

1 Main body CPFC2 Paper tray 1 pick-up clutch Paper tray 1 pickup roller rotation Electromagnetic clutch

2 CPFS2 Paper tray 1 pick-up solenoid Paper tray 1 pickup roller pressing Electromagnetic solenoid

3 DGS Duplex gate solenoid Duplex gate rotation drive Electromagnetic solenoid

4 MPFS Manual feed tray pick-up solenoid Manual feed roller pressing Electromagnetic solenoid

5 PSPS Paper separate solenoid Separation roller pressing Electromagnetic solenoid

6 RRC Resist roller clutch Resist roller rotation Electromagnetic clutch

7

8

9 ADU DDC ADU drive clutch ADU drive Electromagnetic clutch

10 DPFC ADU paper feed clutch ADU paper feed roller rotation Electromagnetic clutch

11 DRRC ADU counter roller clutch ADU counter roller rotation Electromagnetic clutch

12 Desk unit BCL Paper tray 3 separation clutch Paper tray 3 separation roller rotation Electromagnetic clutch

13 DPFC1 Paper tray 2 pick-up clutch Paper tray 2 pickup roller rotation Electromagnetic solenoid

14 DPFS1 Paper tray 2 pick-up solenoid Paper tray 2 pickup roller pressing Electromagnetic solenoid

16 P1CL Paper tray 3 pick-up roller 1 clutch Paper tray 3 pickup roller 1 rotation Electromagnetic clutch

17 P2CL Paper tray 3 pick-up roller 2 clutch Paper tray 3 pickup roller 2 rotation Electromagnetic clutch

18 RCL Paper tray 3 resist roller clutch Paper tray 3 resist roller rotation Electromagnetic clutch

TRCH Paper transport roller clutch (High speed) Paper transport roller rotation (High

speed)

TRCL Paper transport roller clutch (Low speed) Paper transport roller rotation (Low

speed)

1.CRFC2

2.CPFS2

18.RCL

13.DPFC1

12.BCL

14.DPF S1

16.P1CL

17.P2CL

Electromagnetic clutch

Electromagnetic clutch

4 – 8

Page 21

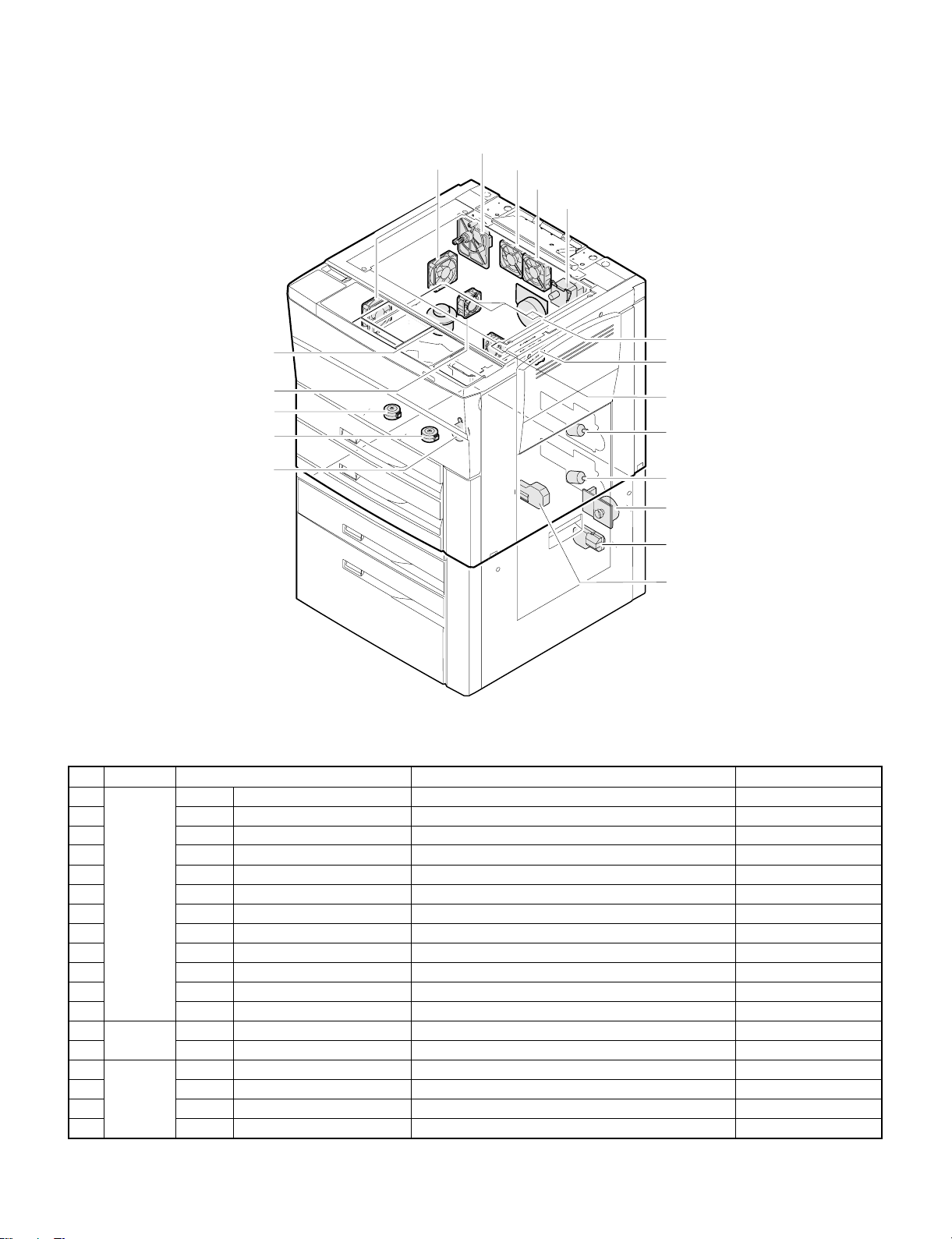

7. Motor

12.VFM

10.SM

1.CFM

4.LFM

3.DM

6.MM

9.SFM

2.DFM

5.LUM1

17.HMOT

15.E1MOT

18.LUM2

16.E2MOT

8.PM

7.PCFM

14.PAM2

13.PAM1

11.TM

No. Section Name Function Type

1 Main body CFM Cooling fan motor Optical system cooling DC brushless motor

2 DFM Power supply motor Power supply cooling DC brushless motor

3 DM Drum motor OPC drum, developing section drive DC brushless motor

4 LFM Process cooling fan motor Process control section cooling DC brushless motor

5 LUM1 Paper tray 1 lift-up motor Paper tray 1 lift-up DC motor

6 MM Main motor Paper feed, transport section drive DC brushless motor

7 PCFM Polygon cooling fan motor Polygon motor cooling DC brushless motor

8 PM Polygon motor Polygon mirror drive DC brushless motor

9 SFM Suction fan motor Suction unit cooling DC brushless motor

10 SM Mirror motor Scanner unit drive DC brushless motor

11 TM Toner motor Toner supply DC brushless motor

12 VFM Ventilation fan motor Ozone discharge DC brushless motor

13 ADU PAM1 ADU alignment plate motor ADU alignment plate drive DC stepping motor

14 PAM2 ADU rear plate motor ADU rear plate drive DC stepping motor

15 Desk unit E1MOT Paper tray 3 lift-up motor 1 Paper tray 3 lift-up DC motor

16 E2MOT Paper tray 3 lift-up motor 2 Paper tray 3 lift-up DC motor

17 HMOT Paper tray 3 transport motor Paper tray 3 paper transport DC brushless motor

18 LUM2 Paper tray 2 lift-up motor Paper tray 2 lift-up DC motor

4 – 9

Page 22

8. PWB unit

23.Manual feed tray paper size sensor PWB

24.Mother PWB

18.ICU PWB

30.Printer PWB

9.CCD drive PWB

25.Ope r at ion co ntrol PWB

13.Discharge lamp PWB

15.Docum ent size sensor PWB (Rec iev e side)

28.Process control volume PWB

21.LCD inverter PWB

20.LCD cont r ol PWB

22.LCD volume PWB

14.Doc ument size sensor PWB (Emit side)

29.Intreface PWB

26.PCU PWB

17.High voltage PWB

16.Drum motor PWB

1.Paper tray1 PWB

7.AC power supply (200V only)

2.Paper t ray2 cass et t e size sensor PWB

3.Paper tray2 lift up motor PWB

12.Desk main PWB

5.Paper tray3 lift up motor PWB

6.AC power supply

(200V: NF PWB)

10.DC power supply

11.Desk drive PWB

27.Polyg on motor drive P WB

19.Laser drive PWB

8.ADU PWB

4.Paper tray3 cassette size

swit ch PWB

No. Name Function

1 Paper tray 1 PWB Paper tray 1 paper size detection/Lift up motor drive

2 Paper tray 2 cassette size sensor PWB Paper tray 2 paper size detection

3 Paper tray 2 lift up motor PWB Lift up motor drive

4 Paper tray 3 cassette size switch PWB Paper tray 3 paper size setting

5 Paper tray 3 lift up motor PWB Lift up motor drive

6 AC power supply (200V: NF PWB) AC voltage supply (200V: Noise filter)

7 AC power supply (200V only) AC voltage supply (200V only)

8 ADU PWB Duplex unit drive

9 CCD drive PWB CCD drive

10 DC power supply DC voltage supply

11 Desk drive PWB Desk unit wiring interface

12 Desk main PWB Desk unit drive

13 Discharge lamp PWB Discharge lamp drive

14 Document size sensor PWB (Emit side) Document size detection (Light emitting side)

15 Document size sensor PWB (Receive side) Document size detection (Light receiving side)

16 Drum motor PWB Drum motor drive

17 High voltage PWB High voltage supply

4 – 10

Page 23

No. Name Function

1.APHPS2

2.DPPD1

3.APHPS1

4.DPPD25.DTPID 6.DPFD

7.PAM2 8.PAM1 9.DPFC 10.DRRC

11.DDC

12.ADUPWB

18 ICU PWB Image process control

19 Laser drive PWB Laser beam drive

20 LCD control PWB LCD display control

21 LCD inverter PWB LCD backlight lighting

22 LCD volume PWB LCD display density control

23 Manual feed tray paper size sensor PWB Manual feed tray paper size detection

24 Mother PWB ICU PWB, printer PWB interface

25 Operation control PWB Operation panel control

26 PCU PWB Process control

27 Polygon motor drive PWB Polygon motor drive

28 Process control volume PWB Bias voltage adjustment

29 Interface PWB Interface when connected with a personal computer Option

30 Printer PWB Used when the machine is used as a printer of the connected computer. Option

9. Duplex copy tray

Signal

name

1 APHPS2 ADU rear plate home position sensor Low when at home position Transmissive photosensor

2 DPPD1 ADU paper transport sensor-1 High when paper passes over Transmissive photosensor

3 APHPS1 ADU alignment plate home position sensor Low when over home position Transmissive photosensor

4 DPPD2 ADU paper transport sensor-2 High when paper detected Transmissive photosensor

5 DTPID ADU tray sensor High when paper detected Transmissive photosensor

6 DPFD ADU paper entry sensor High when paper detected Transmissive photosensor

7 PAM2 ADU rear plate motor ADU rear plate drive DC stepping motor

8 PAM1 ADU alignment plate motor ADU alignment plate drive DC stepping motor

9 DPFC ADU paper feed clutch ADU paper feed roller rotation Electromagnetic clutch

10 DRRC ADU counter roller clutch ADU counter roller rotation Electromagnetic clutch

11 DDC ADU drive clutch ADU drive Electromagnetic clutch

12 ADUPWB Diode PWB Duplex copy tray load driving

Name Output/Function Type

4 – 11

Page 24

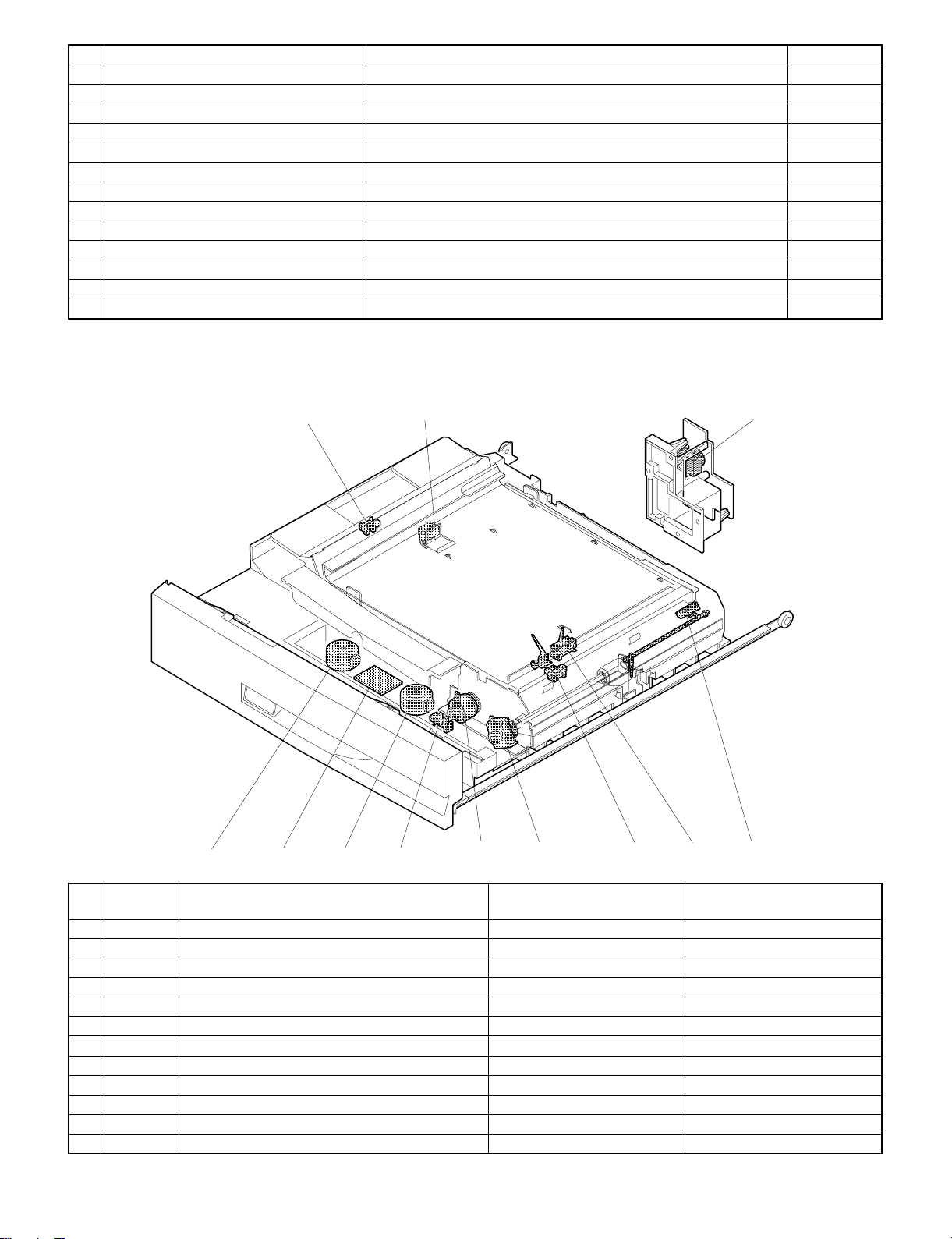

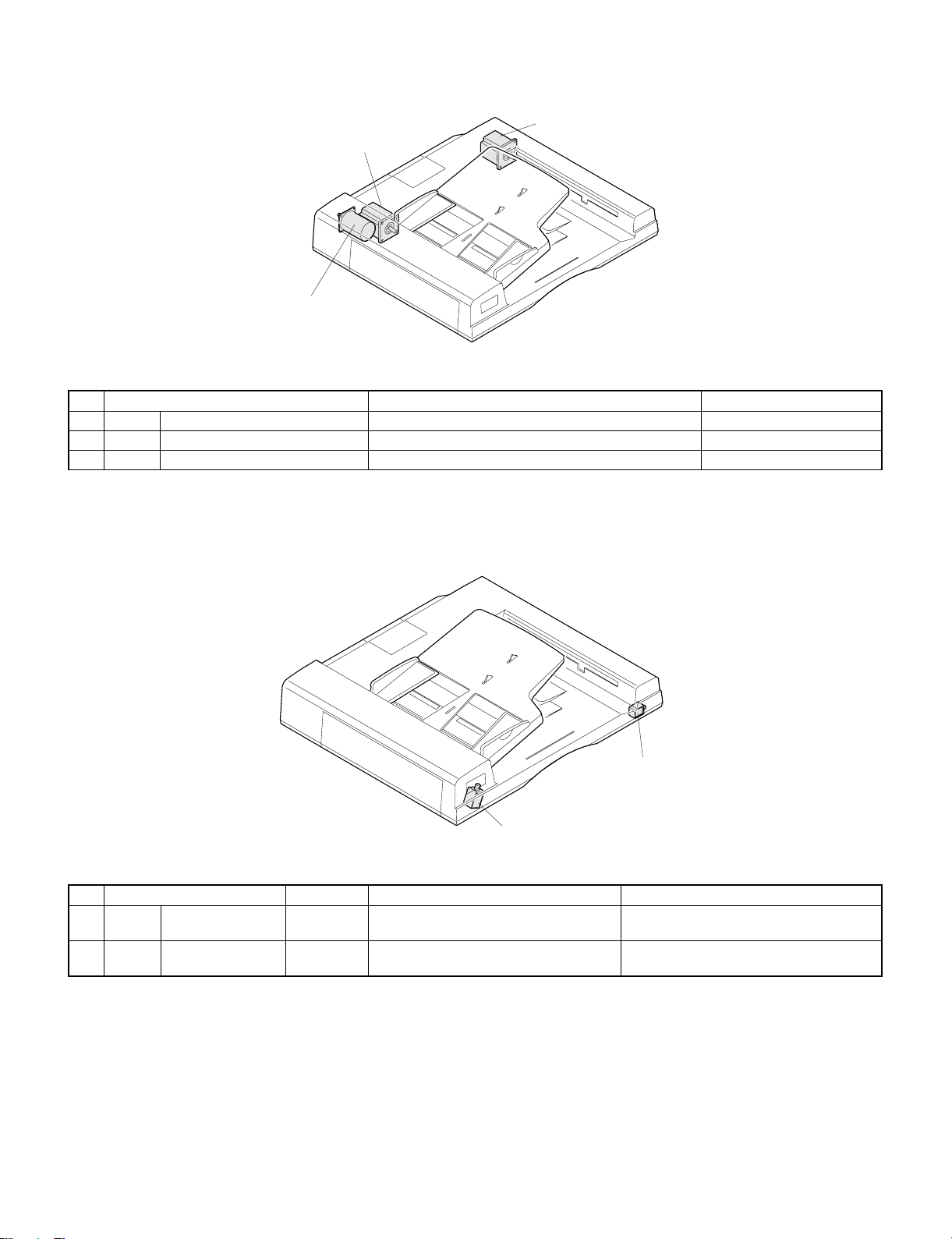

10. Desk unit (Major parts)

7.DPFS1

1.E1MOT

11.RCL

6.DPFC1

5.BCL

3.HMOT

4.LUM2

13.D es k mai n PWB

2.E2MOT

9.P1CL

12.Desk drive PWB

10.P2CL

No. Section Name Function Type

1 Motor E1MOT Paper tray 3 lift-up motor 1 Paper tray 3 lift-up DC motor

2 E2MOT Paper tray 3 lift-up motor 2 Paper tray 3 lift-up DC motor

3 HMOT Paper tray 3 transport motor Paper tray 3 paper transport DC brushless motor

4 LUM2 Paper tray 2 lift-up motor Paper tray 2 lift-up DC motor

5 Clutch

solenoid

6 DPFC1 Paper tray 2 pick-up clutch Paper tray 2 pick-up roller rotation Electromagnetic solenoid

7 DPFS1 Paper tray 2 pick-up solenoid Paper tray 2 pick-up roller pressing Electromagnetic solenoid

9 P1CL Paper tray 3 pick-up roller 1 clutch Paper tray 3 pick-up roller 1 clutch Electromagnetic clutch

10 P2CL Paper tray 3 pick-up roller 2 clutch Paper tray 3 pick-up roller 2 clutch Electromagnetic clutch

11 RCL Paper tray 3 resist clutch Paper tray 3 resist clutch Electromagnetic clutch

12 PWB Desk drive PWB Desk unit wiring interface

13 Desk main PWB Desk unit main control

BCL Paper tray 3 separation clutch Paper tray 3 separation roller rotation Electromagnetic clutch

4 – 12

Page 25

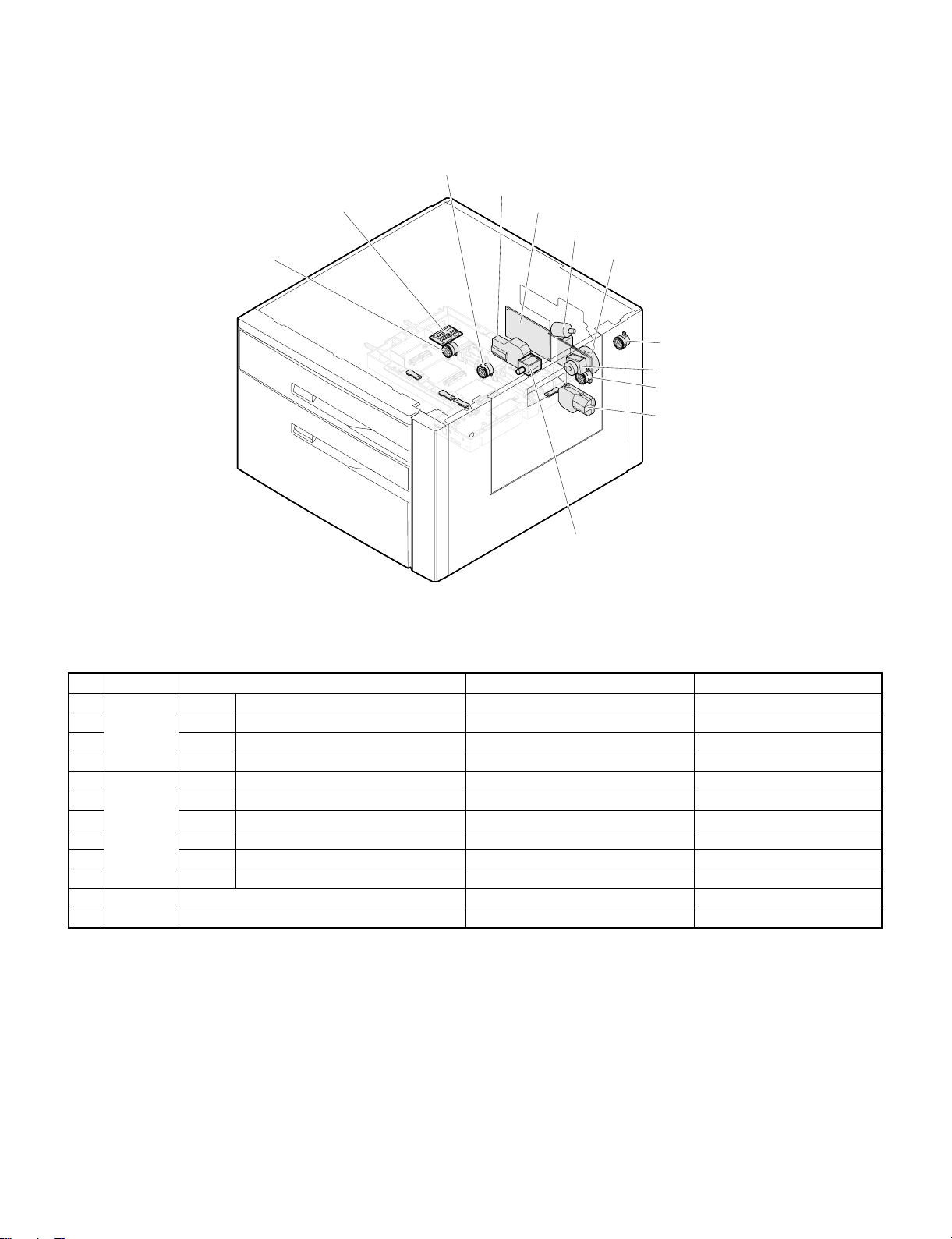

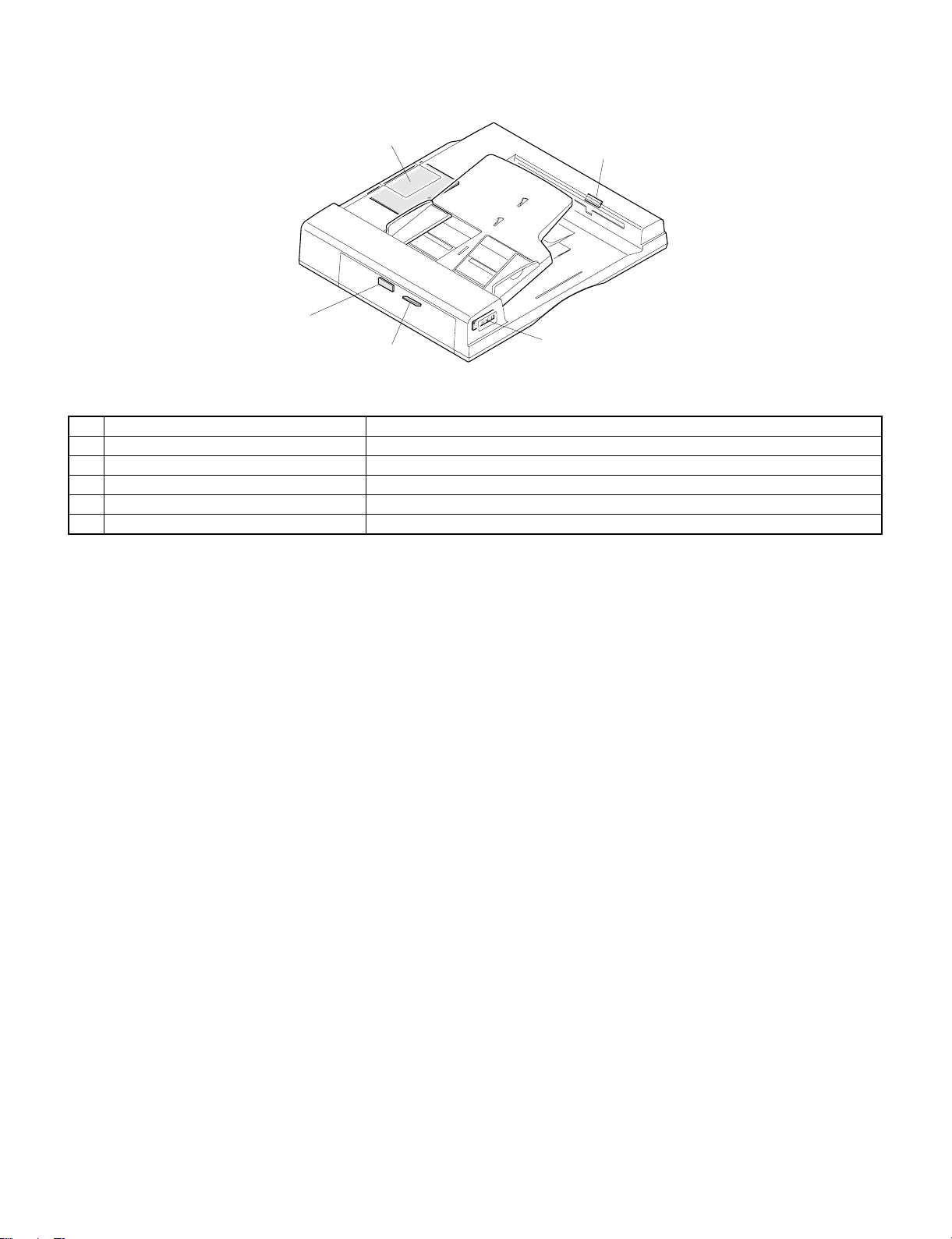

11. Desk unit (Sensor)

19.SIZESW

7.DPE2

6.DLUD2

4.DLPD3

16.LMS2

3.DLPD2

11.DPTD2

13.E2CLK

15.LMS1

10.DPTD1

2.DLPD1

12.E1CLK

17.LUD3

18.PED3

8.DPOD1

9.DPOD2

5.DLUD1

14.F/LSW

1.DDO P

No. Section Name Function Type Contact/output

1 Desk

unit

2 DLPD1 Desk paper pass sensor 0 Paper transport detection 0 Reflection type sensor High when paper pass over

3 DLPD2 Paper tray 3 paper pass sensor1Paper transport detection 1 Reflection type sensor High when paper pass over

4 DLPD3 Paper tray 3 paper pass sensor2Paper transport detection 2 Reflection type sensor High when paper pass over

5 DLUD1 Paper tray 3 lift-up sensor 1 Paper tray 3 lift-up upper limit

6 DLUD2 Paper tray 3 lift-up sensor 2 Paper tray 3 lift-up upper limit

7 DPE2 Paper tray 3 paper empty

8 DPOD1 Desk unit resist sensor 1 Paper pass detection 1 Photo interrupter Low when paper is detected

9 DPOD2 Desk unit resist sensor 2 Paper pass detection 2 Photo interrupter Low when paper is detected

10 DPTD1 Paper tray 3 paper quantity

11 DPTD2 Paper tray 3 paper quantity

12 E1CLK Paper tray 3 lift-up motor 1

13 E2CLK Paper tray 3 lift-up motor 2

14 F/LSW Front loading open/close switch Paper tray 3 open/close

15 LMS1 Limit sensor 1 Prevention against excessive

16 LMS2 Limit sensor 2 Prevention against excessive

17 LUD3 Paper tray 2 lift-up sensor Paper tray 2 lift-up upper limit

18 PED3 Paper tray 2 paper empty

19 SIZESW Paper tray 3 paper size switch Paper tray 3 paper size setting Slide switch

DDOP Desk side open/close sensor Desk side door open/close Photo interrupter Low when desk side door is

open

Photo interrupter High when interrupted

detection

Photo interrupter High when interrupted

detection

sensor

sensor 1

sensor 2

encoder clock detector

encoder clock detector

sensor

Paper tray 3 paper empty

detection

Paper tray 3 paper quantity

detection

Paper tray 3 paper quantity

detection

Lift-up motor encoder clock

detection

Lift-up motor encoder clock

detection

detection

height of cassette paper

height of cassette paper

detection

Paper tray 2 paper empty

detection

Reflection type sensor High when paper is detected

Photo interrupter

Photo interrupter

Photo interrupter Pulse output

Photo interrupter Pulse output

Photo interrupter High when open

Photo interrupter High when interrupted

Photo interrupter High when interrupted

Photo interrupter Low when lift plate detected

Photo interrupter Low when paper is detected

4 – 13

Page 26

12. RADF (Sensor)

6.DLS1

4.DED

7.DSS

10.AUOD

8.DFMRS

11.FGOD

12.TGOD

3.RDD

9.DWS

1.DFD

5.DWVR

2.DTD

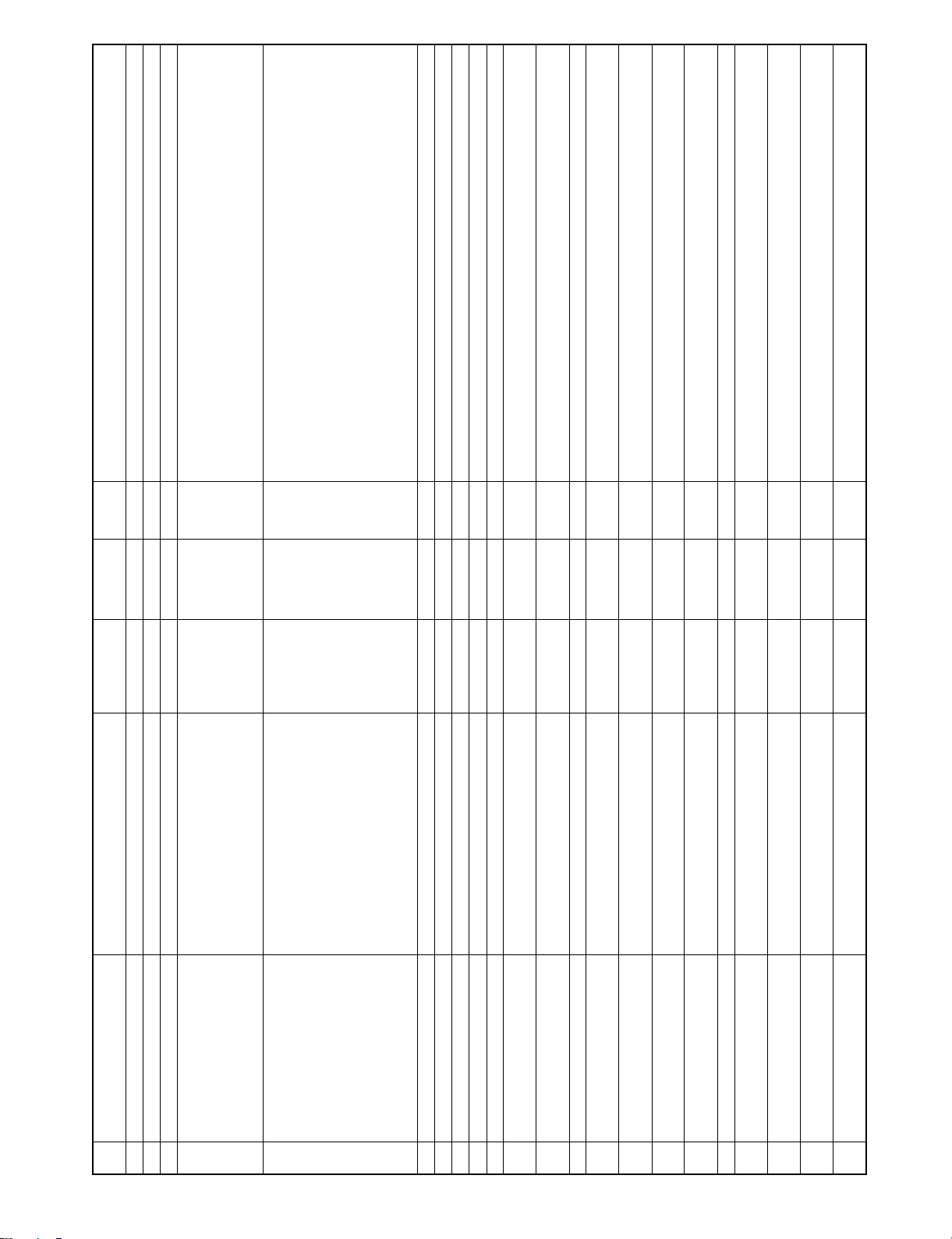

No. Name Type Function, operation Contact point, output

1 DFD Document feed sensor Reflection sensor Becomes H level when the leading

edge of document reaches the

resist roller.

2 DTD Document timing sensor Reflection sensor Becomes H level when the leading

edge of document reaches near the

transport belt.

3 RDD Reversion sensor Reflection sensor Becomes H level when the leading

edge of document is transported to

reversion/paper exit path.

4 DED Document end sensor Photo interrupter Detection of last paper in tray H level when document is detected.

5 DWVR Document width knob Slide knob Detection of document width on tray

(judged by resistance value)

6 DLS1 Document length sensor 1 Photo interrupter Detection of document length on tray H level when document is detected.

7 DSS Document setting sensor Photo interrupter Detection of document set on tray H level when document is detected.

8 DFMRS Paper feed motor rotation sensor Photo interrupter Detection of paper feed motor speed Pulse output

9 DWS Document width sensor Photo interrupter Detection of document width L level when document is detected.

10 AUOD ADF open/close switch Microswitch Detection of ADF unit operation L level when closed

11 FGOD Paper feed guide switch Microswitch Detection of paper feed guide

operation

12 TGOD Reflection guide switch Microswitch Detection of reversion cover

operation

H level when document is detected.

H level when document is detected.

H level when document is detected.

H level when document is detected.

L level when closed.

L level when closed.

4 – 14

Page 27

13. RADF (Motor)

3.DRM

2.DTM

1.DFM

No. Name Function, operation Type

1 DFM Paper feed motor Driving of pick-up roller, separation roller, and resist roller DC motor

2 DTM Transport motor Driving of transport belt roller Stepping motor

3 DRM Reversion motor Driving of reversion roller and paper exit roller Stepping motor

14. RADF (Clutches and solenoid)

2.DRSOL

1.DFSOL

No. Name Type Function, operation Contact point, output

1 DFSOL Paper feed solenoid DC solenoid Presses paper feed weight plate against

document to operate the shutter.

2 DRSOL Reversing solenoid DC solenoid Selects between paper exit and reversion

paths by driving reversing flapper.

Weight plate and shutter go down when

turned ON.

Reversion path is selected when turned ON.

4 – 15

Page 28

15. RADF (PWB)

1.Control PWB

2.Document f eed s enso r PW B

4.LE D PW B

3.Document timing sensor PWB

No. Name Function

1 Control PWB RADF control

2 Document feed sensor PWB Detection of document feed

3 Document timing sensor PWB Detection of document transport timing

4 LED PWB LED lighting

5 Reversing sensor PWB Detection of document reversing

5.Reversi ng sensor P WB

4 – 16

Page 29

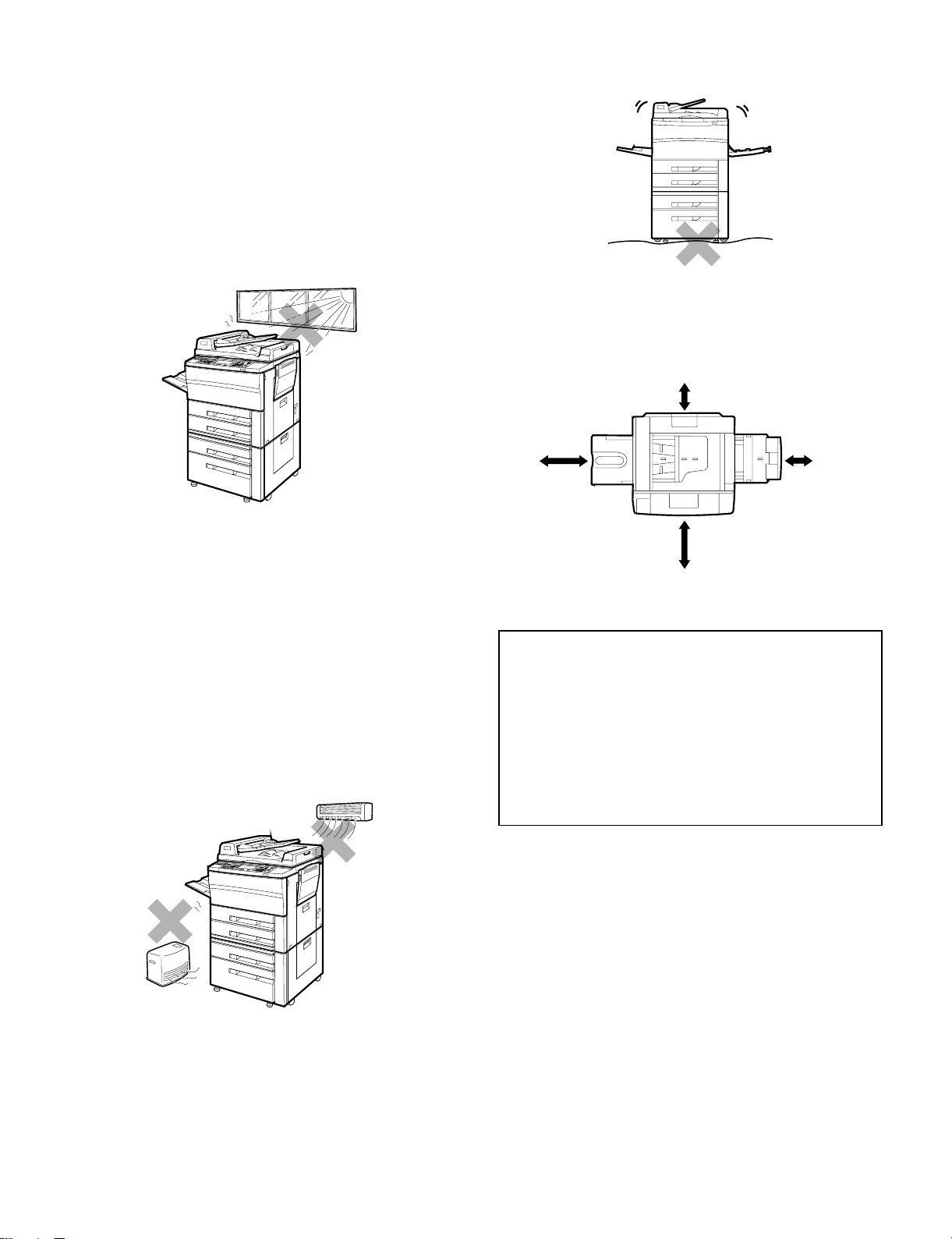

[5] UNPACKING AND

INSTALLATION

1. Use environment

To ensure safety and proper machine performance, please note the

following before initial installation and whenever the machine is to be

relocated.

(1) The copier should be installed near an accessible power outlet for

easy connection.

(4) Ensure that the area chosen for the machine location is level.

(5) Be sure to allow the required space around the machine for ser-

vicing and proper ventilation.

11-13/16"

(30 cm)

(2) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Also make certain the outlet is properly grounded.

The outlet must be kept apart from appliances that consume much

power, such as large motors.

(3) Do not install the machine where it is:

• damp or humid,

• exposed to direct sunlight,

• extremely dusty,

• poorly ventilated,

• subject to extreme temperature or humidity changes (e.g., near

an air conditioner or heater).

23-5/8"

(60 cm)

23-5/8"

(60 cm)

A small amount of ozone is produced within the copier during

operation.

The emission level is insufficient to cause any health hazard.

NOTE:

The present recommended long term exposure limit for ozone is

0.1 ppm (0.2 mg/m3) calculated as an 8 hr. time-weighted average

concentration.

However, since the small amount that is emitted may have an

objectionable odor, it is advisable to place the copier in a ventilated area.

11-13/16"

(30 cm)

5 – 1

Page 30

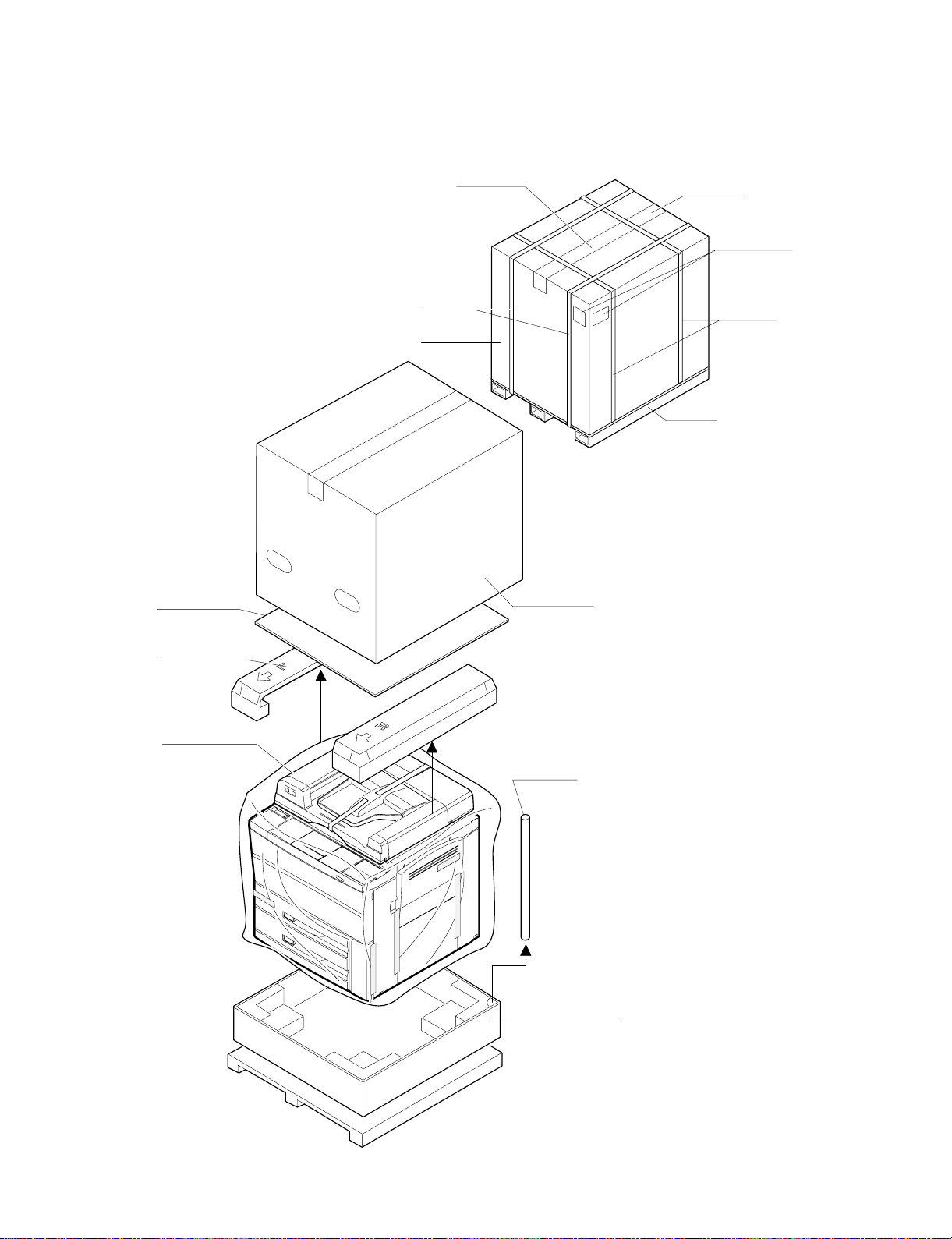

2. Unpacking

Craft tape

50 mm wide

PP band x 2

Stitcher x 4

Package box

indication label

PP band x 2

Skid UN

Upper reinforcing

material

Copier

Pack-AD (upper)

Support x 4

Bottom case assembly

PACK-CASE

PACK-CASE

(1) Package form drawing

The PPC unit and the desk unit are separately packaged.

Unpack the package in the following manner:

A. PPC section

a. Remove the PP band.

b. Remove the packing case.

c. Remove the inside pads and packaged items.

d. Remove the PPC unit.

5 – 2

Page 31

B. Desk unit

a. Cut the PP band.

b. Open the exterior box.

c. Remove the packaged items:

1) Remove the short spacer package assembly

2) Remove the screw package assembly A.

3) Remove the screw package assembly B.

4) Remove the instruction manual.

d. Remove the upper pad.

e. Remove the vinyl sheet.

f. Remove the desk unit.

Exterior box

Screw pa ckage assemb l y B

Taped to recession in the

upper pad

Screw package assembly A

Taped to re cession in the

upper pad

Lower pad

Instruc t io n Ma nu al

Short spacer package assembly

Taped to recession in upper pad

Upper pad

Copier vi nyl sheet

Desk unit

Bottom case

5 – 3

Page 32

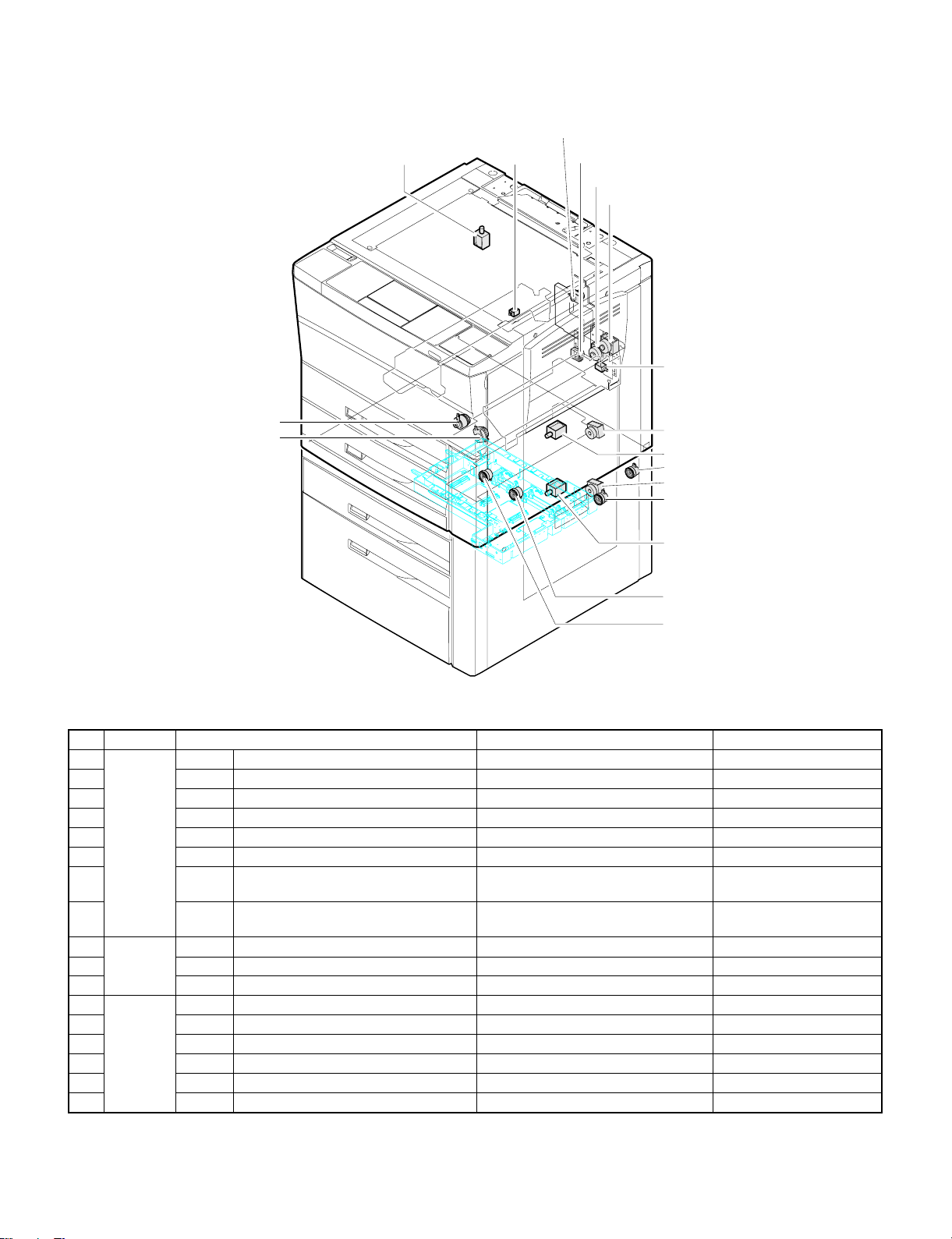

3. Setting-up procedure

(1) Installing desk unit

A Place the copier on the desk

B Secure the copier to the desk

C Connect the desk relay harness

D Secure the desk on the floor

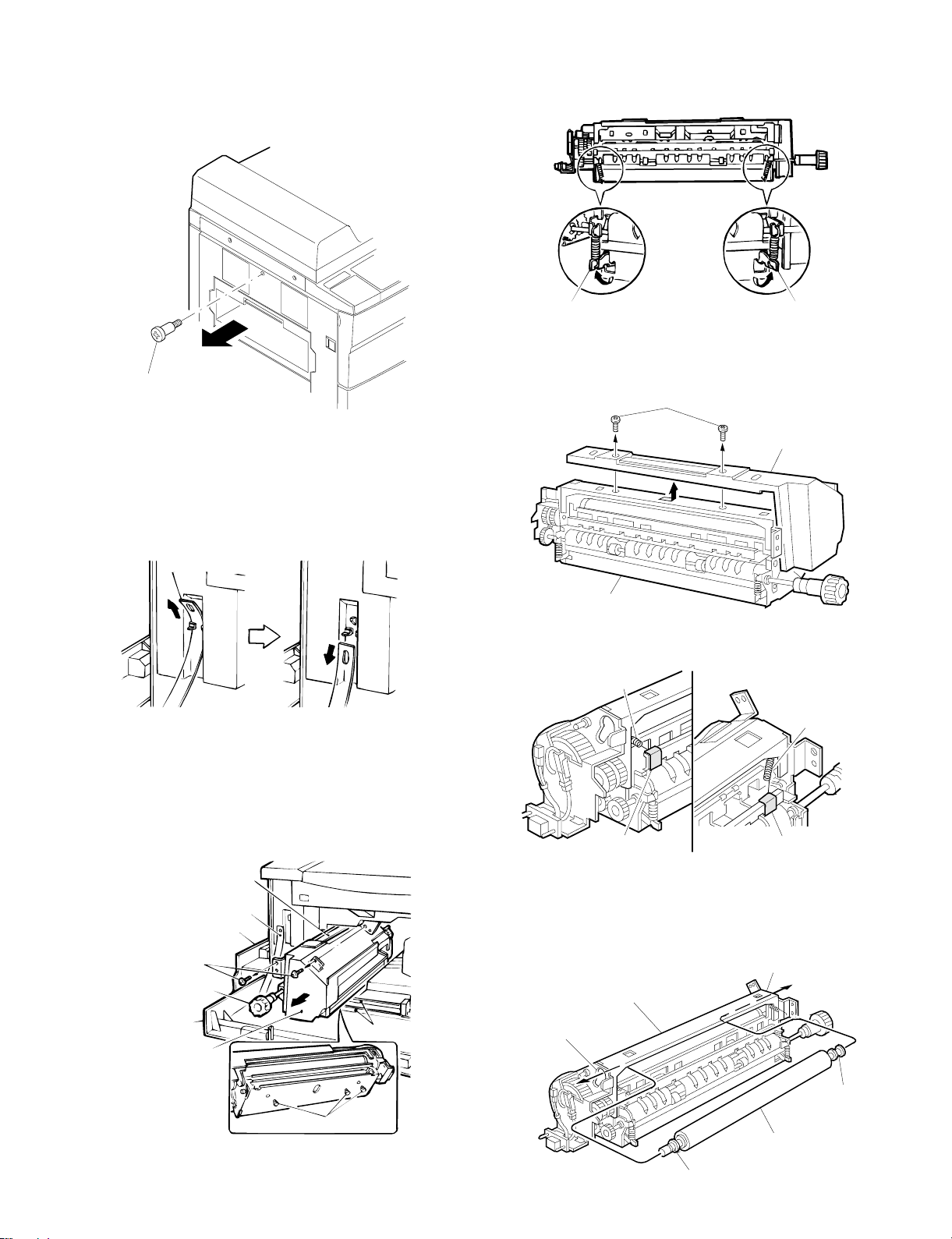

(2) Releasing optical system lock

(3) Setting fusing unit

A Removing fusing unit

B Pressurize heat roller

C Installing cleaning roller

(4) Cleaning charger roller

A Cleaning main charger unit

B Cleaning transfer/separation charger unit wire

(5) Installing RADF tray

A Connecting RADF tray connector

B Installing tray

(6) Setting developer unit

A Removing the developing unit

B Supplying the developer

C Adjusting toner density sensor level

D Checking process control sensor value

(7) Toner supply

(8) Setting up paper tray 1/2

(9) Setting up paper tray 3 (LCC tray)

A Paper size setting

B Adjust any center misalignment

(10) Checking copy density

(11) Installing sorter (SF-S53N) <option>

(12) Installing sorter (SF-S15) <option>

Included parts

Parts for use with the Deck unit

Mounting screws

(4 pcs.)

Parts for use with the SF-S53N

Caster spacers

(4 pcs.)

Caster mounti ng screws (M4 x 60)

(8 pcs.)

Be sure to unplug the copier before carrying out the

following procedures.

A. Place the copier on the desk.

Place the copier on the desk so that the feet of the copier fit into the

corresponding holes in the desk.

When doing this, be careful that the copier does not come to rest on

the paper guide or other parts of the desk that might be damaged by

the weight of the copier.

(1) Installing desk unit

Paper guide

B. Secure the copier to the desk.

Use the included four mounting screws to secure the copier to the

desk.

• In addition to securing the copier to the desk, these screws also

function to electrically ground the desk, so be sure to tighten all

mounting screws securely.

Left side

Copier

Right side

Copier

5 – 4

Mounting

screws

Desk

Desk

Mounting

screws

Page 33

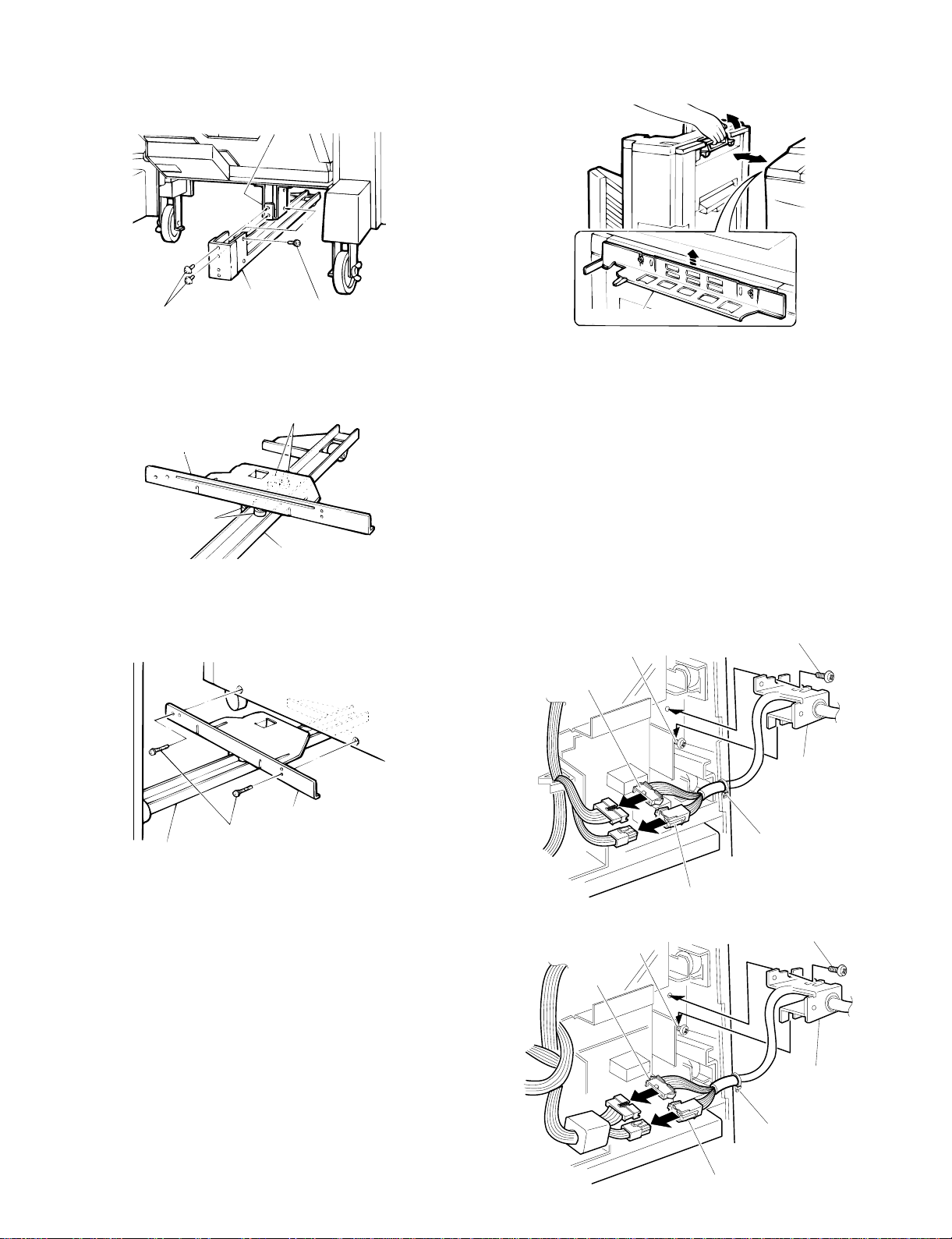

C. Connect the desk relay harness.

Mounting scr ew

Rear coverlet

Rear cabinet panel

Clamp

connector

a. Remove the rear coverlet of the copier.

Remove the mounting screw which holds the rear coverlet to the rear

cabinet panel, then remove the rear coverlet.

b. Connect the desk relay harness.

Remove the connector harness from the clamp which bundles the

desk relay harness together.

Next, remove the temporary connector which is attached to the connector of the desk relay harness, and connect the connector from the

copier into the connector on the desk.

* Note that the temporary connector will no longer be used.

c. Remount the rear coverlet of the copier.

Return the rear coverlet to its document position and use its mounting

screw to mount it.

Rear cabinet panel

Mounting scr ew

coverlet

D. Secure the desk on the floor.

Turn clockwise the two adjusters at the lower front of the desk to

lower them to the floor and secure the desk in place.

Use the caster lock levers on the front side (right and left) of the desk

to lock the casters in place.

Caster

Caster lock lever

Adjuster

Note:

Turning on the power with no desk connected causes the trouble

"U6-00," thereby disabling the machine operation.

5 – 5

Page 34

(2) Releasing optical system lock

Mirror unit fixing screw

Front cabinet band

Carrier strap

Front cabinet band

Paper exit area

Fixing screw

Roller rotation knob

Front cabinet

Fusi ng unit

Rib

Guide pin

Remove the 2nd/3rd mirror unit locks.

Remove the screws securing the 2nd/3rd mirrors on the left side of

the machine.

B. Pressuring heat roller

Move the pressuring levers at the front and rear sides of the fusing

unit as shown in the figure below. This applies pressure on the upper

and lower heat rollers.

(3) Setting fusing unit

A. Remove the fusing unit.

a. Lifting the paper exit knob, open the paper exit. Then, remove the

front cabinet band on the left side of the front cabinet.

Rear side

Pressing lever

Front side

Pressing lever

C. Installing cleaning roller

a. Remove the screw securing the fusing cover. Slide the fusing

cover toward you to remove it.

Fixing screw

Fusing cove r

Fusi ng unit

b. Remove the CL springs secured by tape onto the front and rear

sides of the fusing unit.

Rear side

CL spring

Front side

b. Remove the screw securing the fusing unit.

c. Holding the rotating knob of the fusing unit, remove the fusing unit

carefully pressing the front cabinet. At this time, use caution not to

let the guide pin at the bottom of the fusing unit contact the front

cabinet rib. Then, holding the carrier strap of the fusing unit,

remove the fusing unit.

CL sprin g

CL spring fixing tape

CL spring fixing tape

Note: Make sure to remove fixing tape carefully and thoroughly.

c. Pass the cleaning roller through the round hole in the rear side of

the fusing unit. Insert the cleaning roller through the front round

hole. Then, position the bearings of the cleaning rollers at both the

front side and the rear side.

Front side round hole

Fusing u nit

Rear side round hole

Bearing

Cleaning roller

Bearing

5 – 6

Page 35

d. Hook the CL spring on the front and rear frames of the fusing unit.

Rear side

CL spring

Front side

CL spring

Fixing screw

Fusing cov e r

Fusing unit

Front cabinet band

Paper exit area

Fixing angle

Fixing screw

Front cabinet

Fusing unit

Fixing angle

Positioning pin

Guide pin

Make sure that the CL spring presses the bearing as shown in the

figure below.

e. Reinstall the fusing cover which was removed in step a, and

secure it with screws.

(4) Cleaning the charger

A. Cleaning main charger unit electrode

a. Holding down the hook of the main charger unit, release the lock.

Pull out the main charger unit from the copier and remove it.

Main charger unit

b. Remove the screw securing the electrode to the rear side of the

main charger unit. Remove the electrode.

Fixing screw

Electrode

f. Place the guide pin at the bottom of the fusing unit in the groove

of the copier. Holding down the front cabinet, push in the fusing

unit slowly as far as possible.

At this time, make sure the positioning pin of the copier frame is

securely installed in the positioning hole in the fusing unit fixing

angle. Secure with the fixing screws which were removed in step

(3) A. b., and close the paper exit unit. Reinstall the front cabinet

band which was removed in step (3). A. a. Close the paper exit

unit.

Main charger unit

c. Stick the electrode cleaner to the tips of the electrode for cleaning

two or three times.

Electrode cleaner

Electrode

Note: • Do not move the cleaner with the electrode tips stuck

into the cleaner.

• Cleaning should be evenly on the whole area, but not

partly.

d. Install the electrode on the document position and secure with the

screw.

e. Slide the main charger unit along the copier guide securely to

stop.

Main charger unit

5 – 7

Page 36

B. Cleaning transfer/separation charger unit wire

Transport opening/closing lever

TC loc k plat e

Transfer/separation

charger unit

Transport opening/closing

lever

Separation charger guide

Charger case

A

Charger cleaner

Charge r wir e

a. Bring the transport opening/closing lever down to the left. Turn the

TC lock plate clockwise with a scale or a slotted screwdriver to

release the TC lock. Remove the transfer/separation charger unit

from the copier.

d. Install the separation charger guide on the charger case. Insert

the transfer charger unit, along the groove in the guide, all the way

to stop. Turn the TC lock plate counterclockwise to lock. Back off

the transport unit opening/closing lever clockwise to close the front

cabinet.

b. Remove the part A of the separation charger guide and slide the

guide in the direction indicated by the arrow, to remove the

separation charger guide from the charger case.

c. Clamp the transfer/separation charger wire with the charger

cleaner, and clean the wire by moving the cleaner in the direction

indicated by the arrow.

Transport opening/closing lever

Transport opening/closing

lever

TC lock plate

Transfer/separation

charger unit

(5) Installing RADF tray

A. Connect RADF tray connector

a. Temporarily install the tray fixing screws to connect the RADF

connector to the tray connector.

Tray side connector

Tray fixing

screw

ADF side connector

B. Installing tray

a. Install the tray as shown in the figure below, and secure with the

screws.

Tray fixing

screw

Tray

5 – 8

Page 37

(6) Setting up developer unit

Toner box lever

Developi n g unit loc k lev e rToner box lever

Developing unit lock lever

Carry strap

A. Removing the developing unit.

a. Open the front cabinet.

b. Tilt down the toner box lever and pull out the toner box until it

stops.

B. Supplying developer

a. Remove the connector which is connecting the toner hopper and

the developing unit.

Remove the five toner hopper fixing screws, the developing unit,

and remove the toner hopper.

c. Slide the developing unit lock lever in the arrow direction to

release lock, and hold the toner box lever and pull out the

developing unit until it stops.

[Note]

• When lock is released and the developing unit becomes free to

move, let go of the developing unit lock lever.

Fixing screw (silver)

Fixing screws (silv er )

Ton e r hopp er

Fixing screws (blue)

Developing unit

Fixing screw

(blue)

connector

b. While supplying developer from the developer supply port of the

developing unit, turn the MG gear clockwise with a screwdriver (+)

or a scale to completely supply developer into the developing unit.

Develo pe r

Developer s uppl y port

d. Hold the carry strap of the developing unit and slide the develop-

ing unit lock lever in the arrow direction to release lock. Then

remove the developing unit.

Deve loping unit

MG gear

c. Install the toner hopper to the developing unit, and fix it with the

five screws. Connect the 5P connector of the developing unit with

the toner hopper.

Fixing screw (silver)

Fixing screw (silver)

Ton e r hopp er

Fixing screw (blue)

Developing unit

Fixing screw

(blue)

5P connector

Note: If the hopper and the five screws are not securely fixed,

toner may flow into the developing unit when supplying

toner.

5 – 9

Page 38

C. Adjusting toner density sensor level

C 0 / 5

2

2

Toner box lever

Turn ON the power supply switch of the copier.

Note: Make sure the main charger unit is securely inserted, before

executing simulation 25-1 or 25-2.

a. Carry out the following key operation for the simulation 25-2.

b. The simulation 25-2 is finished in 3 minutes.

Note: Do not cancel the simulation during execution, because

automatic reading cannot be performed.

c. Cancel the simulation 25 with the CA key.

Note: The simulation 25-2 should be performed whenever the

developer is replaced with a new one. The developing adjustment value for servicing should be checked by executing the Sim 25-1. (If the Sim 25-2 is used for this purpose,

toner density trouble might occur.)

D. Checking process control sensor value

Execute Sim44-2 and Sim44-3, to make sure that the results are

within a range of 210 ±30. If any of the results are out of the range,

adjust, referring to the procedure described under "Image Adjustment."

d. Install the toner cartridge to the toner box as shown in the figure

below.

e. Move the toner cartridge in the arrow direction until it stops.

(7) Toner supply

A. Toner supply

a. Open the front cabinet.

b. Tilt down the toner box lever towards you and pull out the toner

box until it stops.

c. Shake the toner cartridge up and down about 5 times.

f. While holding the toner cartridge, pull the seal to supply toner.

[Note]

• It takes about 30 seconds to finish supplying toner.

g. Tap the top of the toner cartridge to put down toner attached

inside the toner cartridge.

Note: Though the cartridge look like that of the SF-2025/2030/

2040, its cap pawl shape and position are different and the

color of the cap slide section is brown for identification.

5 – 10

Page 39

h. Move the empty toner cartridge in the arrow direction to remove.

Toner box lever

Pa ck age fi xi ng scr e w

Package fixing screw

b. Changing the side plates F and R sizes (factory set for A/3 or

double letter size)

Install the side plates F and R on the tray, along with the mark-

ings, so that they form the paper size you want. Secure them with

screws.

i. Push the toner box slowly to the document position, and lift the

toner box lever.

Toner supply is completed with the above procedure. Close the front

cabinet.

Side plate R

Fixing screw

Side plate F

Fixing screw

c. Changing rear end plate position

Remove the rear end plate and reinstall it at the position which the

paper size you want is created.

Rear end plate

(8) Setting up paper tray 1/2

a. Removing the tray package fixing screws.

Remove the package fixing screws securing the paper pressing

plate in the tray.

d. Setting size detection spacer

Install the size detection spacer in an appropriate position so that

your desired paper size is created.

Size det e ction sp acer

(Example) A3 setting

5 – 11

Page 40

e. Changing paper size indication plate

A3

A4R

B4

B5

A4

B5R

A5

Size detection spacer setting

Dummy

slot

W Lett er

Legal

Letter R

Letter

Invoice

Paper siz e indi cat ion plate

Indication line label

Install the paper size indication plate so that the name of the

paper size you preset can be seen through the paper size indication window.

Note: Remember that the paper size indication plate carries

paper size names on its both face and back sides.

f. Setting paper

Set less than the specified amount of sheets of paper in the tray.

Push in the tray into the copier as far as possible.

5 – 12

Page 41

(9) Setting up paper tray 3

A. Paper size setting

a. Pull out the cassette.

Grasp the cassette by the handle and pull it out gently as far as it will

go.

b. Adjust the front and rear paper guides.

Remove the mounting screws holding the front and rear paper guides

(one screw per guide) in place.

Insert the tabs (two on the bottom of each paper guide) into the

cassette in the notches corresponding to the desired paper size.

Next, use the mounting screws to secure the top of the front and rear

paper guides (one screw per guide) in the positions corresponding to

the desired paper size.

Mounting screws

[example\ A4 setting

A4

Front pap er gu i de

LT

B5

c. Adjust the side guides

Remove the mounting screws (one per guide) holding the right and

left paper side guides in place.

Use the mounting screws to secure the right and left paper size

guides (one screw per guide) in the positions corresponding to the

paper size which has been set.

Mounting scr ew

Right paper side guide

Left paper side guide

Mounting screw

Where to set th e moun t ing scr ew for vari o us p aper si zes