1/21July 2003

■ 4-CHANNEL S ERIAL-IN PARALLEL-IN LOW

SIDE PRE-FET DRIVER

■ DEVICES ARE CASCADABLE

■ INTERNAL 55V INDUCTIVE LOAD CLAMP

AND VGS PROTECTION CLAMP FOR

EXTERNAL POWER FETS

■ INDEPENDENT SHORTED-LOAD AND

SHORT-TO-BATTERY FAULT DETECTION

ON ALL GATE TERMINALS

■ INDEPENDENT OFF-STATE OPEN-LOAD

FAULT SENSE

■ OVER-BATTERY-VOLTAGE LOCKOUT

PROTECTION AND FAULT REPORTING

■ UNDER-BATTERY VOLTAGE LOCKOUT

PROTECTION

■ ASYNCRONOUS OPEN-GATE FAULT FLAG

■ DEVICE OUTPUT CANBE WIREDOR WITH

MULTIPLE DEVICES

■ FAULT STATUS RETURNED THROUGH

SERIAL O UTPUT TERMINAL

■ INTERNAL GL OBA L POWER-ON RESET OF

DEVICE AND EXTERNAL RESET TERMINAL

■ HIGH IMPEDANCE CMOS COMPATIBLE

INPUTS WITH HYSTERESIS

■ TRANSITION FROM THE GATEOUTPUT TO

A LOW DUTY CY CLE PWM MODE WHEN A

SHORTEDLOADFAULTOCCURS

DESCRIPTION

The STPIC44L02 is a low-side predriver that

provides serial and parallel input interfaces to

control four external FET power s w itches.

It is mainly desi gned to provide low-frequency

switching, inductive load applicati ons such as

solenoids and relays. Fault status is available in a

serial-data format. Each driver channel has

independent off-state open-load detection and

on-state shorted load short to battery detection.

The STPIC44L02 offers a batteryover voltage and

undervoltage detection and shutdown. If a fault

occurs while using the STPIC44L02, the channel

transitates into a low duty cycle , pulse width

modulated (PWM) signal as long as the fault is

present.

These devices provide control of output channels

through a serial input interface or a parallel input

interface. A command to enable the output from

either interface enables the respective channels

gate output to the external FET. The serial

interface is recom mended when the number of

signals between t he control device and the

predriver are minimized and the speed of

operation is not critical. In applications where the

predriver must respond very quickly or

asynchronously, the parallel input interface is

recommended.

For serial operation, the control device must

transitate C S

from hi gh to low to activate the serial

input interface. When this occurs, SDO, is

enabled, fault data is latched into the serial

interface, and the fault flag is refreshed. Data is

clocked into the serial registers on low to high

transitions of SCLK through SDI. Each string of

data must con sist of at least four bits of data. In

applications where multiple devices are cascaded

together, t he string of data must c onsist of four bits

for each device. A high data bit turns the

respective output c hannel on and a low data bit

turns it off. Fault data for the device is clocked out

of SDO as serial input data is clocked into the

device. Fault data consists of fault flags for

shorted load and open load flags (bits 0-3) for

each of the four output channels. Fault regist er

bits are set or cleared asynchronously to ref lect

the current state of the hardware. A fault must be

present w hen CS

is transitated from high to low to

be captured and reported in the serial fault data.

New faults cannot be captured in the serial

register when CS

is low. CS must be transitated

high after all of the serial dat a has been clocked

into the device. A low to high transition of CS

transfers t he last four bits of serial data to t he

STPIC44L02

4 CHANNEL SERIAL AND PARALLEL

LOW SIDE PRE-FET DRIVER

SOP

STPIC44L02

2/21

output buffer that puts SDO in a high im pedance

state and clears and reenables the fault register.

The STPIC44L02 was designed to allow the serial

input interfaces of multiple devices to be cascated

together to simplify the serial in terfac e of the

controller. Serial input data flows through the

device and is transferred out SDO following t he

fault data in c as caded configurations.

For parallel operation, data is transferred directly

from the parallel input interface IN0-IN3 to the

respective GATE(0-3) output asy nc hronous ly.

SCLK or CS

is not required for parallel control. A 1

on the parallel input turns the respective channel

on, where as a 0 turns it off. Note that either the

serial input interface or the parallel input in terface

can enable a channel. Under parallel operation,

fault data must still be collected t hrough the serial

data interface.

The predriver monitors the drain voltage for each

channel to detect shorted load or open load fault

conditions, in t he on and off st ate respectively.

These devices offer the option of using an

internally genera ted fault reference voltage or an

externally supplied fault reference voltage through

V

COMP

for fault detection. The internal fault

reference is selected by c onnecting V

COMPEN

to

GND and the external reference is selected by

connecting V

COMPEN

to VCC. The drain voltage is

compared to the fault reference when the channel

is turned on to detect shorted load conditions and

when t he channel is off to detect open lo ad

conditions. If a fault occurs, the channel

transitates into a low duty cycle , pulse width

modulated (PWM) signal as long as the fault is

present. Shorted load fault c onditions must be

present for at least the shorted l oad deglicth time,

t

(STBDG)

, to be flagged as a fault. A fault flag is

sent to the control device as well as the serial fault

register bits. More detail on fault detection

operation is presented in the device operation

section of this datasheet.

The device provides prote ction from over battery

voltage and under ba ttery voltage conditions

irrespective of the state of the output channels.

When the battery voltage is greater than the

overvoltage threshold or les s than the

undervotlage threshold, all channels are disabled

and a fault flag is generated. Battery voltage f aults

are not reported in the serial fault data. The

outputs return to normal operation onc e the

battery voltage fault has been corrected. When an

over battery/under battery voltage condition

occurs, the device reports the battery fault, but

disables fault reporting for open and shorted load

conditions. Fault reporting for open and shorted

load conditions are reenabled after the battery

fault condition has been corrected.

This device provides inductive transient protection

on all channels. The drain voltage is clamped to

protect the FET. The c lamp voltage is defined by

the sum of V

CC

and turn on voltage of the external

FET. The predriver also provides a gate to source

voltage (V

GS

) clamp to protect the gate source

terminals of the power FET from exceeding their

rated voltages. An external active low RESET

is

provided to clear all register and flags in the

device. GATE(0-3) outputs are disabled after

RESET has been pulled low.

The d ev ice provide pull-down resistors on all

inputs except CS

and RESET. A pull-up resistor is

usedon CS

and RESET.

ORDERING CODES

Type Package Comments

STPIC44L02PTR SSOP24 (Tape & Reel) 1350 parts per reel

STPIC44L02

3/21

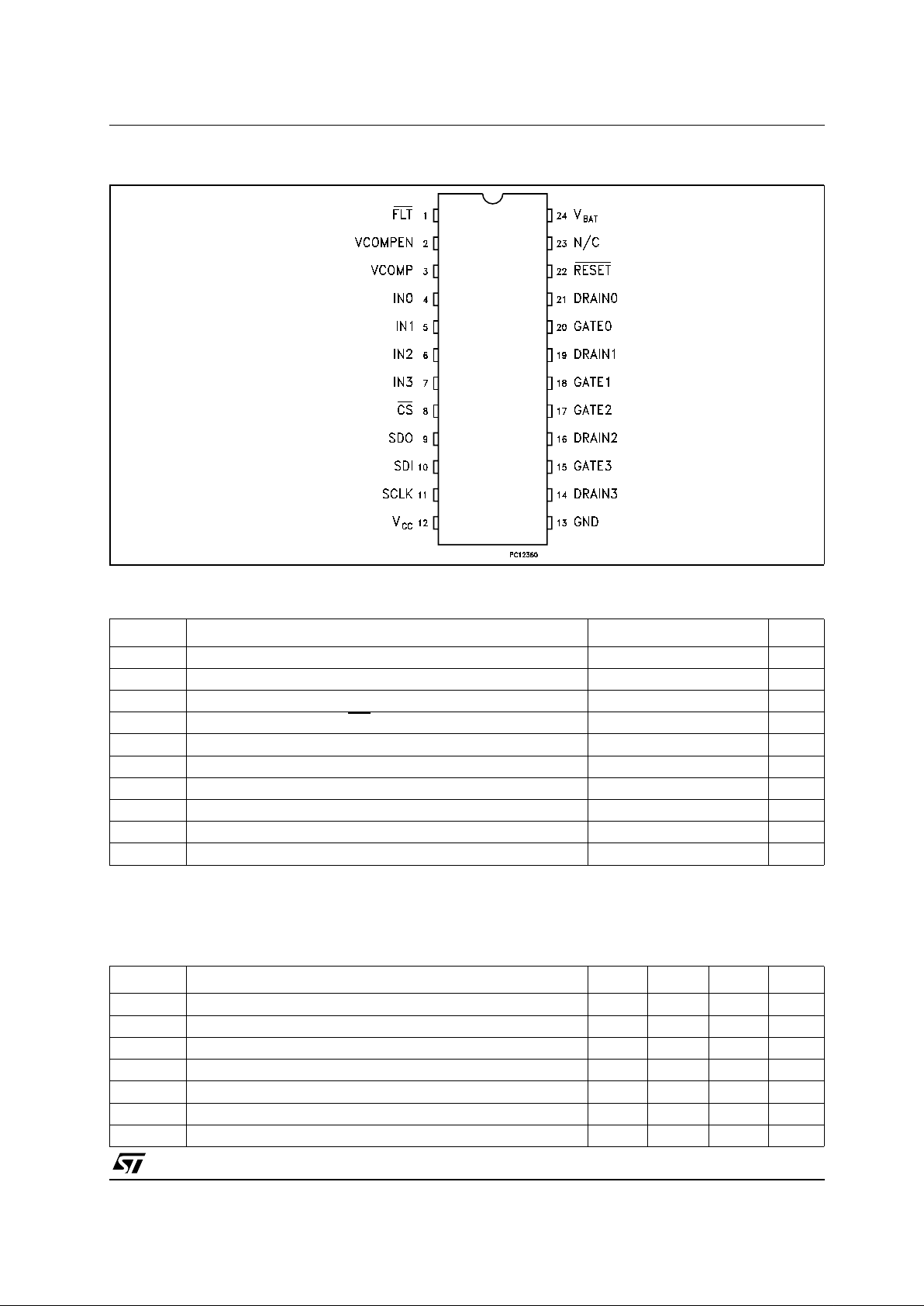

Figure1 : Schematic Diagram

STPIC44L02

4/21

PIN DESCRIPTION

PIN No SYMBOL I/O NAME AND FUNCTION

1FLT

I Fault Flag. FLT is a logic level open-drain output that provides a real time fault flag for

shorted-load, open-load, over-battery voltage, under-battery voltage faults. The

device can be ORed with FLT terminals on other devices for interrupt handling. FLT

requires an external pull-up resistor.

2 VCOMPEN I Fault reference voltage select. VCOMPEN selects the internally generated fault

reference voltage (0) or an external fault reference (1) to be used in the shorted and

open load fault detection circuitry.

3 VCOMP I Fault reference voltage. VCOMP provides an external fault reference voltage for the

shorted-load and open load fault detection circuitry.

4

5

6

7

IN0

IN1

IN2

IN3

I Parallel gate driver. IN0 trough In3 are real-time controls for the gate pre drive

circuitry. They are CMOS compatible with hysteresis.

8CS

I Chip select. A high to low transition on CS enables SDO, latches fault data into the

serial interface, and refreshes FLT. When CS is high, the fault register can change

fault status. On the falling edge of CS

, fault data is latched into the serial output

register and transferred using SDO and SCLK. On a low to high transition of CS

,

serial data is latched in to the output control register.

9 SDO O Serial data output. SDO is a 3-state output that transfers fault data to the controlling

device. It also passes serial input data to the next stage for cascaded operation. SDO

is taken to a high-impedance state when CS

is in a high state.

10 SDI I Serial data input. Output control data is clocked into the serial register through SDI. A

1 on SDI commands a particular gate output on and a 0 turns it off.

11 SCLK I Serial clock. SCLK clocks the shift register. Serial data is clocked into SDI and serial

fault data is clocked out of SDO on the falling edge of the serial clock.

12 V

CC

I Logic Supply Voltage

13 GND I Ground

14

16

19

21

DRAIN0

DRAIN1

DRAIN2

DRAIN3

I FET drain inputs. DRAIN0 through DRAIN3 are used for both open load and short

circuit fault detection at the drain of the external FETs. They are also used for

inductive transient protection.

15

17

18

20

GATE0

GATE1

GATE2

GATE3

O Gate drive output. GATE0 through GATE3 outputs are derived from the V

BAT

supply

voltage. Internal clamps prevent voltages on these nodes from exceeding the VGS

rating of most FETs.

22 RESET

I Reset. A high-to low transition of RESET clears all registers and flags. Gate outputs

turn off and the FLT

flag is cleared.

23 NC Not Connected

24 V

BAT

I Battery Supply Voltage

STPIC44L02

5/21

Figure2 : Pin Configuration

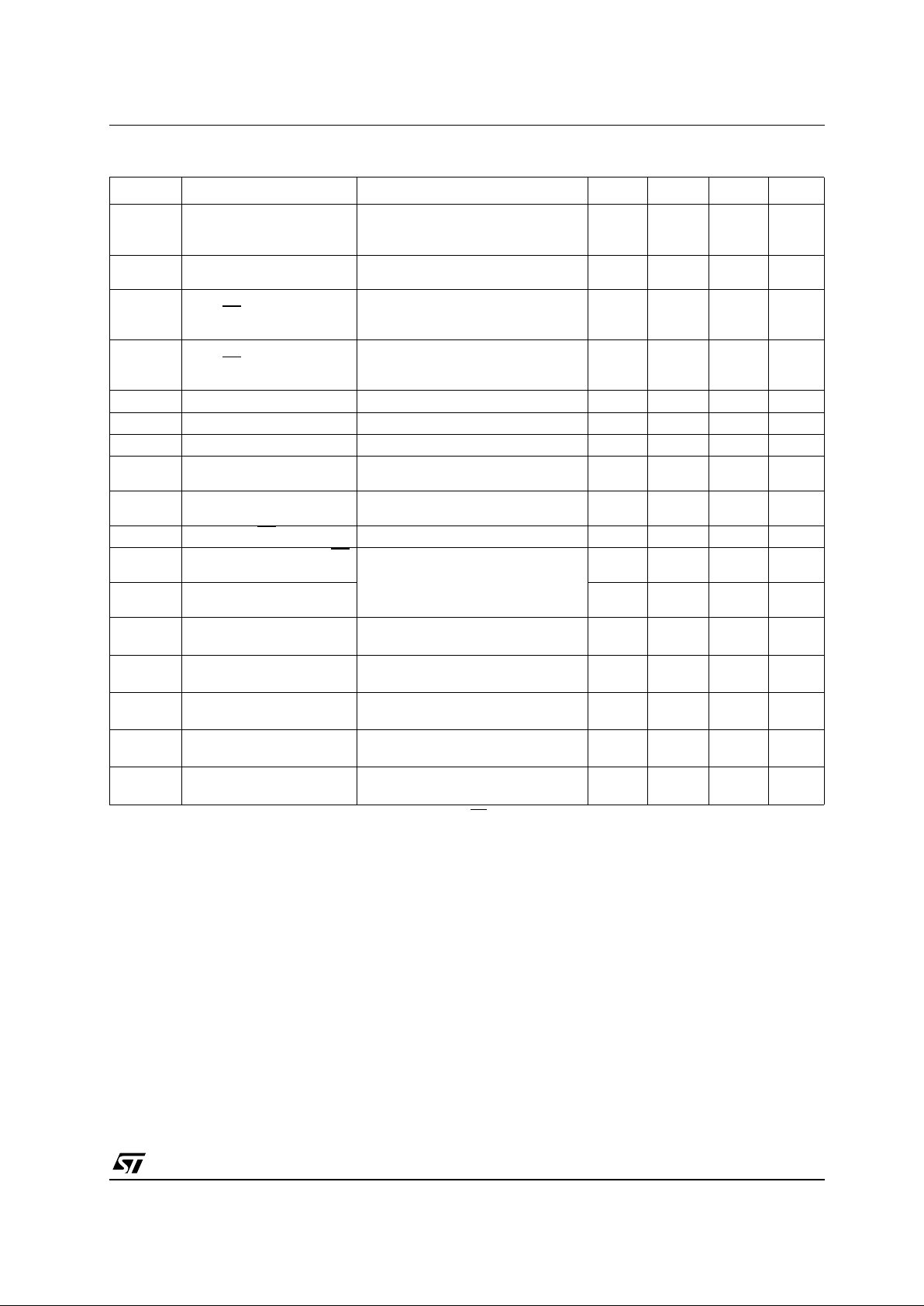

ABSOLUTE MAXIMUM RATING S

Absolute Maximum Ratings are those values beyond which damage to the device may occur. Functional operation under these condition is

not implied.

Note 1: All voltage value are with respect to GND

RECOMMENDED OPERATING CONDITIONS

Symbol Parameter Value Unit

V

CC

Logic Supply Voltage (See Note 1)

-0.3 to 7 V

V

BAT

Battery Supply Voltage

-0.3 to 60 V

V

I

Logic Input Voltage Range

-0.3 to 7 V

V

O

Output Voltage (SDO and FLT)

-0.3 to 7 V

V

O

Output Voltage

-0.3 to 15 V

V

I

Logic Input Voltage Range

-0.3 to 7 V

V

DS

Drain to Source Voltage

-0.3 to 60 V

T

C

Operating Case Temperature Range

-40 to +125 °C

T

J

Maximum Junction Temperature

150 °C

T

stg

Storage Temperature Range

-40 to +150 °C

Symbol Parameter Min. Min. Max. Unit

V

CC

Logic Supply Voltage 4.5 5 5.5 V

V

BAT

Battery Supply Voltage 8 24 V

V

IH

High Level Input Voltage 0.85V

CC

V

CC

V

V

IL

Low Level Input Voltage 0 0.15V

CC

V

t

s

Set-up Time, SDI High Before SCLK ↑ 10 ns

t

h

Hold Time, SDI High After SCLK ↑ 10 ns

T

C

Operating Case Temperature -40 125 °C

STPIC44L02

6/21

ELECTRICAL CHARACTERISTICS OVER RECOMMENDED OPERATING F REE-AIR

TEMPERATURE RANGE (unless otherwise specified.)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

I

BAT

Supply Current All Outputs OFF, V

BAT

= 12V 50 150 250 µA

I

CC

Supply Current All Outputs OFF, V

BAT

= 5.5V 0.5 1.5 3 mA

V

(ovsd)

Over Battery Voltage

Shutdown

Gate Disabled (see figure 21) 32 34 36 V

V

hys(ov)

Over Battery Voltage Reset

Hysteresys

0.1 0.3 0.5 V

V

(uvsd)

Under Battery Voltage

Shutdown

Gate Disabled (see figure 20) 4.1 4.8 5.4 V

V

hys(uv)

Under Battery Voltage

Reset Hysteresys

50 150 300 mV

V

G

Gate Drive Voltage V

BAT

=8to24V IO=100µA 7 13.5 V

V

BAT

= 5.5 to 8V IO=100µA5 8V

I

O(H)

Maximum Current Output

For Drive Terminal Pull-Up

VO= GND 0.5 1.8 2.5 mA

I

O(L)

Maximum Current Output

For Drive Terminal

Pull-Down

V

O

= 7V 0.5 1.2 2.5 mA

V

(stb)

Short to Battery, Shorted

Load, Open Load Detection

Voltage

V

COMPEN

= L 1.1 1.25 1.4 V

V

hys(stb)

Short to Battery Hysteresys 30 mV

V

D(open)

Open Load OFF State

Detection Voltage

Threshold

V

COMPEN

= L 1.1 1.25 1.4 V

V

hys(open)

Open Load Hysteresys 60 mV

I

I(open)

Open Load Off State

Detection Current

V

DRAIN=VREF

= 1.25V 30 60 80 µA

V

DRAIN

= 24V (see figure 24) 250 µA

I

I(PU)

Input Pull-up Current VCC=5V VI=0 10 µA

I

I(PD)

Input Pull-down Current VCC=5V VI=5V 10 µA

V

hys

Input Voltage Hysteresys VCC= 5V 0.6 0.85 1.1 V

V

O(SH)

High Level Serial Output

Voltage

IO= 1mA 0.8V

CC

V

V

O(SL)

Low Level Serial Output

Voltage

IO= 1mA 0.1 0.4 V

I

OZ(SD)

3-State Current Serial Data

Output

VCC= 0 to 5.5V -10 1 10 µA

V

O(CFLT)

Fault Interrupt Output

Voltage

IO= 1mA 0.1 0.5 V

V

I(COMP)

Fault External Reference

Voltage

V

COMPEN

=H 1 3 V

V

C

Output Clamp Voltage dc < 1% tW=100µs 475563V

STPIC44L02

7/21

SWITCHING CHARACTERISTICS (VCC=5V, V

BAT

=5V, TC= 25°C, unlessotherwise specified.)

Note 1: Thetd1is referred to the falling edge of the first clock after theCSfallsdown

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

(STBFM)

Short to Battery, Shorted

Load, Open Load Fault

Mask Time

(see figures 16, 17) 60 µs

t

(STBDG)

Short to Battery, Shorted

Load, Deglitch Time

(see figures 16, 17) 12 µs

t

PLH

Propagation Turn-On Delay

Time, CS

or IN0-IN3 to

Gate0-Gate3

C

(gate)

= 400pF 3.5 µs

t

PHL

Propagation Turn-Off Delay

Time, CS

or IN0-IN3 to

Gate0-Gate3

C

(gate)

= 400pF 4 µs

t

r1

Rise Time, Gate0-Gate3 C

(gate)

= 400pF 1.5 µs

t

f1

Fall Time, Gate0-Gate3 C

(gate)

= 400pF 2 µs

f

(SCLK)

Serial Clock Frequency 10 MHz

t

rf(SB)

Refresh Time Short to

Battery

(see figure 16) 10 ms

t

W)

Refresh pulse width Short

to Battery

(see figure 16) 68 µs

t

su1

Setup Time CS ↓ to SCLK ↓ (see note 1) (see figure 4) 10 ns

t

pd1

Propagation Delay Time CS

to SDO Valid

R

L

=10KΩ CL= 200pF

(see figure 6)

40 ns

t

pd2

Propagation Delay Time

SCLK to SDO Valid

20 ns

t

pd3

Propagation Delay Time CS

to SDO 3-State

RL=10KΩ CL= 50pF

(see figure 6)

2 µs

t

r2

Rise Time, SDO 3-State to

SDO Valid

RL=10KΩto GND CL= 200pF

Over Battery Fault (see figure 7)

30 ns

t

f2

Fall Time, SDO 3-State to

SDO Valid

RL=10KΩto GND CL= 200pF

No Fault (see figure 8)

20 ns

t

r3

Rise Time, FLT RL=10KΩ CL= 50pF

(see figure 9)

1.2 µs

t

f3

Rise Time, FLT RL=10KΩ CL= 50pF

(see figure 9)

15 ns

STPIC44L02

8/21

Figure3 : Switching Time

Figure4 : Setup Time CS

↓ to SCLK ↓

STPIC44L02

9/21

Figure5 : Propagation Delay Time

Figure6 : Propagation Delay Time

Figure7 : SDO Switching Time

STPIC44L02

10/21

Figure8 : SDO Switching Time

Figure9 : FLT

Switching Time

PRINCIPLES OF OPERATION

SERIAL DATA OPERATION

The STPIC44L02 offers serial input interface to

the m icroc ontro ller to transfer cont rol data to the

predriver and fault data back to the controller. The

serial input interface consists of:

SCLK - Serial C lock

CS

- Chip Select

SDI - Serial Data Input

SDO - SeriaL Data Output

Serial data is shifted into the least significant bit

(LSB) of the SDI shift register on the rising edge of

the first SCLK after CS

has t r ans it ated fro m 1 to 0.

The CS

must be transitated from 1 to 0 before the

falling edge of t he first clock (see n ote 1).

Four clock cycles must occur before CS

transitates high for a proper control of the outputs.

Less than four clock cycles result in fault data

being latched into the output control buffer.

Eight bits data can be shifted into the device, but

the first 4 bits shifted out are always the fault dat a

and the last 4 bits shifted in are always the output

control data. A low-to-high transition on CS

latches the contents of the serial shift register into

the output control register. A logic 0 input to SDI

turns of f the corresponding parallel output and a

logic 1 input t urns the output on (s ee figure 10).

Data is shifted out of SDO on the falling edge of

SCLK. The M SB of fault data is available after CS

is transitated low. The rem aining 3 bits of fault

data are shifted out in the following three clock

cycles. Fault data is latched into the serial register

when CS

is transitated low. A fault must be

present on the high to low transition of CS

to be

captured by the device. The CS

input mus t be

transitated to a high state after t he last bit of serial

data has been cloc k ed into the device. The rising

edge of CS

inhibit SDI puts SDO into a high

impedance s tate, latches the 4 bits of serial data

into the output control register, and clears and

reenables the serial fa ult regist ers (see figure 11).

When a shorted load condit ion occurs, the device

automatically retries the output and the fault clears

after the fault condition has been corrected.

STPIC44L02

11/21

Figure10 : Serial Programming Example

Figure11 : 8-Bit Serial Programming Example (single devi ce)

STPIC44L02

12/21

Figure12 : 8-Bit S erial Programming Example (two predrivers cascated)

Figure13 : Fault Reading Example

PARALLEL INPUT DATA OPERATION

In addition to th e serial interface the STPIC44L02

also provid es a pa rallel interface to the

microcontroller. The output turns on when either

the parallel or the serial interface make it turn on.

The parallel data terminals are real t ime control

inputs for t he outputs drivers. SCLK and CS

are

not required to transfer parallel input data to the

output buffer. Fault data must be read over the

serial data bus as de scribed in the serial data

operation section of this datasheet (see figure 13).

The parallel input must be transitated low and then

high to clear and reenable a gate output after it

has been disabled due to a s horted load fault

condition.

CHIPSET PERFORMANCE UNDER FAULT

CONDITIONS

The STPIC44L02 and power FET arrays are

designed for normal operation over a battery

voltage range of 8V to 24V with load fault

detection from 4.8V to 34V. It offers onboard fault

detection to handle a va riety of faults that may

occur within a system. The circuits primary

function is to prevent damage to the load and the

power FETs in the event that a fault occurs.

Note that unused DRAIN0-DRAIN3 inputs must

be connected to V

BAT

through a pull-up resistor to

prevent false reporting of open load fault

conditions. The circuitry detects the fault, shuts off

the output to the FET and reports t he fault to the

microcontroller. The primary faults under

consideration are:

1) Shorted Load

2) Open Load

3) over battery voltage shutdown

4) Under battery voltage shutdown.

SHORTED LOAD FAULT CONDITION

STPIC44L02

13/21

The STPIC44L02 monitors the drai n voltage of

each channel to detect shorted load conditions.

The onboard deglitch timer starts runn ing when

the gat e output to the power FET transitates from

the off state to the on state. The timer provides a

60µs deglitch time, t

(STBFM)

,toallowthedrain

voltage to stabilize after the power FET has been

turned on (see figure 16 and 17).

The deglitch delay time is only enabled for t he first

60µs after the FET has been turned on. After the

deglitch delay time, the drain voltage is checked to

verify that it is le ss th an the fault reference

voltage. When it is greater than the reference

voltage for at least the short to battery deglitch

time, t

(STBDG)

FLT f lags the microcontroller that a

fault condition exists and gate output is

automatically shut off until the error condition has

been corrected.

An overheating condition on the FET occurs when

the controller co ntinually tries to reenable the

output under shorted load fault conditions. When a

shorted load fault is de tect ed, the gate output is

transitated into a low duty cycle PWM signal to

protect the FET f rom overheating. The PWM rate

is defined as t

(SB)

and the pul s e width is defined

as t

W

. The gate output remains in this state until

the f ault has been corrected or until the controller

disables the gate output.

The microcontroller can read the serial port on the

predriver to isolate the channel that reported the

fault condition.

Fault bits 0-3 distingui sh faults for each of the

output channels. W hen a shorted load occurs, the

STPIC44L02 automatically retries the output and

the fault clears after the f ault condition has been

corrected. Figure 16 illustrates operation after a

gate output has been t urned on. The gate to t he

power FET is turned on and the deglitch timer

starts running. Under normal operation, T1 turns

on a nd the drain operates below the ref erence

point set at U1. The output of U1 is low and a fault

condition is not flagged.

Figure14 : Open Load Test Circuit

STPIC44L02

14/21

Figure15 : Normal O perat ion

Figure16 : Shorted Load Condition (Deglitch Time)

OPEN LOAD

The STPiC44L02 mo nitors the drain of each

power FET for open circuit conditions that may

exist. The 60µA current source is provided to

monitor open load faul t conditions. Open-load

faults are only detecte d when the power FET is

turned o ff. When load impedance is open or

substantially high, the 60µA current source has

adequate drive to pull the drain of T1 below the

fault reference thres hold on the detection circuit.

Unused DRAIN0-DRAIN3 inputs must be

connectedtoV

BAT

through a pull-up resistor to

prevent false reporting of open-load fault

conditions. The on-board deglitch timer starts

running when the STPiC44L 02, gate output to the

power FET transitates to the off state. The timer

provides a 60ms deglitch t ime, T

(STBFM)

,toallow

the drain voltage to stabilize after the powerFET

has been turned off. The deglitch time is only

enabled for the f irst 60ms after the FET has been

STPIC44L02

15/21

turned off. After the deglitch delay time, the drain

is check ed to verify that it is greater than the fault

reference voltage. When it is less than the

reference voltage, a fault is f lagged to the

microcontroller through FLAT that an open-load

fault condition exists. The microcontroller can then

read the serial port on the STPiC44L02 to isolate

the channel that reported the fault condit ion. Fault

bits 0-3 distinguish faults for each of the out put

channels. Figures 18 and 19 illustrate the

operation of the open-load detection circuit. This

feature provides useful information to the

microcontrollerto isolatesystem failures and warn

the operator that a problem exists. Examples of

such applications woul d be a warning that a light

bulb filament may be open, solenoid coils may be

open, etc.

Figure17 : Open Load Short Circu it te st Circuitry

Figure18 : Normal Condition Driving Load

STPIC44L02

16/21

Figure19 : Open Load ConditionTime

OVER-BATTERY-VOLTAGE SHUTDOW N

The STPIC44L02 monitors the bat tery voltage to

prevent the power FETs turning on in the event

that the battery voltage is too high. This condition

may occur due to voltage transients resulting from

a loos e battery connection. The TPIC44L02 turns

the power F ET off when the battery voltage is

above 34V to prevent possible damage to the load

and the FET. GATE(0-3) output goes back to

normal operation after the overvoltage condition

has been corrected. An ov er-battery-v oltage f ault

is flagged to the controller through FLT

.The

over-battery-voltage fault is not reported in t he

serial fault word. When an over voltage condition

occurs, the device reports the battery fault, but

disables fault reporting for open and short ed-load

conditions. Fault reporting for open and

shorted-load conditions are re-ena bled after the

battery fault c ondition has been corrected. When

the f ault condition is removed before the CS

signal

transitates low, the fault condition is not captured

in the serial fault regis ter. The fault flag resets on a

high-to-low transition of CS

providing that no other

faults are present in the device. Figure 21

illustrates the operation of the over-b attery voltage

detection circuit.

Figure20 : Under Battery Shutdown

UNDER-BATTERY-VOLTAGE SHUTDOWN

The STPIC44L02 monitors the bat tery voltage to

prevent the power FET s from being turned on in

the event that the battery voltage is too l ow. When

the battery voltage is below 4.8V, then

GATE0-GATE3 m ay not prov ide sufficient gate

voltage to the power FETs to minimize the

on-resistance t hat could result in a thermal stress

on the FET. The output goes back to normal

operation after the under voltage condition has

STPIC44L02

17/21

been corrected. An under-battery-voltage fault is

flagged to the c ontroller through FLT. The

under-battery voltage fault is not reported in the

serial fault word. When an under-battery-voltage

condition occurs, the device reports the battery

fault but di sables fault reporting for open and

shorted load c onditions. When the fault condition

is removed before the CS

signal t rans itates low,

the fault condition is not captured in the serial fault

register. The fault flag resets on a high-to-low

transition of CS

providing that no other fa ults are

present in the device. Figure 21 illustrates the

operation of t he under voltage detection circuit.

Figure21 : Over Battery Shutdown

INDUCTIVE VOLTAGE TRANSIENTS

A typical application for the pre driver/power FET

circuit is to switch inductive loads. When an

inductive load is switched off, a large voltage spike

can occur. These spikes can exceed the

maximum V

DS

rating for the external FET and

damage the device when the proper protection is

not in place. T he FET can be protected from these

transients through a varie ty of methods using

external components.

The STPIC44L02 offers that protection in the form

of a zener diode stack connected between the

DRAIN input and GATE output (see figure 22).

Zener diode Z1 turns the FET on to dissipate the

transient energy. GATE diode Z2 is provided to

prevent the gate voltage from exceeding 13V

during normal operation and transient protec tion.

Figure22 : Switching Time

EXTERNAL FAULT REF ERENCE INPUT

The STPIC44L02 compares each channel drain

voltage to a fault reference to det ec t shorted-load

and open-load conditions. The us er has the option

of using the internal generated 1.25V fault

reference or providing an ext ernal reference

voltage through V

COMP

. The internal reference is

selected by connec ti ng V

COMPEN

to GND a nd

V

COMP

is selected by connecting V

COMPEN

to V

CC

(see Figure 23). Proper layout techniques should

be used in the ground ing network for the V

COMP

circuit on the STPIC44L02. Th e ground for the

STPIC44L02

18/21

predriver and V

COMP

network should be

connected to a Kelvin ground if available;

otherwise, they should make single-point contact

back to the power ground of the FET array.

Improper grounding techniques can result in

inaccuracies in detecting faults.

Figure23 : External Reference Selection

TYPICAL PERFORMANCE CHARACTE RISTICS (unless otherwise specified T

j

=25°C)

Figure24 : Open Load Off State Detection

Current

V

REF

V

COMPEN

1.25V 0

V

COMP

1

STPIC44L02

19/21

DIM.

mm. inch

MIN. TYP MAX. MIN. TYP. MAX.

A 2 0.079

A1 0.05 0.002

A2 1.65 1.75 1.85 0.065 0.069 0.073

b 0.22 0.38 0.009 0.015

c 0.09 0.25 0.004 0.010

D 7.9 8.2 8.5 0.311 0.323 0.335

E 7.4 7.8 8.2 0.291 0.307 0.323

E1 5.00 5.3 5.6 0.197 0.209 0.220

e 0.65 BSC 0.0256 BSC

K0˚ 8˚0˚ 8˚

L 0.55 0.75 0.95 0.022 0.030 0.037

SSOP24 MECHANICAL DATA

c

E

b

A2

A

E1

D

1

PIN 1 IDENTIFICATION

A1

L

K

e

0053237/C

STPIC44L02

20/21

DIM.

mm. inch

MIN. TYP MAX. MIN. TYP. MAX.

A 330 12.992

C 12.8 13.2 0.504 0.519

D 20.2 0.795

N 60 2.362

T 22.4 0.882

Ao 8.4 8.6 0.331 0.339

Bo 8.7 8.9 0.343 0.351

Ko 2.9 3.1 0.114 0.122

Po 3.9 4.1 0.153 0.161

P 11.9 12.1 0.468 0.476

Tape & Reel SSOP24 MECHANICAL DATA

STPIC44L02

21/21

Information furnished is believed to be accurate and reliable . However, STMicroelectronics assumes no responsibility for the

consequences of use o f suc h inf ormat ion n or f or an y infr ingeme nt of paten ts or oth er ri gh ts of third part ies whic h may resul t f rom

its use. No license is granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information

previously supplied. STMicroelectronics products are not authorized for use as critical components in life support devices or

systems without express written approval of STMicroelectronics.

© The ST logo is a registered trademark of STMicroelectronics

© 2003 STMicroelectronics - Printed in Italy - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

© http://www.st.com

Loading...

Loading...