STPC INDUSTRIAL

PC Compatible Embedded Microprocessor

1/555/11/99

Issue 1.1

ISA

I/F

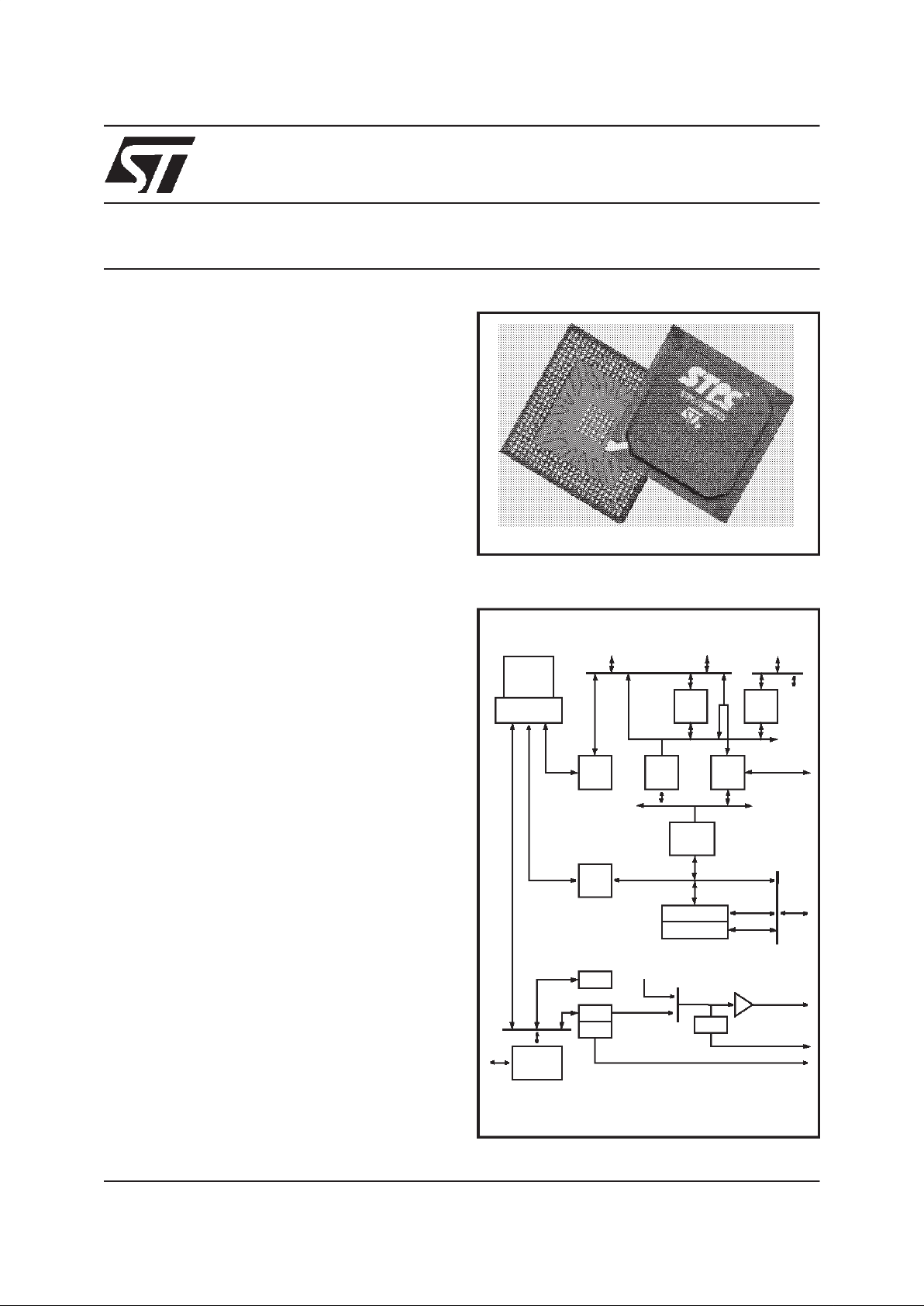

Figure 1. Logic Diagram

■ POWERFUL X86 PROCESSOR

■ 64-BIT BUS ARCHITECTURE

■ 64-BIT 66MHz DRAM CONTROLLER

■ SVGAGRAPHICS CONTROLLER

■ 135MHz RAMDAC

■ UMA ARCHITECTURE

■ TFT DISPLAY CONTROLLER

■ PCI MASTER / SLAVE / ARBITER

■ LOCAL BUS INTERFACE

■ ISA (MASTER/SLAVE) INTERFACE

-INCLUDING THE IPC

■ PC-CARD INTERFACE

- PCMCIA

- CARDBUS

■ I/O FEATURES

- PC/AT+ KEYBOARD CONTROLLER

- PS/2 MOUSE CONTROLLER

- 2 SERIAL PORTS

- 1 PARALLEL PORT

■ IPC

- DMA CONTROLLER

- INTERRUPT CONTROLLER

- TIMER / COUNTERS

■ POWER MANAGEMENT

STPC INDUSTRIAL OVERVIEW

The STPC Industrial integrates a fully static x86

processor, fully compatiblewithstandardfifthgeneration x86 processors,and combines it with powerful chipset, graphics, TFT, PC-Card, Local Bus,

keyboard, mouse, serials andparallelinterfacesto

provide a single Industrial oriented PC compatible

subsystem ona single device.The performanceof

the device is comparable with the performance of

a typical P5 generation system.

The device is packaged in a 388 Plastic Ball Grid

Array (PBGA).

TFT

ext

x86

Core

Host I/F

Serial2

// Port

Serial1

Kbd

Mouse

DRAM

I/F

VGA

GE

PCI

m/s

Local

Bus I/F

PCMCIA

CARDBUS

PCI BUS

IPC

82C206

PCI

CONTROLLER

ISA BUS

CRTC

HW Cursor

Monitor

TFT Output

SYNC Output

TFT I/F

PBGA388

STPC INDUSTRIAL

2/55

Issue 1.1

■ X86 Processor core

■ Fully static 32-bit 5-stage pipeline, x86

processor fully PC compatible.

■ Access up to 4GB of external memory.

■ 8Kbyte unified instruction and data cache

with write back capability.

■ Parallelprocessing integral floating point unit,

with automatic power down.

■ Clock core speeds up to 100 MHz.

■ Fully static design for dynamic clock control.

■ Low power and system management modes.

■ Optimized design for3.3V operation.

■ DRAM Controller

■ Integrated system memory and graphic frame

memory.

■ Supports up to 128-MByte system memory in

4 banks and down to as little as 2Mbytes.

■ Supports 4-MByte, 8-MByte, 16-MByte, and

32-MByte single-sided and double-sided

DRAM SIMMs.

■ Four quad-word write buffers for CPU to

DRAM and PCI to DRAM cycles.

■ Four quad-word read prefetch buffers for PCI

masters.

■ Supports Fast Page Mode & EDO DRAMs.

■ Programmable timing for DRAM parameters

including CAS pulse width, CAS pre-charge

time, and RAS to CAS delay.

■ 60, 70, 80 & 100ns DRAM speeds.

■ Memory hole between 1 MByte & 8 MByte

supported for PCI/ISA busses.

■ Hidden refresh.

■ Graphics Controller

■ 64-bit windows accelerator.

■ Complete backward compatibility to VGA and

SVGAstandards.

■ Hardware acceleration for text (generalized

bit map expansion), bitblts, transparent blts

and fills.

■ Up to 64 x 64 bit graphics hardware cursor.

■ Up to 4MB long linear frame buffer.

■ 8, 16, 24 and 32 bit pixels.

■ Drivers for Windows and other operating

systems.

■ CRT Controller

■ Integrated 135MHz triple RAMDAC allowing

for 1280 x 1024 x 75Hz display.

■ Requires external frequency synthesizer and

reference sources.

■ 8, 16,24 and 32-bit pixels.

■ Interlaced or non-interlaced output.

■ TFT Interface

■ Programmable panel size up to 1024 by 1024

pixels.

■ Support for 640 x 480, 800 x 600 & 1024 x

768 active matrix TFT flat panels with 9, 12,

18-bit interface.

■ Support 1 & 2 Pixels per Clock.

■ Programmable image positionning.

■ Programmable blank space insertion in text

mode.

■ Programmable horizontal and vertical image

expansion in graphic mode.

■ A fully programmable PWM (Pulse Width

Modulator) signals to adjust the flat panel

brightness and contrast.

■ Supports PanelLink

TM

high speed serial

transmitter externally for high resolution

panel interface.

■ PCI Controller

■ Fully compliant with PCI Version 2.1

specification.

■ Integrated PCI arbitration interface. Up to 3

masters can connect directly. External PAL

allows for greater than 3 masters.

■ Translation of PCI cycles to ISA bus.

■ Translation of ISA master initiated cycle to

PCI.

■ Support for burst read/write from PCImaster.

■ 0.33X and 0.5X CPU clock PCI clock.

■ Local Bus interface

■ 66MHz, low latency bus.

■ Asynchronous / synchronous.

■ 22-bit address and 16-bit data busses.

■ 2 Programmable Flash EPROM Chip Select.

■ 4 Programmable I/O Chip Select.

■ Separate memory and I/O address spaces.

■ Memory prefetch (improved performances).

STPC INDUSTRIAL

3/55

Issue 1.1

■ ISA master/slave

■ Generation of the ISA clock from either

14.318MHz oscillator clock or system clock

■ Programmable extra wait state for ISA cycles

■ Supports I/O recovery time for back to back

I/O cycles.

■ Fast Gate A20 and Fast reset.

■ Supports the single ROM that C, D, or E.

blocks shares with F blockBIOS ROM.

■ Supports flash ROM.

■ Supports ISA hidden refresh.

■ Buffered DMA & ISA master cycles to reduce

bandwidth utilization of the PCI and Host bus.

NSP compliant.

■ PC-Card interface

■ Support one PCMCIA 2.0 / JEIDA 4.1 68-pin

standard PC Card Socket.

■ Power Management support.

■ Support PCMCIA/ATA specifications.

■ Support I/O PC Card with pulse-mode

interrupts.

■ Provides an ExCA

TM

implementation to

PCMCIA 2.0 / JEIDA 4.1 standards.

■ DMA support.

■ Keyboard interface

■ Fully PC/AT&compatible

■ Mouse interface

■ Fully PS/2 compatible

■ Serial interface

■ 15540 compatible

■ Programmable word length, stop bits, parity.

■ 16-bit programmable baud rate generator.

■ Interrupt generator.

■ Loop-back mode.

■ 8-bit scratch register.

■ Two 16-bit FIFOs.

■ Two DMA handshake lines.

■ Parallel port

■ Standard Centronics mode supported.

■ Nibblemode supported.

■ Integrated Peripheral Controller

■ Two 8237/AT compatible 7-channel DMA

controllers.

■ Two 8259/AT compatible interrupt Controller.

16 interrupt inputs - ISA and PCI.

■ Three 8254 compatible Timer/Counters.

■ Co-processor error support logic.

■ Power Management

■ Four power saving modes: On, Doze,

Standby, Suspend.

■ Programmable system activity detector

■ Supports SMM.

■ Supports IO trap & restart.

■ Independent peripheral time-out timer to

monitor hard disk, serial & parallel ports.

■ Supports APM

■ Supports RTC,interrupt and DMA wake ups

ExCA is a trademark of PCMCIA / JEIDA.

PanelLink is a trademark of SiliconImage, Inc

GENERAL DESCRIPTION

4/55

Issue 1.1

1 GENERAL DESCRIPTION

At the heart of the STPC Industrial is an

advanced 64-bit processor block, dubbed the

5ST86. The 5ST86 includes a powerful x86

processor core along with a 64-bit DRAM

controller, advanced 64-bit accelerated graphics

and video controller, a high speed PCI local-bus

controller and Industry standard PC chip set

functions (Interrupt controller, DMA Controller,

Interval timer and ISA bus).

The STPC Industrial has in addition to the 5ST86

a TFT output, a Local Bus interface, PC Card and

super I/O features.

The STPC Industrial makes use of a tightly

coupled Unified Memory Architecture (UMA),

where the same memory array is used for CPU

main memory and graphics frame-buffer. This

means a reduction in total system memory for

system performances that are equal to that of a

comparable frame buffer and system memory

based system, and generally much better, due to

the higher memory bandwidth allowed by

attaching the graphics engine directly to the 64-bit

processor host interface running at the speed of

the processor bus rather than the traditional PCI

bus.

The 64-bit wide memory array provides the

system with 320MB/s peak bandwidth, double

that of an equivalent system using 32 bits. This

allows for higher resolution screens and greater

color depth. The processor bus runs at 66Mhz

further increasing “standard” bandwidth by at

least a factor of two.

The ‘standard’ PC chipset functions (DMA,

interrupt controller, timers, power management

logic) are integrated together with the x86

processor core; additional functions such as

communication ports are accessed by the STPC

Industrial via an internal ISA bus.

The PCI bus is the main data communication link

to the STPC Industrial chip. The STPC Industrial

translates appropriate host bus I/O and Memory

cycles onto the PCI bus. It also supports the

generation of Configuration cycles on the PCI

bus. The STPC Industrial, as a PCI bus agent

(host bridge class), fully complies with PCI

specification 2.1. The chip-set also implements

the PCI mandatory header registers in Type0 PCI

configuration space for easy porting of PCI aware

system BIOS. The device contains a PCI

arbitration function for three external PCI devices.

Graphics functions are controlled through the onchip SVGA controller and the monitor display is

produced through the 2D graphics display engine.

This Graphics Engine is tuned to work with the

host CPU to provide a balanced graphics system

with a low silicon area cost. It performs limited

graphics drawing operations which include

hardware acceleration of text, bitblts, transparent

blts and fills. The results of these operations

change the contents of the on-screen or offscreen frame buffer areas of DRAM memory. The

frame buffer can occupy a space up to 4 Mbytes

anywhere in the physical main memory.

The maximum graphics resolution supported is

1280x1024 in 65536 colours at 75Hz refresh rate

and is VGA and SVGA compatible. Horizontal

timing fields areVGA compatible while the vertical

fields are extended by one bit to accommodate

above display resolution.

To generate the TFT output, the STPC Industrial

extracts the digital video stream before the

RAMDAC and reformats it to the TFT format. The

height and width of the flat panel are

programmable through configuration registers up

to a size of 1024 by 1024.

By default, lower resolution images cover only a

part of the larger TFT panel. The STPC Industrial

allows to expand the image vertically and

horizontally in text mode by inserting

programmable blank pixels. It allows expantion of

the image vertically and horizontally in graphics

mode by replicating pixels. The replication of J

times every K pixel is independently

programmable in the vertical and horizontal

directions.

PanelLinkTMis a proprietary interconnect

protocol defined by Silicon Image, Inc. It consists

of a transmitter that takes parallel video/graphics

data from the host LCD graphics controller and

transmits it serially at high speed to the receiver

which controls the TFT panel. The TFT interface

is designed to support the connection of this

control signal to the PanelLinkTMtransmitter.

The STPC Industrial CARDBUS / PCMCIA

controller has been specifically designed to

provide the interface with PC-Cards which contain

additional memory or I/O and provides an

ExCATMimplementation to PCMCIA 2.0 / JEIDA

4.1 standards.

The power management control facilities include

socket power control, insertion/removal capability,

power saving with Windows inactivity, NCS

controlled Chip Power Down, together with further

controls for 3.3v suspend with Modem Ring

Resume Detection.

GENERAL DESCRIPTION

5/55

Issue 1.1

The need for system configuration jumpers is

eliminated by providing address mapping support

for PCMCIA 2.0 / JEIDA 4.1 PC-Card memory

together with address windowing support for I/O

space.

Selectable interrupt steering from PC-Card to

internal system bus is also provided.

The STPC Industrial implements a multi-function

parallel port. The standard PC/AT compatible

logical address assignments for LPT1, LPT2 and

LPT3 are supported.

The parallel port can be configured for any of the

following 3 modes and supports the IEEE

Standard 1284 parallel interface protocol

standards as follow:

-Compatibility Mode (Forward channel, standard)

-Nibble Mode (Reverse channel, PC compatible)

-Byte Mode (Reverse channel, PS/2 compatible)

The STPC Industrial BGA package has 388 balls,

but this is not sufficient for all the integrated

functions, therefore some features are sharing the

same balls and can not be used at the same time.

The STPC Industrial configuration is done by

‘strap options’. It is a set of pull-up or pull-down

resistors on the memory data bus, checked on

reset, which auto-configure the STPC Industrial.

We can distinguish three main blocks

independently configurables

: The ISA / Local

Bus block, the Serial 1 / TFT block, and the PCI /

PC Card block.

From the first block,we can activateeither the ISA

bus and some IPC additionnal features, or the

Local bus, the parallel port and the second serial

interface.

From the second block, we can activate either the

first serial port, or the TFT extension to get from 4

bit per colour to 6 bit per colour.

From the third block, we can activate either the

PCI bus, or the PC Card interface (CardBus/

PCMCIA/ZoomVideo).

The STPC Industrial core is compliant with the

Advanced Power Management (APM)

specification to provide a standard method by

which the BIOS can control the power used by

personal computers. The Power Management

Unit module (PMU) controls the power

consumption providing a comprehensive set of

features that control the power usage and

supports compliance with the United States

Environmental Protection Agency’s Energy Star

Computer Program. The PMU provides following

hardware structures to assist the software in

managing the power consumption by the system.

- System Activity Detection.

- 3 power-down timers detecting system inactivity:

- Doze timer (short durations).

- Stand-by timer (medium durations).

- Suspend timer (long durations).

- House-keeping activity detection.

- House-keeping timer to cope with short bursts of

house-keepingactivity while dozing or in stand-by

state.

- Peripheral activity detection.

- Peripheral timer detecting peripheral inactivity

- SUSP# modulation to adjust the system

performance in various power down states of the

system including full power on state.

- Power control outputs to disable power from

different planes of the board.

Lack of system activity for progressively longer

periods of time is detected by the three power

down timers. These timers can generate SMI

interrupts to CPU so that the SMM software can

put the system in decreasing states of power

consumption. Alternatively, system activity in a

power down state can generate SMI interrupt to

allow the software to bring the system back up to

full power on state. The chip-set supports up to

three power down states described above, these

correspond to decreasing levels ofpower savings.

Power down puts the STPC Industrial into

suspend mode. The processor completes

execution of the current instruction, any pending

decoded instructions and associated bus cycles.

During the suspend mode, internal clocks are

stopped. Removing power down, the processor

resumes instruction fetchingand begins execution

in the instruction stream at the point it had

stopped. Because of the static nature of the core,

no internal data is lost..

GENERAL DESCRIPTION

6/55

Issue 1.1

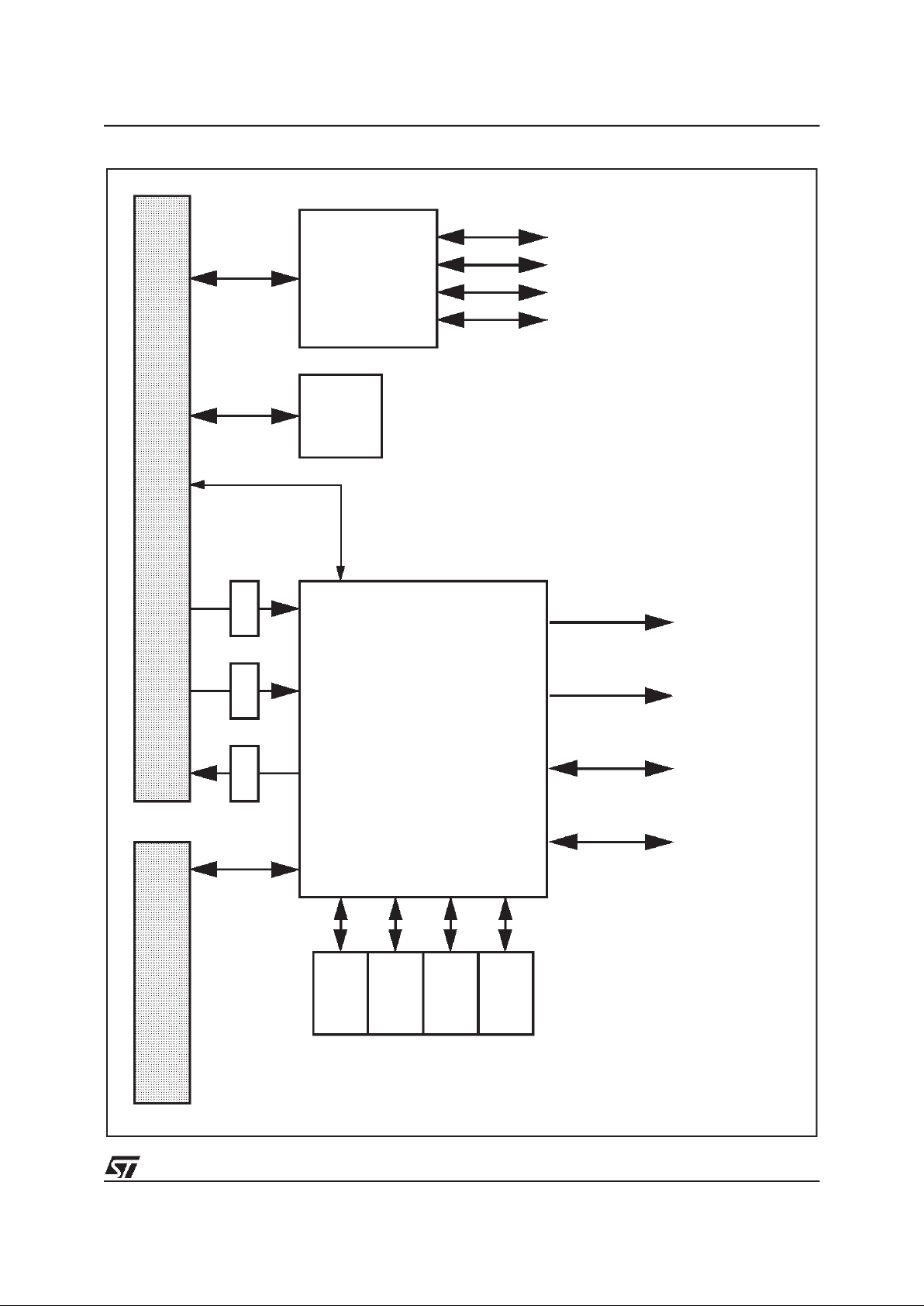

Figure 1.1. Functionnal description.

x86

Core

Host I/F

Serial 2

// Port

Serial 1

DRAM

I/F

VGA

GE

PCI m/s

Local

Bus I/F

PCMCIA

CARDBUS

PCI BUS

ISA

m/s

IPC

82C206

PCI m/s

ISA BUS

CRTC

HW Cursor

Monitor

TFT Output

SYNC Output

TFT I/F

TFT

extension

Kbd

Mouse

GENERAL DESCRIPTION

7/55

Issue 1.1

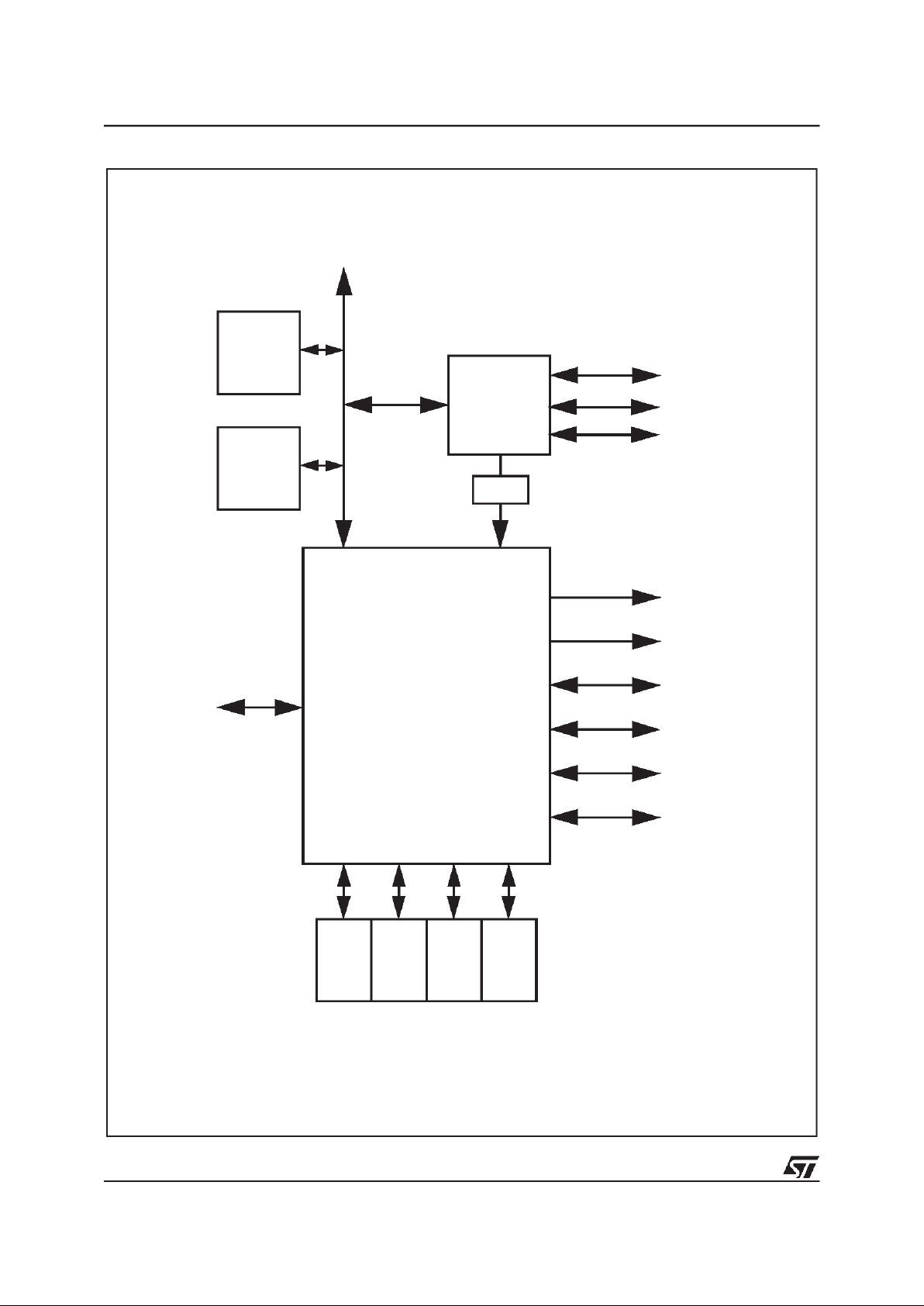

Figure 1.2. PCI, PCMCIA & CARDBUS modes:

PCI m/s

PCMCIA

CARDBUS

PCI BUS

PCI m/s

PCMCIA

CARDBUS

PCI BUS

PCI m/s

PCMCIA

CARDBUS

PCI BUS

GENERAL DESCRIPTION

8/55

Issue 1.1

Figure 1.3. Local Bus and ISA bus modes:

Figure 1.4. TFT in normal (serial 1 available) and extended modes (serial 1 unavailable).

Serial 2

// Port

Local

Bus I/F

ISA

m/s

IPC

82C206

ISA BUS

Serial 2

// Port

Local

Bus I/F

ISA

m/s

IPC

82C206

ISA BUS

Serial 1 TFT

extension

TFT

extension

TFT Output

TFT I/F

Kbd

Mouse

Serial 1Kbd

Mouse

TFT Output

TFT I/F

9-bit mode

12-bit mode

18-bit mode

2 x 9-bit mode

GENERAL DESCRIPTION

9/55

Issue 1.1

Figure 2. Typical PC oriented Application

ISA

PCI

4x 16-bit EDO DRAMs

Super I/O

Flash

IDE

Serial Ports

Parallel Port

Floppy

Monitor

TFT

SVGA

IRQ

DMA.REQ

DMA.ACK

DMUX

MUX

MUX

STPC Industrial

RTC

Mouse

Keyboard

GENERAL DESCRIPTION

10/55

Issue 1.1

Figure 3. Typical Embedded Application

STPC Industrial

PC-Card

4x 16-bit EDO DRAMs

Flash

Peripheral

IRQ

MUX

PCMCIA

CARDBUS

Monitor

TFT

SVGA

Mouse

Keyboard

Serial Ports

Parallel Port

STPC Local Bus

I/O

SRAM

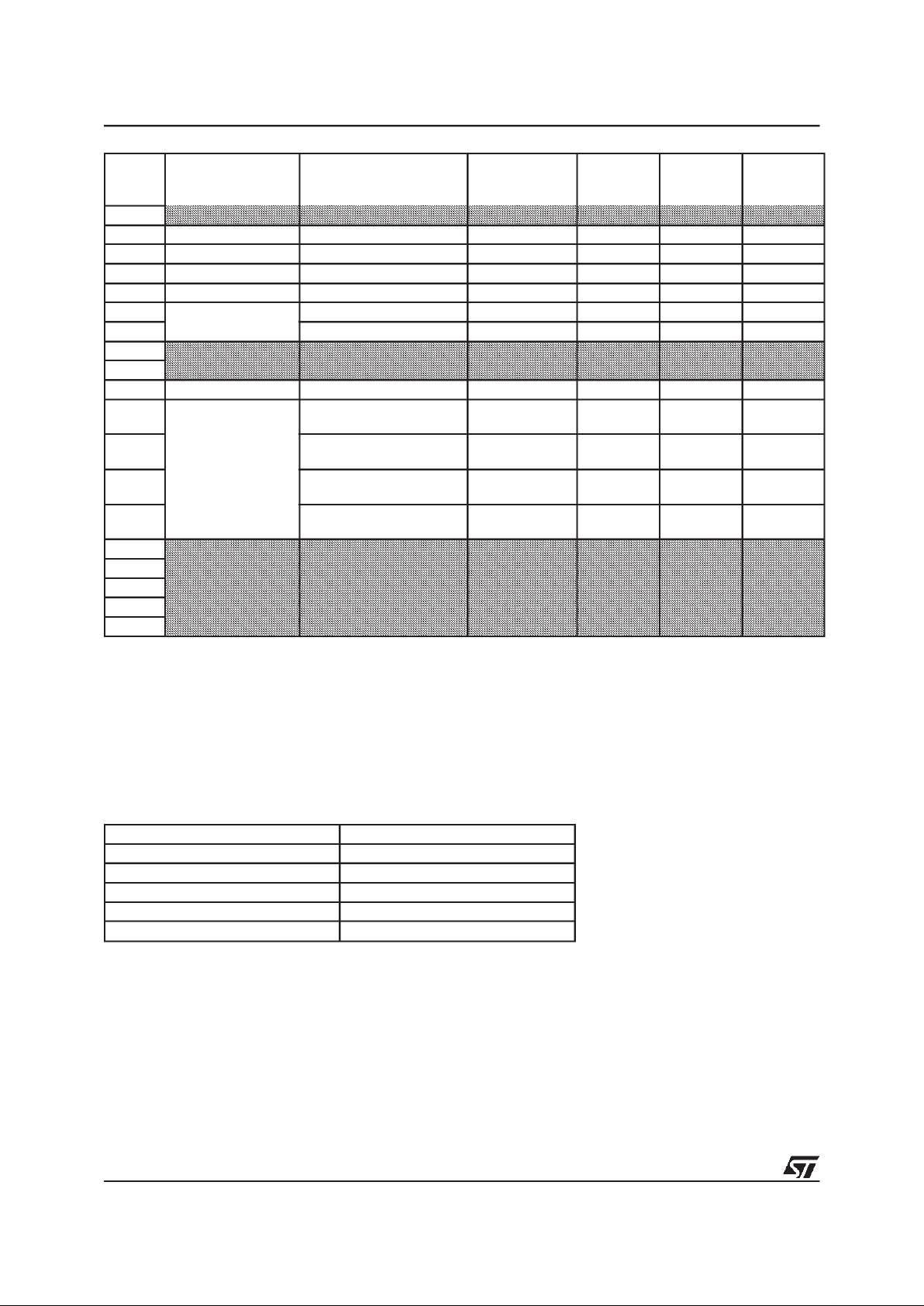

STRAP OPTION

11/55

Issue 1.1

2 STRAP OPTION

This chapter defines the STPC Industrial Strap Options and their location

Memory

Data

Lines

Refer to Designation Location

Actual

Settings

Set to ’0’ Set to ’1’

MD0 - Reserved - - - MD1 - Reserved - - - MD2 DRAM Bank 1 Speed Index 4A,bit 2 User defined 70 ns 60 ns

MD3 Speed Index 4A,bit 3 Pull up

MD4 Type Index 4A,bit 4 User defined EDO FPM

MD5 DRAM Bank 0 Speed Index 4A,bit 5 User defined 70 ns 60 ns

MD6 Speed Index 4A,bit 6 Pull up

MD7 Type Index 4A,bit 7 User defined EDO FPM

MD8 - Reserved - - - -

MD9 - Reserved - - - MD10 DRAM Bank 3 Speed Index 4B,bit 2 User defined 70 ns 60 ns

MD11 Speed Index 4B,bit 3 Pull up

MD12 Type Index 4B,bit 4 User defined EDO FPM

MD13 DRAM Bank 2 Speed Index 4B,bit 5 User defined 70 ns 60 ns

MD14 Speed Index 4B,bit 6 Pull up

MD15 Type Index 4B,bit 7 User defined EDO FPM

MD16 Reserved Index 4C,bit 0

MD17 PCI Clock PCI_CLKO Divisor Index 4C,bit 1 User defined HCLK / 3 HCLK / 2

MD18 Host Clock HCLK Pad Direction Index 4C,bit 2 User defined External Internal

MD19 Graphics Clock GCLK2x Pad Direction Index 4C,bit 3 User defined External Internal

MD20 DOT Clock DCLK Pad Direction Index 4C,bit 4 User defined External Internal

MD21 Reserved Pull up

MD22 External IPC Debug Option Index 5F,bit 1 Pull up External IPC Internal IPC

MD23 - Reserved Index 5F,bit 2 Pull up - MD24 HCLK HCLK PLL Speed Index 5F,bit 3 User defined 000 25 MHz

MD25 Index 5F,bit 4 User defined 001 33 MHz

MD26 Index 5F,bit 5 User defined 010 40 MHz

011 50 MHz

100 60 MHz

101 66 MHz

110 75 MHz

111 80 MHz

MD27 Reserved Pull down

MD28 Reserved Pull down

MD29 Reserved Pull down

MD30 Reserved Pull down

MD31 Reserved Pull down

MD32 Reserved Pull down

MD33 Reserved Pull up

MD34 Reserved Pull down

MD35 Reserved Pull up

MD 36 Reserved Pull up

MD 37 Reserved Pull up

MD 38 Reserved Pull up

STRAP OPTION

12/55

Issue 1.1

2.1 STRAP OPTION REGISTER DESCRIPTION

2.1.1 STRAP REGISTER 0 INDEX 4AH (STRAP0)

Bits 7-0, This register reflect the status of pins MD[7:0] respectively. They are expected to be connected

on the system board to the SIMM configuration pins as follows:

Note that the SIMM speed and type information read here is meant only for the software and is not used

by thehardware. The software must program the Host and graphics DRAM controller configuration registers appropriately based on these bits.

This register defaults to the values sampled on MD[7:0] pins after reset.

MD 39 Reserved Pull up

MD 40 PCMCIA or PCI i/f 3C,bit 0 User defined PCI PCMCIA

MD 41 Local Bus or ISA i/f 3C,bit 1 User defined ISA Local Bus

MD 42 Key Board & Mouse 3C,bit 2 User defined External Internal

MD 43 Parallel Port 3C,bit 3 User defined External Internal

MD 44 Serial Port UART1 3C,bit 4 User defined External Internal

MD 45 UART2 3C,bit 5 User defined External Internal

MD 46 Reserved 3C,bit 6 Pull down

MD 47 Reserved 3C,bit 7 Pull down

MD 48 TFT Outputs on RFU pads 3D,bit 0 User defined Disable Enable

MD 49 Cardbus Socket 5V Availability 3D,bit 1 User defined

Not Availa-

ble

Available

MD 50 3.3V Availability 3D,bit 2 User defined

Not Availa-

ble

Available

MD 51 x.xV Available 3D,bit 3 User defined

Not Availa-

ble

Available

MD 52 y.yV Available 3D,bit 4 User defined

Not Availa-

ble

Available

MD 53 Reserved Pull uo

MD 56 Reserved Pull up

MD 57 Reserved Pull down

MD 58 Reserved Pull up

MD 59 Reserved Pull down

Bit Sampled Description

Bit 7 SIMM 0 DRAM type

Bits 6-5 SIMM 0 speed

Bit 4 SIMM 1 DRAM type

Bits 3-2 SIMM 1 speed

Bits 1-0 Reserved

Memory

Data

Lines

Refer to Designation Location

Actual

Settings

Set to ’0’ Set to ’1’

STRAP OPTION

13/55

Issue 1.1

2.1.2 STRAP REGISTER 1 INDEX 4BH (STRAP1)

Bits 7-0, This register reflect the status of pins MD[15:8] respectively. They are expected tobe connected

on the system board to the SIMM configuration pins as follows:

Note that the SIMM speed and type information read here is meant only for the software and is not used

by the hardware. The software must program the Host and graphics dram controller configuration registers appropriately based on these bits.

This register defaults to the values sampled on MD[15:8] pins after reset.

2.1.3 STRAP REGISTER 2 INDEX 4CH (STRAP2)

Bits 4-0of this register reflect the status of pins MD[20:16] respectively. Bit 5 ofthis register reflect the status of pin MD[23]. Bit 4 is writeable, writes to other bits in this register have no effect.

They are use by the chip as follows:

Bits 7-5, Reserved

Bit 4, This bit reflects the value sampled on MD[20] pin and controls the Dot clock (DCLK) source. Note

this bit is writeable as well as readable.

Bit 3, This bit reflects the value sampled on MD[19] pin and controls the Graphics clock source.

Bit 2, This bit reflects the value sampled on MD[18] pin and controls the Host/CPU clock source as follows: setting to’0’: External. HCLK pin is an input, setting to ’1’: Internal. HCLK pin is an output and is connected to the internal frequency synthesizer output.

Bit 1, This bit reflects the value sampled on MD[17] pin and controls the PCI clock output as follows:

Setting to ’0’, the PCI clock output = HCLK / 3

Setting to ’1’, the PCI clock output = HCLK / 2

Bit 0, Reserved.

This register defaults to the values sampled on MD[23] & MD[20:16] pins after reset.

Bit Sampled Description

Bit 7 SIMM 2 DRAM type

Bits 6-5 SIMM 2 speed

Bit 4 SIMM 3 DRAM type:

Bits 3-2 SIMM 3 speed

Bit 1-0 Reserved

STRAP OPTION

14/55

Issue 1.1

2.1.4 STRAP REGISTER 3 INDEX 3CH (STRAP3)

Bits 7-0 of this register reflect the status of pins MD[47:40] respectively.

They are use by the chip as follows:

Bit 7-6, Reserved.

Bit 5, UART2 internal or external. This bit reflects the value sampled on MD[45] pin and controls the

UART2 I/F as follows:

Setting to ’0’, UART2 is external.

Setting to ’1’, UART2 is internal.

Bit 4, UART1 internal or external and additional TFT outputs. This bit reflects the value sampled on

MD[44] pin and controls the UART1 I/F and the additional TFT I/F as follows:

Setting to ’0’, UART1 is external and anadditional 6 TFT outputs (lowest bits - 2 red, 2 green

and 2 blue) are enabled.

Setting to ’1’, UART1 is internal.

Note that when strap option testbus enabled (see Section 2.1.3 Strap Register 2 bit 0) is driven to 1 it

takes priority over this strap which becomes meaningless.

Bit 3, Parallel Port internal or external. This bitreflects the value sampled on MD[43] pin and controls the

Parallel Port i/f as follows:

Setting to ’0’, the Parallel Port is external

Setting to ’1’, the Parallel Port is internal

Bit 2, KB/Mouse internal or external. This bit reflects the value sampled on MD[42] pin and controls the

KB/Mouse controller i/f as follows:

Setting to ’0’, the KB/Mouse controller is external

Setting to ’1’, the KB/Mouse controller is internal

Bit 1, Local Bus i/for ISA I/F. This bit reflects thevalue sampled on MD[41] pin and sets whether the Local Bus i/f or the ISA i/f is available at the device i/f as follows:

Setting to ’0’, selectes the ISA I/F

Setting to ’1’, selectec the Local Bus I/F

Bit 0 PCMCIA I/F or PCI I/F. This bit reflects the value sampled on MD[40] pin and sets whether the

PCMCIA i/f or the PCI i/f is available at the device i/f as follows:

Setting to ’0’, selects the PCI I/F

Setting to ’1’, selects the PCMCIA I/F

This register defaults to the values sampled on MD[47:40] pins after reset.

STRAP OPTION

15/55

Issue 1.1

2.1.5 STRAP REGISTER 4 INDEX 3Dh (STRAP4)

Bits 5-0 of this register reflect the status of pins MD[53:48] respectively.

They are use by the chip as follows:

Bits 7-5 Reserved.

Bit 4, y.y V present on board. This bit reflects the value sampled on MD[52] pin and is used to notify the

Cardbus socket management unit if the y.y V vcc voltage (where y.y is less than x.x) is present on board

as follows

Setting to ’0’, y.y V Vcc voltage is not available

Setting to ’1’: y.y V Vcc voltage is available.

Bit 3, x.x V present on board. This bit reflects the value sampled on MD[51] pin and is used to notify the

Cardbus socket management unit if the x.x V vcc voltage (where x.x is less than 3.3) is present on board

as follows:

Setting to ’0’, x.x V Vcc voltage is not available.

Setting to ’1’: x.x V Vcc voltage is available.

Bit 2, 3.3 V present on board. This bit reflects the value sampled on MD[50] pin and is usedto notify the

Cardbus socket management unit if the 3.3 V vcc voltage is present on board as follows:

Setting to ’0’, 3.3 V vcc voltage is not available.

Setting to ’1’, 3.3 V vcc voltage is available.

Bit 1, 5 V present on board. This bit reflects the value sampled on MD[49] pin and is used to notify the

Cardbus socket management unit if the 5 V vcc voltage is present on board as follows:

Setting to ’0’, 5 V vcc voltage is not available.

Setting to ’1’, 5 V vcc voltage is available.

Bit 0, This bit reflects the value sampled on MD[48] pin and is used to enable the TFT controller outputs

on pads RFU0-RFU11 as follows:

RFU0 : R[2]

RFU1 : R[3]

RFU2 : R[4]

RFU3 : R[5]

RFU4 : G[2]

RFU5 : G[3]

RFU6 : G[4]

RFU7 : G[5]

RFU8 : B[2]

RFU9 : B[3]

RFU10 : B[4]

RFU11 : B[5]

This register defaults to the values sampled on MD[53:48] pins after reset.

STRAP OPTION

16/55

Issue 1.1

2.1.6 HCLK PLL STRAP REGISTER 0 INDEX 5FH (HCLK_STRAP0)

Bits 5-0 of this register reflect the status of pins MD[26:21] respectively.

They are use by the chip as follows:

Bits 7-6, Reserved.

Bits 5-3,These pins reflect the value sampled on MD[26:24] pinsrespectively and control the Host clock

frequency synthesizer.

Bit 2-1, Reserved.

Bit 0, Reserved.

This register defaults to the values sampled on above pins after reset.

PIN DESCRIPTION

17/55

Issue 1.1

3 PIN DESCRIPTION

3.1. INTRODUCTION

The STPC Industrial integrates most of the functionalities of the PC architecture. Therefore, many

of the traditional interconnections between the

host PC microprocessor and the peripheral devices are totally internal to the STPC Industrial. This

offers improved performance due to the tight coupling of theprocessor coreand it’s peripherals. As

a result many of the external pin connections are

made directly to the on-chip peripheral functions.

Figure 3-1 shows the STPC Industrial’s external

interfaces. It defines the main busses and their

function. Table 3-1 describes the physical implementation listing signal types and their functionalities. Table 3-2 provides a full pin listing and description.

Table 3-4 provides a full listing of theSTPC Industrial package pin location physical connection.

Please refer tothe pin allocation drawing for reference.

Due to the number of pins available for the package, and the number offunctional I/Os, some pins

have several functions, selectable by strap option

on Reset. Table 3-3 provides a summary of these

pins and their functions.

Table 3-1. Signal Description

Group name Qty

Basic Clocks, Reset & Xtal (SYS) 13

DRAM Controller(DRAM) 89

PCI Controller 55

64

PC Card Interface 64

Keyboard/Mouse Controller (SIO) 4

Local Bus I/F, Parallel I/F,Serial 2 75

75

ISA Interface/IPC extensions 73

Serial 1 (SIO) 8

26

TFT output 24

VGA Controller (VGA) 10

Grounds 74

V

DD

16

Analog specific V

CC/VDD

16

Reserved 1

TotalPin Count 388

Figure 3-1. STPC Industrial External Interfaces

PCI

x86 core

DRAM VGA TFT SYS SIO

89 10 24 12 55

13

75 38

STPC Industrial

CARD

PC

ISA/

LOCAL BUS

NORTH BRIDGE SOUTH BRIDGE

PIN DESCRIPTION

18/55

Issue 1.1

Table 3-2. Definition of Signal Pins

Signal Name Dir Description Qty

BASIC CLOCKS AND RESETS

SYSRSTI#* I System Reset / Power good 1

SYSRSTO#* O Reset Output to System 1

XTALI I 14.3MHz Crystal Input 1

XTALO O 14.3MHz Crystal Output 1

PCI_CLKI* I 33MHz PCI/CardBus Input Clock 1

PCI_CLKO O 33MHz PCI/CardBus Output Clock 1

ISA_CLK, ISA_CLK2X O ISA Clock x1 and x2 (also Multiplexer Select Line For IPC) 2

CLK14M O ISA bus synchronisation clock 1

HCLK* I/O 33 / 66MHz Host Clock (Test) 1

DEV_CLK* O 24MHz Peripheral Clock 1

GCLK2X I/O 80MHz Graphics Clock 1

DCLK I/O 135MHz Dot Clock 1

V

DD

_xxx_PLL Power Supply for PLL Clocks

MEMORY INTERFACE

MA[11:0] I/O Memory Address 12

RAS#[3:0] O Row Address Strobe 4

CAS#[7:0] O Column Address Strobe 8

MWE# O Write Enable 1

MD[63:0] I/O Memory Data 64

LOCAL BUS INTERFACE(COMBINED WITH ISA BUS )

PA[21:0]* O Address Bus [21:0] 22

PD[15:0]* I/O Data Bus [15:0] 16

PRDY#* I Ready 1

PWR#[1:0]* O Memory and I/O Write signals 2

PRD#[1:0]* O Memory and I/O Read signals 2

FCS#[1:0]*, IOCS#[3:0]* O Flash Memory and I/O Chip Select 6

ISA BUS INTERFACE (COMBINED WITH LOCAL BUS, PARALLEL PORT, SERIAL INTERFACE)

LA[23:17]* O Unlatched Address 7

SA[19:0]* O Latched Address 20

SD[15:0]* I/O Data Bus 16

IOCHRDY* I I/O Channel Ready 1

ALE* O Address Latch Enable 1

BHE#* O System Bus High Enable 1

MEMR#*, MEMW#* I/O Memory Read & Write 2

SMEMR#*, SMEMW#* O System Memory Read and Write 2

IOR#*, IOW#* I/O I/O Read and Write 2

MASTER#* I Add On Card Owns Bus 1

MCS16#*, IOCS16#* I Memory Chip Select 16, I/O Chip Select 16 2

REF#* I Refresh Cycle 1

AEN* O Address Enable 1

IOCHCK#* I I/O Channel Check (ISA) 1

RTCRW#* O RTC Read / Write# 1

RTCDS#* O RTC Data Strobe 1

RTCAS#* O RTC Address Strobe 1

PIN DESCRIPTION

19/55

Issue 1.1

RMRTCCS#* O ROM / RTC Chip Select 1

GPIOCS#* I/O General Purpose Chip Select 1

IRQ_MUX[3:0]* I Multiplexed Interrupt Request 4

DACK_ENC[2:0]* O DMA Acknowledge 3

DREQ_MUX[1:0]* I Multiplexed DMA Request 2

TC* O ISA Terminal Count 1

KEYBOARD & MOUSE INTERFACE

KBDATA*,MDATA* I Keyboard & Mouse Data Line 2

KBCLK*, MCLK* O Keyboard & Mouse Clock Line 2

SERIAL INTERFACE (SERIAL 1 COMBINED WITH TFT INTERFACE / SERIAL 2 COMBINED WITH IPC )

SIN1*, SIN2* I Serial Data In (Serial 1, 2) 2

SOUT1*, SOUT2* O Serial Data Out (Serial 1, 2) 2

CTS1#*, CTS2#* I Clear ToSend (Serial 1, 2) 2

RTS1#*, RTS2#* O Request ToSend (Serial 1, 2) 2

DSR1#*, DSR2#* I Data Set Ready (Serial 1, 2) 2

DTR1#*, DTR2#* O Data Terminal Ready (Serial 1,2) 2

DCD1#*, DCD2#* I Data Carrier Detect (Serial 1, 2) 2

RI1#*, RI2#* I Ring Indicator (Serial 1, 2) 2

PARALLEL PORT (COMBINED WITH ISA BUS AND IPC)

PE* I Paper End 1

SLCT* I SELECT 1

BUSY#* I BUSY 1

ERR#* I ERROR 1

ACK#* I Acknowledge 1

PDDIR#* O Parallel Device Direction 1

STROBE#* O PCS / STROBE# 1

INIT#* O INIT 1

AUTPFDX#* O Automatic Line Feed 1

SLCTIN#* O SELECT IN 1

PPD[7:0]* I/O Data Bus 8

PCMCIA INTERFACE(COMBINED WITH PCI / CARDBUS)

RESET* O Reset 1

A[25:0]* O Address Bus 26

D[15:0]* I/O Data Bus 16

IORD#*, IOWR#* O I/O Read and Write 2

DREQ#* / WP*/ IOIS16#* I DMA Request // Write Protect // I/O Size is 16 bit 1

BVD1*, BVD2* I Battery Voltage Detect 2

READY#*/BUSY#*/IREQ#* I Ready / Busy // Interrupt Request 1

WAIT#* I Wait 1

INPACK#* I Input Port Acknowledge 1

OE#* / TCw* O Output Enable // DMA Terminal Count 1

WE#* / TCr* O Write Enable // DMA Terminal Count 1

DACK* / REG#* O DMA Acknowledge // Register 1

CD1#*, CD2#* I Card Detect 2

Table 3-2. Definition of Signal Pins

Signal Name Dir Description Qty

PIN DESCRIPTION

20/55

Issue 1.1

CE1#*, CE2#* O Card Enable 2

VS1#*, VS2#* I VoltageSense 2

VCC5_EN* O Power Switch control : 5v power 1

VCC3_EN* O Power Switch control : 3.3v power 1

VPP_PGM* O Power Switch control : Program power 1

VPP_VCC* O Power Switch control : VCC power 1

CARDBUS INTERFACE(COMBINED WITH PCI / PCMCIA)

CCLKRUN* I/O Clock 1

CRST#* O Reset 1

CSTSCHG#* I System Change 1

CAD[31:0]* I/O Address / Data 32

CBE[3:0]* I/O Bus Commands / Byte Enables 4

CFRAME#* I/O Cycle Frame 1

CTRDY#* I/O Target Ready 1

CIRDY#* I/O Initiator Ready 1

CSTOP#* I/O Stop Transaction 1

CDEVSEL#* I/O Device Select 1

CPAR* I/O Parity Signal Transactions 1

CSERR#* I System Error 1

CPERR#* I/O Parity Error 1

CBLOCK#* I/O PCI Lock 1

CCD[2:1]* I Card Detect 2

CINT#* I Interrupt Request 1

CREQ#* I Request 1

CGNT#* O Grant 1

PCI INTERFACE(COMBINED WITH PCMCIA / CARDBUS)

AD[31:0]* I/O Address / Data 32

BE[3:0]* I/O Bus Commands / Byte Enables 4

FRAME#* I/O Cycle Frame 1

TRDY#* I/O Target Ready 1

IRDY#* I/O Initiator Ready 1

STOP#* I/O Stop Transaction 1

DEVSEL#* I/O Device Select 1

PAR* I/O Parity Signal Transactions 1

SERR#* O System Error 1

LOCK#* I PCI Lock 1

PCI_REQ#[2:0]* I PCI Request 3

PCI_GNT#[2:0]* O PCI Grant 3

PCI_INT[3:0]* I PCI Interrupt Request 4

Table 3-2. Definition of Signal Pins

Signal Name Dir Description Qty

PIN DESCRIPTION

21/55

Issue 1.1

Note; *denotes theat the pin is V5T(see Section 4

)

MONITOR INTERFACE

RED, GREEN, BLUE O Red, Green, Blue 3

VSYNC* I/O Vertical Sync 1

HSYNC* I/O Horizontal Sync 1

VREF_DAC I DAC Voltage reference 1

RSET I Resistor Set 1

COMP I Compensation 1

DDC[1:0]* I/O Display Data Channel Serial Link 2

SCL / DDC[1]* I/O I C Interface - Clock / Can be used fo r VG A DDC[1] signal 1

SDA / D DC[0]* I/O I C Interface - Data / Can be used fo r VG A DDC[0] signal 1

TFT INTE RFACE(COMBINE D W ITH S ERIAL 1)

R[5:0], G[5:0], B[ 5:0] O Red, G reen, Blue 18

FPLINE O H orizontal S ync 1

FPFRAME O Vertical S ync 1

DE O Data Enable 1

ENAVDD O E nable Vd d of f lat panel 1

ENVCC O E nable Vc c of fl at panel 1

PWM O P WM back-light control 1

MISCELLA NEO US

SPKRD* O S peaker Device Outp ut 1

SCAN_ENABLE I Test Pin - Reserved 1

Table 3-2. Definition of Signal Pi ns

Signal Name Dir Description Qty

PIN DESCRIPTION

22/55

Issue 1.1

3.2. SIGNAL DESCRIPTIONS

3.2.2 BASIC CLOCKS AND RESETS

SYSRSTI#

System Reset/Power good.

This input

is low when the reset switch is depressed. Otherwise, it reflects the power supply’s power good

signal. PWGD is asynchronous to all clocks, and

acts as a negative active reset. The reset circuit

initiates a hard reset on the rising edge of PWGD.

SYSRSTO#

Reset Output to System.

This is the

system resetsignal and is used to reset the rest of

the components (not on Host bus) in the system.

The ISA bus reset is an externally inverted buffered versionof this output and the PCIbus resetis

an externally buffered version of this output.

XTALI

14.3MHz Crystal Input

XTALO

14.3MHz Crystal Output.

These pins are

the 14.318MHz crystalinput; This clock isused as

the reference clock for the internal frequency synthesizer to generate the HCLK and CLK24M.

A 14.318 MHz Series Cut Quartz Crystal should

be connected between these two pins. Balance

capacitors of 15 pF should also be added. In the

event of an external oscillatorproviding the master

clock signalto the STPC Industrialdevice, the TTL

signal should be provided on XTALO.

PCI_CLKI

33MHz PCI Input Clock

This signal must be connected to a clock generator and is usually connected to PCI_CLKO.

PCI_CLKO

33MHz PCI Output Clock.

This is the

master PCI bus clock output

ISA_CLK

ISA Clock Output (also Multiplexer Se-

lect Line For IPC).

This pin produces the Clock

signal for the ISA bus. It is also used with

ISA_CLK2X as the multiplexor control lines for the

Interrupt Controller Interrupt input lines. This is a

divided down version of the PCICLK or OSC14M.

ISA_CLKX2

ISA Clock Output (also Multiplexer

Select Line For IPC).

This pin produces a signal at

twice the frequency of the ISA bus Clock signal. It

is also used with ISA_CLK as the multiplexor control lines for the Interrupt Controller Interrupt input

lines.

CLK14M

ISA bus synchronisation clock.

This is

the buffered 14.318 Mhzclock to the ISA bus. This

clock also provides the reference clock to the frequency synthesizer that generates GCLK2X and

DCLK.

HCLK

Host Clock.

This is the host 1X clock. Its

frequency can vary from 50 to 75 MHz. All host

transactions and PCI transactions are synchronized to this clock. Host transactions executed by

the DRAM controller are also driven by this clock.

DEV_CLK

24MHz Peripheral Clock (floppydrive).

This 24MHZ signal is provided as a convenience

for the system integration of a Floppy Disk driver

function in an external chip.

GCLK2X

80MHz Graphics Clock.

This is the

Graphics 2X clock, which drives the graphics engine and the DRAM controller to execute the

graphics and display cycles.

Normally GCLK2X isgenerated by the internal frequency synthesizer, and this pin is an output. By

setting a bit in Strap Register 2, this pin can be

made an input so that an external clock can replace the internal frequency synthesizer.

DCLK

135MHz Dot Clock.

This is the dot clock,

which drivesgraphics display cycles.Its frequency

can be as high as 135 MHz, and it is required to

have a worst case duty cycle of 60-40. For further

details, refer to Section 2.1.3 bit 4.

3.2.3 MEMORY INTERFACE

MA[11:0]

Memory Address.

These 12 multiplexed

memory addresspins support external DRAM with

up to 4K refresh. These include all 16M x N and

some 4M x N DRAM modules. The address signals must be externally buffered to support more

than 16 DRAM chips. The timing of these signals

can be adjusted by software to match the timings

of most DRAM modules.

MD[63:0]

Memory Data.

This is the 64-bit memory

data bus. If only half of a bank is populated,

MD63-32 is pulled high, data is on MD31-0.

MD20-0 are also used as inputs at the rising edge

of PWGD to latch in power-up configuration information into the ADPC strap registers.

PIN DESCRIPTION

23/55

Issue 1.1

RAS#[3:0]

Row Address Strobe.

There are 4 active low row address strobe outputs, one each for

each bank of the memory. Each bank contains 4

or 8-Bytes of data. The memory controller allows

half of a bank (4-Bytes) to be populated to enable

memory upgrade at finer granularity.

The RAS# signals drive the SIMMs directly without any external buffering. These pins are always

outputs, but they can also simultaneously be inputs, toallow the memory controller to monitor the

value of the RAS# signals at the pins.

CAS#[7:0]

Column Address Strobe.

There are 8

active low column address strobe outputs, one

each for each Byte of the memory.

The CAS# signals drive the SIMMs either directly

or through external buffers.

These pins are always outputs, but they can also

simultaneously be inputs, to allow the memory

controller to monitor the value of the CAS# signals

at the pins.

MWE#

Write Enable.

Write enable specifies

whether the memory access is a read (MWE# = H)

or a write (MWE# = L). This single write enable

controls all DRAMs. It can be externally buffered

to boost the maximum number of loads (DRAM

chips) supported.

The MWE# signals drive the SIMMs directly without any external buffering.

3.2.4 LOCAL BUS INTERFACE

(Combined with ISA Bus)

PA[21:0]

Memory Address.

This is the 22-bit Lo-

cal Bus Address

PD[15:0]

Data Bus.

This is the 16-bit bidirectional

Local Bus Data bus.

PRDY#

Ready.

This input signals the Local Bus

Ready state.

PWR#1

Memory and I/O Write signal

for MS Byte

PWR#0

Memory and I/O Write signal

for LS Byte

.

PRD#1

Memory and I/O Read signals

for MS

Byte

.

PRD#0

Memory andI/O Read signals

for LS Byte

.

FCS#[1:0], IOCS#[3:0]

Flash Memory and I/O

Chip select.

3.2.5 ISA BUS INTERFACE

LA[23:17]

Unlatched Address.

These unlatched

ISA Bus pins address bits 23-17 on 16-bit devices.

When the ISA bus is accessed by any cycle initiated from the PCI bus, these pins are in output

mode. When an ISA bus master owns the bus,

these pins are tristated.

SA[19:0]

Unlatched Address.

These are the 20

low bits of the system address bus of ISA. These

pins are used as an input when an ISA busmaster

owns the bus and are outputs at all other times.

SD[15:0]

I/O Data Bus (ISA).

These are the exter-

nal ISA databus pins.

IOCHRDY

IOChannel Ready.

IOCHRDY is the IO

channel ready signal of the ISA bus and is driven

as an output in response to an ISA master cycle

targeted to the host bus or an internal register of

the STPC Industrial. The STPC Industrial monitors this signal as an input when performing an

ISA cycle on behalf of the host CPU, DMA master

or refresh.

ISA masters which do not monitor IOCHRDY are

not guaranteed to work with the STPC Industrial

since the access to the system memory can be

considerably delayed due to CRT refresh or a

write back cycle.

ALE

Address Latch Enable.

This is the address

latch enable output of the ISA bus and is asserted

by the STPC Industrial to indicate that LA23-17,

SA19-0, AEN and SBHE# signals are valid. The

ALE is driven high during refresh, DMA master or

an ISA master cycles by the STPC Industrial.

ALE is driven low after reset.

BHE#

System Bus HighEnable.

This signal,when

asserted, indicates that a data Byte is being transferred on SD15-8 lines. It is used as an input when

an ISA master owns the bus and is an output at all

other times.

MEMR#

Memory Read.

This is the memory read

command signal of the ISAbus. It is used as an input when an ISA master owns the bus and is an

output at all other times.

The MEMR# signal is active during refresh.

MEMW#

Memory Write.

This is the memory write

command signal of the ISAbus. It is used as an input when an ISA master owns the bus and is an

output at all other times.

PIN DESCRIPTION

24/55

Issue 1.1

SMEMR#

System Memory Read.

The STPC Industrial generates SMEMR# signal of the ISA bus

only when the address is below one MByte or the

cycle is a refresh cycle.

SMEMW#

System Memory Write.

The STPC Industrial generatesSMEMW# signal of the ISA bus

only when the address is below one MByte.

IOR#

I/O Read.

This is the IO read command signal of the ISA bus. It is an input when an ISA master owns the bus and is an output at all other

times.

IOW#

I/O Write.

This is the IO write command signal of the ISA bus. It is an input when an ISA master owns the bus and is an output at all other

times.

MASTER#

Add On CardOwns Bus.

This signal is

active when an ISA device has been granted bus

ownership.

MCS16#

Memory Chip Select16.

This is the decode of LA23-17 address pins of the ISA address

bus without any qualification of the command signal lines. MCS16# is always an input. The STPC

Industrial ignores this signal during IO and refresh

cycles.

IOCS16#

IO Chip Select16.

This signal is the decode of SA15-0 address pins of the ISA address

bus without any qualification of the command signals. The STPC Industrial does not driveIOCS16#

(similar to PC-AT design). An ISA master access

to an internal register of the STPC Industrial is executed as an extended 8-bit IO cycle.

REF#

Refresh Cycle.

This is the refresh command

signal of the ISA bus. It is driven as an output

when the STPC Industrial performs arefresh cycle

on the ISA bus. It is used as an input when an ISA

master owns the bus and is used to trigger a refresh cycle.

The STPC Industrial performs a pseudo hidden

refresh. It requests the host bus for two host

clocks to drive the refresh address and capture it

in external buffers. The host bus is then relinquished while the refresh cycle continues on the

ISA bus.

AEN

Address Enable.

Address Enable is enabled

when the DMA controller is the bus owner to indicate that a DMA transfer will occur. The enabling

of the signal indicates to IO devices to ignore the

IOR#/IOW# signal during DMA transfers.

IOCHCK#

IO Channel Check.

IO Channel Check

is enabled by any ISA device to signal an error

condition that can not be corrected. NMI signal becomes active upon seeing IOCHCK# active if the

corresponding bit in Port B is enabled.

GPIOCS#

I/O General Purpose Chip Select 1.

This output signal is used by the external latch on

ISA bus to latch the data on the SD[7:0] bus. The

latch can be use by PMU unit to control the external peripheral devices to power down or any other

desired function.

This pin is also serves as a strap input during reset.

RTCRW#

Real Time Clock RW#.

This pin is used

as RTCRW#. This signal is asserted for any I/O

write to port 71h.

RTCDS#

Real Time Clock DS

. This pin is used as

RTCDS. This signal is asserted for any I/O read to

port 71h.

RTCAS#

Real time clock address strobe.

This sig-

nal is asserted for any I/O write to port 70h.

RMRTCCS#

ROM/Real Time clock chip select.

This pin is a multi-function pin. This signal is asserted if a ROM access is decoded during a memory cycle. It should be combined with MEMR# or

MEMW# signals to properly access the ROM.

During an IO cycle, this signal is asserted if access to the Real Time Clock (RTC) is decoded. It

should be combined with IOR# or IOW# signals to

properly access the real time clock.

IRQ_MUX[3:0]

Multiplexed Interrupt Request.

These are the ISA bus interrupt signals. They are

to be encoded before connection to the STPC Industrial using ISACLK and ISACLKX2 as the input

selection strobes.

Note that IRQ8B, which by convention is connected to the RTC, is inverted before being sent to the

interrupt controller, so that it may be connected directly to the IRQ# pin of the RTC.

PIN DESCRIPTION

25/55

Issue 1.1

3.2.6 IPC (Combined with Serial Interface)

DACK_ENC[2:0]

DMA Acknowledge.

These are

the ISA bus DMA acknowledge signals. They are

encoded by the STPC Industrial before output and

should be decoded externally using ISACLK and

ISACLKX2 as the control strobes.

DREQ_MUX[1:0]

ISA Bus Multiplexed DMA Re-

quest.

These are the ISA bus DMA request signals. They are to be encoded before connection to

the STPCIndustrial using ISACLK and ISACLKX2

as the input selection strobes.

TC

ISA Terminal Count.

This is the terminal count

output of the DMA controller and is connected to

the TCline of the ISA bus. It isasserted during the

last DMA transfer, when the Byte count expires.

3.2.7 KEYBOARD/MOUSE INTERFACE

KBCLK,

Keyboard Clock line.

Keyboard data is

latched by the controller on each negative clock

edge produced on this pin. The keyboard can be

disabled by pulling this pinlow by software control.

KBDATA,

Keyboard Data Line.

11-bits of data are

shifted serially through this line when data isbeing

transferred. Data is synchronised to KBCLK.

MCLK,

Mouse Clock line.

Mouse data is latched

by thecontroller on each negative clock edge produced on this pin. The mouse can be disabled by

pulling this pin low by software control.

MDATA,

Mouse Data Line.

11-bits of data are

shifted serially through this line when data isbeing

transferred. Data is synchronised to MCLK.

3.2.8 SERIAL INTERFACE

(Serial 1 combined with TFT Interface)

(Serial 2 combined with IPC)

SIN1, SIN2

Input Serial input.

Data is clocked in

using RCLK/16.

SOUT1, SOUT2

Serial Output.

Data isclocked out

using TCLK/16 (TCLK=BAUD#).

DCD1#, DCD2#

Input Data carrier detect.

RI1#, RI2#

Input Ring indicator.

DSR1#, DSR2#

Input Data set ready.

CTS1#, CTS2#

Input Clear to send.

RTS1#, RTS2#

Output Request to send.

DTR1#, DTR2#

Output Data terminal read.

3.2.9 PARALLEL PORT

(Combined with ISA Bus an IPC)

PE

Paper End.

Input status signal from printer.

SLCT

Printer Select.

Printer selected input.

BUSY#

Printer Busy

.

Input status signal from printer.

ERR#

Error

. Input status signal from printer.

ACK#

Acknowledge.

Input status signal from printer.

PDDIR#

Parallel Device Direction.

Bidirectional control line output.

STROBE#

PCS/Strobe#.

Data transfer strobe line to printer.

INIT#

Initialize Printer.

This output sends an initial-

ize command to the connected printer.

AUTPFDX#

Automatic Line feed.

This output

sends a command to the connected printer to automatically generate line feed on received carriage returns.

SLCTIN#

Select In.

Printer select output.

PPD[7-0]

Printer Data Lines

Data transfer lines to

printer. Bidirectional depending on modes.

PIN DESCRIPTION

26/55

Issue 1.1

3.2.10 PCMCIA INTERFACE

(Combined with PCI / Cardbus)

RESET

Card Reset.

This output forces a hard

reset to a PC Card.

A[25:0]

Address Bus.

These are the 25 low bits of

the system address bus of the PCMCIA bus.

These pins areused as an input when an PCMCIA

bus owns the bus and are outputs at all other

times.

D[15:0]

I/O Data Bus (PCMCIA).

These are the

external PCMCIA databus pins.

CA[25-0]

Card Address

. Used with the lower 11

bits of the ISA Address Bus to generate the Card

Address.

IORD#

I/O Read.

Thisoutput is used with REG#to

gate I/O read data from the PC Card, (only when

REG# is asserted).

IOWR#

I/O Write

. This output is used with REG#

to gate I/O write data from the PC Card, (only

when REG# is asserted).

WP

Write Protect.

This input indicates the status

of the Write Protect switch (iffitted) on memory PC

Cards (asserted when the switch is set to write

protect).

BVD1, BVD2

Battery Voltage Detect.

These inputs will be generated by memory PC Cards that

include batteries and are an indication of the condition of the batteries. BVD1 and BVD2 are kept

asserted high when the battery is in good condition.

READY#/BUSY#/IREQ#

Ready/busy/Interupt re-

quest.

This input is driven low by memory PC

Cards to signal that their circuits are busy

processing a previous write command.

WAIT#

Bus Cycle Wait.

This input is driven by the

PC Card to delay completion of the memory or I/O

cycle in progress.

OE#

Output Enable.

OE# is an active low output

which is driven to the PC Card to gate Memory

Read data from memory PC Cards.

WE#/PRGM#

Write Enable.

This outputis usedby

the host for gating Memory Write data. WE# is

also used for memory PC Cards that have programmable memory.

REG#

Attribute Memory Select.

This output is inactive (high) for all normal accesses to the Main

Memory of the PC Card. I/O PC Cards will only respond to IORD# or IOWR# when REG# is active

(low). Also see Section 3.2.6

CD1#, CD2#

Card Detect.

These inputs provide

for the detection of correct card insertion. CD#1

and CD#2 are positioned at opposite ends of the

connector to assist in the detection process.

These inputs are internally grounded on the PC

Card therefore they will be forced low whenever a

card is inserted in a socket.

CE1#, CE2#

Card Enable

. These are active low

output signals provided from the PCIC. CE#1 enables even Bytes, CE#2 odd Bytes.

ENABLE#

Enable.

Thisoutput is used to activate/

select a PC Card socket. ENABLE# controls the

external address buffer logic.C card has been detected (CD#1 and CD#2 = ’0’).

ENIF#

ENIF

. This output is used to activate/select

a PC Card socket.

EXT_DIR

EXternal Transreceiver Direction Con-

trol.

This outputis high during a read and low during a write. The default power up condition is write

(low). Used for both Low and High Bytes of the

Data Bus.

VCC_EN#, VPP1_EN0, VPP1_EN1, VPP 2_EN0,

VPP2_EN1

Power Control.

Five output signals

used to control voltages (VPP1, VPP2 and VCC)

to a PC Card socket. Also see Section 16.7.5

GPI#

General Purpose Input. This signal is hard-

wired to 1.

PIN DESCRIPTION

27/55

Issue 1.1

3.2.11 CARDBUS INTERFACE

(Combined with PCI / PCMCIA)

For card bus pinouts, refer to the PCI pinout.

3.2.12 PCI INTERFACE

AD[31:0]

PCI Address/Data.

This is the 32-bit

multiplexed address and databus of the PCI. This

bus is driven by the master during the address

phase and data phase of write transactions. It is

driven by the target during data phase of read

transactions.

BE[3:0]#

Bus Commands/Byte Enables.

These

are the multiplexed command and Byte enable

signals of the PCI bus. During the address phase

they define the command and during the data

phase they carry the Byte enable information.

These pins are inputs when a PCI master other

than the STPC Industrial owns the bus and outputs when the STPC Industrial owns the bus.

FRAME#

Cycle Frame.

This is the frame signal of

the PCIbus. Itis aninput when aPCI master owns

the bus and is an output when STPC Industrial

owns the PCI bus.

TRDY#

Target Ready.

This is the target ready signal of the PCI bus. It is driven as an output when

the STPCIndustrial is the target of the current bus

transaction. It is used as an input when STPC Industrial initiates a cycle on the PCI bus.

IRDY#

Initiator Ready.

This is the initiator ready

signal of the PCI bus. It is used as an output when

the STPC Industrial initiates a bus cycle on the

PCI bus. It is used as an input during the PCI cycles targeted to the STPC Industrial to determine

when the current PCI master is ready to complete

the current transaction.

STOP#

Stop Transaction.

STOP# is used to implement the disconnect, retry and abort protocol of

the PCI bus. It is used as an input for the bus cycles initiated by the STPC Industrial and is used

as an output when a PCI master cycle is targeted

to the STPC Industrial.

DEVSEL#

I/O Device Select.

This signal is used

as an input when the STPC Industrial initiates a

bus cycle on the PCI bus to determine if a PCI

slave device has decoded itself to be the target of

the current transaction. It is asserted as an output

either when the STPC Industrial is the target of the

current PCI transaction or when no other device

asserts DEVSEL# prior to the subtractive decode

phase of the current PCI transaction.

PAR

Parity Signal Transactions.

This is the parity

signal of the PCI bus. This signal is used to guarantee even parity across AD[31:0], CBE[3:0]#,

and PAR. This signal is driven by the master during the address phase and data phase of write

transactions. It is driven by the target during data

phase of read transactions. (Its assertion is identical to that of the AD bus delayed by one PCI clock

cycle)

SERR#

System Error.

This is the system error signal of the PCI bus. It may, if enabled, be asserted

for one PCI clock cycle if target aborts a STPC Industrial initiated PCI transaction. Its assertion by

either the STPC Industrial or by another PCI bus

agent will trigger the assertion of NMI to the host

CPU. This is an open drain output.

LOCK#

PCI Lock.

This is the lock signal of the PCI

bus and is used to implement the exclusive bus

operations when acting as a PCI target agent.

PCI_REQ#[2:0]

PCI Request.

These pins are the

three external PCI master request pins. They indicates to the PCI arbiter that the external agents

desire use of the bus.

PCI_GNT#[2:0]

PCI Grant.

These pins indicate

that the PCI bus has been granted to the master

requesting it on its PCI_REQ#.

PCI_INT[3:0]

PCI Interrupt Request.

These are

the PCI bus interrupt signals. They are to be encoded before connection to the STPC Industrial

using ISACLK and ISACLKX2 as the input selection strobes.

3.2.13 MONITOR INTERFACE

RED, GREEN, BLUE

RGB Video Outputs.

These

are the 3 analog color outputs from the RAMDACs

VSYNC

Vertical Synchronisation Pulse.

This is

the vertical synchronization signal from the VGA

controller.

PIN DESCRIPTION

28/55

Issue 1.1

HSYNC

Horizontal Synchronisation Pulse.

This is

the horizontal synchronization signal from the

VGA controller.

VREF_DAC

DAC Voltage reference.

This pin is

an input driving the digital to analog converters.

This allows an external voltage reference source

to be used.

RSET

Resistor Current Set.

This is the reference

current input to the RAMDAC. Used to set the fullscale output of the RAMDAC.

COMP

Compensation.

This is the RAMDAC compensation pin. Normally, an external capacitor

(typically 10nF) is connected between this pin and

VDDto damp oscillations.

DDC[1:0]

Direct Data Channel Serial Link.

These

bidirectional pins are connected to CRTC register

3Fh to implement DDC capabilities. They conform

to I2C electrical specifications, they have opencollector output drivers which are internally connected to VDDthrough pull-up resistors.

They can instead be used for accessing I C devices on board. DDC1 and DDC0 correspond to SCL

and SDA respectively.

3.2.14 FLAT PANEL INTE RFACE SIGNALS

(Combined with Serial 1)

FPFRAME,

Vertical Sync. pulse Output.

FPLINE,

Horizontal S ync. Pulse Output.

DE,

Data Enable.

R5-0,

Red Output.

G5-0,

Green Output.

B5-0,

Blue Output

.

ENAVDD

Enable VDD of Flat Panel.

ENVCC

Enable VCC of Flat Panel.

PWM

PWM Back-Light Control.

3.2.15 MISCELLANEOUS

SPKRD

Speaker Drive.

This is the output t o the

speaker and is th e AND of the counter 2 output

with bit1 of Port 61h and drives an external speaker driver. This output should be connected to a

7407 type high voltage driver.

SCAN_ENABLE

Reserved

. This pin is reserved

for Test and Miscellaneous functions. It has t o be

set to ‘0’ or connected to ground in normal operation.

PIN DESCRIPTION

29/55

Issue 1.1

Table 3-3. Signals sharing the same pin

ISA BUS / IPC LOCAL BUS PARALLEL PORT SERIAL INTERFACE

LA[23:22] FCS#[0], PRD#[1]

LA[21:20] PA[21:20]

LA[19:17] PRD#[0], PWR#[1:0]

SA[19:1] PA[19:1]

SA[0] PRDY#

SD[15:0] PD[15:0]

BHE# FCS#[1]

MEMR#, MEMW# IOCS[3:2]

SMEMR#, SMEMW# IOCS[1:0]

GPIOCS# PE

IOCHRDY SLCT

IOR# BUSY#

IOW# ERR#

MASTER# ACK#

MCS16# PDDIR#

IOCS16# INIT#

REF# AUTPFDX#

AEN SLCTIN#

IOCHCK# PPD[7]

RTCRW# PPD[5]

RTCDS# PPD[4]

RTCAS# PPD[3]

RMRTCCS# PPD[2]

ALE PPD[1]

DACK_ENC[0:2] DCD2#, DSR2#, SIN2

DREQ_MUX[0:1] CTS2#, RTS2#

TC SOUT2

TFT INTERFACE SERIAL 1

B[0,1] DCD1#, CTS1#

G[0,1] DSR1#, RTS1#

R[0,1] SIN1, SOUT1

PCI CARDBUS PCMCIA

CCLK A[16]

CRST# RESET

AD[31:27] CAD[31:27] D[10,9,1,8,0]

AD[26:20] CAD[26:20] A[0:6]

PIN DESCRIPTION

30/55

Issue 1.1

PCI CARDBUS PCMCIA

AD[19] CAD[19] A[25]

AD[18] CAD[18] A[7]

AD[17] CAD[17] A[24]

AD[16] CAD[16] A[17]

AD[15] CAD[15] IOWR#

AD[14] CAD[14] A[9]

AD[13] CAD[13] IORD#

AD[12] CAD[12] A[11]

AD[11] CAD[11] OE# / TCw

AD[10] CAD[10] CE[2]

AD[9] CAD[9] A[10]

AD[8:0] CAD[8:0] D[15,7,13,6,12,5,11,4,3]

BE[3] CBE[3] DACK/REG#

BE[2] CBE[2] A[12]

BE[1] CBE[1] A[8]

BE[0] CBE[0] CE[1]

FRAME# CFRAME# A[23]

TRDY# CTRDY# A[22]

IRDY# CIRDY# A[15]

STOP# CSTOP# A[20]

DEVSEL# CDEVSEL# A[21]

PAR CPAR A[13]

CPERR# A[14]

SERR# CSERR# WAIT

LOCK# CBLOCK# A[19]

PCIREQ#[2] CREQ# INPACK#

PCIREQ#[1] CCD1 CD1#

PCIREQ#[0] CSTSCHG# BVD1

PCIGNT#[2] CGNT# WE# / TCr

PCIGNT#[1] CCD2 CD2#

PCIGNT#[0] BVD2

PCI_INT[3] VCC3_EN

PCI_INT[2] VCC5_EN

PCI_INT[1] VPP_PGM

PCI_INT[0] CINT# READY#

CLKRUN DREQ# / WP / IOIS16#

A[18]

PIN DESCRIPTION

31/55

Issue 1.1

Table 3-4. Pinout.

Pin # Pin name

C4

SYSRSTI#

A3 SYSRSTO#

AB25 XTALI

AB23 XTALO

G25 PCI_CLKI

H23 PCI_CLKO

B20 ISA_CLK

A20 ISA_CLK2X

AC26 CLK14M

H26 HCLK

J26 DEV_CLK

AC15 GCLK2X

AD16 DCLK

AE13 MA[0]

AC12 MA[1]

AF13 MA[2]

AD12 MA[3]

AE14 MA[4]

AC14 MA[5]

AF14 MA[6]

AD13 MA[7]

AE15 MA[8]

AD14 MA[9]

AF15 MA[10]

AE16 MA[11]

AD15 RAS#[0]

AF16 RAS#[1]

AC17 RAS#[2]

AE18 RAS#[3]

AD17 CAS#[0]

AF18 CAS#[1]

AE19 CAS#[2]

AF19 CAS#[3]

AD18 CAS#[4]

AE20 CAS#[5]

AC19 CAS#[6]

AF20 CAS#[7]

AD19 MWE#

AE21 MD[0]

AC20 MD[1]

AF21 MD[2]

AD20 MD[3]

AE22 MD[4]

AF22 MD[5]

AD21 MD[6]

AE23 MD[7]

AC22 MD[8]

AF23 MD[9]

AD22 MD[10]

AE24 MD[11]

AD23 MD[12]

AF24 MD[13]

AE26 MD[14]

AD25 MD[15]

AD26 MD[16]

AC25 MD[17]

AC24 MD[18]

AB24 MD[19]

AB26 MD[20]

AA25 MD[21]

Y23 MD[22]

AA24 MD[23]

AA26 MD[24]

Y25 MD[25]

Y26 MD[26]

Y24 MD[27]

W25 MD[28]

V23 MD[29]

W26 MD[30]

W24 MD[31]

V25 MD[32]

V26 MD[33]

U25 MD[34]

V24 MD[35]

U26 MD[36]

U23 MD[37]

T25 MD[38]

U24 MD[39]

T26 MD[40]

R25 MD[41]

R26 MD[42]

T24 MD[43]

P25 MD[44]

R23 MD[45]

P26 MD[46]

R24 MD[47]

Pin # Pin name

N25 MD[48]

N23 MD[49]

N26 MD[50]

P24 MD[51]

M25 MD[52]

N24 MD[53]

M26 MD[54]

L25 MD[55]

M24 MD[56]

L26 MD[57]

M23 MD[58]

K25 MD[59]

L24 MD[60]

K26 MD[61]

K23 MD[62]

J25 MD[63]

B1 PA[0]

P1 LA[17] / PWR#[0]

N3 LA[18] / PWR#[1]

R2 LA[19] / PRD#[0]

C1 LA[20] / PA[20]

C2 LA[21] / PA[21]

P3 LA[22] / PRD#[1]

R1 LA[23] / FCS#[0]

P4 SA[0] / PRDY#

J2 SA[1] / PA[1]

H3 SA[2] / PA[2]

H1 SA[3] / PA[3]

J4 SA[4] / PA[4]

H2 SA[5] / PA[5]

G3 SA[6] / PA[6]

G1 SA[7] / PA[7]

G2 SA[8] / PA[8]

F1 SA[9] / PA[9]

F3 SA[10] / PA[10]

G4 SA[11] / PA[11]

F2 SA[12] / PA[12]

E1 SA[13] / PA[13]

E3 SA[14] / PA[14]

E4 SA[15] / PA[15]

E2 SA[16] / PA[16]

D1 SA[17] / PA[17]

Pin# Pin name

PIN DESCRIPTION

32/55

Issue 1.1

D3 SA[18] / PA[18]

D2 SA[19] / PA[19]

P2 SD[0] / PD[0]

M3 SD[1] / PD[1]

N1 SD[2] / PD[2]

M4 SD[3] / PD[3]

N2 SD[4] / PD[4]

L3 SD[5] / PD[5]

M1 SD[6] / PD[6]

M2 SD[7] / PD[7]

L1 SD[8] / PD[8]

K3 SD[9] / PD[9]

L2 SD[10] / PD[10]

K4 SD[11] / PD[11]

K1 SD[12] / PD[12]

J3 SD[13] / PD[13]

K2 SD[14] / PD[14]

J1 SD[15] / PD[15]

T2 BHE# / FCS#[1]

R3 MEMR# / IOCS#[3]

T1 MEMW# / IOCS#[2]

R4 SMEMR# / IOCS#[1]

U2 SMEMW# / IOCS#[0]

AB2 IOCHRDY / SLCT

AB1 IOR# / BUSY#

Y3 GPIOCS# / PE

AA3 IOW# / ERR#

AC2 MASTER# / ACK#

AB4 MCS16# / PDDIR#

AB3 IOCS16# / INIT#

AD2 REF# / AUTPFDX#

AC3 AEN / SLCTIN#

E25 IOCHCK# / PPD[7]

E26 PPD[6]

F24 RTCRW# / PPD[5]

D25 RTCDS# / PPD[4]

E23 RTCAS# / PPD[3]

D26 RMRTCCS# / PPD[2]

E24 ALE / PPD[1]

C25 PPD[0]

AC1 STROBE#

D5 IRQ_MUX[0]

A4 IRQ_MUX[1]

Pin # Pin name

C5 IRQ_MUX[2]

B3 IRQ_MUX[3]

AD1 SPKRD

V3 DACK_ENC[0]/DCD2#

Y2 DACK_ENC[1]/DSR2#

W4 DACK_ENC[2] / SIN2

Y1 DREQ_MUX[0]/CTS2#

W3 DREQ_MUX[1]/RTS2#

AA2 TC / SOUT2

Y4 DTR2#

AA1 RI2#

U4 SIN1 / R[0]

V1 SOUT1 / R[1]

V2 CTS1 / B[1]

U3 RTS1# / G[1]

U1 DSR1# / G[0]

W2 DTR1#

T3 DCD1# / B[0]

W1 RI1#

F25 KBCLK

F26 KBDATA

G24 MCLK

G23 MDATA

D18 RESET

C18 A[0]

A17 A[1]

D17 A[2]

B16 A[3]

C17 A[4]

A16 A[5]

B15 A[6]

A15 A[7]

C16 A[8]

B14 A[9]

D15 A[10]

A14 A[11]

C15 A[12]

B13 A[13]

D13 A[14]

A13 A[15]

C14 A[16]

Pin # Pin name

B12 A[17]

C13 A[18]

A12 A[19]

B11 A[20]

A11 A[21]

D12 A[22]

B10 A[23]

C11 A[24]

A10 A[25]

D10 D[0]

B9 D[1]

C10 D[2]

A9 D[3]

B8 D[4]

C9 D[5]

B7 D[6]

D8 D[7]

A7 D[8]

B6 D[9]

D7 D[10]

A6 D[11]

C7 D[12]

A5 D[13]

C6 D[14]

B4 D[15]

B22 IORD#

D22 IOWR#

D24 WP

A18 BVD1

C26 BVD2

A21 READY#

C19 WAIT#

A25 INPACK#

C22 OE#

B18 WE#

B19 REG#

B24 CD1#

A24 CD2#

B23 CE1#

C23 CE2#

C20 VS1#

A19 VS2#

D20 VCC5_EN

C21 VCC3_EN

Pin# Pin name

PIN DESCRIPTION

33/55

Issue 1.1

B21 VPP_PGM

A22 VPP_VCC

AD4 RED

AF4 GREEN

AE5 BLUE

AF3 VSYNC

AE4 HSYNC

AF5 VREF_DAC

AE6 RSET

AF6 COMP

AE3 SDA / DDC[1]

AF2 SCL / DDC[0]

AE7 B[2]

AF7 G[2]

AD7 R[2]

AE8 B[3]

AC9 G[3]

AF8 R[3]

AD8 B[4]

AE9 G[4]

AF9 R[4]

AE10 B[5]

AD9 G[5]

AF10 R[5]

AC10 RESERVED

AD10 FPLINE

AE11 FPFRAME

AF11 DE

AE12 ENAVDD

AF12 ENVCC

AD11 PWM

C8 SCAN_ENABLE

AD5 VDD_DAC1

AC5 VDD_DAC2

AE17 VDD_GCLK_PLL

AF17 VDD_DCLK_PLL

K24 VDD_ZCLK_PLL

H25 VDD_DEVCLK_PLL

J24 VDD_HCLK_PLL

Pin # Pin name

A8 RESERVED

A23 RESERVED

B5 RESERVED

B17 RESERVED

C12 RESERVED

D6 VDD

D11 VDD

D16 VDD

D21 VDD

F4 VDD

F23 VDD

L4 VDD

L23 VDD

T4 VDD

T23 VDD

AA4 VDD

AA23 VDD

AC6 VDD

AC11 VDD

AC16 VDD

AC21 VDD

AC7 VSS_DAC1

AD6 VSS_DAC2

G26 VSS_DLL

H24 VSS_DLL

A1 VSS

A2 VSS

A26 VSS

B2 VSS

B25 VSS

B26 VSS

C3 VSS

C24 VSS

D4 VSS

D9 VSS

D14 VSS

D19 VSS

D23 VSS

H4 VSS

J23 VSS

L11:16 VSS

M11:16 VSS

Pin # Pin name

N4 VSS

N11:16 VSS

P11:16 VSS

P23 VSS

R11:16 VSS

T11:16 VSS

V4 VSS

W23 VSS

AC4 VSS

AC8 VSS

AC13 VSS

AC18 VSS

AC23 VSS

AD3 VSS

AD24 VSS

AE1 VSS

AE2 VSS

AE25 VSS

AF1 VSS

AF25 VSS

AF26 VSS

Pin# Pin name

ELECTRICAL SPECIFICATIONS

34/55

Issue 1.1

4 ELECTRICAL SPECIFICATIONS

4.1 INTRODUCTION

The electrical specifications in this chapter are

valid for the STPC Industrial.

4.2 ELECTRICAL CONNECTIONS

4.2.1 Power/Ground Connections/Decoupling

Due to the high frequency of operation of the

STPC Industrial, it is necessary to install and test

this device using standard high frequency

techniques. The high clock frequencies used in

the STPC Industrial and its output buffer circuits

can cause transient power surges when several

output buffers switch output levels simultaneously.

These effects can be minimized by filtering the

DC power leads with low-inductance decoupling

capacitors, using low impedance wiring, and by

utilizing all of the VSS and VDD pins.

4.2.2 Unused Input Pins

All inputs not used by the designer and not listed

in the table of pin connections in Section 3 should

be connected either to VDD or to VSS. Connect

active-high inputs to VDD through a 20 kΩ

(±10%) pull-down resistor and active-low inputs to

VSS and connect active-low inputs to VCC

through a 20 kΩ (±10%) pull-up resistor to prevent

spurious operation.

4.2.3 Reserved Designated Pins

Pins designated reserved should be left

disconnected. Connecting a reserved pin to a

pull-up resistor, pull-down resistor, or an active

signal could cause unexpected results and

possible circuit malfunctions.

4.3 ABSOLUTE MAXIMUM RATINGS

The following table lists the absolute maximum

ratings for the STPC Industrial device. Stresses

beyond those listed under Table 4-1 limits may

cause permanent damage to the device. These

are stress ratings only and do not imply that

operation under any conditions other than those

specified in section ”Operating Conditions”.

Exposure to conditions beyond those outlined in

Table 4-1 may (1) reduce devicereliability and (2)

result in premature failure even when there is no

immediately apparent sign of failure. Prolonged

exposure to conditions at or near the absolute

maximum ratings (Table 4-1) may also result in

reduced useful life and reliability.

4.3.1 5V Tolerance

The STPC is capable of running with I/O systems

that operate at 5V such as PCI and ISA devices.

Certain pins of the STPC tolerate inputs up to

5.5V. Above this limit thecomponent is likely to

sustain permanent damage.

All the pin that are V5Thave been denoted with a

* besides the Signal Name in Table 3-1 .

Table 4-1. Absolute Maximum Ratings

Symbol Parameter Minimum Maximum Units

V

DDx

DC Supply Voltage -0.3 4.0 V

V

I,VO

Digital Input and Output Voltage -0.3 VDD + 0.3 V

V

5T

5Volt Tolerance 2.5 5.5

T

STG

Storage Temperature -40 +150 °C

T

OPER

Operating Temperature 0 +70 °C

P

TOT

Maximum Power Dissipation - 4.8 W

ELECTRICAL SPECIFICATIONS

35/55

Issue 1.1

4.4 DC CHARACTERISTICS

Notes:

1. MHz ratings refer to CPU clock frequency.

2. Not yet released.

4.5 AC CHARACTERISTICS

Table 4-5 through Table 4-14 list the AC

characteristics including output delays, input

setup requirements, input hold requirements and

output float delays. These measurements are

based on the measurement points identified in

Figure 4-1. The rising clock edge reference level

VREF , and other reference levels are shown in

Table 4-4 below for the STPC Industrial. Input or

output signals must cross these levels during

testing.

Figure 4-1 shows output delay (A and B) and

input setup and hold times (C and D). Input setup