5.0 OR 3.0V, 512 bit (6 4 x 8) SERIAL

FEATURES SUMMARY

■ 5.0 OR 3.0V OPERATING VO LTA G E

■ SERIAL INTERFACE SU PPO R TS I

(400 KHz)

■ NVRAM SUPERVISOR FOR EXTERNAL

LPSRAM

■ OPTIMIZED FOR MINIMAL INTERCONNECT

TO MCU

■ 2.5 TO 5.5V OSCILLATOR OPERATING

VOLTAGE

■ AUTOMATIC SWITCH-OVER and DESELECT

CIRCUITRY

■ CHOICE OF POWER-FAIL DESELECT

VOLTAGES

– M41ST85Y : V

4.20V ≤ V

– M41ST85W: V

2.55V ≤ V

■ 1.25V REFERENCE (for PFI/PFO)

■ COUNTERS FOR TENTHS/HUNDREDTHS

PFD

PFD

= 4.5 to 5.5V;

CC

≤ 4.50V

= 2.7 to 3.6V;

CC

≤ 2.70V

OF SECONDS, SECONDS, MINUTES,

HOURS, DAY, DATE , MONTH, YEAR, and

CENTURY

■ 44 BYTES OF GENERAL PURPOSE RAM

■ PROGRAMMABLE ALARM and INTE RRUPT

FUNCTION (VALID EVEN DURING BATTERY

BACK-UP MODE)

■ WATCHDOG T IME R

■ MICROPROCESSOR POWER-ON RESET

■ BATTERY LOW FLAG

■ POWER-DOWN TIMESTAMP (HT BIT)

■ ULTRA-LOW BATT ERY SU PPL Y C URRE N T

OF 500nA (MAX)

2

C BUS

M41ST85Y

M41ST85W

RTC and NVRAM SUPERVISOR

■ PACKAGING INCLUD ES A 28-LEAD SOIC and

SNAPHAT

■ SOIC SNAPHAT PACKAGE PROVIDES

DIRECT CONNECTION FOR A SNAPHAT

TOP WHICH CONTAINS THE BATTERY and

CRYSTAL

■ SOIC EMBEDDED CR YSTAL P ACKAG E (M X)

OPTION

Figure 1. 28-pi n S O I C Package

Figure 2. 28-pin (300mil) SOIC Package

®

TOP (to be Ordered Separately)

SNAPHAT (SH)

Battery & Crystal

28

1

SOH28 (MH)

EMBEDDED Cryst al

SOX28 (MX)

Rev. 4.0

1/33May 2003

M41ST85Y, M41ST85W

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. 28-pin SOIC Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

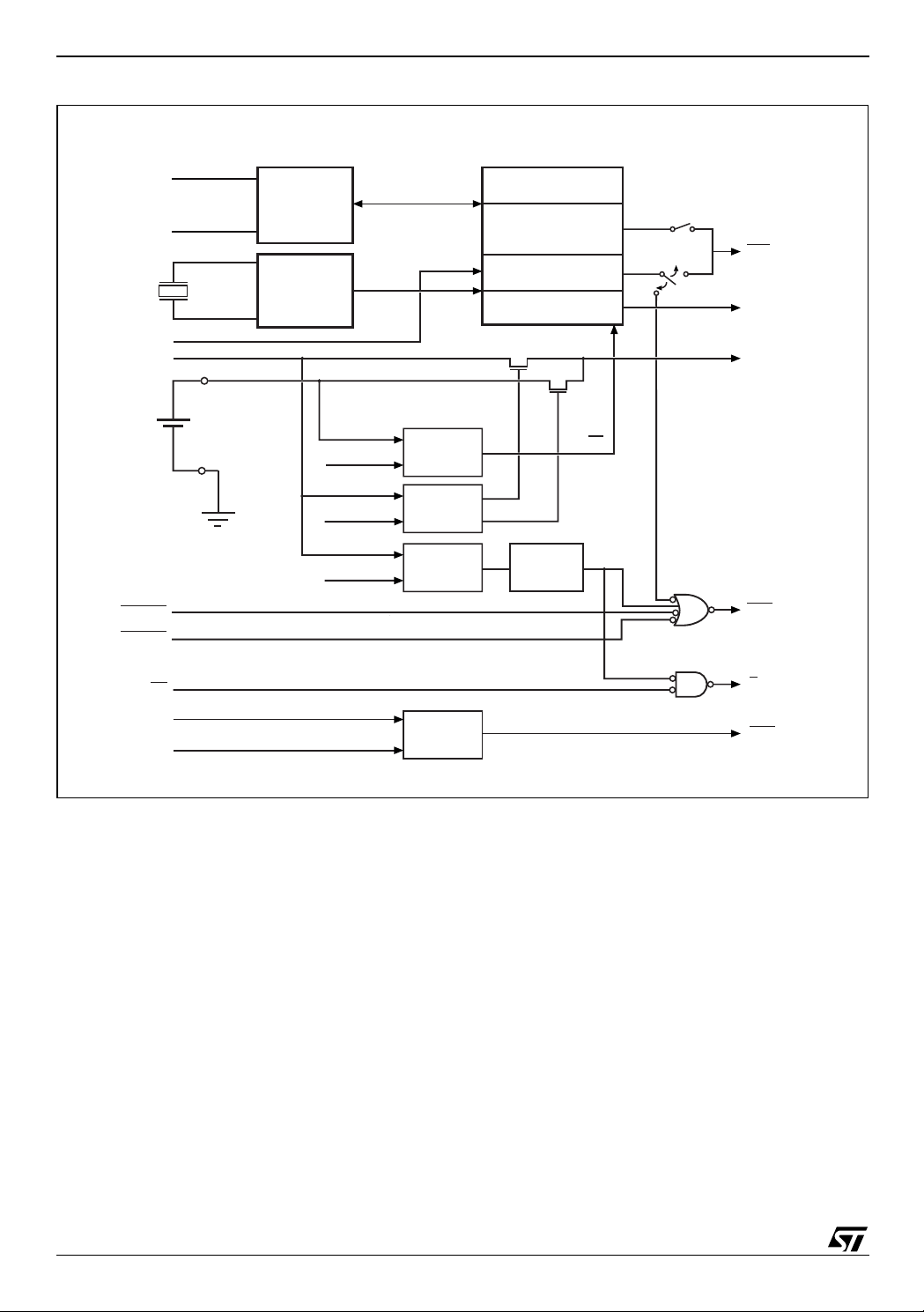

Figure 6. Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

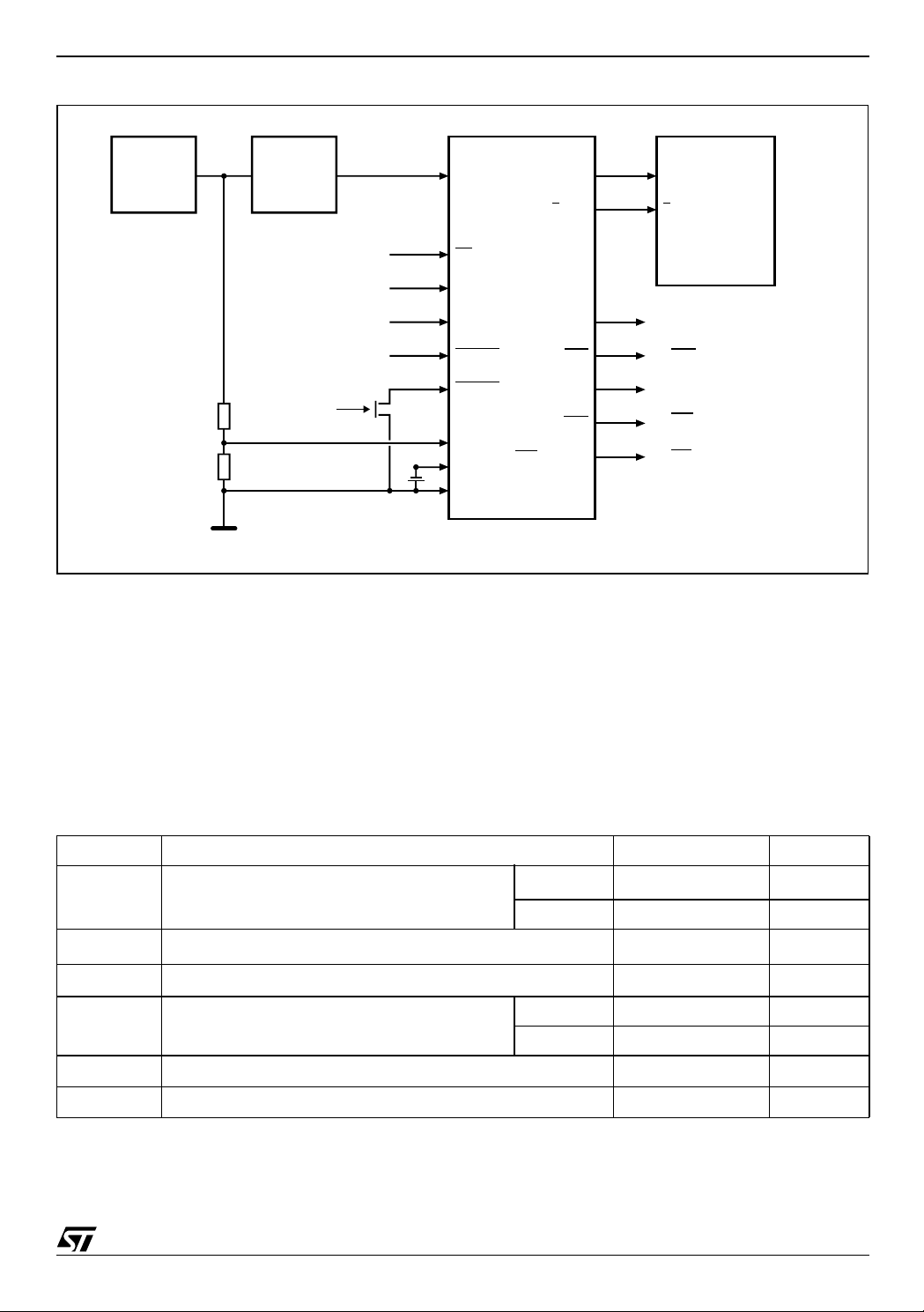

Figure 7. Hardware Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. DC and AC Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 8. AC Testing Input/Output Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-Wire Bus Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 9. Serial Bus Data Transfer Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Figure 11. WRITE Cycle Timing: RTC & External SRAM Control Signals . . . . . . . . . . . . . . . . . . . 12

Figure 12. Bus Timing Requirements Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. AC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

READ Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 13. Slave Address Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 14. READ Mode Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 15. Alternate READ Mode Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

WRITE Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 16. WRITE Mode Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Data Retention Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 17. Power Down/Up Mode AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7. Power Down/Up AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CLOCK OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TIMEKEEPER® Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 8. TIMEKEEPER® Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Calibrating the Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 9

Setting Alarm Clock Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 18. Alarm Interrupt Reset Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 9. Alarm Repeat Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 19. Back-Up Mode Alarm Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/33

M41ST85Y, M41ST85W

Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Square Wave Outp ut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 10. Square Wave Output Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power-on Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Reset Inputs (RSTIN1 & RSTIN2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 20. RSTIN1 & RSTIN2 Timing Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 11. Reset AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 3

Power-fail INPUT/OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Century Bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Output Driver Pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Battery Low Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

t

Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

REC

Initial Power-on Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 12. t

Table 13. Default Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 21. Crystal Accuracy Across Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 22. Calibration Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

REC

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 15. SNAPHAT Battery Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

PACKAGE MECHANICAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3/33

M41ST85Y, M41ST85W

SUMMARY DESCRIPTION

®

The M41ST85Y/W Serial TIMEKEEPER

/Controller SRAM is a low power 512-bit, static CMOS

SRAM organized as 64 words by 8 bi ts. A built-in

32.768 kHz oscilla tor (external crystal controlled)

and 8 bytes of the SRAM (see Table 8, page 18)

are used for the c lock/calendar function and are

configured in binary coded decimal (BCD) format.

An additional 12 bytes of RAM provide status/control of Alarm, Watchdog and Sq uare Wave functions. Addresses and data are transferred serially

via a two line, bi-directional I

2

C interface. The

built-in address register is incremented automatically after each WRITE or READ data byte . The

M41ST85Y/W has a built-in power sense circuit

which detects power failures and automatically

switches to the battery supply when a power f ailure occurs. The energy needed to sustain the

SRAM and clock operations can be supplied by a

small lithium button-cell supply when a power failure occurs.

Functions available to the user inc lude a non-volatile, time-of-day clock/calendar, Alarm interrupts,

Watchdog Timer and programmable Square

Wave output. Other features include a Power-On

Reset as well as two addi tional debounced inputs

(RSTIN1

output Reset (RST

and RSTIN2) which can also generate an

). The eight clock address locations contain the century, year, month, date, day,

hour, minute, second and tenths/hundredt hs of a

second in 24 hour BCD format. Corrections for 28,

29 (leap year - valid until year 2100), 30 and 31

day months are made automatically.

The M41ST85Y/W is supplied in a 28-lead SOIC

SNAPHAT

®

package (which integrates b oth crystal and battery in a single SNAP HA T top) or a 28pin, 300mil SOIC package (MX) which includes an

embedded 32kHz crystal.

The 28-pin, 330mil SOIC provides sockets with

gold plated contacts at both ends for direct connection to a separate SNAPHAT housing cont aining the battery and crystal. The unique design

allows the SNAPHAT battery/crystal package to

be mounted on top of the S OIC pack age after t he

completion of the surface mount process.

Insertion of the SNAPHAT housing after reflow

prevents potential battery and crystal damage due

to the high temperatures required for device surface-mounting. The SNAPHAT housing is also

keyed to prevent reverse insertion.

The SOIC and battery/crystal packages are

shipped separately in plastic anti-static tubes or in

Tape & Reel form. For the 2 8-lead SOIC, t he ba ttery/crystal package (e.g., SNAPHAT) part number is “M4TXX-BR12SH” (see Table 15, page 27).

Caution: Do not place the SNAPHAT battery/crystal top in conductive foam, as this will drain the lithium button-cell battery.

The 300mil, embedded crystal SOIC requires only

a user-supplied battery to provide non-volatile operation.

4/33

M41ST85Y, M41ST85W

Figure 3. Logic Diagram

(1)

V

V

CC

SCL

SDA

EX

M41ST85Y

RSTIN1

M41ST85W

RSTIN2

WDI

PFI

V

Note: 1. For 28-pin , 300mil emb edded crystal SOIC only.

SS

BAT

E

CON

RST

IRQ/FT/OUT

SQW

PFO

V

OUT

AI03658

Table 1. Signal Names

E

CON

EX External Chip Enable

/FT/OUT

IRQ

PFI Power Fail Input

PFO

RST

RSTIN1

RSTIN2

SCL Serial Clock Input

SDA Serial Data Input/Output

SQW Square Wave Output

WDI Watchdog Input

V

CC

V

OUT

V

SS

(1)

V

BAT

Note: 1. For 28-pin , 300mil emb edded crystal SOIC only.

Conditioned Chip Enable Output

Interrupt/Frequency T est/Out Output

(Open Drain)

Power Fail Output

Reset Output (Open Drain)

Reset 1 Input

Reset 2 Input

Supply Voltage

Voltage Output

Ground

Battery Supply Voltage

Figure 4. 28-pin SOIC Connections Figure 5. 28-pin, 300mil SOIC (MX)

Connections

SQW V

NC

NC

NC

NC

NC

NC

WDI

RSTIN1

RSTIN2

NC

1

2

3

4

5

6

7

M41ST85Y

M41ST85W

8

9

10

11

12

PFO

V

SS

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AI03659

CC

EX

IRQ/FT/OUT

V

OUT

NC

NC

PFI

NC

SCL

NC

RST

NCNC

SDA

E

CON

NC V

NC

NC

NC

NC

NC

NC

SQW

WDI

RSTIN1

RSTIN2

PFO

NC

V

SS

1

2

3

4

5

6

7

M41ST85Y

M41ST85W

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

EX

IRQ/FT/OUT

V

V

PFI

SCL

NC

NC

RST

NC

SDA

E

V

CC

OUT

SS

CON

BAT

AI06370c

5/33

M41ST85Y, M41ST85W

Figure 6. Block Diagram

SDA

SCL

(2)

Crystal

I2C

INTERFACE

32KHz

OSCILLA T OR

REAL TIME CLOCK

CALENDAR

44 BYTES

USER RAM

RTC w/ALARM

& CALIBRATION

WATCHDOG

SQUARE W AVE

AFE

WDS

IRQ/FT/OUT

SQW

(1)

WDI

V

CC

V

BA T

VBL= 2.5V

V

SO

V

PFD

RSTIN1

RSTIN2

EX

PFI

1.25V

(Internal)

Note: 1. Open drain output

2. Integra ted into SOIC package for MX package opt ion.

= 2.5V

= 4.4V

(2.65V for ST85W)

COMPARE

COMPARE

COMPARE

COMP ARE

POR

BL

V

OUT

RST

E

CON

PFO

(1)

AI03932

6/33

Figure 7. Hardware Hookup

M41ST85Y, M41ST85W

Unregulated

Voltage

R1

R2

Note: 1. Required for embedded crystal (MX) package only.

Regulator

V

V

IN

Pushbutton

Reset

CC

From MCU

MAXIMUM RATIN G

Stressing the device ab ove the rating listed in the

“Absolute Maximum Ratings” table may cause

permanent damage to the device. These are

stress ratings only and operation of the dev ice at

these or any other conditions above those indicated in the Operating sections of this specification is

M41ST85Y/W

V

CC

EX

SCL

WDI

RSTIN1

RSTIN2

PFI

V

BAT

V

SS

(1)

IRQ/FT/OUT

V

E

CON

SQW

OUT

SDA

RST

PFO

V

CC

E

M68Z128Y/W

or

M68Z512Y/W

To RST

To LED Display

To NMI

To INT

AI03660

not implied. Exposure to Absol ute Maxim um Ra ting conditions for extended periods may affect device reliability. Refer also to the

STMicroelectronics SURE Program and other relevant quality documents.

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

®

T

STG

Storage Temperature (VCC Off, Oscillator Off)

SNAPHAT

SOIC –55 to 125 °C

(1)

T

SLD

V

IO

V

CC

I

O

P

D

Note: 1. Reflow at peak temperature of 215°C to 225° C for < 60 sec onds (total thermal budg et not to exce ed 180°C for between 90 to 120

secon ds).

CAUTION: Negative und ershoots below –0.3V are not allowed on any pin while in the Bat tery Back-u p mode.

CAUTION: Do NOT wave solder SOIC to av oi d damaging SNAPHAT sockets.

Lead Solder Temperature for 10 seconds 260 °C

Input or Output Voltage

M41ST85Y –0.3 to 7 V

Supply Voltage

M41ST85W –0.3 to 4.6 V

Output Current 20 mA

Power Dissipation 1 W

–40 to 85 °C

–0.3 to V

CC

+0.3

V

7/33

M41ST85Y, M41ST85W

DC AND AC PARAMETERS

This section summarizes the operat ing and measurement conditions, as well as the DC and AC

characteristics of the device. The parameters in

the following DC and AC Characteristic tables are

derived from tests performed under the M easure-

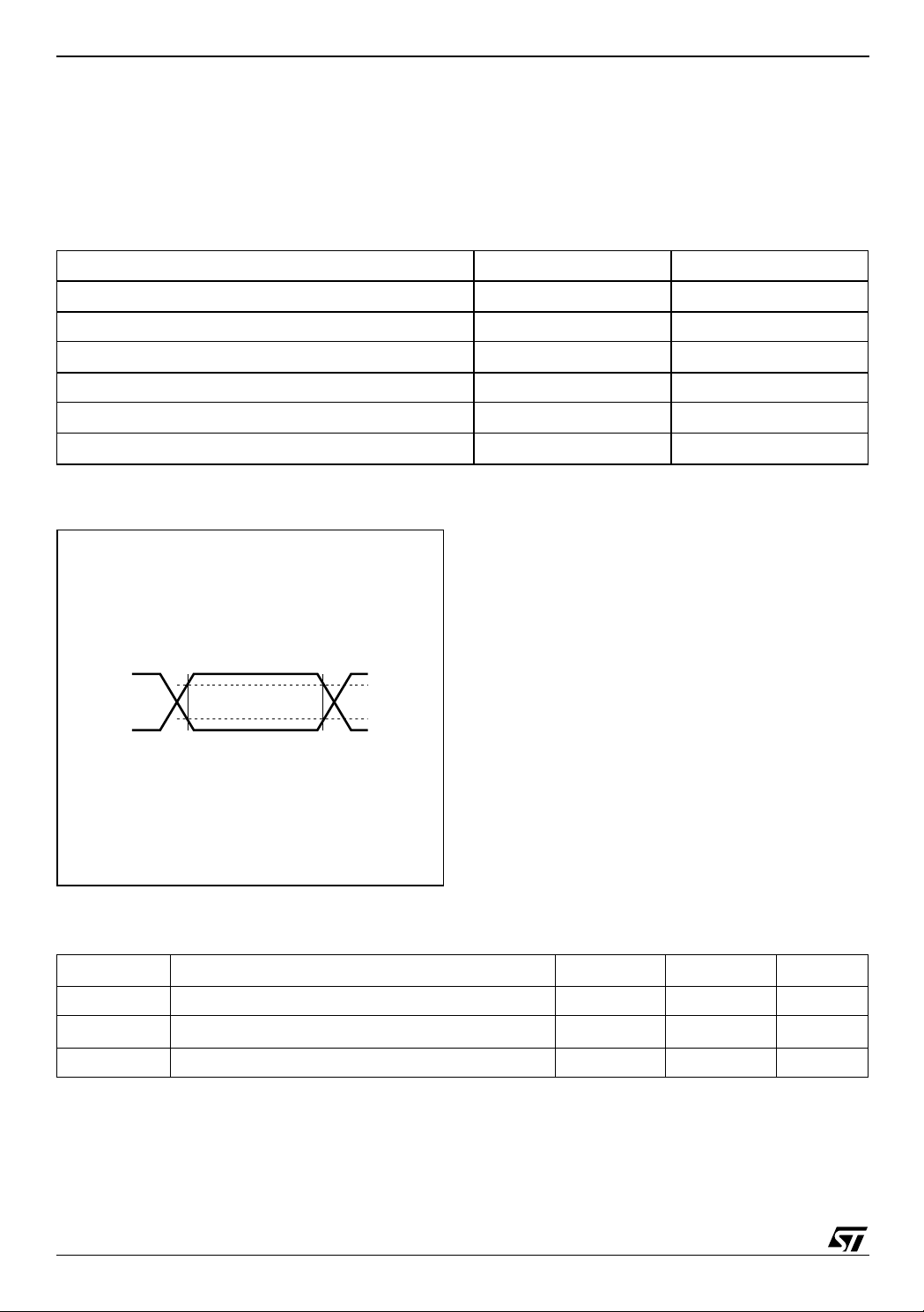

Table 3. DC and AC Measurement Conditions

Parameter M41ST8 5Y M41ST85W

V

Supply Voltage

CC

Ambient Operating Temperature –40 to 85°C –40 to 85°C

Load Capacitance (C

)

L

Input Rise and Fall Times ≤ 50ns ≤ 50ns

Input Pulse Voltages

Input and Output Timing Ref. Voltages

Note: Output Hi gh Z is define d as the point where data is no l onger driven.

Figure 8. AC Testing Input/Output Waveforms

ment Conditions listed in the rel evant tables. Designers should check that the operating conditions

in their projects match the measurement conditions when using the quoted parameters.

4.5 to 5.5V 2.7 to 3.6V

100pF 50pF

0.2 to 0.8V

0.3 to 0.7V

CC

CC

0.2 to 0.8V

0.3 to 0.7V

CC

CC

0.8V

CC

0.2V

CC

Note: 50pF for M41ST85W.

0.7V

0.3V

AI02568

CC

CC

Table 4. Capacitance

Symbol

C

IN

(3)

C

OUT

t

LP

Note: 1. Effective capacitan ce measured wi th power supply at 5V. Sampled onl y, not 100% test ed.

2. At 25°C, f = 1MHz.

3. Outputs are deselect ed.

Input Capacitance 7 pF

Output Capacitance 10 pF

Low-pass filter input time constant (SDA and SCL) 50 ns

Parameter

(1,2)

Min Max Unit

8/33

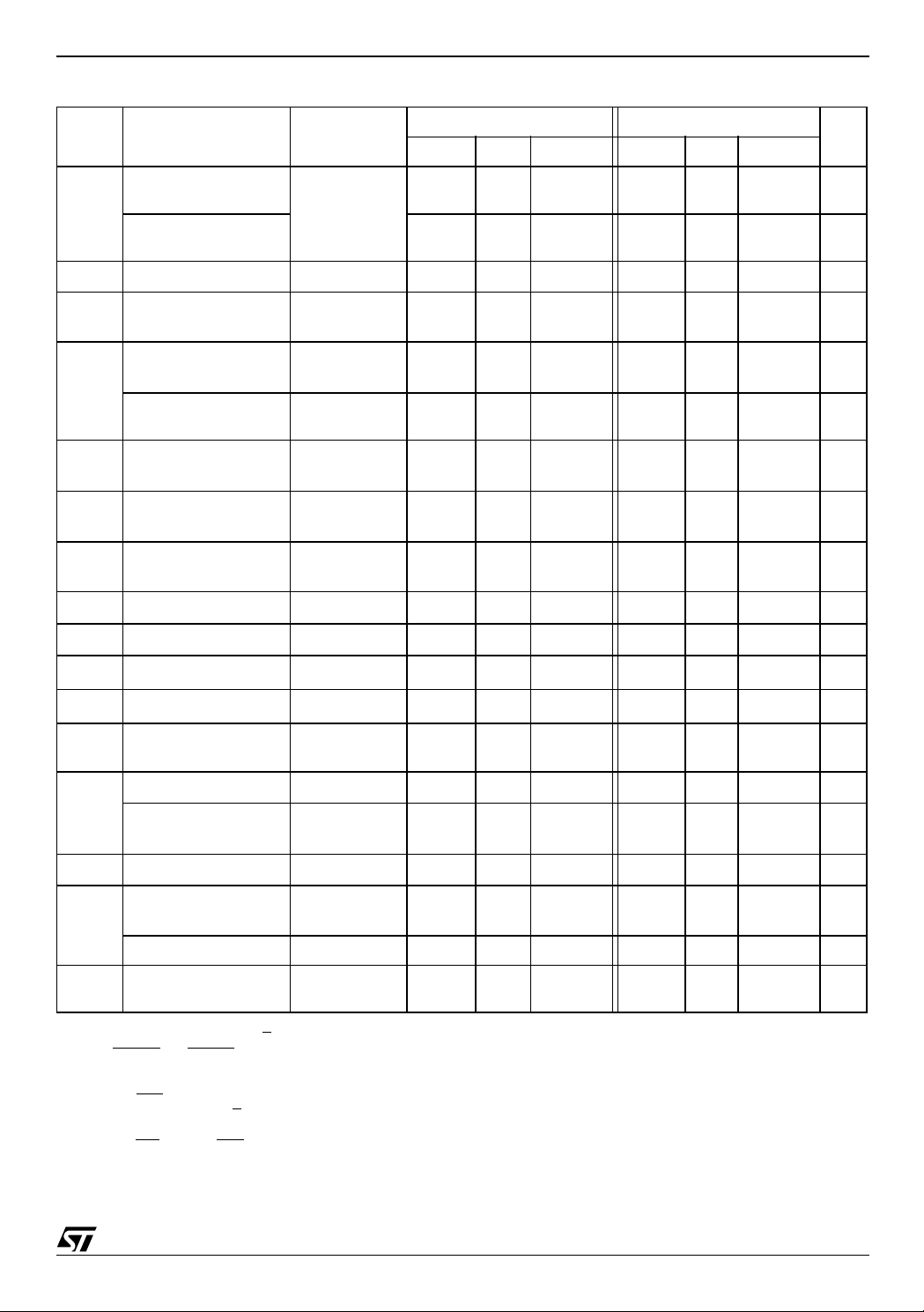

Table 5. DC Characteristics

Sym Parameter

Battery Current OSC

ON

(2)

I

BAT

I

I

I

Battery Current OSC

OFF

Supply Current f = 400kHz 1.4 0.75 mA

CC1

Supply Current

CC2

(Standby)

Input Leakage Current

(3)

LI

Input Leakage Current

(PFI)

Test

Condition

= 25°C,

T

A

V

= 0V,

CC

= 3V

V

BAT

SCL, SDA =

– 0.3V

V

CC

0V ≤ V

≤

IN

V

CC

M41ST85Y, M41ST85W

M41ST85Y M41ST85W

(1)

Min Typ Max Min Typ Max

400 500 400 500 nA

50 50 nA

1 0.50 mA

±1 ±1 µA

–25 2 25 –25 2 25 nA

Unit

I

LO

I

OUT1

I

OUT2

V

V

V

OHB

V

V

V

VCC – 0.3V

V

(6)

IOH = –1.0mA

I

IOL = 10mA

V

VCC = 3V(V)

0V ≤ V

BAT

OL

CC

Output Leakage

(4)

Current

(5)

V

Current (Active)

OUT

V

Current (Battery

OUT

Back-up)

V

Input High Voltage

IH

V

Input Low Voltage –0.3

IL

Battery Voltage 2.5 3.0

BAT

OH

Output High Voltage

(7)

VOH (Battery Back-up)

Output Low Voltage

OL

Output Low Voltage

(Open Drain)

Power Fail Deselect 4.20 4.40 4.50 2.55 2.60 2.70 V

PFD

(8)

PFI Input Threshold

PFI

IN

V

CC

V

OUT1

V

OUT2

– 0.3V

=

I

OUT2

–1.0µA

= 3.0mA

= 5V(Y)

>

>

≤

±1 ±1 µA

175 100 mA

100 100 µA

0.7V

CC

VCC + 0.3 0.7V

0.3V

3.5

CC

(9)

–0.3

2.5 3.0

CC

2.4 2.4 V

2.5 2.9 3.5 2.5 2.9 3.5 V

0.4 0.4 V

0.4 0.4 V

1.225 1.250 1.275 1.225 1.250 1.275 V

VCC + 0.3

0.3V

3.5

PFI Hysteresis PFI Rising 20 70 20 70 mV

V

Note: 1. Valid for A m bi ent Operat in g T em perature: TA = –40 to 85°C ; VCC = 4.5 to 5.5V or 2. 7 to 3.6V (exce pt where noted) .

Battery Back-up

SO

Switchover

2. Measured with V

3. RSTIN1

4. Outputs Dese l ected .

5. External SRAM must match RTC SUPERVISOR chip V

6. For PFO

7. Conditi oned outp ut (E

8. For IRQ

9. For rech argeable back-up, V

and RSTI N2 internally pulled-up t o VCC through 100KΩ resistor. WDI internally pulled-down to VSS through 100KΩ resistor.

and SQW pins (CMOS) .

duce batter y li fe.

/FT/OUT, RST pins (Ope n Drai n): i f pu ll ed- up to supp ly oth e r tha n VCC, this su ppl y mu st be equ al to, or l es s t han 3. 0V when

V

= 0V (durin g battery back -up mode).

CC

OUT

and E

CON

open.

CON

) can only sust ain CMOS le akage curren t in the ba tter y ba ck-u p mode . Highe r leak ag e curre nts w ill re -

(max) may be considered VCC.

BAT

specification.

CC

2.5 2.5 V

(9)

CC

V

V

V

9/33

M41ST85Y, M41ST85W

OPERATING MODES

The M41ST85Y/W clock operates as a slave device on the serial bus. Access is obtained by implementing a start condition followed by the

correct slave address (D0h). The 64 bytes contained in the device can then be accessed sequentially in the following order:

1. Tenths/Hundredths of a Second Register

2. Seconds Register

3. Minutes Register

4. Century/Hours Register

5. Day Register

6. Date Register

7. Month Register

8. Year Register

9. Control Register

10. Watchdog Register

11 - 16. Alarm Registers

17 - 19. Reserved

20. Square Wave Register

21 - 64. User RAM

The M41ST85Y/W clock continually monitors V

for an out-of-tolerance condition. Should VCC fall

below V

, the device terminates an access in

PFD

progress and resets t he device address counter.

Inputs to the device will not be recognized at this

time to prevent erroneous dat a f rom bei ng wri tten

to the device from a an out-of-tolerance system.

When V

falls below VSO, the device a utomati-

CC

cally switches over to the battery and powers

down into an ultra low current mode of operation to

CC

conserve bat tery life. As system p ower returns an d

rises above VSO, the battery is disconnected,

V

CC

and the power supply is switched to external V

Write protection continues until V

V

(min) plus t

PFD

REC

(min).

CC

CC

reaches

For more information on Battery Storage Life refer

to Application Note AN1012.

2-Wire Bus Characteristics

The bus is intended for communication between

different ICs. It consists of two lines: a bi-directional data signal (SDA) and a clock signal (SCL).

Both the SDA and SCL lines must be connected to

a positive supply voltage via a pull-up resistor.

The following protocol has been defined:

– Data transfer may be initiated only when the bus

is not busy.

– During data transfer, the data line must remain

stable whenever the clock line is High.

– Changes in the data line, while the clock line is

High, will be interpreted as control signals.

Accordingly, the following bus conditions have

been defined:

Bus not busy. Both data and clock lines remain

High.

Start data transfer. A c hange in the st ate of the

data line, from High to Low, while the clock is High,

defines the START condition.

Stop data transfer. A change in the state of the

data line, from Low to High, while the clock is High,

defines the STOP condition.

.

10/33

M41ST85Y, M41ST85W

Data Valid. The state of the data line represents

valid data when after a start condition, the data line

is stable for the duration of the high period of the

clock signal. The data on the line may be changed

during the Low period of the clock signal. There is

one clock pulse per bit of data.

Each data transfer is initiated with a start condition

and terminated with a stop condition. The number

of data bytes transferred between the start and

stop conditions is not limited. The information is

transmitted byte-wide and each receiver acknowledges with a ninth bit.

By definition a device that gives out a message is

called “transmitter,” the receiving device that gets

the message is called “receiver.” The device that

controls the message is called “master.” The devices that are controlled by the master are call ed

“slaves.”

Figure 9. Serial Bus Data Transfer Sequence

DATA LINE

STABLE

DATA VALID

Acknowledge. Each byte of eight bits is followed

by one Acknowledge Bit. This Acknowledge Bit is

a low level put on the bus by the receiver whereas

the master generates an extra acknowledge related clock pulse. A slave receiver which is addressed is obliged to generate an acknowledge

after the reception of each byte that has been

clocked out of the slave transmitter.

The device that acknowledges has to pull down

the SDA line during the acknowledge clock pulse

in such a way that the SDA line is a stable Low during the High period of the acknowledge related

clock pulse. Of course, setup and hold times must

be taken into account. A master receiver must signal an end of data to the slave transm itter by not

generating an acknowledge on t he last byte that

has been clocked out of the slave. In this case the

transmitter must leave the data line High to enable

the master to generate the STOP condition.

CLOCK

DATA

START

CONDITION

Figure 10. Acknowledgement Sequence

START

SCL FROM

MASTER

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

12 89

MSB LSB

CHANGE OF

DATA ALLOWED

STOP

CONDITION

AI00587

CLOCK PULSE FOR

ACKNOWLEDGEMENT

AI00601

11/33

M41ST85Y, M41ST85W

Figure 11. WRITE Cycle Timing: RTC & External SRAM Control Signals

EX

tEXPD

tEXPD

E

CON

Figure 12. Bus Timing Requirements Sequence

SDA

AI03663

tHD:STA

tSU:STOtSU:STA

P

AI00589

SCL

tHD:STAtBUF

tR

SP

tHIGH

tLOW

tF

tSU:DAT

tHD:DAT

SR

Table 6. AC Characteristics

Symbol

f

SCL

t

BUF

t

EXPD

t

F

t

HD:DAT

t

HD:STA

t

HIGH

t

LOW

t

R

t

SU:DAT

t

SU:STA

t

SU:STO

Note: 1. Valid for A m bi ent Operat in g T em perature: TA = –40 to 85°C ; VCC = 4.5 to 5.5V or 2. 7 to 3.6V (exce pt where noted) .

2. Transmitter must internally provide a hold time to bridge the undefined region (300ns max) of the falling edge of SCL.

SCL Clock Frequency 0 400 kHz

Time the bus must be free before a new transmission can start 1.3 µs

EX to E

Propagation Delay

CON

SDA and SCL Fall Time 300 ns

(2)

Data Hold Time 0 µs

START Condition Hold Time

(after this period the first clock pulse is generated)

Clock High Period 600 ns

Clock Low Period 1.3 µs

SDA and SCL Rise Time 300 ns

Data Setup Time 100 ns

START Condition Setup Time

(only relevant for a repeated start condition)

STOP Condition Setup Time 600 ns

Parameter

(1)

Min Max Unit

M41ST85Y 10

M41ST85W 15

600 ns

600 ns

ns

12/33

READ Mode

In this mode the master reads th e M41ST85Y/W

slave after setting the slave address (see Figure

13, page 13). Following the WRITE Mode Cont rol

Bit (R/W

=0) and the Acknowledge Bit, the word

address 'An' is written to the on-chip address

pointer. Next the START condition and slave address are repeated followed by the READ Mode

Control Bit (R/W

=1). At this point the master trans-

mitter becomes the master receiver.

The data byte which was add ressed will be trans-

mitted and the master receiver will send an Acknowledge Bit to the slave transmitter. The

address pointer is only i ncremented on reception

of an Acknowledge Clock. The M41ST85Y/W

slave transmitter will now place the data byte at

address An+1 on the bus, the master receiver

reads and acknowledges the new byte and the address pointer is incremented to An+2.

Figure 13. Slave Address Location

M41ST85Y, M41ST85W

This cycle of reading con secutive addresses will

continue until the mast er receiver sends a STOP

condition to the slave transmitter (see F igure 14,

page 13).

The system-to-user transfer of clock data will be

halted whenever the address being read is a clock

address (00h to 07h). The update will resum e either due to a Stop Condition or when the pointer

increments to a non-clock or RAM address.

Note: This is true both in READ Mode and WRITE

Mode.

An alternate READ Mode may also be implemented whereby the master reads the M41ST85Y/W

slave without first writing to the (volatil e) address

pointer. The first address that is read is the last

one stored in the pointer (see Figure 15, page 14).

R/W

START A

Figure 14. READ Mode Sequence

BUS ACTIVITY:

MASTER

SDA LINE

BUS ACTIVITY:

START

S

ADDRESS

R/W

ADDRESS (An)

ACK

SLAVE

DATA n+X

WORD

MSB

STOP

P

SLAVE ADDRESS

0100011

START

S

ACK

SLAVE

ADDRESS

LSB

AI00602

R/W

DATA n DATA n+1

ACK

ACK

ACK

NO ACK

AI00899

13/33

M41ST85Y, M41ST85W

Figure 15. Al te rnat e R E A D Mo de S equence

BUS ACTIVITY:

MASTER

BUS ACTIVITY:

START

S

SLAVE

ADDRESS

R/W

DATA n DATA n+1 DATA n+X

ACK

WRITE Mode

In this mode the master transmitter transmits to

the M41ST85Y/W slave receiver. Bus protocol is

shown in Figure 16, page 14. Following the

START condition and slave address, a logic '0' (R/

=0) is placed on the bus and indicates to the ad-

W

dressed device that word address An will follow

and is to be written to the on-chip address pointer.

The data word to be written to the memory is

Figure 16. WRITE Mode S equence

BUS ACTIVITY:

MASTER

START

R/W

STOP

PSDA LINE

ACK

ACK

ACK

NO ACK

AI00895

strobed in next and the internal address pointer is

incremented to the next memory location within

the RAM on the reception of an acknowledge

clock. The M41ST85Y/W sla ve receiver will send

an acknowledge clock to the master transmitter after it has received the slave address (see Figure

13, page 13) and aga in after it has received the

word address and each data byte.

STOP

BUS ACTIVITY:

S

ADDRESS

SLAVE

WORD

ADDRESS (An)

ACK

DATA n DATA n+1 DATA n+X

ACK

ACK

ACK

PSDA LINE

ACK

AI00591

14/33

Data Retention Mode

With valid V

applied, the M 41ST85Y /W can be

CC

accessed as described above with READ or

WRITE Cycles. Should the s upply voltage d ecay,

the M41ST85Y/W will automatically deselect,

write protecting itself (and any external SRAM)

when V

V

(min). Th is is accomplish ed by internally in-

PFD

falls between V

CC

(max) and

PFD

hibiting access to the clock registers. At this time,

the R eset pin (RS T

main active until V

) is driven active and will re-

returns to nominal levels. Ex-

CC

ternal RAM access is inhibited in a similar manner

by forcing E

0.2 volts of the V

as long as V

dition. When V

Switchover Voltage (V

from the V

to a high level. This level is within

CON

CC

CC

BAT

. E

will remain at this level

CON

remains at an out-of-tolerance con-

falls below the Battery Back-up

CC

), power input is switched

SO

pin to the SNAPHAT® battery, and

the clock registers and external SRAM are m aintained from the attached battery supply.

All outputs become high impedance. The V

OUT

pin

is capable of supplying 100 µA of current to the attached memory with less than 0.3 volts drop under

this condition. On power up, when V

returns to

CC

a nominal value, write protection continues for

by inhibiting E

t

REC

. The RST signal also re-

CON

mains active during this time (see Figure 17, page

16).

Note: Most low power SRAMs on the market to-

day can be used with the M41ST85Y /W RTC S UPERVISOR. There are, however some criteria

which should be used in making the final choice of

M41ST85Y, M41ST85W

an SRAM to use. The SRAM must be designed in

a way where the chip enable input disables all other inputs to the SRAM. This allows inputs to t he

M41ST85Y/W and SRAMs to be “Don’t Care”

once V

should also guarantee data retention down to

V

CC

be sufficient to meet the system needs with the

chip enable output propagation delays included. If

the SRAM includes a second chip enable pin (E2),

this pin should be tied to V

If data retention lifetime is a critical parameter f or

the system, it is importa nt to re view the dat a retention current specifications for the particular

SRAMs being evaluated. M ost SRAMs specify a

data retention current at 3.0 volts. Manufacturers

generally specify a typical condition for room temperature along with a worst case condition (generally at elevated temperatures). The system level

requirements will determine the choice of which

value to use. Th e data retention current value of

the SRAMs can then be added to the I

the M41ST85Y/W to determine the total current requirements for data retention. The available battery capacity for the SNAPHAT

can then be divided b y this current to determine

the amount of data retention ava ilable (see Table

15, page 27).

For a further more detailed review of lifetime calculations, please see Application Note AN1012.

falls below V

CC

(min). The SRAM

PFD

=2.0 volts. The chip enable access time must

.

OUT

value of

BAT

®

of your choice

15/33

M41ST85Y, M41ST85W

Figure 17. Power Down/Up Mode AC Waveforms

V

CC

V

(max)

PFD

V

(min)

PFD

VSO

INPUTS

RST

OUTPUTS

E

CON

tPD

PFO

(PER CONTROL INPUT)

tF

VALID VALID

tFB

tDR

tRB

DON'T CARE

HIGH-Z

tR

tREC

RECOGNIZEDRECOGNIZED

(PER CONTROL INPUT)

AI03661

Table 7. Power Down/Up AC Characteristics

Symbol

(2)

t

F

t

FB

t

PD

t

PFD

t

R

t

RB

t

REC

Note: 1. Valid for A m bi ent Operat in g T em perature: TA = –40 to 85°C ; VCC = 4.5 to 5.5V or 2. 7 to 3.6V (exce pt where noted) .

2. V

3. V

4. Programmable (see Table 12, page 25)

V

(max) to V

PFD

(3)

V

(min) to VSS VCC Fall Time

PFD

EX at VIH before Power Down

PFI to PFO Propagation Delay 15 25 µs

V

(min) to V

PFD

VSS to V

(4)

Power up Deselect Time 40 200 ms

(max) to V

PFD

200µs after V

PFD

CC

(min) to VSS fall time of less than tFB may cause corruption of RAM data.

(min) VCC Rise Time

PFD

(min) fall time of less than tF may result in deselection/write protection not occurring until

PFD

passes V

Parameter

(min) VCC Fall Time

PFD

(max) VCC Rise Time

PFD

(min).

PFD

(1)

Min Typ Max Unit

300 µs

10 µs

0µs

10 µs

1µs

16/33

CLOCK OPERATION

The eight byte clock register (see Table 8, page

18) is used to both set the clock and t o read the

date and time from the clock, in a binary coded

decimal format. Tenths/Hundredths of Seconds,

Seconds, Minutes, and Hours are contained within

the first four registers.

Note: A WRIT E to any c lock reg ister w ill resu lt in

the Tenths/Hundredths of Seconds bei ng reset to

“00,” and Tenths/Hundredths of Seconds cannot

be written to any value other than “00.”

Bits D6 and D7 of Clock Register 03h (Century/

Hours Register) contain the CENTURY ENABLE

Bit (CEB) and the CENTURY Bit (CB). Setting

CEB to a '1' will cause CB to toggle, either from '0'

to '1' or from '1' to '0' at the turn of the century (depending upon its initial state). If CEB is set to a '0,'

CB will not toggle. Bits D0 through D2 of Regi ster

04h contain the Day (day of week). Registers 05h,

06h, and 07h contain the Date (day of month),

Month and Years. The ninth clock register is the

Control Register (this is described in the Clock

Calibration section). Bit D7 of Register 01h contains the S TOP Bit (ST). Setting this bit to a ' 1 ' wil l

cause the oscillator to stop. If the device is expected to spend a significant amount of time on the

shelf, the oscillator may be stopped to reduce current drain. When reset to a '0' the oscillator restarts

within one second.

The eight Clock Registers may be read one byte at

a time, or in a sequential block. T he Control Register (Address location 08h) may be accessed independently. Provision has been made to assure

that a clock update does not occur while any of the

M41ST85Y, M41ST85W

eight clock addresses are being read. If a clock address is being read, an update of the clock registers will be halte d. This will pr event a trans ition of

data during the READ.

Note: When a power failure occurs, the Halt Update Bit (HT) will automatically be set to a '1.' This

will prevent the clock from updating the TIMEKEEPER

the exact time of the power-down event. Resetting

the HT Bit to a '0' will allow the clock to update the

TIMEKEEPER registers with the current time.

TIMEKEEPER

The M41ST85Y/W offers 20 internal registers

which contain Clock, Alarm, Watchdog, Flag,

Square Wave and Control data. These registers

are memory locations which contain external (user

accessible) and internal copies of the data (usually

referred to as BiPORT

external copies are in dependent of internal f unctions except that they are updated p eriodically by

the simultaneous transfer of the incremented internal copy. The internal divider (or clock) chain will

be reset upon the completion of a WRITE to any

clock address.

The system-to-user transfer of clock data will be

halted whenever the address being read is a clock

address (00h to 07h). The update will resum e either due to a Stop Condition or when the pointer

increments to a non-clock or RAM address.

TIMEKEEPER and Alarm Registers store data in

BCD. Control, Watchdog and Square Wave Registers store data in Binary Format.

®

registers, and will allow the user to read

®

Registers

™

TIMEKEEPER cel ls). The

17/33

M41ST85Y, M41ST85W

Table 8. TIMEKEEPER® Register Map

Address

Data

D7 D6 D5 D4 D3 D2 D1 D0

00h 0.1 Seconds 0.01 Seconds Seconds 00-99

01h ST 10 Seconds Seconds Seconds 00-59

02h 0 10 Minutes Minutes Minutes 00-59

03h CEB CB 10 Hours Hours (24 Hour Format) Century/Hours 0-1/00-23

04h TR 0 0 0 0 Day of Week Day 01-7

05h 0 0 10 Date Date: Day of Month Date 01-31

06h 0 0 0 10M Month Month 01-12

07h 10 Years Year Year 00-99

08h OUT FT S Calibration Control

09h WDS BMB4 BMB3 BMB2 BMB1 BMB0 RB1 RB0 Watchdog

0Ah AFE SQWE ABE Al 10M Alarm Month Al Month 01-12

0Bh RPT4 RPT5 AI 10 Date Alarm Date Al Date 01-31

0Ch RPT3 HT AI 10 Hour Alarm Hour Al Hour 00-23

0Dh RPT2 Alarm 10 Minutes Alarm Minutes Al Min 00-59

Function/Ra nge

BCD Format

0Eh RPT1 Alarm 10 Seconds Alarm Seconds Al Sec 00-59

0Fh WDF AF 0 BL 0 0 0 0 Flags

10h 0 0 0 0 0 0 0 0 Reserved

11h 0 0 0 0 0 0 0 0 Reserved

12h 0 0 0 0 0 0 0 0 Reserved

13h RS3 RS2 RS1 RS0 0 0 0 0 SQW

Keys: S = Sign Bit

FT = Frequency Test Bit

ST = Stop Bit

0 = Must be set to zero

BL = Battery Low Flag (Rea d only)

BMB0-BMB4 = Watchdog Multiplier Bits

CEB = Century Enable Bit

CB = Centur y B i t

OUT = Output level

AFE = Alarm Flag Enable Flag

RB0-RB 1 = Watchdog Resolution Bit s

WDS = Watchdog Steering Bit

ABE = Alarm in Battery Back-Up Mode Enable Bit

RPT1-RPT5 = Alarm Repeat Mode Bit s

WDF = Watchdog flag (Read only)

AF = Alarm f l ag (Read only)

SQWE = Square Wave Enable

RS0-RS 3 = S Q W Frequency

HT = Halt Up date Bit

REC

Bit

TR = t

18/33

Calib ratin g t h e C lock

The M41ST85Y/W is driven by a quartz controlled

oscillator with a nominal frequency of 32,768 Hz.

The devices are tested not exceed +/–35 PPM

(parts per million) oscillator frequency error at

o

C, which equates to about +/–1.53 minutes per

25

month. When the Calibration circuit is properly employed, accuracy improves to better than +1/–2

ppm at 25°C.

The oscillation rate of crystals changes with temperature (see Figure 21, page 26). Therefore, the

M41ST85Y/W design employs periodic counter

correction. The calibration circuit adds or subtracts

counts from the oscillator divider circuit at the divide by 256 stage, as shown in Figure 22, page 26.

The number of times pulses which are blanked

(subtracted, negative calibration) or split (added,

positive calibration) depends upon the value loaded into the five Calibration Bits found in the Control

Register. Adding counts speeds the clock up, subtracting counts slows the clock down.

The Calibration Bits occupy the five lower order

bits (D4-D0) in the Control Register (08h). These

bits can be set to represent any value between 0

and 31 in binary form. Bit D5 is a Sign Bit; '1' indicates positive calibration, '0' indicates negative

calibration. Calibration occurs within a 64 m inute

cycle. The first 62 m inutes i n t he c ycle m ay , onc e

per minute, have one second either shortened by

128 or lengthened by 256 oscillator cycles. If a binary '1' is loaded into the register, only the first 2

minutes in the 64 minute cycle will be modified; if

a binary 6 is loaded, t he first 12 will be affected,

and so on.

Therefore, each cal ibration step has the effect of

adding 512 or subtracting 256 oscillator cycles for

every 125,829,120 actual oscillator cycles, that is

+4.068 or –2.034 PPM of adjustm ent per calibration step in the cal ibration registe r. Ass um ing that

the oscillator is running at exactly 32,768 Hz, each

of the 31 increments in the Calibration byte would

represent +10.7 or –5.35 seconds per month

which corresponds to a total range of +5.5 or –2.75

minutes per month.

Two methods are available for ascertaining how

much calibration a given M41ST85Y/W may require.

The first involves setting the clock, letting it run for

a month and comparing it to a known accurate reference and recording deviation over a fixed period

of time. Calibration values, including the number of

seconds lost or gained in a given period, can be

found in Application Note AN934, “TIMEKEEP-

®

CALIBRATION.” This allows the designer to

ER

give the end user the ability to calibrate the clock

as the environment requires, even if the final prod-

M41ST85Y, M41ST85W

uct is packaged in a non-user serviceable enc losure. The designer could provide a simple utility

that accesses the Calibration byte.

The second approach is better suit ed to a manufacturing environment, and involves the use of the

IRQ

/FT/OUT pin. The pin will toggle at 512Hz,

when the Stop Bit (S T, D7 of 01h) is '0, ' the Frequency Test Bit (F T, D6 of 08h) is '1 ,' the Alarm

Flag Enable Bit (AFE, D7 of 0Ah) is '0, ' and the

Watchdog Steering Bit (WDS, D7 of 09h) is '1' or

the Watchdog Register (09h = 0) is reset.

Any deviation from 512 Hz i ndicates the degree

and direction of oscillator frequency shift at the test

temperature. For example, a reading of

512.010124 Hz would indicate a +20 PPM oscillator frequency error, requiring a –10 (XX001010) to

be loaded into the Calibration Byte for correction.

Note that setting or changing the Calibration Byte

does not affect the Frequency test output frequency.

The IRQ

which requires a pull-up resistor to V

operation. A 500 to10k resistor is recommended in

order to control the rise time. The FT Bit i s cleared

on power-down.

Setting Alarm Clock Registers

Address locations 0Ah-0Eh contain the alarm settings. The alarm can be configured to go off at a

prescribed time on a specific mont h, date, hour,

minute, or second, or repeat every year, month,

day, hour, minute, or second. It can al so be programmed to go off while the M41ST85Y/W is in the

battery back-up to serve as a system wake-up call.

Bits RPT5–RPT1 put the alarm in the repeat mode

of operation. Table 9, page 20 shows the possible

configurations. Codes not listed in the table default

to the once per second mode to quickly alert the

user of an incorrect alarm setting.

When the clock information matches the alarm

clock settings based on the m atch criteria d efined

by RPT5–RPT1, the AF (Alarm Flag) is set. If AFE

(Alarm Flag Enable) is also set, the alarm condition activates the IRQ

Figure 18, page 20. To disable alarm, write '0' t o

the Alarm Date Register and to RPT5–RPT1.

Note: If the address pointer is allowed to increment to the Flag Register address, an alarm condition will not cause the Interrupt/Flag to occur until

the address pointer is moved to a different address. It should also be noted that if the last address written is the “Alarm Seconds,” the address

pointer will increment to the Flag address, causing

this situation to occur.

/FT/OUT pin is an open drain output

for proper

CC

/FT/OUT pin as shown in

19/33

M41ST85Y, M41ST85W

The IRQ/FT/OUT output is cleared by a READ to

the Flags Register. A subsequent READ of the

Flags Register is necessary to see that the value

of the Alarm Flag has been reset to '0.'

The IRQ

battery back-up mode. The IRQ

/FT/OUT pin can also be activated in the

/FT/OUT will go

low if an alarm occurs and both ABE (Alarm in Bat -

ABE and AFE Bits are reset during power-up,

therefore an alarm generated during power-up will

only set AF. The user can read the Flag Register

at system boot-up to determine if an alarm was

generated while the M41ST85Y/W wa s in the deselect mode during power-up. Figure 19, page 21

illustrates the back-up mode alarm timing.

tery Back-up Mode Enable) and A FE are set . The

Figure 18. Alarm Interrupt Reset Waveform

0Fh0Eh 10h

ACTIVE FLAG

IRQ/FT/OUT

HIGH-Z

Table 9. Alarm Repeat Modes

RPT5 RPT4 RPT3 RPT2 RPT1 Alarm Setting

11111Once per Second

11110Once per Minute

AI03664

11100Once per Hour

11000Once per Day

10000Once per Month

00000Once per Year

20/33

Figure 19. Back-Up Mode Alarm Waveform

V

CC

V

PFD

V

SO

ABE, AFE Bits in Interrupt Register

AF bit in Flags Register

IRQ/FT/OUT

M41ST85Y, M41ST85W

tREC

HIGH-Z

Watchdog Timer

The watchdog timer can be used to detect an outof-control microprocessor. The user programs the

watchdog timer by setting the desired amount of

time-out into the Watchdog Register, address 09h.

Bits BMB4-BMB0 store a binary multiplier and the

two lower order bits RB1-RB0 select the resolution, where 00=1/16 second, 01=1/4 second, 10=1

second, and 11=4 seconds. The amount of timeout is then determ ined to be the multiplic ation of

the five-bit multiplier value with the resolution. (For

example: writing 00001110 in the Wa tchdo g Register = 3*1 or 3 seconds).

Note: The accuracy of the timer is within ± the selected resolution.

If the processor does not reset the timer within the

specified period, the M41ST85Y/W s ets the WD F

(Watchdog Flag) and generates a watchdog interrupt or a microprocessor reset.

The most significant bit of the Watchdog Register

is the Watchdog Steering Bit (WDS). When set to

a '0,' the wa tchdog will activ ate the IRQ

/FT/OUT

pin when timed-out. When WDS is set to a '1,' the

watchdog will output a negative pulse on the RS T

pin for t

. The Watchdog register, FT, AFE, ABE

REC

and SQWE Bits will reset t o a '0' at the end of a

Watchdog time-out when the WDS Bit is set to a

'1.'

HIGH-Z

AI03920

The watchdog timer can be reset by two methods:

1) a transition (high-to-low or low-to-high) c an be

applied to the Watchdog Input pin (WDI) or 2) the

microprocessor can perform a WRITE of the

Watchdog Register. The time-out period then

starts over.

Note: The WDI pin should be tied to V

SS

if not

used.

In order to perform a software reset of the watch-

dog timer, the original time-out period can be written into the Watchdog Register, effectively

restarting the cou nt-d o wn cycle.

Should the watchdog timer time-out, and the WDS

Bit is programmed to output an interrupt, a value of

00h needs to be written to the Watchdog Register

in order to clear the IRQ

/FT/OUT pin. This will also

disable the watchdog funct ion until i t is agai n programmed correctly. A READ of the Flags Register

will reset the Watchdog Flag (Bit D7; Register

0Fh).

The watchdog function is automatically disabled

upon power-up and the Watchdog Register is

cleared. If the watchdog function is set to output to

the I RQ

/FT/OUT pin and the frequency test function is activated, the watchdog function prevails

and the frequency test function is denied.

21/33

M41ST85Y, M41ST85W

Square Wave Output

The M41ST85Y/W of fers the user a programmable square wave function which is output on the

SQW pin. RS3-RS0 bi ts located in 13h establish

the square wave output frequency. These frequencies are listed in Table 10. Once the selection

Table 10. Square Wave Output Frequency

Square Wave Bits Square Wave

RS3 RS2 RS1 RS0 Frequency Units

0 0 0 0 None –

0 0 0 1 32.768 kHz

0 0 1 0 8.192 kHz

0 0 1 1 4.096 kHz

0 1 0 0 2.048 kHz

0 1 0 1 1.024 kHz

0 1 1 0 512 Hz

0 1 1 1 256 Hz

1 0 0 0 128 Hz

100164Hz

101032Hz

101116Hz

11008Hz

11014Hz

11102Hz

11111Hz

of the SQW frequency has been c ompleted, the

SQW pin can be turned on and off under software

control with the Square Wave Enable Bit (S QWE)

located in Register 0Ah.

22/33

M41ST85Y, M41ST85W

Power-on Reset

The M41ST85Y/W continuously monitors V

When V

the RST

power-up for t

The RST

falls to the power fail detect trip point,

CC

pulls low (open drain) and remains low on

after VCC passes V

REC

pin is an open drain output and an appro-

PFD

CC

(max).

priate pull-up resistor should be chosen to cont rol

rise time.

Figure 20. RSTIN1

RSTIN1

RSTIN2

RST

Note: With pull-up resi s tor

& RSTIN2 Timing Wa vef orm s

tRLRH1

(1)

tR1HRH tR2HRH

Reset Inputs (RSTIN1

.

The M41ST85Y/W provides two independ ent in-

& RSTIN2)

puts which can generate an output reset. The duration and function of these resets is identical to a

reset generated by a power cycle. Ta ble 11 and

Figure 20 illustrate the AC reset characteristics of

this function. Pulses shorter than t

t

will not generate a reset condition. RSTIN1

RLRH2

and RSTIN2 are each internally pull ed up to V

through a 100kΩ resistor.

tRLRH2

AI03665

RLRH1

and

CC

Table 11. Reset AC Characteristics

Symbol

(2)

t

RLRH1

(3)

t

RLRH2

(4)

t

R1HRH

(4)

t

R2HRH

Note: 1. Valid for A m bi ent Operat in g T em perature: TA = –40 to 85°C ; VCC = 4.5 to 5.5V or 2. 7 to 3.6V (exce pt where noted) .

2. Pulse width less than 50ns will result in no RESET (for noise immunity).

3. Pulse width less than 20ms will result in no RESET (for noise immunity).

4. Programmable (see Table 12, page 25).

RSTIN1 Low to RSTIN1 High 200 ns

RSTIN2 Low to RSTIN2 High 100 ms

RSTIN1 High to RST High 40 200 ms

RSTIN2 High to RST High 40 200 ms

Parameter

(1)

Min Max Unit

23/33

M41ST85Y, M41ST85W

Power-fail INPUT/OUTPUT

The Power-Fail Input (PFI) is compared to an internal reference voltage (1.25V). If PFI is less than

the power-fail threshold (V

Output (PFO)

will go low. This function is intended

for use as an undervoltage detector to signal a failing power supply. Typically PFI is connected

through an external voltage divider (see Figure 7,

page 7) to either the unregula ted DC input (if it is

available) or the regulated output of the V

lator. The voltage divider can be set up such that

the voltage at PFI falls below V

onds before the regulated V

M41ST85Y/W or t he m icroproc essor drops below

the minimum operating voltage.

During battery back-up, the power-fail comparator

turns off and PFO

curs after V

er returns, PFO

goes (or remains) low. This oc-

drops below V

CC

is forced high, irrespective of V

for the write protect time (t

from V

(max) until the inputs are recognized. At

PFD

the end of this time, the power-fail comparator is

enabled and PFO

follows PFI. If the comparator is

unused, PFI should be connected to V

left unconnected.

Century Bit

Bits D7 and D6 of Clock Register 03h contain the

CENTURY ENABLE Bit (CEB) and the CENTURY

Bit (CB). Setting CEB to a '1' will cause CB to toggle, either from a '0' to '1' or from '1' to '0' at the turn

of the century (depending upon its initial state). If

CEB is set to a '0,' CB will not toggle.

Output Driver Pin

When the FT Bit, AFE B it and watchdog register

are not set, the IRQ

/FT/OUT pin becomes an output driver that reflects the contents of D7 of the

Control Register. In other words, when D7 (OUT

Bit) and D6 (FT Bit) of address location 08h are a

'0,' then the IRQ

Note: The IRQ

/FT/OUT p in w ill be dr iv en lo w .

/FT/OUT pin is an open drain which

requires an external pull-up resistor.

Battery Low Warning

The M41ST85Y/W auto matically perf orms bat tery

voltage monitoring upon power-up and at factoryprogrammed time intervals of approximately 24

hours. The Battery Low (BL) Bit, Bit D4 of Flags

Register 0Fh, will be asserted if the battery voltage

is found to b e less than approximately 2.5V. T he

), the Power-Fail

PFI

several millisec-

PFI

input to the

CC

(min). When pow-

PFD

), which is the time

REC

SS

regu-

CC

PFI

and PFO

BL Bit will remain asserted until completion of battery replacement and subsequent battery low

monitoring tests, either during the nex t power-up

sequence or the next scheduled 24-hour interval.

If a battery low is generated during a power-up sequence, this indicates that the battery is below approximately 2.5 volts and may not be able to

maintain data integrity in the SRAM. Data sho uld

be considered suspect an d verified as correct. A

fresh battery should be installed.

If a battery low indication is generated during the

24-hour interval check, this indicates that the battery is near end of life. However, data is not compromised due to the fact that a nominal V

CC

is

supplied. In order to insure data integrity during

subsequent periods of bat tery back-up m ode, the

battery should be replaced. The SNAPHAT top

may be replaced while V

is applied to the de-

CC

vice .

Note: This will cause the clock to lose time during

the interval the SNAPHAT battery/crystal top is

disconnected.

The M41ST85Y/W only monitors the battery when

a nominal V

is applied to the device. Thus appli-

CC

cations which require extensive durations in the

battery back-up mode should be powered-up periodically (at least once every few months) in order

for this technique to be beneficial. Additionally, if a

battery low is indicated, data integrity should be

verified upon power-up via a checksum or other

technique.

Bit

t

REC

Bit D7 of Clock Register 04h contains the t

(TR). t

the des elect time af ter V

refers to the automatic continuation of

REC

reaches V

CC

PFD

Bit

REC

. This al lows for a voltage settling time before WRITEs

may again be performed to the device after a power-down condition. The t

Bit will allow the u s er

REC

to set the length of this deselect time as defined by

Table 12, page 25.

Initial Power-on Defaults

Upon initial application of power to the device, the

following register bits are set to a '0' state: Watchdog Register, FT, AFE, ABE, SQWE, and TR. The

following bits are set to a '1' state: ST, OU T, and

HT (see Table 13, page 25).

24/33

M41ST85Y, M41ST85W

Table 12. t

t

REC

REC

Bit (TR)

Definitions

STOP Bit (ST)

0 0 96 98 ms

0140

1 X 50 2000 µs

Note: 1. Default Set ting

Table 13. Default Values

Condition TR ST HT Out FT AFE ABE SQWE

Initial Power-up

Subsequent Power-up (with

battery back-up)

Note: 1. WDS, BMB0-BMB4, RB 0, RB1.

2. State of other contro l b its undefined .

3. UC = Unchanged

(2)

(3)

t

Time

REC

Units

Min Max

200

(1)

ms

WATCHDOG

Register

(1)

0111000 0 0

UC UC 1 UC 0 0 0 0 0

25/33

M41ST85Y, M41ST85W

Figure 21. Crystal Accuracy Across Temp eratur e

Frequency (ppm)

20

0

–20

–40

–60

–80

–100

–120

–140

–160

0 10203040506070

∆F

F

Temperature °C

= -0.038 (T - T

ppm

2

C

T0 = 25 °C

)2 ± 10%

0

80–10–20–30–40

AI00999

Figure 22. Cal ib rat i on Waveform

NORMAL

POSITIVE

CALIBRATION

NEGATIVE

CALIBRATION

AI00594B

26/33

M41ST85Y, M41ST85W

PART NUMBERING

Table 14. Ordering Information Scheme

Example: M41ST 85Y MH 6 TR

Device Type

M41ST

Supply Voltage and Write Protect Voltage

85Y = V

85W = V

Package

MH

MX

= 4.5 to 5.5V; 4.20V ≤ V

CC

= 2.7 to 3.6V; 2.55V ≤ V

CC

(1)

= SOH28

(2)

= SOX28

PFD

PFD

≤ 4.50V

≤ 2.70V

Temperature Rang e

6 = –40 to 85°C

Shipping Method for SOIC

blank = Tubes

TR = Tape & Reel

Note: 1. The 28-pi n S O IC package (S OH28) requires the battery/crystal pac kage (SNAP HA T®) which is ordered s eparately under the p art

number “M 4T XX-BR12SHX” in plastic tube or “M4TXX-BR12SHXTR” in T ape & Reel form.

2. The SOX28 package incl udes an embedded 32,768Hz crystal .

Caution: Do not place the S NAPHAT bat tery pac kage “M4TXX-BR12SH” in conductive foam as i t will drai n t he l ithi um but ton-ce ll bat tery.

For a list of available options (e.g., Speed, Package) or for further information on any aspect of this device,

please contact the ST Sales Office nearest to you.

Table 15. SNAPHAT Battery Table

Part Number Description Package

M4T28-BR12SH Lithium Battery (48mAh) and Crystal SNAPHAT SH

M4T32-BR12SH Lithium Battery (120mAh) and Crystal SNAPHAT SH

27/33

M41ST85Y, M41ST85W

PACKAGE MECHANICAL INFORMATION

Figure 23. SOH28 – 28-lead Plastic Small Outline, Battery SNAPHAT, Package Outline

A2

A

C

Be

eB

CP

D

N

E

H

LA1 α

1

SOH-A

Note: Drawing is not to scale.

Table 16. SOH28 – 28-lead Plastic Small Outline, battery SNAPHAT, Package Mechanical Data

Symbol

A 3.05 0.120

A1 0.05 0.36 0.002 0.014

A2 2.34 2.69 0.092 0.106

B 0.36 0.51 0.014 0.020

C 0.15 0.32 0. 006 0.012

D 17.71 18.49 0.697 0.728

E 8.23 8.89 0.324 0.350

e 1.27 – – 0.050 – –

eB 3.20 3.61 0.126 0.142

H 11.51 12.70 0.453 0.500

L 0.41 1.27 0.016 0.050

α 0° 8° 0° 8°

N 28 28

CP 0.10 0.004

Typ Min Max Typ Min Max

millimeters inches

28/33

M41ST85Y, M41ST85W

Figure 24. SH – 4-pin SNAPHAT Housing for 48mAh Battery & Crystal, Package Outline

A2

A3

L

eA

D

A1

A

B

eB

E

SHTK-A

Note: Drawing is not to scale.

Table 17. SH – 4-pin SN AP HAT Hous i n g for 48mA h Batt ery & Crystal, Package Mechanical Data

Symbol

A 9.78 0.3850

A1 6.73 7.24 0.2650 0.2850

A2 6.48 6.99 0.2551 0.2752

A3 0.38 0.0150

B 0.46 0.56 0.0181 0.0220

D 21.21 21.84 0.8350 0.8598

E 14.22 14.99 0.5598 0.5902

eA 15.55 15.95 0.6122 0.6280

eB 3.20 3.61 0.1260 0.1421

L 2.03 2.29 0.0799 0.0902

T yp Min Max Typ Min Max

millimeters inches

29/33

M41ST85Y, M41ST85W

Figure 25. SH – 4-pi n SNAPHAT Housin g for 120mAh Batt ery & Crystal, Package Outline

A2

A3

L

eA

D

A1

A

B

eB

E

SHTK-A

Note: Drawing is not to scale.

Table 18. SH – 4-pin SNAPH AT Housing for 120mAh Battery & Crystal, Package Mechanical Data

Symbol

A 10.54 0.4150

A1 6.73 7.24 0.2650 0.2850

A2 6.48 6.99 0.2551 0.2752

A3 0.38 0.0150

B 0.46 0.56 0.0181 0.0220

D 21.21 21.84 0.8350 0.8598

E 14.22 14.99 0.5598 0.5902

eA 15.55 15.95 0.6122 0.6280

eB 3.20 3.61 0.1260 0.1421

L 2.03 2.29 0.0799 0.0902

T yp Min Max Typ Min Max

millimeters inches

30/33

M41ST85Y, M41ST85W

Figure 26. SOX28 – 28-lead Plastic Small Outline, 300mils, Embedded Crystal, Package Outline

D

14

1

h x 45û

C

E

H

15

28

AA2

B

e

A1

ddd

LA1 α

SO-E

Note: Drawing is not to scale.

Table 19. SOX28 – 28-lead Plastic Small Outline, 300mils, Embedded Crystal, Package Mechanical

Symbol

A 2.44 2.69 0.096 0.106

A1 0.15 0.31 0.006 0.012

A2 2.29 2.39 0.090 0.094

B 0.41 0.51 0.016 0.020

C 0.20 0.31 0.008 0.012

D 17.91 18.01 0.705 0.709

ddd 0.10 0.004

E 7.57 7.67 0.298 0.302

e 1.27 – – 0.050 – –

H 10.16 10.52 0.400 0.414

L 0.51 0.81 0.020 0.032

α 0° 8° 0° 8°

N 28 28

T yp Min Max Typ Min Max

millimeters inches

31/33

M41ST85Y, M41ST85W

REVISION HIST ORY

Table 20. Document Revision History

Date Rev. # Revision Details

August 2000 1.0 First issue

24-Aug-00 1.1 Block Diagram added (Figure 3)

t

12-Oct-00 1.2

18-Dec-00 2.0 Reformatted, TOC added, and PFI Input Leakage Current added (Table 5)

18-Jun-01 2.1

22-Jun-01 2.2 Note added to Clock Operation section

26-Jul-01 3.0 Change in Product Maturity

07-Aug-01 3.1 Improve text in “Setting the Alarm Clock” section

20-Aug-01 3.2

06-Sep-01 3.3

Table removed, cross references corrected

REC

Addition of t

information, table changed, one added (Tables 8, 12); changed PFI/PFO

REC

graphic (see Figure 6); change to DC and AC Characteristics, Order Information (T ables 5,

6, 14); note added to “Setting Alarm Clock Registers” section; added temp./voltage info. to

tables (Table 4, 5, 6, 6, 7); addition of Default Values (Table 13)

Change V

DC Characteristics V

values in document

PFD

BAT

changed; V

changed; PFI Hysteresis (PFI Rising) spec.

OHB

added; and Crystal Electrical Characteristics table removed (Tables 5, 6)

03-Dec-01 3.4

01-May-02 3.5

Changed READ/WRITE Mode Sequences (Figure 14, 16); change in V

5V (M41ST85Y) part only (Table 5, 14)

Change t

Definition (Table 12); modify reflow time and temperature footnote (Table 2)

REC

lower limit for

PFD

03-Jul-02 3.6 Modify DC Characteristics table footnote, Default Values (Tables 5, 13)

15-Nov-02 3.7

Added embedded crystal (MX) package option; corrected initial power-up condition (Figure

2, 3, 5, 6, 7, 26, Table 1, 13, 14, 19)

24-Jan-03 3.8 Update diagrams (Figure 6, 7, 26); update values (Table 7, 11, 12, 13, 19)

25-Feb-03 4.0 New Si changes (Table 7, 11, 12); corrected dimensions (Figure 26; Table 19)

32/33

M41ST85Y, M41ST85W

M41ST85, M41ST85Y, M41ST85W, 41ST85, ST85, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial,

Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial,

Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, Serial, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC,

RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RT C, RTC, RTC, RTC, RT C, RTC, RTC, RTC, RTC,

RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microproce ssor, Microprocessor, Micr oprocess or , Microprocessor, M icroproce ssor, Mic r oprocesso r , M i cr oprocess or , Microprocessor, Microprocessor, I2 C , I 2C , I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C,

I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator,

Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Crystal, Crystal, Crystal, Crystal, Crystal,

Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal, Crystal,

Crystal, Crystal, Crystal, Crystal, Crystal, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm,

Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm , A larm, Alarm, Ala rm, A larm,

Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm , A larm, Alarm, Ala rm, A larm,

Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, Alarm, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ,

IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, IRQ, PFI, PFI, PFI, PFI, PFI, PFI, PFI,

PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO,

PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, PFO, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset,

Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset,

Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset,

Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Lo w, Low, Low, Low, Low, Low,

Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Low, Battery, Battery, Batte r y , Battery,

Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery , Battery, Batt ery, Batt ery, Batt ery, Battery ,

Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery , Battery, Batt ery, Batt ery, Batt ery, Battery ,

Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Switchover, Switchover, Switchover, Switchover, Switchover, Switchover, Switchover, Switchover, Switchover,

Switc hover, Switchov er, Swi t c hover, Sw itchover, Swi t c hover, Sw itchover, Bac kup, Bac ku p, Back up , Backup, Backup, Backup, Bac ku p, Backup, B ac ku p, Bac k up, Backup, Bac ku p, Backup, B ac kup, Backup, Ba ck up, Backup, Backup, Backup, Backup, Backup, Backup, Backup, Backup, Backup, Power-fail, Power-fail, Power-fail, Power-fail, Power-fail, Power-fail, Power-fail, Power-fail, Power-fail, Power-fail, Power-fail,

Power-fail, Power-fail, Power-fail, Power-fail, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, Comparator,