Page 1

MD-200 & 250

Quiznos™ Beverage/Ice Dispenser

INSTALLATION & SERVICE GUIDE

Part Number 5030765

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

October 19, 2006 REV6

Page 2

Page 3

FOREWORD

Manitowoc Beverage Equipment (MBE) developed this manual as a reference guide for the owner/

operator , service agent, and installer of this equipment. Please read this manual before installation

or operation of the machine. A qualified service technician should perform installation and startup of this equipment, consult the Troubleshooting Guide within this manual for service assistance.

If you cannot correct the service problem, call your MBE Service Agent or Distributor. Always have your model and

serial number available when you call.

Your Service Agent___________________________________________________________________

Service Agent Telephone Number ______________________________________________________

Your Local MBE Distributor ___________________________________________________________

Distributor Telephone Number _________________________________________________________

Model Number ______________________________________________________________________

Serial Number _______________________________________________________________________

Installation Date _____________________________________________________________________

UNPACKING AND INSPECTION

Note: The unit was thoroughly inspected before leaving the factory. Any damage or irregularities should

be noted at the time of delivery.

WARRANTY INFORMATION

Consult your local MBE Distributor for terms and conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general adjustments, cleaning, accessories and related servicing.

Your warranty card must be returned to Manitowoc Beverage Equipment to activate the warranty on this

equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves

the MBE factory .

No equipment may be returned to Manitowoc Beverage Equipment without a written Return Goods

Authorization (RGA). Equipment returned without an RGA will be refused by MBE’s Receiving Department

and returned to the sender at the sender’s expense.

Please contact your local MBE distributor for return procedures.

Page 4

TABLE OF CONTENTS

FOREWORD ........................................................................................................ 3

UNPACKING AND INSPECTION ........................................................................3

WARRANTY INFORMA TION ............................................................................... 3

SAFETY ...............................................................................................................6

IMPORT ANT SAFETY INSTRUCTIONS ............................................................................. 6

CARBON DIOXIDE WARNING........................................................................................... 6

QUALIFIED SERVICE PERSONNEL .................................................................................. 6

SHIPPING , STORAGE, AND RELOCATION....................................................................... 6

ADDITIONAL WARNINGS ................................................................................................. 6

GROUNDING IN STRUCTIONS ......................................................................................... 7

INSTALLATION.................................................................................................... 8

PRE-INSTALLA TION CHECK LIST .................................................................................... 8

LEGS ................................................................................................................................8

INTERNAL CARBONA TION ............................................................................................... 8

COLD CARB BAG-IN-BOX (B-I-B) SYSTEM ....................................................................... 9

COLD CARB SYSTEM PRESSURES ................................................................................. 9

UNIT INST ALLATION .......................................................................................................10

DRAINAGE OPTIONS ......................................................................................................10

CARB TANK PURGE TUBE ROUTING .............................................................................11

TOP MOUNTED ICEMAKER REQUIREMENTS .................................................................12

BAFFLE FOR MANITOWOC™ CUBERS ..........................................................................13

BAFFLE FOR "Q" SERIES ICE MACHINES......................................................................13

MANUAL FILL LID FOR DISPENSERS MOUNTED WITH A CUBER.................................13

PLUMBING DIAGRAM LOCA TION & FLEX MANIFOLD ...................................................14

DIAGRAM ........................................................................................................................14

OPERATION ...................................................................................................... 15

UNIT INSPECTION ...........................................................................................................15

ICE STORAGE AND DISPENSING ...................................................................................15

COLD PLA TE BEVERAGE COOLING ...............................................................................15

ROCKING CHUTE ICE DISPENSING ................................................................................15

BEVERAGE V ALVES ........................................................................................................16

POST-MIX BEVERAGE DISPENSERS.............................................................................16

BACK ROOM PACKAGE ..................................................................................................17

BAG-IN-BOX SYSTEM .....................................................................................................17

COUNTERTOP MEASUREMENTS....................................................................................18

SPECIFICA TIONS ............................................................................................................19

115V/220V NON ADJUST ABLE AGITA TION TIMER ..........................................................20

ICE CHUTE SEQUENCE OF OPERA TION .........................................................................20

Page 5

Installation and Service Manual

TABLE OF CONTENTS

USER MAINTENANCE ......................................................................................21

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE .......................................21

DAIL Y CLEANING.............................................................................................................24

MONTHL Y CLEANING ......................................................................................................25

BEVERAGE SYSTEM CLEANING .....................................................................................26

BAG-IN-BOX SYSTEM .....................................................................................................26

PREVENT ATIVE MAINTENANCE......................................................................................27

EXPLODED VIEWS, PARTS & DIAGRAMS ..................................................... 28

MD-200 & 250 QUIZNOS™ UNIT EXPLODED VIEW .........................................................28

MD-200 & 250 QUIZNOS™ UNIT PARTS LIST .................................................................29

MD-200 QUIZNOS™ MERCHANDISER .............................................................................30

MD-250 QUIZNOS™ MERCHANDISER .............................................................................31

WIRING MD-200 & 250 QUIZNOS™ UNIT 115V...............................................................32

TROUBLESHOOTING.......................................................................................33

PUMP...............................................................................................................................33

DRINKS............................................................................................................................34

DRINKS............................................................................................................................35

LIQUID LEVEL CONTROL................................................................................................36

INDEX ................................................................................................................ 39

5

Page 6

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual. Learn how to operate the MD unit properly . Do not

allow anyone to operate the unit without proper training and keep it in proper working condition.

Unauthorized modifications to the MD may impair function and/or safety and affect the life of the unit.

CARBON DIOXIDE WARNING

DANGER: Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas causes

tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO2 gas leak is

suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO2 lines

and pumps should not be installed in an enclosed space. An enclosed space can be a cooler or small

room or closet. This may include convenience stores with glass door self serve coolers. If you suspect CO

may build up in an area, venting of the B-I-B pumps and / or CO2 monitors should be utilized.

QUALIFIED SERVICE PERSONNEL

WARNING: Only trained and certified electrical and plumbing technicians should service this unit. All

wiring and plumbing must conform to national and local codes.

2

SHIPPING, STORAGE, AND RELOCATION

CAUTION: Before shipping, storing, or relocating this unit, syrup systems must be sanitized. After

sanitizing, all liquids (sanitizing solution and water) must be purged from the unit. A freezing environment causes residual sanitizing solution or water remaining inside the unit to freeze, resulting in

damage to internal components.

ADDITIONAL WARNINGS

Installation and start-up of this equipment should be done by a qualified service technician. Operation,

maintenance, and cleaning information in this manual are provided for the user/operator of the equipment.

Save these instructions.

Page 7

Installation and Service Manual

SAFETY

GROUNDING IN STRUCTIONS

WARNING: Risk of electrical shock. Connect to a properly grounded outlet only .

This appliance must be grounded. In the event of malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of electric shock. This appliance is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor with insulation having an outer surface that is green with or without yellow

stripes is the equipment grounding conductor. If repair or replacement of the cord or plug is necessary , do not connect the equipment-grounding conductor to a live terminal. Check with a qualified

electrician or serviceman if the grounding instructions are not completely understood, or if in doubt

as to whether the appliance is properly grounded. Do not modify the plug provided with the appliance – if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING – When using electric appliances, basic precautions should always be followed, including the following:

a) Read all the instructions before using the appliance.

b) T o reduce he risk of injury , close supervision is necessary when an appliance is used near

children.

c) Do not contact moving parts.

d) Only use attachments recommended or sold by the manufacturer .

e) Do not use outdoors.

f) For a cord-connected appliance, the following shall be included:

• Do not unplug by pulling on cord. T o unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use and before servicing or cleaning.

• Do not operate any appliance with a damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in any manner . Return appliance to the nearest

authorized service facility for examination, repair , or electrical or mechanical adjustment.

g) For a permanently connected appliance – Turn the power switch to the of f position when

the appliance is not in use and before servicing or cleaning.

h) For an appliance with a replaceable lamp – always unplug before replacing the lamp.

Replace the bulb with the same type.

i) For a grounded appliance – Connect to a properly grounded outlet only. See Grounding

Instructions.

SAVE THESE INSTRUCTIONS

7

Page 8

Installation and Service Manual

INSTALLATION

PRE-INSTALLATION CHECK LIST

Do you have enough space to install the dispenser or a dispenser and top mounted cuber?

Does the top mounted cuber (if utilized) have

a minimum of 6 inches (15.3) cm) clearance

on all sides?

Is the countertop level?

Can the countertop support the weight of the

dispenser, or the dispenser/cuber combination

plus the weight of the stored ice?

Also consider the location of the following items before

installation:

• Water line

• Drain

• Power outlet

• Heating and air conditioning ducts

LEGS

It is recommended if an icemaker is installed on top of

the dispenser, legs should not be installed.

Legs are optional equipment with most Servend dispensers. Standard legs are four-inch (10.2 cm) tall painted

steel legs.

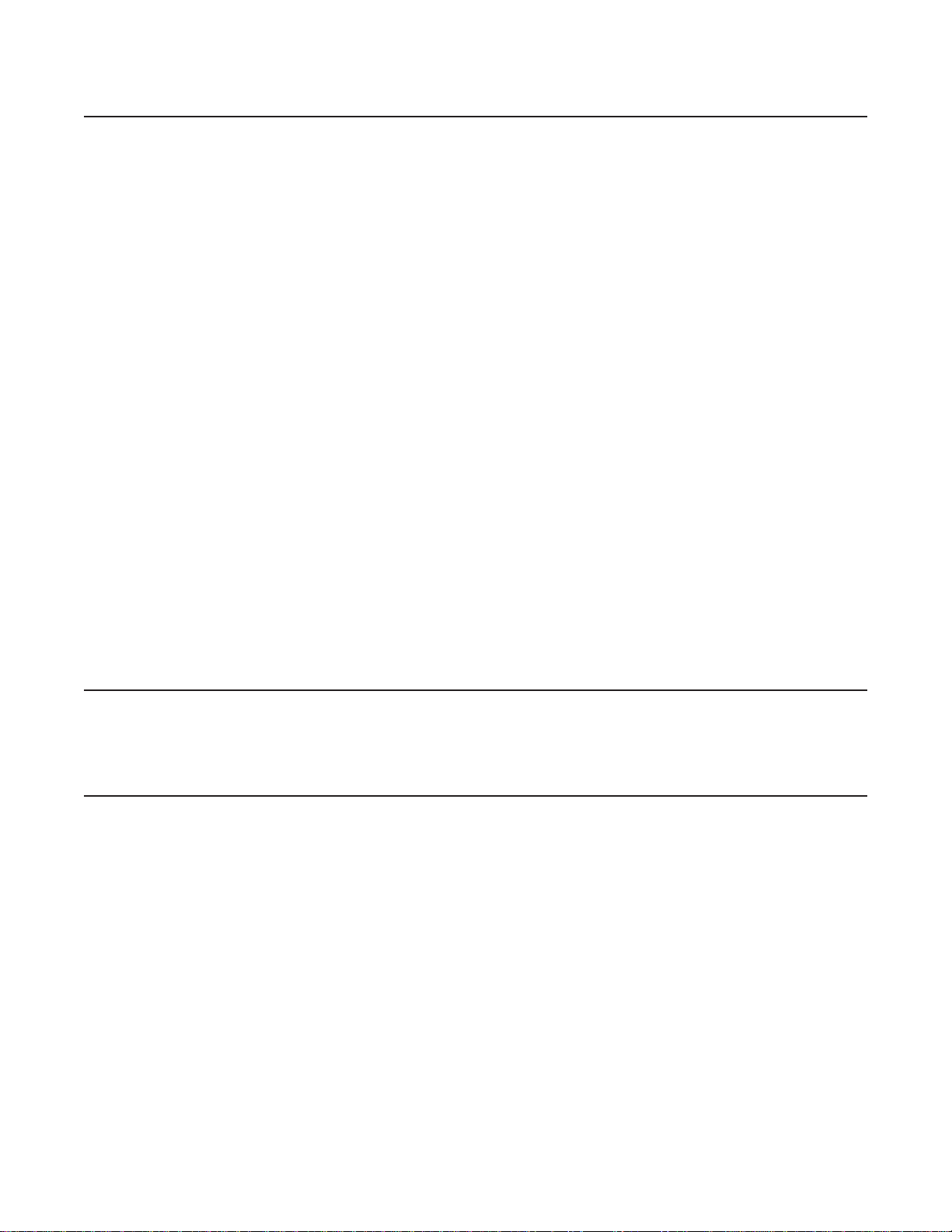

INTERNAL CARBONATION

The carbonator has two inlets and one outlet connection, as well as a relief valve and two conductivity probes.

The water inlet is a 3/8" flared fitting. The carbonator will

be pre-plumbed as it leaves the factory. If the carbonator needs to be serviced or if the fittings need to be

replaced, make sure a nylon washer is used inside the

swivel fittings to prevent leaks.

The conductivity probes are used to control the level of

water inside the carbonator tank. The red probe, or the

“high” probe, is the shorter of the two. When the level of

the water reaches the bottom of the red probe, the pump

shuts off. The black, or “low” probe activates the pump

Inlet

2

Pressure

Relief Valve

Carbonated

Water Outlet

Electronic

Probes

Water Inlet

CO

When installing legs on a MD Series dispenser, leg

braces should be used. These are metal braces fitting

side to side under the dispenser that reinforce the leg

attachment area.

The pump motor and electrical box are mounted together on a single platform. The pump is a standard

125 GPH Procon pump. The flared fittings accept the

same swivel/ barb scheme used on the carbonator

water connections. The pump outlet is a double check

valve topped with a 3/8" flared fitting. T eflon t ape or some

other means of sealing must be used on the fittings to

prevent leaks. Also, water enters the pump from the

water source on the side that has the filter.

when the water level inside the tank goes below the bottom tip of the probe. Both probes are wired to the electronic liquid level control, which is a circuit board mounted

inside the electrical box. Removing the cover of the electrical box will grant access to the circuit board. As the

control receives a signal from the conductivity probes, it

activates the pump motor, which will pump water into

the carbonator until the water reaches the high probe.

8

Carbonator Pump Deck

(Power Supply)

Installation Notes:

• Pump Decks for internal carb units must be

within 6 feet of unit.

• Installation of a carbonator any further away

than the recomended distance is at installer/

owner's risk. Known issues can include, but is

not limited to poor carbonation and/or erratic

carbonation.

Page 9

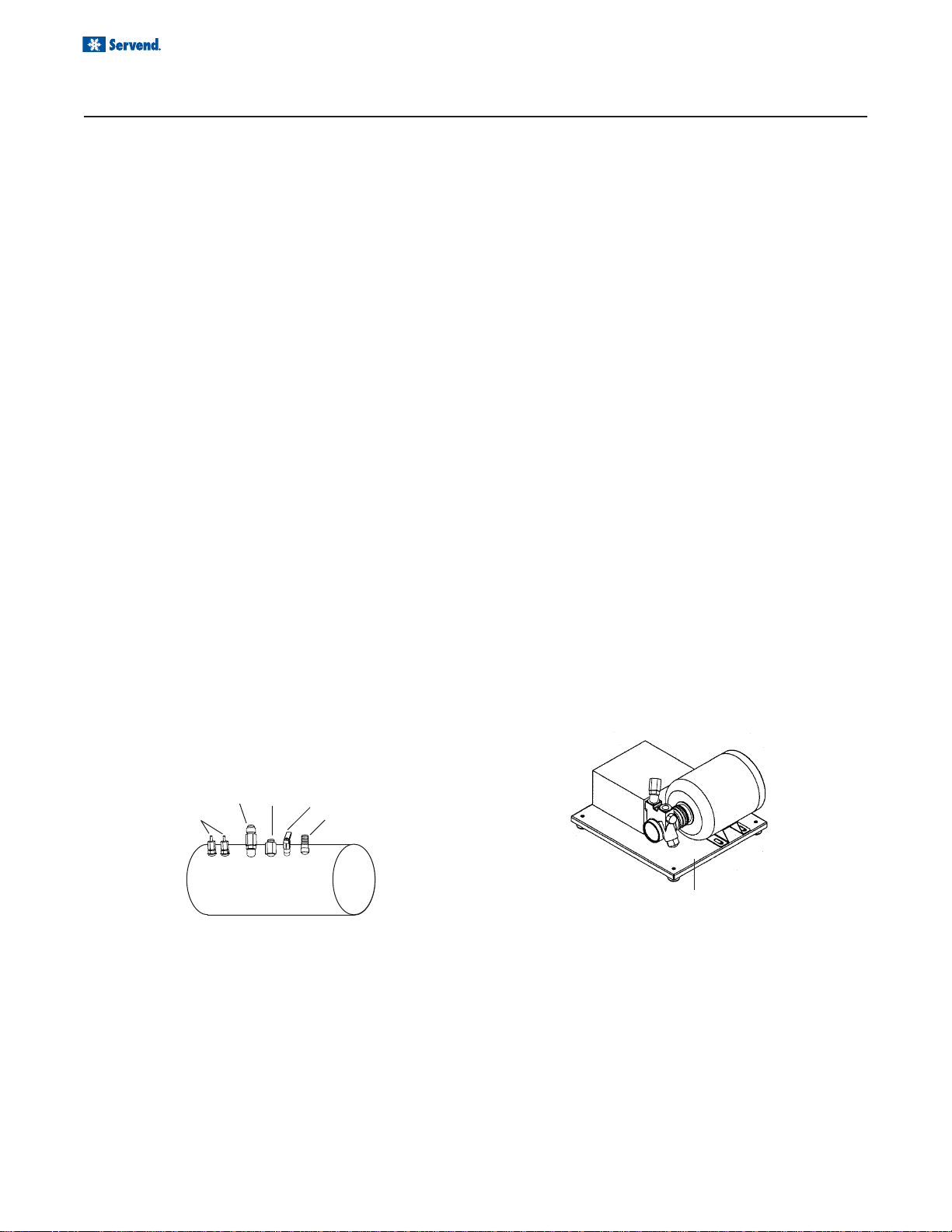

COLD CARB BAG-IN-BOX (B-I-B) SYSTEM

Quiznos

Internal Carbonation

Beverage Dispensing System

TM

MD-250

INSTALLATION

Installation and Service Manual

NOTE:

This is a simplified schematic to

show the basic operation of the

beverage system.

Dispenser

Carbonated/Non-carbonated

Beverage Manifold

Carbonator Tank

Countertop

SYRUP

BIB

Syrup Pump

SYRUP

Bag-In-Box

4

Syrup

Carton

Dwg#: 5010301-0

1

Tap Water

Tap Water

75

1800

2

CO

3

Cylinder

2

CO

2

60

CO

2

COLD CARB SYSTEM PRESSURES

1. Incoming tap water should be at a minimum pressure of 40 psi and a maximum of 55psi.

2. BIB pressure gauge set for 60 psi.

NOTE: If incoming water pressure is under 40 psi, a water booster is recommended. If incoming water pressure is

over 55 psi, a water regulating valve is required.

3. Carbonator Pressure gauge:

• Cold Carbonation set for 75 psi.

9

Page 10

Installation and Service Manual

INSTALLATION

UNIT INSTALLATION

1. Place the dispenser in the desired location.

2. Run the beverage lines and water lines(make sure

to install the water connections to the proper inlets.

Connection “A” comes from the procon pump and is

your carbonated water supply and Connection “B” is

your plain water supply . (Refer to plumbing diagrams.)

3. Install drain plumbing and insulate.

4. Set flexible manifold for correct drink settings.

NOTE: The manifold is preset for the far right

valve to be a non-carbonated beverage.

DRAINAGE OPTIONS

The drains for MD Series connects to the drain pan.

5. Turn water supply on to the dispenser . Water pressure should be between 40 and 55 psi.If not inbetween those pressures proper measures must

be taken to regulate them to correct settings.

6. Turn CO2 supply on to the dispenser. Each cold carb

pump deck is furnished with a fixed regulator set at

75 psi. Ambient units need to be set between 90

and 100 psi.

7. Fill bin with ice.

8. Connect power supply.

9. Brix beverage valves.

10. Meet all code requirements.

Option One

Drainage through the bottom of the unit:

Radiator clamp

90 elbow fitting

Radiator clamp

Flexible tubing

Option Tw o

Drainage through the back of the unit:

Straight fitting

Radiator clamp

Flexible tubing

10

Holes for

beverage

lines

Holes for

drain pan

drain

Page 11

B

INSTALLATION

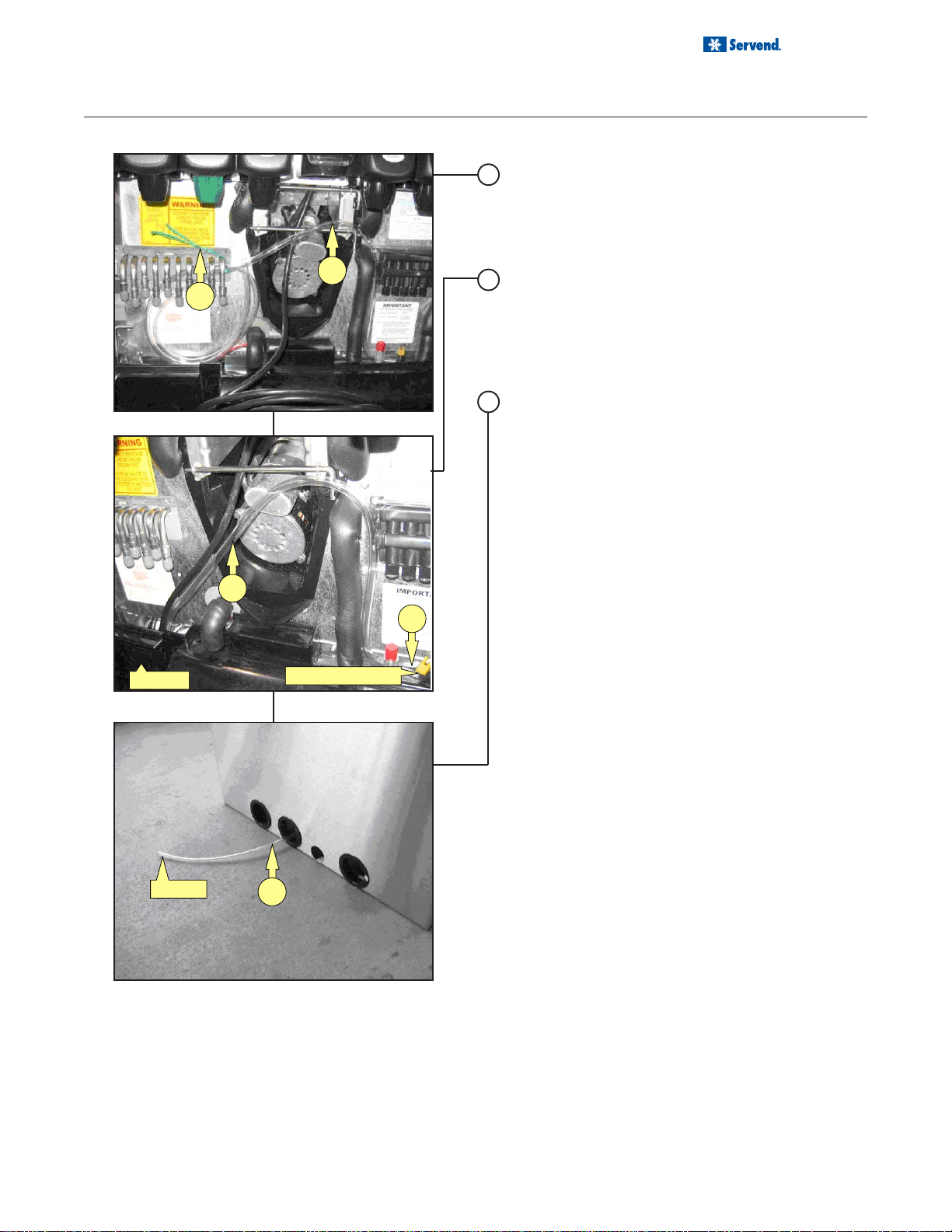

CARB TANK PURGE TUBE ROUTING

1. During installation of unit the carbonator tank purge

tube (A) must be properly routed to a drain. Once

the splash panel has been removed from unit remove twist tie (B) that holds carbonator tank purge

tube.

A

2. Route carbonator tank purge tube (A) down front of

unit and behind drain pan. Be sure not to collapse

or kink carbonator tank purge tube during routing

from unit to drain. (C) Purge tube is connected to

the pressure relief valve on carbonator tank and must

be routed to a drain

3. The carbonator tank purge tube (A) can be routed

down through the counter top that unit has been

installed on or out the rear of unit. Then install

carbonator tank purge tube to a drain. Follow all local and national plumbing codes when routing

carbonator tank purge tube to the drain.

Installation and Service Manual

Drain Pan

To Drain

A

C

Pressure Relif Valve

A

11

Page 12

Installation and Service Manual

INSTALLATION

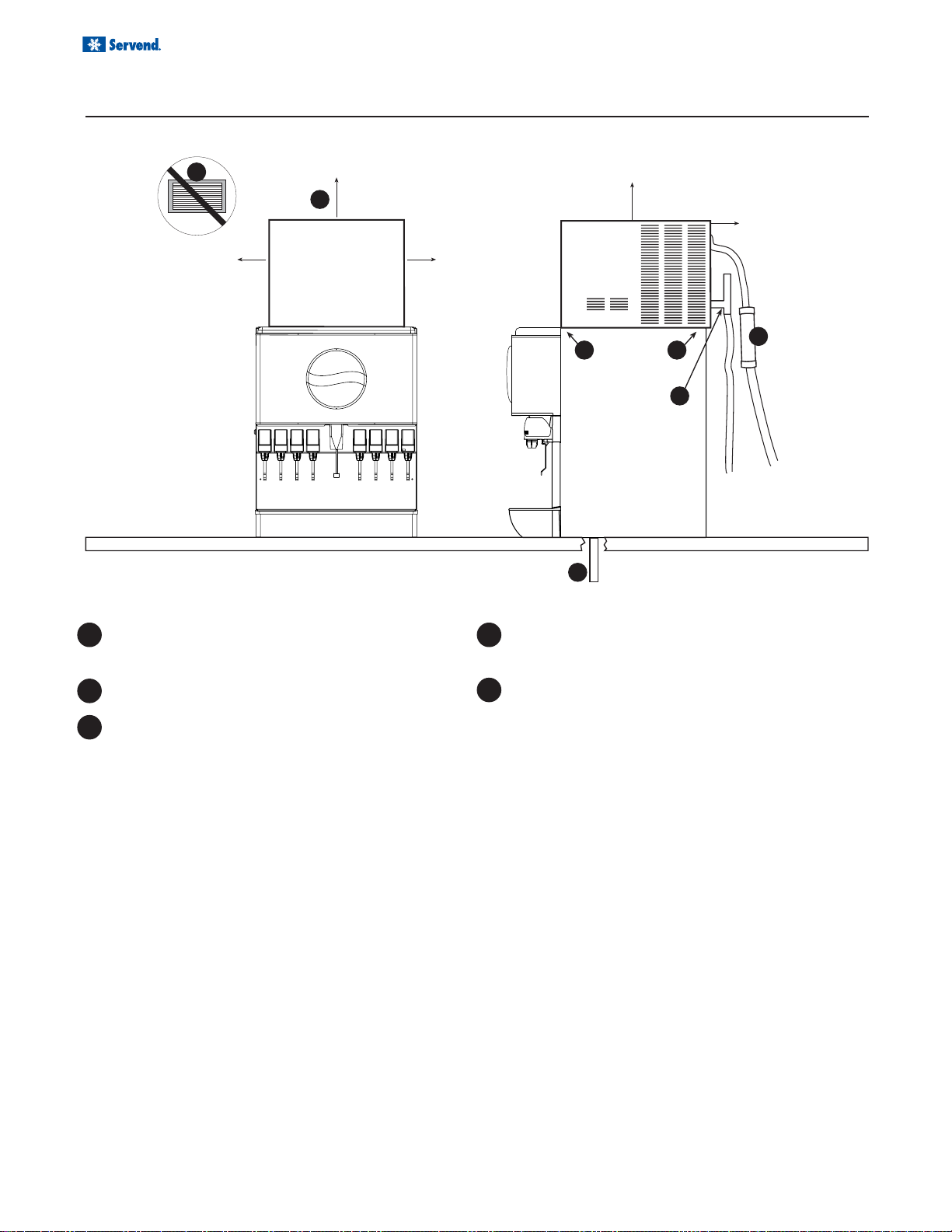

TOP MOUNTED ICEMAKER REQUIREMENTS

1

6"

(15.2 cm)

2

cuber

6" (15.2 cm)

clearance

for cuber

6"

(15.2 cm)

6" (15.2 cm)

6" (15.2 cm)

3

4

3

4

5

1 Location - Avoid placing the dispenser and/or ice

machine near heat sources such as radiators, ovens, refrigeration equipment and direct sunlight.

2 Clearances - Six inch (15.2 cm) clearance on all

sides of the icemaker is needed.

3 Front of icemaker to be flush with front of dis-

penser- The front of the icemaker should be flush

with the front of the dispenser, as shown in the

drawing above. Because the icemaker is flush with

the front of the dispenser, some icemakers may

overhang at the back of the dispenser.

4 Drains - A separate drain line is required for the

ice machine, in addition to a drain line for the ice/

beverage dispenser.

5 MD Series dispensers require an adapter kit to

install a top-mounted icemaker . Contact your lo-

cal Servend distributor for the correct adapter kit.

For full information about icemaker installation, including plumbing lines connections and electrical requirements,

see the icemaker installation manual.

12

Page 13

Installation and Service Manual

INSTALLATION

BAFFLE FOR MANITOWOC™ CUBERS

When installing a Manitowoc™ “S” series Ice Machine on a Servend MD-series dispenser, a baf fle kit is required for

proper installation. The baffle kit is designed to prevent ice from lying against the front of the ice machine, and

melting down the front of the dispenser. There are two dif ferent baffle kit s available from Servend. One kit is for the

30" wide “S” series ice machine, and the other kit is for the 22" wide “S” series ice machine.

These two Kits are available through your local Manitowoc Distributor . List prices may be subject to change without

notification. Please call your local parts distributor for current pricing before ordering.

Ice Maker Baffle Installation:

1. Remove both front panels.

2. Examine the ice machine to see if the machine has

four screws on the lower front plastic panels.

3. If there are screws, remove them from the countersunk holes on the front surface of the machine,

save the screws.

4. Install the deflector , using the four screws removed

in step three.

5. Four screws and two backing plates are in the kit.

6. If there are no screws on the ice machine (step 2),

pierce the thin plastic countersunk holes, install the

backing plates and install the deflector using the

screws from the kit.

7. Replace the front panels.

Part Number Description

5029518 ........................ Baffle Kit 30”

5029517 ........................ Baffle Kit 22”

BAFFLE FOR "Q" SERIES ICE MACHINES

1. Position baffle on top of water well with tab on the

front and the other tab inside the water well.

2. Mount the baffle on the left side of the ice maker

using the hole and screw provided.

MANUAL FILL LID FOR DISPENSERS MOUNTED WITH A CUBER

If you are top mounting your MD Series dispenser with a

cuber, you will require a lid for the manual fill area at the

top, front of the dispenser.

If you ordered a Servend dispenser and a cuber at the

same time, the manual fill lid was included with the unit.

The manual fill lid can be ordered from your local Servend distributor.

13

Page 14

Installation and Service Manual

PUSH FOR ICE

4

INSTALLATION

PLUMBING DIAGRAM LOCATION & FLEX MANIFOLD

The plumbing diagram is prinited on a white vinyl label located above the inlet tubes for syrup and water. It can be

accessed by removing the splash panel of the dispenser . The plumbing diagram label explains which inlet coldplate

fittings supply which dispenser valves and water manifolds.

The water supply must first be connected to the carbonator pump before plumbing to connection “A” shown on

plumbing diagram. The carbonator pump deck must be

within six feet of the dispenser for optimum performance.

See BIB installation diagram for system pressure settings.

NOTE: Valves are read from left toright. The manifold

is preset for the far right valve to be a non-carbonated

beverage.NOTE: The manifold is preset for the far right

valve to be a non-carbonated beverage.

PUSH FOR ICE

PLUMBING

DIAGRAM

Plumbing Diagram

SAMPLE

DIAGRAM

14

Page 15

Installation and Service Manual

OPERATION

UNIT INSPECTION

Thoroughly inspect the unit upon delivery . Immediately report any damage that occurred during transportation to the

delivery carrier. Request a written inspection report from a claims inspector to document any necessary claim.

ICE STORAGE AND DISPENSING

Servend dispensers are designed to dispense hard, cube ice up to one-inch square. The ice shapes and sizes listed

below are recommended for dispensing. Warm “Super Cooled” Ice Before Dispensing “Super Cooled” ice is not

recommended for dispensing. “Super cooled” ice is ice that has been stored in freezers below 32oF. Should it be

necessary to temporarily use “super cooled” ice, allow the ice to warm at room temperature for 25 to 30 minutes before

placing the ice in the dispenser. Dispensing compressed flake “nugget” ice in Servend dispensers takes special

handling. Most dispensers require special bin components plus a universal ice management kit. Contact MBE regarding details for your particular installation.

Ice is stored in the dispenser’s bin. Ice below the stainless steel bin liner is used to cool the aluminum cold plate, at

the bottom of the ice dispenser bin. Ice above the stainless steel bin liner is dispensed into the customer’s cup. Ice is

transported from the bottom of the bin to the ice dispense point by the paddle wheel. The injection molded paddle

wheel has paddles which lift the ice to the dispense point.

COLD PLATE BEVERAGE COOLING

A cold plate is a block of aluminum with serpentine stainless steel tubes molded inside the aluminum block. The

cold plate is approximately the same length and width as

the bottom of the dispenser bin. Ice sits on top of the cold

plate and cools the cold plate. The stainless steel tubes

inside the cold plate carry carbonated water (soda water),

noncarbonated water (plain water) and syrup to the beverage valves. While flowing through the stainless steel tubes

in the cold plate, water and syrup are chilled to serving

temperature.

ROCKING CHUTE ICE DISPENSING

As the customer presses the rocking chute , the arm at

the top left rear of the chute pushes upward on the door

lock. The door opens until it contacts the stops in the

mounting brackets. The plastic arm on the ice chute also

activates the lever of the ice dispening switch. When activated, the micro switch starts the gear motor . The gear

motor turns the paddle wheel and agitator arm. The

paddlewheel carries ice. Periodic agitation is standard

on the MD-250. During periodic agitation, the paddle

wheel and agitator turn for approximately three seconds

every three and one half-hours. The door lock prevents

ice from being dispensed during the agitation cycle.

15

Page 16

Installation and Service Manual

OPERATION

BEVERAGE VALVES

Post-mix beverage valves are designed to precisely meter the flow of both water and syrup to obtain the proper mixing

ratio. The syrup and soda water components of the post-mix beverage are mixed as they leave the beverage valve.

POST-MIX BEVERAGE DISPENSERS

Post-Mix

Most beverage systems are Post-Mix. Permanent dispensing locations with a mid to high volume dispensing

have Post-Mix systems, such as self-service dispensers in Convenience Stores, Restaurants and Cafeterias.

Post-Mix means that syrup and carbonated water (or

plain tap water for non-carbonated drinks) are mixed together in the valve nozzle of the dispenser, just before

the finished beverage flows into the customer’s cup.

A memory peg for the meaning of Post-Mix is that the syrup

and water are mixed after leaving the beverage valve.

PLUMBING DIAGRAM EXAMPLEPLUMBING DIAGRAM EXAMPLE

Servend Recommended Plumbing

1 2 3 4 5 6 7 8

EXAMPLE:

Water / soda manifold is supplied

with water by the inlet labeled

‘#1, #2, #3, WATER / SODA’

MANIFOLD MANIFOLD

Post-Mix System

The most common Post-Mix System is the Bag-in-Box

(BIB) - Most often, five gallons of syrup is stored in a

plastic bag inside a carton.

3-1-1-3 FLEX

6005433

RI

EXAMPLE:

Valve 8 is supplied with syrup

by the inlet labled '#8 SYRUP'

COLD PLATE

WATER/SODA

#1 SYRUP

#2 SYRUP

#3 SYRUP

#4

#4 SYRUP

Plumbing Diagram Label

The plumbing diagram lebel explains which inlet cold

plate fittings supply which dispenser valves.

16

NOTE: SYRUP LINES NOT SHOWN

WATER/SODA

#1, #2, #3 WATER/SODA

#5

#6, #7, #8 WATER/SODA

#7 SYRUP

#8 SYRUP

#6 SYRUP

#5 SYRUP

Page 17

OPERATION

BACK ROOM PACKAGE

Installation and Service Manual

BAG-IN-BOX SYSTEM

Creating Carbonated Water:

1. Incoming tap water - should be at a minimum pres-

sure of 40 psi and maximum of 55psi.

2. Carbonator Water pump motor - Powers the water pump. The water pump motor is part of the carbonator pump deck.

3. Carbonator Water pump - Pumps tap water into

the carbonator tank. The water pump is part of the

carbonator. The incoming water for the carbonator

must be first ran through the pump before conneting

to the proper cold plate inlet.

4. Internal/External Carbonator tank - Combines

CO2 gas and tap water to form carbonated water.

The “carbonator” is the carbonator tank, water

pump and water pump motor.

After being carbonated, the carbonated water is fed from

the carbonator to the dispenser cold plate for chilling. At

the beverage valve, chilled water and chilled syrup are

mixed to create the finished beverage.

Pumping Syrup to the Dispenser:

5. CO2 cylinder - Holds highly pressurized carbon di-

oxide (CO2). The CO2 cylinder is a steel or aluminum cylinder tank. CO2 gas flows to the primary

pressure regulator.

6. Cylinder pressure gauge - Set for 60 psi. Indicates CO2 pressure going to B-I-B pumps.

7. Primary pressure regulator - Lowers the CO2 gas

pressure, to 100 psi, so the CO2 gas will be at the

proper pressure to enter the carbonator regulator.

8. Lowered outgoing pressure - Set for 75 psi.

Gauge indicated lowered outgoing pressure from

the CO2 cylinder after being routed through the primary pressure regulator at 100 psi..

9. Secondary pressure regulator - Lowers the CO

gas pressure before the CO2 gas flows to the syrup

pump. CO2 pressure, 60 psi, activates the syrup

pump.

10. Syrup pump - Draws syrup out of the bag-inbox

syrup package. Syrup flows through the syrup lines

to the dispenser for chilling, then dispensing. There

is a syrup pump for each bag-in-box syrup system.

11. Bag-In-Box syrup cartons - Box which contains

a plastic bag, filled with syrup. Usually, six bag-inbox cartons are placed on a rack.

2

17

Page 18

Installation and Service Manual

OPERATION

COUNTERTOP MEASUREMENTS

18

Letter Description MD-250

A

Uni t Width 30”

B

Uni t Depth 31"

C

Outside Ice Bin Depth 22 1/2"

D

Under Uni t Width 26"

E

Under Uni t Depth 20 1/2"

F

Recommended countertop Cut-out* 3"x18"

G

Maxi mum Countertop Cut-out* 26"x20 1/2"

CAUTION: Cutting the countertop may decrease its strength. Counter should

be braced to support the dispenser countertop weight plus ice storage capacity and weight of icemaker, if applicable.

Page 19

Installation and Service Manual

OPERATION

SPECIFICATIONS

MD Series dispensers have a stainless steel cabinet and lighted merchandiser standard. Beverage valves, coldplate

connections, drain connections and electrical components are front serviceable. MD Series dispensers drain through

a single 3/4" NPT connection to the drain pan. The standard voltage for MD-250 Quiznos™ dispenser is 120VAC60Hz, a power cord is provided. MD Series dispensers use a 1/7 hp gearmotor. Optimum ambient conditions for MD

Series dispensers are between 500F and 950F.

DIMENSIONS

UNIT WIDTH DEPTH HEIGHT

MD-250-IC

Ice Storage

Beverage Valves

Coldplate

Amperage

Agitation Timer

Shipping Weight

30"

76.2 cm

SPECIFICATIONS

31"

78.7 cm

250 lbs

8

8 valve: 12 circuit

2-1-1-3-1 manifold

2.5 FLA

Standard

338 lbs

39"

99.7 cm

19

Page 20

Installation and Service Manual

115V/220V NON ADJUSTABLE AGITATION TIMER

OPERATION

ICE CHUTE SEQUENCE OF OPERATION

Customer’s cup presses rocking chute push lever or

customer’s hand presses push button. The translucent

plastic arm at the top and the left rear of the translucent

plastic chute pushes upward on the door. The door pivots

up from the left and right mounting brackets. The same plastic arm also activates the lever of the micro switch. When

activated, the micro switch starts the gear motor. The

gear motor turns the paddle wheel and agitator arm.

When the paddle wheel turns, ice is carried from the

bottom of the bin to the dispense point. Ice falls forward

through the open door, into the ice chute and to the

customer’s cup.

The door lock keeps the door shut during periodic agitation. Periodic agitation is standard on the MD-250.

During periodic agitation, the paddle wheel and agitator

turn for approximately three seconds every three and

one half-hours of non-use. Since ice is brought forward

during periodic agitation, ice would fall through the ice

dispense door if the door lock was not present.

20

Page 21

Installation and Service Manual

PUSH FOR ICE

DANGER

C

D

E

F

G

A

B

USER MAINTENANCE

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE

NOTE: Sanitize the ice dispenser at Initial Start-UP in

addition to monthly sanitizing. You will need screwdriver

in order to disassemble.

Disassemble parts in the following order:

A. Merchandiser

B. Ice chute

C. Paddle wheel pin

D. Agitator

E. Paddle wheel

F. Bin liner

G. Paddle wheel Area

Accessing a Dispenser Bin Top Mounted with a

Manitowoc

1. Remove the front panel of the ice machine.

2. Remove the ice deflection baffle. This will give you

access to the dispenser bin.

Disassembling the Dispenser Parts for Bin Cleaning:

1. Remove the front panel of the Manitowoc ice maker.

2. If the Manitowoc ice maker is operating, wait for

the sheet of ice to fall into the dispenser bin.

When the ice sheet falls into the dispenser bin, immediately place toggle switch of the ice machine to the “OFF”

position.

If the Manitowoc ice maker is NOT operating, place the

toggle switch of the ice machine to the “OFF” position.

3. On MD models without a top mounted cuber, remove the plastic lit from the top of the dispenser.

4. Remove all ice from the dispenser.

5. Disconnect electrical power to the dispenser.

™

Cuber:

DANGER

PUSH FOR ICE

21

Page 22

Installation and Service Manual

6

7

8

9

PUSH FOR ICE

12

14

15

13

DANGER

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE

USER MAINTENANCE

Agitatior arm and paddlewheel pin:

6. Rotate the agitator arm so the paddle wheel pin

handle is pointing up, toward the ceiling.

7. Prepare agitator pin for removal by removing the

stainless steel split ring.

8. Then remove the paddle wheel pin from the hole in

the agitator.

9. Push the agitator bar toward the back of the unit

until the agitator is free of the paddle wheel hub.

Paddlewheel, bin liner and paddle wheel area:

10. Remove the agitator from the bin area.

1 1. Move the front of the agitator to one side and slide

the agitator forward until the rear of the agitator

shaft is clear of the bushing.

12. Slide the paddle wheel from its shaft.

13. Loosen the four knurled fasteners that hold the bin

liner in place.

14. Remove the bin liner.

15. Remove the paddle wheel area from the bin.

16. Discard the remaining ice in the bin.

DANGER

PUSH FOR ICE

22

Page 23

Installation and Service Manual

PLUMBING

DIAGRAM

PUSH FOR ICE

1

4

3

2

P

L

U

M

B

I

N

G

D

I

A

G

R

A

M

P

U

S

H

F

O

R

I

C

E

5

6

USER MAINTENANCE

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE

Disassemble the rocking chute:

1. Loosen the two knurled fasteners that hold the merchandiser in place.

2. Remove the merchandiser.

3. Remove outer bracket.

4. Remove door lock.

5. Remove door.

6. Remove ice chute.

PLUMBING

DIAGRAM

G

N

I

B

M

U

L

P

M

A

R

G

A

I

D

PUSH FOR ICE

E

C

I

R

O

F

H

S

U

P

23

Page 24

Installation and Service Manual

USER MAINTENANCE

DAILY CLEANING

All cleaning must meet your local health department regulations. The following cleaning instructions are

provided as a guide.

CAUTION: Use only warm soapy water to clean the exterior of the tower . Do not use solvent s or

other cleaning agents. Do not pour hot coffee into the drain pan. Pouring hot coffee down the drain

pan can eventually crack the drain pan, especially if the drain pan is cold or still contains ice.

Clean the exterior and drain pan:

1. Turn off the key switch located on either right or lef t

side of the unit.

2. Lift the grid and remove it from the drain pan.

3. Using mild soap, warm water and a clean cloth, wipe

the drain pan and splash panel. Then, rinse with clean,

warm water. Allow plenty of warm (not hot) water to

run down the drain of the drain pan, to remove syrup

residue that can clog the drain opening.

4. Wash the grid, then rinse with clean water. Place

the grid back in the drain pan.

5. Wash all exterior surfaces of the unit with warm

water and a clean cloth. Wipe again with a clean,

dry cloth.

Removable front

merchandiser

Beverage valve

Water

Syrup

Cold plate

Gear motor

Drain pan

Agitator

Rocking chute

ice dispense chute

Ice bin

Stainless steel

bin liner

Cold plate

Ice

Paddle wheel

24

Page 25

USER MAINTENANCE

PLUMBING

DIAGRAM

PUSH FOR ICE

MONTHLY CLEANING

Clean and sanitize the ice bin and cold plate:

1. Unpug unit and remove all ice from the ice bin.

2. Mix a solution of mild detergent to clean the dispenser

bin and components.

3. Wash the ice bin using a sponge and the mild detergent solution.

4. Using the mild detergent solution and a soft bristle

brush or clean cloth, clean the following dispenser

parts:

• Cold plate

• Entire bin

• Paddle wheel

• Paddle wheel area

• Agitator

• Paddle wheel pin

• Ice Chute

• Rear bushing

• Motor shaft

• Strip lids (where applicable)

5. Rinse all the parts in clean, running water.

6. Prepare 2 gallons of sanitizing solution by mixing a

1

/2 ounce of household bleach (that contains 5.25%

sodium hypochlorite) with 2 gallons of 120 °F water. The mixture should not exceed 100 PPM of chlorine. Or mix a solution of any approved sanitizer,

following the directions for mixing and applying the

sanitizer.

7. Sanitize the ice bin and cold plate with the sanitizing solution for at least 10 seconds.

8. Allow to air dry. Do not rinse.

Installation and Service Manual

PLUMBING

DIAGRAM

Re-assembling the dispenser parts:

9. Re-assemble parts in the following order:

• Bin liner

• Paddle wheel

• Agitator

• Paddle wheel pin

• Ice chute

• Merchandiser

10. Hand tighten all knurled fasteners.

11. Pour in fresh, sanitary ice and replace the plastic

lid on the top of the dispenser.

12. Plug in the unit’s electrical cord.

13. Check for proper ice dispensing.

PUSH FOR ICE

25

Page 26

Installation and Service Manual

USER MAINTENANCE

BEVERAGE SYSTEM CLEANING

Sanitize the beverage system at initial start-up as well as regularly scheduled cleanings. The drain pan must be in

place under soda valves, to carry away detergent and sanitizing agents that will be flushed through valves.

BAG-IN-BOX SYSTEM

The procedure below is for the sanitation of one syrup circuit at a time. Repeat to sanitize additional circuits.

You will need the following items to clean and sanitize

the Bag-in-Box (BIB) beverage system:

• Three (3) clean buckets

• Plastic brush or soft cloth

• Mild detergent

• Unscented bleach (5% Na CL O) or

Commercial sanitizer

• Bag-In-Box bag connector

1. Prepare the following in the buckets:

• Bucket 1 - warm to hot tap water for rinsing.

• Bucket 2 - mild detergent and warm to hot water.

• Bucket 3 - mix a solution of unscented bleach

(5% Na CL O) or commercial sanitizer and warm

to hot water. Mixture should supply 100 PPM available chlorine (1/4 oz. bleach to 1 gallon water).

2. Disconnect the “syrup-line side” of the bag-in-box

connector.

3. Rinse connector with warm tap water.

4. Connect syrup connector to BIB connector and immerse both into Bucket 1. A “bag-side” connector

can be created by cutting the connector from an

empty disposable syrup bag.

5. Draw rinse water through system until clean water

is dispensed. Most beverage valves allow the syrup

side to be manually activated by depressing the

syrup pallet.

6. Connect Bucket 2 to system.

7. Draw detergent solution through system until solution is dispensed.

8. Repeat steps 2-7 until all syrup circuits contain detergent solution.

9. Allow detergent solution to remain in the system

for 5 minutes.

26

Page 27

Installation and Service Manual

USER MAINTENANCE

BAG-IN-BOX SYSTEM

10. Connect Bucket 3 to system.

1 1. Draw sanitizing solution through system until solu-

tion is dispensed.

12. Repeat step 11 until all syrup circuits contain sanitizer solution.

13. Allow sanitizer solution to remain in system for 15

minutes.

14. Remove nozzles and diffusers from beverage valves.

15. Scrub nozzles, diffusers and all removable valve

parts (except electrical parts) with a plastic brush

or a soft cloth and the detergent solution.

PREVENTATIVE MAINTENANCE

There is little preventative maintenance needed with your Servend dispenser. Following the guidelines below will

assist in trouble free operation.

16. Soak nozzles, diffusers and removable valve part s

(except electrical parts) in sanitizer for 15 minutes.

17. Replace nozzles, diffusers and valve parts.

18. Connect Bucket 1 to system.

19. Draw rinse water through system until no presence

of sanitizer is detected.

20. Attach syrup connectors to BIB’s.

21. Draw syrup through system until only syrup is dispensed.

22. Discard first 2 drinks.

1. Conduct daily cleaning of the machine.

2. Perform monthly cleaning of the machine.

3. Perform periodic cleaning and sanitizing of beverage system.

4. Do not overfill the dispenser bin with ice.

5. Do not allow the dispenser to sit for prolonged periods of non use with ice in the bin.

6. Most ice dispenser service problems are caused

by low usage of the ice dispenser.

7. Do not store more than one day’s supply of ice.

Possible excess ice storage reasons:

• Storage capacity exceeds daily requirements.

• Low demand during the off season.

• Dispenser oversized with future growth in mind.

Lower ice storage to meet one day’s needs. If you manually fill ice, fill only with the appropriate amount of ice.

Fill the dispenser with fresh ice each morning. Do not fill

the dispenser at night just before shut down. Ice cubes

can freeze together if not dispensed.

27

Page 28

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

MD-200 & 250 QUIZNOS™ UNIT EXPLODED VIEW

28

Page 29

EXPLODED VIEWS, PARTS & DIAGRAMS

MD-200 & 250 QUIZNOS™ UNIT PARTS LIST

No.Part NumberModel Description

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

Installation and Service Manual

MD-200 & 250

MD-250

5030880

5030851 Included in Gear Motor Assembly

5030746

5010131

MD-200

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

MD-200 & 250

Quiznos SS Merchandiser

Plumbing Label

Flex Manifold Label

29

Page 30

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

MD-200 QUIZNOS™ MERCHANDISER

30

Page 31

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

MD-250 QUIZNOS™ MERCHANDISER

31

Page 32

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

WIRING MD-200 & 250 QUIZNOS™ UNIT 115V

CAUTION

ELECTRICAL SHOCK HAZARD

DISCONNECT POWER

BEFORE SERVICING

B

RED

VALVE

KEYSWITCH

OPTIONAL

PURPLE

LIGHT

BLACK

WHITE

RED

STARTER

RED

BLACK

LIGHT

STARTER

POWER CORD

OPTIONAL

AGITATION

TIMER

2

531

WHITE

BLACK

WHITE

TO RESET TRANSFORMER:

1. DISCONNECT POWER SUPPLY.

2. PRESS RESET BREAKER SWITCH ON TRANSFORMER.

3. REPLACE MERCHANDISER (FRONT ENCLOSURE).

4. RECONNECT POWER SUPPLY.

(115 VOLT UNITS ONLY)

OPTIONAL MERCHANDISING LAMP

OPTIONAL MERCHANDISING LAMP

BLACK

BLACK

YELLOW

4

BLUE

WHITE

G

BLUE

BALLAST

BALLAST

BLACK

WHITE

WHITE

BLACK

BLACK

BLACK

W

WHITE

BLUE

BLACK

LINE

LOAD

LOAD

LINE

BLACK

BLACK

TRANSFORMER

MOTOR

PURPLE

BLUE

YELLOW

ICE DISPENSE

SWITCH

115 VOLT

PURPLE

WHITE

BLUE

ORANGE

BLUE

OR

ANG

NO

NC

WHIT

COMMON

OPTIONAL

AUDIBLE ALARM

BLUE

GRAY

E

E

BLACK

OPTIONAL

THERMOSTAT

IN

OUT

BUZZER

3

2

1

TIMER

OPTIONAL

EMPTY LIGHT

32

PUSH

BEVERAGE

VALVES

BLACK

WHITE

BLACK

BLACK

WHITE

PUSH

BEVERAGE

VALVES

PN#:5029414

REV. 0

Page 33

Installation and Service Manual

.

l

l

TROUBLESHOOTING

PUMP

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Pump motor does not

pump.

P ump w il l not run but

tank appears to be

alwa ys full.

P ump w il l not run but

tank level appears to

be below start level.

Pump motor does not

shut of f .

Black and/or red probe shorted

Problem with motor or motor wiring

Problem with Liquid Level Control

Board.

Water pre s sure fro m wa te r so urc e i s

not high enough.

Common Lead (Green) shorted out to

Red wi re (High Probe)

Common Lead (Green) shorted out to

Black wi re (Low Probe)

Problem with Liquid Level Control

Board

Probe Harness Connection may be

open.

Remove probes and bend straight or replace with new

probe(s)

Check line voltage first. Check AC voltage across

load terminals on Liquid Level Control. If voltage is

120 plus or minus 10%, replace motor or motor wiring

Check line voltage first. If AC voltage across load

termi nals is not 120 plus or minus 10%, replace the

Liquid Level Control Board.

Veri fy water pressure leading into pump i nlet is 40 psi

minimum with pum p r unning.

Veri fy Green and Red wires are not touching.

Veri fy Green and Black wires are not touching.

Short the "H & L" termi nals on the Liquid Level Contro

Board. If motor does not shut off, replace Liquid Leve

Control Board.

Veri fy connections are good or replace the wiring

harness.

Pump motor

intermittent

Water may not be reaching top probe

in carb tank.

High Lead (Red) open or not

connected.

Common lead (Green) open or not

connected.

Problem with probe or probe harness.

Problem with motor or motor wiring.

Verify tank is not filled with CO

valve up and letting air escape until water begins

coming out.

Veri fy Red lead wi re is connected from tank to unit.

Veri fy Green lead wi re is connected from tank to unit.

Check motor and motor wires by removi ng red and

black wires from the Liquid Level Control Board. If

okay, short "H & L" terminal on Liquid Level Control

Board. If motor stays off, verify probes and bend

straight or replace. Verify with meter.

Measure AC voltage across load terminals on Liquid

Level Control Board. If line voltage is 120 plus or

minus 10% replace motor or motor wiring.

or air by pulli ng relief

2

33

Page 34

Installation and Service Manual

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

TROUBLESHOOTING

PUMP

Pump motor intermittent Problem with Liquid Level Control

Pump motor starts a nd

stops, short cycles, as soon

as water level dr ops belo w

Red (High) probe.

Pump motor starts a nd

stops, short cycles, as soon

as water level dr ops belo w

Black (Low) probe.

Pump short cycles from

below hi gh probe to just

above hi gh probe - Low

probe has no effect.

Board.

Black (Low) Lea d wire is open or

disconnected.

Red and Bla ck Leads are switched with

each other.

Red and Green Leads are switched with

each other.

Black and Green Leads are switched

with each other.

Check line voltage first. If AC voltage across

load terminals on Liqui d Le vel Control Board is

not 12 0 plus or minus 10%, replace the Liquid

Level Contorl board.

Verify conne ctions and continuity of black wire

from Liqui d Le vel Control Board to Probes on

Carb Tank.

Verify Red Lead is going to Red probe and

Balck Lead is going to Black probe.

Verify Red Lead is going to Red Probe and

Green Lead i s goi ng to Ground Screw on tank

Verify Black Lead is going to Black Probe and

Green Lead i s goi ng to Ground Screw on tank.

DRINKS

CONDITION INVESTIGATION CHECK CORRECTION

Warm drinks Is the compressor

Note A: It is important to remember that anytime the refrigeration system is opened the refrigerant

should be recovered, a new drier installed and the proper charge of refrigerant weighed into the

refrigeration system.

No water, syrup or gas

dispensing

runni ng? No

Is there power to the

unit?

Is power coming

throught t he key

switch?

Is there power to the

key swi tch?

Power switch off or

Compressor switch off

Ice bank control Check / replace control box

Compressor overload Check / replace overload

Start relay Check / replace relay

Compressor Check / replace compressor

No power Plug in unit or reset breaker

Power to control box Replace fuse or control box

Key switch "off" Turn switch "on"

Key swi tch defective Replace key switch

No power through the

transformer

Move switch to "on" po sition

Reset/replace transformer

34

Page 35

Installation and Service Manual

TROUBLESHOOTING

DRINKS

CONDITION INVESTIGATION CHECK CORRECTION

Water only dispensing No pressure Regulator(s) out of

adjustment

Out of CO

2

Defective regulator(s) Check/repair/replace regulator(s)

CO

li ne p inc hed , ki nked o r

2

obstructed

Syrup and CO

dispensing

only

2

Carbonator No power Check power supply. Plug in

Water supply Make sure water is turned "on"

Defective carbonator Check/repair/replace carbonator

Syrup and plain water

only dispensing

No pressure Out of CO

HP regulator out of

2

adjustment

Defective HP regulator Check/repair/replace HP regulator

CO

li ne p inc hed , ki nked o r

2

obstructed

One valve will not

dispense anythi ng

Is there power to the

valve?

Broken wire or loose

connection

Bad microswitch Replace mi croswitch

Beverage dispense d

is too sweet

Is the ratio (brix) of

the drink correct?

Flow control out of

adjustment

Insufficient soda flow due to

low ca rbonator pressure

Low CO

leaks

pressure due to

2

Obstruction in the water or

soda line

Beverage is not sweet

enough

Is the ratio (brix) of

the drink correct?

Flow control out of

adjustment

Soda flow too hi gh Reset CO

Obstruction in syrup line Clean out the syrup line

Drinks are foaming Are system

Over carbonation C heck CO

pressures correct?

Dirty lines/valves Clean/sanitize entire syste m

Check/adjust regulator(s)

Install fres h ta nk

Check/repair/replace C O2 line

carbonator or reset breaker.

Replace water filter

Check/clean/replace pump strainer

Check/clean/repair water check

valve

Che ck for fr ozen wate r line.

Internal Carbonator unit only.

pump, motor, electrode or liquid

level c ontrol.

Install fres h ta nk

Adjust HP regulator to the proper

setting

Check/repair/replaceCO2 line

Replace/repair wire or connector

Ad just the flow co ntrol

Adjust CO

tank

pressure or chang e the

2

Repair CO2 leaks

Clean out the lines

Ad just the flow co ntrol

pressure or replace

regulator if ne cessary

pressure or replace regulator if

2

supply. Reset

2

necessary

35

Page 36

TROUBLESHOOTING

LIQUID LEVEL CONTROL

START

START

Does

Does

Yes

Yes

Yes

Yes

Is pump

Is pump

motor

motor

operation

operation

intermitten t

intermitten t

?

?

No

No

Pump

Pump

motor

motor

come on?

come on?

No

No

Rem ove red

Rem ove red

and black

and black

wires from

wires from

LLC.

LLC.

Black and/or red probe

Black and/or red probe

shorted. Rem ove

shorted. Rem ove

probes , s traighten or

probes , s traighten or

replace if necessary.

replace if necessary.

Check pump

Check pump

motor and

motor and

wiring.

wiring.

Yes

Yes

Yes

Yes

Does

Does

pum p

pum p

motor

motor

come

come

on?

on?

No

No

Measure AC

Measure AC

voltage

voltage

across load

across load

term inals on

term inals on

LLC.

LLC.

Is line

Is line

voltage

voltage

(± 10%)

(± 10%)

present

present

?

?

No

No

Short “H” and

Short “H” and

“C” terminals

“C” terminals

on LLC.

on LLC.

Does

Does

the

the

pum p

pum p

motor

motor

shut

shut

off?

off?

No

No

Replace

Replace

LLC

LLC

Yes

Yes

Check probe

Check probe

harness, harness

harness, harness

connections and

connections and

water supply.

water supply.

END

END

Page 37

Page 38

Page 39

INDEX

B

Back Room Package............... 17

brixing ....................................... 3

C

Carbon Dioxide ......................... 6

CAUTION .......................... 18, 25

claims ...................................... 15

Cleaning .................................... 3

CO 2........................................... 7

CO2 monitors ............................ 7

D

damage .............................. 3, 15

delivery .............................. 3, 15

distributor.................................. 3

Drain.......................................... 8

ducts ......................................... 8

E

exterior ................................... 24

F

FOREWORD .............................. 3

H

health department................... 24

I

INSPECTION .............................. 3

INSTALLATION

8, 9, 10, 11, 12, 13

Installation Date ........................ 3

Instructions ............................. 24

irregularities .............................. 3

L

location ..................................... 8

M

MBE ........................................... 3

Model Number ........................... 3

modifications............................. 6

Monthly Cleaning .................... 25

O

Operation .................................. 6

P

Power outlet ............................. 8

Q

Qualified Service Personnel..... 6

R

regulations .............................. 24

Relocation ................................. 6

return procedures .................... 3

S

SAFETY ............................... 6, 7

sanitizing................................... 7

Serial Number ........................... 3

service assistance ................... 3

Service Personnel .................... 6

Shipping .................................... 6

Shipping, Storage, Relocation .. 6

soa py wate r ........................... 25

solvents .................................. 25

start-up ..................................... 6

Storage ..................................... 6

T

TROUBLESHOOTING

33, 34, 35, 36

U

Unit Inspection ........................ 15

UNPACKING .............................. 3

W

Warning .................................... 6

WARRANTY INFORMA TION ..... 3

Water line.................................. 8

water-to-syrup ratio. See brixing

Page 40

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

5030765 October 19, 2006 REV6

Loading...

Loading...