Page 1

RND-0049 REV 1

SERVICE MANUAL

CASH CUBE

Before using this product, read this SERVICE MANUAL carefully to understand the contents stated herein.

After reading this manual, be sure to keep it available nearby the product or somewhere convenient in

order to be able to refer to it whenever necessary.

Manufactured in the UK by

Page 2

CONTENTS

1. BEFORE USING THIS PRODUCT.................................................................................................. 3

1.1. INSPECTIONS IMMEDIATELY AFTER TRANSPORTING THE PRODUCT TO THE LOCATION4

2. INTRODUCTION TO THIS SERVICE MANUAL.............................................................................. 6

3. INSTALLATION AND MAINTENANCE INSTRUCTIONS ................................................................. 7

3.1. HANDLING AND INSTALLATION PRECAUTIONS...................................................................... 7

3.2. NAME OF PARTS........................................................................................................................ 8

3.3. ACCESSORIES..........................................................................................................................10

3.4. ASSEMBLY INSTRUCTIONS.....................................................................................................12

3.4.1. INSTALLING THE POP PANEL.(PUB-5006)........................................................................13

3.4.2. SECURING IN PLACE (LEG ADJUSTER ADJUSTMENT)...................................................14

3.4.3. CONNECTION TO THE POWER SUPPLY..........................................................................15

3.5. MOVING THE MACHINE............................................................................................................16

3.6. ELECTRICAL ASSEMBLY..........................................................................................................17

3.6.1. REMOVING THE ELECTRICAL ASSEMBLY .......................................................................17

3.7. CONTROL PANEL......................................................................................................................18

3.7.1. REPLACING THE CONTROL PANEL..................................................................................18

3.8. GAME BOARD ...........................................................................................................................20

3.8.1. TAKING OUT THE GAME BOARD......................................................................................20

3.8.2. COMPOSITION OF GAME BOARD.....................................................................................21

3.9. MONITOR ADJUSTMENT..........................................................................................................22

3.10. TROUBLESHOOTING.............................................................................................................24

3.11. HOPPER ASSEMBLY.............................................................................................................25

3.11.1. HOPPER OPERATION ....................................................................................................25

3.11.2. HOPPER ASSEMBLY FAULT FINDING...........................................................................25

3.12. COIN MECHANISMS ..............................................................................................................27

3.12.1. COIN MECHANISM OPERATION (FOR UK MACHINES)................................................27

3.12.2. COIN MECHANISM FAULT FINDING ..............................................................................27

3.13. FUSES....................................................................................................................................28

4. REFILL MODE ...............................................................................................................................29

4.1. WHAT IS REFILL MODE?..........................................................................................................29

4.2. LANDLORD REFILL ...................................................................................................................29

4.3. COLLECTOR REFILL.................................................................................................................30

4.4. DEALING WITH A HOPPER EMPTY ERROR............................................................................31

4.5. METERS.....................................................................................................................................32

5. DATAPORT....................................................................................................................................33

5.1. WHAT IS THE DATAPORT? ......................................................................................................33

5.2. SETTING PROCEDURE.............................................................................................................33

5.3. DATAPORT SETTING................................................................................................................34

5.4. ERROR.......................................................................................................................................35

6. PERIODIC CHECK AND INSPECTION ..........................................................................................36

6.1. CLEANING THE CABINET SURFACES.....................................................................................36

7. CONTENTS OF GAME..................................................................................................................37

7.1. HOW TO PLAY...........................................................................................................................37

7.1.1. OBJECTIVE.........................................................................................................................37

7.1.2. SELECT A STAGE ..............................................................................................................37

7.1.3. BASIC TRAINING................................................................................................................37

7.1.4. BREAK SHOT......................................................................................................................38

7.1.5. FOLLOWING THE BREAK SHOT .......................................................................................38

7.1.6. CONTINUE SELECTION.....................................................................................................39

7.1.7. PRIZE COLLECTION...........................................................................................................39

7.2. USING THE AIM / CONTROLLER..............................................................................................40

7.2.1. GAME SCREEN ..................................................................................................................40

7.2.2. CONTROL PANEL ...............................................................................................................40

7.2.3. POSITION THE CUE TIP.....................................................................................................40

7.2.4. MAKE YOUR SHOT.............................................................................................................41

8. EXPLANATION OF TEST AND DATA DISPLAY............................................................................42

8.1. SYSTEM TEST MODE ...............................................................................................................43

8.1.1. RAM TEST...........................................................................................................................44

8.1.2. JVS TEST............................................................................................................................45

i

Page 3

8.1.3. INPUT TEST SCREEN ........................................................................................................46

8.1.4. SOUND TEST......................................................................................................................46

8.1.5. CRT TEST...........................................................................................................................47

8.1.6. SYSTEM ASSIGNMENTS ...................................................................................................48

8.1.7. COIN ASSIGNMENTS.........................................................................................................49

8.1.8. BOOKKEEPING...................................................................................................................50

8.1.9. BACKUP DATA CLEAR.......................................................................................................50

8.1.10. CLOCK SETTING .............................................................................................................51

8.1.11. DIMM BOARD TEST........................................................................................................51

8.2. GAME TEST DESCRIPTION MODE ..........................................................................................52

8.2.1. GAME TEST MENU SCREEN.............................................................................................52

8.2.2. INPUT TEST SCREEN ........................................................................................................52

8.2.3. OUTPUT TEST SCREEN ....................................................................................................53

8.2.4. CONTROLLER ADJUSTMENT SCREEN ............................................................................53

8.2.5. GAME ASSIGNMENT SCREEN ..........................................................................................54

8.2.6. PAYOUT SETTING SCREEN..............................................................................................55

8.2.7. CREDIT SETTING SCREEN................................................................................................57

8.2.8. HOPPER TEST MENU SCREEN .........................................................................................59

8.2.8.1. INPUT TEST SCREEN .................................................................................................60

8.2.8.2. OUTPUT TEST SCREEN .............................................................................................61

8.2.8.3. COIN TEST SCREEN...................................................................................................62

8.2.8.4. TROUBLE LOG SCREEN.............................................................................................64

8.2.8.5. MEMORY SETTING .....................................................................................................66

8.2.8.6. DATAPORT SETTING..................................................................................................66

8.2.8.7. COIN ASSIGNMENTS SETTING..................................................................................67

8.2.9. BOOKKEEPING SCREEN...................................................................................................68

8.2.10. BACKUP DATA CLEAR SCREEN....................................................................................75

9. DESIGN RELATED PARTS............................................................................................................76

10. APPENDIX A - ELECTRICAL SCHEMATIC....................................................................................77

10.1. WIRE COLOURS....................................................................................................................77

10.2. ELECTRICAL SCHEMATIC.....................................................................................................77

10.3. SCHEMATIC DRAWING 1......................................................................................................78

10.4. SCHEMATIC DRAWING 2......................................................................................................79

ii

Page 4

1. BEFORE USING THIS PRODUCT

To ensure the safe usage, be sure to read the following before using the product. The following instructions are

intended for the use of QUALIFIED SERVICE PERSONNEL ONLY.

If any activity is carried out on the product, this should be done only after carefully reading and sufficiently

understanding the instructions.

Only qualified service personnel should carry out maintenance on the product.

Depending on the potential risk, terms such as” WARNING!” “CAUTION” and “IMPORTANT!” are used where an

explanation is given that requires special attention. SEGA is not responsible for injury or damage caused by use in a

manner contrary to the instructions given in this document.

In order to prevent accidents warning stickers and printed instructions are applied in the places where a potentially

hazardous situation relating to the product could arise. Be sure to comply with these warnings.

Indicates that mishandling the product by disregarding this warning will cause a potentially

hazardous situation that can result in death or serious injury.

Indicates that mishandling the product by disregarding this caution will cause a potentially

hazardous situation that can result in personal injury and or material damage.

This is cautionary information that should be complied with when handling the product.

Indicates that mishandling the product by disregarding this will cause a potentially

hazardous situation that may not result in personal injury but could damage the product.

Be sure to turn off the power and disconnect from the mains supply before working on the machine.

Ensure that the correct fuses are fitted to the machine. Details of these are enclosed in the Service Manual.

Ensure that only qualified Service Engineers perform any maintenance work on the machine.

Specification changes, removal of equipment, conversion and/or additions not designated by SEGA are not permitted

and will invalidate this product’s CE conformity.

Warning labels or safety covers for personal protection etc, are component parts of the product. A potential hazard

will be created if the machine is operated while any parts have been removed. Do not operate the product if any

doors, lids or protective covers become damaged or lost. SEGA is not liable in any whatsoever for any injury and/or

damage caused by specification changes not designated by SEGA.

Before installing the product, check for the Electrical Specification Sticker, SEGA products have a sticker on which the

electrical specifications are detailed. Ensure that the product is compatible with the power supply voltage and

frequency requirements of the location in which the machine is to be installed.

Install and operate the machine only in places where appropriate lighting is available, allowing warning stickers to be

clearly read.

To ensure maximum safety for customers and operators, stickers and printed instructions describing potentially

hazardous situations are applied to potentially hazardous locations. Ensure that the product’s operating location has

sufficient lighting to allow any warnings to be read. If any sticker or printed warning is removed or defaced, do not

operate the machine until an identical item has replaced it.

Exercise great care when handling the monitor (applies only to product with monitor). Some of the monitor (TV) parts

are subject to high-tension voltage. Even after turning the power off some components are liable to high-tension

voltage. Only qualified service engineers should perform monitor repair and replacement.

In cases where commercially available monitors and printers are used, only the items relating to this product are

contained in this manual. Some commercially available equipment will have functions and reactions not referred to in

this manual. This manual should be read in conjunction with the specific manufacturer’s manual for such equipment.

Descriptions contained herein may be subject to change without prior notification.

The contents described herein are fully prepared with due care. However, should any question arise or errors be found

please contact SEGA AMUSEMENTS EUROPE LTD.

3

Page 5

1.1. INSPECTIONS IMMEDIATELY AFTER TRANSPORTING THE PRODUCT

TO THE LOCATION

• Only QUALIFIED SERVICE PERSONNEL should carry out inspection.

Normally, at the time of shipment, SEGA products are in a state to allowing usage immediately after

transporting to the location. Nevertheless, an irregular situation may arise during transportation preventing

this. Before turning on the power, check the following points to ensure that the product has been

transported safely.

• Are then any dented parts or defects (cuts, etc.) on the external surfaces of the product?

• Are castors and leg adjusters present and undamaged?

• Do the power supply voltage and frequency requirements meet with the local supply?

• Are all wiring connectors correctly and securely connected? Unless connected in the correct direction,

connector connections cannot be made successfully. Do not insert connectors forcibly.

• Are all IC’s of each IC BD firmly inserted?

• Does the power cord have any cuts or dents?

• Do fuses meet the specified rating?

• Are such units such as monitors, control equipment, IC BD, etc. firmly secured?

• Are all earth wires connected?

• Are all accessories available?

• Can all doors and lids be opened with the accessory keys and/or tools?

4

Page 6

CONCERNING THE STICKER DISPLAY CONCERNING WARNING STICKERS

SEGA product has stickers describing the product

manufacture number (Serial Number) and

electrical specification. If you require service

assistance you will require the Serial Number.

Identical machines may have different parts fitted

internally. Only by quoting the Serial Number will

the correct parts be identified.

SEGA product has warning displays on

stickers, labels or printed instructions

adhered/attached to or incorporated in the

places where hazardous situations can arise.

The warning displays are intended for the

accident prevention of customers and service

personnel.

SPECIFICATIONS

Installation Space (mm): 650 (W) 840 (D)

Height (mm): 1576

Height with Pop Panel (mm): 1916

Weight (kg): 100 Kg (approx.)

Rated Voltage (VAC): 220 - 240

Rated Current (A): 1

Note: Descriptions in this manual are subject to change without prior notice.

5

Page 7

2. INTRODUCTION TO THIS SERVICE MANUAL

SEGA ENTERPRISES LTD., supported by its experience in electronic high technology of VLSI’s,

microprocessors etc. and with a wealth of experience, have for more than 30 years been supplying various

innovative and popular games to the world market. This Service Manual is intended to provide detailed

descriptions together with all the necessary information covering the general operation of electronic

assemblies, electro-mechanicals, servicing controls, spare parts, etc. as regards this new SEGA product.

This manual is intended for those who have knowledge of electricity and technical expertise especially in

IC’s, CRT’s, microprocessors etc. Carefully read this manual to acquire sufficient knowledge before

working on the machine. Should there be any malfunction, non-technical personnel should under no

circumstances touch the internal systems. Should such a situation arise contact the nearest branch listed

below, or our head office.

SEGA AMUSEMENTS EUROPE LTD./ SEGA SERVICE CENTRE

Suite 3a

Oaks House

12 - 22 West Street

Epsom

Surrey

United Kingdom

KT18 7RG

Telephone: +44 (0) 1372 731820

Fax: +44 (0) 1372 731849

6

Page 8

3. INSTALLATION AND MAINTENANCE INSTRUCTIONS

• Only QUALIFIED SERVICE PERSONNEL should carry out installation and

maintenance.

3.1. HANDLING AND INSTALLATION PRECAUTIONS

When installing or inspecting the machine, be very careful of the following points and pay attention to

ensure that the player can enjoy the game safely.

The game must NOT be installed under the following conditions:

• Outside, the game is designed for indoor use only.

• In areas directly exposed to sunlight, high humidity, dust, excessive heat or extreme cold.

• In locations that would present an obstacle in the case of an emergency i.e. near fire equipment or

emergency exits.

• On unstable surfaces or surfaces subject to vibration.

• Where liquids, other than routine cleaning, may come into contact with the game.

Important:

• Only Qualified Service Personnel should install this machine.

• Be sure to switch the supply power OFF and remove the mains supply plug from the machine before

any work is carried out on the machine.

• Do not attempt to repair the PCB’s (Printed Circuit Boards) yourself. This will void the warranty. The

PCB’s contain static sensitive devices that could be damaged.

• Always return a faulty part to your distributor with adequate packaging and protection.

• When removing the plug from the mains always grasp the plug not the cable.

• Do not use a fuse that does not meet the specified rating.

• Make sure all connections are secure before applying power.

• Ensure that the mains lead is not damaged. If the mains lead is damaged in any

way there could be a danger of electric shock or a fire hazard.

• Ensure that the power supply is fitted with circuit protection. Using the power

7

supply without circuit protection is a fire hazard.

Page 9

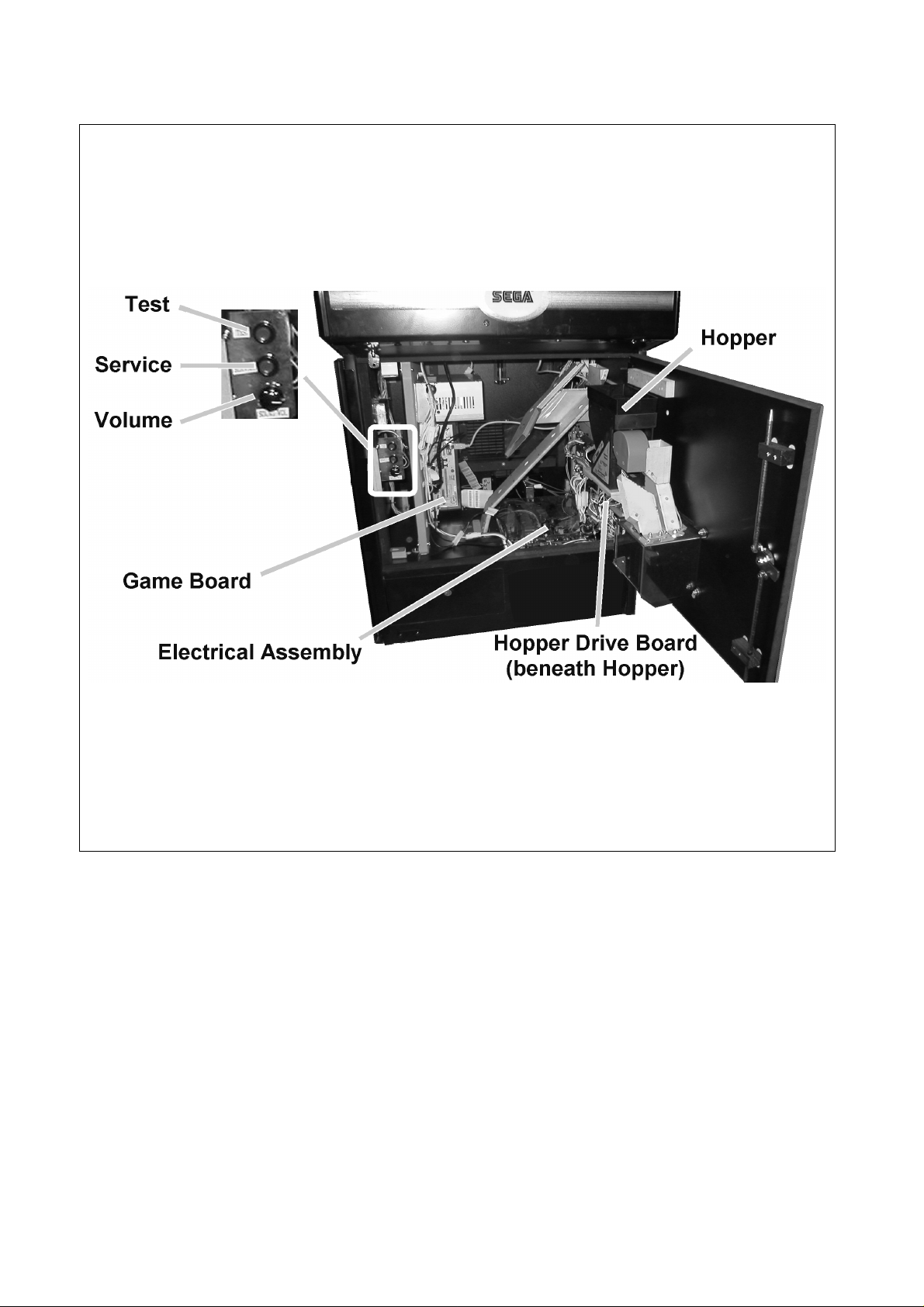

3.2. NAME OF PARTS

8

Page 10

9

Page 11

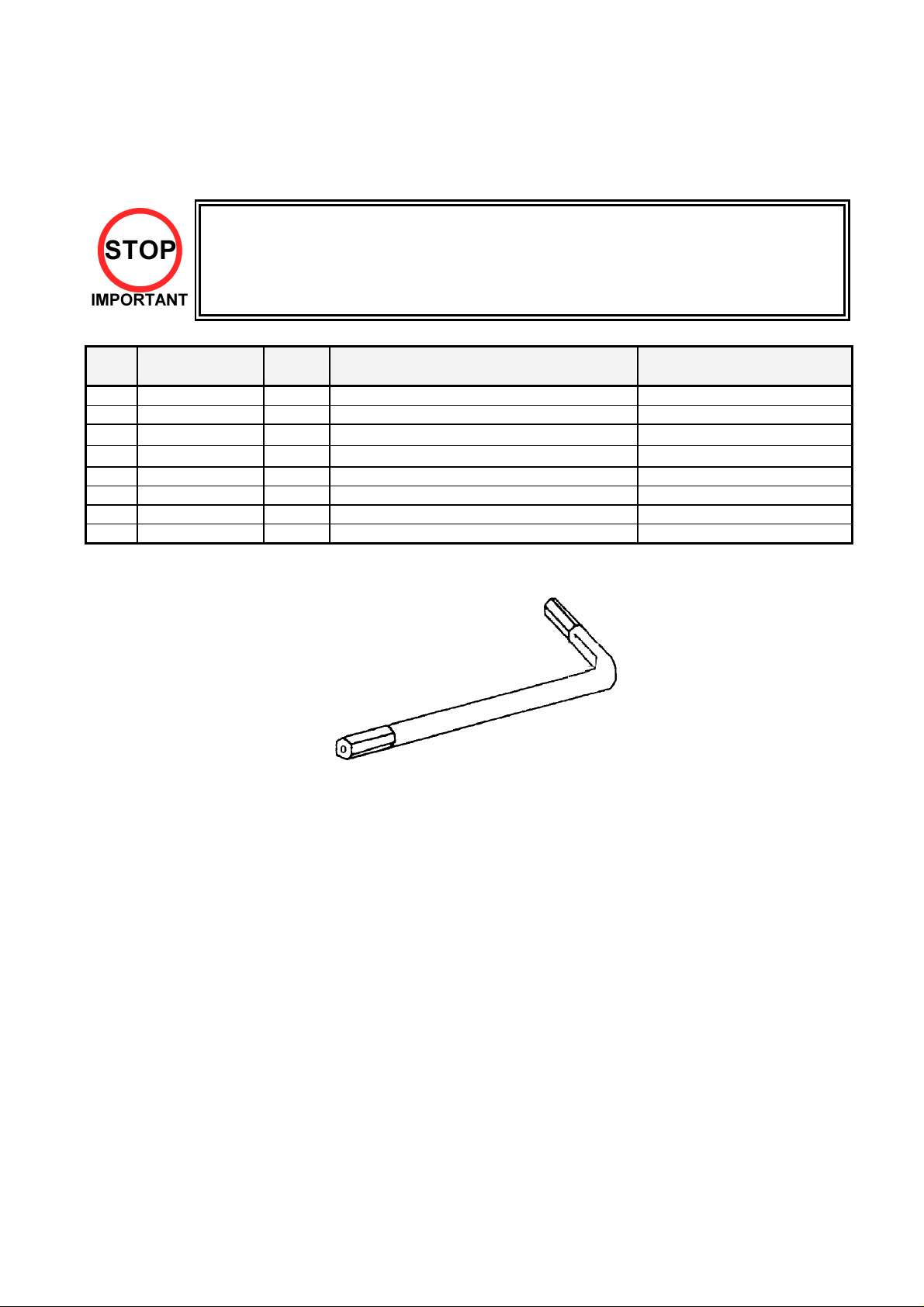

3.3. ACCESSORIES

The machine is supplied with an installation kit. Please ensure the following parts are supplied:

• The Installation Kit will be placed in the Cashbox. However larger items (e.g. the Pop

Panel) will be placed in the recess beneath the Test and Service buttons inside the

cabinet body.

• You must ensure that these items are removed before the machine is powered up.

No. PART NUMBER QTY DESCRIPTION COMPONENT REFERENCE

1 PUB-5006 1 POP CASHCUBE

2 PUB-2501UK 1 CUE PUB spare

3 SAECE-123

401 RND-0049

402 OS1019 1 SELF SEAL BAG 9X12.3/4

404 PK0061 0.025 BUBBLE WRAP LARGE 1.5M X 45M

405 540-0006-01 1 WRENCH M4 TMP PRF

406 540-0015-01 1 WRENCH M6 TMP PRF

1

DECLARATION OF CONFORMITY SPP

1

SERVICE MANUAL SPP PUB SWP

Items 405 & 406 - Tamperproof TORX wrench.

10

Page 12

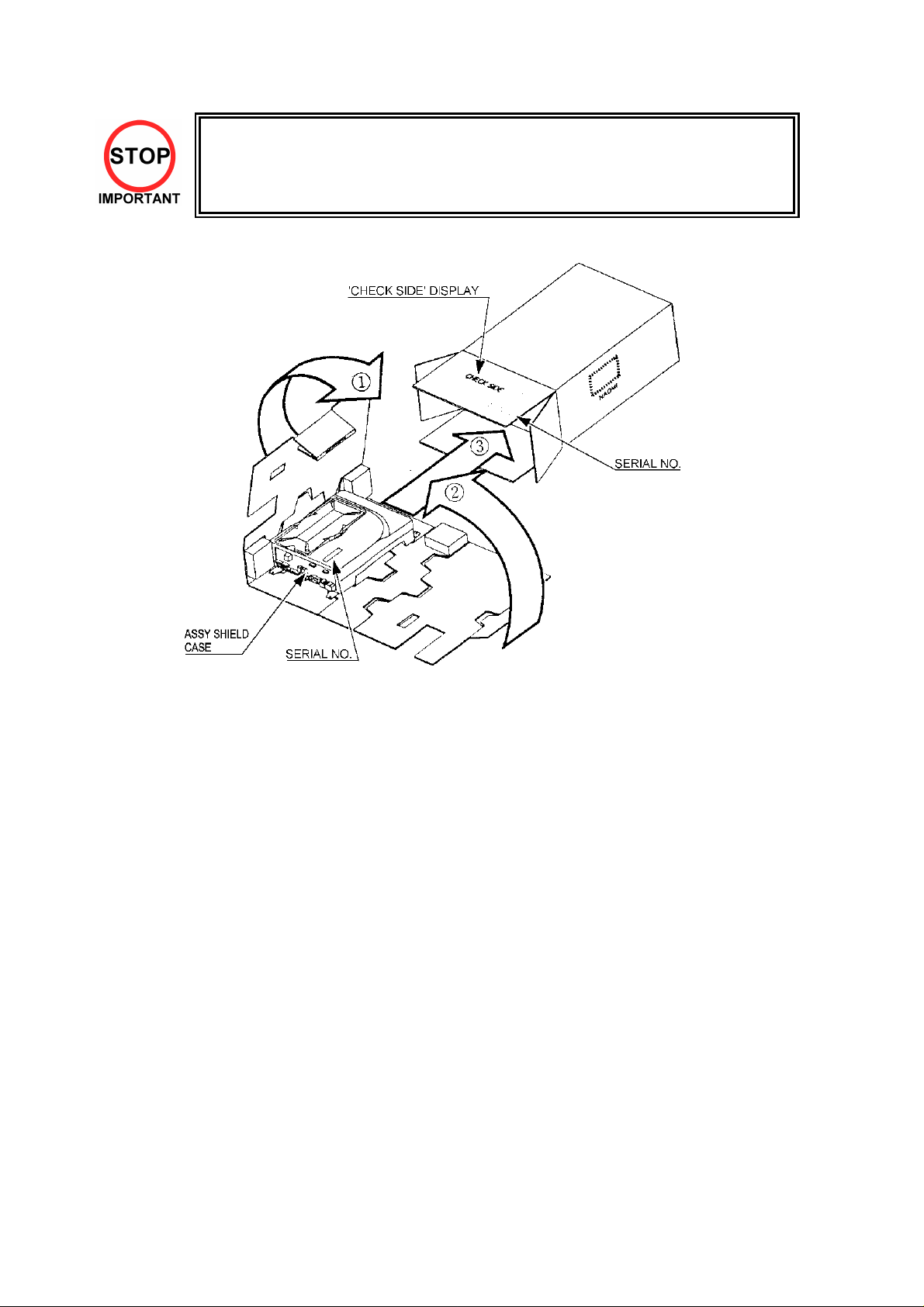

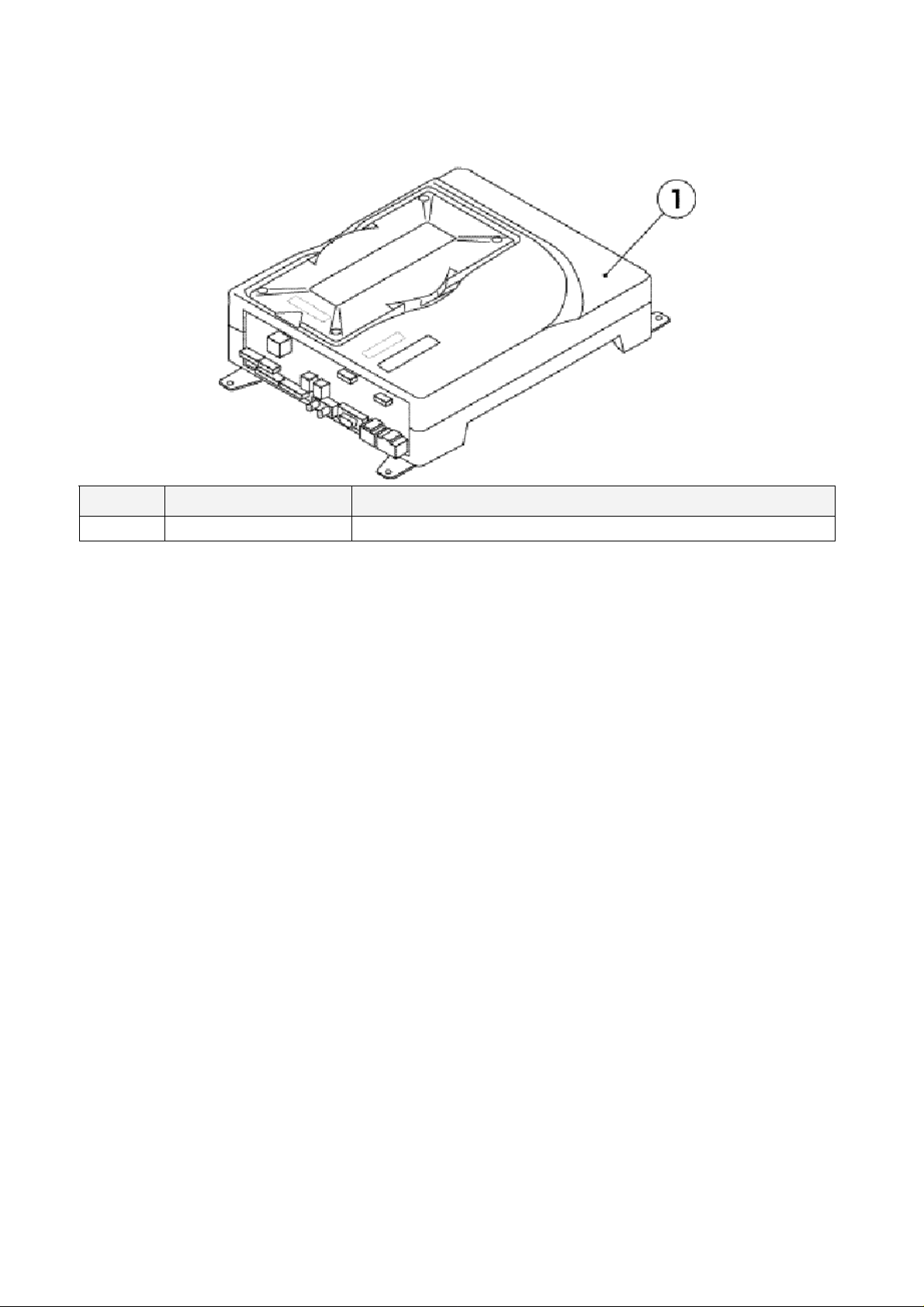

• When returning the GAME BOARD for repair or replacement, be sure to

package the entire ASSY SHIELD CASE in the original card transit box - THERE

ARE NO USER-SERVICEABLE PARTS INSIDE.

• Failure to return the GAME BOARD in this manner may invalidate the warranty.

Wrap the ASSY SHIELD CASE with the packaging material and put it in the original transit box as shown.

Putting it upside down or packing other than as shown can damage the GAME BOARD and parts.

11

Page 13

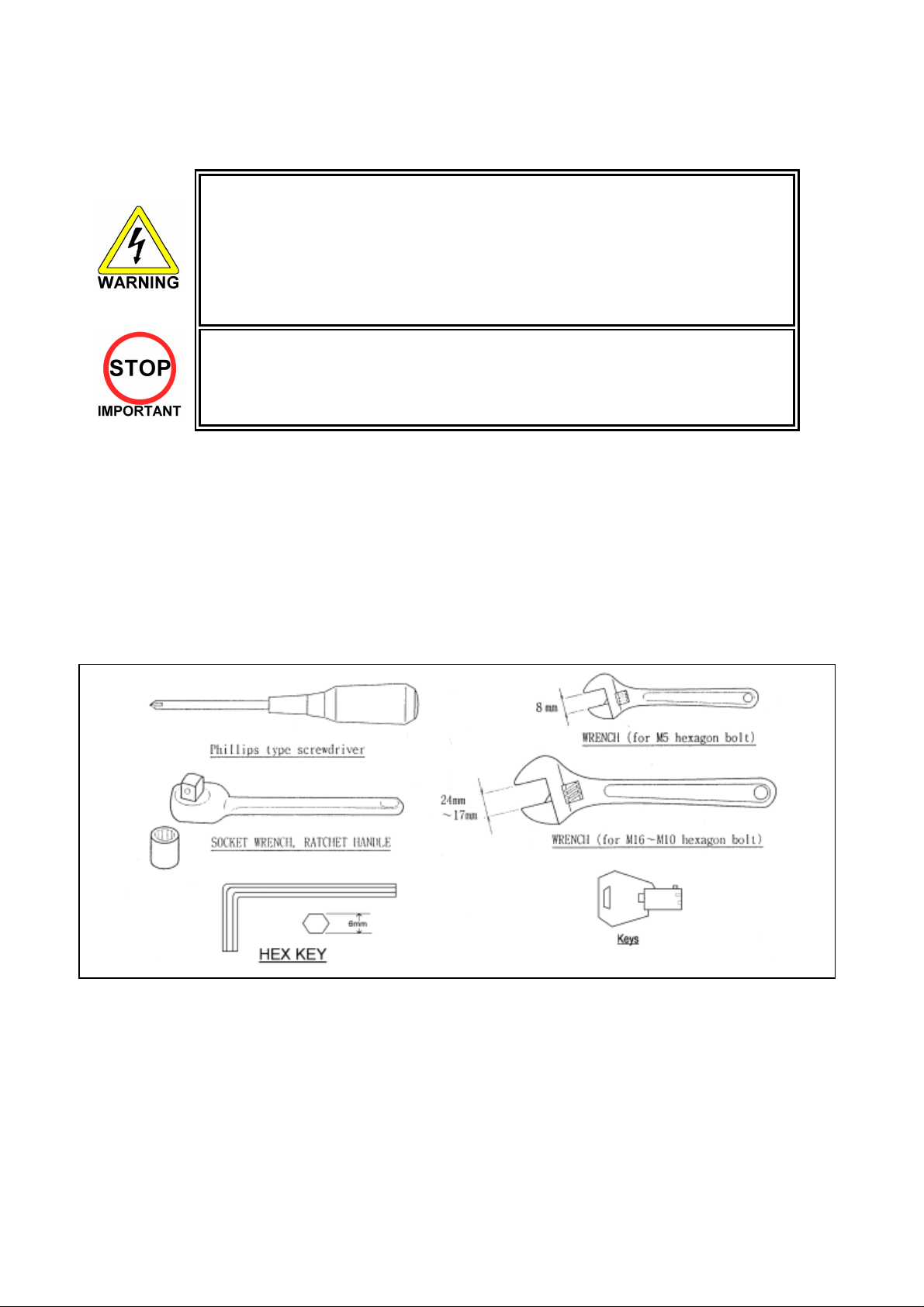

3.4. ASSEMBLY INSTRUCTIONS

• Perform the assembly by following the procedure herein stated. Failure to

comply with the instructions, for example, inserting the plug into an outlet at a

stage not mentioned in this manual can cause an electric shock

• Assembling should be performed as per this manual. Since this is a complex

machine, erroneous assembling can cause damage to the machine, or

malfunction to occur.

• Do not attempt to complete this work alone, a minimum of 2 people are required.

• Only QUALIFIED SERVICE PERSONNEL should carry out assembly.

When carrying out the assembly work, follow the procedure in the following three item sequence:

STEP 1

STEP 2

STEP 3

Note that the parts contained within the installation kit are required for the assembly work.

The following tools will be required when installing this machine:

INSTALLING THE POP PANEL

SECURING IN PLACE (LEG ADJUSTER ADJUSTMENT)

CONNECTION TO THE POWER SUPPLY

12

Page 14

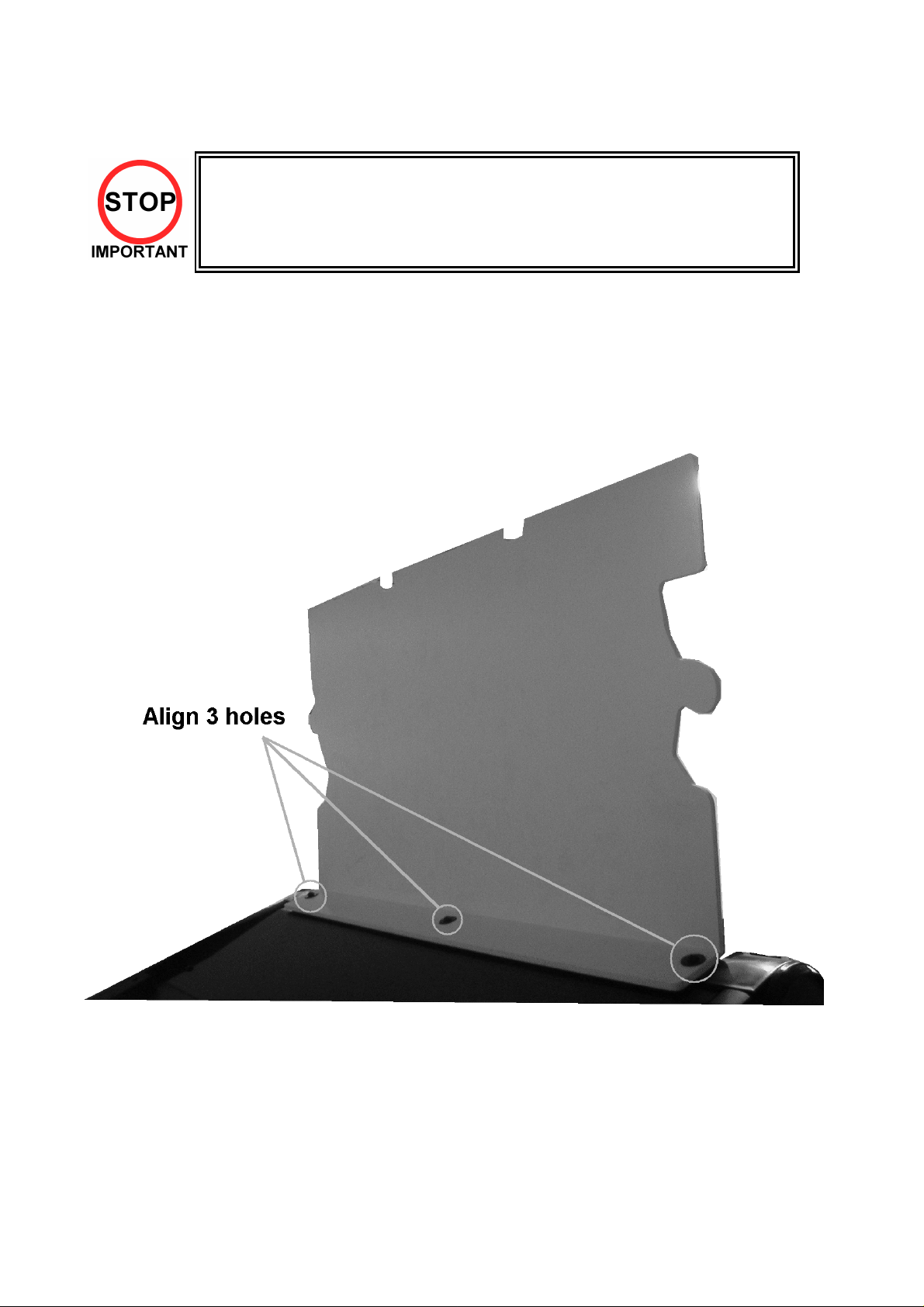

3.4.1. INSTALLING THE POP PANEL.(PUB-5006)

• QUALIFIED SERVICE PERSONNEL should only carry out this operation.

The Pop Panel picks up on the three top fixings of the Monitor Mask Moulding.

To fit:

1 Remove the three screws and washers on top of the Monitor Mask Moulding.

2 Offer up the Pop Panel and align over three fixing holes.

3 Re-fix the screws and washers.

4 Ensure the Monitor Mask Moulding is pushed back and seated properly to the cabinet.

13

Page 15

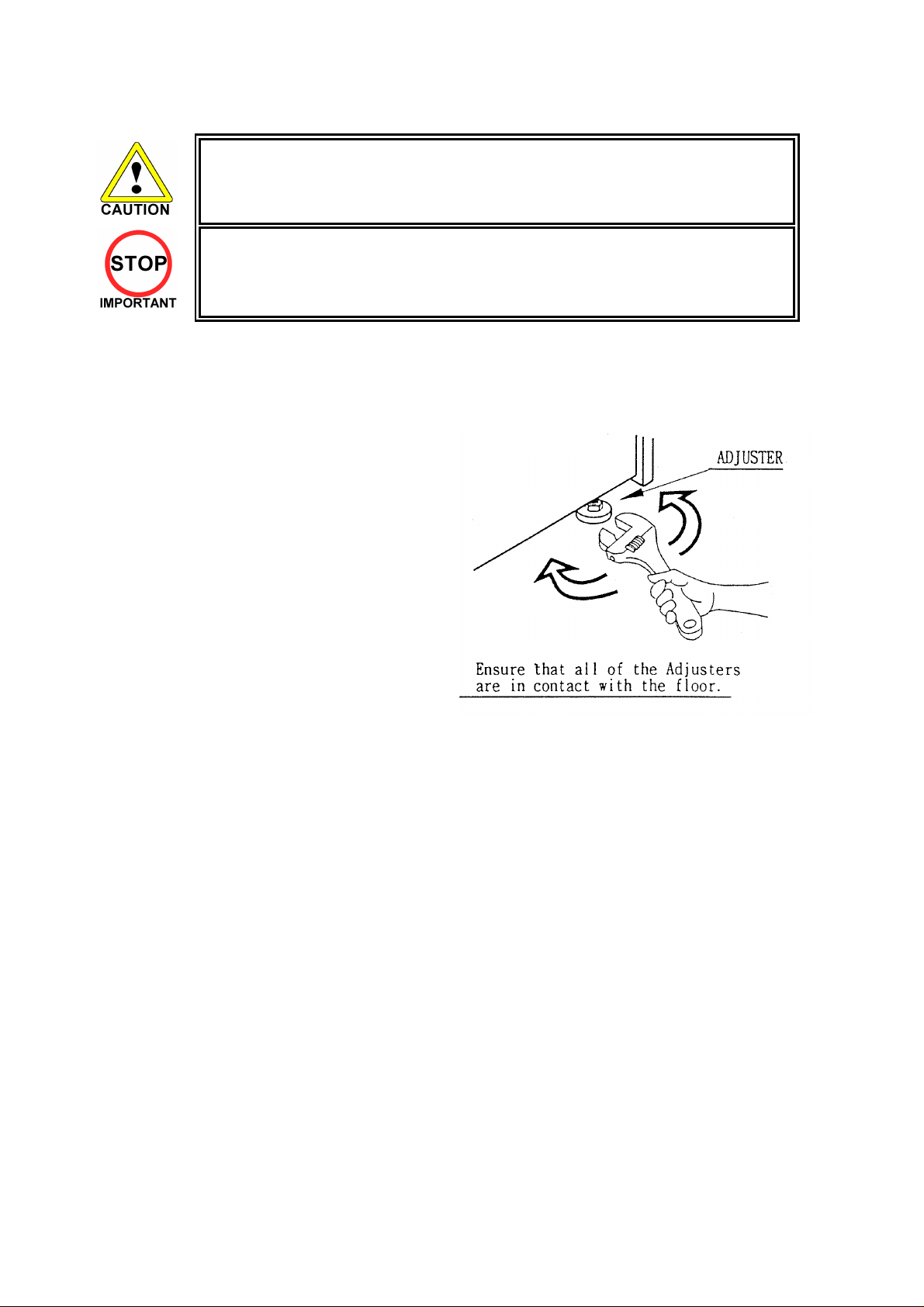

3.4.2. SECURING IN PLACE (LEG ADJUSTER ADJUSTMENT)

• The nominal position for the leg adjusters is fully retracted. Only

extend them if the machine is sited on an uneven surface.

• Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

This machine has two castors (at rear) and two leg adjusters (at front). Where the installation is flat and

level, the adjuster should not need to be extended. Only extend the adjusters to prevent the machine from

rocking.

To extend the led adjusters:

1. Use a wrench to turn them until the machine is

stable and level.

Ensure adequate ventilation is maintained by ensuring there is at least a 150mm gap between the

back on the machine and any wall.

14

Page 16

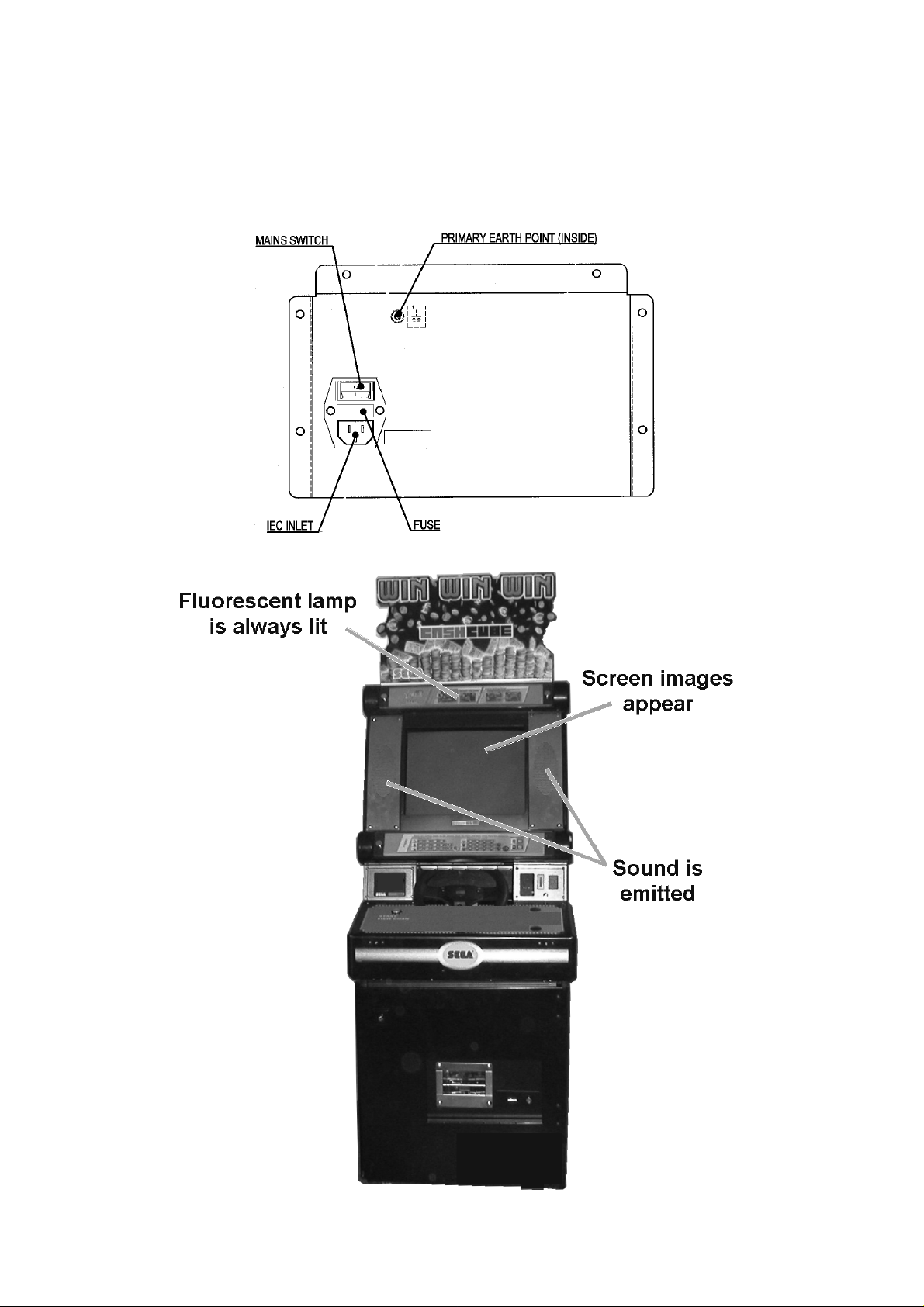

3.4.3. CONNECTION TO THE POWER SUPPLY

To connect the machine to the power supply:

1. With the Mains Switch in the ‘O’ position, insert the IEC mains lead plug into the IEC socket.

2. Turn the machine on by switching the Mains Switch to the ‘I’ position.

15

Page 17

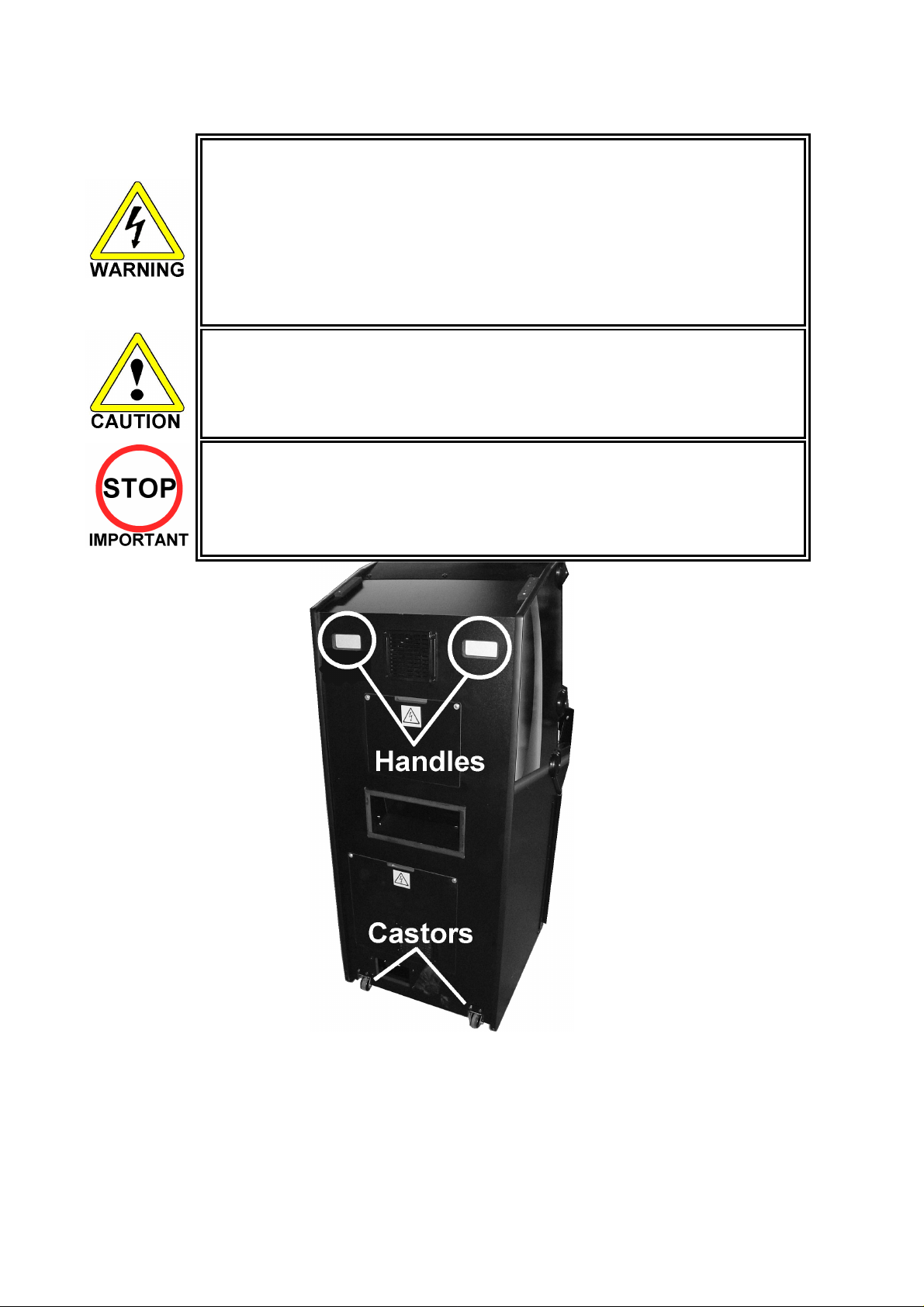

3.5. MOVING THE MACHINE

• When moving the machine, be sure to remove the plug from the power

supply. Moving the machine with the plug inserted can cause the power cord

to be damaged, resulting in a fire or electric shock.

• When moving the machine, retract the leg adjusters fully. During movement

pay careful attention so that the casters or leg adjusters do not damage any

other cabling laid on the floor. Such damage could result in a fire or electric

shock.

• Do not push the upper part of the cabinet. Failure to observe this can cause

the cabinet to fall forwards and result in accidents.

• When transporting the machine, be sure to hold the handles on the rear of

the cabinet. Inclining the machine by holding portions other than the handles

can damage the cabinet and/or the floor surface.

• Do not push the pop panel. Failure to observe this may damage the

installation portions and may cause unexpected accidents.

• The machine weighs approximately 100Kg and should only be moved by a

minimum of 2 people..

To move the machine:

1. Using the handles at the back of the cabinet, tilt the cabinet back until it is balanced safely on the

rear castors. EXTREME CARE SHOULD BE TAKEN DURING THIS OPERATION TO AVOID

INJURY OR DAMAGE TO THE MACHINE.

2. Carefully roll the machine to the desired position.

3. Tilt cabinet forward until front legs are in contact with the ground – CAUTION, THE MACHINE

MAY PULL FORWARDS.

4. Adjust the leg adjusters to ensure cabinet is square and steady if required.

16

Page 18

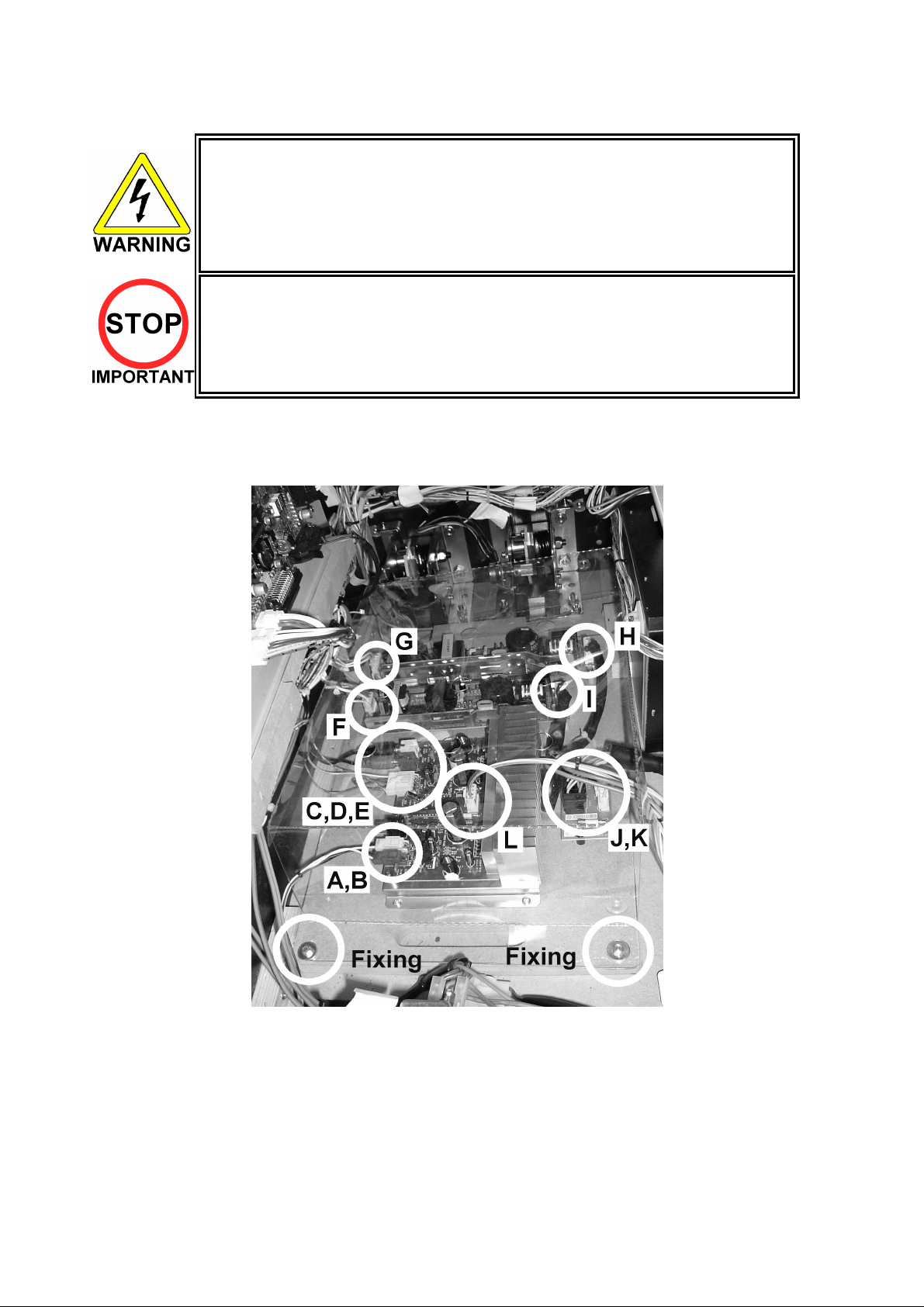

3.6. ELECTRICAL ASSEMBLY

• Before performing work, be sure to turn power off. Working with power on can

cause an electric shock or short circuit.

• Use care to ensure the wiring is not damaged. Damaged wiring can cause

electric shock or short circuit.

• Touching parts of the machine other than those specified here can cause electric

shock of short circuit.

• This procedure to be carried out only by QUALIFIED SERVICE PERSONNEL.

3.6.1. REMOVING THE ELECTRICAL ASSEMBLY

1. Remove the two fixings (bolt m4x30 and washer) securing the board.

2. Remove the plastic board cover.

3. Uncouple the loom connectors A to L.

4. Carefully slide the board out from the rear of the cabinet ensuring no damage takes place to the

board.

17

Page 19

3.7. CONTROL PANEL

• Before starting work, ensure that the cabinet is isolated from the mains by

switching off and removing the IEC mains lead from the wall outlet.

• Be careful not to damage wiring. Damaged wiring can cause electric shock

and short circuits.

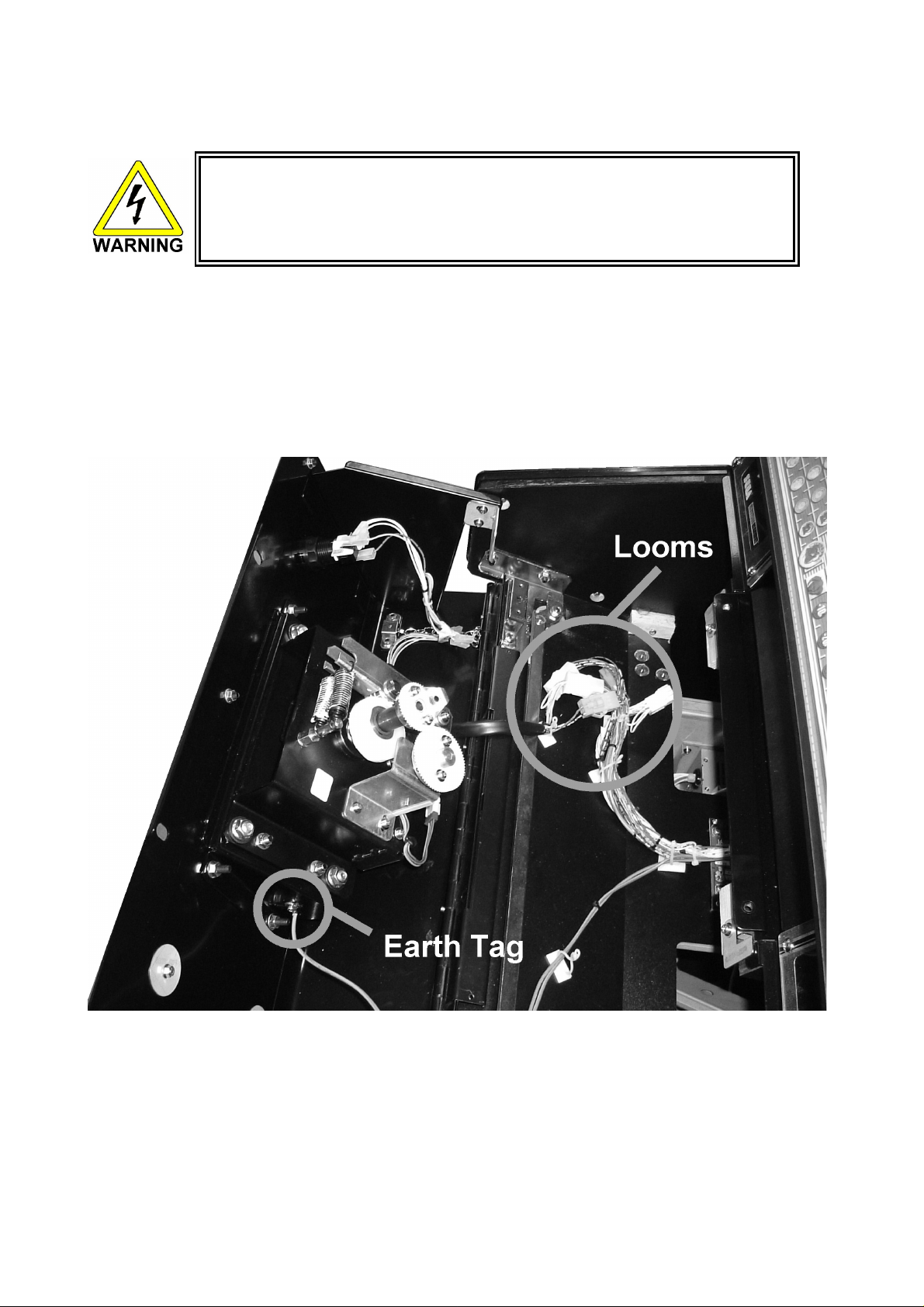

3.7.1. REPLACING THE CONTROL PANEL

1. Power OFF the machine and remove the IEC lead from the wall outlet.

2. Remove the 2 M6 security screws ion the top of the Panel.

3. Unlock the Control Panel using the Control Panel Key and open the Panel.

4. Disconnect the looms and the earth tag.

Note: This illustration may not reflect the actual control panel shipped.

18

Page 20

5. Remove the 6 bolts that secure the Control Panel in place.

Be sure to support the weight of the control panel when doing this!!

6. Remove the Control Panel

Note: This illustration may not reflect the actual control panel shipped.

19

Page 21

3.8. GAME BOARD

• When performing work, be sure to turn power off. Working with power on

can cause an electric shock or short circuit.

• Be careful not to damage wiring. Damaged wiring can cause an electric

shock or short circuit.

• The voltage/amperage ratings for the Game Board are 3.3V 12A, 5.0V 10A

and 12V 2A. To avoid risk of fire, never use any board with supply

requirements exceeding the above.

• When replacing the Game Board with one not of JAMMA standard, be sure

to use only the harness supplied by the manufacturer of the Game Board.

Using other harnesses constitutes a fire risk.

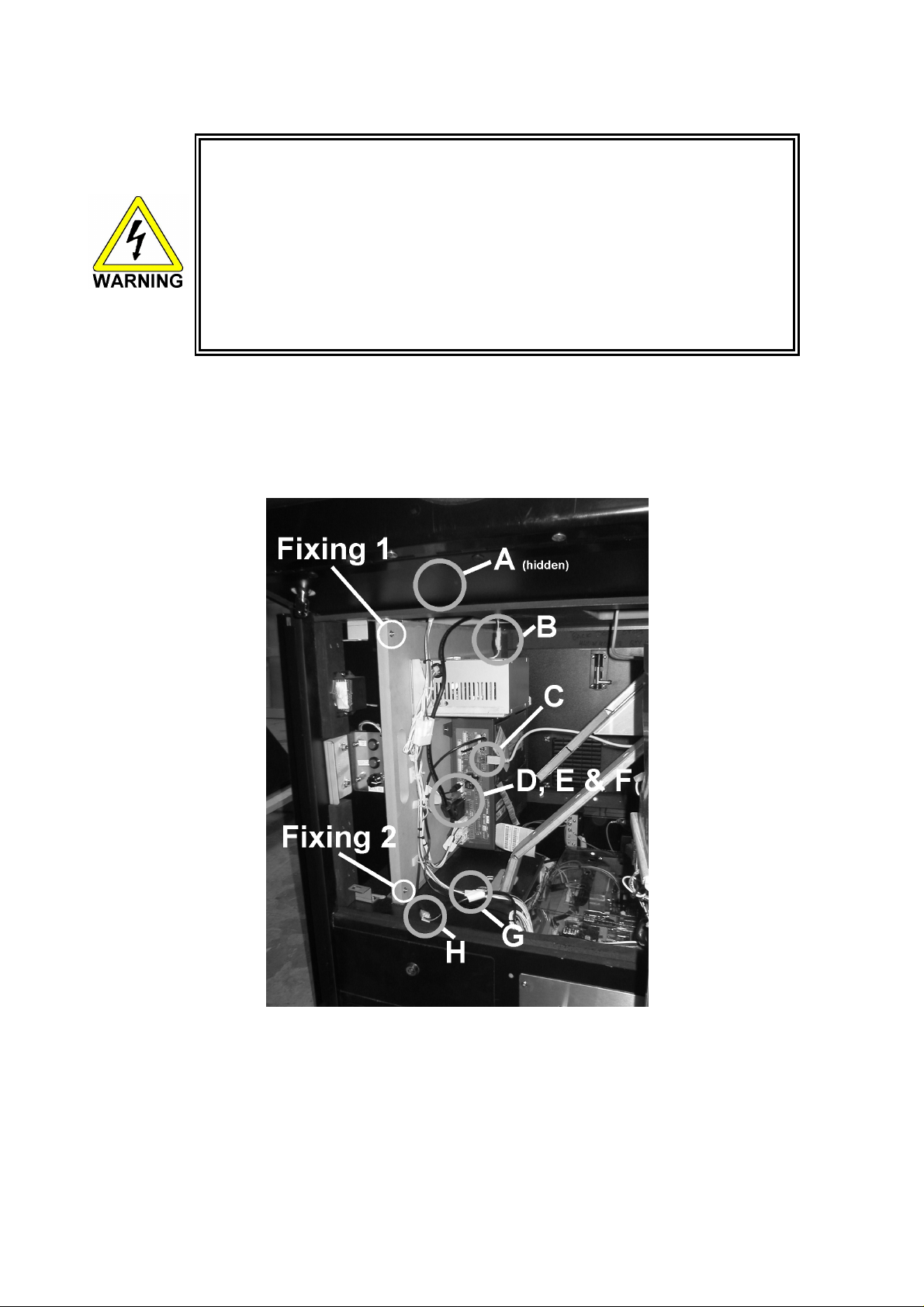

3.8.1. TAKING OUT THE GAME BOARD

To take out the game board, remove together with the wooden base on which the Game Board is mounted.

1. Turn power OFF by removing the IEC lead from the wall socket.

2. Disconnect all of the connectors A to H as shown below.

3. Remove fixings 1 and 2.

4. Slide the board assembly out from the cabinet being careful to avoid any damage during removal.

20

Page 22

3.8.2. COMPOSITION OF GAME BOARD

PART NO. DESCRIPTION

1 840-0137D-02 ASSY CASE NAT CKT PUB EXP

21

Page 23

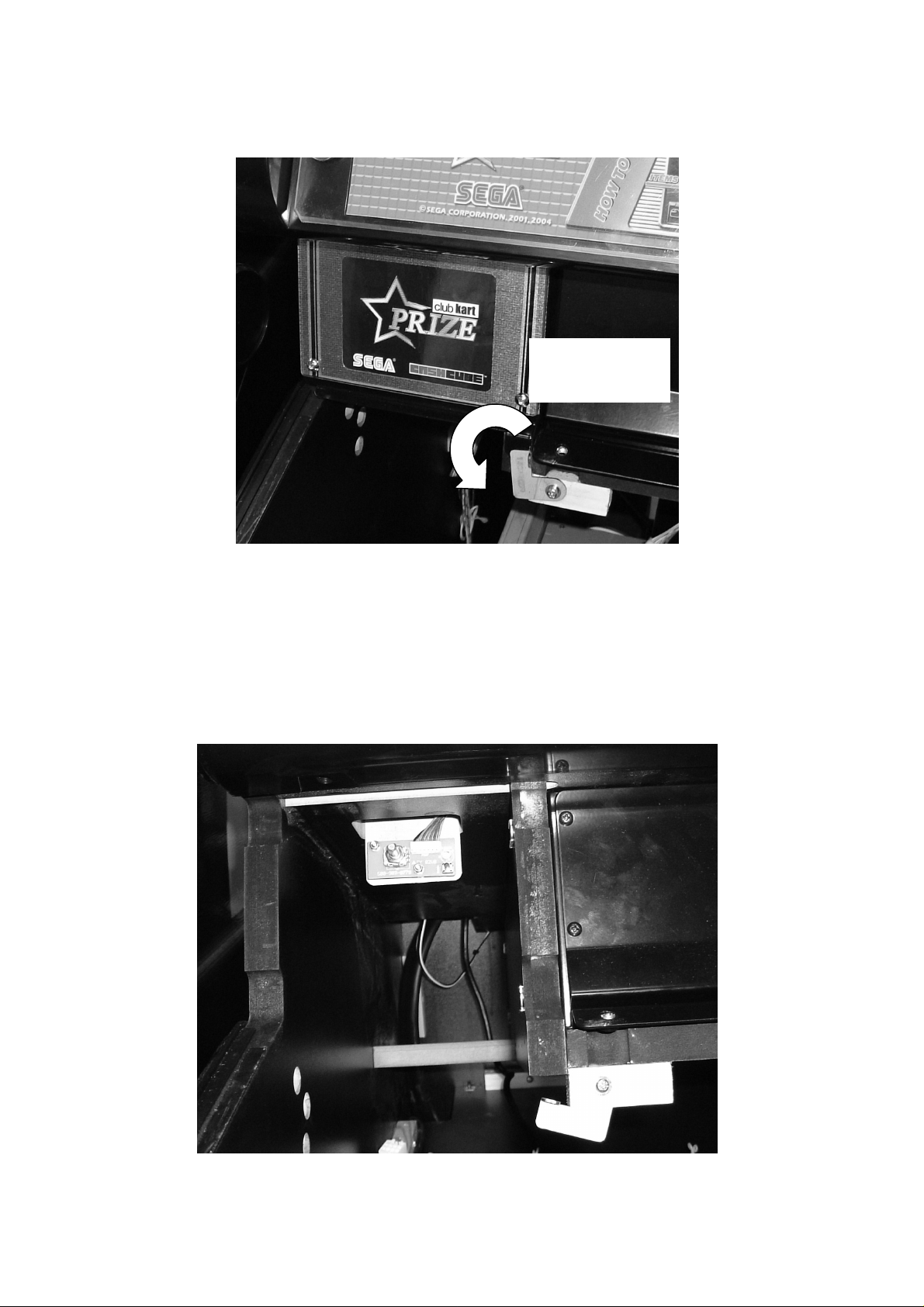

3.9. MONITOR ADJUSTMENT

The monitor adjustment pcb is located behind the logo plate on the opposite side to the coin entry bezel.

Rotate retaining

bracket to free

Logo Plate.

To gain access to the pcb:

1. Open the control panel after removing the two M6 security screws and using the Control Panel key

(see 3.7.1).

2. Loosen the retaining bracket held on with 1 M4 screw to the lower right of the Logo Plate. This

allows the bracket to rotate enabling the Logo Plate to be removed.

3. The Monitor Adjustment pcb is located directly behind this plate.

22

Page 24

Note:

Problems with the monitor that cannot be corrected by simple adjustment using the pcb are beyond the

scope of this manual. Please refer to the monitor manufacturer for further information.

Pentranic Limited.

4 Michaelson Square

Kirkton Campus

Livingston

Scotland

UK

EH54 7DP

www.pentranic.com

23

Page 25

3.10. TROUBLESHOOTING

reinstate the circuit protection device to its original

Check all harness connections for loose wires and

• Only QUALIFIED SERVICE PERSONNEL should carry out these procedures.

If a problem occurs, first check the wiring connections.

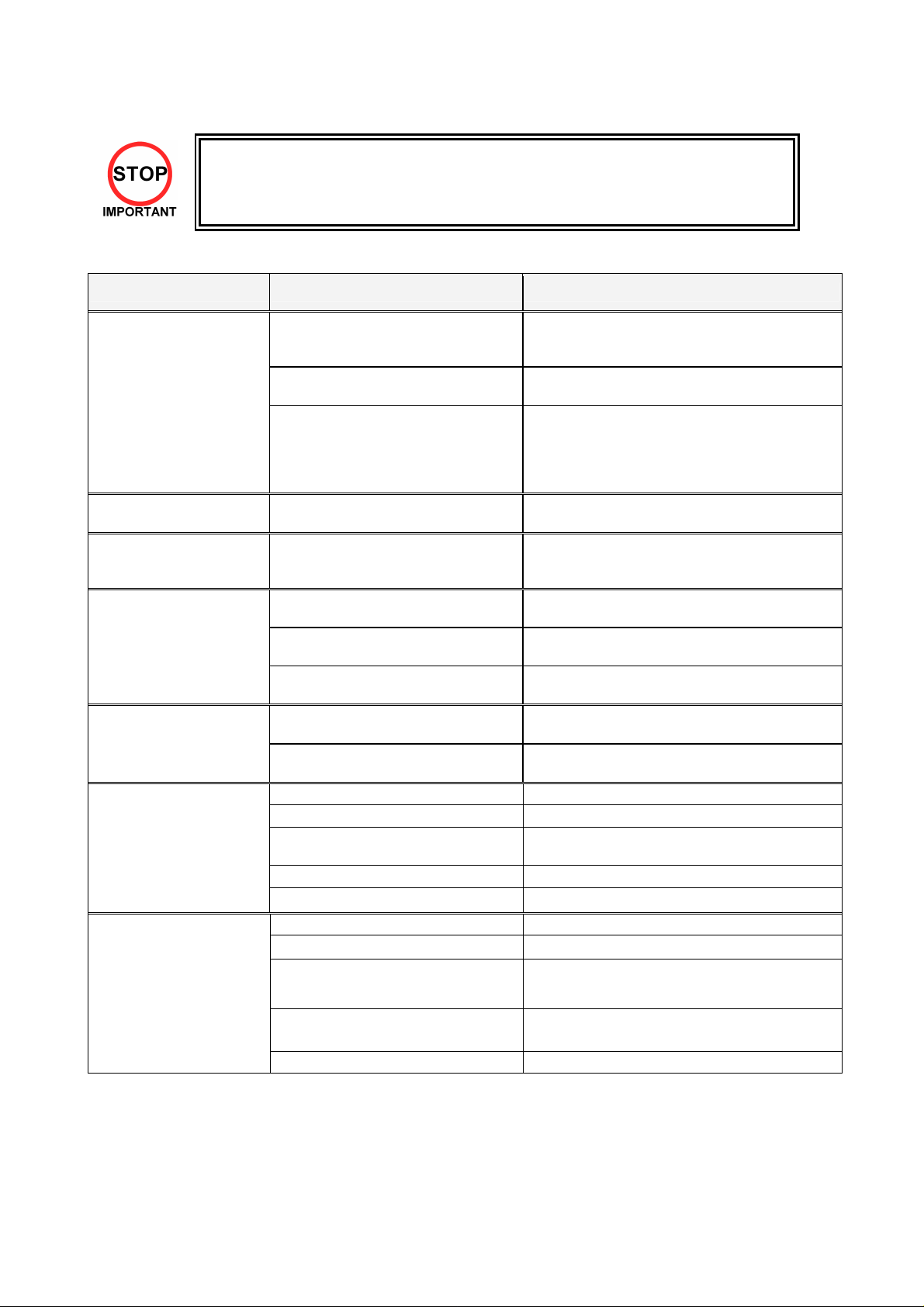

PROBLEMS CAUSE COUNTERMEASURES

When the main switch is

turned ON, the machine is

not activated

Incorrect power source/voltage. Make sure that the power supply/voltage are

The colour image on

the screen is incorrect

The on-screen image of the

monitor sways and/or

shrinks

Sound is not emitted Sound volume adjustment is not

Malfunctioning BD and Amp.

The fluorescent lamp

does not light up

The connector is disconnected

No coin recognition.

Or

Poor coin acceptance rate

Machine not paying out.

The power is not ON. Firmly insert the plug into the outlet.

correct.

AC Unit CIRCUIT PROTECTION

DEVICE (i.e.; fuse) was activated due

to an instantaneous overcurrent.

Incorrect monitor adjustment. Make appropriate adjustments. Refer to section

The power source and voltage are not

correct.

correct.

Connector connection is incorrect Check connector connection from Base to

Fluorescent lamp needs replacement Replace the fluorescent lamp.

Coin mech dirty. Clean mech.

Coin mech faulty. Replace coin mech.

Bad loom connections.

Mech not programmed. Replace mech.

Payout Gameboard faulty. Replace Payout Gameboard.

No coins or coins jammed in Hopper. Add coins or clear jam.

Faulty Hopper or Hopper drive PCB Replace hopper or drive PCB

Faulty Hopper internal or external loom

to motherboard or drive PCB

First, remove the cause of overcurrent and

status.

Then identify the cause of the fault on the item

which caused the overcurrent & fix.

3.9.

Make sure that the power supply and voltage are

correct.

Adjust the volume setting located near the Test

and Service switches.

Perform Sound Test to check it.

Speaker

Check connector connections behind the monitor

mask.

fitments.

Check connectors.

24V DC fuse blown on hopper drive

board.

Payout Gameboard faulty. Replace Payout Gameboard.

24

Check fuse.

Page 26

3.11. HOPPER ASSEMBLY

b.

NB.

The machine uses a Coin Controls 24V DC hopper assembly.

3.11.1.HOPPER OPERATION

Each disc contains a number of holes in which coins are held in short stacks. The motor drives the disc via

a gear train. As the disc rotates, the coin at the bottom of one of the stacks will make contact with the

ejector fingers and start to push the fingers back. Further rotation of the disc will cause the coin to start to

move outwards into the exit slot. At this point the spring will be free to pull the ejector fingers forward and

push the coin through the exit slot.

A LED transmitter and opto-receiver form an optical detector. The infrared light beam is routed across the

exit slot via a light guide. When coin passes through the exit the light beam will be broken and coin output

signal will be generated.

The hopper will automatically brake when power is interrupted, or machine placed in the off state, thus

preventing overrun and excessive coin payout.

An over current detection circuit reverses the hopper momentarily in the event of a coin jam, and then

attempts to continue payout. This oscillation of the disc will continue until either the coins are freed, the

hopper is switched off, or the overload trip switches. Should the latter occur the hopper supply must be

disconnected, the fault condition must be corrected and the trip be allowed time to cool (Approx. 30

seconds) before the hopper will start.

3.11.2.HOPPER ASSEMBLY FAULT FINDING

Coins fail to unjam

1. Ensure coin exit clear.

2. Ensure no incorrect coins or foreign objects are in the hopper.

3. Ensure no badly bent coins in hopper.

Clearing a coin jam

1. Open the Outer and Service doors to gain access to the Hopper area..

2. Detach the metalwork surrounding the hopper by removing the 2 screws and 3 nuts that hold it in

place.

3. Remove all coins from bowl.

4. Remove motor assembly from base.

5. Clear the jammed coin by either:

a. Rotating the disc manually first anti-clockwise then clockwise to free the coin.

OR

6. Remove any debris from the disc bed assembly.

7. Clean the exit window opto with a clean dry cloth.

8. Reassemble as described earlier.

9. Refill and test the hopper.

Motor fails to run.

1. Check 24v 5A fuse on the Hopper Drive Board.

2. Hopper over-current protective device tripped (Wait 30 seconds while supply off).

Over payout of coins

Push the coin back in using the edge of similar coin.

Common cause is damaged or bent coins. Do not return damaged coins to bowl.

1. Check opto area/coin exit for dirt.

Under Payout of coins

1. Ensure hopper contains sufficient coins.

2. Poor connection (check common return wires) to hopper.

25

Page 27

Dismantling the Hopper

1. Gently pull outwards the securing clips on the back of the base.

2. Tilt the bowl forward until it is clear of the clips.

3. Slide the bowl forward until the locating lugs, at the front of the bowl, are clear of the slots in the

base.

4. Lift the motor assembly out of the base.

5. Disconnect the cable from the motor assembly.

Hopper Assembly

1. Connect the cable to the motor assembly, ensuring that the 4-pin connector is the correct way

round.

2. Lower the motor assembly into the base, ensuring that the coin exit is in the rear exit position.

(Towards Coin exit position).

3. Locate the lugs, on the front of the bowl, into the slots at the front of the base.

4. Gently press down until the securing clips, on the base, click into the slots in the bowl.

Routine cleaning:

All accessible parts of the coin route should be cleaned periodically using a mild detergent on a damp

cloth. No spray solvents should be used. Particular attention should be paid to the opto sensor at the coin

exit to remove any build up of dirt.

26

Page 28

3.12. COIN MECHANISMS

The machine uses a Coin Controls SR5 Coin Mechanism.

3.12.1.COIN MECHANISM OPERATION (FOR UK MACHINES).

COINS ACCEPTED: 5P, 10P, 20P, 50P, £1, £2

COIN ROUTING

The coin mech automatically routes all coins

other than £1 coins to the cash box (exit C). £1

coins are routed to the hopper (exit A) until the

float is achieved, afterwards they are diverted to

the cash box (exit B). The float is maintained by

software counting the number of £1 coins

entered.

The coin mech exits are as follows:

A Hopper

B Cash Box

C Cash Box

D Not Used.

SR5 – COIN CONTROL

ROUTING PLUG: 18 WAY

Pt No PUB-64101UK

5-7,8-15,1à13, 10à13, 12à13, 16à13, 17à13,

18à13

The diode direction is shown as ‘à’.

Note: Cash Payout - £1 Hopper only fitted.

3.12.2.COIN MECHANISM FAULT FINDING

There is a green diagnostic LED used to provide a visual indication of the mechanisms current operation

and error condition.

1. LED ON = Power ON

2. LED OFF = Power OFF

3. LED will flash OFF once when Coins or Tokens are accepted or if reject Lever is pressed.

4. LED will flash OFF twice if Coin or Token is unrecognised.

5. LED will flash OFF three times if validator or machine has inhibited Coin or Token.

6. LED will flash continuously when in Token Teaching Mode.

For further information on the operation of the coin mechanism, please refer to the Money Controls

website:

www.moneycontrols.com/support/

27

Page 29

3.13. FUSES

• Never touch places other than those specified. Touching places other than those

specified can cause electric shock and short circuit. Disconnect the machine

from the supply before attempting the replacement of any fuse.

• Only QUALIFIED SERVICE PERSONNEL should replace FUSES.

• Only replace fuses with ones of the same value and type.

There are a number of fuses used on this machine to protect the user and the machine from damage. Only

replace the fuse once you have removed the cause of its failure. Detailed below is a list of the fuses used,

their location and if relevant PCB reference:

PART NUMBER LOCATION TYPE & DETAILS QTY

514-5078-3150 STEREO AMP REF. F1, F2 5x20mm CERAMIC SB 3.15A 2

514-5078-4000 SWITCH REG REF. F1 5x20mm CERAMIC SB 4A 1

514-5078-5000 IEC INLET REF. F1 5x20mm CERAMIC SB 5A 1

514-5078-6300 CONN. BD. REF. F1 5x20mm CERAMIC SB 6.3A 1

There are also fuses located on the Monitor PCB. Refer to the monitor manufacturer for further

information.

28

Page 30

4. REFILL MODE

4.1. WHAT IS REFILL MODE?

The REFILL MODE is used to refill the Hopper with coins or to pay out coins from the Hopper. To enter

REFILL MODE, hold the Key Switch in the "ON" position for around one second. Setting the Key Switch

back to "OFF" will then exit REFILL MODE. Except during game play or in Test Mode, REFILL MODE can

be accessed at any time. However, it is possible to enter REFILL MODE during game play if a "HOPPER

EMPTY" error occurs.

There are two different submodes used in REFILL MODE, depending on the status of the machine doors.

When the doors are closed, "LANDLORD REFILL" is used, and when the front door or cash door are open,

"COLLECTOR REFILL" is used.

4.2. LANDLORD REFILL

During LANDLORD REFILL, a screen like the one below will be displayed.

LANDLORD REFILL Screen

Display Meaning

LAST WIN The number of wins in the last game.

FLOAT

During LANDLORD REFILL, the Hopper coin stock can be replenished by inserting coins into the coin slot.

It is possible to fill the Hopper up to the FLOAT maximum value setting (shown as 70 in the above table).

LAST WIN and FLOAT values will not be displayed under the default settings. To display these values,

change the display option in the MEMORY SETTING section of the HOPPER BOARD TEST Menu.

The number of coins in the Hopper. (current number / maximum number) Any coins

inserted beyond the maximum number will be diverted to the Cash Box.

29

Page 31

4.3. COLLECTOR REFILL

During COLLECTOR REFILL, a Screen like the one below will be displayed.

COLLECTOR REFILL Screen

Display Meaning

IN Total number of coins inserted.

OUT Total number of coins paid out.

REFILL Total number of coins refilled.

LAST WIN Same as LAST WIN in LANDLORD.

FLOAT Same as FLOAT in LANDLORD.

DUMP Number of coins paid out with Dump Switch.

In COLLECTOR REFILL mode, the Hopper coin stock can be replenished just like in LANDLORD, only in

COLLECTOR REFILL mode, coins can be added directly into the Hopper.

After refilling coins directly into the Hopper, be sure to press the Top Up Switch and set the FLOAT current

coin number to the maximum coin number. Neglecting to set the current coin number could result in a coin

overflow.

Also note that pressing the Dump Switch will release the entire Hopper coin stock.

30

Page 32

4.4. DEALING WITH A HOPPER EMPTY ERROR

Following is the procedure for dealing with a HOPPER EMPTY/JAM error:

1. Get a WIN in the game.

2. Payout will commence.

3. The error occurs (as shown in the figure below).

4. Set the Key Switch to ON and enter REFILL MODE.

5. Refill the coin stock.

6. Setting the Key Switch to OFF will exit REFILL MODE and return to payout.

7. End the game.

HOPPER EMPTY / JAM Error Occurrence 1

HOPPER EMPTY / JAM Error Occurrence 2

31

Page 33

4.5. METERS

The machine is fitted with three mechanical meters that record the following information:

• Total Coin In

Total of all the coins fed in through the coin mechanism.

• Total Coin Out

Total of all the coins paid out from the hopper.

• Total Coin Refill

Total of all the coins refilled through the coin mechanism

Note: These meters cannot be reset and therefore record the totals since the machine was delivered.

32

Page 34

5. DATAPORT

5.1. WHAT IS THE DATAPORT?

The DATAPORT is a data organization device used to aid U.K. AWP/SWP income collection. The

DATAPORT, when connected to the game unit, can exchange information with the HOPPER BOARD

machine regarding settings and states, coin IN/OUT quantities, etc. via serial data transfer.

The DATAPORT and HOPPER BOARD share information, and typically when there is no response from

the DATAPORT an error will occur, but settings can be changed to prevent this from happening.

This change is made in the DATAPORT SETTING of the HOPPER BOARD TEST Menu (see section

8.2.8.6). The Menu item, however, is not normally displayed among the other setting selection items.

Displaying the Menu item requires a special dongle, explained in the next section (SETTING

PROCEDURE).

DATAPORT SETTING Menu.

5.2. SETTING PROCEDURE

The following procedure explains how to use a dongle to access the DATAPORT SETTING Menu and

change the aforementioned error display setting:

1. Make sure power is off and connect dongle.

2. Turn on power.

3. Enter HOPPER BOARD TEST Menu.

4. Change setting in DATAPORT SETTING.

5. Turn off power.

6. Disconnect dongle.

7. Turn on power.

33

Page 35

5.3. DATAPORT SETTING

In the DATAPORT SETTING Menu, two setting values can be changed.

The OPTION setting determines whether or not the HOPPER BOARD watches over communications from

the DATAPORT, and the CONDITION setting controls whether the OPTION setting is active perpetually or

temporarily.

Menu Item Content Setting Type

OPTION PROTOCOL setting PROTOCOL (watches over DATAPORT) / NON-PROT (does

not watch over DATAPORT)

CONDITION OPTION setting type FOREVER (perpetual) / TEMP (temporary)

Setting the CONDITION to TEMP will not eliminate the DATAPORT SETTING Menu item, however setting

CONDITION to FOREVER will render it hidden. The Menu item will remain hidden until connecting the

dongle as mentioned above.

DATAPORT SETTING Menu

Setting CONDITION to TEMP will result in the following screen (blue window) coming up whenever

restarting an application. Turning the Key Switch ON and OFF again will allow the application to startup.

Startup Screen with TEMP Setting

34

Page 36

5.4. ERROR

With CONDITION set to PROTOCOL, an error (#202) will result when there is no response from the

DATAPORT. This error will be cancelled when there is a normal response from the DATAPORT.

Error #202 Screen

35

Page 37

6. PERIODIC CHECK AND INSPECTION

The items listed below require periodic check and maintenance to retain the performance of the machine

and ensure safe operation:

• Be sure to check annually to see if the power cords are damaged, the plug is

securely inserted and that there is no dust in the interior of the machine or

between the socket and the power cord. Using the product in an unclean

condition may cause a fire or electric shock.

DESCRIPTION WHAT TO CHECK INTERVAL

CABINET Check Adjusters’ contact with surface Daily

MONITOR Cleaning CRT face

Check settings

GAME BD Setting check Monthly

CONTROL PANEL Input test Monthly

Speaker, sound Sound test, check volume adjustment Monthly

COIN SELECTOR Coin insertion test

Cleaning

POWER SUPPLY CORD Check condition Annually

INTERIOR

CABINET SURFACE

Clean (Do Not use water jet)

Clean (Do Not use water jet)

Weekly

Monthly

Monthly

Tri-Monthly

Annually

As required

6.1. CLEANING THE CABINET SURFACES

When the cabinet surfaces are badly soiled, remove stains with a soft cloth dipped in water or chemical

detergent (diluted with water) and squeezed dry. To avoid damaging surface finish, do not use such

solvents as thinner, benzene, etc. (other than ethyl alcohol), abrasives or bleaching agents. DO NOT USE

A WATER JET.

36

Page 38

7. CONTENTS OF GAME

7.1. HOW TO PLAY

7.1.1. OBJECTIVE

7.1.2. SELECT A STAGE

Pocket all 15 balls to win the Jackpot!!

Once you miss a pocket, the game will be over

and you loose your winnings.

You can stop during the game to collect your

current winnings.

Select between 2 stages (Pool Bar or Convention

Hall) of where you play.

The difference is background graphics and sound.

7.1.3. BASIC TRAINING

Basic Training allows you have one practice shot

before the game.

The transparent ball is a suggested aiming point.

37

Page 39

7.1.4. BREAK SHOT

Press START BUTTON to decide where you

want to place cue ball when break shot.

Even if you cannot get ball in a pocket at break

shot, this will NOT mean that the game is over.

If a scratch (Out of Time) occurs and 4 or more

balls have not hit cushion, this be recognized as

a foul. The software will then automatically

perform the Break Shot.

7.1.5. FOLLOWING THE BREAK SHOT

The HELP MODE may appear on first few shots of game play. The number of HELP MODE

appearances will vary from game to game.

1) A semi-transparent ball will appear, marking the best place to aim.

2) Line up the cue direction line with the semi-transparent ball.

38

Generally, if you fail to get a ball inside a

pocket every time you make a shot this would

normally mean GAME OVER.

However anytime that HELP MODE is shown in

the right top of screen, this will allow “ONE

MORE CHANCE!” enabling you to play an

additional shot, and to continue game play.

Note: if you scratch the ball, it will be game

over in this case.

Page 40

7.1.6. CONTINUE SELECTION

When you reach to the level of winning a prize, you have a choice of stopping and collecting a prize,

or continuing in order to win more prizes.

7.1.7. PRIZE COLLECTION

If you select collection of prize, the prize will be

paid out from hopper.

39

Page 41

7.2. USING THE AIM / CONTROLLER

7.2.1. GAME SCREEN

7.2.2. CONTROL PANEL

Track Ball

Rotate a trackball to aim cue.

Change View / Start Button

Used to switch top view during the game.

Cue point, Cue controller

7.2.3. POSITION THE CUE TIP

Move the entire Controller to position the cue tip (the area on the cue ball to be struck).

40

Page 42

7.2.4. MAKE YOUR SHOT

To pull the cue back, use the roller located at the centre of the controller.

The cue on the screen will change from semi-transparent to opaque. Make your shot by pushing the

cue forward.

41

Page 43

8. EXPLANATION OF TEST AND DATA DISPLAY

Use the switches on the VTS to enter the TEST MODE. This will allow you to carry out post installation and

periodic checks and adjustments. The following section details the function of each of the tests:

ITEM DESCRIPTION INTERVAL

INSTALLATION OF

THE MACHINE

MEMORY

PERIODIC CHECKS Periodically perform the following

CONTROL SYSTEM

MONITOR

IC BOARD MEMORY TEST

DATA CHECK

EXTERIOR

MAINTENANCE

COIN MECHANISM

When the machine is installed perform the following

checks:

• Check to see that each setting is as per the standard

settings input at the time of shipment.

• In the INPUT TEST mode, check each switch and V.R.

• In the OUTPUT TEST mode, check each of the lamps.

• In the MEMORY TEST mode check all of the IC’s on the

IC BD.

• On the TEST MENU screen choosing the MEMORY

TEST allows self-test to be performed. In this test RAM

& ROM are tested.

• MEMORY TEST.

• Ascertain each setting.

• In the INPUT TEST mode, test the control devices.

• In the OUTPUT TEST mode, check each of the lamps.

• In the INPUT TEST mode, check each switch and V.R.

• Adjust or replace each switch and V.R.

• In the C.R.T. TEST mode, check to ensure the monitor

is adjusted correctly

• Clean screen (switch off machine and remove the plug)

• In the SOUND TEST mode, check the sound related

ROMs

• Check such data as held in the bookkeeping screens,

relating to number and length of plays

• Clean surfaces

• Lubricate seat sliders

• Check switch operation (if fitted)

Monthly

Monthly

Monthly

Monthly

Monthly

Weekly

Monthly

Monthly

Monthly

Monthly

42

Page 44

8.1. SYSTEM TEST MODE

• Setting changes made in SYSTEM ASSIGNMENTS, COIN ASSIGNMENTS and

GAME TEST MODE are stored only when the TEST mode is exited properly. If

the power is turned off before exiting, and changes made will be ineffectual.

• Do not activate any system test mode while the system is reading the GD-ROM

(if fitted), otherwise error messages may appear.

• Only QUALIFIED SERVICE PERSONNEL should carry out these procedures.

The SYSTEM TEST MODE allows the IC Board to be checked for correct operation, monitor colour to be

adjusted, and COIN and GAME ASSIGNMENTS to be adjusted.

The Test and Service button are located on the left-hand side of the cabinet behind the service door.

43

Page 45

To enter the Test mode:

1. After turning power ON, press the TEST Button to display the following menu:

2. Press the SERVICE Button to move the arrow to the desired item, and press TEST to select.

3. Select GAME TEST MODE to display the test menu for that specific game. For further information

about GAME TEST MODE, refer to the service manual for the game.

4. Upon finishing the test, select EXIT to return to the game.

8.1.1. RAM TEST

This screen carries out a test on the RAM on the NAOMI Main Board. The test begins immediately that the

screen appears.

TESTING NOW is displayed while the system is testing.

GOOD should appear next to each IC number if the RAM is satisfactory. BAD will appear next to

abnormal IC’s. The test takes about two and a half minutes to complete testing on all IC’s.

After testing, press TEST to return to the system menu screen.

44

Page 46

8.1.2. JVS TEST

Use this test to check specifications of the I/O Board connected to the NAOMI Main Board, while INPUT

TEST can be performed on the input switches. First, I/O Board specifications are displayed.

Select from the following:

INPUT TEST: Proceed to the INPUT TEST of the I/O BOARD displayed.

NEXT NODE: In the case of more than two I/O Boards being connected, this proceeds to the

next I/O Board.

EXIT: Returns to the Menu Mode.

45

Page 47

8.1.3. INPUT TEST SCREEN

8.1.4. SOUND TEST

Select the sound test to check the status of the amplifiers, sound boards and speakers.

Press the SERVICE button or view change button to move the arrow to the desired test item.

Press TEST button to output the sound.

• Select the sound source with SERVICE.

• On pressing TEST, the test sound is emitted

from the selected source.

Front speakers are located on the Control Panel.

Rear speakers are located in the seat back.

Select EXIT to return to MENU screen.

46

Page 48

8.1.5. CRT TEST

C.R.T. TEST 1/2

C.R.T TEST

PAGE 1/2

RED

GREEN

BLUE

WHITE

PRESS TEST BUTTON TO CONTINUE

Selecting CRT test allows the projector adjustment

to be checked for colour and distortion.

Press the test or start button to have the second

CRT test screen appear.

C.R.T. TEST 2/2

PRESS TEST BUTTON TO EXIT

47

Page 49

8.1.6. SYSTEM ASSIGNMENTS

• If the settings of CABINET and MONITOR TYPE are not suitable for the

connected game, an ERROR message is displayed when the game is turned on

and TEST mode has finished, and the game cannot be played. Refer to the

game’s service manual for the correct settings, or enter settings corresponding to

the cabinet and control panel specifications.

• Only QUALIFIED SERVICE PERSONNEL should carry out these procedures.

This mode configures the cabinet and board settings. For settings relating to game difficulty, etc., refer to

the dedicated service manual for the game software.

1. Select the setting to be changed using SERVICE and TEST.

2. Select EXIT after settings have been performed.

• CABINET TYPE [1PLAYER(S), 2PLAYER(S), 3PLAYER(S), 4PLAYER(S)]

Sets the number of players between one and four.

• ADVERTISE SOUND (ON, OFF)

Sets whether ADVERTISE sound is emitted or not.

• MONITOR TYPE (HORIZONTAL, VERTICAL)

Sets the on-screen display according to the orientation of the monitor.

• SERVICE TYPE (COMMON, INDIVIDUAL)

If several SERVICE buttons exist, this setting decides the function.

COMMON: Service credit is obtained for all players when any SERVICE button is pressed.

INDIVIDUAL: Service credit is obtained for the player corresponding to the SERVICE button

used.

48

Page 50

8.1.7. COIN ASSIGNMENTS

Ensure machine is set to 1 Coin 1 Credit.

Go to Game Test menu for further coin test

settings.

49

Page 51

8.1.8. BOOKKEEPING

BOOKKEEPING 2/2

P1 SEQ 1 0

P1 SEQ 2 0

P1 SEQ 3 0

P1 SEQ 4 0

P1 SEQ 5 0

P1 SEQ 6 0

P1 SEQ 7 0

P1 SEQ 8 0

This mode consists of 2 pages that allow the data

relating to credit and game play time to be checked.

In page 1 mode press SERVICE to proceed to page

2, in page 2 mode press TEST to return to the test

menu.

• Total time is displayed as XXH XXM XXS and no

date will be displayed after exceeding 24 hours.

• The displays for number of coin and number of

service vary depending on the CABINET TYPE

set in SYSTEM ASSIGNMENTS. Number of

credit displays 1 if COIN CHUTE TYPE is set to

COMMON in COIN ASSIGNMENTS. If COIN

CHUTE TYPE is set to INDIVIDUAL, the

applicable number in CABINET TYPE setting will

be displayed.

• On the second screen, each sequence displays

the frequency of functioning.

8.1.9. BACKUP DATA CLEAR

Clears the contents of bookkeeping. When clearing

bring the arrow to “YES (CLEAR)” and press the test

button. When the data has been cleared

“COMPLETED” will be displayed. Bring the arrow to

“NO (CANCEL)” and press the test button to return

to the menu mode.

Note that this does not clear the contents of

BOOKKEEPING in GAME TEST MODE. For this,

use the BACKUP DATA CLEAR in GAME TEST

MODE (see dedicated service manual for the game

software).

50

Page 52

8.1.10.CLOCK SETTING

YEAR, MONTH, DAY, HOUR and MINUTE are changed in this mode. Select the desired item with

SERVICE button and press TEST to increase the value. Select EXIT to return to MENU mode.

8.1.11.DIMM BOARD TEST

This mode appears only if a DIMM Board is connected to the NAOMI. If not, ROM BOARD TEST will

appear.

In this test, the DIMM memory and IC’s are checked. If GOOD is displayed, it is satisfactory. Press TEST

to exit.

51

Page 53

8.2. GAME TEST DESCRIPTION MODE

Test menu Flow is: System test è Game test è Hopper Board test

Select GAME TEST MODE from the System Menu screen to display the Game Test Menu screen as

shown below. Use the SERVICE Button to move the cursor to the desired test item. Press the TEST Button

to enter the selected item.

The default settings are shown below. Pressing the TEST Button will enter the selected item, displaying the

possible setting choices. Select DEFAULT SETTING and press the TEST Button to return all items to their

default settings.

After making changes, be sure to select EXIT and press the TEST Button in order to enable the new

settings.

8.2.1. GAME TEST MENU SCREEN

Return to system test menu screen by pressing test button on EXIT.

When you select INPUT TEST, following screen appears.

This screen is to confirm all buttons working properly,

If OFF changes to ON when pressing each buttons. It means buttons are properly functioning.

8.2.2. INPUT TEST SCREEN

Return to GAME TEST MENU screen, if you press TEST and SERVICE buttons at same time.

Select OUTPUT TEST to display the following screen and check the status of each lamp. The lamps will

light up when ON is selected, and turn off again when OFF is selected.

52

Page 54

8.2.3. OUTPUT TEST SCREEN

Pressing the TEST Button causes ON to be displayed and the corresponding lamp to light up.

Pressing the TEST Button again causes OFF to be displayed and the corresponding lamp to turn off.

You can set controller volume setting, by selecting CONTROLLER ADJUSTMENT and following screen

appears.

Note: The BET LAMP option will only be shown if BET BUTTON [USED] is selected in the CREDIT

SETTING.

Move the cursor to EXIT and press the TEST Button to return to the Game Test Menu screen.

Select CONTROLLER ADJUSTMENT to bring up the following screen and adjust the controller sensitivity

settings.

8.2.4. CONTROLLER ADJUSTMENT SCREEN

----------------------------------------------------

CONTROLLER ADJUSTMENT

1: MOVE CONTROLLER TO UPPER AND LOWER

RIGHT AND LEFT MAXIMUM

2: RETURN CONTROLLER TO THE CENTRE

AND SELECT "EXIT WITH SAVE"

UP [ XXH ](XXH)

LEFT [ XXH ](XXH) RIGHT [ XXH ](XXH)

DOWN [ XXH ](XXH)

EXIT WITH SAVE

EXIT WITHOUT SAVE

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

The value shown in ( ) of the “XXH (XXH)” settings will display the value left over from the previous use.

Move the controller all the way left and right, up and down, and then after returning it to the centre position,

use the TEST Button to select EXIT WITH SAVE. The new settings will be enabled and the screen will

return to the GAME TEST MENU.

If the adjustments made are not valid, the following error message will be displayed:

“ADJUSTMENT VALUE IS NOT SUITABLE / PLEASE ADJUST AGAIN OR EXIT WITHOUT SAVE”

Move the cursor to EXIT WITHOUT SAVE and press the TEST Button to return to the Game Test Menu

screen without changing the setting.

Select GAME ASSIGNMENTS to display the current game settings and make changes.

53

Page 55

8.2.5. GAME ASSIGNMENT SCREEN

-

BREAK SHOT STYLE : Pocket shape during break shot, OPEN is for ordinary players.

-

FREE PLAY

DIFFICULTY:

-

COUNTDOWN SPEED: Setting of speed on countdown time. Larger the setting, more difficult

-

POCKET SIZE: Setting of size of pocket. Larger the setting, more difficult the game.

-

TABLE SPEED Setting of friction on pool table. Larger the setting, more difficult the

-

IMAGINATION BALL COMBO value setting for translucent imagination balls.

Changes difficulty of game during free play, Has nothing to do with

difficulty of game play during normal coin operated game.

the game.

game.

54

Page 56

8.2.6. PAYOUT SETTING SCREEN

Select PAYOUT SETTING to display the following screen, where payout (game) related settings can be

changed.

Menu for POUND, DOLLAR, EURO, or ANY CASH Setting.

---------------------------------------------------PAYOUT SETTING

CURRENCY TYPE [ POUND ] ( POUND, DOLLAR, EURO, ANY CASH, TOKEN )

PAYOUT RATIO [ 30 ] ( 30, 35,..., 95, 100)

LANGUAGE [ ENGLISH ] ( ENGLISH, RUSSIAN )

JACKPOT ODDS [ X40 ] (X10, X20, X40, X100)

ODDS TABLE [ 2 ] ( 1, 2, 3, 4, 5 )

DEFAULT SETTING

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

Menu for TOKEN Setting

---------------------------------------------------PAYOUT SETTING

CURRENCY TYPE [ TOKEN ] ( POUND, DOLLAR, EURO, ANY CASH, TOKEN )

PAYOUT RATIO [ ** ] ( 30, 35, ..., 95, 100)

LANGUAGE [ ENGLISH ] ( ENGLISH, RUSSIAN )

JACKPOT ODDS [ X40 ] (X10, X20, X40, X100)

(IF MAX BET PREMIUM IS ON,

x 2.5 EXTRA)

MAX BET PREMIUM [ ON ] ( ON, OFF )

(ONLY IF BET BUTTON IS USED)

ODDS TABLE [ 2 ] ( 1, 2, 3, 4, 5 )

DEFAULT SETTING

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

CURRENCY TYPE: Setting for currency denomination. Changing currency will clear INCOME DATA

(2/*) in BOOKKEEPING.

PAYOUT RATIO: Payout ratio setting. The default setting for POUND, DOLLAR, EURO, or ANY

CASH is 30. For TOKEN, the default ratio is decided by the application in use.

LANGUAGE: Language setting. This can be changed between ENGLISH and RUSSIAN. When

CURRENCY TYPE is set to POUND, this setting will not be displayed and will be

automatically set to ENGLISH.

JACKPOT ODDS: Corresponding Jackpot odds settings for each play value. When CURRENCY

TYPE is set to POUND, this setting will not be displayed.

MAX BET PREMIUM: Setting to turn special odds for a Max Bet ON or OFF. When this setting is ON,

anything beyond a 10-Combo will cause the normal odds setting to be multiplied

by 2.5 during a Max Bet.

55

Page 57

ODDS TABLE: Odds table setting.

The game is programmed to adjust payout automatically, depending on various game elements. Manual

alteration of the payout factors in the odds table should only be used as a last resort. The default odds are

shown in T2 of the following table and will provide the best income balance. The setting level should only

be changed “± 1” if the payout ratio doesn’t fall within ±10% of the expected rate after more than 2000

games.

ODDS TABLE settings [1] to [5] are shown from T1 to T5 in the following tables.

The following tables reflect a POUND setting with the BET as 0.5 or 1. For settings other than POUND, the

JACKPOT ODDS and MAX BET PREMIUM value settings will be different.

<1 Pound Play>

-------------------------------------------------------Combo T1 T2 T3 T4 T5

15 40 40 40 40 40

14 20 20 20 20 20

13 18 16 16 16 12

12 16 14 12 10 8

11 14 12 10 8 6

10 12 10 8 6 4

9 10 8 6 4 3

8 8 6 4 3 2

7 6 4 3 2 1

6 4 3 2 1

5 3 2 1

4 2 1

3 1

2

1

-------------------------------------------------------<50P play>

-------------------------------------------------------Combo T1 T2 T3 T4 T5

15 20 20 20 20 20

14 10 10 10 10 10

13 9 8 8 8 6

12 8 7 6 5 4

11 7 6 5 4 3

10 6 5 4 3 2

9 5 4 3 2 1

8 4 3 2 1 1

7 3 2 1 1

6 2 1 1

5 1 1

4 1

3

2

1

--------------------------------------------------------

56

Page 58

8.2.7. CREDIT SETTING SCREEN

Select CREDIT SETTING to display the following screen and adjust payout (Hopper) related settings.

<For POUND, DOLLAR, EURO, or ANY CASH Settings>

---------------------------------------------------CREDIT SETTING

FREE PLAY [ OFF ] ( ON, OFF )

BET [ 1.0 ] (0.5, 1.0)

MAX PAY [ 100 ] (5, 10, 15,,,95, 100)

DEFAULT SETTING

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

FREE PLAY: Turns Free Play ON or OFF. Setting to ON allows play without the use of coins.

BET: Number of coins required for a single play.

MAX PAY: Maximum payout value. This will not be displayed when set to POUND.

<For TOKEN and BET BUTTON [USED] Setting>

---------------------------------------------------CREDIT SETTING

FREE PLAY [ OFF ] ( ON, OFF )

BET BUTTON [ USED ] ( USED, NOT USED )

MIN BET [ 1 ] ( 1, 2, 3, ..., 100 )

MAX BET [ 100 ] ( 1, 2, 3, ..., 100 )

ADD BET [ 1 ] ( 1, 2, 3, ..., 100 )

AUTOMATIC PAYOUT [ OFF ] ( ON, OFF )

MAX PAY [ 19999 ] ( 499, 999, 1499, 1999, ... 19999 )

MAX CREDIT [ 19999 ] ( 499, 999, 1499, 1999, ...19999 )

HOPPER SIZE [ 399 ] ( 19, 39, 59, 79, ... 399 )

DEFAULT SETTING

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

57

Page 59

<For TOKEN and BET BUTTON [NOT USED] Setting>

---------------------------------------------------CREDIT SETTING

FREE PLAY [ OFF ] ( ON, OFF )

BET BUTTON [ NOT USED ] ( USED, NOT USED )

BET [ 1 ] ( 1, 2, 3, ..., 100 )

AUTOMATIC PAYOUT [ OFF ] ( ON,OFF )

MAX PAY [ 19999 ] ( 499, 999, 1499, 1999, ...19999 )

MAX CREDIT [ 19999 ] ( 499, 999, 1499, 1999, ...19999 )

HOPPER SIZE [ 399 ] ( 19, 39, 59, 79, ...399 )

DEFAULT SETTING

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

FREE PLAY:

Turns Free Play ON or OFF. Setting to ON allows play without the use of coins.

BET BUTTON:

MIN BET:

MAX BET:

ADD BET:

BET:

AUTOMATIC

PAYOUT:

MAX PAY:

MAX CREDIT:

HOPPER SIZE:

Turns use of BET Button ON or OFF. This will not be displayed when set to

POUND, DOLLAR, EURO, or ANY CASH.

Minimum bet allowed to start a game. (When BET BUTTON is set to USED)

Maximum bet allowed to start a game. (When BET BUTTON is set to USED)

Additional bet amount. (When BET BUTTON is set to USED)

Number of coins required to start a game. (When BET BUTTON is set to NOT

USED)

Switches whether coins are paid out, or added to the player’s credits.

Maximum number of coins that can be paid out.

Maximum number of credits.

Payout exceeding this value requires payout from attendant.

58

Page 60

8.2.8. HOPPER TEST MENU SCREEN

Select HOPPER BOARD TEST to display the following screen and adjust Hopper-related settings.

---------------------------------------------------HOPPER BOARD TEST Screen

---------------------------------------------------HOPPER BOARD TEST

INPUT TEST

OUTPUT TEST

COIN TEST

TROUBLE LOG

MEMORY SETTING

DATAPORT SETTING

COIN ASSIGNMENTS

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

a) INPUT TEST: Executes INPUT TEST.

b) OUTPUT TEST: Executes OUTPUT TEST.

c) COIN TEST: Executes Hopper COIN TEST.

d) TROUBLE LOG: Displays error data encountered.

e) MEMORY SETTING: Enters MEMORY SETTING menu.

f) DATAPORT SETTING: Enters DATAPORT SETTING menu. This will only be displayed under

particular setting conditions.

g) COIN

ASSIGNMENTS:

Allows adjustment of coin value. This will not be displayed when set to

POUND.

59

Page 61

8.2.8.1.INPUT TEST SCREEN

Select INPUT TEST to display the following screen and check the status of input devices.

Press the switch/button. If it is functioning correctly, the START indicator will switch from OFF to ON.

<For POUND, DOLLAR, EURO, or ANY CASH Settings>

---------------------------------------------------INPUT TEST

RESET KEY SW [ OFF ] ( ON )

COIN ACCEPT #1 [ OFF ] ( ON )

COIN ACCEPT #2 [ OFF ] ( ON )

COIN ACCEPT #3 [ OFF ] ( ON )

COIN ACCEPT #4 [ OFF ] ( ON )

COIN ACCEPT #5 [ OFF ] ( ON )

COIN ACCEPT #6 [ ON ] ( OFF )

TOKEN IN SW [ OFF ] ( ON )

HOPPER COUNT SW [ ON ] ( OFF )

HOPPER TOP UP SW [ OFF ] ( ON )

DUMP SW [ OFF ] ( ON )

FRONT DOOR SW [ CLOSE ] ( OPEN )

BACK DOOR SW [ CLOSE ] ( OPEN )

CASH DOOR SW [ CLOSE ] ( OPEN )

PRESS TEST AND SERVICE BUTTON TO EXIT

----------------------------------------------------

Note: The TOKEN IN SW is the switch signal for the mechanical coin selector. This option will not be

displayed when set to POUND.

<For TOKEN Setting>

---------------------------------------------------INPUT TEST

RESET KEY SW [ OFF ] ( ON )

PAYOUT SW [ OFF ] ( ON )

COIN ACCEPT #1 [ OFF ] ( ON )

COIN ACCEPT #2 [ OFF ] ( ON )

COIN ACCEPT #3 [ OFF ] ( ON )

COIN ACCEPT #4 [ OFF ] ( ON )

COIN ACCEPT #5 [ OFF ] ( ON )

COIN ACCEPT #6 [ ON ] ( OFF )

TOKEN IN SW [ OFF ] ( ON )

HOPPER COUNT SW [ ON ] ( OFF )

HOPPER TOP UP SW [ OFF ] ( ON )

DUMP SW [ OFF ] ( ON )

FRONT DOOR SW [ CLOSE ] ( OPEN )

BACK DOOR SW [ CLOSE ] ( OPEN )

CASH DOOR SW [ CLOSE ] ( OPEN )

PRESS TEST AND SERVICE BUTTON TO EXIT

----------------------------------------------------

60

Page 62

8.2.8.2.OUTPUT TEST SCREEN

Select OUTPUT TEST to display the following screen and check the status of each lamp.

Pressing the TEST Button causes ON to be displayed and the corresponding lamp to light up.

Pressing the TEST Button again causes OFF to be displayed and the corresponding lamp to turn off.

---------------------------------------------------OUTPUT TEST

COIN INHIBIT [ INHIBIT ] ( INHIBIT,ACCEPT )

DIVIDER [ HOPPER ] ( CASHBOX,HOPPER )

PAYOUT SW LAMP [ OFF ] ( ON )

COIN IN LAMP [ OFF ] ( ON )

REFILL METER LAMP [ OFF ] ( ON )

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

Note: The PAYOUT SW LAMP option will not be displayed when set to POUND, DOLLAR, EURO, or ANY

CASH.

Selecting the lamp and pressing the TEST Button will turn it from OFF to ON.

61

Page 63

8.2.8.3.COIN TEST SCREEN

Select COIN TEST to display the following screen and view the Hopper status.

<For POUND Setting>

---------------------------------------------------COIN TEST

- HOPPER HOPPER OUT LAP = 0

HOPPER OUT TOTAL = 0

- HOPPER COUNT SWITCH MAX ACTIVE TIME = 0 [msec]

MIN ACTIVE TIME = 0 [msec]

ERROR COUNT = 0

- COIN IN COUNT COIN 0.05 = 0

COIN 0.10 = 0

COIN 0.20 = 0

COIN 0.50(N) = 0

COIN 0.50(O) = 0

COIN 1.00 = 0

COIN 2.00 = 0

TOKEN = 0

PAY 1 COIN [ STOP ]

DIVERT TO [ CASHBOX ] ( CASHBOX, HOPPER )

COIN IN [ ACCEPT ] ( INHIBIT, ACCEPT )

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

62

Page 64

<For DOLLAR, EURO, or ANY CASH Settings>

---------------------------------------------------COIN TEST

- HOPPER HOPPER OUT LAP = 0

HOPPER OUT TOTAL = 0

- HOPPER COUNT SWITCH MAX ACTIVE TIME = 0 [msec]

MIN ACTIVE TIME = 0 [msec]

ERROR COUNT = 0

- COIN IN COUNT COIN 0.05 = 0

COIN 0.10 = 0

COIN 0.20 = 0

COIN 0.25 = 0

COIN 0.50 = 0

COIN 1.00 = 0

COIN 2.00 = 0

TOKEN = 0

PAY 1 COIN [ STOP ]

DIVERT TO [ CASHBOX ] ( CASHBOX, HOPPER )

COIN IN [ ACCEPT ] ( INHIBIT, ACCEPT )

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

<For TOKEN Setting>

---------------------------------------------------COIN TEST

- HOPPER HOPPER OUT LAP = 0

HOPPER OUT TOTAL = 0

- HOPPER COUNT SWITCH MAX ACTIVE TIME = 0 [msec]

MIN ACTIVE TIME = 0 [msec]

ERROR COUNT = 0

- COIN IN COUNT TOKEN = 0

PAY 1 COIN [ STOP ]

DIVERT TO [ CASHBOX ] ( CASHBOX, HOPPER )

COIN IN [ ACCEPT ] ( INHIBIT, ACCEPT )

EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

----------------------------------------------------

63

Page 65

HOPPER OUT LAP:

HOPPER OUT TOTAL:

MAX ACTIVE TIME:

MIN ACTIVE TIME:

ERROR COUNT:

COIN COUNT:

PAY 1 COIN:

DIVERT TO:

COIN IN:

Number of coins paid out for the current test.

Total number of coins paid out.

Longest Hopper Switch activity period.

Shortest Hopper Switch activity period.

Number of errors encountered.

Number of coins inserted. When set to DOLLAR, EURO, or ANY CASH, the

COIN ASSIGNMENTS setting display will change.

Pays out a single coin.

Tests sorting of inserted coins.

Confirms receipt of inserted coins.

8.2.8.4.TROUBLE LOG SCREEN

Select TROUBLE LOG to display the following screen and show error data/status.

---------------------------------------------------TROUBLE LOG (1/2)

NO ERROR

PRESS TEST BUTTON FOR NEXT PAGE

----------------------------------------------------