Page 1

Electric Deadbolt Installation Manual

Specifications

Operation

Operation voltage

Current draw

Status sensor

Adjustable delay timer

Weight (approx.)

Standby

Active

SD-997A-DQ

Fail-secure

12VDC

320mA@12VDC

880mA@12VDC

SPDT, 500mA @ 12VDC (NO/NC/COM)

0/3/5/9 secs.

2-lbs,5-oz (1kg)

SD-997B-GBQ

12/24 VDC

340mA@12VDC / 180mA@24VDC

900mA@12VDC / 440mA@24VDC

0/2.5/5/9 secs.

1-lb,13-oz (0.8kg)

Troubleshooting:

Problem:

Deadbolt does not activate

when the door closes.

Deadbolt activates when

the door is closed, but

does not lock the door.

How to reset unit.

For any other problems

Possible cause:

The sensor in the lock body

is too far from the magnet

in the strike plate.

Deadbolt may not be

properly going into the

deadbolt hole in the door.

Solutions:

• Try adjusting the strike plate, lock body position, or shims.

• Make sure the deadbolt is going into the hole and not hitting the

strike plate. If not, you must reposition the strike plate.

• If the deadbolt is going into the hole, it may be hitting the bottom of

the hole (if it is in a wooden door). In this case, drill a deeper hole.

• When testing, if necessary, reset the unit by grounding the orange

wire momentarily.

• Replace the unit, and test again. A problem unit can also be substituted

for a working unit in another door frame to see if it works there.

Optional Mounting Brackets Available for SD-997B Series :

Surface-Mount Bracket

SD-997SMB-AQ

•

Mount the deadbolt

and strike plate on

the door jamb instead

of in the door frame.

WARRANTY: This SECO-LARM product is warranted against defects in material and workmanship while used in normal service

for a period of one (1) year from the date of sale to the original consumer customer. SECO-LARM’s obligation is limited to the repair

or replacement of any defective part if the unit is returned, transportation prepaid, to SECO-LARM.

This Warranty is void if damage is caused by or attributed to acts of God, physical or electrical misuse or abuse, neglect, repair, or

alteration, improper or abnormal usage, or faulty installation, or if for any other reason SECO-LARM determines that such equipment

is not operating properly as a result of causes other than defects in material and workmanship.

The sole obligation of SECO-LARM, and the purchaser’s exclusive remedy, shall be limited to replacement or repair only, at SECO-LARM’s

option. In no event shall SECO-LARM be liable for any special, collateral, incidental, or consequential personal or property damages of any

kind to the purchaser or anyone else.

NOTICE:

SECO-LARM policy is one of continual development and improvement. For this reason, SECO-LARM reserves the right to change

specifications without notice. SECO-LARM is also not responsible for misprints or typographical errors.

Copyright © 2013 SECO-LARM U.S.A., Inc. All rights reserved. This material may not be reproduced or copied, in whole or in part,

without the written permission of SECO-LARM.

SECO-LARM

The information and specifications printed in this manual are current at the time of publication. However, the

®

U.S.A., Inc.U.S.A., Inc.

U.S.A., Inc.

U.S.A., Inc.U.S.A., Inc.

16842 Millikan Avenue, Irvine, CA 92606

Tel: 800-662-0800 / 949-261-2999 Fax: 949-261-7326

Page 4

“U” Bracket

SD-997UB-AQ

•

Mount the deadbolt

and strike plate on

glass doors.

SD-997BQ

Fail-safe

12VDC

MiSD997x-xxQ_032814.pmd

Website: www.seco-larm.com

E-mail: sales

@

seco-larm.com

SECO-LARM U.S.A., Inc.

PITSW2

Installation Manual

SD-997A-DQ – Fail-Secure,12VDC

SD-997BQ – Fail-Safe,12VDC

SD-997B-GBQ – Fail-Safe,12/24 VDC

Electric Deadbolt

SECO-LARM Electric Deadbolts are designed for hollow

metal door frames. They are not recommended for

wooden door frames. However, door can be wood or metal.

Features

•

Adds concealed deadbolt security to most wood or hollow

metal doors, with the convenience of electrical operation.

•

Stainless steel bolt, 5/8” diameter, 5/8” throw.

•

SD-997A-DQ --

•

SD-997B Series-- Fail-safe operation (unlocks if power

is lost).

• Magnetic switch senses door position for positive

locking.

•

Attempts to relock multiple times if the door is not

closed properly

•

Door open/close monitor (NO/C/NC).

•

Adjustable door lock delay timer - see Specifications.

•

Use with an optional digital keypad for high security

without a key.

•

Easily connects to SECO-LARM’s SK-1011-SQ Digital

Access Keypad.

•

Suitable for office-type applications.

3

“

/

4

(19.3mm)

Fail-secure operation (locks if power is lost).

(SD-997A-DQ & SD-997B-GBQ only)

1

“

/

8

4

(105mm)

5

SD-997A-DQ

3

“

(162mm)

/

6

8

SD-997B series

Note: Products with model numbers that end with "Q" or that have a round green"Q"sticker are RoHS compliant.

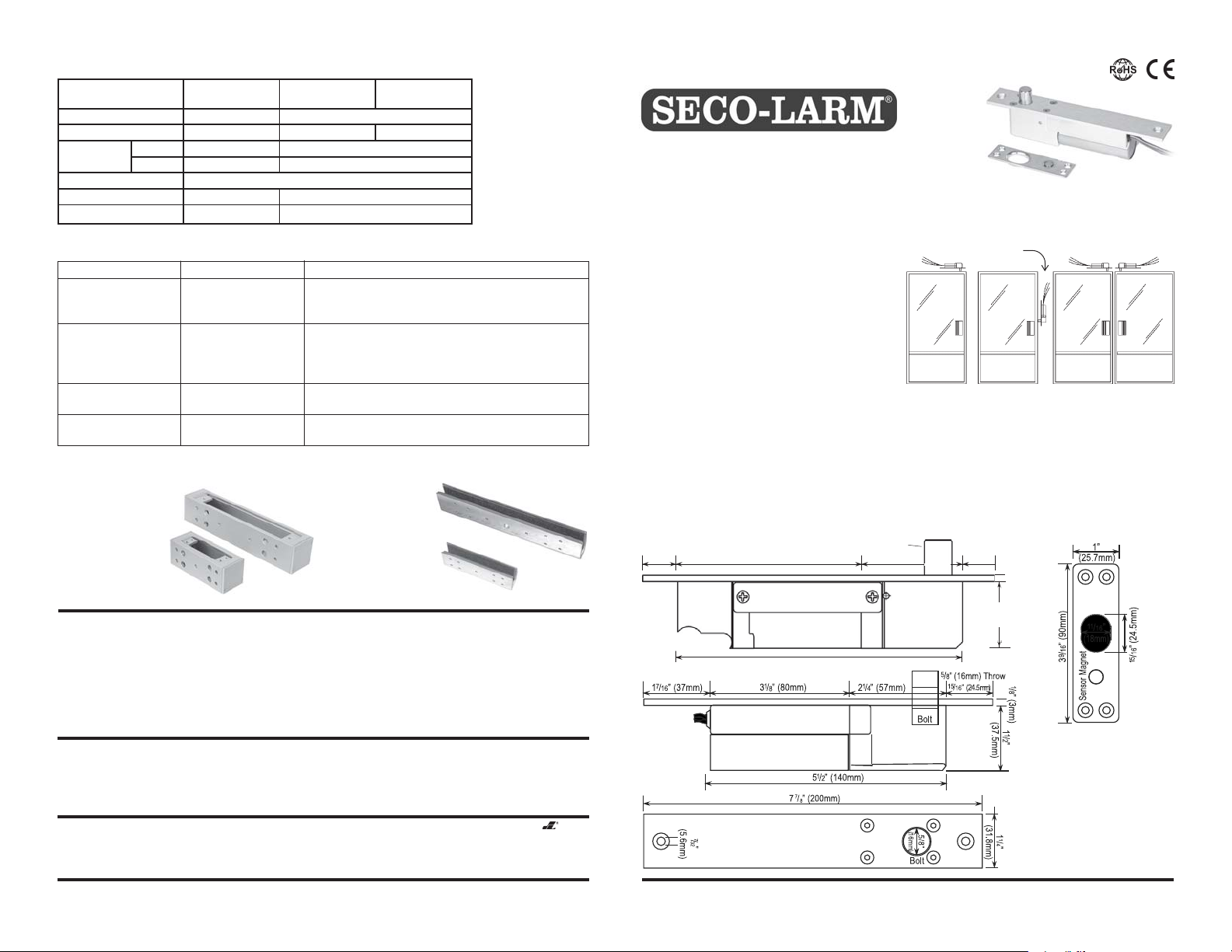

Fig. 1 - Possible Mounting Locations

Important - For vertical mounting of SD-997B series only, wires must come out

the top of the unit.

For single door

•

Optional mounting brackets available.

•

Shallow design for use with most metal door jambs.

.

•

Powered by a solenoid.

•

Stainless steel for strength and long life.

For single door For double doors

Mounting Location

Can be mounted opposite the door hinges, or on the header

or on top of the door away from the hinges. Mounting on the

bottom of the door is not recommended because of the

possibility of dirt and dust buildup. (see fig. 1)

“

/8

(16mm) Throw

1

“

/

(57.5mm)

2

4

3

/

4

(19mm)

(37.5mm)

“

(3.5mm)

1

“

/

2

1

SD-997B series shown

1

“

/

8

Dimensions:*

*Note: Original measurements

taken in millimeters. Inches are

closest 1/16” approximation.

Page 1

Page 2

Electric Deadbolt Installation Manual Electric Deadbolt Installation Manual

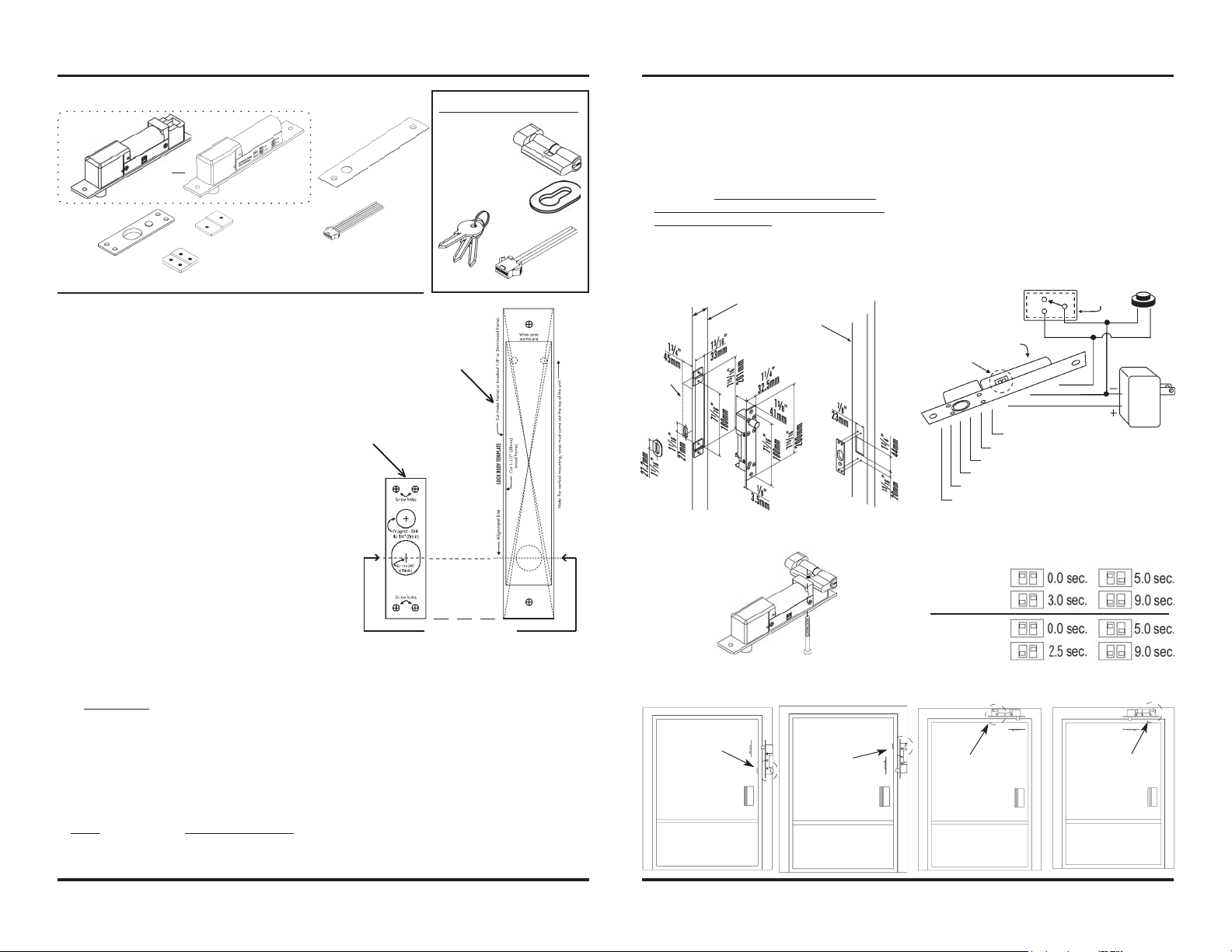

Fig. 2 - Parts List:

Lock body x 1

or

SD-997A-DQ

Strike

Plate x 1

SD-997BQ/

SD-997B-GBQ

Mounting tabs

(large) x 2

Mounting tabs

(small) x 2

Installation

1. Determine where the deadbolt will be mounted (see fig. 1).

2. Tape the templates to the door frame and door (see fig. 3)

A. Align the templates so that the deadbolt of the lock body template

is centered on the deadbolt hole of the strike plate template.

B. Make sure to leave enough room at the ends of the lock body

and strike plate templates for mounting the mounting tabs.

3. Door frame cut (see fig. 4)

A. Cut out the space for the lock body.

B. Test the fit. The lock body should fit snugly inside the space.

C. Drill two 5mm screw holes as shown on the

4. Door cut and mount. (see fig. 4)

A. For wood doors:

1) Use a chisel to knock out a 3mm (

shown on the template.

2) Drill the magnet hole, 12mm (

3) Use four wood screws to mount the strike plate in the

chiseled space. The magnet should fit in the magnet hole.

4) Use a drill to drill out the deadbolt hole to a depth of 16mm (

B. For hollow metal doors:

1) Cut out the space for the strike plate.

2) Drill two screw holes for each of the two mounting tabs.

3) Use screws to fix the mounting tabs inside the hollow metal door.

4) Use screws to fix the strike plate to the mounting tabs.

5. Door jamb cut and mount (see fig. 4)

A. Cut out the space for the face of the lock body.

B. Drill one 5mm hole for each of the two mounting tabs.

C. Use screws to fix the mounting tabs inside the door jamb.

D.

SD-997A-DQ only: Insert the lock/unlock cylinder (see fig. 5).

E. Connect the wires, and insulate them (see fig. 7):

1) Red – Power input (+)

2) Brown – Power input (-)

3) Orange – Control wire (ground to release bolt)

4) Green – Door monitor, COM

5) Yellow – Door monitor, N.C. (active when door closed)

{

*

6) Blue – Door monitor, N.O. (active when door open)

1

/2”) wide by 6mm (1/4”) deep.

IMPORTANT – Correct polarity of the red and brown wires is

critical. Incorrect polarity will burn out the solenoid !

*Connect to an alarm control panel or warning device to show if

the door is open or closed.

template.

1

/8-inch) deep space as

SD-997A-DQ Also Includes:

Manual

lock/unlock

cylinder x 1

Faceplate x 1

Oval cylinder

plate x 2

6-Pin

connector x 1

• Templates x 4

• Mounting screws

Keys x 3

connector x 1

Fig. 3 - Aligning

Lock body template

Strike plate template

5

/8”).

Line up these marks

IMPORTANT – Push all the wires into the door frame. If

space is a problem, cut away part of the dust catcher inside

the frame, or carefully chip away part of the drywall, being

careful not to damage the wall.

F. Set the door lock delay timer (see fig. 8). This is the

time it takes the deadbolt to automatically lock after

the door is closed.

NOTE: For SD-997A-DQ & SD-997B-GBQ only – The

deadbolt automatically relocks 4 seconds after an

optional external push button (egress button) is

pressed, if the door was not opened.

The lock body has a sensor mechanism

wherein it can detect if the strike plate is in

close proximity (such as when the door is

closed). If the door was closed but somehow

the strike plate was not aligned properly, the

door monitor indicator may indicate that the

SECO-LARM U.S.A., Inc. SECO-LARM U.S.A., Inc.

3-Pin

door is closed but the deadbolt remains unlock.

During this time the lock body may attempt multiple

times to relock the door and if it fails, it will stop to

prevent the solenoid from burning out.

However if the lock body and the strike plate are too far

apart, the lock body will not attempt to lock the door and the

deadbolt will not throw out.

IMPORTANT –

properly aligned and next to each other in order for the

product to function properly.

G.

The lock body and strike plate must be

Pull the vinyl covering off the faceplate, and place the

faceplate over the face of the lock body. Use screws to

fix the faceplate and lock body to the mounting tabs.

Fig. 4 - Door and Frame Cuts

Max. 50mm

SD-997A-DQ

only*

See separate

*

template.

Door frame

Door

Fig. 5 - Manual Lock/Unlock Cylinder

(SD-997A-DQ only):

Note:

If cylinder is used,

max. depth of door

frame is 50mm.

Screw to secure

cylinder to lock

6. For SD-997A-DQ only (see figs. 5 and 6)

Because the SD-997A-DQ offers fail-secure operation, the door

locks if power to the unit is cut. For such a situation, a separate

manual lock/unlock cylinder is provided for manual operation.

A. Insert the cylinder as shown in Fig. 5, and secure it to the

lock body with the provided long screw. Turning the key or

the manual knob will unlock the SD-997A-DQ manually.

B. Two separate templates are included for drilling holes in the

door frame for the key and manual knob.

C. A separate 3-pin connector for the SD-997A-DQ can be

connected to an alarm panel or annunciator to alert when

the door is locked or unlocked.

Fig. 7 - Wiring

N.C.

N.O.

SD-997A-DQ/SD-997B series

See fig. 8

Red wire

Green wire - door monitor, COM

Yellow wire - door monitor, N.C.

Blue wire - door monitor, N.O.

Purple wire - active if door is locked (N.C.)

Gray wire - manual lock/unlock (COM)

Black wire - active if door is unlocked (N.O.)

IMPORTANT – Do not cut wires before the plug as warranty

will be voided.

Fig. 8 - Setting Door Lock Delay Timer

SD-997A-DQ

body

SD-997BQ /

SD-997B-GBQ

Fig. 6 - Installation of Manual Lock/Unlock Cylinder (SD-997A-DQ only):

Installation at side of door

Drill hole

for lock

Drill hole

for lock

Installation at top of door

Drill hole for lock

COM

Brown wire

Card reader

or keypad

Orange

(active when door closed)

(active when door open)

Drill hole for lock

Push

button

Power

Supply

{

For

SD-997A-DQ

only

Page 3Page 2

Loading...

Loading...