SEA USER 1-24V DG R1B User Manual

International registered trademark n. 2.777.971

USER 1 - 24V DG R1B

24V ELECTRONIC CONTROL UNIT FOR SLIDING GATES AND BARRIERS

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172 USA

:++1-305.594.1151 ++1-305.594.7325

Tel. -

Toll free:

web site: www.sea-usa.com

e-mail: sales@sea-usa.com

67411535 REV 08 - 12/2015

800.689.4716

USER 1 - 24V DG R1B

International registered trademark n. 2.777.971

Details

General

An appliance shall be provided with an instruction manual. The instruction manual shall give instructions for the installation,

operation, and user maintenance of the appliance.

The installation instructions shall specify the need for a grounding-type receptacle for connection to the supply and shall stress the

importance of proper grounding.

The installation instructions shall inform the installer that permanent wiring is to be employed as required by local codes, and

instructions for conversion to permanent wiring shall be supplied.

Information shall be supplied with a gate operator for:

a) The required installation and adjustment of all devices and systems to effect the primary and secondary protection against

entrapment (where included with the operator).

b) The intended connections for all devices and systems to effect the primary and secondary protection against entrapment. The

information shall be supplied in the instruction manual, wiring diagrams, separate instructions, or the equivalent.

Vehicular gate operators (or systems)

A vehicular gate operator shall be provided with the information in the instruction manual that defines the different vehicular gate

operator Class categories and give examples of each usage. The manual shall also indicate the use for which the particular unit is

intended as defined in Glossary, Section 3. The installation instructions for vehicular gate operators shall include information on

the Types of gate for which the gate operator is intended.

A gate operator shall be provided with the specific instructions describing all user adjustments required for proper operation of the

gate. Detailed instructions shall be provided regarding user adjustment of any clutch or pressure relief adjustments provided. The

instructions shall also indicate the need for periodic checking and adjustment by a qualified technician of the control mechanism

for force, speed, and sensitivity.

Instructions for the installation, adjustment, and wiring of external controls and devices serving as required protection against

entrapment shall be provided with the operator when such controls are shipped with the operator.

Instructions regarding intended installation of the gate operator shall be supplied as part of the installation instructions or as a

separate document. The following instructions or the equivalent shall be supplied where applicable:

a) Install the gate operator only when:

1) The operator is appropriate for the construction of the gate and the usage Class of the gate,

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4 feet (1.22

m) above the ground to prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the openings anywhere in

the gate, and in that portion of the adjacent fence that the gate covers in the open position,

3) All exposed pinch points are eliminated or guarded, and

4) Guarding is supplied for exposed rollers.

b) The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will

not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

c) The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

d) The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do not overtighten the operator clutch or pressure relief valve to compensate for a damaged gate.

e) (not applicable)

f) Controls intended for user activation must be located at least six feet (6’) away from any moving part of the gate and where the

user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily accessible

controls shall have a security feature to prevent unauthorized use.

2

USER 1 - 24V DG R1B

International registered trademark n. 2.777.971

g) The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall not cause the

operator to start.

h) A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

i) For gate operators utilizing a non-contact sensor:

1) See instructions on the placement of non-contact sensors for each Type of application,

2) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the gate is

still moving, and

3) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier.

j) For a gate operator utilizing a contact sensor:

1) One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading

edge, trailing edge, and postmounted both inside and outside of a vehicular horizontal slide gate.

2) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3) One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4) A hardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor and

the gate operator is not subjected to mechanical damage.

5) A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for entrapment

protection functions shall be located where the transmission of the signals are not obstructed or impeded by building

structures, natural landscaping or similar obstruction. A wireless contact sensor shall function under the intended enduse conditions.

6) One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the

bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of travel, one or

more contact sensors shall be located on the bottom edge.

Revised 56.8.4 effective February 21, 2008

7) One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

Instruction regarding intended operation of the gate operator shall be provided as part of the user instructions or as a separate

document. The following instructions or the equivalent shall be provided:

IMPORTANT SAFETY INSTRUCTIONS

WARNING – To reduce the risk of injury or death:

ATTENTION: pour réduire le risque de dommages ou mort:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object activates the noncontact sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and retest the gate

operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a qualified service person make repairs to gate

hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. SAVE THESE INSTRUCTIONS.

3

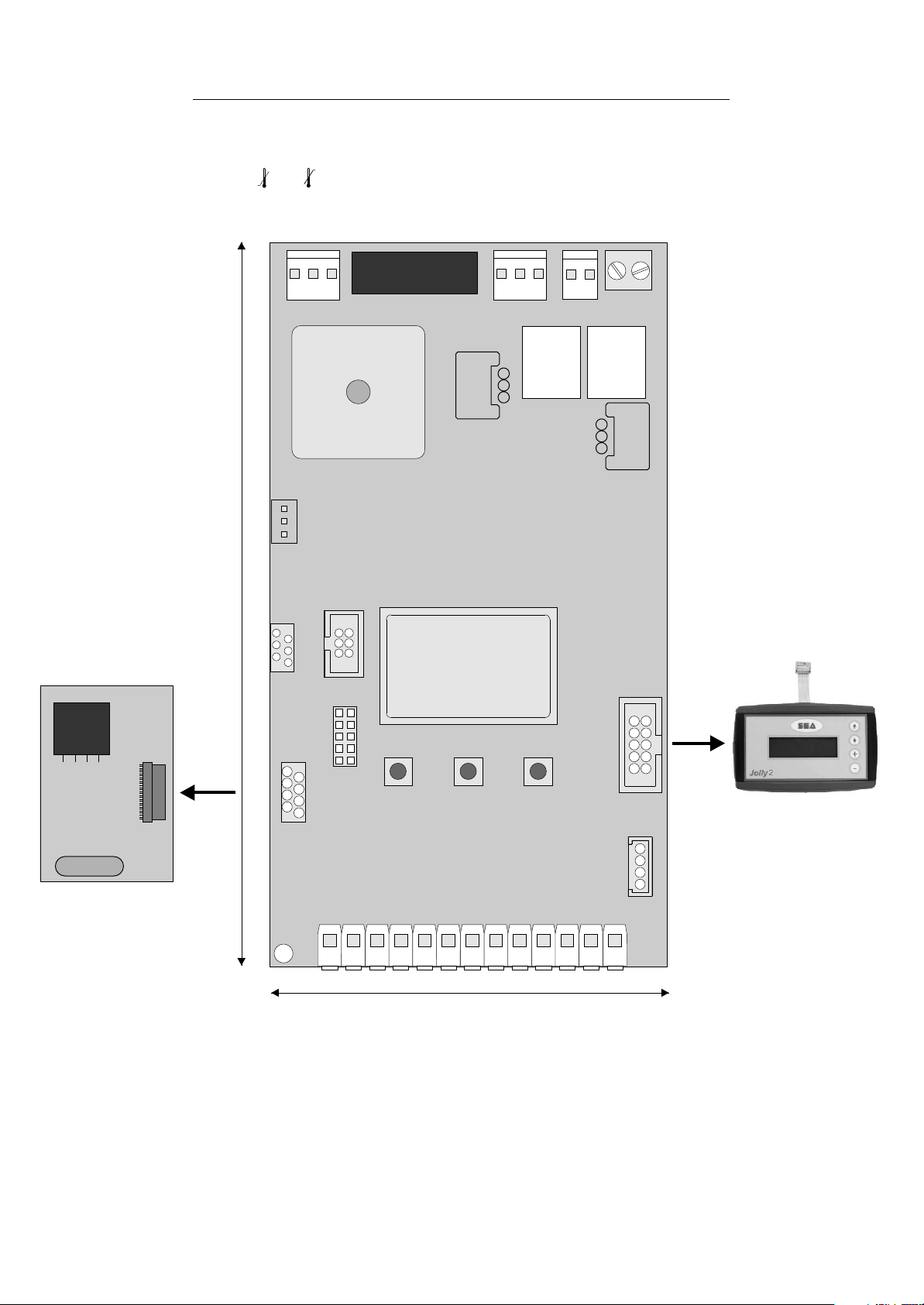

DESCRIPTION OF THE COMPONENTS

TECHNICAL SPECIFICATIONS

Control unit power supply: 24 V~

Absorption in stand by: 30 mA

Environment temperature: -20 +55 (-4°F +122°F)

Specifications of external enclosure: 305 x 225 x 125 mm (12 x 9 x 5 inches) - Ip55

USER 1 - 24V DG R1B

RECEIVER RX

156 mm

1

CNE

CN4

CN8

POWER

ENCODER

MASTER/SLAVE

PROG

PR1

EXP

CNP

F1

FUSE

DISPLAY

RD1

CN7

BATTERY

RL1

CN6

MOTOR

CN5

LIGHT

RL2

RD3

CN3

CNA

RADIO MODULE

UP

DOWN

OK

JOLLY

JOLLY-JOLLY2

CN2

LIMIT SWITCH

CN1

1

1 2 3 4 5 6 7 8 9 10 11 12 13

100 mm

CN1 = Input/Output connector

CN2 = Limit switch connector

CN3 = Jolly-Jolly 2 connector

CN4 = Master/slave connector

CN5 = Courtesy light output plug

CN6 = Motors connector

CN7 = Batteries connector - Quick connection

CN8 = Power connector

CNA = RX Receiver connector

CNE = Encoder connector

4

CNP = Programming connector

EXP = External module connector

OK = Programming button

DOWN = Programming button

UP = Programming button

RD1 =Motors piloting Mosfet

RD3 = Motors piloting Mosfet

R1 = Motors command relay

R2 = Motors command relay

PR1 = Rectifier jumper

F1 = Fuse 10 AT

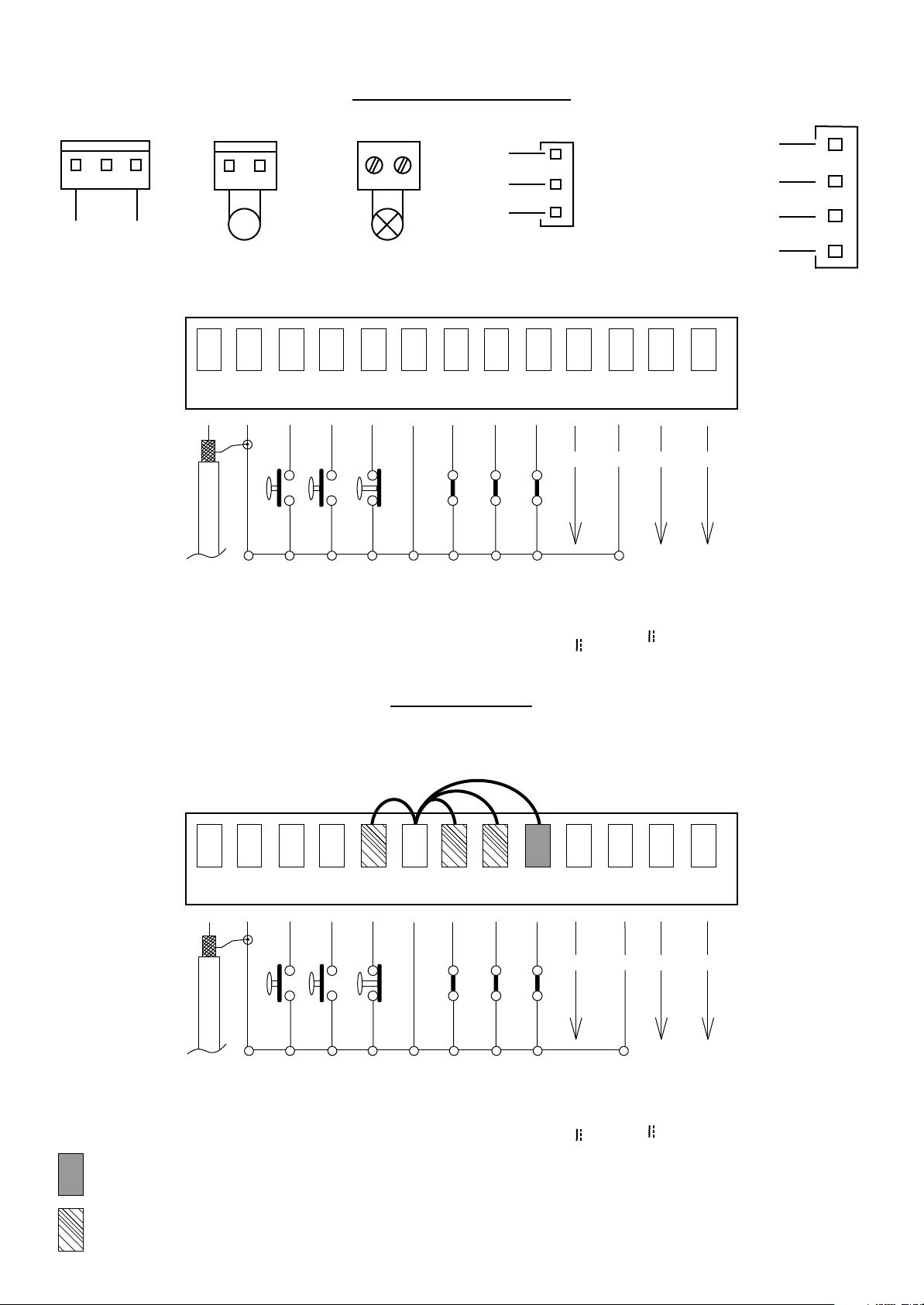

POWER (CN8)

MOTOR (CN6)

CONNECTIONS

LIGHT (CN5)

Brown

1

USER 1 - 24V DG R1B

ENCODER (CNE)

24V (Red)

LIMIT SWITCH (CN2)

24V~

M

Max 200W

2

1

ANT COM START

Antenna

3 4

Start

Common

Max 100mA

5 6

PEDST

STOP COM PH1 PH2

Stop

Common

START Ped.

White

Green

CN1

7 8

Photocell 1

Limit switch Cl.1 (Yellow)

Limit switch Op.1 (Green)

Common (White)

1

9

10

EDGE

AUX

+ +

Photocell 2

Safety edge

AUX Programmable

(24V 300 mA max)

12

11

COM 24V (FL)-

- -

Common

13

(Accessori)

24V 750 mA max

Flash (-)

JUMPERS

WARNING: The control unit is designed with the automatic detection of not used N.C. inputs (photocells, Stop and Limit switch) except the

SAFETY EDGE input. The exclude inputs in self-programming can be restored in the “Check inputs” menu without need to repeat the

programming (pag.14).

CN1

2

1

ANT COM START

Antenna

Obligatory jumper without accessory connection.

Optional

Common

3 4

PEDST

Start

5 6

STOP COM PH1 PH2

Stop

START Ped.

Common

7 8

Photocell 1

Photocell 2

9

EDGE

Safety edge

10

11

AUX

COM 24V (FL)-

+ +

AUX Programmable

- -

Common

(24V 300 mA max)

12

13

Flash (-)

(Accessori)

24V 750 mA max

The herein reported functions

are available starting from

revision 73.

5

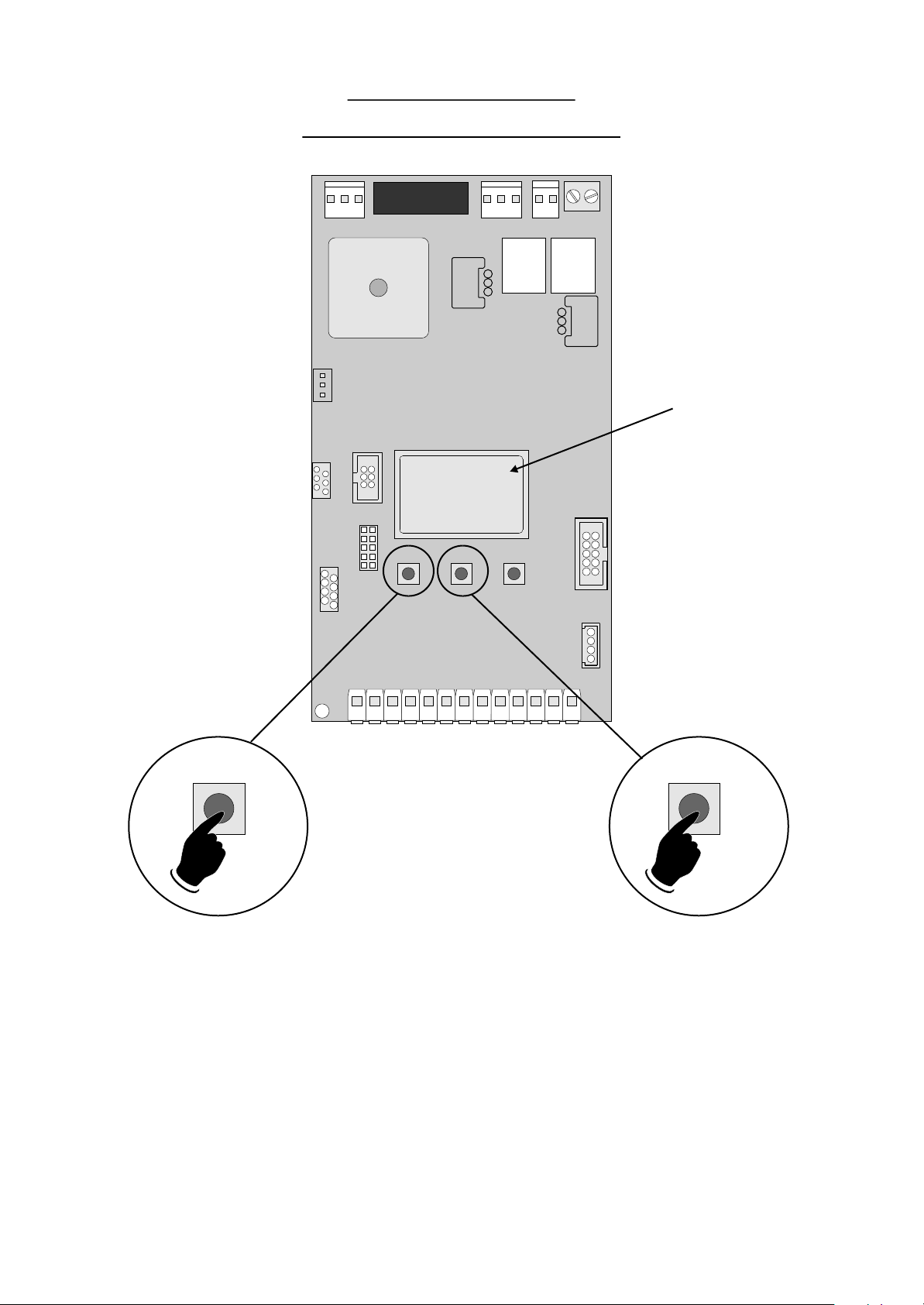

PROGRAMMING

FAST SELF-LEARNING

DISPLAY

---

--

---

UP

DOWN

OK

USER 1 - 24V DG R1B

nput check

“I

menu

"

1 2 3 4 5 6 7 8 9 10 11 12 13

UP DOWN

5 s 5 s

Start quick programming

You can start the quick programming by

holding UP for 5 s in the “I

menu

", until the motor starts.

nput check

Fast self-learning START command by

radio control

You can store the START button of the

remote control while pressing DOWN for 5 s

in the “I ".

Once the writing "Press button" appears,

press the button of the transmitter, which

you want to store for the START command.

By pressing OK, you can exit the menu,

otherwise it will be left automatically after 5

seconds.

nput check menu

6

PROGRAMMING

USER 1 - 24V DG R1B

1

2

3

5

6

(See

page 8)

UP

SEA

MENU

SET

LANGUAGE

UP

SEA

MENU

SET

TRANSMITTERS

UP

SEA

MENU

SET

MOTOR

UP

SEA

MENU

SET

REVERSE

MOTOR

UP

SEA

MENU

SET

LOGIC

UP

QUICK START

SEA

MENU

OK

ITALIANO

Skip this step if you do not want to program a transmitter

MENU

OK

If on the display

appears the item:

OK

programming the motor starts

OK OK

SET

SEA

START

MENU

SET

SEA

RECEIVER

MISSING

OK

SET

MENU

BUTTON

Check if a receiver has

been connceted

(see page 4)

Choose the type of

motor with

UP or DOWN

Choose "ON" with UP or

DOWN button only if in

in opening

With UP or DOWN

choose

the desired logic

PRESS

OKOK

SEA

SET

button of the

To confirm and return

to main menu

OK

To confirm and return

to main menu

Press the

TX to be

stored

Return to menu 7,

place the gate halfway

and repeat

the times programming

PROGRAMMING

BUTTONS

SEA

MENU

SET

STORED

If the motor has

magnetic limit switches,

select "Magnetic"

in the special menu:

104 - SELECT LIMIT SWITCH

OK to exit

Menu or press

the button of

the next TX to

be stored

DOWNUP

OK

7

8

9

(See

page 8)

10

15

SEA

MENU

SET

PAUSE TIME

UP

SEA

MENU

SET

START IN

PAUSE

UP

SEA

MENU

SET

PROGRAM-

MING

UP

SEA

MENU

SET

TEST START

UP

SEA

MENU

SET

END

OK OK

choose a delay for

With UP or DOWN

To confirm and return

automatic closing

With UP or DOWN

OK OK

To confirm and return

Choose ON

OK OK

With UP or DOWN choose ON

to start times learning

The gate will execute a CLOSING-OPENING-CLOSING CYCLE

Skip this step if a TX has already been stored

OK OK

UP or DOWN Choose

OK

With

ON to start test

Press OK to return to the

display of the inputs state.

to main menu

to main menu

At the end of the selflearning

the control unit returns automatically

To confirm and return to

Skip this step

if you wna tto work

in half-automatic

logic

to the main menu

main menu

UP

SEA

16

MENU

SPECIAL

MENU

SET

OK

Press OK to enter the special menu.

ALL OTHER PARAMETERS HAVE DEFAULT SETTINGS WHICH ARE USEFUL FOR THE 90% OF THE APPLICATIONS

BUT CAN BE HOWEVER SET THROUGH THE SPECIAL MENU. FOR ENTERING INTO THE SPECIAL MENU MOVE

ON ONE OF THE MENU AND PRESS THE UP AND DOWN BUTTONS AT THE SAME TIME FOR 5 S.

UPDOWN

7

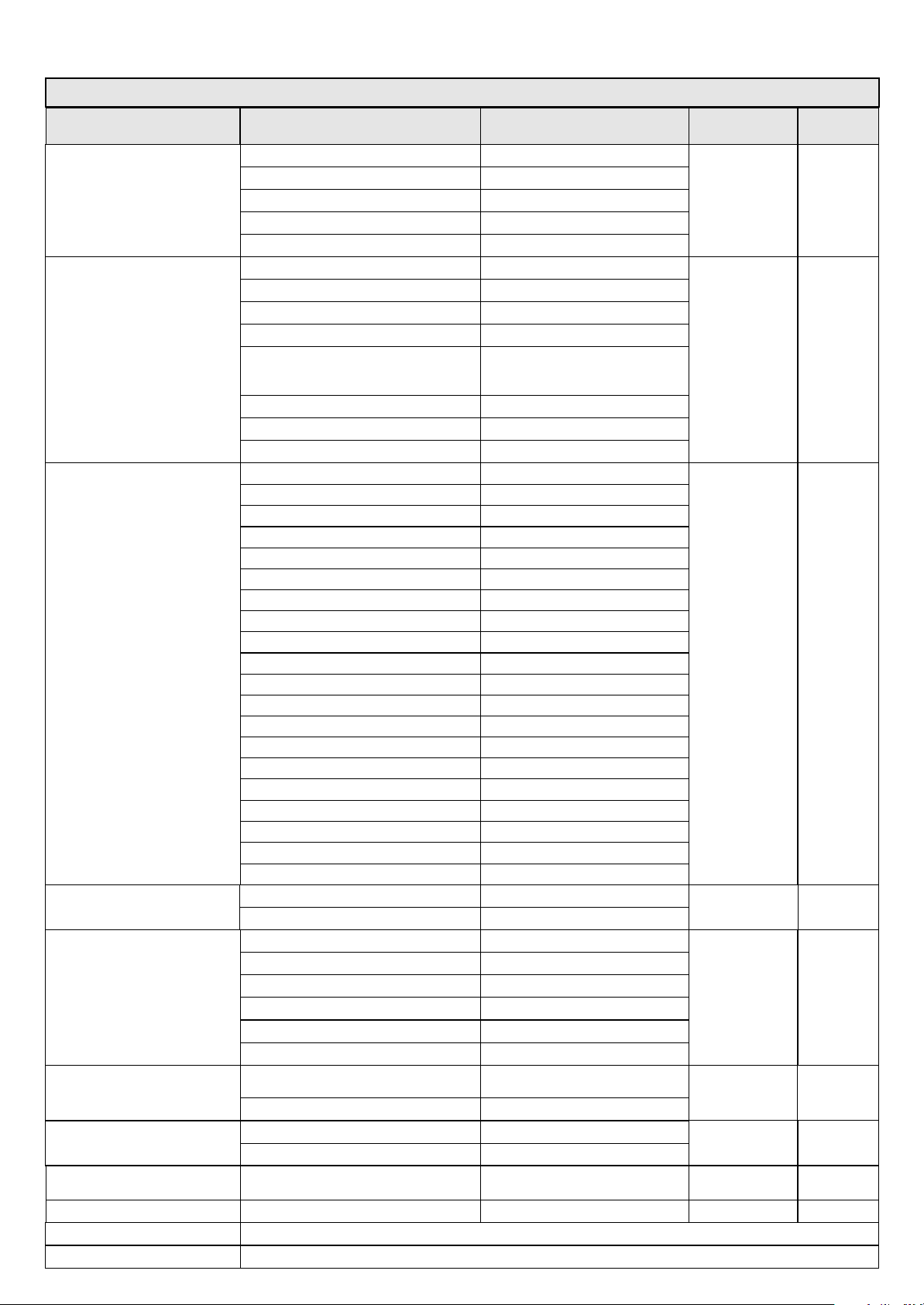

USER 1 - 24V DG R1B

MENU FUNCTIONS TABLE USER1 24V DG R1B

MENU

1 - LANGUAGE

2 - TRANSMITTERS

3 - MOTOR

5 - REVERSE MOTOR

6 - LOGIC

(See page 9)

7 - PAUSE TIME

8 - START IN PAUSE

9 - PROGRAMMING

(See page 9)

10 - TEST START

15 - END

16 - SPECIAL MENU

8

SET

Italiano

English

Français

Español

Dutch

Start

Pedestrian Start

External module

Stop

Unloch

Delete a transmitter

Clear memory

End

Sliding

Saturn Fast - Saturn Super Fast

Joint

Sprint 3 meters

Sprint 4 meters

Sprint 5 meters

Storm 5 meters

Storm 6 meters

Storm 7,5 meters

Saturn

Mercury 800

VergL.5 meters

VergL.4 meters

VergL.3 meters

Erg Maxi

Erg

Verg

Reversible sliding gate

Mercury Fast Mercury Fast

Saturn 1500

Off

On

Automatic

Open-stop-close-stop-open

Open-stop-close-open

2 buttons

Safety

Dead man

Off

1 240

Off

On

Off On

Off On

Press OK to return to the display of the firmware version and to the one of inputs state.

Press OK to enter the special menu.

Italian

English

French

Spanish

Olandese

Start

Pedestrian Start

External module

Stop

Storing of a command for

unlocking an electric brake

Delete single transmitter

Delete transmitter memory

“Transmitters” menu output

Sliding/B 200/B 500

Saturn Fast - Saturn Super Fast

Joint

Sprint 3 meters

Sprint 4 meters

Sprint 5 meters

Storm 5 meters

Storm 6 meters

Storm 7 and 7.5 meters

Saturn

Mercury 800

VergL.5 meters

VergL.4 meters

VergL.3 meters

Erg Maxi

Erg

Verg

C500 - Puma

Saturn 1500

Synchronized right motor

Synchronized left motor

Automatic

Step by step type 1

Step by step type 2

Two buttons

Safety

Dead man

OFF

(semi-automatic logics)

Setting from 1s to 4min.

In pause start is not acceped

In pause start is accepted

Times learning start

Start command

Description

Default

Italiano

Start

Pedestrian

Start

Sliding

Off

Open-stopclose-open

Off

Off

Off

Off

Set value

Loading...

Loading...