OMGC00390 K9

k9

21-Inch Walk-Behind Rotary Mowers

SP6211 and SP6213

OPERATOR’S MANUAL

North American Version

Litho in U.S.A.

Introduction

INTRODUCTION

Introduction

Thank You for Purchasing a Scotts Product

We appreciate your business and wish you many years of

safe and satisfied use of your machine.

Using Your Operator’s Manual

This manual is an important part of your machine and

should remain with the machine when you sell it.

Reading your operator’s manual will help you and others

avoid personal injury or damage to the machine.

Information given in this manual will provide the operator

with the safest and most effective use of the machine.

Knowing how to operate this machine safely and correctly

will allow you to train others who may operate t his machine.

Section in your operator’s manual are placed in a specific

order to help you understand all the safety messages and

learn the controls so you can operate this machine safely.

You can also use this manual to answer any specific

operating or ser vicing questions. A convenient index

located at the end of this book will help you to find needed

information quickly.

The machine shown in this manual may differ slightly from

your machine, but will be similar enough to help you

understand our instructions.

RIGHT-HAND and LEFT-HAND sides are determined by

facing in the direction the machine will travel when going

forward. When you see a broken line arrow (------>), the

item referred to is hidden from view.

Special Messages

Your manual contains special messages to bring attention

to potential safety concerns, machine damage as well as

helpful operating and servicing information. Please read all

the highlighted information carefully to avoid injury and

machine damage.

NOTE: General information is given throughout the

manual that may help the operator in the operation of

the machine.

CALIFORNIA Proposition 65 Warning

cCAUTION: Avoid injury!

This symbol and text highlight potential

hazards or death to the operator or bystanders

may occur if the hazards or procedures are

ignored.

IMPORTANT: Avoid damage! This text is used to

tell the operator of actions or conditions that might

result in damage to the machine.

Warning:g

The Engine Exhaust from

this product contains chemicals known to the

State of California t o cause cancer, birth

defects or other reproductive harm.

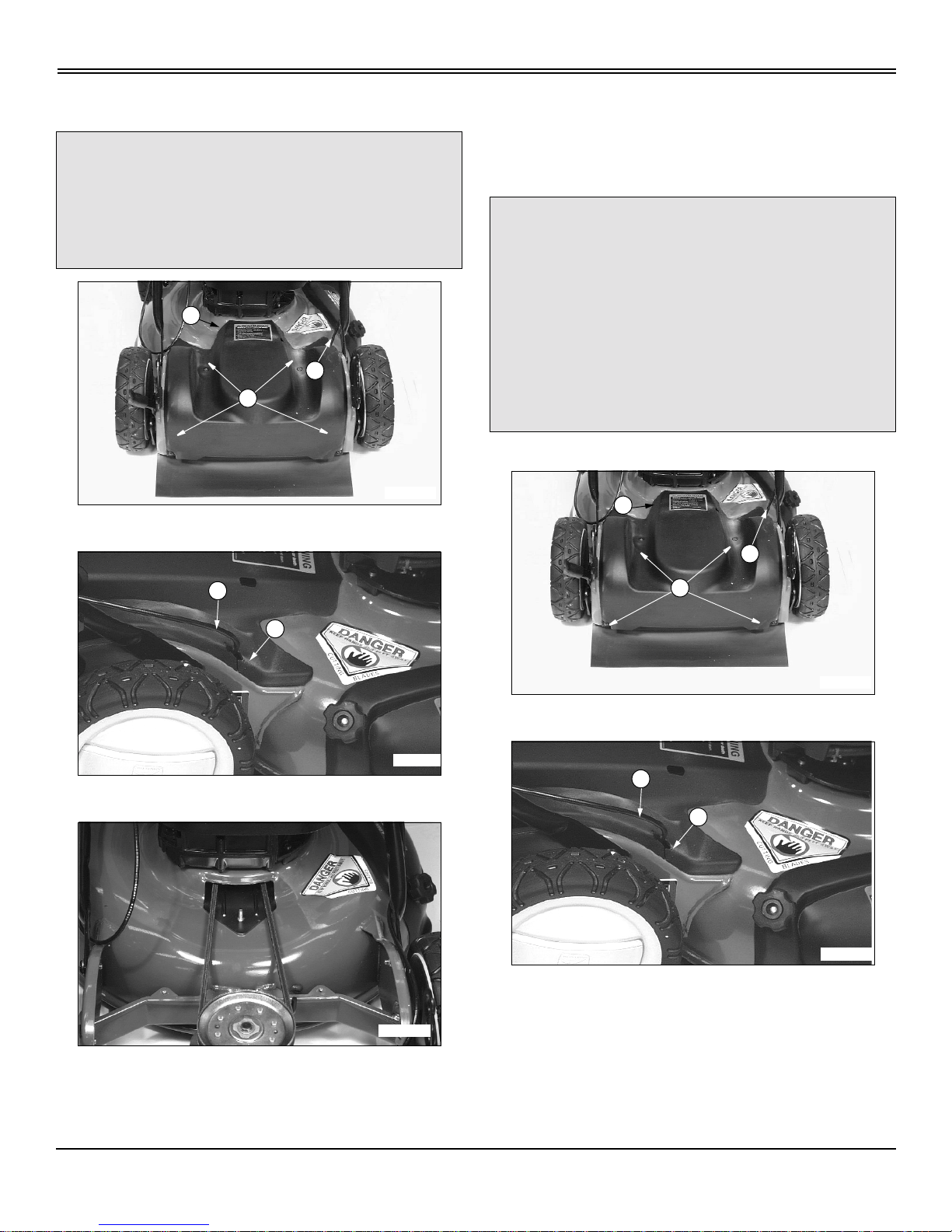

Product Identification

PRODUCT IDENTIFICATION

ProductIdentification

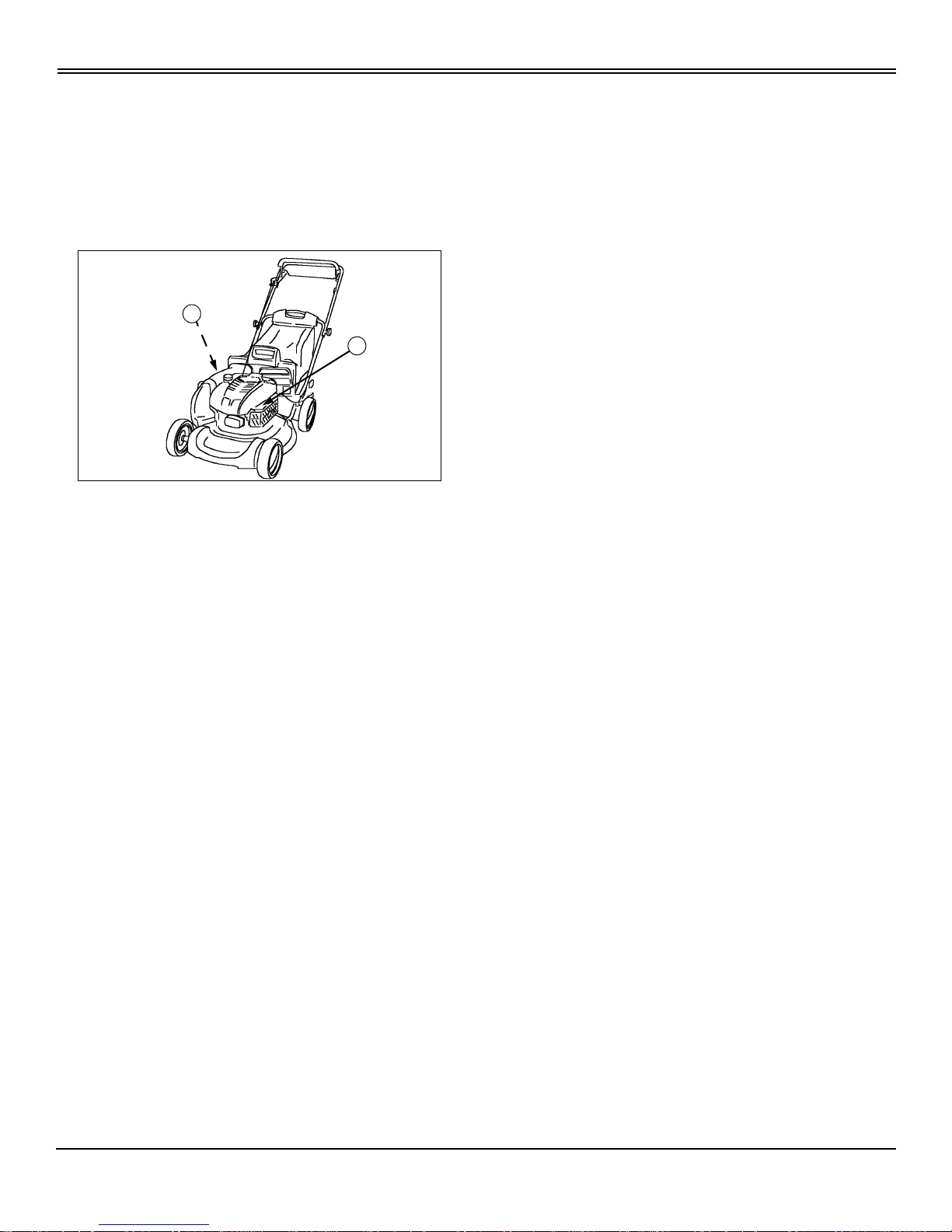

Record Identification Numbers

If youneedtocontact an authorizedScottsservicing dealer

for information on servicing, always provide the product

model and serial number.

You will need to locate the model and serial number for the

machine and fortheengineofyour machine and record the

information in the spaces provided below.

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

PRODUCT IDENTIFICATION NUMBER (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER (B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

MX1575

B

A

Table of Contents

TABLE OF CONTENTS

All information, illustrations and

specifications in this manual are based

on the latest information at the time of

publication. The right is reserved to

make changes at any time without

notice.

COPYRIGHT© 1999

Deere & Co.

John Deere Worldwide Commercial and

Consumer Equipment Division

Horicon, WI

All rights reserved

Previous Editions

COPYRIGHT©

OMGC00390 K9 - English

Tableof Contents

Contents

Safety .....................................................................................................................................................................................1

Operating................................................................................................................................................................................5

Replacement Parts...............................................................................................................................................................12

Service Intervals...................................................................................................................................................................13

Service .................................................................................................................................................................................14

Troubleshooting....................................................................................................................................................................25

Storing Machine....................................................................................................................................................................27

Assembly..............................................................................................................................................................................29

Specifications .......................................................................................................................................................................33

Warranty...............................................................................................................................................................................35

Index.....................................................................................................................................................................................38

Safety - 1

SAFETY

Safety

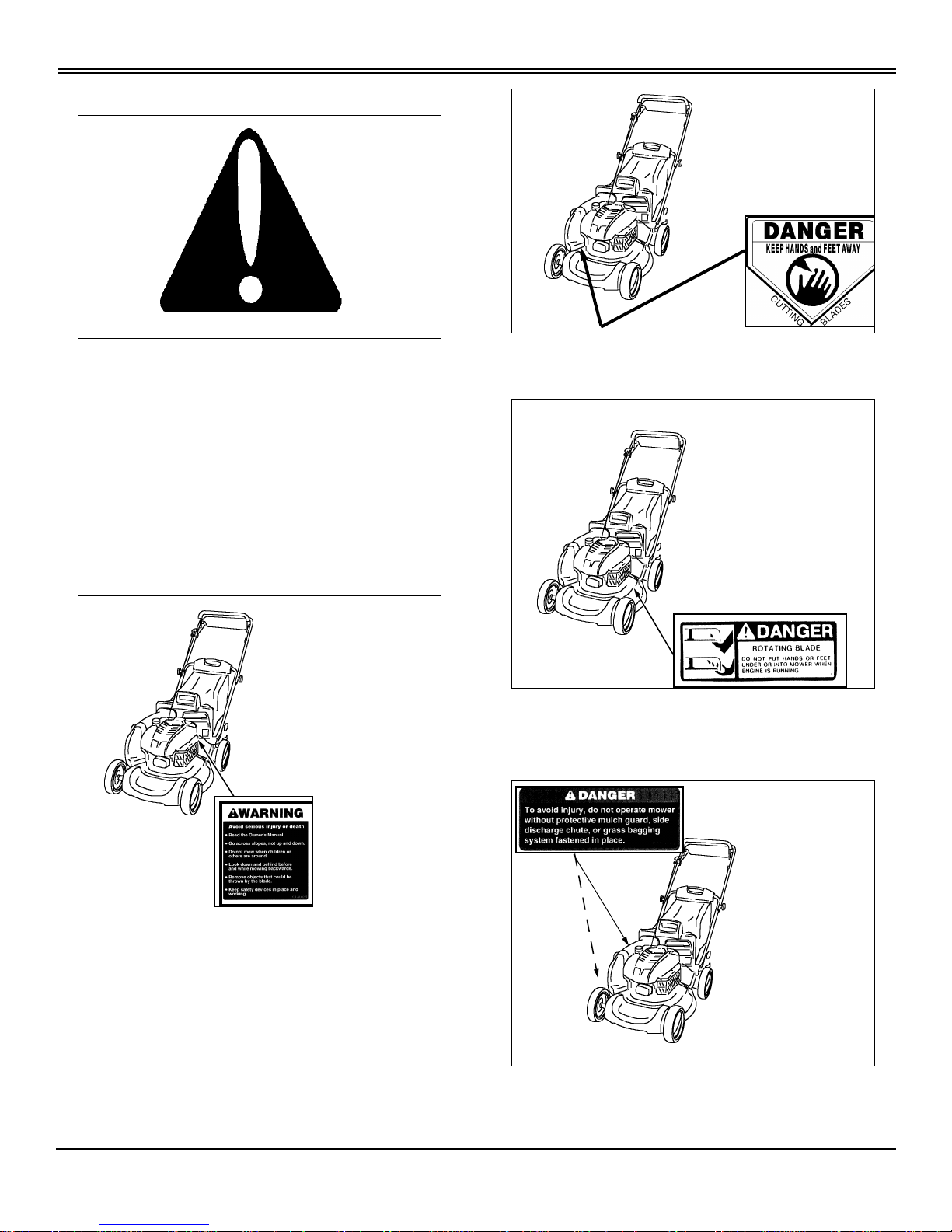

Safety-Alert Symbol

Read and recognize safety information. Be alert to the

potential for personal injury when you see this safety-alert

symbol.

On your machine safety labels, the words DANGER,

WARNING, a nd CAUTION are used with this safety-alert

symbol. DANGER identifies the most serious hazards. In

this manual, the word CAUTION and this symbol call

attention to safety messages.

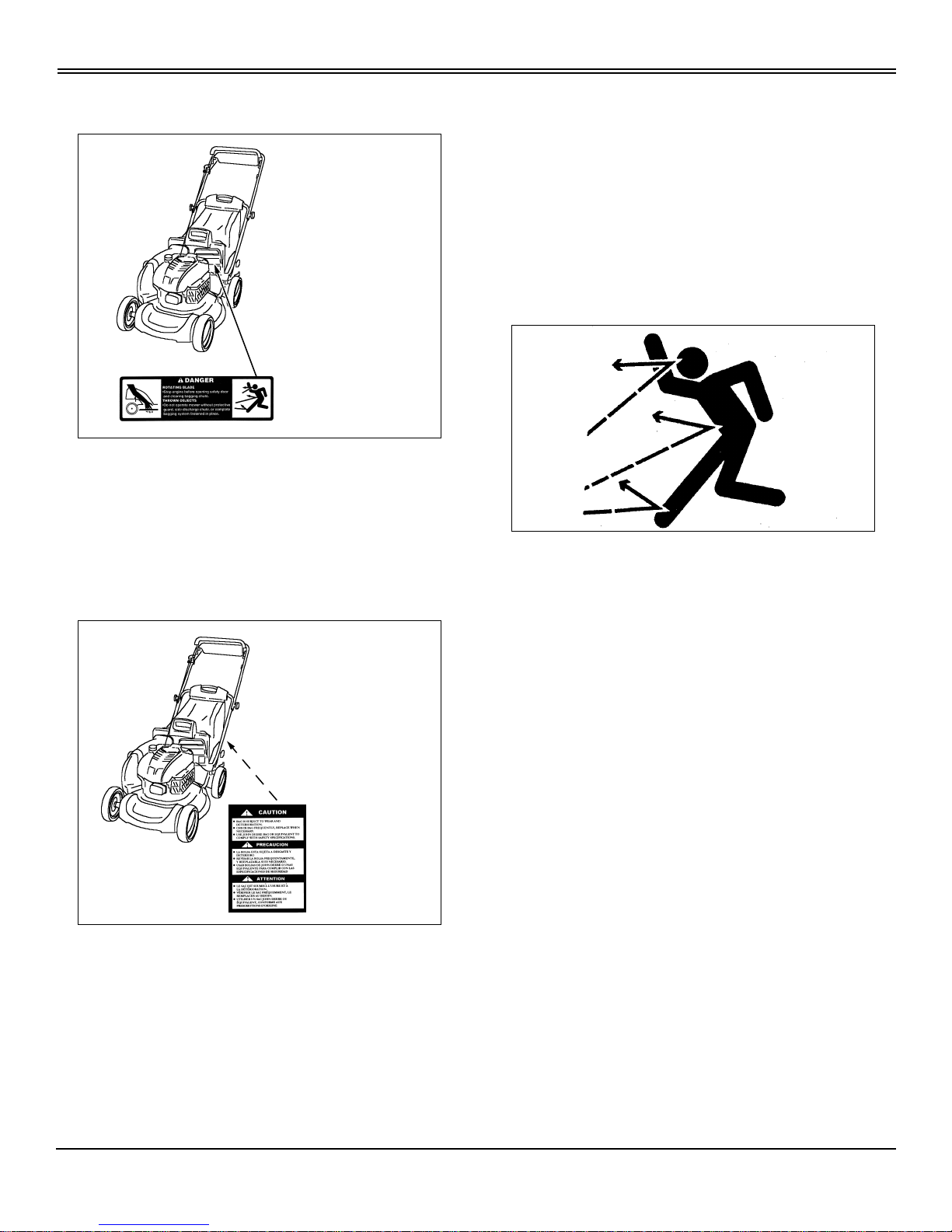

Machine Safety Labels

WARNING: AVOID SERIOUS INJURY OR DEATH

• Read the Owner’sManual.

• Go across slopes, not up and down.

• Do not mow when children or others are around.

• Look down and behind before and while mowing

backwards.

• Remove objects that could be thrown by the blade.

• Keep safety devices in place and working.

DANGER: KEEP HANDS AND FEET AWAY FROM

CUTTING BLADES

DANGER:ROTATINGBLADE

DO NOT PUT HANDS OR FEET UNDER OR INTO

MOWER WHEN ENGINE IS RUNNING

DANGER:

To avoid injury, do not operate mower without protective

Safety - 2

SAFETY

mulch guard, side discharge chute or grass bagging

system fastened in place.

DANGER:ROTATINGBLADE

• Stop engine before opening safety door and clearing

bagging chute.

THROWN OBJECTS

• Do not operate mower without protective guard, side

discharge chute, or complete bagging system fastened in

place.

CAUTION

• Bag is subject to wear deterioration.

• Check bag frequently, replace when necessary.

• Use John Deere bag or equivalent to comply with safety

specifications.

Certification Label

The OPEI label on your mower indicates that this model

has been certified by an independent laboratory for

compliance with American National Standard B-71.1,

“Safety Specifications” for Power Lawn Mowers, Lawn and

Garden Tractors, and Lawn Tractors.

SAFETY

Operate Safely

• Inspect machine before you operate. Be sure hardware

is tight. Repair or replace damaged, badly worn, or missing

parts. Be sure proper guards, plates, grass catcher, or

other safety protective devices are in good condition and

fastened in place. Make any necessary adjustments before

you operate.

• Clear work area of objects that might be thrown. Keep

people and pets out of the work area. Stop machine if

anyone enters the area.

• If you hit an object, stop the machine and inspect it.

Make repairs before you operate. Keep machine properly

maintained and in good working order.

• DO NOT leave machine unattended when it is running.

• Only operate during daylight or with good artificial light.

• Be sure of footing. Be especially careful when you pull

machine backwards with the engine running.

• Mow across a hill - not up and down. Be careful when

you change direction on a slope. DO NOTmow excessively

steep slopes.

• DO NOT mow wet grass. Reduced traction could cause

you to slip.

• Keepafirmholdonthemachinehandle.

• DO NOT wear radio or music headphones while

operating the machine. Safe operation requires your full

attention.

• DO NOToperate mower if youare under the influence of

drugs or alcohol.

Safety - 3

SAFETY

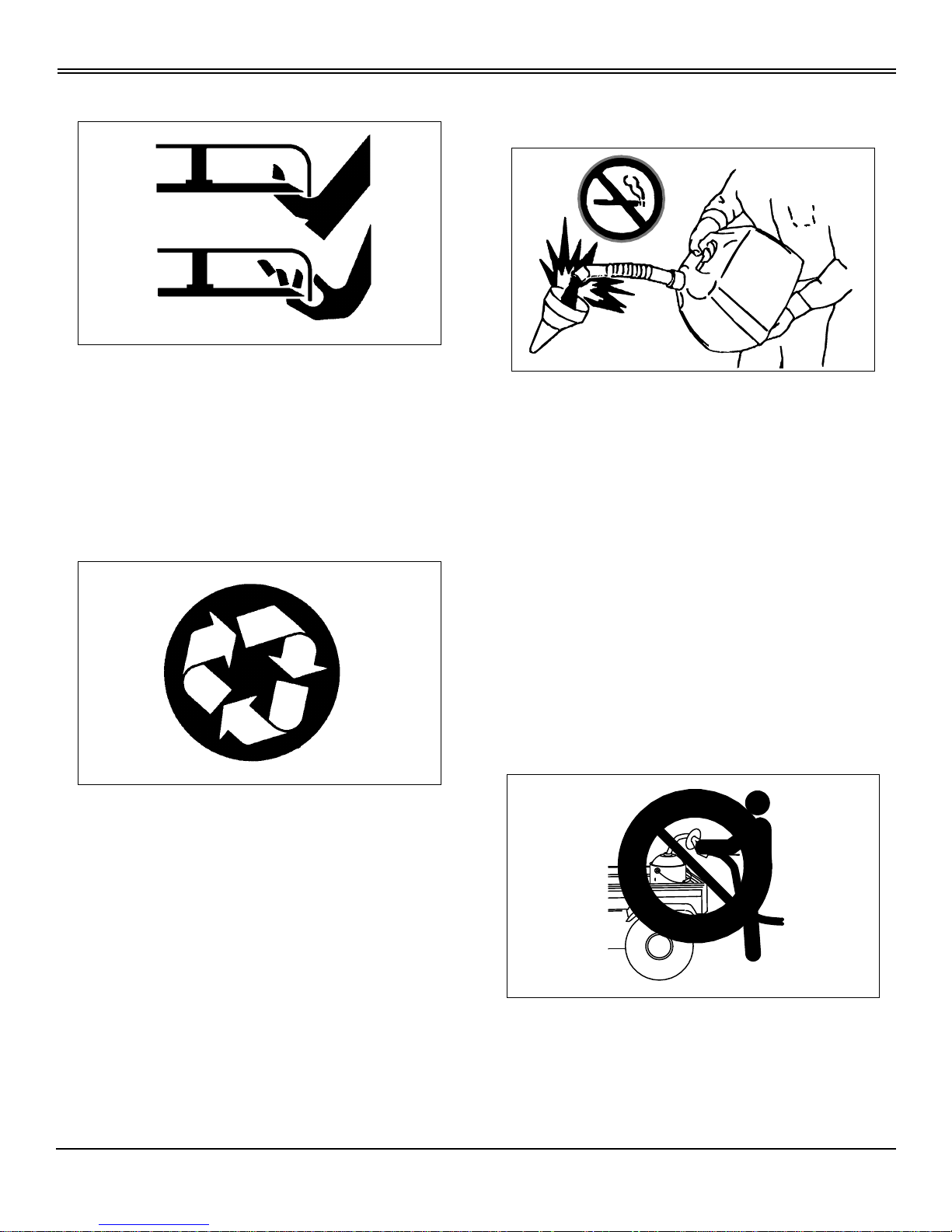

Rotating Blades are Dangerous - Protect

Children and Prevent Accidents

PROTECT CHILDREN:

• Never assume that children will remain where you last

saw them. Children are attracted to mowing activity, stay

alert to the presence of children.

• Keep children in the house when you are operating the

machine.

• Turn machine off if a child enters the area.

• Use extra care when you come to blind corners, shrubs,

trees, or other objects that may block your vision.

• DO NOT let children or an untrained person operate the

machine.

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

• Be alert at all times, people especially children can

move quickly into the area before you know it.

• Stop the blade when crossing gravel drives, walks, or

roads.

• Shut off blades when you are not mowing.

• Keep hands, feet, and clothing away from rotating

blades.

Wear Appropriate Clothing

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Do Not operate the equipmentwhen barefootor wearing

open sandals. Always wear substantial footwear.

• Loud noise can cause impairment or loss of hearing,

wearasuitableprotectivedevicesuchasearplugs.

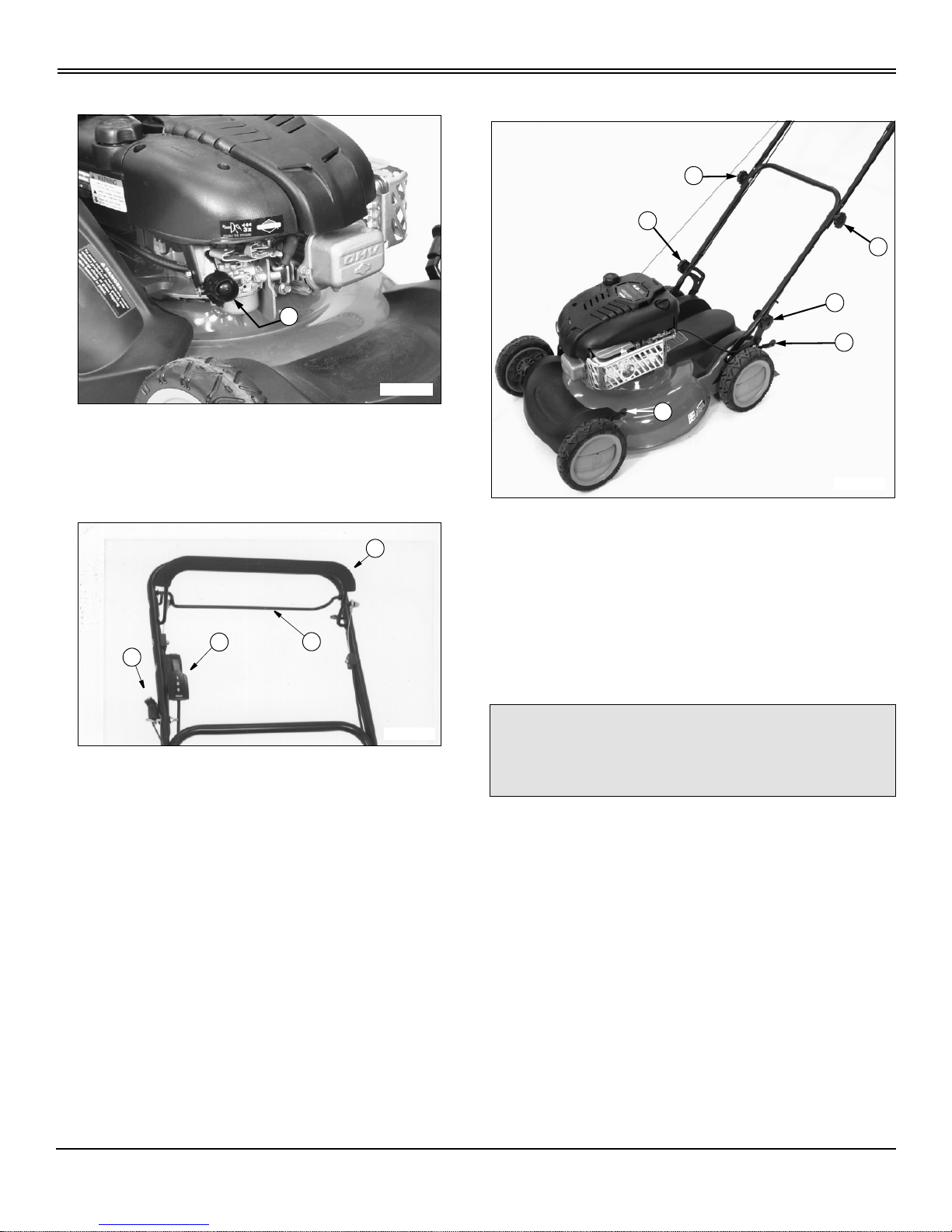

Practice Safe Maintenance

• Understand service procedure before doing work. Keep

area clean and dry.

• Never lubricate, service, or adjust machine while it is

moving. Keep safety devices in place and in working

condition. Keep hardware tight.

• To prevent them from getting caught, keep hands, feet,

clothing, jewelry, and long hair awayfrom any moving parts.

• Beforeservicing machine,disengage all power and stop

the engine. Let engine cool.

• Securely support any machine elements that must be

raised for service work.

• Keep all parts in good condition and proper ly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

• Unauthorized modifications to the machine may impair

its function and safety.

Safety - 4

SAFETY

Avoid Injury from Contacting Blade

Before you unplug or adjust machine:

• STOP the engine.

• Wait for blade to STOP.

• Keep hands, feet and clothing away from blade when

engine is running.

Handling Waste Products

• Waste products, such as, used oil, fuel, and batteries,

can harm the environment and people.

• DO NOT use beverage containers for waste fluids someone may drink from them.

• See your local Recycling Center or authorized Scotts

servicing dealer to learn how to recycle or get rid of waste

products.

• A Material Safety Data Sheet (MSDS) provides specific

details on chemical products: physical and health hazards,

safety procedures, and emergency response techniques.

The seller of the chemical products used with your machine

is responsible for providing the MSDS for that product.

Handling Fuel Safely

Fuel and fuel vapors are highly flammable:

• DO NOT refuel machine while you smoke, when

machine is near an open flame or spar ks, or when engine

is running. STOP engine.

• Fill fuel tank outdoors.

• Prevent fires: clean oil, grease and dirt from machine.

Clean up spilled fuel immediately.

• Do not store machine with fuel in tank in a building

where fumes may reach an open flame or spark.

• Prevent fire and explosion caused by static electric

discharge. Use only non-metal, portable fuel containers

approved by the Underwriter’s Laboratory (U.L.) or the

American Society for Testing & Materials (ASTM). If using a

funnel, make sure it is plastic and has no screen or filter.

• Static electric discharge can ignite gasoline vaporsin an

ungrounded fuel container. Remove the fuel container from

the bed of a vehicle or the trunk of a car and place on the

ground away from the vehicle before filling. Keep nozzle in

contact with container opening while filling.

• When practical, remove equipment from trailers or truck

beds and refuel them on the ground. If this is not possible,

use a portable, plastic fuel container to refuel equipment on

atruckbedortrailer.

• DO NOT use METHANOL gasoline. METHANOL is

harmful to the environment and to your health.

Operating - 5

OPERATING

Operating

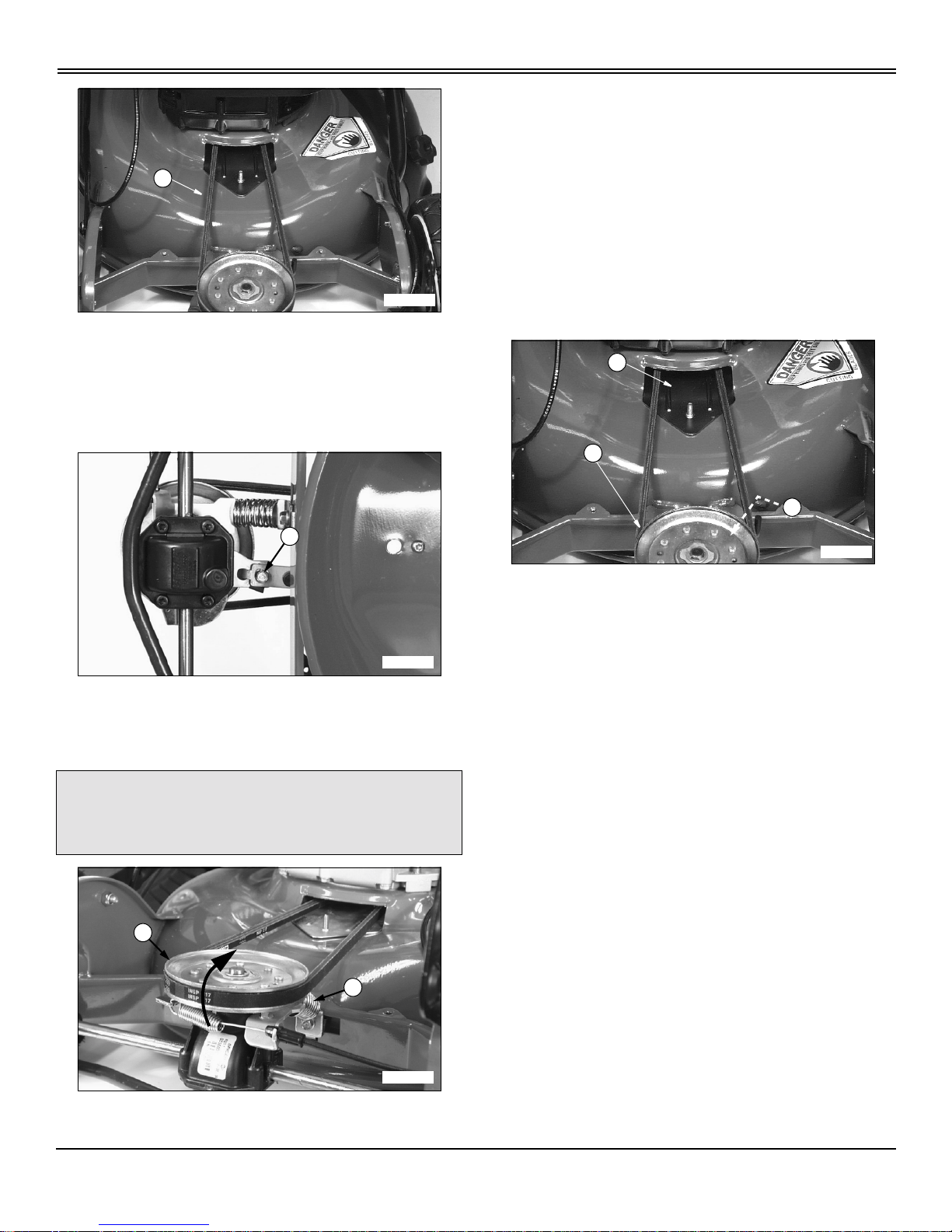

Engine Controls

A - Primer Bulb

Handle Controls

A - Blade Control Lever

B - Traction Clutch Lever

C - Starter Handle

D - Travel Speed Lever (SP6213)

Handle and Cutting Height Controls

A - Fold Handle Knobs

B - Handle Height Knobs

C-CuttingHeightLevers

ADJUSTMENTS

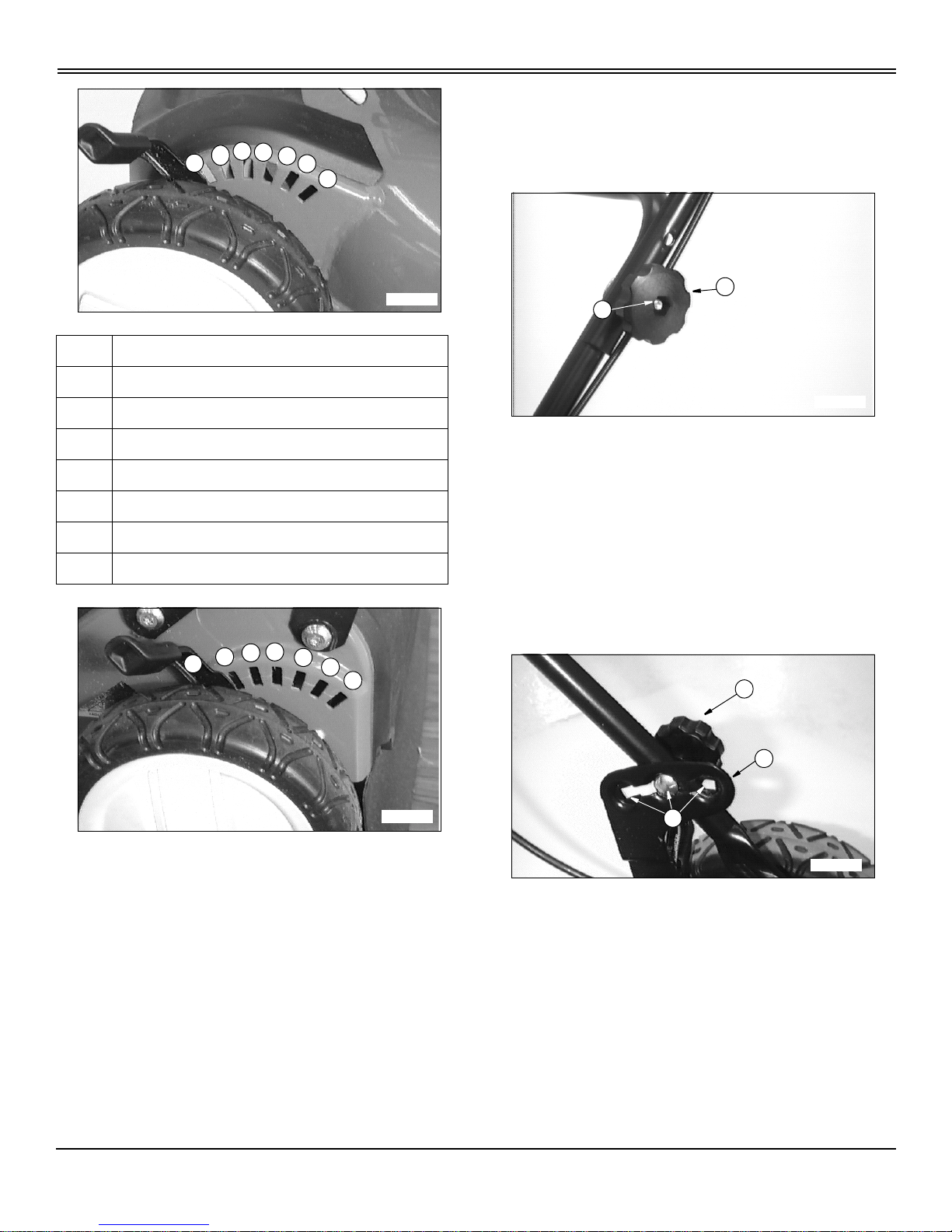

Adjusting Cutting Height

NOTE: Adjust both levers to same height except for

LOWEST cutting height (A). This adjustment improves

mulching performance at lowest cutting height:

• Put front wheel levers in 25 mm (1 in.) notch: First

rear notch.

• Put rear wheel levers in 38 mm (1-1/2 in.) notch:

Second rear notch.

To help move rear wheel lever:

1. Lift lower handlebar slightly with one hand to take some

weight off wheel.

2. Move height adjustment lever to desired position with

other hand.

MX1568

A

M93034

B

A

C

D

cCAUTION: Avoid injury! Before you adjust

cutting height:

STOP ENGINE.

M96540

B

A

A

B

C

C

Operating - 6

OPERATING

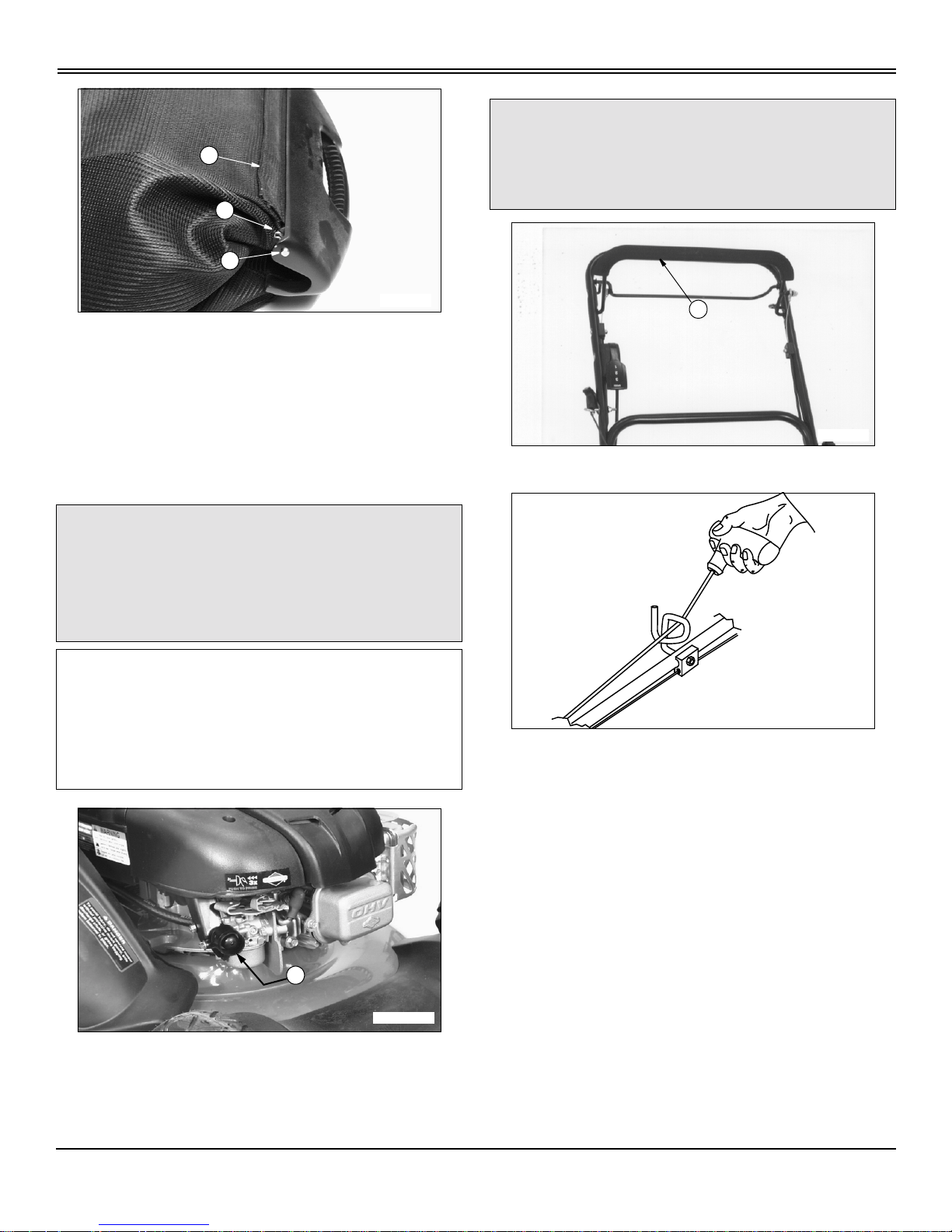

Adjusting Handle Height

Upper Handle:

NOTE: Upper handle height can be independently

adjusted to two positions.

1. Remove knob (A) and bolt (B) from each side of upper

handle.

2. Move handle to desired height.

3. Install bolt through matching holes in upper and lower

handles on each side.

4. Install and tighten knob (A).

Lower Handle:

NOTE: Lower handle height can be independently

adjusted to three positions.

1. Loosen knob (C) approximately 25 mm (1 in.) on each

side of handle.

NOTE: Carriage bolts must travel within slotted

adjustment brackets and come to rest within one of the

three height setting positions (E) before tightening.

2. Pivot handle to a desired height within slotted

adjustment bracket (D).

Key Cutting Height Adjustments In mm (Inches)

(A) 25mm(1in.)

(B) 38 mm (1-1/2 in.)

(C) 50mm(2in.)

(D) 64 mm (2-1/2 in.)

(E) 75mm(3in.)

(F) 90 mm (3-1/2 in.)

(G) 102 mm (4 in.)

A

B

C

D

E

F

G

M87101

A

B

C

D

E

F

G

M87102

A

B

M92146

M88835

C

D

E

Operating - 7

OPERATING

3. If bag preventslowering of handle, remove clip (F) to

remove rod (G). Remove rod from lower position (H) and

insert in upper position as shown to lengthen bag.

4. Tighten knob (C) on each side of handle.

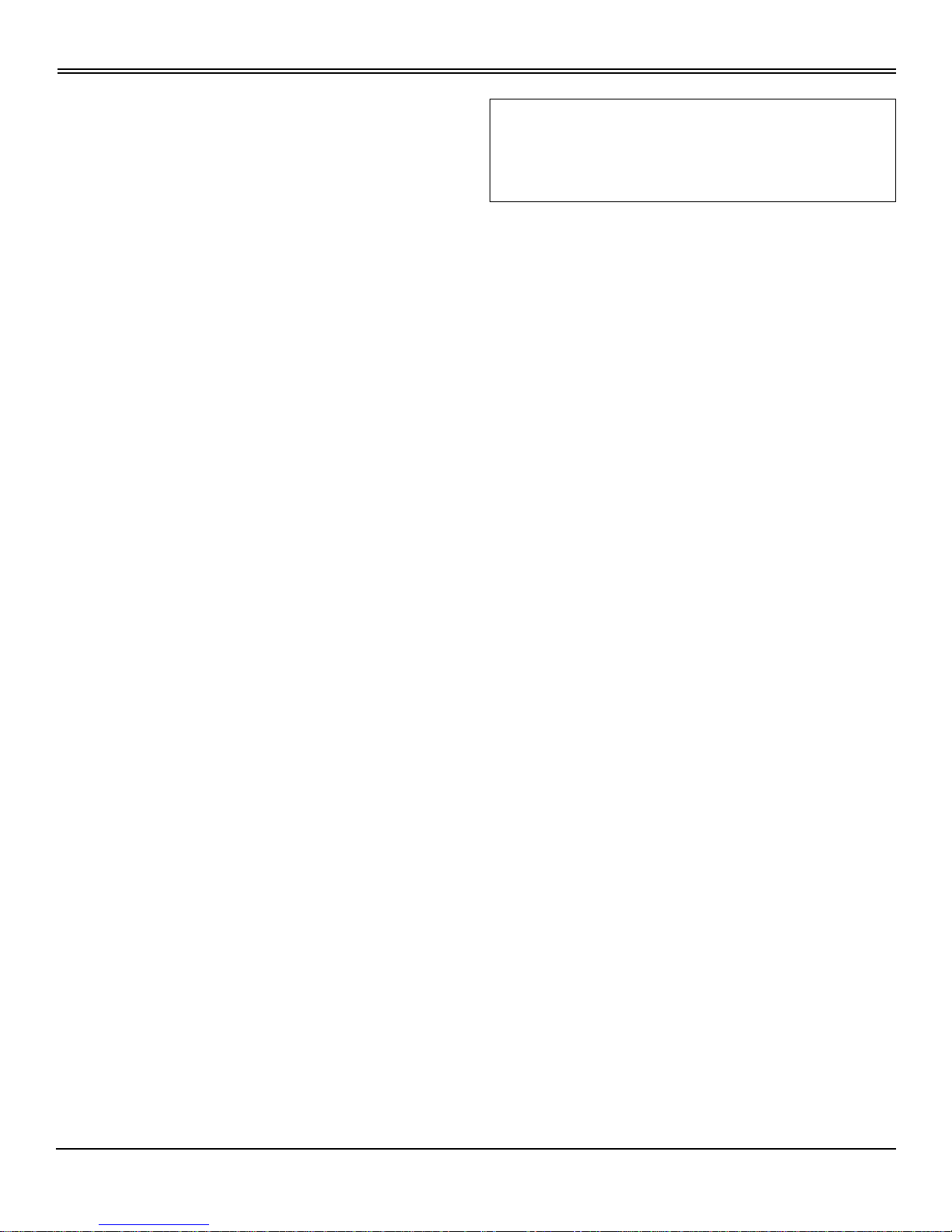

Starting Engine

1. Primeenginebypressingprimerbulb(A):

• COLD Engine - 3 times

• WARM Engine - 1 or 2 times

2. Hold blade control lever (B) against handle.

3. Pull starter handle until you feel resistance. Then pull

fast and steady.

4. When engine starts, return rope slowly.

cCAUTION: Avoid injury! Engine exhaust fumes

can cause sickness or death.

Run engine only in a ventilated area.

If engine is run in an enclosed area, open doors

to bring in outside air.

IMPORTANT: Avoid damage! To help prevent

damage to recoil starter and band brake , do not start

engine:

• When blade is under load, such as, in heavy

grass.

• When blade control lever is released.

M96559

F

G

H

MX1568

A

cCAUTION: Avoid injury! WHEN ENGINE IS

RUNNING, BLADE IS TURNING.

Keep hands, feet and clothing away from the

blade.

B

M93034

M88828

Operating - 8

OPERATING

Forward Travel

To Travel Forward:

Pull and hold traction clutch lever (A) against upper handle.

To Stop Forward Travel:

NOTE: Rear wheels will make a clicking noise when

mower is pushed forward. This indicates that the drive

train is operating correctly.

Release lever (A). Release traction clutch lever before

turning the mower.

Travel Speeds

Travel speed: (SP6211)

• 1stGear:3.9km/h(2.4mph)

Travel speeds: (SP6213)

• 1stGear:3.1km/h(1.9mph)

• 2nd Gear: 3.9 km/h (2.4 mph)

• 3rd Gear: 5.0 km/h (3.1 mph)

To change travel speeds: (SP6213)

NOTE: Mower travel speed can be changed when the

traction clutch lever is engaged and the mower is

moving forward.

• Raise or lower speed control lever (A) to engage desired

gear.

Stopping Engine

Release handle and levers:

• Mower will stop.

• Blade will stop.

• Engine will stop.

M93034

A

IMPORTANT: Avoid damage! If blade does not stop

within 3 seconds after you release blade stop lever,

see your authorized Scotts servicing dealer.

M93035

A

M73293a

Operating - 9

OPERATING

Using Side Discharge Chute

1. Release blade control lever to stop engine.

2. Remove mulch guard knob (A).

3. Lift and hold spring loaded mulch guard (B) up.

4. Install side discharge chute (C).

• Slide side discharge chute under mulch guard

mounting bracket.

• Lower mulch guard.

• Reinstall and tighten knob (A).

Using Grass Bag

NOTE: Bag may wear and deteriorate. Check condition

of bag often. Use a John Deere bag or equivalent to

comply with safety specifications.

1. Release blade control lever to stop engine.

2. Grasp handle (A) and handle (B) from left side of mower.

Lift bag off mower.

3. Lower front of bag. Raise rear of bag grasping handle

(A) and handle (B).

4. Allow doors (C) to swingopen. Shake contents of bag to

empty out.

Mowing Tips

Beforebeginningtomow,besuredeckislevelandproper

cutting height is selected.

cCAUTION:Avoidinjury! DO NOT operate mower

unless grass bag assembly, side discharge

chute or mulch guard is in place.

MX1566

A

B

MX1570

B

C

A

cCAUTION: Avoidinjury! DO NOT operate mower

unless mulch guard, side discharge chute or

grass bag and bagging chute are in place.

BaggingchuteMUSTberemovedandmulch

guard secured in place when grass bag is not

being used.

M96549

B

A

M96558

C

Operating - 10

OPERATING

When you mow an area for the first time, travel SLOW and

cut HIGH so you can:

• Learn the terrain.

• Learn the best mowing pattern.

• Help prevent hitting objects hidden in the grass.

Try to m ow grass only when it is dry: Wet grass may plug

mower and leave a trail of grass clumps.

Use a travel speed that fits the conditions:

• Travel SLOW when you mow thick, tall grass.

• FAST travel or sharp turns may produce stripes or

uneven cut. Slow down. Short, fast turns may scuff ground

and pull grass out by the roots.

• Travel at MODERATE speed when youmow a thin stand

of grass.

Mow often enough so you cut only 1/3 of grass blade in one

mowing. Cutting grass too short may kill grass and let

weeds grow easily.

Aerate lawn to help stimulate soil organisms and root

growth.

To Avoid Scalping

• Pay attention to the way you mow: scalping can be

eliminated.

• If mower scalps easily, cutting height may be too low for

ground conditions–especially on lawns with many small

mounds and r idges.

• Mow over ridges and through shallow ditches straighton, not at an angle.

Keep blade sharp: A dull blade will tear grass; tips of grass

will then turn brown.

Check lawn regularly for uneven cut. If cut is uneven:

• Mower may not be level. Adjust cutting height levers.

Bagging Tips

For best performance, bagger needs good airflow. To help

increase airflow:

• Keep underside of deck and chute clean.

• Cut grass high.

• Clean bag often with water from garden hose, from

outsidetoinsideofbag.Letbagdrybeforeuse.

When bag is full:

• Mower may leave a trail of clippings.

• Clippings may blow out from under deck.

• Top of bag will deflate.

Bagging and Composting

Many communities will no longer haul lawn clippings and

leaves to landfills. Bagging and composting clippings and

leaves is one way to solve this problem.

Clippings from grass bag may also be used as mulch, or

sheet compost, between garden rows and around trees

and shrubs. This mulch will:

• Keep weeds from growing.

• Help soil keep moisture.

• Add nutrients to soil as it decays.

• Help keep soil temperature down during hot weather.

You may compost clippings and leaves in various ways.

See garden magazines or clubs for information, or go to

your local library for help.

Finished compost is crumbly. It is rich in soil nutrients, and

can be spread on your lawn. Compost may also be worked

into soil. It adds humus to soil and improves soil texture,

making soil looser and easier to work.

Mulching Tips

Advantages:

• You d o not have to rake or bag grass or leaves.

• Lawn holds moisture better during dry weather.

• Soil temperatures stay down during hot weather.

• Mulch adds nutrients to soil, and reduces need for

fertilizer.

Mulching does not make thatch. Frequentshallow watering

and fertilizer application produce thatch from roots that

grow close to surface.

Be careful when you mulch leaves in Fall. Grass needs

IMPORTANT: Avoid damage! DO NOT leave

clippings in bag:

• Moisture may damage bag.

• Damp clippings are a fire hazard.

Operating - 11

OPERATING

sunlight in Fall to help store food for Winter. A thick layer of

mulched leaves can prevent sunlight from getting to grass

andsmotherit.Youmayhavetomowwithgrassbagto

remove this layer.

Mulch leaves only when they are dr y.

Mulching wet or damp grass or leaves may cause

problems:

• Clippings and leaves may build up on the underside of

the mower deck.

• Cut grass and leaves may form clumps.

• Leaves may not be cut into small bits.

• Engine will work harder and use more fuel.

• Clean underside of mower deck after mulching wet or

damp grass.

If possible cut only top 1/3 of grass at a time.

Useadifferentmowingpatterneachtimeyoumow.

Overlap mowing paths 50–100 mm (2–4 in.) instead of

cutting a full swath with each pass.

Operate mower at a slower ground speed. Mulching takes

more power.

Keep blade sharp. Check it often.

Keep underside of deck clean.

If clippings are not dispersed evenly or quality of cut is

marginal, raise cutting height one or more positions.

After Mowing

• STOP engine. Let it cool. This will help prevent starting

afirewhenyoustorethemower.

• Remove and shake bag to remove all clippings. This will

help to prevent deterioration of bag and starting a fire.

• Clean top of deck, engine, and chute with brush or

compressed air,if possible. This will help to prevent buildup

andstartingafire.

• Spray under deck with water under pressure to remove

corrosive lawn chemicals and buildup.

• Put mower in safe storage.

Replacement Parts - 12

REPLACEMENT PARTS

ReplacementParts

Service Literature

If you would like a copy of the Parts Catalog or Technical

Manual for this machine call:

• U.S. & Canada: 1-800-522-7448.

• All Other Regions: Your John Deere dealer.

John Deere Quality

We recommend John Deere quality parts and lubricants,

available at your authorized Scotts servicing dealer.

Part numbers may change, use part numbers listed below

when you order. If a number changes, your dealer will have

the latest number.

When you order parts, your authorized Scotts servicing

dealer needs your machine product identification number

and engine serial number. These are the numbers that you

have recorded in the Product Identification section of this

manual.

Touch-up paint is available in 340 grams (12 oz.) aerosol

cans. Scotts Orange (part number: TY24745).

(Part numbers are subject to change without notice. Part

Numbers may be different outside the U.S.A.)

ITEM PART NUMBER

Air Cleaner:

• Foam Pre-cleaner

• Paper Element

GC00440

GC00441

Traction Drive Belt

• SP6211

• SP6213

GC00073

GC00081

Standard Mulch Blade GC00344

Bagging Blade

(Optional)

GC00175

Spark Plug Champion RC12YC

SAE 30, Engine Oil (1 quart) TY22070

Service Intervals - 13

SERVICE INTERVALS

ServiceIntervals

Service Intervals

Please use the following timetables to perform routine

maintenance on your machine. Service procedures

included in this manual but not on this chart are to be

performed on an as needed basis.

Before Each Use

• Check oil level.

After Each Use

• Clean the mower.

First 5 Hour

• Change engine oil. (Break-in)

• Lubricate mower axles.

• Lubricate drive shaft hub bushings.

Every 25 Hours Or Once A Year

• Tighten blade bolt.

• Clean or replace air cleaner paper element.

• Clean and gap spark plug.

• Clean belt and transmission area.

• Change engine oil.

• Lubricate mower axles.

• Lubricate drive shaft hub bushings.

IMPORTANT: Avoid damage! If you operate mower

in extreme heat, dust or other severe conditions,

service more often than shown below.

Service - 14

SERVICE

Service

Engine Warranty Maintenance Statement

Maintenance,repair,or replacementof the emissioncontrol

devices and systems on this engine, which are being done

at the customers expense, may be performed by any

nonroad engine repair establishment or individual.

Warrantyrepairs must be performed by an authorized

Scotts servicing dealer.

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine

manufacturer and should not require any adjustments.

NOTE: If engine is operated at altitudes above 1829 m

(6,000 ft), some carburetors may require a special high

altitude main jet. See your authorized Scotts servicing

dealer.

If engine is hard to start or runs rough, check the

TROUBLESHOOTING section of this manual.

After performing the checks in the troubleshooting section

and your engine is still not performing correctly, contact

your authorized Scotts servicing dealer.

Avoid Fumes

Engine Oil

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

The following John D eere oils are preferred:

• TORQ-GARD SUPREME® (SAE 30)

The following John Deere oils are also recommended,

based on their specified temperature range:

• TURF-GARD® (SAE 10W-30)

• PLUS-4® (SAE 10W-30)

Other oils may be used if above John Deere oil is not

available, provided they meet one of the following

specifications:

• SAE 10W-30–API Service Classification SG or higher

• SAE 30–API Service Classification SC or higher

Checking Engine Oil Level

1. Stop engine. Put mower on a level surface.

cCAUTION: Avoid injury! Engine exhaust fumes

can cause sickness or death:

• If it is necessary to run an engine in an

enclosed area, use an exhaust pipe extension

to remove the fumes.

• Always try to work in a well ventilated area.

cCAUTION: Avoid injury! Before you check or

add oil, STOP engine. Let it cool.

AIR TEMPERATURE

SAE 30

SAE10W-30

SAE 5W-30

122° F

104° F

86° F

68° F

50° F

32° F

14° F

-4° F

-22° F

-40° F

50° C

40° C

30° C

20° C

10° C

0° C

-10° C

-20° C

-30° C

-40° C

Service - 15

SERVICE

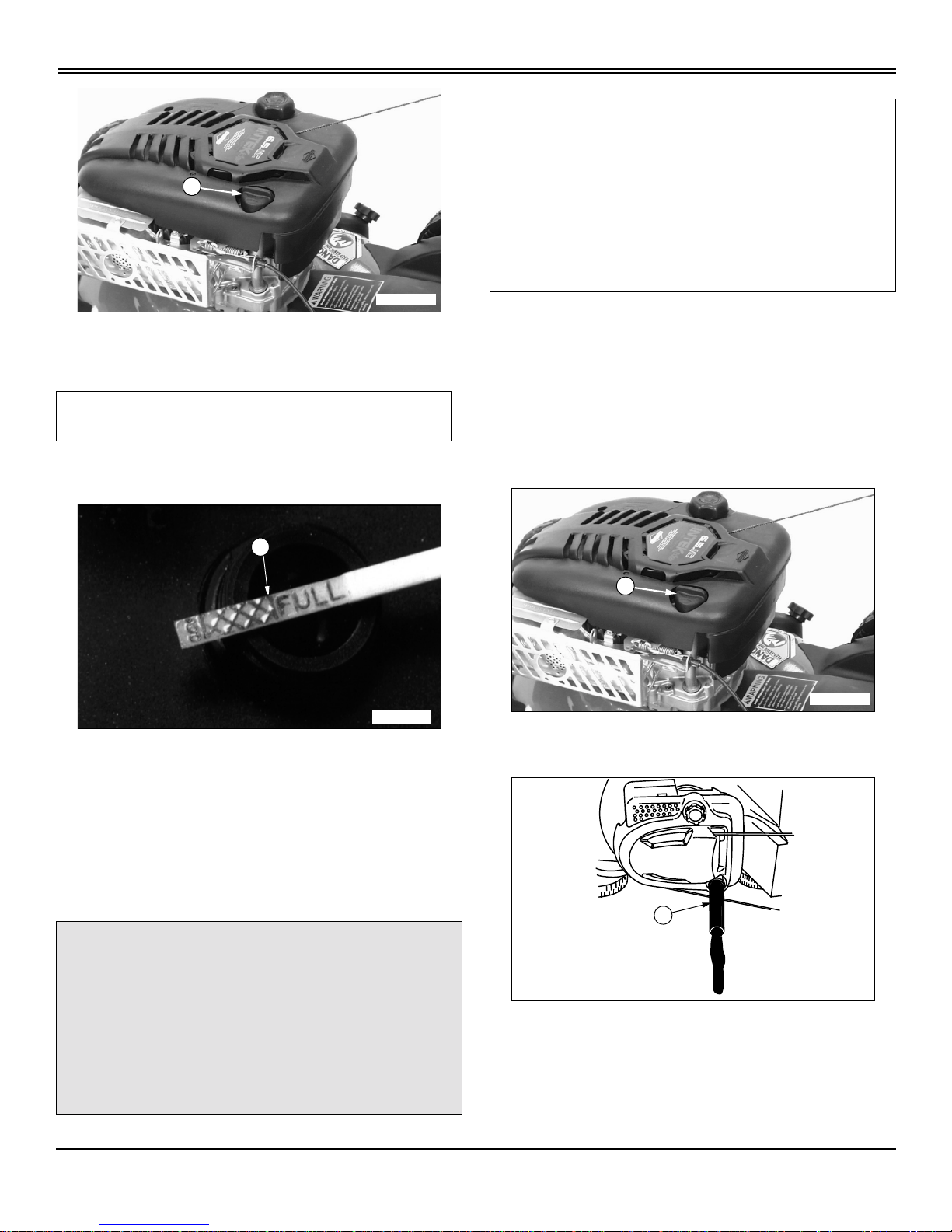

2. Turn oil dipstick (A) 1/4 turn counterclockwise. Remove

dipstickandwipeitwithacleancloth.

3. Install dipstick. Turn dipstick 1/4 turn clockwise and

tighten.

4. Remove dipstick. Check oil level. Oil level MUST BE

between ADD and FULL marks. If not, pour oil into dipstick

tube to bring level to FULL mark (B).

5. Install and tighten dipstick.

Changing Engine Oil

NOTE: Two different methods can be used for

changing the engine oil. Both options are acceptable

service procedures based on customer preference.

TO CHANGE ENGINE OIL FROM THE TOP:

1. Park mower on a level surface.

2. Run engine until fuel tank is empty or near empty.

3. Stop engine and disconnect spark plug wire.

4. Turn oil dipstick (A) 1/4 turn left and remove from the

filler tube.

5. Insert plastic drain tube (B) firmly inside filler tube

opening.

6. Place a drain pan on the left side of the mower.

IMPORTANT: Avoid damage! If oil level is below

the ADD mark, DO NOT run the engine.

cCAUTION: Avoid injury!

• Used oil may harm environment and people

if it is dumped on the ground or into a drain or a

body of water. Call your local Recycling Center

or authorized Scotts servicing dealer to learn

how to recycle used oil.

• Engine may be hot, use caution to avoid

burns to the hands.

MX1567

A

B

M61459

IMPORTANT: Avoid damage!

• Change oil after first 5 hours of operation.

• Change oil while engine is warm.

• If mower is not operated 25 hours during the

mowing season, change oil before storing mower.

• Help prevent air cleaner damage and hard

starting, turn mower onto the LEFT side when

servicing.

MX1567

A

B

M87111d

Service - 16

SERVICE

7. Turn mower onto its LEFT SIDE.

8. Allow engine oil to drain from the dipstick filler tube

location into the drain pan.

9. After oil has drained, return mower to an upright

position.

10.Remove plastic drain tube. Clean area around filler tube.

11.Add 0.47 L (16 oz) oil through dipstick filler tube.

12.Install dipstick. Turn dipstick 1/4 turn right to tighten.

13.Removedipstick. Check oil level. Add oil to FULL mark if

necessary.

14.Install and tighten dipstick.

15.Connect spark plug wire.

TO CHANGE ENGINE OIL FROM THE BOTTOM:

1. Stop engine and disconnect spark plug wire.

2. Raise cutting height adjustment levers (A) to the highest

cutting position. (See Adjusting Cutting Height in the

Operating section.) Elevate entire mower an additional 102

mm - 203mm (4-8 in.) using wooden blocks or bricks.

3. Place a drain pan under the mower.

4. Remove drain plug (B) from underside of mower using a

3/8 in. square drive.

5. After oil has drained, clean and install drain plug.

6. Turn oil dipstick 1/4 turn to the left. Remove dipstick.

7. Add 0.47 L (16 oz) oil through dipstick filler tube.

8. Install dipstick. Turn dipstick 1/4 tur n right to tighten.

9. Removedipstick. Check oil level. Add oil to FULL mark if

necessary.

10.Install and tighten dipstick.

11.Lower mower.

12.Return cutting height adjustment levers to a desirable

cutting height.

13.Connect spark plug wire.

Cleaning and Replacing Air Cleaner Element

1. Stop engine and disconnect spark plug wire.

cCAUTION: Avoid injury! Fuel is highly

flammable. Prevent fuel from contacting hot

surfaces: DO NOT drain fuel tank. Run engine

until fuel tank is very low or empty before

turning mower on side to change oil.

cCAUTION: Avoid injury! Be careful of s harp

edges on mower blades. Wear gloves when

working under deck.

A

A

cCAUTION: Avoid injury! Before you work on

engine:

• STOP engine. Let it cool.

IMPORTANT: Avoid damage!

• If operation of the mower is done in very dusty

conditions, clean element often.

• Replace paper element when engine starts hard,

begins to lose power, or runs rough.

• DO NOT use a damaged element. Replace when

necessary.

• DO NOT run engine without element.

M87113

B

Service - 17

SERVICE

2. Clean area around cover (A).

3. Loosen screws (B) and remove cover.

NOTE: If precleaner or paper element has a break or is

damaged, replace it.

4. If precleaner (C) is dirty, carefully remove paper element

and precleaner. Remove precleaner from element (D).

5. If paper element is excessively dirty, replace it with a

new element.

6. If precleaner is dirty, clean it as follows:

• Wash it in a solution of warm water and liquid

detergent. DO NOT wash paper element.

• Rinse precleaner.

• Allow precleaner to air dry.

7. Install precleaner on paper element and install air

cleaner.

8. Install air cleaner cover and tighten screws.

Cleaning and Gapping Spark Plug

1. Disconnect spark plug wire (A). Remove plug (B).

2. Carefully wire brush carbon from plug. Do not clean it

with abrasives in a machine.

3. Inspect plug for damage. Replace damaged plug.

4. Adjustgapto0.51mm(0.020in.).

5. Install and tighten plug to 20 N•m(15lb-ft).

6. Connect spark plug wire.

Cleaning Engine Cooling Fins

Clean fins (A) with a brush, rag, or compressed air.

Also, blow compressed air under the shroud.

cCAUTION: Avoid injury! Before you remove

plug:

• STOP engine. Let it cool.

MX1571

A

B

MX1572

D

C

cCAUTION: Avoid injury! Wear eye protection to

guard against flying debris.

IMPORTANT: Avoid damage! Keep fins clean or

engine may overheat.

MX1573

B

A

MX1574

A

Service - 18

SERVICE

Cleaning Drive Belt and Transmission Area

1. Remove hardware (A) and belt shield (B).

2. Remove control cables (C) from belt shield notch (D).

3. Remove clippings from belt area and top of the

transmission.

4. Slide control cable into belt shield notch.

5. Install belt shield.

Checking and Replacing Drive Belt

1. Stop engine and disconnect spark plug wire.

2. Remove hardware (A) and belt shield (B).

3. Remove control cables (C) from belt shield notch (D).

cCAUTION: Avoid injury! Before you remove

shield:

• STOP engine. Let it cool.

• DO NOToperate mower without belt shield in

place.

M96556

A

B

C

M93055

D

C

M96557

cCAUTION: Avoid injury! Before removing belt

shield:

• Stop engine and wait for all moving parts to

stop.

• Prevent burns by allowing engine to cool.

• Disconnect spark plug wire.

• Wear protective gloves when service is

performed within the mower blade area.

• DO NOT operate mower without belt shield.

M96556

A

B

C

M93055

D

C

Service - 19

SERVICE

4. Inspect belt (E) for excessive wear or damage.

TO REPLACE DRIVE BELT:

NOTE: On model SP6211 only,the anti-rotation bracket

must be removed prior to pushing the drive sheave

forwardtoremovethedrivebelt.

Picture Note: View is from underside of differential.

1. Remove cap screw (F) and anti-rotation bracket.

2. Pushdrivesheave(G)forwardtorelievespringtension

on belt.

NOTE: Tension spring (H) may come loose w hen belt

is removed.

3. Remove belt from drive sheave.

4. Move belt into underside of mower deck.

5. Turn mower onto its LEFT SIDE.

6. Remove mower blade. (See Check Blade in this

section.)

7. Remove drive belt from blade sheave.

8. Install new drive belt to blade sheave.

9. Insert belt through deck opening (I).

10.Install tension spring (H) if removed.

11.Check that drive belt is installed on engine sheave.

12.Push drive sheave (J) forward and install belt to sheave.

13.Install anti-rotation bracket and secure with cap screw.

14.Install mower blade.

• Tighten mower blade bolt to 75 N•m(55lb-ft).

15.Lower mower.

16.Slide control cables into belt shield notch.

17.Install belt shield and connect spark plug wire.

cCAUTION: Avoid injury! Wear protective

eyewearwhen removingbelt from drive sheave.

Tension spring may come loose.

M96557

E

MX1578

F

MX1576

H

G

M96554

J

H

I

Service - 20

SERVICE

Transmission Cable Adjustment—SP6213

1. Stop engine and disconnect spark plug wire.

2. Remove hardware (A) and belt shield (B).

NOTE: Transmission cable adjustment can be

performed without removing belt and pulley. The belt

and pulley have been removed for clarity of pictures.

3. Remove control cables (C) from belt shield notch (D).

4. Push drive sheave (E) forward to relieve spring tension

on belt and remove drive belt (F).

5. Remove E-clip (G) and drive sheave.

6. Measure the clutch spring length (H) in the relaxed

position. Record this value.

7. Engage the transmission bail (at handle bar) and

measure the spring length in the extended position (I).

The spring extension length (the difference between A and

B measurements) must be 10 mm (0.390 in.).

cCAUTION: Avoid injury! Before removing belt

shield:

• Stop engine and wait for all moving parts to

stop.

• Prevent burns by allowing engine to cool.

• Disconnect spark plug wire.

• Wear protective gloves when service is

performed within the mower blade area.

• DO NOT operate mower without belt shield.

cCAUTION: Avoid injury! Wear protective eye

wear when removing belt from drive sheave.

Tension spring may come loose.

M96556

A

B

C

M93055

D

C

MX1577

F

E

G

M96828

H

M96831

I

Service - 21

SERVICE

8. To adjust spring extension, use an 8 mm wrench, loosen

(do not remove) the cable mount bracket capscrews (J).

NOTE: For transmission clutch to operate properly,

there must be a certain amount of spring pressure

engaging the cones or the transmission will slip and

NOT drive the wheels.

9. Slidebracket(K)therequireddistancetoobtainthe10

mm (0.390 in.) spring extension length (difference between

thelengthoftherelaxedspringandthelengthofthe

extended spring). Tighten capscrews.

10.Repeat steps 6 and 7 to verify the 10 mm (0.390 in.)

spring extension length.

11.Install drive sheave and E-clip.

12.Check that drive belt is installed on engine sheave.

13.Install transmission drive belt.

14.Install cables through notch in cover.

15.Install cover and secure with two bolts and two bolts and

nuts. Make sure shield is installed with cover.

16.Start engine and verify the transmission is operating

properly.

NOTE: Make sure the transmission immediately

disengages when the bail is released.

17.If transmission does not disengage when bail is

released, reduce spring extension length, and verify

transmission is operating properly.

Lubricate Drive Shaft Hub Bushings

1. Remove hardware (A) and belt shield (B).

2. Remove control cable (C) from belt shield notch (D).

3. Tilt mower slightly to one side. Lubricate driveshaft hub

bushing (E) with a few drops of light weight motor oil.

Repeat procedure for other side.

4. Slide control cables (C) into belt shield notch (D).

5. Install belt shield.

Lubricate Mower Axles

1. Tip mower to one side to elevate mower wheels slightly

off the ground. Use a wood block to keep side of mowerin a

M96827

J

M96827

K

M96556

A

B

C

M93055

D

C

M93048

E

Service - 22

SERVICE

raised position.

2. Remove plastic hubcaps (A).

• Use a screwdriver in slot (B) to pry the hubcap from

each wheel.

3. Remove locknut (C) and washer (D).

4. Remove wheel from each axle.

5. Apply a light coating of grease to each a xle (E).

6. Install wheels, hardware and hubcaps.

7. Lower mower.

8. Repeat procedure on other side of mower.

Check Blade

NOTE: Sharpened edges on blade tips must face

upward when installing blade.

CHECK BLADE:

• Replace damaged blade.

• Tighten Bolt (A) to 75 N•m(55lb-ft).

• Sharpen dull blade. (See Sharpening Blade in this

section.)

TO REMOVE BLAD E:

• Remove bolt (A), washer (B), and blade.

Sharpening Blade

Sharpen blade with grinder, hand file or electric blade

M93049

A

B

M93051

C

D

E

M93050

cCAUTION: Avoid injury! Ser v ice blade safely:

• STOP engine. Let it cool.

• Disconnect spark plug wire.

• Wear gloves or wrap blade with a rag.

IMPORTANT: Avoid damage!

Turn mower on its LEFT SIDE to help prevent air

cleaner damage and hard starting.

cCAUTION: Avoid injury! Wear gloves and

goggles when sharpening, balancing or

installing blade.

IMPORTANT: Avoid damage! Balance blade after

you sharpen it. An unbalanced blade may cause

excessive vibration.

M87085

B

A

Service - 23

SERVICE

sharpener.

Keep original bevel (A) when you grind. Blade should have

0.40 mm (1/64 in.) cutting edge (B).

Balance and Install Blade

1. Cleanblade.Putitonanailinviseoronawall.Heavy

end of blade will drop. Grind bevel of heavy end. Do not

change bevel.

2. Install blade, washer, and bolt.

3. Tightenboltto75N•m (55 lb-ft).

Filling Fuel Tank

Use regular grade 87 octane unleaded fuel.

Add John Deere fuel stabilizer to fuel before using it in your

machine to preventengine damage due to stale fuel. Follow

directions on stabilizer container.

1. STOP engine. If engine is hot let it cool several minutes

before you add fuel.

2. Remove grass clippings and other trash from tank area.

3. Remove fuel tank cap (A).

4. Fill tank with fuel only to bottom of filler neck.

5. Install fuel tank cap.

A

B

M61830

M61524

IMPORTANT: Avoid damage! Dirt and water in fuel

are major causes of engine performance problems.

Prevent dirt and debris from entering the fuel tank

when filling.

• Use a non-metallic funnel with a non-metallic

mesh strainer when filling fuel containers.

• Use a non-metallic funnel with a non-metallic

mesh strainer when filling the fuel tank.

• Fillthefueltankattheendofeachday’s

operation to keep condensation out of the fuel tank.

• Use clean, fresh, stabilized fuel.

Fueltankcapacityis1.5L(1.6qt).

MX1571

A

Service - 24

SERVICE

Cleaning Fuel Cap Vent

1. Check two vents (A) under metal ring of fuel cap and

vent in top, center of cap.

2. Clean cap and vents in nonflammable solvent.Allow cap

to dry.

3. Install the cap.

A

M73283

Troubleshooting - 25

TROUBLESHOOTING

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this

chart, see your authorized Scotts servicing dealer.

Whenyouhavecheckedallthepossiblecauseslistedand

you are still experiencing the problem, see your authorized

Scotts servicing dealer.

IF CHECK

Engine Will Not Start • Prime engine, (Cold - three times, Warm - 1 or 2 times)

• Fuel tank is empty.

• Stale or dirty fuel.

• Disconnected or dirty spark plug.

Engine Starts Hard Or Loses Power • Dirty fuel tank cap vents.

• Stale or dirty fuel.

• Dirty air cleaner element.

• Disconnected or dirty spark plug.

Engine Runs Rough • Carburetor needs to be cleaned.

• Disconnected or dirty spark plug.

• Dirty air cleaner element.

• Dirty cooling fins.

Engine Overheats • Dirty blower housing and cooling fins.

• Improper oil level.

Engine Vibrates Too Much • Loose blade bolt.

• Blade dull.

• Blade improperly balanced.

• Bent blade or crankshaft.

Mower Mows Unevenly • Pushingmowertoofast.

• Mowing too fast around corners and mowing pattern not

changed.

• Insufficient overlapping of cuts when mowing.

• Blade dull or not balanced.

Bagging Chute Plugs • Grass not dry.

• Cutting height not raised high enough.

• Dirty or full grass bag.

• Mowing too fast.

Mower Will Not Self-propel • Traction belt broken.

• Traction belt jumped off pulley.

• SP6213 Only, Adjust Transmission Cable

• Traction cable stretched or broken.

Troubleshooting - 26

TROUBLESHOOTING

Mulched Grass Appearance Is Poor: Clumps,

Excessive Clippings, Rough Cut, Etc.

• Grass buildup under deck.

• Travel speed too fast.

• Blade dull or not balanced.

• Cutting height set too low.

• Tall grass conditions may dictate that more overlapping of cuts is

required.

IF CHECK

Storing Machine - 27

STORING MACHINE

StoringMachine

Storing Safety

Preparing Machine for Storage

1. Repair any worn or damaged parts. Replace parts if

necessary. Tighten loose hardware.

2. Clean under the deck.

3. Sharpen mower blades.

4. Paint scratched or chipped metal surfaces to prevent

rust.

5. Apply light coat of engine oil to pivot and wear points to

prevent rust.

6. Lubricate grease points.

Preparing Fuel and Engine For Storage

Fuel:

Ifyouhavebeenusing“Stabilized Fuel”, add stabilized fuel

to tank until the tank is full.

NOTE: Filling the fuel tank reduces the amount of air in

the fuel tank and helps reduce deterioration of fuel.

If you are not using “Stabilized Fuel”:

1. Stop mower in a well-ventilated area.

NOTE: Try to anticipate the last time the mower will be

used for the season so very little fuel is left in the fuel

tank.

2. Allow engine to run until it runs out of fuel.

3. Change engine oil and filter while engine is warm.

4. Mix fresh fuel and fuel s tabilizer in separate container.

Follow stabilizer instructions for mixing.

5. Fill fuel tank with stabilized fuel.

6. Run engine for a few minutes to allow fuel mixture to

circulate through carburetor.

Engine:

Engine storage procedure should be used when mower is

not to be used for longer than 60 days.

1. Service air filter if necessary.

2. Clean debris from engine air intake screen.

3. Removesparkplug.Put30mL(1oz.)ofcleanengine

oil in cylinder.

4. Install spark plug, but do not connect spark plug wire.

5. Slowly pull starter handle severaltimes to a llow oil to be

distributed.

6. Store the mower in a dry, protected place. If mower is

stored outside, put a waterproof cover over it.

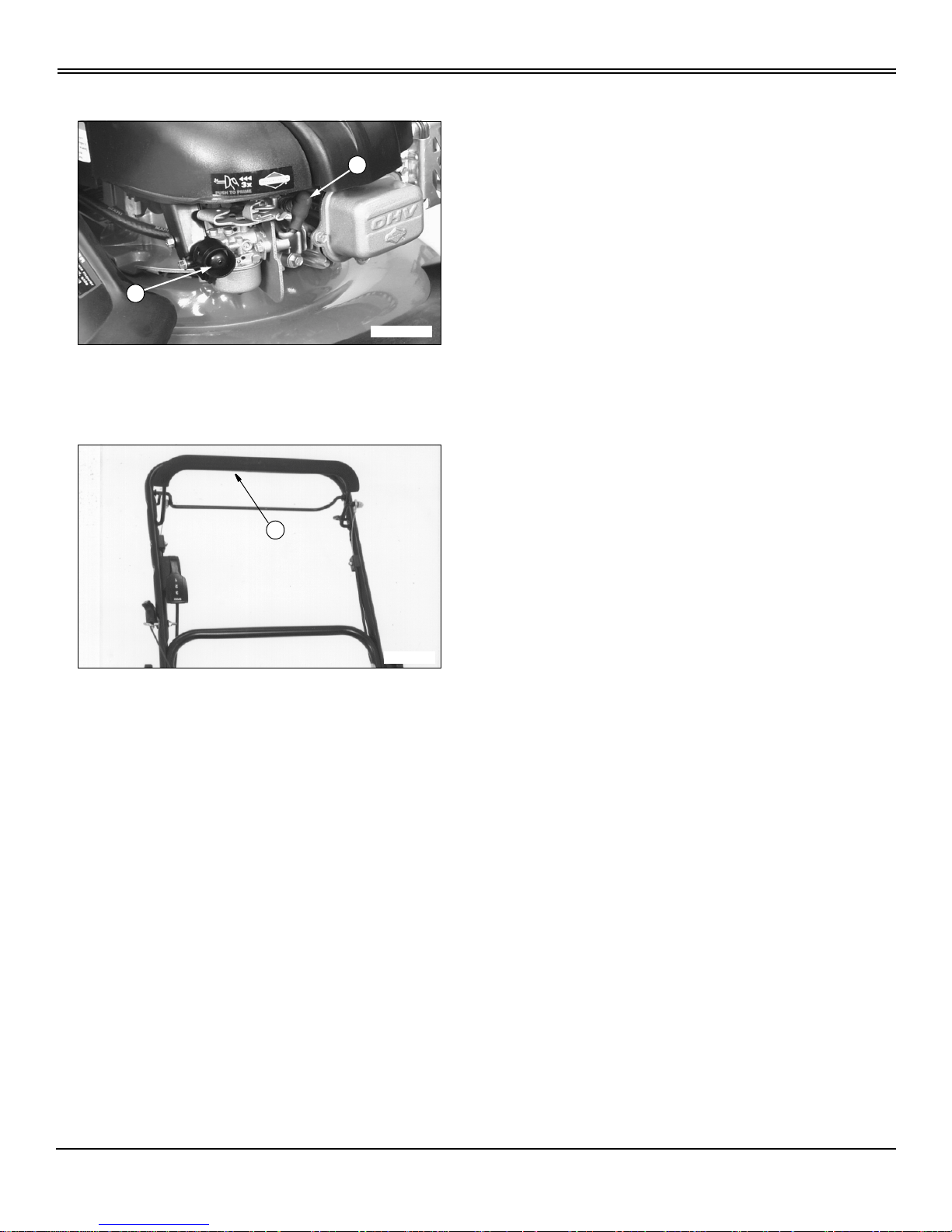

Fold Handles

1. Remove grass bag and bagging chute if installed.

2. Remove starter handle (A) from rope guide.

cCAUTION: Avoid injury! Engine exhaust fumes

can cause sickness or death.

• If it is necessary to run an engine in an

enclosed area, use an exhaust pipe extension

to remove the fumes. Always try to work in a

well ventilated area.

• DONOTstoremowerwithfuelinthetank

inside a building where fumes may reach an

open flame or spark.

• Allow engine to cool before storing in any

enclosure.

IMPORTANT: Avoid damage! Fuel without stabilizer

can varnish and partially plug carburetor jets and

passageways in a stored machine.

• Use fresh fuel when adding fuel stabilizer. Fuel

stabilizers are ineffective when added to fuels that

aremorethan30daysold.

IMPORTANT: Avoid damage! DO NOT CRIMP

CABLES when folding handle bars.

A

M87088

Storing Machine - 28

STORING MACHINE

3. Loosenknob(B)25mm(1in.)oneachside.Allow

upper handle (C) to pivot down.

4. Remove knob (D) and carriage bolt (E) from each side.

5. CAREFULLY fold lower handle (F) forward. Guide

cables inside lower handle. DO NOT CRIMP CABLES.

6. Install bolts and knobs in lower handle.

Remove Mower from Storage

1. Unfold handles. Tighten knobs. Do not crimp cables.

2. Check engine oil level.

3. Connect wire to spark plug.

4. Inspect shields, safety devices and hardware.

B

C

M87116a

B

M88835

D

E

M96553

F

Assembly - 29

ASSEMBLY

Assembly

Identify Parts (SP6211 and SP6213)

A - Lawnmower Assembly

B - Side Discharge Chute

C-Bagger

D-BaggerChute

Unfold Handles

1. Carefully remove mower from shipping carton.

2. Loosen knob (A) approximately 25 mm (1 in.) on each

side of upper handle.

3. Remove knob (B) and carriage bolt from each side.

4. Carefully pull folded handle assembly rearward.

5. Rotate slotted bracket (C) to match a desirable height

setting with hole in handle.

6. Install carriage bolt (D) from the inside through hole in

slottedbracket(C)andthroughhandleoneachsideof

handle. Use same hole on each side.

NOTE: If handle height is not satisfactory, move

handle to another hole and height position. Bolts must

travel within slotted adjustment brackets and come to

rest within one of the three height setting positions (E)

before tightening.

7. Install and tighten knob (B) on each bolt. Both handle

knobs should be positioned on the outside of the handles.

8. Pivot upper portion of handle assembly to a straight and

aligning position. Hold handle and tighten knob (A) on each

side.

Install Starter Rope

NOTE: To make installation of the starter rope onto the

rope guide easier, hold the blade control lever against

the handle while pulling the starter rope.

IMPORTANT: Avoid damage! Prevent damage to

mower control cables when i nstalling handle

assembly. DO NOT pinch or crimp the control

cables. Control cables must be i nside of handle and

unrestricted before tightening hardware.

A

MX1564

B

C

D

MX1565

A

A

B

B

C

D

E

B

M88835

A

M92146

Assembly - 30

ASSEMBLY

Pull and install starter rope (A) onto rope guide (B)

mounted on the right side of the handle.

AddEngineOil

1. Park mower on a level surface.

2. Turn oil dipstick (A) 1/4 turn to the left. Remove dipstick.

3. Add 0.47 L (16 oz) oil through d ipstick filler tube.

4. Check oil level:

• Install dipstick. Turn dipstick 1/4 turn right to tighten.

• Remove dipstick.

• Check oil level. Oil should be to the FULL mark (B). If

not, add oil.

5. Install and tighten dipstick.

6. Remove "NO OIL" tag from top of engine.

Install Grass Bag

1. Remove mulch guard knob (A).

2. Lift and hold spring loaded mulch guard (B) up.

3. Install bagging chute:

IMPORTANT: Avoid damage! ENGINE IS SHIPPED

WITHOUT OIL.

You MUST add oil before running the engine. See

Service section for correct oil application.

M88828

B

A

MX1567

A

cCAUTION: Avoidinjury! DO NOT operate mower

unless mulch guard, side discharge chute or

grass bag and bagging chute are in place.

BaggingchuteMUSTberemovedandmulch

guard secured in place when grass bag is not

being used.

M61459

B

MX1566

A

B

Assembly - 31

ASSEMBLY

• Slide bagging chute (C) into position under the mulch

guard mounting bracket (D).

• Insert bagging chute tab (E) into rear mower shield

slot (F).

• Reinstall and tighten knob (A).

NOTE: Doors (H) on grass bag must be closed prior to

installation onto the bagging chute.

4. Hang grass bag on lower handlebar.

5. Open spring loaded bagging chute safety door (I).

6. Install grass bag onto bagging chute.

• Grass bag handle (J) should “snap” down onto tab

(K).

• Make sure front of grass bag (L) rests in bagging

chute bracket (M).

M93036

C

D

M96547

E

F

M96548

A

M96549

I

H

H

M96550

K

J

M96552

L

M

Assembly - 32

ASSEMBLY

Test Mower

1. Verify that spark plug wire (A) is attached to spark plug.

2. Put enough fuel in fuel tank to test mower operation.

3. Press primer bulb (B) three times to prime engine.

4. Hold blade control lever (C) against handle.

5. Start engine and check mower operation. (See

Operating section.)

MX1568

A

B

C

M93034

Specifications - 33

SPECIFICATIONS

Specifications

Engine

Manufacturer.......................................................................Briggs&Stratton

Model..................................................................................... 121602

Horsepower .........................................................................4.8kW(6.5hp)

Cycle..........................................................................................4

ValveType ...................................................................OverHeadValve(OHV)

Displacement.................................................................... 190cc(11.6cuin)

Choke ................................................................................PrimerBulb

Starter.....................................................................................Recoil

ThrottleControl.........................................................................FixedSpeed

Lubrication................................................................................ Splash

SparkPlug.......................................................................ChampionRC12YC

SparkPlugGap ....................................................................0.51mm(.020in)

SparkPlugTorque...................................................................20N•m (15 lb-ft)

Travel Speed Range

SP6211

FirstGear ........................................................................3.9km/h(2.4mph)

SP6213

FirstGear ........................................................................3.1km/h(1.9mph)

SecondGear .....................................................................3.9km/h(2.4mph)

ThirdGear .......................................................................5.0km/h(3.1mph)

Capacities

Fuel..................................................................................1.5L(1.6qt)

EngineOil.............................................................................0.6L(20oz)

Machine Specifications

DeckMaterial ................................................................................Steel

AdjustableHandle .........................................................................Standard

RearGrassBag............................................................................Standard

SideDischargeChute ......................................................................Standard

Mulching.................................................................................Standard

MowerBladeBoltTorque .............................................................75N•m (55 lb-ft)

SafetySystem........................................................................... ZoneStart

Specifications - 34

SPECIFICATIONS

Dimensions

WheelSize.............................................................................. 8.75x2.25

Mower Weight without Attachments

•SP6211 ............................................................................ 36.7kg(81lb)

•SP6213 ............................................................................ 38.6kg(85lb)

CuttingHeightRange .............................................................2.5-10.2cm(1-4in)

CuttingWidth........................................................................53.3cm(21in)

Recommended Lubricants

Fuel.......................................................SeeFillingFuelTankintheServicesection.

EngineOil.............................................TORQ-GARDSUPREME® (SAE 30 or SAE 10W-30)

Grease.............................................JohnDeereMOLYHIGHTEMPERATUREEPGREASE

.........................................................JohnDeereHIGHTEMPERATUREEPGREASE

.......................................................................JohnDeereGREASEGARD™

(Specifications and design subject to change without notice)

Warranty - 35

WARRANTY

Warranty

LIMITED WARRANTY FOR NEW SCOTTS BRAND

PRODUCTS

Manufactured by John Deere

(U.S.Only)

A. GENERAL PROVISIONS - The warranties described below are

provided by John Deere Company (“John Deere”) to the original

purchasers of new Scotts Brand Products Manufactured by John Deere.

Under these warranties, John Deere will repair or replace, at its option,

any covered part which is found to be defective in material or

workmanship during the applicable warranty term. Warranty service must

be performed by a dealer or service center authorized by John Deere to

service the type of product involved,which will use only new or

remanufactured parts or components furnished by John Deere. Warranty

service will be performed without charge to the purchaser for parts or

labor. The purchaser will be responsible, however, for any service call and/

or transportation of product to and from the dealer's or service center’s

place of business, for any premium charged for overtime labor requested

by the purchaser and for any service and/or maintenance not directly

related to any defect covered under the warranties below.

B. WHATIS WARRANTED - All parts of any new Scotts Brand Product

Manufactured by John Deere, except batteries, are warranted for the

number of months or operating hours specified below. Warranty

statements required by law covering engine emission-related parts and

components, are found in the Operator’s M anual delivered with the

machine.

Each warranty term begins on the date of product sale to the purchaser.

C. WHAT IS NOT WARRANTED - JOHN DEERE IS NOTRESPONSIBLE

FOR THE FOLLOWING: (1) Used products; (2) Any product that has been

altered or modified in ways not approved by John Deere; (3) Depreciation

or damage caused by normal wear, lack of reasonable and proper

maintenance, failure to follow operating instructions, misuse, lack of

proper protection during storage or accident; (4) Normal maintenance

parts and service.

D.SECURING WARRANTY SERVICE - To secure warranty service, the

purchaser must (1) report the product defect to an authorized dealer and

request repair within the applicable warranty term, (2) present evidence of

the warranty start date, and (3) make the product availableto the dealer or

service center within a reasonable period of time.

E. LIMITATION OF IMPLIED WARRANTIES AND OTHER REMEDIES SCOTTS BRAND PRODUCTS MANUFACTURED BY JOHN DEERE - to

the extent permitted by law,neither John Deere nor any company affiliated

with it makes any warranties, representations, or promises as to the

quality, performance or freedom from defect of the Scotts Brand Products

Manufactured by John Deere covered by this warranty. IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, TO THE EXTENT APPLICABLE, SHALL BE

LIMITED IN DURATION TO THE APPLICABLE PERIOD OF WARRANTY

SET FORTH ON THIS PAGE. THE PURCHASER’S ONLYREMEDIES IN

CONNECTION WITH THE BREACH OR PERFORMANCE OF ANY

WARRANTY ON THE SCOTTS BRAND PRODUCTS MANUFACTURED

BY JOHN DEERE ARE THOSE SET FORTH ON THIS PAGE. IN NO

EVENT WILL THE DEALER, JOHN DEERE OR ANY COMPANY

AFFILIATED WITH JOHN DEERE BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES. (Note: Some states do not allow

limitations on how long an implied warranty lasts or the exclusion or

limitation of incidental or consequential damages so the above limitations

and exclusions may not apply to you.) This warranty gives you specific

legal rights, and you may also have other rights which vary from state to

state.

F. NO DEALER WARRANTY - THE SELLING DEALER MAKES NO

WARRANTY OF ITS OWN AND THE DEALER HAS NO AUTHORITY TO

MAKE ANY REPRESENTATION OR PROMISE ON BEHALF OF JOHN

DEERE, OR TO MODIFY THE TERMS OR LIMITATIONS OF THIS

WARRANTY IN ANY WAY.

G. FAILURE DUE TO IMPROPER SET-UP IS NOT COVERED UNDER

WARRANTY

.

H. If further information is desired, contact a servicing dealer. For the

location of servicing dealers in your area call

1-877-356-3698.

LIMITED WARRANTY FOR NEW SCOTTS BRAND

PRODUCTS

Manufactured by John Deere

(Canada Only)

A. GENERAL PROVISIONS - The warranties described below are

provided by John Deere Limited ("John Deere") to the original purchasers

of new Scotts Brand Products Manufactured by John Deere. Under these

warranties, John Deere will repair or replace, at its option, any part

covered under these warranties which is found to be defective in material

or workmanship during the applicable warranty term. Warranty service

must be performed by a dealer or service center authorized by John

Deere to service the type of product involved, which will use only new or

remanufactured parts or components furnished by John Deere. Warranty

service will be performed without charge to the purchaser for parts or

labor.The purchaser will be responsible, however,for any service call and/

or transportation of product to and from the dealer's or service center’s

place of business, except where prohibited by law, for any premium

charged for overtime labor requested by the purchaser and for any service

and/or maintenance not directly related to any defect covered under the

warranties below.

B. WHAT IS WARRANTED- Subject to paragraph C below,all parts of any

new Scotts Brand Product Manufactured by John Deere, except batteries,

are warranted for the number of months or days specified below.Warranty

statements required by law covering engine emission-related parts and

components, if any, are found in the Operator’s Manual delivered with the

product.

Each warranty term begins on the date of product sale to the purchaser.

C. WHAT IS NOT WARRANTED - JOHN DEERE IS NOT RESPONSIBLE

FOR THE FOLLOWING: (1) Used products; (2) Any product that has been

altered or modified in ways not approved by John Deere; (3) Depreciation

or damage caused by normal wear,lack of reasonable and proper

maintenance, failure to follow operating instructions, misuse, lack of

proper protection during storage or accident; (4) Normal maintenance

parts and service

D.SECURING WARRANTY SERVICE - To secure warranty service, the

purchaser must (1) report the product defect to an authorized dealer and

request repair or replacement within the applicable warranty term, (2)

present evidence of the warranty start date, and (3) make the product

availableto the dealer or service center within a reasonable period of time.

E. LIMITATION OF IMPLIED WARRANTIES AND OTHER REMEDIES SCOTTSBRAND PRODUCTS MANUFACTUREDBY JOHN DEERE - TO

THE EXTENT PERMITTED BY LAW,NEITHER JOHN DEERE NOR ANY

EQUIPMENT USE WARRANTY

TERM

1) IN RESIDENTIAL (Private Homeowner)

APPLICATION

24 Months

2) IN ANY OTHER APPLICATION 90 Days

EQUIPMENT USE WARRANTY

TERM

1) IN RESIDENTIAL (Private Homeowner)

APPLICATION

24 Months

2) IN ANY OTHER APPLICATION 90 Days

Warranty - 36

WARRANTY

COMPANY AFFILIATED WITH IT MAKES ANY WARRANTIES,

REPRESENTATIONS,CONDITIONS ORPROMISESRESPECTING THE

SCOTTS BRAND PRODUCTS MANUFACTURED BY JOHN DEERE

AND COVERED BY THIS WARRANTY OTHER THAN THOSE LISTED

ABOVE. THIS EXCLUSION INCLUDES FUNDAMENTAL TERMS,

REPRESENTATIONS, CONDITIONS AND WARRANTIES WHICH MAY

BE EXPRESSED OR IMPLIED, VERBAL OR OTHERWISE, INCLUDING

IMPLIED OR STATUTORY CONDITIONS OR WARRANTIES OF

MERCHANTABILITY AND FITNESS, WHETHER PURSUANT TO THE

SALE OF GOODS ACT OR ANY OTHER STATUTEOF ANY PROVINCE

OR OTHERWISE, EXCEPT WHERE SUCH IMPLIED OR STATUTORY

CONDITIONS OR WARRANTIES MAY NOT BE EXCLUDED BY LAW.

F. REMEDIES EXCLUSIVE - THE PURCHASER’SONLYREMEDIESIN

CONNECTION WITH THE BREACH OR PERFORMANCE OF ANY

WARRANTY ON THE SCOTTS BRAND PRODUCTS MANUFACTURED

BY JOHN DEERE ARE THOSE SET FORTH IN THIS WARRANTY

EXCEPT FOR THOSE REMEDIES PROVIDEDBY LAW WHICH MAY

NOT BE EXCLUDED.IN NO EVENT WILL THE DEALER, JOHN DEERE

OR ANY COMPANYAFFILIATED WITH JOHN DEERE, BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGESOR INJURIES OR BE

LIABLE FOR DAMAGES SUFFERED BY THE PURCHASER AS A

RESULT OF FUNDAMENTAL BREACHES OF CONTRACT OR

BREACHES OF FUNDAMENTAL TERMS. The limitations of liability

contained in this warranty shall only be effective to the extent permitted by

law.This warranty gives you specific legal rights and you may also have

other rights which vary from jurisdiction to jurisdiction.

G. NO DEALER WARRANTY - EXCEPT FOR WARRANTIES WHICH

MAY NOT BE EXCLUDED BY LAW,THE SELLING DEALER MAKES NO

WARRANTY OF ITS OWN AND THE SELLING DEALER HAS NO

AUTHORITY TO MAKE ANY REPRESENTATION OR PROMISE ON

BEHALF OF JOHN DEERE, OR TO MODIFY THE TERMS OR

LIMITATIONS OF THIS WARRANTY IN ANY WAY.

H. FAILURE DUE TO IMPROPER SET-UP IS NOT COVERED UNDER

WARRANTY

.

I. If further information is desired, contact a servicing

dealer.Forthe location of servicing dealers in yourarea call

1-877-864-2295

.

Tire Warranty

John Deere warranty applies for tires available through the John Deere

parts system. For tires not availablethrough the John Deere parts system,

the tire manufacturer’swarranty applicable to your machine may not apply

outside the U.S. (See your John Deere dealer for specific information.)

Limited Engine Warranty

FEDERAL AND CALIFORNIA EMISSION CONTROL DEFECTS

WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The United States Environmental Protection Agency (EPA), the California

Air Resources Board (CARB) and Deere & Company (John Deere) are

pleased to explainthe emission control system warranty on your 1995 and

later utility or lawn and garden equipment engine. In California new utility

and lawn and garden equipment engines must be designed, built and

equipped to meet the State’s stringent anti-smog standards. In other

states, new 1997 and later model year equipment engines must be

designed, built and equipped, at the time of sale, to meet the U.S.EPA

regulations for small non-road engines. The engine must be free from

defectsin materials and workmanship which cause it to fail to conform with

U.S. EPA standards for the first two years of engine use from the date of

sale to the ultimate purchaser. John Deere must warrant the emission

control system on your utility or lawn and garden equipment engine for the

periods of time listed below provided there has been no abuse, neglect or

improper maintenance of your utility or lawn and garden equipment

engine.

Your emission control system may include parts such as the carburetor or

fuel-injection system, the ignition system, and catalytic converter. Also

included may be hoses, belts, connectors and other emission related

assemblies.

Where a warrantable condition exists, John Deere will repair your utility or

lawn and garden equipment engine at no cost to you including diagnosis,

parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

In California, the 1995 and later utility and lawn and garden equipment

engines are warranted for two years.In other states, 1997 and later model

year equipment engines are warranted for two years. If any emission

related part on your engine is defective,the part will be repaired or

replaced by John Deere.

OWNER’S WARRANTY RESPONSIBILITIES

As the utility or lawn and garden equipment engine owner, you are

responsible for the performance of the required maintenance listed in your

owners manual. John Deere recommends that you retain all receipts

covering maintenance on your utility or lawn and garden equipment

engine, but John Deere cannot deny warranty solely for lack of receipts or

for your failure to ensure the performance of all scheduled maintenance.

As the utility or lawn and garden equipment engine owner, you should

howeverbe aware that John Deere may deny you warranty coverage if

your utility or lawn and garden equipment engine or a part has failed due

to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your utility or lawn and garden

equipment engine to an authorized John Deere Commercial and

Consumer Equipment Retailer as soon as a problem exists. The warranty

repairs should be completed in a reasonable amount of time, not to

exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact your John Deere Commercial and

Consumer Equipment Retailer, or the John Deere Customer

Communications Center, 1-800-537-8233.

JOHN DEERE EMISSION CONTROL SYSTEM WARRANTY

COVERAGE

LENGTH OF WARRANTY COVERAGE

John Deere warrants to the initial owner and each subsequent purchaser

that the lawn and garden equipment engine is:

• Designed, built and equipped so as to conform with all applicable

regulations adopted by the California Air Resources Board (CARB)

pursuant to its authority in Chapters 1 and 2, Part 5, Division 26 of the

Health and Safety Code for 1995 and later equipment engines, and all

applicable regulations of the United States Environmental Protection

Agency (EPA) for 1997 and later equipment engines; and

• Free from defects in materials and workmanship which can cause the

failure of an emission warranted part for a period of two years after the

engine is delivered to the initial retail purchaser. John Deere is liable for

damages to other engine components caused bythe failure of a warranted

part during the warranty period. If any emission related part on your

engine is defective, the part will be repaired or replaced by John Deere.

Warranty - 37

WARRANTY

WARRANTED PARTS

Coverage under this warranty extends only to the parts listed below (the

emission control system parts) to the extent these parts were present on

the engine purchased.

Since emission related parts may vary slightly from model to model,

certain models may not contain all of these parts and certain models may

contain functionally equivalent parts.

WARRANTY SERVICE AND CHARGES

Warranty service shall be provided during customary business hours at

any authorized John Deere Commercial and Consumer Equipment

Retailer located within the United States of America. Repair or

replacement of any warranted part will be performed at no charge to the

owner, including diagnostic labor which leads to the determination that a

warranted part is defective, if the diagnostic work is performed at an

authorized John Deere Commercial and Consumer Equipment Retailer.

Any parts replaced under this warranty shall become the property of John

Deere.

MAINTENANCE WARRANTY COVERAGE

a) Any warranted part which is not scheduled for replacement as required

maintenance shall be warranted as to defects for the warranty period. Any

such part repaired or replaced under the warranty shall be warranted for

the remaining warranty period.

b) Any warranted part which is scheduled only for regular inspection to the

effect of “repair or replace as necessary” shall be warranted as to defects

for the warranty period. Any such part repaired or replaced under the

warranty shall be warranted for the remaining warranty period.

c) Any warranted part which is scheduled for replacement as required

maintenance shall be warrantedas to defects only forthe period of time up

to the first scheduled replacement for that part. Any such part repaired or

replaced under the warranty shall be warranted for the remainder of the

period prior to the first scheduled replacement point for that part.

d) Normal maintenance, replacement or repair of emission control devices

and systems, which are being done at the customers expense, may be

performed by any repair establishment or individual; however,warranty

repairs must be performed by an authorized John Deere Commercial and

Consumer Equipment Retailer.

e) Any replacement part that is equivalent in performance and durability

may be used in the performance of any non-warranty maintenance or

repairs, and shall not reduce the warranty obligations of John Deere.

CONSEQUENTIAL WARRANTY COVERAGE

Warranty coverage shall extend to the failure of any engine components

caused by the failure of any warranted part still under warranty.

LIMITATIONS

This Emission Control System Warranty shall NOT cover any of the

following:

a) Repair or replacement required as a result of (i) misuse or neglect, (ii)

improper maintenance or unapproved modifications, (iii) repairs

improperly performed or replacements improperly installed, (iv) use of

replacement parts or accessories not conforming to John Deere

specifications which adversely affect performance and/or durability, (v)

alterations or modifications not recommended or approved in writing by

John Deere.

b) Replacement parts, other services and adjustments necessary for

normal maintenance.

c) Transportation to and from the John Deere Commercial and Consumer

Equipment Retailer, or service calls made by the Retailer.

LIMITED LIABILITY

a) The liability of John Dee re under this Emission Control System

Warranty is limited solely to the remedying of defects in materials or

workmanship. This warranty does not cover inconvenience or loss of use