Scotts S2048, S2554 User Manual

L8 |

S2048 Yard Tractor |

||

|

|

and |

|

|

S2554 Garden Tractor |

||

|

|

Serial No. (010,001- ) |

|

|

|

|

|

|

|

|

|

OPERATOR’S MANUAL

OMM138757 L8

North American Version

Litho in U.S.A.

English

INTRODUCTION

THANK YOU for purchasing a Scotts product.

Read this manual and your attachment manual thoroughly. Failure to do so could result in personal injury or equipment damage.

c WARNING: The Engine Exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

CALIFORNIA Proposition 65 Warning

This manual should be considered a permanent part of your machine and should remain with the machine when you sell it.

Measurements in this manual are metric units and their U.S. customary equivalents. RIGHT-HAND and LEFTHAND sides are determined by facing in the direction the machine will travel when going forward. When you see a broken line arrow (------>), it indicates the part it is pointing to is hidden.

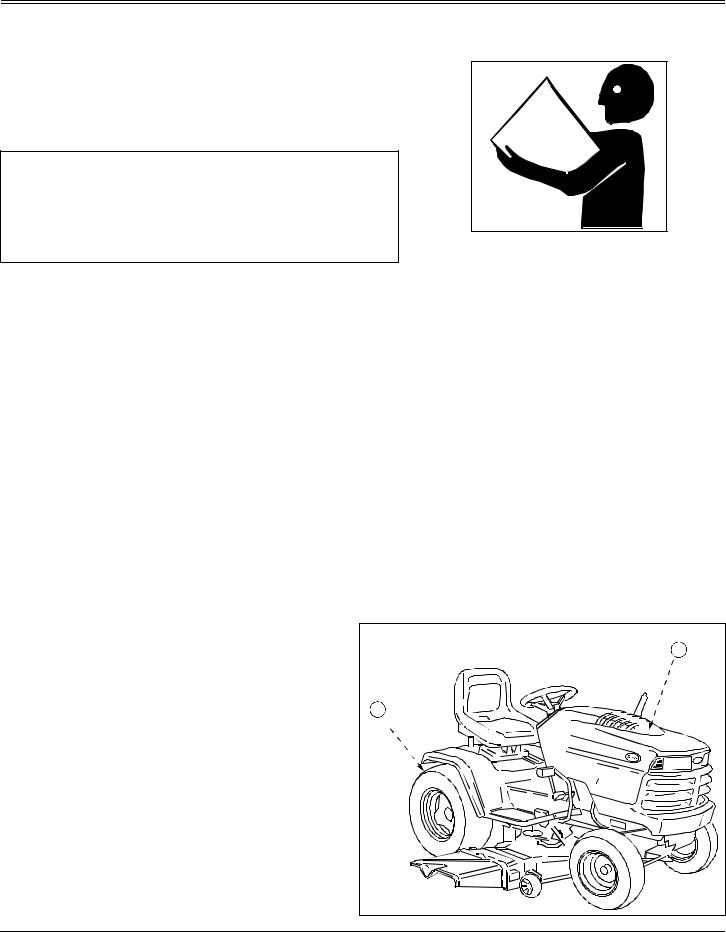

Record identification numbers below. Be sure to record all the numbers to help in tracing the machine if it is stolen. You also need to give these numbers to your dealer when you order parts.

DATE OF PURCHASE: _______________________________

DEALER NAME: ____________________________________

DEALER PHONE: ___________________________________

TRACTOR SERIAL NUMBER (A), (Located on rear

of tractor): __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER (B), (Located on engine):

__ __ __ __ __ __ __ __ __ __ __ __ __

B |

A |

Introduction

|

TABLE OF CONTENTS |

Assembly ............................................................................................................................................... |

1 |

Safety Signs........................................................................................................................................... |

5 |

Controls ................................................................................................................................................. |

8 |

Operating Machine ................................................................................................................................ |

9 |

Operating Mower ................................................................................................................................. |

26 |

Replacement Parts .............................................................................................................. |

............... 32 |

Service Machine Safely ....................................................................................................................... |

33 |

Service Interval Chart.......................................................................................................................... |

35 |

Service Engine .................................................................................................................................... |

37 |

Service Transmission........................................................................................................................... |

44 |

Service Mower ..................................................................................................................................... |

45 |

Service Electrical ................................................................................................................................. |

49 |

Service Miscellaneous......................................................................................................................... |

54 |

Removing Mower................................................................................................................................. |

62 |

Installing Mower................................................................................................................................... |

64 |

Troubleshooting .................................................................................................................................. |

65 |

Storing Machine................................................................................................................................... |

70 |

Specifications....................................................................................................................................... |

73 |

Warranty .............................................................................................................................................. |

76 |

Index .................................................................................................................................................... |

82 |

Service Literature ............................................................................................................................... |

87 |

All information, illustrations and specifications in this manual are based on the latest information at the time of publication. The right is reserved to make changes at any time without notice.

COPYRIGHT© 1998

Deere & Co.

OMM138757 L8

Table of Contents

NOTES

Notes

NOTES

Notes

NOTES

Notes

ASSEMBLY

Identify Parts

Clear Plastic Bag Contains:

•Scotts Operator’s Manual

•Engine Owner’s Manual

•Safety Video

•Warranty Cards

Bag of Parts Contains:

•Hardware for Steering Wheel

•Hardware for Battery Cables

•Key Chain

•Padded Key

NOTE: There is an extra ignition key strapped to one of the seat suspension springs.

Check and Connect Battery

cCAUTION: Prevent Battery Explosions:

-Keep sparks, lighted matches, and open flame away from the top of battery. Battery gas can explode.

-Never check battery charge by placing a metal object across the posts. Use a voltmeter or hydrometer.

-Do not charge a frozen battery; it may explode. Warm battery to 16 degrees C (60 degrees F).

IMPORTANT: This battery comes fully charged. If the mower is not used by the Service Expiration Date indicated on the battery, charge the battery. (See Charging the Battery in the Service - Electrical section.)

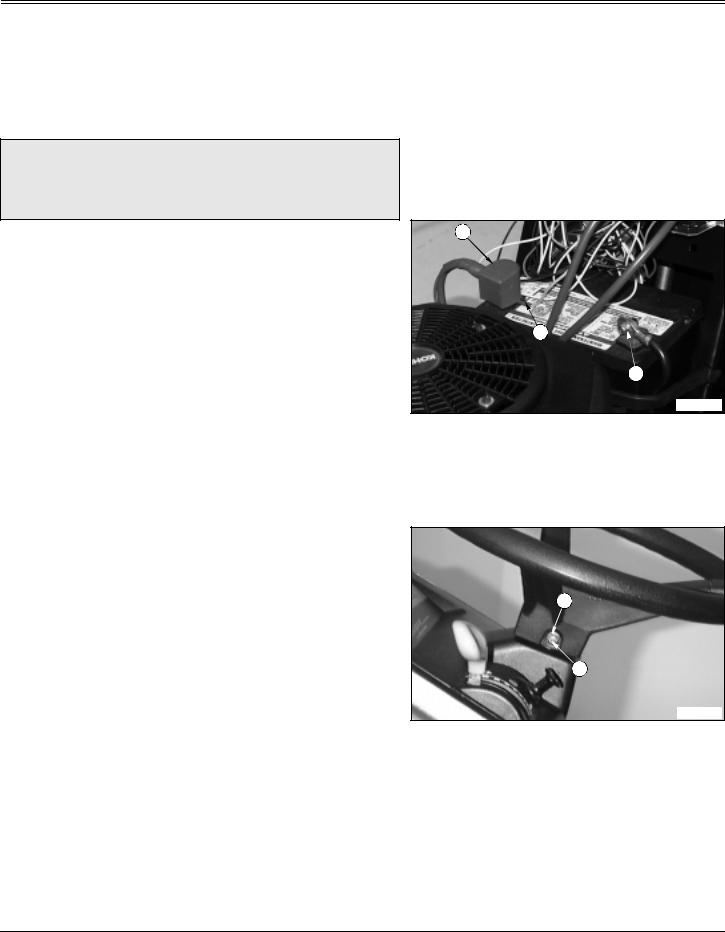

Check Battery

Battery is filled with acid and charged when it left the factory. If necessary, charge the battery prior to operation. (See Charging the Battery in ServiceElectrical Section.)

Locate label attached to battery. Find the service expiration date information (A).

If battery is put into service after date shown, charge the battery for a minimum of 1 hour at 6 - 10 amps.

Check battery voltage. Battery is fully charged at 12.6 volts.

A

M86467

Assembly - Page 1

ASSEMBLY

Connect Battery

NOTE: Do not remove the BLACK negative (–) protective cap at this time.

1. Remove and discard the RED positive (+) protective cap from the positive (+) battery terminal.

cCAUTION: DO NOT attempt to open, add fluid or service battery. Any attempt to do so will void warranty and lead to possible injury.

2.Connect blue harness wire (A) and RED positive (+) cable (B) to battery. Apply petroleum jelly or silicone spray to terminal to prevent corrosion. Make sure connection is tight. Install the red terminal cover.

3.Remove and discard the BLACK (–) protective cap from the negative battery terminal.

4.Connect black negative (–) cable (C) to battery. Apply petroleum jelly or silicone spray to terminal to prevent corrosion. Make sure connection is tight.

B

A

C

M97159

Install Steering Wheel

1.Put front wheels in the straight forward position.

2.Lubricate the steering shaft.

3.Install steering wheel with logo in the upright position.

4.Install shoulder bolt (A). Drive bolt in until head of bolt contacts steering wheel.

5.Install washer and nut (B).

6.Tighten lock nut until it is snug. Do not tighten lock nut to pull washer or head of bolt into steering wheel.

B

A

M88566

Assembly - Page 2

ASSEMBLY

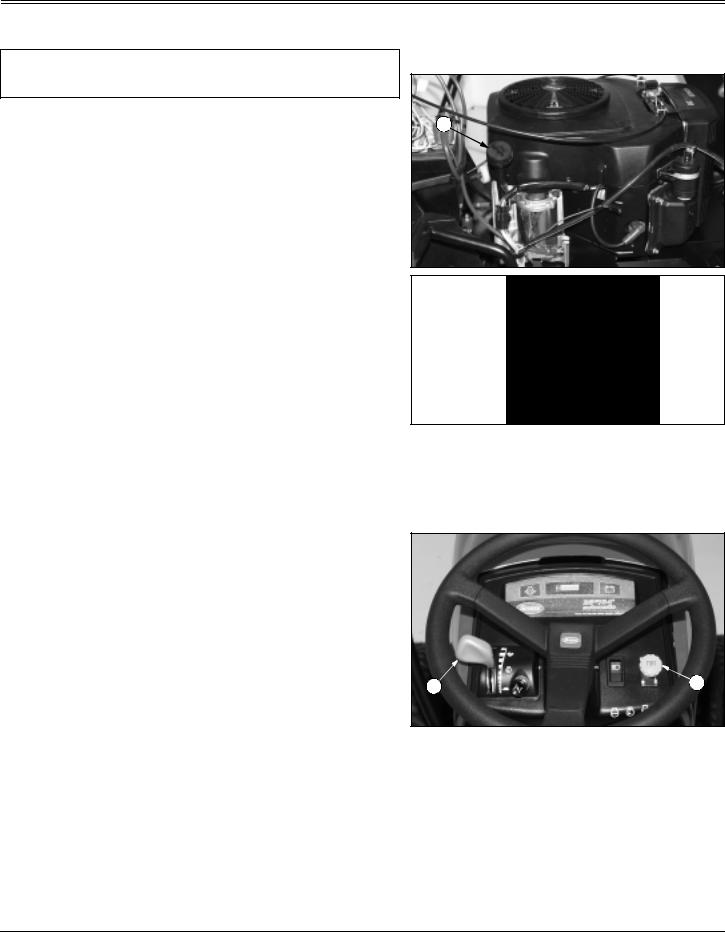

Check Engine Oil

IMPORTANT: To avoid engine damage, DO NOT run engine if oil level is below ADD mark.

1. Lift hood.

A

Picture Note: Model S2048 used for photo purposes.

2.Remove dipstick (A). Wipe with clean cloth.

3.Insert the dipstick into the tube and rest the oil fill cap on the tube. Do not thread the cap onto the tube.

4.Remove dipstick to check oil level.

5. Oil must be between ADD and FULL marks. |

|

M97157 |

6.Add oil to FULL mark if necessary. DO NOT overfill. (See See Engine Oil in Service Engine section.)

7.Install and tighten dipstick. Lower hood.

Break-In Electric PTO Clutch

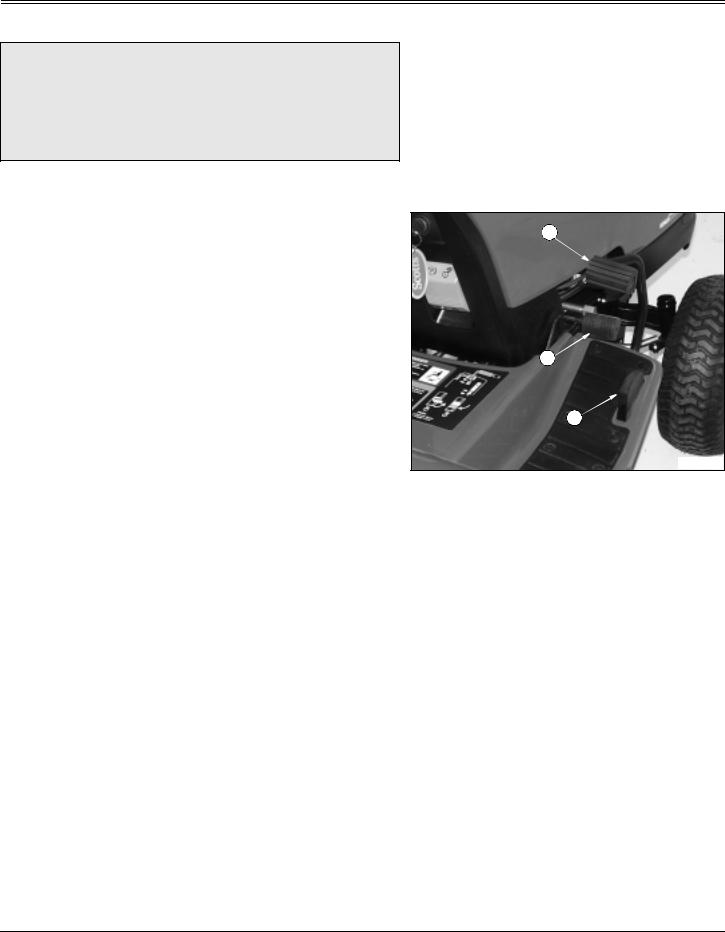

Picture Note: Model S2554 used for photo purposes.

1.Start engine and push throttle lever (A) up to full throttle (r) position.

2.With no load on mower, ENGAGE PTO (B) and allow mower to run for 10 seconds.

3. DISENGAGE PTO and wait 10 seconds.

4. |

Repeat Steps 2 and 3 for 12-15 cycles. |

A |

B |

|

|||

|

|

||

5. |

PTO clutch is now properly burnished. |

|

|

|

M97167 |

Assembly - Page 3

ASSEMBLY

Check Machine Safety System

Perform safety system check to make sure the electronic safety interlock circuit is functioning properly. Perform all six Tests. (See Testing Safety System in the Operating section.)

Checking Tire Pressure

cCAUTION: Explosive separation of a tire and rim parts can cause serious injury or death:

- Do not attempt to mount a tire without the proper equipment and experience to perform the job.

- Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

-When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly.

-Check tires for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.

1.Check tires for damage.

2.Check tire pressure with an accurate gauge.

3.Add or remove air, if necessary:

Tire Size |

Pressure |

|

|

|

|

Model S2048: |

|

Front = 16 x 6.5 x 8 |

97 kPa (14 psi) |

Rear = 23 x 9.50 x 12 |

83 kPa (12 psi) |

|

|

Models S2554: |

|

Front = 16 x 7.5 x 8 |

83 kPa (12 psi) |

Rear = 24 x 12 x 12 |

69 kPa (10 psi) |

|

|

Assembly - Page 4

SAFETY SIGNS

Safety-Alert Symbol

Read and recognize safety information. Be alert to the potential for personal injury when you see this safetyalert symbol.

On your machine safety labels, the words DANGER, WARNING, and CAUTION are used with this safetyalert symbol. DANGER identifies the most serious hazards.

In this manual, the word CAUTION and this symbol call attention to safety messages.

Machine Safety Labels

DANGER

ROTATING BLADES CUT OFF ARMS AND LEGS

• Do not mow when children or others are around

• Do not mow in reverse

•Look down and behind before and while backing

•Never carry children

WARNING

AVOID SERIOUS INJURY OR DEATH

•Drive up and down slopes, not across

•Avoid sudden turns

•If machine stops going uphill, stop blade and back down slowly

•Keep safety devices (guards, shields, and switches)

in place and working |

M97152 |

|

•Read operator’s manual

•When leaving machine: –Stop engine

–Set park brake –Remove key

Safety Signs - Page 5

SAFETY SIGNS

WARNING

LOADED SPRING

LOCK LIFT LEVER FORWARD BEFORE CHANGING ATTACHMENTS

Picture Note: One decal on each side of tractor frame.

M97152 |

DANGER/POISON

SHIELD EYES.

EXPLOSIVE GASES CAN CAUSE BLINDNESS OR

INJURY.

NO

• |

SPARKS |

|

|

|

• |

FLAMES |

|

|

|

• |

SMOKING |

|

|

|

SULFURIC ACID CAN CAUSE BLINDNESS OR |

|

|

|

|

SEVERE BURNS |

|

|

|

|

FLUSH EYES IMMEDIATELY WITH WATER. |

|

|

|

|

GET MEDICAL HELP FAST. |

|

|

|

|

MAINTENANCE-FREE |

|

|

|

|

KEEP OUT OF THE REACH OF CHILDREN. DO NOT |

|

|

|

|

M97152 |

|

|||

TIP. DO NOT OPEN BATTERY! |

|

|

|

|

|

|

|

||

|

Picture Note: Located on Battery |

|

|

|

Safety Signs - Page 6

SAFETY SIGNS

DANGER

ROTATING BLADE

DO NOT PUT HANDS OR FEET UNDER OR INTO MOWER WHEN ENGINE IS RUNNING

THROWN OBJECTS

BEFORE MOWING, CLEAR AREA OF OBJECTS THAT MAY BE THROWN BY BLADE

DO NOT OPERATE MOWER WITHOUT DISCHARGE CHUTE OR ENTIRE GRASS CATCHER IN PLACE

DANGER

ROTATING BLADE

DO NOT PUT HANDS OR FEET UNDER OR INTO MOWER WHEN ENGINE IS RUNNING

Picture Note: Located on Left-Hand side of deck.

Certification Label

This OPEI label on your mower indicates that this model has been certified by an independent laboratory for compliance with American National Standard B-71.1- 1996, “Safety Specifications” for Power Lawn Mowers, Lawn and Garden Tractors, and Lawn Tractors.

M97152

M97152

1-1996

1-1996

Safety Signs - Page 7

CONTROLS

Controls

Picture Note: Model S2554 used for photo purposes.

A |

- Engine Oil Pressure Light (Model S2554 Only) |

|

B |

|

|

A |

|

B |

- Hour Meter (Model S2554 Only) |

|

|

|

C |

||

C |

- Battery Discharge Light |

|

|

|

|

||

D |

- Light Switch |

|

|

E |

- PTO Switch/RIO Switch |

|

E |

F |

- Choke Knob |

|

D |

|

|

||

G |

- Throttle Lever |

|

|

H |

- Key Switch |

|

|

I |

- Park Brake Lever |

G |

|

|

|

|

J - Brake Pedal

F

K - Forward Travel Pedal

L - Reverse Travel Pedal M97167

M - Mower Deck Lift Lever

N - Cut Height Adjustment Lever |

H |

J |

|

|

|

|

|

I |

K

L

M97165

M

N

M97160

Controls - Page 8

OPERATING MACHINE

Operate Safely

•In addition to reading your Operator’s Manual, view your Mowing Safety Video.

•Check brake action before you operate. Adjust or service brakes as necessary.

•Inspect machine before you operate. Be sure hardware is tight. Repair or replace damaged, badly worn, or missing parts. Be sure guards and shields are in good condition and fastened in place. Make any necessary adjustments before you operate.

•Clear work area of objects that might be thrown. Keep people and pets out of the work area. Stop machine if anyone enters the area.

•If you hit an object, stop the machine and inspect it. Make repairs before you operate. Keep machine and attachments properly maintained and in good working order.

•DO NOT leave machine unattended when it is running.

•Only operate during daylight or with good artificial light.

•Be careful of traffic when operating near or crossing roadways.

•Do not wear radio or music headphones while operating the machine. Safe operation requires your full attention.

Park Safely

•Stop machine on a level surface, not on a slope.

•Disengage mower blades.

•Lower attachments to the ground.

•Engage park brake.

•STOP engine.

•Remove key.

•Before you leave the operator’s seat, wait for engine and all moving parts to STOP.

Operating Machine - Page 9

OPERATING MACHINE

Rotating Blades are Dangerous - Protect Children and Prevent Accidents

PROTECT CHILDREN:

•Never assume that children will remain where you last saw them. Children are attracted to mowing activity, stay alert to the presence of children.

•Keep children in the house when you are operating the machine.

•Turn machine off if a child enters the mowing area.

•Use extra care when you come to blind corners, shrubs, trees, or other objects that may block your vision.

•DO NOT let children or an untrained person operate the machine.

•DO NOT carry or let children ride on machine or any attachment. DO NOT tow children in a cart or trailer.

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

•Be alert at all times, drive forward carefully. People especially children can move quickly into the mowing area before you know it.

•Back carefully. Disengage mower blades and look behind the machine carefully, especially for children, before you back up.

•DO NOT mow in reverse unless it is absolutely necessary.

•Disengage mower blades when you are not mowing.

•DO NOT operate machine if you are under the influence of drugs or alcohol.

Operating Machine - Page 10

OPERATING MACHINE

Avoid Tipping

•DO NOT drive where machine could slip or tip.

•Stay alert for holes and other hidden hazards in the terrain.

•Keep away from drop-offs.

•Slow down before you make a sharp turn or operate on a slope.

•When pulling loads or using heavy equipment, use only approved hitches, limit loads to those you can safely control, and use counterweights or wheel weights when required per this manual or your attachment manual.

•Drive up and down a hill—not across. Be careful when you change direction on a slope.

•DO NOT stop when going up hill or down hill. If machine stops going up hill, DISENGAGE mower blades and back down slowly.

•DO NOT mow wet grass. Reduced traction could cause sliding.

•DO NOT try to stabilize the machine by putting your foot on the ground.

Keep Riders Off

•Only allow the operator on the machine. Keep riders off.

•Riders on the machine or attachment may be struck by foreign objects or thrown off the machine causing serious injury.

•Riders obstruct the operator’s view resulting in the machine being operated in an unsafe manner.

Operating Machine - Page 11

OPERATING MACHINE

Wear Appropriate Clothing

• Wear close fitting clothing and safety equipment appropriate for the job.

• Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as earplugs.

Transport Safely

• Use safety lights and devices. Slow moving machines when driven on public roads are hard to see, especially at night. Avoid personal injury or death resulting from a collision with a vehicle.

• Whenever driving on public roads, use flashing warning lights and turn signals according to local regulations. Extra flashing warning lights may need to be installed.

Adjusting Seat

1.Tip seat forward and loosen two knobs (A) to slide seat assembly forward or rearward to most comfortable OPERATOR position.

2.Tighten knobs after adjustment to keep seat in place.

A

M97164

Operating Machine - Page 12

OPERATING MACHINE

Using the Park Brake

cCAUTION: The machine may begin to move when engine is shut off and park brake is not engaged. To avoid injury, always LOCK park brake before getting off tractor or leaving tractor unattended.

LOCKING PARK BRAKE:

1.Push brake pedal (A) all the way down.

2.Lift park brake lever (B) up.

3.Release pedal and park brake lever. Pedal should stay down and park brake lever should stay LOCKED in UP position.

UNLOCKING PARK BRAKE:

1.Push and hold brake pedal (A) down.

2.Push park brake lever (B) down to UNLOCK park brake.

3.Release pedal.

Using Headlights

Picture Note: Model S2554 used for photo purposes.

Push top of light switch (A) to turn headlights ON.

Push bottom of light switch to turn headlights OFF.

A

B

M97165

A

M97167

Operating Machine - Page 13

OPERATING MACHINE

Checking Indicator Lights and Hour Meter

Picture Note: Model S2554 used for photo purposes.

•(b) BATTERY DISCHARGE light (A) should go out

when throttle lever is moved to the HIGH IDLE/Mowing (a) position. The voltage light may remain on for several minutes while the battery is being charged.

•(o) OIL PRESSURE light (B), on Model S2554 only, will come on when engine starts and should go out within 5 seconds.

If indicator lights stay on longer than given time, STOP engine.

• HOUR METER (C), on Model S2554 only, shows the number of hours the engine has run. To display hours, key must be in the “ON” position. Check the hour meter daily to see what services need to be done.

Starting Engine

cCAUTION: Engine exhaust fumes can cause sickness or death. • If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension. • If you do not have an exhaust pipe extension, open the doors and get outside air into the area.

IMPORTANT: Do not operate starter more than 20 seconds at a time, or you may damage it. If engine does not start: Wait two minutes before you try again. See Troubleshooting section.

Picture Note: Model S2554 used for photo purposes.

1.Lock the park brake or depress brake pedal.

2.Push PTO switch (A) down to DISENGAGE.

3.Pull choke knob (B) out to the ON (k) position.

4.Move throttle lever (C) to the HALF-SPEED (R) position.

5.Turn key (D) to START position.

6.When engine starts, release key to RUN position.

B C A

M97167

C A

B

D

M97167

Operating Machine - Page 14

OPERATING MACHINE

7.Check starting conditions:

•If engine is COLD: Gradually return the choke to the OFF position after the engine starts and warms up.

•If engine is WARM: Return choke to the OFF position as soon as the engine starts.

8.Let engine run for a couple of minutes to warm-up before operating machine.

Warming and Idling Engine

WARMING ENGINE:

Picture Note: Model S2554 shown for photo purposes.

•Run Engine at half speed for 2–3 minutes. IDLING ENGINE:

•Engine is air-cooled and needs a large volume of air to keep cool. Keep air intake screen (A) on top of engine clean.

•Avoid unnecessary engine idling.

Stopping Engine

1.STOP tractor travel.

2.Move throttle lever (A) MIDWAY between slow (t) and fast (r) positions. Let the engine run a minimum of

15seconds.

Picture Note: Model S2554 shown for photo purposes.

3.Turn key (B) to OFF position.

4.LOCK the park brake.

5.Remove key.

A

M97151

A

B

M97151

Operating Machine - Page 15

OPERATING MACHINE

Using and Stopping Automatic Transmission

cCAUTION: TO AVOID INJURY:

•Before moving forward or rearward, make sure area is clear of bystanders, especially children.

•Disengage mower before backing up.

UNLOCK park brake.

To Travel Forward:

•Slowly push down forward pedal (A). Tractor will travel faster the farther down you push the pedal.

•Release forward pedal, tractor will automatically return to neutral and STOP.

To Travel in Reverse:

NOTE: The engine and any operating attachment will stop as the REVERSE pedal is depressed with attachment engaged.

1.Bring the vehicle to a stop.

2.Push PTO knob down to the OFF position to disengage attachment.

3.Look behind the vehicle to be sure there are no bystanders nearby.

4.Push down reverse pedal (B).

For Emergency Stopping:

•Release either travel pedal. Tractor will automatically return to neutral and STOP.

•Push down on brake pedal (C). Tractor brakes will be applied to assist in stopping.

C

A

B

M97165

Operating Machine - Page 16

OPERATING MACHINE

Pushing Machine

IMPORTANT: Avoid transmission damage, DO NOT tow machine.

To move machine when engine is STOPPED:

•Unlock the park brake (A).

•Pull out on free-wheeling lever (B).

•Push machine to desired location.

NOTE: Push free-wheeling lever (B) in before operating tractor.

A

M97165

B

M97163

Operating Machine - Page 17

OPERATING MACHINE

Using Reverse Implement Option

CAUTION: TO AVOID INJURY:

cBefore moving forward or rearward, make sure area is clear of bystanders, especially children.

NOTE: Operating the mower while backing up is strongly discouraged. The Reverse Implement Option should be used ONLY when operating another attachment or when the operator deems it necessary to reposition the machine with the mower engaged.

1.Stop the machine FORWARD travel with the attachment still engaged.

2.Look behind the vehicle to be sure there are no bystanders.

3.Lift and hold the PTO knob (A) up past the PTO engagement position to activate the reverse implement position while depressing REVERSE foot pedal slightly.

NOTE: If the engine and attachment stop while repositioning the machine, return PTO knob to the OFF position and restart the machine. (See Starting The Engine in this section.) Begin again with Step 2.

4.As the machine begins to move backward, release the PTO knob and reposition the machine.

5.Resume FORWARD travel. The attachment should continue operating.

6.Repeat Steps 1 through 5 to reposition the machine again.

Daily Operating Checklist

•Test safety systems.

•Check tire pressure.

•Check fuel level.

•Check engine oil level.

•Remove grass and debris from machine.

A

M96052

Operating Machine - Page 18

OPERATING MACHINE

Testing Safety Systems

cCAUTION: Engine exhaust fumes can cause sickness or death. • If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension. • If you do not have an exhaust pipe extension, open the doors and get outside air into the area.

NOTE: Your Tractor is equipped with a ELECTRONIC SAFETY INTERLOCK. Engine will not start unless: PTO switch is DISENGAGED; Brake pedal is depressed OR parking brake is set.

Use the following checkout procedure to check for normal operation of tractor.

If there is a malfunction during one of these procedures, DO NOT operate tractor. (Contact your Authorized Service Center for service.)

Perform these tests in a clear open area. Keep bystanders away.

Test 1

Check operation of indicator lights:

1. Turn key to RUN position.

Picture Note: Model S2554 used for photo purposes.

2. LOOK:

A

•Engine Oil Pressure Light (A), on Model S2554 Only, MUST light.

•Battery Discharge Light (B) will momentarily light, this indicates the system is functioning properly. If the light remains on start engine and move throttle to high idle, the light should go out.

NOTE: The battery discharge light may remain on for several minutes while the battery is being charged.

3.If one indicator does not light, see Replacing Indicator Light Bulb in Service – Electrical section.

4.If new indicator bulb does not light or no indicators work, contact your Authorized Service Center for service.

B

C

M97167

Operating Machine - Page 19

OPERATING MACHINE

Test 2

Picture Note: Model S2554 used for photo purposes.

1.Operator on seat.

2.UNLOCK the park brake.

3.Push PTO switch (A) down to DISENGAGE.

A

4.Try to start engine.

5.Engine MUST NOT start. If engine starts, there is a problem with your safety interlock circuit.

M97167

Test 3

Picture Note: Model S2554 used for photo purposes.

1.Operator on seat.

2.LOCK the park brake.

3.Pull PTO switch (A) up to ENGAGE.

A

4.Try to start engine.

5.Engine MUST NOT start. If engine starts, there is a problem with your safety interlock circuit.

M97167

Test 4

Picture Note: Model S2554 used for photo purposes.

1.Operator on seat.

2.LOCK the park brake.

3. |

Push PTO switch (A) down to DISENGAGE. |

B |

4. |

Start engine and move throttle lever (B) to HALF- |

A |

SPEED (R) position. |

|

|

5.Pull PTO switch (A) up to ENGAGE.

6.Move throttle lever (B) to FAST (r) speed position.

7. Raise up off of seat. DO NOT get off tractor. |

|

M97167 |

8. Engine MUST stop. If engine does not stop, there is a problem with your safety interlock circuit.

Operating Machine - Page 20

OPERATING MACHINE

Test 5

1.Operator on seat.

2.Push brake pedal (A) down.

Picture Note: Model S2554 used for photo purposes.

3.Push PTO switch (B) down to DISENGAGE.

4.Release forward travel pedal (C) to N (NEUTRAL) position.

5.Start engine and move throttle lever (D) to FAST (r) speed position.

6.Release brake slowly.

7.Raise up off of seat. DO NOT get off tractor.

8.Engine MUST stop. If engine does not stop, there is a problem with your safety interlock circuit.

Test 6

1.Operator on seat.

2.Lock the park brake.

Picture Note: Model S2554 used for photo purposes.

3.Push PTO switch (A) down to DISENGAGE.

4.Start engine and move throttle lever (B) to FAST (r) speed position.

5.Raise up off of seat. DO NOT get off tractor.

6.Engine MUST remain running. If engine does stop, there is a problem with your safety interlock circuit.

Test 7

1.LOCK the park brake (A).

2.Pull out free-wheeling lever.

3.Try to push machine manually.

4.Park brake MUST prevent machine from moving. If machine moves, parking brake needs to be adjusted.

A

C

M97165

D

B

M97167

B

A

M97167

A

M97165

Operating Machine - Page 21

OPERATING MACHINE

Test 8

cCAUTION: TO AVOID INJURY: Before moving rearward, make sure area is clear of bystanders, especially children.

Test Reverse Implement Option:

1.Start engine.

2.Engage PTO to start attachment.

3.Look behind the vehicle to be sure there are no bystanders.

4.Begin REVERSE travel by depressing REVERSE foot pedal.

5.Attachment and engine should stop operation. If attachment or engine continues to operate while tractor travels in REVERSE, do not continue to operate attachment. See your Authorized service center for service.

Avoid Damage to Plastic and Painted

Surfaces

•DO NOT wipe plastic parts unless rinsed first. (See Correct Cleaning Care in Service-Miscellaneous section.)

•Insect repellent spray may damage plastic and painted surfaces. Do not spray insect repellent near machine.

•Be careful not to spill fuel on machine. Fuel may damage surface. Wipe up spilled fuel immediately.

Operating Machine - Page 22

OPERATING MACHINE

Avoid Using Ground Engaging Equipment

(Model S2048 Only)

IMPORTANT: Your S2048 tractor is NOT intended for use with ground engaging equipment. Use of such equipment could result in damage to transmission components.

Tractor Model S2048 is not intended for use with ground engaging equipment such as a rear tiller, disk, dirt blade or plow.

Using Front Weights

cCAUTION: Tractor front wheel weights improve stability in most slope operation. To avoid injury, add front wheel weights for better front-end stability and steering when using a rear mounted attachment or pulling a cart.

NOTE: Before installing wheel weights on your machine, MAKE SURE that the tire valve stems are facing the inside.

Install front wheel weights for better stability and steering control when you use equipment such as the rear-mounted grass bagger or dumpcart.

Remove front wheel weights when not required.

Using Rear Wheel Weights

IMPORTANT: When adding weight to rear of tractor, use wheel weights only.

34 kg (75 lbs.) MAX. each wheel.

Use of rear wheel weights is recommended when an attachment, such as snowthrower or snow blade is used.

Operating Machine - Page 23

Loading...

Loading...