Page 1

K9

Lawn Tractor

S2546

OPERATOR’S MANUAL

яюэюьыъщшъюьючц

яюэюьыъщшъюьючц

яюэюьыъщшъюьючцяюэюьыъщшъюьючц

Manufactured by John Deere

OMGX10722 K9

North American

Litho in U.S.A.

D

Page 2

INTRODUCTION

Introduc tion

THANK YOU for purchasing a Scotts product.

Read this manual and your attachment manual thoroughly.

Failure to do so could result in personal injury or equipment

damage.

B

A

DATE OF PURCHASE:

_______________________________

WARNING: The Engine Exhaust

c

This manual should be considered a permanent part of

your machine and should remain with the machine when

you sell it.

Product warranty is provided as part of John Deere’s

support program for customers who operate and maintain

their equipment as described in this manual. The product

warranty is explained on the warranty certificate you

received from your dealer.

Measurements in this manual are metric units and their

U.S. customary equivalents. RIGHT-HAND and LEFTHAND sides are determined by facing in the direction the

machine will travel when going forward. When you see a

broken line arrow (------>), it indicates the part it is pointing

to is hidden.

Record identification numbers below. Be sure to record all

the numbers to help in tracing the machine if it is stolen.

You also need to give these numbers to your dealer when

you order parts.

from this product contains chemicals

known to the State of California to

cause cancer, birth defects or other

reproductive harm.

CALIFORNIA Proposition 65 Warning

DEALER NAME:

____________________________________

DEALER PHONE:

___________________________________

TRACTOR SERIAL NUMBER (A), (Under seat):

__ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER (B), (Right side of engine):

__ __ __ __ __ __ __ __ __ __ __ __ __

Introduction

Page 3

TABLE OF CONTENTS

Tabl e of C ont ent s

Contents

Assembly...............................................................................................................................................1

Safety Signs ...........................................................................................................................................3

Controls .................................................................................................................................................5

Operating Machine ................................................................................................................................6

Operating Mower .................................................................................................................................16

Replacement Parts ............................................................................................................................. 20

Service Machine Safely.......................................................................................................................21

Service Interval Chart..........................................................................................................................22

Service Engine ....................................................................................................................................24

Service Steering and Brakes...............................................................................................................29

Service Mower.....................................................................................................................................31

Service Electrical.................................................................................................................................36

Service Miscellaneous.........................................................................................................................40

Removing Mower.................................................................................................................................44

Installing Mower...................................................................................................................................45

Troubleshooting ..................................................................................................................................47

Storing Machine...................................................................................................................................51

Specifications.......................................................................................................................................53

Warranty.............................................................................................................................................. 55

Index....................................................................................................................................................59

Service Literature ...............................................................................................................................61

All information, illustrations and

specifications in this manual are based

on the latest information at the time of

publication. The right is reserved to

make c hanges at any time without

John Deer e Worldwide Commercial and

Consumer Equipment Division

notice.

COPYRIGHT© 1999

Deere & Co.

Horicon, WI

All rights reserved

OMGX10722 K9

Tableof Contents

Page 4

Assembly

Identify Parts

ASSEMBLY

A Operator’s Manual

B Safety Video

C Bag of Hardware

DKey

Bag of Hardware:

• 2 - M8x16 Bolts - Battery

• 2 - M8x16 Nuts - Battery

Connect and Check Battery

cCAUTION: Avoid injury. Prevent Battery

Explosions:

- Keep sparks, lighted matches, and open flame

away from the top of battery. Battery gas can

explode.

- Never check battery charge by placing a metal

object across the posts. Use a volt-meter or

hydrometer.

-Donotchargeafrozenbattery;itmay

explode. Warm batter y to 16° C (60° F)

IMPORTANT: Avoid machine damage. This

battery comes fully charged. If the mower is not

used by the Service Expiration Date indicated on the

battery, charge the battery. (See Charging the

Battery in the Service - Electrical section.)

cCAUTION: Avoid injury. DO NOT attempt to

open, add fluid or service battery. Any attempt

to do so will void warranty and lead to possible

injury.

NOTE: Do not remove the BLACK negative (–)

protective cap at this time.

1. Remove and discard the RED positive (+) protective cap

from the positive (+) battery terminal.

C

B

2. Connect RED positive (+) cable (A) to battery with 6mm

hex head bolt and 6 mm flange nut. Tighten securely. Apply

petroleum jelly or silicone spray to terminal to prevent

corrosion. Install the red terminal cover.

3. Remove and discard the BLACK (–) protective cap from

the negative battery terminal.

4. Connect silver braided grounding cable (B) to the

negative (–) terminal (C) with remaining 6 mm hex head

bolt and 6 mm flange nut and tighten securely. Apply

petroleum jelly or silicone spray to terminal to prevent

corrosion.

A

Assembly - Page 1

Page 5

ASSEMBLY

Checking Tire Pressure

cCAUTION: Avoid injury. Explosive separation

of a tire and rim parts can cause serious injury

or death:

- Do not attempt to mount a tire without the

proper equipment and experience to perform

the job.

- Always maintain the correct tire pressure. Do

not inflate the tires above the recommended

pressure. Never weld or heat a wheel and tire

assembly. The heat can cause an increase in air

pressure resulting in a tire explosion. Welding

can structurally weaken or deform the wheel.

- When inflating tires, use a clip-on chuck and

extension hose long enough to allow you to

stand to one side and NOT in front of or over

the tire assembly.

- Check tires for low pressure, cuts, bubbles,

damaged rims or missing lug bolts and nuts.

1. Check tires for damage.

2. Check tire pressure with an accurate gauge.

3. Add or remove air, if necessary:

Tire Size Pressure-kPa (psi)

Front: 15-Inch 97 kPa (14 psi)

Rear: 20-Inch 69 kPa (10 psi)

Assembly - Page 2

Page 6

SAFETY SIGNS

Safety Signs

Safety-Alert Symbol

Read and recognize safety information. Be alert to the

potential for personal injury when you see this safety-alert

symbol.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-alert

symbol. DANGER identifies the most serious hazards.

In this manual, the word CAUTION and this symbol call

attention to safety messages.

• Do not mow in reverse

• Look down and behind before and while backing

• Never carry children

WARNING

AVOID SERIOUS INJURY OR DEATH

• Drive up and down slopes, not across

• Avoid sudden turns

• If machine stops going uphill, stop blade and back down

slowly

• Keep safety devices (guards, shields, and switches) in

place and working

• Read operator’s manual

• When leaving machine:

–Stop engine

–Set park brake

–Remove key

DANGER/POISON

Certification

Your mower has been certified by an independent

laboratory for compliance with American National Standard

B-71.1, “Safety Specifications” for Power Lawn Mowers,

Lawn and Garden Tractors, and Lawn Tractors.

Machine Safety Labels

DANGER

AVOID SERIOUS INJURY OR DEATH

SHIELD EYES.

EXPLOSIVE GASES CAN CAUSE BLINDNESS OR

INJURY.

NO

•SPARKS

•FLAMES

•SMOKING

SULFURIC ACID CAN CAUSE BLINDNESS OR SEVERE

BURNS

FLUSH EYES IMMEDIATELY WITH WATER.

GET MEDICAL HELP FAST.

MAINTENANCE-FREE

KEEP OUT OF THE REACH OF CHILDREN. DO NOT TIP.

DO NOT OPEN BATTERY!

M96445

• Do not mow when children or others are around

SafetySigns - Page 3

Page 7

Picture Note: Located on Battery under seat

DANGER

SAFETY SIGNS

DANGER

ROTATING BLADE

DO NOT PUT HANDS OR FEET UNDER OR INTO

MOWER WHEN ENGINE IS RUNNING

M96445

ROTATING BLADE

DO NOT PUT HANDS OR FEET UNDER OR INTO

MOWER WHEN ENGINE IS RUNNING

THROWN OBJECTS

BEFORE MOWING, CLEAR AREA OF OBJECTS THAT

MAYBETHROWNBYBLADE

DO NOT OPERATE MOWER WITHOUT DISCHARGE

CHUTE OR ENTIRE GRASS CATCHER IN PLACE

M96445

Picture Note: Located on Left-Hand side of deck

M96445

Picture Note: Located on Right-Hand side of deck

SafetySigns - Page 4

Page 8

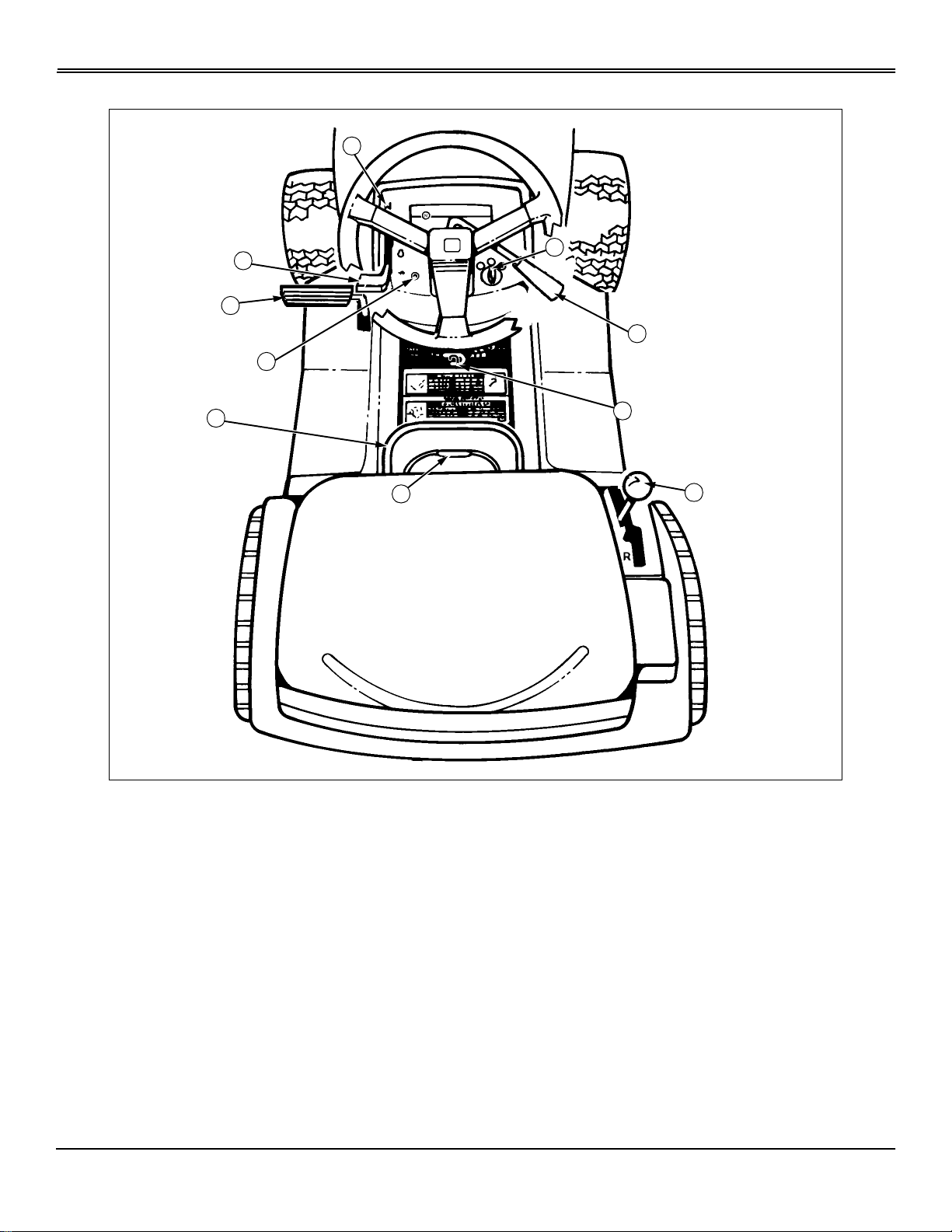

Controls

Tractor Controls

CONTROLS

J

A

B

C

D

E

I

H

G

F

A - Throttle Control

B - Foot Pedal - Brake/Return to Neutral

C - Reverse Implement Option Switch

D - Attachment Lift Lever

E - Locking Lever

F - Transmission Shift Lever

G - Park Brake

H-PTODriveLever

I - Ignition Switch

J - Choke Control

Controls - Page5

Page 9

OPERATING MACHINE

Operating Machine

Operate Safely

• In additionto reading yourOperator’s Manual,view your

Mowing Safety Video.

• Check brake action before you operate. Adjust or

servicebrakesasnecessary.

• Inspect machine before you operate. Be sure hardware

is tight. Repair or replace damaged, badly worn, or missing

parts. Be sure guards and shields are in good condition

and fastened in place. Make any necessary adjustments

before you operate.

• Clear work area of objects that might be thrown. Keep

people and pets out of the work area. Stop machine if

anyone enters the area.

• If you hit an object, stop the machine and inspect it.

Make repairs before you operate. Keep machine and

attachments properly maintained and in good working

order.

• DO NOT leave machine unattended when it is running.

• Only operate during daylight or with good artificial light.

• Be careful of traffic when operating near or crossing

roadways.

• Do not wear radio or music headphones while operating

the machine. Safe operation requires your full attention.

• Older adults are involved in a large percentage of riding

mower accidents involving injury. These operators should

evaluate their ability to operate a mower safely enough to

protect the operator and others from serious injury.

Park Safely

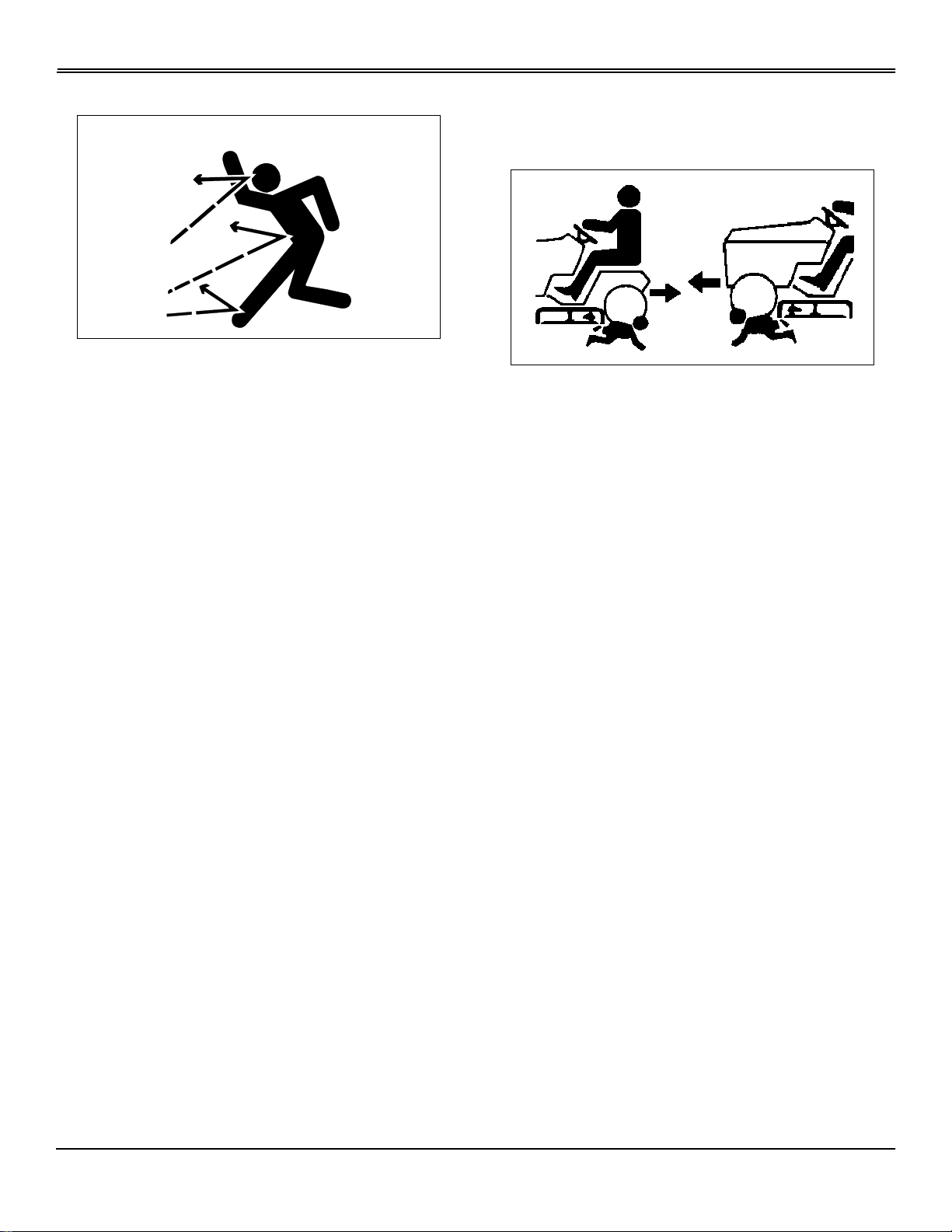

Rotating Blades are Dangerous - Protect Children and Prevent Accidents

PROTECT CHILDREN:

• Never assume that children will remain where you last

saw them. Children are attracted to mowing activity, stay

alert to the presence of children.

• Keep children in the house when you are operating the

machine.

• Turn machine off if a child enters the mowing area.

• Use extra care when you come to blind corners, shrubs,

trees, or other objects that may block your vision.

• DO NOT let children or an untrained person operate the

machine.

• DO NOT carry or let children ride on machine or any

attachment.DO NOT tow children in a car t or trailer.

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

• Be alert at all times, drive forward carefully. People

especially children can move quickly into the mowing area

before you know it.

• Back carefully. Disengage mower blades and look

behind the machine carefully,especially for children, before

you back up.

• DO NOT mow in reverse unless it is absolutely

necessary.

• Disengage mower blades when you are not mowing.

• DO NOT operate machine if you are under the influence

of drugs or alcohol.

• Stop machine on a level surface, not on a slope.

• Disengage mower blades.

• Lower attachments to the ground.

• Engage park brake.

• STOP engine.

• Remove key.

• Before you leavethe operator’s seat, wait for engine and

all moving parts to STOP.

Operating Machine - Page 6

Page 10

OPERATING MACHINE

Avoid Tipping

• DONOTdrivewheremachinecouldsliportip.

• Stay alert for holes and other hidden hazards in the

terrain.

• Keep away from drop-offs.

• Slow down before you make a sharp turn or operate on

aslope.

• When pulling loads or using heavy equipment, use only

approved hitches, limit loads to those you can safely

control, and use counterweights or wheel weights when

required per this manual or your attachment manual.

Keep Riders Off

• Only allow the operator on the machine. Keep riders off

even if blades are shut off.

• Riders on the machine or attachment may be struck by

foreign objects or thrown off the machine causing serious

injury.

• Riders obstruct the operator’s view resulting in the

machine being operated in an unsafe manner.

Wear Appropriate Clothing

• Drive up and down a hill—not across. Be careful when

you change direction on a slope.

• DO NOT stop when going up hill or down hill. If machine

stops going up hill, DISENGAGE mower blades and back

down slowly.

• DO NOT mow wet grass.Reduced traction could cause

sliding.

• DO NOT try to stabilize the machine by putting your foot

on the ground.

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Loud noise can cause impairment or loss of hearing,

wear a suitable protective device such as earplugs.

Operating Machine - Page 7

Page 11

OPERATING MACHINE

Transport Safely

• Use safety lights and devices. Slow moving machines

when driven on public roads are hard to see, especially at

night. Avoid personal injury or death resulting from a

collision with a vehicle.

• Whenever driving on public roads, use flashing warning

lights and turn signals according to local regulations. Extra

flashing warning lights may need to be installed.

Adjusting Seat

Using the Park Brake

cCAUTION: Avoid injury. Always LOCK park

brake before getting off tractor or leaving

tractor unattended.

LOCKING PARK BRAKE:

A

B

1. Pivot seat forward on its mounting bracket.

A

M96454

2. Loosen front seat knobs (A).

3. Slide forward or rearward on mounting bracket to

desired position.

4. Tighten seat knobs.

5. Lower seat.

1. Push and hold foot pedal (A) all the way down.

2. Move park brake lever(B) forward, then to the left to lock

position.

3. Remove foot from pedal. Pedal should not return to the

up position.

Operating Machine - Page 8

Page 12

OPERATING MACHINE

UNLOCKING PARK BRAKE

1. Push and hold foot pedal (A) all the way down.

2. Move park brake lever (B) to the right, then to the rear.

3. Remove foot from pedal. Pedal should return to the up

position.

Starting Engine

cCAUTION: Avoid injury. Start engine ONLY

outdoors or in a well ventilated place. Exhaust

fumes are da ngerous.

IMPORTANT: Avoid machine damage. Do not

operate starter more than 20 seconds at a time, or

you may damage it. If engine does not start: Wait

two minutes before you try again. See

Troubleshooting section.

NOTE: Engine will not start unless: PTO lever is

DISENGAGED, park brake is LOCKED or brake pedal

pushed down. The transmission shift lever should be

in N (NEUTRAL) position.

4. Push throttle lever (D) up to the FAST (

pull out choke knob (E). As the engine begins to run

smoothly, push the choke knob in until it is fully seated.

5. Turn ignition key (F) to start position to crank the engine.

Crank engine until it starts, but no longer than 5 seconds.

6. Release key to run position when engine starts. If

engine does not start, release key to run position and wait

10 seconds before cranking the engine again.

7. Let engine run for a couple of minutes to warm-up

before operating tractor.

r) position and

Using Throttle Control

Always operate the engine at FULL (r)THROTTLE.

Operating the engine at less that full throttle reduces the

battery charging rate and reduces fan cooling efficiency of

the engine.

Full throttle offers the best bagging and mower

performance.

Cold Weather Starting Tips

Always use fresh winter grade fuel.

E

F

D

A

1. Move transmission shift lever (A) to N (NEUTRAL)

position.

C

B

Do not crank engine for more than 30 seconds in any single

attempt.

During first minute of operation engine may be operated in

partial choke to allow smoother running. As engine warms

slowly reduce engine speed to the full throttle detent

position.

Allow engine to run for a few minutes before using tractor to

allow automatic transmission oil to warm. Sluggish

transmission response in cold weather indicates that oil has

not warmed to allow optimum performance.

2. Lock the park brake (B).

3. Pull PTO lever (C) all the way back to the (OFF)

position.

Operating Machine - Page 9

Page 13

OPERATING MACHINE

Warming and Idling Engine

WARMING ENGINE:

• Run Engine at half speed for 2–3 minutes.

IDLING ENGINE:

A

M96455

• Engine is air-cooled and needs a large volume of air to

keep cool. Keep air intake screen (A) on top of engine

clean.

• Avoid unnecessary engine idling.

4. Move throttle lever (D) to SLOW (t) position. Let engine

run at low throttle a few seconds.

5. Turn key (E) to OFF position.

6. Remove key.

7. LOCK the park brake.

Using Travel Controls

cCAUTION: Avoid injury:

• Before moving forward or rearward, make sure

area is clear of bystanders, especially children.

• Disengage mower or attachment before

backing up.

TO TRAVEL FORWARD:

B

Stopping Engine

A

D

C

E

A

C

B

Move shift lever (A) to the right and forward to desired

FORWARD speed.

1. Push down on foot pedal (A).

2. Move transmission shift lever (B) to N (NEUTRAL)

position.

3. Pull PTO lever (C) all the way back to the rearward

(OFF) position.

Operating Machine - Page 10

Page 14

OPERATING MACHINE

TO TRAVEL IN REVERSE:

NOTE: The engine and mower will stop as the shift

lever is moved to the R (REVERSE) position with

mower engaged.

1. Pull PTO lever (C) all the way back to the rearward

(OFF) position.

2. Look behind the vehicle to be sure there are no

bystanders nearby.

3. Move shift lever (A) rearward to the R (REVERSE)

position.

FOR EMERGENCY STOPPING:

1. Push foot pedal (B) fully to stop machine. Transmission

shift lever (A) will automatically return to NEUTRAL.

Using Reverse Implement Option

cCAUTION: Avoid injury. Before moving forward

or rearward, make sure area is clear of

bystanders, especially children.

NOTE: Operating the mower while backing up is

strongly discouraged. The Reverse Implement Option

should be used O NLY when operating another

attachment or when the operator d eems it necessary to

reposition the machine with the mower engaged.

1. Stop the machine FORWARD travel with mower

engaged.

2. Look behind the vehicle to be sure there are no

bystanders.

A

3. Push and hold in the reverse implement switch (A)

while:

4. Move the drive lever to the R (REVERSE) position.

NOTE: If the engine and mower stop while

repositioning the machine, return mower engagement

lever to the OFF position and restart the machine. (See

Starting The Engine in this section.) Begin again with

Step 2.

5. As the machine begins to move rearward, release the

reverse implement switch and reposition the machine.

6. Resume FORWARD travel. The mower should continue

operating.

7. Repeat Steps 1 through 5 to reposition the machine

again.

Operating Machine - Page 11

Page 15

OPERATING MACHINE

Pushing Machine

IMPORTANT: Avoid transmission damage, DO

NOT tow machine.

To move machine when engine is STOPPED:

A

B

T esting Safety Systems

cCAUTION: Avoid injury. Engine exhaust fumes

can cause sickness or death.

If it is necessary to run an engine in an

enclosed area, remove the exhaust fumes from

the area with an exhaust pipe extension.

If you do not have an exhaust pipe extension,

open the doors and get outside air into the

area.

Use the following checkout procedure to check for normal

operation of machine.

If there is a malfunction during one of these procedures,

DO NOT operate machine. (See your Authorized Service

Center for service.)

Perf orm these tests in a clear open area. Keep bystanders

away.

NOTE: Your Lawn Tractor is equipped with a

ELECTRONIC SAFETY INTERLOCK. Engine will not

start unless: PTO lever is DISENGAGED. Brake pedal is

depressed OR parking brake is set.

1. Unlock the park brake (A).

2. Put transmission shift lever (B) in N (Neutral).

3. Push machine to desired location.

Daily Operating Checklist

• Test safety systems.

• Check tire pressure.

• Checkfuel level.

• Check engine oil level.

• Remove grass and debris from machine.

Test 1

1. Operator on seat.

2. Unlock the park brake.

A

3. Pull PTO lever (A) back to DISENGAGE.

4. Try to start engine.

5. Engine MUST NOT start. If engine starts, there is a

problem with your safety interlock circuit. (See your

Authorized Service Center.)

Operating Machine - Page 12

Page 16

OPERATING MACHINE

Test 2

1. Operator on seat.

2. Lock the park brake.

A

3. Push PTO lever (A) forward to ENGAGE.

4. Try to start engine.

5. Engine MUST NOTstart. If engine starts, there is a

problem with your safety interlock circuit. (See your

Authorized Service Center.)

Test 4

1. Operator on seat.

2. Push brake pedal down.

C

A

B

Test 3

1. Operator on seat.

2. Lock the park brake.

A

3. Pull PTO lever (A) back to DISENGAGE.

4. Start engine and move throttle lever (B) to HALFSPEED (

5. Push PTO lever (A) forward to ENGAGE.

6. Move throttle lever to FAST (

7. Raise up off of seat. DO NOT get off tractor.

R)position.

r) speed position.

3. Pull PTO lever (A) back to DISENGAGE.

4. Put transmission shift lever (B) in N (NEUTRAL)

position.

5. Start engine and move throttle lever (C) to FAST(

speed position.

6. Release brake slowly.

7. Raise up off of seat. DO NOT get off tractor.

8. Engine will begin to stop. If engine does not begin to

stop, there is a problem with your safety interlock circuit.

(See your Authorized Service Center.)

r)

Test 5

1. Operator on seat.

2. Lock the park brake.

8. Engine will begin to stop. If engine does not begin to

stop, there is a problem with your safety interlock circuit.

(See your Authorized Service Center.)

Operating Machine - Page 13

Page 17

OPERATING MACHINE

Test 7

B

3. Pull PTO lever (A) back to DISENGAGE.

4. Start engine and move throttle lever (B) to FAST (

speed position.

5. Raise up off of seat. DO NOT get off tractor.

6. Engine MUST remain running. If engine does stop,

there is a problem with your safety interlock circuit. (See

your Authorized Service Center.)

A

r)

Test 6

cCAUTION: Avoid injury. Before moving

rearward, make sure area is clear of

bystanders, especially children.

Test Reverse Implement Option:

1. Start engine.

A

2. Push PTO lever (A) forward to ENGAGE.

3. Look behind the vehicle to be sure there are no

bystanders.

4. Begin REVERSE travel by moving the transmission shift

lever to R (REVERSE) position.

Mower and engine should stop operation. If mower or

engine continues to operate as tractor begins travel in

REVERSE, do not continue to operate mower. (See your

Authorized Service Center for service.)

A

B

C

1. Lock the park brake (A).

2. Put transmission shift lever (B) in N (Neutral).

3. Try to push machine manually.

4. Park brake MUST prevent machine from moving. If

machine moves, parking brake needs to be adjusted. (See

your Authorized Service Center.)

Operating Machine - Page 14

Avoid Damage to Plastic and Painted Surfaces

• DO NOT wipe plastic parts unless rinsed first. (See

Correct Cleaning Care in Service-Miscellaneous section.)

• Insect repellent spray may damage plastic and painted

surfaces. Do not spray insect repellent near machine.

• Be careful not to spill fuel on machine. Fuel may

damage surface. Wipe up spilled fuel immediately.

Page 18

OPERATING MACHINE

Avoid Using Ground Engaging Equipment

IMPORTANT: Avoid machine damage. This tractor

is NOT intended for use with ground engaging

equipment. Use of such equipment could result in

damage to transmission components.

This tractor is not intended for use with ground engaging

equipment such as a rear tiller, disk, blade or plow.

Using Front Weights

cCAUTION: Avoid injury. Tractor front wheel

weights improve stability in most slope

operation. To avoid injury, add front wheel

weights for better front-end stability and

steering when using a rear mounted

attachment.

Install front wheel weights, two required, for better stability

and steering control when you use equipment such as the

rear-mounted grass bagger or dumpcart.

See your Authorized Service Center for Front Weights.

Transporting

Do not tow machine.

Use a heavy-duty trailer to transport your machine.

Raise mower deck to highest position when transporting to

trailer.

Disengage PTO.

Drive forward onto trailer.

Lower mower or any attachment to trailer deck.

LOCK park brake.

Be sure trailer has all the necessary lights and signs

required by law.

Fasten machine to trailer with heavy-duty straps, chains, or

cables. Both front and rear straps must be directed down

and outward from tractor.

Remove front wheel weights when not required.

Using Rear Wheel Weights

Use of rear wheel weights is recommended for improved

traction when an attachment, such as snowthrower orblade

is used.

See your Authorized Service Center for Rear Weights.

Using Tire Chains

Tire chains are recommended for use with snowthrower

and, under certain conditions, the front blade.

See your Authorized Service Center for Tire Chains.

Operating Machine - Page 15

Page 19

OPERATING MOWER

Operating Mower

Operate Mower Safely

• In additionto reading yourOperator’s Manual,view your

Mowing Safety Video.

Check Ground Conditions

• Clear mowing area of objects that might be thrown.

Keep people and pets out of mowing area.

• Study mowing area. Set up safe mowing pattern. Do not

mow under conditions where traction or stability is doubtful.

• First, test drive area with PTO lever DISENGAGED and

mower lowered. Slow down when you travel over rough

ground.

• DISENGAGE PTOleverto stop mower bladeswhen you

are not using mower.

Using Lift Lever to Raise and Lower Mower

A

B

1. Push down on lift lever (A) slightly and hold locking lever

(B)downwiththumb.

2. Move lift lever (A) DOWN to LOWER mower or UP to

RAISE mower.

3. Release locking lever lock (B) to keep lift lever (A) in

position.

Adjusting Cutting Height

Avoid Injury From Contacting Blades

Before you dismount to unplug or adjust mower:

• DISENGAGE PTO lever to stop mower blades.

• STOP the engine.

• LOCK the park brake.

• Remove key.

• Wait for mower blades to STOP.

• Keep hands, feet and clothing away from mower deck

when engine is running.

Cutting height can be adjusted from 38 – 102 mm (1-1/2 –

4in).

Check tractor tire pressure. (See Checking Tire Pressure in

Service Miscellaneous section.)

To adjust cutting height:

A

B

1. Push down on lift lever (A) slightly and hold locking lever

(B)downwiththumb.

2. Move lift lever (A) to desired cutting height.

3. Release locking lever (B) to keep lift lever (A) in position.

4. Adjust gage wheels to match cut height desired. (See

Adjusting Mower Gage Wheels below.)

Operating Mower - Page 16

Page 20

OPERATING MOWER

Adjusting Mower Gage Wheels

cCAUTION: Avoid injury, before you adjust gage

wheels: STOP engine, remove key, and wait for

blades to STOP.

IMPORTANT: Avoid machine damage. Mower

gage wheels must not ride on ground to support

mower weight. Adjust gage wheels each time you

change cutting height.

1. Check tractor tire pressure. Inflate tires to the correct

pressure. (See Checking Tire Pressure in Service Miscellaneous section.)

2. Raise mower lift lever to TRANSPORT (upper) position

and adjust cutting height. (See Adjusting Cutting Height in

this section.)

D

Adjusting Mower Level (Side-to-Side)

cCAUTION: Avoid injury, before you adjust

mower: STOP engine, remove key, and wait for

blades to STOP.

Be careful, sharp edges on mower blades.

Always wear gloves when handling mower

blades.

NOTE: A deck leveling gauge (Part Number TY15272)

to aid in deck leveling may be obtained through your

local Authorized Service Center at a nominal cost.

1. Park tractor on a hard, level surface.

2. Stop engine and remove key .

3. CHECK: Tire pressures must be correct. (See Checking

Tire Pressure in Service – Miscellaneous section.)

4. Adjust cutting height to middle position.

C

B

3. Remove bolt (A), bushing (B), washer (C), and nut (D).

4. Move lift lever down to desired MOWING position.

5. Move mower gage wheels, one on each side, to one of

four holes for desired position. On 46-Inch Mower Deck,

move front and rear gage wheels.

6. Bottom of gage wheels should be approximately 6-13

mm (1/4-1/2 in) from the ground when properly adjusted.

7. Install bolt and tighten with nut.

A

M88571

A

5. Turn left blade parallel to tractor axle. Hold drive belt and

turn right blade parallel to axle.

A

A

M40161

6. Measure from each outside blade tip (A) to the level

surface. The difference between measurements must not

be more than 3 mm (1/8 in).

Operating Mower - Page 17

Page 21

OPERATING MOWER

A

C

B

D

E

7. Loosen top clamping nut (C) facing inside of mower, on

left hand side J-bolt (B), approximately one turn.

8. Loosen upper adjusting nut (D).

9. Raise or lower left side of deck.

• To raise: Turn lower adjusting nut (E) towards rear of

tractor.

• To lower: Turn lower adjusting nut (E) towards front of

tractor.

10.Tighten upper adjusting nut.

11.Tighten clamping nut.

12.Check side-to-side measurements and readjust if

necessary.

4. Turn blades so front blade tips (A) point straight forward.

5. Measure from the front of each blade tip to the level

surface. The front blade tips must be 6–9 mm

(1/4–3/8 in.) lower than rear blade tips or blades will cut

grass twice and grass tips will turn brown.

C

C

B

B

Adjusting Mower Level (Front-to-Rear)

cCAUTION: Avoid injury, before you adjust

mower: STOP engine, remove key, and wait for

blades to STOP.

Be careful, sharp edges on mower blades.

Always wear gloves when handling mower

blades.

IMPORTANT: Avoid machine damage. Make sure

each front draft rod is equally tensioned. The

installed rods should exhibit identical amounts of

movement between left and right rods. If one rod

moves more freely than the other, the adjustment

nut should be tightened until the movement of the

assembly matches that of the other side.

1. Park tractor on a hard, level surface.

2. Stop engine and remove key.

3. CHECK: Tire pressure must be correct. (See Checking

Tire Pressure in Service – Miscellaneous section.)

6. Turn nuts (B) on front draft rods (C) equally until

adjustment is correct. Tur n nut clockwise to RAISE front of

mower deck or counterclockwise to LOWER front of mower

deck.

7. Check front-to-rear deck measurements and readjust if

necessary.

Operating Mower - Page 18

Page 22

OPERATING MOWER

Engaging and Disengaging Mower

IMPORTANT: Avoid machine damage. Operate

engine at maximum speed when mowing or after

mower blade is engaged.

Machine may require 2–3 minutes warm-up period

before engaging the mower deck.

Engaging Mower

1. START engine.

A

B

Dismounting to Inspect or Unplug Mower or Optional Bagger

cCAUTION: Avoid injury. To help prevent

personal injury, do the following steps before

you dismount to inspect or unplug mower or

bagger.

1. STOP machine.

A

2. Move throttle lever (A) to the FAST (

3. Lower mower to cutting height.

4. Push PTO drive lever (B) forward to ENGAGE mower

blades.

NOTE: The engine and mower will stop as the gear

shiftleverismovedtotheR(REVERSE)positionwith

mower engaged.

5. Disengage PTO before shifting to REVERSE.

Disengaging Mower

1. Pull PTO drive lever (A) back to DISENGAGE mower

blades.

2. If you hit an object with mower while mowing, STOP

mower and engine immediately. Inspect mower for

damage.

r) position.

2. Pull PTO drive lever (A) back to DISENGAGE mower

blades.

3. Move throttle lever to SLOW (

4. Lower mower to the ground.

5. LOCK park brake.

6. STOP engine.

7. Remove key.

8. Wait for all moving parts to STOP.

t) position.

Operating Mower - Page 19

Page 23

REPLACEMENT PARTS

Replacement Parts

John Deere Quality

WE RECOMMEND JOHN DEERE quality parts and

lubricants, available at your Authorized Service Center.

PART NUMBERS MAY CHANGE, use part numbers listed

below when you order. If a number changes, your dealer

will have the latest number.

WHEN YOU ORDER PARTS, your Authorized Service

Center needs your machine serial number and engine

serial number. These are the numbers that you have

recorded on the inside front cover of this manual.

Touch-up paint is available in 340 grams (12 oz.) aerosol

cans. Scotts Orange (part number: TY24745) and Scotts

Grey (part number: TY 24747)

Parts for Tractor

ITEM PART NUMBER

Air Cleaner Elements:

• Foam

• Paper

LG273638S

LG499486S

Fuel Filter AM116304

Oil Filter AM125424

Battery TY21752

Spark Plug (Champion – RC-12YC)

Fuse-15 amp 99M7065

Headlight Bulb AD2062R

Ground Drive Belt GX10065

Parts for Mower Decks

ITEM 46-Inch Deck

Blades:

Standard

Mulch

Mower Drive Belts GX10176

Leveling Gauge TY15272

(Part numbers are subject to change without notice. Part

Numbers may be different outside the U.S.A.)

If you would like a copy of the Parts Catalog for this

machine, please use the Order Form in the SERVICE

LITERATURE section.

M127466

M119232

Replacement Parts - Page 20

Page 24

SERVICE MACHINE SAFELY

ServiceMachine Safely

Practice Safe Maintenance

• Understand service procedure before doing work. Keep

area clean and dry.

• Never lubricate, service, or adjust machine while it is

moving.Keep safety devices in place and in working

condition. Keep hardware tight.

• To prevent them from getting caught, keep hands, feet,

clothing, jewelry, and long hair away from any moving parts.

• Before servicing machine, disengage all power and stop

the engine. Lock park brake and remove the key. Let

engine cool.

• Securely support any machine elements that must be

raised for service work.

• Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

wear a suitable protective device such as earplugs.

• Do not wear radio or music headphones while servicing

the machine. Safe service requires your full attention.

Avoid Injury From Contacting Blades

Before you unplug or adjust machine:

• STOP the engine.

• Remove key.

• Wait for blades to STOP.

• Keep hands, feet and clothing away from blades when

engine is running.

Handling Waste Product and Chemicals

• Disconnect battery ground cable (-) before making

adjustments on electrical systems or welding on machine.

• Unauthorized modifications to the machine may impair

its function and safety.

Wear Appropriate Clothing

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Loud noise can cause impairment or loss of hearing,

• Waste products such as used oil, fuel, coolant, brake

fluid, and batteries, can harm the environment and people.

• DO NOT use beverage containers for waste fluids someone may drink from them.

• See your local Recycling Center or John Deere dealer to

learn how to recycle or get rid of waste products.

• A Material Safety Data Sheet (MSDS) provides specific

details on chemical products: physical and health hazards,

safety procedures, and emergency response techniques.

See your John Deere dealer for the MSDS on chemical

products used with your machine.

Service Machine Safely - Page21

Page 25

SERVICE INTERVAL CHART

Service Interval Chart

Service Intervals

Please use the following timetables to perform routine

maintenance on your machine. Service procedures

included in this manual but not on this chart are to be

performed on an as needed basis.

IMPORTANT: Avoid machine damage. If you

operate mower in extreme heat, dust or other severe

conditions, service more often than shown below.

Before Each Use

After First 2 Hours

Every 8 Hours

Every 25 Hours

Every 50 Hours

Test safety systems.

Check brakes.

Check tire pressure.

Check/tighten loose hardware.

Check engine oil level.

Adjust blade belt tension.

Change engine oil.

Check brakes.

Check tire pressure.

Check engine oil level.

Sharpen/replace blades.

Lubricatefrontaxle.

Check battery and clean battery terminals.

Check transaxle cooling.

Change engine oil. *

Service air filter pre-cleaner. *

Clean air intake screen. *

Inspect muffler

Every 100 Hours

Every Season

Before Storage

Check/tighten loose hardware.

Adjust drive belt tension.

Clean engine cooling fins

Replace engine oil filter.*

Replace spark plugs.

Replace air filter paper cartridge. *

Adjust blade belt tension.

Service air filter pre-cleaner.

Clean air screen.

Replace spark plugs.

Replace fuel filter.

Check/tighten loose hardware.

Lubricate front axle and mower spindles.

Clean battery terminals.

Change engine oil.

Inspect muffler

Service Interval Chart - Page 22

Page 26

SERVICE INTERVAL CHART

Service Record

DATE SERVICE PERFORMED

Service Interval Chart - Page 23

Page 27

SERVICE ENGINE

ServiceEngine

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine

manufacturer and should not require any adjustments.

If engine is operated at altitudes above 1829 m (6,000

ft.), some carburetors may require a special high

altitude main jet. See your John Deere dealer.

Possible engine surging will occur at high rpm with no

load (with transmission in “N” neutral and mower

blade engagement lever disengaged). This is a normal

condition due to the emission control system.

If engine is hard to start or runs rough, check the

Troubleshooting section of this manual.

After performing the checks in the troubleshooting section

and your engine is still not performing correctly, contact

your John Deere dealer.

Avoid Fumes

engines. The use of multi-viscosity oil such as (10W-

30) in ambient temperatures above 4° C (40° F) will

result in higher than normal oil consumption. If multiviscosity oil used, check oil level more frequently to

prevent any possible damage due to lack of lubrication.

cCAUTION: Avoid injury. Engine exhaust fumes

can cause sickness or death:

- If it is necessary to run an engine in an

enclosed area, use an exhaust pipe extension

to remove the fumes.

- Always try to work in a well ventilated area.

Engine Oil

cCAUTION: Avoid injury. To prevent injury from

accidental starting, always remove wire from

spark plugs and disconnect battery at negative

terminal before servicing engine.

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

Use a high quality detergent oil classified as:

• API Service Classification SG

• API Service Classification SF

NOTE: Air cooled engines run hotter than automobile

Service Engine - Page 24

Page 28

SERVICE ENGINE

Checking Engine Oil

IMPORTANT: Avoid machine damage. To avoid

engine damage, DO NOT run engine if oil level is

below ADD mark.

NOTE: Engine must not be running.

Make sure engine is COLD when checking engine oil

level.

1. Park tractor on a level surface.STOP engine. Let engine

cool.

2. Lift hood.

3. Clean area around dipstick to prevent debris from falling

into crankcase.

A

Changing Engine Oil and Filter

cCAUTION: Avoid injury. Engine may be hot, be

careful not to burn hands.

IMPORTANT: Avoid machine damage. To extend

engine life, when operating mower in extreme heat,

dust or other severe conditions, it may be necessary

to change engine oil and filter mor e frequently.

1. Run engine to warm oil.

2. Park tractor on level surface. STOP engine. LOCK park

brake and remove key.

3. Lift hood.

4. Put drain pan under drain valve.

A

M96093

4. Remove dipstick (A). Wipe with clean cloth.

5. Reinsert the dipstick into the tube and thread cap tightly

onto fill tube. Remove dipstick to check oil level.

6. Oil must be between ADD and FULL marks.

7. Add oil to FULL mark if necessary. DO NOT OVERFILL.

(See Engine Oil in this section.)

8. Install and tighten dipstick. Lower hood.

5. Unsnap the dust cap, push and twist to open oil drain

(A) and drain oil into oil drain pan.

A

6. Close drain cap.

M96093

Service Engine - Page 25

Page 29

SERVICE ENGINE

C

MX1529

7. Remove old filter (C) and wipe off filter tray with a clean

cloth.

8. Lightly oil filter gasket with fresh, clean oil.

9. Install replacement oil filter. Turn oil filter to the right

(clockwise) until rubber gasket contacts filter adapter.

Tighten filter an additional one-half turn.

10.Remove dipstick (B) and refill with new oil of

recommended grade. (See Engine Oil in this section.)

Checking and Cleaning Air Cleaner

Elements

IMPORTANT: Avoid machine damage. To extend

engine life, when operating mower in extreme heat,

dust or other severe conditions, it may be necessary

to check/replace air cleaner more frequently.

1. Lift hood.

2. Clean any dirt and debris from the air cleaner before

removing cover.

3. Loosen knob (A) and remove cover (B).

A

B

11.Check oil level. For correct procedure see Checking Oil

Level in this section.

12.Oil level must be between ADD and FULL marks. Do not

overfill.

13.Install and tighten dipstick. Lower hood.

14.Start engine and check for oil leaks. Correct any leaks

before operating.

15.Run engine at idle for 30 seconds. Stop engine. Wait 30

seconds and check oil level.

16.If necessary, add oil to bring level to FULL mark on

dipstick.

Service Engine - Page 26

Page 30

SERVICE ENGINE

IMPORTANT: Avoid machine damage. To prevent

engine damage, DO NOTallow any foreign objects to

fall into the carburetor air intak e (C).

D

C

E

if necessary.

8. Carefully clean air cleaner housing. Prevent any dirt

from falling into carburetor.

9. Install foam precleaner (E) mesh side up.

10.Install cartridge. Make sure cartridge and seal are

properly seated and sealing the carburetor air intake area.

11.Install air cleaner cover and tighten knobs. DO NOT

overtighten.

12.Lower hood.

Cleaning Air Intake Screen

IMPORTANT: Avoid machine damage from

overheating and damage to e n gine:

• Keep air intake screen free of dust.

• Keep cooling shrouds in place.

1. STOP engine. LOCK park brake and remove key.

2. Lift hood.

4. Avoid dropping anything into the carburetor air intake

(C). If anything falls into the carburetor air intake it MUST

be remove.

5. Lift out filter cartridge (D) and foam precleaner (E).

Service precleaner:

6.

• Wash precleaner in a solution of warm water and

liquid detergent.

• Rinse precleaner thoroughly. Squeeze out excess

water in a dry cloth until precleaner is completely dry.

• Put approximately 30 ml. (1 oz.) of clean engine oil

onto precleaner. Squeeze precleaner to distribute oil

evenly. Squeeze out excess oil with a clean cloth.

IMPORTANT: Avoidmachine damage. A damaged

cartridge (D) can allow dirt into the carburetor and

can cause poor engine performance, engine damage

or failure:

• DO NOT attempt to clean cartridge by tapping

against another object.

• Replace cartridge ONLY if very dirty.

• DO NOT use pressurized air to clean cartridge.

• If cartridge is damaged or the seal is cracked,

replace.

A

MX1529

3. Clean air intake screen (A) and external surfaces with

rag, brush, vacuum or compressedair.

4. Clean air intake screen (A) and external surfaces with

rag, brush, vacuum or compressed air. Lower hood.

Checking Spark Plugs

cCAUTION: Avoid injury. Before you remove

spark plugs, STOP engine and wa it until engine

is cool.

1. Stop engine. LOCK park brake. Remove key. Lift hood.

7. Inspect cartridge for damage or excessive dirt. Replace

Service Engine - Page 27

Page 31

SERVICE ENGINE

Replacing Fuel Filter

A

cCAUTION: Avoid injury. Keep cigarettes,

sparks, and flames away from the fuel system.

Make sure engine is cool to the touch.

IMPORTANT: Avoid machine damage. When

disconnecting fuel tank hose from filter, be sure to

A

hold hose above fuel tank level so fuel does not run

out.

NOTE: Change filter when fuel is low in fuel tank.

2. Disconnect spark plug wires (A) and remove spark

plugs.

3. Clean spark plugs carefully with a wire brush.

4. Inspect plug for:

• Cracked porcelain.

• Pitted or damaged electrodes.

• Other wear or damage.

5. Replace spark plug(s) if necessary.

6. Check plug gap with a wire feeler gauge, gap should be

0.76 mm (0.030 in.)

7. To change gap, move the outer electrode.

8. Install and tighten spark plugs. Tighten plugs to 24.4 to

29.8N•m(18to22lb-ft).

1. Park tractor on a level surface.

2. STOP engine. LOCK park brake. Remove key. Let

engine COOL.

3. Lift hood.

A

B

4. Using pliers, slide hose clamps (A) away from fuel filter

(B).

5. Disconnect hoses from filter.

IMPORTANT: Avoid machine damage. Filter must

be installed with FLOW ARROW pointing in the

directionoffuelflow.

6. Position new filter with FLOW ARROW pointing in the

direction of fuel flow and connect hoses.

7. Install clamps and check for leaks.

8. Lower hood.

9. Connect the spark plug wire(s).

10.Lower hood.

Service Engine - Page 28

Page 32

SERVICE STEERING AND BRAKES

ServiceSteeringand Brakes

Grease

JD Moly High Temp

JD High Temp

GREASE-

BIO-GREASE-

- 10°C

- 20°C

- 30°C

- 40°C

- 55°C

50°C

40°C

30°C

20°C

10°C

0°C

122°F

104°F

86°F

68°F

50°F

32°F

14°F

-4°F

- 22°F

- 40°F

- 67°F

Lubricating Front Wheel Spindles, Wheel

Bearings and Axle Pivot

B

A

NGLI Number

NGLI Number

NGLI Number

Arctic

Park tractor on flat, level surface. STOPengine, LOCK park

brake, DISENGAGE PTO lever, turn key to the OFF

position, and remove key.

With a safe lifting device,lift front of tractor just high enough

TS1417

to pivot axle.

C

B

Use grease based on the expected air temperature range

during the service interval.

The following greases may be used:

• SAE Multipurpose EP Grease with 3 to 5 percent

molybdenum disulfide.

• SAE Multipurpose EP Grease.

• Greases meeting Military Specification

MIL-G-10924C may be used as arctic grease.

Wheel Spindles

Lubricate wheel spindles (A), one on each side of tractor

with multipurpose EP grease or an equivalent.

Turn steering wheel to a full left turn and then full right turn

to distribute grease in spindles.

Axle Pivot

Lubricate axle pivot (C) with multipurpose EP grease or an

equivalent.

Pivot axle up and down to distribute grease in pivot.

Wheel Bearings

Lubricate front wheel bearings (B), one on each side of

tractor with multipurpose EP grease or an equivalent.

Spin wheels to distribute grease in bearings.

Lower front of tractor to ground.

Service Steering and Brakes - Page 29

Page 33

SERVICE STEERING AND BRAKES

Adjusting Brakes

cCAUTION: Avoid injury. Before adjusting

brakes: STOP engine. Remove key. Wait for all

moving parts to STOP.

1. Park tractor on flat, level surface. STOP engine, turn key

to the OFF position, and remove key.

2. UNLOCK the park brake and release brake pedal.

E

A

B

C

spring bracket and front edge of brake rod stop tabs.

Gap should have a minimum distance of 2 mm (0.08 in).

• Check brake rod compression spring (E). It should

not be completely compressed when park brake is

locked. A slight air gap should be visible between the

coils when proper adjustment is reached.

• Recycle park brake a few times and measure

distances each time until specified measurements are

obtained.

• Brake lever (F) travel should not exceed 30° (G). If it

does, measure brake components individually.

SPECIFICATIONS:

• Spring bracket to stop tabs (minimum): 2 mm (0.08 in)

• Brake lever travel (maximum): 30°

3. Measure distance from inside of brake rod stop tabs (A)

to outside of compression spring bracket (B) (located below

foot tread area on left-hand side of transmission). Distance

(C) should be 2 – 10 mm (0.08 – 0.40 in).

G

D

F

4. If distance is less than or equal to 2 mm (0.08 in):

• Gradually adjust jam nuts (D) until specified

measurement is obtained.

• Depress brake pedal and LOCK park brake.

• Measure the distancebetween edge of compression

Service Steering and Brakes - Page 30

Page 34

SERVICE MOWER

Service Mower

Avoid Injury From Contacting Blades

cCAUTION: Avoid injury. Before you unplug,

adjust or service mower:

-DISENGAGEPTOswitchtostopmower

blades.

- Wait for mower blades to STOP.

- LOCK the park brake.

- STOP the engine.

Grease

JD Moly High Temp

JD High Temp

GREASE-

BIO-GREASE-

- 10°C

- 20°C

- 30°C

- 40°C

- 55°C

50°C

40°C

30°C

20°C

10°C

0°C

122°F

104°F

86°F

68°F

50°F

32°F

14°F

-4°F

- 22°F

- 40°F

- 67°F

NGLI Number

NGLI Number

NGLI Number

Arctic

TS1417

-Removethekey.

Clean unit by removing all grass clippings and

dirt from mower deck.

Disconnect spark plug wire from spark plug.

Use grease based on the expected air temperature range

during the service interval.

The following greases may be used:

• SAE Multipurpose EP Grease with 3 to 5 percent

molybdenum disulfide.

• SAE Multipurpose EP Grease.

• Greases meeting Military Specification

MIL-G-10924C may be used as arctic grease.

Service Mower - Page 31

Page 35

SERVICE MOWER

Replacing Mower Drive Belt

cCAUTION: Avoid injury. Before replacing

mower drive belt: STOP engine, remove key,

wait for all moving parts to STOP, and wear

gloves when replacing belt.

1. STOP engine, LOCK park brake, place gear shift lever in

NEUTRAL (N) position, pull PTO drive lever back to

DISENGAGE, turn key to the OFF position, and remove

key .

2. Remove mower deck. (See Removing Mower in

Removing Mower section.)

3. Remove six capscrews and left and right belt guards.

A

A B

D

5. Measure distance from bracket (A) to washer (B) on

tension rod (C). Distance (D) should be: 20 – 25 mm (0.78

–0.98in).

C

C

F

E

F

4. Pull pulley (A) to the left and remove mower drive belt

from engine pulley and then remove from mower.

5. Install belt in reverse order of removal.

6. Reinstall belt guards and tighten capscrews securely.

Adjusting Mower Belt Tension

cCAUTION: Avoid injury. Before adjusting

Mower Belt Tension: STOPengine. Remove key.

Wait for all moving parts to STOP.

IMPORTANT: Avoid machine damage. Spindle

brake engagement must be checked every time the

mower belt tension is adjusted or belt damage may

occur.

6. If adjustment is required, continue with Step 7.

7. DISENGAGE PTO lever.

8. Remove spring locking pin and washer (E) and

disconnect tension rod from blade drive arm.

9. Loosen lock nut (F).

10.Turn fitting on tension rod clockwise to shorten and

counterclockwise to lengthen effective rod length.

11.Tighten lock nut (F) to 27 N•m (20 lb-ft.).

12.Assemble tension rod and recheck dimension (D).

13.Check brake clearance. (See Adjusting Spindle Brake in

this section.

1. Park tractor on a hard, level surface.

2. Stop the engine, remove key, wait for moving parts to

stop.

3. Place mower deck in LOWEST setting.

4. Engage PTO drive lever.

Service Mower - Page 32

Page 36

SERVICE MOWER

Adjusting Spindle Brake

cCAUTION: Avoid injury from rotating blades.

Mower blades must stop within 5 seconds after

mower is turned off. Check spindle brake

measurement every 25 hours or once a year

(whichever comes first).

IMPORTANT: Avoid machine damage and belt

damage.

Spindle brake engagement must be checked and

corrected every time the mower belt tension is

adjusted.

Mower belt tension should be adjusted, if required,

BEFORE brakes are adjusted.

1. Park tractor on a hard, level surface.

2. Stop the engine, remove key, wait for moving parts to

stop.

3. Place mower deck in LOWEST setting.

4. Engage PTO drive lever.

5. Check mower belt tension. (See Adjusting Mower Belt

Tension in this section.)

7. Measure distance from brake surface (A) to pulley

braking surface (B). Brake to Pulley Distance should be: 2 –

3mm(0.08–0.12in).

8. If adjustment is required, turn nut (C) on end of brake

rod (D) in correct direction to set brake at proper distance

from pulley.

9. Repeat on all brakes.

10.Install belt guard.

6. Remove belt guard.

IMPORTANT: Avoid machine damage. ALL brakes

MUST be adjusted. There are THREE spindle brakes

on the deck.

A

B

C

D

Service Mower - Page 33

Page 37

Checking Mower Blades

SERVICE MOWER

cCAUTION: Avoid injury. Before adjusting

Mower Belt Tension: STOPengine. Remove key.

Wait for all moving parts to STOP.

To check for a bent blade:

1. Lower mower. Measure distance between blade tip and

flat ground surface.

2. Turn blade 180 degrees. Measure distance between

blades other tip and flat ground surface.

3. If the distance between the two measurements is more

than 3 mm (1/8 in), install new blade.

D

C

B

A

M88119b

3. Loosen and remove cap screw (A), hardened washer

(B), cupped blade washer (C) and blade (D).

4. Inspect blades; sharpen/balance or replace as

necessary.

INSTALLING MOWER BLADES

1. Lightly lubricate cap screw threads with a general

purpose grease or oil. This lubrication is to prevent rusting

and seizing.

C

D

Servicing Mower Blades

cCAUTION: Avoid injury. Be careful, sharp

edges on mower blades. Always wear gloves

when handling mower blades.

REMOVING MOWER BLADES

1. Raise mower deck to gain access to mower blades. If

necessary, remove mower deck.

2. Using a wooden block, prevent mower blades from

spinning.

B

A

M88112h

2. Position mower blade (D) with the cutting edge towards

the ground onto the mower spindle.

3. Install cupped blade washer (C) with cup side toward the

blade.

4. Install hardened washer (B).

5. Install and tighten cap screw (A) by hand until mower

blade is in full contact (fully seated) with spindle.

6. With mower blade blocked, to prevent spinning, tighten

cap screws to 56 N•m (41 lb-ft.)).

Service Mower - Page 34

Page 38

SERVICE MOWER

Sharpening Blades

cCAUTION: Avoid injury. Wear goggles and

gloves when you handle blades.

1. Sharpen blades with grinder, hand file or electric blade

sharpener.

A

B

2. Keep original bevel (A) when you grind.

3. Blade should have 0.40 mm (1/64 in.) cutting edge (B).

Balancing Blades

cCAUTION: Avoid injury. Wear goggles and

gloves when you handle blades.

1. Clean blade.

2. Put blade on nail in vise or on vertical wall stud. Turn

blade to horizontal position.

3. If blade is not balanced, heavy end of blade will drop.

4. Grind bevel of heavy end. Do not change bevel.

Service Mower - Page 35

Page 39

Service Electrical

Checking the Battery

SERVICE ELECTRICAL

B

cCAUTION: Avoid injury. Sulfuric acid in battery

electrolyte is poisonous. It is strong enough to

burn skin, eat holes in clothing, and cause

blindness if splashed into eyes. Wear eye

protection and avoid spilling or dripping

electrolyte.

Flush eyes with water for 15-30 minutes if acid

is splashed into eyes.

If acid is swallowed, get medical attention

immediately.

DO NOT attempt to open, add fluid or service

battery. Any attempt to do so will void warranty

andleadtopossibleinjury.

C

A

M96453

2. Remove rubber hold-down strap (A).

3. Disconnect negative (–) battery cable (B).

4. Remove red cover (C) from positive (+) battery terminal.

Remove positive (+) cable from battery.

5. Remove battery.

6. Install the battery following these steps in reverse order.

(See Connect the Battery in the Assembly section.)

Clean Battery and Terminals

•Keep battery and terminals clean.

•Keep battery bolts tight.

•Keep small vent holes open.

•Recharge, if necessary, at 6–10 amperes for 1 hour. (See

Charging the Battery in this section.)

Removing and Installing the Battery

cCAUTION: Avoid injury. Always remove

negative (–) battery cable first,and install it las t,

to prevent electrical short circuit to chassis.

1. Turn ignition key off and raise seat.

cCAUTION: Avoid injury. Battery gas can

explode, to avoid injury:

- Keep sparks and flames away from batteries.

Use a flashlight to check battery electrolyte

level.

- Never check battery charge by placing a metal

object across the posts. Use a voltmeter or

hydrometer.

- Always remove grounded (-) battery clamp

first and replace it la st.

1. Turn ignition key off and raise seat.

Service Electrical - Page 36

Page 40

SERVICE ELECTRICAL

B

C

A

M96453

2. Remove rubber hold-down strap (A).

3. Disconnect BLACK (–) battery cable (B) first.

4. Disconnect RED (+) battery cable (C). Remove battery

from mower.

5. Wash battery with solution of four tablespoons of baking

soda to one gallon of water. Be careful not to get the soda

solution into the cells.

6. Rinse the battery with clean water. Let dry.

7. Clean terminals and battery cable ends with wire brush

until bright.

8. Apply petroleum jelly or silicone spray to terminal to

prevent corrosion.

9. Install battery.(See Removing and Installing the Battery

in this section and Connect the Battery in the Assembly

section.)

cCAUTION: Avoid injury. BE VERY CAREFUL:

Battery fluid (electrolyte), is a solution of water

and sulfuric acid. It is very harmful to eyes,

skin, or clothing.

- Wear goggles or an eye shield when you work

with a battery.

- If the acid contacts your eyes, skin, or

clothing, flush the area imme diately with water.

Get medical help, if necessary.

A battery gives o ff gas which can explode. An

exploding battery will spray sulfuric acid in all

directions.

- Keep cigarettes, sparks, andflames away from

the battery.

- Charge the battery in an area with good

ventilation.

-DONOTchargeafrozenbattery.

Before you charge a battery:

• Wait until the battery has warmed to room temperature.

Do not charge a frozen battery.

Turn OFF and unplug the charger before you connect

cables to the battery or disconnect cables from the battery.

If the battery becomes warm to touch during charging:

• Reduce the charging rate OR

Charging the Battery

• Stop charging the battery until it cools.

NOTE: Your charger may have an AUTOMATIC STOP

to prevent charging the battery:

• When the battery is fully charged OR

• When the battery is not in condition to take a charge.

cCAUTION: Avoid injury. DO NOT attempt to

open, add fluid or service battery. Any attempt

to do so will void warranty and lead to possible

injury.Battery gas is explosive:

- DO NOT smoke whil e you charge battery.

- Keep all flames and sparks away.

- DO NOT charge frozen battery.

- DO NOT connect booster battery negative (-)

cable to starting vehicle negative (-) terminal.

1. Remove battery from mower. (See Removing and

Installing Battery in this section.)

Service Electrical - Page 37

Page 41

SERVICE ELECTRICAL

2. Connect positive (+) charger cable to positive (+) battery

terminal.

3. Connect negative (–) charger cable to negative (–)

battery terminal.

4. Plug in charger cord.

5. Charge battery using a 12 Volt battery charger at a rate

of 6–10 amperes for a minimum of 1 hour and no more than

2 hours.

6. Unplug charger cord. Remove charger cables.

7. Install battery. (See Removing and Installing Battery in

this section.)

TO ENGINE

GROUND

A

VEHICLE

BATTERY

2. Connect the other end of positive (+) booster cable to

vehicle battery positive (+) post (A).

3. Connect negative (–) booster cable to booster battery

negative (–) post (C).

4. Connect the other end of negative (–) booster cable (B)

to engine ground away from battery.

B

D

C

BOOSTER

BATTERY

Replacing Headlight Bulb

1. Lift hood.

Using Booster Battery

cCAUTION: Avoid injury. Battery gas is

explosive:

- DO NOT smoke while you charge battery.

- Keep all flames and sparks away.

- DO NOT charge frozen battery.

- DO NOT connect booster battery negative (-)

cable to starting vehicle negative (-) terminal.

A

M88559

2. Push in and turn bulb socket (A) 1/4 turn

counterclockwise to remove.

3. Replace defective bulb with a new bulb.

4. Insert bulb socket into housing, push in and turn 1/4 turn

clockwise to install.

5. Lower hood.

1. Connect positive (+) booster cable to booster battery

positive(+) post (D).

Service Electrical - Page 38

Page 42

SERVICE ELECTRICAL

Replacing Fuse

1. Open hood.

A

MX1535

2. Pull defective fuse (A) out of socket.

3. Check metal clip in fuse window and discard fuse if clip

is broken.

4. Push new fuse into socket.

5. Close hood.

Service Electrical - Page 39

Page 43

SERVICE MISCELLANEOUS

Service Miscellaneous

Checking Tire Pressure

cCAUTION: Avoid injury. Explosive separation

of a tire and rim parts can cause serious injury

or death:

- Do not attempt to mount a tire without the

proper equipment and experience to perform

the job.

- Always maintain the correct tire pressure. Do

not inflate the tires above the recommended

pressure. Never weld or heat a wheel and tire

assembly. The heat can cause an increase in air

pressure resulting in a tire explosion. Welding

can structurally weaken or deform the wheel.

- When inflating tires, use a clip-on chuck and

extension hose long enough to allow you to

stand to one side and NOT in front of or over

the tire assembly.

- Check tires for low pressure, cuts, bubbles,

damaged rims or missing lug bolts and nuts.

1. Check tires for damage.

2. Check tire pressure with an accurate gauge.

3. Add or remove air, if necessary:

Tire Size Pressure-kPa (psi)

Front: 15-Inch 97 kPa (14 psi)

Rear: 20-Inch 69 kPa (10 psi)

Fuel

cCAUTION: Avoid injury. Handle fuel with care,

it is highly flammable and can cause serious

injury or death:

- DO NOT refuel machine while you smoke,

when machine is near an open flame or sparks,

or when engine is running. STOP engine .

- Fill fuel tank outdoors.

- Prevent fires: clean oil, grease and dirt from

machine. Clean up spilled fuel immediately.

- Do not store machine with fuel in tank in a

building where fumes may reach an open flame

or spark.

- To prevent fire and explosion caused by static

electric discharge, while you fill tank, use a

non-metal fuel container. I f you use a funnel,

MAKE SURE IT IS PLASTIC. Avoid using a

funnel which has a metal screen or filter.

- Use only clean approved containers and

funnels.

- Store oil and fuel in an area protected from

dust, moisture and other contamination.

- DO NOT use METHANOL gasoline.

METHANOL is harmful to the environment and

to your health.

IMPORTANT: Avoid machine damage. Avoid

spilling fuel. Fuel can damage plastic and painted

surfaces.

DO NOT mix oil with gasoline. Unleaded gasoline

with an octane rating of 87 or higher is

recommended.

Service Miscellaneous - Page 40

Page 44

SERVICE MISCELLANEOUS

Using Clean Fuels

Dirt in the fuel system is a major cause of performance

problems. Be sure to clean any grass or trash from the top

of the tank before removing lid. Use of a PLASTIC funnel

with a plastic mesh strainer when filling the tank will prevent

most foreign material from entering the tank.

Octane Rating

Regular grade 87 octane unleaded fuel is recommended

for use in your tractor.Higher octane fuels will seldom make

your tractor perform better. If your tractor develops a

starting or performance problem immediately after use of

new fuel, change supplier or fuel brand. If the problem still

exists after switching fuel, see your John Deere dealer for

service.

Fuel Blends

varnish deposits, especially if fuel is stored for several

weeks or more.

Using clean, fresh fuel will help to prevent damage to the

fuel system and will help maintain peak engine

performance. If engine performance problems occur, use

fuel from another supplier before suspecting machine

problems. Suppliers blend fuels differently and changing

suppliers will generally solve any performance problems.

Using Fresh Fuel and Stabilizers

The best thing you can do to ensure peak performance of

your engine is to use “fresh” fuel. Your tractor’s engine will

perform well with most good-quality fresh fuels regardless

of additives. Any fuel will begin to deteriorate and evaporate

over time and begin to form gum and varnish deposits in

the fuel system. Help to avoid this by buying only enough

fuel to last approximately 30 days or add fuel stabilizer

immediately.

Adding a fuel stabilizer to the fuel system is recommended

any time the tractor will not be operated for more than 60

days. Varnish deposits may build up in the carburetor in as

little as a few weeks by using stale, oxygenated fuel.

No stabilizer will work with “stale” fuel, any fuel that is more

than 30 days old. (See Preparing Your Engine For Storage

in this section for information on adding stabilizer to the

fuel.)

Filling Fuel Tank

Fuels are blended to give peak performance during cold

weather and warm weather. For cold weather, gasoline is

specially blended to provide better starting capabilities.

However, avoid prolonged storage of cold-weather blended

fuel because it will evaporate more quickly. You may

experience longer cranking times in cold weather with “old”

fuel. Buy smaller amounts of cold-weather blended fuel in

winter.

Fuels used during the summer are not required to provide

improved starting properties so they are blended differently.

As a result, you may experience hard starting or other

performance problems during cold weather if you use fuel

remaining from summer uses.

Oxygenated or Reformulated Fuels

Many areas are now required to add “oxygenates” (either

alcohol or ether) which blend oxygen into the fuel to help

reduce exhaust emissions. If you use oxygenated fuel be

sure it is unleaded and meets the minimum octane rating

requirement. DO NOT use fuel that contains methanol to

avoid producing excess emissions.

Although fuels blended with alcohol or ether allow your

engine to run cleaner, they may contribute to fuel system

damage and performance problems by causing gum and

IMPORTANT: Avoid machine damage. Dirt and

water in fuel are major causes of engine

performance problems. Prevent dirt and debris from

entering the fuel tank when filling.

Fillthetankattheendofeachday’soperationto

help keep condensation out of the fuel tank.

Fuel tank capacity: 4.7 L (1.25 gal).

1. STOP engine. If engine is hot let it cool several minutes

before you add fuel.

2. Lift hood.

3. Remove grass clippings and other trash from tank area.

Service Miscellaneous - Page 41

Page 45

SERVICE MISCELLANEOUS

Avoid Damage:

• “Dry wiping” or wiping the plastic surface when it is dry

is a major source of minor surface scratches.

A

M96452

4. Remove fuel tank cap (A).

5. Fill tank with fresh fuel only to bottom of filler neck.

6. Install fuel tank cap and lower hood.

Care for Plastic and Painted Surfaces

PLASTIC SURFACES

The plastic parts on your tractor are made of a blend of

polycarbonate and polyester materials. These parts are

extremely strong and durable. Unlike painted metal, the

plastic parts will never dent or rust. If the plastic parts get

scratched, the color will remain the same since the color

goes through the entire part.

IMPORTANT: Avoid machine damage. “Dry

wiping” or wiping the plastic surface when it is dry

will result in minor surface scratches. Always wet

the surface before cleaning. Follow correct cleaning

and waxing procedures.

Correct Cleaning Care:

NOTE: Follow cleaning procedure every time plastic

surfaces are cleaned. DO NOT wipe dry plastic surface

with hand or towel.

1. Before washing, rinse hood and entire machine with

clean water to remove dirt and dust that may scratch the

surface.

2. Wash plastic surface with clean water and a mild liquid